Buckle type connecting structure of solid wood or raw wood furniture

A connection structure and furniture technology, which is applied in the direction of furniture connection, connection components, thin plate connection, etc., can solve problems that affect the firmness and stability of the connection, cannot be assembled, and reduce the grade or grade of the finished product, so as to reduce labor intensity and manpower. The effect of cost, firm installation and tight connection, easy installation, use and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

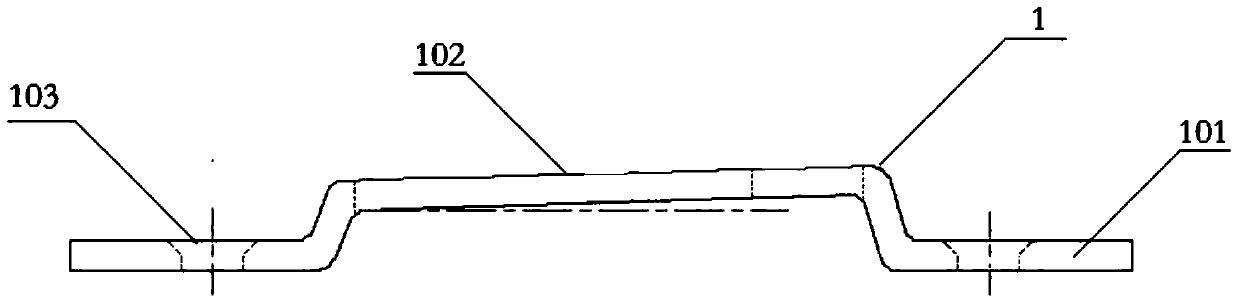

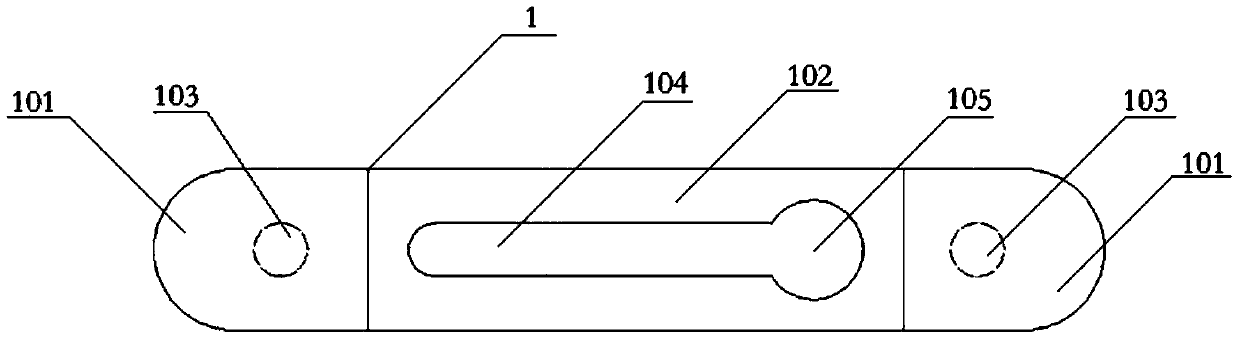

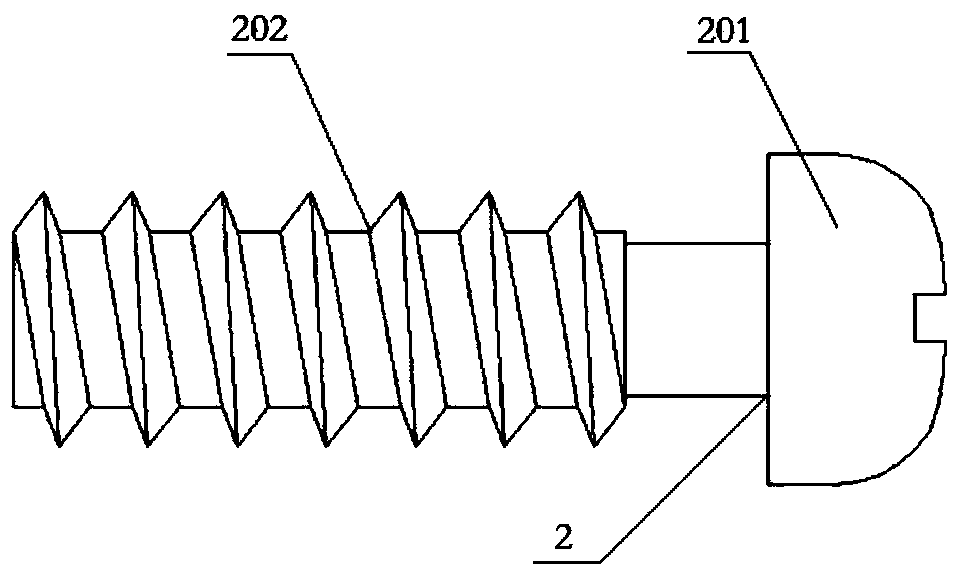

[0030] Embodiment 1: see attached Figure 1-9 , reflecting a specific structure of the present invention, the lock-type connection structure of solid wood or log furniture includes correspondingly connected first furniture boards 6 (side boards), second furniture boards 5 (layer boards) and connectors, so The connecting piece is composed of two parts: a fastening plate 1 and a fastening screw: the fastening screw includes two parts: a bolt 2 and an embedded nut 3 installed on the first furniture plate 6; the embedded nut 3 is provided with an intermittent outer The thread 301 and the internal thread 302, the external thread 301 is locked into the first furniture plate 6, and the external thread 301 is provided with anti-slip raised lines. A non-threaded portion is provided on the bolt 2 , that is, the bolt shank 202 below the bottom surface of the bolt head 201 . The buckle plate 1 includes two fixing parts 101 at both ends and a raised connecting part 102 in the middle, and ...

Embodiment 2

[0031] Embodiment 2: see attached Figure 10 , the second furniture board 10 is provided with a mounting groove 11 for accommodating the fastening plate 13, the difference from Embodiment 1 is that the entry end of the locking groove 14 on the fastening plate 13 is provided with a side where the bolt shank can enter Opening 15 , the mounting groove 11 is also provided with a corresponding side opening 12 . All the rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0032] Embodiment 3: see attached Figure 11 , the difference from Example 1 is that the two walls inside the slot body of the buckle plate slot 20 are provided with sawtooth structures 21, please combine Figure 12 , the sawtooth has a smooth arc-shaped top 217, and the slope of the slope 217 toward the entry end of the sawtooth is smaller than the slope of the slope 216 toward the buckle end. The arrow A in the illustration is pointing towards the buckle end. All the rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com