Patents

Literature

4132 results about "Solid wood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid wood is a term most commonly used to distinguish between ordinary lumber and engineered wood, but it also refers to structures that do not have hollow spaces. Engineered wood products are manufactured by binding together wood strands, fibers, or veneers with adhesives to form a composite material. Engineered wood includes plywood, oriented strand board (OSB) and fiberboard. The fact that a product is made from solid wood is often touted in advertisements. However, using solid wood has advantages and disadvantages.

Weatherable building products

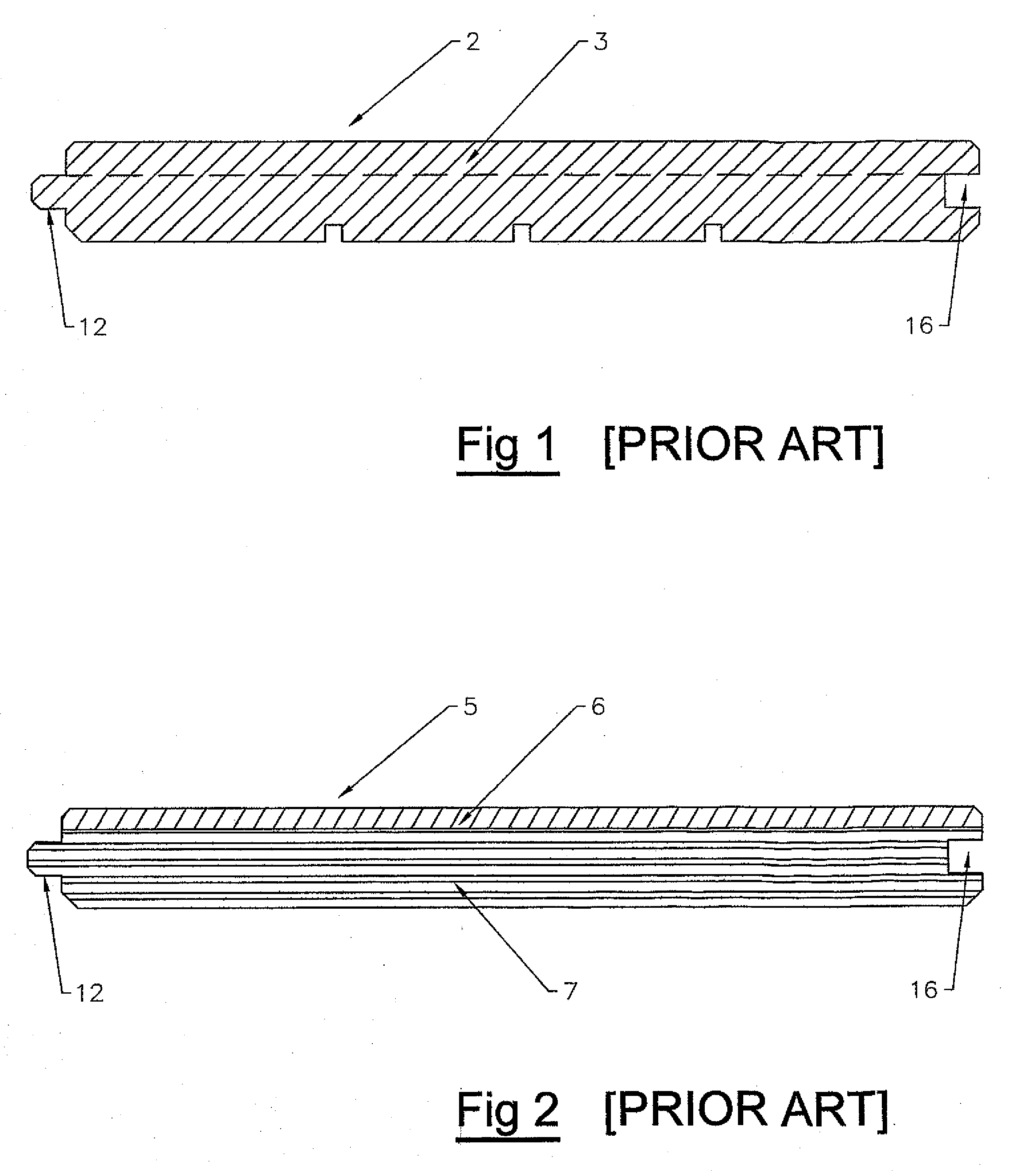

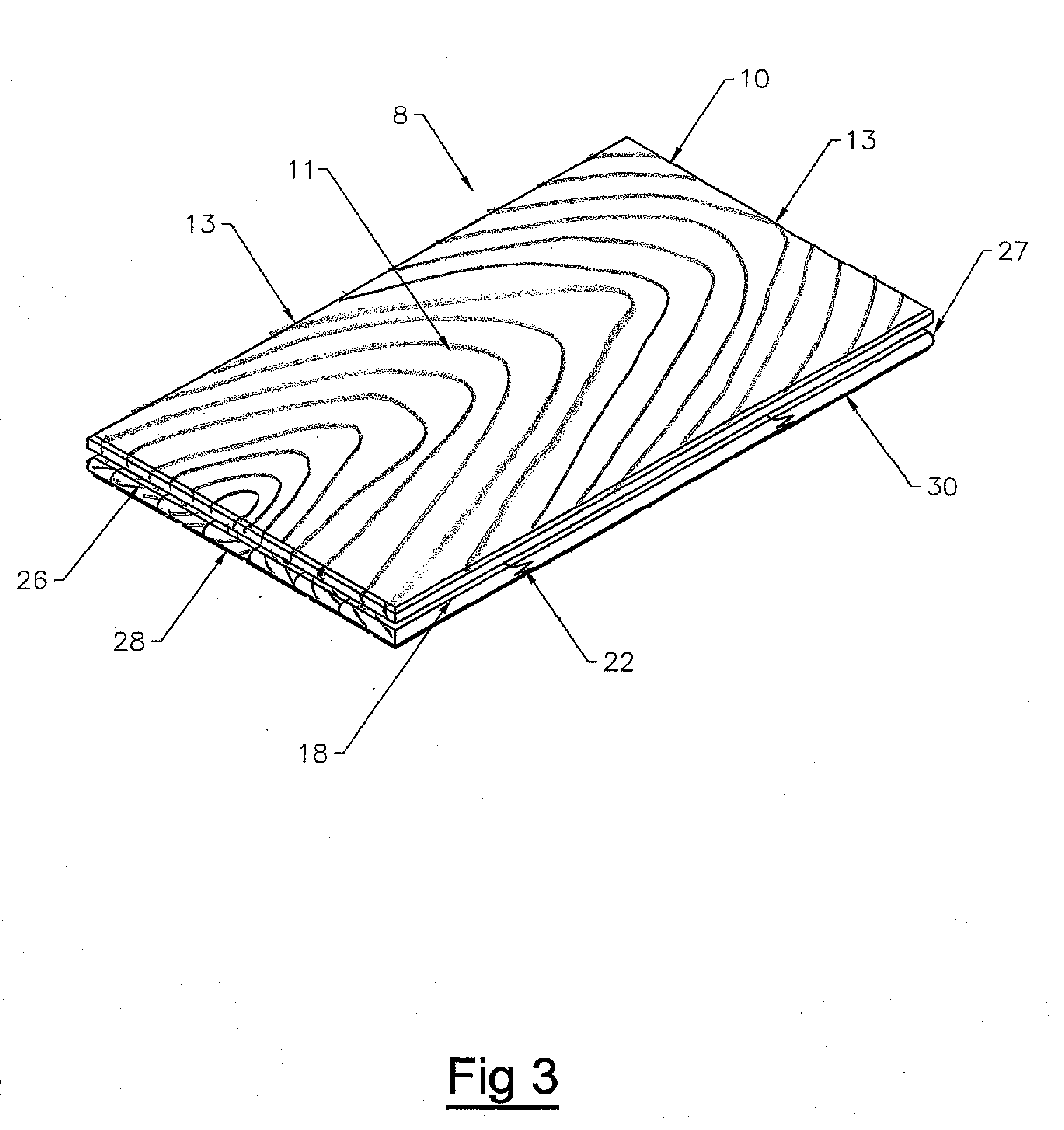

InactiveUS6383652B1Eliminate accumulated volatileAvoid blistersSynthetic resin layered productsCellulosic plastic layered productsBuilding productSolid wood

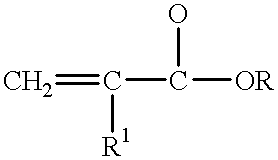

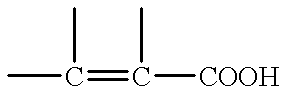

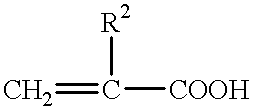

The present invention relates to a weatherable building product comprising a wood member. The wood member has at least a portion which is coated with a coating composition comprising an interpenetrating polymer network of an acrylic latex and a vinylidene chloride polymer. The wood member comprises solid wood or fiber-based materials.

Owner:TTTECH

Fuel pellet briquettes from biomass and recovered coal slurries

The invention makes burnable renewal fuel (RF) briquettes from recovered coal from coal slurry ponds, biomass, and a binder. The briquettes may be augmented with one or more of recovered environmental burnable fraction from municipal solid waste (MSW), agricultural livestock waste, lumber processing residue, solid wood waste material, agricultural by-products and crops, and like burnable waste material. Accordingly, the method for making burnable renewal fuel (RF) briquettes includes the steps of recovering coal from coal slurry ponds; recovering biomass; adding a binder to said recovered coal and said biomass; and forming solid burnable RF fuel briquettes therefrom.

Owner:NEW ENERGY USA

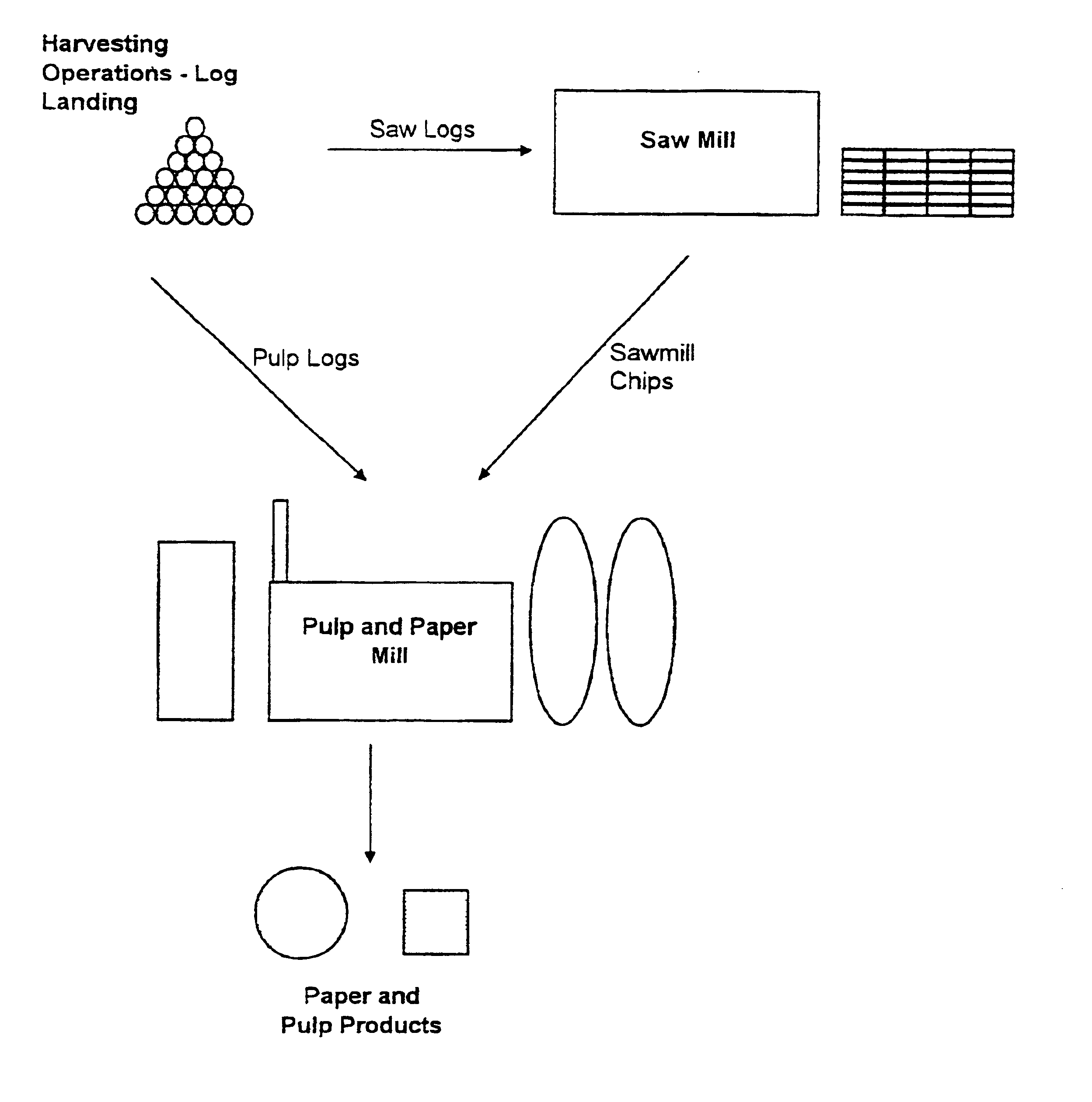

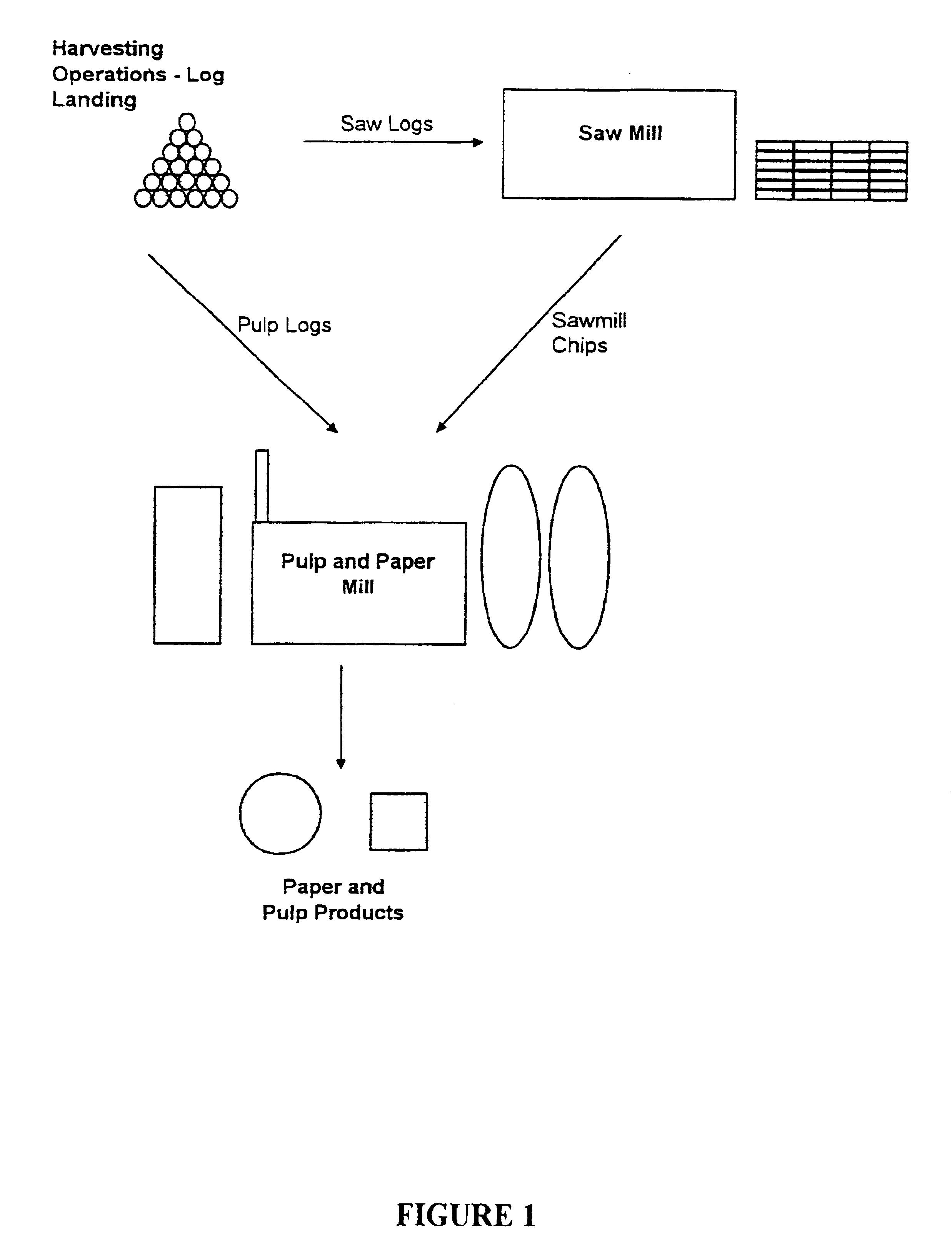

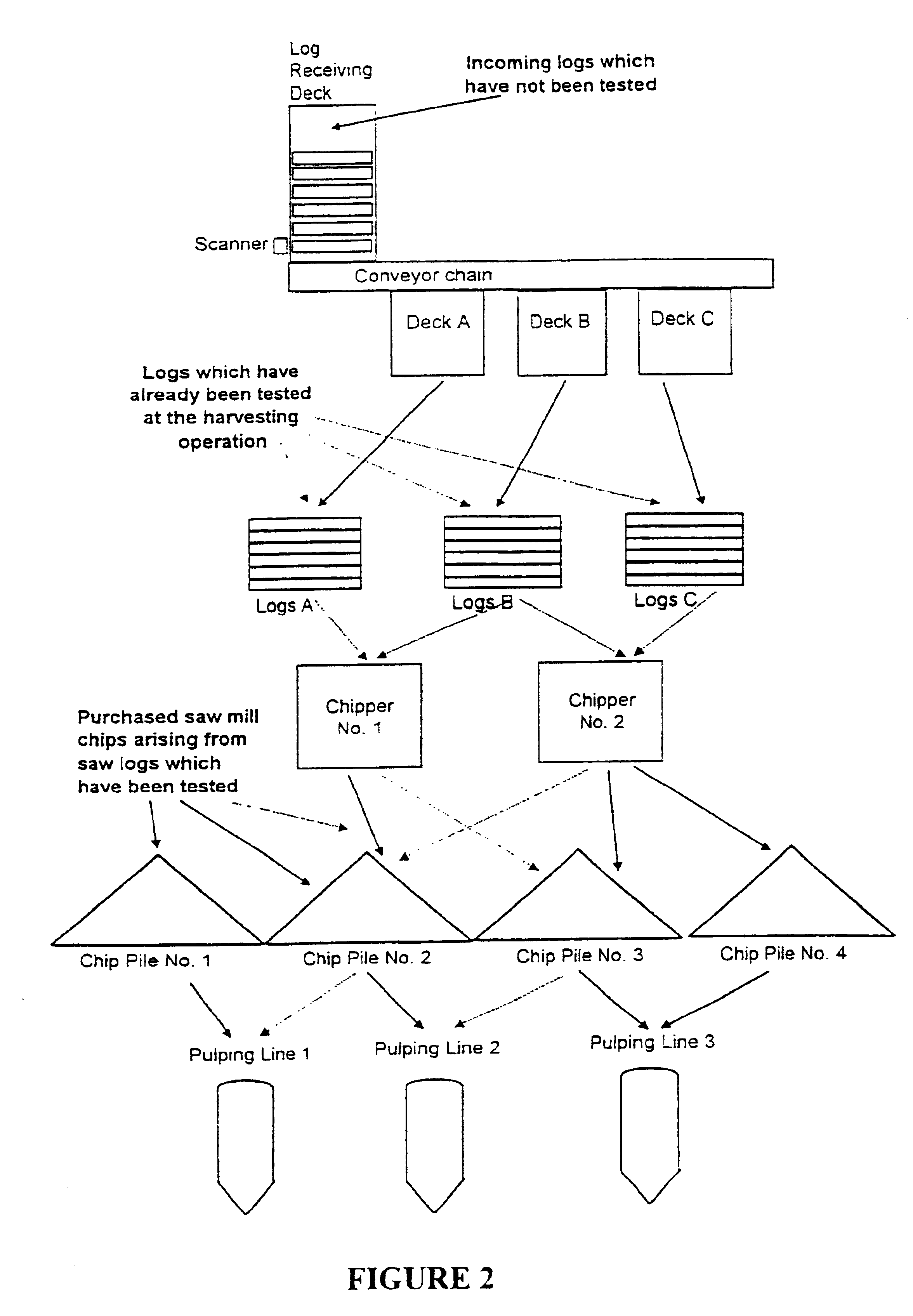

Method of selecting and/or processing wood according to fibre characteristics

InactiveUS6773552B1Analysing solids using sonic/ultrasonic/infrasonic wavesDigestersSolid woodWood fibre

The invention provides a method for predictively assessing one or more characteristics of wood pulp produced from solid wood. The method comprises the steps of determining the velocity of sound through the solid wood, and assessing characteristic(s) of wood fiber or wood pulp produced from the wood by reference to the velocity of sound through the solid wood. The method may also comprise the steps of causing a sound wave to be transmitted through the wood, determining the velocity of the sound wave through the wood, and comparing the result to stored information on fiber characteristic(s) versus sound velocity through the wood-type to determine the fiber characteristic(s) for the wood.

Owner:FIBER GEN INSTR

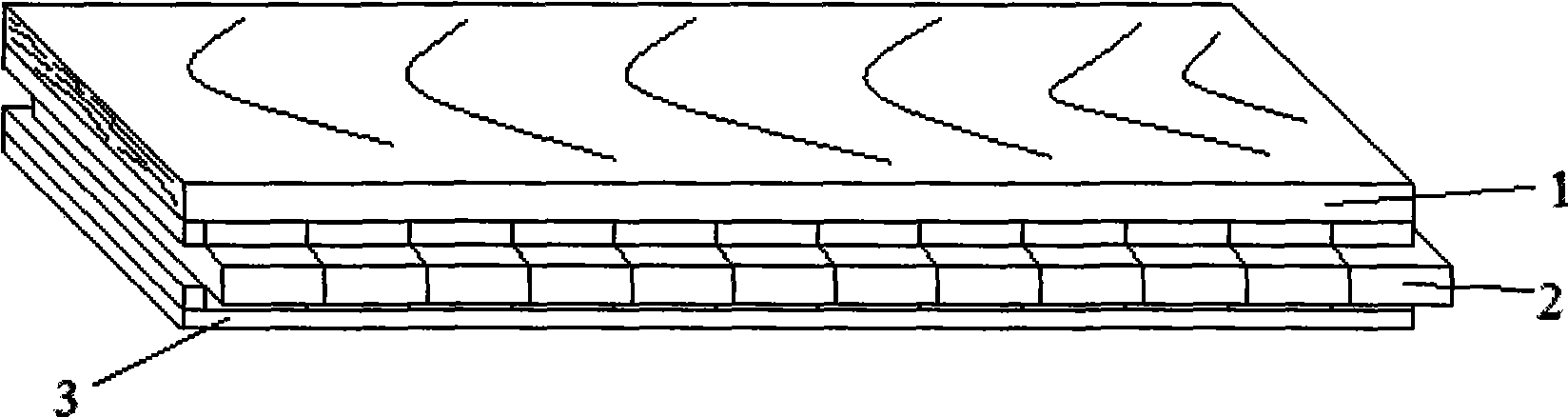

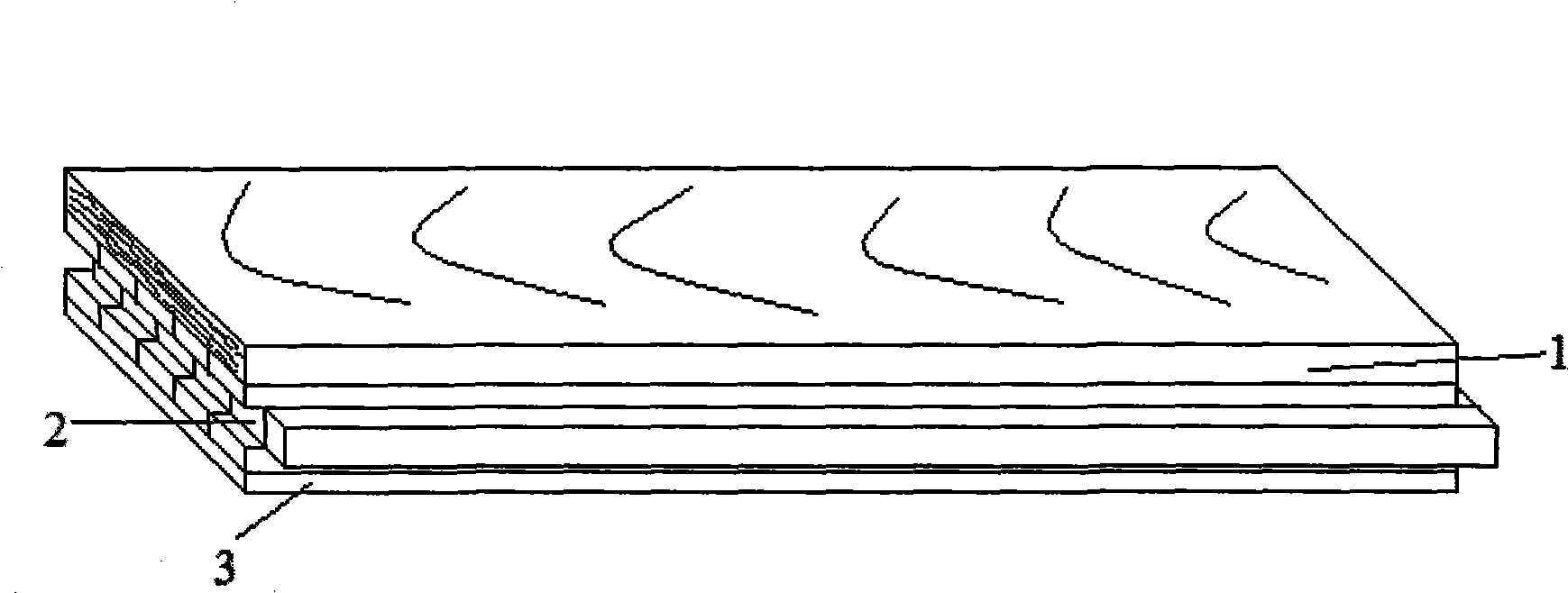

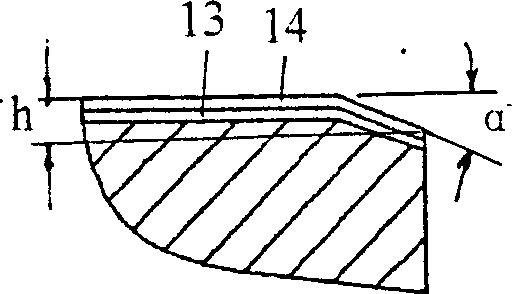

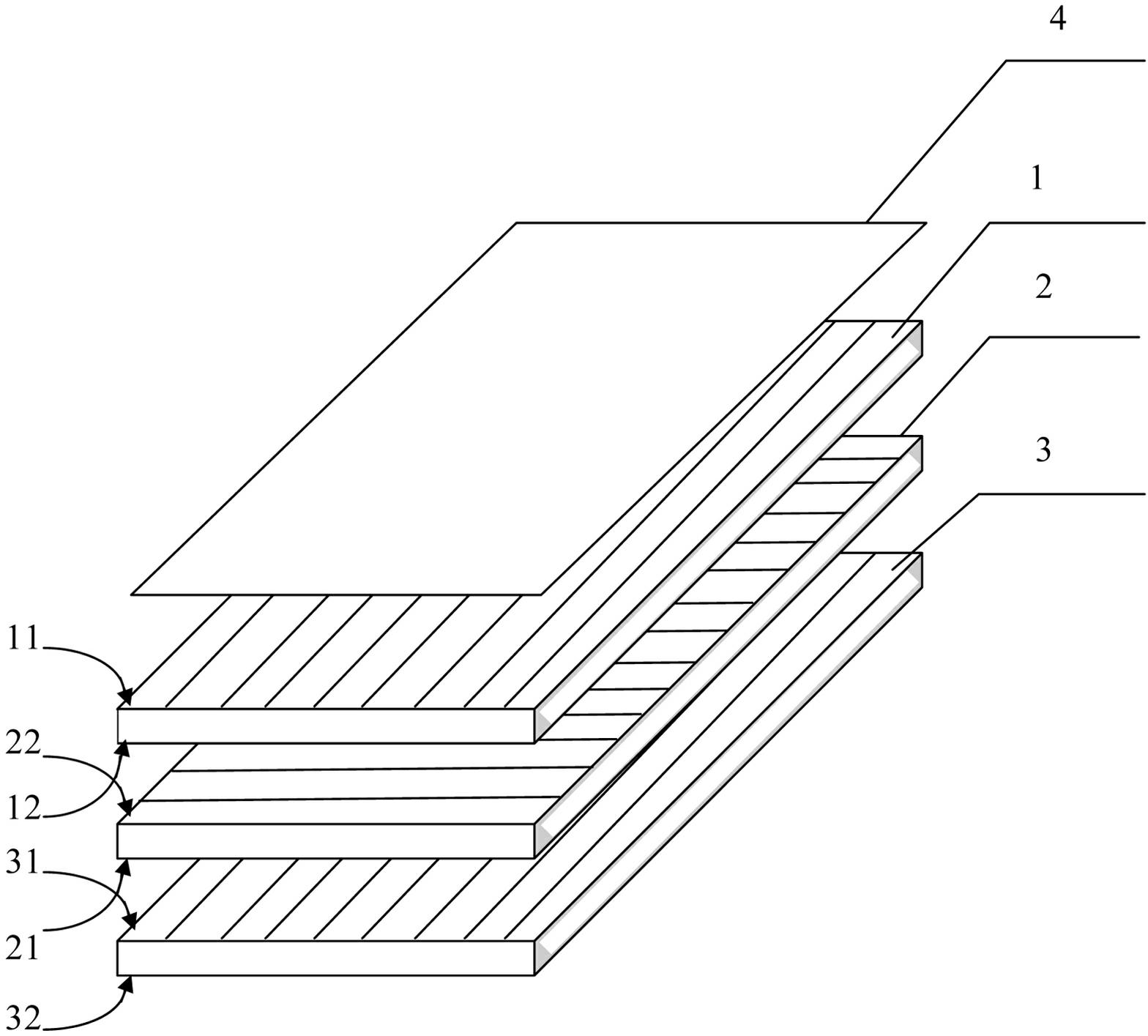

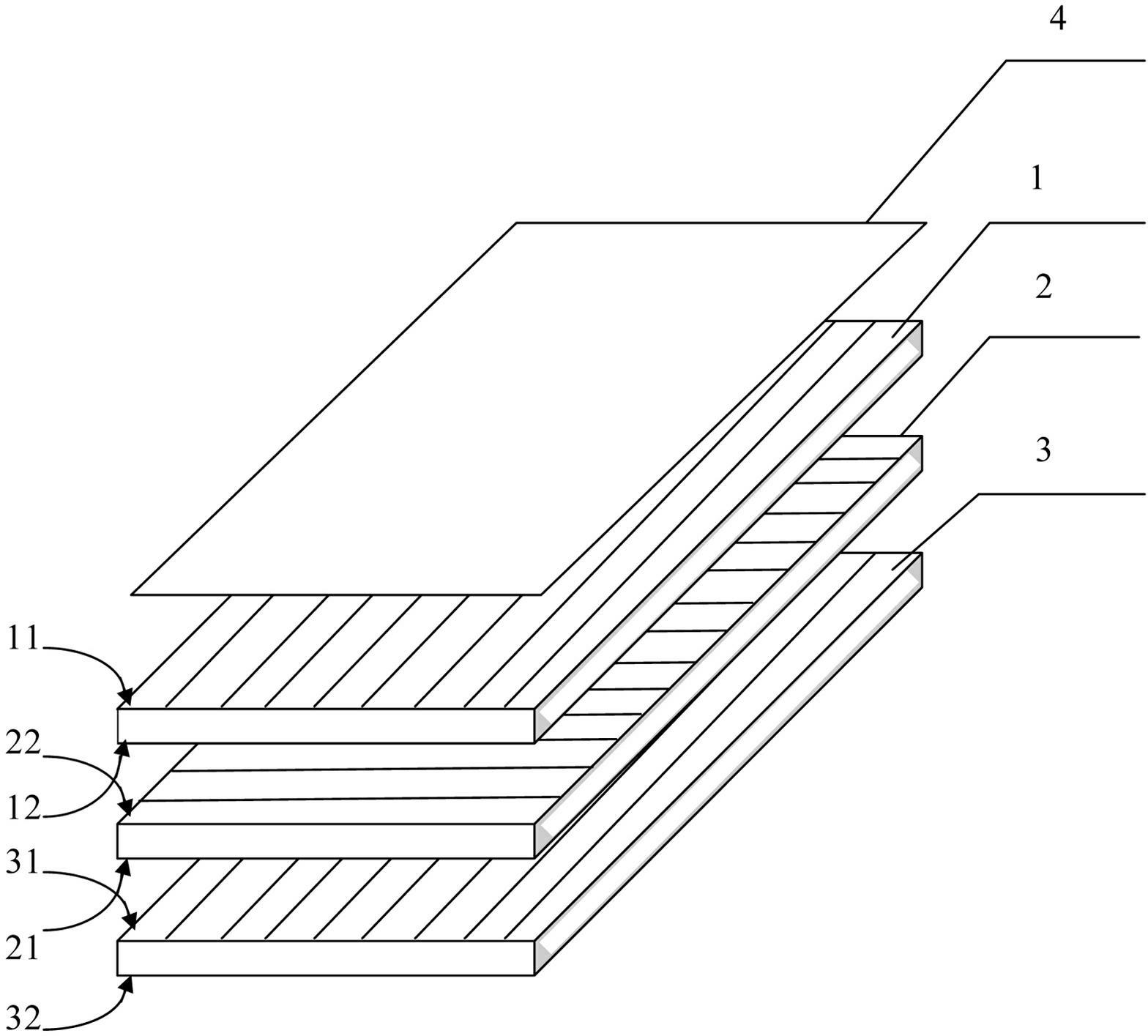

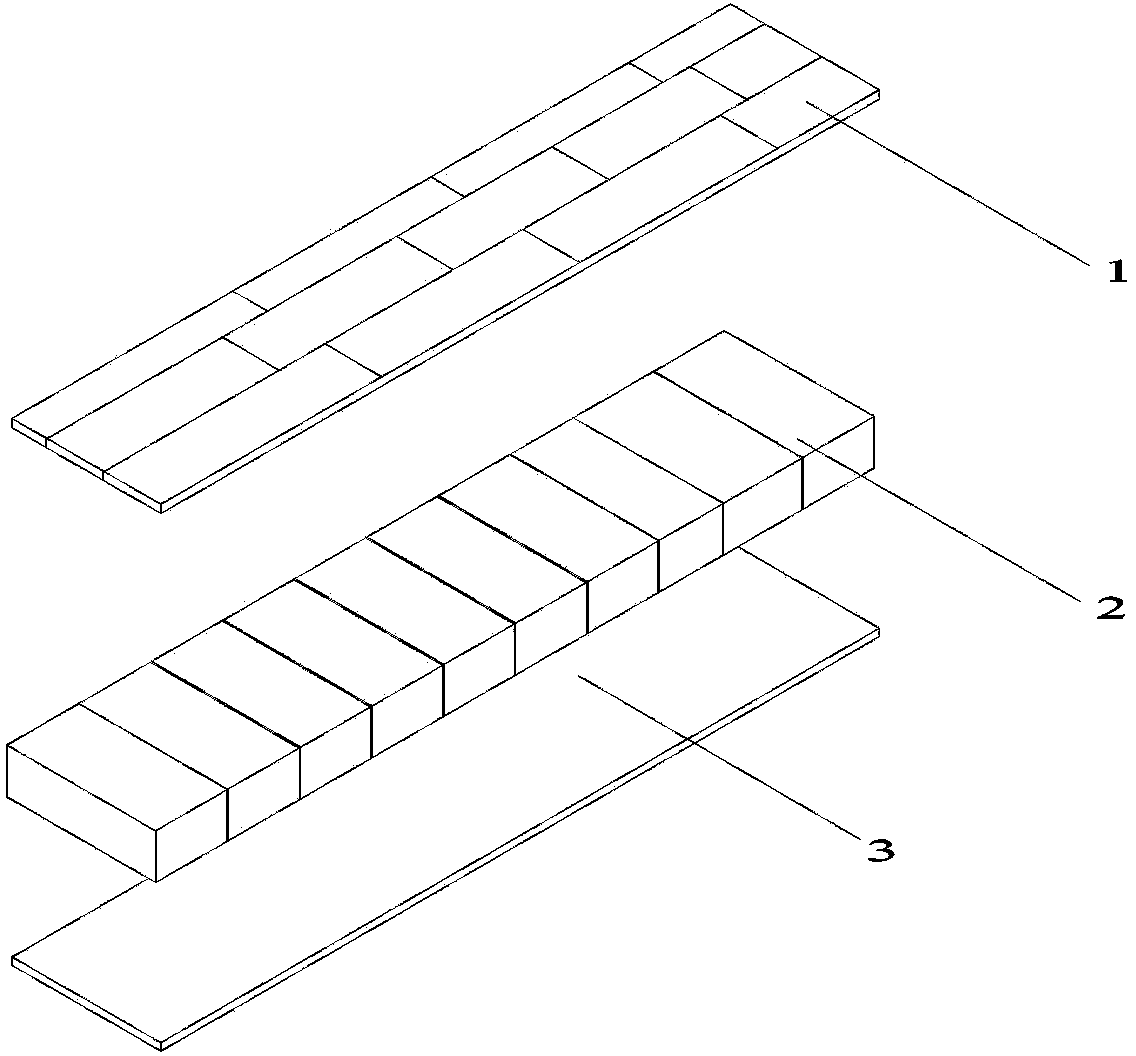

Method for producing compressed charing poplar three-layer wood composite flooring

InactiveCN101486212ALow costHigh densityWood treatment detailsWood veneer joiningSolid woodSurface layer

The invention discloses technology for producing compressed and carbonized poplar three-layer solid wood composite floor fully through utilization of a fast-growing material of poplar. A poplar sheet obtained by a special densification process is used as a surface layer; a common poplar core veneer is used as a core layer; a poplar veneer is used as a bottom layer to manufacture three-layer solid wood composite floor; each performance reaches the requirement of national standard GB / T 18103-2000 on the solid wood composite floor; the technology totally adopts the fast-growing material of the poplar as a raw material, does not add any chemical reagent in the special densification process of the poplar sheet, and does not cause any pollution to environment; after the poplar sheet is subjected to compaction treatment, the density and the hard sense of the wood are strengthened; the late high-temperature carbonization treatment solves the problem of rebounding after the poplar is compressed, changes luster of the wood, and strengthens high grade; and the technology is simple and feasible and has low manufacturing cost.

Owner:NANJING FORESTRY UNIV

Composite floor board and method for producing the same

ActiveCN101487336AWith natural textureWith comfortWood working apparatusFlooringThermoplasticSolid wood

The invention relates to a composite floor and a preparation method thereof. Thermoplastic plastics and wood powder are mixed and extruded to obtain a mixed layer, and then the mixed layer is mixed with thermofusible resin and extruded to obtain a profile which is taken as basic material of the floor, a decorating layer and an exterior wear-resisting layer are laid on the surface of the basic material of floor in sequence to obtain a floor blank, finally, after processes like conventional gouging and the like, an end product of composite floor is obtained. The obtained composite floor has the natural grain and the amenity of the solid wood floor, and overcomes the shortcomings of non-watertight, being easy to rot, easy to be deformed and low wear resistance of the conventional wood floor. The preparation method of the composite floor is simple and feasible and has low cost.

Owner:来安县扬子地板有限公司

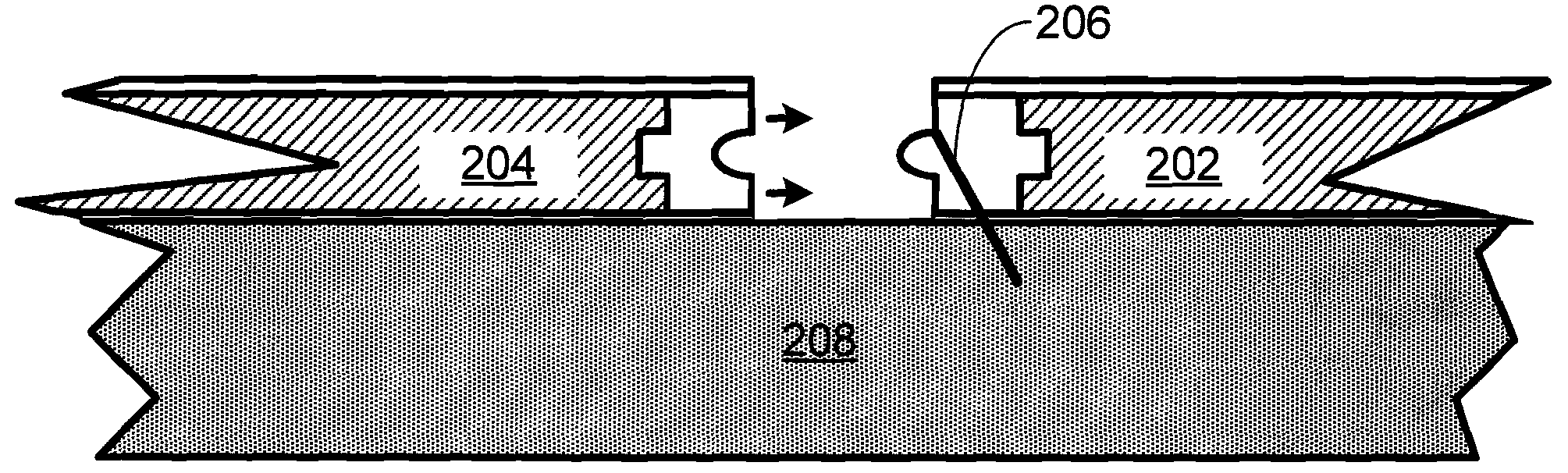

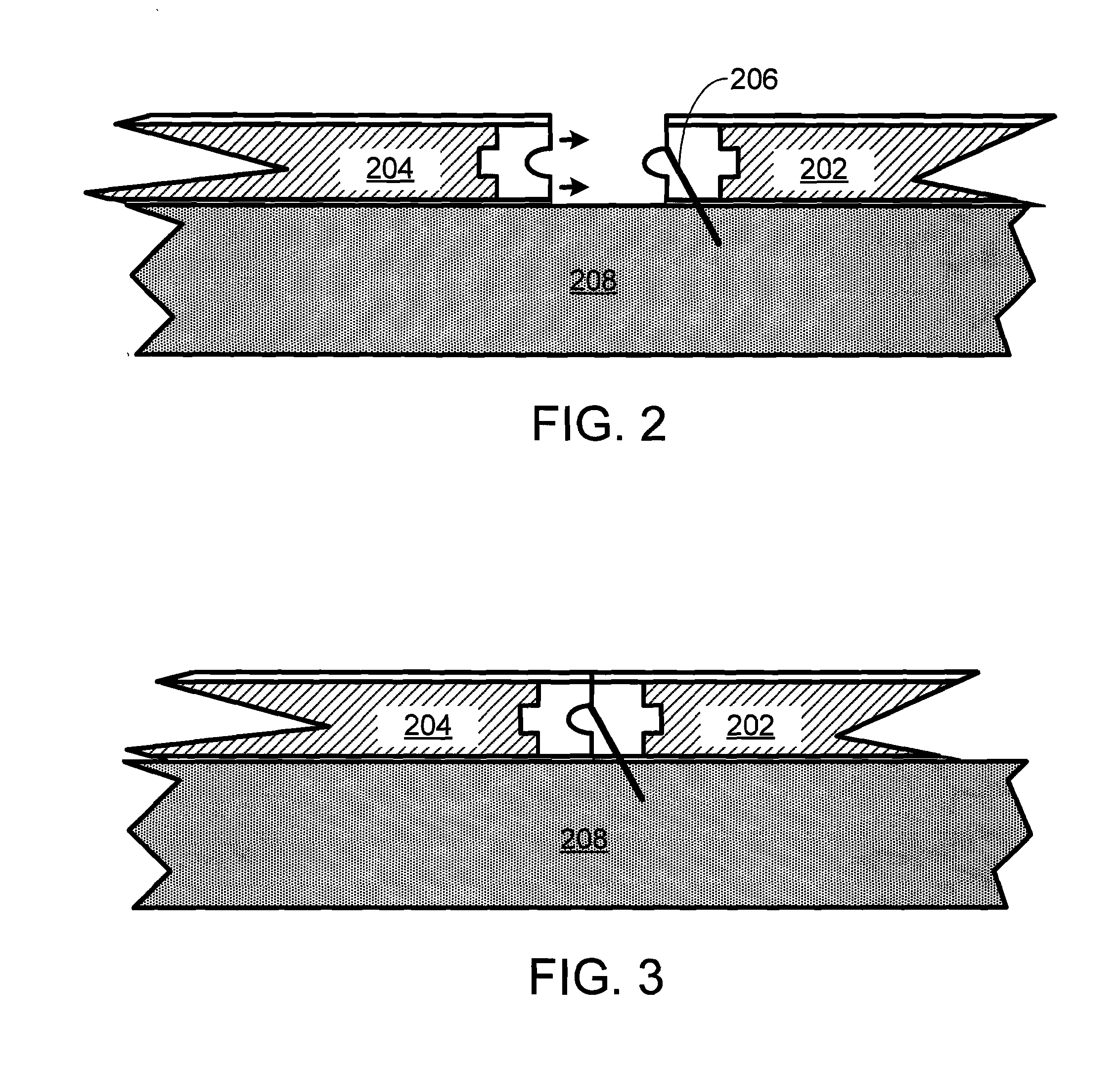

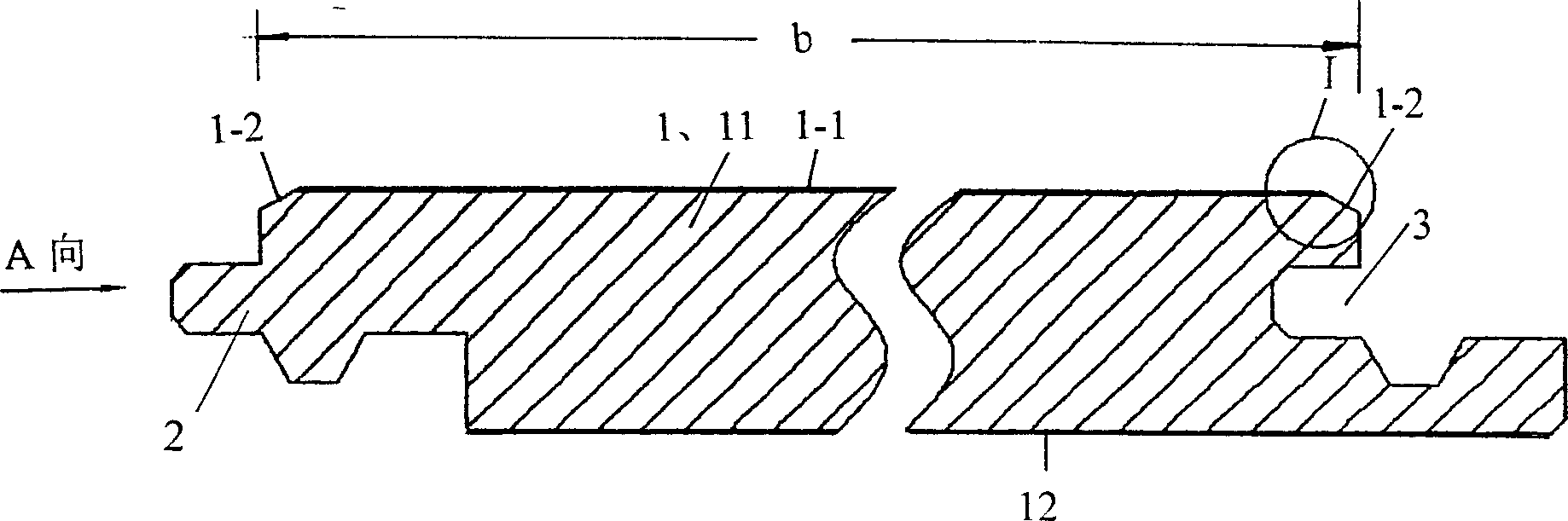

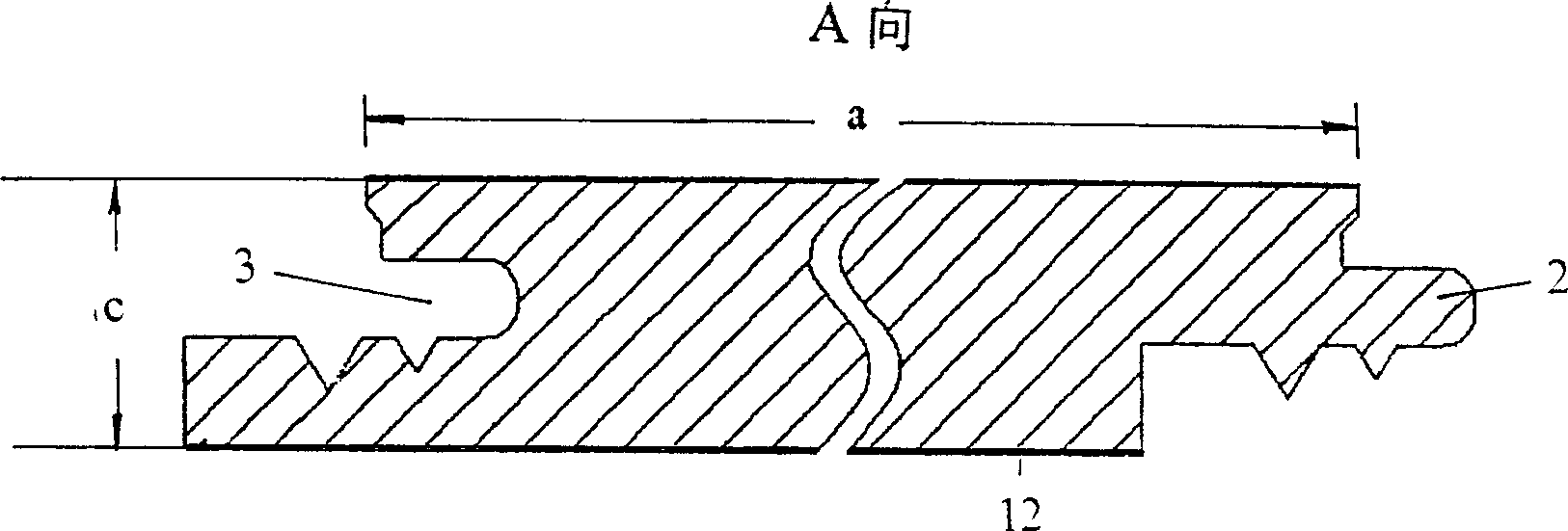

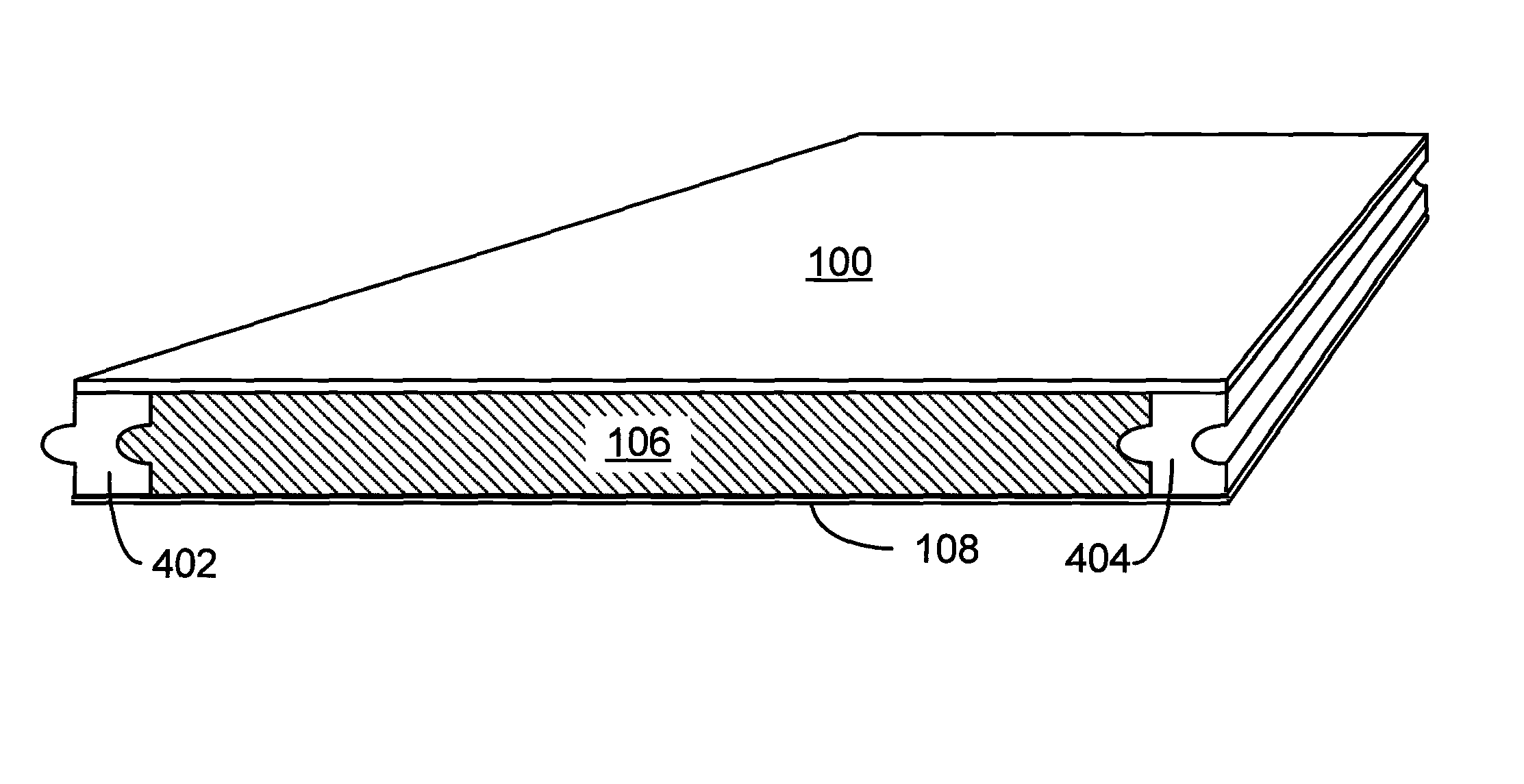

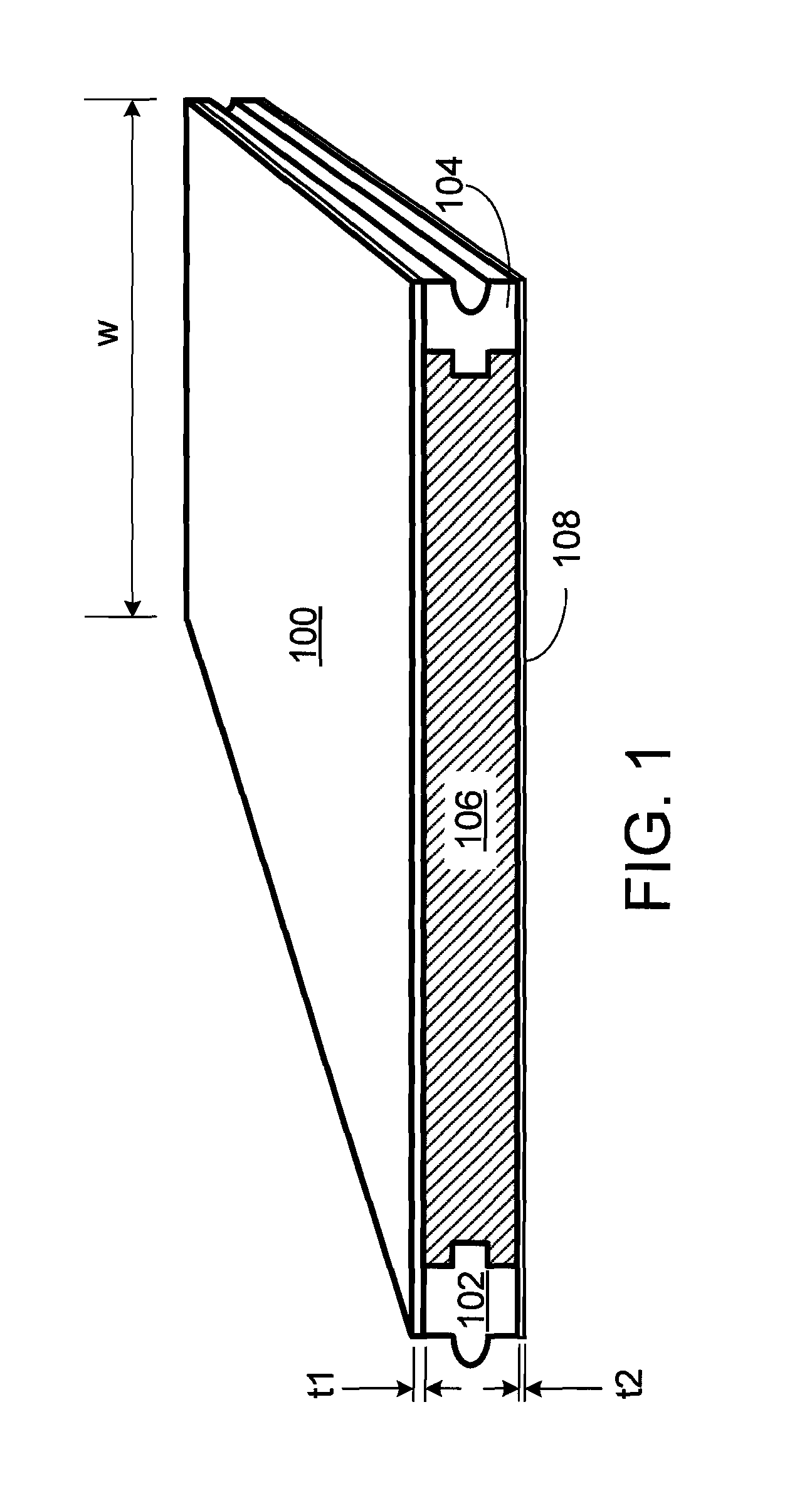

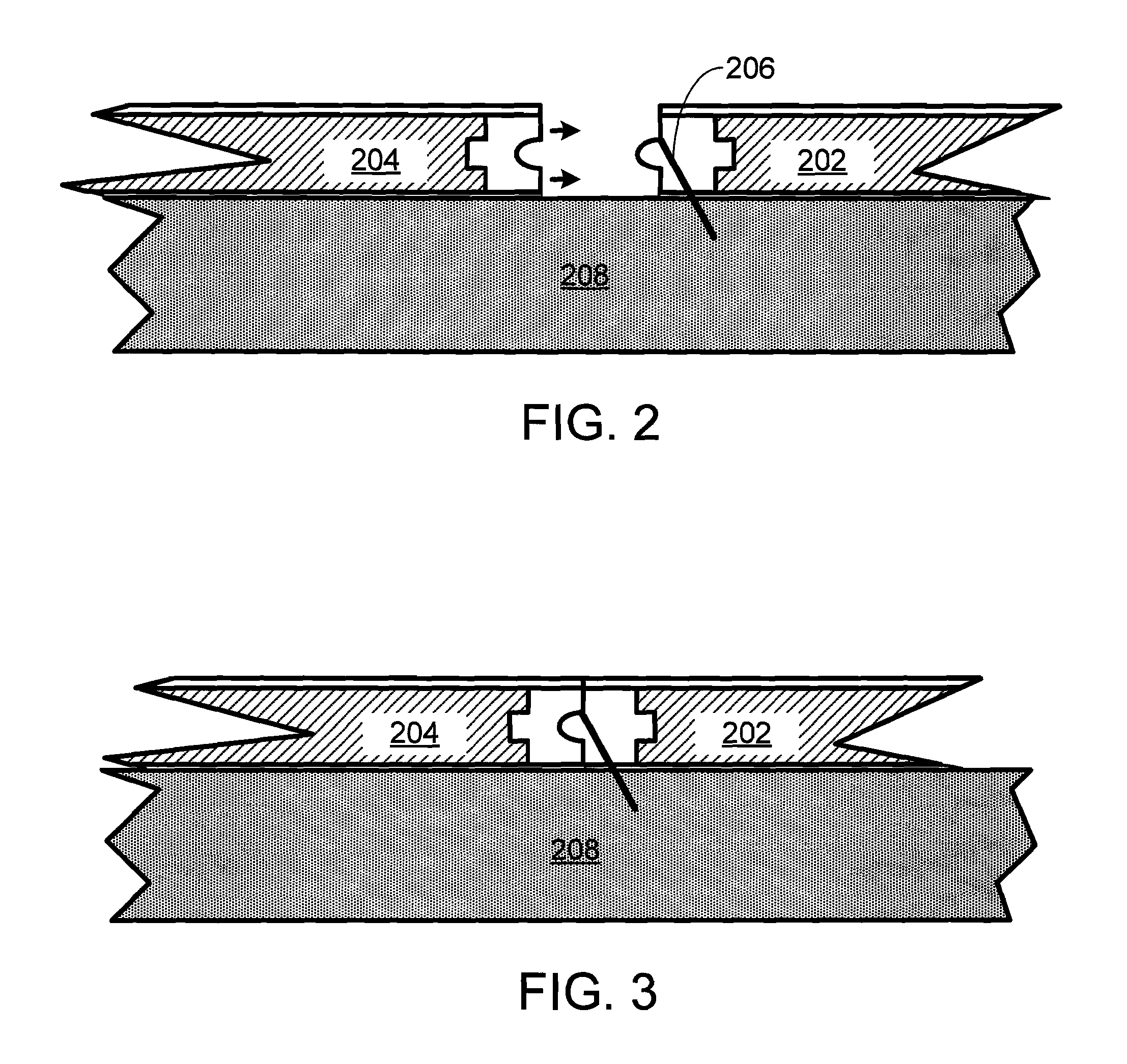

Water Resistant Wide Flooring Boards

A water resistant floor board comprises a top layer, a tongue connector, a groove connector, a body, and a bottom layer. The body is made from a man-made material and placed between the tongue connector and the groove connector, and the top layer is placed above the body, the tongue connector, and the groove connector. The bottom layer is a moisture resistant aluminum foil covering the body, the tongue connector, and the groove connector. The tongue and groove connectors are made from moisture resistant solid wood, and the body is made from man-made material. The top layer has a moisture resistant coating.

Owner:LIU DAVID C

Plank for interior use

InactiveUS20050136234A1Advantageous cost priceGood pricePaper/cardboard layered productsConstructions elementsSolid woodEngineering

The present invention is a plank incorporating a base layer with a thickness ranging from 12 to 25 mm, a solid wood top layer, with a thickness ranging from 4.6 to 6 mm, glued to base layer, wherein the base layer is made of a wood based compound, also containing non flammable polymers, hardeners, etc., wherein the wood content of the compound is at least 2% by volume and 95% by volume at maximum, wherein the wood and the polymers are distributed homogeneously, or distributed, depending only on the perpendicular distance to the glued surface, wherein the glue between base layer and top layer is a non flammable glue. The plank of the invention combines the stability and homogeneity of the base layer with the appearance of a solid plank, and moreover has a flame retardant effect, caused by the structure of the product and by the use of fire retardant polymers.

Owner:HAK GIJSBERTUS +1

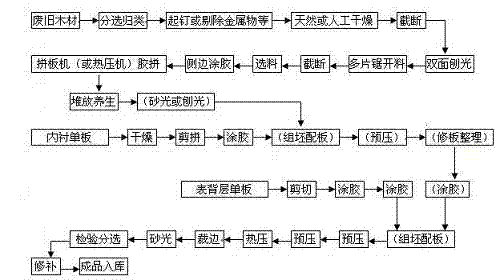

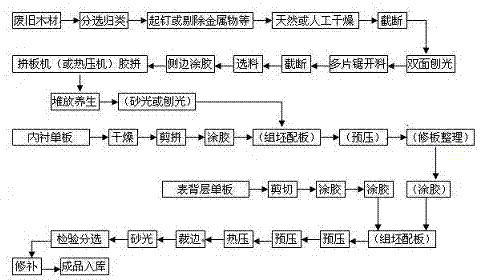

Method for producing recombinant composite board by using waste wood

InactiveCN102229159AFlat surfaceUniform thicknessOther plywood/veneer working apparatusLaminationSolid woodPulp and paper industry

The invention discloses a method for producing a recombinant composite board by using waste wood. The method comprises the following steps of: (1) preparation of a core board, (2) veneer finishing, (3) board blank gluing, blank matching and pre-pressing, (4) hot pressing, (5) trimming and sanding, and (6) inspection, grading and repair. The method has the advantages that: the square board of certain specification is manufactured by making full use of the waste wood, the core layer is spliced by using glue, two layers of veneers are covered on two sides of the core layer respectively, the recombinant composite board with five-layer structure is manufactured by hot pressing, and the reclaimed waste wood is used for substituting solid wood, so the material channel is broadened; low carbon, environment friendliness, greenness and resource property of the recombinant composite board are highlighted; the comprehensive utilization rate of the waste wood is improved, and the additional value and the technological content of the waste wood product are increased; and high use of small material, preferential use of poor material, fine use of coarse material and elaborate use of weak materialare realized in the waste wood.

Owner:玉环市众创人才科技创新服务中心

Stiffened timber floor and the manufacturing method thereof

InactiveCN1485184ALow priceExtended service lifeWood working apparatusWood layered productsSolid woodPulp and paper industry

An intensified wood floor board and its manufacturing method. One measure is, the upper surface of the floor mainbody is composed of the walking plane and inclined planes of the two sides of the walking plane; the upper surface of fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by pressing mold, balanced paper layer, fiberboard, the paper layer with wood texture and a durable paper layer are adhered with each other. The second measure is, the upper surface of the floor mainbody is composed of the walking plane parallel to the base surface and inclined planes of the two sides of the walking plane, the upper surface of the upper surface of the fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by bonding, the inclinedplanes on two sides are adhered with the paper layers with wood texture; resin varnish is coated on the paper layers with wood texture. due to inclined planes of two sides of the upper surface of floor mainbody, it is convenient to pave floor board. The floor board is durable, inexpensive and could use for a long time.

Owner:葛跃进

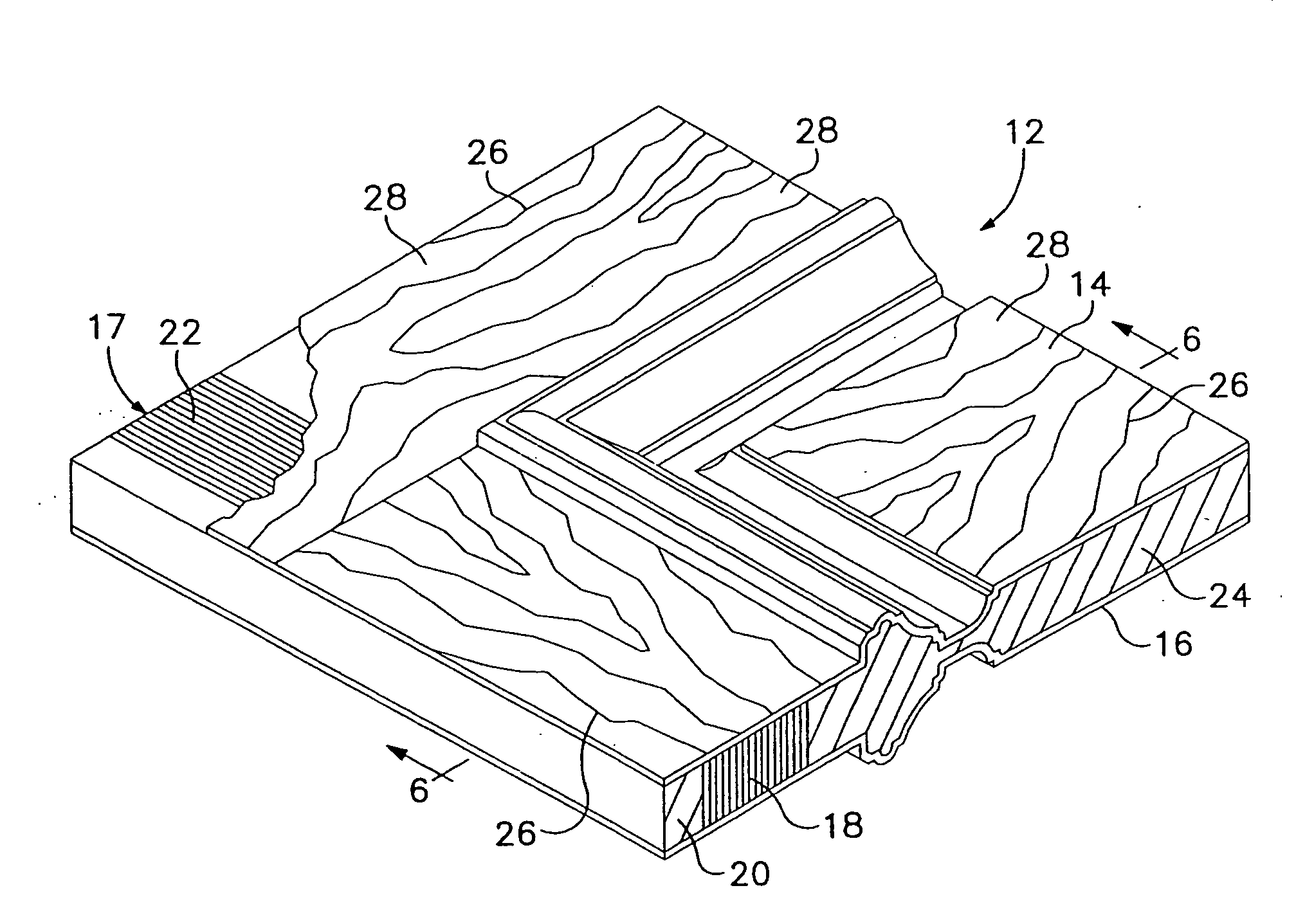

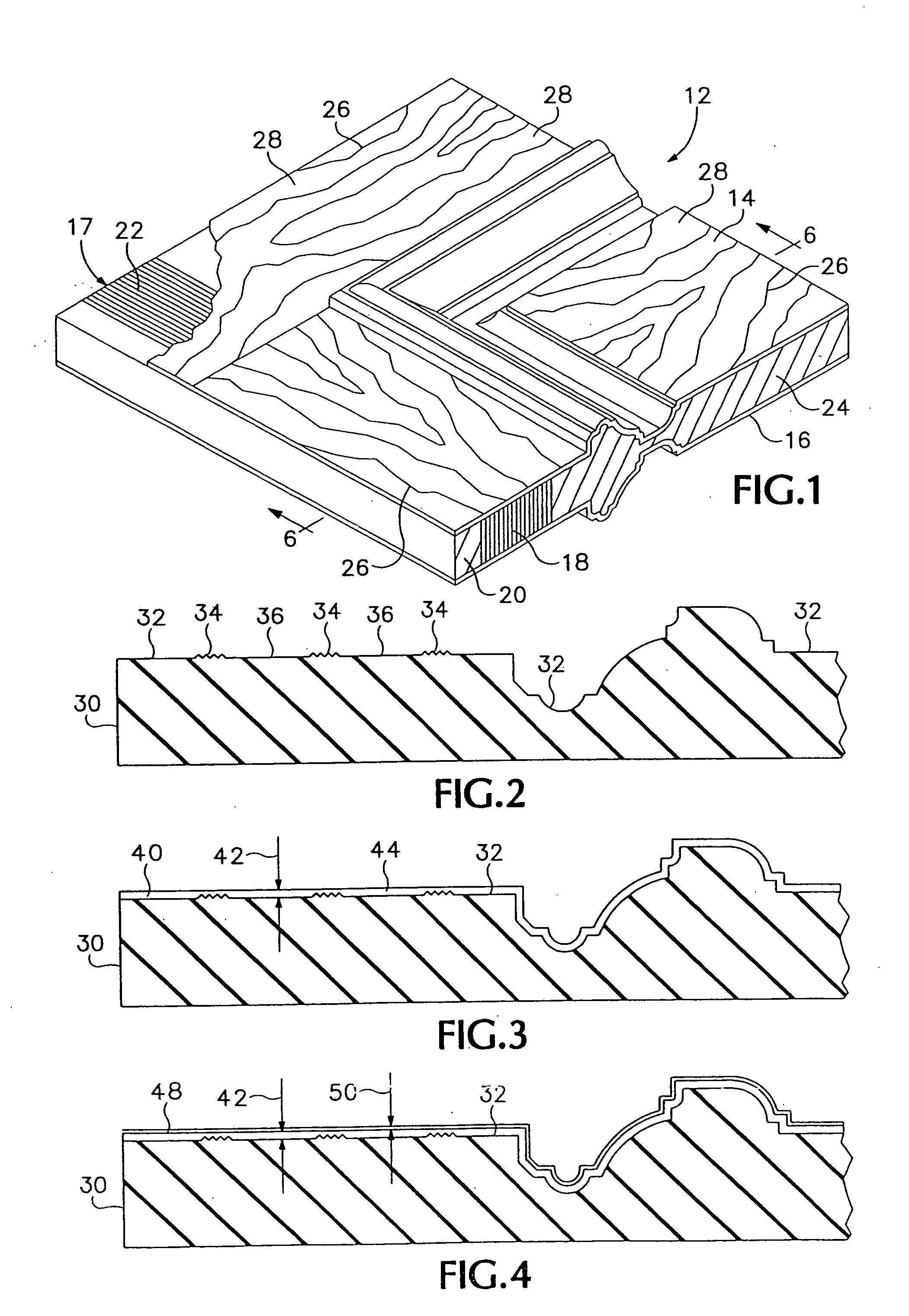

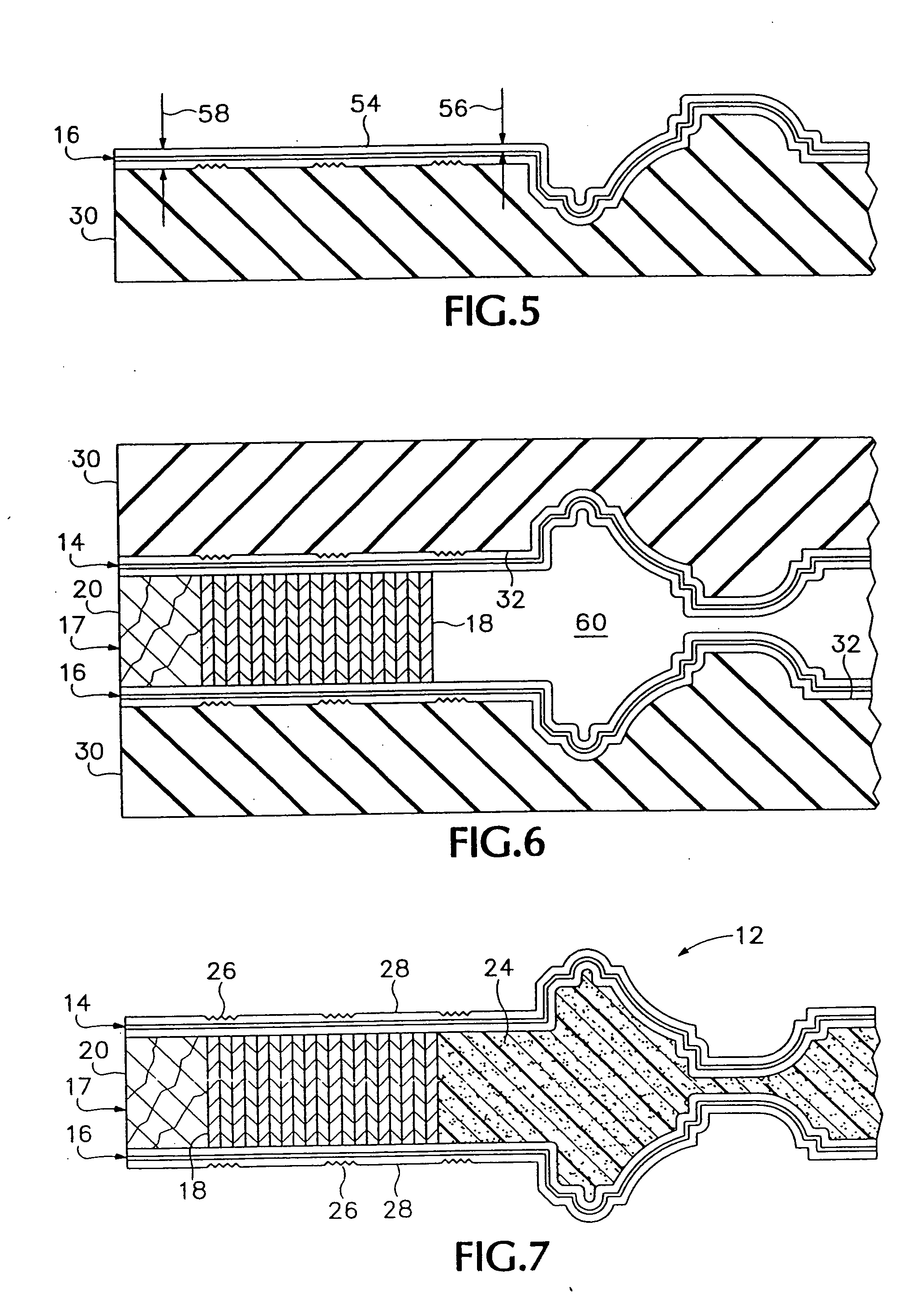

Articles of composite structure having appearance of wood

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

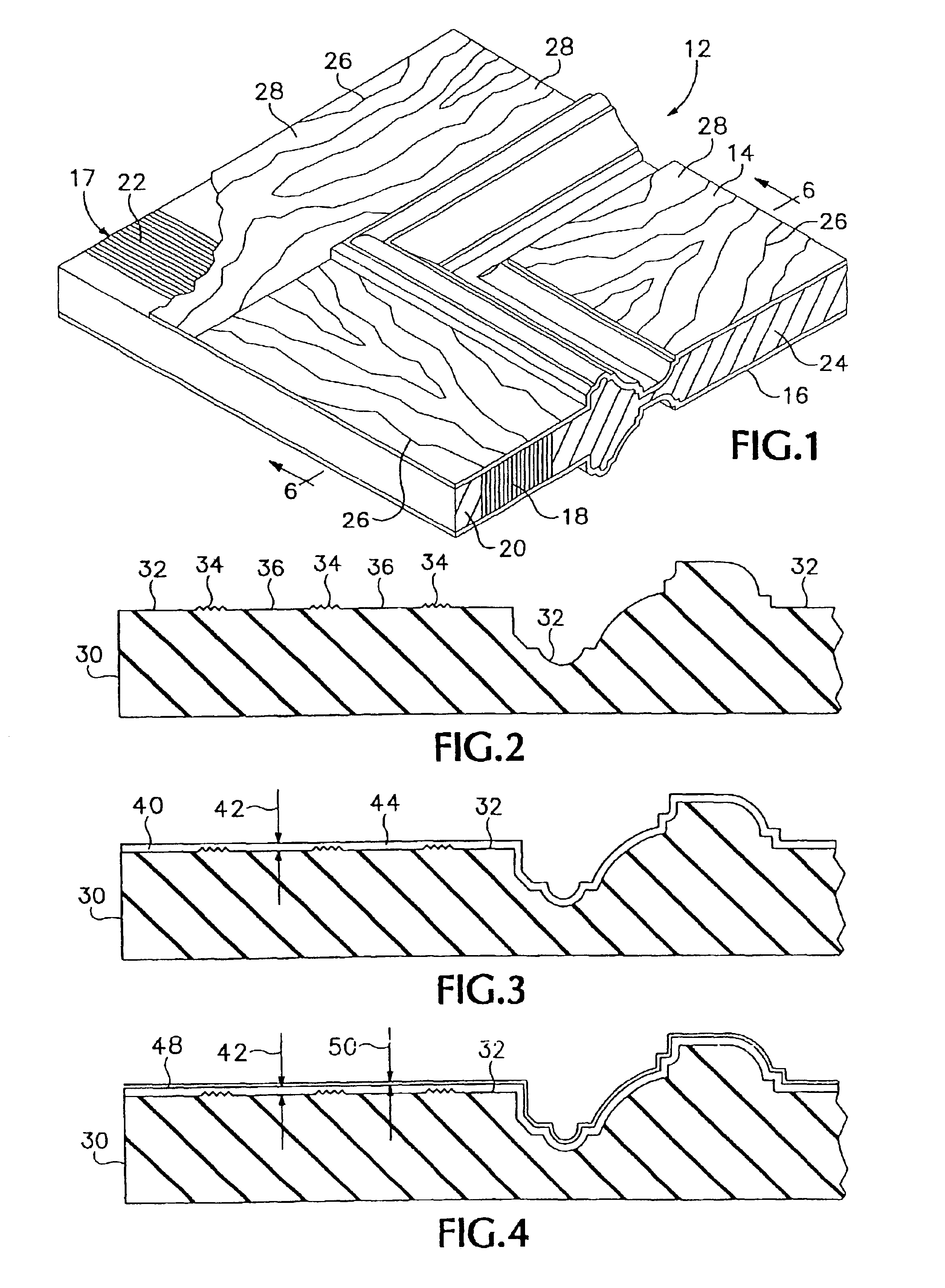

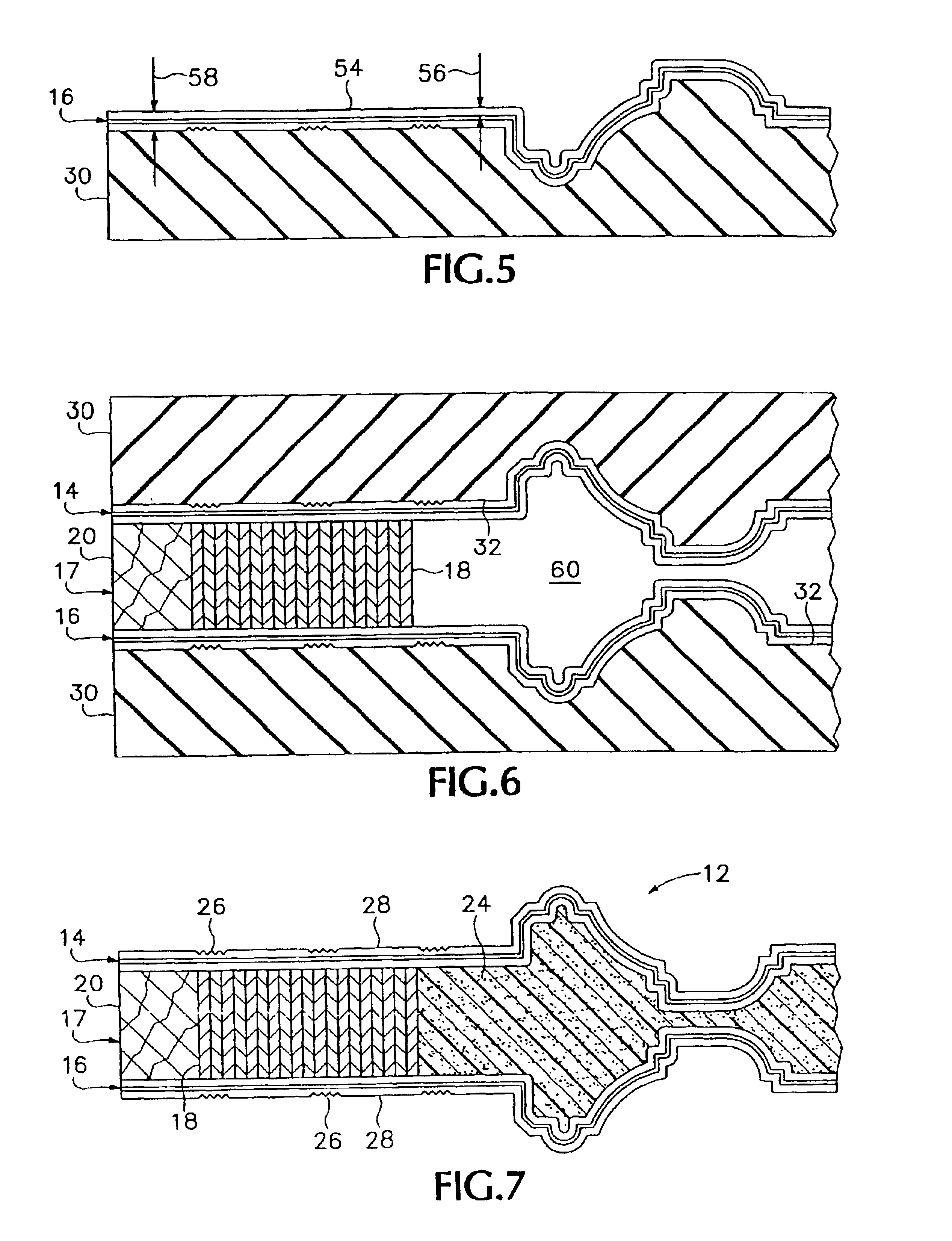

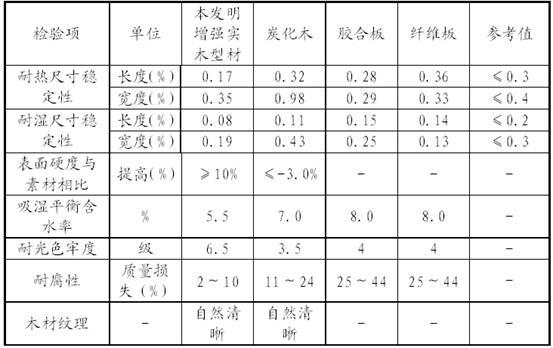

Stable enhanced type solid wood profile and production method thereof

ActiveCN101879736AReduce surface hardnessReduce surface strengthWood impregnation detailsSolid woodWeather resistance

The invention provides a production method of a stable enhanced type solid wood profile improved by a wood carbonization and acetylation process, which belongs woodwork production technique. The production method comprises the following steps of: a, drying treatment, wherein the wood moisture content is reduced to be as low as 5.0 to 8.0 percent, the moisture content deviation in the wood thickness is less than 2.0 percent, and the wood internal residual stress is less than 2.0 percent; b, carbonizing treatment; c, acetylation treatment; and d, equalization treatment. The invention also discloses a stable enhanced type solid wood profile prepared by the production method. The solid wood profile prepared by the method is stable, has high corrosion resistance and weathering resistance, high output, long product service life and wide utilization ways, is favorable for realizing flow line production, and is convenient for industrialization.

Owner:ZHEJIANG SHIYOU TIMBER

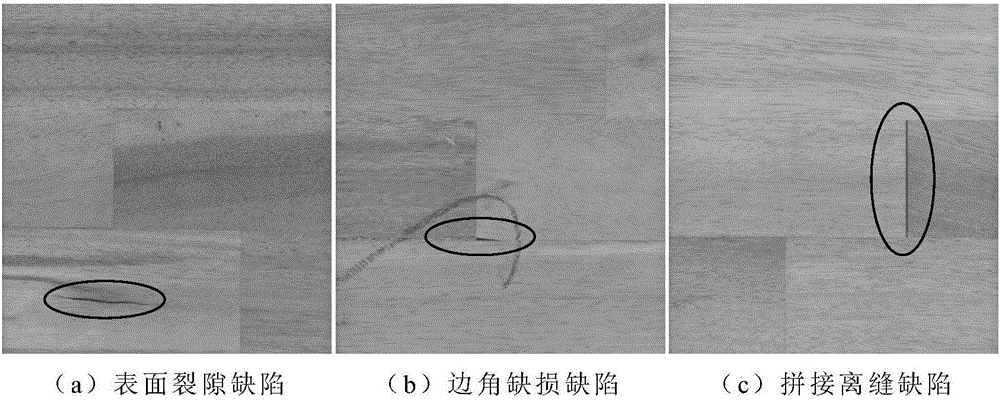

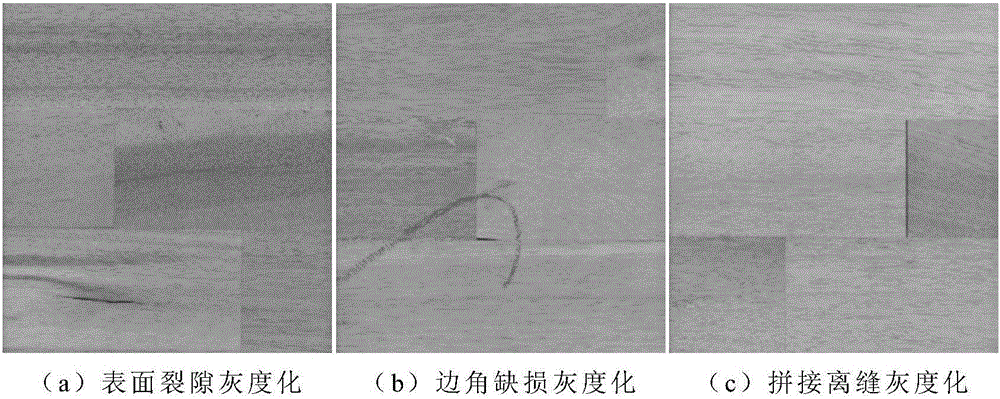

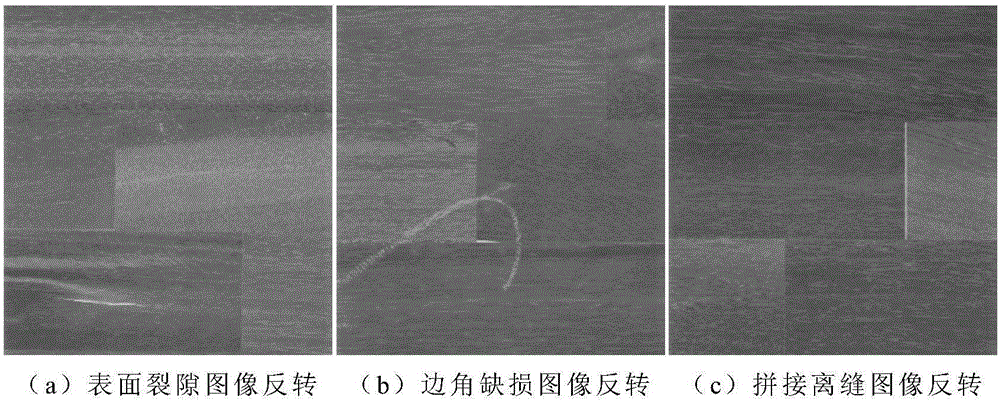

Recognition method of surface defects of multilayer solid wood composite floor with surface board being jointed board

InactiveCN106338520AImprove visual inspection efficiencyImprove the level ofOptically investigating flaws/contaminationSolid woodSupport vector machine

The invention provides an recognition method of surface defects of a multilayer solid wood composite floor with a surface board being a jointed board, which is basically the same in the classification standards, high in recognition rate and low in error rate, can realize industrial on-line detection, and can accurately recognize three types of defects of the multilayer solid composite floor: corner defects, surface fractures and splicing open joints. The recognition method comprises the following steps: performing image graying processing, image grey level transformation, image smoothing processing, image segmentation and image segmentation postprocessing on a collected RGB color image on the surface of the solid wood composite floor to extract target defects; adding characteristic values of the target defects, with defect characteristics being extracted, to a support vector machine, so as to be trained; after training, adding the characteristic values of the target defects, with defect characteristics being extracted, to the support vector machine, so as to be recognized.

Owner:NANJING FORESTRY UNIV

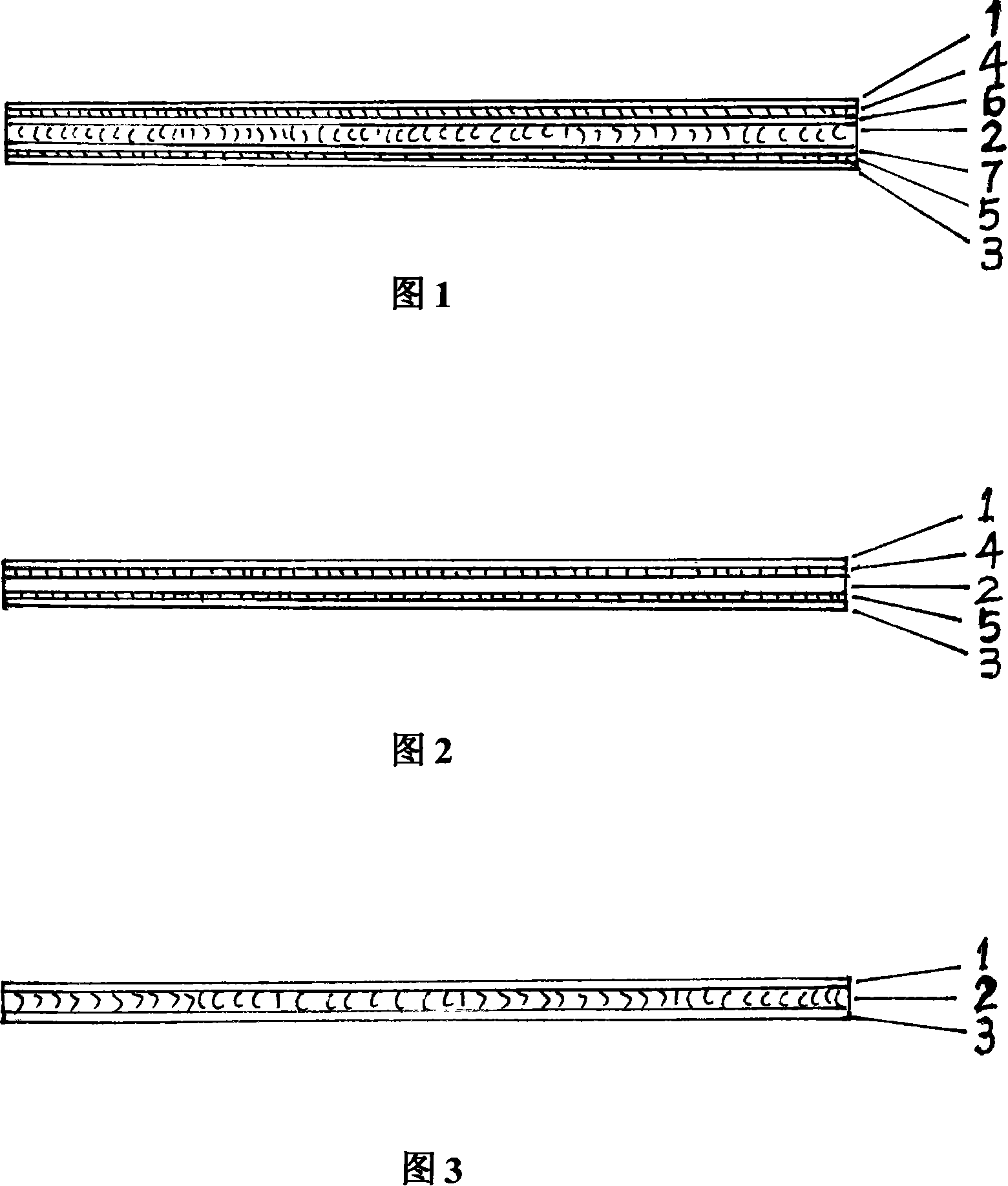

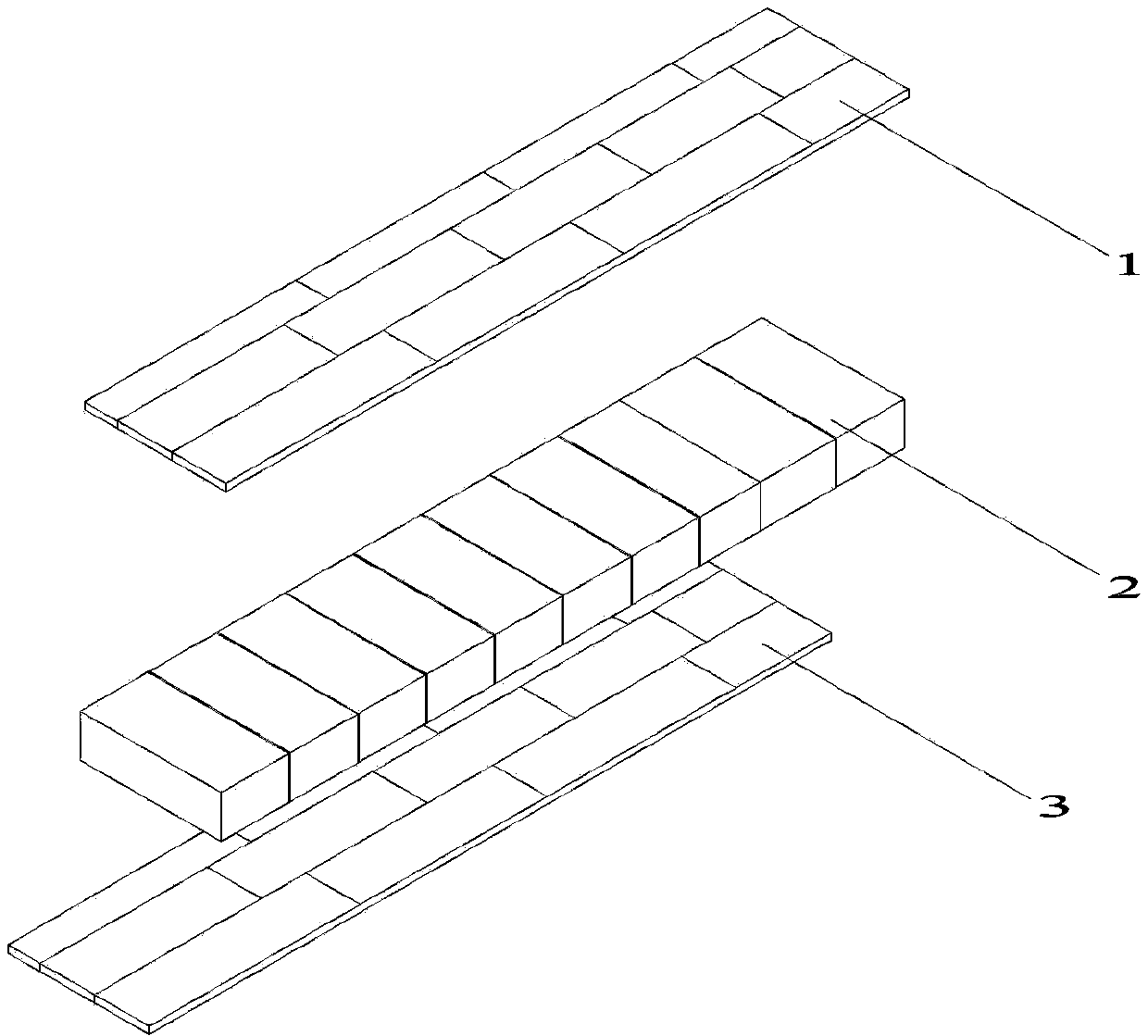

Non-formaldehyde solid wood composite floor using low-density cottonwood veneers as base materials and manufacturing method thereof

ActiveCN102423891AHigh densityEfficient value-added utilizationWood working apparatusWood layered productsSolid woodSurface layer

The invention provides a manufacturing method of a non-formaldehyde solid wood composite floor using low-density cottonwood veneers as base materials. The non-formaldehyde solid wood composite floor is at least a cottonwood base plate assembly manufactured by combining following two raw materials: first, cottonwood veneers formed by stewing cottonwood logs at a low temperature of 10 to 50 DEC C, then rotary-cutting or slicing the cottonwood logs and afterwards drying the cottonwood logs, and second, plastic adhesive films manufactured by adopting thermoplastic resin; the treated cottonwood veneers are coated with coupling agents and are then assembled with the plastic adhesive films, and after hot-pressing and setting treatment, a cottonwood base plate is manufactured; afterwards, decorative thin wood is adopted as a surface layer and is combined with the cottonwood base plate assembly, and after cold-pressing, a floor blank is manufactured; and finally, the floor blank is milled, tenoned, slotted, and subjected to paint curing, and then a product is manufactured. Through using high polymer materials, from which no harmful substance escapes, in both the machining process and the use process, the environmentally friendly solid wood composite floor is produced.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Water resistant wide flooring boards

Owner:LIU DAVID C

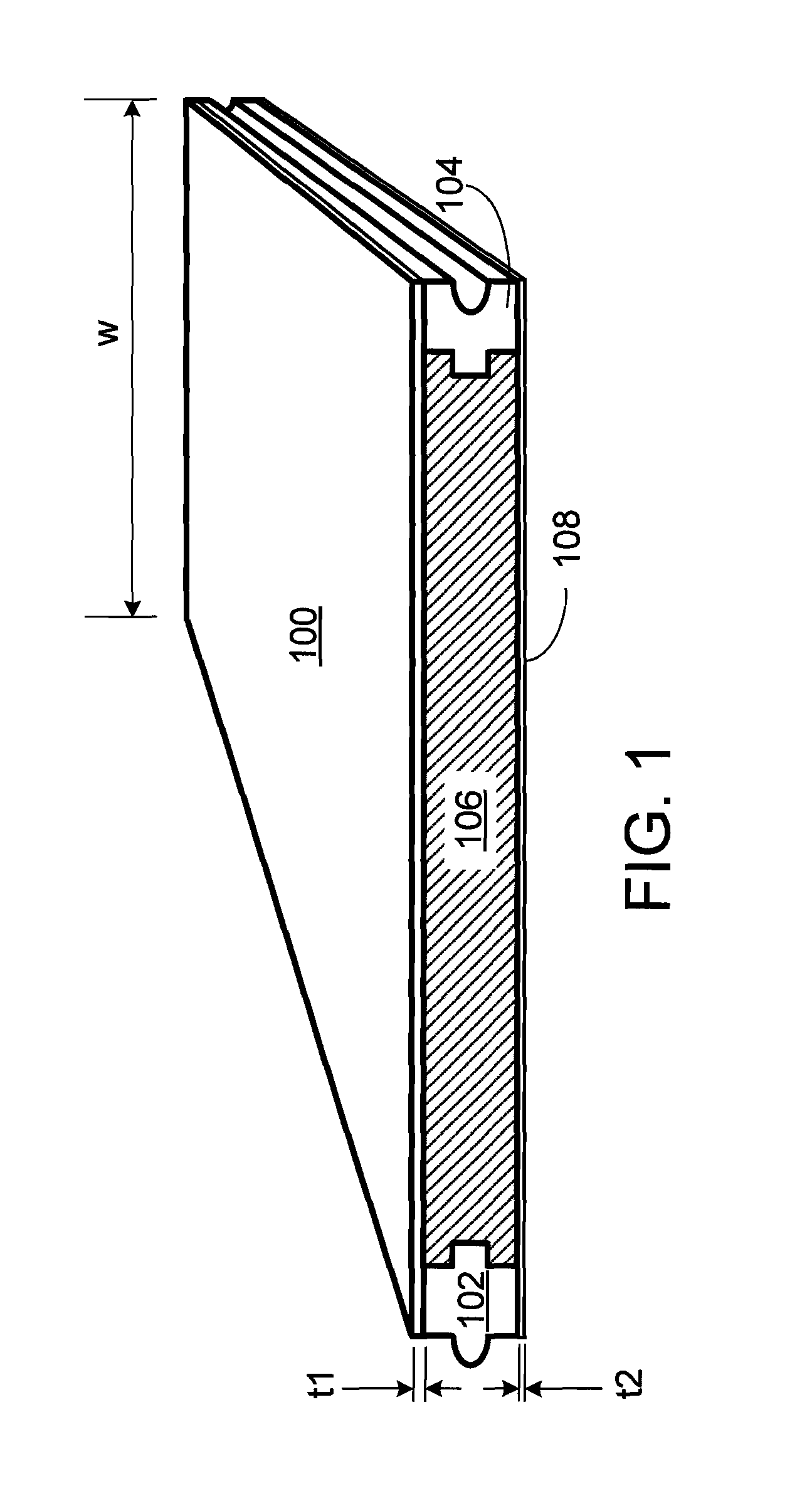

Hardwood Flooring System

InactiveUS20080184647A1Superior hydroscopic dimensional stabilityProvide durabilityConstruction materialStrutsSolid woodEngineering

An improved fabricated hardwood flooring product providing the advantage of a thick wood wear layer similar to a traditional ¾ inch solid wood floor with the dimensional stability characteristics of engineered wood floor products.

Owner:BEST WOODS

Soft material solid-wood reinforced board and its producing method

ActiveCN101007415AImprove use valueOvercoming odd problemsCork treatment detailsVolumetric Mass DensityNormal conditions

A soft material quality wood material strengthening board is flat plate. It is characterized by: it has natural grains of raw wood, its color is the mixture color of raw wood self color, charring color and resin color, the density is 450-720kg / m<3>, surface hardness is 25-65MPa, vertical MOR is 35 - 90MPa, vertical elastic modulus is 1~10GPa, resin content (solid content) is 3% - 10%. The strengthening board can be produced floors or furniture raw materials after preliminary working, drying, rough planing, heating, resin soaking, hot pressing, placing in normal condition and fine finishing. The invention produces the strengthening board using soft material as raw material, covers the shortage of hardwood product raw materials, it increases the use-value of soft material, while meets the popular consumer demand of liking wood, and provides new materials for hardwood furniture and flooring manufacturing industry.

Owner:ZHEJIANG NENGFU TOURIST PRODS

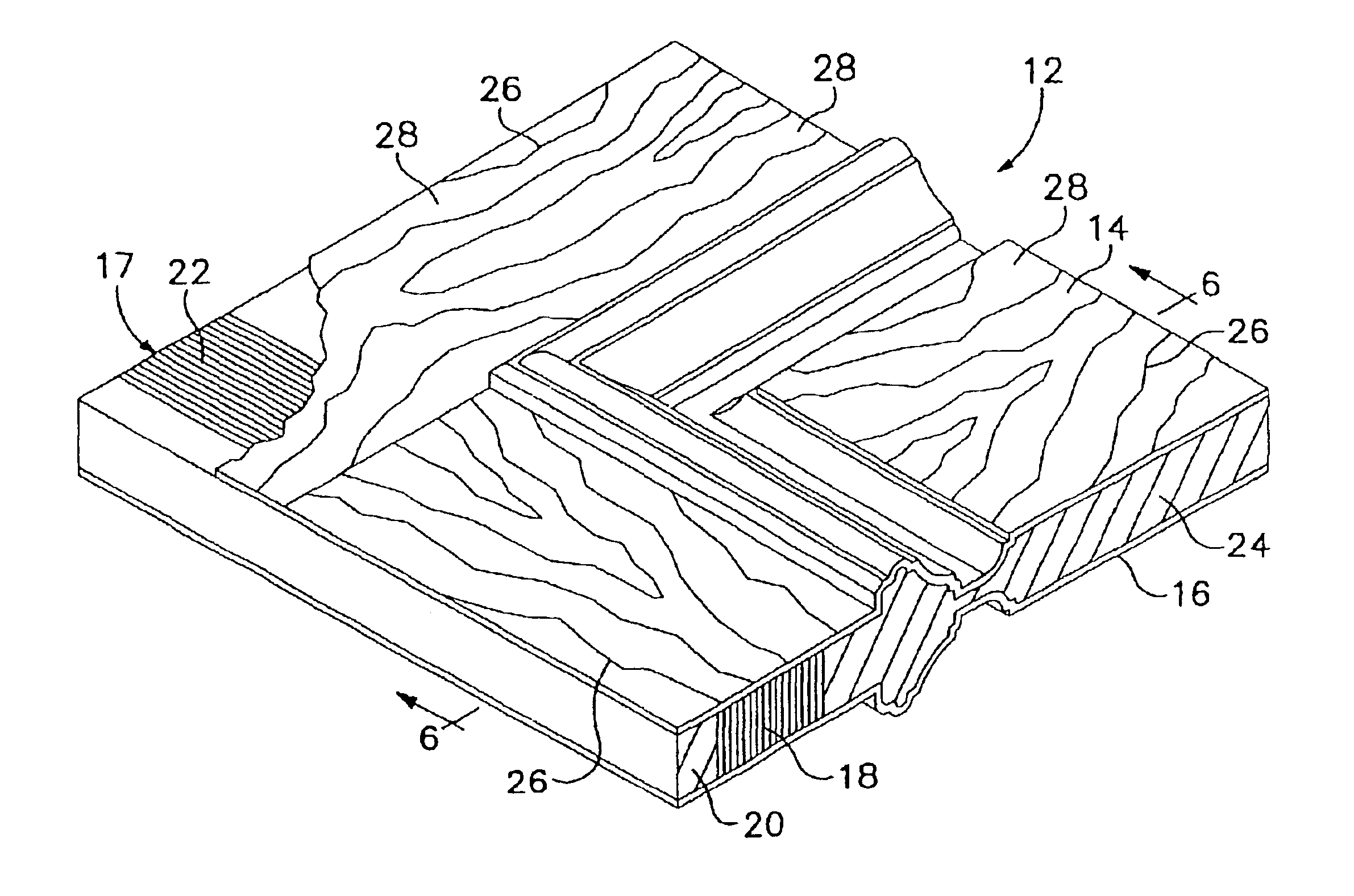

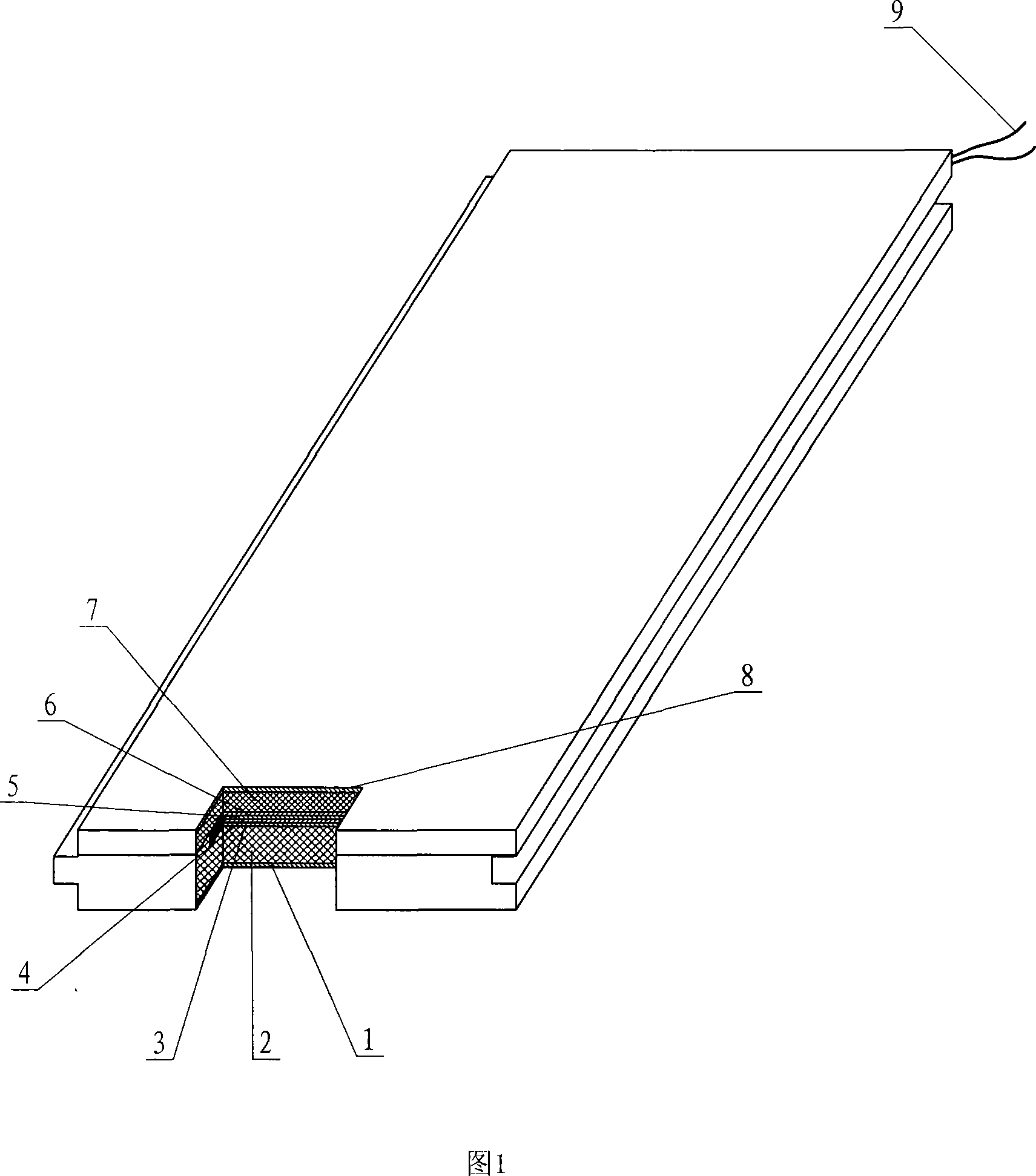

Wood-plastic coated solid wood composite material and preparation method thereof

InactiveCN104228236AHigh mechanical strengthImprove impact resistanceWood layered productsSolid woodCo extrusion

The invention discloses a wood-plastic coated solid wood composite material and a preparation method thereof and aims at solving the problems in the prior art that the combination of a wood-plastic composite material and a solid wood material is poor in firmness, the end of a sectional material is unclosed, the wood-plastic composite material is prone to creep deformation and low in tenacity, and the solid wood material is prone to decaying, hygroscopic deformation and cracking. The wood-plastic coated solid wood composite material is made by wrapping a solid wood core with a wood-plastic composite material. The method comprises the following steps: firstly, processing a groove in the side of solid wood to obtain the solid wood core; secondly, coating the surface of the solid wood core with the wood-plastic composite material through a co-extrusion method and filling the side groove with the wood-plastic composite material to obtain a wood-plastic coated solid wood composite sectional material; and thirdly, sealing the wood-plastic coated solid wood composite sectional material by virtue of the wood-plastic composite material to obtain the wood-plastic coated solid wood composite material. The wood-plastic coated solid wood composite material disclosed by the invention is used for manufacturing a door or window and furniture, and also can be used as a bearing structure material.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Surface reinforced solid wood section material, floor board and manufacturing method thereof

ActiveCN101603623AReduce pollutionStable moisture contentWood compressionFurniture partsSolid woodVolumetric Mass Density

Owner:ZHEJIANG SHIYOU TIMBER +1

Articles of composite structure having appearance of wood

InactiveUS20050166402A1Metal rolling stand detailsSpecial ornamental structuresSolid woodSurface layer

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

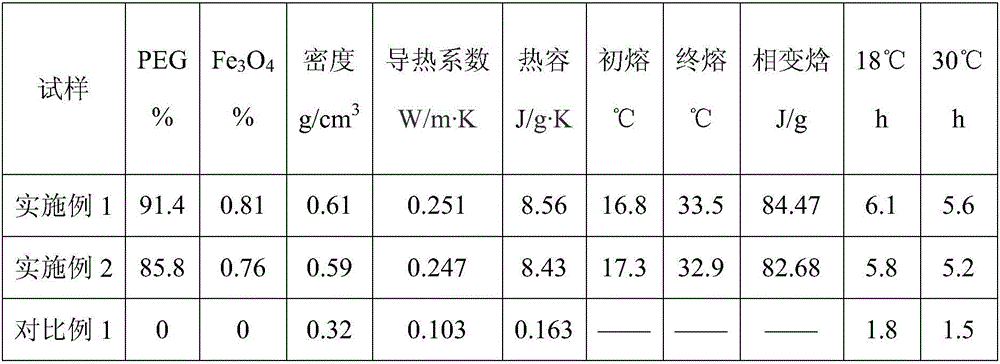

Phase-change energy storage heat-insulation solid wood and manufacturing method thereof

ActiveCN106625930ALow viscosityFacilitated Diffusion MigrationPressure wood treatmentWood treatment detailsSolid woodCell cavity

The invention provides phase-change energy storage heat-insulation solid wood. The wood comprises a solid wood component, wherein magnetic Fe3O4 nanoparticles are formed in a conduit and a cell cavity of the solid wood component through in-situ attached growth, and the conduit and the cell cavity are filled with composite phase-change energy storage materials of polyethylene glycol 600 and polyethylene glycol 800; and a protective coating is painted on the surface of the heat-insulation solid wood. The heat-insulation solid wood is capable of absorbing heat to withstand excessive rise of an indoor temperature during the day, releasing phase-change latent heat for thermal retention and cold dispelling during the night, and maintaining a human body within a comfort temperature range. The invention further provides a manufacturing method of the heat-insulation solid wood. The method comprises the steps of firstly processing the solid wood component according to the required dimension; carrying out degreasing and drying pretreatment on the solid wood component, forming the magnetic Fe3O4 nanoparticles in the solid wood component through in-situ attached growth and then impregnating and filling the composite phase-change energy storage material of the polyethylene glycol 600 and the polyethylene glycol 800; and finally carrying out sanding shaping and painting the protecting coating. According to the manufacturing method, the process is simple and the cost is low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

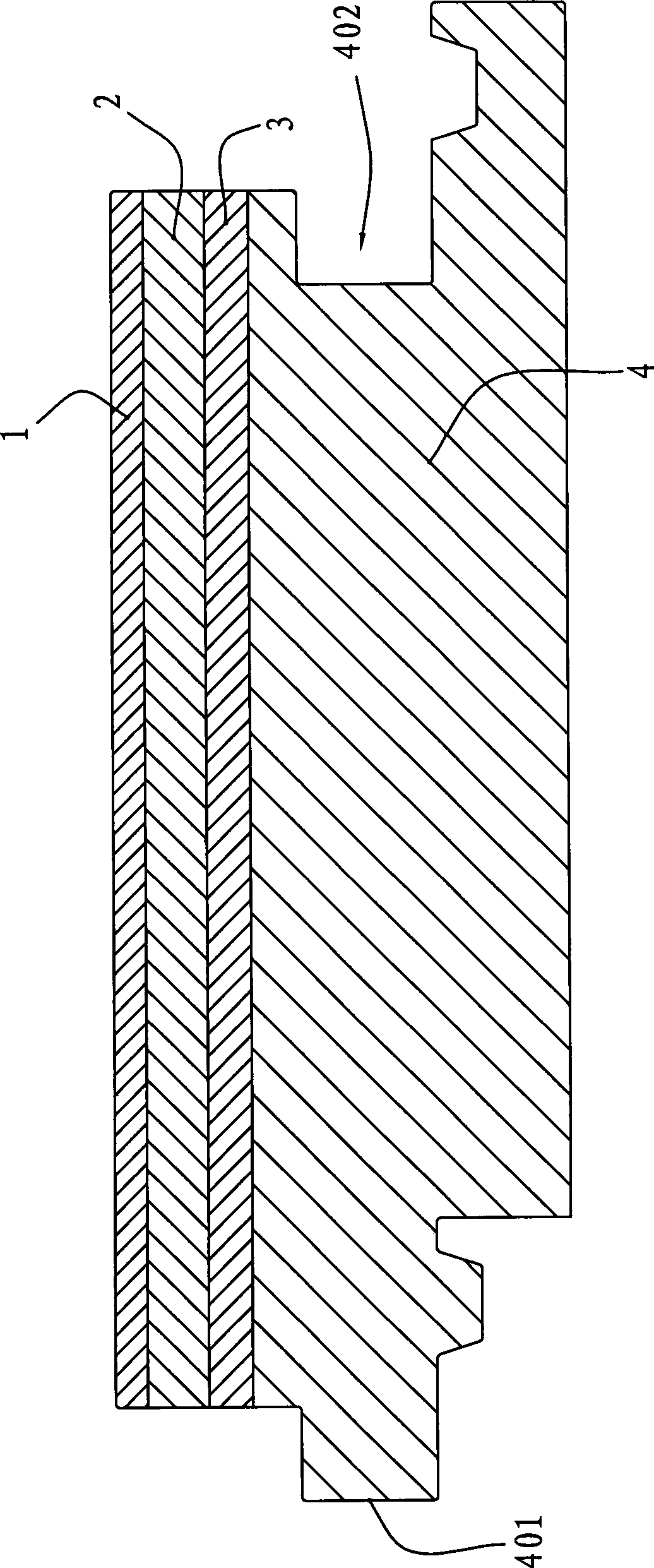

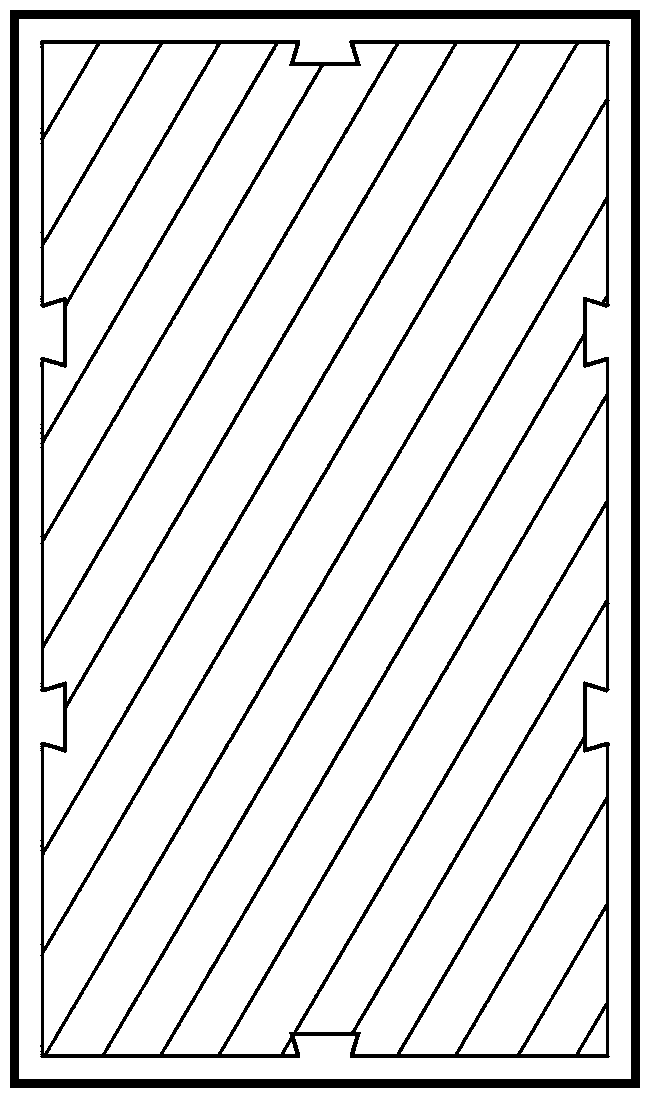

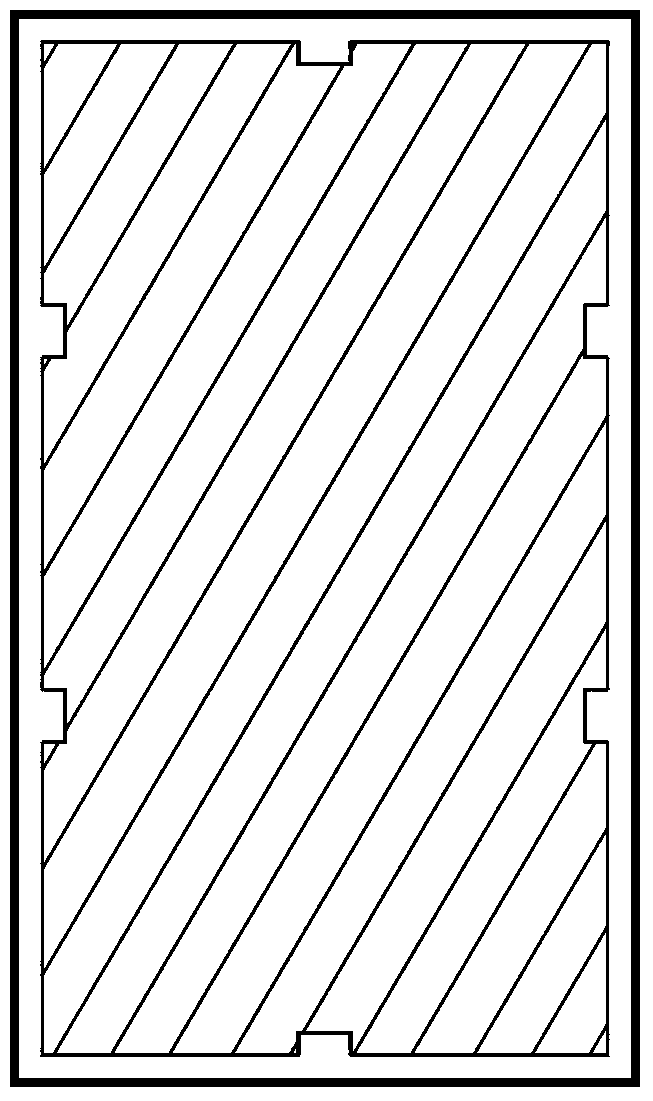

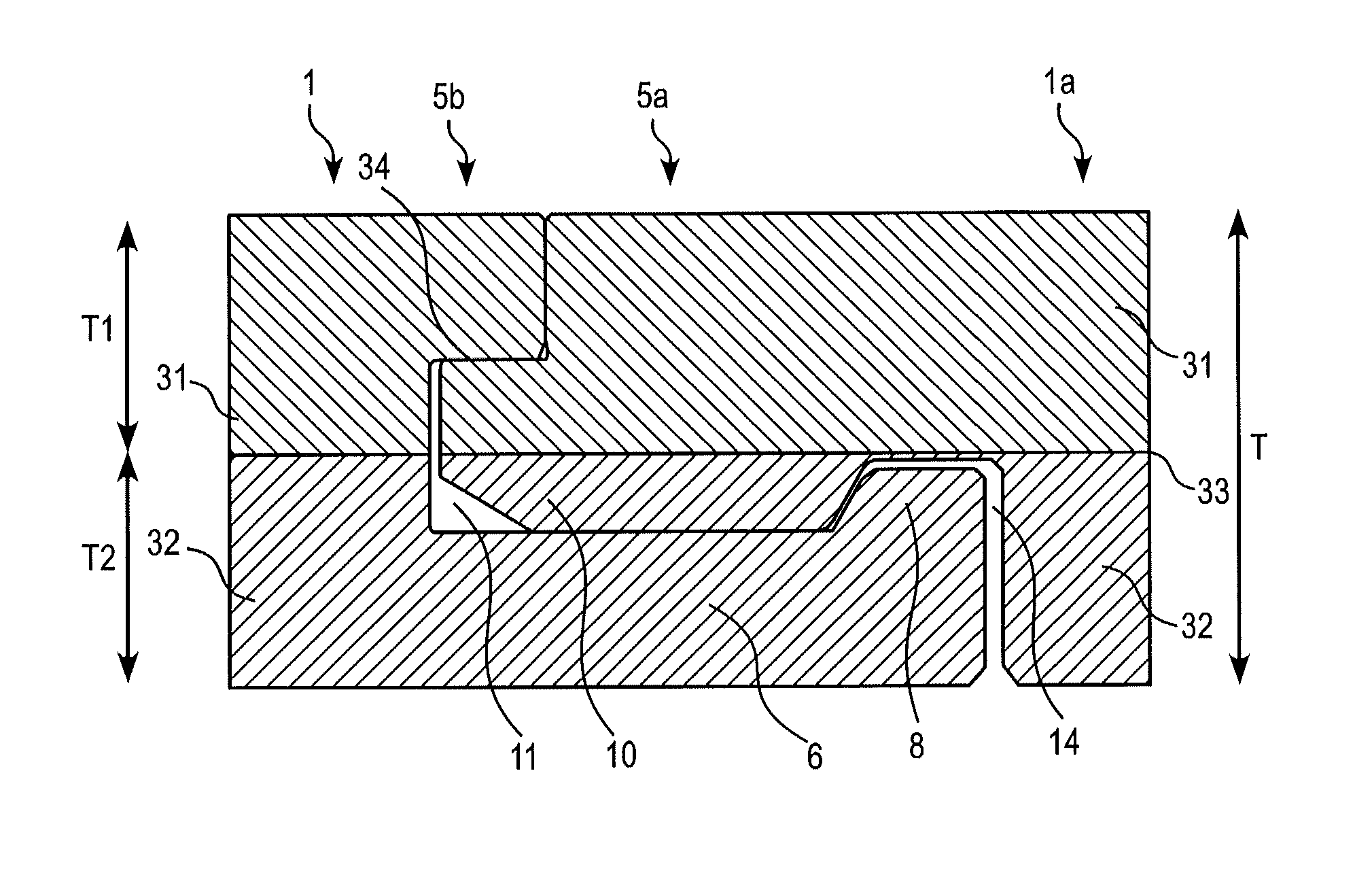

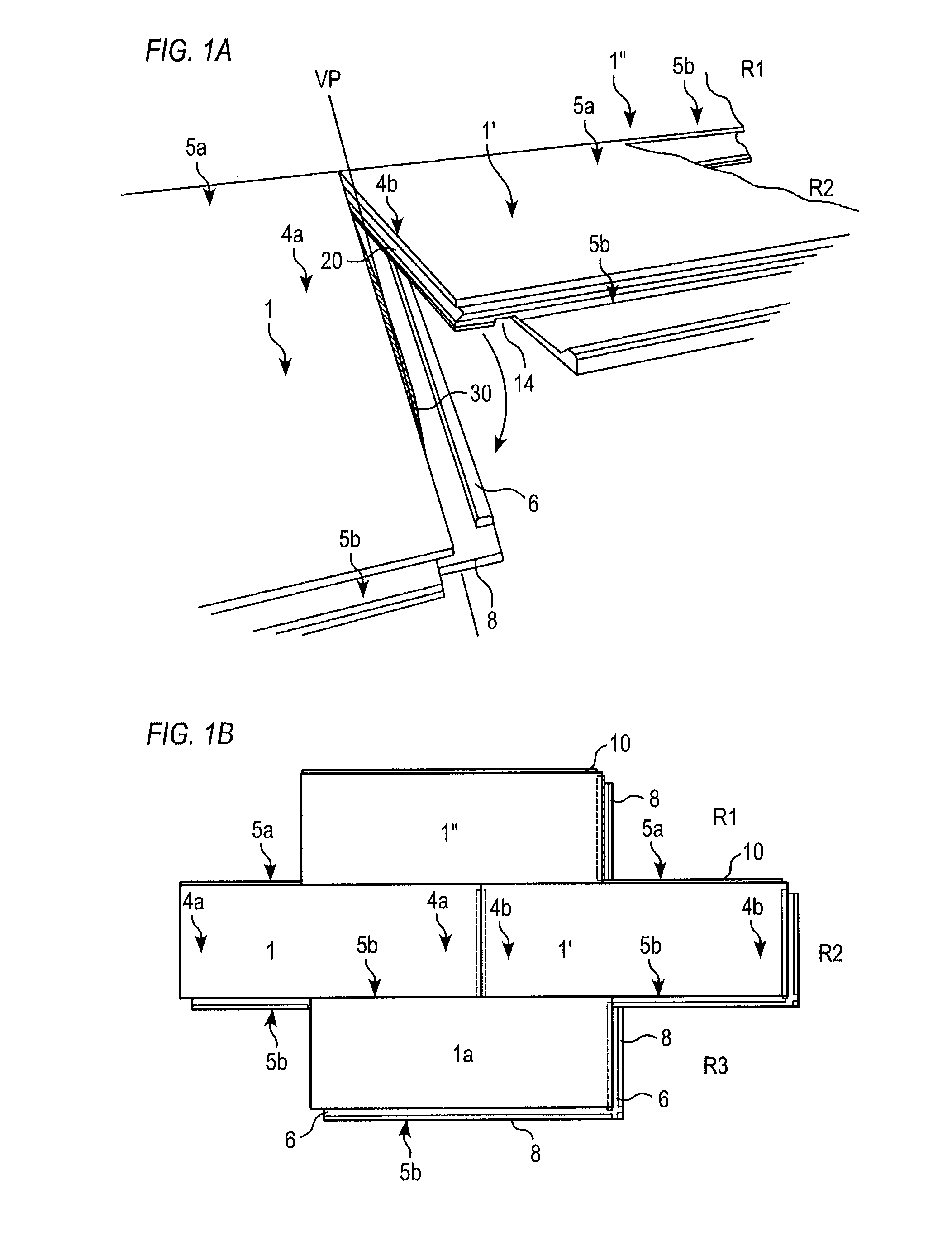

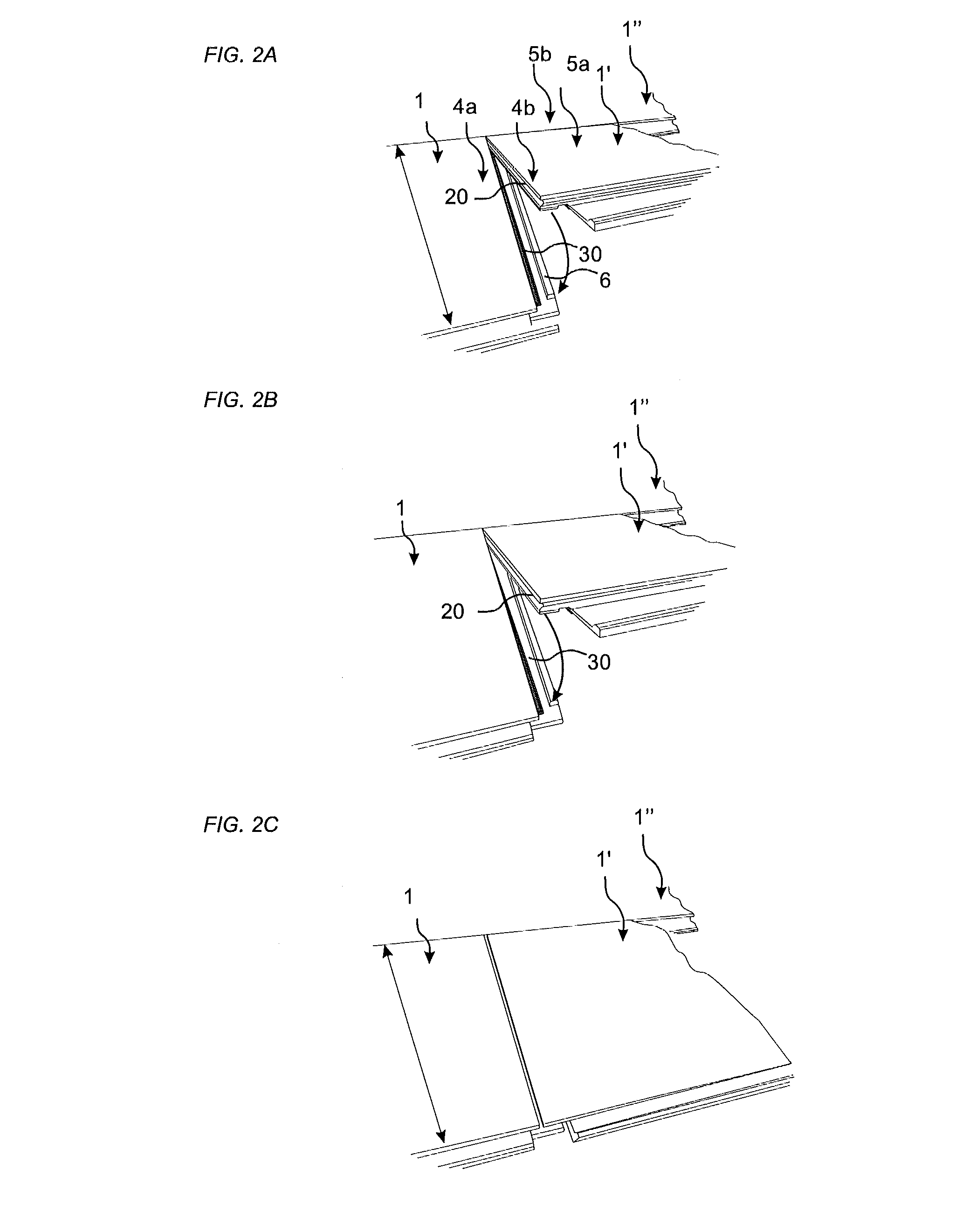

Building panels of solid wood

Building panels each comprise an upper first element of solid wood fixed to a lower second element of solid wood. The first and the lower second element are of different wood species. The building panels are provided with a mechanical locking system which comprises a locking strip at a first edge of a first building panel. The locking strip is provided with a locking element configured to cooperate with a locking groove at a second edge of a second building panel for horizontal locking of the first and the second building panels when a tension force is applied. The fibre direction of the first and the lower second elements is essentially along the first and the second edges. The lower second element has about the same or higher moisture shrinkage value than the first element. The locking strip comprises material of the lower second element.

Owner:VÄLINGE INNOVATION AB

3D (three dimensional) wood printing supply and preparation method thereof

The invention provides a 3D (three dimensional) wood printing supply which comprises components in percentage by mass as follows: 60%-90% of wood meal, 3%-15% of ABS (acrylonitrile butadiene styrene) plastics, 4%-15% of PLA (poly lactic acid), 2%-10% of PHA (polyhydroxyalkanoate), 1%-2% of PP (polypropylene) and 1%-2% of a compatilizer. The 3D wood printing supply has the characteristics such as water proofing, corrosion resistance, moisture resistance, freeness of worm damage, mildew and toxicity, acid and alkali resistance, environment protection and the like, the real flavor of wood is diffused; the wood printing supply is fused and deposited by a 3D printer at the temperature of 190-230 GDE C to form various different 3D models, the 3D models have the hand feel, the impression and the fragrance of natural wood and have an effect approaching to a solid wood effect and wood properties, and the printing supply can be nailed, drilled, planed, carved, adhered and painted as wood; and the comprehensive physical properties and chemical properties can be well improved and optimized, the performance requirement of the 3D printer can be effectively reduced, and accordingly, the printing supply is suitable for both high-end printers and low and medium-end 3D printers and has a wider application range.

Owner:广东傲趣三维科技有限公司

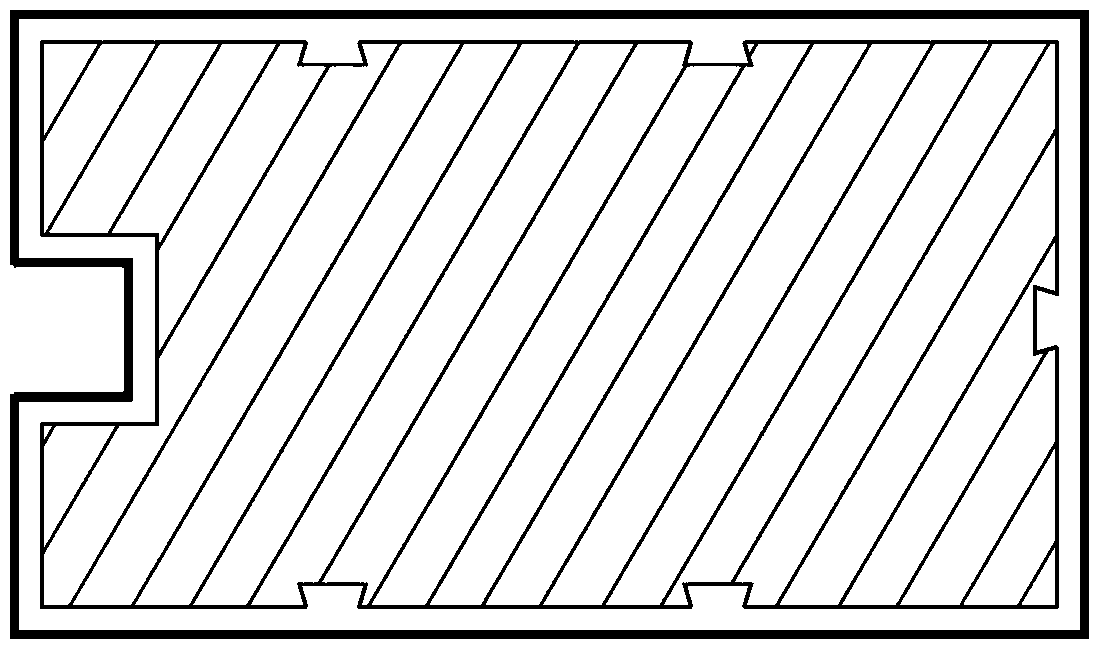

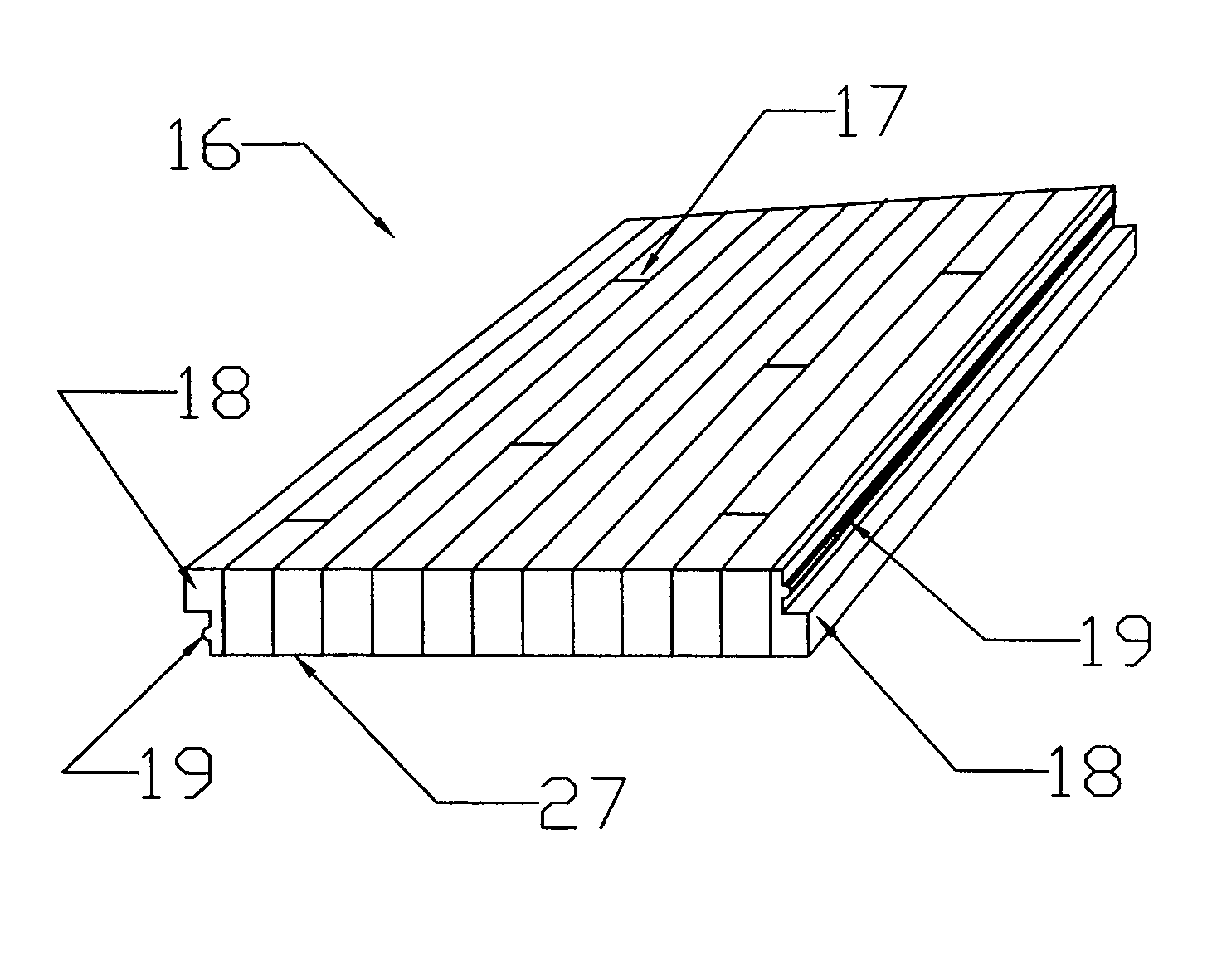

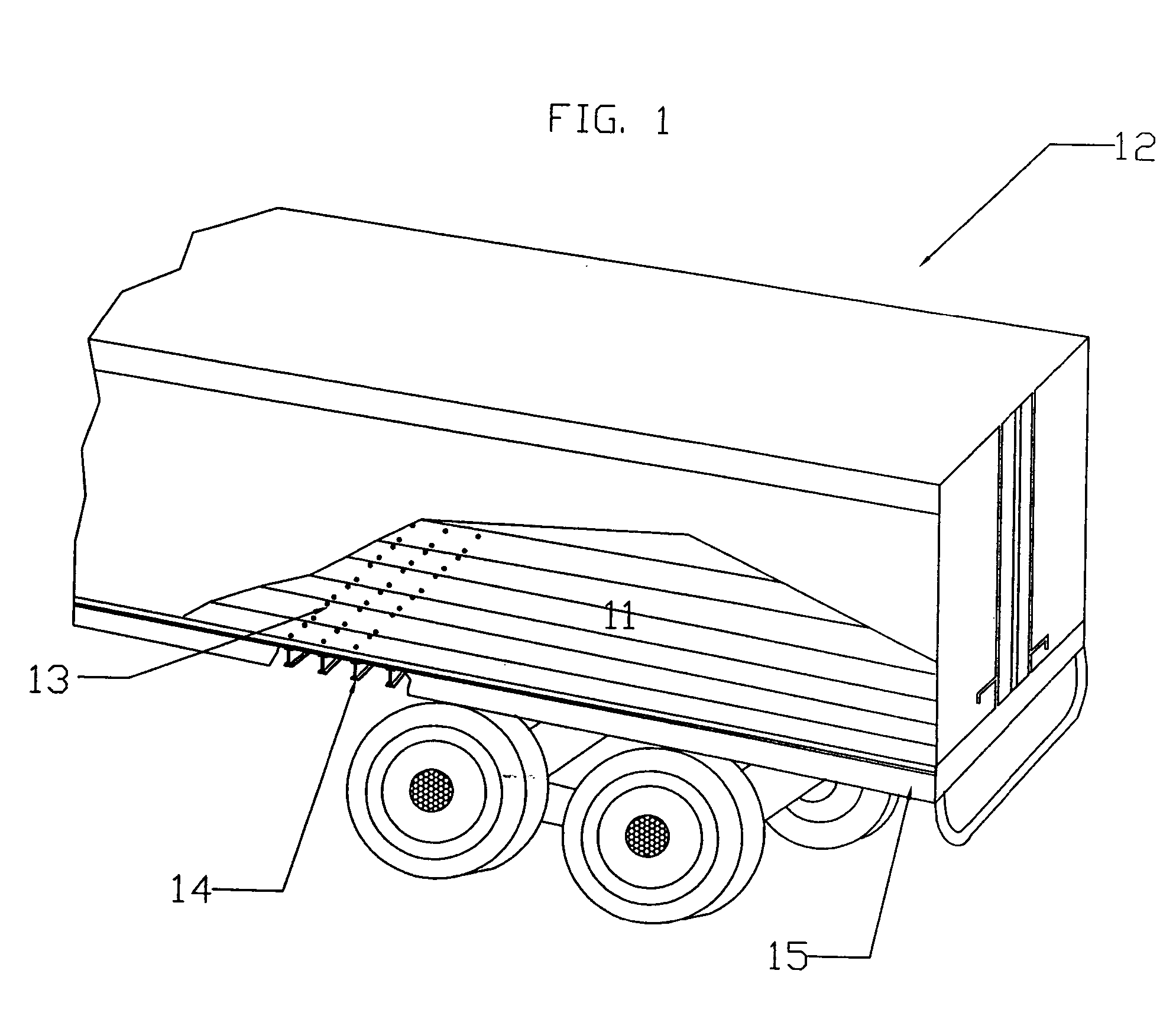

Trailer flooring with hotmelt coating

ActiveUS20050266200A1Broaden applicationBonding is affectedLiquid surface applicatorsSynthetic resin layered productsSolid woodHot melt

A coated wood board flooring having improved moisture protection, the flooring comprising: a plurality of solid wood components which together form the wood board, such that the wood board has a first surface and a second surface; and a coating substantially free of water and solvents, wherein the coating is applied to at least one of the first and second surfaces of the wood board.

Owner:HAVCO WOOD PRODS

Wood multi-layer floor composed of cut-plate and veneer and method for making same

InactiveCN101139864ASave woodImprove product qualityWood working apparatusFlooringSolid woodSurface layer

The invention relates to a real-wood composite floor panel, which adopts a sheet-cut board with a sheet-cutting method as a core layer, a shave-cut single plate with a shave-cutting method as a surface layer, a rotary cut single plate with a rotary cutting method as a base layer, as well as all the other intermediate layers. The invention belongs to a real-wood composite floor panel, which is an artificial board in the industry of wood materials. The invention is characterized in that the core layer of the real-wood composite floor panel is a sheet-cut board that is produced with a sheet-cutting method; the surface layer of the real-wood composite floor panel is a shave-cut single-plate that is processed with a shave-cutting method; the base layer and all the other intermediate layers of the real-wood composite floor panel are rotary-cut single-plates produced with a rotary cutting method. The fabrication method is that the core layer of the real-wood composite floor panel is produced in a one-through mode covering adhesive coating, blank combination and glueing. The invention has advantages of perfect product quality, small deformation, needing no too much investment, saving wood materials, comprehensive utilization of wood materials and low cost. Except for pruducing real-wood composite floor panels, the invention can also be used to make such base material products as fine woodwork boards, real-wood doors and sheet-type furniture.

Owner:吴立忠

Water-thinned isocyanate adhesive with corn starch as main material and its prepn process

The present invention belongs to the field of adhesive technology, and features that the present invention is double component no-aldehyde waterproof timber adhesive comprising main adhesive component, which is prepared with corn starch and through esterification to form emulsion and copolymerization with grafting stabilizer under certain pH condition, and curing agent, which is prepared with polyisocyanate through closing the isocyanate radical. The present invention has the features of unique composition, no environmental pollution, low cost, etc. and is used in various timber products.

Owner:时君友

Adhesive for solid wood floor and preparation method thereof

ActiveCN103013425AIncrease elasticityGood adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolid woodLow noise

The invention discloses an adhesive for a solid wood floor and a preparation method of the adhesive. The adhesive is a one-component moisturecuring polyurethane elastic adhesive which consists of polyether polyol, polyisocyanates, a plasticizer, padding, a catalyst, a water removing agent, a coupler and an antioxygen. The adhesive used to pave the solid floor overcomes the deficiencies that at present, in solid wood floor pavement, the solid wood floor is large in noise, free from elasticity, poor in stability, has sound like an empty drum, and cannot be used in a ground heating system and the like due to rough grounds which have to be used. The adhesive has the advantages of one-component moisturecuring, convenience in operation, strong adhesive strength, safety, environment friendliness and the like, and can be adjusted in different colors according to colors of the solid wood floors. The solid wood floors paved have the advantages of elasticity, comfort, low noise, and can be used in the ground heating system and the like, and the risk of deformation and crack of the solid wood floor can be reduced. The adhesive is suitable for paving various solid wood floors and elastically adhering skirting lines, thresholds and stairs and the like, and meanwhile the adhesive is further used for paving ceramic tiles.

Owner:NANTONG GAOMENG NEW MATERIAL

Bamboo wood-grain plate and the preparing method

InactiveCN101036999AShun goodIncreased shear strengthWood treatment detailsCane mechanical workingSolid woodEngineering

The invention discloses a wood grain board made of bamboo and manufacturing method, the wood grain board made of bamboo includes a faceplate made by bonding and pressing the bamboo pieces arrangement, the bamboo pieces are arranged with inclination less than 90 degrees to the board plane, the inclination is adjusted and set based on the grain of required boards. The bamboo boards made by the invention technique project, because the faceplate is pressed by form of inclined arrangement of the bamboo, so the grain of faceplate has solid wood grain of top grade; because the core plate and base plate use interlaced in length and breadth arrangement form of bamboo mat, bamboo curtain, bamboo filament and piece plate, the multiple indexes of shear strength, bending intensity and elastic modulus for long and cross grain of the whole boards are better.

Owner:张世庆

Preparation method of environmental protection type solid-wood composite floor

InactiveCN101396839ATake advantage ofReduce pollutionOther plywood/veneer working apparatusWood treatment detailsSolid woodEngineering

The invention relates to a preparation method for an engineered flooring, in particular to a preparation method for an environment-friendly engineered flooring, belonging to the wood manufacturing industry. The invention aims at providing a preparation method for an environment-friendly engineered flooring which has strong non-deformability, high processing efficiency and can fully use resources, thus overcoming the deficiencies of the prior art. Due to the adoption of the technical program, the invention has the advantages of making full use of wood resources, improving labor efficiency and relieving the pollution of formaldehyde to the environment.

Owner:汤可新

Electric heat floor

The invention relates to a wood electro-thermal floor with far infrared electro-thermal wave of health physiotherapy, which is installed conveniently and quickly. It comprises floor base and electrical heating layer. The technical point is that insulation thermal reflecting layer, far infrared electrical heating layer, insulation heat-transferring layer and solid-wood panel layer with face paint layer are set in turn upwards from the floor base. Because electro-thermal physiotherapy structure with far infrared electro-thermal wave of health physiotherapy is added on prior solid-wood floor, characteristics are shown as follows. Because the physiotherapy far infrared electro-thermal structure is set in the interlayer of floor, the thermal efficiency is high. The room is heated while physiotherapy wave absorbed by foot is provided for human. It is provided with high thermal efficiency, small starting current, no pollution, no noise, energy saving, good anti-aging performance and long service life. It also has the action that by infrared ray radiation of carbon fiber, human blood cycle is promoted; cell viability is strengthened and human health function is improved. It is killing two birds with one stone.

Owner:庞志忠

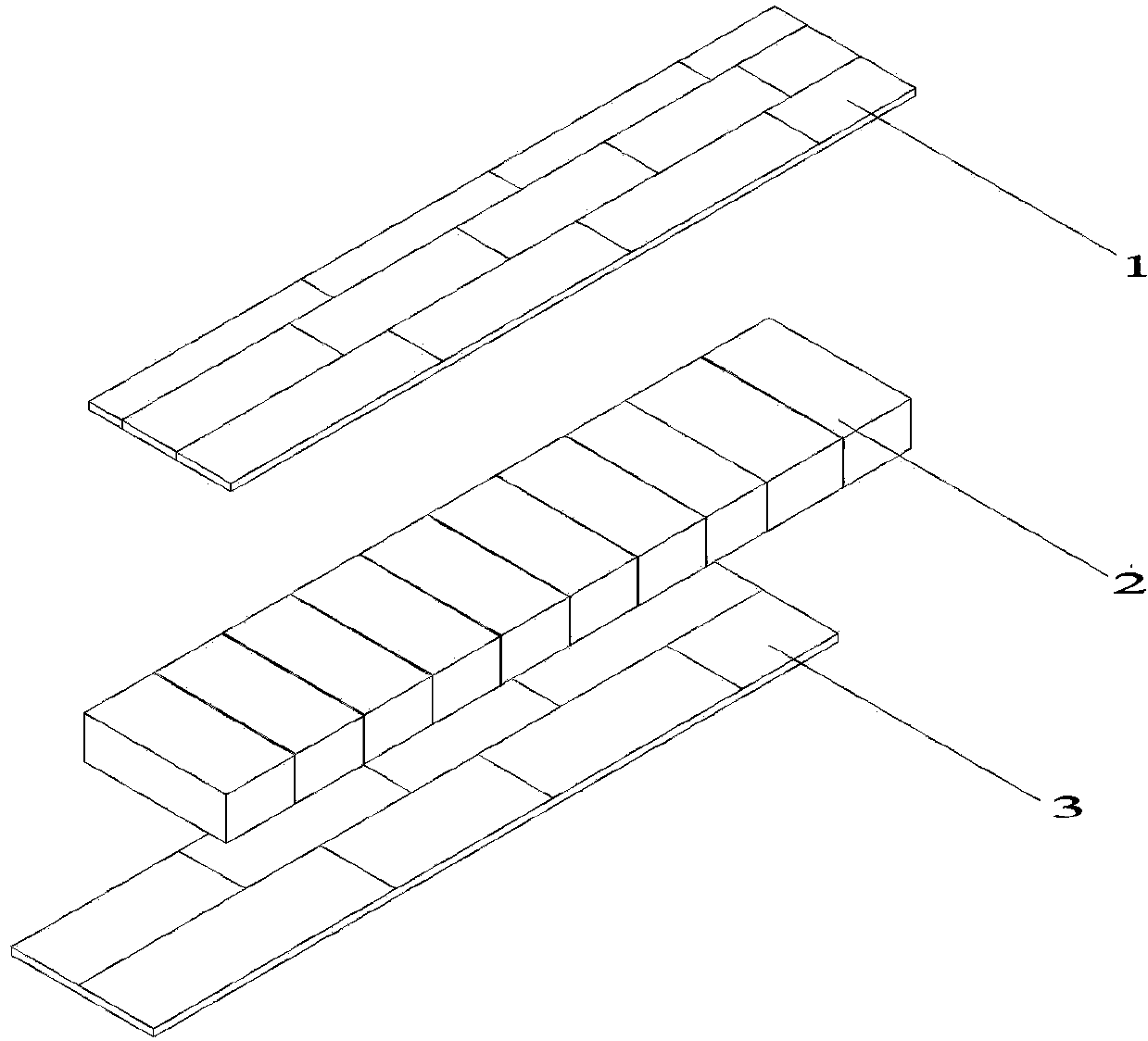

Three-layer composite solid wood flooring made from same type of trees and production process thereof

ActiveCN103395101AOvercome the disadvantage of easy deformationReduce waste of resourcesWood veneer joiningWood layered productsSolid woodPulp and paper industry

The invention belongs to the technical field of building decorative materials, relates to three-layer composite solid wood flooring, in particular to three-layer composite solid wood flooring made from the same type of trees and a production process thereof. The three-layer composite solid wood flooring consists of surface boards, core boards and back boards, wherein the surface boards, the core boards and the back boards are all made from the same type of timber pressed into a whole according to crisscross grains; the thickness of the surface boards is 3-4mm, the thickness of the core boards is 8-9mm, and the thickness of the back boards is 2-3mm. The invention further discloses a production process of the three-layer composite solid wood flooring made from the same type of trees. As the three-layer composite solid wood flooring is made from the same type of trees integrally, physical properties of the three layers are the same, the three layers can be bound effectively during production, and different physical properties can keep consistent highly. Since the solid wood flooring is composited by three layers, the defect that single-unit solid wood flooring is easy to deform is overcome, and the solid wood flooring is more stable and adaptable to geothermal environments. By the production process of the three-layer composite solid wood flooring, valuable timber can be utilized reasonably and the percentage of outturn can be increased while waste of timber can be reduced.

Owner:DAYA JIANGSU FLOOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com