Three-layer composite solid wood flooring made from same type of trees and production process thereof

A technology of solid wood composite flooring and production technology, which is applied in the field of building decoration materials, can solve problems such as deformation of solid wood flooring, achieve good consistency, increase material yield, and rationally utilize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

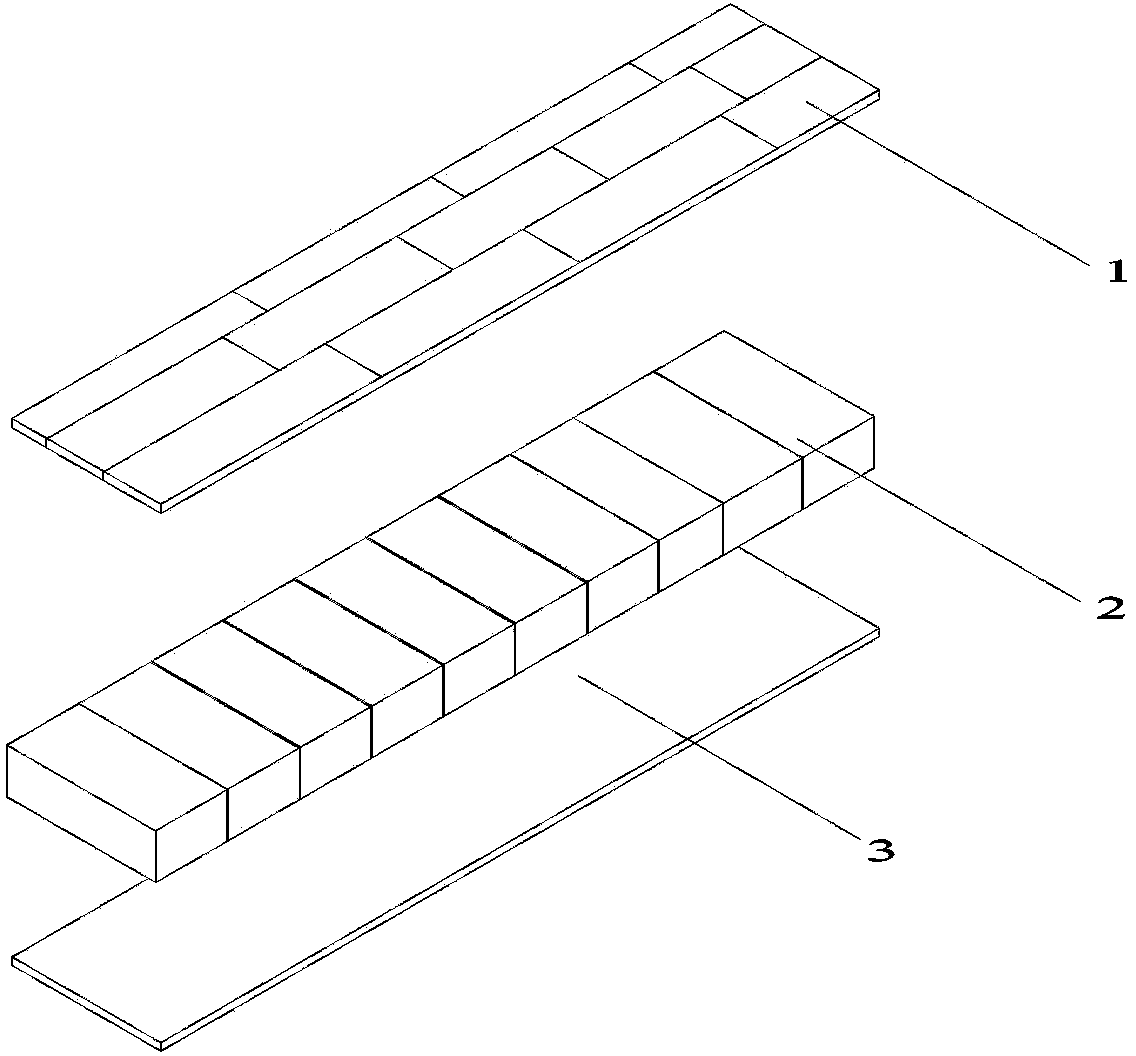

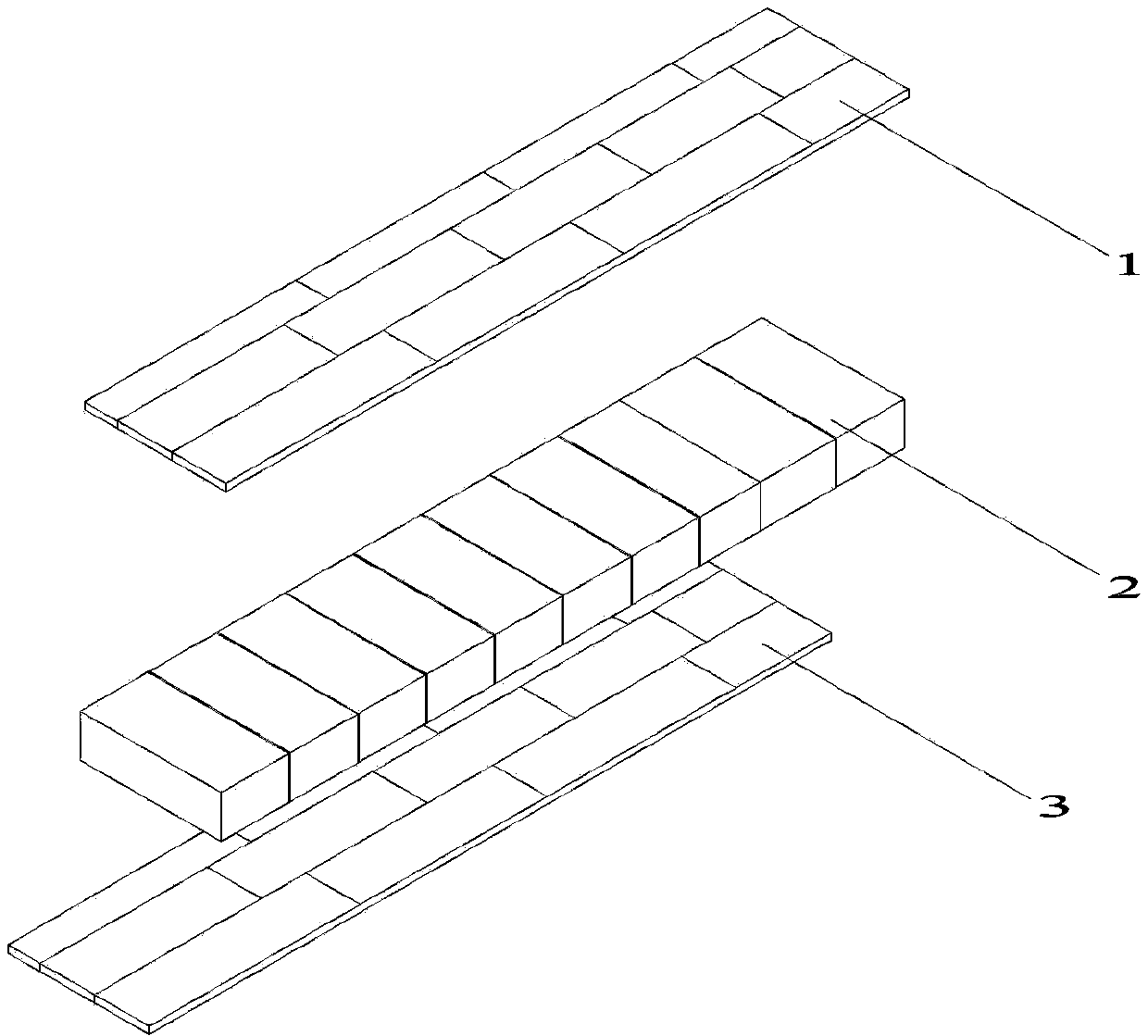

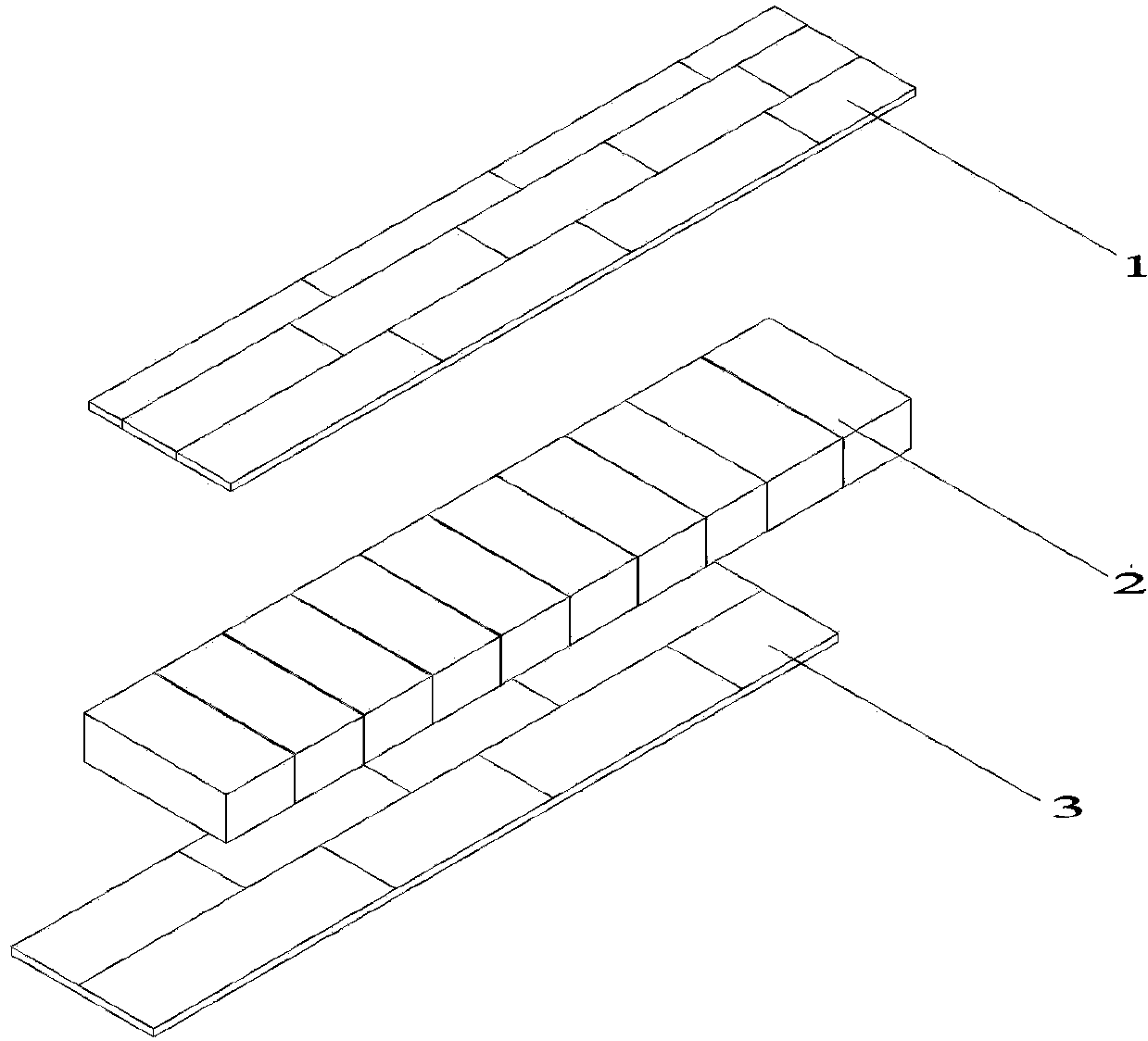

[0042] A three-layer solid wood composite floor of the same tree species, which is composed of a surface board 1, a core board 2 and a back board 3. The board, core board and back board are made of the same kind of wood with the same material and pressed into one body according to the criss-cross texture. The surface plate 1 has a thickness of 3-4 mm, the core plate 2 has a thickness of 8-9 mm, and the back plate 3 has a thickness of 2-3 mm. The said front board 1 is three pieces; the said back board 3 is three pieces; the said front board 1, core board 2 and back board 3 are all made of the same kind of solid wood, and the tree species are ebony, sapele, oak Any of wood, pineapple lattice, white oak, red oak, black walnut, birch, hard maple.

Embodiment 2

[0044] A three-layer solid wood composite floor of the same tree species, which is composed of a surface board 1, a core board 2 and a back board 3. The board, core board and back board are made of the same kind of wood with the same material and pressed into one body according to the criss-cross texture. The surface plate 1 has a thickness of 3-4 mm, the core plate 2 has a thickness of 8-9 mm, and the back plate 3 has a thickness of 2-3 mm. The said table board 1 is a pair; the said back board 3 is a double board; Any of wood, pineapple lattice, white oak, red oak, black walnut, birch, hard maple.

Embodiment 3

[0046] A three-layer solid wood composite floor of the same tree species, which is composed of a surface board 1, a core board 2 and a back board 3. The board, core board and back board are made of the same kind of wood with the same material and pressed into one body according to the criss-cross texture. The surface plate 1 has a thickness of 3-4 mm, the core plate 2 has a thickness of 8-9 mm, and the back plate 3 has a thickness of 2-3 mm. Said front panel 1 is a single panel; said back panel 3 is a single panel; said panel 1, core panel 2 and back panel 3 all adopt the same kind of solid wood, and the tree species are selected from ebony, Sapele, oak Any of wood, pineapple lattice, white oak, red oak, black walnut, birch, hard maple.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com