A Cylindrical Deep Hole Boring Device with Auxiliary Support

A cylindrical deep hole boring and auxiliary support technology, applied in the direction of boring bars, boring heads, boring/drilling, etc., can solve the problems of unqualified surface roughness, affecting processing quality, and easy deformation of boring bars, etc., to avoid The effect of scratching the surface, avoiding the difficulty of observing the cutting condition, and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

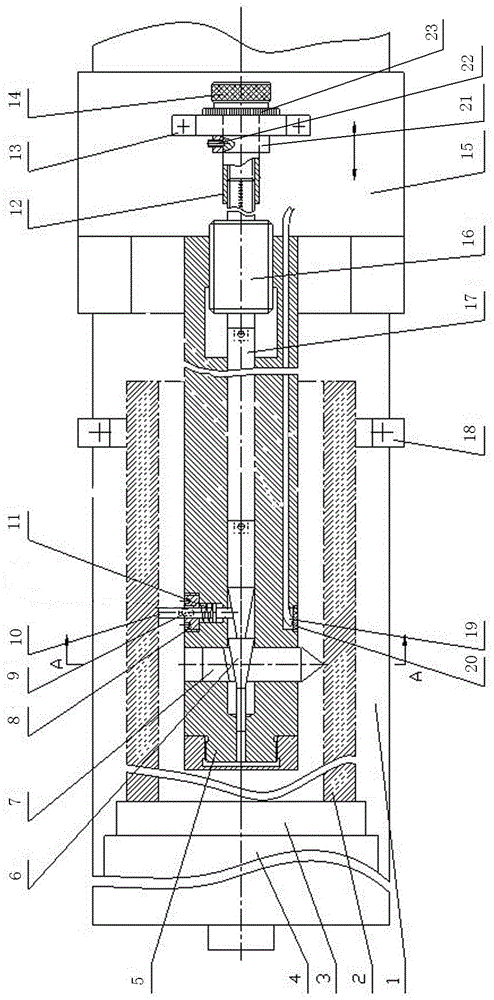

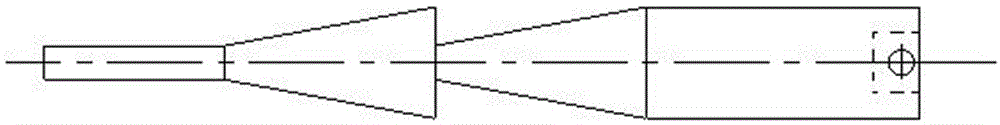

[0025] The present invention comprises dozens of parts such as boring bar 5, boring tool 7, double cone core rod 6, cylindrical core rod 17, screw spline core rod 16.

[0026] A three-jaw chuck 3 is installed on the spindle box 4 to clamp the workpiece 2 with a cylindrical deep hole, and the center frame 18 supports the other end of the workpiece.

[0027] One end of the boring bar 5 is fixedly connected with the slide plate 15, and the boring bar 5 is fed axially as the slide plate 15 moves along the bed guide rail.

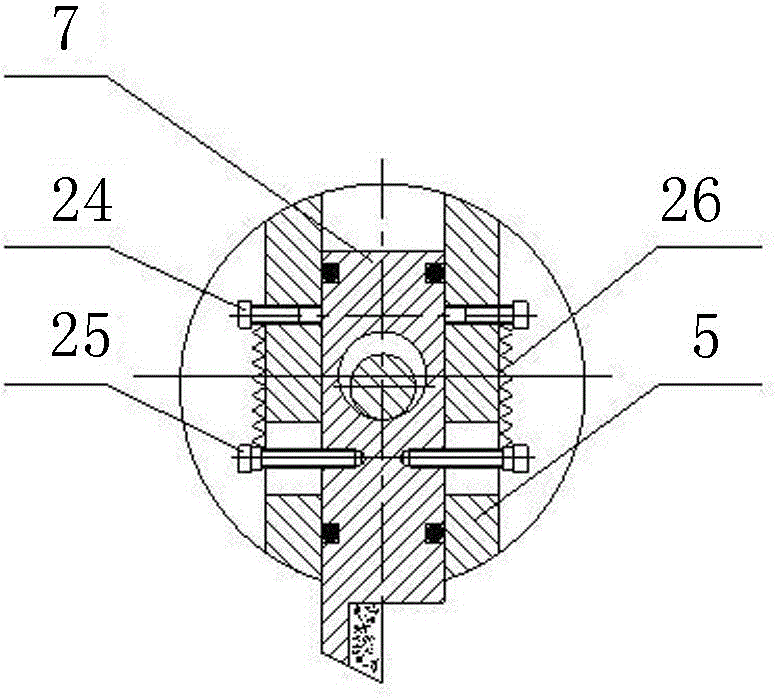

[0028] A boring tool 7 that can move relative to the boring bar is installed in the horizontal hole of the boring bar 5, and a double-taper core rod 6, a cylindrical core rod 17, and a threaded spline core rod 16 are placed in the axial hole in the center of the boring bar. , screw sleeve 8, spring 11, floating support are installed on the boring bar. The invention sets floating supports as auxiliary supports, which can increase the rigidity of the boring bar, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com