Substrate storage container and method for manufacturing the same

a technology for storage containers and substrates, applied in the direction of packaging, other accessories, electrical appliances, etc., can solve the problems of affecting the service life of substrates, being susceptible to shocks, and becoming contaminated by particulates, etc., to suppress the scratching of substrates and reduce friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described below with reference to the attached figures.

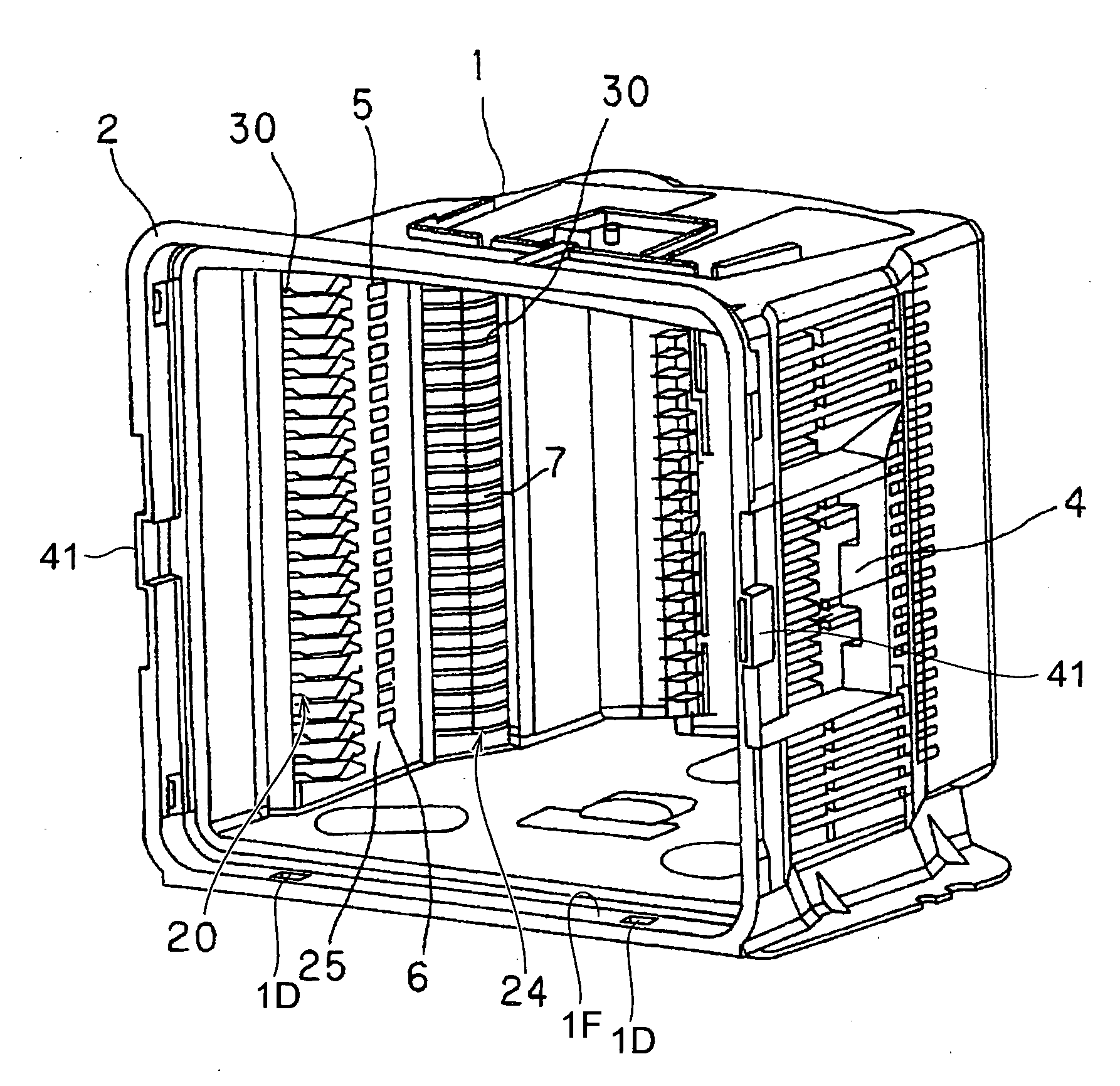

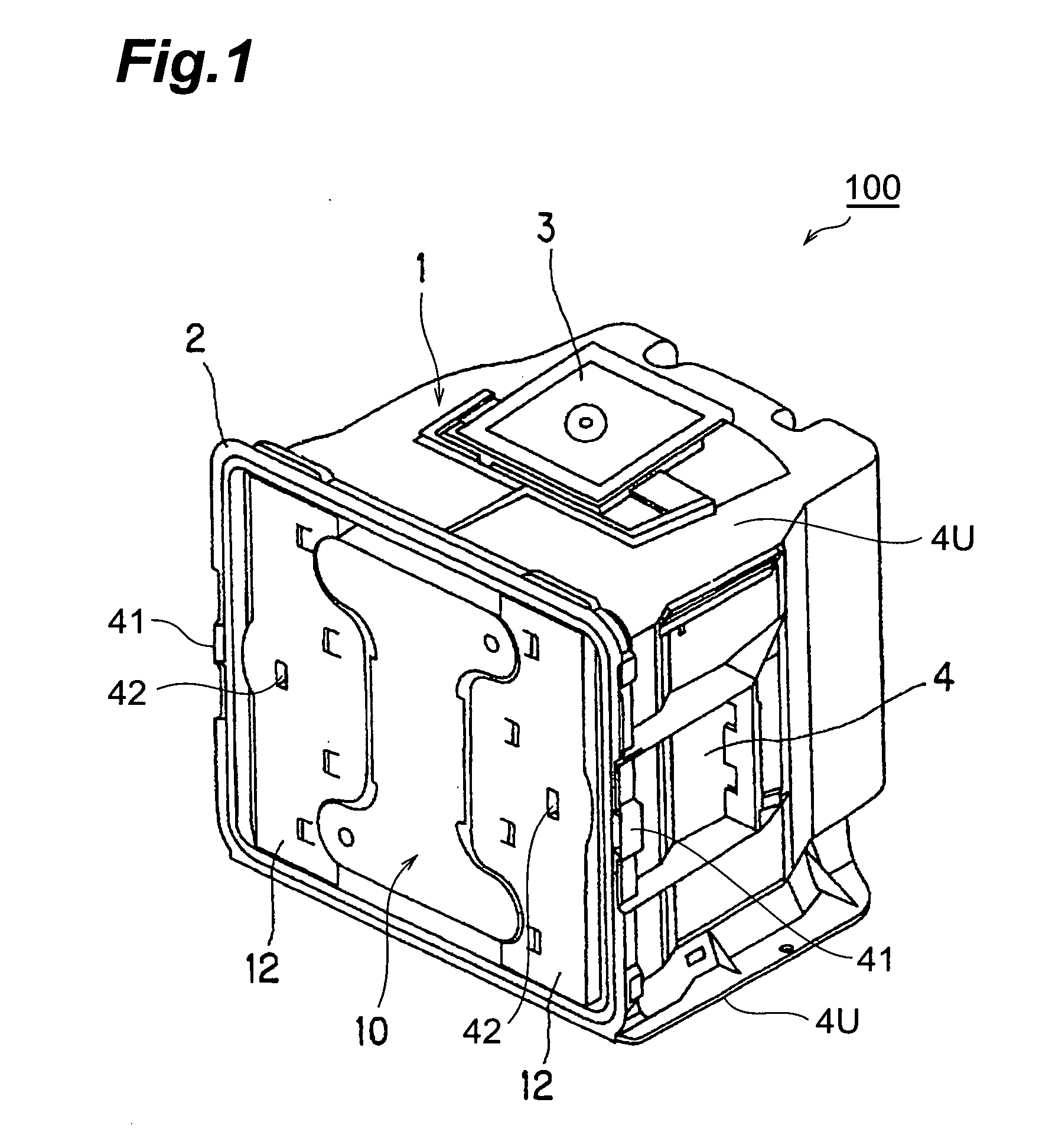

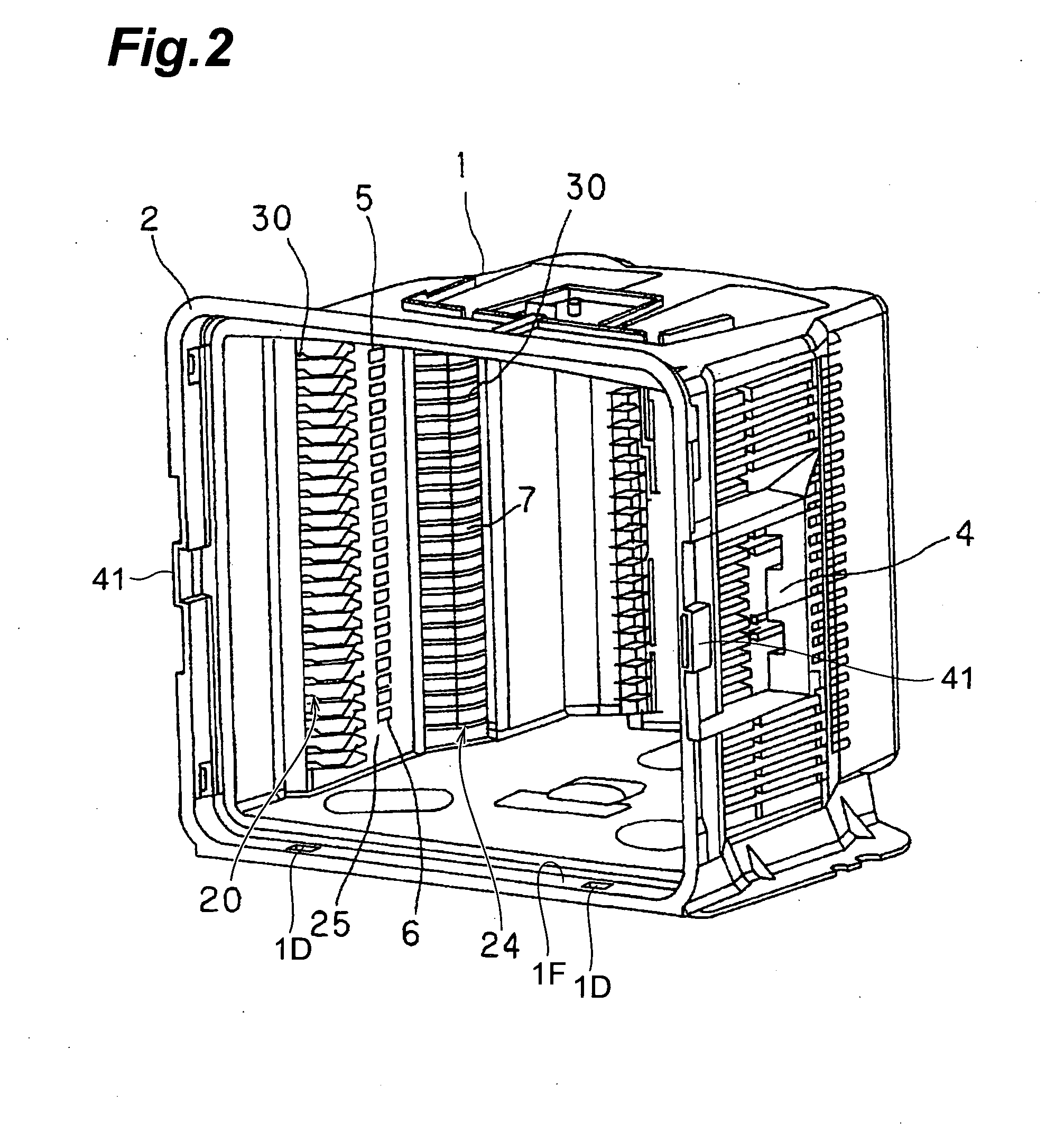

[0034] FIGS. 1 to 9 show a precision substrate storage container 100 used for shipping according to the first embodiment of the present invention. As shown in FIGS. 1 to 9, the substrate storage container 100 comprises a container main body 1, a lid member 10, a plurality of first supporting parts 20, and a plurality of second supporting parts 24.

[0035] A container main body 1 includes an opening portion 1F, a back wall 1B opposing the opening portion 1F, and two pairs of side walls 4 and side walls 4U, and the container main body 1 stores a plurality of substrates W between the side walls 4 and side walls 4U. The lid member 10 closes the front side of the container main body 1, which is the opening portion 1F of the container main body 1.

[0036] A plurality of first supporting parts 20 are respectively disposed on the pair of left and right side walls 4 forming par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com