Patents

Literature

2030 results about "Machined surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

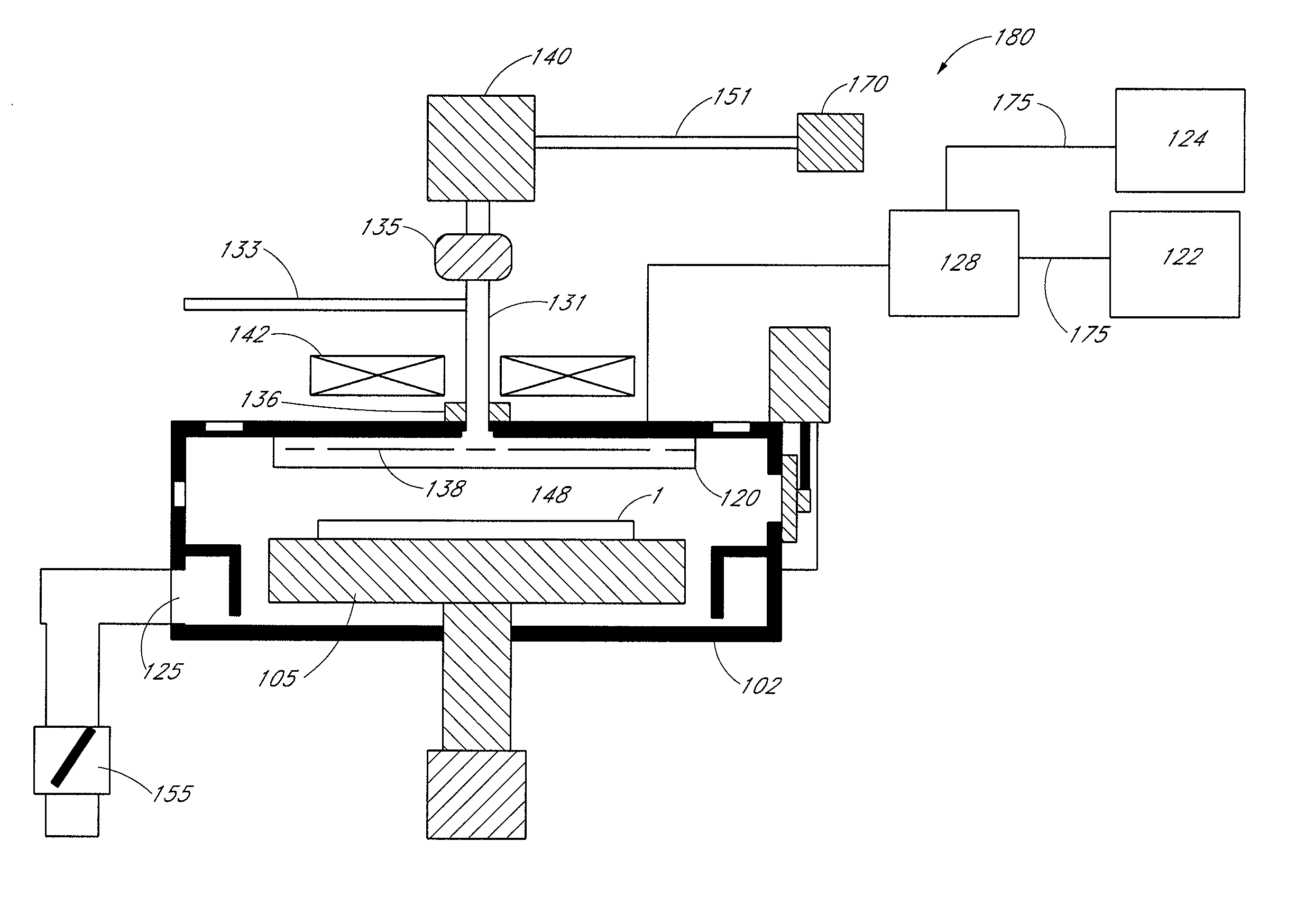

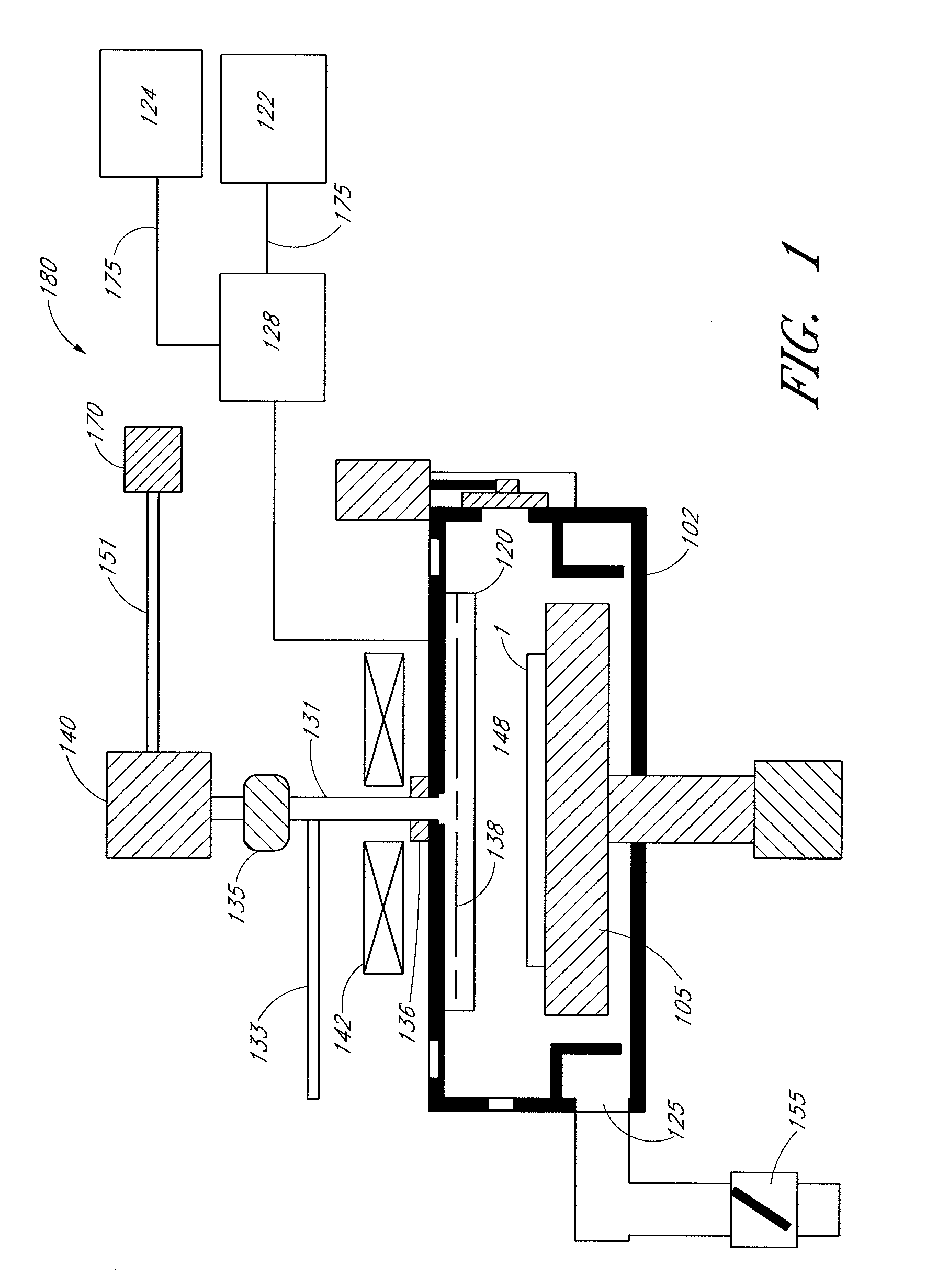

Shower plate electrode for plasma CVD reactor

InactiveUS20090155488A1Uniform cross-sectional areaElectrostatic cleaningChemical vapor deposition coatingMachined surfaceEngineering

Methods and apparatuses for plasma chemical vapor deposition (CVD). In particular, a plasma CVD apparatus having a cleaning function, has an improved shower plate with holes having a uniform cross-sectional area to yield a high cleaning rate. The shower plate may serve as an electrode, and may have an electrically conductive extension connected to a power source. The shower plate, through which both cleaning gases and reaction source gases flow, may include a hole machined surface area with a size different than conventionally used to ensure a good film thickness uniformity during a deposition process. The size of the hole machined surface area may vary based on the size of a substrate to be processed, or the size of the entire surface of the shower plate.

Owner:ASM JAPAN

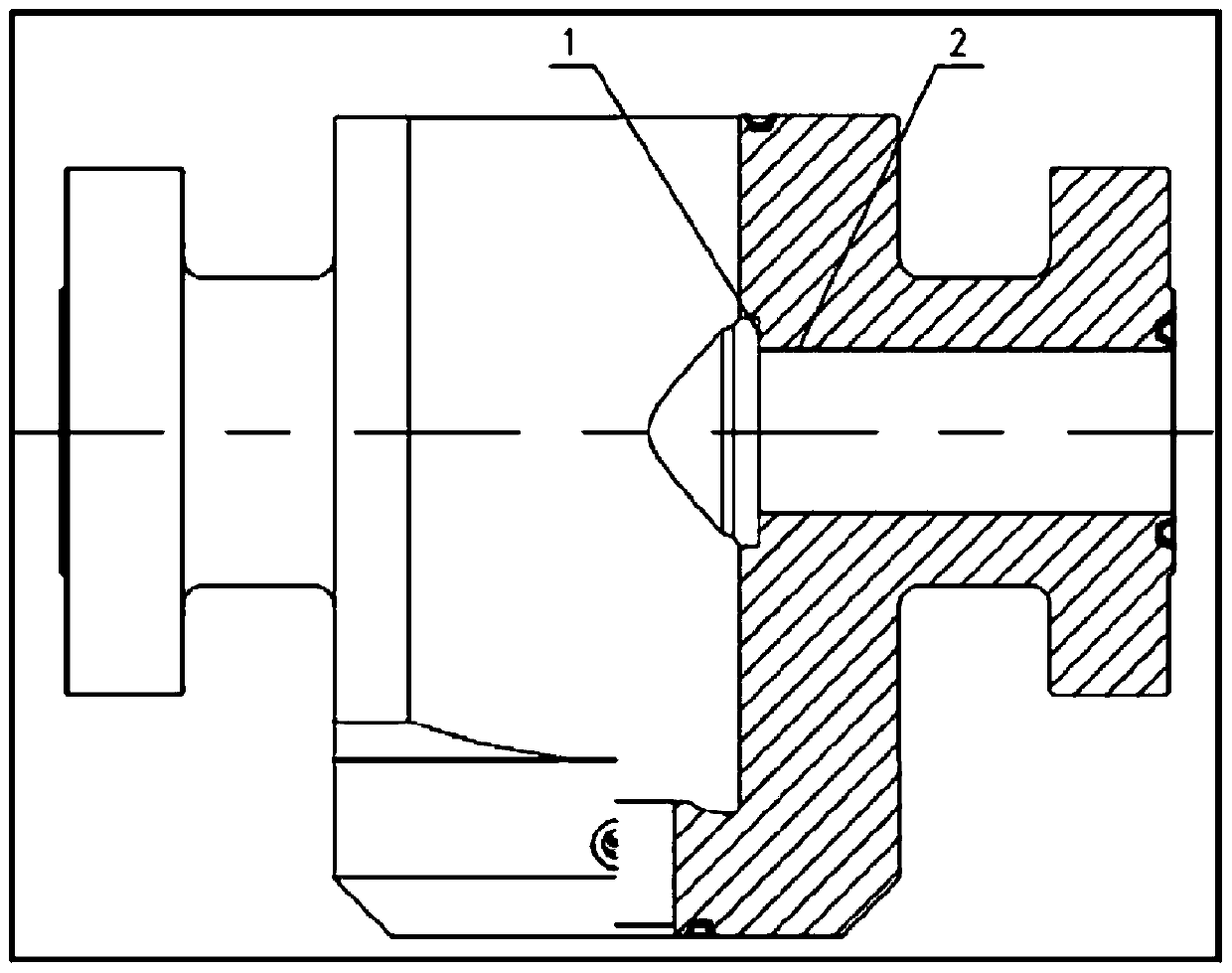

A welding repair method for anti-sulfur wellhead valve body

ActiveCN107520526BMeet the requirements of low temperature impact absorption energy greater than 27JAvoid softeningArc welding apparatusWelding/cutting media/materialsMachined surfaceMixed gas

The invention belongs to the welding industry, and particularly relates to an anti-sulfur well mouth valve body welding repair method, and in particular to a welding repair method of 4130 medium-carbon alloy steel in an anti-sulfur valve body with the hardness being 197 HBW -237 HBW. The anti-sulfur well mouth valve body welding repair method is characterized by comprising the following steps that a product to be repaired is cleaned to determine a damage position; a pit badly eroded needs to be polished; a workpiece is totally preheated to 130 DEG C before welding; filling of the pit is firstly achieved by adopting the argon tungsten-arc welding; then, the machined surface is subject to repair welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C; in the welding repair method, preheating is performed to reach 130 DEG C before welding; the local or total heat treatment insulation is performed for 3 hours at 640 DEG C after welding; and the Ar+CO2 mixed gas arc welding is adopted in the method, and the method greatly increases the product utilization rate and improves the comprehensive efficiency.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

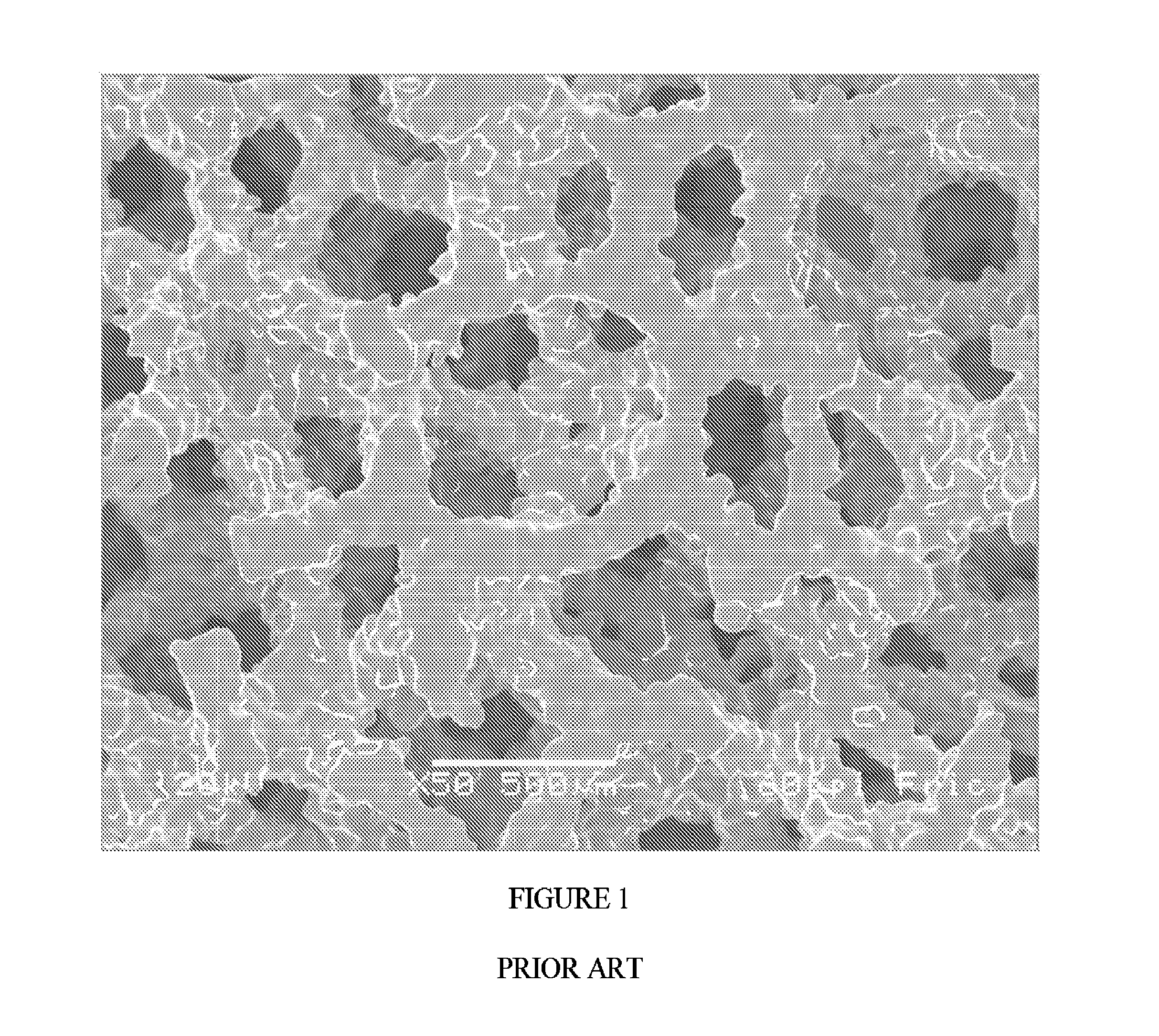

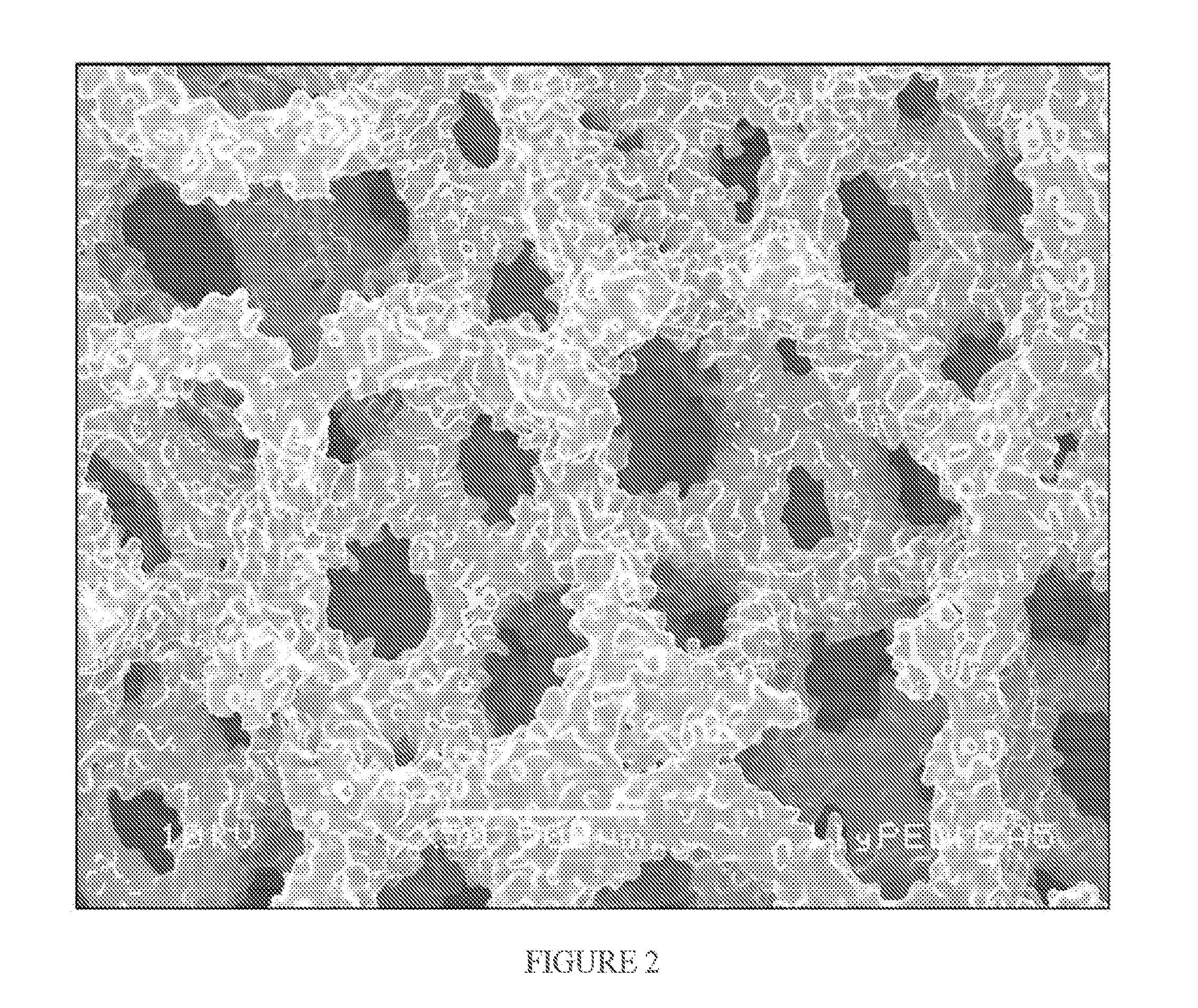

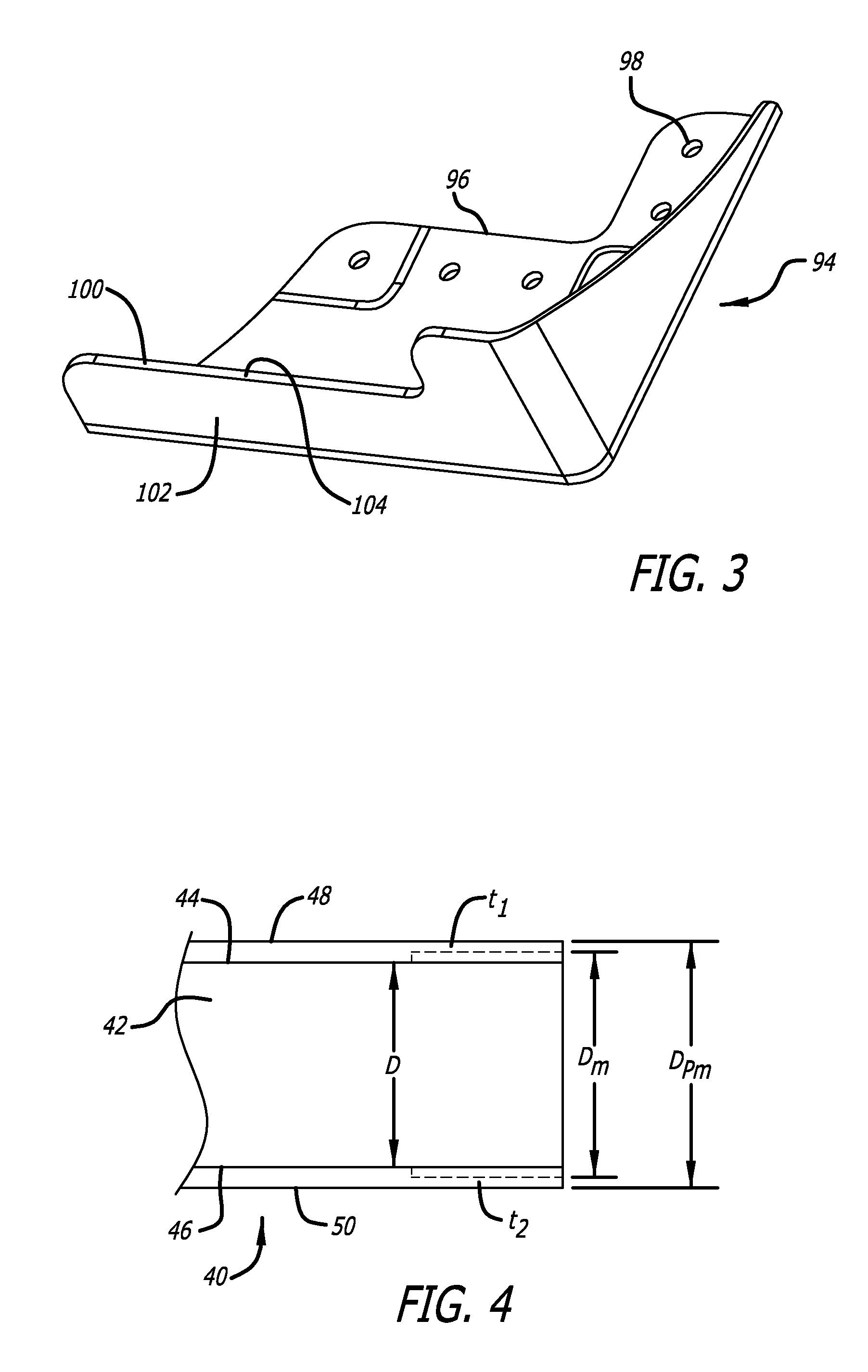

Porous surface layers with increased surface roughness and implants incorporating the same

InactiveUS20110245930A1Improve surface roughnessIncrease roughnessBone implantPharmaceutical containersSurface layerMetallurgy

Owner:SMITH & NEPHEW INC

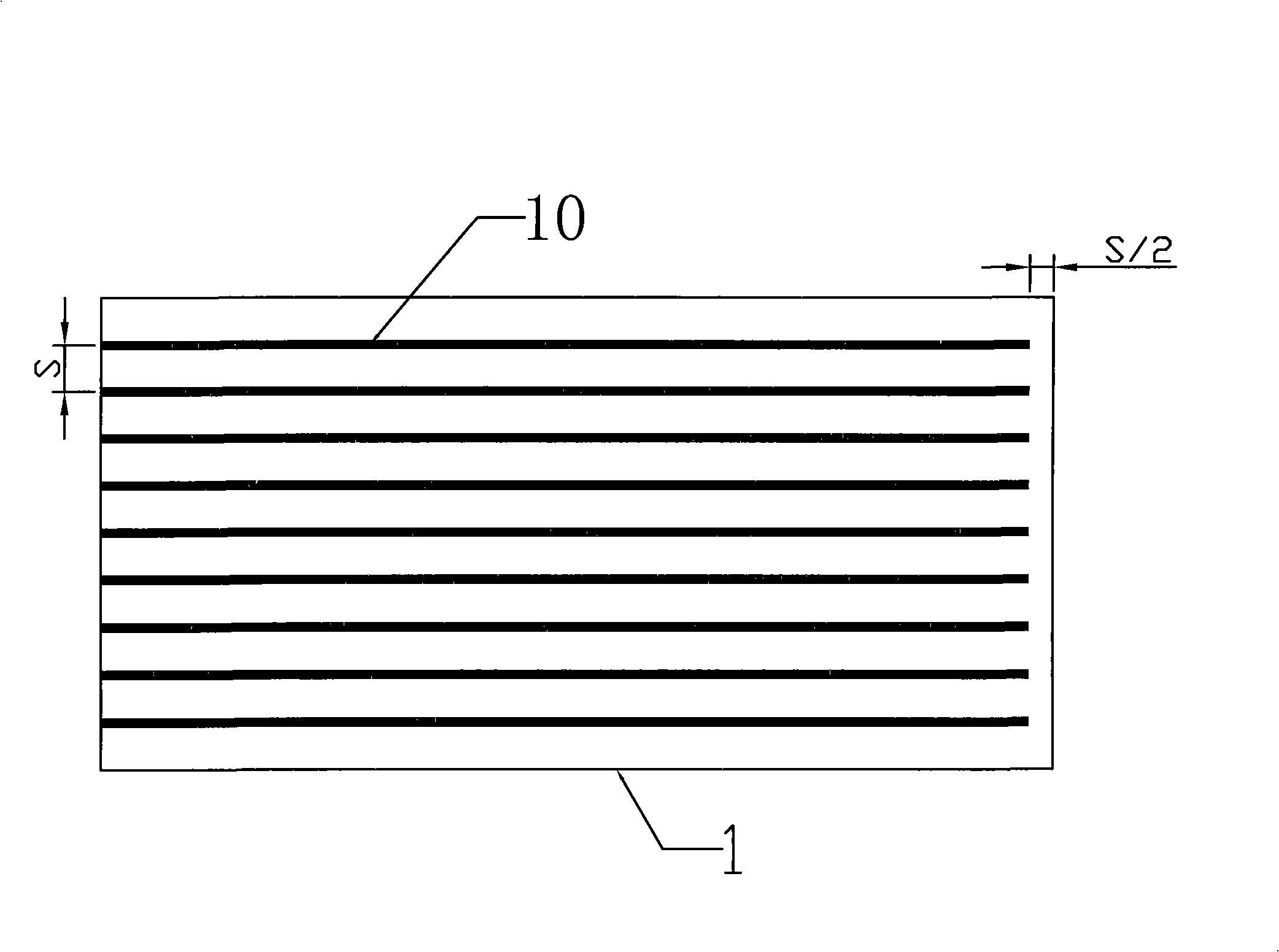

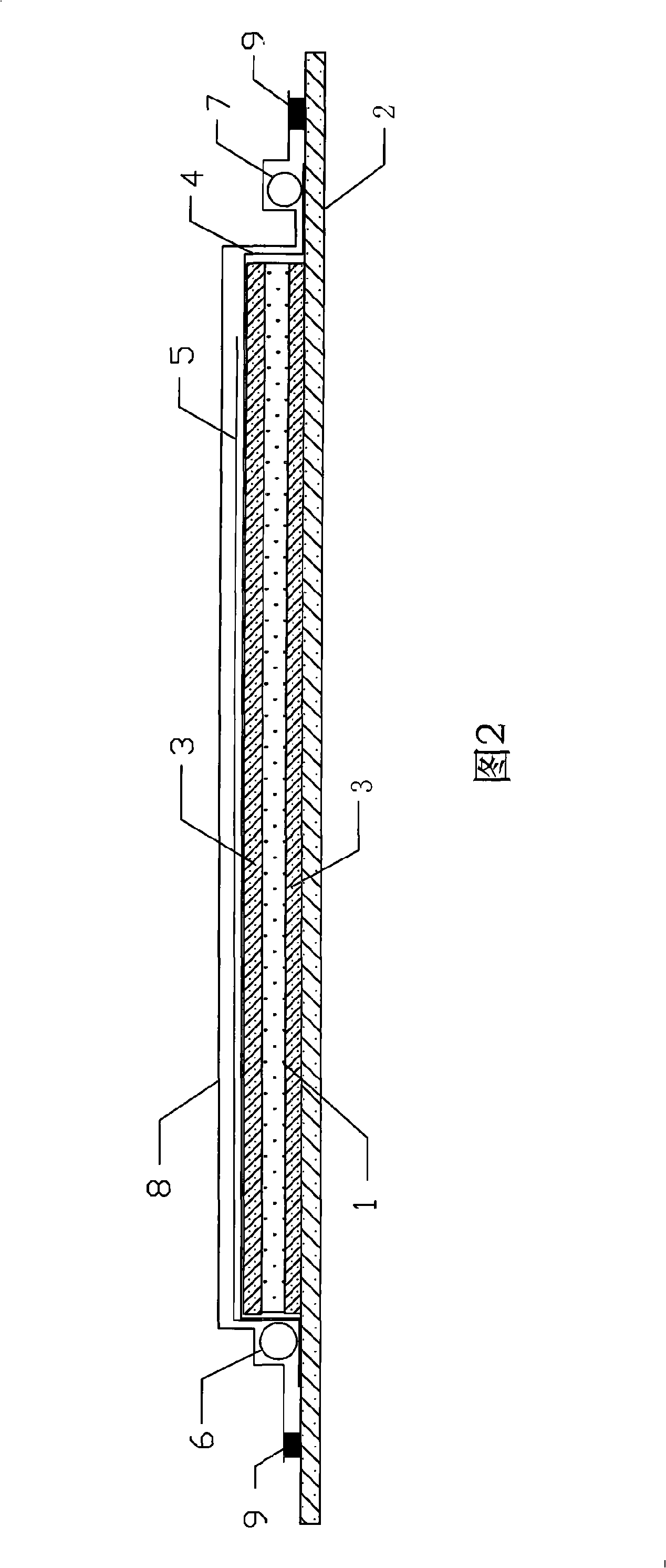

Vacuum auxiliary molding technique produced by large-sized sandwich composite material

The invention provides a vacuum assistant resin infused method for molding a large part of sandwich composite materials as follows: a set of grooves parallel to each other are arranged at the bottom of the foam core material; fiber fabrics are paved on a processed die according to the specified thickness, and then the grooved foam core material is arranged on the already-paved fiber fabrics, wherein, the machined surface of the grooves of foam core material contacts to the already-paved fiber fabrics, and then the fiber fabrics with a specified thickness are paved on the foam core material; a conduction pipe is arranged at one foam core material end with grooves and a vacuum pipe is arranged at the other end; sealed vacuum bag film and sealed adhesive tape are adopted to seal the fiber fabrics; when the vacuum pressure in the sealed bag film is equal to or less than negative 0.095Mpa, resin solution is inducted to the resin conduction system consisting of the conduction pipe and the conduction cloth after being poured with glue; after the resin immerses the fiber fabrics completely, glue pouring and evacuation are stopped; after the poured-in resin is heat-released and solidified, sandwich composite materials are obtained after 24 hours solidification under indoor temperature condition.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

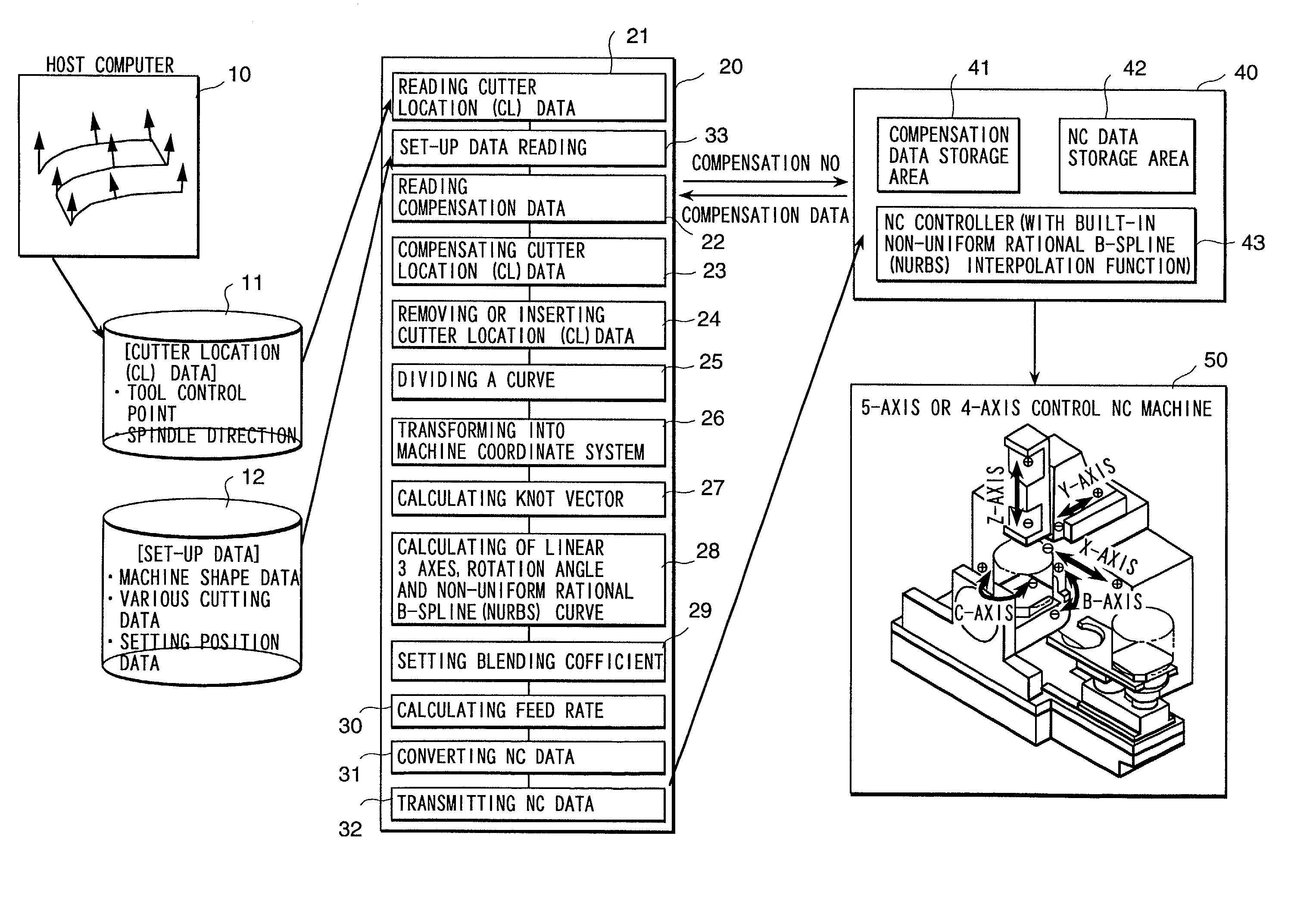

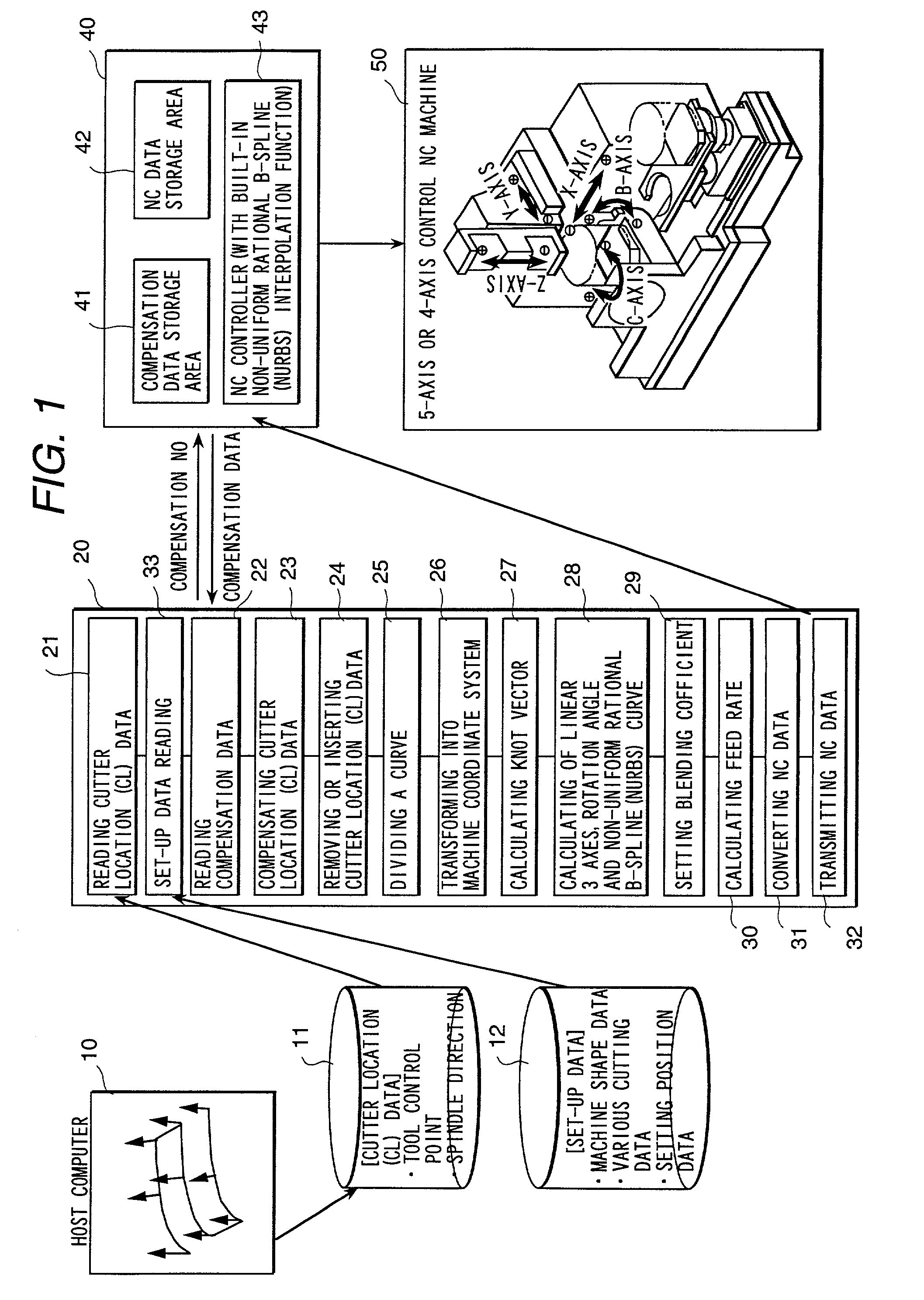

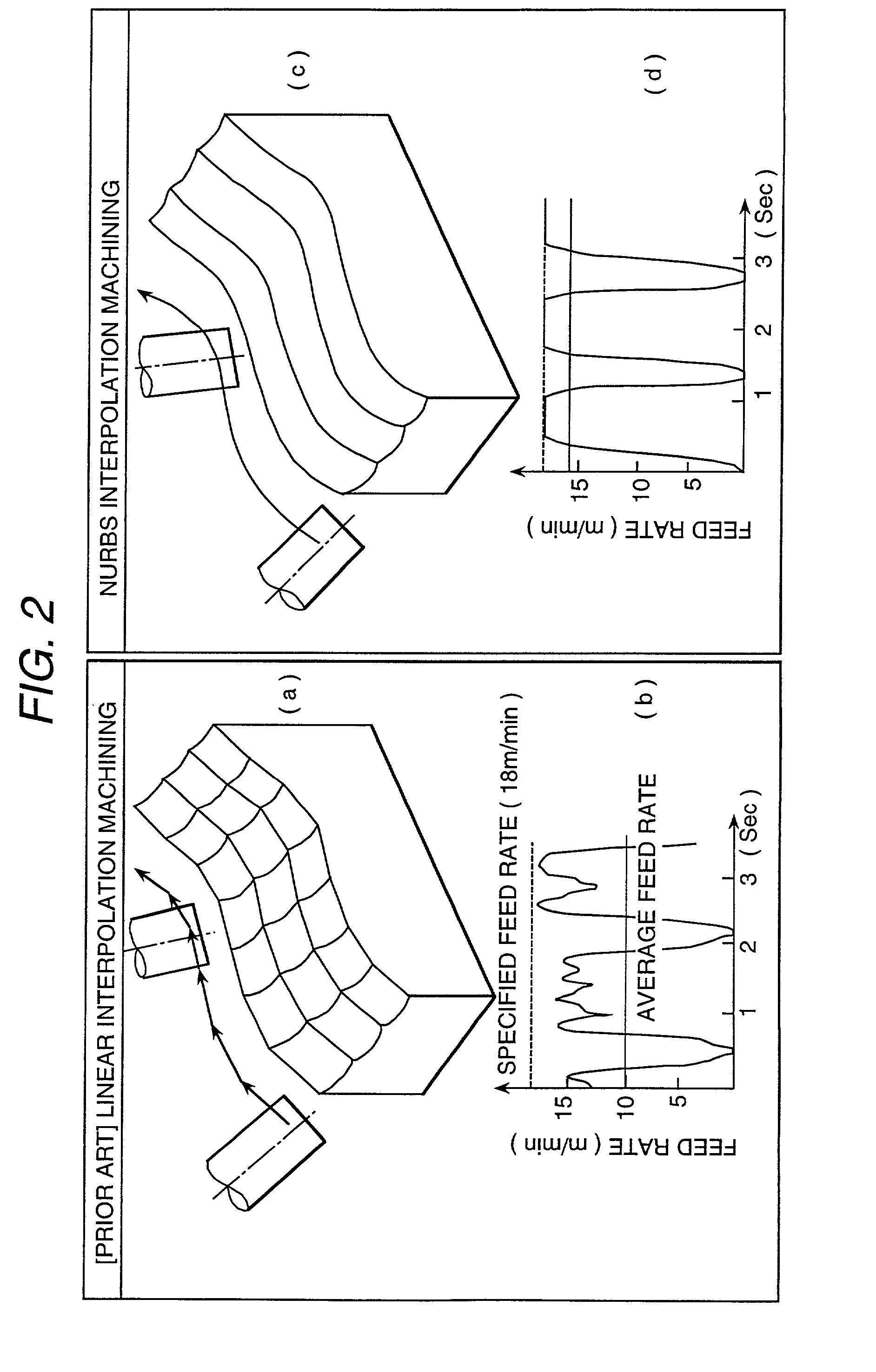

Numerically controlled curved surface machining unit

InactiveUS20020002420A1Automatic control devicesDrawing from basic elementsCutter locationSurface roughness

To provide a numerically controlled curved surface machining unit, and a method or program thereof, which, by moving a tool smoothly along a NURBS (non-uniform rational B-spline) curve, enables not only to improve the machining surface roughness and machining surface accuracy but to achieve high-speed machining so as to be able to eliminate hand finishing and reduce machining steps drastically. Performing NURBS (non-uniform rational B-spline) interpolation machining by a machine equipped with a means for reading cutter location (CL) data consisting of a tool control point vector and a tool axis vector on a workpiece coordinate system, a means for converting the CL data into a position vector of three linear axes and a rotation angle on a machine coordinate system in accordance with the machine configuration of a simultaneous multiple-axis NC machine, a means for calculating knot vectors of a NURBS curve with the most suitable chord length on the basis of a position vector of the three linear axes and a rotation angle, a means for calculating NURBS curve of the three linear axes and one rotary axis using the knot vectors, a means for converting the NURBS curve into NURBS interpolation NC data, a means for converting the feed rate on a workpiece coordinate system into the feed rate per minute on a machine coordinate system, and a means for transmitting NC data to a NC machine.

Owner:HITACHI SOFTWARE ENG +1

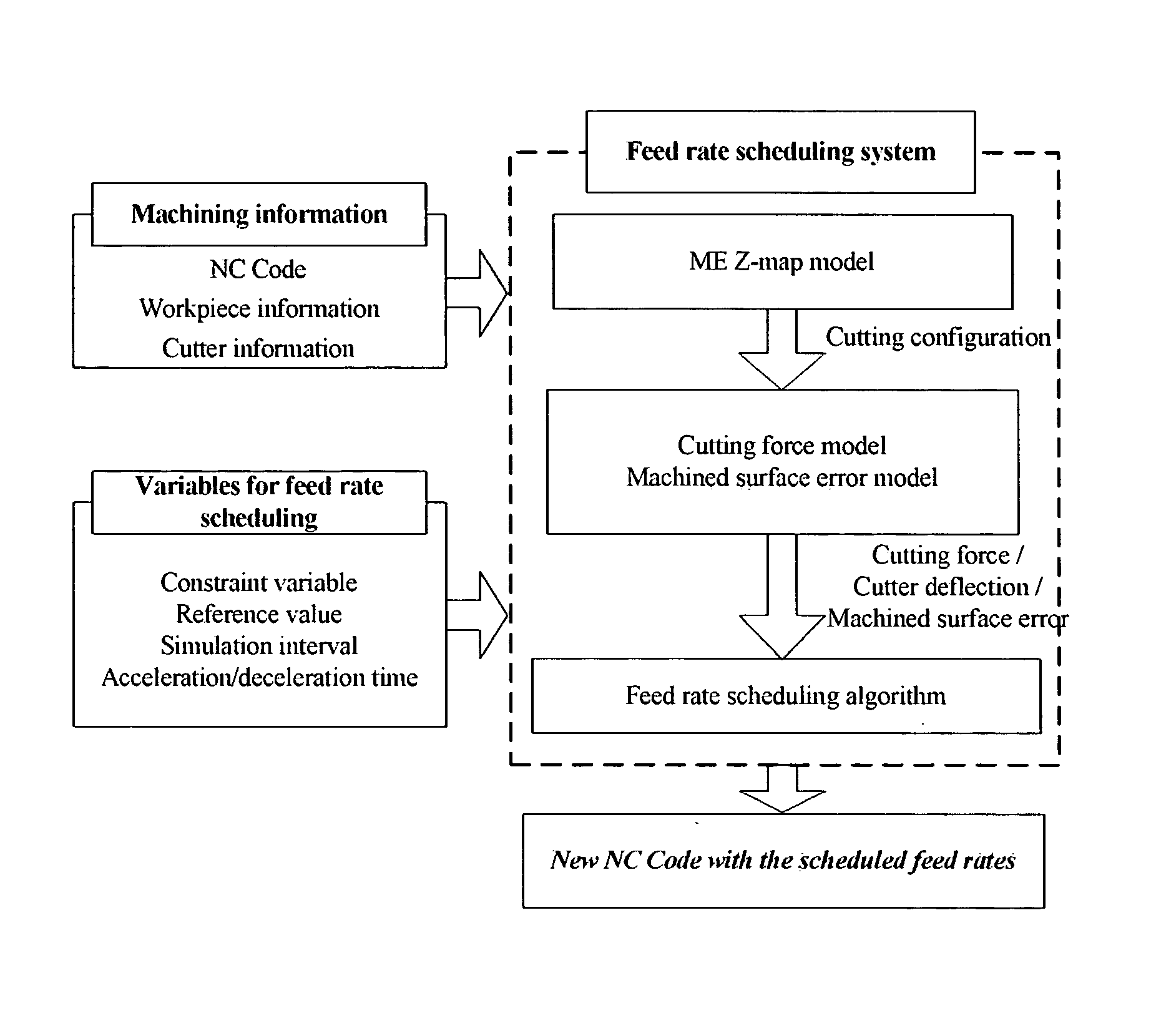

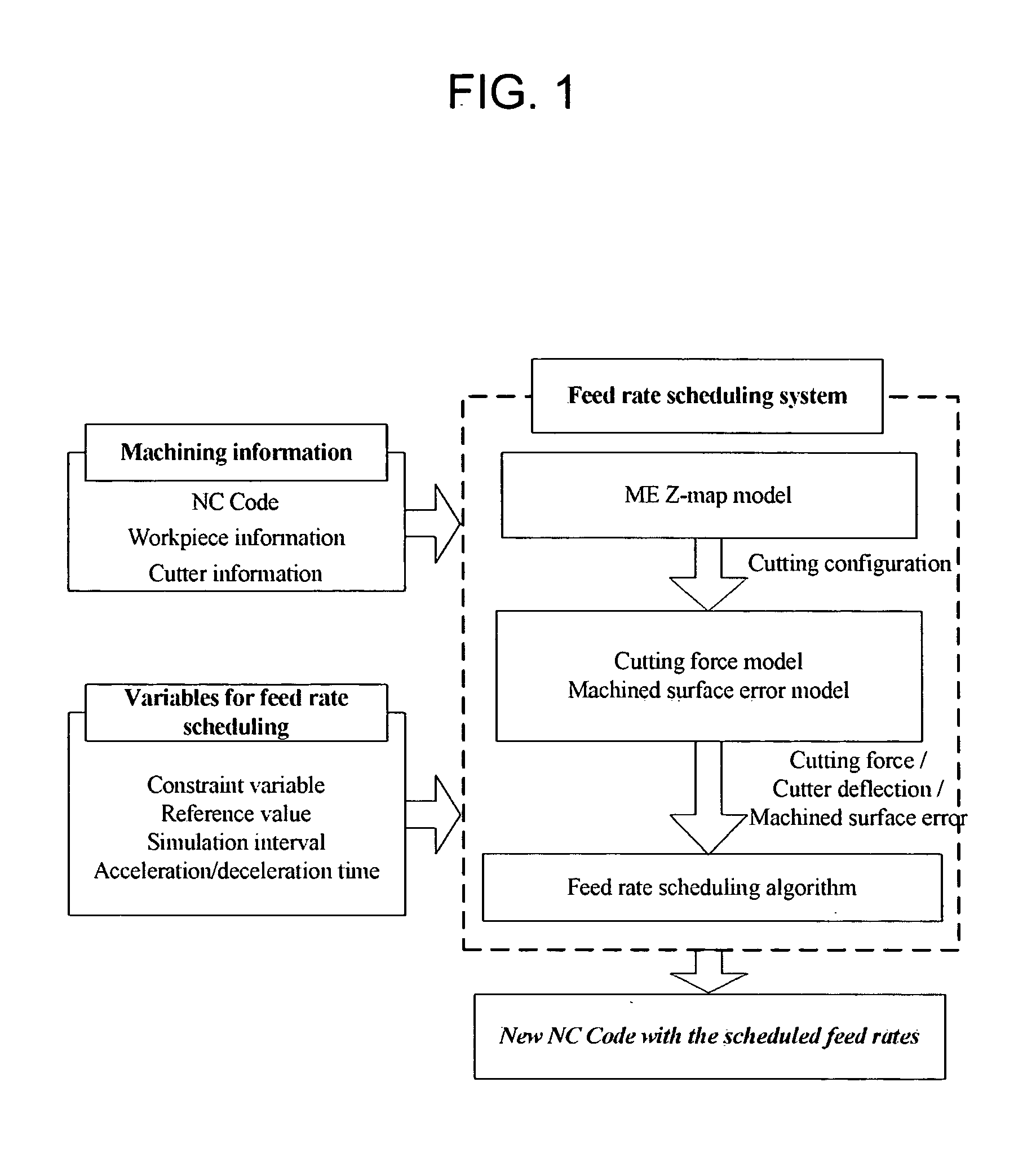

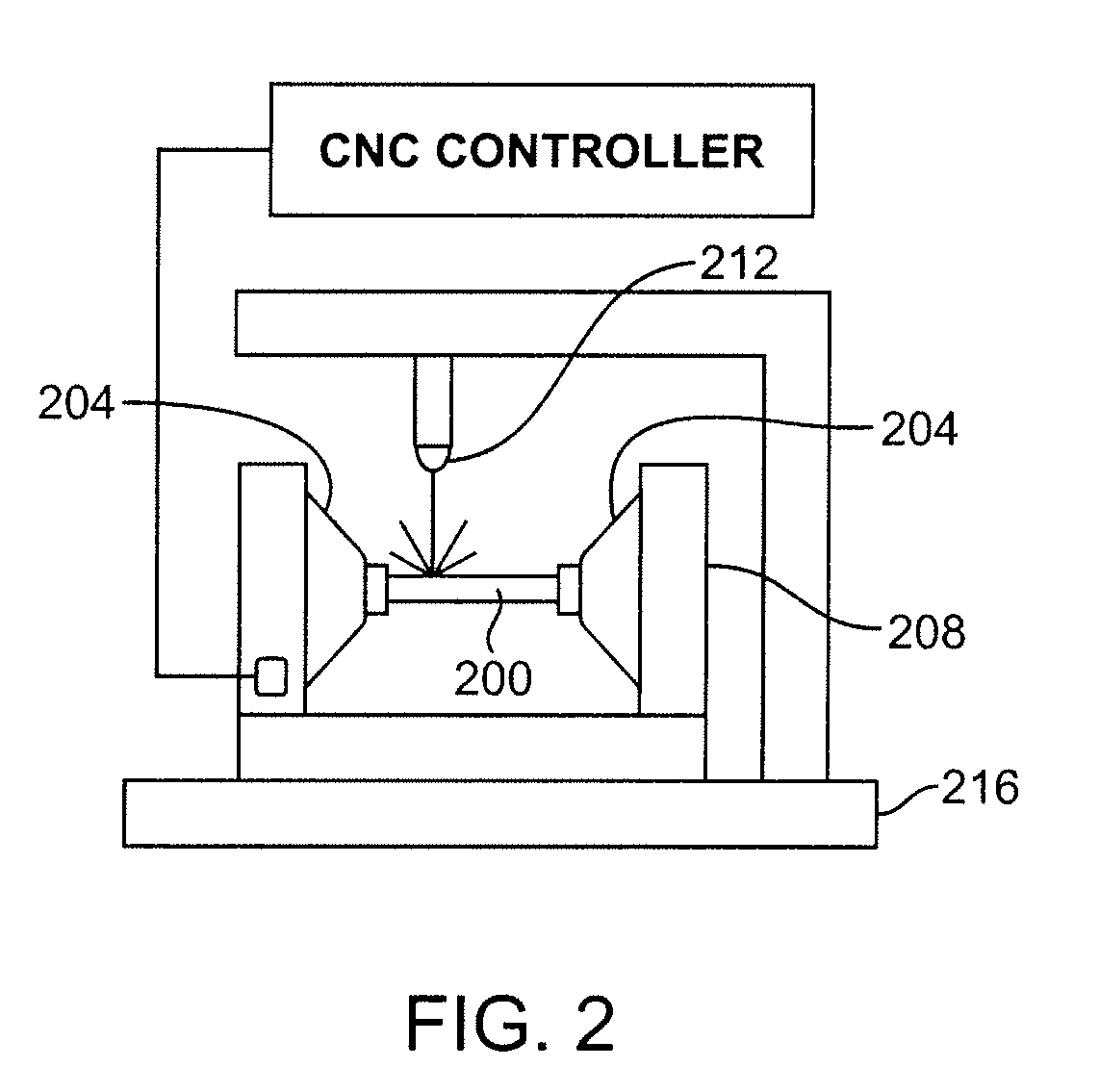

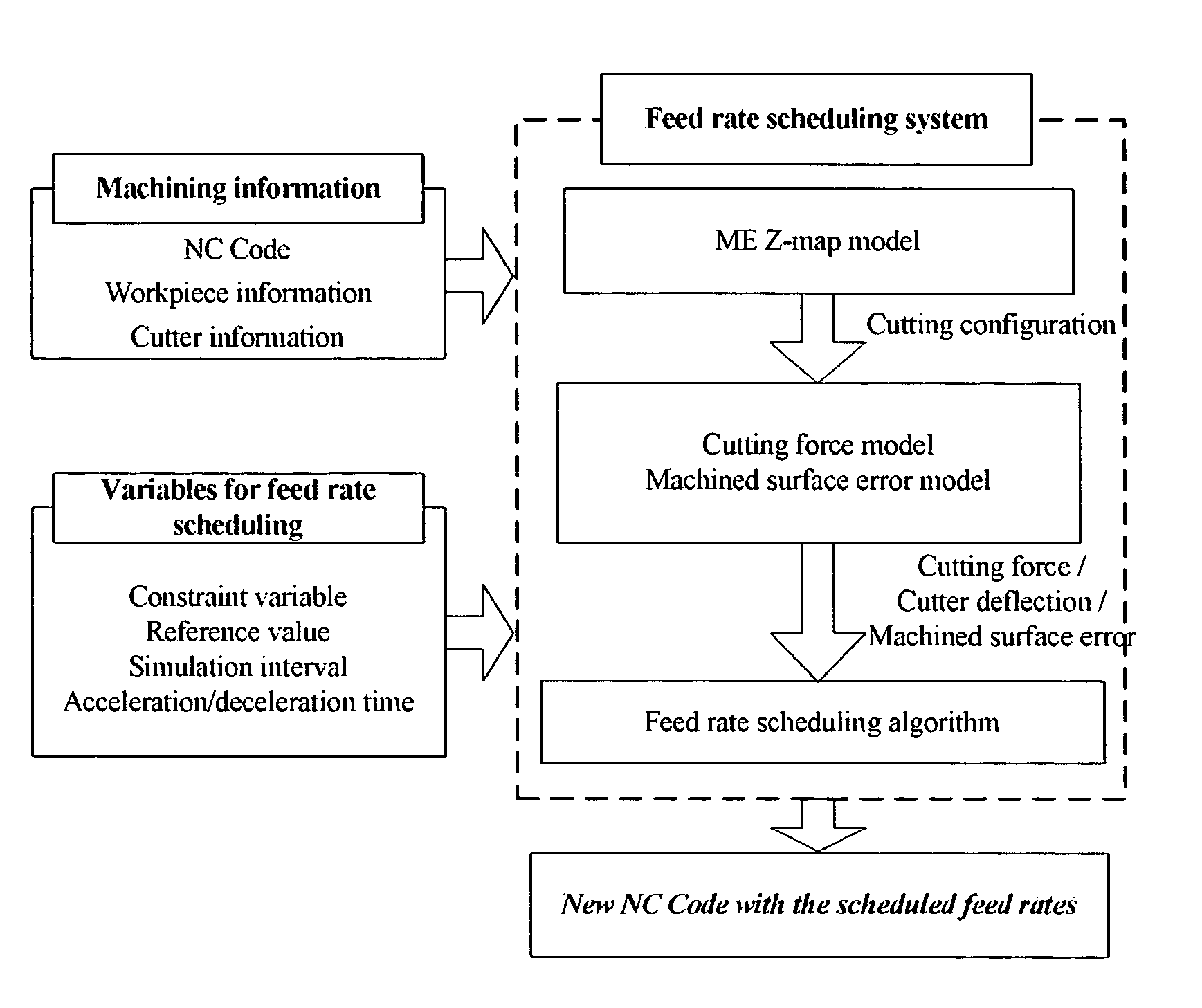

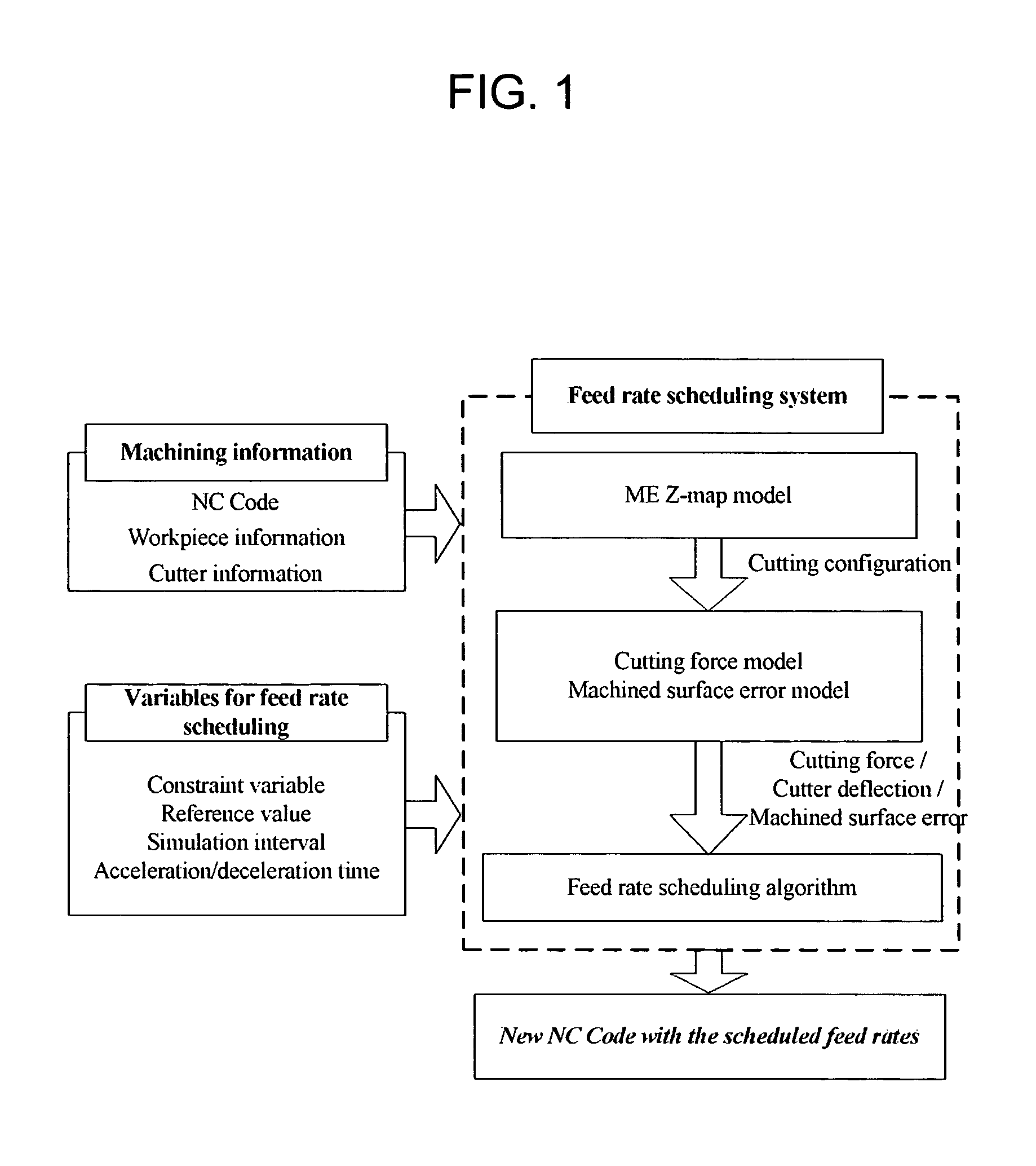

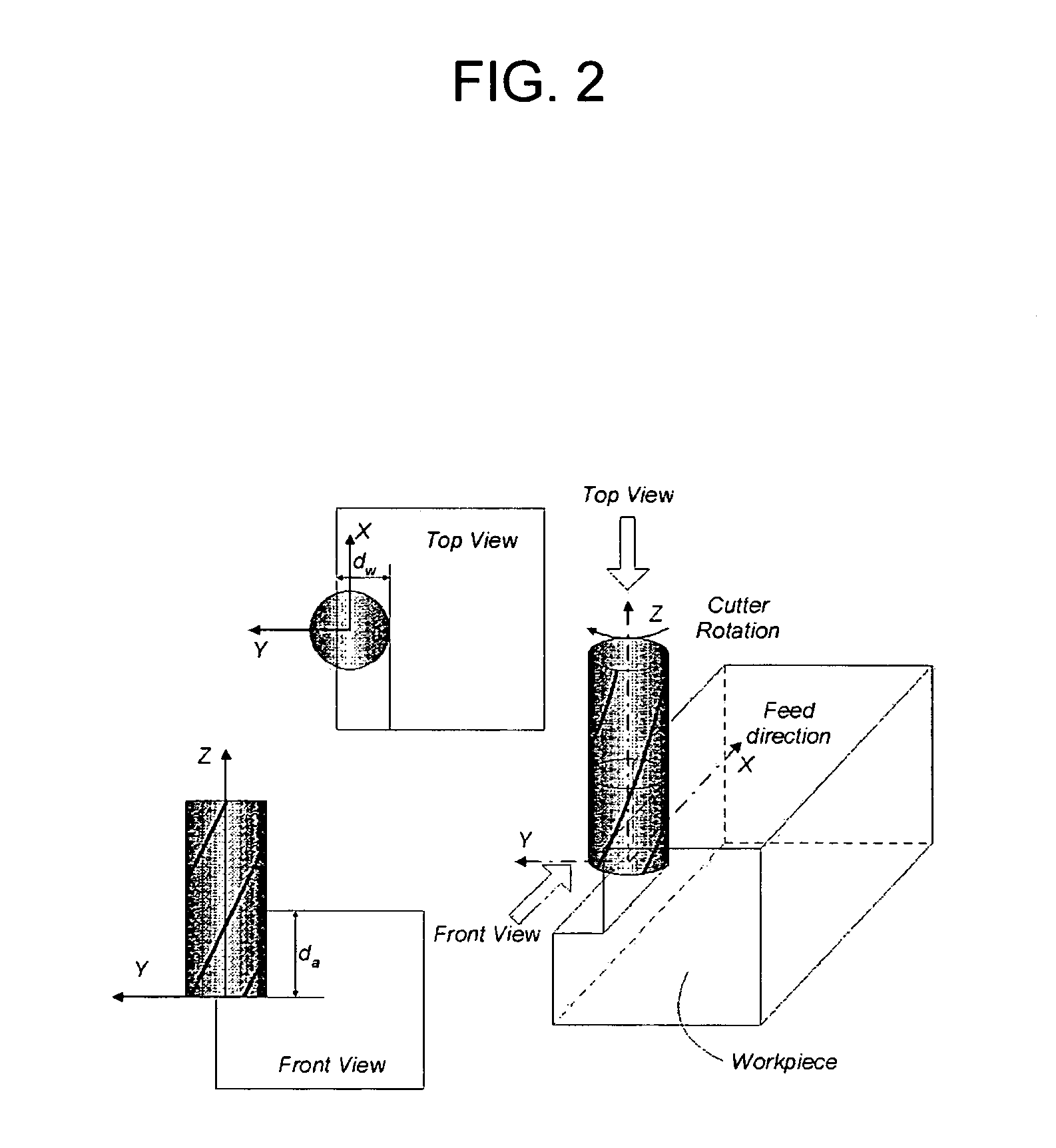

Off-line feed rate scheduling for reduction of machining time and enhancement of machining accuracy in CNC machining

InactiveUS20050113963A1Improve machining precisionIncrease productivityComputation using non-denominational number representationNumerical controlMachined surfaceSpecific rotation

An off-line feed rate scheduling method of a CNC machining process includes selecting a constraint variable and inputting a reference value related to the constraint variable; estimating a cutting configuration where a maximum constraint variable value (CVV) occurs through ME Z-map modeling; receiving the estimated cutting configuration and estimating a specific rotation angle (φs) where the maximum constraint variable value occurs through constraint variable modeling; calculating a feed rate that satisfies the reference value of the constraint variable at the estimated specific rotation angle; and applying the calculated feed rate to the NC code. Cutting force or machined surface error may be selected as a constraint variable depending on machining conditions.

Owner:POSTECH ACAD IND FOUND

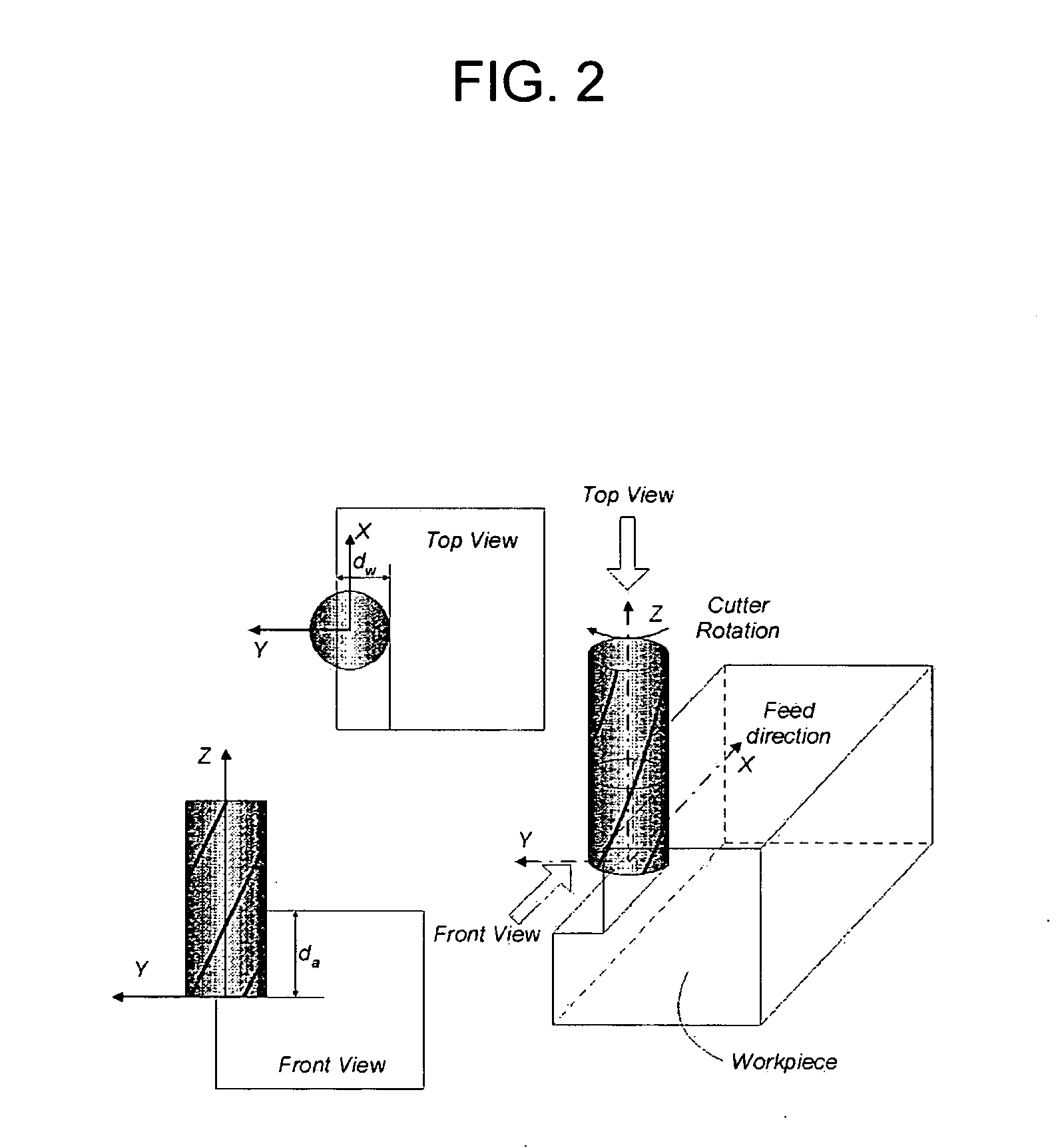

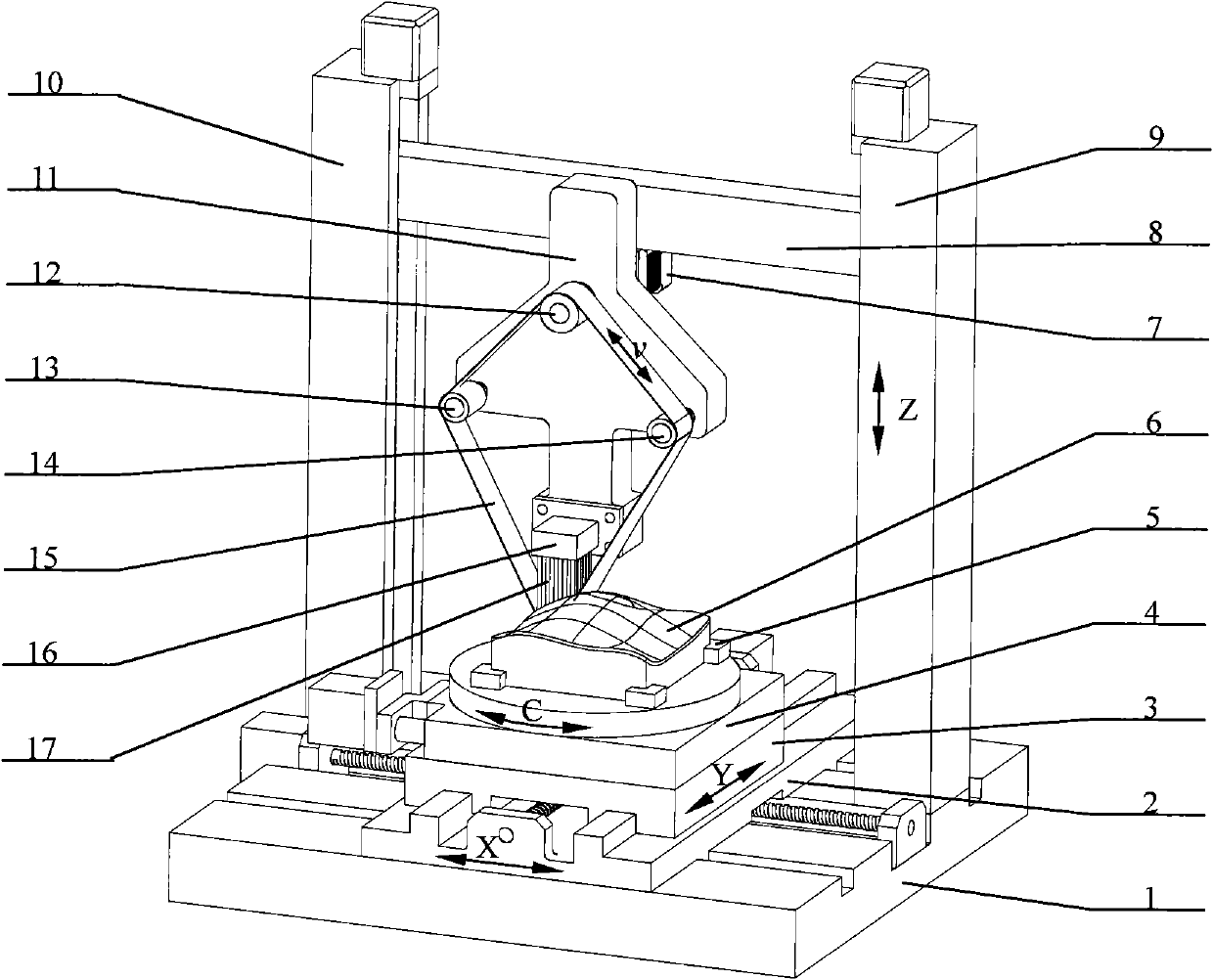

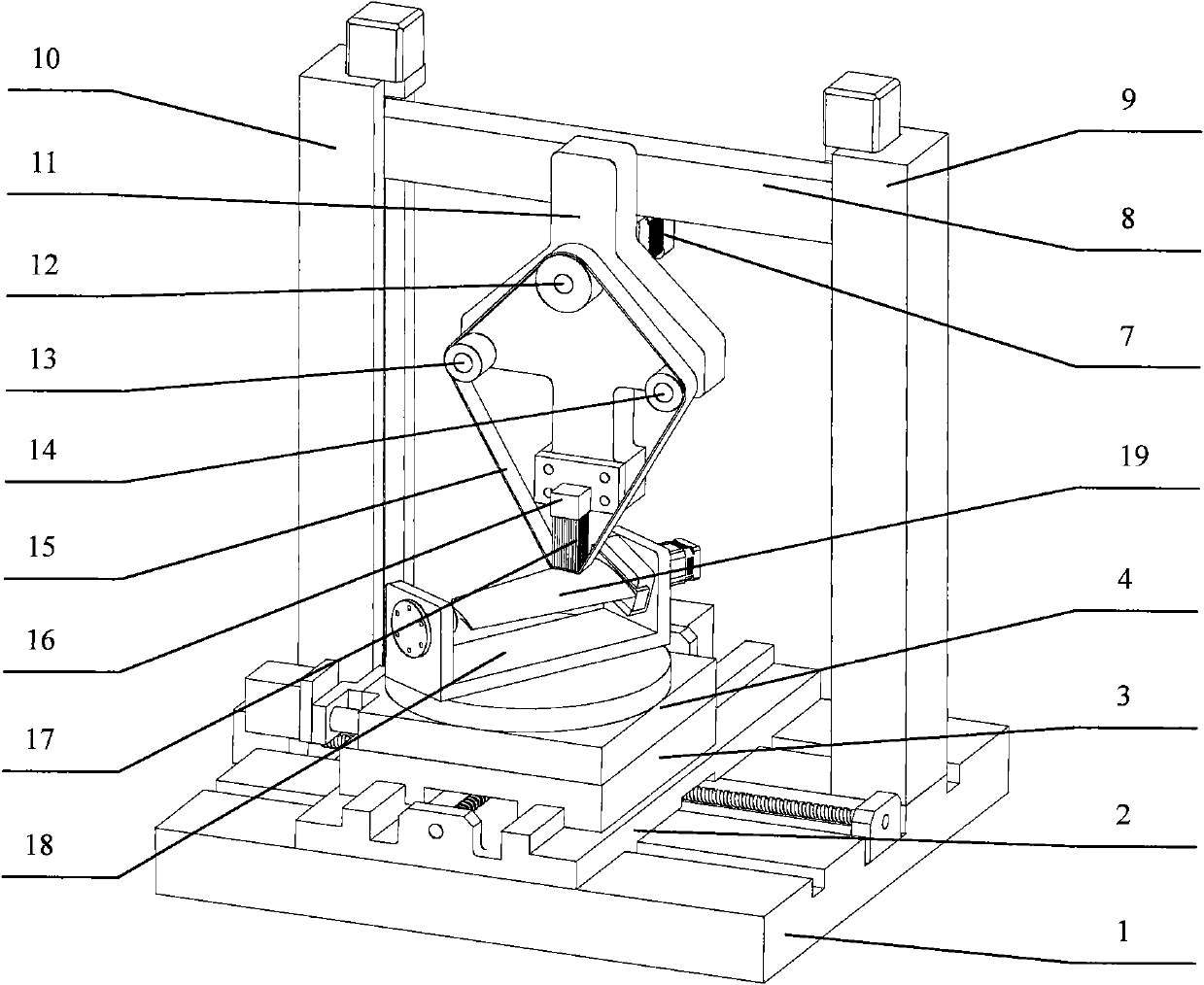

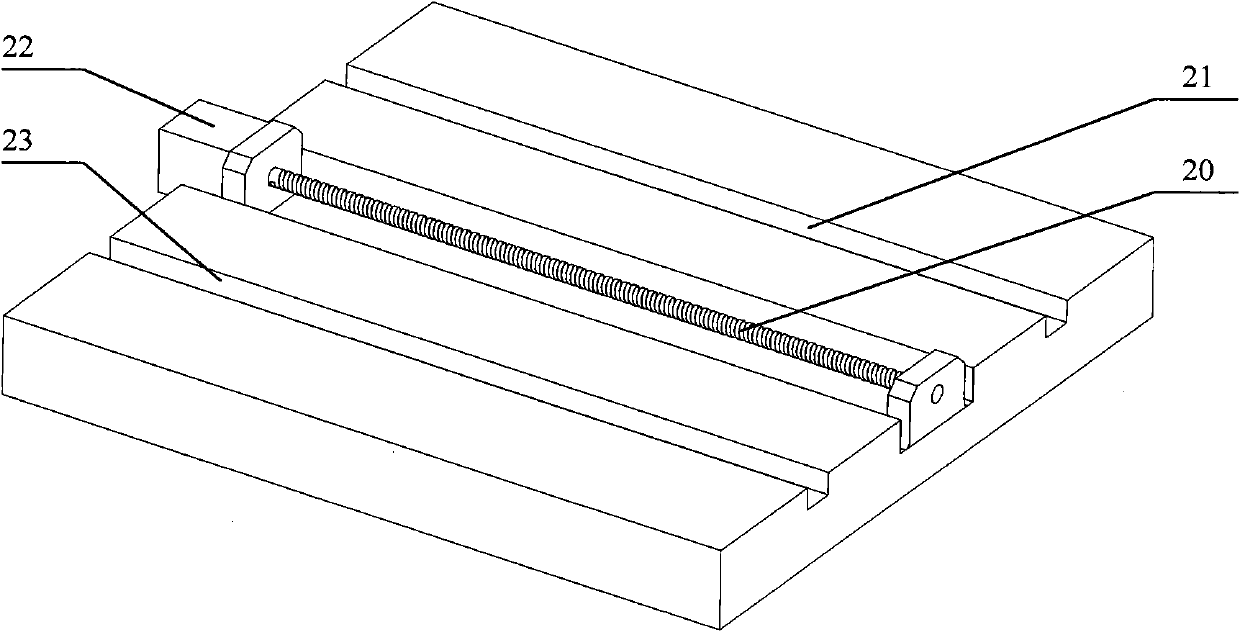

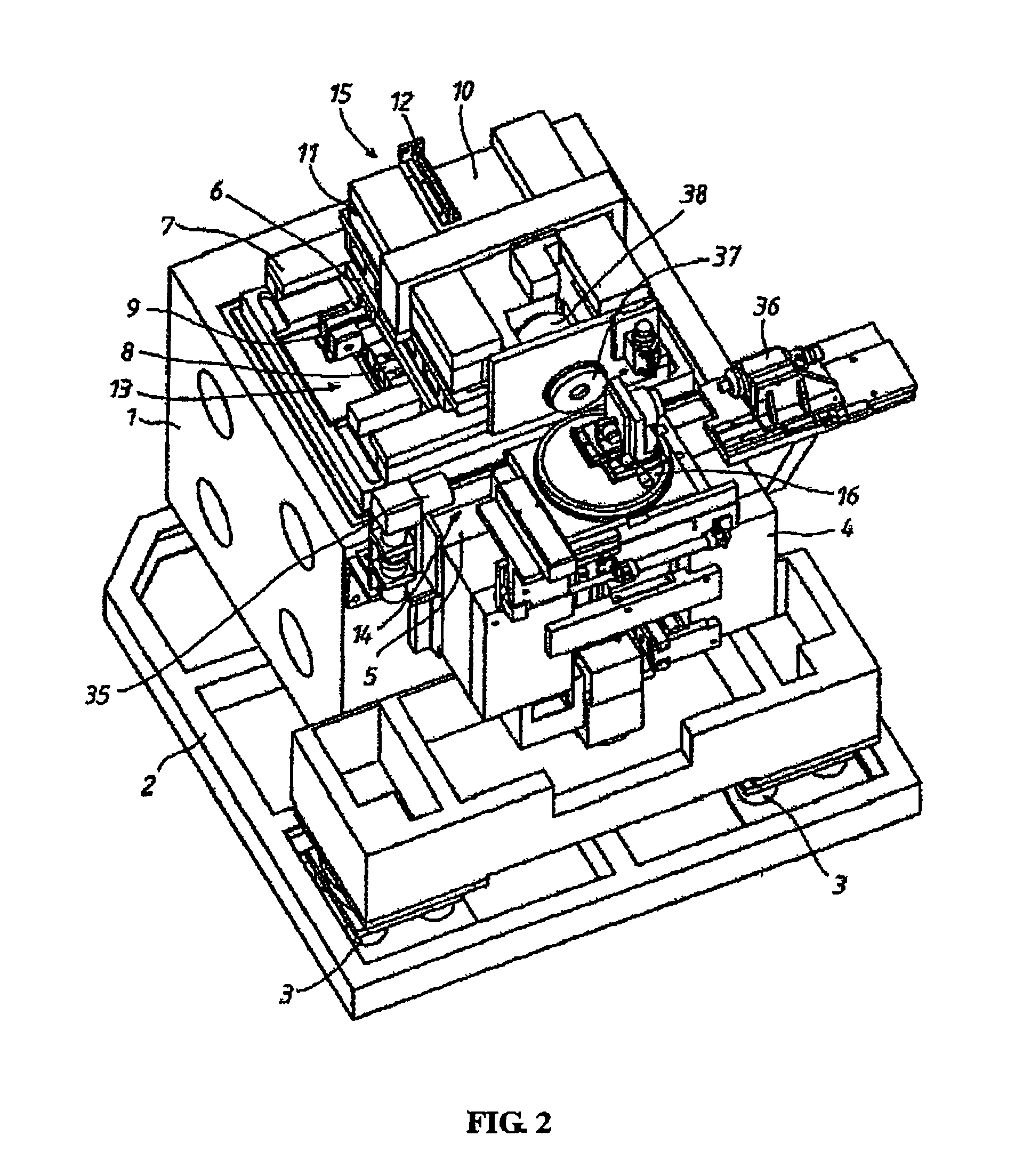

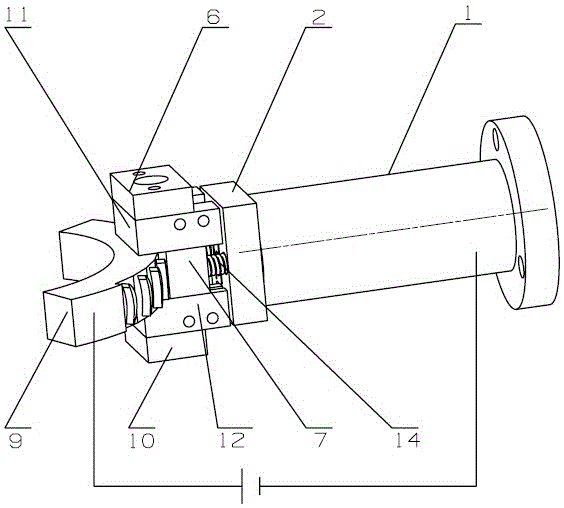

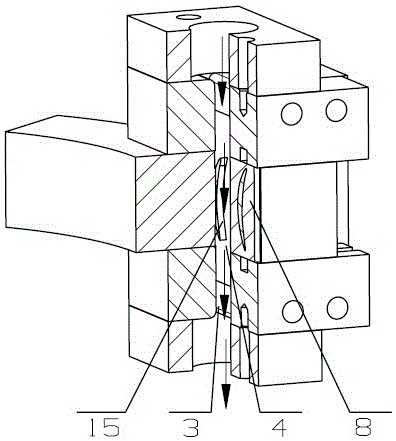

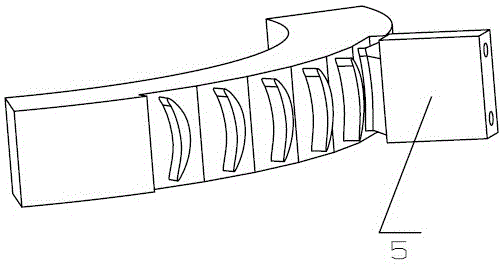

Adaptive machine tool for grinding and polishing complex surfaces

InactiveCN102019571AImprove efficiencyImprove machining accuracyGrinding machinesMachined surfaceEngineering

The invention provides an adaptive machine tool for grinding and polishing complex surfaces, belonging to the technical field of mechanical manufacture. The adaptive machine tool is characterized in that the lower ends of a left column and a right column are fixedly connected with a base; the left column is connected with the left end of a cross beam via a screw and a slide guide of the left column; the right column is connected with the right end of the cross beam via a screw and a slide guide of the right column; the middle of the cross beam is fixedly connected with a tool plate; a lower slide carriage is connected with the base via a screw, a front guide and a rear guide of the lower slide carriage; an upper slide carriage is connected with the lower slide carriage via a screw, a left guide and a right guide of the upper slide carriage; and a rotary table is fixedly connected with the upper slide carriage. The adaptive machine tool has the following advantages: the zones at the four sides are divided to serve as the grinding and polishing contact surfaces to grind and polish the parts with complex surfaces, so that the machine tool has high grinding and polishing efficiency and strong adaptability and can maintain the sharp shape characteristic of the complex surfaces; and the appearance of the contact tool head of the novel grinding and polishing tool system built based on multipoint forming technology can be regulated in real time according to the shape of the ideal machined surface, thus reducing the degree of freedom of design of the machine tool and enhancing the flexibility of the machine tool.

Owner:JILIN UNIV

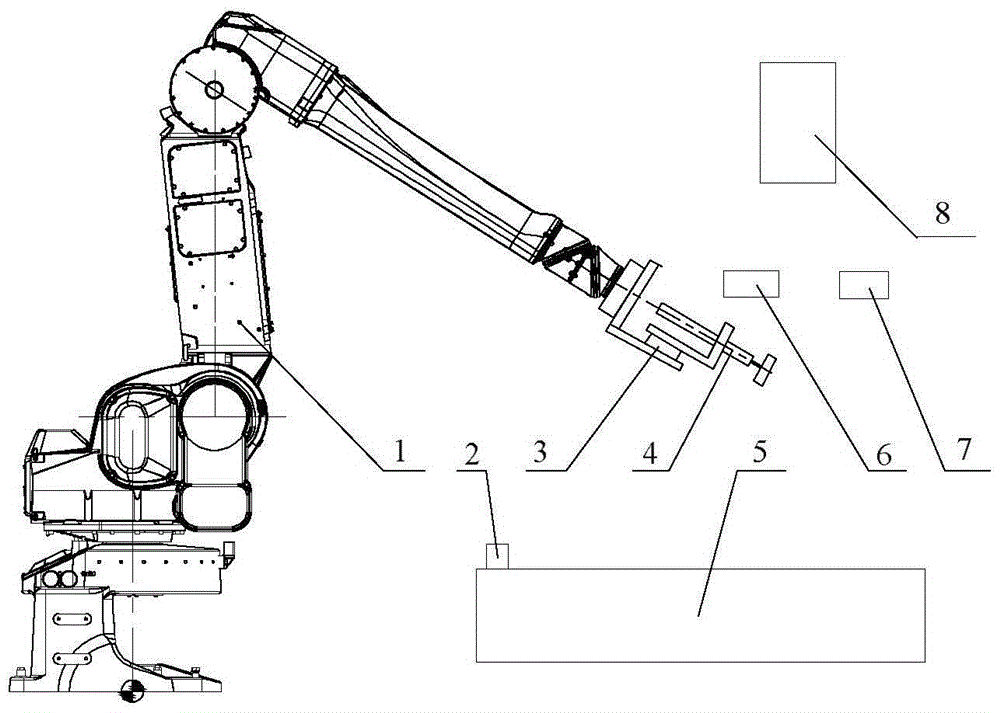

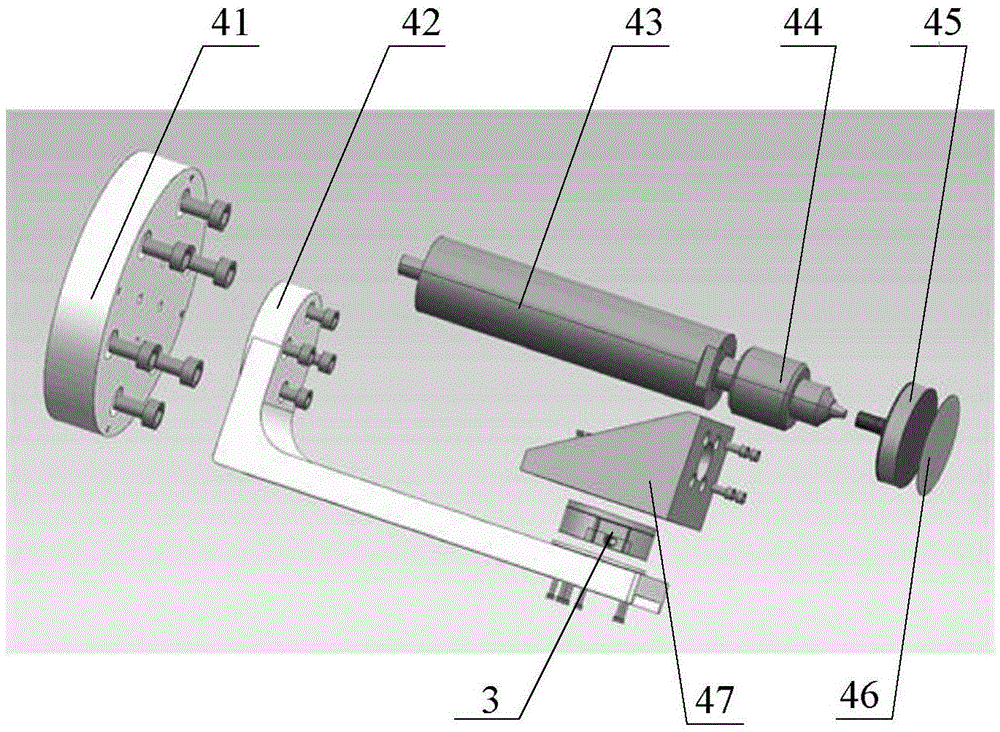

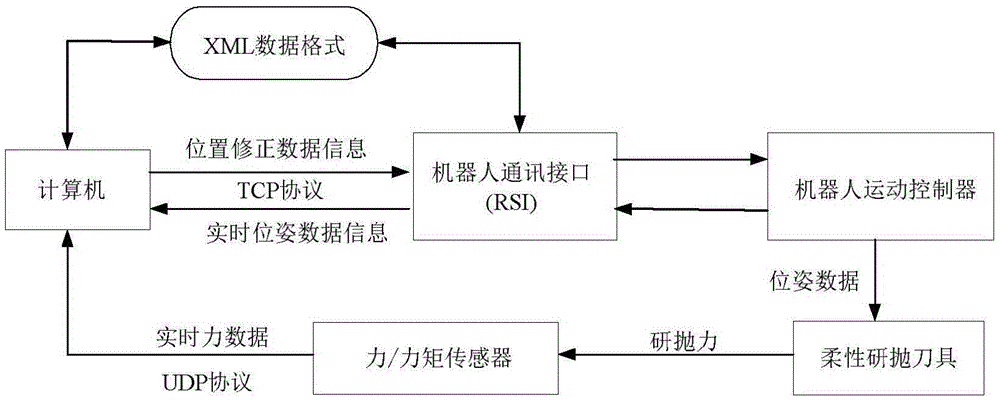

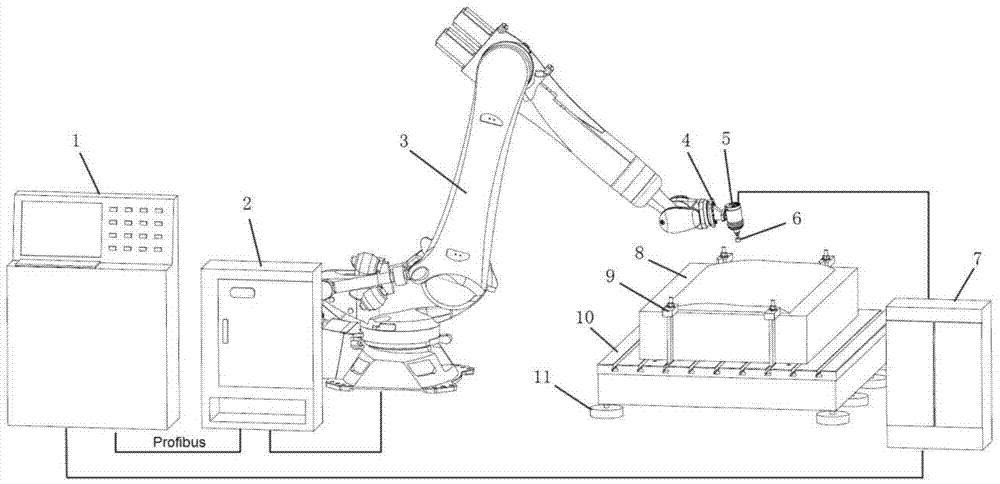

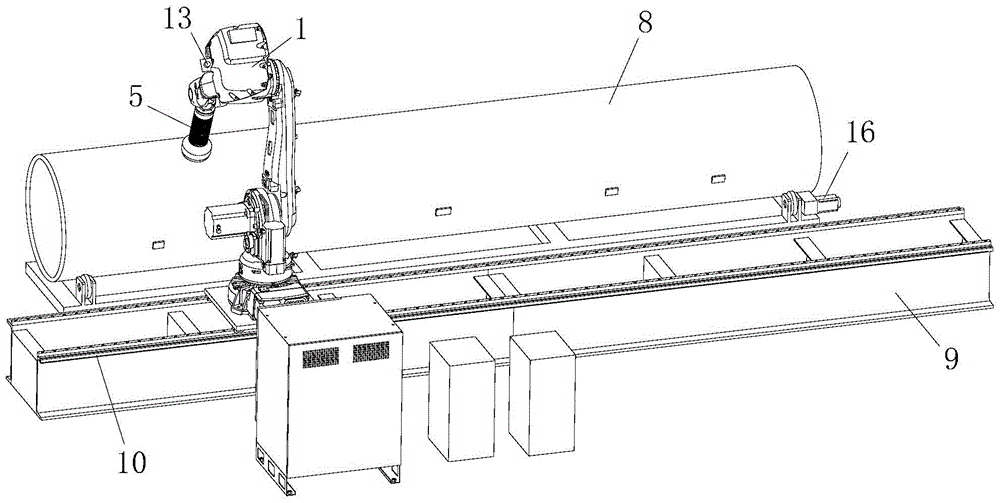

Automatic lapping and polishing system for complex surface of compliant control-based robot and machining method

InactiveCN105643399AReduce manual labor intensityReduce processing costsGrinding wheel securing apparatusGrinding drivesProcess systemsAudio power amplifier

The invention relates to an automatic lapping and polishing system for a complex surface of a compliant control-based robot and a machining method. The automatic lapping and polishing system comprises an industrial robot, a worktable, a force sensor, a flexible lapping and polishing cutter, a signal conversion amplifier, a computer and a robot controller; the method comprises the following steps: performing machining trace planning before lapping and polishing a complex surface workpiece to obtain cutter contact point trace of the lapping and polishing cutter to obtain a surface machining cutter location point trace; converting the surface machining cutter location point trace into a code format program file which can be identified by the robot controller, and inputting the code format program file into the robot controller; positioning and clamping the workpiece to complete coordinate labeling and unification of a process system; and driving the robot to move according to a machining trace planning program file to drive the lapping and polishing cutter arranged on an end executor of the robot to perform contact machining on a machined surface. According to the automatic lapping and polishing system and the machining method disclosed by the invention, manual operation at a finish machining stage of the complex surface workpiece, especially a large-sized complex surface workpiece, can be replaced; labor strength and machining cost are reduced; and quality stability and quality consistency of a machined molded surface are increased.

Owner:SHENYANG LIGONG UNIV

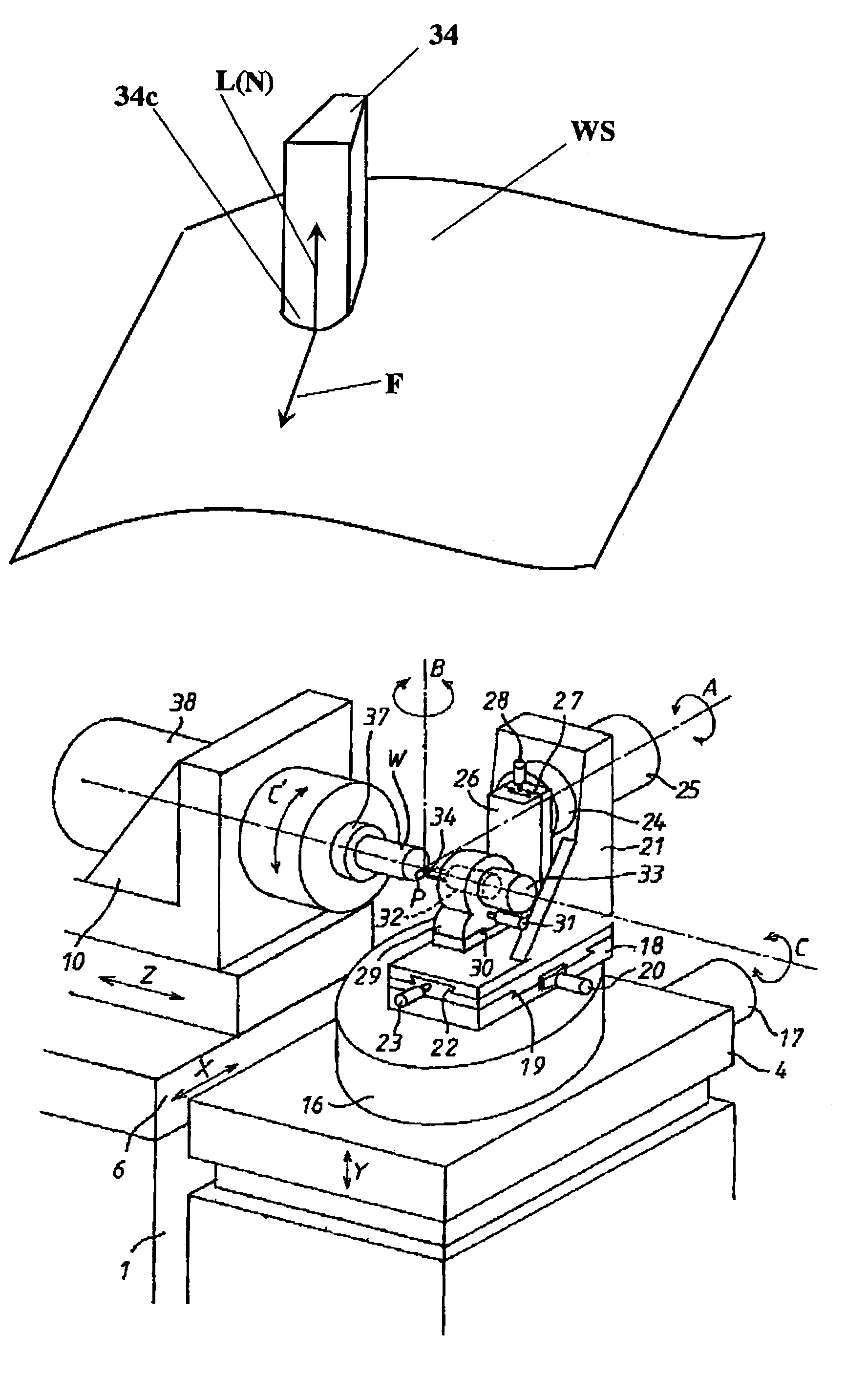

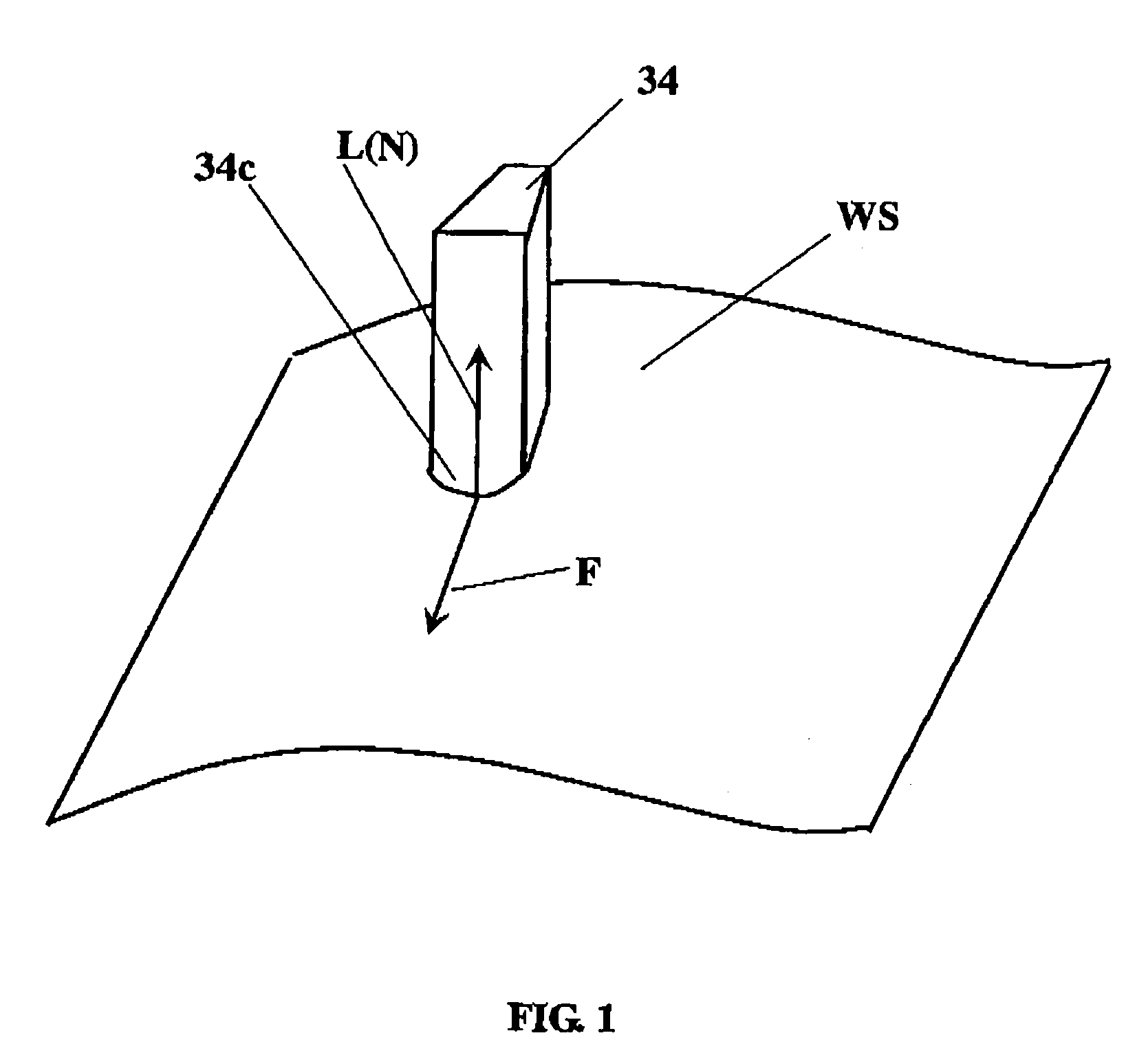

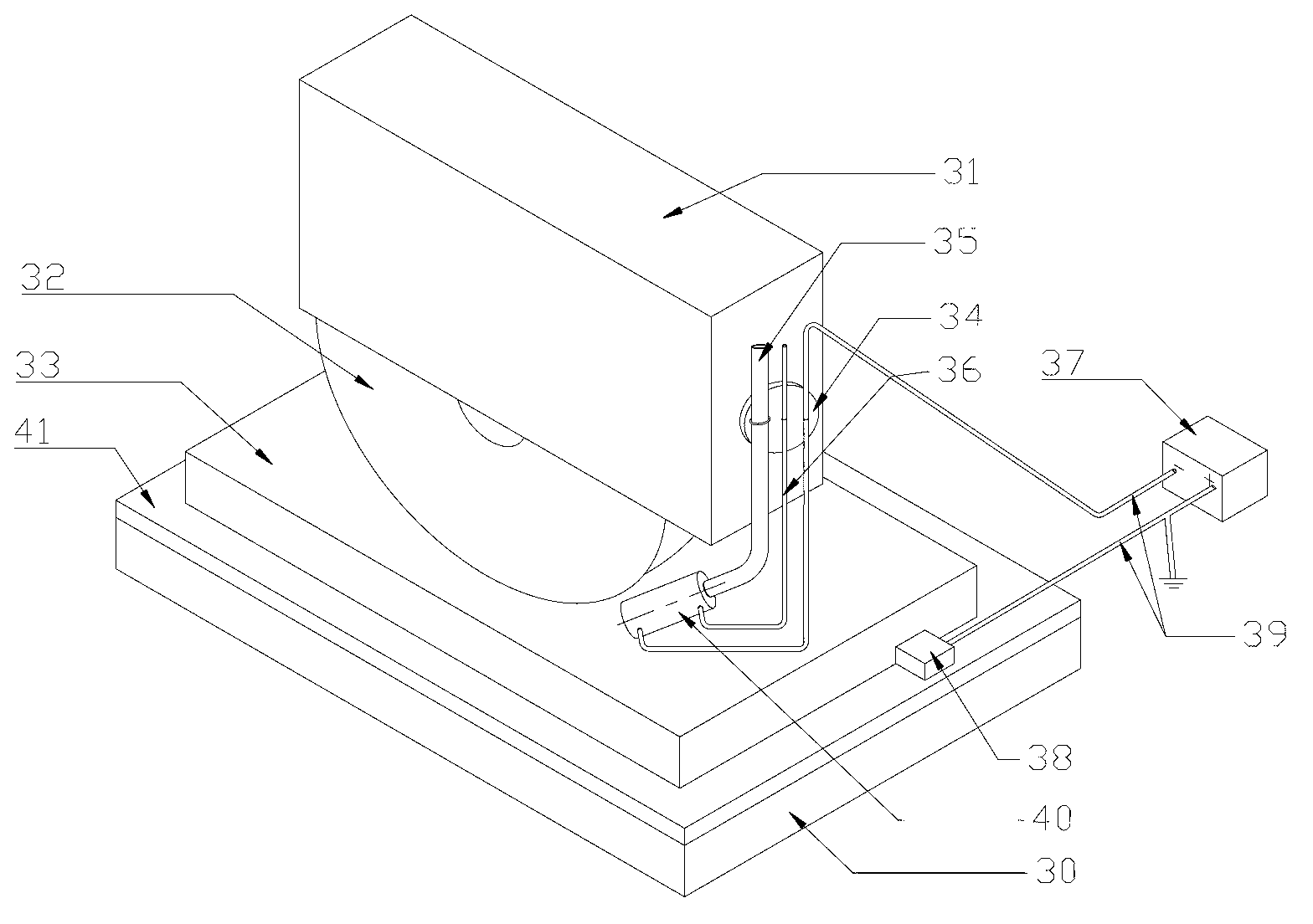

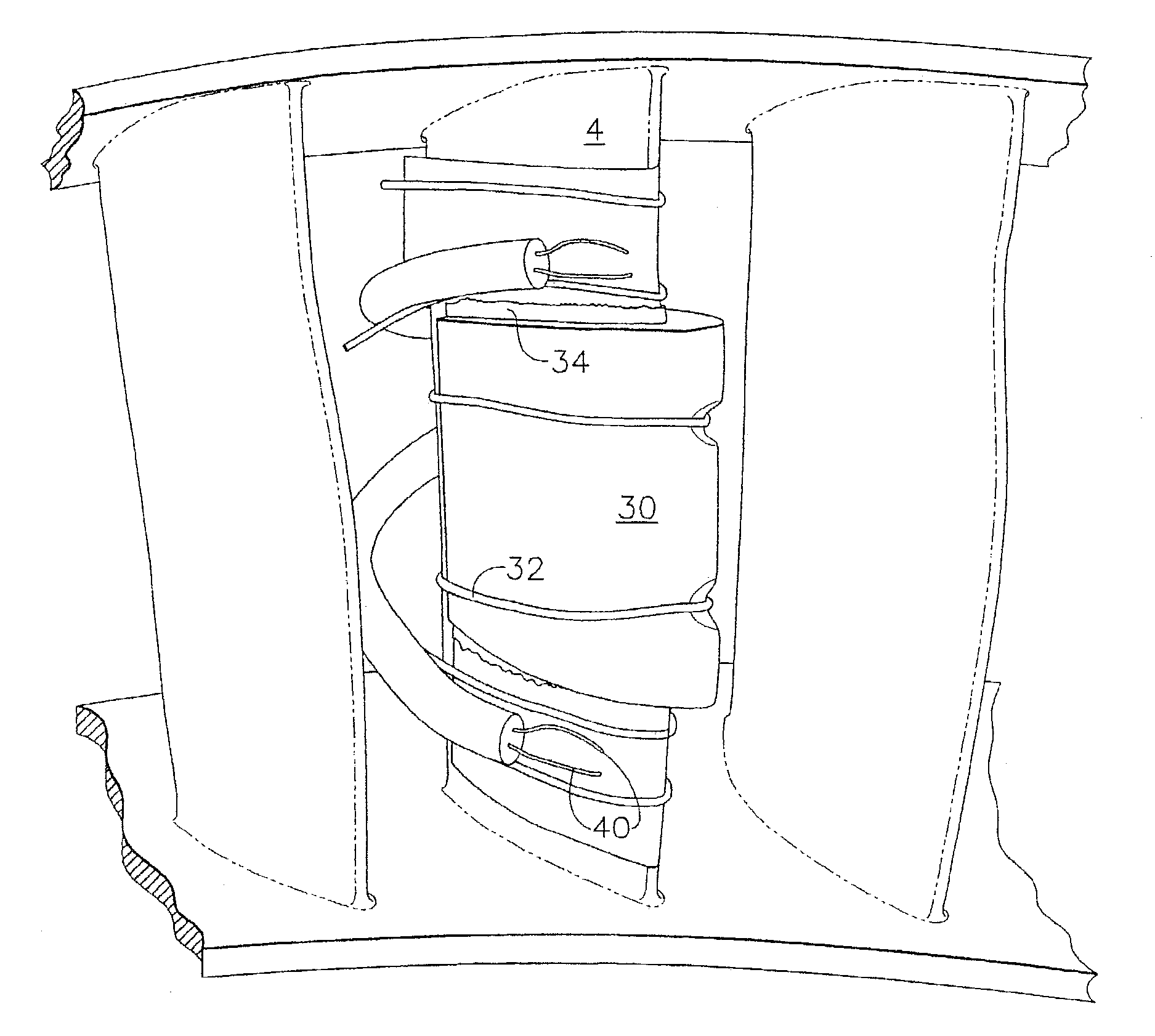

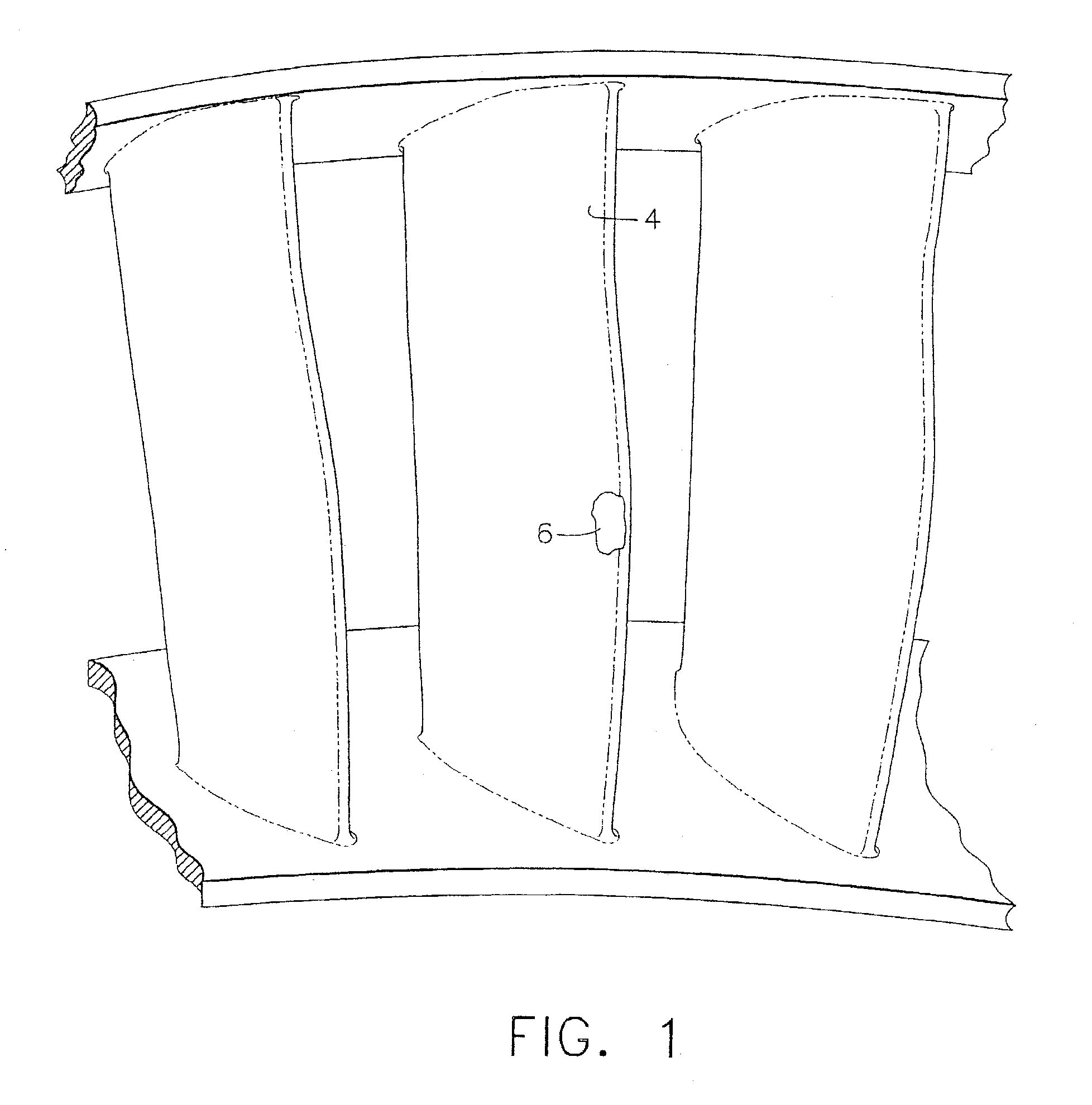

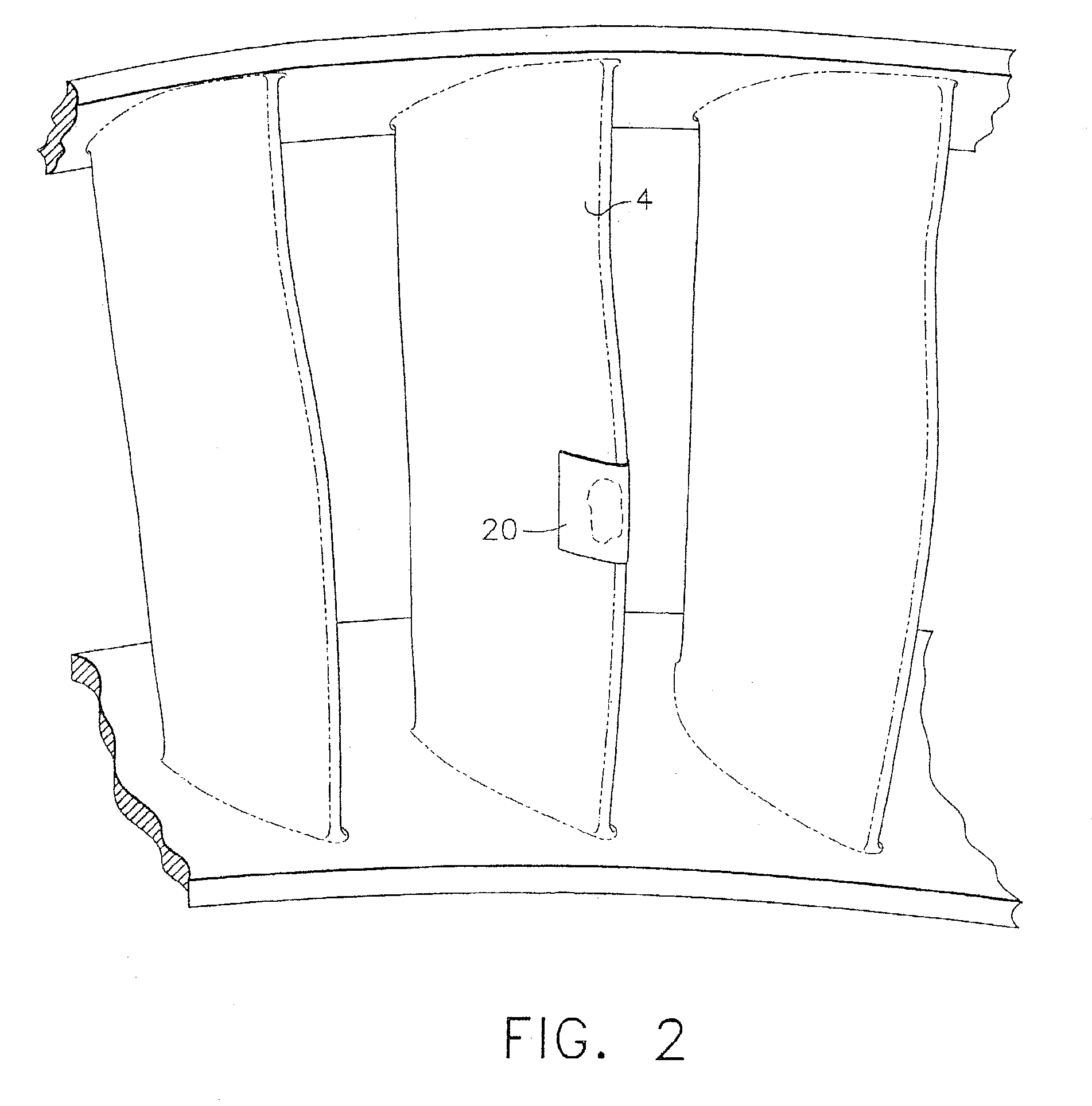

Hale-machining method and apparatus

InactiveUS7089836B2Easy to prepareHigh geometric accuracyLathesAutomatic/semiautomatic turning machinesRotary stageRotational axis

It is one object of a hale-machining method and apparatus thereof according to the present invention to achieve an easy preparation of an NC machining program and perform a high geometrical accuracy in the predetermined three-dimensional free curved surface.A haling tool 34 is set on a tool holder 32 in such a manner that a cutting point P of the haling tool 34 is substantially coincided with an intersection of a first rotating axis B, a second rotating axis A and a third rotating axis C. A rotary table 16 and a rotary base 24 are rotated in such a manner that a tool axis direction of said haling tool is substantially coincided with a normal direction of said machined surface. A tool holder 32 is rotated in such a manner that a front rake surface of the haling tool 34 is substantially directed in perpendicular to a feeding direction of said haling tool 34. A workpiece table holding a workpiece and the tool holder are relatively moved along a machined surface of said workpiece in three perpendicular axes including an axis parallel to said first rotating axis.

Owner:TOYODA MASCH WORKS LTD

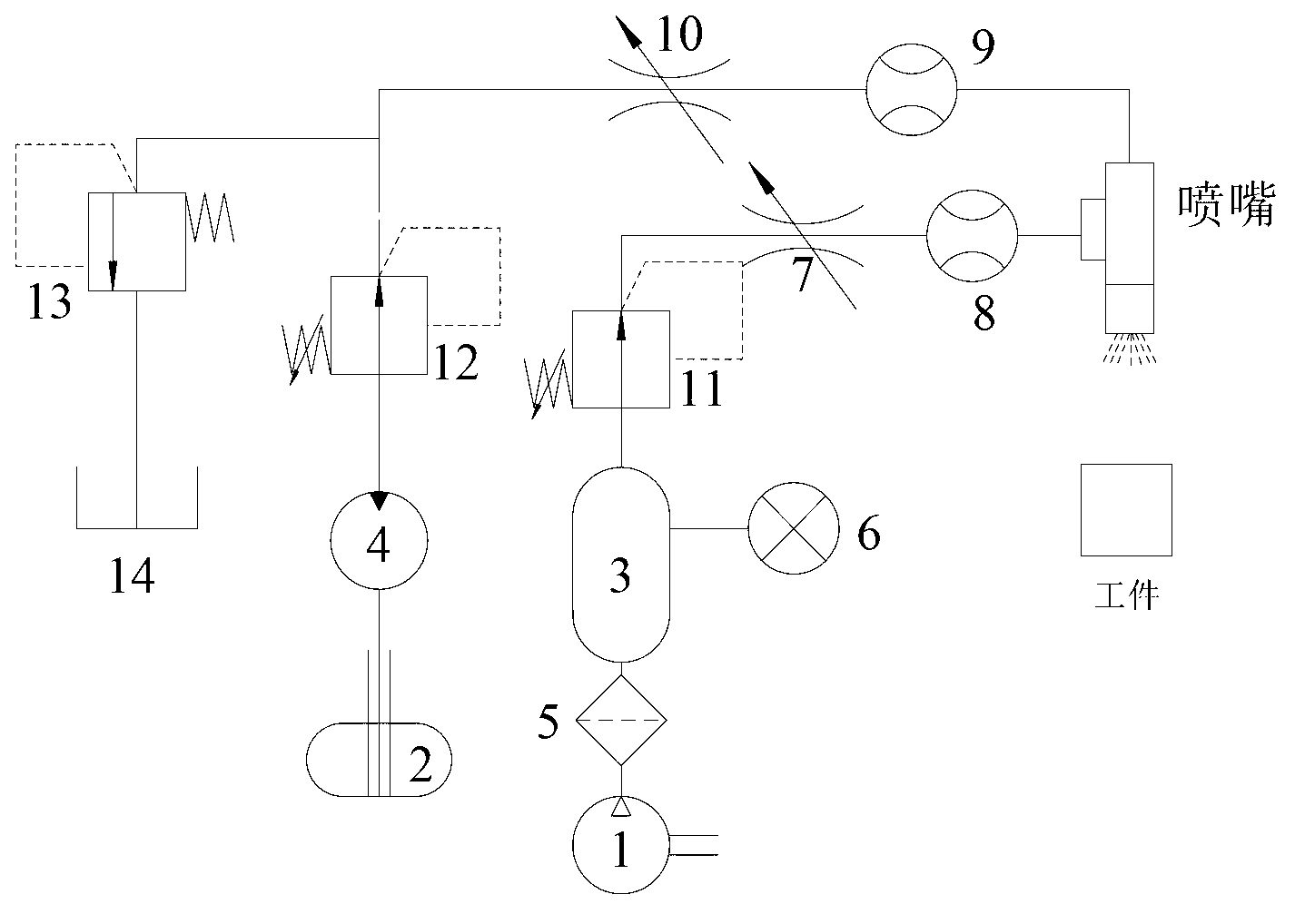

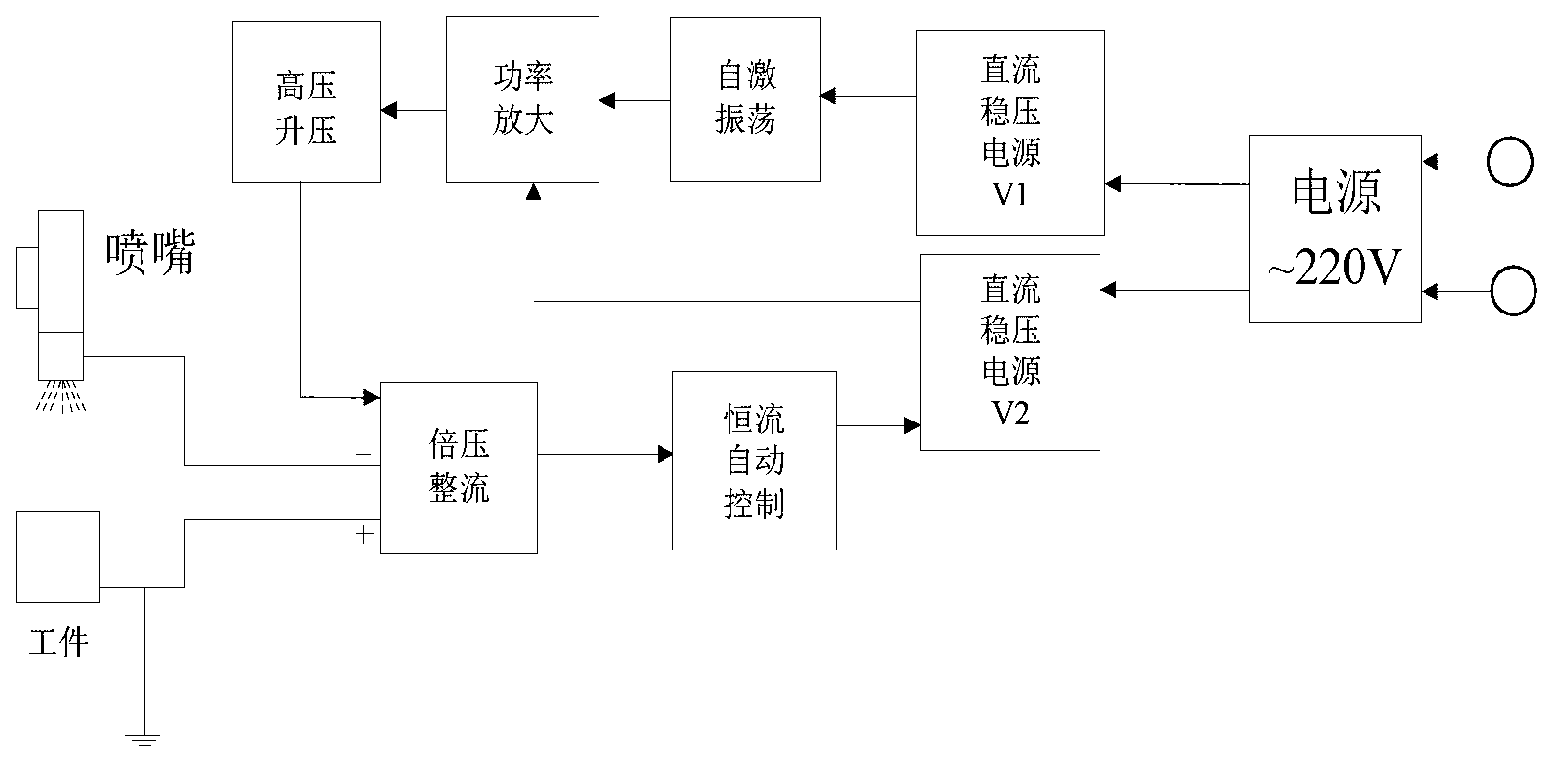

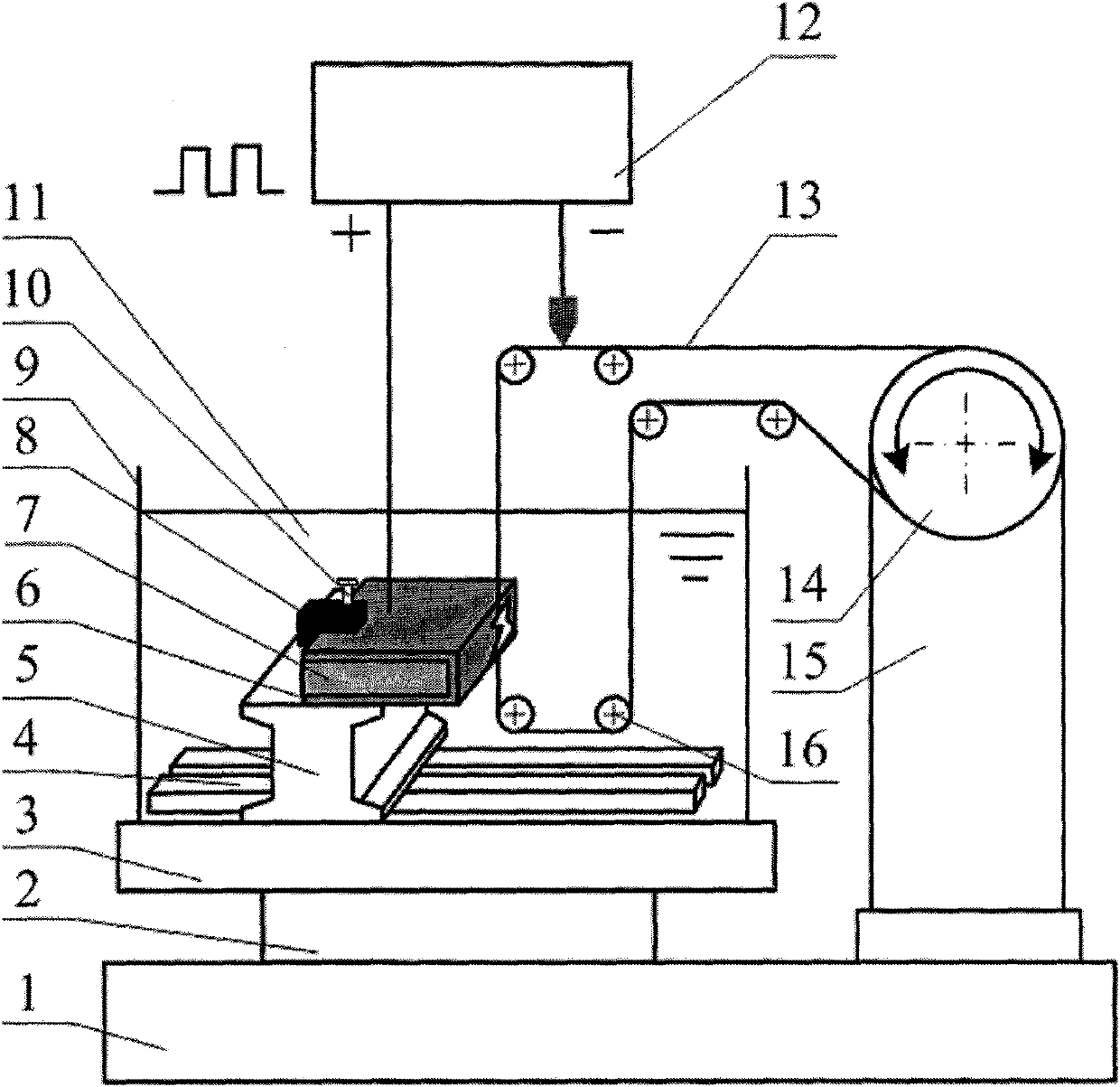

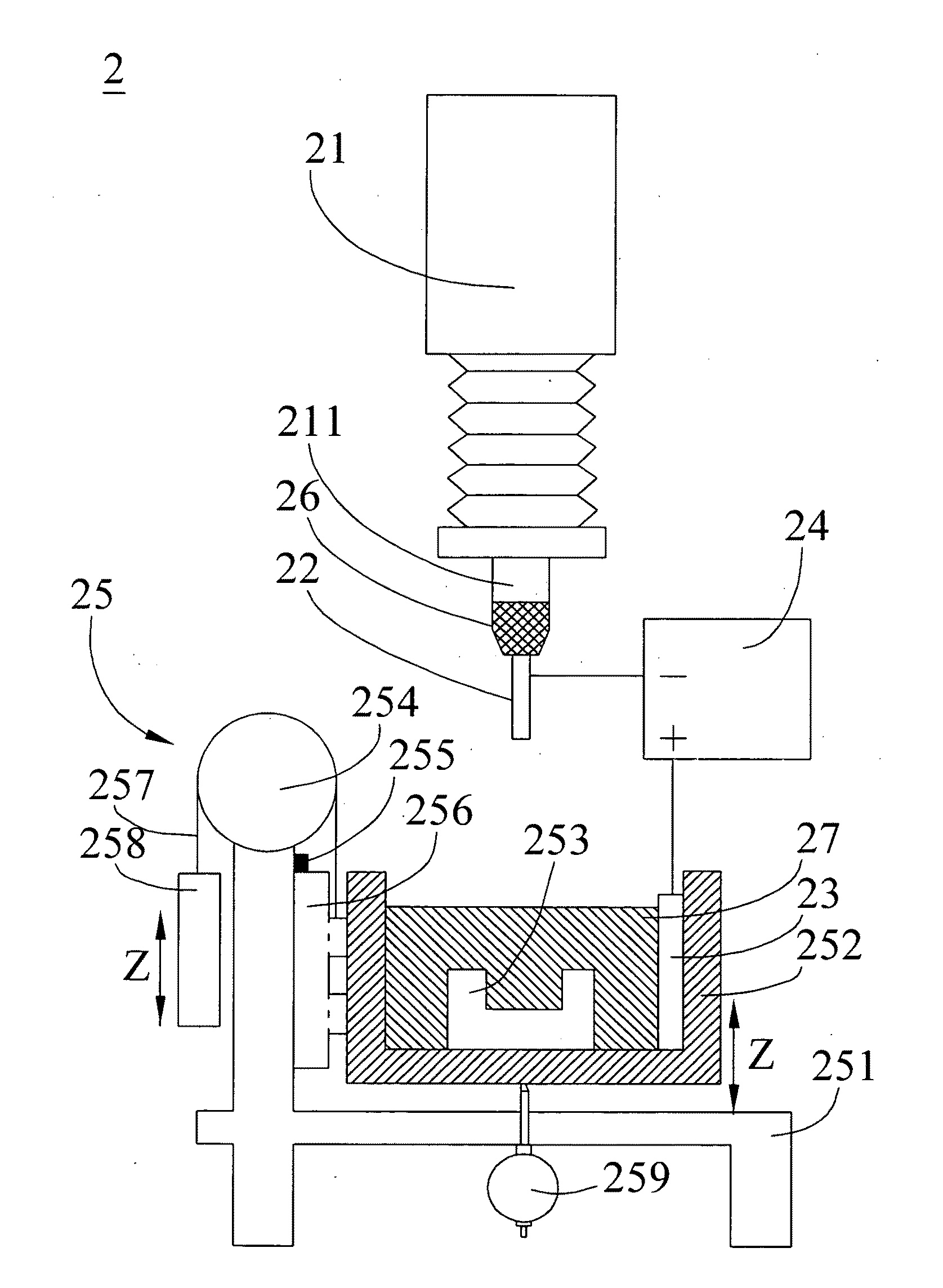

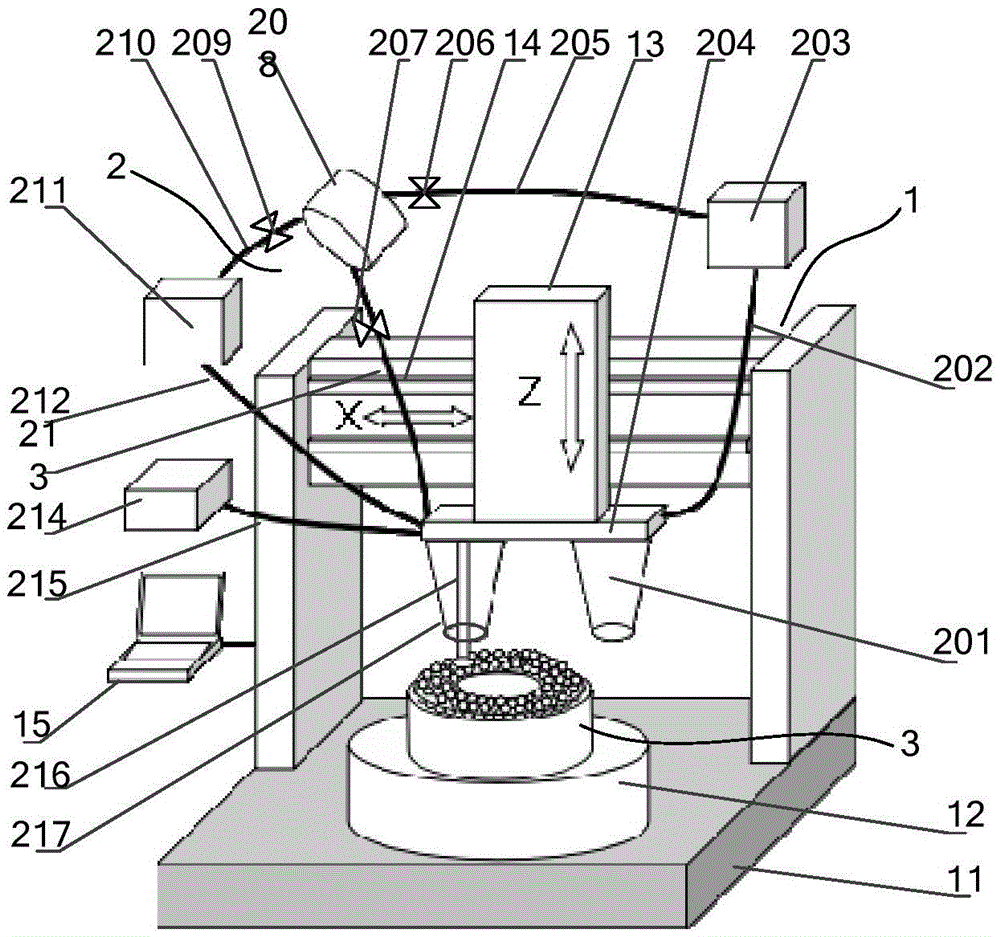

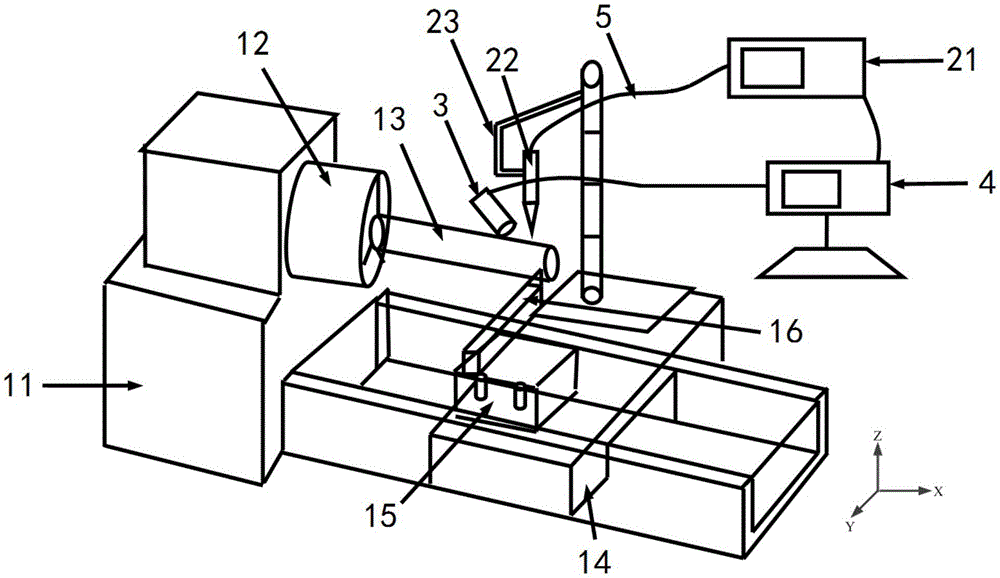

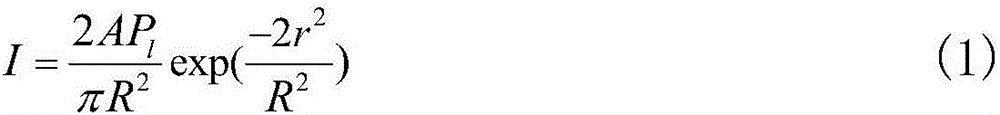

Nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system

ActiveCN103072084AReduce drift lossIncrease profitGrinding/polishing safety devicesMachined surfaceHigh-voltage direct current

The invention relates to a nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system. Sprayed fog drops can be controllably distributed through the electrostatic principle, so that the pollution to environment is reduced, and better health security is provided to workers. A grinding system is provided with a corona charging nozzle, wherein a nozzle body of the corona charging nozzle is connected with a liquid supply system and an air supply system; a high-voltage direct-current electrostatic generator on the lower part of the nozzle body is connected with the cathode of an adjustable high-voltage direct-current power supply; the anode of the adjustable high-voltage direct-current power supply is connected with a workpiece charging device; and the workpiece charging device is attached to the non-machined surface of a workpiece. Nano fluid grinding liquid is fed into the corona charging nozzle through the liquid supply system, meanwhile the air supply system feeds compressed air into the corona charging nozzle, the nano fluid grinding liquid is charged into controllable jet stream by the high-voltage direct-current electrostatic generator while being driven by the compressed air to be sprayed out and atomized from the nozzle body, and the controllable jet stream is controllably distributed to a grinding area of the machined workpiece under the actions of electric field force and aerodynamic force.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Free-form surface robot polishing system

ActiveCN103878666AWith soft force control functionKeep the pressure constantGrinding drivesGrinding machinesFree formMachined surface

The invention discloses a free-form surface robot polishing system. The system comprises a workbench, an industrial robot, a robot control cabinet, a polishing tool, a pneumatic main shaft, a connecting part, a pneumatic control cabinet and a system control cabinet. The system is high in automation degree, high in flexibility and particularly suitable for polishing a free-form surface. Specifically, the pneumatic main shaft fixed at the tail end of the industrial robot is used for clamping the polishing tool, the machined surface is tightly pressed by the polishing tool all the time by means of the pneumatic compliant force control function of the pneumatic main shaft, constant pressure is kept, the pose of the industrial robot is adjusted according to a planned route, the polishing pressure is in the normal direction of the machined surface, the polishing tool rotates at high speed through a pneumatic motor of the pneumatic main shaft, and then the industrial robot drives the polishing tool to polish a part according to the planned route.

Owner:中科君胜(深圳)智能数据科技发展有限公司

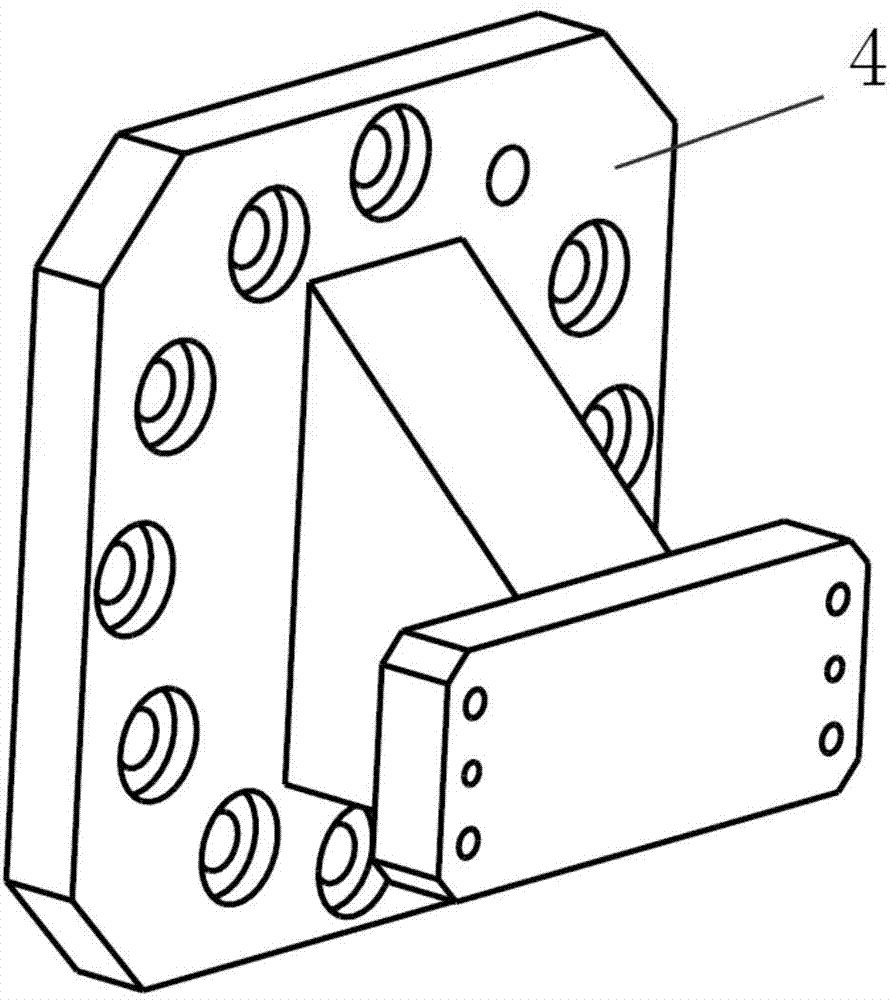

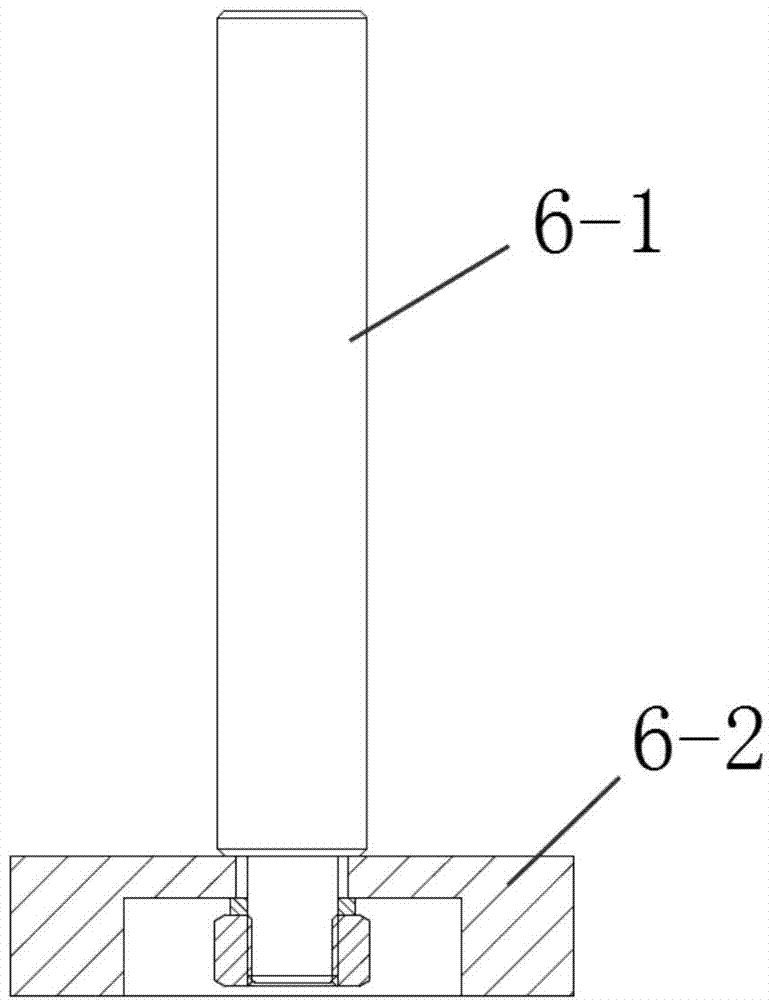

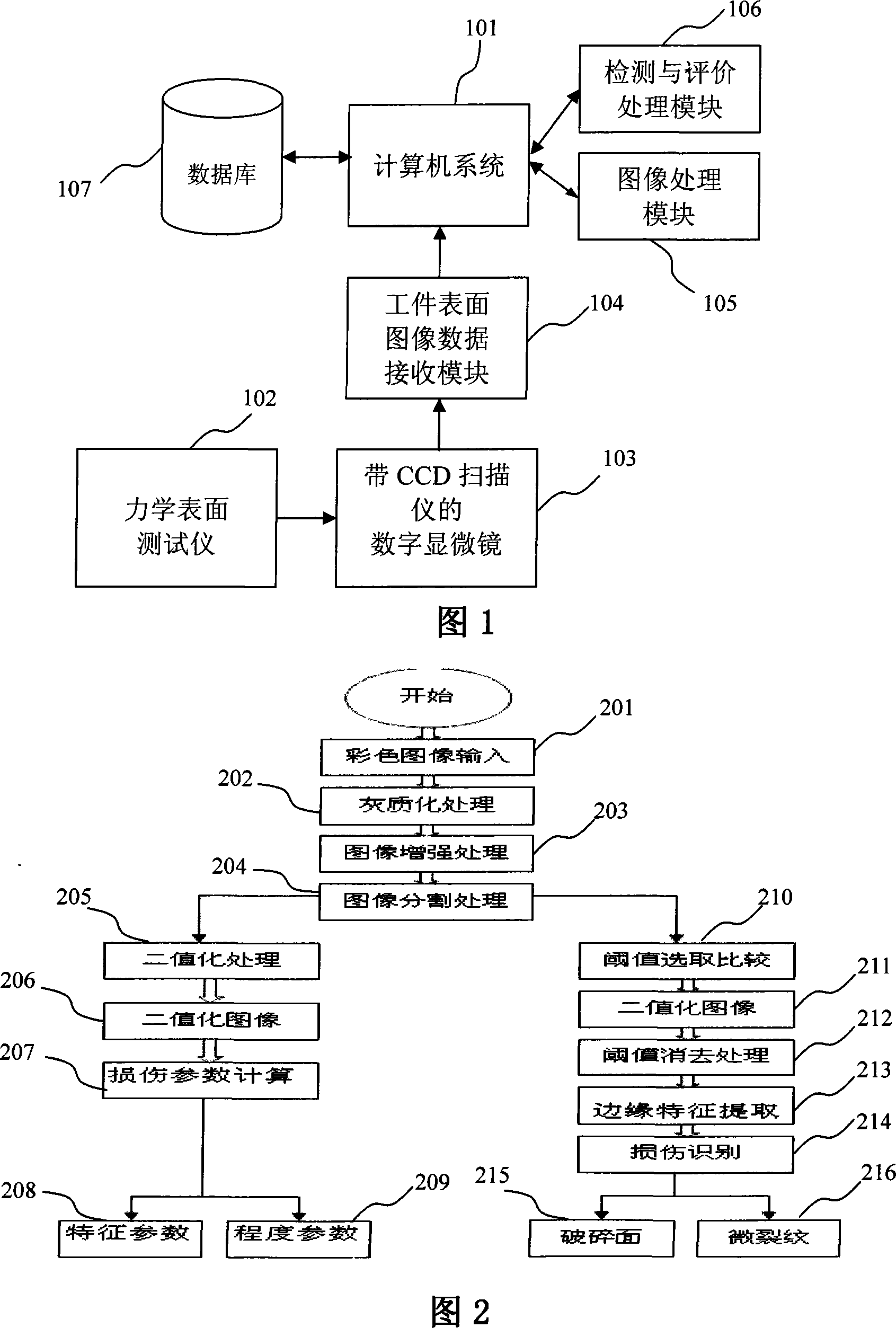

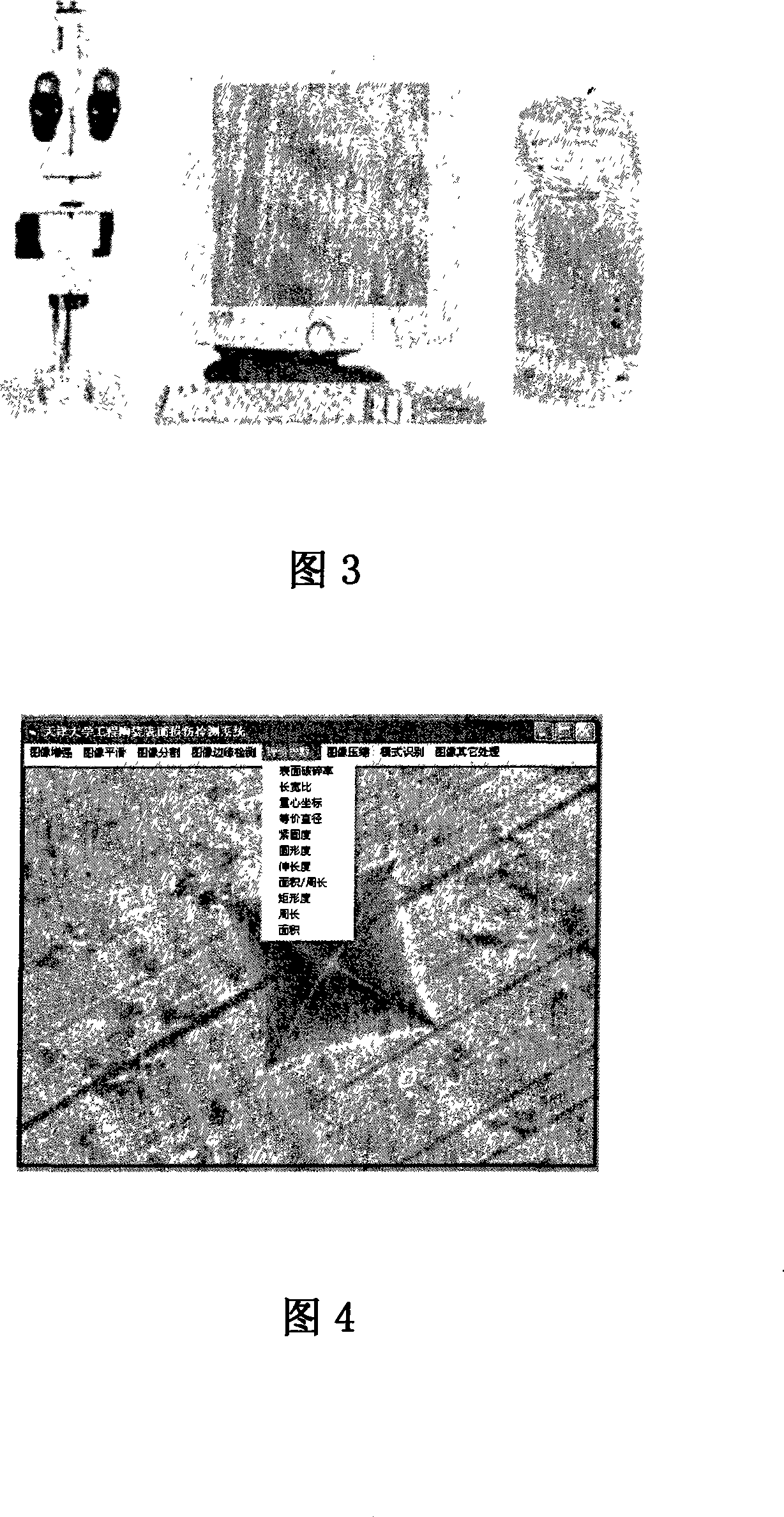

Ceramic working surface damnification detecting system

InactiveCN101178367ALow costOptically investigating flaws/contaminationSoftware systemMachined surface

The invention discloses a ceramic processing surface damage detection system, which collects the processing status of the processing surface in the high-efficiency precision grinding process and the characteristic data of the grinding surface topography by the computer, and performs classification processing to obtain the edge contour characteristics of the damage, and identify The macro-quantitative index surface breakage rate, stability, diffusion and damage characteristic parameters that characterize the damage degree of the processed surface are extracted, combined with computer digital image processing technology and algorithms, to complete the detection and evaluation of ceramic surface processing damage. Compared with the existing technology, the system can effectively detect the surface damage type, characteristics, and surface damage degree of advanced ceramics and other related materials, and can be used as an important reference index for comprehensively evaluating the surface quality of ceramic processing. The detection software written in the system is simple and practical, low in cost, more conducive to popularization, reliable and effective, and has greater economic benefits.

Owner:TIANJIN UNIV

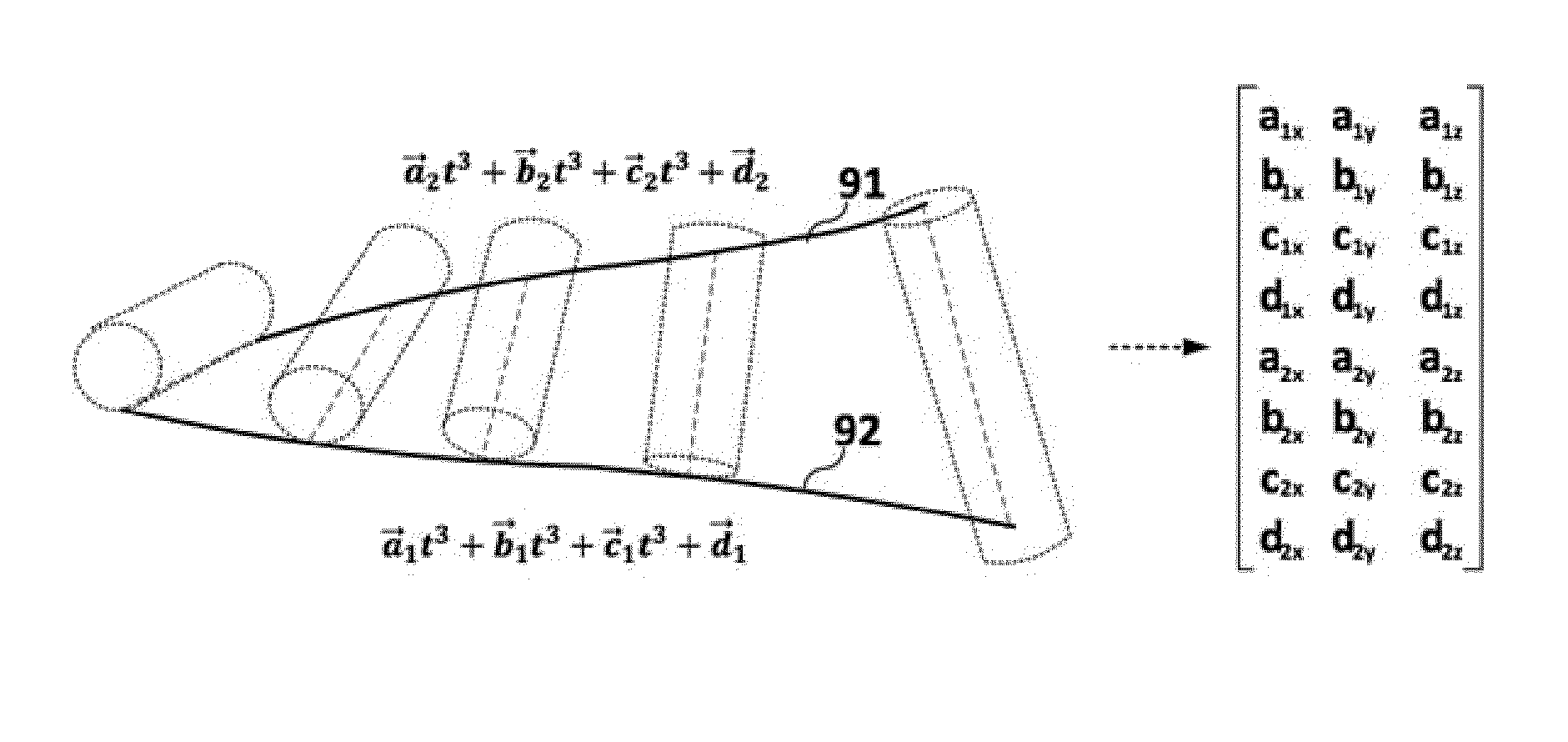

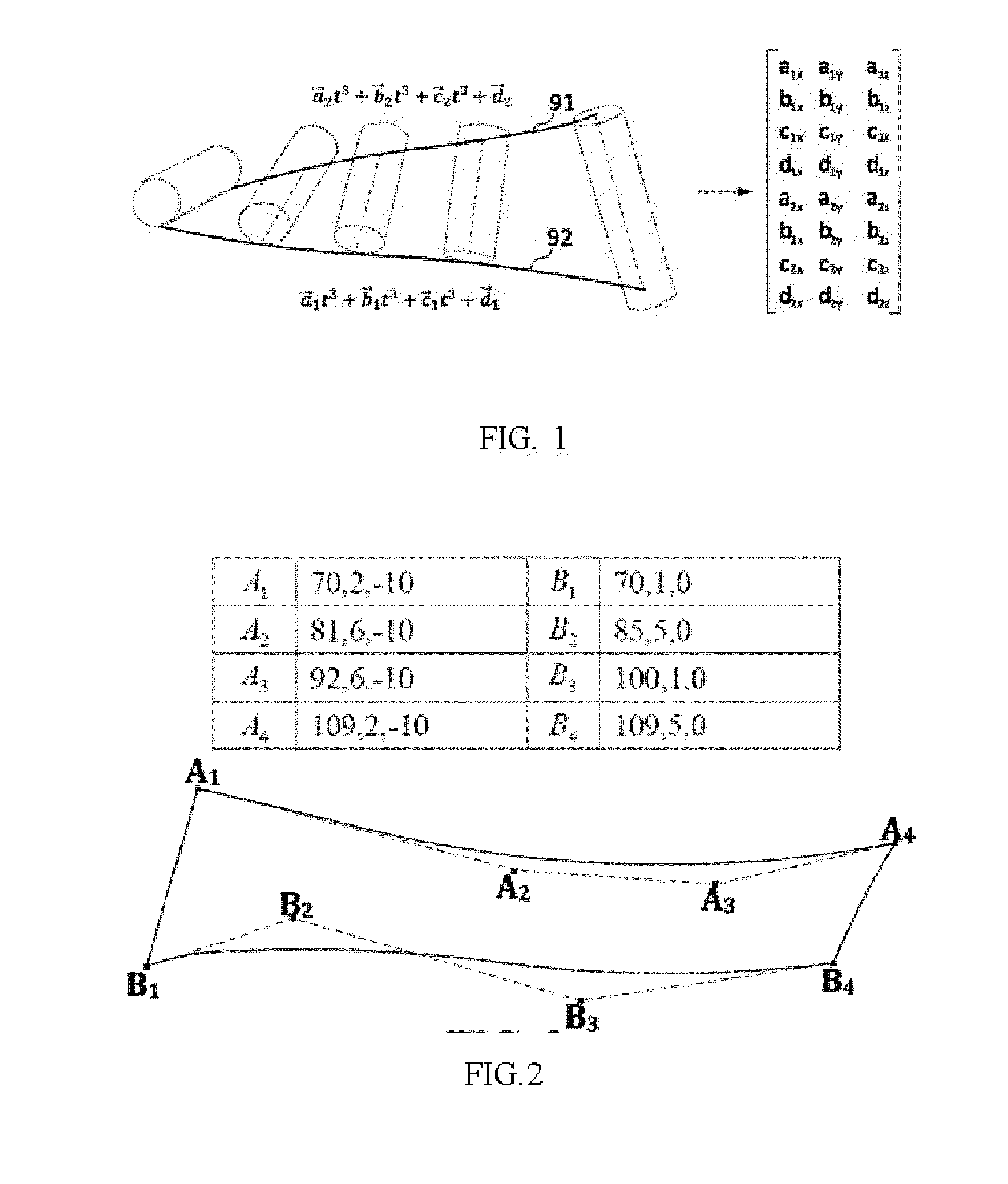

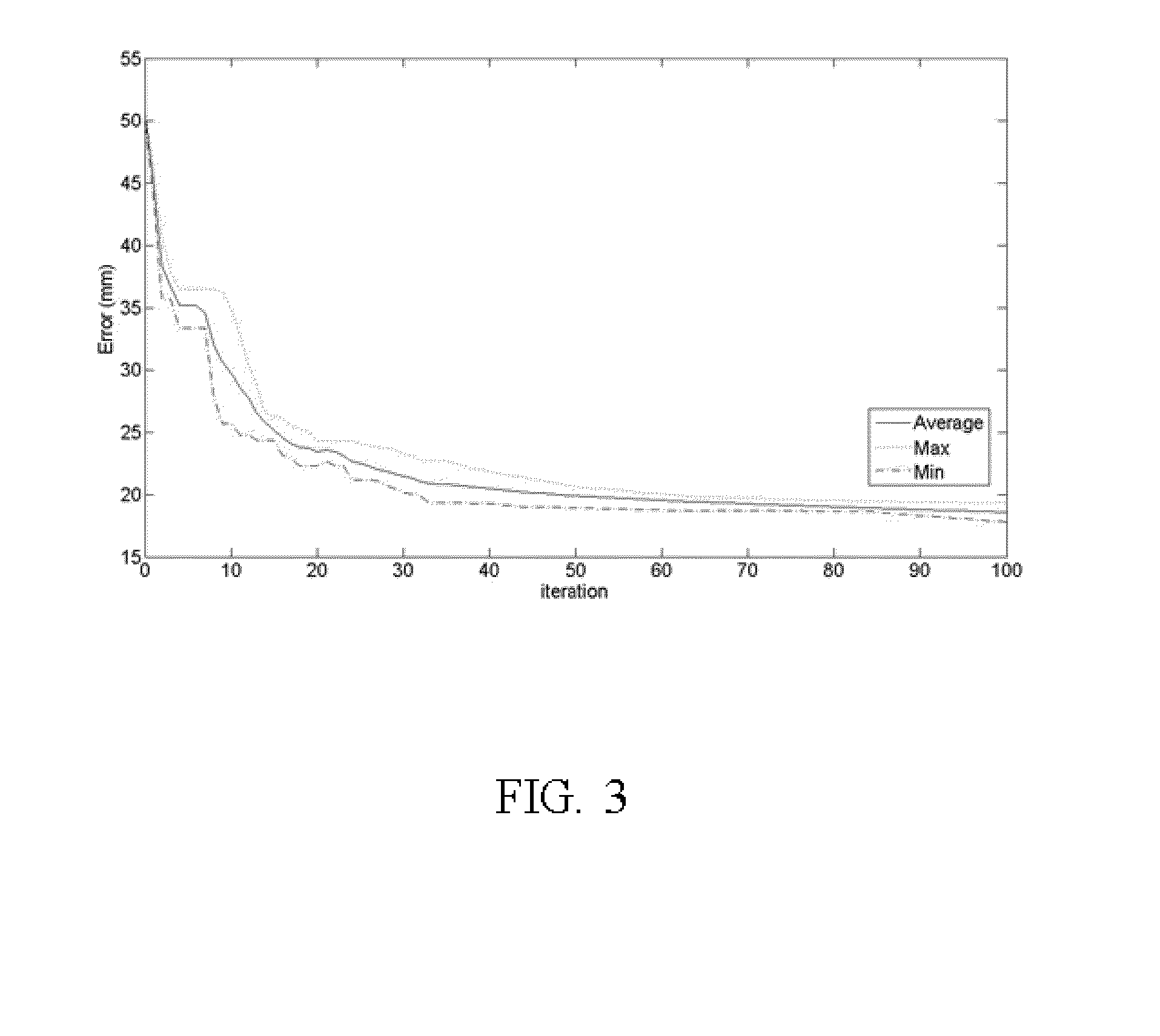

Five-axis flank milling system for machining curved surface and toolpath planning method thereof

ActiveUS20150032250A1Reduces uneven modificationQuality improvementSpecial data processing applicationsNumerical controlCutter locationMachined surface

This invention provides a novel tool path planning method for five-axis flank milling by imposing the constraints of curve interpolation on the tool path. The tool motion is described in the form of spline curves during its optimization-driven calculation process, instead of discrete cutter locations in CNC linear interpolation. The coefficients of the curve equations are generated by minimizing accumulated geometrical errors on the machined surface using optimization algorithms. The continuity imposed by the spline motion reduces uneven modifications of cutter locations during the optimization process. The resultant tool path yields superior.

Owner:NATIONAL TSING HUA UNIVERSITY

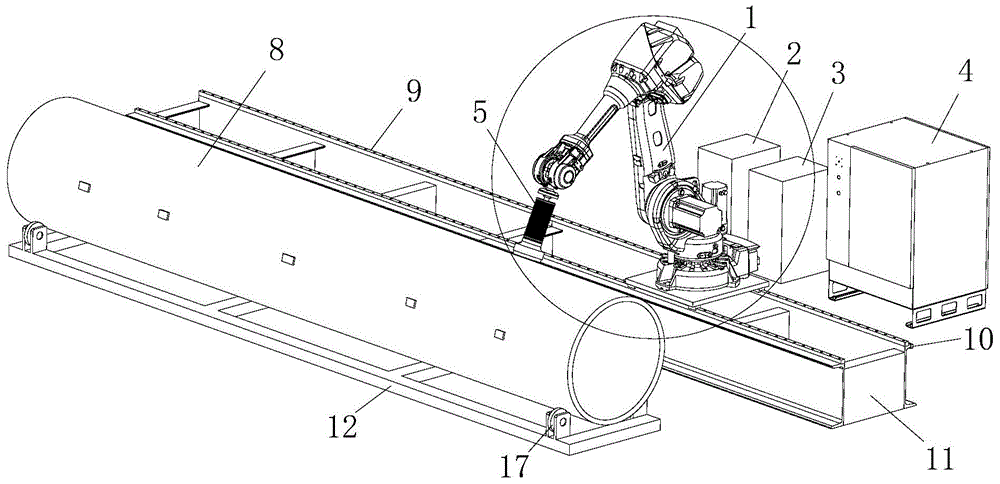

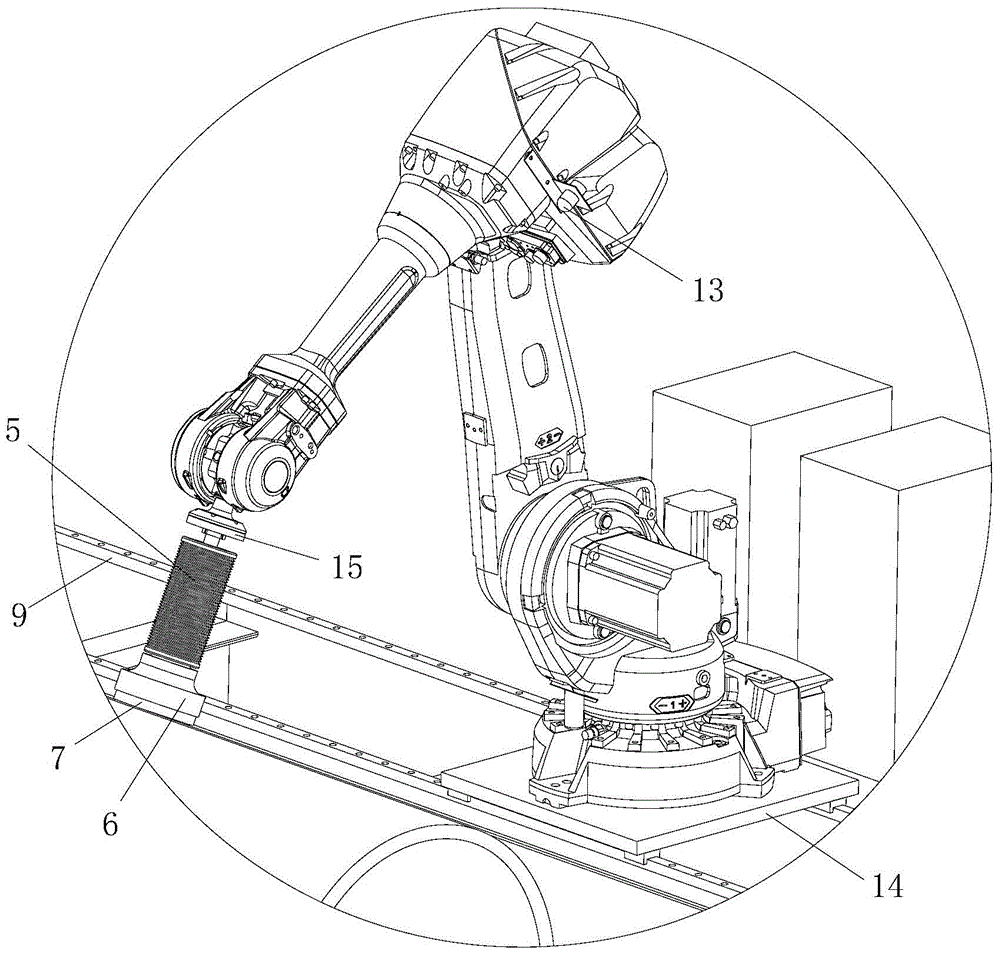

Robot grinding system for outer surface of cylinder with boss

InactiveCN105081903AGuaranteed accuracy consistencyEnsure consistent qualityRevolution surface grinding machinesMachined surfaceRobot control

The invention discloses a robot grinding system for the outer surface of a cylinder with a boss. The robot grinding system comprises a movable rail, an industrial robot, a robot control cabinet, a barostata, a pneumatic control cabinet, an electric system control cabinet, a grinding tool and a visual camera. The industrial robot is arranged on the movable rail. The barostata is fixed to a front arm of the industrial robot. The grinding tool is installed at the front end of the barostata. The visual camera is installed on the industrial robot, connected with the robot cabinet and used for monitoring the position of the boss on the surface of the workpiece. The barostata enables a grinding wheel to press the machined surface with the constant pressure all the time, and meanwhile the industrial robot enables the grinding pressure to be in the normal direction of the machined surface. When encountering a protruding part, the visual camera immediately feeds the information back to the industrial robot to avoid the protruding part. The consistency of the grinding accuracy and quality of the outer surface of the cylinder workpiece with the boss can be effectively guaranteed, the production efficiency is improved, safety is improved, and labor intensity of workers is relieved.

Owner:DONGGUAN ZHAOKE HARDWARE IND CO LTD

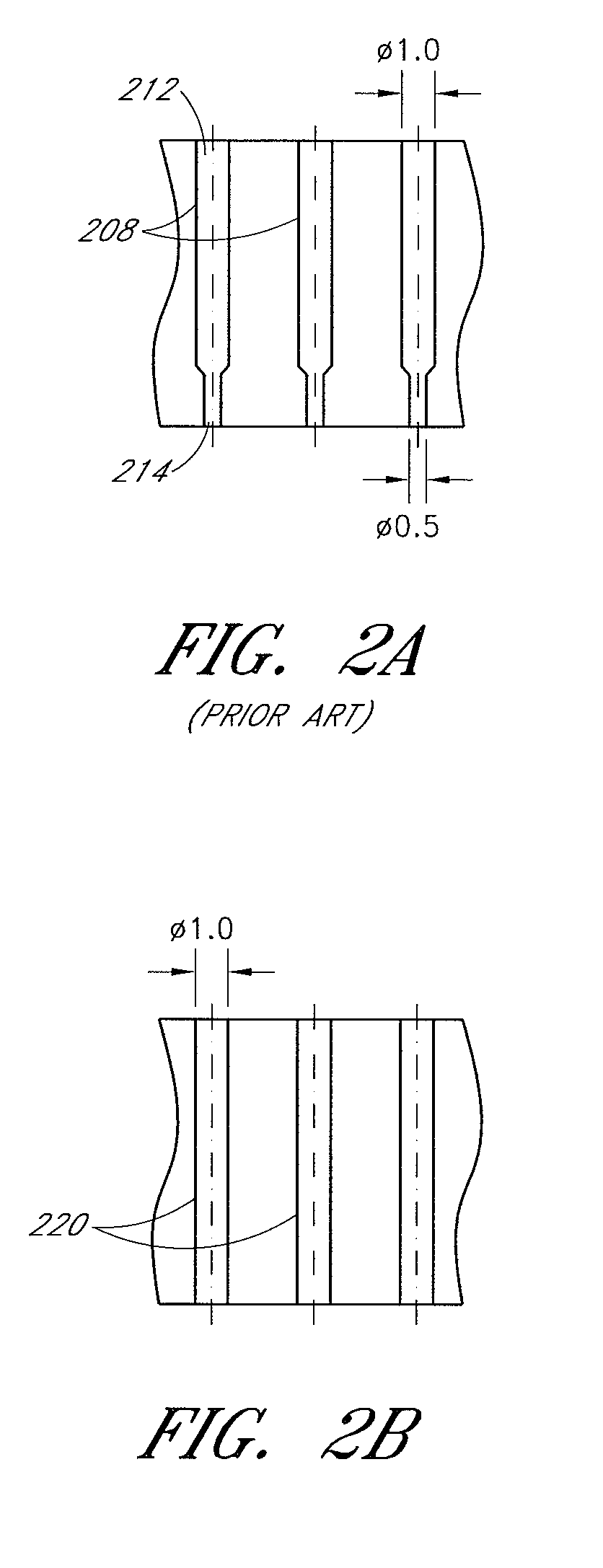

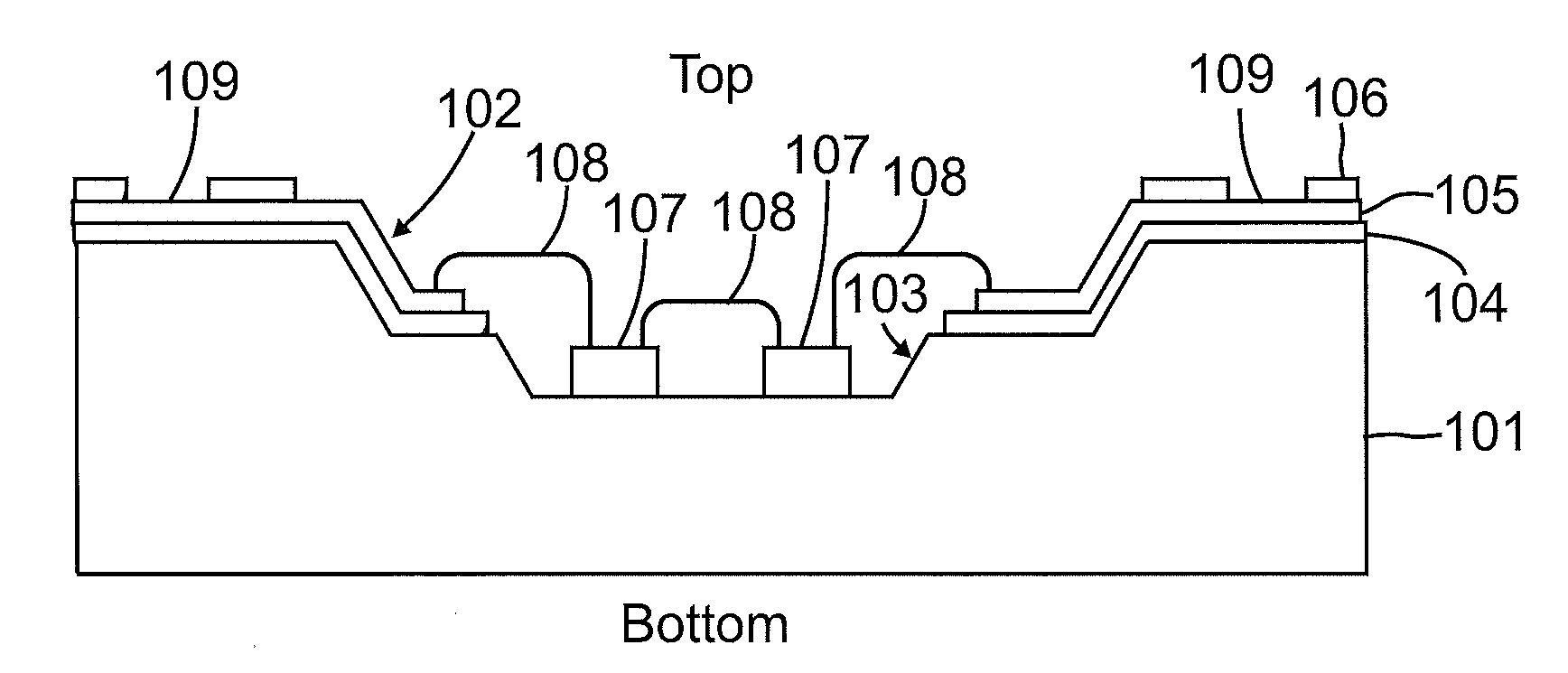

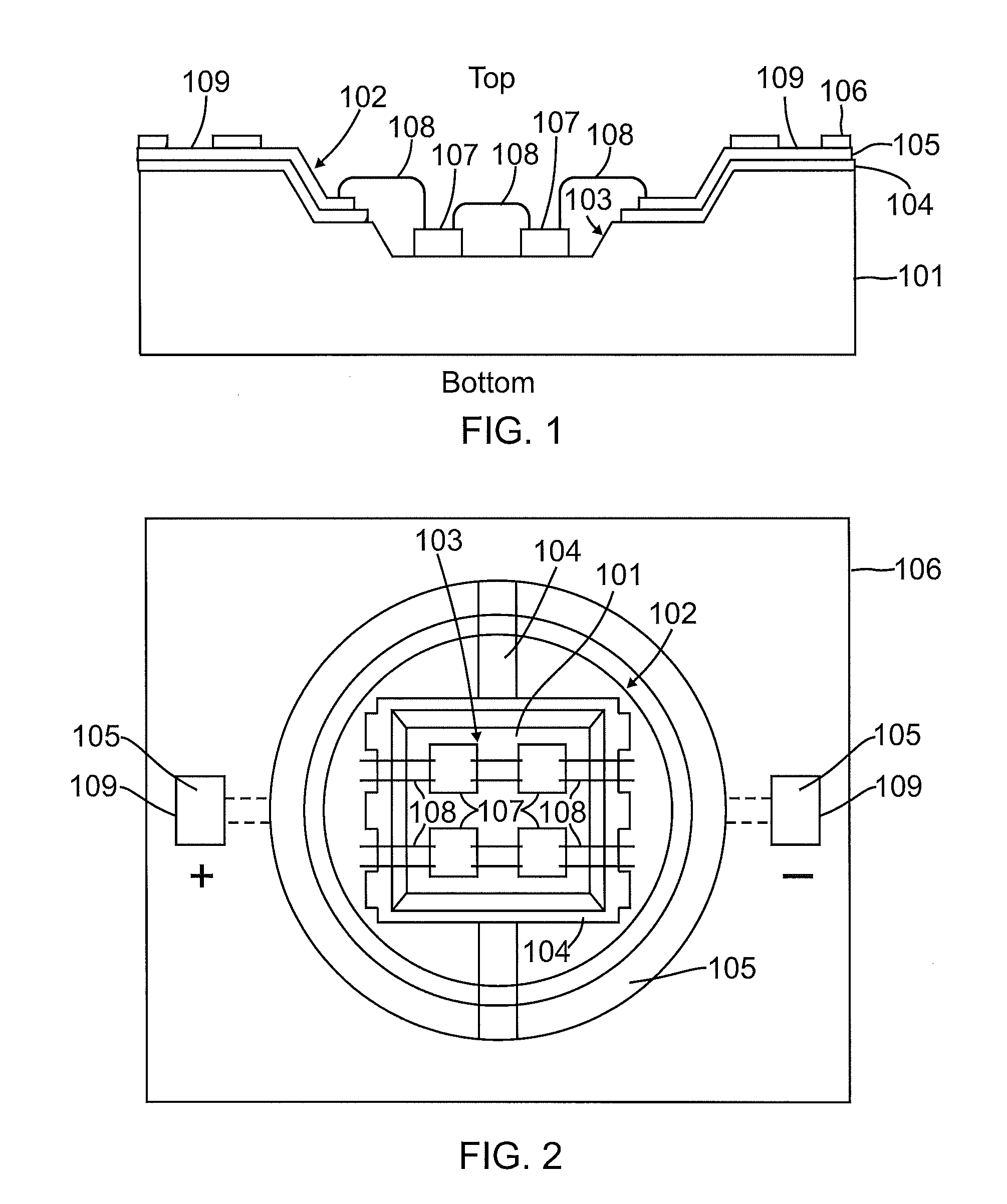

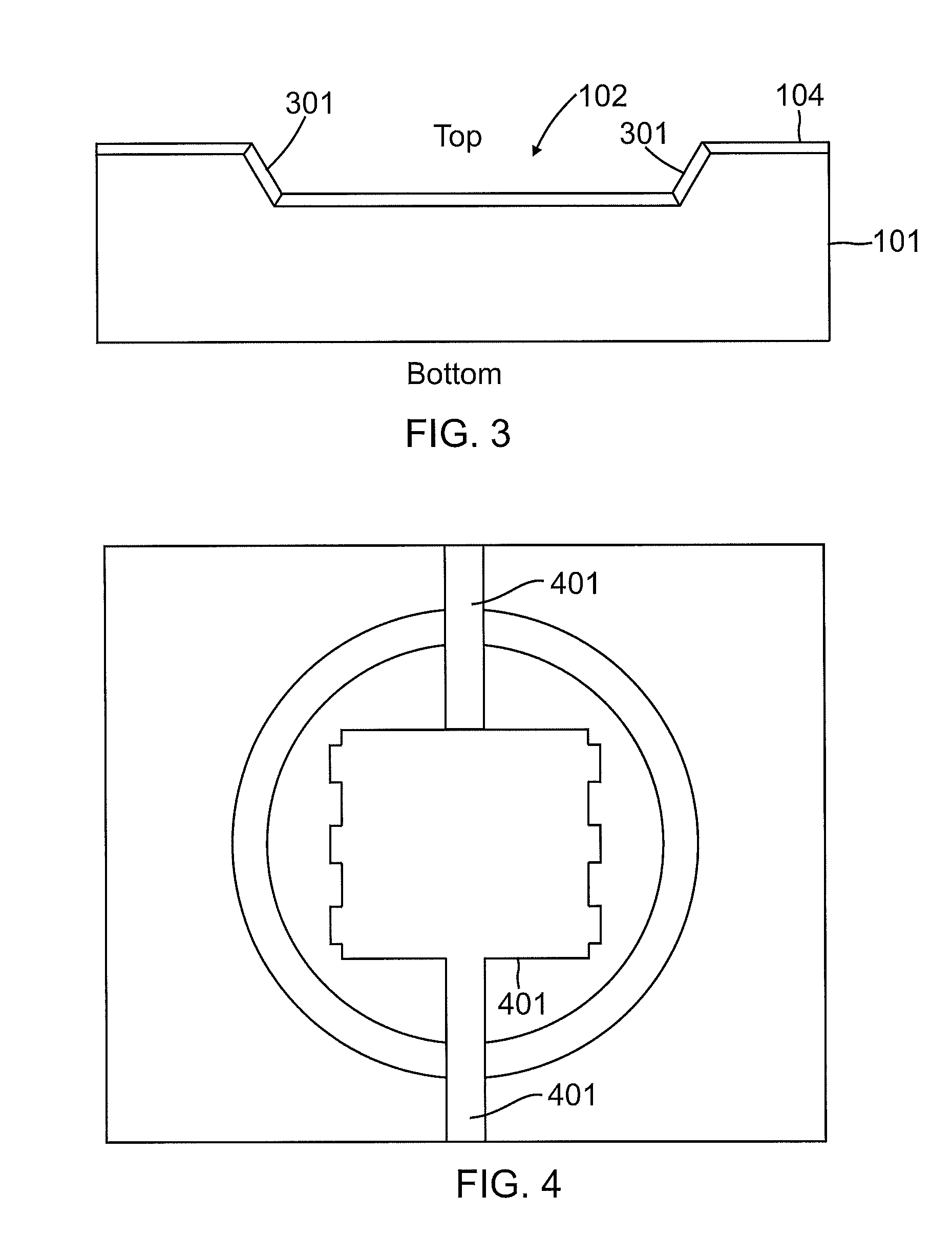

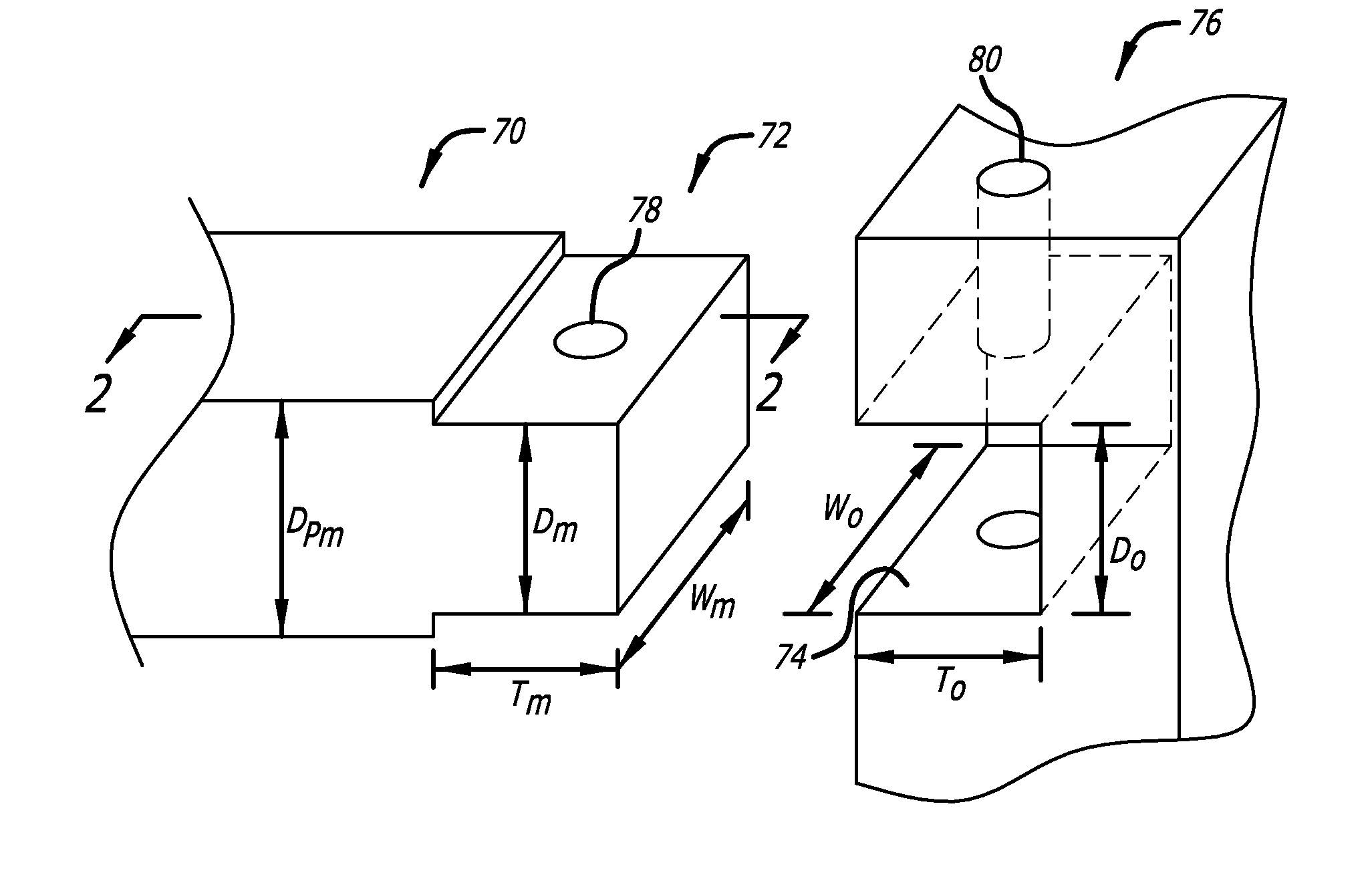

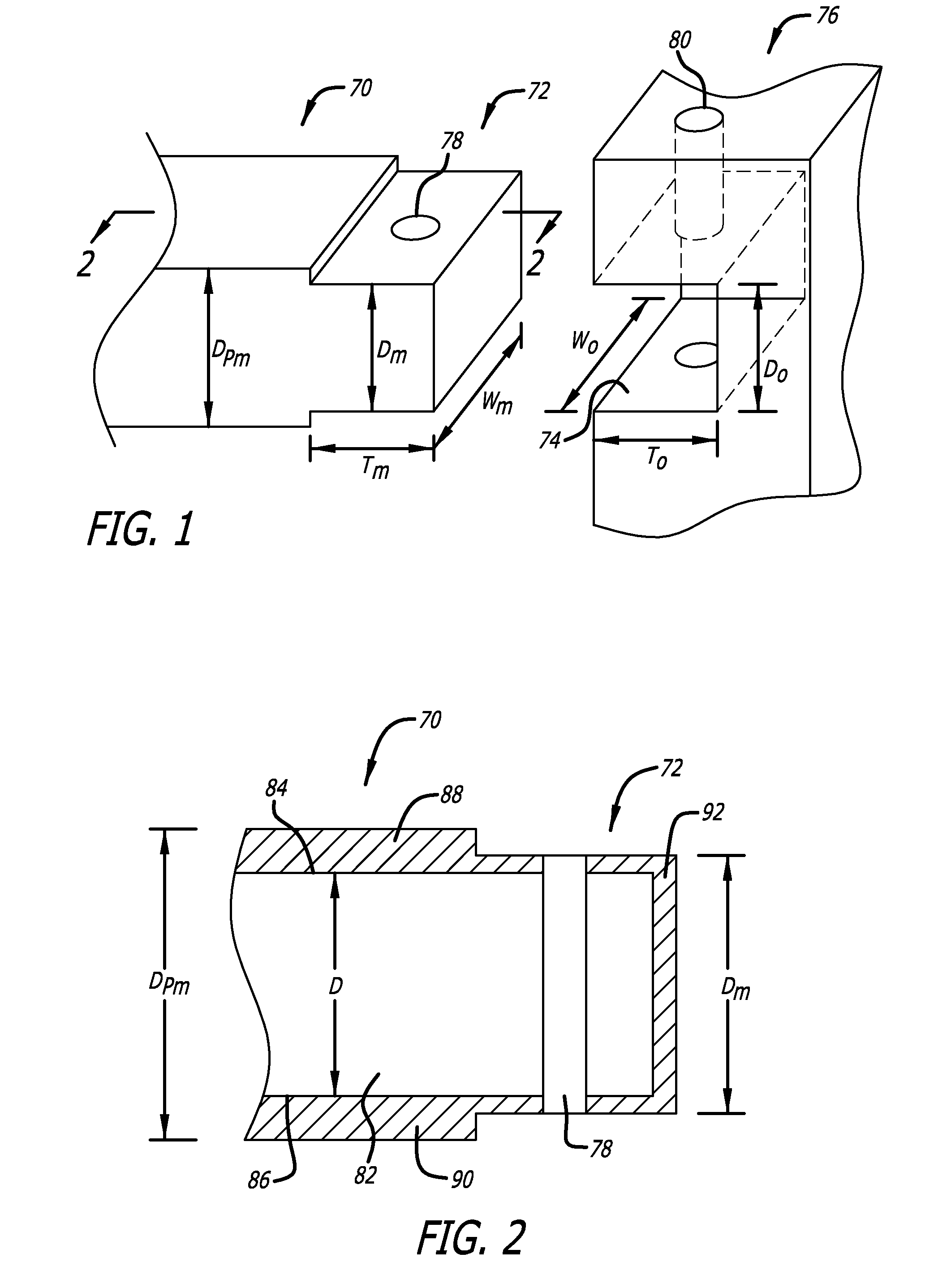

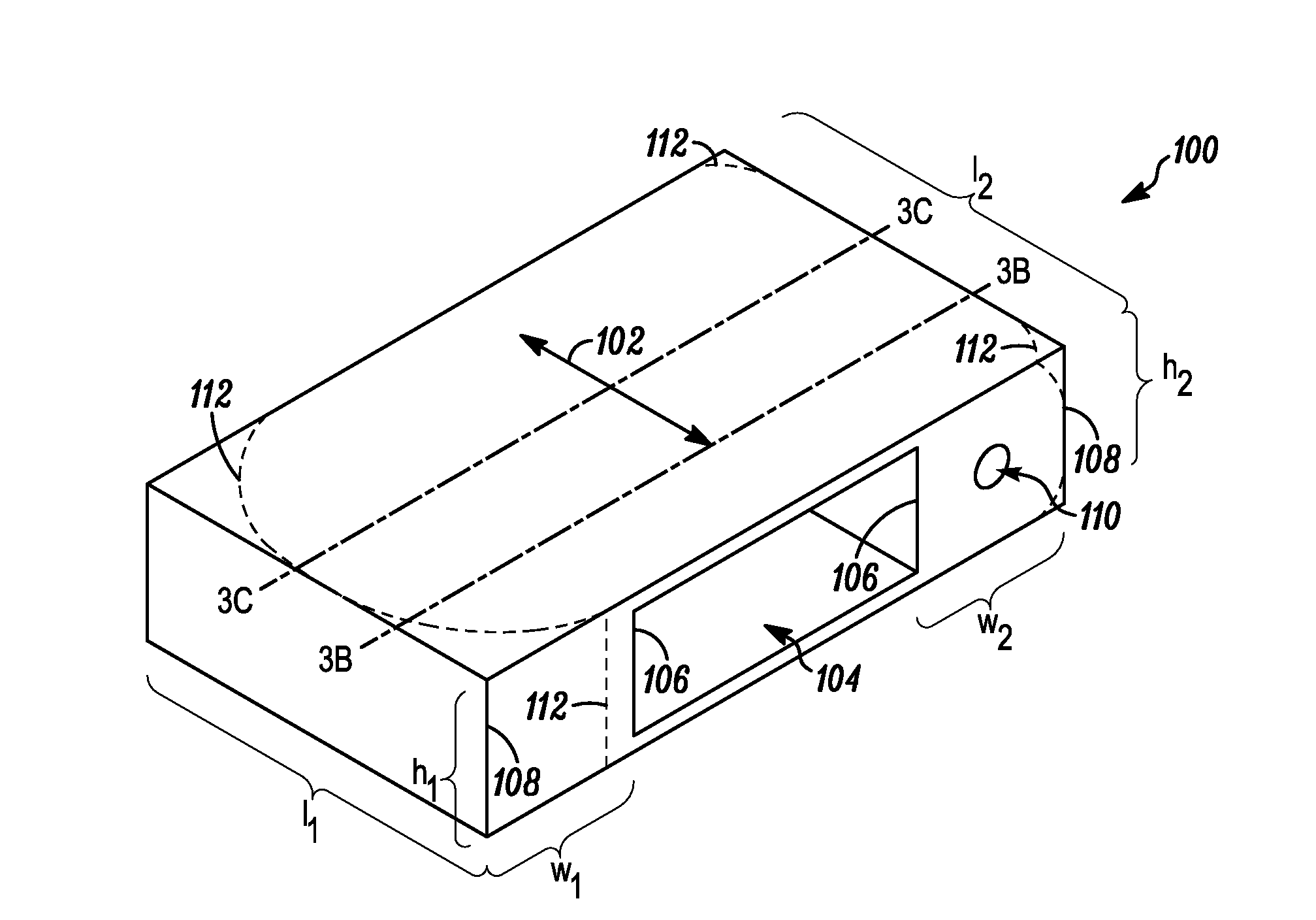

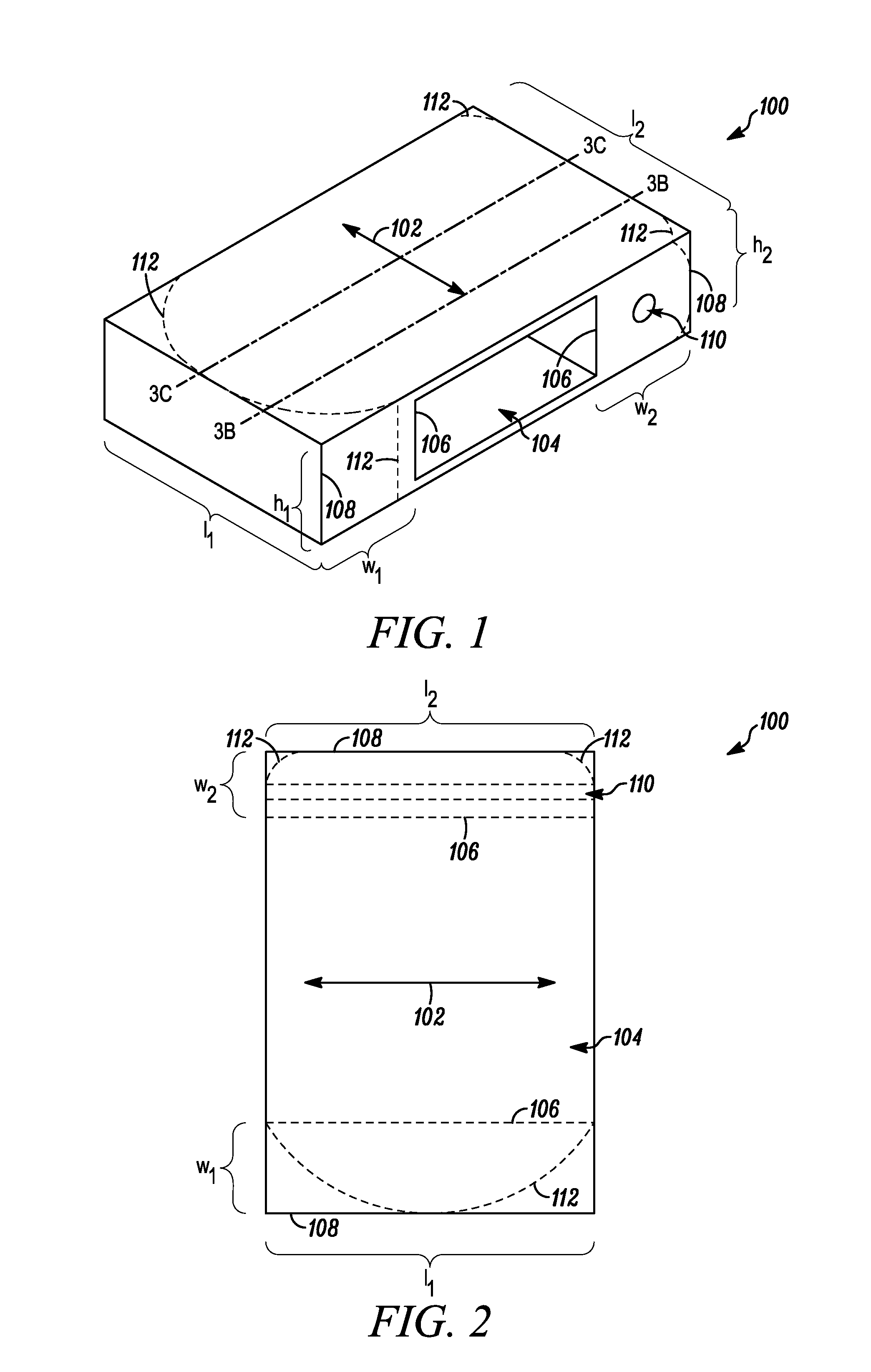

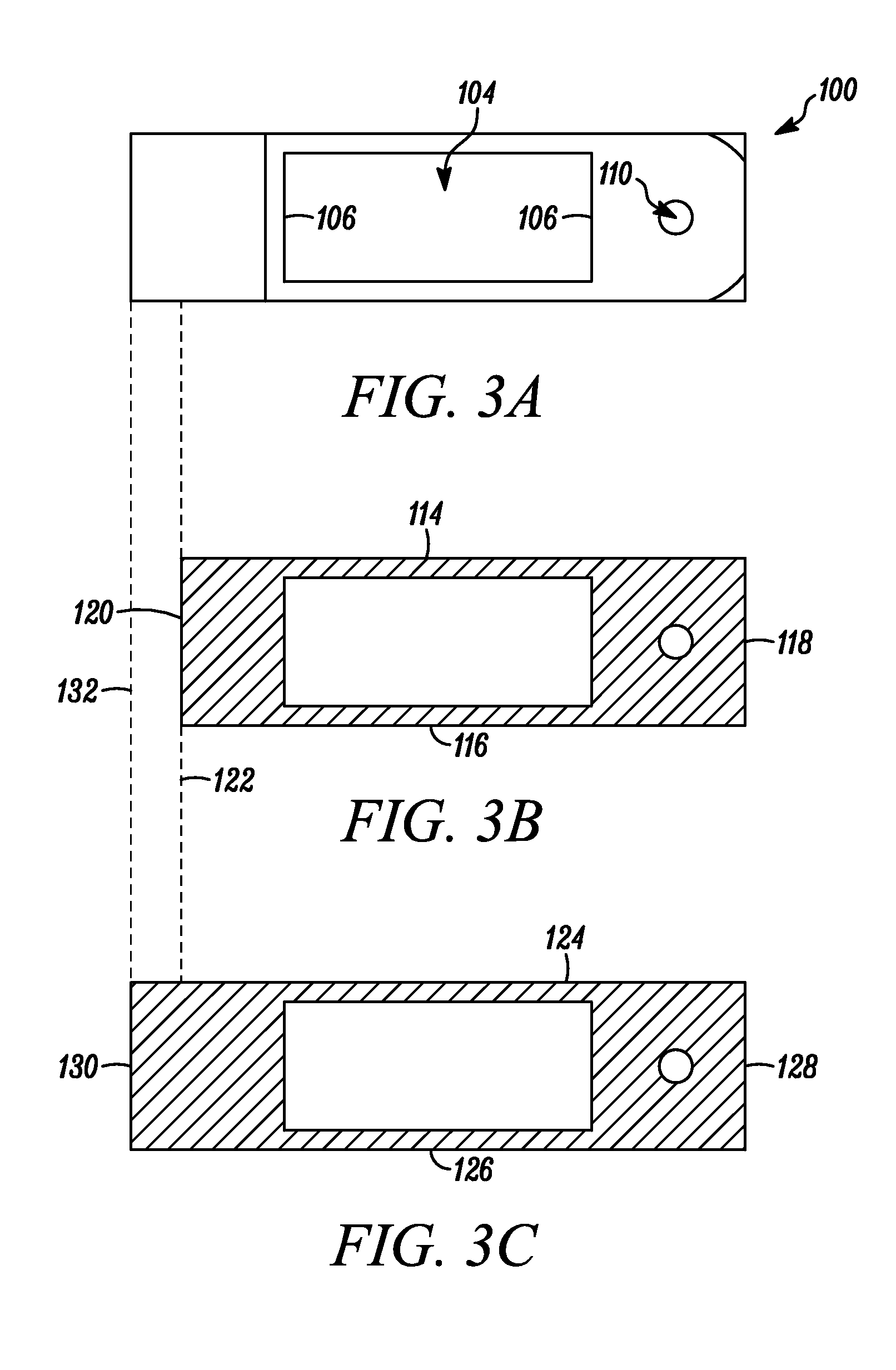

Machined surface LED assembly

InactiveUS20100078661A1Reduce wasteImprove reflectivitySolid-state devicesSemiconductor/solid-state device manufacturingSolder maskMachined surface

A substrate for an LED assembly can have a plurality of cups formed therein. At least one cup can be formed within another cup. The cups can be co-axial with respect to one another, for example. A machined surface of the substrate can enhance reflectivity of the LED assembly. A transparent and / or non-global solder mask can enhance reflectivity of the LED assembly. A transparent ring can enhance reflectivity of the LED assembly. By enhancing reflectivity of the LED assembly, the brightness of the LED assembly can be increased. Brighter LED assemblies can be used in applications such as flashlights, displays, and general illumination.

Owner:BRIDGELUX INC

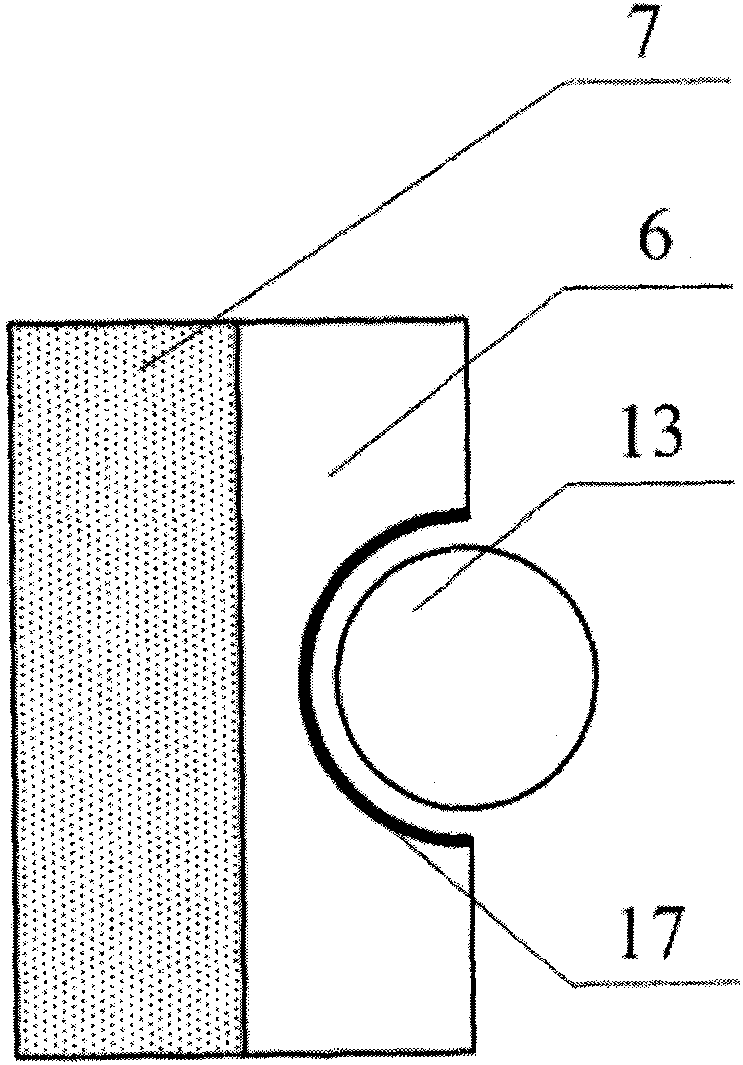

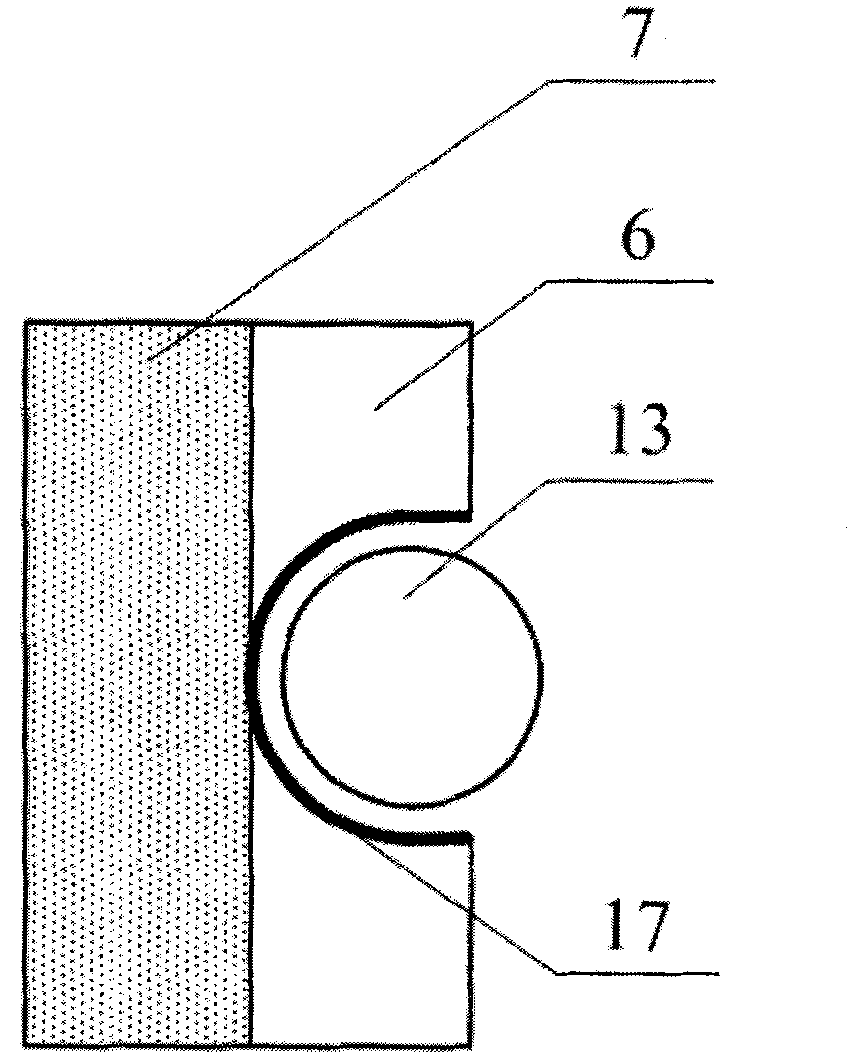

Method and device for machining insulating ceramic by reciprocating wire-cut electrical discharge machining

The invention relates to the technical field of insulating ceramics machining. In order to solve the problems that the conventional insulating ceramic machining method and device are low in machining accuracy and low in quality of the machined surface, the invention provides a method for machining insulating ceramic by reciprocating wire-cut electrical discharge machining. The method comprises the following steps of: immersing insulating ceramics of which the outer surface is fixed with an auxiliary electrode in electrospark liquid or kerosene working solution; putting a wire electrode into the working solution, connecting the auxiliary electrode and the wire electrode to the anode and cathode of a high-frequency pulse power supply respectively, and controlling the distance between the auxiliary electrode and the wire electrode until electrical discharge can be realized; and controlling relative motion between the wire electrode and the insulating ceramics according to the machining requirement. The invention also provides a device, wherein the insulating ceramics of which the outer surface is fixed with the auxiliary electrode and the wire electrode are arranged in the electrospark liquid or kerosene working solution and are connected with the anode and cathode of the high-frequency pulse power supply respectively; and the insulating ceramics are fixed on a work table and are driven by the work table to move. The method is stable in machining process and favorable for popularization and application.

Owner:HARBIN INST OF TECH

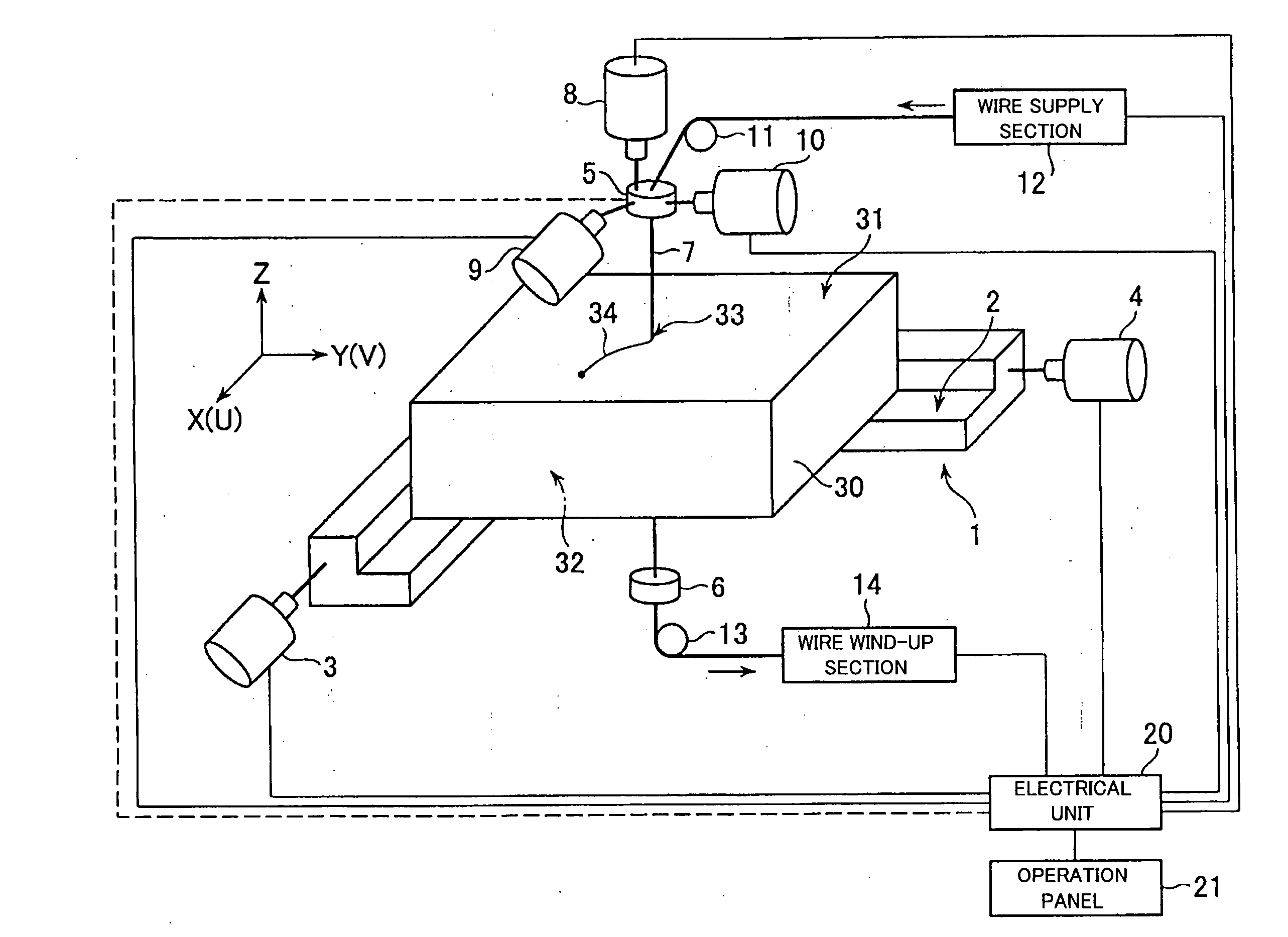

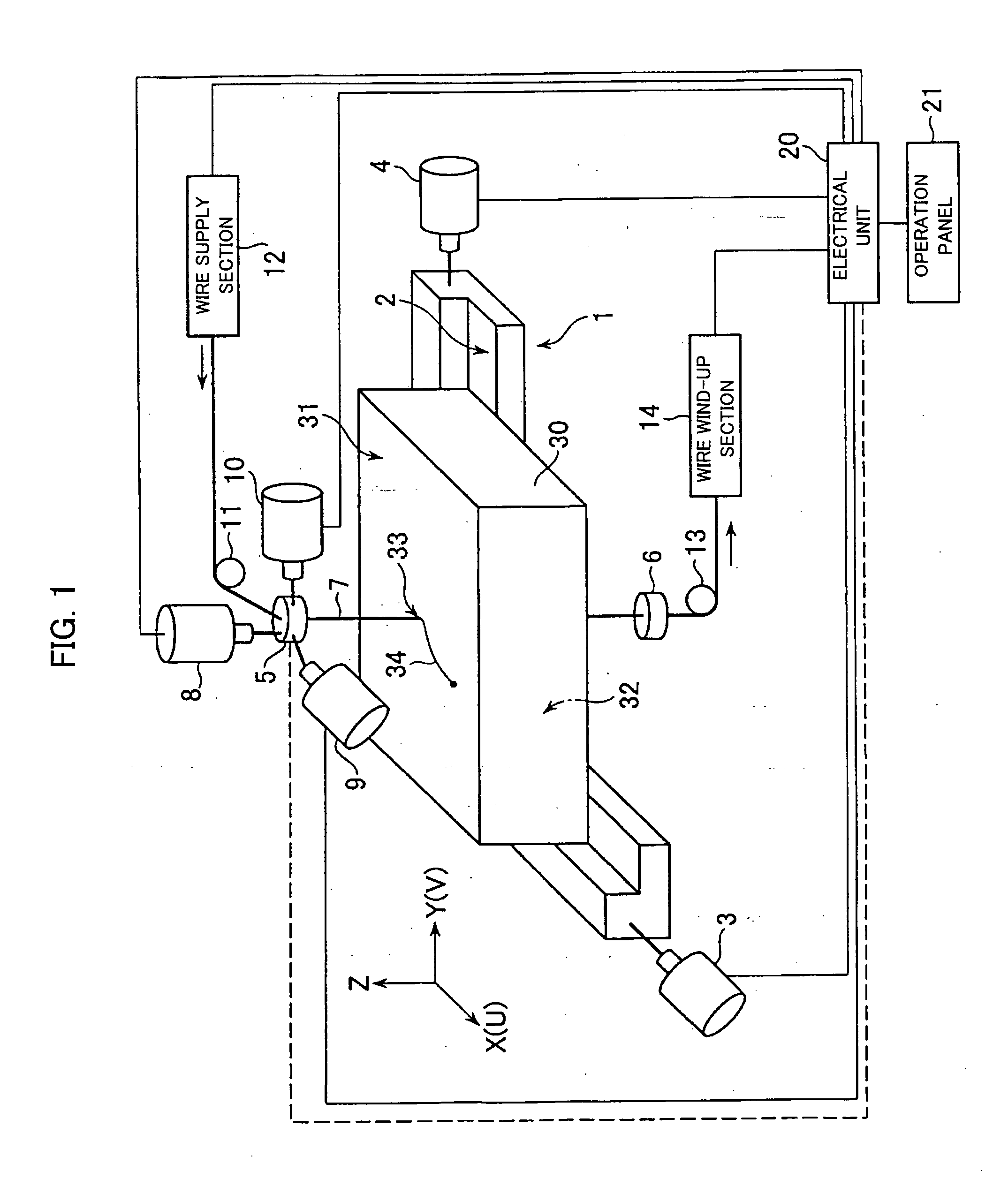

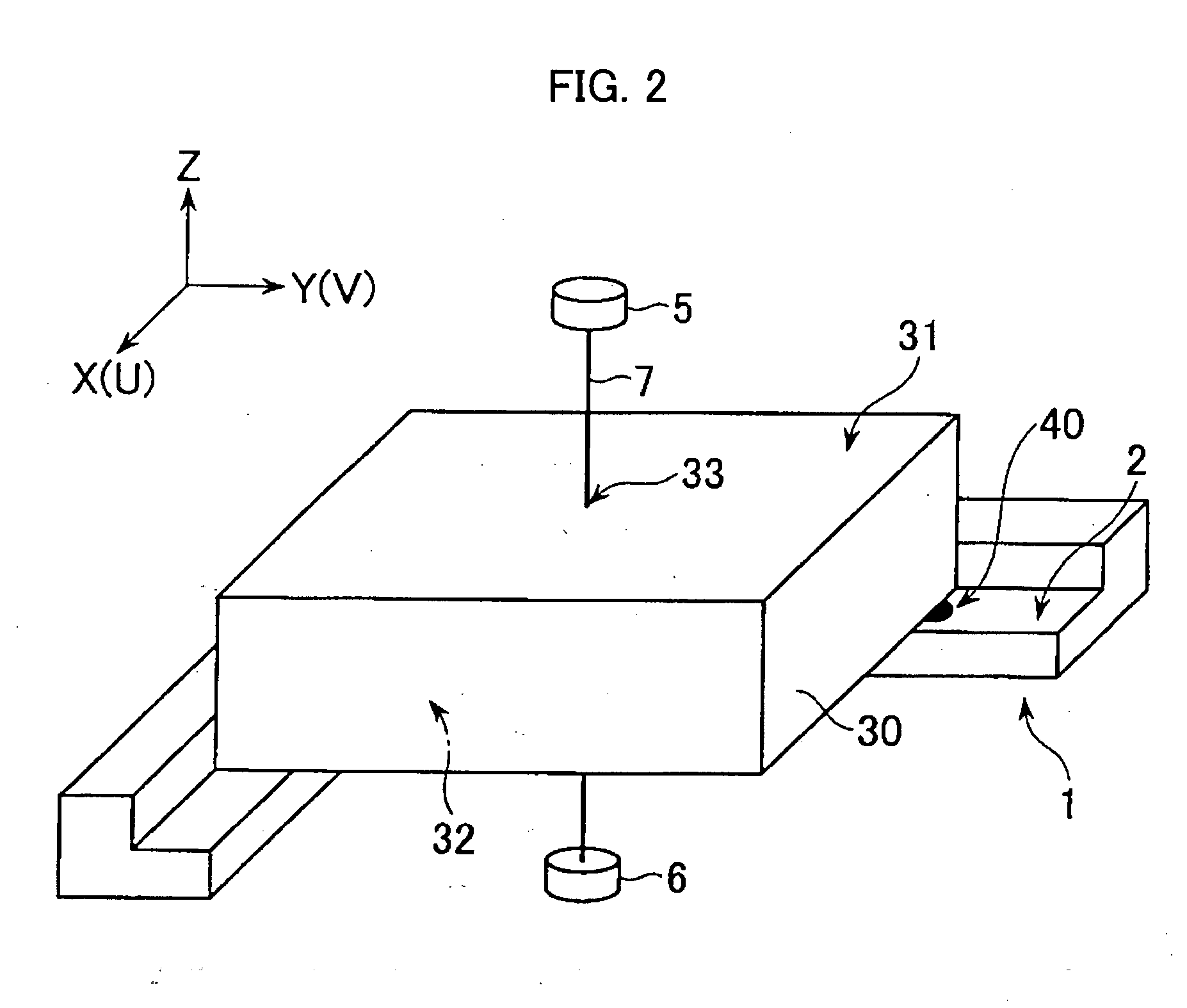

Wire electric discharge machine and wire electric discharge machining method

InactiveUS20060102596A1Improve machining accuracyAccuracy be easeArc welding apparatusElectrical-based machining electrodesElectric dischargeMachined surface

A wire electric discharge machine and a wire electric discharge machining method in which a workpiece set posture is compensated for an error. After a workpiece is set and fixed on a workpiece table, an upper guide measures three or more three-dimensional positions that are not situated on one straight line on an upper surface of the workpiece, utilizing detection of contact with the upper surface. A unit normal vector Nincl (Xn, Yn, Zn) is obtained, and a shift amount Δshif (ΔU, ΔV) for shift from an originally set vertical position (U0, V0) to a corrected position (Uc, Vc) is calculated. In machining, the shift amount Δshif (ΔU, ΔV) is added to the position (U0, V0) to compensate for an angle error of a machined surface, and a deviation of a machined point position caused by inclination of the workpiece is collaterally compensated for as required by correcting the upper and lower wire guides. Thus, the machined shape cannot be distorted, and the workpiece set posture error can be compensated for.

Owner:FANUC LTD

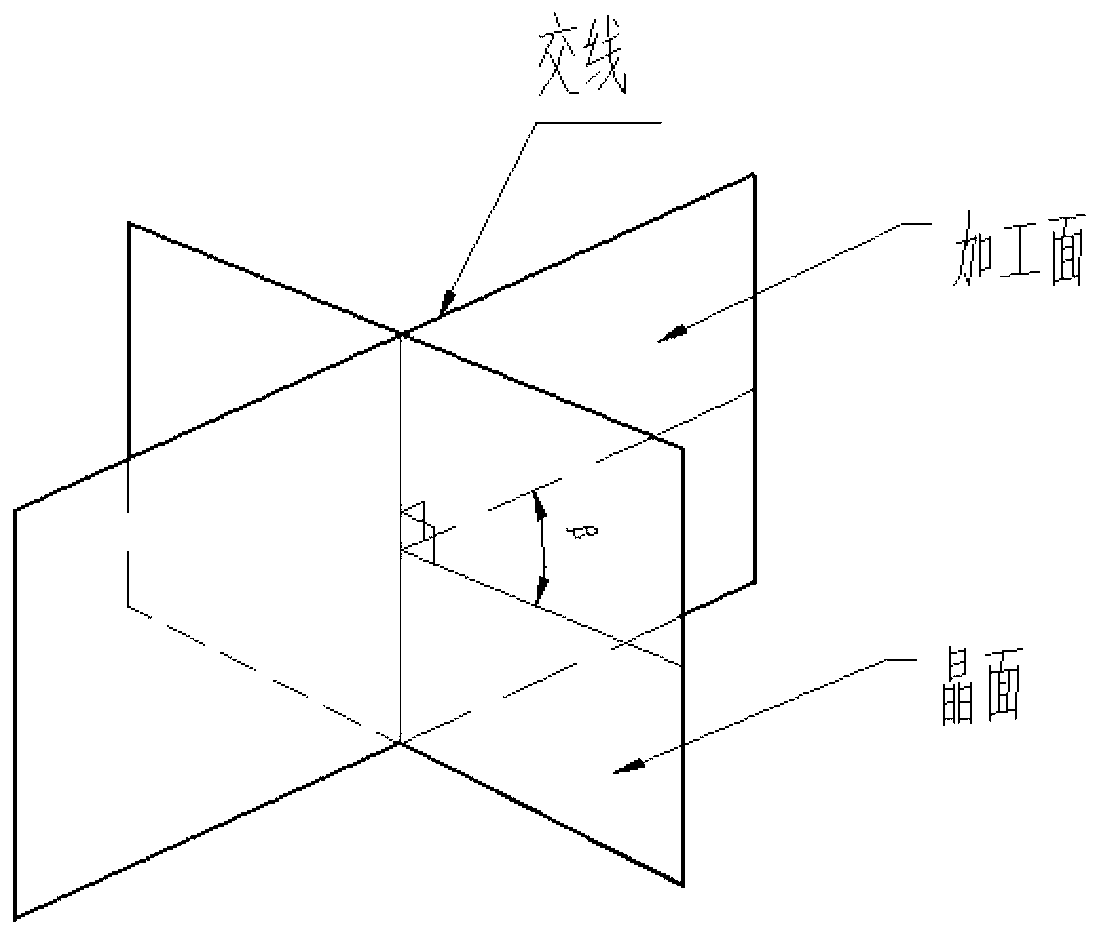

Crystal direction finder for directly measuring deflecting angle in crystal orientation and measurement method thereof

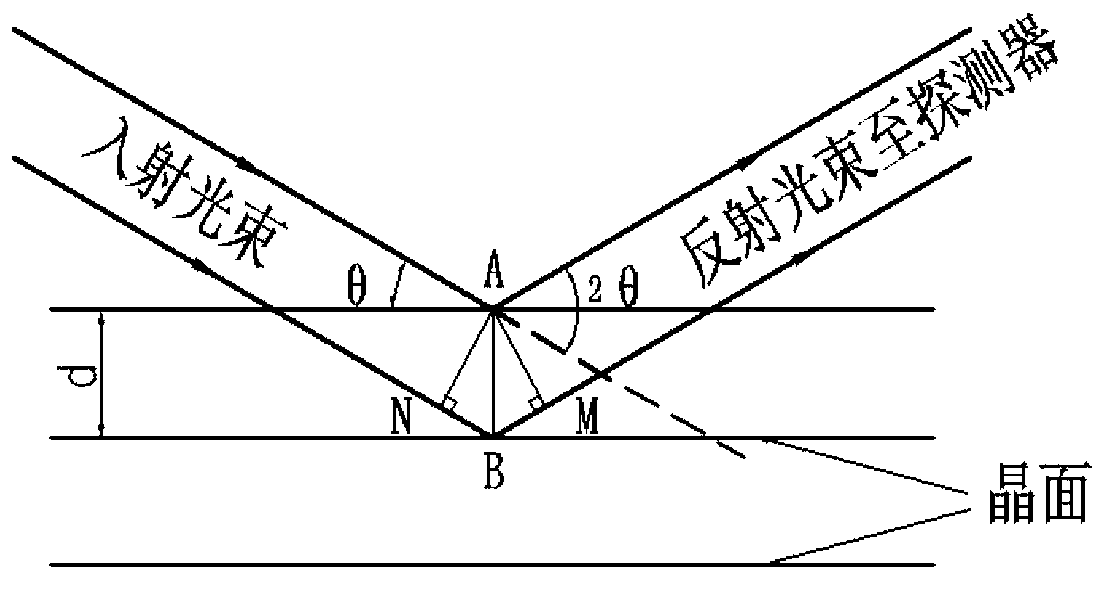

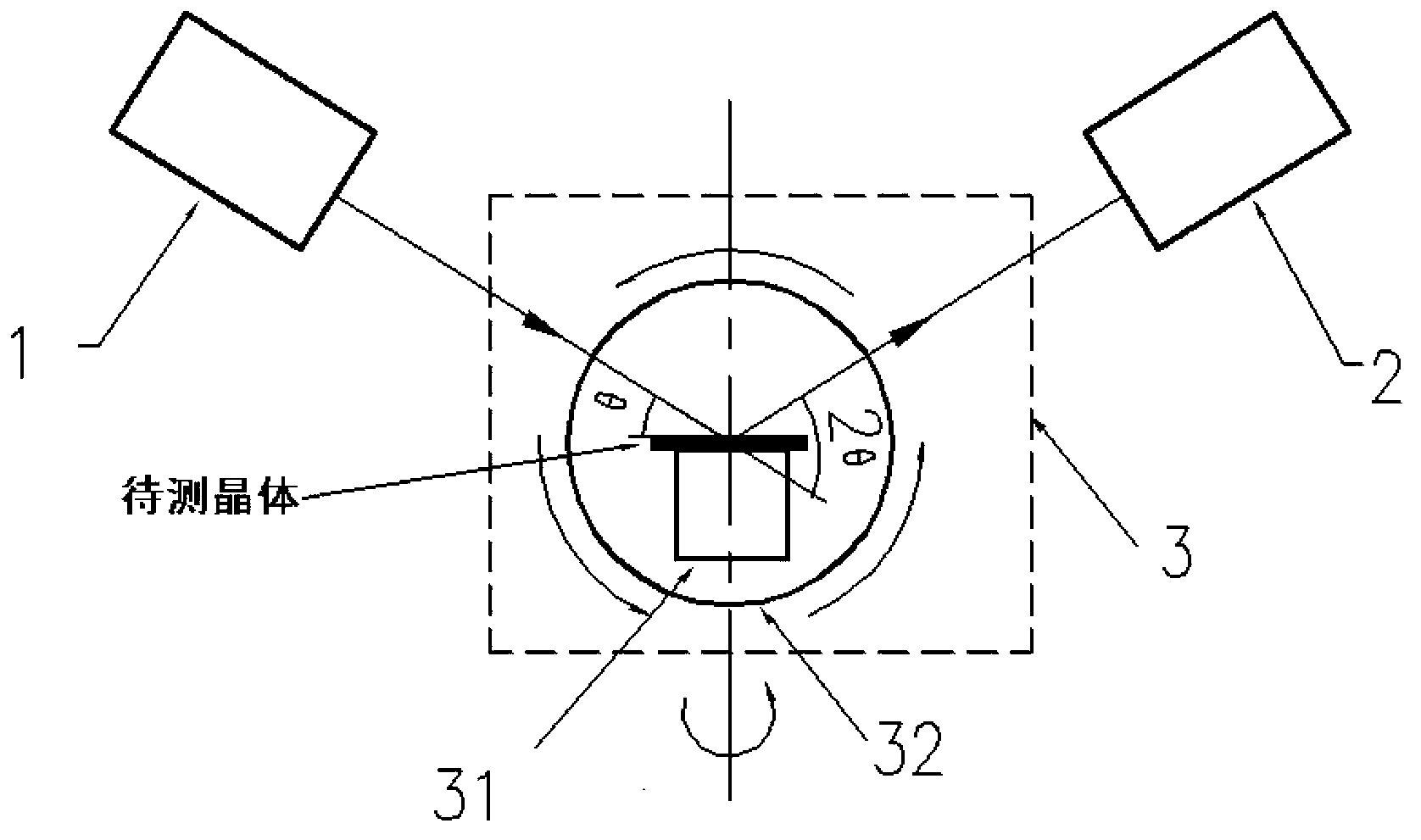

InactiveCN103257150APrevent leakageAvoid duplicationMaterial analysis using wave/particle radiationRotary stageMachined surface

The invention provides a crystal direction finder for directly measuring deflecting angle in crystal orientation, which is characterized in that one side of an objective table is connected with an X-ray generator, and the other side is connected with an X-ray detector, and an objective table is provided with a horizontal revolving bench, and the horizontal revolving stage can revolve a crystal to be measured parallely to the light propagation surface, and the center of the horizontal revolving bench is fixed with a vertical revolving stage, and the vertical revolving stage can revolve the crystal to be measured on the plane which is perpendicular to the light propagation surface; the crystal direction finder is used for directly finding the intersection line of the machined surface and the crystal face, and an angle measuring instrument of the objective table can be used for directly reading the deflecting angle beta in crystal orientation. The invention overcomes the defects that the present X-ray crystal direction finder has a complex operating method, wherein, the measurement process needs multiple times of rotations, dismountings and fixations of the detected crystal with low measurement efficiency, which is easy to induce cumulative errors and X-ray leakage.

Owner:YUNNAN KIRO CH PHOTONICS

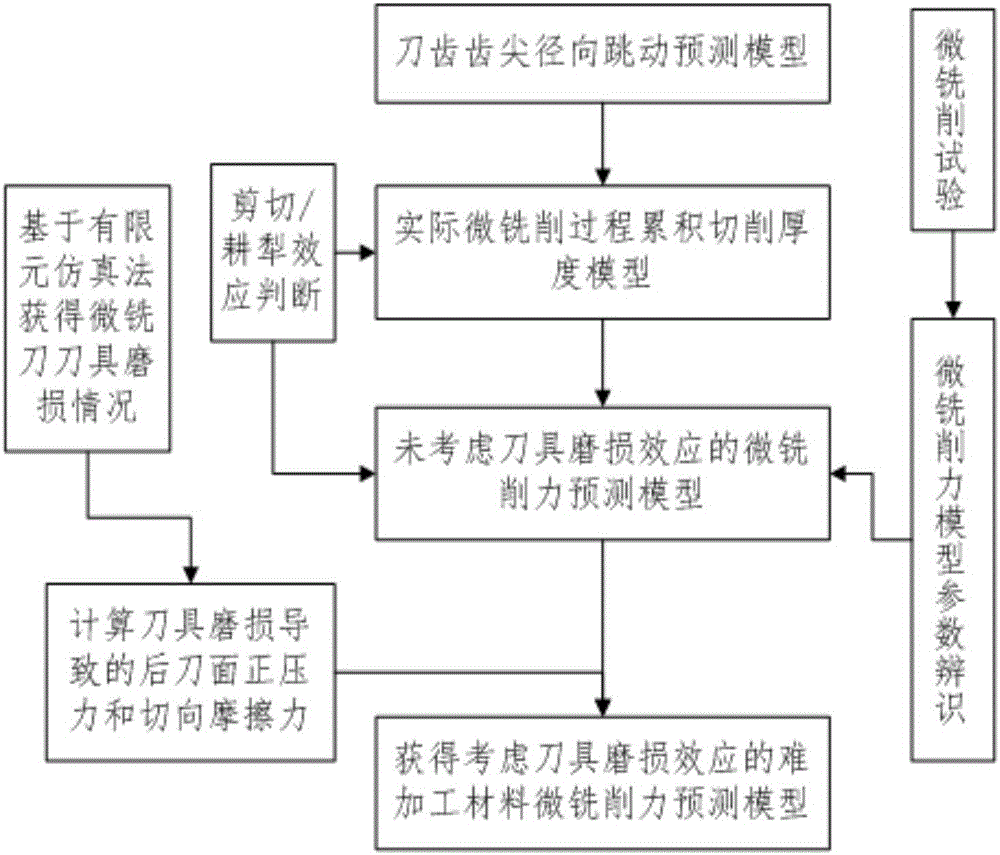

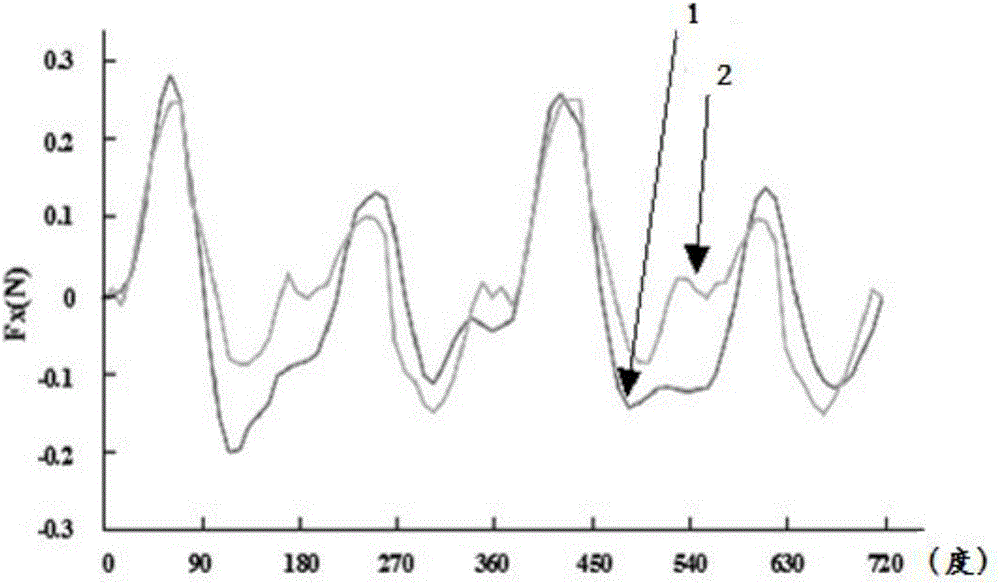

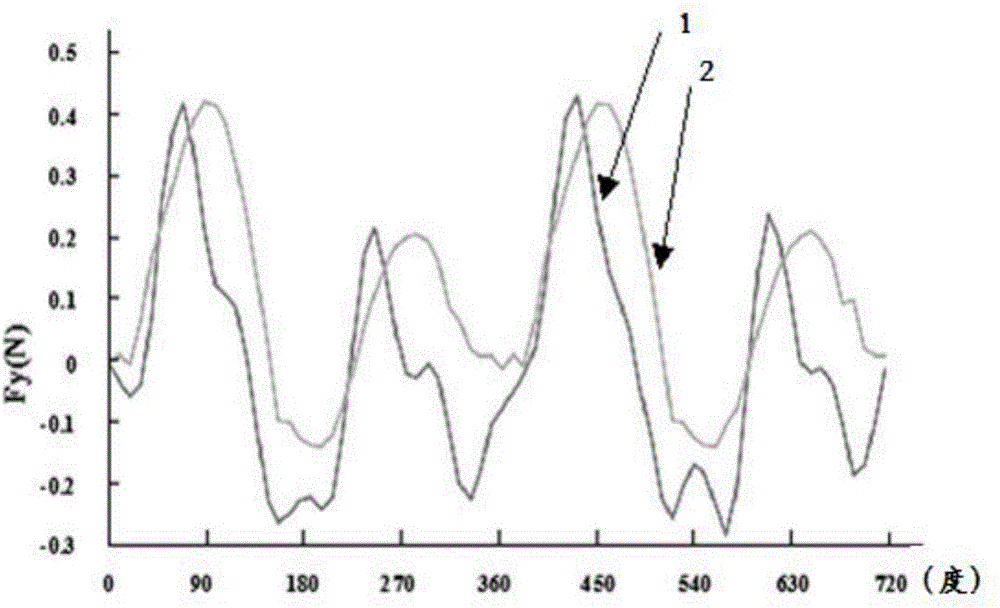

Micro-milling-force modeling method based on tool abrasion effect

ActiveCN106156430AImprove modeling efficiencyDesign optimisation/simulationSpecial data processing applicationsMachined surfaceEngineering

The invention relates to a micro-milling-force modeling method based on a tool abrasion effect and belongs to the field of precision and efficient machining of micro-parts. The method comprises the steps that the influence of tool tooth top trochoid motion trail, radial run-out of tooth tops, elastic recovery of machined surfaces and other factors is comprehensively considered to obtain a micro-milling-force prediction model which is not based on tool abrasion; then, the tool abrasion situation in the micro-milling process is obtained based on a finite element method, and the positive pressure and tangential friction force produced due to the fact that tool abrasion causes that the rear tool surface extrudes a workpiece are calculated based on a simulation result; finally, models of the two forces are superposed to obtain the micro-milling-force modeling method based on tool abrasion. The micro-milling-force modeling method achieves accurate micro-milling-force prediction through one model, improves the model robustness, is wide in application range and improves the micro-milling machining quality and efficiency of the micro-parts.

Owner:DALIAN UNIV OF TECH

Machinable composite material

ActiveUS20120040169A1Small sizeStructural integrity is not compromisedSynthetic resin layered productsEfficient propulsion technologiesMachined surfaceResin matrix

An assembly that includes a first part composed of a fibrous structure that includes fibers and a cured resin matrix. The fibrous structure has at least one surface and a layer that is located on the surface. The layer includes a discontinuous fiber composite that is composed of randomly oriented short fibers and a cured resin matrix wherein the layer has been machined to provide a machined surface. The assembly also includes a second part that is attached to the first part. The second part includes at least one surface that fits against the machined surface on the first part.

Owner:HEXCEL

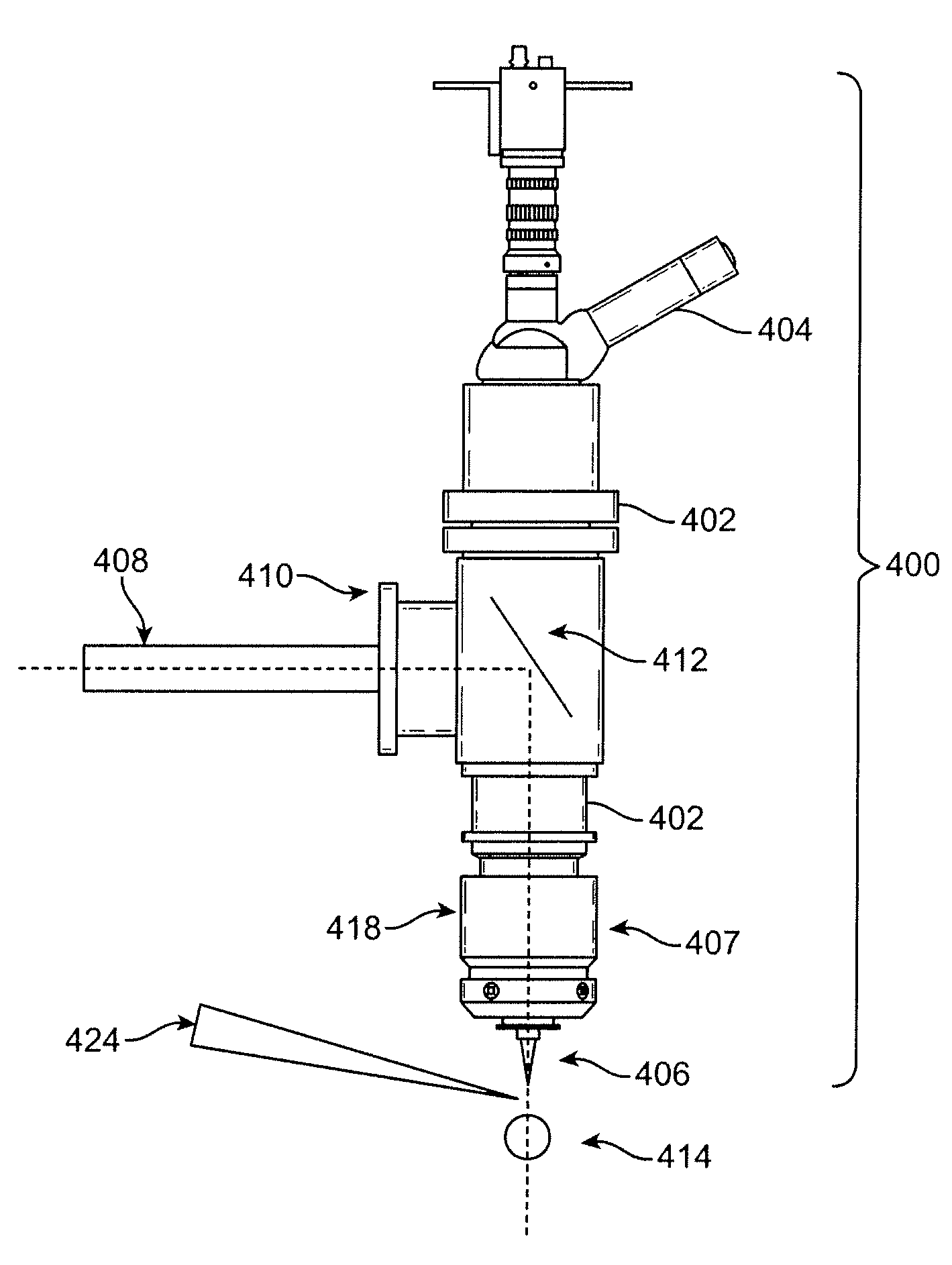

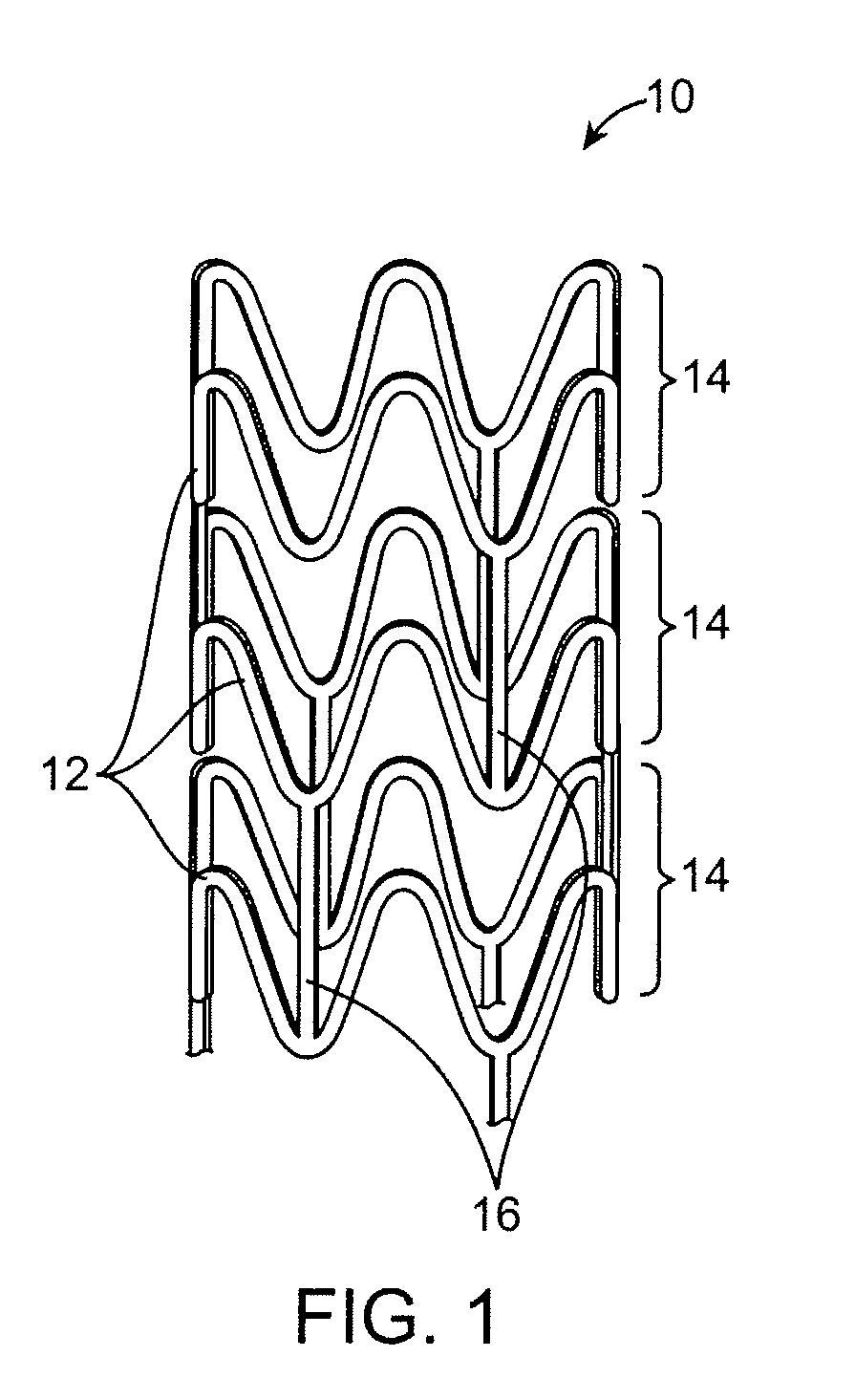

Laser Machining Medical Devices With Localized Cooling

InactiveUS20100102046A1Reduce and prevent heat transferReduces and prevents heat transferStentsWelding/soldering/cutting articlesLaser processingMachined surface

Laser machining a tubular construct comprising a polymer layer to form a stent pattern in the construct with localized cooling of the machined surface to reduce or prevent heat transfer to uncut polymer of the polymer layer is disclosed.

Owner:ABBOTT CARDIOVASCULAR

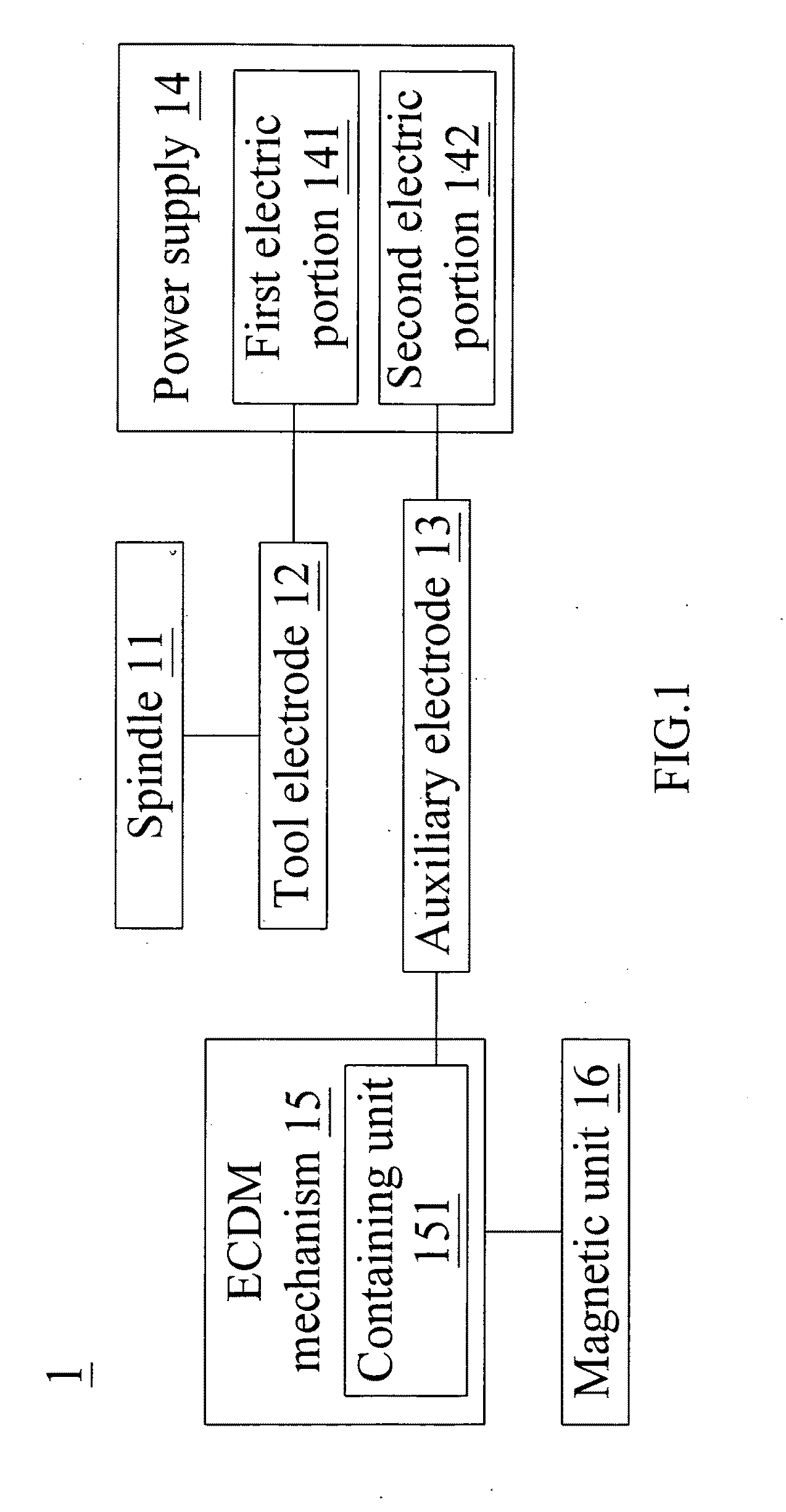

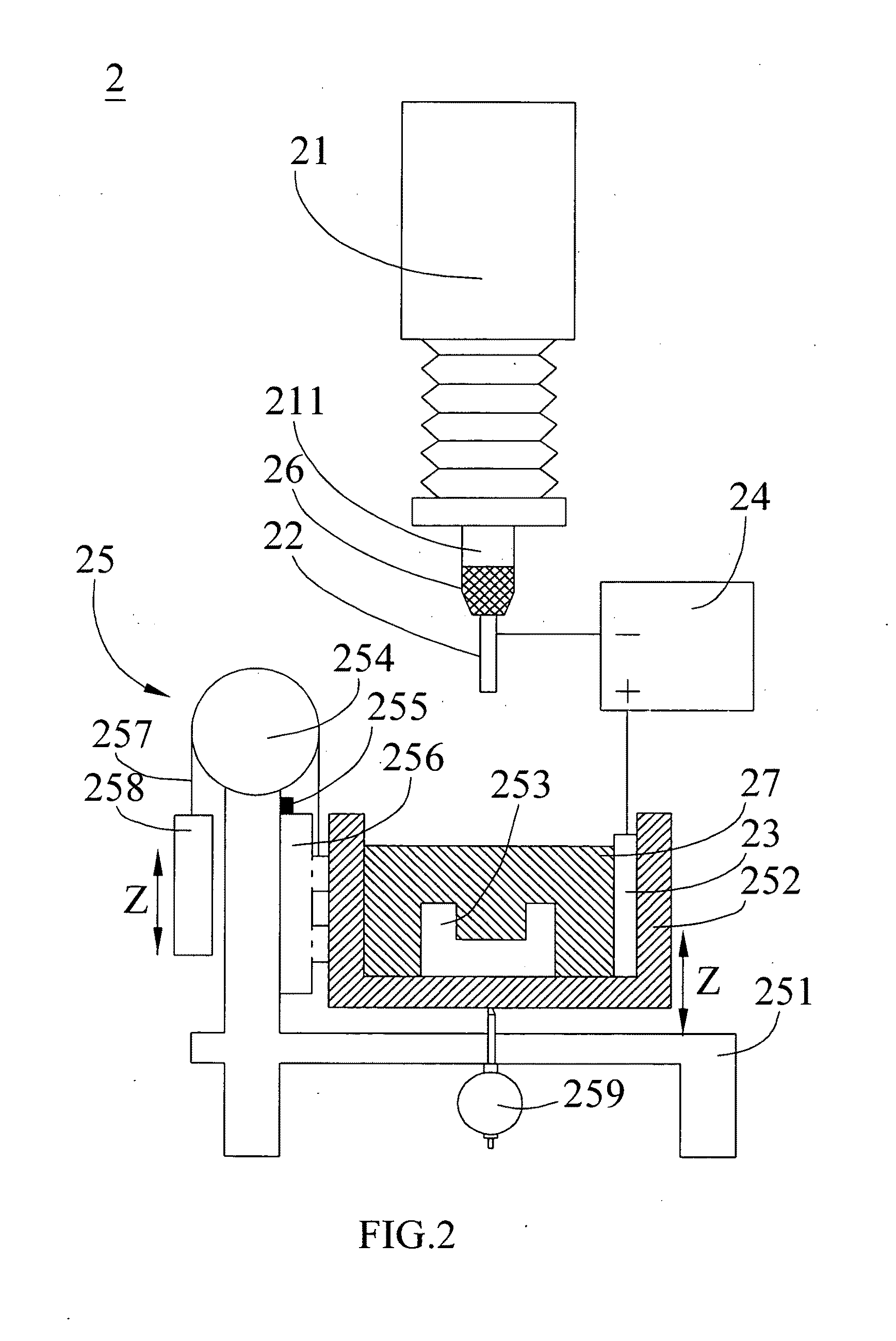

Apparatus and method for magnetic field assisted electrochemical discharge machining

ActiveUS20100243430A1Reduce thicknessIncrease loopCellsVacuum evaporation coatingElectrolysisMachined surface

In an apparatus and method for magnetic field assisted electrochemical discharge machining (ECDM), the magneto hydrodynamic (MHD) effect is utilized to improve the thickness of bubble film and the electrolyte circulation so as to enhance the machining accuracy and efficiency. Since charged ions in a magnetic field are induced by Lorenz force to move, and the electrolysis bubbles generated in the ECDM process are suffused with electrification ions on their surfaces, the electrolysis bubbles can be forced to move in the direction of the magnetic field without the need of mechanical disturbance. The present invention can be widely applied in the micro-machining of non-conductive brittle materials of different dimensions and shapes, comprising the forming of microchannels and microholes on a biochip, and in the micro-opto-electro-mechanical system (MOEMS) and various kinds of micro-machining fields. The machined surface is smooth and does not require a second time machining.

Owner:NAT CENT UNIV

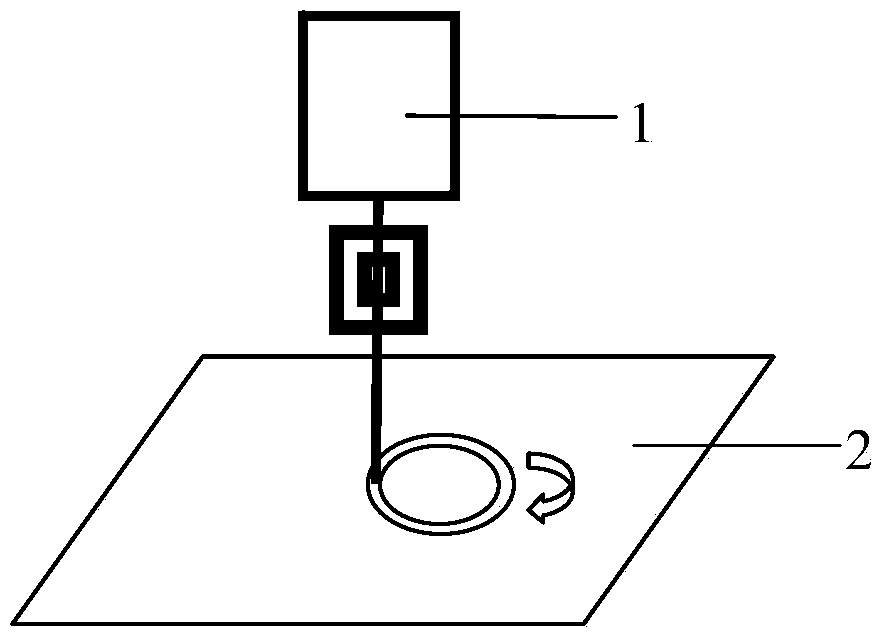

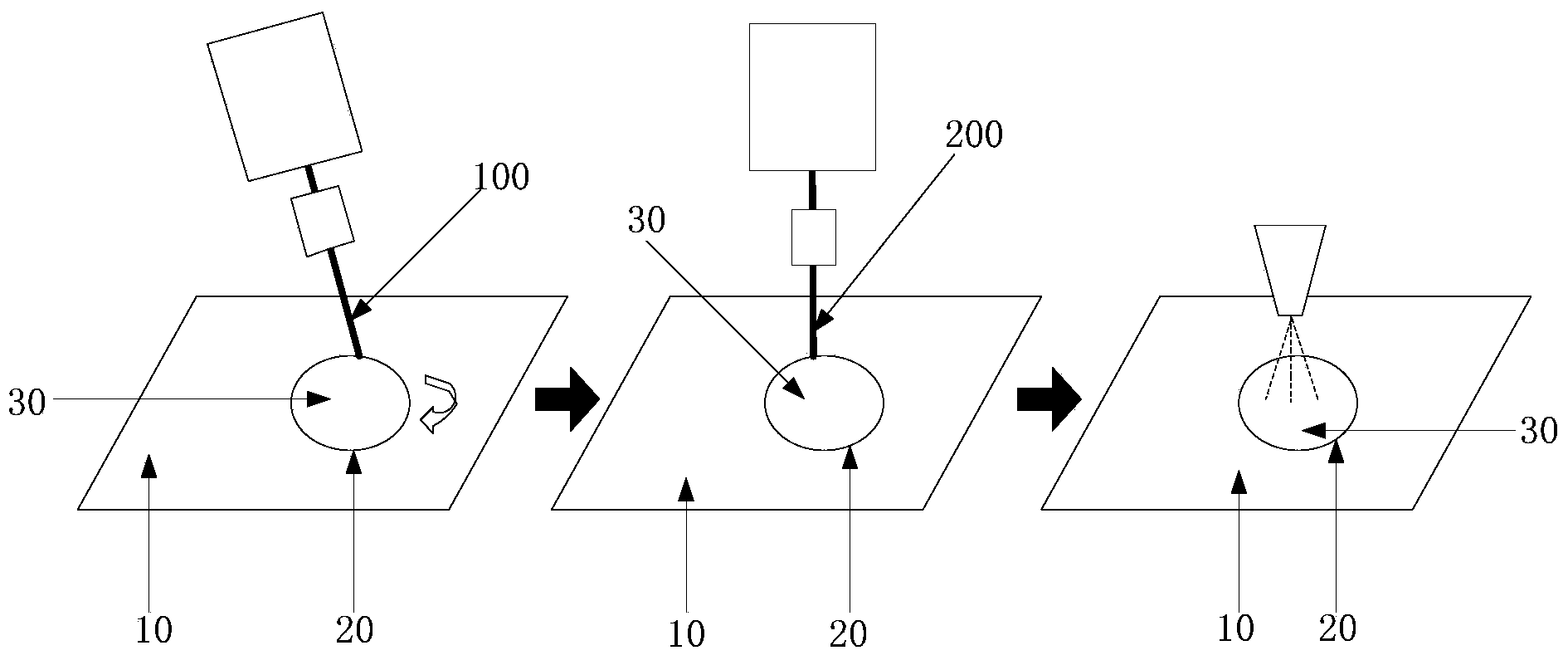

Laser drilling method and laser drilling system

ActiveCN103831539AGuaranteed qualityHole punchingGlass severing apparatusWelding/soldering/cutting articlesMachined surfaceLight beam

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

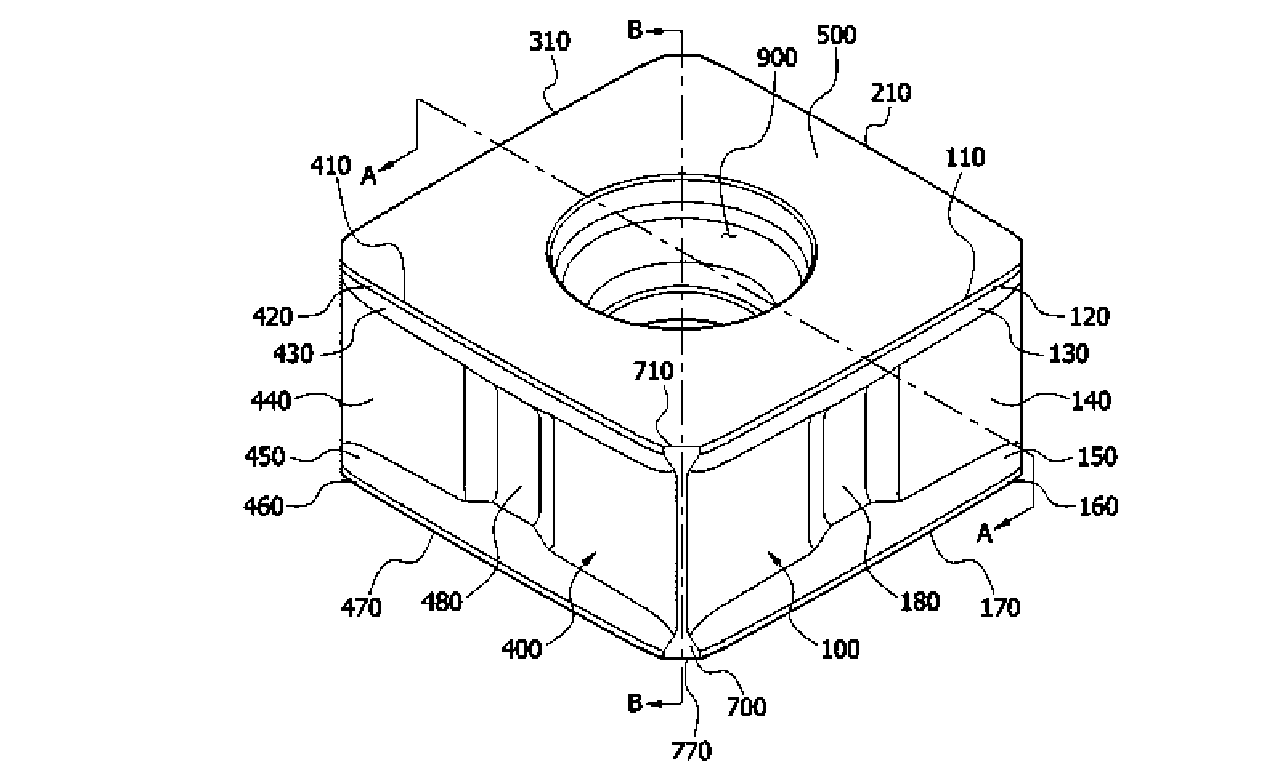

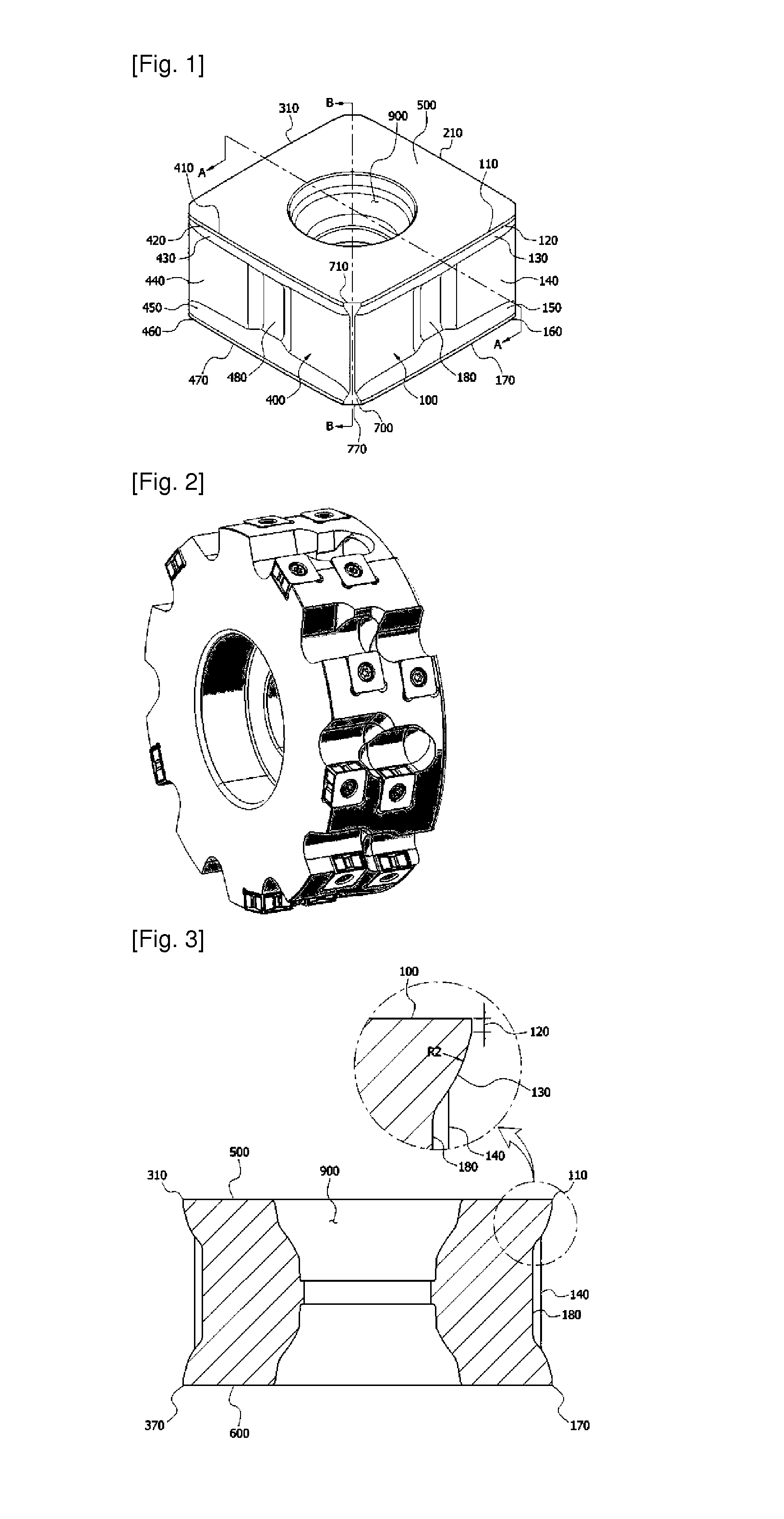

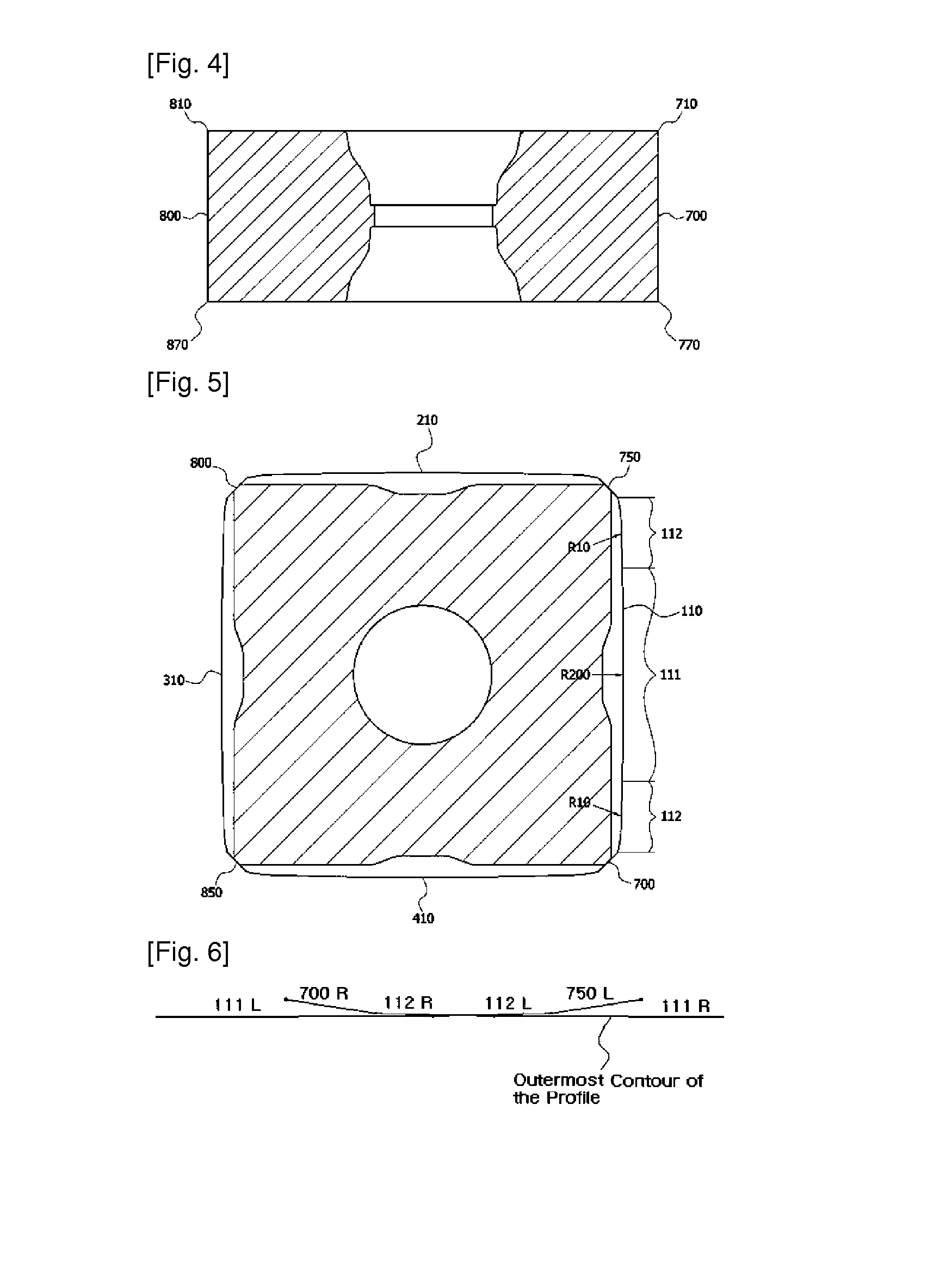

Tangential cutting insert

ActiveUS20130302099A1Avoid scratchesLower resistanceMilling cuttersTurning toolsMachined surfaceMechanical engineering

A hexahedral insert has top and bottom faces and two pairs of opposing side faces with main cutting edges formed on the borders of the top and bottom faces to the side faces and a screw hole passing through each central portion of the top and bottom faces. The top and bottom faces are flat planes parallel to each other; each of the side faces consecutively from top to bottom includes an upper land portion, an upper inwardly-inclined portion, a flat support surface, a lower inwardly-inclined portion, and a lower land portion. Each of two adjacent side faces has a corner surface therebetween which forms corner edges on the borders to the top and bottom faces. The cutting insert enhances the cutting power by reducing cutting resistance and prevents scratches on a machined surface.

Owner:TAEGUTEC

Overall process linear flow flexible protection sleeve material electrochemical machining device and method

ActiveCN106141343AImprove stabilityImprove machining accuracyMachining electrodesElectrical-based machining electrodesElectrolysisMachined surface

The invention relates to an overall process linear flow flexible protection sleeve material electrochemical machining device and method, and belongs to the field of electrochemical machining. The device is formed by a cathode assembly and an auxiliary assembly. The flow mode of the electrochemical machining method is an overall process linear flow manner, electrolyte flows from the front edge of a blade to the back edge of the blade, and a flow field is in a convergence state; the cathode assembly moves and drives the auxiliary assembly to move at the same time, the electrolyte is supplied in a manner of aligning at a machining area all the time, and it is ensured that the flow field is stable; and in the electrochemical machining process, a flexible insulation block seals a machined area, and scattered corrosion caused by the fact that the electrolyte flows to the machined surface is effectively reduced. By means of the overall process linear flow flexible protection sleeve material electrochemical machining device and method, the sleeve material electrochemical machining flow field stability is better improved; the taper of the blade is reduced, and the machining accuracy is improved; and the surface quality is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

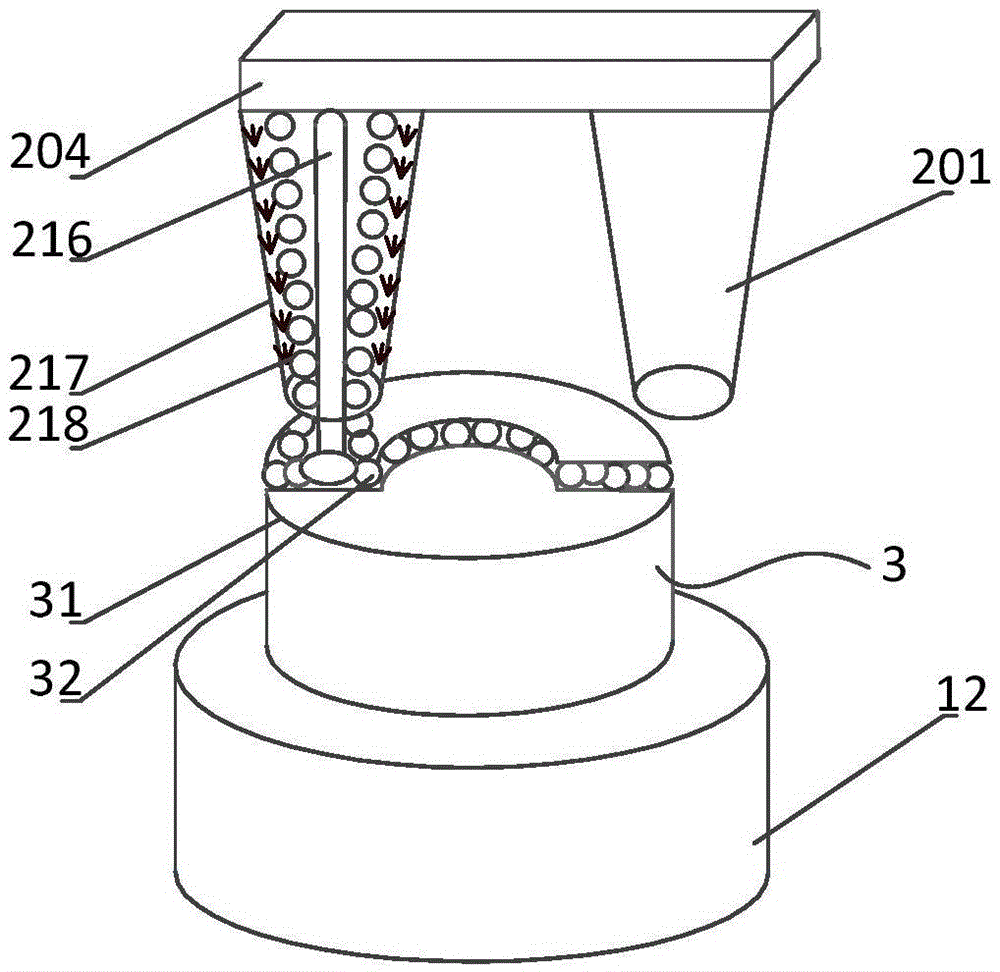

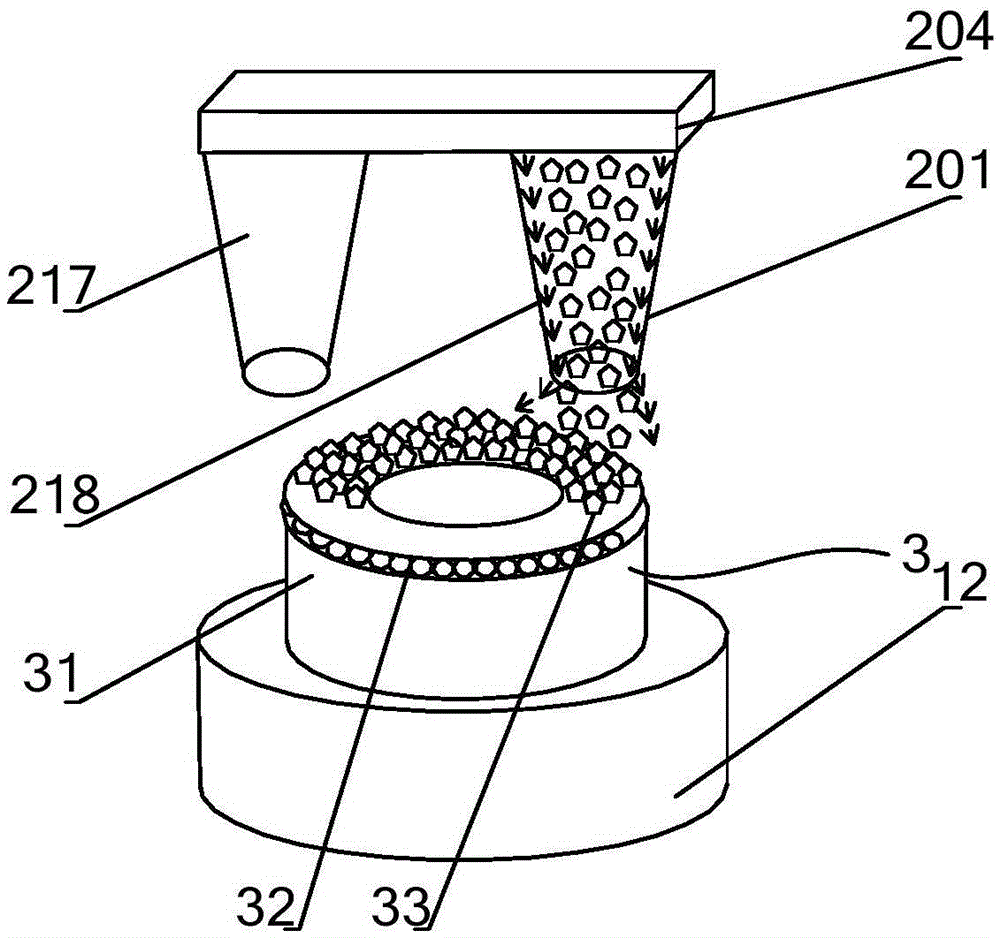

Manufacturing method for 3D printing diamond grinding wheel with abrasive particles arranged regularly

ActiveCN105415216AImprove grinding efficiencyUniform grinding forceGrinding devicesManufacturing technologyMachined surface

The invention belongs to the technical field of grinding machining and 3D printing and relates to a manufacturing method for a diamond grinding wheel with abrasive particles arranged regularly. Related devices mainly comprise a movement control platform, a grinding wheel printing system and a 3D printing grinding wheel. The movement control platform comprises a base, a rotation movement table, a lifting platform, a horizontal-moving platform, a movement control device and a supporting frame. The grinding wheel printing system comprises a diamond abrasive particle nozzle, a conveying pipe I, a diamond abrasive particle box, a nozzle supporting plate, an air pipe I, an air valve I, an air valve III, an air source, an air valve II, an air pipe II, a metal bonding agent powder box, a conveying pipe II, an air pipe III, a laser source, a laser optical path, a laser beam, a bonding agent nozzle and airflow. The 3D printing grinding wheel comprises a grinding wheel base body, a metal bonding agent and the diamond abrasive particles. The abrasive particles can be regularly arranged in the grinding wheel, when the grinding wheel of this kind is ground, the machined surface is high in quality, grinding efficiency is high, grinding force is even, and the service life of the grinding wheel is prolonged. Thus, the manufacturing technology of the special-shaped grinding wheel is simplified, platform constructing is convenient, and operation is easy and convenient.

Owner:HUNAN UNIV

Off-line feed rate scheduling for reduction of machining time and enhancement of machining accuracy in CNC machining

InactiveUS7050883B2Improve precisionIncrease productivityComputation using non-denominational number representationNumerical controlMachined surfaceEngineering

An off-line feed rate scheduling method of a CNC machining process includes selecting a constraint variable and inputting a reference value related to the constraint variable; estimating a cutting configuration where a maximum constraint variable value (CVV) occurs through ME Z-map modeling; receiving the estimated cutting configuration and estimating a specific rotation angle (φs) where the maximum constraint variable value occurs through constraint variable modeling; calculating a feed rate that satisfies the reference value of the constraint variable at the estimated specific rotation angle; and applying the calculated feed rate to the NC code. Cutting force or machined surface error may be selected as a constraint variable depending on machining conditions.

Owner:POSTECH ACAD IND FOUND

Housing for Hand-Held Device with Extruded Element having Area of Bulk Material and Corresponding Method

InactiveUS20100056231A1Maintain continuityWave amplification devicesDigital data processing detailsMachined surfaceHand held

A housing for a hand-held electronic device and a corresponding method for forming the same are provided. The housing includes an extruded element having a profile corresponding to a cross-section of the element, which is perpendicular to the direction of extrusion, where the extruded element includes within the profile, one or more areas of bulk material. The one or more areas of the bulk material include a machined surface along the length of the extruded element in the direction of the extrusion including a resulting machined profile. The resulting machined profile varies along the length of the extruded element in the direction of extrusion, while maintaining the continuity of the formed surface.

Owner:GOOGLE TECH HLDG LLC

System for applying a diffusion aluminide coating on a selective area of a turbine engine component

InactiveUS6993811B2Low costReduce heatAutomatic control devicesBlade accessoriesMachined surfaceInfrared lamp

A method for applying diffusion aluminide coating on a selective area of a turbine engine component and the coating produced by that method is disclosed. A quartz infrared lamp heats only substantially the localized area of the component to be coated, rather than the complete part. Either halide activated or non-activated tape is applied on the area to be coated and is held in place during coating using a high temperature dimensionally stable tape holder manufactured from graphite or ceramic. The quartz infrared lamp is used to heat only the desired area to a coating temperature of about 1800° F. to about 2000° F. under an inert atmosphere for about 3 to about 8 hours to achieve the desired aluminide coating thickness. No powder masking of the machined surface area is required. Due to the localized heating, aluminum vapor generated from the tape will only deposit aluminide coating on the taped area.

Owner:GENERAL ELECTRIC CO

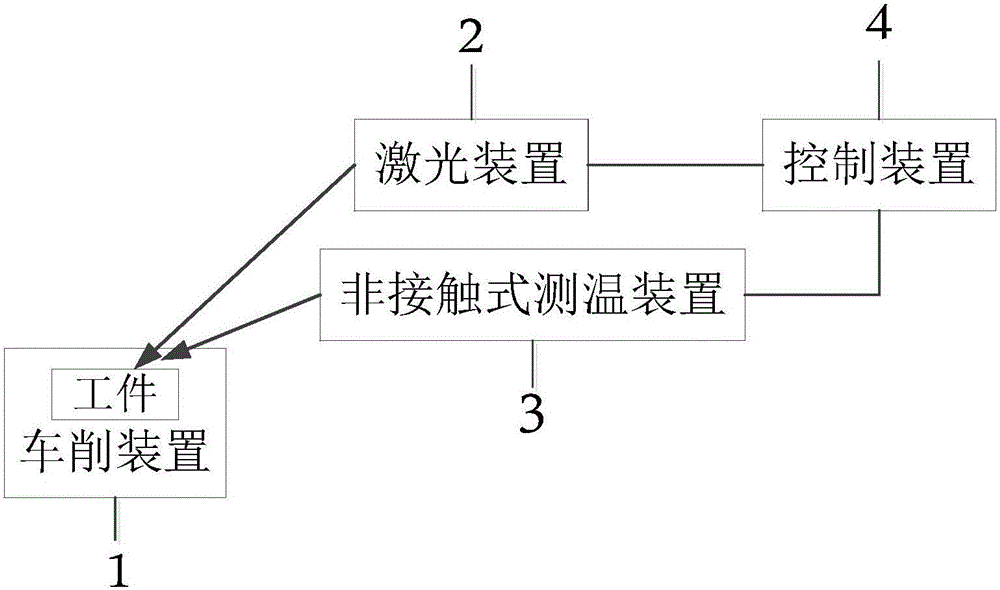

Laser heating assisted turning device and method

InactiveCN106001613ASolution to short lifeImprove surface qualityMeasurement/indication equipmentsMetal working apparatusData matchingMachined surface

The invention provides a laser heating assisted turning device and method. The laser heating assisted turning device comprises a turning device body, a laser device, a non-contact temperature measuring device and a control device, wherein a tool and a workpiece are fixed to the turning device body, the tool is detachably connected with the turning device body, the laser device is used for heating the workpiece through laser, the non-contact temperature measuring device is used for acquiring the temperature at the cutting position of the workpiece in real time, and the control device is used for comparing data of an optimum temperature field stored in the control device with temperature data acquired by the non-contact temperature measuring device in real time and controlling the laser device to adjust laser parameters so as to achieve the optimum temperature field if difference exists. The laser heating assisted turning device has the advantages that the laser parameters are adjusted in a data matching mode so that the temperature field at the cutting position of the workpiece can be always consistent to the optimum temperature field, the cutting performed in the temperature field makes the service life of the tool longest, the machined surface quality of the workpiece is the best, and the turning efficiency is the highest.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com