Patents

Literature

33results about How to "Hole punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

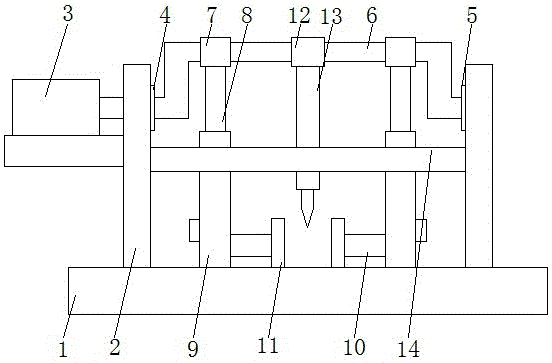

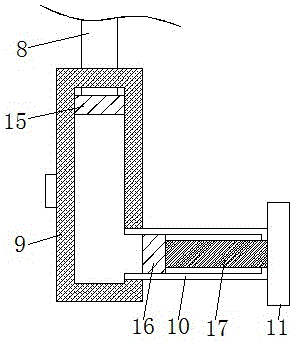

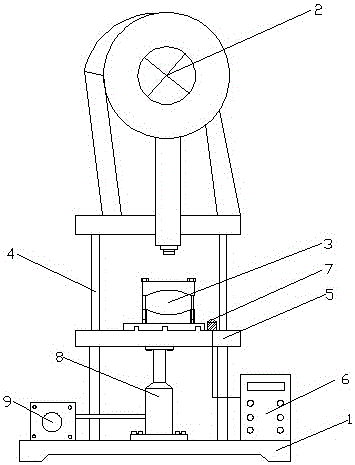

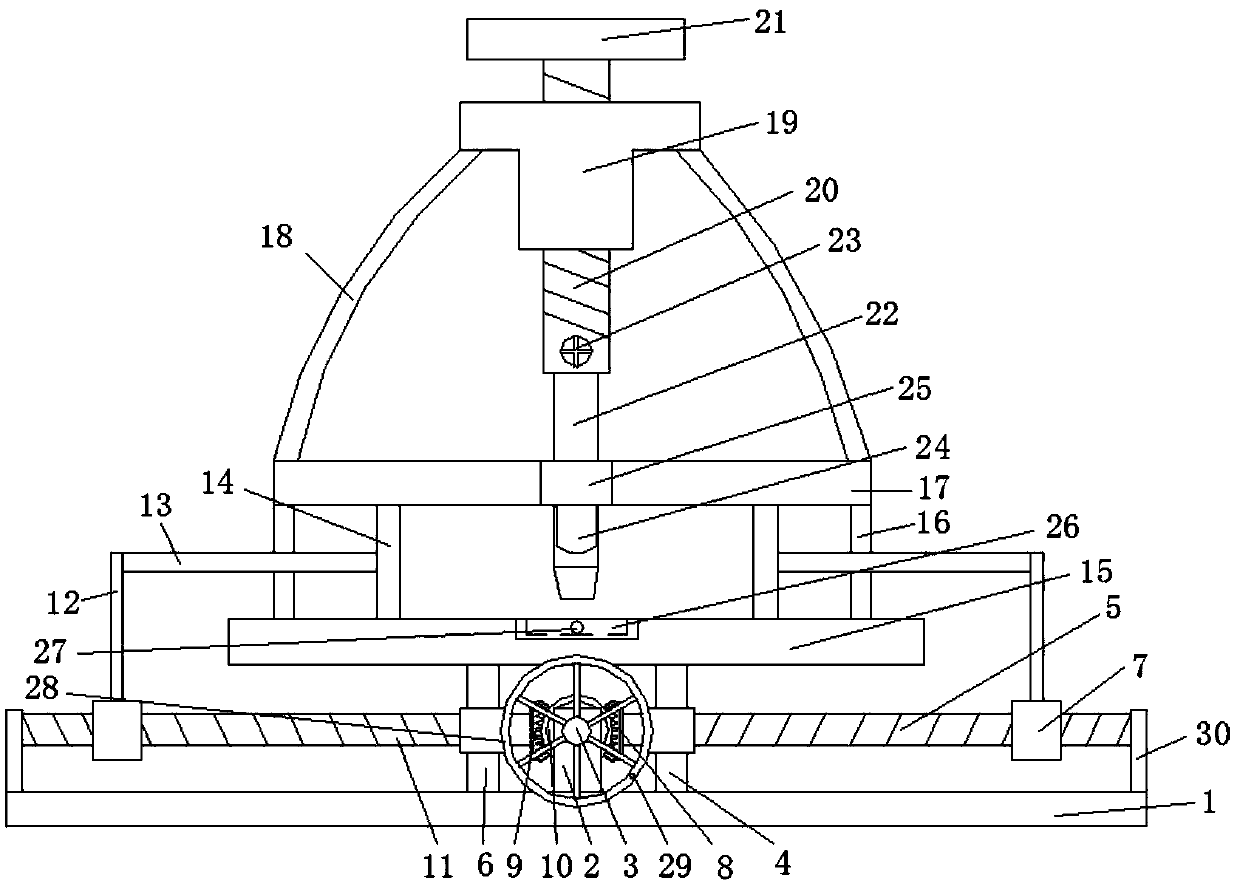

Punching machine for hardware parts

ActiveCN106041175AHole punchingReduce laborFeeding apparatusDriving apparatusPunchingArchitectural engineering

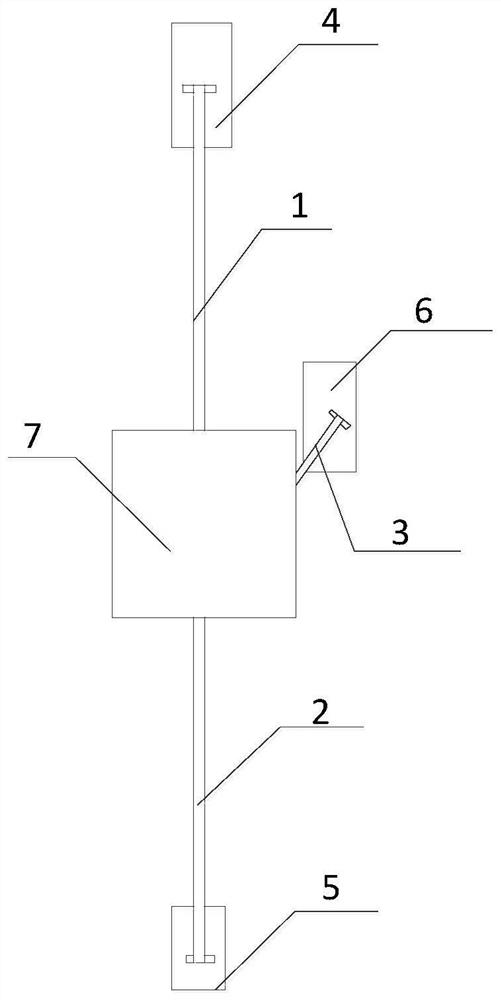

The invention discloses a punching machine for hardware parts. The punching machine comprises a base, wherein symmetrical support rods are fixedly connected to the top of the base, a motor is arranged on one sides of the support rods, the inner walls of the support rods are fixedly connected with a first bearing and a second bearing respectively, one end of the first bearing penetrates the inner wall of the corresponding support rod and extends to the outer surface of the support rod, the outer surface of a rotary shaft of the motor is fixedly connected inside the first bearing, a rotary rod is arranged between the two support rods, one end of the rotary rod is fixedly connected inside the second bearing, the other end of the rotary rod is arranged inside the first bearing and fixedly connected with the rotary shaft of the motor, symmetrical third bearings are arranged on the outer surface of the rotary rod, and push rods are fixedly connected with the outer surfaces of the two third bearings. According to the punching machine for the hardware parts, clamping plates can perform clamping automatically, manual clamping is avoided, the labor amount is reduced, the working risk is reduced, and the working efficiency is increased.

Owner:WUXI CITY DAWN HIGH STRENGTH FASTENERS

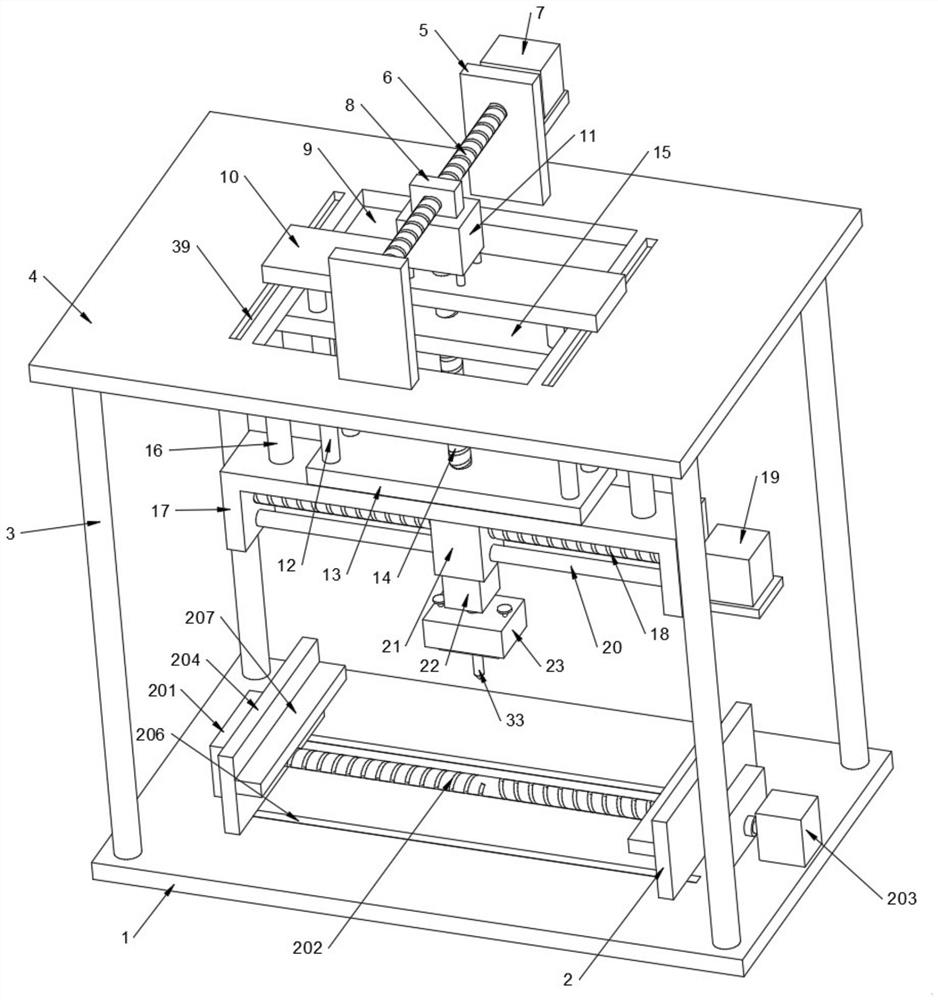

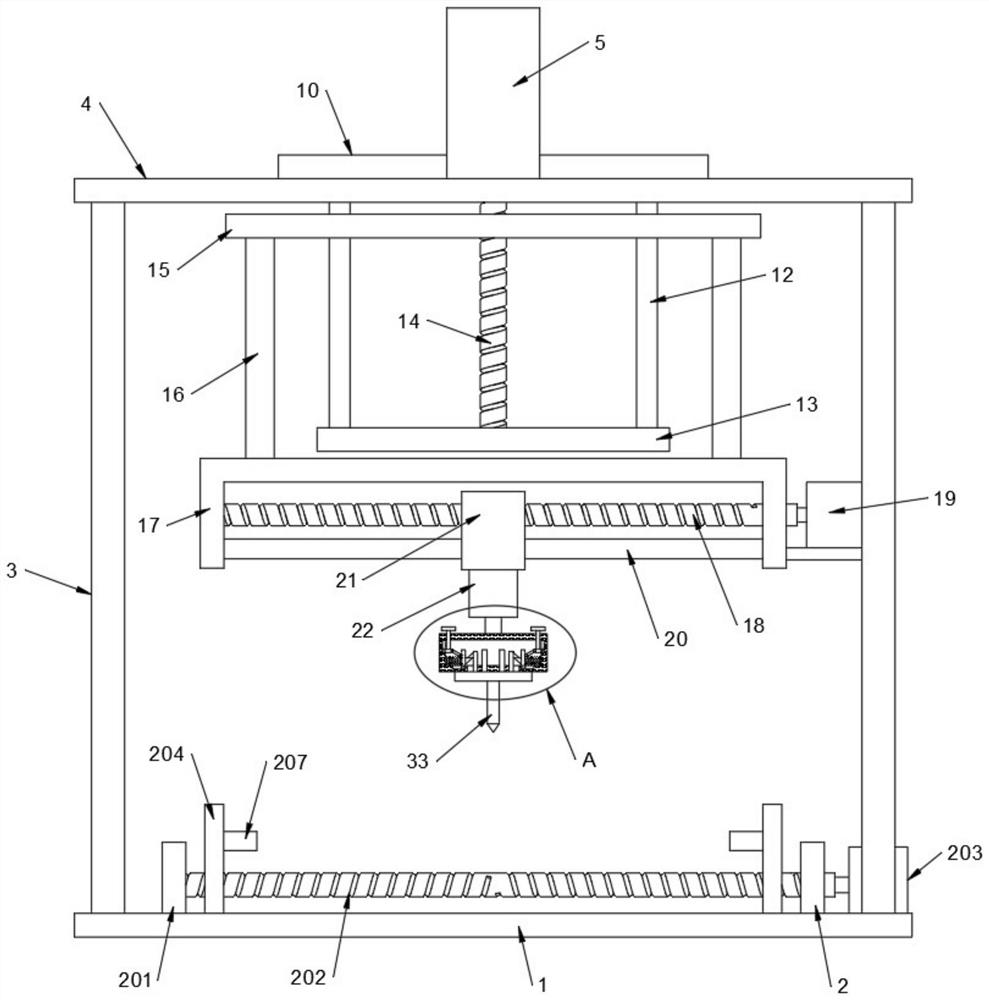

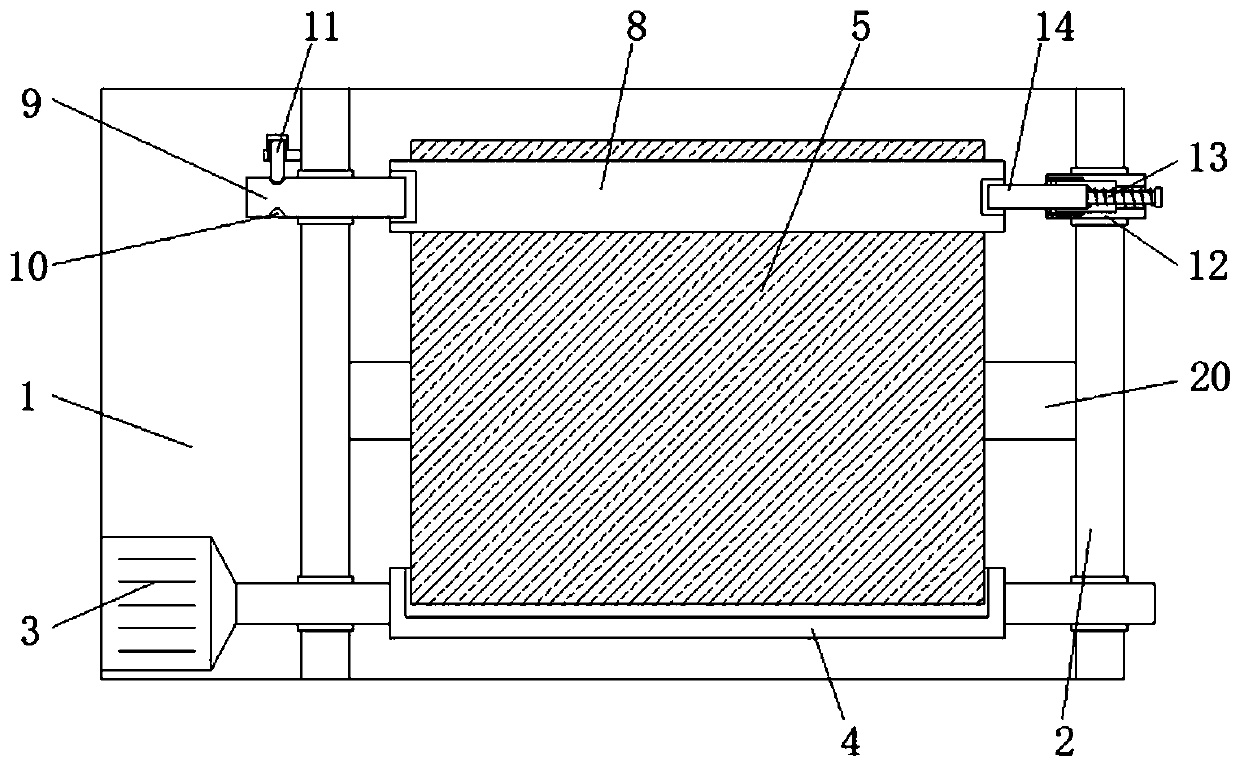

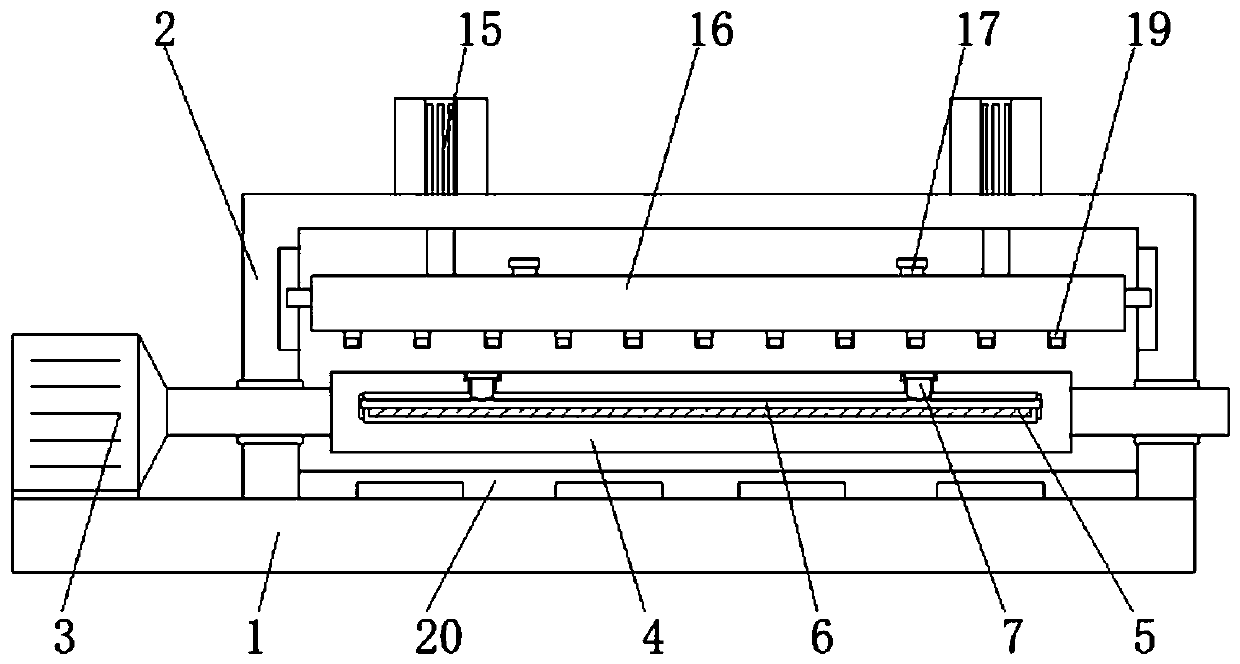

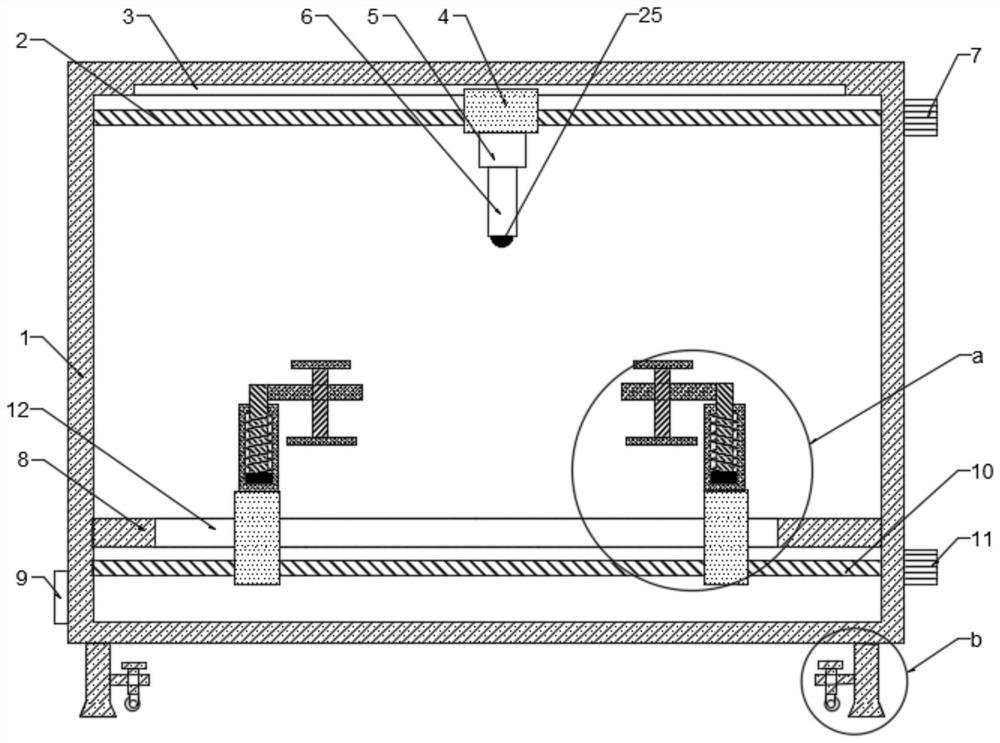

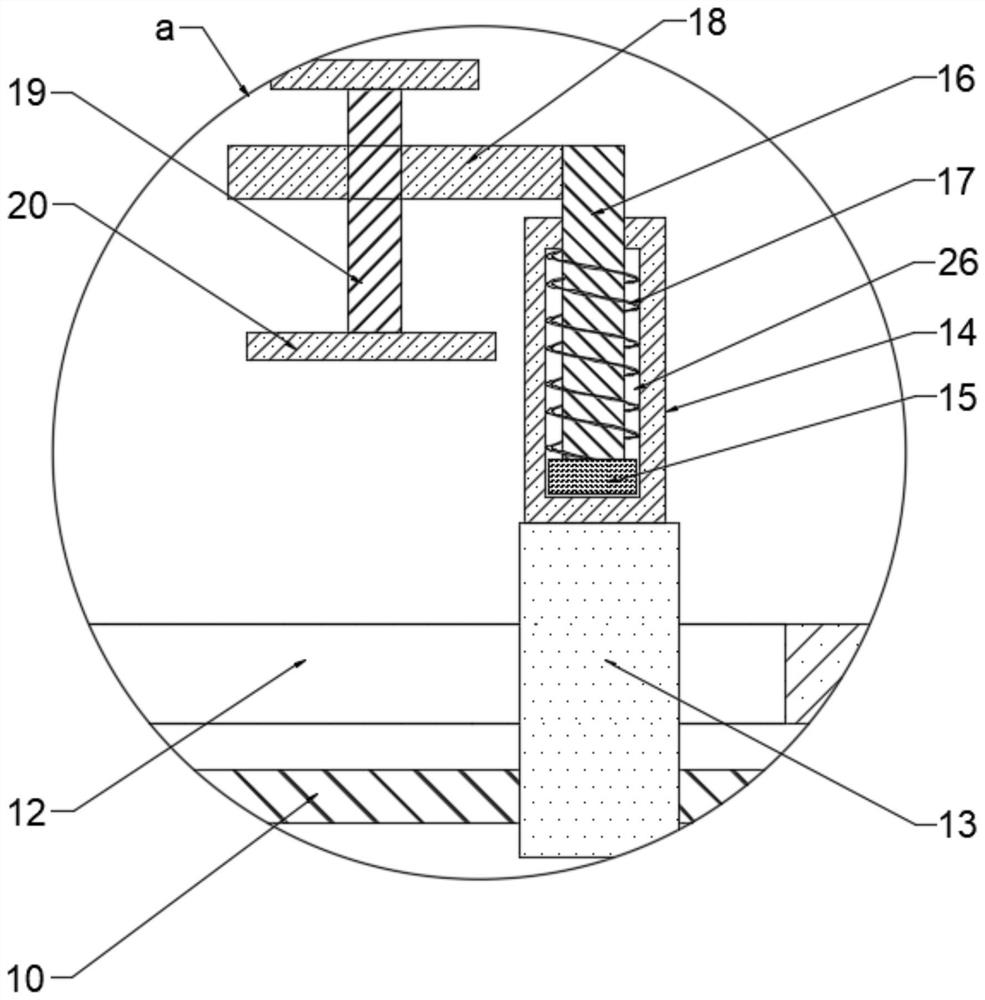

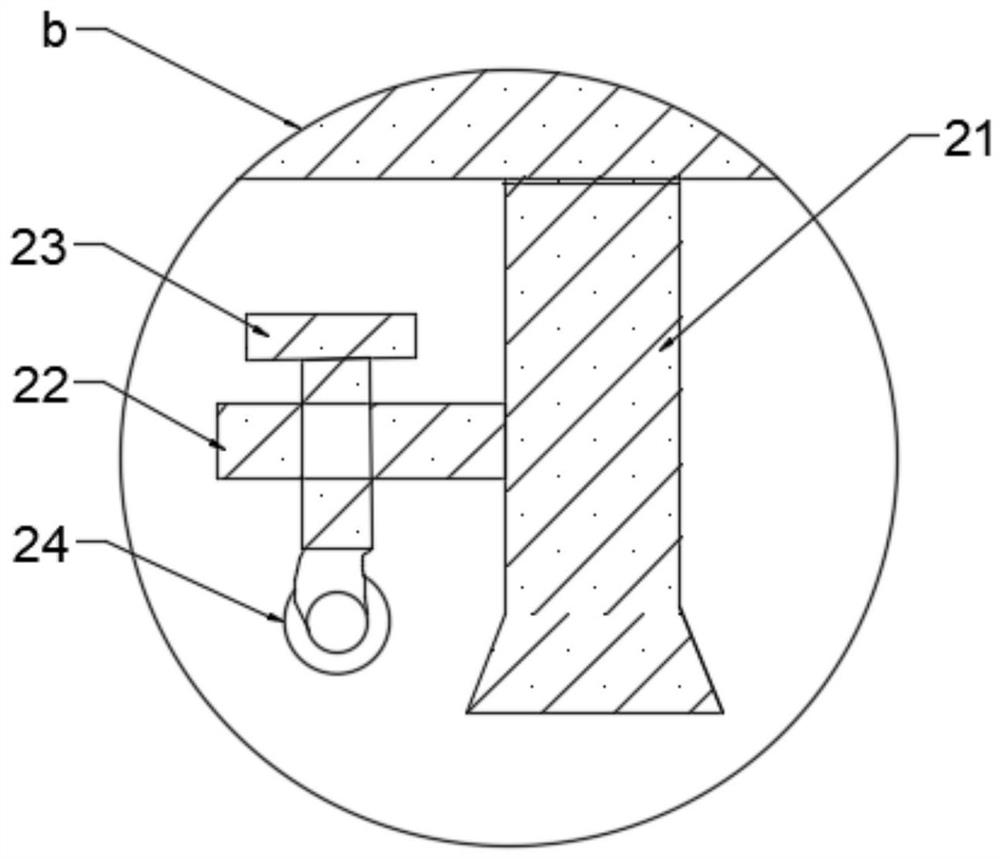

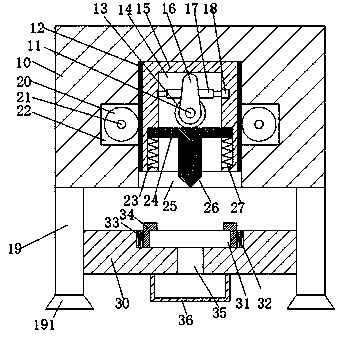

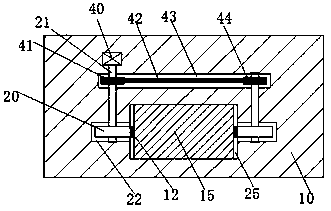

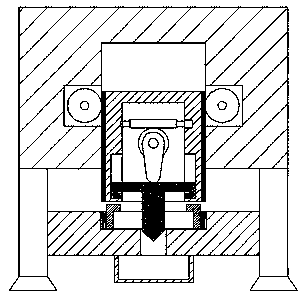

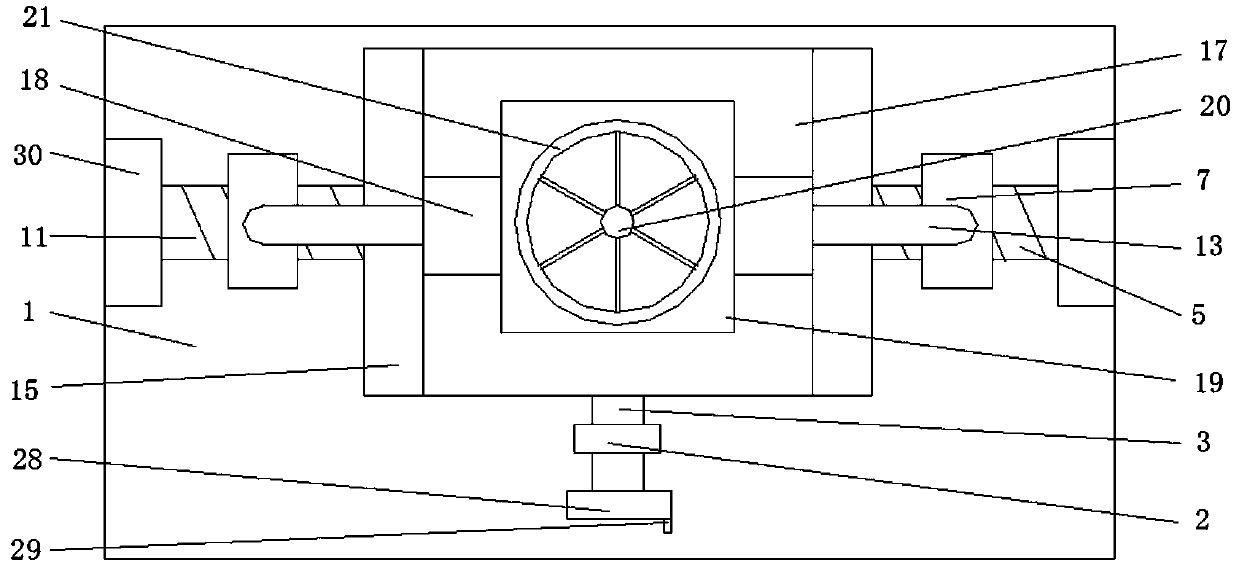

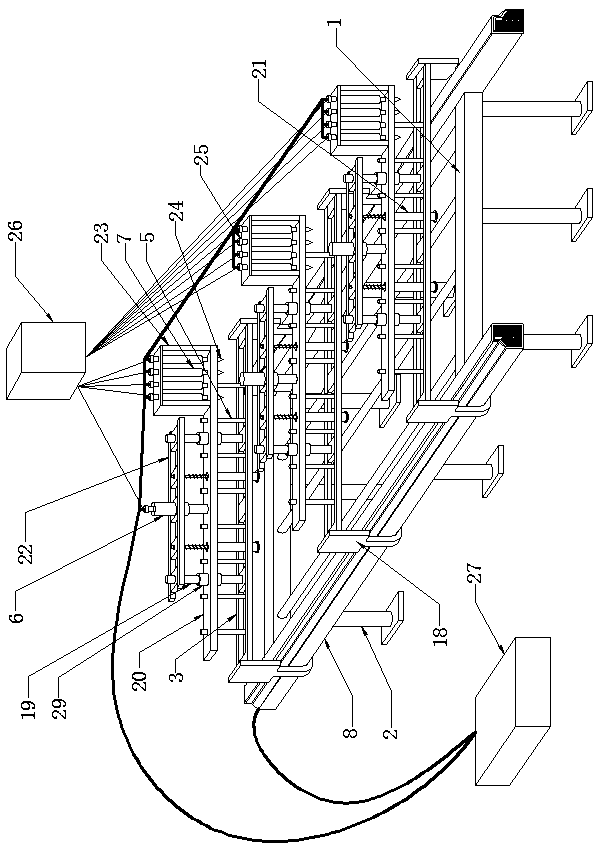

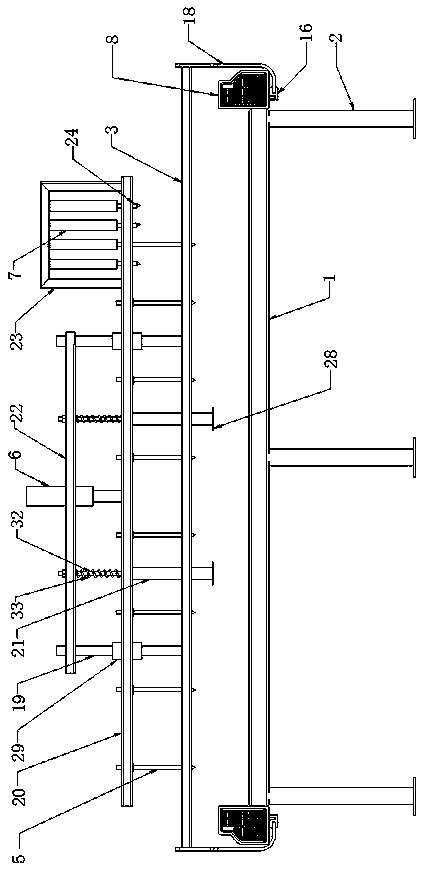

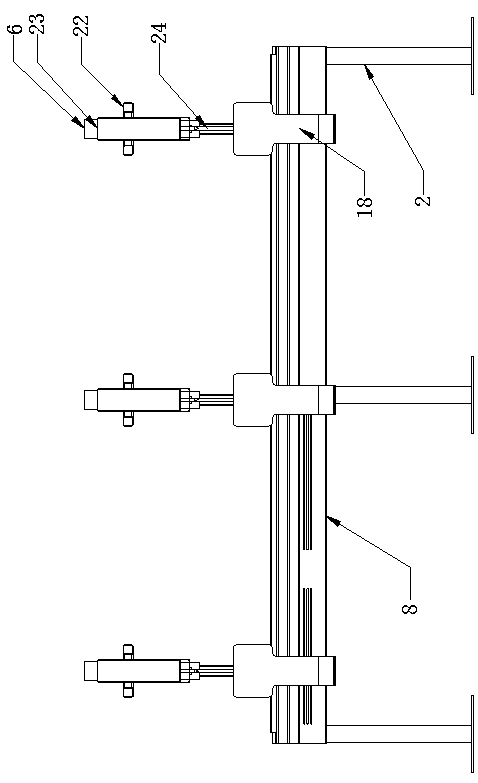

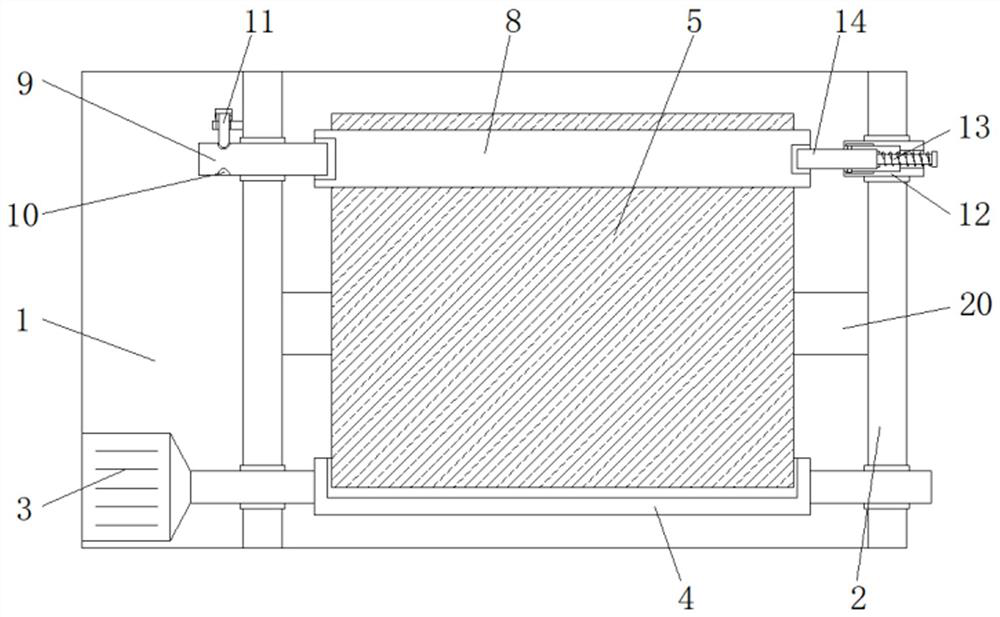

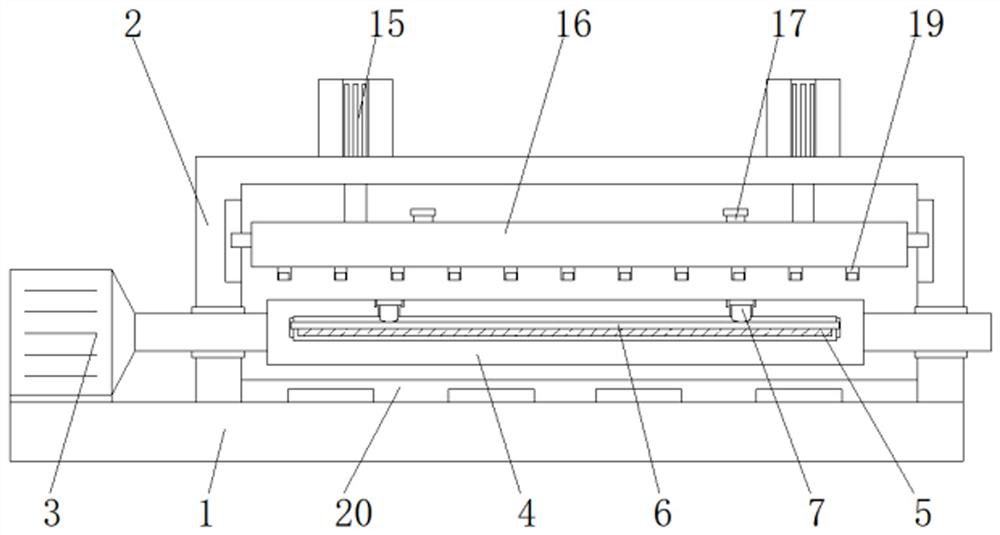

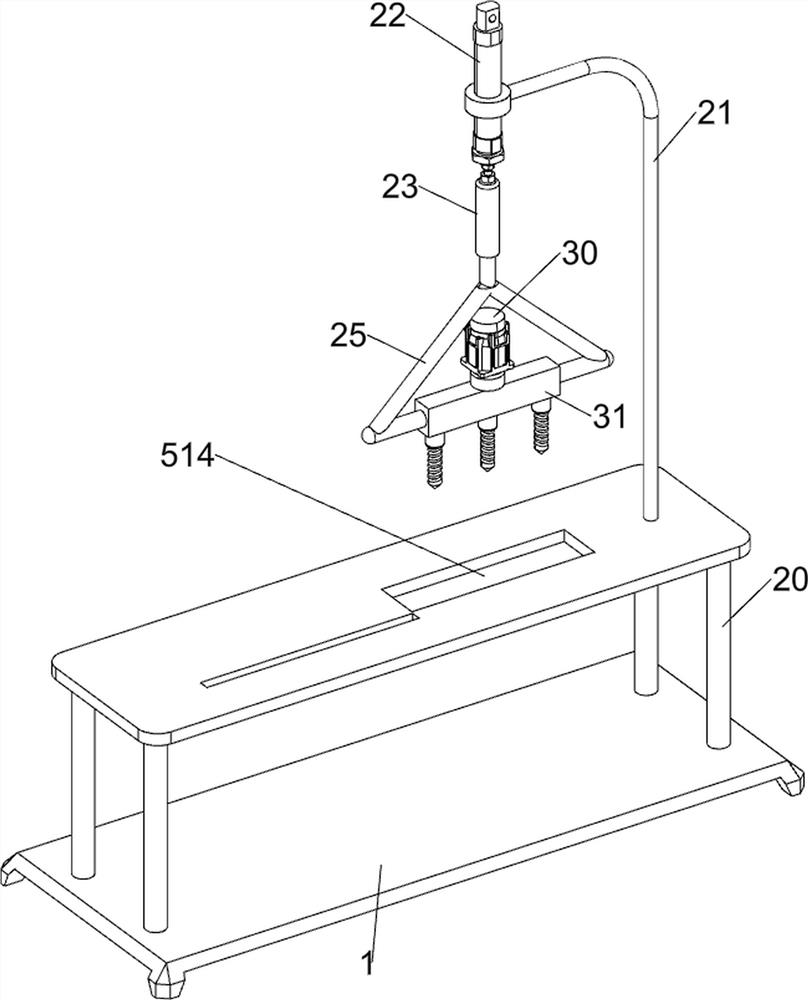

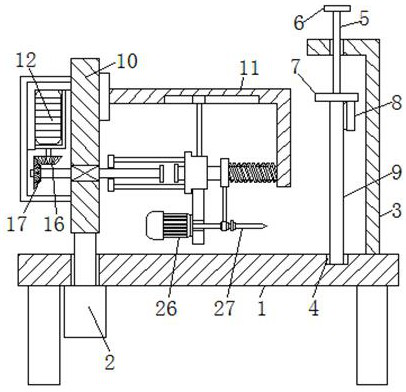

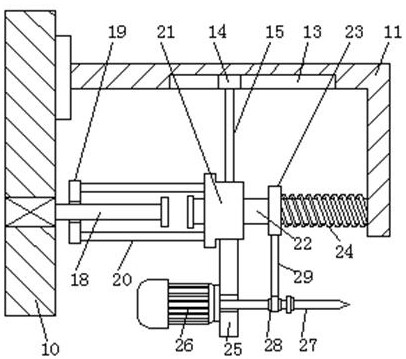

Material processing and punching equipment for satellite equipment manufacturing and punching method of material processing and punching equipment

InactiveCN111906341AEasy to installEasy to disassembleBoring/drilling machinesPunchingElectric machinery

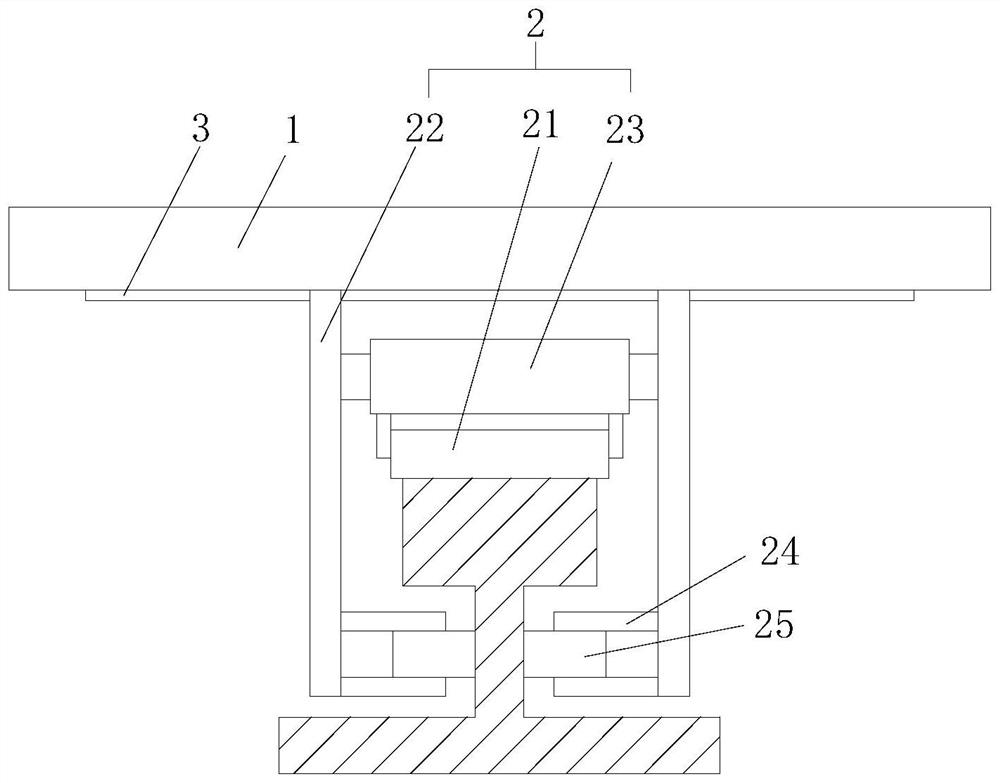

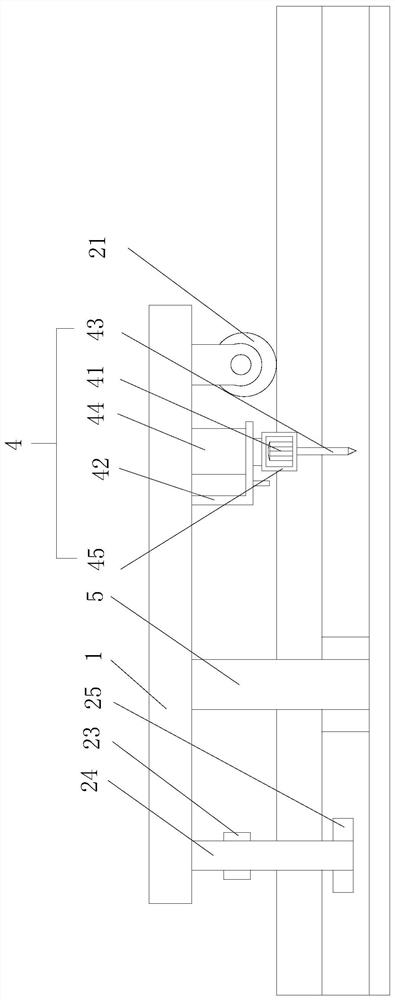

The invention discloses material processing and punching equipment for satellite equipment manufacturing and a punching method of the material processing and punching equipment, and belongs to the technical field of punching equipment. The material processing and punching equipment for satellite equipment manufacturing comprises a bottom plate, wherein a fixing device is arranged at the top of thebottom plate, stand columns are fixed to the four corners of the top of the bottom plate correspondingly, a top plate is fixed to the tops of the four stand columns, and fixing plates are symmetrically fixed to the top of the top plate. According to the material processing and punching equipment, by arranging a box body, springs, limiting plates, first wedge-shaped blocks, connecting rods, a connecting plate, second wedge-shaped blocks and other structures, after a drill bit is damaged, the drill bit can be replaced conveniently and rapidly; and by arranging the fixing plates, a first one-waylead screw, a servo motor, a stepping motor, a second one-way lead screw, a connecting plate, connecting rods, a U-shaped plate, a third one-way lead screw, a gear motor, a guide rod, a mounting block and other structures, the drill bit can move front and back, left and right and up and down, and therefore all-around punching can be achieved.

Owner:JIANGSU JIUGAO ELECTRONICS TECH

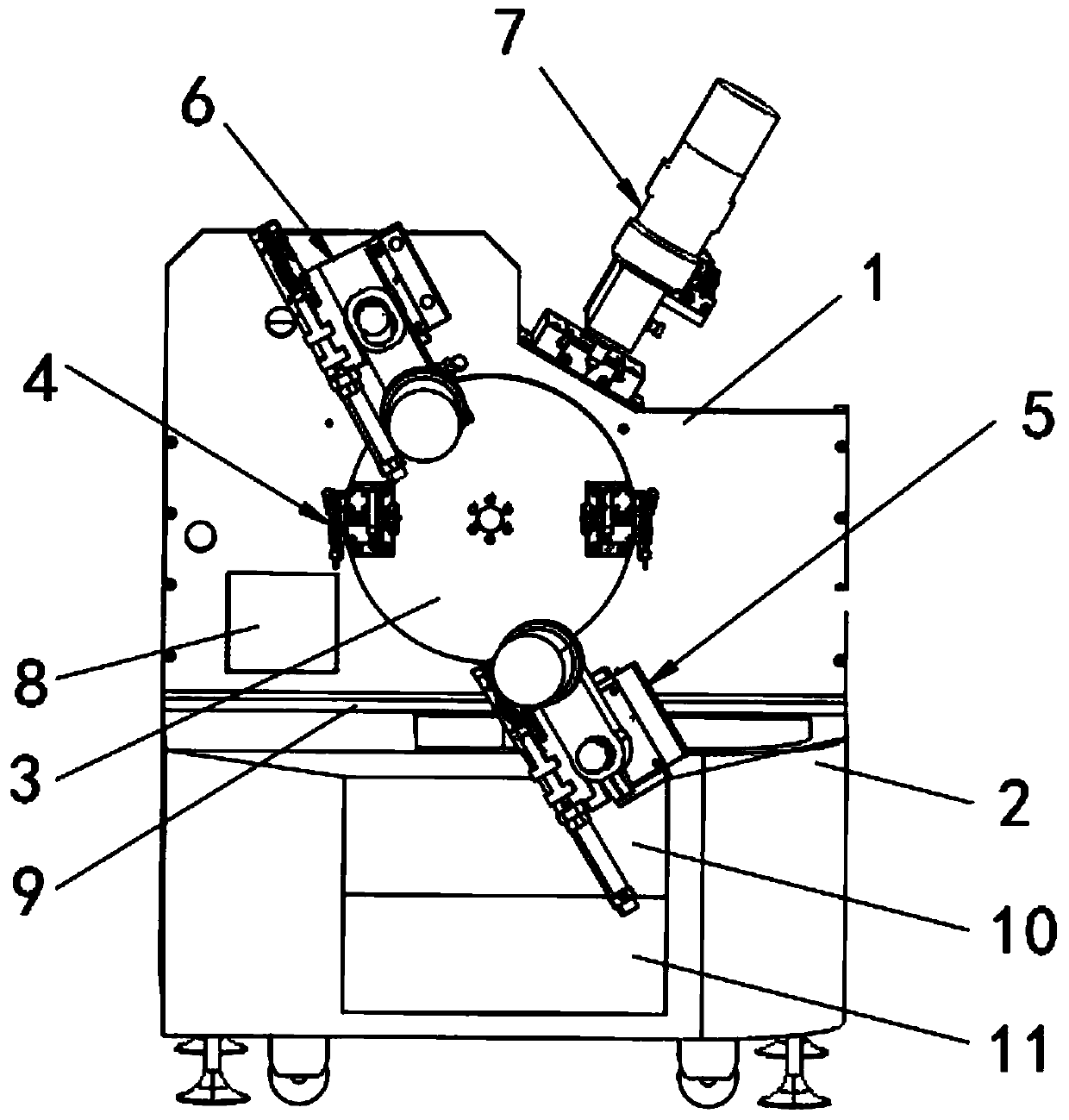

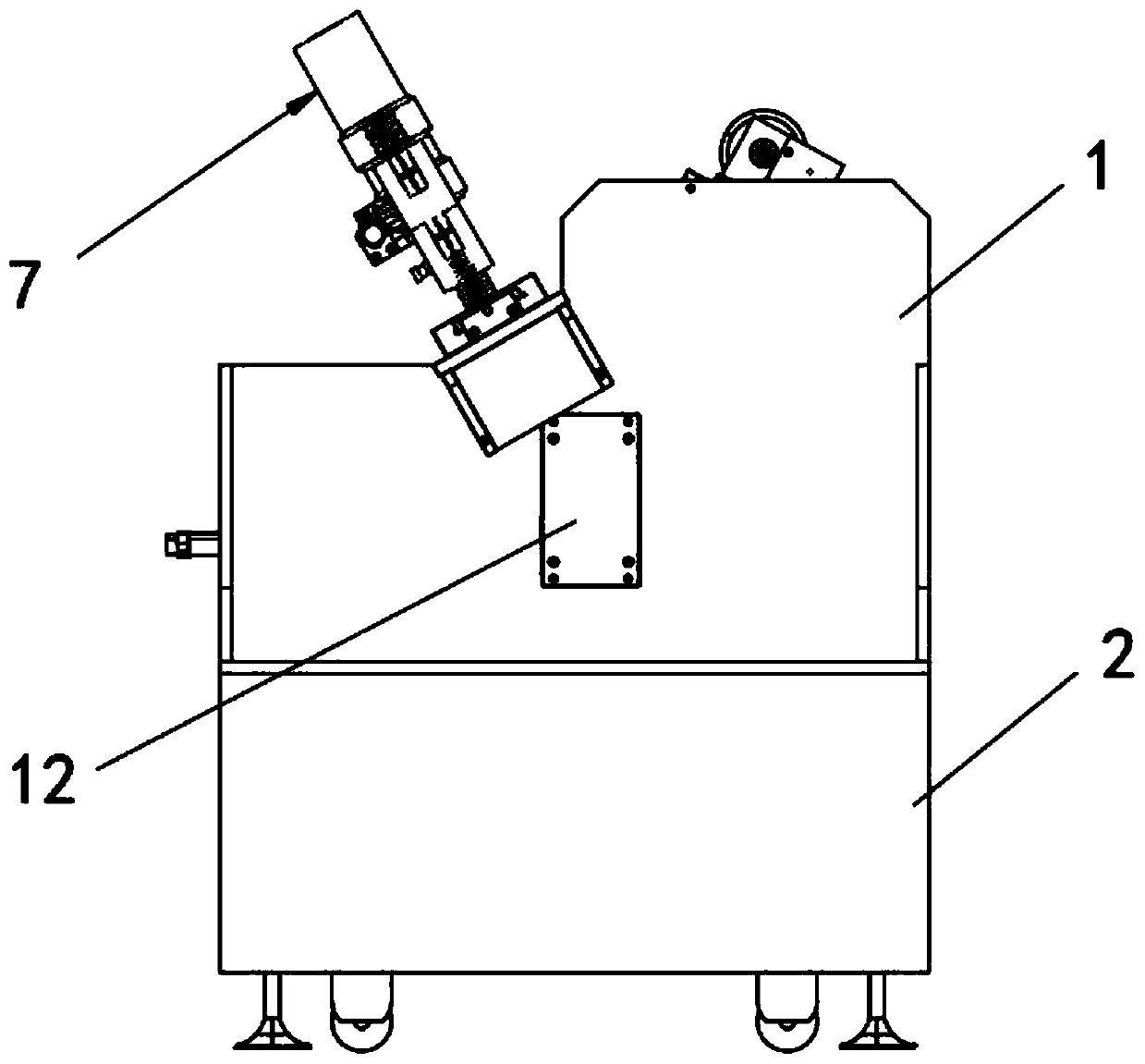

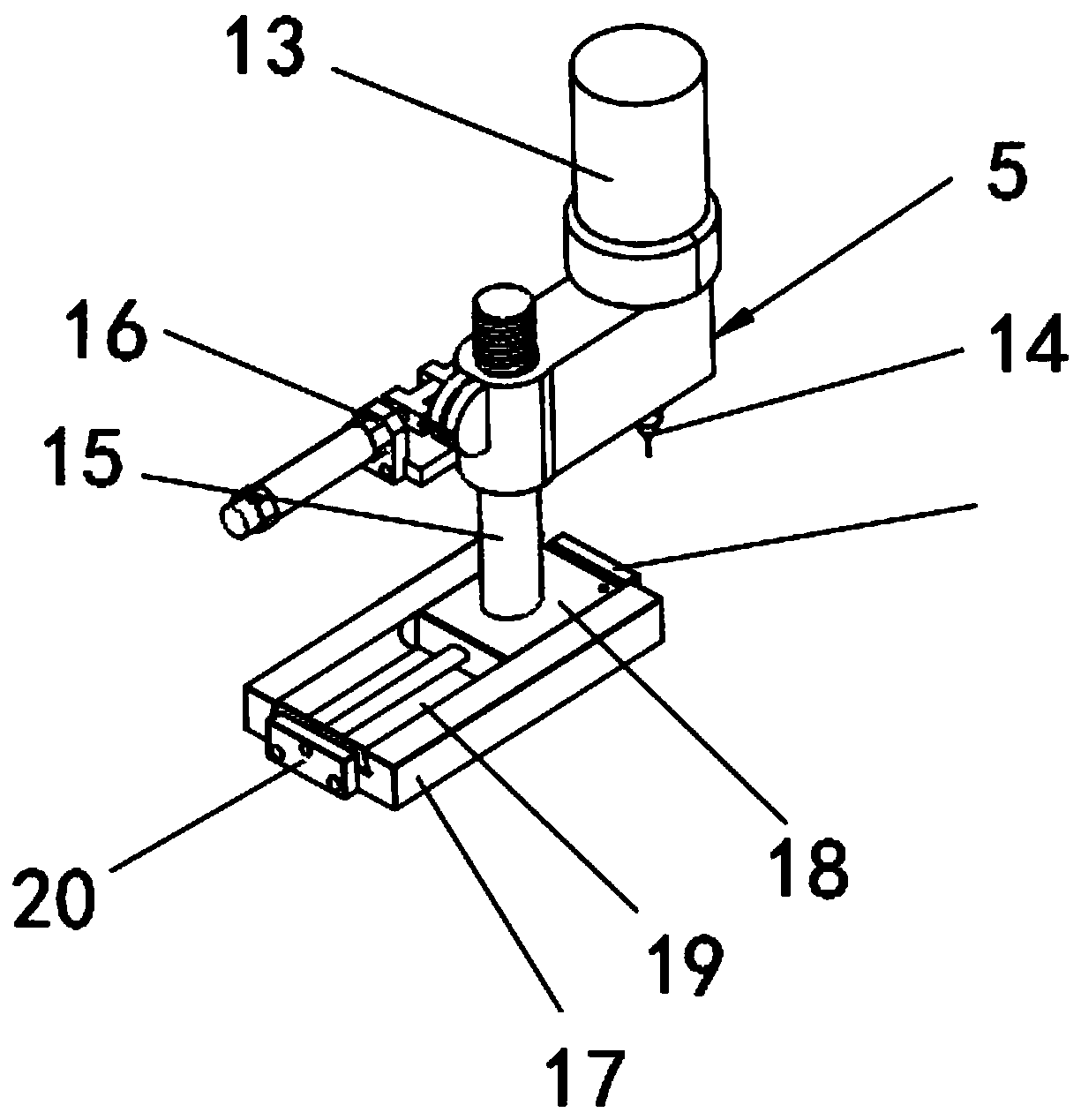

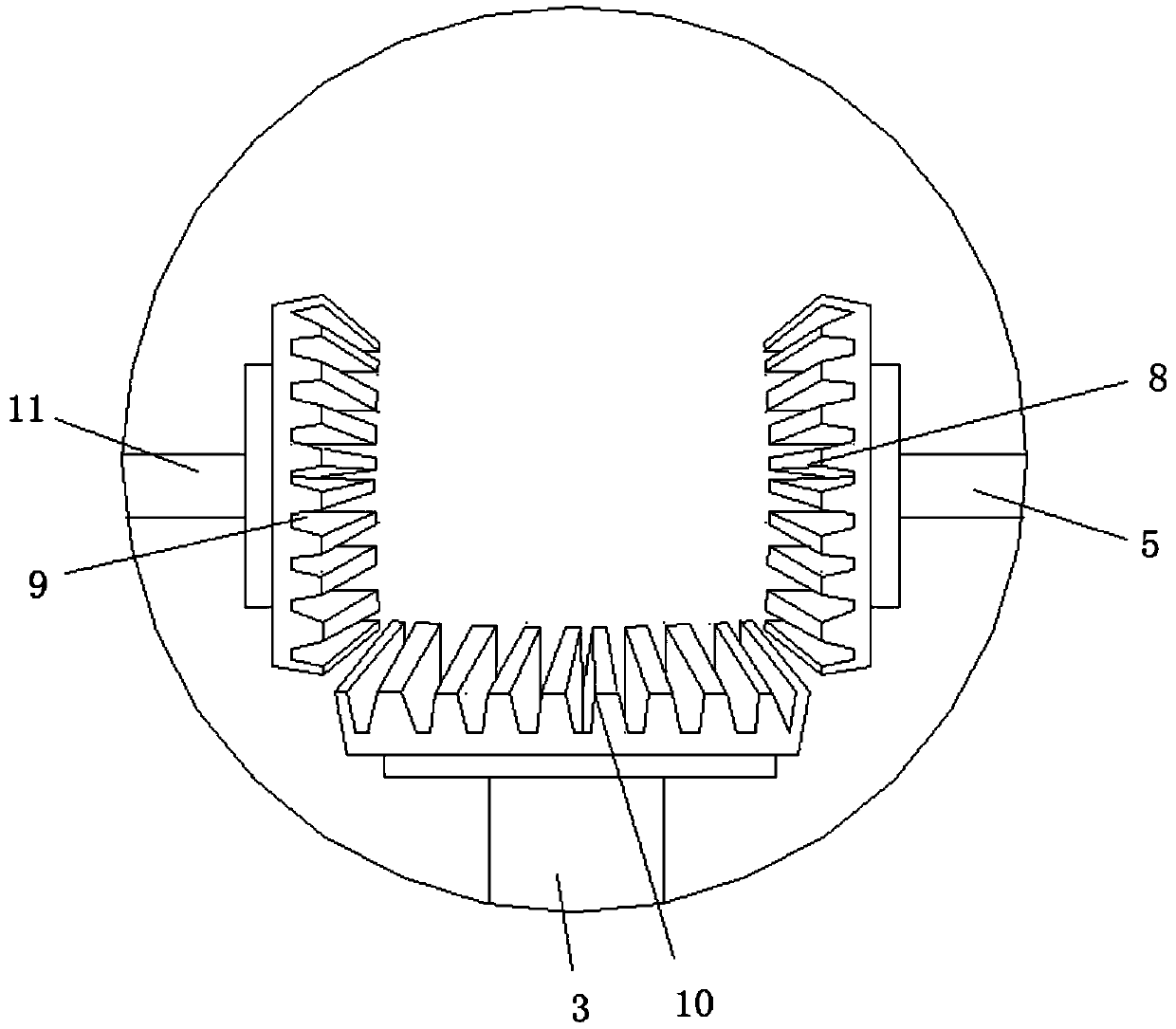

Wooden strip drilling device for wood furniture processing and working method thereof

InactiveCN110733078AHigh speedImprove efficiencyStationary drilling machinesBark-zones/chip/dust/waste removalElectric machineryStructural engineering

The invention discloses a wooden strip drilling device for wood furniture processing. The wooden strip drilling device comprises a top frame and a bottom seat, wherein the top frame is located on thetop part of the bottom seat, a rotary table is installed in the middle part of the side wall of the top frame, the rotary table is connected with a transmission shaft of a motor, two clamps are fixedly arranged on the edge part of the rotary table, one side of the rotary table is provided with a first surface drilling mechanism, an end part drilling mechanism is arranged above the first surface drilling mechanism and fixed on the back side wall of the top frame, and one side of the end part drilling mechanism is provided with a second surface drilling mechanism which is fixed on the side wallof the top frame. According to the wooden strip drilling device for wood furniture processing, the problem that the existing drilling device has low drilling efficiency and slow drilling speed, the position of a wood strip in the process of drilling needs to be constantly moved, so that the operation is more troublesome, and in the process of drilling, not only debris is flying, but also the manual cleaning is needed after the wood strip which completes drilling is taken down, so that time and labor are wasted can be solved.

Owner:安徽持家汉家居工艺品有限公司

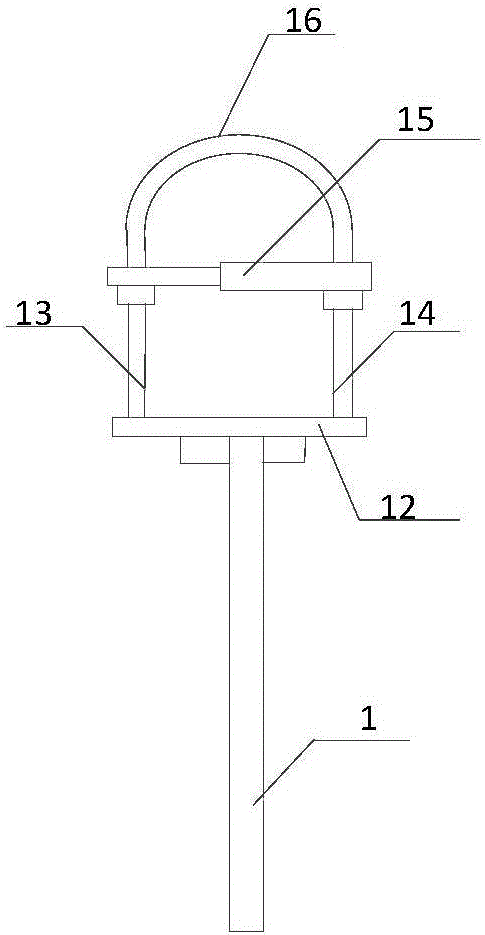

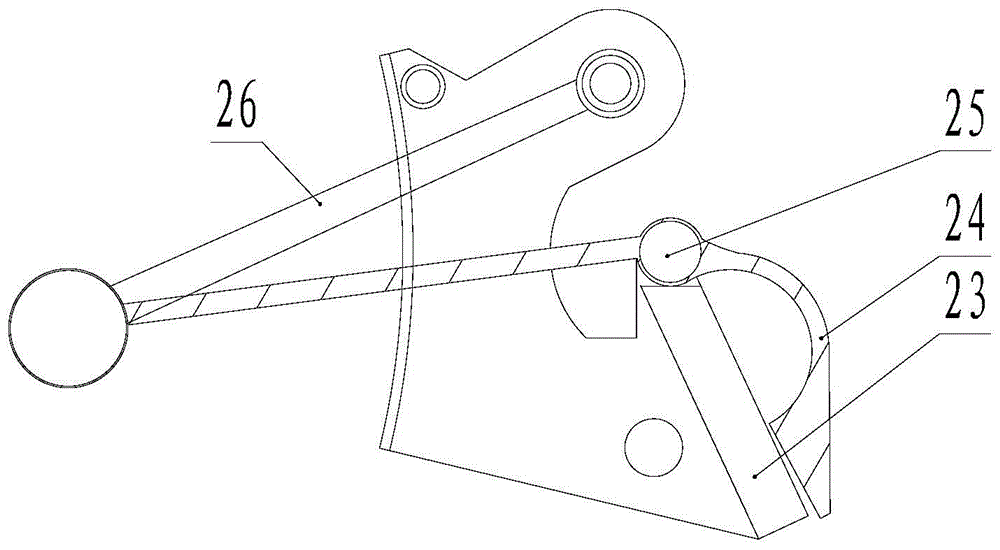

Perforating device for raw bamboo

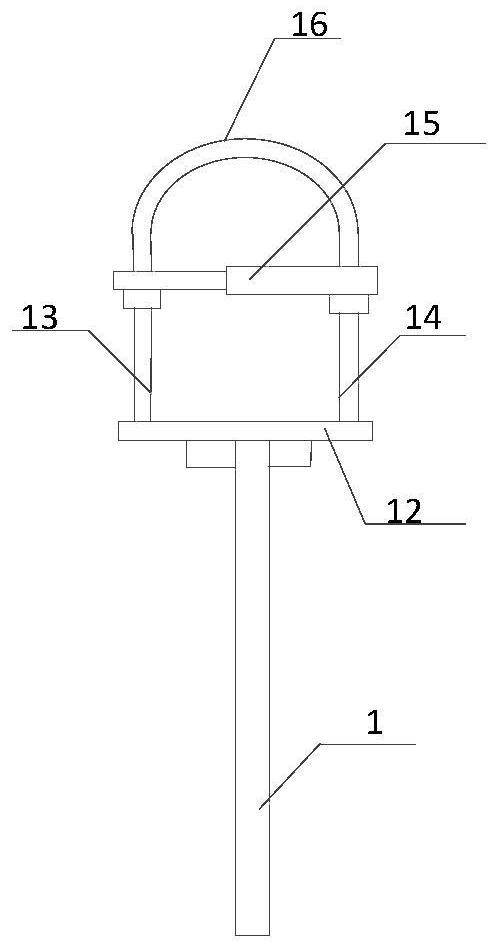

ActiveCN106738133AAvoid the phenomenon of drill bit slippingAvoid the phenomenon that the drill bit slips, and at the same time ensure that the drilling position remains unchangedDrilling machinesCane mechanical workingEngineeringDrill bit

The invention discloses a perforating device for raw bamboo. The perforating device comprises a first connecting rod, a second connecting rod, a third connecting rod, a first clamp, a second clamp, a third clamp, a perforating machine and a first fixing plate; each of the first clamp, the second clamp and the third clamp comprises a connector, a fourth connecting rod, a fifth connecting rod, a second fixing plate and a limiting plate. The device can effectively prevent a drill bit from sliding off, and the perforated holes are accurate in position.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

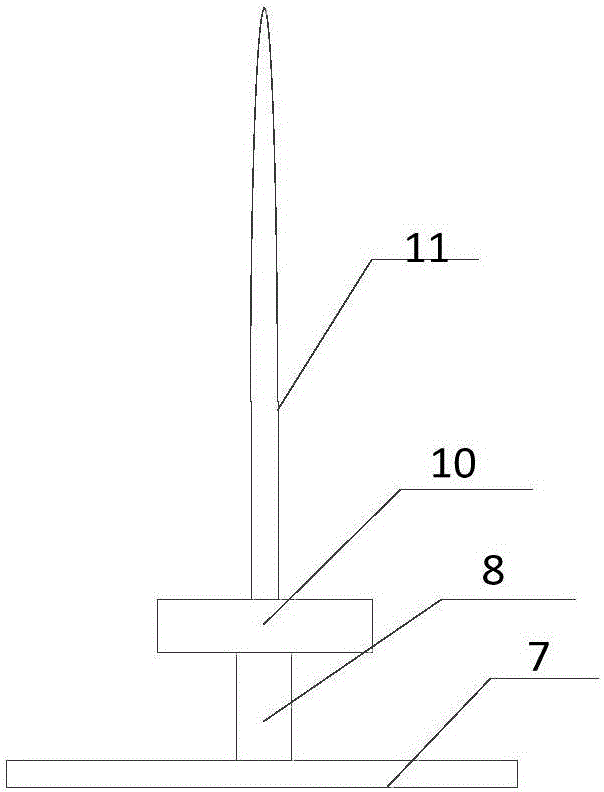

Hydraulic lifting-type pipe perforator

InactiveCN105798353AHole punchingSimple structureFeeding apparatusBoring/drilling componentsEngineeringDistance sensors

The invention discloses a hydraulic lifting-type pipe perforator, belonging to the technical field of pipe perforators. The hydraulic lifting-type pipe perforator comprises a machine body and a machining part and a clamping part located on the machine body, and is characterized in that supporting guide posts are connected between the machining part and the clamping part; a supporting plate is fixedly connected with the clamping part; a sliding device is arranged among the supporting plate and the supporting guide posts; a lifting device which is used for driving the supporting plate to slide is fixedly connected onto the lower part of the supporting plate; the lifting device is connected with a controller; the controller is provided with a distance sensor; and the distance sensor is located on one side, close to the machining part, of the supporting plate. By adopting the hydraulic lifting-type pipe perforator, the problems of a current pipe perforator that the perforation efficiency is low; a perforation drill bit structure is relatively complexed; and whether a drill bit drills through a hole in a pipe cannot be controlled are solved.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

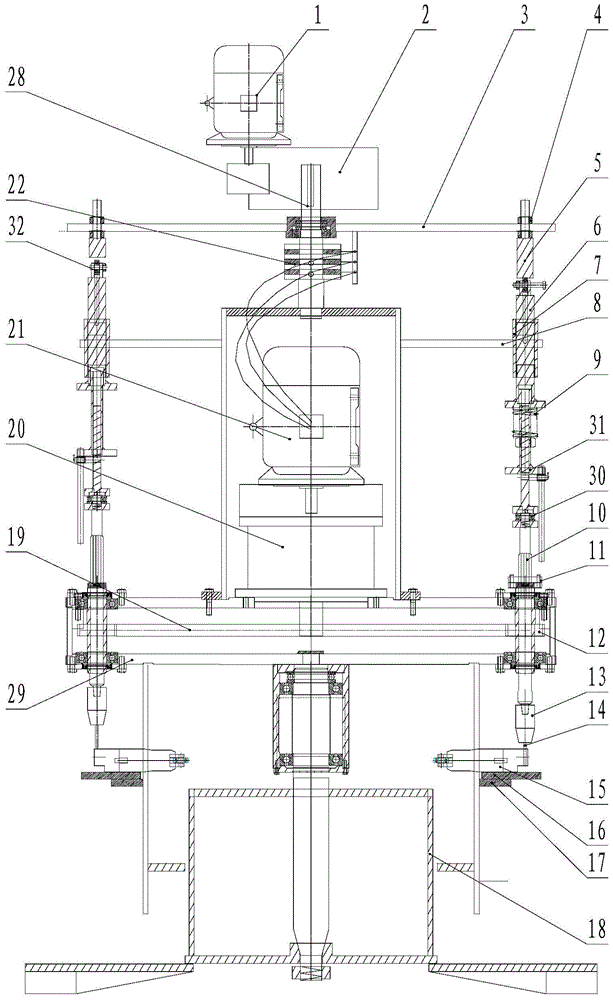

Fully-automatic perforating machine

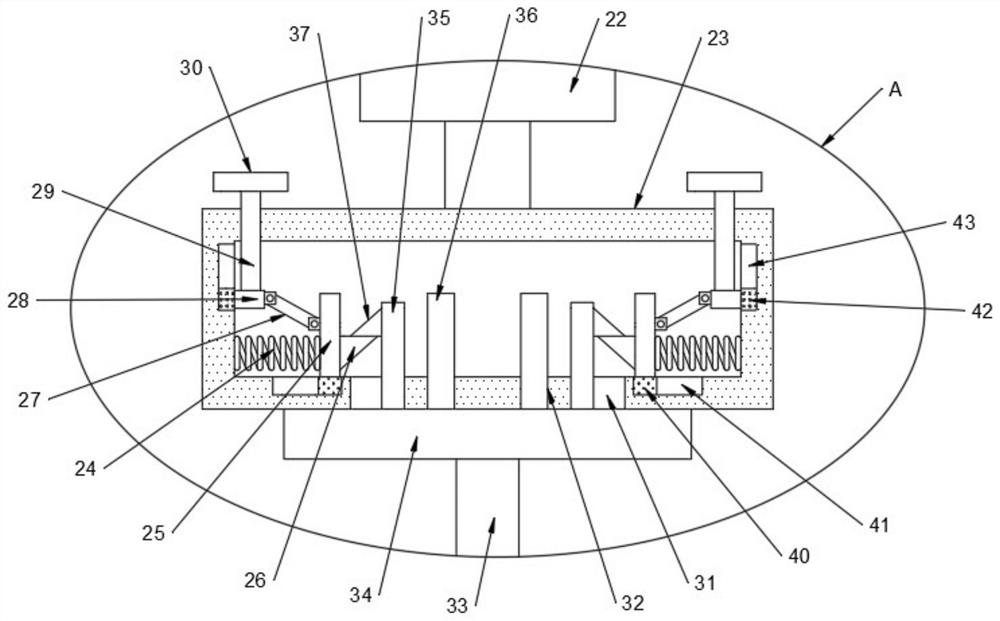

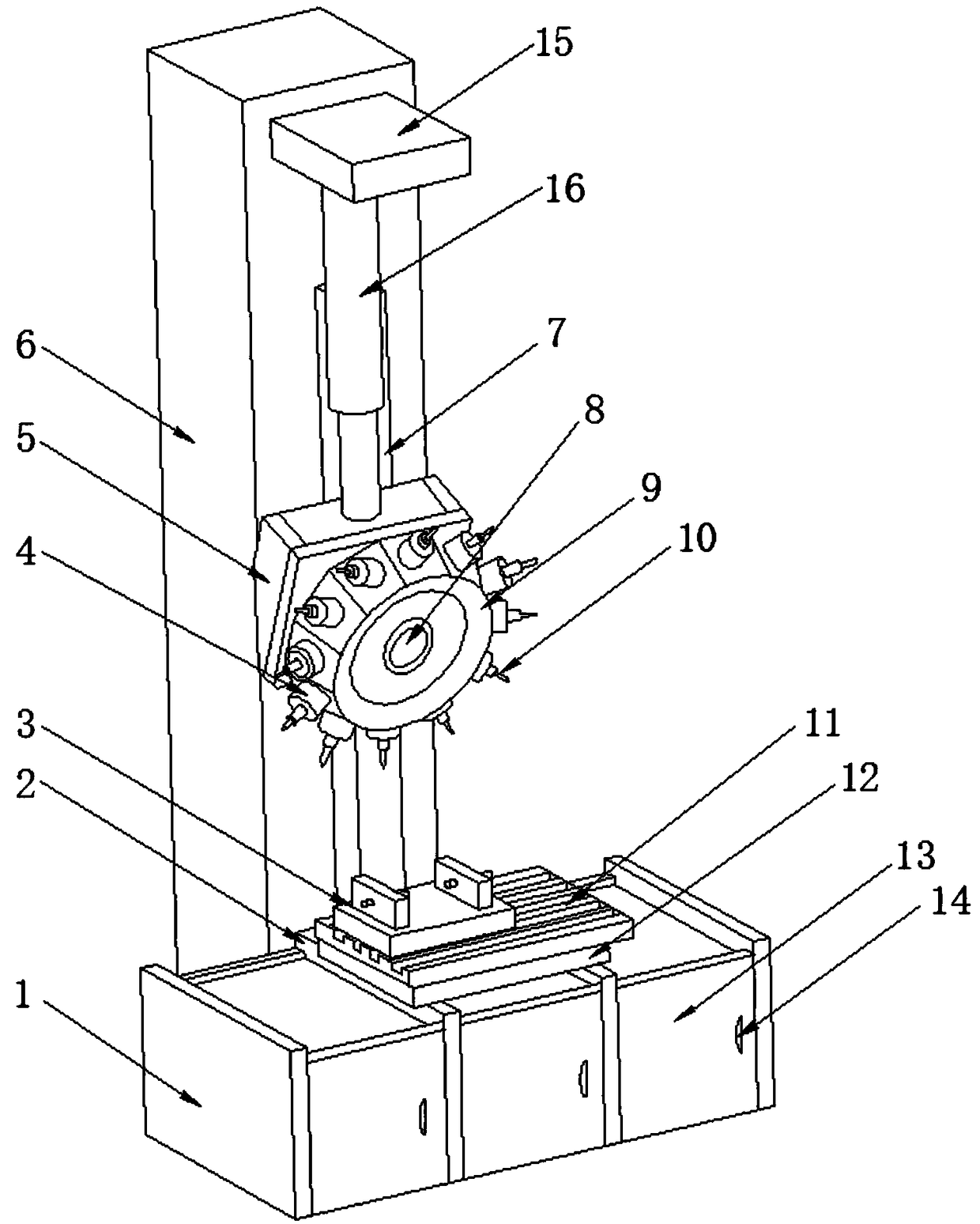

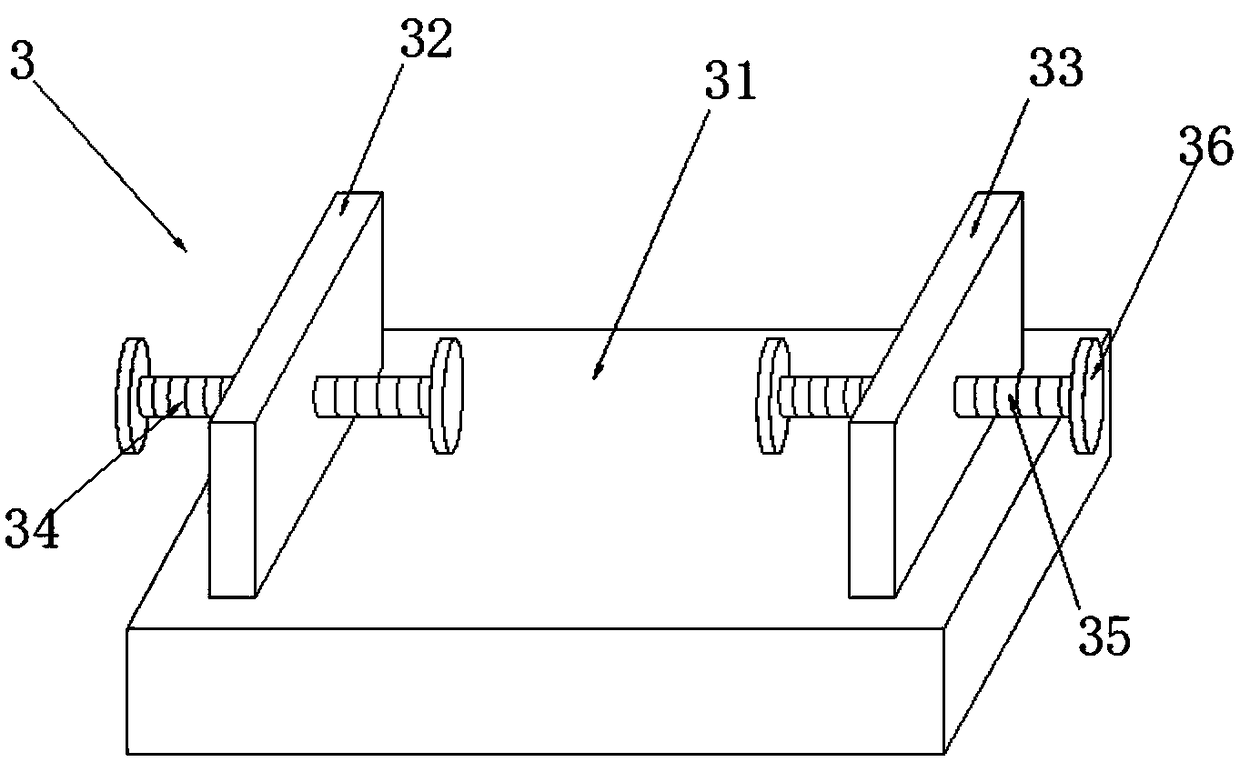

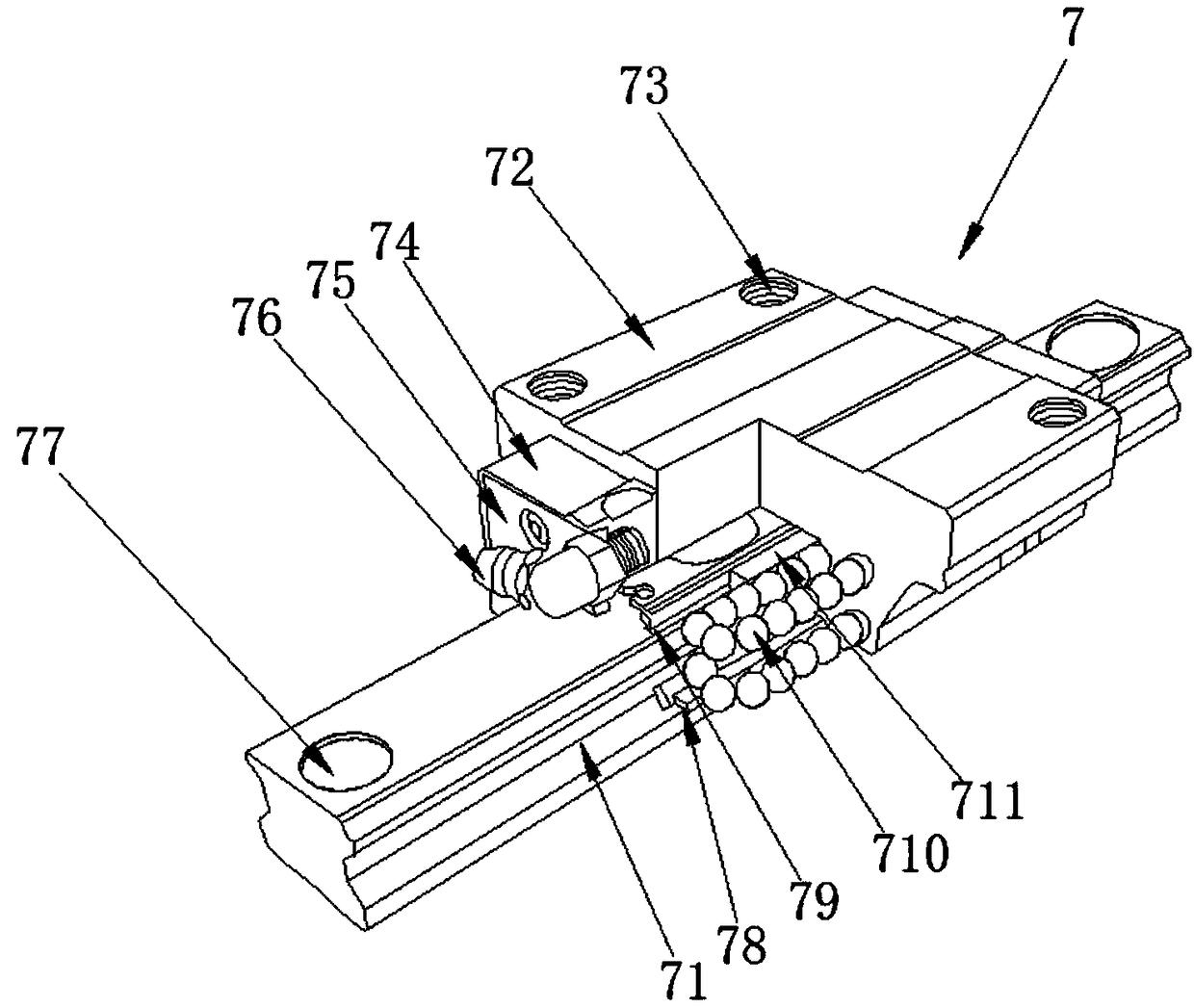

InactiveCN108176868AEasy to installImprove work efficiencyFeeding apparatusLarge fixed membersCushionDrill bit

The invention discloses a fully-automatic perforating machine. The fully-automatic perforating machine comprises a support table, transverse supports, a clamping mechanism, a support plate, a first limiting block, a second limiting block, a first adjustment stud, a second adjustment stud, round blocks, electric motors, a support block, a support pillar, an elevating device, a linear guide rail, aslide block body, first threaded fixing holes, end covers, end face sealing pieces, grease nipples, second threaded fixing holes, lower sealing pieces, upper sealing pieces, steel balls, retainers, arotating shaft, a rotating disc, drill bits, a grooved carrying table, a rubber buffer cushion plate, containing cabinets, pull handles, a support seat, an electric push rod, a stepping motor and a connecting flange. By means of the fully-automatic perforating machine, the different drill bits can be conveniently and rapidly adjusted and used for machining objects as needed; the fully-automatic perforating machine is good in stability, high in work efficiency and convenient and fast to use and operate; and the objects can be fixed and mounted conveniently and rapidly.

Owner:周月灿

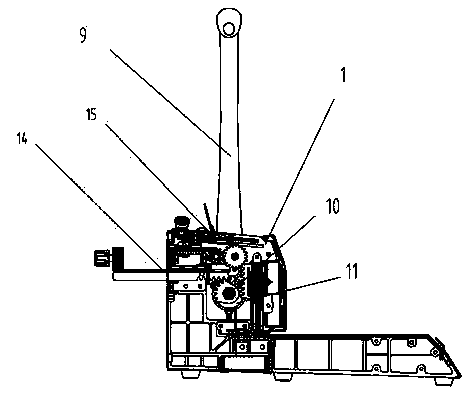

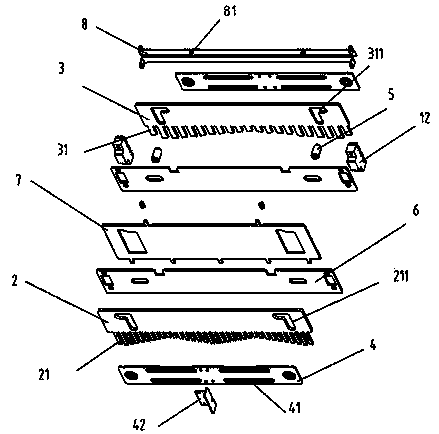

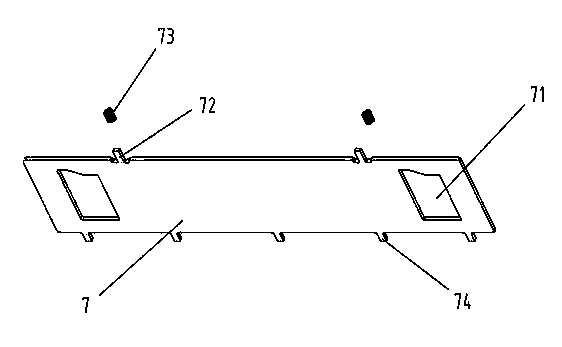

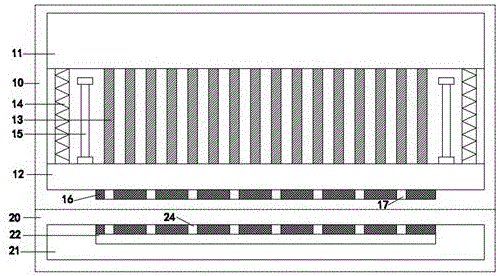

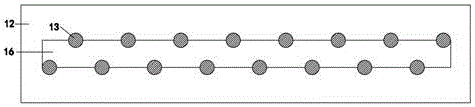

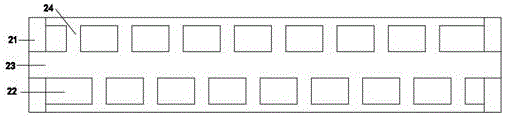

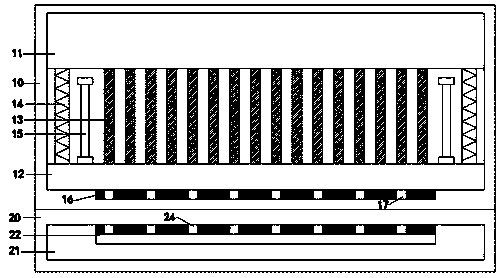

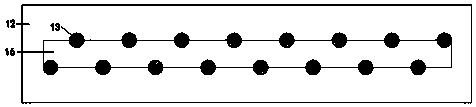

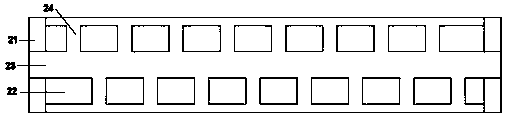

Double-blade punching bookbinding machine

The invention relates to a double-blade punching bookbinding machine. The double-blade punching bookbinding machine comprises a machine frame, a punching structure, a transmission mechanism and a bookbinding mechanism, wherein the punching structure, the transmission mechanism and the bookbinding mechanism are arranged on the machine frame; the punching structure comprises a punching blade group, the punching group comprises a first punching part provided with a plurality of first punching blades and a second punching part provided with a plurality of second punching blades, and a switching mechanism is arranged between the first punching part and the second punching part; the bookbinding mechanism comprises an iron ring bookbinding mechanism and a rubber ring bookbinding mechanism. The double-blade punching bookbinding machine comprises the two punching parts provided with different punching blades, and the switching device is arranged between the two punching parts to achieve free switching, and punching can be achieved separately. Besides, the double-blade punching bookbinding machine is provided with two different bookbinding mechanisms to meet bookbinding requirements of different hole types, and the dualization of the punching and the bookbinding can both be achieved.

Owner:ZHEJIANG ZHIYUAN OFFICE EQUIP MFG

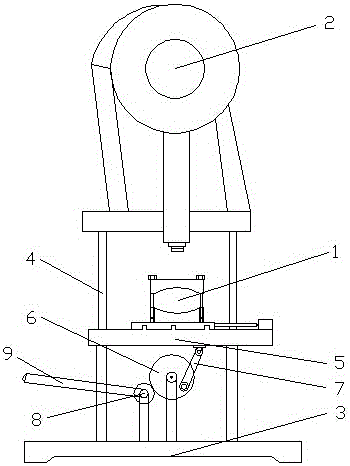

Pipe punching machine with lifting device

The invention discloses a pipe punching machine with a lifting device, which belongs to the technical field of pipe punching machines, and includes a machine body, a processing part and a clamping part located on the machine body, and is characterized in that the processing part and the clamping part There is a support guide column connected between them; the clamping part is fixedly connected with a support plate, and the support plate and the support guide column are slidably arranged; the lower part of the support plate is fixedly connected with a lifting device that drives it to slide, which solves the problem of existing pipes. The drilling efficiency of the punching machine is low, and the drilling mechanism of the drilling is relatively complicated.

Owner:CHENGDU MATSUKAWA METAL MATERIALS

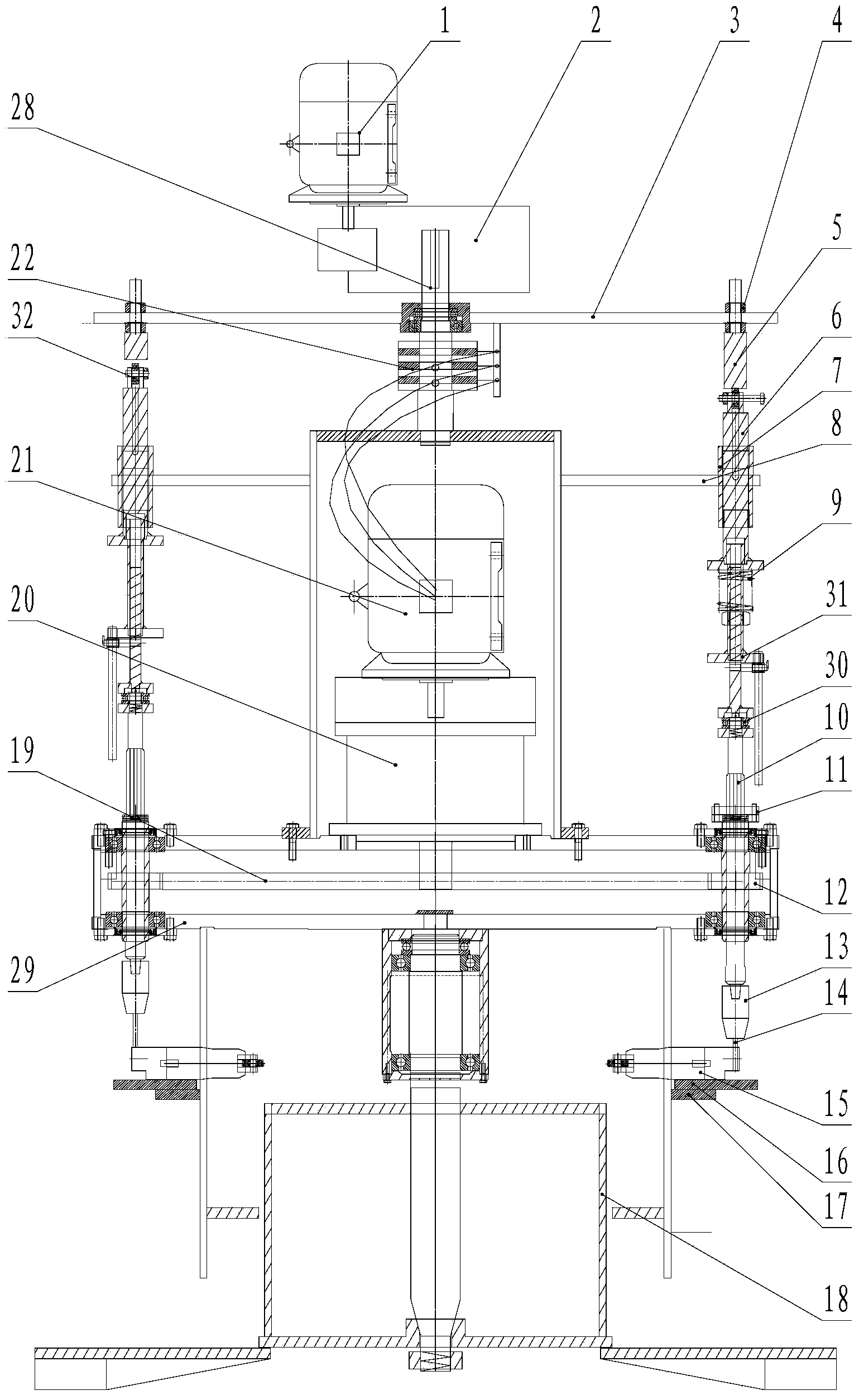

Machining mechanism for rail transit

PendingCN114131357AReduce manual operationsImprove drilling efficiencyLarge fixed membersMaintainance and safety accessoriesElectric machineryProcess engineering

The invention relates to a machining mechanism for rail transit, which comprises a machine table, a self-walking mechanism is arranged on one side of the bottom of the machine table, the self-walking mechanism comprises a suspension, a driving roller is rotatably mounted at the bottom of the suspension through a bearing, and the driving roller is driven by a motor and is in contact with the upper surface of a rail; a drilling mechanism is arranged at the bottom of the machine table and used for drilling holes in a bottom panel of the track. The problems that drilling machines in the market generally need to be manually operated to drill holes in steel rails, the number of operators is large, and operation is inconvenient are solved, the self-walking mechanism and the drilling mechanism are arranged on the track, and therefore the drilling machine can be directly installed on the track and automatically walks to the preset position to conduct positioning and drilling, and the drilling efficiency is improved. The effect of reducing manual operation is achieved, the punching efficiency is high, the precision is high, and the actual application value of the machining mechanism for rail transit is improved.

Owner:东莞市翰娅汽车配件有限公司

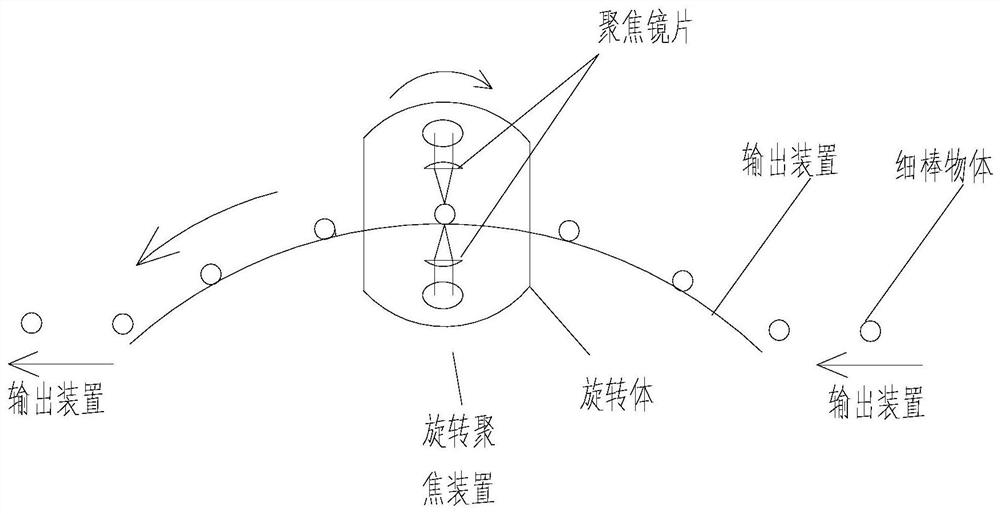

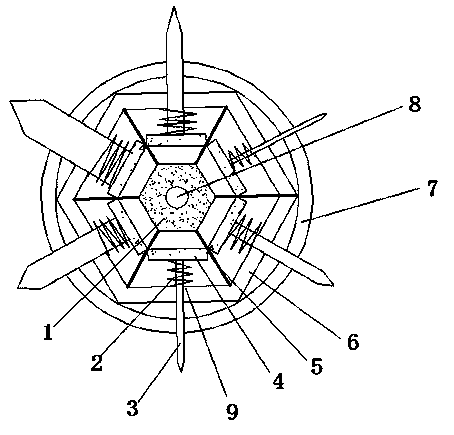

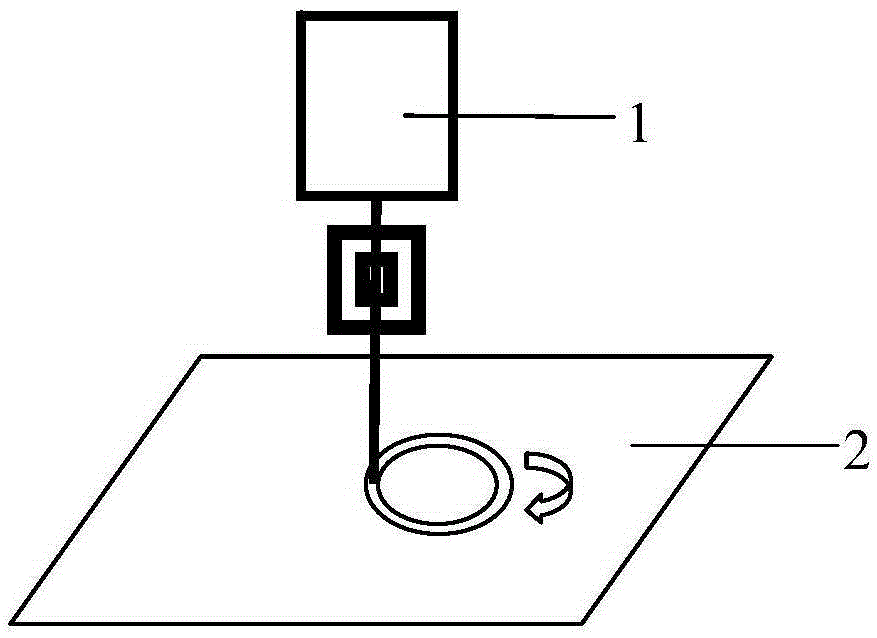

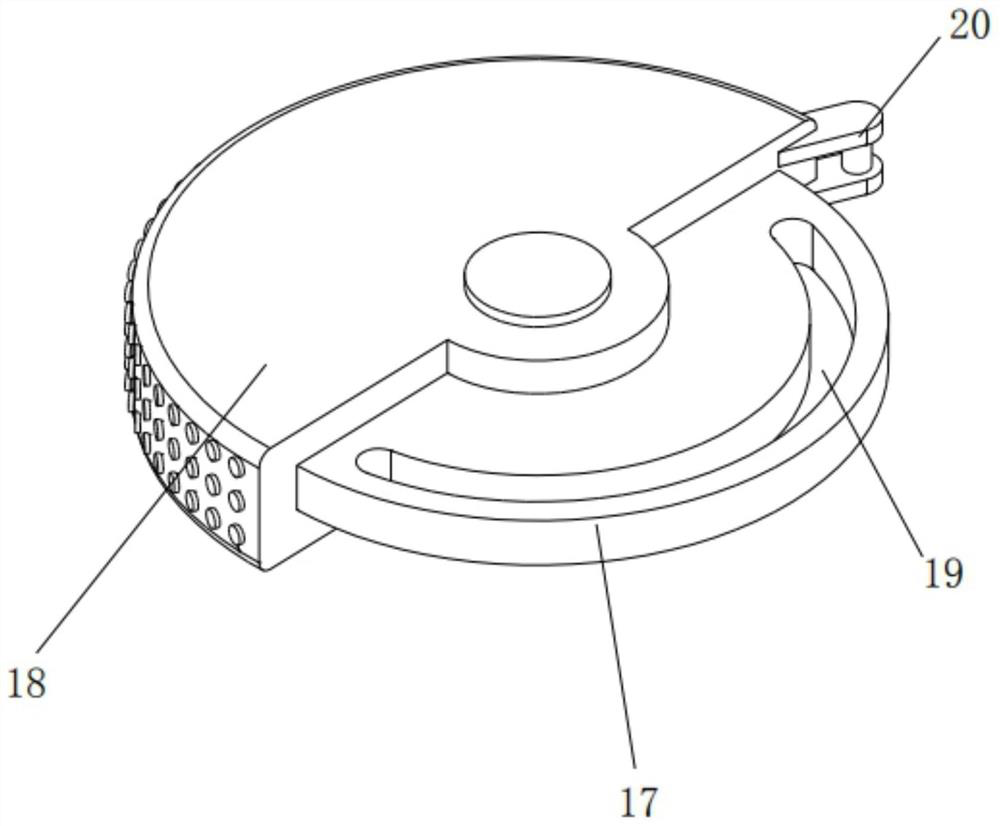

Rotary focusing device for laser drilling of thin-rod object

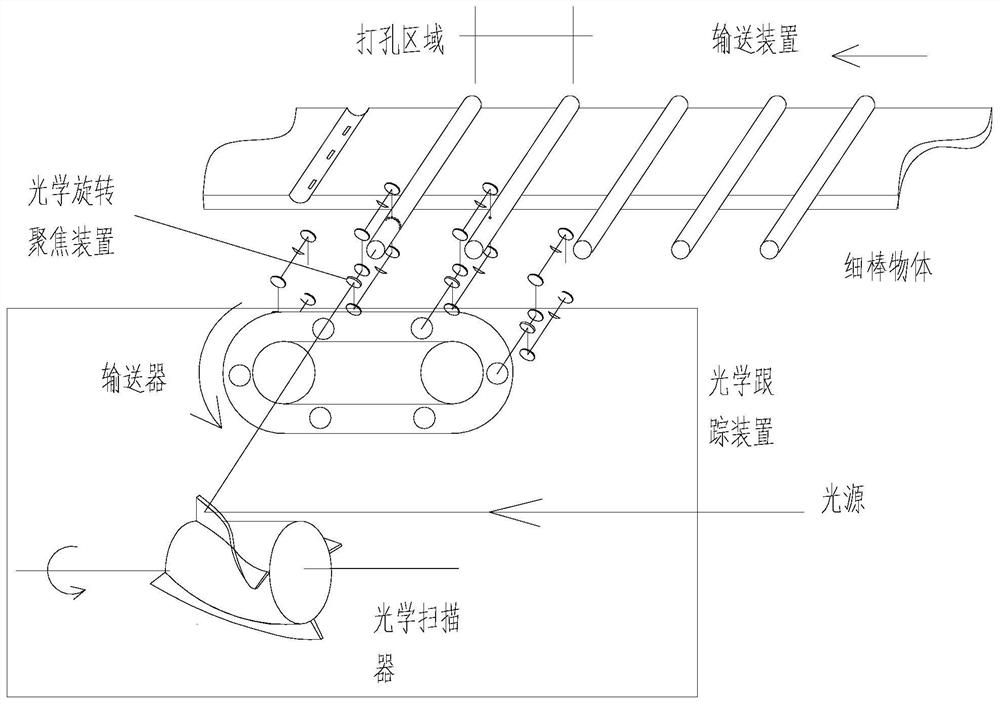

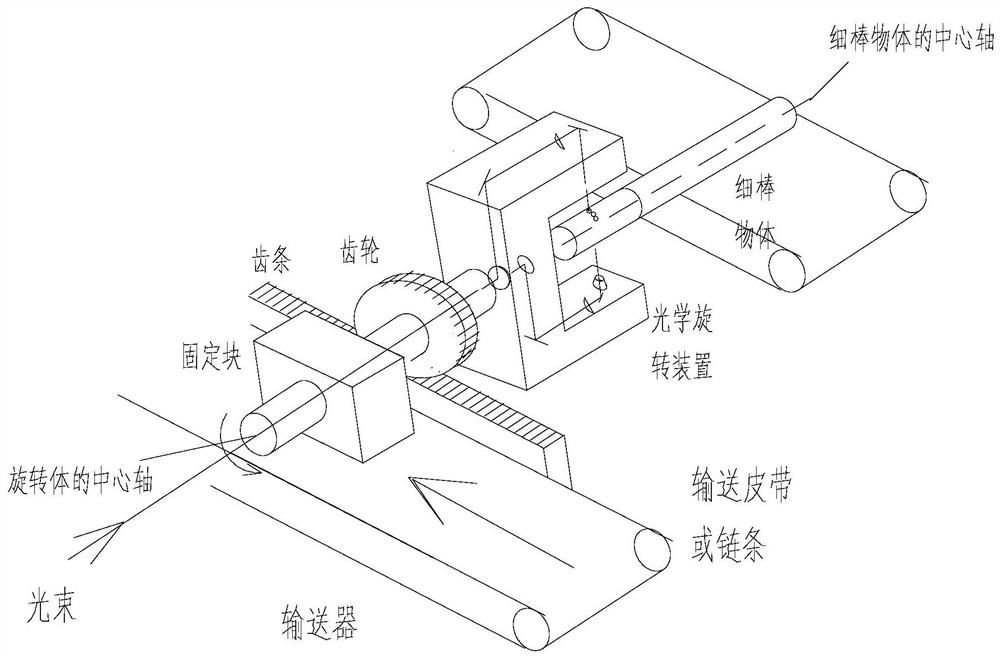

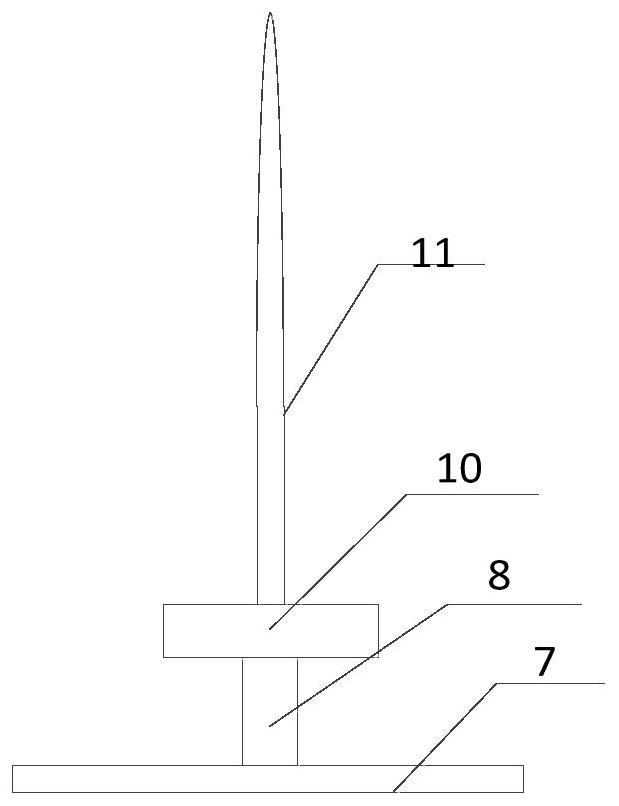

PendingCN111671142AHole punchingReduce rotation speedCigarette manufactureLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses a rotary focusing device for laser drilling of a thin rod object. The rotary focusing device is arranged on one side of a cigarette conveying device, is used for drilling cigarettes and mainly comprises an optical rotary focusing device, and the optical rotary focusing device rotates around a single cigarette at a high speed and emits laser to the surface of the cigarettes;a traditional perforating thought is changed through the design, and multiple cigarettes can be drilled at the same time under the condition that the cigarettes are not moved.

Owner:梅林 +1

Multi-aperture perforating device for automobile parts

The invention relates to the field of machining of automobile parts, and provides a multi-aperture perforating device for automobile parts. The multi-aperture perforating device for automobile parts comprises a device outer wall, a fixed bottom plate, supporting beams, springs, a permanent magnet, perforators, electromagnets and a transmission shaft, wherein the permanent magnet is annularly mounted on the transmission shaft and is in riveted connection with the supporting beams; one end of each supporting beam is connected to the permanent magnet while the other end of each supporting beam isin riveted connection to the fixed bottom plate; the outer wall is mounted on the outside of the fixed bottom plate; a hole is formed in the middle of each side of the fixed plate; each perforator penetrates through the corresponding hole; each electromagnet is mounted on the top of the corresponding perforator; and each spring is arranged between the corresponding electromagnet and the fixed bottom plate. The perforators with different apertures are mounted on the device, when different perforating apertures are required, the device is adjusted, and thus, perforation of holes with differentapertures can be implemented.

Owner:成都劲升精密机械制造有限公司

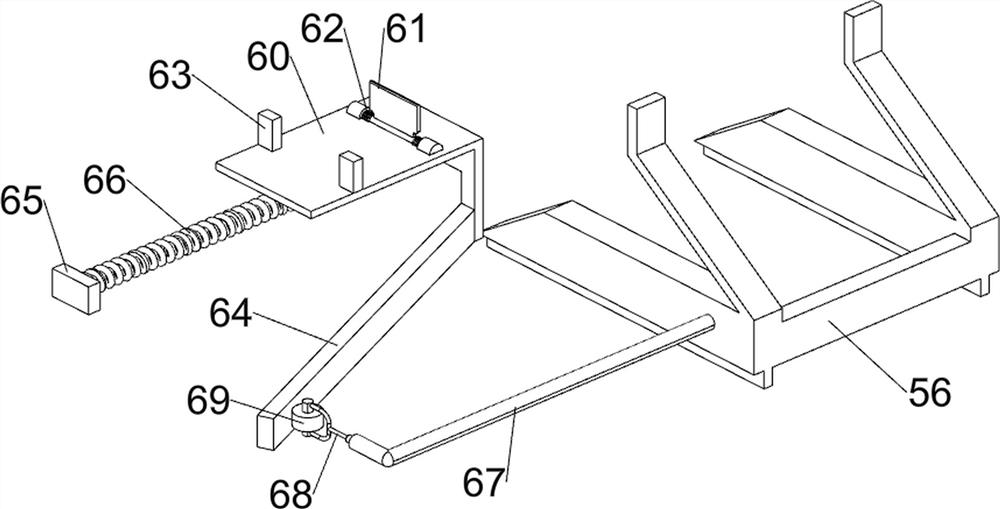

Plastic protecting film perforating machine provided with perforation calibration auxiliary device

ActiveCN111331672AImprove drilling efficiencySolve the problem of inconvenient replacement of workpiecesMetal working apparatusWebs handlingEngineeringPellicle membrane

The invention belongs to the technical field of plastic protecting film perforating machines, and in particular relates to a plastic protecting film perforating machine provided with a perforation calibration auxiliary device. The plastic protecting film perforating machine comprises a bottom plate and a film rolling barrel. A supporting rack is fixed to the upper end of the bottom plate, the inner side of a rolling rod is connected to a protecting film body, the film rolling barrel is mounted on the inner side of the protecting film body, a positioning groove is formed in the outer side of arotating rod, a rotary drum is mounted on the right side of the supporting rack, an air cylinder is mounted at the upper end of the supporting rack, the lower end of a working rod is connected to a positioning plate, and a rod groove is formed in the middle of the bottom plate. According to the plastic protecting film perforating machine provided with the perforation calibration auxiliary device,a structure with a rolling locking function is designed, so that the problem that a conventional device is low in perforating efficiency is solved. A structure with an extruding locking function is designed, so that the problem that it is inconvenient to replace a processed part in the conventional device is solved. Meanwhile, a structure with a sliding function is designed, so that the problem that it is inconvenient to adjust the perforating position in the conventional device is solved.

Owner:苏州名顺包装材料有限公司

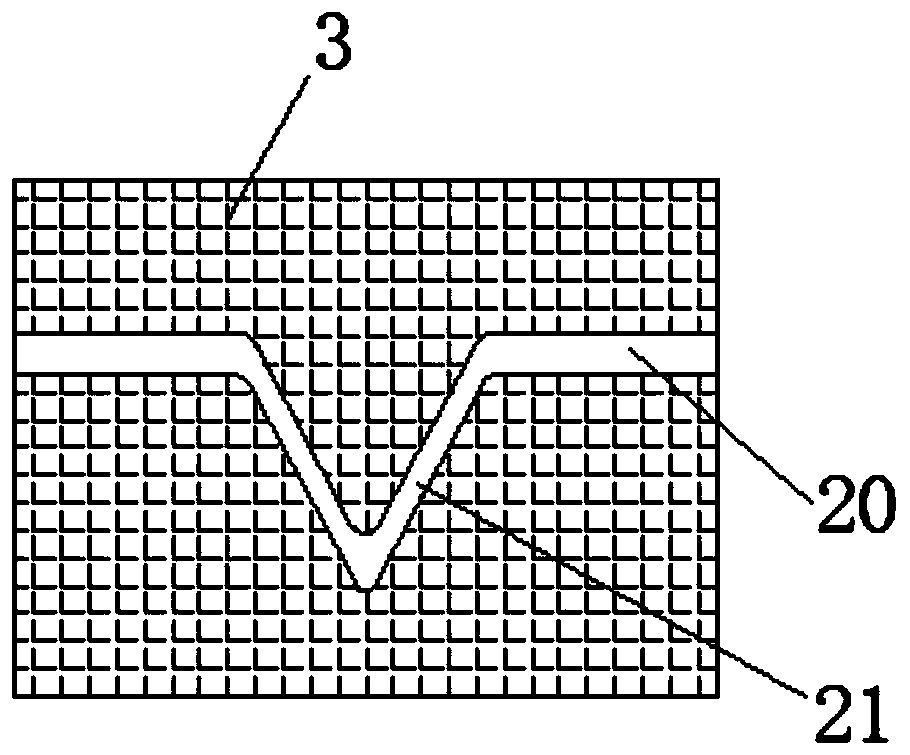

Elastic drainage pipeline punching die

The invention discloses an elastic drainage pipeline punching die. The elastic drainage pipeline punching die comprises an upper die body and a lower die body. The upper die body comprises an ejector block, a base and a plurality of tools. The ejector block and the base are connected through a plurality of bolts. One end of each tool is fixed to the ejector block, and the other end of each tool penetrates the base. The base is provided with pressing protrusions, and the pressing protrusions are arranged on the lower surface of the base. The lower die body comprises a base and a gasket, the gasket is arranged on the base, and the upper die body is arranged over the lower die body. The punching die is provided with the pressing protrusions, and therefore an elastic drainage pipeline can be flattened, and punching is facilitated; the silica gel or rubber gasket is arranged, tenacity is good, and meanwhile the drainage pipeline is prevented from being damaged; the tools are arranged and can rapidly cut off the drainage pipeline, and punching is achieved; the die is simple in structure, convenient to operate and exquisite in detail design; and the punching precision is high.

Owner:JIANGSU YUANCHUANG MEDICAL TECH

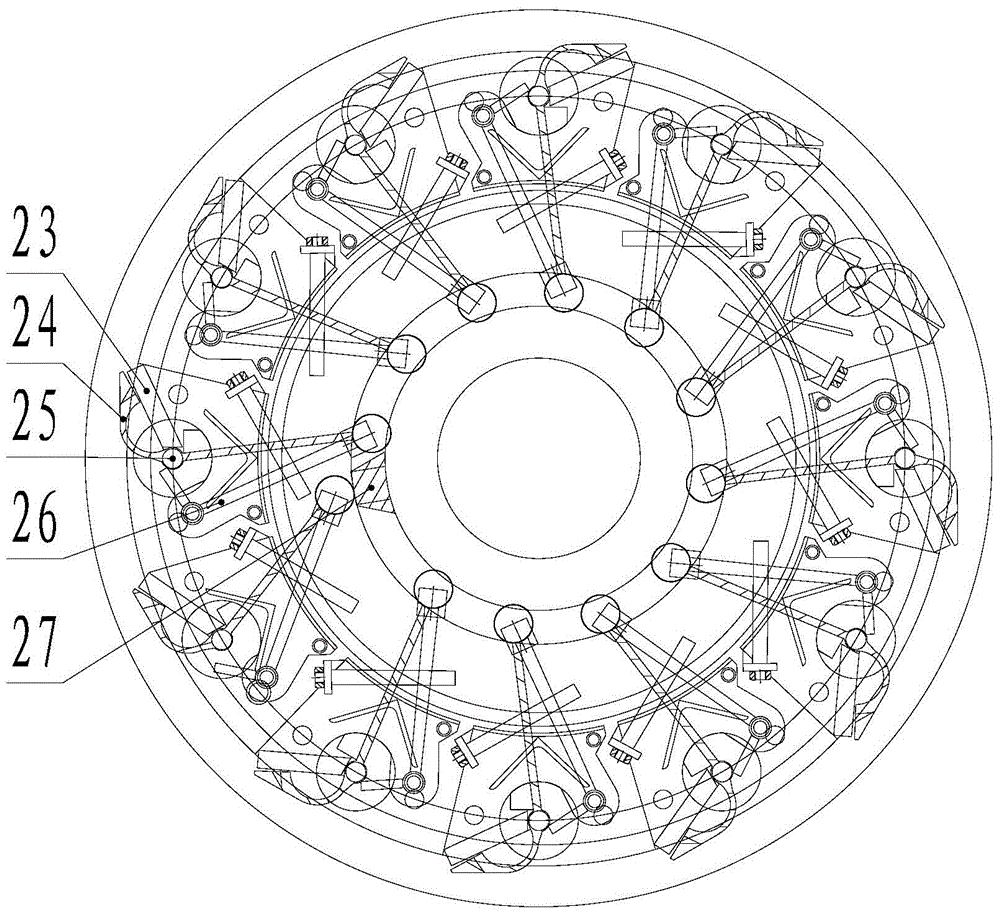

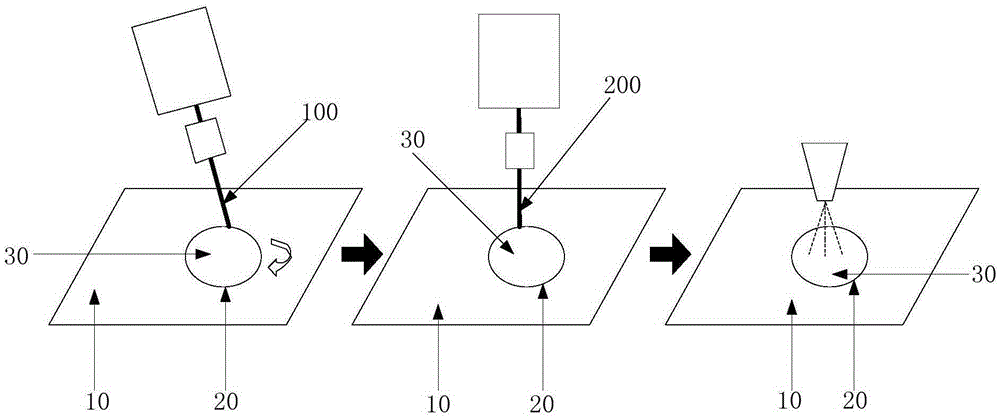

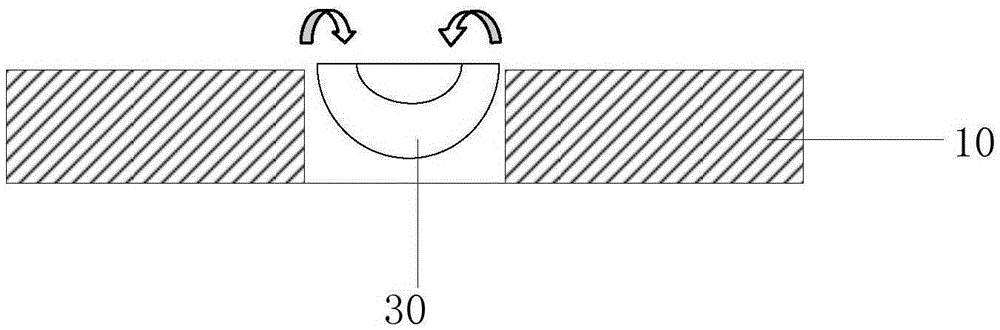

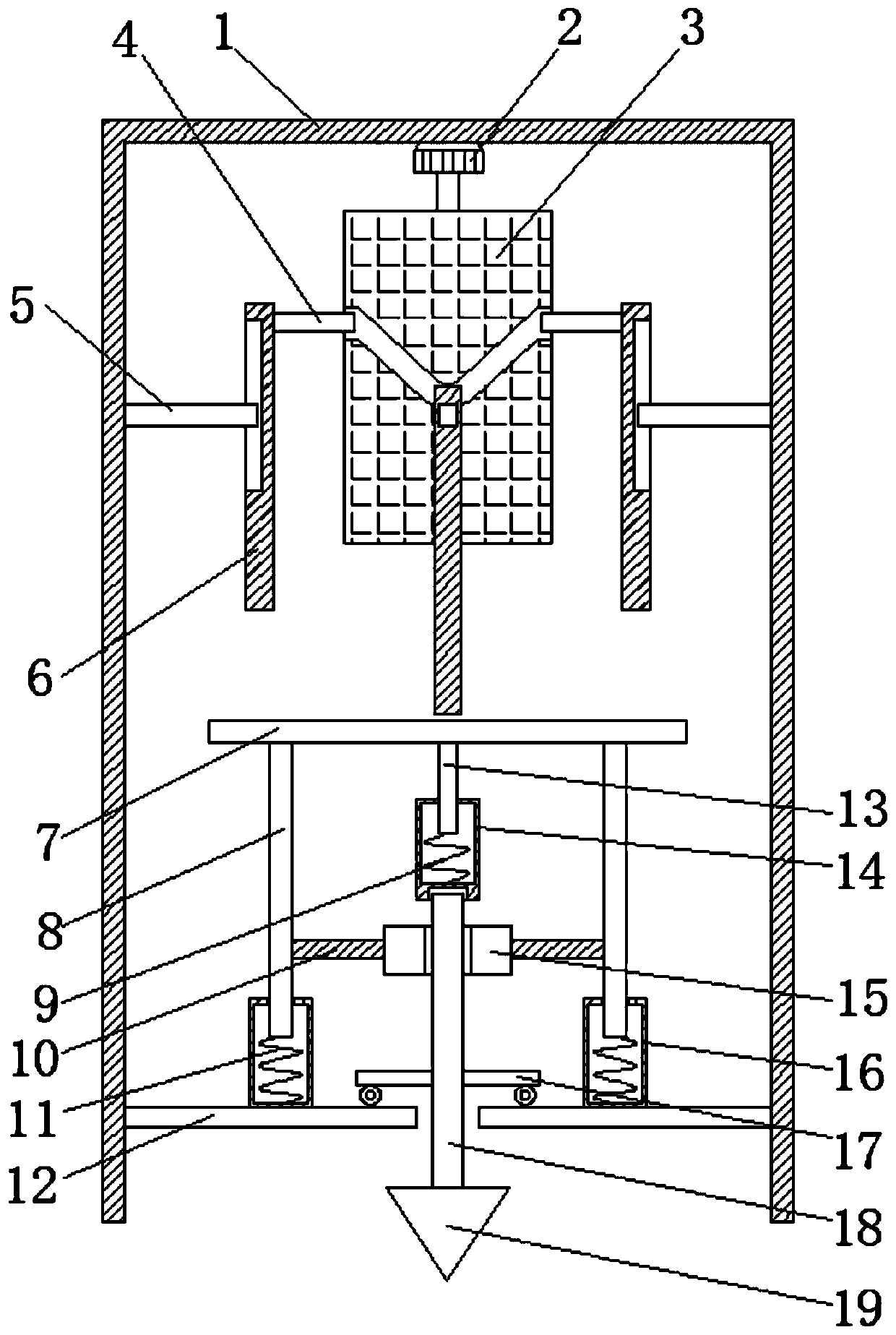

Fully automatic punching method

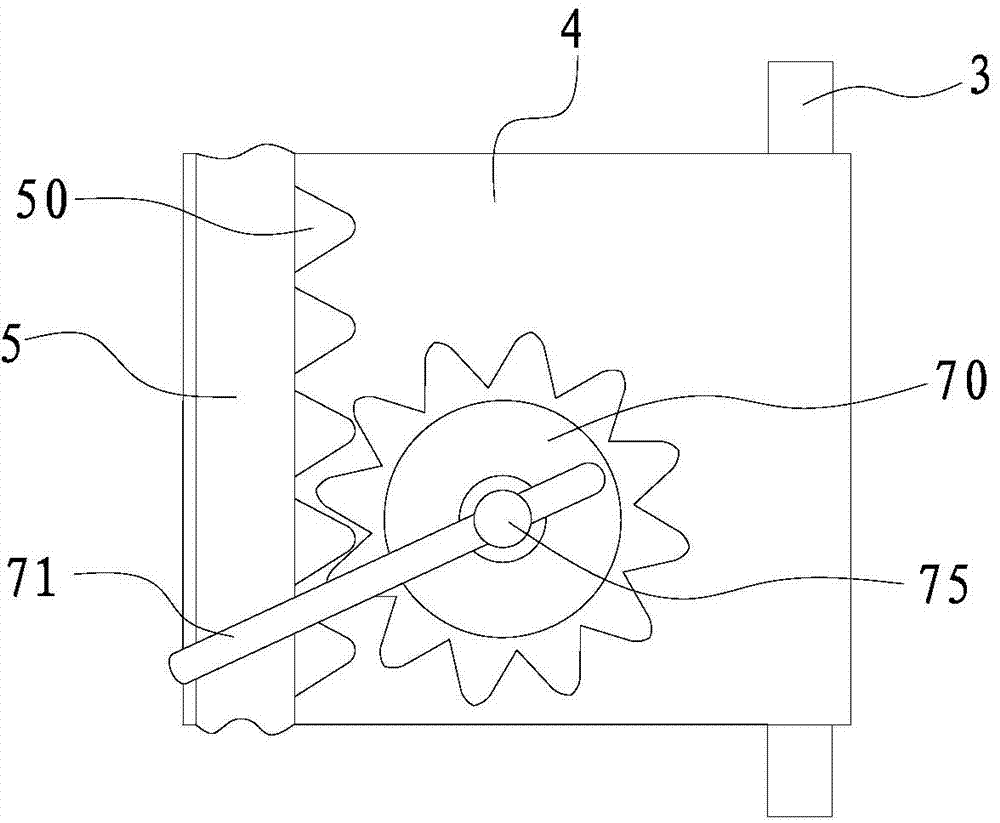

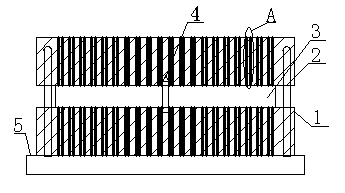

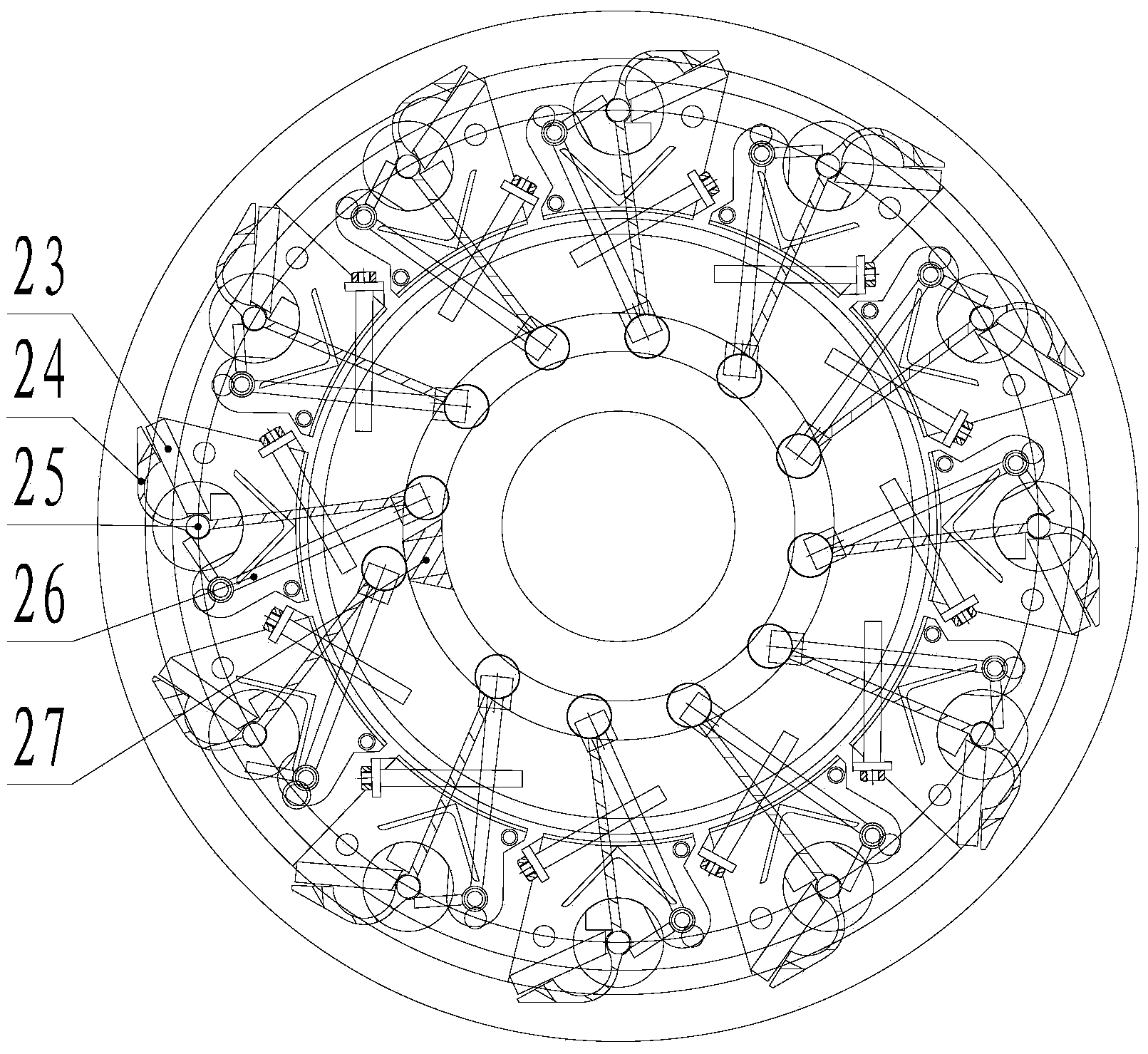

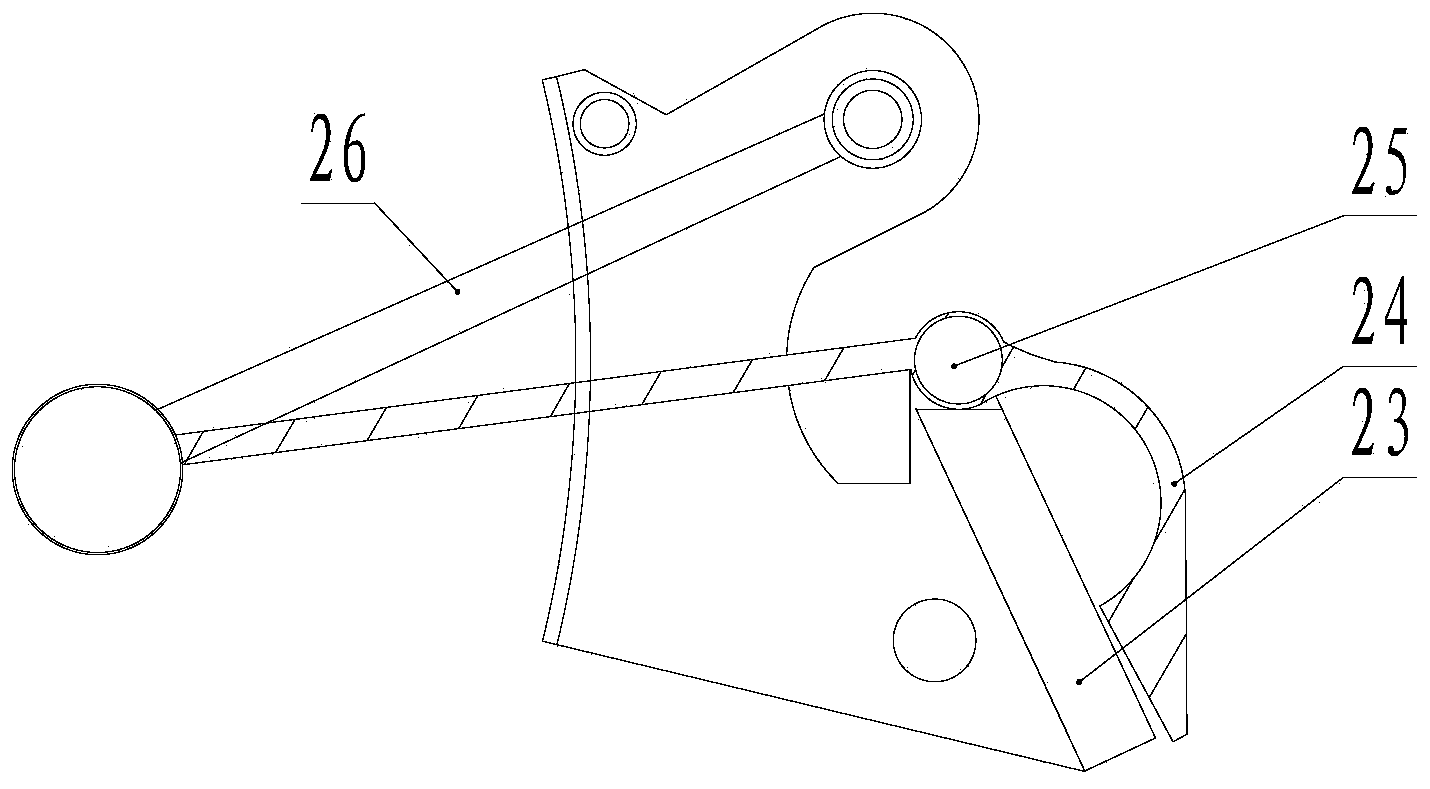

ActiveCN104014840BHole punchingImprove work efficiencyFeeding apparatusDriving apparatusGear wheelEngineering

The invention relates to the field of machining, in particular to a full-automatic hole punching method. According to the method, a drill bit is driven to carry out rotation and revolution through a planetary gear on a planetary gear set, and rotating force is provided for the drill bit. By arranging a spiral guiding track, pressure in a workpiece direction is exerted on the drill bit, and accordingly hole punching on a workpiece is achieved. According to the full-automatic hole punching method, the planetary gear set is used for achieving simultaneous rotation and revolution of a plurality of drill bits, the spiral guiding track is arranged, during revolution, down-pressing force is exerted on the drill bits, and then hole punching on the workpiece is achieved. According to a full-automatic hole punching machine, a plurality of holes can be punched at the same time, or hole punching is carried out on a plurality of workpieces at the same time, and working efficiency is greatly improved.

Owner:董静

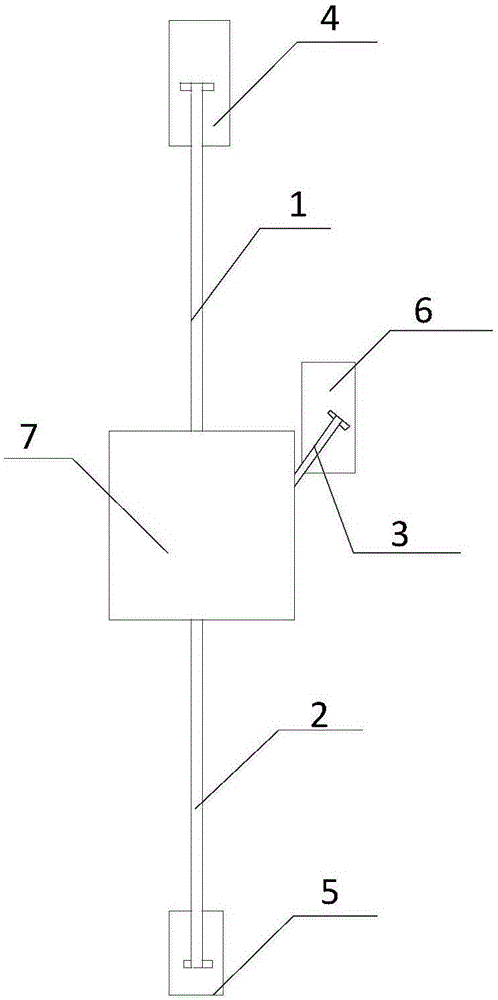

Manual punching method

The invention discloses a manual punching method. A punch adopted by the punching method comprises a bottom die, a positioning post, a positioning module, a mandril, a punch pin and an adjusting mechanism, the bottom die is arranged on a working platform, the positioning post is vertically arranged on the working platform, the positioning module is sleeved on the positioning post and located over the bottom die, the mandril is parallel with the positioning post and is arranged on the positioning module, the punch pin is arranged on the lower end of the mandril, the adjusting mechanism is used for adjusting the mandril to move up and down along the length direction of the mandril, the bottom die is provided with a positioning trough for containing a part to be machined, the punch pin is located over the positioning trough, and moreover, the bottom of the positioning trough is provided with a hole matched with the punch pin. The punching method utilizes the adjusting mechanism to control the mandril to move up and down along the length direction of the mandril, so that the punch pin can pass through the hole of the positioning trough on the bottom die to punch a workpiece, meanwhile, the structure adopted by the invention is simple, the manual punching method can be conveniently put into practice, and the cost is low.

Owner:ZHANGJIAGANG XIAFEI PLASTIC

Corrugated paper punching device

The invention discloses a corrugated paper punching device which is technically characterized by comprising a punching mechanism and a clamping mechanism, wherein a transmission rod on the punching mechanism is in threaded connection with a sliding part capable of driving a punching needle to slide, and punching of different positions of corrugated paper is achieved; the clamping mechanism comprises a longitudinal clamping assembly and a transverse clamping assembly, a limiting groove for guiding movement of the moving part is formed in a fixing frame on the longitudinal clamping assembly, the longitudinal clamping assembly comprises a sliding component and a clamping component, and a sliding rod in the sliding component penetrates through a spring for limiting the sliding rod; an adjusting rod in the clamping component is connected to a fixing plate through threads, a sliding block capable of driving the longitudinal clamping assembly to move is slidably connected to a rotating rod on the transverse clamping assembly, and through cooperation of the longitudinal clamping assembly and the transverse clamping assembly, corrugated paper of different specifications can be clamped, and meanwhile, the corrugated paper can also be pressed and fixed.

Owner:丰城市星泽科技有限公司

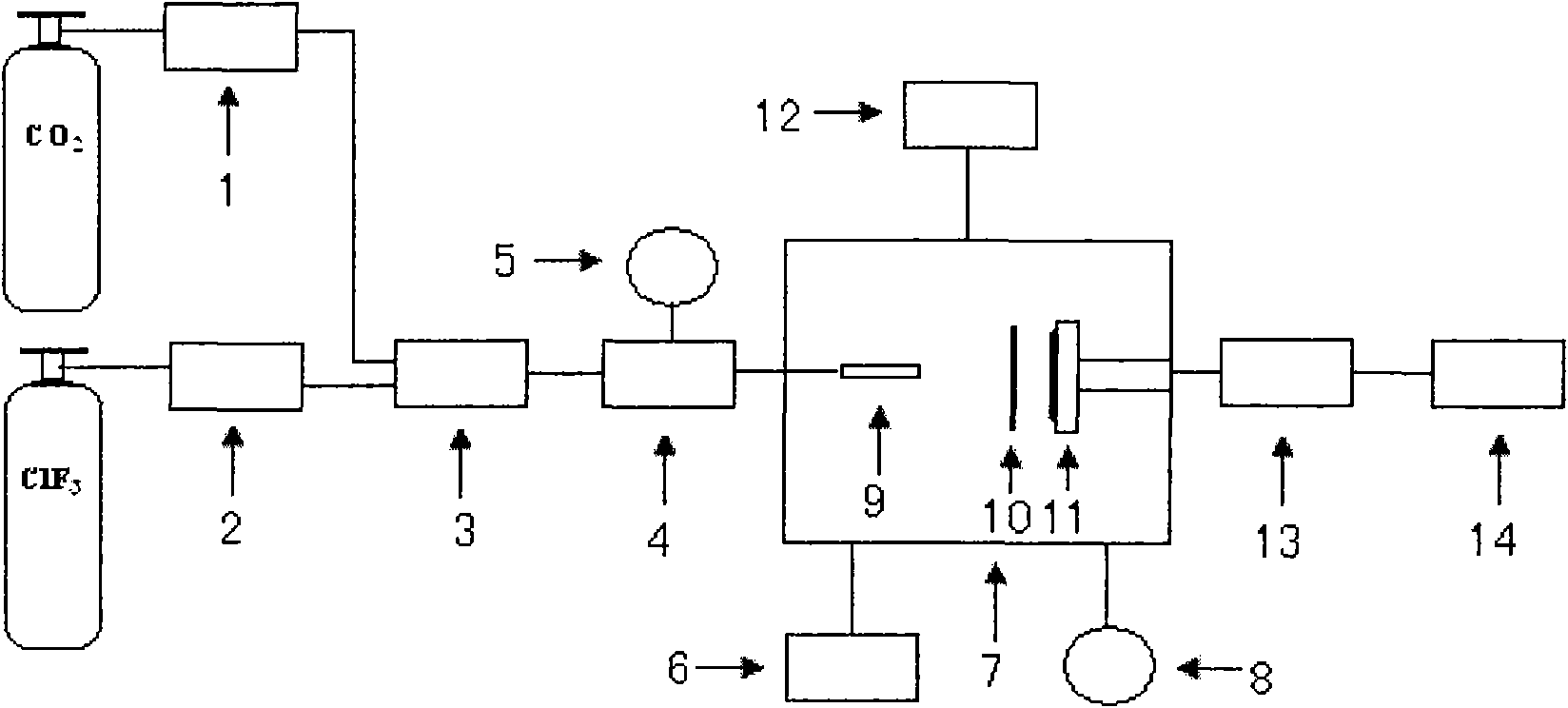

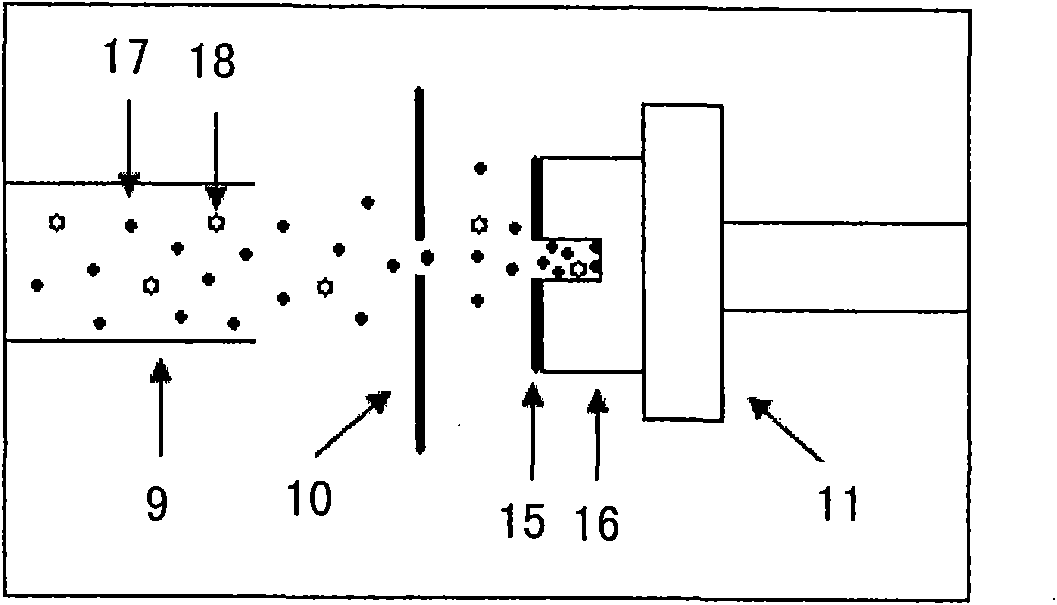

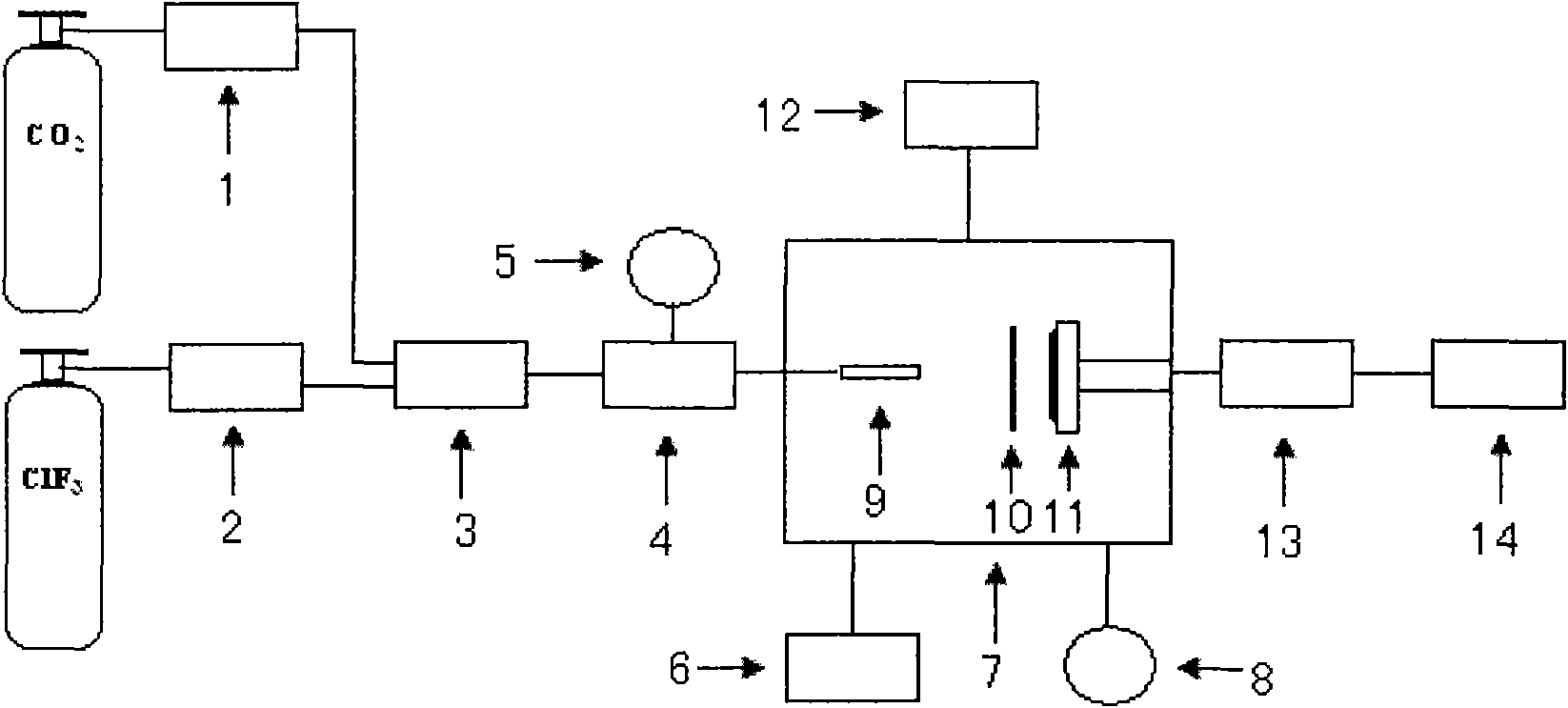

Hole punching device for carbon dioxide buffer silicon wafer

The invention relates to a hole punching device for a carbon dioxide buffer silicon wafer, which comprises a carbon dioxide flow controller, a chlorine triflouride flow controller, a mixer, a reducing valve, a pressure gage, a vacuum pump, a vacuum chamber, a vacuum chamber pressure gage, a sprayer, a masking plate, a silicon water bracket, a vacuum chamber temperature control device, a backward stage pump and a tail gas treating device. The reducing valve, the vacuum pump, the vacuum chamber pressure gage, the vacuum chamber temperature control device, and the backward stage pump are respectively connected with the vacuum chamber. Carbon dioxide gas enters the mixer through the carbon dioxide flow controller and chlorine triflouride gas enters the mixer through the chlorine triflouride flow controller. Carbon dioxide gas and chlorine triflouride gas are mixed in the mixer and the mixed gas enters the vacuum chamber through the reducing valve and the sprayer in sequence and is masked and adjusted by means of beam convergence by the masking plate to punch holes on the silicon wafer on the silicon wafer bracket. The invention has the advantages of simple device, rapid etching speed, good smoothness of the lateral wall and great selection ratio and realizes hole punching for the silicon wafer.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Laser drilling method and laser drilling system

ActiveCN103831539BGuaranteed qualityHole punchingGlass severing apparatusWelding/soldering/cutting articlesLight beamOptoelectronics

The present disclosure provides a laser drilling method and a laser drilling system. The laser drilling method includes a hole-boundary formation step of outputting a pulse laser beam and scanning a substrate to be drilled, to form a boundary cutting groove of a preformed hole; a material-in-hole heating step of outputting a CO2 laser beam, aligning the CO2 laser beam with the preformed hole, and heating a substrate material of the preformed hole for a predetermined period of time; and a hole formation step of cooling the substrate material of the preformed hole, to deform the substrate material and enable the substrate material to fall off from the substrate to be drilled.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

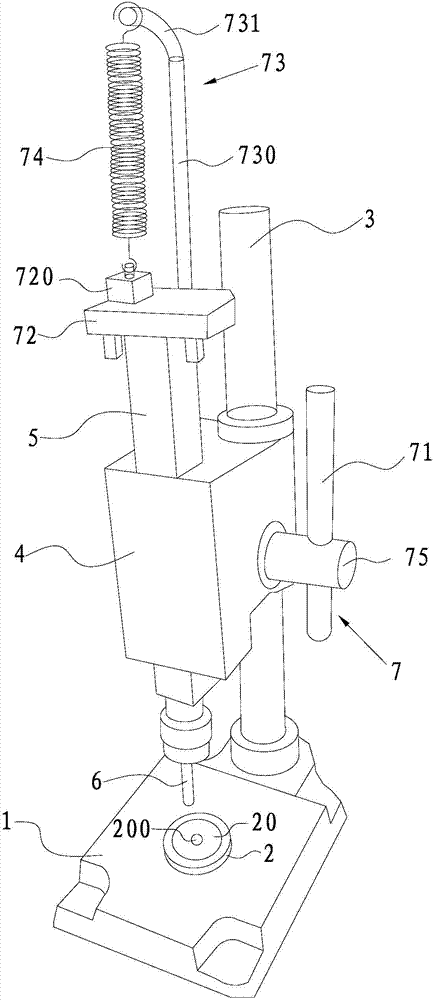

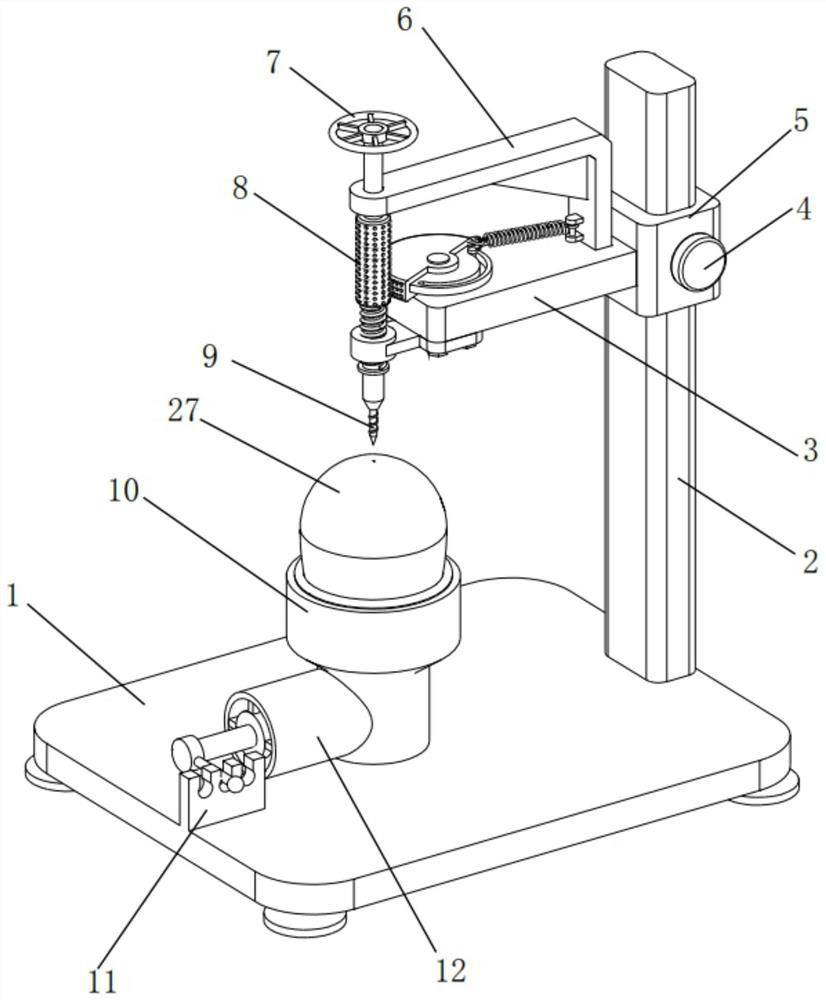

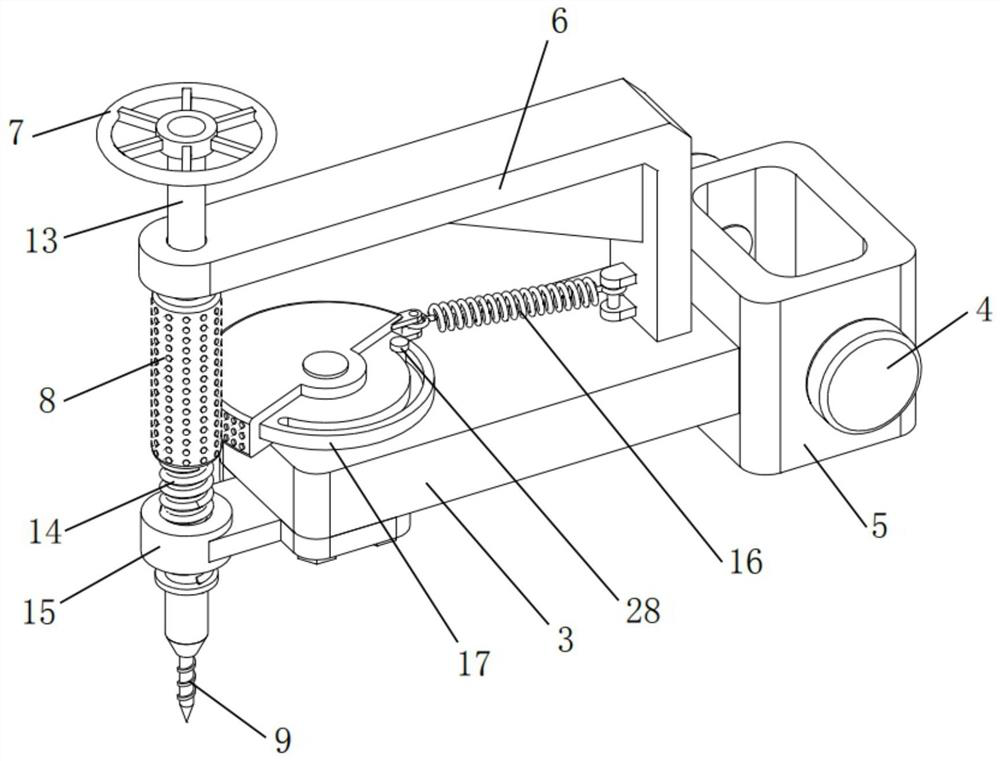

Handheld hole puncher for chick embryo eggshell

The invention discloses a handheld hole puncher for a chick embryo eggshell. The hole puncher comprises a bottom plate, an egg, a fixing assembly, a punching assembly and a reset assembly, a fixing column is fixedly connected to one side of the upper end face of the bottom plate, a sliding seat is slidably connected to the fixing column, fixing rotary knobs used for fixing the sliding seat are arranged on the two sides of the sliding seat, and a mounting plate is fixedly connected to one side of the sliding seat. Through the arrangement of a placing cylinder and a sealing ring arranged at an upper end opening of the placing cylinder, the egg can be conveniently placed, meanwhile, through a connecting buckle arranged in a drawing pipe, after the egg is placed, a drawing rod and a piston block can be pulled out by drawing a drawing handle, and after being pulled out, the drawing rod is hung and buckled in a groove in the side of a groove plate. A negative pressure state can be formed in a fixing barrel, an adsorption effect on the egg is achieved, the situation that the egg shakes during perforating is effectively avoided, and the arranged sealing ring has a sealing effect and can prevent the egg from being collided during placement.

Owner:JILIN ZHENGYE BIOLOGICAL PROD

Information storage device

The invention discloses an information storage device. The device comprises a fixing shell and supporting feet arranged on the bottom surface of the fixing shell in a bilaterally symmetrical manner, afixing machining table is fixedly arranged between the left supporting foot and the right supporting foot, the bottom of each of the left supporting foot and the right supporting foot is fixedly provided with a powerful suction cup, a collecting box is detachably arranged in the center of the bottom of the fixing machining table, a fixing device is arranged in the fixing machining table, a sliding cavity with an opening in the bottom is arranged in the center of the fixing shell, a sliding shell is arranged in the sliding cavity, the sliding shell is in sliding fit connection with the slidingcavity, sliding tooth edge strips which extend up and down are fixedly arranged in the center of the left side surface and the center of the right side surface of the sliding shell, and a cavity withan opening at the bottom is arranged in the center of the sliding shell. According to the information storage device, the structure is simple, the use is convenient, a circuit board is firmly fixed,in the punching process, the lifting of the sliding shell can be controlled according to the required punching depth, and after the punching is finished, the sliding shell is completely retracted intothe sliding cavity, so that a punching head is protected.

Owner:潘军权

Novel belt punching device of hardware material

InactiveCN108676932AEasy to useImprove securityLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringMetal

The invention discloses a novel belt punching device of a hardware material. The device comprises a base, the top of the base is fixedly connected with a first connecting plate, the middle of the first connecting plate is rotationally connected with a rotating shaft, and one end of the rotating shaft is fixedly connected with a first gear, one end, close to the first gear, of the first screw rod is fixedly connected with a second gear, and the middle of a third connecting plate is rotationally connected with a second screw rod; the surface of the first screw rod and the surface of the second screw rod are in threaded connection with sliding blocks, the top of the first connecting rod is fixedly connected with a second connecting rod, and one end, far away from the first connecting rod, ofthe second connecting rod is fixedly connected with a baffle; and the invention relates to the technical field of punching. The belt punching device of the hardware material solves the problems that an existing belt puncher is mostly a metal rod with a groove hole, when in operation, the hand is required to hold the metal rod, the metal rod is knocked by a heavy object, the operation is not easy to master, the hurting is prone to occur, moreover, the metal rod can not fixed as well, the center can not be punched, and attractiveness is influenced.

Owner:湖州吉斯安机械有限公司

A high-efficiency punching device

ActiveCN107717014BSimple structureHole punchingBoring/drilling componentsBoring/drilling machinesPunchingReciprocating motion

The invention discloses an efficient punching device which comprises a frame. A motor is fixedly connected to the inner top wall of the frame, a roller is fixedly connected to the output end of the motor, a workpiece is placed below a drill bit, the motor is started by turning on an external power supply to drive the roller to rotate, four extruding rods can perform vertical reciprocating motionsunder the effect of a sliding rod, a connecting plate is downward extruded four times once the roller rotates for one circle, and accordingly the punching efficiency is improved. The workpiece to be punched is placed below the drill bit, a second spring is compressed when the connecting plate moves down, a twist rod and a sliding block move down, and when universal wheels on a baffle abut againstthe upper end face of a supporting plate, the lower end of the drill bit is in contact with the workpiece, a first insertion rod continues to move down, the twist rod moved down on longer, the first spring is compressed, the sliding block moves down to make the twist rod rotate and thus make the drill bit rotate, and workpiece punching is efficiently achieved.

Owner:ZHEJIANGSHENGANG SAIOU TECH CO LTD

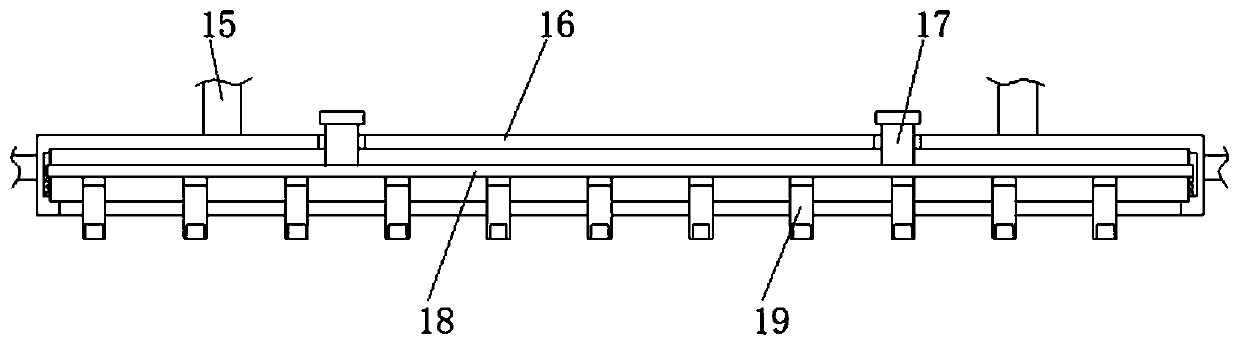

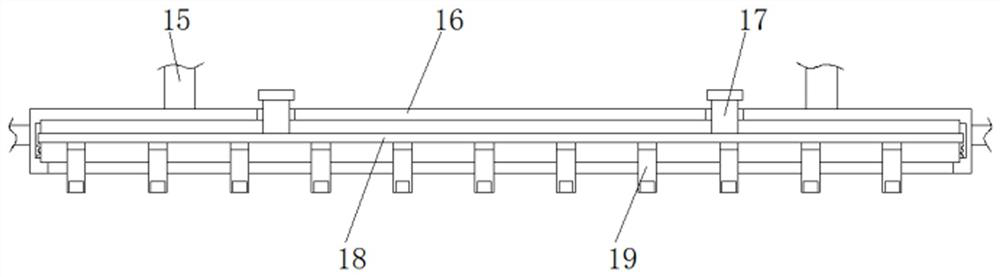

Heat preservation plate perforating machine

PendingCN110802671AHole punchingEvenly punchedNon-rotating vibration suppressionMetal working apparatusGear wheelEngineering

The invention discloses a heat preservation plate perforating machine. The heat preservation plate perforating machine comprises a workbench, supporting legs, a lower cross beam, a longitudinal guiderail, a fixed perforating cone, a stroke air cylinder and a telescopic air cylinder, wherein the workbench is mounted on the upper parts of the supporting legs; the lower cross beam is arranged on theupper part of the workbench; the two ends of the lower cross beam are mounted on the lower parts of sliding blocks through L-shaped supporting bases; servo motors mounted on the sliding blocks can drive gears to move on racks, and then the lower cross beam can move; a movable beam is mounted on the lower cross beam; the fixed perforating cone and the telescopic perforating cone are mounted on themovable beam; and a heat preservation plate is perforated under pushing of the stroke air cylinder. In general, the heat preservation plate perforating machine has the beneficial effects of being easy and convenient to operate, safe, reliable, uniform in hole distribution and high in perforating efficiency.

Owner:PUYANG HENGRUI BUILDING MATERIAL TECH CO LTD

A kind of punching device of raw bamboo

ActiveCN106738133BAvoid the phenomenon of drill bit slippingImprove securityDrilling machinesCane mechanical workingPunchingStructural engineering

The invention discloses a punching device for raw bamboo, which comprises a first connecting rod, a second connecting rod, a third connecting rod, a first clamp, a second clamp, a third clamp, a punching machine and a first fixing plate; The first clamp, the second clamp and the third clamp all include a connecting piece, a fourth connecting rod, a fifth connecting rod, a second fixing plate and a limiting plate. This device can effectively prevent the drill bit from slipping, and the drilling The location is more accurate.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

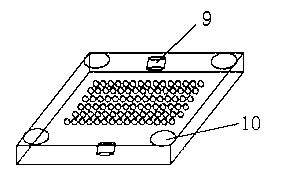

Mold, device and method for punching chip component ceramic diaphragm

ActiveCN102152408BHole punchingUniform hole diameterStone-like material working toolsPunchingHigh pressure water

The invention discloses a mold, a device and a method for punching a chip component ceramic diaphragm. The punching mold comprises an upper mold, a lower mold and a fixing and positioning device, wherein an upper mold hole and a lower mold hole are correspondingly formed on the upper and lower molds. The punching device comprises a high-pressure water injector and the punching mold, wherein the high-pressure water injector is arranged directly opposite to the upper mold; and when the punching device is used, the ceramic diaphragm is fixed on the positioning device and positioned between the upper mold and the lower mold, and the water injected from the high-pressure water injector breaks through the ceramic diaphragm. The punching method comprises: 1) placing the ceramic diaphragm between the upper mold and the lower mold, 2) fixing and positioning the ceramic diaphragm between the aligned upper mold hole and lower mold hole by using the fixing and positioning device; and 3) allowing the high-pressure water injector to inject water to break through the ceramic diaphragm. The mold, the device and the method have the advantages that: the equipment investment is low; the maintenance cost is low; the device is simply operated; the production cost is low; and the mold, the device and the method can be widely applied to punching of electronic component ceramic materials.

Owner:SHENZHEN SUNLORD ELECTRONICS

A plastic protective film punching machine with a punching calibration auxiliary device

ActiveCN111331672BImprove drilling efficiencySolve the problem of inconvenient replacement of workpiecesMetal working apparatusWebs handlingPunchingMachine

The invention belongs to the technical field of plastic protective film punching machines, in particular to a plastic protective film punching machine with a punching calibration auxiliary device, including a bottom plate and a roll film tube, the upper end of the bottom plate is fixed with a support frame, and the retractable The inner side of the roll bar is connected with the protective film body, the roll film tube is installed on the inner side of the protective film body, the outer side of the rotating rod is provided with a positioning groove, the right side of the supporting frame is equipped with a rotating drum, and the supporting frame A cylinder is installed on the upper end of the working rod, a positioning plate is connected to the lower end of the working rod, and a rod groove is installed on the middle part of the bottom plate. The plastic protective film punching machine with a punching calibration auxiliary device is designed with a structure with a rewinding and snapping function, which solves the problem of low punching efficiency of the traditional device, and designs a structure with an extrusion snapping function, which solves the problem The problem that the traditional device is inconvenient to replace the workpiece, and a structure with a sliding function is designed to solve the problem that the traditional device is inconvenient to adjust the punching position.

Owner:苏州名顺包装材料有限公司

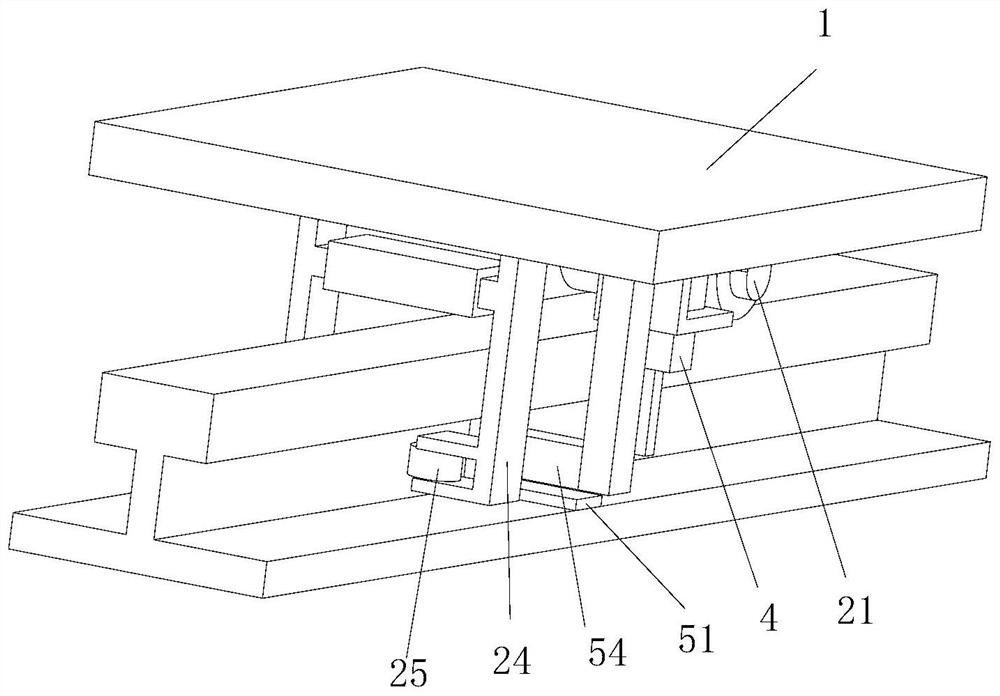

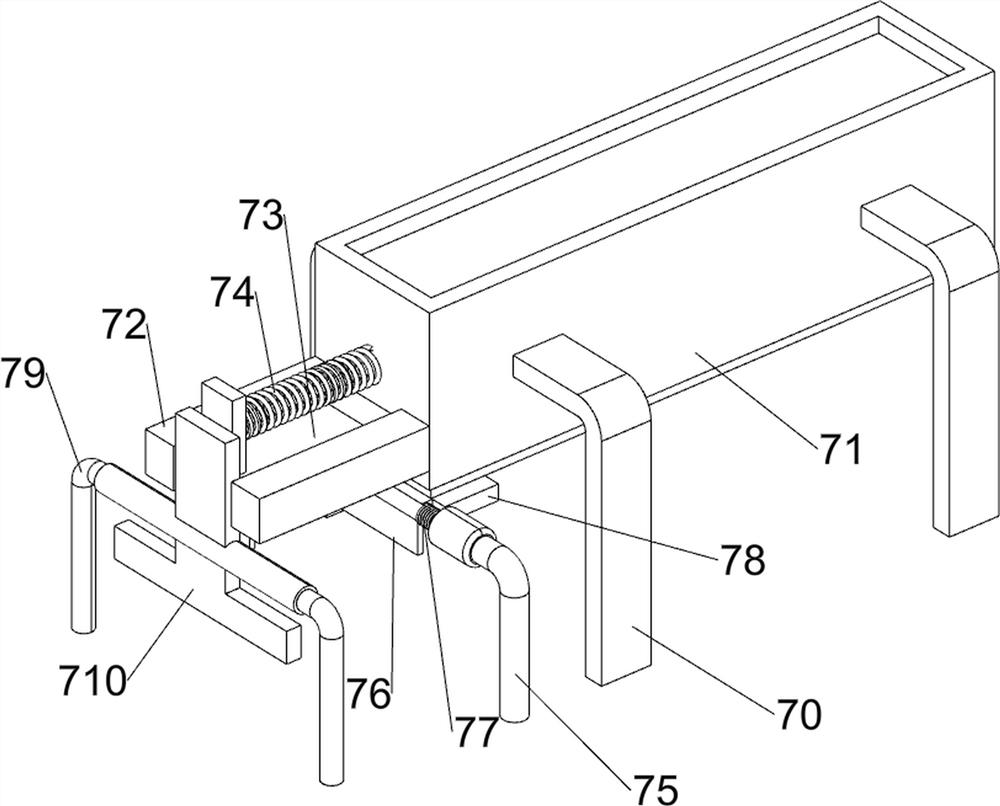

A rough processing equipment for children's wooden block building blocks

ActiveCN112405718BRealize moving up and downHole punchingStationary drilling machinesBark-zones/chip/dust/waste removalPunchingConstruction engineering

The invention relates to a processing device, in particular to a rough processing device for children's wooden block building blocks. The invention provides a rough processing equipment for children's wooden block building blocks, which can automatically fix wood blocks and automatically clean up wood chips. A rough processing equipment for children's wooden block building blocks, comprising: a base with a lifting mechanism; a punching mechanism with a punching mechanism on the lifting mechanism. The present invention realizes the punching of the wooden block through the punching mechanism, and then realizes the up and down movement of the punching mechanism with the cooperation of the lifting mechanism, and then realizes the efficient punching of the wooden block; by providing a clamping mechanism, when When the punching mechanism punches the wooden block, the clamping mechanism clamps the wooden block, so that the wooden block is less prone to displacement when being punched.

Owner:广东省贝恩施科技股份有限公司

Elastic drainage pipeline punching mold

The invention discloses an elastic drainage pipeline punching die. The elastic drainage pipeline punching die comprises an upper die body and a lower die body. The upper die body comprises an ejector block, a base and a plurality of tools. The ejector block and the base are connected through a plurality of bolts. One end of each tool is fixed to the ejector block, and the other end of each tool penetrates the base. The base is provided with pressing protrusions, and the pressing protrusions are arranged on the lower surface of the base. The lower die body comprises a base and a gasket, the gasket is arranged on the base, and the upper die body is arranged over the lower die body. The punching die is provided with the pressing protrusions, and therefore an elastic drainage pipeline can be flattened, and punching is facilitated; the silica gel or rubber gasket is arranged, tenacity is good, and meanwhile the drainage pipeline is prevented from being damaged; the tools are arranged and can rapidly cut off the drainage pipeline, and punching is achieved; the die is simple in structure, convenient to operate and exquisite in detail design; and the punching precision is high.

Owner:JIANGSU YUANCHUANG MEDICAL TECH

Full-automatic hole punching method

ActiveCN104014840AHole punchingImprove work efficiencyFeeding apparatusDriving apparatusGear wheelEngineering

The invention relates to the field of machining, in particular to a full-automatic hole punching method. According to the method, a drill bit is driven to carry out rotation and revolution through a planetary gear on a planetary gear set, and rotating force is provided for the drill bit. By arranging a spiral guiding track, pressure in a workpiece direction is exerted on the drill bit, and accordingly hole punching on a workpiece is achieved. According to the full-automatic hole punching method, the planetary gear set is used for achieving simultaneous rotation and revolution of a plurality of drill bits, the spiral guiding track is arranged, during revolution, down-pressing force is exerted on the drill bits, and then hole punching on the workpiece is achieved. According to a full-automatic hole punching machine, a plurality of holes can be punched at the same time, or hole punching is carried out on a plurality of workpieces at the same time, and working efficiency is greatly improved.

Owner:董静

Plate drilling device for building construction

PendingCN112108686AAvoid displacementAvoid shakingPositioning apparatusMetal-working holdersHydraulic cylinderArchitectural engineering

The invention relates to the technical field of building equipment, and discloses a plate drilling device for building construction. The plate drilling device comprises a workbench, wherein a hydraulic cylinder is fixedly connected to the bottom of one side of the workbench; a fixing plate is fixedly connected to the top of one side of the workbench; a limiting groove is formed in the end, close to the fixing plate, of the workbench; a threaded hole is formed in the top of the fixing plate; a threaded rod is in threaded connection with the interior of the threaded hole; a rotary knob is fixedly connected to the top end of the threaded rod; a pressing plate is fixedly connected to the bottom end of the threaded rod; and a limiting plate is fixedly connected to one side of the pressing plate. According to the plate drilling device for building construction, the threaded rod is rotated, so that a plate body is clamped and fixed by the pressing plate, the plate is prevented from moving, and the drilling precision is guaranteed; and a first motor is started, so that a screw rod rotates, then a movable sleeve drives a drilling device to move transversely, a drilling rod rotates, then thepurpose of drilling can be achieved, and the labor intensity of people is reduced.

Owner:湖南傲创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com