Corrugated paper punching device

A punching device and technology for corrugated paper, applied in the field of corrugated paper processing, can solve the problems of corrugated paper that cannot meet different specifications, difficult to popularize and apply, and clamp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

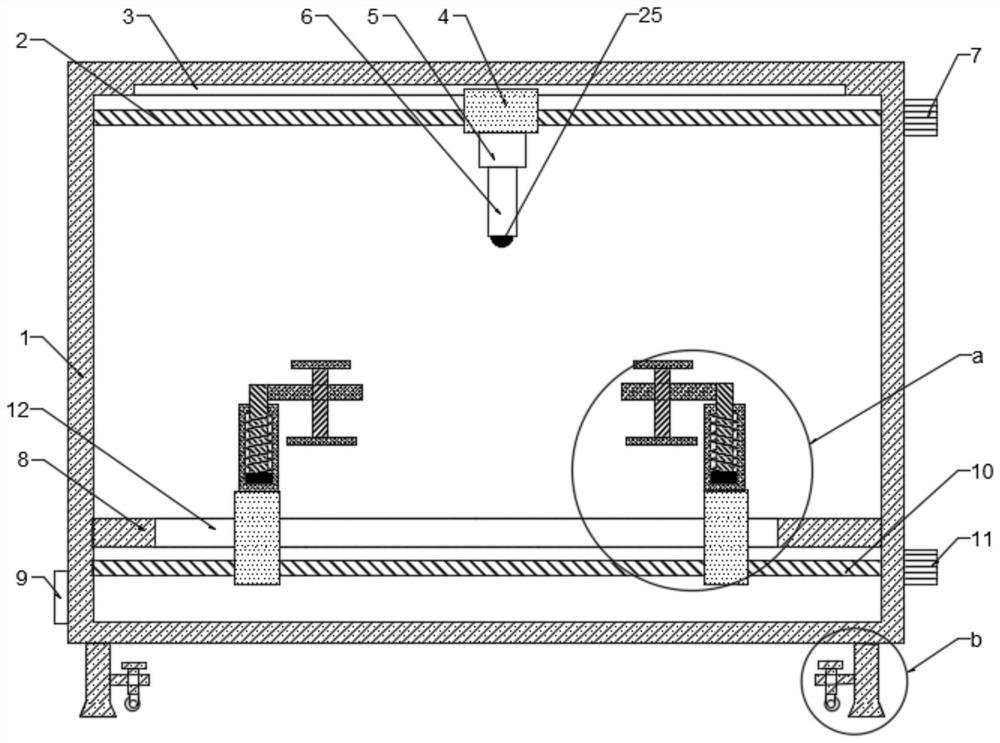

[0024] see Figure 1 ~ Figure 3 , a corrugated paper punching device, comprising:

[0025] body 1;

[0026] Punching mechanism, the transmission rod 2 on the described punching mechanism is connected with the sliding member 4 that can drive the perforating needle 25 to slide by being threaded;

[0027] Clamping mechanism, the clamping mechanism includes:

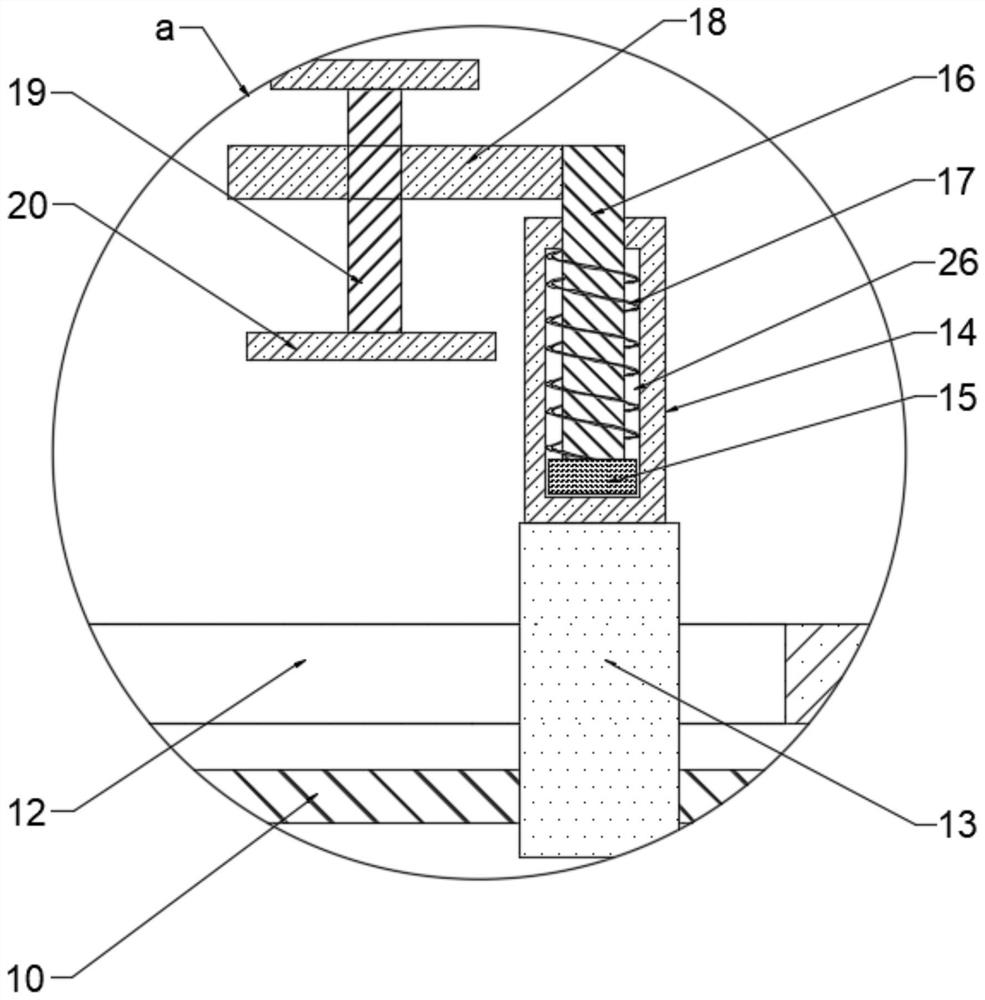

[0028] Longitudinal clamping components such as Figure 1-Figure 2 As shown, the fixed frame 14 on the longitudinal clamping assembly is provided with a limiting groove 26 for moving and guiding the moving part 15. The longitudinal clamping assembly includes a sliding member and a clamping member, and the sliding member The slide bar 16 runs through the spring 17 that limits it. The slide member includes a fixed mount 14, a moving piece 15, a slide rod 16, a spring 17 and a limit groove 26. The inside of the fixed mount 14 is limited. Position slot 26 , the moving part 15 is slidably connected in the limiting slot 26 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com