A rough processing equipment for children's wooden block building blocks

A woody and blocky technology, applied in the field of rough processing equipment for children's wooden blocky building blocks, can solve the problems such as inconvenient cleaning of sawdust, and achieve good support and efficient punching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

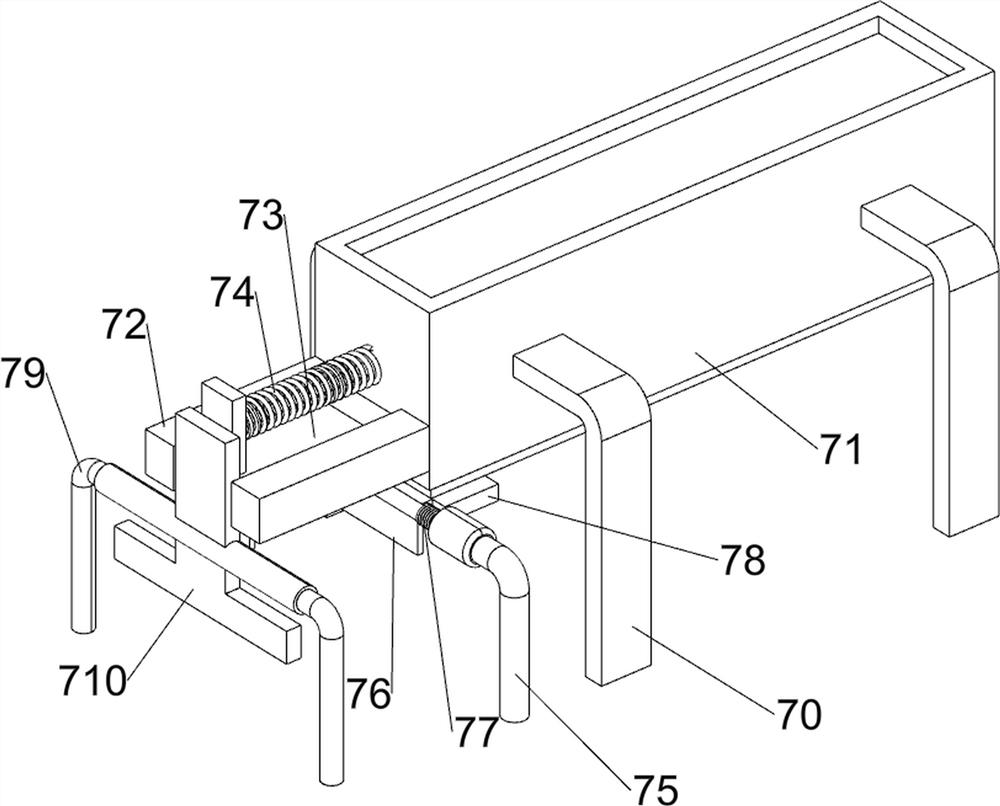

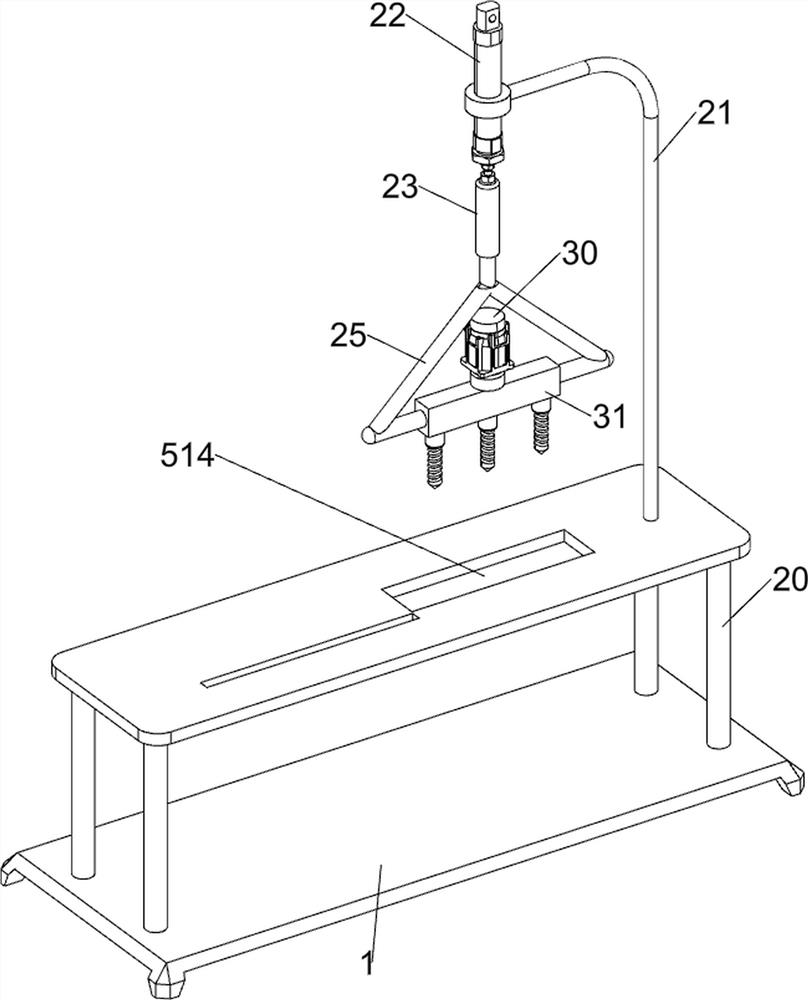

[0032] A children's wooden block building block rough processing equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1 , a lifting mechanism 2 and a punching mechanism 3 . The base 1 is provided with a lifting mechanism 2 , and the lifting mechanism 2 is provided with a punching mechanism 3 .

[0033] When people need to use the equipment, they first place the wooden block on the lifting mechanism 2, then start the lifting mechanism 2 and the punching mechanism 3, and the lifting mechanism 2 then drives the punching mechanism 3 to move downward. When the punching mechanism 3 When it moves down to contact with the wooden block, the punching mechanism 3 punches the wooden block. After the punching is completed, people can control the lifting mechanism 2 to drive the punching mechanism 3 to move up and reset, and then people can finish the punching. When people do not need to use the equipment, just close the lifting mechanism 2 and the punching me...

Embodiment 2

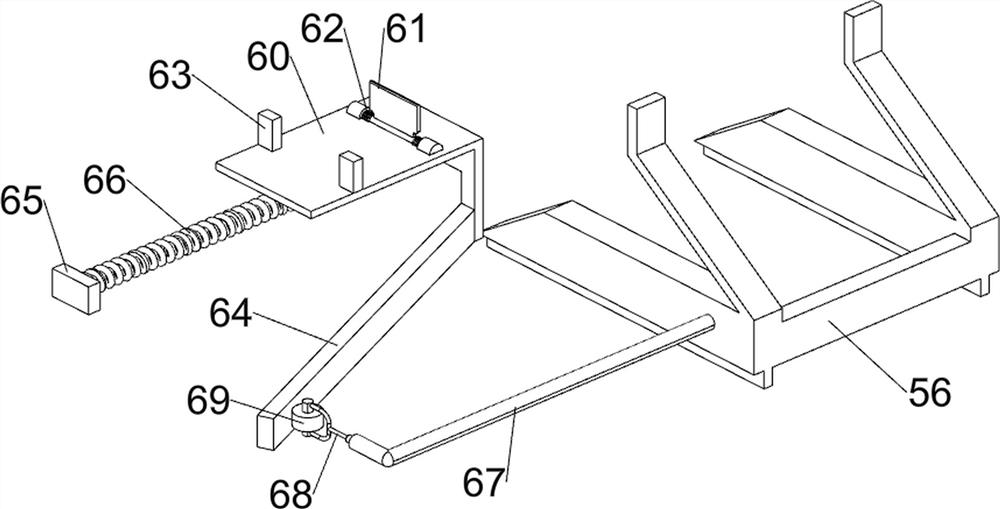

[0038] On the basis of Example 1, as figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, it also includes a clamping mechanism 4. The clamping mechanism 4 includes a second support rod 40, a mounting plate 41, a ratchet tooth 42, a second spring 43, a first bearing seat 44, a third support rod 45, and a rack 46. , the second hollow shaft 47, the clamping block 48, the fixed shaft 49, the third spring 410, the ratchet 411, the circular gear 412 and the first return spring 413, the first hollow shaft 23 is provided with a plurality of second support rods 40, Mounting plates 41 are provided on the second support rods 40 , and ratchets 42 are slidably provided on the mounting plates 41 . A second spring 43 is symmetrically arranged between the ratchets 42 and the mounting plate 41 , and two sides of the table 20 are symmetrically arranged. For the first bearing seat 44, a third support rod 45 is provided betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com