Patents

Literature

51results about How to "Efficient punching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

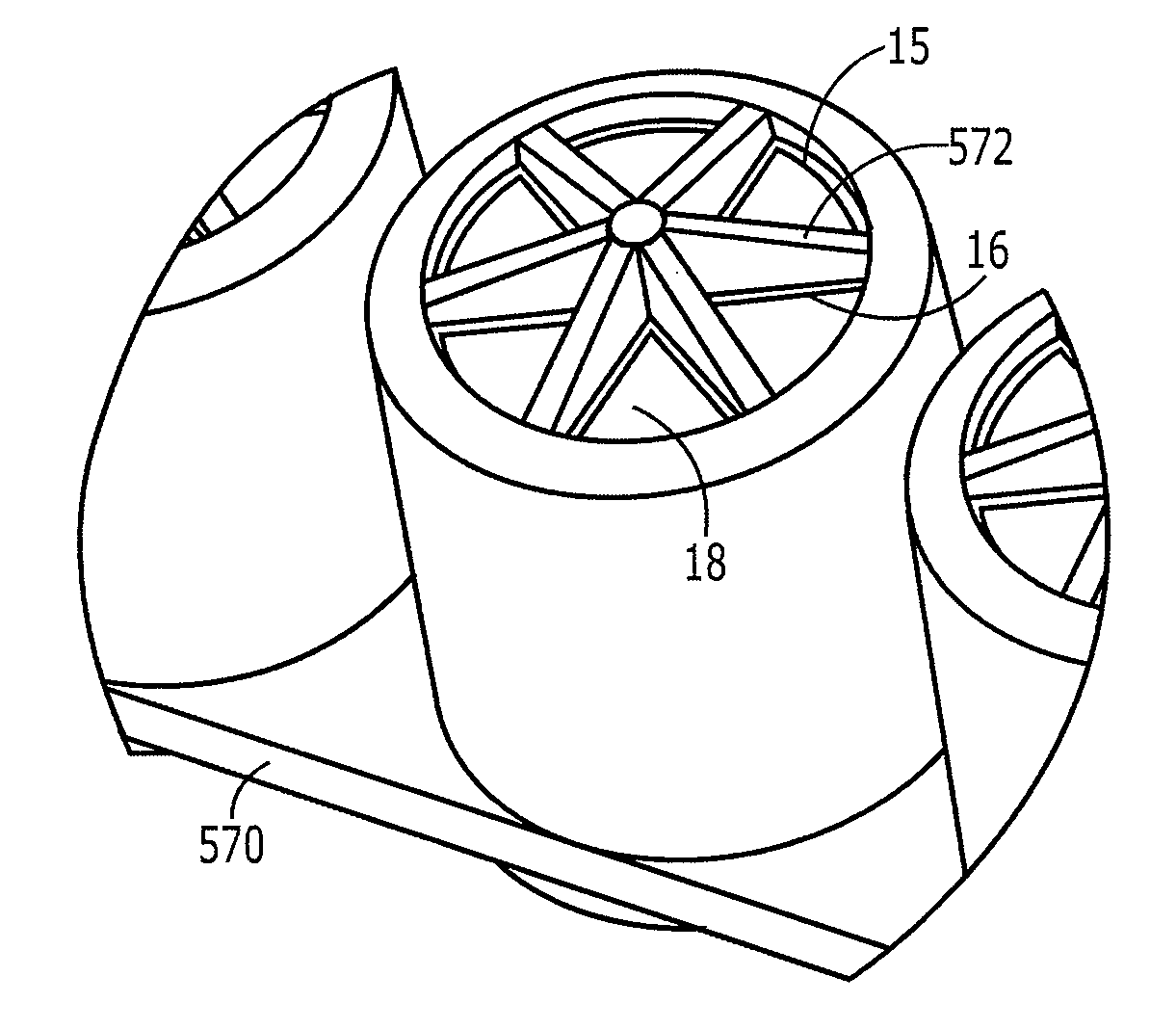

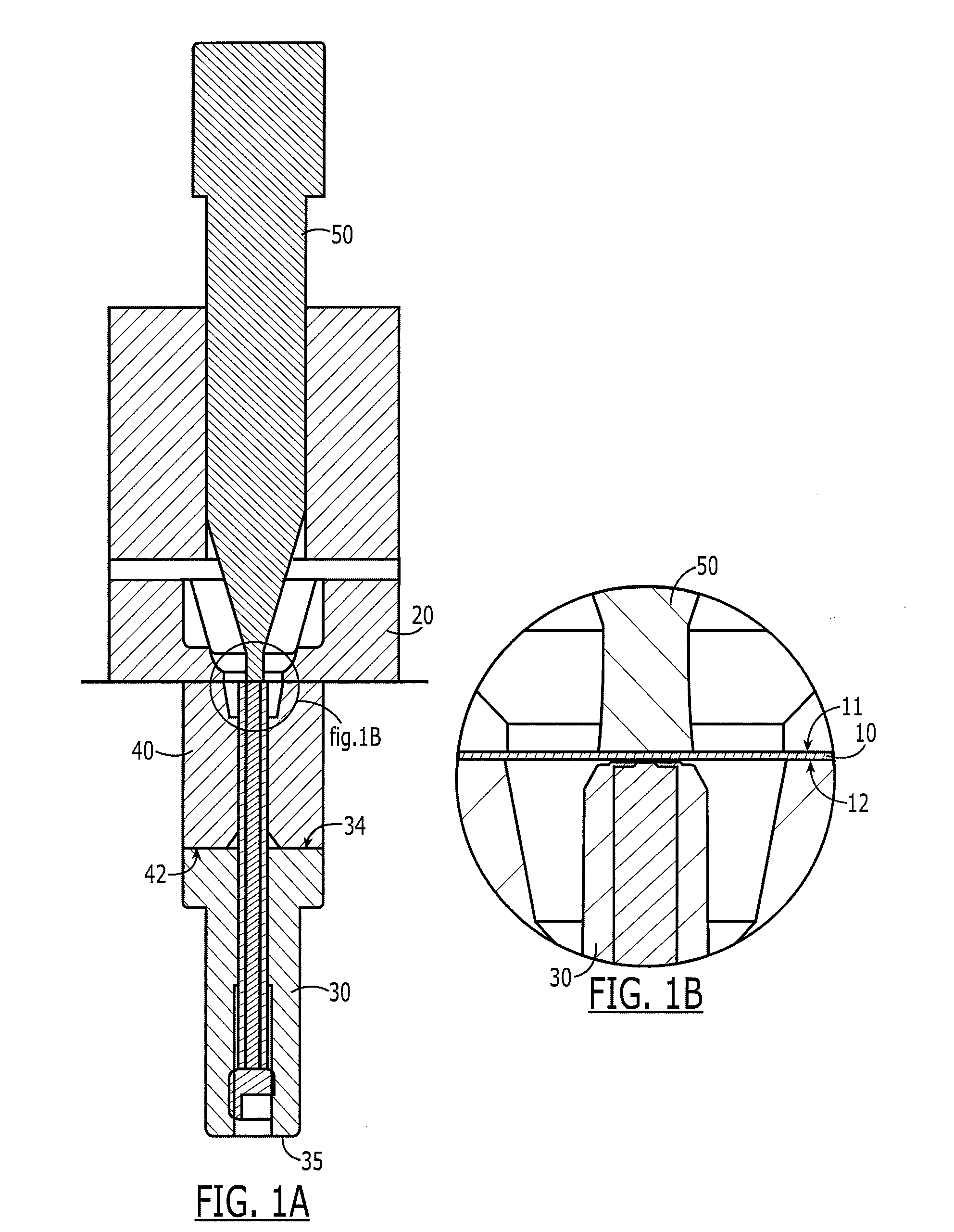

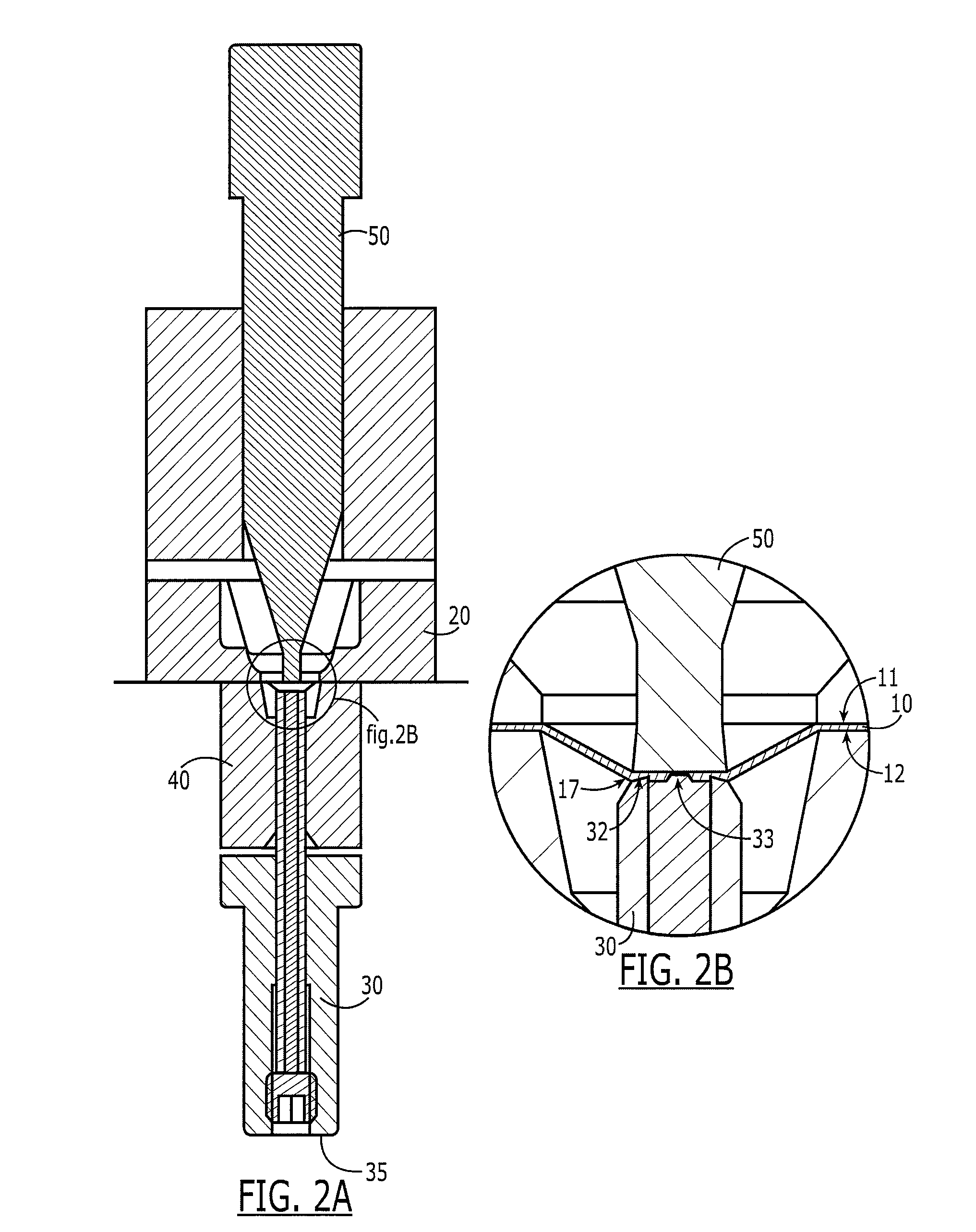

Small volume unitary molded filters and supports for adsorbent beds

InactiveUS20080128346A1Less squeezeMaintain permeabilityButtonsLaboratory glasswaresAnalyteFiltration

Methods and devices are provided for preparing and separating biological analytes. In one embodiment, one or more filtration devices or filter plate wells can be formed by clamping a filter sheet between first and second plates having at least one connecting cavity. First and second moveable core pins positioned on opposed sides of the sheet can be moved to remove portions of the sheet. A molten plastic can be injected to fill the volume between the cores and cavities and to form a liquid-impermeable sleeve wall or walls, each being separately sealed at the bottom to the perimeter of the sheet portion, each having liquid permeable regions of said removed and sealed sheet portion, and each remaining open at the top. Various exemplary configurations for filtration devices or filter plate wells are also disclosed.

Owner:ORBITAL BIOSCI

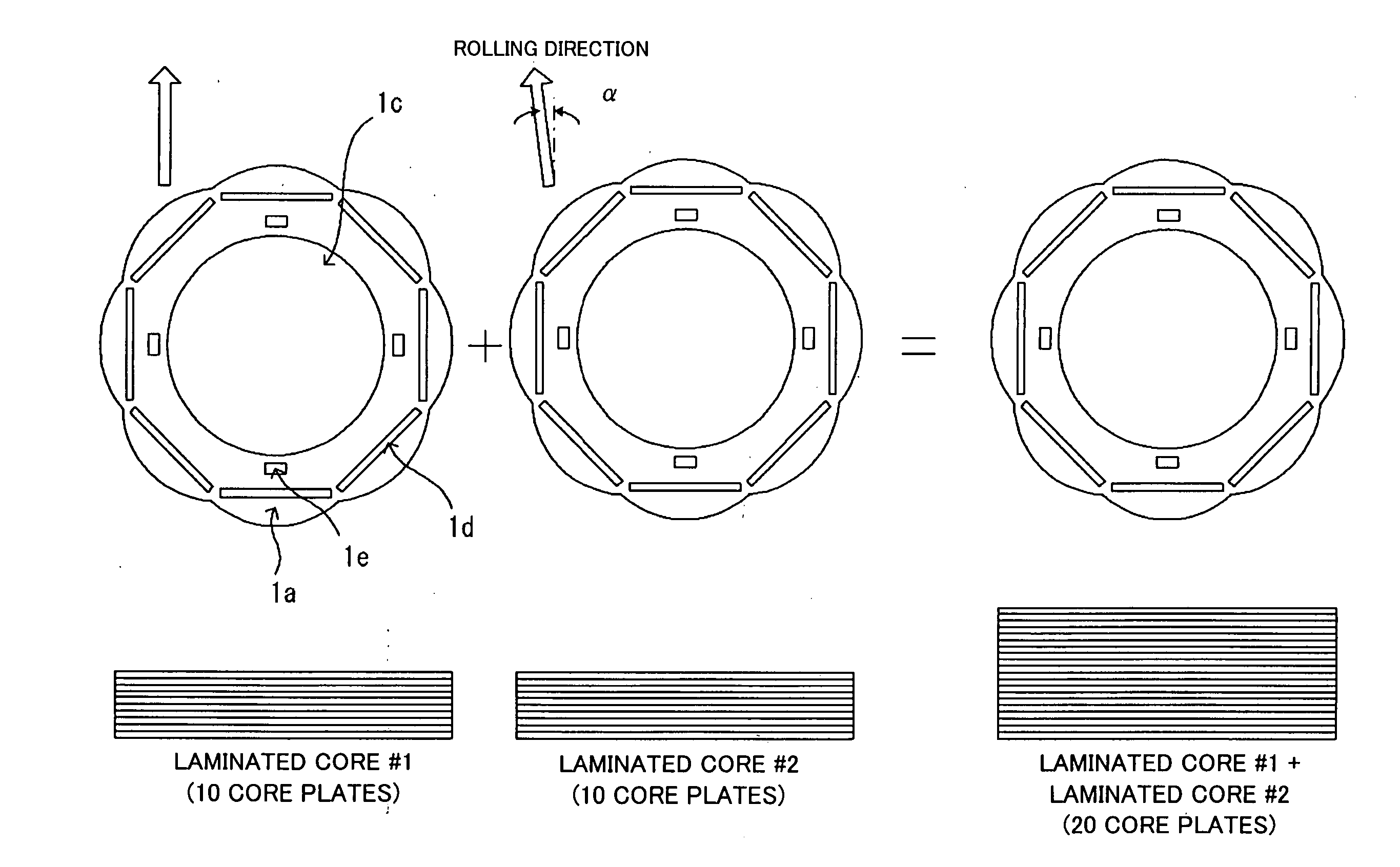

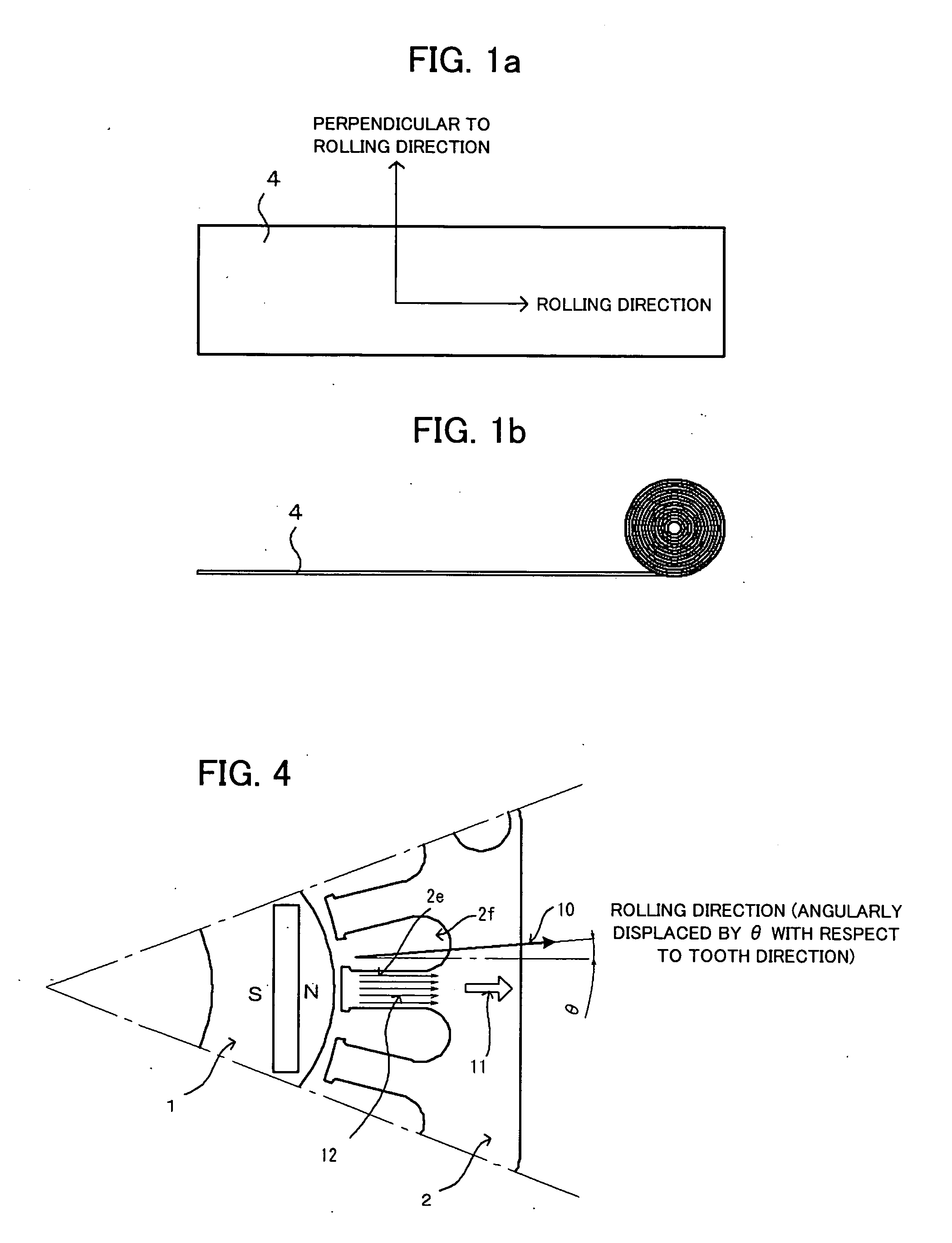

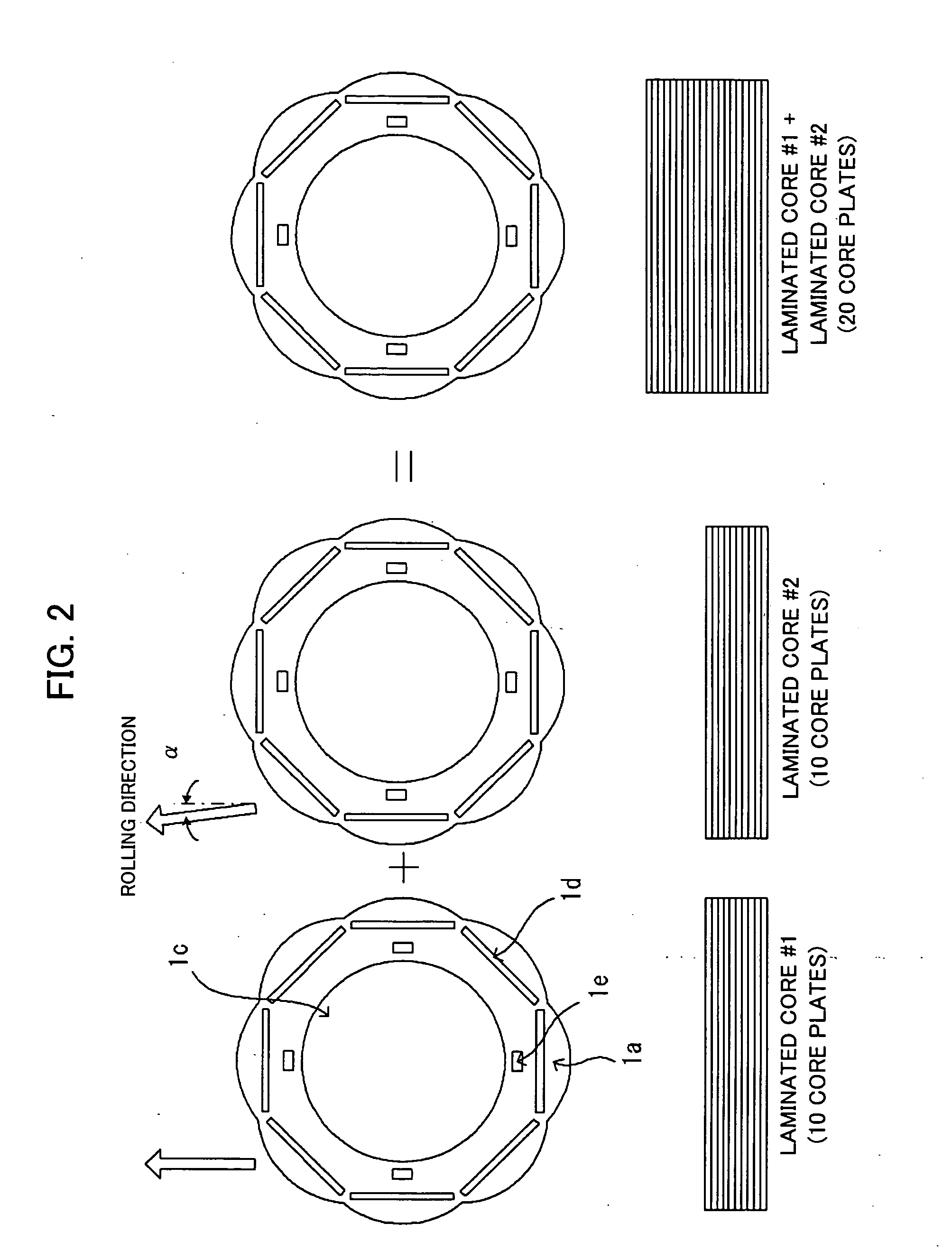

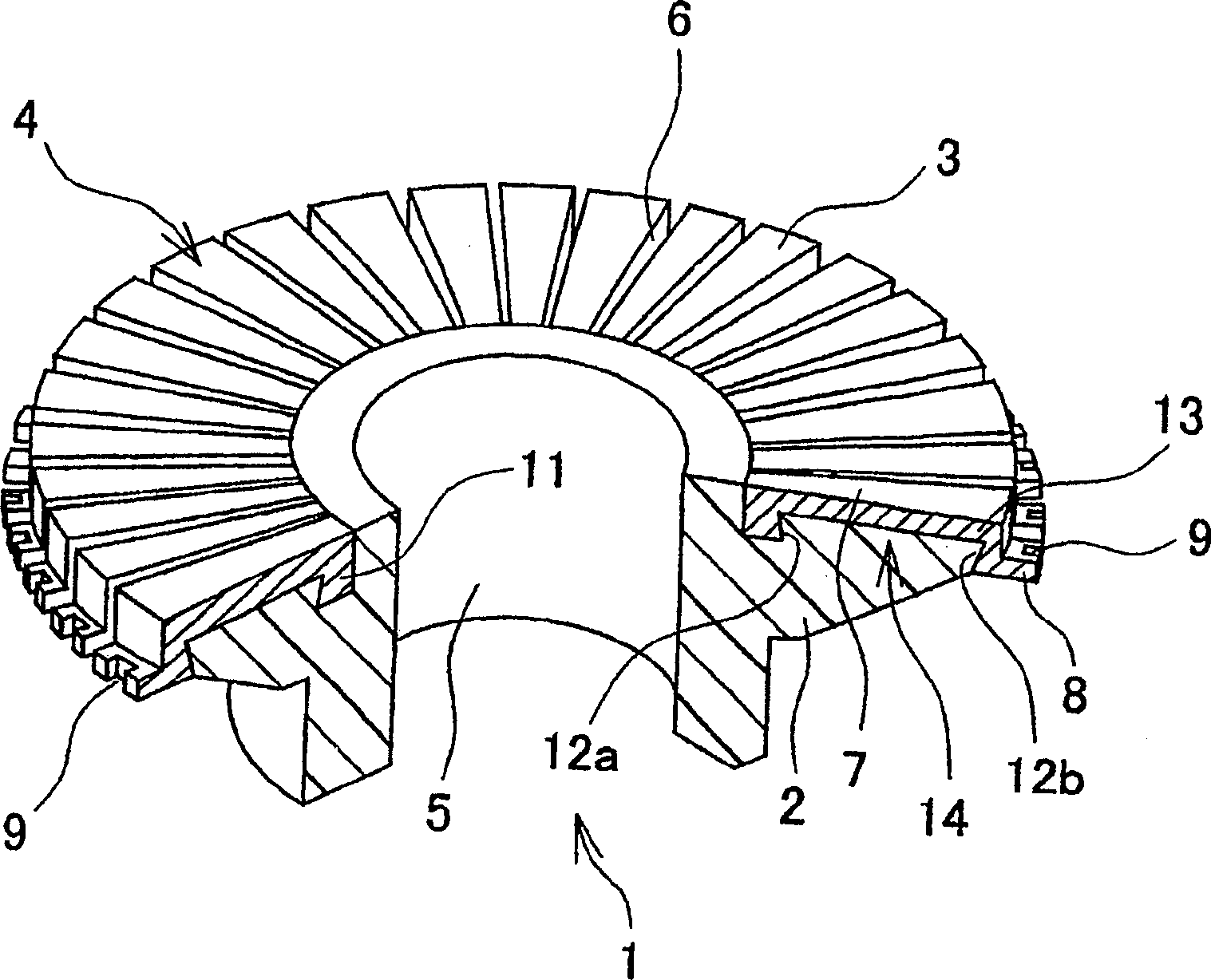

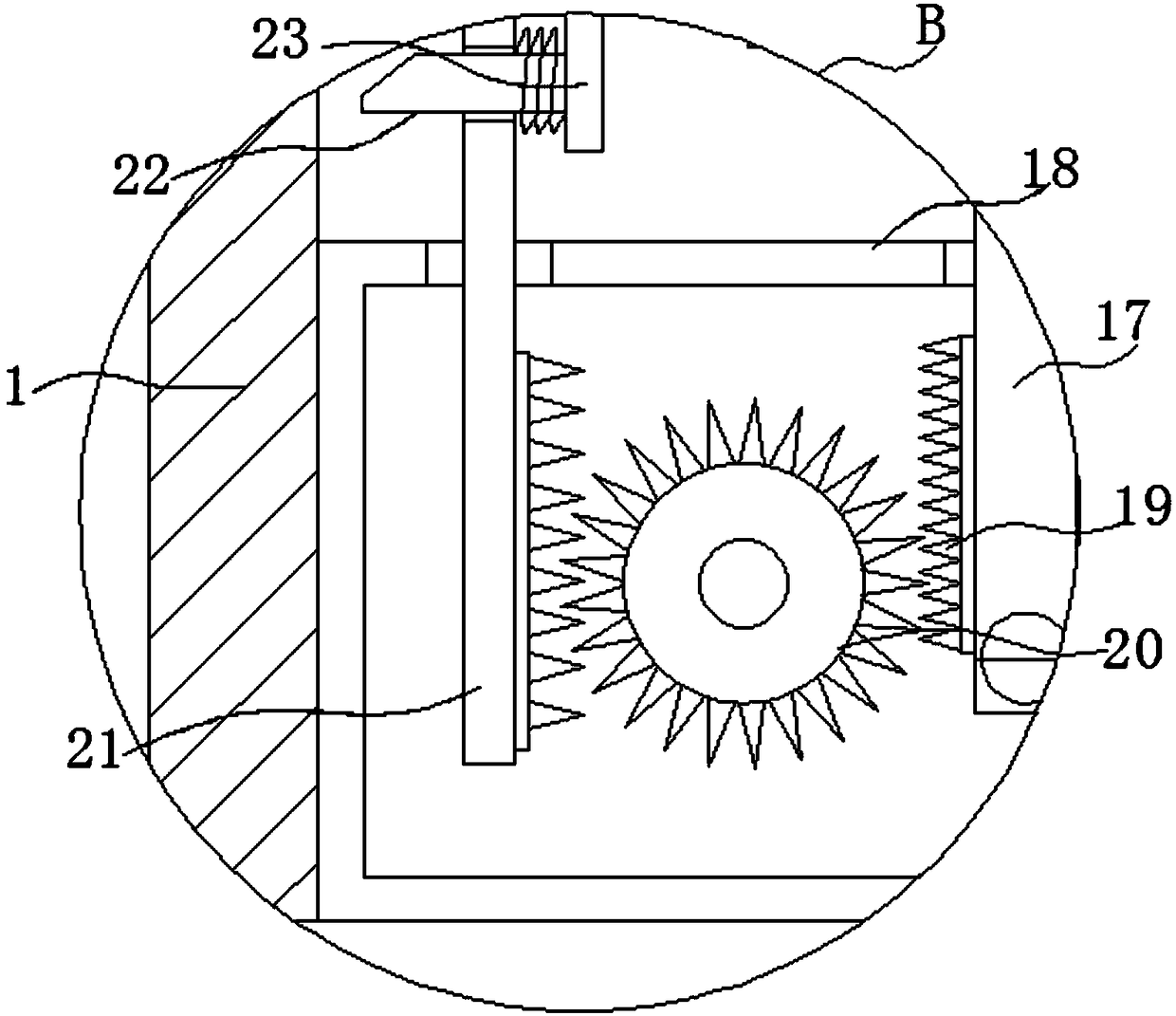

Electric motor and apparatus for manufacturing electric motor

ActiveUS20060163967A1Long processEfficient punchingMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsMagnetic anisotropySheet steel

A motor capable of reducing cogging torque depending on teeth of a stator, and a motor manufacturing apparatus for manufacturing this motor. The angles of rolling directions of cores stacked are set so that the phase difference between the phases of cogging torques produced on the cores is 180° so that the cogging torques produced on the cores cancel each other to reduce the total cogging torque in the motor. The motor comprises a laminated core formed by stacking a plurality of cores made from a rolled electromagnetic sheet steel. The cores forming the laminated core have rolling directions different from each other by a specified machine angle determined depending on the number of slots and / or the number of poles, where the specified machine angle is an angle which produces a phase difference of 180° between the phases of cogging torques produced due to magnetic anisotropy of the cores and the arrangement of teeth depending on the number of slots and / or poles of the motor.

Owner:FANUC LTD

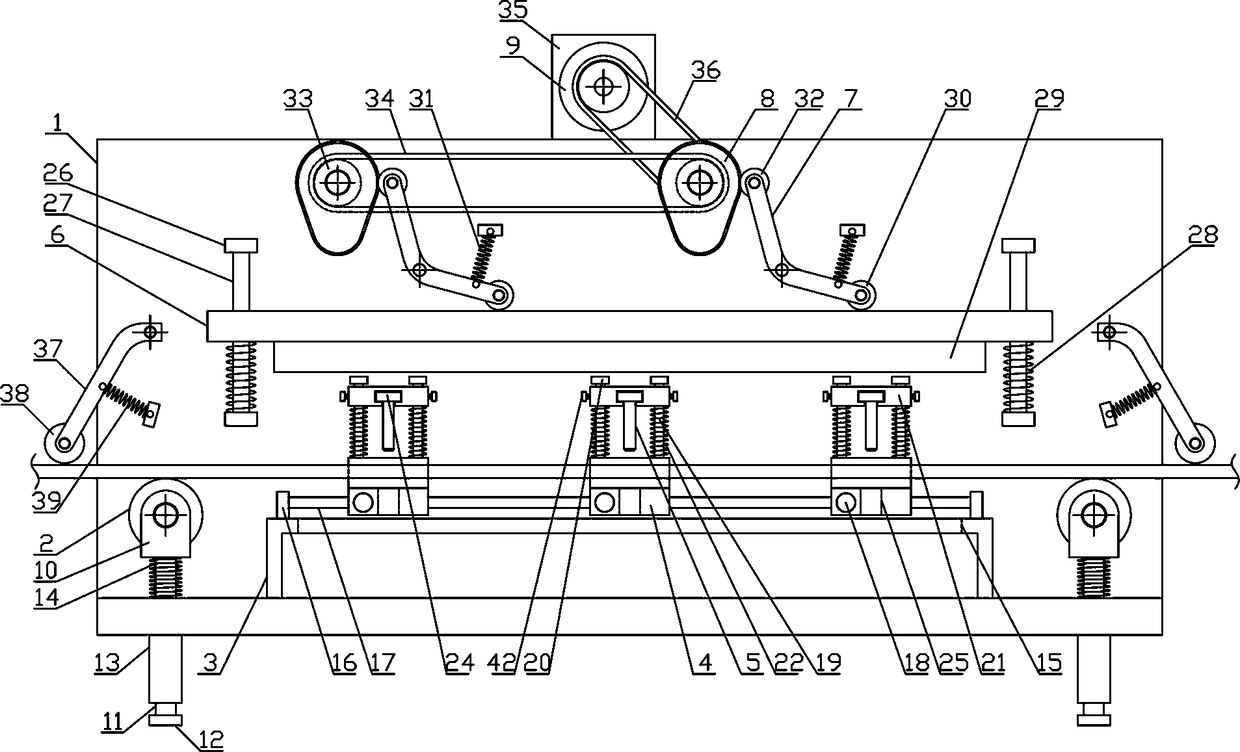

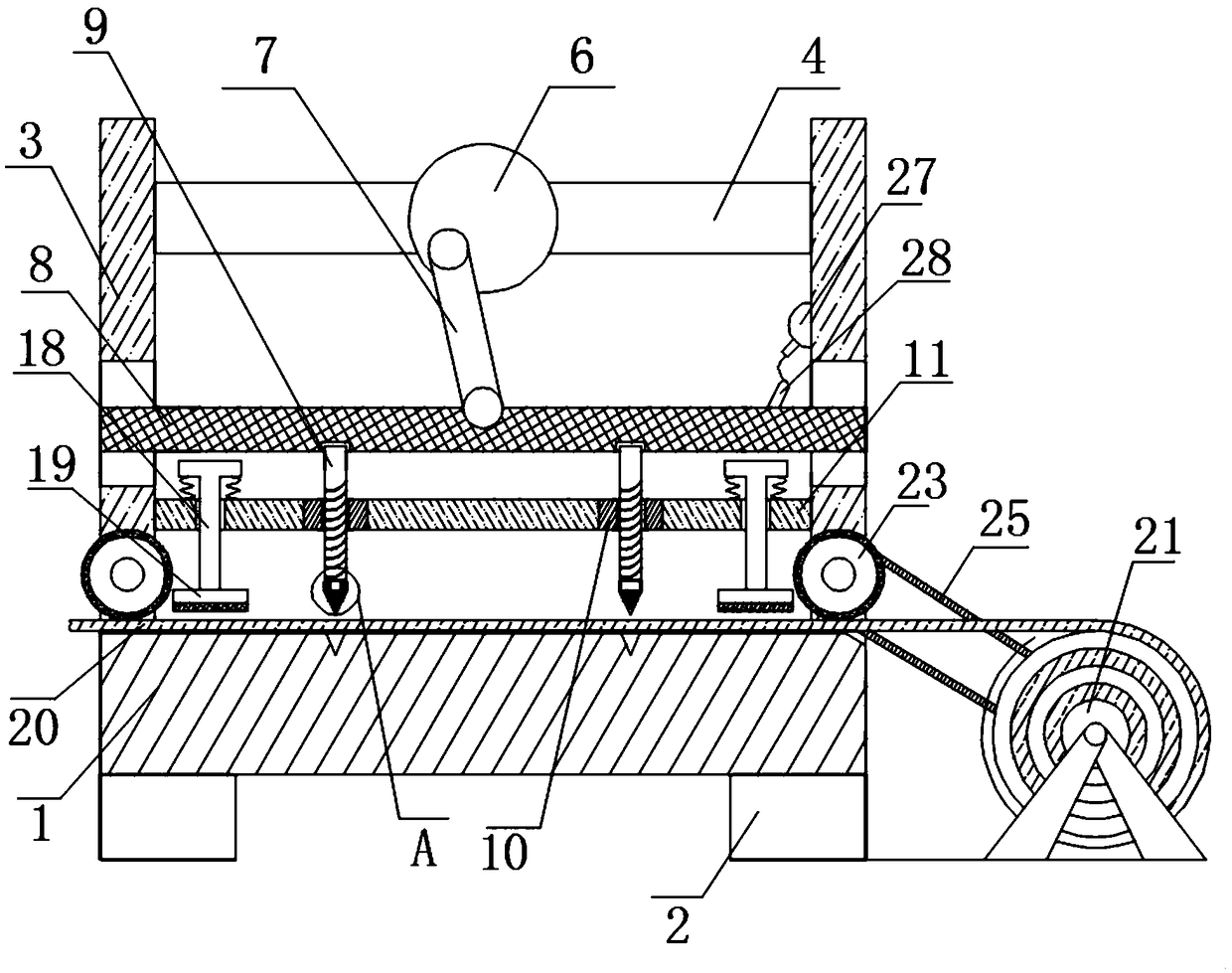

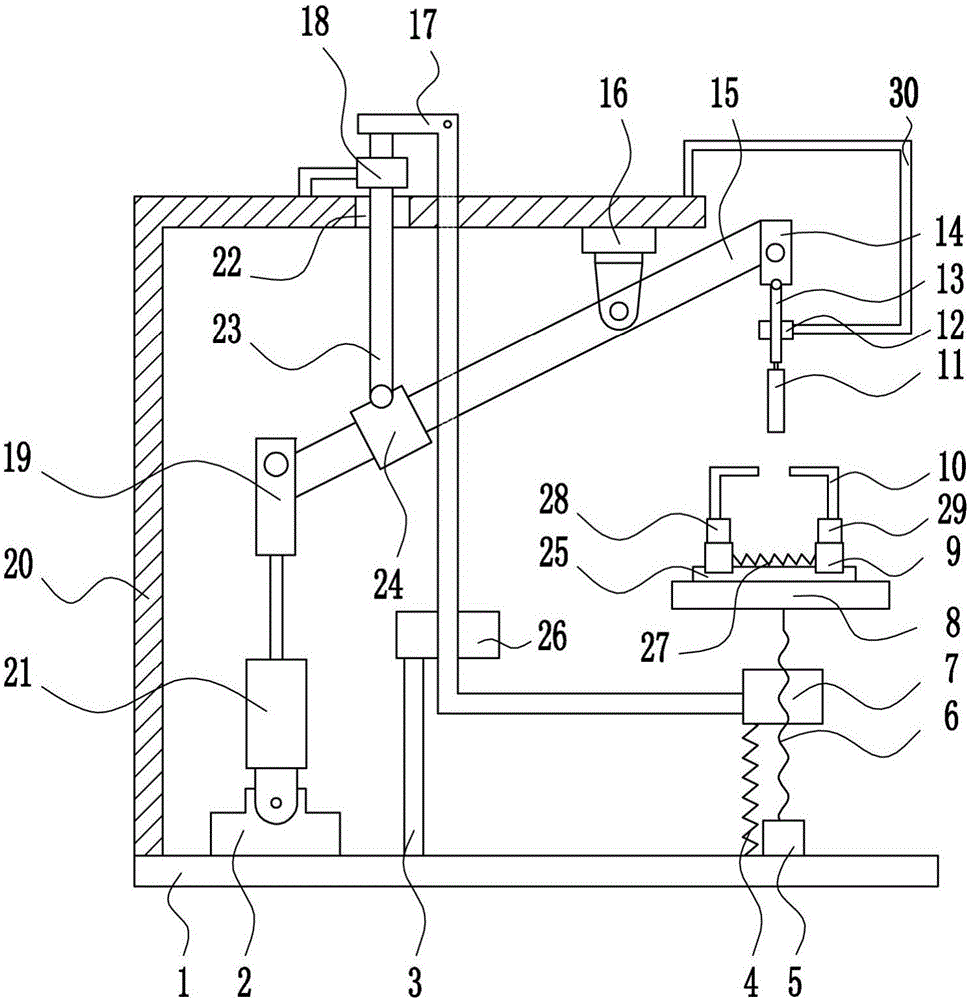

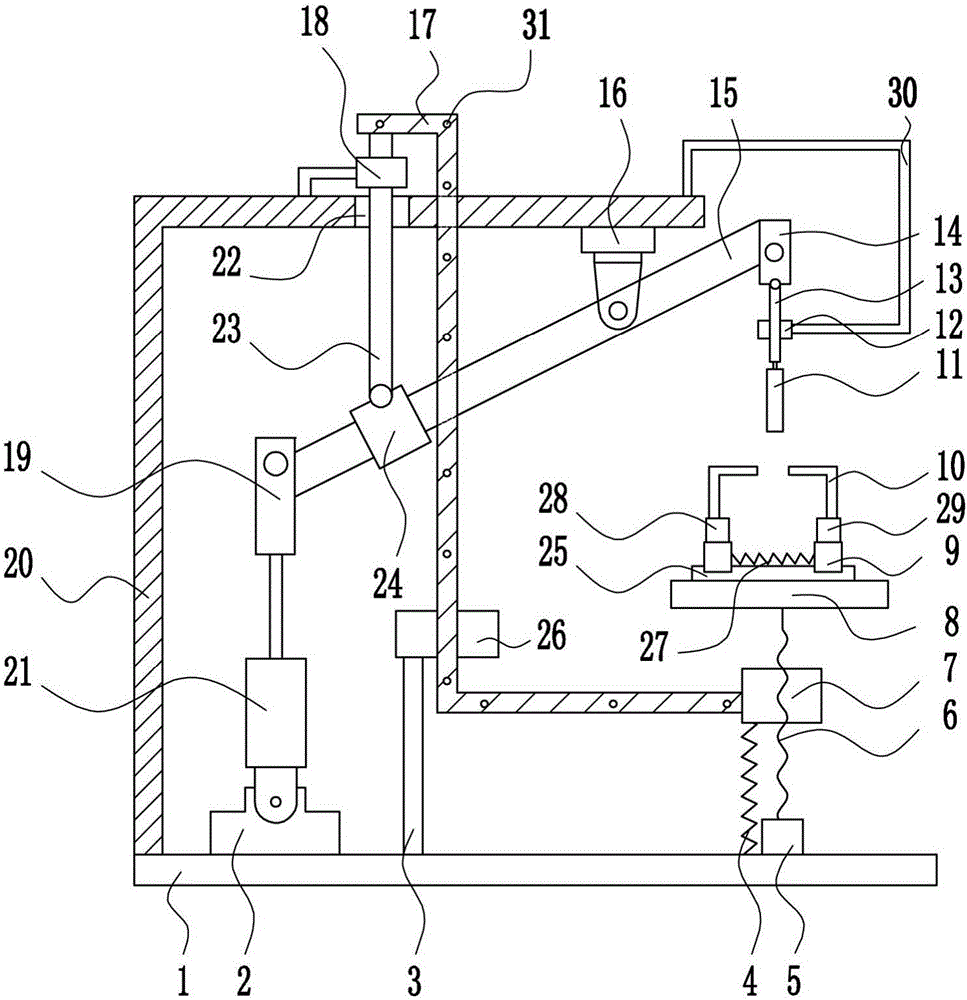

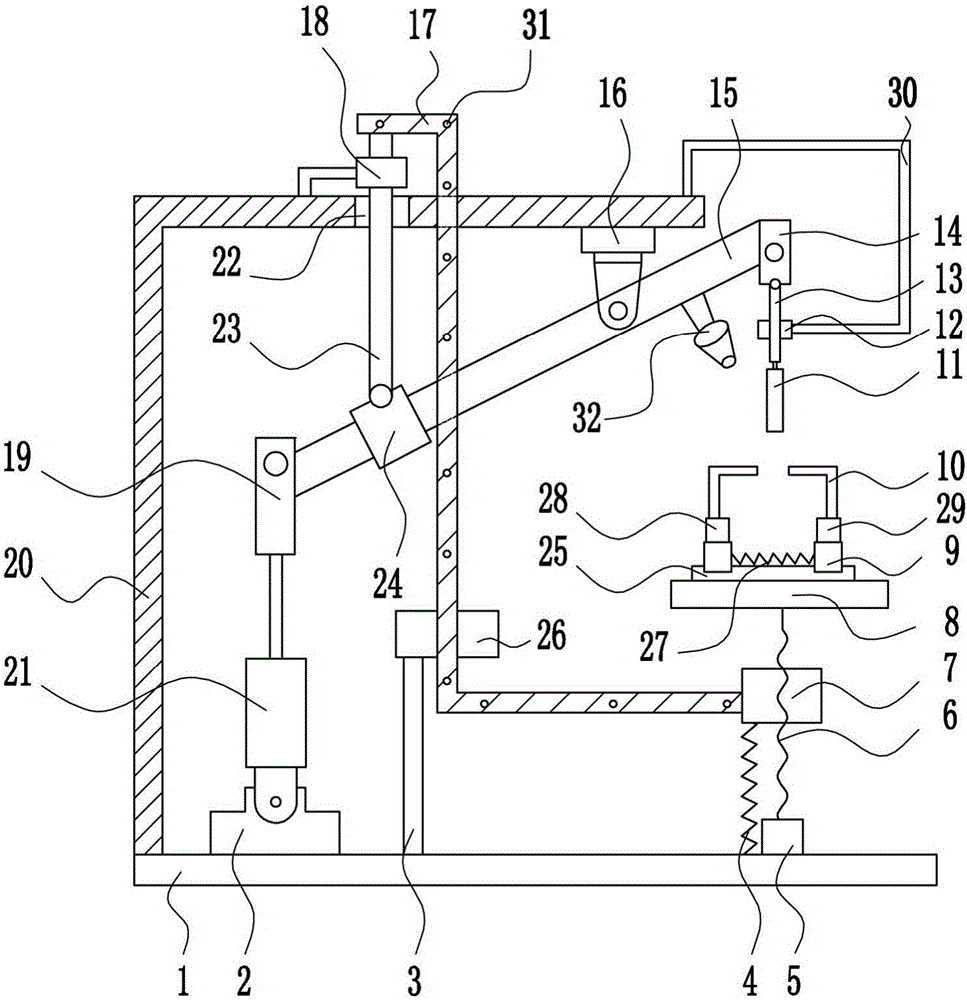

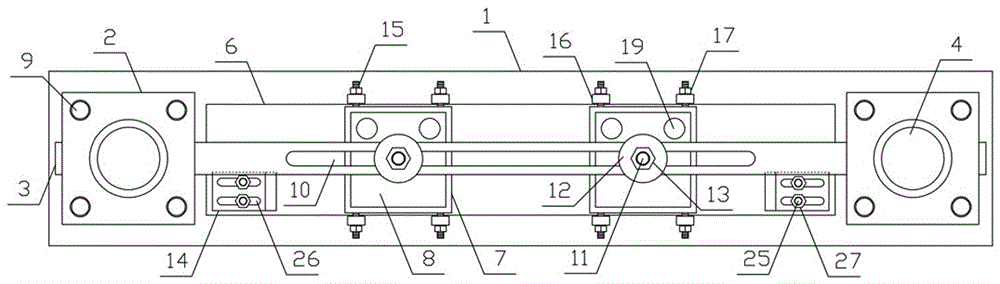

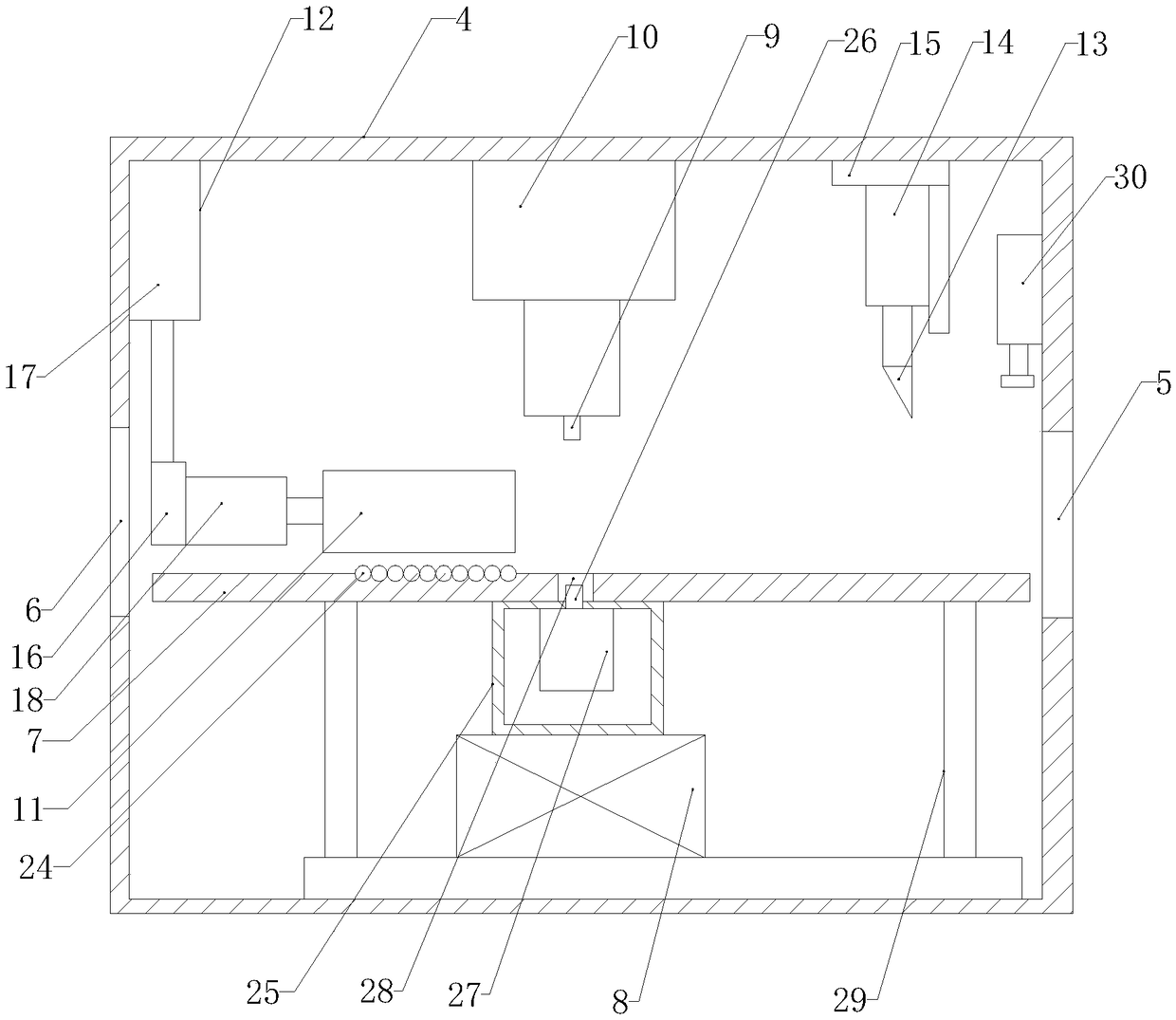

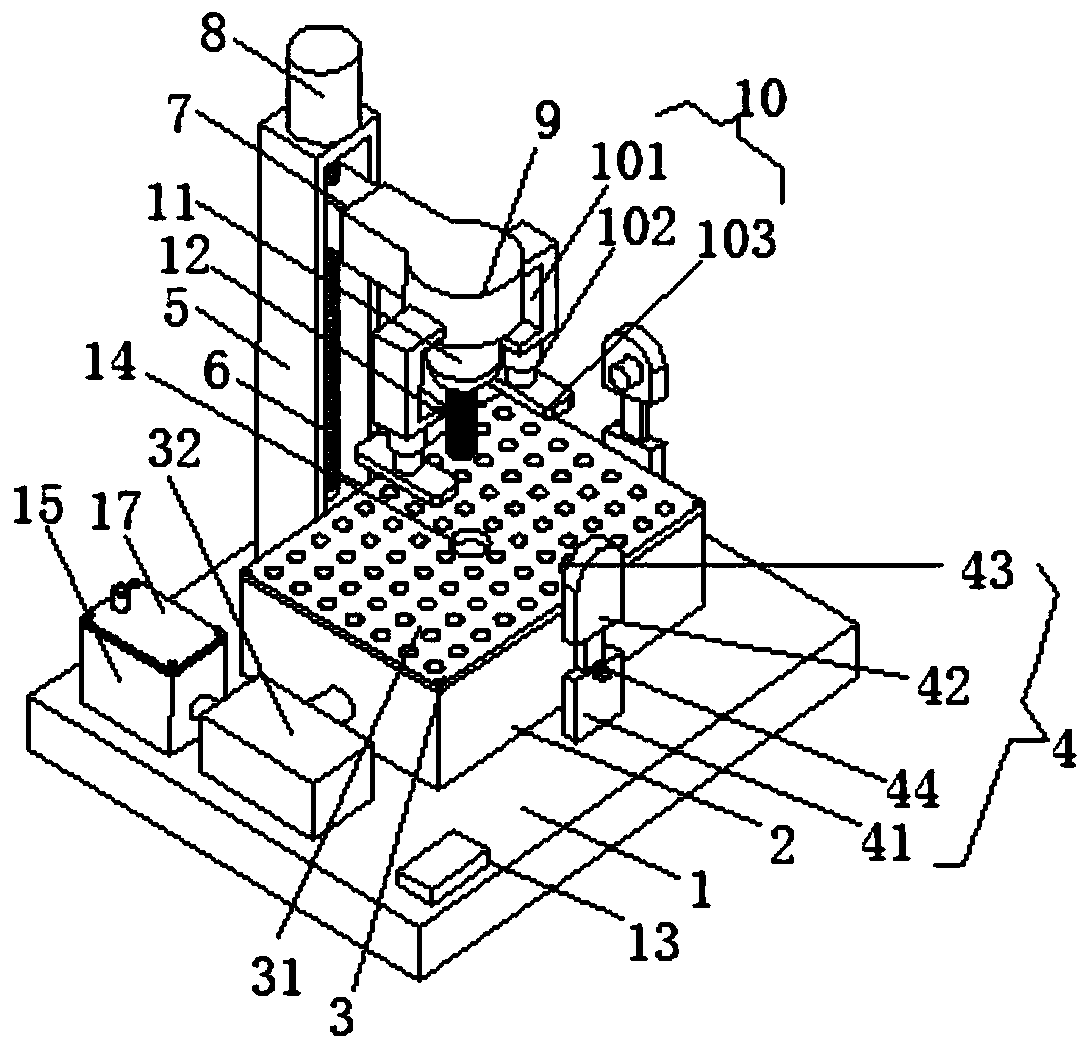

Aluminum product continuous punching mechanism

InactiveCN108787856AEasy to assemble and disassembleReasonable structural designMetal-working feeding devicesStripping-off devicesPunchingEngineering

The invention discloses an aluminum product continuous punching mechanism and belongs to the field of sectional material machining equipment. Rotating roller brackets on the two sides of a space belowa material conveying bracket are rotationally connected with material guide rotating rollers; a plurality of punching brackets are arranged on a horizontal movement guide rod in a sliding manner in the horizontal direction; punching pressure rods are vertically and fixedly arranged at the middle parts of the lower sides of adjusting guide plates; a punching pressure plate is horizontally and fixedly arranged on the lower side of a lifting pressure plate; rotating pressure rods are correspondingly and vertically arranged at the parts, on the two sides of a space above the lifting pressure plate, on the material conveying bracket; pushing rod cams are arranged at the parts, on one sides of the rotating pressure rods, on the material conveying bracket; and the output end of a rotary electromagnet is in transmission connection with the pushing rod cam on one side of the material conveying bracket by a punching belt. The structural design is reasonable, aluminum products can be subjected to punching machining conveniently, rapidly, stably and efficiently in the conveying process according to the requirement, scratched marks on the surfaces of the aluminum products in the machining process can be avoided, the punching machining efficiency and the punching machining quality of the aluminum products are improved, and the machining and using requirements are met.

Owner:蔡燕

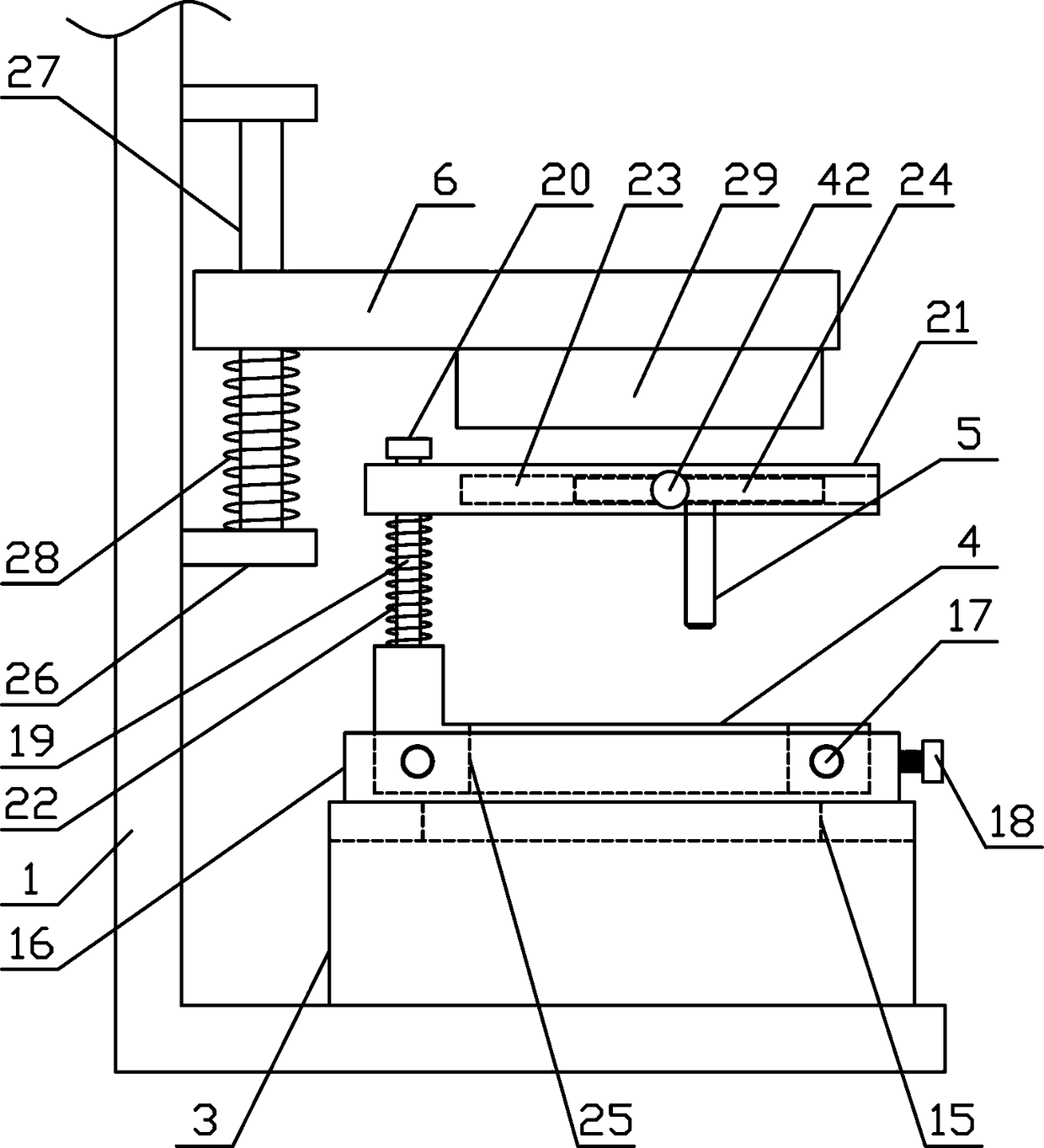

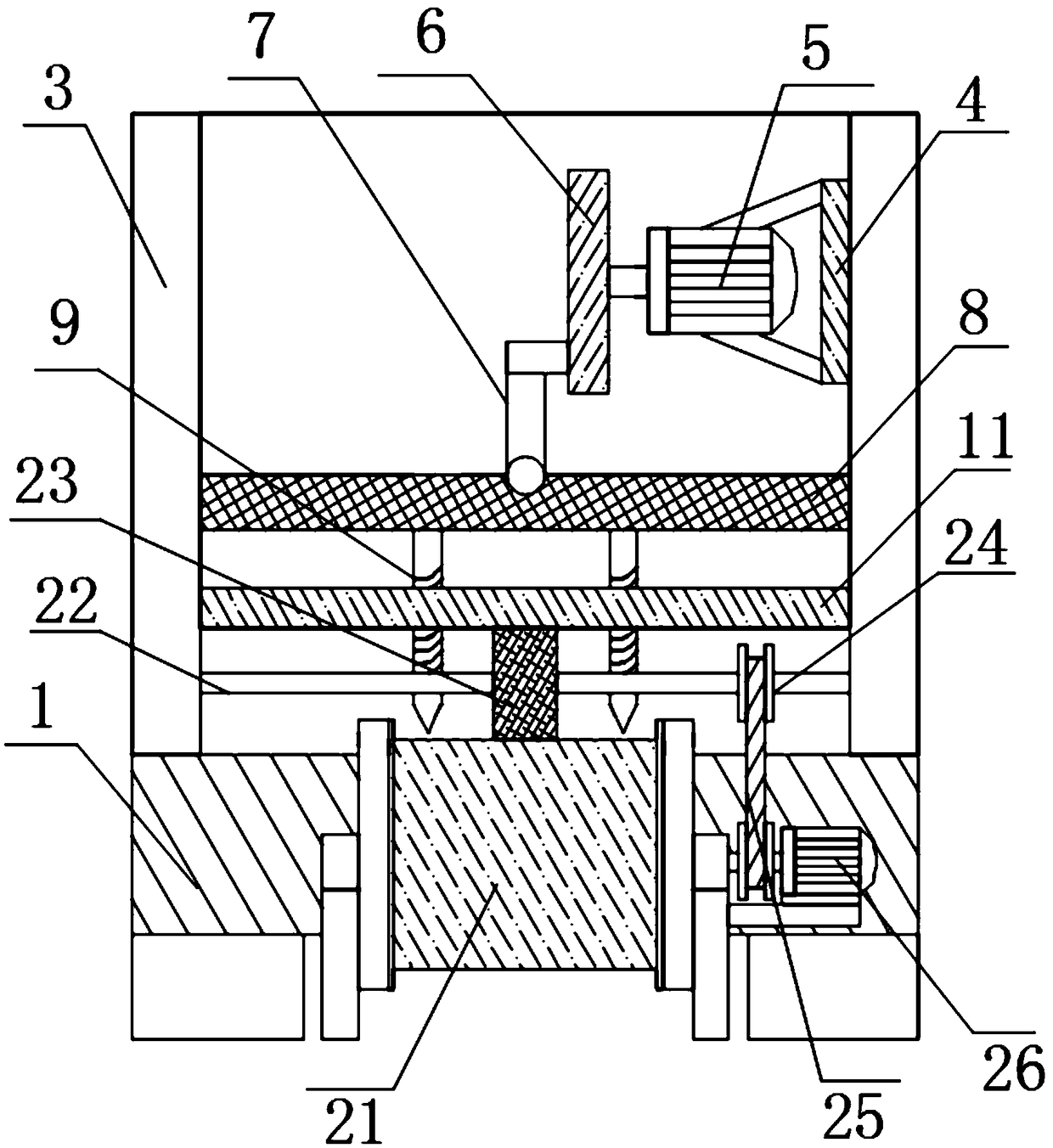

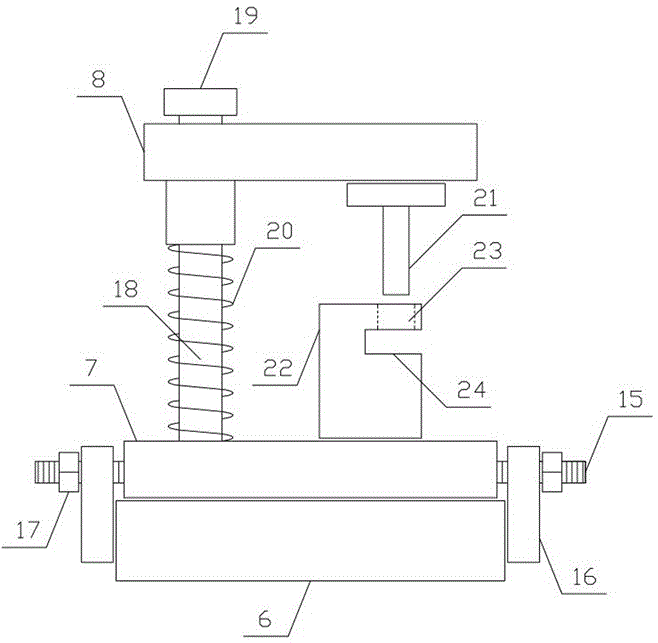

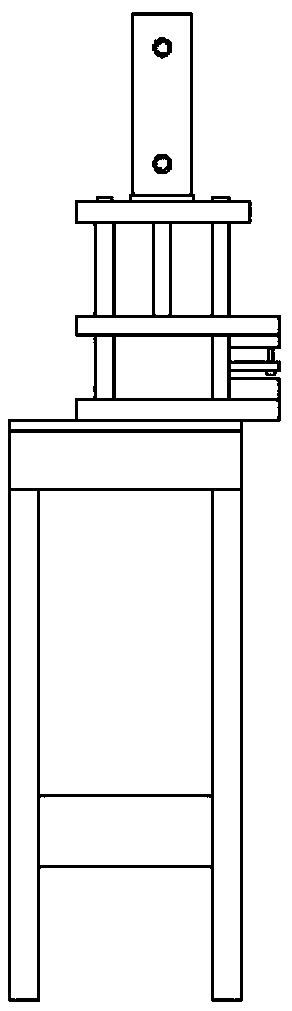

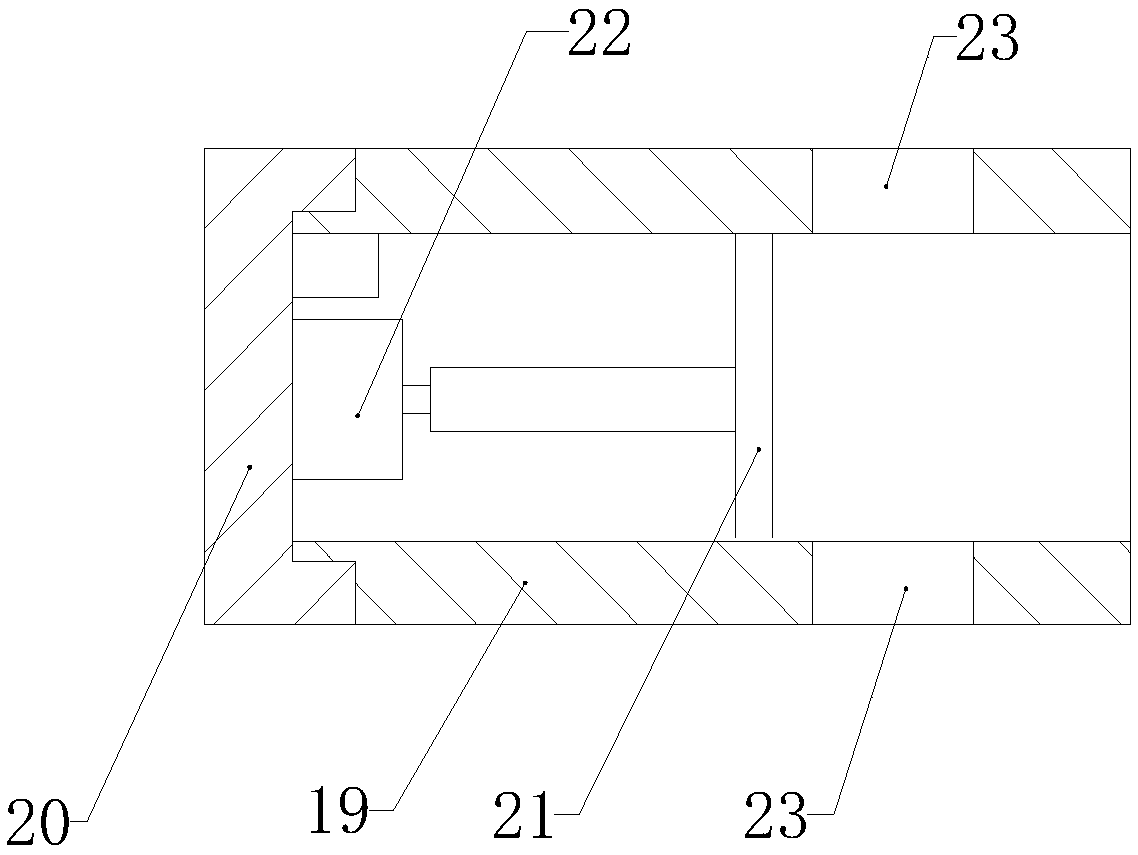

Efficient perforation device for processing shape memory titanium-nickel alloy coiled material

InactiveCN108857441AUniform feedingReduce manual operationsEdge grinding machinesMachine tool componentsAutomatic controlMotor drive

The invention discloses an efficient perforation device for processing a shape memory titanium-nickel alloy coiled material. The efficient perforation device has the advantages that the device is simple in structure, a first motor drives a slide plate to move vertically, the slide plate moves downwardly to drive screws to move downwardly, the screws drive drill bit to move downwardly to be abuttedagainst the titanium-nickel alloy coiled material and start rotating to drill the titanium-nickel alloy coiled material due to the fact that the screws are connected with nuts in a threaded manner, and titanium-nickel alloy coiled material abutting sliders move upwardly at the same time to allow polishing pieces to be abutted against the holes and start polishing the holes so as to achieve smoothholes; the slide plate moves upwardly to drive the screws and the drill bits to move upwardly to leave the titanium-nickel alloy coiled material, a touch rod is abutted against and pushes a shiftingpiece on a switch to start a second motor to perform feeding again, and accordingly automatic control, efficient perforation and hole polishing are achieved, and perforation device is high in practicality.

Owner:梁玉燕

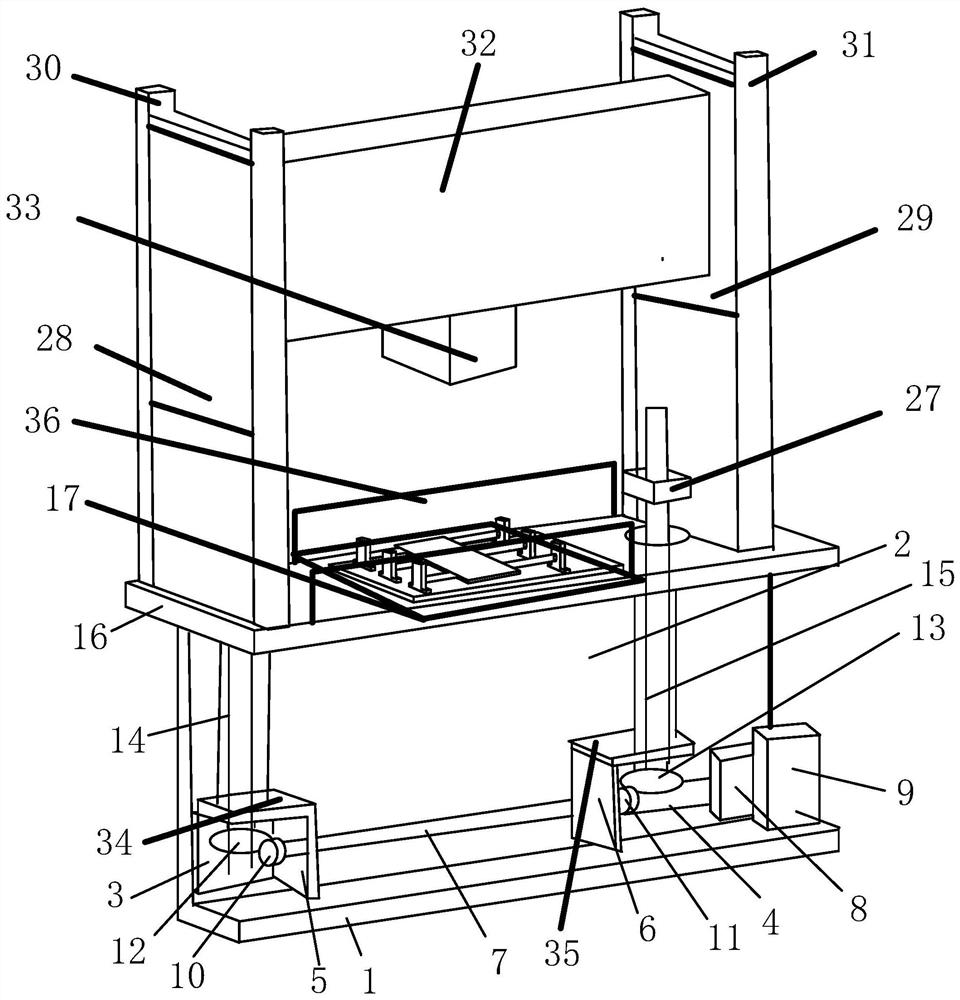

Fast key punching device for hardware manufacturing

ActiveCN106141244AReduce weightGood for up and down movementLarge fixed membersDriving apparatusPunchingEngineering

The invention relates to a punching device, in particular to a fast key punching device for hardware manufacturing. The technical aim of providing the precise punching fast key punching device for hardware manufacturing is achieved. In order to achieve the technical aim, the fast key punching device for hardware manufacturing comprises a bottom support, a first swing seat, a third connecting rod, a first spring, a bearing pedestal, a lead screw, a nut, a fixed plate, sliding blocks, first supporting rods, an electric drill, a first guide sleeve, a second supporting rod, a first connecting rod, a swing rod, a second swing seat, a supporting rod and the like. A left support, the first swing seat, the third connecting rod, the first spring and the bearing pedestal are sequentially arranged at the top of the bottom support from left to right. The fast key punching device achieves the effects of being precise and efficient in key punching for hardware manufacturing, punching is fast and convenient, the punching device is easy to operate and convenient to use, the conception of rotary punching is novel, and time and labor are saved.

Owner:宁津润科创投有限公司

Fixed punching device for aluminum materials

ActiveCN105689495AEfficient punchingImprove drilling efficiencyMetal-working feeding devicesPositioning devicesHydraulic cylinderPunching

The invention discloses a fixed punching device for aluminum materials and belongs to the field of building material machining equipment. The fixed punching device comprises a fixed support, support plates, a lifting plate, lifting hydraulic cylinders, squeezing boards, a fixed guiding plate, translation boards and punching boards. The two lifting hydraulic cylinders are arranged vertically downwards on the two support plates correspondingly. The lifting plate can lift vertically along lifting guiding bars. The squeezing boards are horizontally arranged at two sides below the lifting plate correspondingly. Limiting boards are arranged at the two ends of the upper side of the fixed guiding plate correspondingly. The translation boards are horizontally arranged at two sides of the upper portion of the fixed guiding plate correspondingly. The squeezing boards are horizontally arranged above the translation boards. The squeezing boards can lift vertically along punching guiding bars. A punching bar is arranged vertically downwards at one side of the lower side of each squeezing board. An aluminum material holding board is arranged horizontally on each translation board below the corresponding punching bar. The fixed punching device is reasonable in design and capable of punching aluminum materials of various size specifications fast, efficiently and conveniently, and therefore the requirements of production and application are met.

Owner:ZHEJIANG ZHUOYI ALUMINUM

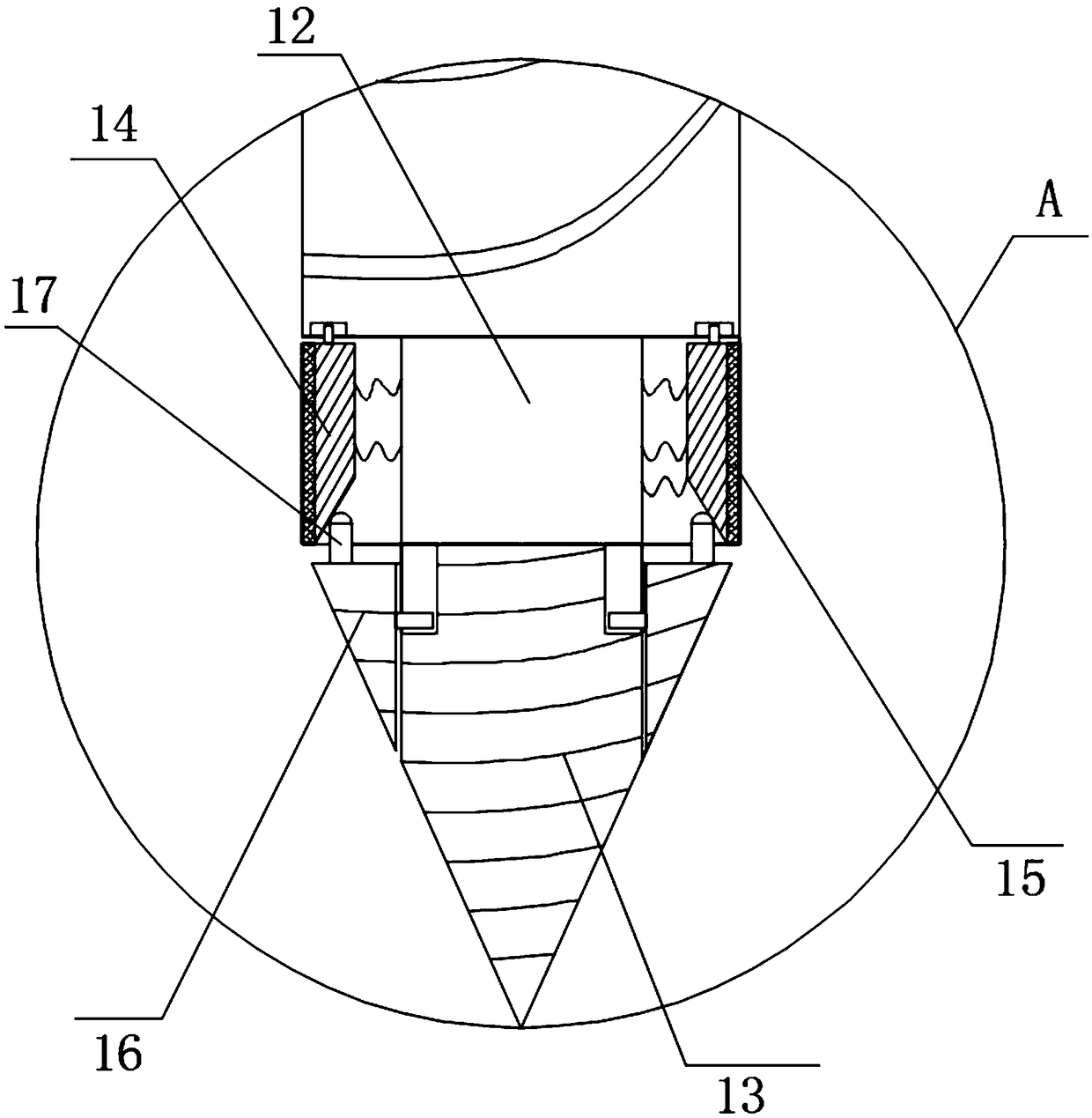

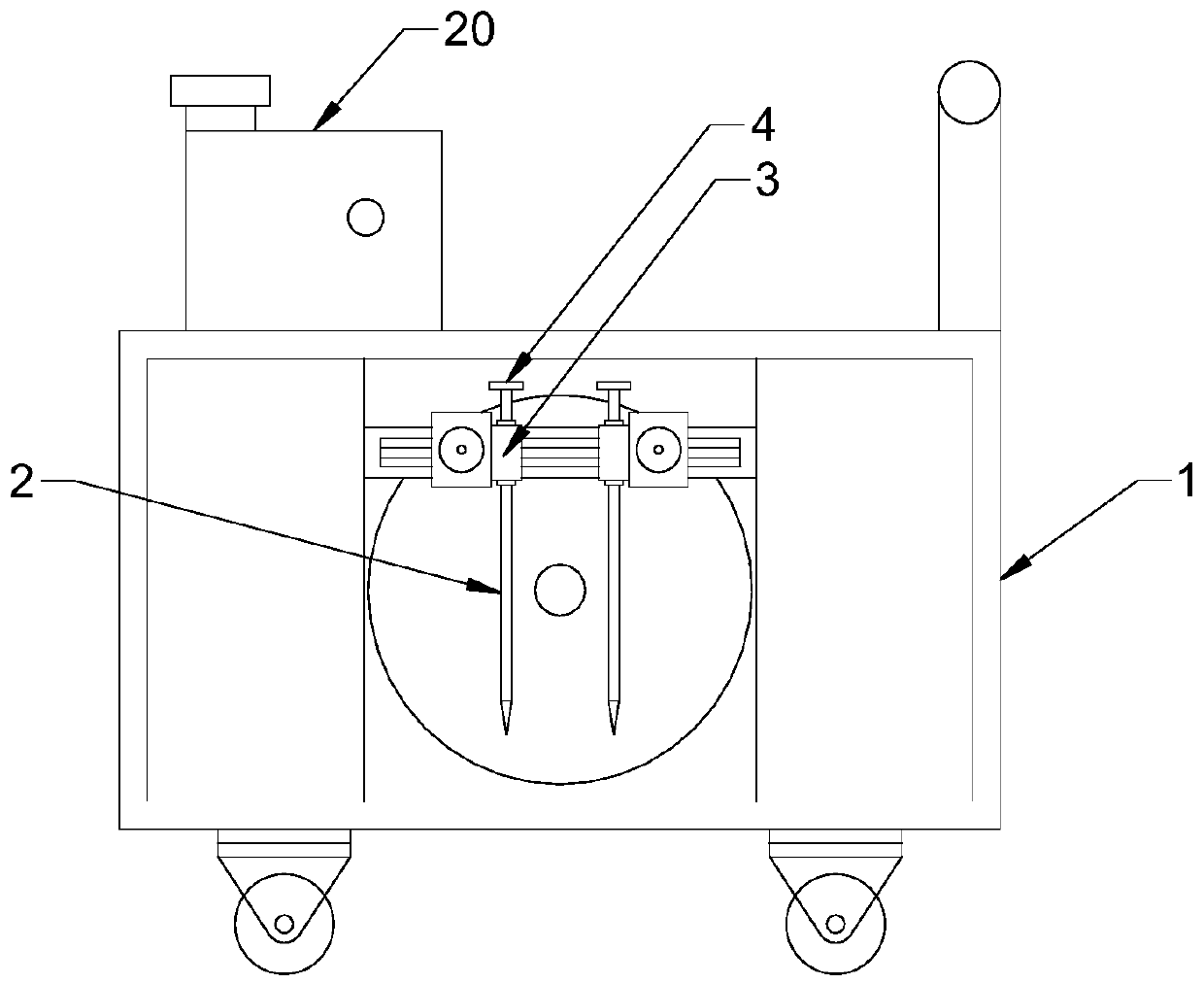

Adjustable perforating device for agricultural planting

InactiveCN110199623AImprove drilling accuracyEasy to adjustPlantingFurrow making/coveringCartAgricultural engineering

The invention discloses an adjustable perforating device for agricultural planting, comprising a cart. Two groups of perforating rods arranged relatively are arranged outside the cart; a carrier blockis arranged at the upper end of each perforating rod in penetrated manner; a longitudinal slider is fixedly connected to each carrier block; the corresponding longitudinal sliders are embedded in onelongitudinal slide-groove plate; a transverse slider is fixedly connected to the tail end of each longitudinal slide-groove plate; the transverse sliders are embedded in a lifting plate; the liftingplate is connected with a lifting mechanism. The carrier blocks in threaded connection with the perforating rods are provided, so that perforating depth is convenient to adjust; the transverse slidersand longitudinal sliders driven by bidirectional screws are provided, so that perforation transverse spacing and longitudinal spacing are convenient to adjust, and perforating precision and perforating efficiency are improved; an eccentric disc with the lifting plate and an eccentric post is provided, so that the perforating rods are driven to move up and down periodically to arrive at efficientperforating.

Owner:安利英

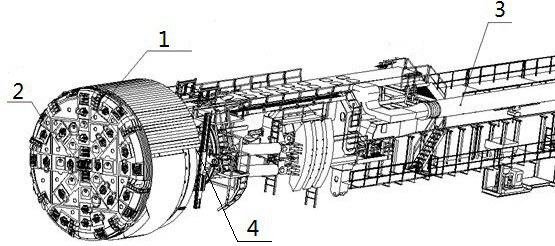

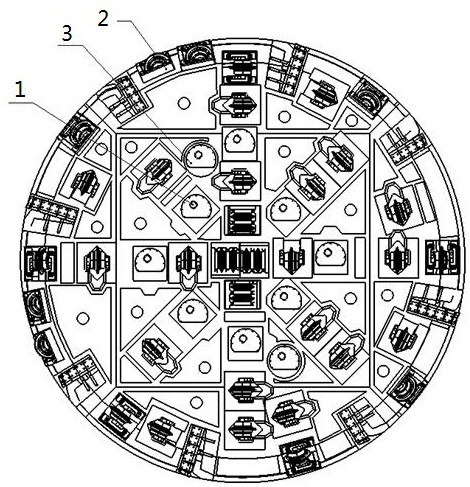

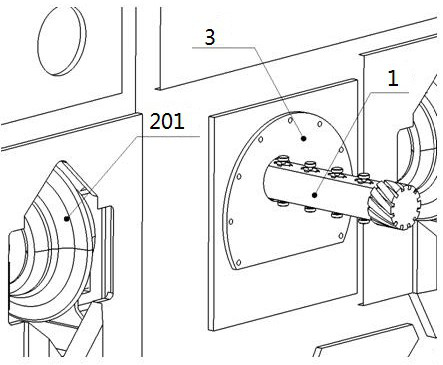

Novel TBM and construction method thereof

ActiveCN111963192ADoes not affect the excavation functionReduce wearTunnelsAnchoring boltsSupporting systemArchitectural engineering

The invention discloses a novel TBM and a construction method thereof. The problems of low tunneling efficiency and serous wear to a cutterhead when a TBM is used for excavating hard rocks in the prior art are solved. The novel TBM comprises a tunneling mainframe and a rear supporting system. The tunneling mainframe comprises a cutterhead. The cutterhead is a master driver arranged in the tunneling mainframe. The cutterhead is provided with an excavation tool and an anchor drilling and splitting device used for conducting anchor drilling and splitting to assist in rock breaking. The novel TBMintegrates the functions of a jumbolter and a hydraulic splitting rod, drilling holes in a tunnel face through an anchor drilling device, bursts the drilled holes through the splitting device, conducts anchor drilling and splitting to drill and break the hard rocks on the tunnel face in advance of the cutterhead, then conducts excavation on the drilled and broken tunnel face through the cutterhead, reduces wear to the excavation tool and improves the excavation efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Small volume unitary molded filters and supports for adsorbent beds

Methods and devices are provided for preparing and separating biological analytes. In one embodiment, one or more filtration devices or filter plate wells can be formed by clamping a filter sheet between first and second plates having at least one connecting cavity. First and second moveable core pins positioned on opposed sides of the sheet can be moved to remove portions of the sheet. A molten plastic can be injected to fill the volume between the cores and cavities and to form a liquid-impermeable sleeve wall or walls, each being separately sealed at the bottom to the perimeter of the sheet portion, each having liquid permeable regions of said removed and sealed sheet portion, and each remaining open at the top. Various exemplary configurations for filtration devices or filter plate wells are also disclosed.

Owner:ORBITAL BIOSCI

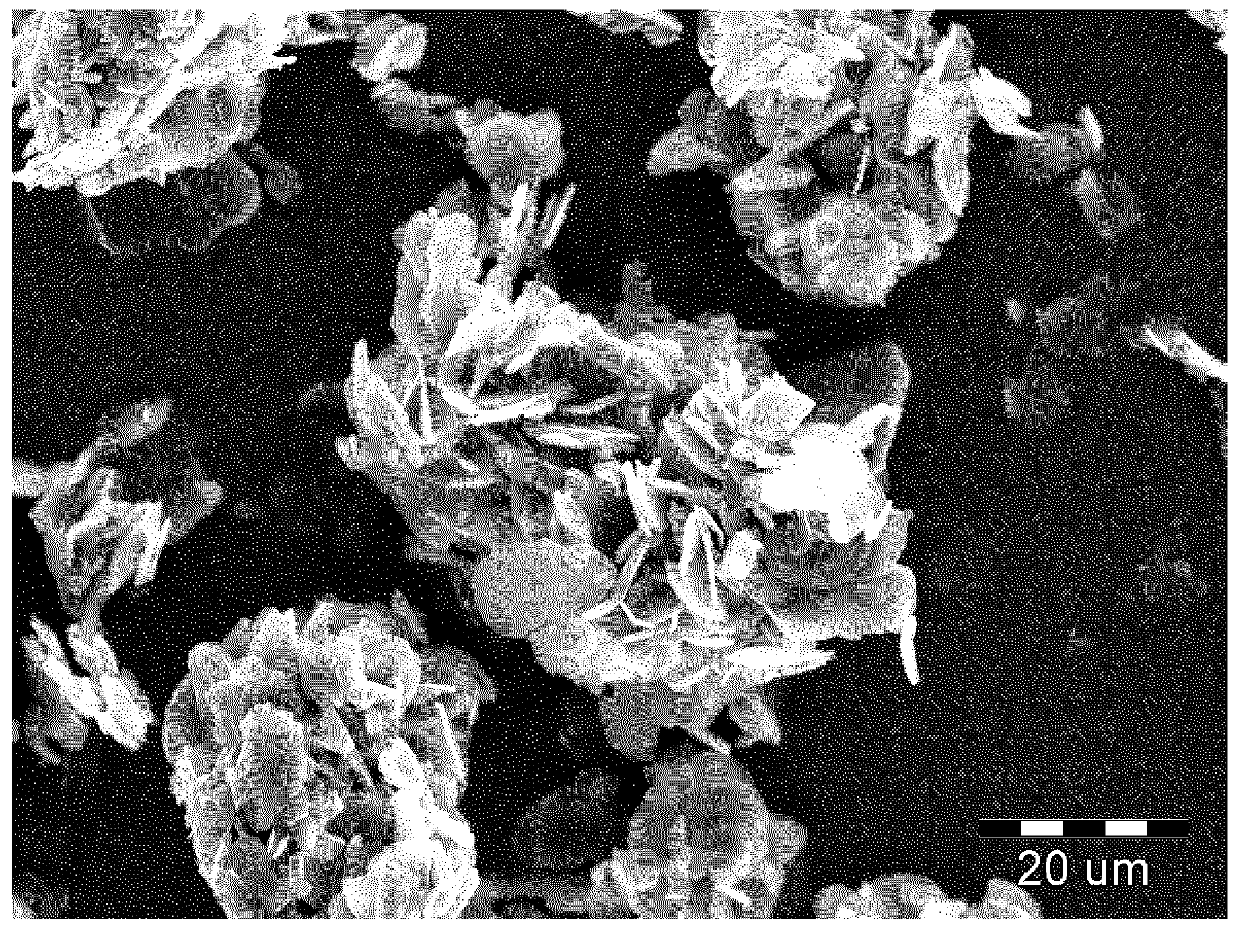

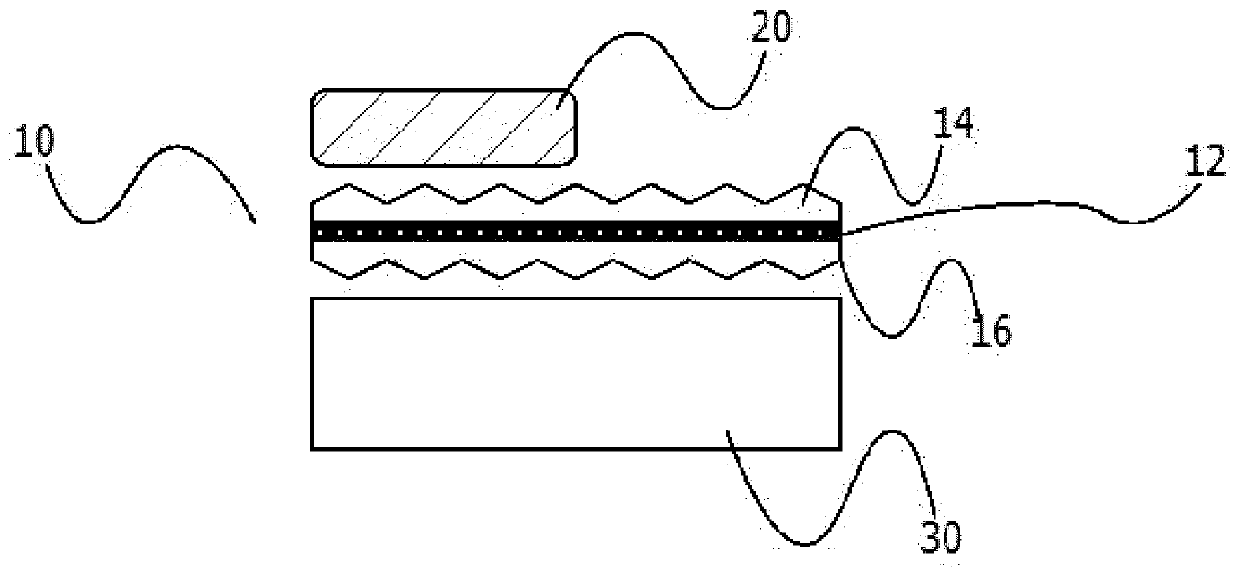

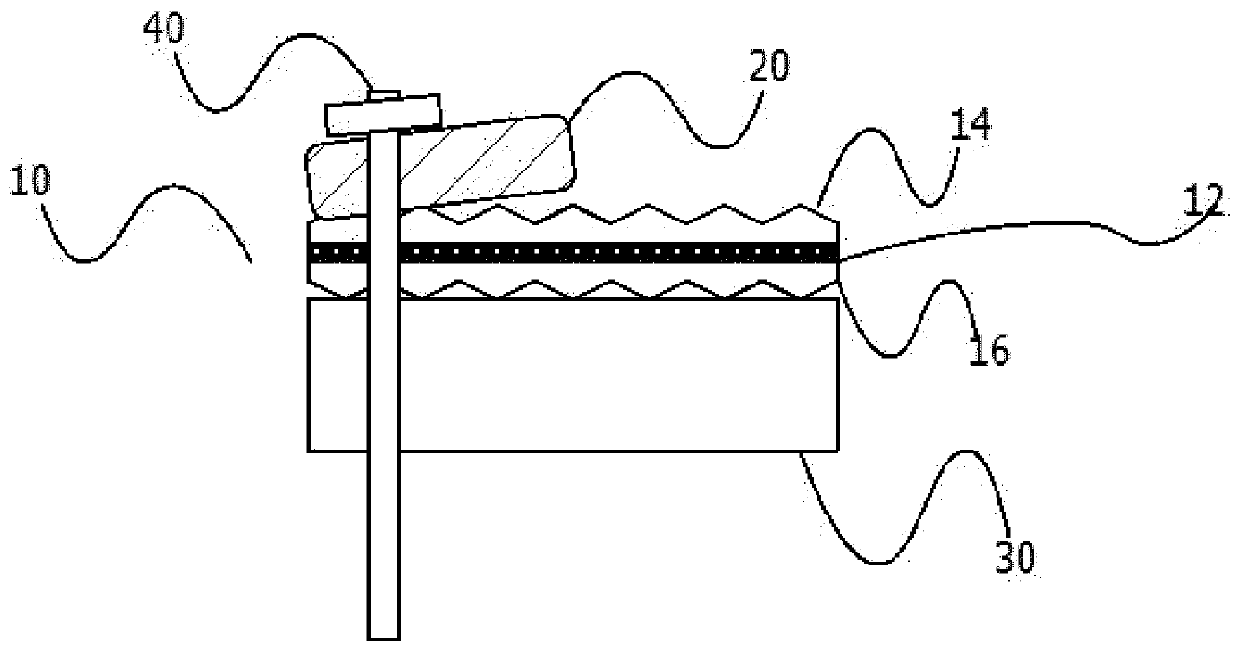

Heat dissipation sheet having high load carrying capacity and high thermal conductivity

ActiveCN109997423ALow costIncrease loading capacitySemiconductor/solid-state device detailsSynthetic resin layered productsFilling materialsHardness

The invention provides a heat dissipation sheet which achieves a good balance between high load carrying capacity and high thermal conductivity at a low cost. A heat dissipation sheet which has a configuration wherein silicone composition layers containing a thermally conductive filler are laminated on both surfaces of a reinforcing layer. The heat dissipation sheet is configured such that: the ten-point average roughness (RzJIS) of a surface of at least one of the silicone composition layers on the both surfaces of the reinforcing layer, the surface being not bonded to the reinforcing layer,is within the range of from 15 [mu]m to 70 [mu]m (inclusive); the durometer A hardness of the silicone composition layers is within the range of from 25 to 90 (inclusive); and the thermal conductivityof the heat dissipation sheet in the thickness direction is 2.5 W / (m.K) or more.

Owner:DENKA CO LTD

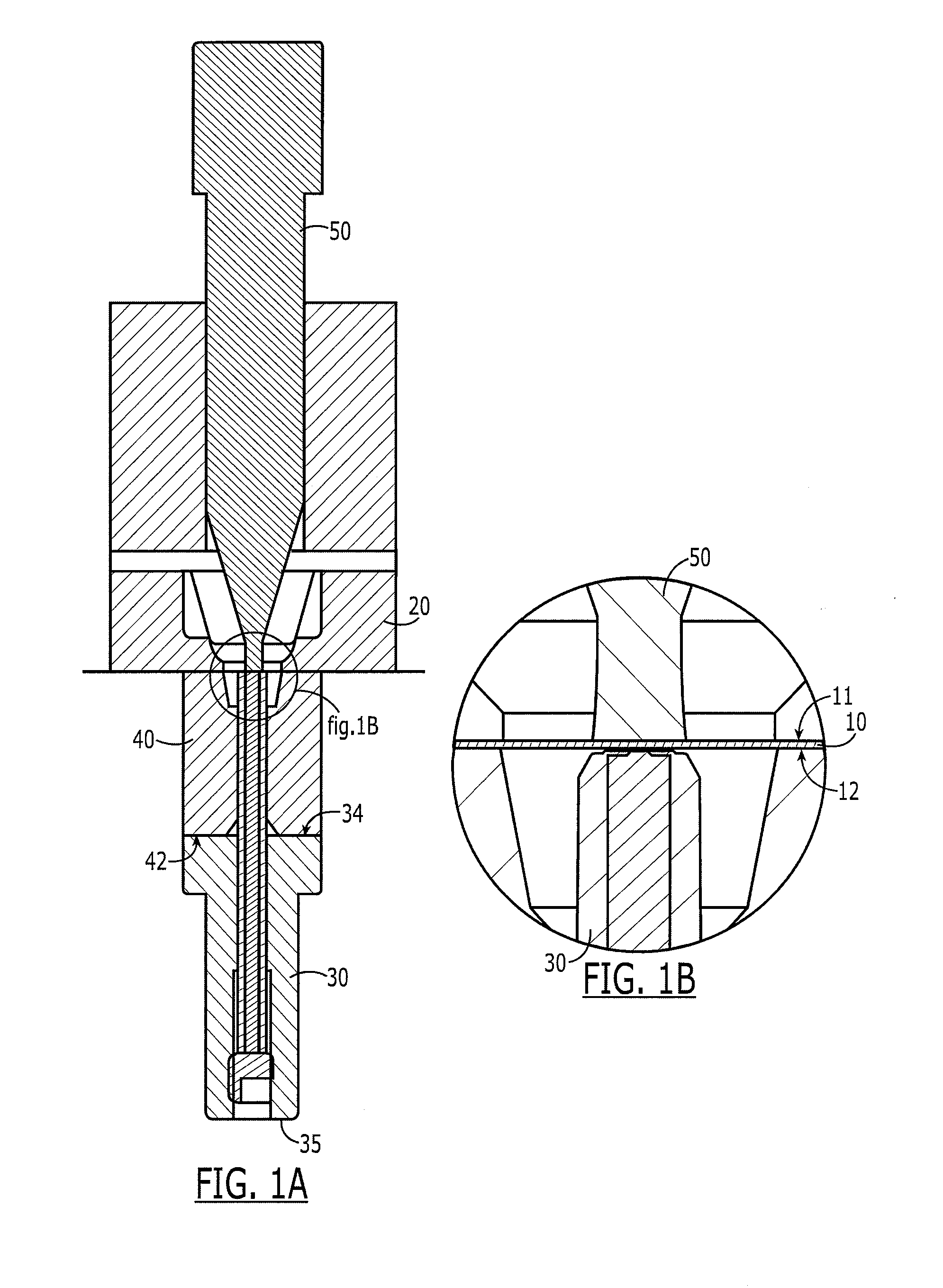

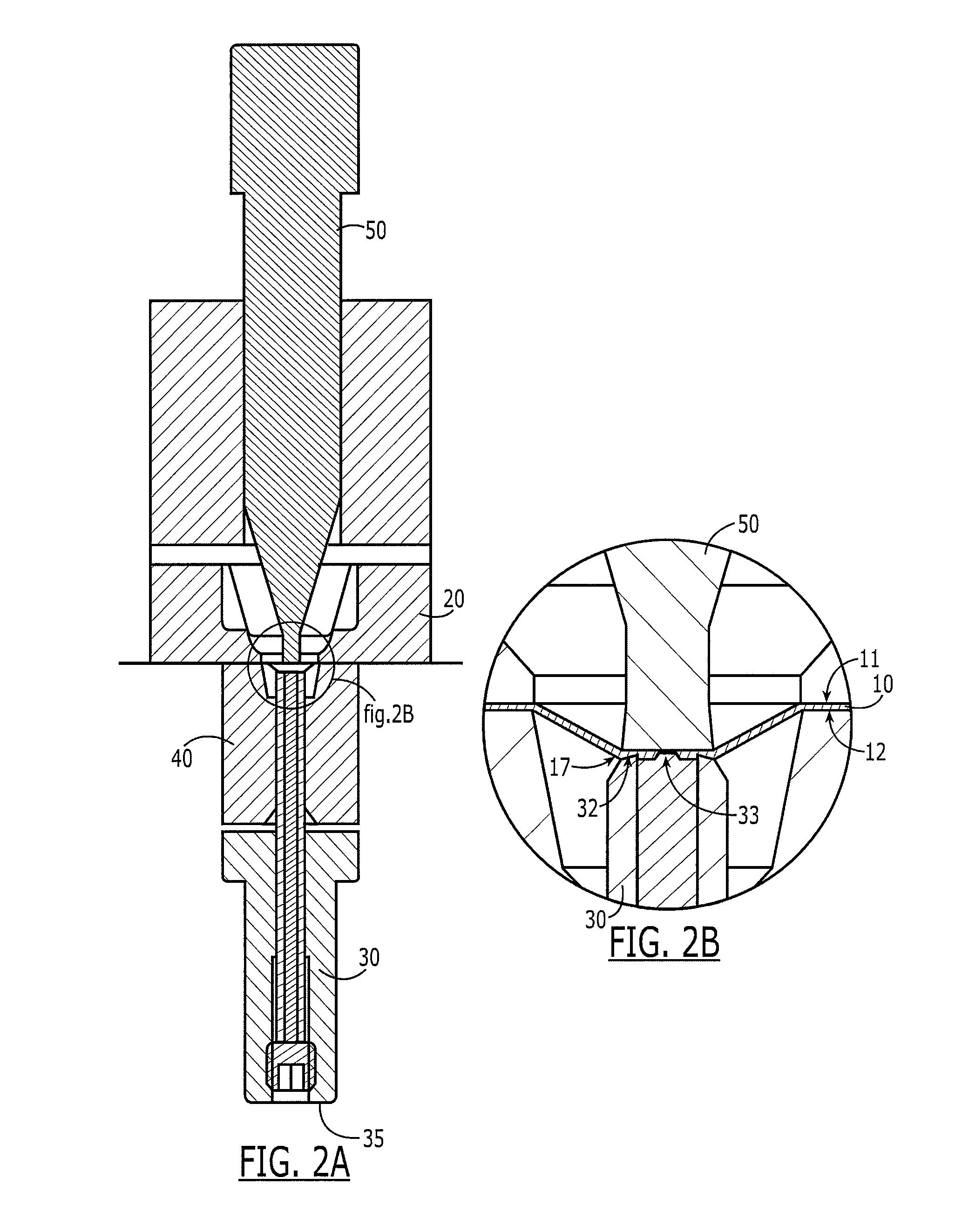

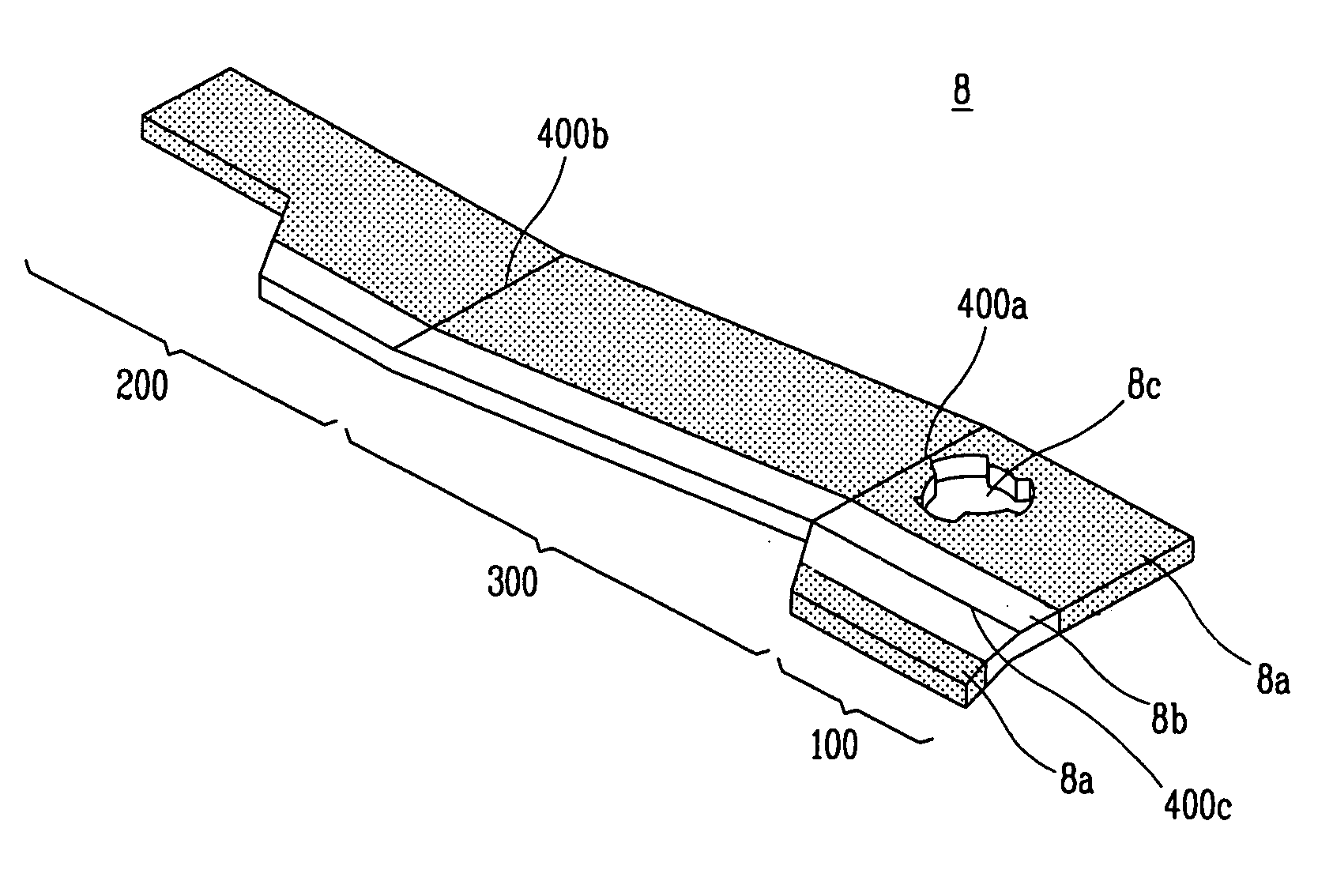

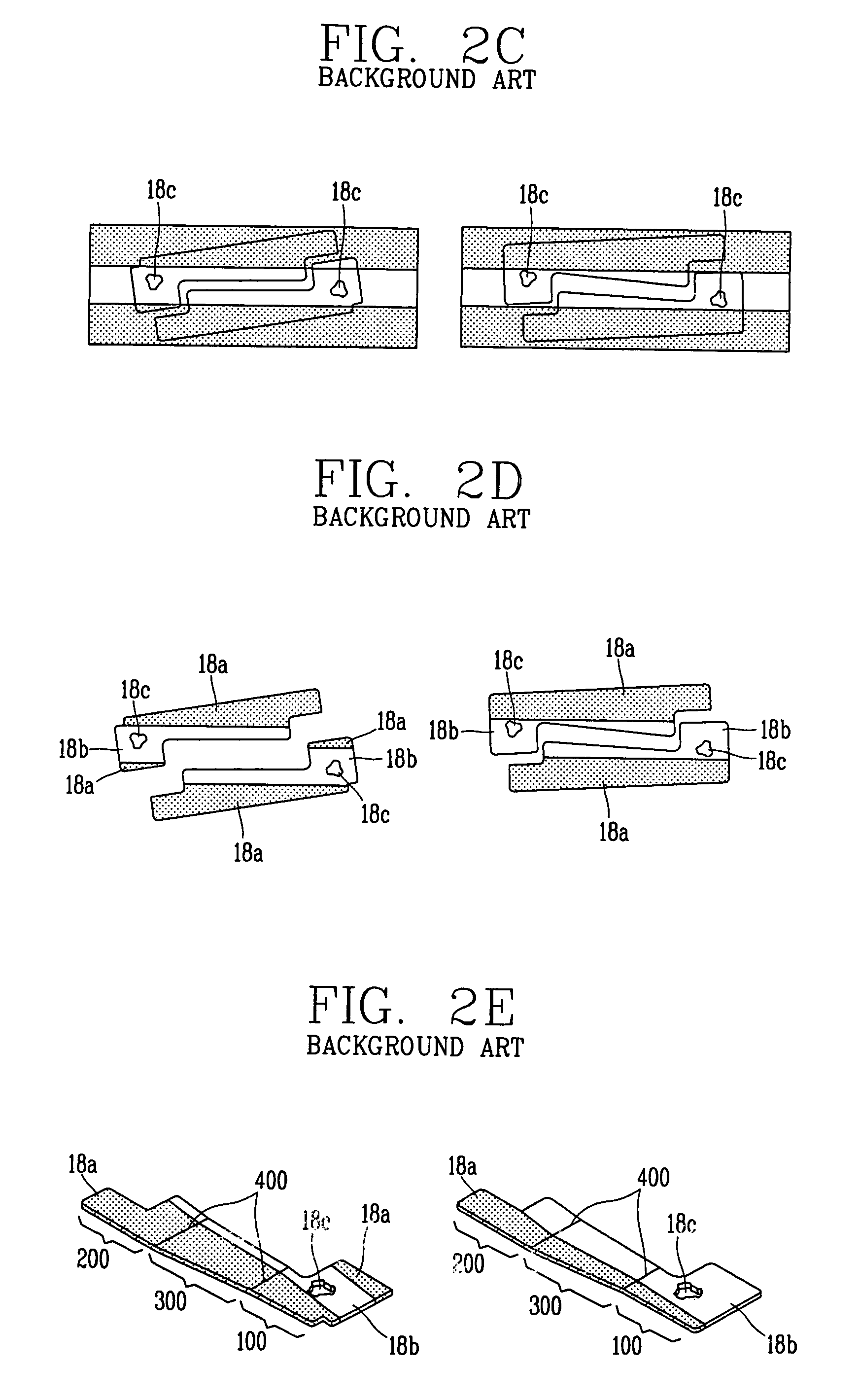

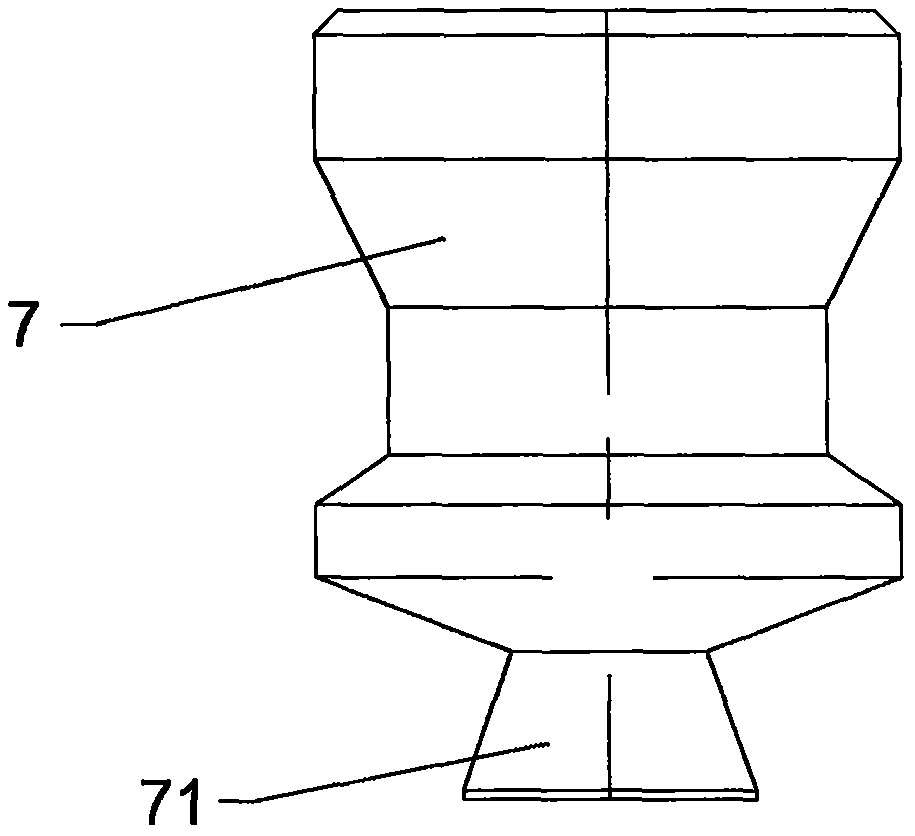

Holder for cathode ray tube and fabrication method thereof

InactiveUS7045940B2Efficient punchingEfficient slittingElectrically conductive connectionsLeaf springsEngineeringCathode ray

A holder for a cathode ray tube includes a stud engaging portion having an engaging hole in order to be engaged to a stud pin mounted inside a panel, a frame engaging portion engaged to a mask frame which supports a shadow mask, and a connecting portion for connecting the stud engaging portion and the frame engaging portion. Lower end surfaces of a pair of holders are arranged facing toward each other so that the lower end surfaces of the connecting portion are in substantial contact with each other.

Owner:MERIDIAN SOLAR & DISPLAY

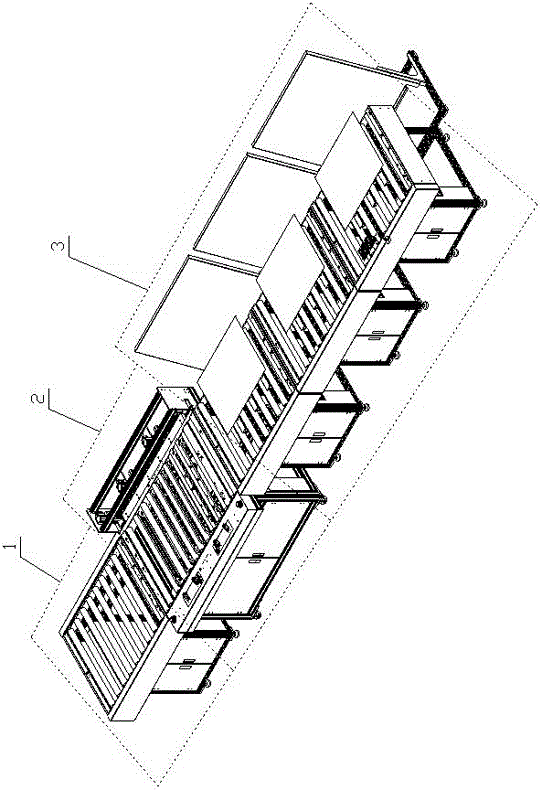

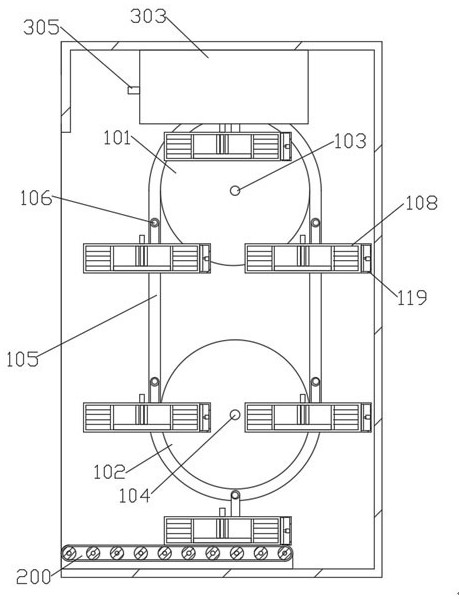

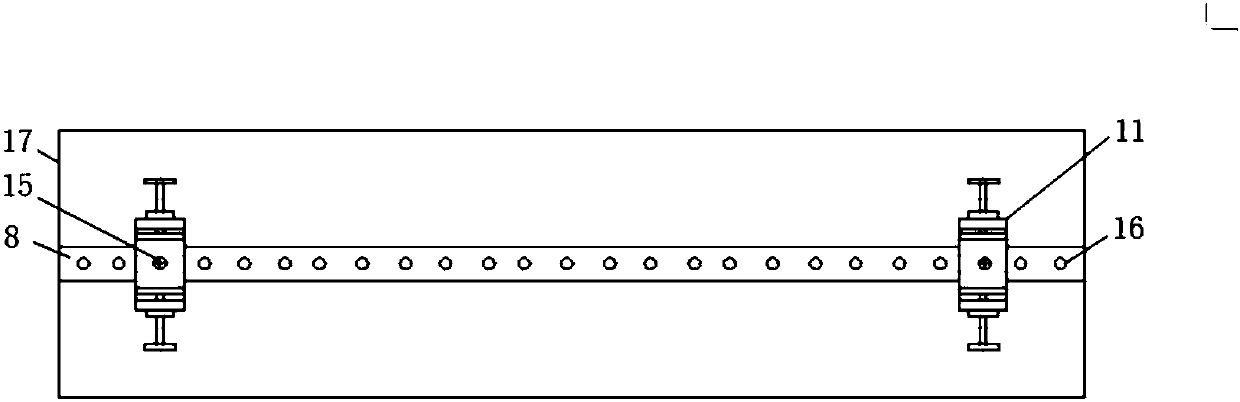

Full-automatic online punching bending plate system

The invention discloses a full-automatic online punching bending plate system. The full-automatic online punching bending plate system comprises a plate inlet correcting mechanism, a bending plate punching mechanism and a plurality of plate collecting mechanisms. The system is designed and manufactured for CTP platemaking users so as to achieve the full-automatic platemaking flow, a large amount of manpower is saved, and work efficiency is improved.

Owner:上海上尊机械制造有限公司

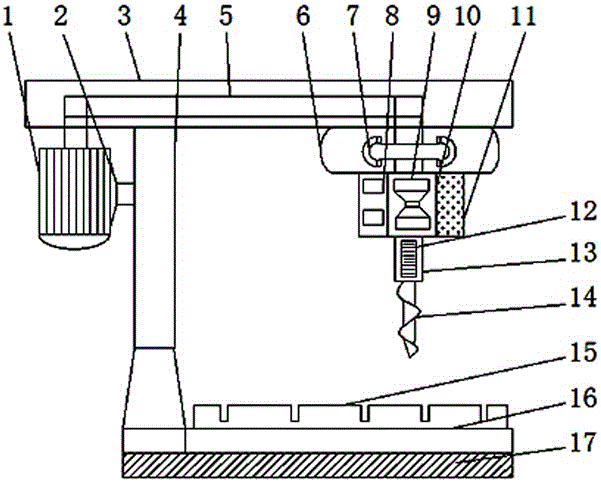

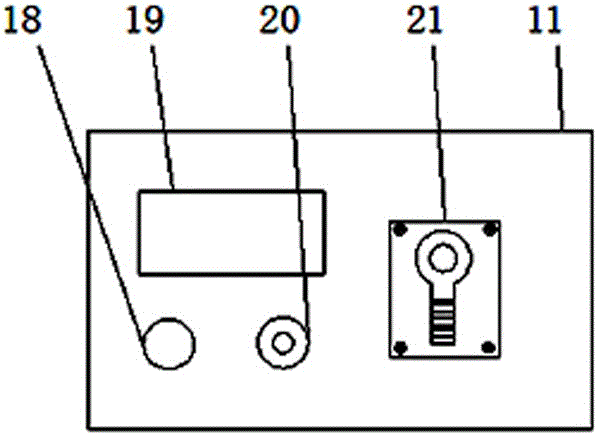

Steel plate puncher with stable performance

InactiveCN106180915AImprove stabilityReduce wearThread cutting toolsThread cutting machinesSteel platesSheet steel

The invention discloses a steel plate puncher with stable performance. The steel plate puncher comprises a beam, a tapping upper mould, a control box, a tapping lower mould and a base; a motor is mounted at the left side of the lower portion of the beam; a fixed frame is mounted at the right side of the motor; a bearing shaft is mounted below the beam; the base is mounted below the bearing shaft; an operating table is arranged above the base; a linkage rod is mounted inside the beam; the tapping upper mould is mounted at the right side of the lower portion of the beam; a shaft stabilizer is mounted inside the tapping upper mould; the control box is mounted below the tapping upper mould; a power supply button is mounted at the left side of the surface of the control box; a return button is mounted at the right side of the power supply button; and a travel knob is mounted at the right side of the surface of the control box. According to the steel plate puncher disclosed by the invention, the tapping shaft with a helically corrugated structure below the tapping mould can quickly and efficiently punch a steel plate, so that degree of wear of the tapping shaft can be reduced, and service life of the puncher is prolonged.

Owner:张艳

Thin plate punching device for automobile part machining

ActiveCN114799574AEasy to fixConvenient laser drillingVehicle componentsMetal working apparatusPunchingTransmission belt

The invention discloses a thin plate punching device for automobile part machining, and relates to the technical field of thin plate punching, the thin plate punching device for automobile part machining comprises a punching frame, a fixing frame is fixedly installed at the bottom of the punching frame, a feeding and taking belt is rotatably installed on the fixing frame, and through the arrangement of the feeding and taking belt, automatic plate feeding and taking convenient for thin plate punching are achieved; the two transmission belts are arranged to be matched with the first connecting shell and the second connecting shell, corresponding assemblies can be driven to move circularly, the cohesion of the thin plate before and after punching is effectively improved, meanwhile, an operator does not need to fix the thin plate to the punching position any more, unnecessary labor cost is saved, and the production efficiency is improved. The multiple positioning assemblies and the liftable clamping assemblies are arranged on the first connecting shell and the second connecting shell, the sheets can be sequentially stacked when facing the sheets conveyed from the conveying and taking belt, simultaneous laser drilling of the multiple sheets is facilitated, and the laser drilling efficiency is effectively improved.

Owner:徐州天启新材料科技有限公司

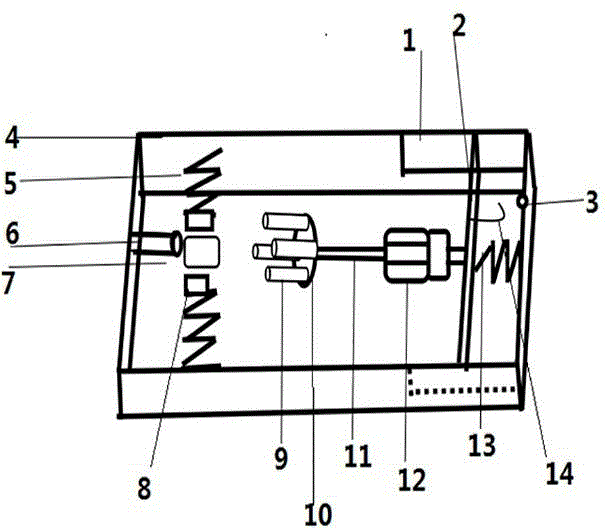

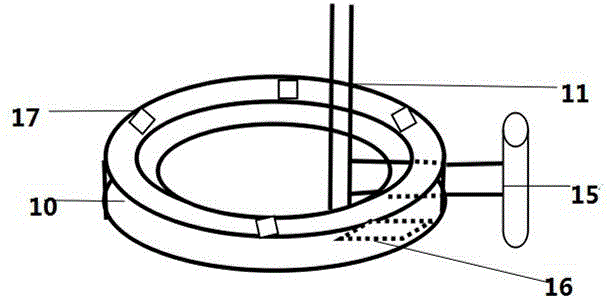

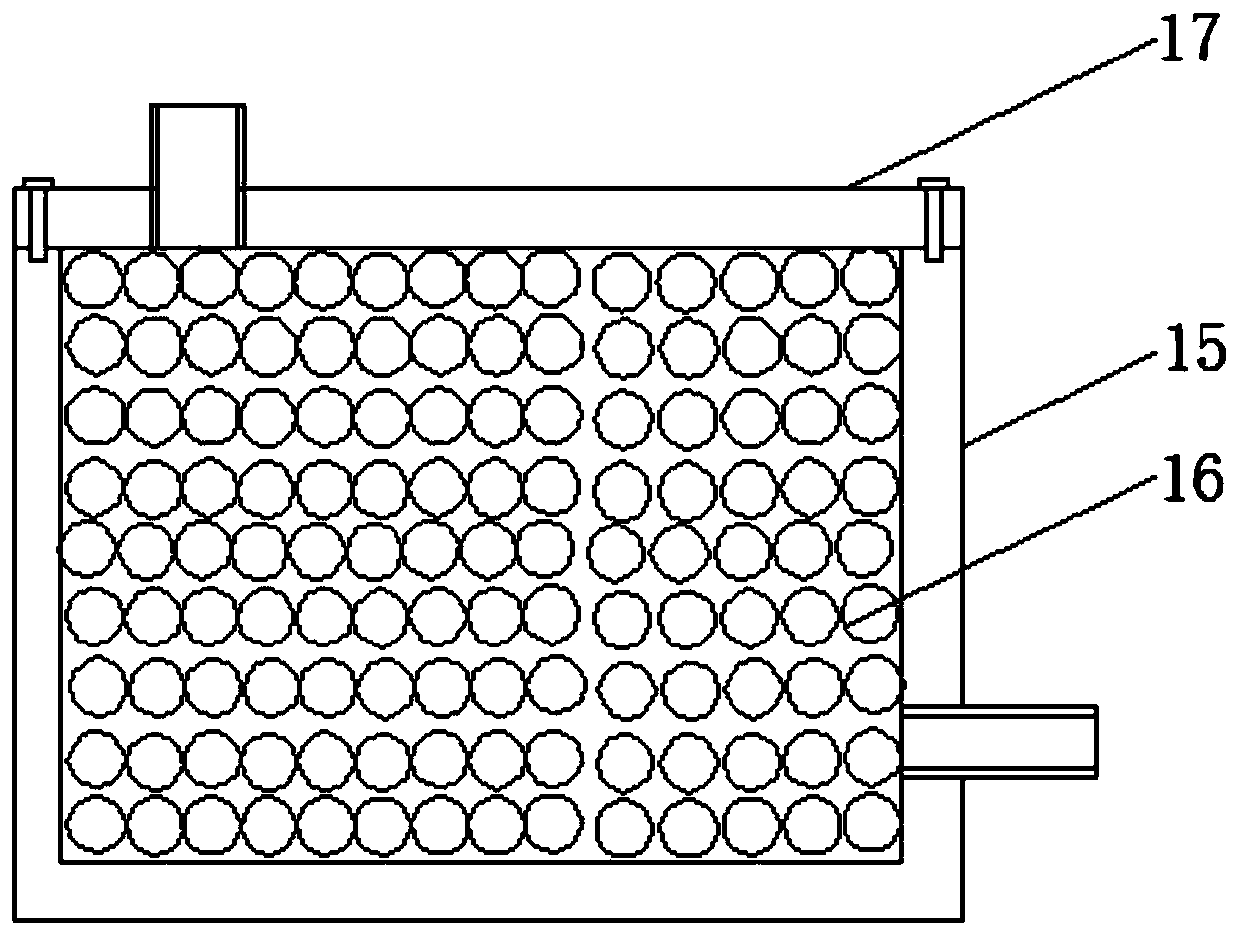

Rotary bit change type rubber sieve perforating machine

A rotary bit change type rubber sieve perforating machine overcomes the defects that rubber sieves are manually perforated in most cases in laboratories in the prior art, time and labor are wasted, perforators have too many models and are prone to loss, rubber sieve perforating machines in the existing patented technology are not efficient, and drill bits are troublesome to replace. The rotary bit change type rubber sieve perforating machine is characterized in that two identical sliding grooves are formed in the inner wall of a machine enclosure, a round hole is formed in the right sidewall of the machine enclosure, the left end and the right end of a baffle are connected with a spring b and a motor respectively, a rotor of the motor is connected with a rotary rod, the rotary rod is cylindrical, a supporting plate is arranged at the lower end of the rotary rod, a disc is arranged on the supporting plate, a knob penetrates through the sidewall of the disc, a plurality of dials are arranged at the upper end of the disc, a plurality of drill bits with different diameters are arranged at the lower end of the disc, the front end and the rear end of the inner wall of the machine enclosure are connected with two identical springs a respectively, the other ends of the springs a are connected with two identical partition plates respectively, one end of a brace is connected to the inner wall of the machine enclosure, and a storage plate is arranged at the bottom end of the machine enclosure. The rotary bit change type rubber sieve perforating machine is simple in design, convenient to use, low in cost and easy to popularize.

Owner:MIANYANG XIAODI SHENGDIAN CREATIVE SCI & TECH

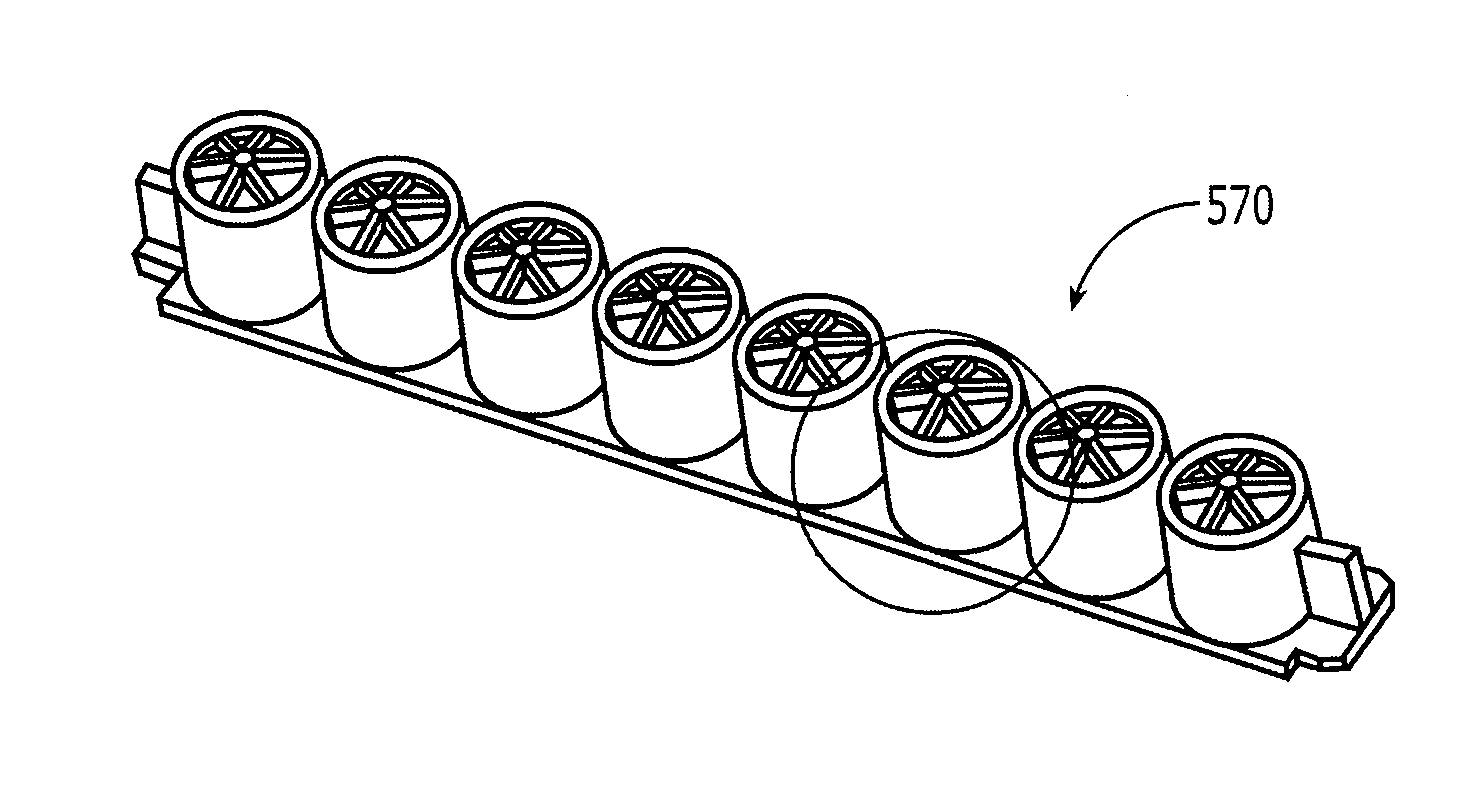

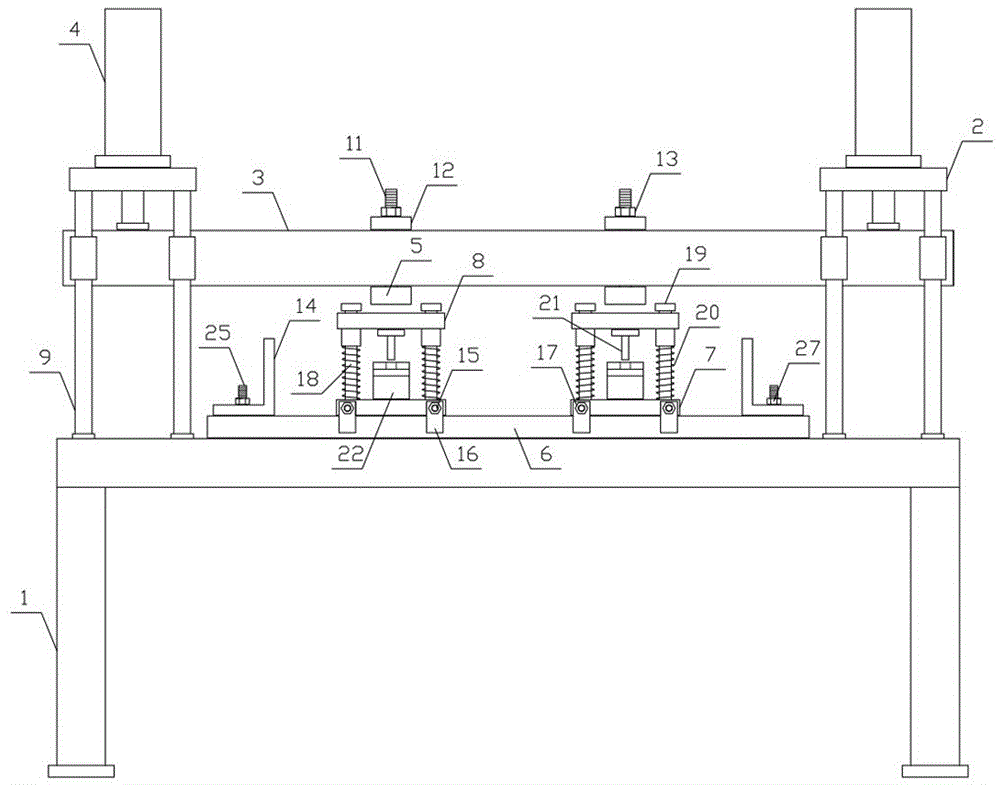

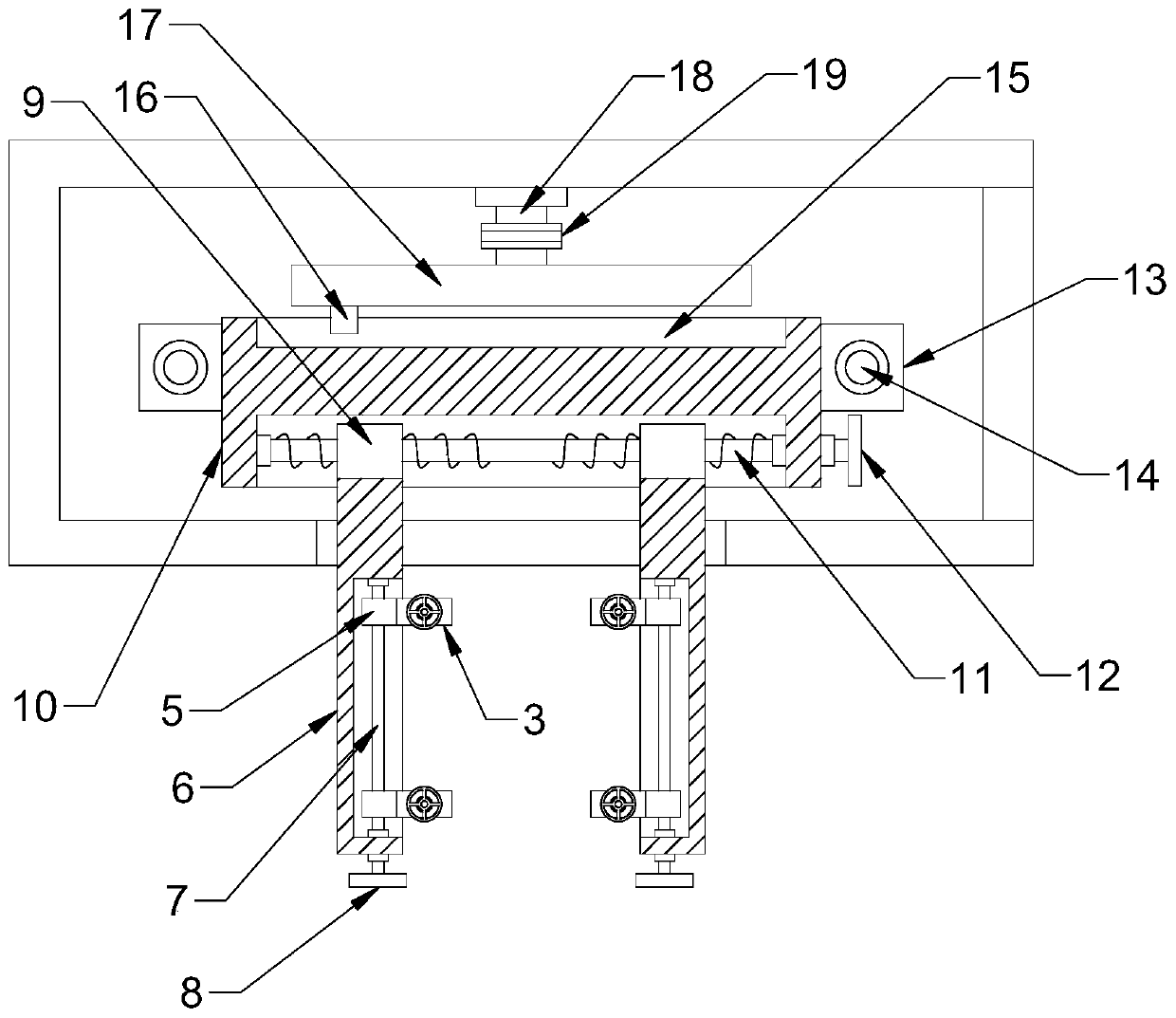

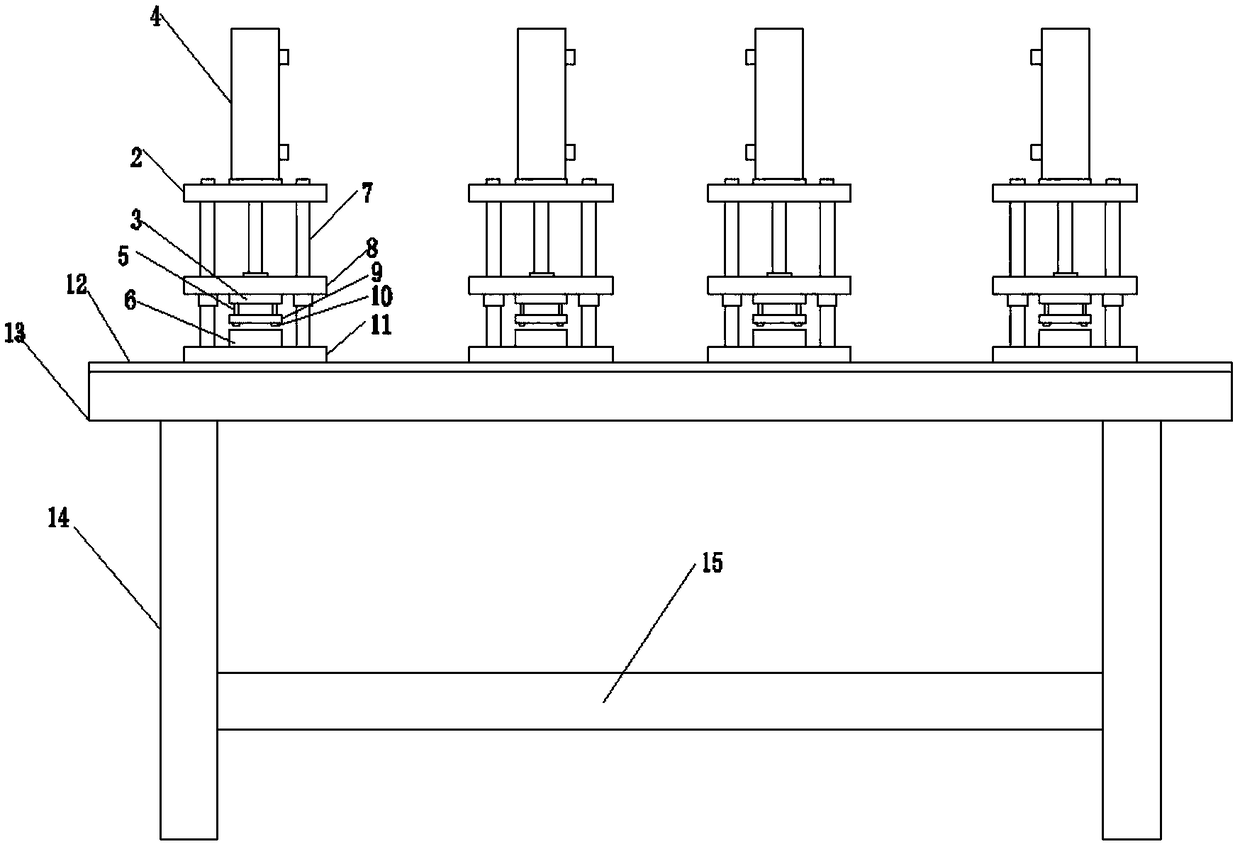

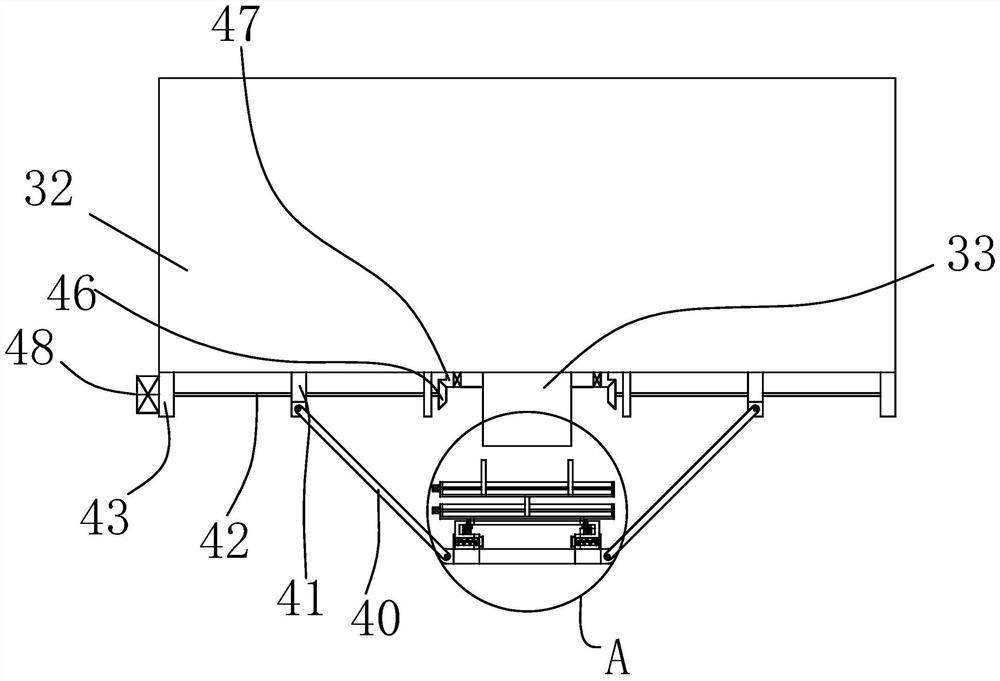

Pipe penetrating type aluminum alloy template punching equipment

PendingCN109175083AEfficient clamping and punchingEffective clampingPerforating toolsEngineeringAluminium alloy

The invention relates to pipe penetrating type aluminum alloy template punching equipment. The pipe penetrating type aluminum alloy template punching equipment comprises a rack, clamping systems and punching systems. The multiple clamping systems are arranged on the rack. An interval is formed between every two adjacent clamping systems. The clamping systems are located on one straight line. Eachclamping system is provided with one punching system. The clamping systems are used for clamping an aluminum alloy template. The punching systems are used for punching the aluminum alloy template. Thepipe penetrating type aluminum alloy template punching equipment has the advantages that through the arrangement of the clamping systems and the punching systems, the aluminum alloy template can be efficiently clamped and punched, other additional equipment components do not exist in the upper space or the lower space of a work table plate, and accordingly, machining of inner rib assembling holesof the pipe penetrating type aluminum alloy template can be achieved.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

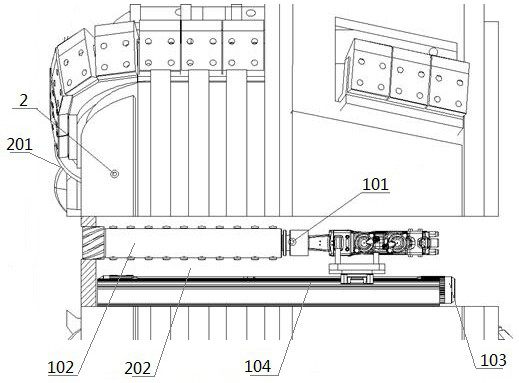

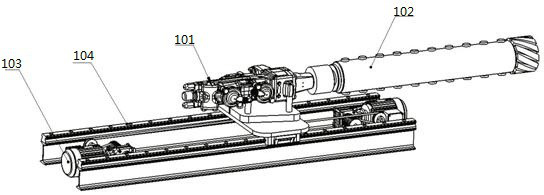

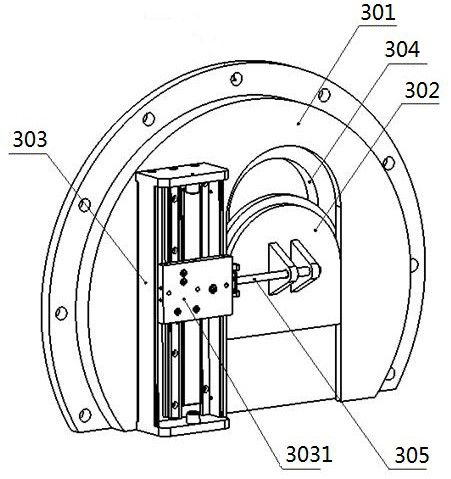

Drilling and splitting sealing cutter head

ActiveCN111963191ADoes not affect the excavation functionReduce wearTunnelsAnchoring boltsMechanical engineeringRock breaking

The invention discloses a drilling and splitting sealing cutter head for solving the problem of low tunneling efficiency when a TBM cutter head in the prior art excavates hard rock. The drilling and splitting sealing cutter head includes a cutter head. The cutter head is provided with an axial installation hole and a hob. The axial installation hole is internally provided with an anchor drilling and splitting device and an opening and closing sealing device for blocking the axial installation hole. The anchor drilling and splitting device can extend out of the opening and closing sealing device and can move back and forth along the axial installation hole. Ballast is effectively prevented from entering the installation hole through the opening and closing sealing device, the anchor drilling and splitting device is protected, and the construction safety is further improved. The anchor drilling and splitting device integrates the anchor drilling, splitting and the cutter head well, the effect that drilling and splitting can be carried out efficiently is ensured, the auxiliary rock breaking efficiency is improved, and the original tunneling function of the cutter head is not affected,so that abrasion of a TBM cutter head hob is reduced, and efficient tunnel excavation is achieved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

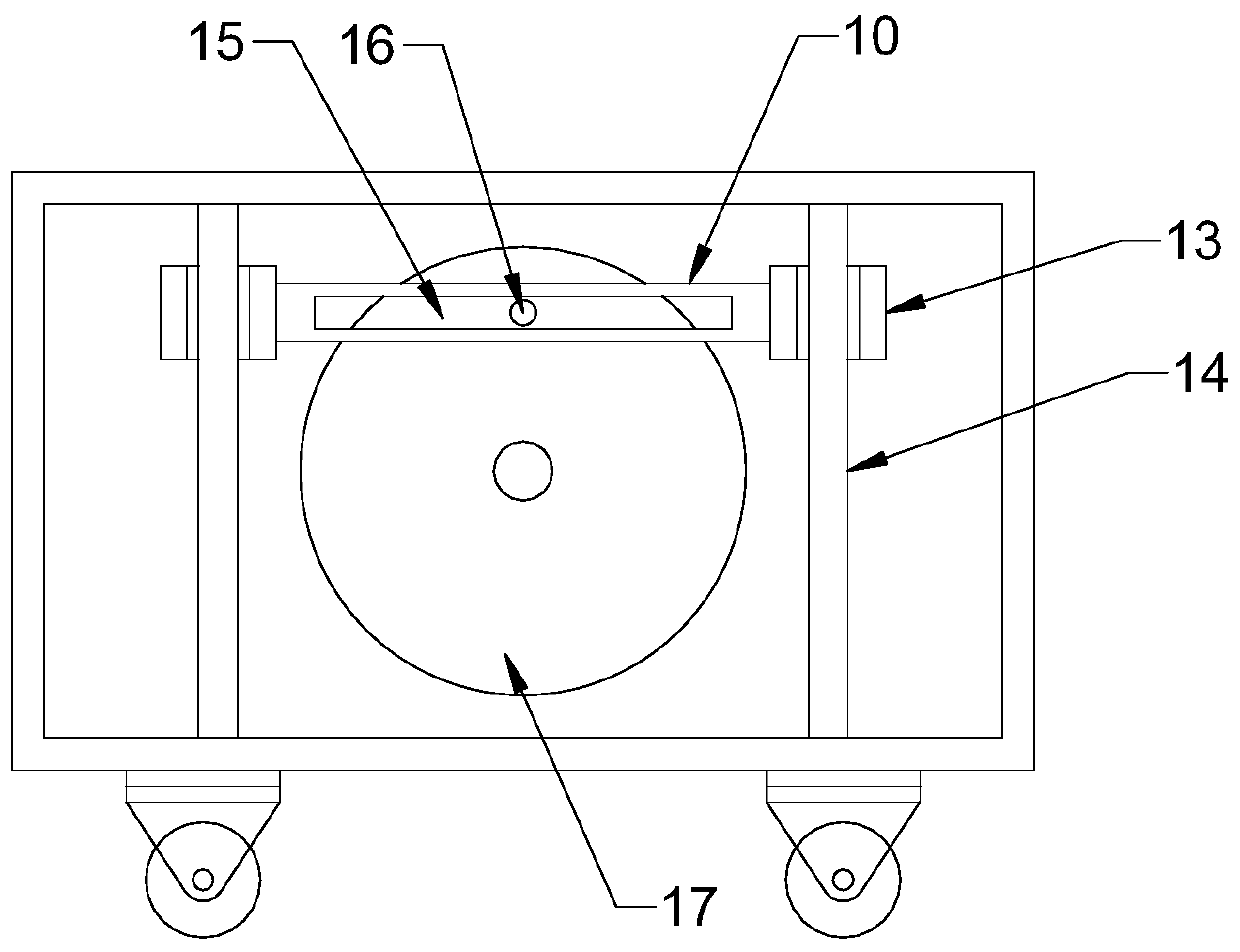

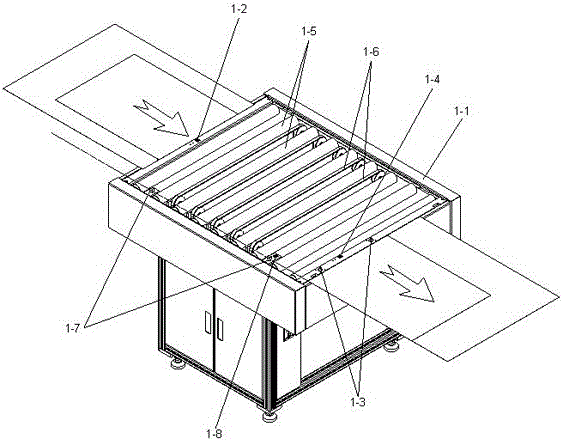

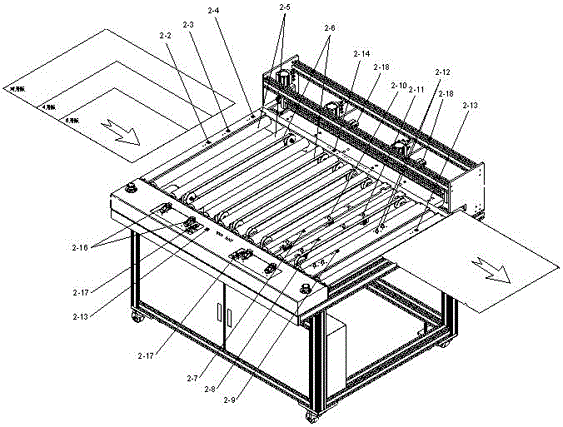

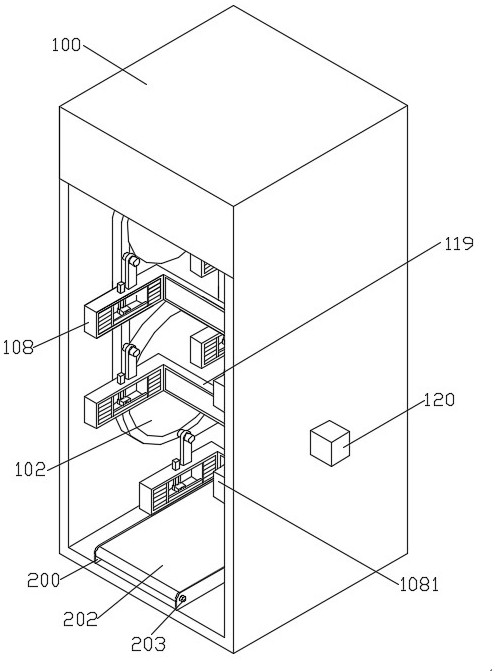

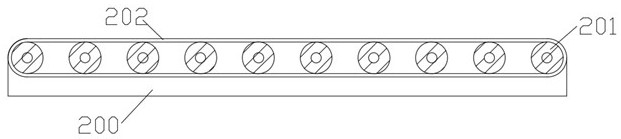

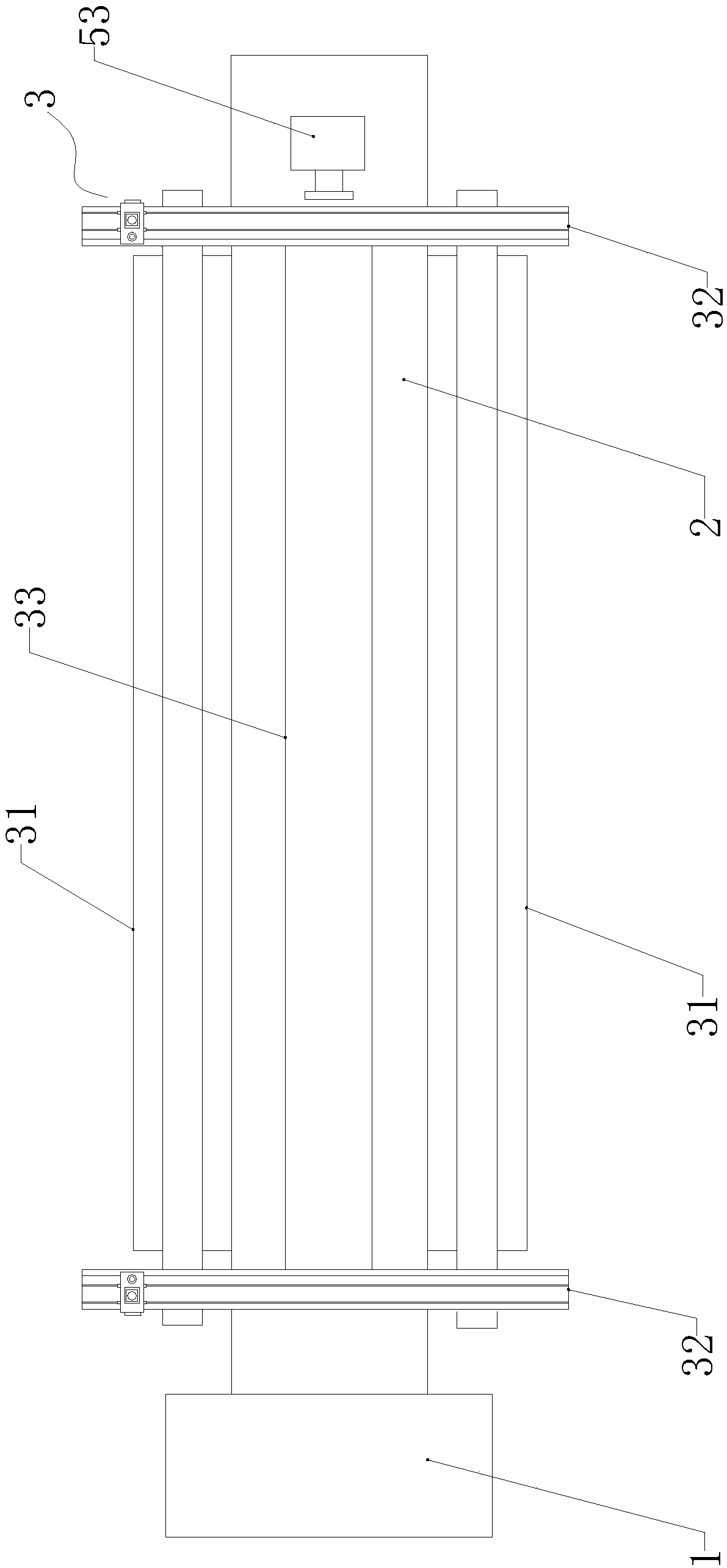

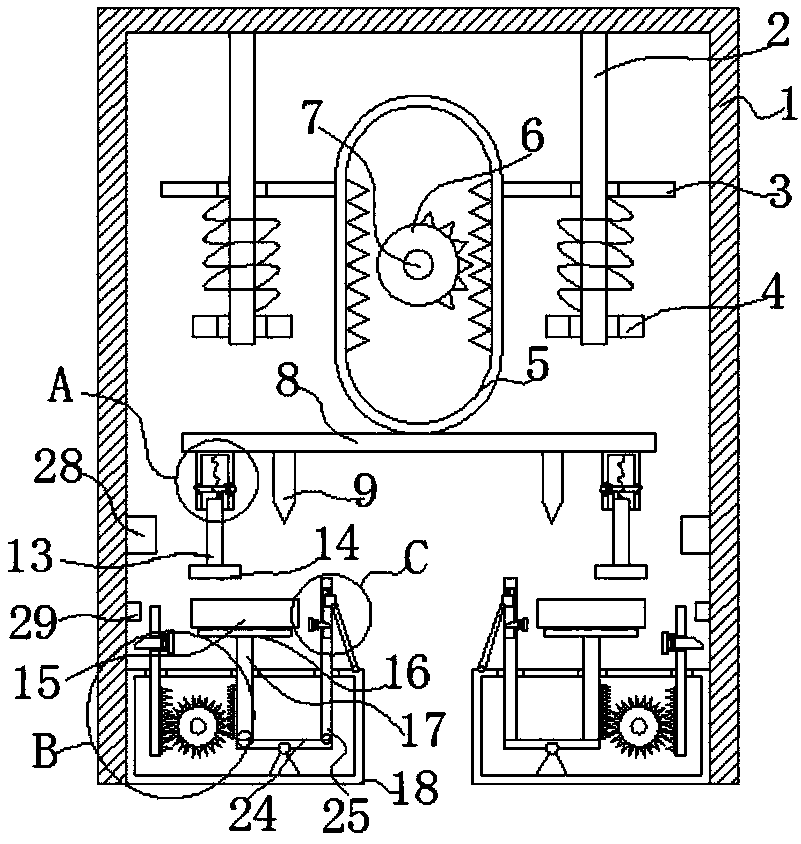

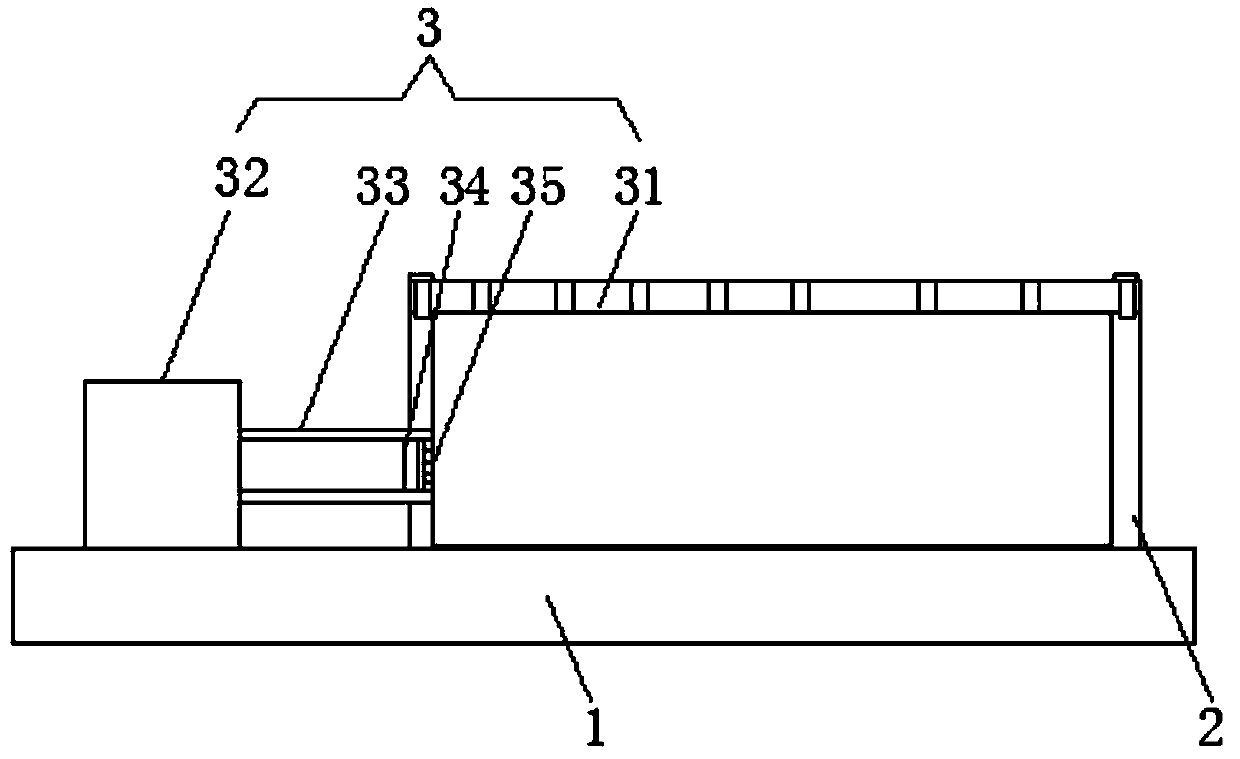

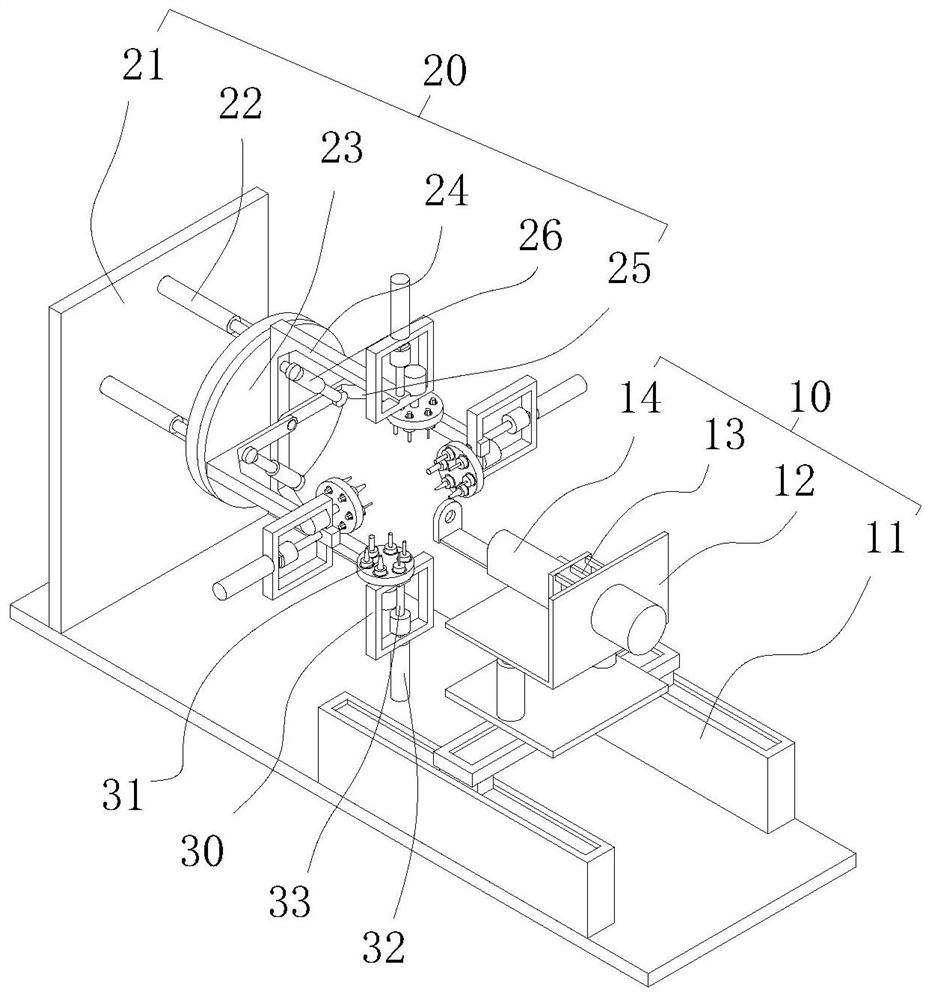

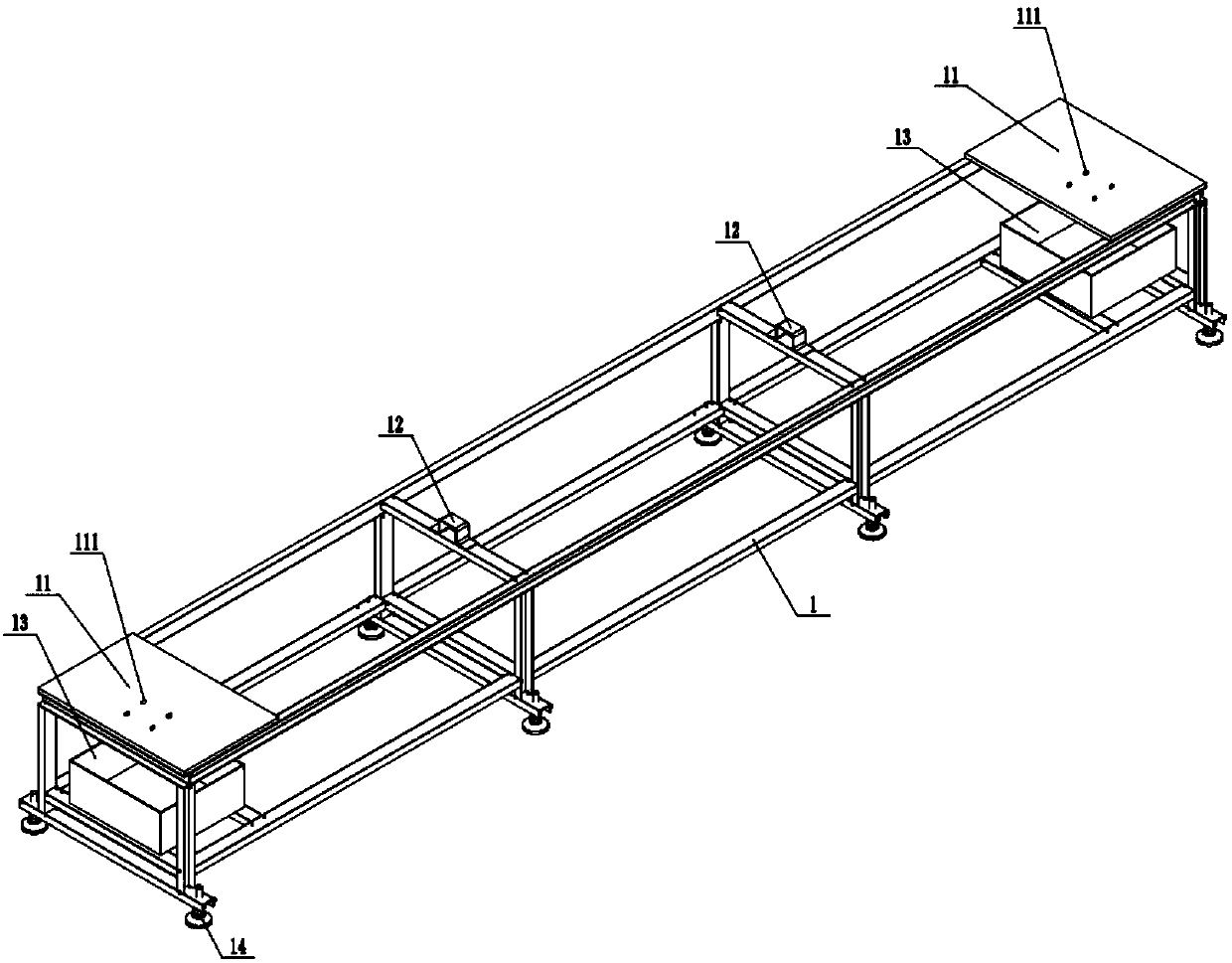

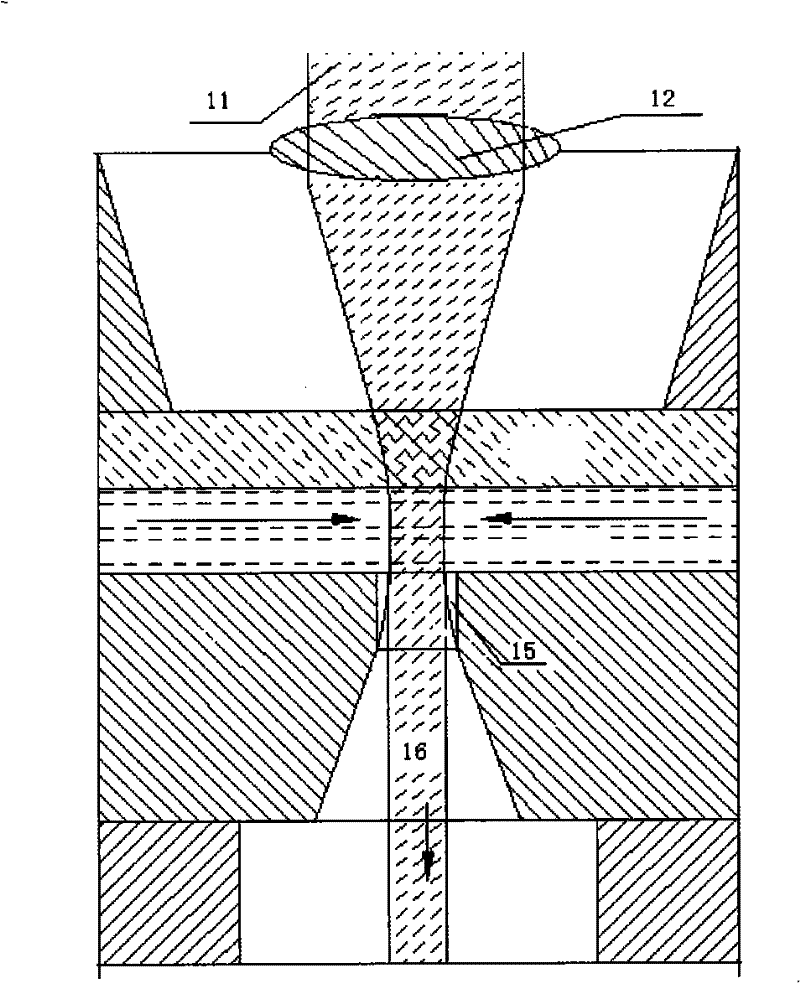

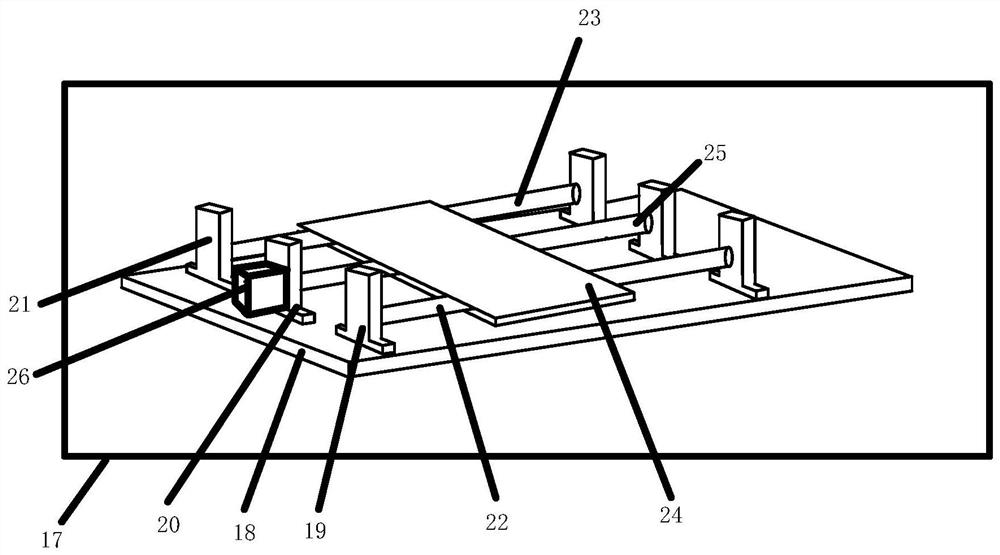

Automatic long sectional material production line

PendingCN108607928AEfficient feedingEfficient punching and cuttingMetal-working feeding devicesPositioning devicesSlide plateProduction line

The invention relates to an automatic long sectional material production line. The automatic long sectional material production line comprises punching and cutting-off equipment, a conveying platformand a lifting type feeding device. The punching and cutting-off equipment comprises a shell, the shell is further internally provided with a bottom plate and a bottom plate lifting platform, and the shell is internally provided with an upper punching device. The left side of the upper punching device is provided with a die core and a two-dimensional displacement device, and the right side is provided with a cutting-off device. The lifting type feeding device comprises discharging devices, sectional material lateral movement devices and a sectional material push device. Each discharging devicecomprises a bottom shell, sectional material baffles, a sectional material supporting plate and supporting plate drive devices. Each sectional material lateral movement device comprises supporting pillars and a cross beam, each cross beam is provided with a cross beam sliding plate, and one end of each cross beam sliding plate is provided with a sectional material lateral movement push plate. Thesectional material push device comprises a vertical beam and a vertical beam sliding plate slidably arranged on the vertical beam, and a material jacking plate and a material jacking plate lifting device are arranged below the vertical beam sliding plate. The automatic long sectional material production line is suitable for long sectional materials or pipes and can perform automatic feeding and ishigh in punching and cutting-off efficiency.

Owner:江苏国强兴晟能源科技有限公司

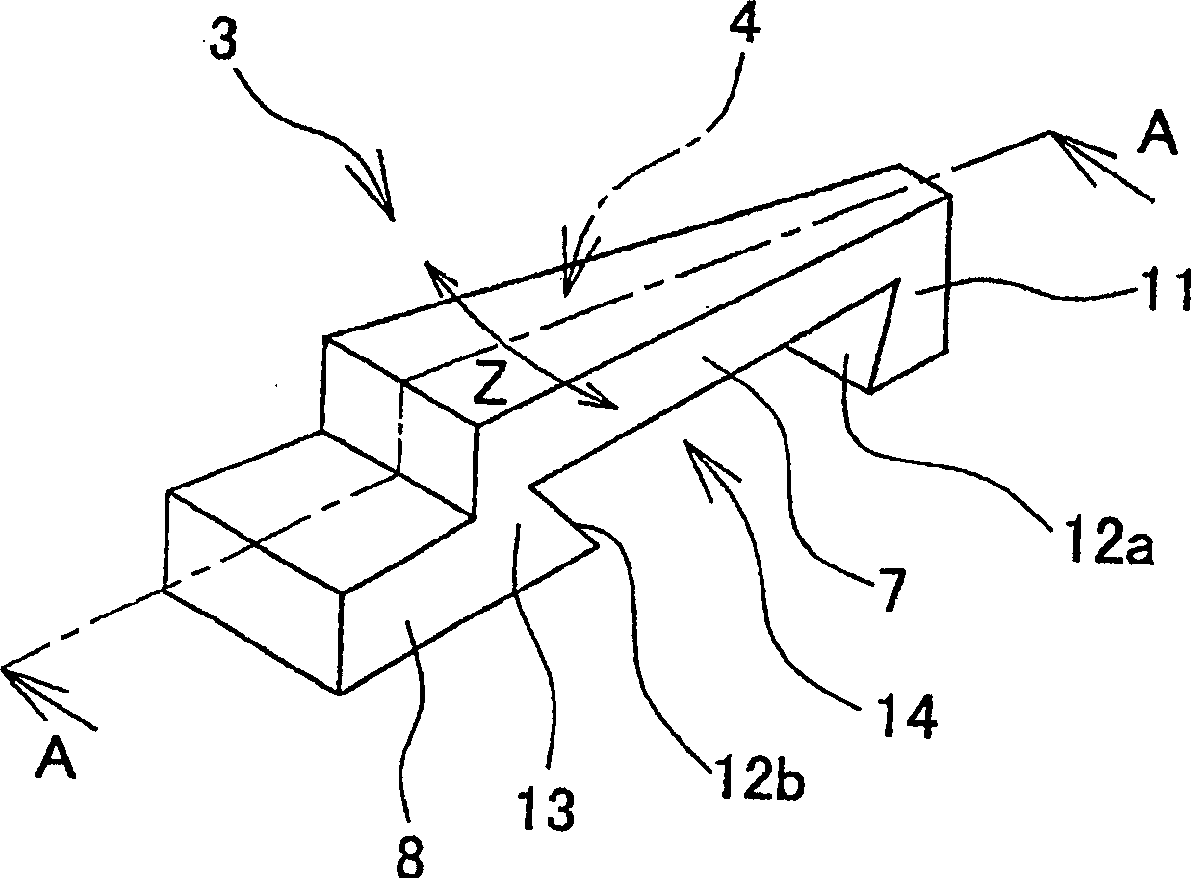

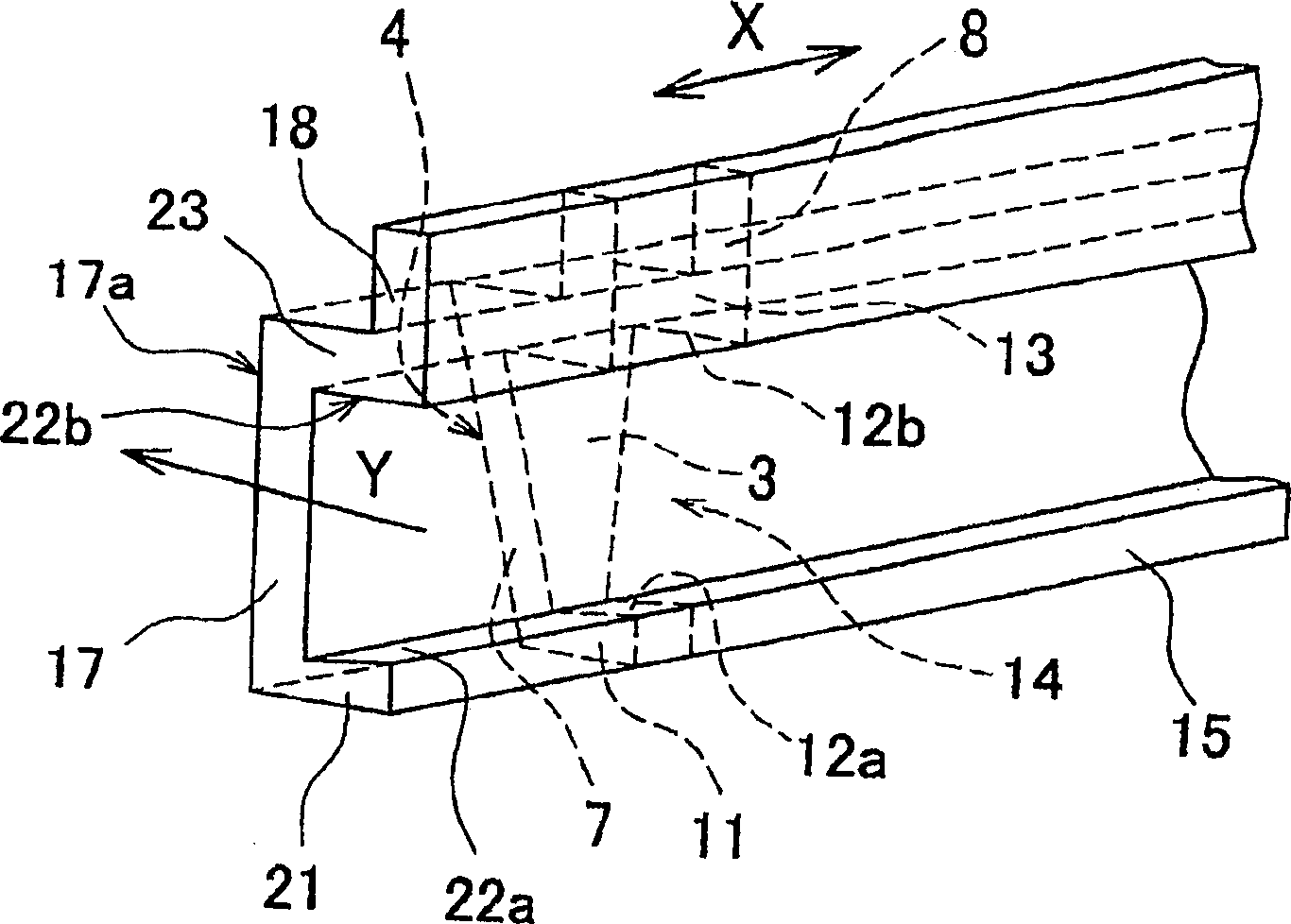

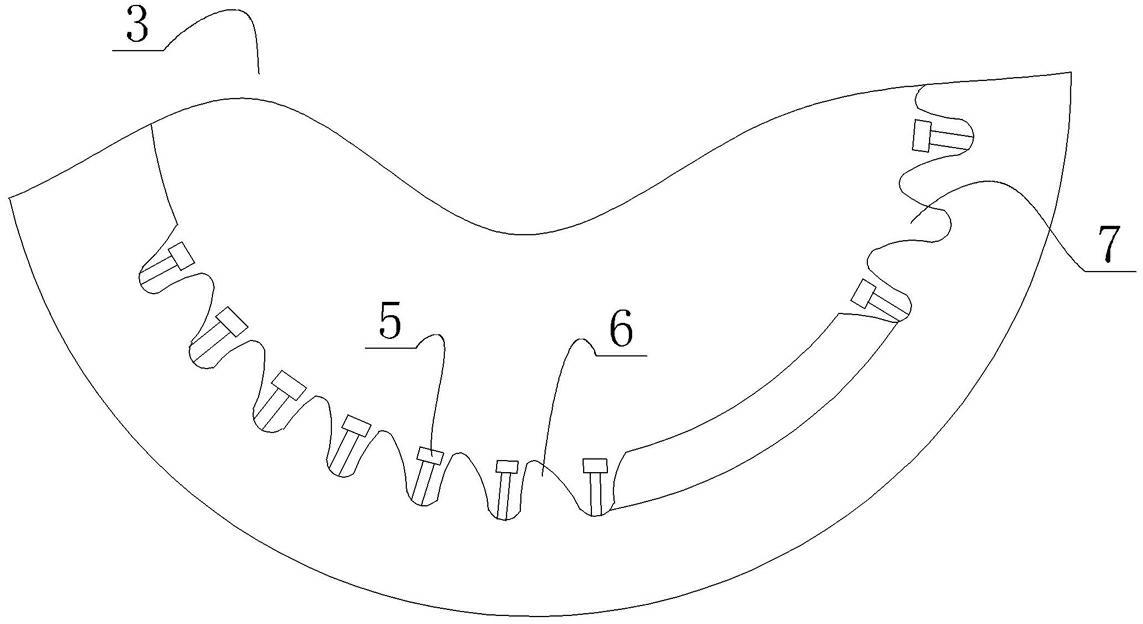

Method of manufacturing segment for flat commutator

ActiveCN1723598AReduce processing stepsEfficient punchingRotary current collectorManufacturing stator/rotor bodiesStructural engineeringEngineering

A method of manufacturing a segment (3) for a flat commutator, comprising the steps of forming a theta section bar (15) having the same cross sectional shape as that of the segment (3) by drawing, punching out the theta section bar (15) in a direction Z perpendicular to a drawing direction X to form the segment (3) for the flat commutator, wherein the drawing direction X for the theta section bar (15) is aligned in the generally same direction as the slidable contact direction of a brush on the segment (3) and a draw-finished surface is formed to be used as a brush sliding surface (4) of the segment (3), and an anchor part (14) forming an extraction stopper for the segment (3) is formed on the theta section bar (15) in drawing, whereby the segment for the flat commutator capable of preventing the leakage of resin in a resin mold process can be easily manufactured at a low cost.

Owner:MITSUBA CORP

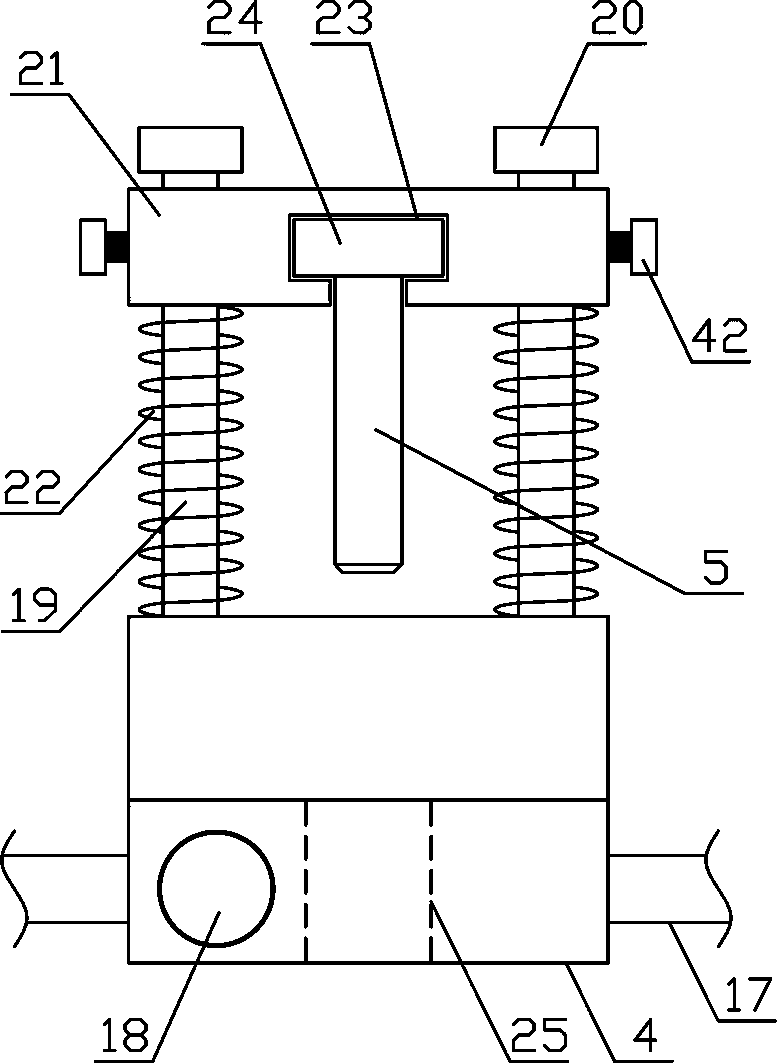

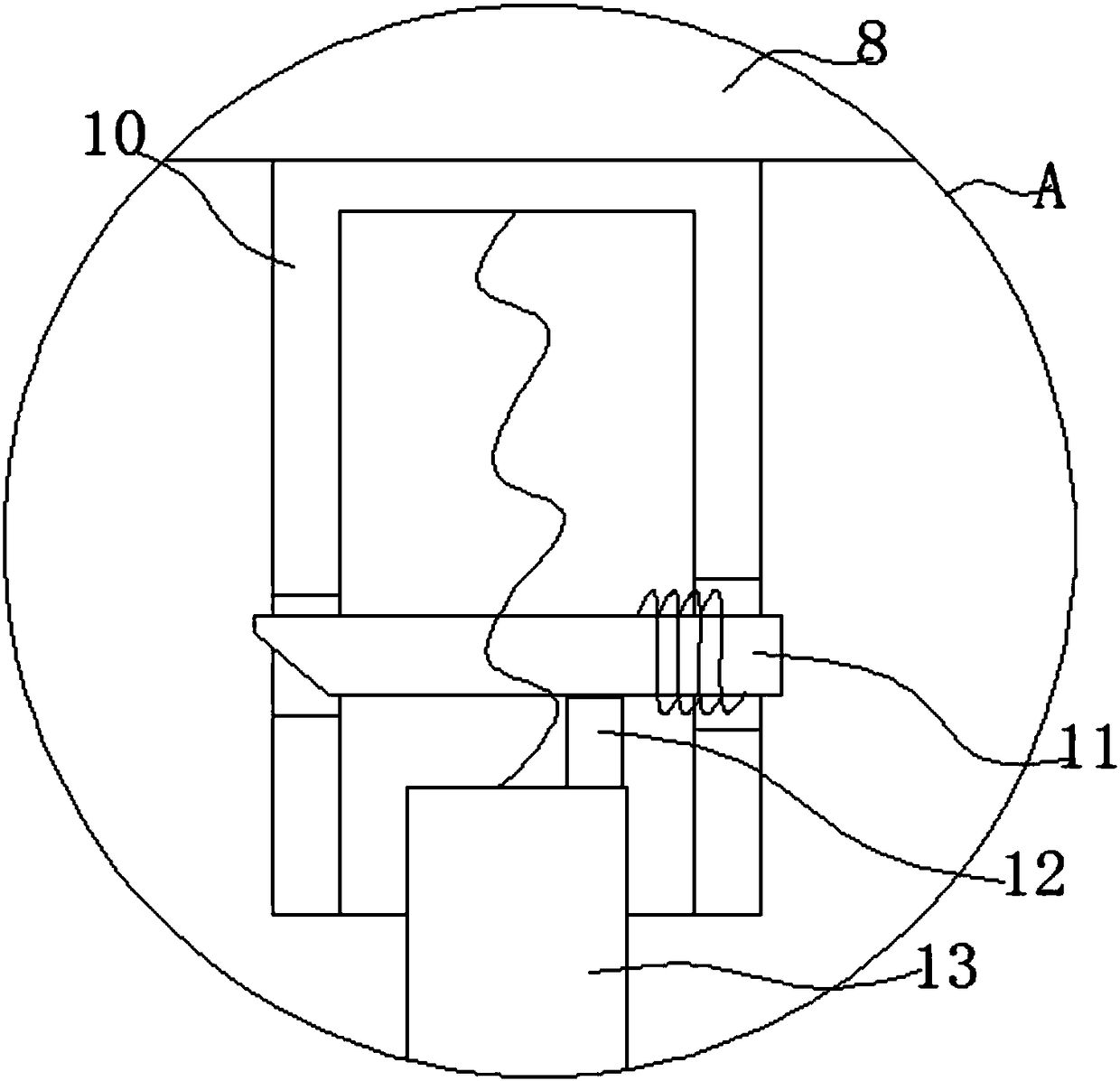

Novel perforating machine of industrial equipment with fixing function

InactiveCN108580653AAchieve fixationEfficient punchingMetal-working feeding devicesPress ramIndustrial engineeringFixed-function

The invention discloses a novel perforating machine of industrial equipment with a fixing function. The novel perforating machine of the industrial equipment comprises a supporting frame, two first fixing rods are symmetrically and fixedly connected to the inner top wall of the supporting frame, first movable rods are movably sleeved with the two first fixing rods, so that second movable rods canmove upwards. The novel perforating machine of the industrial equipment with the fixing function has the beneficial effects that as a moving plate continues to move, the perforating machine can move to the position above a workpiece for perforating, due to the fact that the quantity of the perforating machines is large, the back-and-forth movement time of an annular gear is short, so that high-efficiency perforating can be achieved; and therefore the perforating machine can be used for fixing the workpiece, and the effect of high-efficiency perforating can be achieved.

Owner:郑伟杰

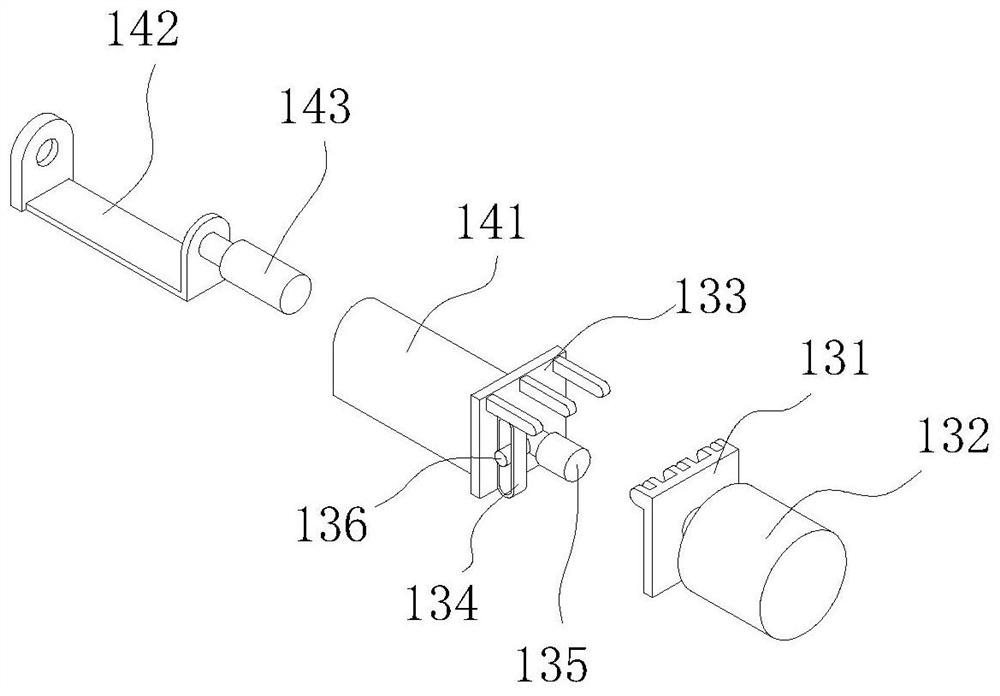

Dotting drilling device for connector drilling machine

PendingCN110695397AEfficient punchingAvoid Poor Punch Quality SituationsMaintainance and safety accessoriesBoring/drilling machinesElectric machineryScrew thread

The invention discloses a dotting drilling device for a connector drilling machine. The dotting drilling device comprises a bottom plate, a scrap sucking structure, a positioning structure and a material pressing structure, a frame plate is arranged at the upper end of the bottom plate in a matched mode, a groove standing plate is arranged on the back side of the upper end of the bottom plate, theupper and lower inner walls of the groove standing plate are rotatably connected to the two ends of a lead screw through a bearing correspondingly, the lead screw is in thread connection with an adjusting supporting block, sliding blocks on the two sides of the adjusting supporting block are slidably connected in sliding grooves in the inner walls of the groove standing plate, a motor is arrangedat the upper end of the groove standing plate, and an output shaft of the motor penetrates through a through hole in the upper end of the groove standing plate and is fixedly connected to the upper end of the lead screw. According to the dotting drilling device for the drilling machine, a drilling position can be quickly positioned, the efficient drilling operation is achieved, an object can be always pressed and fixed, the poor drilling quality due to offset is avoided, the ash and residue scrap can be sucked away in time, deodorizing can be conducted, cleaning and maintenance of the devicecomponent are facilitated, and the drilling processing environment is ensured.

Owner:SUZHOU JUNCHANG COMM TECH CO LTD

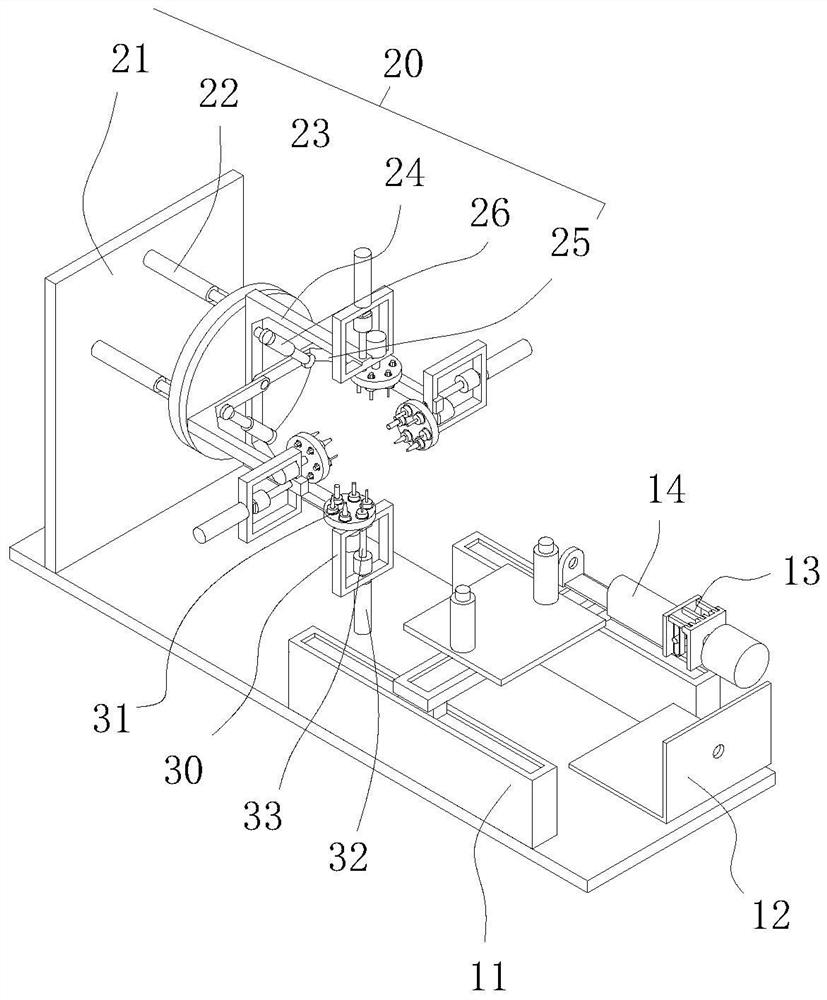

Intelligent multidirectional synchronous punching device for vehicle-mounted brake pump shell

PendingCN113385709AFirmly connectedEasy to separateMeasurement/indication equipmentsLarge fixed membersIn vehicleMoving parts

The invention discloses an intelligent multidirectional synchronous punching device for a vehicle-mounted brake pump shell. The device comprises a clamping and feeding device and a multidirectional angle adjusting device, the clamping and feeding device comprises a three-axis moving part, an L-shaped bottom plate arranged at the execution end of the three-axis moving part, an inclination angle adjusting part arranged on one side of the L-shaped bottom plate, and a clamping part is arranged at the execution end of the inclination angle adjusting part. The multidirectional angle adjusting device comprises a vertical plate, a transverse moving part arranged on one side of the vertical plate, a rotating part arranged at the execution end of the transverse moving part, a U-shaped supporting frame arranged at the execution end of the rotating part, L-shaped supporting frames rotationally connected with the U-shaped supporting frame, and included angle adjusting parts arranged between the U-shaped supporting frame and the L-shaped supporting frames. Fixing frames are arranged at one ends of the L-shaped supporting frame and the U-shaped supporting frame, drill bit switching parts are arranged at the bottoms of the fixing frames, and intelligent drill bit driving parts are arranged at the tops of the fixing frames. The punching device can synchronously punch workpieces at multiple angles and in multiple directions.

Owner:芜湖市球精汽车部件铸模有限公司

Efficient aluminum profile fixing and punching device

InactiveCN107900408APrecise punchingEfficient punchingFeeding apparatusPositioning apparatusAluminum canEngineering

The invention discloses a high-efficiency fixed punching device for aluminum profiles. The high-efficiency fixed punching device for aluminum profiles includes a drill power device and a support plate. The drill power device is slidably connected to the support plate, and the support plate The two sides of the bottom are welded with hydraulic lifting rods. The bottom of the hydraulic lifting rods is provided with a base, and the top surface of the base is provided with a sliding platform. The supporting legs are fixed, the inner bottom of the chute is uniformly provided with screw holes, the inner side of the chute is slidably connected with a fastening fixture, and the center of the fastening fixture is provided with a screw, and the bottom of the bottom sliding platform passes through The sprockets are connected with gears. In the present invention, the double-drilling drill bit structure is adopted, and when the aluminum profile requires multiple holes, the number of repeated operations can be reduced, the work efficiency can be improved, and manpower can be saved.

Owner:HENAN ZHIYING ELECTRONICS TECH CO LTD

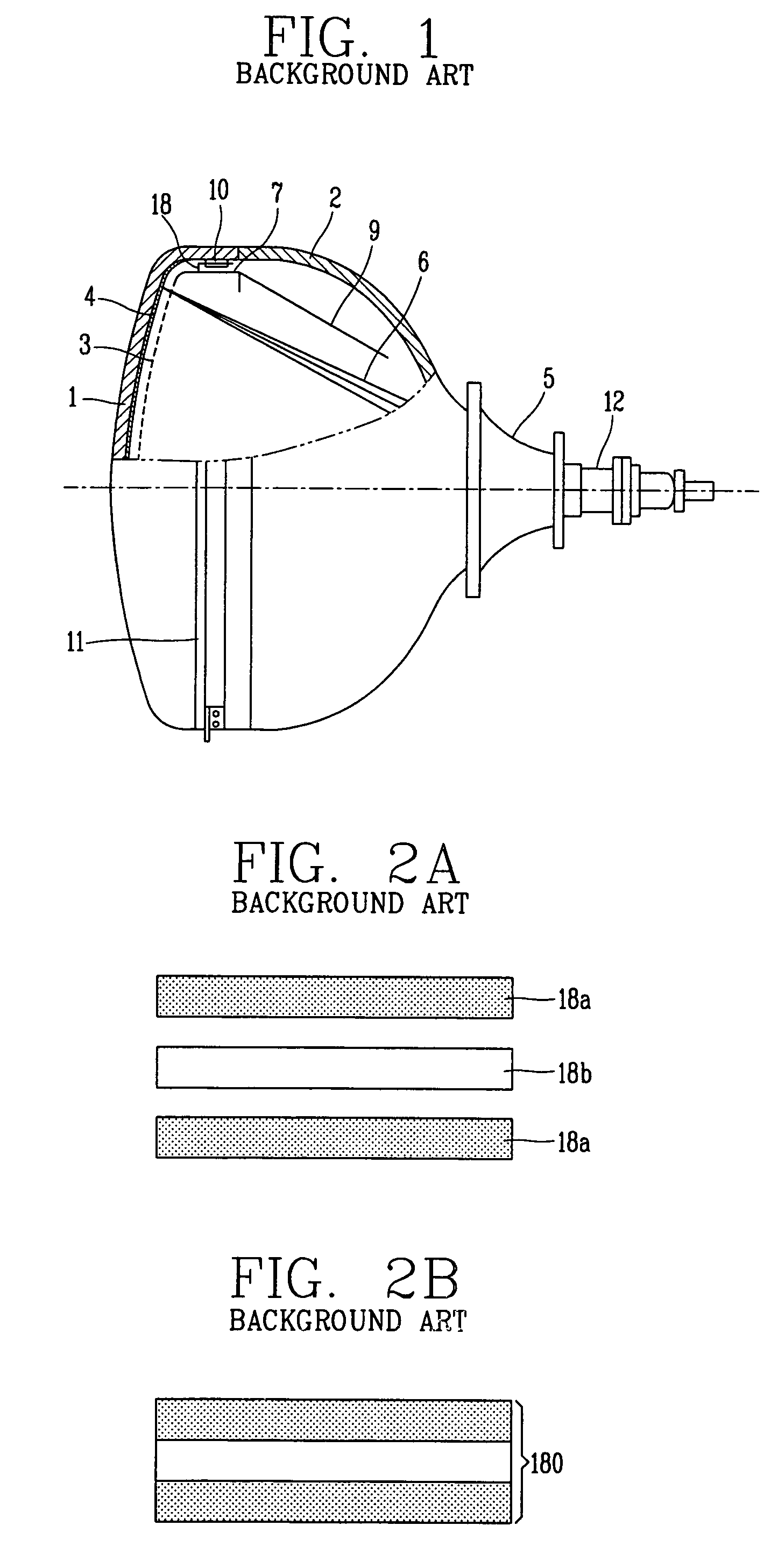

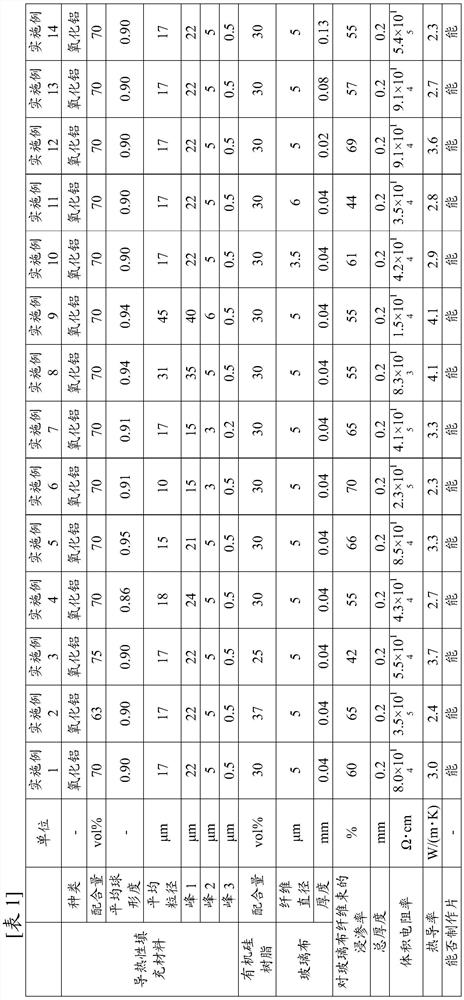

Heat sink and heat dissipation member including the heat sink

ActiveCN110892798BImprove thermal conductivityImprove insulation performanceSemiconductor/solid-state device detailsSolid-state devicesGlass fiberHeat sink

A heat sink characterized in that it has a structure in which layers of a silicone composition containing aluminum oxide are laminated on both sides of a glass cloth of a reinforcing layer, and the inside of the glass cloth contains a silicone composition, wherein the average sphericity of aluminum oxide is 0.85 or more, in the frequency particle size distribution of alumina, there are extremely large peaks in the region of 15-50 μm, 1-7 μm and 0.1-0.8 μm, the average particle size of alumina is 7-50 μm, the organic silicon composition The content of alumina in the glass is 62-78% by volume, the content of silicone resin is in the range of 22-38% by volume, and the glass cloth is a woven glass fiber bundle made of bundled glass filaments. The impregnation rate of the silicon composition to the glass fiber bundle is 20% or more.

Owner:DENKA CO LTD

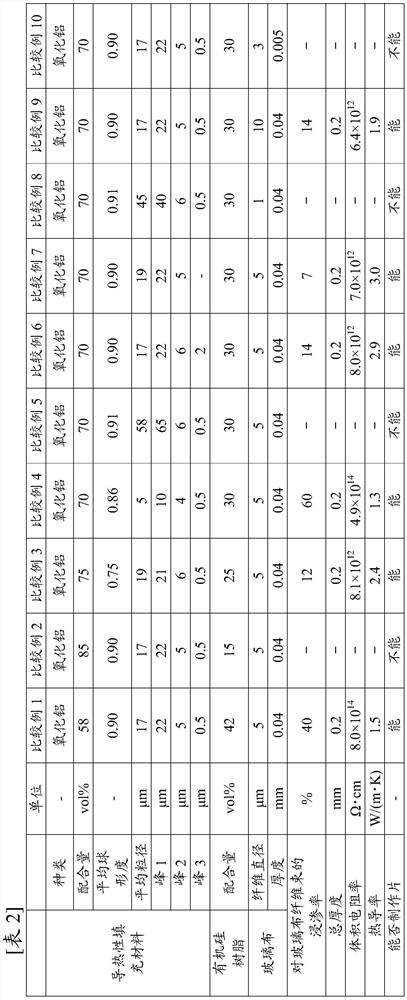

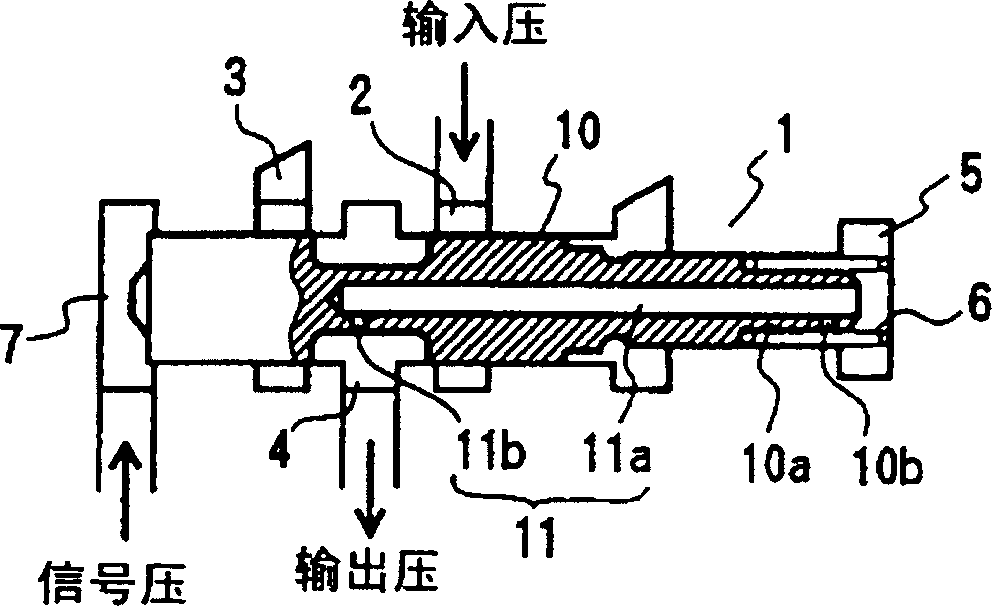

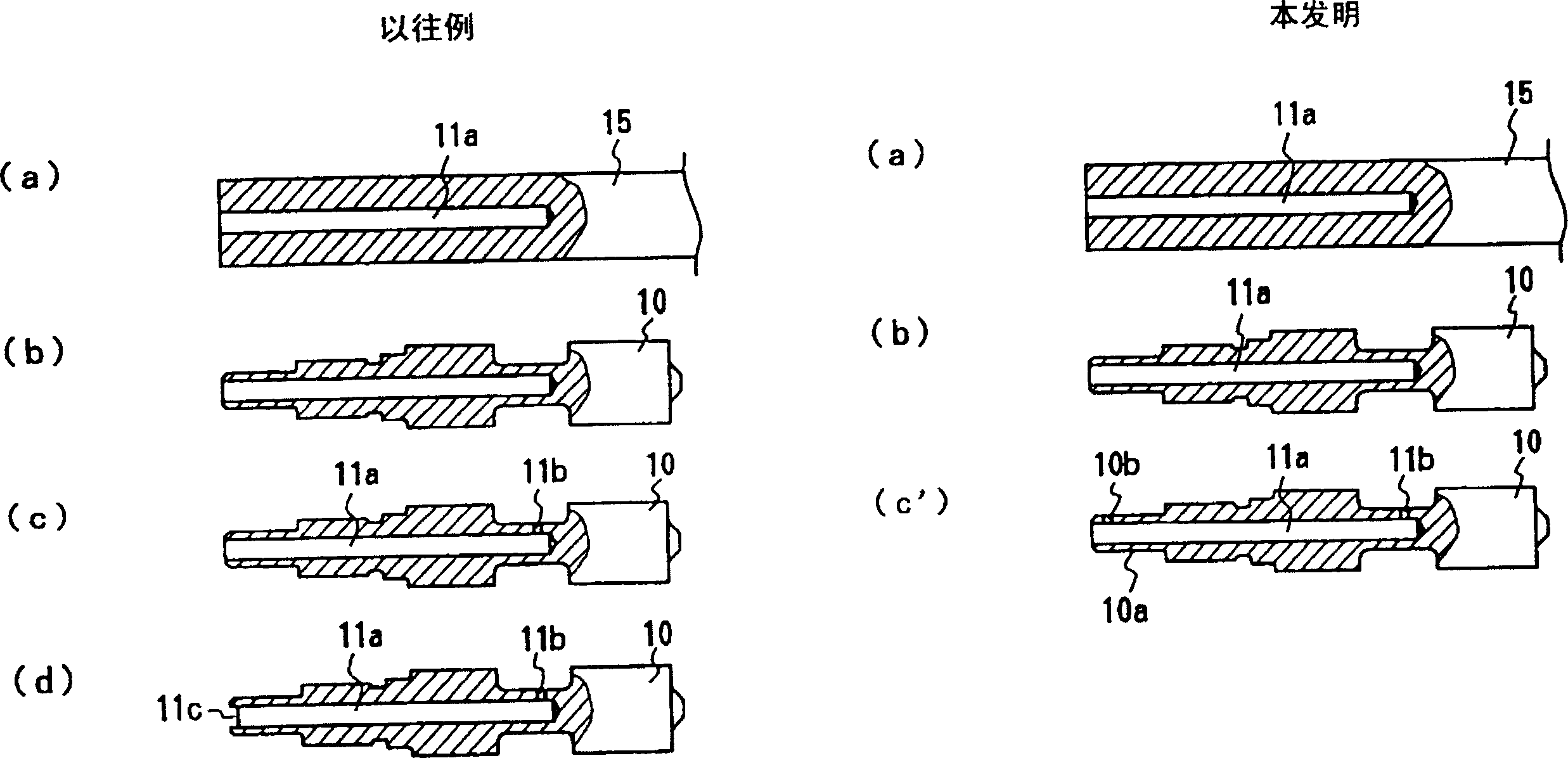

Pressure-regulating valve

InactiveCN1155775CAbolish millingSave man hoursEqualizing valvesMultiple way valvesPressure regulatorVALVE PORT

This pressure regulator comprises a valve body provided with an input port, a drain port, an output port and a feedback port, and the spool axially movably mounted in the valve body for selectively communicating the output port with the input port or the drain port, and the output port and the feedback port are communicated through a communication hole formed on the spool. The communication hole has a shaft center hole communicated with the feedback port formed on a shaft center of the spool and an orifice hole for supplying the oil pressure of the output port to the shaft center hole, a small diameter part is formed on an end part facing to the feedback port, of the spool, and a hole of a diameter same as the orifice hole is formed between an outer peripheral face of the small diameter part and the shaft center hole.

Owner:DAIHATSU MOTOR CO LTD

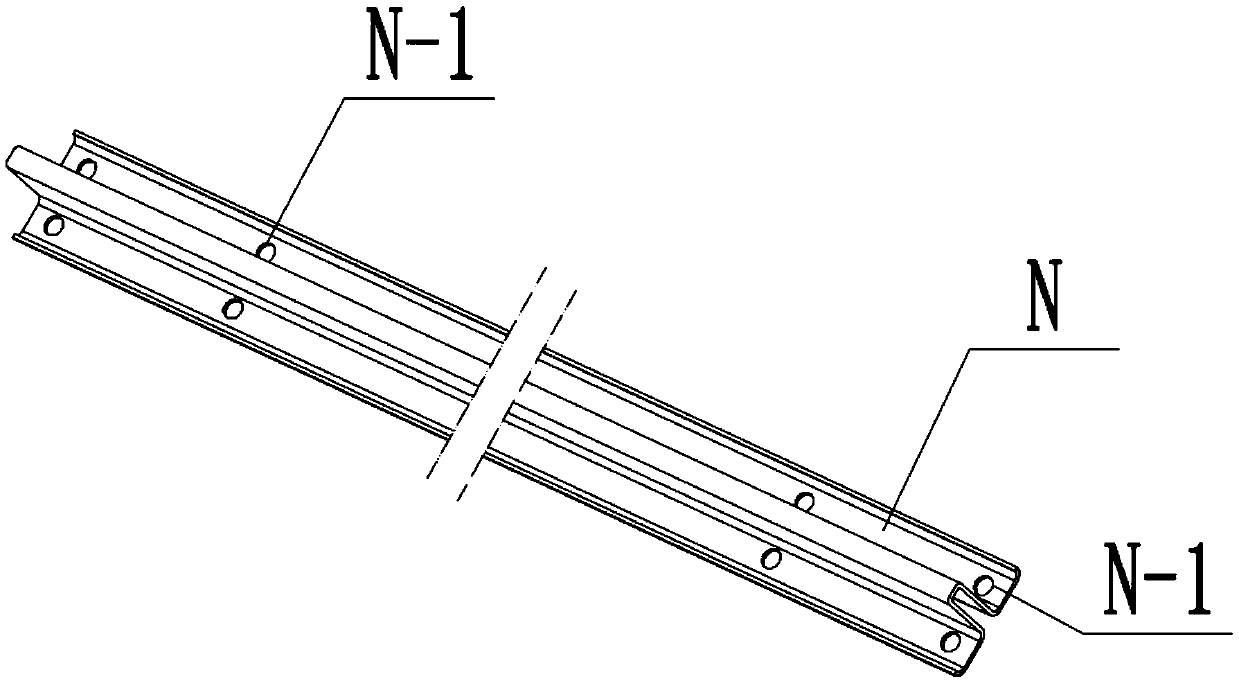

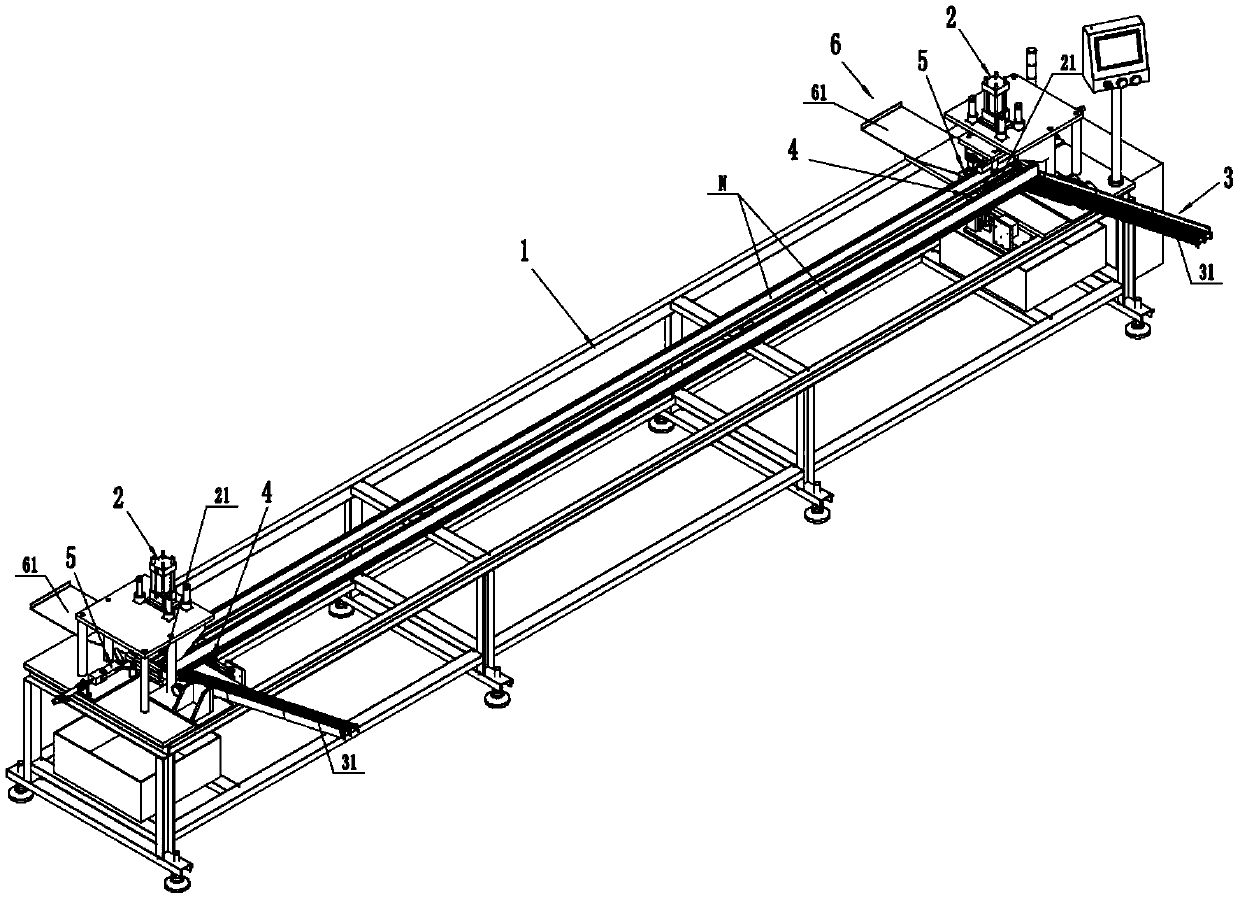

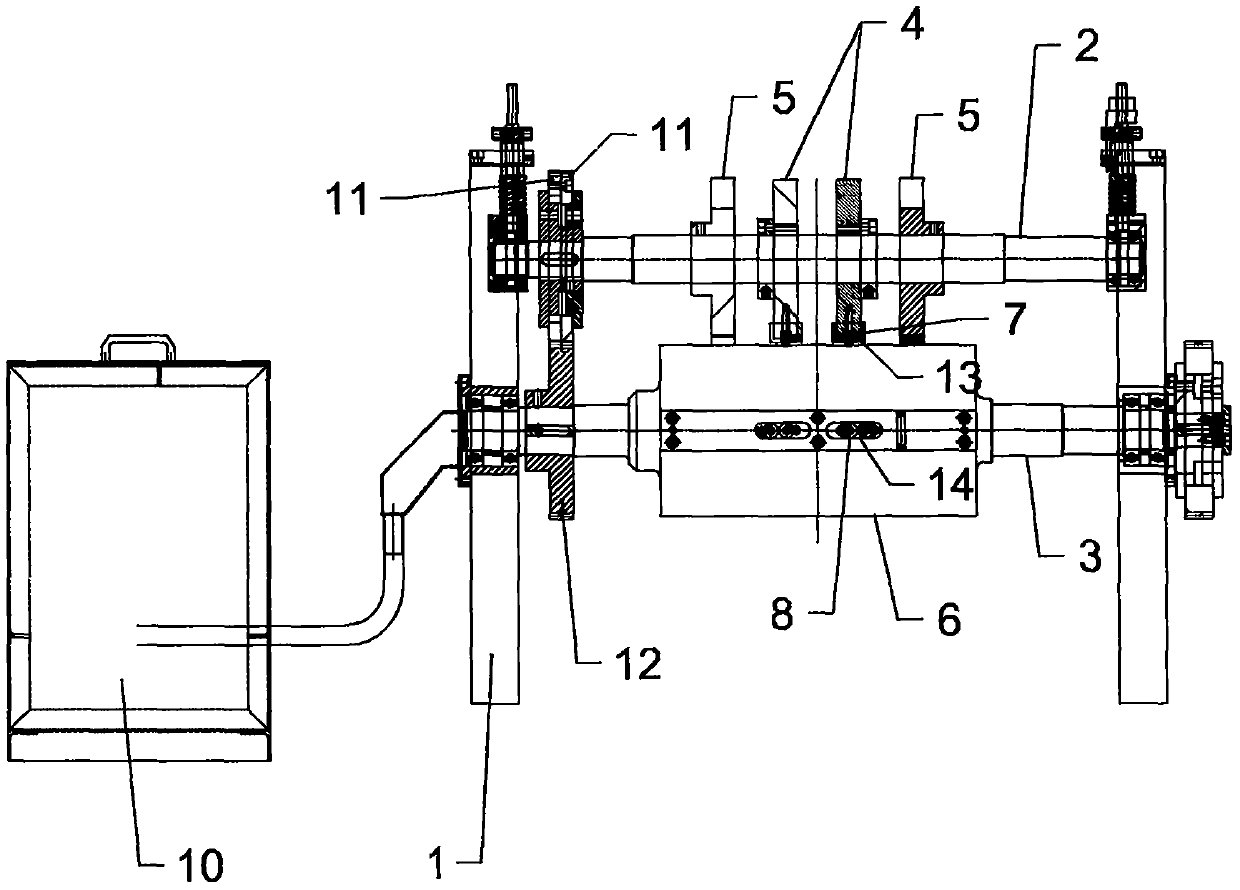

Synchronous punching equipment at both ends of a few-shaped steel beam

ActiveCN107737834BEasy to produceReduce labor intensityPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses n-shaped steel beam two-end synchronous punching equipment. The n-shaped steel beam two-end synchronous punching equipment comprises a machine frame, two punching mechanisms, amaterial placing frame, a material passing control mechanism, a material blocking control mechanism and a material receiving frame; the two punching mechanisms are arranged on the two sides of the machine frame in the length direction correspondingly; the material placing frame and the material receiving frame are positioned on the two sides of the machine frame in the width direction correspondingly; the material placing frame is provided with an inclined discharging support; the material passing control mechanism is used for performing blocking and passing control on an n-shaped steel beamat the lowest position of the inclined discharging support; the two ends of the n-shaped steel beam slide on the workbenches of the two punching mechanism correspondingly after the material passing control mechanism allows to pass; the material blocking control mechanism is used for performing positioning blocking during processing of the n-shaped steel beam on the machine frame and performing passing control after processing; and the material receiving frame is provided with a material receiving support. The n-shaped steel beam two-end synchronous punching equipment can perform punching processing on the two ends of the n-shaped steel beam simultaneously, can perform secondary positioning processing without turning 180 degrees and can realize automatic continuous production.

Owner:芜湖恒驰钢构有限公司

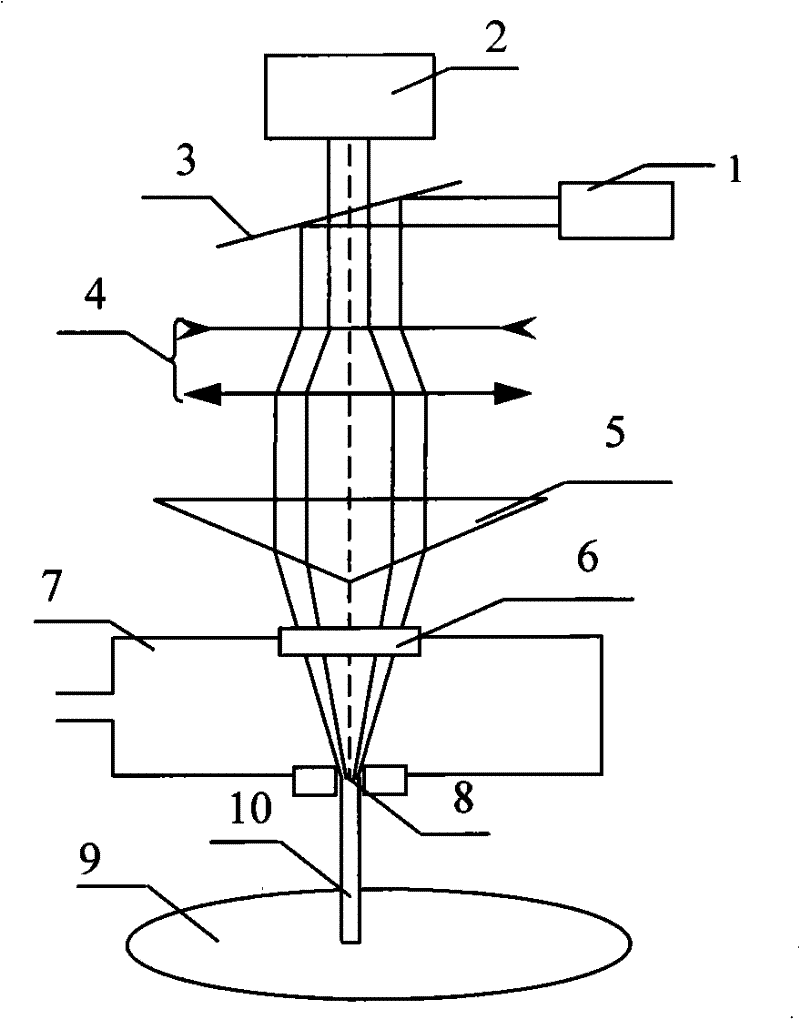

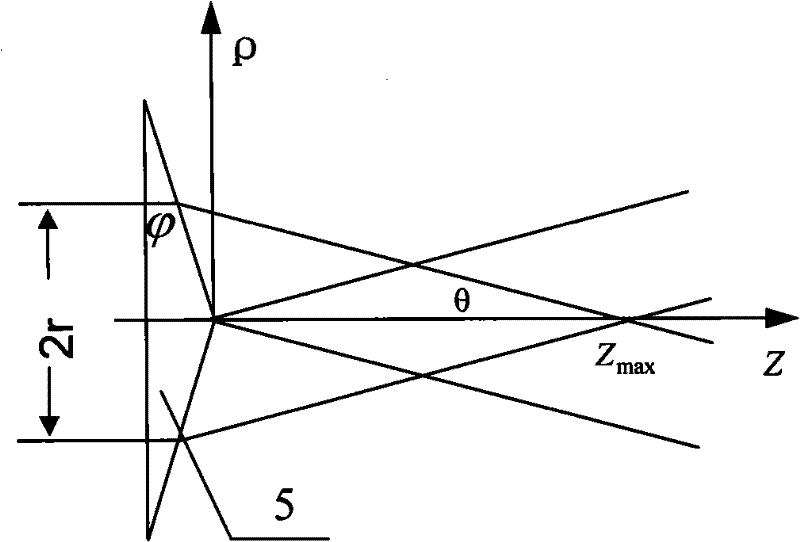

Micro laser beam precise finishing optical device

InactiveCN101508060BOvercoming matching couplingEasy matching and couplingLaser beam welding apparatusOptical elementsLaser beamsFlat mirror

Owner:XIAMEN UNIV

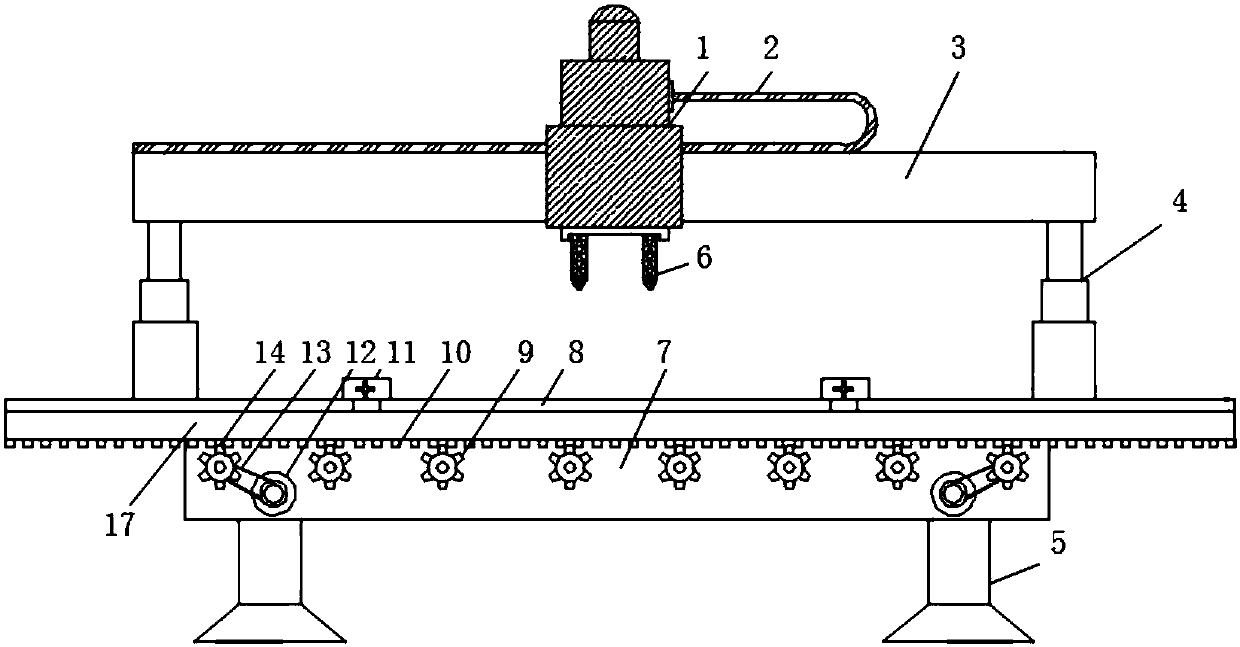

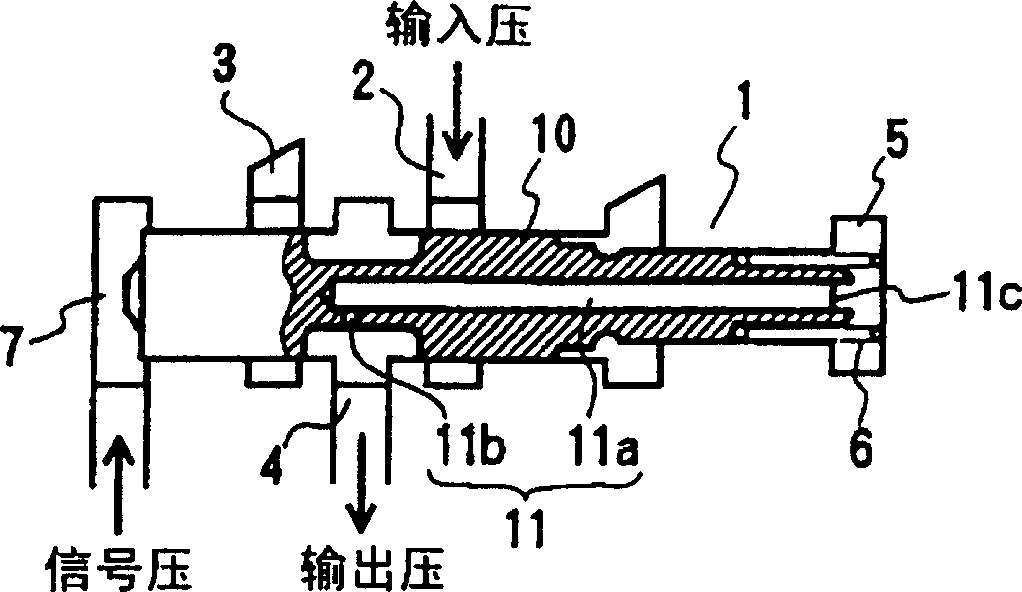

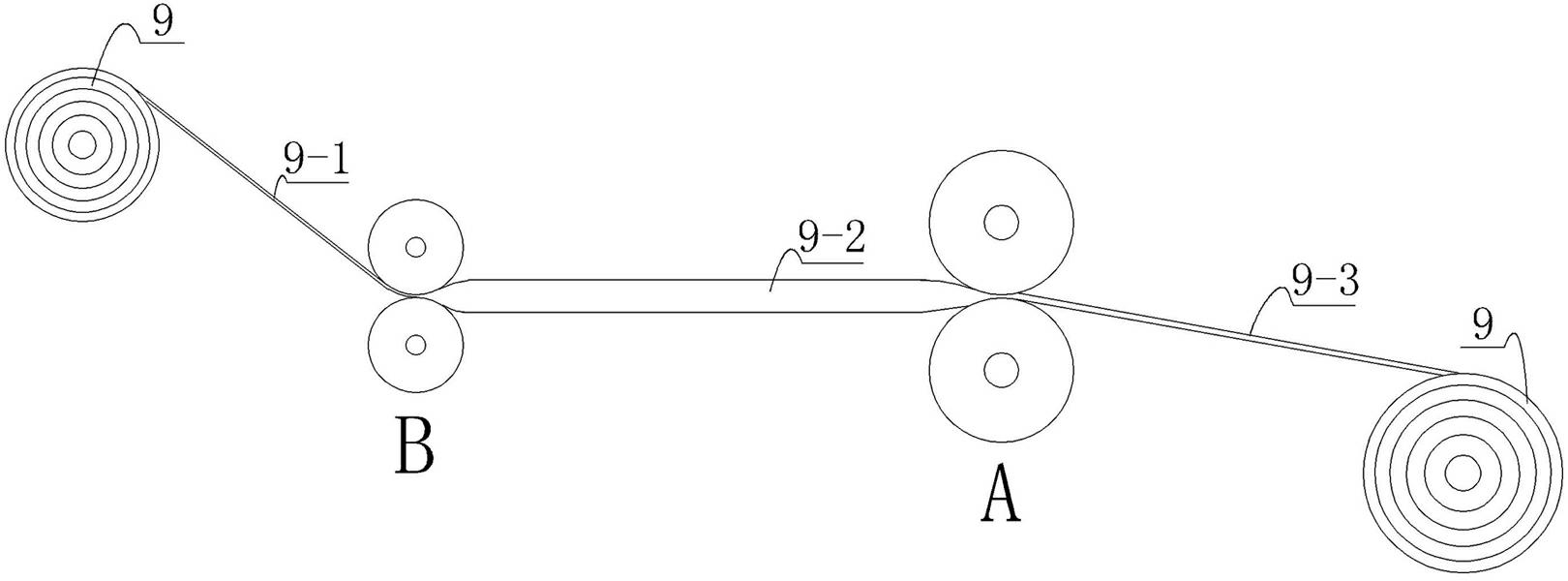

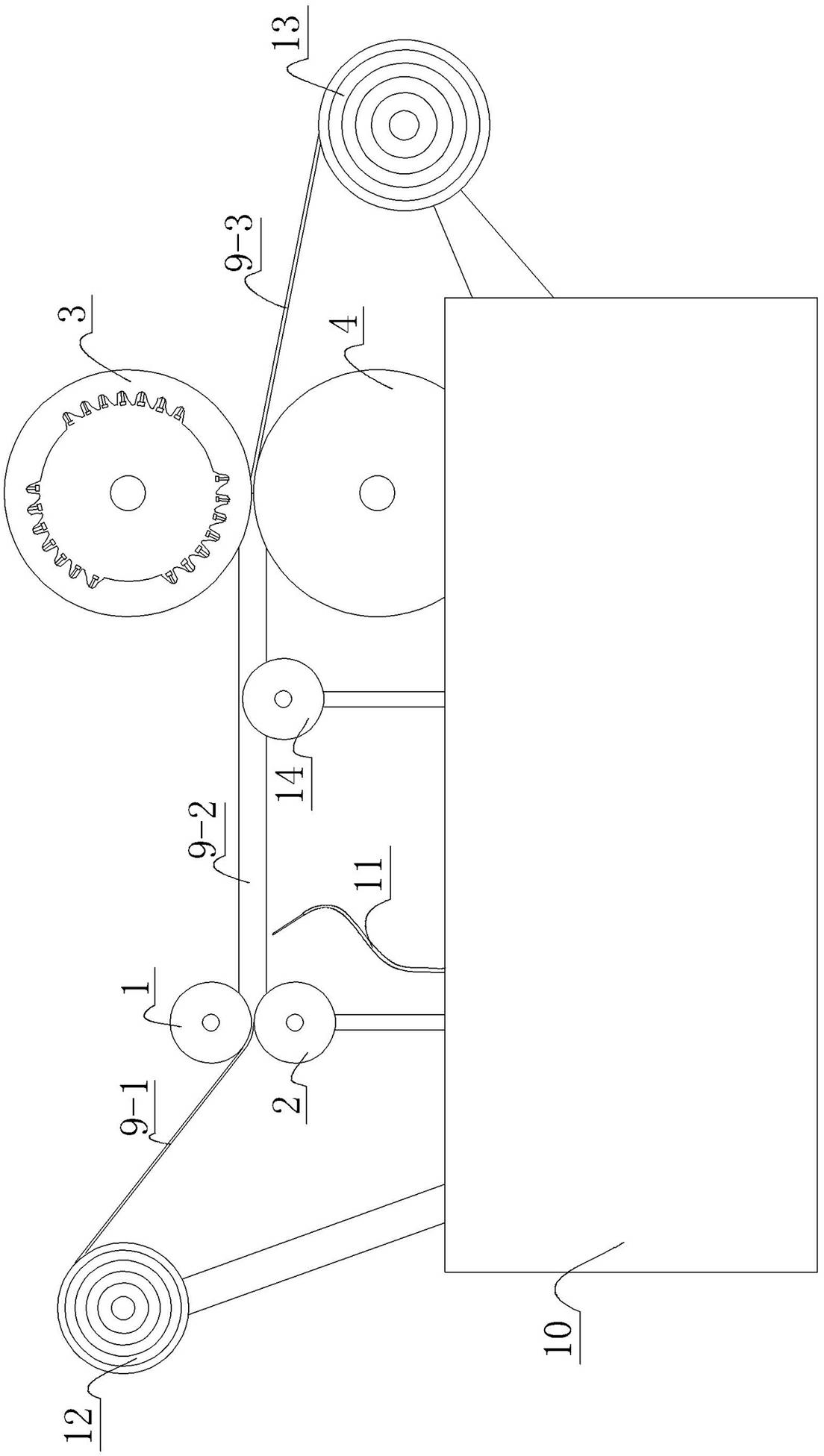

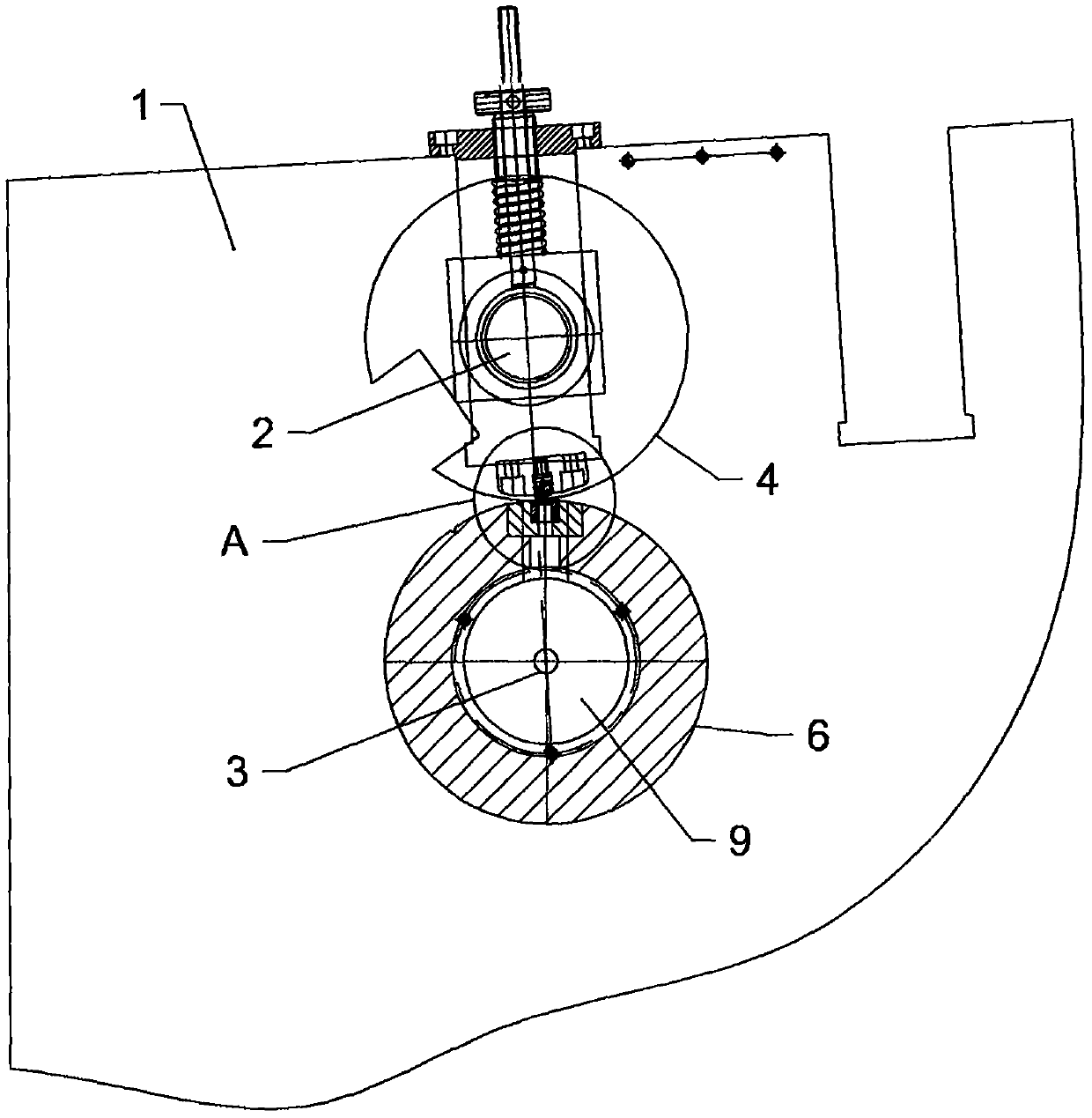

Inflatable punching method and punching equipment for micro-spraying belt

InactiveCN102423884AGuaranteed uniformityUniform pressureMetal working apparatusPunchingSpray irrigation

The invention discloses an inflatable punching method which comprises the following steps of: a, extrusion sealing: forming an AB segment in a sealed state; b, inflation: inflating into the AB segment of the micro-spraying belt; c, punching: punching on a single side in a state that the AB segment is airtight; d, traction: pulling out the punched micro-spraying belt; and e, finishing the punching of the whole micro-spraying belt. The punching equipment disclosed by the invention comprises two rear pressure rollers, a punching pressure roller and a front pressure roller; when in work, the micro-spraying belt between the rear pressure rollers and the front pressure roller is in an inflation state; and the punching pressure roller is provided with a punching device for punching on the wall of the micro-spraying belt attached to the punching pressure roller. Through the inflatable punching method and equipment disclosed by the invention, single-sided punching is realized, the situation of punching both sides of the micro-spraying belt is avoided, and the occurrence of narrow holes, closed holes and blind holes is avoided. By adopting the spraying irrigation of the micro-spraying belt, the beneficial effects of water conservation, energy conservation and uniform spraying irrigation can be realized; and the equipment has a reasonable structure and good beneficial effects and is convenient to popularize and use.

Owner:刘士龙

A punching device with adjustable punching depth

ActiveCN112571529BAdjust the drilling depthAdjust the punching positionStationary drilling machinesPunchingGear wheel

Owner:SHANDONG LEDE CNC MACHINERY

Punching device for paper bag machine

ActiveCN105881973BImprove the piercing effectEliminate movement togetherBag making operationsPaper-makingPunchingPulp and paper industry

The invention discloses a perforating device of a paper bag making machine. The perforating device comprises a support. An upper pressing shaft and a lower pressing shaft are arranged on the support, an upper punching wheel and a traction pressing roller are arranged on the upper pressing shaft, and a lower roller is arranged on the lower pressing shaft. An upper punching knife is arranged on the upper punching wheel, a lower punching knife matched with the upper punching knife is arranged on the lower roller, and the upper pressing shaft and the lower pressing shaft move synchronously. A cavity is formed in the lower roller, the lower punching knife is communicated with the cavity, and thus waste paper generated after punching of the upper punching knife can enter the cavity. The cavity is connected with a waste removing fan. The perforating device of the paper bag making machine improves perforating efficiency and accuracy through a structural improvement, and is provided with a waste paper removing and recycling device.

Owner:温州巨凯机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com