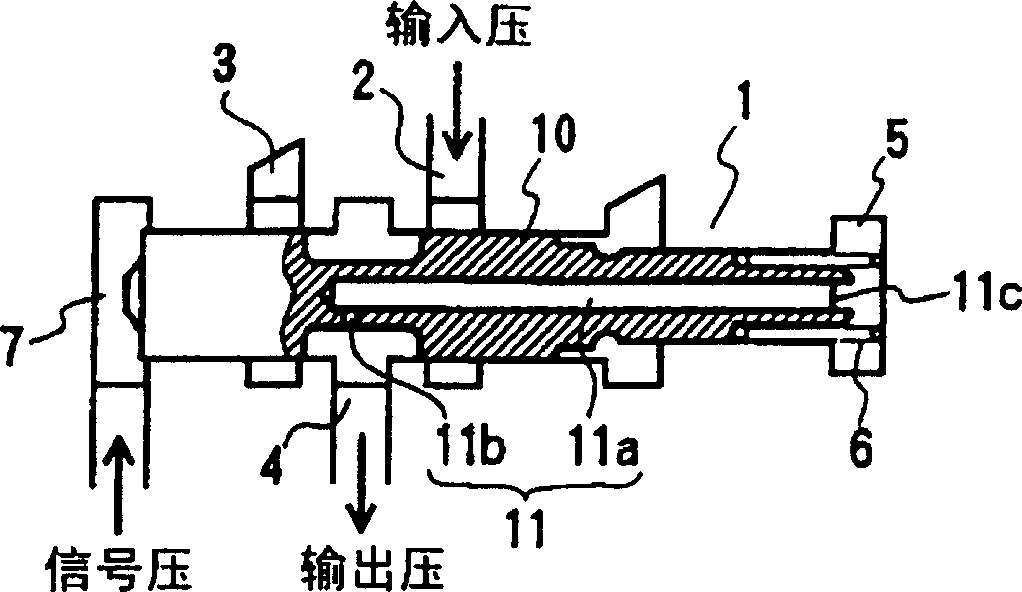

Pressure-regulating valve

A technology of pressure regulating valve and slide valve, applied in the field of pressure regulating valve, can solve the problems of high cost, increased man-hours, long processing hours, etc., and achieves the effect of reducing energy consumption and man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

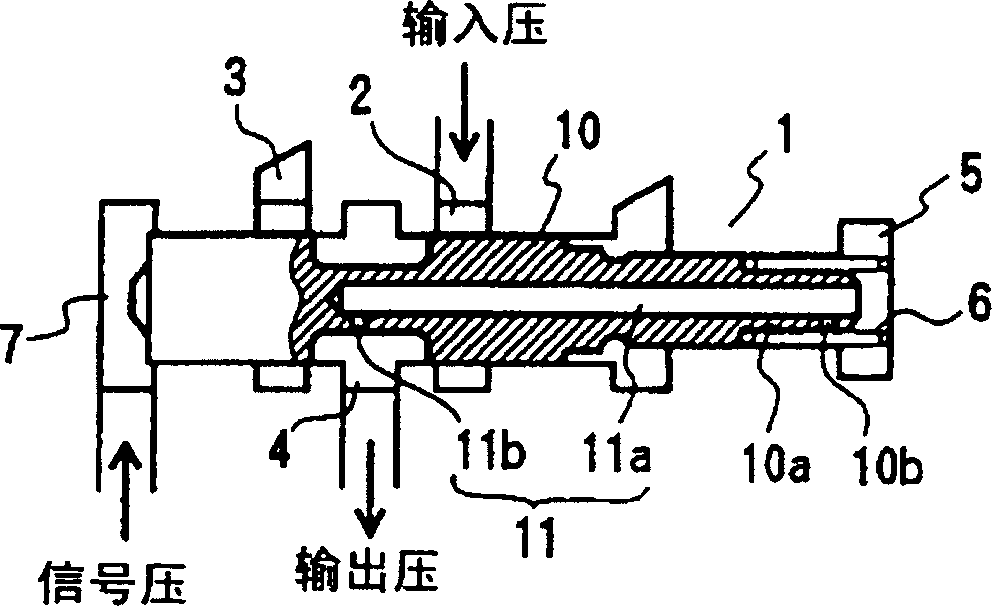

Embodiment 2

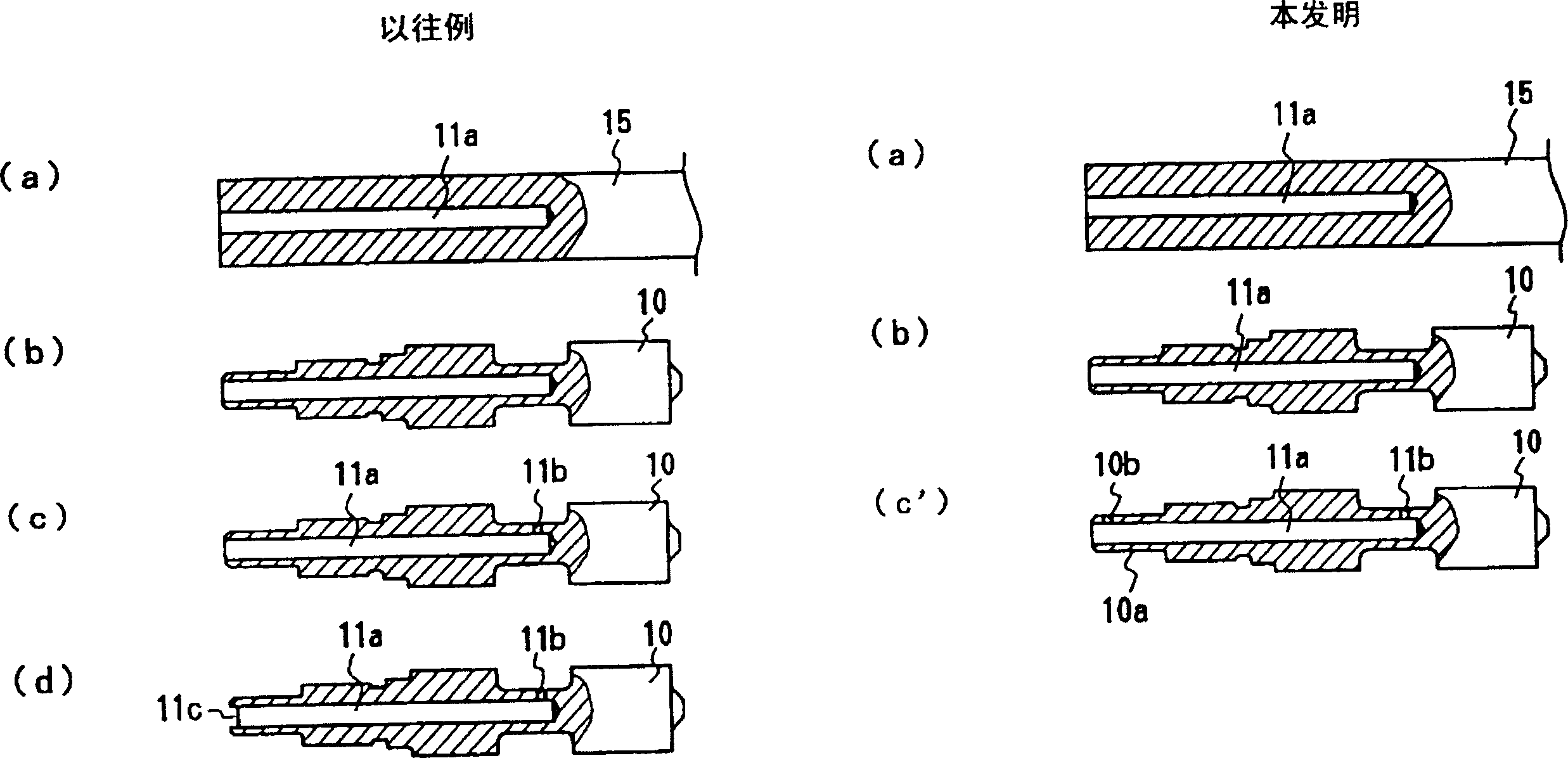

[0031] This pressure regulating valve has a valve body 20 and a spool valve 30 that can move freely in the valve body 20. In the valve body 20, there are input holes 21, discharge holes 22, output holes 23 and feedback holes 24, output holes 23 is provided between the input hole 21 and the discharge hole 22 , and the feedback hole 24 is provided at the end on the side of the input hole 21 and closed by a plug 25 . The spool valve 30 selectively communicates with the output hole 23 with the input hole 21 or the discharge hole 22 , and communicates with the output hole 23 and the feedback hole 24 through a communication hole 31 formed on the spool valve 30 . The communication hole 31 is composed of an axial center hole 31 a communicating with the feedback hole side of the spool valve 30 , and a passage hole 31 b processed radially from the position facing the output hole 23 to the axial center hole 31 a. When the feedback hole 24 feeds back the output pressure, since the communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com