Standardized node connector of steel structure

A node connection and steel structure technology, applied in the direction of building structure, construction, etc., can solve the problems of not giving full play to the bearing capacity of steel columns, not forming serialization, and low strength, etc., to facilitate query and call, improve efficiency, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

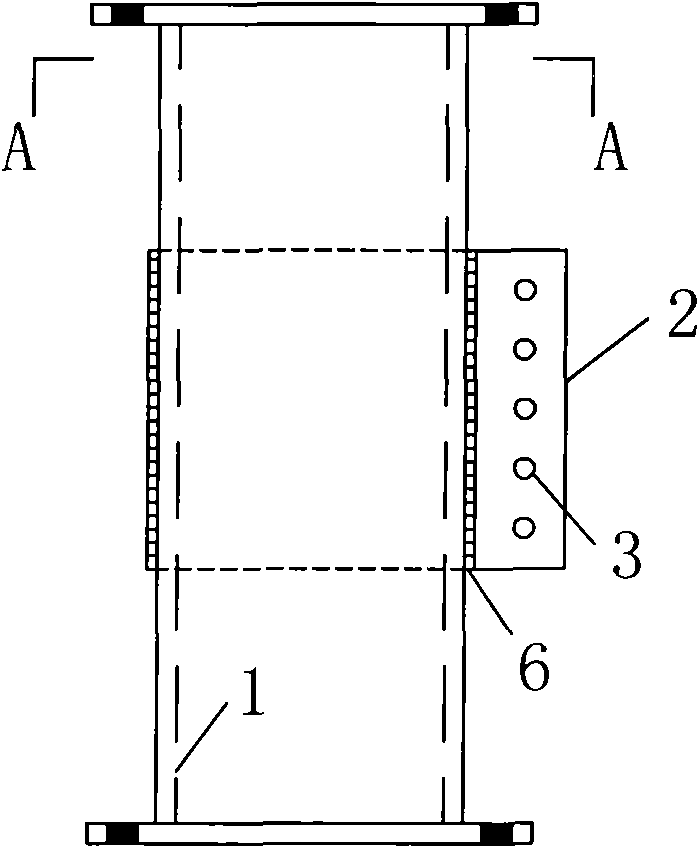

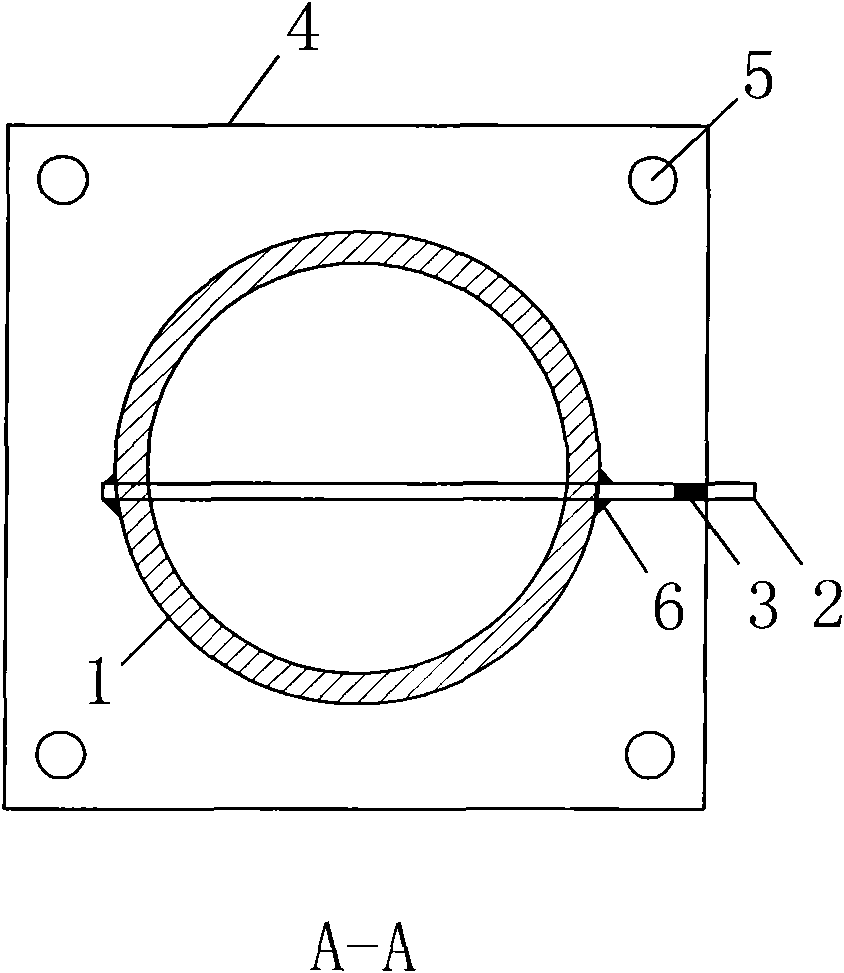

[0073] Example 1: see figure 1 , figure 2 , in the figure 1. Steel column, 2. Connecting plate, 3. Bolted joint, 4. Flange, 5. Connecting hole, 6. Welding seam, a standardized steel structure node connector in the figure, containing a steel column 1. The connection plate fixedly connected to the side of the steel cylinder, the free end of the connection plate is a bolt joint, the fixed connection at the two ends of the steel cylinder is provided with a flange, the flange is provided with a connection hole, the The steel column is provided with a vertical through seam matching the connecting plate, the connecting plate penetrates the vertical through seam, and the part where the connecting plate and the steel column intersect is fixed by welding. The steel cylinder is a steel pipe with a circular cross section, the vertical through seam penetrates along the center line of the steel pipe, and the connection plate is welded to the intersecting part of the steel pipe. The conne...

Embodiment 2

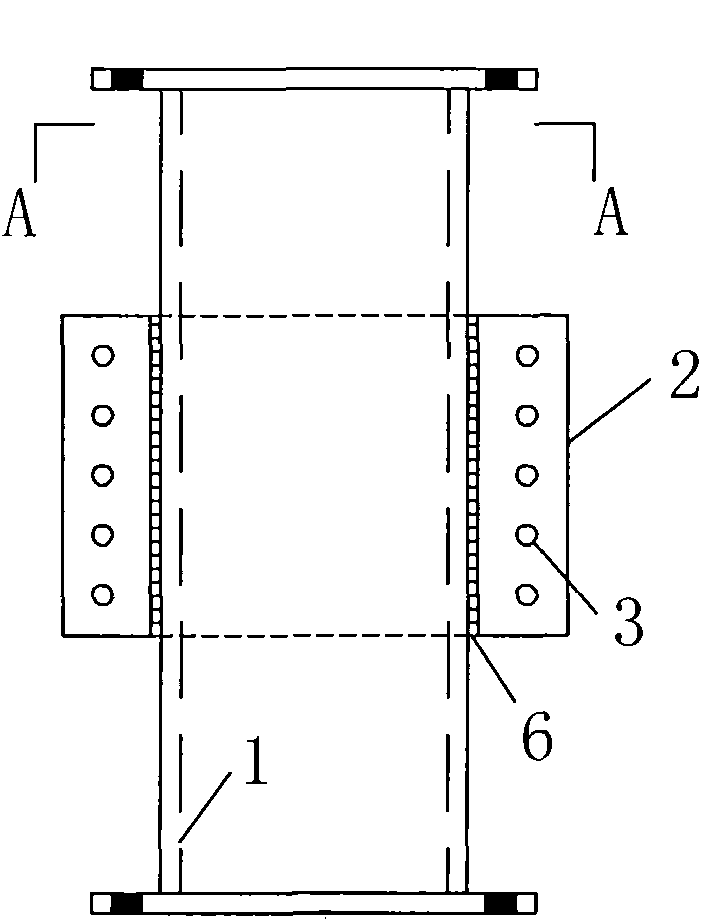

[0082] Example 2: see image 3 , Figure 4 , in the figure 1. Steel column, 2. Connecting plate, 3. Bolted joint, 4. Flange, 5. Connecting hole, 6. Welding seam, a standardized steel structure node connector in the figure, containing a steel column 1. The connection plate fixedly connected to the side of the steel cylinder, the free end of the connection plate is a bolt joint, the fixed connection at the two ends of the steel cylinder is provided with a flange, the flange is provided with a connection hole, the The steel column is provided with a vertical through seam matching the connecting plate, the connecting plate penetrates the vertical through seam, and the part where the connecting plate and the steel column intersect is fixed by welding. The steel cylinder is a steel pipe with a circular cross section, the vertical through seam penetrates along the center line of the steel pipe, and the connection plate is welded to the intersecting part of the steel pipe. The conne...

Embodiment 3

[0083] Embodiment three: see Figure 5 , Image 6 , in the figure 1. Steel column, 2. Connecting plate, 3. Bolted joint, 4. Flange, 5. Connecting hole, 6. Welding seam, a standardized steel structure node connector in the figure, containing a steel column 1. The connection plate fixedly connected to the side of the steel cylinder, the free end of the connection plate is a bolt joint, the fixed connection at the two ends of the steel cylinder is provided with a flange, the flange is provided with a connection hole, the The steel column is provided with a vertical through seam matching the connecting plate, the connecting plate penetrates the vertical through seam, and the part where the connecting plate and the steel column intersect is fixed by welding. The steel cylinder is a steel pipe with a circular cross section, the vertical through seam penetrates along the center line of the steel pipe, and the connection plate is welded to the intersecting part of the steel pipe. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum stress | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com