Patents

Literature

894 results about "Bolted joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bolted joints are one of the most common elements in construction and machine design. They consist of fasteners that capture and join other parts, and are secured with the mating of screw threads. There are two main types of bolted joint designs: tension joints and shear joints.

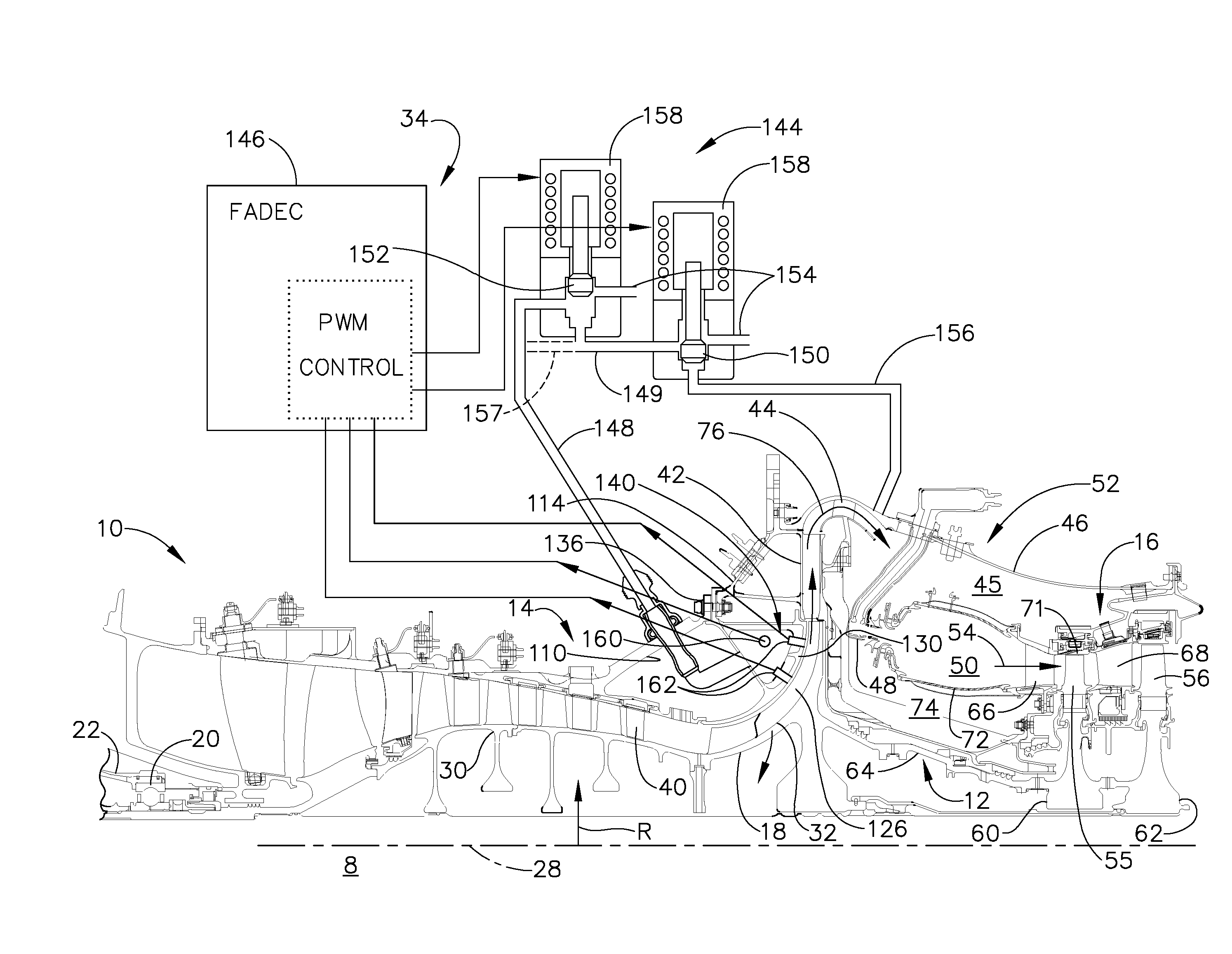

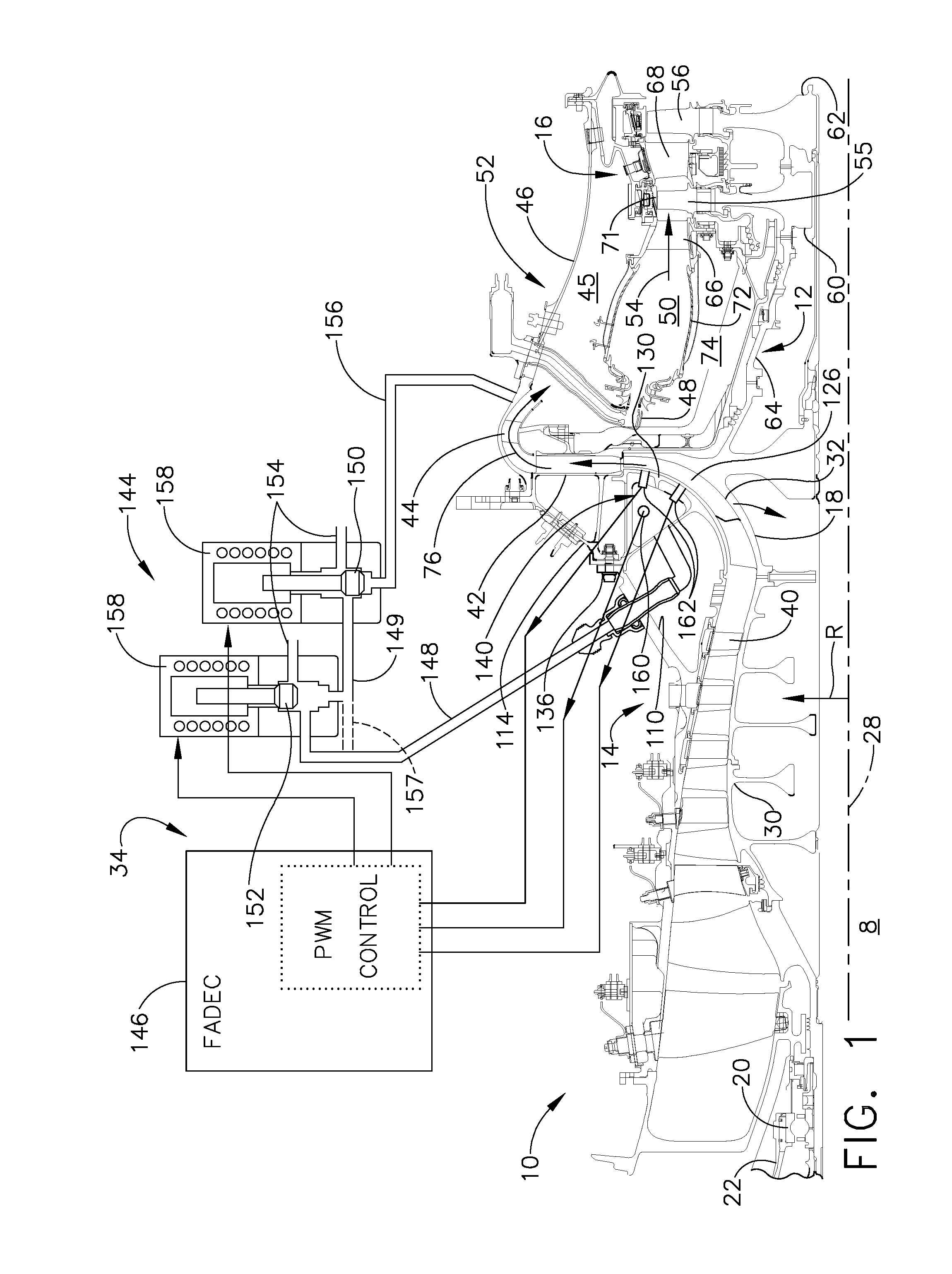

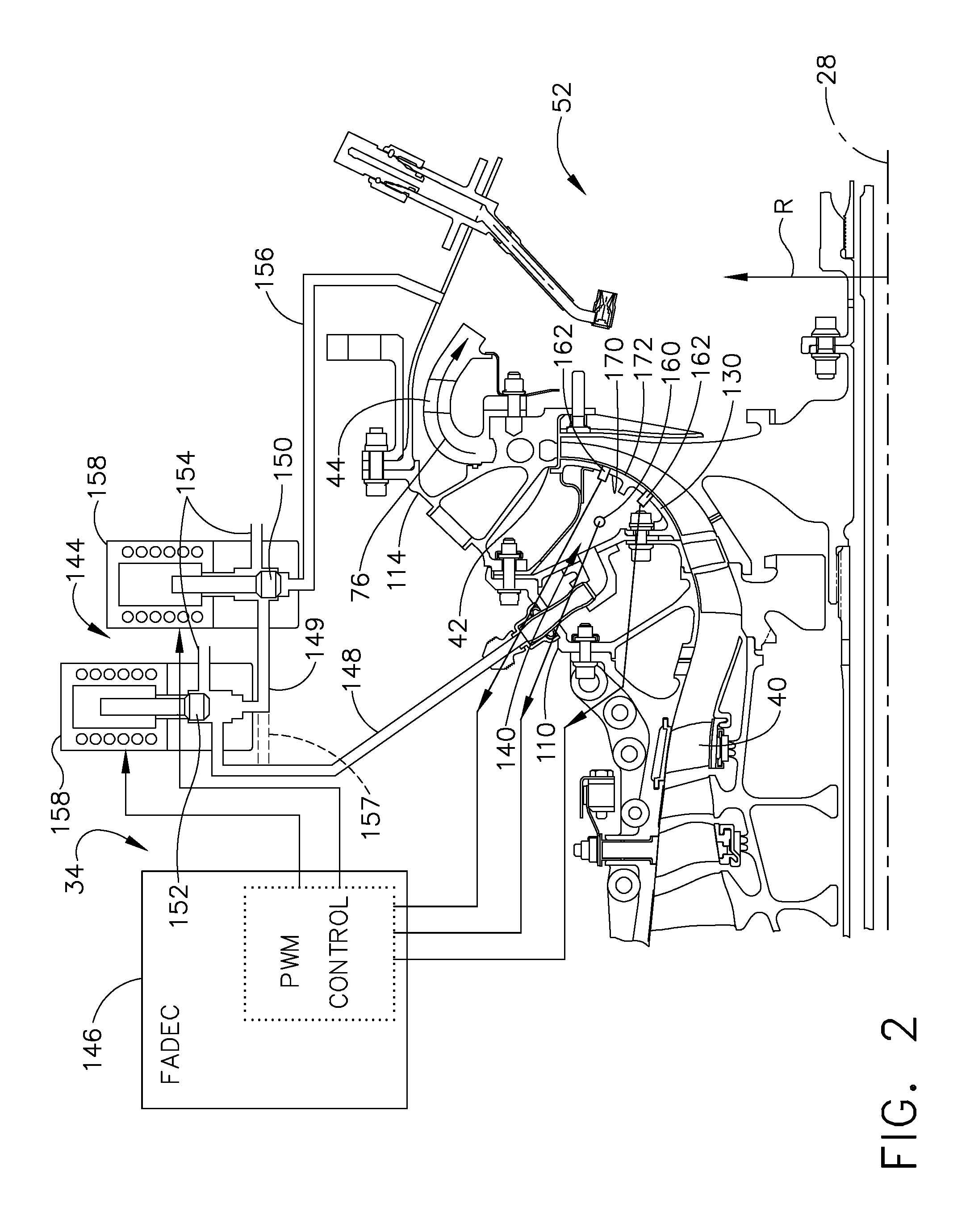

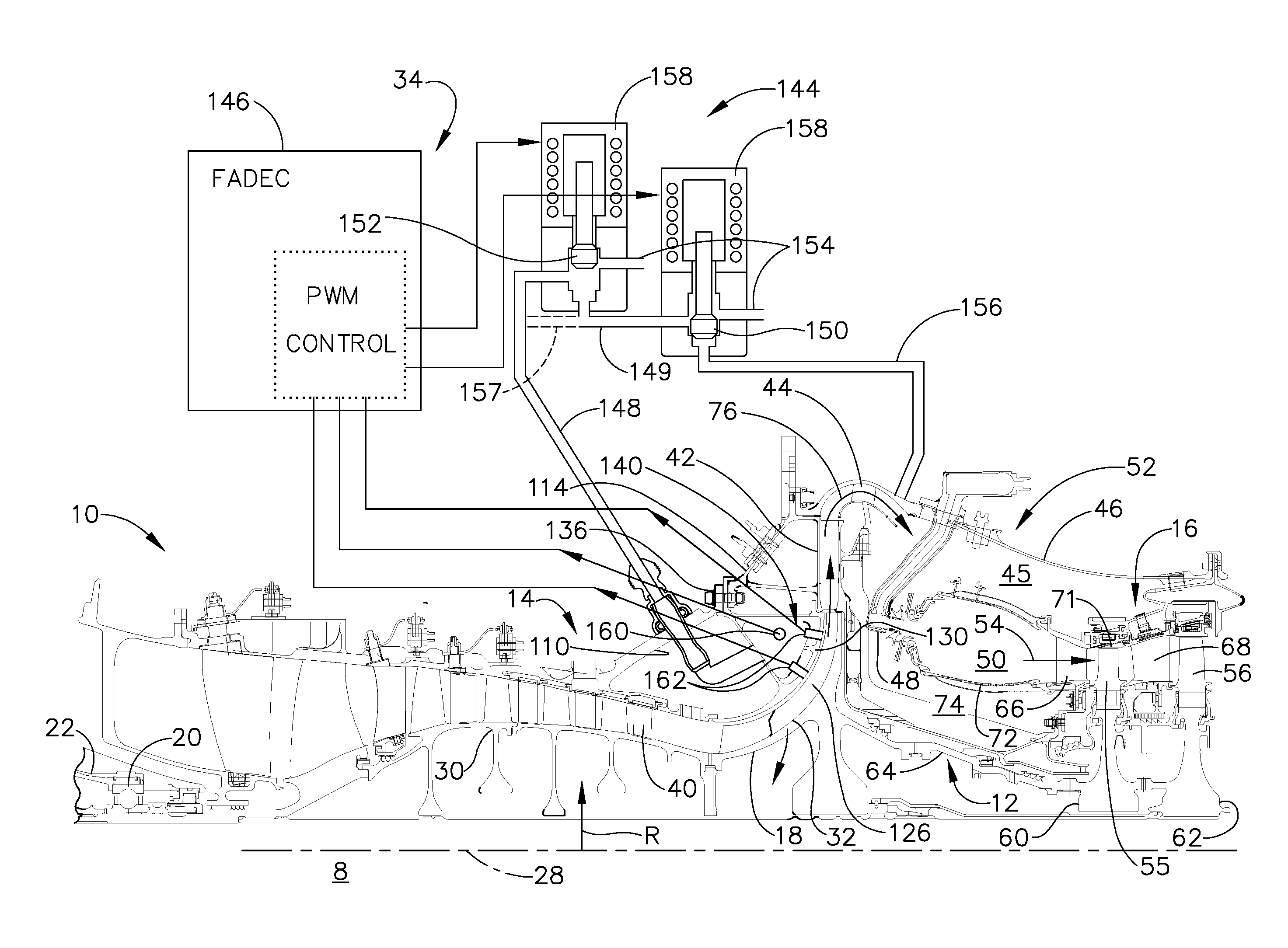

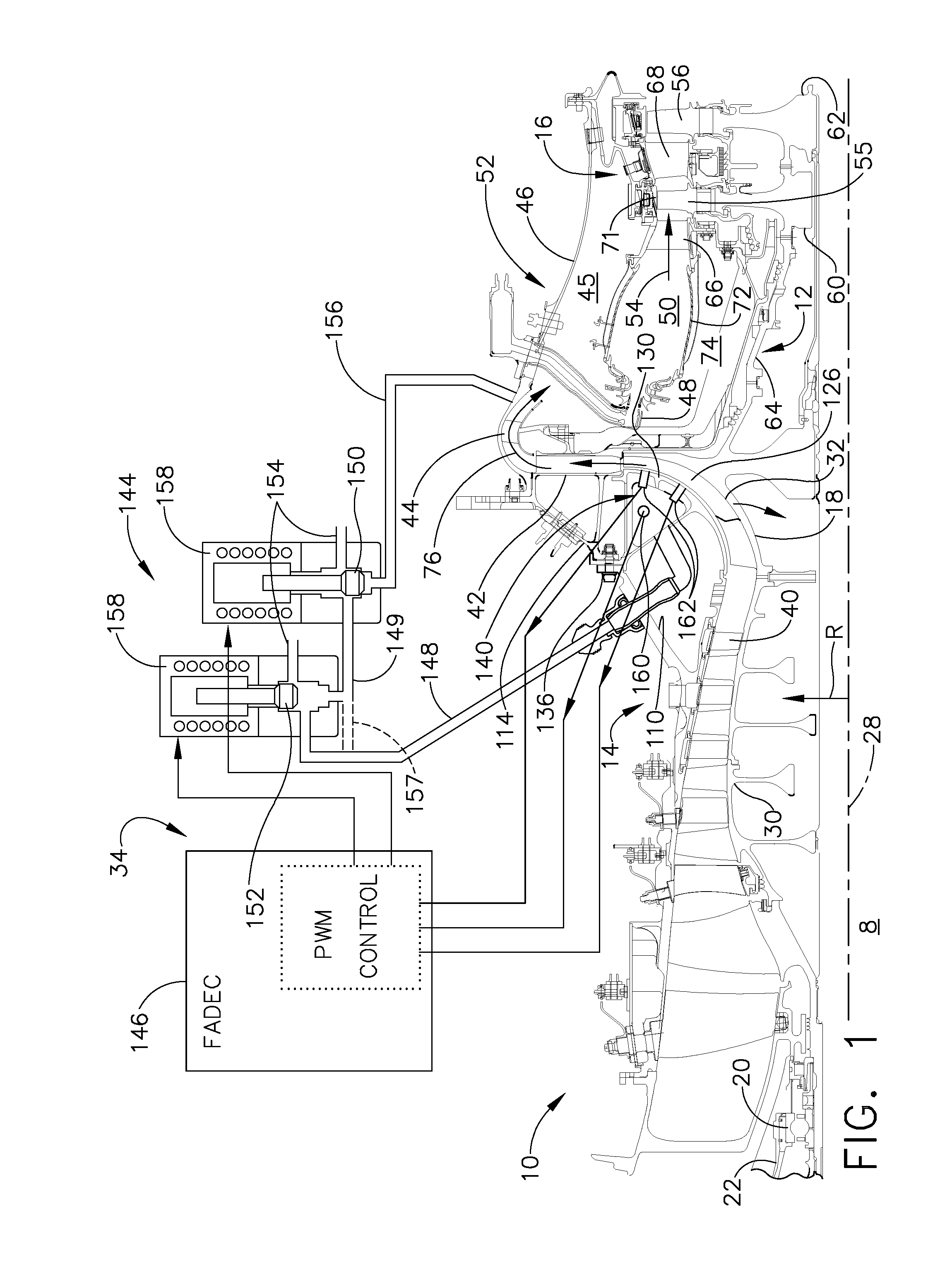

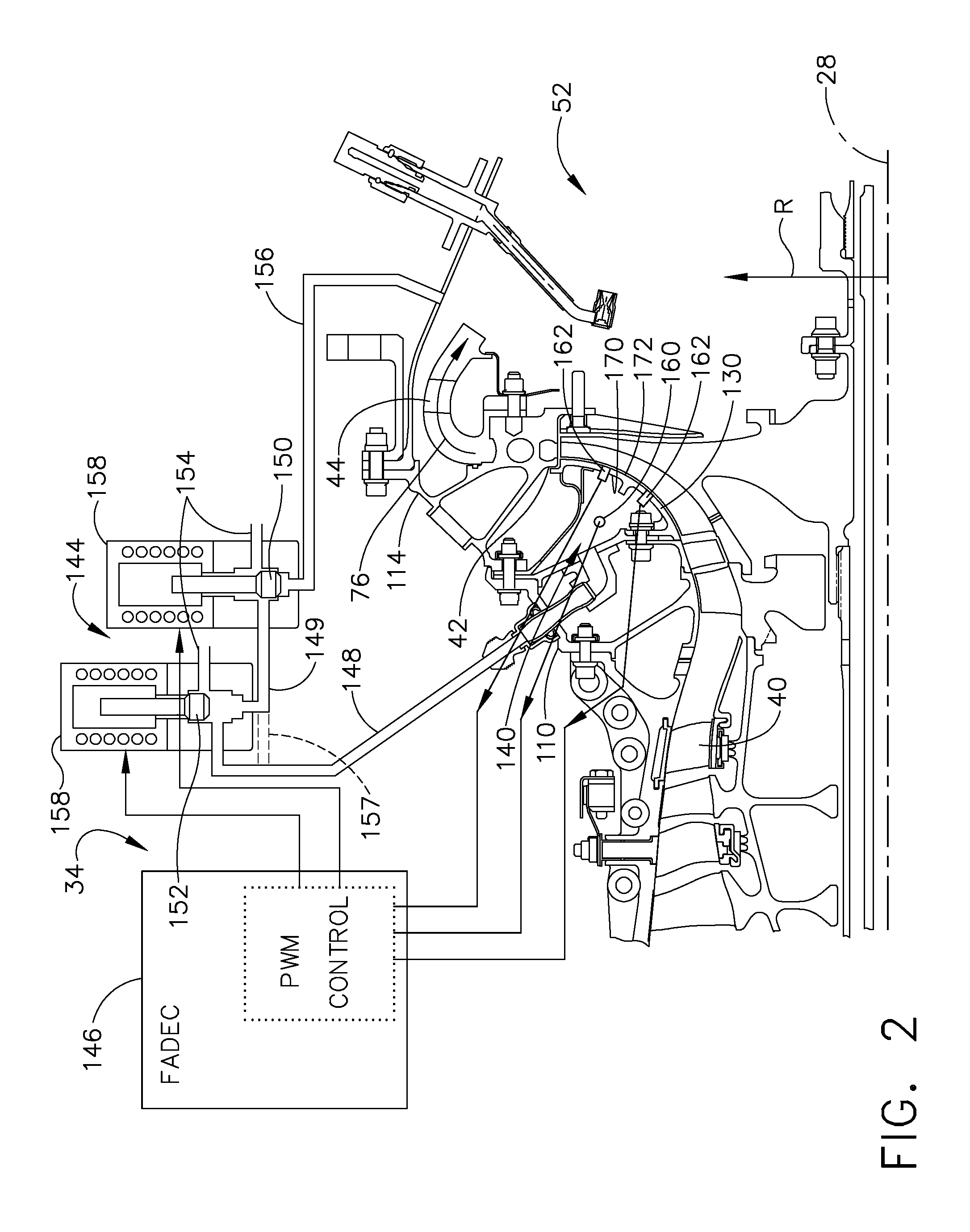

Active clearance control for a centrifugal compressor

Apparatus and method of operating a centrifugal compressor and active control system includes a centrifugal compressor with compressor blades mounted on an impeller, an annular cavity bounded in part by a shroud adjacent to the blades, and an active control system for controlling a clearance between the shroud and the blades by controlling a cavity pressure in the cavity. An electronic controller for controlling a control pressure valve for pressurizing using a source of compressor discharge pressure air and depressurizing the cavity respectively may open and close the valves using pulse width modulation. Pressure and clearance sensors positioned for measuring the cavity pressure the blade tip clearance respectively in signal supply communication with the electronic controller may be used. The shroud may be supported by radially spaced apart annular radially outer and inner supports connected to a casing by a bolted joint bounding the cavity.

Owner:GENERAL ELECTRIC CO

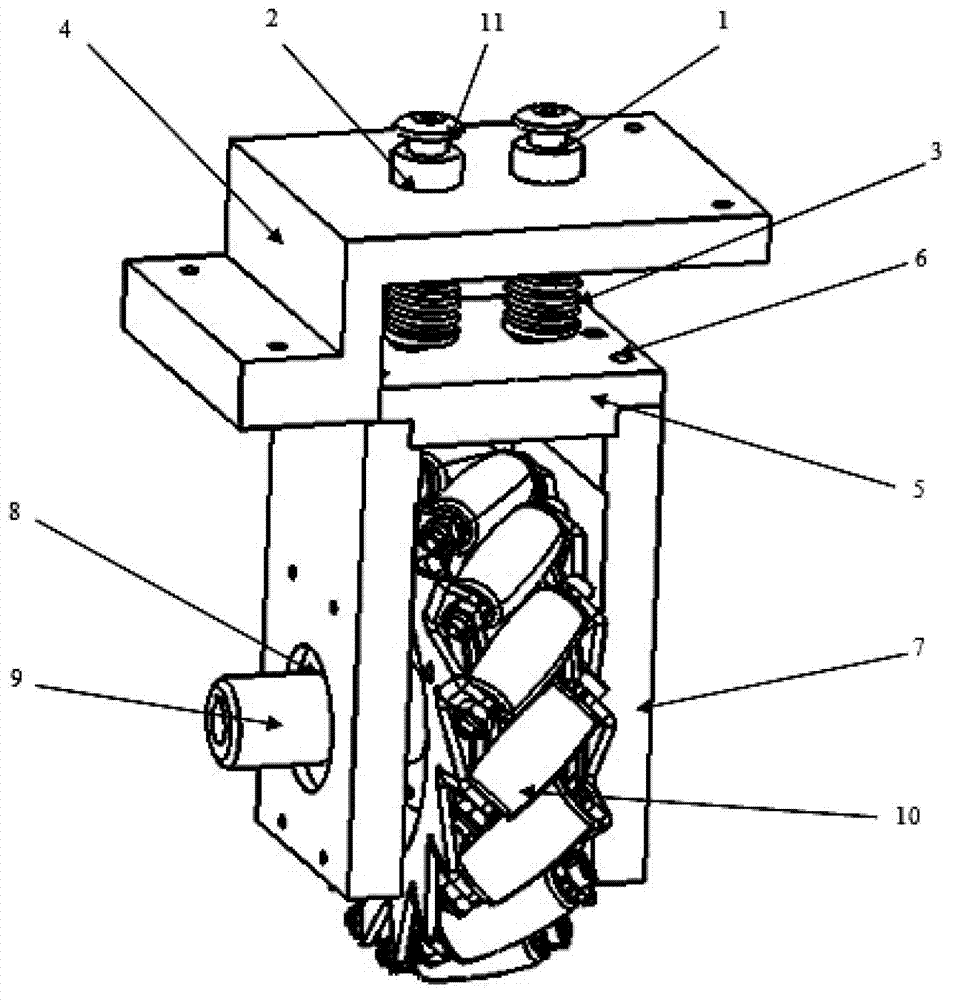

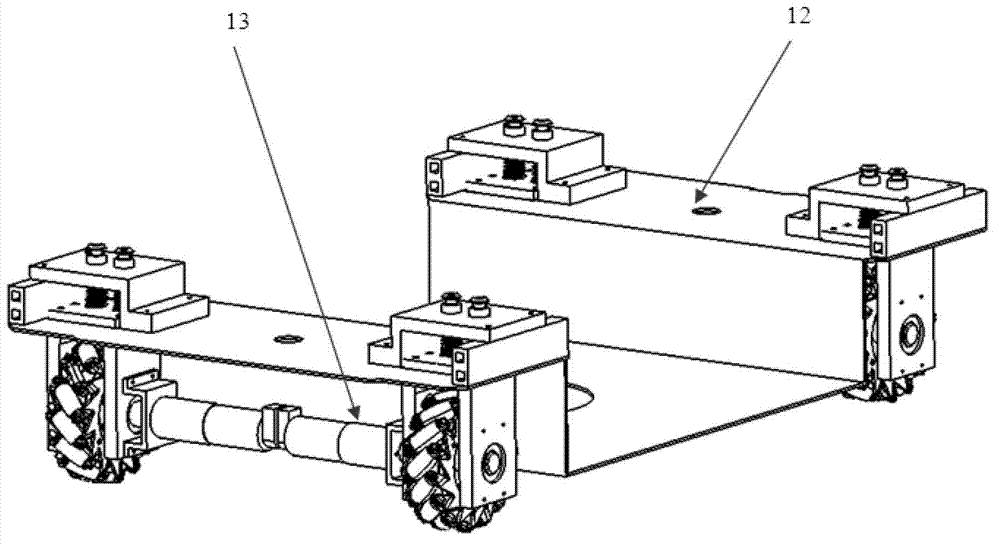

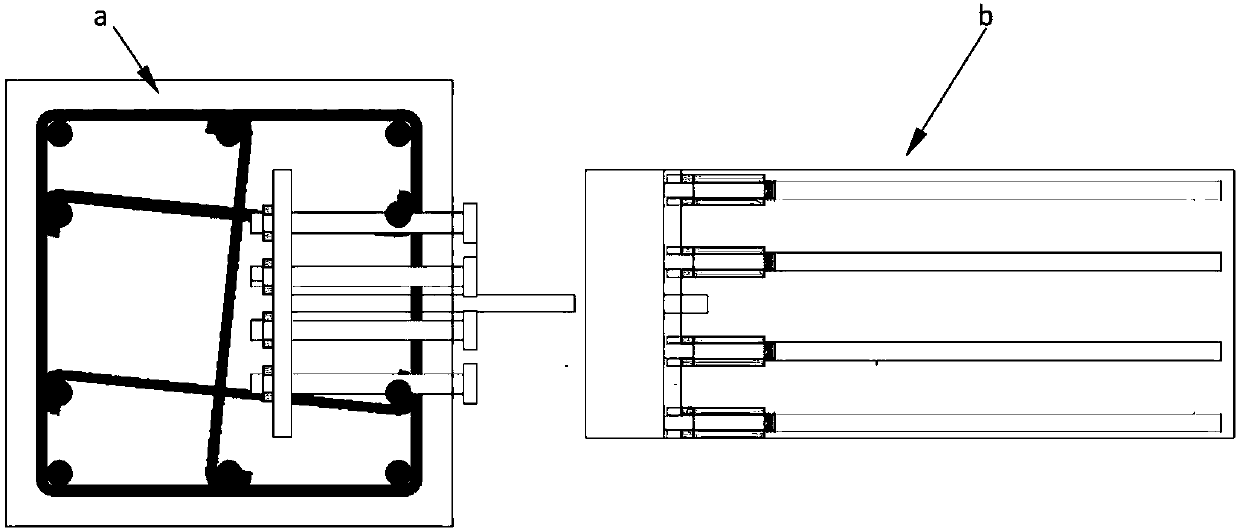

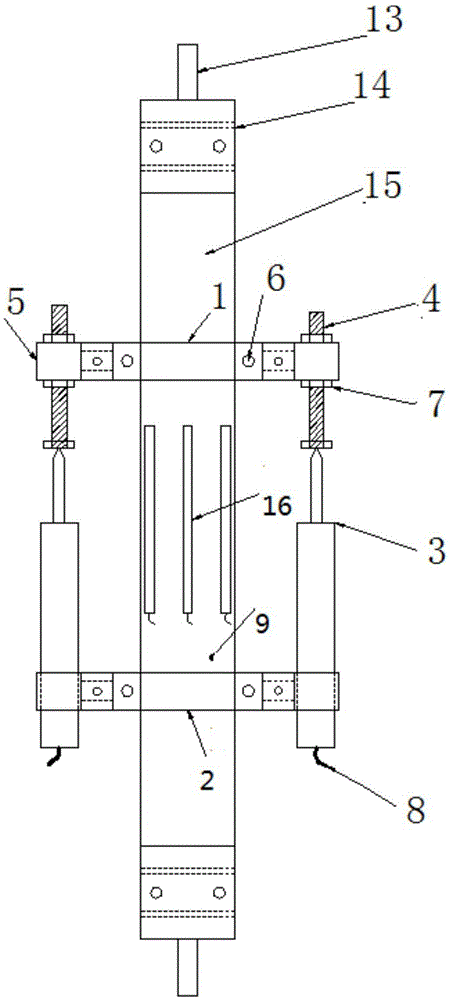

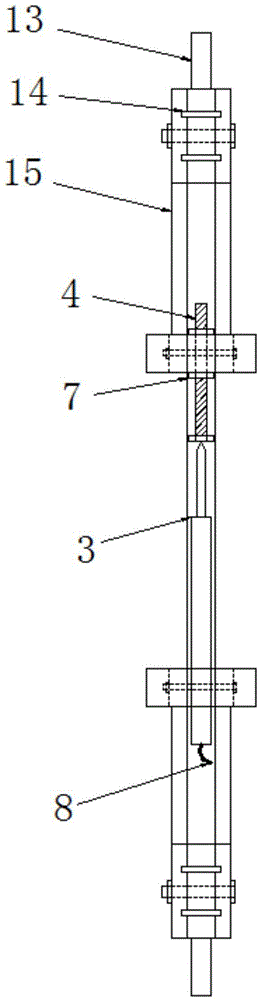

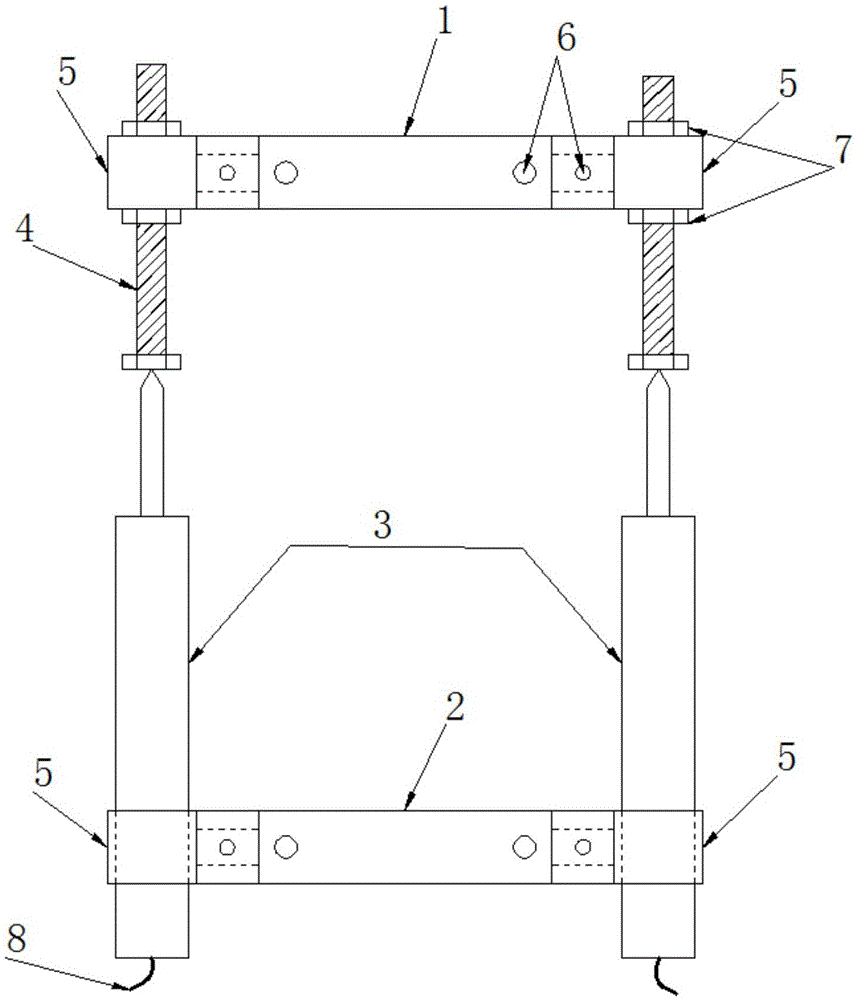

Dual-sliding shaft floatation supporting mechanism of omnibearing movable AGV (Automatic Guided Vehicle)

The invention discloses a dual-sliding shaft floatation supporting mechanism of an omnibearing movable AGV (Automatic Guided Vehicle), wherein a Mecanum wheel is fixed on a motor shaft; two annular ball bearings are arranged at two ends of the motor shaft and then are arranged in bearing seats; the two bearing seats are arranged on a bracket by virtue of locating of two locating pins; two sliding shafts are fixed on the bracket by virtue of bolted joint; two sliding linear bearings with flanges are fixed on fixing plates by virtue of screws; two rectangular helical springs are arranged at the lower parts of the sliding shafts; and two sliding shafts penetrate through the two sliding linear bearing with the flanges and are locked up. The dual-sliding shaft floatation supporting mechanism ensures that the Mecanum wheel rotates freely in the vertical direction and floats so as to realize the floatation support in the vertical direction, so that when a road surface is uneven, the Mecanum wheel can not be contacted with the ground and idle or can not idle while being slightly contacted with the ground, and simultaneously the vibration during the Mecanum wheel traveling process can be weakened, and the traveling direction accuracy and movement stability of the AGV can be greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

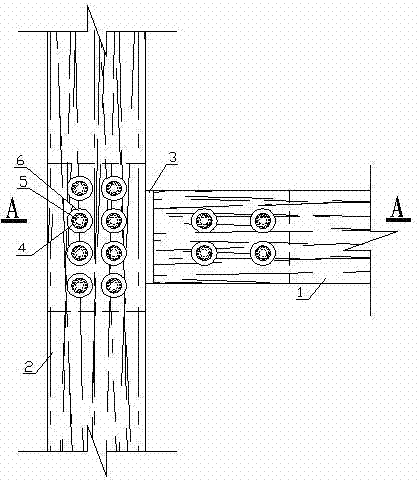

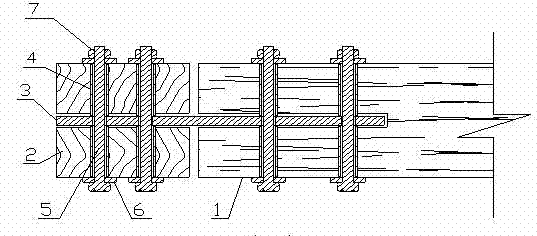

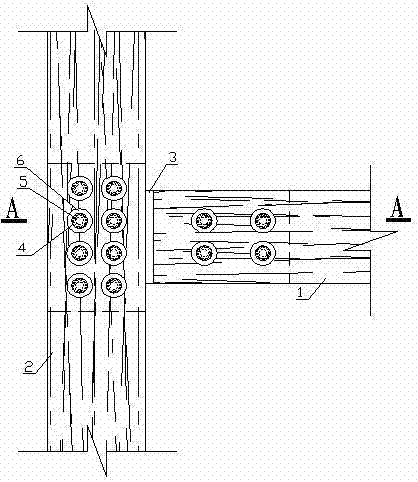

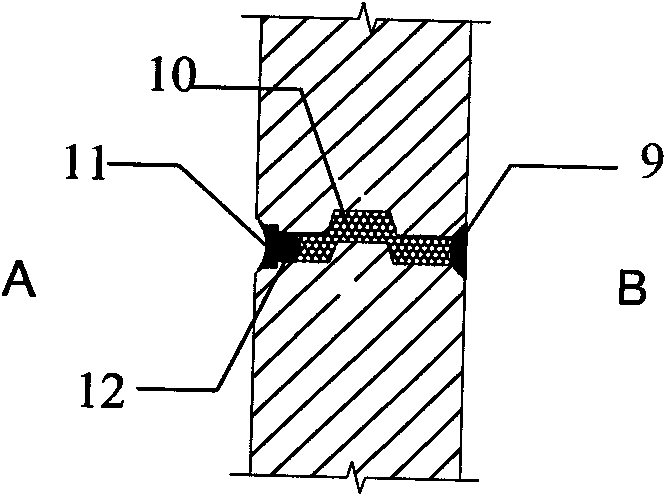

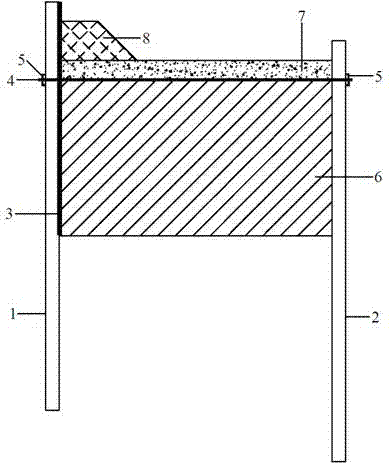

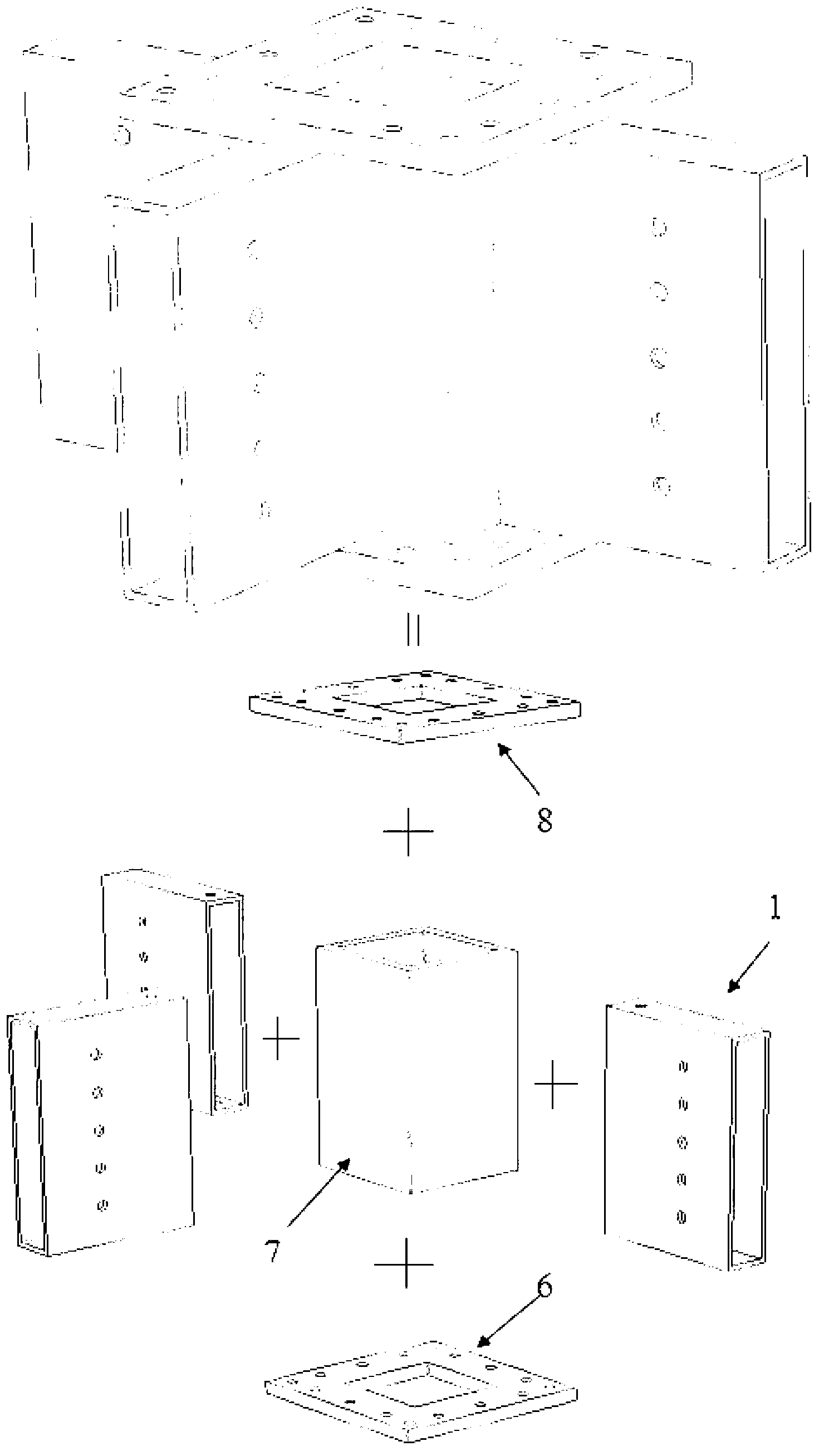

Bolted steel filling plate-sleeve connection node for beam-post wood structure

The invention belongs to the field of civil engineering technology, and particularly relates to a bolted steel filling plate-sleeve connection node for a beam-post wood structure. The connection node comprises a wood beam, a wood post, a steel filling plate, a sleeve, a bolt, a gasket and a nut. The the beam-post connection node is formed by inserting steel filling plates in grooves of the wood beam and the wood post, the sleeve is embedded in the bolt hole on the beam-post connection node; after the bolt passes through the sleeve, the sleeve is pressed by the gasket through a stretch-draw bolt, so that the sleeve pushes against the steel filling plates to generate larger pressure, friction generated by pressure is utilized for shear resistance and the increasing and decreasing of pressure stress is utilized for bending resistance. The connection node is definite in force transfer and convenient for construction, and gaps at the nodes almost have no influence on the load-carrying property and rigidity of the structure; in addition, the introduction of the sleeve can also prevent the local bearing damage of the wood below the gasket and reduce the contact pressure stress at the bolt of the wood beam (post), thus being beneficial to the exertion of strength of the wood. Compared with the existing connection mode, the connection node of the beam-post wood frame has large and stable bending-resistant rigidity.

Owner:何敏娟 +1

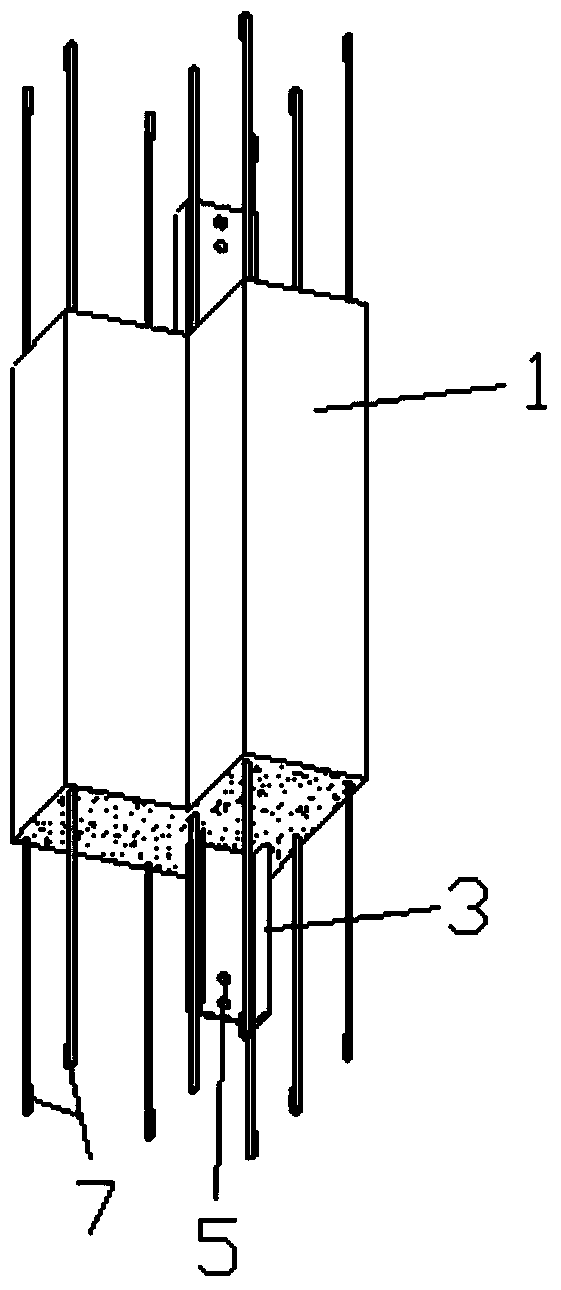

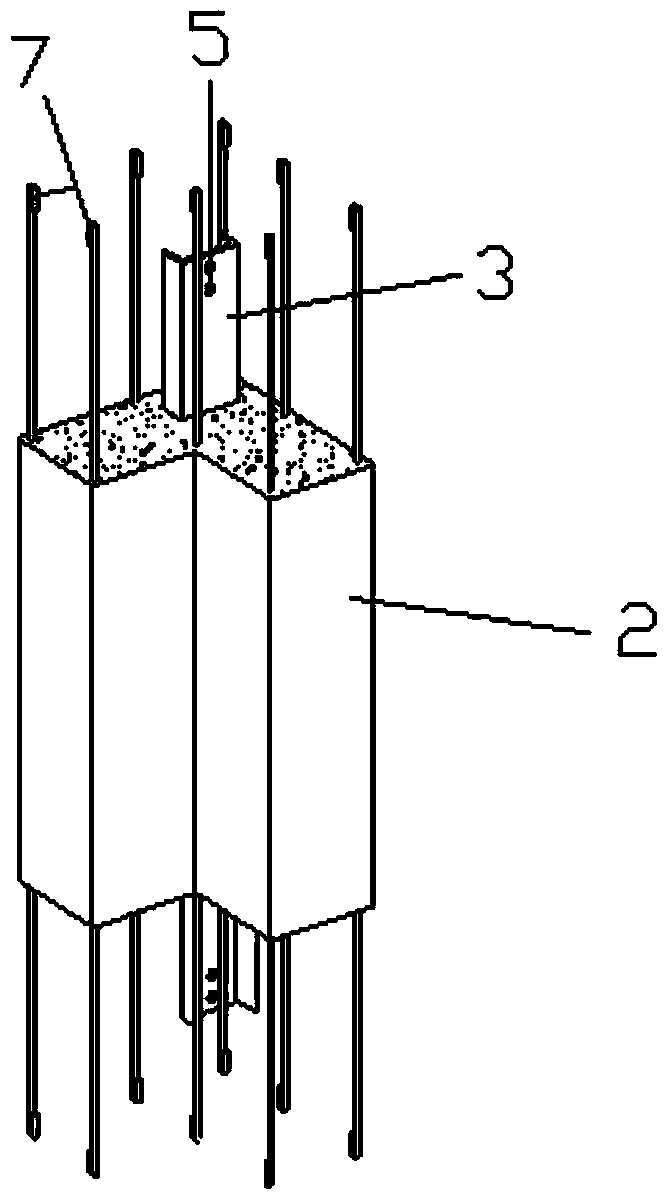

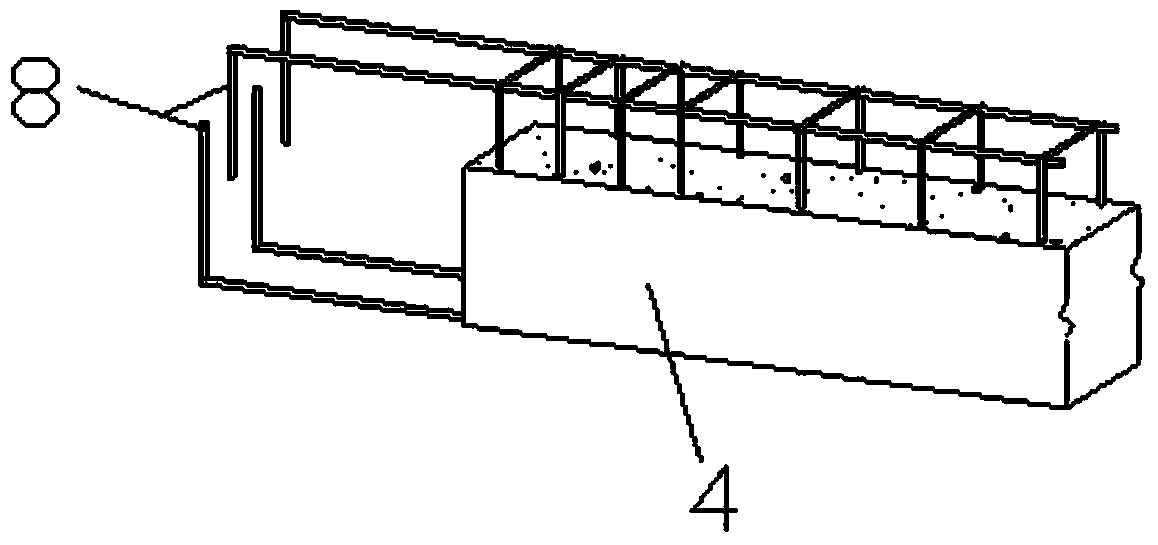

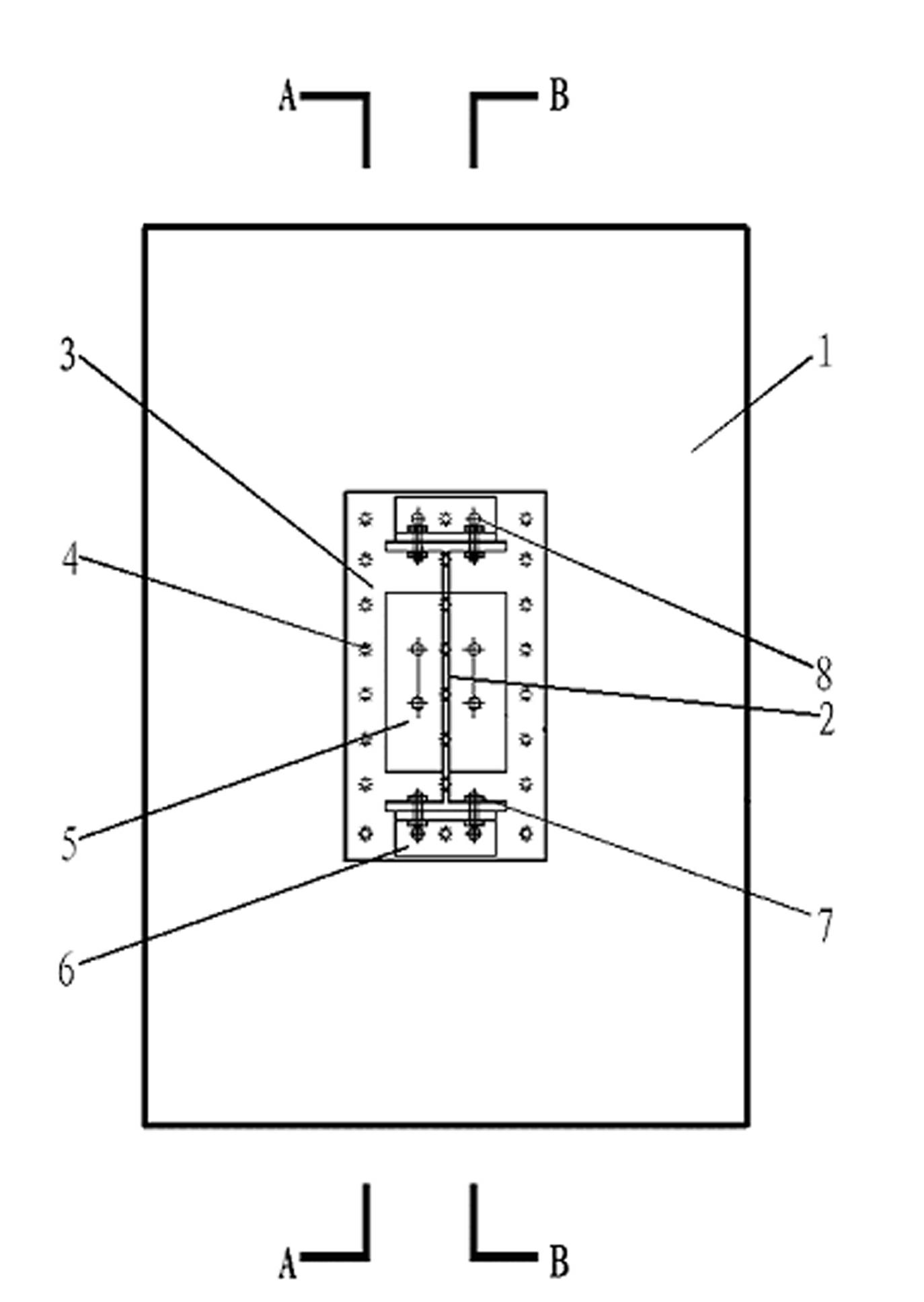

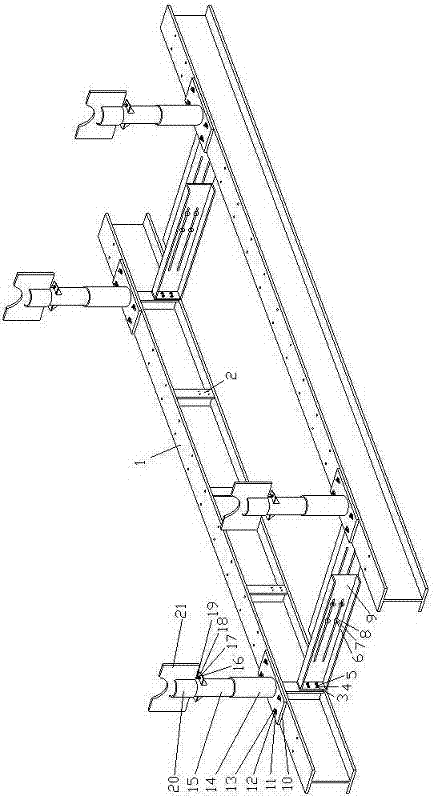

Prefabricated, assembled and integrated type special-shaped column structure and jointing construction method thereof

InactiveCN103850350AImprove integrityEliminate weaknessBuilding material handlingWhole bodyBolted joint

The invention discloses a prefabricated, assembled and integrated type special-shaped column structure and a jointing construction method of the column structure. The prefabricated, assembled and integrated type special-shaped column structure comprises a prefabricated upper column, a prefabricated lower column and a prefabricated laminated beam, wherein the prefabricated upper column and the prefabricated lower column are respectively provided with channel steel in an embedding manner, reserved bolt holes are formed in each channel steel, the adjacent prefabricated upper column and prefabricated lower column are connected through the channel steel by bolts to form an upper and lower through special-shaped column provided with a cast-in-place area, and reinforcing hoops are arranged in the cast-in-place area; the prefabricated laminated beam is anchored in the abnormal column through a longitudinal rib of the prefabricated laminated beam; cast-in-place concrete is injected in the cast-in-place areas of the adjacent two prefabricated upper column and prefabricated lower column and a part, not pouring the concrete, of the prefabricated laminated beam, so as to form a beam and column combined whole body. According to the prefabricated, assembled and integrated type special-shaped column structure and the jointing construction method of the column structure, which are disclosed by the invention, the problems that the vibration of concrete in joint core area of the special-shaped column is not dense and is difficult can be remarkably modified, so that the vibration resistance of joints can be improved; furthermore, the construction speed further can be increased, the construction period is shortened, and the development of building industrialization is facilitated.

Owner:NANJING TECH UNIV +1

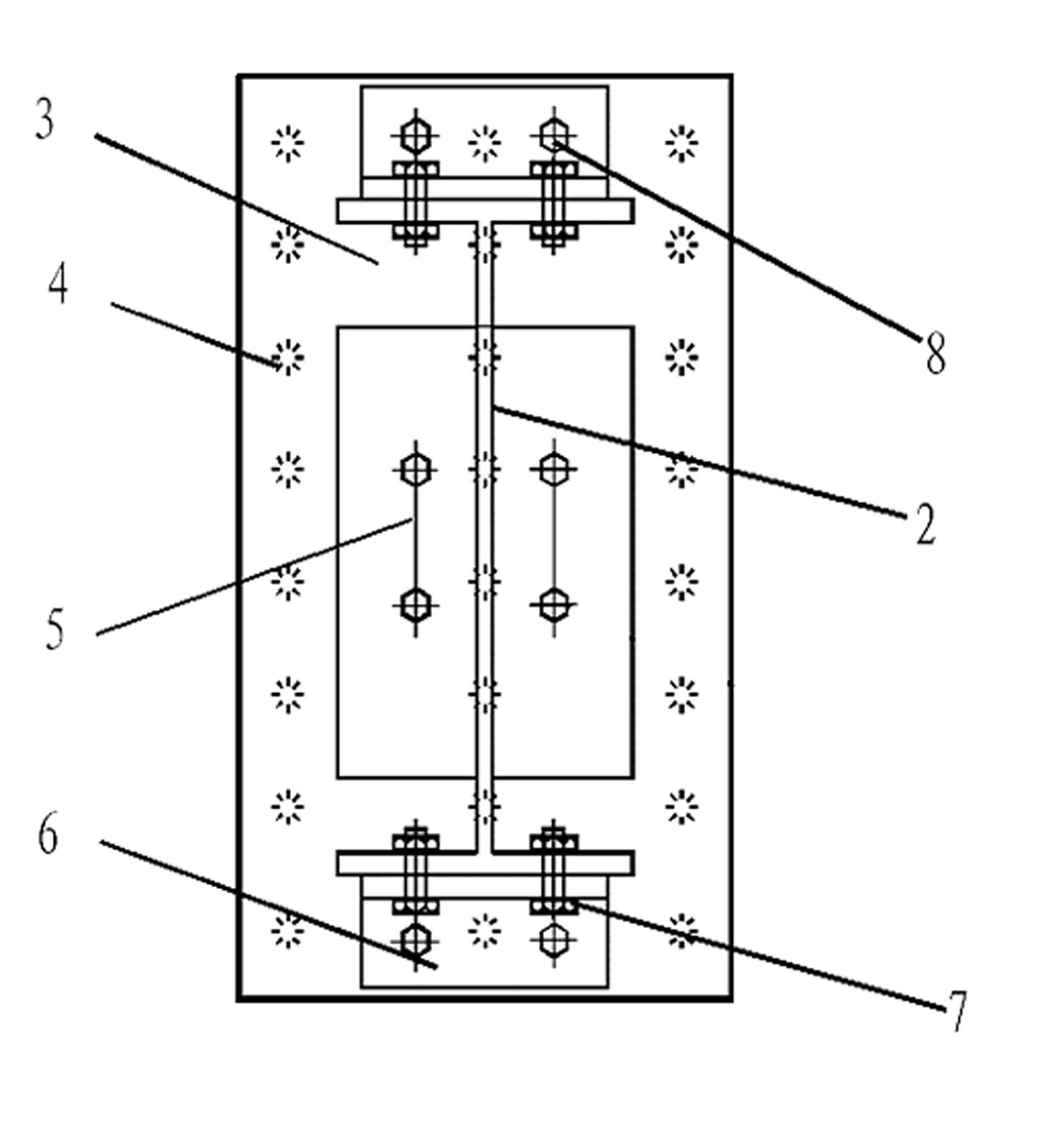

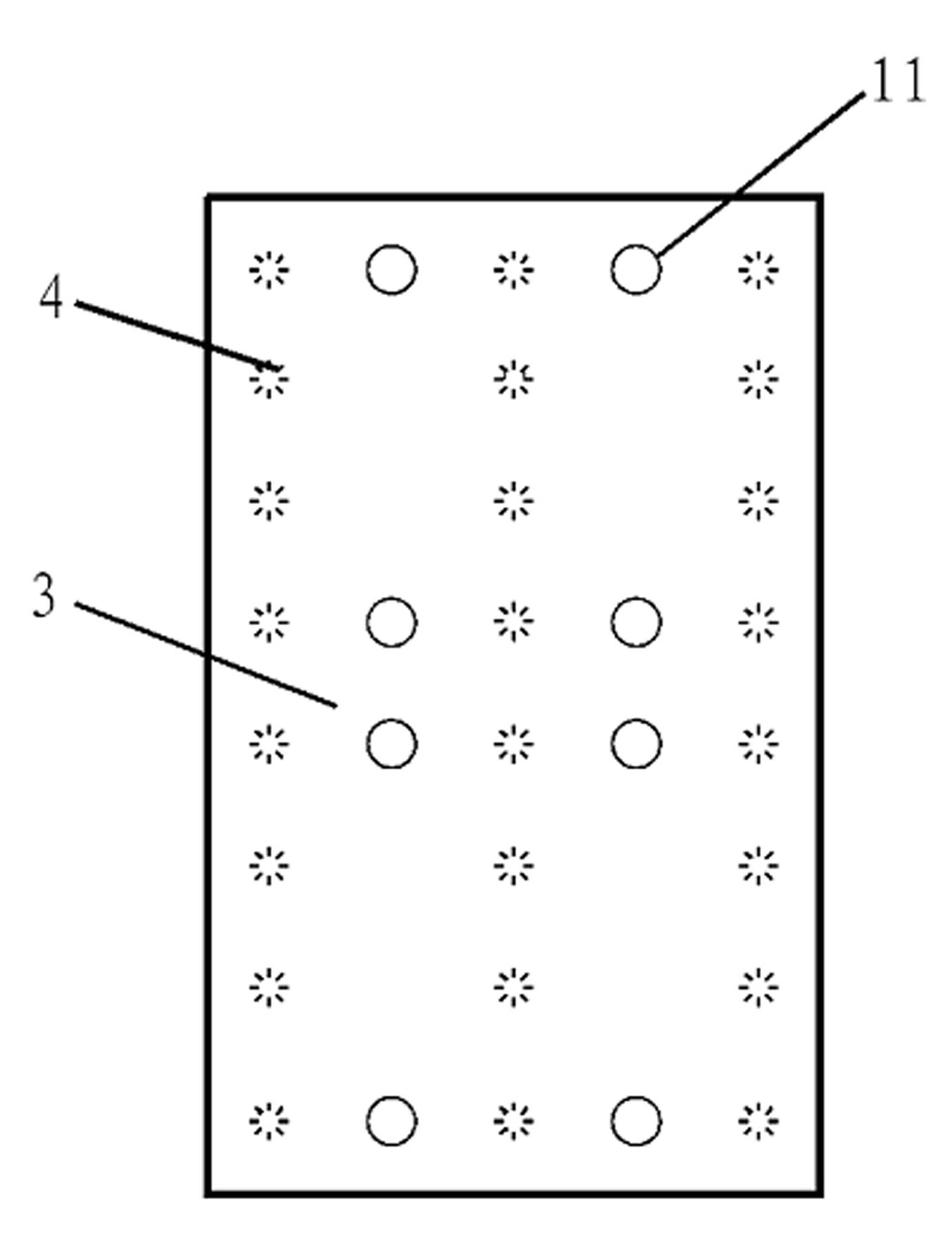

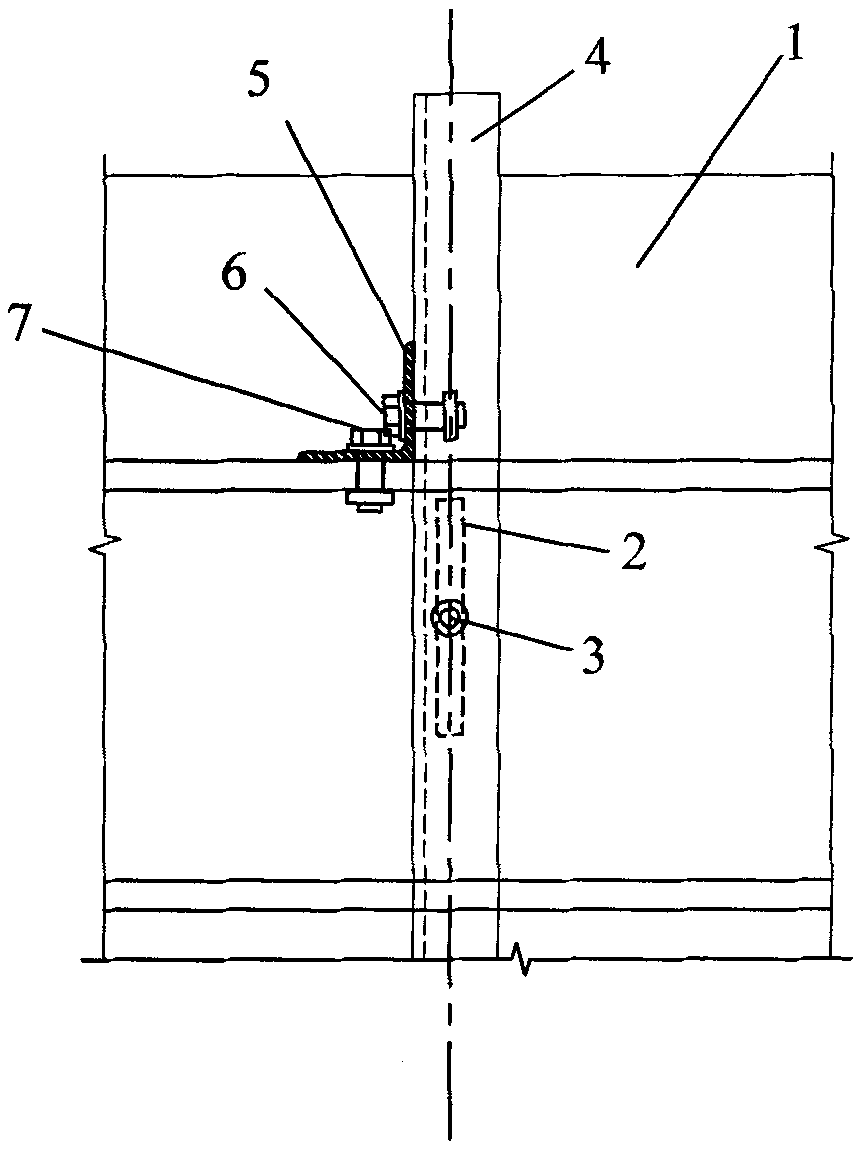

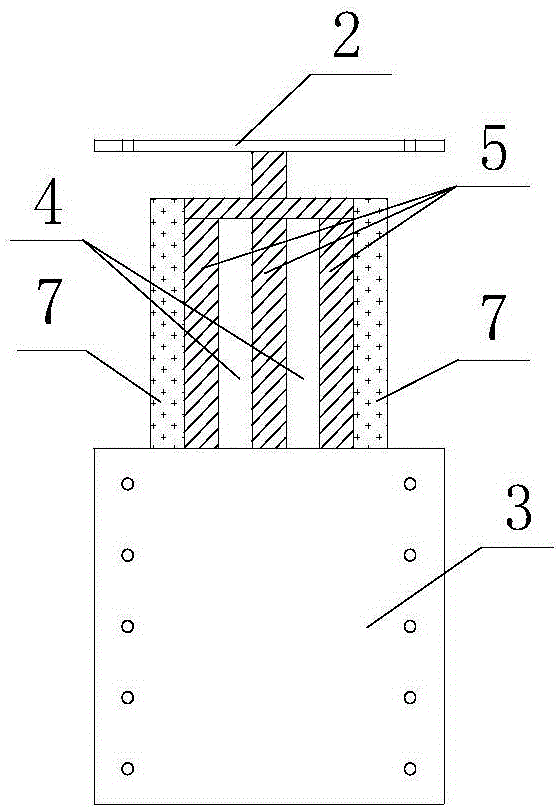

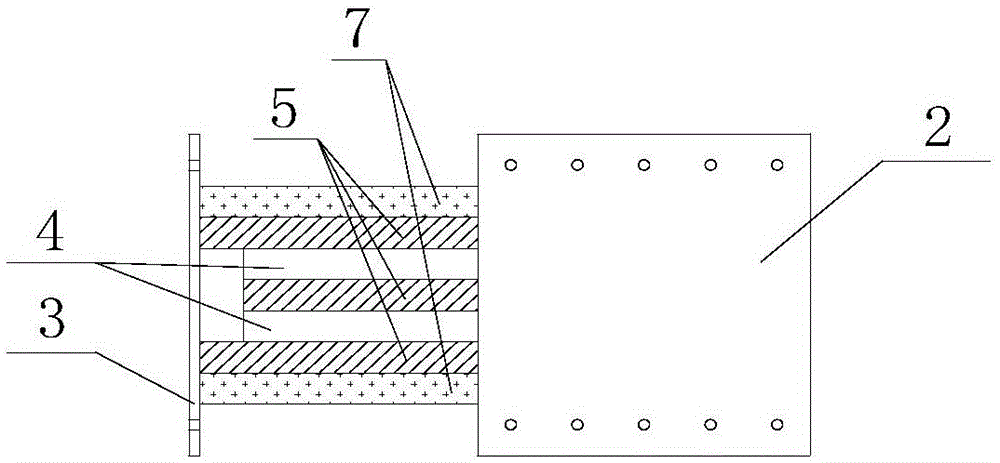

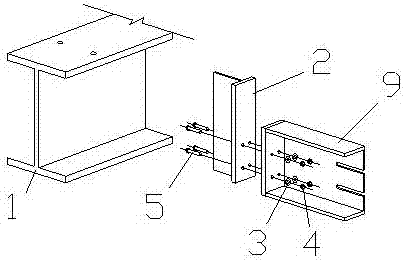

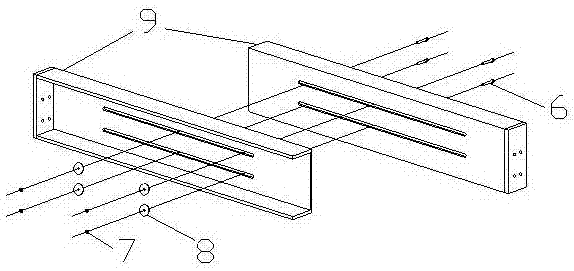

Steel beam and concrete wall semi-rigid full-bolted-connection joint

ActiveCN102587495AAchieve full bolted connectionAvoid difficultiesBuilding constructionsReinforced concreteClassical mechanics

A steel beam and concrete wall semi-rigid full-bolted-connection joint comprises a reinforced concrete wall body (1), an H-shaped steel beam (2), web plate angle steel (5), upper and lower flange angle steel (6), a bolt (7) and a bolt (8). A tailored embedded part is arranged in the reinforced concrete wall body (1) and consists of reinforcement connectors (9), two steel plates (3), a plurality of straight anchor bars (4) and L-shaped anchor bars (12), the sizes of the two steel plates are identical, the steel plates are vertically placed on two sides of a reinforcement cage, the straight anchor bars (4) are welded between the two steel plates (3), at least eight circular holes (11) are drilled on one of the steel plates (3) and are arrayed to form two rows, each reinforcement connector (9) is arranged in the corresponding circular hole (11) by means of plug welding, the reinforcement connectors (9) are connected with the L-shaped anchor bars (12) between the two steel plates (3), and the H-shaped steel beam (3) is connected with the tailored embedded part by the web plate angle steel (5), the upper and lower flange angle steel (6), the bolt (7) and the bolt (8).

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

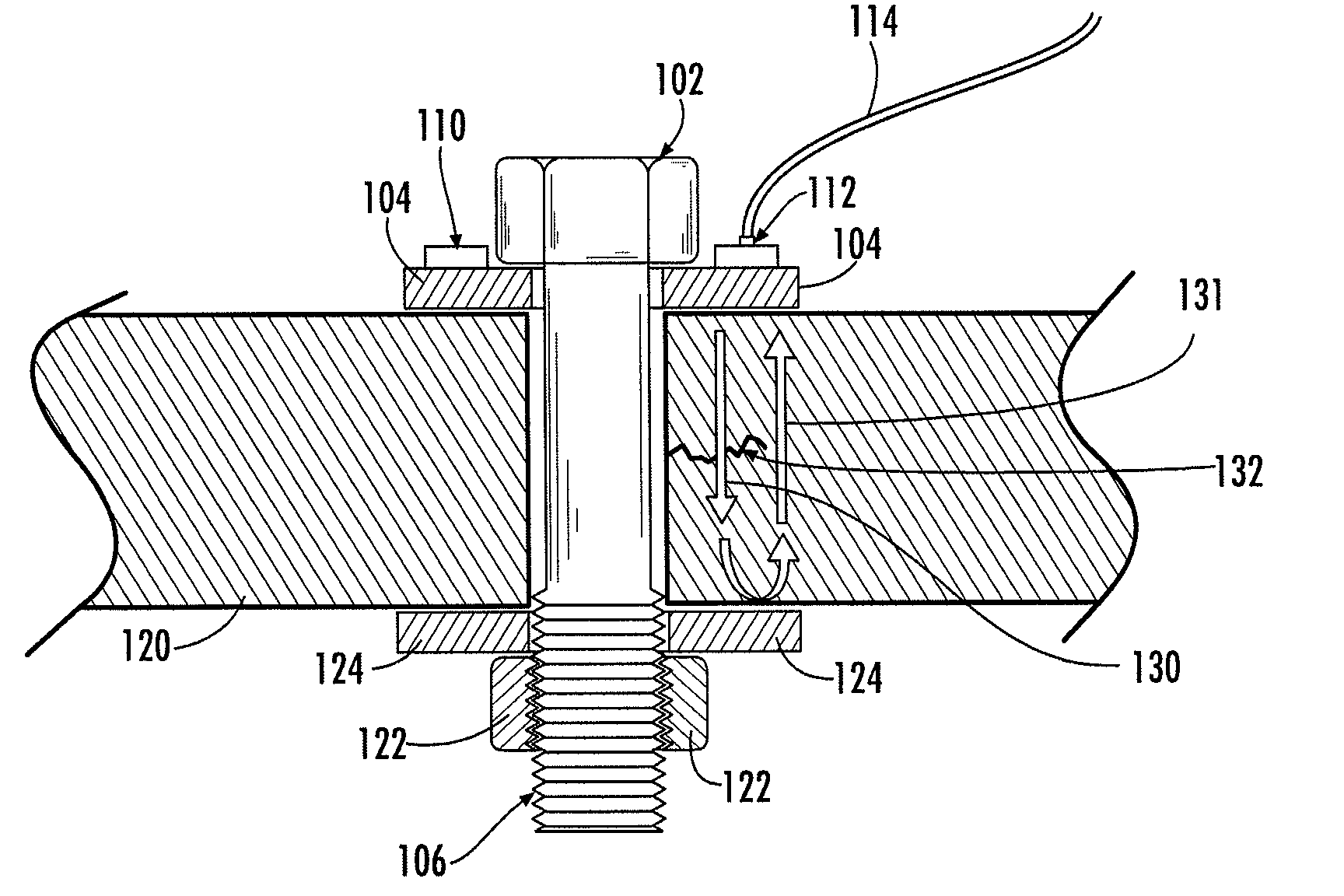

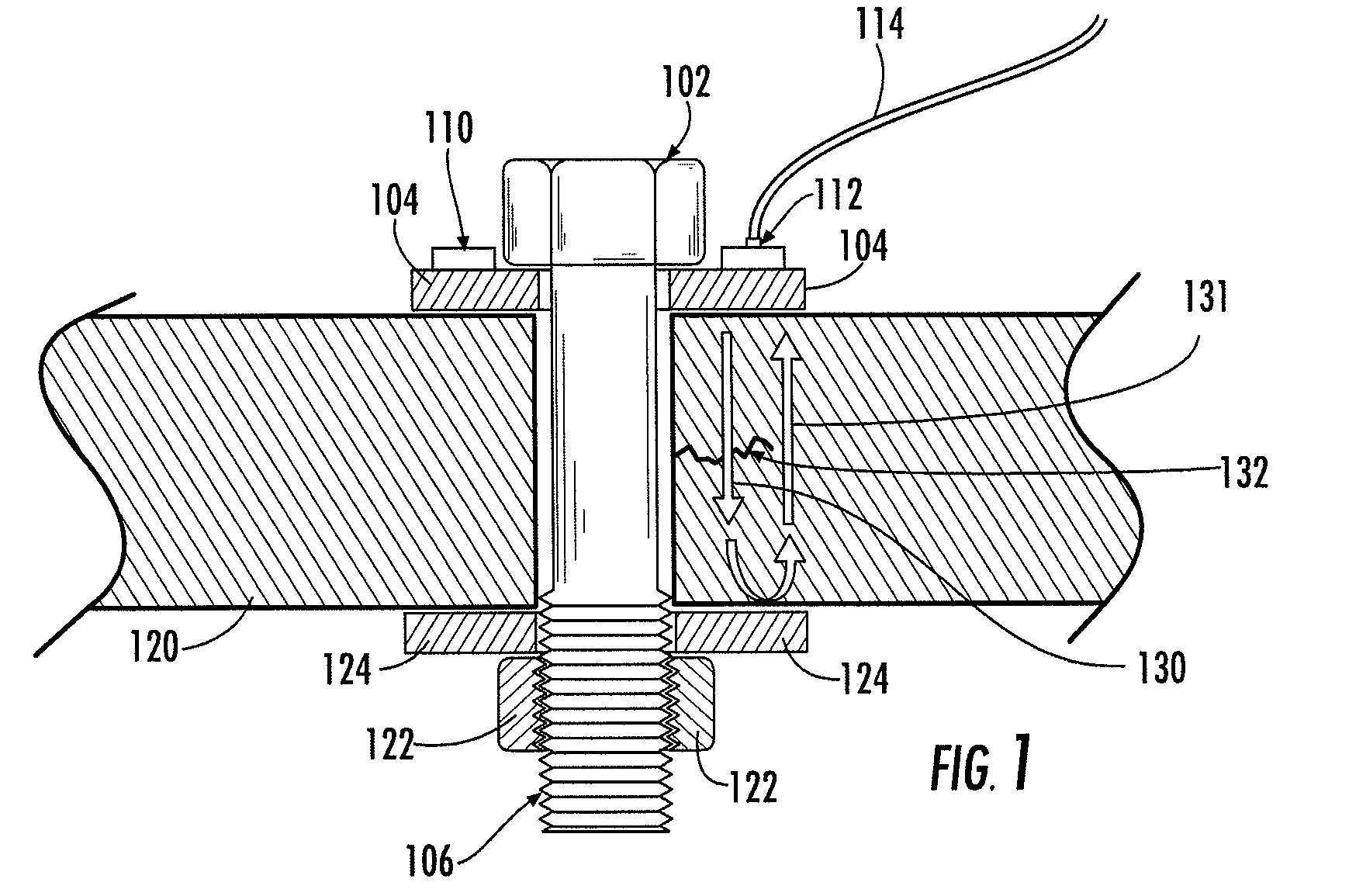

Active washers for monitoring bolted joints

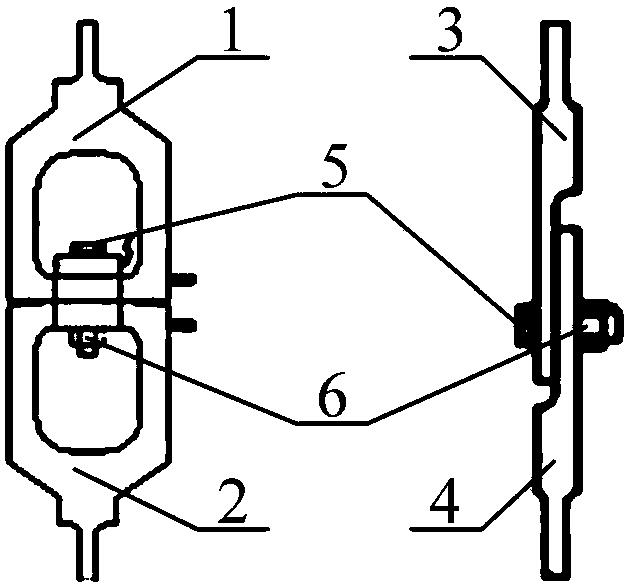

ActiveUS7698949B2Eliminate needLow costMaterial analysis using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementEngineeringThrough transmission

Apparatus, systems, and methods for inspecting and monitoring bolted joints of metallic and composite structures for defects such as delamination and fatigue cracking are provided that incorporate ultrasonic transducers with load bearing washers. These active washers may be used for inspecting and monitoring a structure beneath such load bearing fasteners as bolts and nuts. Active washers may be used for continuous, periodic, and controlled inspections of bolted joints. Ultrasonic transducers may be permanently applied to a surface of a washer or recessed in a cavity on a surface of the washer. Inspection signals may be transmitted from ultrasonic transducers into a structure and reflected in pulse-echo application or received by another active washer on the opposing side of the structure in a through-transmission application.

Owner:THE BOEING CO

Large autoclaved lightweight aerated concrete slab and installation method thereof

InactiveCN101892717ALarge external wall areaReduce the amount of work at heightsWallsBuilding material handlingWeight lightSteel structures

Owner:SHENZHEN YJY BUILDING TECH +1

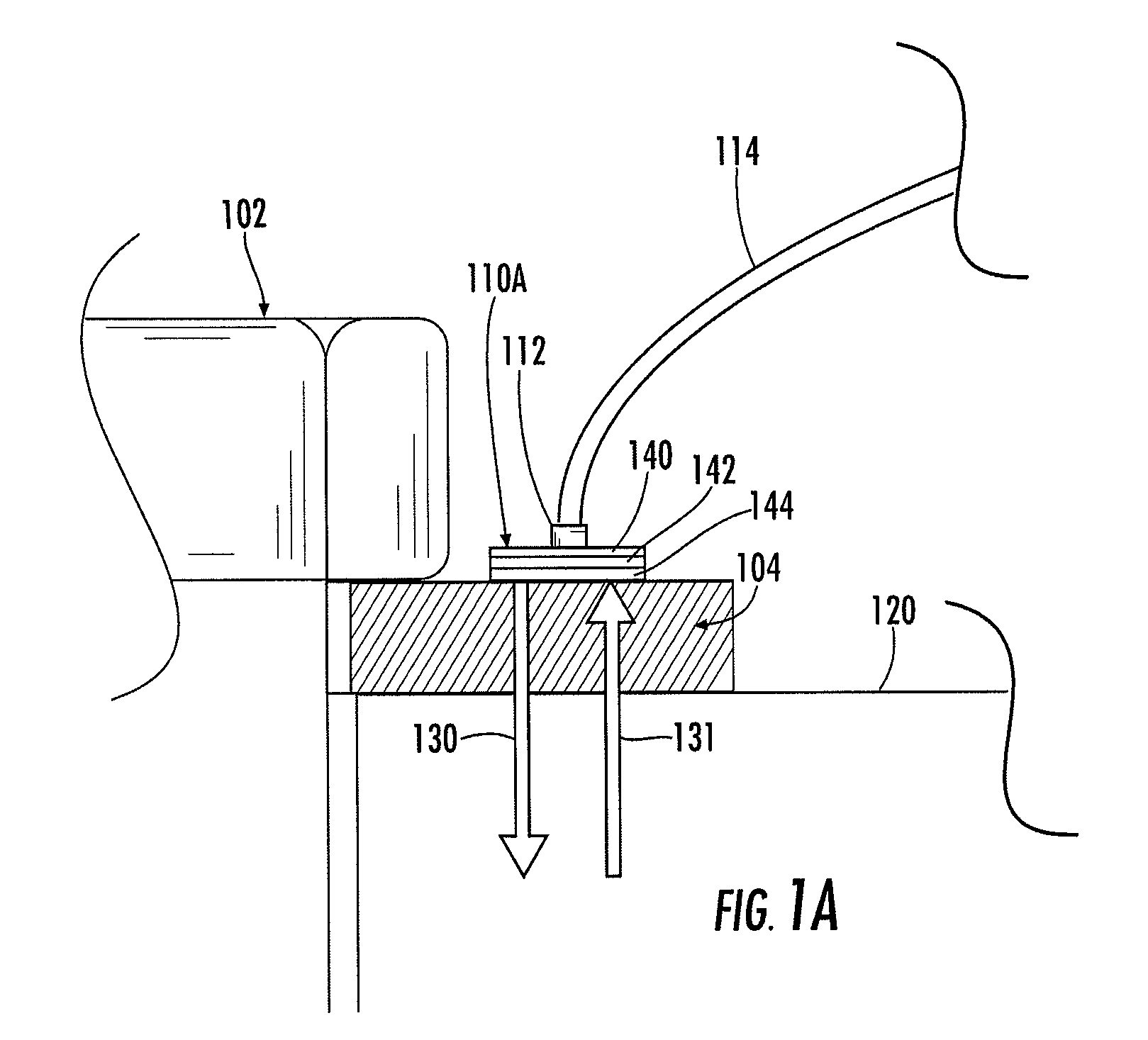

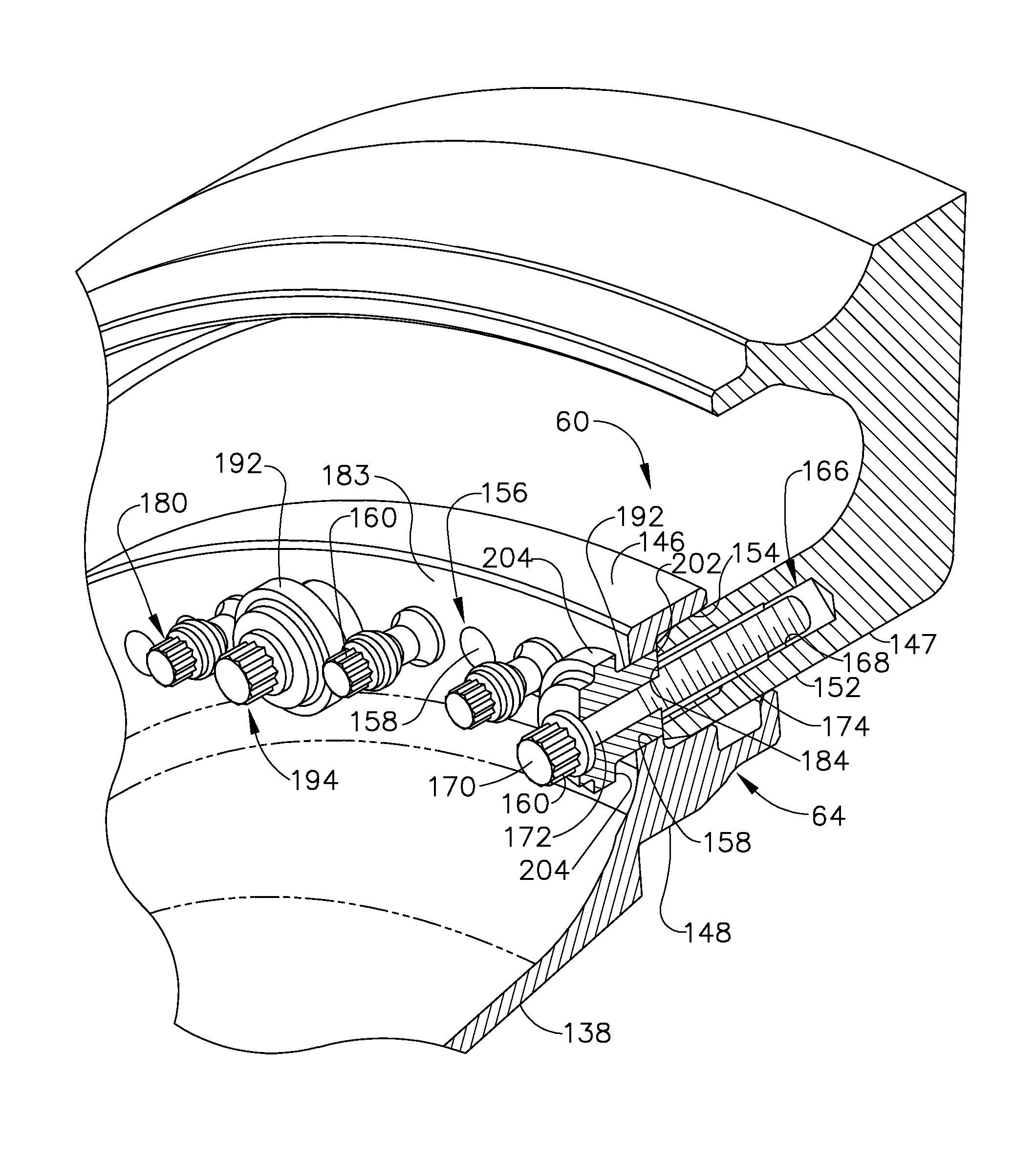

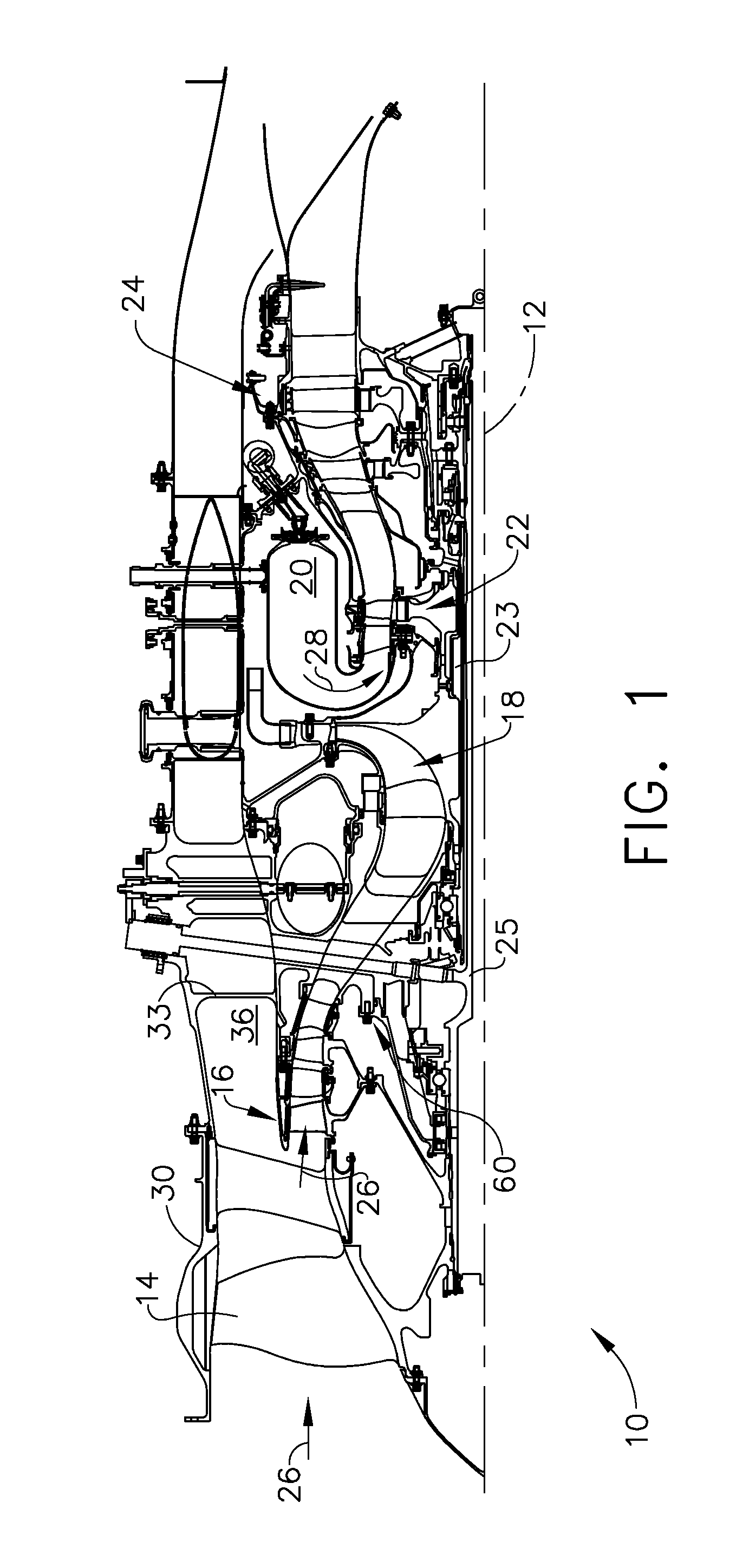

Active clearance control for a centrifugal compressor

Apparatus and method of operating a centrifugal compressor and active control system includes a centrifugal compressor with compressor blades mounted on an impeller, an annular cavity bounded in part by a shroud adjacent to the blades, and an active control system for controlling a clearance between the shroud and the blades by controlling a cavity pressure in the cavity. An electronic controller for controlling a control pressure valve for pressurizing using a source of compressor discharge pressure air and depressurizing the cavity respectively may open and close the valves using pulse width modulation. Pressure and clearance sensors positioned for measuring the cavity pressure the blade tip clearance respectively in signal supply communication with the electronic controller may be used. The shroud may be supported by radially spaced apart annular radially outer and inner supports connected to a casing by a bolted joint bounding the cavity.

Owner:GENERAL ELECTRIC CO

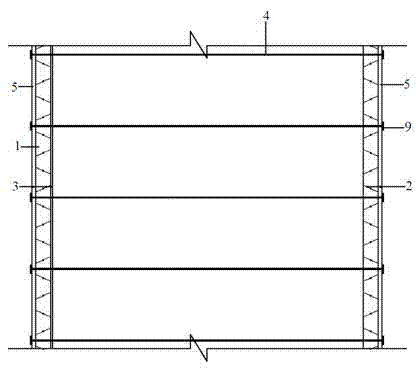

Double-layer steel sheet pile soil core composite cofferdam structure without inner support and application thereof

InactiveCN103669375ASolve the problem of large deformation of flexible structuresSolve the actual situation of easy water seepageFoundation engineeringGeomembraneCofferdam

The invention discloses a double-layer steel sheet pile soil core composite cofferdam structure without an inner support and the application of the double-layer steel sheet pile soil core composite cofferdam structure without an inner support, and belongs to the field of water conservancy projects. The double-layer steel sheet pile soil core composite cofferdam structure without an inner support comprises an upstream-face steel sheet pile and a downstream-face steel sheet pile, and the space between the steel sheet piles is filled with cohesive soil to form a cofferdam; a composite geo-membrane is laid on the portion, inside the cofferdam, of the upstream-face steel sheet pile; the upper portions of the two steel sheet piles are connected through a pull rod, middle beams are arranged outside the steel sheet piles, and the pull rod is connected with the middle beams through bolts arranged outside the corresponding middle beams. When the filling cofferdam core cohesive soil is in the same level with the pull rod, the space between the steel sheet piles is further filled with a layer of hairy residues, and a sub-cofferdam is arranged on the upstream-face steel sheet pile. The cofferdam structure can be used for building strip-shaped subsurface structures in a river or lake through the open-cut method. The cofferdam structure is stable and safe, and the problem that a steel sheet pile flexible structure is large in deformation is solved by arranging the pull rod on the tops of the two steel sheet piles; a three-level waterproofing system improves the anti-penetrability performance of the steel sheet pile cofferdam significantly.

Owner:张安政

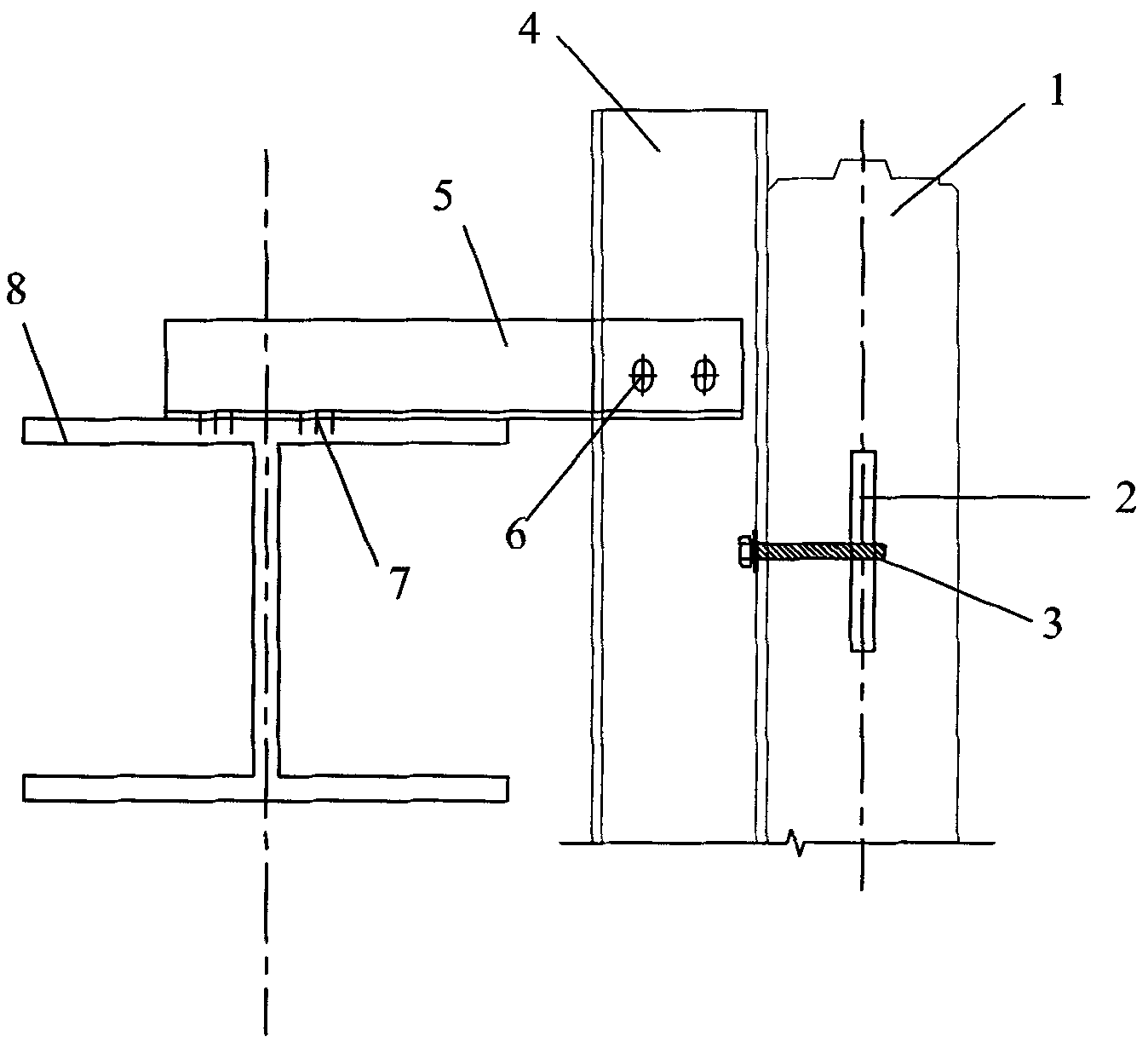

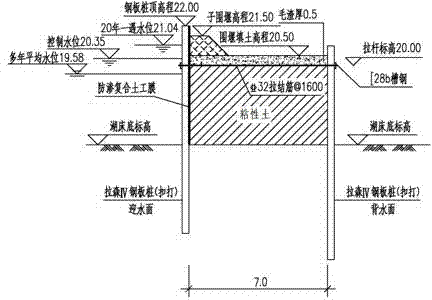

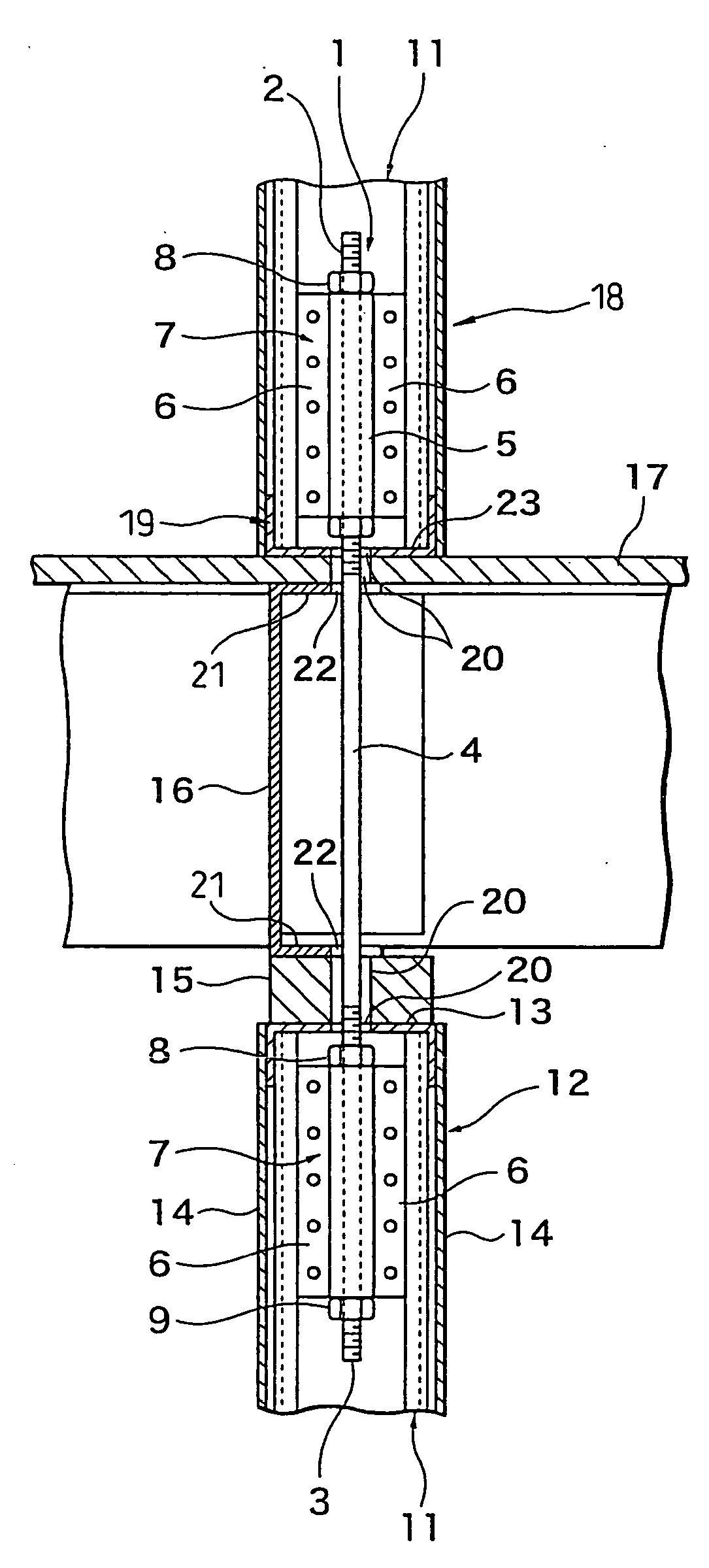

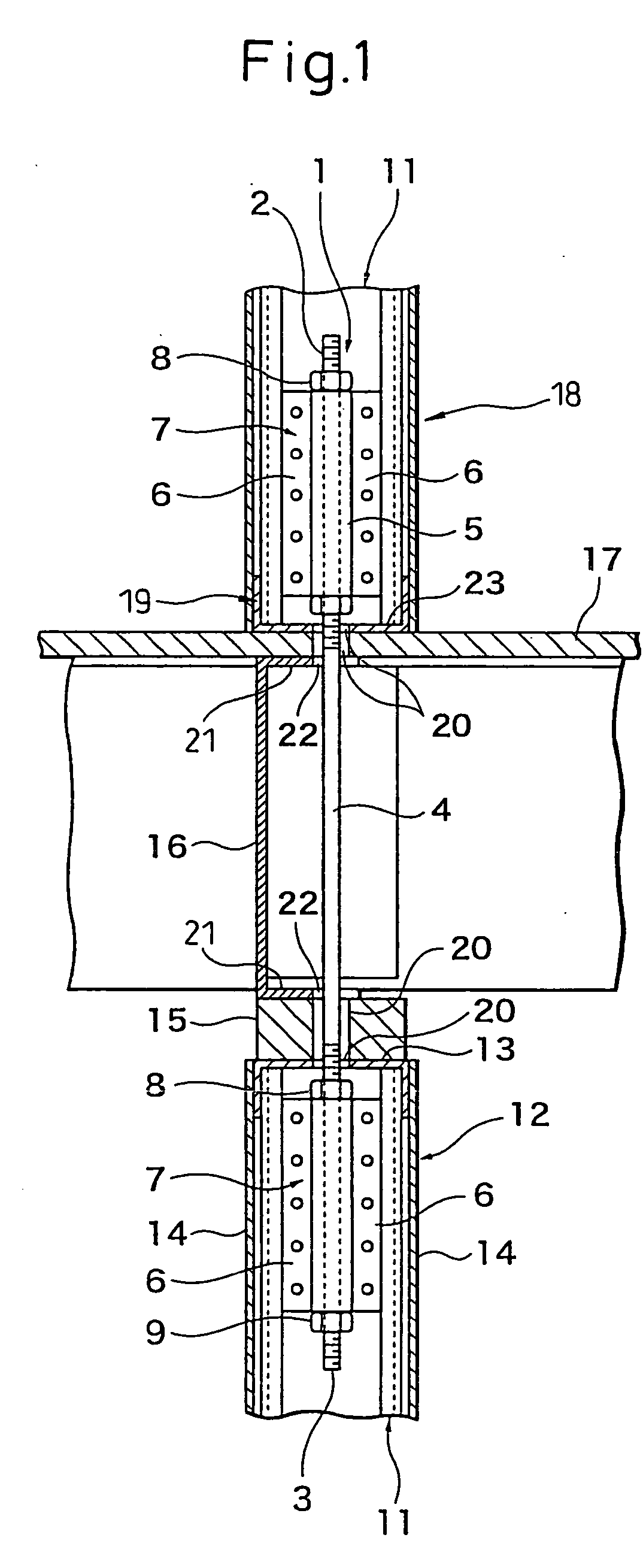

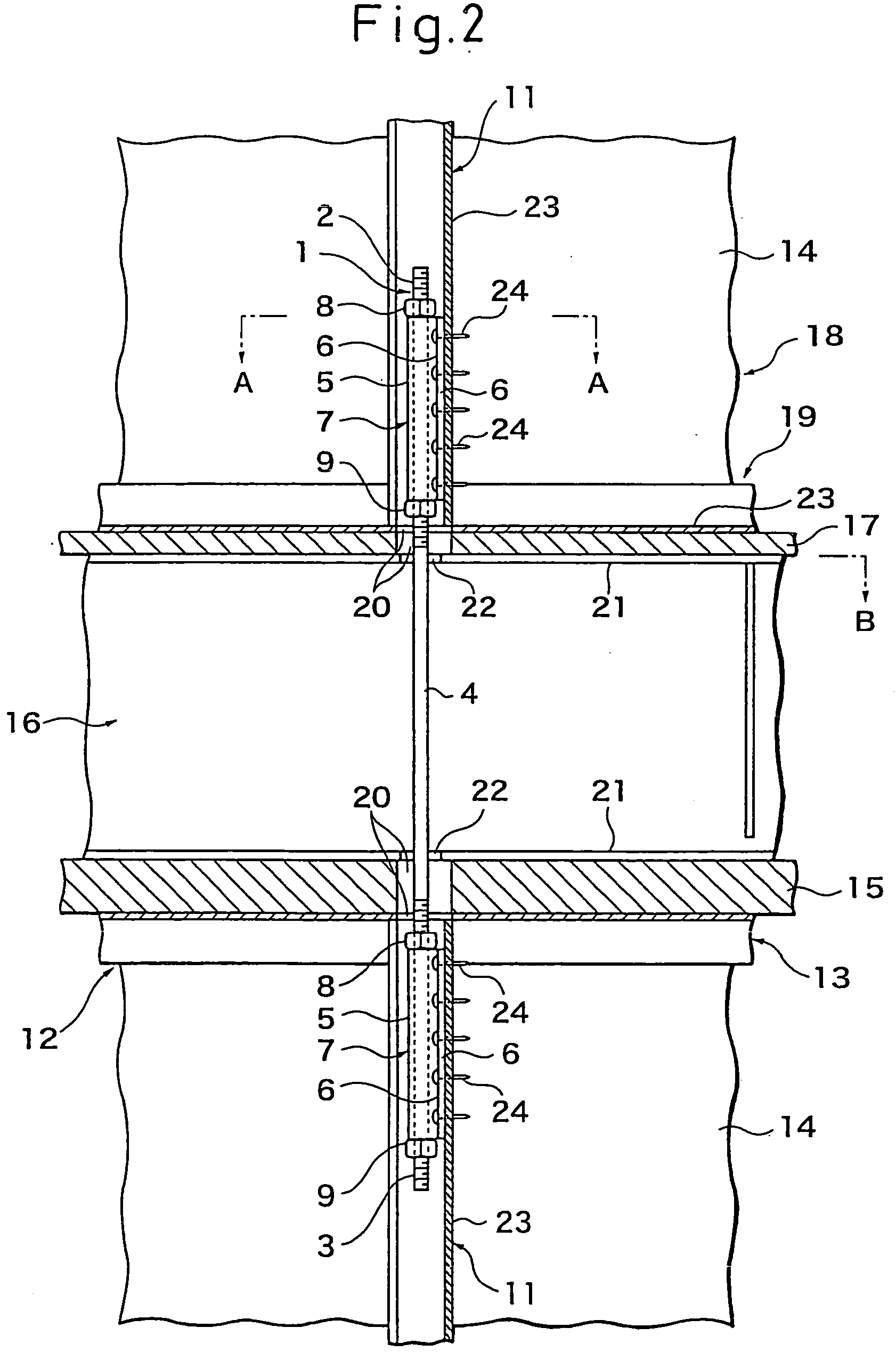

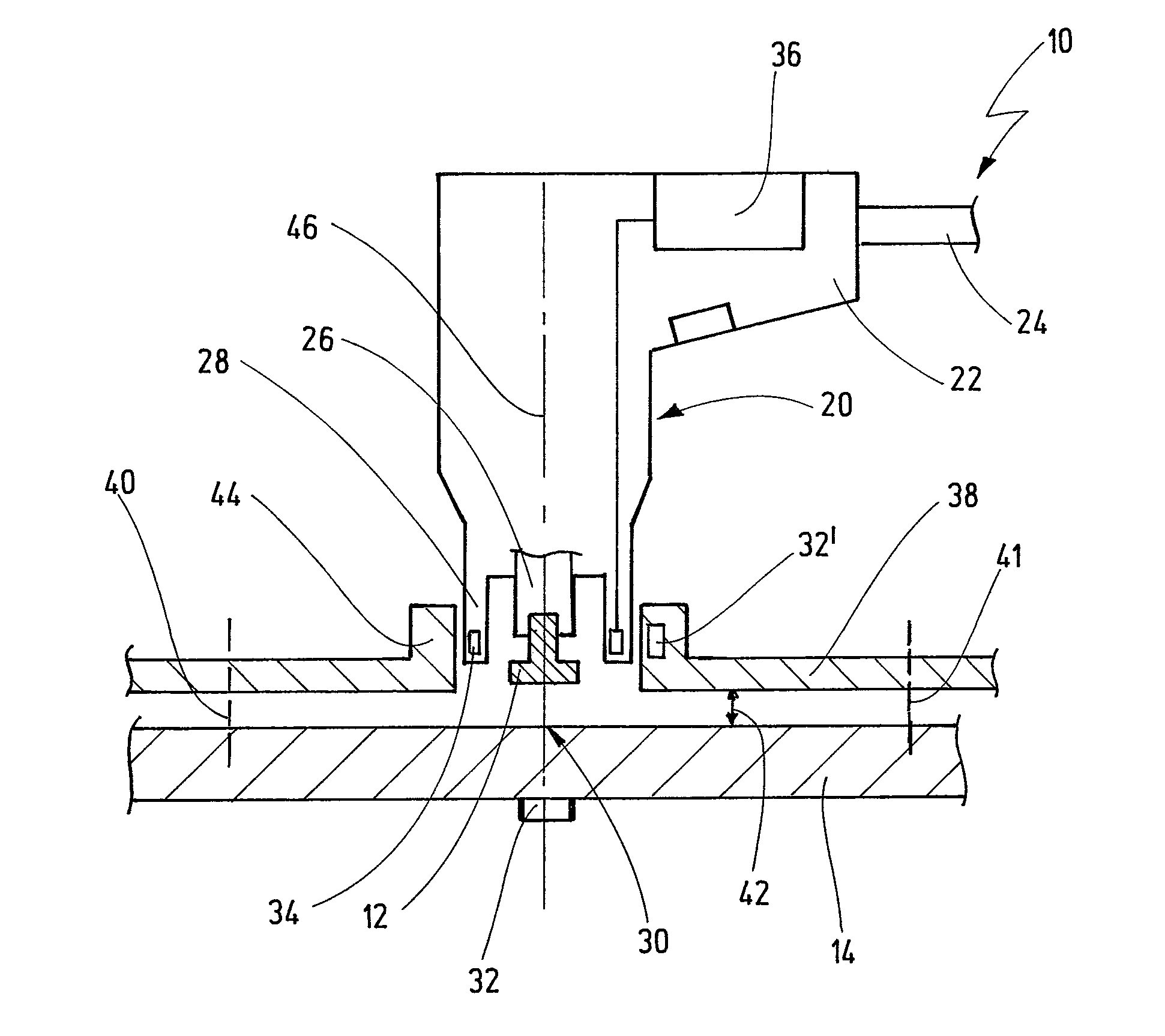

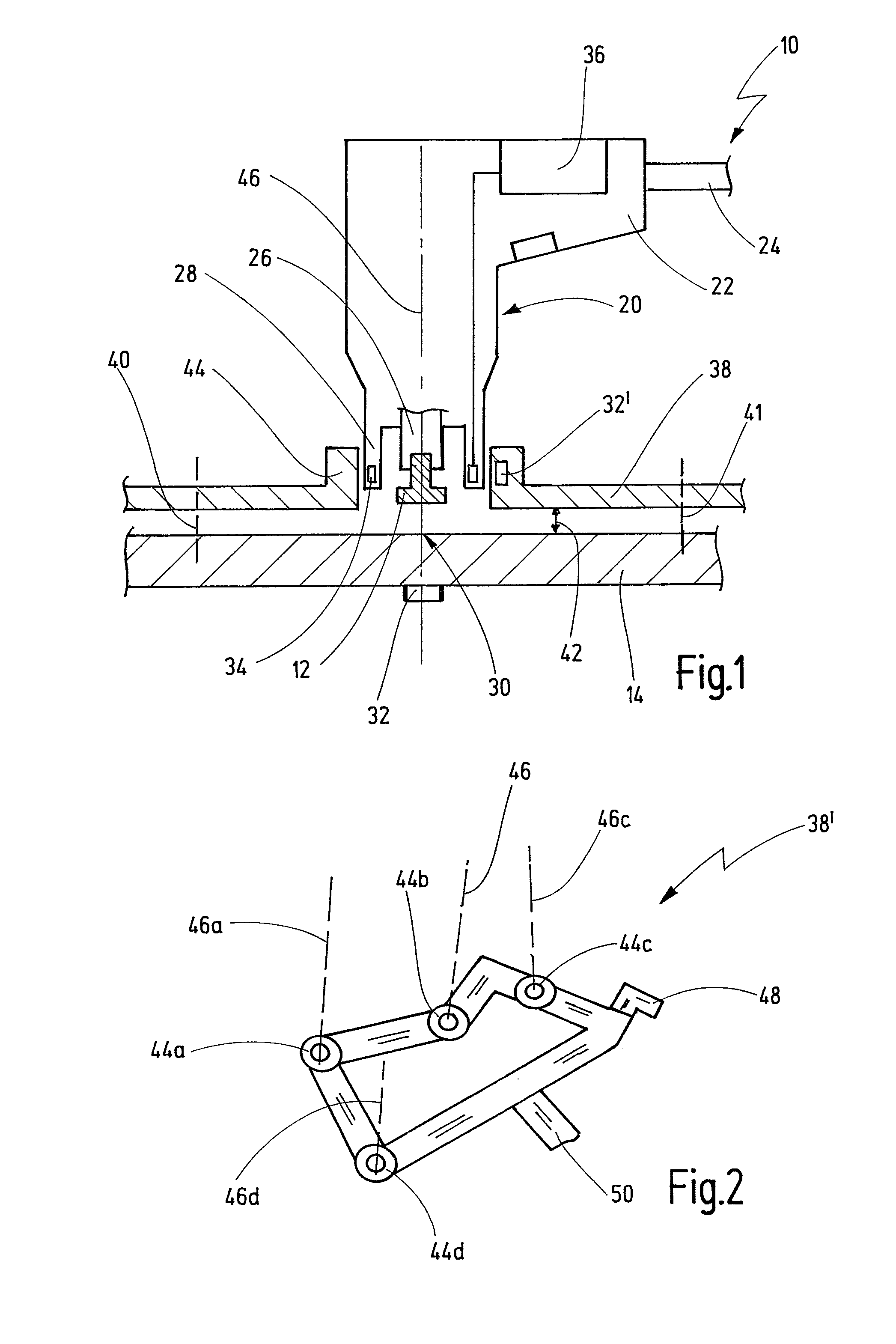

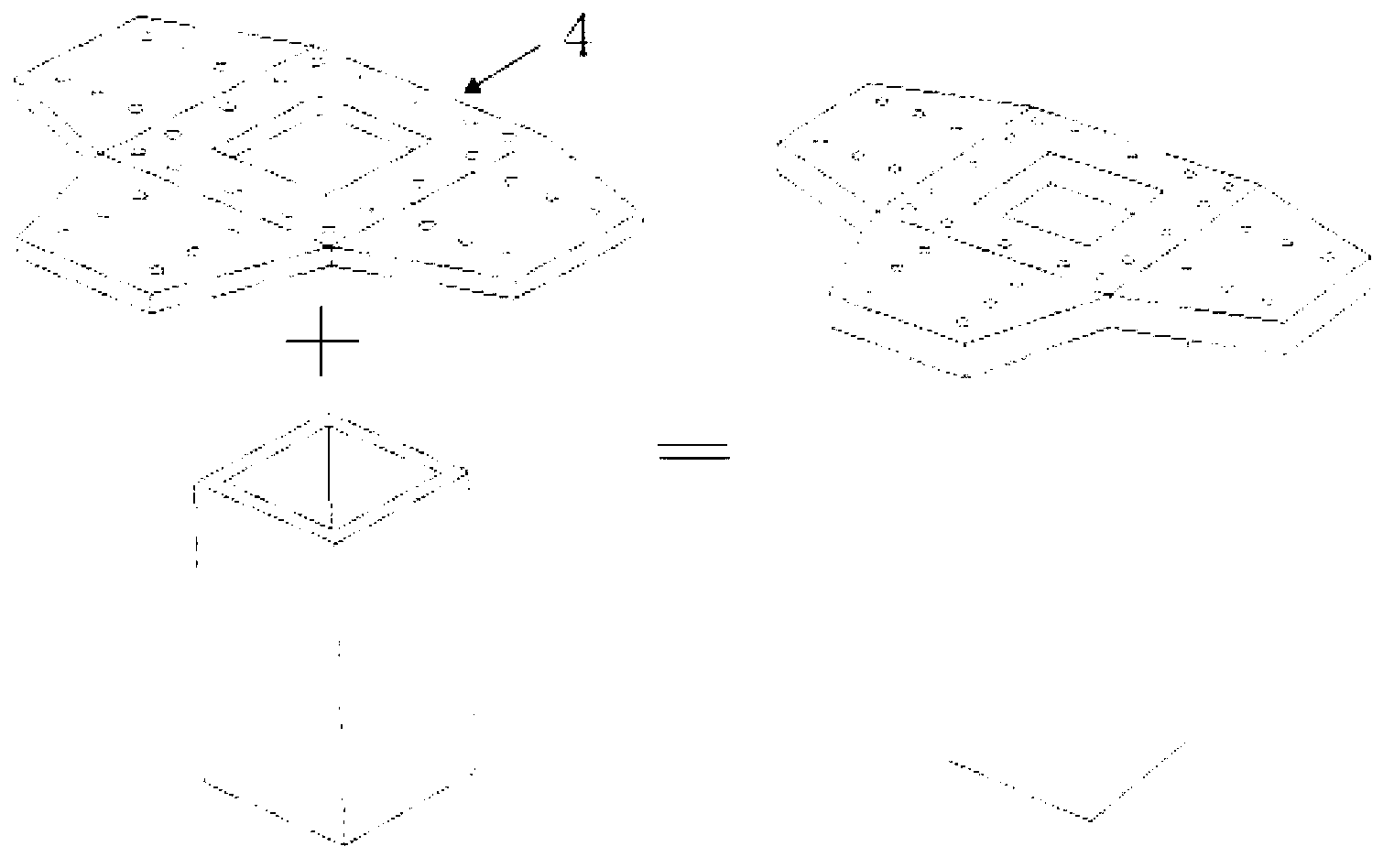

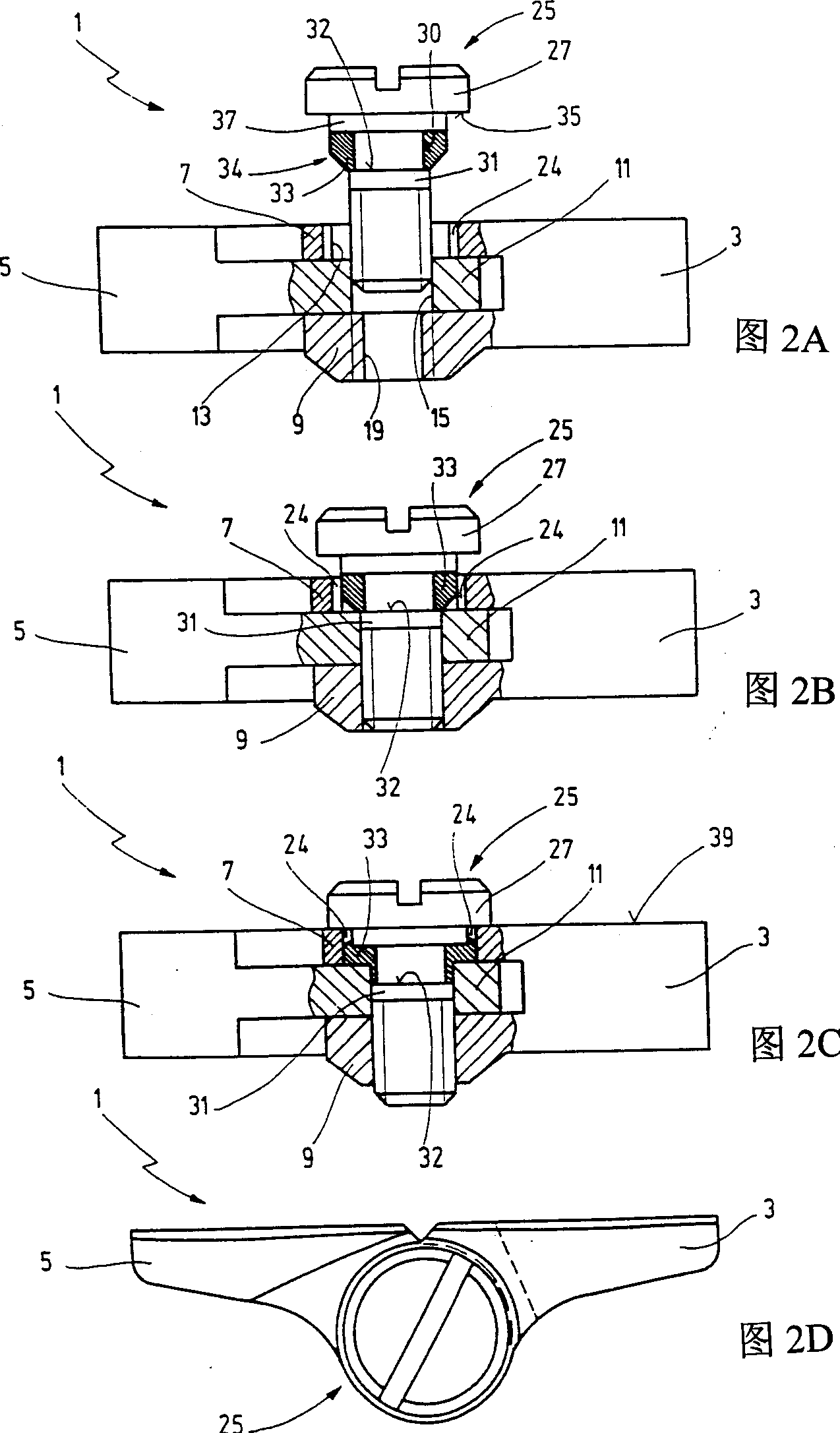

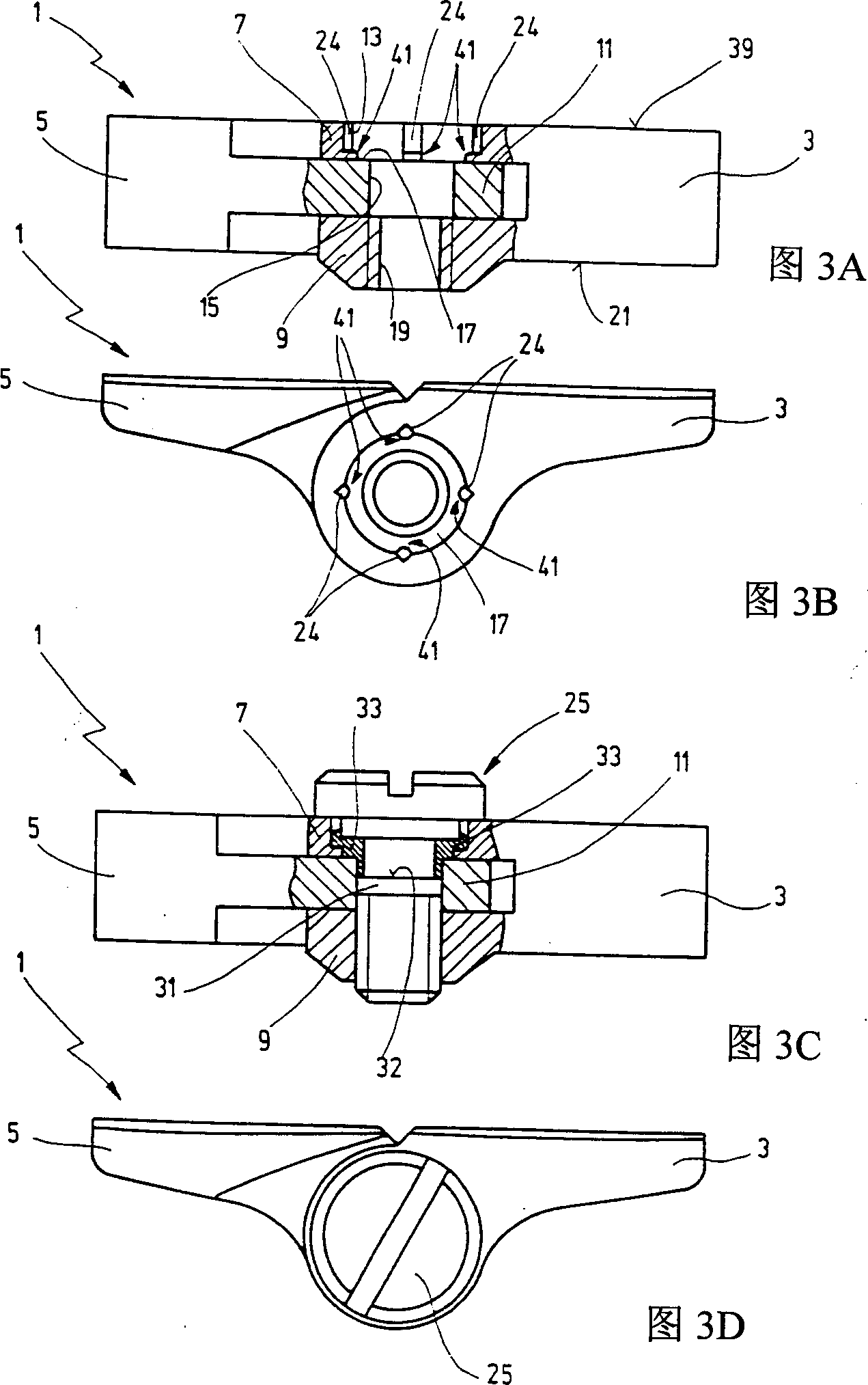

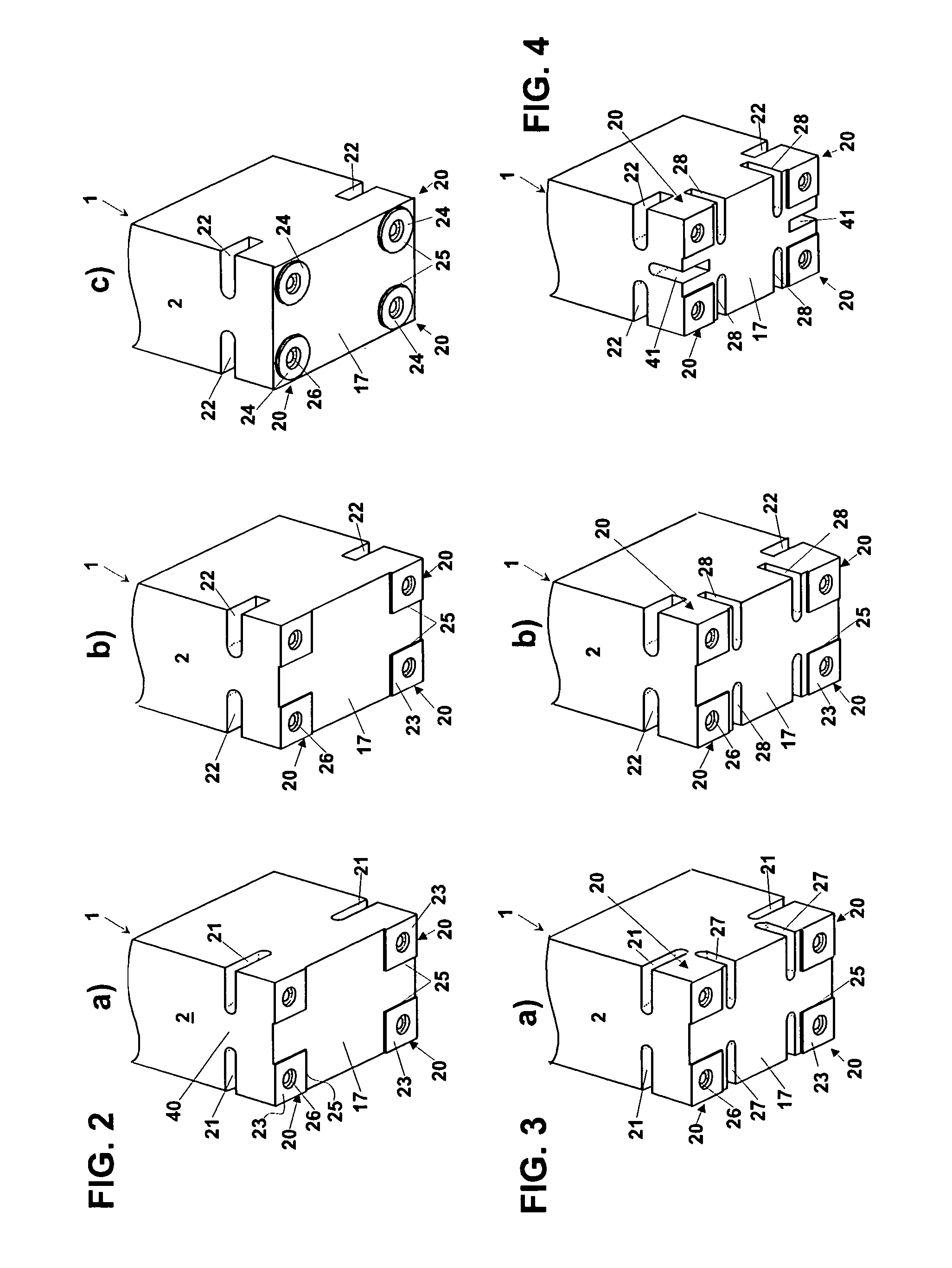

Joint fitting between members and joint structure and joining method of upper and lower floor vertical frame members

InactiveUS20070110513A1Stress transmittedEasy to placeBuilding roofsRecord information storageHorizontal orientationUpper floor

The present invention provides a joint fitting between members of a simple structure able to transmit stress of both compressive force and tensile force and a joint structure and method of joining, that is, a joint fitting 1 between members comprising a single bolt 4 having a length enabling it to be arranged vertically oriented bridging an upper floor vertical frame member and a lower floor vertical frame member at intervals along the axial direction of which bolt joint hardware 7 to be fastened to vertical frame members of the floors arranged at the upper floor side and lower floor side and having side opening groove cross-sections are arranged, the side opening grooves in the joint hardware 7 being able to detachably receive the bolt, and the joint hardware 7 being attached to be able to be fastened positioned along the longitudinal direction of the bolt 4, the joint hardware arranged at the upper and lower floors in the joint hardware being butted against vertical side surfaces of the vertical frame members 11 of the floors and fastened by drill screws 24 or other fasteners screwed in bridging the joint hardware 7 and the vertical frame members 11 in a horizontal orientation. Further, a method of joining members using the joint fitting 1 between members.

Owner:NIPPON STEEL CORP

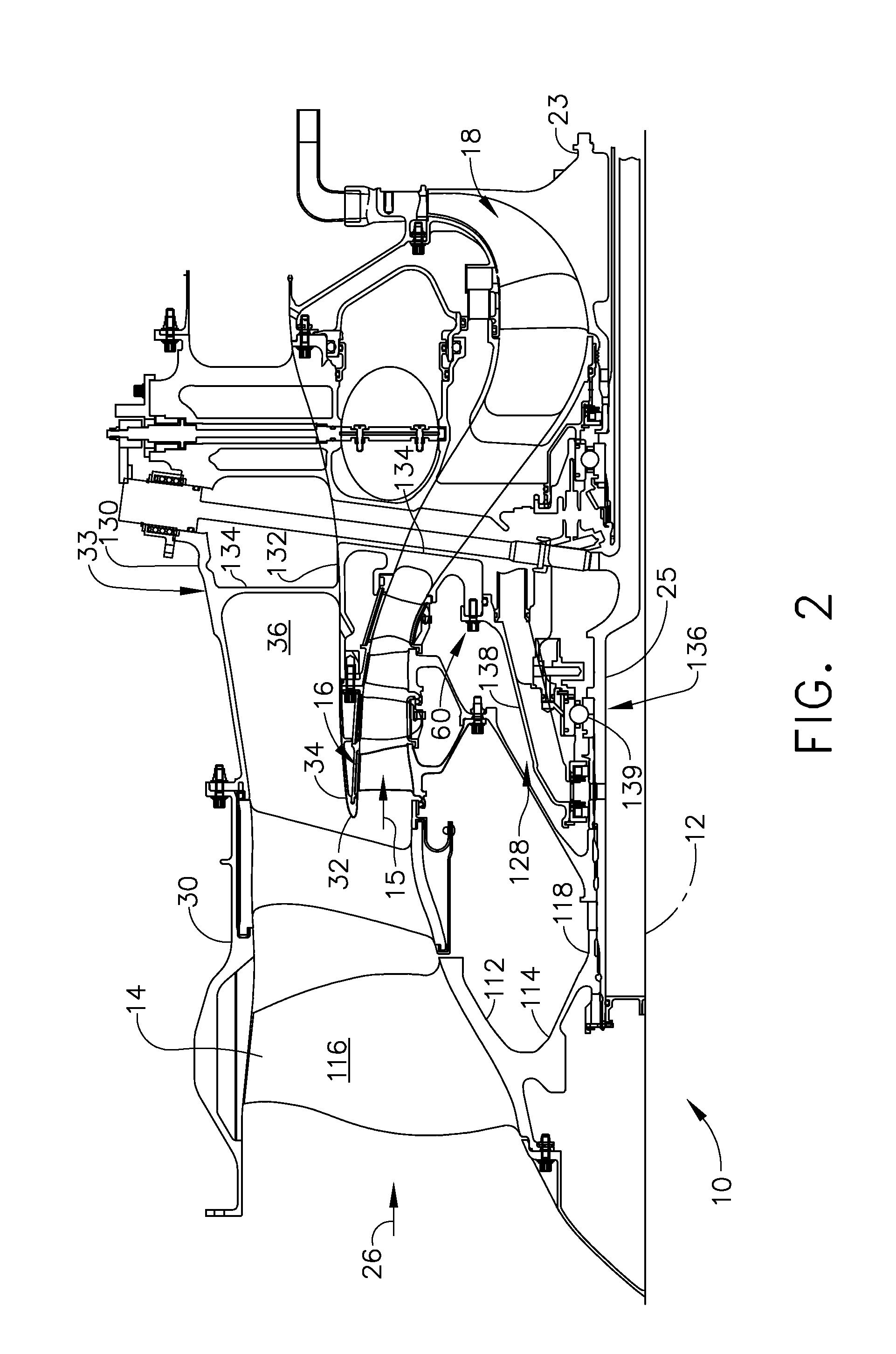

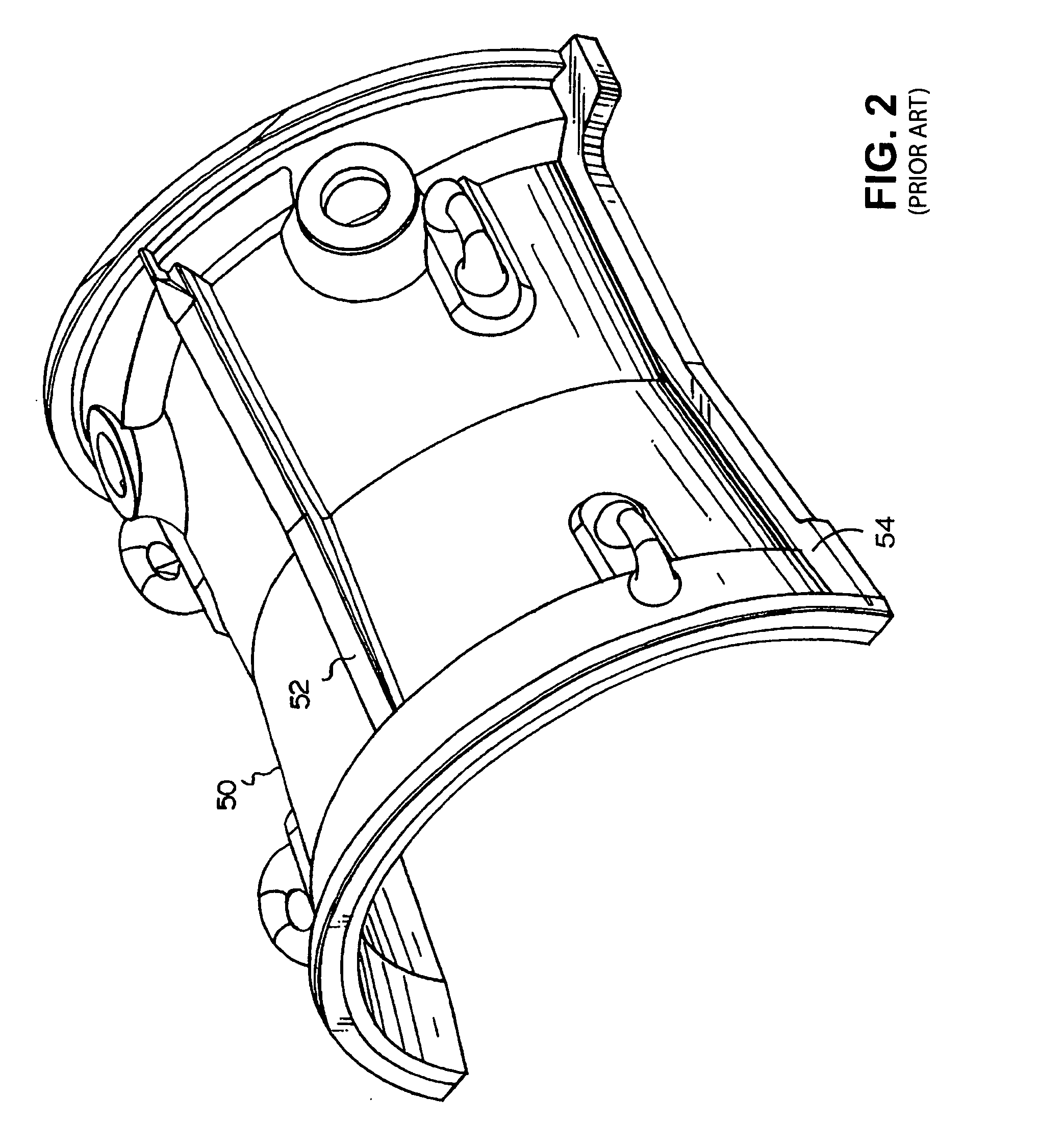

Dynamic load reduction system

Bolted together first and second flanges include bolts disposed through first bolt holes in the first flange. The bolts extend at least partially through second holes in the second flange. Bolt include bolt heads, threads, and shanks therebetween. Crushable spacers disposed around the shanks of a first plurality of the bolts and contacting and axially extending between the bolt heads and the first flange. Bushings disposed around a second plurality of the bolts and contacting and axially extending between the bolt heads and the second flange. A shank outer diameter may be smaller than a thread diameter and heat shrink tubing may be disposed around the bolt shanks of at least some of the spacers. First bolt holes may extend into an open annular slot on first flange and second holes may extend partially through a forward extending annular rail of second flange with rail received within slot.

Owner:GENERAL ELECTRIC CO

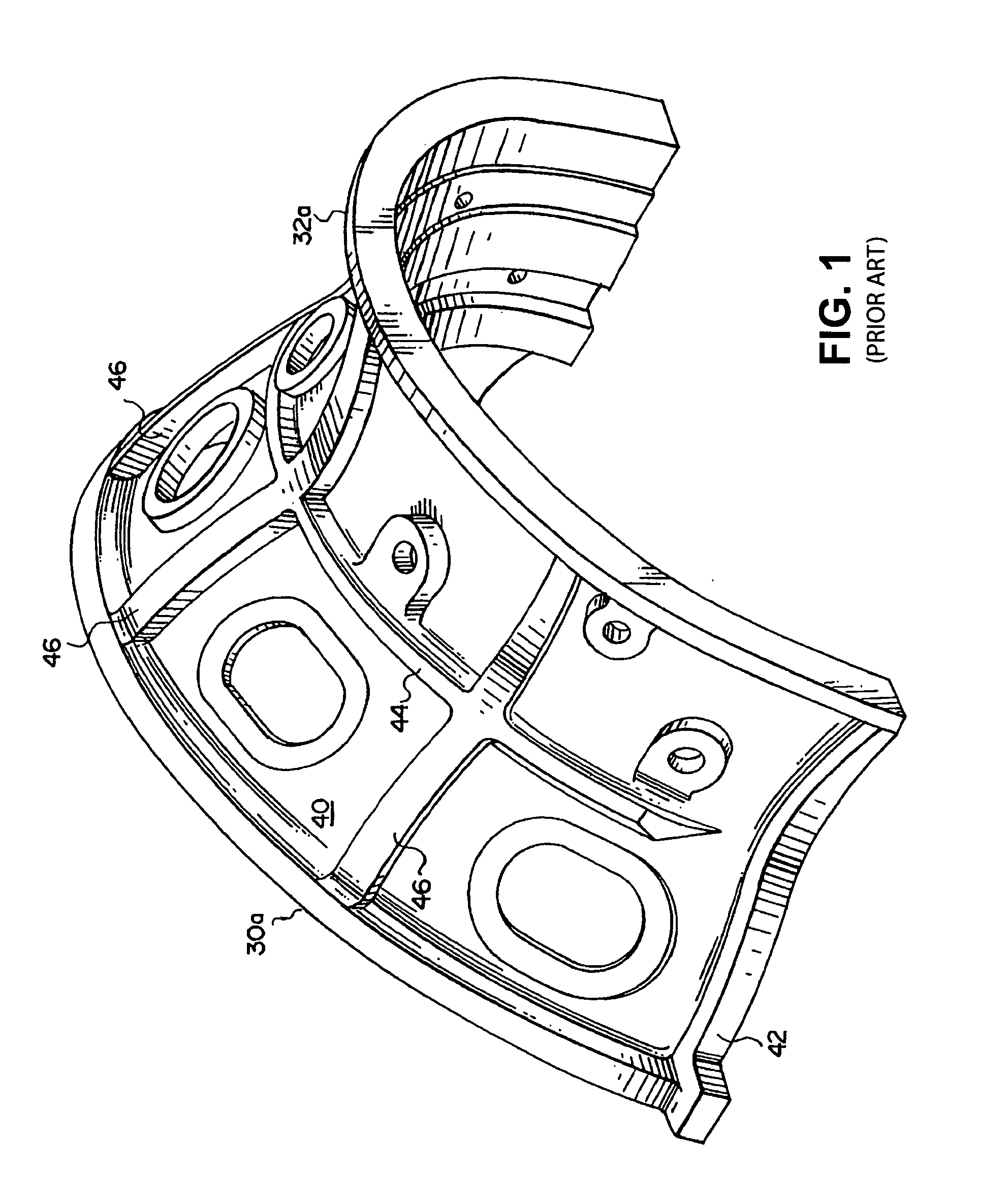

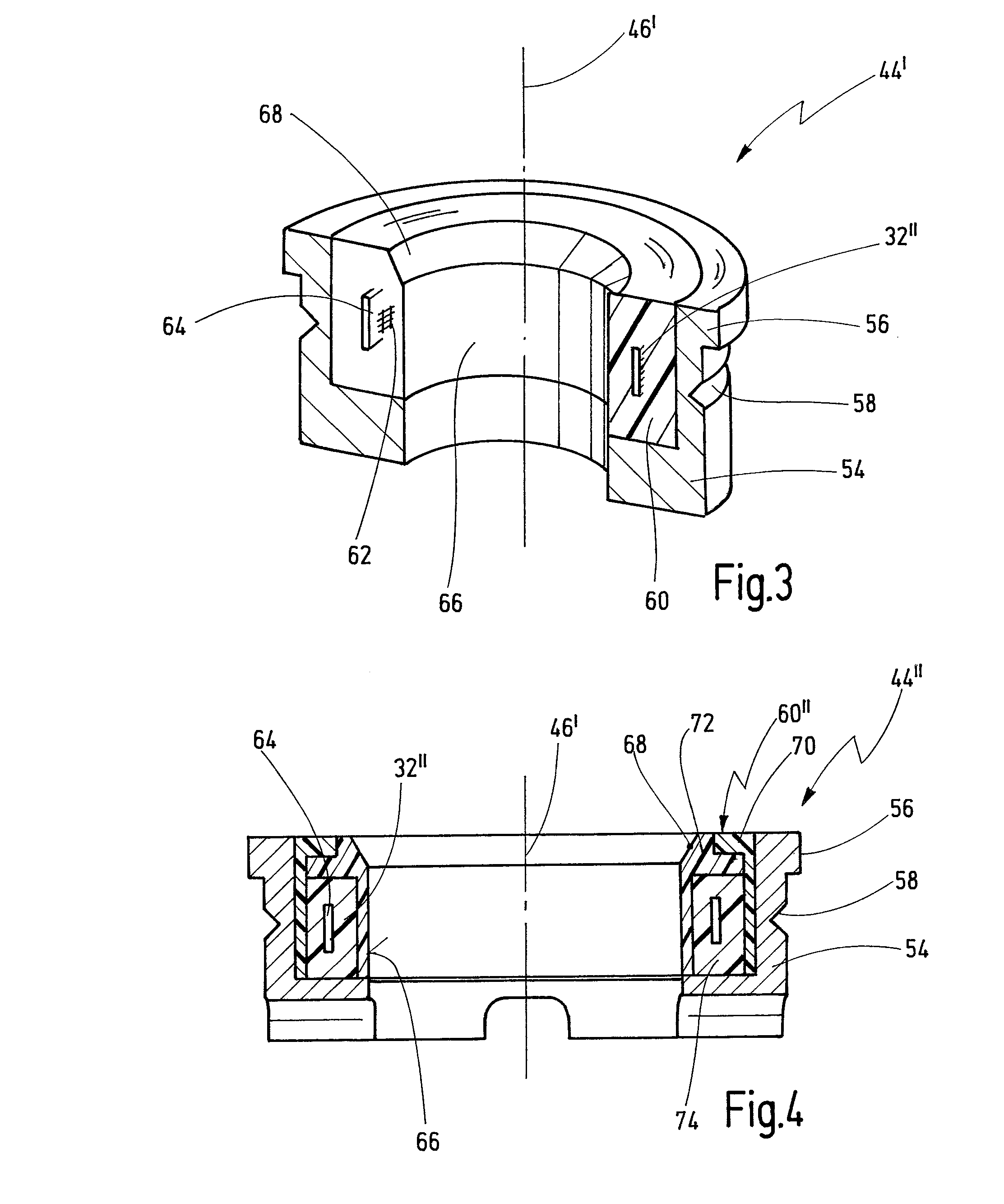

Method and apparatus for matching the thermal mass and stiffness of bolted split rings

A method and apparatus for controlling distortion in the casing of a gas turbine are disclosed. The method uses a split in the flange ID underneath “false” flanges to tune the hoop stiffness of the casing to match the stiffness and behavior of the bolted joint. By matching the hoop carrying capability and load path of the split-line flange, as well as the thermal mass effect, the distortion can be channeled to a higher order distortion mode that can evenly distribute the deflection and approach a pure circular form.

Owner:GENERAL ELECTRIC CO

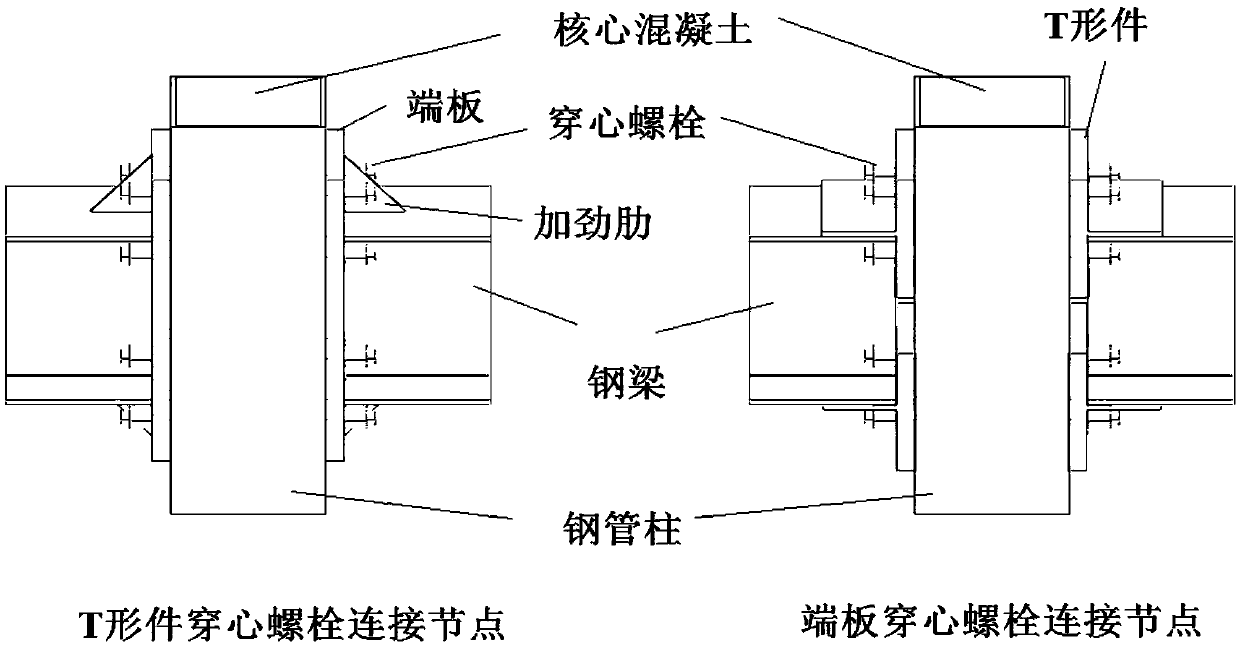

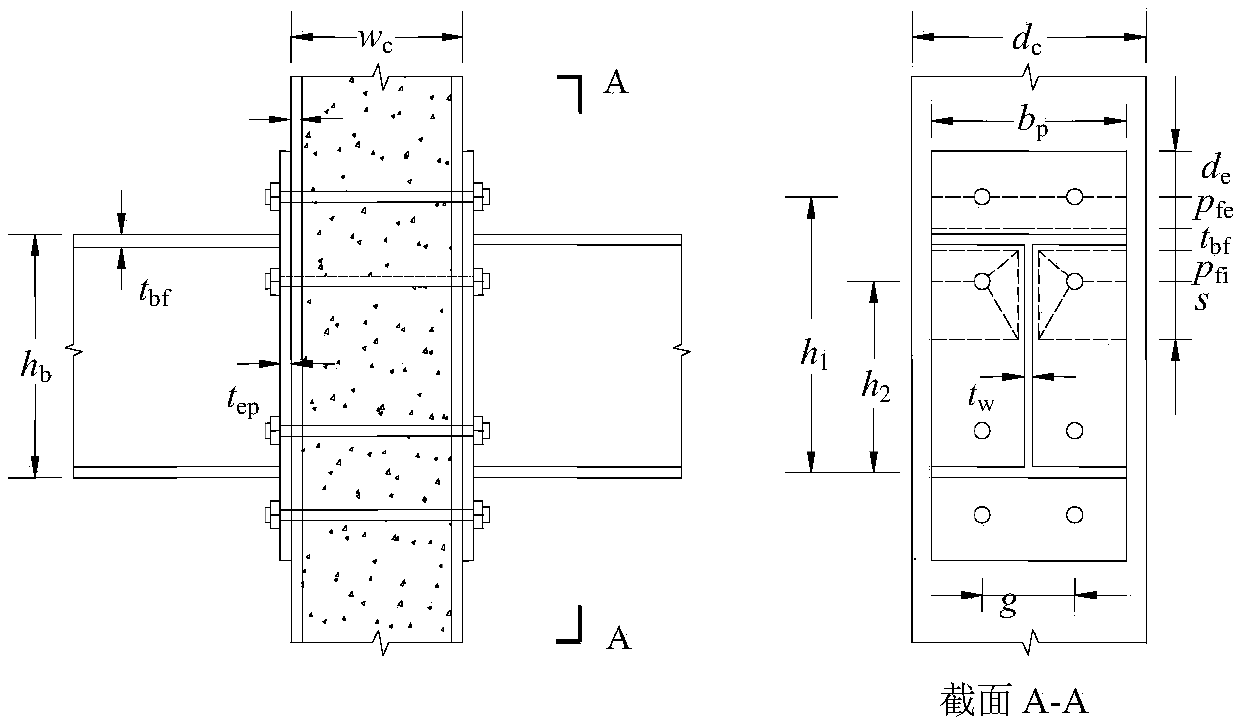

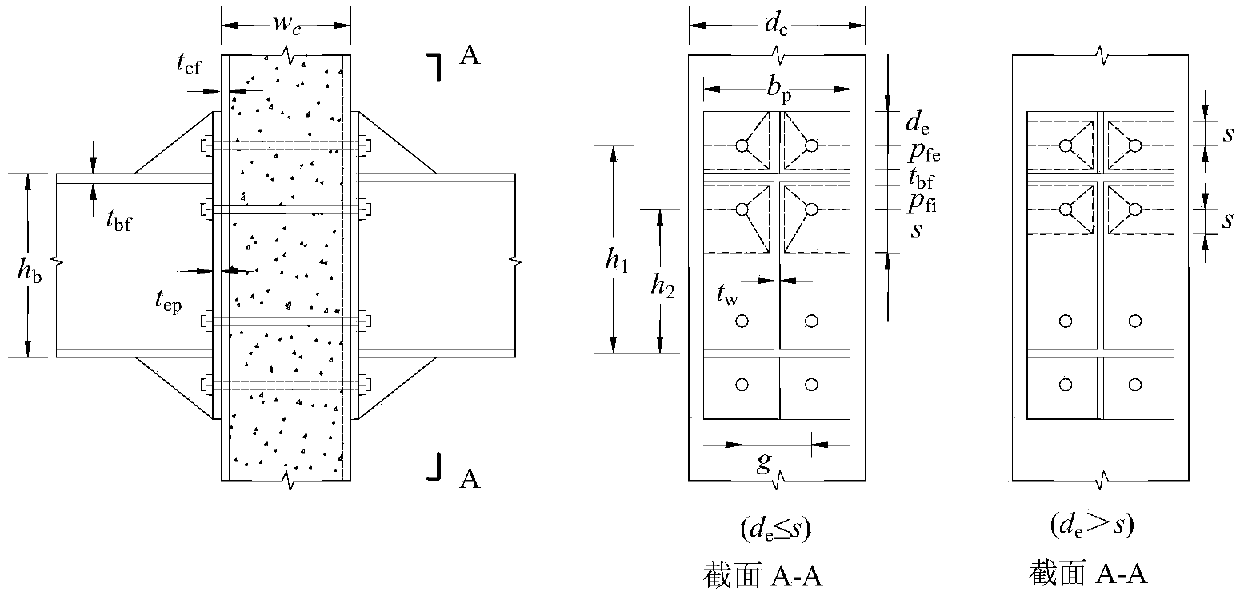

Calculating method for flexural bearing capacity and bending moment-rotation curve of concrete-filled steel tube column-steel beam penetrated bolt connecting joint

ActiveCN109610650AShorten the timeSave time and other costsMeasurement of torque/twisting force while tighteningBuilding constructionsClassical mechanicsPlastic hinge

The invention discloses a calculating method for flexural bearing capacity and a bending moment-rotation curve of a concrete-filled steel tube column-steel beam penetrated bolt connecting joint. The calculating method for the joint flexural bearing capacity comprises the following steps that the corresponding joint flexural bearing capacities are calculated when bending failure of a terminal plateor a T-shaped piece flange occurs to the joint, when pulling failure of penetrated bolts occurs to the joint, when transversely pressing failure of columns occurs to the joint, when shearing failureof a joint region occurs to the joint and when a steel beam forms plastic hinge failure is calculated, the minimum value of the five flexural bearing capacities is the actual flexural bearing capacityof the joint, and a corresponding failure mode is an actual failure mode of the joint. The calculating method for the bending moment-rotation curve of the joint comprises the following steps that initial rotating rigidity of the joint is obtained through an experiment or simulation or theoretical calculation, and then the initial rotating rigidity of the joint and the joint flexural bearing capacity are substituted into a provided exponential model of a bending moment-rotation relationship to obtain the bending moment-rotation curve of the joint. The calculating method for the flexural bearing capacity and the moment-rotation curve of the concrete-filled steel tubular column-steel beam penetrated bolt connecting joint avoids large quantity of experiments or simulation which are needed inprevious design of joints of the type and has the advantages that the calculation is easy and convenient, the time and labor are saved, the cost is low and the like.

Owner:DALIAN UNIV OF TECH

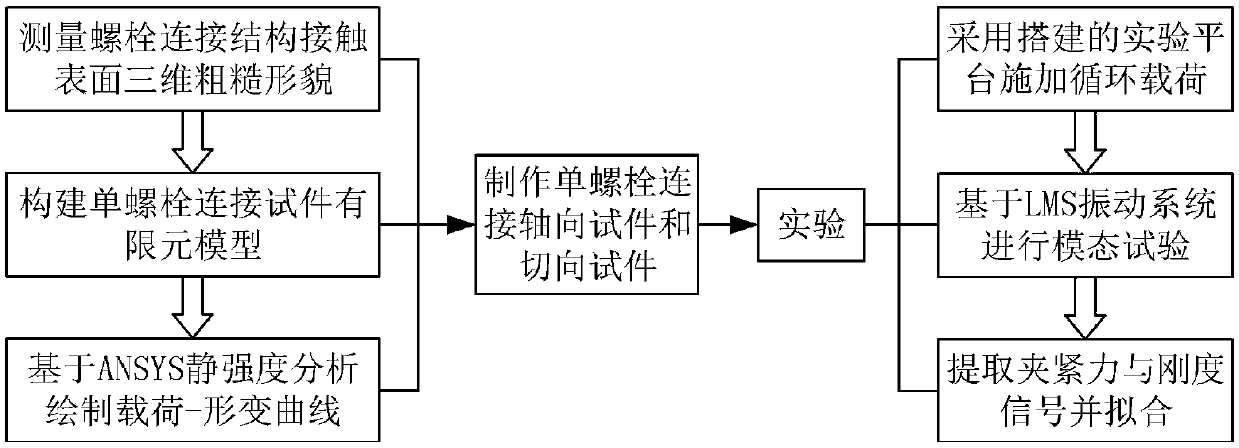

Experimental method for characterizing relaxation characteristics of bolted joint structure

ActiveCN108388696ASolve the problem of high costAvoid safety hazardsMachine part testingDesign optimisation/simulationElement modelExperimental methods

The present invention discloses an experimental method for characterizing relaxation characteristics of a bolted joint structure. The method comprises: constructing a finite element model of a singlebolted joint test piece based on the obtained three-dimensional rough shape of the contact surface of the bolted joint structure; performing static strength analysis on the single bolted jointed testpiece by using ANSYS software, and drawing the deformation curve of the single bolted jointed test piece under load conditions; making a single bolted joint axial test piece and a tangential test piece to analyze the influence law of the axial external load and the outward shear load on the relaxation characteristics of the bolted joint structure; establishing an experiment platform, and through the cyclic load control software, applying a cyclic load with a certain frequency on the single-bolt test piece clamped on the fatigue testing machine; performing the modal test on the single bolted joint test piece by using the LMS vibration system at the same time interval; and extracting a clamp force signal output by a pressure sensor and a stiffness signal in the modal test, and fitting the curve for the clamp force signal and the stiffness signal for comparison. The method disclosed by the present invention provides technical support for the relaxation determination and refastening of thejoint bolts of the key precise complicated components.

Owner:BEIJING UNIV OF TECH

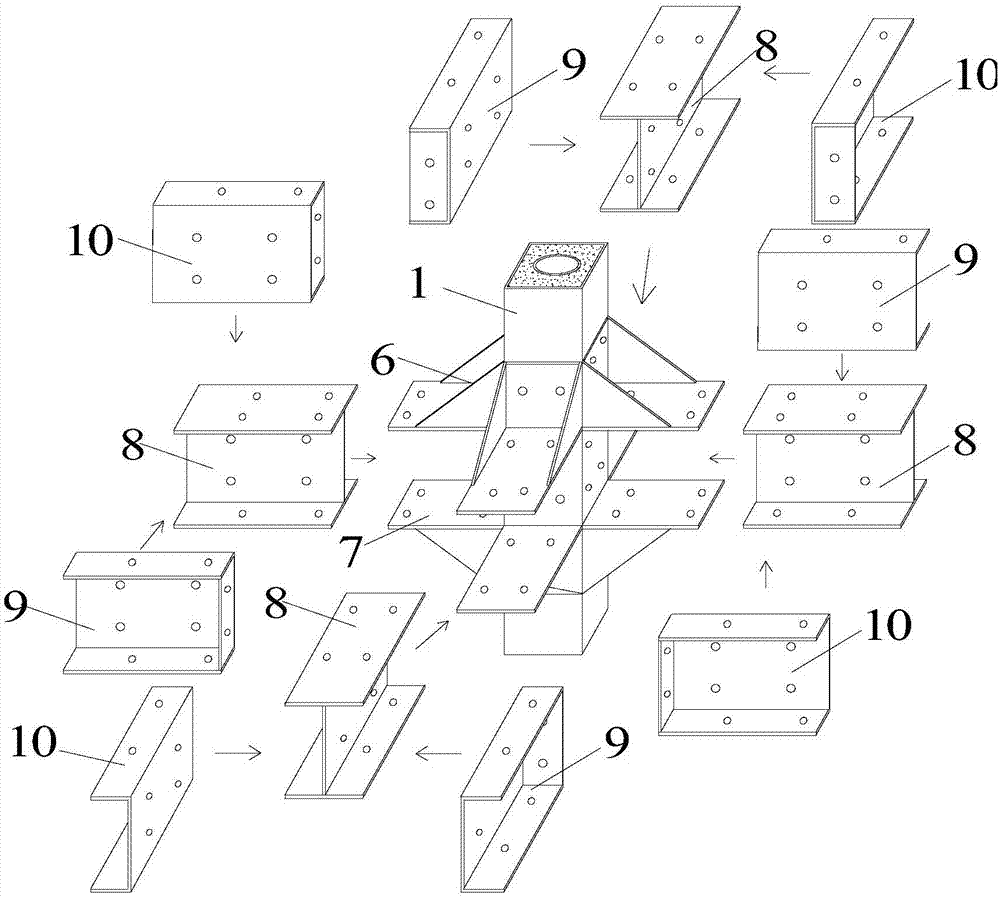

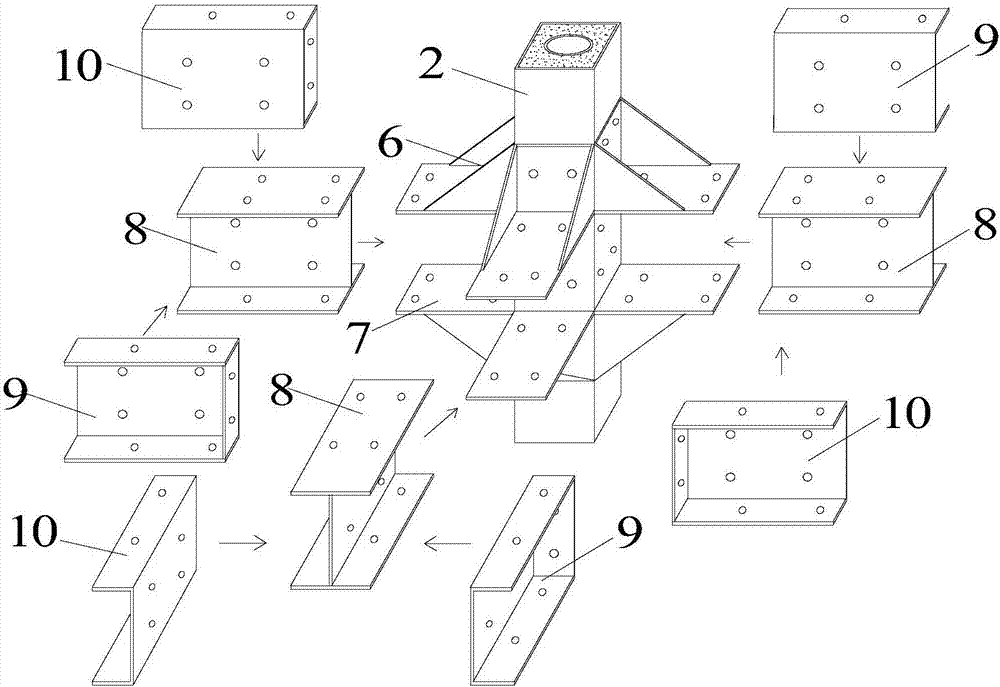

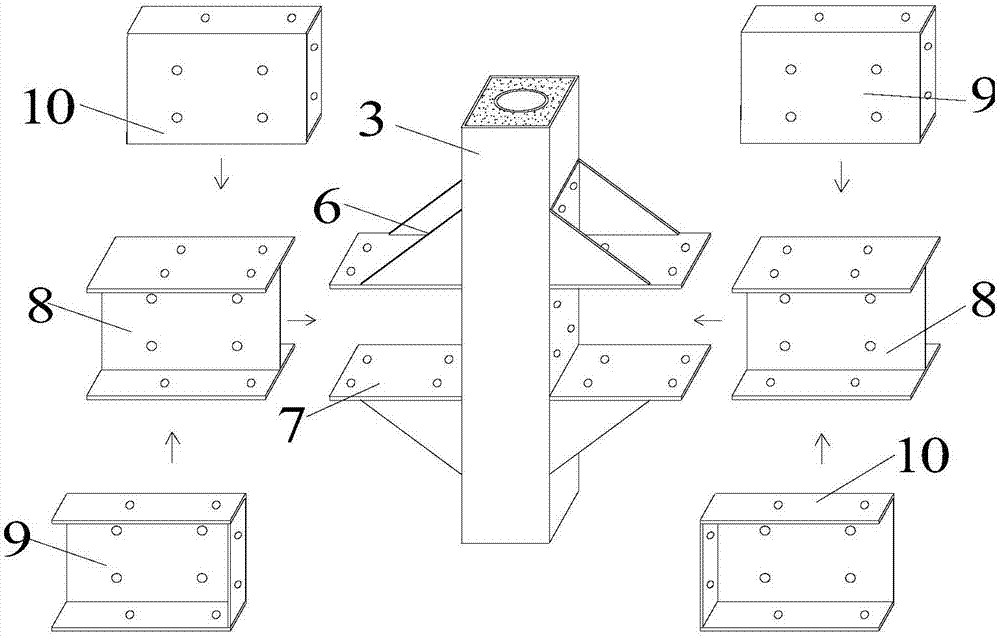

Constraint type assembly compound concrete filled-steel tubular column and steel beam joints provided with reinforcing blocks

InactiveCN107237401AReduce construction difficultyReduce construction workloadBuilding constructionsBolted jointPressure function

The invention discloses constraint type assembly compound concrete-filled steel tubular column and steel beam joints provided with reinforcing blocks. The constraint type assembly compound concrete-filled steel tubular column and steel beam joints provided with the reinforcing blocks fall into crossed joints, T-shaped joints, straight joints and L-shaped joints. Each joint comprises a compound concrete-filled steel tubular column, a first beam end connector, a second beam end connector, the first reinforcing block and the second reinforcing block, wherein the first beam end connector and the second beam end connector are each formed by welding a beam end cover board, a beam end connection board and two beam end reinforcing ribs, a second bolt hole is formed in the beam end connection cover board, a first bolt hole is formed in the beam end connection board, the first reinforcing block and the second reinforcing block are each formed by welding a piece of channel steel and a reinforcing block connection board, second bolt holes are formed in two sides of the channel steel, and a third bolt hole is formed in the other side of the channel steel. All the joints are connected through bolts completely, traditional stud welded connection is abandoned, construction and installation are convenient, the constraint pressure function is formed for concrete in the columns, and the joints can be detached and replaced.

Owner:CHANGAN UNIV

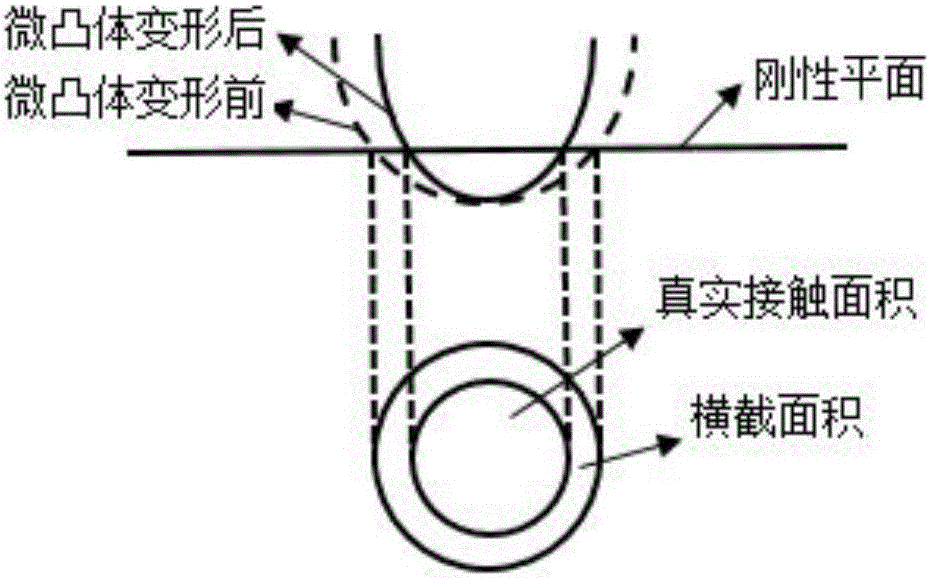

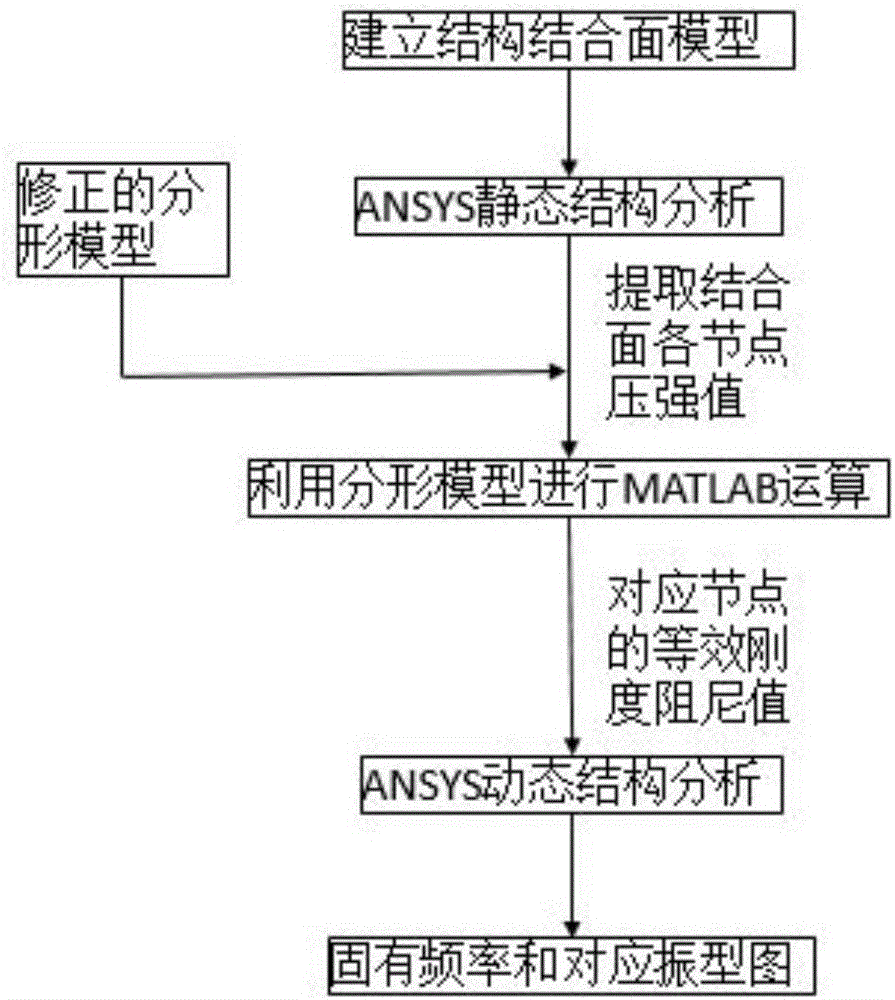

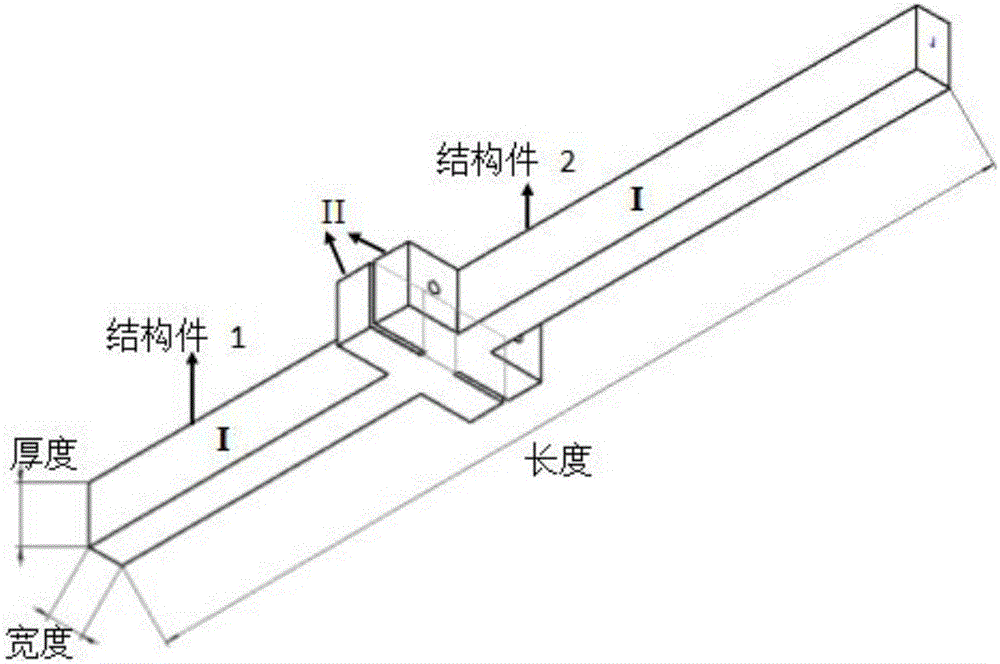

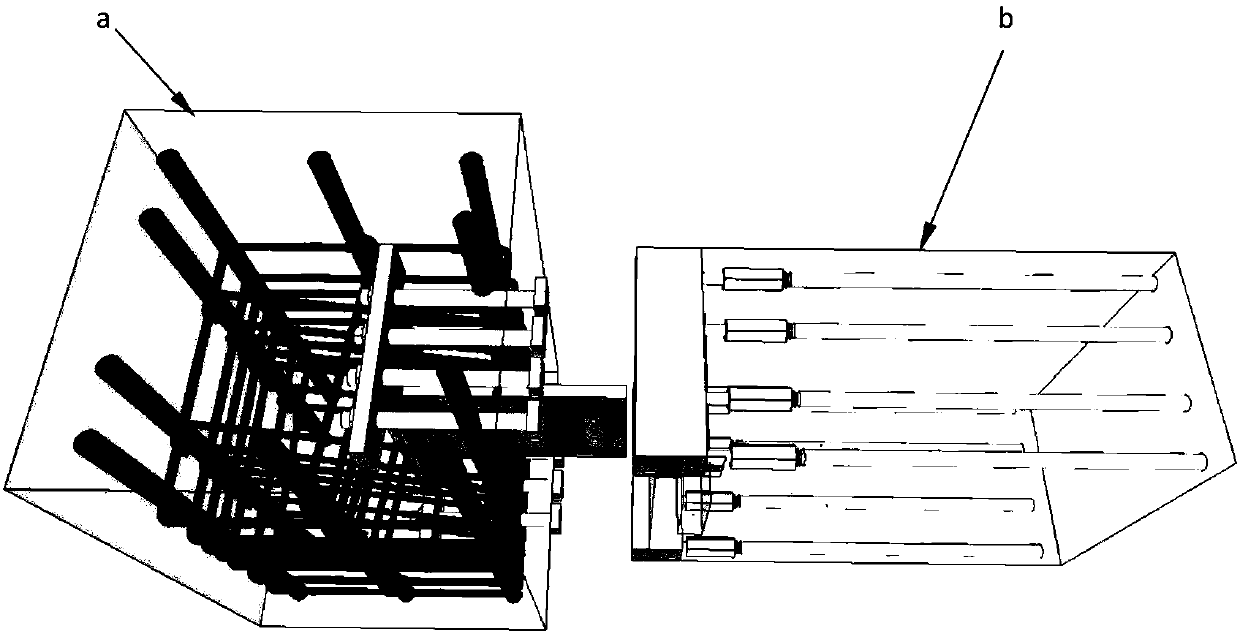

Method for analyzing dynamic characteristics of bolted structure based on three-dimensional fractal theory

InactiveCN106529035AAchieving accurate estimatesGeometric CADDesign optimisation/simulationFinite element analysis softwareMATLAB

The invention relates to a method for analyzing dynamic characteristics of a bolted structure based on a three-dimensional fractal theory. Modern industries rapidly develop; therefore, requirements on the machining precision of a machine tool are also increasingly high; but, the contact quality of a joint part between machine tool parts has a great influence on the machining precision of the machine tool; researches show that 60-80% of the total rigidity and 90% of the total damping of the machine tool come from the joint part; but, the integral rigidity and damping of the machine tool determine the machining precision of the machine tool; and thus, the theoretical basis can be provided for researching the integral dynamic performance of the machine tool by accurately estimating the contact rigidity and damping of the joint part. For a bolted joint surface, in combination with MATLAB numerical value simulation software and ANSYS finite element analysis software, a method for estimating the dynamic performance of the bolted joint surface is provided based on a three-dimensional fractal surface and a contact rigidity and damping model built by considering the influence of an elastoplastic deformation stage simultaneously.

Owner:BEIJING UNIV OF TECH

Full-fabricated concrete beam-column connector based on energy dissipation pieces and shearing resistance pieces and beam-column connecting method

ActiveCN107905363AImprove ductilityEasy to controlProtective buildings/sheltersShock proofingConcrete beamsRebar

The invention relates to a beam-column connector and a method for connecting beams and columns. The connector comprises energy dissipation pieces (2) pre-embedded in prefabricated concrete frame columns, anchoring pieces (1), shearing resistance pieces (4) and conversion blocks (10) pre-embedded in the ends of prefabricated concrete frame beams; the energy dissipation pieces (2) are fixedly connected with the anchoring pieces (1) through bolts, T-shaped connecting heads (5) are mounted on the side faces of the conversion blocks (10), and the T-shaped connecting heads (5) and steel bars (7) inthe beams are connected through sleeves (6); beam end clamping grooves (9) are formed in the conversion blocks (10), and the beam end clamping grooves (9) and column end protrusions (8) are mutually fastened, so that quick connecting of tensile steel bars (compression steel bars) is achieved; the shearing resistance pieces (4) at the beam ends penetrate through column end shearing resistance piececonnection columns (3), the shearing resistance pieces (4) and the column end shearing resistance piece connection columns (3) are connected by inserting bolts into screw holes in the side faces, andthrough the device, the beams and the columns are firmly connected. The beam-column connector can not only transmit shearing force, but also can transmit beam end bending moment, and the beam-columnconnector is more close to a cast-in-place joint; and in addition, the beam-column connector applies a ductility material, so that ductility of the beam-column connector under action of the earthquakeload is increased.

Owner:HUNAN UNIV

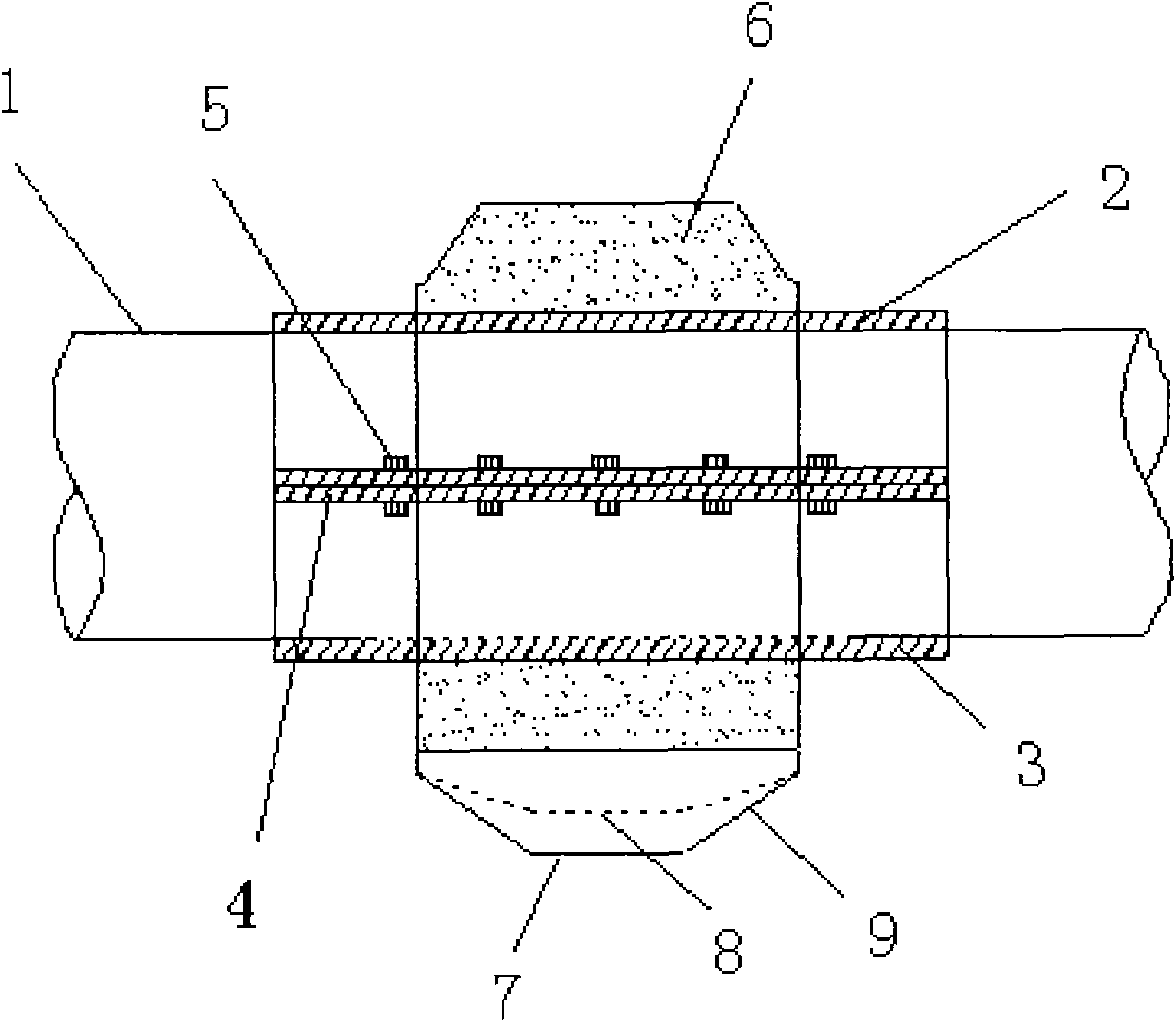

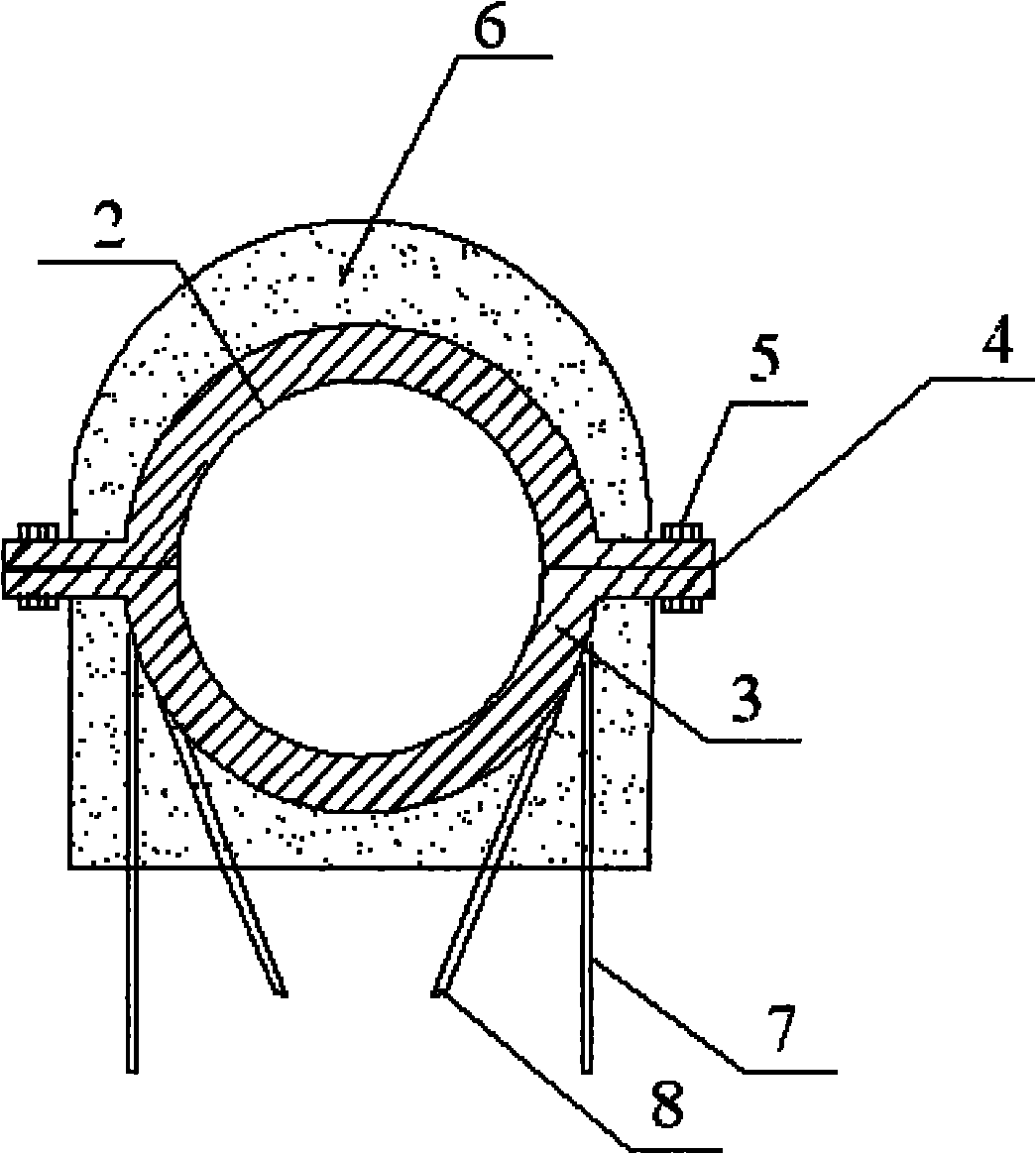

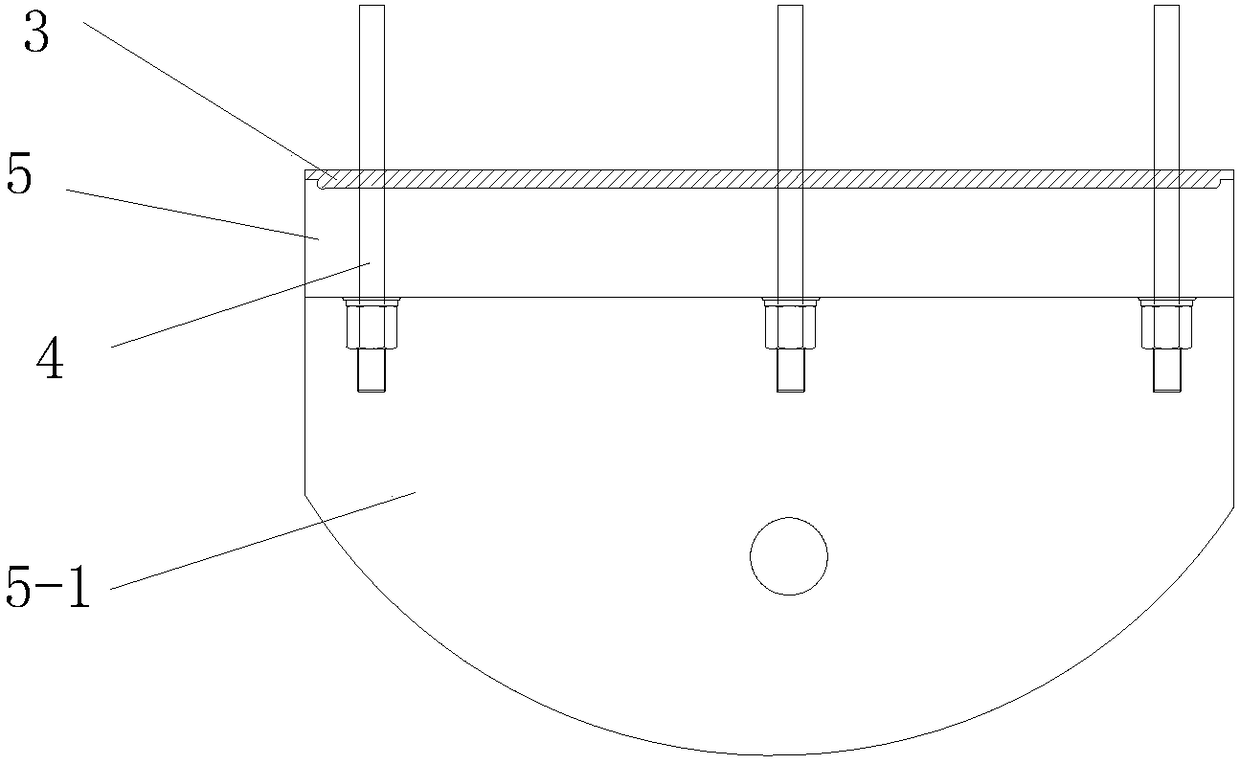

Submarine pipeline buckling preventing device, and manufacturing method and mounting method thereof

ActiveCN102022585AEffective control of buckling propagationIncrease in-place stabilityPipe supportsPipe laying and repairThick wallEngineering

The invention relates to a submarine pipeline buckling preventing device, and a manufacturing method and a mounting method thereof. The device comprises two annular thick-wall shells, wherein the two sides of each shell are symmetrically extended to form an elongated eye plate respectively. The two shells are integrated by bolts. Concrete pressure blocks with horseshoe-shaped sections are poured outside the shells in the eye plates on the two sides. Two vertical anchor plates and two oblique anchor plates are symmetrically welded on the two sides of each shell along the length directions of the concrete pressure blocks. The upper parts of all the anchor plates are poured in the concrete pressure blocks. The device provided by the invention can be applied to unburied submarine pipelines arranged at seat bottom and greatly reduces the ditching and pipeline burying cost. The device, and the manufacturing method and the mounting method thereof effectively control the buckle propagation of the submarine pipelines, enhance the positioning stability of the submarine pipelines, and realize the uniformity of economy and safety.

Owner:CHINA NAT OFFSHORE OIL CORP +2

General drop-proof parallel groove clamp

ActiveCN106848620AAvoid sliding offImprove stabilitySuspension arrangements for electric cablesClamped/spring connectionsEngineeringMiddle line

Owner:JIANGSU CHUANDU ELECTRICAL TECH

Bolt joining method and tools therefor

InactiveUS20140025196A1Guaranteed usageInterferenceProgramme controlComputer controlMechanical engineeringCommunication device

A method for carrying out a stud joining process by a tool performing a working step on a workpiece and the working step is carried out while taking into account at least one parameter value which is selected from a set of values, and the working step is to be carried out at a certain position on the workpiece, and the position determines the parameter value. The method comprises the steps of: storing the parameter value for the position in an RFID transponder; locating the RFID transponder on the workpiece in the region of the position before the working step is carried out, reading the parameter value out from the RFID transponder with an RFID communication device associated with the tool.

Owner:NEWFREY

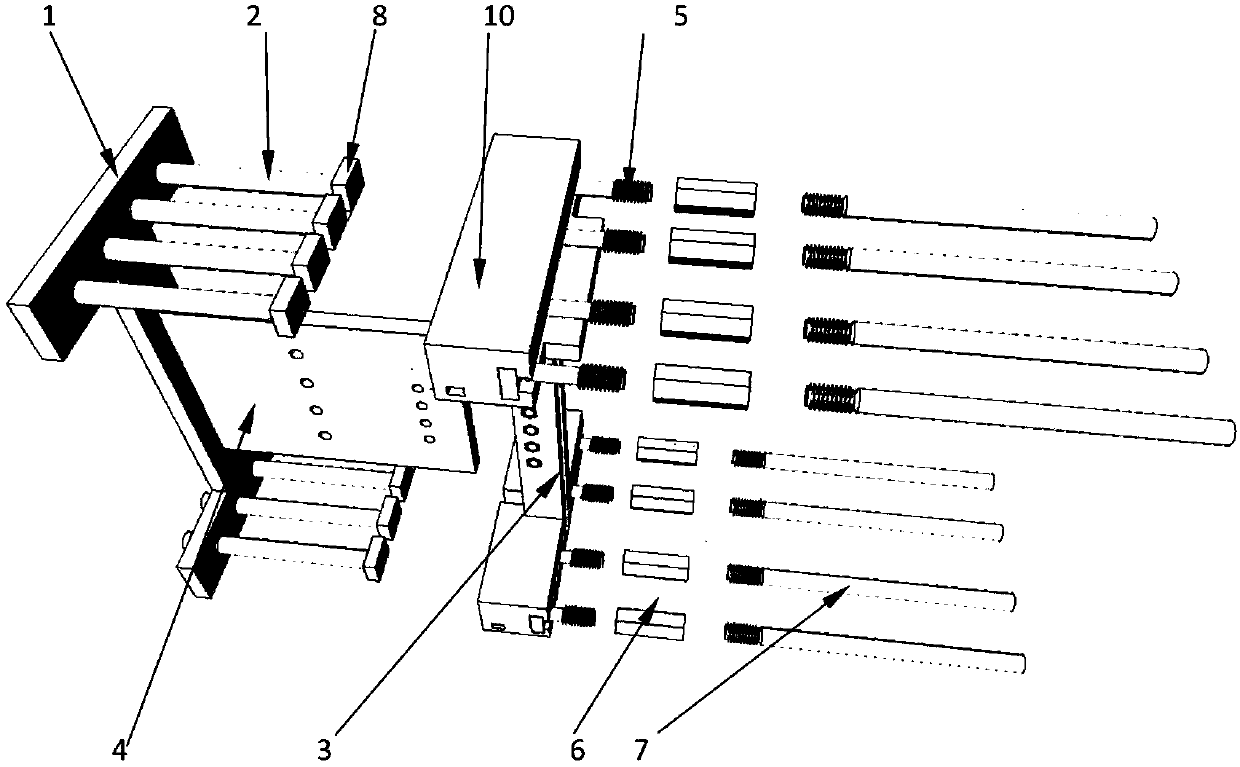

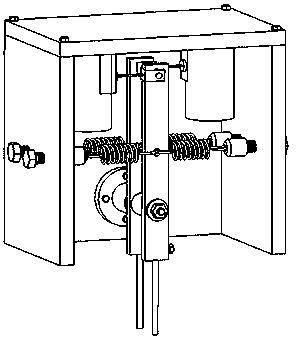

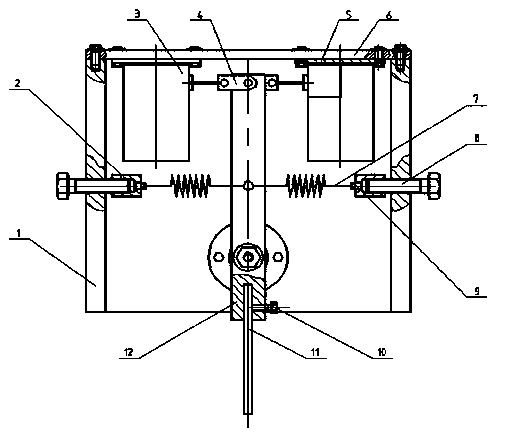

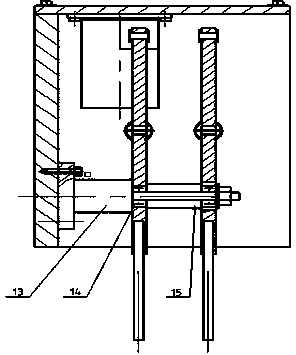

Seam tracking device with double tracking probes

InactiveCN103386536ASimple structureEasy to manufactureArc welding apparatusMicrocomputerCantilevered beam

The invention discloses a seam tracking device with double tracking probes, and relates to a seam tracking device. The seam tracking device comprises a box body, bolt connecting blocks, displacement sensors, guide rod connectors, sensor mounting flanges, an upper box cover, springs, adjusting bolts, spring hooks, probe fixing bolts, the tracking probes, guide rods, a cantilever beam, a rolling bearing and a shaft sleeve, wherein the cantilever beam is arranged on the inner wall of the box body; two guide rods are arranged on the cantilever beam; through holes are formed in the centers of the two guide rods; two springs are arranged on each of the left and right parts of the guide rods; and the tail ends of the springs are connected to the adjusting bolts through the spring connecting blocks and the spring hooks. Inclination angles of the guide rods are adjusted by screwing and unscrewing left and right nuts, so that the two tracking probes at the tail ends of the two guide rods cling to the inner wall of a seam. The displacement sensor connected to the upper ends of the guide rods is used for processing deviation information through a singlechip microcomputer, and controlling an executor to correct a deviation between the trajectory of a welding gun and the seam, so that the tracking accuracy and reliability are improved, the working efficiency is improved, and the cost is reduced.

Owner:SHENYANG UNIV

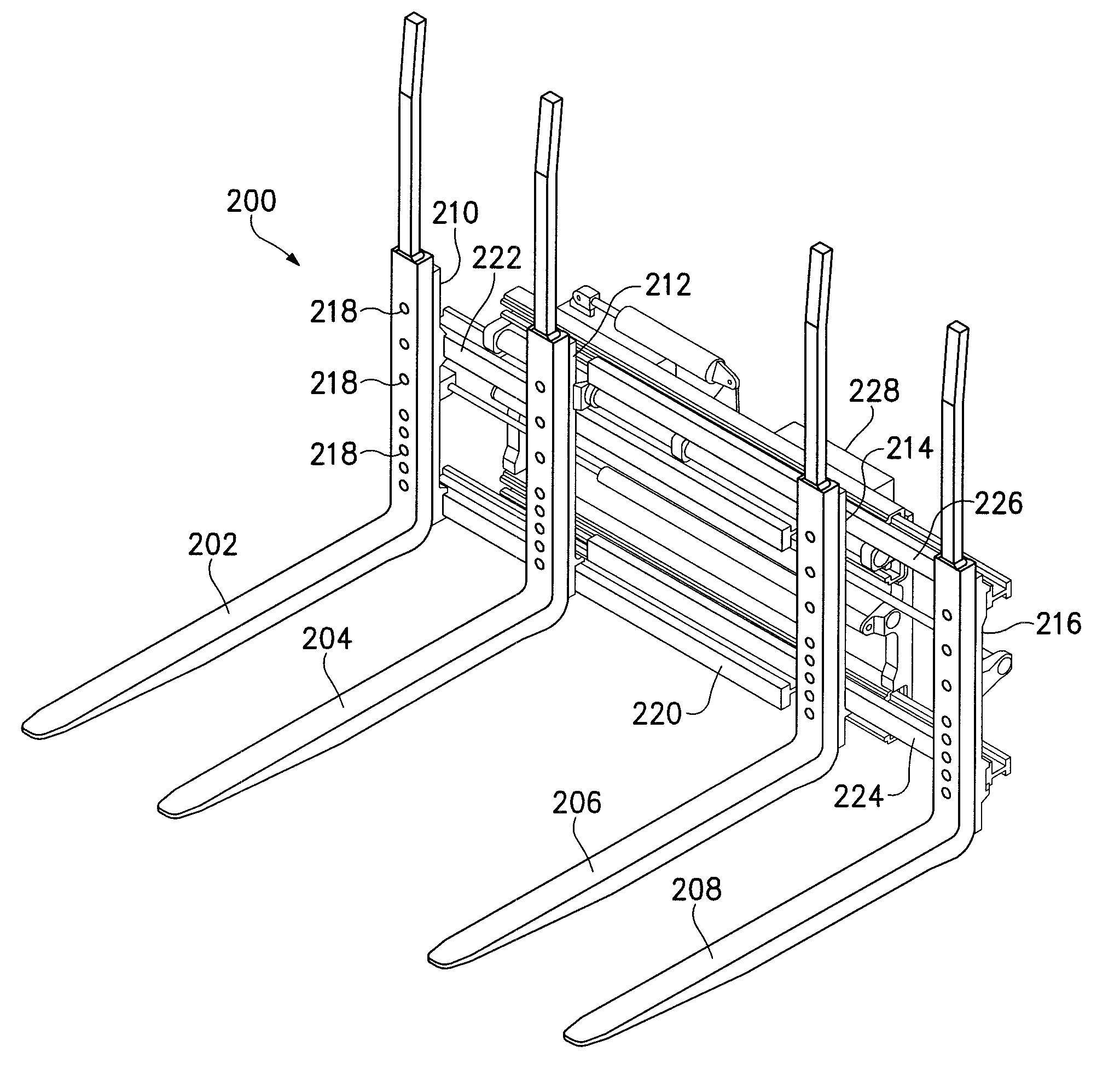

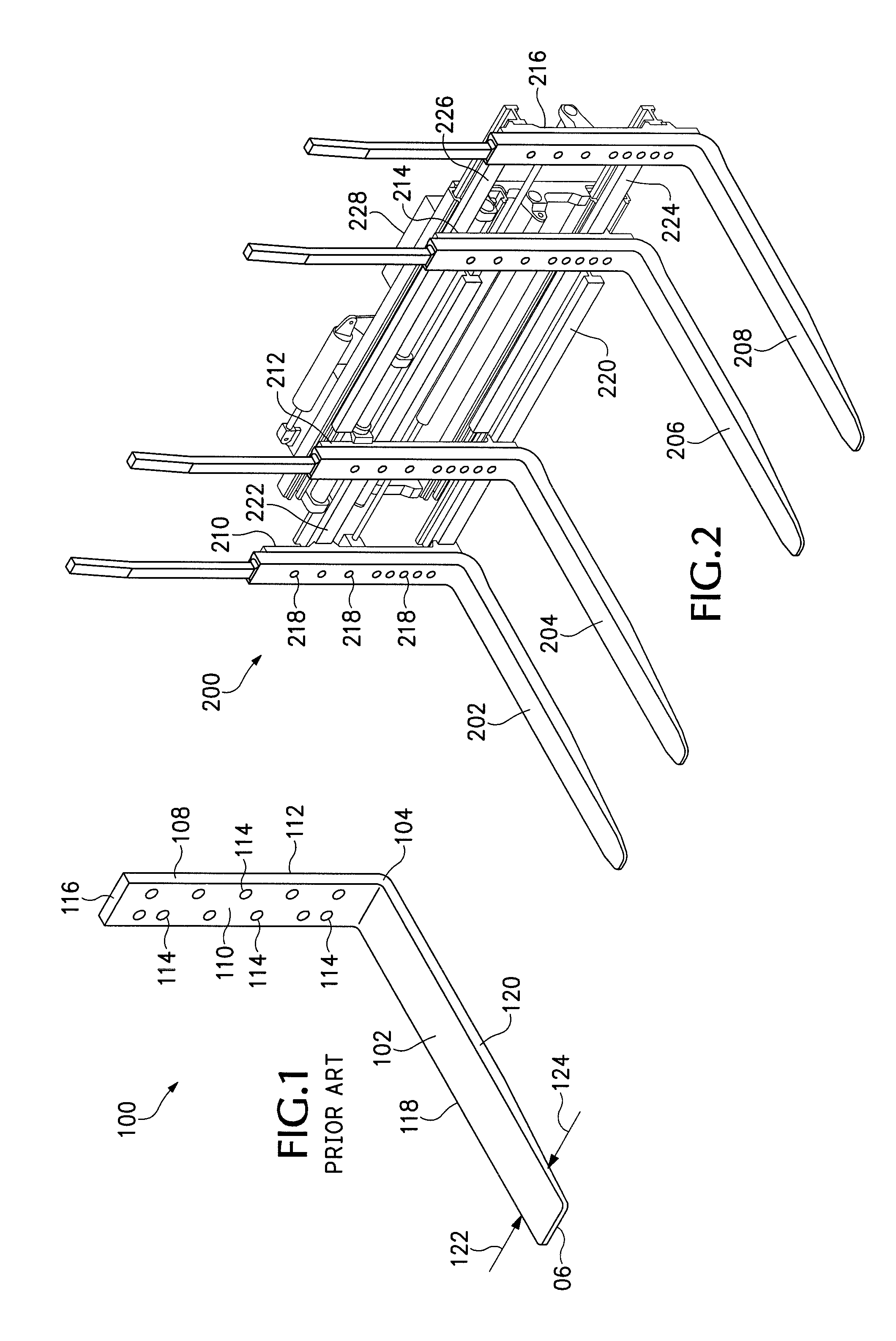

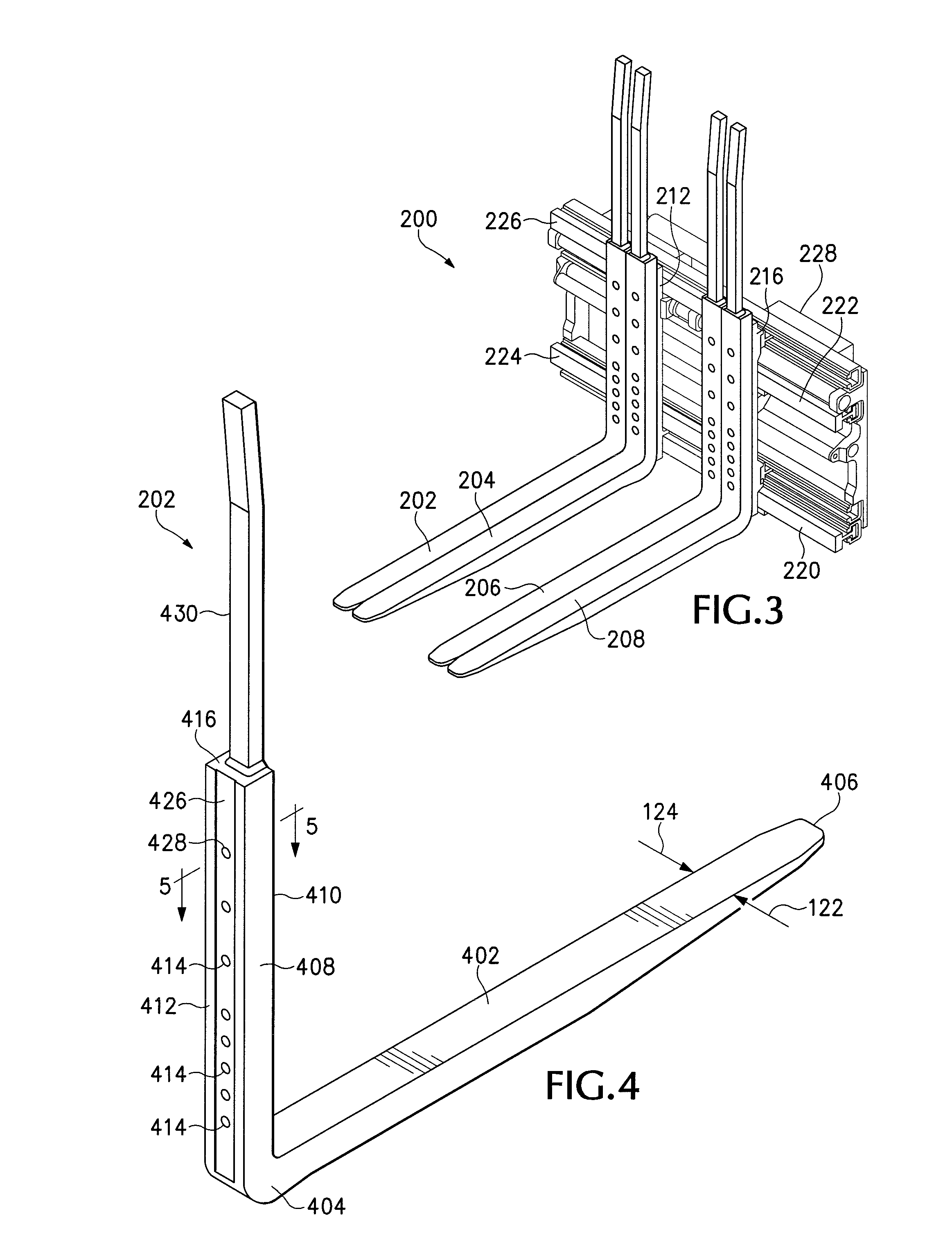

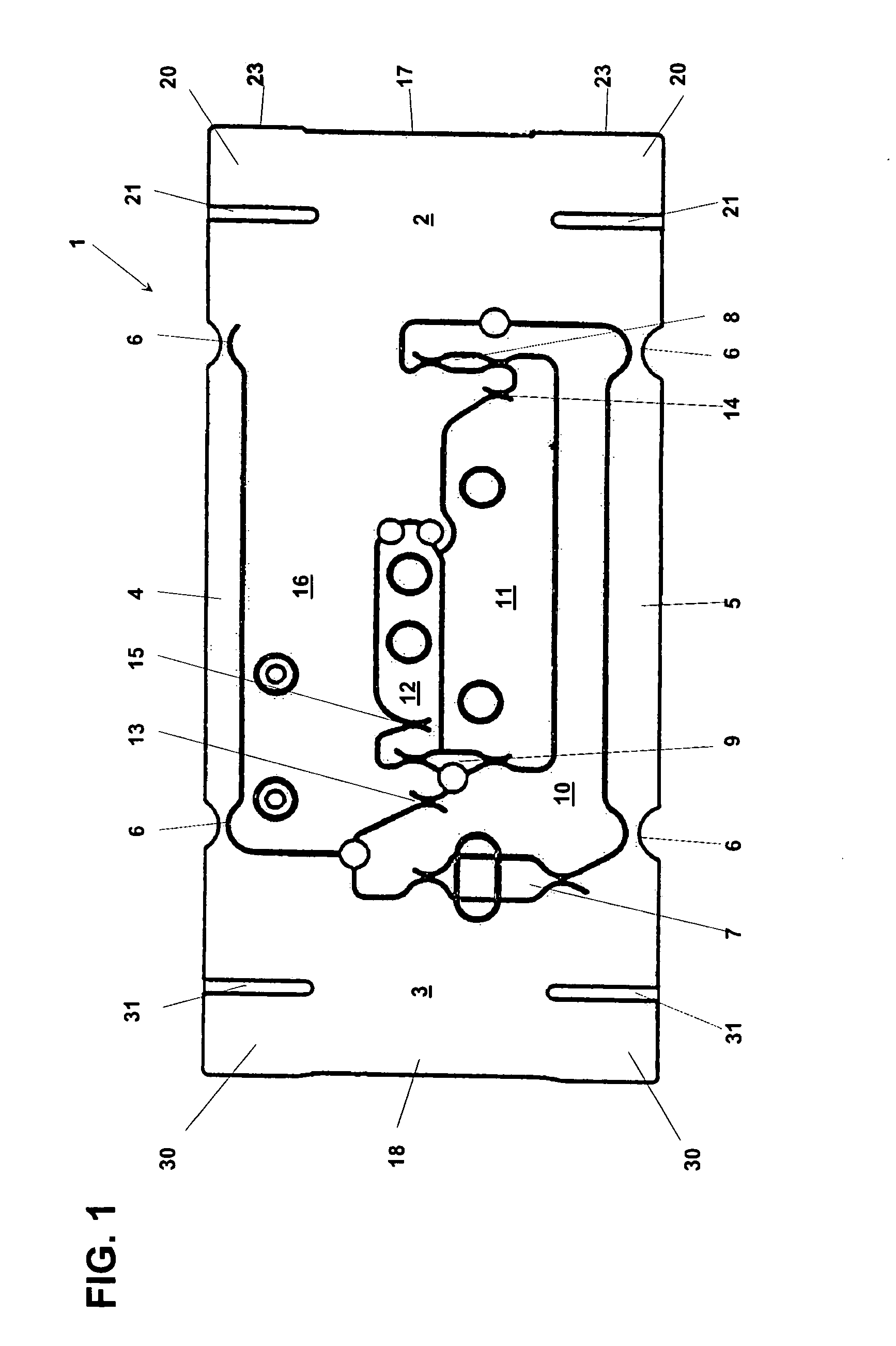

Load-lifting member with bolted joint

Improved bolted joint designs are used for a joint between a bolt-on load-lifting member such as a fork or clamp arm and a carriage or carrier associated with a material handling device. In various embodiments, an elongate rear vertical shank of one or the other of the load-lifting member or the carrier may have a plurality of mounting bolt holes spaced longitudinally along its length, each mounting bolt hole extending from a respective recessed area formed in one or both of the joined surfaces. Each bolt hole has a respective bolt-hole width dimension transverse to the elongate member, and each recessed area has a recess width dimension parallel to and greater than the bolt-hole width dimension.

Owner:CASCADE CORP

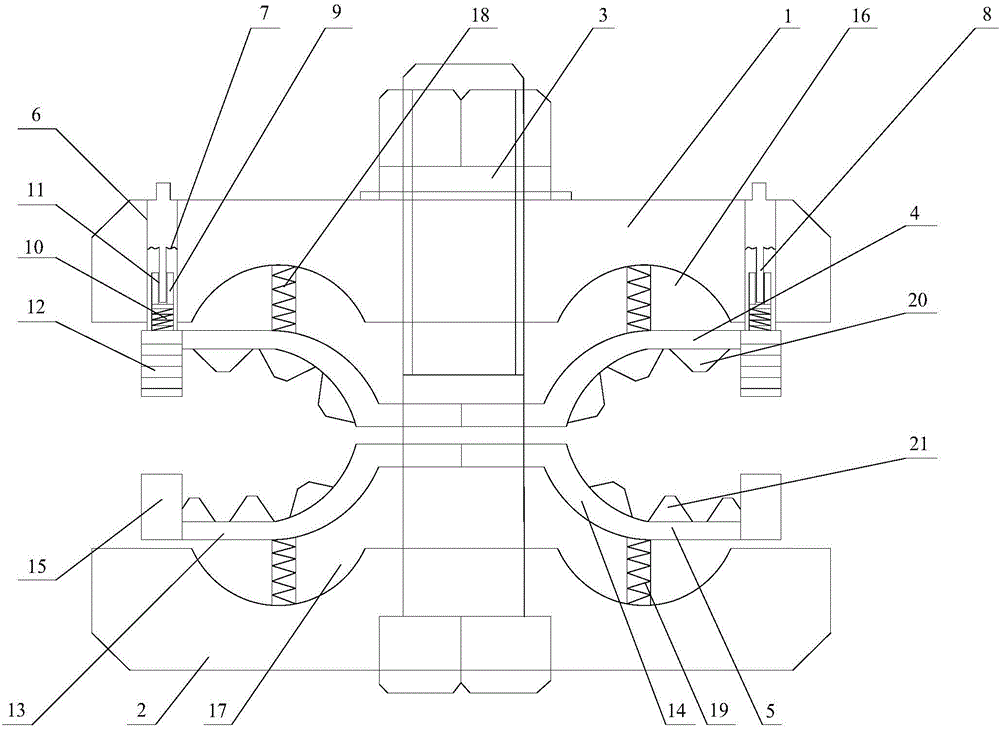

Beam-column joint connecting device for multi-story/high-rise assembly type steel structure system

The invention relates to a beam-column joint connecting device for a multi-story / high-rise assembly type steel structure system, and belongs to the technical field of structural engineering. The device comprises beam end box type connecting pieces, vertical connecting channel steel, upper column flanges, lower column flanges, truss beam end upper and lower chord members, a joint short column lower-end flange, a joint short column and a join short column upper-end flange, wherein the beam end box type connecting pieces, the joint short column, the joint short column upper-end flange and the joint short column lower-end flange can be welded into a whole in a factory; two pieces of vertical connecting channel steel and the truss beam end upper and lower chord members are welded into a whole in the factory; and the two pieces of vertical connecting channel steel are connected with the beam end box type connecting pieces through bolts. Welded parts of the joint connecting device can be finished in the factory, and are assembled in situ by the bolts, the fastening work of the bolts is convenient and quick, the construction speed is greatly increased, the construction quality is greatly improved, and the device is adapted to the development of an assembly type steel structure; and in addition, a joint is a rigid joint, and is high in ductility and bearing capacity.

Owner:BEIJING UNIV OF TECH

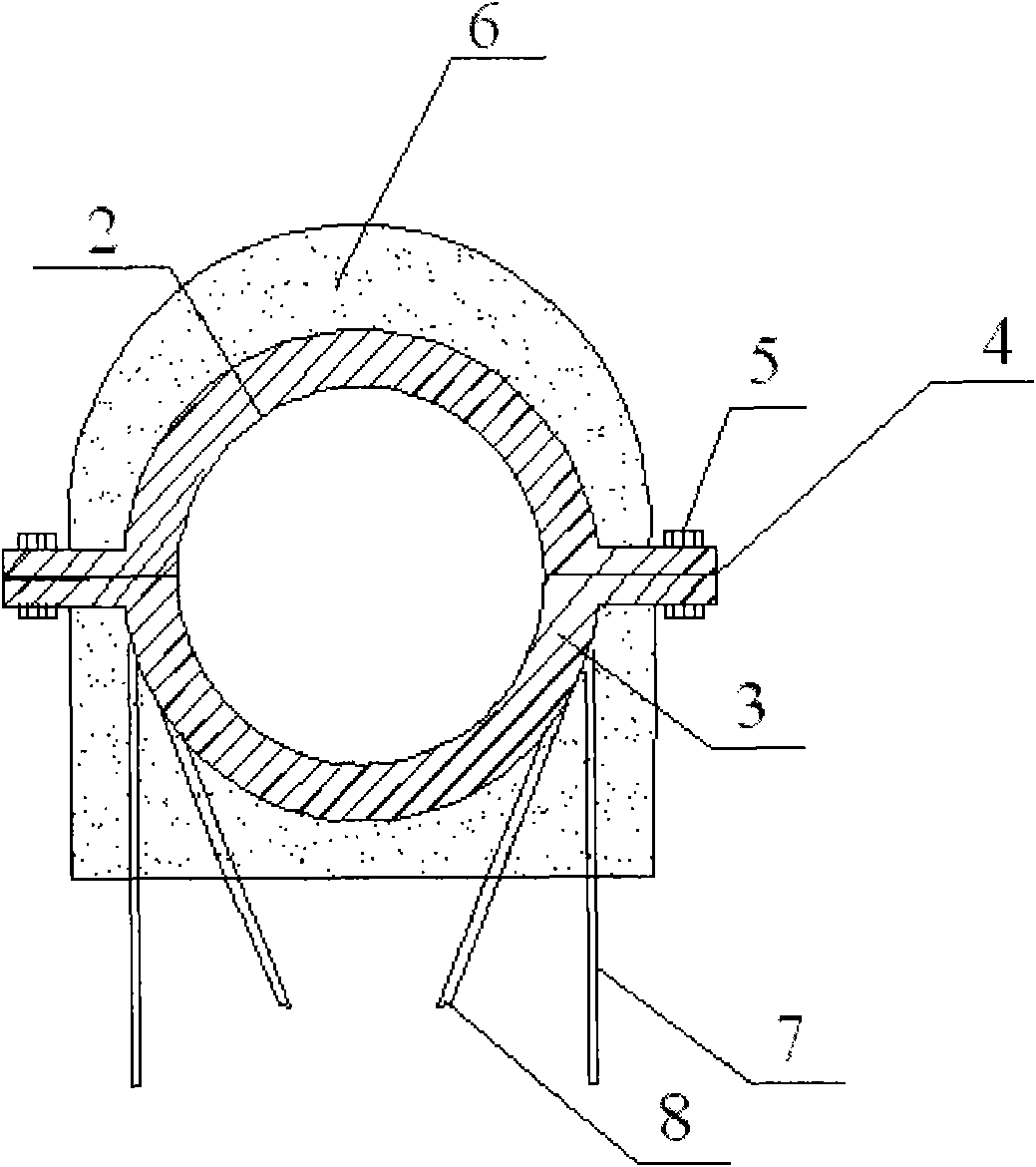

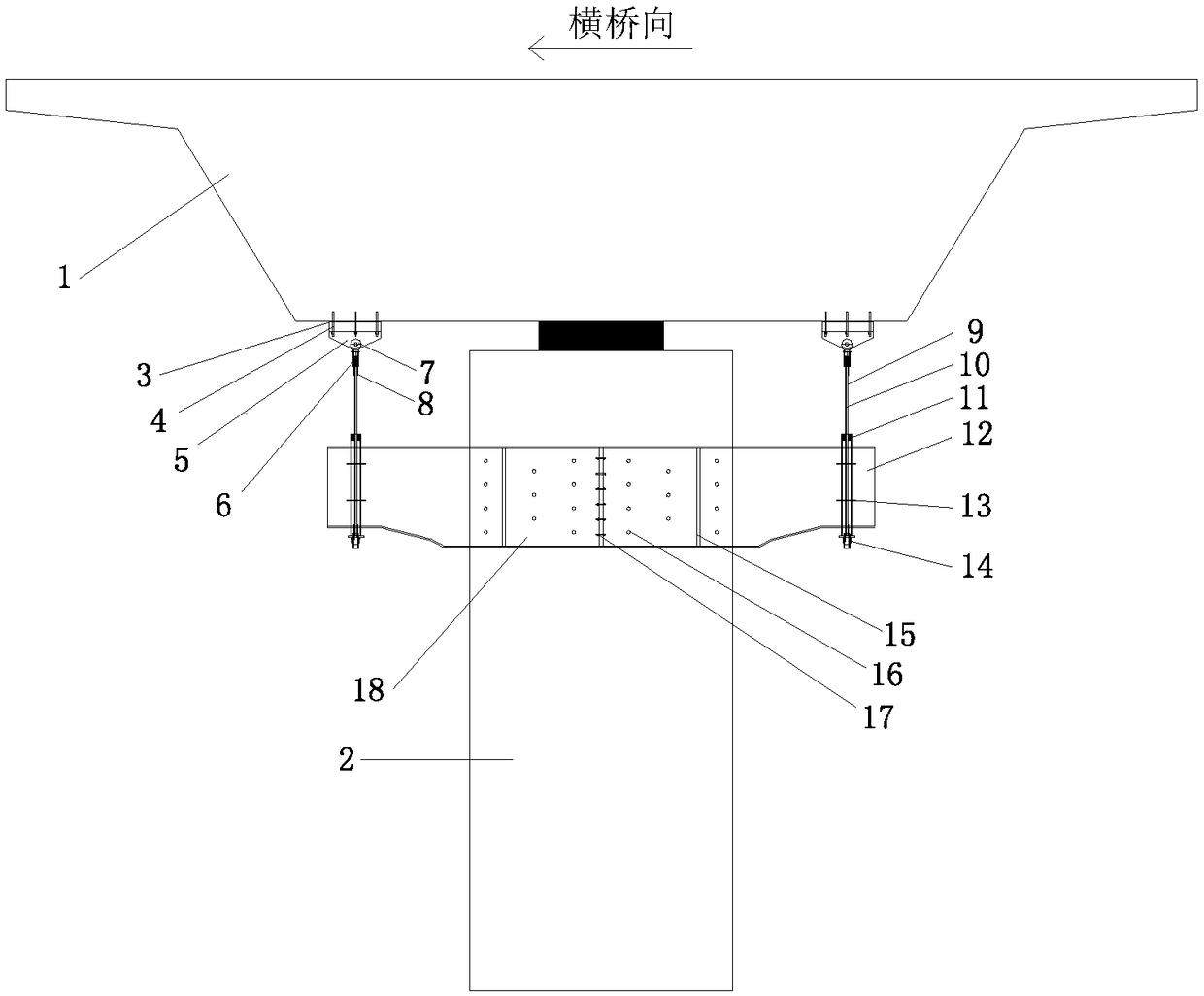

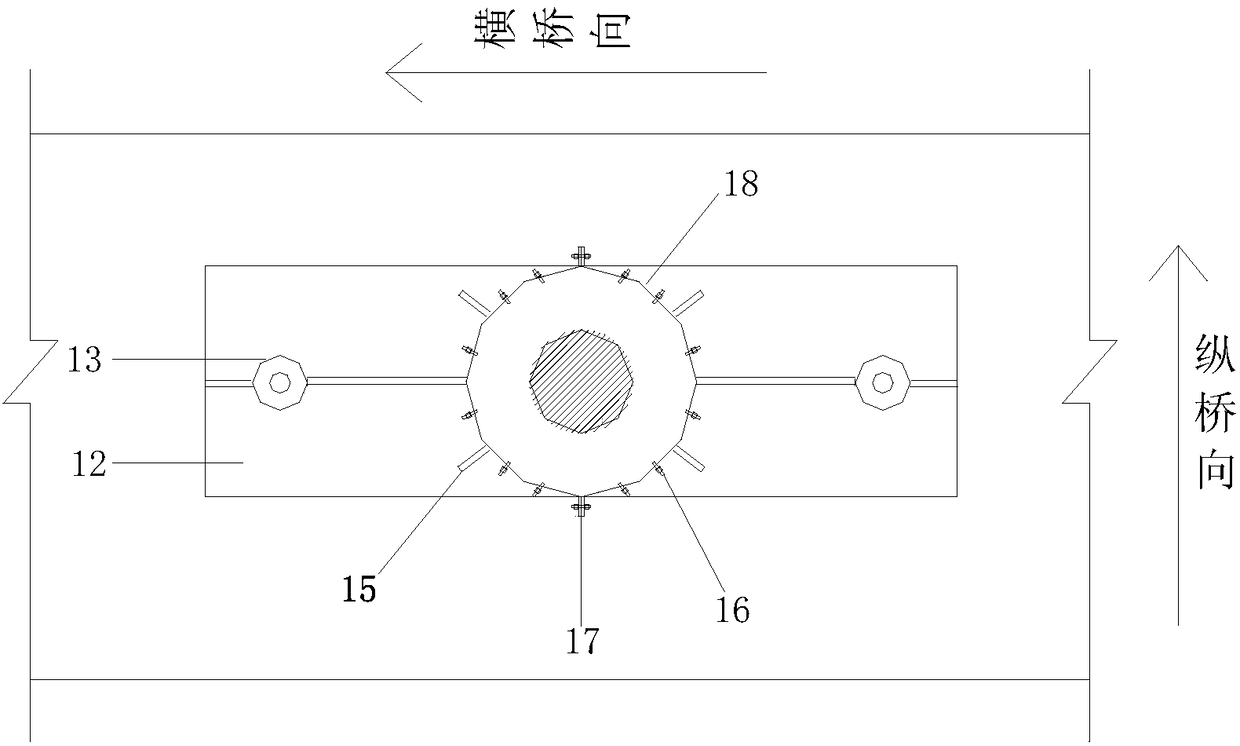

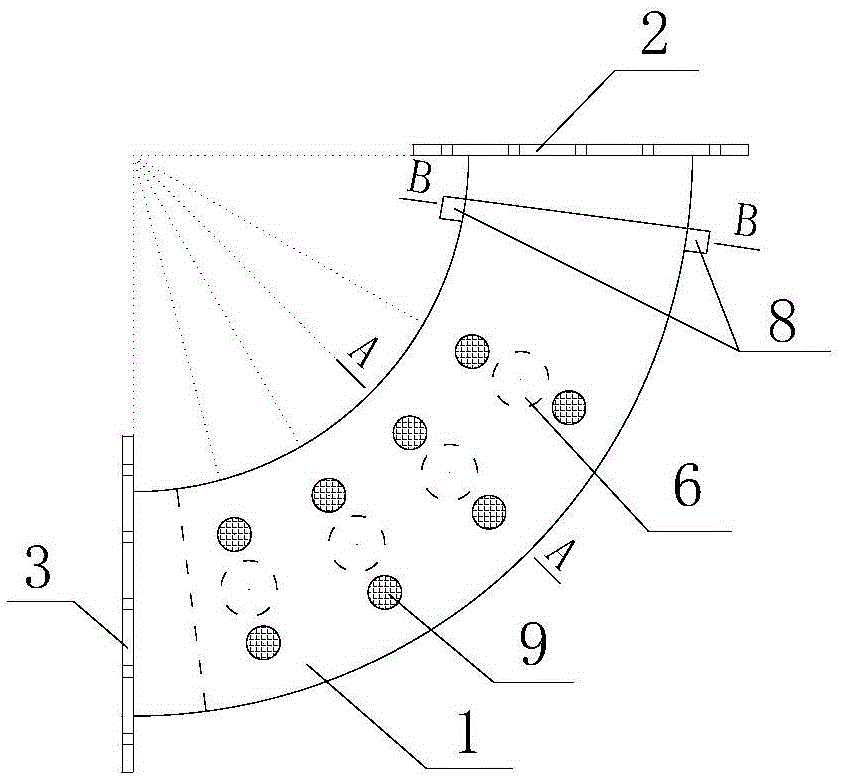

Anti-overturning reinforcement system for single-column pier bridges and mounting method

ActiveCN108532474AAvoid voidsPrevent overturning damageBridge erection/assemblyBridge strengtheningCantileverBolted joint

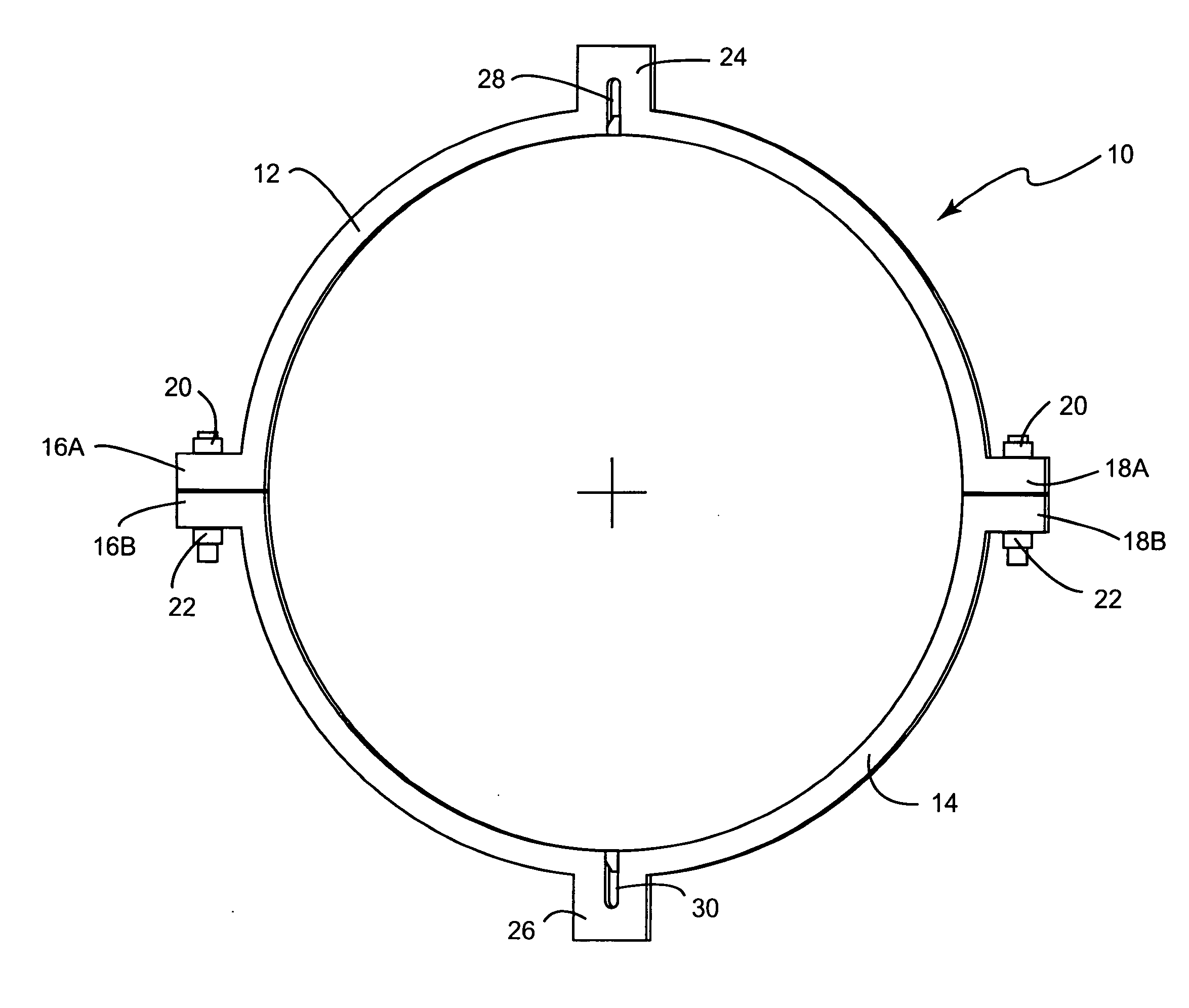

The invention provides an anti-overturning reinforcement system for single-column pier bridges, which comprises a steel structure support, a steel connecting base, and rigid tie rods; the steel structure support comprises two semicircular hoops with cantilevers, and the surface, which is in contact with a pier, of each semicircular hoop is provided with reserved holes for the mounting of anchor bolts at intervals; the external surfaces of the semicircular hoops are provided with axial reinforcing ribs; the two semicircular hoops are connected through first high-strength bolts to hoop both sides of the pier, and the semicircular hoops and the cantilevers are of an integrated structure; one end, which is far from the hoop, of each cantilever is provided with a vertically through mounting through hole; the steel connecting base is fixed on the bottom of a bridge, the center of the steel connecting base and the center of the through hole are on the same vertical line, and both ends of eachrigid tie rod are respectively fixedly connected to the steel structure support and the steel connecting base. The invention can effectively enhance the anti-overturning performance of a single-column pier bridge, the structure is simple, stress is clear, construction is convenient, the anti-overturning reinforcement system has relatively good economical efficiency and appearance, and the invention is suitable for popularization and application in the field of bridge reinforcement.

Owner:HUATIAN ENG & TECH CORP MCC

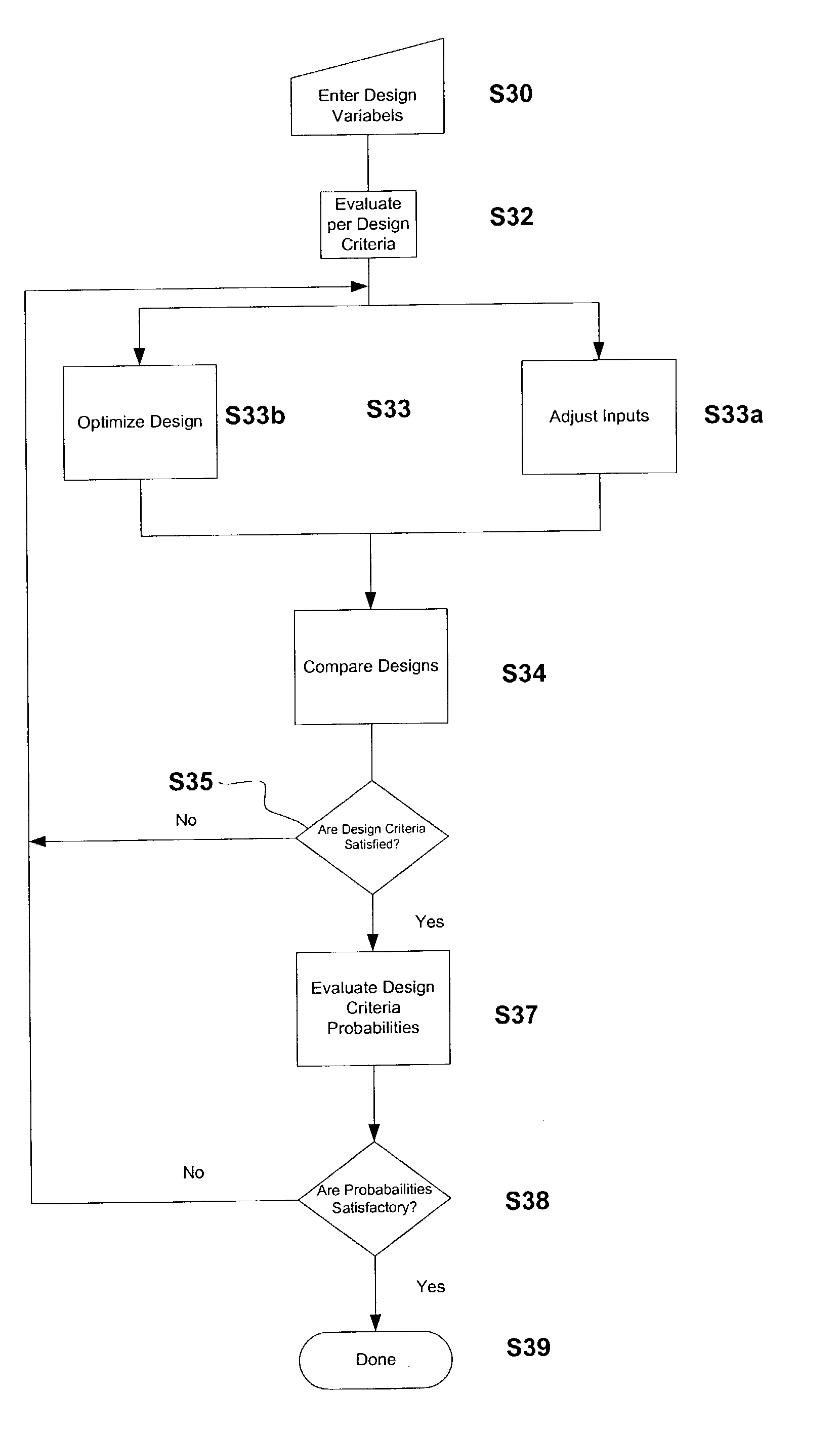

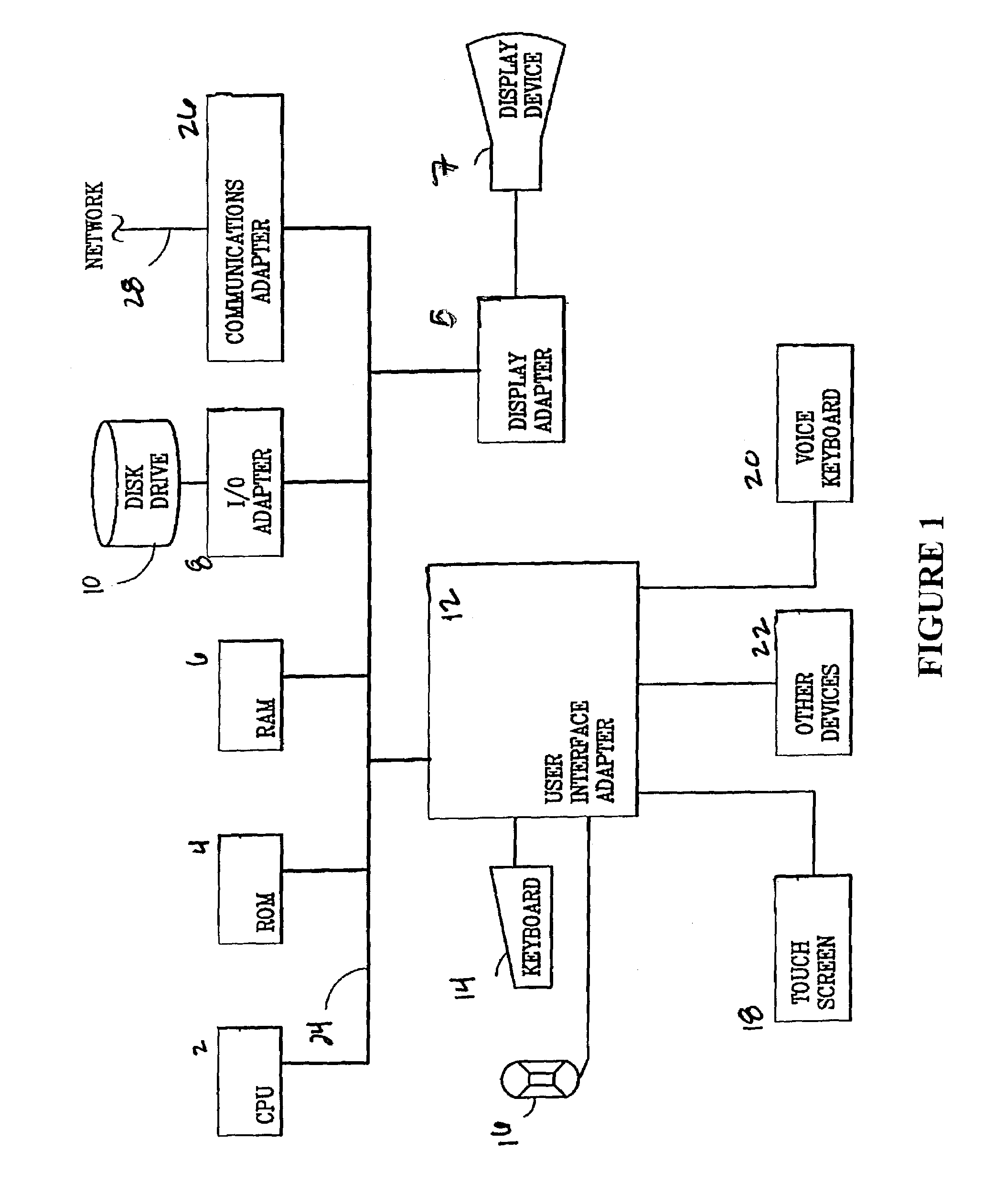

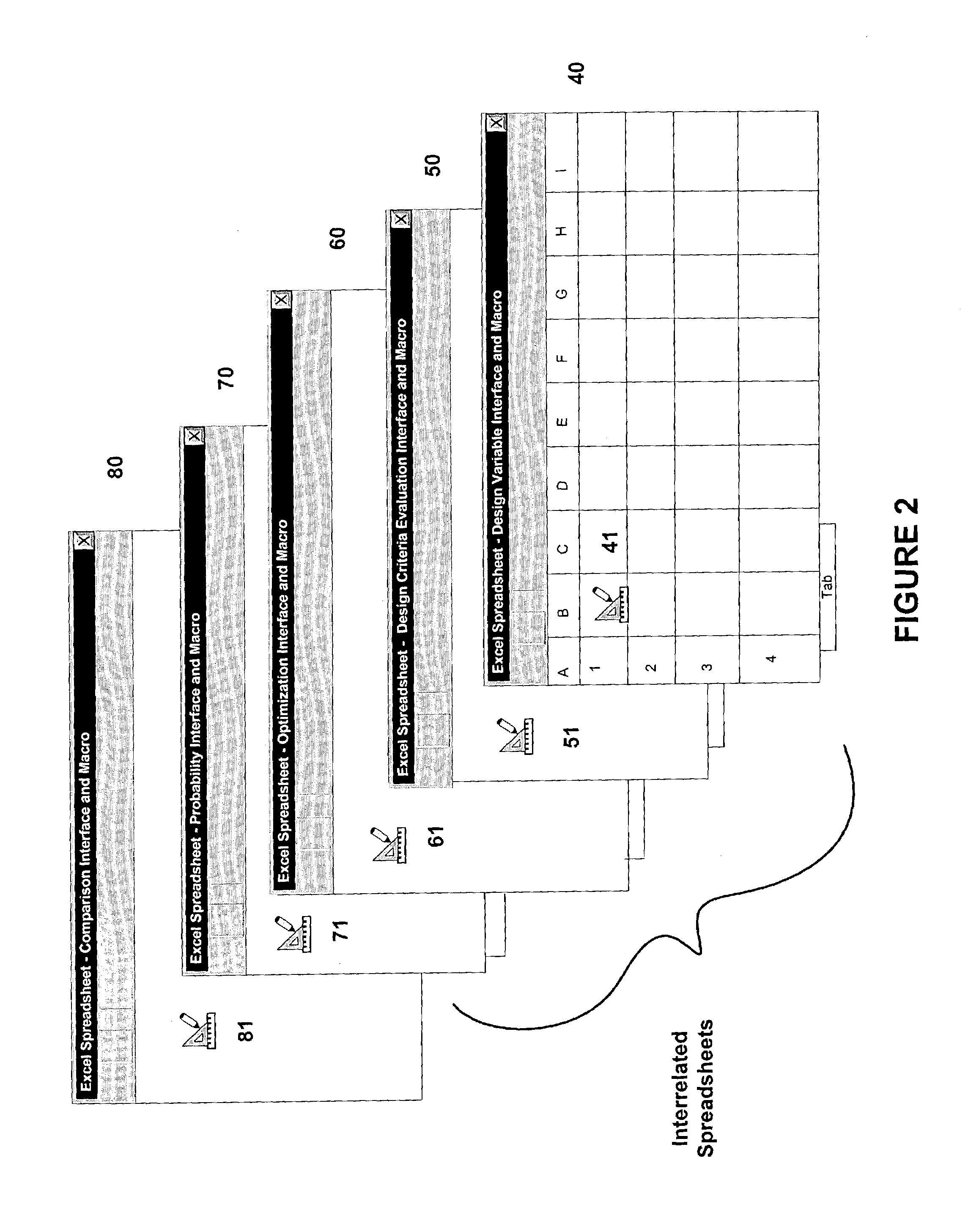

Bolted joint statistical spreadsheet

InactiveUS7136785B2Improve accuracyConfidencePlug gaugesForce measurementDesign standardElectronic form

A system and method for statistically analyzing a structural member design is provided to obtain a probability that the structural design will meet predetermined design criteria. The present invention provides for numerous spreadsheets, interrelated by way of a macro, to performing statistical analysis on a design, wherein one spreadsheet accepts design input variables. The design input variables are then evaluated by a number of recommended design criteria. If the design fails to meet the recommended design criteria, the user can establish the design (e.g., optimize it in one embodiment) using the optimization spreadsheet. The optimization spreadsheet established the structural member design by automatically adjusting various design inputs so that the structural member design satisfies as many design criteria as possible. Once the desired design input values are discovered, a probability spreadsheet uses random data points to calculate the probability that the structural member design will fail to meet the design criteria.

Owner:CATERPILLAR INC

ECC axial tension test deformation monitoring system and method

InactiveCN105547809AGuaranteed Axial StickingPrevent slippingClimate change adaptationMaterial strength using tensile/compressive forcesSheet steelDeformation monitoring

The invention discloses an ECC axial tension test deformation monitoring system and method. The system mainly comprises a tension clamp, a template for fixing the tension clamp in the test-piece pasting process, a displacement sensor fixing support, a springback displacement sensor and a collecting box. The tension clamp comprises two steel plates and a chuck. The steel plates and the chuck are clamped by tooth grooves and anchored by two bolts, and therefore it is ensured that the test-piece is axially tensioned in the direct tension process. The template for fixing the tension clamp in the test-piece pasting process comprises two clamping plates and two baffles, the clamping plates and the baffles are connected through bolts, the width of the baffles is consistent to the width of the test-piece, and it is ensured that the test-piece does not deflect in the pasting process. The displacement sensor fixing support comprises two top beams and bottom beams. The beams are fixed to the test-piece through rapid-hardening glue and anchoring of bolts, and meanwhile, the two ends of the top beams and the two ends of the bottom beams are installed on sliding blocks in a screwed mode, wherein the sliding blocks move on the beams left and right. The fixing support is suitable for testing test-pieces of different sizes.

Owner:SHANDONG UNIV

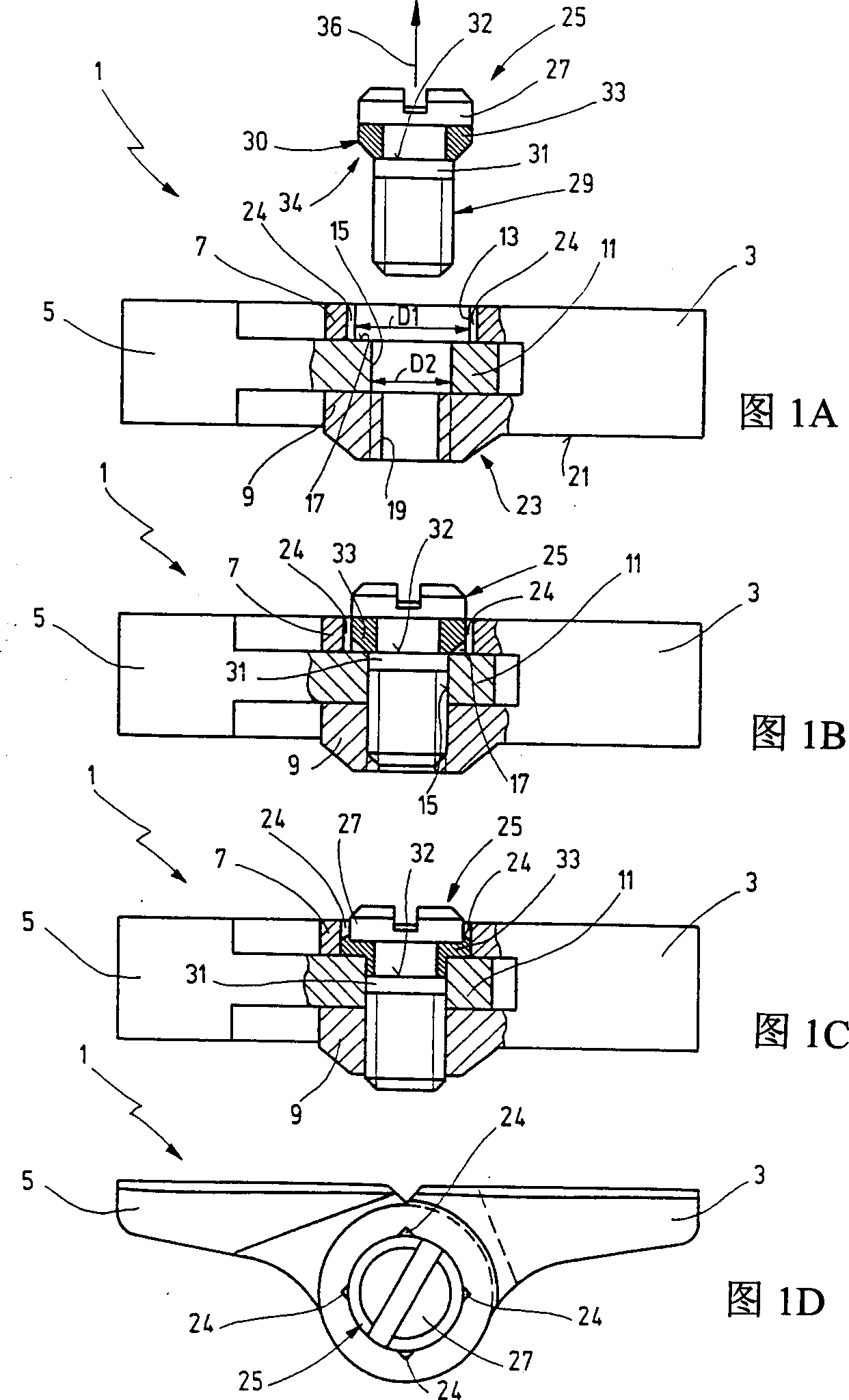

Screw connection of hinge parts

A screw connection for hinge parts, especially of an eyeglass frame, comprising a screw that interconnects the hinge parts that engage one inside the other and that have an upper hinge lobe, a lower hinge lobe, and at least one middle hinge lobe, the screw having a screw head and a screw shank that extends through a first through opening in the upper hinge lobe and extends through a second through opening in the middle hinge lobe, with a thread permitting the screw shank to be screwed into the lower hinge lobe, and comprising a sleeve that surrounds the screw shank, has elastic properties, and interacts with the upper and middle hinge lobes when the screw is in a screwed-in state, whereby the diameter (D 2 ) of the second through opening is less than or equal to the diameter (D 1 ) of the first through opening. The screw connection is distinguished by the fact that the screw ( 25 ) has at least one bearing surface for the sleeve ( 33 ) with at least one engaging surface ( 32 ) that is aligned in the direction of movement in which the screw ( 25 ) is unscrewed.

Owner:OBE奥马赫特&鲍姆格特纳有限公司

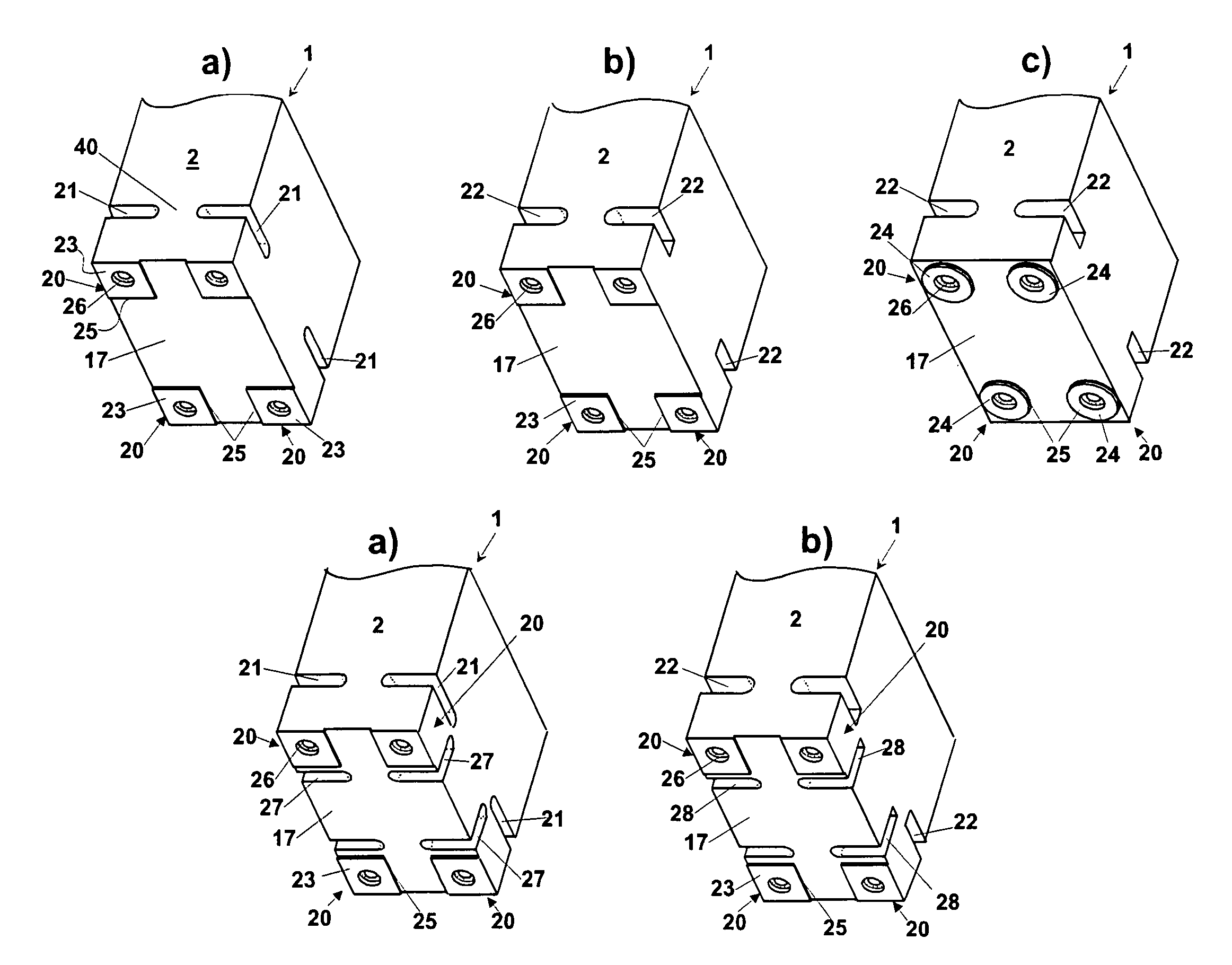

Fastening arrangement of a force-transmitting device

ActiveUS7220924B2Rigid enoughEqually distributedWeighing apparatus using counterbalanceWeighing apparatus using elastically-deformable membersEngineeringMechanical engineering

In a force-transmitting device of a force-measuring cell with a parallel-guiding mechanism in which a stationary parallelogram leg and a movably guided parallelogram leg are connected to each other by parallelogram guides, each of the parallelogram legs has a fastening part with at least two fastening portions. The fastening portions have fastening pads with tapped holes running perpendicular to the fastening pad surfaces, so that a load carrier can be bolted to the force-transmitting device and / or the device can be fastened to a housing. The parallelogram legs have slot-shaped incisions that serve to uncouple the fastening portions from the rest of the parallelogram leg, so as to prevent the propagation of assembly stresses from the fastening portions into the working parts of the force-measuring cell.

Owner:METTLER TOLEDO GMBH

Angle-adjustable fan-shaped lead viscoelastic corner damper

ActiveCN105155719AThe angle can be adjusted convenientlyReduce volumeShock proofingElastomerShock absorber

The invention relates to a building component used for node angle displacement limitation and shock absorption, in particular to an angle-adjustable fan-shaped lead viscoelastic corner damper, and belongs to the field of structure engineering. The angle-adjustable fan-shaped lead viscoelastic corner damper mainly solves the problem that the existing fan-shaped lead viscoelastic corner damper component is only limited to be used at a 90-degree angle beam post node position and is difficult to adapt to the modern building structure form diversification. The angle-adjustable fan-shaped lead viscoelastic corner damper comprises a composite elastic body and two connecting plates, wherein the composite elastic body consists of elastic bodies, shearing steel plates, a cylindrical lead core and angle regulating steel plates; the elastic bodies and the shearing steel plates are alternately laminated; the cylindrical lead core transversely passes through the shearing steel plates and the elastic bodies; the shearing steel plates arranged at the outer side are connected with the angle regulating steel plates through screw bolts; and each elastic body, each shearing steel plate and each angle regulating steel plate are all in a fan shape concentric with the composite elastic body. The angle of the damper can be regulated into four different values, and the angle-adjustable fan-shaped lead viscoelastic corner damper is applicable to building structures with various angles.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Adjustable fabricated jig frame for steel structure assembling and using method of adjustable fabricated jig frame

InactiveCN107476585AEffective combination regulationAny combination adjustmentBuilding material handlingRelative motionThreaded rod

The invention relates to the field of steel structure fabrication, in particular to an assembling jig frame for a steel structure. The assembling jig frame for the steel structure comprises a base part and support parts. The assembling jig frame is characterized in that the base part comprises base main beams and tie beams perpendicularly connected with the main beams in a bolted mode, each tie beam is divided into two sections, the two sections of each tie beam are connected by adopting a long-hole bolt, and the separation distance of the main beams can be adjusted through relative motion; each support part comprises a support bottom plate, a bottom circular tube, a support circular tube, corbels, nuts, threaded rods, a top circular tube and a bracket, the support bottom plates are connected with a base in a bolted mode, the bottom circular tubes are perpendicularly welded to the support bottom plates, the support circular tubes are inserted into the bottom circular tubes, the corbels are symmetrically welded to the two side faces of each support circular tube, the brackets are perpendicularly welded to the upper portions of the top circular tubes and inserted to the upper ends of the support circular tubes, and the brackets are in contact connection with the threaded rods which are screwed in the corbels. According to the assembling jig frame for the steel structure, the assembling precision is improved, meanwhile the geometry applicable range is greatly widened, mounting and dismounting are easy, turnover and transportation are convenient, and the assembling efficiency is improved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com