Calculating method for flexural bearing capacity and bending moment-rotation curve of concrete-filled steel tube column-steel beam penetrated bolt connecting joint

A technology of concrete-filled steel tube columns and connection nodes, which is used to measure torque/torsion force, construction, building construction and other directions during tightening, and can solve the large economic cost, laborious, and inability to directly apply steel tube concrete column-steel beam through-bolt connection Node and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] In order to make the above features of the present invention more understandable, the calculation method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

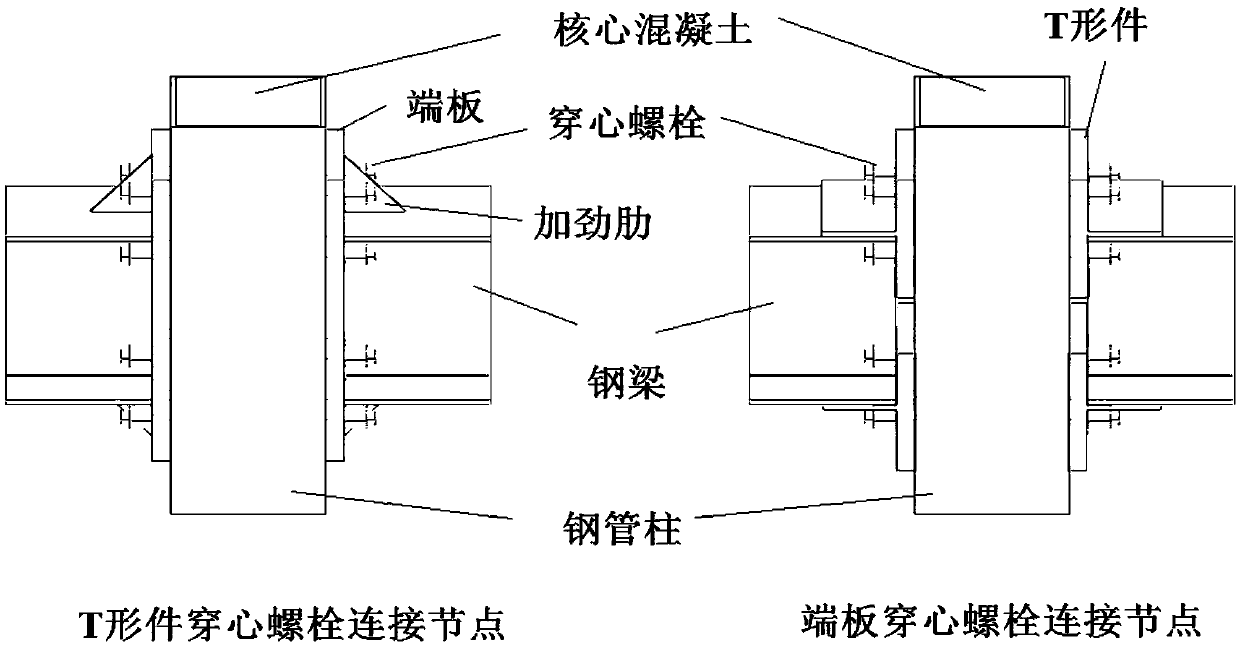

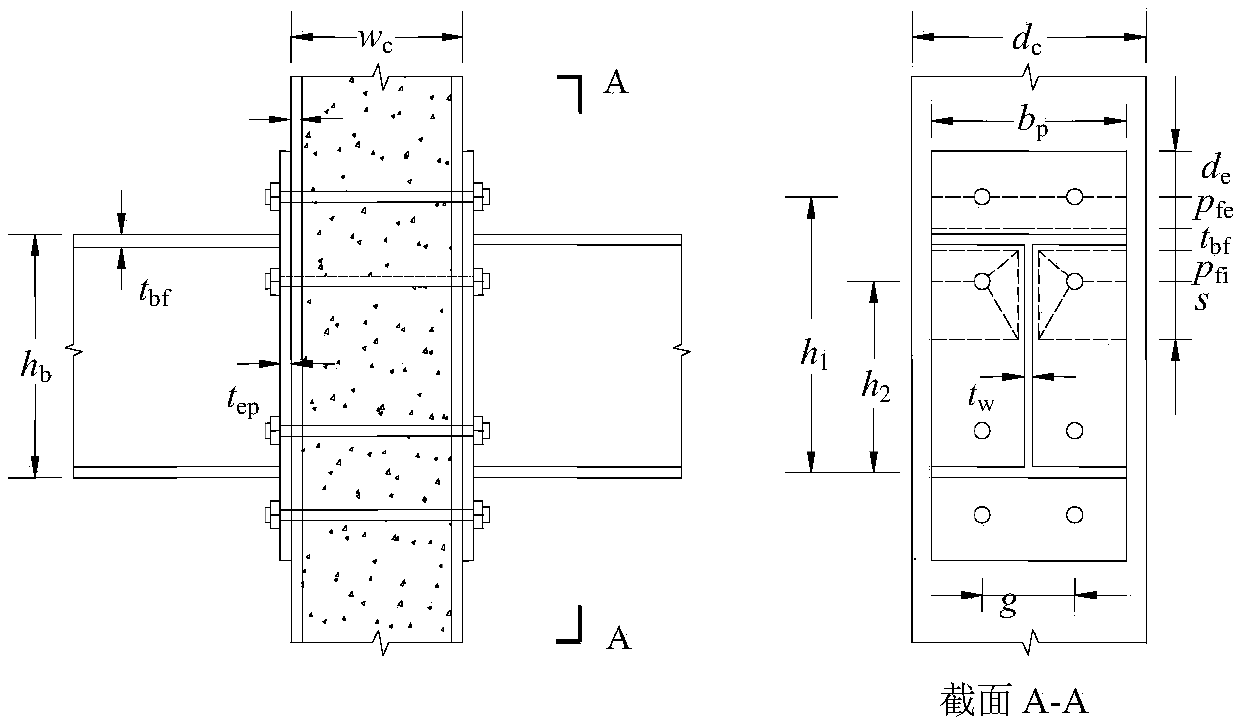

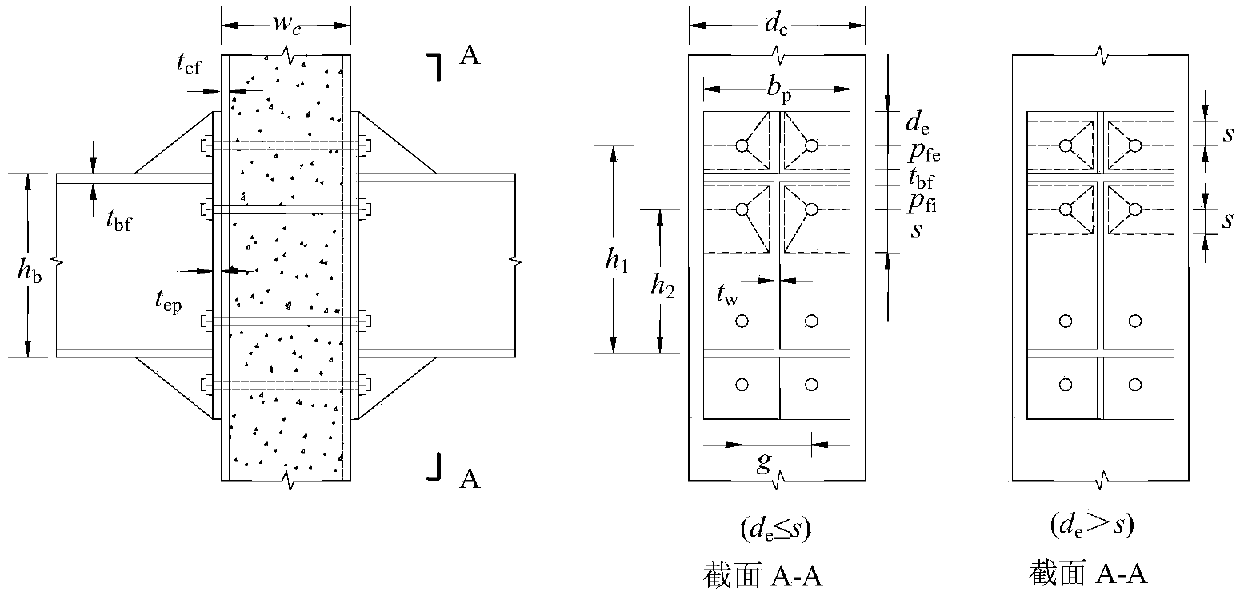

[0082] figure 1 Schematic diagrams of the three-dimensional configurations of two of the four connection node types to which the present invention is adapted are given. Figure 2-6 It is a schematic plan view of four connection node types, and the physical meanings corresponding to the symbols in the calculation formulas of the yield line parameters of each node type are marked in the figure. Figure 7 It is the structural diagram of the connecting node in this embodiment, which is a connecting node of the through-bolt of the stiffened outrigger end plate, and its relevant parameters are derived from the previous literature, as shown in Table 1:

[0083] Table 1. Node related parameters

[0084]

[0085] A calculation method for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com