Patents

Literature

411 results about "Plastic hinge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the structural engineering beam theory term, plastic hinge, is used to describe the deformation of a section of a beam where plastic bending occurs. In earthquake engineering plastic hinge is also a type of energy damping device allowing plastic rotation [deformation] of an otherwise rigid column connection.

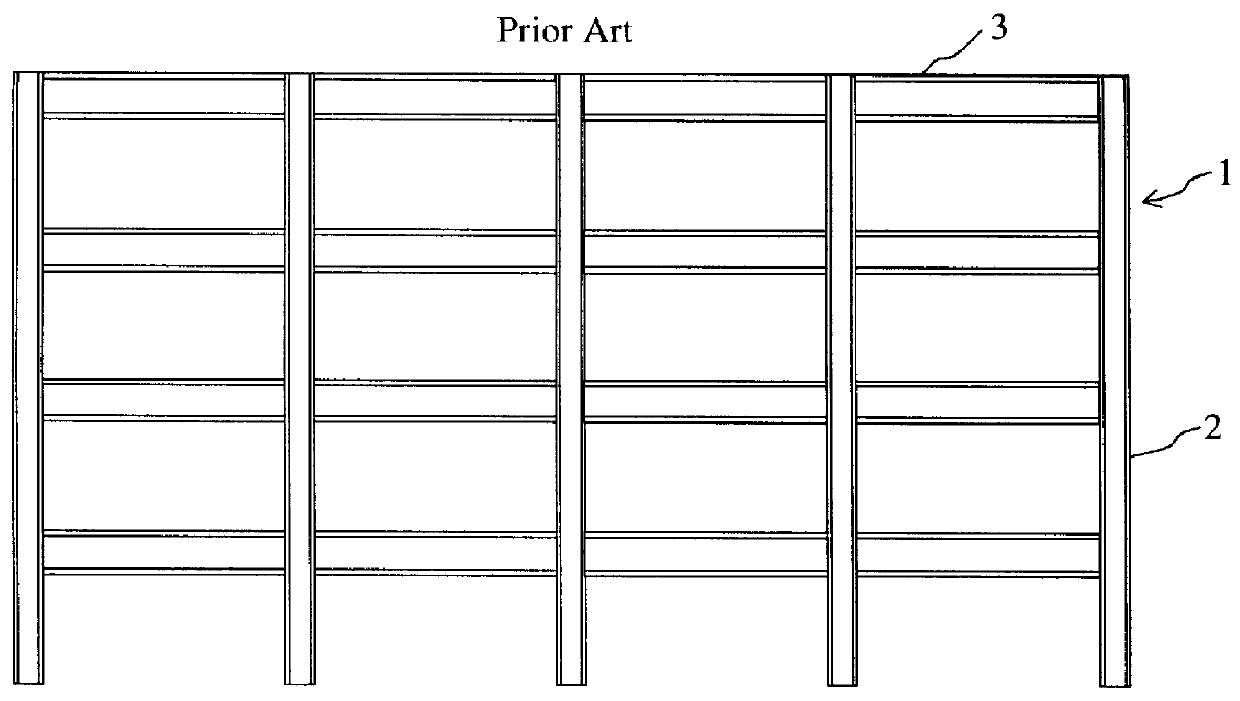

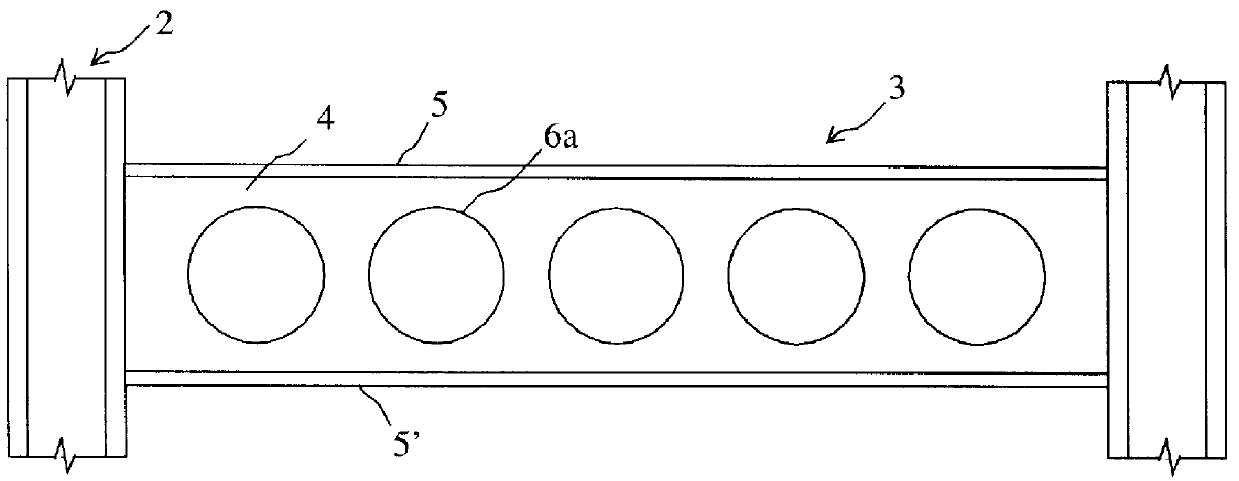

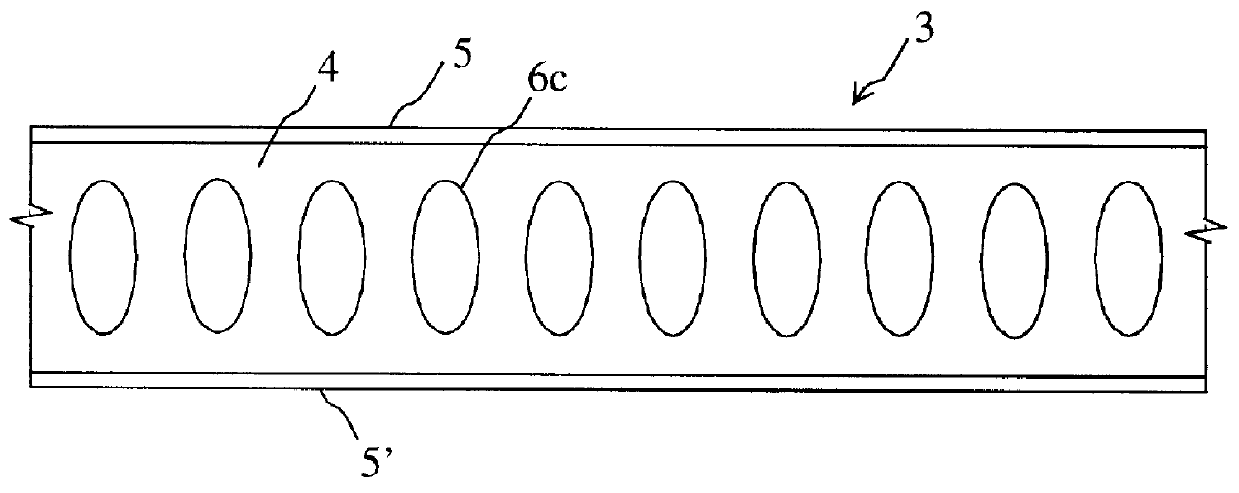

Moment-resistant structure, sustainer and method of resisting episodic loads

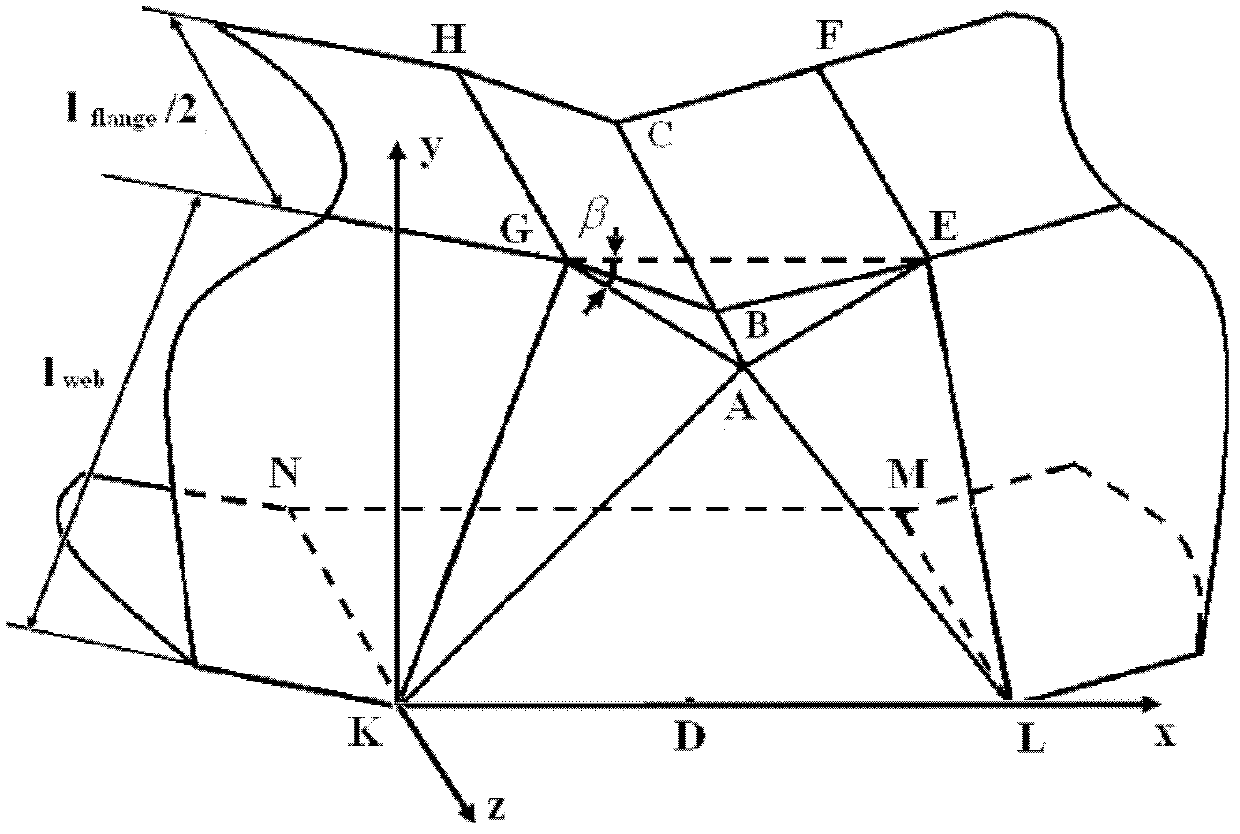

The present invention relates to a moment-resistant structure, sustainer, and method of construction for deformably resisting episodic loads, particularly those of high intensity. The episodic loads may be due to earthquake, impact, or other intense episodic sources. The structure and sustainer may be in buildings, bridges, or other civil works, land vehicles, watercraft, aircraft, spacecraft, machinery, or other structural systems or apparati. Deformation capacity is enhanced by the use of multiple dissipative zones. Dissipative zones that function in a manner similar to plastic hinges are determined by one or more voids that are located in the web of a sustainer. The one or more voids are of a size, shape, and configuration to assure that the dissipative zones deform inelastically when a critical stress, i.e., a maximum allowable demand, is reached, thereby developing the action of a structural fuse, preventing the occurrence of stress and strain demands sufficient to cause fracture of the connection welds or adjacent heat-affected zones, i.e., preventing the stress and strain demands from exceeding the strength capacity of the connection welds or adjacent heat-affected zones. The sustainers may be removably connected to the remainder of the structure, facilitating their replacement after inelastic deformation. The structure, sustainer, and method of construction may be utilized in new construction and in the rehabilitation of existing construction. Mechanical equipment and utilities may pass through the voids.

Owner:ASCHHEIM MARK AMOS

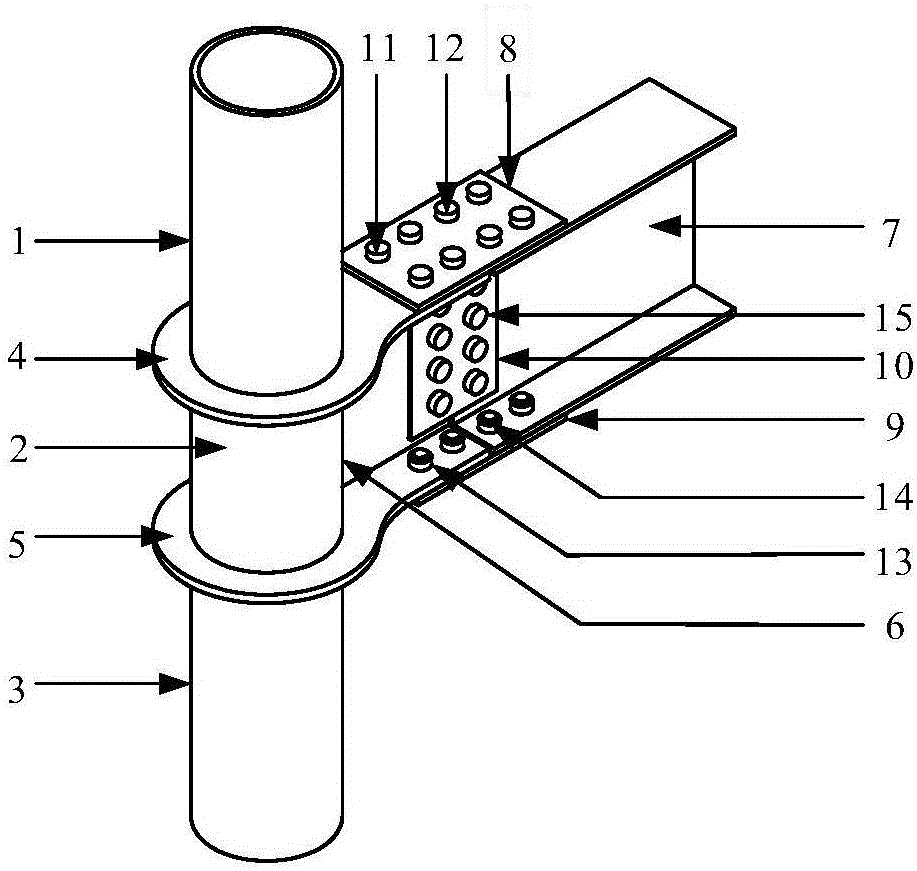

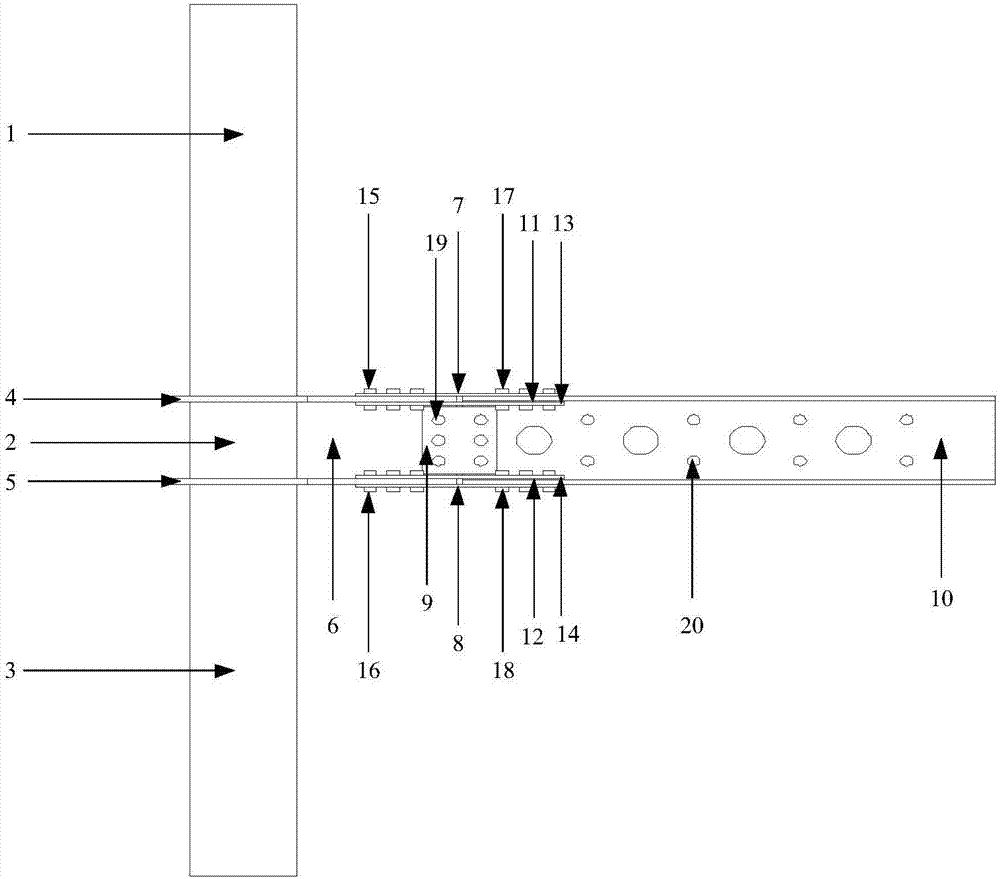

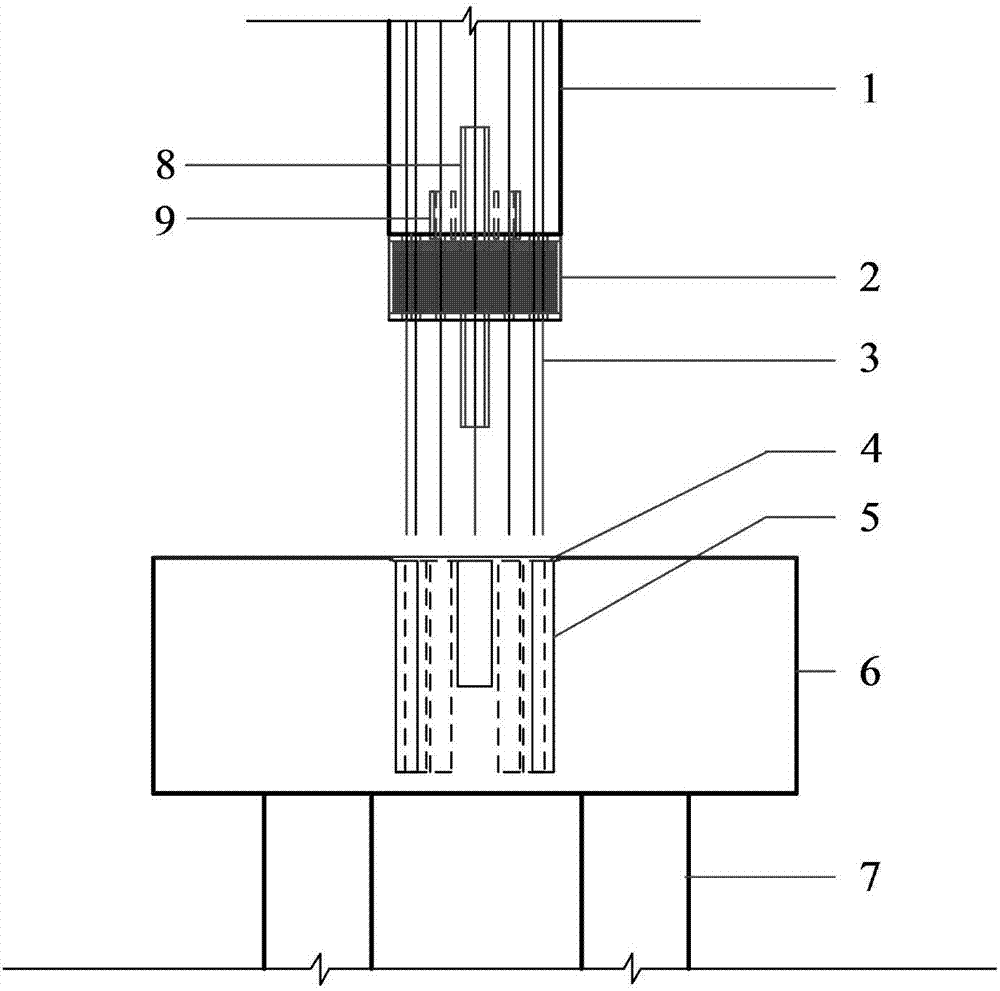

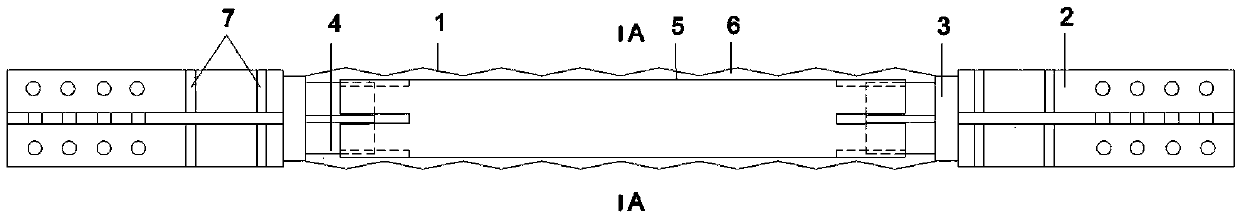

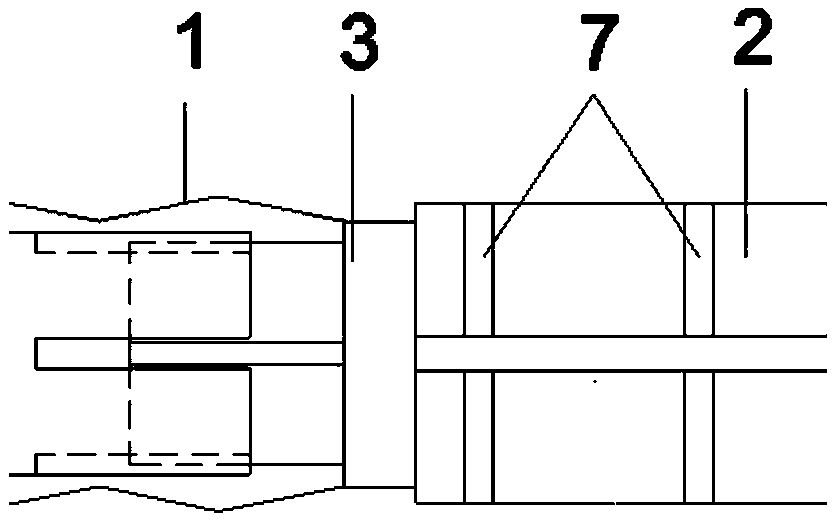

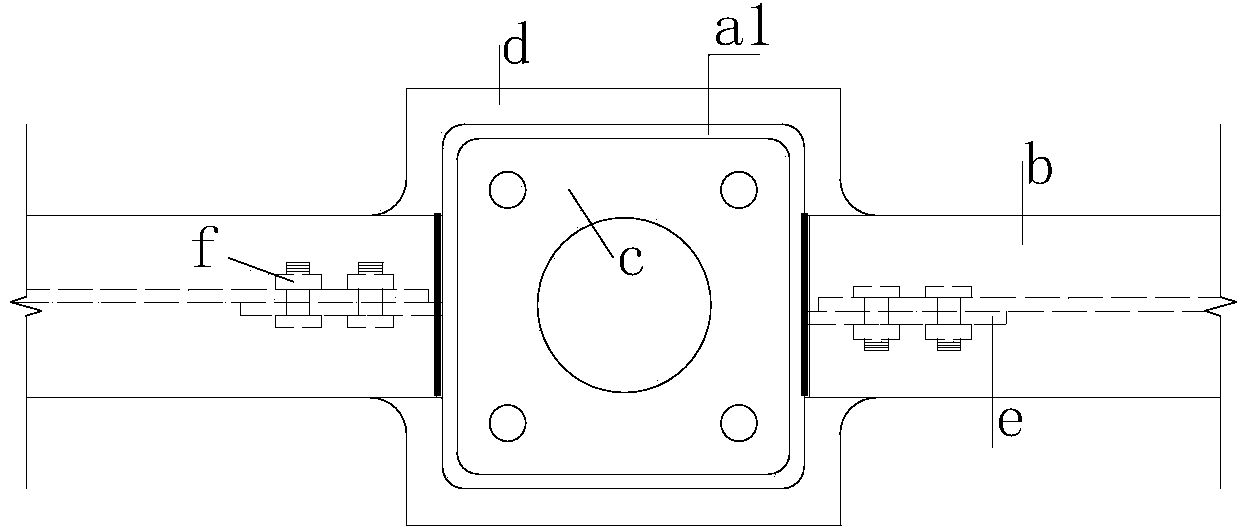

Assembly type beam-column node connection device with function recovery effect

ActiveCN105735472AImprove control accuracyQuality is easy to controlBuilding constructionsEngineeringWeld seam

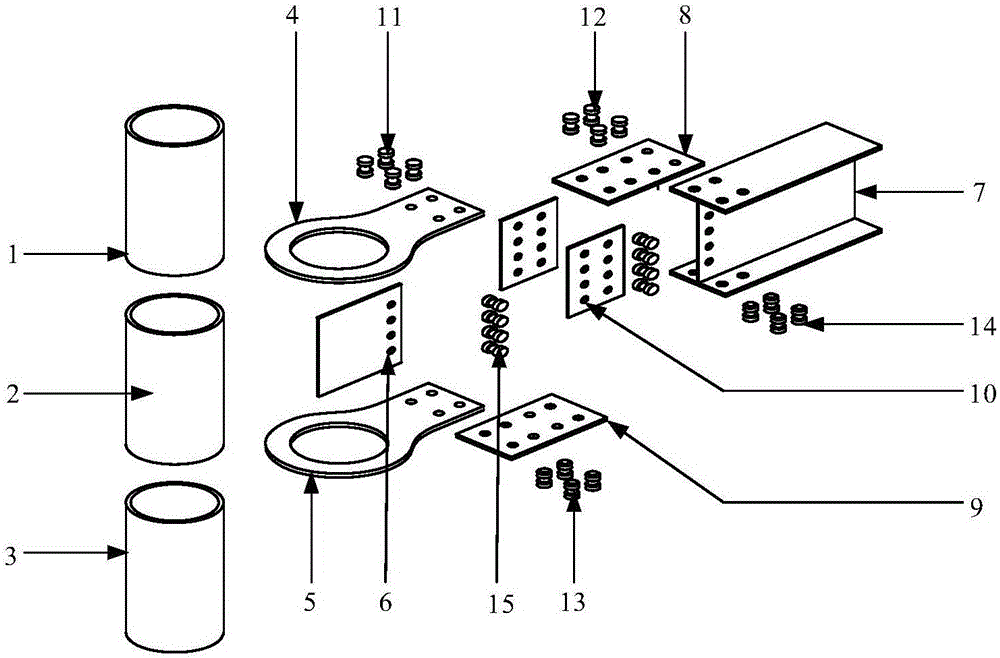

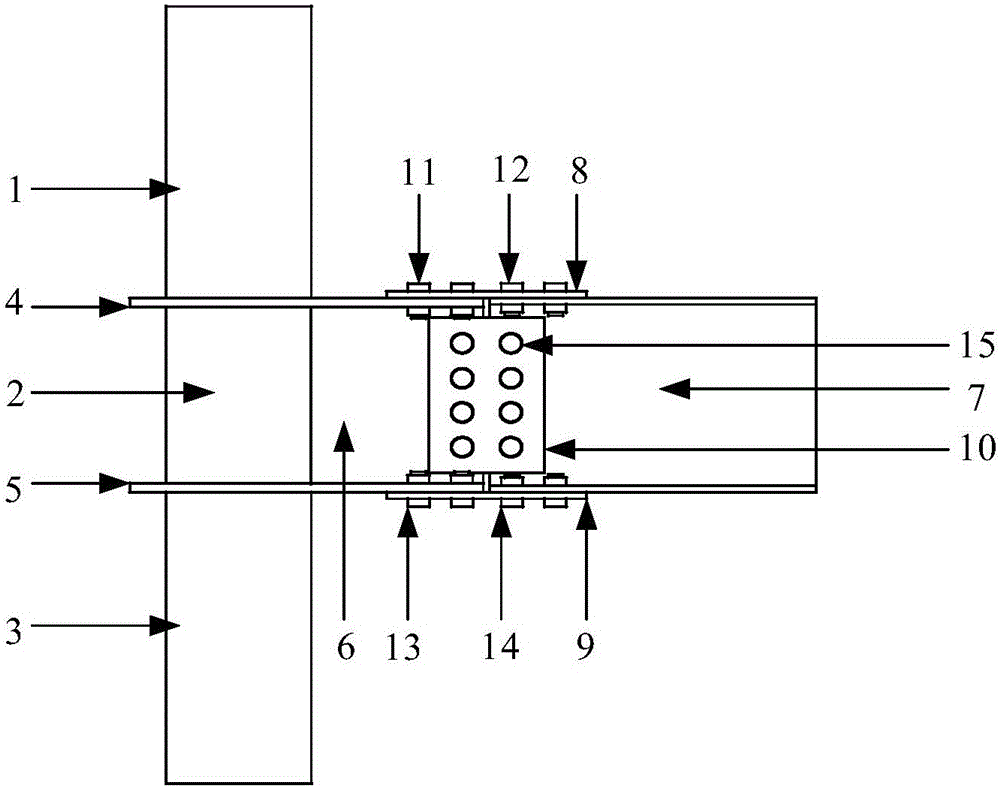

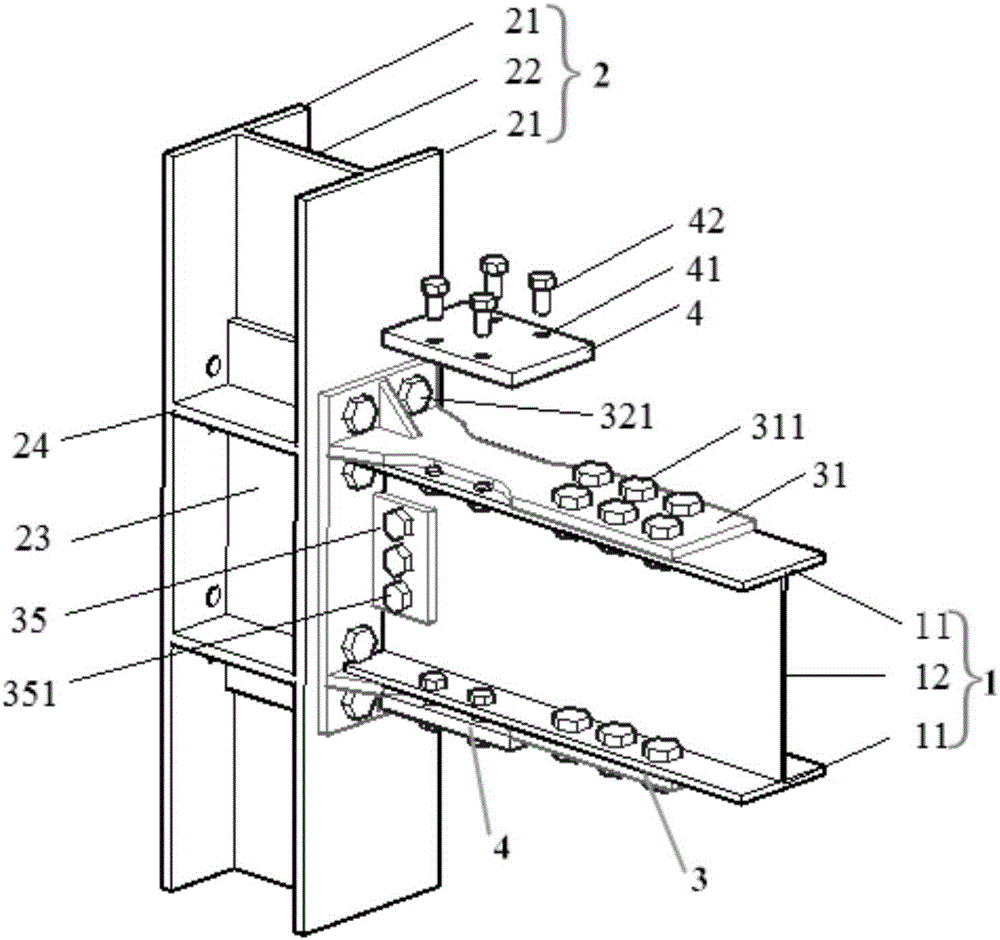

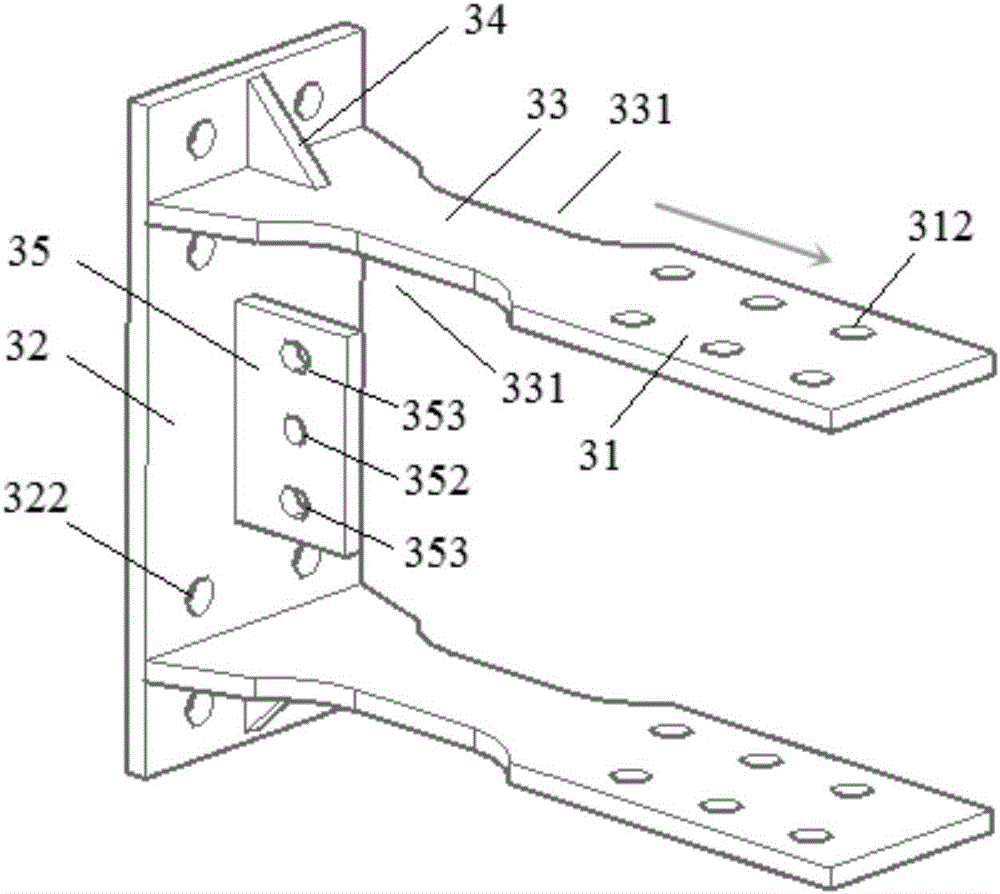

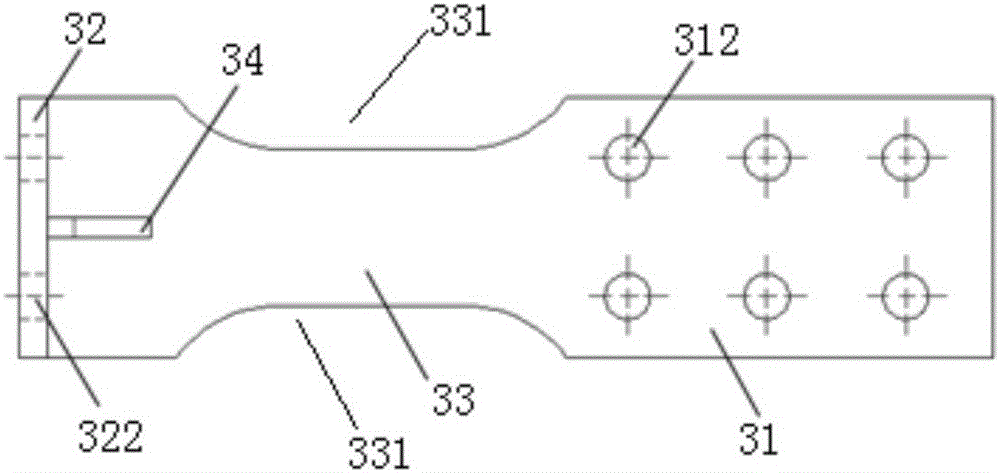

The invention relates to an assembly type beam-column node connection device with a function recovery effect, and belongs to the field of structure engineering. The assembly type beam-column node connection device with the function recovery effect consists of a round steel pipe column with a cantilever beam section, a general beam section and a connection device for the round steel pipe column and the general beam section. According to the node connection device, welded parts are all finished in a factory, so that the weld seam quality and the machining precision can be more easily controlled; the round steel pipe column with the cantilever beam section and the general beam section are assembled by adopting a high-strength bolt and a connection plate on site, so that the construction speed is greatly increased and the construction quality is greatly improved; meanwhile, the general beam section can be arranged on the connection plate at the lower part of the cantilever beam section, so that the difficulty in construction is lowered and the field assembly and positioning are easy; a node is used for both beam end reinforcement and cover plate connection weakening; through reasonable parameter design, double energy consumption of frictional sliding of the bolt and plastic deformation of the connection plate and the bolt can be realized and a plastic hinge can be transferred to the connection plate; and the function of the structure can be recovered only by replacing the connection plate after earthquake.

Owner:BEIJING UNIV OF TECH

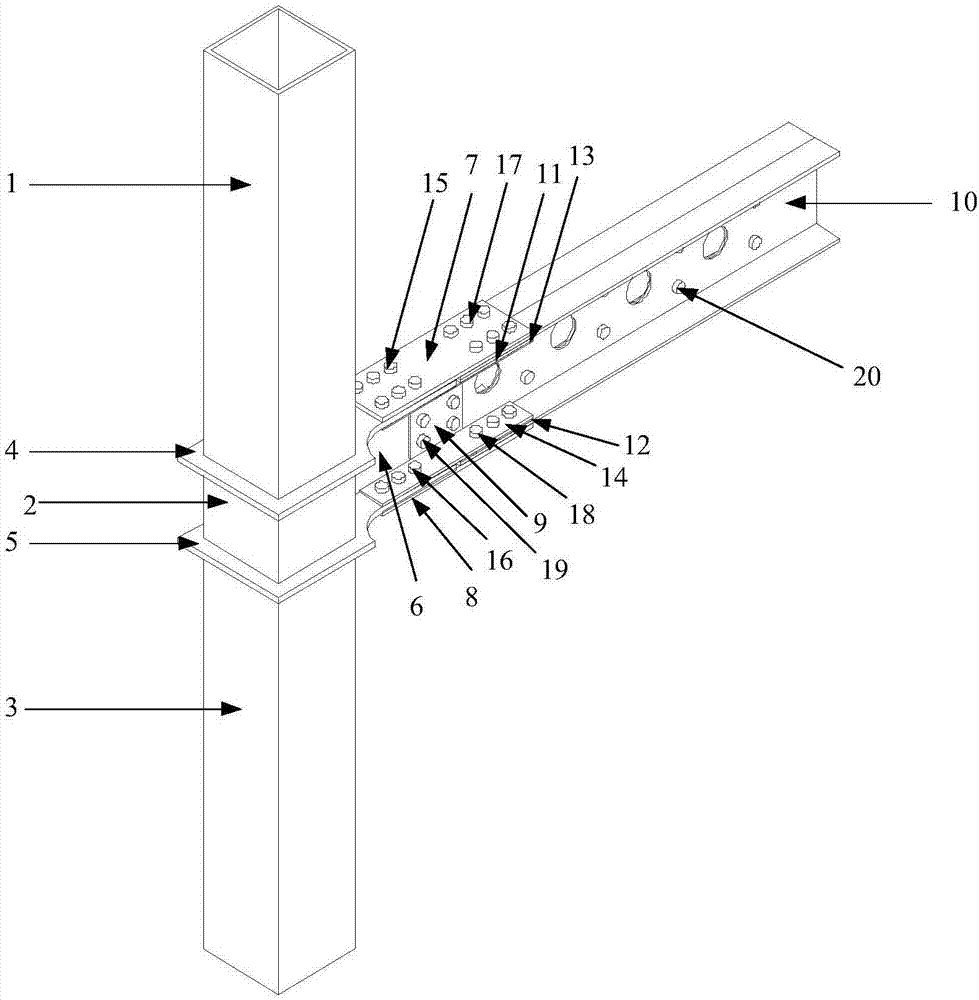

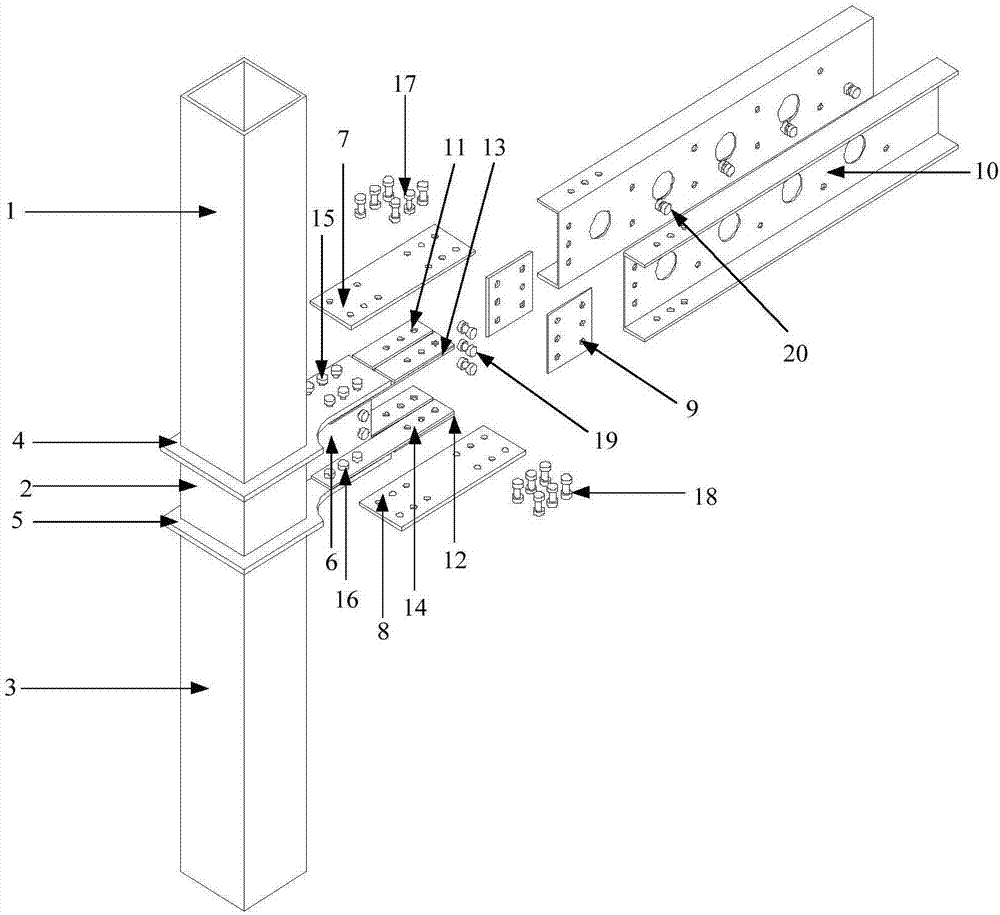

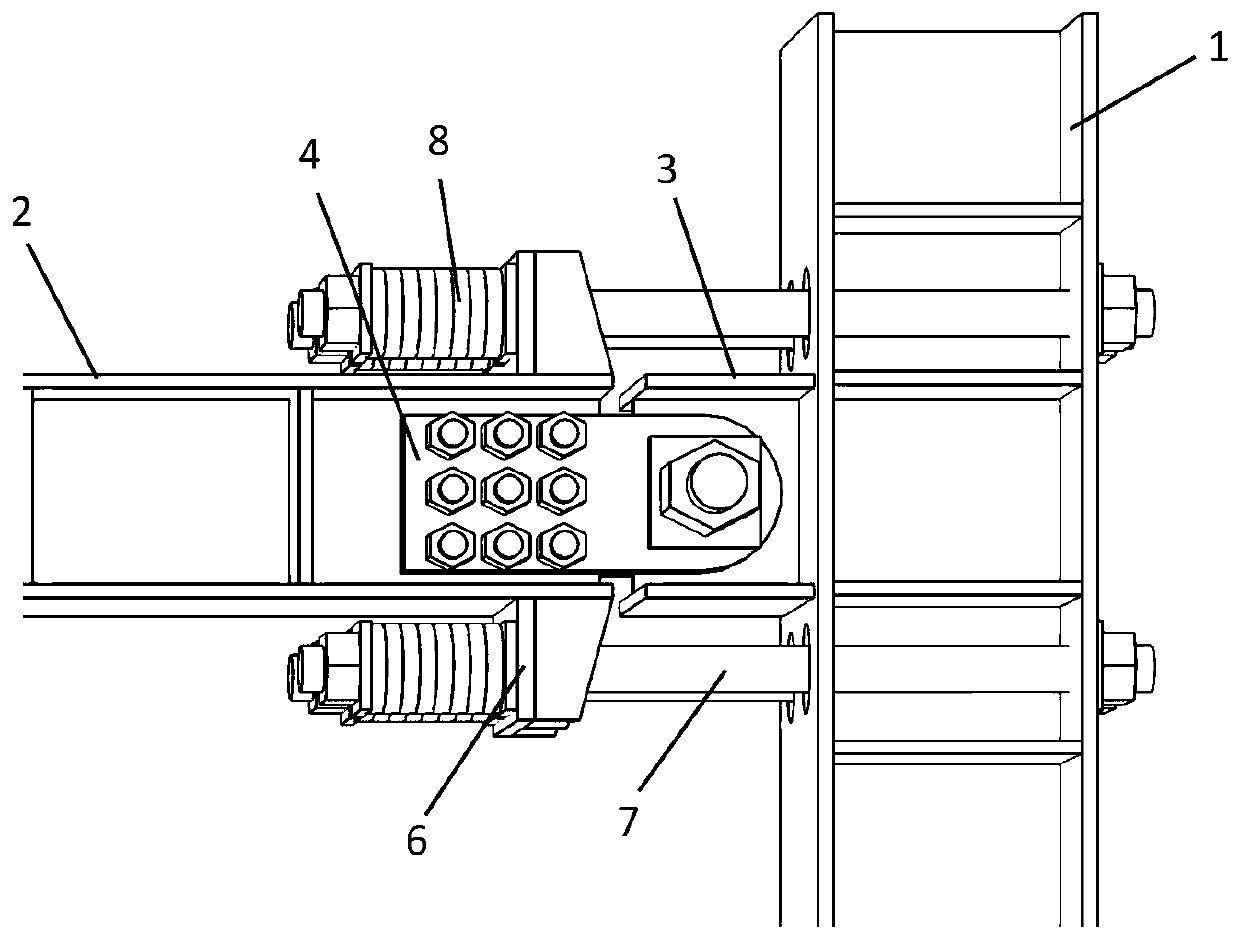

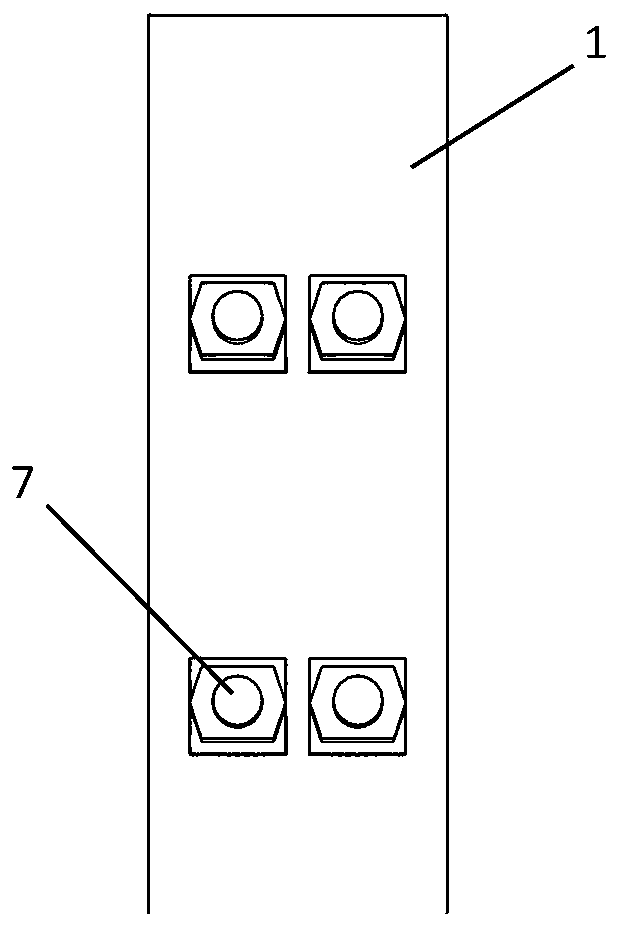

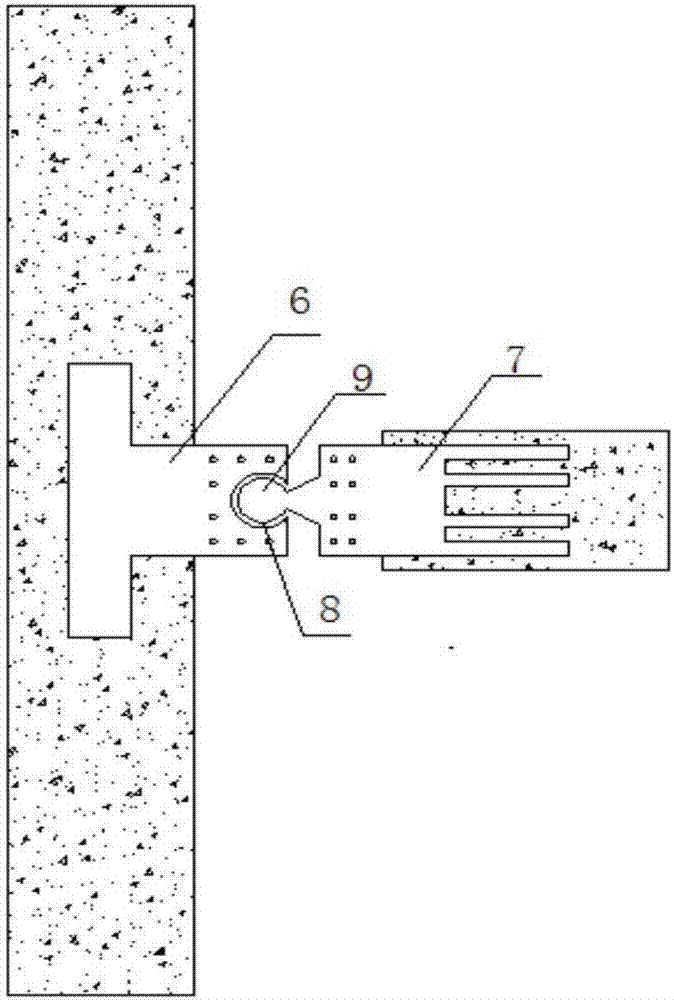

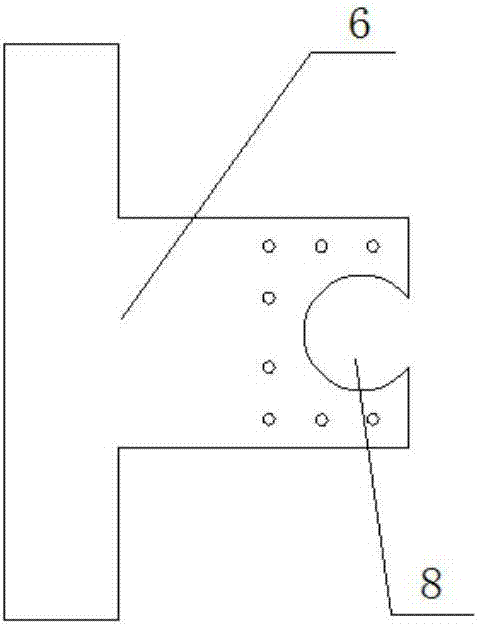

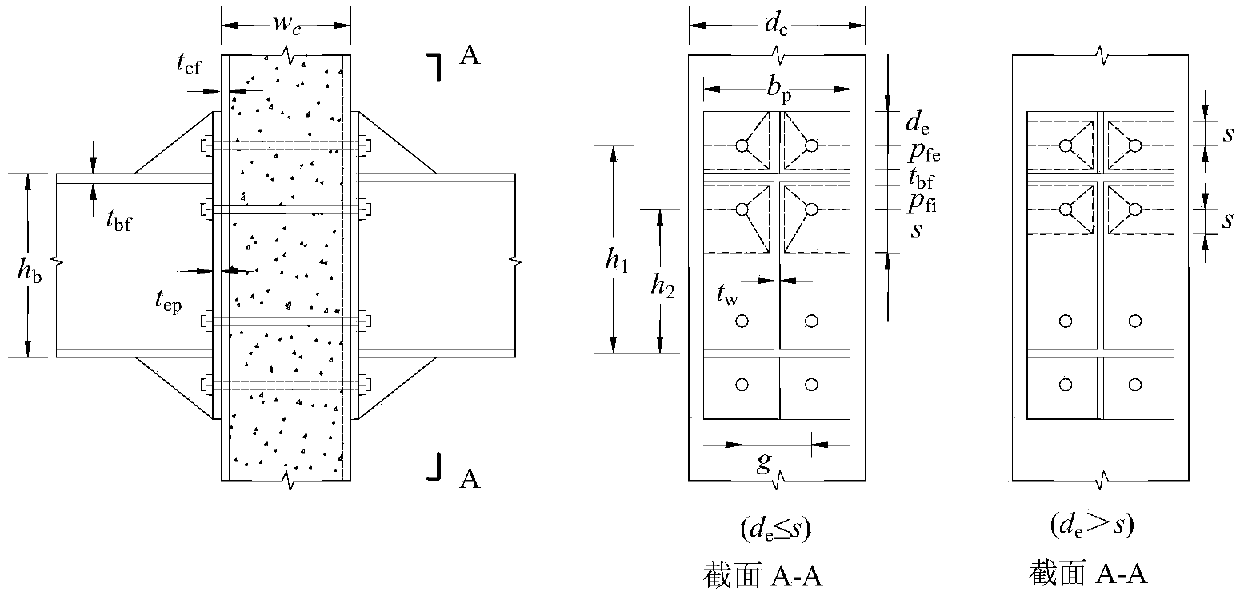

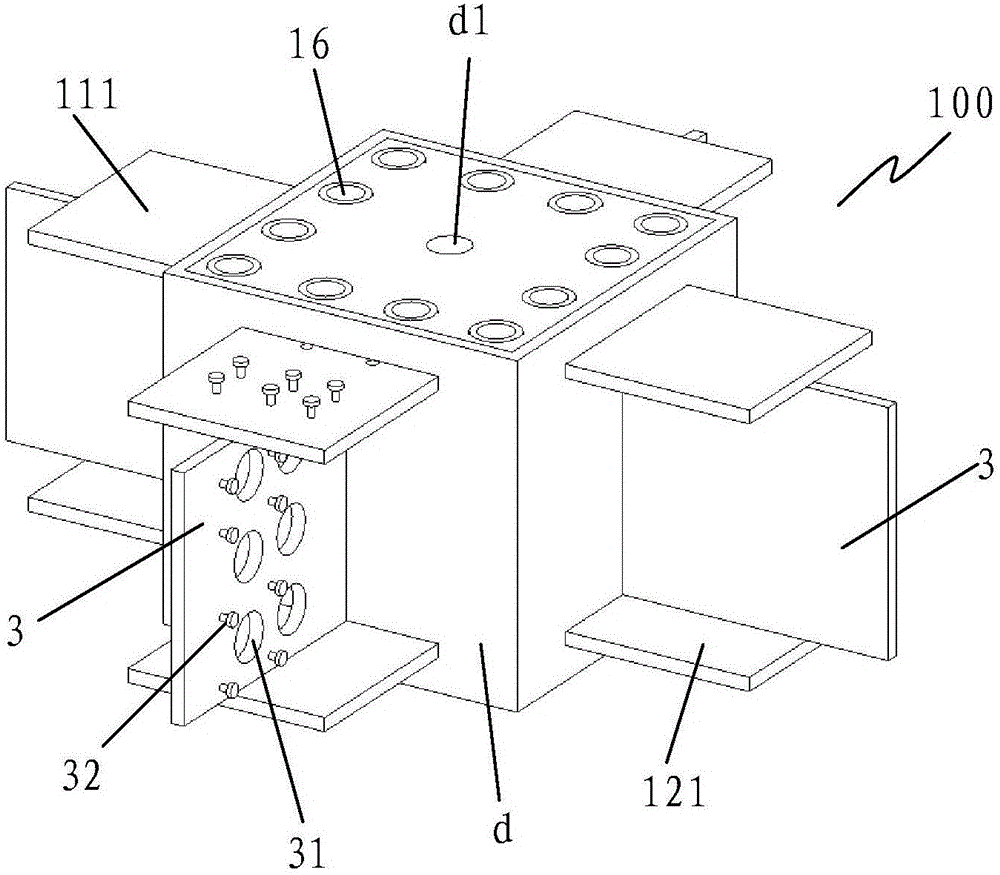

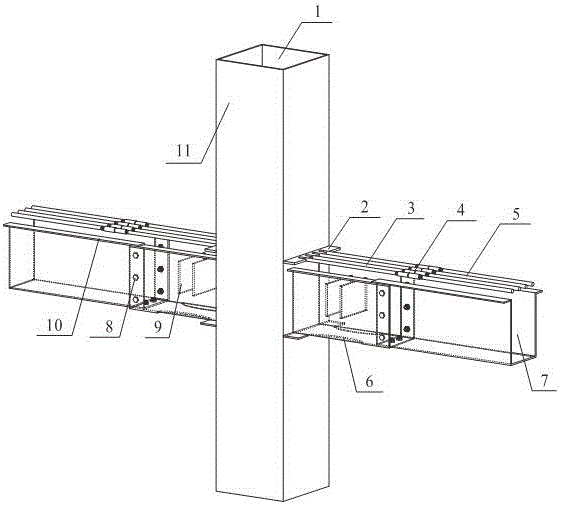

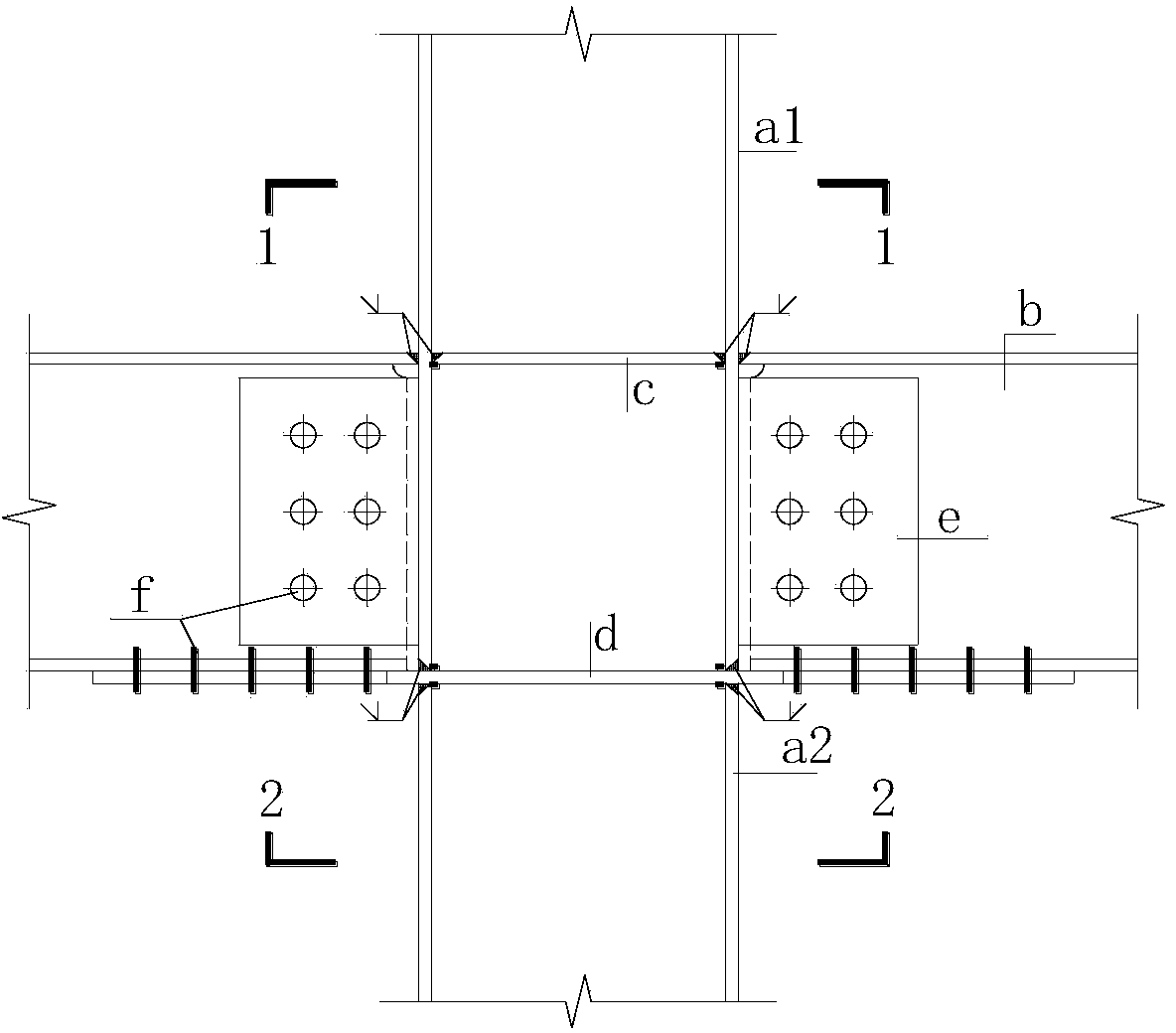

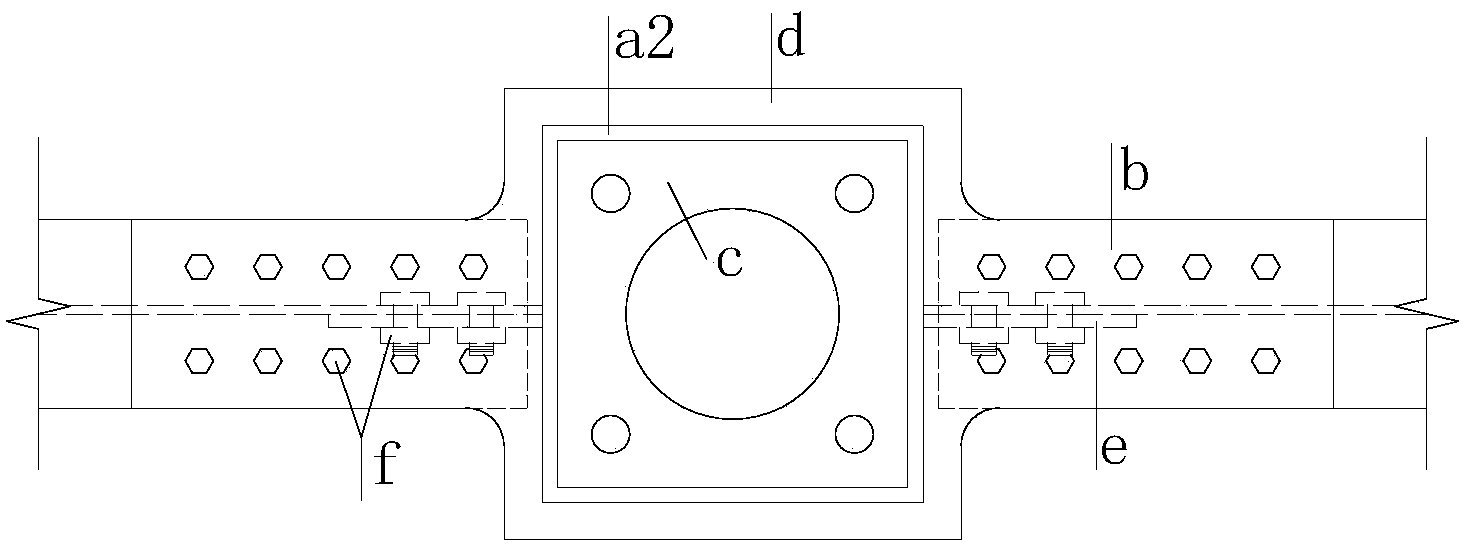

Assembly channel steel punching beam column joint connecting device capable of achieving function recovery

InactiveCN106869325AAvoid complex stress fieldsReduce construction difficultyFloorsFloor slabPunching

The invention relates to an assembly channel steel punching beam column joint connecting device capable of achieving function recovery and belongs to the field of structural engineering. The assembly channel steel punching beam column joint connecting device capable of achieving function recovery is composed of a square steel pipe column with a cantilever beam section, a channel steel punching beam section and a connecting device of the cantilever beam section and the channel punch beam section. All welding parts of the joint connection device are all finished in a factory, so that precision and quality of welds are easier to control. Construction speed is greatly increased and construction quality is greatly improved, and a spatial structure of the channel punch beam section of the channel is conducive to pipeline penetration; the channel steel punching beam and a floor can be assembled and molded in the factory to form modular assembly units. Then all the modular assembly unit and the square steel pipe column with the cantilever beam section achieve assembly connection through the channel steel punching beam. Joints of the connection device can be used for both of beam end reinforcing and cover plate connection weakening. A multi-energy dissipation mechanism can be realized, a plastic hinge is transferred to a cover plate and a connecting plate. The function of structures can be recovered only by replacing the connecting plate after an earthquake.

Owner:BEIJING UNIV OF TECH

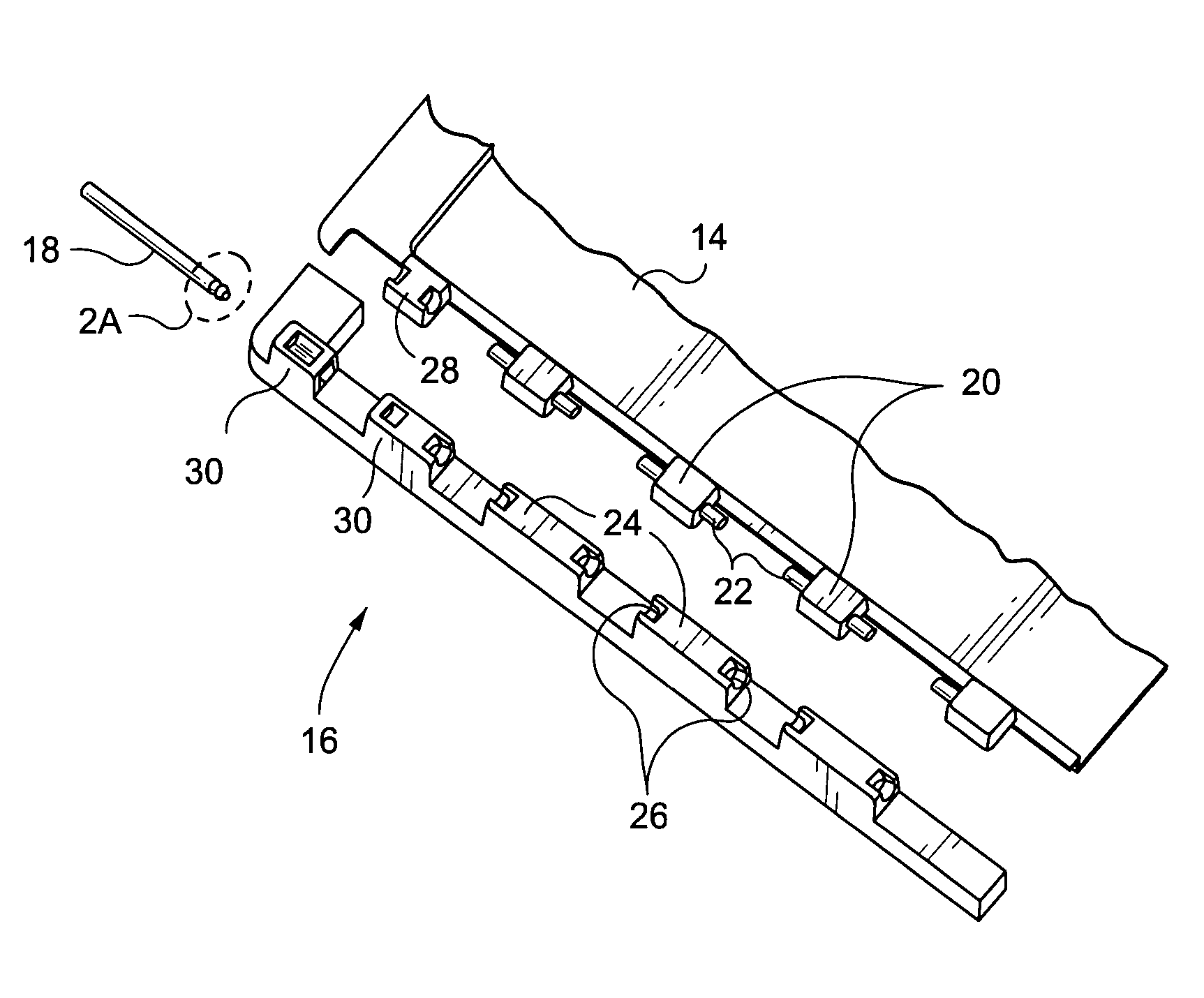

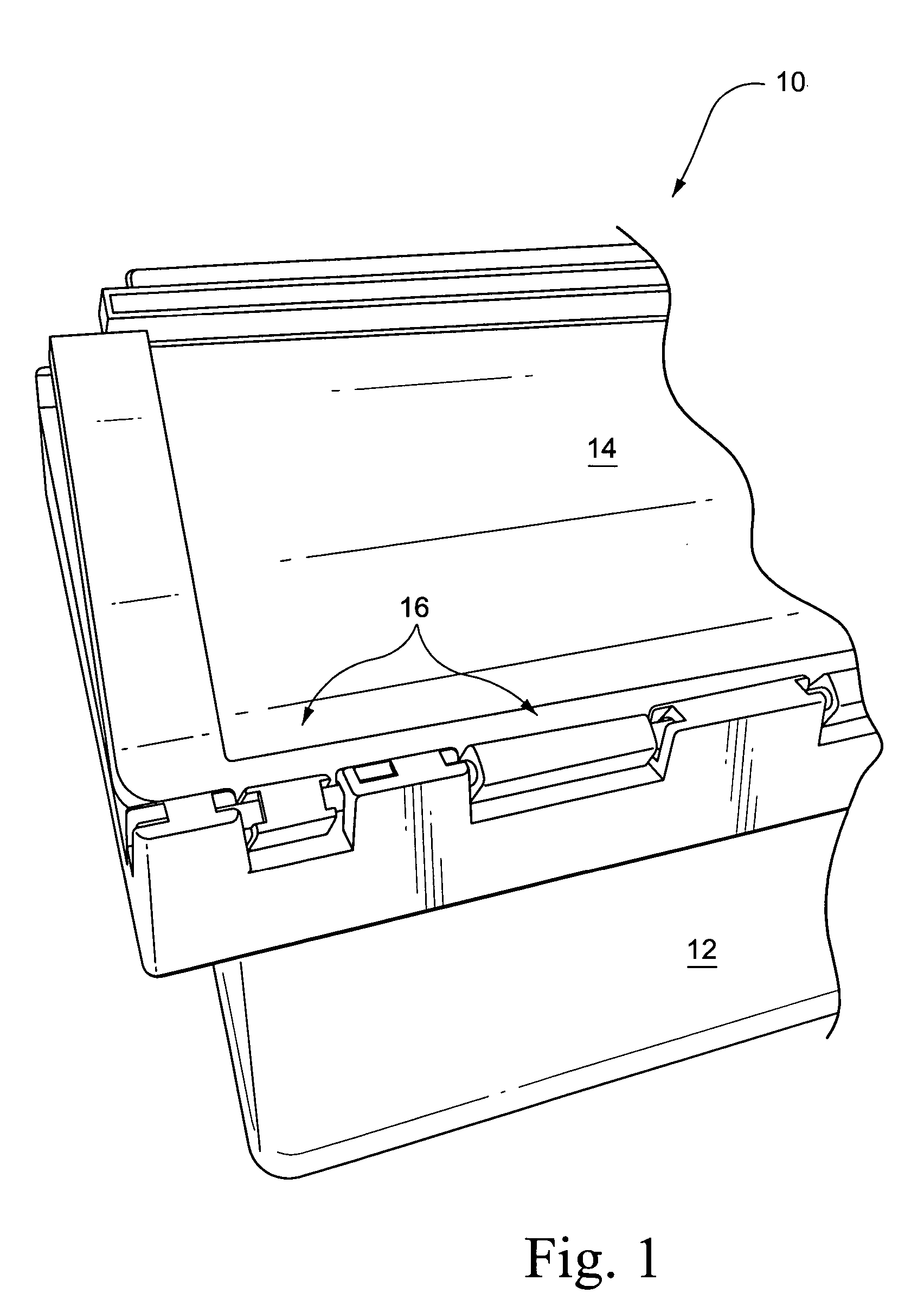

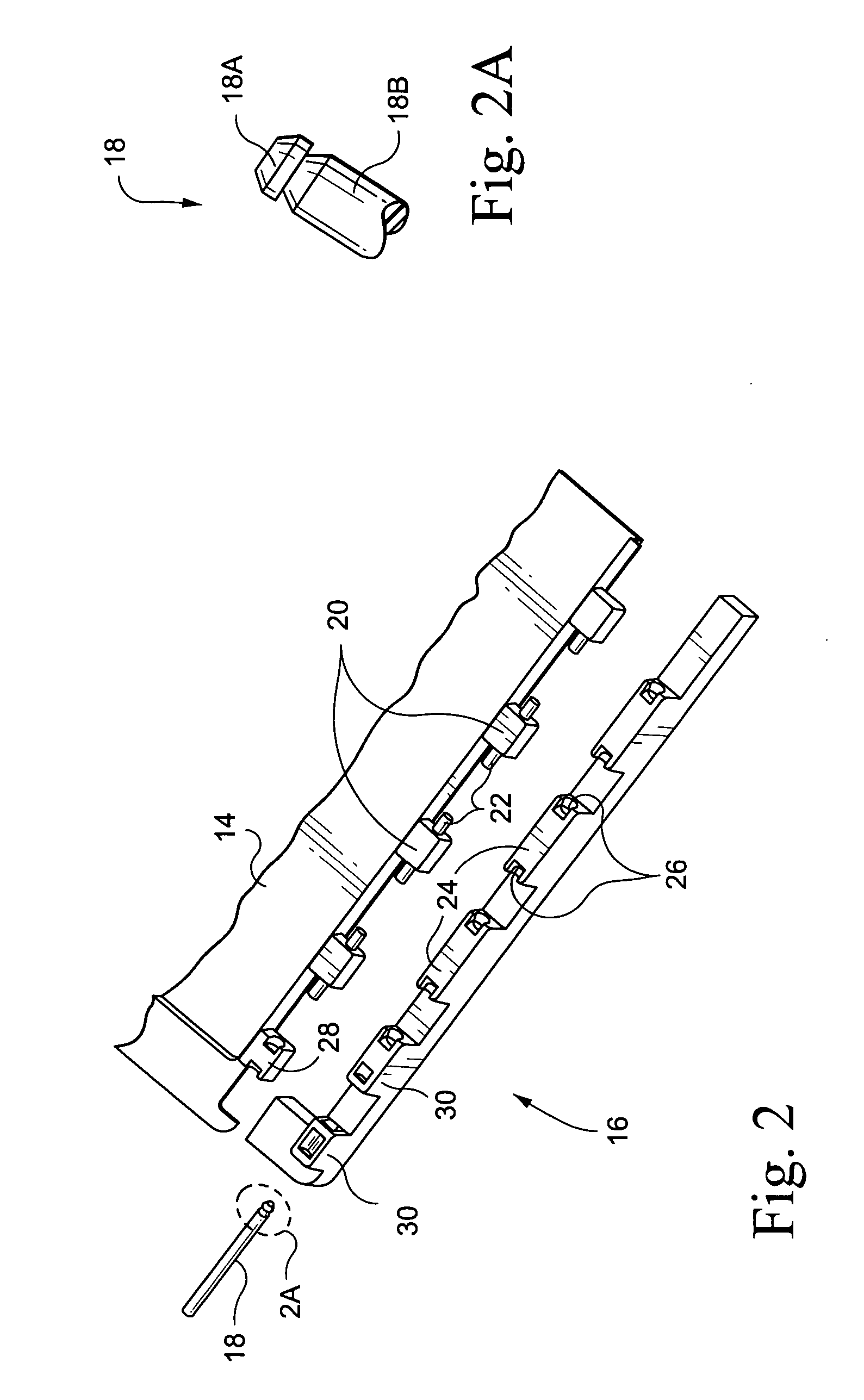

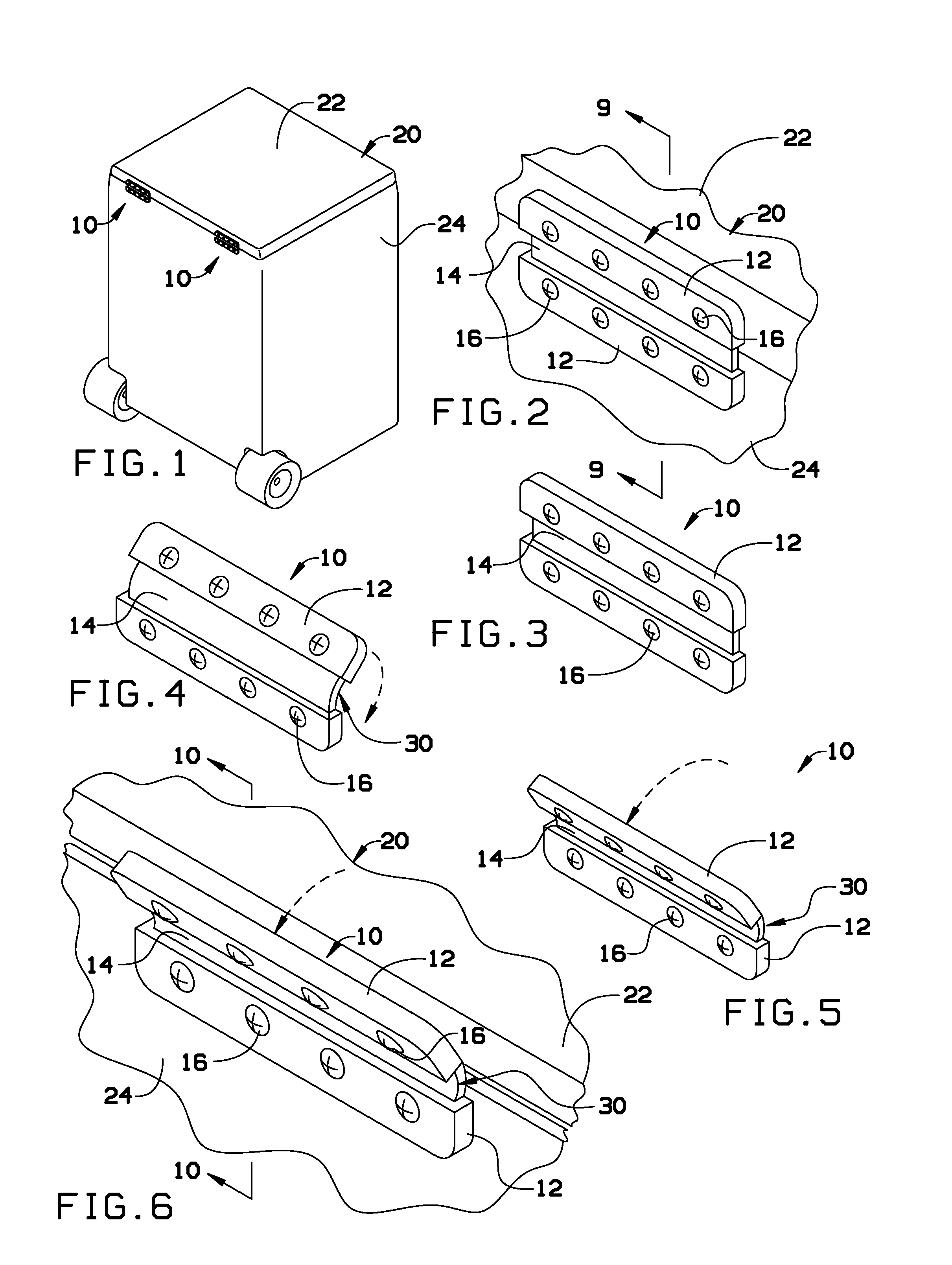

Plastic container including plastic hinge assembly

A container that is preferably formed entirely of molded plastic materials includes a container body and a lid secured to the container body via a hinge assembly. The hinge assembly includes a hinge pin having a head and a shaft, where the hinge pin head has a maximum diameter substantially matching a maximum diameter of the shaft. With this construction, the container assembly can be easily and cost-effectively automated.

Owner:MONOFLO INT

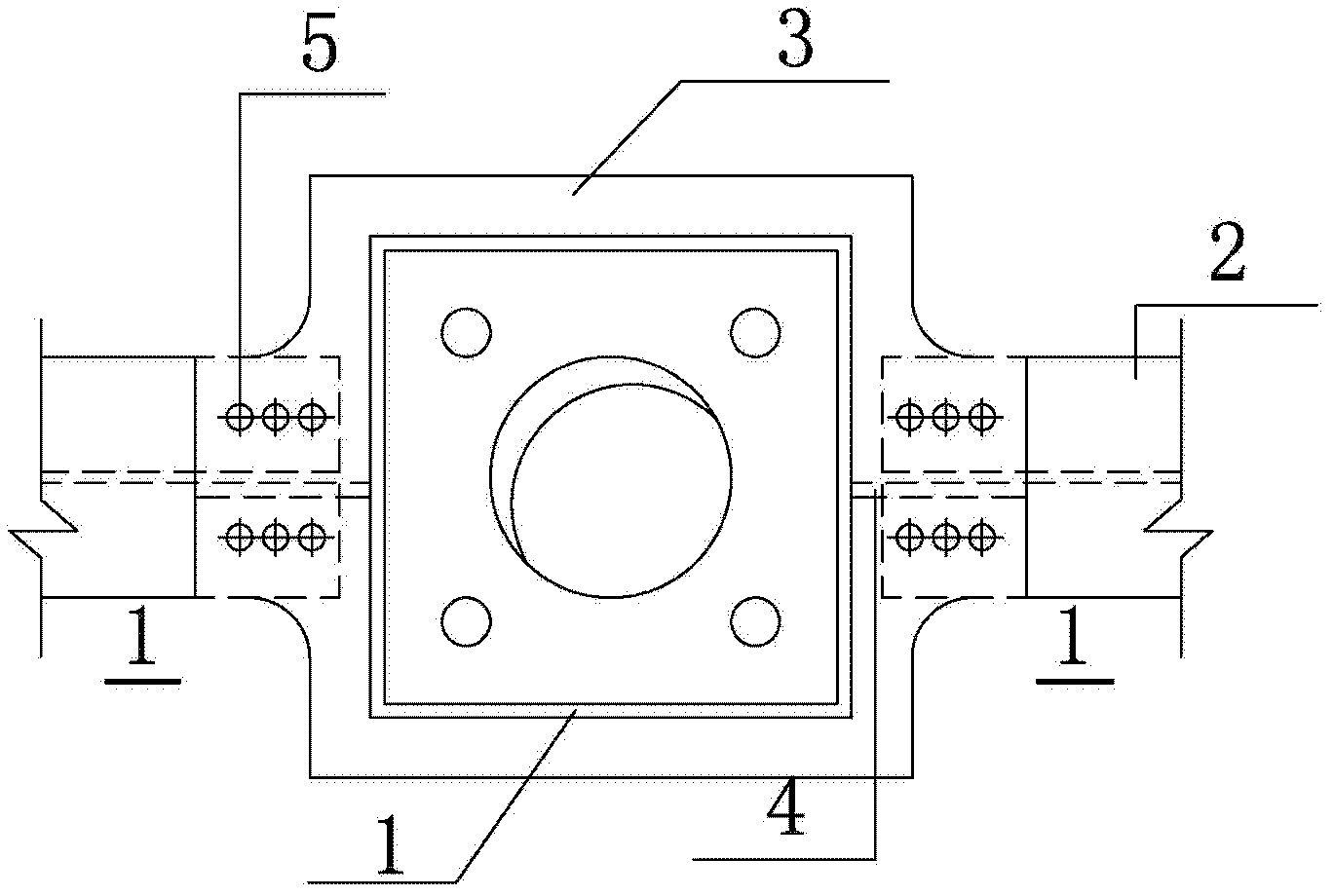

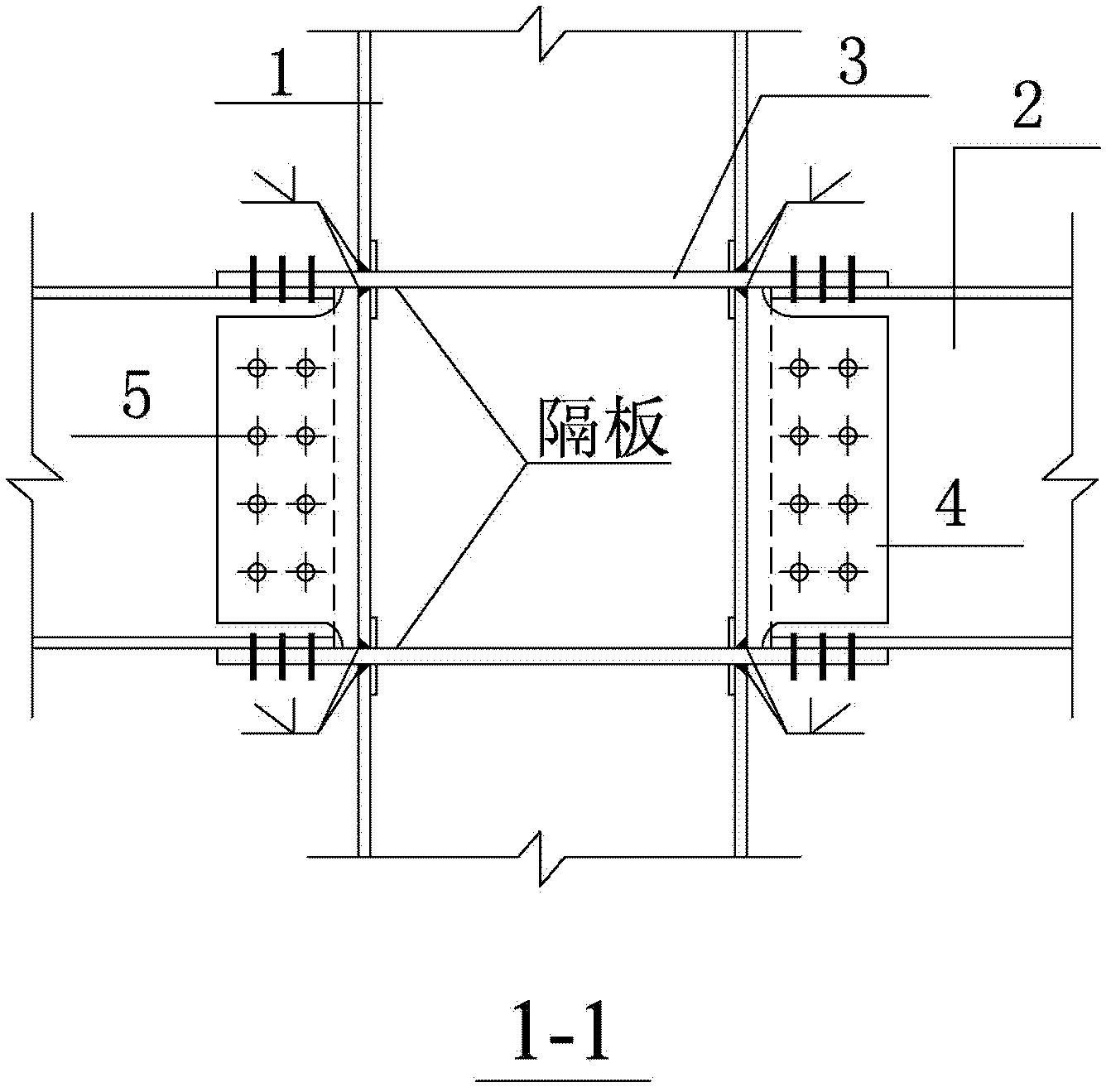

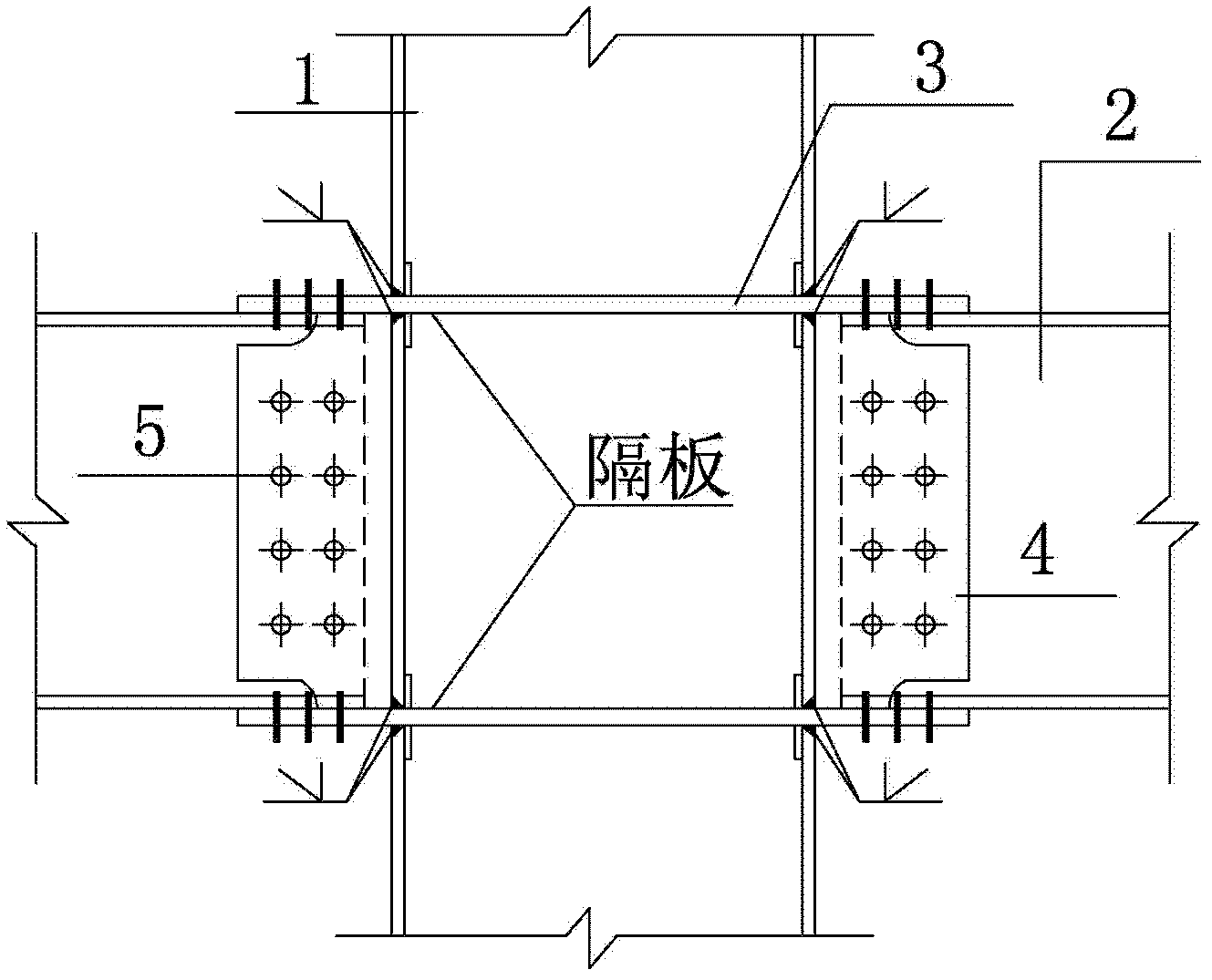

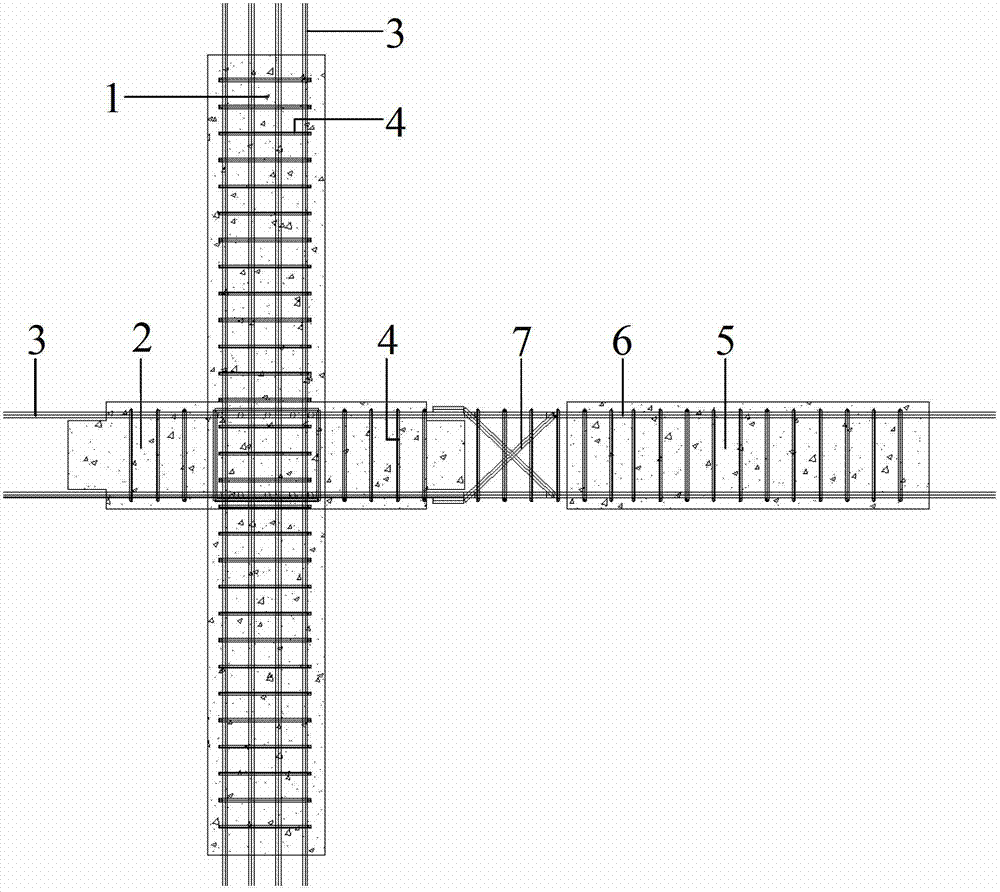

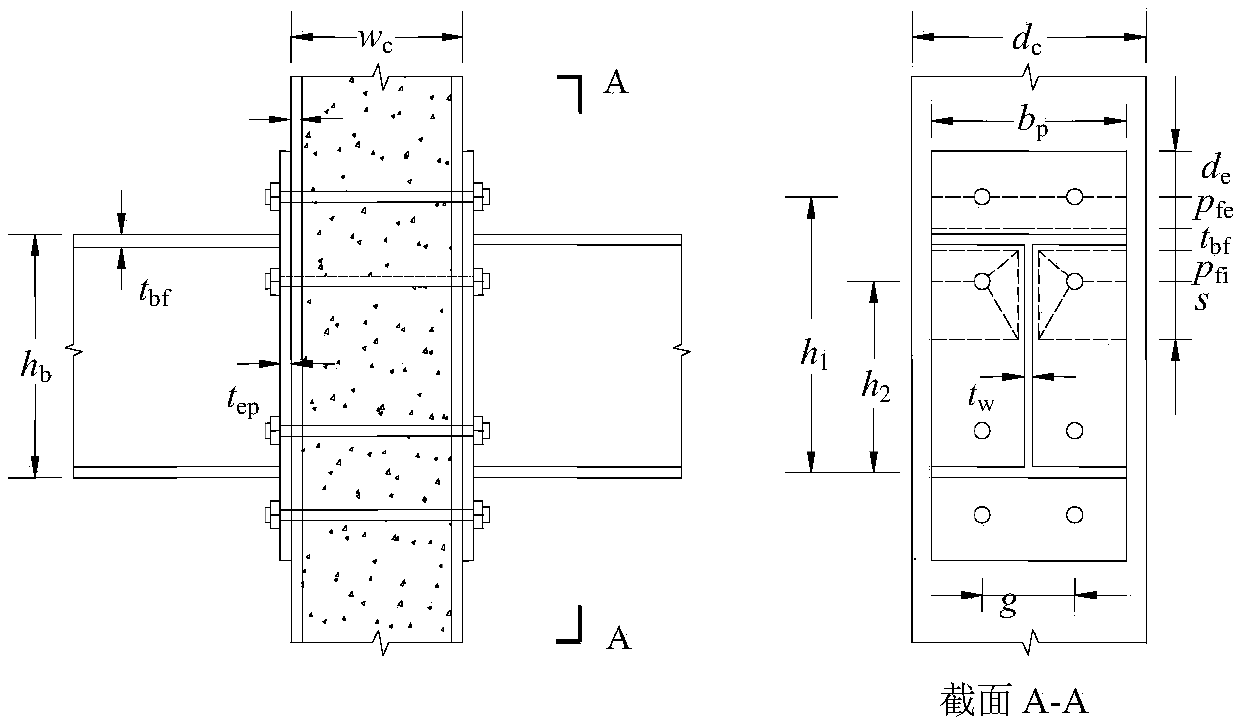

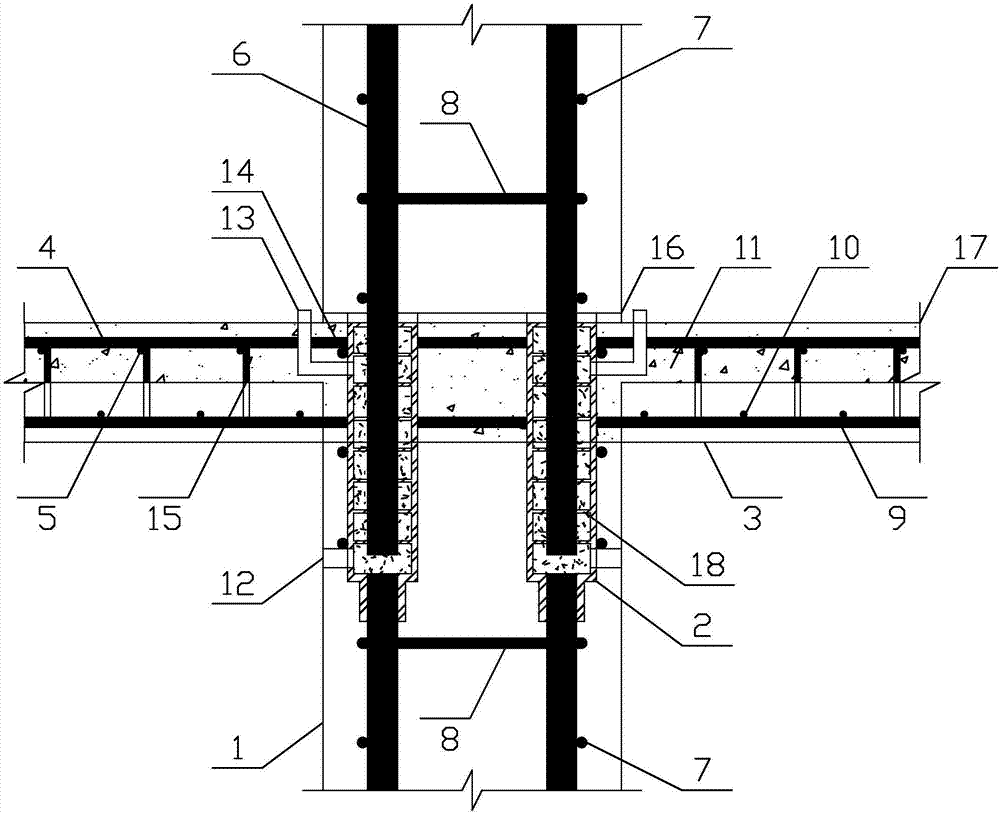

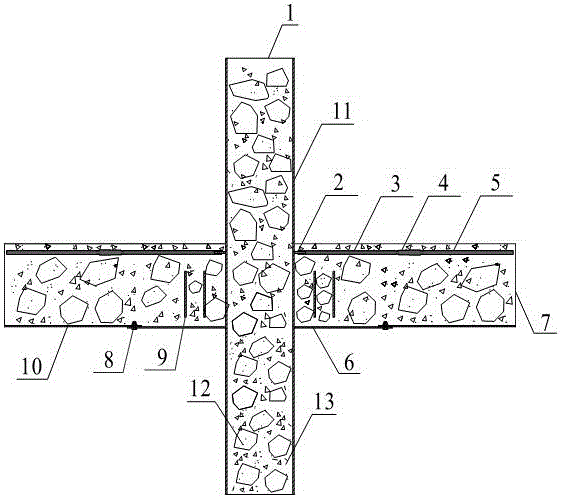

Rectangular steel tube concrete column and steel beam all-bolt connecting joint

ActiveCN102561530AAvoid multiple weldingReduce concentrated stressBuilding constructionsPlastic hingeMaterials science

The invention belongs to the technical field of building structure engineering, and relates to a rectangular steel tube concrete column and steel beam all-bolt connecting joint, which comprises a rectangular steel tube concrete column, a steel beam, an upper through partition board, a lower through partition board, a connecting plate and high-strength bolts. The upper through partition board and the lower through partition board penetrate through a wall of the rectangular steel tube concrete column, and are connected with the periphery of the wall of the rectangular steel tube concrete column via grooved weld joints, the connecting plate is welded with a side wall of the column, the upper through partition board and the lower through partition board, a web plate of the steel beam is connected with the connecting plate via the high-strength bolts, and an upper flange and a lower flange of the web plate of the steel beam are respectively connected with the upper through partition board and the lower through partition board via the high-strength bolts. The invention further discloses a method for manufacturing the rectangular steel tube concrete column and steel beam all-bolt connecting joint. The joint is fast in construction, simple in structure and fine in stress performance and seismic performance, and can meet requirements of outwards movement of plastic hinges.

Owner:TIANJIN UNIV

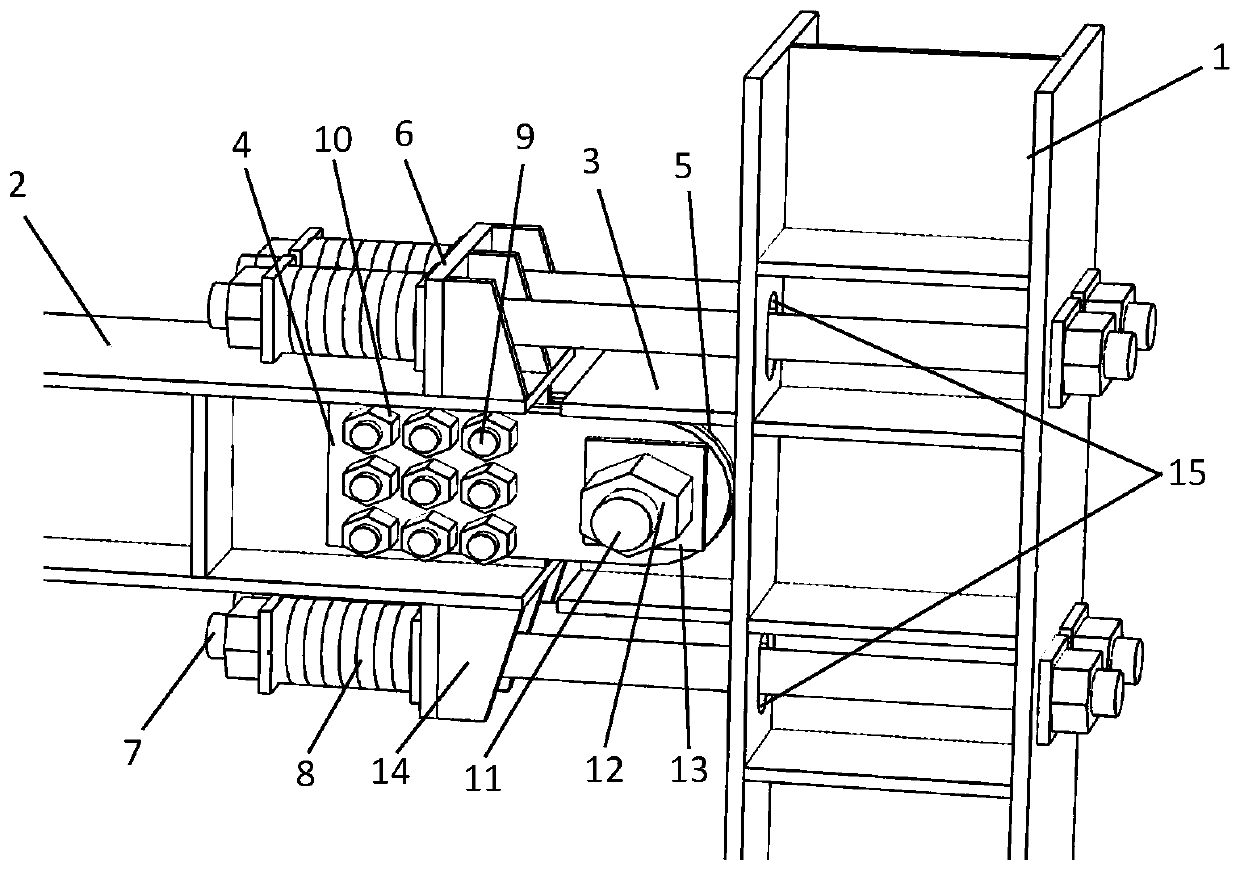

Self-resetting beam column friction energy dissipation joint structure and construction method thereof

ActiveCN109914593AGood self-resetting performanceNo damageProtective buildings/sheltersShock proofingSteel frameSteel columns

The invention discloses a self-resetting beam column friction energy dissipation joint structure and a construction method thereof. The self-resetting beam column friction energy dissipation joint structure comprises a steel column, a middle beam, short beams, connecting plates, a brass friction plate, spring baffles, high-strength anchor rods and disc springs. One ends of the short beams are fixedly connected with the flanges of the side wall of the steel column, and a gap exists between the middle beam and the short beams; one ends of the connecting plates are fixedly connected with the webof the middle beam, and the other ends are hinged to the webs of the short beams; the brass friction plate is arranged between the connecting plates and the webs of the short beams; one ends of the high-strength anchor rods penetrate through the spring baffles, and the other ends of the high-strength anchor rods penetrate through the two flanges of the steel column and are fixed. The spring discsare sleeved on the high-strength anchor rod on one side, far away from the steel column, of the spring baffles. Structural construction is completed through basic construction, small earthquake testing, parameter selection, node performance design and large earthquake inspection. According to the invention, the formation of a plastic hinge of a traditional steel frame beam-column joint is effectively avoided, the beam column joint is not damaged or slightly damaged under the action of a large earthquake, and the post-earthquake joint can be put into use without repair.

Owner:HAINAN UNIVERSITY

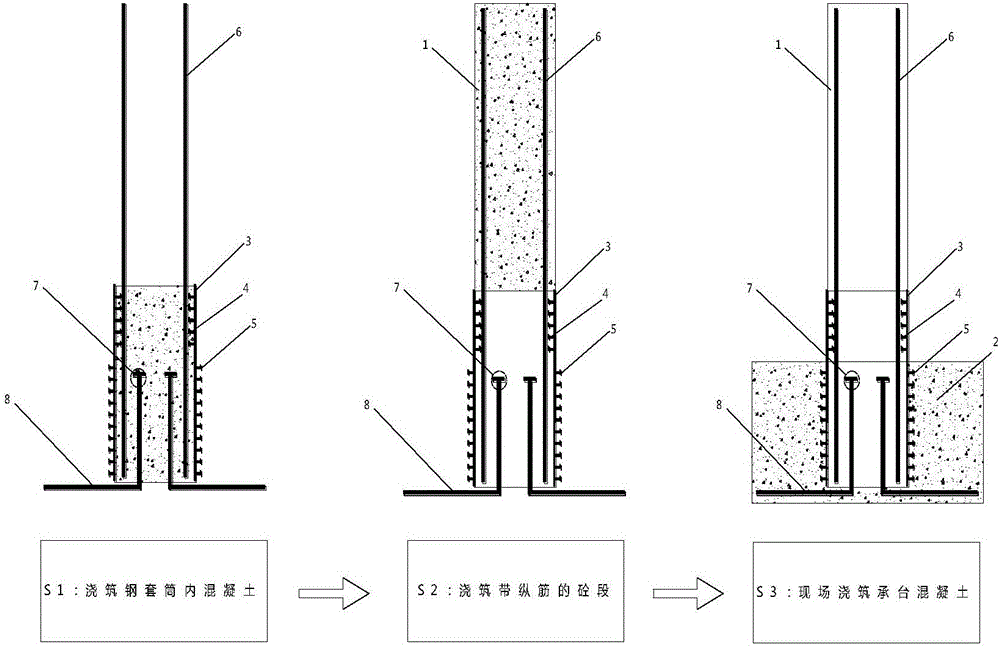

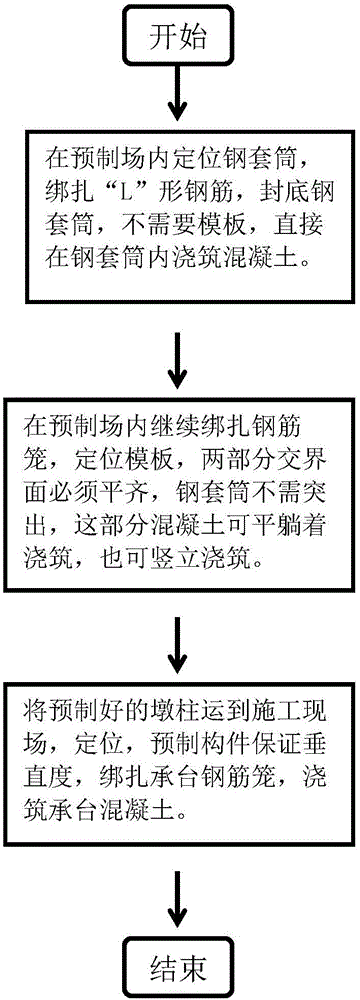

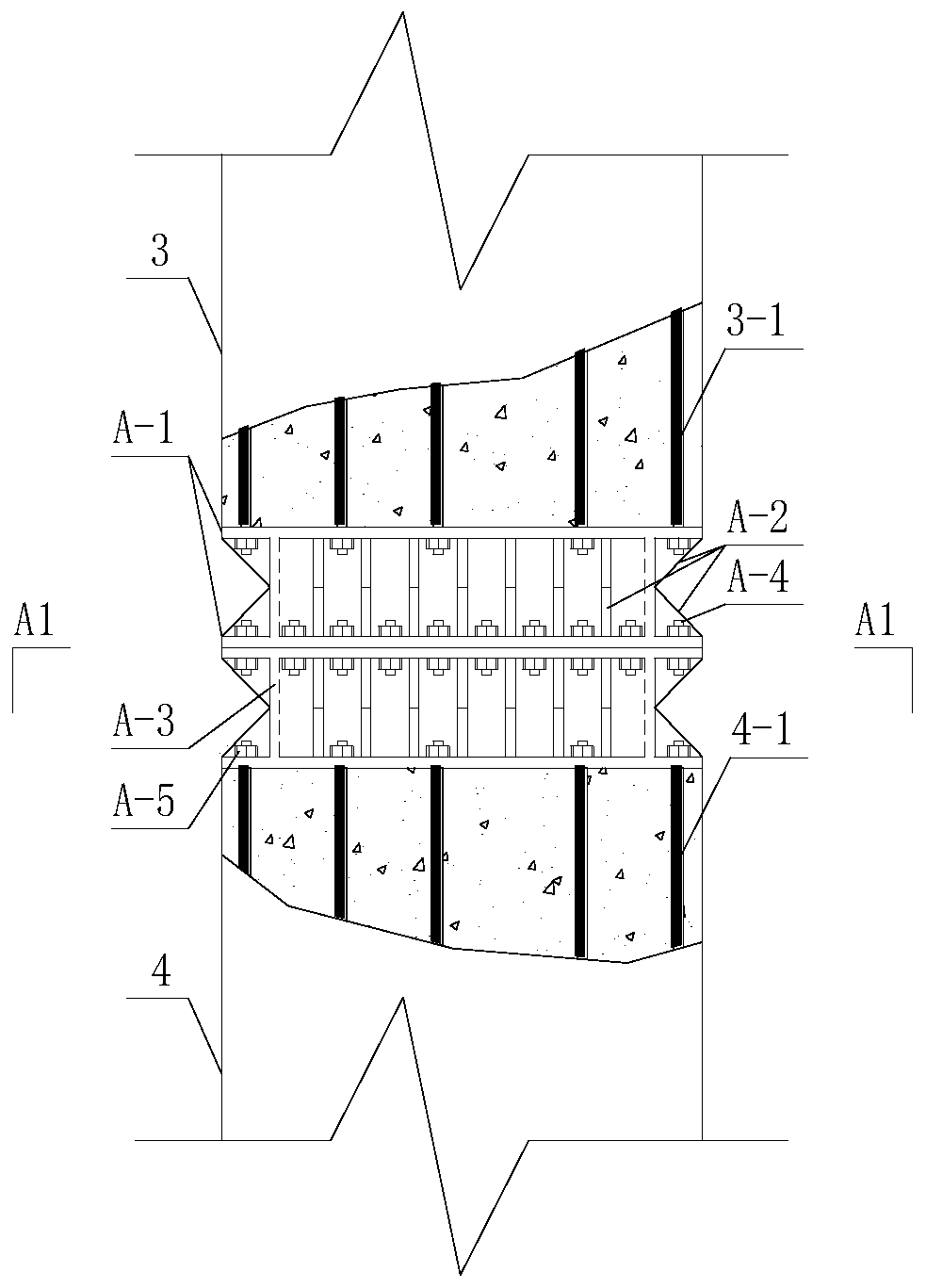

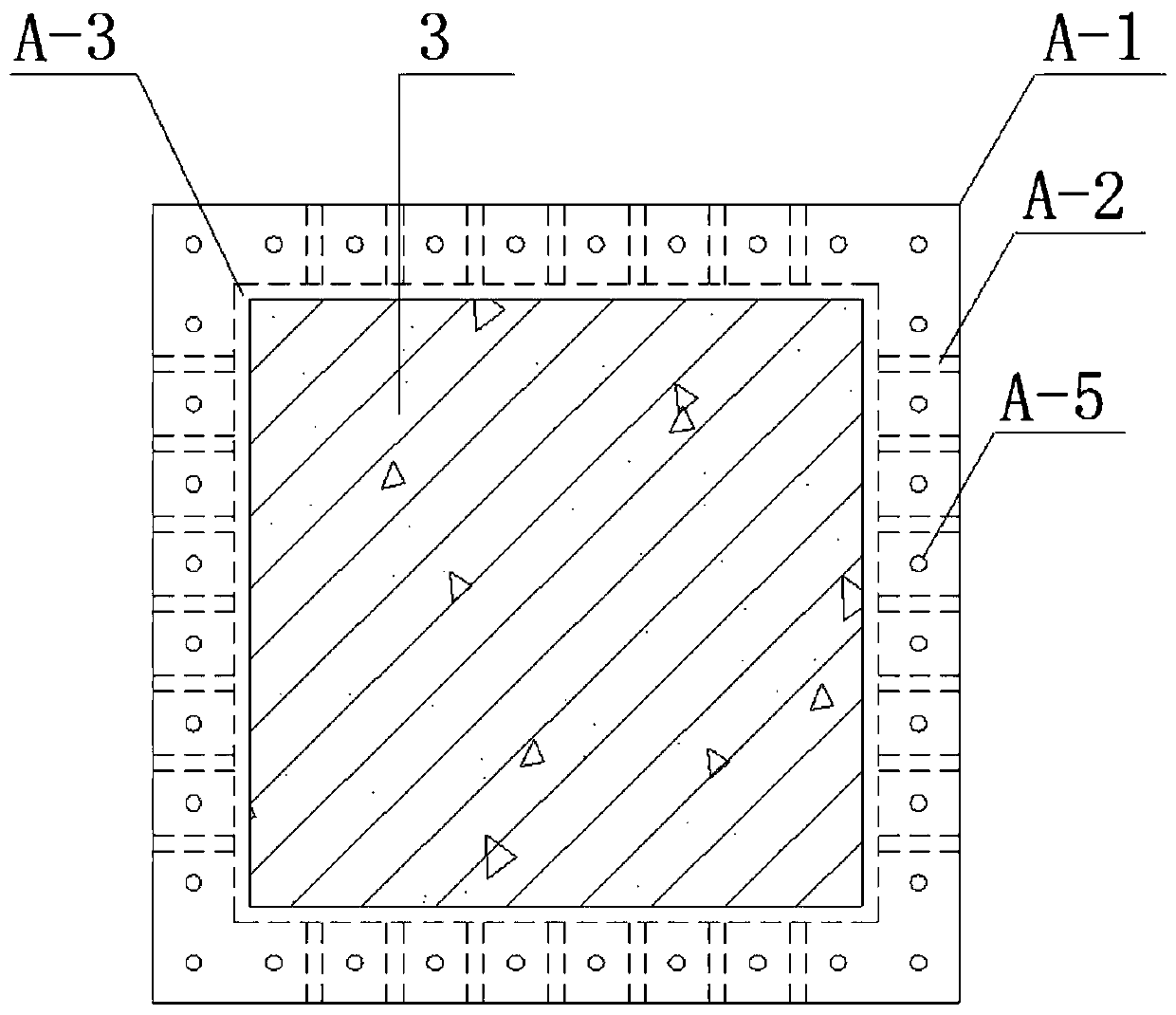

Joint connection mode for prefabricated spliced bridge pier with flexible layer arranged at bottom of pier and cushion cap and realization method thereof

The invention discloses a joint connection mode for a prefabricated spliced bridge pier with a flexible layer arranged at the bottom of the pier and a cushion cap and a realization method thereof. The flexible layer at the bottom of the prefabricated pier, longitudinal reinforcements extending out from the bottom of the prefabricated pier, pre-buried metallic bellows in the cushion cap, preserved grooves in the top face of the cushion cap and self-compaction high-strength micro-expansion grouting materials grouted through the metallic bellows are involved in the joint connection mode. An overlapped steel plate rubber layer is installed at the bottom of the bridge pier and formed with the bridge pier in a cast and prefabricated mode, the self-compaction high-strength micro-expansion grouting materials are grouted into the pre-buried metallic bellows in the cushion cap and overflow so that the grooves can be filled with the grouting materials, and then the longitudinal reinforcements extending out from the bottom of the prefabricated bridge pier are inserted into the pre-buried metallic bellows until the bottom of the prefabricated bridge pier is inserted into the grooves to be compacted. The construction mode is simple; the bridge pier is formed in a prefabricated mode, in this way, the on-site construction speed of projects is increased, and the quality of the projects is improved; due to the overlapped steel plate rubber layer arranged at the bottom of the prefabricated bridge pier, the ductility of the bridge pier can be obviously improved, and the damage degree of the plastic hinge region of a pier stud is reduced.

Owner:BEIJING UNIV OF TECH

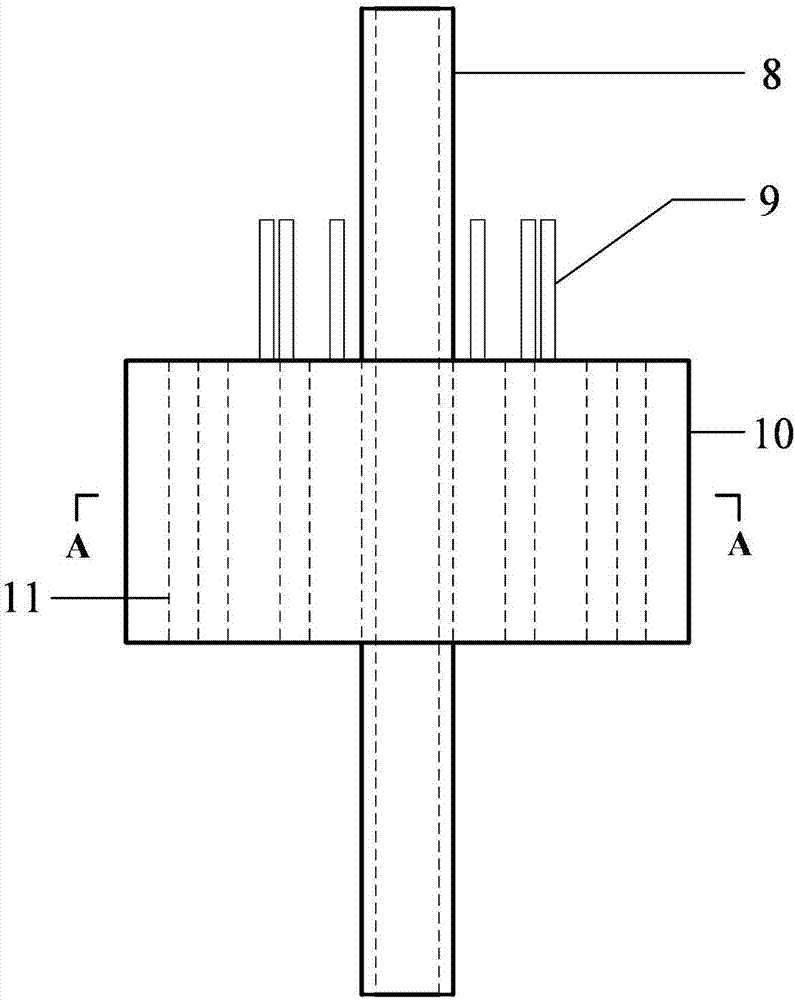

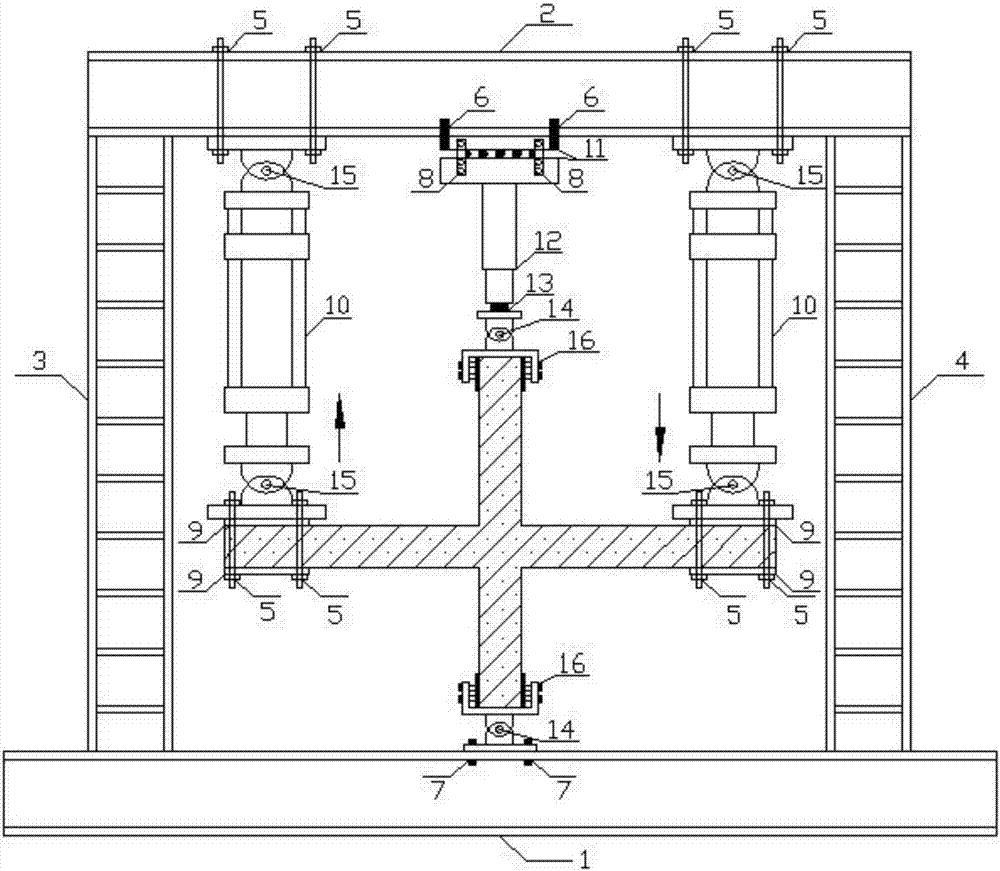

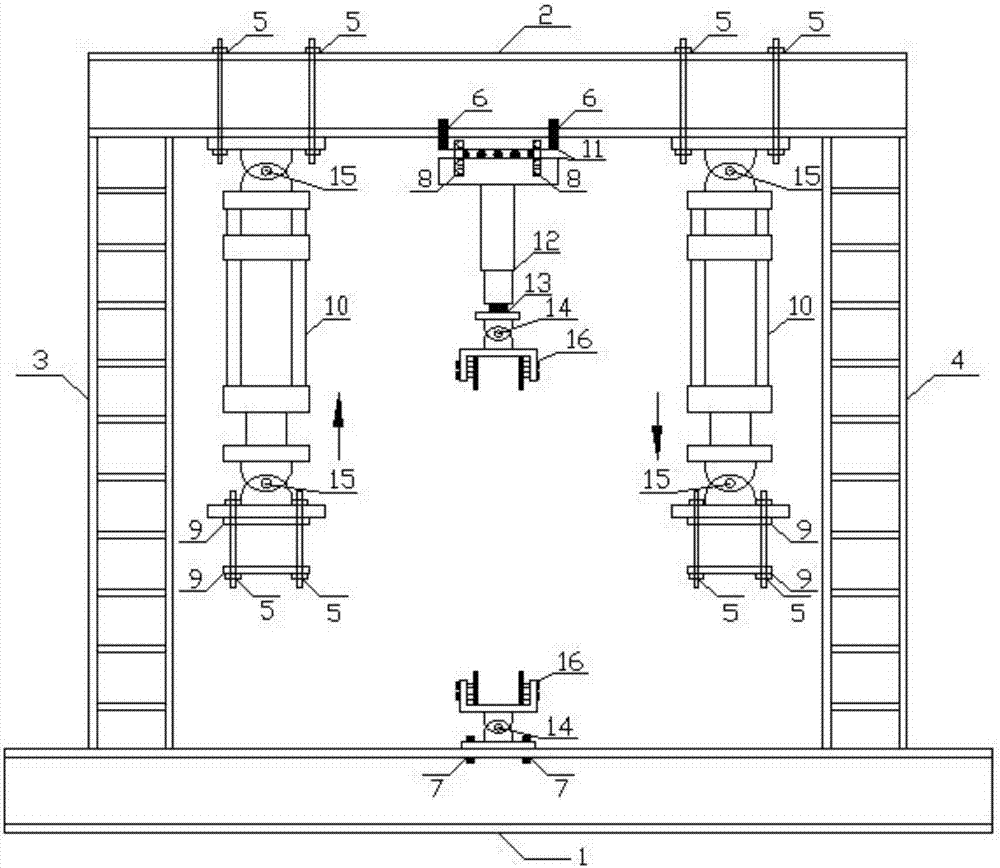

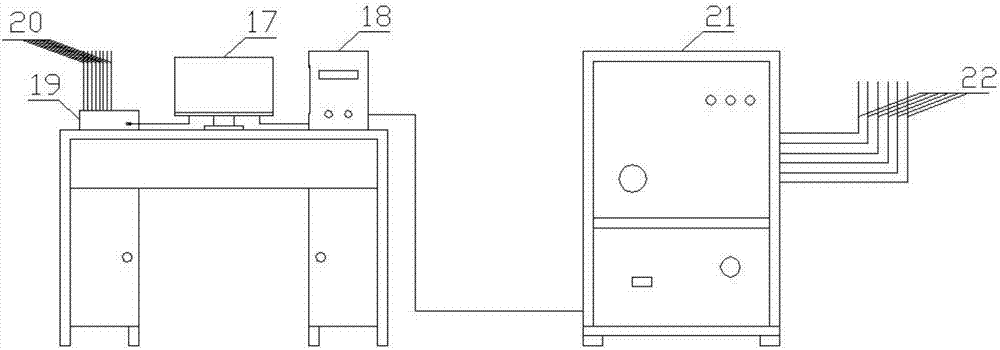

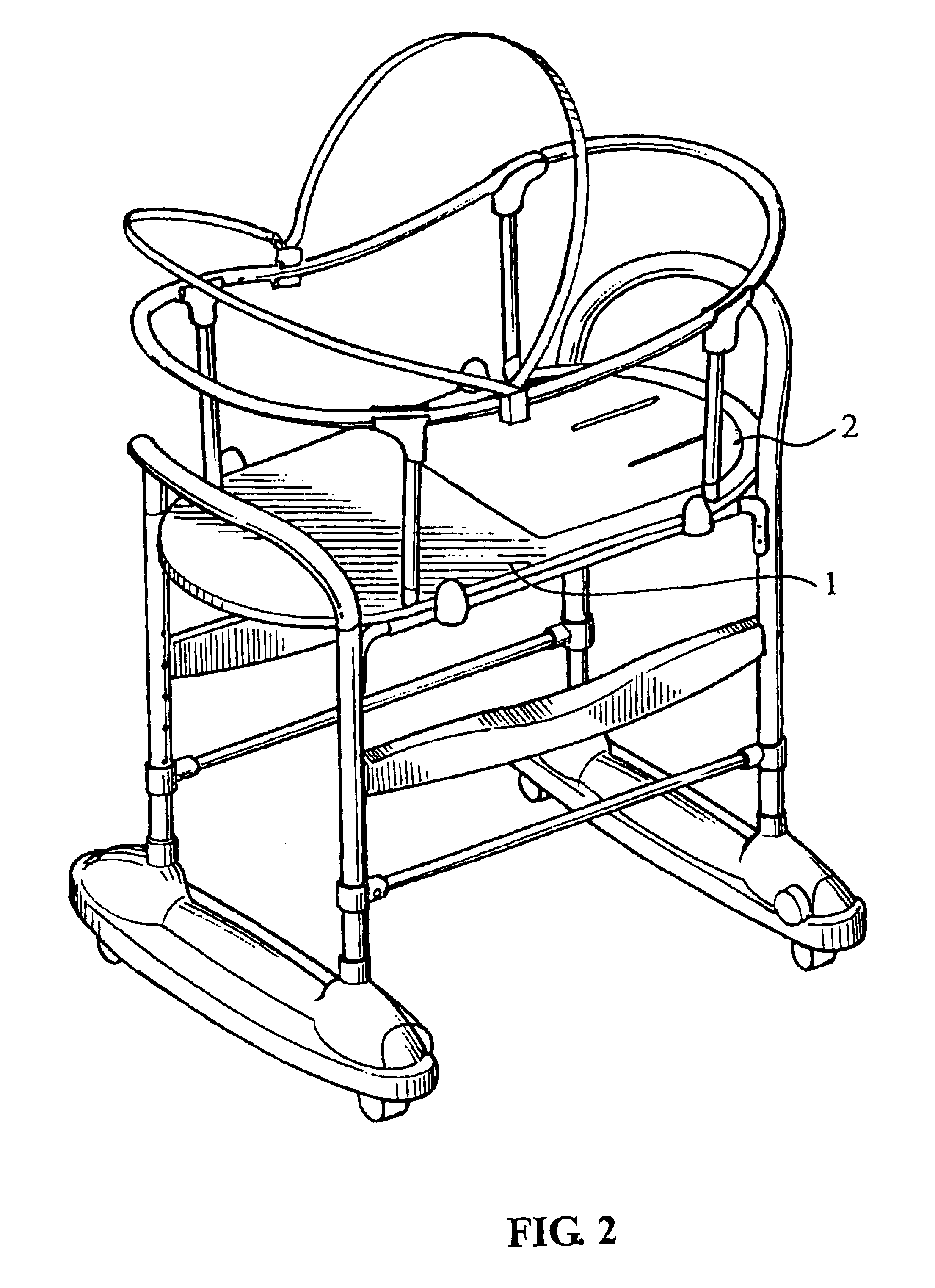

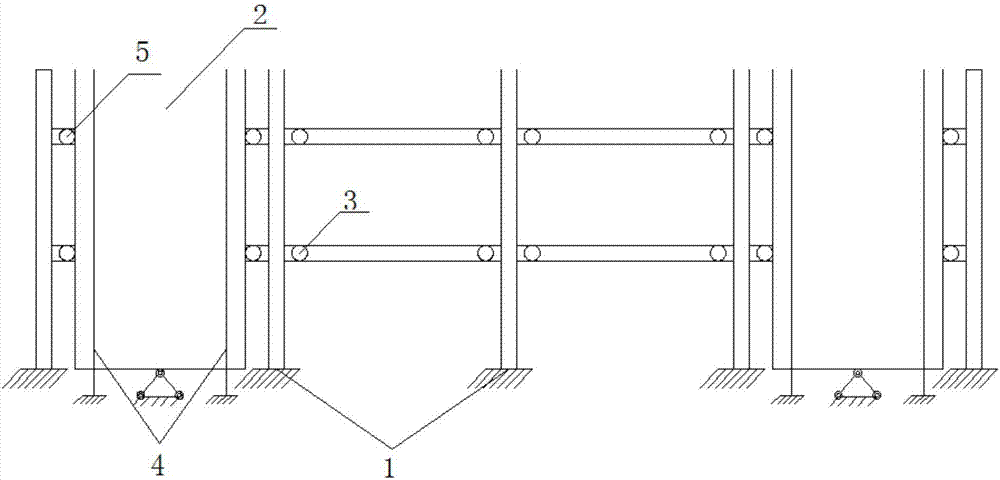

Beam-end loading test device of beam-column joint and test method of test device

InactiveCN106885745AExact axial pressure ratioMaterial strength using repeated/pulsating forcesData acquisitionEngineering

The invention belongs to the technical field of reinforced concrete building testing, and particularly relates to a beam-end loading test device of a beam-column joint. The beam-end loading test device comprises an external frame fixing device, a specimen loading device and a data collection system, wherein a beam-column joint specimen is arranged on the specimen loading device; and a hydraulic oil source is controlled through a controller to adjust the vertical shift motion of a vertical actuator, so that the beam-column joint specimen is arranged in an unloaded condition. The method comprises the steps of designing parameters through a computer, controlling a jack and the vertical actuator to apply loads to the beam-column joint specimen through the controller; carrying out loading test according to the requirements until the specimen is destroyed; and collecting vertical force P(t) on the beam-column joint specimen and generated vertical displacement S(t) in the test process by a multi-channel strain collection instrument, drawing a hysteretic curve of the beam-column joint specimen and analyzing the hysteretic performance. By adopting a beam-end loading mode, the shear conditions of a beam-end plastic hinge and a core area can be researched while the earthquake action is simulated, and the beam-end loading test device is of great significance.

Owner:WUHAN UNIV OF SCI & TECH

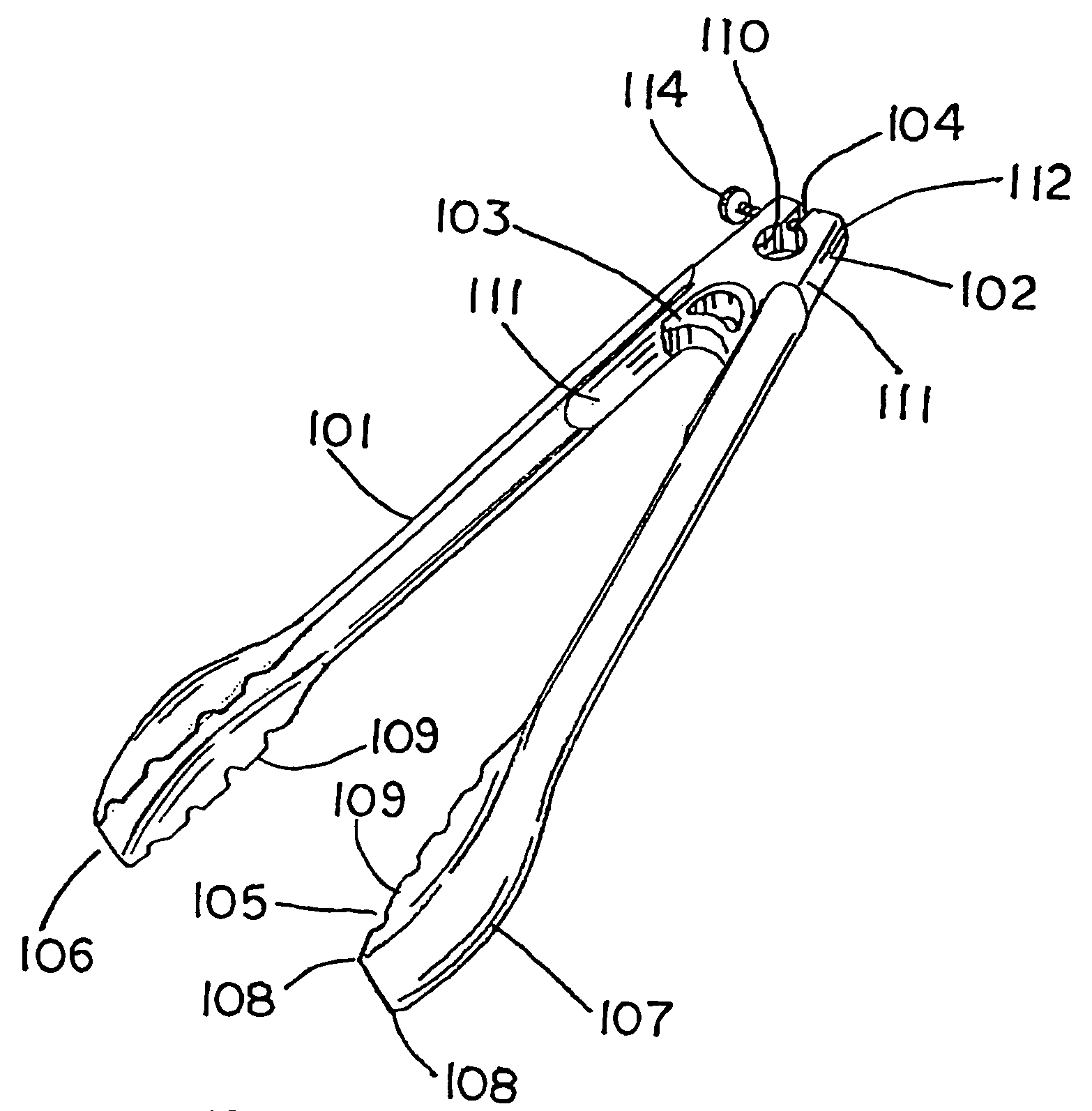

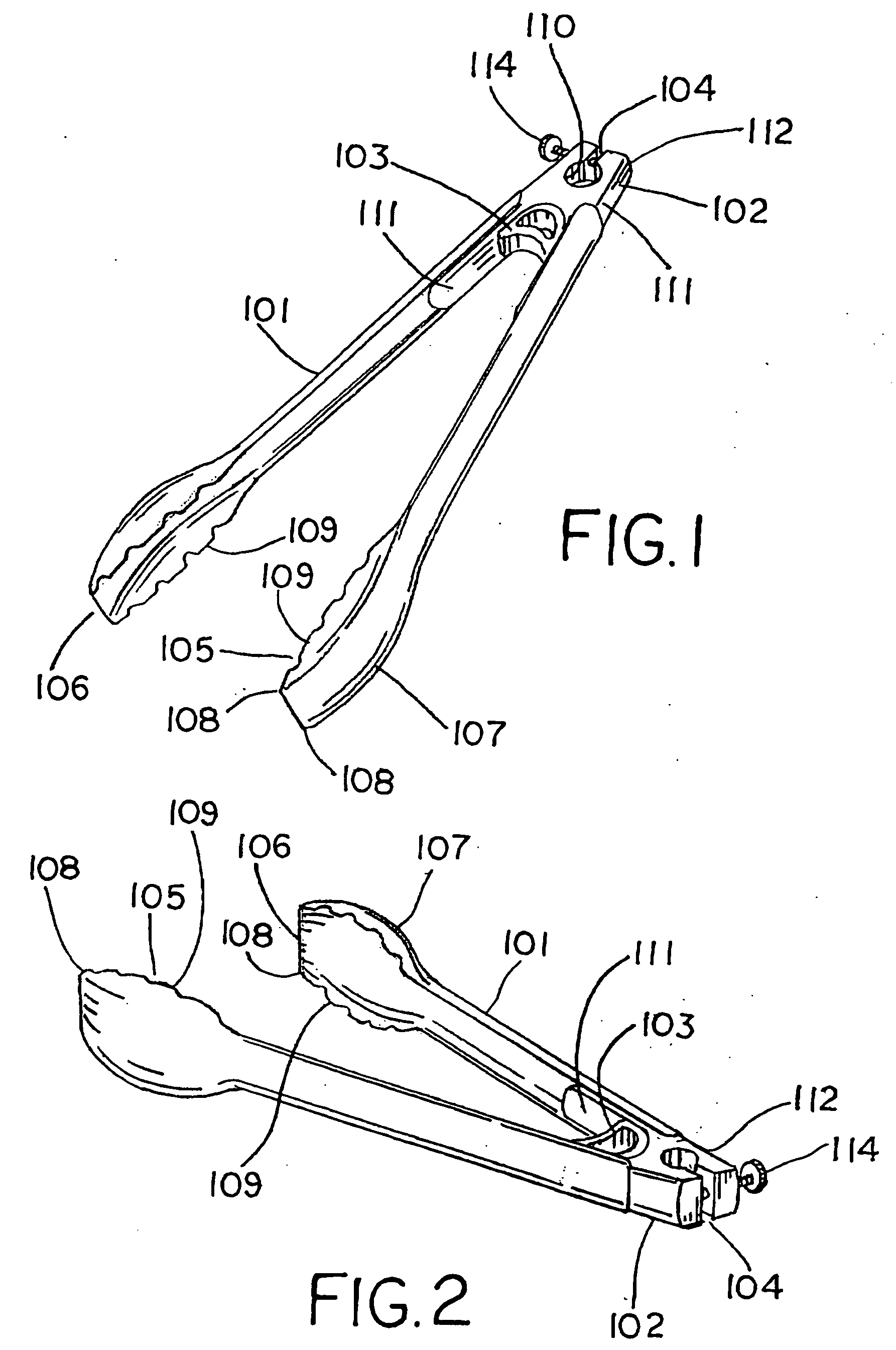

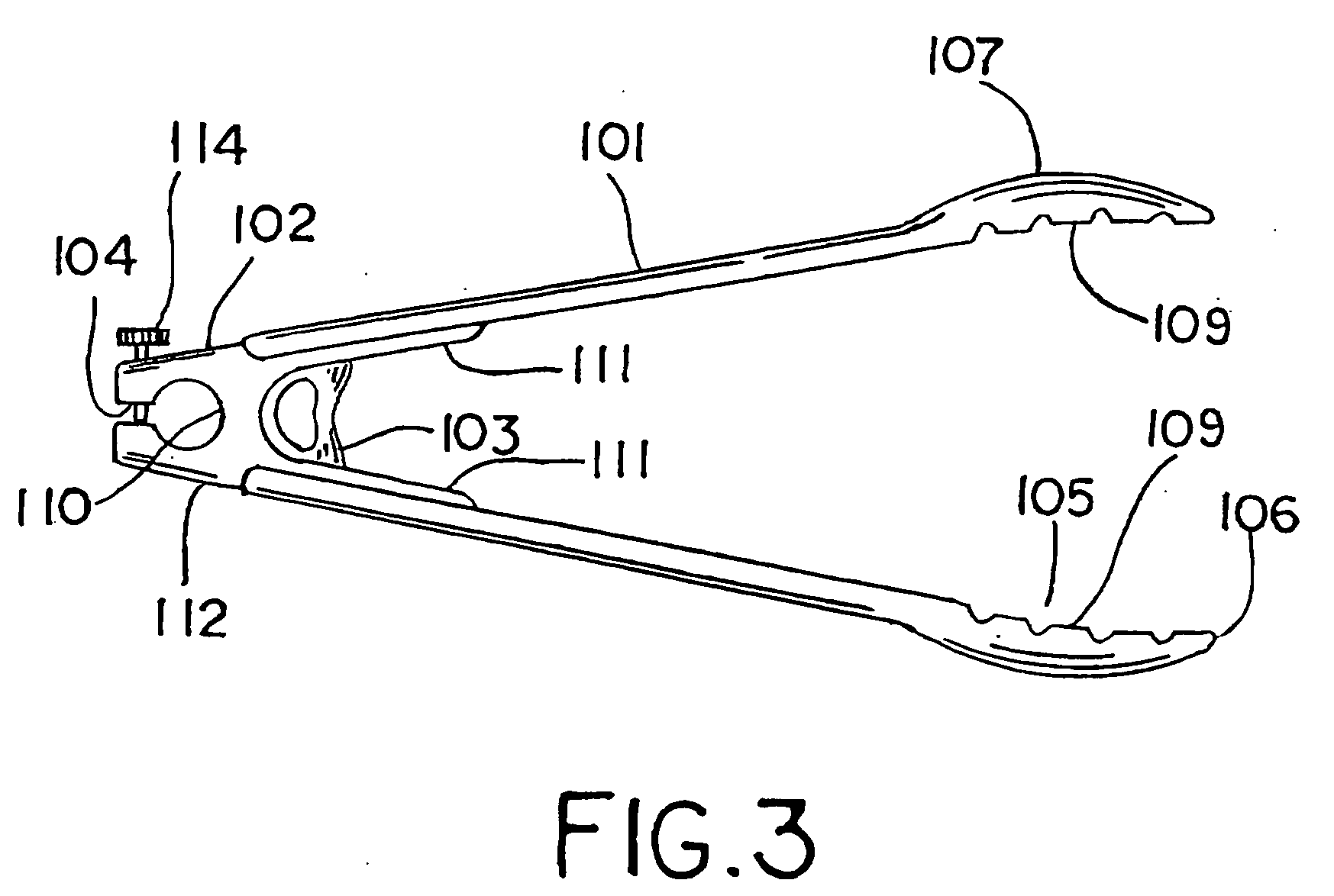

Tongs

InactiveUS20060157996A1Kitchen equipmentManual conveyance devicesPlastic hingeMechanical engineering

A pair of tongs includes a first arm, a second arm, and a plastic hinge structure, constructed at least in part from a material different from at least one of the first arm and the second arm, joining the first arm to the second arm. The tongs may further include a steel spring, and the plastic hinge structure may be over molded to cover the steel spring.

Owner:RUBBERMAID

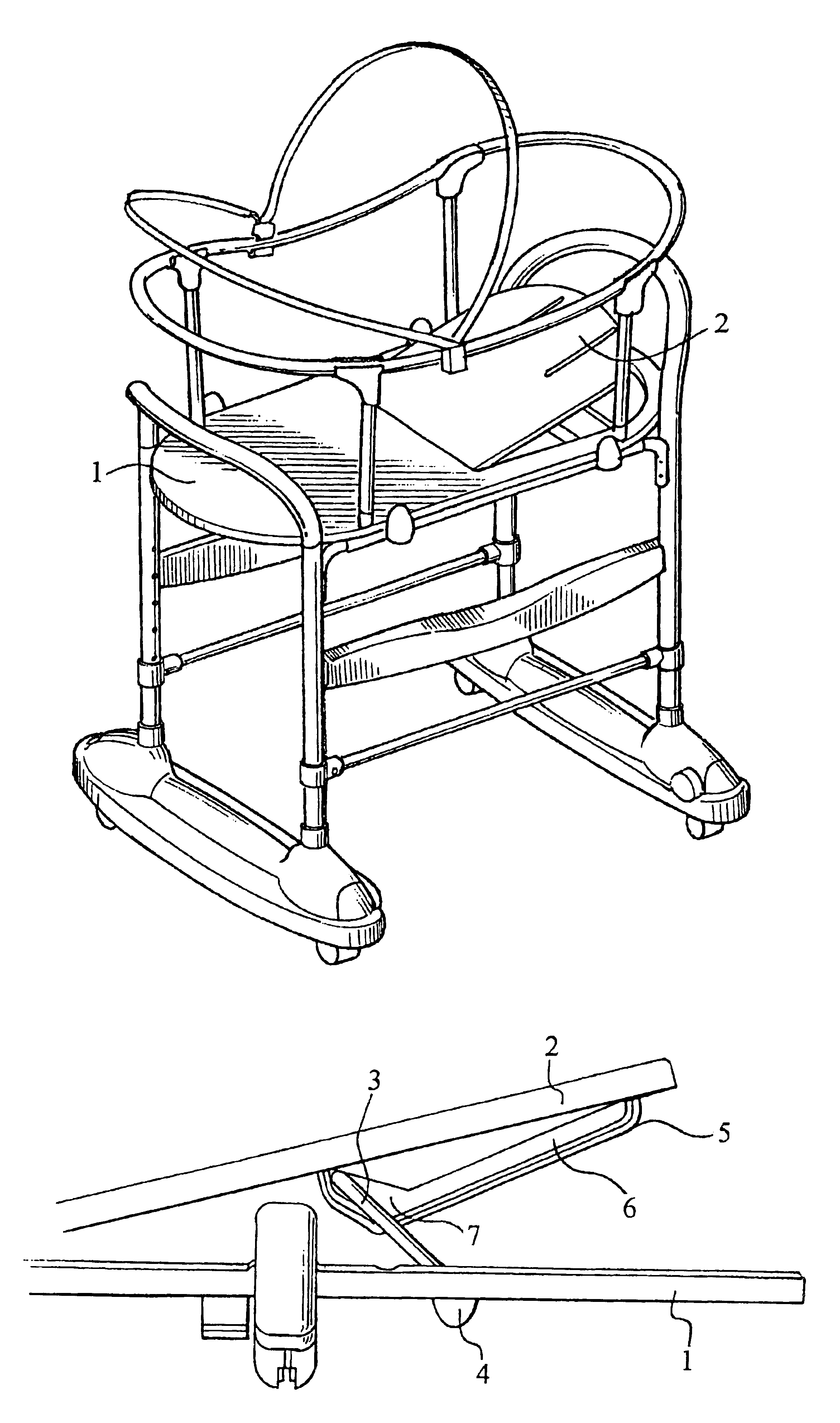

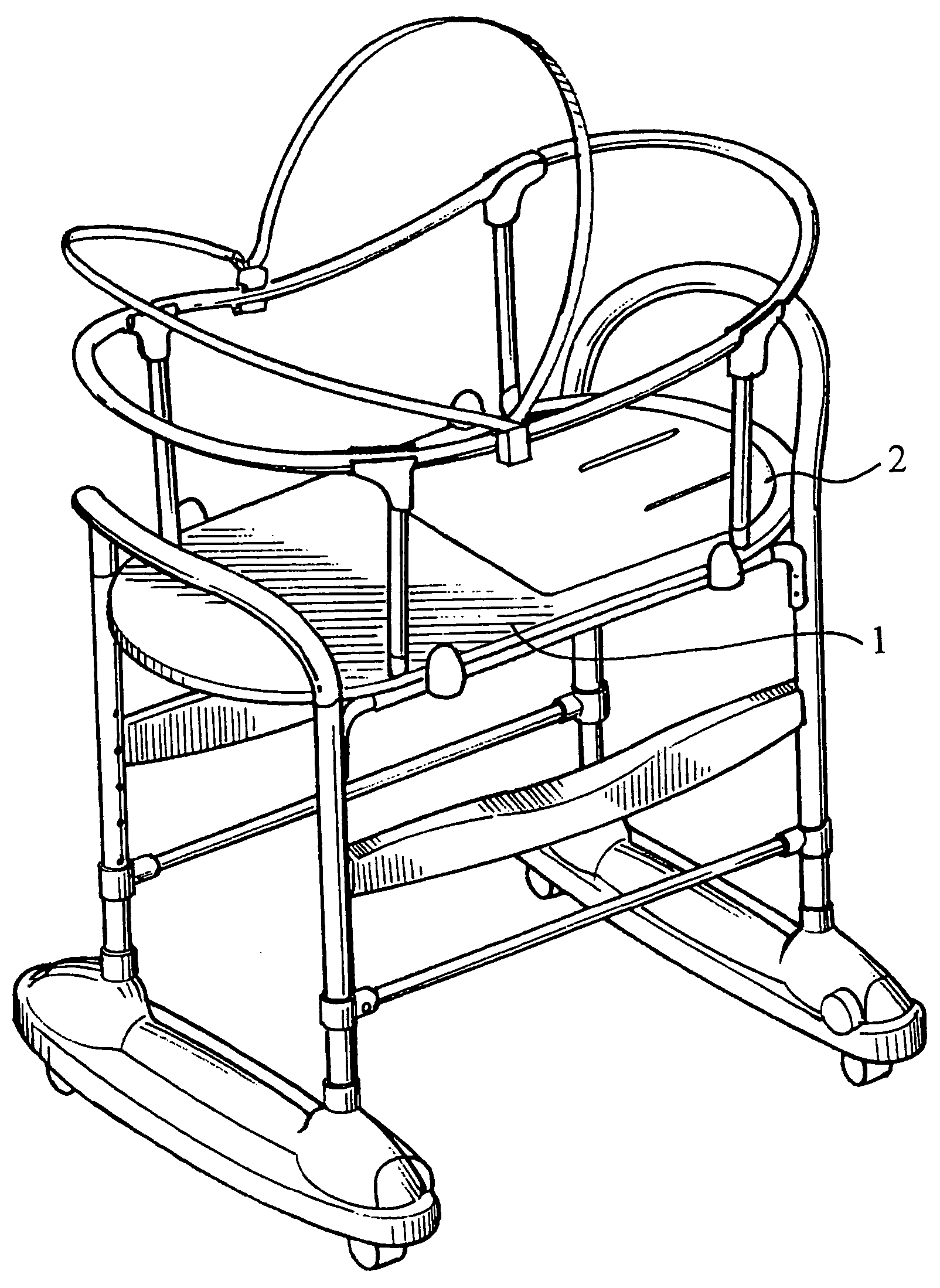

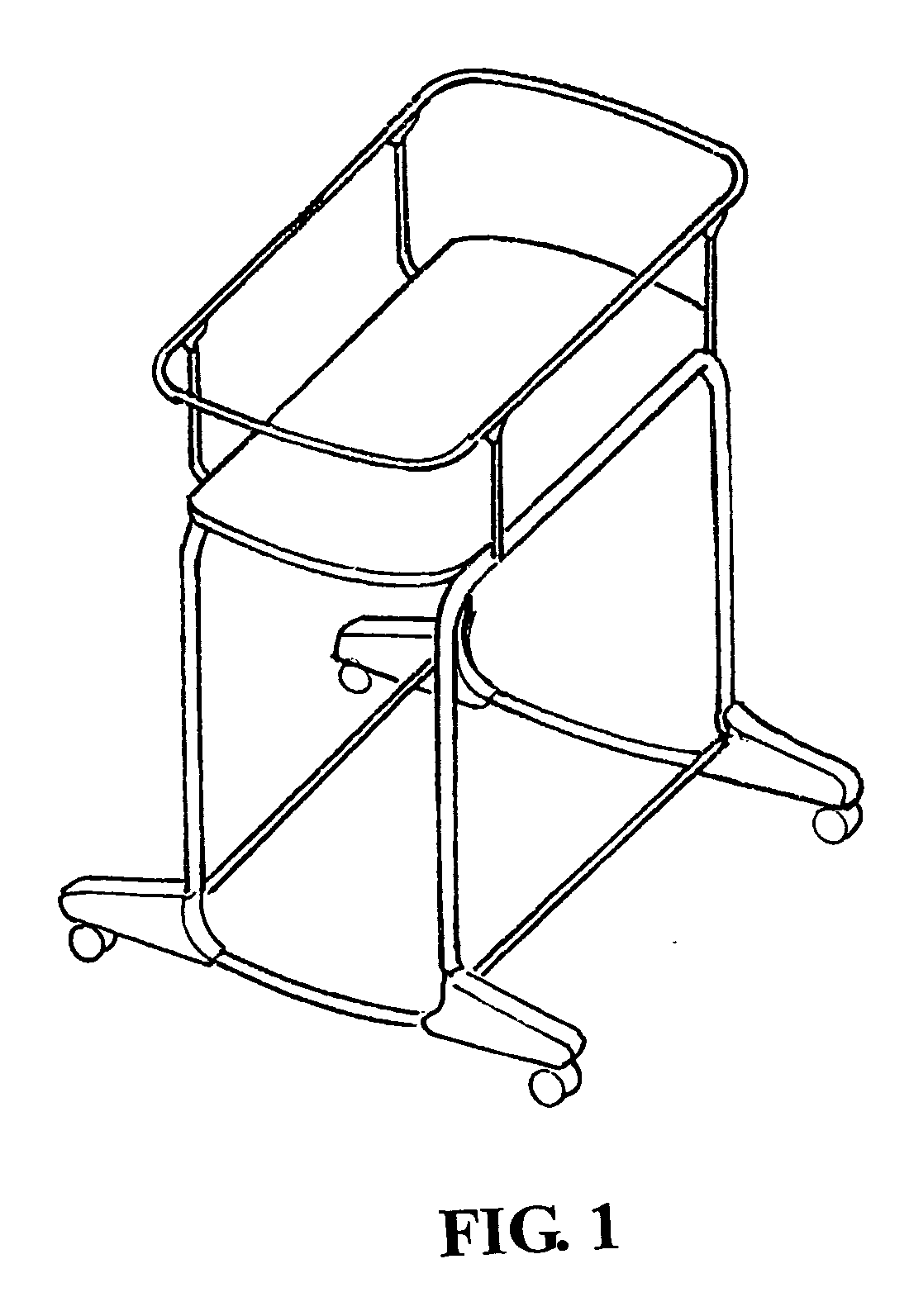

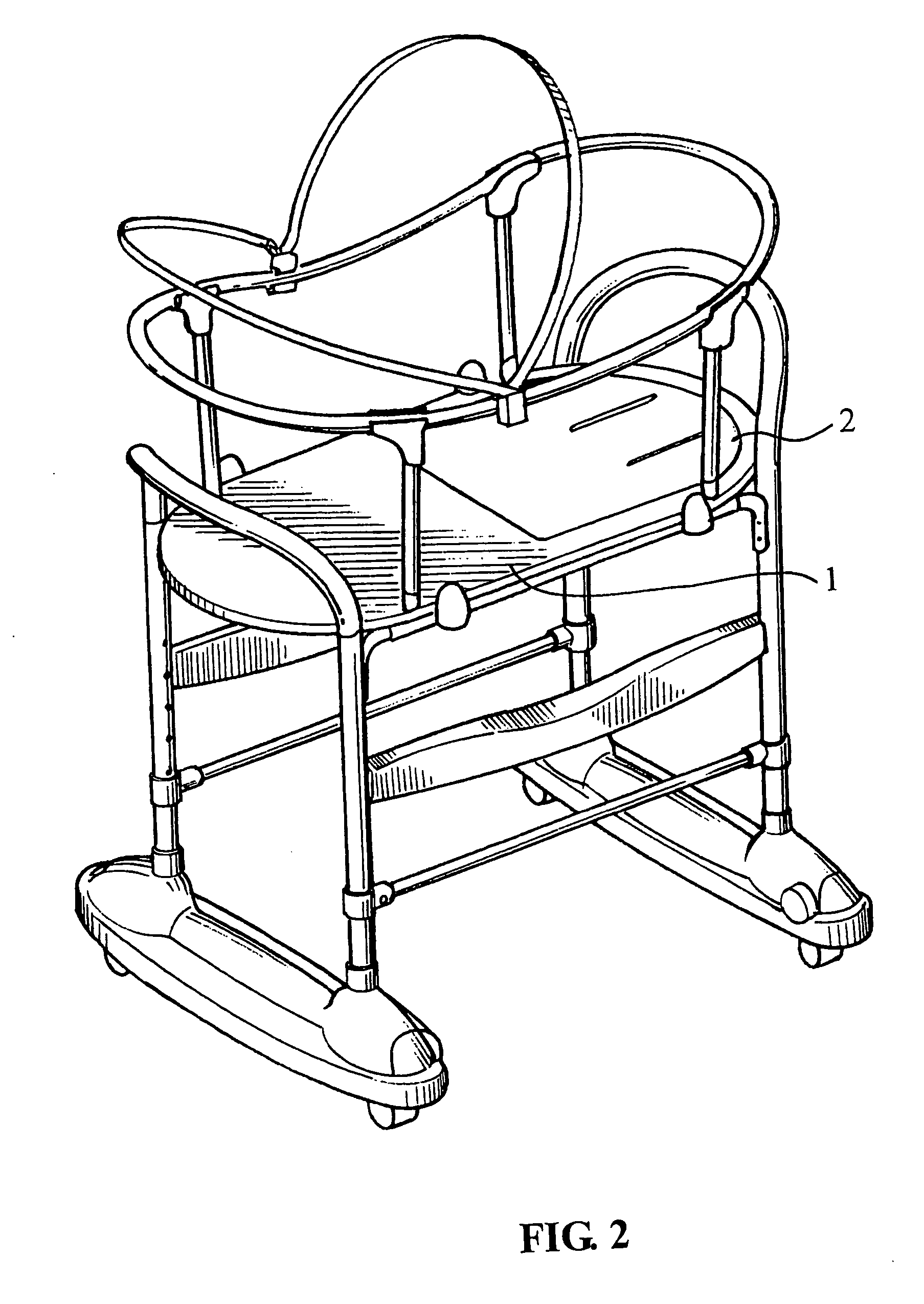

Inclination adjusting means for backrest of bassinet

An inclination adjusting means for the backrest of a bassinet is provided, which comprises a bedplate, a backrest, a supporting rod and a band. The bedplate and the backrest are integrally formed in one component and are connected together via plastic hinges. The supporting rod is pivotally connected to the bedplate with a centrally-protruding portion passing through the sliding slot of the backrest. The band is tied in the middle of the centrally-protruding portion of the supporting rod and the free end of the band is suspended and drooped out of the backrest so that a user can easily draw out the band from the rear of the backrest.When a user intends to raise the backrest, he / she can lift the backrest with his finger passing through a semicircular hole provided on the rear portion of the backrest so that the protruding portion of the supporting rod 3 can slide to the lowest point along a slopping slot. Then, when the user releases his finger, the supporting rod will be directed to engage in the front portion of the sliding slot due to its weight. According, the inclination of the backrest is well defined by the supporting rod. When the user intends to level the backrest, he only needs to hold the backrest with his finger hooking the semicircular hole on the backrest and draw the band toward the rear of the backrest with the other hand so that the backrest enters the front portion of the slopping slot to complete the leveling of the backrest.

Owner:WONDERLAND NURSERYGOODS CO LTD

Assembly type recycled concrete node with steel bar truss girders at end parts and manufacturing method thereof

The invention discloses an assembly type recycled concrete node with steel bar truss girders at end parts and a manufacturing method thereof, belonging to the technical field of constructing of prefabricated parts and key nodes and regenerating of concrete. The assembly type recycled concrete node has the advantages of environment friendliness, energy saving and convenience in construction, and is applicable to prefabricated construction, so that the problems that the key nodes of the existing prefabricated parts are poor in seismic performance and severe in seismic hazard, and the defect that the node construction is difficult can be overcome by integrally casting a wing-tip beam and an upright post; and moreover, autoclaved curing prefabrication forming is adopted, so the compactness, the casting quality and the strength of the concrete at the nodes are remarkably improved, thereby realizing an anti-seismic design target of strong nodes and weak rods, as well as connecting the wing-tip beam with the prefabricated beam with the steel bar truss girders by bar splicing. A stirrup strengthening zone is arranged at the connecting part, and the connecting part is set to be a post-cast strip, so that plastic hinges are easily formed under earthquake load action. An ideal failure mechanism with the anti-seismic design concept of strong columns and weak beams, and strong shear and weak bending can be extensively applied to precast construction.

Owner:BEIJING UNIV OF TECH

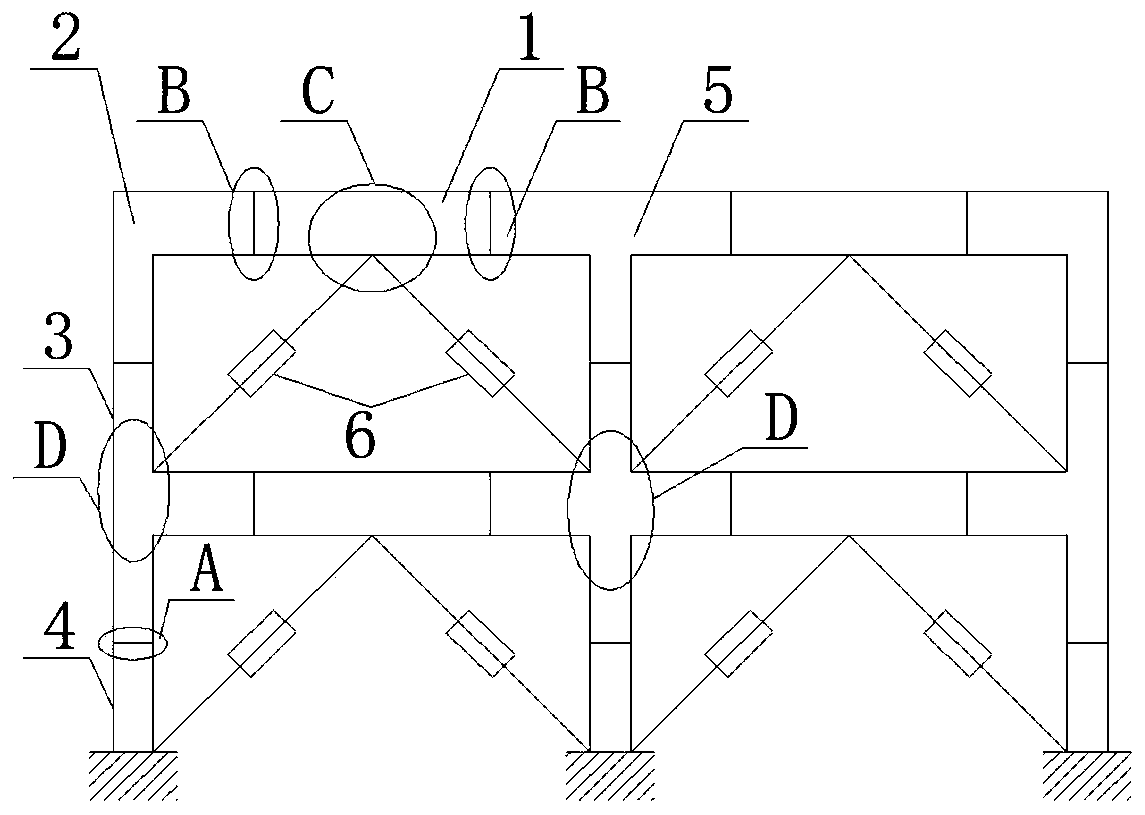

Multi-defensive line anti-seismic self-restoration assembly type frame-swinging wall energy consumption structure

InactiveCN106906907AGuaranteed energy consumptionSelf-recovery after earthquakeProtective buildings/sheltersShock proofingResidual deformationPre stress

The invention relates to the field of building structures and discloses a multi-defensive line anti-seismic self-restoration assembly type frame-swinging wall energy consumption structure which comprises frame structure bodies and swinging wall structure bodies. The frame structure bodies are hinged to swinging wall bodies. The bottoms of the swinging wall bodies are hinged to a foundation. The frame structure bodies are provided with a plurality of controllable plastic hinge joints which comprise column end short beam sections connected with concrete columns in a pouring mode and main beam built-in fittings connected with a main beam in a pouring mode. The ends of the column end short beam sections are spherical grooves, ant the ends of the main beam built-in fittings are universal balls which are matched with the spherical grooves to enable the main beam built-in fittings and the column end short beam sections to be connected in a hinged mode. The two sides of the swinging wall bodies are provided with pre-stressed ribs. One ends of the pre-stressed ribs are fixedly connected to the foundation, and the other ends of the pre-stressed ribs are anchored to swinging walls. According to the multi-defensive line anti-seismic self-restoration assembly type frame-swinging wall energy consumption structure, the problems that existing buildings are centralized in damage, and frame-swinging wall structures are overlarge in horizontal displacement peak and residual deformation and deform due to vibration are effectively solved through three defensive lines.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for manufacturing assembled type bridge pier by utilizing steel fiber reinforced self-compacting concrete

InactiveCN103758031AImprove seismic performanceStrong impact resistanceCeramic shaping apparatusBridge structural detailsFiberEngineering

The invention discloses a method for manufacturing an assembled type bridge pier by utilizing steel fiber reinforced self-compacting concrete. The method comprises the steps of preparing the concrete, prefabricating bridge pier segments, assembling the bridge pier segments, fixing the bridge pier segments and the like. By the adoption of the assembled type bridge pier manufactured through the method, construction and pouring quality can be guaranteed, the construction efficiency of a bridge is enhanced, and the seismic performance of the bridge pier can also be improved. The assembled type bridge pier is made of certain steel fiber reinforced self-compacting concrete, the comprehensive power performance of the segments is superior, and seismic performance of connector parts is 2-3 times that of existing common concrete prefabricated segments under the condition that structures and sizes are equal. The bridge pier segments in the structure are assembled in the mode that a shear key is connected with a short reinforcing steel bar in an inserted mode, the shock resistance, pier energy consumption, post-earthquake restoration in potential plastic hinge areas between the segments and other seismic-area dynamic properties are superior, and the method can be applicable to construction of the bridge pier. By the adoption of the steel fiber reinforced self-compacting concrete, concrete on the surface of a finished bridge pier is not prone to cracking, and therefore durability is good.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

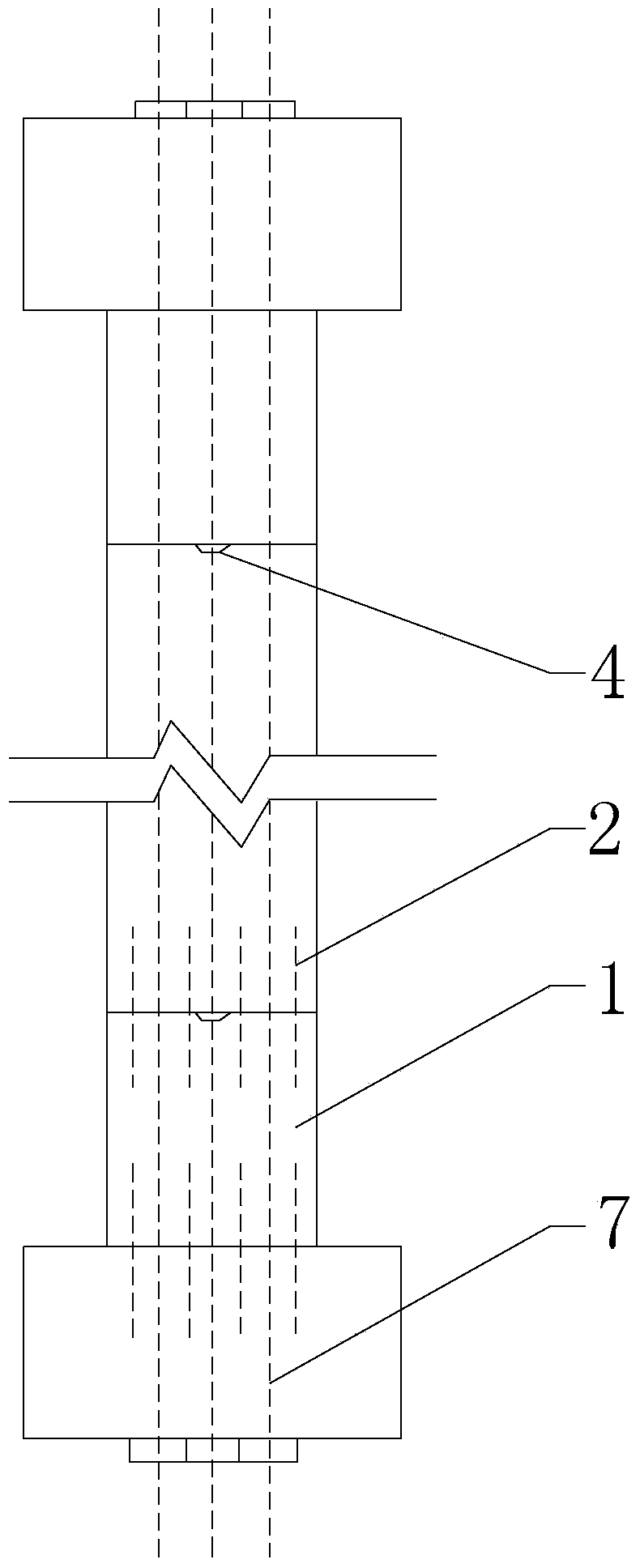

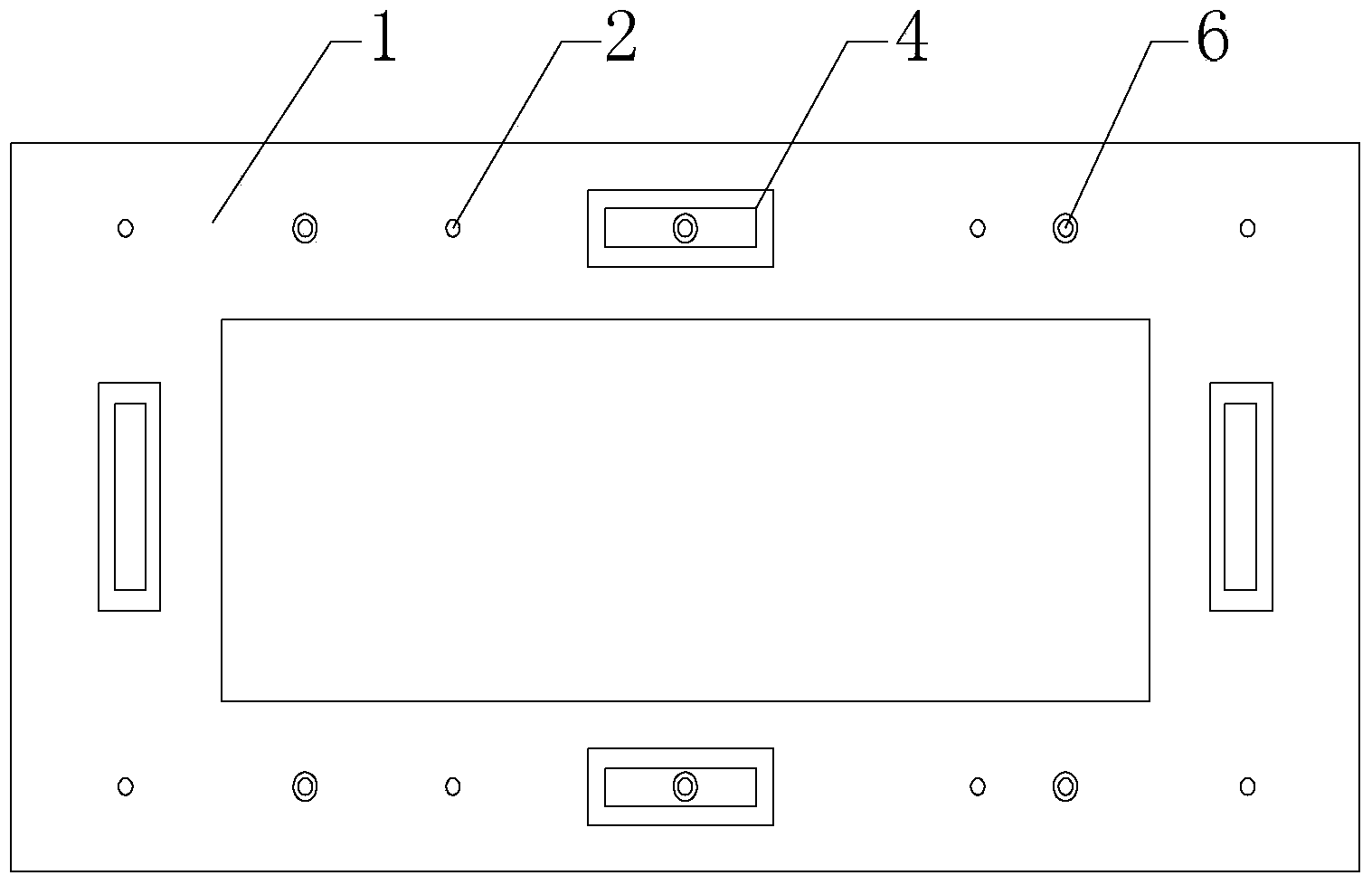

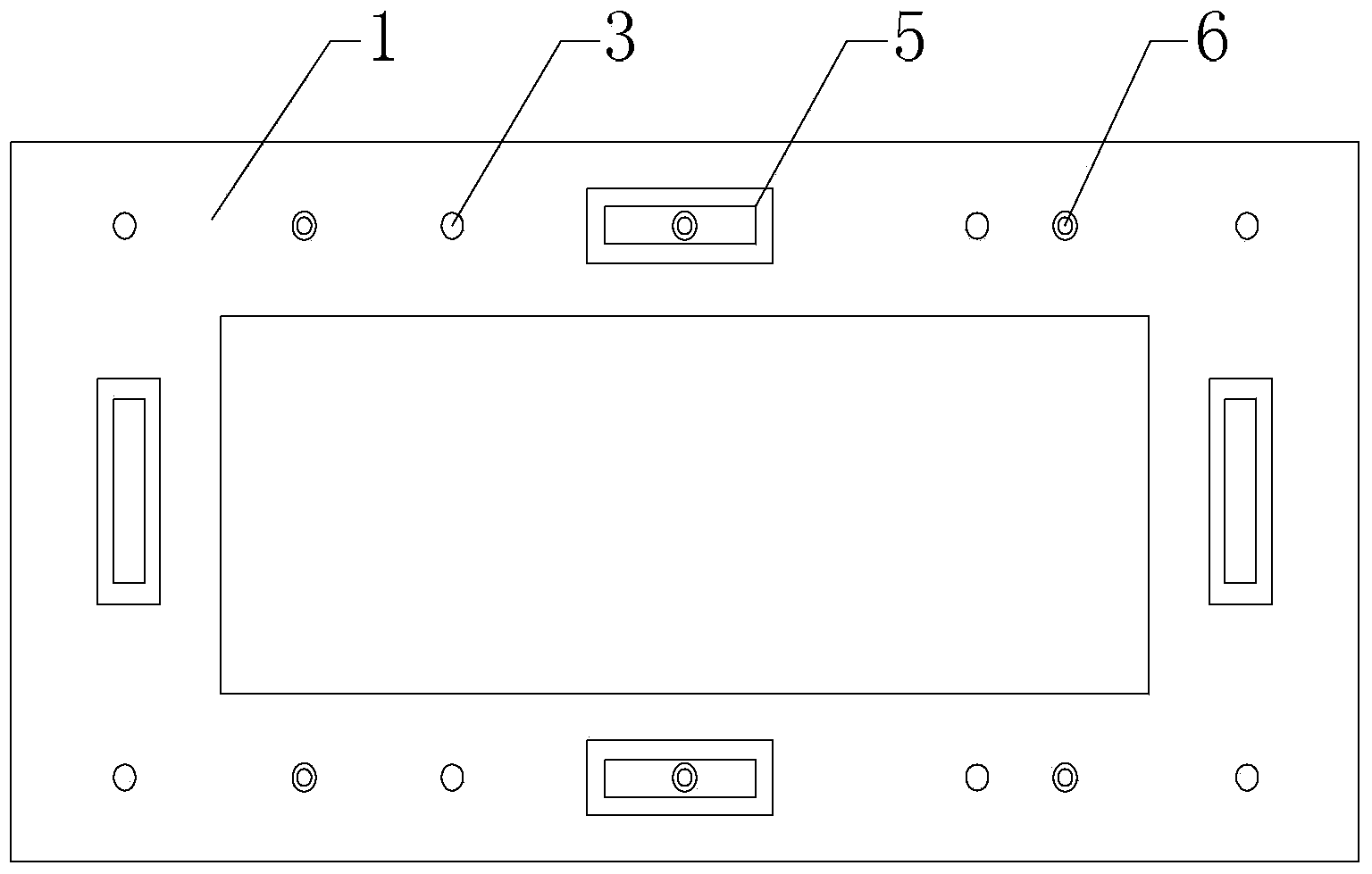

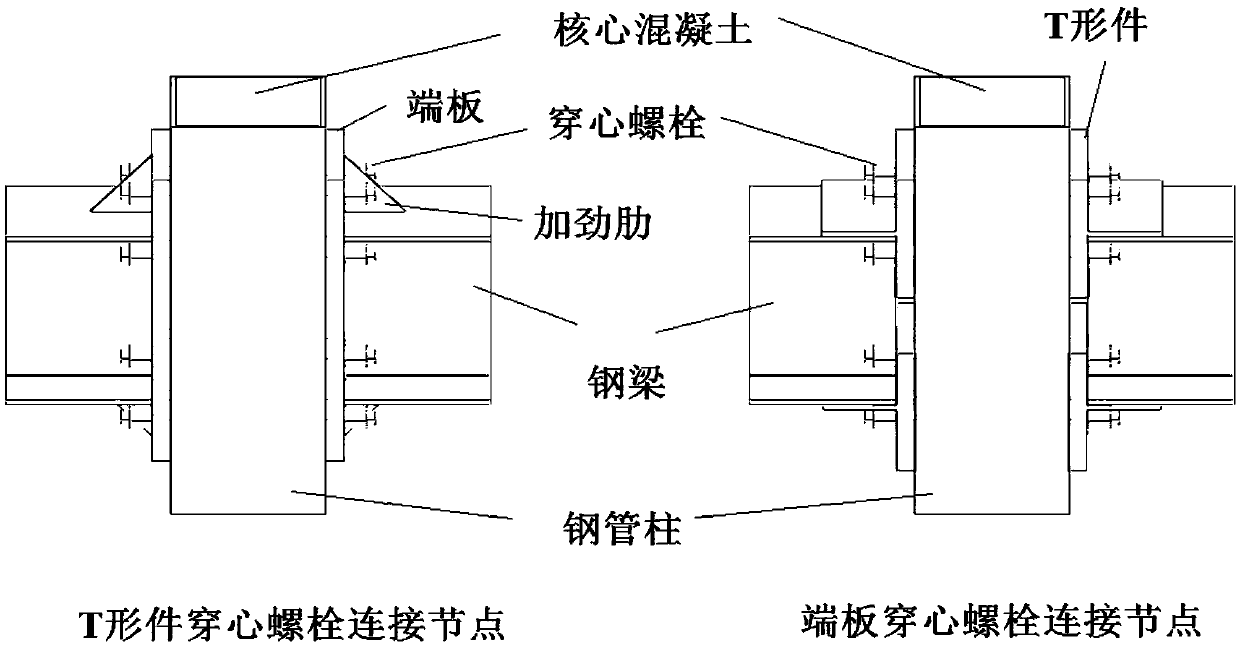

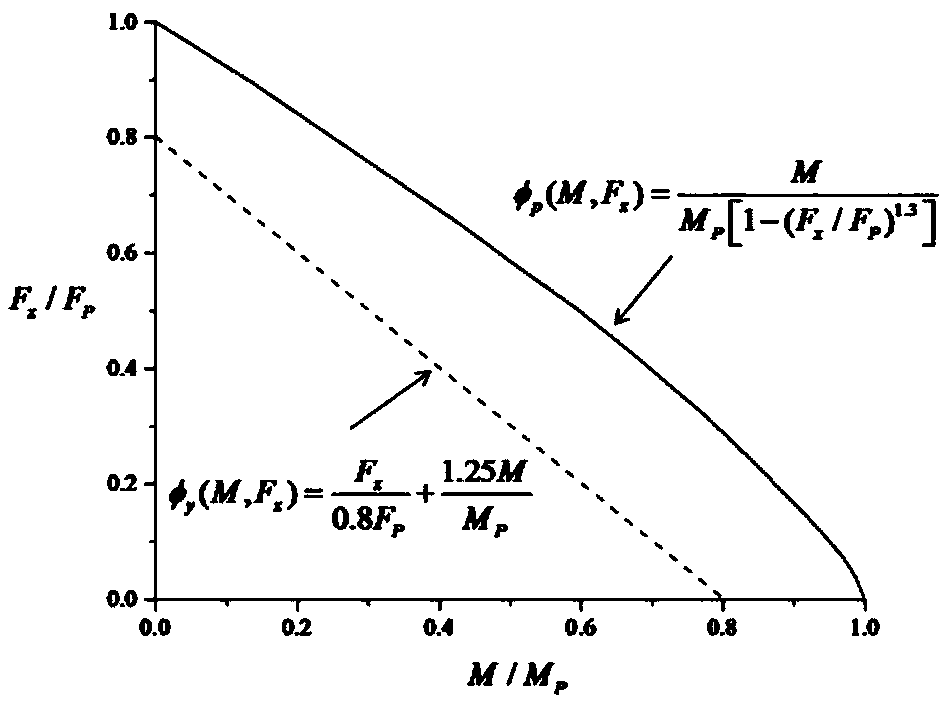

Calculating method for flexural bearing capacity and bending moment-rotation curve of concrete-filled steel tube column-steel beam penetrated bolt connecting joint

ActiveCN109610650AShorten the timeSave time and other costsMeasurement of torque/twisting force while tighteningBuilding constructionsClassical mechanicsPlastic hinge

The invention discloses a calculating method for flexural bearing capacity and a bending moment-rotation curve of a concrete-filled steel tube column-steel beam penetrated bolt connecting joint. The calculating method for the joint flexural bearing capacity comprises the following steps that the corresponding joint flexural bearing capacities are calculated when bending failure of a terminal plateor a T-shaped piece flange occurs to the joint, when pulling failure of penetrated bolts occurs to the joint, when transversely pressing failure of columns occurs to the joint, when shearing failureof a joint region occurs to the joint and when a steel beam forms plastic hinge failure is calculated, the minimum value of the five flexural bearing capacities is the actual flexural bearing capacityof the joint, and a corresponding failure mode is an actual failure mode of the joint. The calculating method for the bending moment-rotation curve of the joint comprises the following steps that initial rotating rigidity of the joint is obtained through an experiment or simulation or theoretical calculation, and then the initial rotating rigidity of the joint and the joint flexural bearing capacity are substituted into a provided exponential model of a bending moment-rotation relationship to obtain the bending moment-rotation curve of the joint. The calculating method for the flexural bearing capacity and the moment-rotation curve of the concrete-filled steel tubular column-steel beam penetrated bolt connecting joint avoids large quantity of experiments or simulation which are needed inprevious design of joints of the type and has the advantages that the calculation is easy and convenient, the time and labor are saved, the cost is low and the like.

Owner:DALIAN UNIV OF TECH

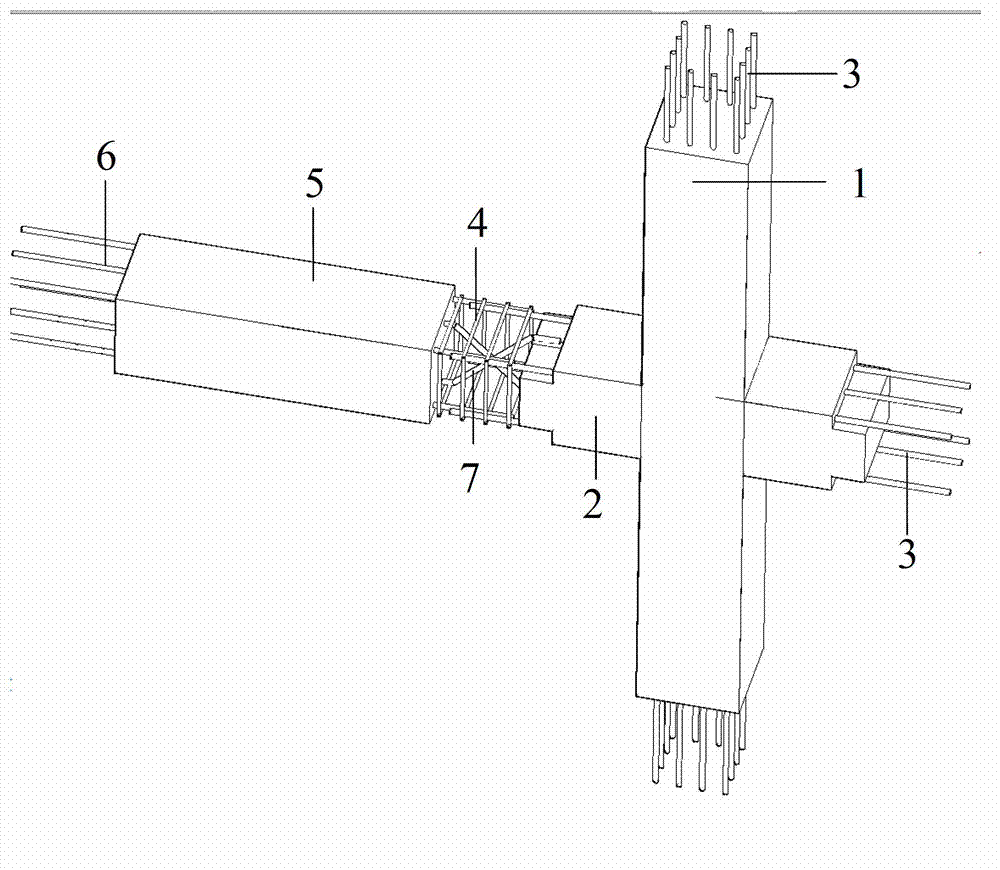

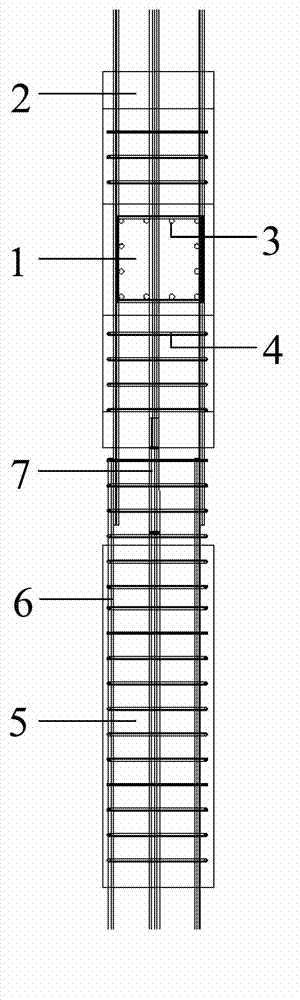

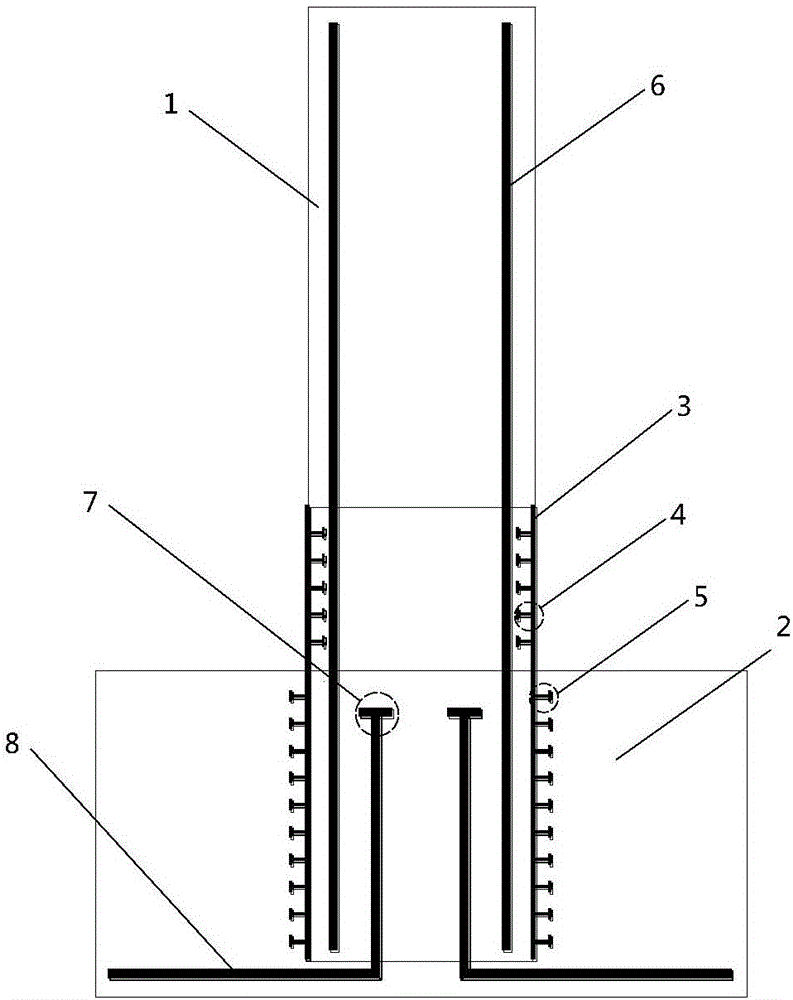

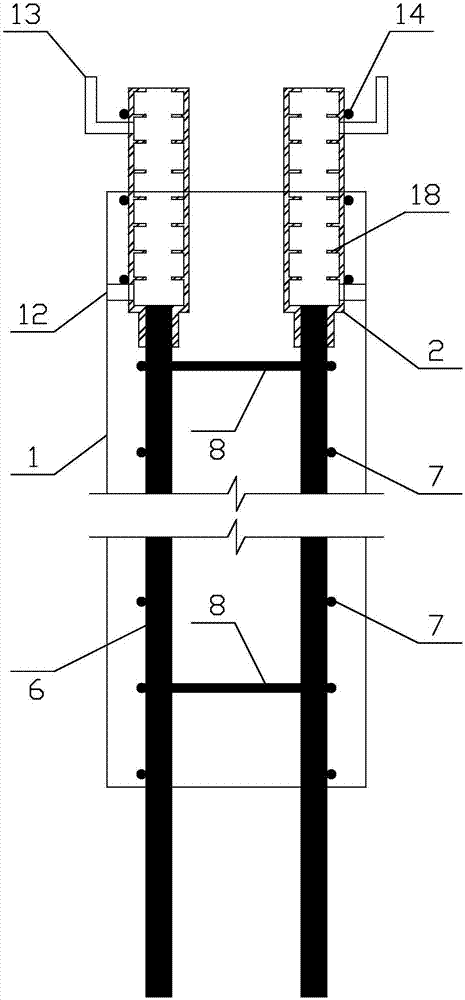

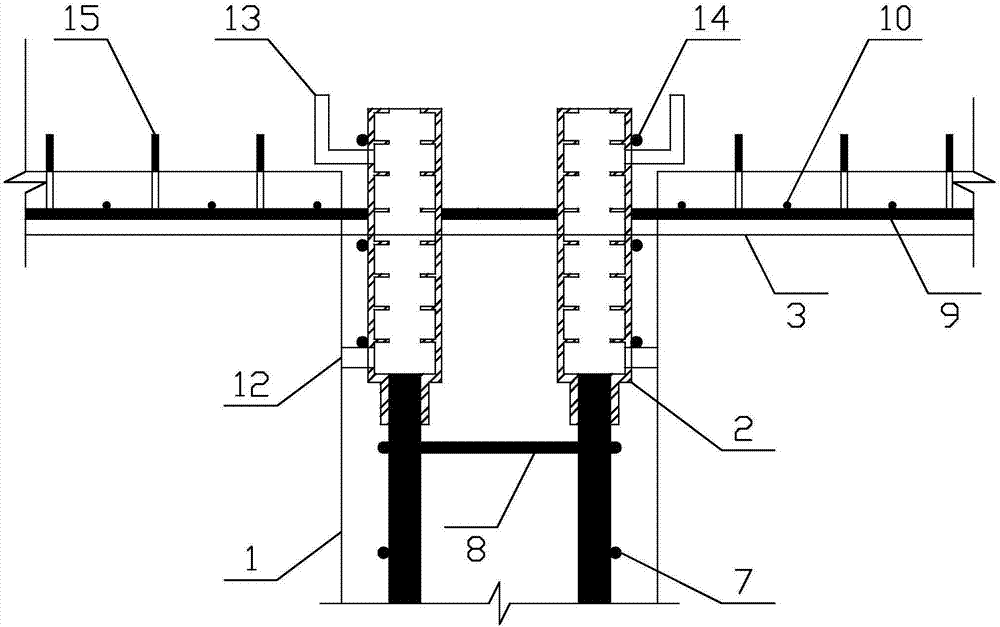

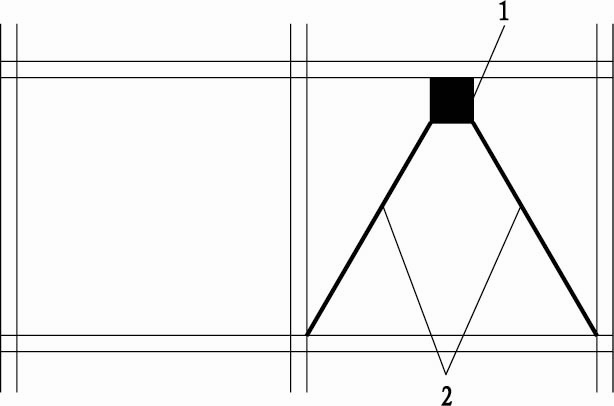

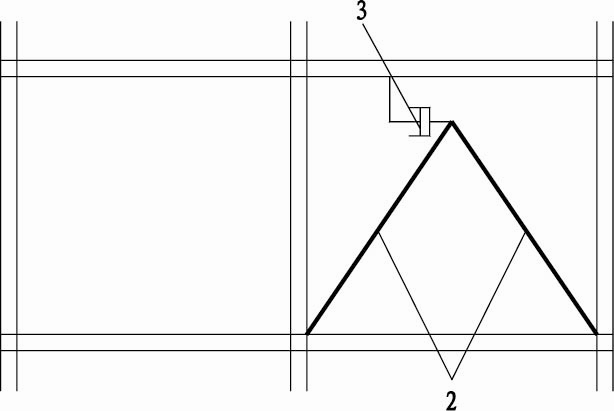

Steel sleeve prefabricated assembly type pier with shear nails

InactiveCN106192730AReduce workloadSave steelBridge structural detailsBridge erection/assemblyRebarPlastic hinge

The invention discloses a steel sleeve prefabricated assembly type pier with shear nails. The pier comprises a pier column 1 and a bearing platform 2. A steel sleeve 3 with the shear nails is connected with the bearing platform 2 and the pier column 1. The shear nails 4 on the part, connected with the pier column 1, of the steel sleeve are arranged on the inner side of the steel sleeve, and the shear nails 5 on the part, located in the bearing platform, of the steel sleeve are arranged on the outer side of the steel sleeve. Longitudinal ribs 6 embedded in a pier body are inserted into the part, located in the bearing platform 2, of the steel sleeve. The longitudinal ribs 6 and L-shaped rebars 8 are poured together, and an upsetting head 7 is reserved at the end, located in the bearing platform 2, of each L-shaped rebar 8. The steel sleeve with the shear nails is adopted for connecting the pier column and the bearing platform, a plastic hinge zone is wrapped with the steel sleeve in advance, the earthquake damage that a large amount of surface layer concrete peels off can be avoided, and the normal using performance can be restored through a little restoration work after earthquakes.

Owner:SHANGHAI INST OF TECH

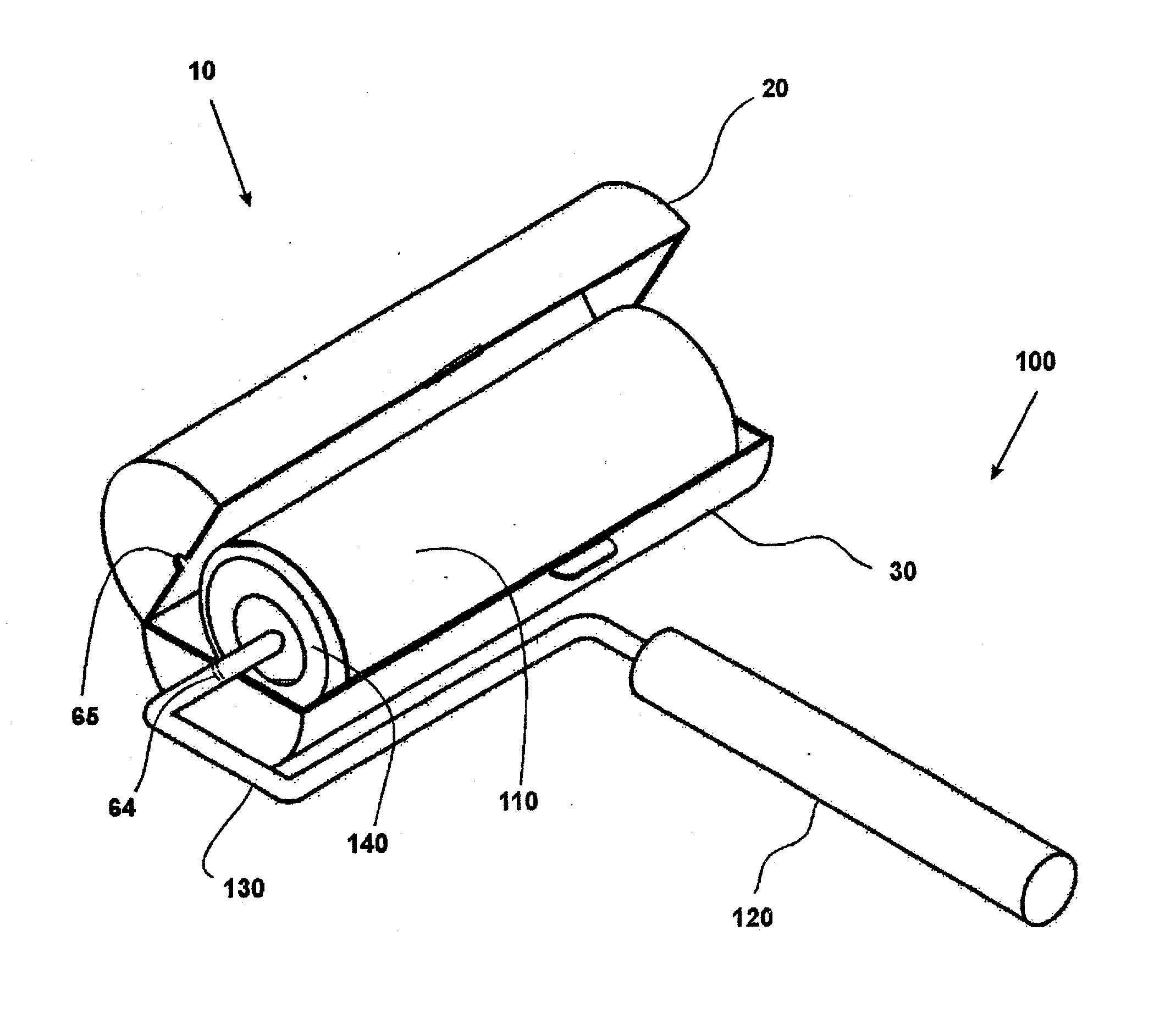

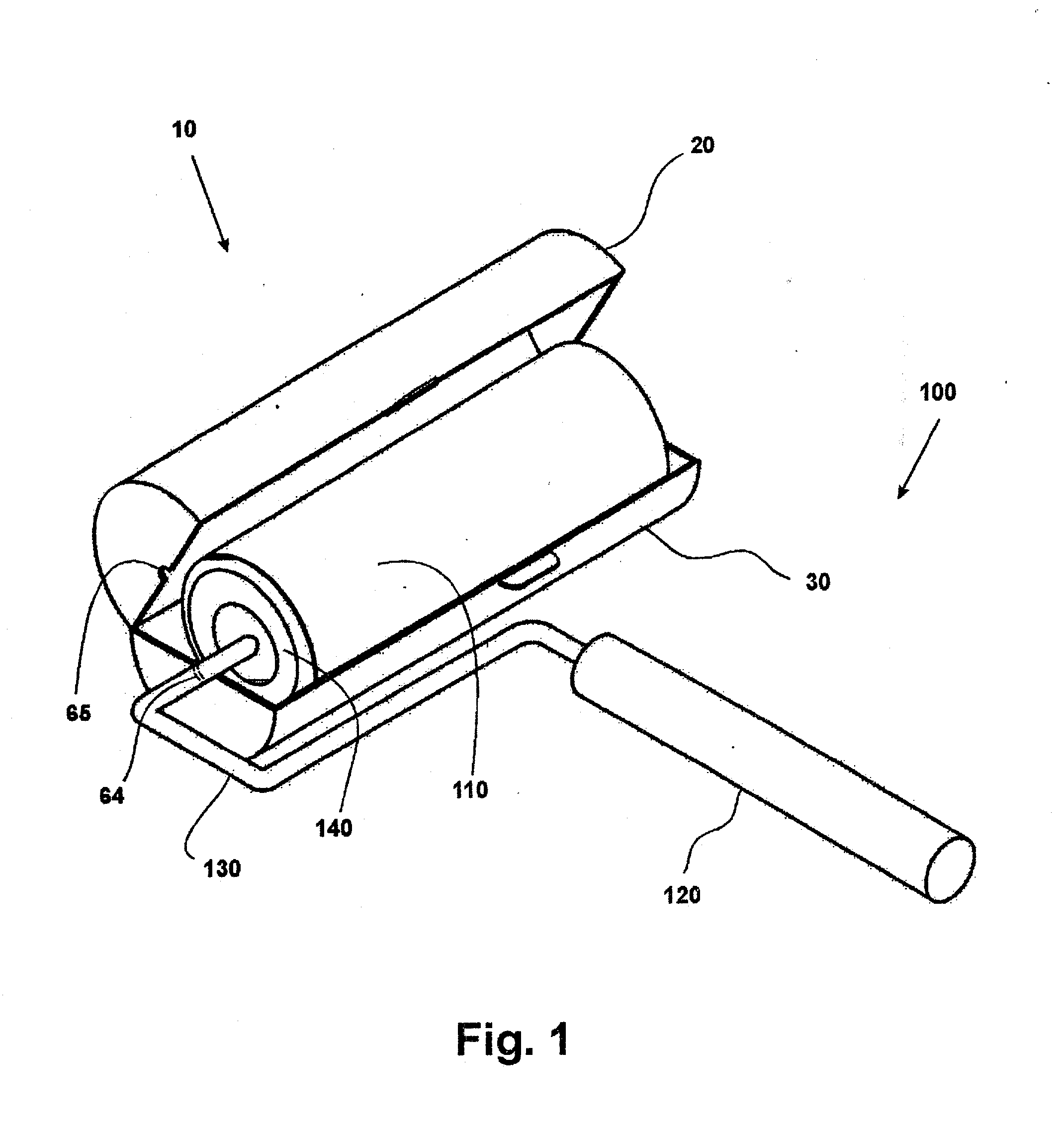

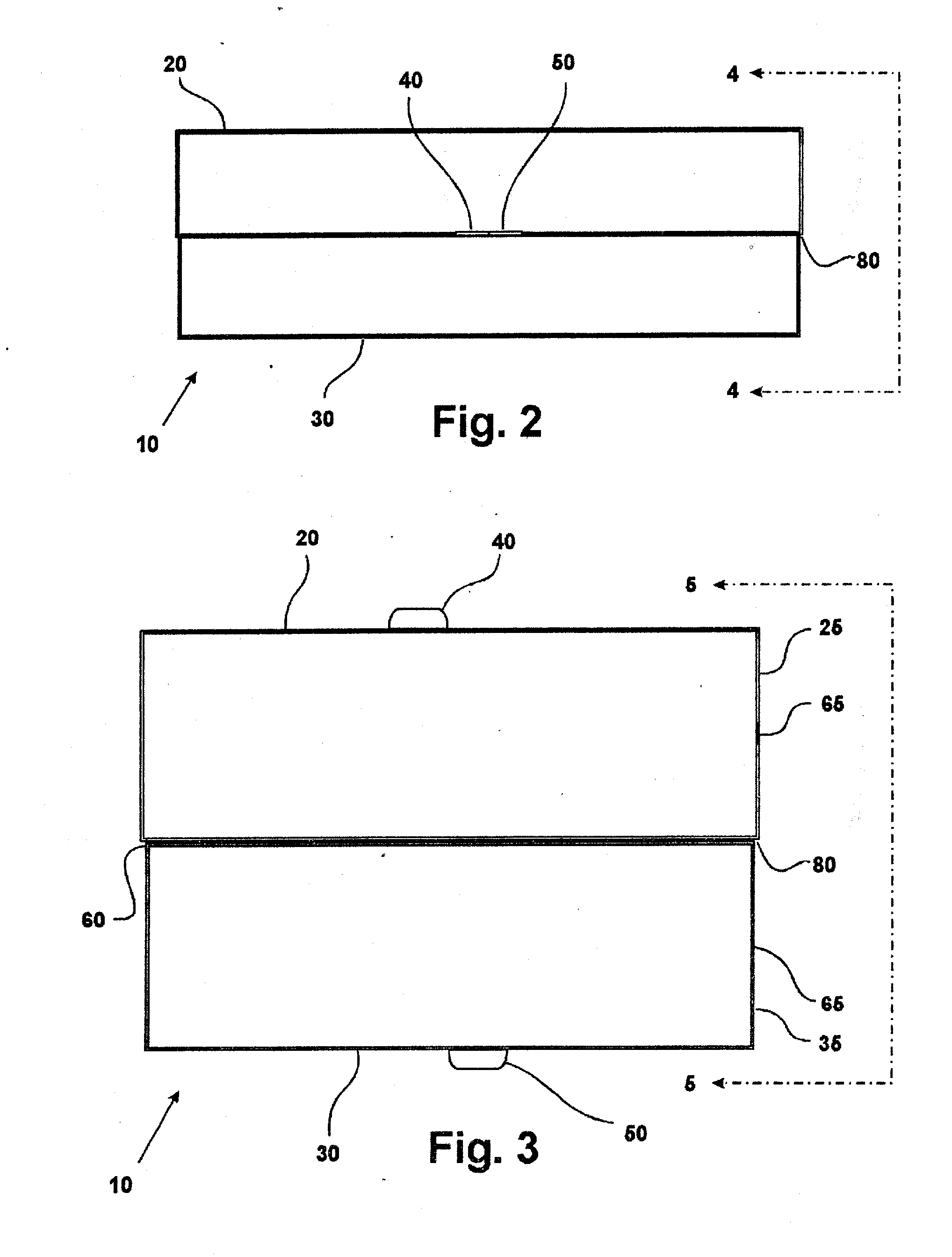

Paint roller case

The present invention involves a molded plastic housing with an integral plastic hinge that opens to receive a wet paint roller cover and roller handle assembly. The present invention provides a hole to allow the paint roller handle shaft to protrude out of the housing. The present invention provides a relatively airtight housing by means of molded overlapping ridges.

Owner:MYERS KENNETH W

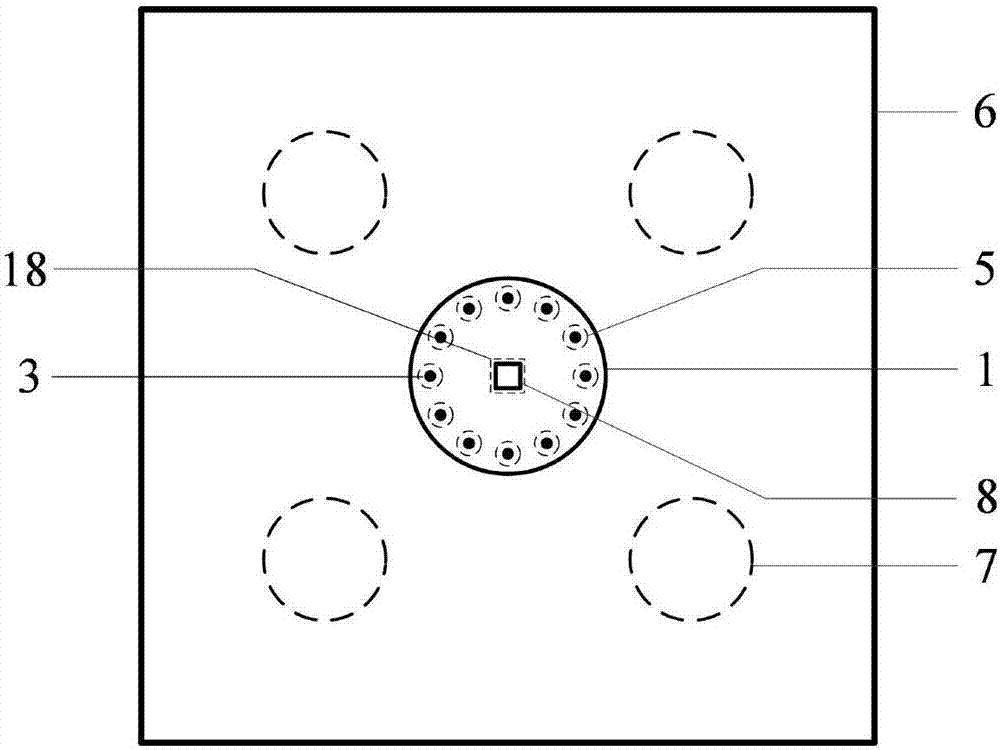

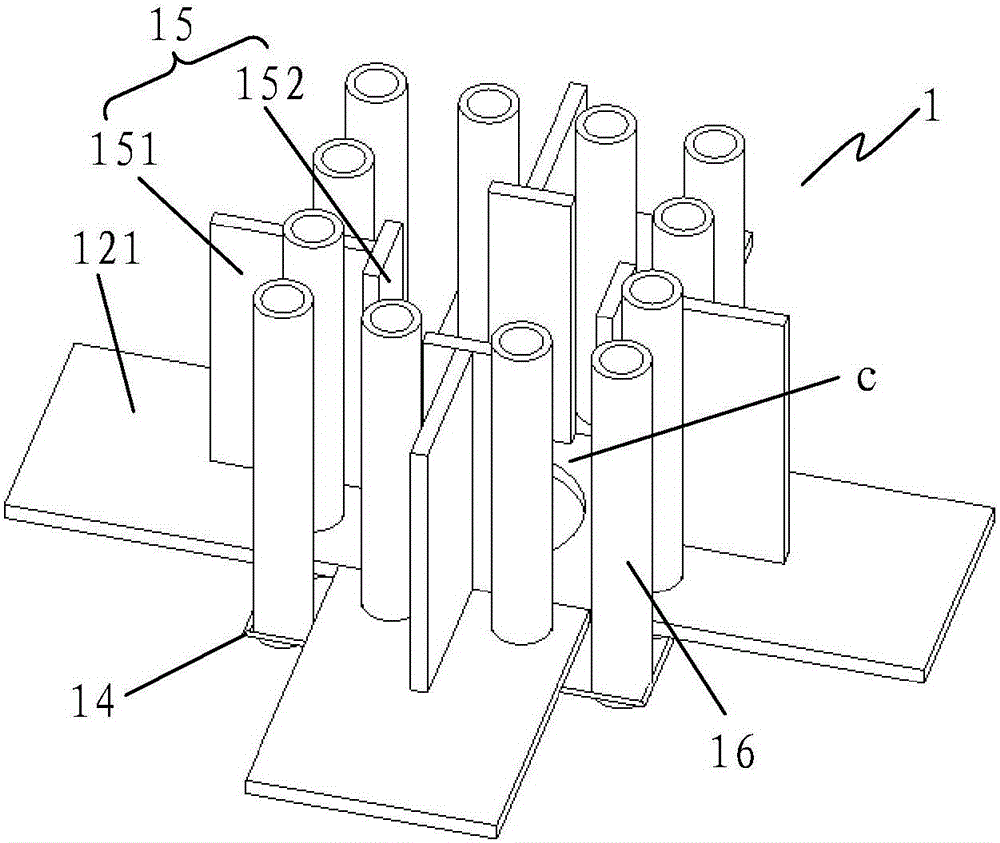

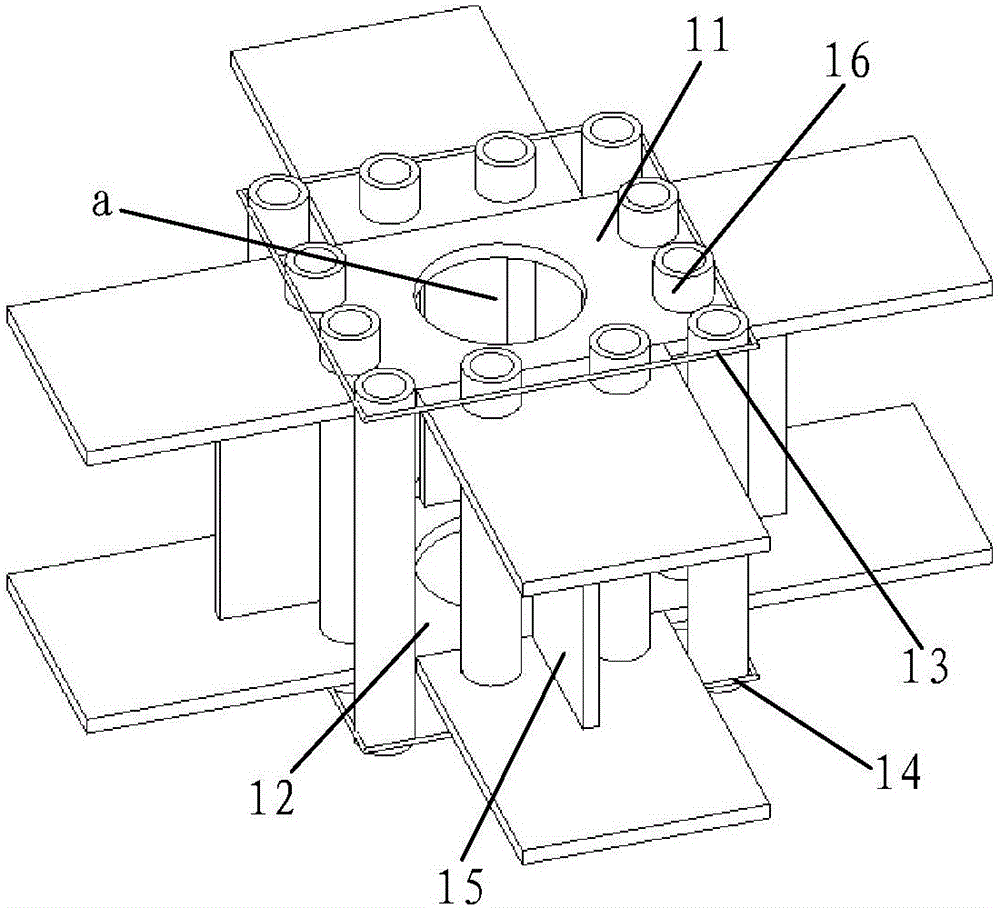

Prefabricated assembling type steel pipe restrained energy-dissipation connection node and construction method

The invention provides a prefabricated assembling type steel pipe restrained energy-dissipation connection node. The steel pipe restrained energy-dissipation connection node comprises a core region pre-buried steel assembly, four porous outer steel plates matched with the core region pre-buried steel assembly, and a plurality of beam end edge web plates, wherein the four porous outer steel plates are arranged around the outer side of the core region pre-buried steel assembly to form an outer steel pipe; steel fiber self-compacting concrete is poured in the outer steel pipe to form a steel fiber self-compacting concrete core region; the beam end edge web plates are arranged between upper and lower flanges of the core region pre-buried steel assembly; and the upper and lower flanges are connected with a prefabricated beam through a cast-in-situ steel fiber self-compacting concrete connection section. The prefabricated assembling type steel pipe restrained energy-dissipation connection node has the advantages that the strength and ductility of concrete of the core region of the node can be improved, and an anti-seismic design concept of a strong node and a weak member is realized; and the energy-dissipation capability of a beam end plastic hinge can be expressed very well, the rigidity degeneration of the plastic hinge is delayed, the shearing-resisting capability of a beam end is improved, and the beam end plastic hinge can move outwards.

Owner:建盟设计集团有限公司

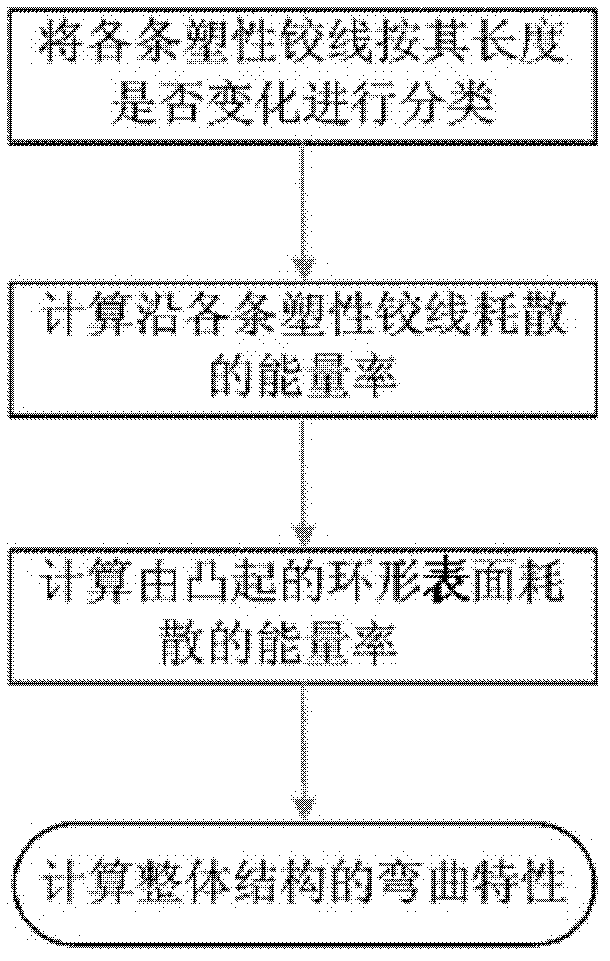

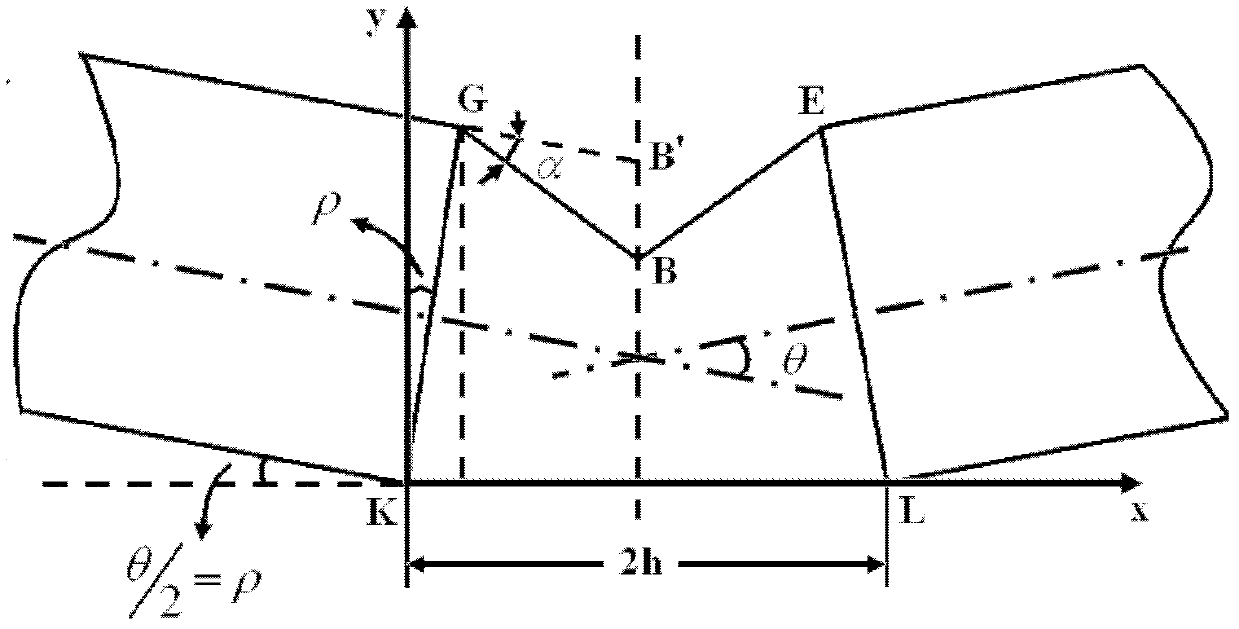

Simplified analysis method for bending property of box-section thin-wall beam

InactiveCN102322842ARapid assessmentMeet the structureMeasurement devicesDesign planElement analysis

The invention discloses a simplified analysis method for the bending property of a box-section thin-wall beam, belonging to the field of car body design. The simplified analysis method for the bending property of the box-section thin-wall beam is mainly used for analyzing the bending deformation of the box-section thin-wall beam during car body collision in a concept car body finite element modelfor anti-collision researches at the concept design stage of a car. The simplified analysis method for the bending property of the box-section thin-wall beam mainly comprises four steps, i.e. classifying plastic hinge lines according to whether the lengths of the plastic hinge lines are changed or not, calculating rate of energy dissipated by the plastic hinge lines, calculating rate of energy dissipated by convex annular surfaces and calculating the bending property of the entire structure. The simplified analysis method for the bending property of the box-section thin-wall beam has the advantages that the requirements on the modeling of the simplified frame structure and the anti-collision analysis of the car body can be satisfied very well, designers can be assisted to rapidly extract the bending properties of the thin-wall beams, the cockamamie work for traditional finite element analysis and tests is avoided, the rapid performance assessment and the rapid modification of a preliminary design plan are realized, and the design cycle is shortened.

Owner:JILIN UNIV

Plastic power distribution cabinet

InactiveCN101908726AImprove insulation performanceReduce weightSubstation/switching arrangement casingsCompression moldingGlass fiber

The invention relates to a plastic power distribution cabinet. The plastic power distribution cabinet is mainly manufactured by manufacturing a front door and a back shell of the plastic power distribution cabinet by performing injection molding or compression molding on a flame-retardant polypropylene resin or a flame-retardant nylon resin or a polyvinyl chloride resin and metal meshes (or manufacturing a front door and a back shell of the plastic power distribution cabinet by performing injection molding on a flame-retardant polypropylene resin or a flame-retardant nylon resin or a polyvinyl chloride resin and glass fiber meshes) and assembling the front door and the back shell by using a plastic hinge. The plastic power distribution cabinet has the characteristics of high insulating property, flame resistance, light weight, paint-free property, aging resistance and low production cost and is widely applied to power distribution systems of power plants, communication departments and enterprises and public institutions.

Owner:王崇高

Inner sleeve constraint folding steel plate energy dissipation support

ActiveCN105507444AImprove stabilityLess prone to out-of-plane bucklingShock proofingGusset plateEngineering

The invention discloses an inner sleeve constraint folding steel plate energy dissipation support. The energy dissipation support comprises a core cylinder, an inner sleeve arranged in the core cylinder, end load bearing plates arranged at cylinder openings in the two sides of the core cylinder, a crossed fixed plate arranged in the inner sleeve and connected with the inner sides of the end load bearing plates and a crossed gusset plate connected to the outer sides of the end load bearing plates. The core cylinder is formed by sequentially connecting multiple energy consumption units. Each energy consumption unit consists of 4n triangles with different surfaces. The energy dissipation support produces pre-folding traces through folding steel plates and can produce plastic hinge lines at the folding traces when bearing a load, and the energy consumption capacity of the support is enhanced through the plastic hinge lines; meanwhile, the sleeve is arranged in the core cylinder to improve annular constraint to the core cylinder, and therefore the rigidity and ultimate bearing capacity of the support can be improved conveniently.

Owner:SOUTHEAST UNIV

Buckling constraint type steel-beam-and-column end-plate connection joint and steel structure building

ActiveCN105839776APosition is easy to controlImprove ductilityProtective buildings/sheltersShock proofingSteel frameEngineering

The invention discloses a buckling constraint type steel-beam-and-column end-plate connection joint and a steel structure building, and belongs to the field of a building steel structure. The buckling constraint type steel-beam-and-column end-plate connection joint comprises a steel beam and a steel column; an end connecting piece is arranged at a joint of the steel beam and the steel column; the end connecting piece comprises a pair of horizontally arranged flange connecting plates and end plates arranged at the tail ends of the flange connecting plates; the free ends of the flange connecting plates are used for being connected with upper and lower flanges of the steel beam; both ends of the end plates are used for being connected with flanges of the steel column; the middle parts of the flange connecting plates are weakened regions. According to the buckling constraint type steel-beam-and-column end-plate connection joint and the steel structure building which are disclosed by the invention, seismic performance is superior, and ductility and the energy consumption ability of a steel frame structure can be obviously improved; plastic hinges are moved outside, so that appearance of the plastic hinges at the welded positions at the end parts of the steel beam is avoided; after an earthquake, the steel beam and the steel column are not damaged, and can be reused only by replacing or repairing the end connecting pieces; moreover, the buckling constraint type steel-beam-and-column end-plate connection joint is convenient to mount.

Owner:SHANDONG UNIV

Self-resetting energy dissipation system with fabricated frame structure and construction method of self-resetting energy dissipation system

ActiveCN109707037AReduce or avoid residual deformationImprove reliabilityProtective buildings/sheltersShock proofingResidual deformationEngineering

The invention discloses a self-resetting energy dissipation system with a fabricated frame structure and a construction method of the self-resetting energy dissipation system. The self-resetting energy dissipation system includes a prefabricated column connected with a foundation, a prefabricated reinforced concrete cross beam, a prefabricated reinforced concrete beam column sub-structure and dryconnection, and further includes a self-resetting energy dissipation device arranged between interbedded prefabricated frames; and the dry connection includes friction-type high-strength bolt connection between columns and pin shaft connection between beam-beam artificial plastic hinge connecting nodes. The invention further discloses the construction method for the self-resetting energy dissipation system with the fabricated frame structure. According to the self-resetting energy dissipation system with the fabricated frame structure and the construction method of the self-resetting energy dissipation system, the shortcomings of current prefabricated structural systems are overcome, and an anti-seismic target of 'strong column and weak beam, strong node and weak component' is realized; through reasonable arrangement of the self-resetting energy dissipation device, the energy dissipation capacity of the structural system is enhanced, residual deformation of the structure is effectivelyreduced or avoided, and the allimportant social value and economic significance for effectively mitigating earthquake disasters in high-intensity areas are achieved; and meanwhile, the construction process is simplified, the construction quality is guaranteed, practicality is high, and use and promotion are convenient.

Owner:CHANGAN UNIV

Fabricated prefabricated shear wall and laminated slab node

PendingCN107100290AAvoid the situation of pulling offImprove integrityWallsProtective buildings/sheltersSlurryShock resistance

The invention discloses a fabricated prefabricated shear wall and laminated slab node. The fabricated prefabricated shear wall and laminated slab node comprises a prefabricated shear wall and a laminated slab; a grouting sleeve is arranged at a node body of the prefabricated shear wall and the laminated slab, the lower portion of the grouting sleeve is buried in the upper end of the prefabricated shear wall, and the rest part of the grouting sleeve is located in a post-poured concrete laminated layer of the laminated slab; the bottom end of the grouting sleeve is arranged at the top ends of vertical steel bars located in the prefabricated shear wall, the vertical steel bars downwards and outwards extend out of a prefabricated shear wall located on an upper floor, and the vertical steel bars are inserted into the grouting sleeve from the top end of the grouting sleeve; and a slurry discharging pipe and a grouting pipe are arranged on the upper portion and the lower portion of the grouting sleeve correspondingly, and a grouting material is poured into the grouting sleeve from the grouting pipe till the grouting material overflows from the slurry discharging pipe to enable the grouting sleeve to be completely filled with the grouting material. The grouting sleeve is a connecting piece of the upper-layer shear wall and the lower-layer shear wall, and a plastic hinge is formed at the bottom of the grouting sleeve. The prefabricated shear wall and a prefabricated plate form the wall plate node in an engaged mode through mutual connecting and binding among the grouting sleeve, a steel bar net piece and the post-poured concrete, and integrality and shock resistance of the node are improved.

Owner:广东省建科建筑设计院有限公司 +1

Energy-dissipation beam column node of buckling-restrained bracing

InactiveCN101831959AAvoid soldering processReduce adverse effectsShock proofingEngineeringSteel columns

The invention discloses an energy-dissipation beam column node of a buckling-restrained bracing, relating to a beam column node and aiming to solve the problems that an energy-dissipation damper which is additionally arranged to dissipate seismic energy results in the use functional limitation of buildings, a plastic hinge which is formed by the yielding of a structural member (a beam end) to dissipate the energy results in difficult seismic rehabilitation, and the like. In the invention, two steel base plates are fixed on the column flange of an I-steel column and positioned between the I-steel column and angle steel connectors, the column flange of the I-steel column is in fastening connection with the two base plates and the two angle steel connector, the two angle steel connectors are in fastening connection with a girder web of an I-steel girder, an upper buckling-restrained energy-dissipation bracing member is arranged close to the upper girder flange of the I-steel girder, a lower buckling-restrained energy-dissipation bracing member is arranged close to the lower girder flange of the I-steel girder, and the upper and the lower buckling-restrained energy-dissipation bracing members are respectively in fastening connection with the column flange of the I-steel column and the girder web of the I-steel girder. The invention is applied to the seismic resistance and earthquake proofing of building main bodies.

Owner:HARBIN INST OF TECH

Universal hinge

Owner:PENDARVIS ERIC DEMPSEY

Joint connection of regeneration cubage concrete combination beam-column and construction method thereof

ActiveCN106522381ASolve delivery difficultiesReduce deliveryBuilding constructionsConcrete beamsRebar

The invention discloses joint connection of a regeneration cubage concrete combination beam-column. A square steel pipe regeneration cubage concrete column, a U-shaped steel-encased regeneration cubage concrete beam, a U-shaped steel connecting piece of which a bottom plate is weakened locally and the single end is widened, a steel connecting plate with a groove, and a short reinforcing bar of which the single end is provided with a thread are included. The invention further provides a construction method of joint connection of the regeneration cubage concrete combination beam-column. According to joint connection of the regeneration cubage concrete combination beam-column and the construction method thereof, on the one hand, as no core penetrating component exists in a joint core area, the problem that large-dimension waste concrete block throwing construction is difficult is solved, moreover, the procedures of rebar binding, formwork assembling, formwork disassembling and the like can be decreased by adopting a U-shaped steel-encased part, construction is convenient and rapid, and the building industrialized requirement is met; and on the other hand, by arranging the U-shaped steel connecting piece of which the bottom plate is weakened locally and the single end is widened, and the short reinforcing bar of which the diameter is smaller than that of a longitudinal rebar on the upper portion of the beam and the single end is provided with the thread, the end of the beam is formed into a plastic hinge through yielding at first so that a large amount of earthquake energy can be consumed, and the overall anti-seismic property of the structure is improved.

Owner:SOUTH CHINA UNIV OF TECH

Inclination adjusting means for backrest of bassinet

An inclination adjusting means for the backrest of a bassinet is provided, which comprises a bedplate, a backrest, a supporting rod and a band. The bedplate and the backrest are integrally formed in one component and are connected together via plastic hinges. The supporting rod is pivotally connected to the bedplate with a centrally-protruding portion passing through the sliding slot of the backrest. The band is tied in the middle of the centrally-protruding portion of the supporting rod and the free end of the band is suspended and drooped out of the backrest so that a user can easily draw out the band from the rear of the backrest. When a user intends to raise the backrest, he / she can lift the backrest with his finger passing through a semicircular hole provided on the rear portion of the backrest so that the protruding portion of the supporting rod 3 can slide to the lowest point along a slopping slot. Then, when the user releases his finger, the supporting rod will be directed to engage in the front portion of the sliding slot due to its weight. According, the inclination of the backrest is well defined by the supporting rod. When the user intends to level the backrest, he only needs to hold the backrest with his finger hooking the semicircular hole on the backrest and draw the band toward the rear of the backrest with the other hand so that the backrest enters the front portion of the slopping slot to complete the leveling of the backrest.

Owner:WONDERLAND NURSERYGOODS CO LTD

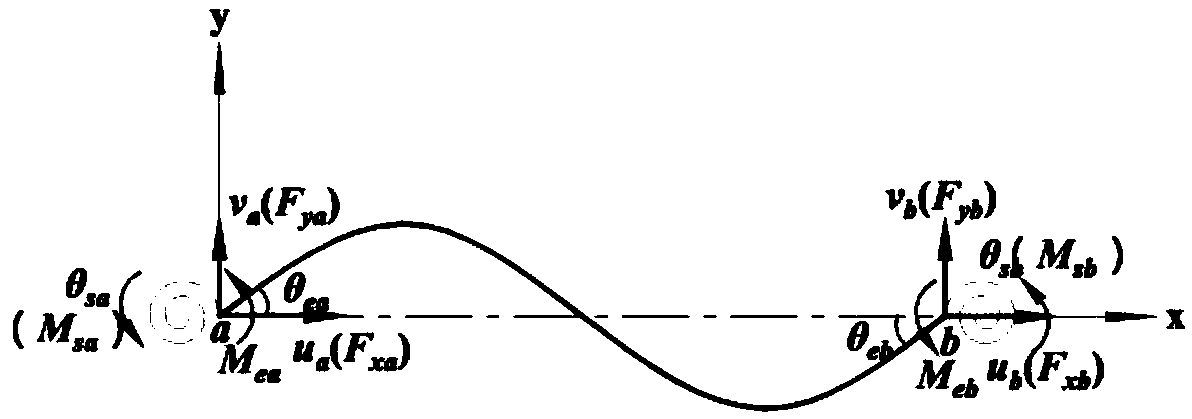

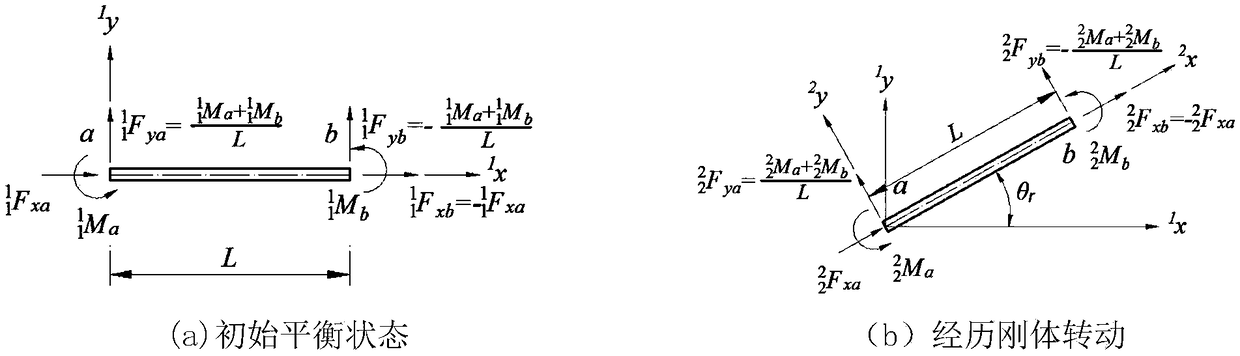

Static nonlinear analysis method of plane frame structure based on rigid body criterion

InactiveCN109299540AWell formedDerivation is simpleDesign optimisation/simulationSpecial data processing applicationsElement modelLinear matrix

The invention discloses a method for analyzing the coupling problem of static geometric nonlinearity and material nonlinearity of a plane frame structure based on a rigid body criterion, aiming at solving the problems that the prior method needs to adopt a complex element stiffness matrix, the number of divided elements is large, and the calculation efficiency and precision are insufficient. The method comprises the following steps: step 1, establishing a concentrated plastic hinge spring planar beam element model; 2, establishing an element stiffness matrix corresponding to the model satisfying the rigid body criterion; 3, establish an incremental iterative process for sol that equation based on the updated Lagrangian scheme and the rigid body criterion; Step 4, iteratively solving the incremental equation to obtain the load-displacement curve and the limit load in the loading process of the structure. The invention has the advantages of being applicable to the coupling problem of geometrical non-linearity and material non-linearity of plane frame structure, simple geometrical stiffness matrix form, linear stiffness matrix, less element division, high calculation efficiency and precision, and is suitable for engineering application.

Owner:CHONGQING UNIV

Stud welding mixed connection node of rectangular concrete filled steel tubular column and H-shaped steel girder

InactiveCN103967133AAddress stressImprove prefabrication rateBuilding constructionsArchitectural engineeringEngineering

The invention discloses a stud welding mixed connection node of a rectangular concrete filled steel tubular column and an H-shaped steel girder. The H-shaped steel girder comprises an upper flange, a web and a lower flange, wherein the upper flange, the web and the lower flange are formed together. The rectangular concrete filled steel tubular column comprises an upper steel tube and a lower steel tube which are vertically arranged adjacently. The node comprises an inner separating board welded to the bottom in the upper steel tube, a through separating board welded to the bottom end of the upper steel tube and a vertical connecting board welded to the side of the bottom of the upper steel tube. The top end of the lower steel tube is welded to the lower surface of the through separating board. The upper flange is opposite to the inner separating board and welded to the upper steel tube. The web is connected with the vertical connecting board through high strength bolts. The lower flange is fixedly connected with the through separating board. According to the node, stud welding mixed connection is adopted, the node can be fast installed in the position in a field, a construction period can be obviously shortened, and the assembly process is facilitated. Meanwhile, due to the arrangement of the through separating board, a girder-end plastic hinge is moved outwards, the steel girder is damaged before the node, and safety of the node is guaranteed.

Owner:TIANJIN UNIV

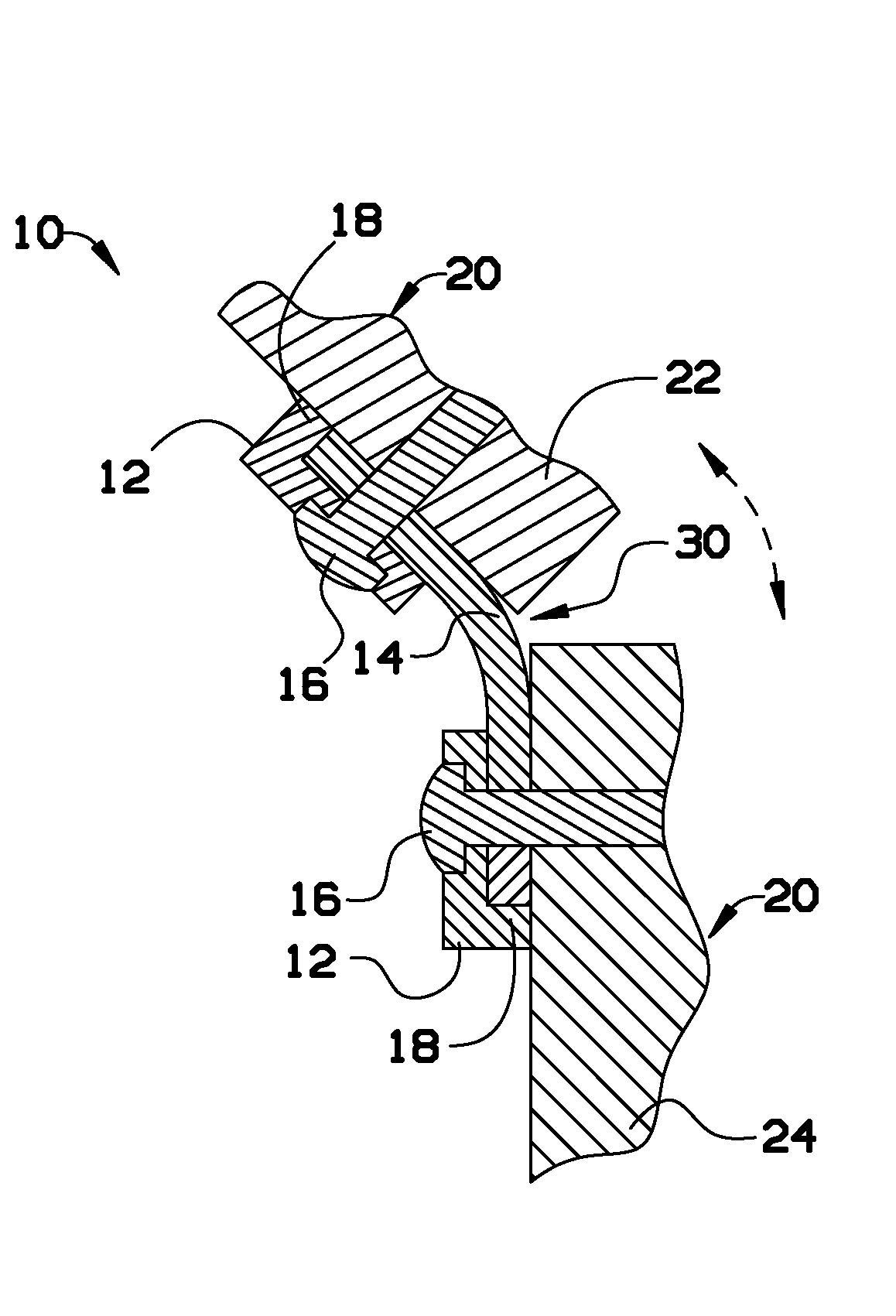

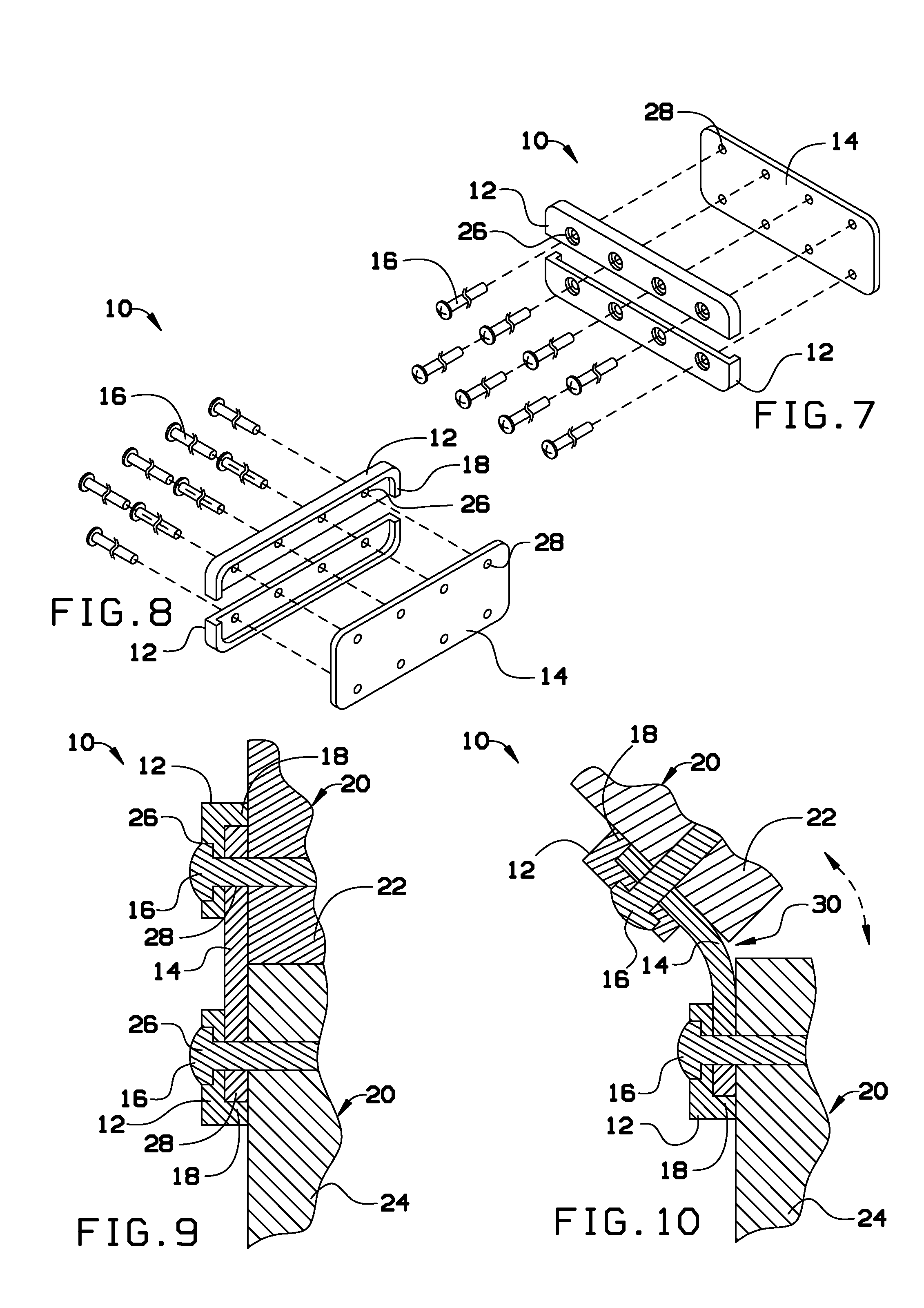

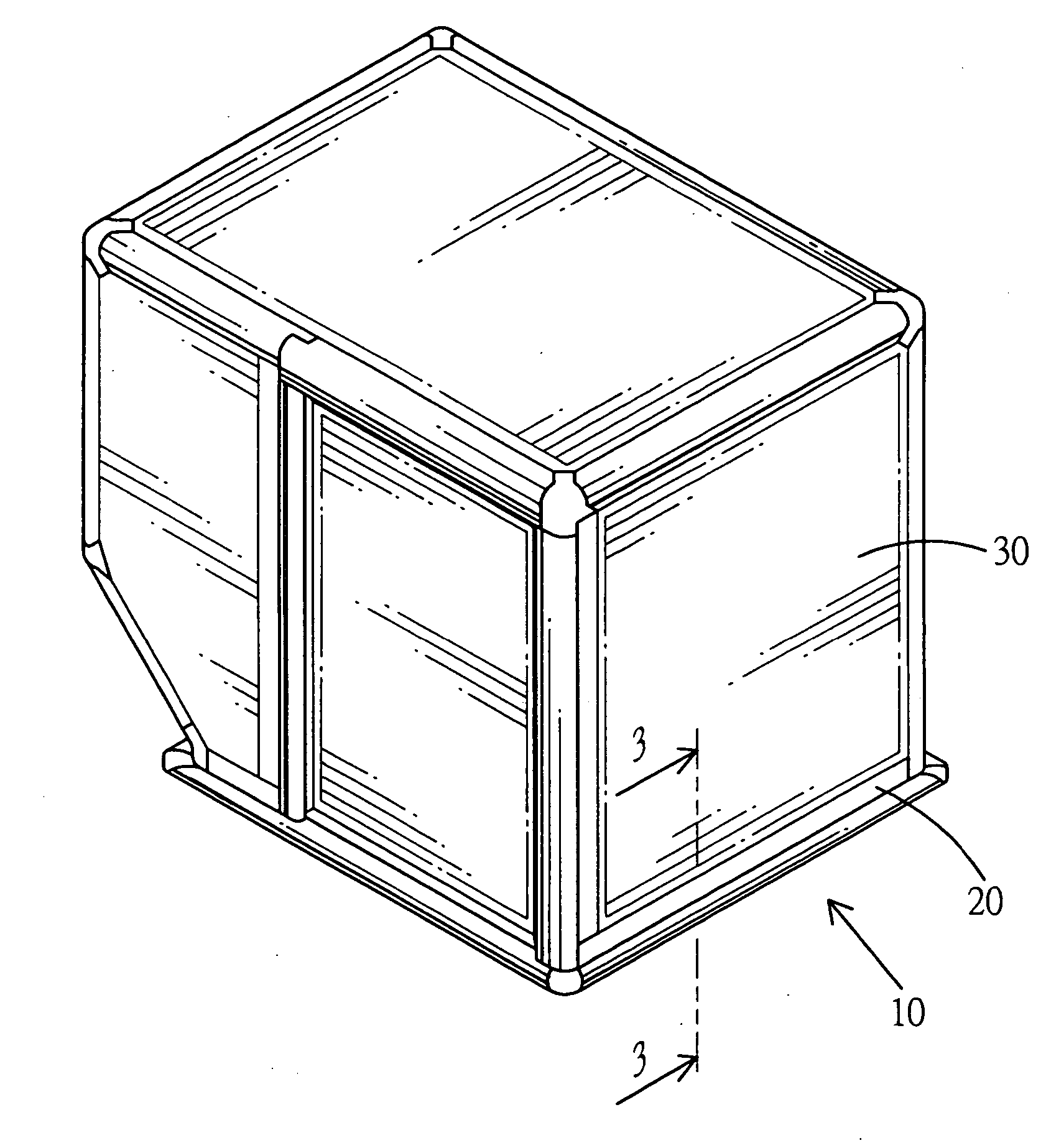

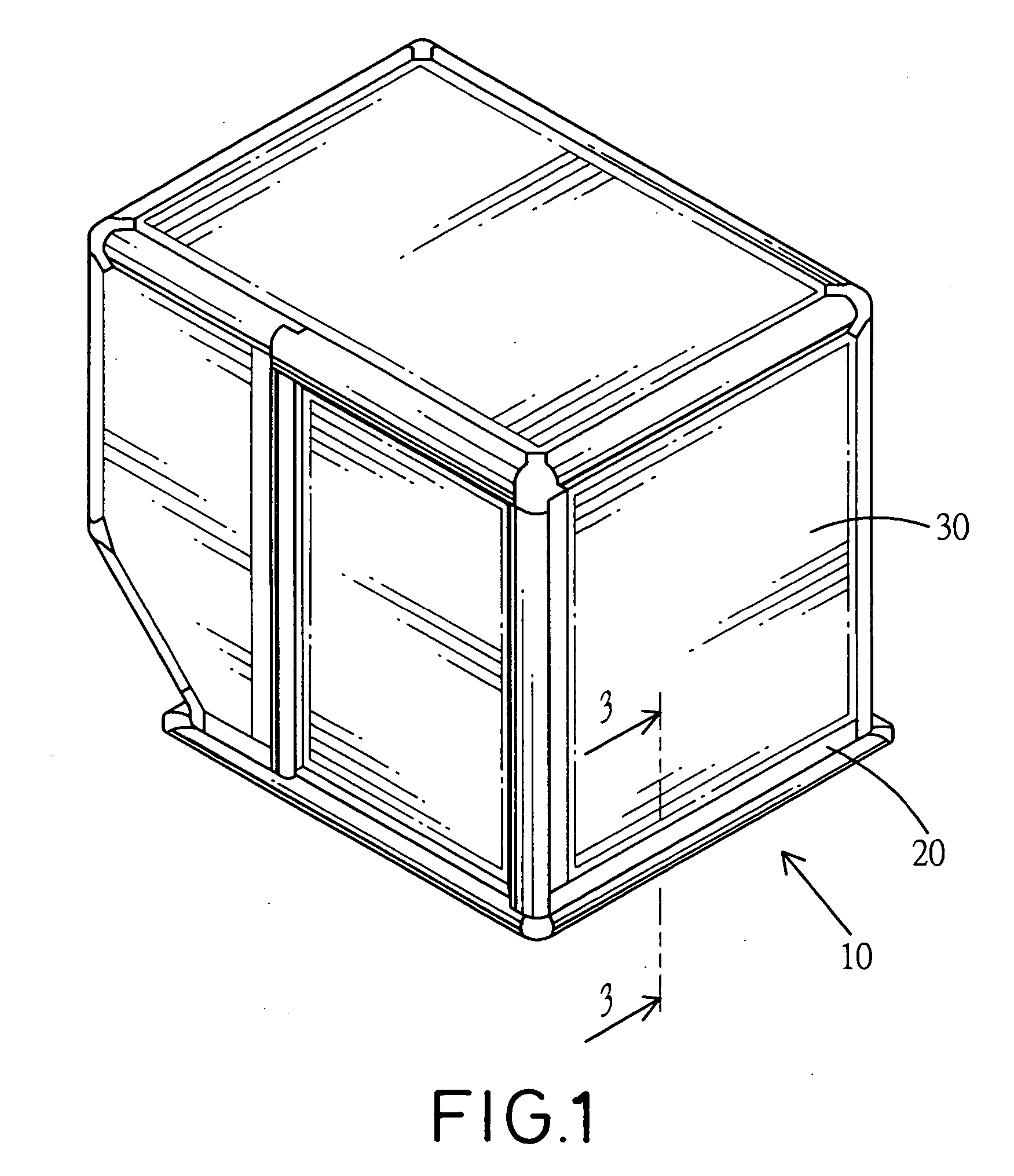

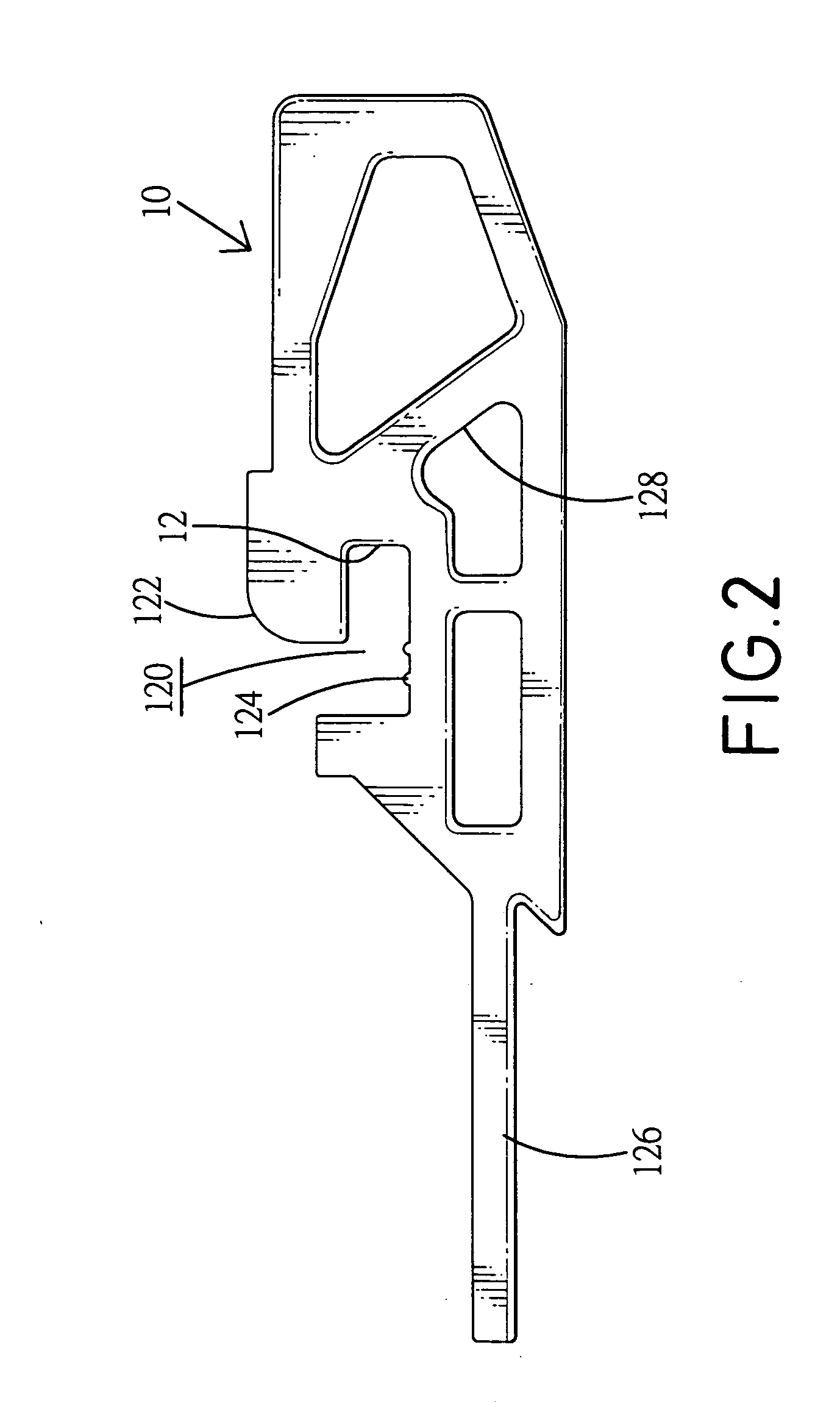

Connection device for use with a blast-resistant container

InactiveUS20070039954A1Large strainStrong forceLarge containersRigid containersPlastic hingeElectrical and Electronics engineering

A connection device for use with a blast-resistant container comprises a frame with a recess, and a connecting member. An arcuate surface is formed on the outside of the opening of the recess. The connecting member is connected to the frame at one end with a head engaged in the recess and connected to a side panel at the other end. Thus, this connection device can transmit strong membrane force between each two panels of a container and meet the connection requirement of a blast-resistant container. When there is a blast, the connection device is able to confine the blast within the container in that the maximum strain of the plastic hinge in the connecting member can be controlled by the curvature of that arcuate surface formed on the frame.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com