Patents

Literature

401results about How to "Reduce shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

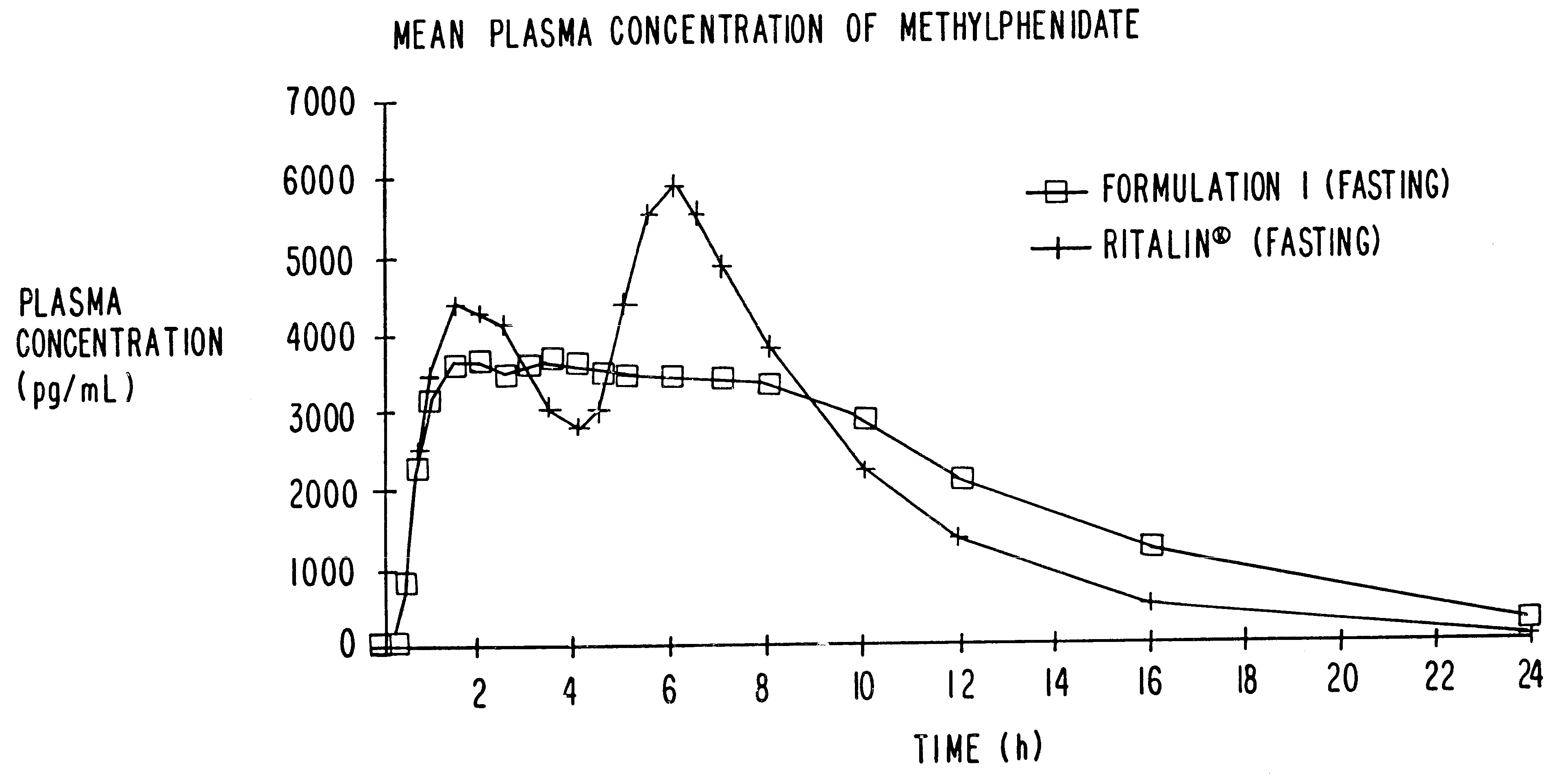

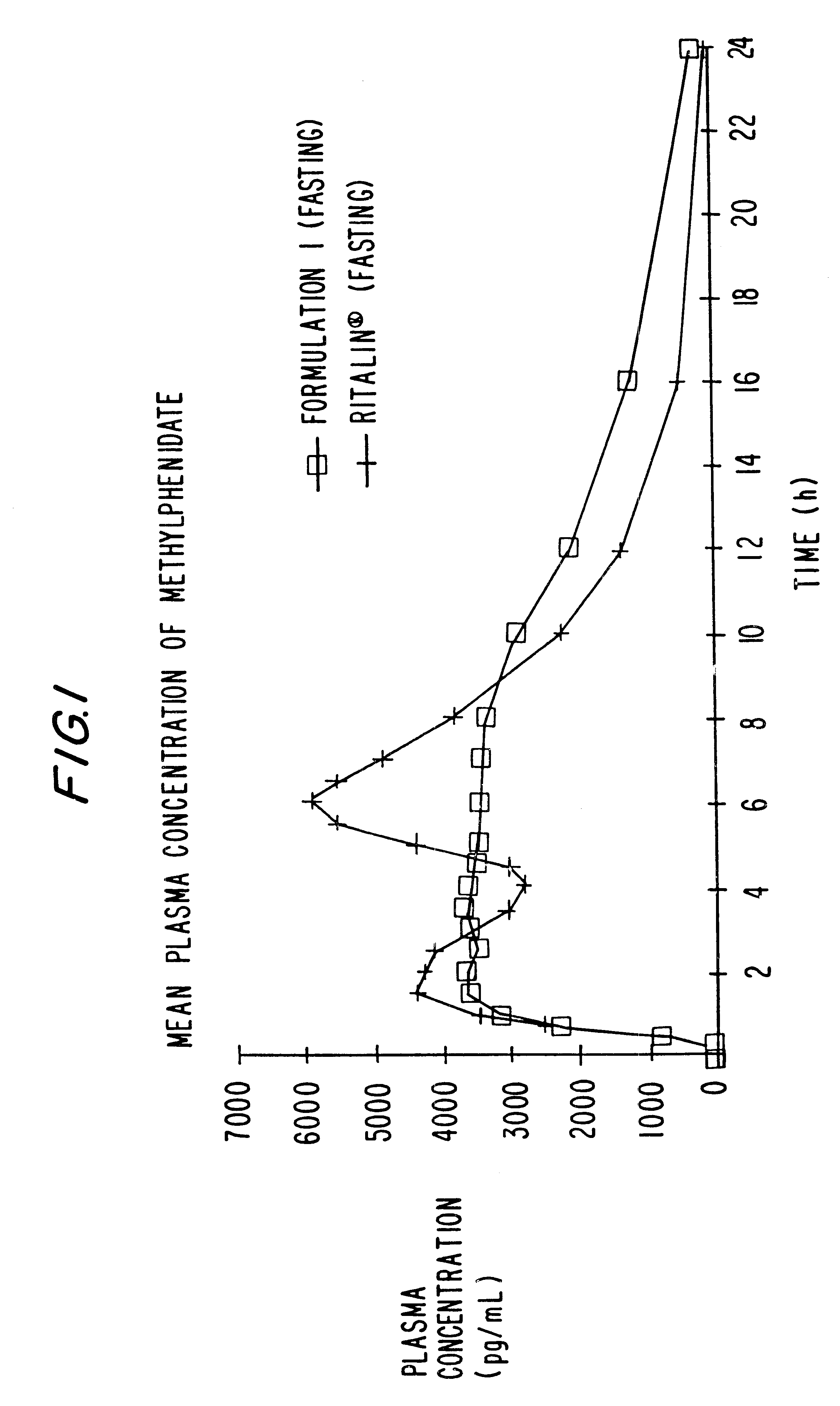

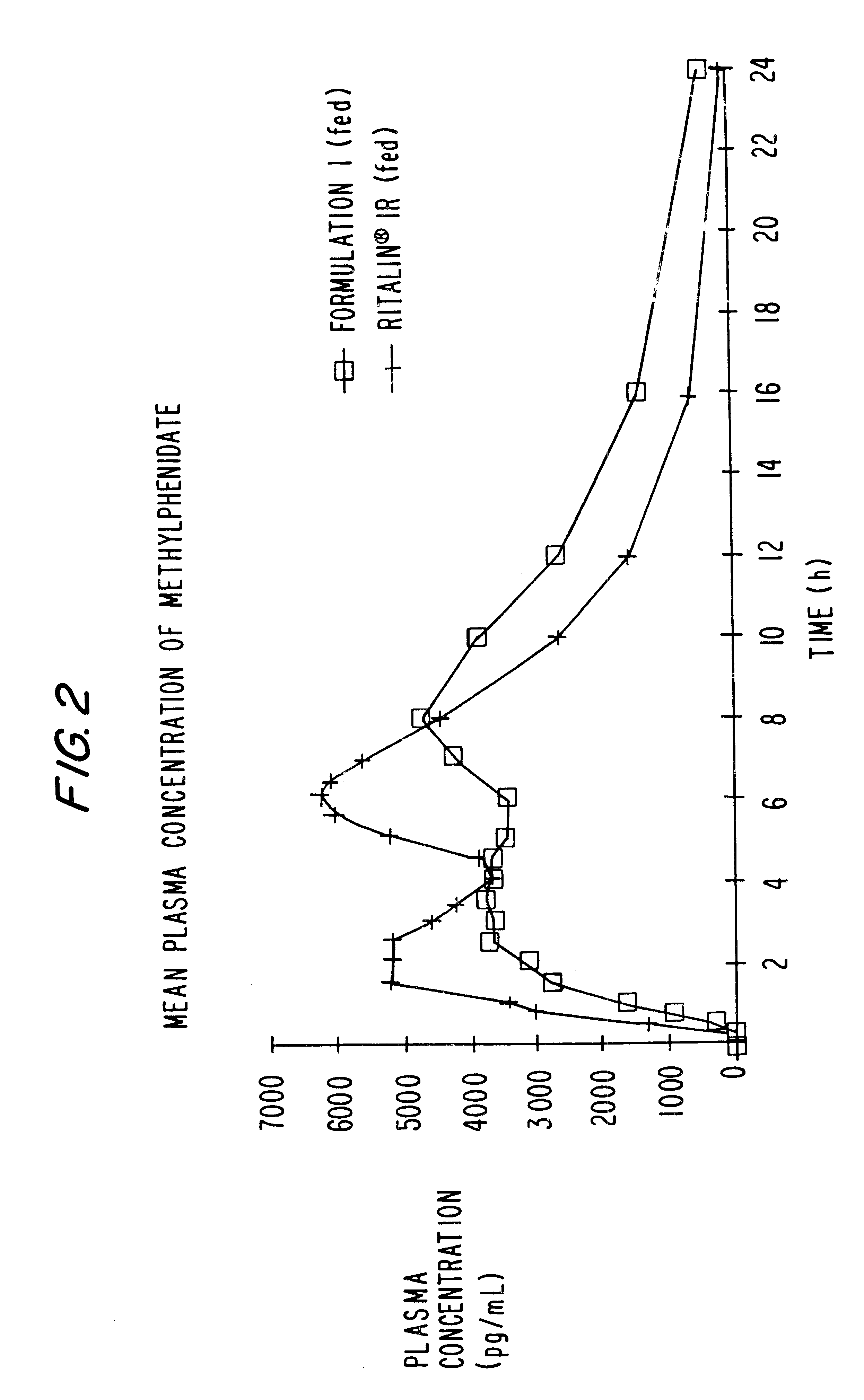

Controlled release formulations having rapid onset and rapid decline of effective plasma drug concentrations

InactiveUS6419960B1Patient compliance is goodGood retarding effectPowder deliveryOrganic active ingredientsImmediate releasePlasma drug concentration

The invention is directed to oral modified / controlled release drug formulations which provide a rapid initial onset of effect and a prolonged duration of effect. Preferably, the peak concentration is lower than that provided by the reference standard for immediate release formulations of the drug, and the duration of effect falls rapidly at the end of the dosing interval.

Owner:RHODES PHARMA LP

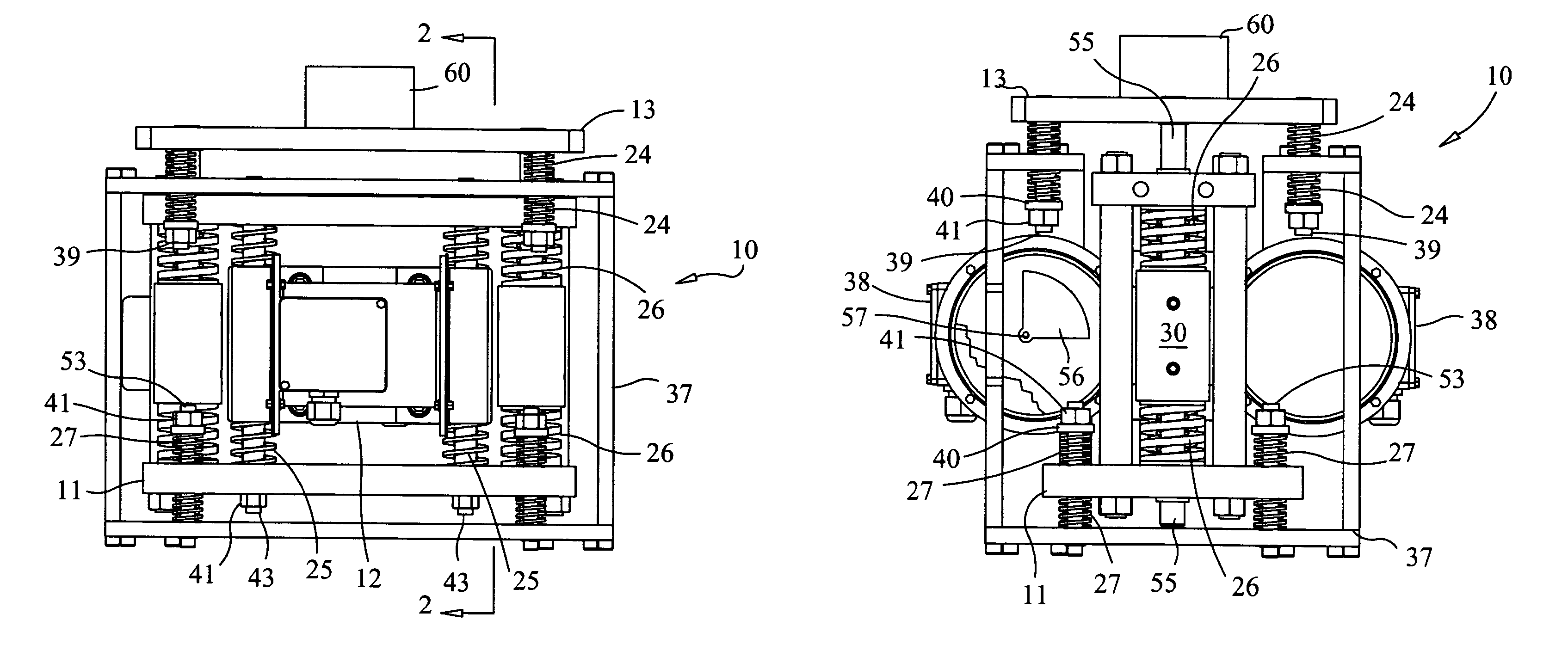

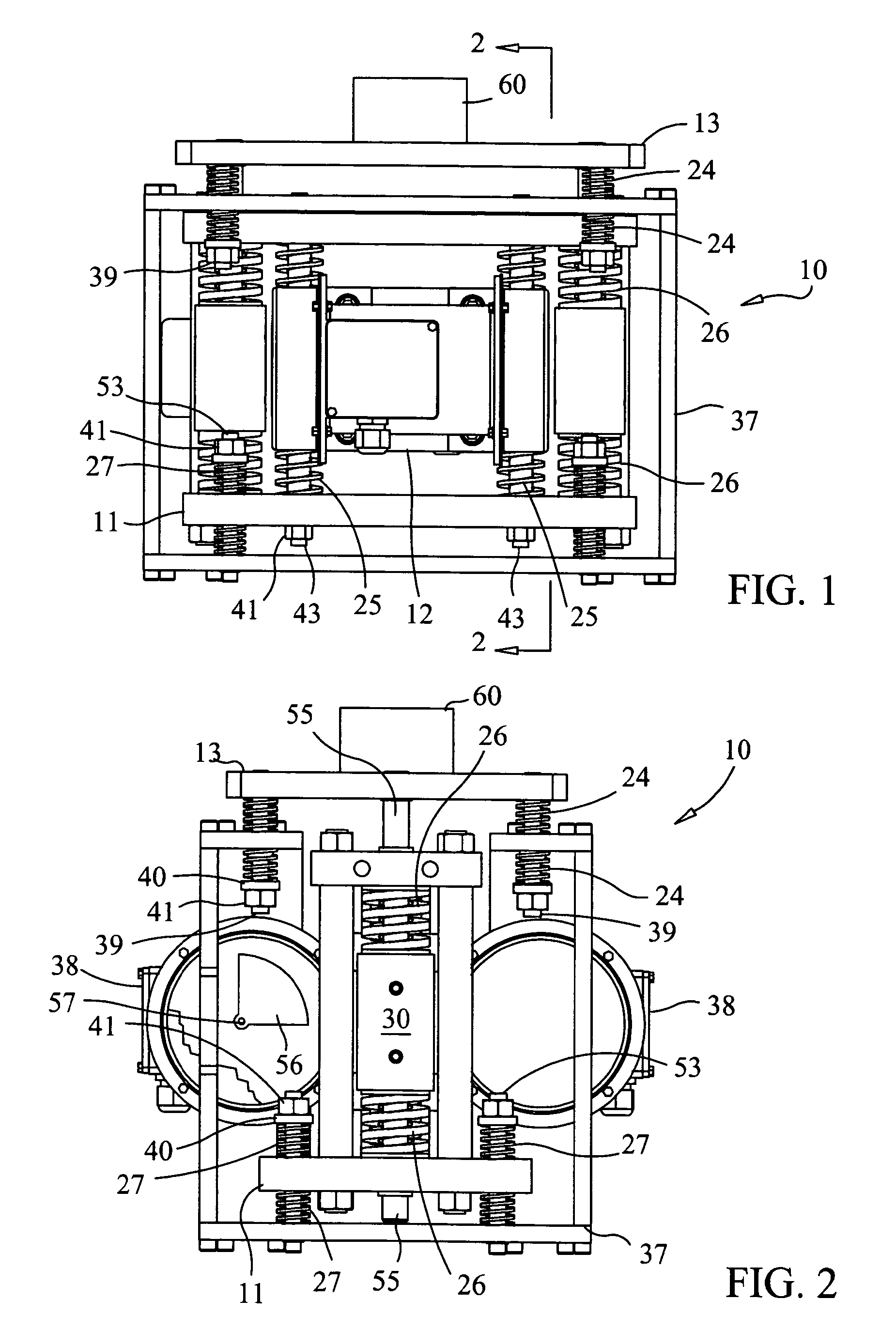

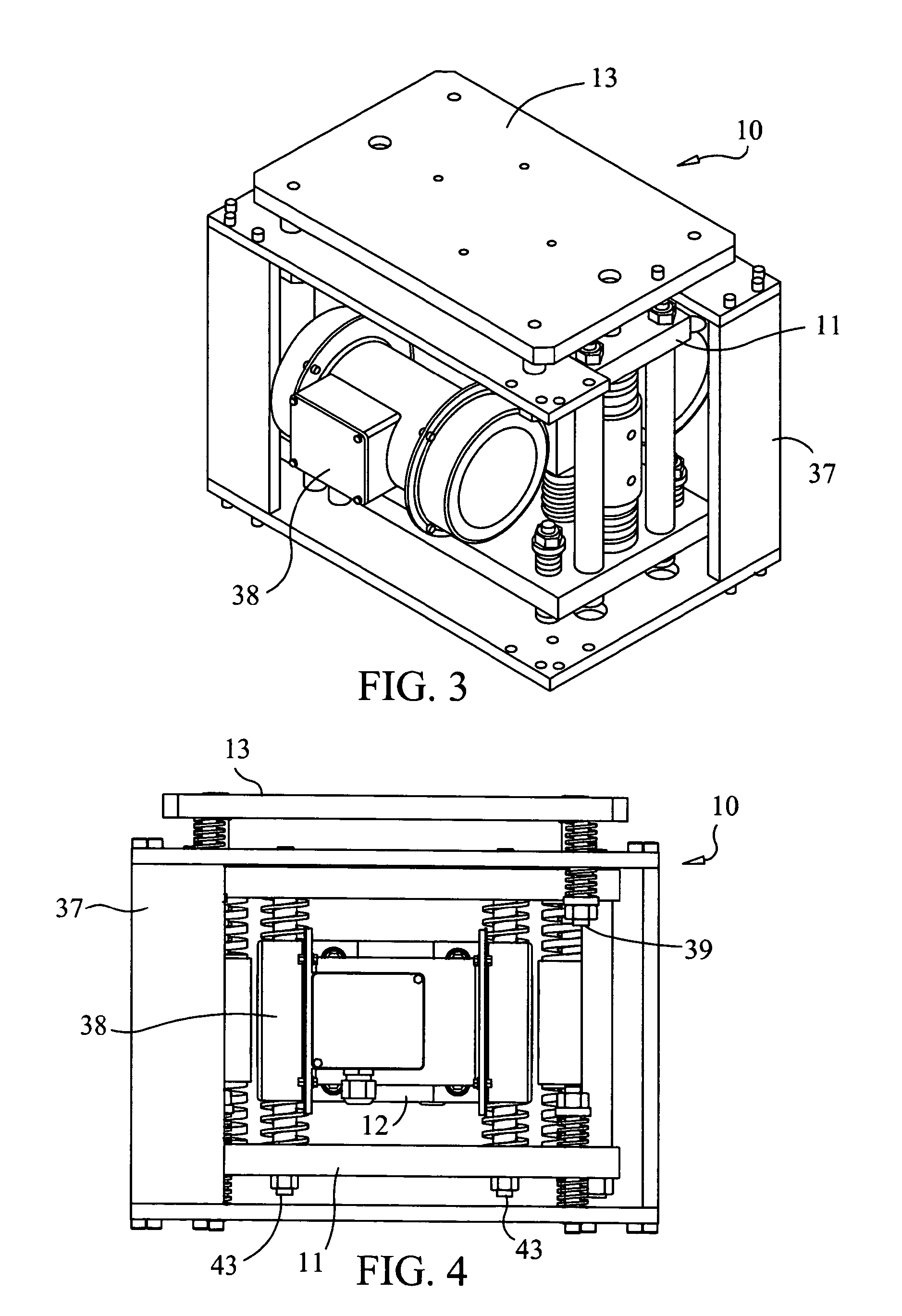

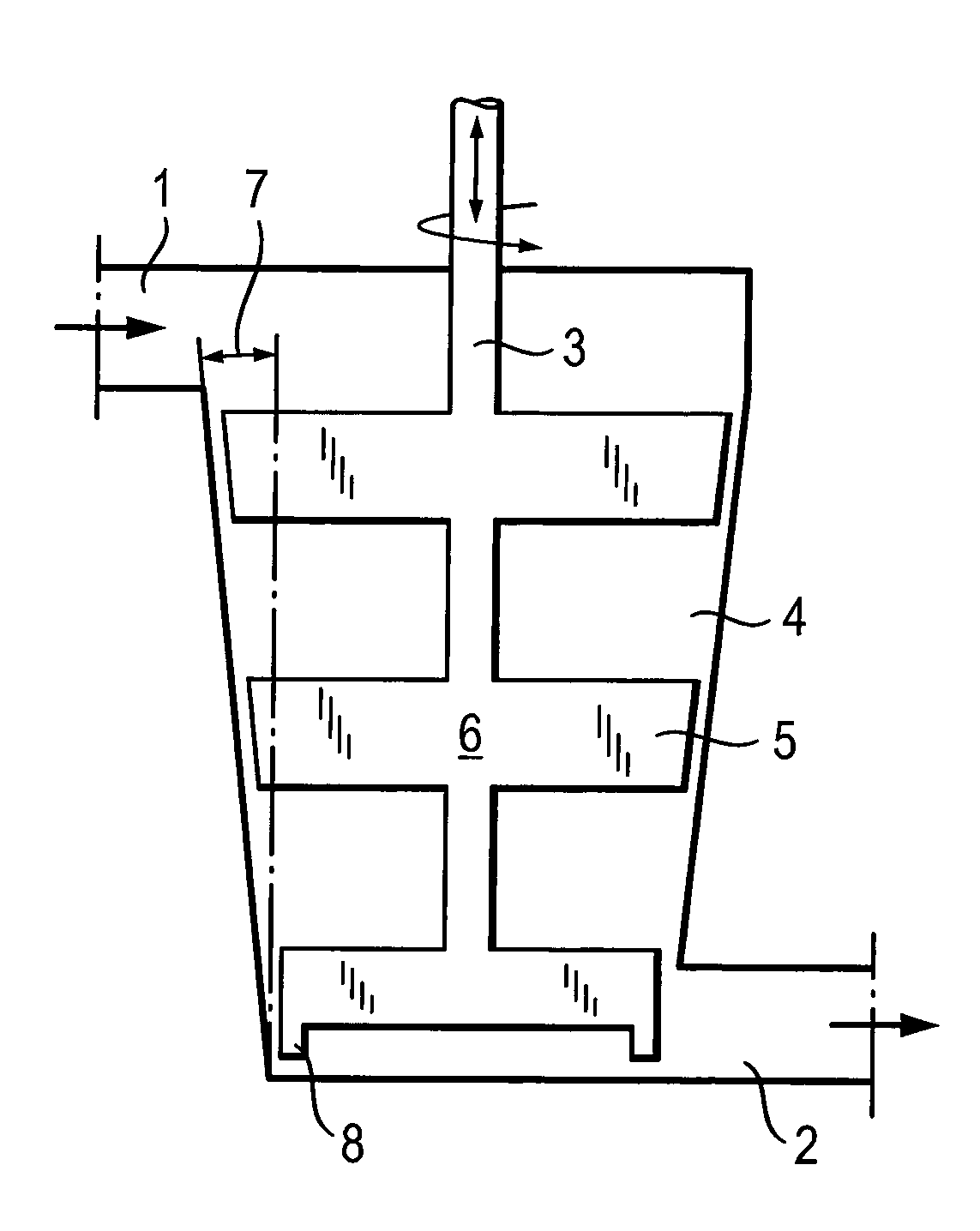

Apparatus and method for resonant-vibratory mixing

ActiveUS7188993B1Reduce the overall heightImprove bearing lifeShaking/oscillating/vibrating mixersTransportation and packagingLinear motionElectronic controller

An apparatus and method for mixing fluids and / or solids in a manner that can be varied from maintaining the integrity of fragile molecular and biological materials in the mixing vessel to homogenizing heavy aggregate material by supplying large amounts of energy. Variation in the manner of mixing is accomplished using an electronic controller to generate signals to control the frequency and amplitude of the motor(s), which drive an unbalanced shaft assembly to produce a linear vibratory motion. The motor may be a stepper motors a linear motor or a DC continuous motor. By placing a sensor on the mixing vessel platform to provide feedback control of the mixing motor, the characteristics of agitation in the fluid or solid can be adjusted to optimize the degree of mixing and produce a high quality mixant.

Owner:RESODYN ACOUSTIC MIXERS

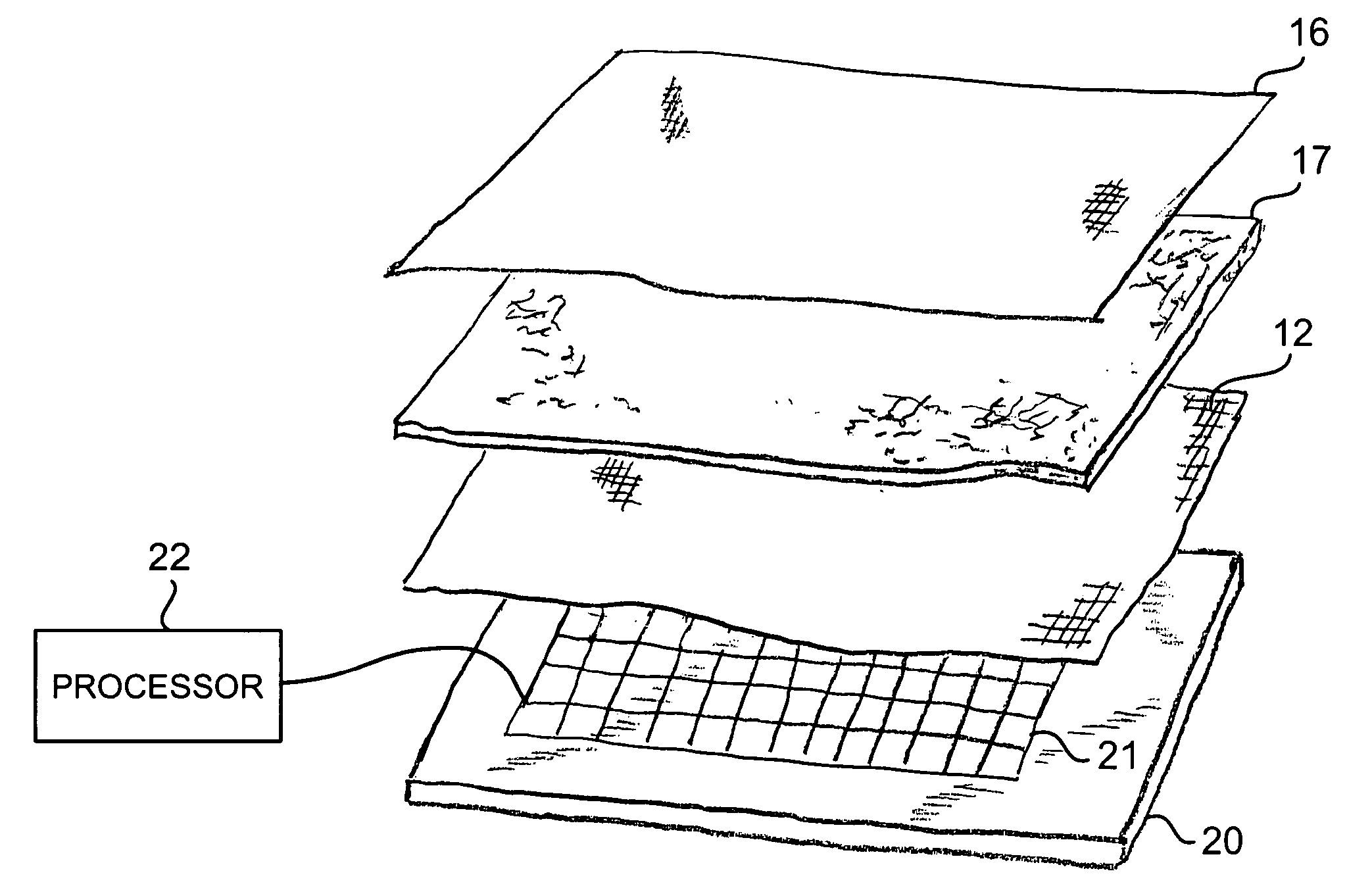

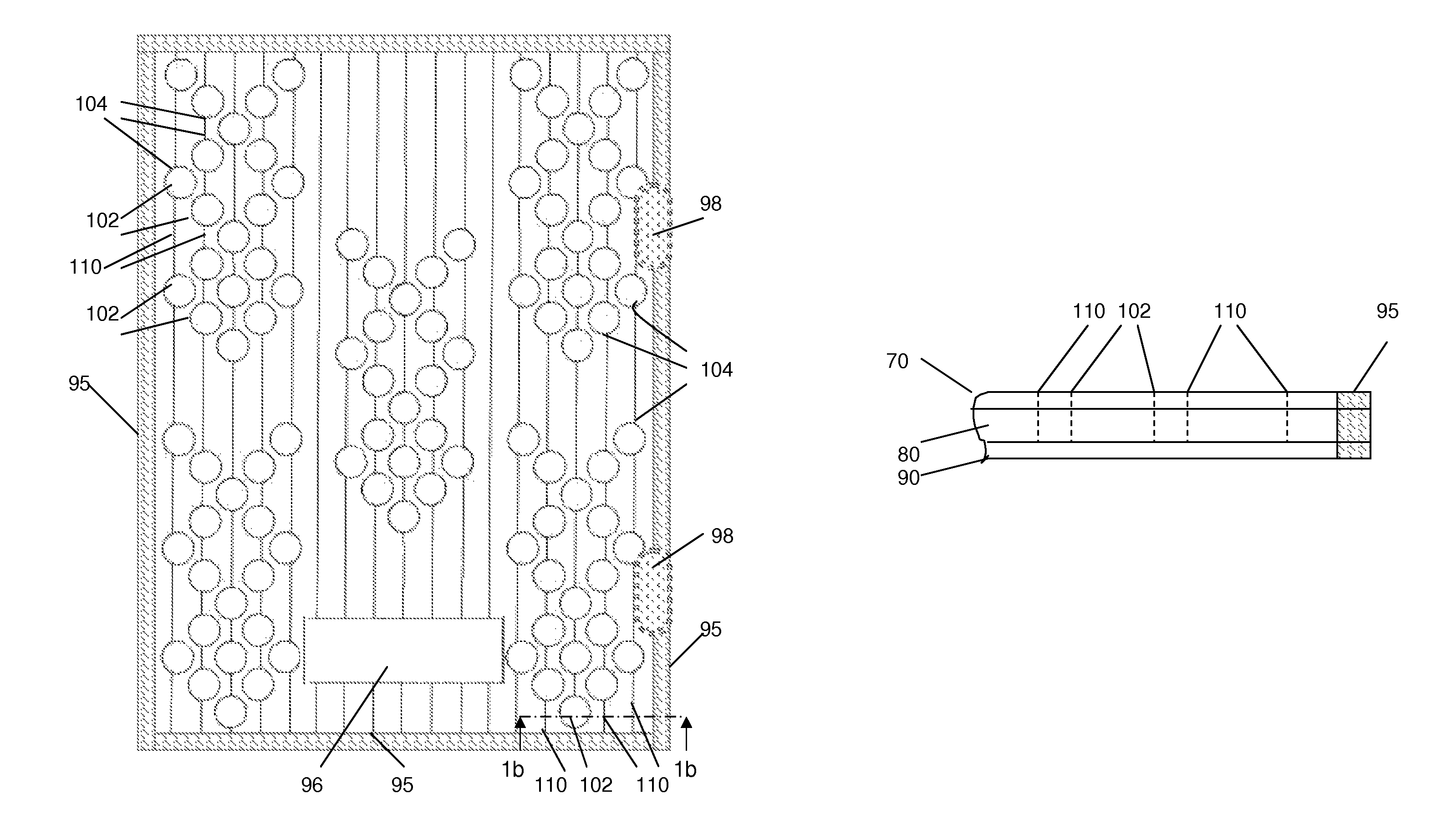

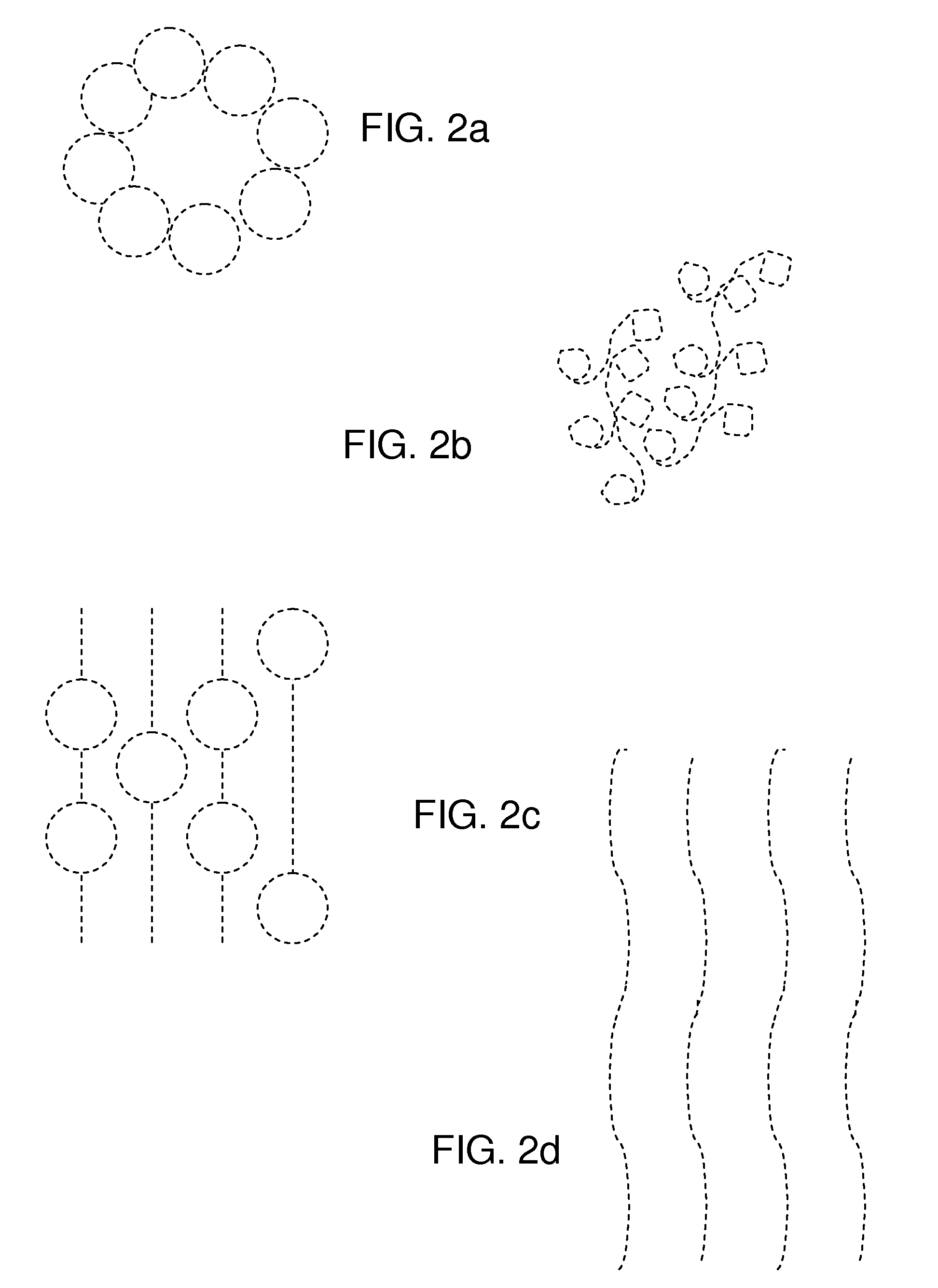

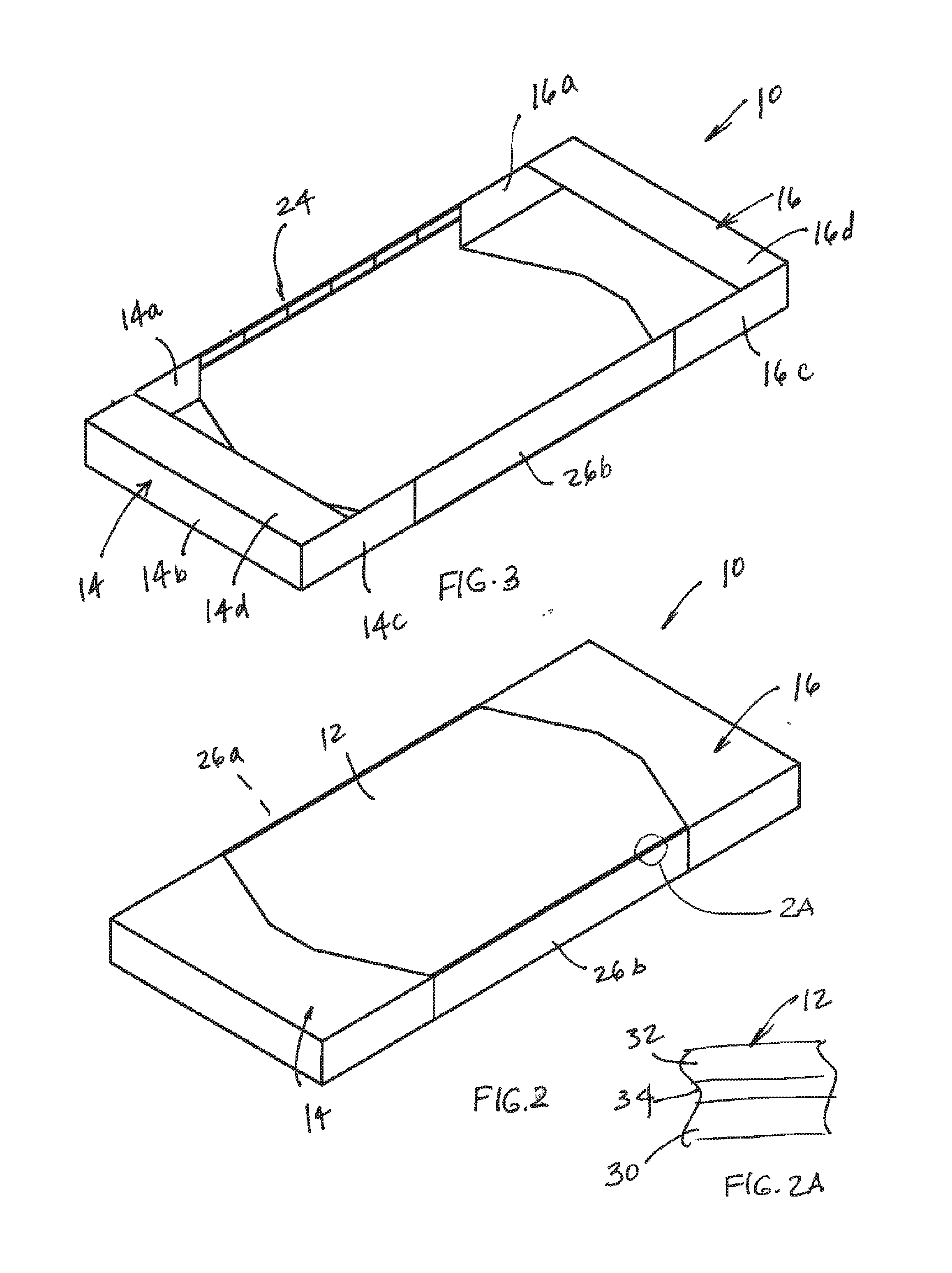

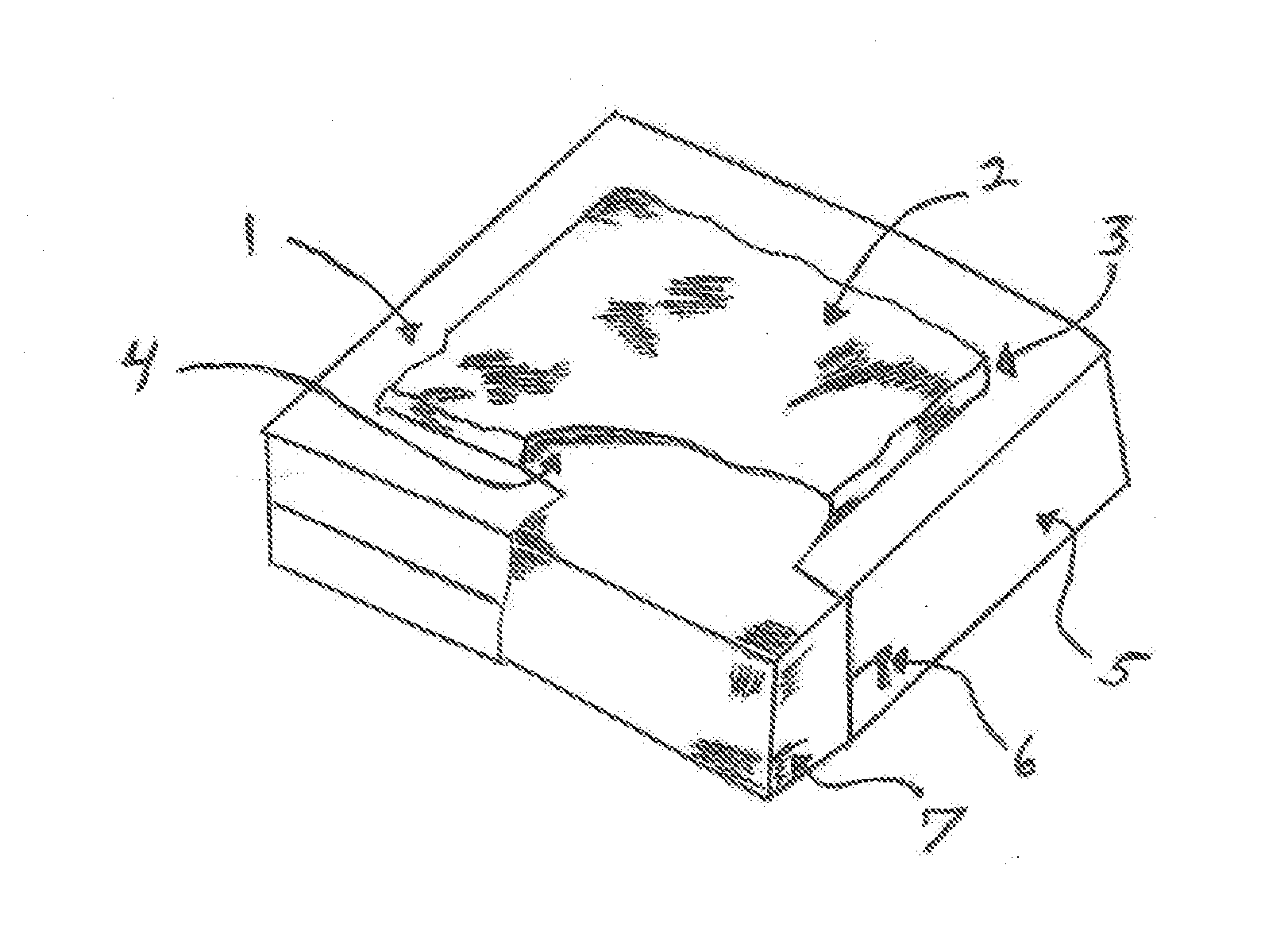

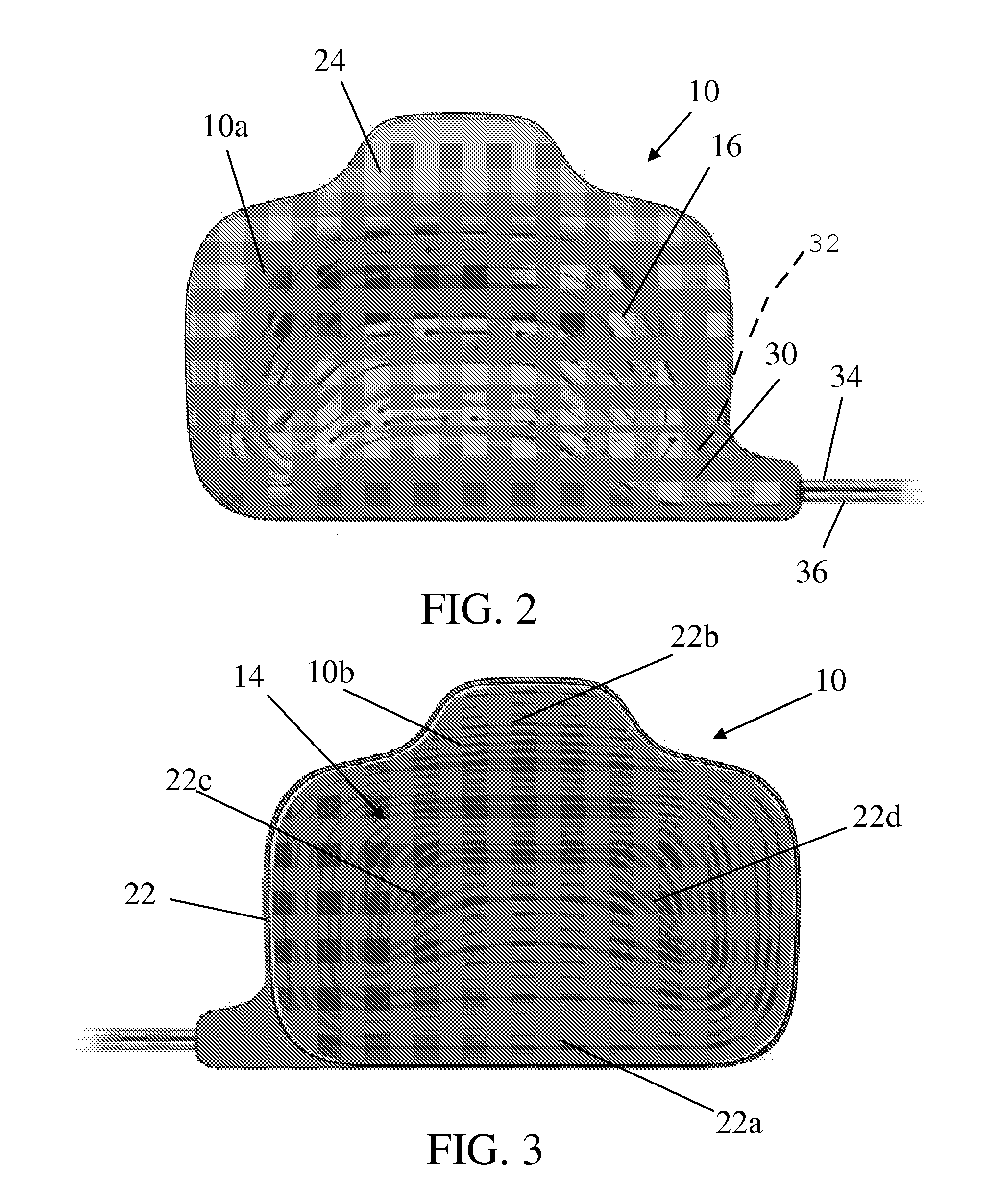

Devices for prevention of pressure ulcers

InactiveUS20090070939A1Avoid pressure soresMinimal puckeringStuffed mattressesSpring mattressesInter layerSkin contact

A support surface, such as an underpad, for preventing pressure sores in a patient is a multi-layer textile assembly having a skin contact layer formed from a fabric of synthetic filament yarns woven to provide air permeability and moisture vapor permeability and having a thickness of less than 1 mm. An absorbent middle layer is formed from a breathable microfiber fabric woven to provide for moisture transition from an upper surface of the middle layer to a bottom surface of the middle layer. The skin contact layer and the middle layer are stitched together using a stitching pattern optimized to produce an open pattern with minimal puckering. A bottom layer is formed from a breathable, waterproof fabric woven from synthetic yarn to produce a moisture vapor transfer rate within the range of 5,000 to 20,000 grams per meter squared per 24 hours. The three layers are attached together around their outer edges.

Owner:PERSIMMON SCI

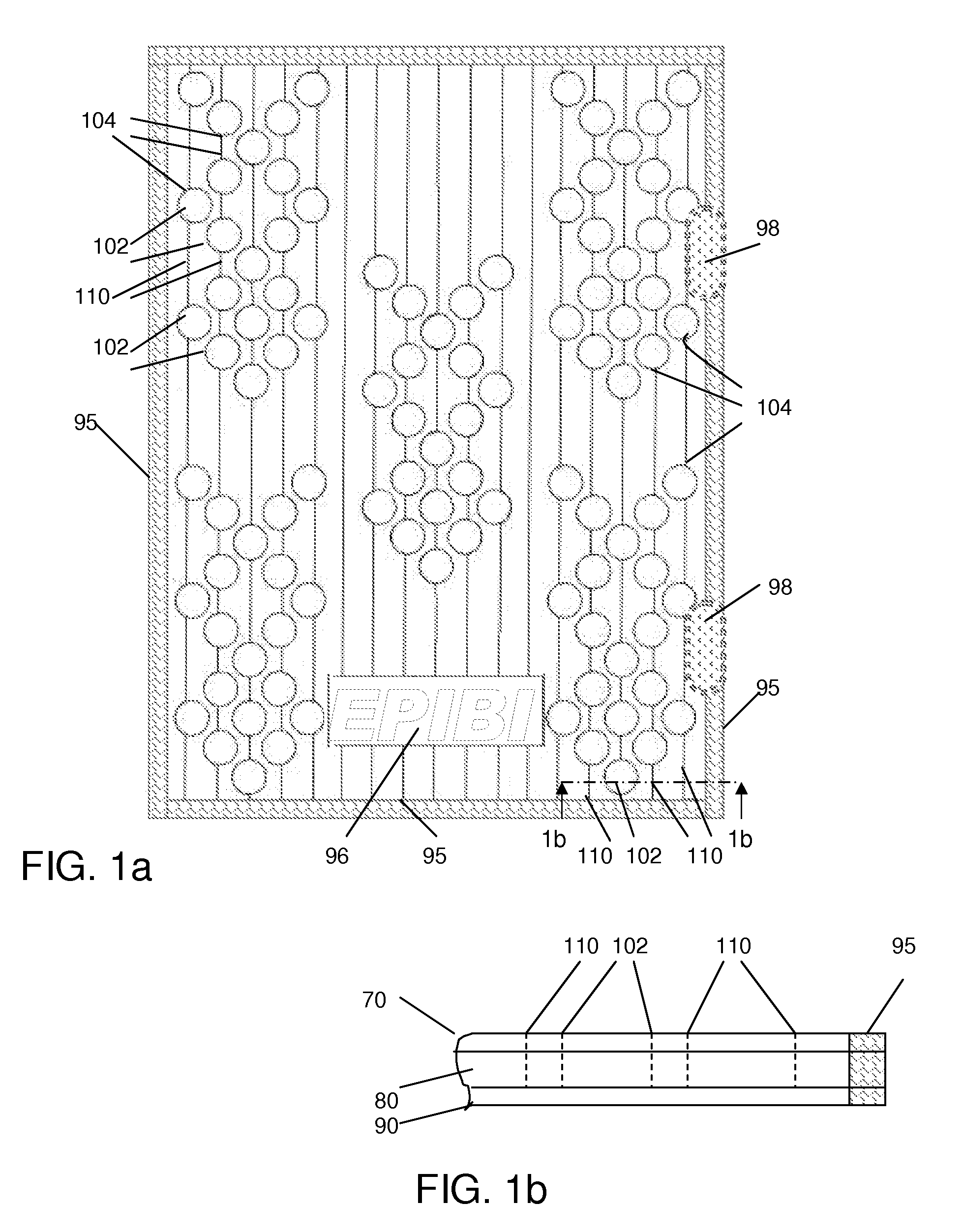

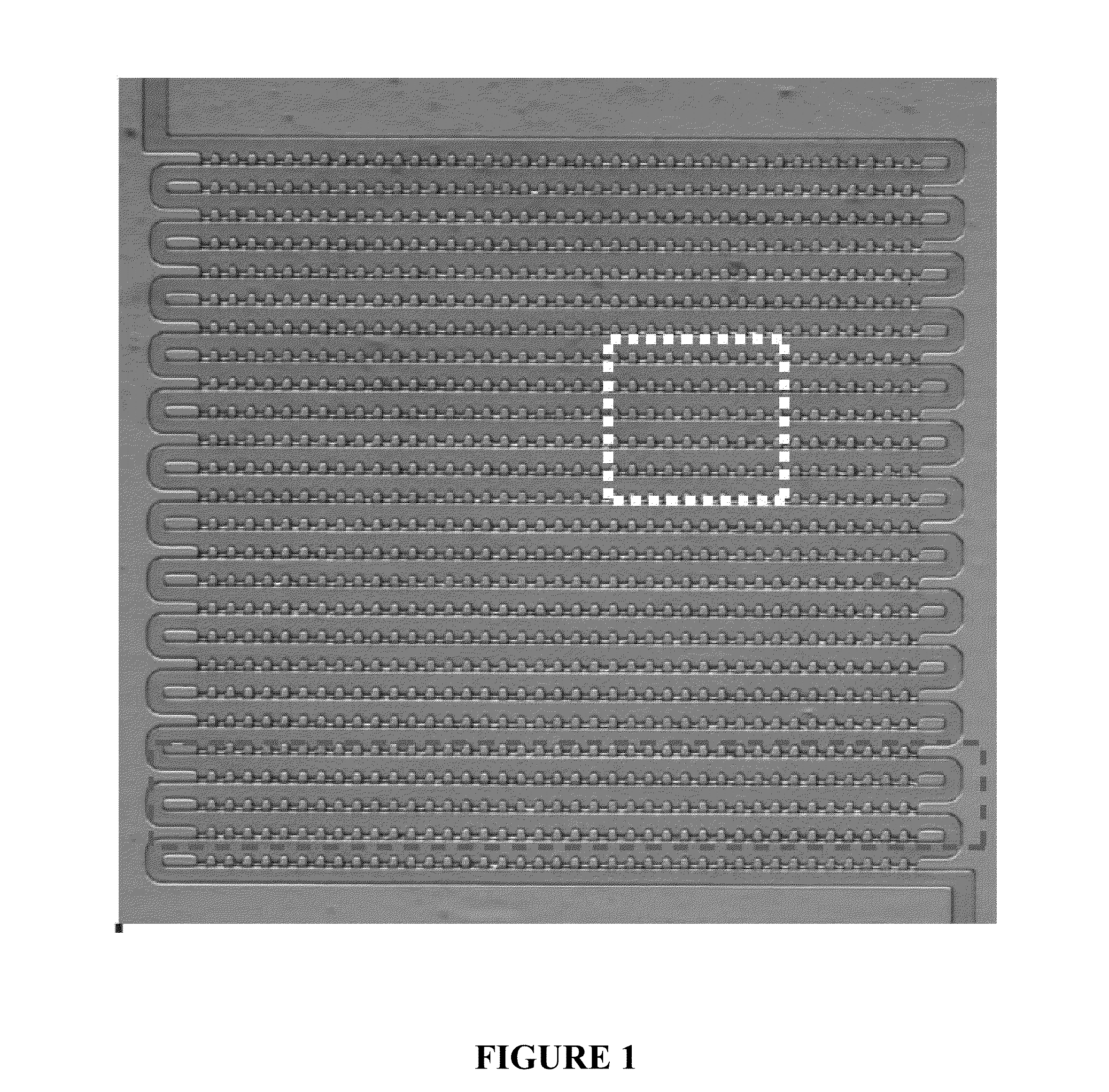

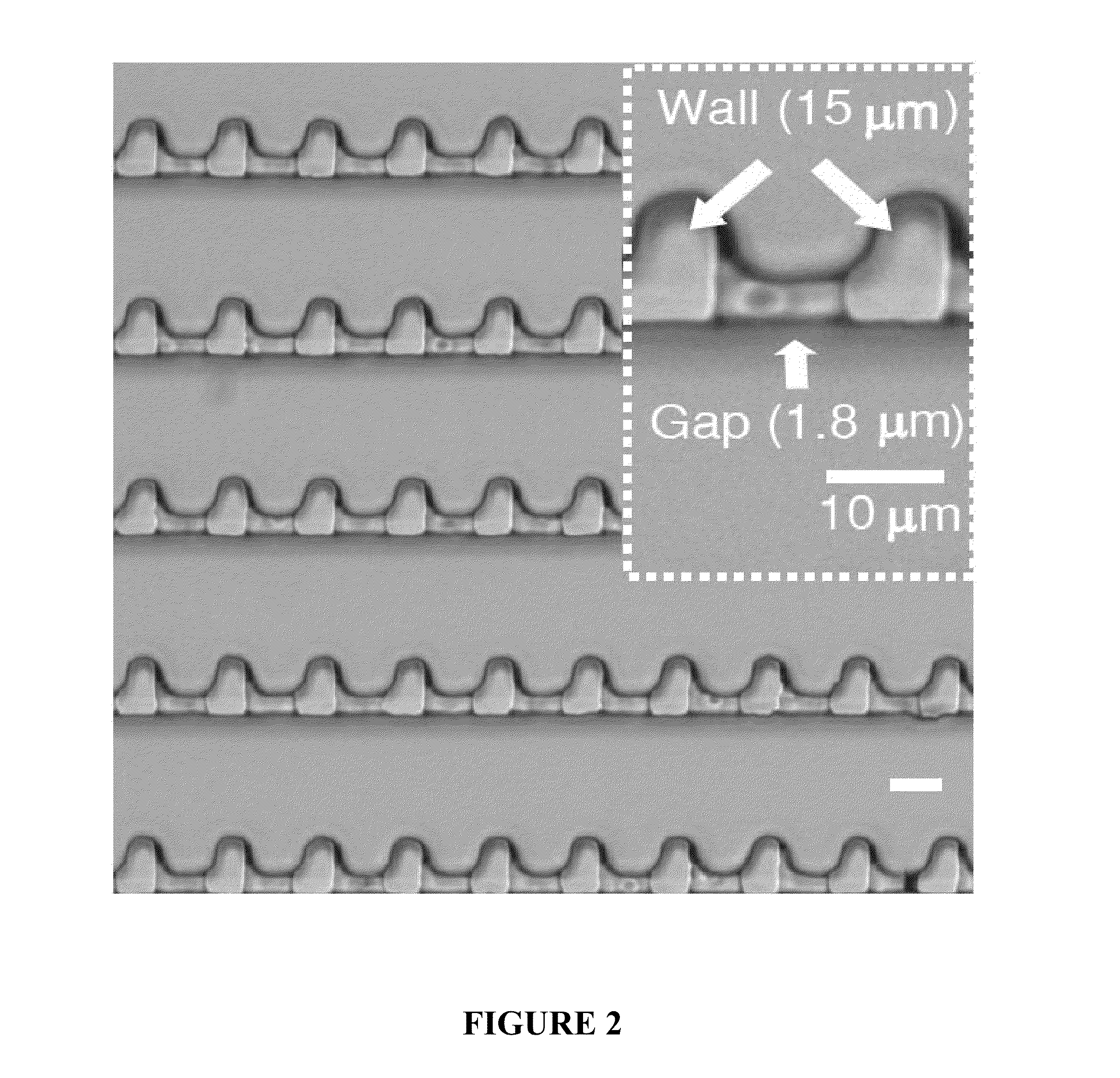

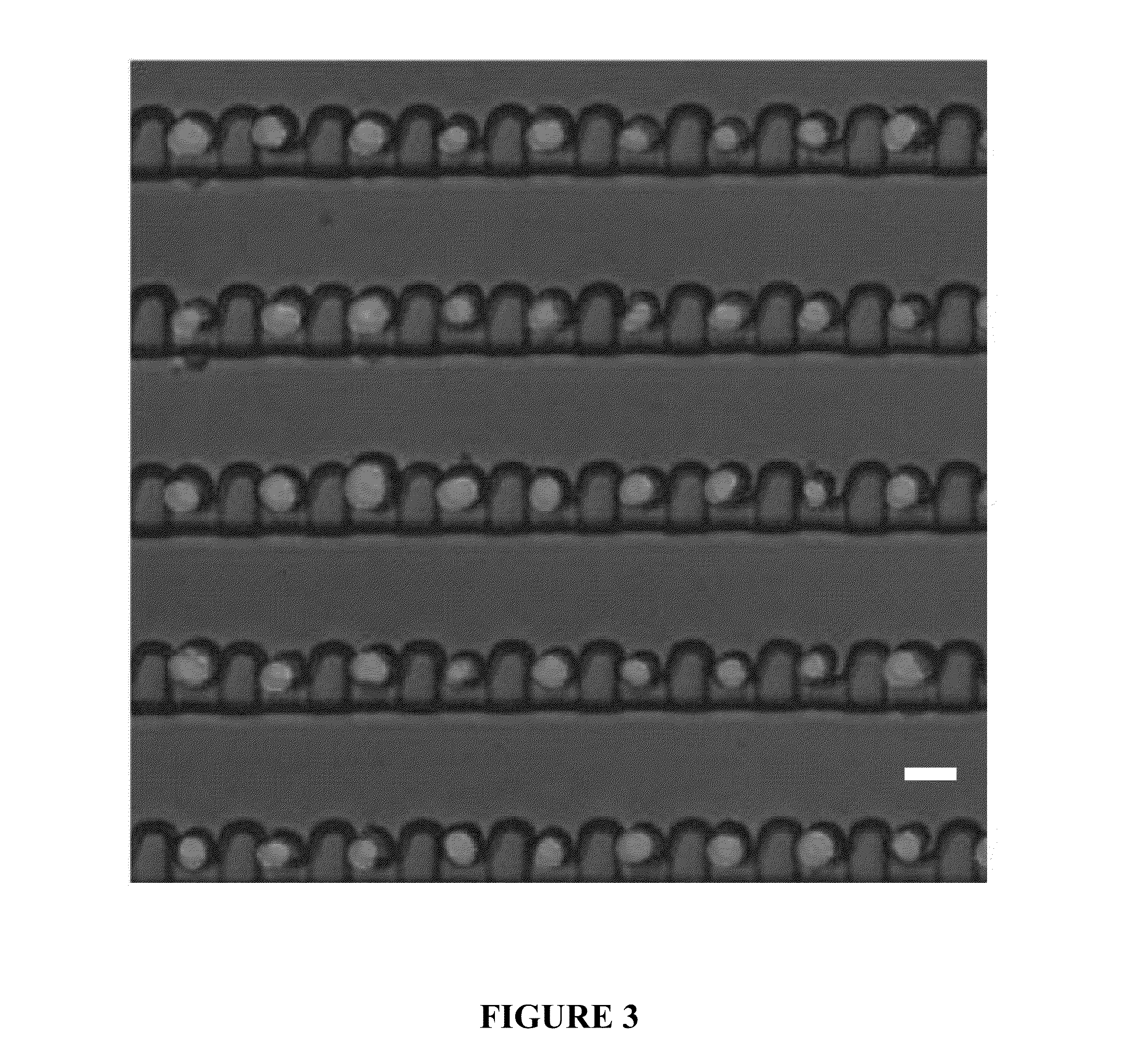

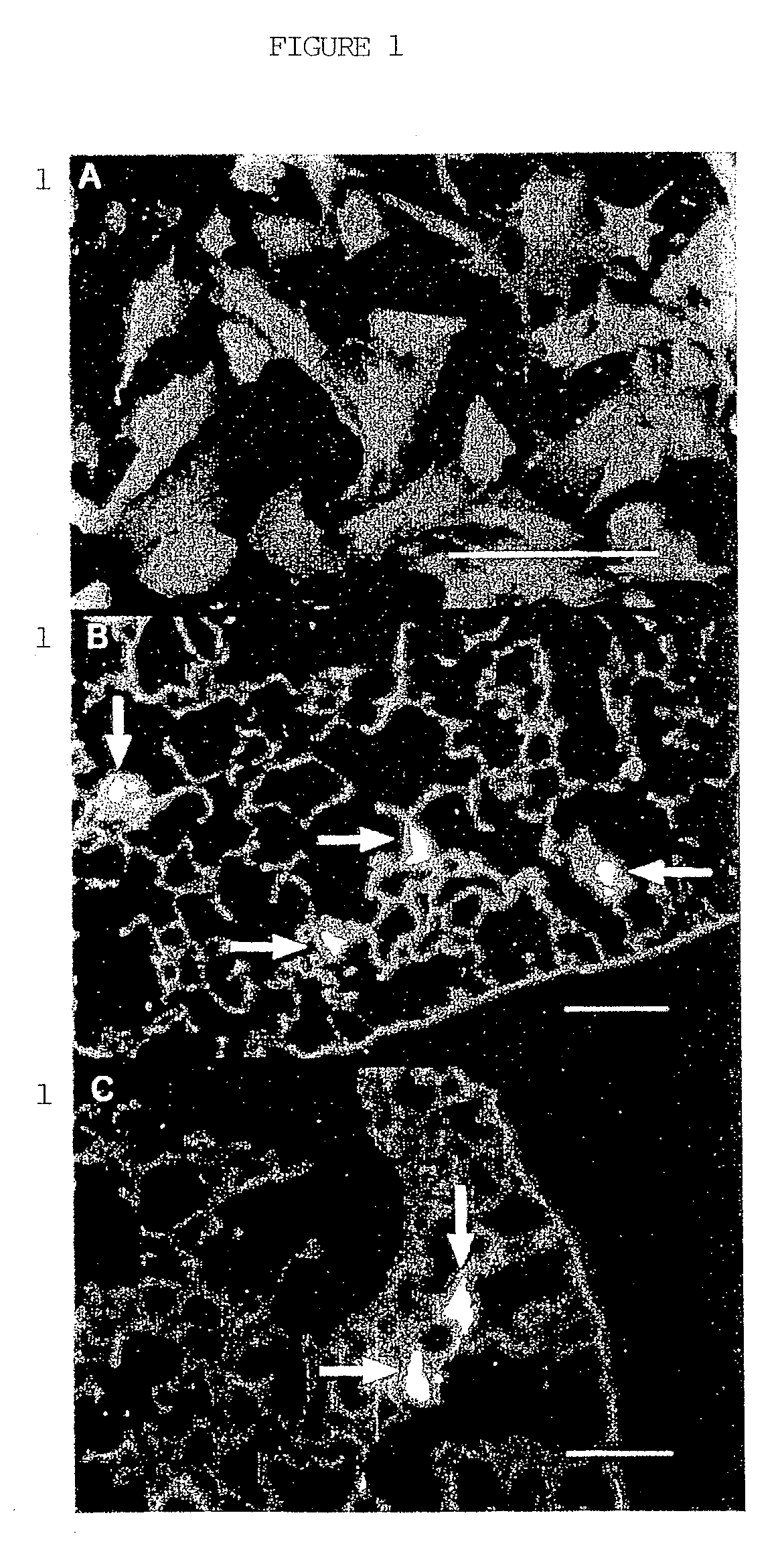

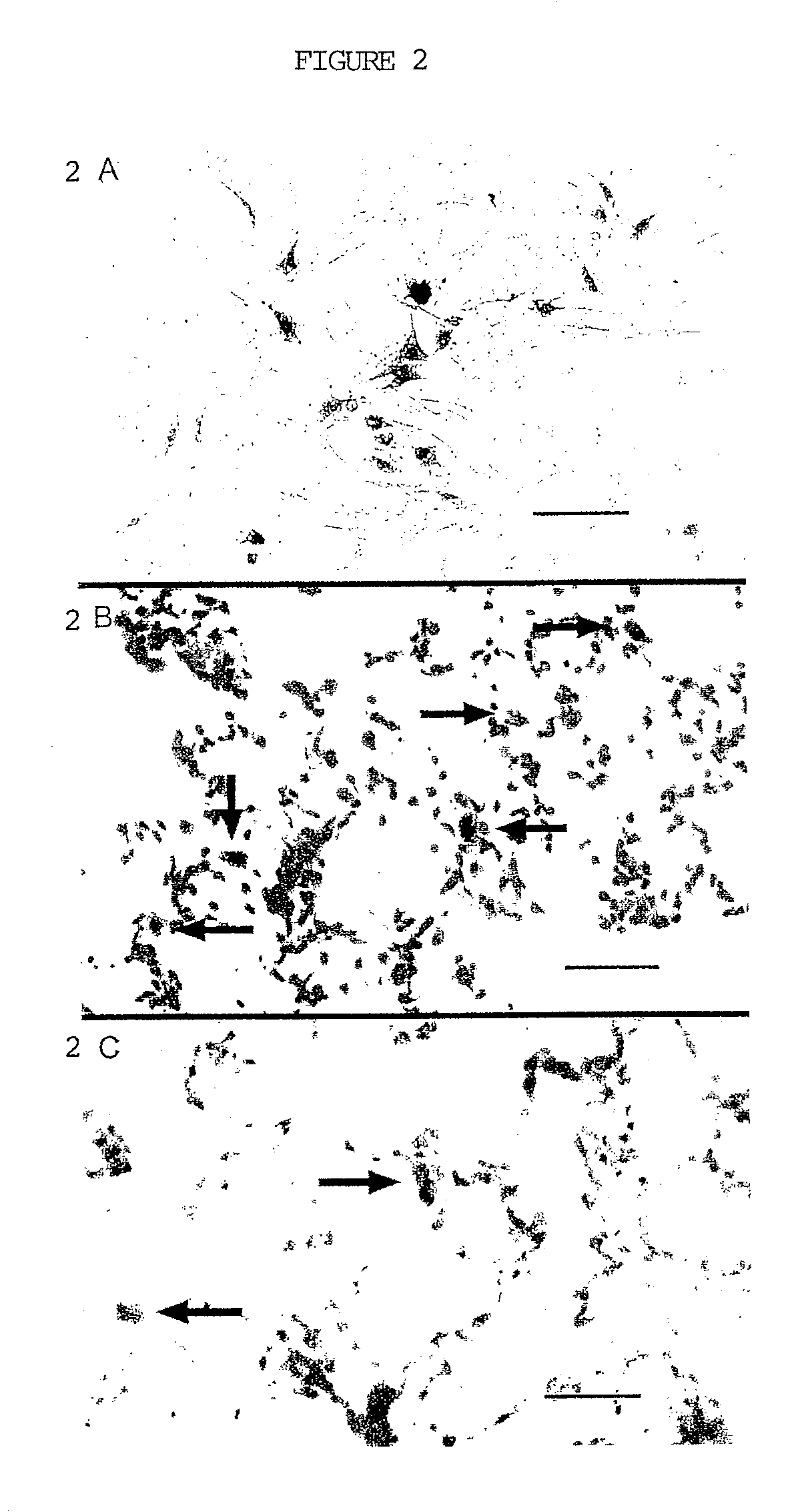

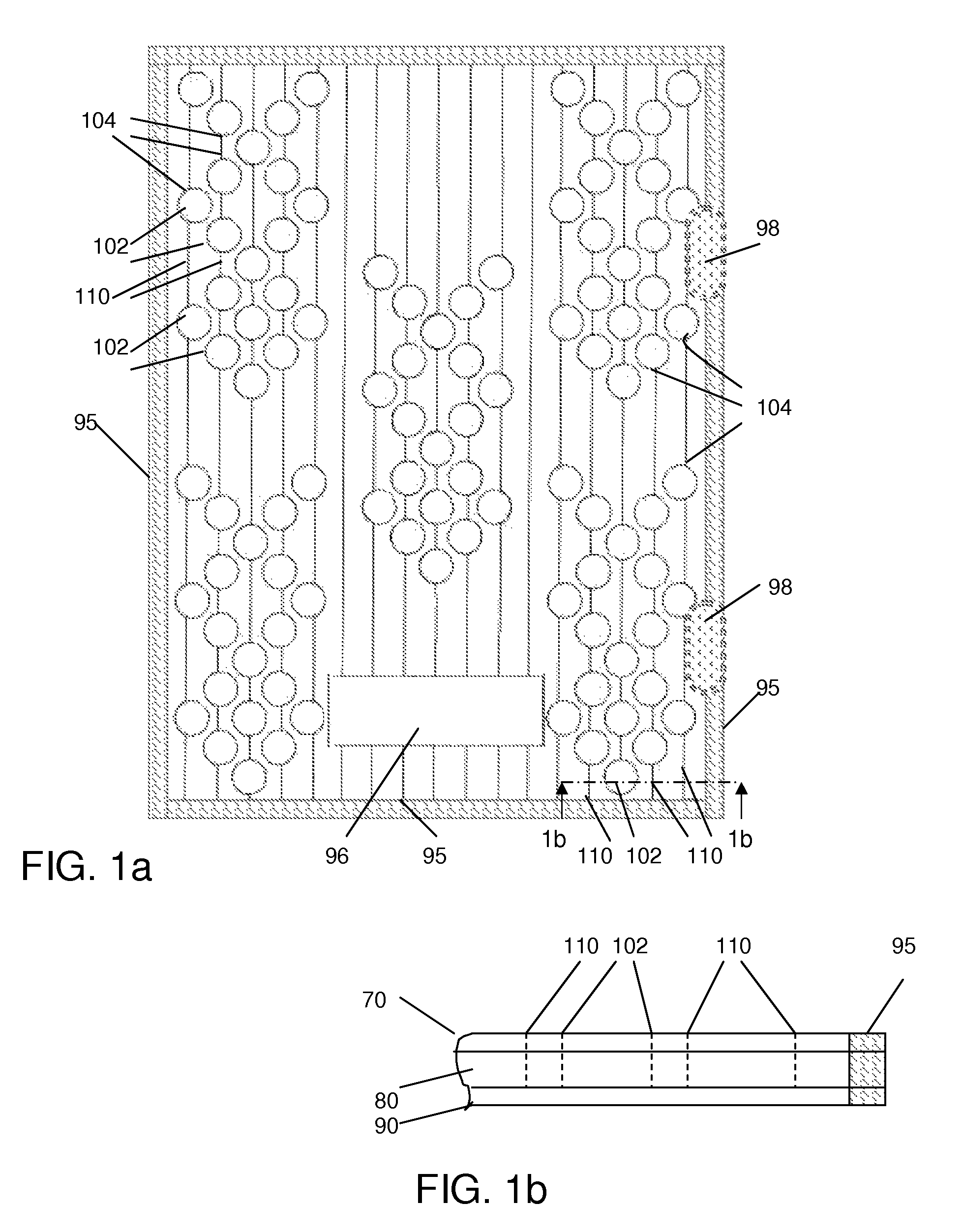

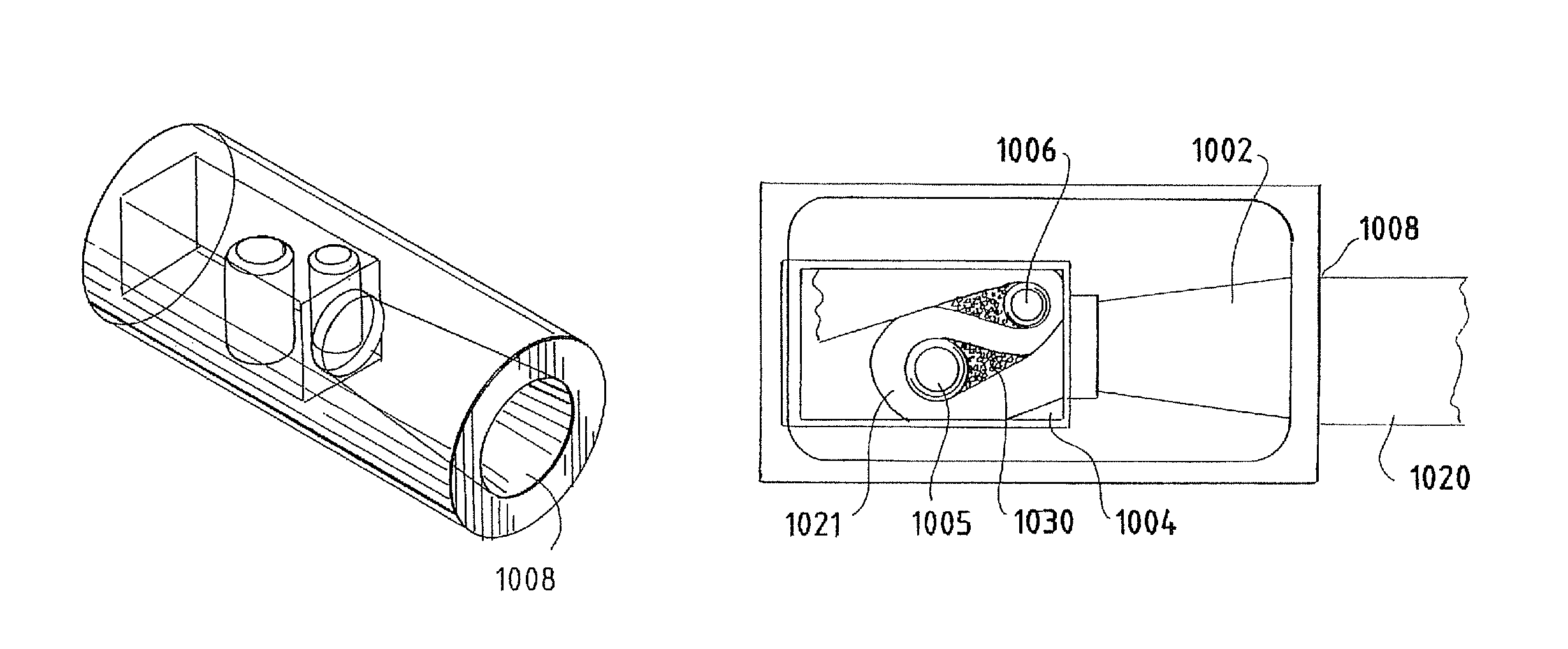

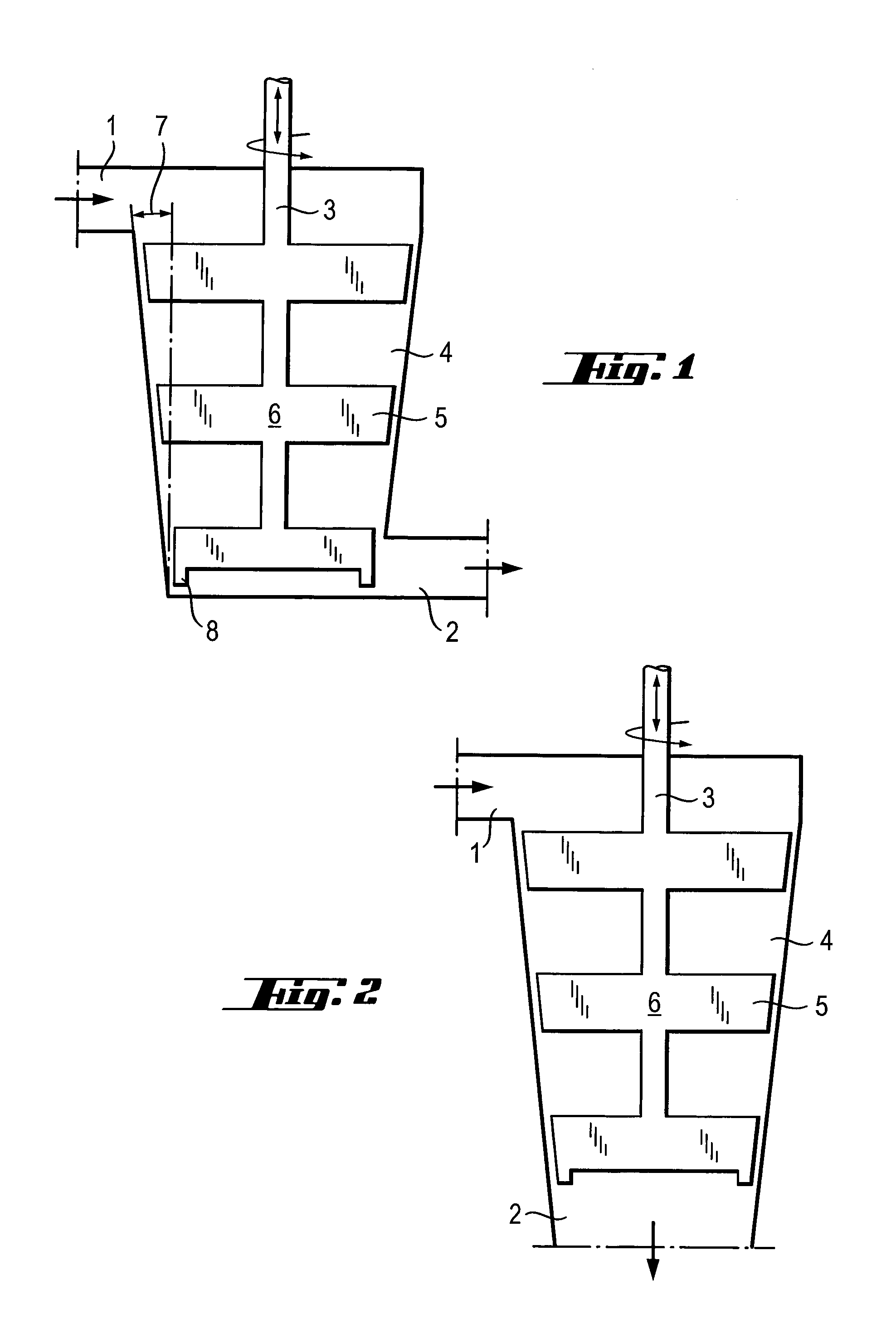

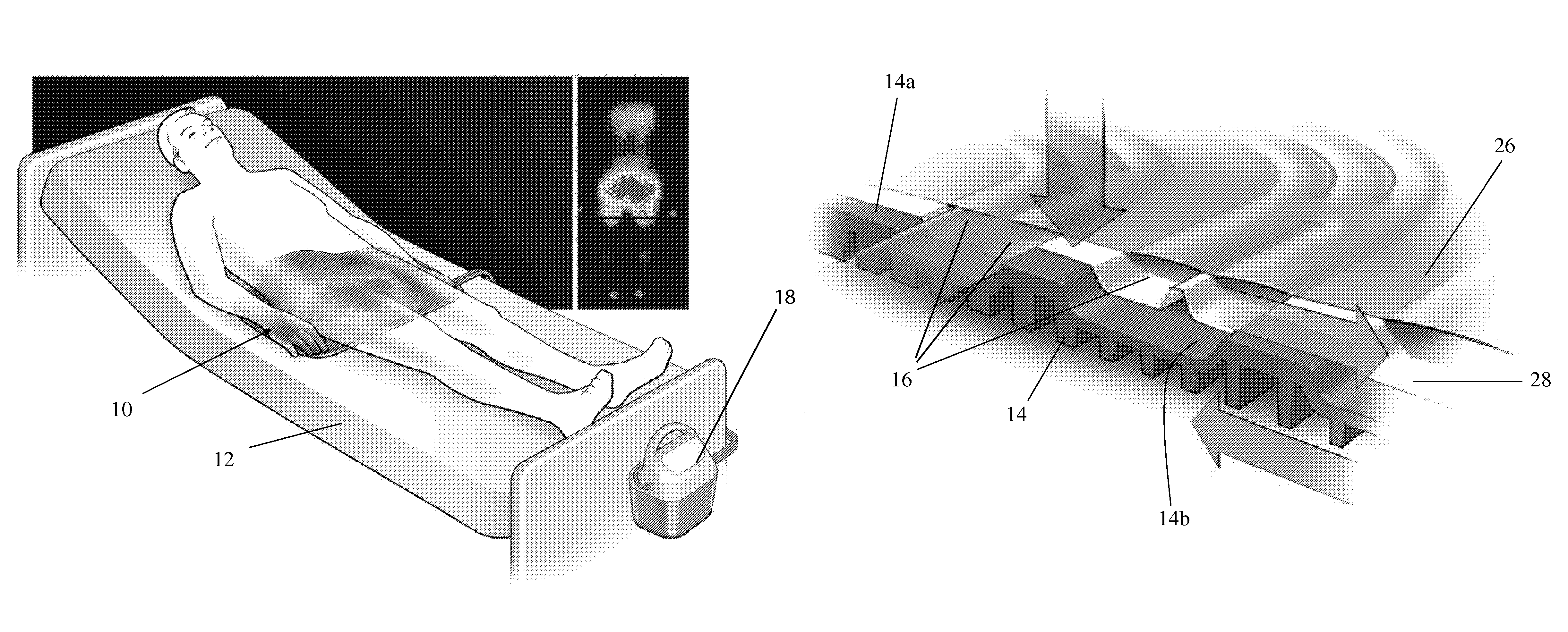

Deterministic High-Density Single-Cell Trap Array

ActiveUS20130078163A1Meet needsReduce shearBioreactor/fermenter combinationsBiological substance pretreatmentsHigh densityShear stress

A microfluidic platform for single-cell capture, stimulation, and imaging. It passively traps 4,000 single cells on a 4.5 mm2 footprint in 30 seconds, with a single-cell loading efficiency of 95%. The array format and optimized geometry allows for easy, robust and efficient single-cell loading, while maintaining captured cells in a low shear stress environment for long-term studies. Because cells are captured sequentially, the system is adequate for rare cell samples. Trapped cells can be exposed to various environmental conditions and chemical stimulus and their dynamic response can be monitored over time. The information gained from high-throughput, single-cell time lapsed imaging presents new opportunities in quantifying cellular responses, as averaged information by other measurement methods eliminates sub-population phenotypes.

Owner:GEORGIA TECH RES CORP

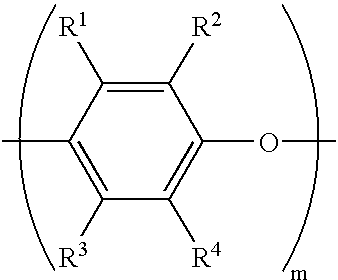

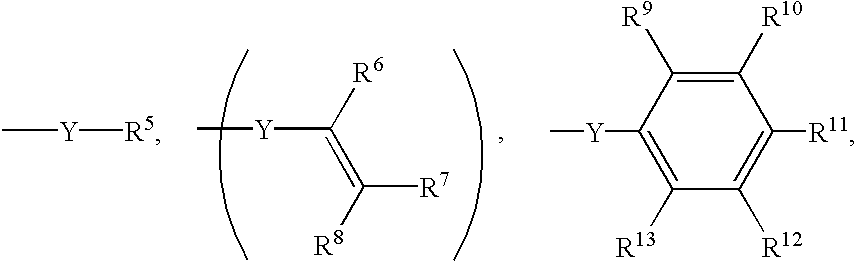

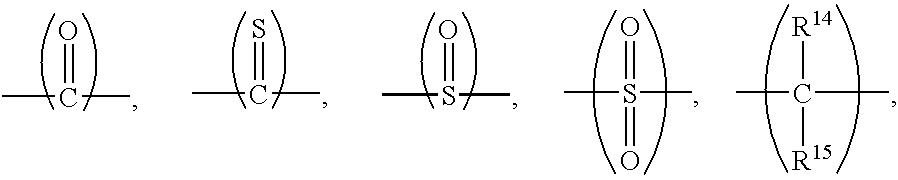

Electrically conductive thermoset composition, method for the preparation thereof, and articles derived therefrom

InactiveUS20020177027A1Good compatibilityImprove adhesionElectrode carriers/collectorsConductive materialFuel cellsHeat resistance

A conductive thermosetting composition comprises a functionalized poly(arylene ether), an alkenyl aromatic monomer, an acryloyl monomer, and a conductive agent. After curing, the composition exhibits good stiffness, toughness, heat resistance, and conductivity, and it is useful in the fabrication of a variety of conductive components, including the bipolar plates of fuel cells.

Owner:SABIC GLOBAL TECH BV

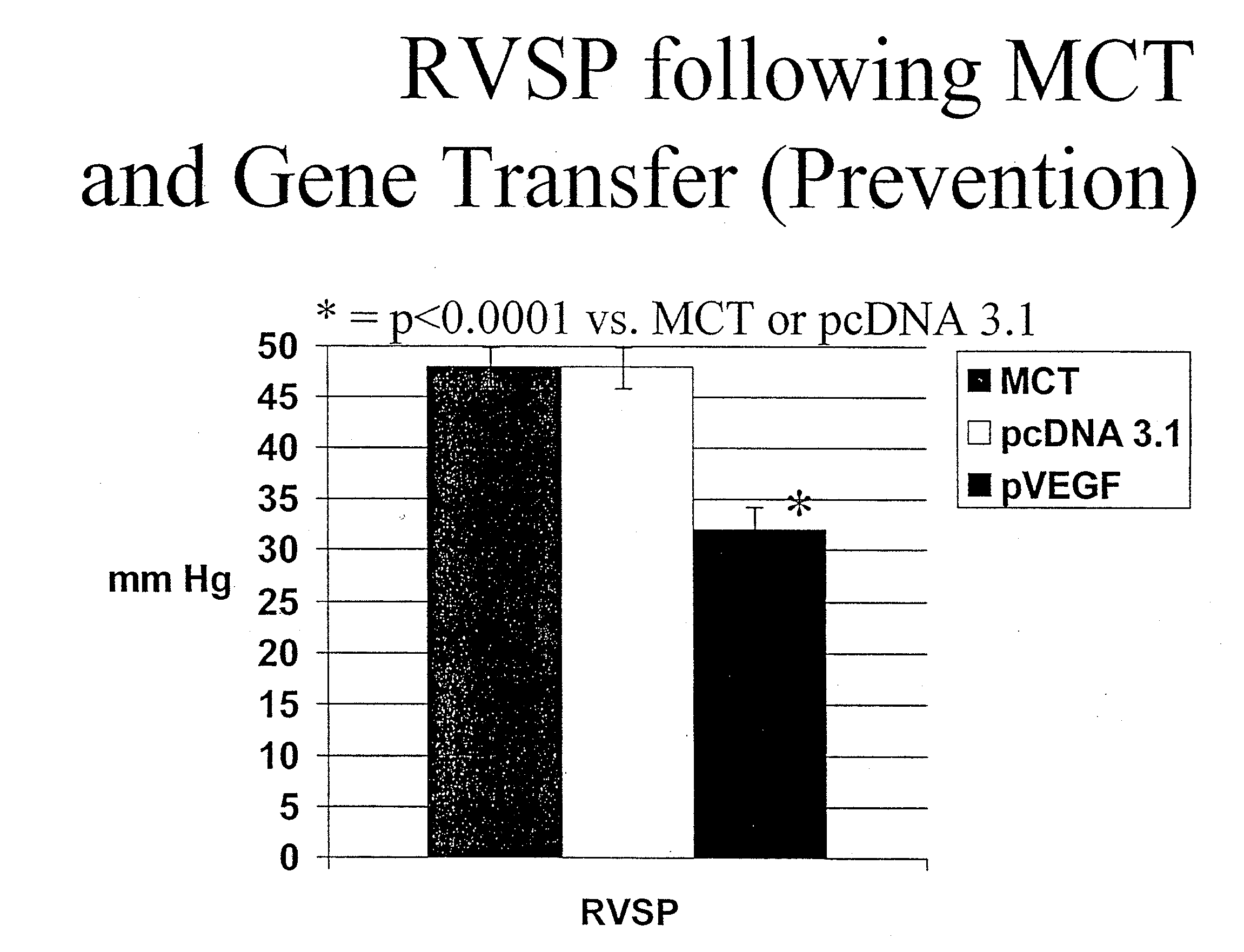

Cell based therapy for the pulmonary system

ActiveUS20080050349A1Increase chances of survivalImprove survivabilityBiocidePeptide/protein ingredientsDiseaseSurgery

Cell based therapy comprises administration to the lung by injection into the blood system of viable, mammalian cells effective for alleviating or inhibiting pulmonary disorders. The cells may express a therapeutic transgene or the cells may be therapeutic in their own right by inducing regenerative effects.

Owner:NORTHERN THERAPEUTICS

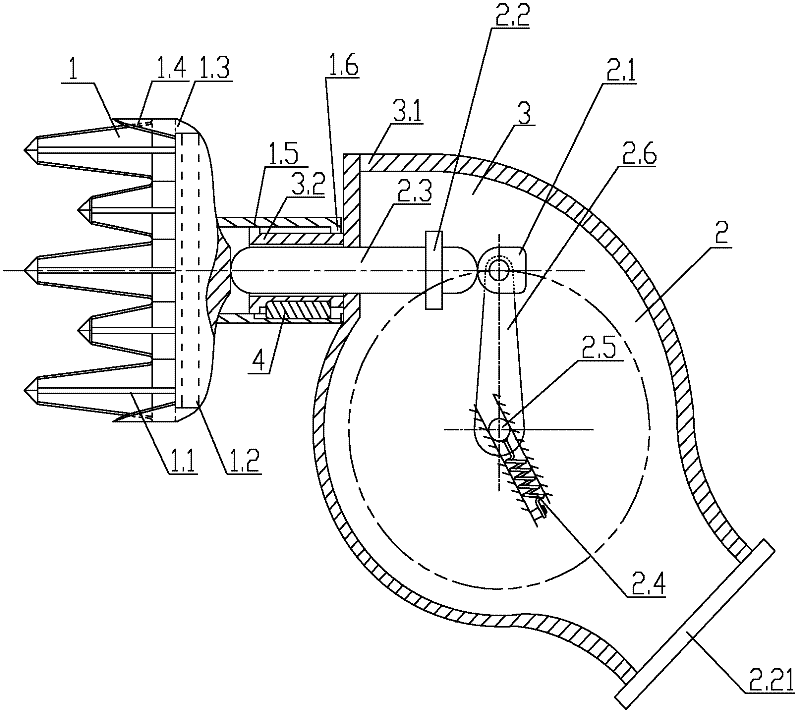

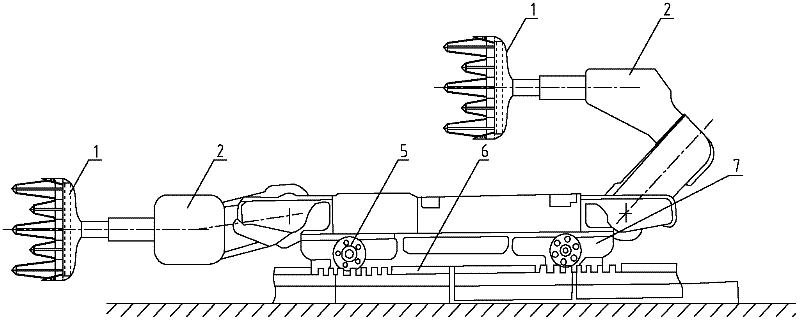

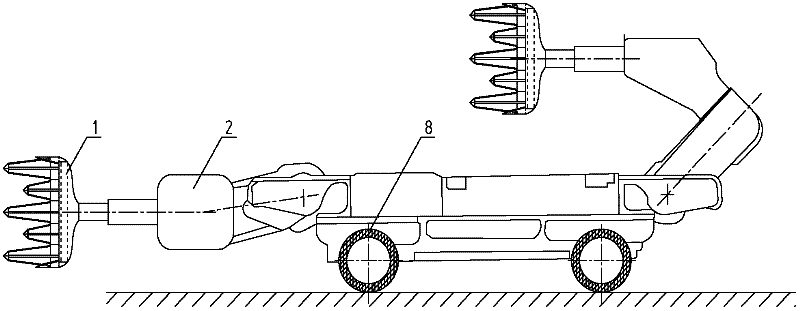

High-efficiency blocking coal shovel

The invention relates to coal mining equipment and specially, relates to a high-efficiency blocking coal shovel. The high-efficiency blocking coal shovel comprises a shovel body. The shovel body comprises a frame. The high-efficiency blocking coal shovel also comprises an impulsion shovel mechanism. The impulsion shovel mechanism comprises a shovel head and an impulsion device. The shovel head comprises shovel teeth and a fixing part. The shovel teeth are installed on the fixing part. A rear part of the fixing part is provided with an impulsion stroke guiding mechanism. The impulsion stroke guiding mechanism is sildingly connected to a guiding sleeve. The guiding sleeve is arranged on the impulsion device and / or the frame. The impulsion device impacts the impulsion stroke guiding mechanism. Only through one impulsion process, the shovel head can complete both coal falling and surface cleaning. The impulsion shovel mechanism is arranged on the shovel body. The shovel body drives the whole high-efficiency blocking coal shovel to walk. Coal mined by the high-efficiency blocking coal shovel is not broken fully. The high-efficiency blocking coal shovel has a high blocking rate and low power consumption, produces a small quantity of coal dust, provides a good work environment, realizes continuous coal mining, synchronously completes both coal falling and surface cleaning, and saves a mass of energy.

Owner:刘素华

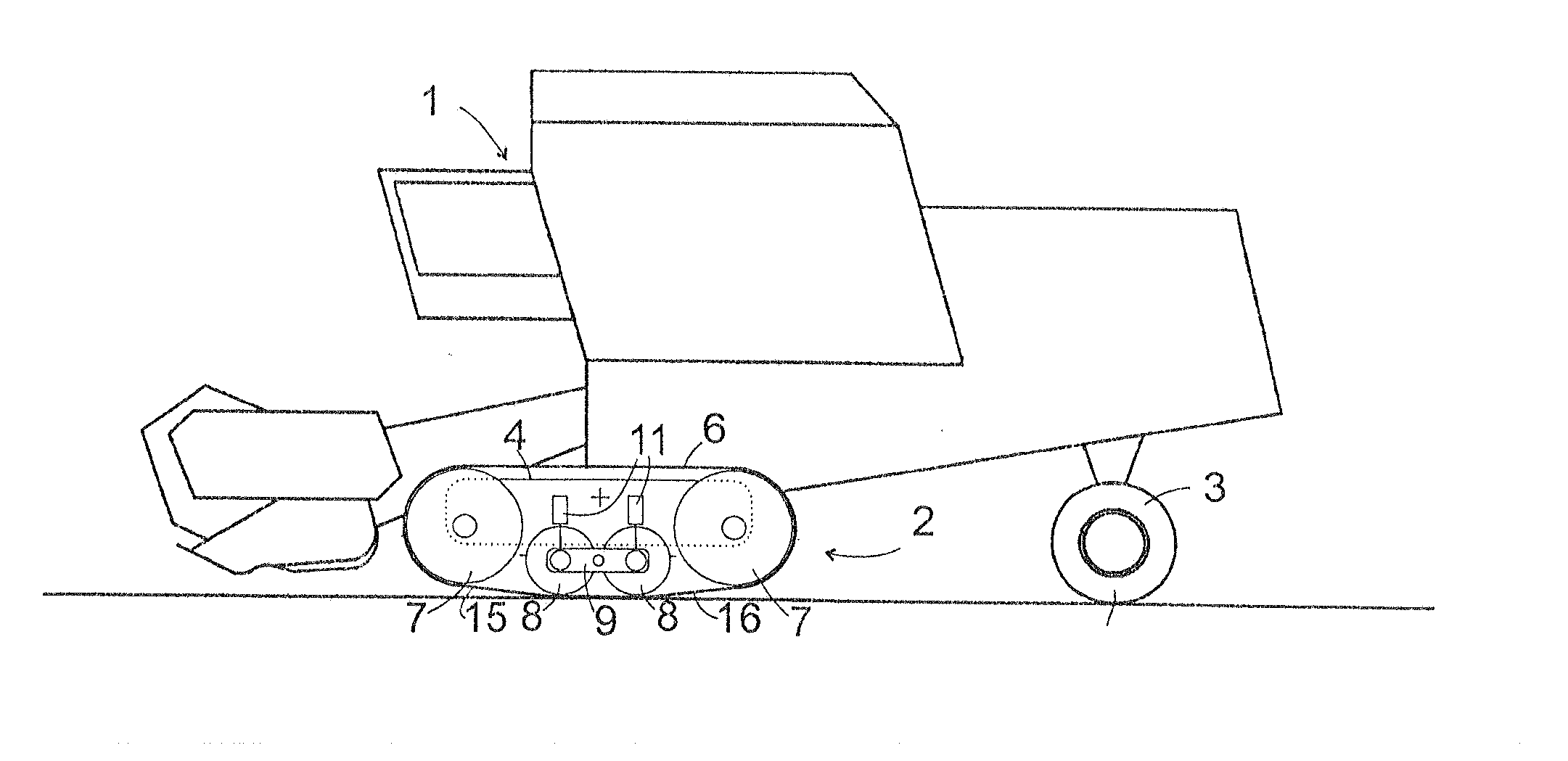

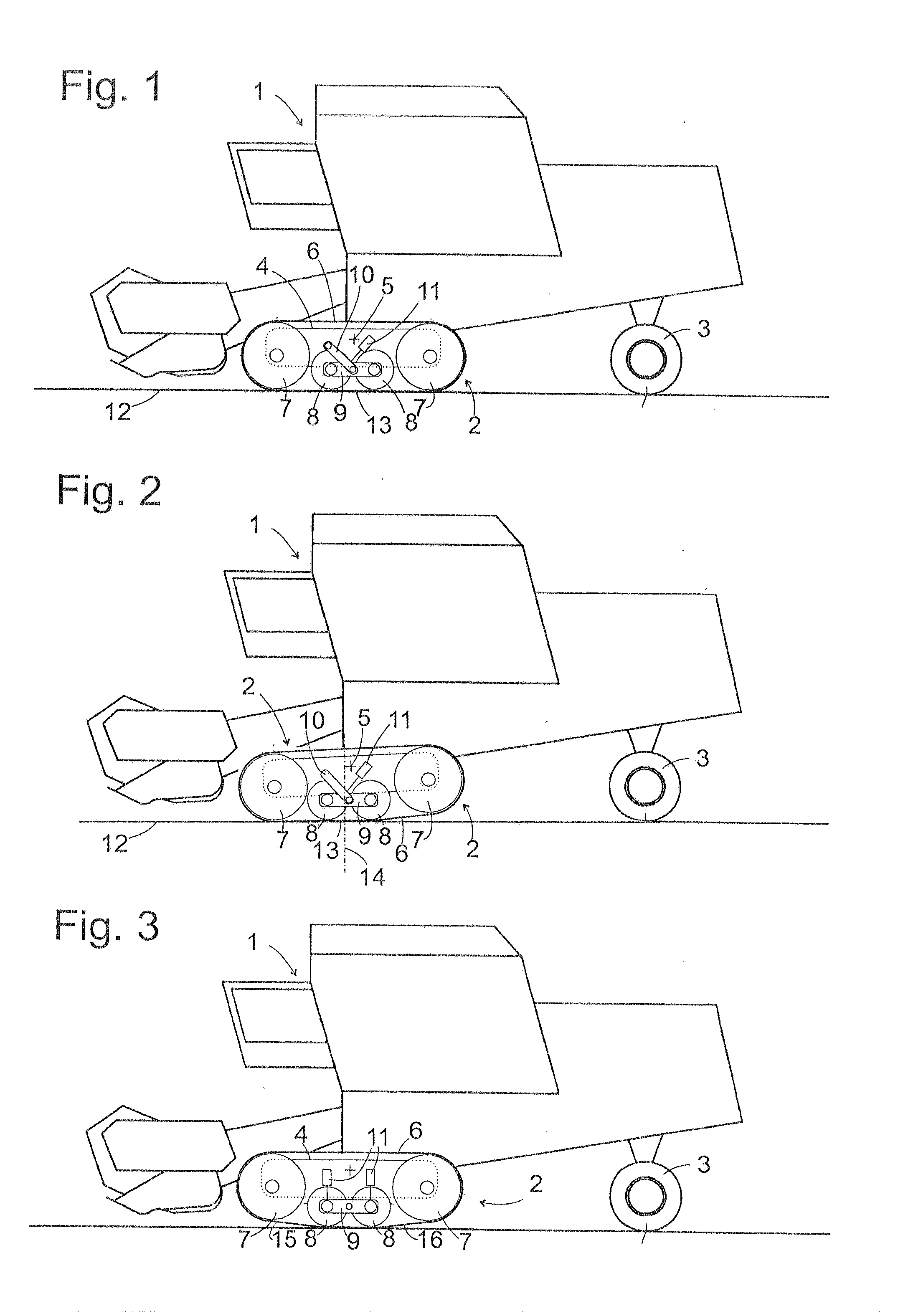

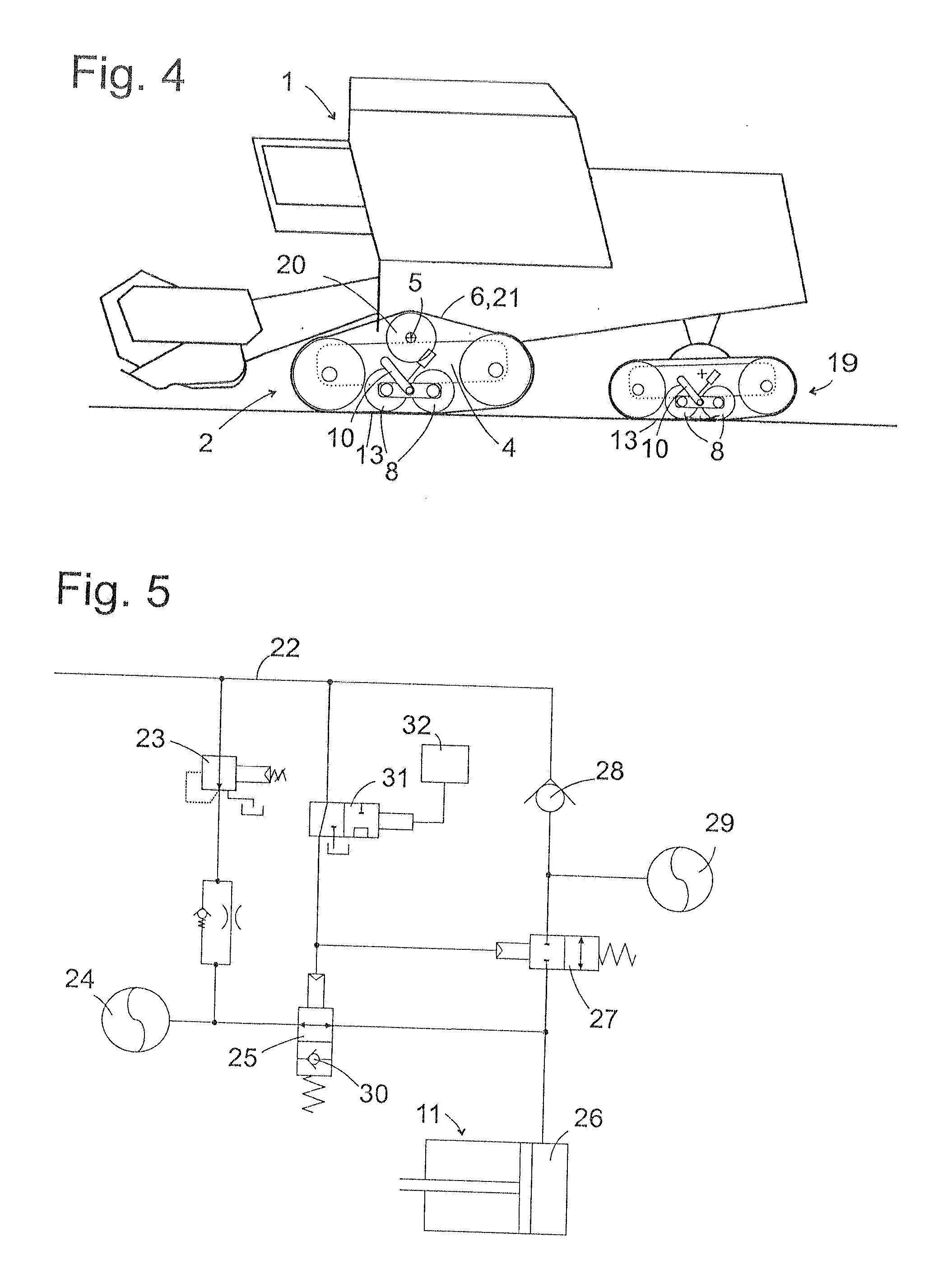

Vehicle comprising a crawler track assembly

InactiveUS20130154345A1Improve vehicle tractionGreat tractionSuspensionsEndless track vehiclesActuatorControl theory

An agricultural vehicle includes comprises a crawler track assembly having a plurality of supporting rollers arranged one behind the other in the direction of travel of the vehicle and around which a belt is wrapped. The rollers are adjusted by way of an actuator between a first configuration, in which all supporting rollers are loaded, and a second configuration, in which at least one outer roller of the supporting rollers is relieved. An energy accumulator is charged by a drive energy source and connected to the actuator in order to provide the actuator with the drive energy required to adjust the configuration.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Devices for prevention of pressure ulcers

A support surface, such as an underpad, for preventing pressure sores in a patient is a multi-layer textile assembly having a skin contact layer formed from a fabric of synthetic filament yarns woven to provide air permeability and moisture vapor permeability and having a thickness of less than 1 mm. An absorbent middle layer is formed from a breathable microfiber fabric woven to provide for moisture transition from an upper surface of the middle layer to a bottom surface of the middle layer. The skin contact layer and the middle layer are stitched together using a stitching pattern optimized to produce an open pattern with minimal puckering. A bottom layer is formed from a breathable, waterproof fabric woven from synthetic yarn to produce a moisture vapor transfer rate within the range of 5,000 to 20,000 grams per meter squared per 24 hours. The three layers are attached together around their outer edges.

Owner:PERSIMMON SCI

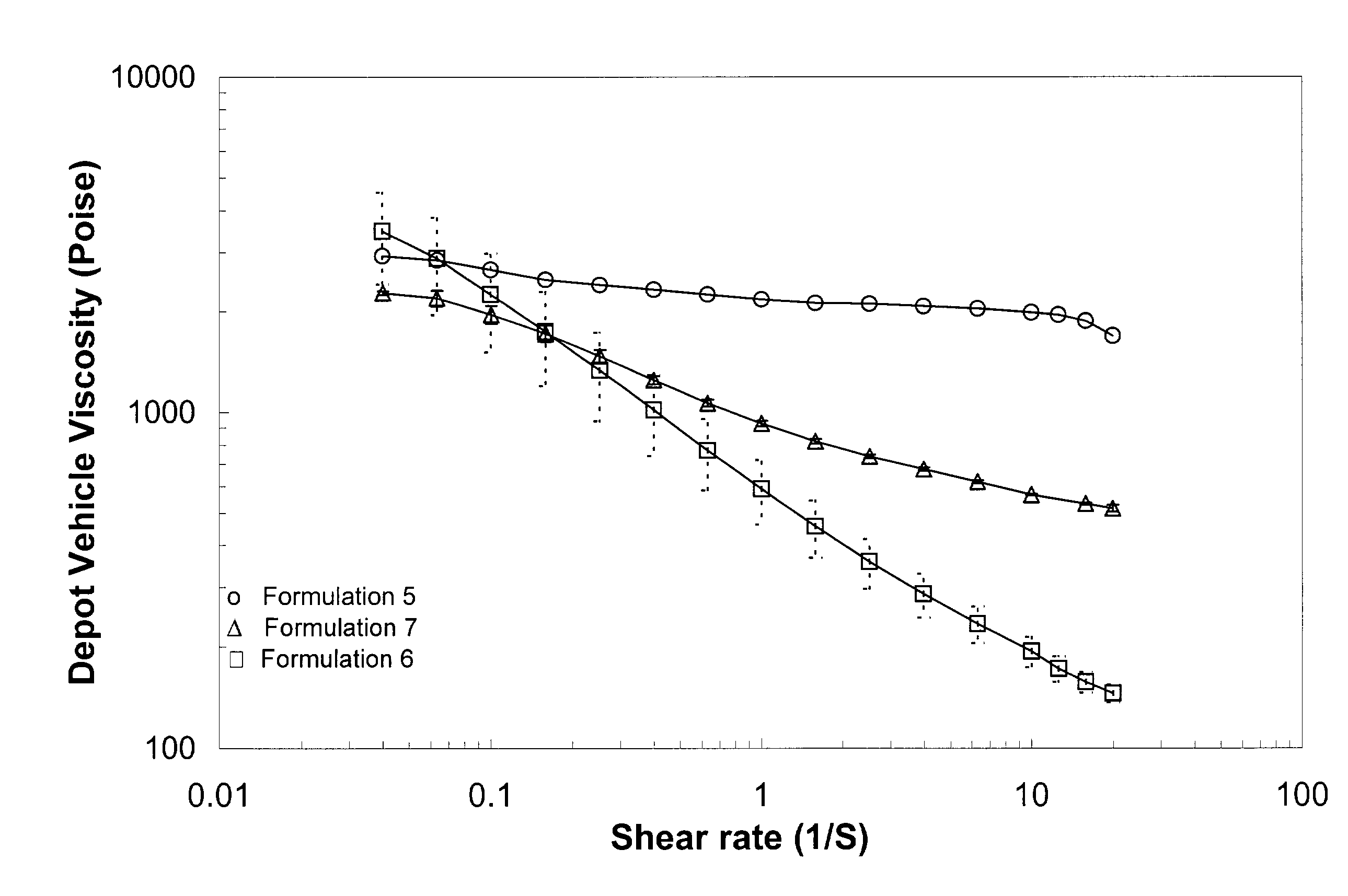

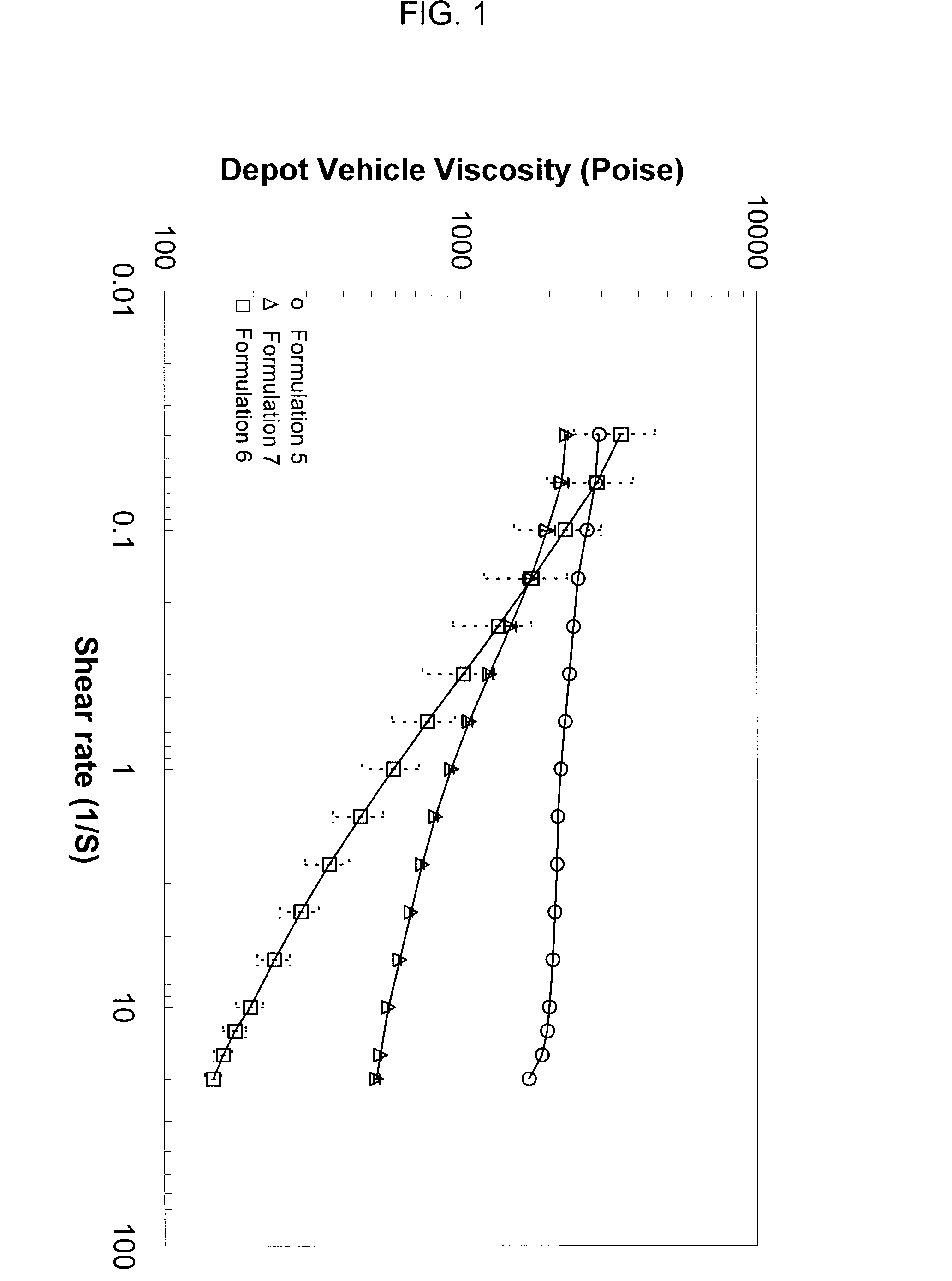

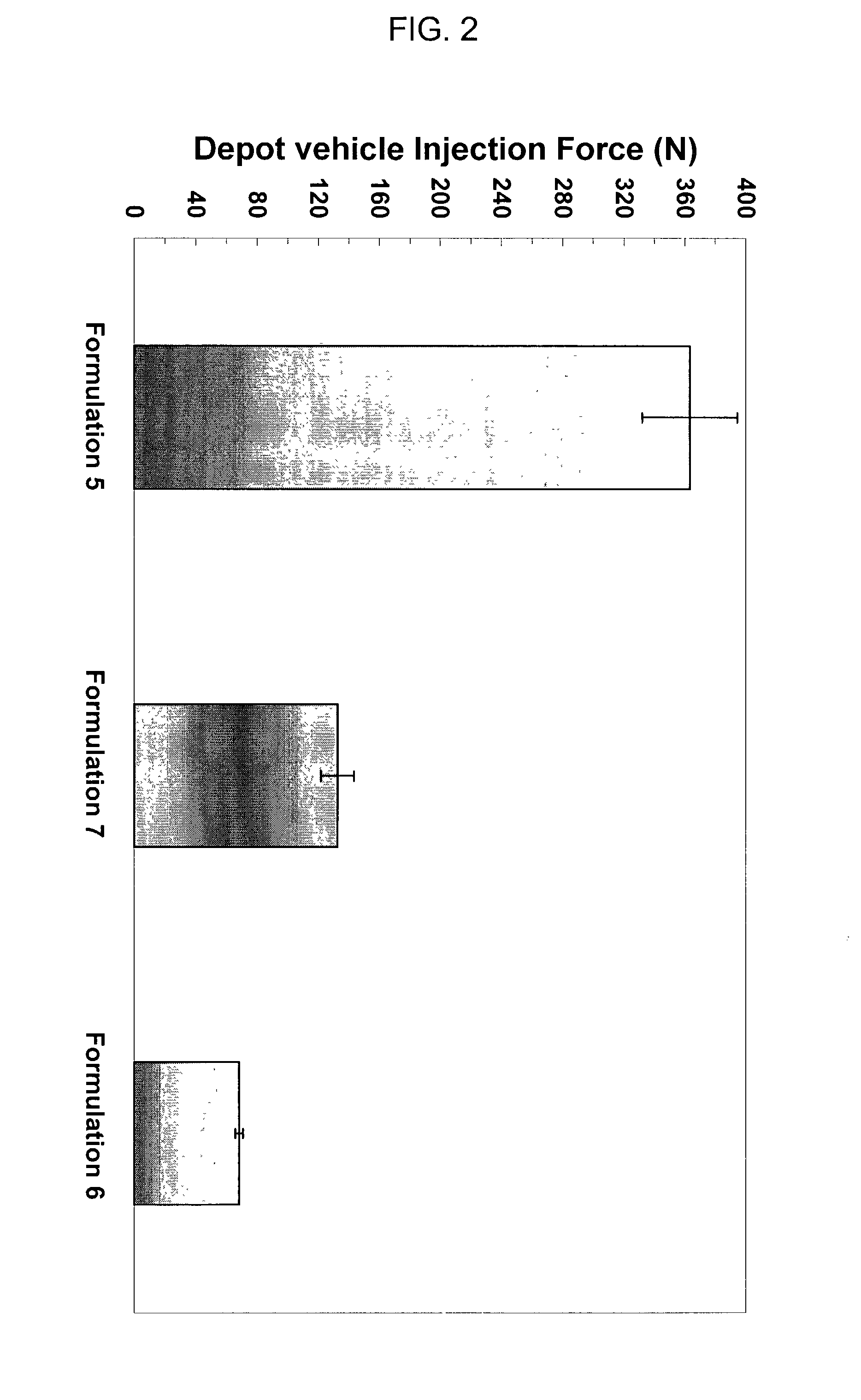

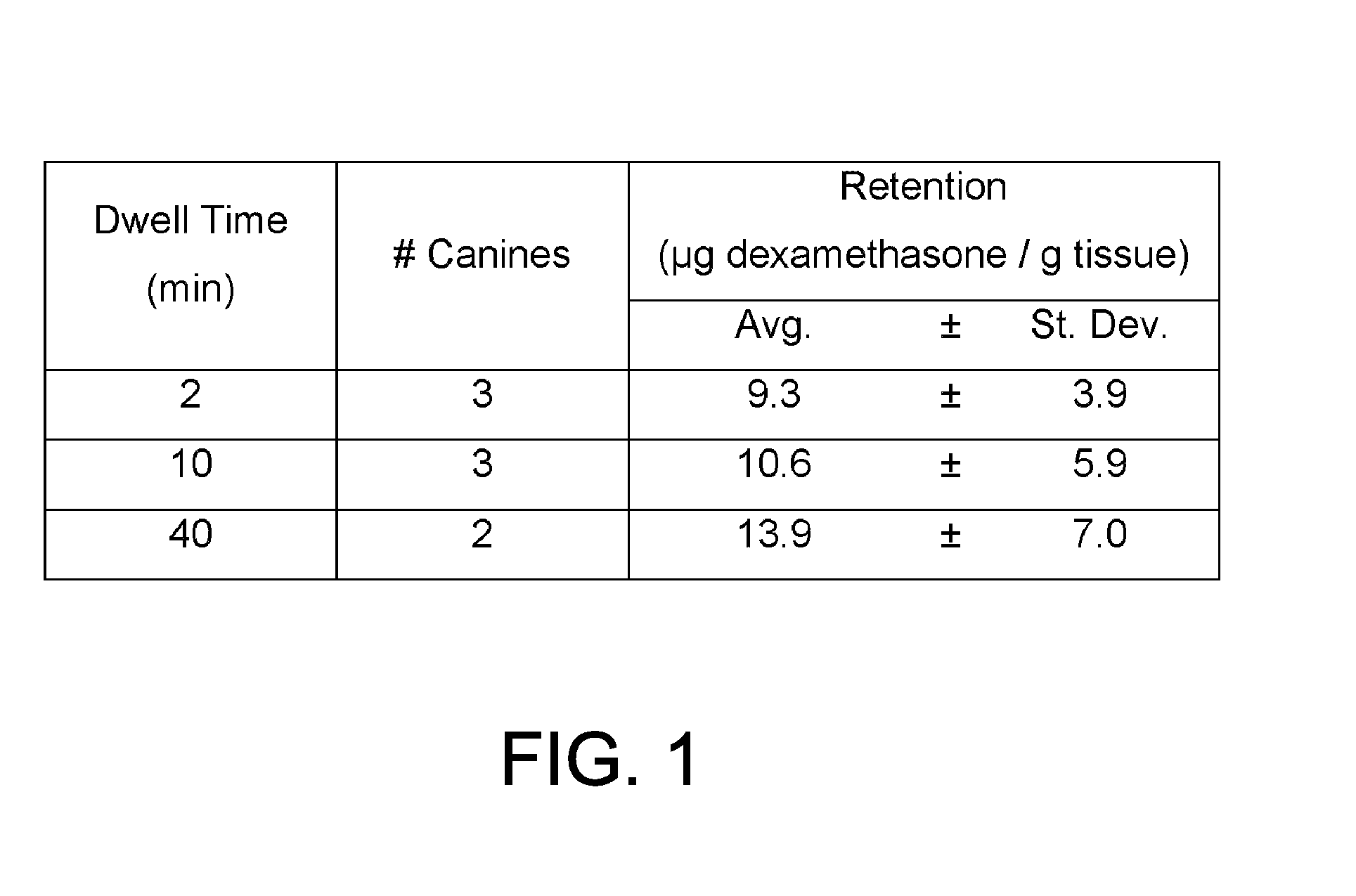

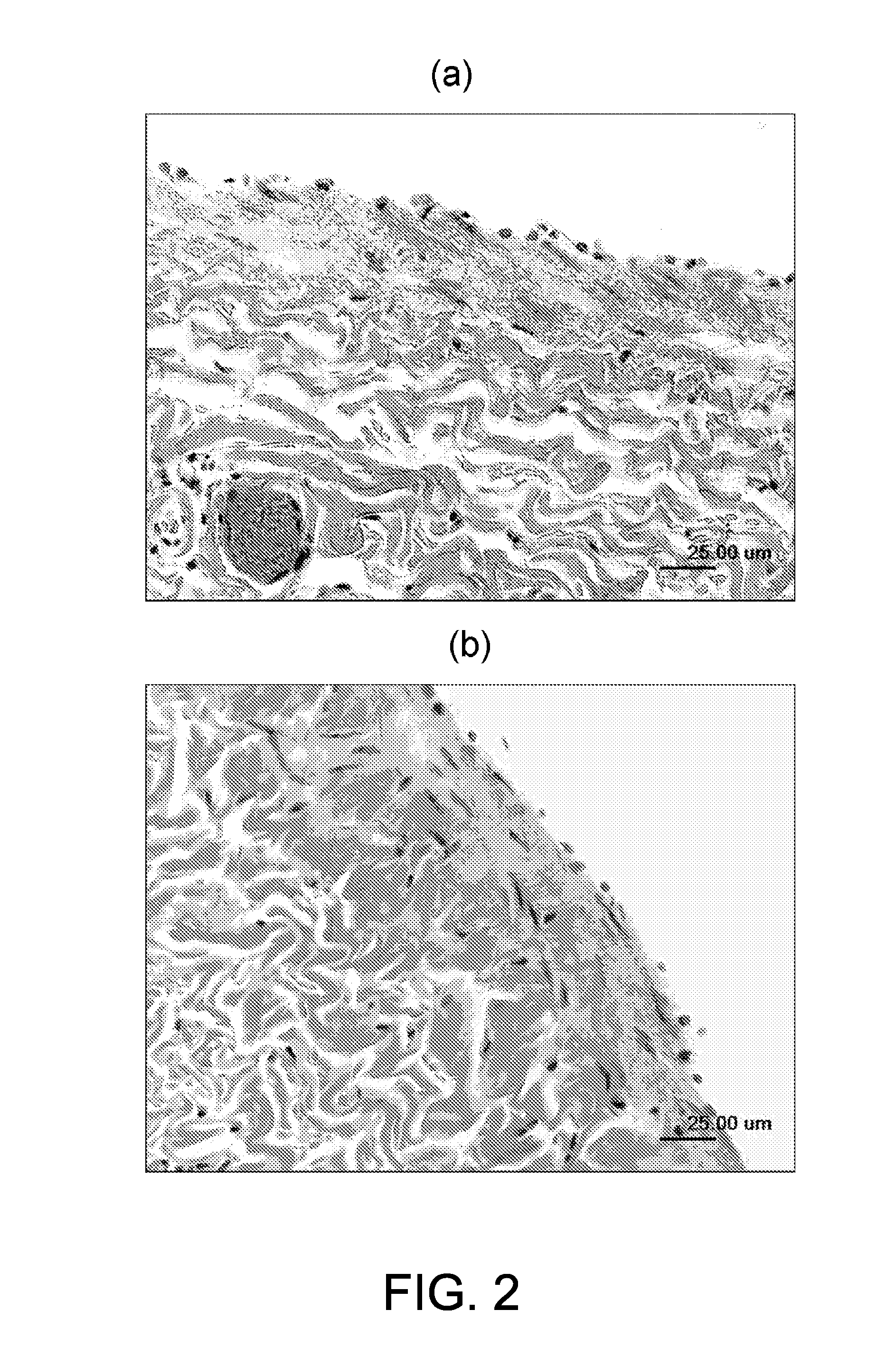

Catheter injectable depot compositions and uses thereof

InactiveUS7829109B2Improved shear thinning behaviorReduce injection forcePowder deliverySenses disorderMedicineAromatic alcohol

Catheter injectable depot compositions are provided that include a bioerodible, biocompatible polymer, a solvent having miscibility in water of less than or equal to 7 wt. % at 25° C., in an amount effective to plasticize the polymer and form a gel therewith, a thixotropic agent, and a beneficial agent. The solvent comprises an aromatic alcohol, an ester of an aromatic acid, an aromatic ketone, or mixtures thereof. The compositions have substantially improved shear thinning behavior and reduced injection force, rendering the compositions readily implanted beneath a patient's body surface by injection.

Owner:DURECT CORP

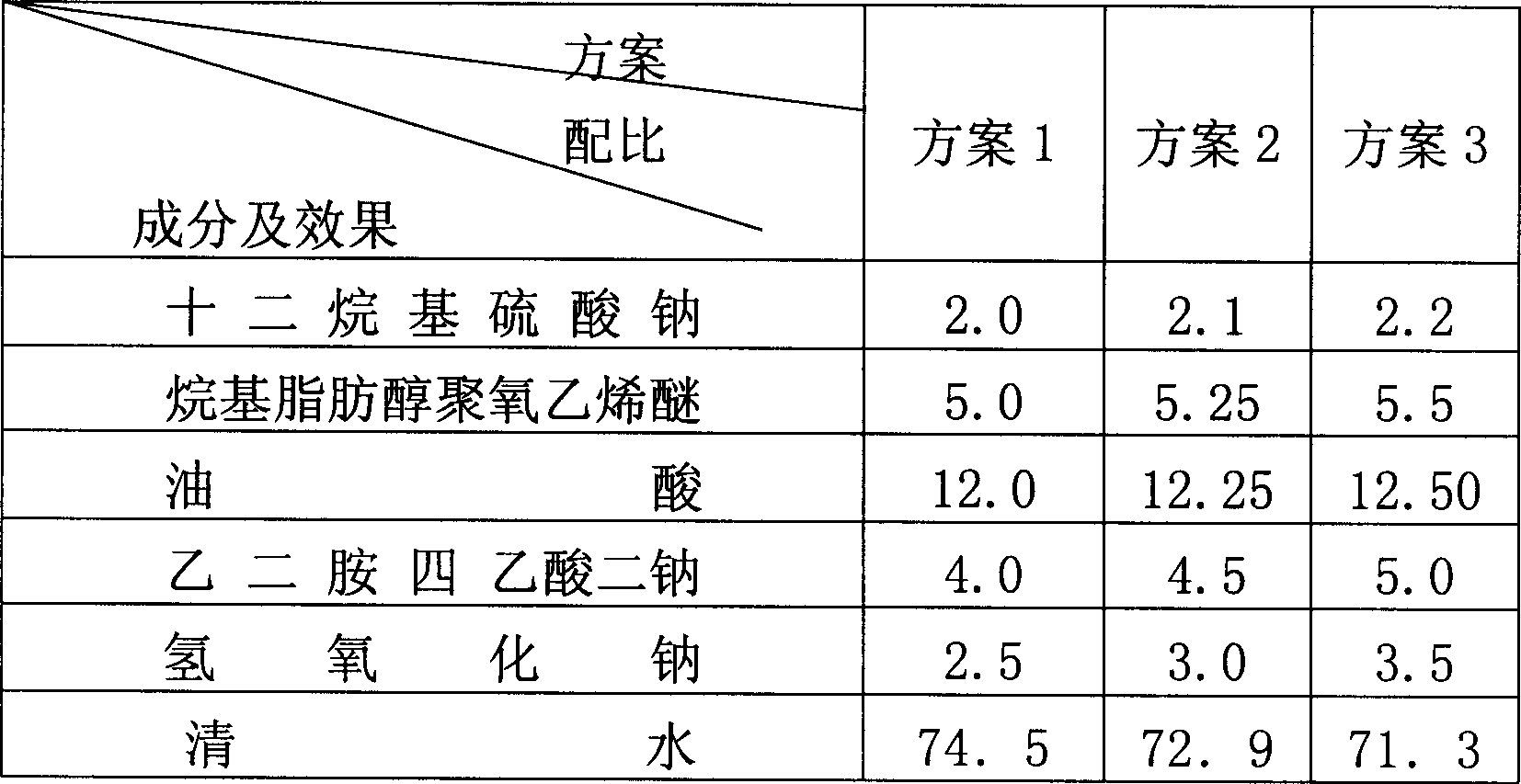

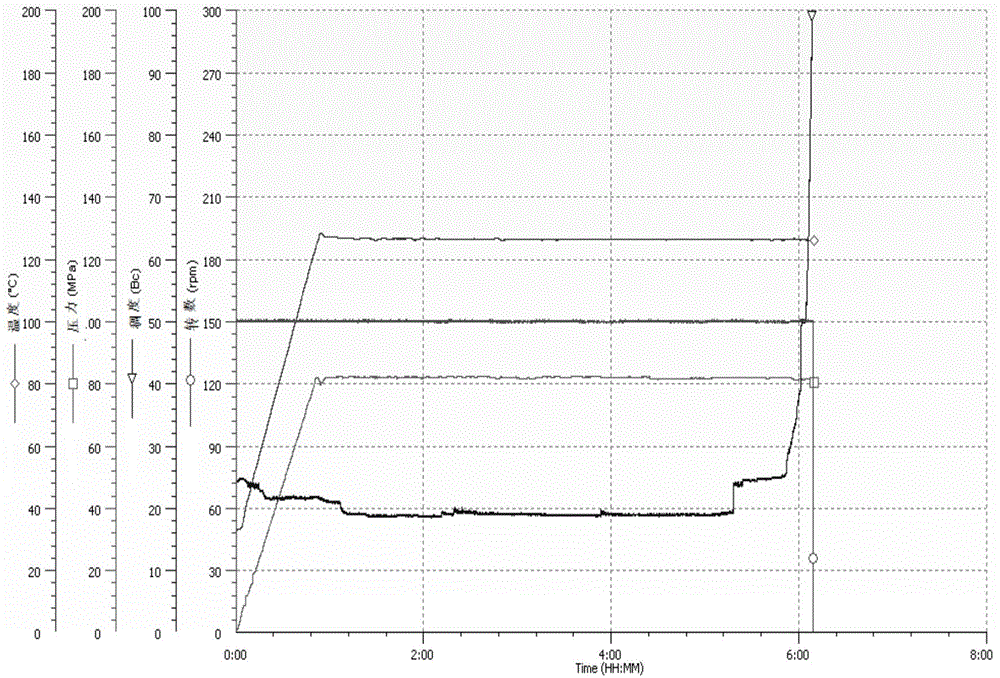

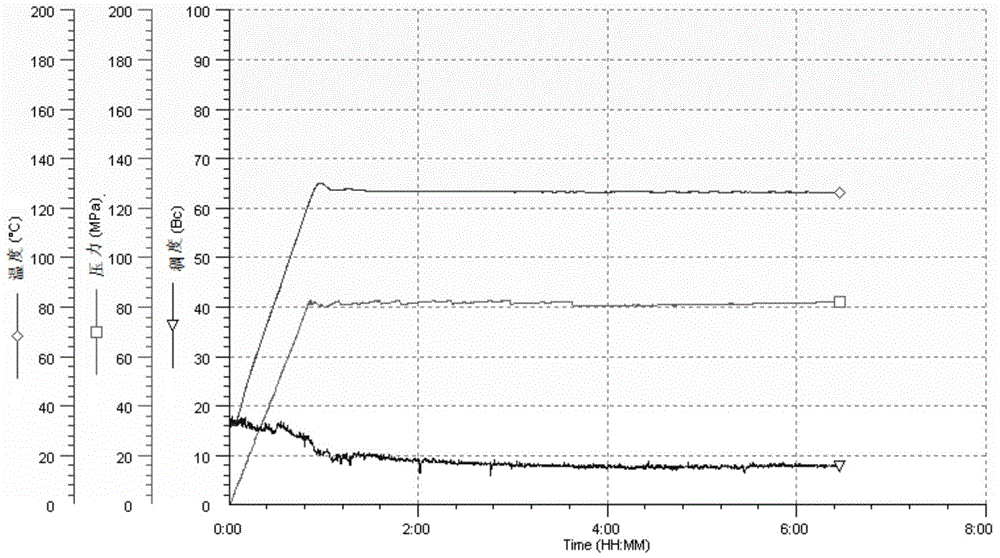

Oil-based mud flushing liquor and preparation method thereof

The invention refers to an oil rinse liquid for mud and the manufacturing method. It resolves the problem that the second interface cementation is bad. Its character lies in: add 2.5-3.5 shares sodium hydroxide and 4.0-5.0 shares ethyl diamine fourthacetic acid to clean water and blend to make them dissolve completely, then add 12.0-12.5 share oleic acid and blend for 20-30 minutes, add 2.0-2.2 shares dideakly natrium sulphate and 5.0-5.5 shares alkyl fatty ethanol poly-oxy ethene aether and blend for 55-65 minutes, finally add in the organic silicon anti-foamer. It can change the "oil wet" into "water wet", improve the cementation of cement interface and enhance the quality of fixing mine.

Owner:DAQING PETROLEUM ADMINISTRATION

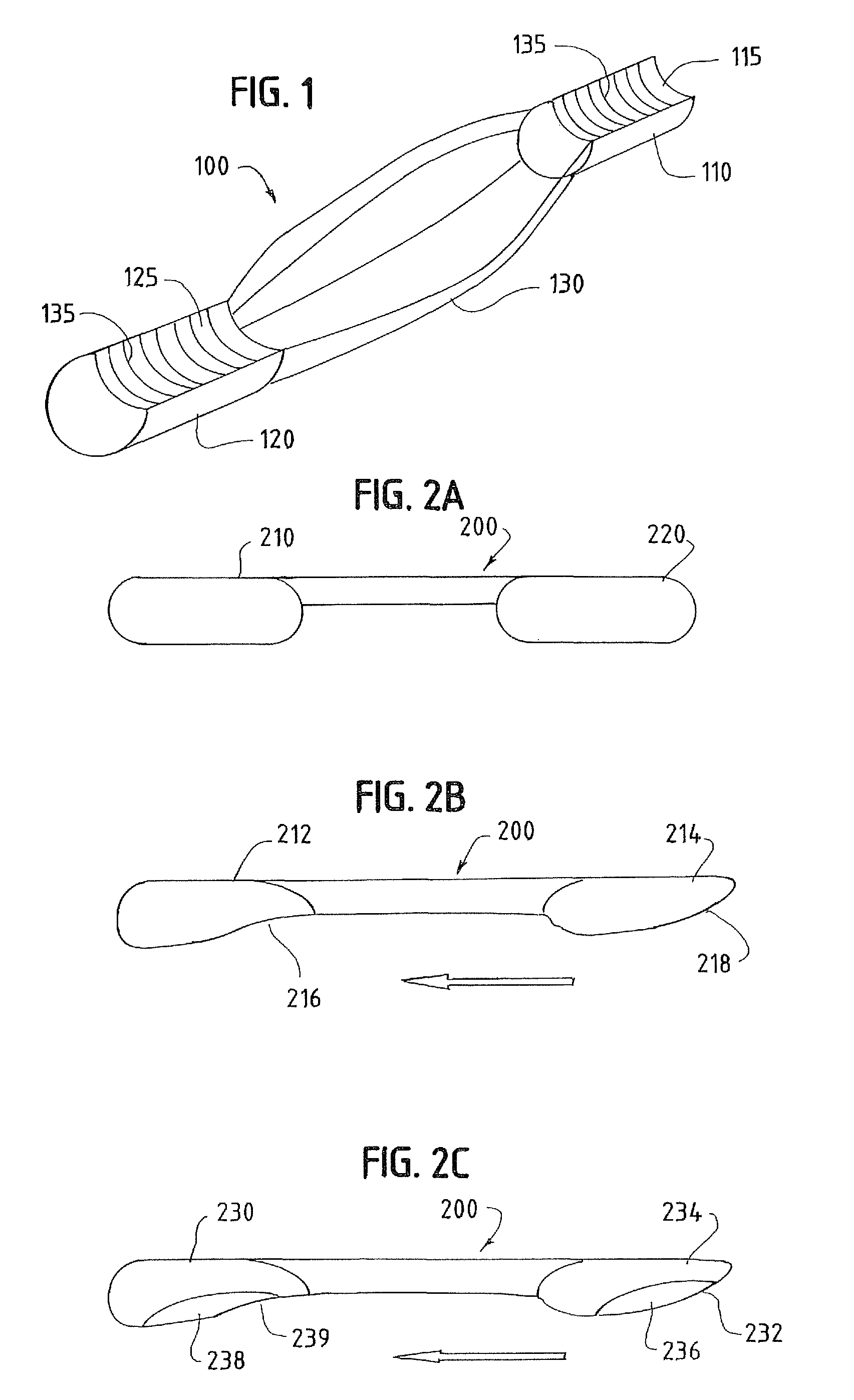

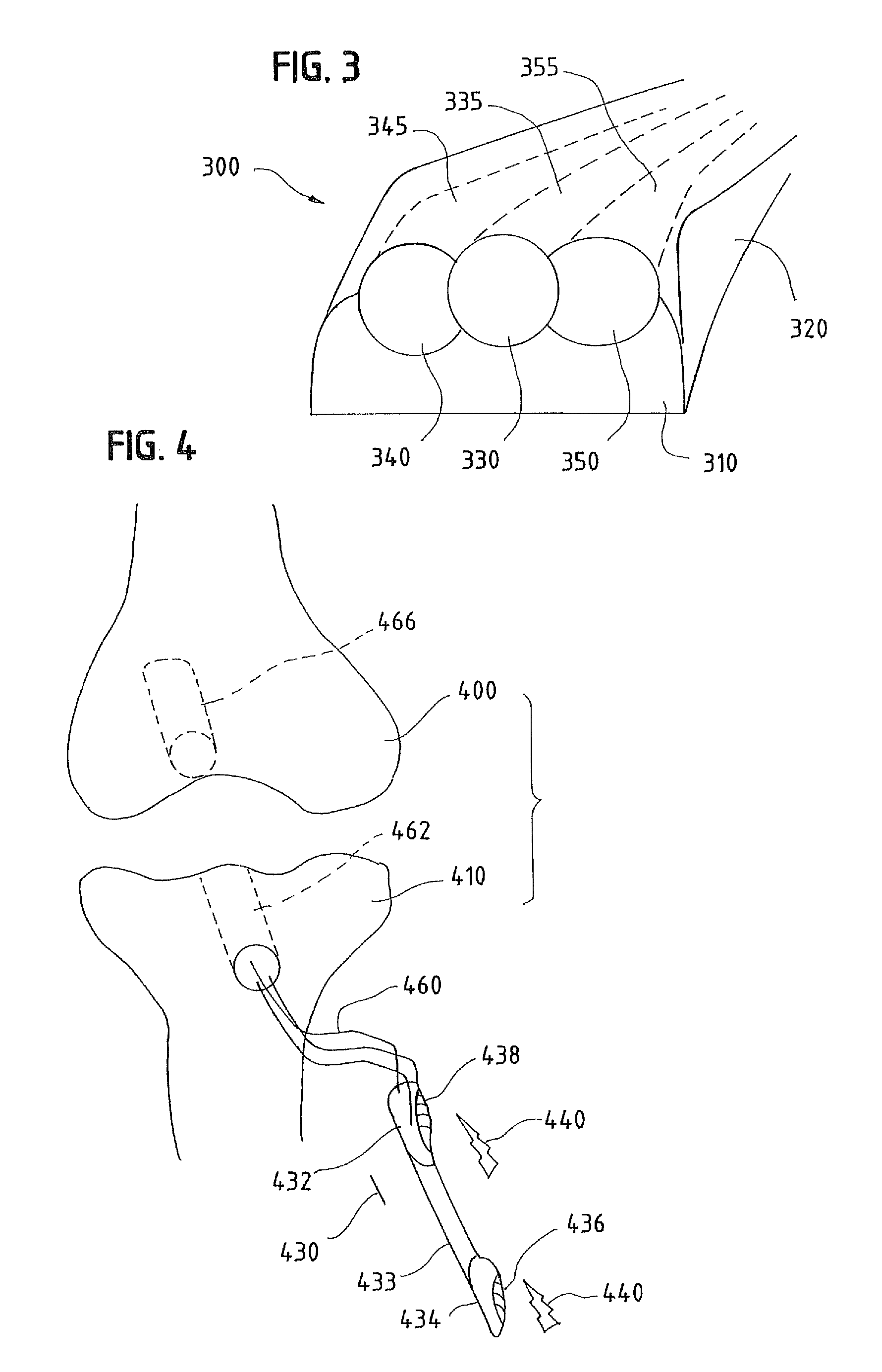

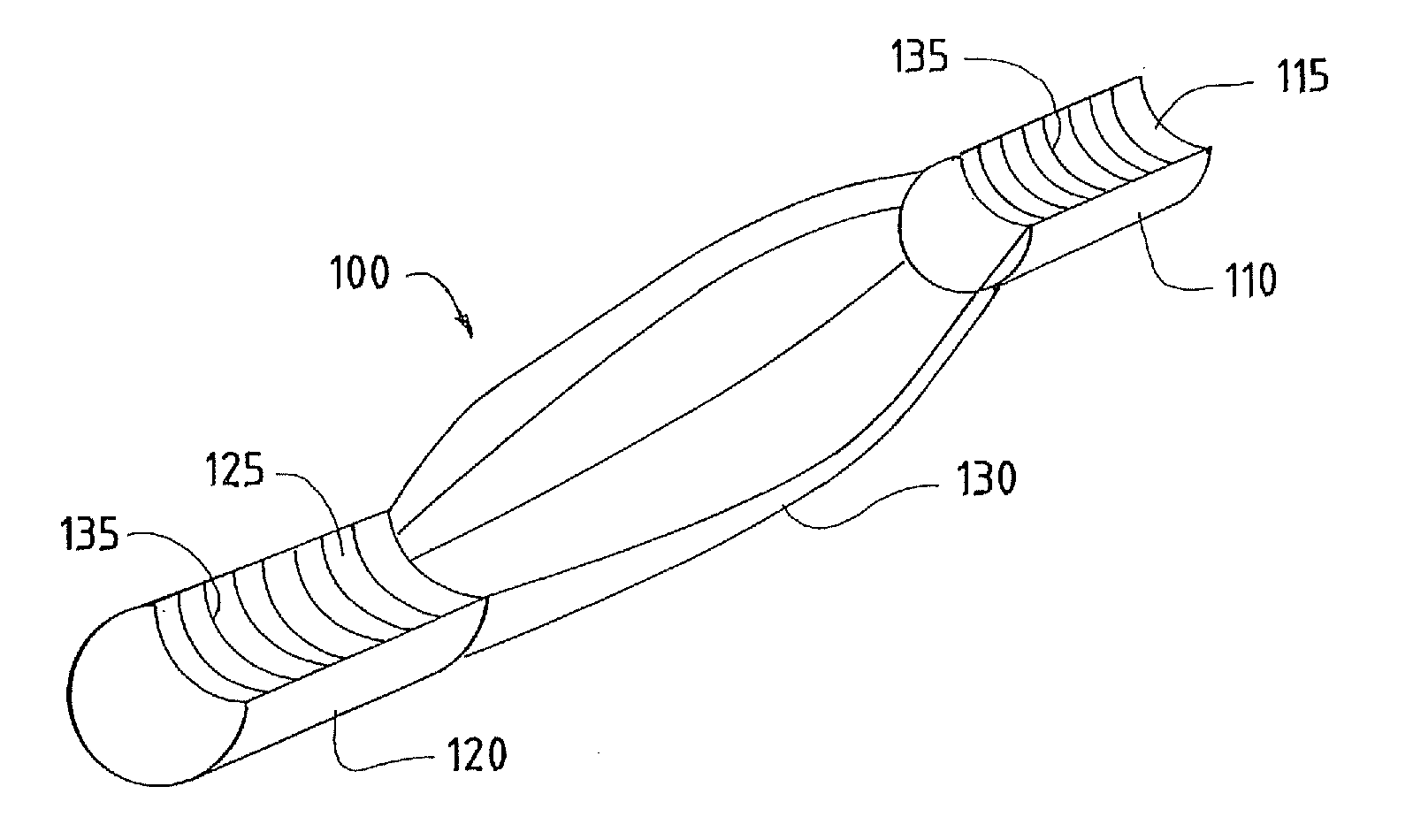

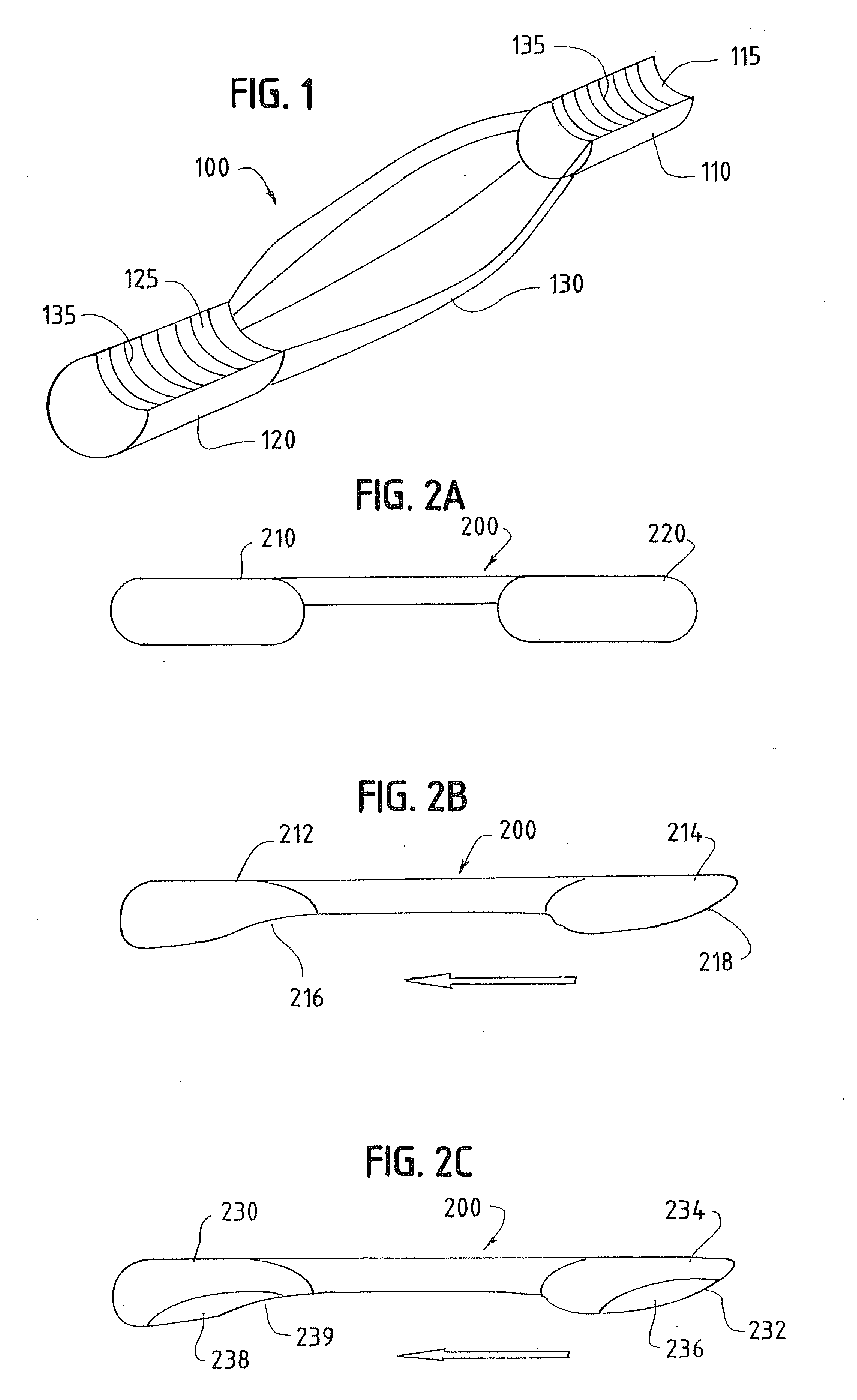

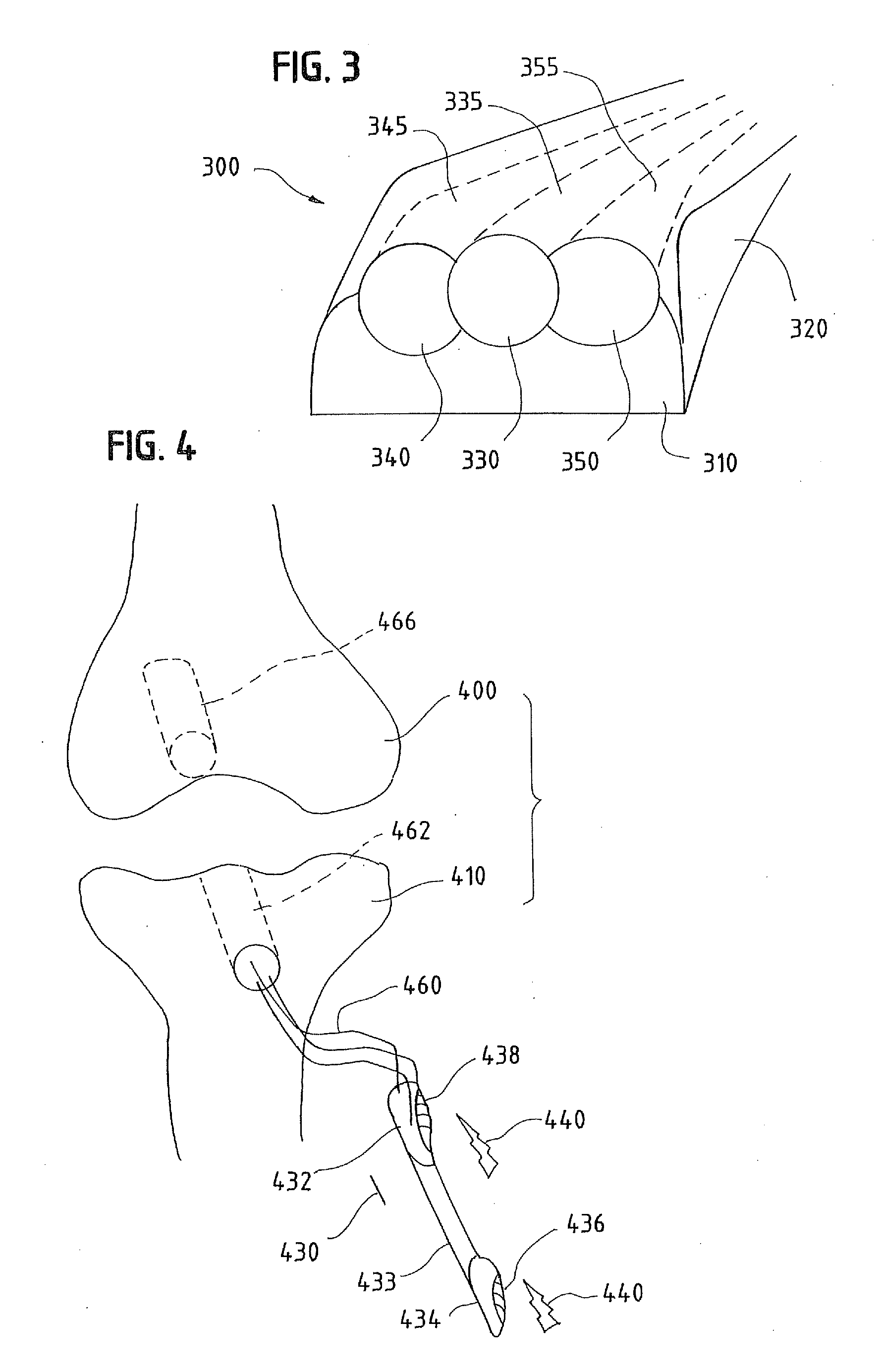

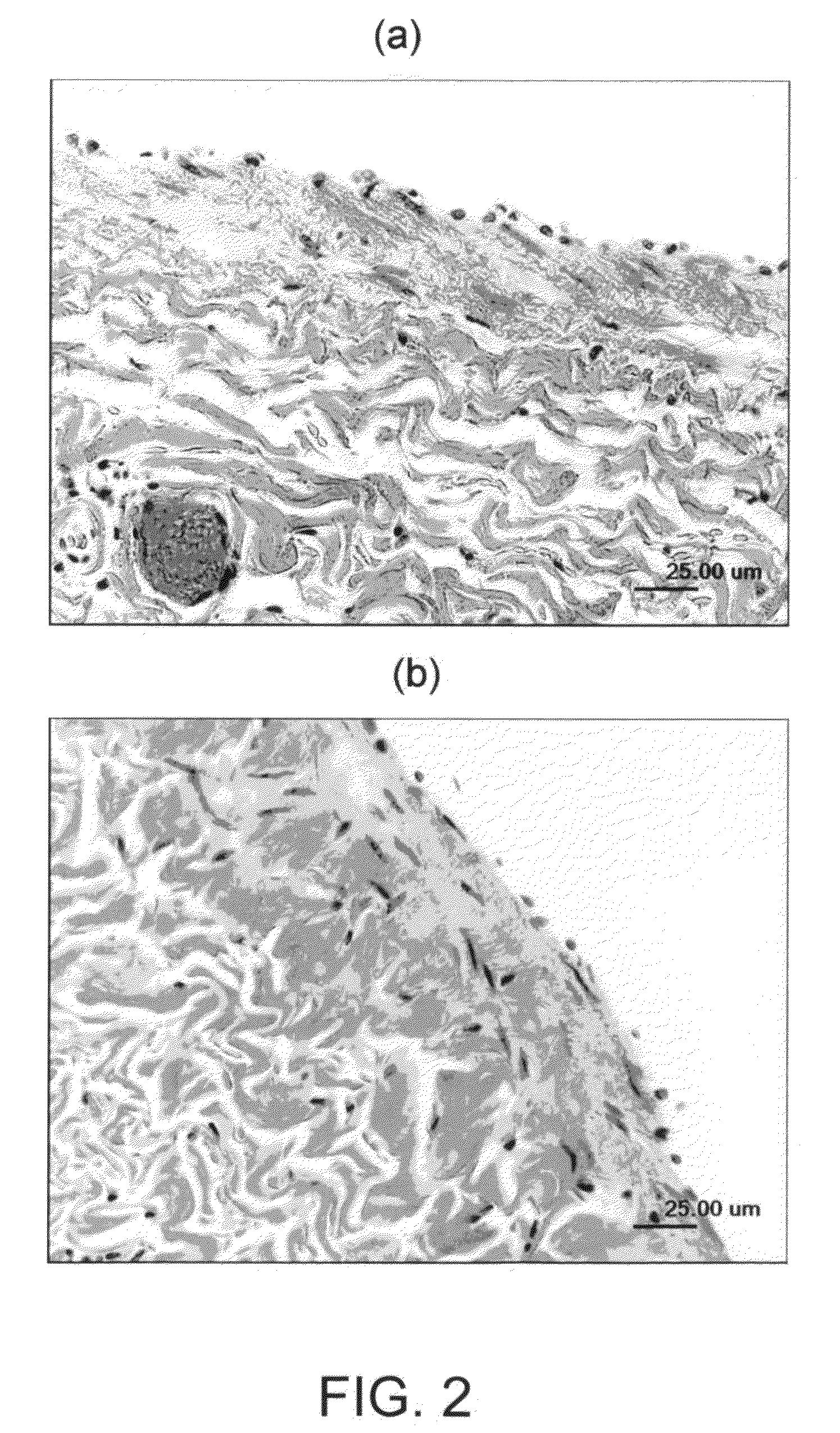

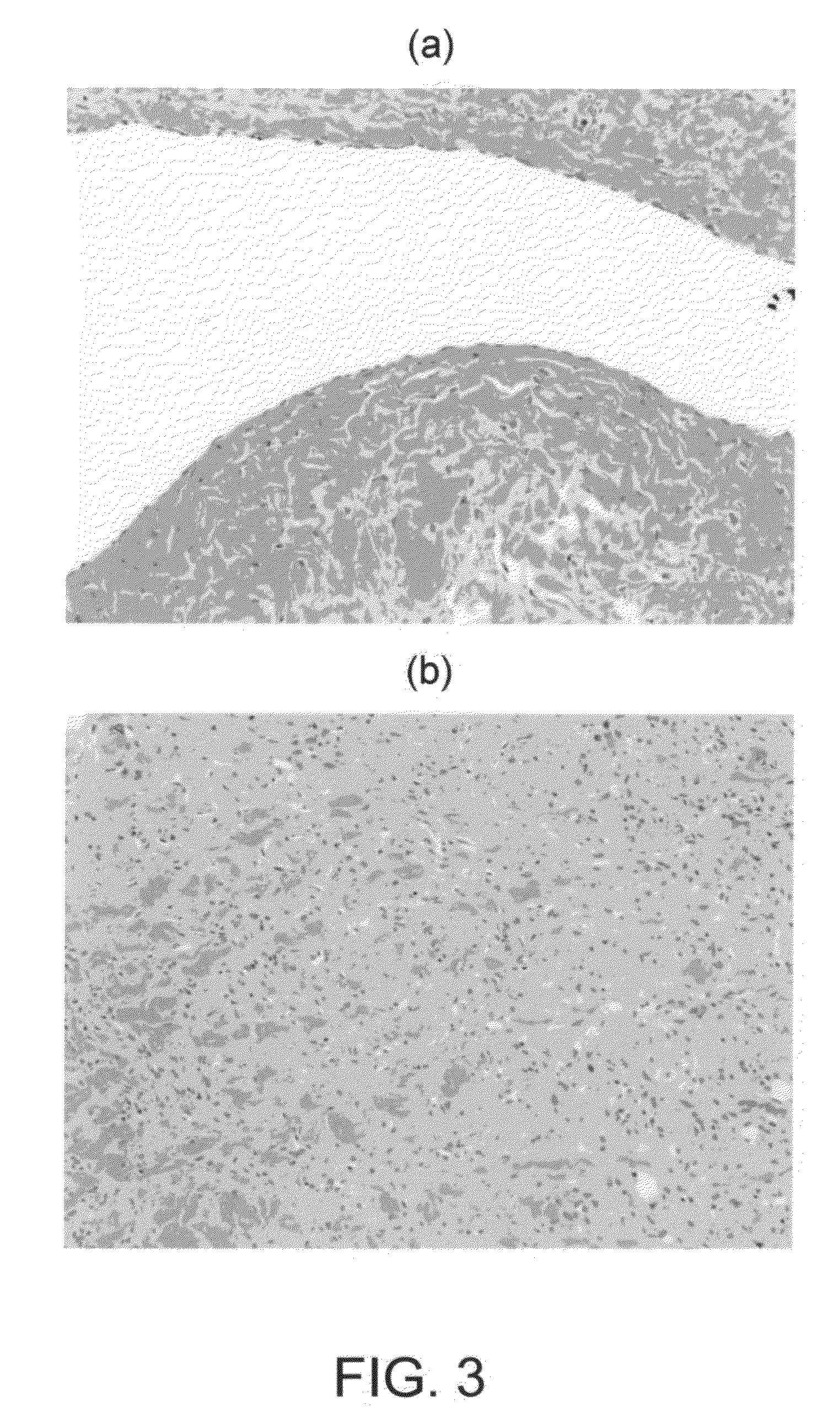

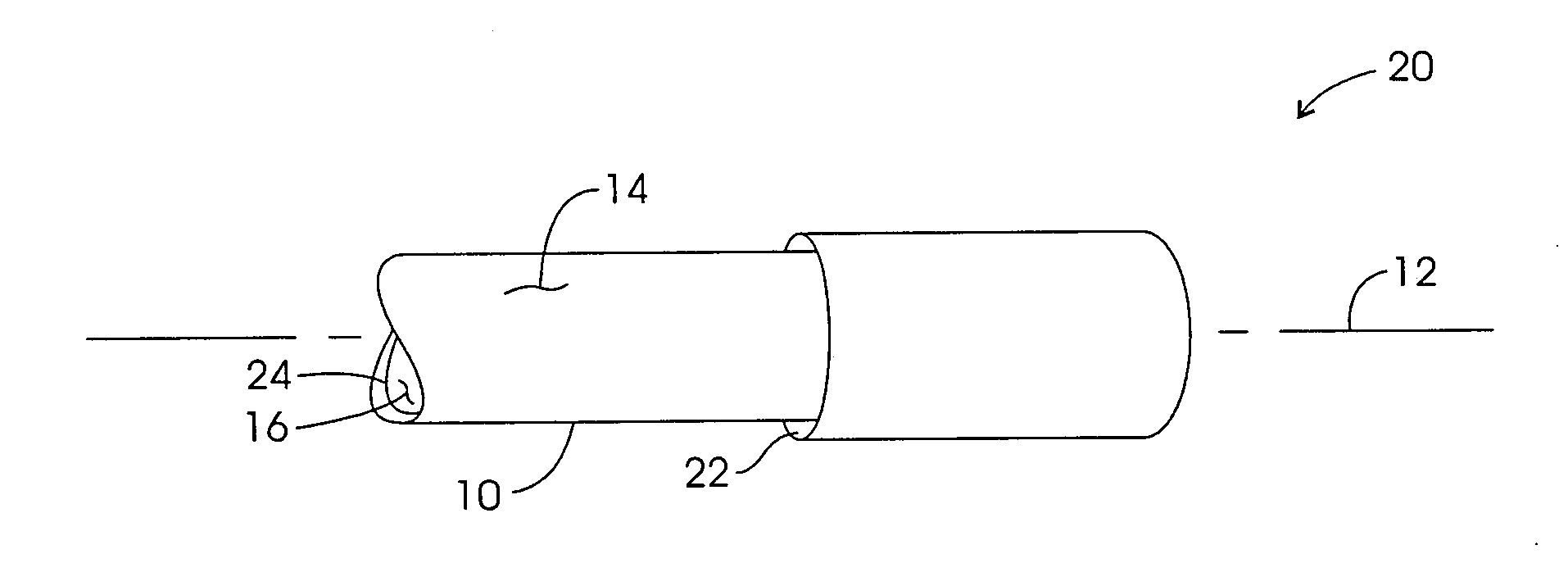

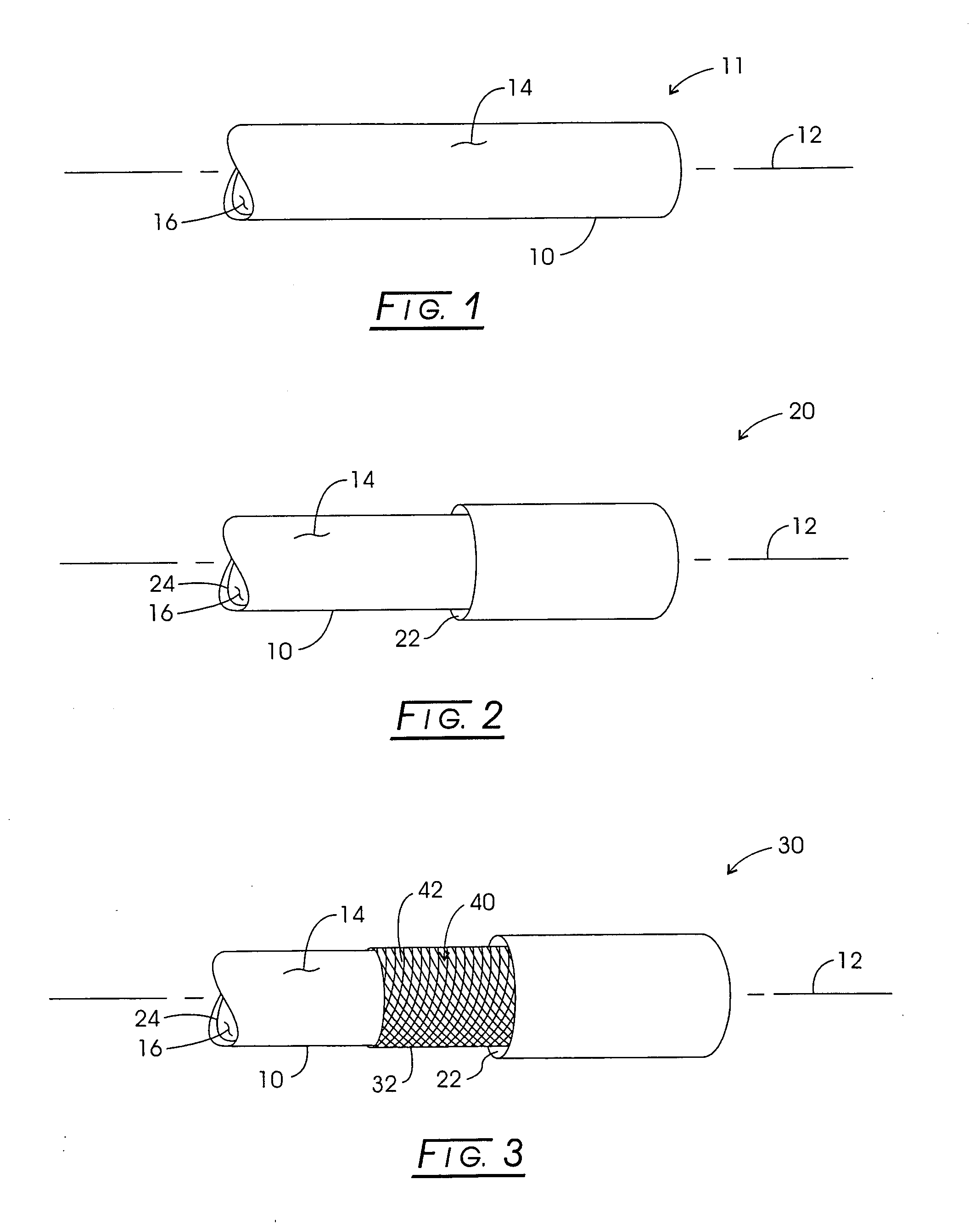

Materials and methods for improved bone tendon bone transplantation

Disclosed herein is an improved Bone Tendon Bone graft for use in orthopedic surgical procedures. Specifically exemplified herein is a Bone Tendon Bone graft comprising one or more bone blocks having a groove cut into the surface thereof, wherein said groove is sufficient to accommodate a fixation screw. Also disclosed is a porcine bone tendon bone graft for use in orthopedic procedures. Also disclosed are multiple embodiments of assembled bone tendon bone blocks for use in orthopedic surgeries. Additionally, a method of harvesting grafts that has improved efficiency, increases the quantity of extracted tissue and minimizes time required by surgeon for implantation is disclosed.

Owner:RTI BIOLOGICS INC

Materials and Methods for Improved Bone Tendon Bone Transplantation

InactiveUS20100082104A1High strengthReduce shearBone implantSurgeryOrthopedic ProceduresPorcine bone

Disclosed herein is an improved Bone Tendon Bone graft for use in orthopedic surgical procedures. Specifically exemplified herein is a Bone Tendon Bone graft comprising one or more bone blocks having a groove cut into the surface thereof, wherein said groove is sufficient to accommodate a fixation screw. Also disclosed is a porcine bone tendon bone graft for use in orthopedic procedures. Also disclosed are multiple embodiments of assembled bone tendon bone blocks for use in orthopedic surgeries. Additionally, a method of harvesting grafts that has improved efficiency, increases the quantity of extracted tissue and minimizes time required by surgeon for implantation is disclosed.

Owner:RTI BIOLOGICS INC

Mixing Apparatus

InactiveUS20120180529A1Well adjustmentImprove mixingGlass furnace apparatusRotary stirring mixersEngineering

The present invention is related to a glass stirrer providing for improved stirring, reduced glass cord and easy adjustment of processing parameters during operation.

Owner:UMICORE AG & CO KG

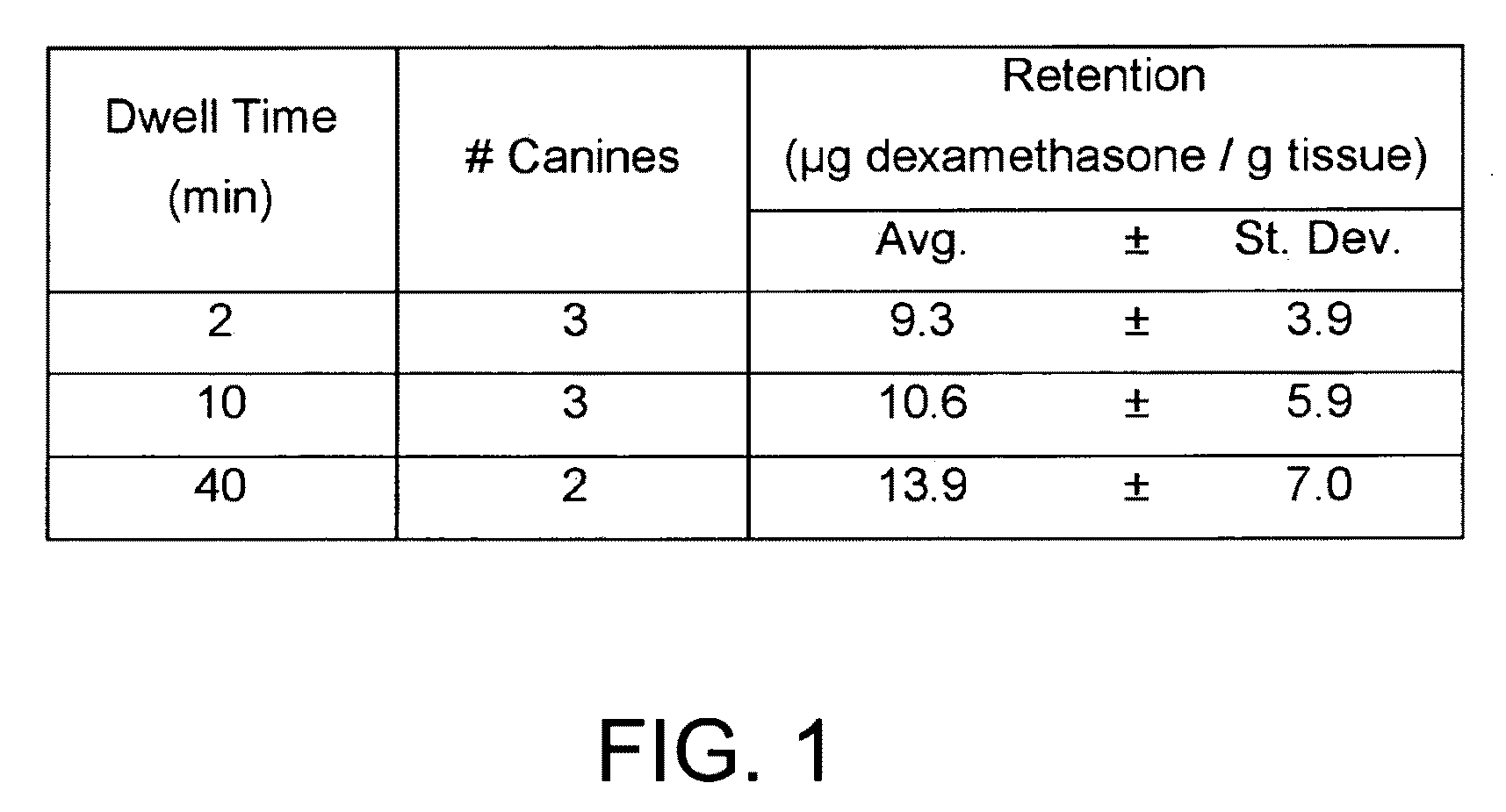

Articles and methods of treating vascular conditions

ActiveUS20140364404A1Reduce deliveryHigh viscosityBiocideAerosol deliveryVascular diseaseImplantation Site

The present invention relates to articles and methods of treating vascular conditions with a thixotropic, turbid, bioactive agent-containing gel material capable of being essentially removed from an implantation site upon re-establishment of fluid flow at the implantation site.

Owner:WL GORE & ASSOC INC

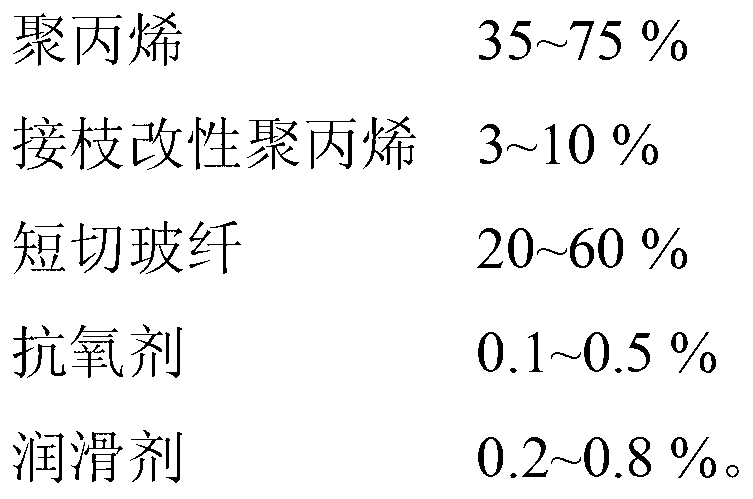

Chopped glass fiber reinforced polypropylene composite material and preparation method and application thereof

The invention belongs to the technical field of polypropylene modification and discloses a chopped glass fiber reinforced polypropylene composite material and a preparation method and application thereof. The chopped glass fiber reinforced polypropylene composite material is prepared from the following ingredients in percentage by mass: 35-75% of polypropylene, 3-10% of grafted modified polypropylene, 20-60% of chopped glass fibers, 0.1-0.5% of antioxidant and 0.2-0.8% of lubricant. During the preparation of the chopped glass fiber reinforced polypropylene composite material disclosed by the invention, glass fiber dispersion zones of screws of a twin-screw extruder adopt large-lead and non-meshed screw elements, so that the damage and destruction to the glass fibers caused by chopping are reduced, and the reserved length of the glass fibers is guaranteed; and the obtained composite material has the advantages that the mechanical properties are excellent, the tensile strength reaches up to 132MPa, the bending strength reaches up to 187MPa, the bending modulus reaches up to 12,733MPa, and the notched impact strength reaches up to 51 KJ / m<2>.

Owner:WUHAN JINFA TECH CO LTD

Articles and methods of treating vascular conditions

InactiveUS20100233266A1Reduce deliveryHigh viscosityBiocidePowder deliveryVascular diseaseActive agent

The present invention relates to articles and methods of treating vascular conditions with a thixotropic, turbid, bioactive agent-containing gel material capable of being essentially removed from an implantation site upon re-establishment of fluid flow at the implantation site.

Owner:WL GORE & ASSOC INC

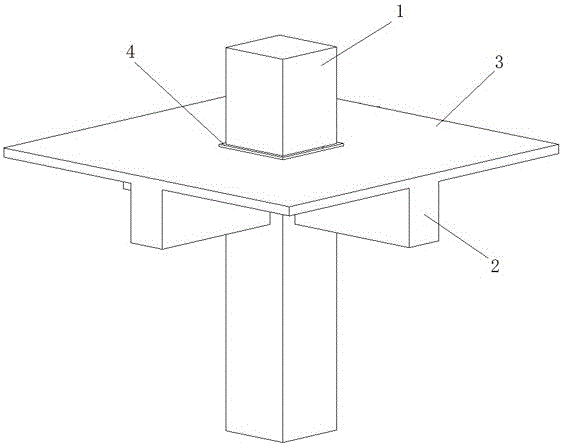

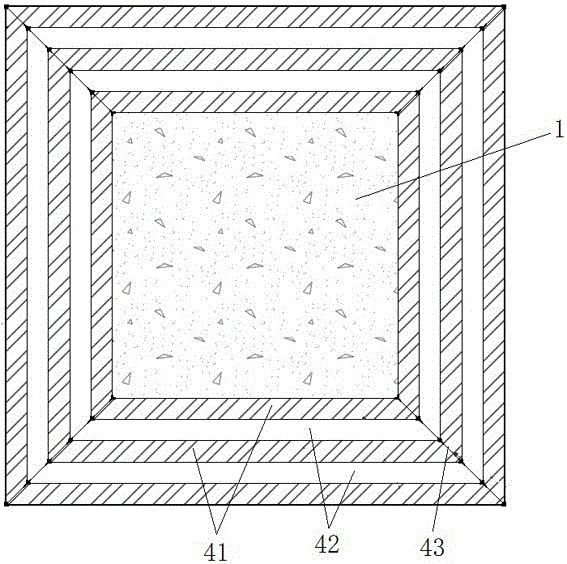

Shock insulation structure of reinforced concrete beam column node and construction method thereof

InactiveCN106368332AImprove bending deformation abilityImprove seismic performanceProtective buildings/sheltersShock proofingReinforced concreteEngineering

The invention relates to a shock insulation structure of a reinforced concrete beam column node and a construction method thereof. The shock insulation structure comprises a beam column node formed by an integrally poured reinforced concrete bearing column and a supporting beam. The supporting beam is fixedly connected with a reinforced concrete floor, and the joint of the floor and the bearing column is provided with a shock insulation material capable of preventing the floor and the bearing column from contacting each other. The shock insulation structure is simple in structure and good in damping effect.

Owner:FUZHOU UNIV

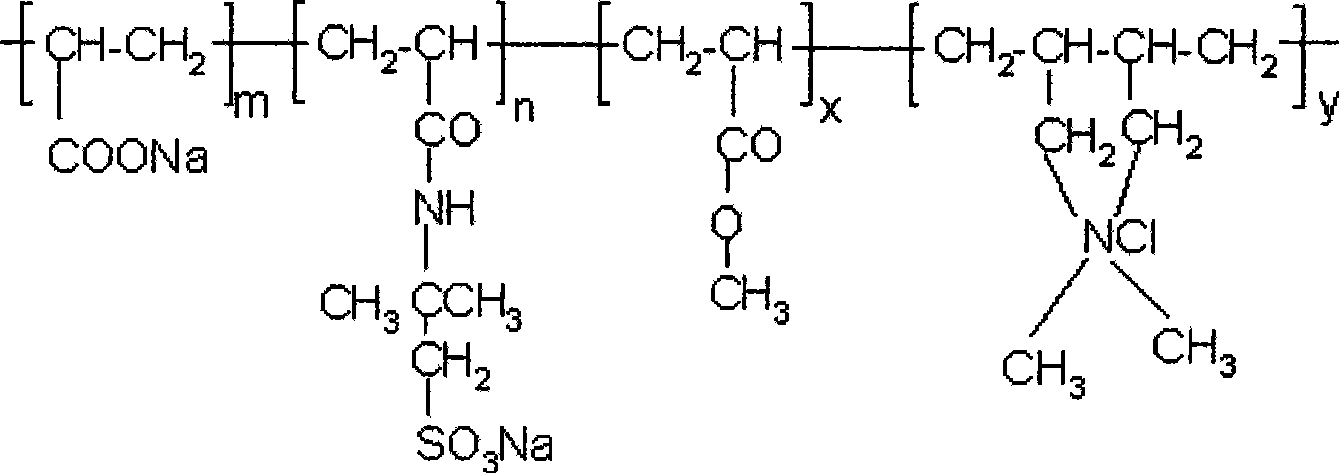

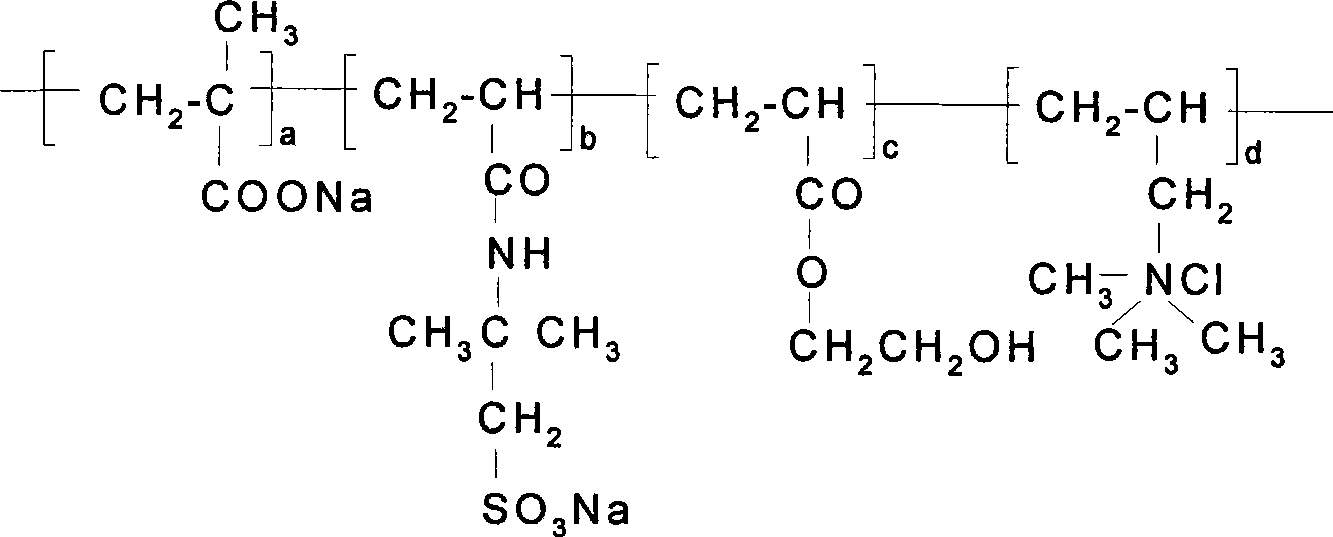

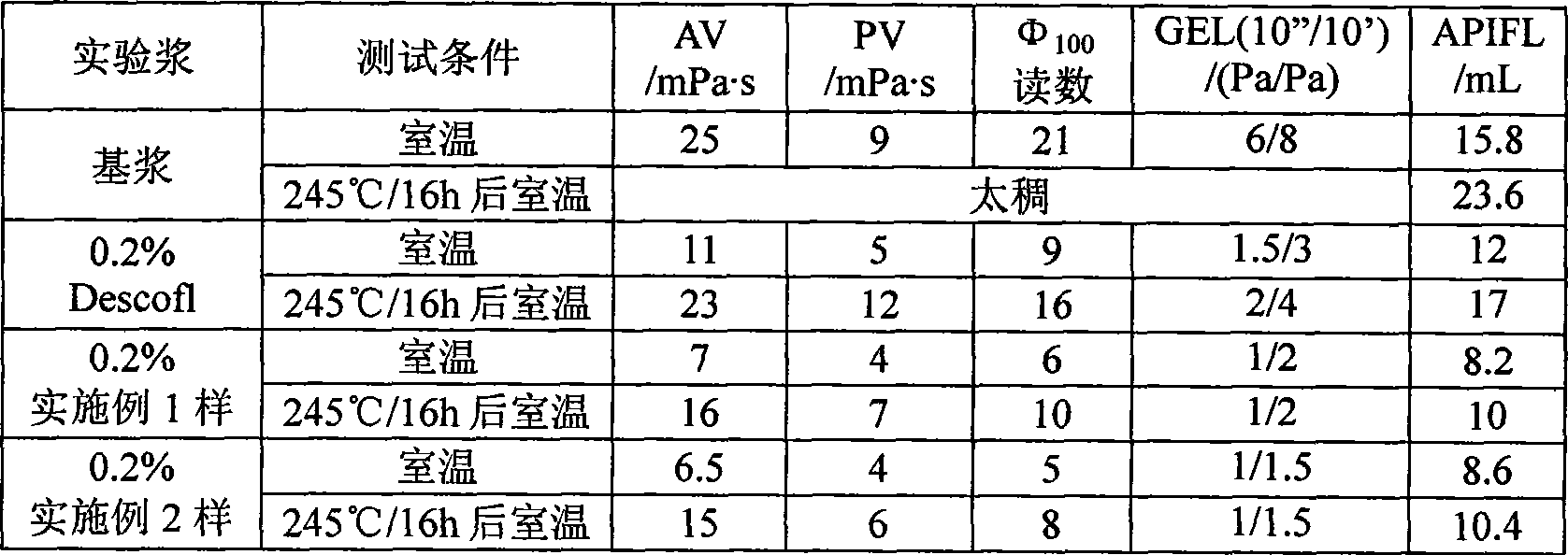

High-temperature resistant polymer viscosity reducer for drilling fluid and preparation method thereof

InactiveCN101531886AImprove efficiencyImprove adsorption capacityDrilling compositionPolymer scienceChemical reaction

The invention discloses a high-temperature resistant polymer viscosity reducer for drilling fluid and a preparation method thereof. The polymer viscosity reducer is a copolymer generated by olefine acid, olefine sulfoacid, olefine acid ester and alkenyl quaternary ammonium through chemical reaction, molecules of the copolymer contain 5 to 60 structural units, and viscosity average molecular weight is 2,500 to 30,000. The polymer viscosity reducer can resist temperature of more than 245 DEG C in the drilling liquid, and effectively disperse a grid structure of the drilling liquid, has good viscosity reduction effect in fresh water, aggravated fresh water and a calcium chloride and sodium chloride composite saline water drilling fluid, and can simultaneously inhibit hydration and swelling of clay and reduce filtration loss.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

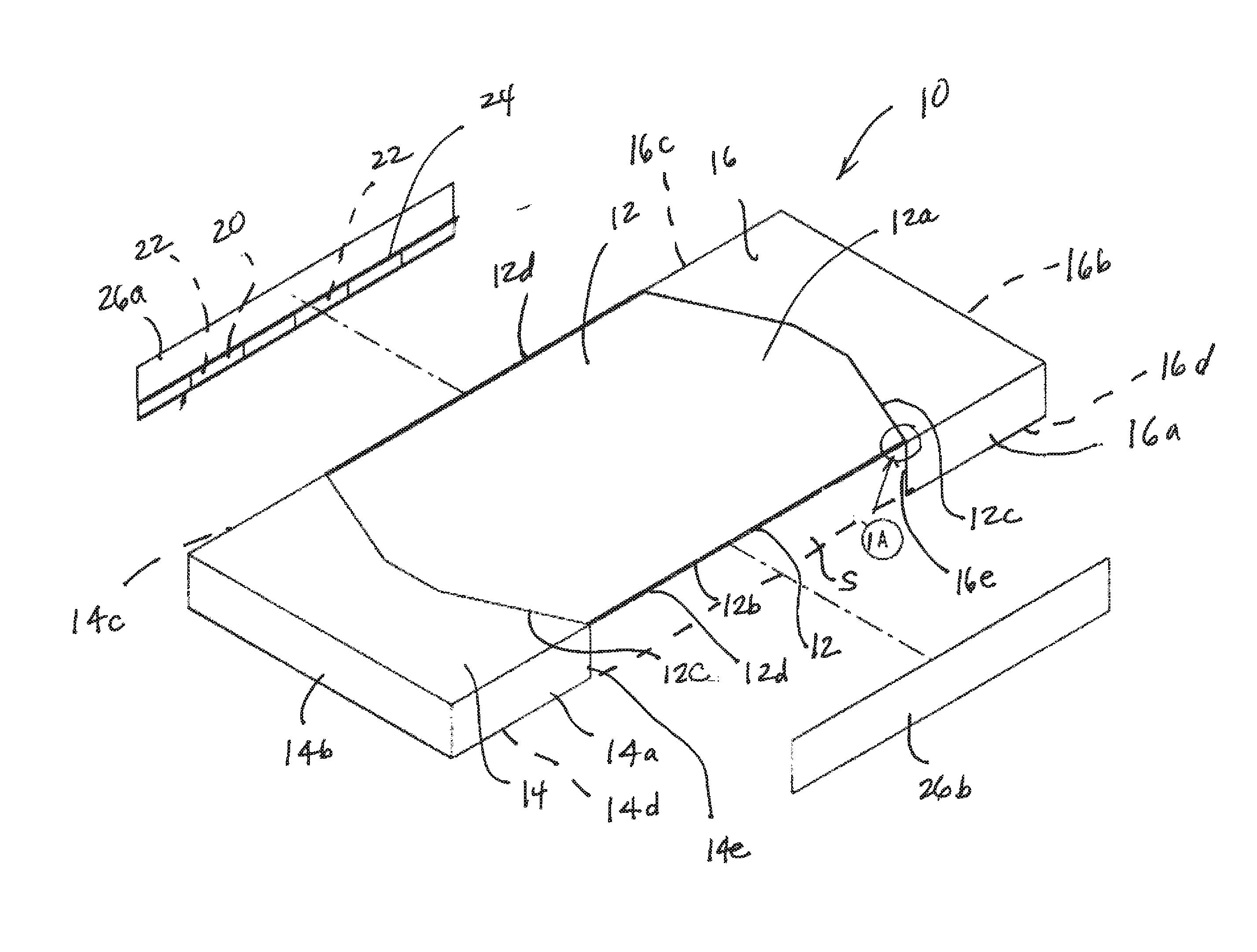

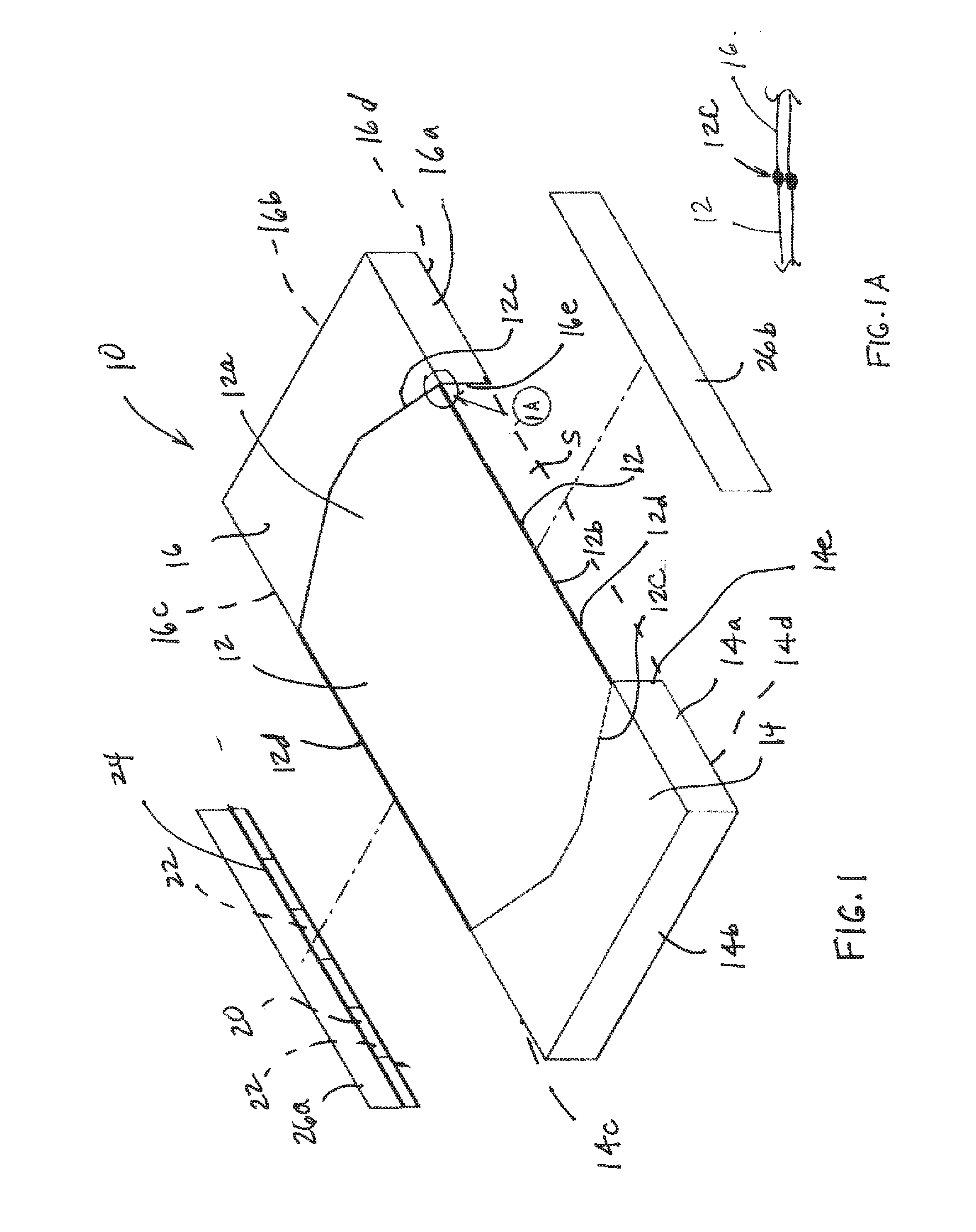

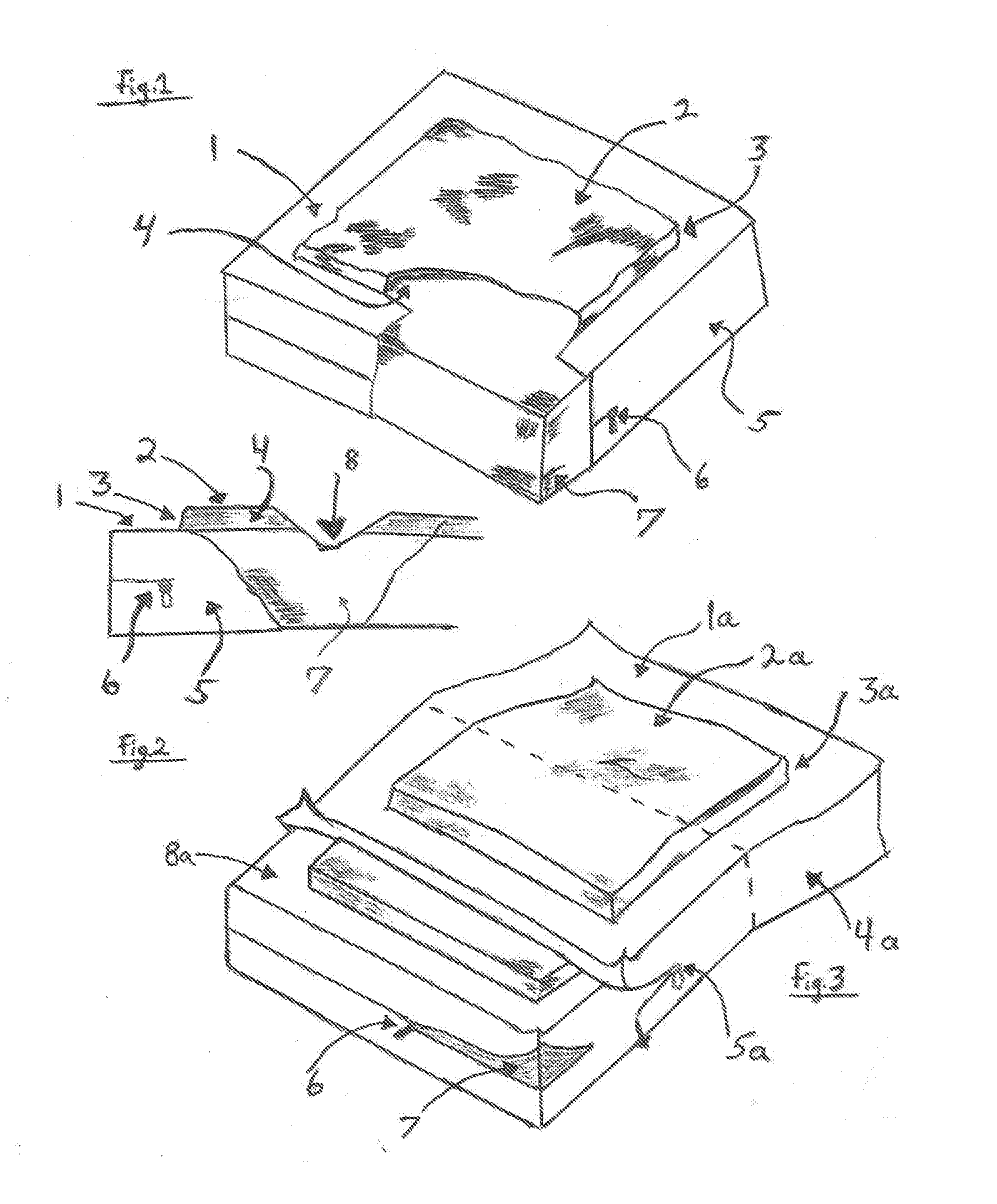

Vapor Proof Dual Cover System for Pet Beds with Pressure Relief Zones

InactiveUS20160192617A1Good reproducibilityEasy to assembleBlanketBed linenCovering systemMechanical engineering

A Dual Cover System for pet bed mattresses comprised of a water proof and vapor proof inner covering and a machine washable, decorative outer covering. Both inner and outer covers have corresponding Pressure Relieving Zones that allow the animal's unique shape and weight to descend into the cushioning layers without the resistance otherwise created by the taught fabric of a form fitted cover.

Owner:MURPHY MICHAEL E

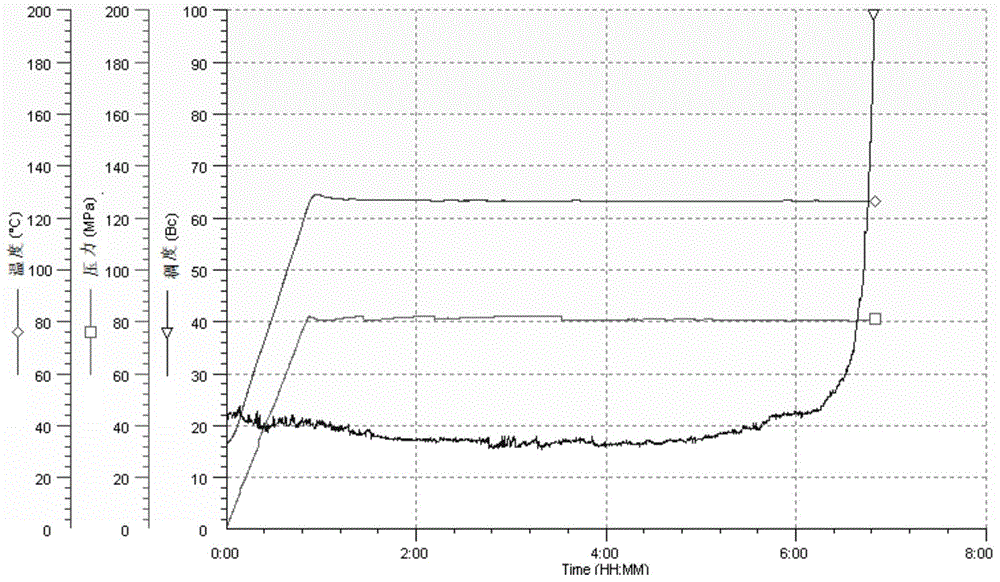

High temperature resistant well-cementing spacer fluid and preparation method thereof

ActiveCN104449606AGood thickeningGood suspensionDrilling compositionSodium BentoniteSuspending Agents

The invention relates to a high temperature resistant well-cementing spacer fluid and a preparation method thereof. The spacer fluid consists of: 100 parts by weight of fresh water, 2-8 parts by weight of a suspending agent, 2-10 parts by weight of a diluents, 25-400 parts by weight of a weighting agent, and 1-15 parts by weight of a flushing agent. Specifically, the suspending agent is composed of 100 parts by weight of OCMA bentonite, 2 parts by weight of hydroxypropyl guar gum and 8 parts by weight of xanthan gum; the diluent is composed of 100 parts by weight of sodium lignin sulfonate and 20 parts by weight of sulfonated tannin; the flushing agent consists of 40 parts by weight of fatty alcohol-polyoxyethylene ether, 40 parts by weight of triethanolamine oleate and 20 parts by weight of sodium tripolyphosphate; and the weighting material is barite. The spacer fluid has stable performance under 180DEG C high temperature condition, still has good rheological performance under the premise of ensuring the system good suspension stability, is compatible with conventional cement slurry and drilling fluid systems, improves the rheological properties of drilling fluid, enhances the displacement efficiency, and reinforces the cementation quality of a cement ring with a well cementation first interface and a second interface.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

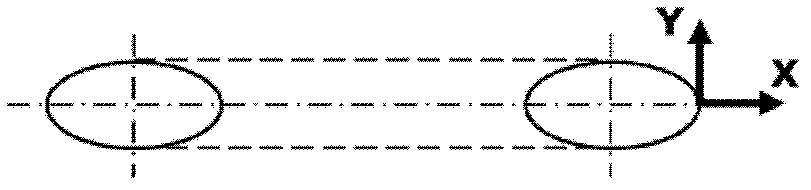

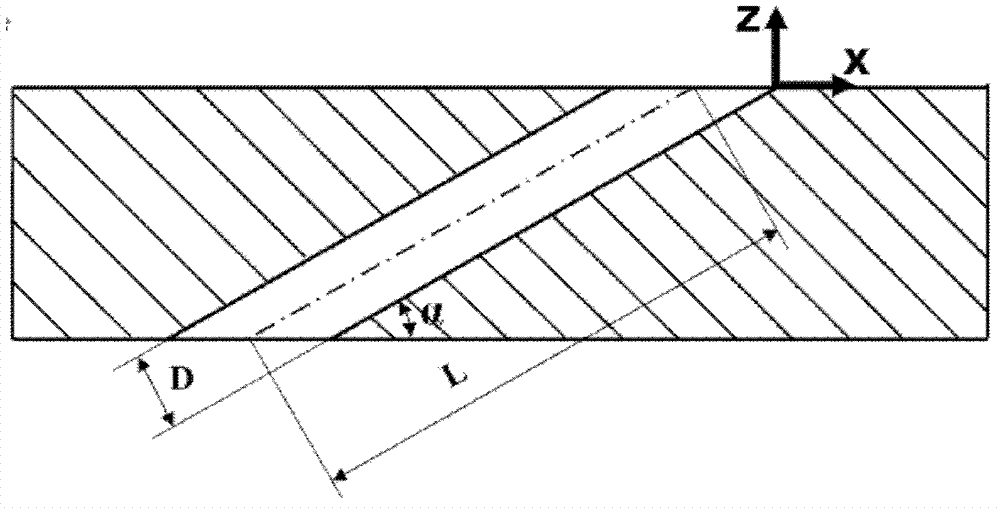

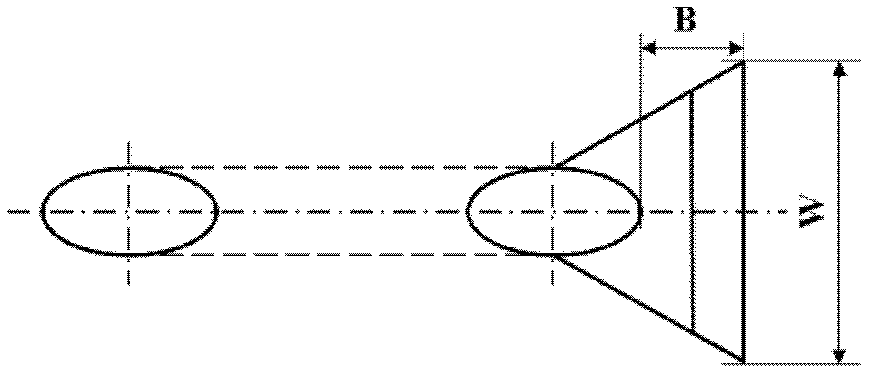

Discrete air film cooling hole shape

ActiveCN103244196AImprove cooling efficiencyReduce export momentumBlade accessoriesMachines/enginesTurbine bladeCooling effect

The invention discloses a discrete air film cooling hole shape and relates to the technology of gas turbines. In the discrete air film cooling hole shape, a cylindrical hole outlet sinks for a depth from a cooled surface and is provided with an expanding structure starting at the center of the cylindrical hole outlet, the expanding structure is in bilateral symmetry with a cylindrical hole central line as the symmetrical axis, the sink depth H is 0.2-0.5 times of the diameter of a cylindrical hole, the expanding width W is 3-4 times of the diameter of the cylindrical hole, and the expanding length B is 1.0-2.0 times of the diameter of the cylindrical hole. The hole shape comprises: 1) a fundamental form; and 2) an expanded boss arranged in the space between the lower stream of an air outlet edge of the cylindrical hole and an air outlet edge of the expanding structure on the basis of the fundamental form. The discrete air film cooling hole shape has the advantages of being high in crosswise average air film cooling efficiency, good in cooling effect in high blowing ratio, less in pneumatic loss and easy to achieve. The discrete air film cooling hole shape is used in air film cooling of the gas turbines and is suitable for pressure surface, suction surface and end wall discrete hole air film cooling of turbine blades.

Owner:中科合肥中型燃气轮机研究院有限公司

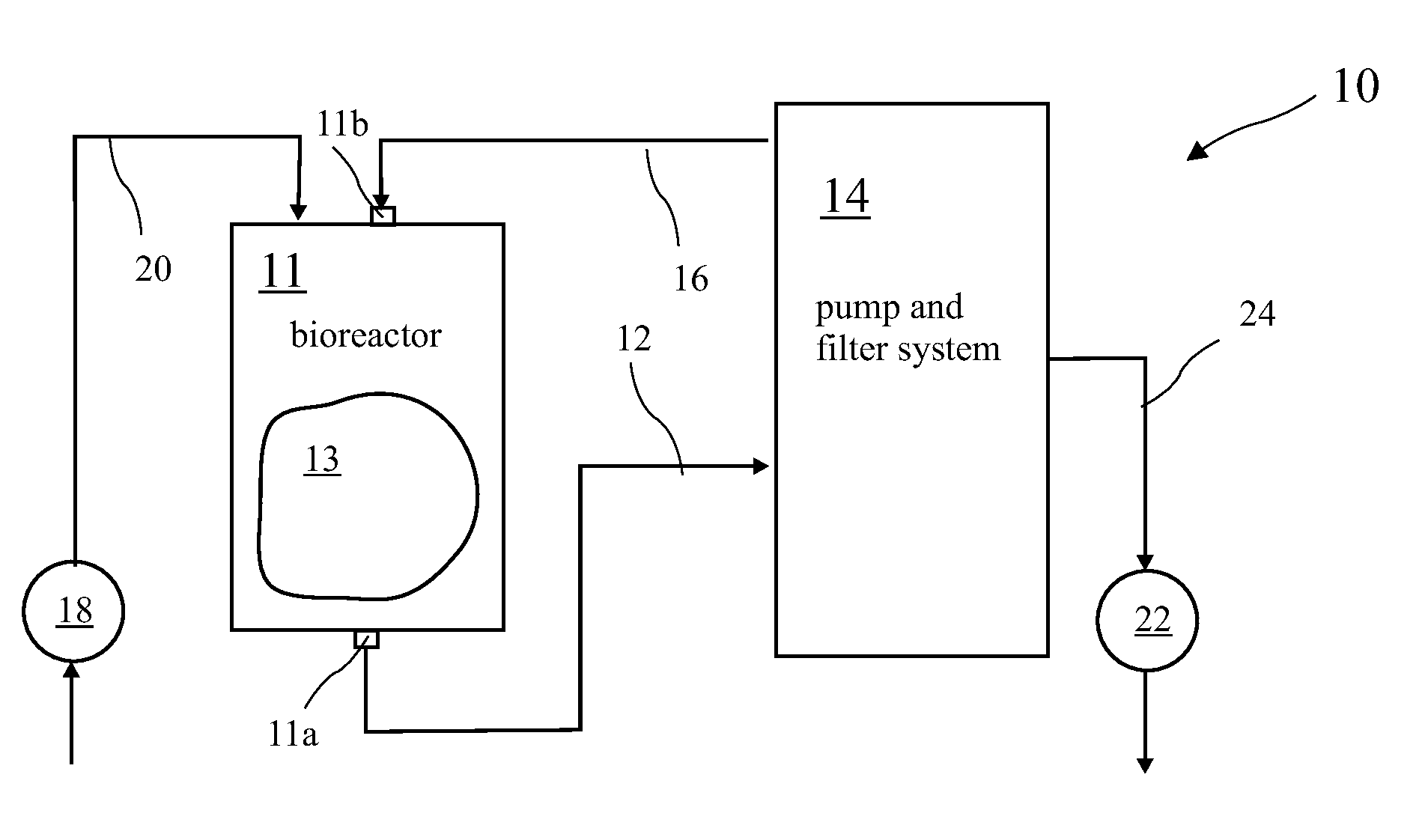

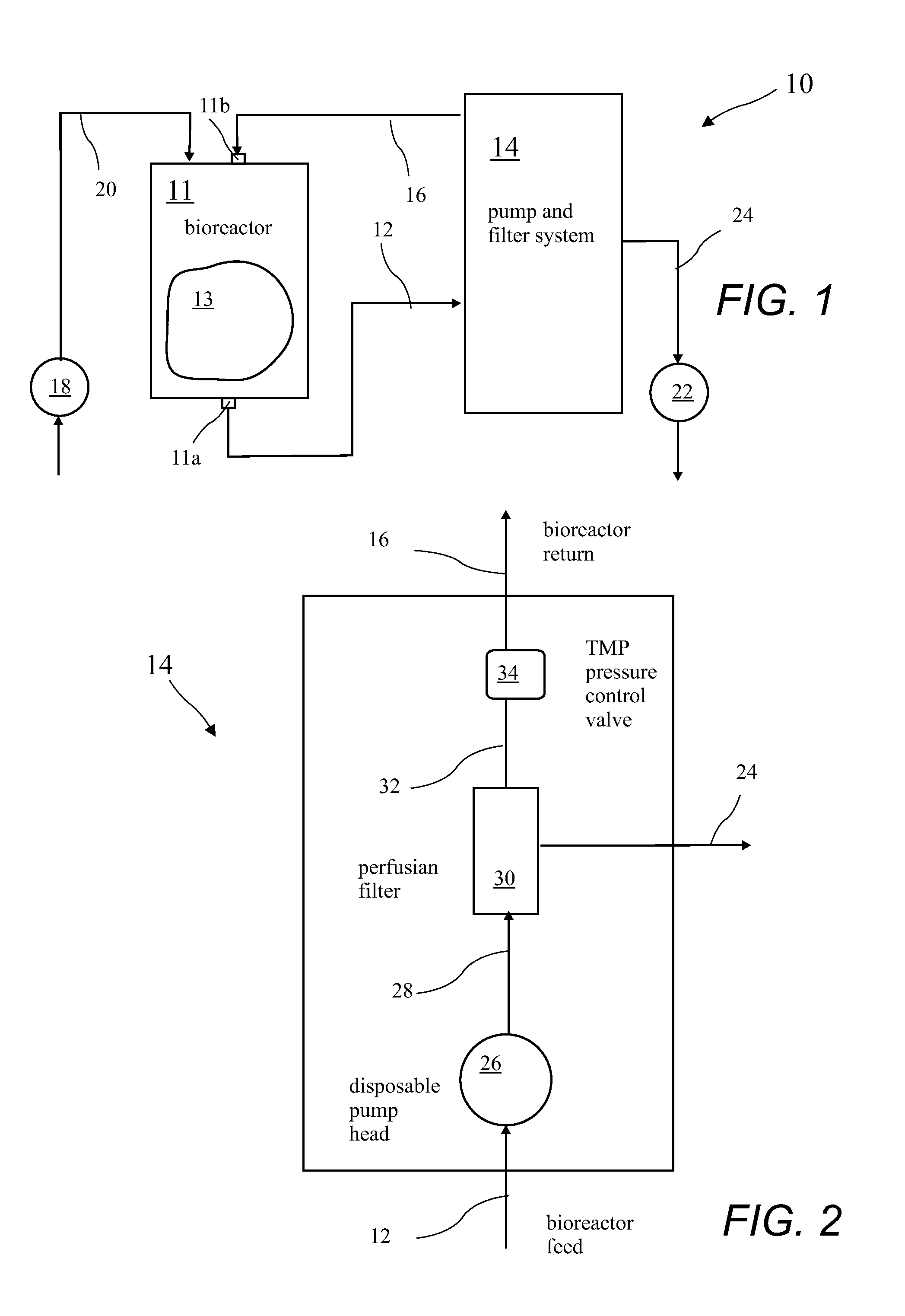

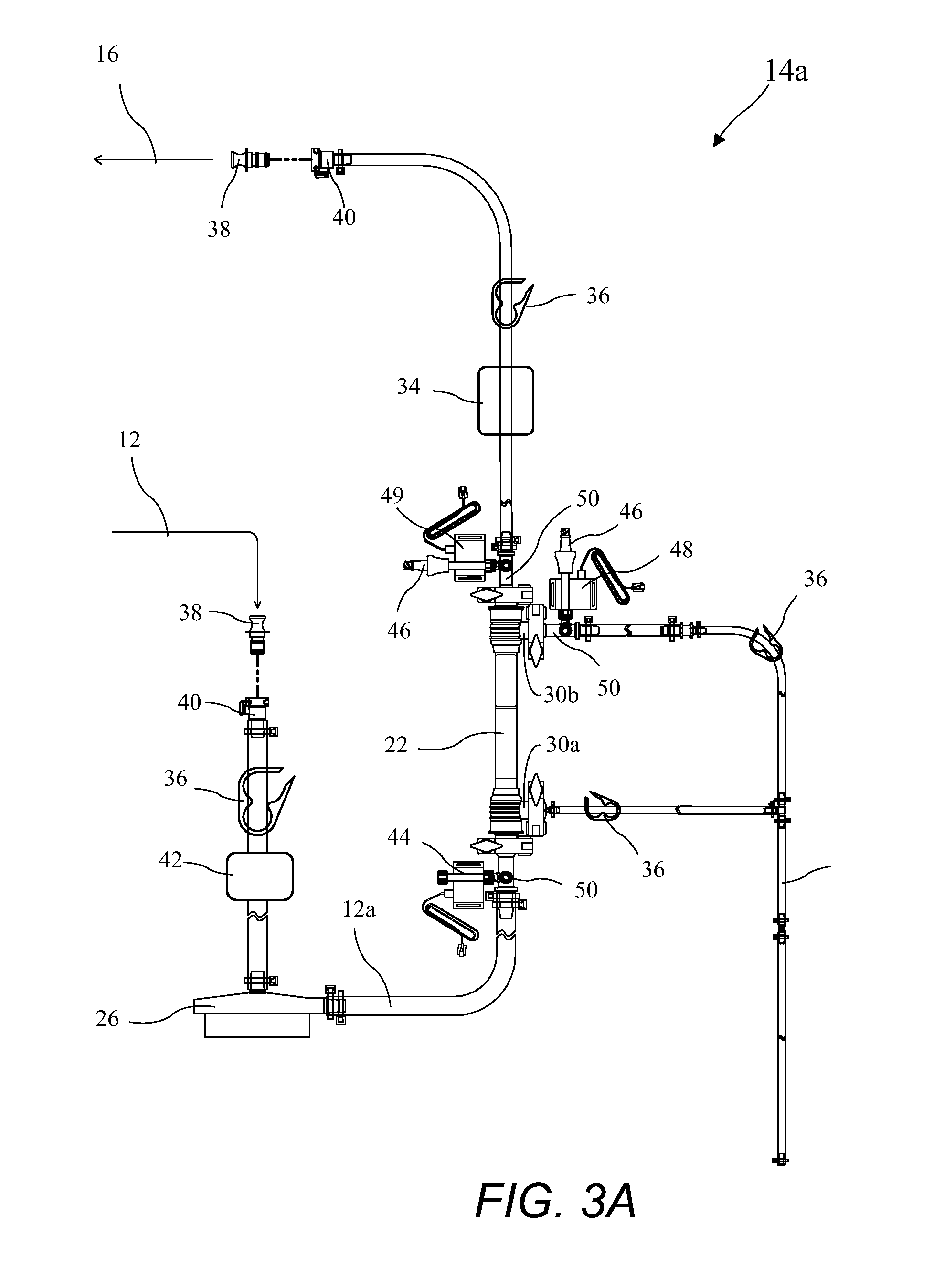

Bioreactor Tangential Flow Perfusion Filter System

InactiveUS20140093952A1Increase capacityReduce shearBioreactor/fermenter combinationsBiological substance pretreatmentsHollow fibreFiber

A bioreactor hollow fiber perfusion system increases the capacity of standard fed batch bioreactors. The bioreactor hollow fiber perfusion system cycles bioreactor mass through a hollow fiber tangential flow filter which separates the metabolic wastes (as well as proteins) from the biomass material allowing the reactions in the bioreactor to continue when compared to a fed batch bioreactor. The bioreactor hollow fiber perfusion system preferably includes a low shear gamma stable disposable pumphead responsible for biomass re-cycling and can be easy installed or replaced without the risk of contamination.

Owner:SERWAY DAVID

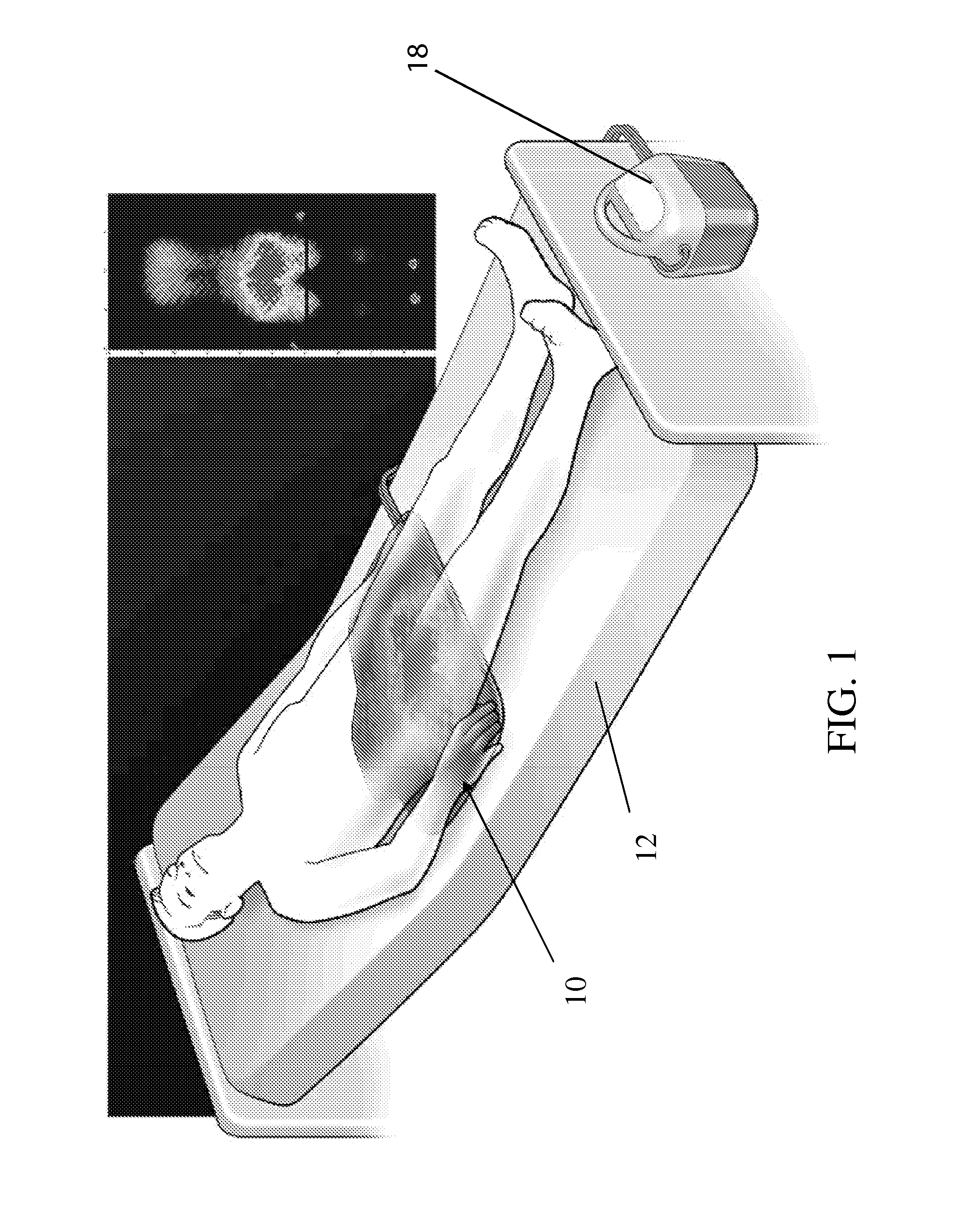

Pressure ulcer management pad

A temperature management pad includes a patient facing side, a cushioning layer for supporting the patient facing side above a surface, a cooling component located in, on, or adjacent the cushioning layer for cooling the patient facing side of the pad for cooling a patient lying thereon, wherein the cooling component includes a conduit formed between the patient facing side and the cushioning layer for circulating fluid through the pad across the cushioning layer. The cushioning layer comprises a gel cushioning layer with a continuous upper surface supporting the patient facing side, which includes channels formed therein. The conduit is supported in the channels for circulating fluid laterally across the gel cushioning layer and through the pad.

Owner:STRYKER CORP

Tubular nylon alloy members for tubing and hose constructions

InactiveUS20060280889A1Easy to installReduces migratory extrudationSynthetic resin layered productsFlexible pipesPolyolefinPolyamide

Tubular polymeric member for articles such as tubing and hoses. The member is formed of an alloy which is a blend of a polyamide and a polyolefin, and a compatibilizing copolymer.

Owner:PARKER HANNIFIN CORP

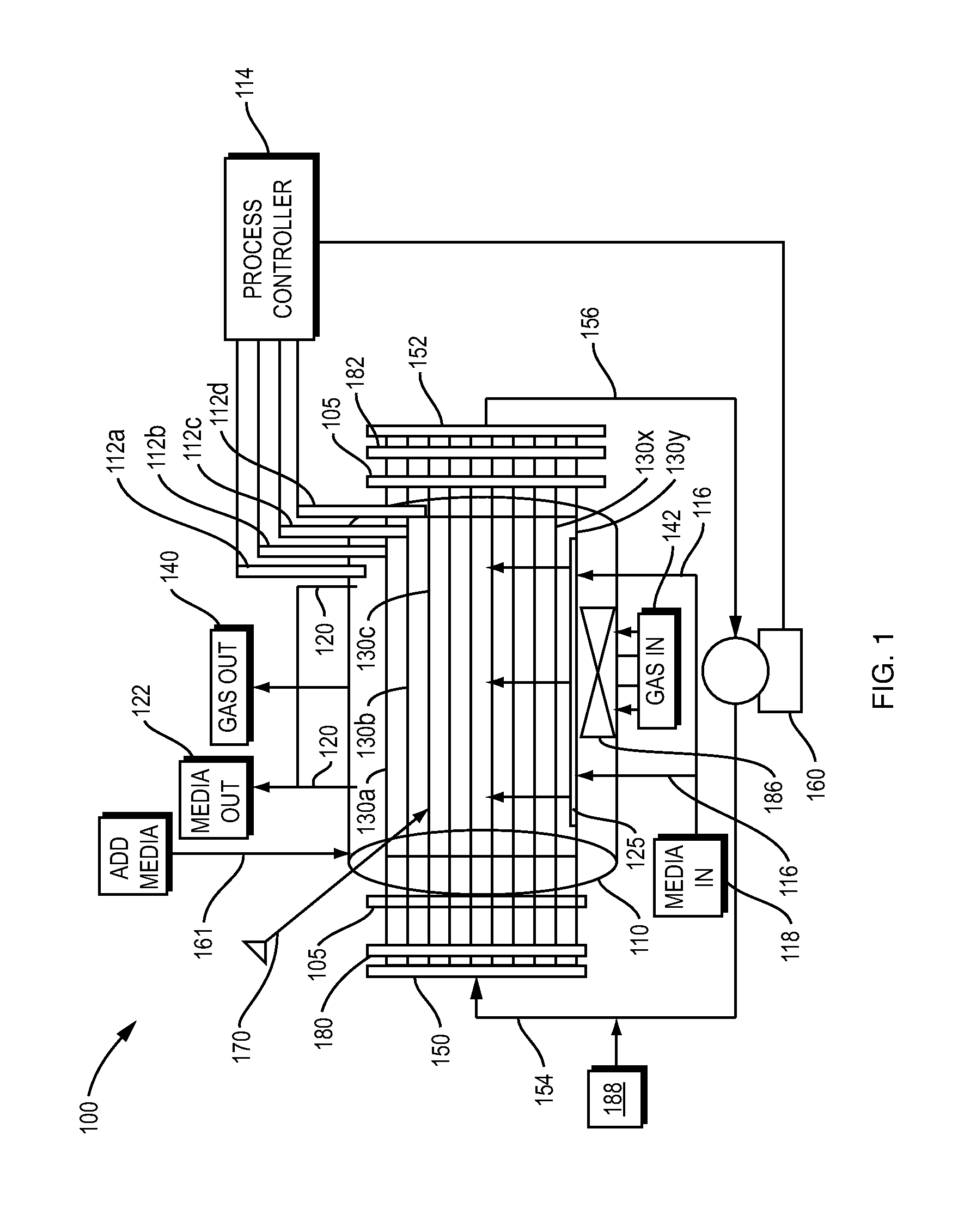

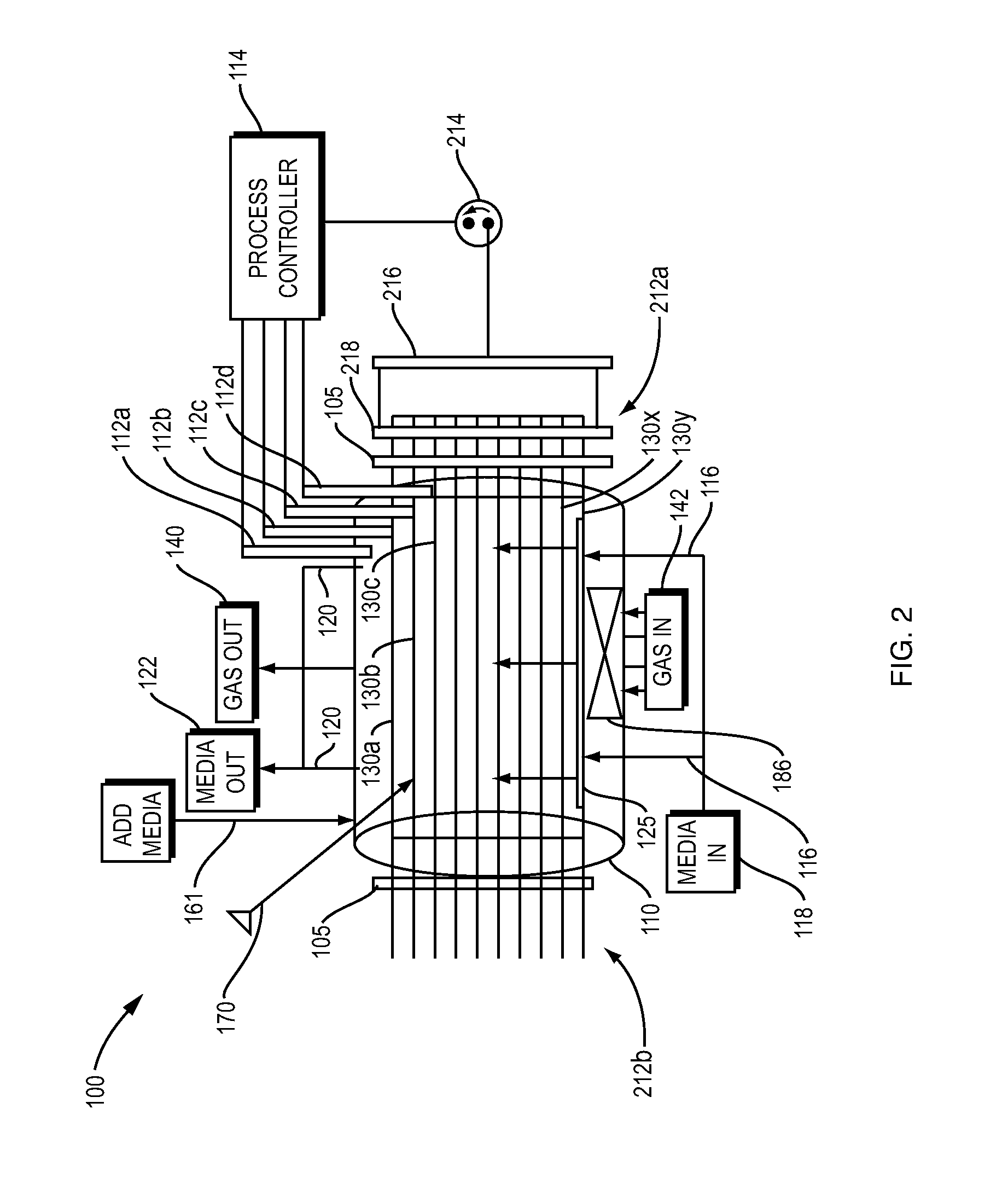

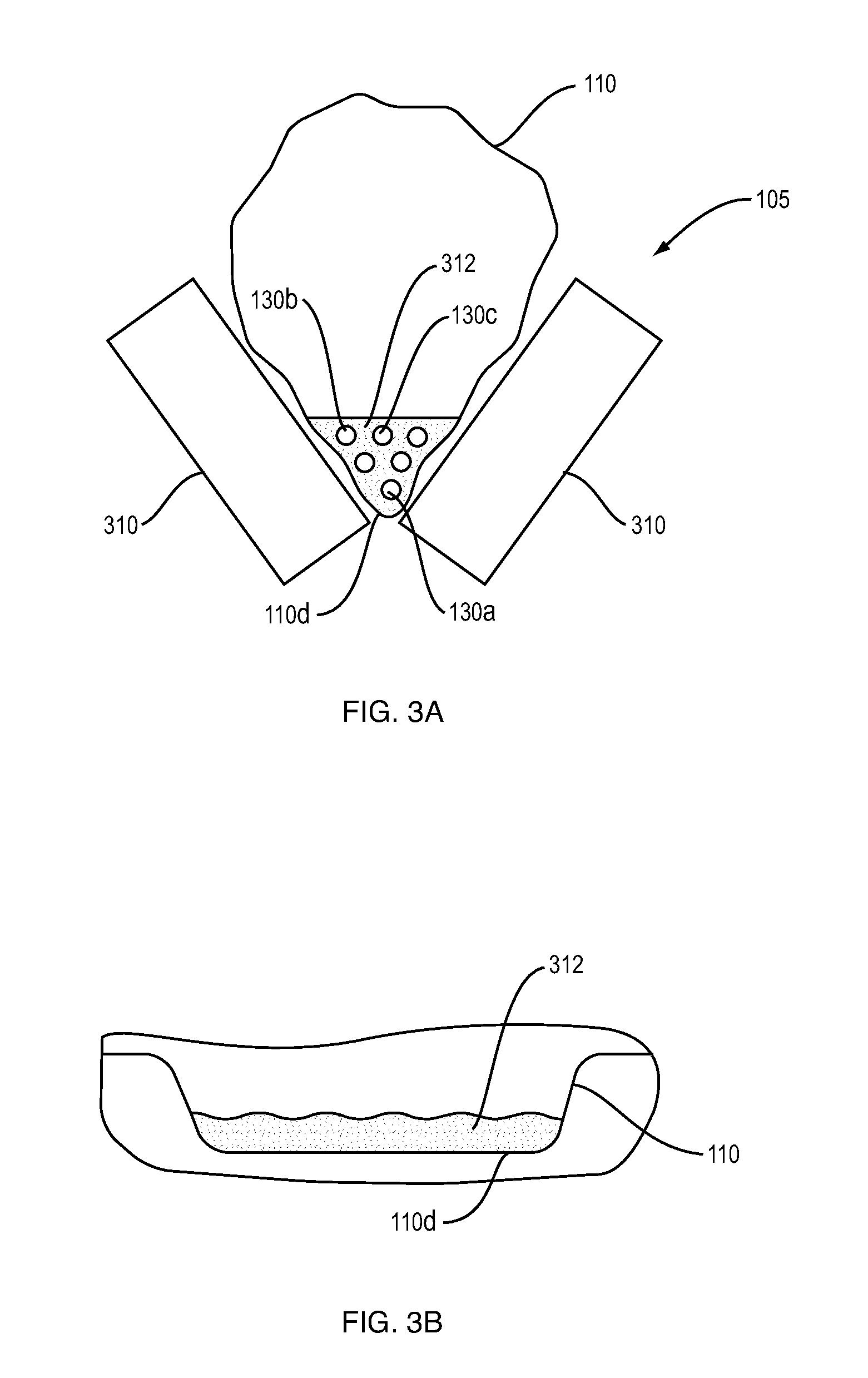

Tissue and organ graft bioreactor and method of operation

ActiveUS20120028234A1Improve concentrationReduce shearBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemUnit operation

A single-use, single or multiple tissue, organ, and graft bioreactor and environmental control system is designed to replicate the necessary conditions for growth of tissues, organs, or grafts, while addressing problems in scaling up the tissue growth; adaptation to a single-use or disposable format; and operation as a stand-alone unit that provides full environmental control of cell culture conditions.

Owner:HUMACYTE INC +1

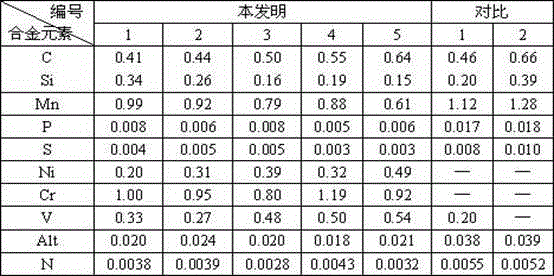

Automotive cold-rolled diaphragm spring steel and production method thereof

The invention relates to automotive cold-rolled diaphragm spring steel and a production method thereof. The automotive cold-rolled diaphragm spring steel comprises the following components by weight percentage: C of 0.40-0.65, Si of 0.15-0.35, Mn of 0.60-1.00, P of less than or equal to 0.010. S of less than or equal to 0.007, Alt of less than or equal to 0.040, Ni of 0.20-0.50, Cr of 0.80-1.20, V of 0.27-0.55 and N of less than or equal to 0.005, and a tempered sorbite body is adopted as a control metallographic structure. The process comprises the steps of: desulphurization, smelting, refining, vacuum processing, continuous casting into a billet, thermal insulation in segments according to the temperature, heating of the cast billet, rolling, coiling, slow cooling, cutting, first annealing, first cold rolling, second annealing, second cold rolling, formation, quenching, tempering and preparation for use. The automotive cold-rolled diaphragm spring steel has excellent comprehensive mechanical properties. Difficulties in cutting and cold rolling can be reduced due to annealing, a tempered martensite structure is obtained due to heat treatment of quenching and tempering, and sufficient strength and wear resistance of the steel can be ensured due to composite reinforcing effects of micro-alloys such as Cr, Ni and V in the steel.

Owner:武汉钢铁有限公司

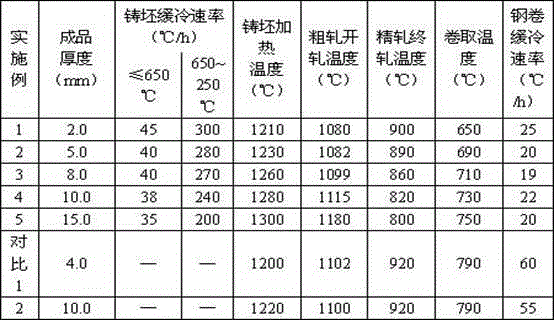

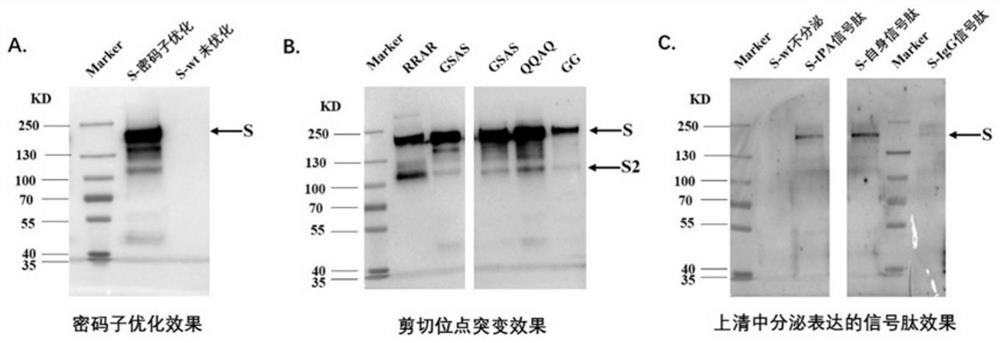

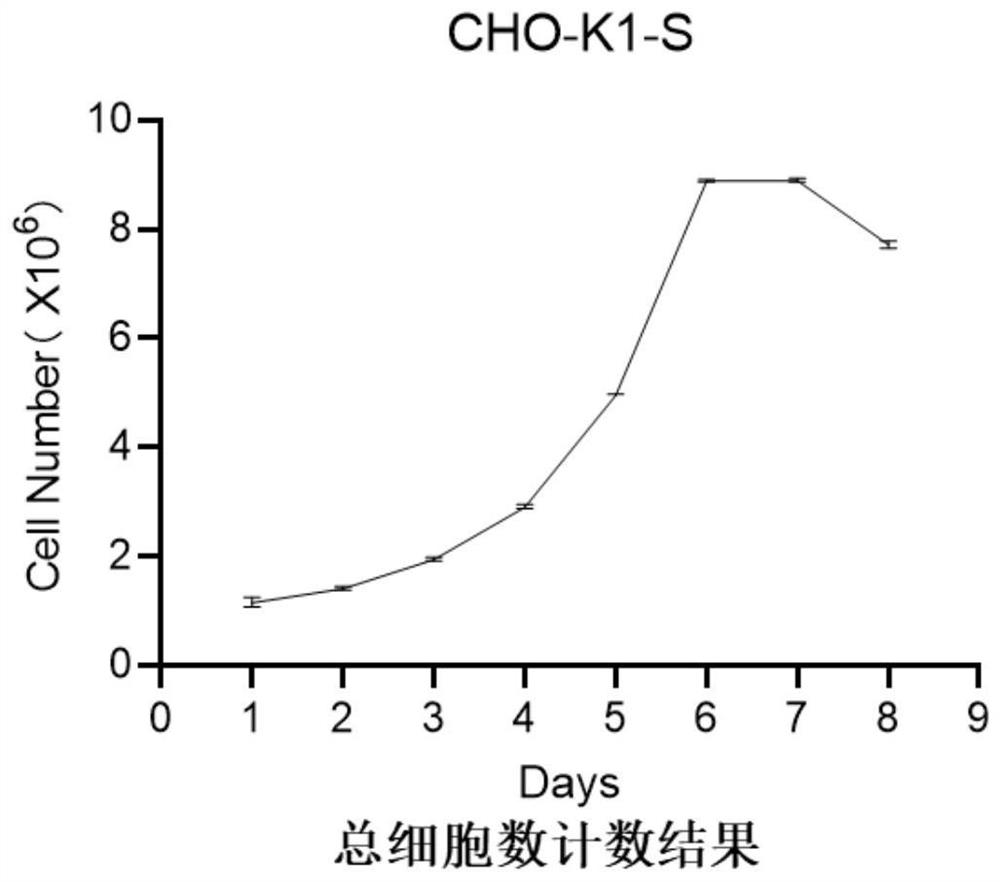

Novel coronavirus S protein and subunit vaccine thereof

ActiveCN113185613AProtect cut wellReduce shearSsRNA viruses positive-senseAntibody mimetics/scaffoldsMolecular biologyAdjuvant

The invention provides a novel coronavirus S protein and a subunit vaccine thereof. The novel coronavirus S protein is characterized in that a furin cleavage site 682-RRAR-685 between two subunits S1 and S2 of the novel coronavirus S protein is replaced by a flexible protein linker. The linker is a GSAS and GS combination composed of glycine G and serine S, (GGGS) n or (GGGGS)n or (G)n, and n is an integer larger than or equal to 1. The novel coronavirus subunit vaccine comprises the recombinant S protein and a pharmaceutically acceptable adjuvant. The obtained S protein of the trimer conformation with biological activity is used for preparing a trimer subunit vaccine, after a mouse is immunized, the mouse can be induced to generate a neutralizing antibody which aims at SARS-CoV-2 and has an immune protection effect, and after the immunized mouse is subjected to lethal challenge infection of novel coronavirus, the protection efficiency of 100% can be provided.

Owner:WUHAN UNIV

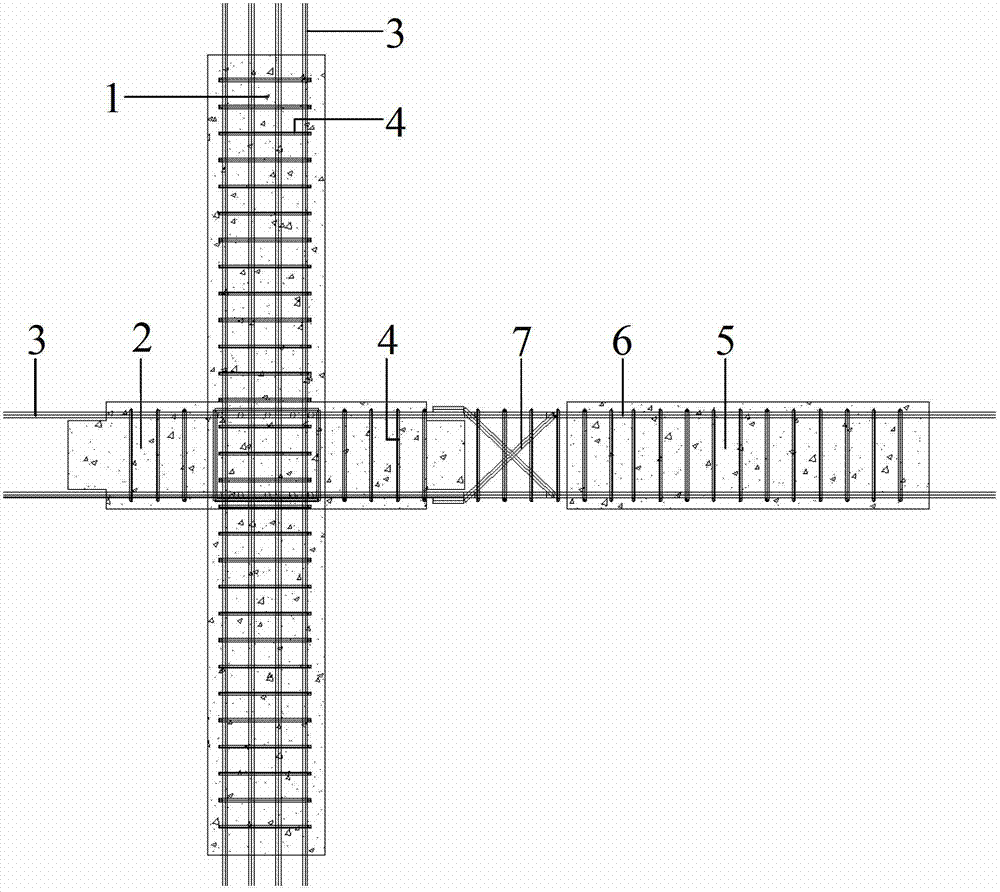

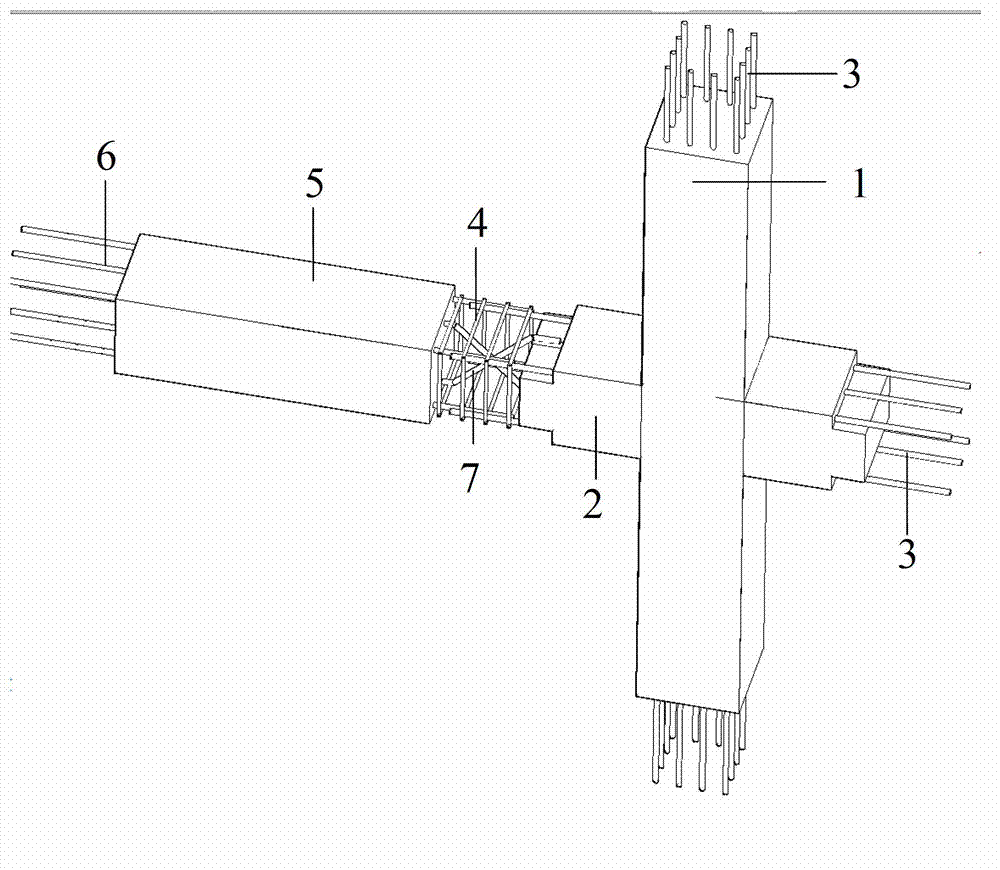

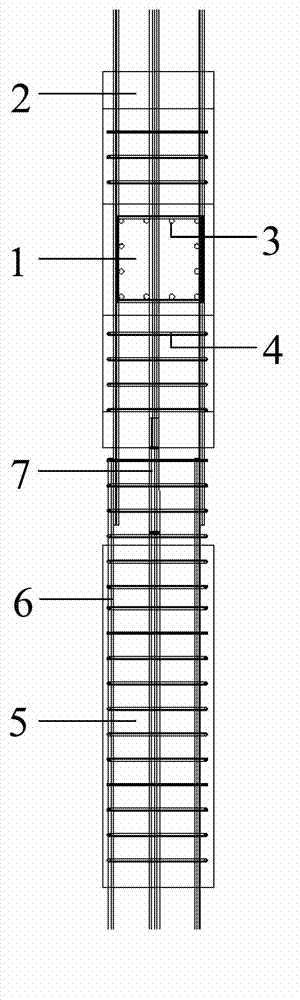

Assembly type recycled concrete node with steel bar truss girders at end parts and manufacturing method thereof

The invention discloses an assembly type recycled concrete node with steel bar truss girders at end parts and a manufacturing method thereof, belonging to the technical field of constructing of prefabricated parts and key nodes and regenerating of concrete. The assembly type recycled concrete node has the advantages of environment friendliness, energy saving and convenience in construction, and is applicable to prefabricated construction, so that the problems that the key nodes of the existing prefabricated parts are poor in seismic performance and severe in seismic hazard, and the defect that the node construction is difficult can be overcome by integrally casting a wing-tip beam and an upright post; and moreover, autoclaved curing prefabrication forming is adopted, so the compactness, the casting quality and the strength of the concrete at the nodes are remarkably improved, thereby realizing an anti-seismic design target of strong nodes and weak rods, as well as connecting the wing-tip beam with the prefabricated beam with the steel bar truss girders by bar splicing. A stirrup strengthening zone is arranged at the connecting part, and the connecting part is set to be a post-cast strip, so that plastic hinges are easily formed under earthquake load action. An ideal failure mechanism with the anti-seismic design concept of strong columns and weak beams, and strong shear and weak bending can be extensively applied to precast construction.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com