High-temperature resistant polymer viscosity reducer for drilling fluid and preparation method thereof

A technology of high temperature resistance and polymer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc. It can solve the physical and chemical effects of poor temperature resistance, viscosity reducer without temperature resistance, and affect the performance of drilling fluid system, etc. problem, to achieve high efficiency, good viscosity reduction effect, and viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

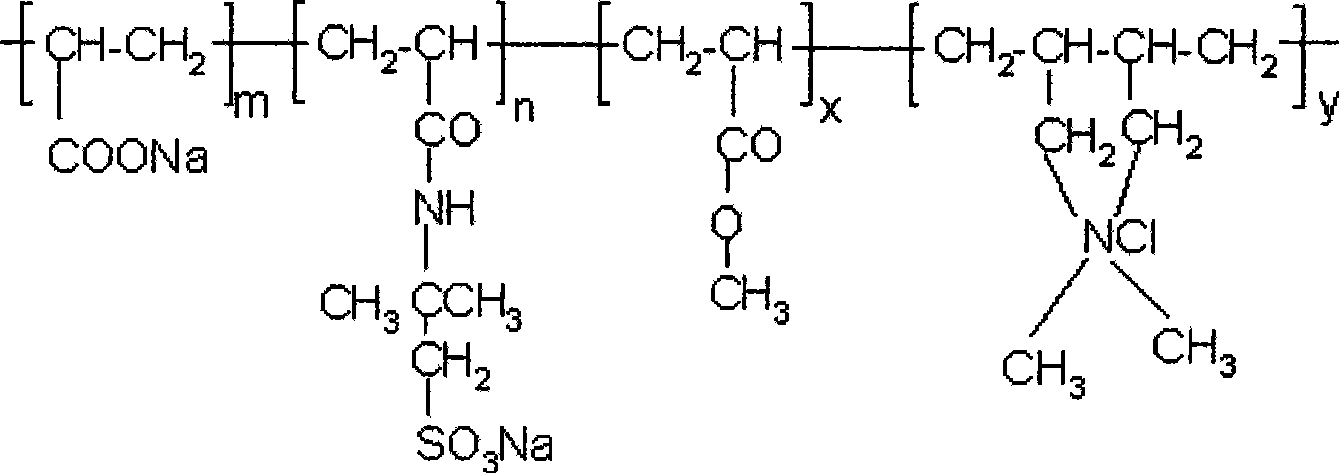

example 1

[0021] Example 1: In a four-neck flask equipped with a stirrer, reflux condenser, thermometer and heating device, add 200mL of distilled water, add 12.3g of acrylic acid and 24.2g of 2-methyl-2-acrylamidopropanesulfonic acid while stirring , 11.3g of methyl acrylate and 11.5g of dimethyl diallyl ammonium chloride, adjust pH=7.0 with sodium hydroxide, heat to 60°C while stirring, add 2.0g of ammonium persulfate, and react for 20 minutes, Add 0.8 g of thioglycolic acid to terminate the reaction. The viscous liquid in the reaction kettle is dried and crushed through a 20-mesh sample sieve to obtain the high temperature resistant polymer viscosity reducer. In this polymer, m:n:x:y=10:8:7:4, the viscosity average molecular weight is about 6000, and the number of structural units is about 12.

example 2

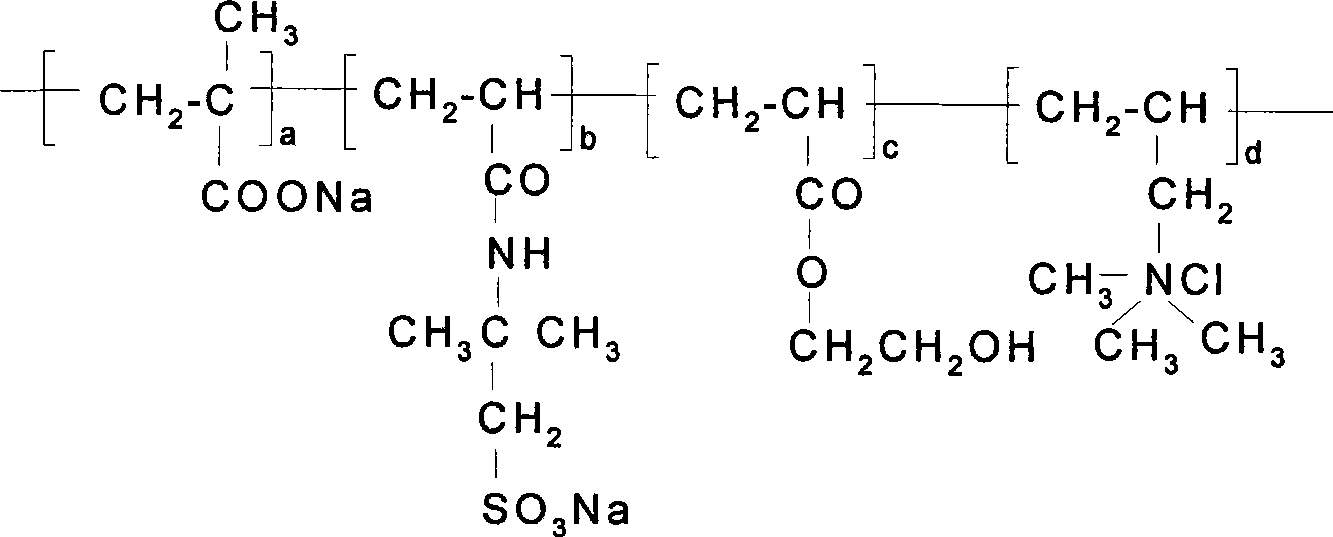

[0022] Example 2: In a four-necked flask equipped with a stirrer, a reflux condenser, a thermometer and a heating device, add 200 mL of distilled water, and add 18.4 g of methacrylic acid and 2-methyl-2-acrylamidopropanesulfonic acid while stirring 24.2g, 12.2g of 2-hydroxyethyl acrylate and 10.8g of allyltrimethylammonium chloride, adjust pH=7.0 with sodium hydroxide, heat to 60°C while stirring, add 2.0g of ammonium persulfate , reacted for 20 minutes, and added 0.8 g of thioglycolic acid to terminate the reaction. The viscous liquid in the reaction kettle is dried and crushed through a 20-mesh sample sieve to obtain the high temperature resistant polymer viscosity reducer. In this polymer, a:b:c:d=10:7:5:4, the viscosity average molecular weight is about 5000, and the number of structural units is about 9.

example 3

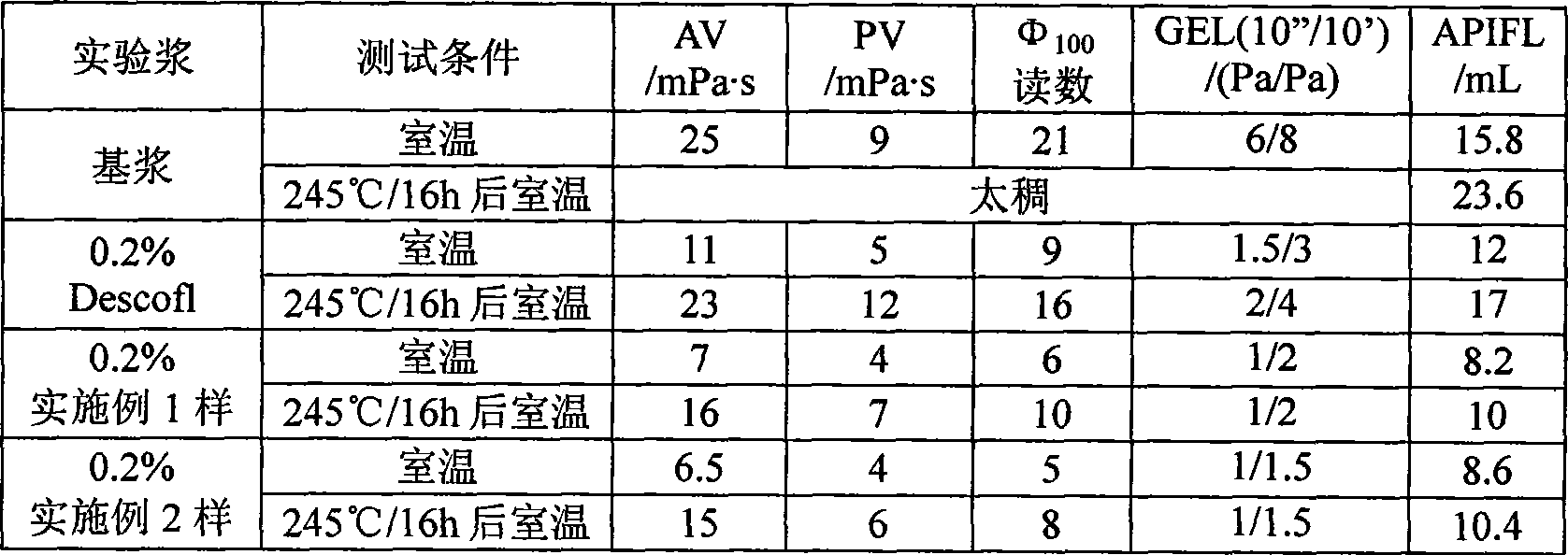

[0023] Example 3: Evaluation of temperature resistance and viscosity reduction effect

[0024] Test method: adopt GB / T16783-1997: Field test procedure for water-based drilling fluid.

[0025] 1. Tested in fresh water base slurry

[0026] Preparation of base slurry: Add 400mL tap water into a high stirring cup, add 1.6g of anhydrous sodium carbonate, 32g of secondary bentonite and 40g of evaluation soil under constant stirring, stir for 20 minutes, seal and let stand for 24 hours to prepare the base slurry.

[0027] Experimental pulp preparation and testing: Add 0.2% of evaluation samples (Descofl, Example 1 sample, Example 2 sample) to the prehydrated base pulp respectively, stir evenly at high speed, and measure the rheological parameters. Put the experimental slurry into a high-temperature aging tank, roll it at 245°C for 16 hours, take it out and measure its rheological parameters in the same way.

[0028] Table 1 Test results in freshwater base slurry

[0029]

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com