Patents

Literature

139results about How to "Improve bearing life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

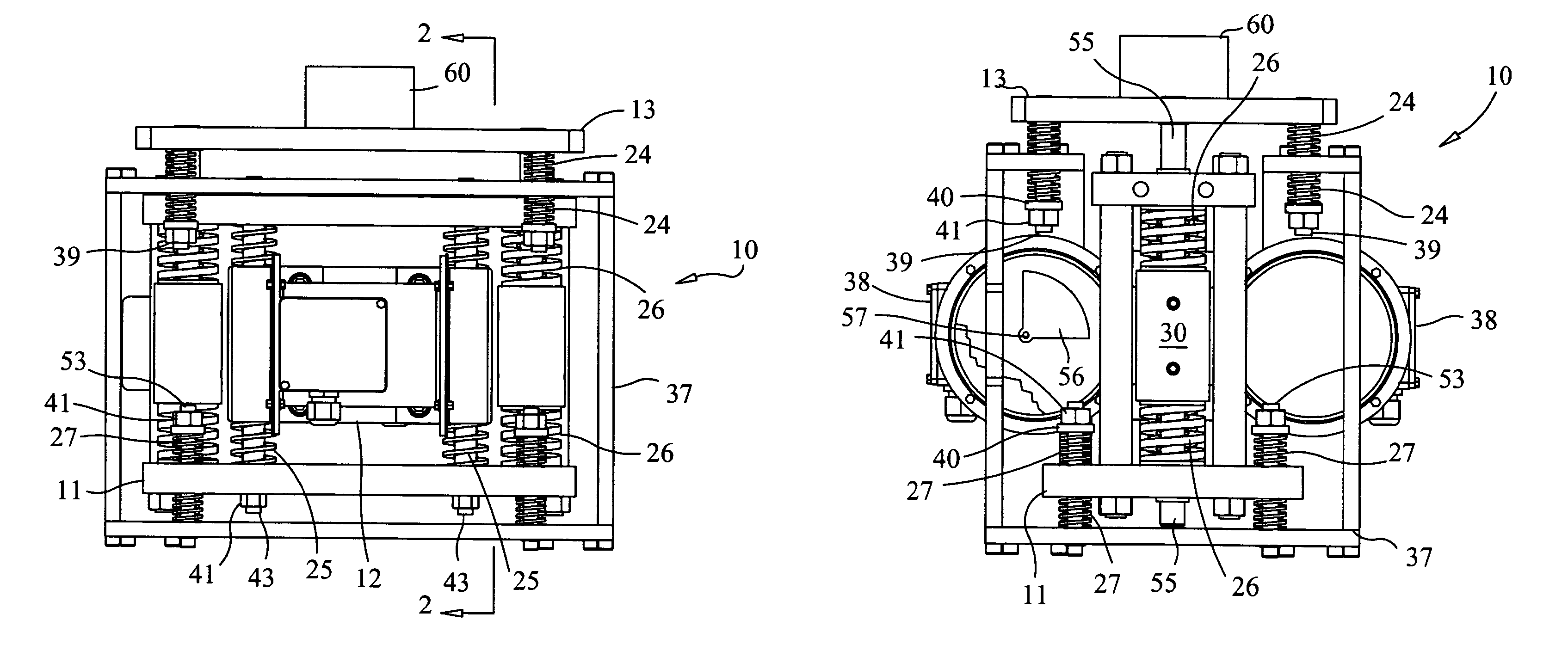

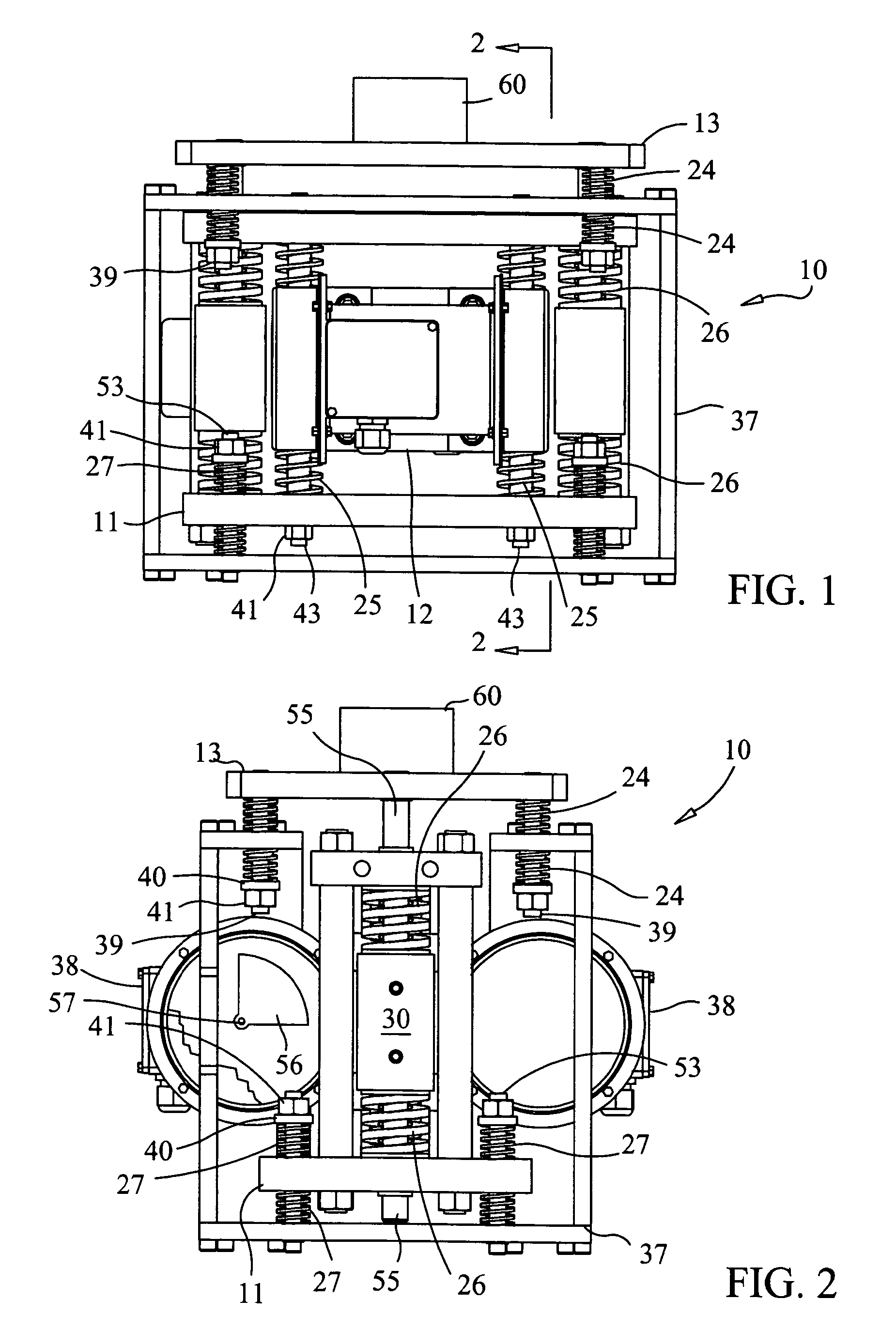

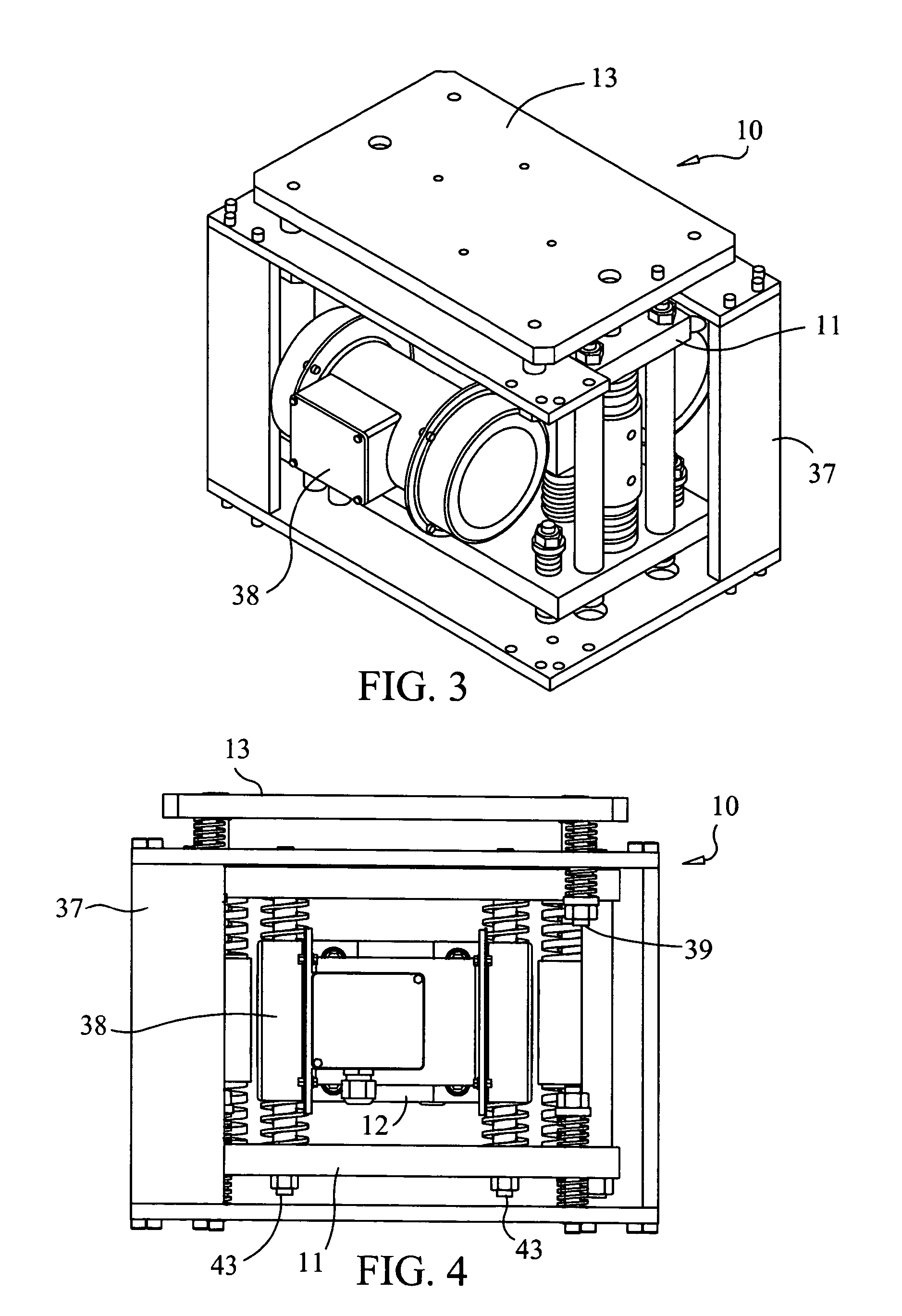

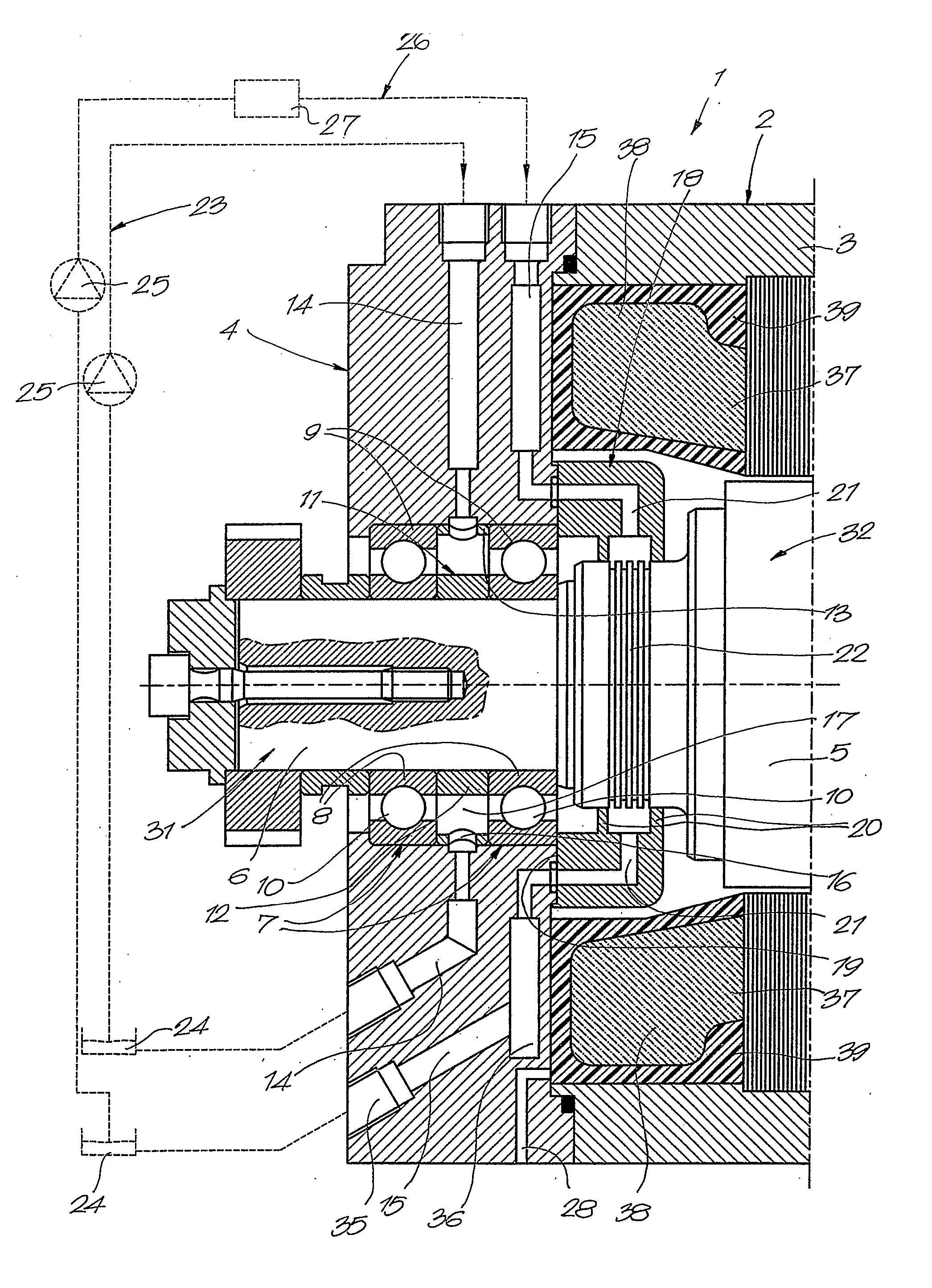

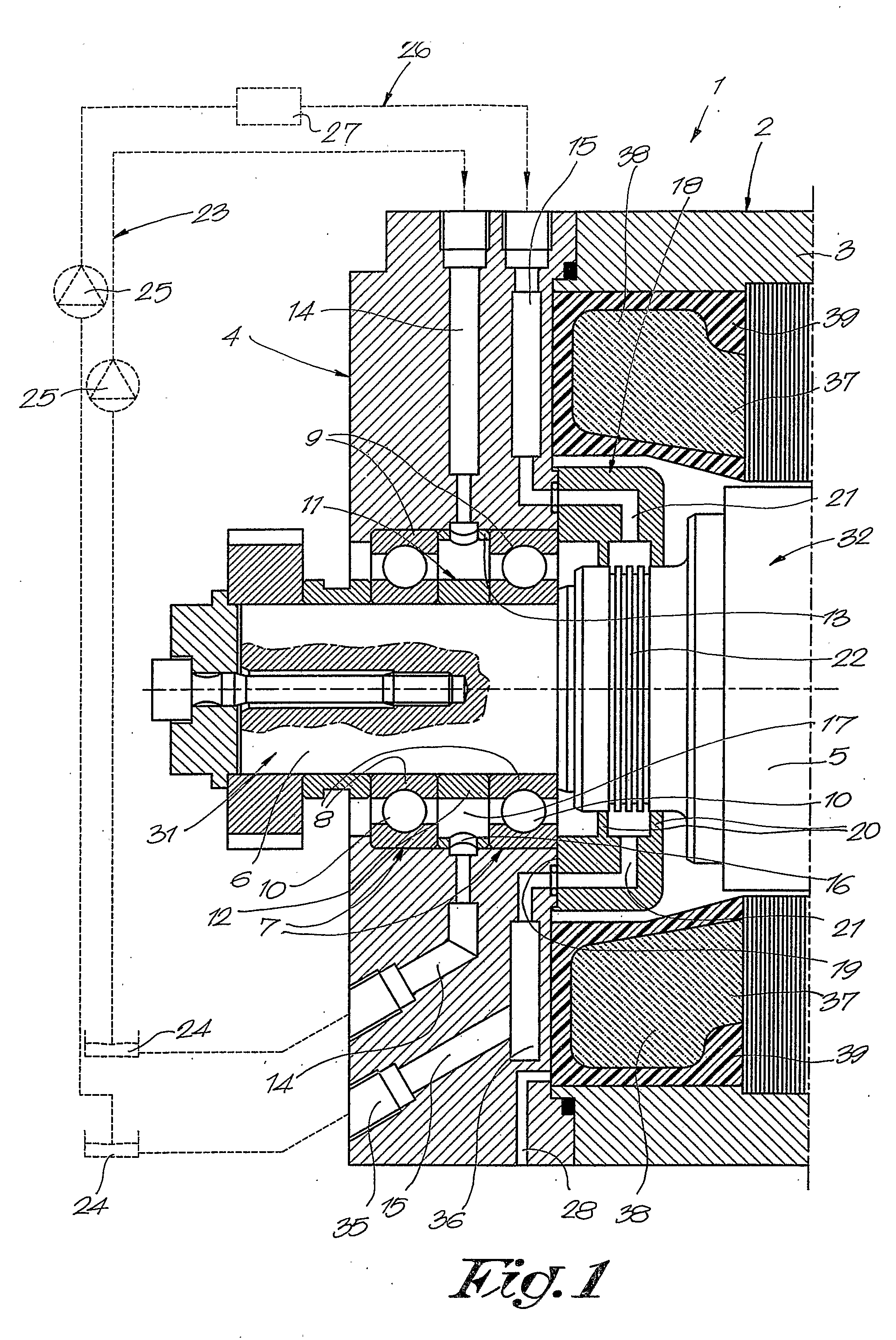

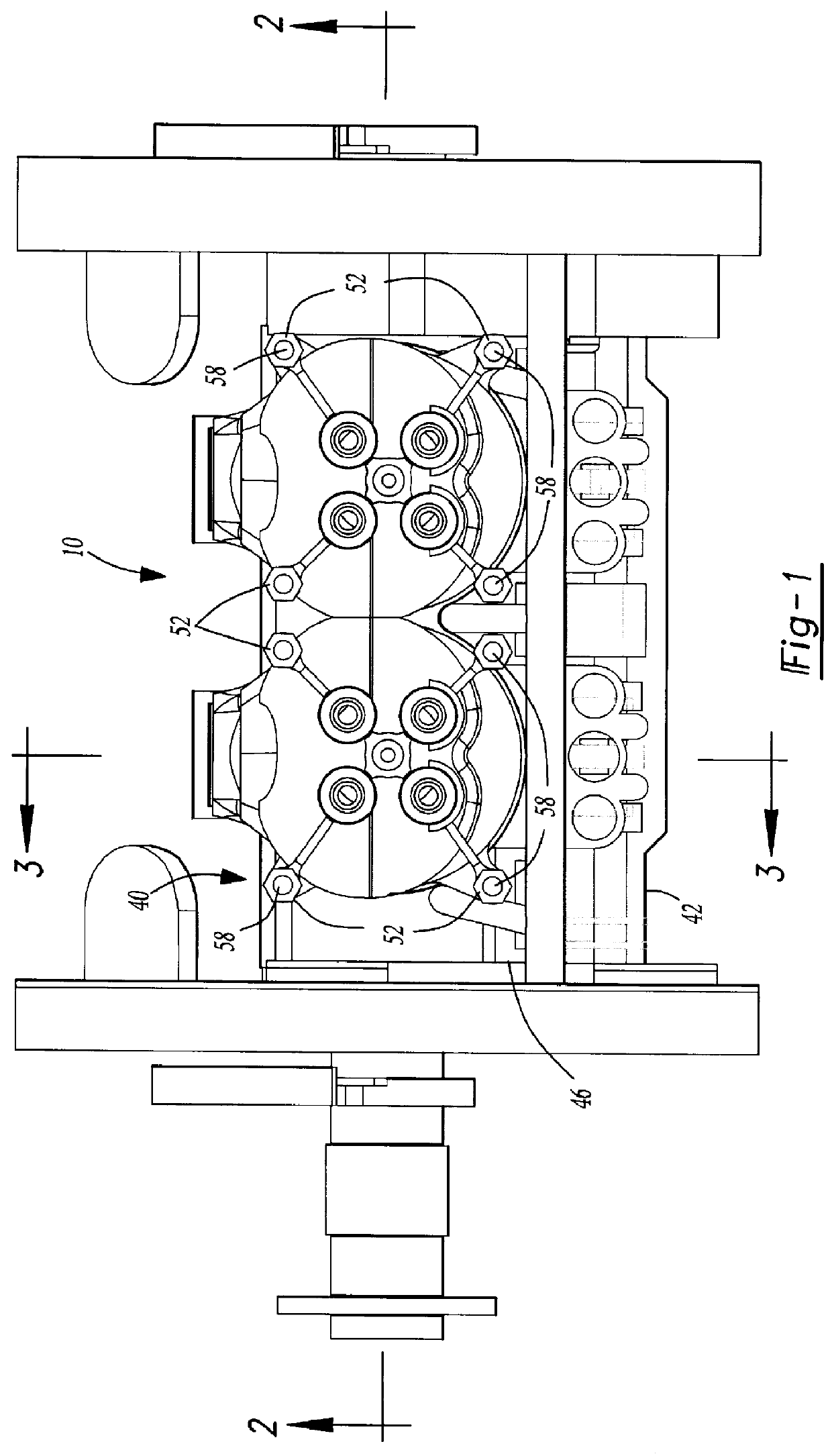

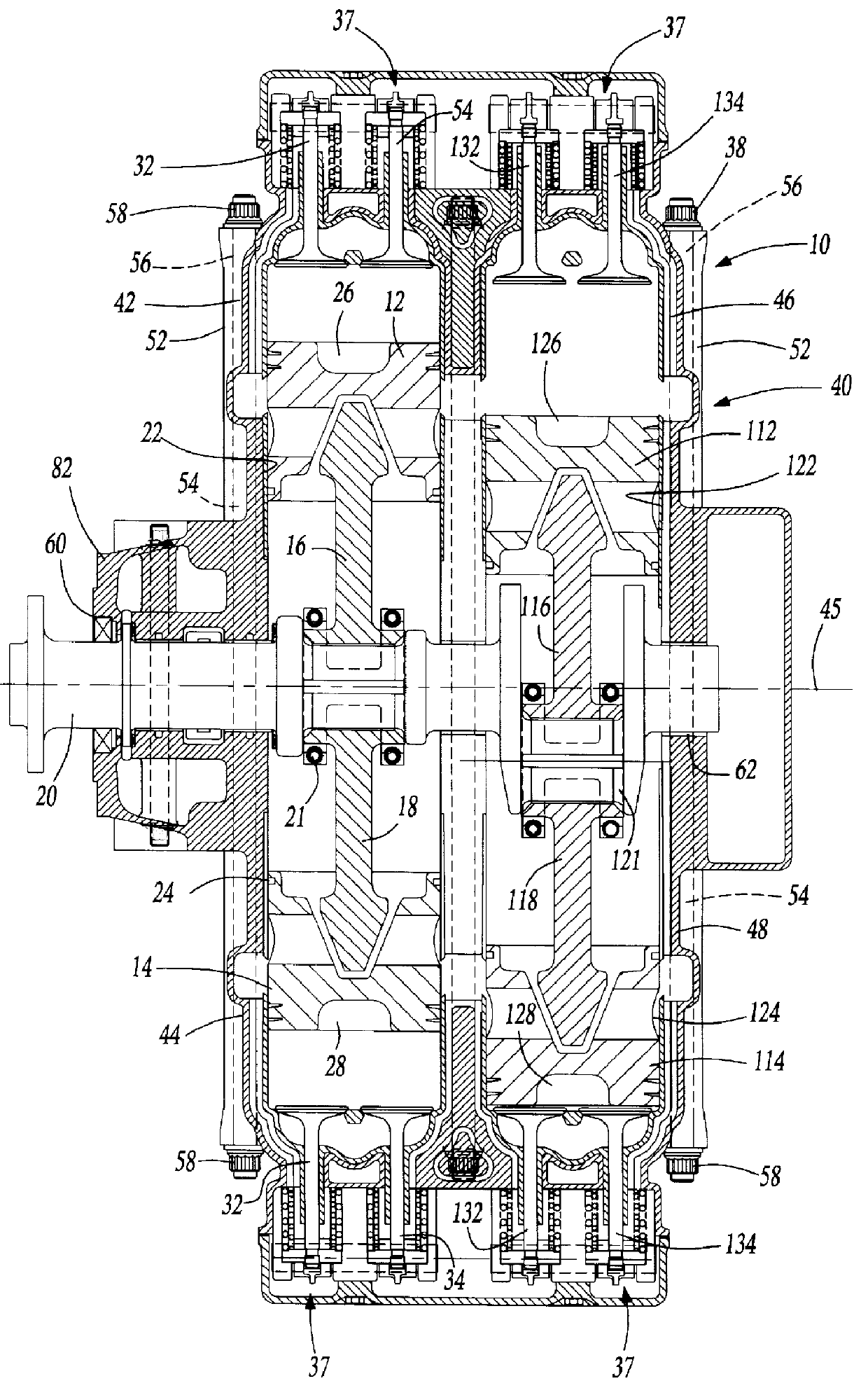

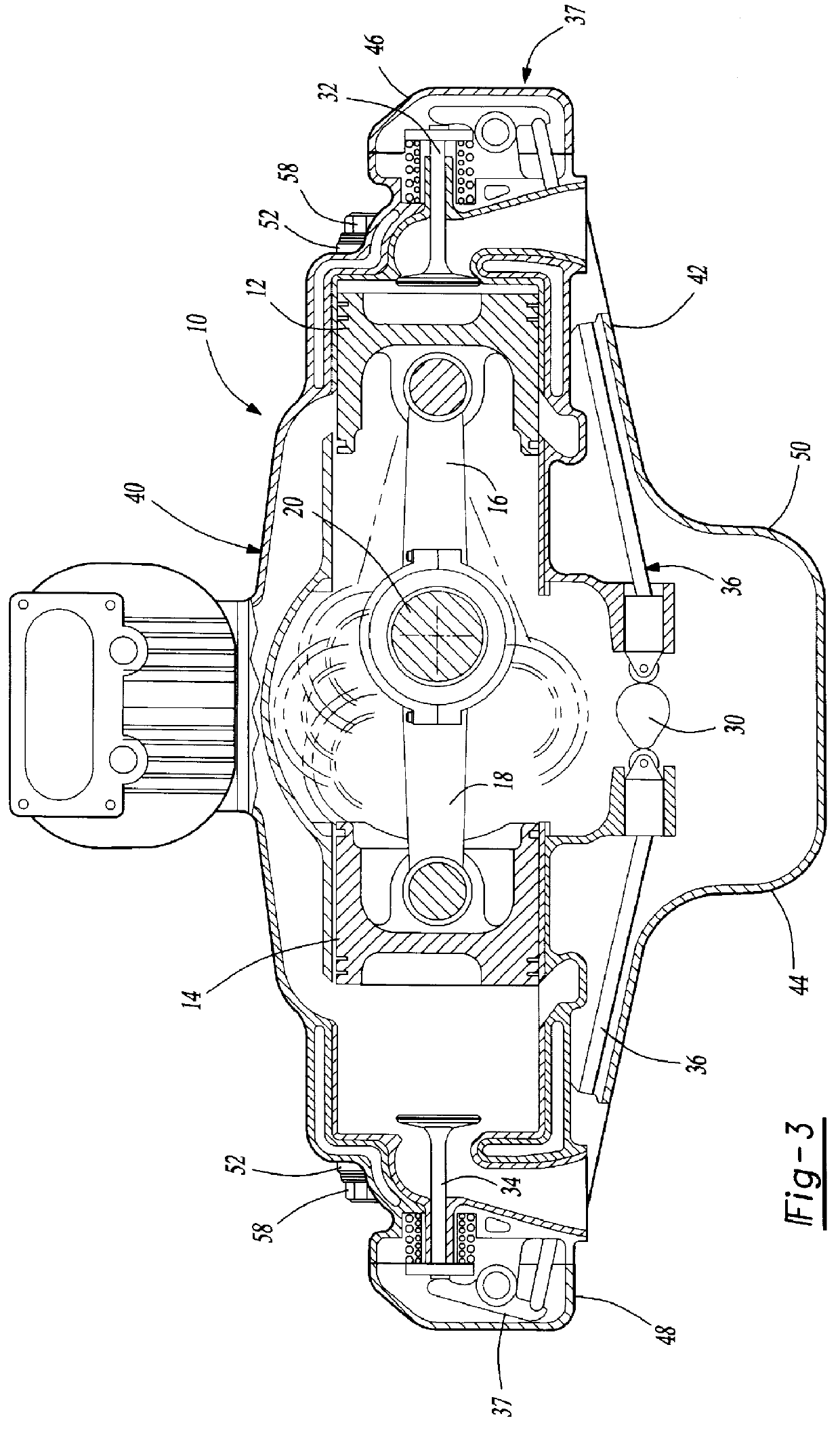

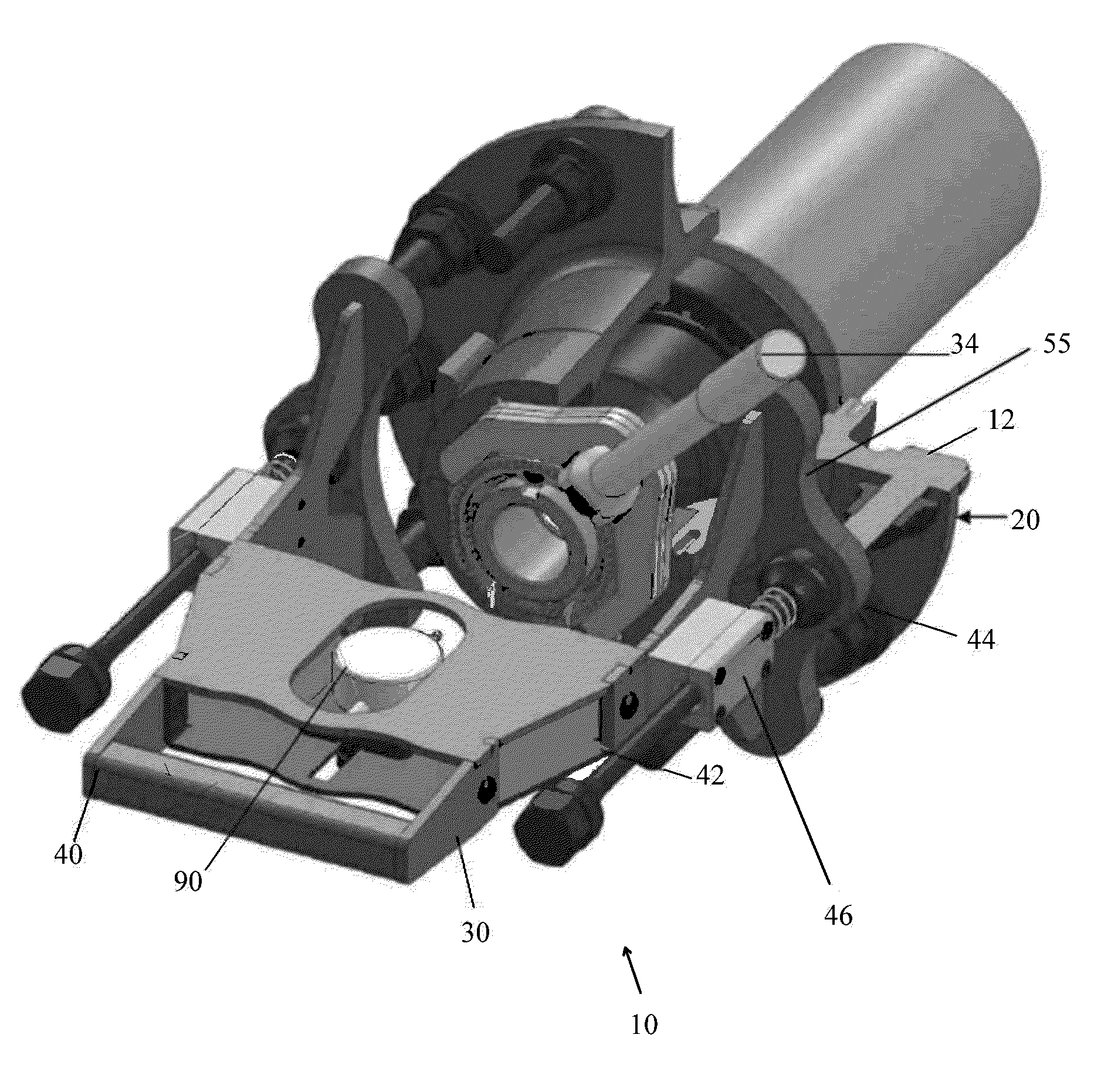

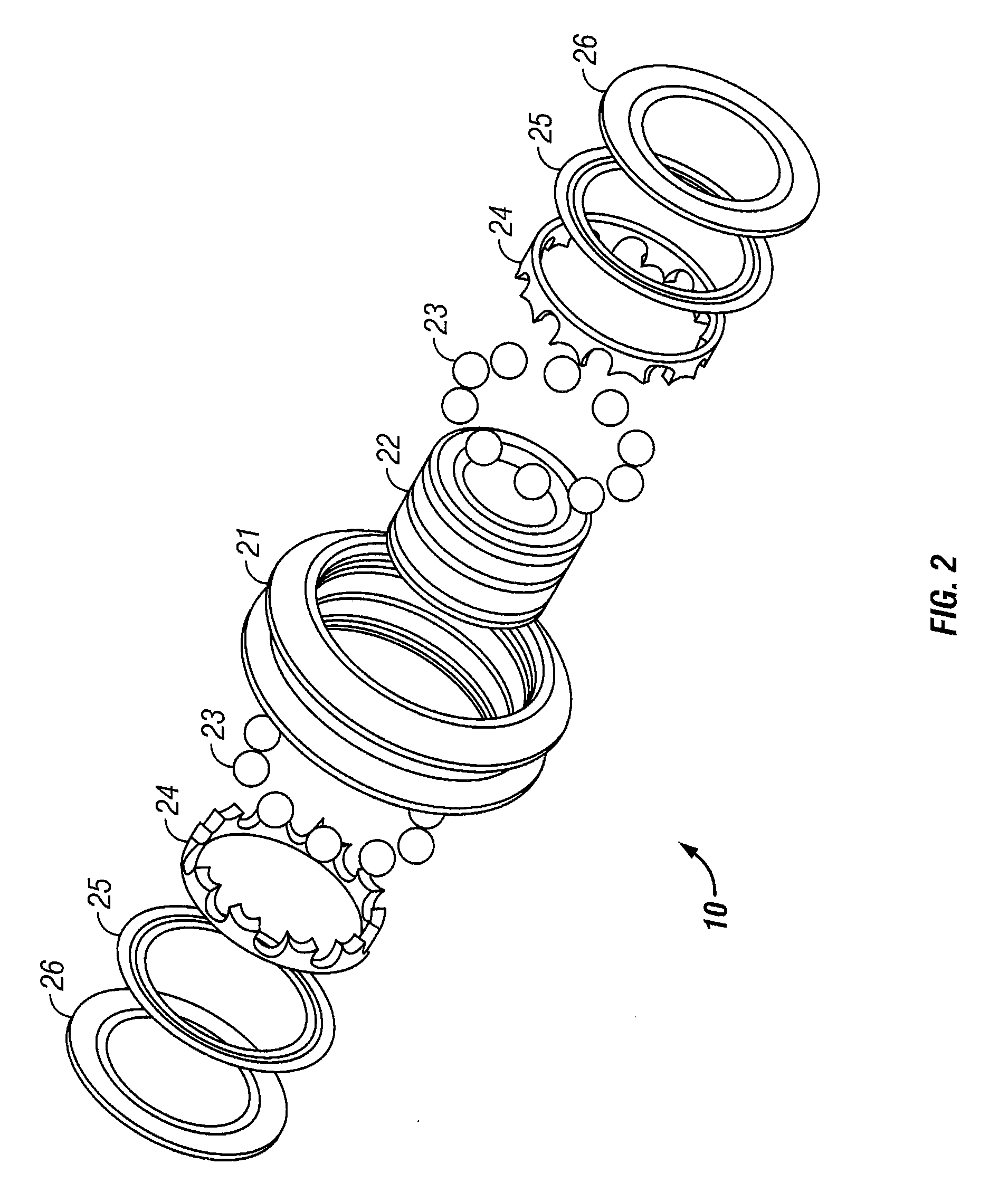

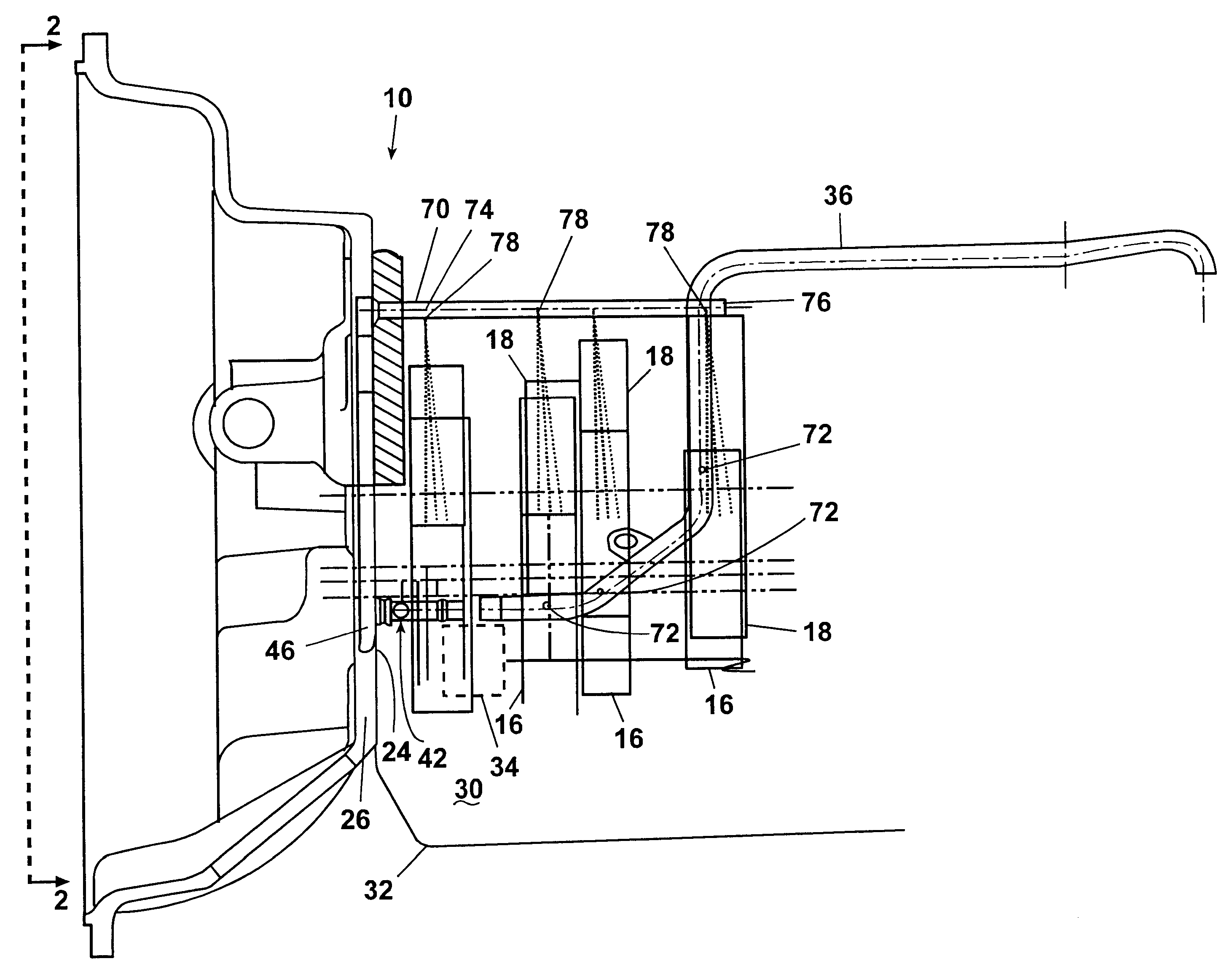

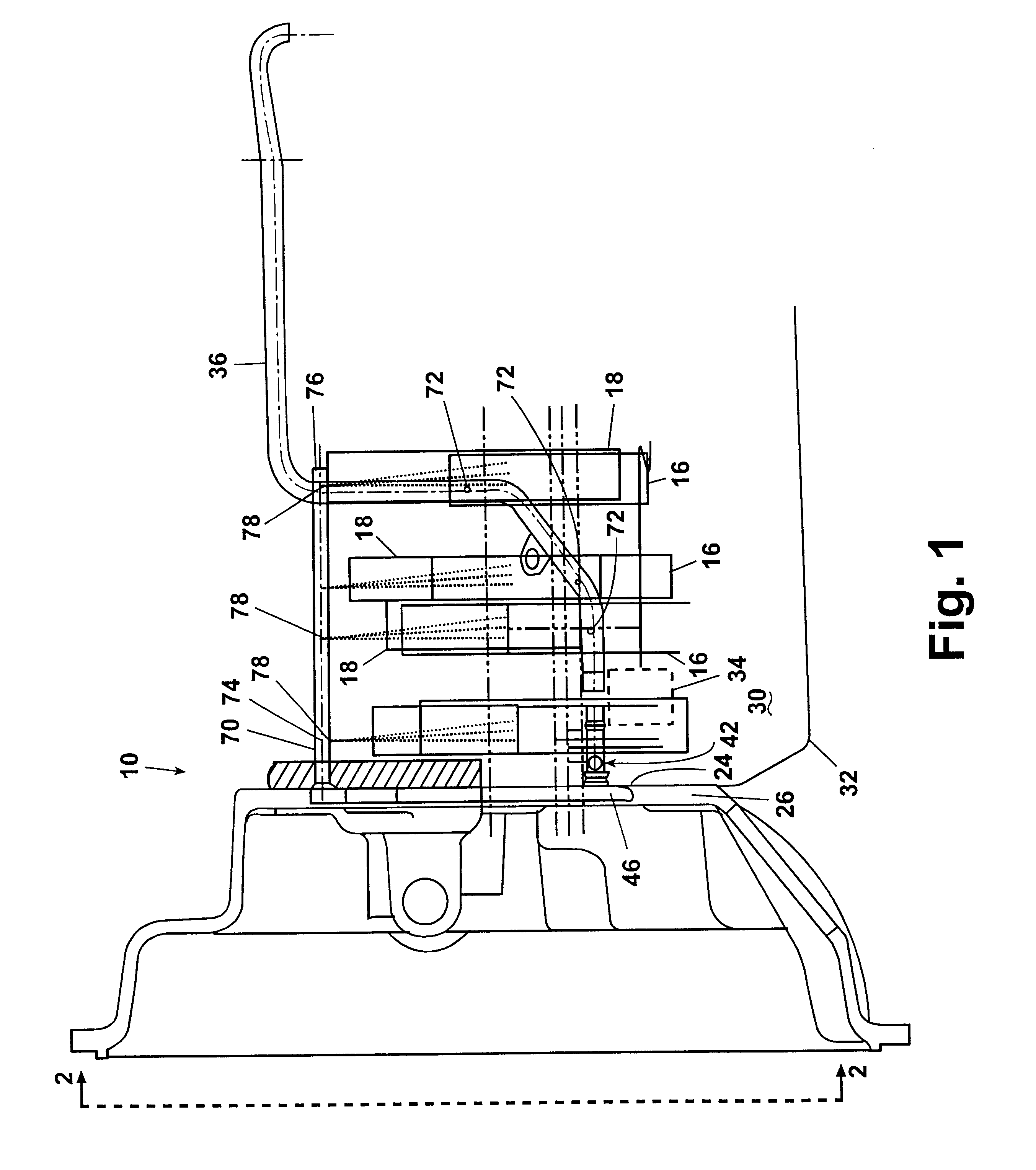

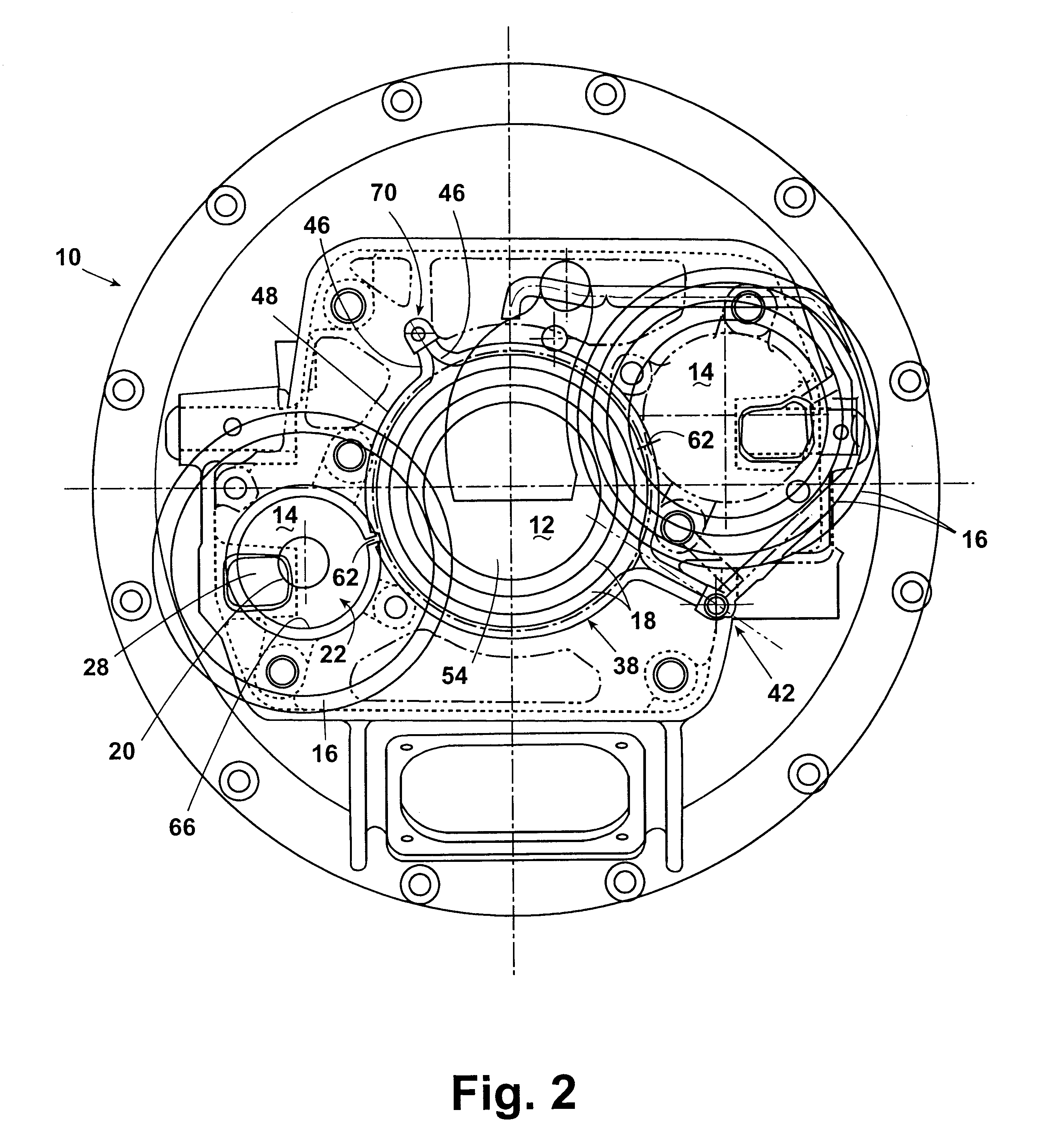

Apparatus and method for resonant-vibratory mixing

ActiveUS7188993B1Reduce the overall heightImprove bearing lifeShaking/oscillating/vibrating mixersTransportation and packagingLinear motionElectronic controller

An apparatus and method for mixing fluids and / or solids in a manner that can be varied from maintaining the integrity of fragile molecular and biological materials in the mixing vessel to homogenizing heavy aggregate material by supplying large amounts of energy. Variation in the manner of mixing is accomplished using an electronic controller to generate signals to control the frequency and amplitude of the motor(s), which drive an unbalanced shaft assembly to produce a linear vibratory motion. The motor may be a stepper motors a linear motor or a DC continuous motor. By placing a sensor on the mixing vessel platform to provide feedback control of the mixing motor, the characteristics of agitation in the fluid or solid can be adjusted to optimize the degree of mixing and produce a high quality mixant.

Owner:RESODYN ACOUSTIC MIXERS

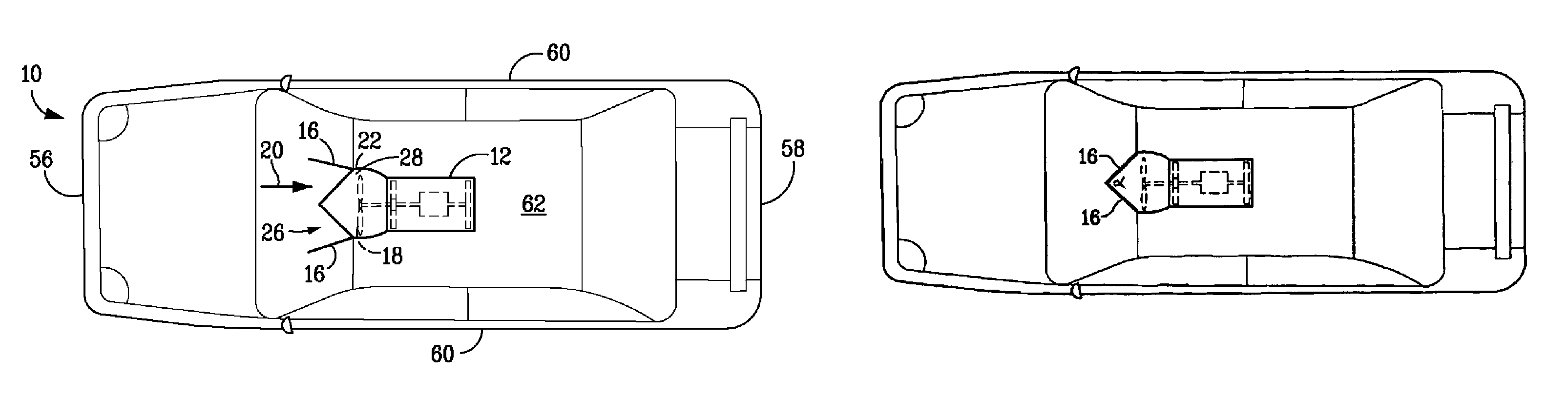

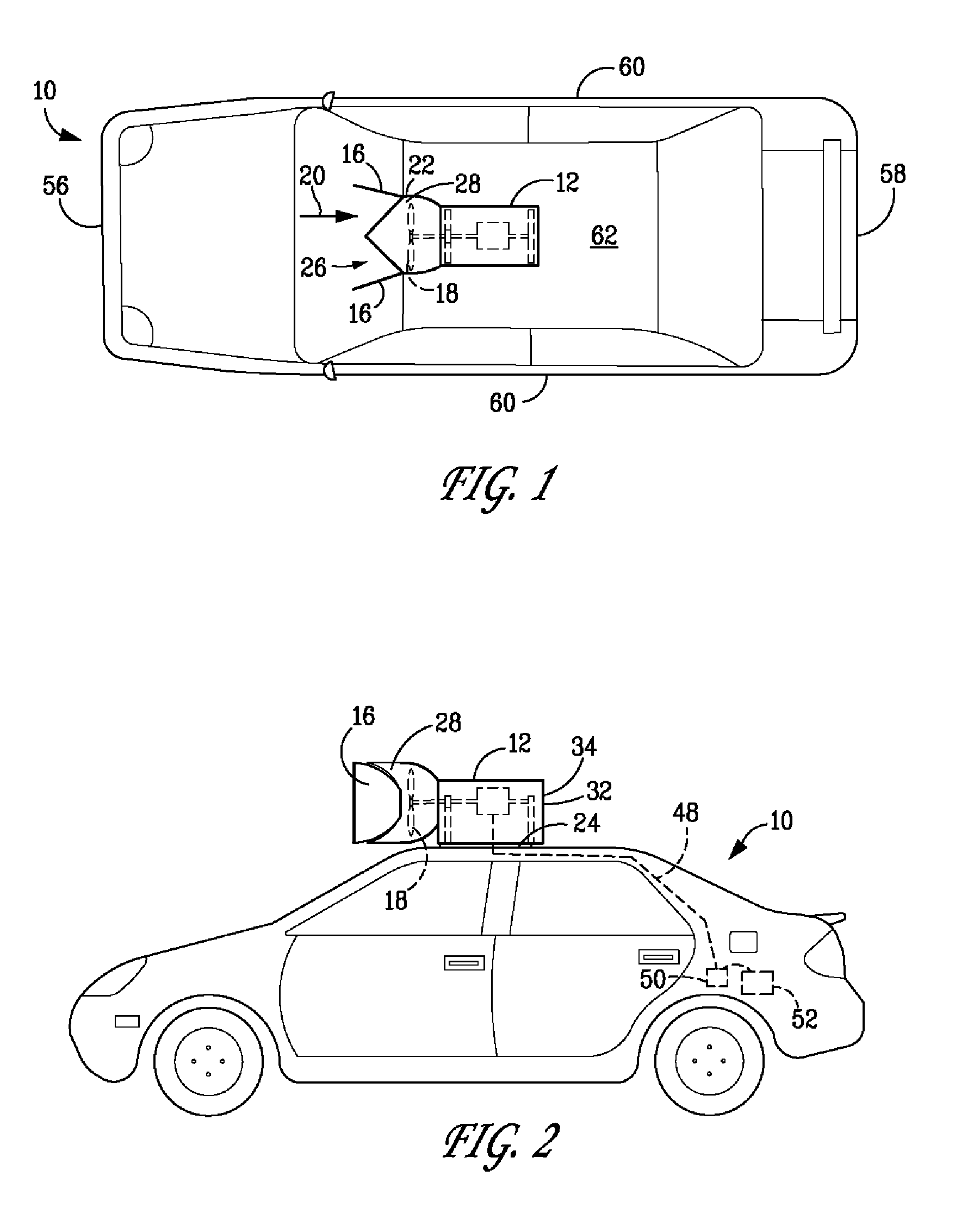

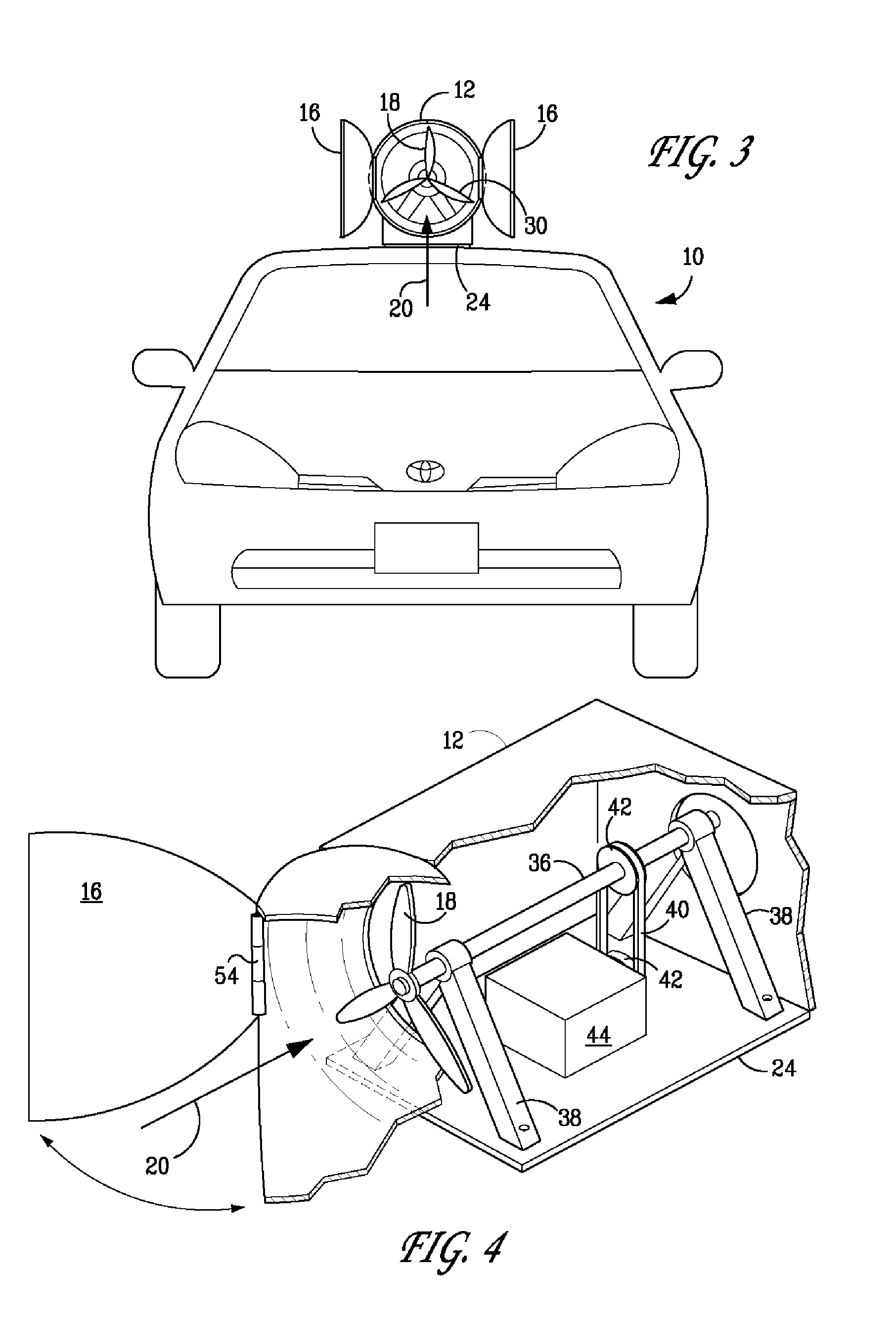

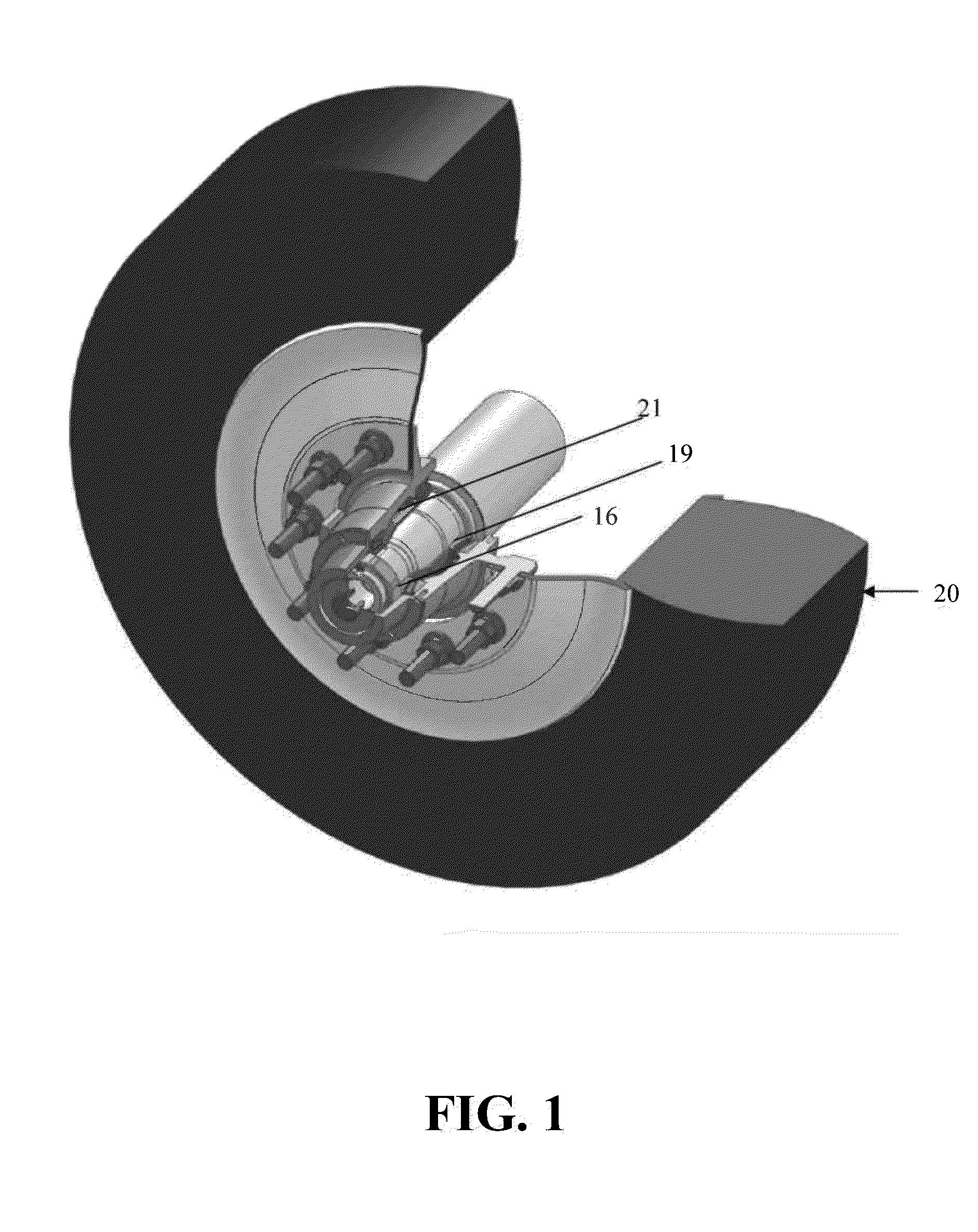

Wind driven generator for powered vehicles

InactiveUS7135786B1Enhance air intakeReduce air resistanceWind motor supports/mountsWind motor combinationsWind drivenElectricity

A shrouded enclosure is mounted to a vehicle roof, the shrouded enclosure comprising an air intake formed by controllable shrouds, a turbine, an electricity generating device, and a discharge outlet. The turbine is interposed between the air intake and the discharge outlet, operatively connected to the electricity generating device and adapted to operate by the air passing through the shrouded enclosure when the vehicle is in motion. The turbine rotates about a turbine shaft mounted on a pair of bearing towers. The rotational energy of the turbine shaft is transferred to the electricity generating device. A base plate is interposed between the shrouded enclosure and the mounting surface of the vehicle. An electrical circuit provides electrical continuity between the electricity generating device and the battery during predetermined periods thereby generating electrical energy to charge the battery with the generated electrical energy. The controllable shrouds are opened to a predetermined position during the predetermined periods of electrical continuity and are otherwise closed to form a predetermined aerodynamic shape to reduce drag during vehicle movement.

Owner:DEETS EDWARD

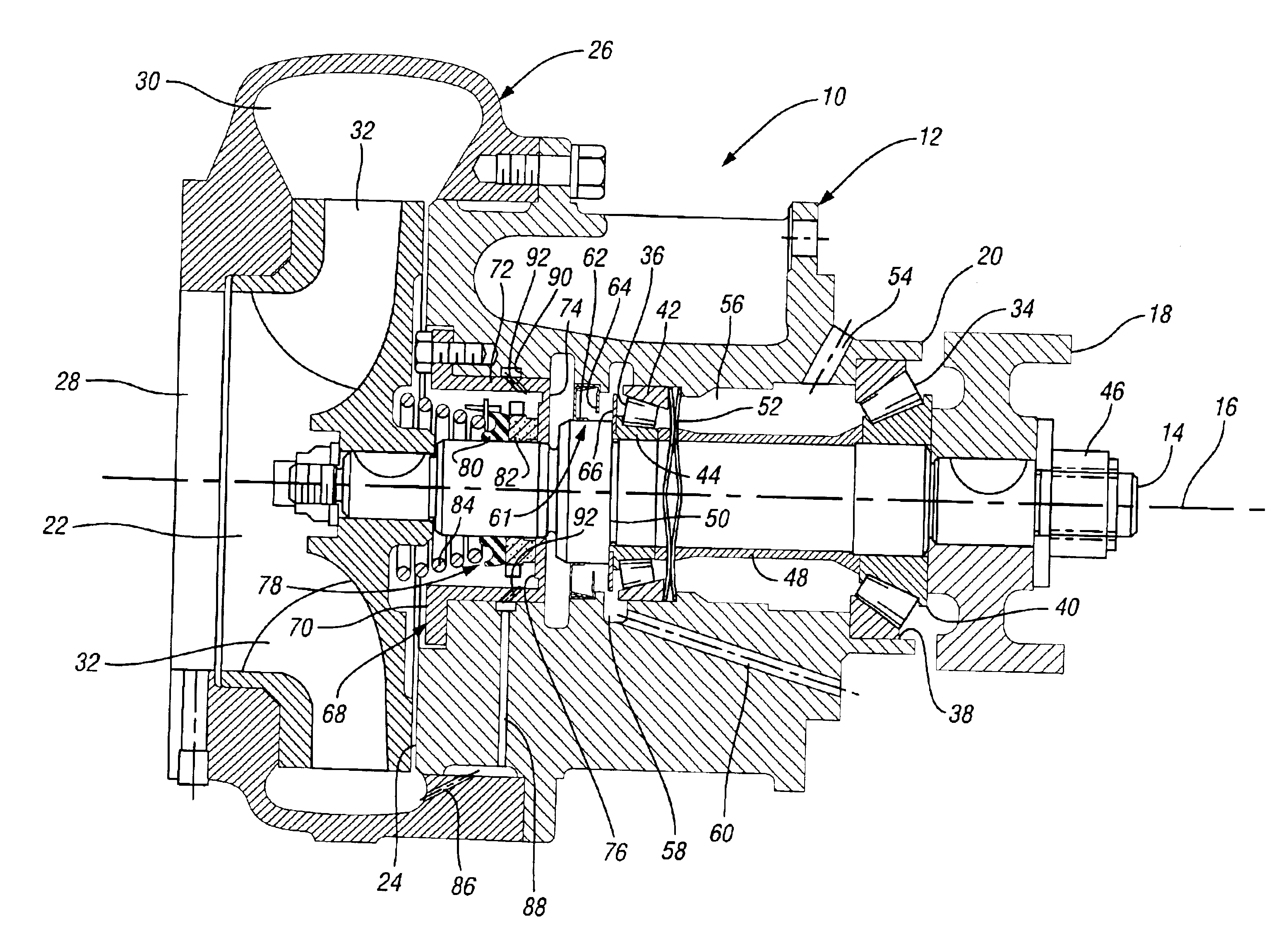

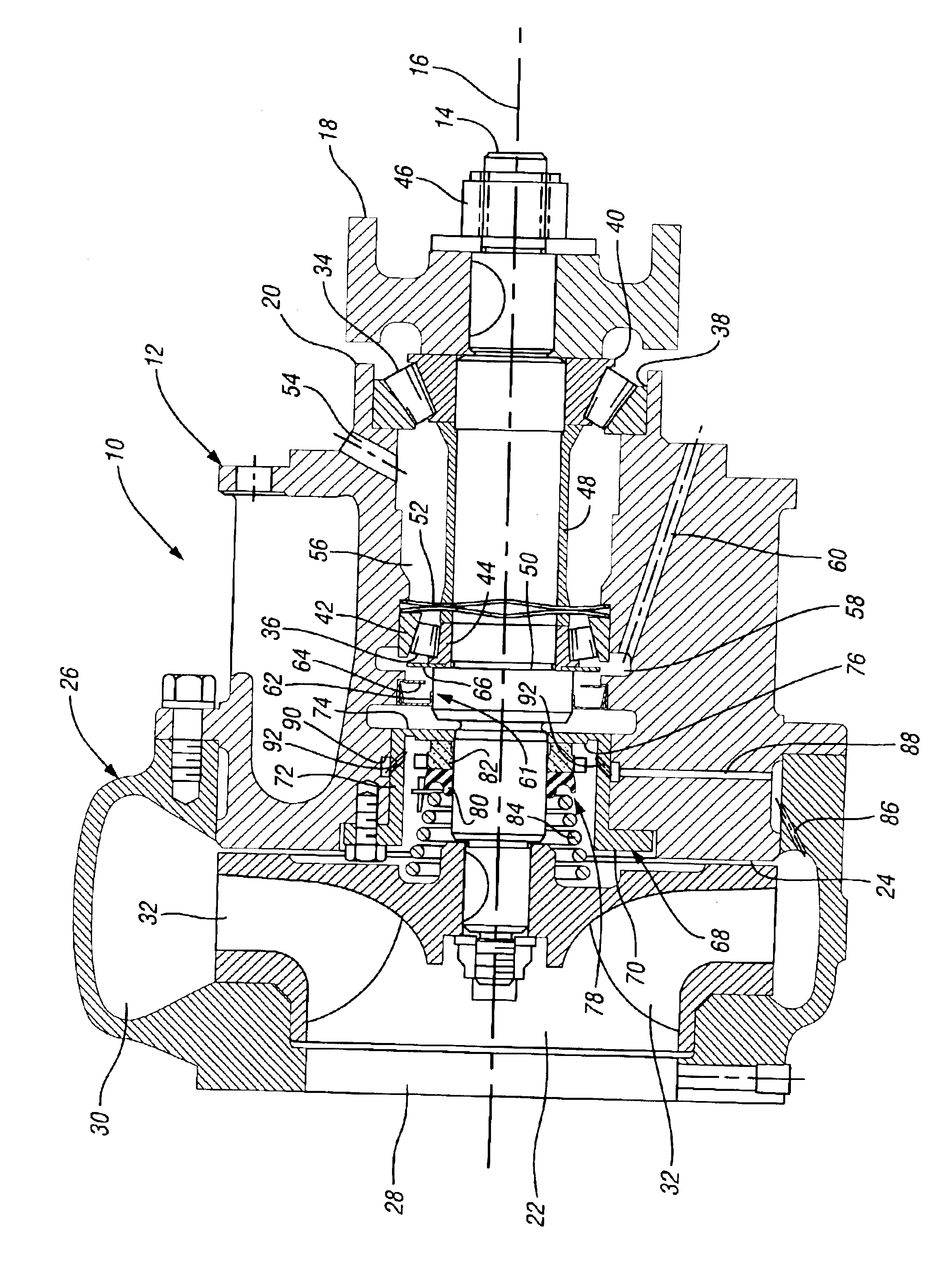

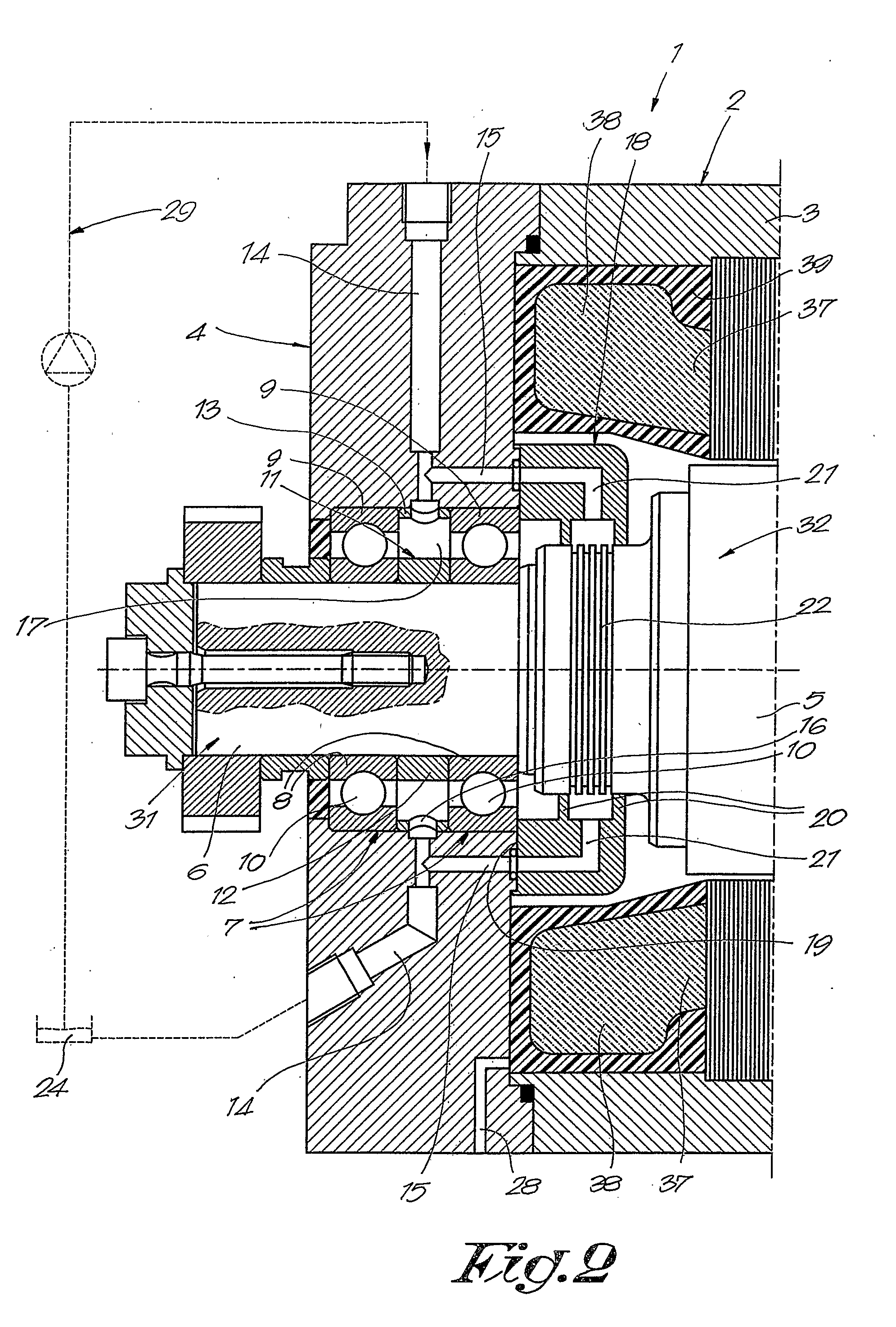

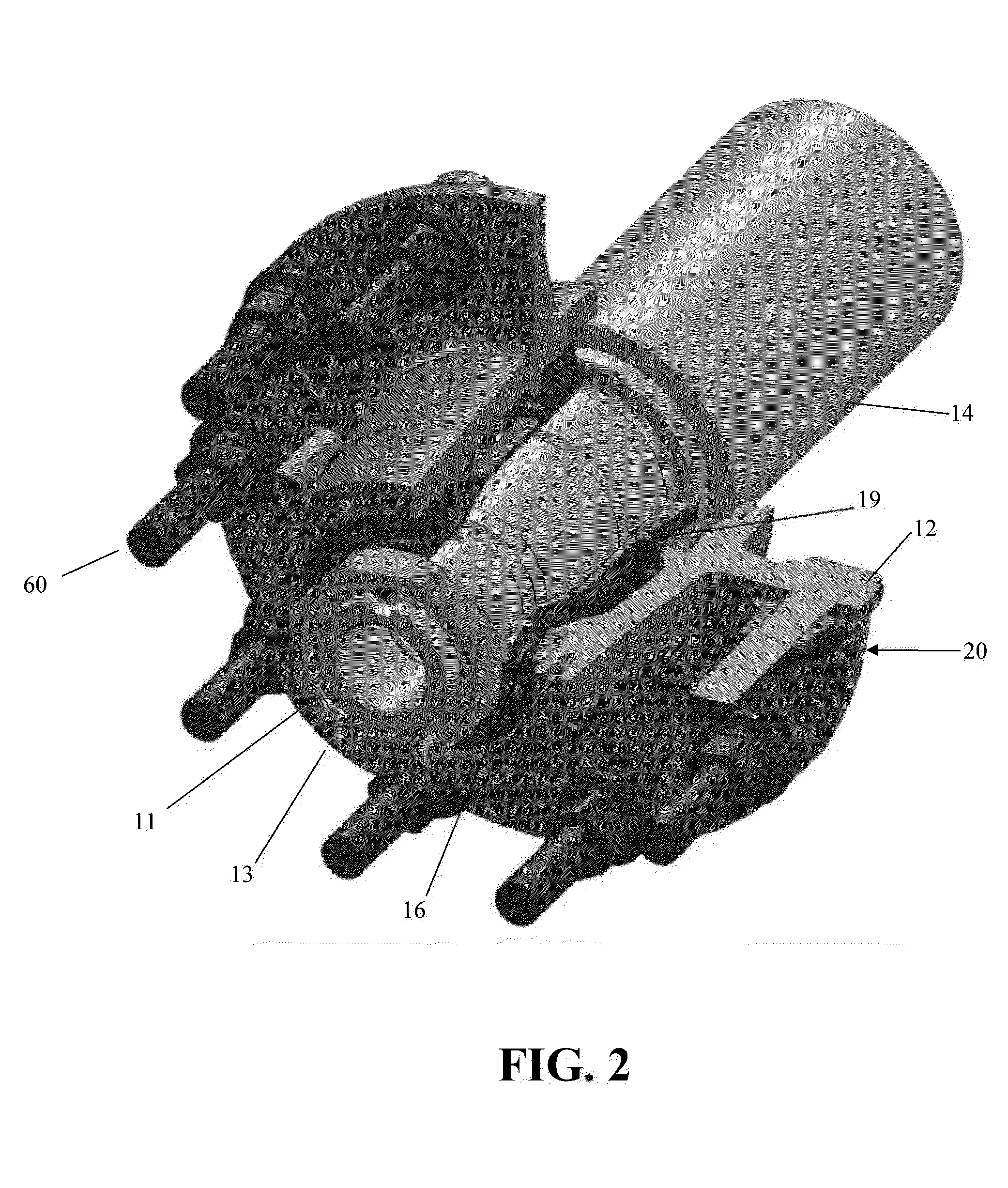

Diesel engine water pump with improved water seal

ActiveUS6884022B2Extended service lifeEasy constructionRotary bearingsEngine sealsImpellerWear particle

An improved diesel engine water pump includes three main features that aid in extending the maintenance-free life of the pump. The impeller shaft is carried by tapered roller shaft support bearings of which the impeller bearing has a floating outer race that is urged axially by a preload spring to provide a prescribed axial preload that maintains concentricity of the shaft with the axis and prolongs bearing life. An improved oil seal combines an oil slinger, a stationary deflector and a lip oil seal with a return passage to the engine to more effectively limit oil leakage from the pump. An improved water seal includes pressurized water jets fed from the pump volute that flush wear particles from the water seal surface and increase water seal life. Further details of these features are also disclosed.

Owner:ELECTRO-MOTIVE DIESEL

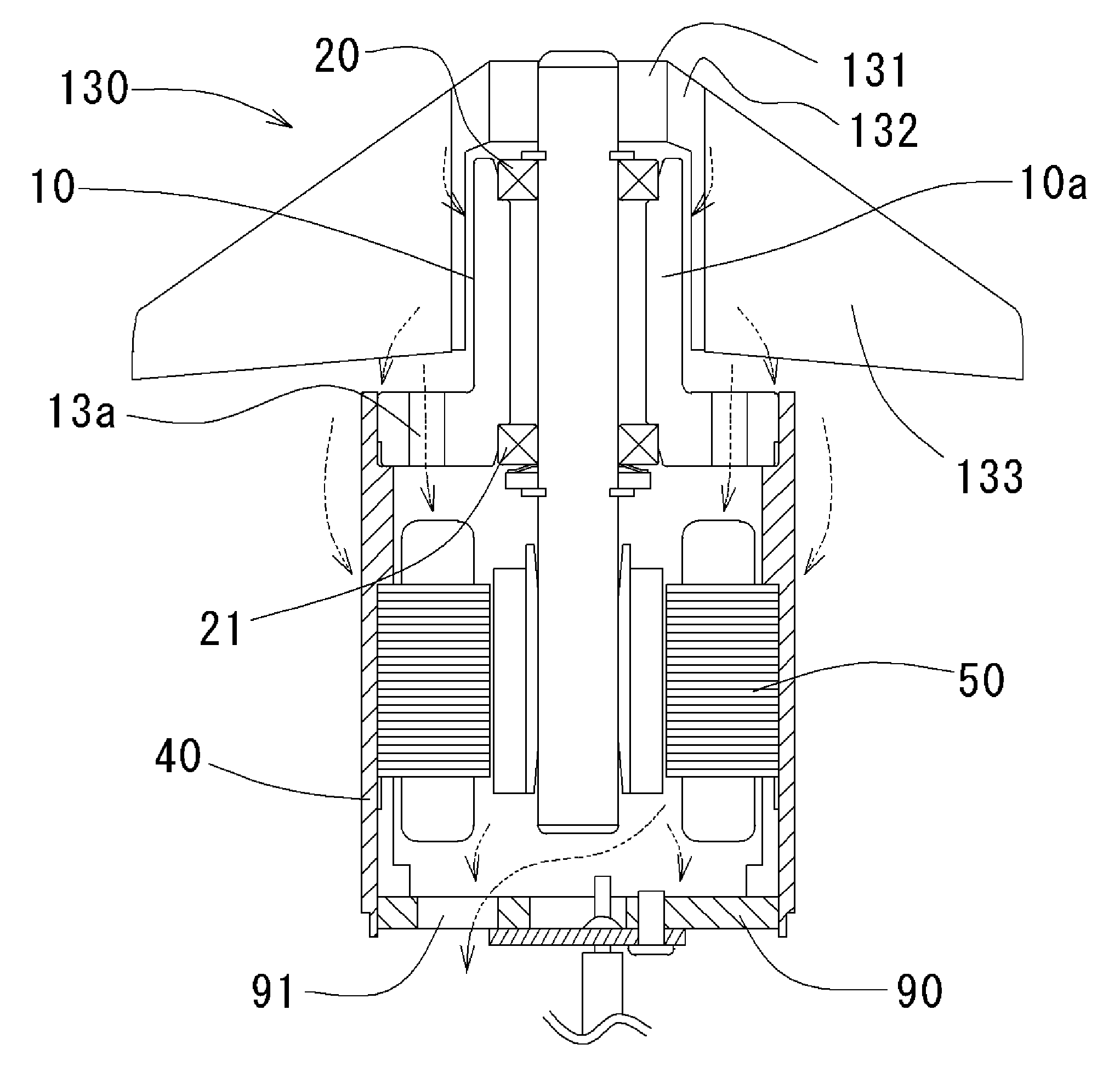

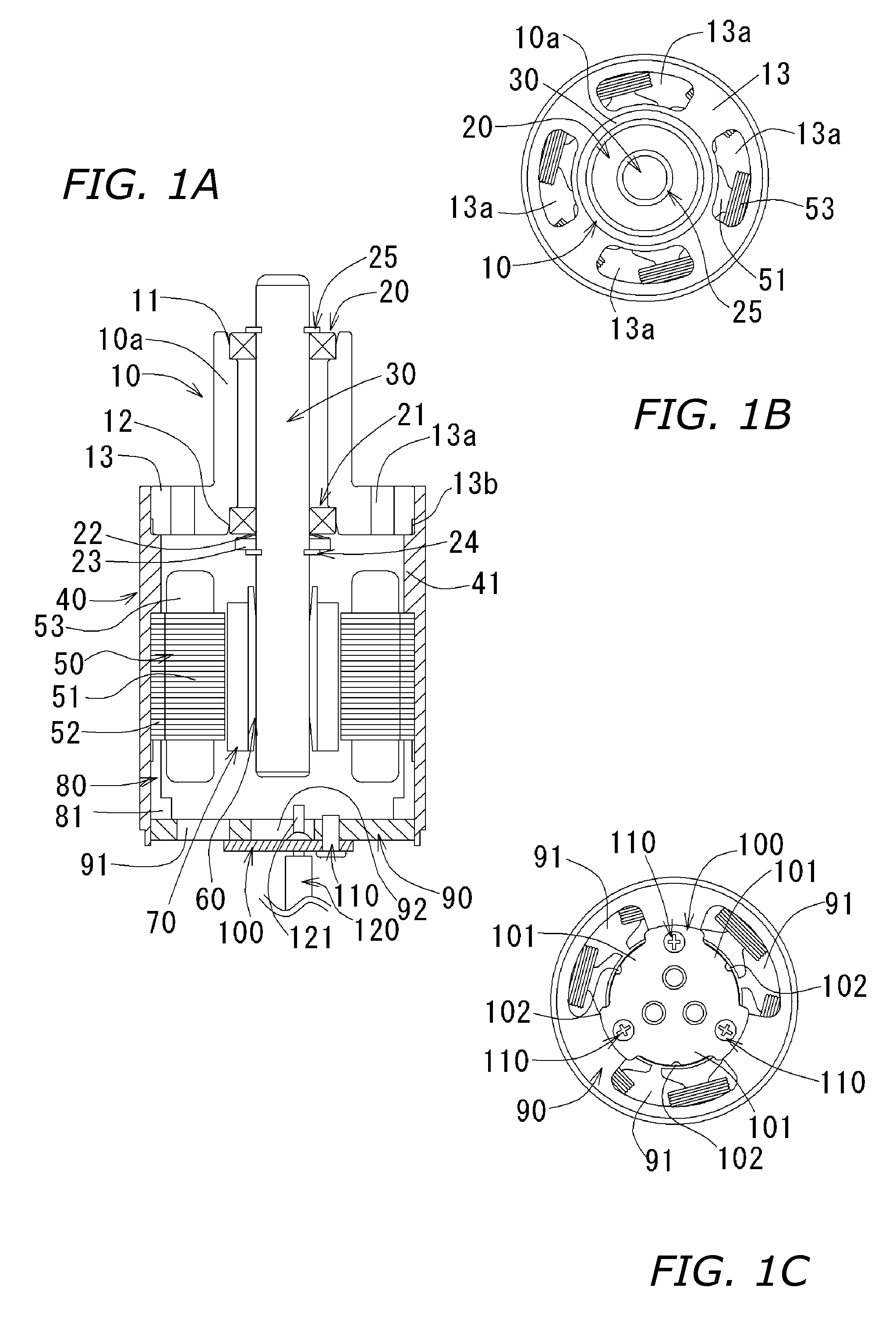

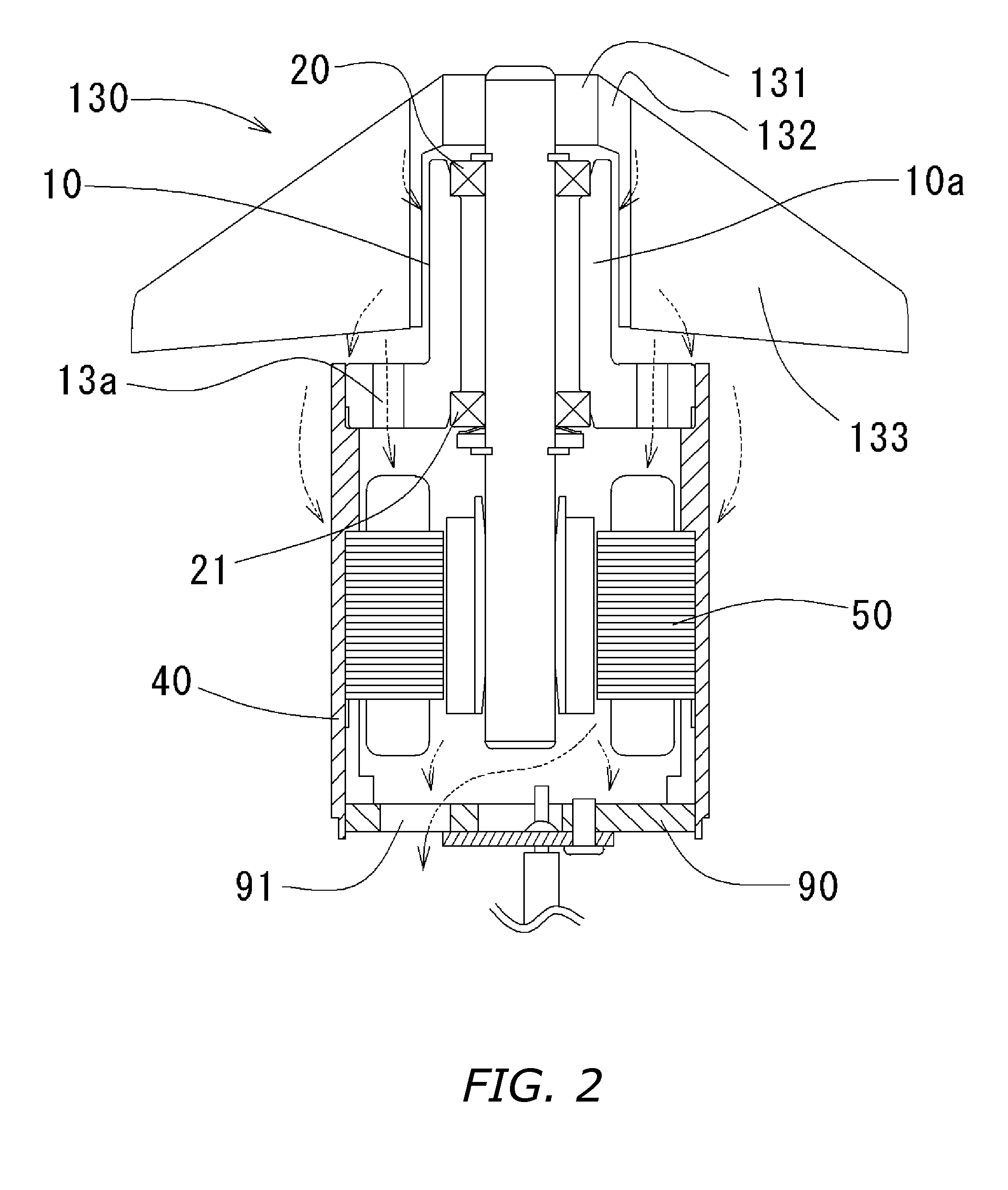

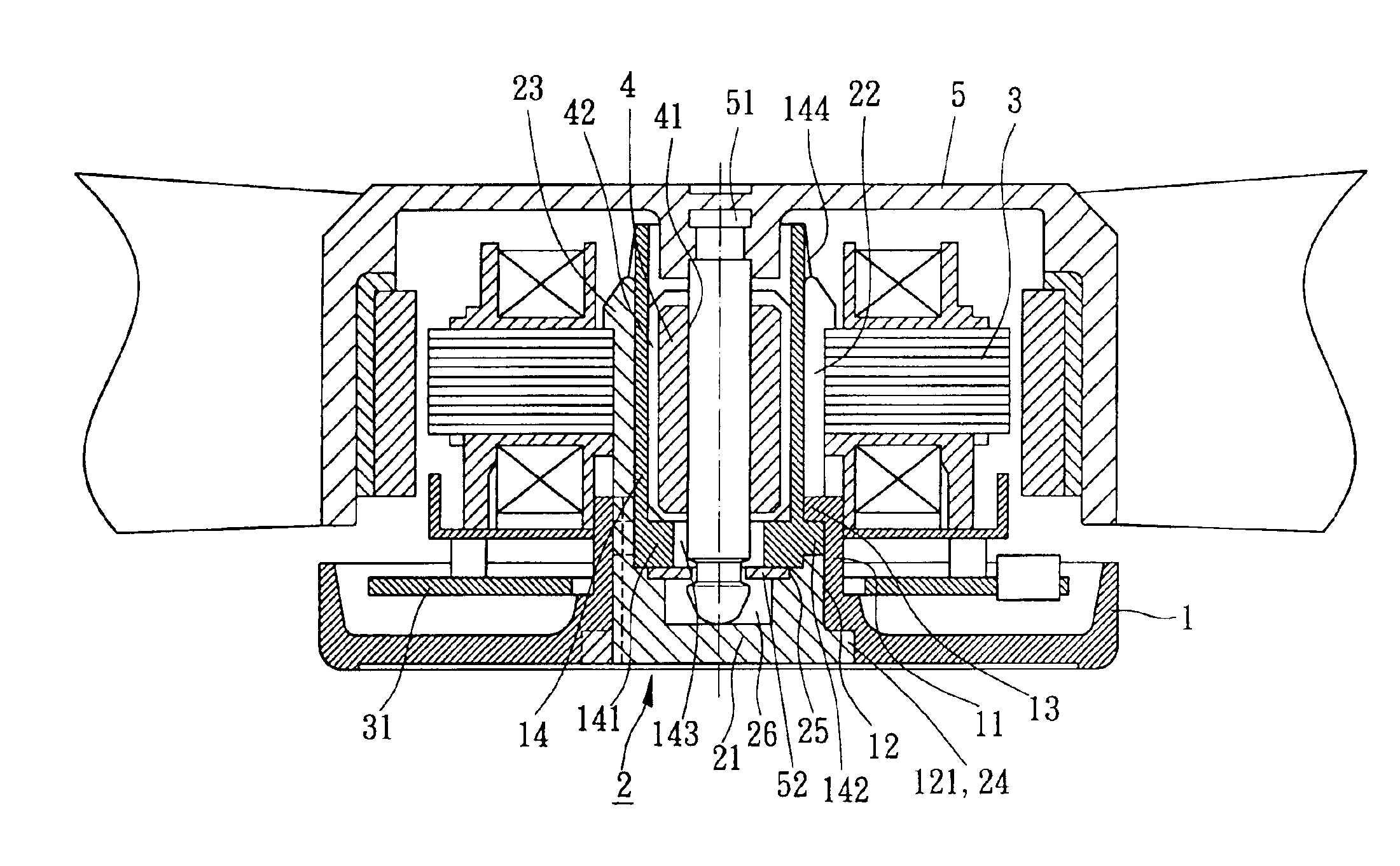

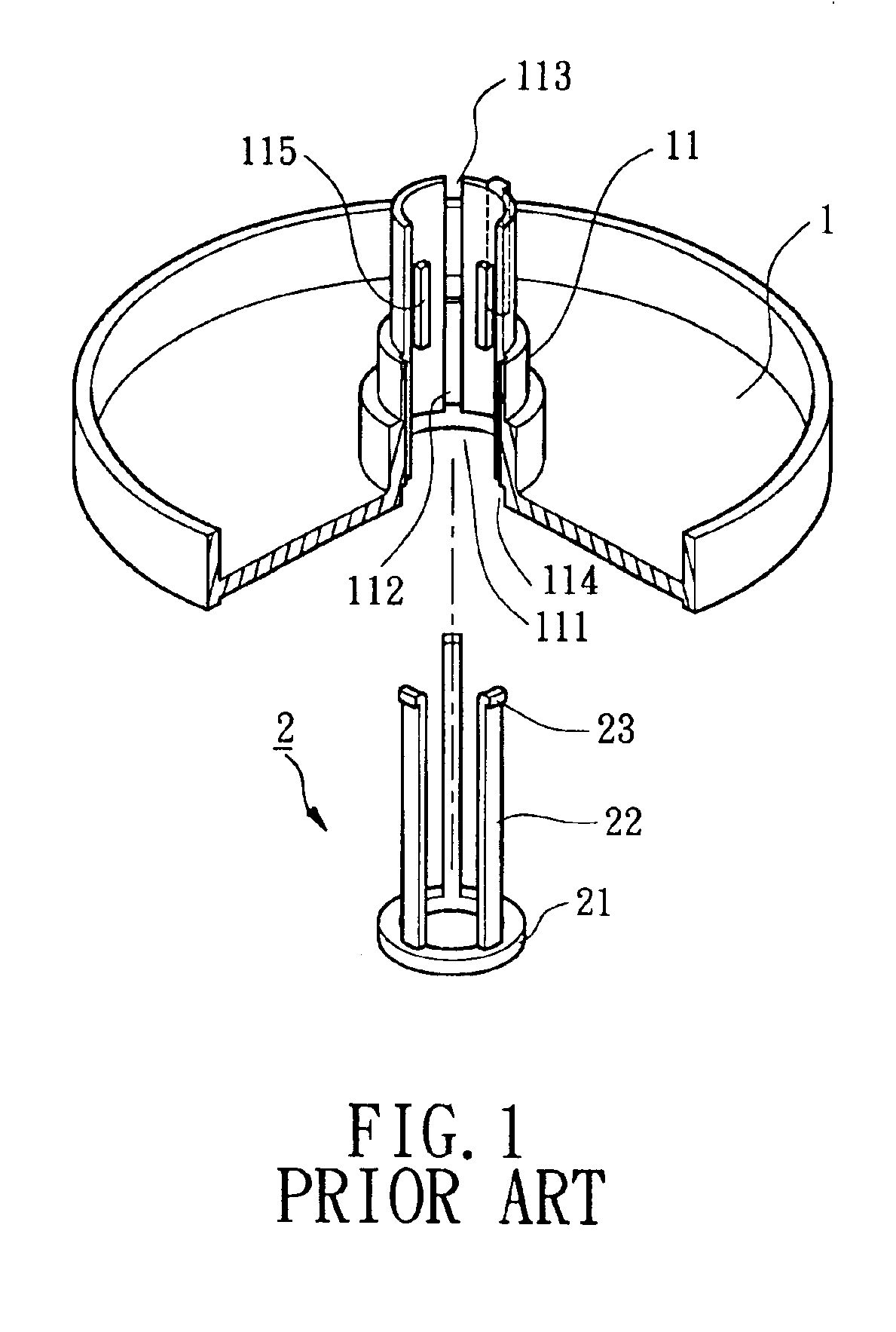

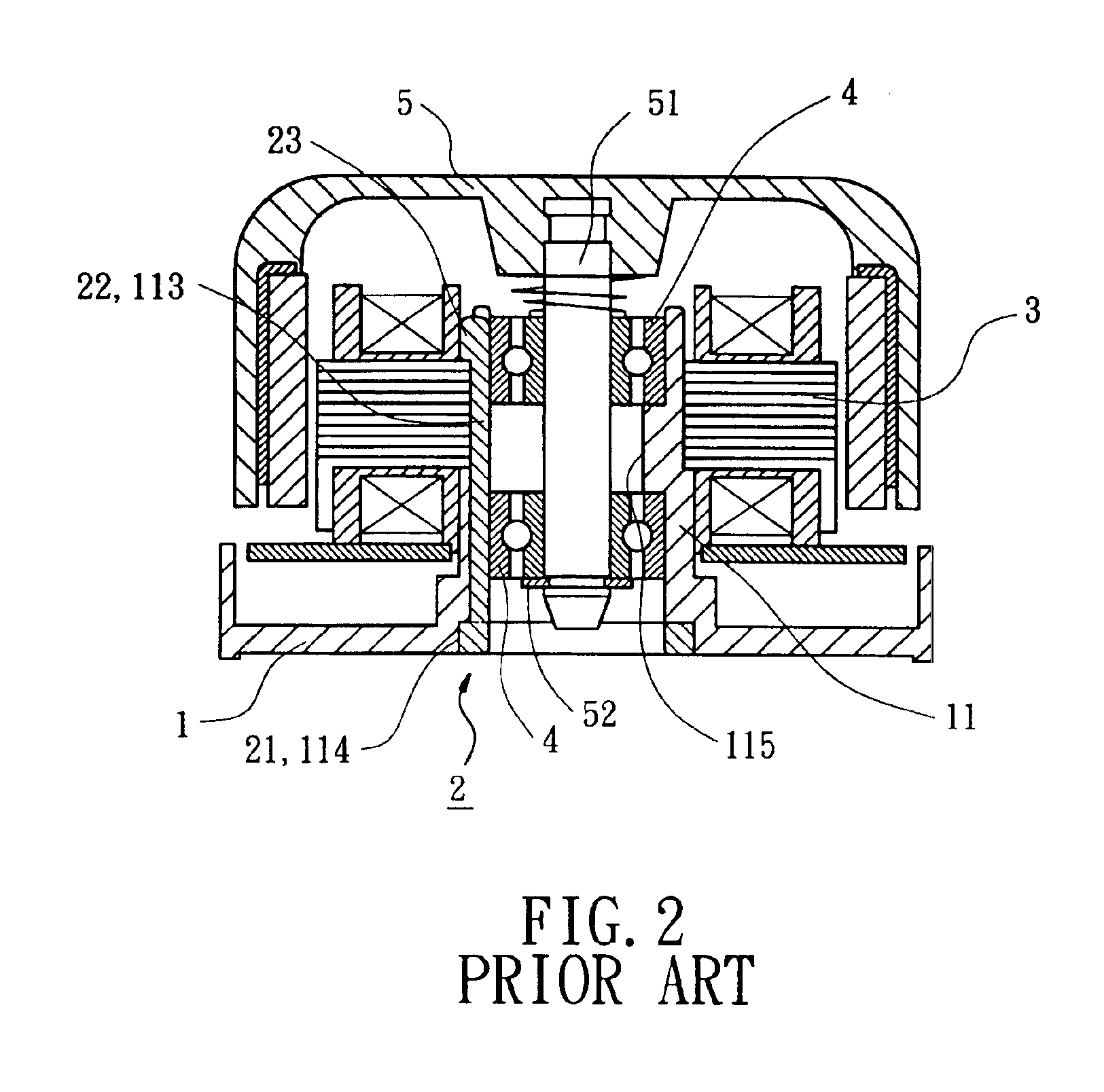

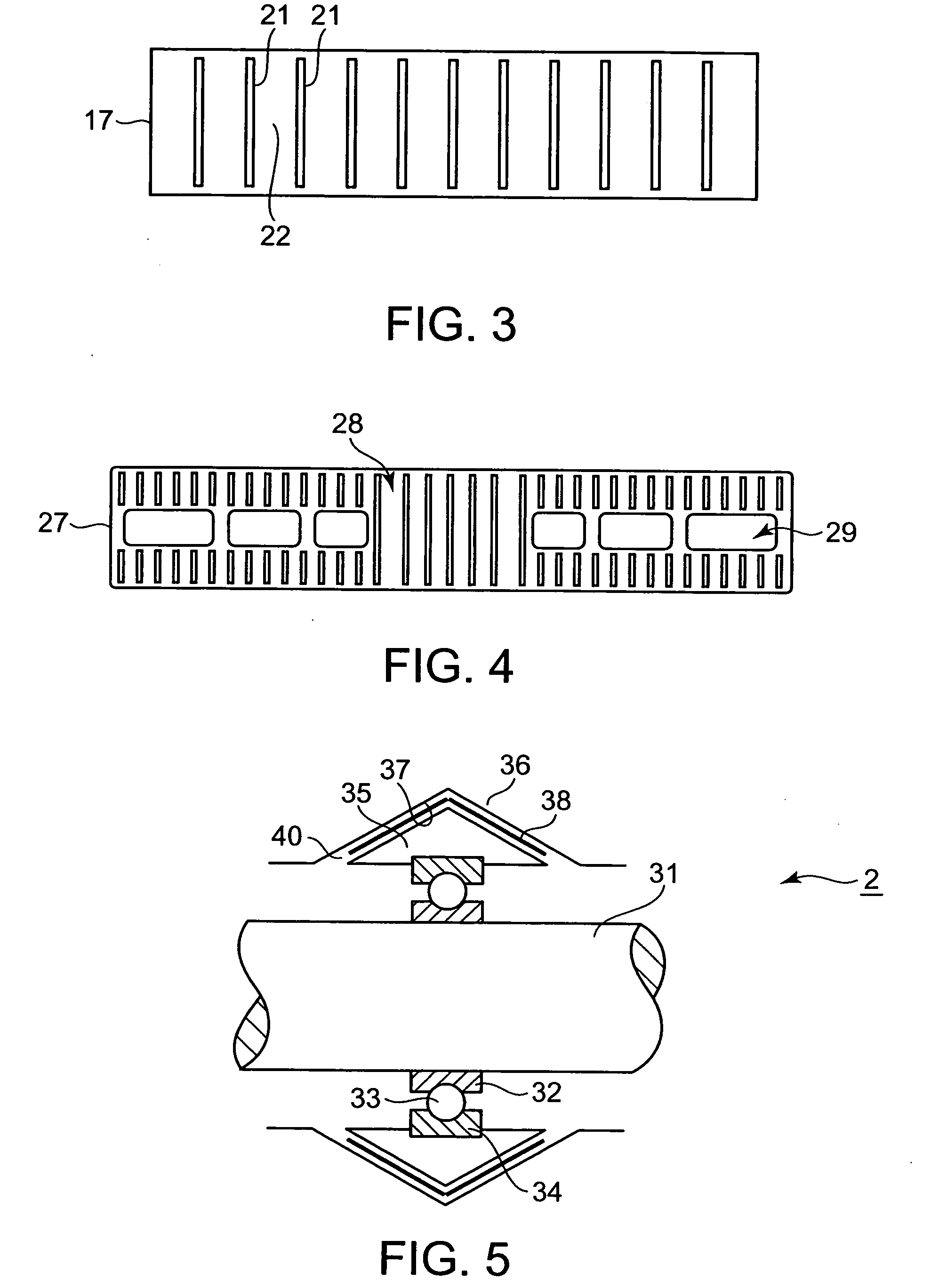

Axial Fan

ActiveUS20060250039A1Increase air volumeImprove bearing lifeMagnetic circuit rotating partsPump componentsBall bearingElectrical and Electronics engineering

In an axial fan, a case (40) accommodating the fan motor stator (50) is anchored into a bearing retainer (10), in which ball bearings (20, 21) as a bearing unit are accommodated, along a bulge part (13) formed on the lower end portion thereof. The case (40) extends heading axially downward, wherein there is no diametrical overlap between the ball bearings (20, 21) and the stator (50). Since only the bulge part (13) of the bearing retainer (10) is fixed to the case (40), heat arising from the stator (50) is thermally conveyed via the case (40) only to the bulge part (13). The fact that the thermal conveyance zone is minimal enables unrestrained curtailment of heat transmitted to the ball bearings (20, 21). As a result the axial fan can be designed for prolonged bearing lifespan.

Owner:NIPPON DENSAN CORP

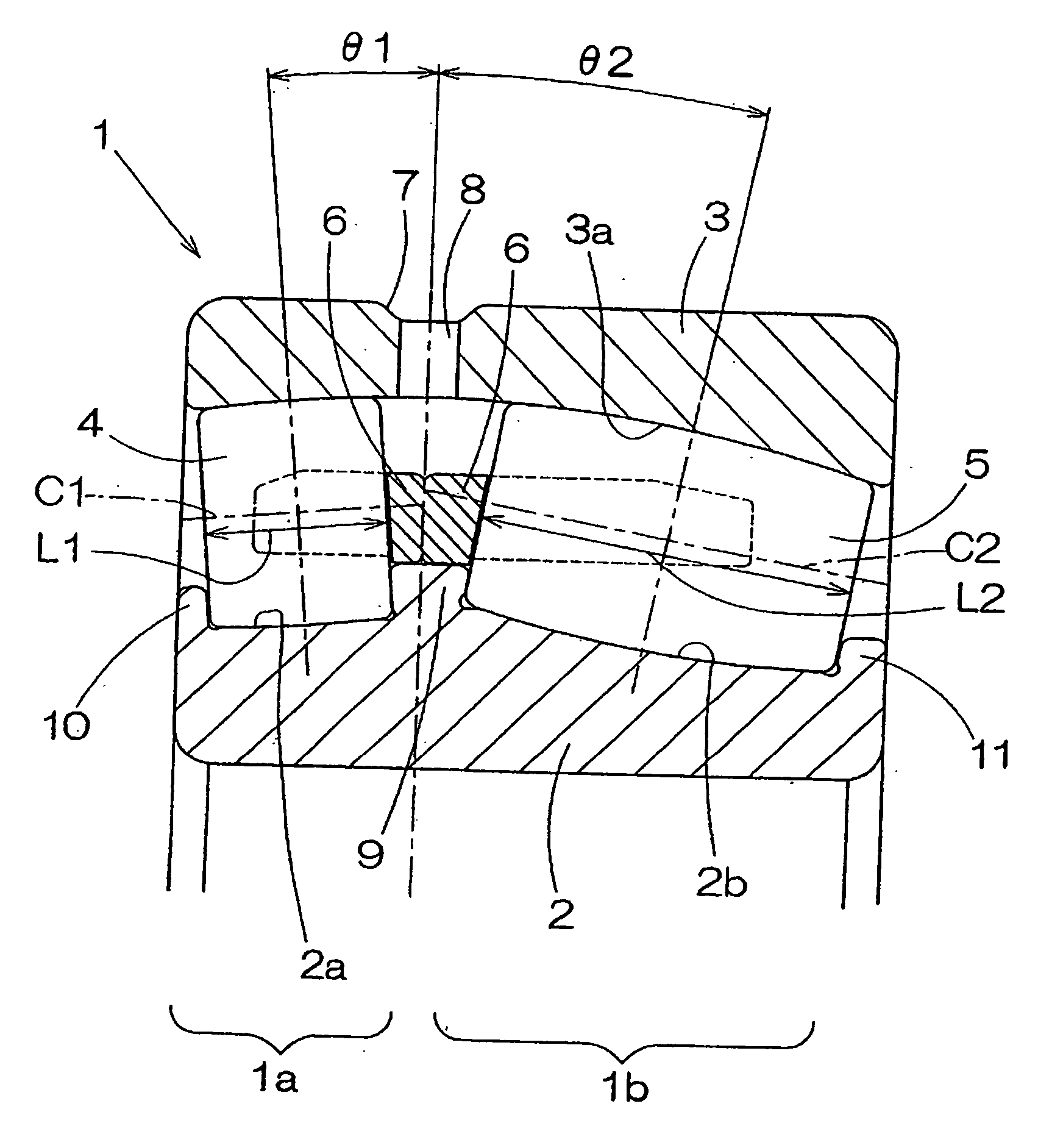

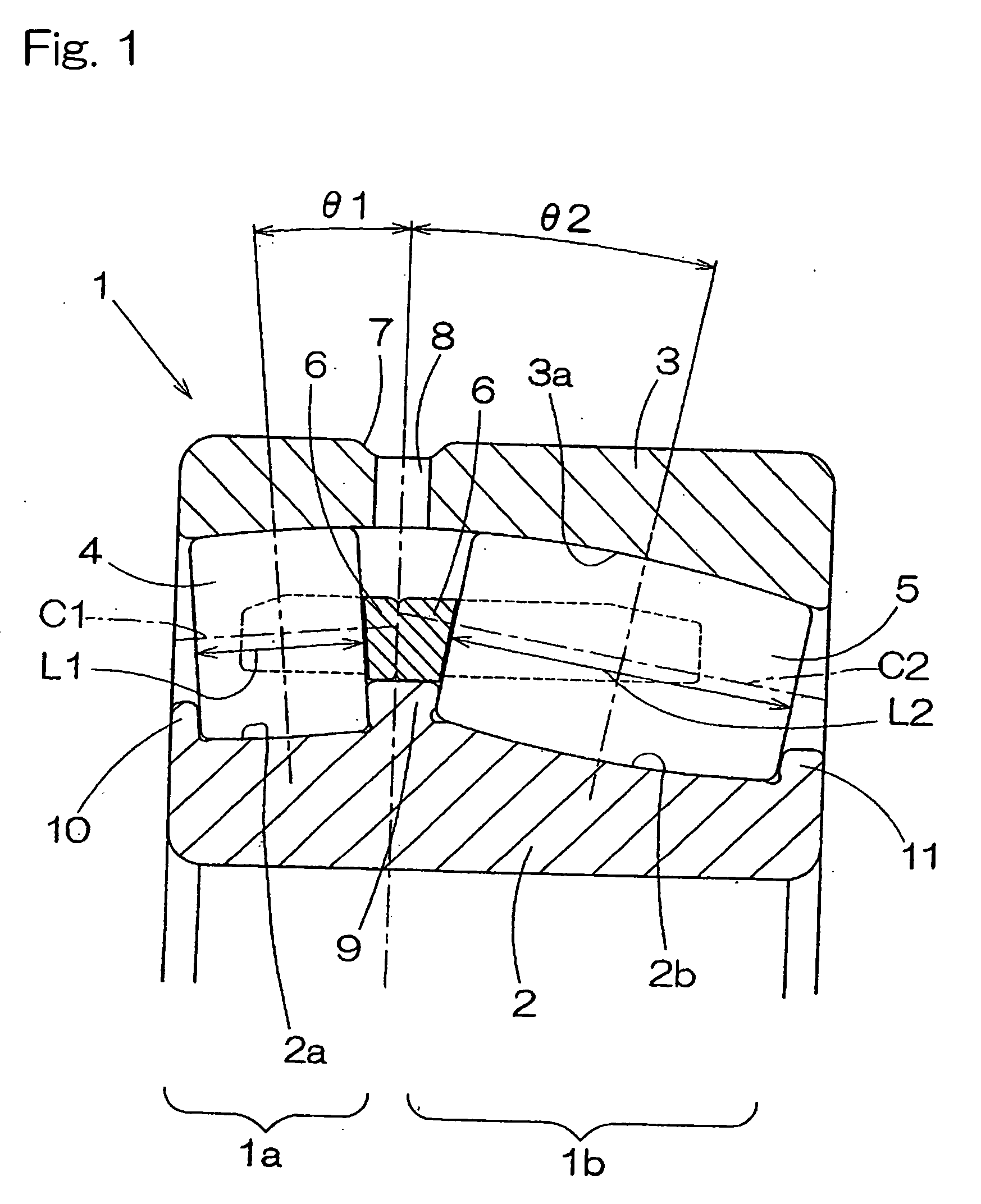

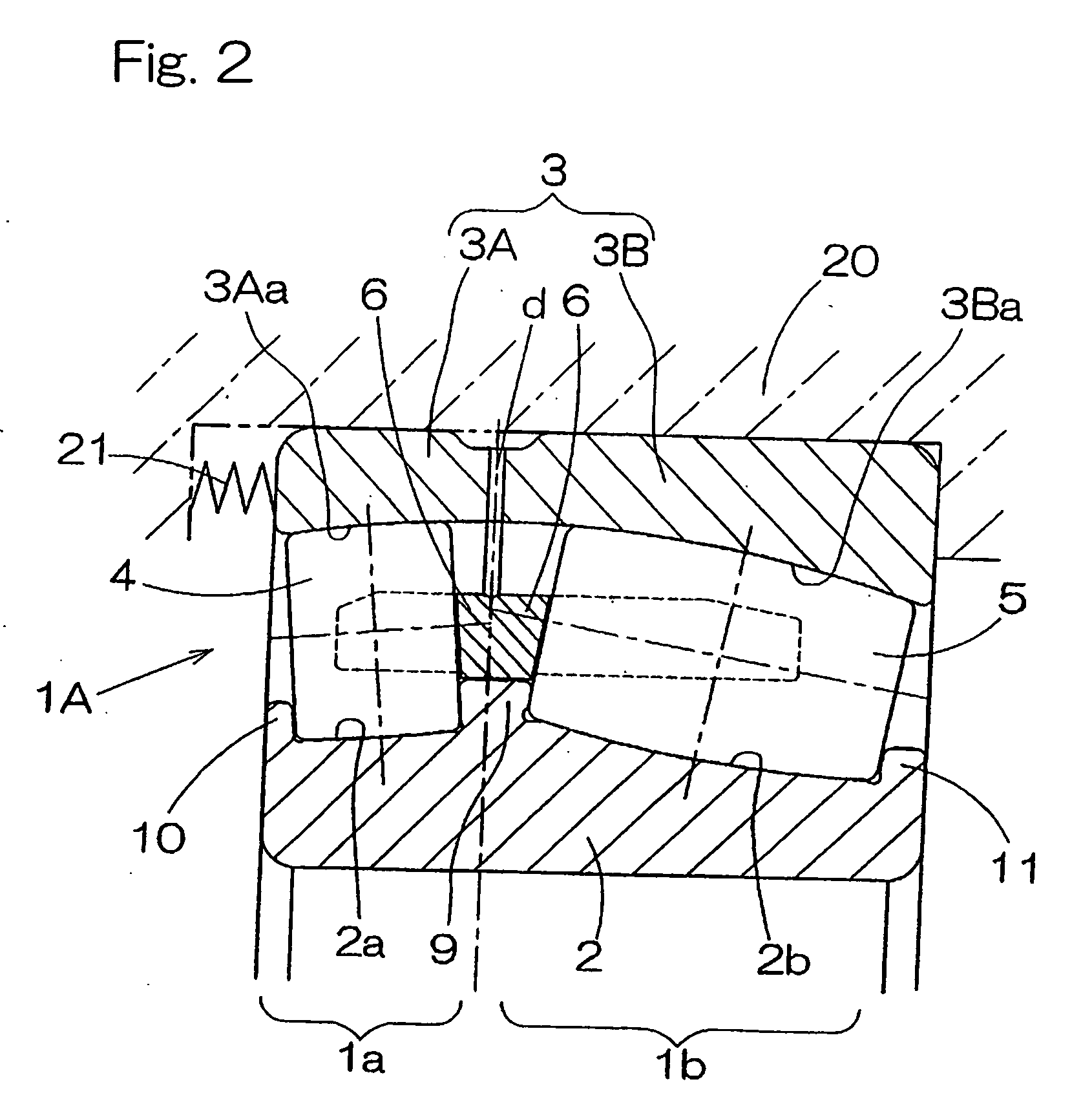

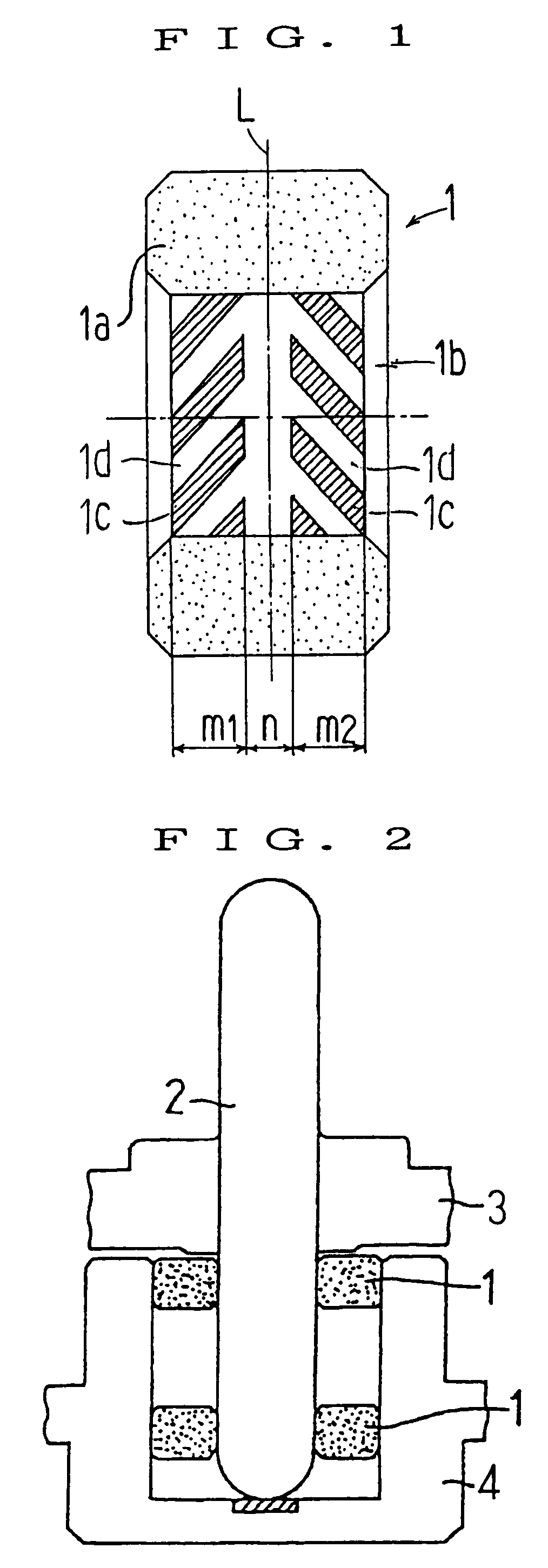

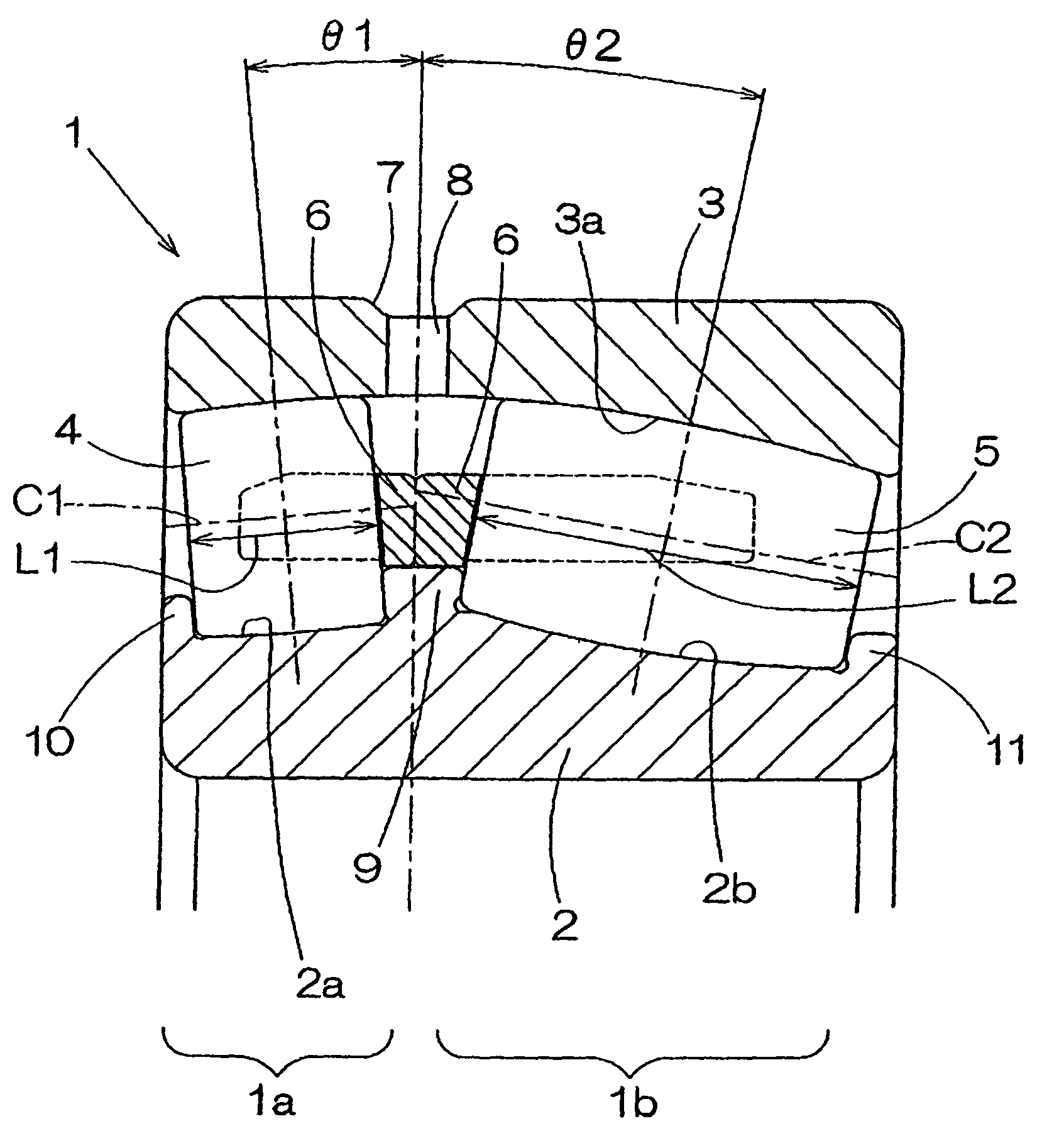

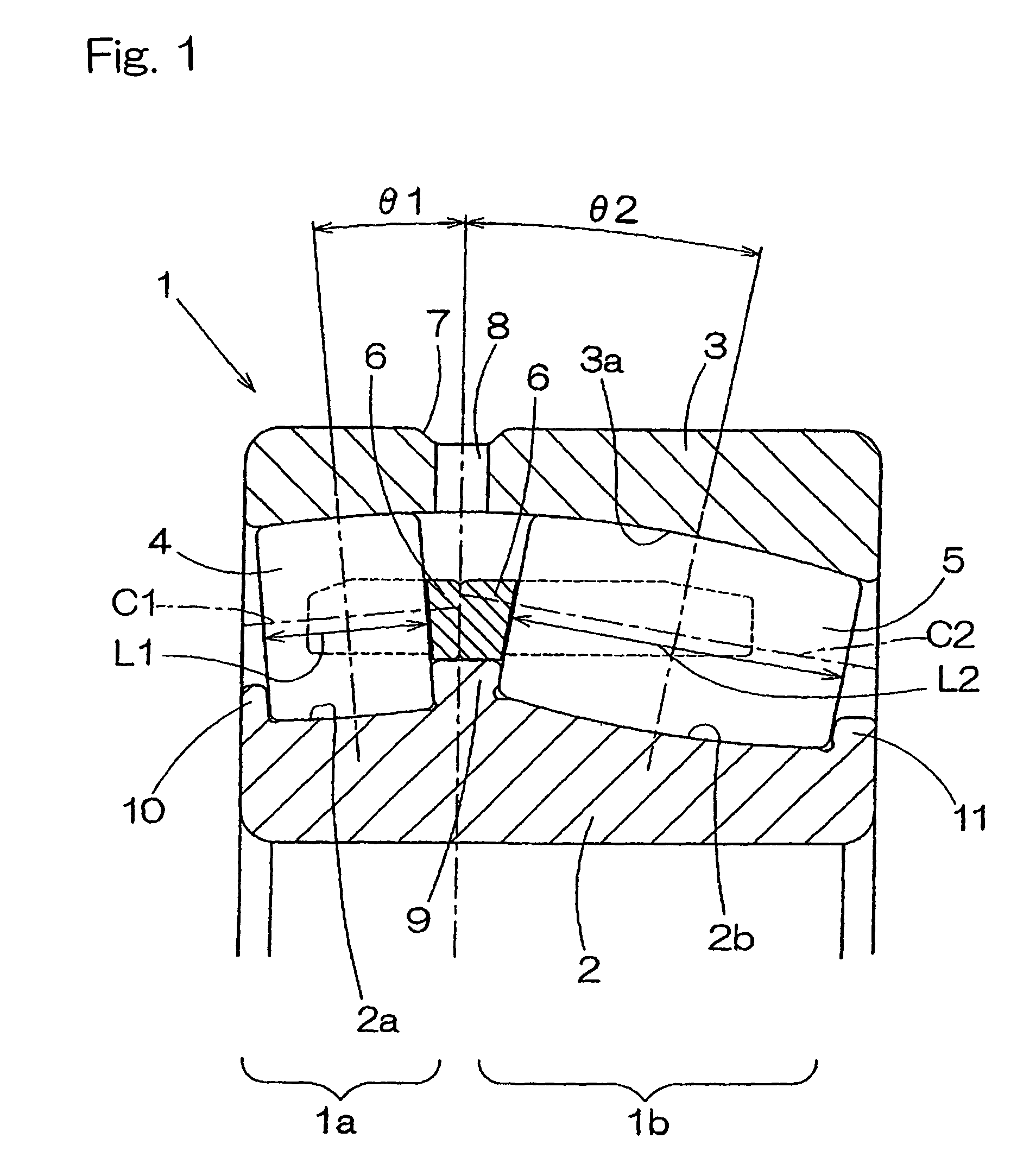

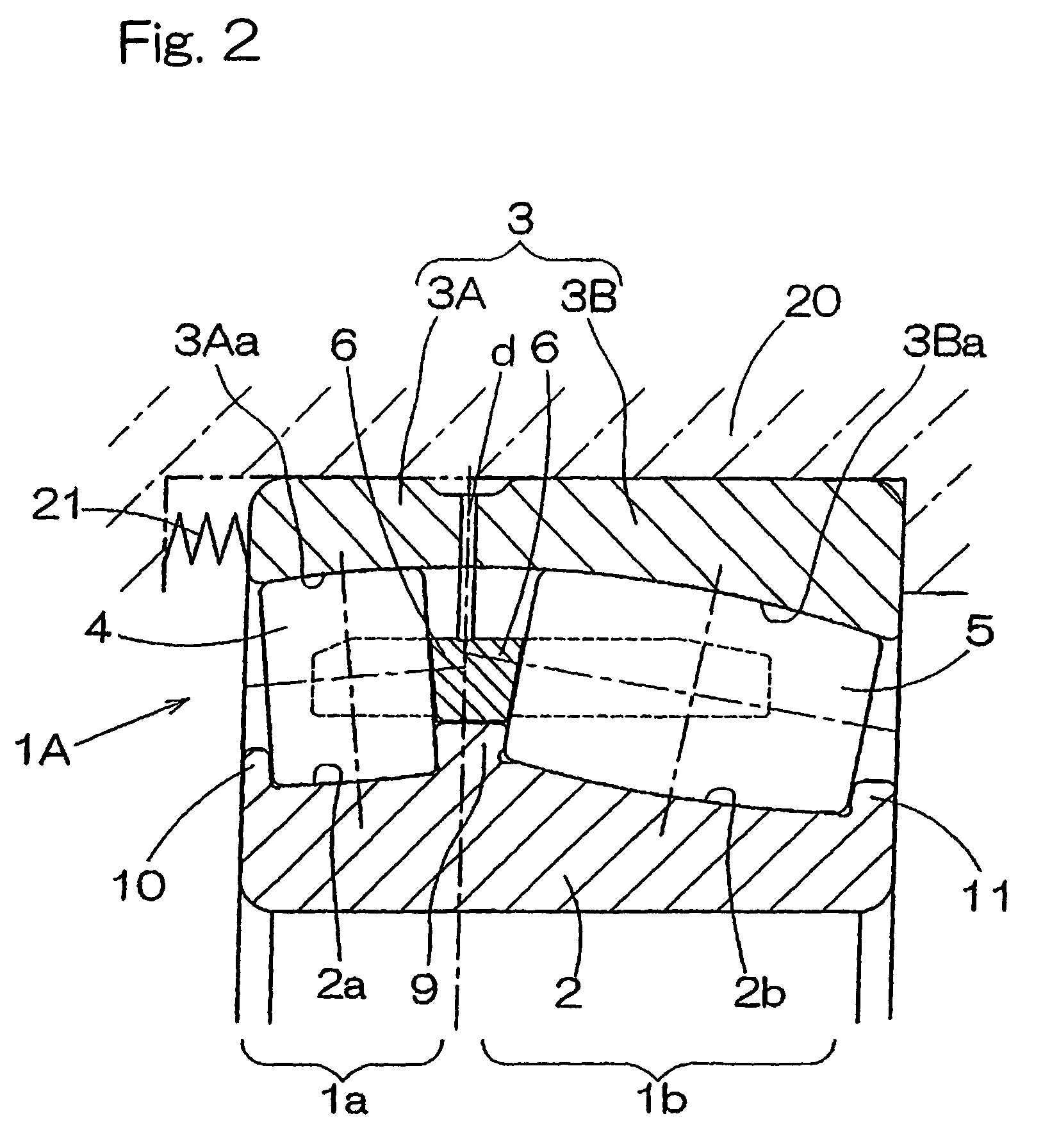

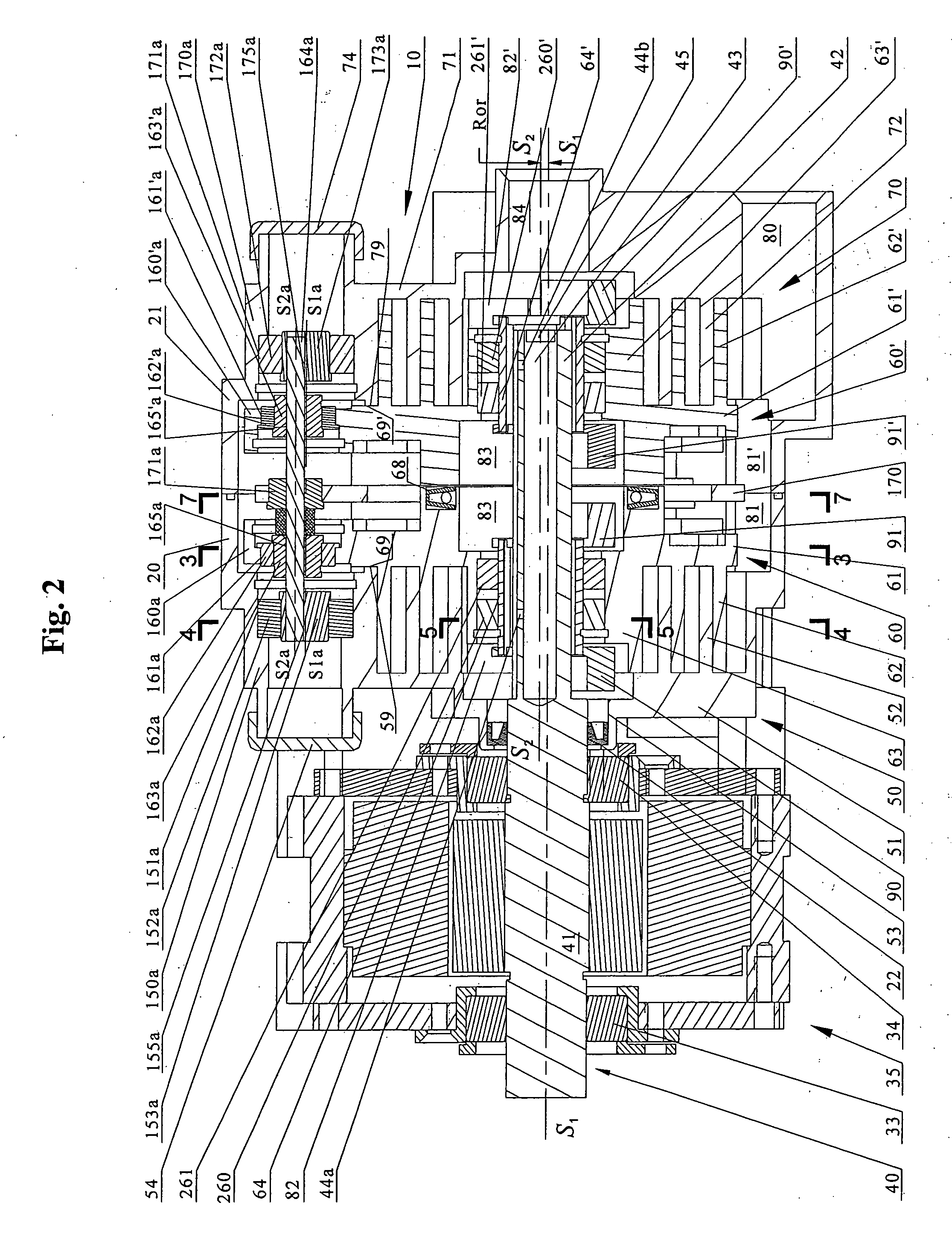

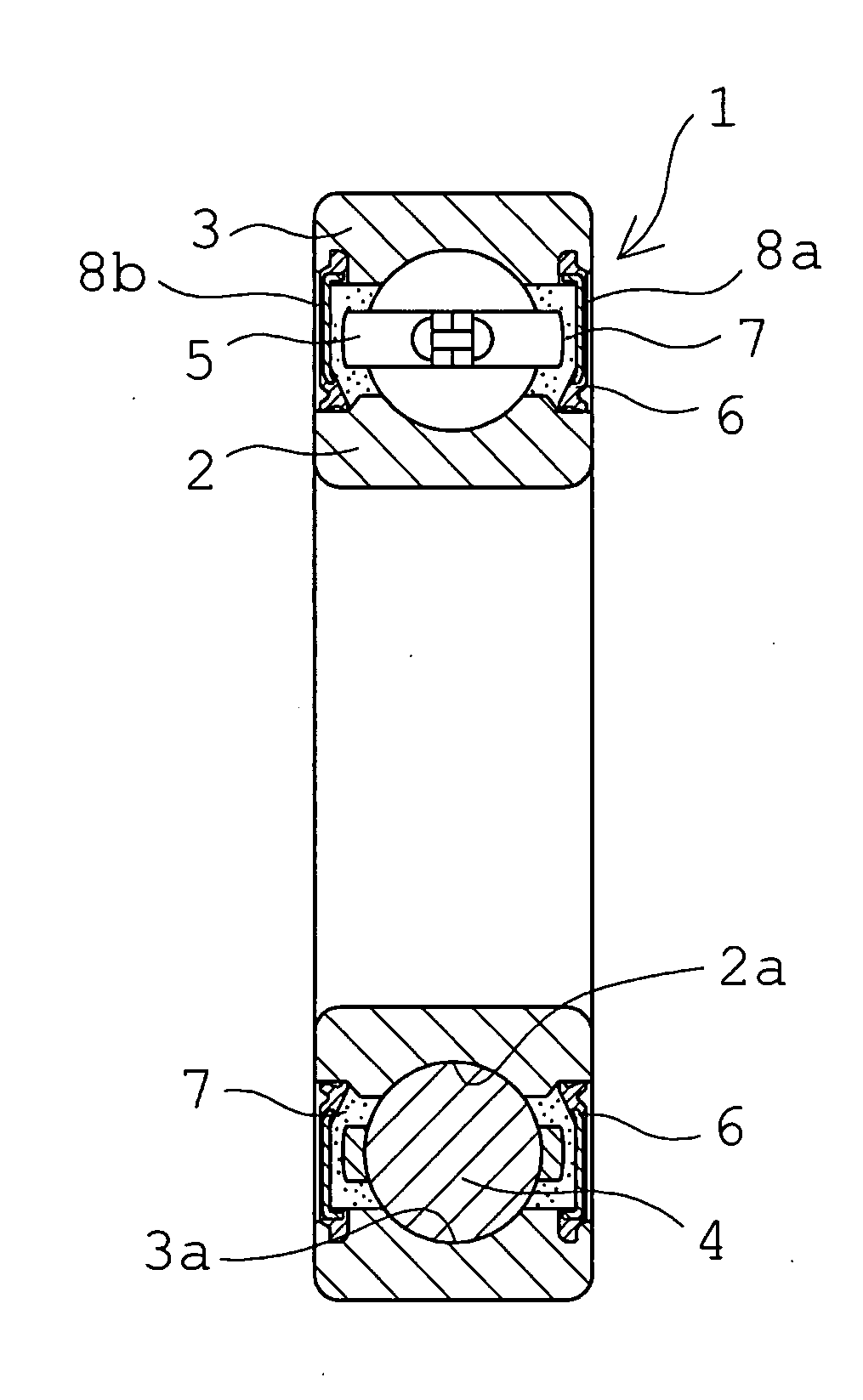

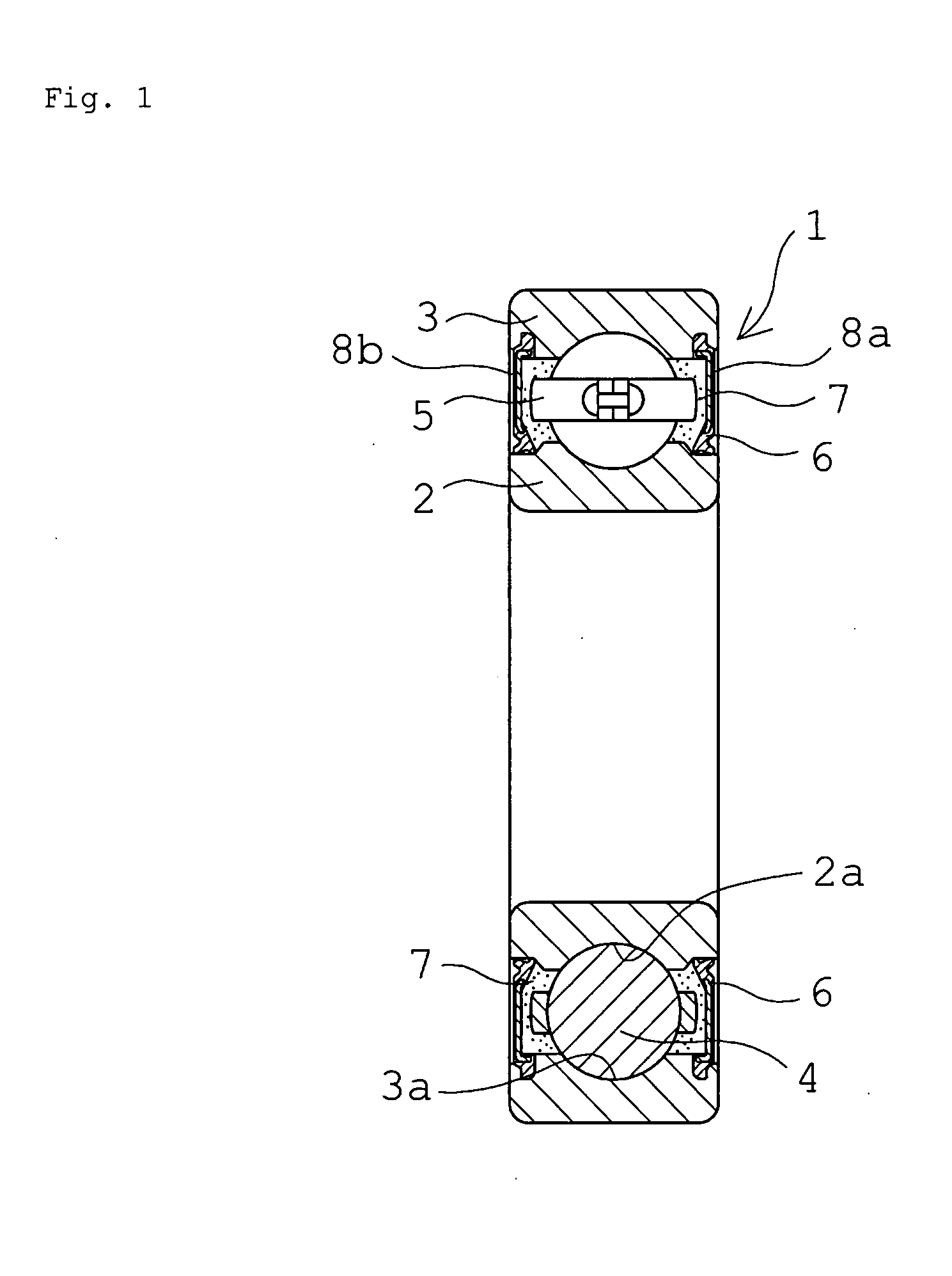

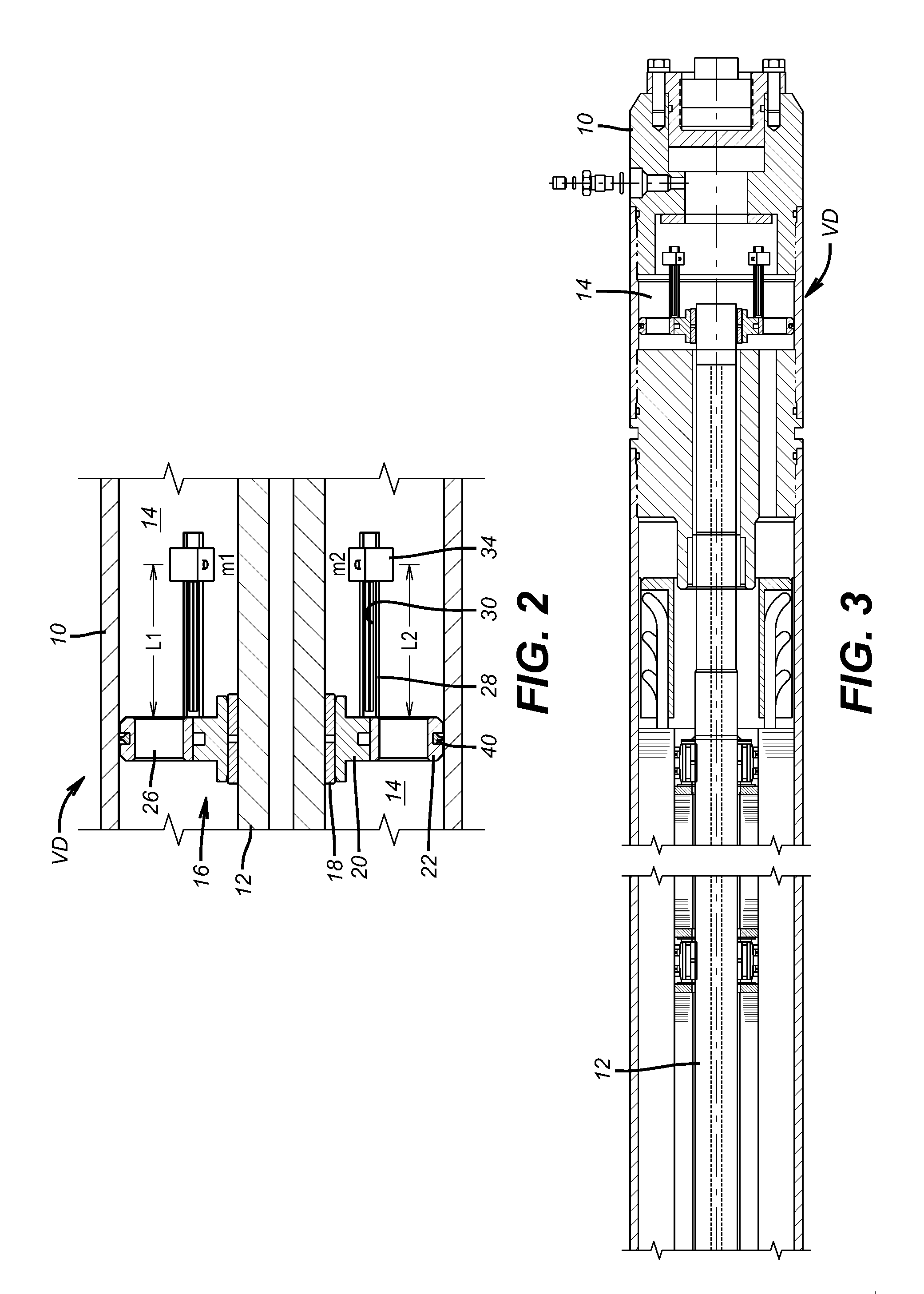

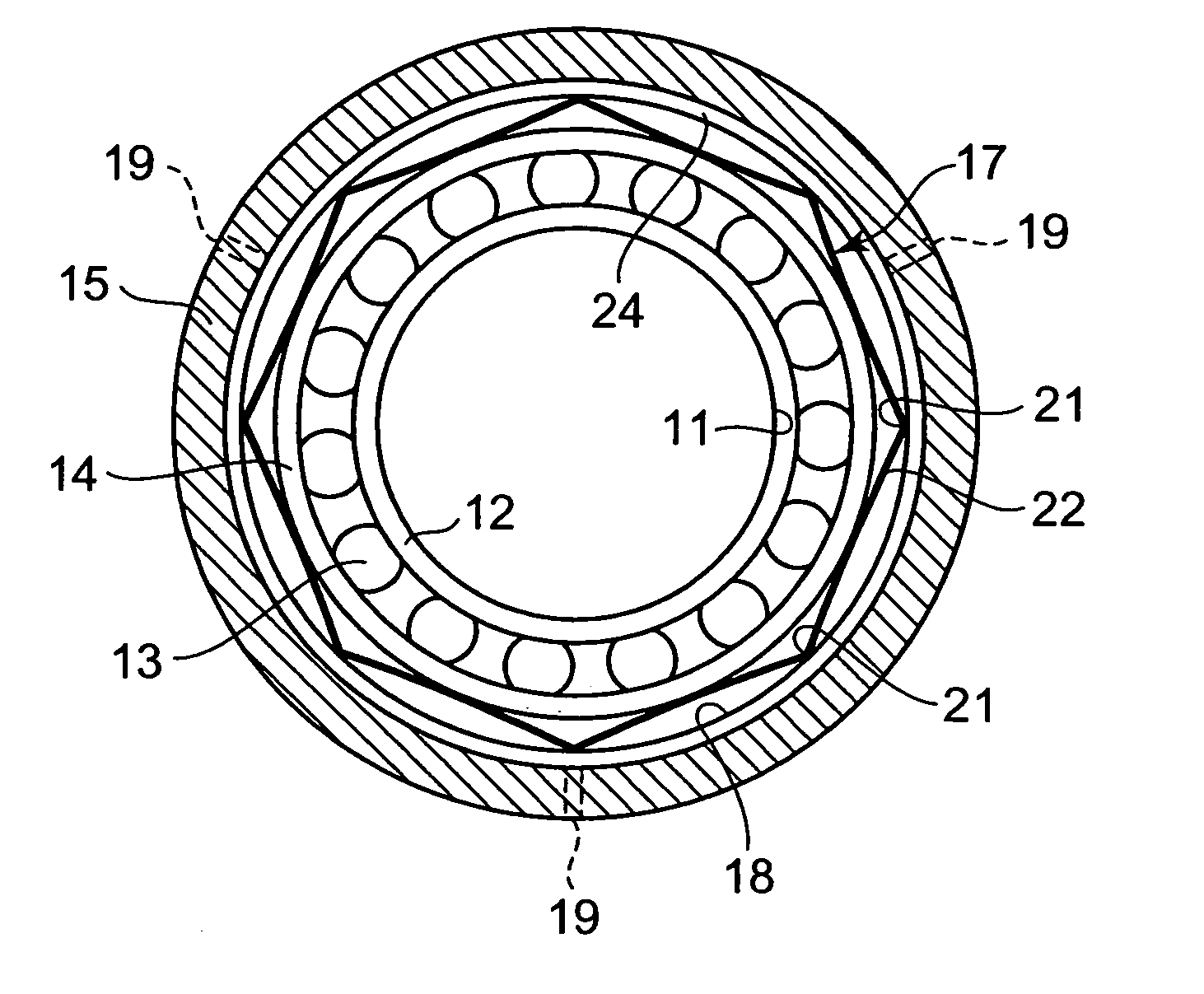

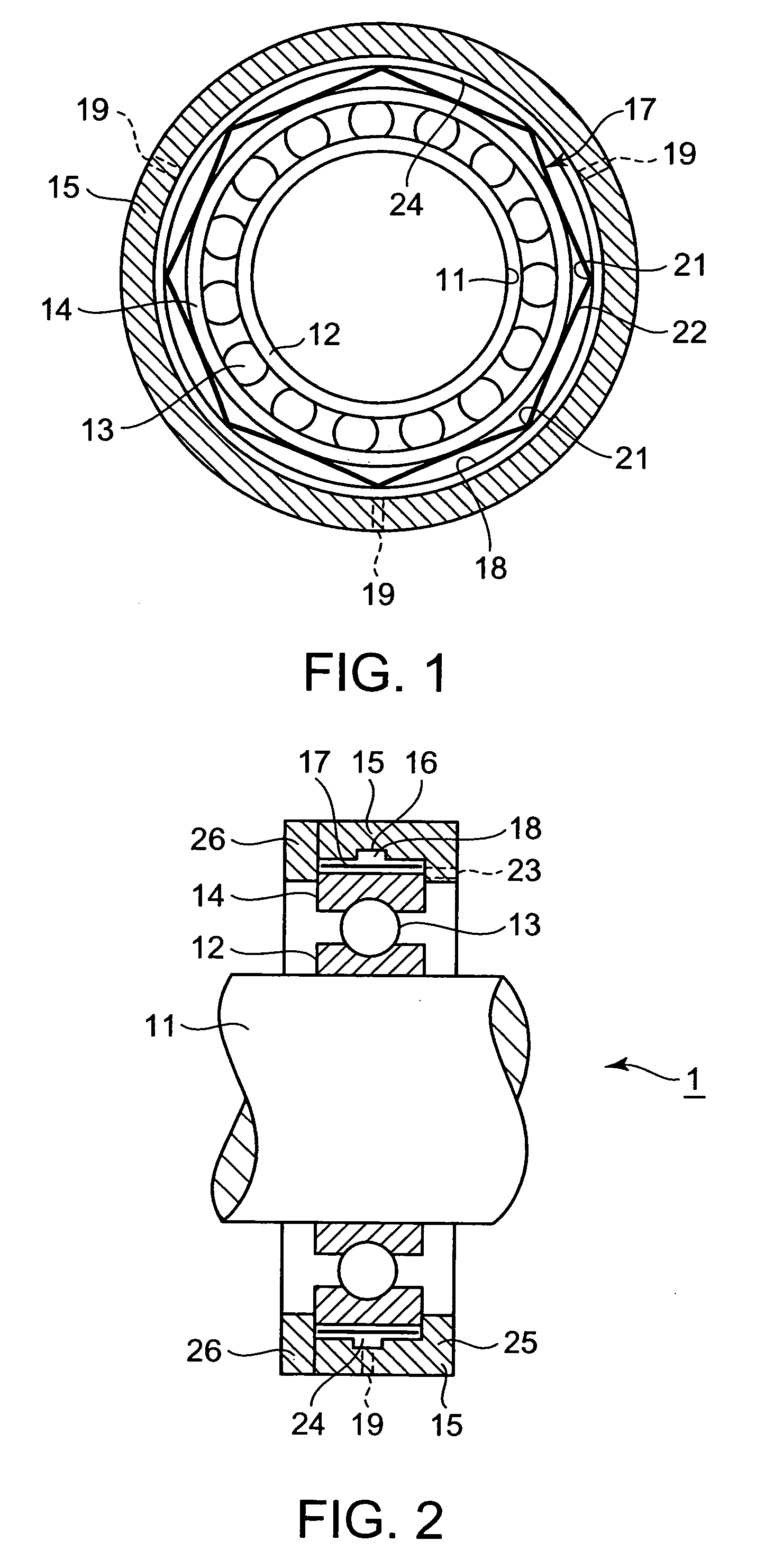

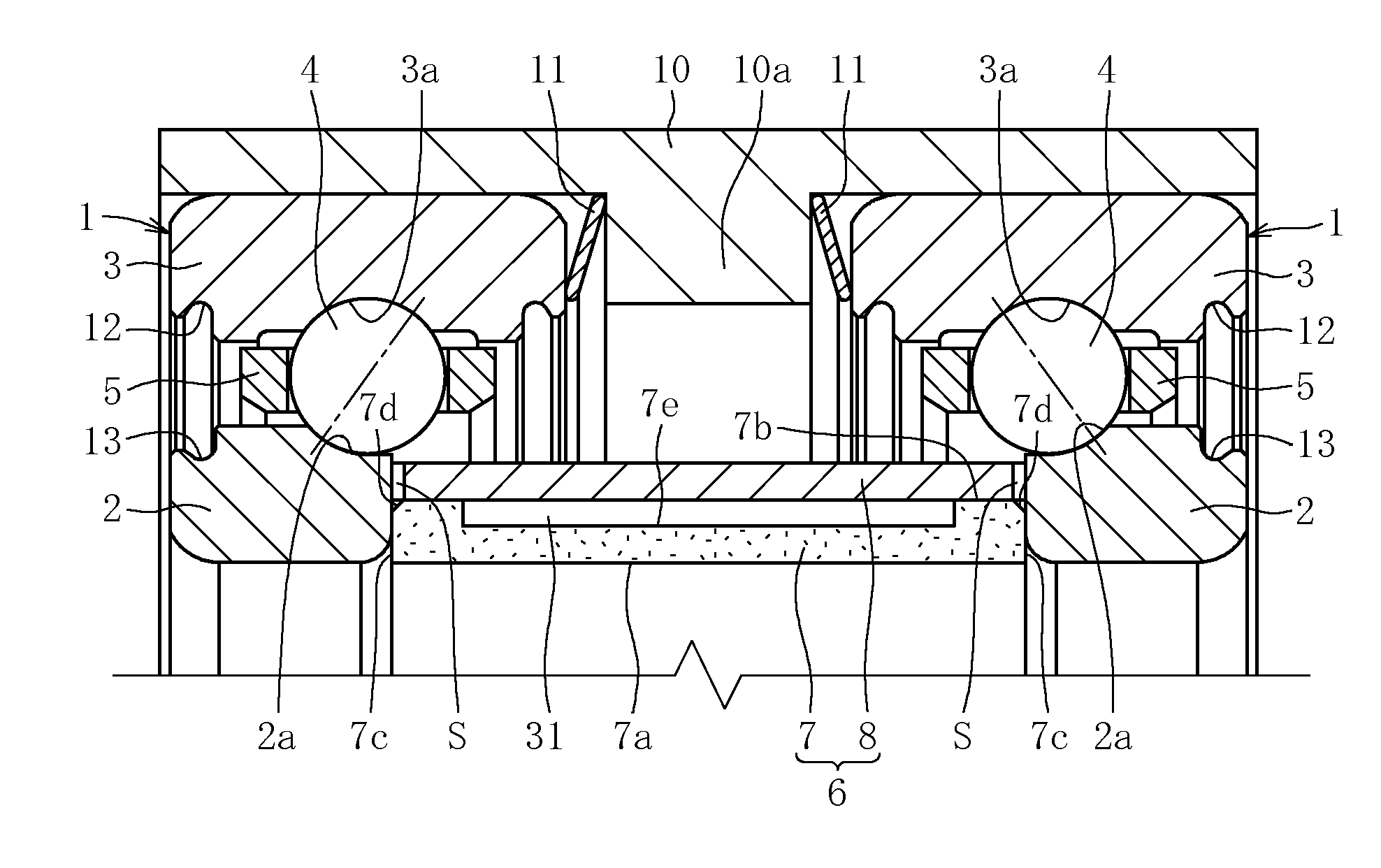

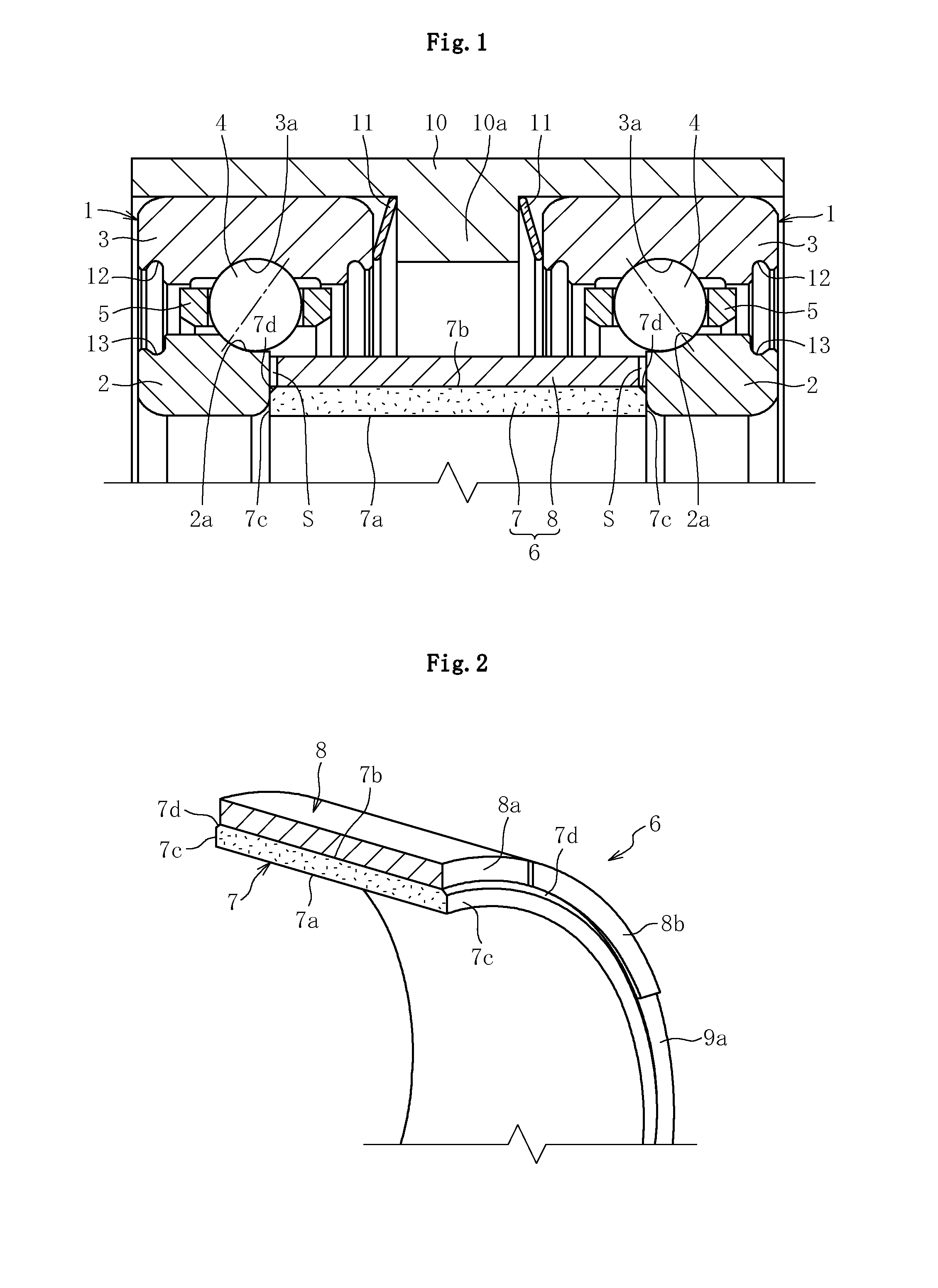

Double-row self-aligning roller bearing and device for supporting wind turbine generator main shaft

A double-row self-aligning roller bearing includes left and right rows of rollers 4 and 5, arranged between an inner race 2 and an outer race 3. A raceway surface 3a of the outer race 3 represents a spherical shape and the rollers 4 and 5 have an outer peripheral surface following the shape of the raceway surface 3a of the outer race 3. The rollers 4 and 5 of the left and right roller rows have respective lengths L1 and L2 different from each other. Also, the left and right roller rows have respective contact angles θ1 and θ2 different from each other.

Owner:NTN CORP +1

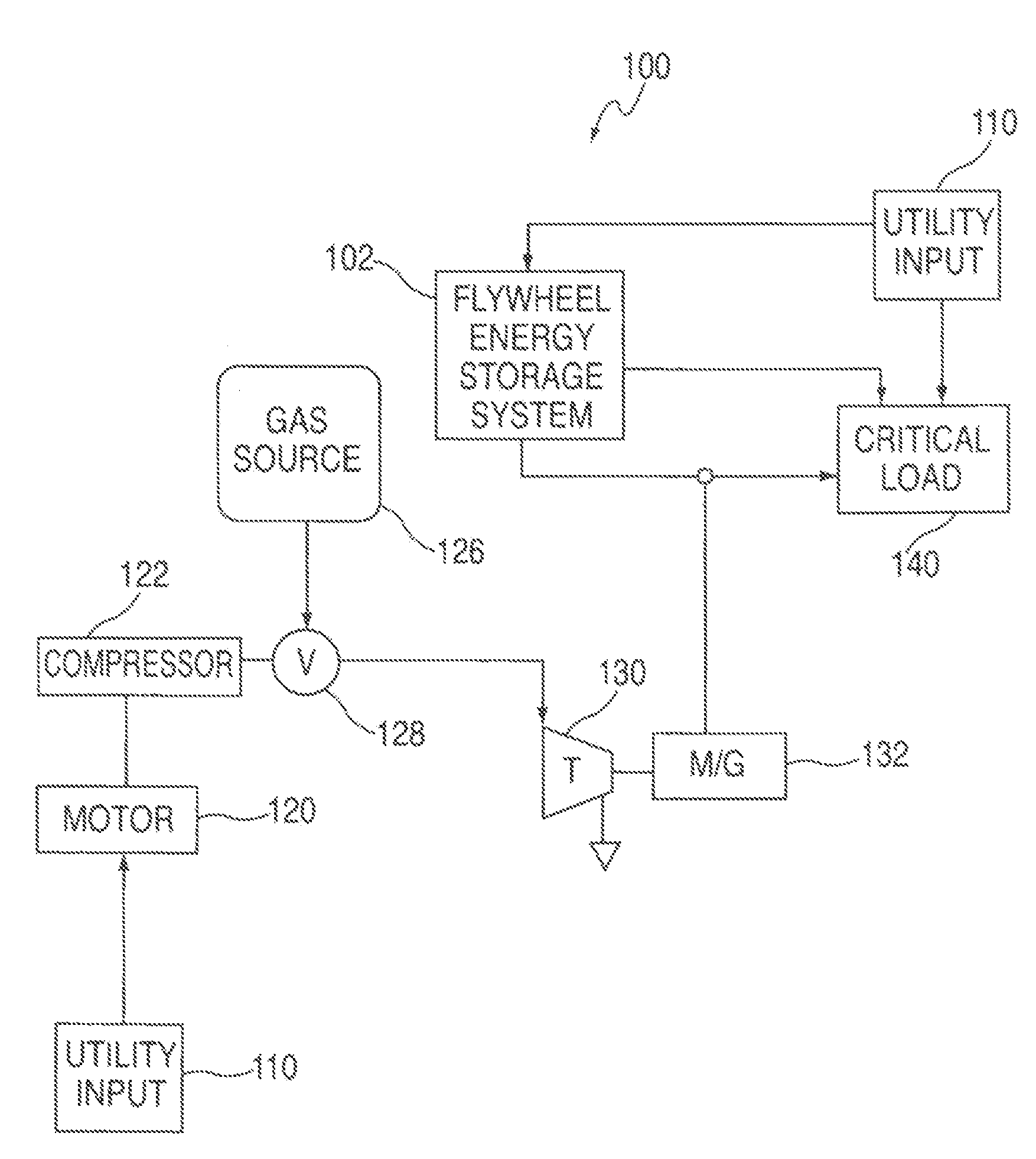

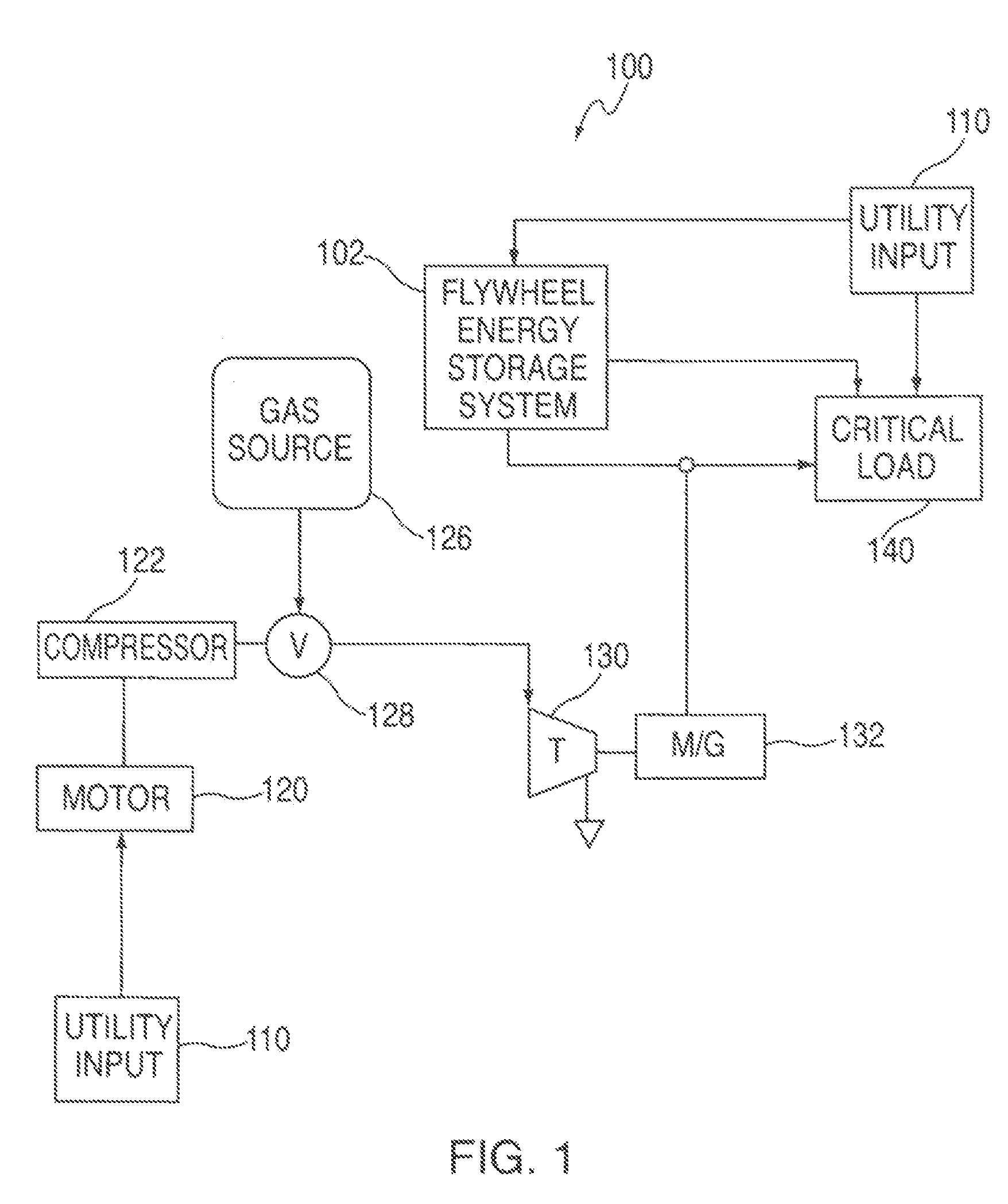

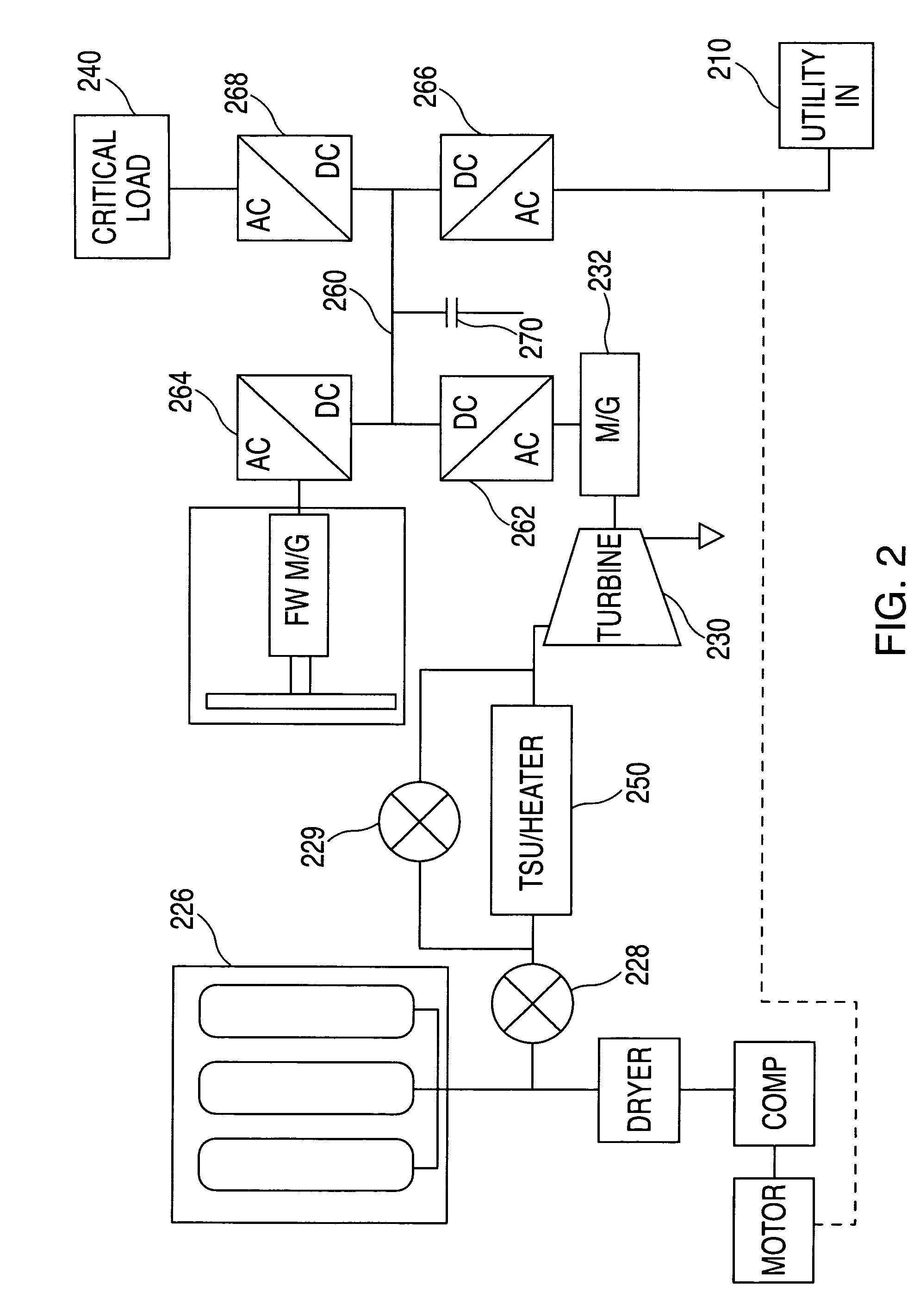

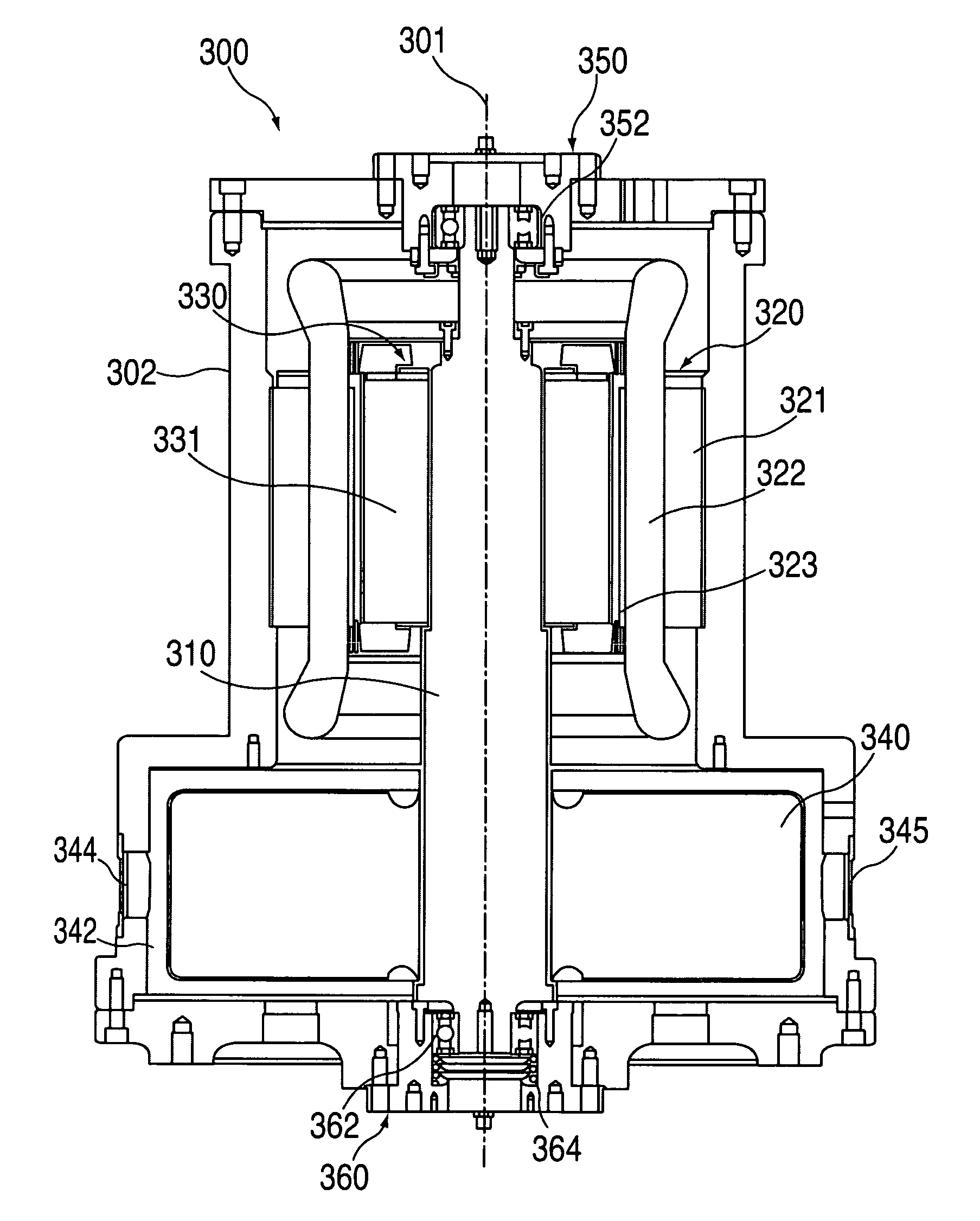

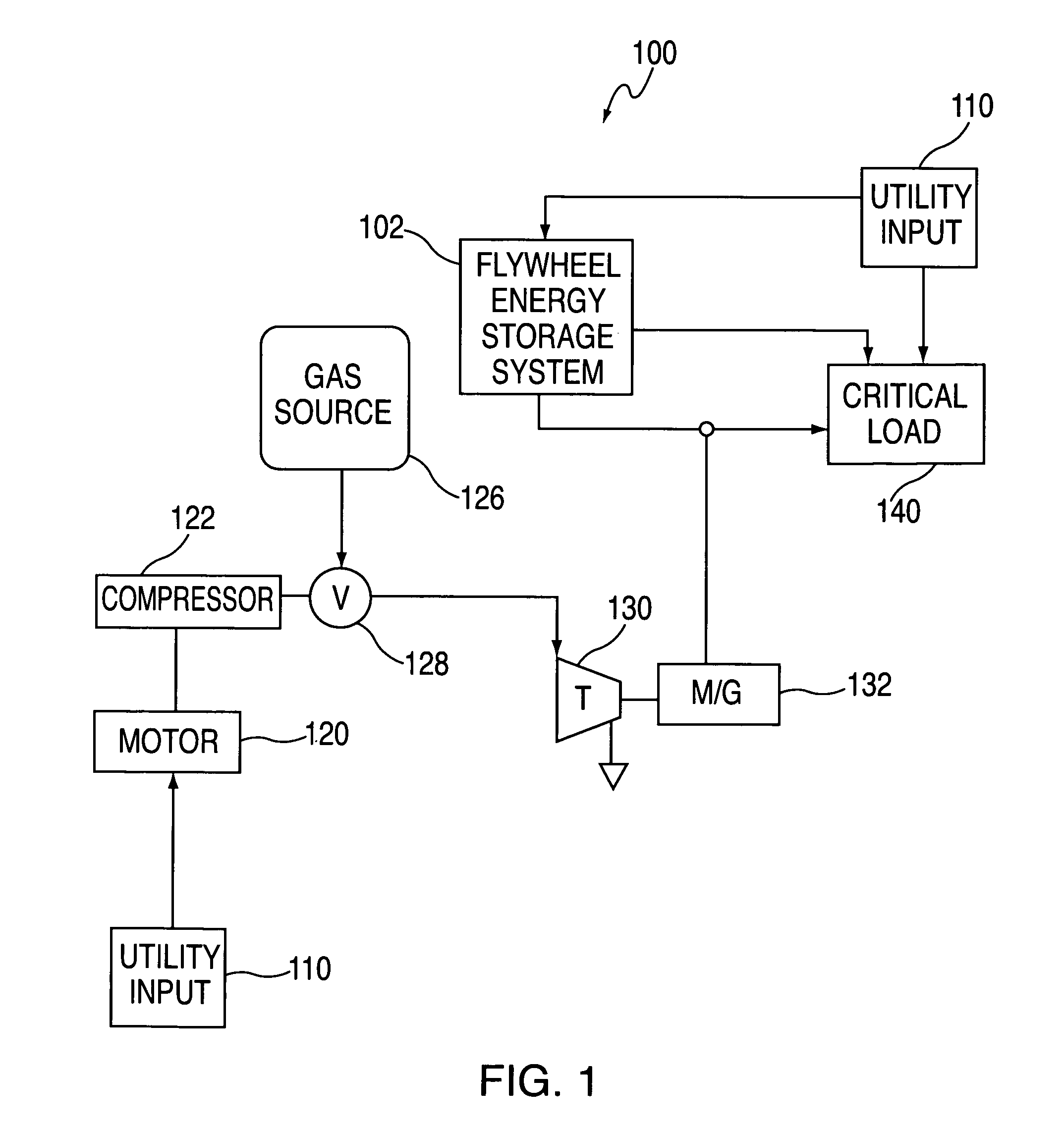

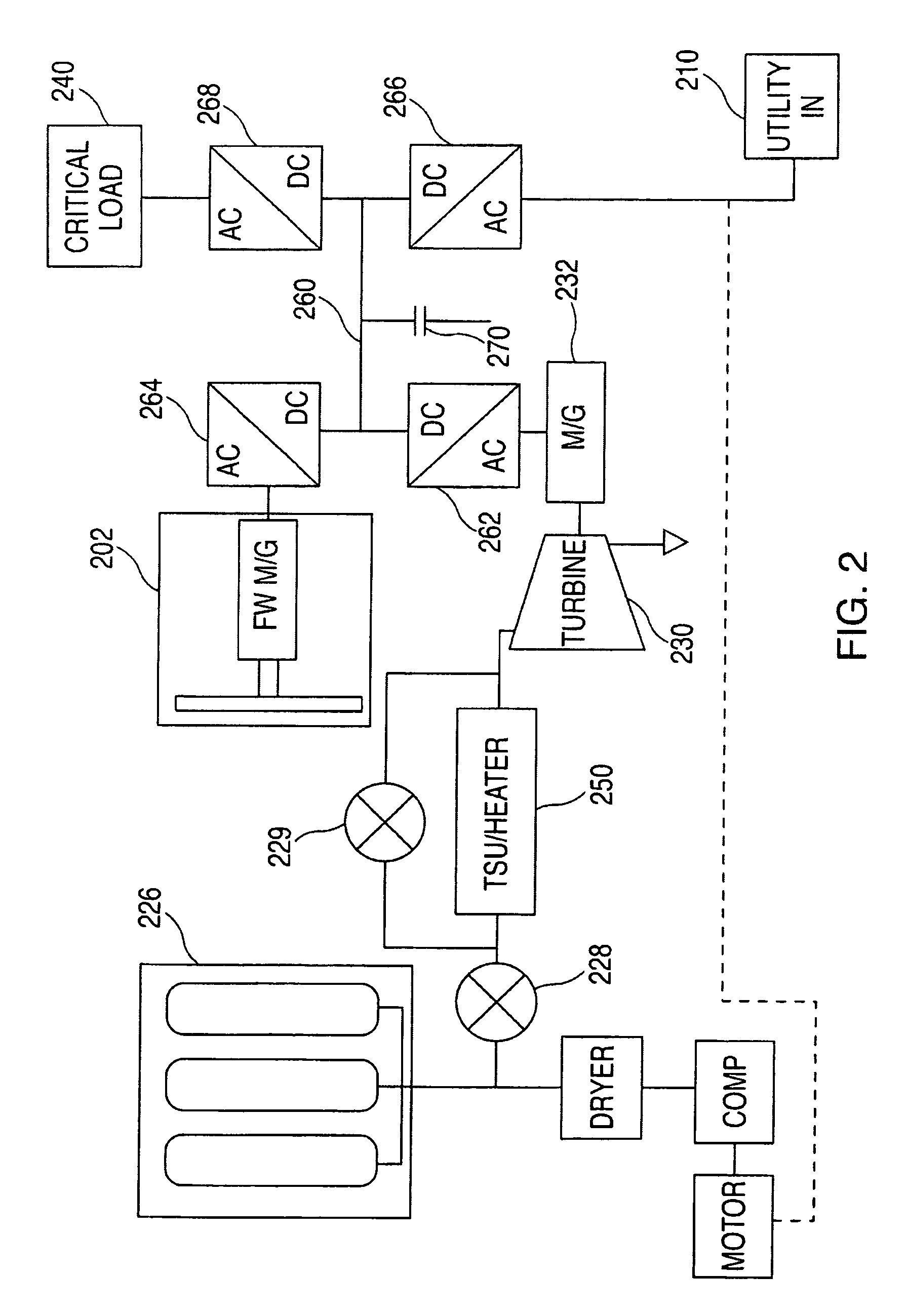

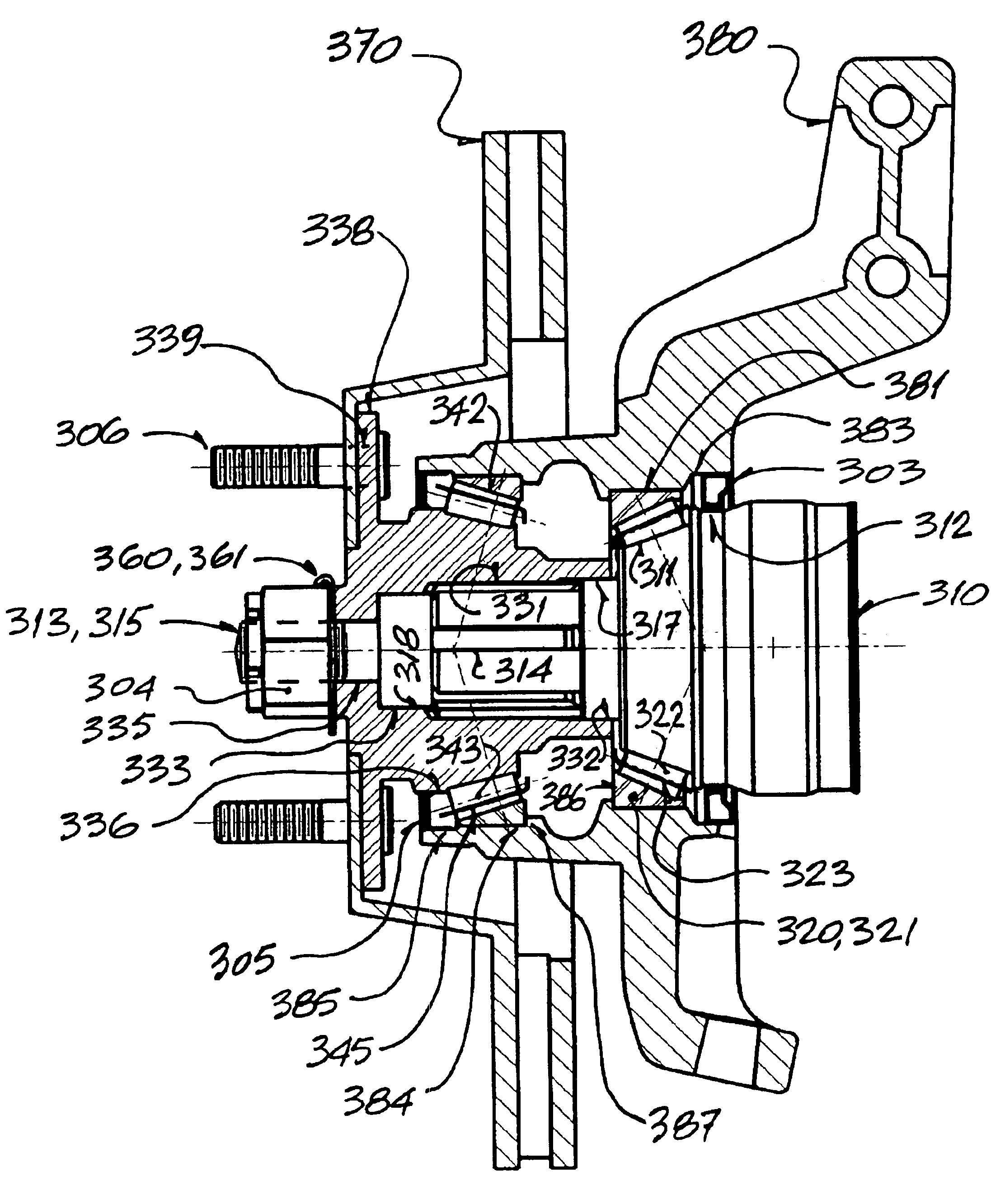

Transient energy systems and methods for use of the same

InactiveUS7400052B1Improve bearing lifeBearing loadElectrical storage systemBatteries circuit arrangementsInduction motorEngineering

This disclosure relates to transient energy systems for supplying power to a load substantially instantaneously on demand. Transient energy systems may include a flywheel coupled the rotor of an induction motor generator. One embodiment of the disclosure refers to systems and methods for reducing loads on a bearing in a transient energy system. In another embodiment, the disclosure refers to an induction motor generator that is optimized for high power transient power generation, yet low power motor operation. Yet another embodiment of the disclosure refers to using a flywheel as a drag pump to cool components of a transient energy system. In yet another embodiment, a slip control scheme is discussed for regulating a DC bus. In yet a further embodiment of the disclosure a method is provided for reducing unnecessary turbine starts by making turbine start a function of the rotational velocity of a flywheel.

Owner:PILLER USA INC

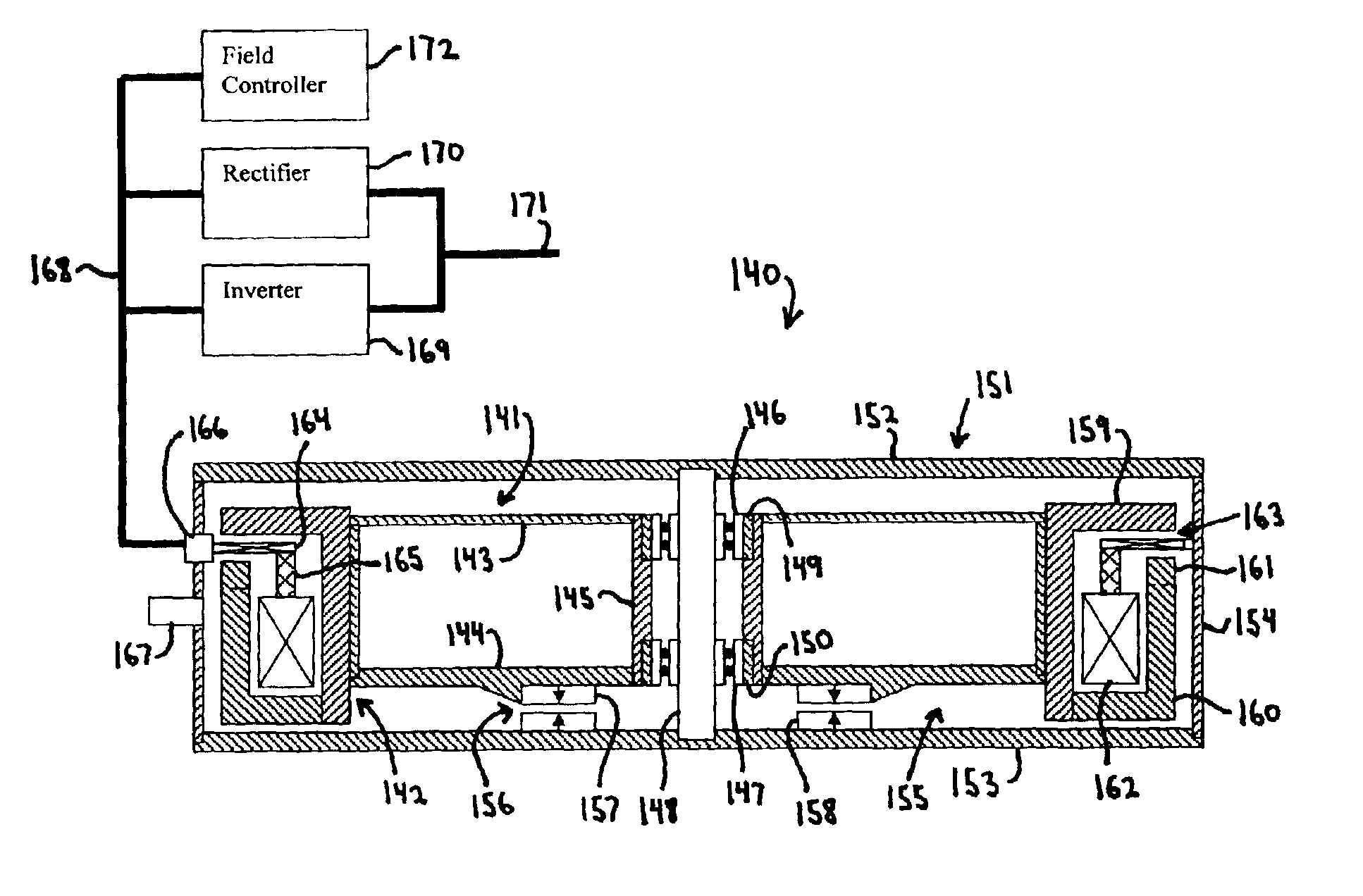

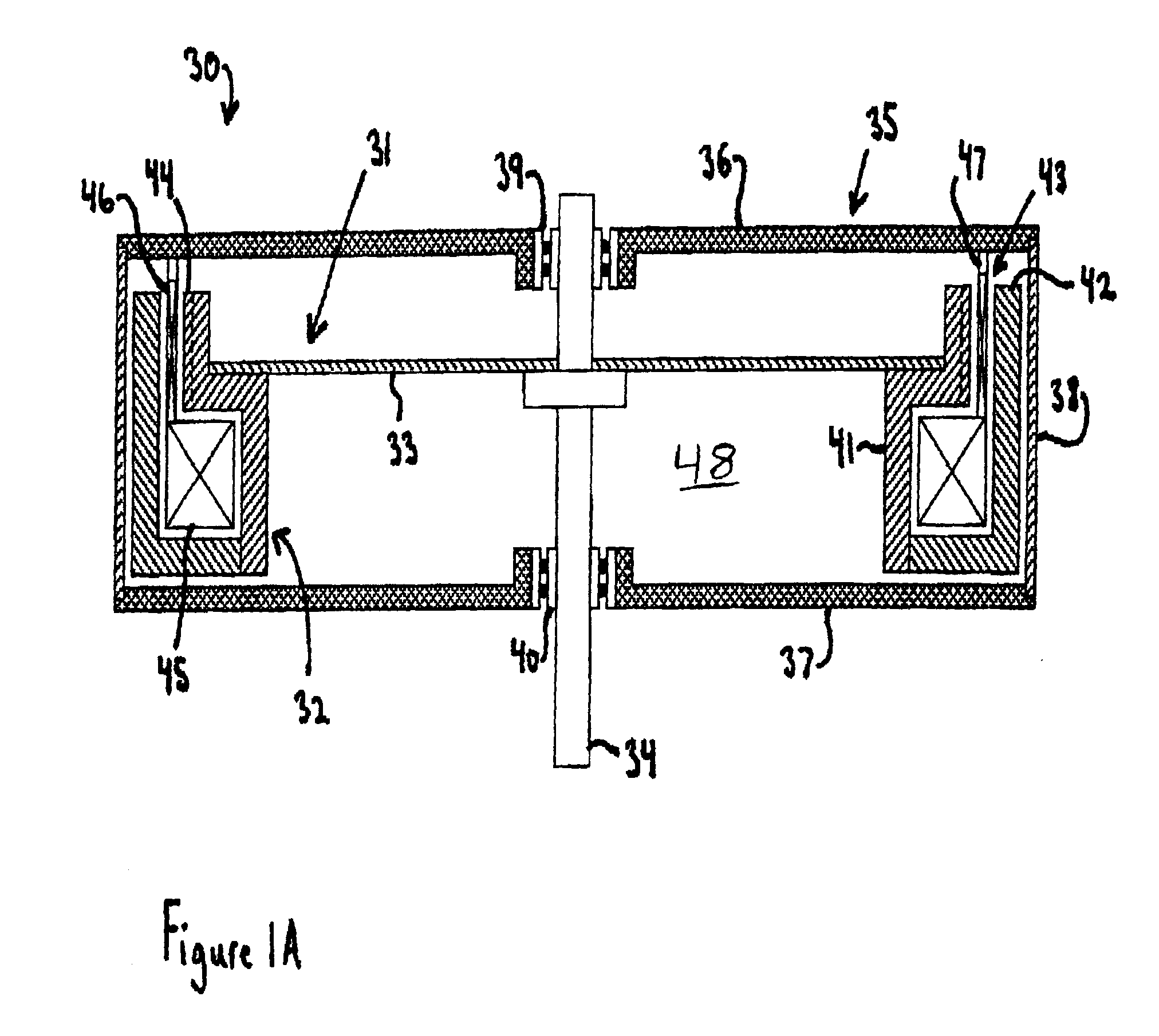

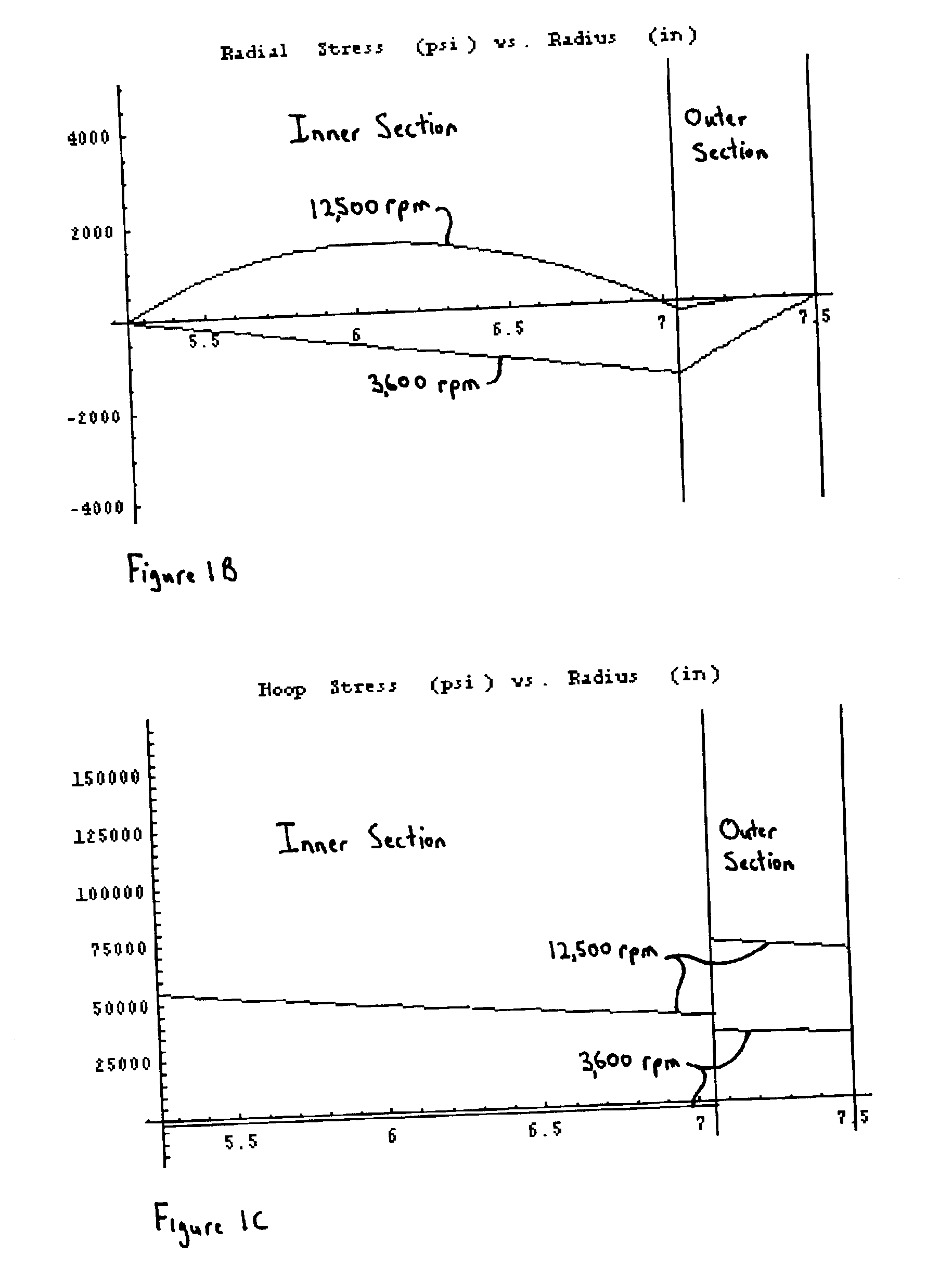

Light-weight high-power electrical machine

InactiveUS6891302B1High energyMotor/generator magnetic lossHybrid vehiclesWindingsAlternatorElectrical polarity

A brushless electrical machine, usable as a motor, generator, or alternator, has a rotor that is comprised of a rim portion and a substantially open center portion. The rim portion has a partially hollow core in which a stationary field coil is supported. Current to the field coil generates magnetic flux that circulates in a poloidal flux path in the rim, crossing a single magnetic air gap formed by the rim. Protrusions in the rim located around the circumference form poles all having the same polarity. As the rotor rotates, the flux exiting the poles passes through multiple stationary armature windings around the circumference that are located in the single air gap. An AC voltage is induced in the armature windings from rotation.

Owner:REVOLUTION ELECTRIC MOTOR

Bearing cleaning composition and method of use

ActiveUS7241723B2Easy to distinguishHigh in calciumRotary combination bearingsBearing componentsSulfonateEngineering

A composition for cleaning bearings in rotating equipment and industrial machinery that contains powdered limestone having a high calcium content dispersed in a calcium sulfonate grease, together with a colorant that readily enables a user to differentiate between contaminated grease, cleaning composition and fresh grease. A method is also disclosed that enables a user to clean and re-lubricate bearings without the need for removing the bearings from service or for shutting down the associated equipment or machinery.

Owner:NCH CORP

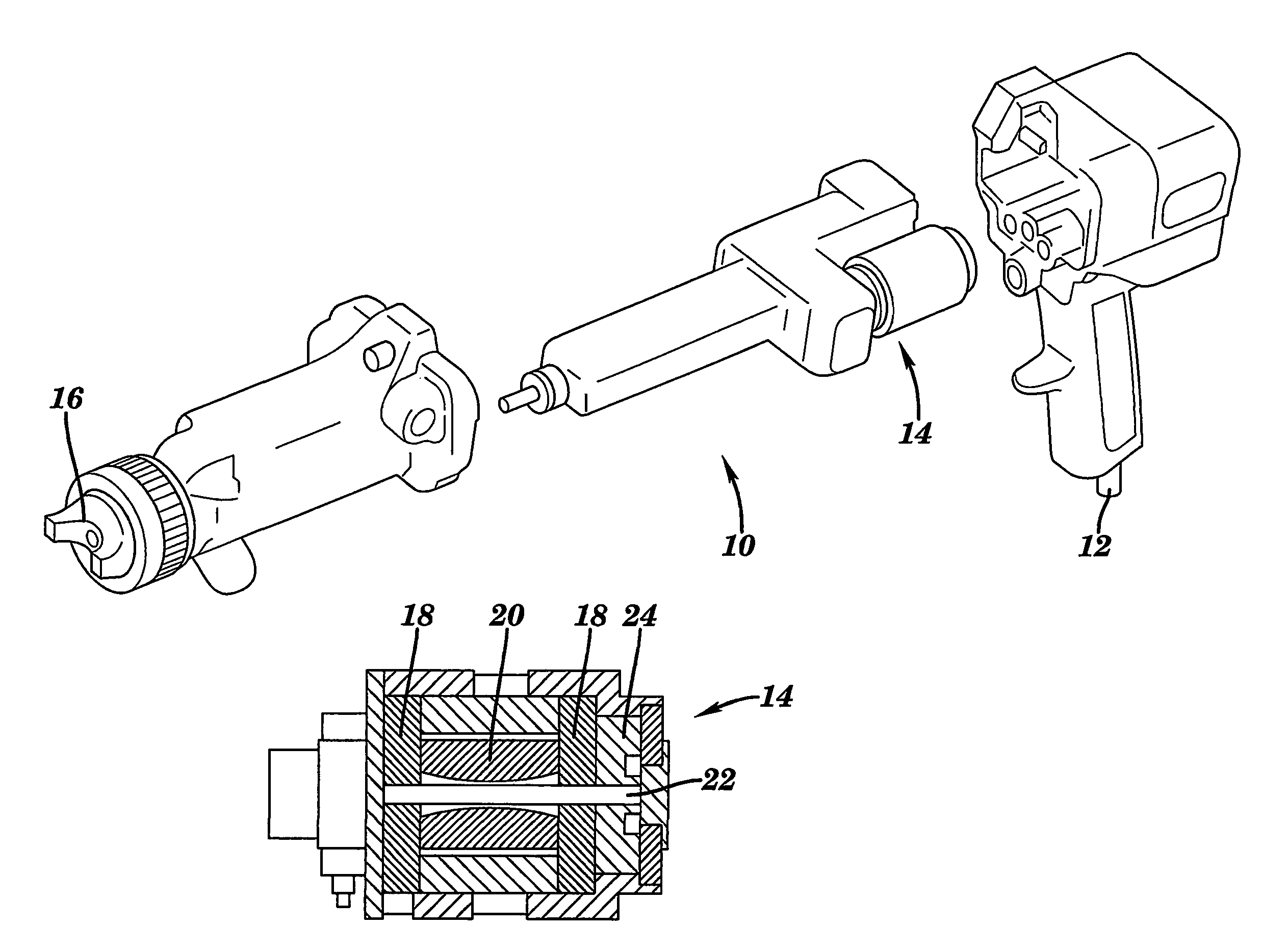

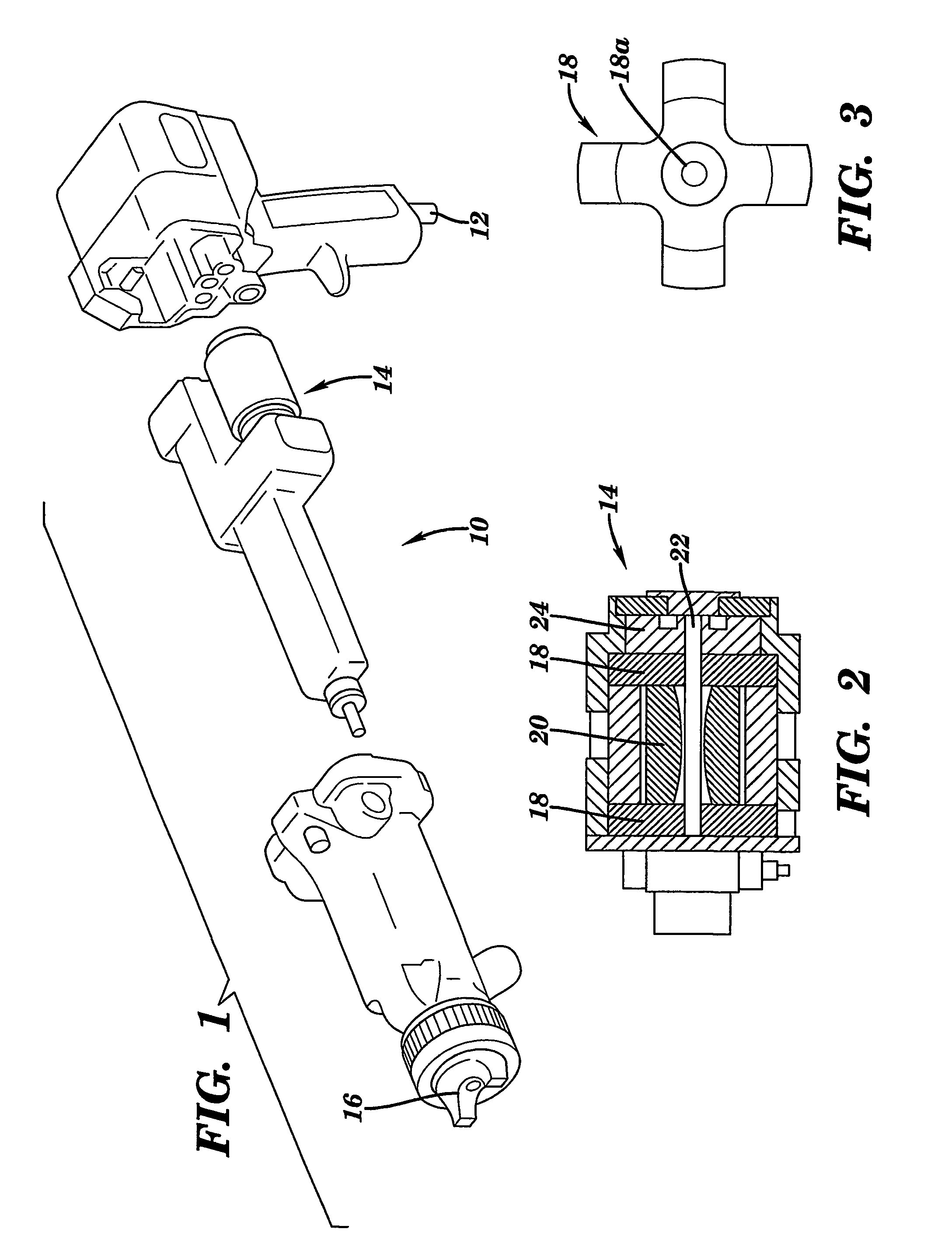

Solvent resistant bearings for self-generating electrostatic spray gun

InactiveUS7226004B2Improve bearing lifeFailure can be causedBurnersLiquid spraying plantsImpellerAlternator

An electrostatic spray gun (10) having an air powered alternator-turbine (14) with a rotating impeller (24) therein mounted in bearings (18) is provided with bearings (18) which are coated with a solvent resistant material. This coating is provided on all surfaces of the bearing (18) except for the inner diameter (18A) which contains the impeller (24). This construction prevents leaching of the oil out of the bearing (18) and into the airstream and also is resistant to paint should the spray gun (10) become immersed in such.

Owner:GRACO INC

Machine with an improved bearing lubrication

ActiveUS20070177835A1Bearing losses are strongly reducedConvenient amountRolling contact bearingsShaftsLubricationCooling channel

Machine with an improved bearing lubrication, including a housing (2) and a rotor (5) which is provided on a shaft (6), provided in a rotatable manner in the above-mentioned housing (2) by means of oil-lubricated bearings (7), wherein, inside the housing (2), lubrication ducts (14) to supply and discharge oil to and from the bearings (7), and cooling channels (21, 15) to supply and discharge a cooling agent, are provided which cooling channels (21, 15) open opposite to the shaft (6), in a place between the rotor (5) and a bearing (7).

Owner:ATLAS COPCO AIRPOWER NV

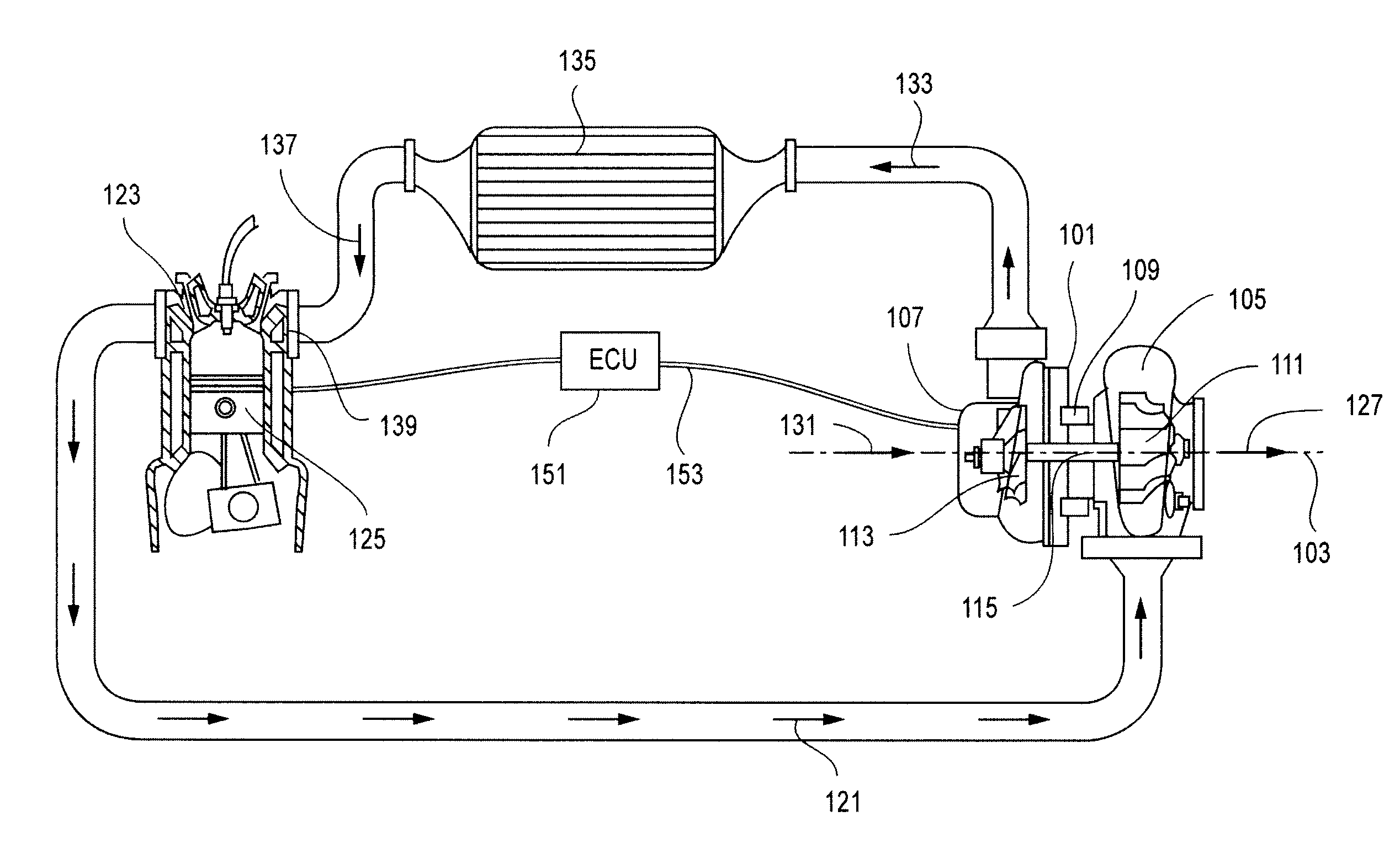

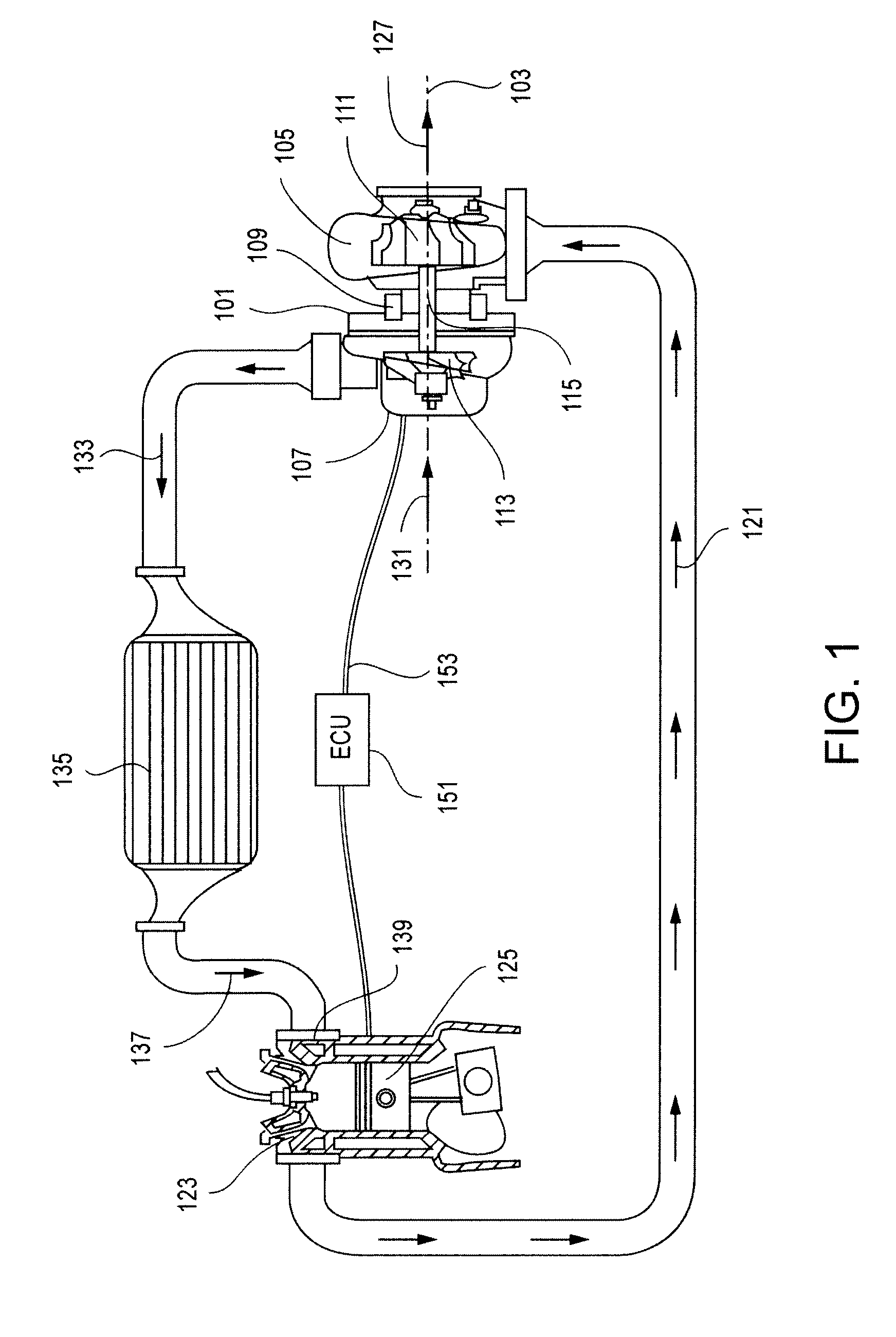

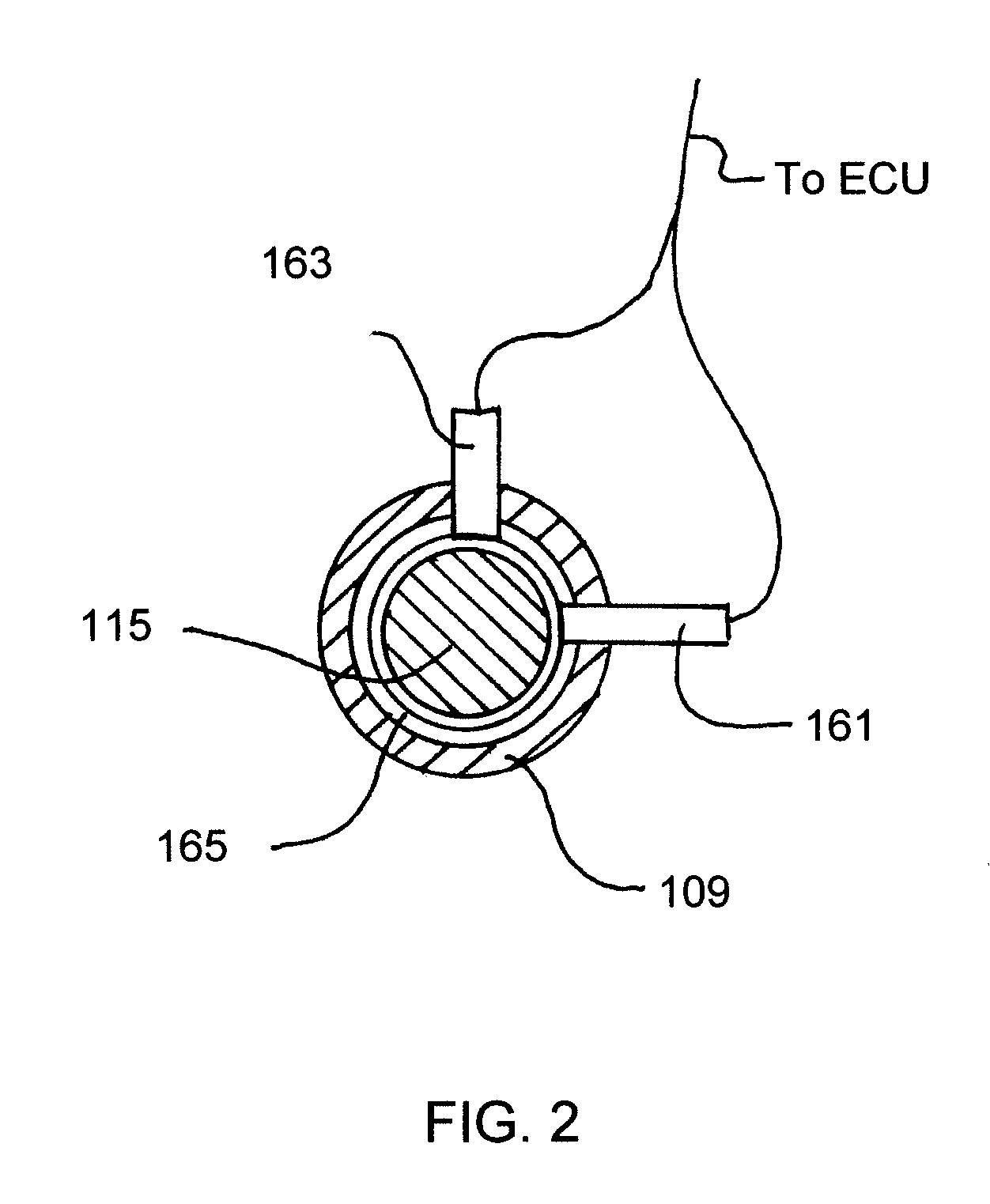

Turbocharger bearing health monitor

InactiveUS20100292937A1Robust resultAccurate monitoringMachine part testingPlug gaugesTurbochargerProbability of failure

A method for signaling a failure condition of a bearing of a turbocharger that includes a sensor configured for sensing information on off-axis rotor motion. The method entails receiving a stream of information from the sensor, decomposing the stream of information into a set of components representing different frequencies, using a subset of components that represent a range of frequencies known to be indicative of bearing failure to calculate a probability of failure of the bearing, signaling a failure condition of the bearing if the probability of failure exceeds a critical threshold, and if the present indicia of off-axis rotor motion does not indicate a complete failure condition has occurred, determining a time interval until another probability of failure of the bearing will be calculated. The time interval can vary based upon the rate that the probability of failure has changed over multiple time intervals.

Owner:HONEYWELL INT INC

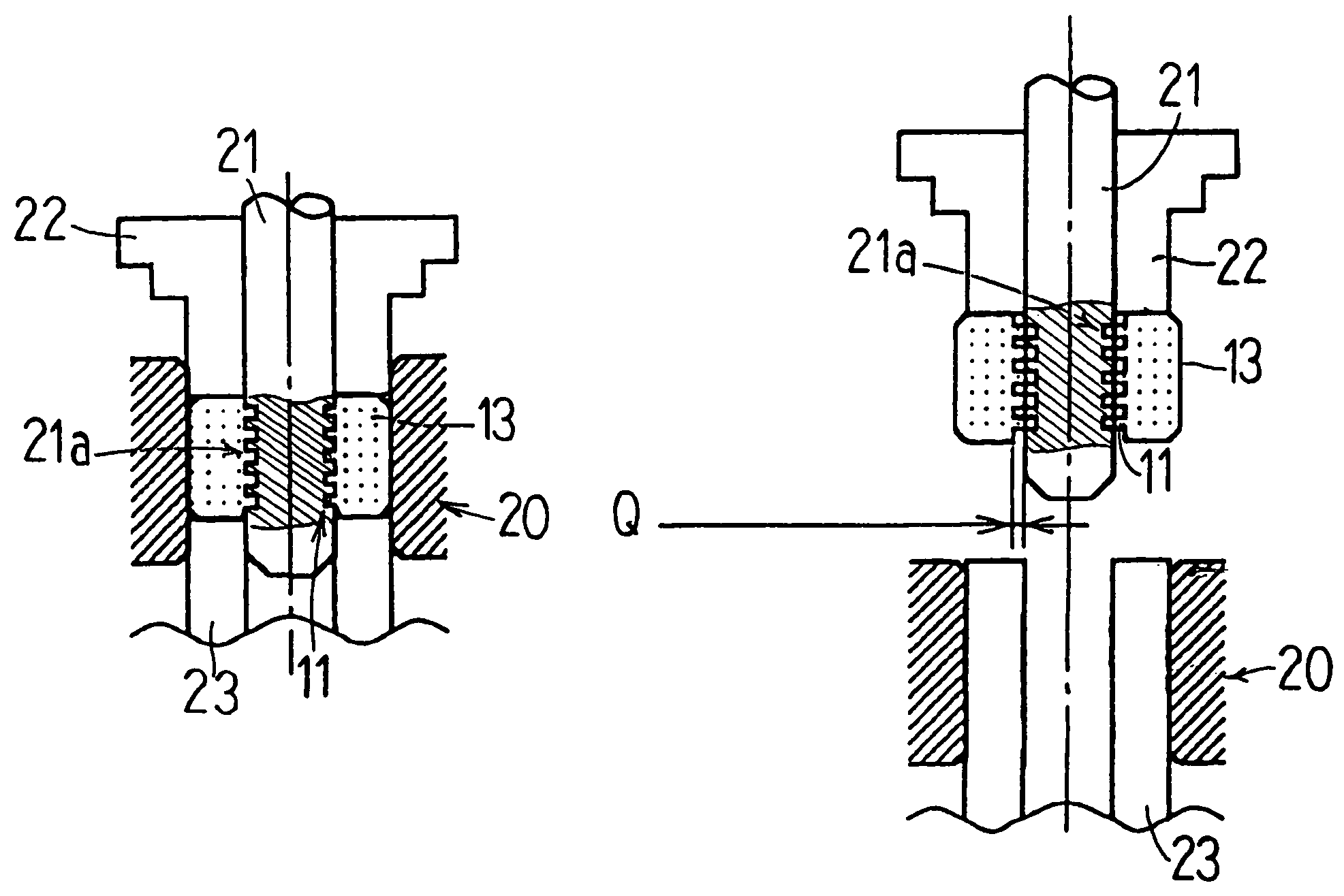

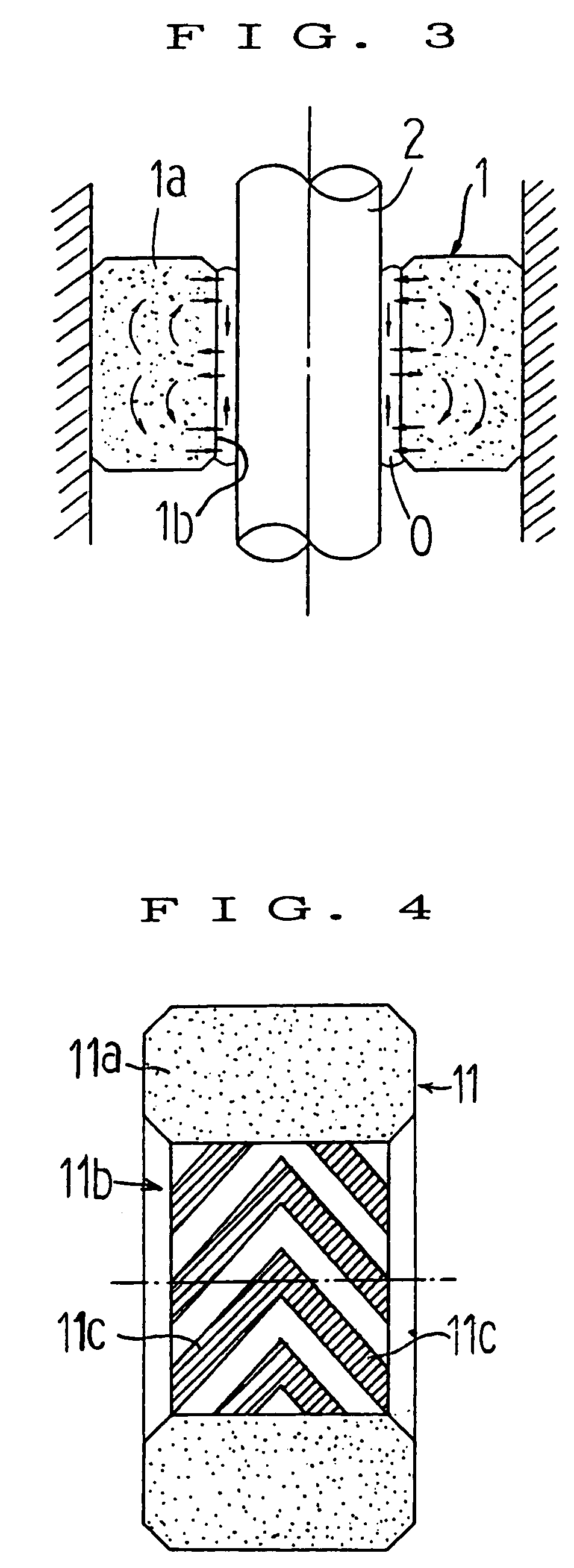

Hydrodynamic type porous oil-impregnated bearing

InactiveUS7059052B2Inhibit deteriorationGood effectMetal-working apparatusBearing componentsEngineeringBearing surface

The porous oil-impregnated bearing 1 comprises a bearing body 1a made of a porous material, and oil retained in the pores of the bearing body 1a by impregnation with lubricating oil or lubricating grease. The inner peripheral surface of the bearing body 1a is formed with a bearing surface 1b opposed to an outer peripheral surface of a shaft to be supported, with a bearing clearance defined therebetween. The bearing surface 1b has a first region m1 in which a plurality of hydrodynamic pressure generating grooves 1c inclined in one direction with respect to the axial direction are circumferentially disposed, a second region m2 which is axially spaced from said first region m1 and in which a plurality of hydrodynamic pressure generating grooves 1c inclined in the other direction with respect to the axial direction are circumferentially disposed, and an annular smooth region n disposed between the first and second regions m1 and m2.

Owner:NTN CORP

Double-row self-aligning roller bearing and device for supporting wind turbine generator main shaft

A double-row self-aligning roller bearing includes left and right rows of rollers, arranged between an inner race and an outer race. A raceway surface of the outer race represents a spherical shape and the rollers have an outer peripheral surface following the shape of the raceway surface of the outer race. The rollers of the left and right roller rows have respective lengths different from each other. Also, the left and right roller rows have respective contact angles different from each other.

Owner:NTN CORP +1

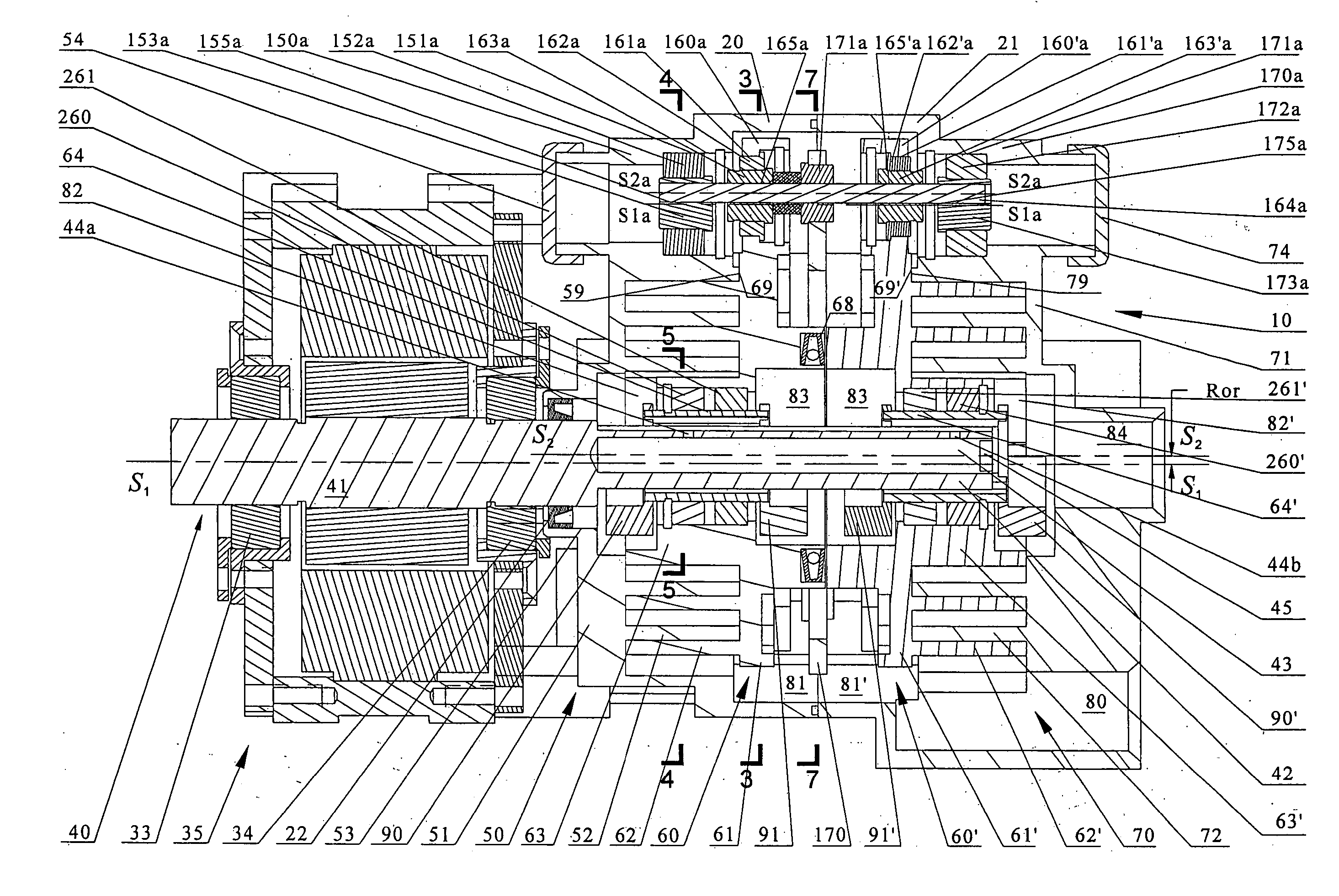

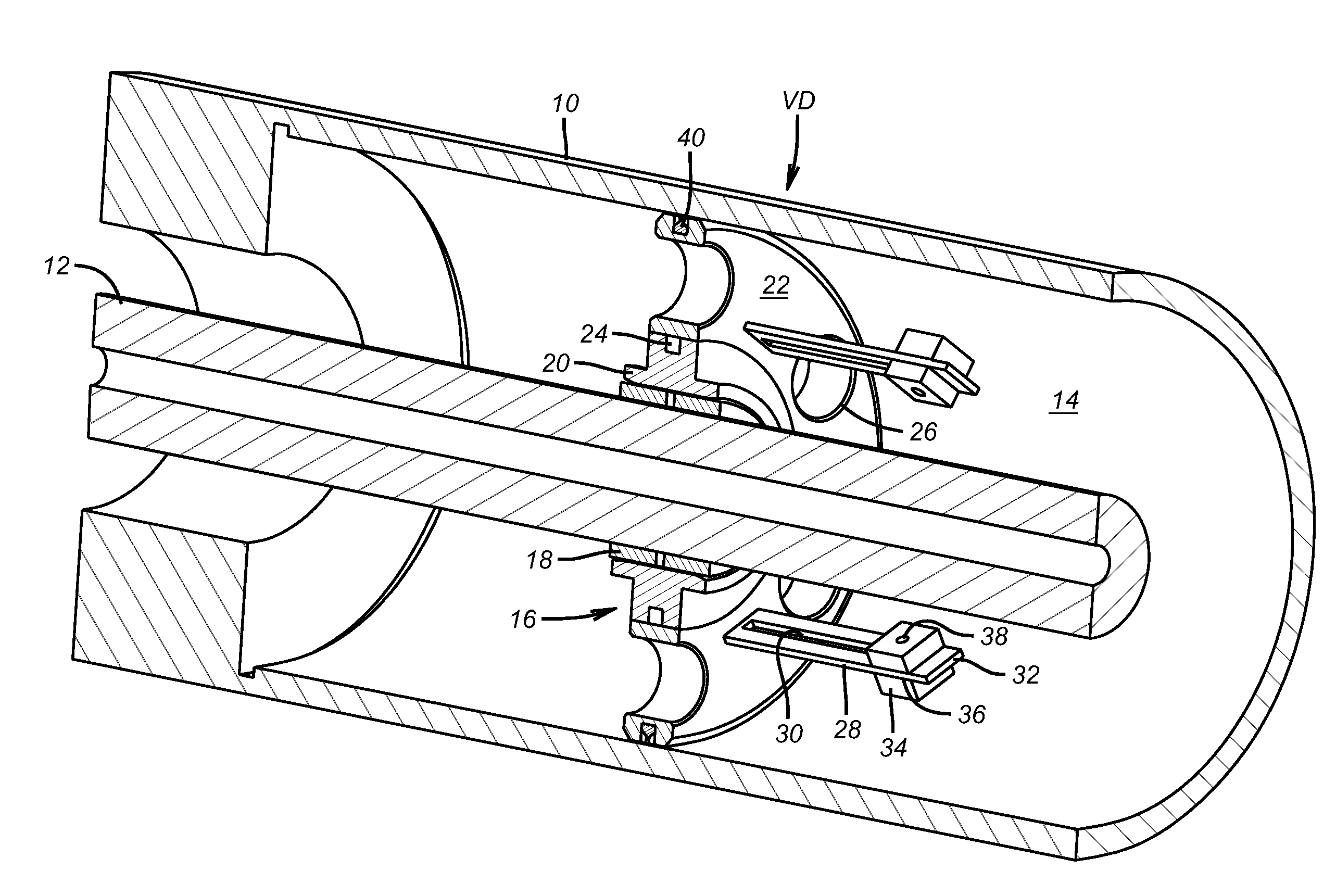

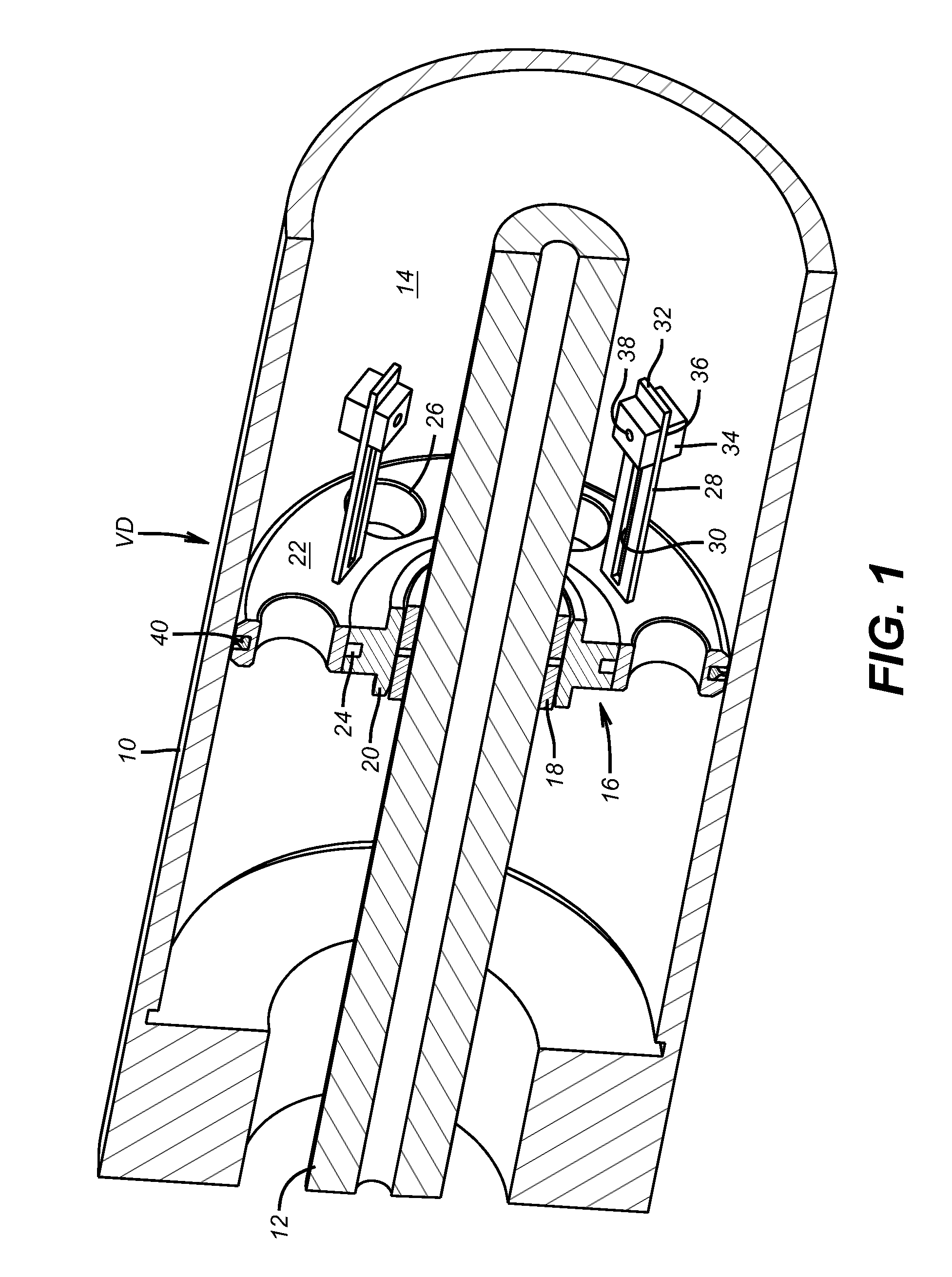

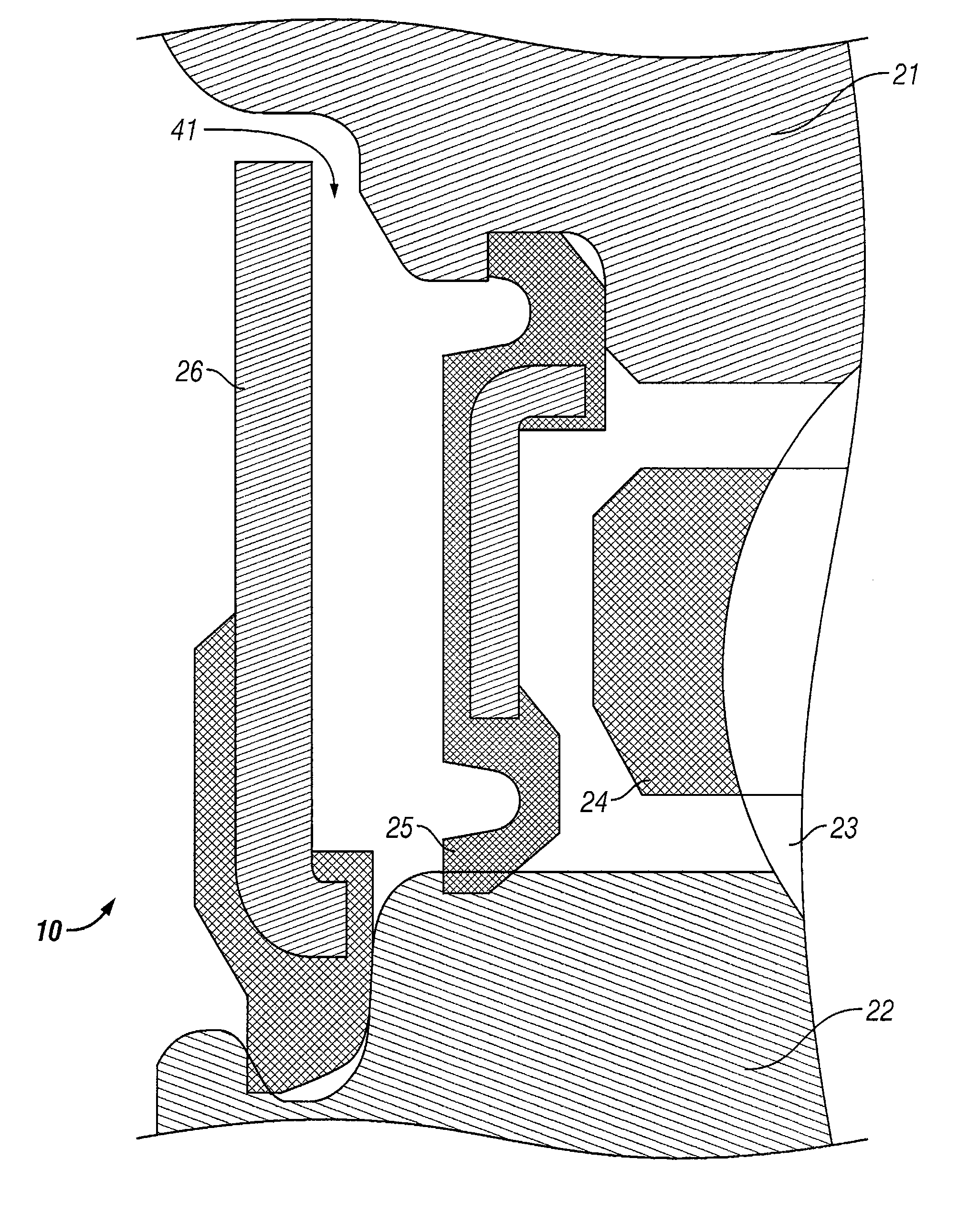

Scroll-type fluid displacement apparatus with fully compliant floating scrolls

ActiveUS20070172373A1Improve bearing lifeReduce friction and wearRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeBall bearingDrive shaft

A central drive shaft-sliding knuckle combined with a peripheral crank pin-swing link mechanism (CSPS) to provide an orbiting scroll with radial and axial compliant capability. The CSPS mechanism can be applied to both dual floating scroll and single floating scroll structures to improve performances of scroll devices, particularly in oil-free operations. In addition, an orbiting dual thrust ball bearing mechanism is provided to take thrust load in, for example, a floating scroll compressor with a CSPS mechanism.

Owner:NI & ASSOC

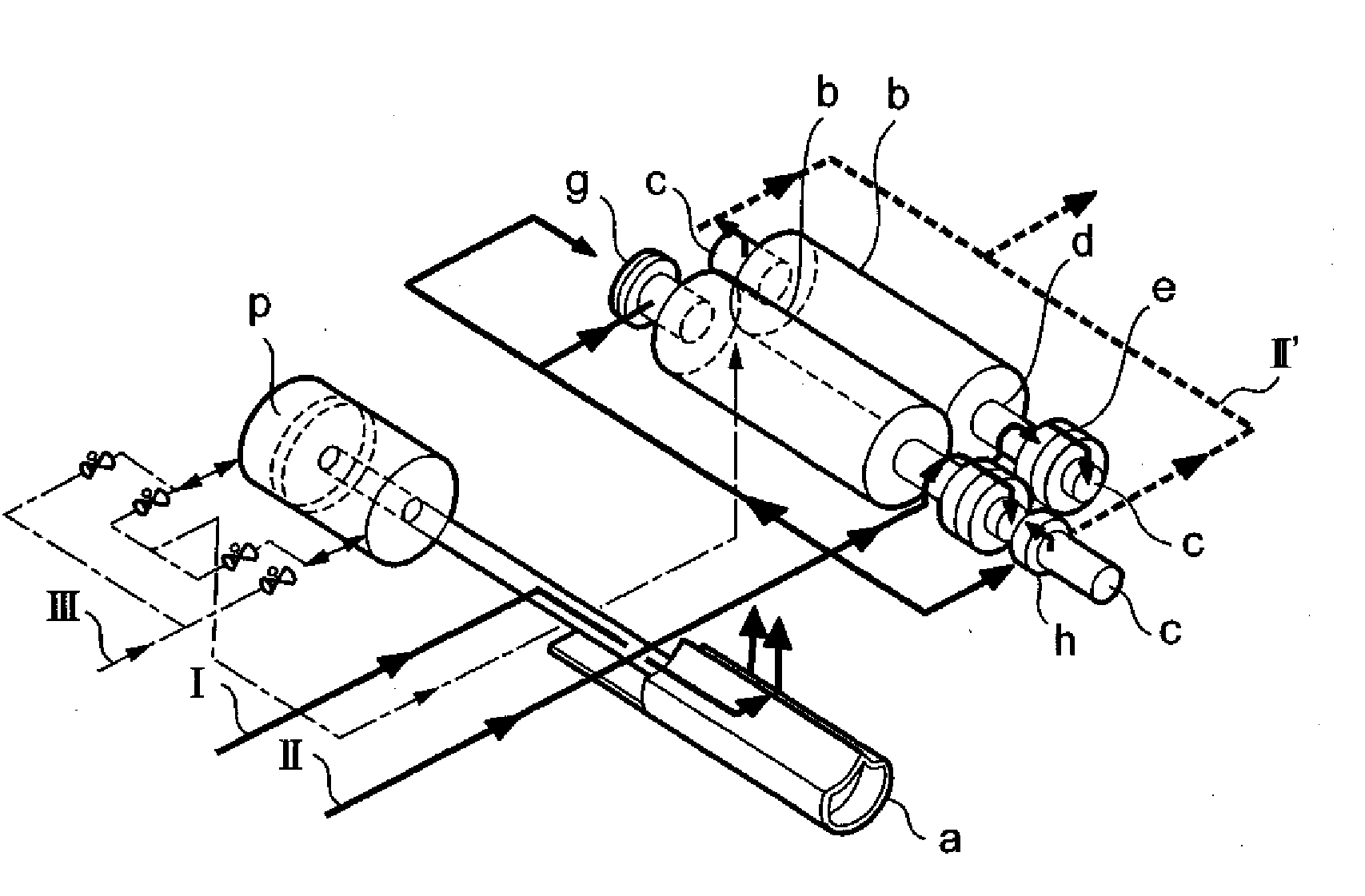

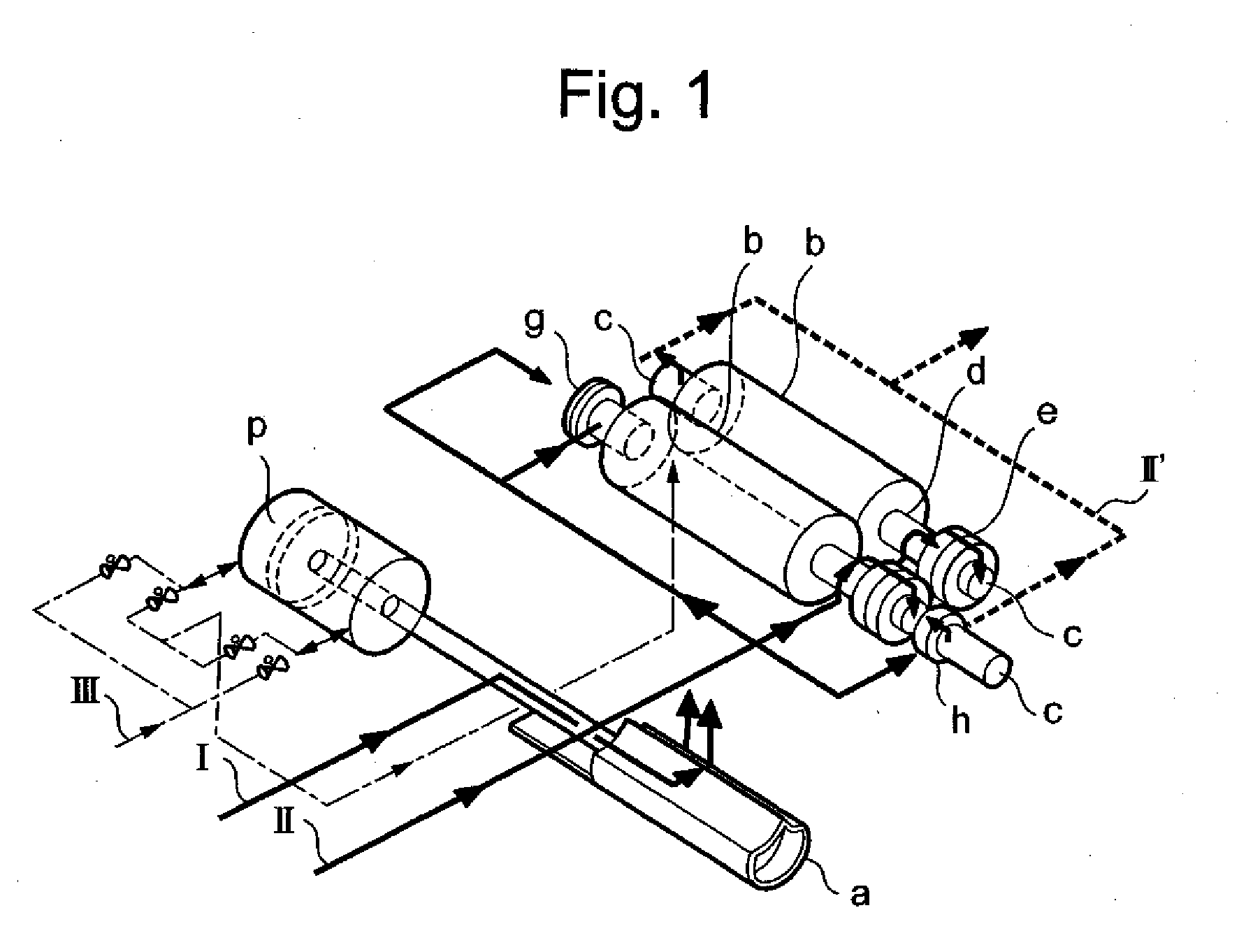

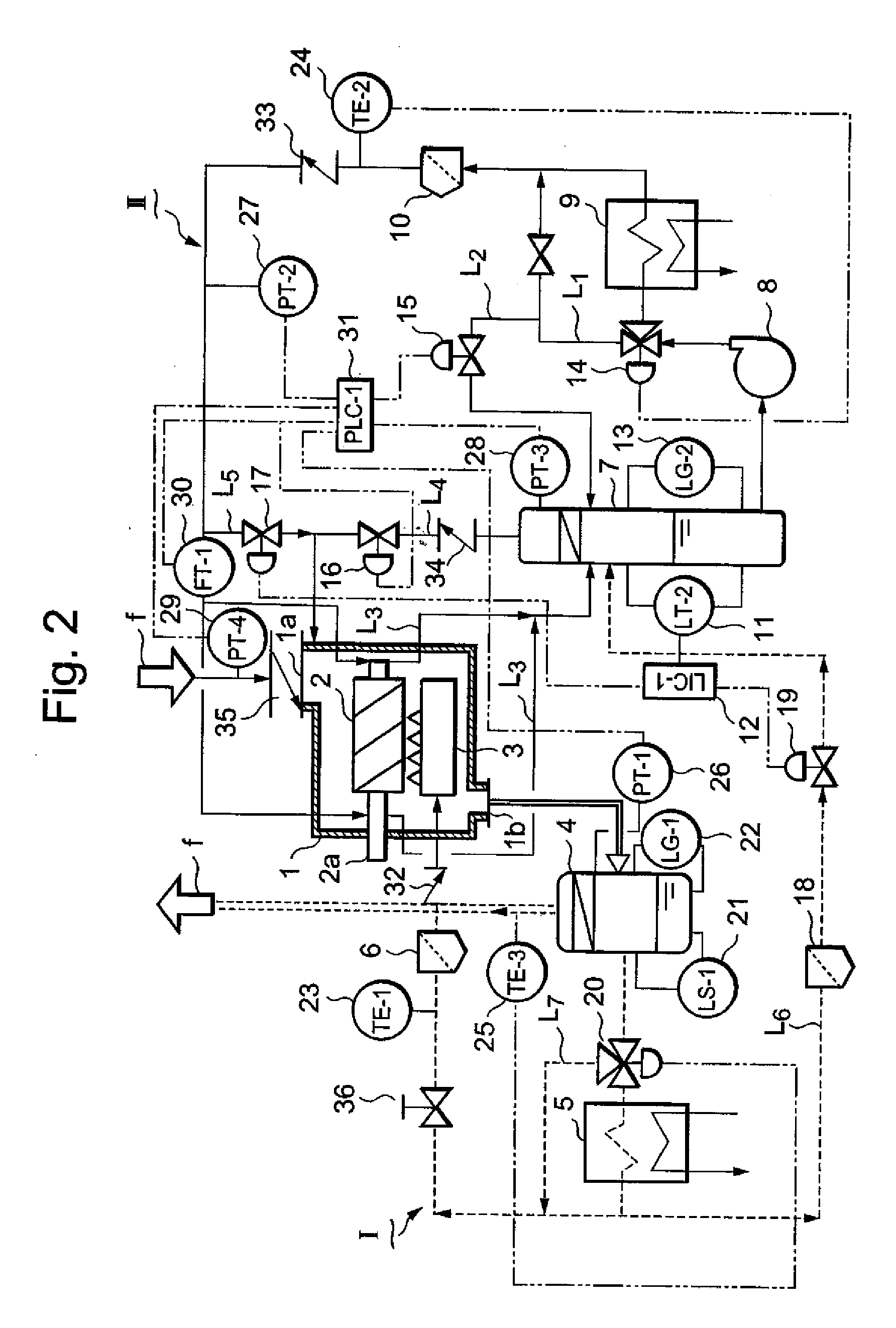

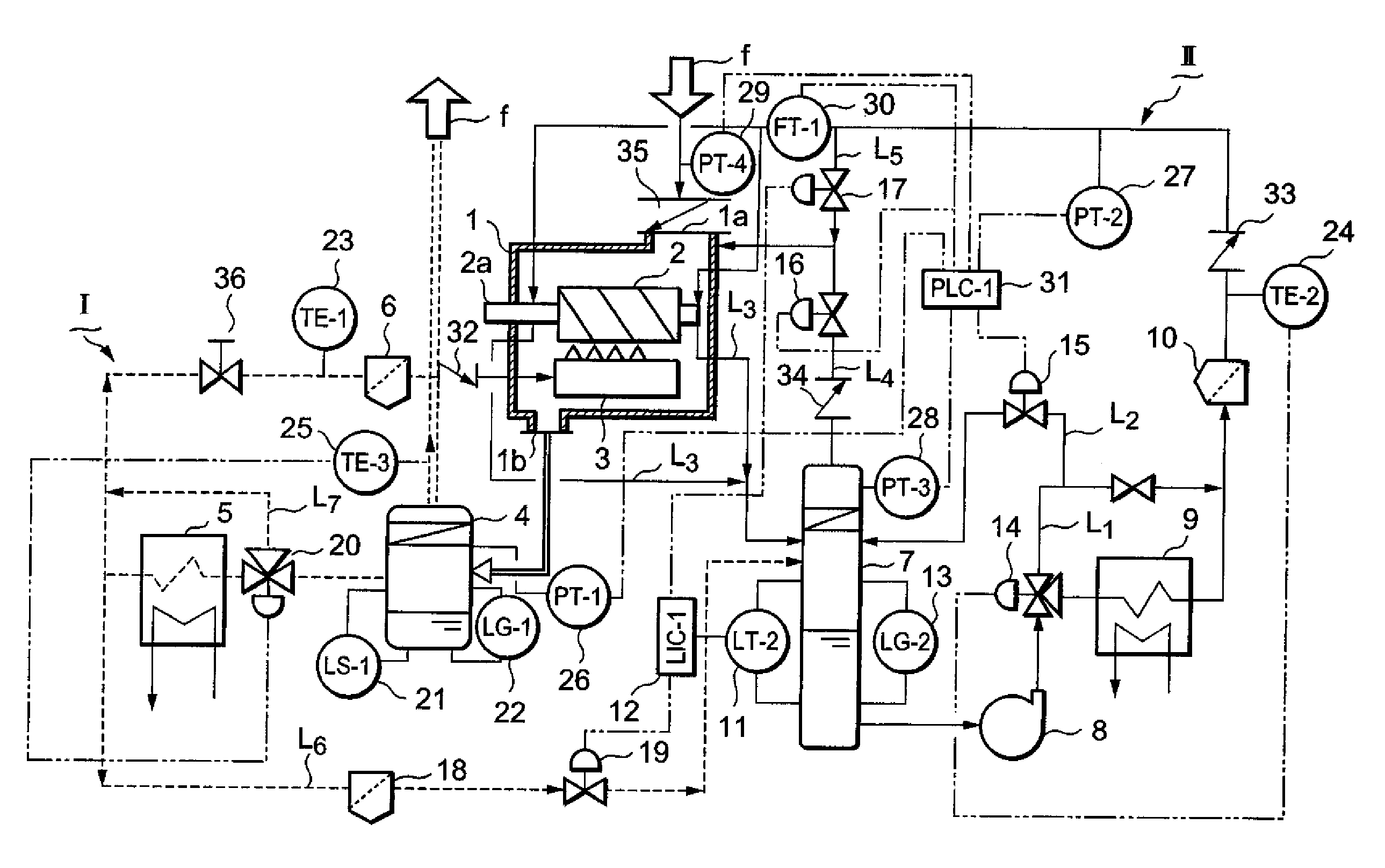

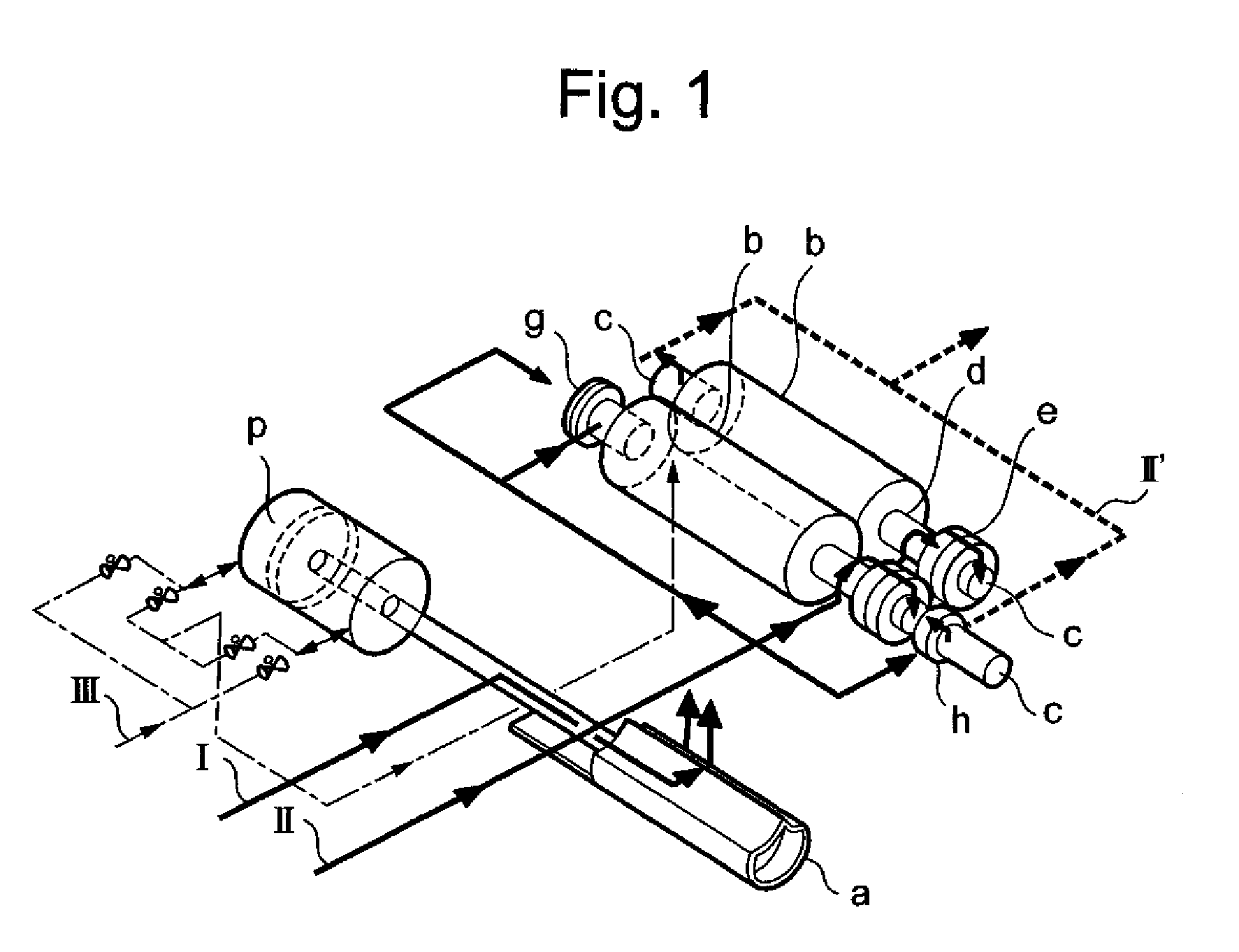

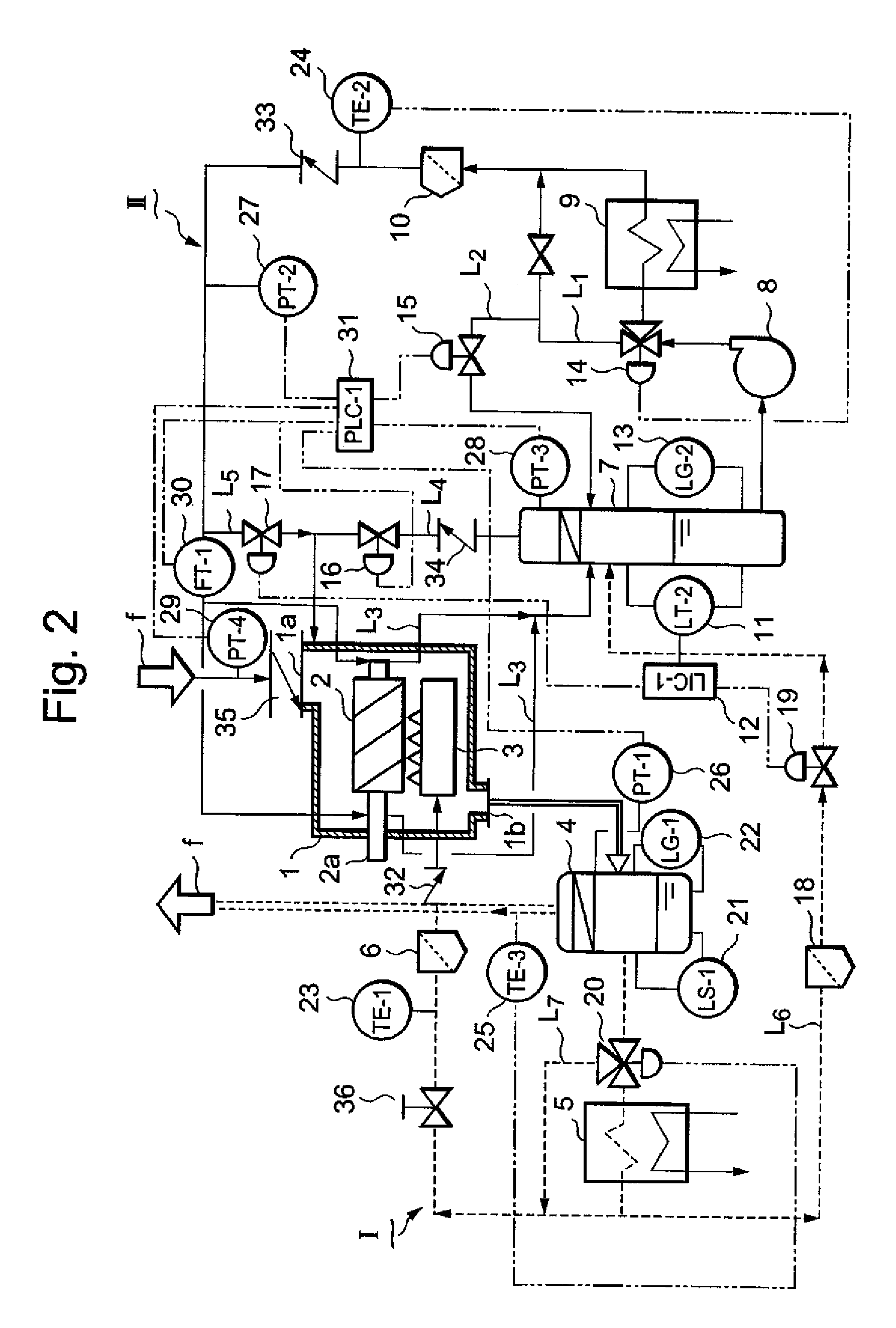

Lubricant supply system and operating method of multisystem lubrication screw compressor

ActiveUS20070163840A1Reduced strengthLower performance requirementsRotary piston pumpsRotary piston liquid enginesTemperature controlHigh pressure

An oil refrigeration screw compressor being applied to a refrigeration system etc., in which the problem of strength reduction of a bearing material under high temperatures and that of lifetime reduction of the bearing material due to viscosity lowering of lubricant are solved. A lubricant supply system to a compressor body is divided into a bearing oil supply system for supplying lubricant to each bearing of the compressor body at low pressure and into a temperature control oil supply system for supplying lubricant into the compressor body at high pressure. The bearing oil supply system is a closed circuit oil supply system comprising an oil supply tank, an oil cooler, and an oil supply pump, and the temperature control oil supply system is a closed circuit oil supply system comprising an oil separator and an oil cooler.

Owner:MAYEKAWA MFG CO LTD

Transient energy systems and methods for use of the same

InactiveUS7750518B1Improve bearing lifeBearing loadLoad balancing in dc networkMechanical energy handlingInduction motorEngineering

This disclosure relates to transient energy systems for supplying power to a load substantially instantaneously on demand. Transient energy systems may include a flywheel coupled the rotor of an induction motor generator. One embodiment of the disclosure refers to systems and methods for reducing loads on a bearing in a transient energy system. In another embodiment, the disclosure refers to an induction motor generator that is optimized for high power transient power generation, yet low power motor operation. Yet another embodiment of the disclosure refers to using a flywheel as a drag pump to cool components of a transient energy system. In yet another embodiment, a slip control scheme is discussed for regulating a DC bus. In yet a further embodiment of the disclosure a method is provided for reducing unnecessary turbine starts by making turbine start a function of the rotational velocity of a flywheel.

Owner:PILLER USA INC

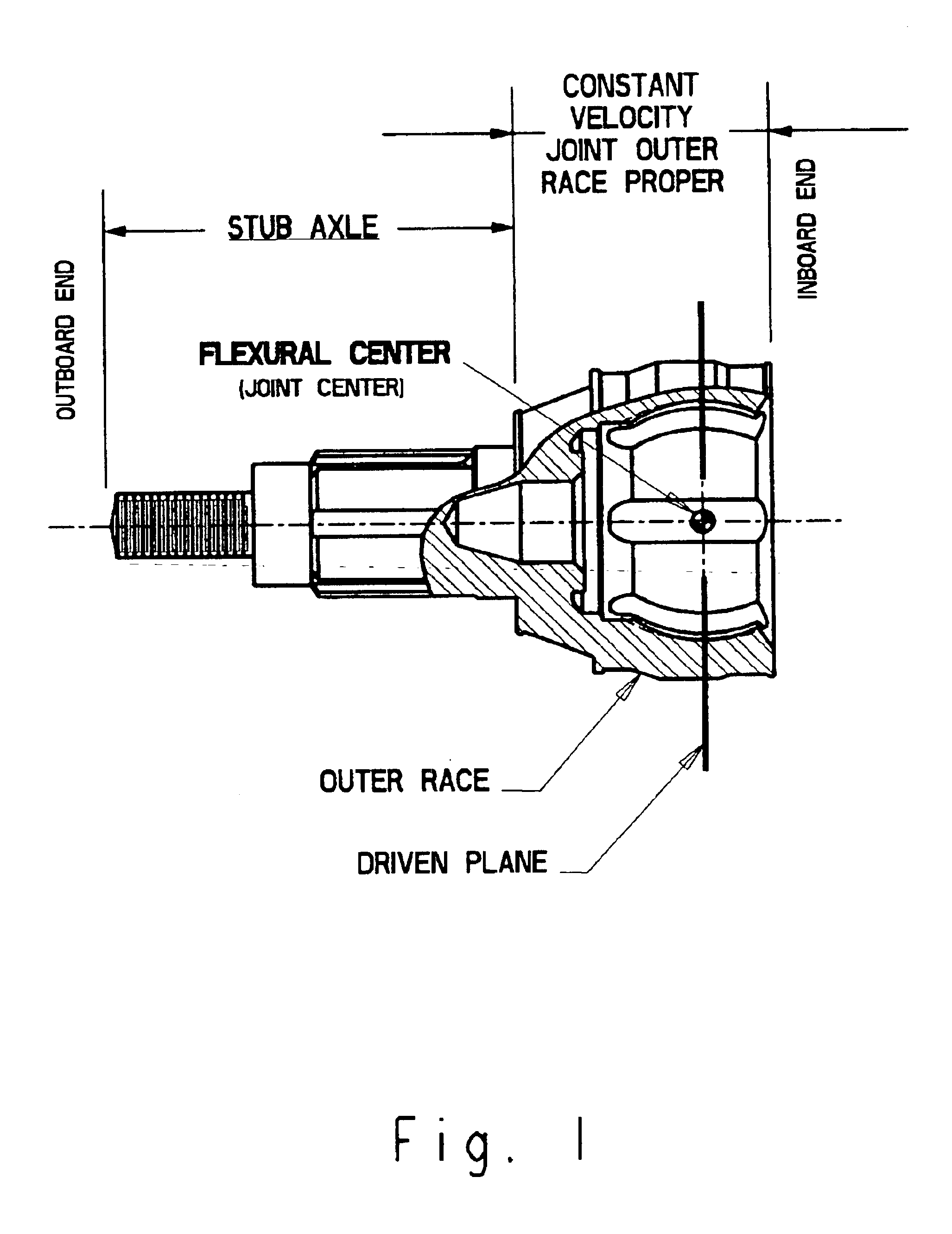

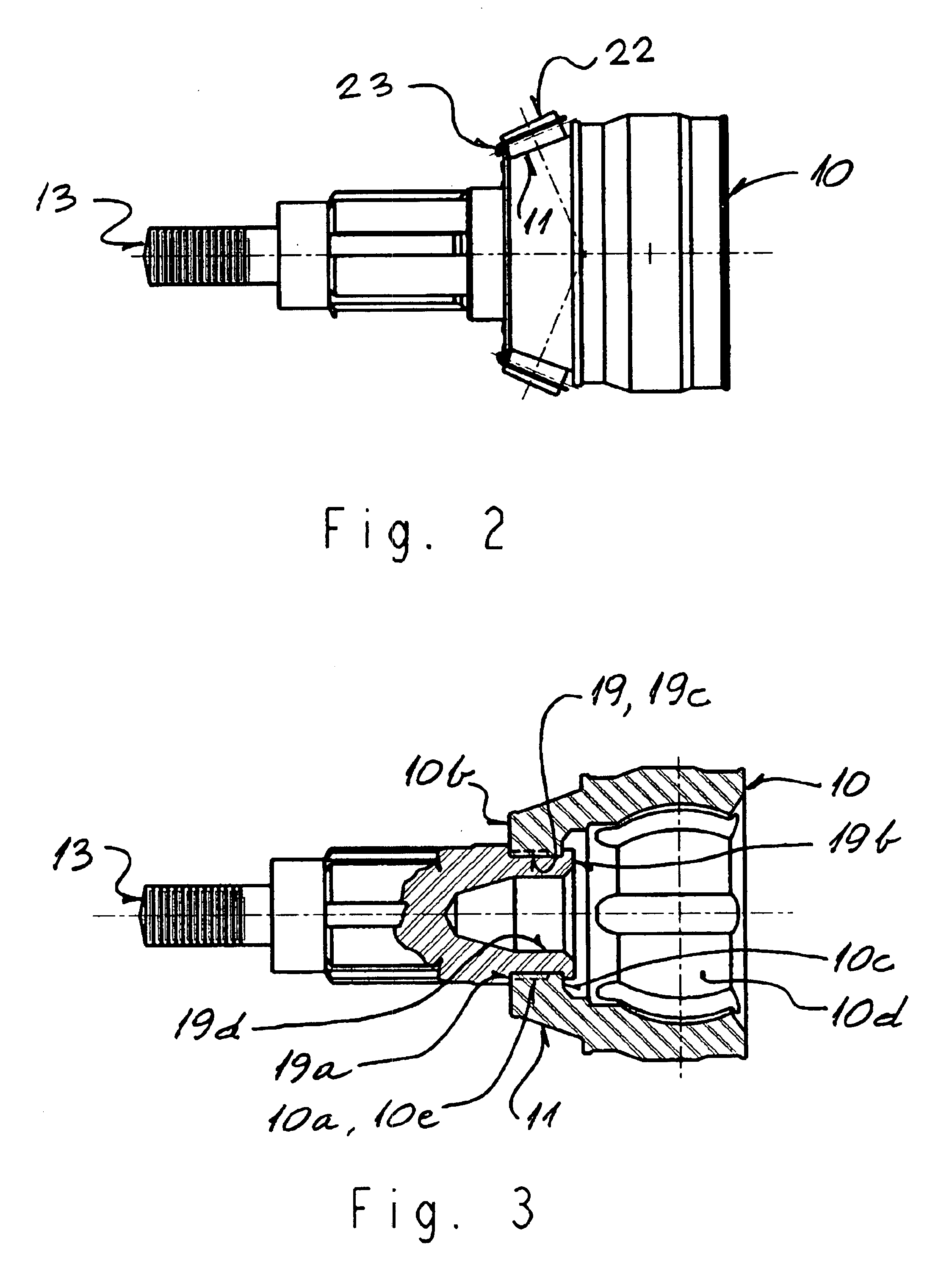

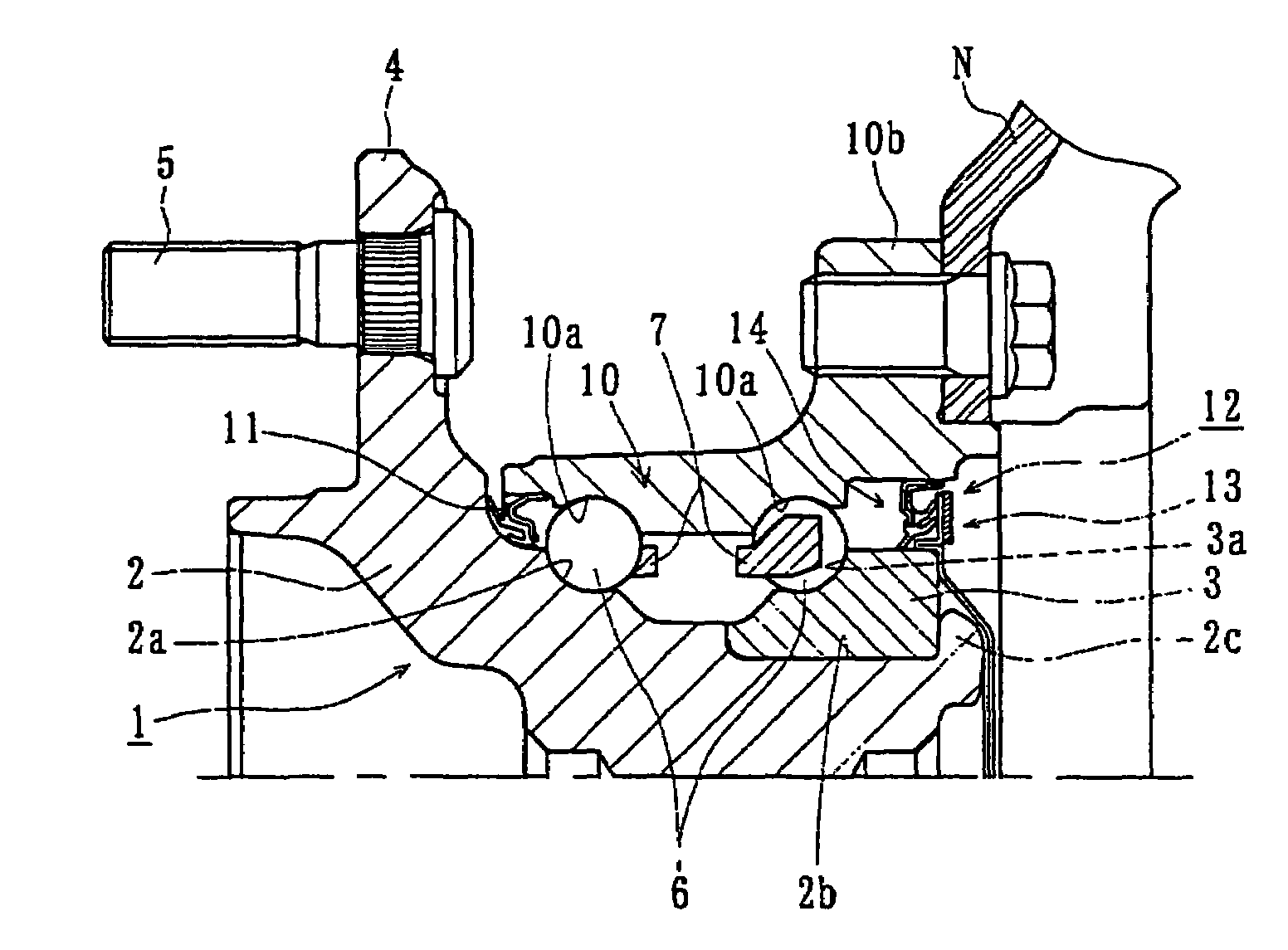

Constant velocity joint integrated to wheel bearing and to axially adjustable hub

InactiveUS6857786B2Increased axial spacingIncrease spacingYielding couplingRolling contact bearingsConstant-velocity jointEngineering

Mounted in a suspension upright for land vehicles, there is provided an arrangement comprising a constant velocity joint, a hub and two wheel bearings with provision for preload adjustment, wherein the CV joint's outer race proper is the inboard wheel bearing's inner race. The bearing raceway formed on the exterior surface of the CV joint's outer race proper is located so as to be in the general area occupied by the driven plane in line with the CV joint's flexural center, providing full end support to the CV joint itself, and concurrently bring about increased axial spacing between the inboard and outboard bearings. Having the CV joint's outer race proper thus integrated to the inboard wheel bearing, a robust hub assembly is provided, wherein the CV joint's flexural center can be placed more closely to the wheel center plane than is normally possible, making negative scrub radius with low kingpin inclination easily achievable.

Owner:CSIK FRANK VICTOR

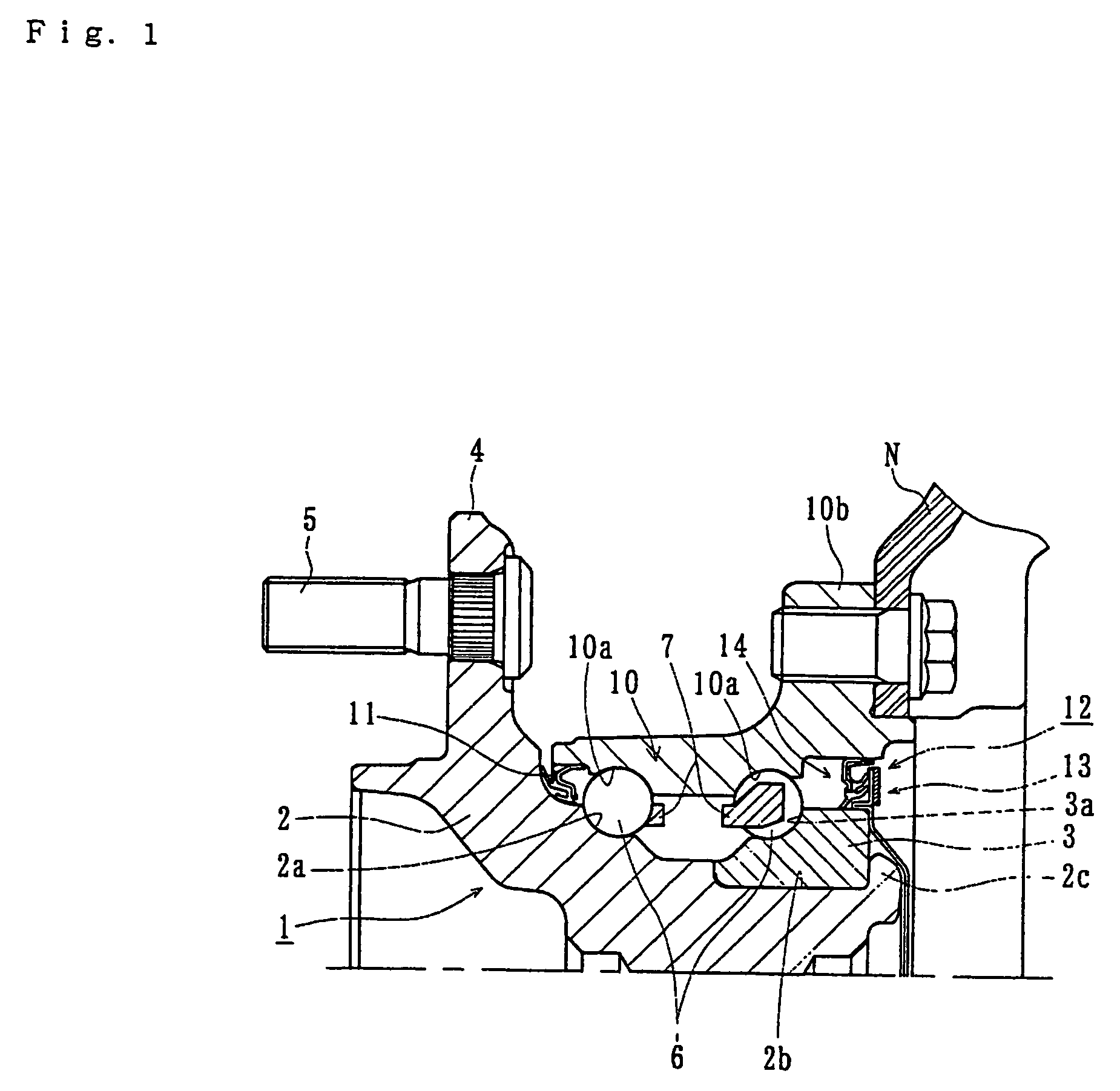

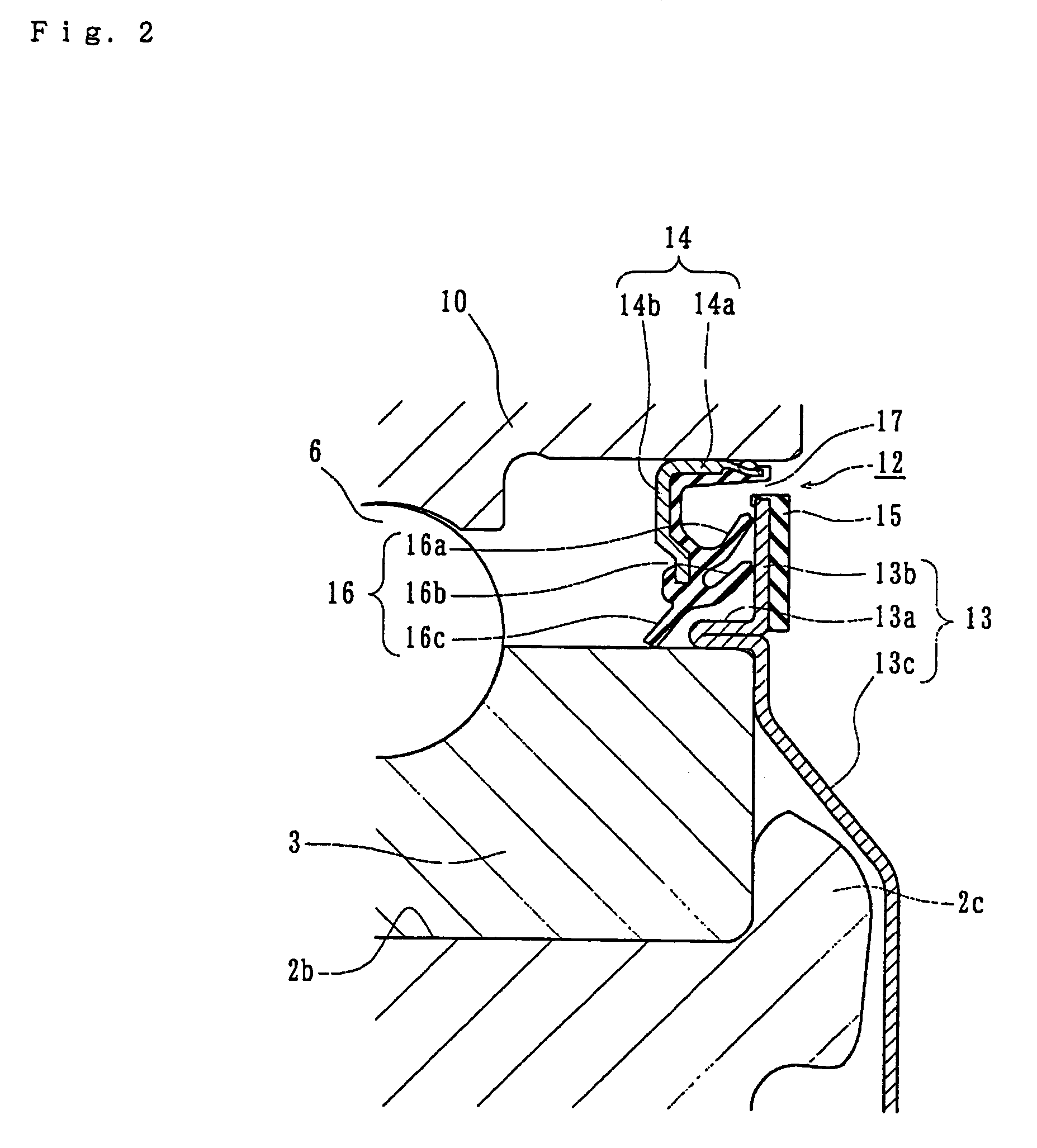

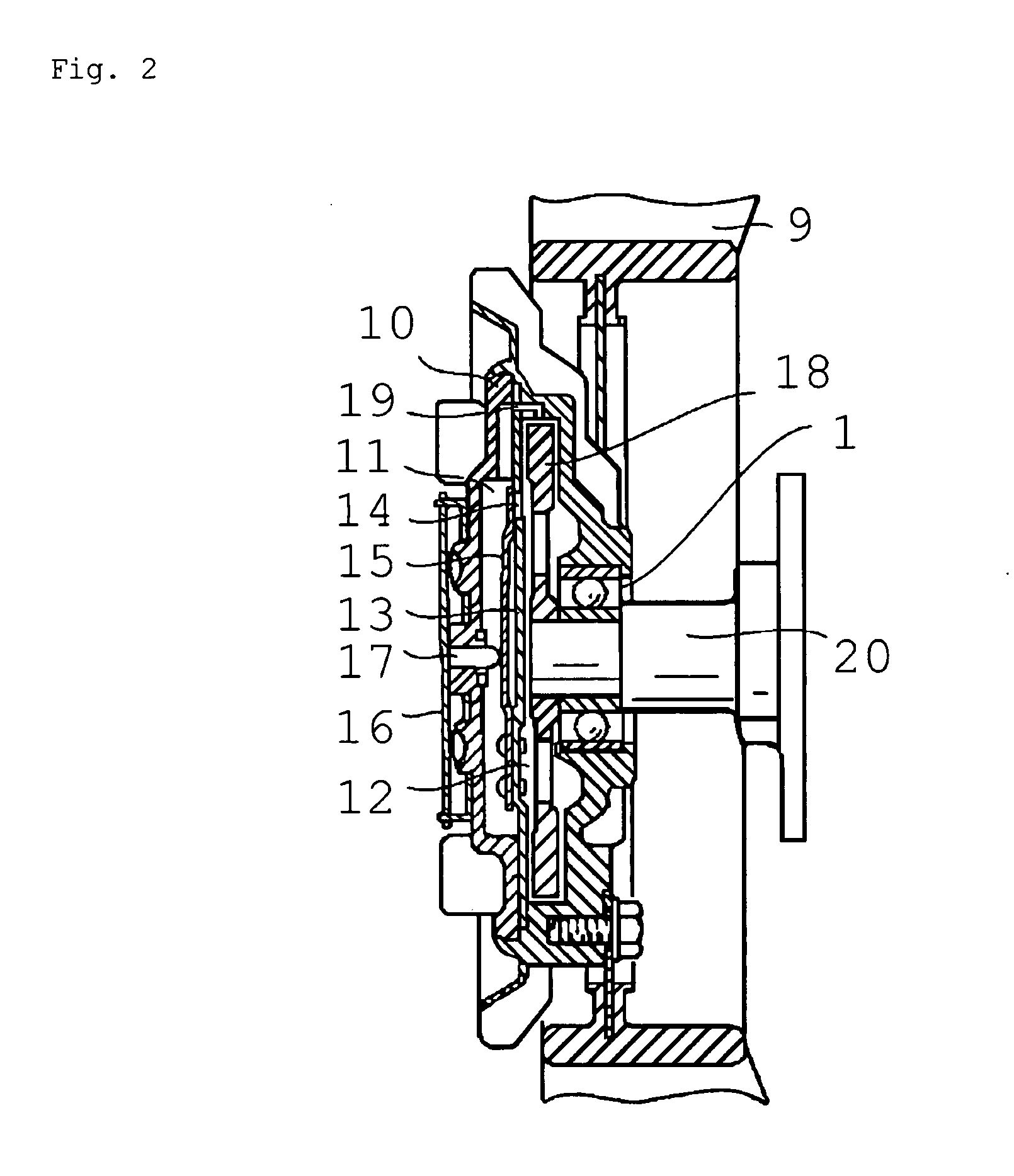

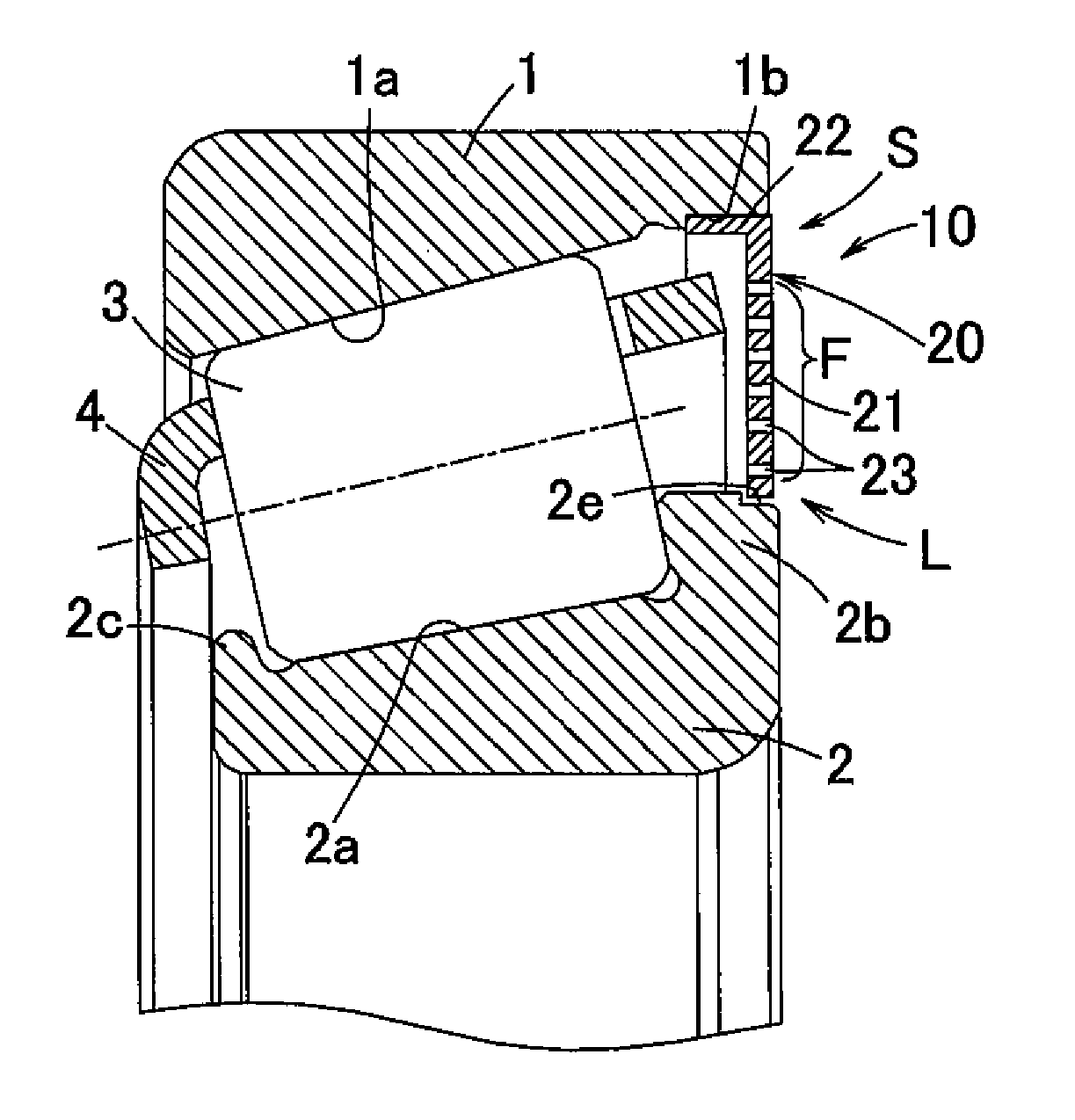

Bearing for a wheel of vehicle

InactiveUS7350976B2Improve lifeImprove bearing lifeRolling contact bearingsBearing assemblyMechanical engineeringElastomer

A vehicle wheel bearing has a sealing device (12) on an inboard side of the bearing with a first sealing plate (23) mounted on an inner ring (3), and a second sealing plate (24) mounted on an outer member (10), arranged opposite to the first sealing plate (23). The first sealing plate (23) has a radially extending portion arranged on the inboard side of the bearing. An encoder (25) is bonded on the radially extending portion. The encoder (25) is made of elastomer material which includes magnetic substance powder. The N and S poles are alternately magnetized along the circumferential direction. The second sealing plate (24) has a substantially “L”-shaped cross-section formed by a cylindrical portion and a radially extending portion. Integral side-lip(s) slidingly contact the radially extending portion of the first sealing plate (23). A protecting cover (27) is mounted on the first sealing plate (23) so that it intimately contacts with the encoder (25).

Owner:NTN CORP

Bearing cleaning composition and method of use

ActiveUS20050054541A1Improve waterproof performanceImprove detergencyRotary combination bearingsWork treatment devicesSulfonateEngineering

A composition for cleaning bearings in rotating equipment and industrial machinery that contains powdered limestone having a high calcium content dispersed in a calcium sulfonate grease, together with a colorant that readily enables a user to differentiate between contaminated grease, cleaning composition and fresh grease. A method is also disclosed that enables a user to clean and re-lubricate bearings without the need for removing the bearings from service or for shutting down the associated equipment or machinery.

Owner:NCH CORP

Grease Composition and Grease-Enclosed Rolling Bearing

InactiveUS20080166080A1Avoid unusual noisePrevent viscosity lossRolling contact bearingsShaftsHeat resistanceRolling-element bearing

The present invention provides a grease composition capable of securely preventing an abnormal noise from being generated when it is cold and having a long life at a high temperature, and a rolling bearing in which this grease is enclosed. The grease composition having heat-resistant properties and performance of preventing the generation of a low-temperature abnormal noise contains a base oil, a thickener, and an additive, and is used for a rolling bearing. A worked penetration of the grease composition at 25° C. is 300 or less, and an unworked penetration thereof at −20° C. is 200 or more. The grease-enclosed rolling bearing has an inner ring, an outer ring, rolling elements interposed between the inner ring and the outer ring, and the above-described grease composition enclosed on a periphery of the rolling elements. The grease-enclosed rolling bearing is used for an automotive electric auxiliary machine.

Owner:NTN CORP

Axial tube assembly of a motor

ActiveUS6897586B2Firmly assembledImprove rotational stabilityRecord information storageMechanical energy handlingEngineeringElectric motor

An axial tube assembly of a motor includes an axial tube around which a stator assembly is mounted, an engaging member, and a sleeve in which a bearing is mounted. The engaging member includes a base and a plurality of resilient legs projecting from the base. Each resilient leg has a hook on a distal end thereof. The base of the engaging member is engaged with and thus seals a bottom end of an axial hole of the axial tube. The sleeve is mounted in the engaging member and has a base portion. The hook of each resilient leg is pressed outward to thereby retain the stator assembly in place when the sleeve and the engaging member are received in the axial tube, with the resilient legs of the engaging member together holding the sleeve to thereby allow tight engagement between the sleeve and the bearing.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Engine construction

InactiveUS6073595AEasy to useSmall bendCasingsSealing arrangements for enginesMain bearingEngineering

An in-line opposed cylinder engine constructed of a pair of half blocks which when combined form a pair of spaced cylinder heads and an intermediate crankcase and in which the cylinder heads and the intermediate crankcase are tied together by a plurality of spaced elongated through bolts which extend through the cylinder heads and through the half blocks. Each cylinder head is integral with the remainder of the half block and is preferably of a composite construction with a core of steel or the like which forms the cylinder bore, the firing deck, the exhaust ports and the valve guide as well as the main bearing supports. A matrix structure of lighter material such as aluminum is cast around the core and forms the induction air passages to the intake ports, the coolant passages, oil passages, and the main bearing bosses.

Owner:CONTINENTAL MOTORS

Motor Shaft Vibration Isolator for Electric Submersible Pumps

InactiveUS20110182535A1Sacrificing bearing lifeImprove cooling effectRotating vibration suppressionNon-rotating vibration suppressionRotational axisElectricity

A vibration dampening system for a motor shaft in an ESP uses axially extending arms in one or opposed directions from a fixed portion of a motor shaft bearing. The weights can have their location adjusted to tune the device to the natural frequencies of the rotating shaft and to add an ability to address vibration in more than one plane. Openings are provided in the support for the arms that hold the weight so that arm vibration can create turbulence and improve heat dissipation in the oil for improved bearing life. Bearing cost can be reduced using more economical materials without sacrificing bearing life.

Owner:BAKER HUGHES INC

Setting of wheel hub assembly having a spacer therein

ActiveUS8893364B2Improve endplayImprove bearing lifeHubsMeasurement arrangements for variableMechanical engineering

Owner:TEMPER +1

Lubricant supply system and operating method of multisystem lubrication screw compressor

ActiveUS7347301B2Reduced strengthLower performance requirementsRotary piston pumpsRotary piston liquid enginesTemperature controlFuel tank

Owner:MAYEKAWA MFG CO LTD

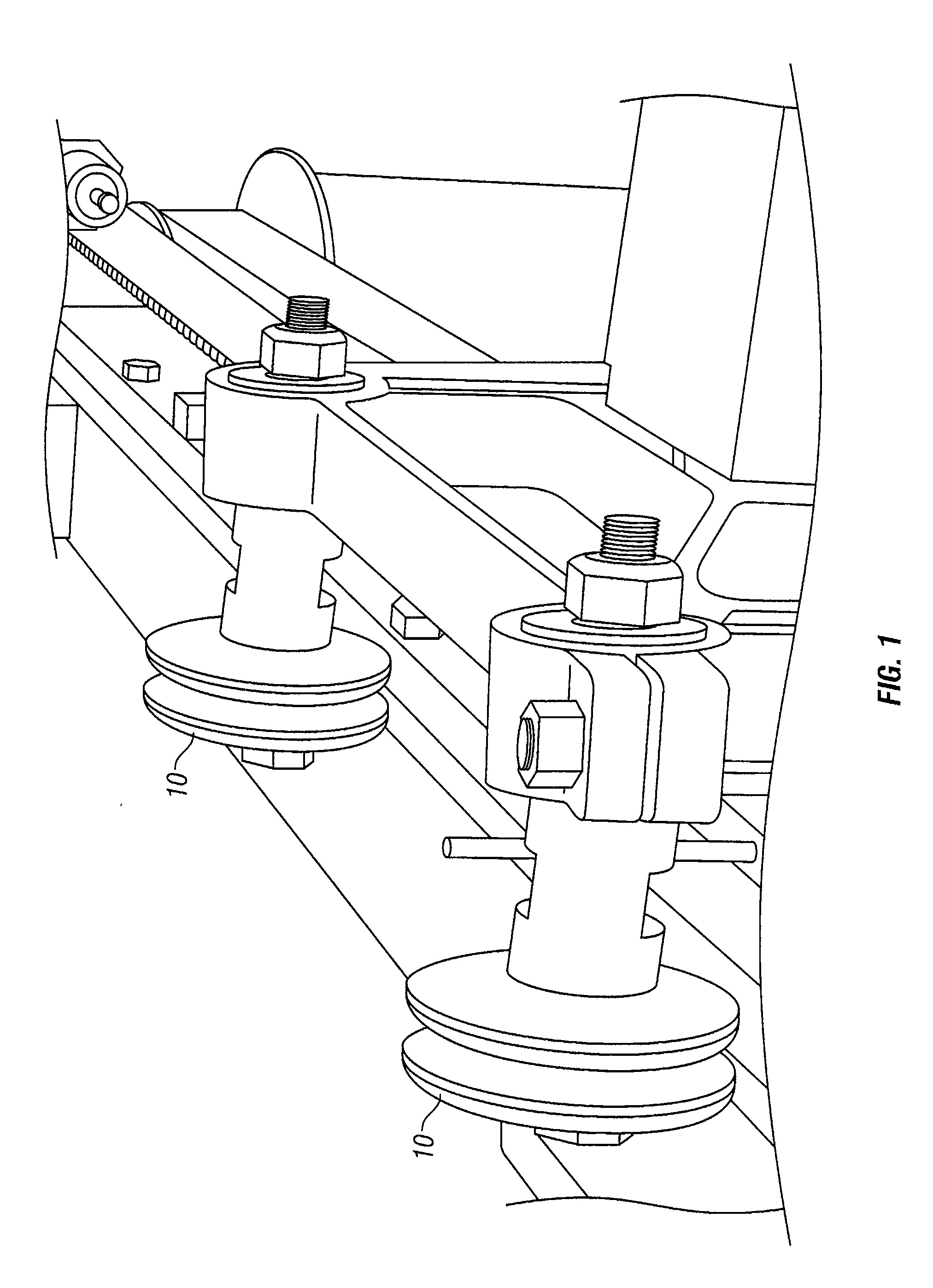

Bearing Vibration Damping Mechanism

ActiveUS20080292234A1Necessary rigidityReduce stiffnessLeaf springsShaftsRolling-element bearingEngineering

A squeeze film damper for a bearing and a vibration damping mechanism capable of damping the vibration of a rolling bearing are provided. The squeeze film damper is small in construction and can be easily made by mass production. The vibration damping mechanism is capable of damping both radial and axial vibrations. A bearing housing 15 is provided with a bearing holding bore 16 of a diameter greater than the outside diameter of the outer ring 14 of a bearing, and an oil hole 19 through which oil is supplied into the bearing holding bore 16. A vibration damping mechanism 1 is formed by inserting a thin, flat sheet 17 provided with slits into an annular space formed between the inner wall of the bearing holding bore 16 and the outside surface of a bearing held in the bearing holding bore 16 so as to surround the bearing. Parts of the thin, flat sheet extending between the adjacent slits serve as elastic beams. The elastic beams center the bearing and support the centered bearing elastically. The vibration of the bearing is damped by the squeeze film effect of an oil film formed by supplying oil into the annular space.

Owner:KAWASAKI HEAVY IND LTD

Guide wheel having a bearing for food and beverage applications

ActiveUS20070242909A1Eliminate direct liquid pressureIncrease guide wheel lifeLinear bearingsBall bearingsEngineeringDirect path

The invention provides a wheel design that incorporates both a shield and seal on both sides of the guide wheel to eliminate direct liquid pressure on the seal. By retaining the lubrication, bearing life is extended, dramatically reducing machine downtime. In the presently preferred embodiment, the combination of a guide wheel with two rubber spring return (RSR) seals in-bound of two shields, increases guide wheel life through the following: The shields prevent the direct force of a high pressure wash-down from reaching the seal directly. There is a non-direct path between the shield and the outer raceway of the guide wheel to allow any trapped liquid to seep back out of the guide wheel. Also, as the guide wheel rotates, any liquid between the shield and seal is spun-out by centrifugal force.

Owner:BISHOP WISECARVER CORP

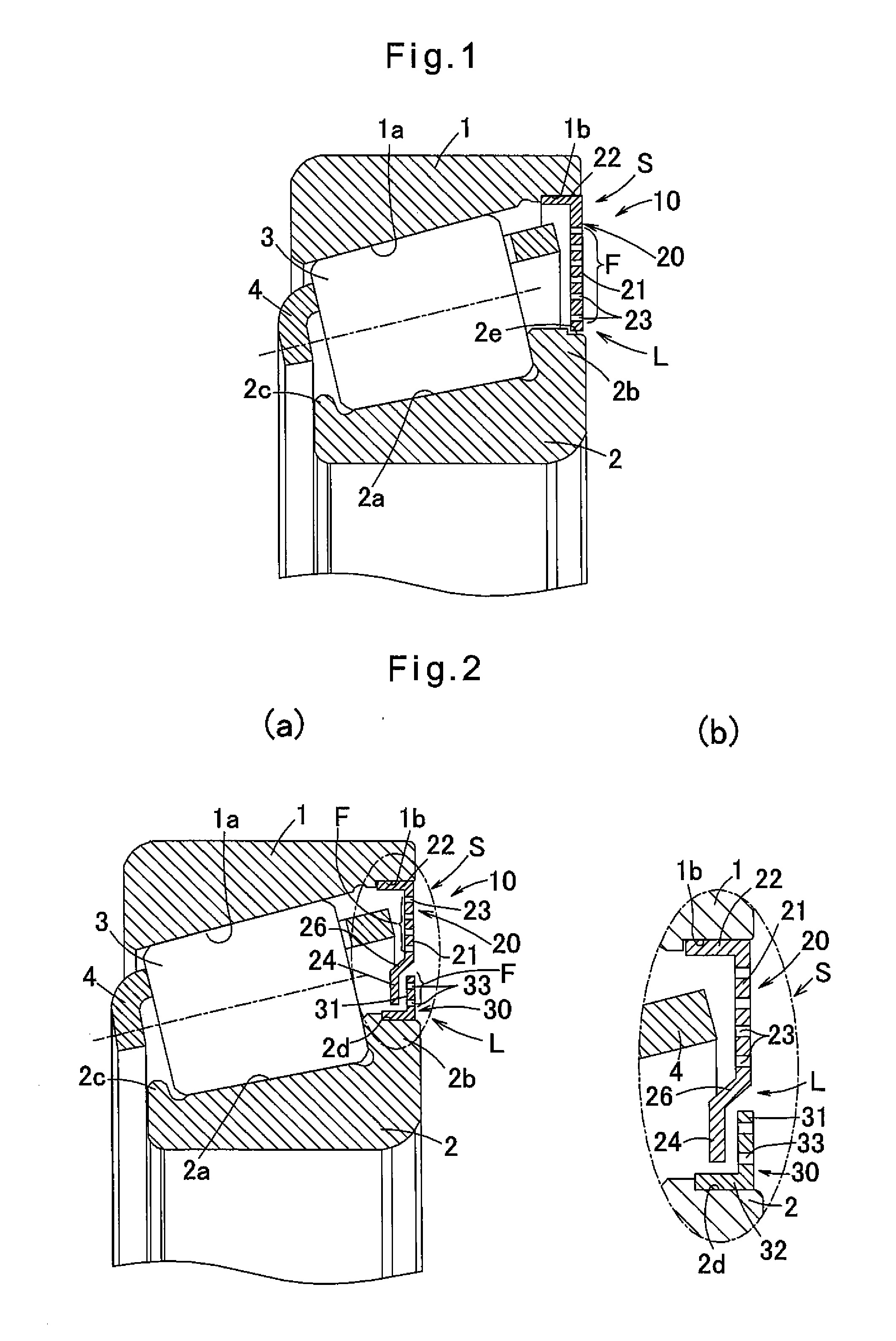

Rolling bearing

ActiveUS20160108962A1Prevent damage to the sealIncreased durabilityRoller bearingsShaftsMechanical engineeringForeign substance

A rolling bearing includes an outer bearing race and an inner bearing race defining a bearing space therebetween. Rolling elements are mounted in the bearing space. A seal device is provided at one axial opening of the bearing space and includes a ring member formed of a metal and formed with through holes configured such that lubricating oil can pass through the through holes and solid foreign substances cannot pass through the through holes. One of the outer bearing race and the inner bearing race is stationary, and the other is rotatable. The ring member is in engagement with the stationary bearing race. A sub-ring member, which is a separate member from the ring member and made of a metal, is fixed to the rotatable bearing race. Between the ring member and the sub-ring member, a gap is defined which constitutes a labyrinth seal structure.

Owner:NTN CORP

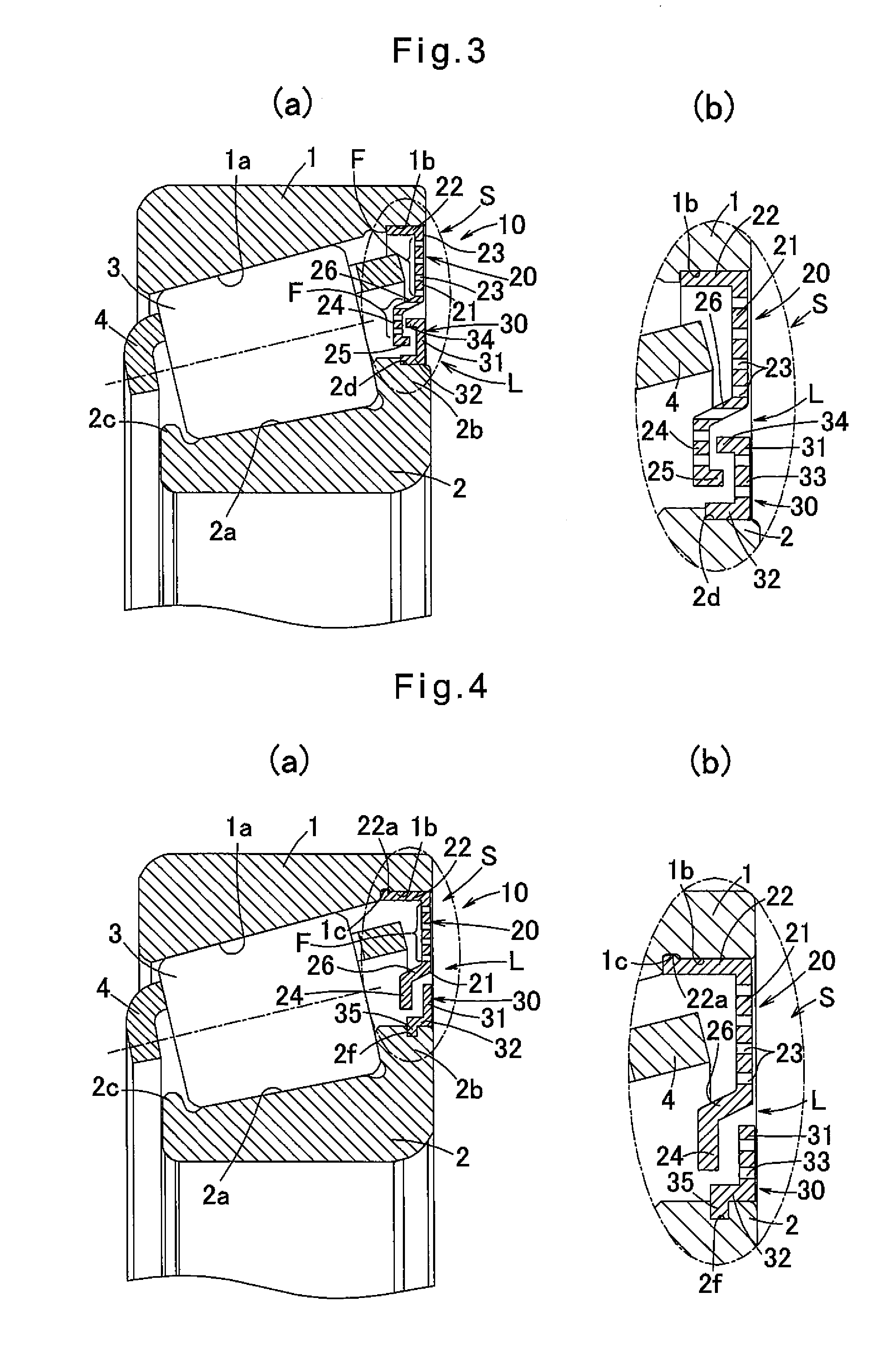

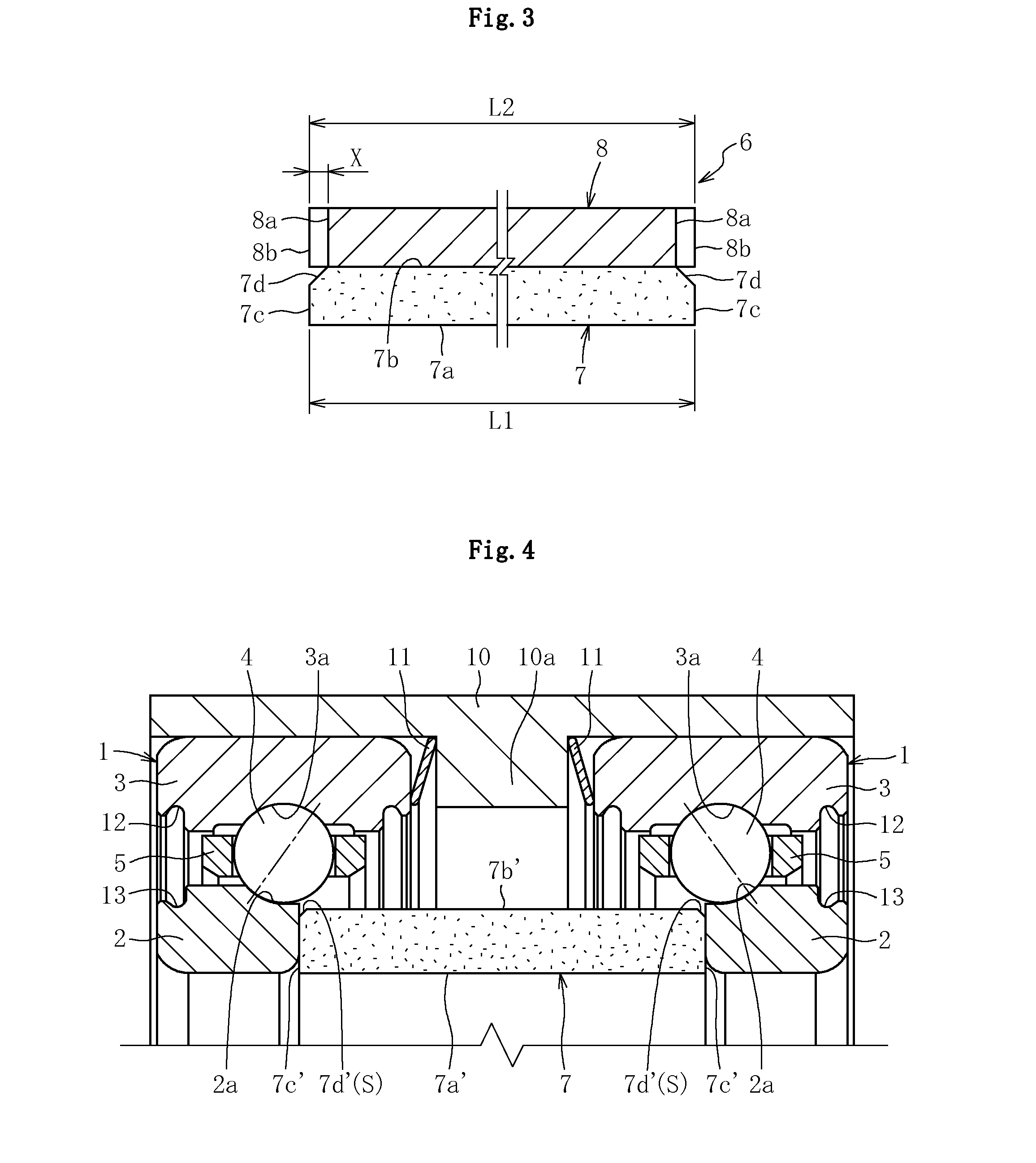

Rolling bearing device

InactiveUS20120328225A1Increase bearing lifeEasily manufactureRolling contact bearingsVehiclesEngineeringMetal

Provided is a rolling bearing device comprising inner races (2), outer races (3), rolling elements (4), a retainer (5), and an inner race spacer (6). The inner race spacer (6) is formed of an oil reservoir member (7) made of a sintered metal impregnated with lubricating oil, and a spacer cover (8) fitted onto an outer periphery of the oil reservoir member (7). Through a centrifugal force to be applied to the oil reservoir member (7) at the time of bearing rotation, the lubricating oil is scattered radially outward through a chamfered portion (7d) of the oil reservoir member (7) via an oil supply passage (S), to thereby lubricate the interior of the bearing with oil.

Owner:NTN CORP

Pressure lubrication system for countershaft transmission

InactiveUS6206140B1Improve bearing lifeReduce maintenance costsGear lubrication/coolingLubricating pumpsClutchLubrication

A lubrication system for transmissions is provided wherein a lubrication flow path is provided from an oil pump located within a transmission casing to front countershaft bearings. A second flow path provides oil directly to a predetermined number of gear sets located along a main shaft. In one embodiment, oil flows through a first tube from the oil pump to an annular ring located in a groove between a front wall of the transmission main case and a rear face of a clutch housing. The ring is provided with a plurality of apertures along its outer circumference spaced to allow oil to flow directly to front bearings of any counter shaft placed adjacent the main shaft. A closed ended tube connects to the annular ring and extends perpendicularly from the annular ring through the front wall of the transmission main case. The closed ended tube extends substantially parallel to the driven main shaft, and includes spaced apertures that deliver oil directly to a predetermined number of gear sets located axially along the main shaft.

Owner:EATON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com