Patents

Literature

31 results about "Dual-thrust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

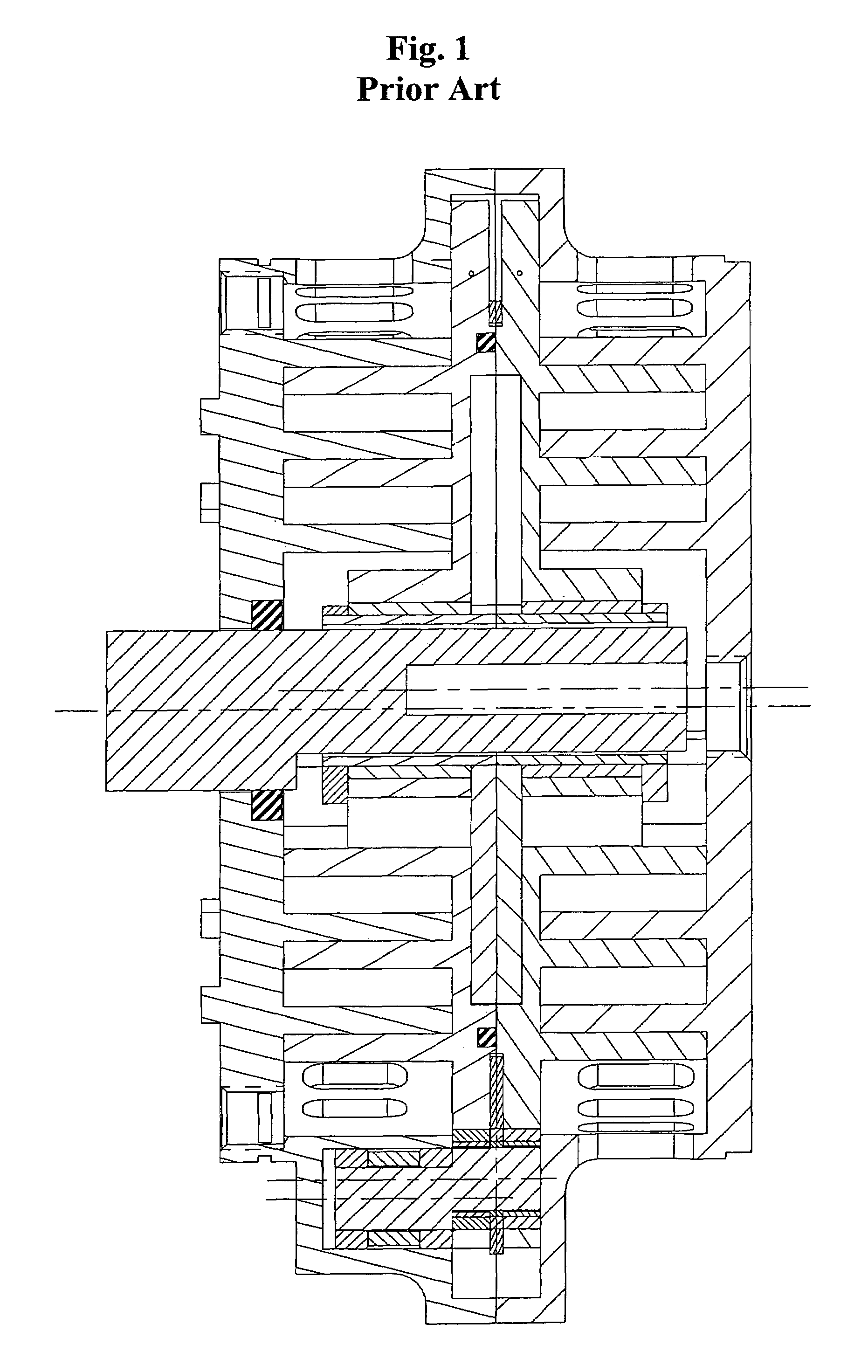

In a dual-thrust solid propellant rocket engine, the propellant mass is composed of two different types (densities) of fuel. In the case of a tandem dual-thrust motor, the fuel closest to the rocket nozzle burns fast and the fuel further into the motor's body burns slower. This has the effect of giving the rocket a lot of thrust initially, accelerating it rapidly to high speed. When all the fast-burning propellant has burnt, the slow-burning propellant delivers a much lower level of thrust. The first phase of acceleration is called "boost" and the second phase "sustain". Not all dual-thrust motors are in a tandem arrangement but non-tandem motors function much the same; they just have a different physical layout of fuel. For example, they might burn from the inside to the outside (core burning), rather than from the end in (end burning).

Hybrid Gas Turbine Propulsion System

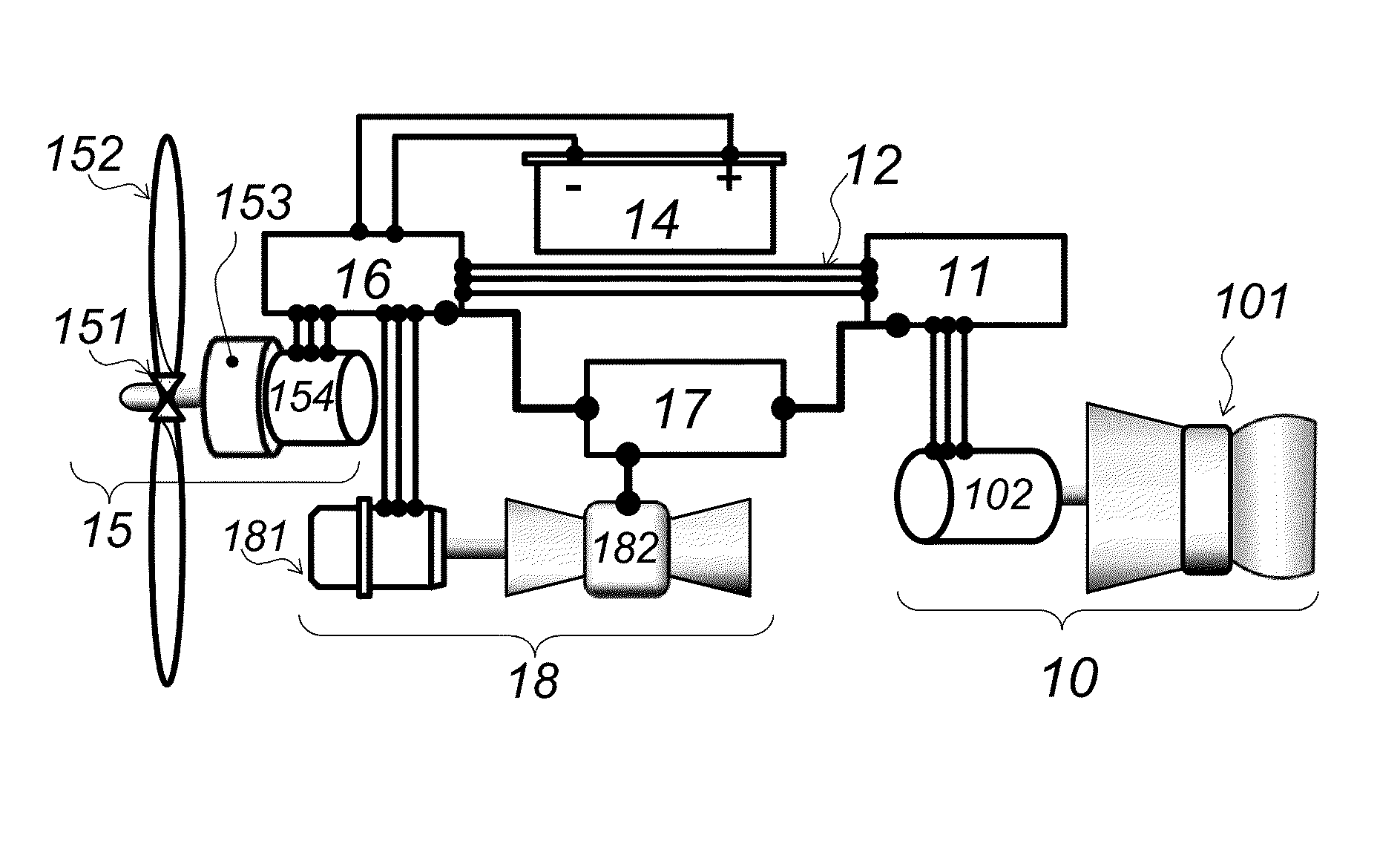

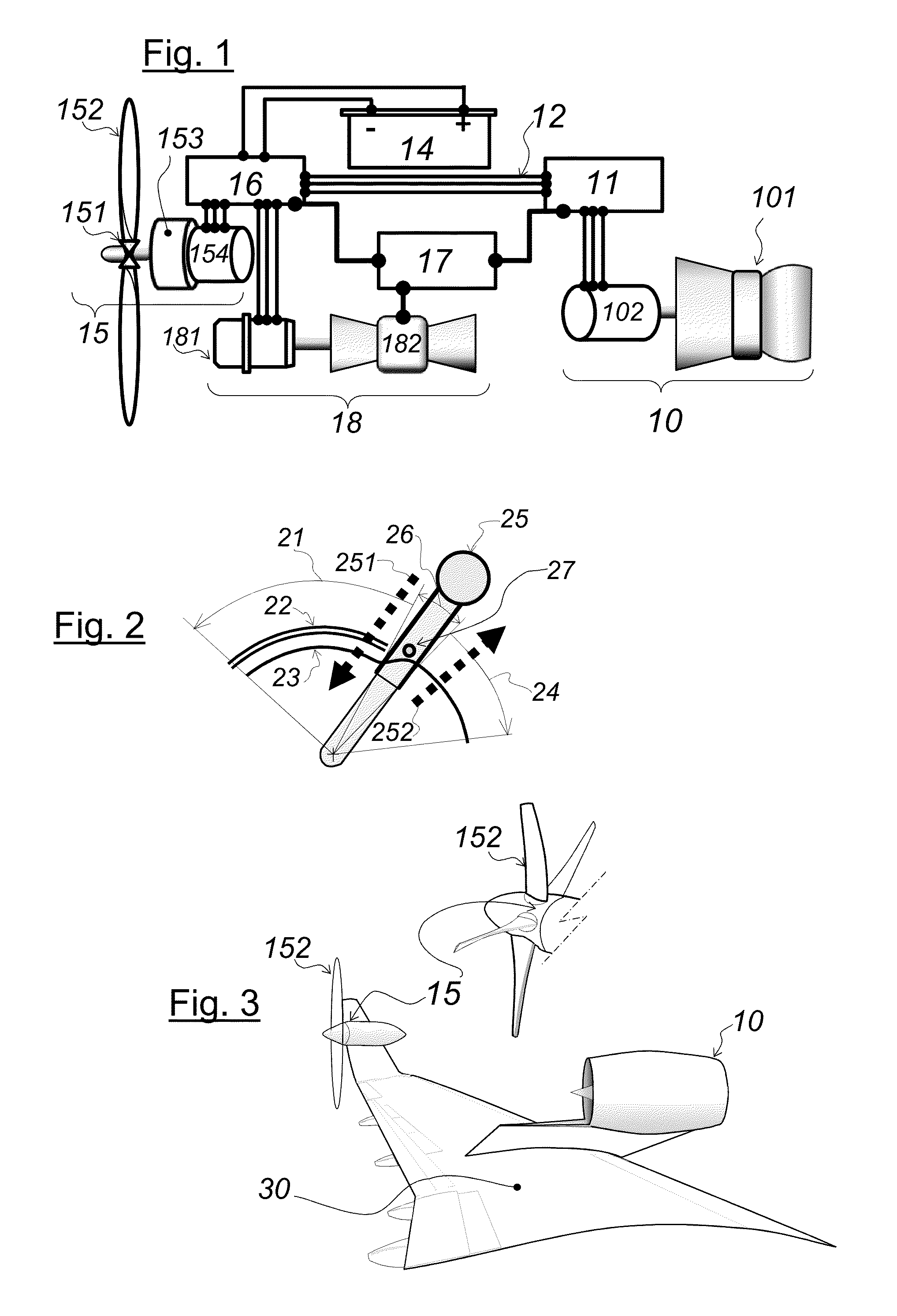

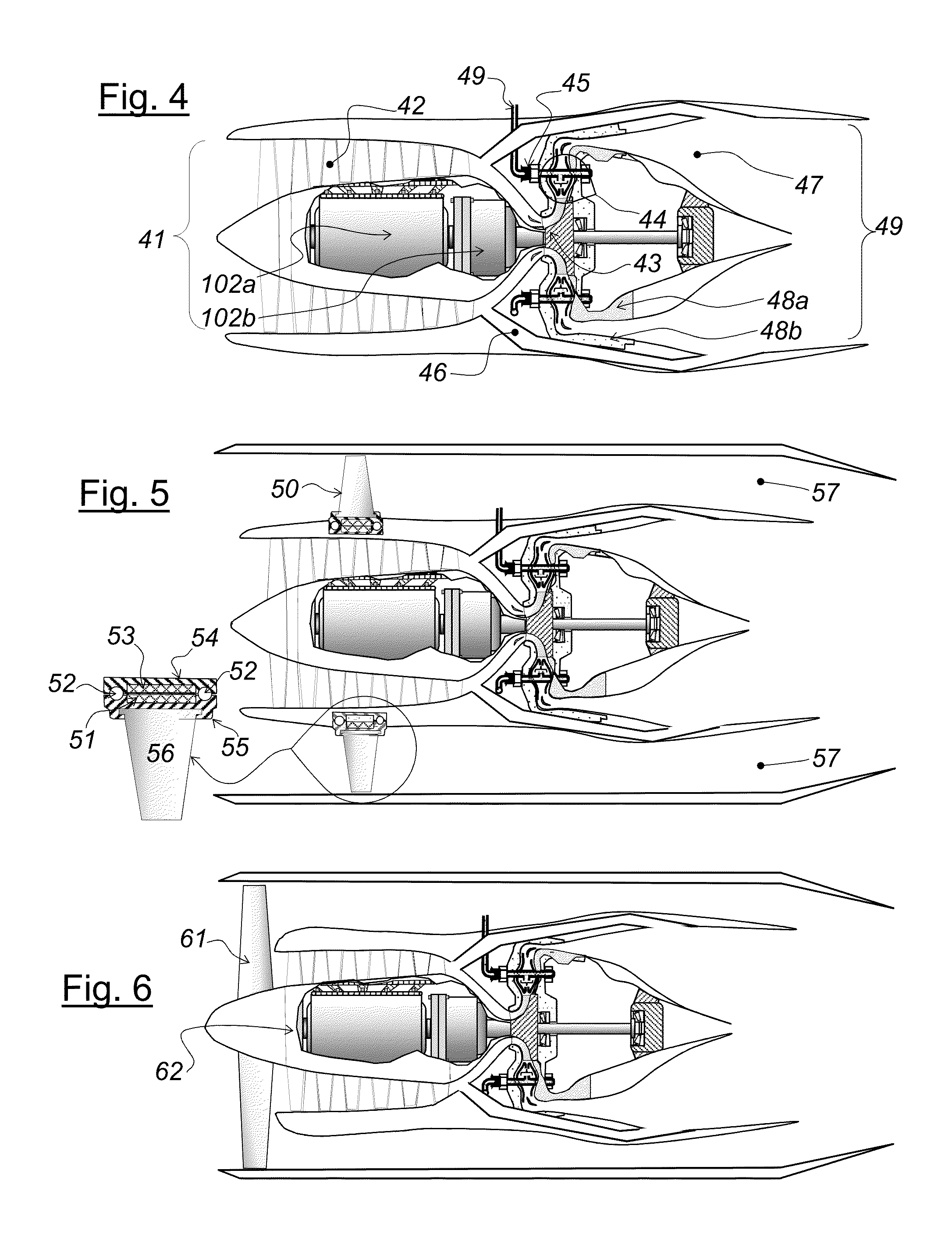

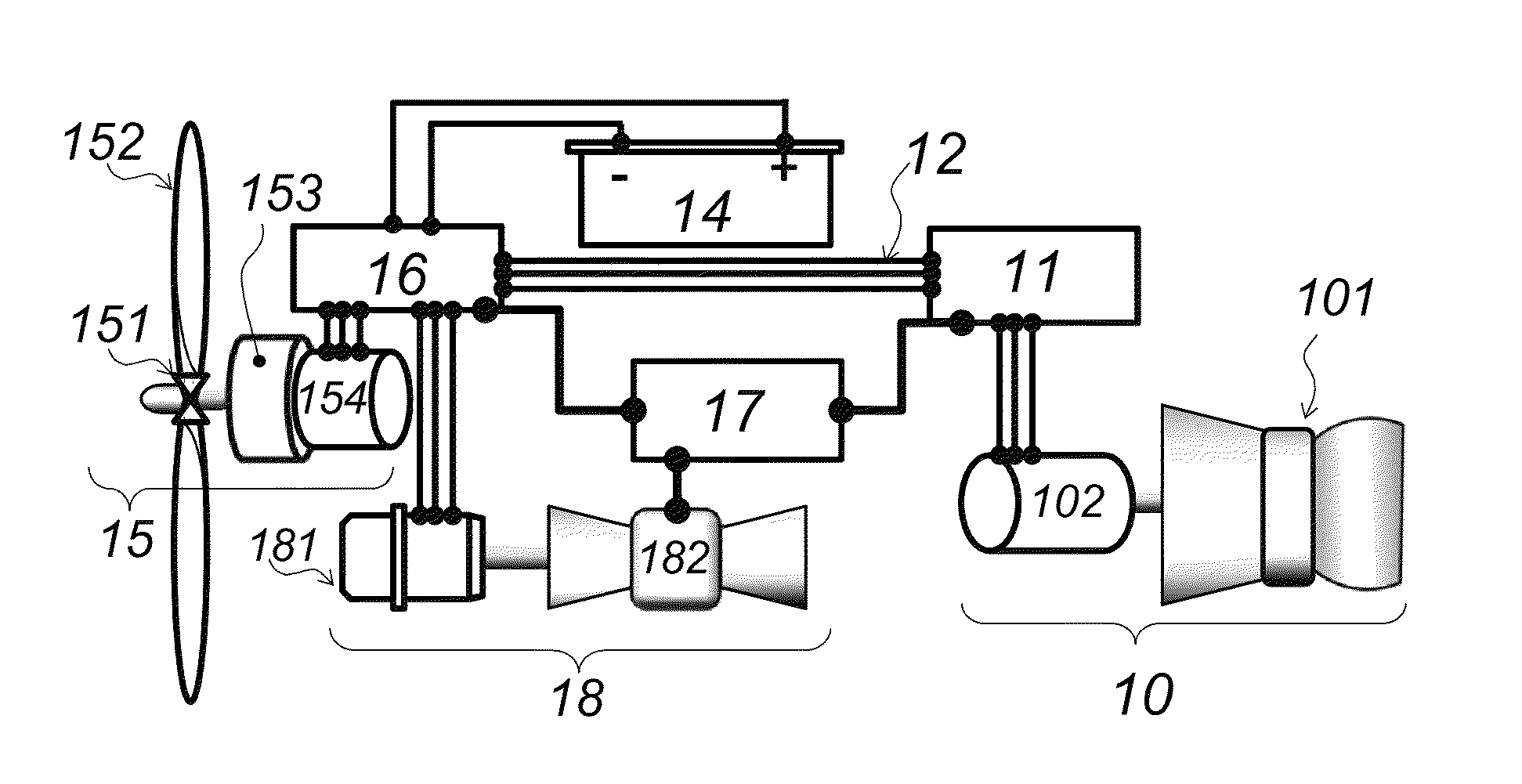

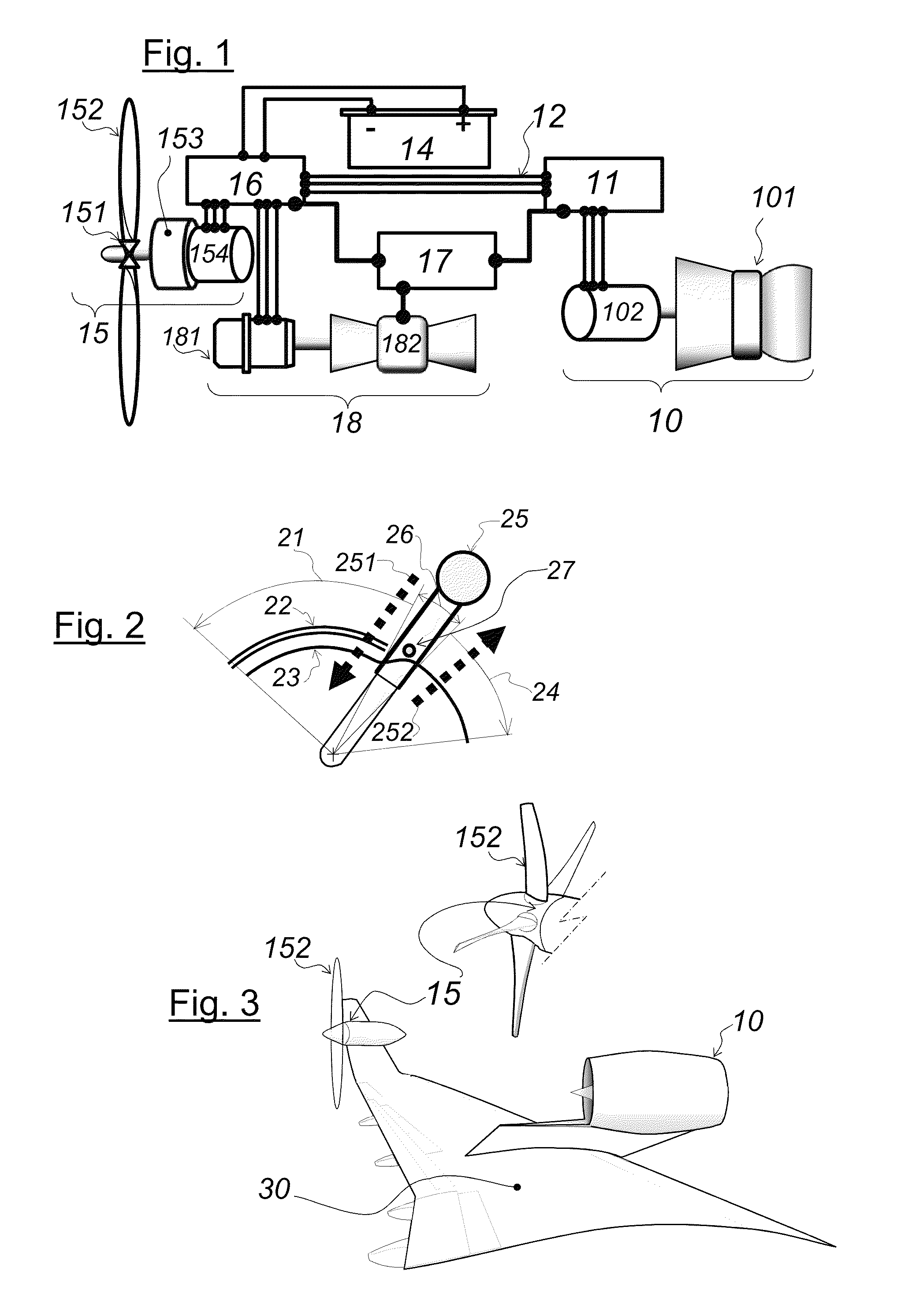

ActiveUS20150013306A1Reduce fuel consumptionImprove responsivenessGas turbine type power plantsEfficient propulsion technologiesAir compressionDual-thrust

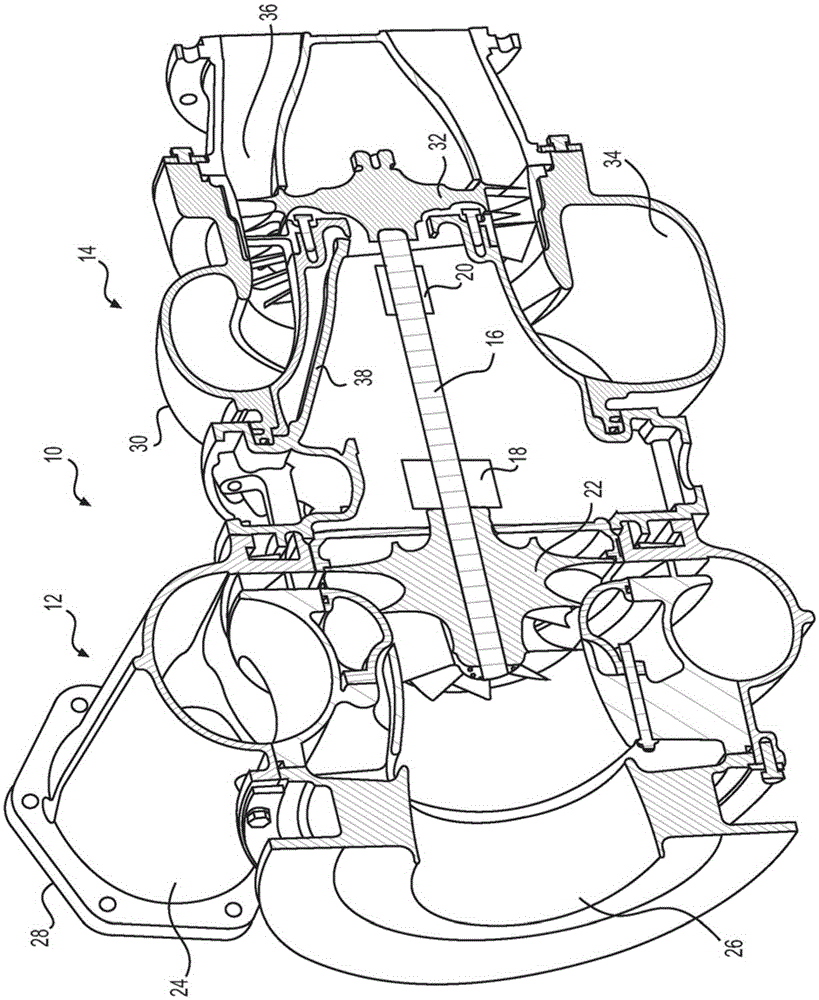

A hybrid aerodynamic thrust system as a prime mover for aircraft or other high-speed vehicles. An arrangement of dual thrust resources to alternately accommodate low and high airspeed regimes. Electromotive force is used in lieu of hot section power turbines to achieve engine air compression or alternately perform thrust work at low velocities.

Owner:SHELLEY RUDOLPH ALLEN

Hybrid gas turbine propulsion system

ActiveUS9212625B2Reduce fuel consumptionImprove responsivenessGas turbine type power plantsGas turbine plantsJet aeroplaneAir compression

Owner:SHELLEY RUDOLPH ALLEN

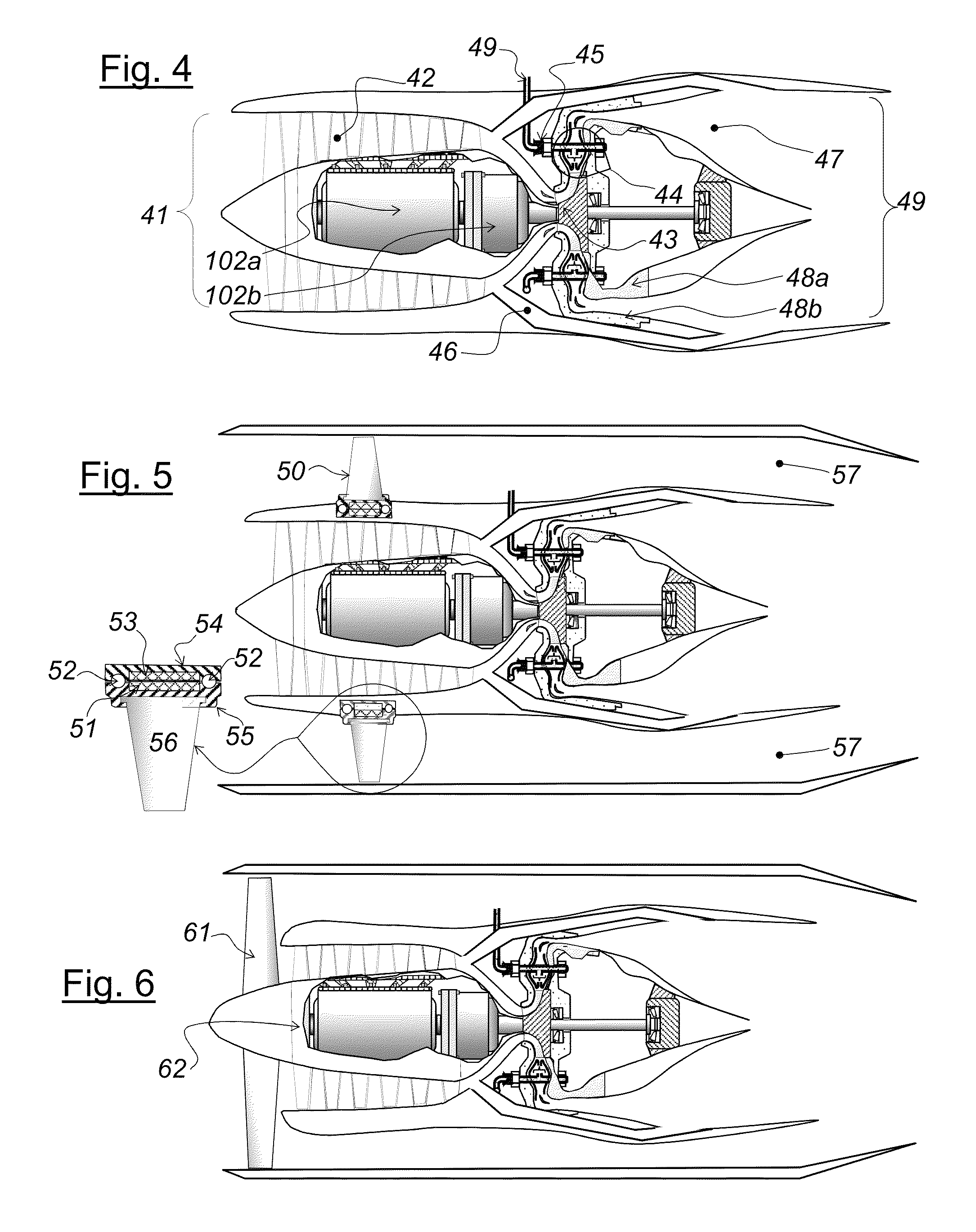

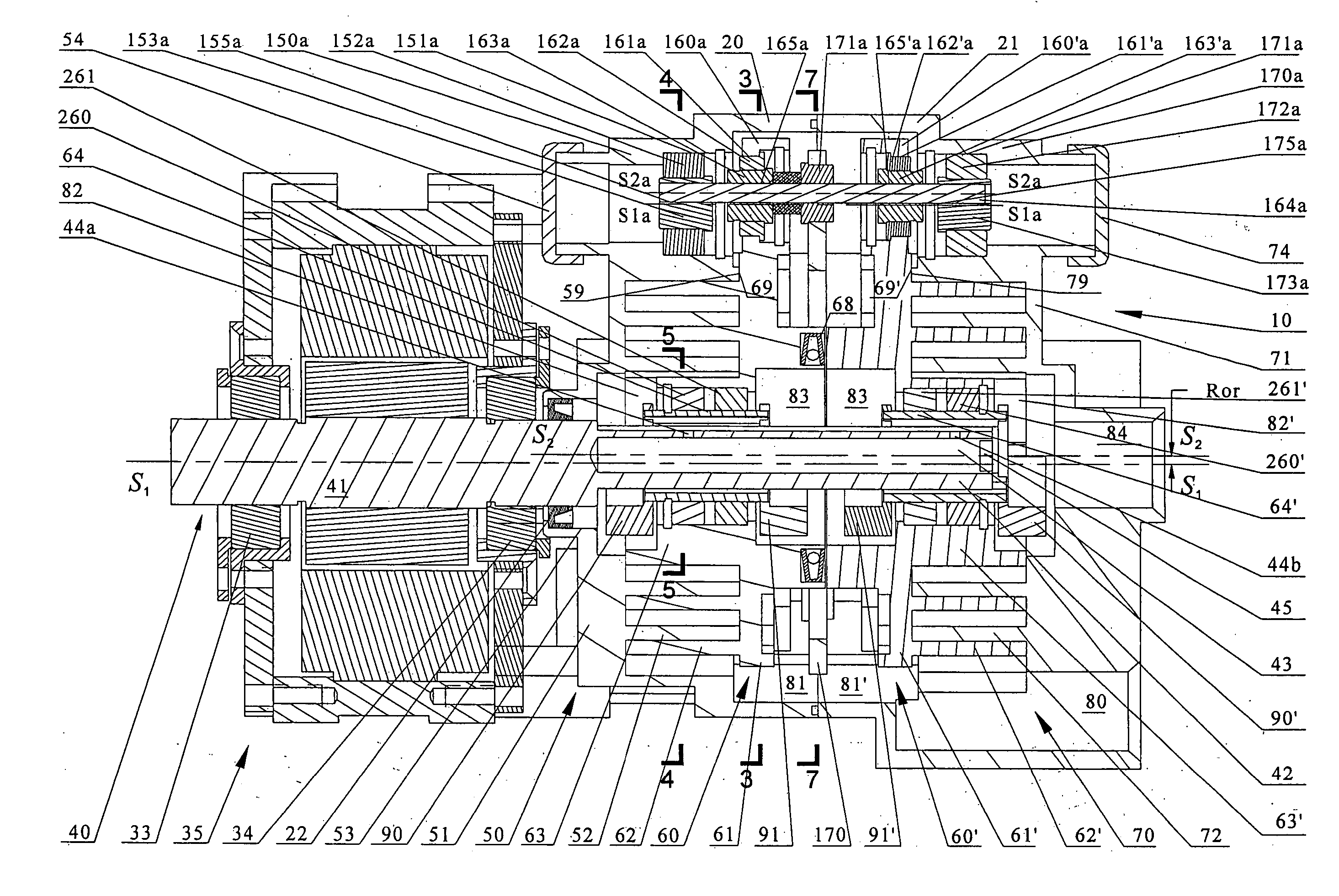

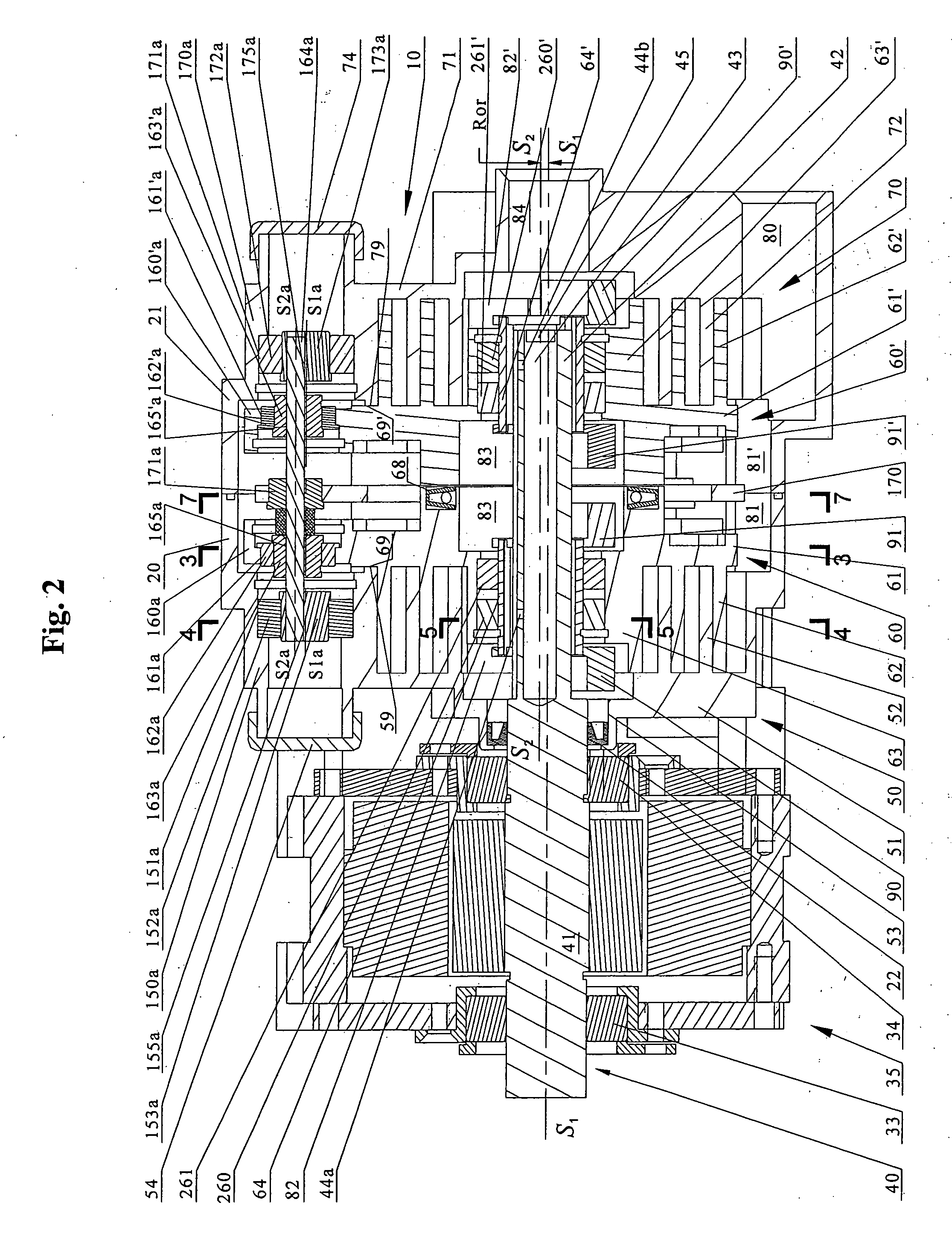

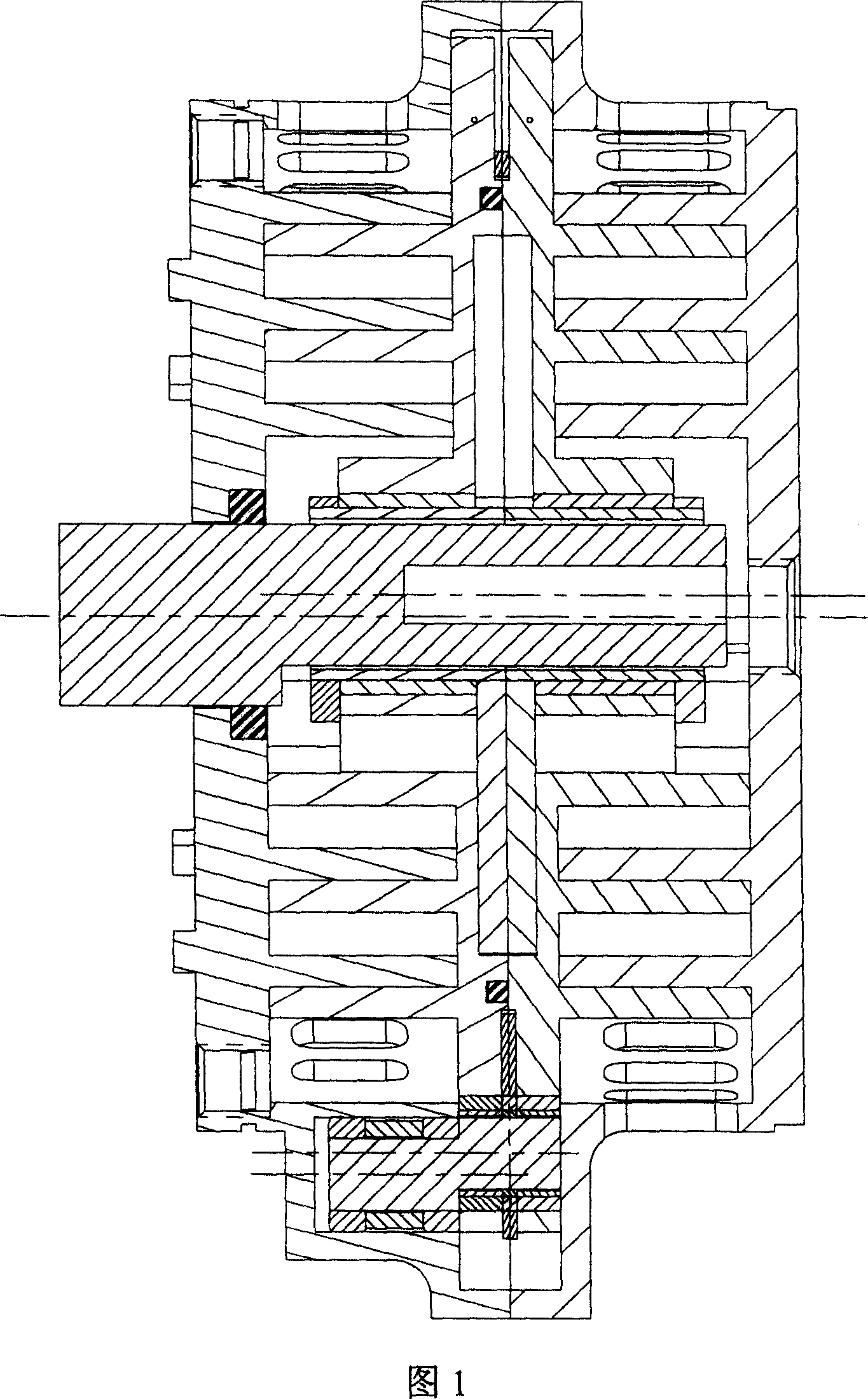

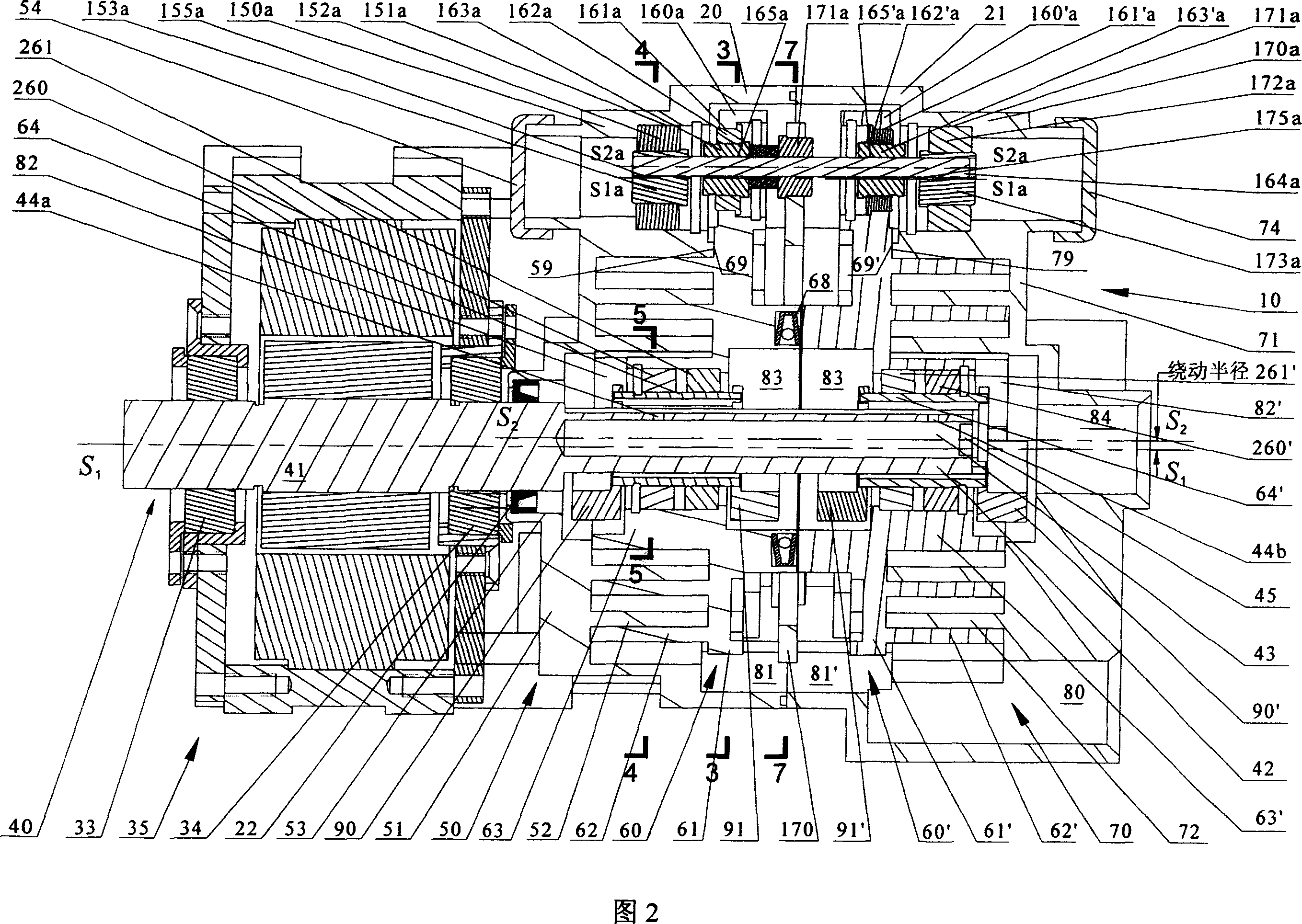

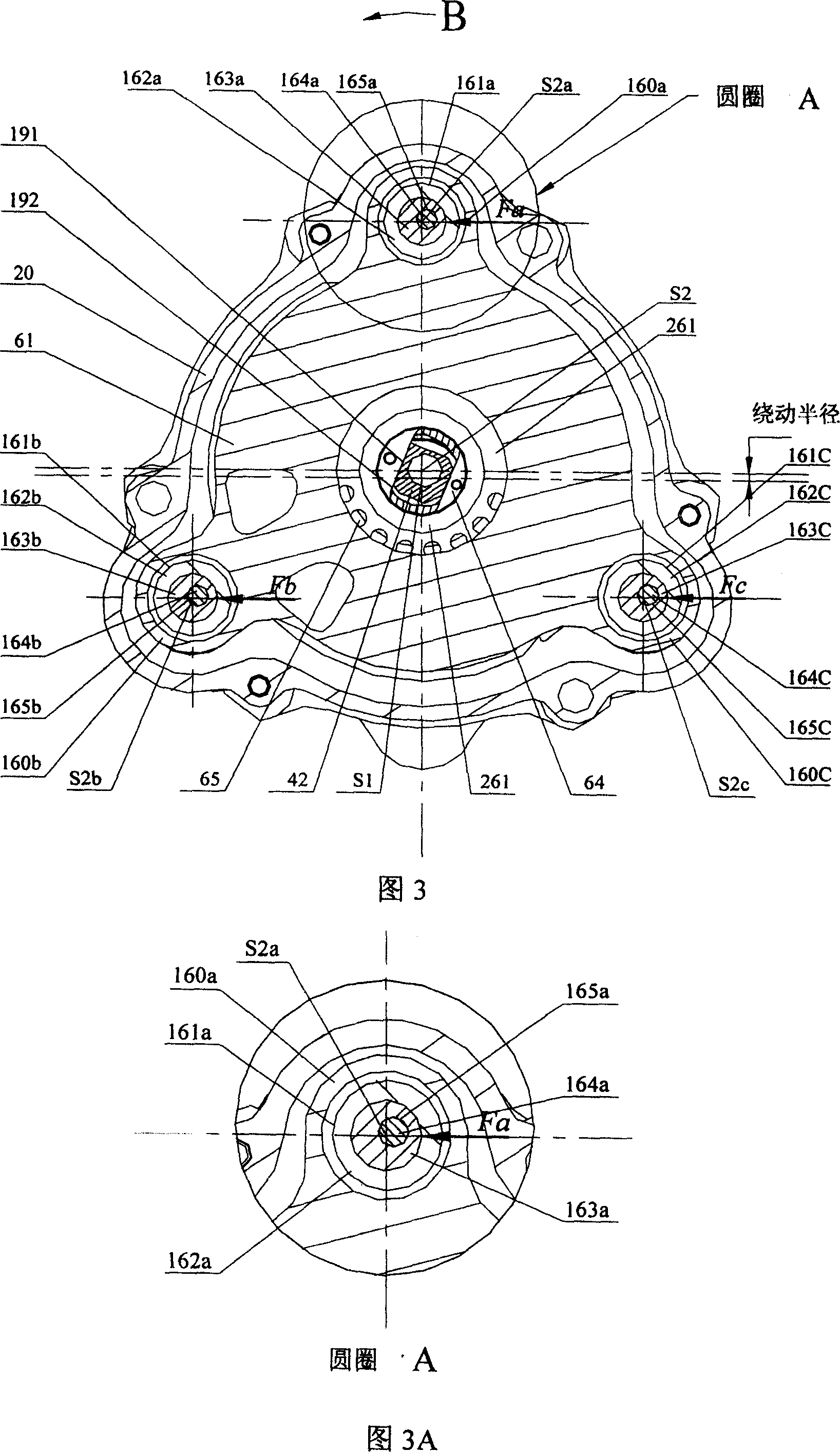

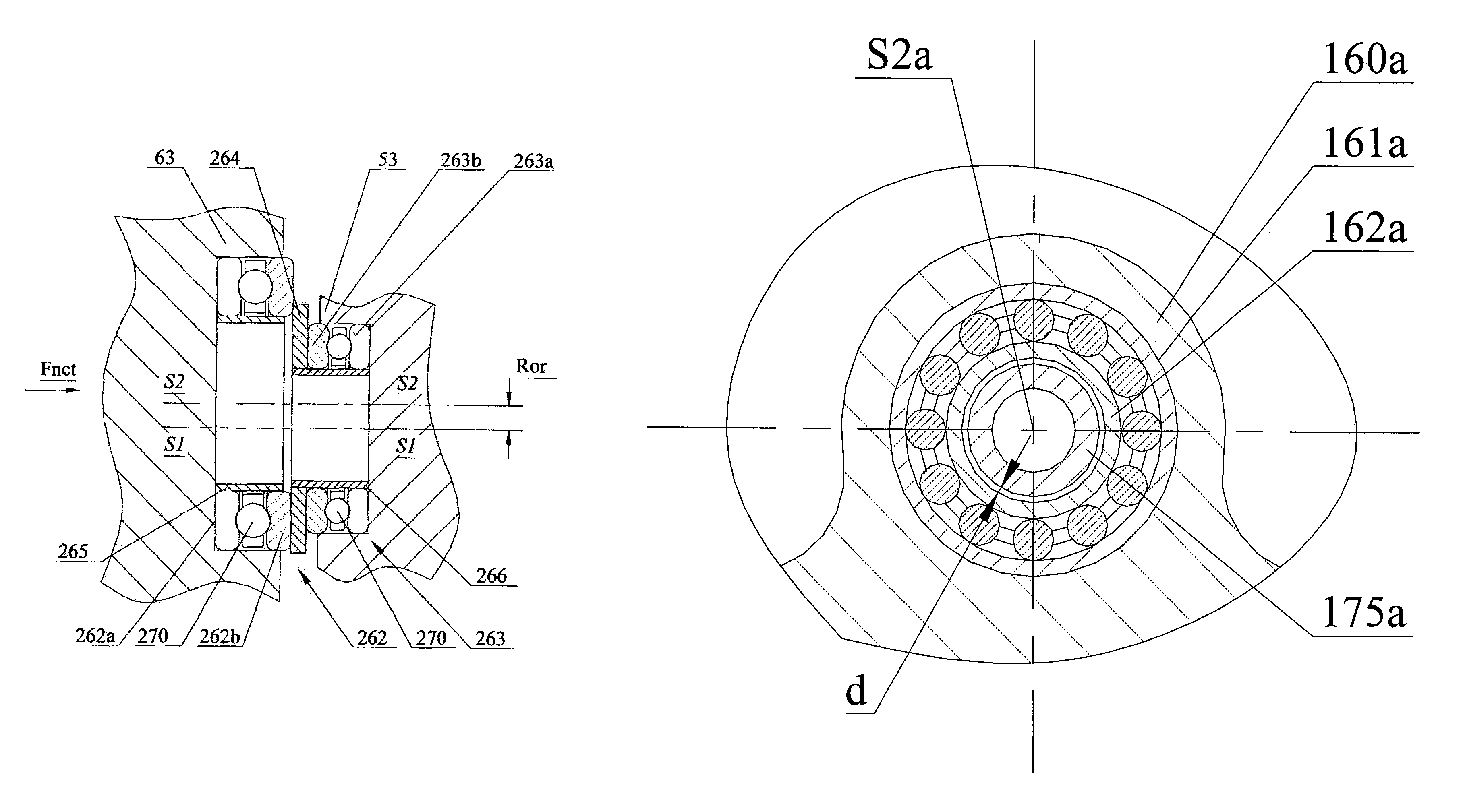

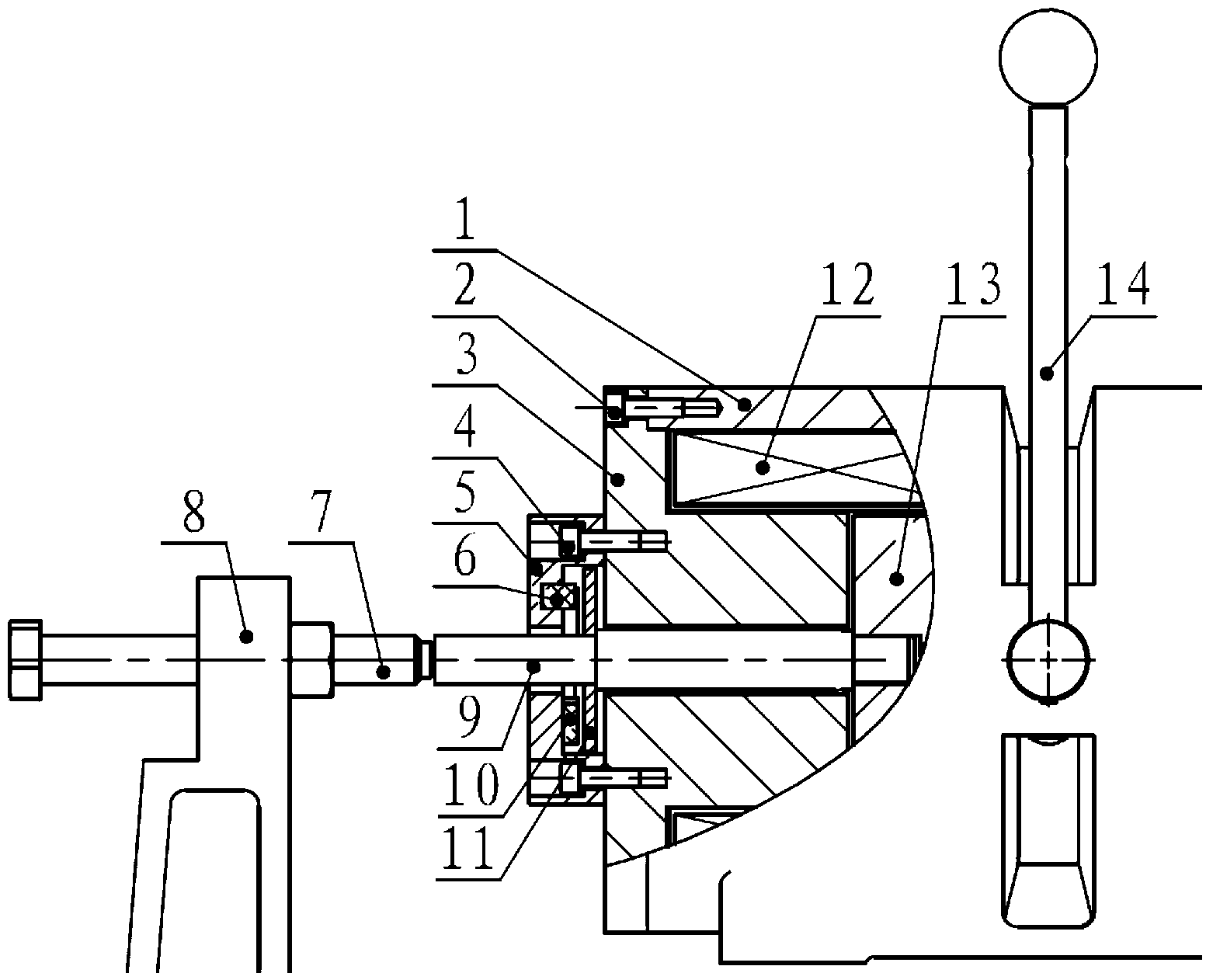

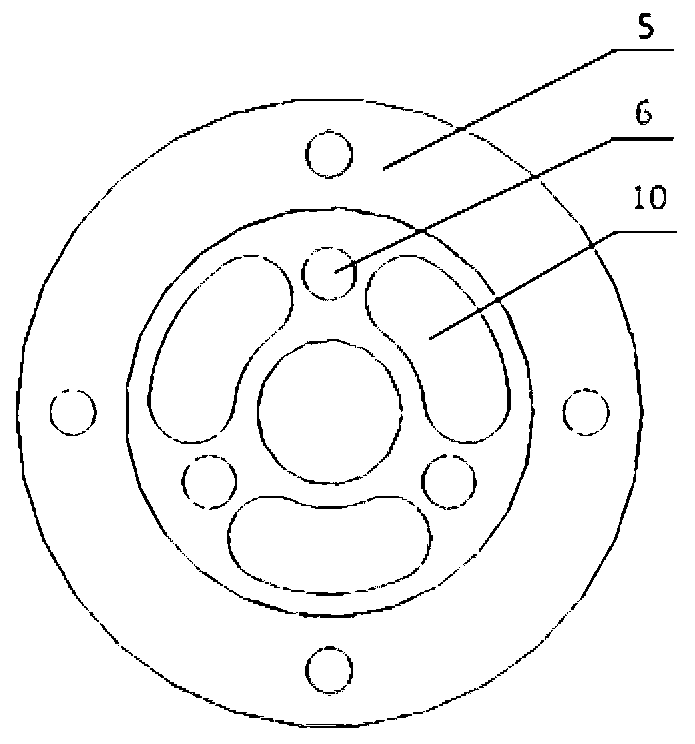

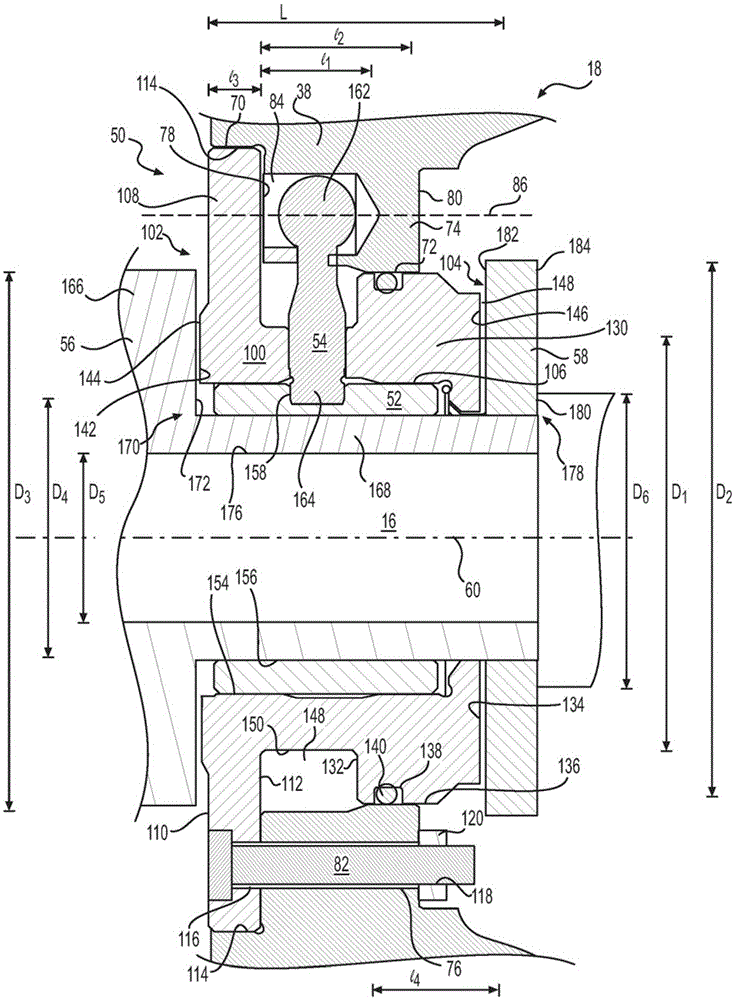

Scroll-type fluid displacement apparatus with fully compliant floating scrolls

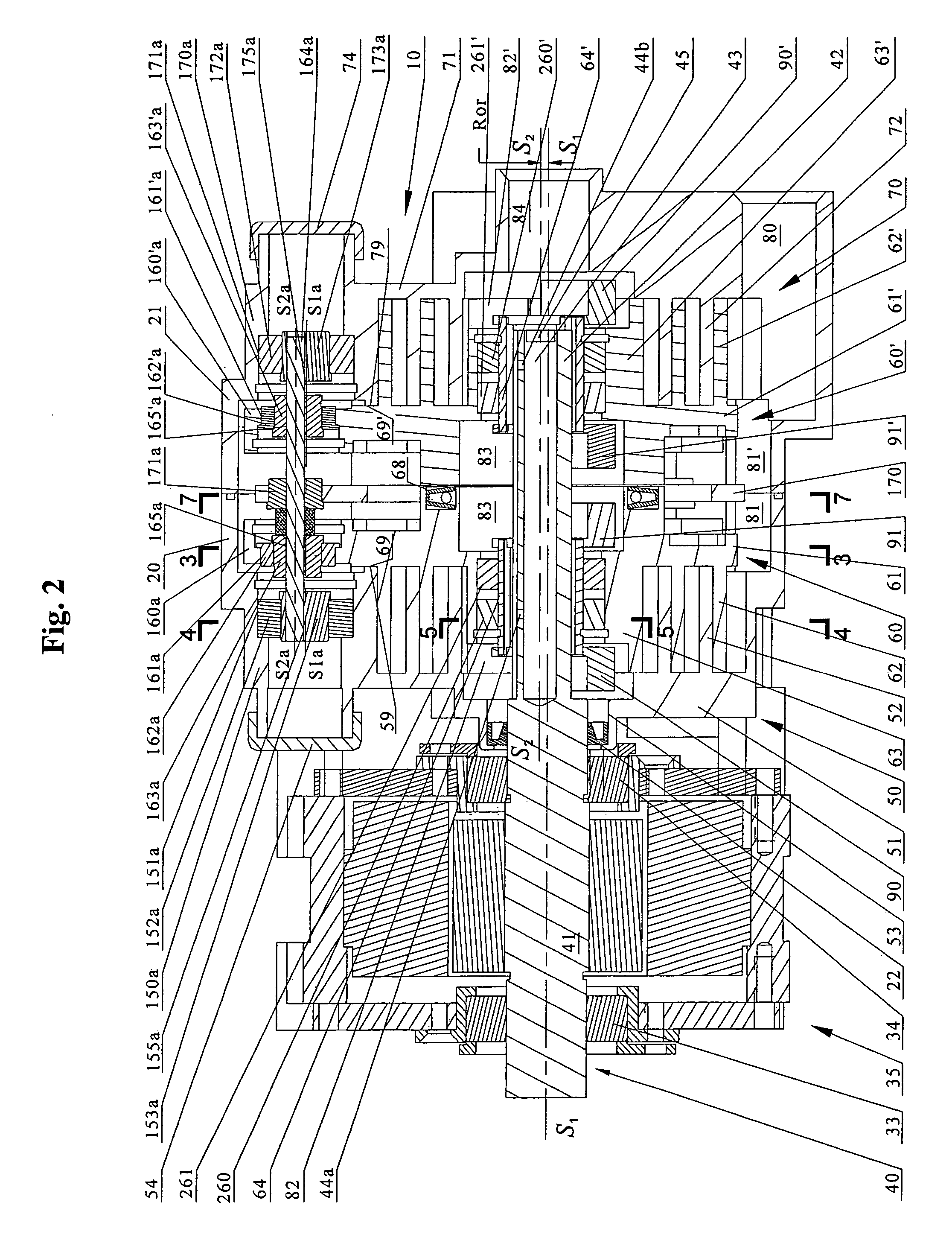

ActiveUS20070172373A1Improve bearing lifeReduce friction and wearRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeBall bearingDrive shaft

A central drive shaft-sliding knuckle combined with a peripheral crank pin-swing link mechanism (CSPS) to provide an orbiting scroll with radial and axial compliant capability. The CSPS mechanism can be applied to both dual floating scroll and single floating scroll structures to improve performances of scroll devices, particularly in oil-free operations. In addition, an orbiting dual thrust ball bearing mechanism is provided to take thrust load in, for example, a floating scroll compressor with a CSPS mechanism.

Owner:NI & ASSOC

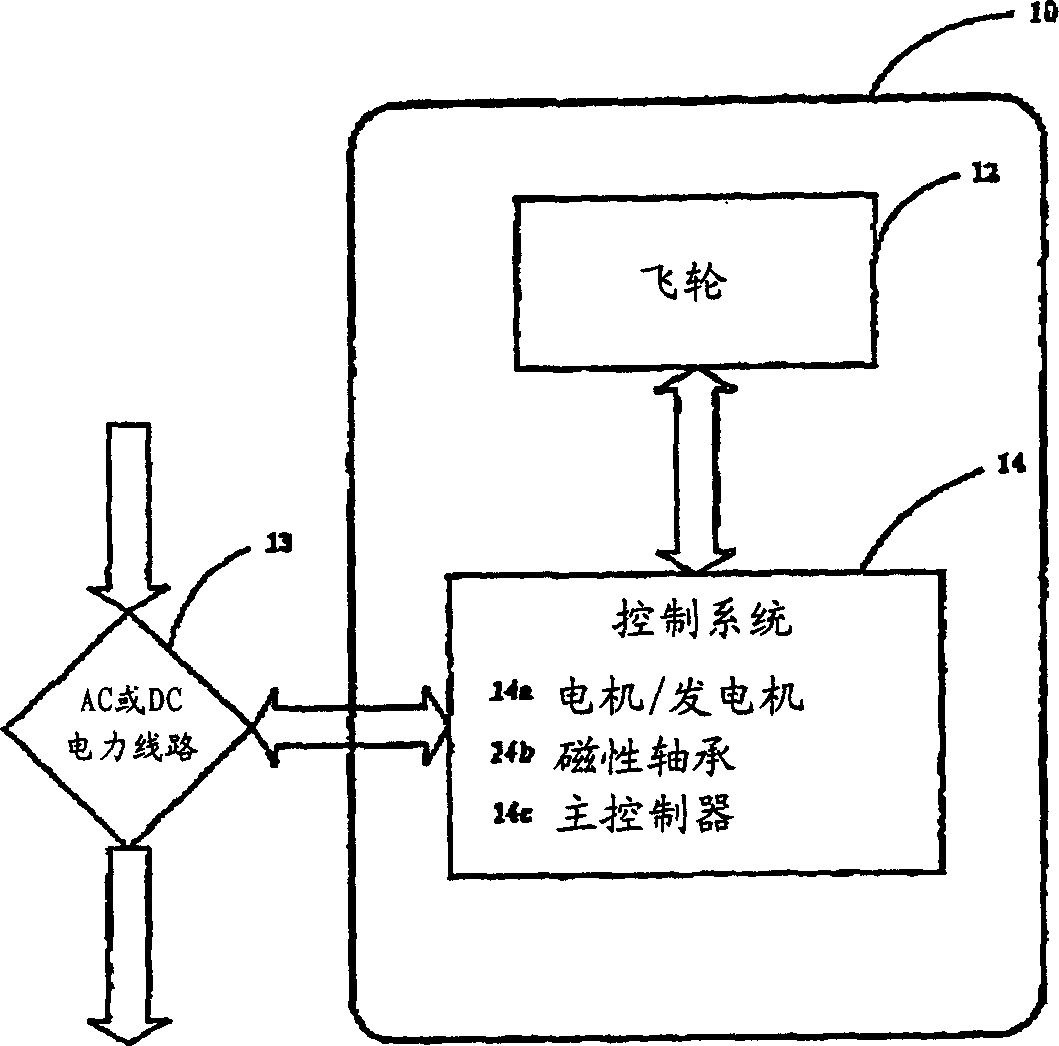

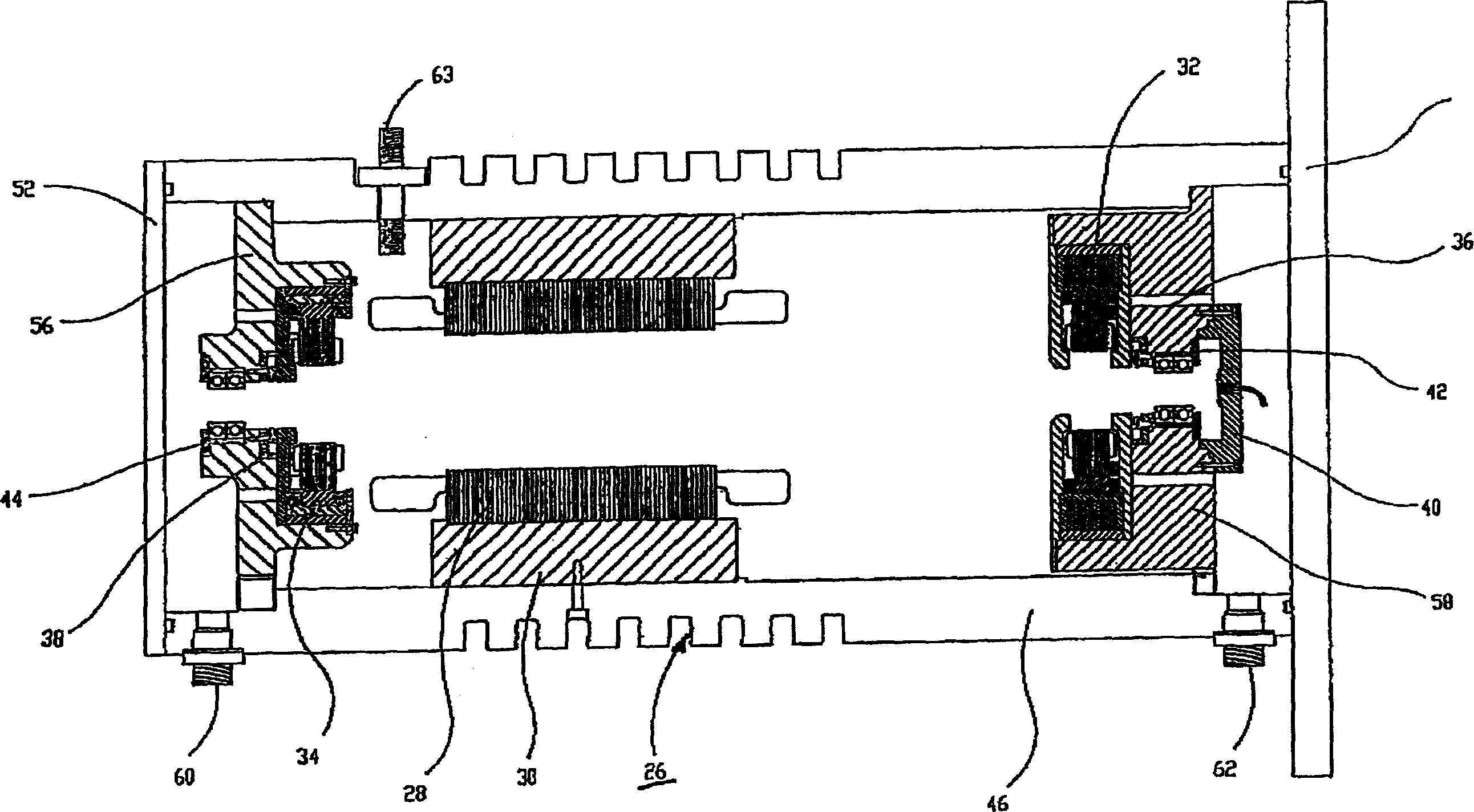

Energy storage flywheel with minimum power magnetic bearing and motor/generator

InactiveCN1759518AImprove power densityLow costMagnetic circuit rotating partsEngine componentsMagnetic bearingElectric machine

An optimized flywheel energy storage system utilizing magnetic bearings, a high speed permanent magnet motor / generator, and a flywheel member. The flywheel system is constructed using a high strength steel wheel for kinetic energy storage, high efficiency magnetic bearings configured with dual thrust acting permanent magnet combination bearings, and a high efficiency permanent magnet motor generator. The steel wheel provides a cost effective, high speed construction for the energy storage rotor.

Owner:帕特里克·T·麦克马伦 +1

Improved scroll-type fluid displacement apparatus with fully compliant floating scrolls

ActiveCN101008321AReduce wearReduce energy consumptionRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsBall bearingDrive shaft

A central drive shaft-sliding knuckle combined with a peripheral crank pin-swing link mechanism (CSPS) to provide an orbiting scroll with radial and axial compliant capability. The CSPS mechanism can be applied to both dual floating scroll and single floating scroll structures to improve performances of scroll devices, particularly in oil-free operations. In addition, an orbiting dual thrust ball bearing mechanism is provided to take thrust load in, for example, a floating scroll compressor with a CSPS mechanism.

Owner:ADVANCED SCROLL TECHNOLOGIES (HANGZHOU) INC

Scroll-type fluid displacement apparatus with fully compliant floating scrolls

ActiveUS7467933B2Improve bearing lifeReduce friction and wearRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeBall bearingDrive shaft

Owner:NI & ASSOC

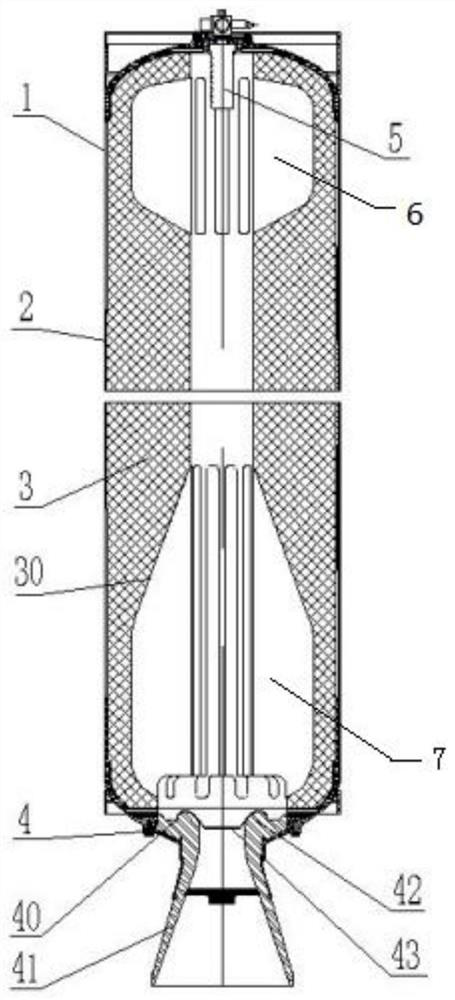

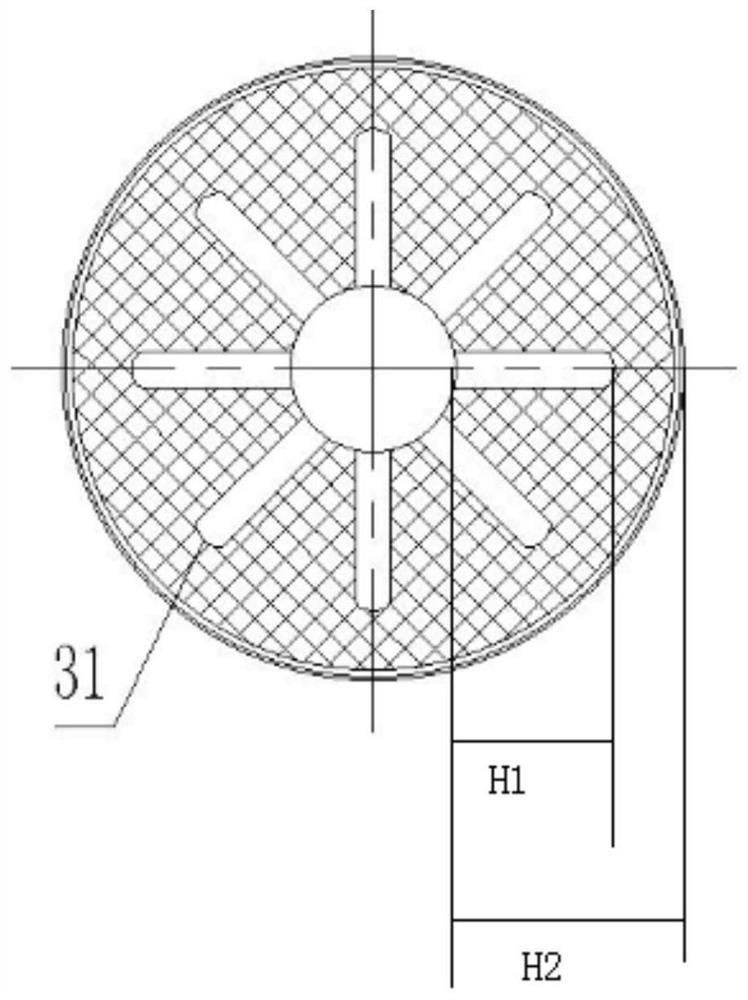

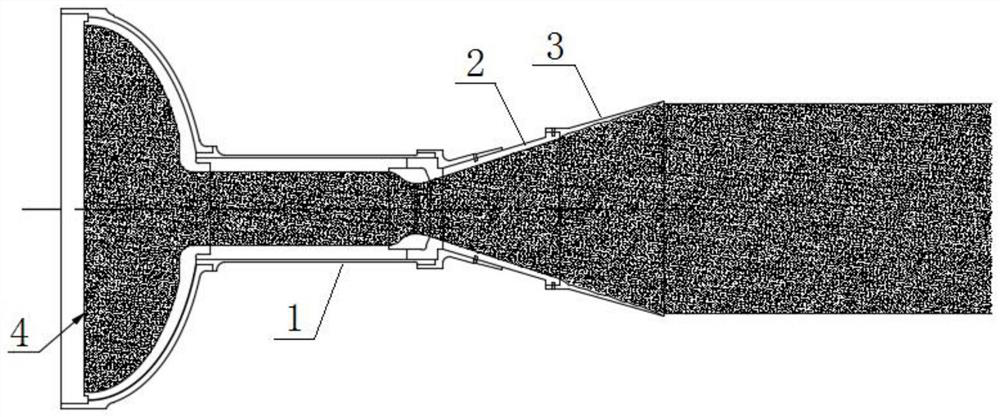

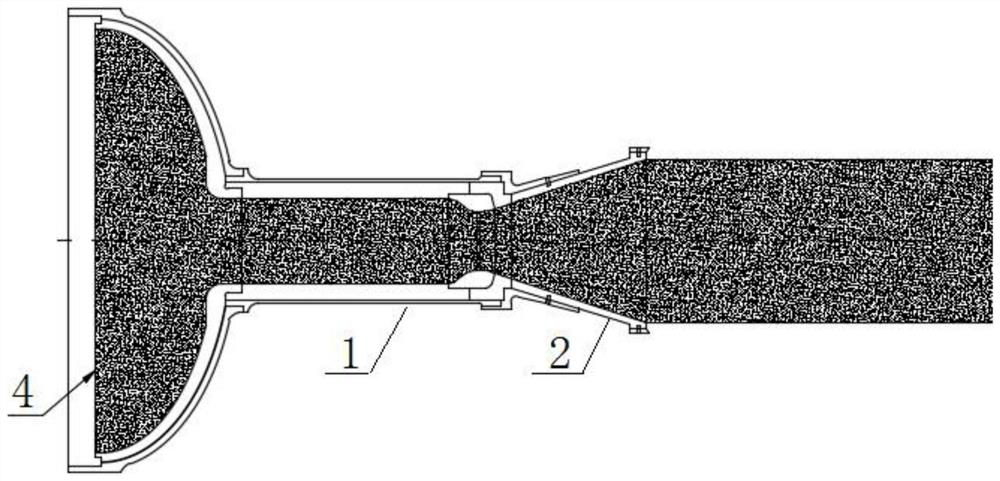

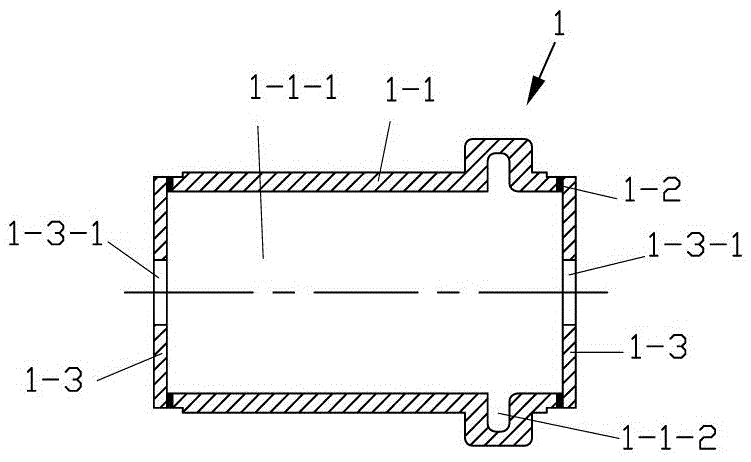

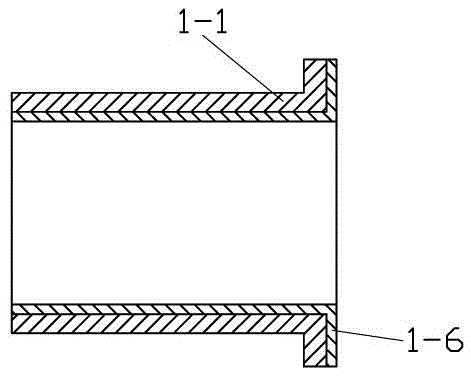

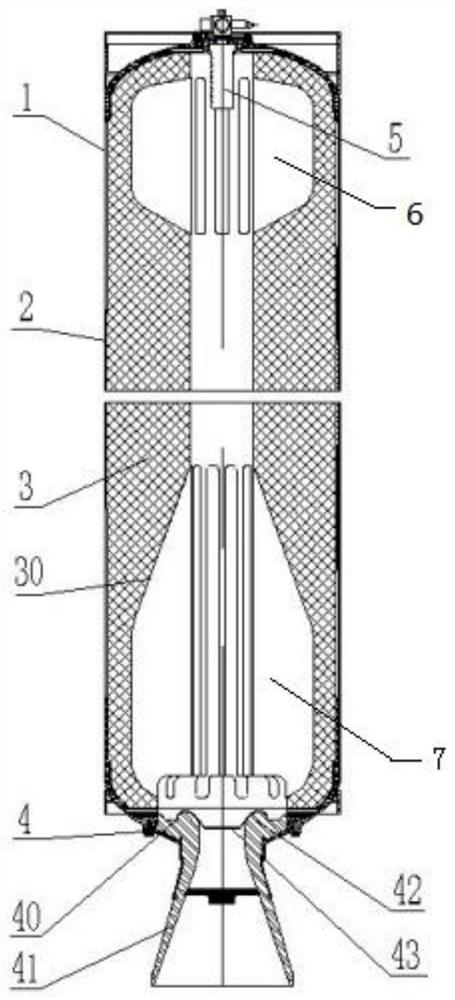

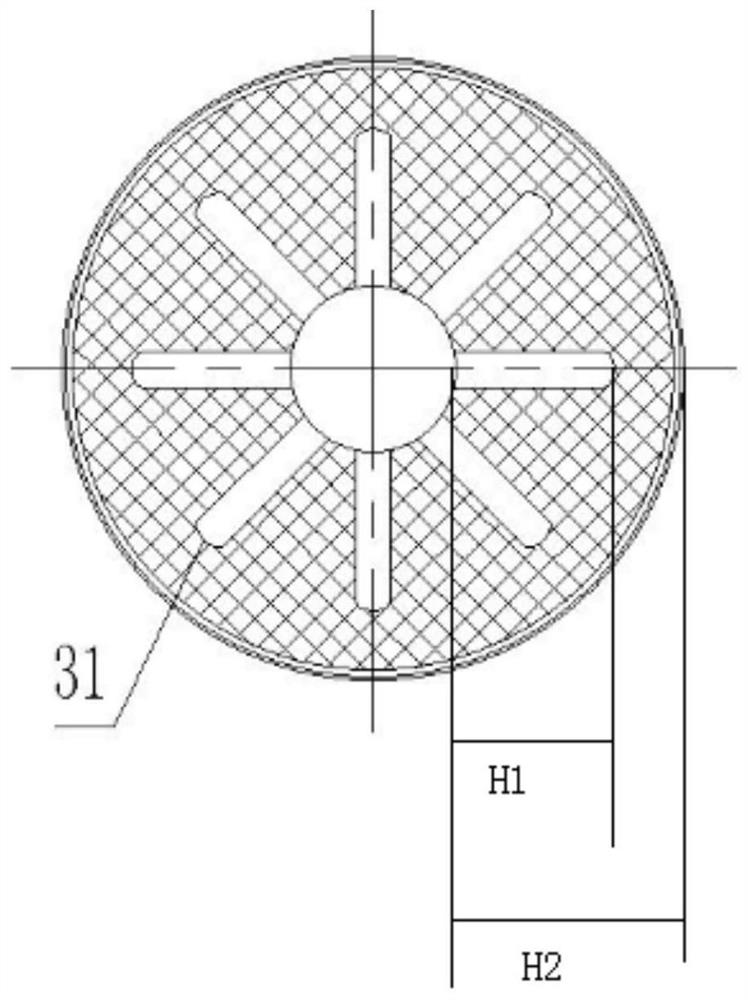

Single-compartment dual-thrust solid rocket engine and rocket

ActiveCN111810318AIncreased thrust rangeLess severeRocket engine plantsCombustion chamberClassical mechanics

The invention provides a single-compartment dual-thrust solid rocket engine and a rocket. The engine comprises a combustion chamber housing, a heat insulating layer attached to the inner surface of the combustion chamber housing, a propellant grain positioned in the combustion chamber housing, an igniter arranged at one end of the combustion chamber housing and a spray tube assembly arranged at the other end of the combustion chamber housing, wherein the propellant grain is provided with an inner hole which penetrates through the two ends of the propellant grain; the position, at one end closeto the igniter, of the inner hole, of the propellant grain is uniformly provided with a front wing slot which extends in a radial direction, and the position, at one end close to the spray tube assembly, of the inner hole, of the propellant grain is provided with a tail wing slot which extends in the radial direction; a ratio of wing slot depth of the front wing slot and the tail wing slot to thebiggest thickness of the propellant grain is greater than or equal to 0.81; and the slope range of the rear wing axial slope of the grain ranges from 160 degrees to 170 degrees. The single-compartment dual-thrust solid rocket engine is great in thrust change range, is stable in grain structure, is small in grain combustion surface change speed while an engine thrust mode is converted, can effectively reduce pressure intensity change speed of the combustion chamber, and enables thrust change speed to be gentle.

Owner:北京凌空天行科技有限责任公司

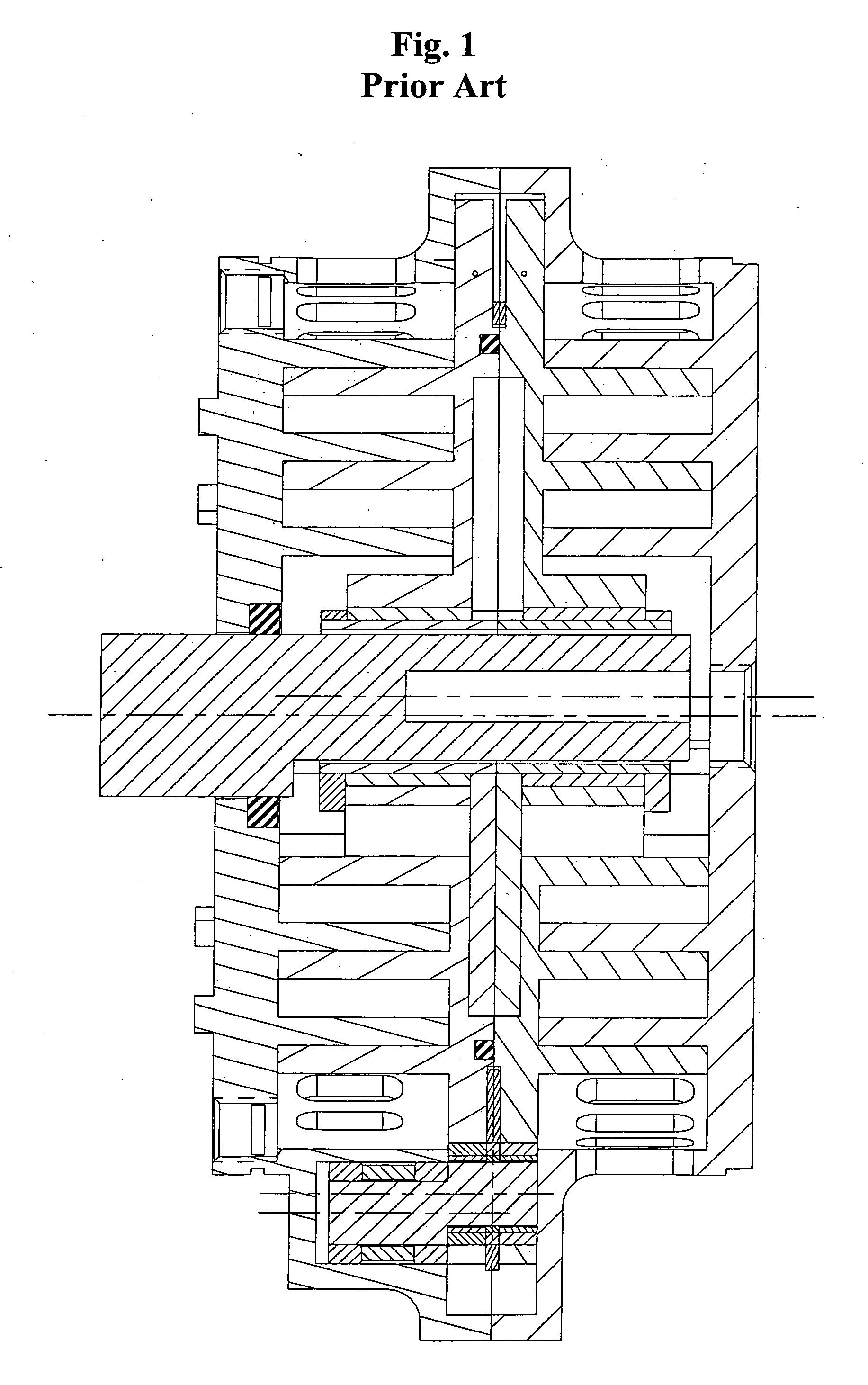

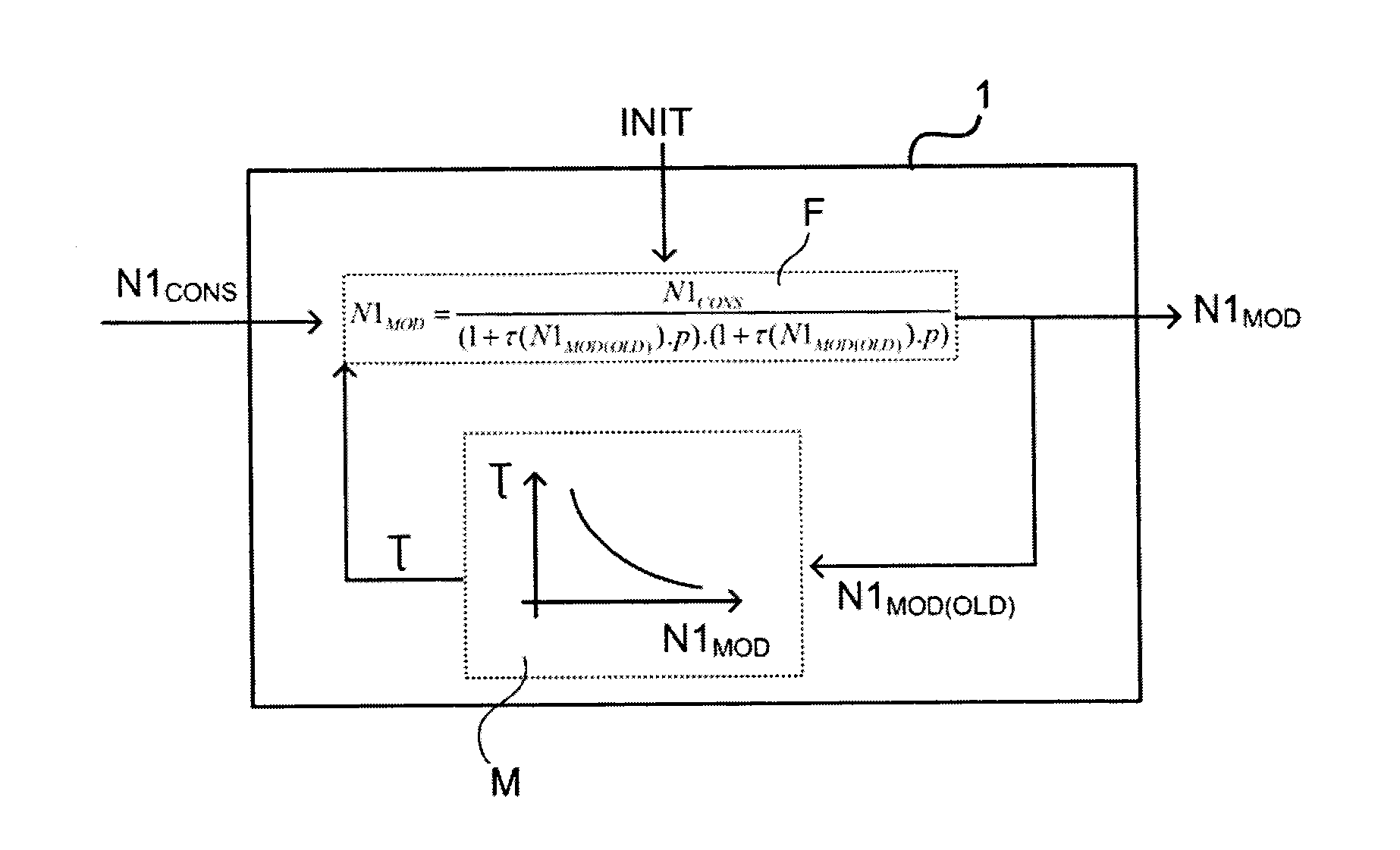

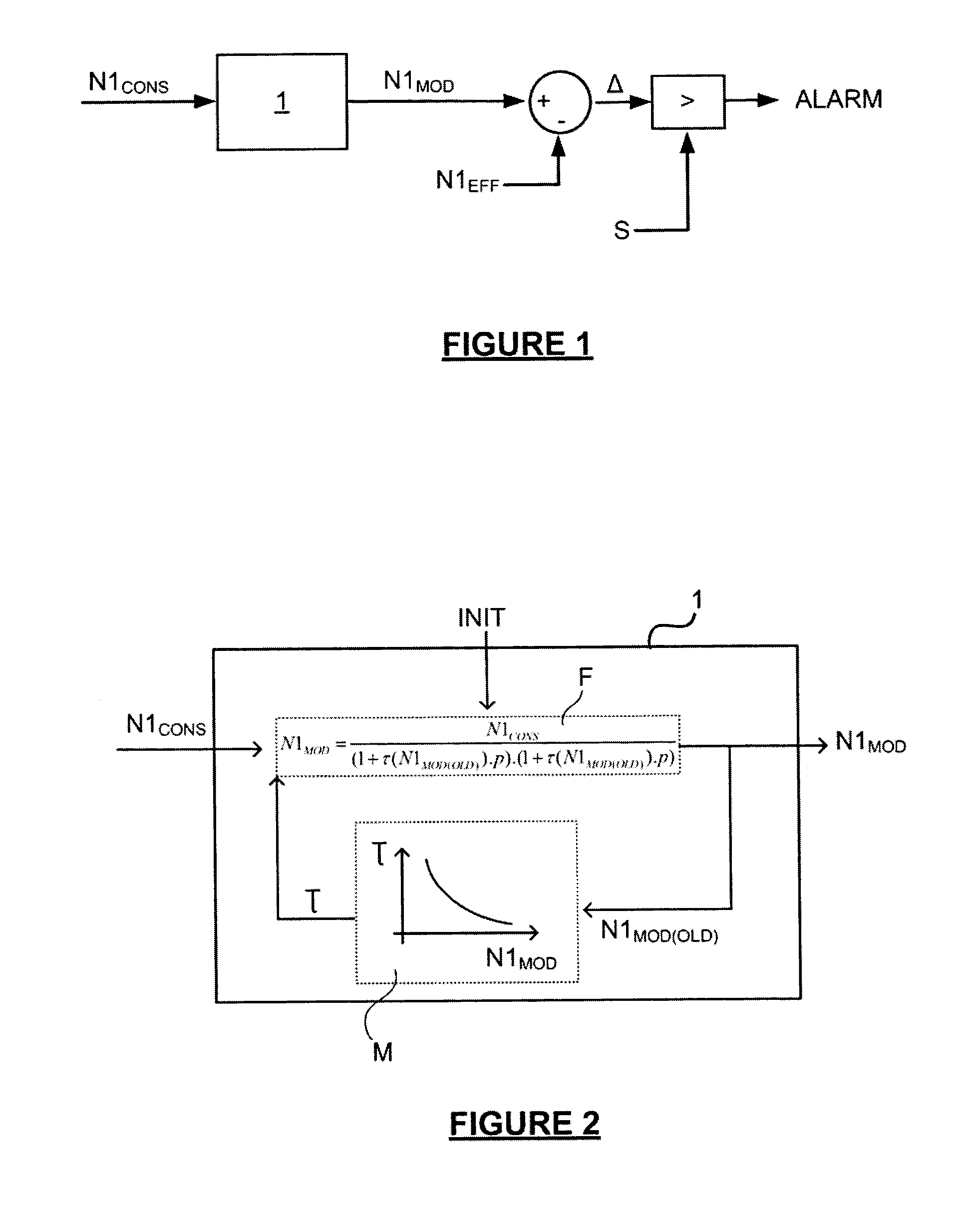

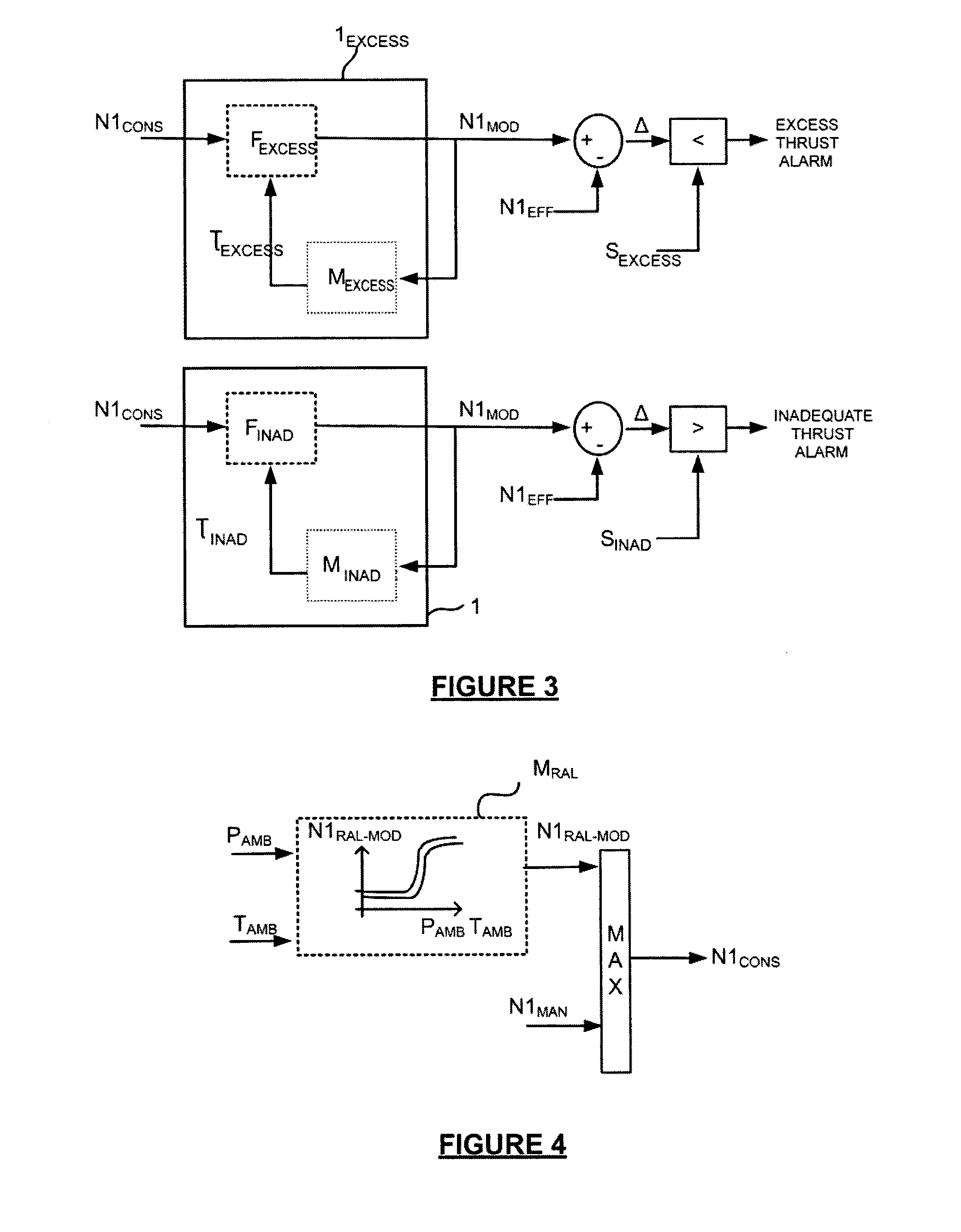

Method for monitoring a thrust fault of an aircraft turbofan

ActiveUS20150219528A1Controlling the riskImprove reliabilityGas-turbine engine testingEngine fuctionsDual-thrustThrust fault

A method for monitoring a thrust fault of a turbofan during a modification of the thrust setting of the turbofan, the method including a step of processing the thrust setting via a filtering function and a transient-phase model such as to obtain a modelled thrust, a step of comparing the modelled thrust to the actual thrust such as to determine a thrust difference, a step of comparing the thrust difference to an alarm threshold; and a step of emitting an alarm in the event of exceeding the alarm threshold, wherein at a given iteration, in which the prior modelled thrust is known, the transient-phase model provides a time constant in accordance with the prior modelled thrust, and the filtering function provides a modelled thrust in accordance with the time constant obtained, the prior modelled thrust and the thrust setting.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

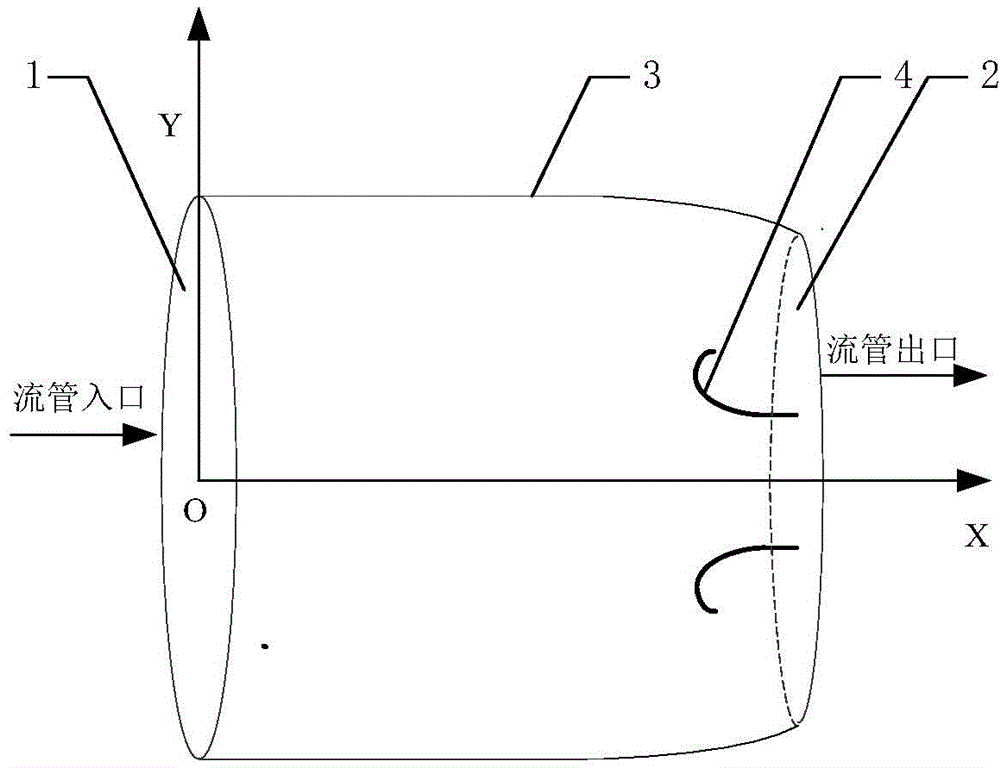

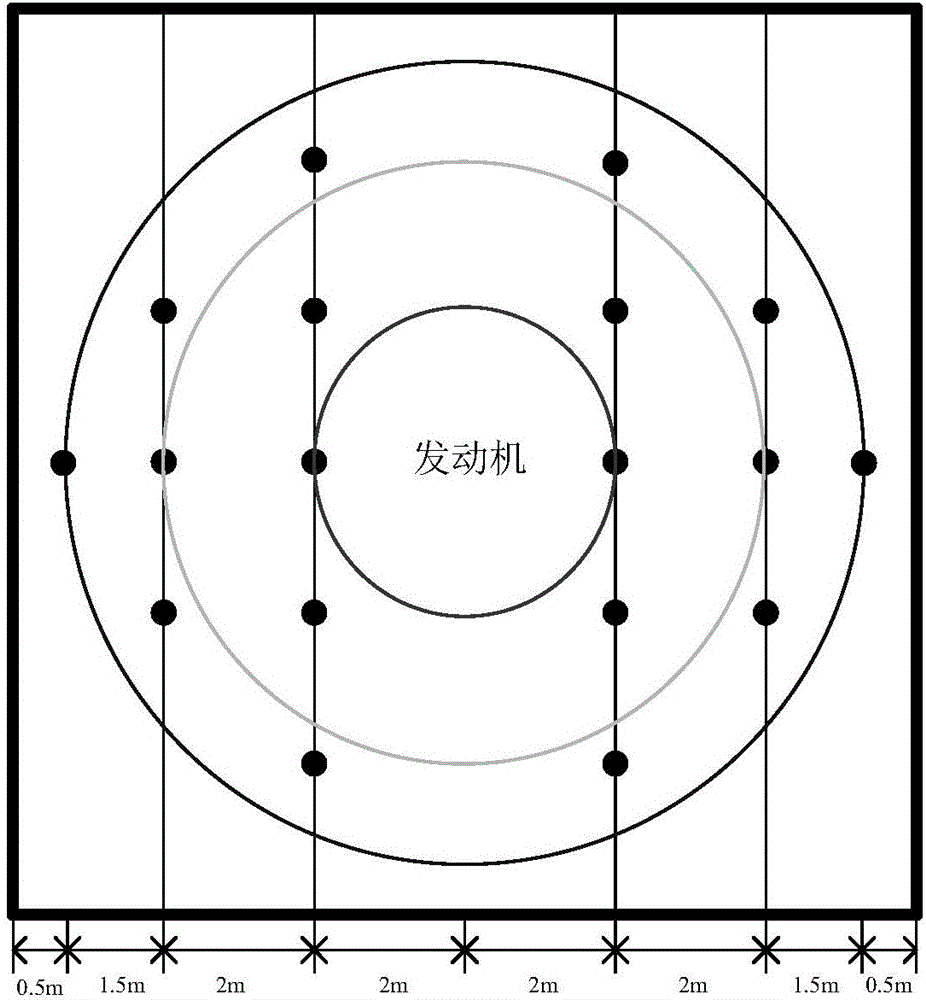

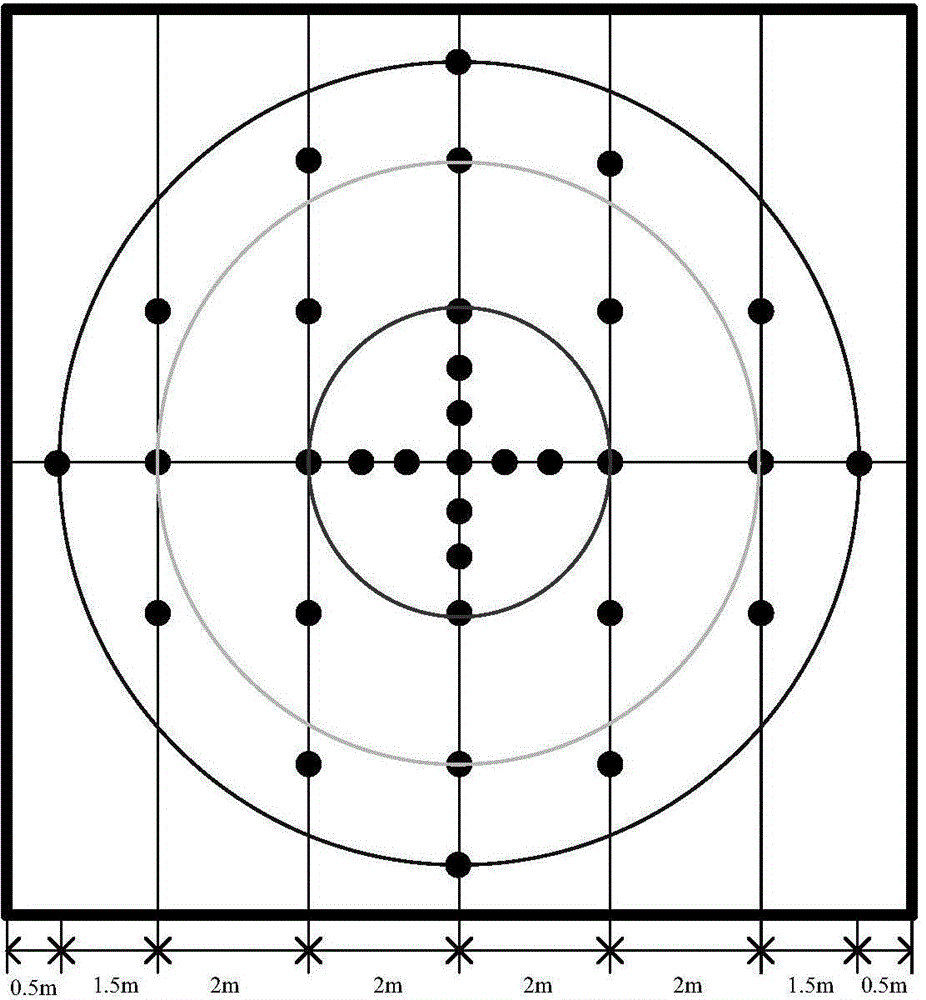

Real thrust measuring and calculating method for test run of aero-engine on indoor test bed

The invention belongs to the technical field of aero-engines and particularly relates to a real thrust measuring and calculating method for test run of an aero-engine on an indoor test bed. The real thrust measuring and calculating method specifically comprises the steps of 1 determining the spatial position of a control body, 2 arranging a rear cross section measuring point on a lip rear cross section (2), 3 arranging front cross section measuring point on a far front cross section (1), 4 obtaining wind speed values and static pressure values on the measuring points, and 5 obtaining a real thrust value of the test run of the aero-engine on the indoor test bed. According to the real thrust measuring and calculating method, the area of air intake cross section of the engine is reasonably selected, the flow pipe surface for air flowing in a test run workshop serves as a control face, an air intake channel additional resistance correction formula is derived and real thrust is calculated by applying momentum theorem. The real thrust measuring and calculating method has the advantages of being clear in control body division, fewer in correction terms, simple and convenient to calculate and the like, and the problem of real thrust measurement and calculation during the test run of the aero-engine on the indoor test bed can be solved.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

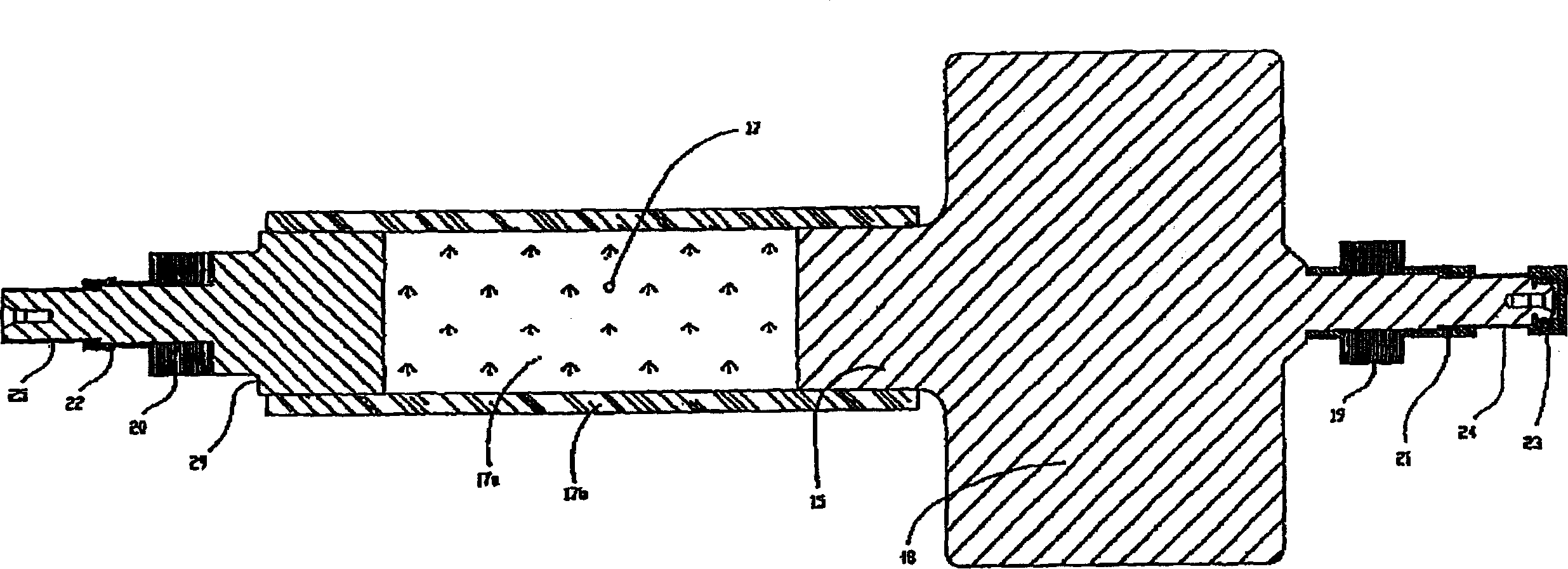

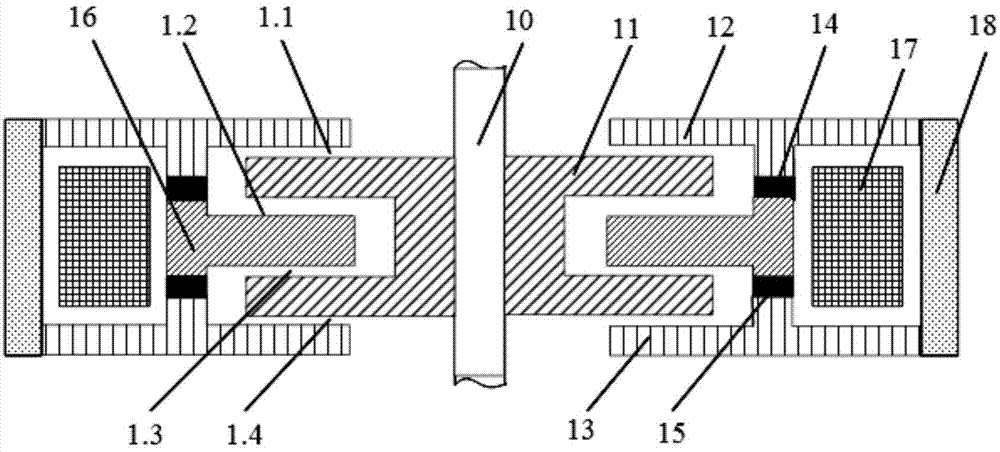

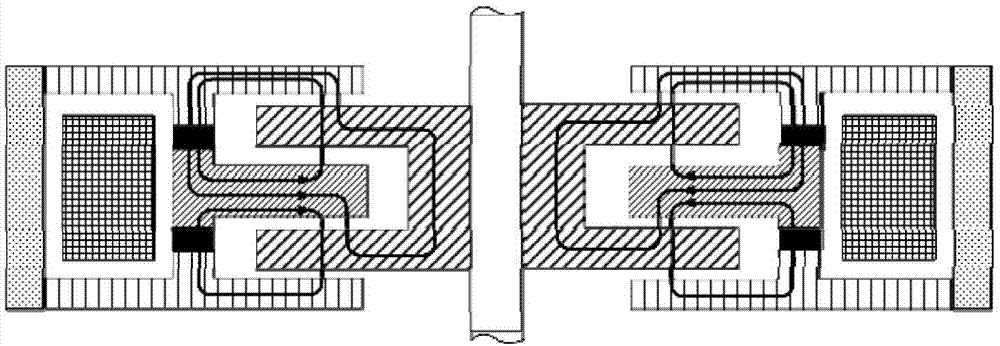

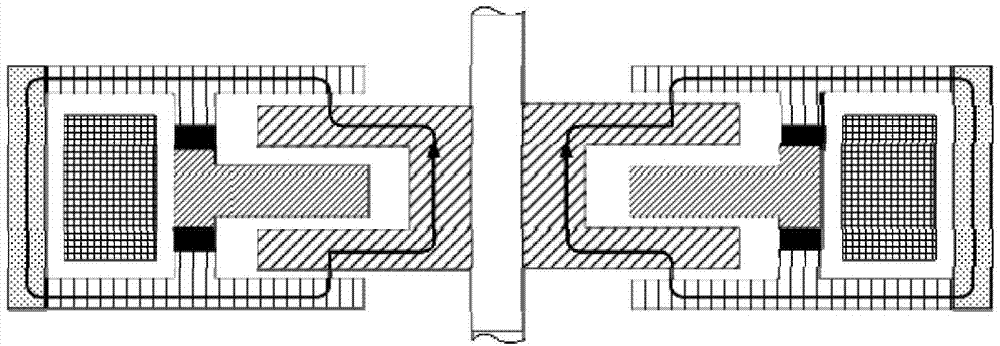

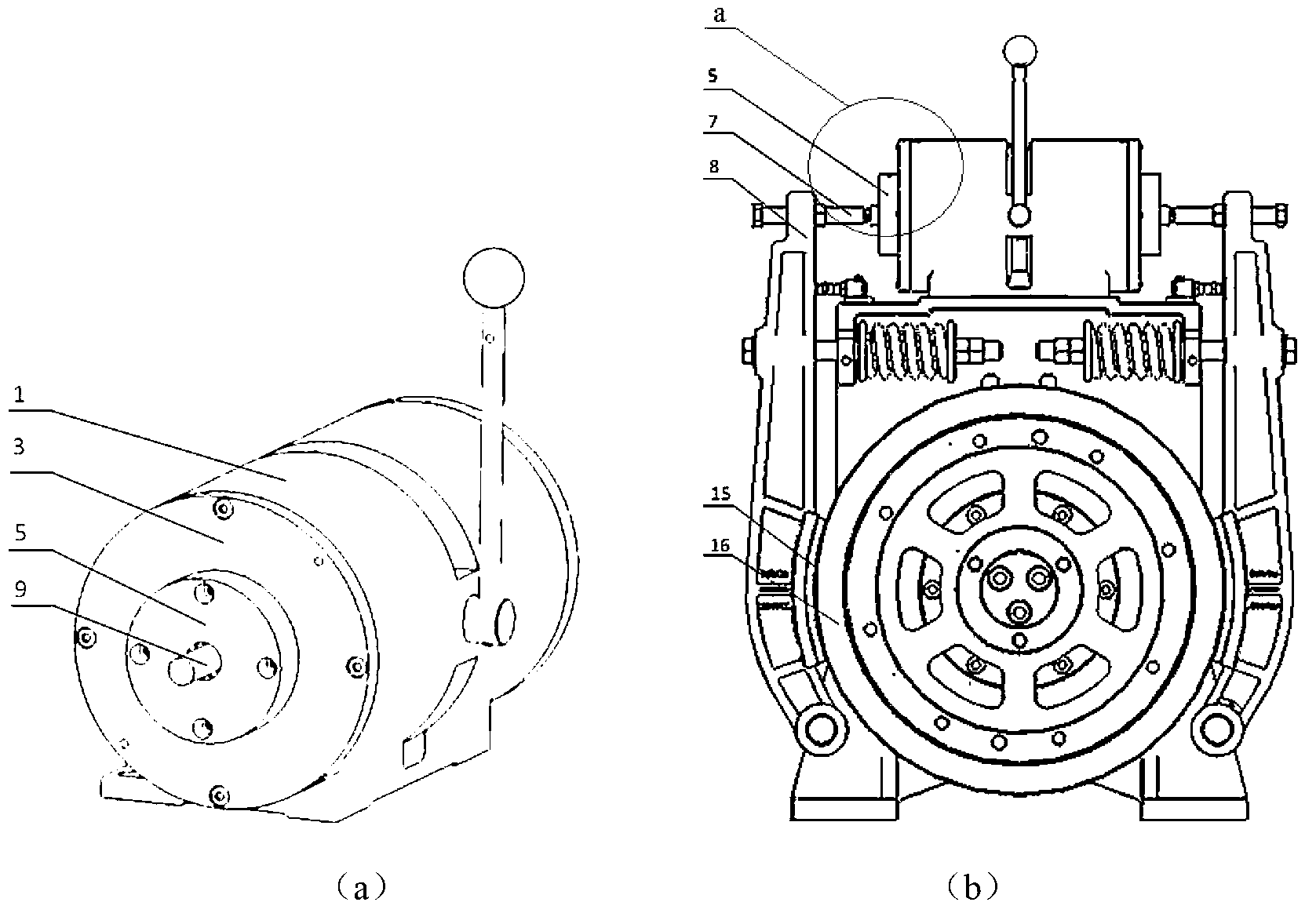

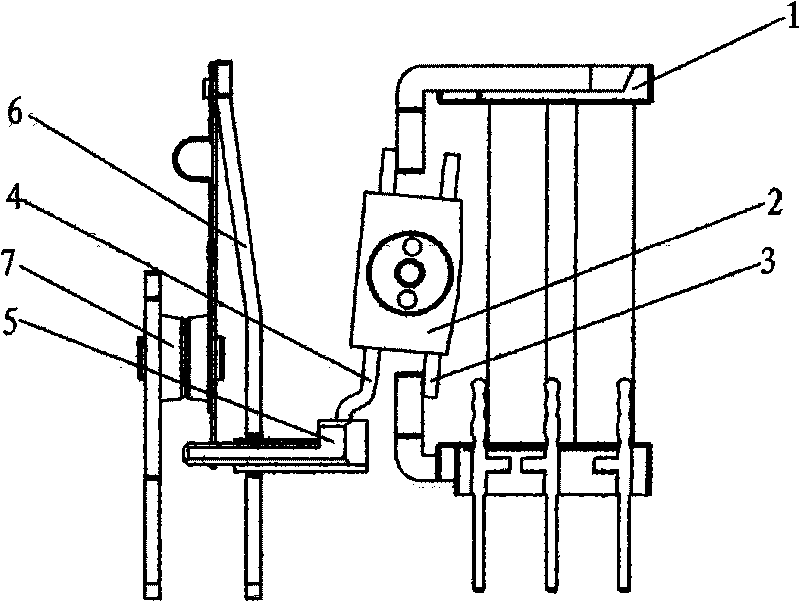

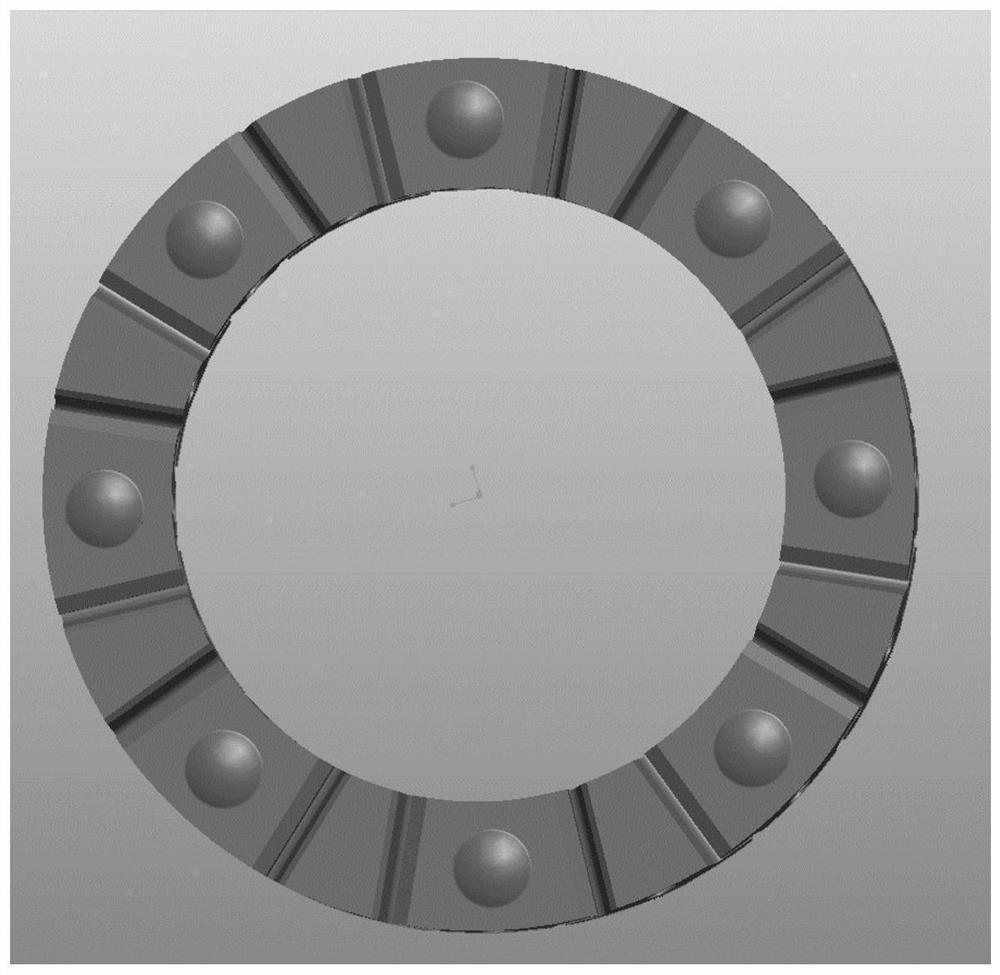

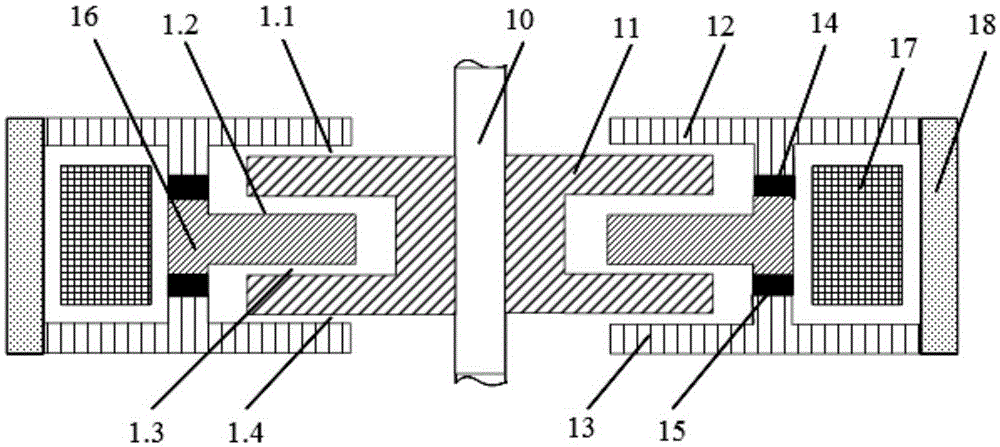

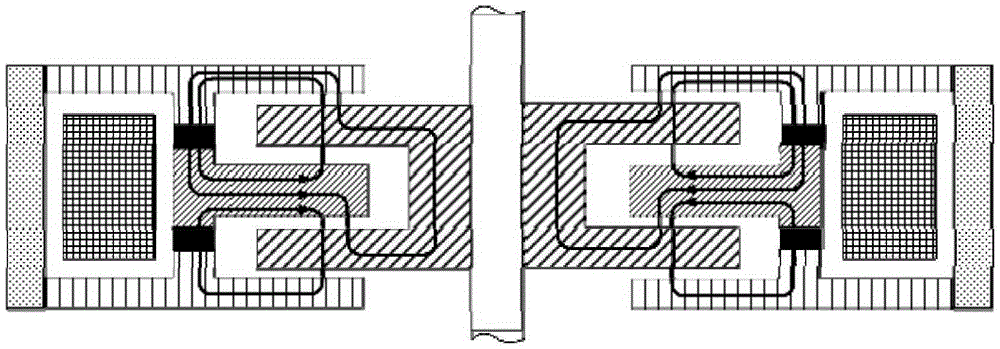

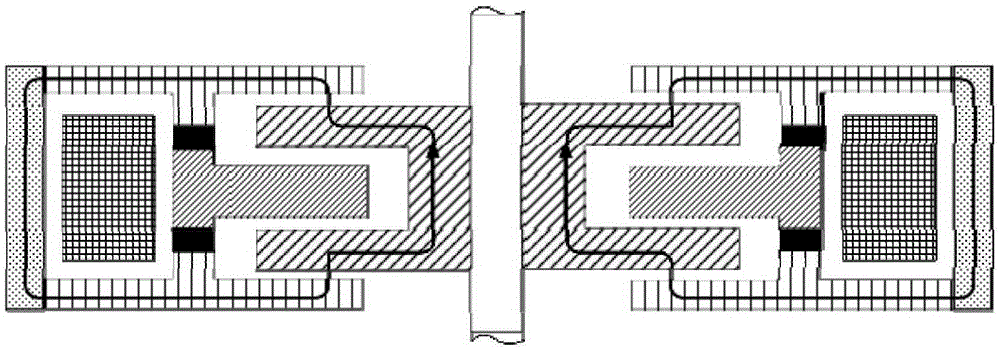

Permanent magnet polarization hybrid axial magnetic bearing

ActiveCN103925291AReduce the impactWill not cause irreversible demagnetizationBearingsMagnetic bearingHigh energy

The invention discloses a permanent magnet polarization hybrid axial magnetic bearing. The permanent magnet polarization hybrid axial magnetic bearing comprises a rotor assembly and a stator assembly, wherein the rotor assembly comprises a rotating shaft and a rotor dual-thrust disc; the stator assembly comprises a stator shell, an upper stator end plate, an upper permanent magnet, a stator center plate, a lower permanent magnet, a lower stator end plate and a stator magnet exciting coil; the upper stator end plate and the lower stator end plate can form an outer upper air gap and an outer lower air gap together with the outer end surface of the rotor dual-thrust disc respectively, and the stator center plate and the inner end surface of the rotor dual-thrust disc can form an inner upper air gap and an inner lower air gap; the upper permanent magnet and the lower permanent magnet can axially magnetized, and magnetizing directions of the upper permanent magnet and the lower permanent magnet are opposite; the inner and outer air gaps can internally generate a permanent magnet polarization magnetic field, a magnetic field generated by the stator magnet exciting coil can regulate the permanent magnet polarization magnetic field. The magnetic bearing provided by the invention has a firm and reliable structure and high energy density, can be applied in a high-speed operation occasion, and is suitable for a high-speed system which has high power and large capacity.

Owner:NAVAL UNIV OF ENG PLA

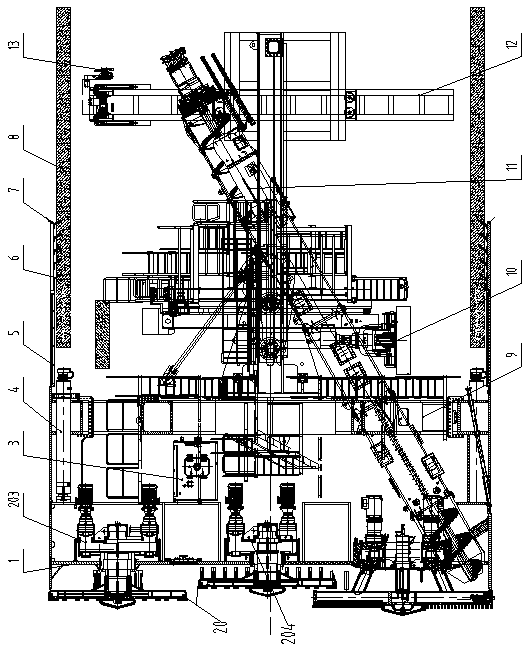

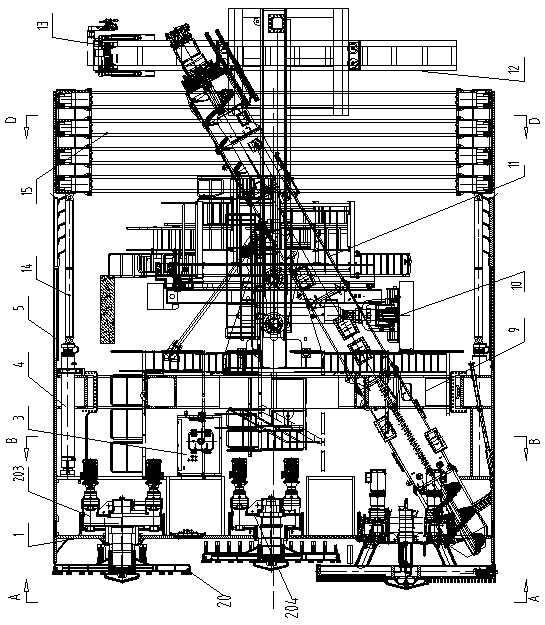

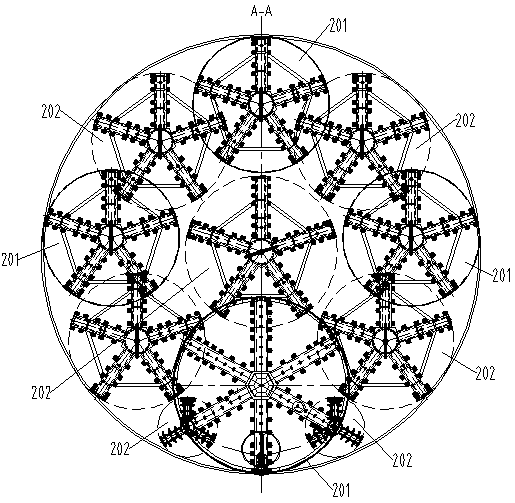

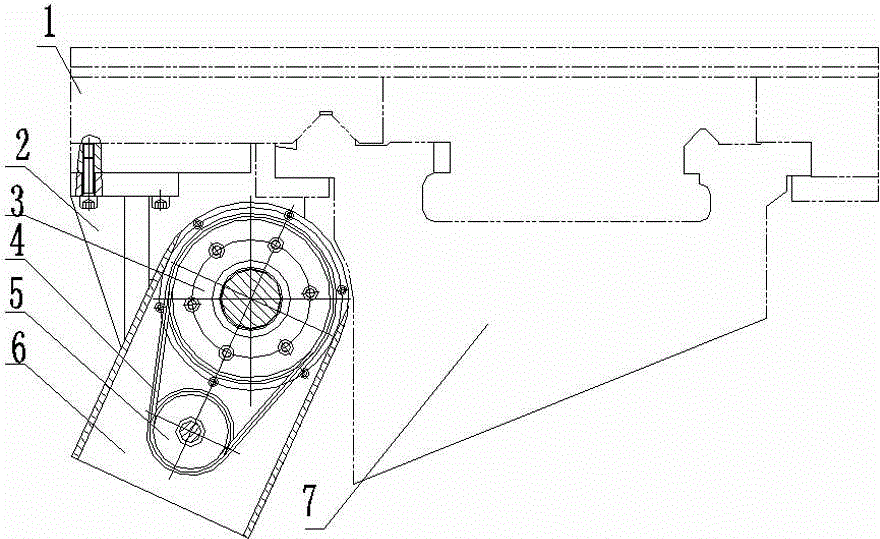

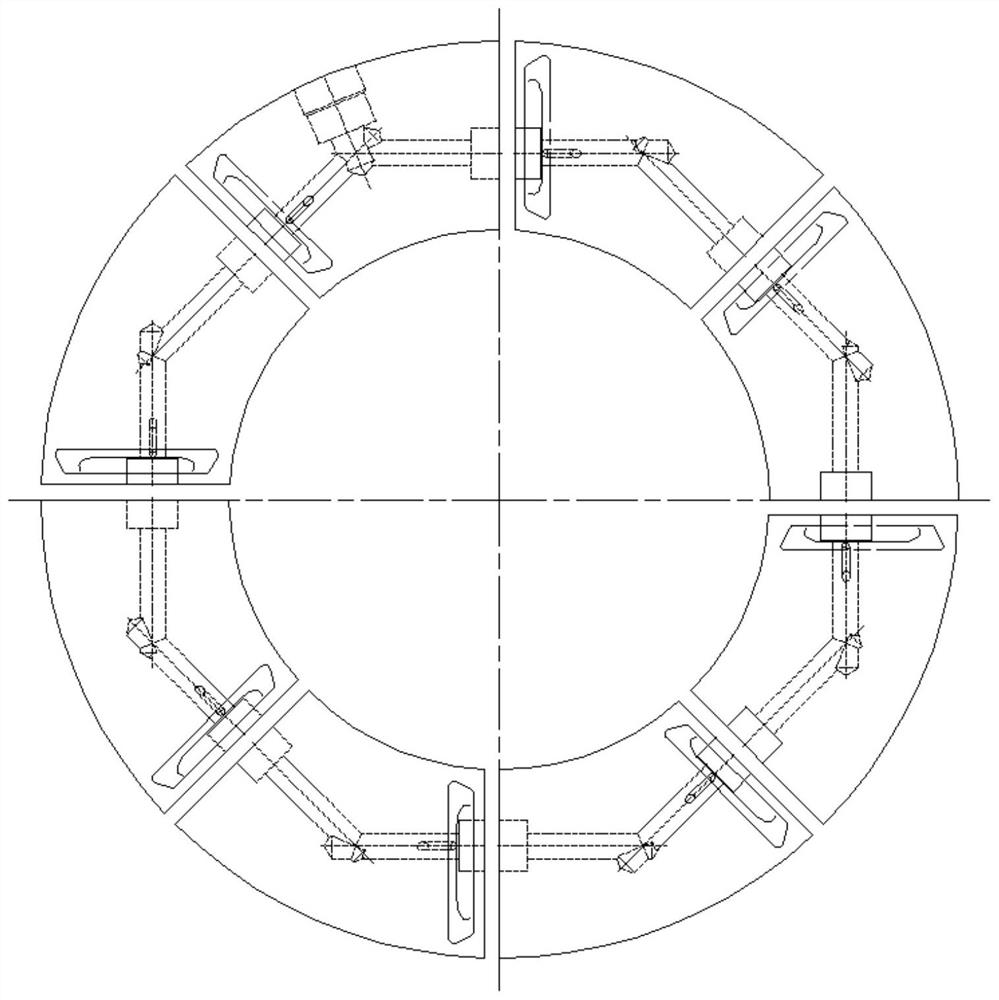

Dual-thrust multi-cutter tunneling machine and tunneling method thereof

PendingCN109630148ALow costSwitching time is shortUnderground chambersTunnel liningShaped beamDual mode

The invention discloses a dual-thrust multi-cutter tunneling machine and a tunneling method thereof. The problems are solved that in the prior art, mode switching of a dual-mode tunneling machine is large in workload, long in time and high in cost. The dual-thrust multi-cutter tunneling machine includes a tunneling system, a segment splicing machine system and a slag discharging system; the tunneling system includes a shield, a cutter main body and an M-shaped beam, a plurality of split-type cutters are arranged at the front end of the cutter main body, and a segment splicing machine, an arc frame mounting device and a concrete spraying device are arranged on the M-shaped beam, wherein the arc frame mounting device is used for mounting a second thrust mechanism, the segment splicing machine is located in front of the arc frame mounting device, and the concrete spraying device is mounted in front of the arc frame mounting device; a thrust oil cylinder is arranged on the periphery of theouter ring of the M-shaped beam, and the split-type cutters correspond to the slag discharging system. According to the dual-thrust multi-cutter tunneling machine, the dual-thrust multi-cutter designis adopted; the split-type cutters replace a large cutter, the drive mode of the split-type cutters is correspondingly changed into an individual drive mode, and in this way, through the multi-cutterdesign, the cost of the cutters is greatly reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

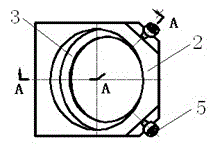

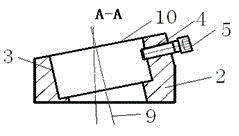

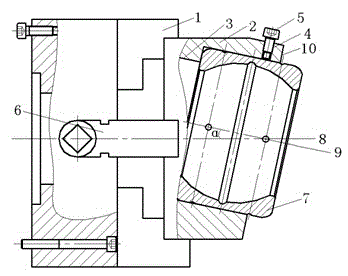

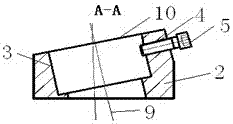

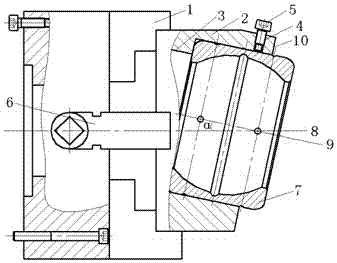

Clamp for machining oil groove, shaped like Arabic number 8, of inner spherical face of joint bearing and producing and using method of clamp

InactiveCN105081802ARealize processingClamp firmlyWork clamping meansPositioning apparatusDual-thrustEngineering

The invention relates to a bearing oil groove machining technology, in particular to a clamp for machining an oil groove, shaped like the Arabic number 8, of the inner spherical face of a joint bearing and a producing and using method of the clamp. The clamp is composed of a mold with an alpha angle face, a clamping hole, a screw hole and a fastening screw rod. The screw hole is located in the surface of the mold. The fastening screw rod is correspondingly screwed into the screw hole. The center line of the mold is perpendicular to the alpha angle face of the mold. An angle alpha is formed between the center line of the mold and the rotation axis of a lathe spindle, and the angle alpha is larger than 0 degree and equal to or smaller than 15 degrees. The clamp is used for clamping the oil groove, shaped like the Arabic number 8, of the inner spherical face of the joint bearing, and therefore an oil groove, shaped like the Arabic number 8, of the inner arc spherical face of a dual-thrust joint bearing can be machined on a common lathe, the bearing can be effectively protected by the copper head fastening screw rod, and when clamped, the bearing can be clamped many times by performing alignment one time; and the using method is easy to operate, and size control is more convenient and accurate.

Owner:BAOTA IND CO LTD +1

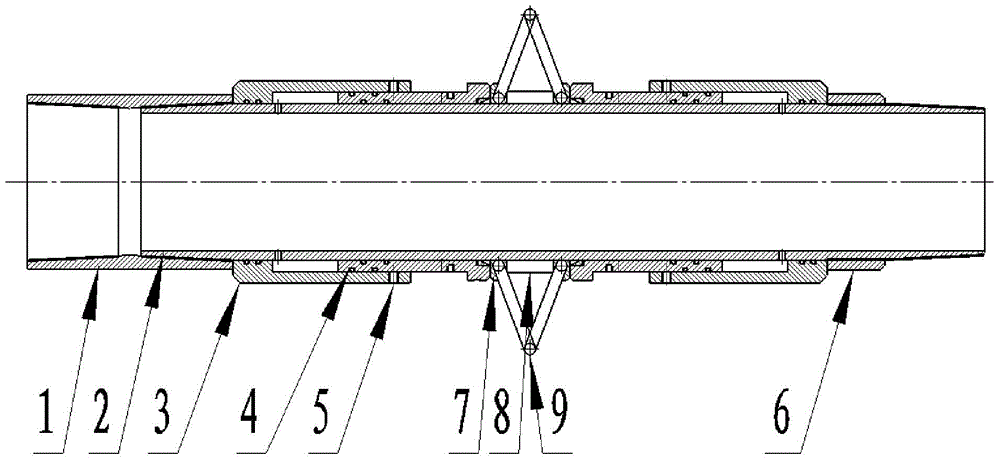

Elbow-type dual-thrust hydraulic centralizer

InactiveCN105178882ASmall outer diameterSmall starting forceDrilling rodsDrilling casingsAxial displacementHydraulic cylinder

The invention provides an elbow-type dual-thrust hydraulic centralizer. The elbow-type dual-thrust hydraulic centralizer comprises a hydraulic thrust system and a centering system, wherein the hydraulic thrust system comprises a main body, hydraulic cylinders and a retaining system; the hydraulic cylinders are arranged on the main body; a piston is arranged in each hydraulic cylinder; the hydraulic cylinders and the pistons act on the centering system through in-pipe pressure building to realize centering; the retaining system can realize permanent centering after in-pipe pressure relief; the centering system comprises a push ring, a positioning block and at least four groups of elbows uniformly distributed on the circumference of the main body; the push ring is connected with the pistons; the positioning block is fixed to the middle of the main body; one end of each elbow is fixed on the push ring, and the other end of each elbow is fixed on the positioning block; an included angle is formed between each elbow and the main body; and the centering system can be started up by an extremely small starting force. The bidirectional hydraulic system ensures no axial displacement of the centering system; owing to the unique pre-bending structural design, the starting force of the centering system becomes smaller; and the elbow-type dual-thrust hydraulic centralizer is suitable for centering casings of both horizontal wells and highly-deviated wells.

Owner:CNPC BOHAI DRILLING ENG

Dual-thrust electromagnet damping mechanism

ActiveCN103198916AImprove buffering effectAvoid failureElectromagnets with armaturesLow noiseDual-thrust

The invention discloses a dual-thrust electromagnet damping mechanism, and belongs to the technical field of elevator traction machines. The damping mechanism is symmetrically sleeved on the outside of a push rod and arranged on the outside of an electromagnet core. The damping mechanism on each side comprises a cover plate, a striking plate and multiple stages of damping pads, wherein the cover plate and the striking plate are oppositely arranged to form a cavity, and the multiple stages of damping pads are arranged in the cavity; each stage of damping pad in the multi-stage damping pad is composed of a plurality of damping blocks, the damping blocks are centrosymmetrically arranged through taking the push rod as a central shaft, and the two sides of each damping block are respectively in vertical contact with the cover plate and the striking plate; and each stage of damping pad at least contains two independent columnar structures. According to the invention, because mutually-separated multi-body damping pads are adopted, the damping pads can be repaired or replaced without adjusting key components such as braking arms and electromagnets and the like; and due the application of a multi-stage damping principle, the damping pads are effectively protected while low noises are ensured, so that a situation that the damping pads are over-impacted is avoided, thereby greatly prolonging the service life of the damping pads.

Owner:THYSSENKRUPP ELEVATORS SHANGHAI CO LTD

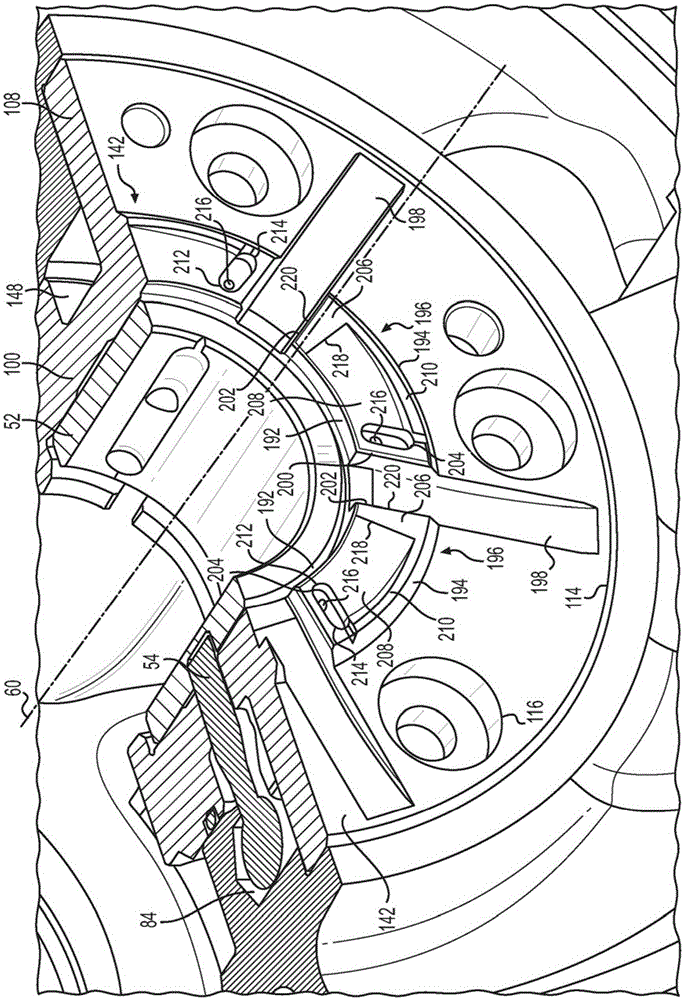

Dual thrust bearing for a turbocharger

A dual thrust bearing is disclosed. The dual thrust bearing may have a shell. The shell may extend from a compressor end to a turbine end opposite the compressor end. The shell may have a shell bore extending from the compressor end to the turbine end. The shell bore may be configured to receive a journal bearing. The shell may also have a first thrust bearing face disposed adjacent the compressor end. In addition, the shell may have a second thrust bearing face disposed adjacent the turbine end.

Owner:ELECTRO-MOTIVE DIESEL

Equidirectional dual-thrust electromagnetic relay

InactiveCN101763985AActive connectionFirmly connectedElectromagnetic relay detailsNon-polarised relaysDual-thrustEngineering

The invention relates to an equidirectional dual-thrust electromagnetic relay, which consists of a main body, an electromagnetic contact, a permanent magnet and double spring plates. Input ends of two upper and lower contacts of the main body are connected with an input power, while output ends thereof are adapted with the electromagnetic contact. The electromagnetic contact is fixed between the output ends of the two contacts of the main body by rotating contenting points. A lower end of a static spring plate of the double spring plates is connected on a phase output end. An upper end of a dynamic spring plate of the double spring plates is fixedly connected with an upper end of the static spring plate, while a lower end thereof is linked with the permanent magnet. The permanent magnet takes a shape of right-angle trisquare. The permanent magnet connected with a connecting end of a conducting strip is arranged on one side, and a static contact fixedly connected with the dynamic spring plate of the double spring plates and a dynamic contact movably connected with the static spring plate of the double spring plates are arranged on the other side. The invention has meticulous design and light and reliable structure, realizes improvement of the functions of the relay by using the basic physical principles, has high practical value and can effectively improve the working reliability of the electric power circuit.

Owner:SANYOU CORP LTD

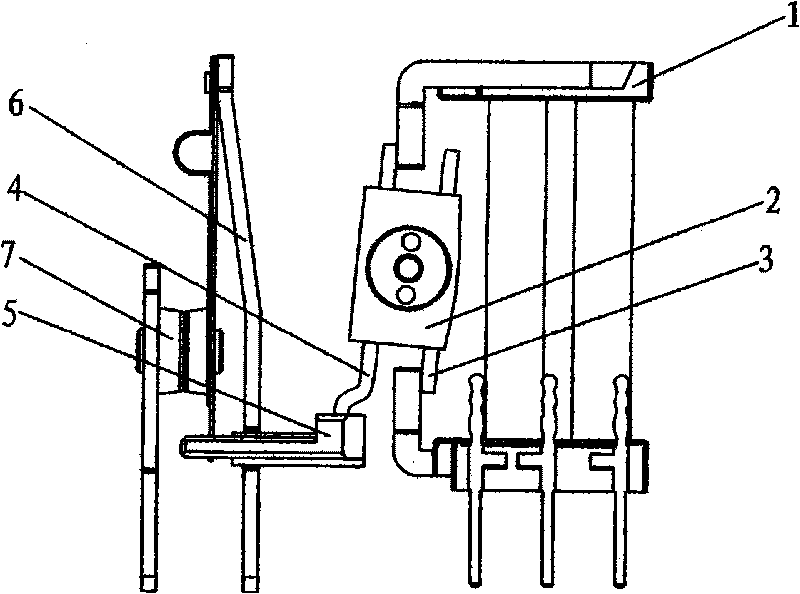

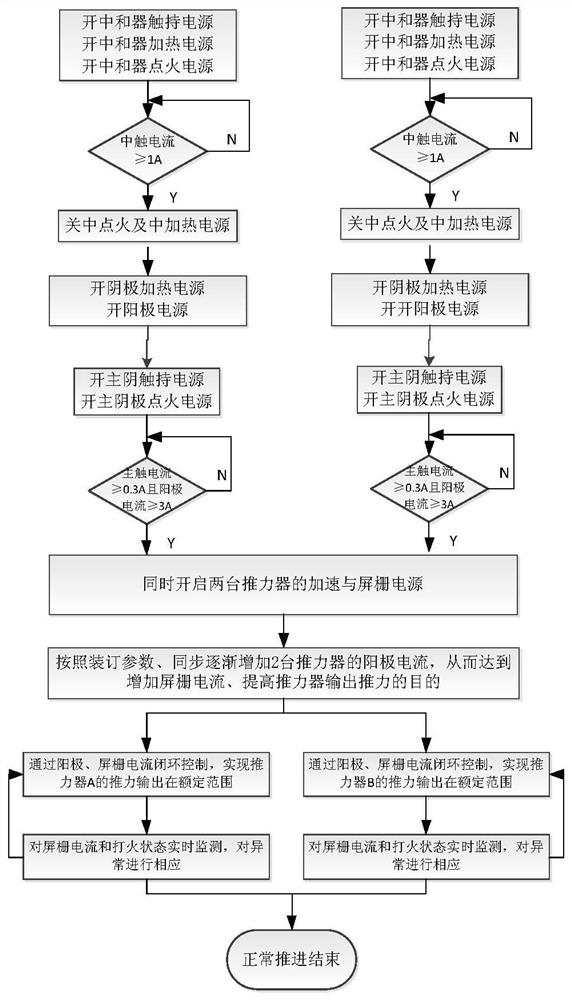

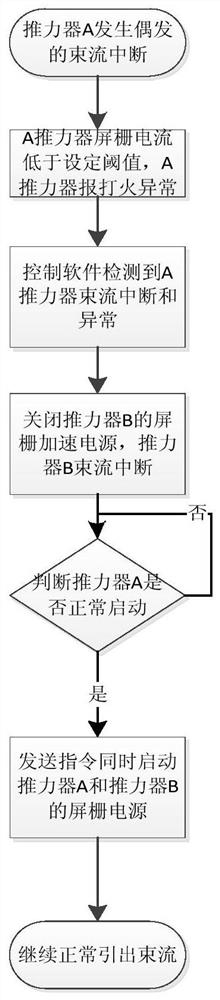

Synchronous working method and system for double thrusters of electric propulsion system

ActiveCN113931816AConsistency of thrustMeet job requirementsMachines/enginesUsing plasmaLoop controlDual-thrust

The invention discloses a synchronous working method and system for double thrusters of an electric propulsion system. The method is suitable for a synchronous working mode of multiple thrusters of a spaceflight electric propulsion system. According to the method, an ignition process is optimized, synchronous thrust generation of double thrusters is achieved through the functions of anode slow start, closed-loop control and the like, and the thrust magnitude is basically consistent; and through fault diagnosis logic, the problem of inconsistent thrust of the thruster caused by accidental abnormality of a single thruster is solved. Attitude instability caused by accumulation of angular momentum of a spacecraft is avoided.

Owner:BEIJING INST OF CONTROL ENG

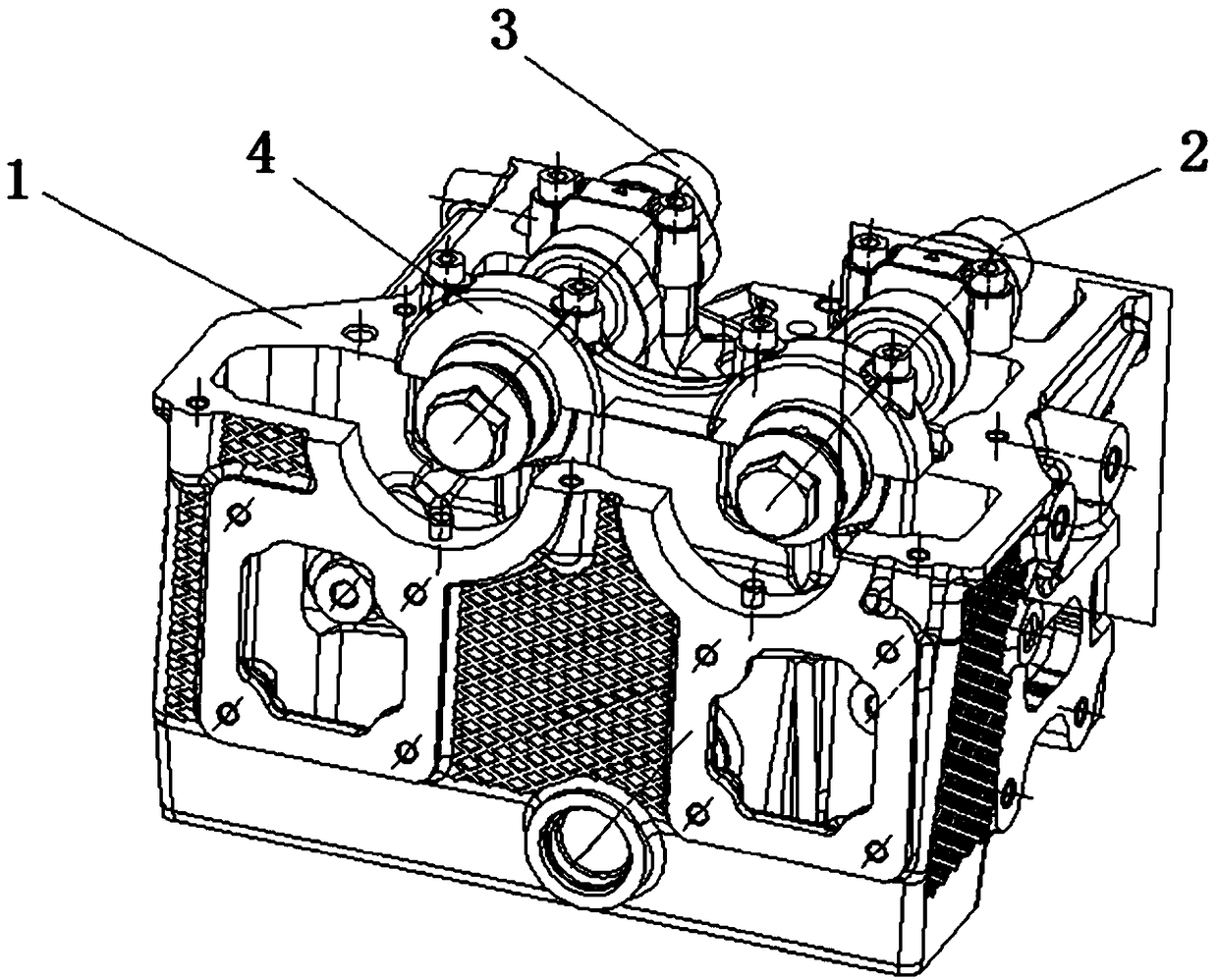

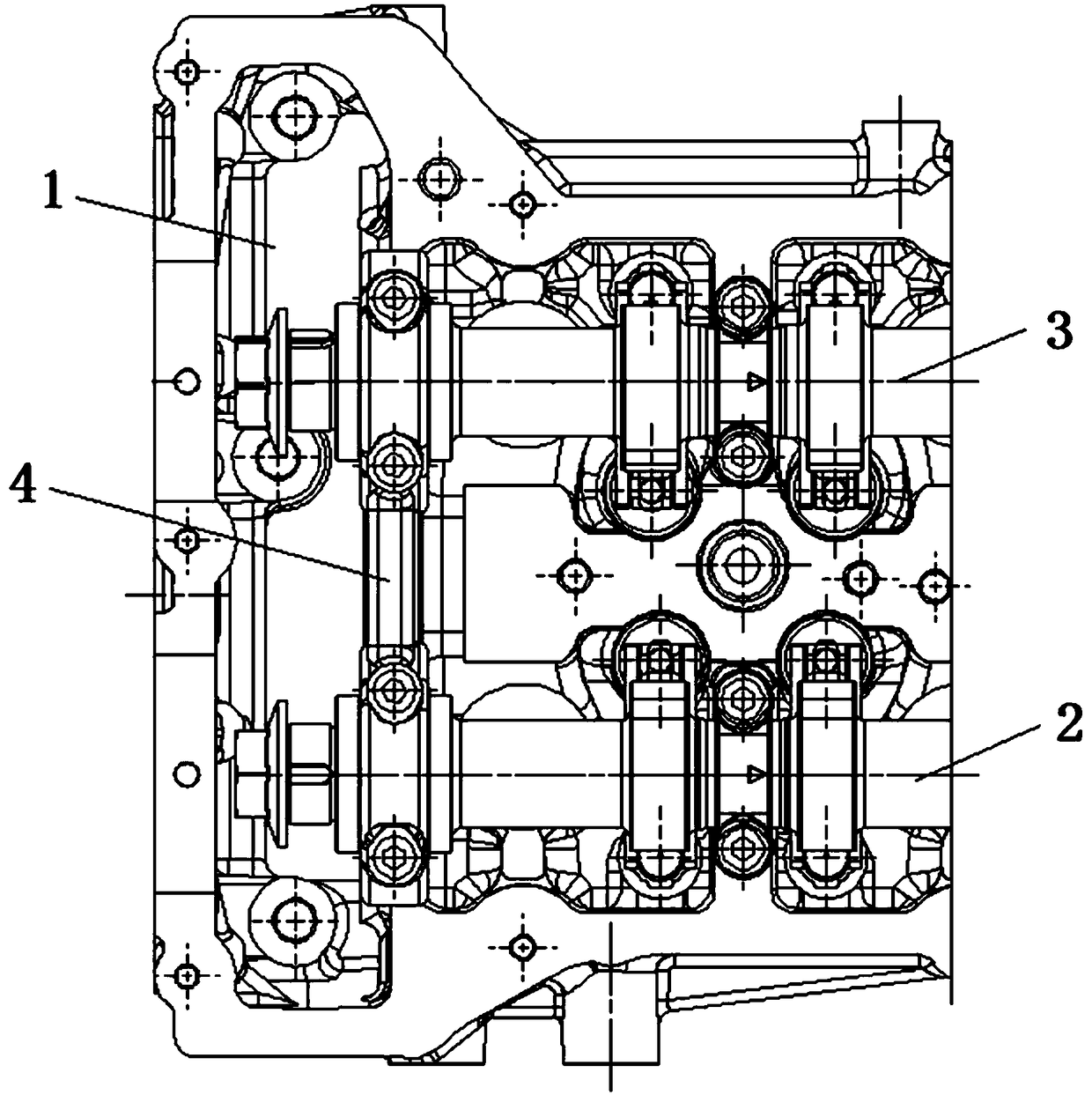

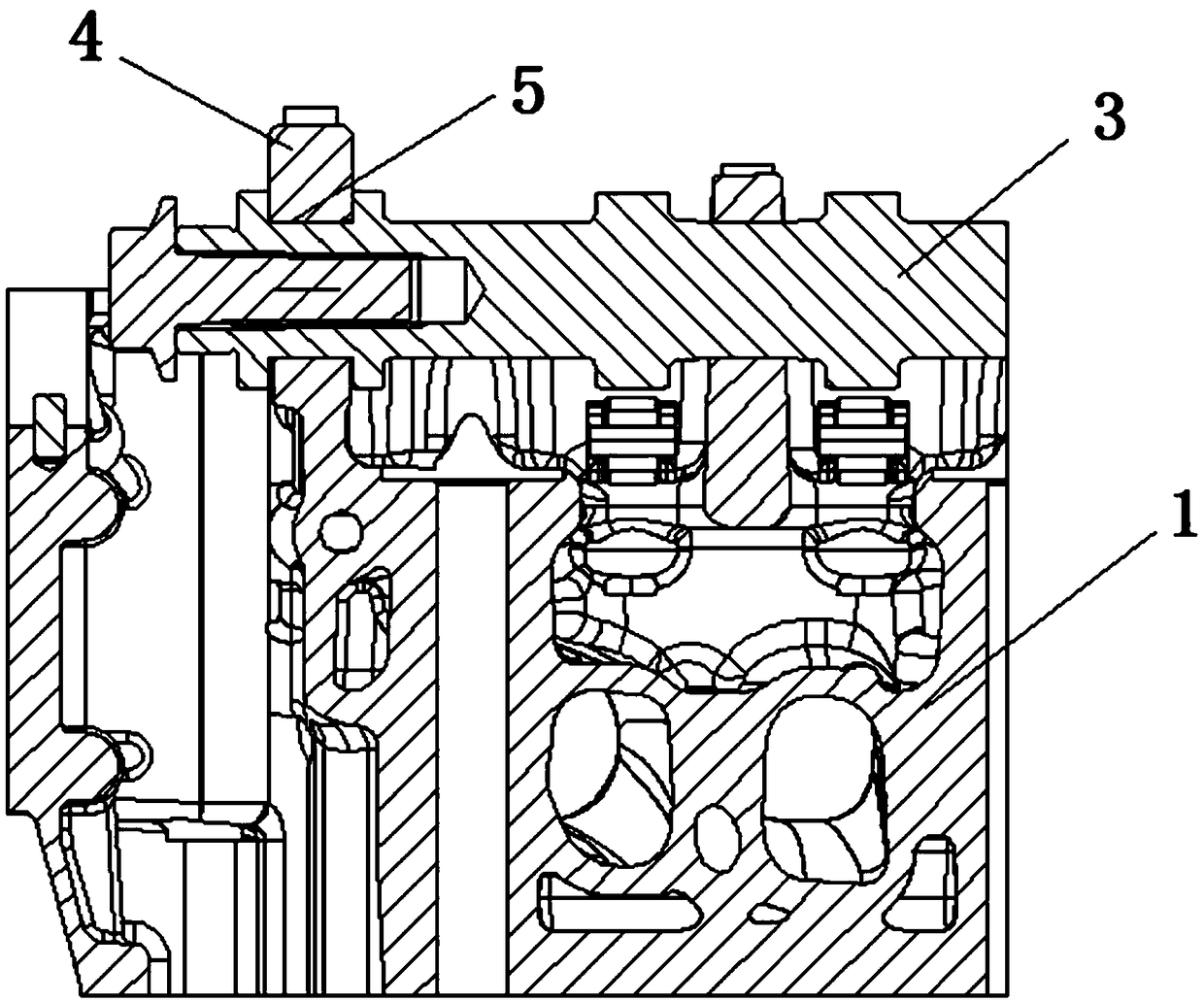

Camshaft bearing cover thrust structure

InactiveCN108952871AReasonable structureReduce manufacturing costCasingsValve arrangementsDual-thrustCam

The invention discloses a camshaft bearing cover thrust structure. The camshaft bearing cover thrust structure comprises a cylinder cover, a camshaft and a camshaft bearing cover, wherein an intake side cam bearing base and an exhaust side cam bearing base are arranged at the top end of the cylinder cover; the camshaft comprises an intake side camshaft and an exhaust side camshaft; thrust stop ring grooves are formed in the inner ends of the intake side camshaft and the exhaust side camshaft; the inner ends of the intake side camshaft and the exhaust side camshaft are arranged in the intake side cam bearing base and the exhaust side cam bearing base, arranged at the top end of the cylinder cover side by side, through the respective thrust stop ring grooves; the camshaft bearing cover is anintegral camshaft bearing cover, and is provided with an intake side camshaft bearing cover and an exhaust side camshaft bearing cover; and the intake side camshaft bearing cover and the exhaust sidecamshaft bearing cover cooperate with the intake side cam bearing base and the exhaust side cam bearing base of the cylinder cover to fasten the intake side camshaft and the exhaust side camshaft. The camshaft bearing cover thrust structure achieves dual thrust functions, and is reasonable in structure, low in production cost and easy to popularize.

Owner:GUANGXI YUCHAI MASCH CO LTD

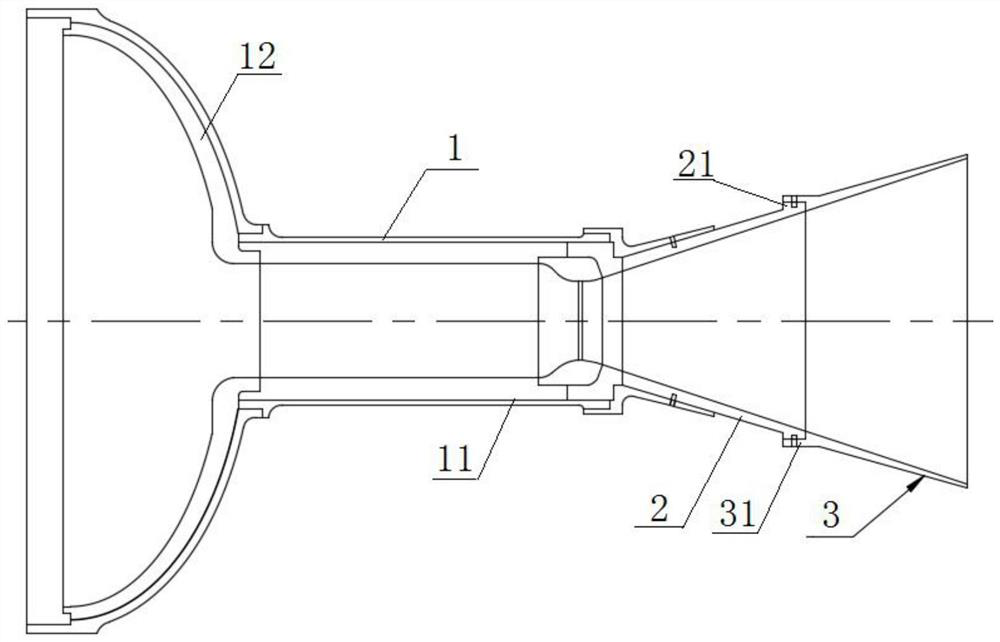

Variable-expansion-ratio spray pipe of single-chamber double-thrust solid rocket engine

The invention provides a variable-expansion-ratio spray pipe of a single-chamber double-thrust solid rocket engine. The variable-expansion-ratio spray pipe comprises an engine rear end socket, a rear end socket inner heat insulation layer, a long tail pipe, a long tail pipe inner heat insulation layer, a spray pipe shell, a throat liner assembly and a spray pipe expansion section. The nozzle expansion section is of a segmented structure with a front section and a rear section, and the rear section is made of a metal material which is easy to ablate. When the high pressure intensity of the single-chamber double-thrust engine is converted into the low pressure intensity, the expansion ratio of the spray pipe is automatically converted to adapt to the change of the pressure intensity of an outlet of the spray pipe, and the expansion ratio requirement for complete expansion of the single-chamber double-thrust solid rocket engine under different thrust sections is met.

Owner:北京中科宇航技术有限公司

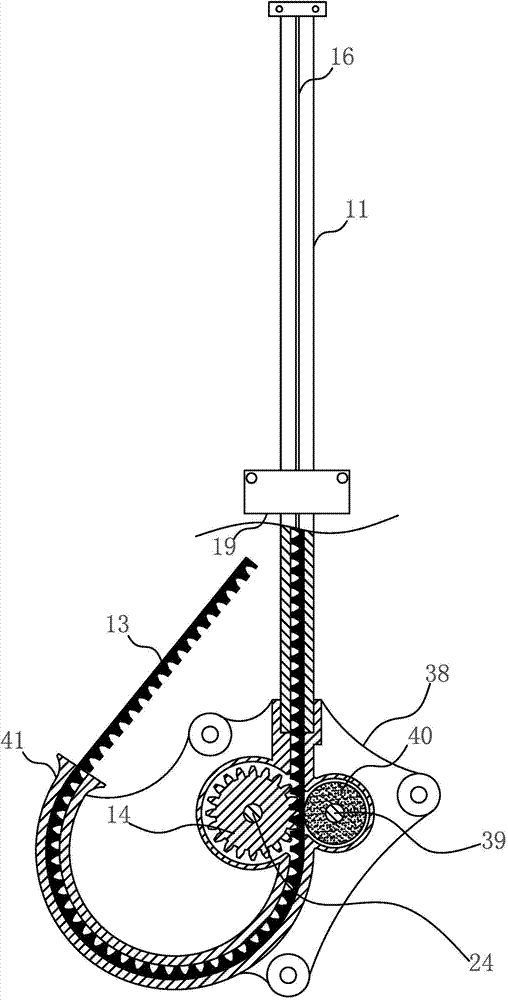

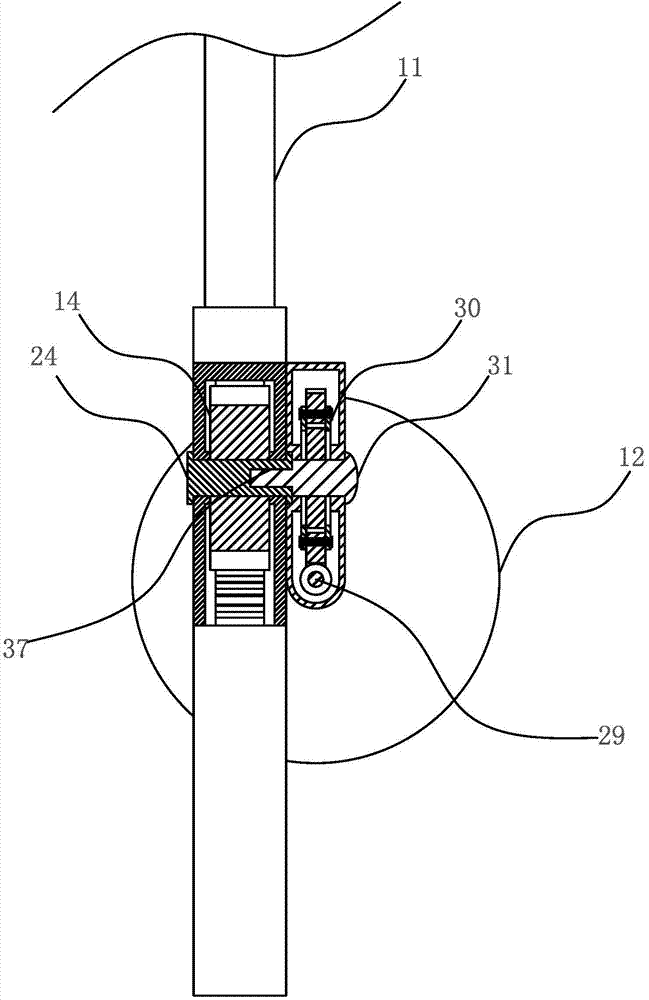

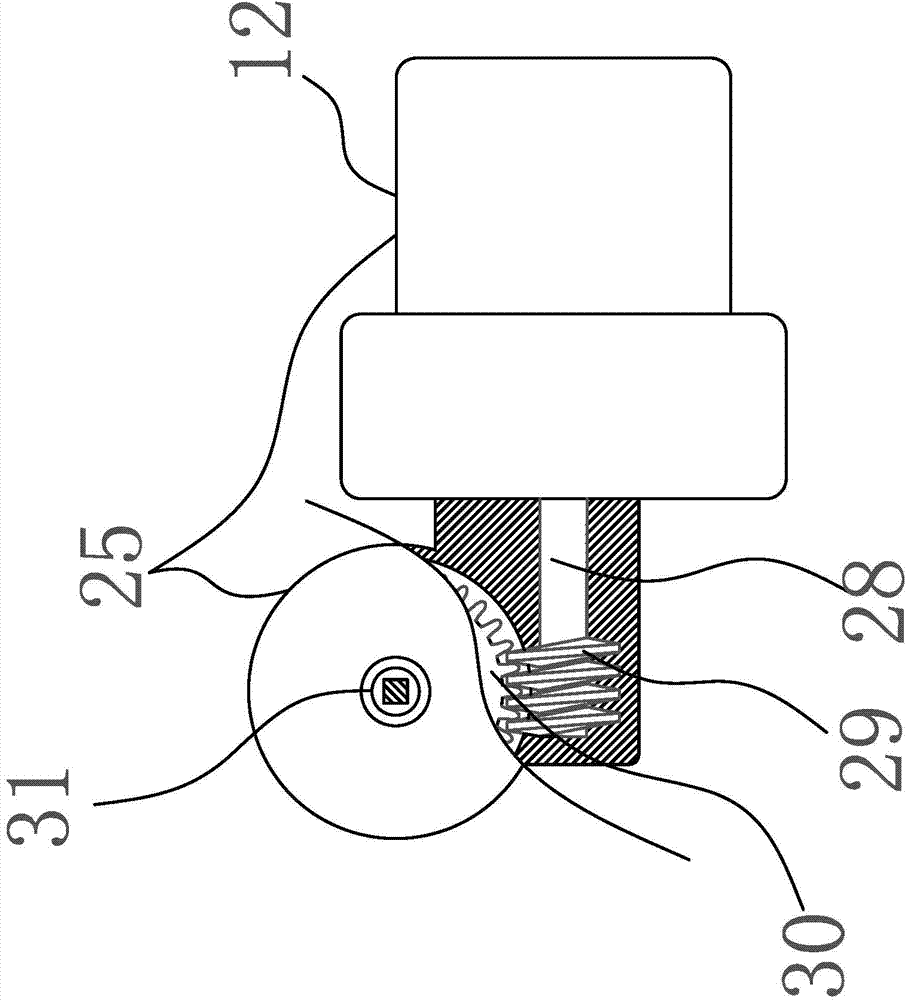

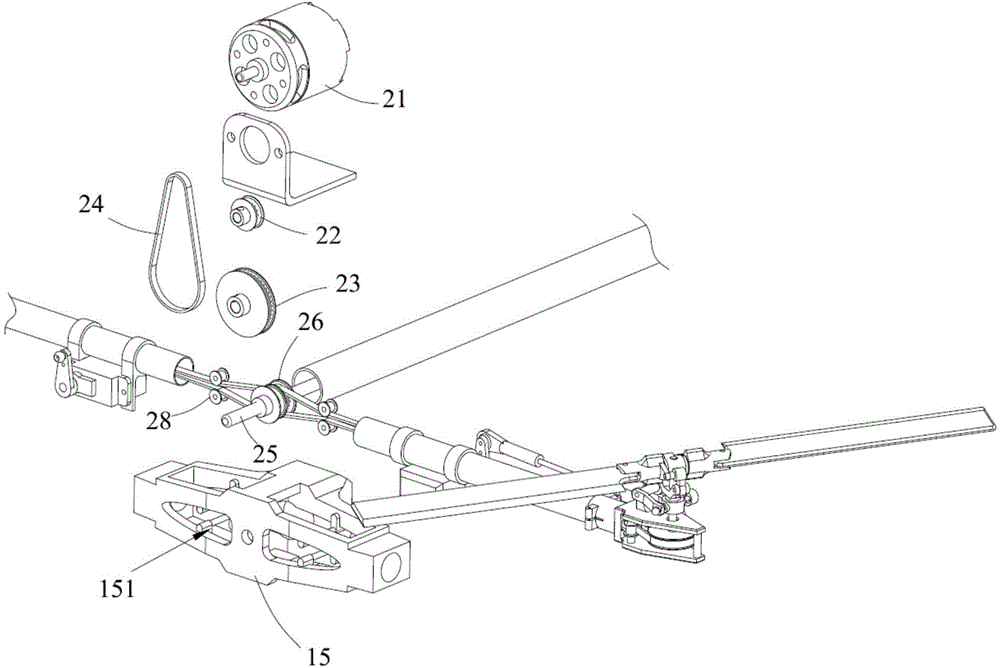

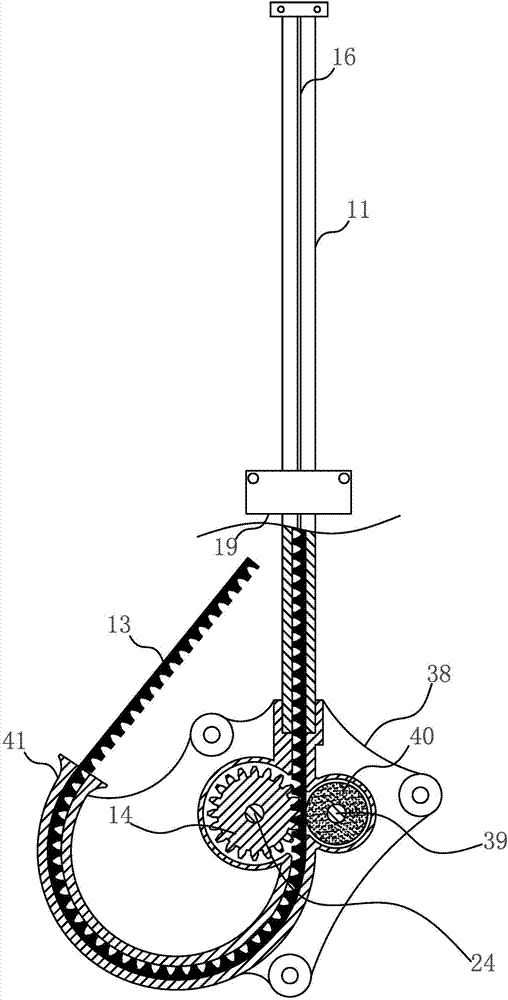

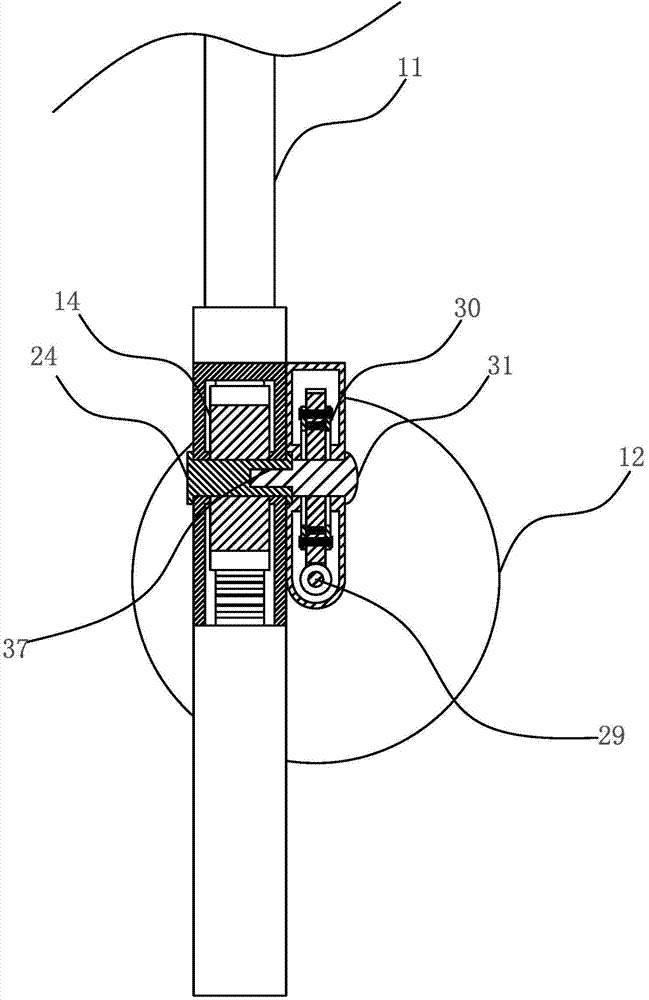

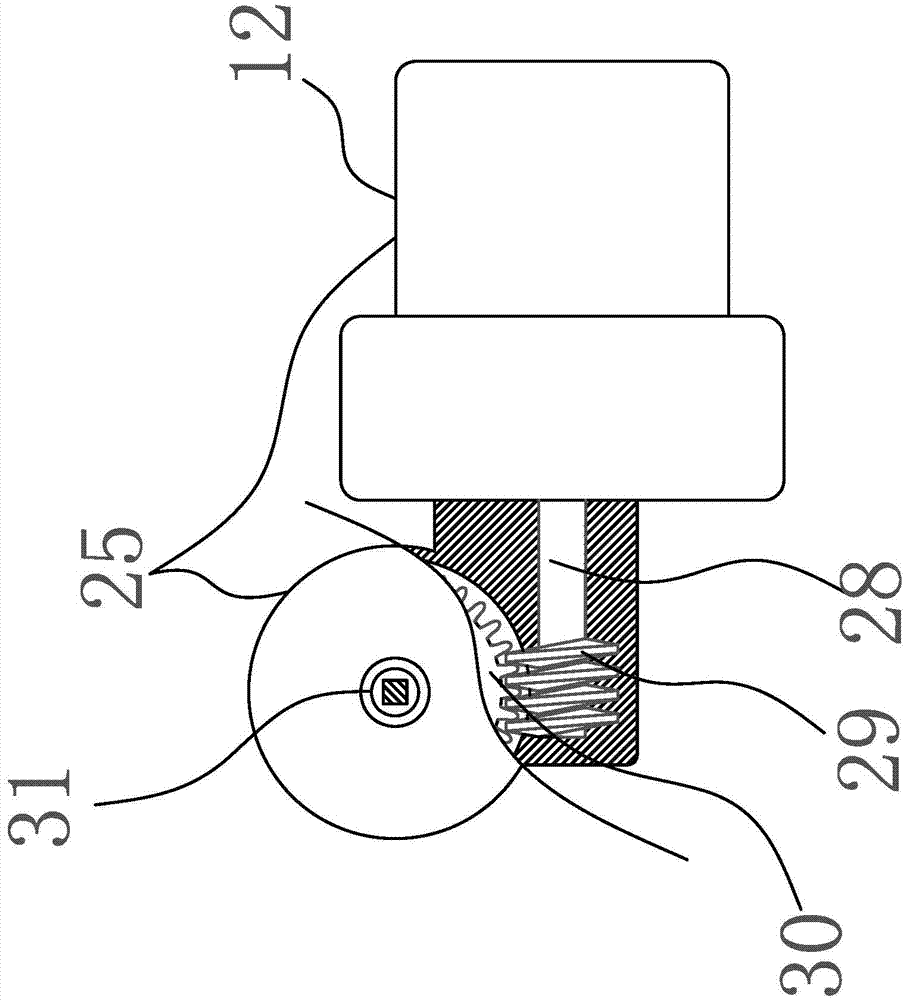

Dual-thrust toothed belt type lifter with spring-strip buffering gear and self-adaptive sliding block

InactiveCN104763268AReduce wearCompensation for wearPower-operated mechanismDual-thrustBlock and tackle

A dual-thrust toothed belt type lifter with a spring-strip buffering gear and a self-adaptive sliding block comprises a drive mechanism, a lifter bracket and a lifter base and is characterized in that the lifter bracket is of a rectangular strip-shaped tube body; a seam is formed longitudinally in the side wall of the tube body to form a sliding rail; a rectangular toothed belt guide groove is formed in the internal wall of the tube body of the lifter bracket; and a flexible toothed belt capable of twitching up and down is arranged in the toothed belt guide groove; the toothed belt is engaged with a toothed belt drive gear, which is arranged on the lifter base, at the lower end of the lifter bracket; and a pinch roller for compacting, extruding and pushing the toothed belt is arranged on the back of the toothed belt at the engaged position. The beneficial effects are as follows: the roller body capable of rolling is arranged on the back of the toothed belt at the engaged position of the toothed belt, so that the abrasion is reduced; when the sliding block suffers from abrasion, a pressure spring props against a pulley block to move forward so as to compensate the abrasion of the sliding block; the drive gear is a buffering gear which plays a role in protecting the gear, so that the service life of the lifter is prolonged.

Owner:陈学琴

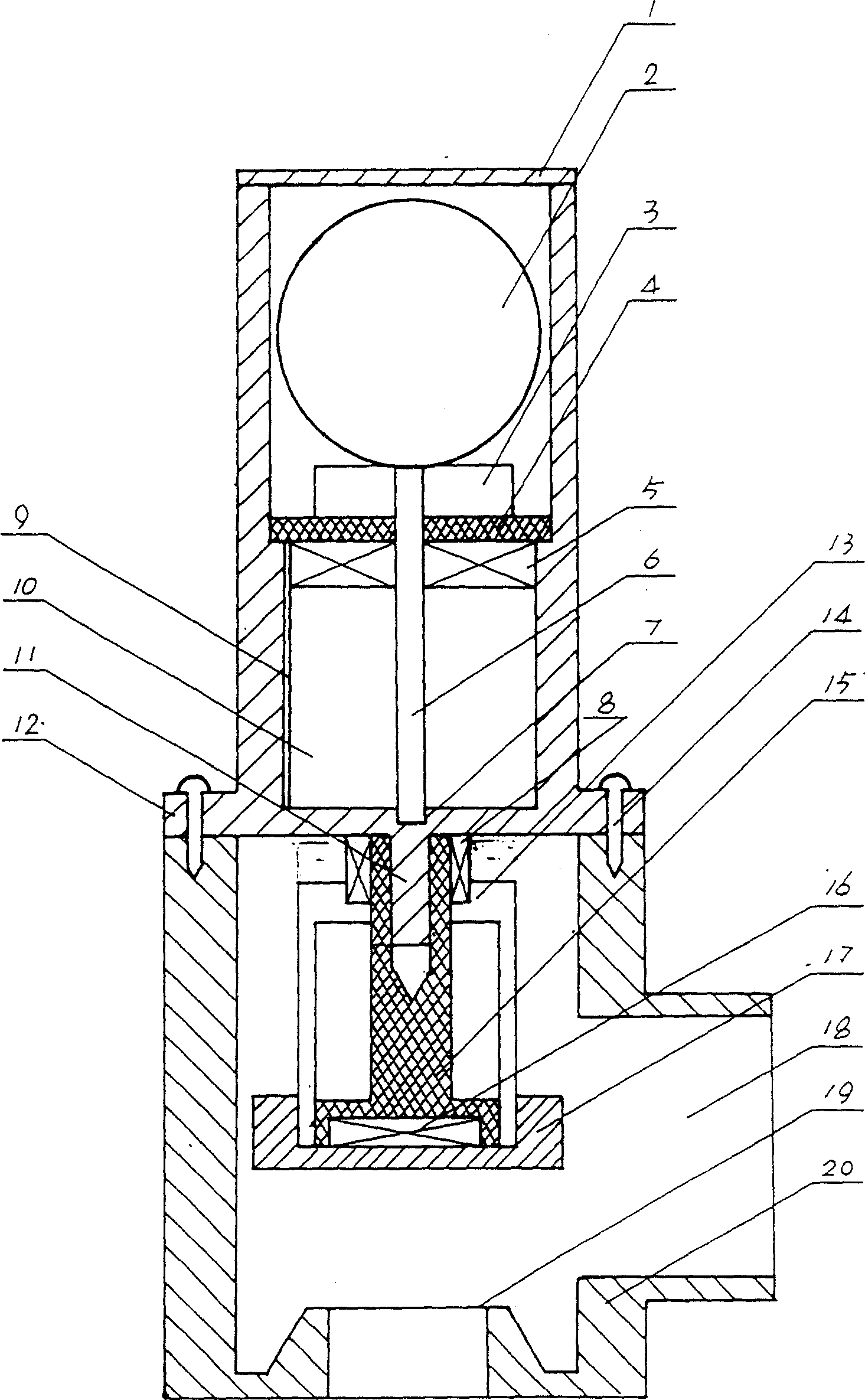

Process for making double-magnetic-repulsion gas safety valve of motor

InactiveCN1936379AEnsure safetyEnsure reliabilityOperating means/releasing devices for valvesLift valveManufacturing technologyElectric machine

This invention discloses a manufacturing technology for gas safety valves of a magnetic dual-thrust motor including the following steps: a, providing a primary alnico shift guide-way matched to the groove on the primary at the place opposite to motor box and the primary alnico, b, providing a system connector to connect and fix the motor box and a valve, c, providing a sub-alnico shift guide-way by a connecting bolt under the system connector and an inverted repulsion alnico is set at its bottom, d, a U-shape matcher with the sub-alnico is provided out of it, in which, the opposite faces of the primary and the sub-alnicos are homopolar and the opposite faces of the sub-alnico and the inverted-repulsion alnico are also homopolar. Since the motor and gas are isolated completely, it stops the contact of electric sparks with gas when the motor is working to avoid burning or explosion caused possibly.

Owner:SHANGHAI JIENENG ENVIRONMENT PROTECTION HIGH TECH

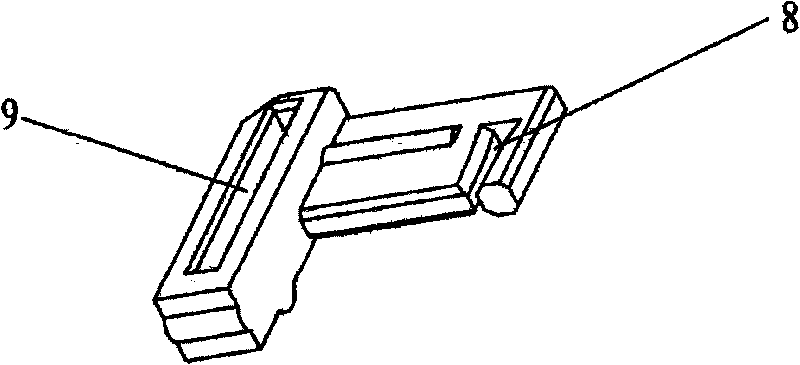

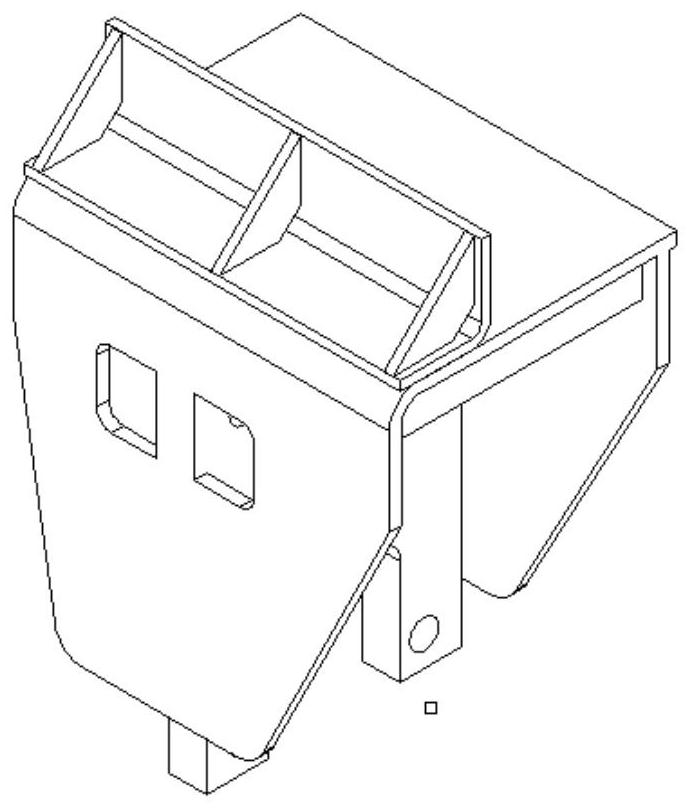

Double-thrust-rod fixing seat based on 8.1-meter full-bearing city bus

PendingCN112046232AReduce dosageReduce manufacturing costInterconnection systemsPivoted suspension armsMaterial consumptionDual-thrust

The invention discloses a double-thrust-rod fixing seat based on an 8.1-meter full-bearing city bus. The double-thrust-rod fixing seat comprises a fixing seat bottom plate, two fixing seat bodies, a left reinforcing vertical plate and a right reinforcing vertical plate; the fixing seat bodies are left square bracket-shaped, and the two fixing seat bodies are fixedly connected with the two ends ofthe same side of the fixing seat bottom plate through the back surfaces correspondingly; grooves of the two fixing seat bodies correspond to each other, and mounting holes are formed in the top ends of two supporting legs of the two fixing seat bodies correspondingly; the left reinforcing vertical plate and the right reinforcing vertical plate are fixed to the outer side walls of the two ends of the two fixing seat bodies correspondingly; and the side wall faces of the left reinforcing vertical plate and the right reinforcing vertical plate are fixedly connected with the fixing seat bottom plate. According to the double-thrust-rod fixing seat, the structure is compact, the material consumption is reduced, the overall welding composition is simple, the overall weight after welding is light,the design target of light weight of the whole vehicle is met, the severe condition of long-term overload operation is met, and the manufacturing cost is greatly reduced.

Owner:CHERY & WANDA GUIZHOU BUS

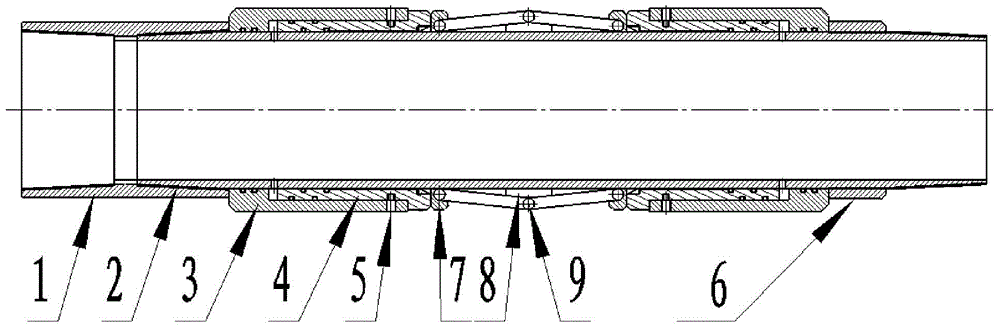

Bimetal thrust sliding bearing blank preparation method and used tooling

The invention discloses a method for preparing a blank of a bimetallic thrust sliding bearing and the tooling used. The method includes the following steps: the first step, mixing alloy materials and auxiliary materials: uniformly mixing copper alloy particles, copper gas flux, and charcoal particles; The second step is to put the mixed alloy material and auxiliary materials into the mold, and press the two clamping flange devices on the two ends of the mold respectively through the external force application device; the third step is to place the induction heating device on the outer periphery of the mold , then rotate the mold, adjust the centrifugal speed and the heating power of the induction heating device, and melt the alloy particle mixture; the fourth step, remove the induction heating device, and place the bimetallic blank prepared in the third step in a mobile cooling device, First use the lower water spray device to cool for a certain period of time, and then turn on the upper water spray device to work together to cool the bimetallic blank to room temperature. Tooling consists of moulds, clamping flange units and mobile cooling units. The invention has reasonable process and can reduce the defects of bimetallic blanks.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

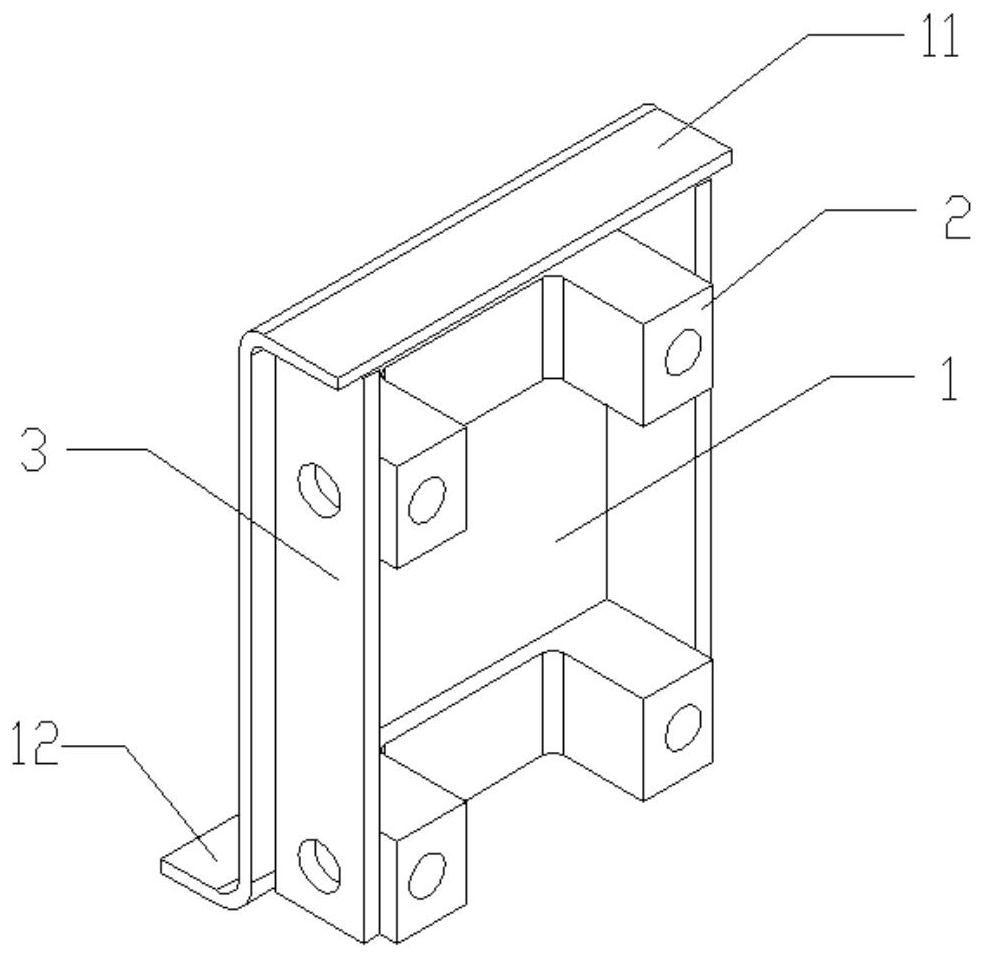

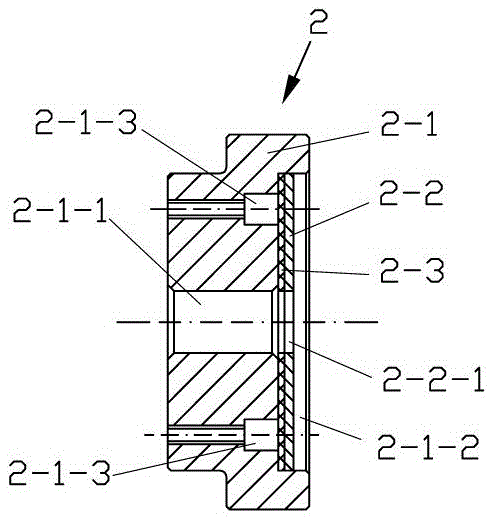

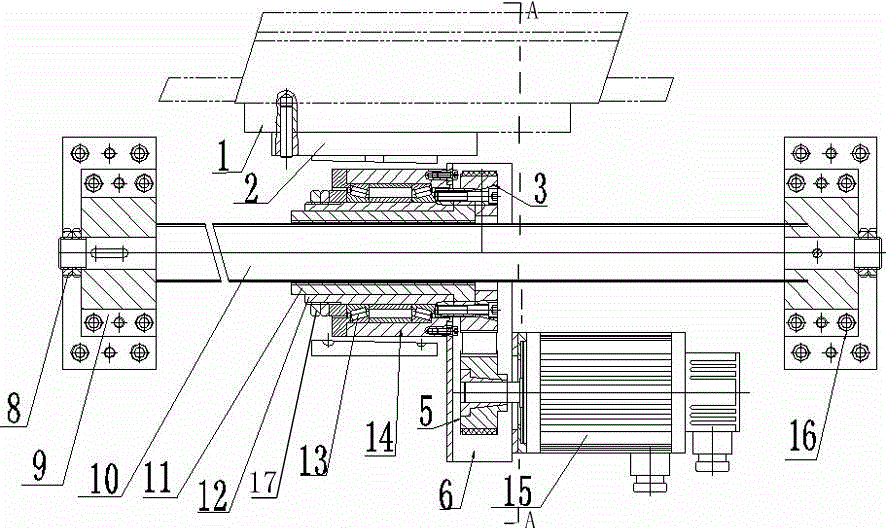

Longitudinal driving device for numerical control lathe

The invention provides a longitudinal driving device for a numerical control lathe. One end of a ball screw is fixed to the tail end of a lathe body, and the other end of the ball screw penetrates a fixing support and is firmly fixed through a nut. A screw nut is screwed on the ball screw and is externally provided with a transition sleeve. The transition sleeve is externally provided with a dual thrust bearing which is externally provided with a bearing block. A first belt wheel is fixed to one end of the transition sleeve and one end of the screw nut through a bolt, and the other end of the transition sleeve is provided with a second nut to fix the dual thrust bearing in the bearing block. A connecting support is arranged below a large supporting plate, and the bearing block is fixed in the connecting support. A motor support is arranged below the connecting support, and a servo motor is transversely arranged on the motor support. The motor is provided with a second belt wheel. The first belt wheel and the second belt wheel are connected through a synchronous belt. According to the longitudinal driving device for the numerical control lathe, the screw nut drives the large supporting plate to move through the thrust bearing, the longitudinal driving device is suitable for lathes with the length larger than 2 m, the problem of resonance is solved, machining precision is improved, and the service life of the ball screw and the screw nut is prolonged.

Owner:SHIYAN OUKAI IND & TRADE

A single-chamber double-thrust solid rocket motor and rocket

ActiveCN111810318BIncreased thrust rangeLess severeRocket engine plantsCombustion chamberDual-thrust

The application provides a single-chamber double-thrust solid rocket motor and the rocket, wherein the motor includes a combustion chamber casing, a thermal insulation layer attached to the inner surface of the combustion chamber casing, a propellant grain located in the combustion chamber casing, and a The igniter at one end of the casing and the nozzle assembly arranged at the other end of the combustion chamber casing; the propellant grain is provided with an inner hole passing through both ends; The front wing slot extending to the direction, and the end of the inner hole close to the nozzle assembly is evenly provided with a radially extending tail slot; the ratio of the wing slot depth of the front wing slot and the tail slot to the maximum thickness of the propellant grain is greater than or equal to 0.81; The slope range of the axial slope of the rear wing of the grain column is 160-170 degrees. The present invention has a large thrust variation range and stable grain structure. When the thrust mode of the engine is switched, the combustion surface of the grain changes at a low speed, which can effectively reduce the pressure change speed of the combustion chamber and ease the thrust change speed.

Owner:北京凌空天行科技有限责任公司

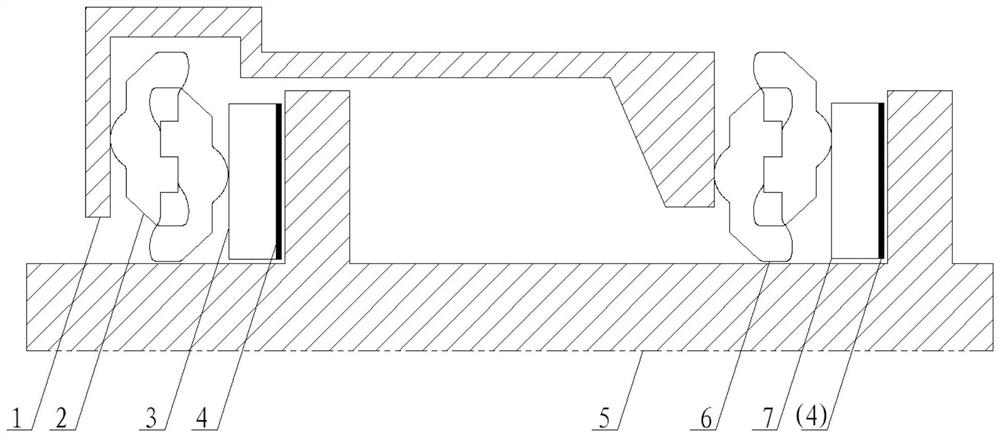

Double-thrust self-balancing uniform-load structure bearing for high-speed rotor

PendingCN114233745AOvercome limitationsOptimize structure sizeSliding contact bearingsBearing unit rigid supportDual-thrustClassical mechanics

The invention belongs to the field of engineering machinery design, and particularly relates to a double-thrust self-balancing uniform-load structure bearing for a high-speed rotor. A double-thrust self-balancing uniform-load structure bearing for a high-speed rotor comprises a feedback assembly, a front balance block, a front thrust pad, a bearing copper alloy, the rotor, a rear balance block and a rear thrust pad, the inner edge of the front end of the feedback assembly is in press fit with the front balance block, the outer edge of the rear end of the feedback assembly is in press fit with the rear balance block, the front balance block tightly presses the front thrust pad, and the rear balance block tightly presses the rear thrust pad. The rear balance block compresses the rear thrust pad, and the surfaces, attached to the rotor, of the front thrust pad and the rear thrust pad are plated with bearing copper alloy. The double-thrust self-balancing structure avoids the limitation that an existing thrust bearing can only bear thrust through a single thrust surface, optimizes the structural size, meets the rotor operation requirements of strict structural size requirements, large load and high rotating speed, and has wide application value.

Owner:中国船舶重工集团公司第七0三研究所

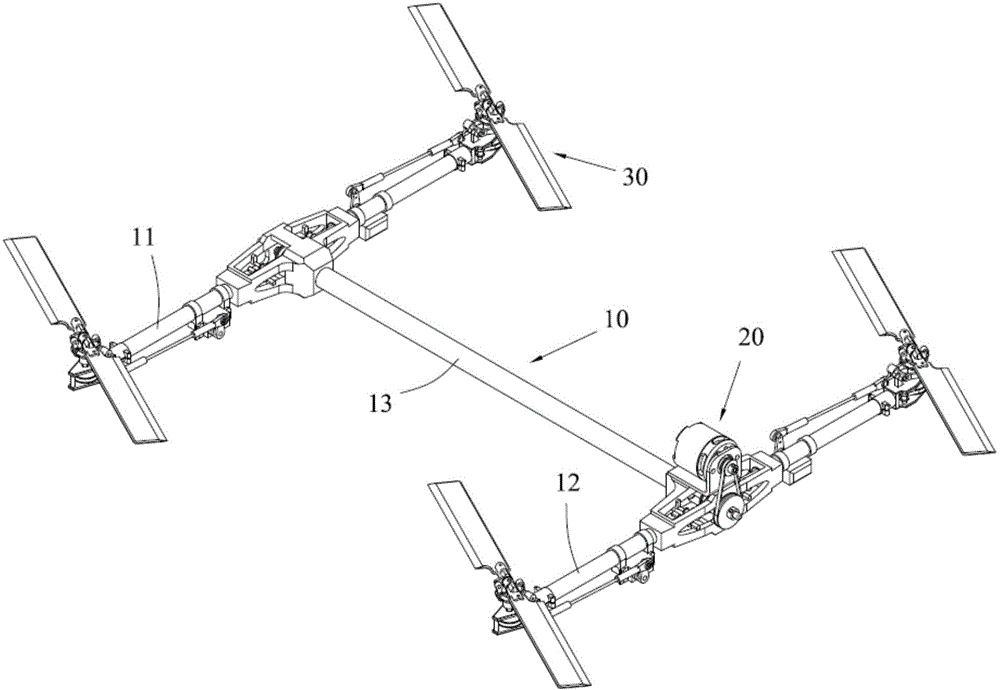

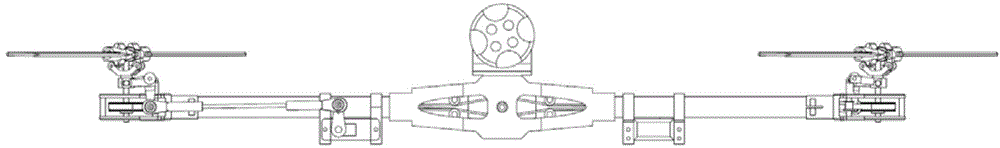

a pitch-changing aircraft

Disclosed is a variable-pitch flight unit, comprising: a support and a plurality of rotor blades mounted on the support; each rotor blade comprises a drive shaft, a first flap, a second flap, a hub and a drive part; the drive part comprises a first slider sleeved on the drive shaft and located below the hub; the drive part further comprises a power device capable of driving the first slider to rise; the power device comprises a second slider, a variable-pitch rocker arm, a connecting rod and a steering engine; a first connecting part and a second connecting part are symmetrically disposed at two sides of the second slider; and the variable-pitch rocker arm has a first branch arm rotatably connected to the first connecting part and a second branch arm rotatably connected to the second connecting part. The variable-pitch rocker arm of the present invention is a dual-thrust structure, such that the variable-pitch rocker arm applies symmetrical force on the second slider, extending the service life of the power device.

Owner:江苏謇公湖农业科技发展有限责任公司

A Permanent Magnetic Bias Hybrid Axial Magnetic Bearing

ActiveCN103925291BWill not cause irreversible demagnetizationElectric excitation magnetomotive force is smallBearingsMagnetic bearingHigh energy

The invention discloses a permanent magnet polarization hybrid axial magnetic bearing. The permanent magnet polarization hybrid axial magnetic bearing comprises a rotor assembly and a stator assembly, wherein the rotor assembly comprises a rotating shaft and a rotor dual-thrust disc; the stator assembly comprises a stator shell, an upper stator end plate, an upper permanent magnet, a stator center plate, a lower permanent magnet, a lower stator end plate and a stator magnet exciting coil; the upper stator end plate and the lower stator end plate can form an outer upper air gap and an outer lower air gap together with the outer end surface of the rotor dual-thrust disc respectively, and the stator center plate and the inner end surface of the rotor dual-thrust disc can form an inner upper air gap and an inner lower air gap; the upper permanent magnet and the lower permanent magnet can axially magnetized, and magnetizing directions of the upper permanent magnet and the lower permanent magnet are opposite; the inner and outer air gaps can internally generate a permanent magnet polarization magnetic field, a magnetic field generated by the stator magnet exciting coil can regulate the permanent magnet polarization magnetic field. The magnetic bearing provided by the invention has a firm and reliable structure and high energy density, can be applied in a high-speed operation occasion, and is suitable for a high-speed system which has high power and large capacity.

Owner:NAVAL UNIV OF ENG PLA

Dual-thrust toothed belt type lifter with buffering gear and self-adoptive sliding block

InactiveCN104763272AReduce wearCompensation for wearPower-operated mechanismDual-thrustBlock and tackle

A dual-thrust toothed belt type lifter with a buffering gear and a self-adoptive sliding block comprises a drive mechanism, a lifter bracket and a lifter base and is characterized in that the lifter bracket is of a rectangular strip-shaped tube body; a seam is formed longitudinally in the side wall of the tube body to form a sliding rail; a rectangular toothed belt guide groove is formed in the internal wall of the tube body of the lifter bracket; and a flexible toothed belt capable of twitching up and down is arranged in the toothed belt guide groove; the toothed belt is engaged with a toothed belt drive gear, which is arranged on the lifter base, at the lower end of the lifter bracket; and a pinch roller for compacting, extruding and pushing the toothed belt is arranged on the back of the toothed belt at the engaged position. The beneficial effects are as follows: the roller body capable of rolling is arranged on the back of the toothed belt at the engaged position of the toothed belt, so that the abrasion is reduced; when the sliding block suffers from abrasion, a pressure spring props against a pulley block to move forward so as to compensate the abrasion of the sliding block; the drive gear is a buffering gear which plays a role in protecting the gear, so that the service life of the lifter is prolonged.

Owner:陈学琴

A jig for processing an inner spherical 8-shaped oil groove of a joint bearing and its production and use method

InactiveCN105081802BRealize processingEffective protectionWork clamping meansTurning machinesDual-thrustEngineering

The invention relates to a bearing oil groove machining technology, in particular to a clamp for machining an oil groove, shaped like the Arabic number 8, of the inner spherical face of a joint bearing and a producing and using method of the clamp. The clamp is composed of a mold with an alpha angle face, a clamping hole, a screw hole and a fastening screw rod. The screw hole is located in the surface of the mold. The fastening screw rod is correspondingly screwed into the screw hole. The center line of the mold is perpendicular to the alpha angle face of the mold. An angle alpha is formed between the center line of the mold and the rotation axis of a lathe spindle, and the angle alpha is larger than 0 degree and equal to or smaller than 15 degrees. The clamp is used for clamping the oil groove, shaped like the Arabic number 8, of the inner spherical face of the joint bearing, and therefore an oil groove, shaped like the Arabic number 8, of the inner arc spherical face of a dual-thrust joint bearing can be machined on a common lathe, the bearing can be effectively protected by the copper head fastening screw rod, and when clamped, the bearing can be clamped many times by performing alignment one time; and the using method is easy to operate, and size control is more convenient and accurate.

Owner:BAOTA IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com