Patents

Literature

84results about How to "Optimize structure size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing copper and nickel alloy seamless copper tube

InactiveCN101058142AOptimize structure sizeImprove plastic deformation abilityRoll mill control devicesFurnace typesElectrolysisCupronickel

The invention relates to a copper nickel seamless copper tube with 92. 9-93. 6% copper and 6. 4-7. 1% nickel. It takes electrolytic copper and nickel to a low frequency electric oven to heat to 1320-1340deg.C, casting into solid ingot which is heated to 650-750deg.C for heat piercing to get the surface smooth ingot to heat to 650-750deg.C for squeezing to gross blank tube which is extended and peeled for cold reeling, to get the size of the product after annealing. Through calibration and rectification, cleaning and annealing, the product is inspected and put to stock. The content for nickel is 6. 4-7. 1%. It is better in processing feature due to the low nickel and better in corrosion resistant features than copper due to the content of nickel. It is also low in cost.

Owner:江阴和宏精工科技有限公司

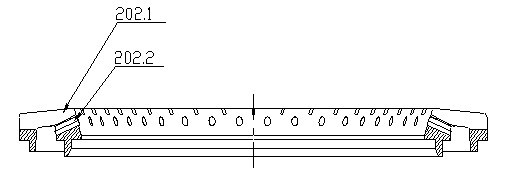

Non-contact capacitance induction touch panel

InactiveCN101271373ANo wearExtended service lifeInput/output processes for data processingCapacitanceTouchscreen

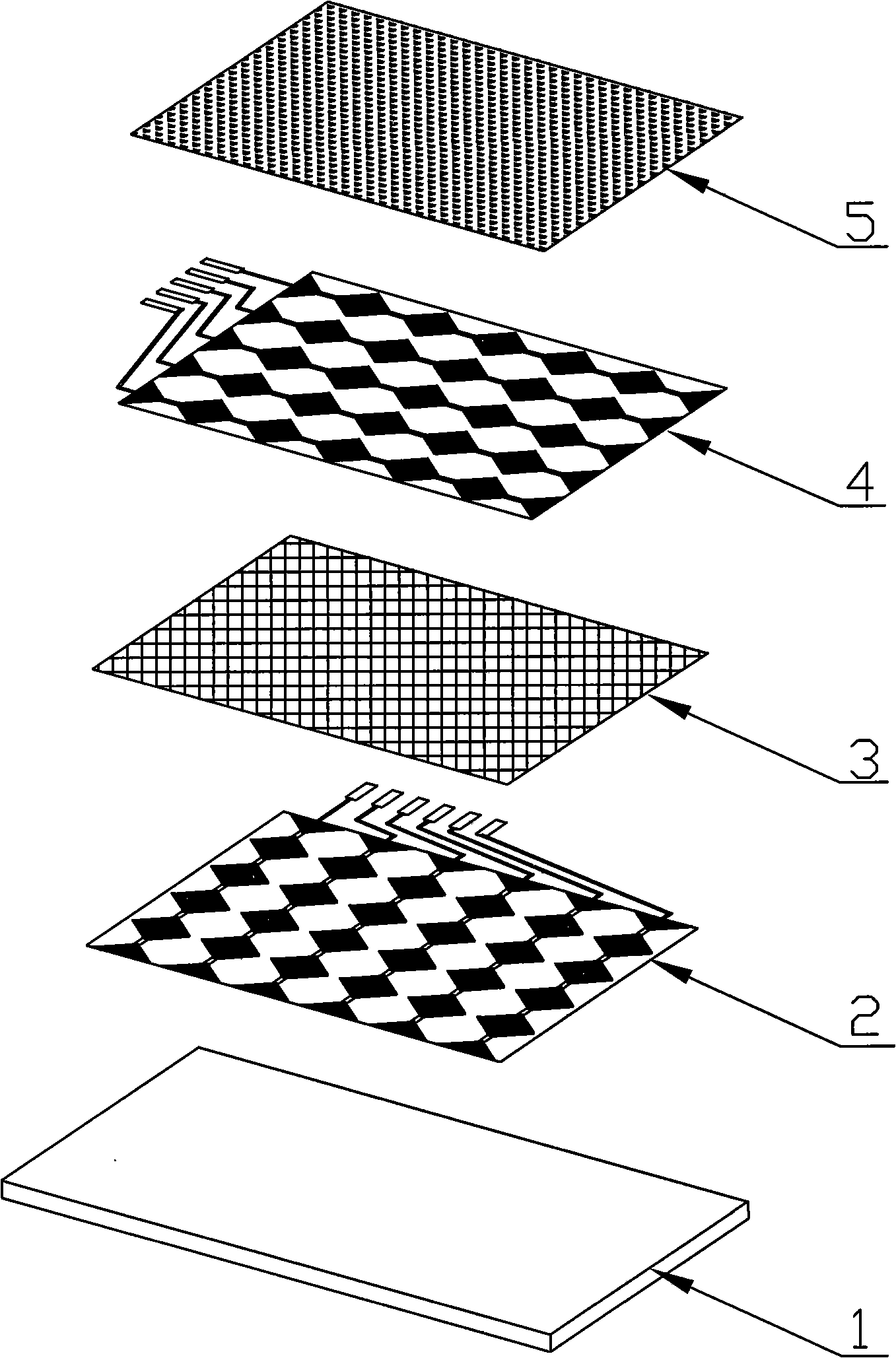

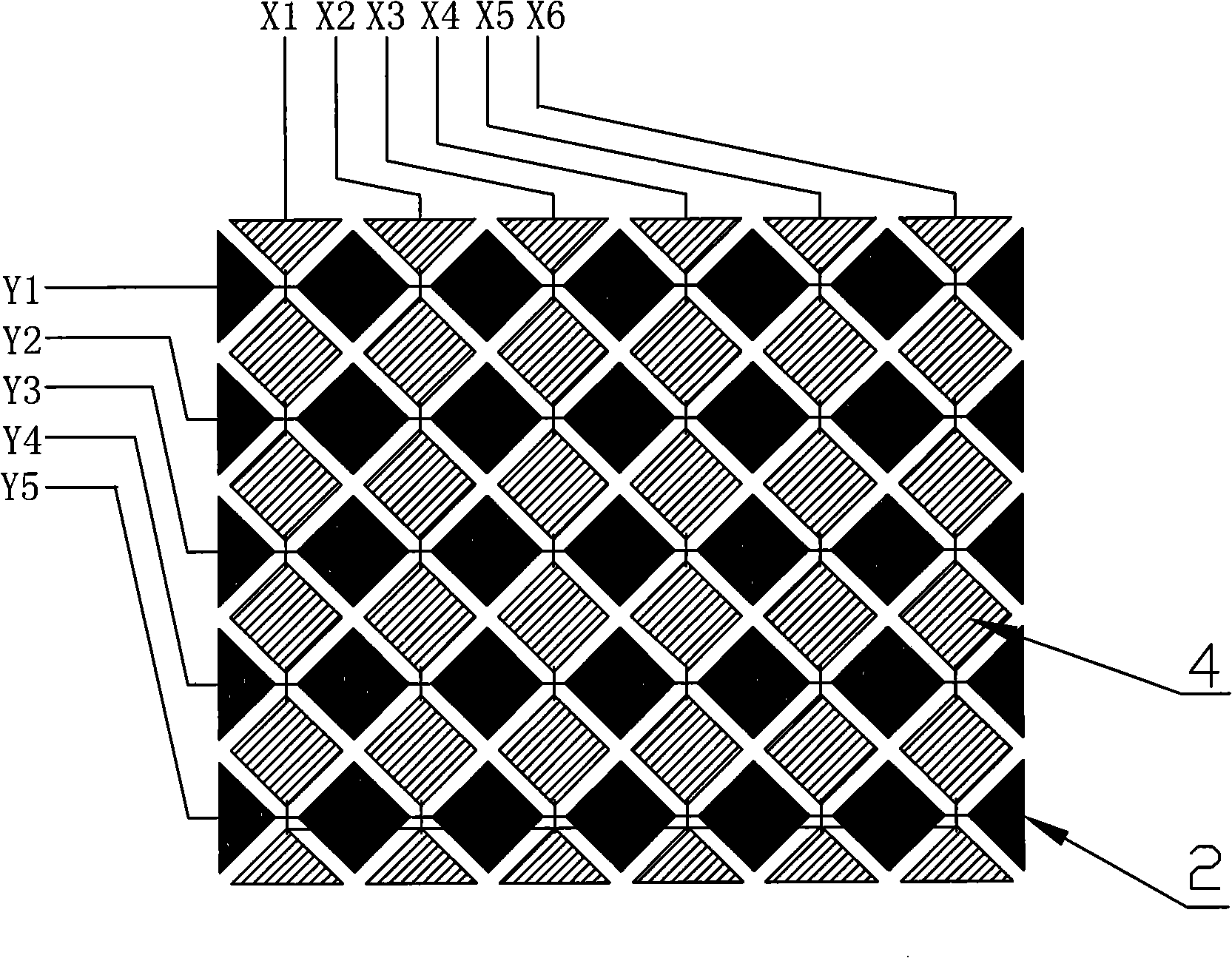

The invention discloses a non-contact capacitance induction touch screen, including a baseplate glass. One surface of the baseplate glass is plated by a horizontally connected ITO electrode matrix along the reticular Y direction; the ITO electrode matrix along the reticular Y direction is plated by an insulating layer; the insulating layer is plated by a longitudinally connected ITO electrode matrix along the X direction which is approximately complemented with the blank part of the ITO electrode matrix along the reticular Y direction. The non-contact capacitance induction touch screen provided by the invention, with built-in double-layer ITO design and an additional control processor, can achieve continuous hand-writing simulation control and operation. With no wear and tear, long service life, high luminousness, small thickness, low cost and easy operation, the touch screen can be rapidly applied to various screens of high-end and low-end electronic products of all sizes and all types, thus facilitating humanized design and industrial output.

Owner:MATRIX CRYSTAL

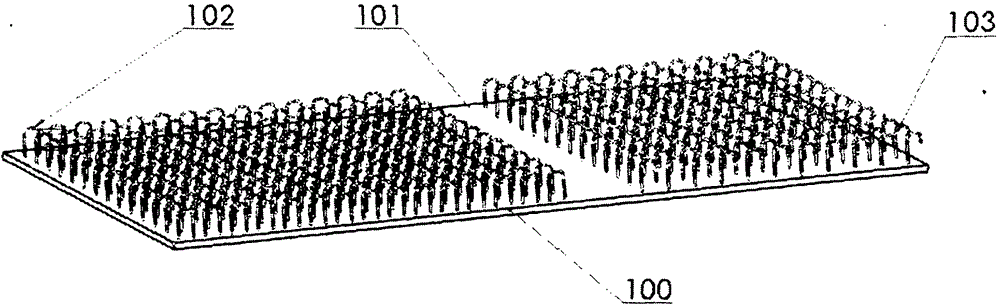

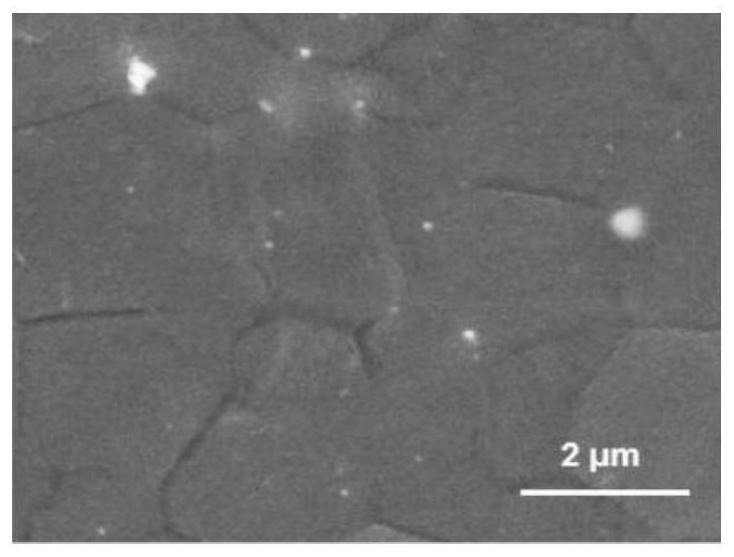

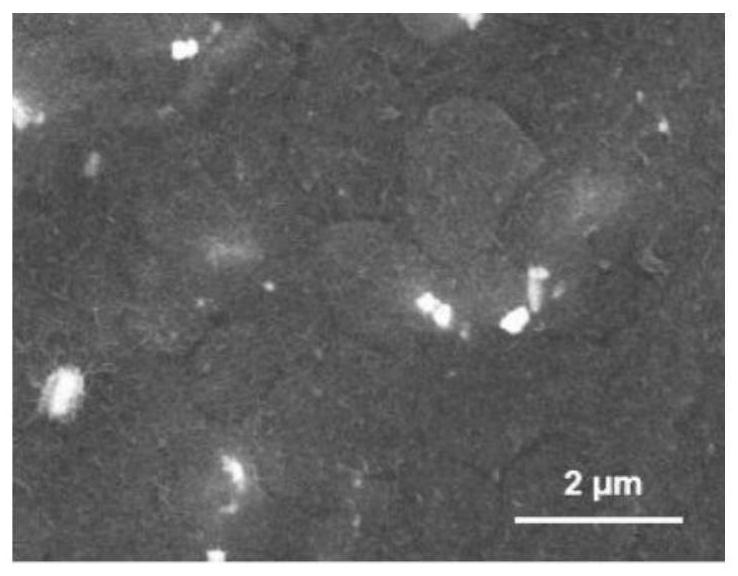

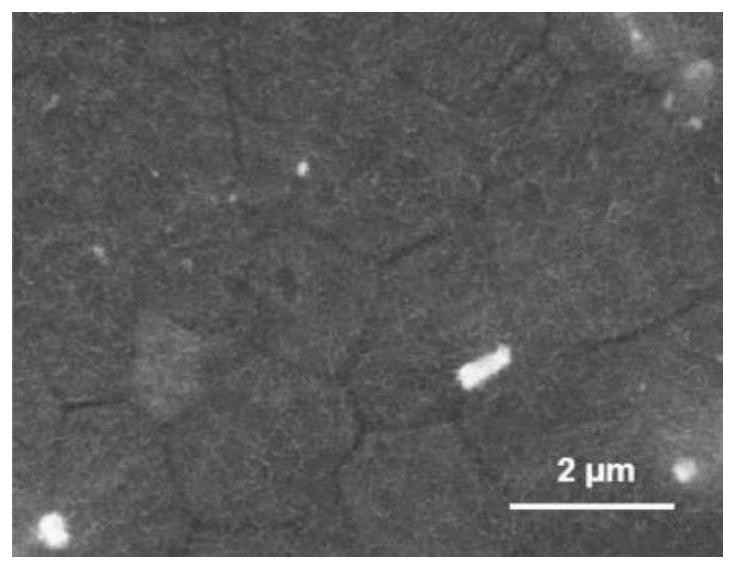

Flexible wearable sensor and corresponding wearable device and preparation method thereof

InactiveCN109738095AImprove output performanceHigh acquisition sensitivityFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesEngineeringMechanical engineering

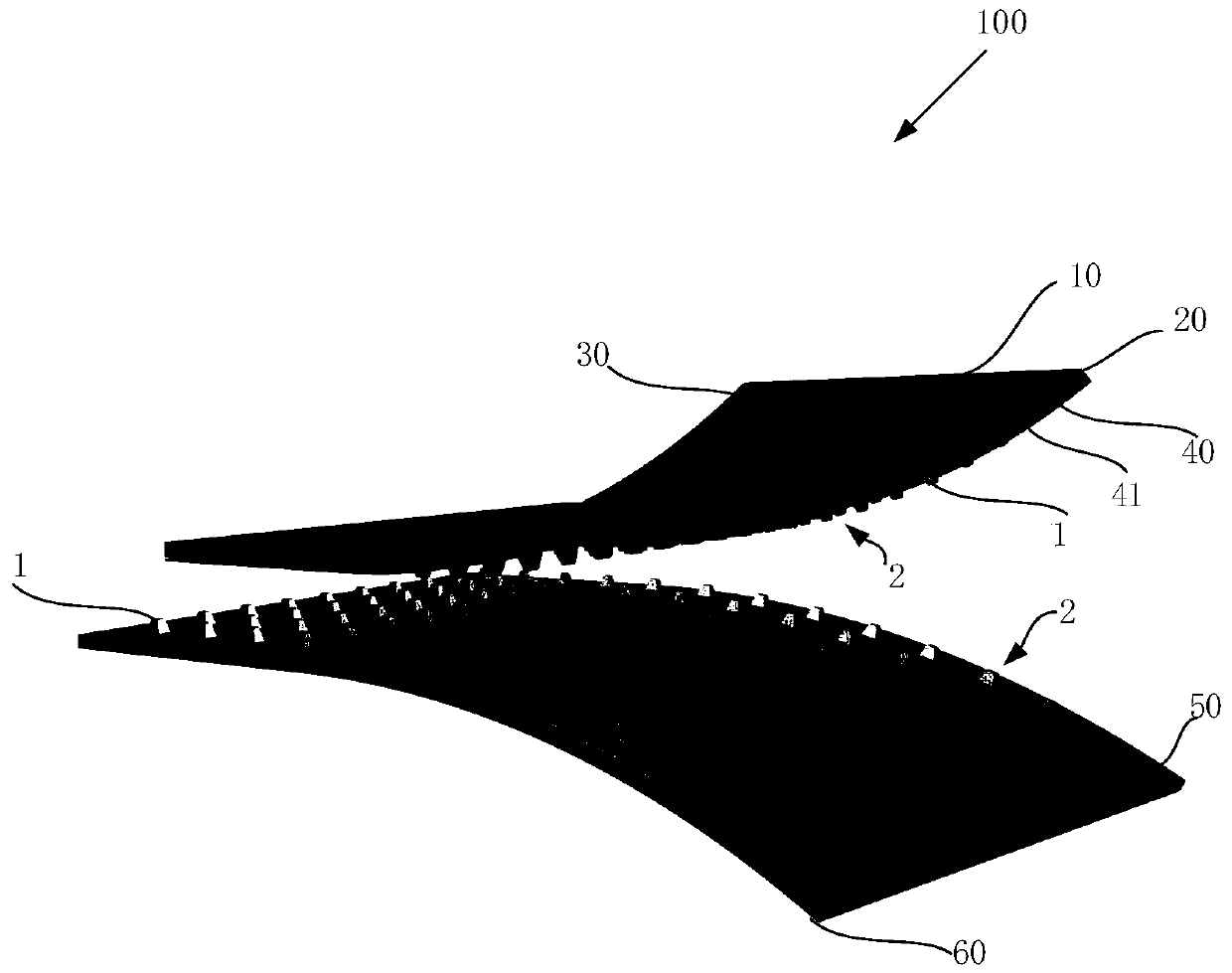

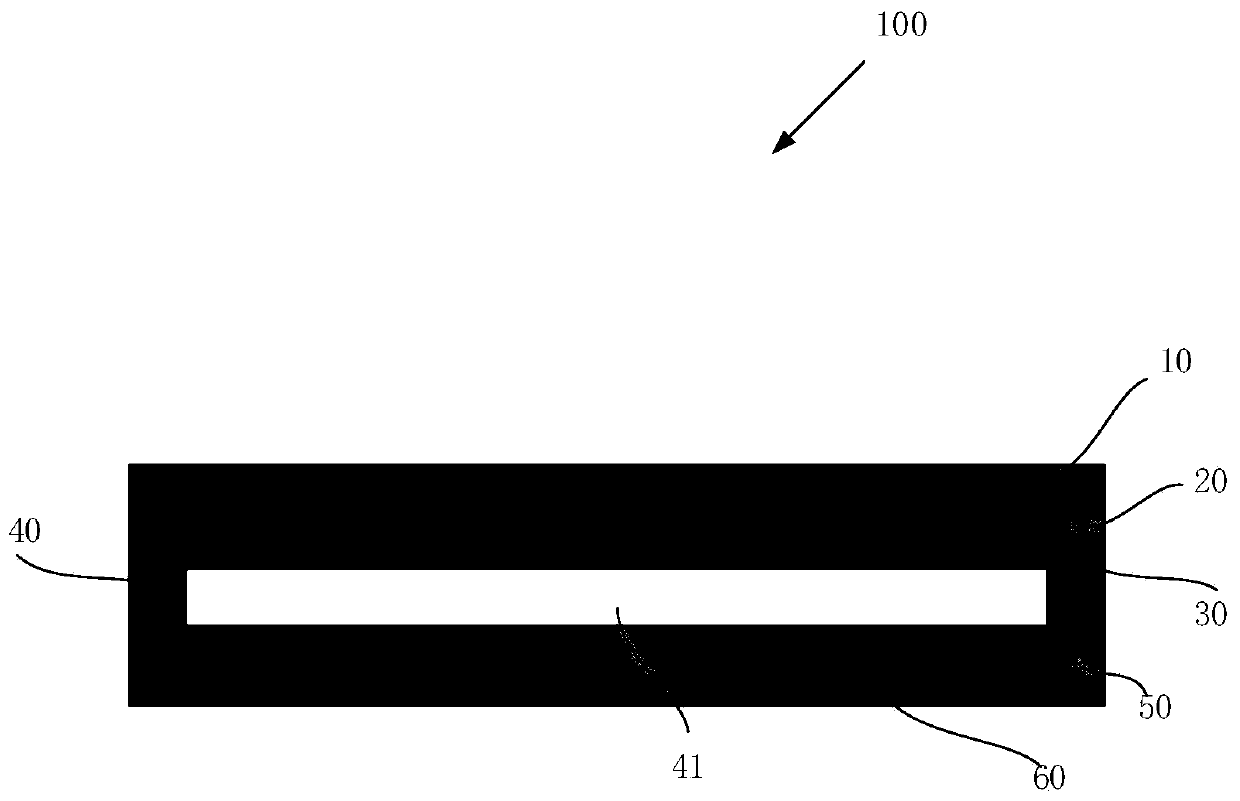

The invention provides a flexible wearable sensor and a corresponding wearable device and preparation method thereof, wherein the flexible wearable sensor is small in size and high in flexible degreeand output capacity. The flexible wearable sensor comprises a first electrode layer, a piezoelectric layer, a second electrode layer, an interval layer, a friction layer and a third electrode layer which are arranged in sequence; a flexible mixed material at least constituted by a piezoelectric material and silicone rubber is contained in the piezoelectric layer, and the piezoelectric layer can generate a piezoelectric signal after being subjected to polarization treatment; a flexible mixed material at least constituted by silicone rubber is contained in the friction layer, a plurality of protrusion parts formed by a plurality of protrusion structures which are configured in an arrayed mode are formed on the opposite areas in the inner surface of the piezoelectric layer and the inner surface of the friction layer correspondingly, and the two inner surfaces are oppositely arranged; the outer surface and the inner surface of the piezoelectric layer are covered with the first electrode layer and the second electrode layer correspondingly; and the interval layer is provided with hollow parts opposite to the protrusion parts on the inner surface of the piezoelectric layer, and the outersurface of the friction layer is covered with the third electrode layer.

Owner:ZHONGBEI UNIV

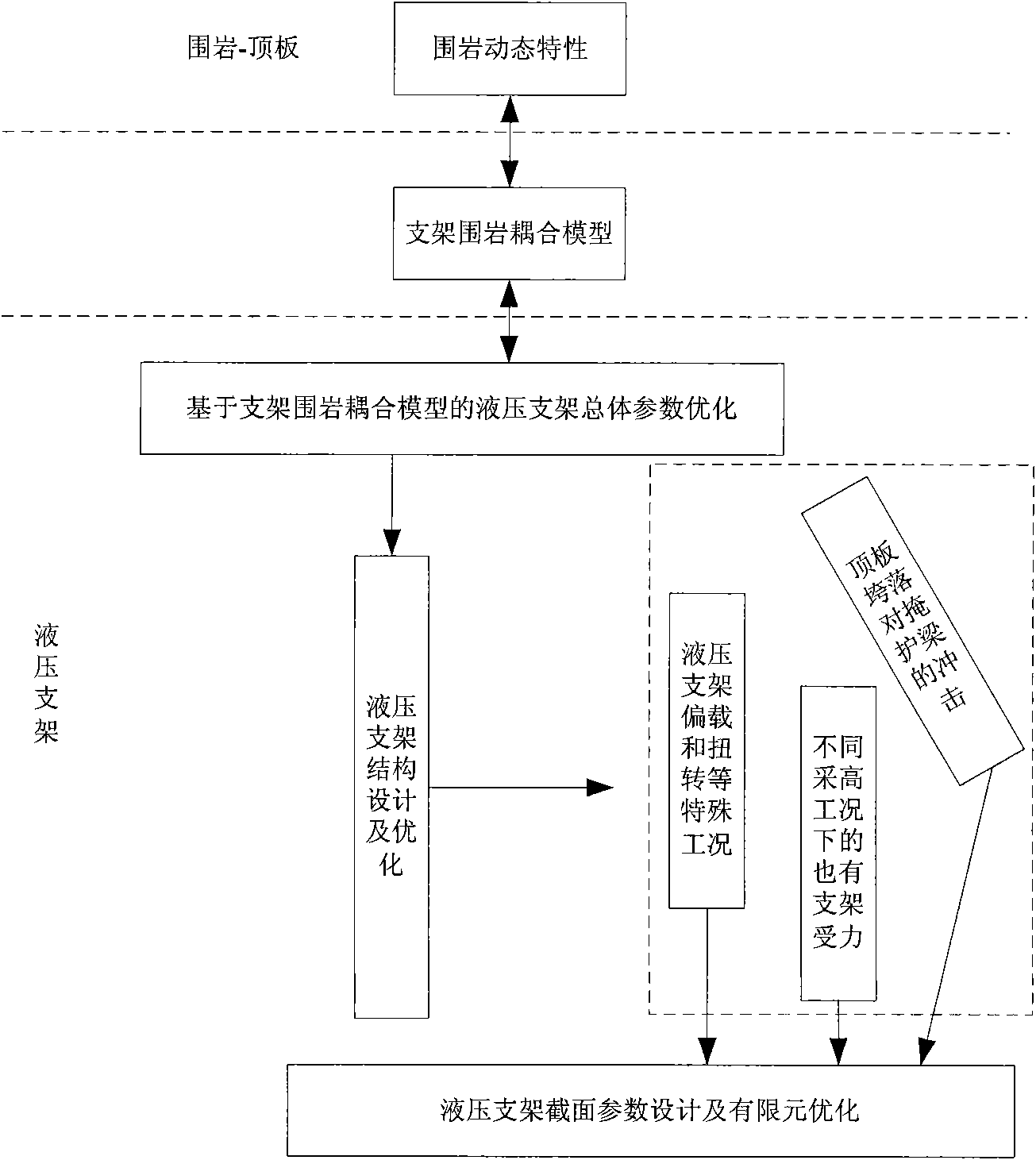

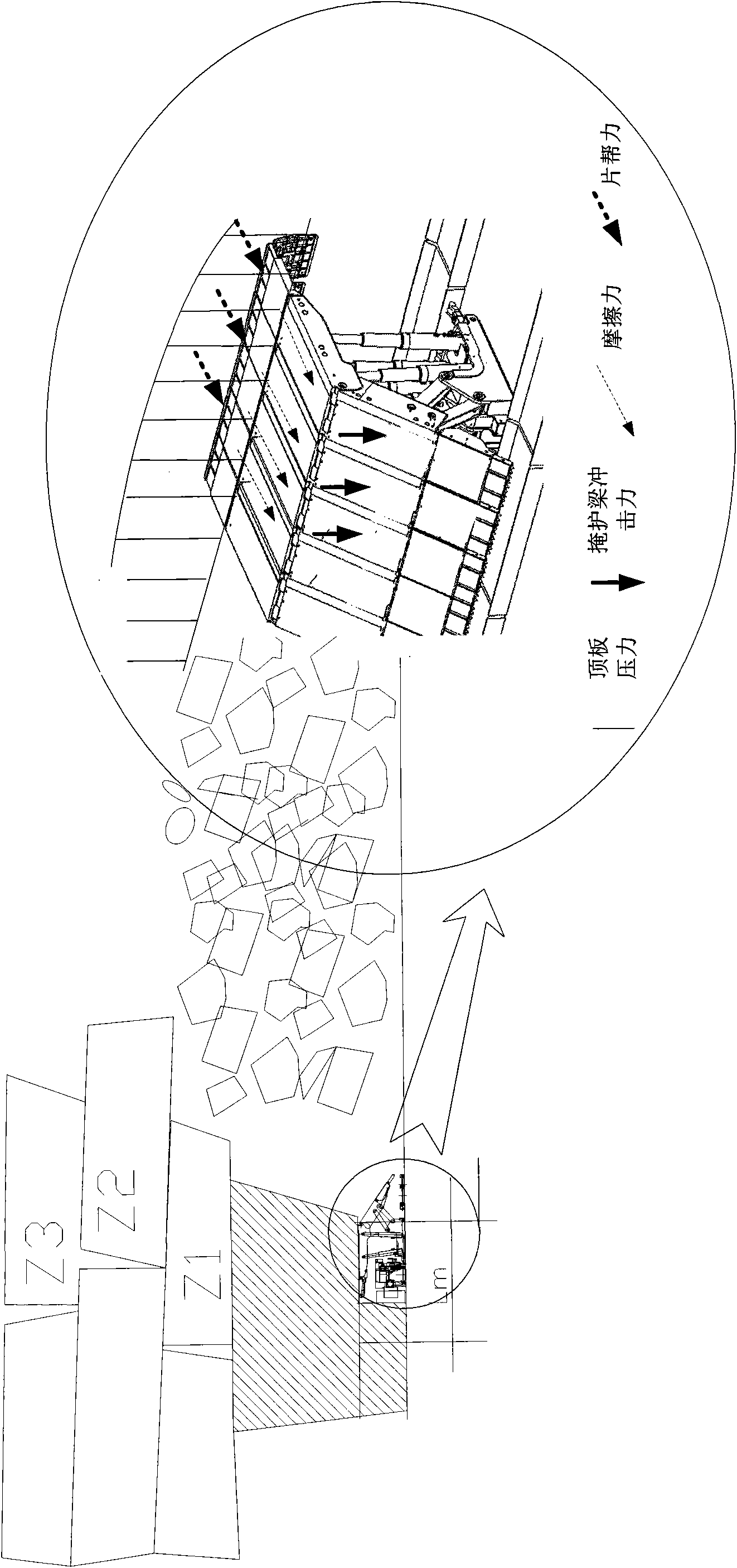

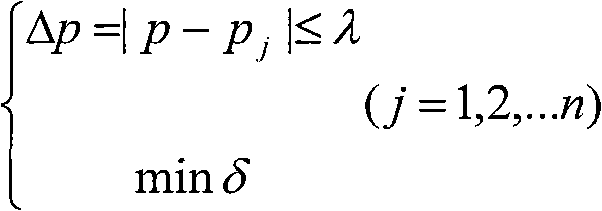

Hydraulic support and surrounding rock coupling three-dimensional dynamic design method

The invention discloses a three-dimensional design method of a hydraulic support, which considers the dynamic effect of surrounding rocks positioned on a coal face. The three-dimensional design method of the hydraulic support comprises the following steps of: simulating the motions of a top plate, a coal bed and a bottom plate in the advancing process of the coal face by adopting discrete element software; building a support-surrounding rock three-dimensional coupling model, and computing the reverse supporting effect and the control action of the hydraulic support on surrounding rock motion; circularly optimizing support parameters to obtain a structure which has optimal supporting effect on the surrounding rocks; simulating to obtain the distribution regularity of the tension, the bending and the torsion internal force of a part of the hydraulic support by adopting dynamic software under the stress conditions, i.e. unbalance loading, torsion, impact of caving rocks on a shield beam of the hydraulic support, and the like, of the hydraulic support at different time, on different positions and under different geological conditions of coal face advancing; and designing and optimizing the structure form of the hydraulic support by combining with structure arrangement requirements and adopting a finite element method. The three-dimensional design method can effectively enhance the adaptive capacity of the hydraulic support on surrounding rock change, strengthen the stability and the reliability and ensure that the coal mining work is safely and efficiently carried out.

Owner:CCTEG COAL MINING RES INST

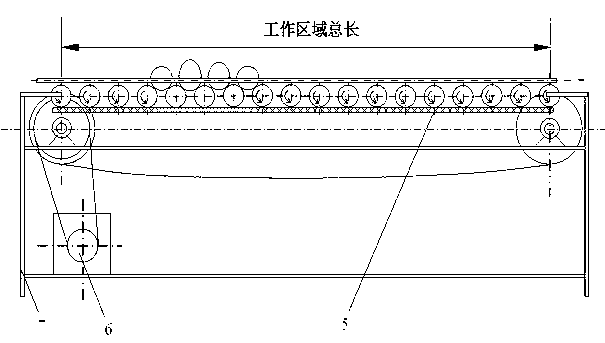

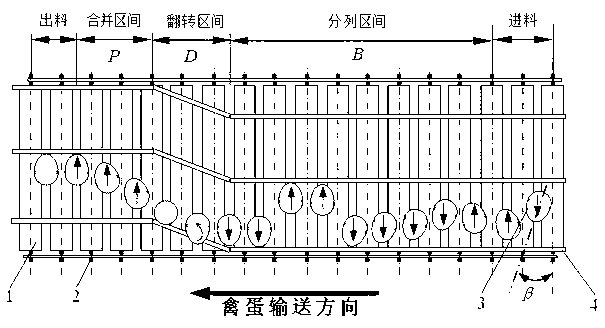

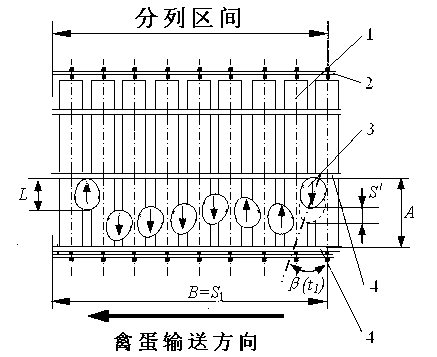

Design method of automatic orienting device for big ends of eggs

InactiveCN102717914AStructural parameter optimizationOptimize structure sizePackaging eggsMachineMaximum displacement

The invention discloses a design method of an automatic orienting device for big ends of eggs. The automatic orienting device for the big ends of eggs comprises a rowing region, an overturning region and a combing region in sequential arrangement. Time t1 required for an egg to complete the maximum displacement A-L on support rollers along an axial direction within the rowing section is computed via a formula, length of the rowing section is obtained according to the time t1 and the formula; length W of a bending section of each limit guide rod in the overturning region is computed via the formula; length D' of the overturning region, time t2 required for an egg to complete the maximum displacement A-L on support rollers along an axial direction within the combing region is computed, and length of the combing region is computed; and total length of a working area is obtained by summing the B, the D', the P, the length of a feeding region and the length of a discharging region. By the aid of the design method of the automatic orienting device for the big heads of eggs, structural parameters of above regions and bending sections of the limit guide rods are optimized, structural size of a whole machine is further optimized, and transmission efficiency between the eggs and the support rollers is improved.

Owner:JIANGSU UNIV

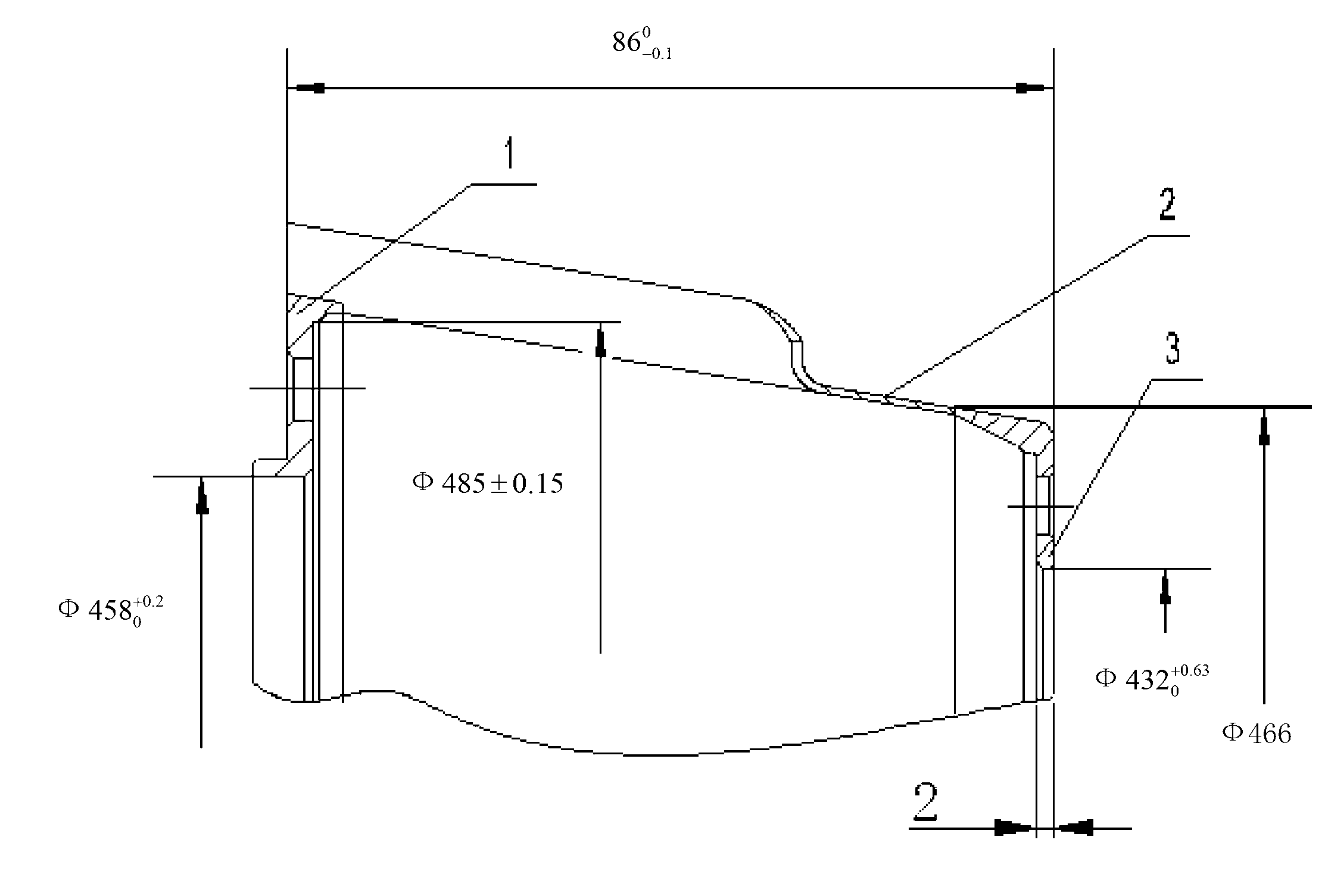

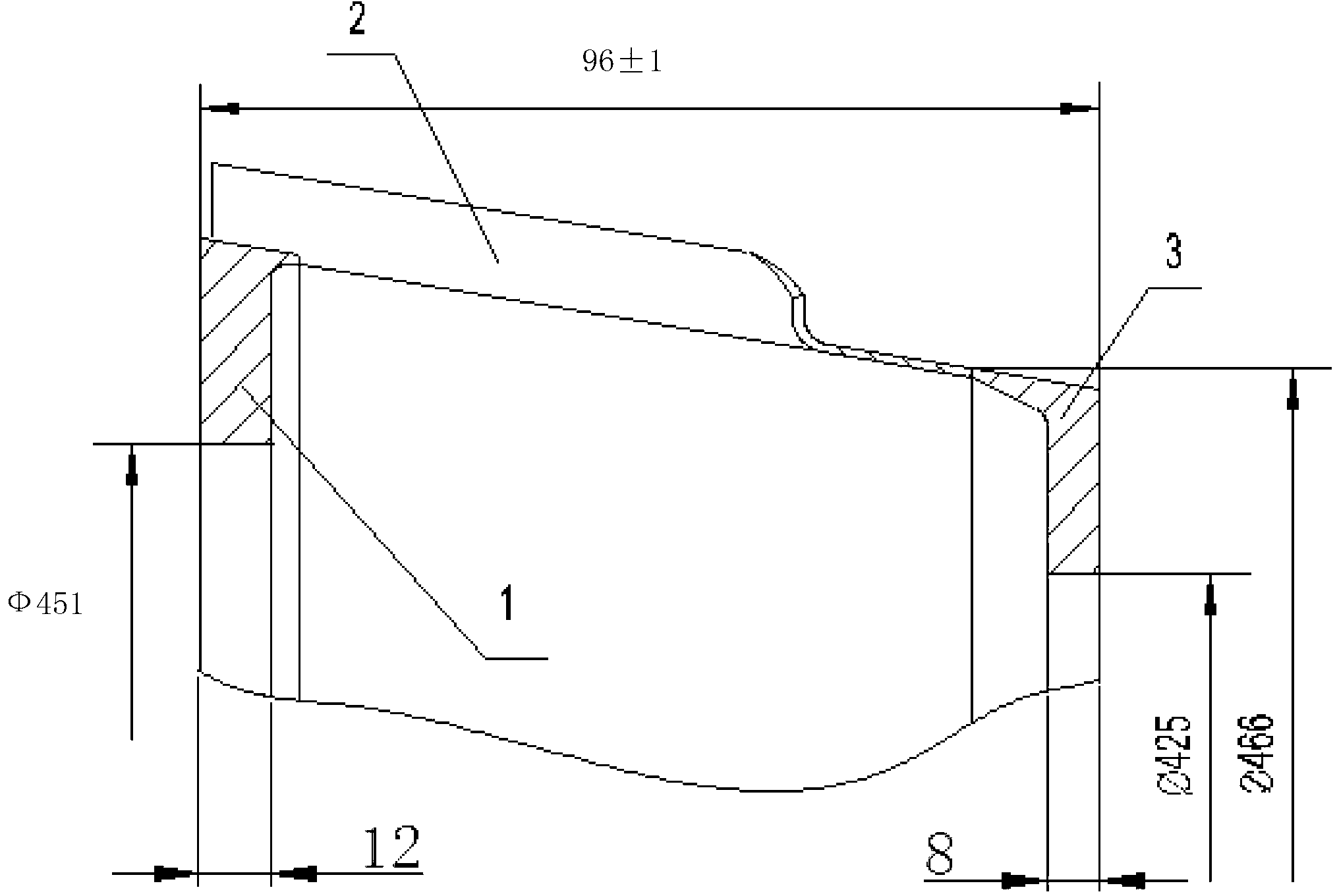

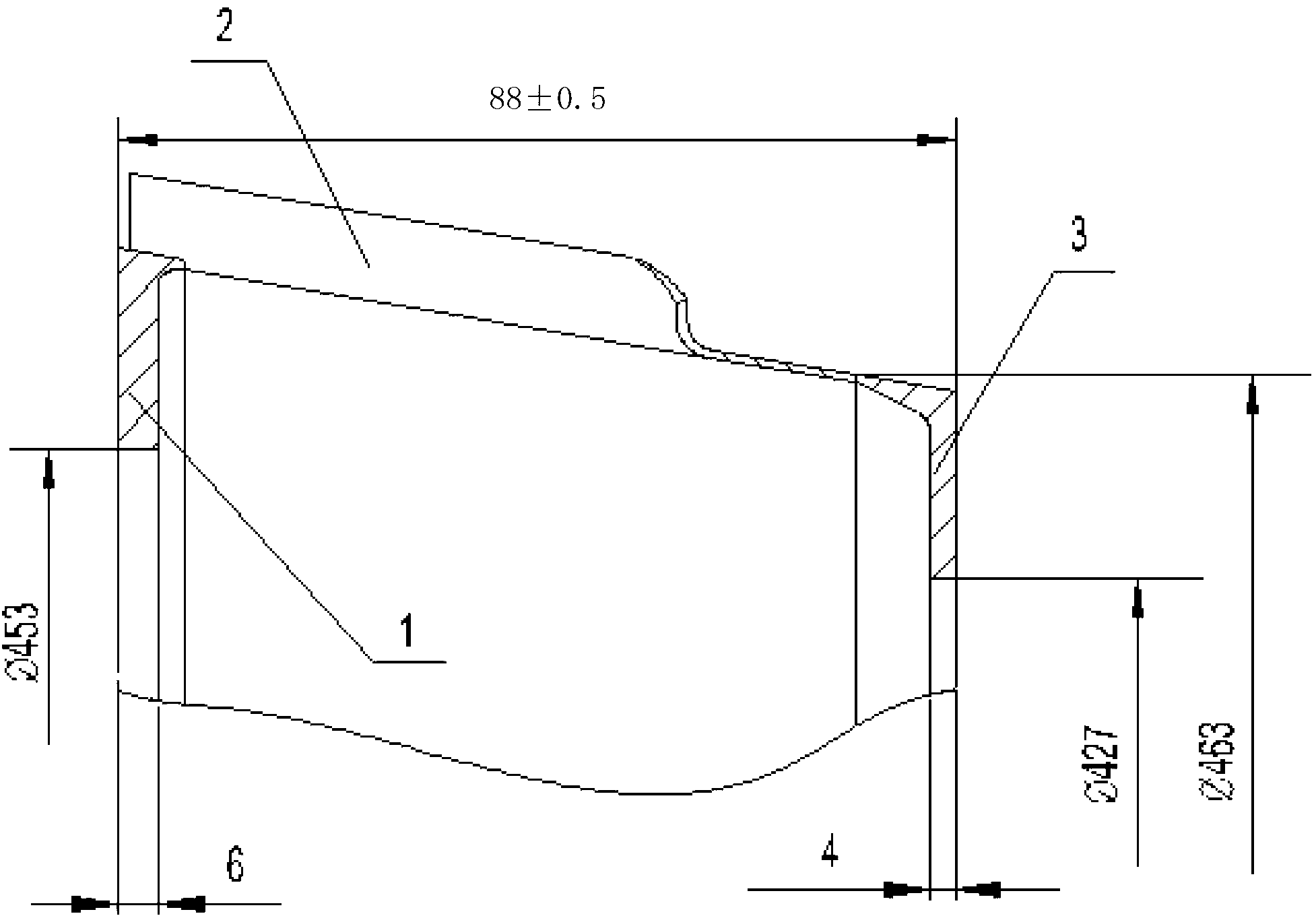

Method for processing thin wall welder cases of revolving body structures

InactiveCN102794610ASolve the structural sizeSolve the coaxial problem of front and rear installation side weldingArc welding apparatusPre deformationEngineering

The invention discloses a method for processing thin wall welder cases of revolving body structures, belonging to the technical field of aero-engine metal plate forming and welding. According to the invention, a whole pre-deformation welding / forming method is used for solving the problems that sizes of mounting edges are out of tolerance, coaxiality of front and rear mounting edges with main bodies after welding is out of tolerance and residual stress distribution of welding components is unbalanced. The method provided by the invention comprises the following steps of: carrying out technological structure welding deformation allowance compensation design on a mounting edge and a main body of a thin wall welder case before the welding according to the plastic deformation characteristics of materials; plastically forming an expansion block according to an expander work part, size and final structural size requirement of parts; carrying out automatic argon arc welding on the mounting edge and the main body; assembling the welded welder case and expansion block on the expander work part to carry out expansion plastic forming and controlling the expansion forming size through adjusting pressure of the expander; and unloading the pressure of the expander, recovering the expander work part and unloading the parts to complete the welding / forming process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

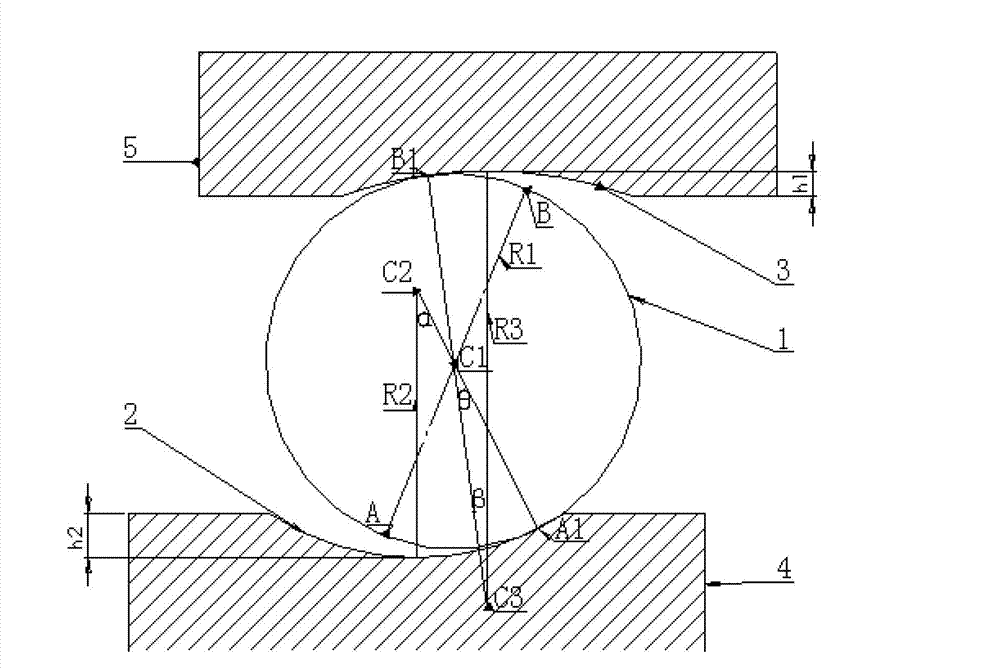

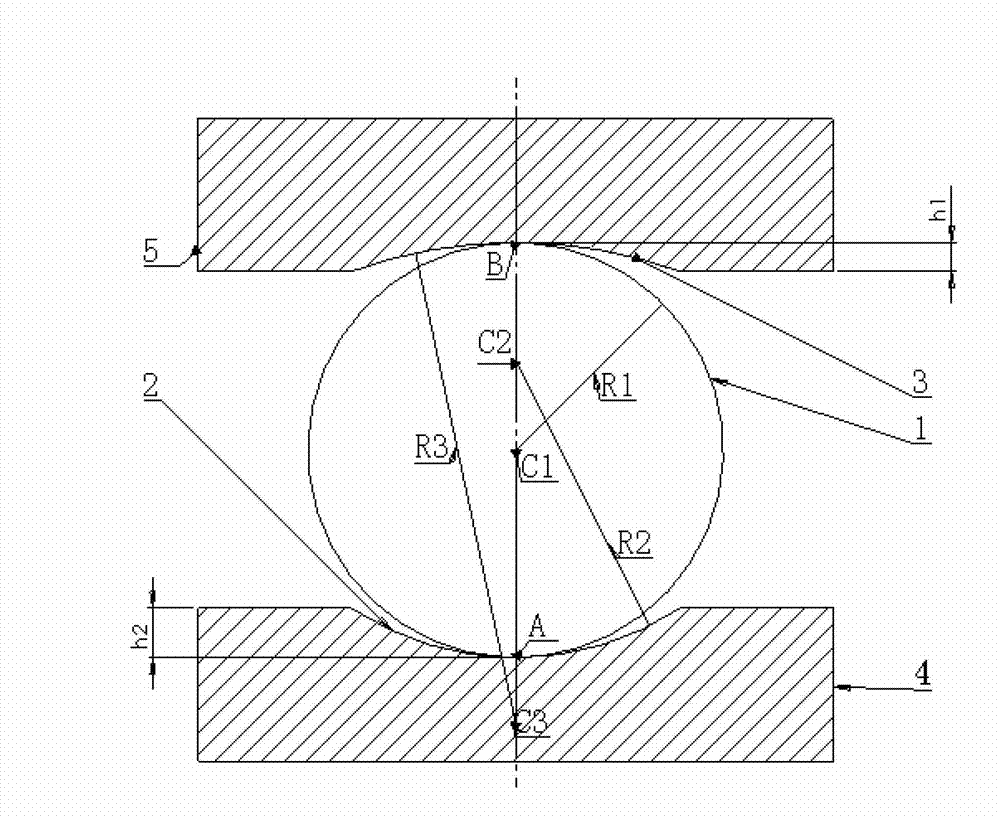

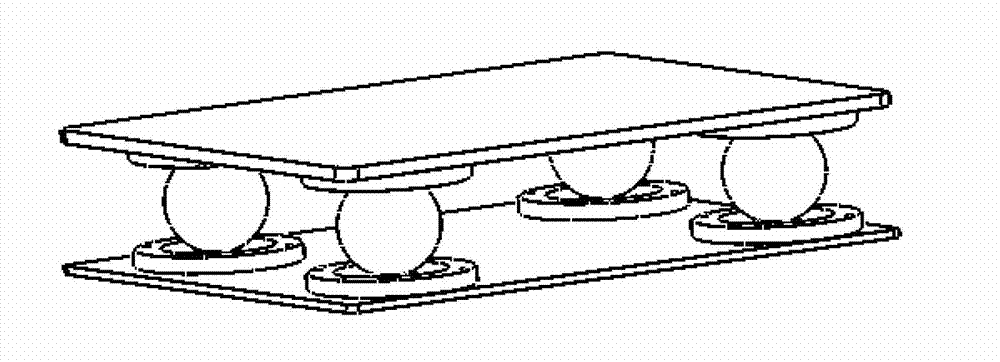

Low-frequency two-degree-of-freedom horizontal vibration isolation mechanism

The invention relates to a low-frequency two-degree-of-freedom horizontal vibration isolation mechanism which comprises three parts, namely an upper support plate, a rigid ball and a lower support plate, wherein the upper support plate is provided with an upper support plate arc; the lower support plate is provided with a lower support plate arc; the rigid ball is positioned between the upper support plate arc and the lower support plate arc; the upper support plate arc is in point contact with the rigid ball; and the lower support plate arc is in the point contact with the rigid ball. When the lower support plate generates displacement in a horizontal direction by being subjected to external force from a substrate, the rigid ball can take pure rolling relative to the lower support plate arc so that the upper support plate arc takes the pure rolling relative to the rigid ball, the integral mechanism can generate displacement relative to an original balance position, and the integral mechanism can be reset to the original balance position under the action of the gravity of the mechanism and loads. The low-frequency two-degree-of-freedom horizontal vibration isolation mechanism disclosed by the invention has the characteristics of simple and compact structure, high space utilization ratio, irrelevance of inherent frequency and the loads, and the like.

Owner:TSINGHUA UNIV +1

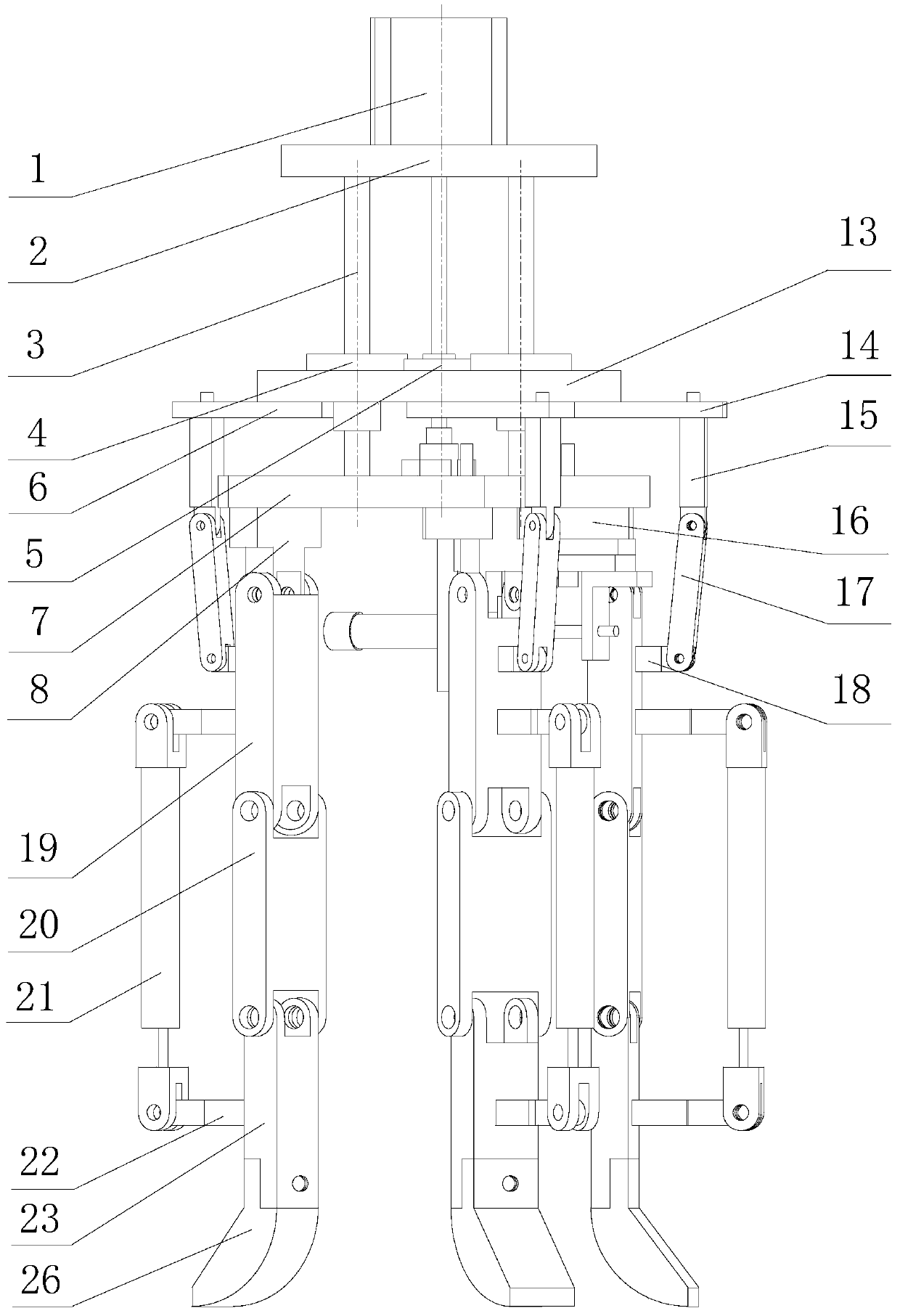

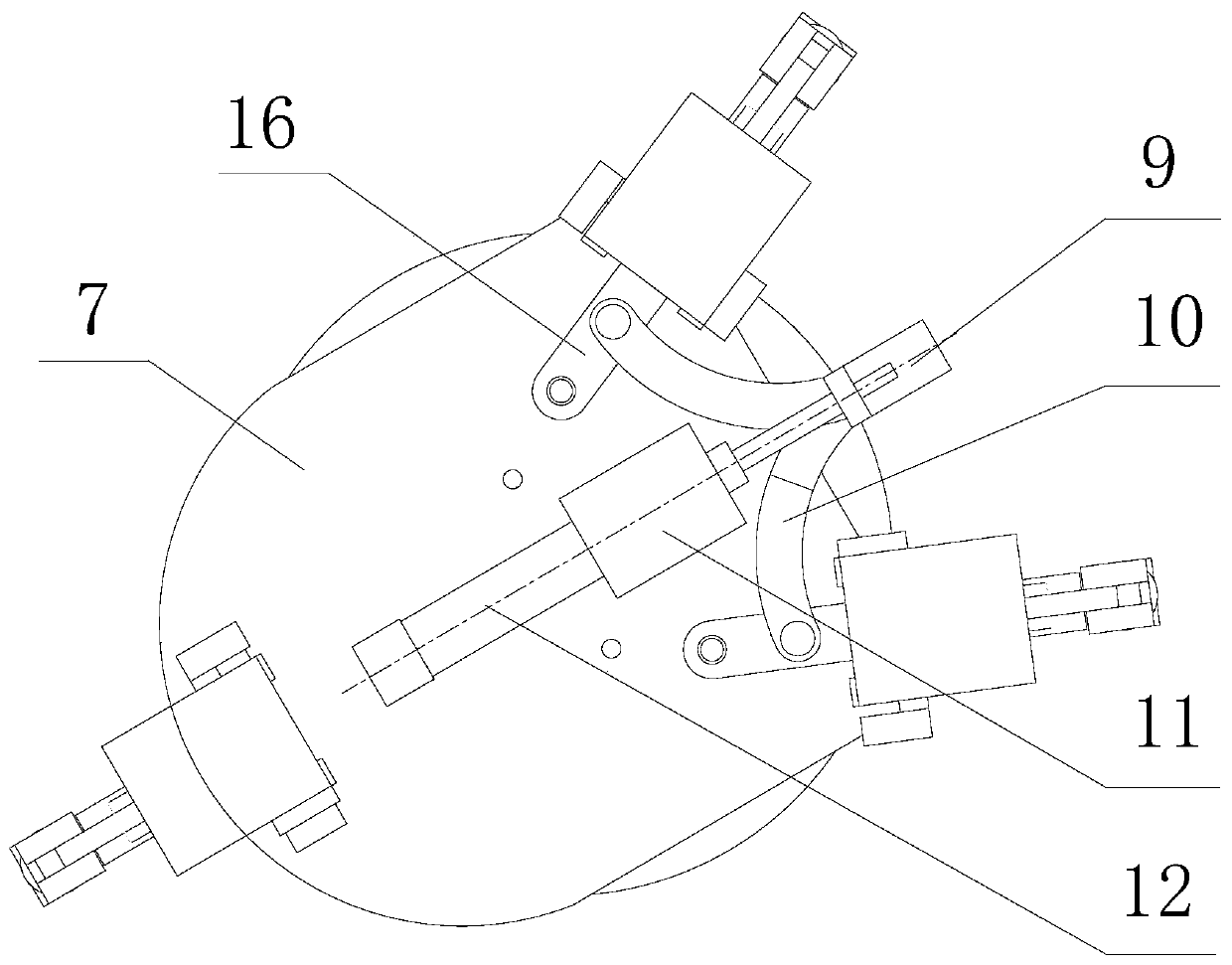

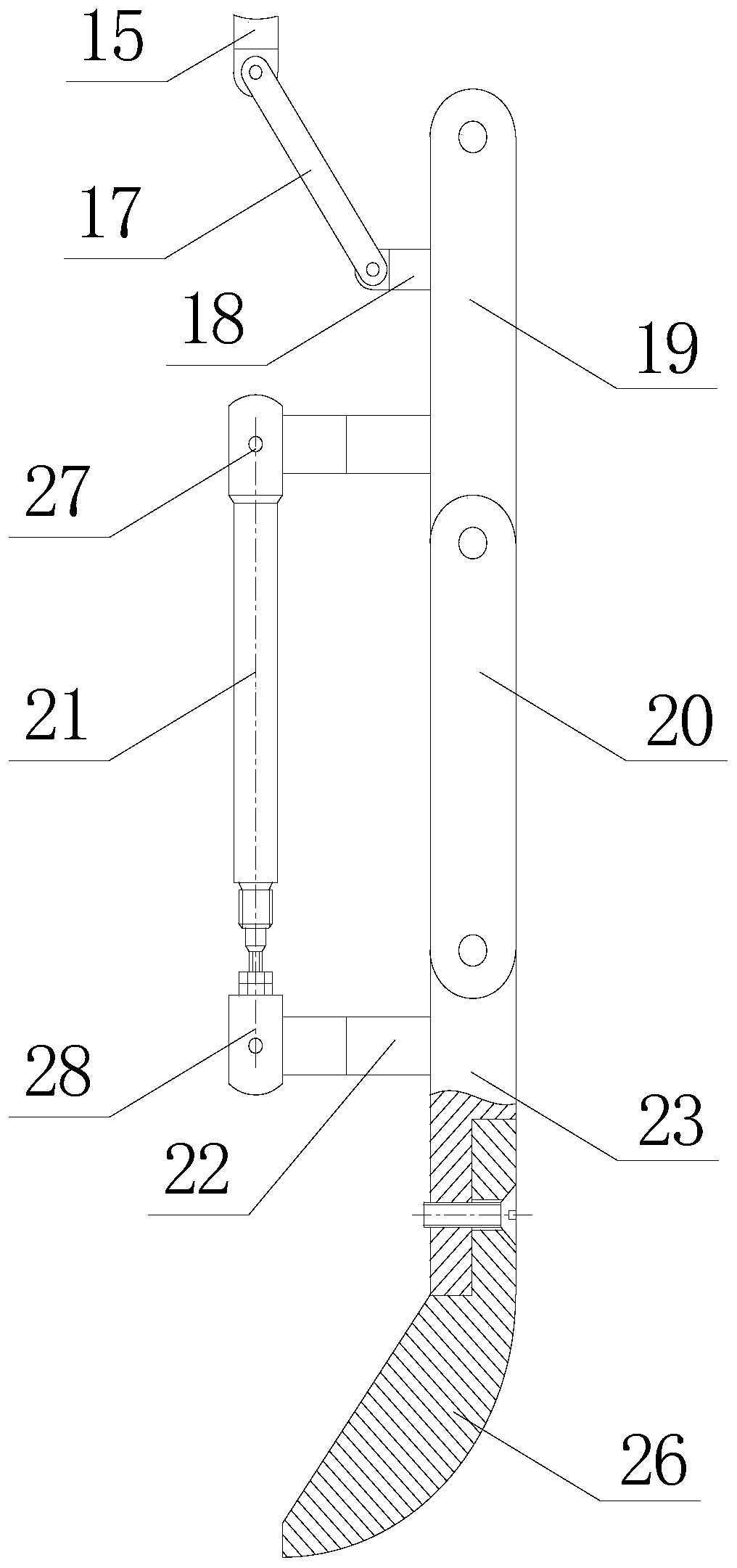

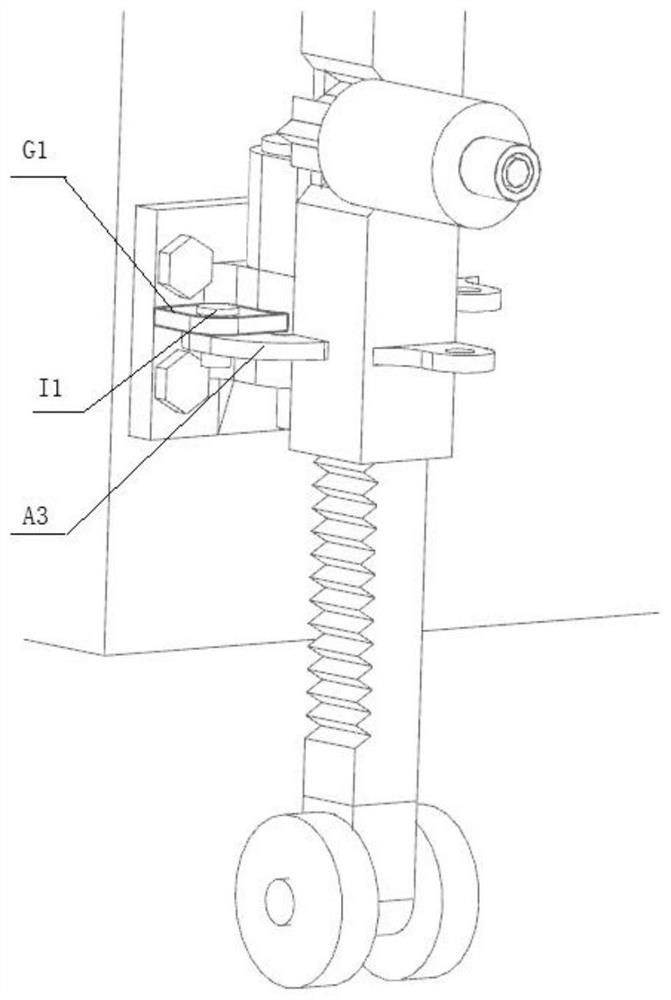

Pneumatic finger clamping and finger root rotation electric finger root rotatable flexible manipulator

ActiveCN109910039APneumatic clamping fast responseAdjustable grasping attitudeGripping headsHorizontal axisEngineering

The invention relates to a pneumatic finger clamping and finger root rotation electric finger root rotatable flexible manipulator. The manipulator comprises a fixed plate. A lead screw shaft motor ismounted on the upper surface of the fixed plate. The lower surface of the fixed plate is connected with a bottom plate through guide rods. The portions, located between the bottom plate and the fixedplate, of the guide rods are sleeved with a moving plate. A lead screw nut fixed into the moving plate is screwed on a lead screw shaft of the lead screw shaft motor. The manipulator further comprisesa fixed finger and two rotary fingers, and the fixed finger and the rotary fingers are of the same structure. The fixed finger is connected to a push rod fixing plate on one side of the bottom surface of the moving plate and rotates along the horizontal axis parallel to the axes of two torsion springs. The rotary fingers are connected to a rotary push rod fixing plate on the other side of the bottom surface of the moving plate and rotate along the vertical axis perpendicular to the different surface of the horizontal axis at equal angular displacement in the opposite direction. The pneumaticfinger clamping and finger root rotation electric finger root rotatable flexible manipulator is suitable for vertically and horizontally grabbing objects in various types of complex shapes, wide in grabbing range, high in rotation precision and high in response speed.

Owner:JIANGNAN UNIV

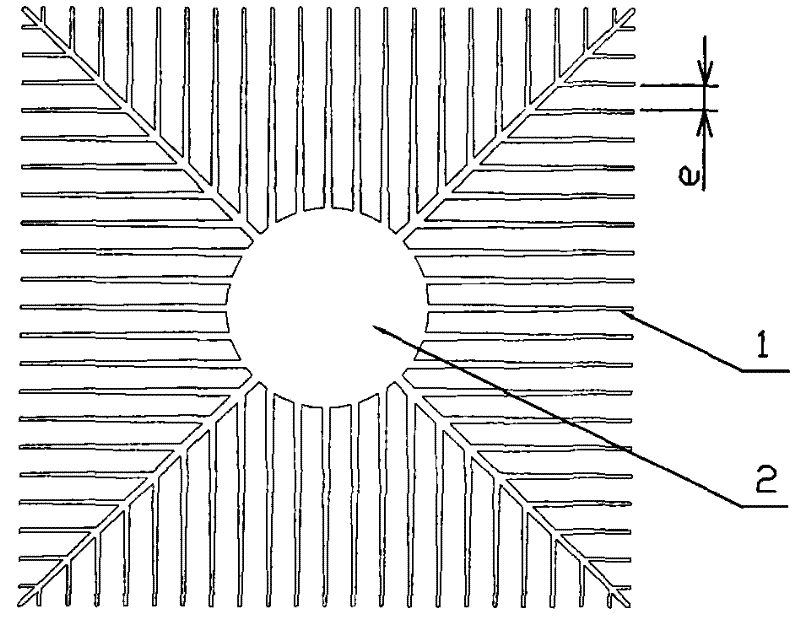

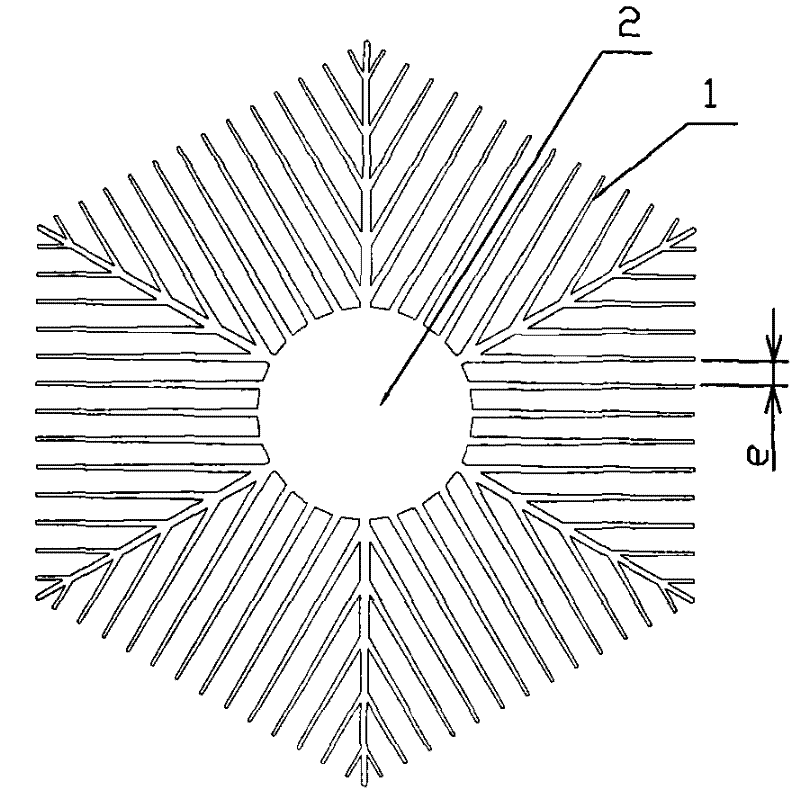

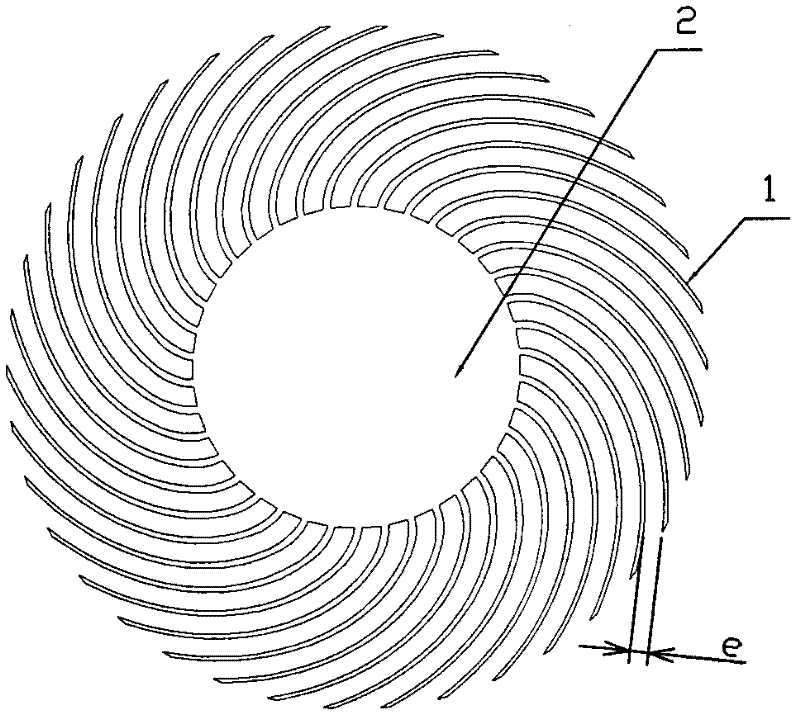

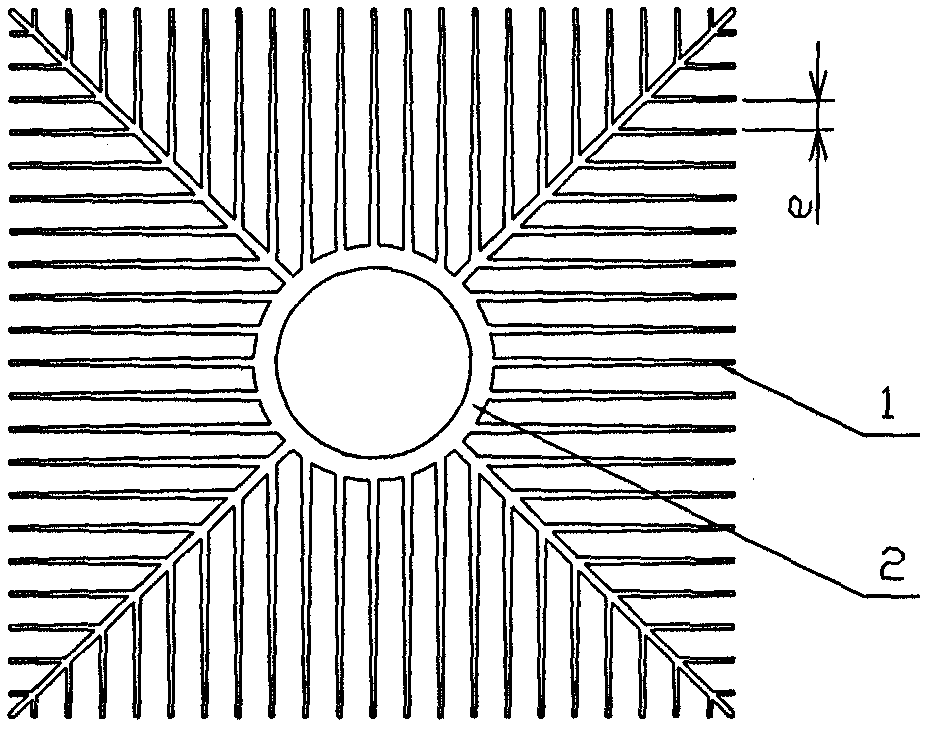

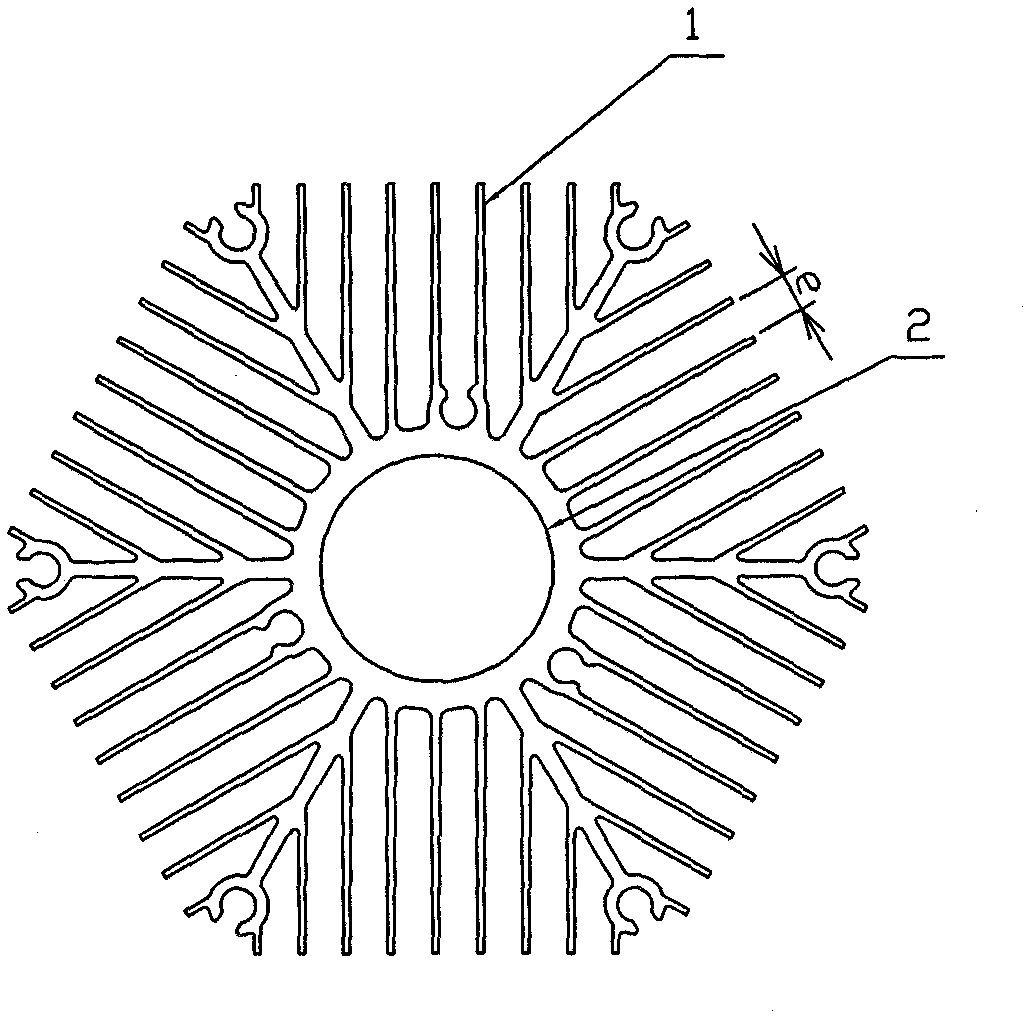

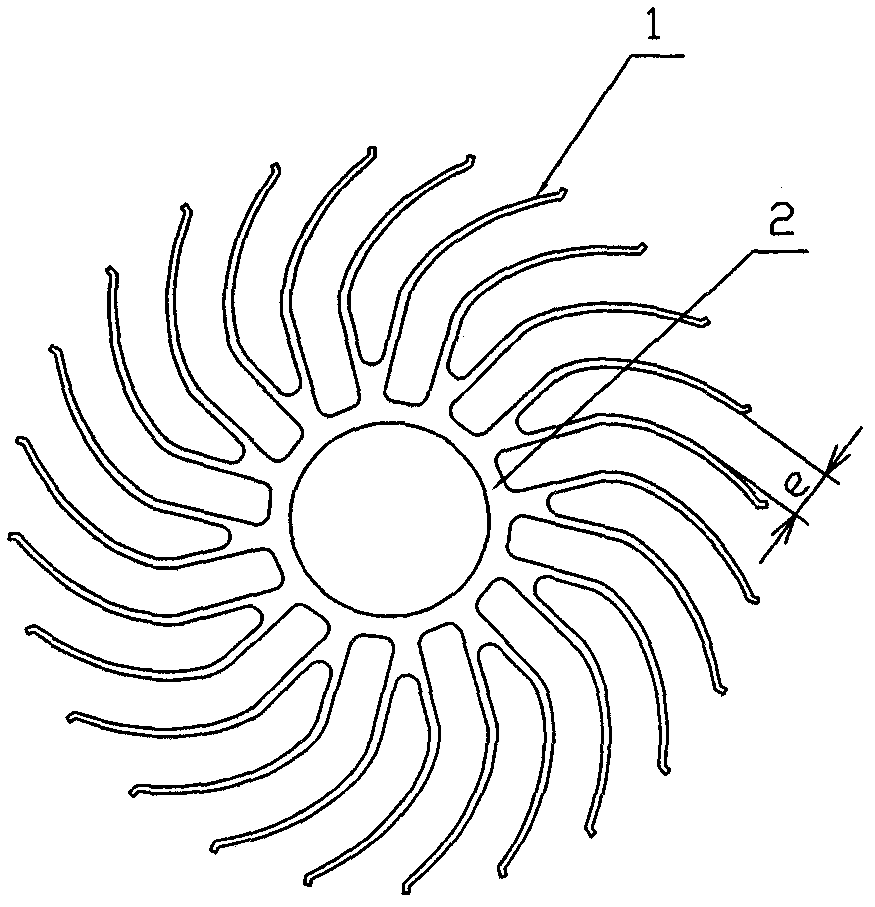

Solid State Lighting

InactiveCN102287686AReduces severe performance degradation issuesLow costPoint-like light sourceLighting heating/cooling arrangementsHeat conductingCooling effect

The present invention discloses a solid state lamp, comprising an LED light source and a heat sink, the LED light source is provided in the distal end of the heat conducting column, wherein the heat sink uses a sunflower structure with ribs projecting from the side of the heat conducting column, mainly characterized in that the ribs are opened with airflow grooves perpendicular to the axis and penetrating through the circumferential ring, wherein the depth of the deepest airflow groove is greater than half the rib length, the airflow groove has a width of not less than 2mm, and the average height of the short rib is less than five times the average rib gap; the averaged rib length on the heat sink is greater than10mm. The present invention solves the problems of poor air circulation and serious deterioration in heat dissipation efficiency when the heat sink axis level is transversely placed. The present invention also discloses an LED bulb having optimal structure size and the new structure to enable efficacies of lower cost and higher cooling effect.

Owner:深圳市秦博核芯科技开发有限公司

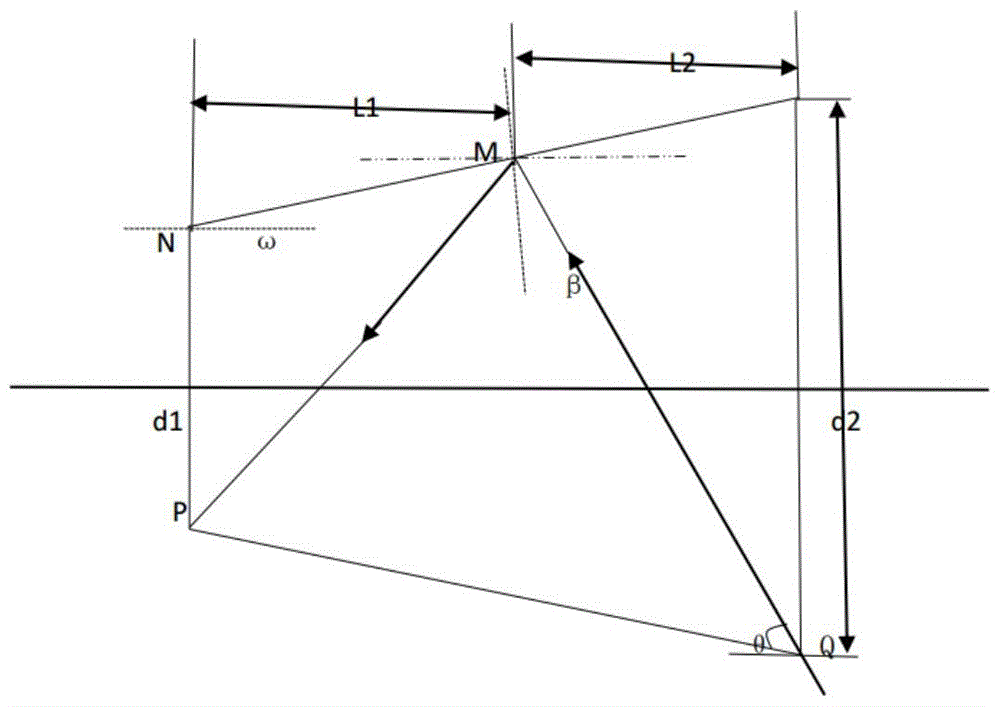

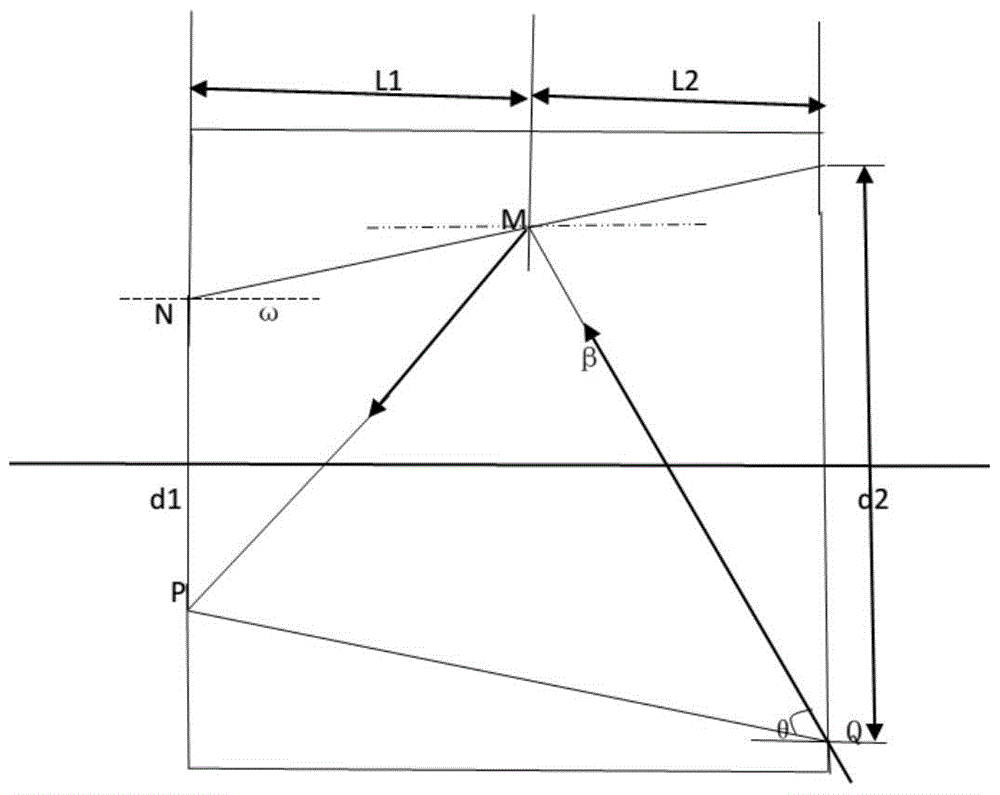

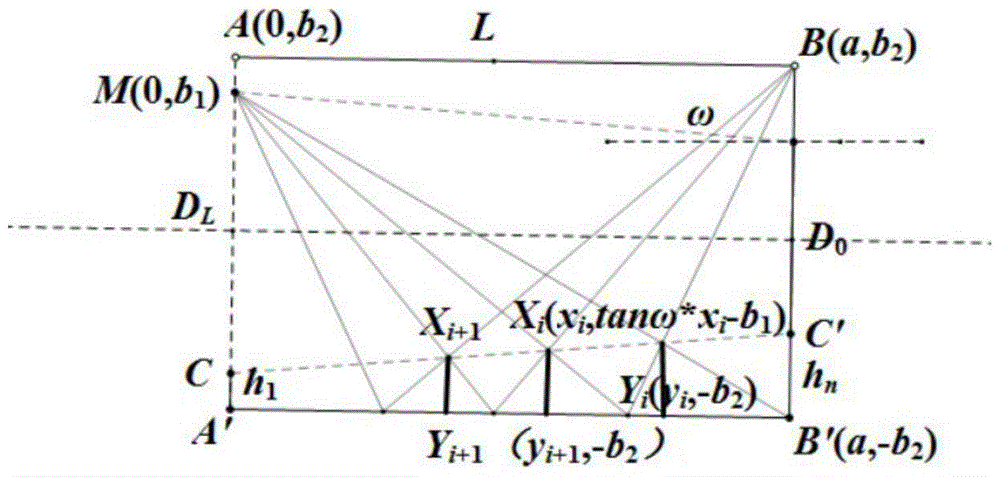

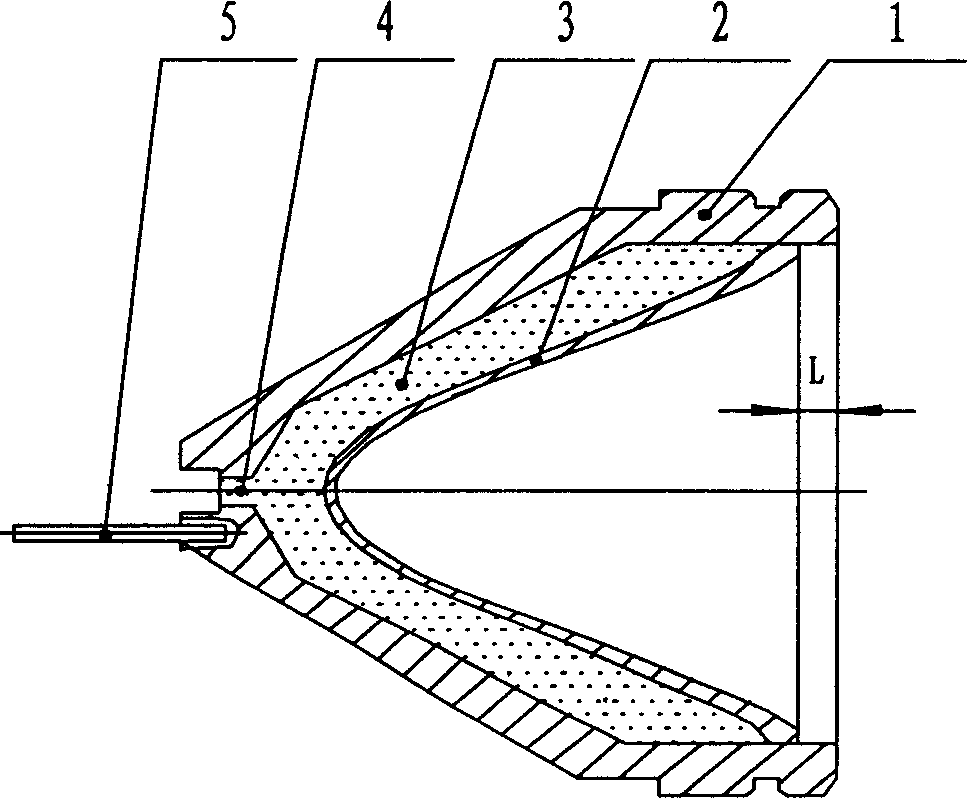

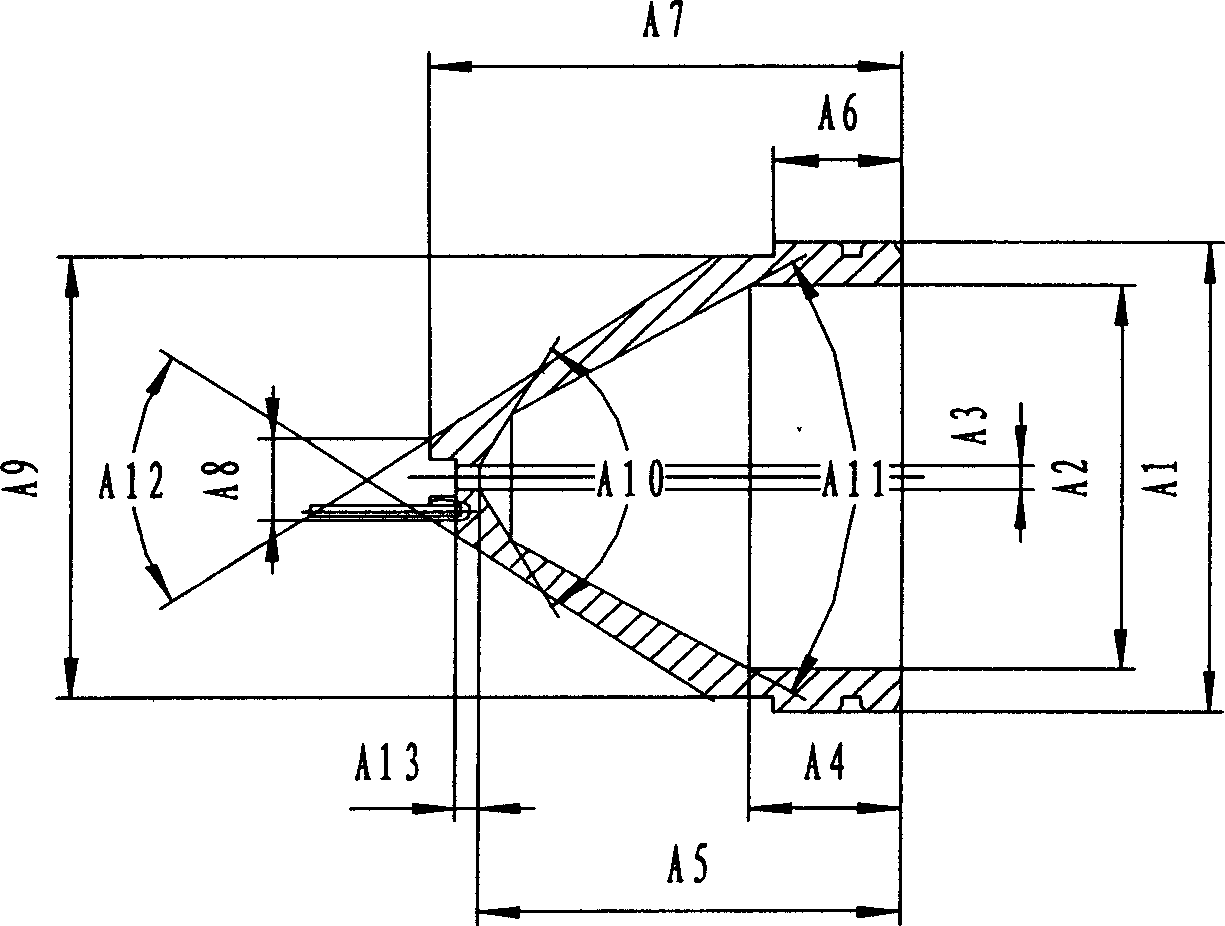

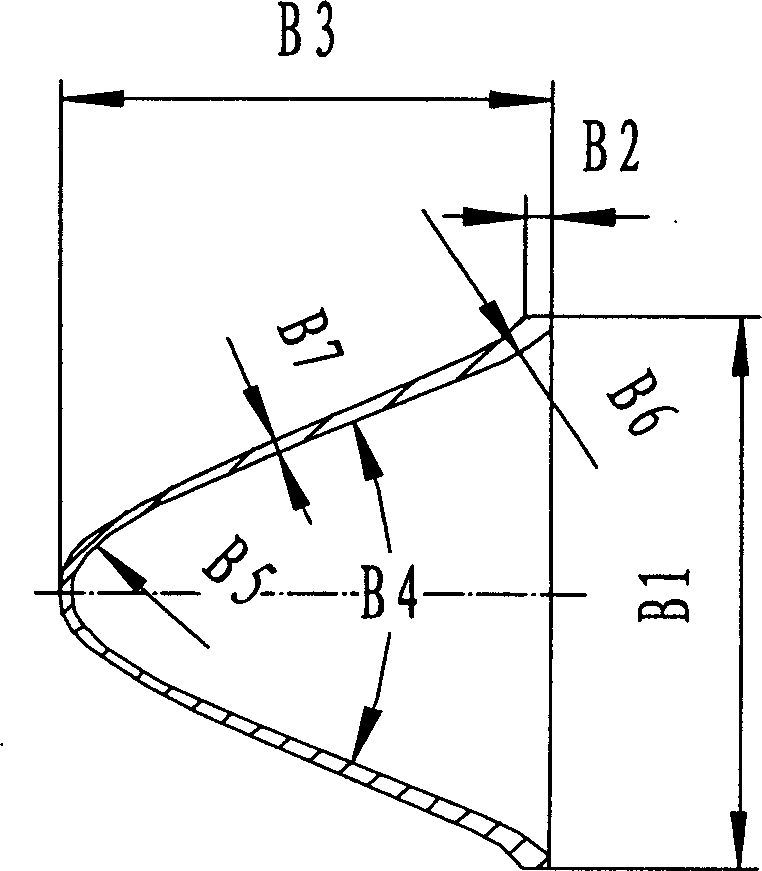

Star sensor hood and design method thereof

ActiveCN105758399AOptimize structure sizeStructure size controlNavigation by astronomical meansStar sensorHoneycomb structure

The invention discloses a star sensor hood and a design method thereof.The method includes: calculating the length a and the upper port diameter d2 of the hood according to the known sun inhibition angle theta, CCD field angle omega and entrance pupil diameter d1, and symmetrically expanding two ends of an upper port to expand the hood into a cylindrical structure, wherein the bottom diameter of the cylindrical structure is equal to the diameter of the expanded upper port; designing a plurality of transverse light blocking rings and a plurality of vertical light blocking rings in the cylindrical structure; or designing a honeycomb structure and a plurality of vertical light blocking rings in the cylindrical structure.The star sensor hood is high in stray-light inhibition ability.

Owner:NAT UNIV OF DEFENSE TECH

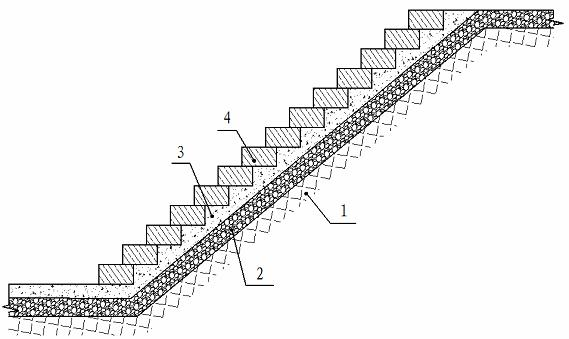

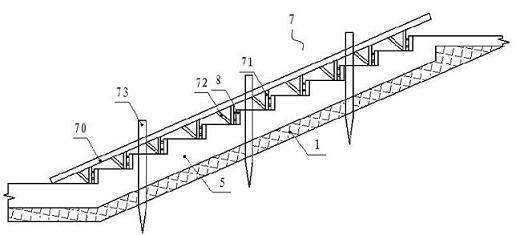

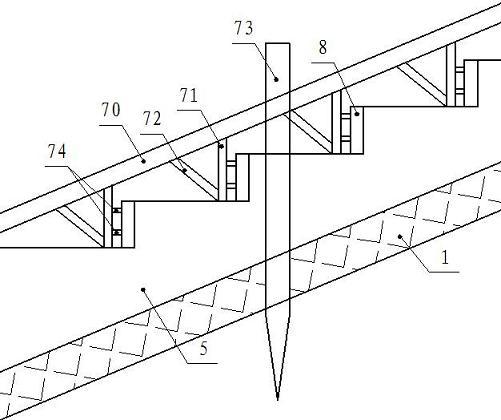

Suspended formwork pouring method for concrete foundation steps

ActiveCN102677895AEasy to assemblePrecise positioningForms/shuttering/falseworksBuilding material handlingStructural engineeringUltimate tensile strength

The invention relates to a suspended formwork for concrete foundation steps and a suspended formwork pouring method for pouring concrete foundation steps by using the suspended formwork. The suspended formwork comprises one or a plurality of formwork racks, each formwork rack comprises at least one longitudinal beam and a plurality of structural units distributed along the longitudinal beams in turn, each structural unit comprises a vertical formwork rack for mounting a vertical formwork and an inclined strengthening rib for fixing the vertical formwork rack, one end of the vertical formwork rack is fixedly connected with the longitudinal beam, and the two ends of the inclined strengthening rib are fixedly connected with the longitudinal beam and the vertical formwork rack respectively to form a steady triangular structure. The method comprises the following steps: (1) leveling up and tamping a foundation; (2) mounting a suspended formwork; and (3) pouring concrete foundation steps by use of the suspended formwork fabricated in step (2). The suspended formwork provided by the invention has the advantages of simple structure, accurate positioning and easiness in operation, and can be repeatedly used. The steps constructed using the method provided by the invention have the advantages of regular structure, esthetic appearance, high strength, and greatly improved quality.

Owner:北京正和恒基滨水生态环境治理股份有限公司

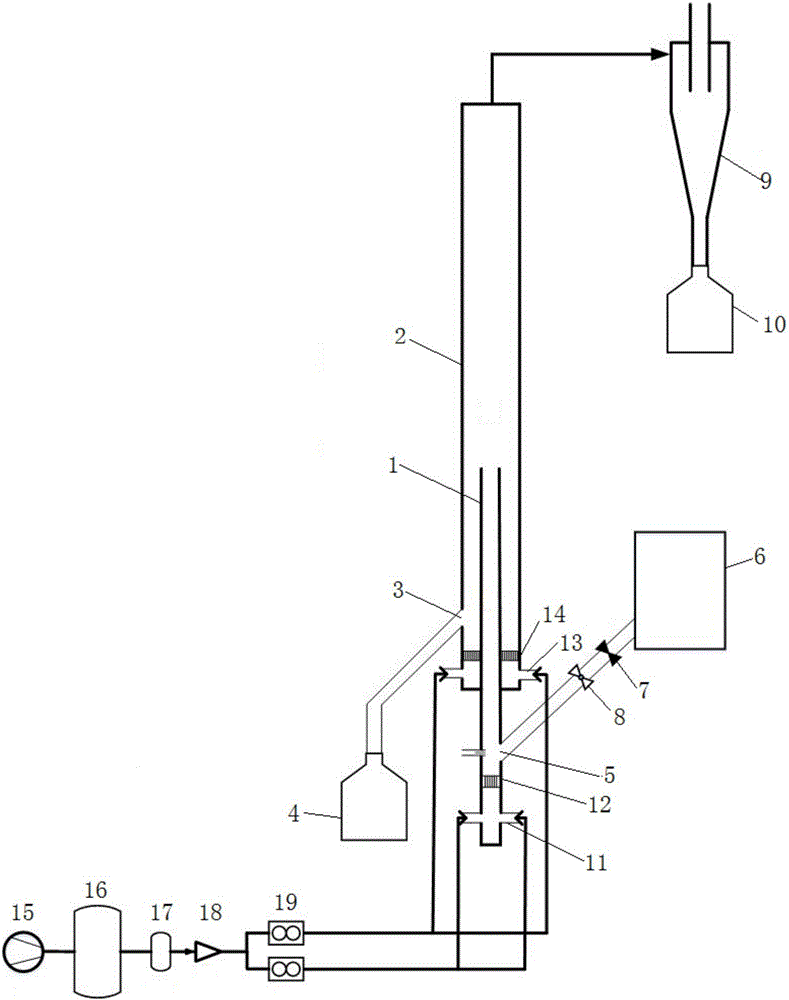

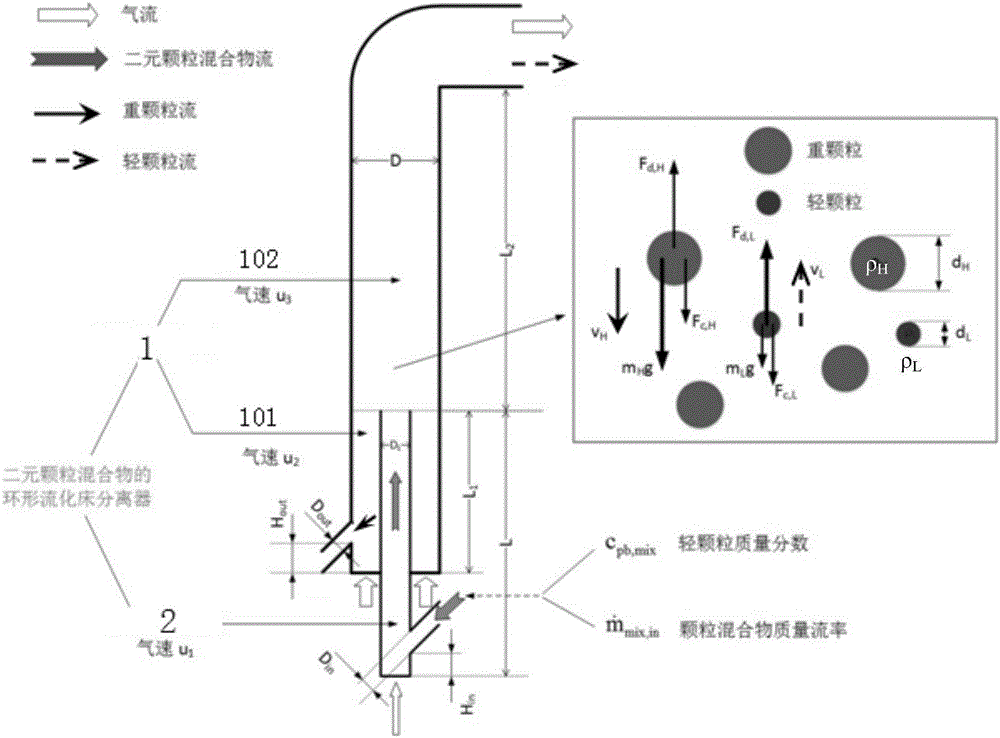

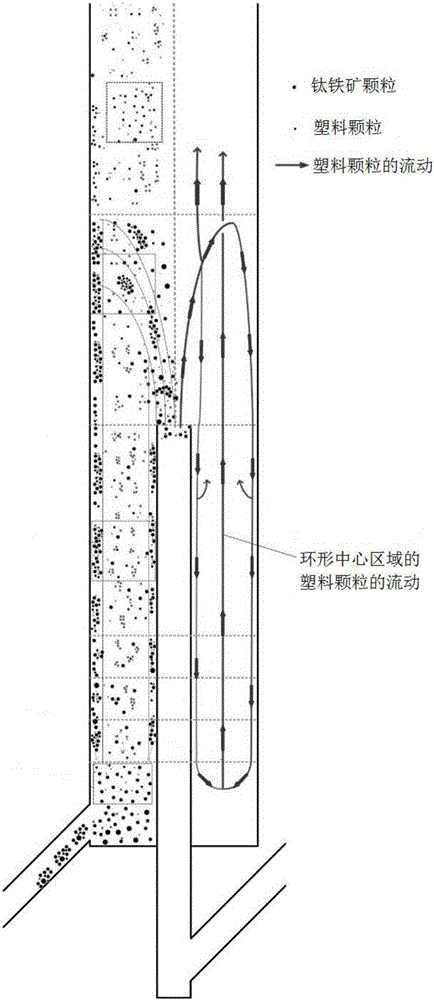

Annular fluidized bed separator of particle mixture

ActiveCN106269508AEfficient separationImprove dispersionGas current separationHeavy particleReactor system

The invention relates to an annular fluidized bed separator of a particle mixture. The upper end of a center lifting pipe extends into an annular fluidized bed by a certain height, so that the annular fluidized bed is divided into an annular area at the lower part and a cylindrical area at the upper part; an air inlet and a wind distribution plate are respectively arranged at the bottoms of the center lifting pipe and the annular fluidized bed; a feed port is formed in the bottom of the center lifting pipe; a heavy particle outlet is formed in the bottom of an annular area of the annular fluidized bed, and is connected with a heavy particle collecting tank; and an airflow outlet at the top of the annular fluidized bed is connected to a light particle collecting tank by a cyclone separator. The particle mixture is quickly fluidized in the center lifting pipe for primary dispersion, and is ascended along with air currents to enter the annular fluidized bed for secondary dispersion. The annular fluidized bed separator can continuously and quickly perform high-efficiency separation for light and heavy particle mixtures under the condition of normal temperature or high temperature. The annular fluidized bed separator can be coupled with a circulating fluidized bed reactor system, and can continuously and stably operate.

Owner:TSINGHUA UNIV

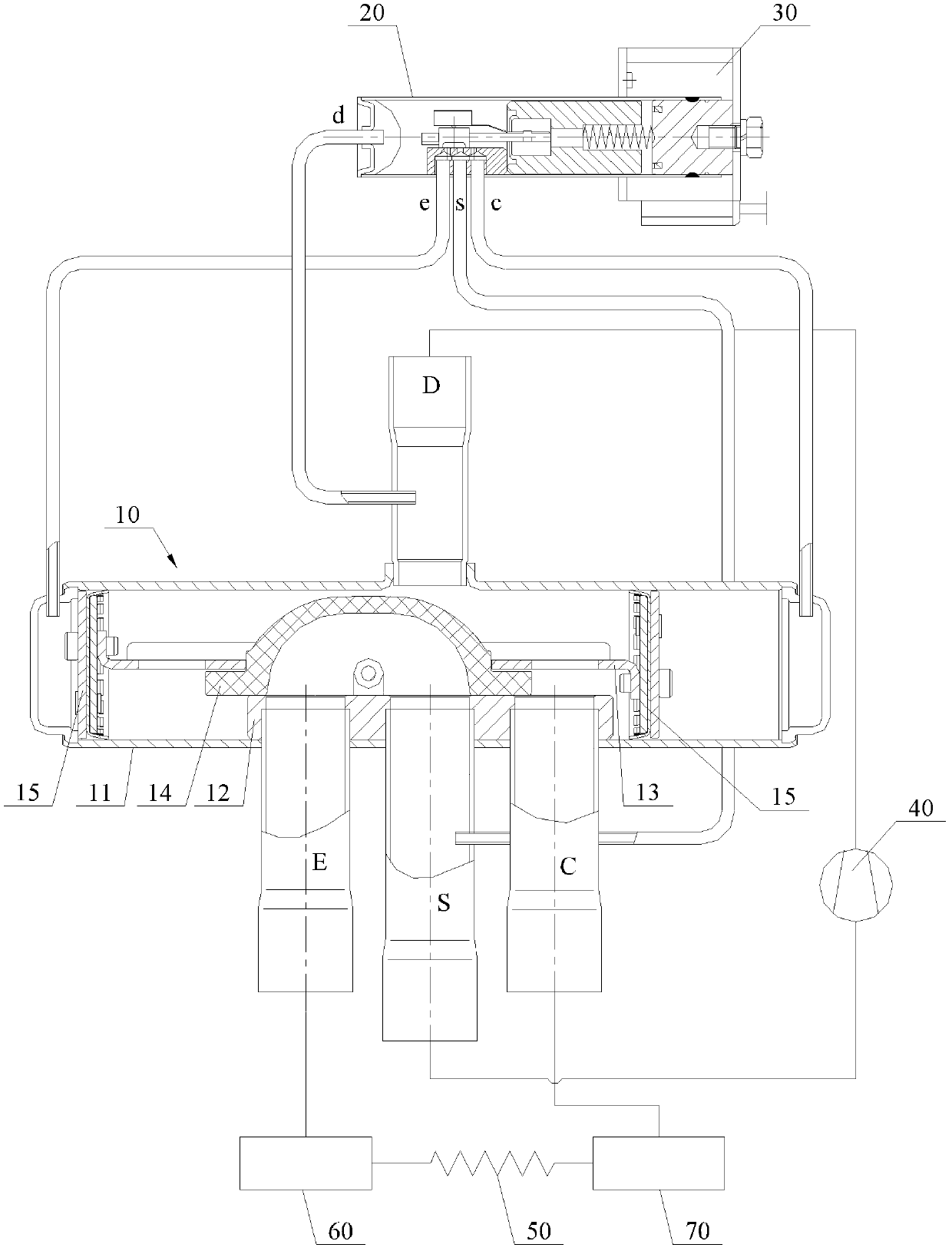

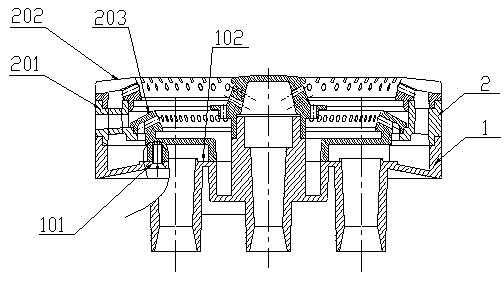

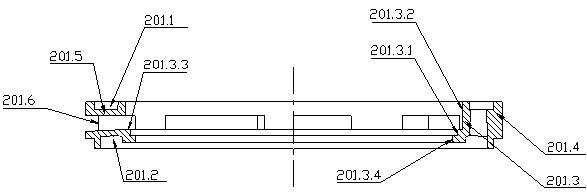

Main valve of four-way reversing valve and four-way reversing valve provided with main valve

InactiveCN103291957AOptimize structure sizeReduce coefficient of frictionOperating means/releasing devices for valvesMultiple way valvesEngineeringAir conditioning

The invention discloses a main valve of a four-way reversing valve. The main valve comprises a valve body, two piston devices and sliding blocks, wherein the piston devices are arranged in the valve body and connected through a connecting rod; the sliding blocks and the piston devices move synchronously; piston cups and piston spring pieces are arranged in the piston devices, the piston cups are glidingly matched with the inner wall of the valve body, and the piston spring pieces are arranged in the piston cups and provide radial action force; the thickness of each piston cup is 0.55-0.65mm, and the thickness of each piston spring piece is 0.11-0.15mm; and the piston cups are made of materials by weight of 85%-95% of a polytetrafluoroethylene base material and 5%-15% of an additive capable of reducing friction coefficients. By means of optimization and improvement in two aspects of structure dimension and material selection, the adaptability of the four-way reversing valve is effectively improved, and configuration requirements of different air conditioning systems can be met. On the basis, the invention further provides a four-way reversing valve provided with the main valve.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

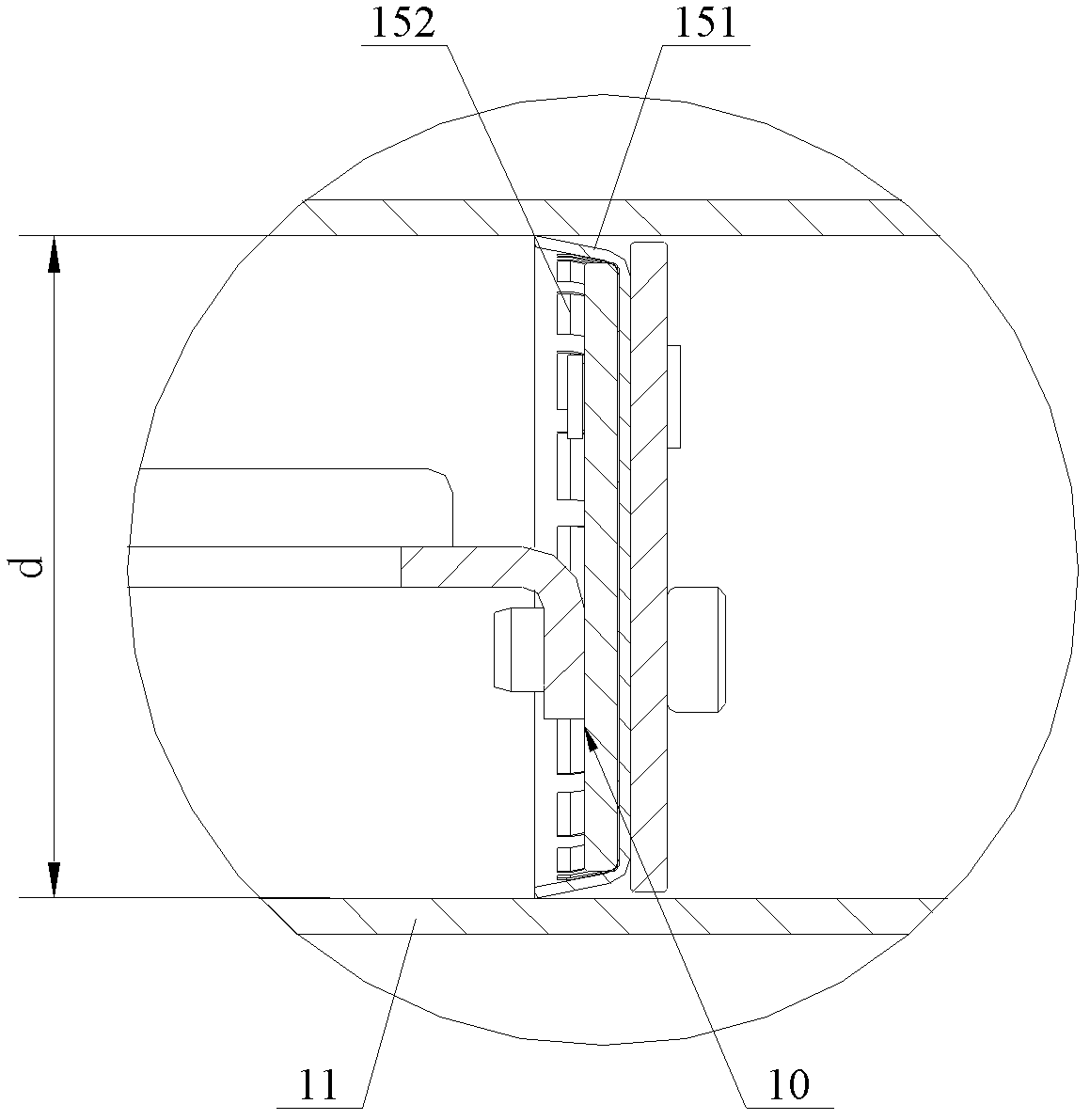

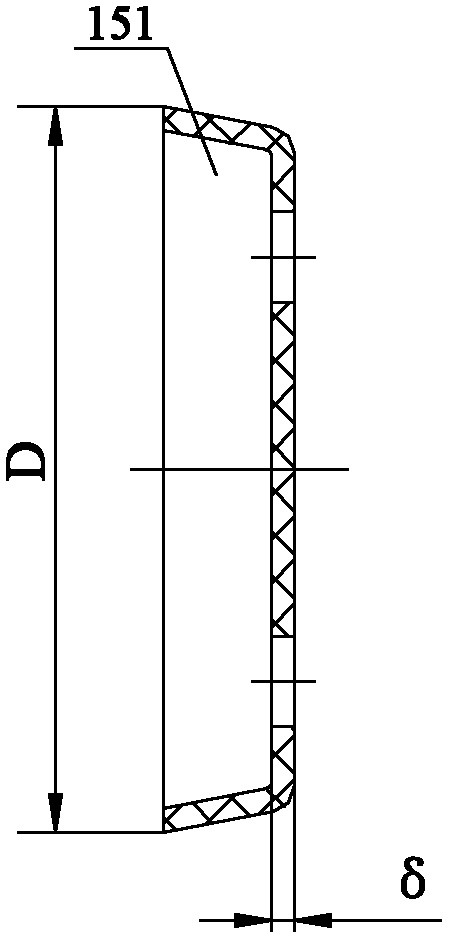

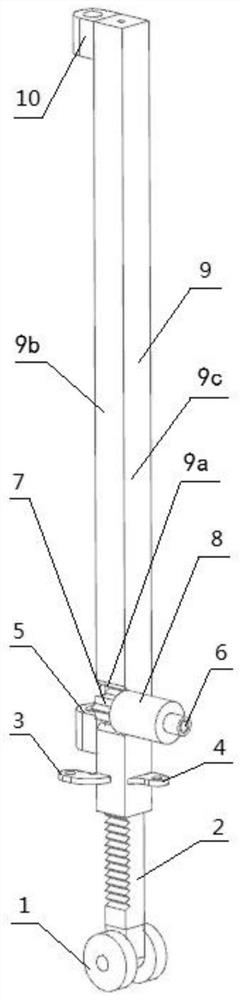

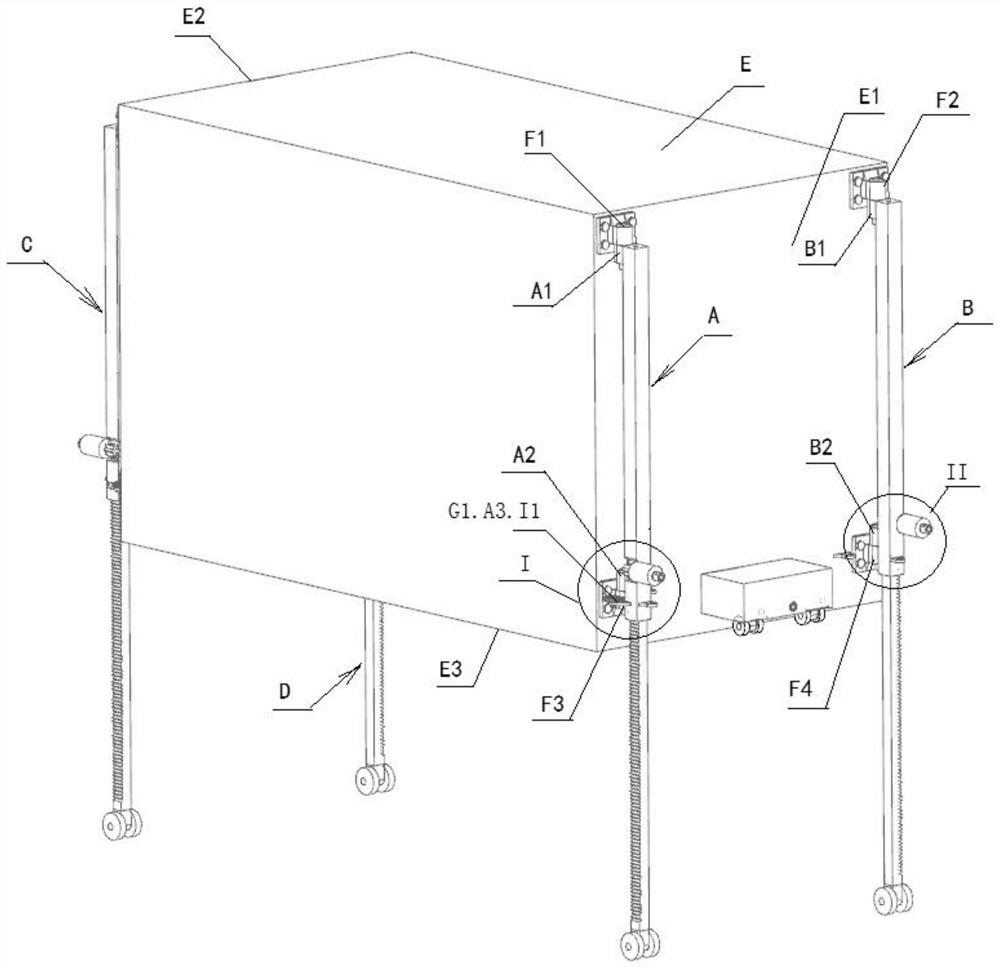

Container loading and unloading and transferring device and using method thereof

ActiveCN112093499AQuick loading and unloadingOptimize structure sizeLoading/unloadingConveyor partsGear driveGear wheel

The invention discloses a container loading and unloading and transferring device. The container loading and unloading and transferring device comprises at least one set of lifting and transferring modules, wherein each set of lifting and transferring modules comprises a rack, a walking wheel installed at the bottom of the rack, a rack sleeve arranged on the rack in a sleeving mode and a gear driving mechanism installed at the lower end of the rack sleeve; a gear in each gear driving mechanism extends into the corresponding rack sleeve and is engaged with the corresponding rack, and the gearsrotate to drive the rack sleeves and the racks to move relatively through engagement with the racks; and a walking wheel shaft is arranged at the bottom of each rack. The invention further discloses ausing method of the container loading and unloading and transferring device. The container loading and unloading and transferring device and the using method thereof have the following beneficial effects that (1) emergency rapid loading and unloading and transferring of containers for transportation such as land transportation, train transportation, sea transportation and air transportation can be achieved; (2) electric and manual dual-redundancy backup operation of main movement mechanisms can be achieved; and (3) the container loading and unloading and transferring device is designed in a modularized and integrated mode, and the structural size is optimized to be capable of being stored along with the containers.

Owner:衡阳泰豪通信车辆有限公司

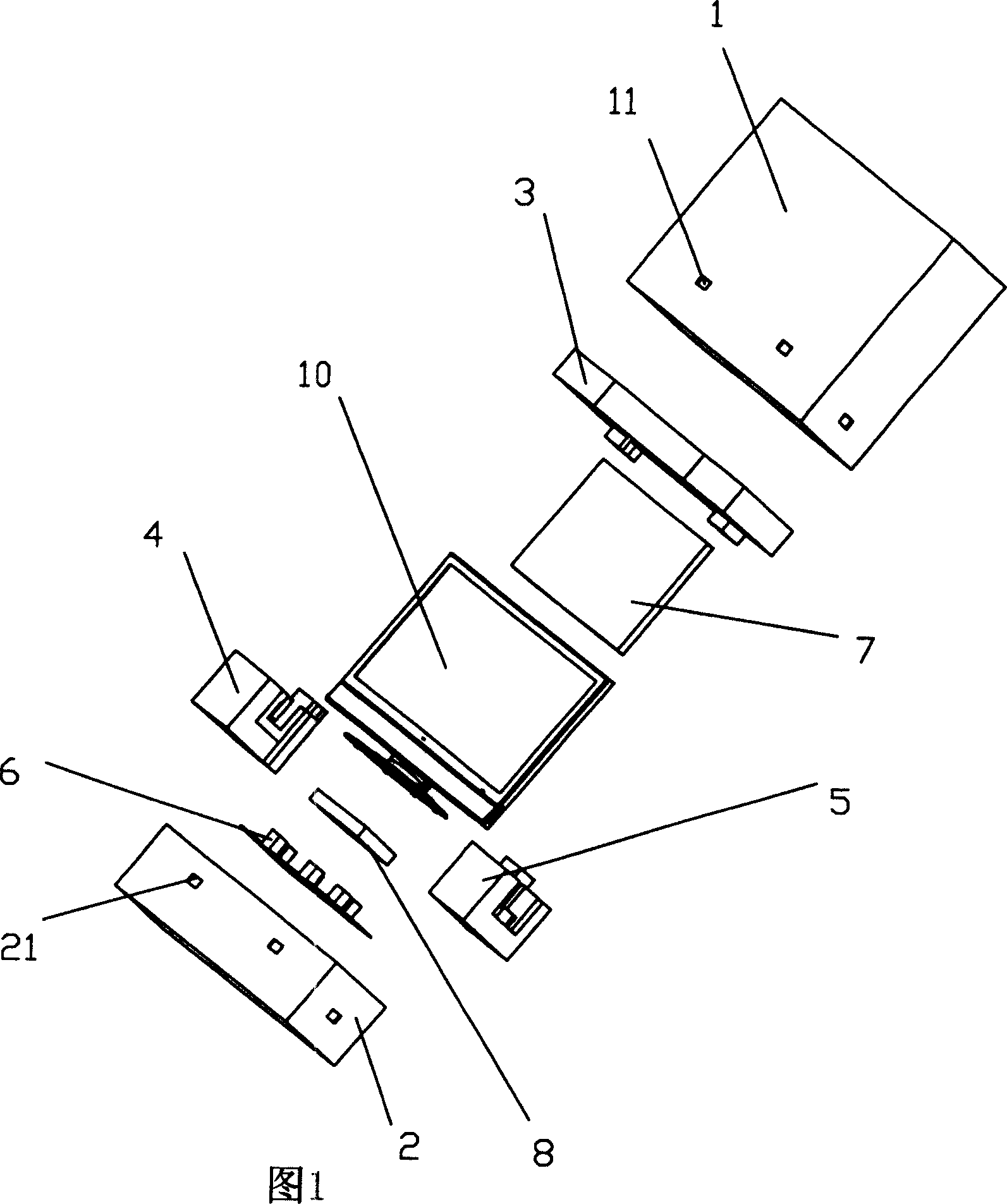

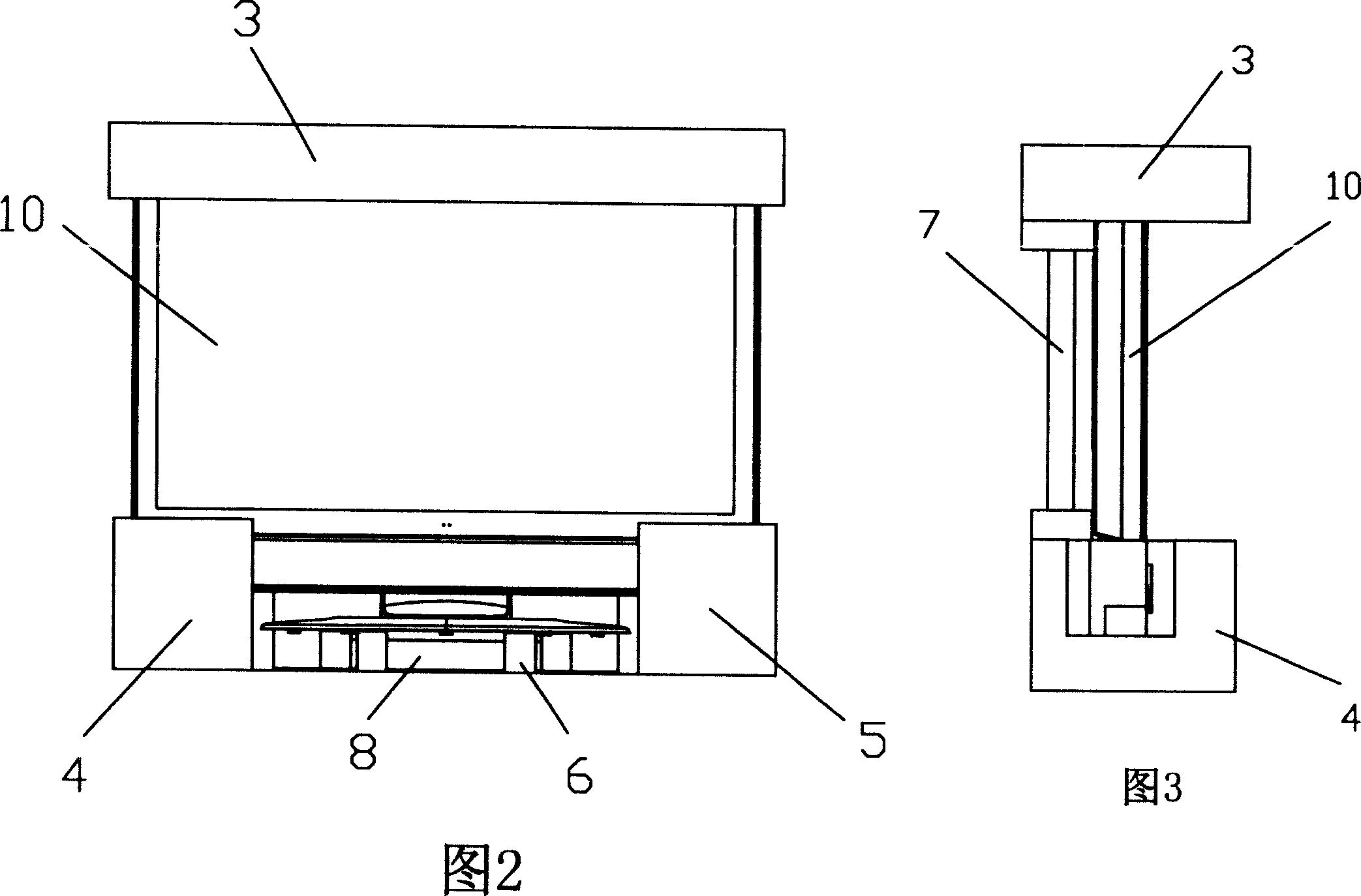

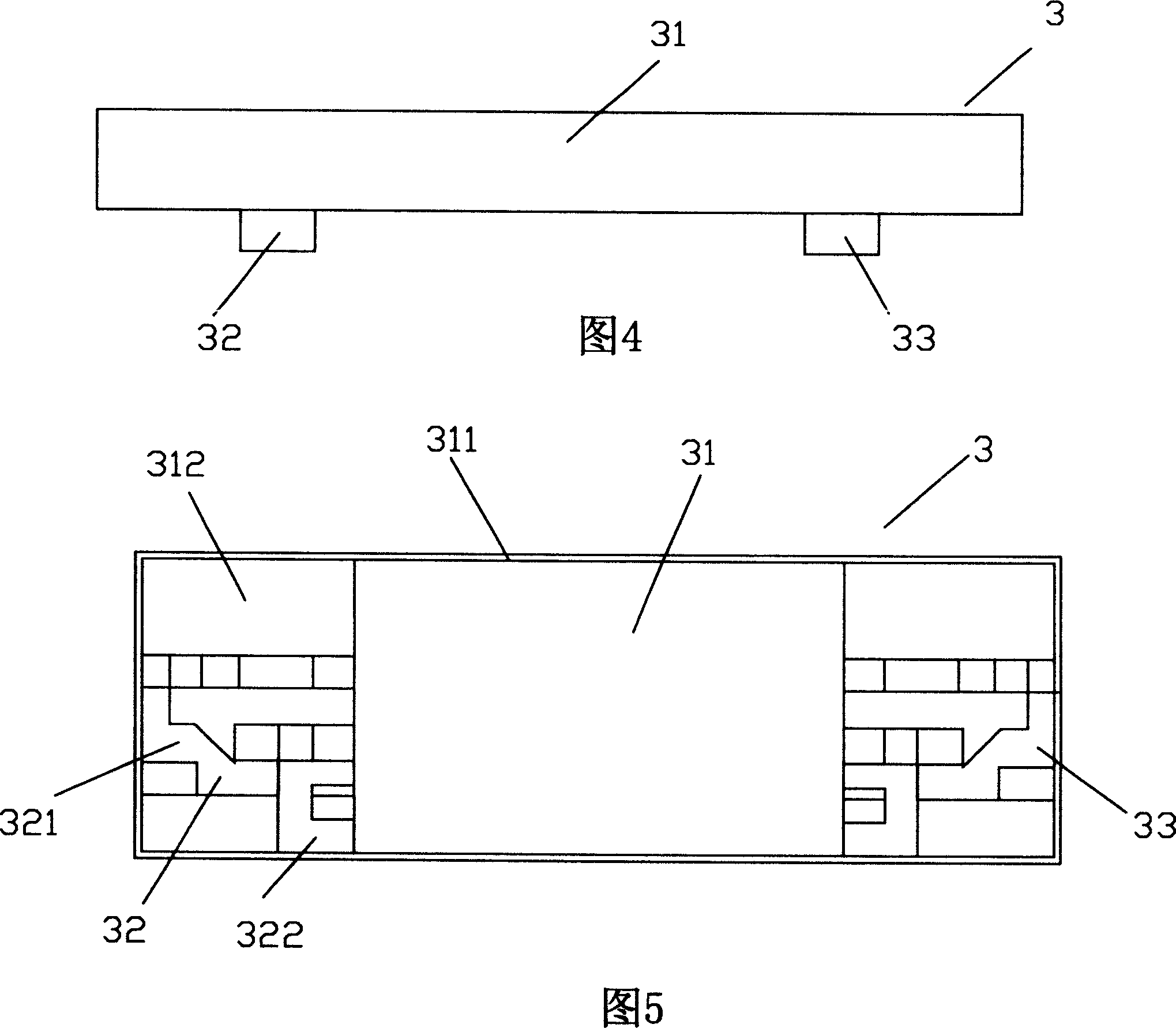

Complex buffering pad for packaging TV set

ActiveCN101108680ALow vapor transmission rateLow water absorptionPackaging vehiclesContainers for machinesBursting strengthPolystyrene

The invention discloses a composite cushion pad for packing TV sets, which is a pad between an outer packing case and the TV sets. The invention comprises a corrugated paper buffer and a foam plastic buffer. Wherein, the corrugated paper buffer and the foam plastic buffer are fixed by bond or splicing; the corrugated paper buffer is provided with a shape coordinated with the inner wall of the outer packing case and is one or a plurality of monolithic structures; the connection parts among a plurality of monolithic structures are fixed by bond; the foam plastic buffer is provided with a slot coordinated with the connection part of the TV set and is one or a plurality of monolithic structures made of polyethylene foam EPE or polystyrene foam EPS and the connection parts among a plurality of monolithic structures are fixed are fixed by bond. After adopting the structure, the invention can improve the stacking strength, the burst strength and the integral packaging strength of the TV set package and greatly reduce the amount of the foam plastics easily polluting the environment, thus achieving the aims of lowering the cost and protecting the environment.

Owner:XIAMEN PRIMA TECH

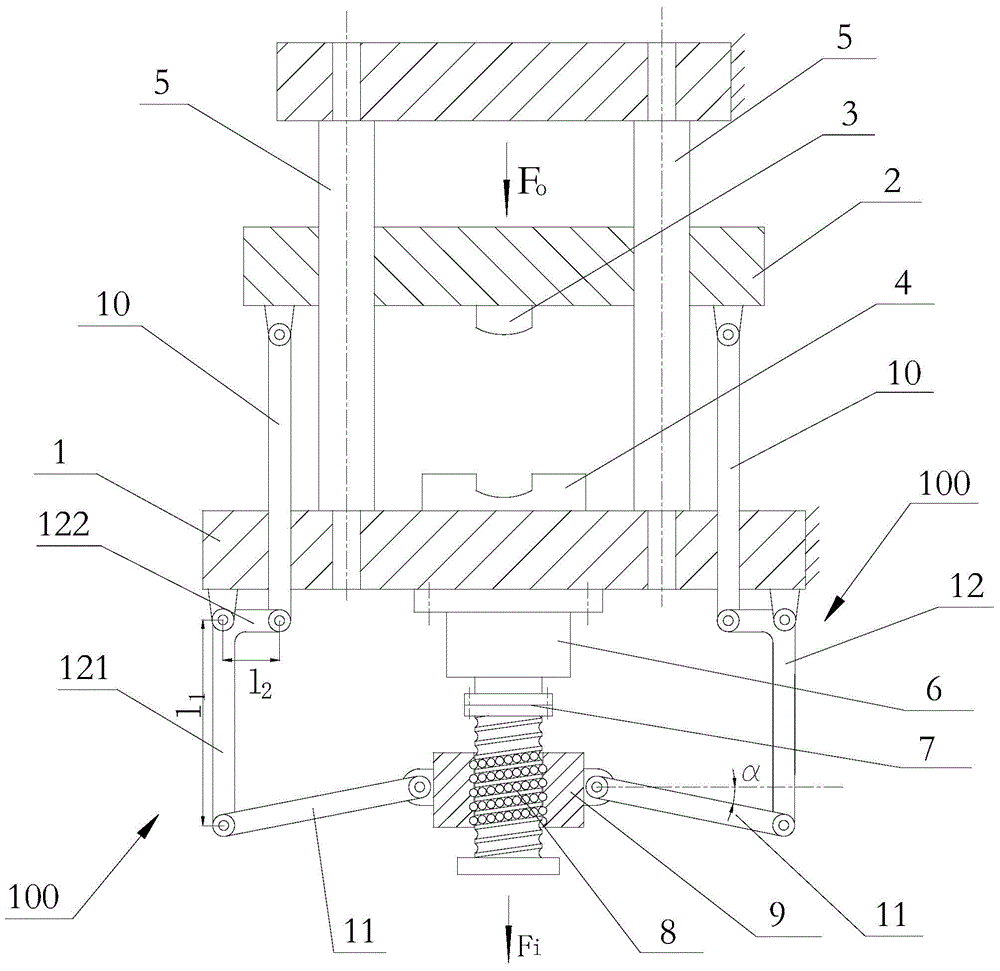

Pull rod press machine with power arranged at lower portion

ActiveCN104015389ALower center of gravityImprove dynamic performancePress ramGravity centerEngineering

The invention discloses a pull rod press machine with power arranged at the lower portion. A motor, a screw and a nut are combined as a power system and arranged under a work table. Force-amplifying mechanisms are arranged between an upper die assembly and the nut so that the upper mold assembly can output large output force, and forming and machining of work-pieces are convenient. Under the condition of needing certain tonnage of the press machine, the low-power motor can be adopted, so that the energy is saved and the cost is lowered. Meanwhile, due to the fact that the power system is arranged at the lower portion, the stress state of a base under the work table is improved, the base of the press machine can meet the strength and rigidity requirements more easily, shock absorption and noise reduction are facilitated, and the gravity center of the press machine descends, so that the dynamic property of the press machine is improved. Compared with a structure in the prior art, the structure size of the press machine is greatly reduced, the impact force is large, the work efficiency is high, the energy utilization rate is high, the work noise is low, and excellent combination property is achieved.

Owner:苏州市东望医疗设备有限公司

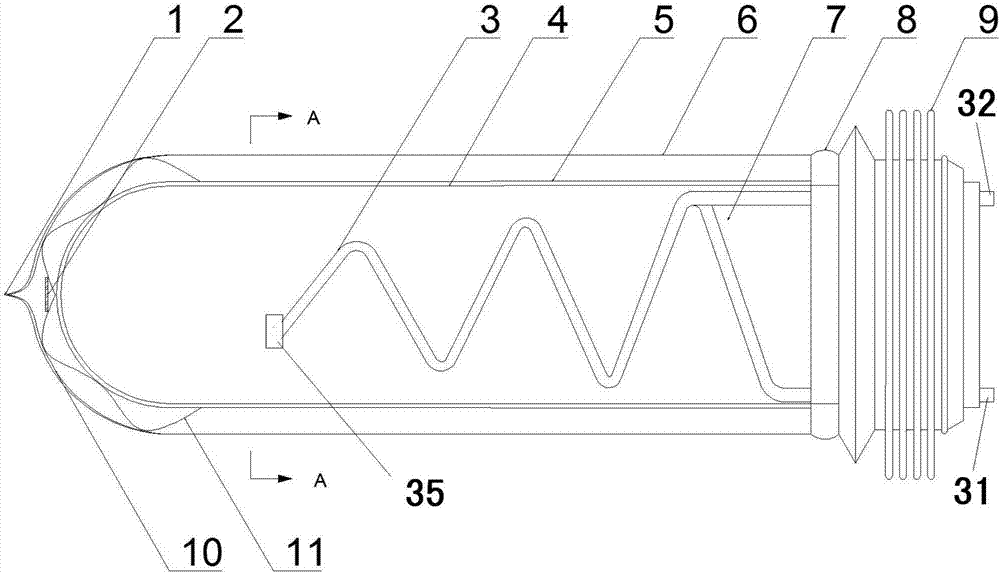

Spiral elastic pipe bundle solar vacuum heat collecting pipe and vacuum heat collecting system

ActiveCN107062642AIncrease disturbanceImprove heat transfer efficiencySolar heating energySolar heat devicesEngineeringPhase-change material

The invention provides a spiral elastic pipe bundle solar vacuum heat collecting pipe and a vacuum heat collecting system. The spiral elastic pipe bundle solar vacuum heat collecting pipe comprises an outer pipe and an inner pipe; the inner pipe is sleeved with the outer pipe; a vacuum cavity is formed between the outer pipe and the inner pipe; a heat exchange pipe is arranged in the inner pipe; the space between the inner pipe and the heat exchange pipe is filled with a phase-change material; the first end of the inner pipe and the first end of the outer pipe are sealed; the second end of the inner pipe and the second end of the outer pipe are connected through a sealing connecting piece; the heat exchange pipe is a spiral elastic coil pipe; and from the first end to the second end, the spiral outer diameter of the heat exchange pipe becomes gradually larger. According to the spiral elastic pipe bundle solar vacuum heat collecting pipe and the vacuum heat collecting system, a conical spiral elastic pipe bundle structure is firstly adopted as the heat collecting pipe, a conical spiral elastic pipe bundle and the phase-change material are combined together, and the conical spiral elastic pipe bundle has the characteristics of being uniform in space arrangement, light in mass and the like, so that the conical spiral elastic pipe bundle has good response to the phase-change material, larger disturbance can be produced, the heat exchange efficiency is improved, and vibration of multi-level frequency is motivated, and energy distribution is uniform.

Owner:SHANDONG UNIV

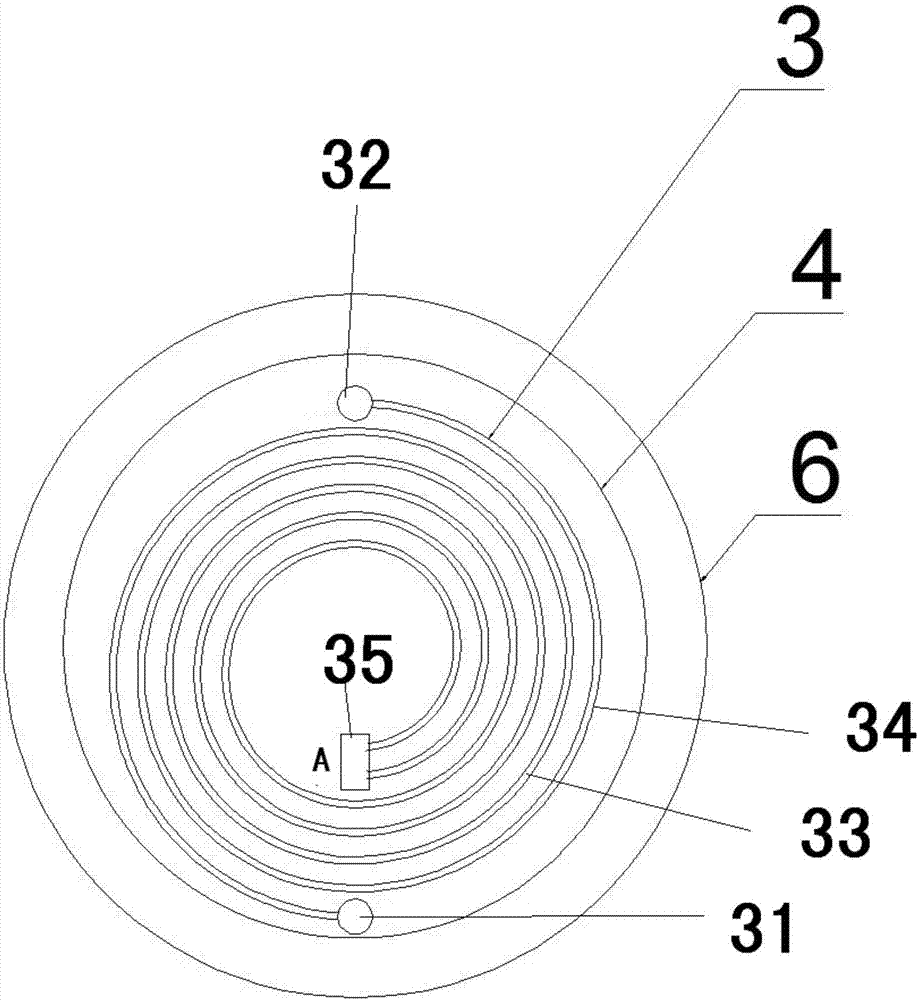

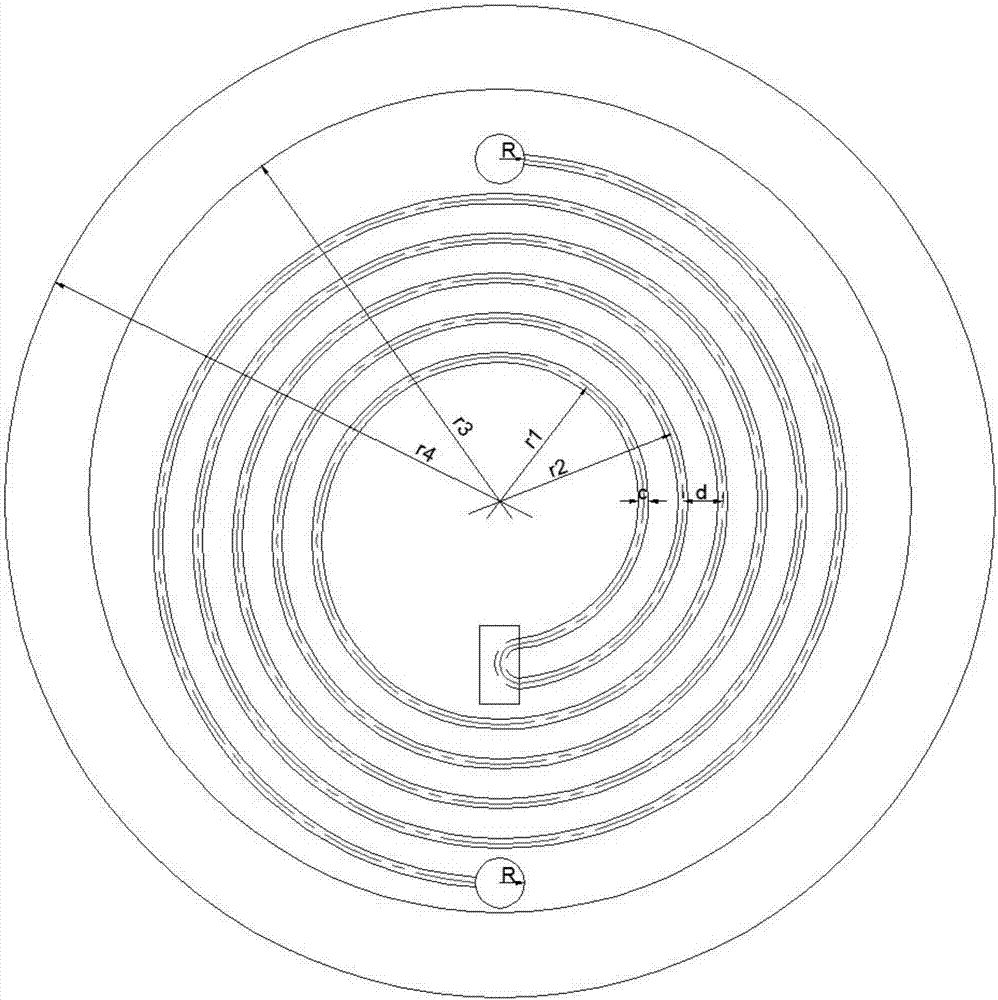

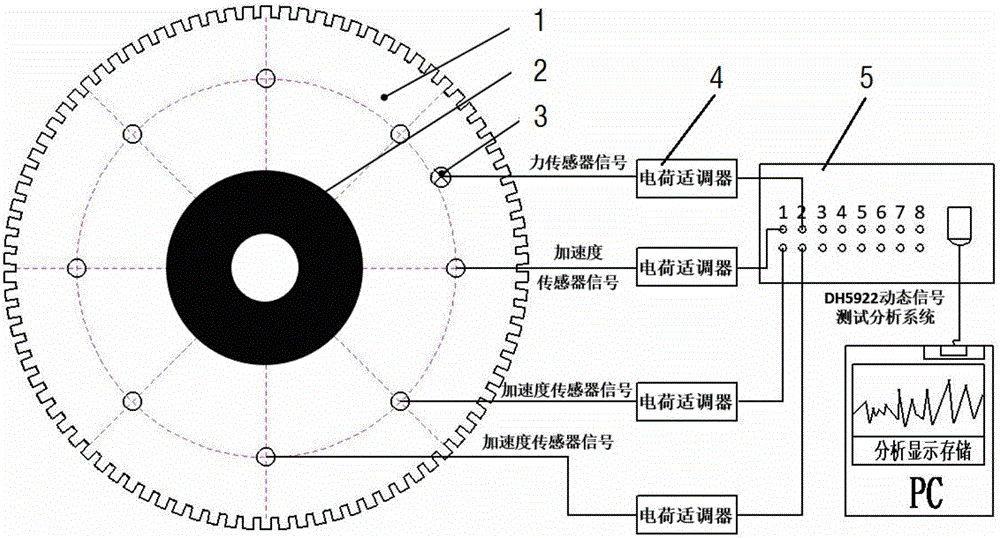

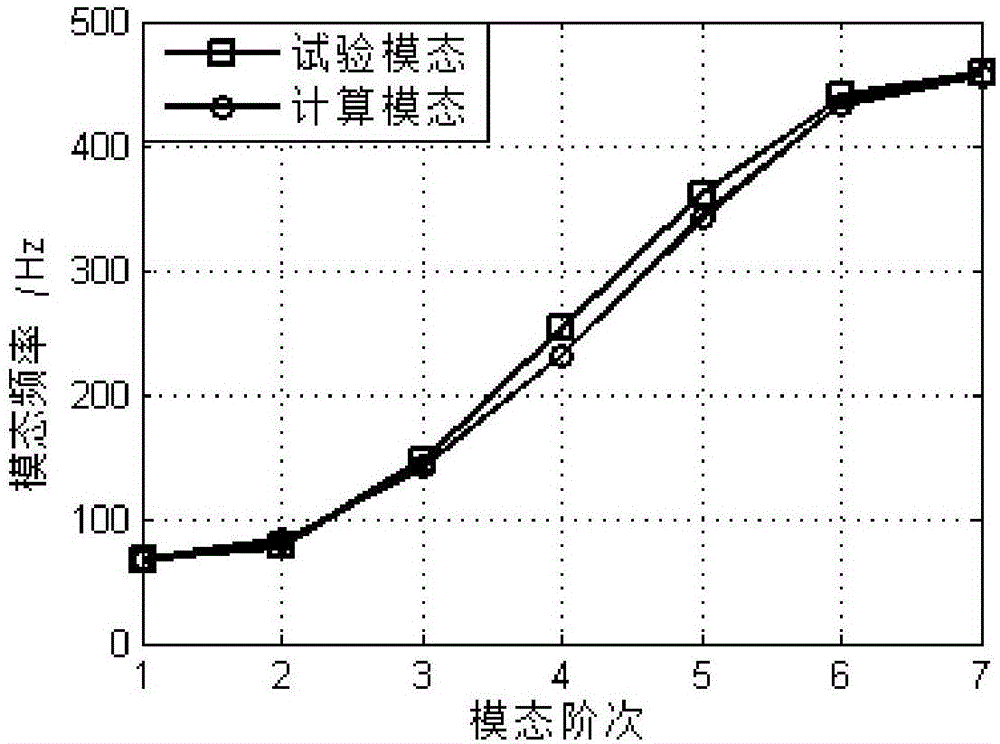

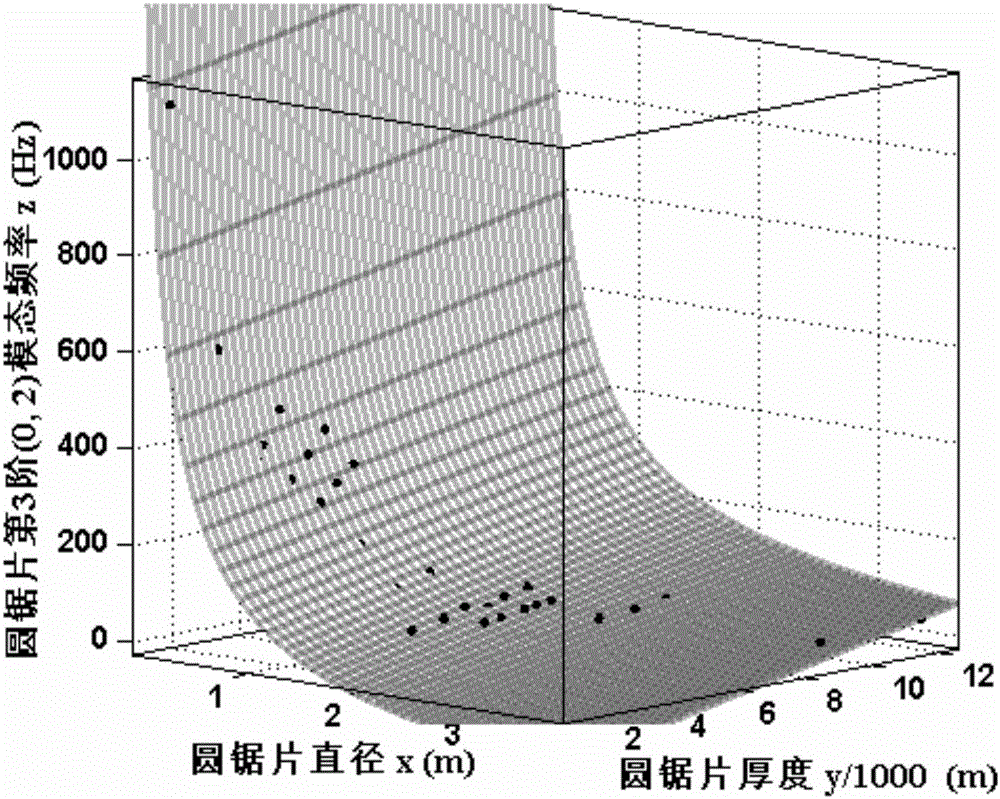

Diamond circular saw web design and sawing process parameter setting method

ActiveCN106777773AThe first 6 resonance frequencies are fast and accurateAccurate calculationGeometric CADDesign optimisation/simulationResonanceCircular saw

The invention relates to a diamond circular saw web design and sawing process parameter setting method. The method includes: a model experiment is used to verify the reliability of a modal simulation analysis method; different types of diamond circular saw webs are selected, and the diameters and thicknesses of the diamond circular saw webs are used as the independent variables to perform constraint modal analysis to obtain the function relationship between the first 6 order of resonance frequency of the diamond circular saw webs and the diameters and thicknesses of the diamond circular saw webs; determining the diameters, linear cutting speed and machining rotation speed of the diamond circular saw webs and the relationship between each order of resonance frequency and the diameters and thicknesses of the diamond circular saw webs according to the size and hardness of to-be-machined materials, acquiring the relationship between excitation frequency generated during machining and the rotation speed and tooth number of the diamond circular saw webs, and setting the appropriate thicknesses and tooth number of the diamond circular saw webs to build a diamond circular saw web design and sawing process parameter constraint model under the condition that the situation that resonance and working rotation speed is smaller than critical rotation speed is avoided. The method is high in universality and applicable to the design and sawing process parameter optimization of various diamond circular saw webs.

Owner:深圳市博金硬质工具有限公司

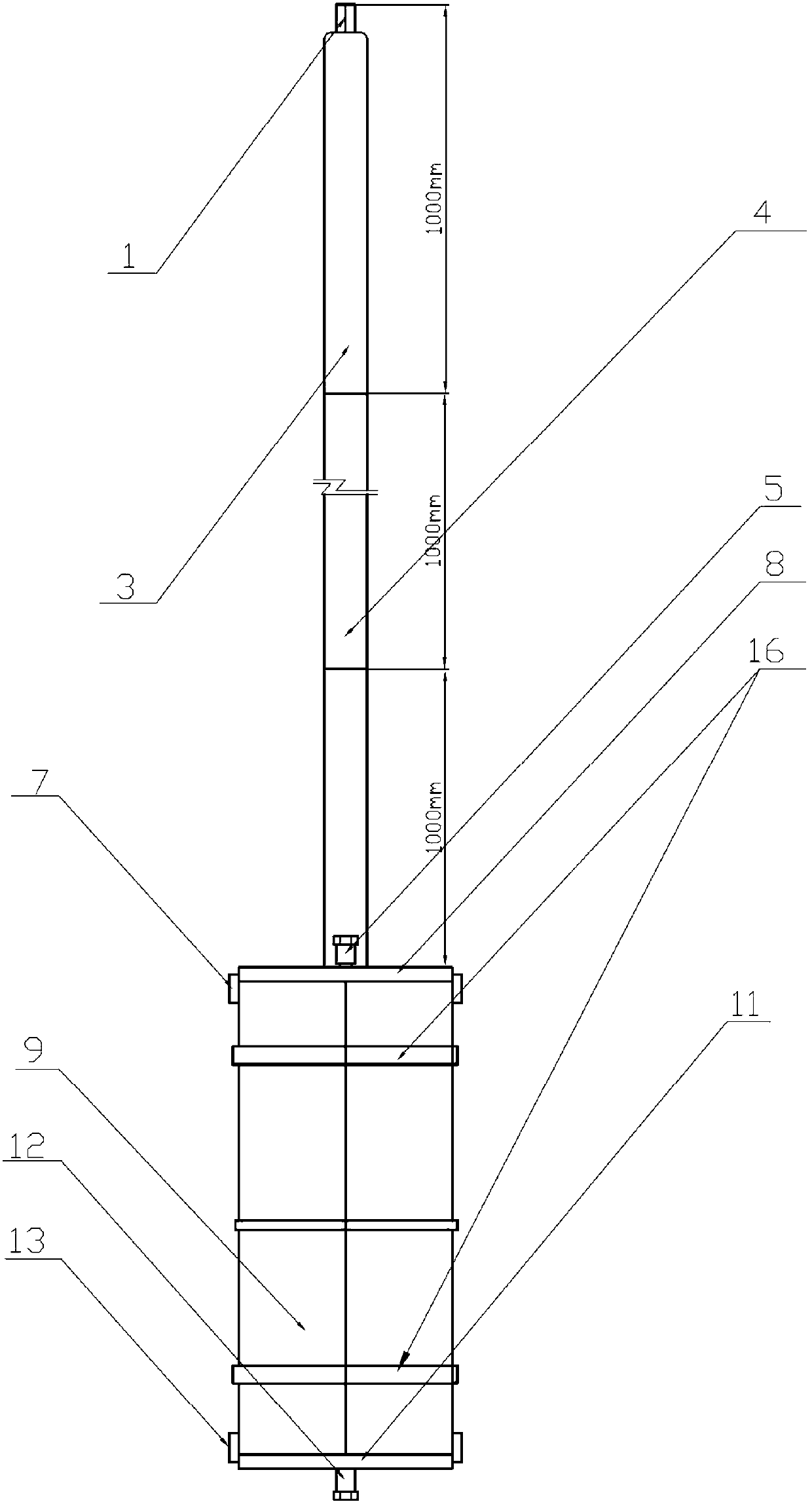

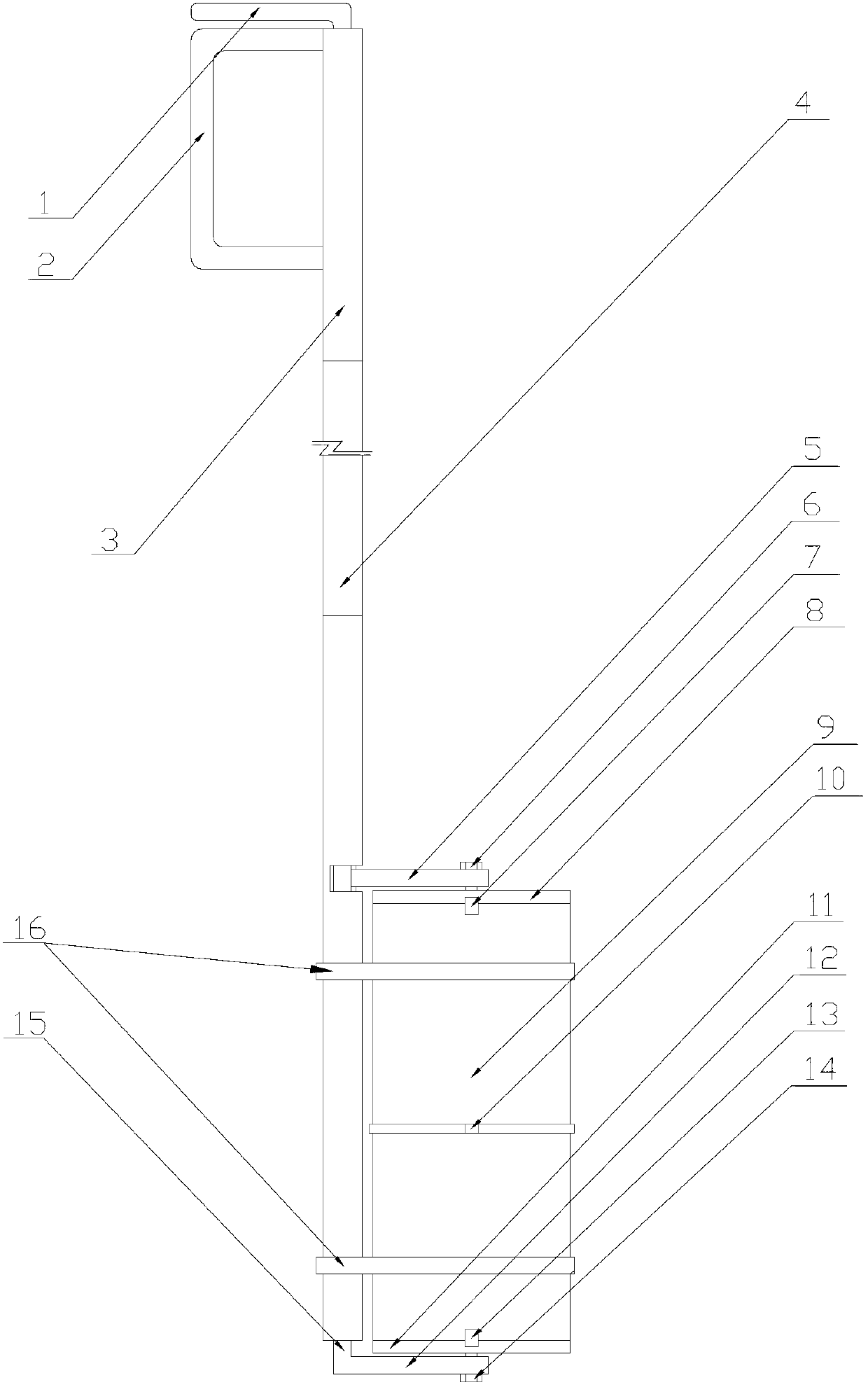

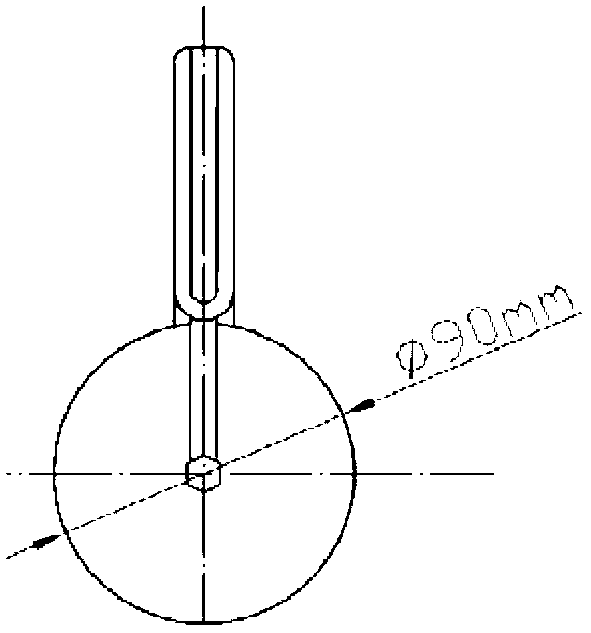

Field sampling device and sampling method of filling slurry

InactiveCN102998147AAccurate placementSimple structureWithdrawing sample devicesControl cellEngineering

The invention provides a field sampling device and a use method of filling slurry. The sampling device comprises a slurry cylinder control unit and a slurry cylinder, wherein the slurry cylinder control unit comprises a sampling rod, an upper transverse rod 5, and a lower transverse rod 12, and a control rod 15 is axially inserted into a main rod 3; the slurry cylinder comprises a slurry cylinder upper baffle 8, a slurry cylinder pipe 9 and a slurry cylinder lower baffle 11; and one end of the upper / lower transverse rod is fixedly connected with the control rod, and the other end of the upper / lower transverse rod is detachably connected with the slurry cylinder upper / lower baffle 8. According to the field sampling device and a sampling method of the filling slurry, the field sampling of the filling slurry is realized by driving the opening and the closing of the upper baffle 8 and the lower baffle 11 by the control rod of the slurry cylinder control unit; and the slurry at a fixed point can be precisely collected, the sampling can not be influenced by low-concentration filling slurry at the upper part of a collecting field in the rising processes of sampled samples, and the property of the filling slurry in the collecting field can be accurately acquired.

Owner:UNIV OF SCI & TECH BEIJING

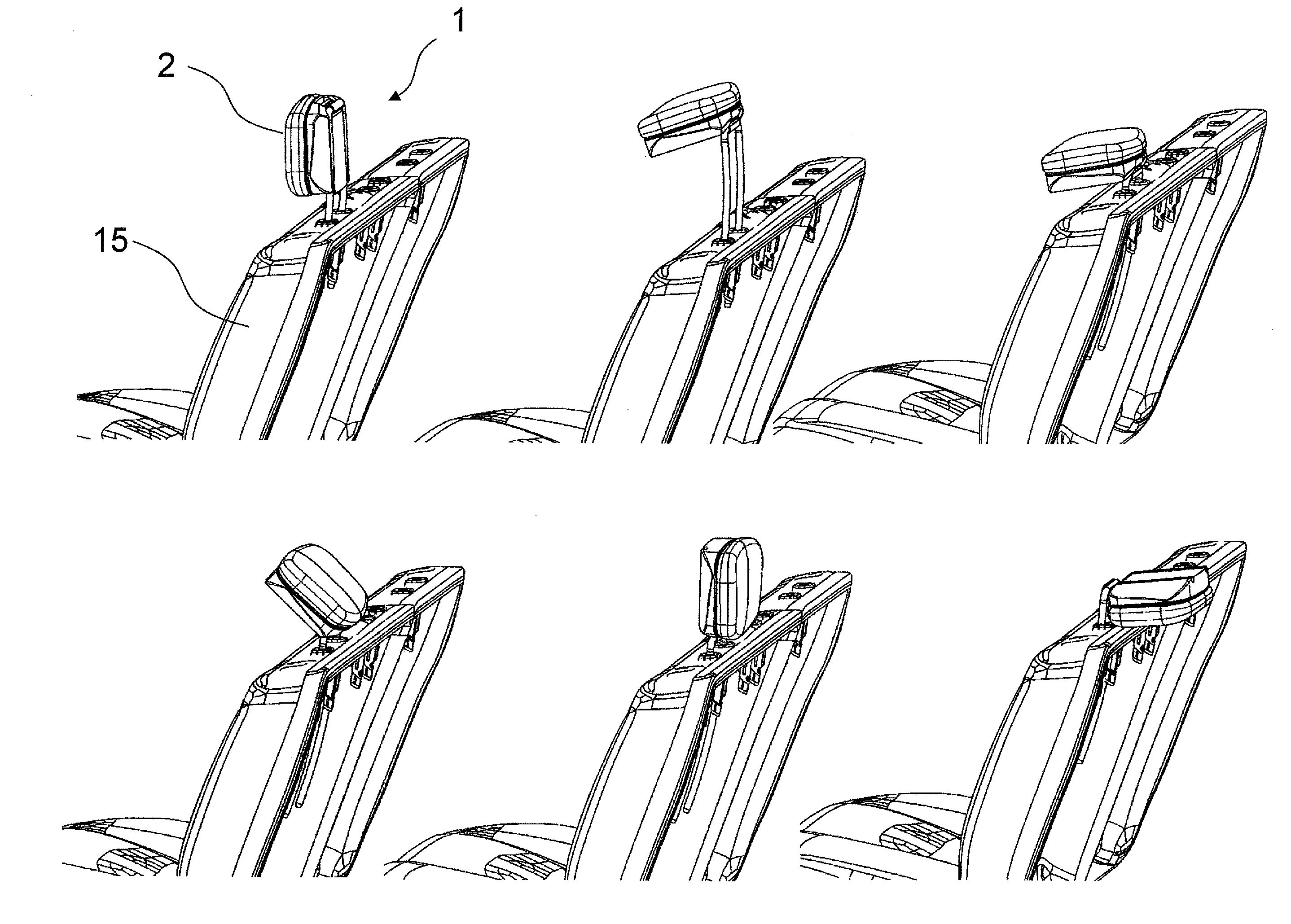

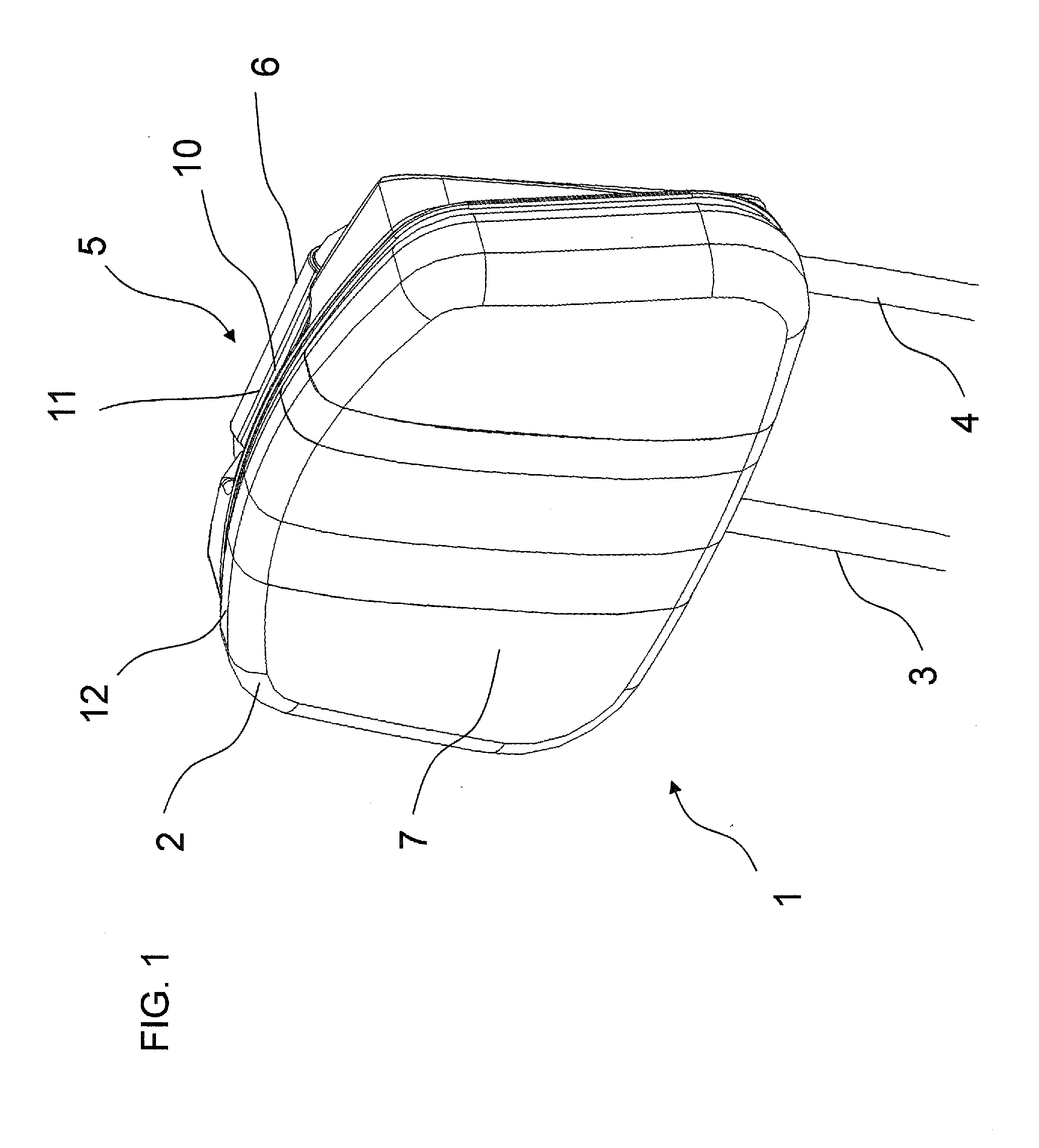

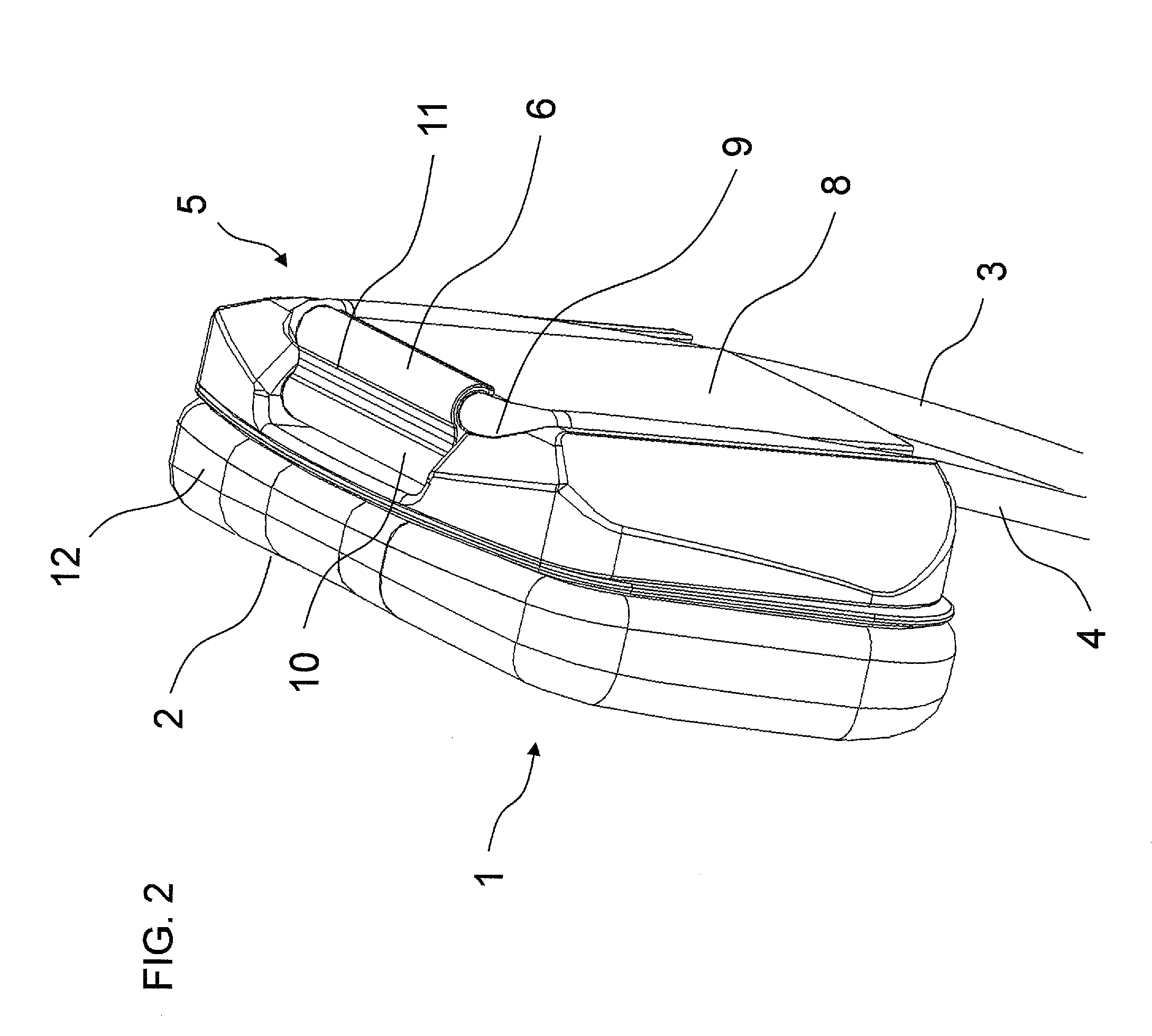

Foldable headrest with double hinge

ActiveUS20160046217A1Great possible swivel angle rangeOptimize structure sizeVehicle seatsOperating chairsRotational axisEngineering

Owner:FORD GLOBAL TECH LLC

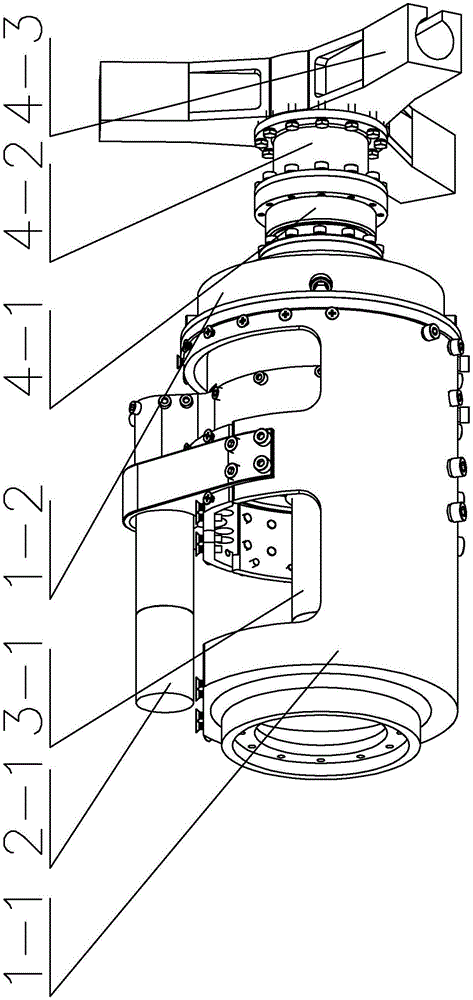

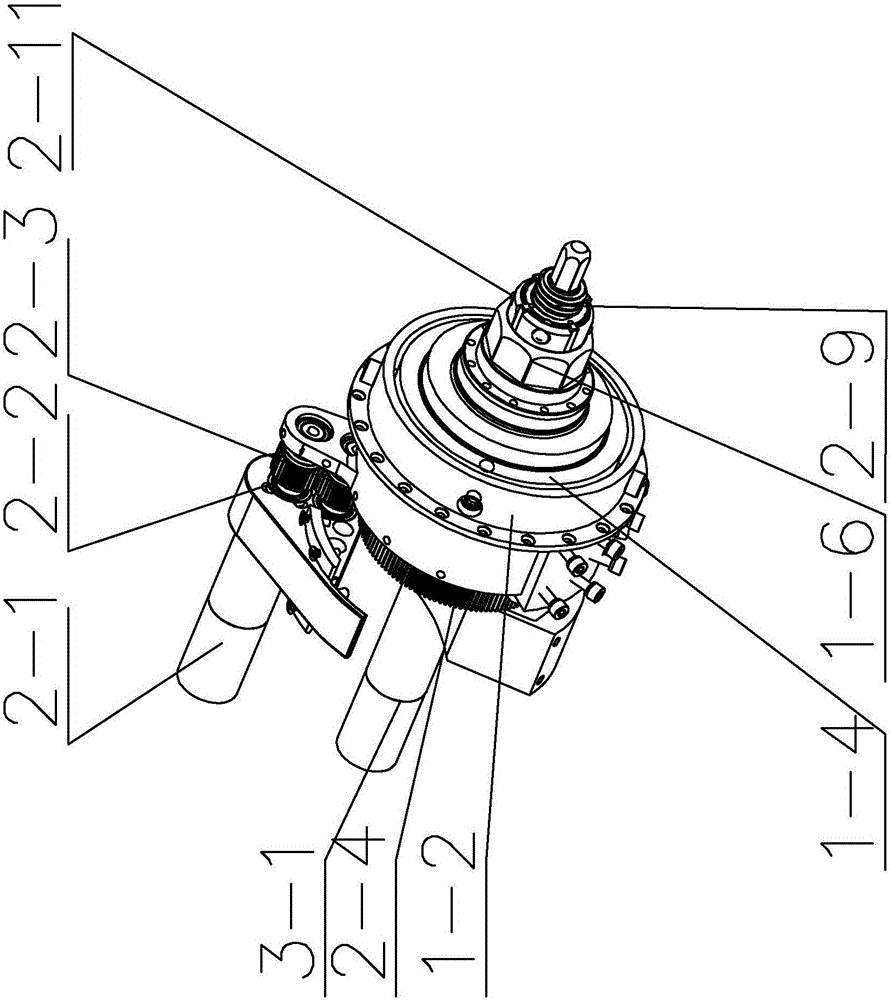

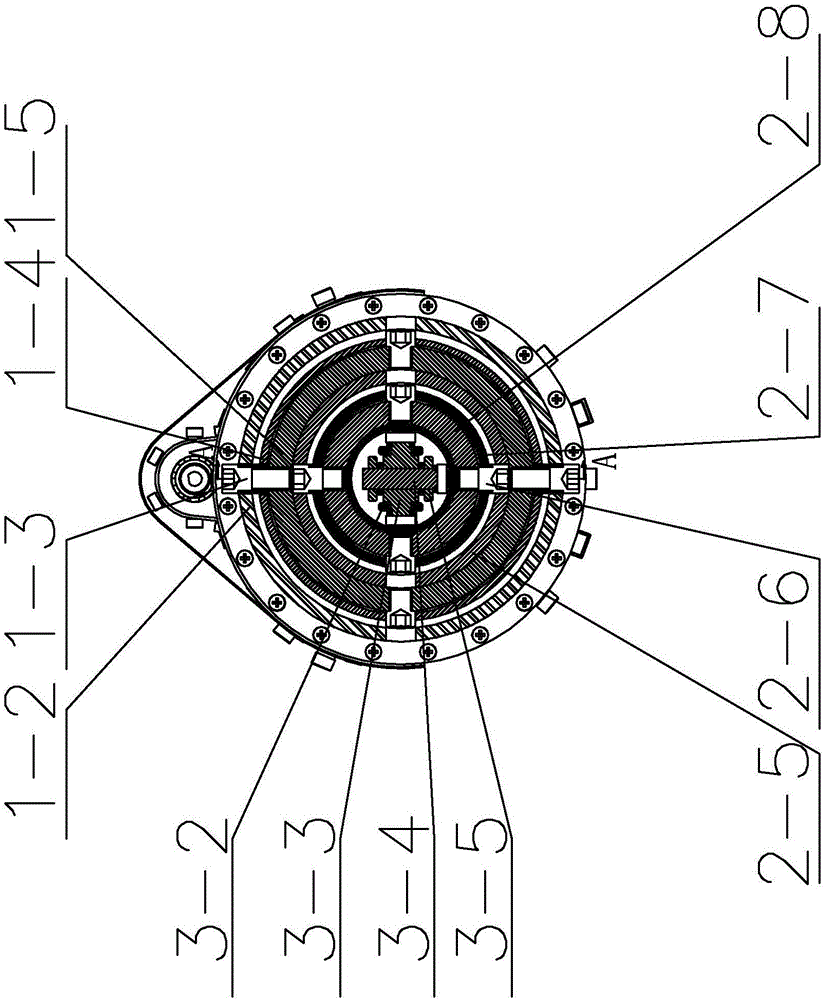

Multifunctional robot wrist with replaceable end actuator

ActiveCN105082171ASimple structureEasy to protectProgramme-controlled manipulatorJointsMode-lockingMultiple function

The invention relates to a multifunctional robot wrist with a replaceable end actuator. The multifunctional robot wrist is aimed at solving the problems that in the prior art, most robot wrists are connected with end actuators, so that the function that one wrist drives various end actuators can not be achieved, manufacturing cost is high, and using is inconvenient. The multifunctional robot wrist comprises an outer power output mechanism, a middle locking and unlocking mechanism, an inner power output mechanism and a tool mechanism. The outer power output mechanism and the middle locking and unlocking mechanism are sequentially arranged on the inner power output mechanism from outside to inside in a sleeving mode. The tool mechanism is installed at the power output end of the outer power output mechanism, the power output end of the middle locking and unlocking mechanism and the power output end of the inner power output mechanism. The multifunctional robot wrist is applied to the field where end actuators need to be replaced and actuators need to be locked.

Owner:HARBIN INST OF TECH

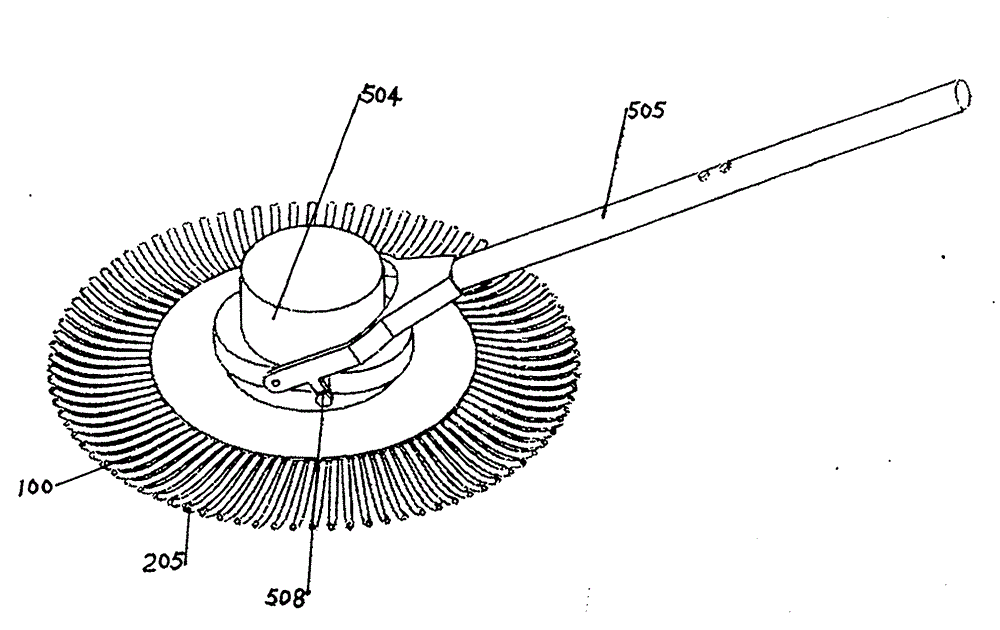

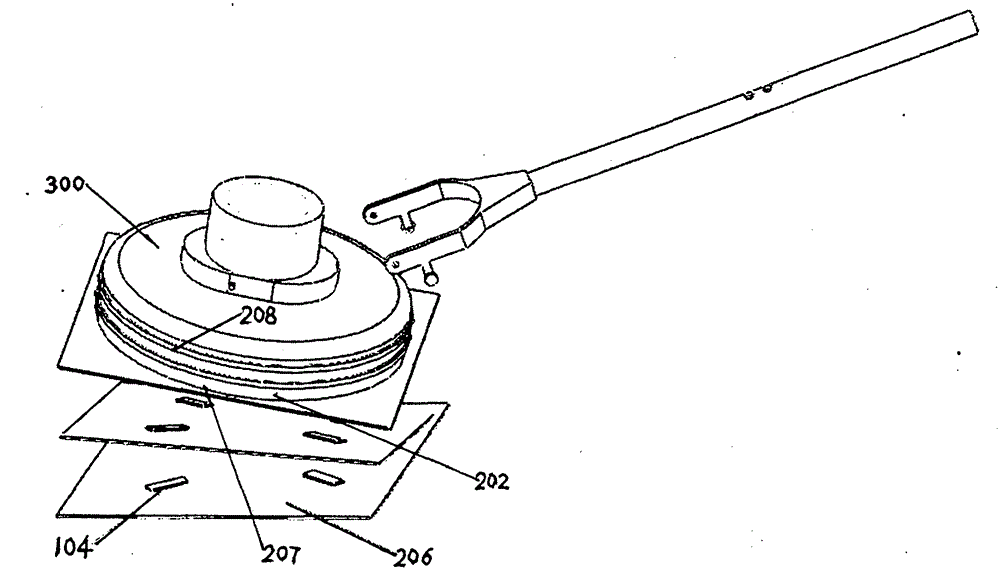

Nylon bristlelike monofilament fabric for cleaning, and cleaning tools formed by the same

InactiveCN103600555AEfficient cleaningStrong stimulating effectSynthetic resin layered productsMachine detailsToxicityPolyester

The present invention discloses a nylon bristlelike monofilament fabric for cleaning. The nylon bristlelike monofilament fabric comprises a nylon bristlelike monofilament weaving mesh, or a cloth base and nylon projection point groups weaved on the cloth base surface, nylon bristlelike monofilament terry groups weaved on the cloth base surface or nylon bristlelike monofilament hook groups weaved on the cloth base surface, wherein the nylon comprises modified nylon. According to the present invention, the hardness of the material is in the cleaning material hardness range of the steel wire ball and the polyester fiber, and characteristics of high cleaning decontamination quality and efficiency and no damage on the cleaned surface are provided; the nylon bristlelike monofilament fabric has characteristics of large mass production, low cost, no toxicity, no odor, wear resistance and durability; the present invention further discloses a plurality of cleaning tools made by using the nylon bristlelike monofilament fabric, wherein the cleaning tools can be used in all aspects of daily life; and the nylon bristlelike monofilament fabric can be combined with the wiping material layer to especially make into a mop tool so as to form the work state with double effects such as wiping and brushing, such that cleaning quality and cleaning efficiency are significantly improved, and the tool is the optimal selection of the cleaning work.

Owner:宋大勇

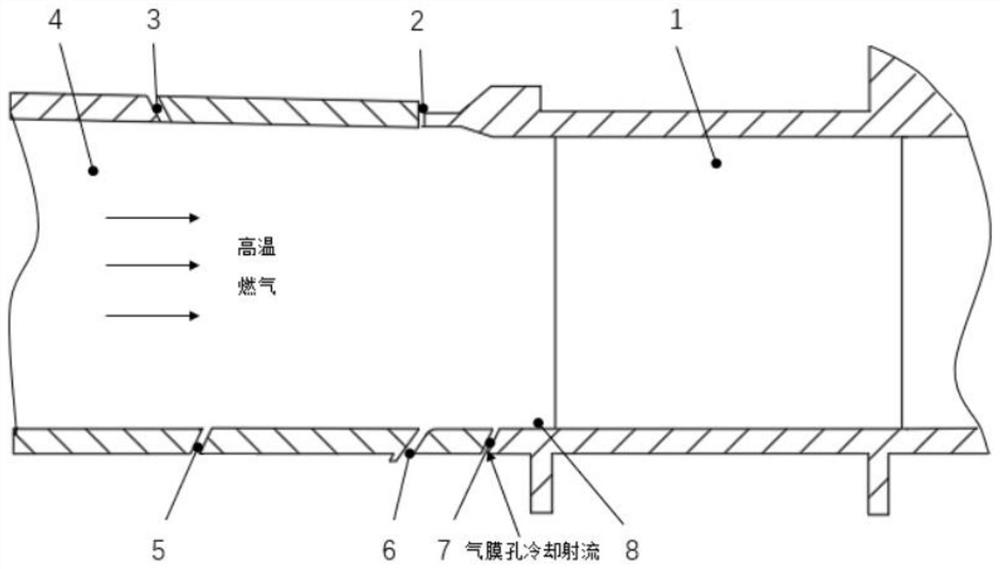

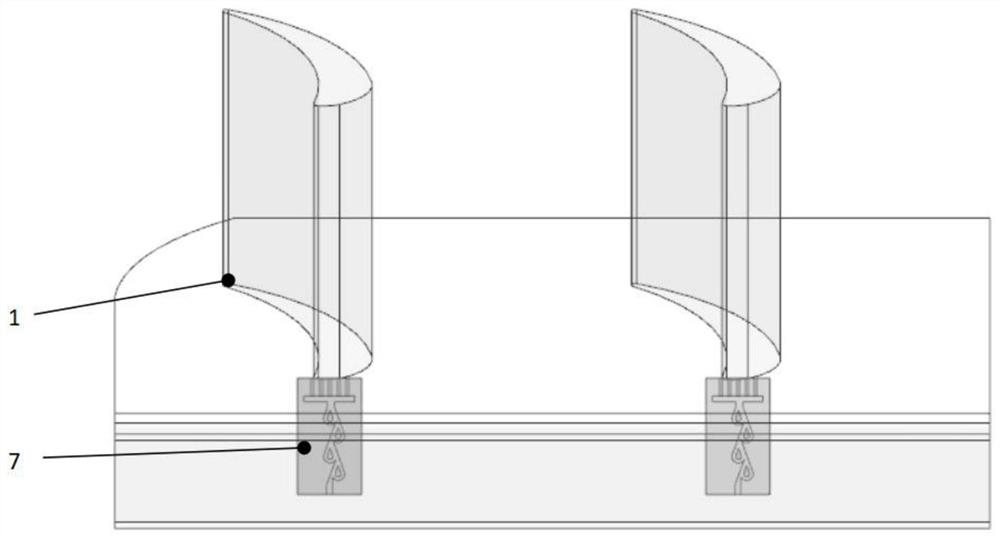

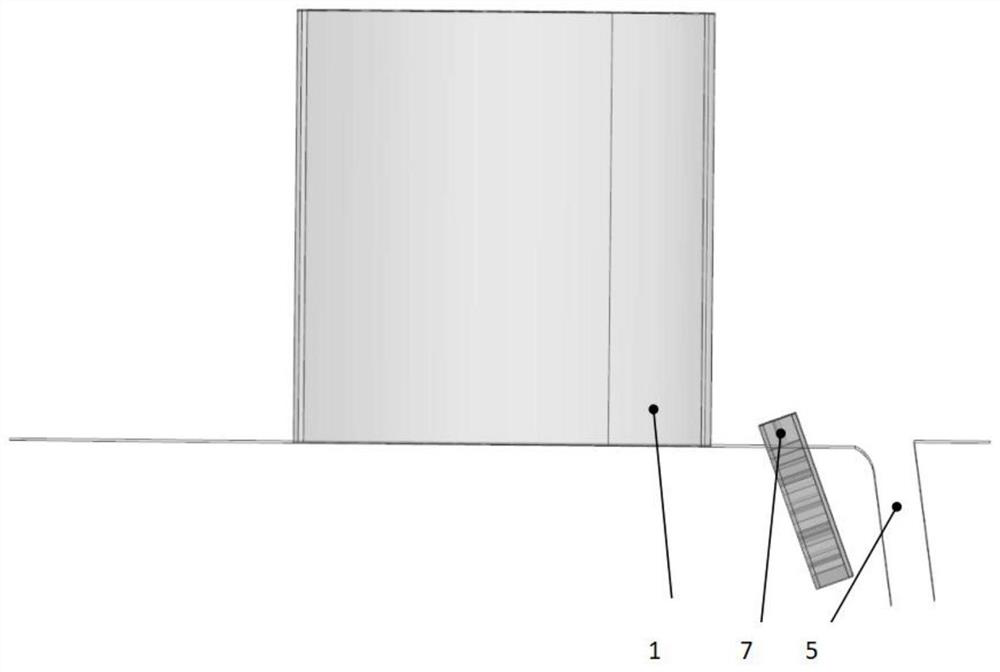

Air film hole channel structure based on Tesla valve and application of air film hole channel structure to front edge of turbine blade

ActiveCN113236373AOptimize structure sizePrevent backflowStatorsMachines/enginesSuction forceTurbine blade

The invention discloses an air film hole channel structure based on a Tesla valve and application of the air film hole channel structure to the front edge of a turbine blade, and belongs to the field of gas turbines. The air film hole channel structure comprises a Tesla valve channel and outlet air film holes, wherein the Tesla valve channel is of a Tesla valve structure, cooling airflow flows from an inlet to an outlet of the Tesla valve channel in a one-way mode, the multiple outlet air film holes are located at the outlet of the Tesla valve channel and used for introducing cooling gas into the wall face to be cooled, and the axial direction of the outlet gas film holes is parallel to the axial direction of the outlet of the Tesla valve channel. According to the air film hole channel structure, the Tesla valve channel is introduced to a film hole in the front edge of the end wall of a stationary blade, and the geometric dimension of the Tesla valve channel is matched with that of the film hole; and due to the introduction of the Tesla valve channel, not only is the backflow of high-temperature airflow obviously weakened, but also the end wall near the stagnation point of the front edge of the stationary blade and the suction surface of the stationary blade can be cooled more sufficiently and uniformly, so that the cooling efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

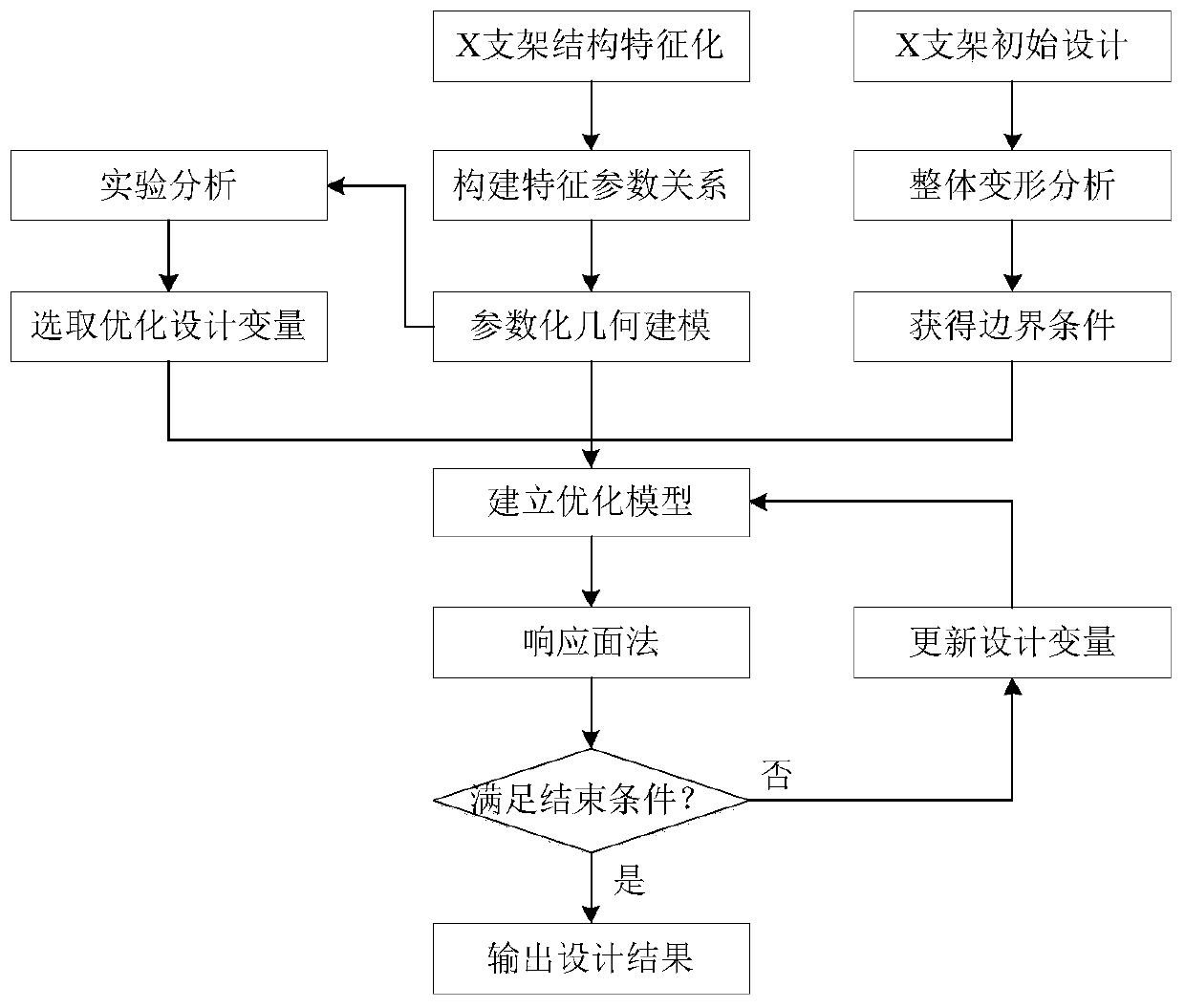

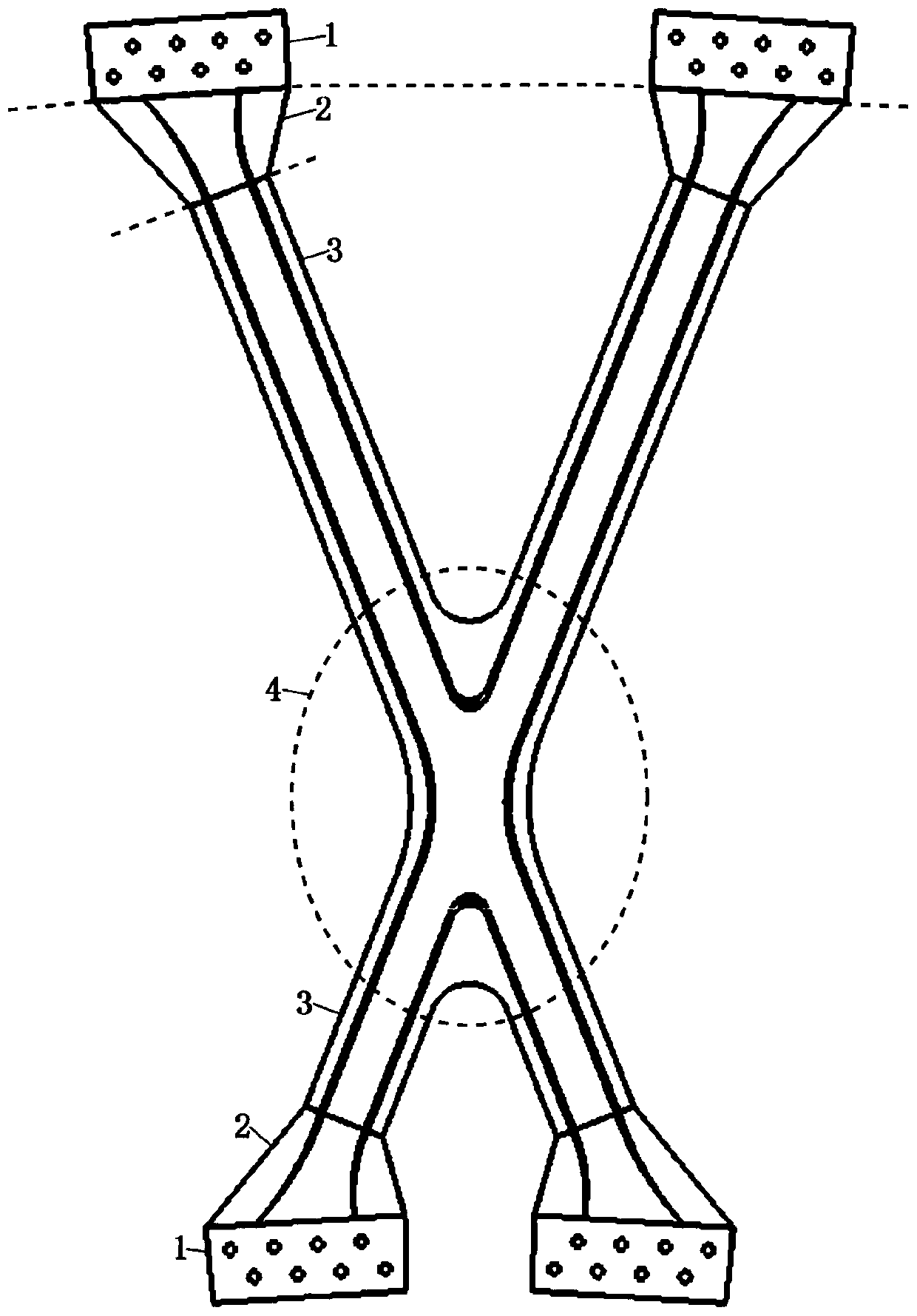

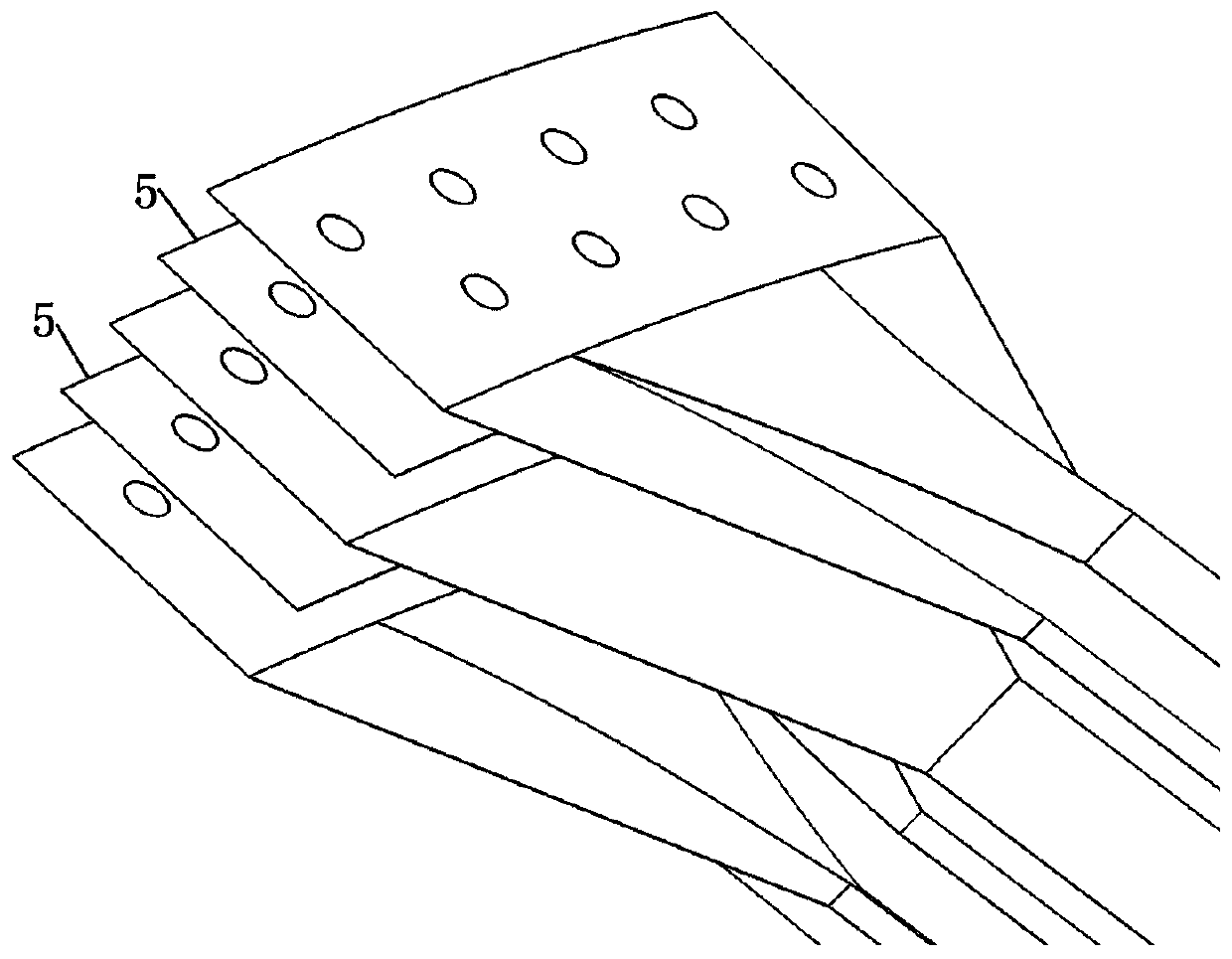

Composite material X-shaped support structure optimization design method and system for connecting fuel storage tank

ActiveCN110727998AMeet lightweight requirementsLess design parametersGeometric CADDesign optimisation/simulationElement modelElement analysis

The invention discloses a composite material X-shaped support structure optimization design method and system for connecting a fuel storage tank, and the method comprises the steps: firstly determining design parameters according to the structural features of a composite material X-shaped support, and building a parameterized geometric model; carrying out finite element analysis on the integral model containing the fuel storage tank and the composite material X-shaped support, and determining a displacement boundary condition; based on the parameterized geometric model, establishing a finite element model of the composite material X-shaped support, and utilizing an experiment design method to obtain an optimization design variable; establishing an optimization design model based on the parameterized geometric model, the displacement boundary conditions and the optimization design variables, and obtaining optimization design parameters meeting constraint conditions; and finally, based on optimization design parameters and selection of a layering mode, establishing a finite element model based on layering for strength check analysis, and obtaining the composite material X-shaped support structure meeting the strength design requirement. The composite material X-shaped support structure designed by the design method has the advantages of light weight and high strength.

Owner:NAT UNIV OF DEFENSE TECH

Degradable magnesium alloy femoral internal fixation screw and preparation method thereof

The invention provides a degradable magnesium alloy femoral internal fixation screw and a preparation method thereof. Pure magnesium cast ingots, zinc particles, magnesium-calcium intermediate alloy and magnesium-manganese intermediate alloy are used as raw materials, and Mg-Zn-Ca-Mn alloy with excellent mechanical properties and a lower degradation rate is obtained through smelting, solution treatment, hot extrusion and other preparation methods; and the femoral internal fixation screw is designed and machined through the magnesium alloy material, meanwhile, the structure and the size of thescrew are optimized, a screw structure comprises a screw head, a screw body with threads and a transition circular bead connecting the screw head and the screw body, and the screw head is provided with a plum blossom groove. The optimized magnesium alloy screw has the mechanical property meeting the implantation requirement and the lower degradation rate.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Multi-layer inner flame combustor and gas cooker with same

ActiveCN102141246AOptimize structure sizeEasy to manufactureGaseous fuel burnerCookerPressure casting

The invention discloses a multi-layer inner flame combustor and a gas cooker with the same. The multi-layer inner flame combustor comprises a combustor main body 1 and a distributor device 2, wherein the combustor main body is combined with the distributor device together through a cylindrical surface, a circular conical surface or a flat surface; the combustor main body has an upper wind inlet structure; the distributor device consists of a distributor main body 201, an upper flame cover 202 and a lower flame cover 203; the distributor main body is not provided with a flame hole and is molded by pressure casting through an aluminum alloy material; the upper flame cover is arranged at the upper end of the distributor main body; a plurality of screw holes 101 and an installation surface 102 corresponding to the lower flame cover are formed at the position of the combustor main body corresponding to the lower flame cover; and the lower flame cover is integrally connected with the distributor main body and the combustor main body through screws. In the combustor and the gas cooker, a plurality of layers of inner flames are subjected to layered combustion and segmentation oxygen supplementation to form cubic flames which are spatially distributed in a staggered way, low CO and NO emission is realized, and obvious effects of energy saving and environmental friendliness are achieved.

Owner:MIDEA GRP CO LTD

Light-emitting diode (LED) optical engine and LED illuminating lamp

InactiveCN103032721AReduces severe performance degradation issuesLow costPoint-like light sourceElectric circuit arrangementsEngineeringHeat sink

The invention provides a light-emitting diode (LED) optical engine which is a standard module of an LED illuminating device and can be conveniently realized. The LED optical engine comprises an LED light source (3) and cooling fins, wherein the cooling fins form a sunflower-shaped structure. The LED optical engine is mainly characterized in that the cooling fins (1) are respectively provided with cross flow grooves (5); each cooling fin is divided into a plurality of short fins (4), so that the problems that the ventilation performance is poor and the heat dissipation performance seriously worsens when axes of the cooling fins are horizontally arranged are solved. The LED light source (3) and an external power supply are connected by adopting a splicing structure, so that assembly and maintenance are convenient. The invention also provides an LED bulb lamp with an optimized structure size and a novel structure, and thus, lower manufacturing cost and a higher heat dissipation effect can be realized.

Owner:秦彪

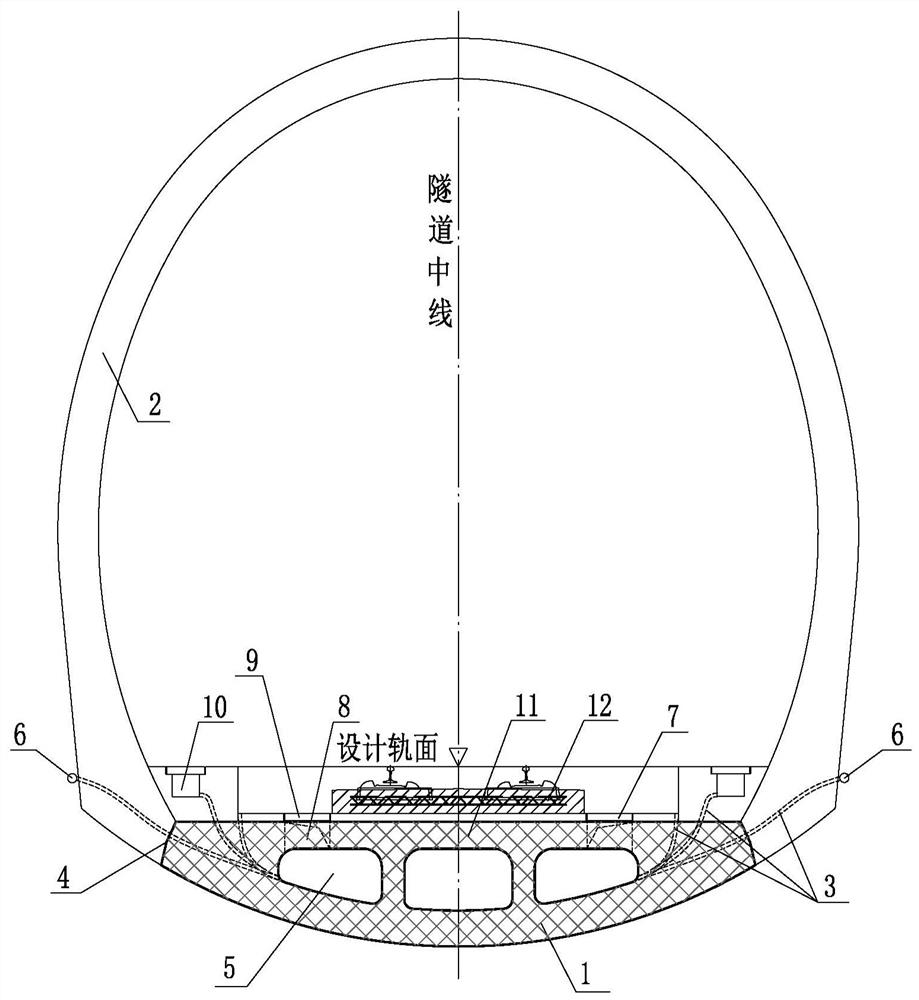

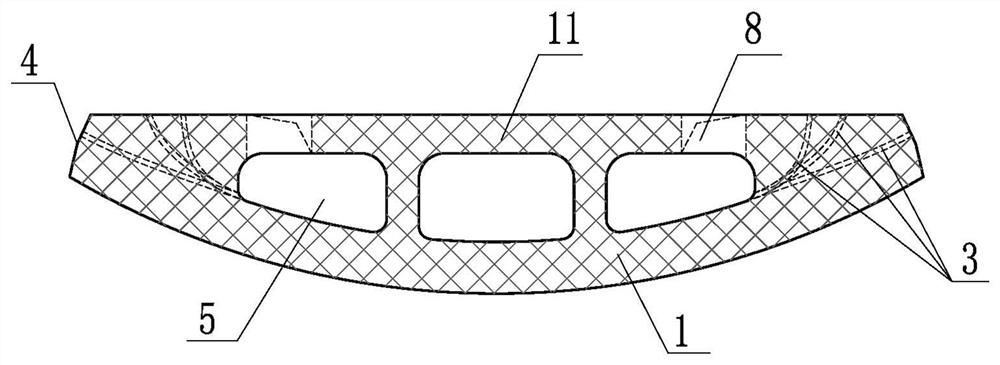

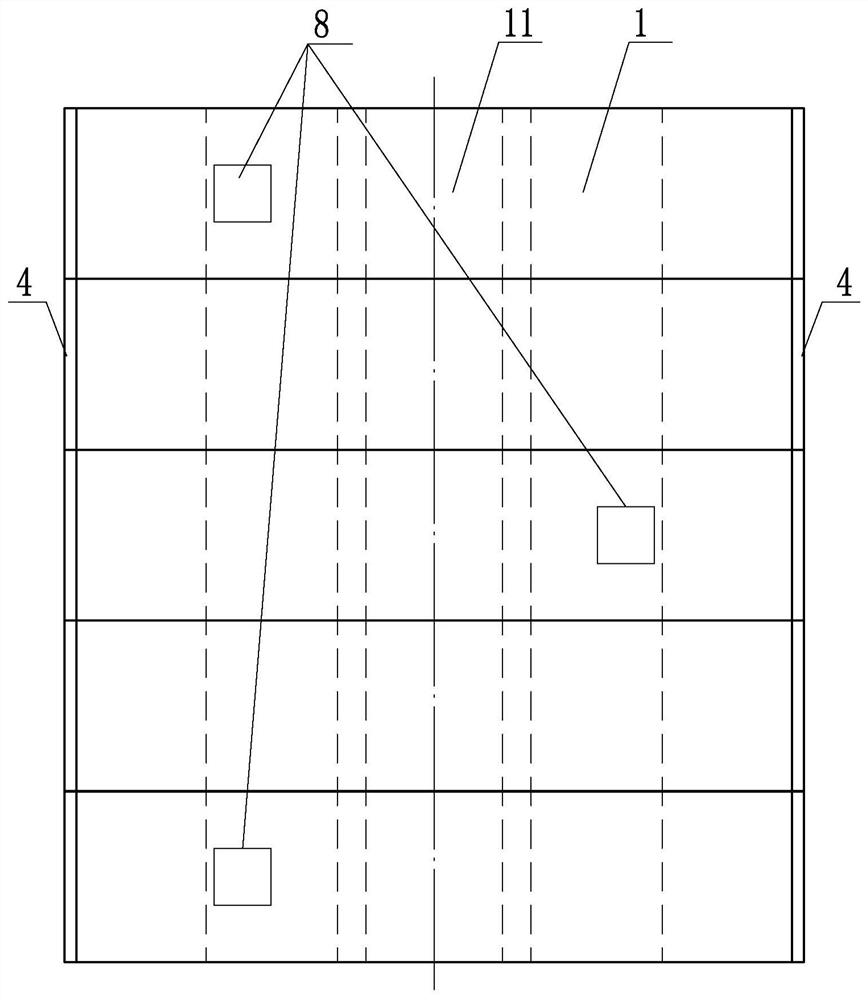

Tunnel assembly type inverted arch precast block structure

PendingCN113958341AGuaranteed thicknessGuaranteed shapeMining devicesUnderground chambersArchitectural engineeringBlock structure

The invention relates to a tunnel assembly type inverted arch precast block structure. An assembly type inverted arch precast block is of a precast structure, the bottom face is an arc face, the top face is a plane, the two sides are contact faces with an arch wall cast-in-place secondary lining, and a longitudinally-through through hole is reserved in the assembly type inverted arch precast block; and assembly type inverted arch precast blocks are longitudinally and sequentially spliced in the line direction to form a tunnel inverted arch structure. According to the tunnel assembly type inverted arch precast block structure, the structure type requirement of a tunnel assembly type inverted arch is met, the space below the inverted arch precast block is used as a tunnel longitudinal drainage ditch, ditches on the two sides of a drilling and blasting method tunnel can be adjusted to the interior of the assembly type inverted arch block, the space on the two sides of the tunnel is saved, the section outline of the tunnel is optimized, and the concrete consumption is reduced, so that the engineering investment is reduced; and the inverted arch precast block structure can be prefabricated in a factory-like and standardized manner, so that the quality is more reliable; the inverted arch precast block is more reasonable in structural form stress, can improve the concrete grade, reduce the structural size and reduce the manufacturing cost, and is suitable for underground engineering such as tunnel construction through a drilling and blasting method.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

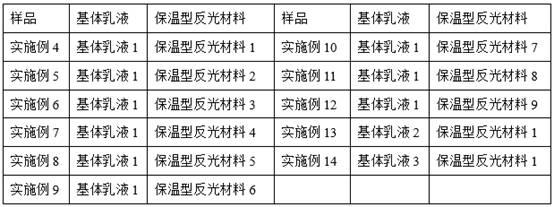

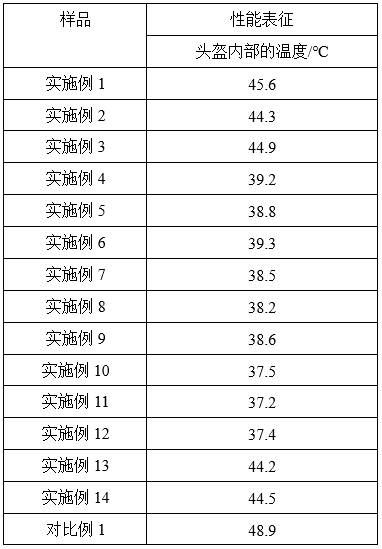

Heat insulation and heat preservation type reflective coating for helmet and preparation method of heat insulation and heat preservation type reflective coating

InactiveCN114181569AImprove reflective effectIncrease reflectionConjugated diene hydrocarbon coatingsReflecting/signal paintsPolymer scienceEmulsion

The invention relates to the field of coatings, and particularly discloses a heat insulation and heat preservation type reflective coating for a helmet and a preparation method of the heat insulation and heat preservation type reflective coating. The heat insulation and heat preservation type reflective coating for the helmet comprises the following substances in parts by weight: 80-100 parts of matrix emulsion, 6-8 parts of a heat preservation type reflective material, 1-3 parts of polyvinyl alcohol, 3-5 parts of a functional additive, 25-40 parts of water and 1-2 parts of composite filler, the heat preservation type reflective material is hollow glass microsphere particles, the particle size of the hollow glass microsphere particles is 20-150 microns, and the refractive index of the hollow glass microsphere particles is 1.8-2.0. The preparation method comprises the following steps: S1, premixing; s2, performing secondary mixing; and S3, uniformly mixing. The formula of the heat insulation and heat preservation type reflective coating for the helmet is optimized, transmission between external temperature and internal temperature is effectively isolated through the hollow structure of the hollow glass microspheres, and the heat insulation and heat preservation performance of the reflective coating for the helmet is improved.

Owner:常州市勤源新材料有限公司

Method for making low clast bullet and bullet made by the method

InactiveCN1737489AImprove securityImprove perforation effectExplosive chargesCartridge ammunitionDie castingFerrosilicon

This invention relates to a method for manufacturing the small-chip projectile in oil well operation, characterized in that the shell case is die cast with aluminum zinc alloy, wherein the weight ratio is: zinc 75-98, aluminum 25-2; the weight ratio of the nodular graphite cast iron shell case is: carbon 1-5, silicon 1-3, iron 92-98. The projectile comprises shell case, booster, main charge and medical shield, wherein the front of the shell case is tack conical, and the booster is set in the front of the shell case; the rear of the shell case is cylinder shape; the medical shield is set in the shell case, and between the medical shield and the shell case inner it sets the booster and the main charge. After gun perforation, the shell case chip is small in powder or particle shape, which does not damage the sand control pipe column and the well facilities.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com