Method for processing thin wall welder cases of revolving body structures

A technology of welding casing and processing method, which is applied to the manufacture of thin-walled welded casing of the rear mounting side, and the processing field of the thin-walled welded casing of the belt front and rotary structure, can solve the residual stress distribution of welded components Unbalanced, main body coaxiality is out of tolerance, size is out of tolerance, etc., to achieve the effect of improving machining quality and processing efficiency, good structure and size, and small welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A method for processing a thin-wall welded casing with a rotary structure, comprising the following steps:

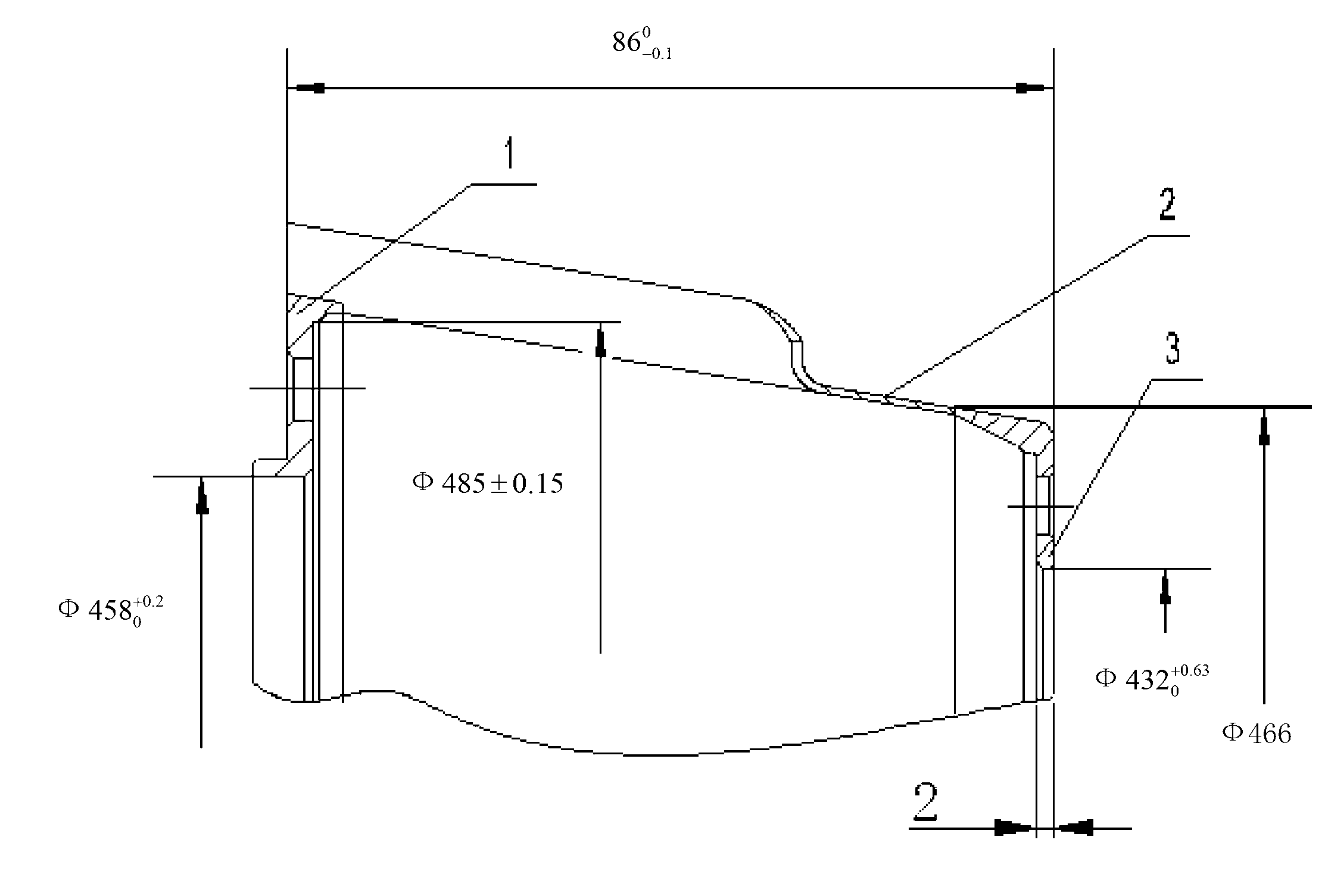

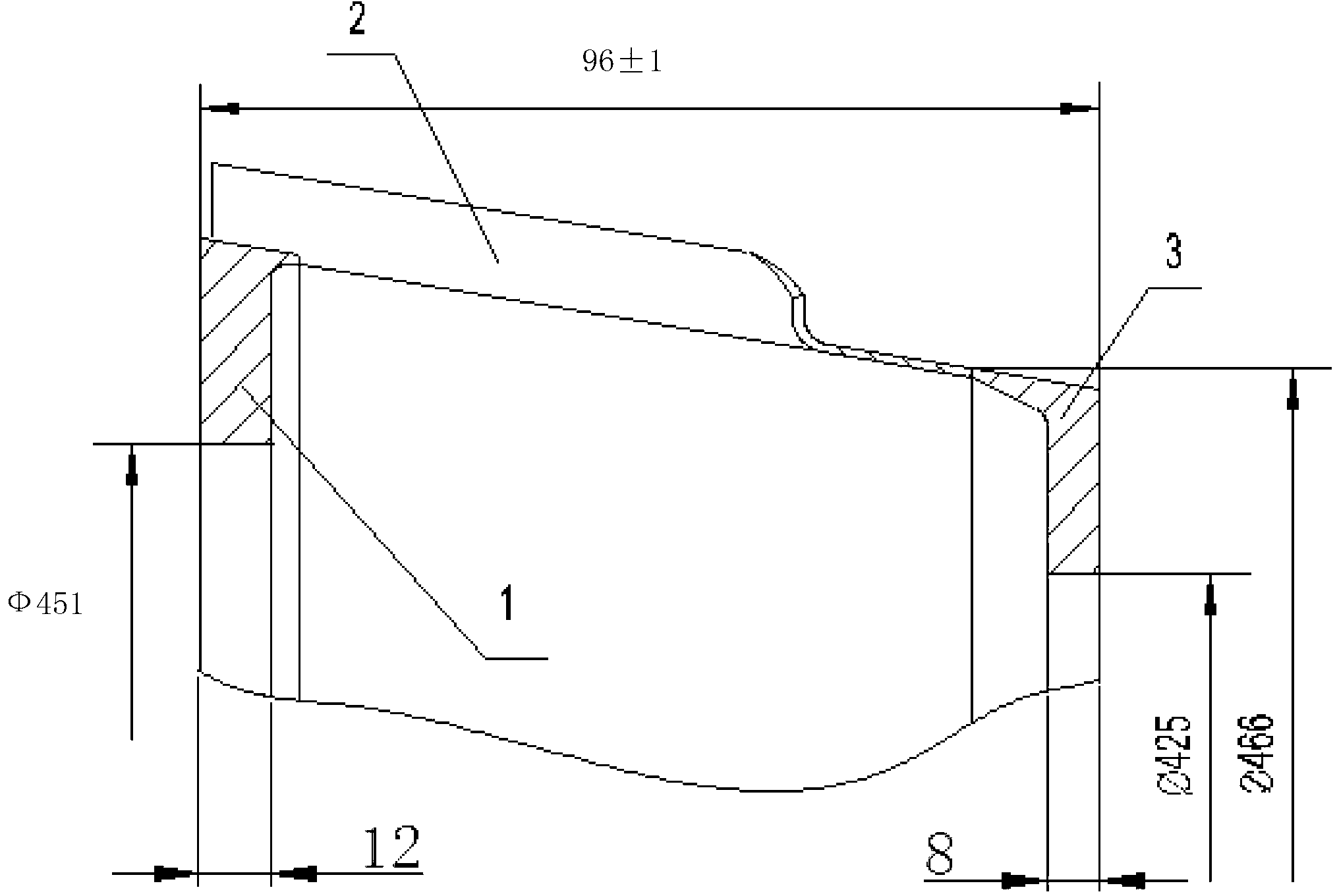

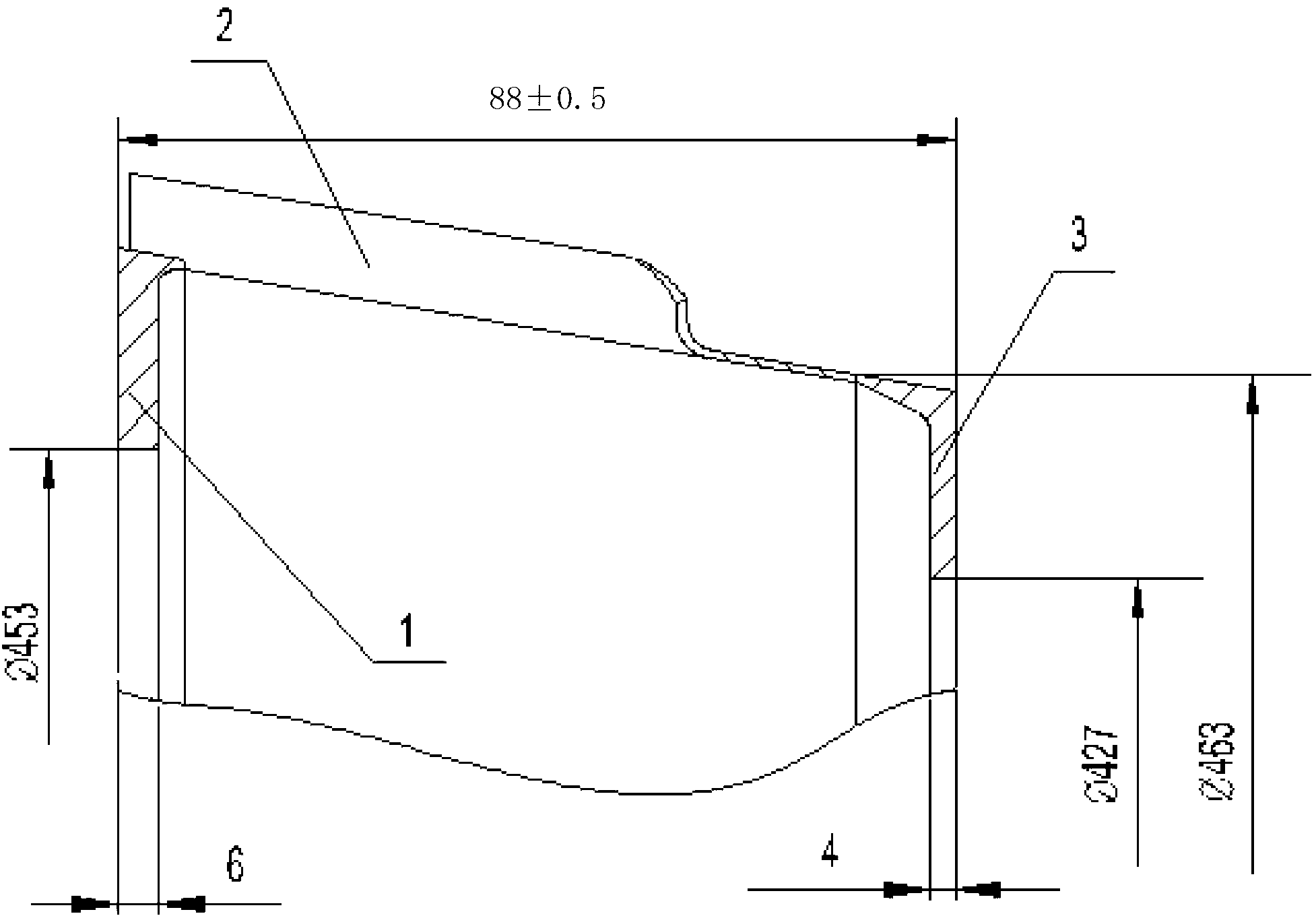

[0022] Step 1: The material selected in this embodiment is gh3128. According to the plastic deformation characteristics of the selected material, it is judged that the welding shrinkage (that is, the welding deformation) is 1.5 mm, and the welding deformation in the diameter direction is 3 mm; The size and structure compensation design of the main body of the box, design and manufacture the front and rear mounting sides and the main body of the inner runner with a small margin structure, compared with the traditional processing method: the diameter of the main body is reduced by 3, and the diameter of the non-processing part of the mounting side The size is reduced by 3, the margin is reduced by 2, and the diameter of the overall front and rear mounting edges is reduced by 5; that is, the size of the front mounting edge is Ф456mm, the size of the rear mounting edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com