Patents

Literature

427 results about "Pre deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stent and method for the production thereof (variants)

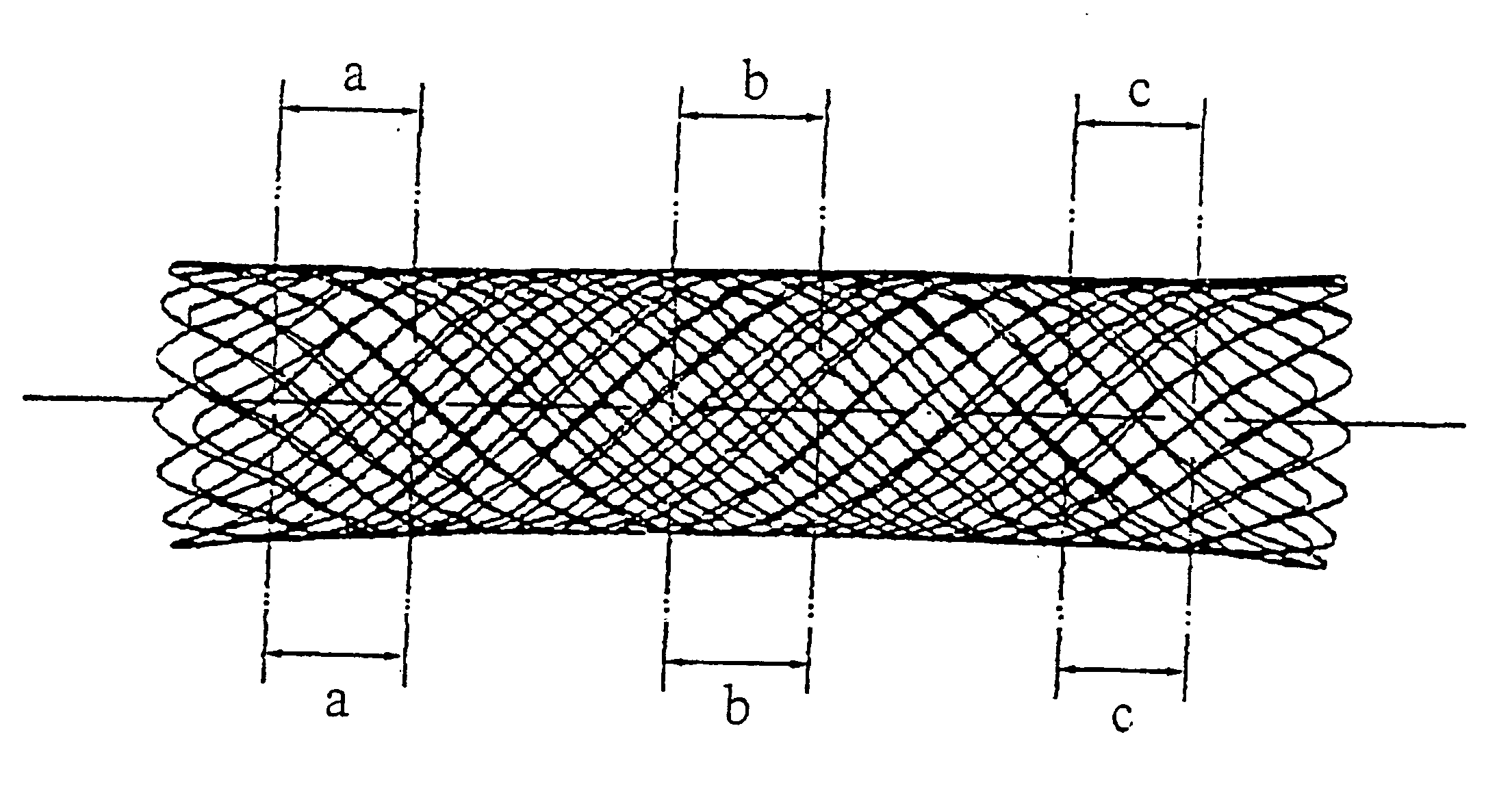

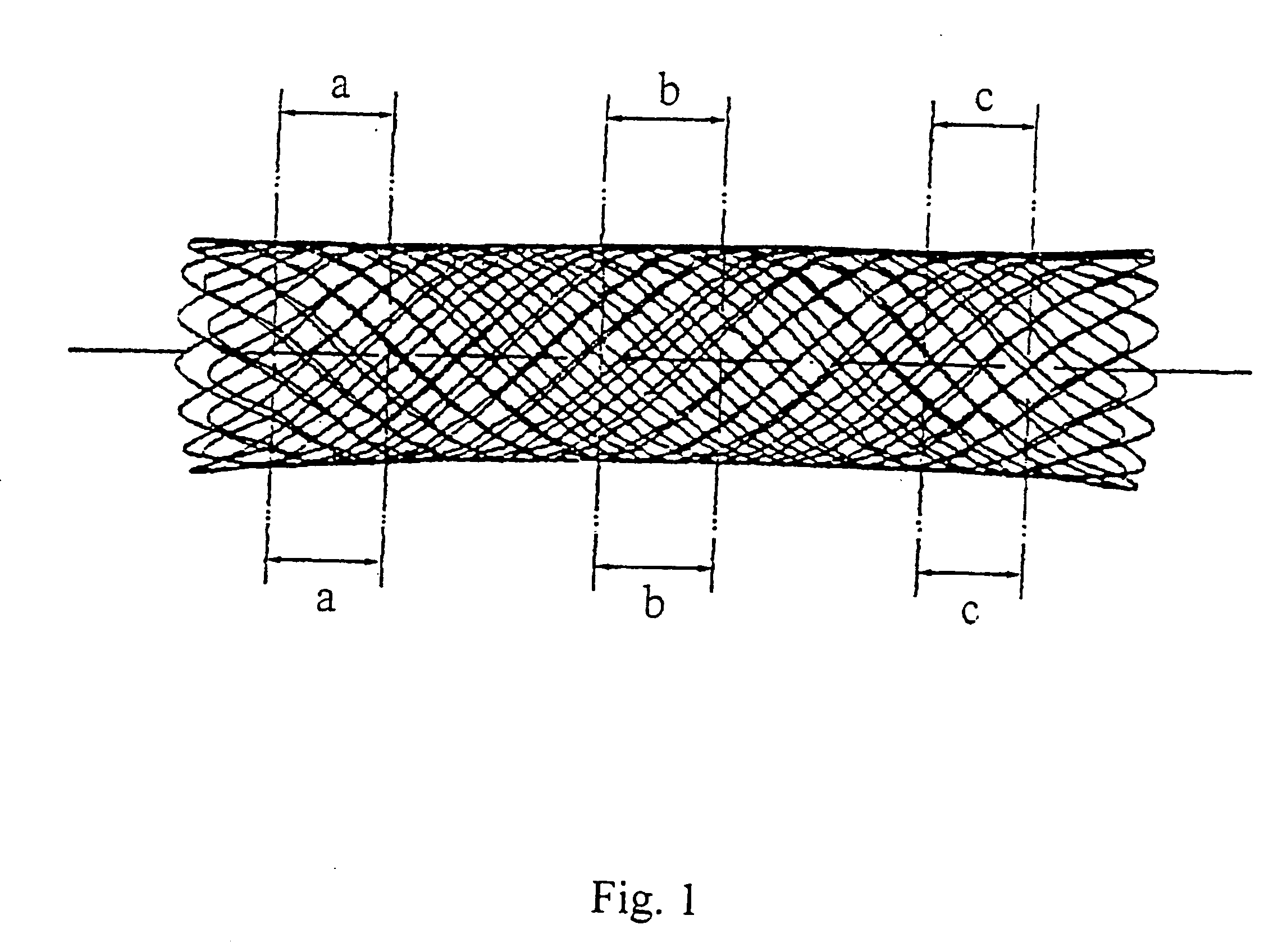

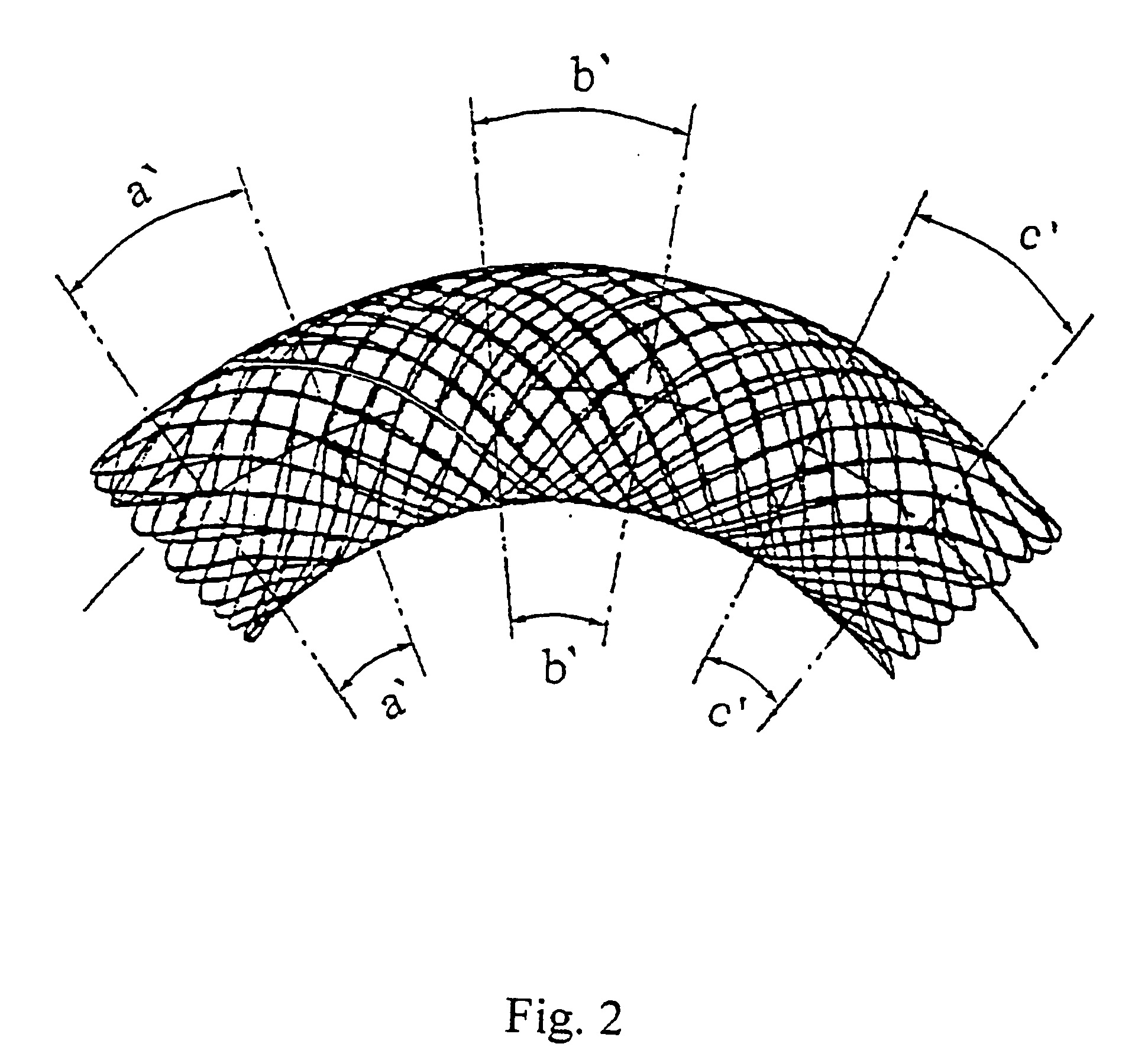

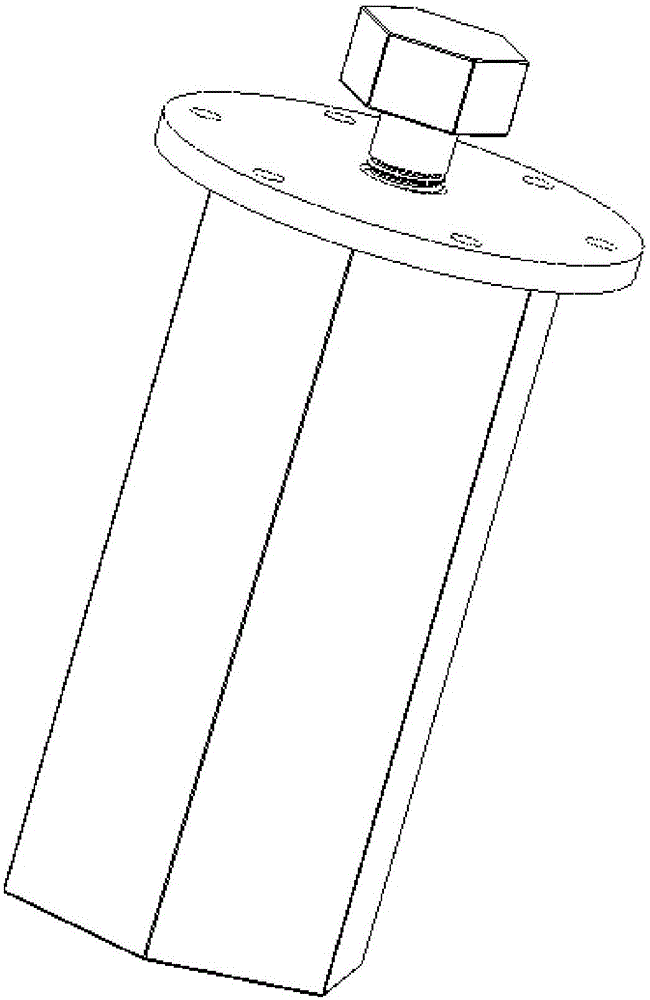

The inventions relate to the field of medicine and can be used in endoprosthetics for restoring a lumen in narrowed sections of vessels and other hollow organs. The stent is made as a netted hollow volumetric body, formed by interweaving of several groups of windings from a single length of a thread, placed along helical spirals with opposite entry directions. A material of the thread possesses elasticity and shape memory effect. Cells which are opposite with respect to the axis of the stent, are displaced with respect to each other, and the stoat thread has different elasticity in its separate sections, preserving the same thickness of the thread along the whole length of the stent. In the second variant of the stent its geometry is changed by way of making the stent with separate areas having a different axial curvature. The third variant of the stent unites the first and the second variants of the stent. In addition to that in all three variants the stent is manufactured from a medical nitinol Ti Ni. The method of stent manufacturing includes the formation of a netted hollow metallic body from a metallic thread by interweaving its windings, wound on a mandrel made as a body of revolution with a rectlinear longitudinal axis, and a pre-deformation of the stent on the mandrel by way of its quenching from the temperature 630-660° C. into water, which attributes a maximum elasticity to this stent. After the mandrel is removed the elasticity of separate sections of the stent is reduced, subjecting them to a secondary heat treatment at the temperature of 330-550° C. during from 1 to 30 minutes. In the rest variants of the method, the pre-deformation of the stent is conducted twice, first by way of primary heat treatment of the stent on the mandrel with a rectilinear longitudinal axis at the temperature of 330-390° C. during 5-20 minutes, and then on the mandrel with a curvilinear longitudinal axis, the form of which corresponds to the form of a prostheticated vessel. By that, by changing the time and temperature of the secondary heat treatment, the elasticity of the thread in separate sections of the stent and / or axial curvature of the stent are changed.

Owner:KOVNERISTY JULY K +6

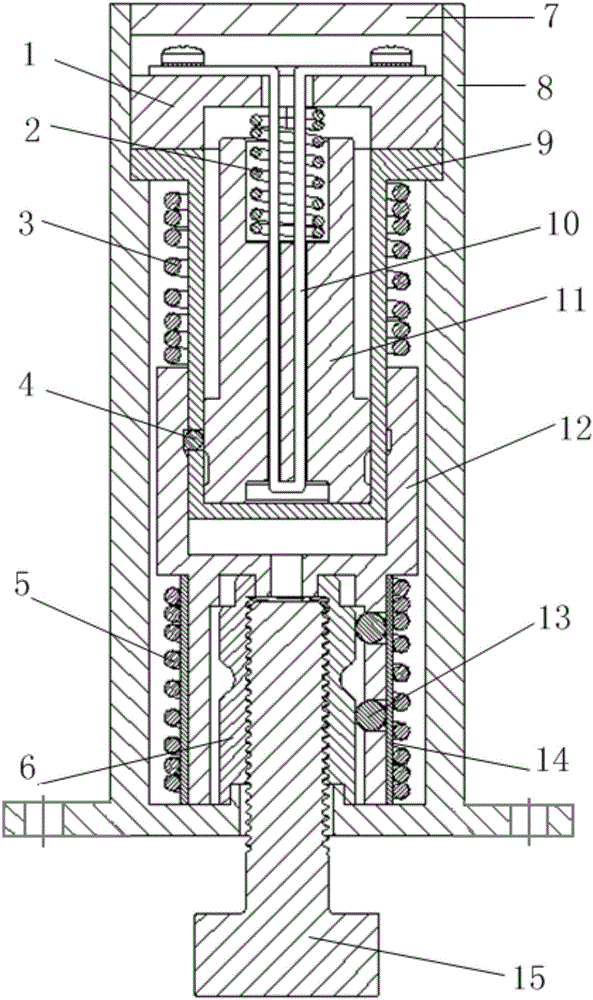

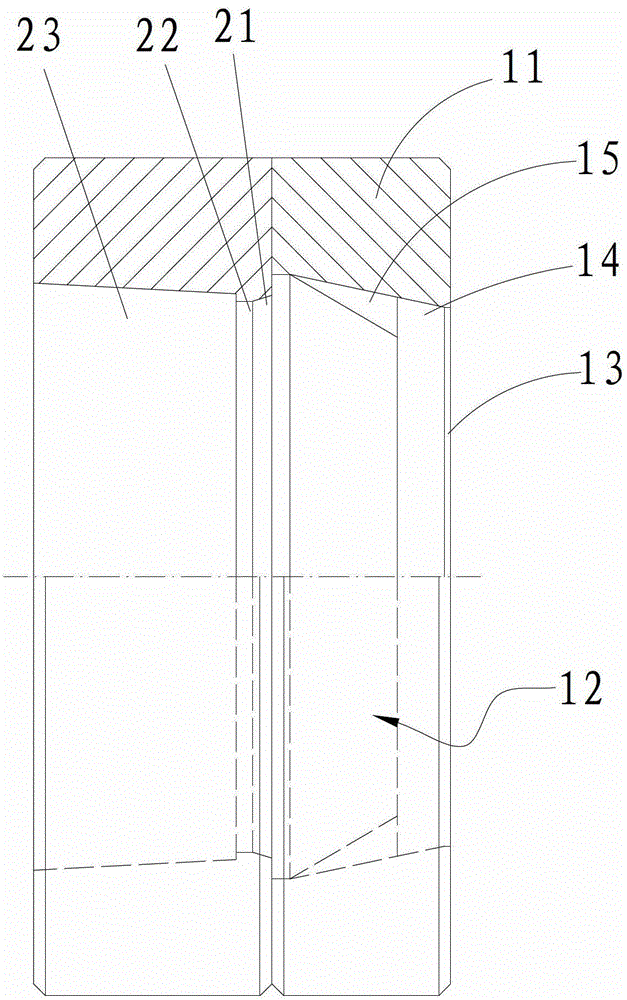

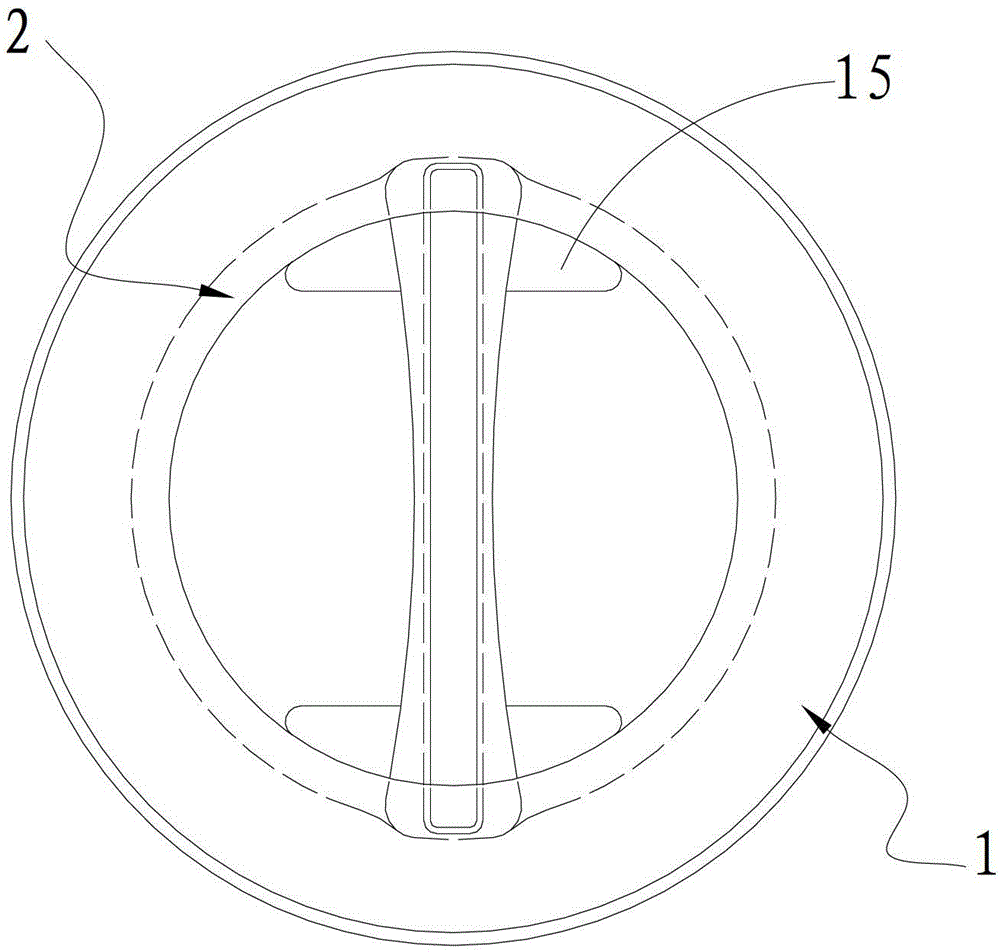

Low-impact non-pyrotechnic separation device

InactiveCN106494651AKeep the position fixedGuaranteed fixed effectCosmonautic vehiclesCosmonautic component separationMemory effectPre deformation

The invention discloses a low-impact non-pyrotechnic separation device, which is used for the locking and release between stages of a rocket, between a satellite and a launch vehicle, and of a satellite solar panel substrate, an antenna and the like. The low-impact non-pyrotechnic separation device is formed by using a shape memory alloy as a triggering switch and being provided with components and parts of springs, a locking sleeve, a split nut and the like in a matching manner. Based on the shape memory effect of the shape memory alloy, stretching and pre-deformation are firstly carried out on the shape memory alloy during assembly; when separation and unlocking are needed, an alloy material is electrified and heated to be at a phase-transition temperature of the alloy material; the alloy material is recovered to be in a shape before the pre-deformation; thus, a triggering block is driven to act; the locking sleeve is disengaged from the split nut; the release of loads of the satellite and the like is realized. After the one-time separation is completed, a trigger part inside a shell can be conventionally taken out; a shape memory alloy wire is loaded in the low-impact non-pyrotechnic separation device after the pre-deformation is carried out on the shape memory alloy wire once again by adopting a special tool; thus, the low-impact non-pyrotechnic separation device can be repeatedly used. The separation device provided by the invention is low in impact, can be repeatedly used, has no pollution, is low in cost, is safe to use, and is especially applicable to an occasion which is high in the requirement on a separation impact.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

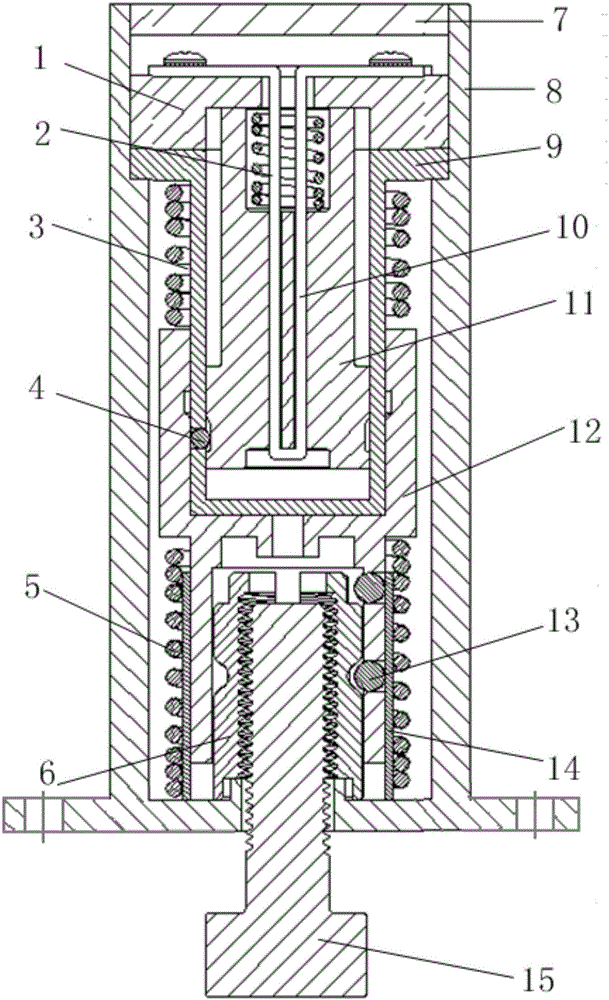

Self-adapting morphing trailing edge based on SMA

InactiveCN101693467ARealize continuous deformationImprove aerodynamicsHeat reducing structuresMorphing wingPower flow

The invention relates to a self-adapting morphing trailing edge based on SMA, belonging to a self-adapting morphing wing which combines intellectual materials and structures. The wing is divided into 2-5 trailing edge segments, the adjacent trailing edge segments are connected by joints (5, 6 and 7) arranged at wing ribs, a deflection driving mechanism is arranged between the adjacent trailing edge segments, and the deflection of the entire trailing edge is realized by accumulative effects of the trailing edge segments. The self-adapting morphing wing is characterized in that the deflection driving mechanism comprises an upper SMA wire (10), a lower SMA wire (11) and a current excitation unit (15) which are respectively connected with the adjacent trailing edge segments. The self-adapting morphing trailing edge has the advantages of simple structure and easy control and achieves the goal of quick, stable and accurate pre-deformation of the trailing edge.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

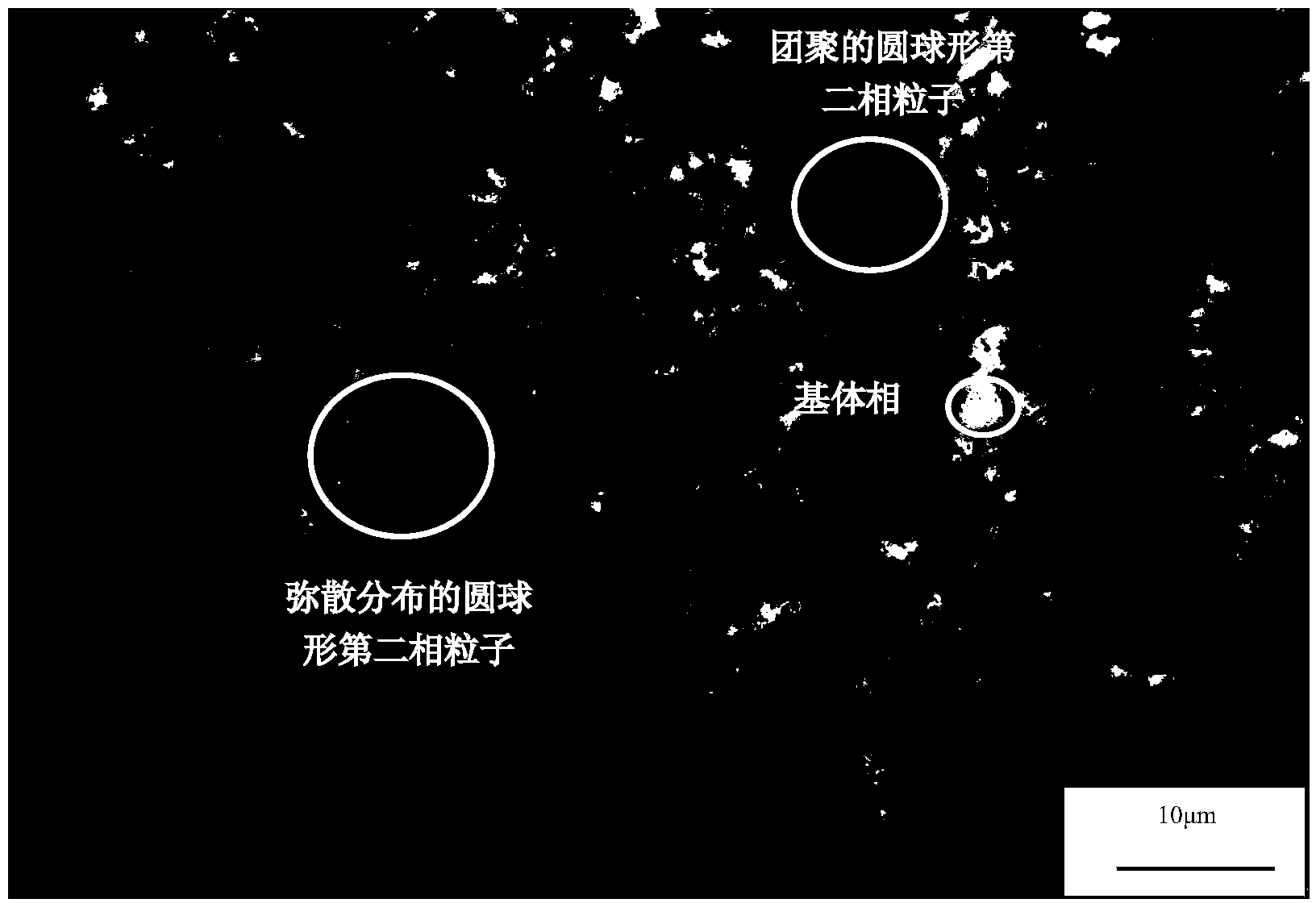

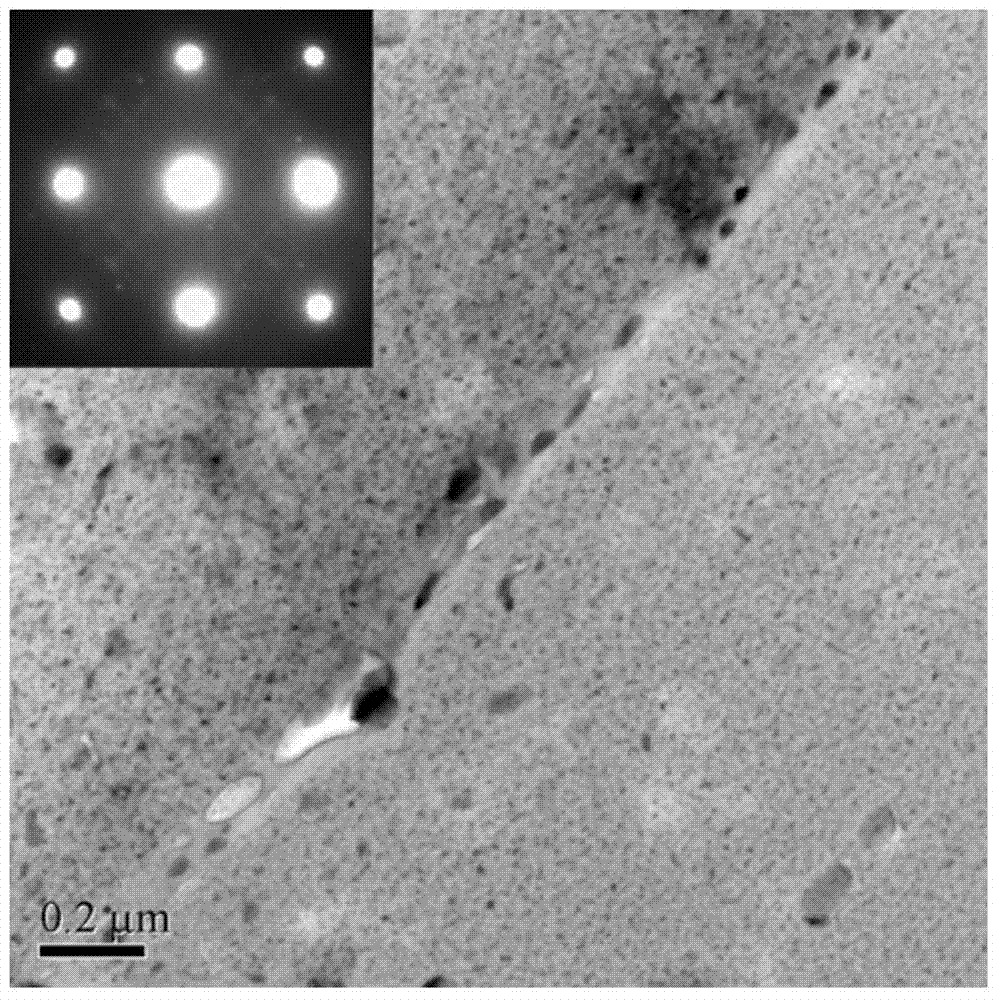

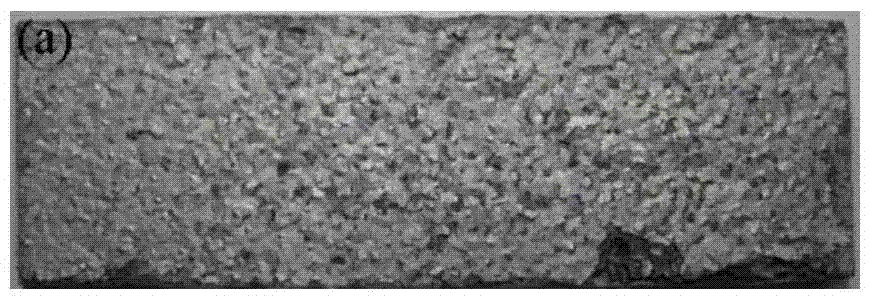

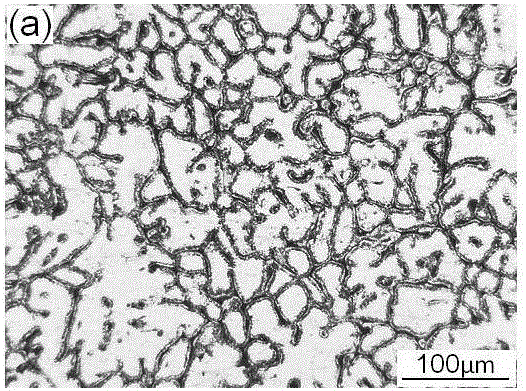

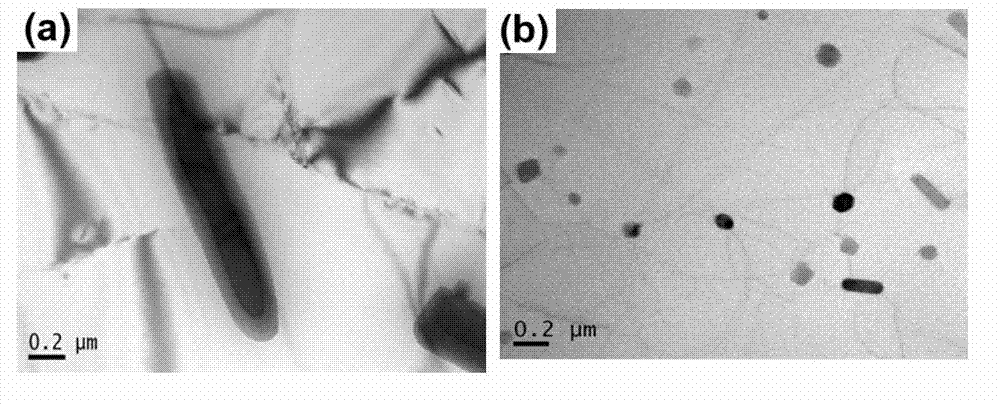

Preparation method of high-performance magnesium alloy plate with double-phase structure

The invention belongs to the technical field of non-ferrous metal magnesium alloy preparation and processing, and particularly relates to a preparation method of a high-performance magnesium alloy plate with a double-phase structure. In the method provided by the invention, a virgin alloy blank of a double-phase microstructure magnesium alloy is prepared by a spray deposition or quick-flow powder preparation or powder metallurgy process; the virgin alloy blank of the double-phase microstructure magnesium alloy is subjected to extrusion, forging, rolling and stamping 'pre-deformation' to form a pre-deformed blank with a 'double-phase texture'; and the pre-deformed blank is subjected to hot rolling or cold rolling to obtain the finished product. The magnesium alloy provided by the invention has the characteristics of 'double-phase structure' (consisting of fine alpha-Mg matrix phase and stable fine second-phase particles) and 'double-phase texture', and a magnesium alloy plate with good comprehensive performance can be obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

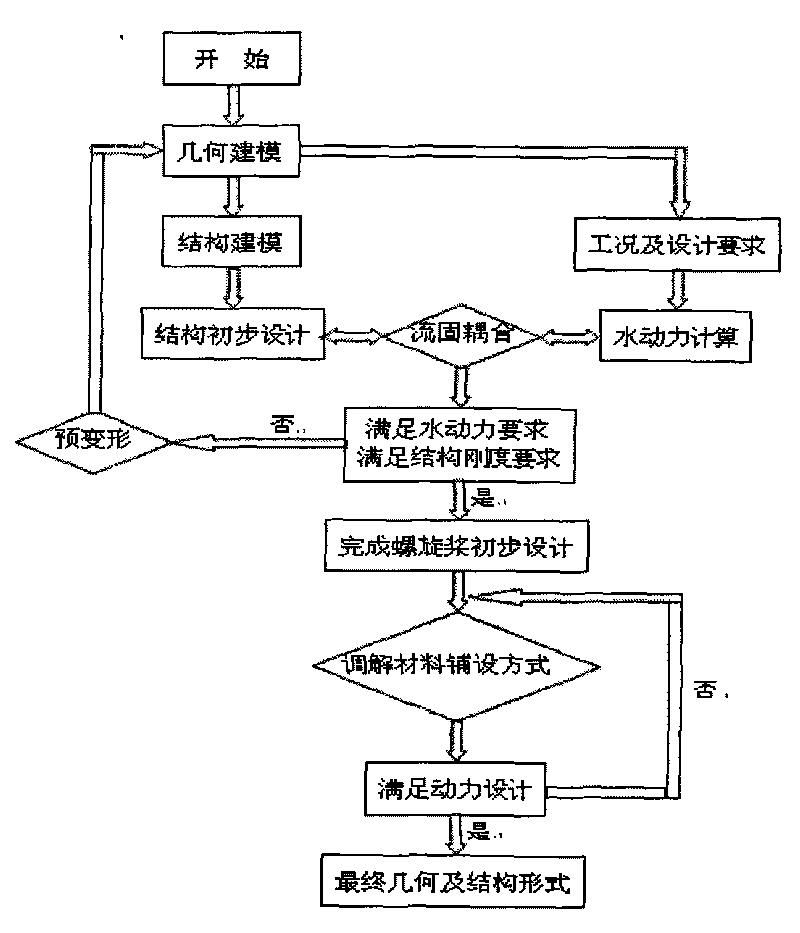

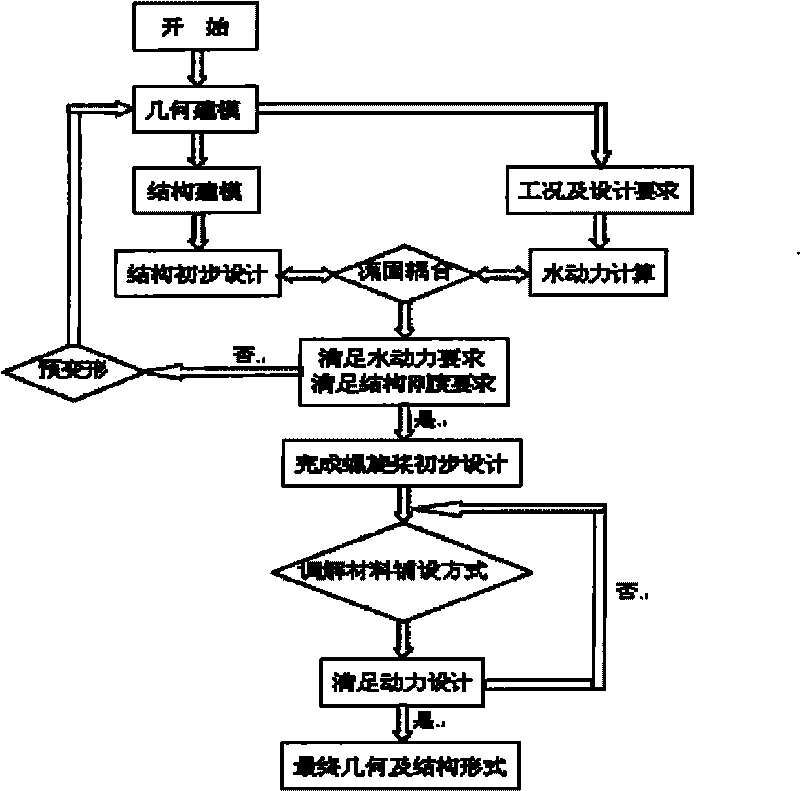

Design method for marine propeller made of carbon fiber composite material

InactiveCN101706833AImprove flow elasticityMeet propulsion performance requirementsRotary propellersSpecial data processing applicationsMaterial DesignPre deformation

A design method for marine propeller made of carbon fiber composite material relates to a design method for a propeller. The invention solves the problem that the current design method for the marine propeller made of carbon fiber composite material is imperfect. The geometrical appearance of the blade by the design method for marine propeller made of carbon fiber composite material is calculated by fully using the flexibility and designable performance of the composite material on the basis of the value data of the original MAU metal propeller blade and combining the fluid-structure coupling method with the implementation of the pre-deformation tactics; and the outside of the propeller hub is wrapped by the carbon fiber composite material. The marine propeller made of carbon fiber composite material designed by the method has the geometrical appearance and the internal structure more suitable for the propeller made of carbon fiber composite material, thereby being capable of effectively improving the fluid elasticity of the propeller and improving the propulsive efficiency.

Owner:HARBIN INST OF TECH

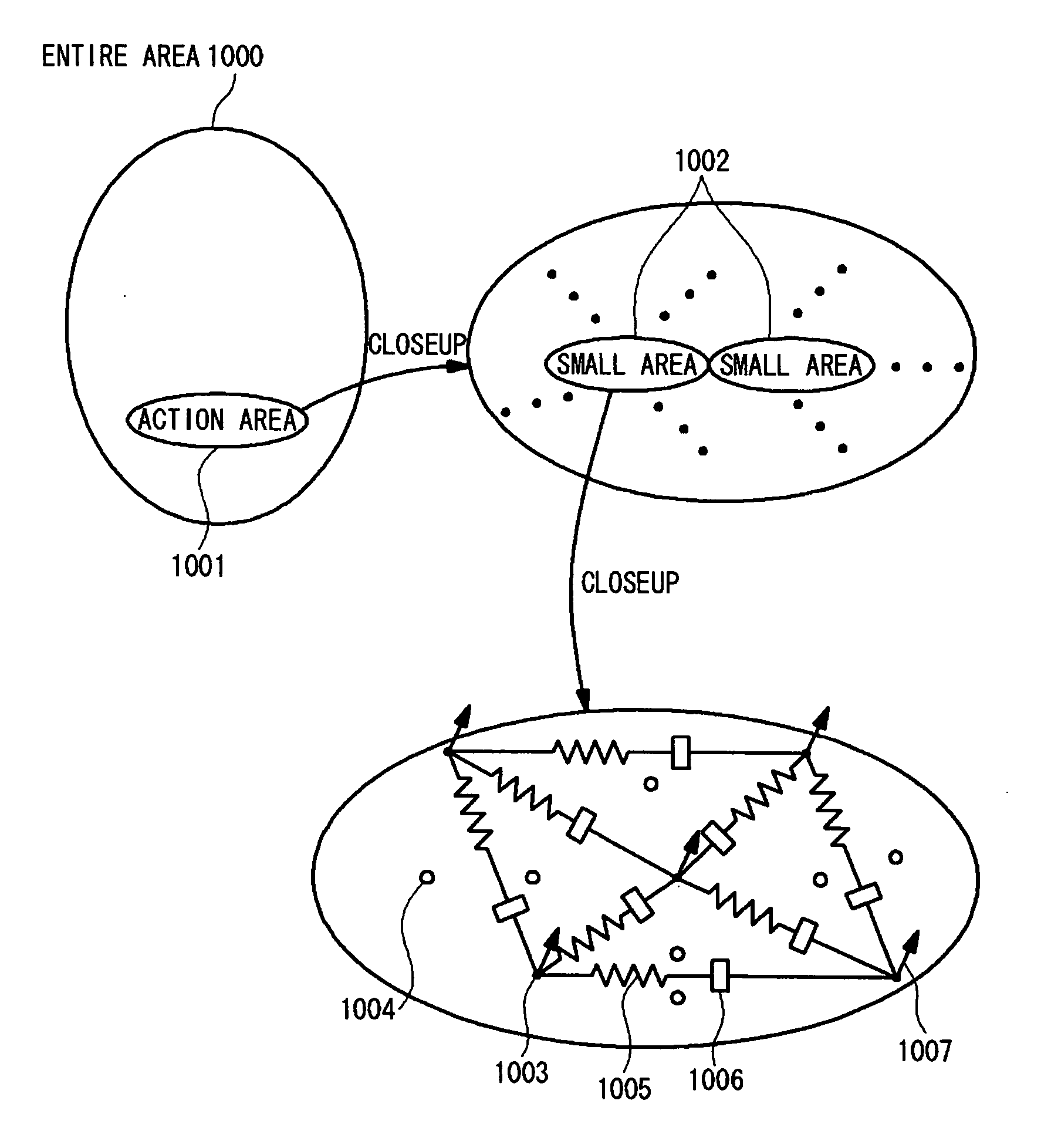

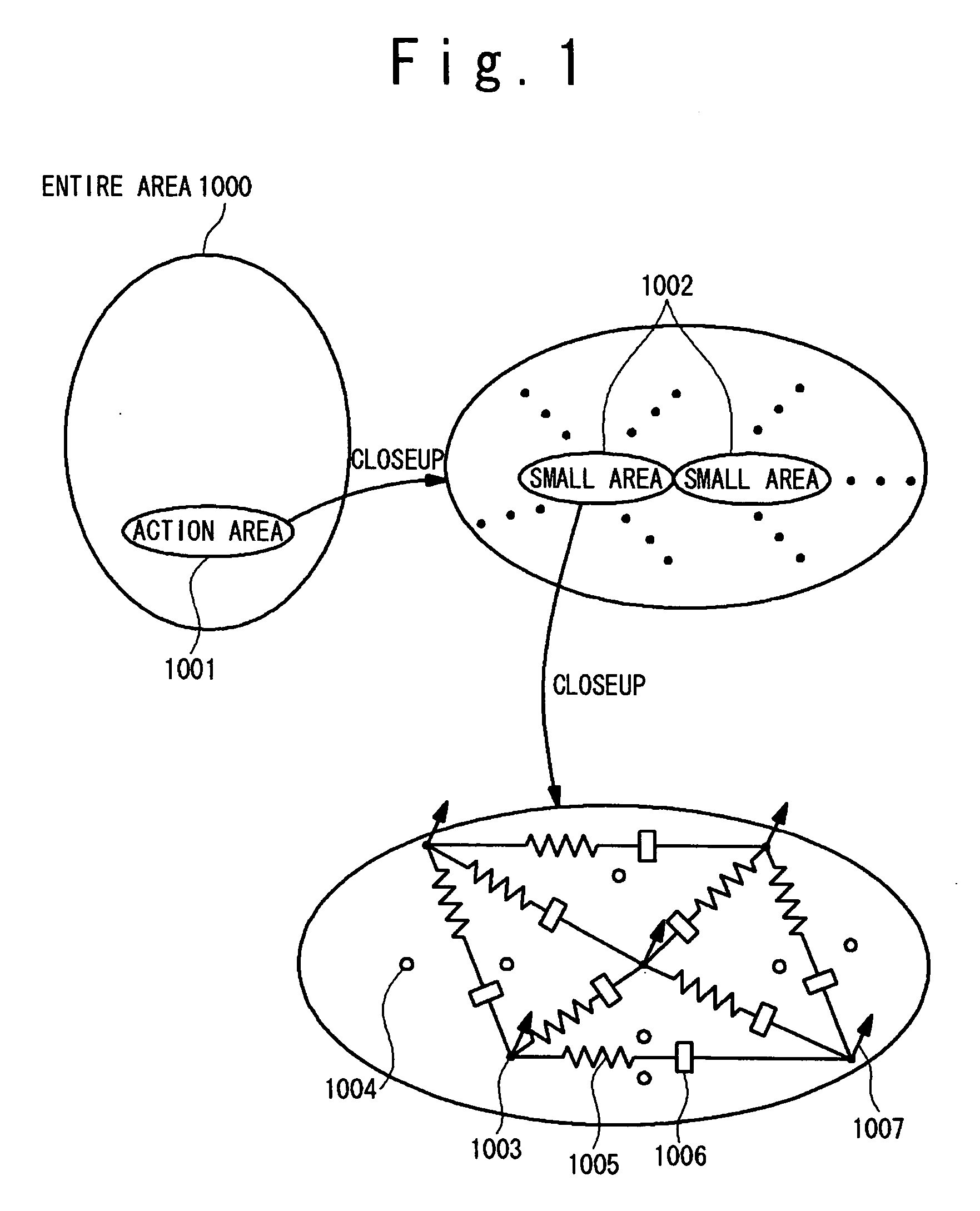

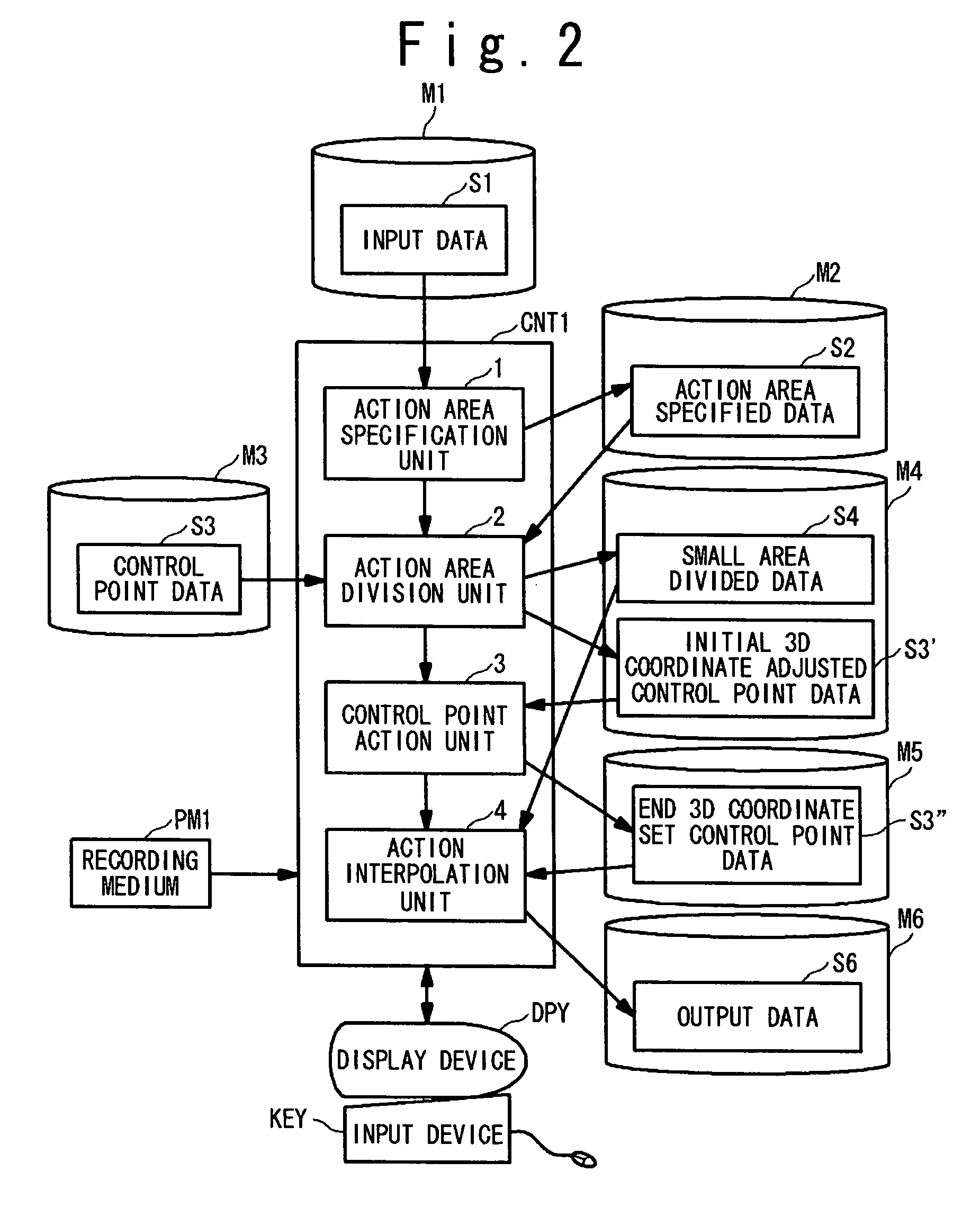

Form changing device, object action encoding device, and object action decoding device

ActiveUS20060285758A1Eliminate calculation amountReduce synthesisImage codingCharacter and pattern recognitionShape changePre deformation

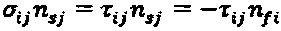

A shape deformation encoding device includes: a calculation unit for calculating a difference data between a pre-deformation shape data which represents a shape of an object before shape change and a post-deformation shape data which represents a shape of the object after shape change; and a determination unit for determining an action area on which the shape change of the object is arisen and an external force which is acted to the action area for the shape change, based on the pre-deformation shape data and the difference data. The action area includes a plurality of small areas, each of the plurality of small areas includes a plurality of control points, and the external force is calculated as an external force required to deform the plurality of small areas from before to after the shape change independently based on the physical model structure of each of the plurality of small areas. The physical model structure in which the plurality of control points are connected together with springs and dampers are used as a physical model structure.

Owner:NEC CORP

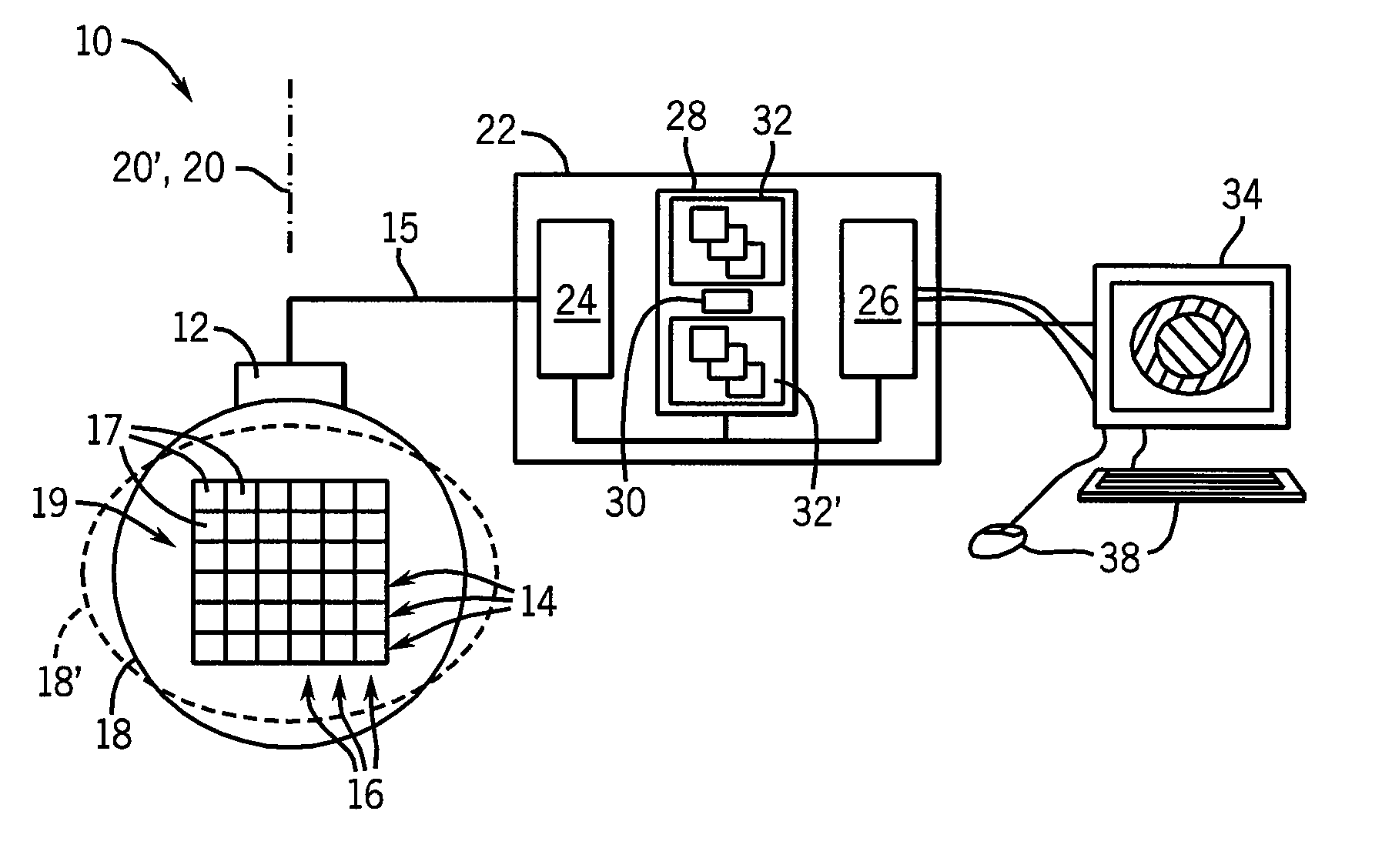

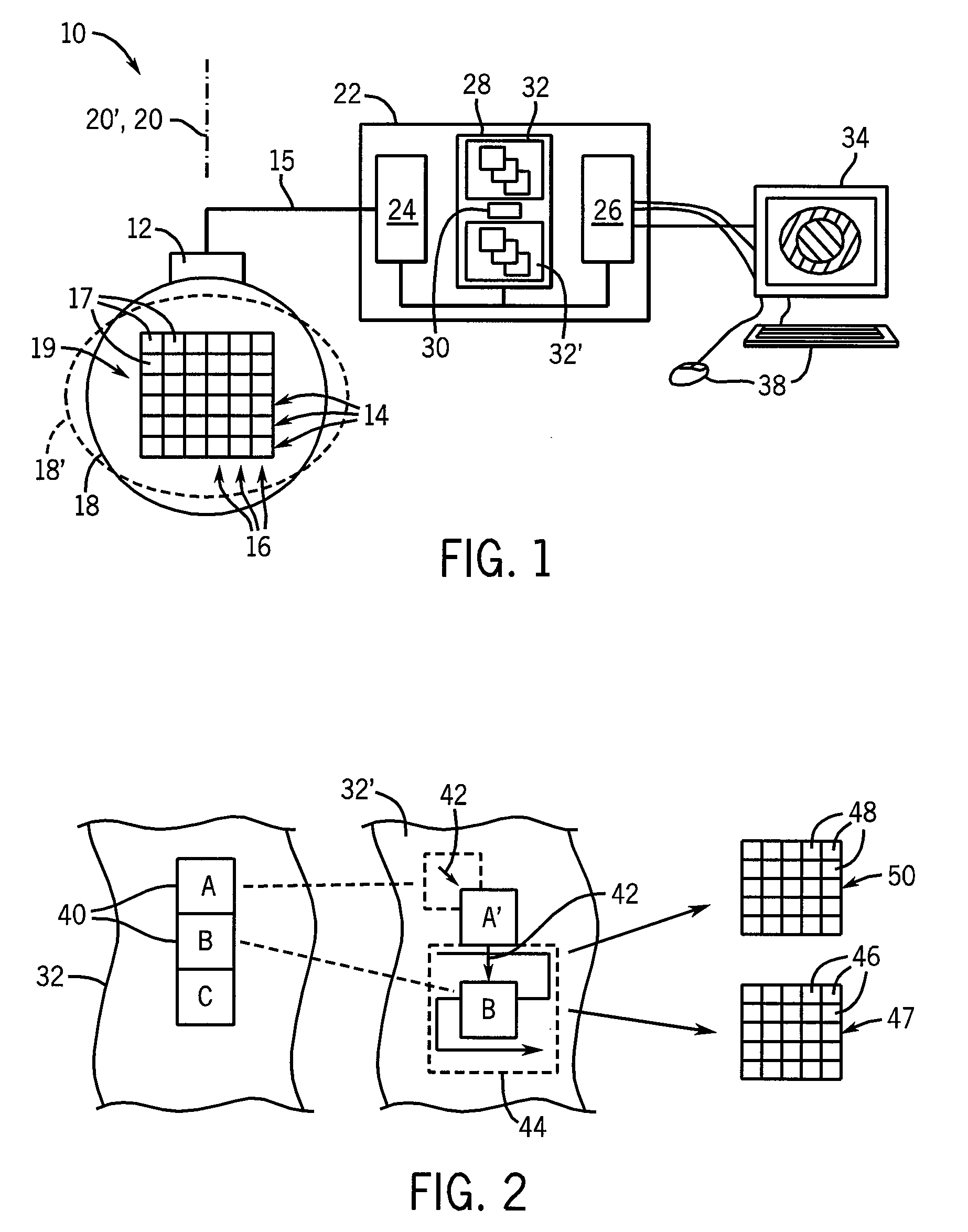

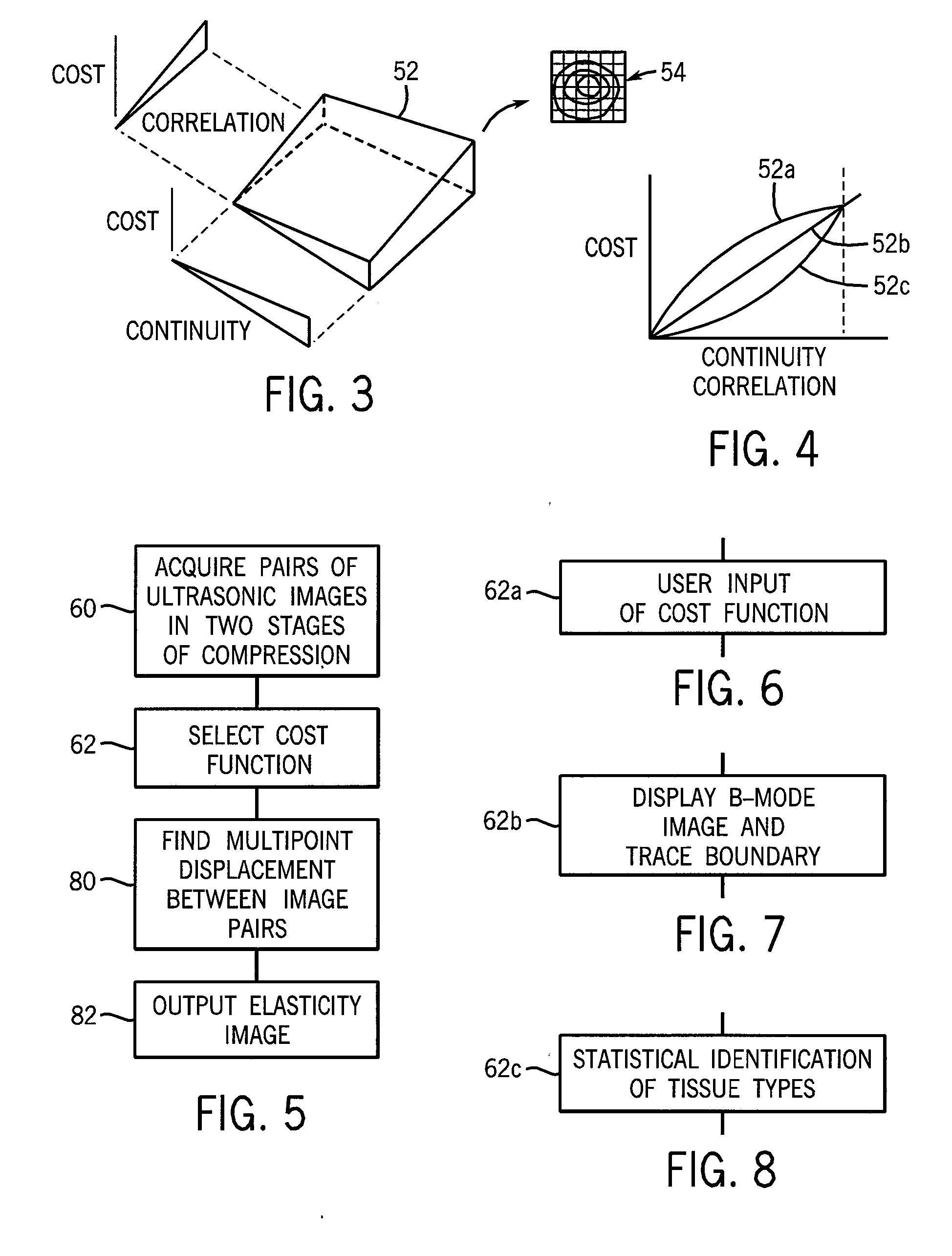

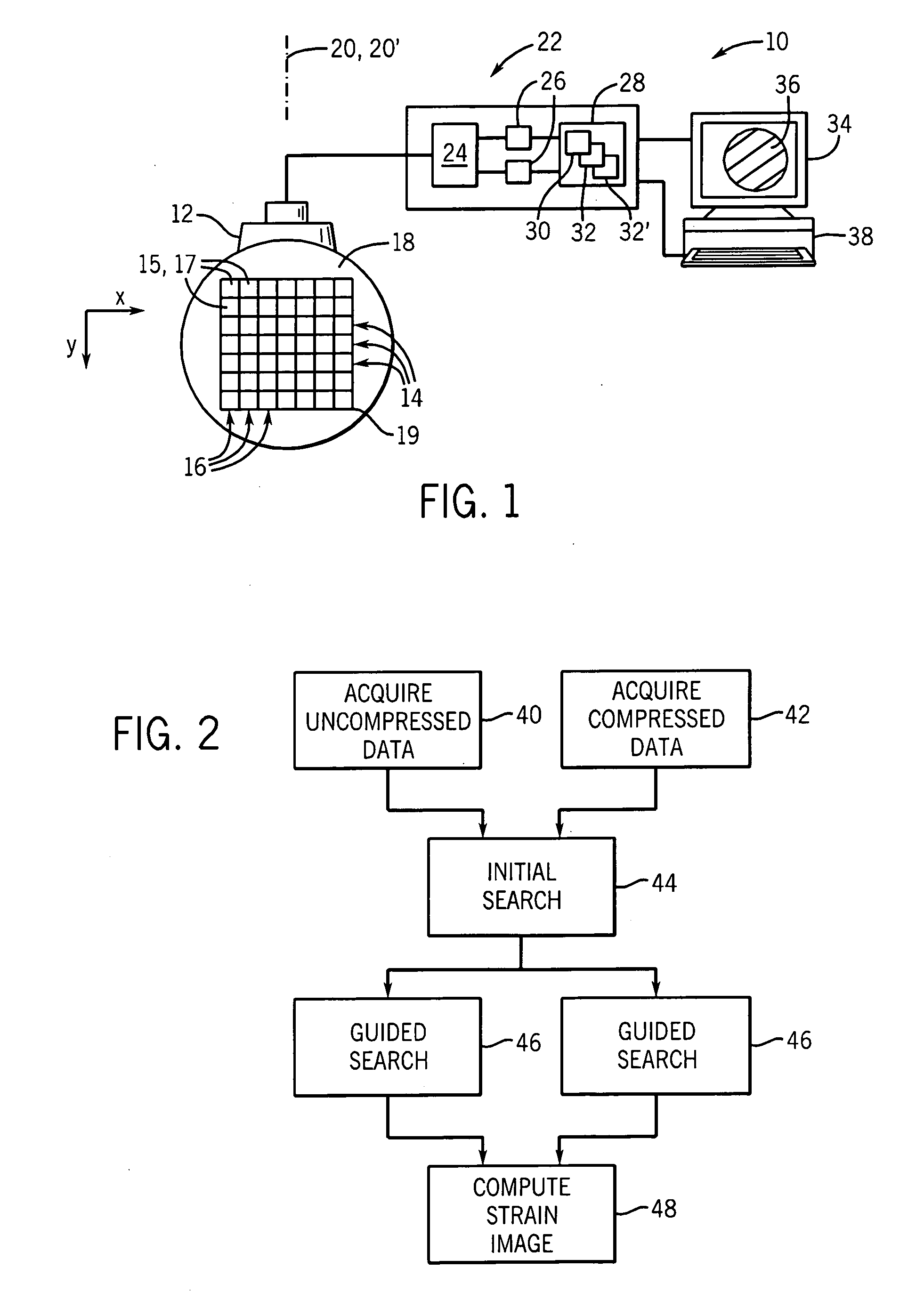

Ultrasonic strain imaging device with selectable cost-function

ActiveUS20100106018A1Enhance the imageInherent tensionOrgan movement/changes detectionInfrasonic diagnosticsPre deformationTissues types

An elasticity measuring system determines tissue displacement between a pre-deformation and post-deformation image by a matching process using a cost function accepting as its arguments continuity of the tissue motion and correlation of the tissue in making the block matching. The invention allows the selection among different cost functions for different imaging situations or tissue types, to provide improved displacement calculations using a priori knowledge about the tissue and structure of tissue interfaces or information derived during the scanning process.

Owner:WISCONSIN ALUMNI RES FOUND

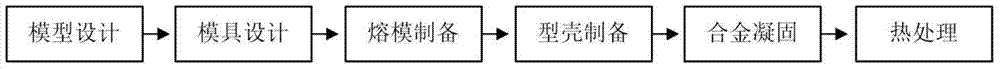

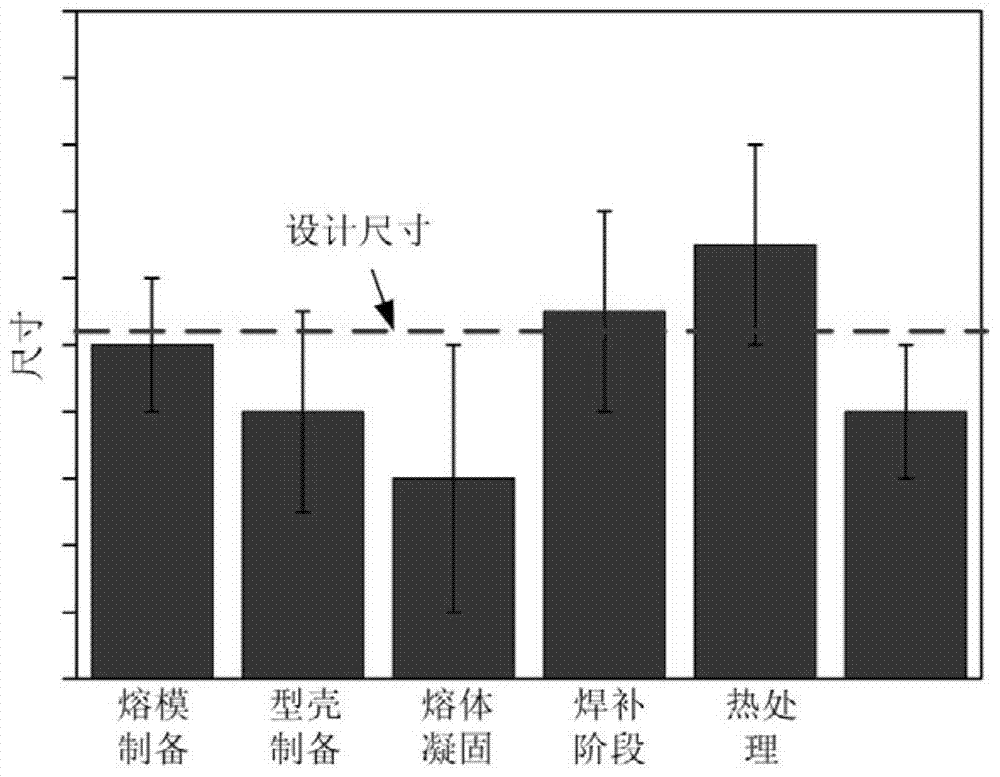

Method for determining shrinking percentages of investment pattern precision casting mold

InactiveCN104504195ALess Corrective WorkHigh precisionFoundry mouldsFoundry coresPre deformationInvestment casting

The invention relates to a method for determining the shrinking percentages of an investment pattern precision casting mold. The method comprises the steps of (1) establishing numerical analysis models for various operation stages of investment casting, (2) taking the analog output of a previous numerical analysis model as the analog input of a next numerical analysis model, establishing an error flow of the whole process and obtaining the final casting simulation deformation result, (3) performing reversible deformation to a mold design stage from the final casting simulation deformation result and determining the profile shrinking percentage of each key dimension. Compared with the prior art, the method has the advantages that the error flow is established or the error evolution of the key dimensions, more accurate and detailed shrinking percentages can be obtained based on the backtracking of the error flow, and the design detail accuracy of the mold design can be enriched; besides, pre-deformation is performed on the error evolution of the whole process of the castings at the source of the mold design, and therefore, the correction work on the castings in the subsequent steps can be saved, the workload is saved and the precision of the castings is improved.

Owner:SHANGHAI JIAO TONG UNIV

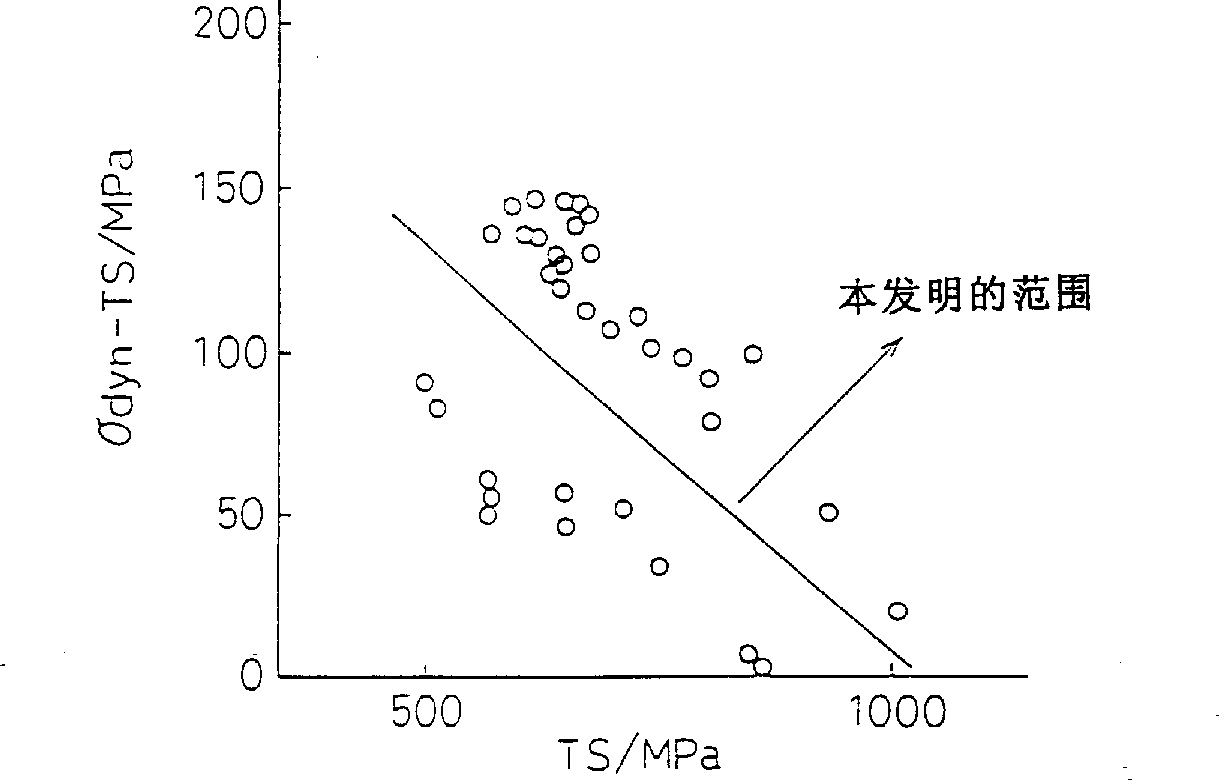

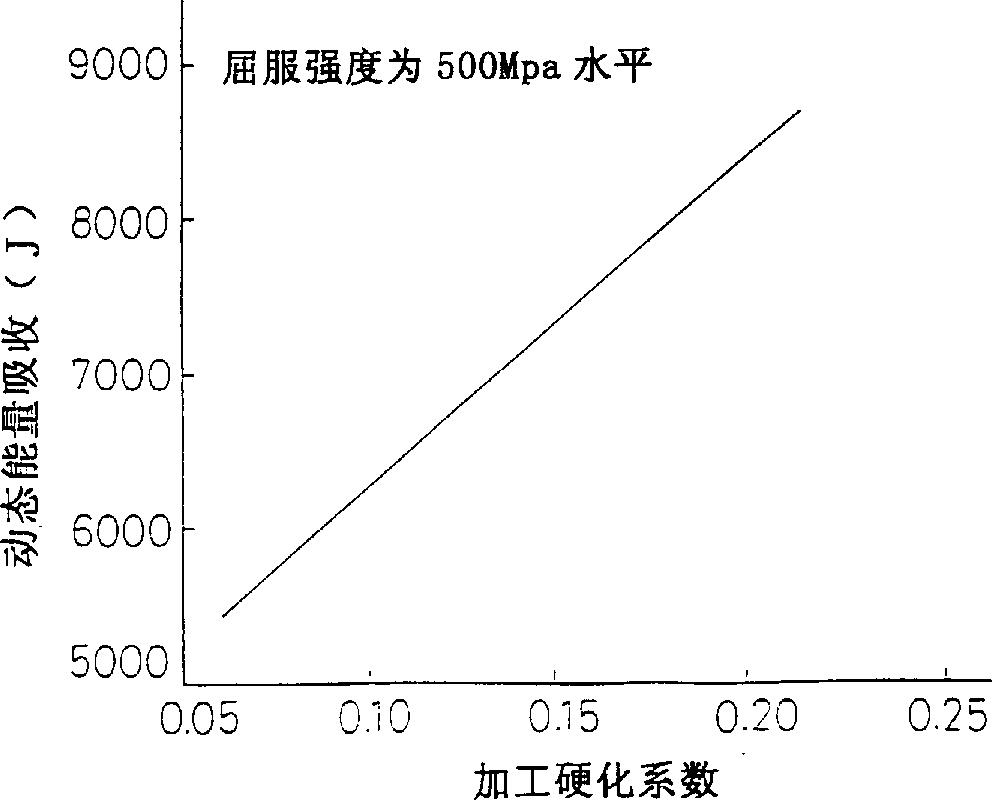

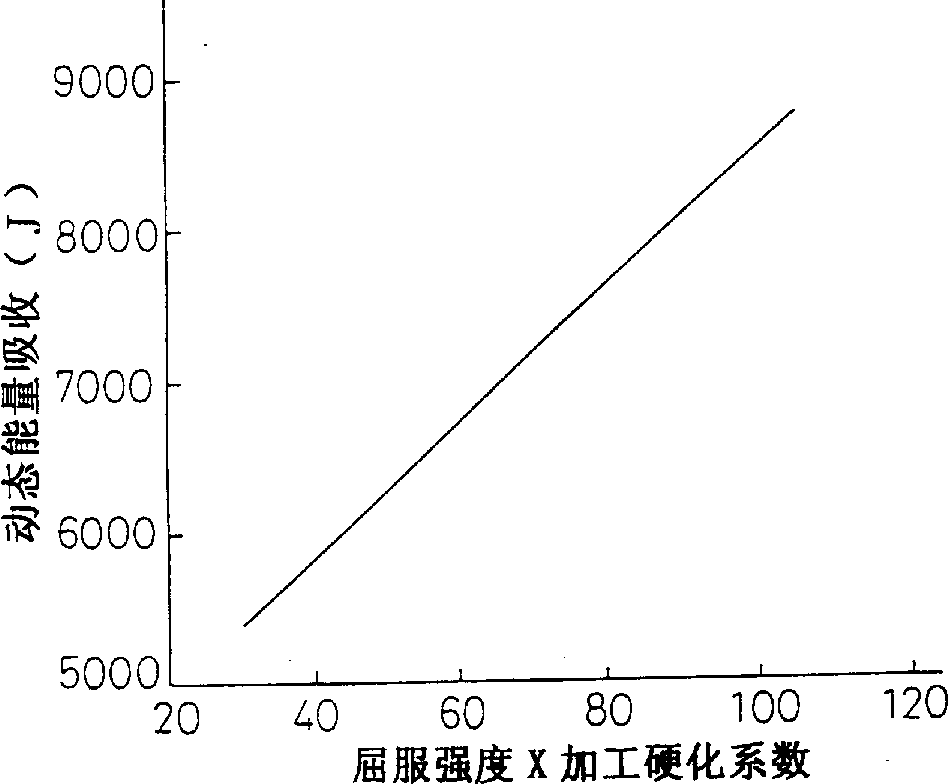

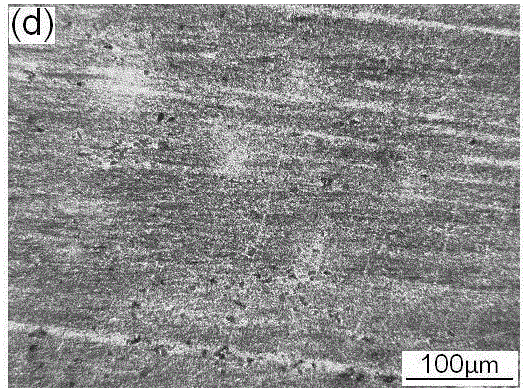

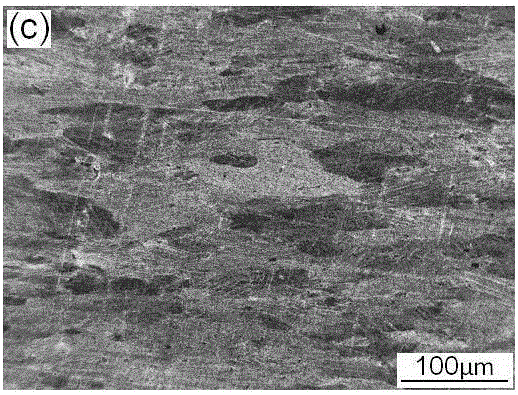

High-strength steel having high impact energy absorption power and method for mfg. same

A high-strength steel sheet to be formed and worked into parts for absorbing striking energy occurring at a collision, for example, front-side members, which exhibits a high absorbing power against striking energy; and a process for the production thereof. The sheet is a high-strength steel sheet exhibiting high dynamic deformation resistance and excellent workability and is characterized in that the microstructure of the finally obtained sheet is a composite one comprising ferrite and / or bainite with either of them being present as the main phase and containing as the third phase another phase containing residual austenite at a volume fraction of 3 to 50 %, that the difference between the quasi-static deformation strength observed when the sheet is subjected to pre-deformation of equivalent strain exceeding 0 % and up to 10 % and then deformed at a strain rate of 5 x 10[-4] to 5 x 10[-3] (1 / s) and the dynamic deformation strength (sigma d) observed when the sheet is subjected to the above pre-deformation and then deformed at a strain rate of 5 x 10[2] to 5 x 10[3] (1 / s), i.e., sigma d, is 60 MPa or above, and that the work hardening exponent at a strain of 1 to 5 % is 0.080 or above.

Owner:NIPPON STEEL CORP

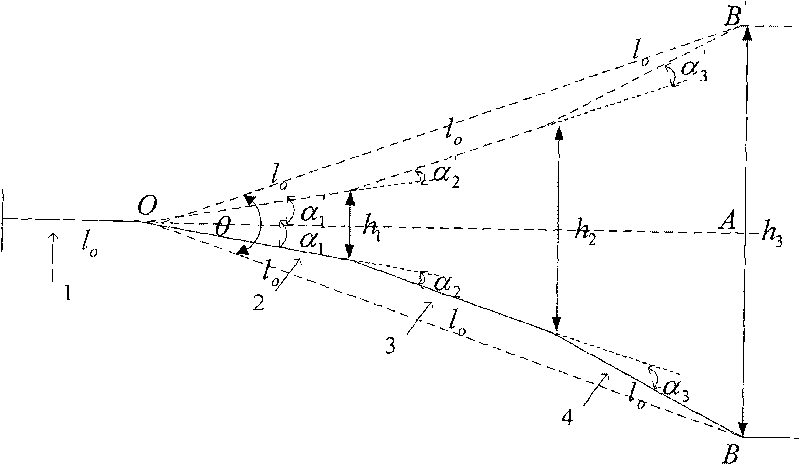

Stereo image stitching method based on content of images

InactiveCN105678687AEfficient splicingNo artificial ghostingGeometric image transformationParallaxImaging processing

The invention belongs to the technical field of stereo images, being able to realize effective stitching of stereo images, avoiding local deformation and reasonably reducing the vertical parallax. The invention relates to a stereo image stitching method based on content of images. The method comprises the steps: utilizing a consistent homography matrix after optimization to perform pre-deformation on the left and right images; utilizing an image tuning and warping method based on contents to optimize image stitching and avoid distortion of vision; and at last, utilizing a lookup algorithm based on kerf and a multi-tape mixed algorithm to acquire the final image stitching result. The stereo image stitching method based on content of images is mainly used for image processing.

Owner:TIANJIN UNIV

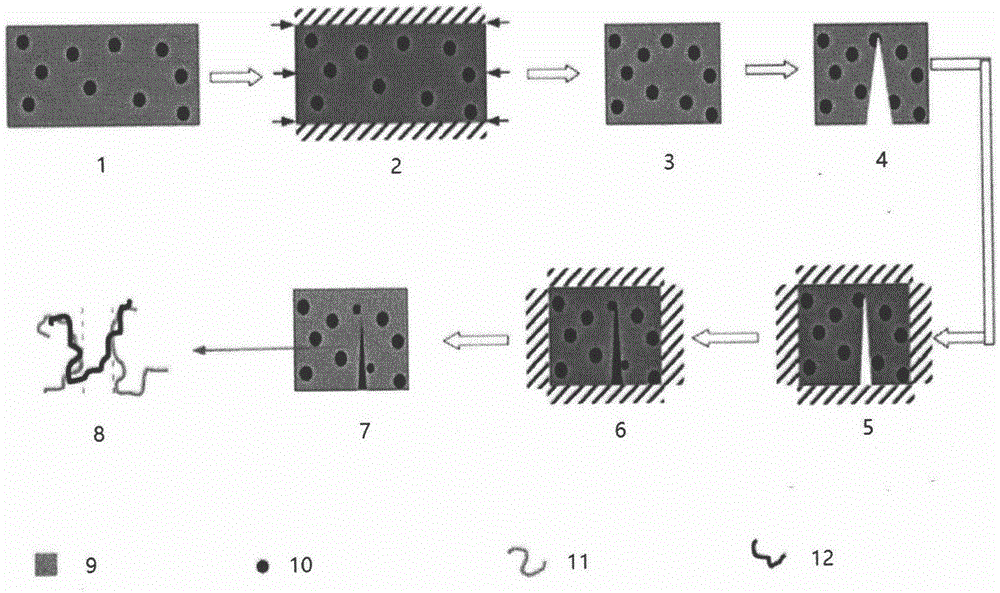

Method for preparing semisolid blank

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

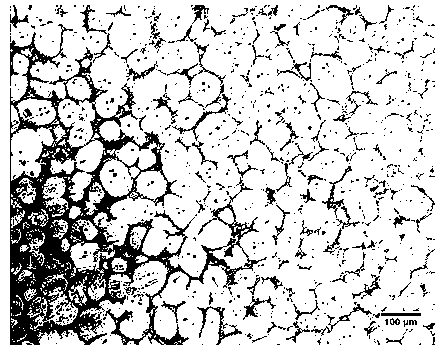

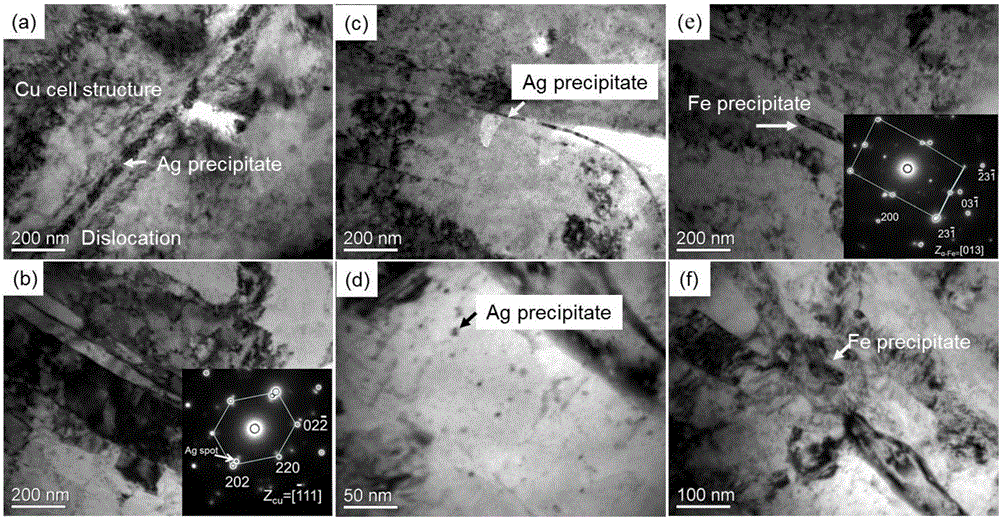

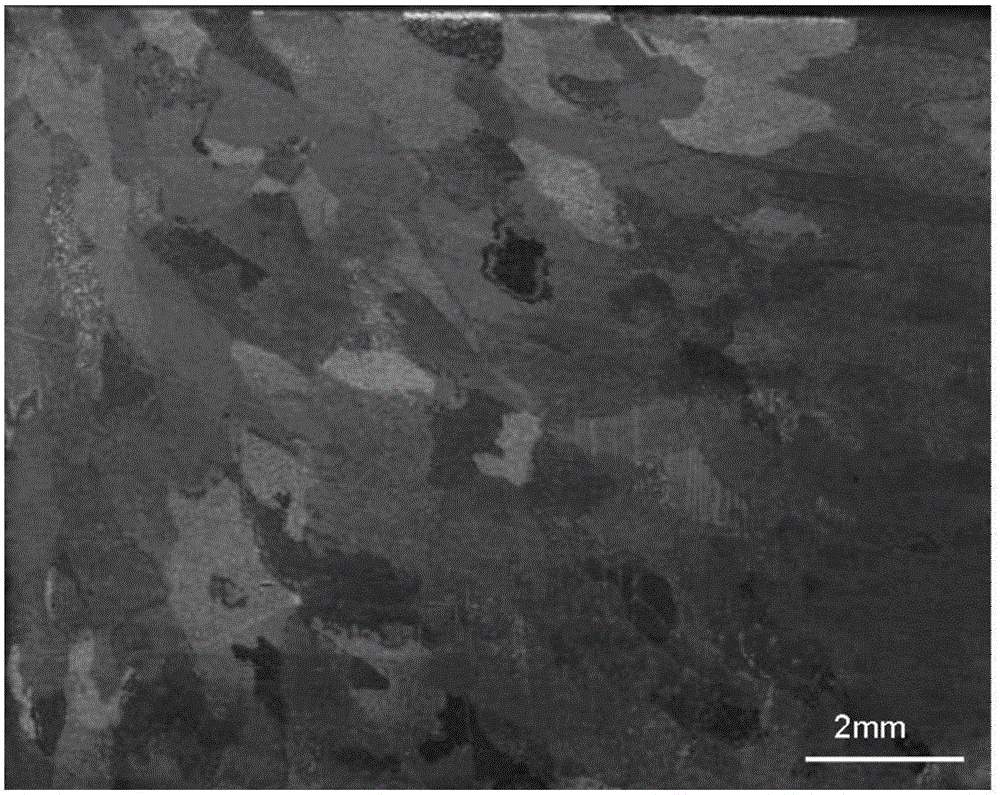

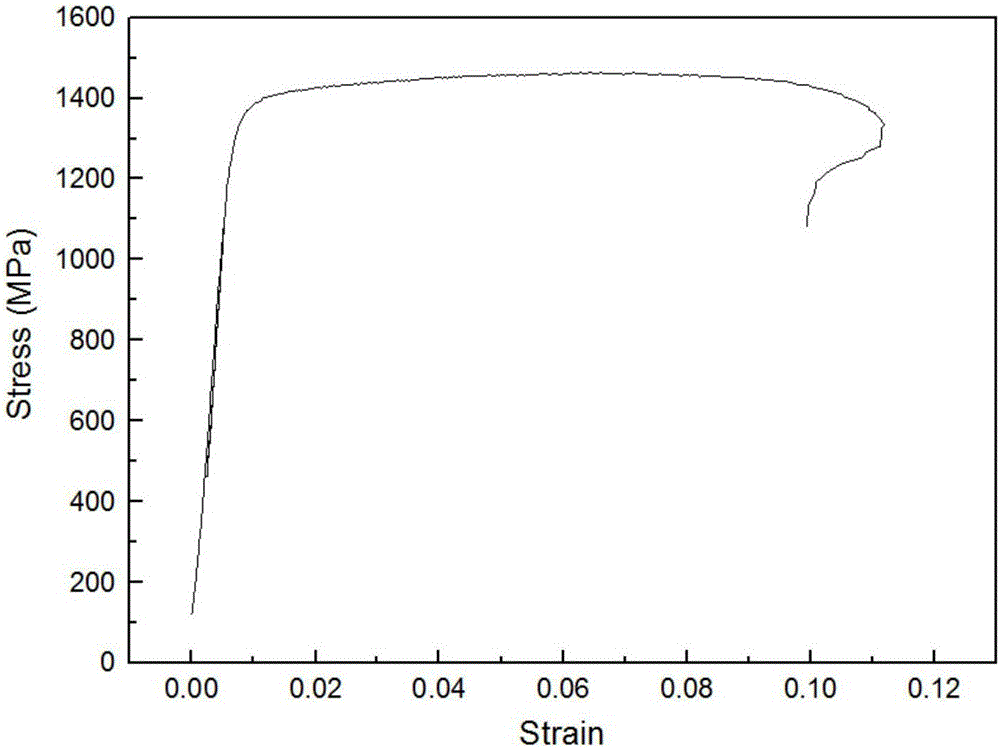

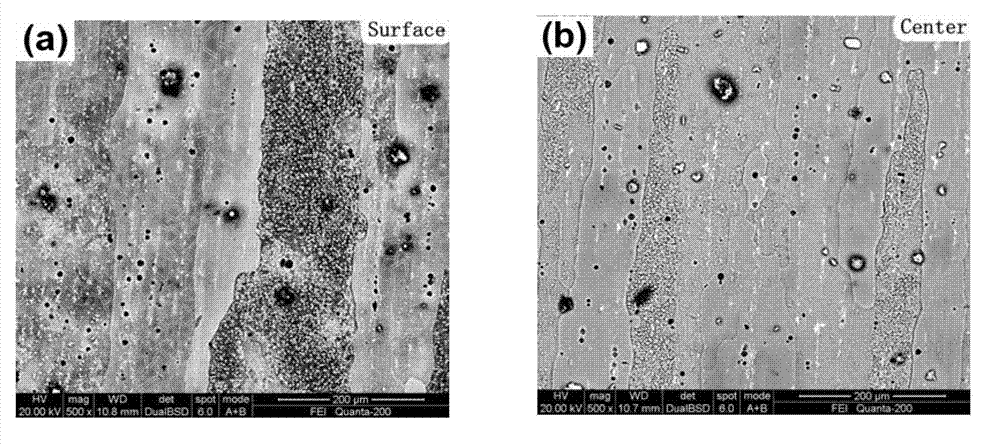

Preparation method for high-strength high-conductivity Cu-Ag-Fe alloy

The invention discloses a preparation method for a high-strength high-conductivity Cu-Ag-Fe alloy, belonging to the technical field of non-ferrous alloys. The preparation method comprises the following steps that raw materials of the Cu-Ag-Fe alloy are smelted according to proportions, and then are poured at 1000-1300 DEG C to form a cast-condition Cu-Ag-Fe mother alloy; the Cu-Ag-Fe alloy is solidified under the effect of a 0.1-1 T alternating magnetic field; the alloy is subjected to homogenization treatment under the effect of a 0.1-30 T steady-state magnetic field; and then the alloy is subjected to pre-deformation, intermediate annealing heat treatment and re-deformation, and finally is subjected to final annealing heat treatment under the effect of a 0.1-30 T steady-state magnetic field so as to obtain a high-strength high-conductivity Cu-Ag-Fe alloy wire / plate, of which the conductivity is 55-88% IACS and the extension strength is 750-1760 MPa. According to the method, the Cu-Ag-Fe alloy is prepared by utilizing the electromagnetic fields and deformation combined with heat treatment, so that the excellent conductivity of a Cu-Ag alloy is reserved, and the strength of the alloy is improved; and the raw material cost of the alloy is lowered.

Owner:NORTHEASTERN UNIV

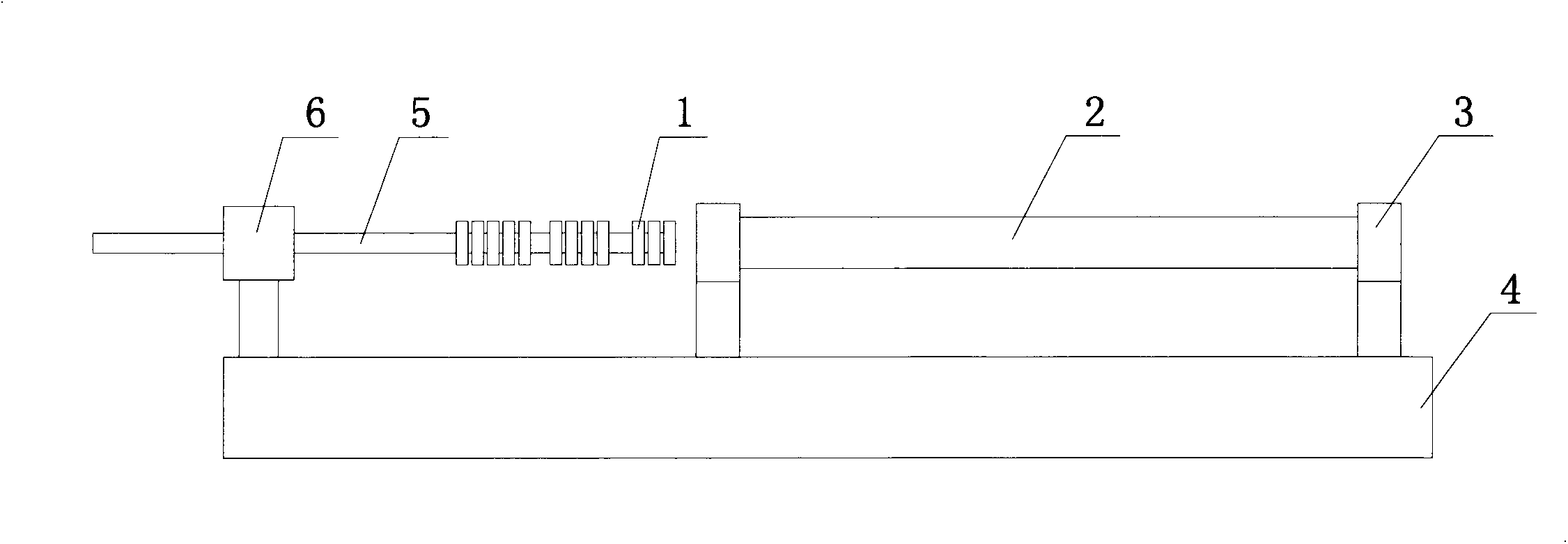

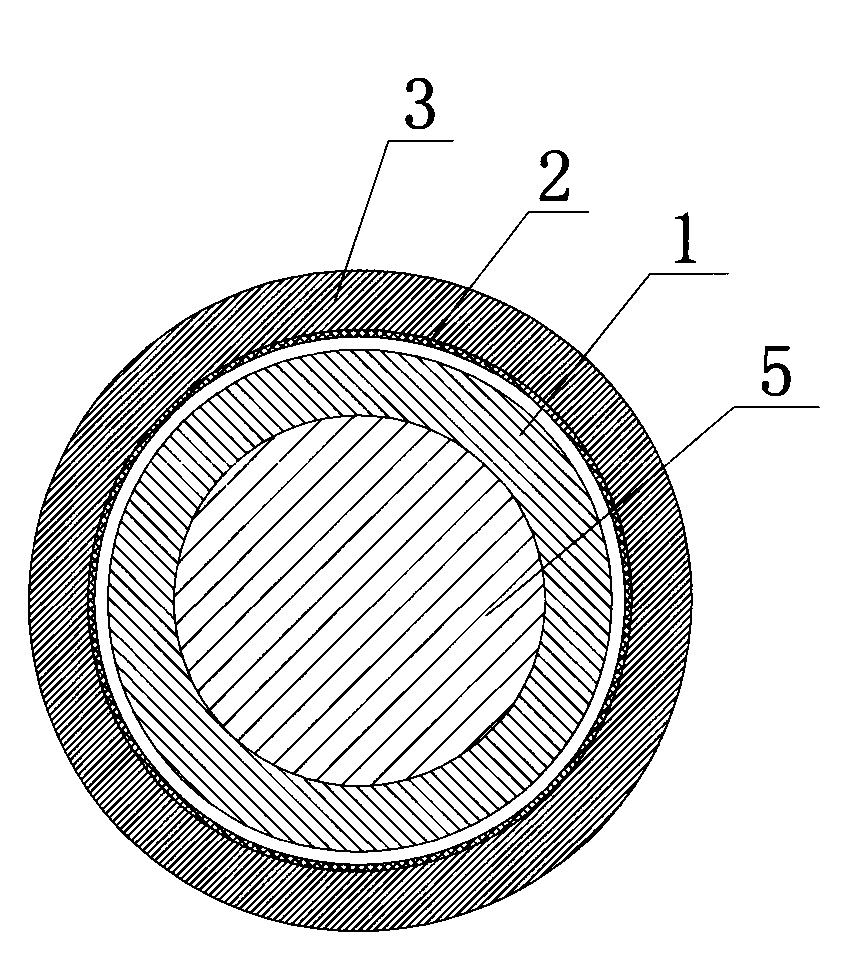

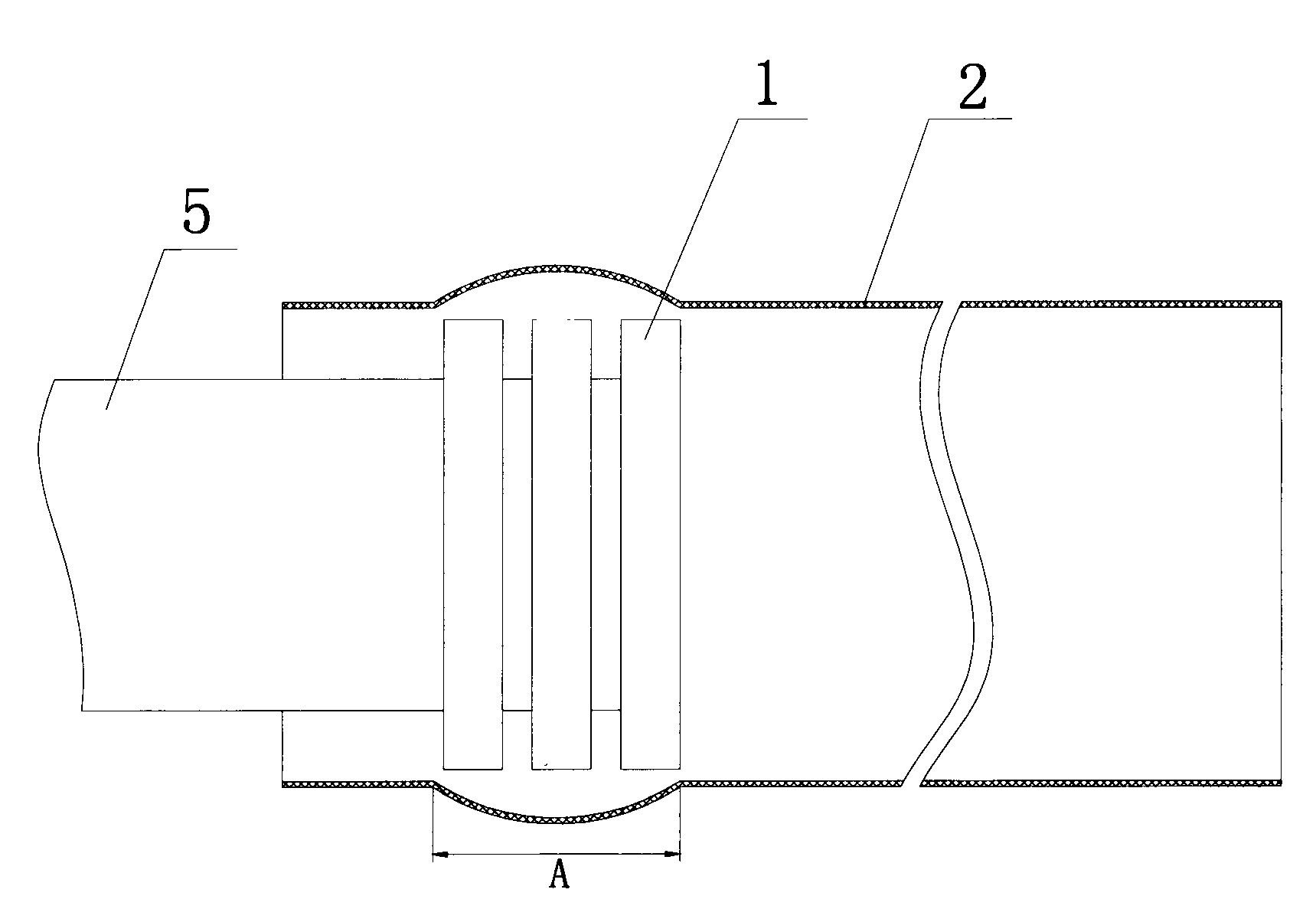

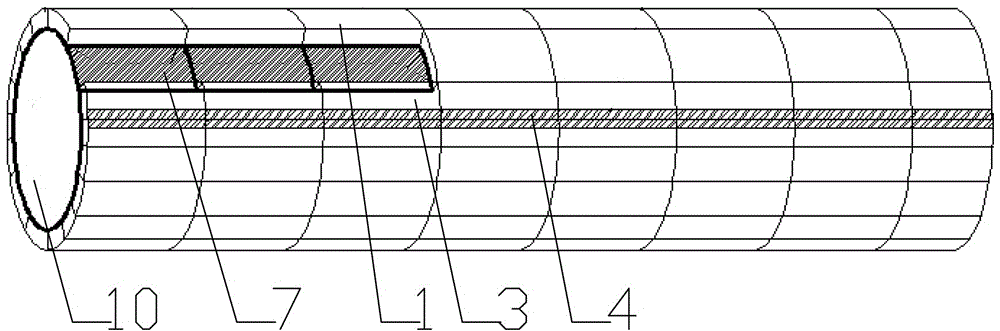

Process for machining corrugated pipe fitting by means of electromagnetic pre-deformation forming technique

The invention discloses a process for machining a corrugated pipe fitting by means of an electromagnetic pre-deformation forming technique. The process includes the steps of (1) pipe fitting installation and (2) discharging forming of the corrugated pipe fitting, wherein in the step of pipe fitting installation, the pipe fitting is fixed well through a pipe fitting restraint device, the pipe fitting restraint device is overlapped with the axis of the pipe fitting, and a solenoid coil is arranged in the portion, needing to form, in the pipe fitting; in the step of discharging forming of the corrugated pipe fitting, the electric capacity of a charging capacitor set of the solenoid coil is 768-1152 mu F, a discharging control switch is turned off, the capacitor set is discharged through the solenoid coil, expansion and deformation of the pipe fitting are caused and corrugation is formed. The process has the following technical advantages that the corrugated aluminum alloy energy-absorption pipe fitting is machined by means of the electromagnetic pre-deformation forming technique, the method is easy and convenient to carry out, operations are easy to carry out, the forming speed is high, and cost is saved; the shape and the size of corrugation can be effectively controlled, and adaptability needed by energy absorption is flexible; yield strength of materials on the expansion portion is quite different from that on the trough positions, the strength of the pipe fitting in the axial direction is different, and the deformation mold is controllable; and energy absorbing efficiency of a thin-walled round pipe can be obviously improved.

Owner:XIANGTAN UNIV

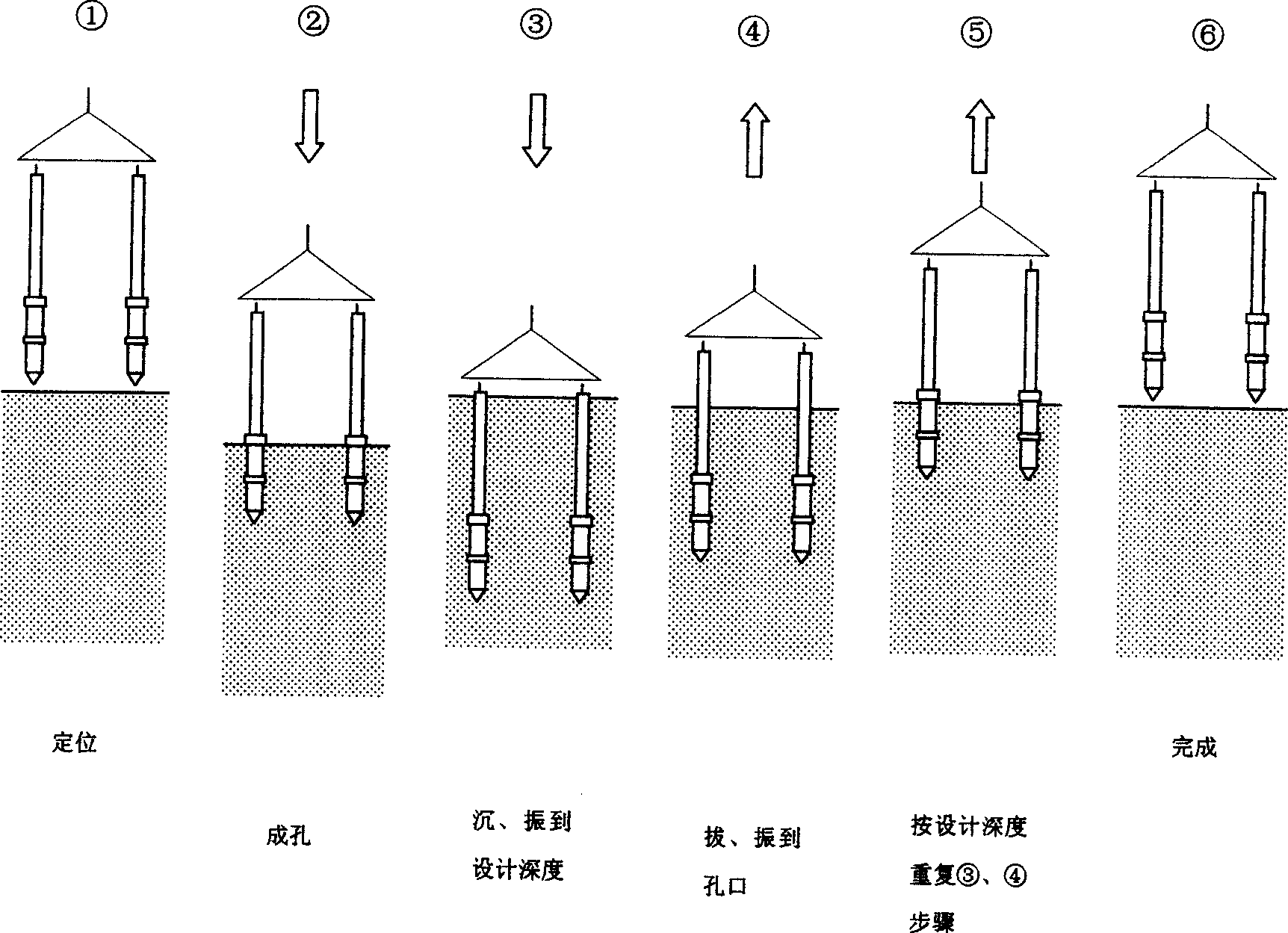

Multi-point stress vibrating-punching combined compacting method

ActiveCN1743560AProcess characteristics without fillerEfficient constructionSoil preservationPunchingPre deformation

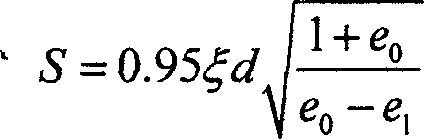

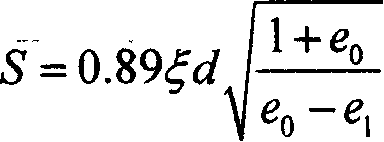

This invention applies a combined method of vibration and striking rolling and squeezing of multi-point forced vibration to compact loose sand ground base, among which, the combined squeezing method applies a pre-force action to the loose sand bone, namely, a vibration and striking force is applied to urge the saturated loose sand earth to generate a pre-deformation and pre-sink to let the processed basic earth meet the deforming requirement of the project in the usage stage. To the filled sand ground base for a strengthening port, its pre-force standard is controlled in the sphere of 0.85~0.65 and the vibration-squeezed compact work is finished within 1-7days after the vibration and striking.

Owner:NANJING UNIV OF TECH +1

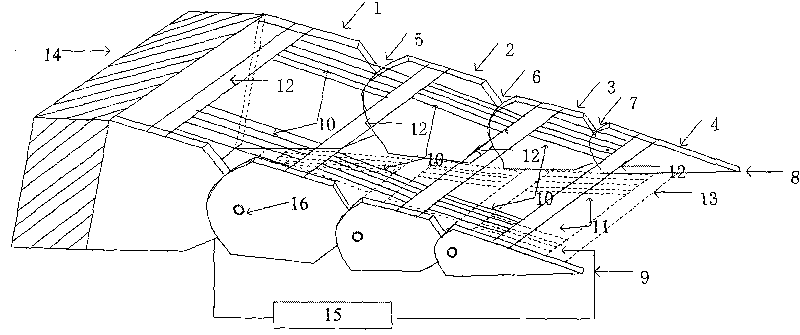

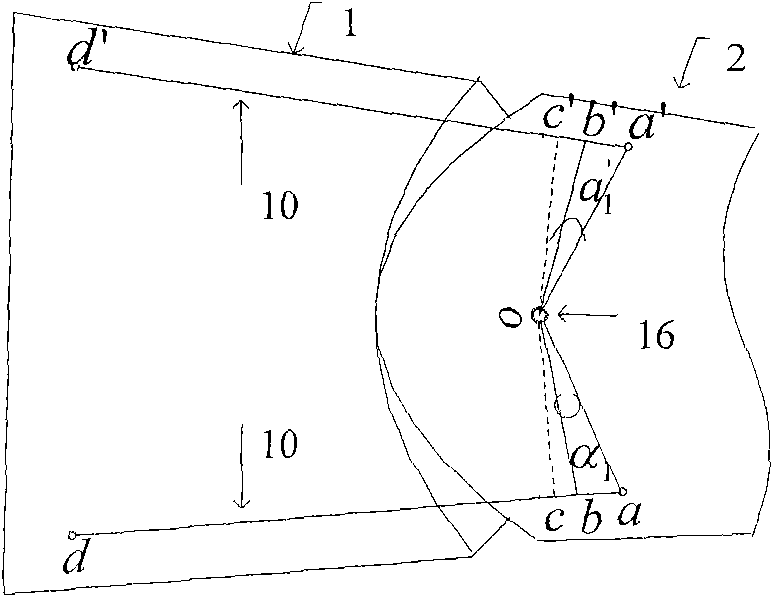

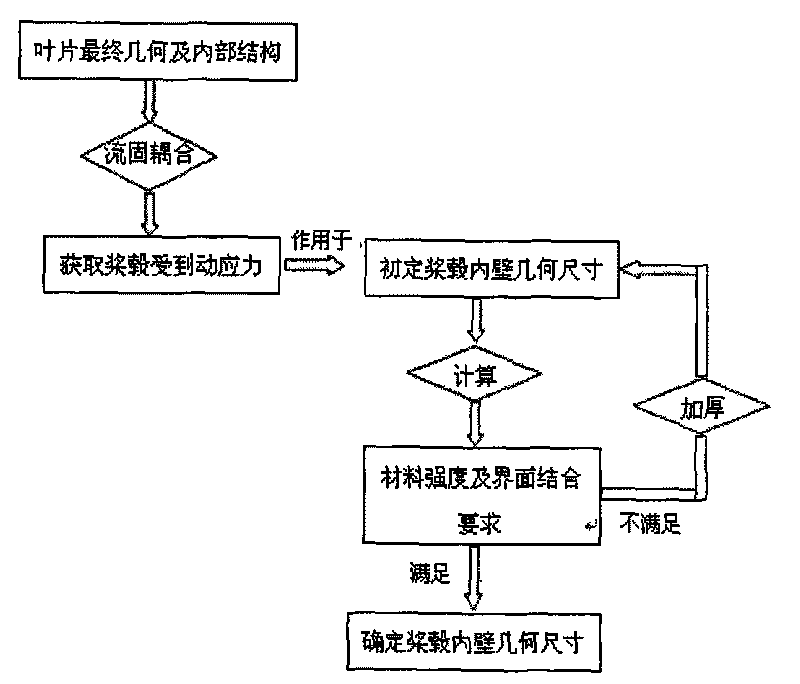

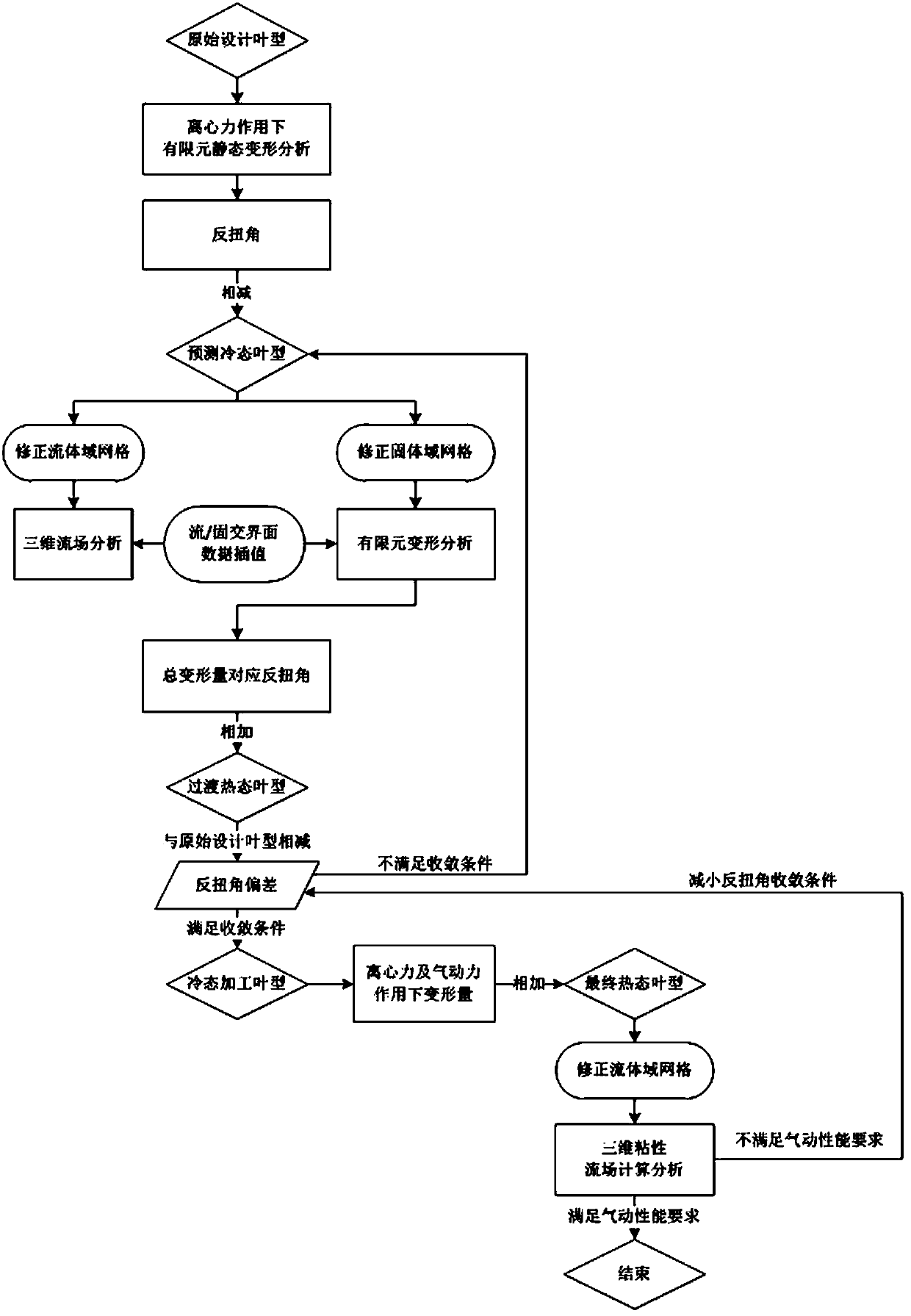

Reverse twist designing method of pre-deformation influence of moving blades of marine combustion engine gas compressor

InactiveCN108710746AAchieve seamless connectionImprove the efficiency of anti-torsion designGeometric CADSustainable transportationGas compressorEngineering

The invention belongs to the technical field of gas turbines, in particular to a reverse twist designing method of pre-deformation influence of moving blades of a marine combustion engine gas compressor. The method comprises the following steps: carrying out nonlinear static analysis on original pneumatic designed blade forms under a centrifugal force action so as to acquire initial prediction cold-state blade forms; then carrying out repeated iteration on fluid-solid coupling solution to acquire final transitional heat-state blade forms and corresponding cold-state processing blade forms; carrying out three-dimensional viscous flow field analysis solution on the whole working conditions of the whole gas compressor according to the final heat-state blade forms of the cold-state processingblade forms under different working conditions, and verifying a reverse twist design result. By using twist twist angle numerical values as a convergence condition, based on that, a reverse twist design process of the moving blades of the marine combustion engine gas compressor is built, and the pneumatic performance checking result of the whole gas compressor as a final judgement evidence of thereverse twist design, so that seamless connection between the reverse twist design and gas compressor engineering design is realized, the reverse twist design efficiency is improved, and the reverse twist designing method has an important engineering application values.

Owner:HARBIN GUANGHAN GAS TURBINE

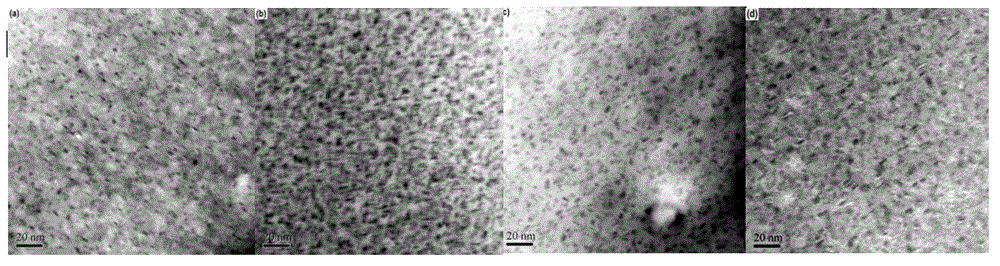

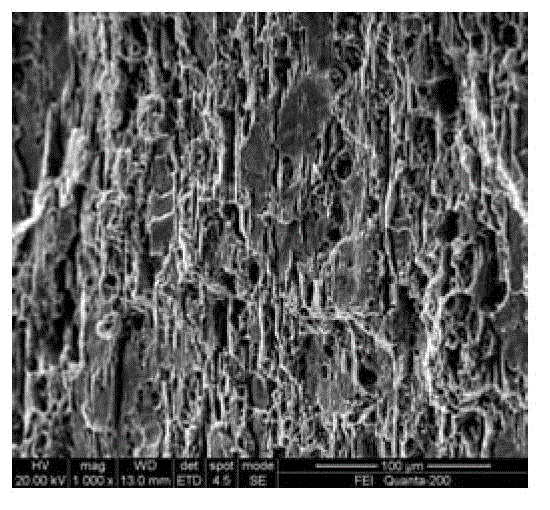

Anti-exfoliation corrosion high-strength aluminum-zinc-magnesium-copper alloy and heat treatment process

ActiveCN103614597AAvoid the disadvantage of serious strength dropHigh strengthHeat treatingExfoliation corrosion

The invention discloses an anti-exfoliation corrosion high-strength aluminum-zinc-magnesium-copper alloy and a heat treatment process. The heat treatment process comprises the steps of controlling the Zn content and Zn / Mg weight ratio in the alloy; performing solution treatment and water quenching on the alloy, and performing pre-deformation; then performing first-level low-temperature aging at 122-132 DEG C and second-level aging at 163-180 DEG C. The alloy has relatively high strength and toughness, the self-corrosion current of the alloy in a corrosive medium is reduced, and the corrosion resistance of the alloy is improved. In the alloy disclosed by the invention, the ratio of the components is reasonable, the process is simple, the production period is short, and the operation is convenient; the total aging time is shortened to 10-15 hours from the traditional two-level aging time 25-30 hours, and the production efficiency is high; the alloy has the performance characteristics of high strength, good toughness and exfoliation corrosion resistance, and is suitable for the industrial application of the fields of aerospace and the like.

Owner:CENT SOUTH UNIV

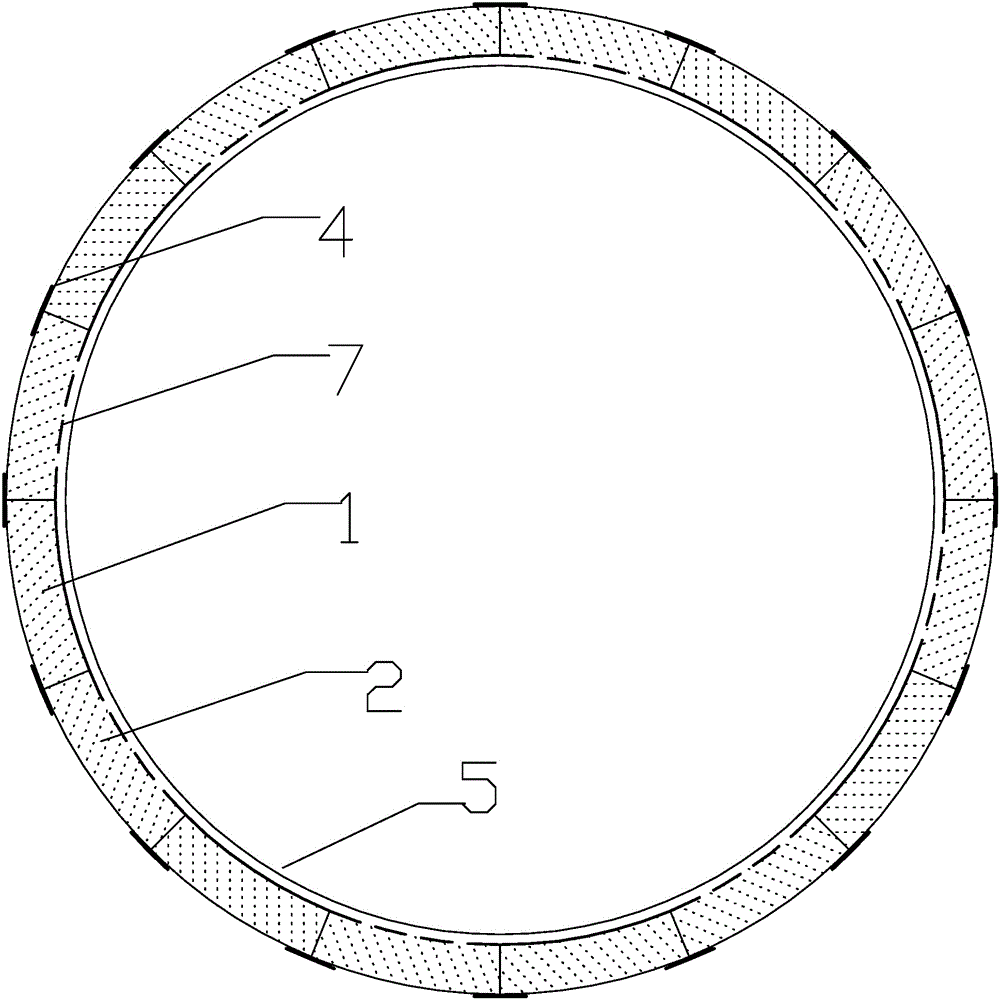

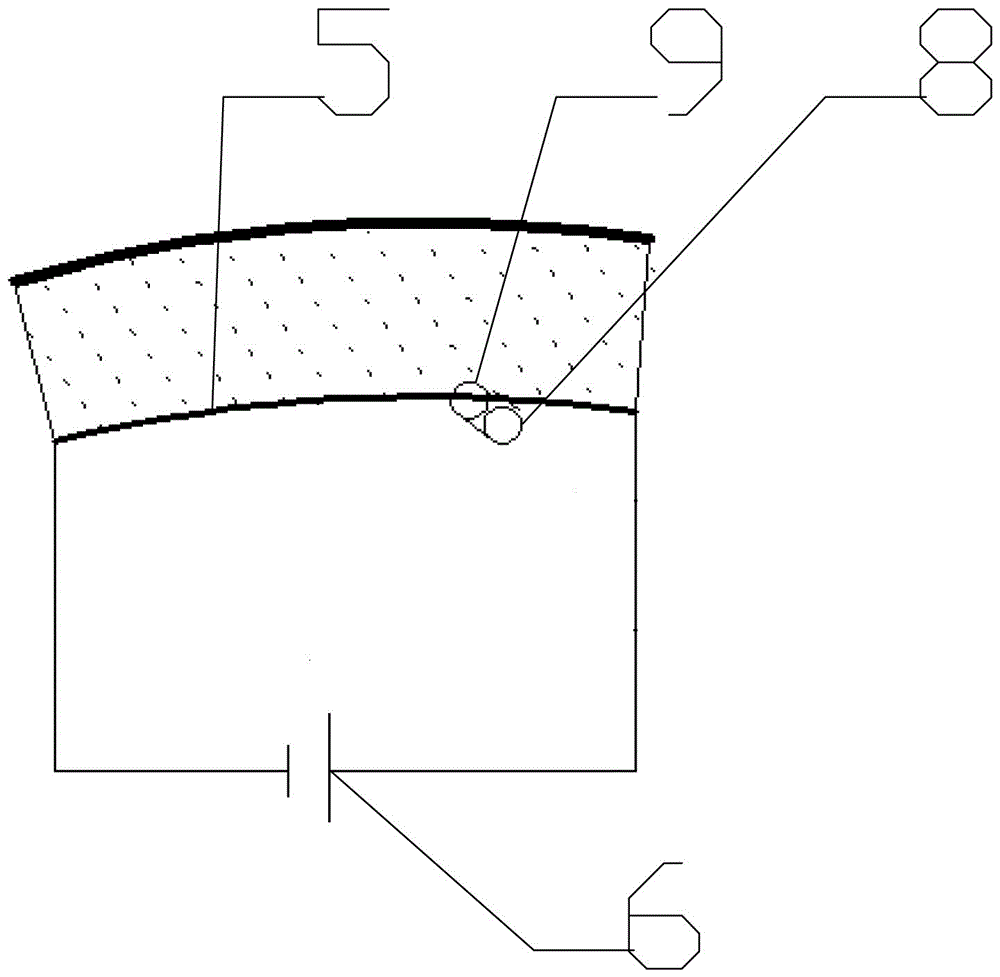

Tire type lining structure between tunnel and shield lining segment and method

ActiveCN106437757AStrong resistance to deformationSupport ability is not affectedUnderground chambersTunnel liningRubber materialPre deformation

The invention discloses a tire type lining structure between a tunnel and a shield lining segment and a method. The tire type lining structure comprises a lining tire sacs, wherein the lining tire sac is made of a rubber material; the lining tire sacs are fitted to the outer wall of the lining segment and are filled with water saturated sand; the inner parts of the lining tire sacs are smooth and facilitate the flowing of the water saturated sand; and all the lining tire sacs are closely laid with the splicing of the lining segments. By means of pre-deformation of the tire sacs, the deformation of the shield lining segments is prevented, so that long-term stability and safety of the shield lining segments in the tunnel can be guaranteed.

Owner:CHINA THREE GORGES UNIV

Mould for extruding aluminum alloy

ActiveCN103331322ASmall coarse crystal layerReduce extrusion pressureExtrusion diesPre deformationIngot

The invention discloses a mould for extruding aluminum alloy. The mould comprises a flow guide mould and a section mould, which are arranged at the front and the back along a fluid direction, wherein the corresponding cavity sizes of the flow guide mould and the section mould are designed according to parts, the flow guide mould consists of a sinking table and a transition cavity, the sinking table is in an inner cone structure, the front end of the transition cavity is in a counter bore structure, the diameter size of the counter bore structure is less than the diameter of an external circle, the rear end of the counter bore structure further adopts a broadsiding structure, and a connection place between the cavity and the flow guide mould is in an inverted cone structure. The mould disclosed by the invention has the beneficial effects that the flow guide mould of the side broadsiding of the first counter bore is designed, an ingot is peeled by the side broadsiding of the first counter bore, the extrusion force and broadsiding pre-deformation can be reduced, the high-precision forming can be carried out by the inverted cone section mould, and the extrusion force can be further reduced as well as the tissue can be further improved.

Owner:FUJIAN NANPING ALUMINUM

Rolling method for ultrahigh-strength aluminum alloy plate

The invention discloses a rolling method for an ultrahigh-strength aluminum alloy plate. The rolling method comprises the following steps: A, a refined aluminum alloy ingot blank is annealed for 24-48 h uniformly at 450-550 DEG C; B, the annealing temperature is controlled to be 360-440 DEG C; single-pass 2-5% hot rolling pre-deformation is performed after inner temperature and outer temperature are uniform; temperature is continuously controlled to be 360-440 DEG C; then single-pass high reduction rolling deformation not less than 60% is performed, so that a thick plate blank is obtained; then water cooling or air cooling is performed; C, the cooled thick plate blank is subjected to 0.5-3h solid solution treatment at 450-550 DEG C, and then is subjected to water quenching; D, the water quenched thick plate blank is subjected to 6h of pre-aging treatment at 150-250 DEG C, and then is air-cooled to room temperature; and E, the thick plate blank which is air cooled to the room temperature is subjected to 40-60% of cold rolling deformation, and then is subjected to final-aging treatment at 120-200 DEG C. The plate made with the rolling method has ultrahigh strength, high damage-resistance and long service life.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

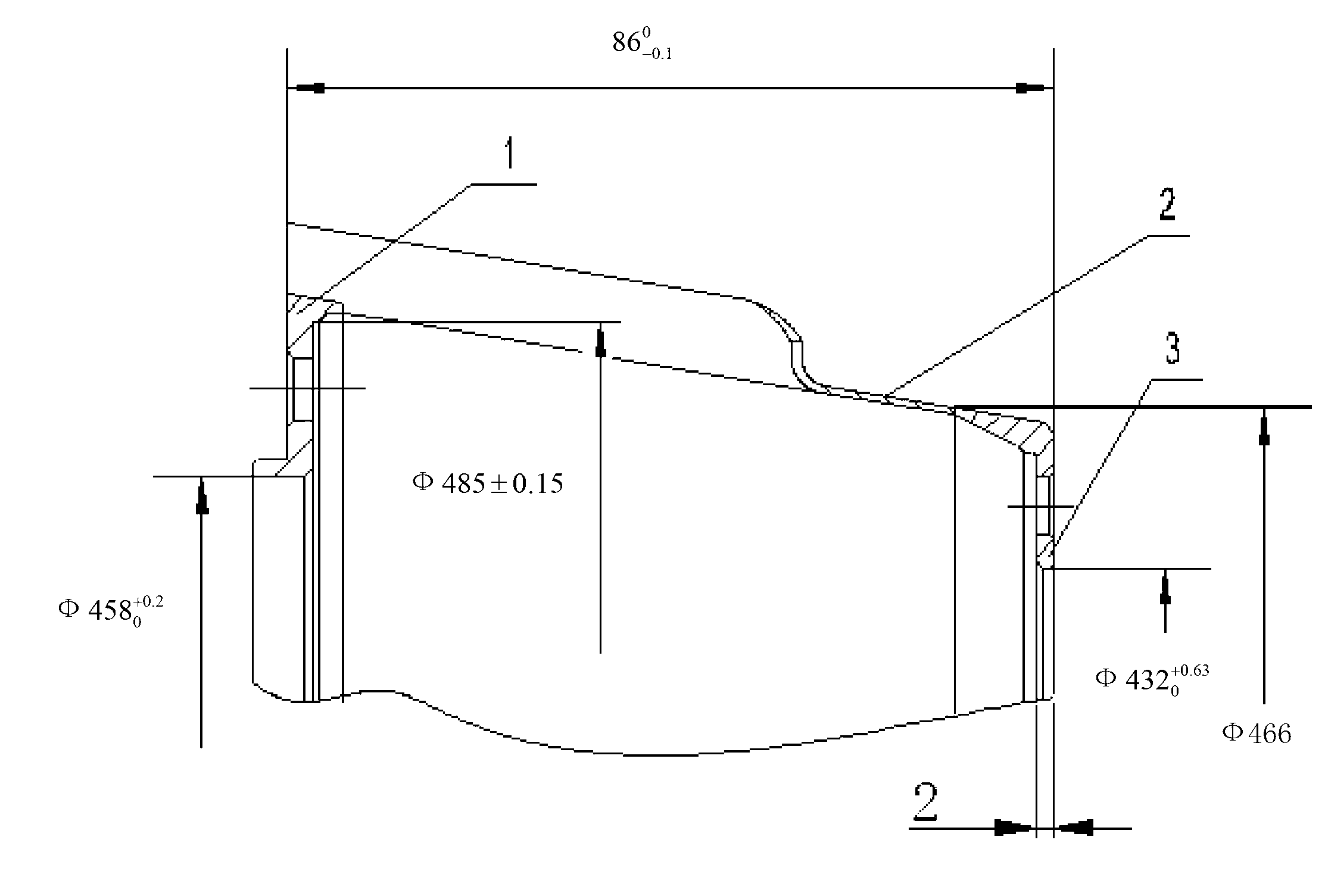

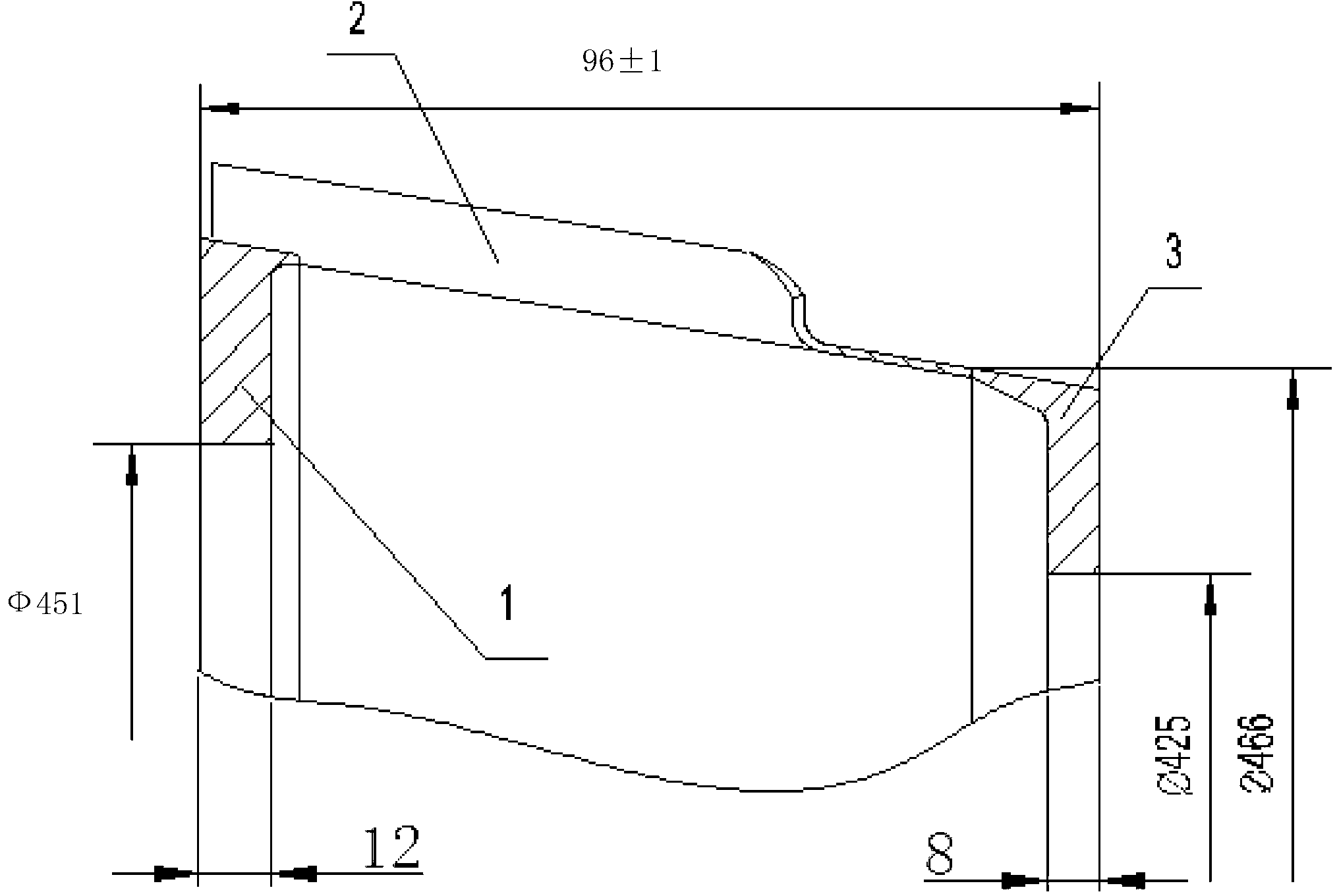

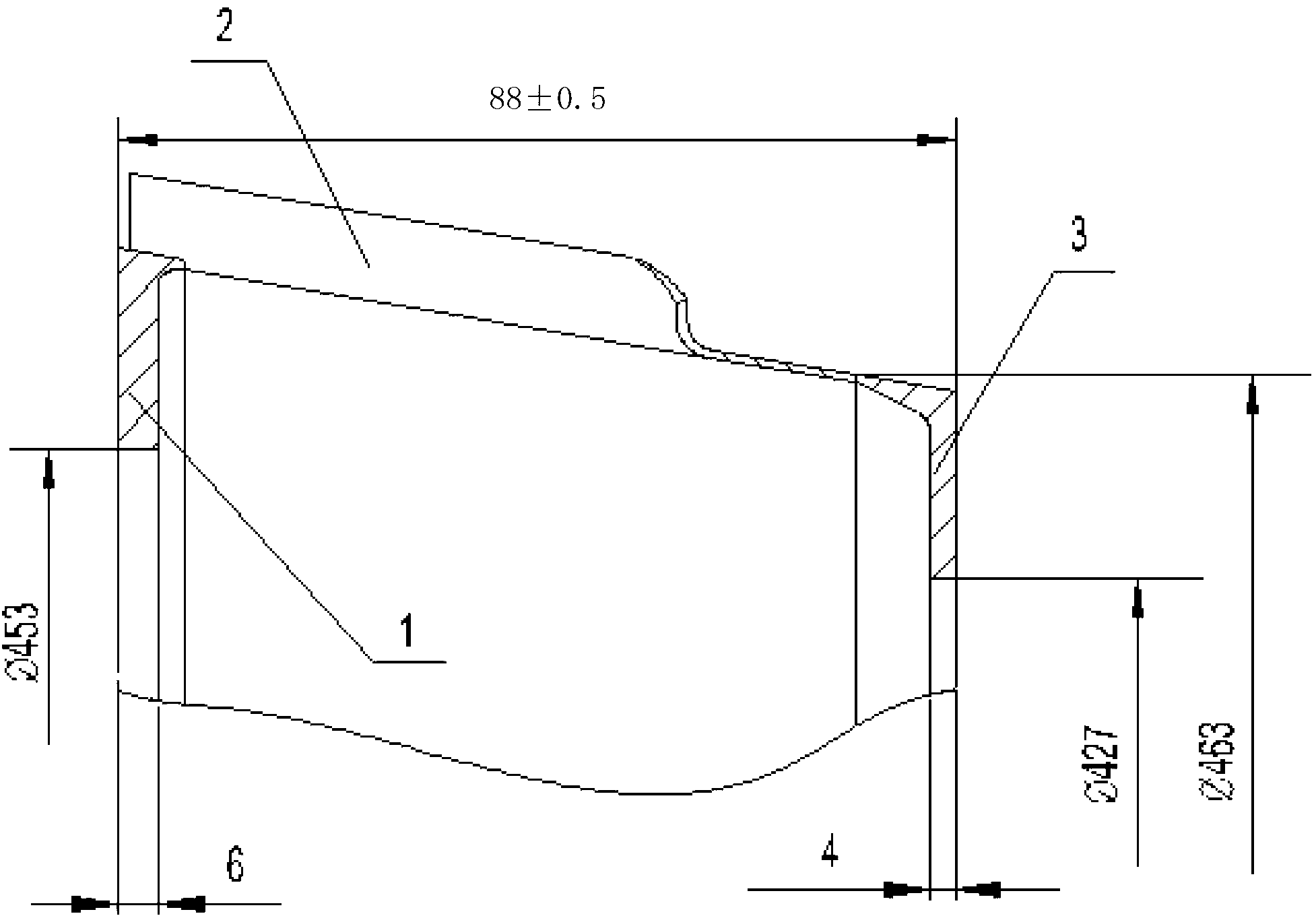

Method for processing thin wall welder cases of revolving body structures

InactiveCN102794610ASolve the structural sizeSolve the coaxial problem of front and rear installation side weldingArc welding apparatusPre deformationEngineering

The invention discloses a method for processing thin wall welder cases of revolving body structures, belonging to the technical field of aero-engine metal plate forming and welding. According to the invention, a whole pre-deformation welding / forming method is used for solving the problems that sizes of mounting edges are out of tolerance, coaxiality of front and rear mounting edges with main bodies after welding is out of tolerance and residual stress distribution of welding components is unbalanced. The method provided by the invention comprises the following steps of: carrying out technological structure welding deformation allowance compensation design on a mounting edge and a main body of a thin wall welder case before the welding according to the plastic deformation characteristics of materials; plastically forming an expansion block according to an expander work part, size and final structural size requirement of parts; carrying out automatic argon arc welding on the mounting edge and the main body; assembling the welded welder case and expansion block on the expander work part to carry out expansion plastic forming and controlling the expansion forming size through adjusting pressure of the expander; and unloading the pressure of the expander, recovering the expander work part and unloading the parts to complete the welding / forming process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

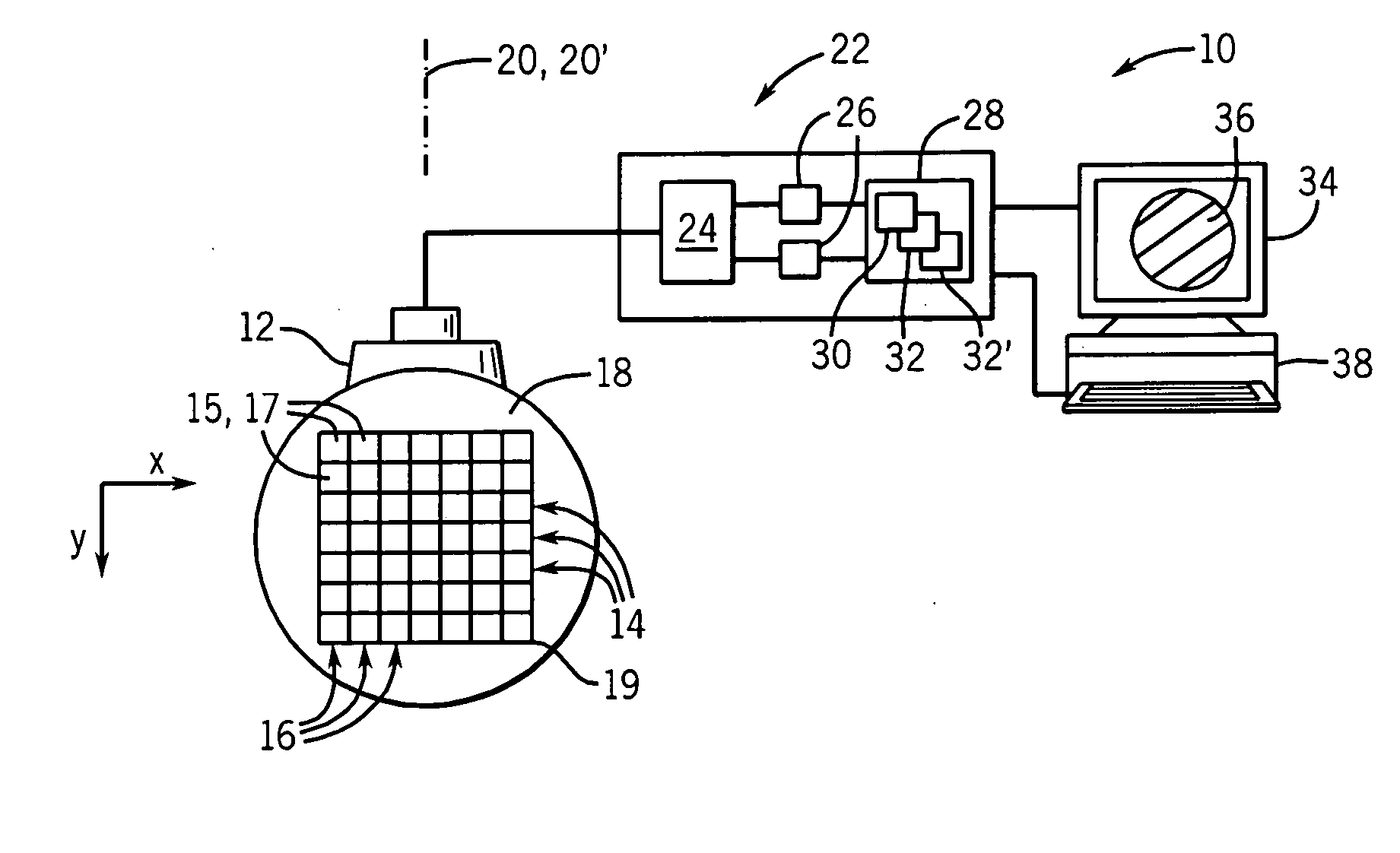

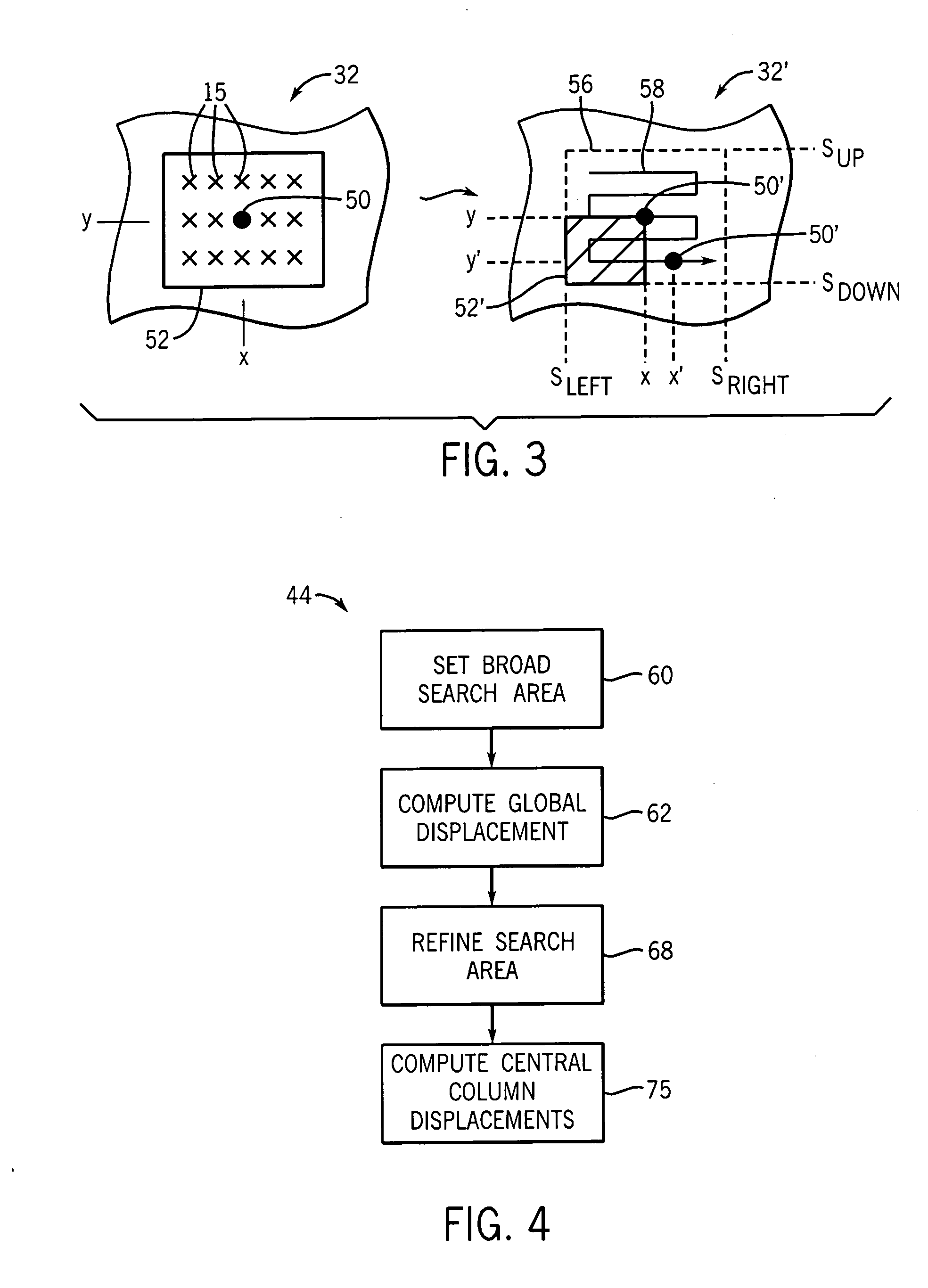

Ultrasonic strain imaging device and method providing parallel displacement processing

ActiveUS20070234806A1Eliminate the problemEliminate CollisionsAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesData setPre deformation

A device for ultrasonic strain imaging computes displacement of tissue between a pre-deformation and post-deformation data set along columns to provide for independent calculations that may be parallelized for multiprocessor systems.

Owner:WISCONSIN ALUMNI RES FOUND

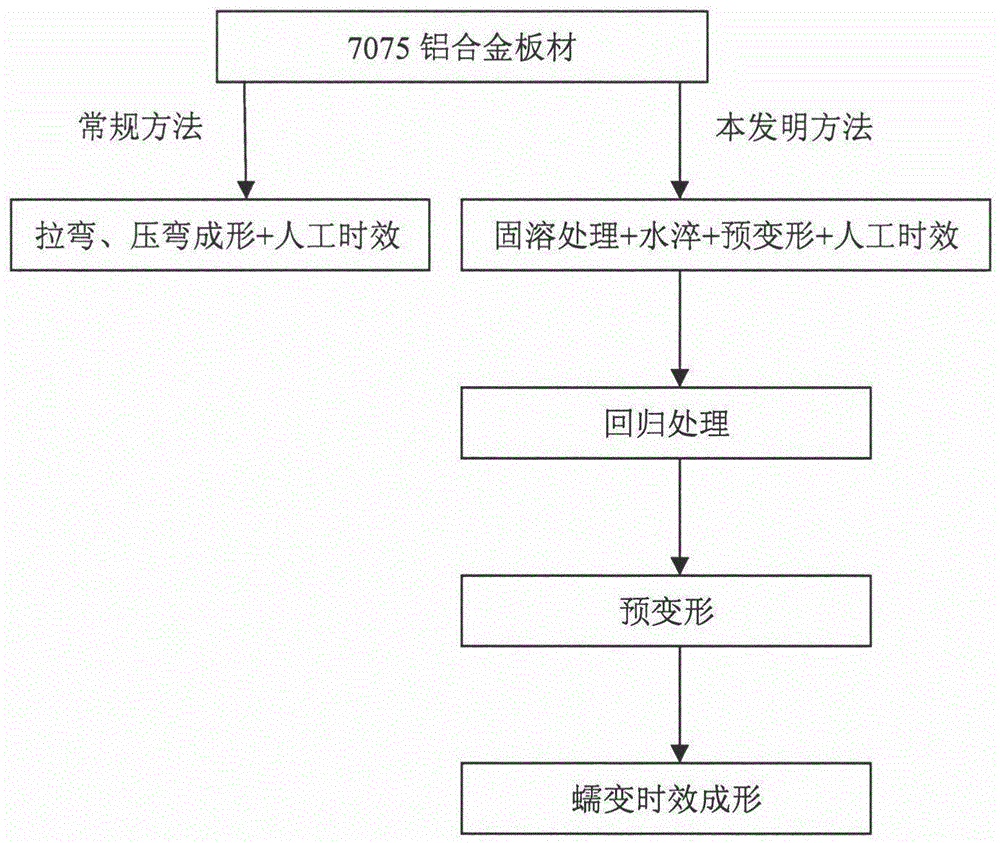

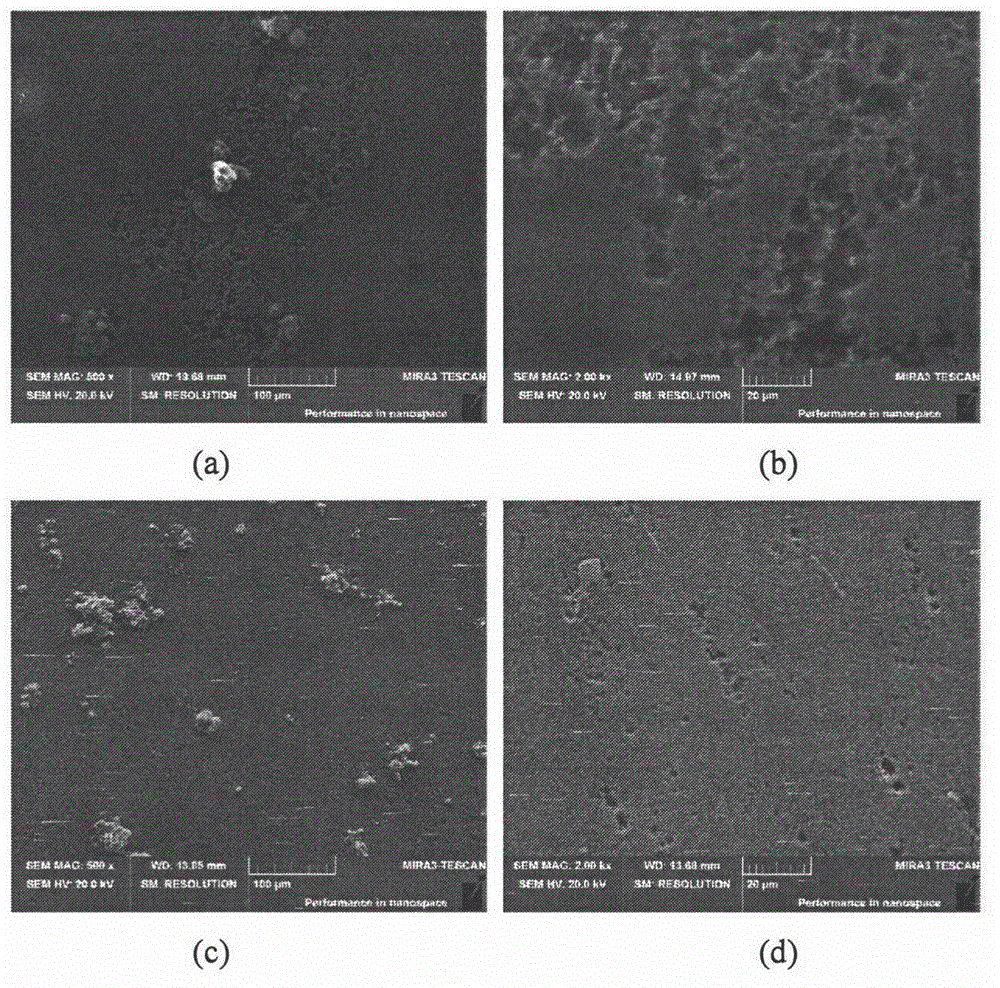

7075 aluminum alloy plate creep age forming method

InactiveCN104404414ARegulating Precipitation BehaviorImprove corrosion resistanceSolution treatmentPre deformation

The invention discloses a 7075 aluminum alloy plate creep age forming method. The method comprises the following steps: (1) carrying out solid-solution treatment on a 7075 aluminum alloy plate with a thickness of 2-40 mm for 30-90 minutes at a temperature of 466-480 DEG C, then water-quenching, subsequently carrying out 1-5 percent of pre-deformation and finally carrying out artificial aging treatment for 6-24 hours at a temperature of 80-120 DEG C; (2) carrying out retrogression treatment, wherein the retrogression treatment temperature is 160-200 DEG C, and the heat preservation time is 20-180 minutes, and then carrying out water quenching at a room temperature; (3) carrying out 1-5 percent of pre-deformation on the plate subjected to the retrogression treatment, then placing the plate in a mould and fixing; (4) carrying out creep age forming, wherein the creep age forming temperature is 120-160 DEG C, the applied stress is 200-260 MPa, and the forming time is 12-24 hours; (5) unloading the plate from the mould. When the method disclosed by the invention is utilized for processing the 7075 aluminum alloy plate, while the strength of the aluminum alloy plate is ensured, the corrosion resistance of the 7075 aluminum alloy plate can be effectively improved.

Owner:CENT SOUTH UNIV

Manufacturing method for tube blank made of high-silicon titanium-contained austenitic stainless steel

ActiveCN108866271AGuaranteed Chemical CompositionAssurance Control RequirementsIncreasing energy efficiencyFurnace typesVacuum arc remeltingAustenite

The invention belongs to the technical field of metallurgical materials, and relates to a manufacturing method for a tube blank made of high-silicon titanium-contained austenitic stainless steel. Themanufacturing method sequentially comprises the following steps that (1) ingredients of the high-silicon titanium-contained austenitic stainless steel are smelted in a vacuum induction furnace; (2) vacuum arc remelting is carried out; and (3) homogenization and forging are carried out, specifically, forging in a rapid forging machine and forging in a precision forging machine are carried out in sequence, wherein in the forging process of the rapid forging machine, the tong handle forging process, the pre-deformation process, the homogenization heat treatment process, the rapid forging processand the cutting process are carried out in sequence, and in the forging sequence of the precision forging machine, the heat preservation process and the precision forging process are carried out in sequence. The manufacturing method for the tube blank made of the high-silicon titanium-contained austenitic stainless steel has the advantage that the produced tube blank can meet the uniformity control requirements of a fast reactor core cladding material on the content of harmful elements O and S, the inclusion level and the tissues in the tube blank.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

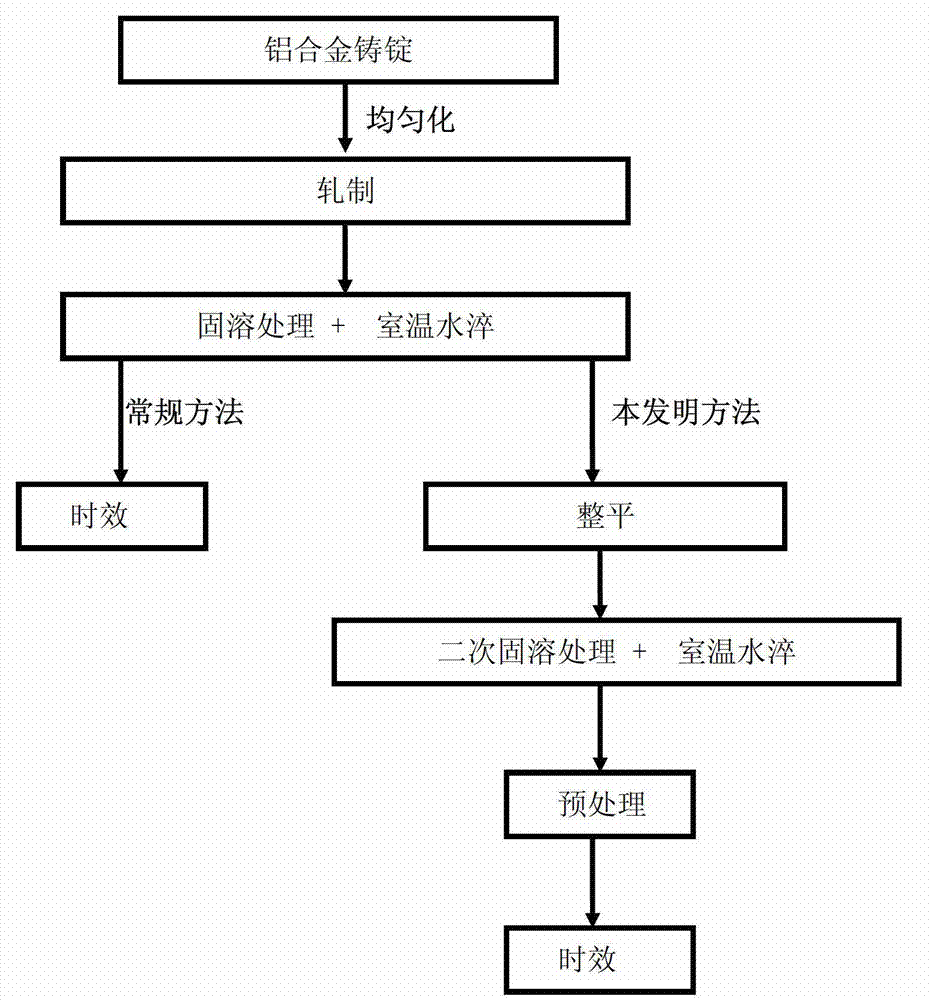

Heat treatment method for reducing quenching residual stress of wrought aluminum alloy and improving performance of the aluminum alloy

The invention discloses a heat treatment method for reducing quenching residual stress of wrought aluminum alloy and improving performance of the aluminum alloy. The key of the invention is by adopting a reasonable system of deformation-solution hardening-leveling-solution hardening, and the invention is applicable to the wrought aluminum alloy sheet. The method is as below: conducting solution treatment according to a conventional system; conducting water quenching; cleaning quenching medium on the plate surface after quenching treatment; applying 0.5-2% of deformation on a thickness direction of the plate to straighten the plate; placing the straightened plate into the heating furnace for second solution hardening, wherein the solution hardening uses the conventional system of water quenching after solution treatment; and after quenching, conducting 0-8% of pre-deformation on the plate, and ageing for further reducing residual stress from quenching. According to the invention, a reasonable double quenching process can be used to promote uniform tissue and texture on the thickness direction of the alloy, so as to effectively reduce the residual stress in the premise of maintaining the mechanical properties. Compared with a conventional solution and aging treatment method, the method provided by the invention reduces residual stress by at least 35%, and increases room temperature tensile strength by at least 5%. The process is simple, cost-saving, and easy for application to industrial production.

Owner:邓运来

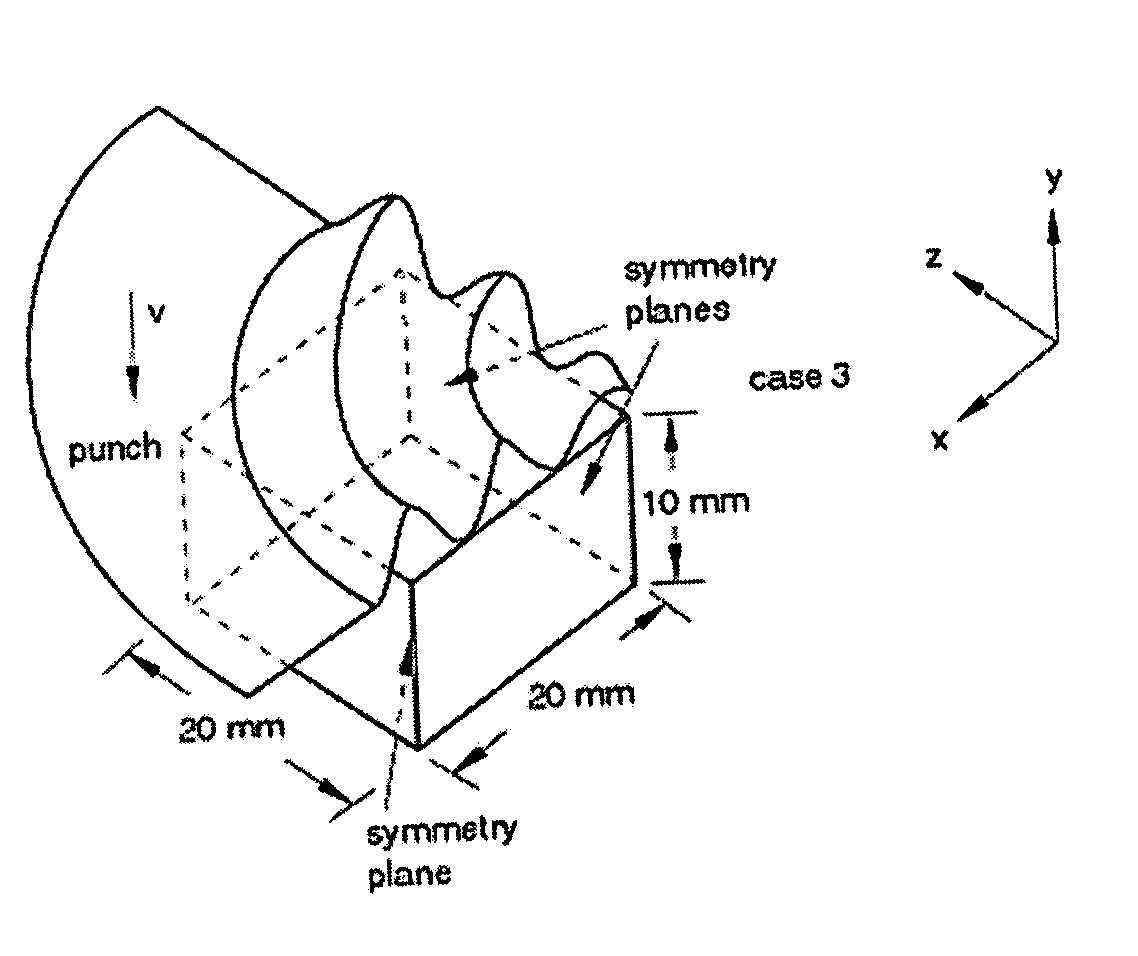

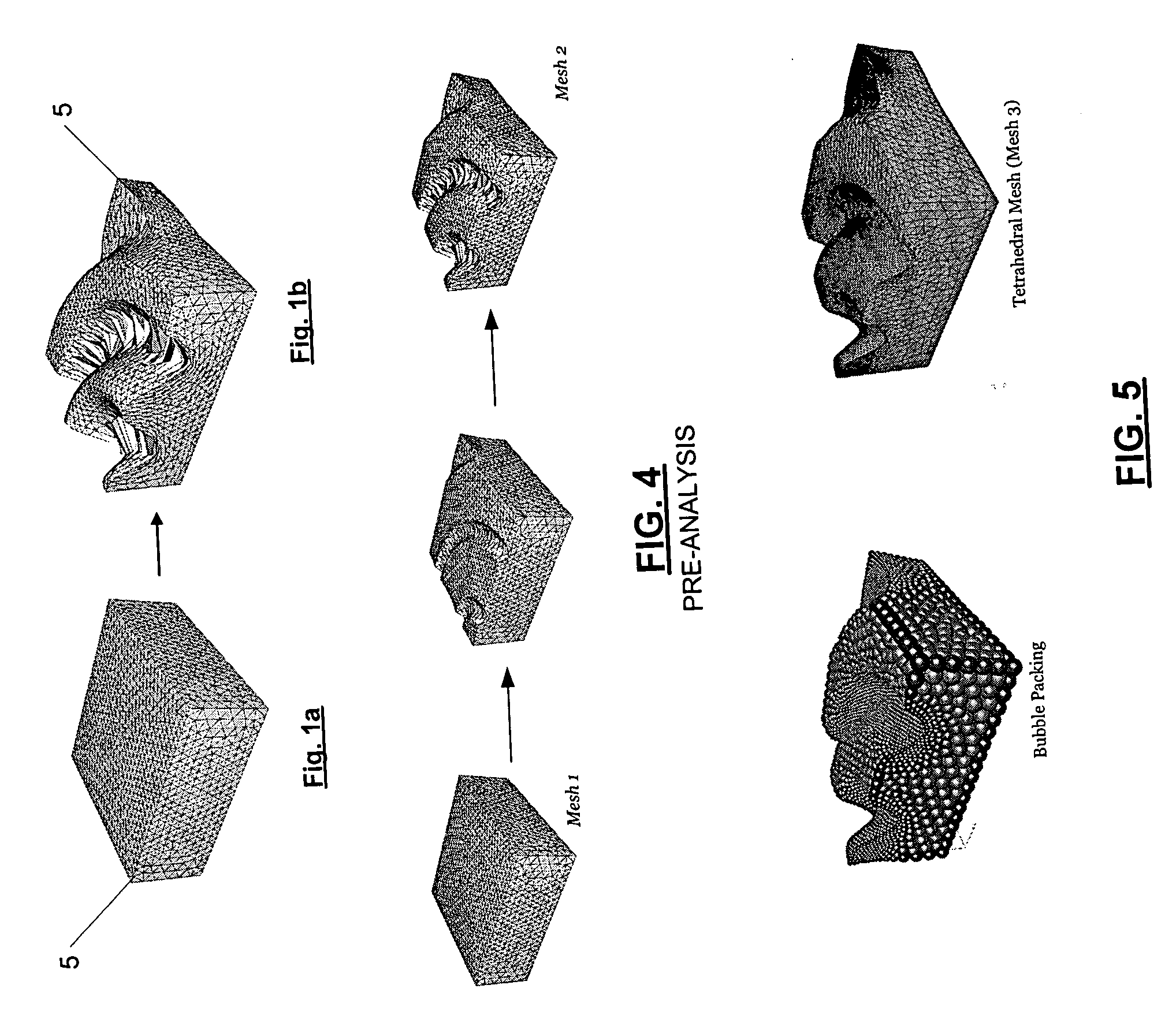

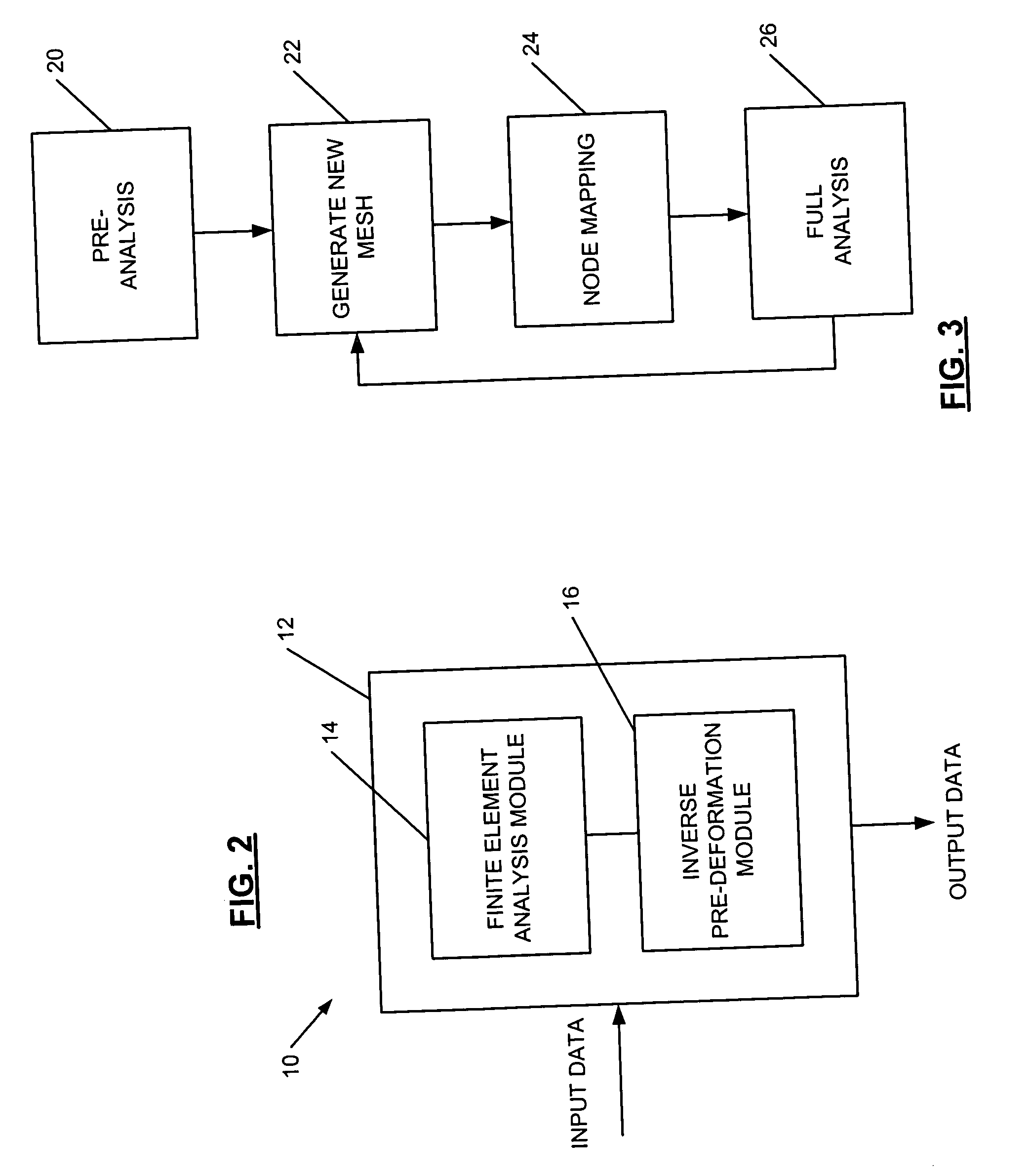

System and method for deformation analysis using inverse pre-deformation of finite element mesh

ActiveUS20060050987A1Reduce in quantityReduce inputDrawing from basic elementsCharacter and pattern recognitionObject basedPre deformation

Finite element analysis methods and computer systems for analyzing deformation to an object are disclosed. According to various embodiments, the method includes the steps of: (1) performing a partial analysis on the object to generate a deformed boundary for the object from an undeformed boundary for the object; (2) generating a first deformed input mesh for the object based on the deformed boundary; (3) mapping node locations from the first deformed input mesh to the undeformed boundary for the object; and (4) performing an analysis on the undeformed boundary of the object using the first deformed input mesh.

Owner:CARNEGIE MELLON UNIV

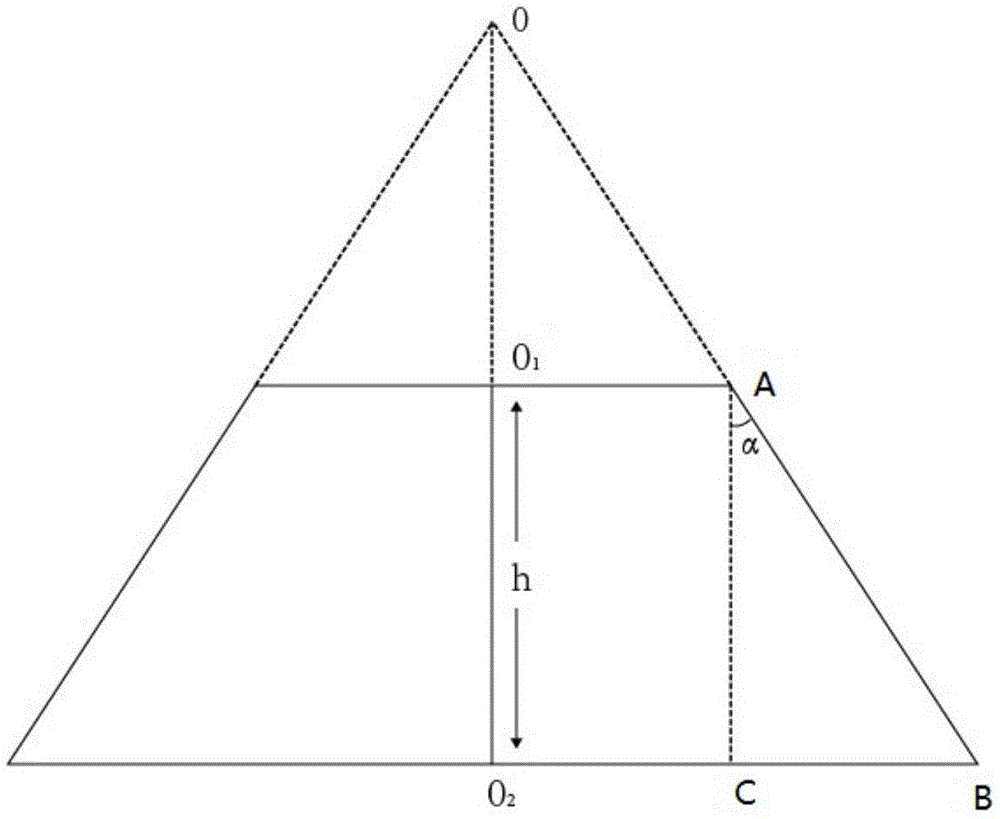

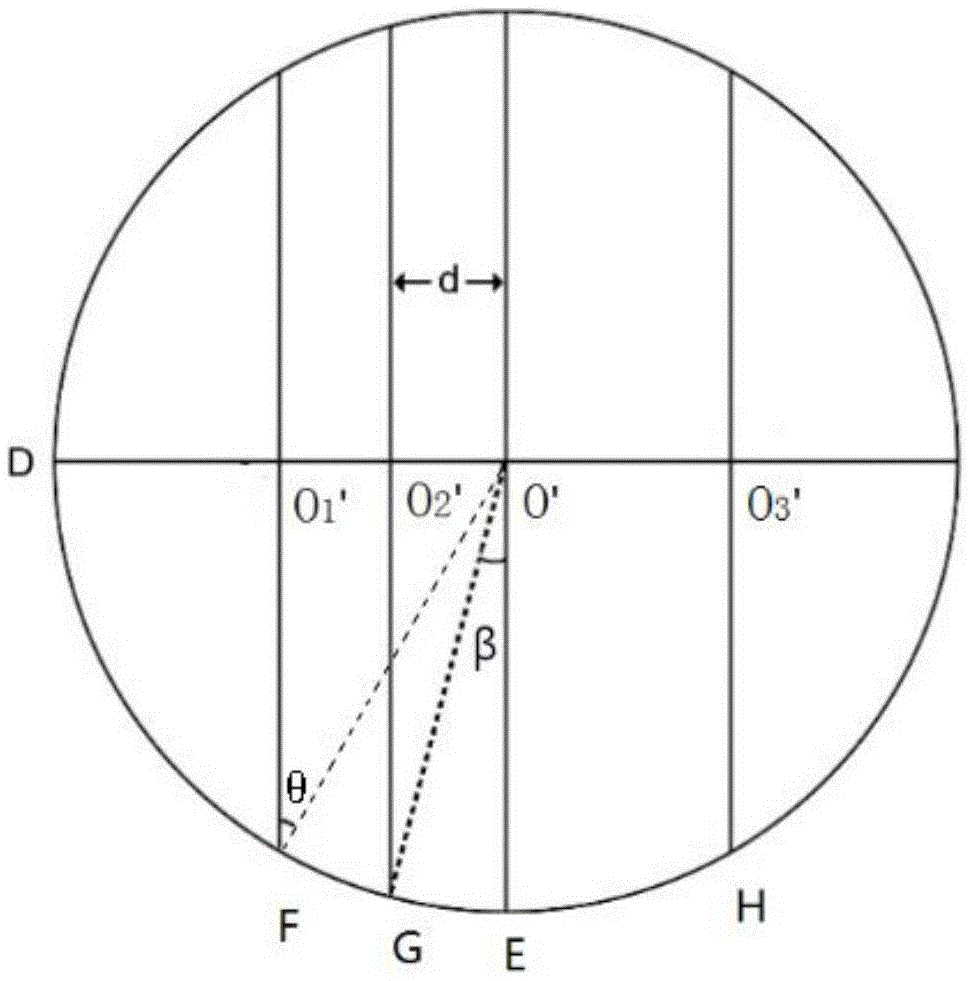

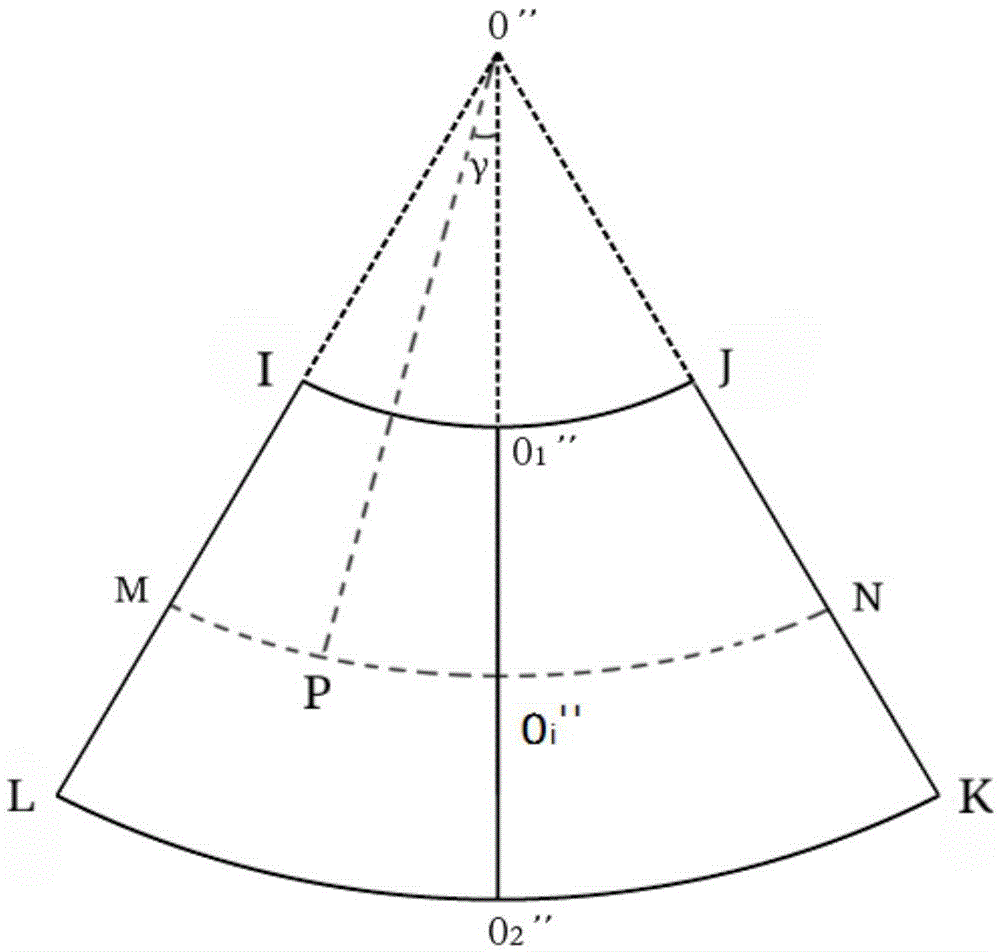

Two-dimensional code pre-deformation design method on conical surface

InactiveCN105678692AGeometric image transformationRecord carriers used with machinesComputer hardwarePre deformation

The present invention discloses a two-dimensional code pre-deformation design method on a conical surface. The method comprises the steps of laterally stretching an original two-dimensional code image to obtain a first deformation two-dimensional code image; and longitudinally stretching the first deformation two-dimensional code image to obtain a pre-deformed two-dimensional code image. The laterally stretching operation and the longitudinally stretching operation are conducted according to a certain spatial geometry relation to realize the image mapping. According to the above technical scheme of the two-dimensional code pre-deformation design method on the conical surface, the original two-dimensional code image is pre-deformed according to the certain spatial geometry relation and the pre-deformed two-dimensional code image is printed on the plane of a conical presswork. In the curved-surface condition, the projection plane thereof is just a undistorted two-dimensional code. The two-dimensional code can be scanned and decoded at the center thereof by any decoding software. Therefore, the application range of the two-dimensional codes is improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

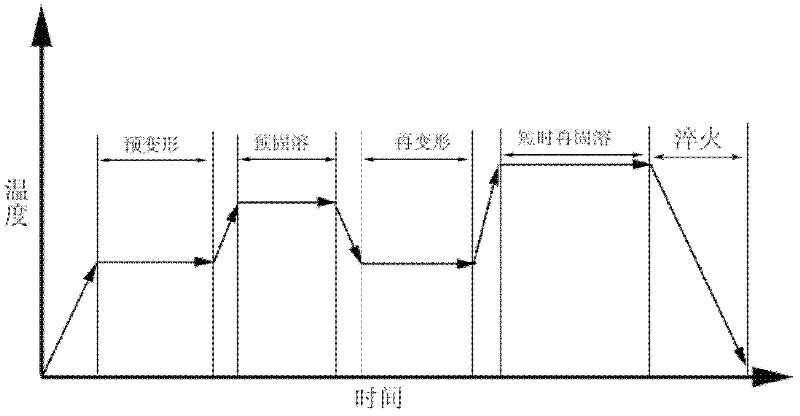

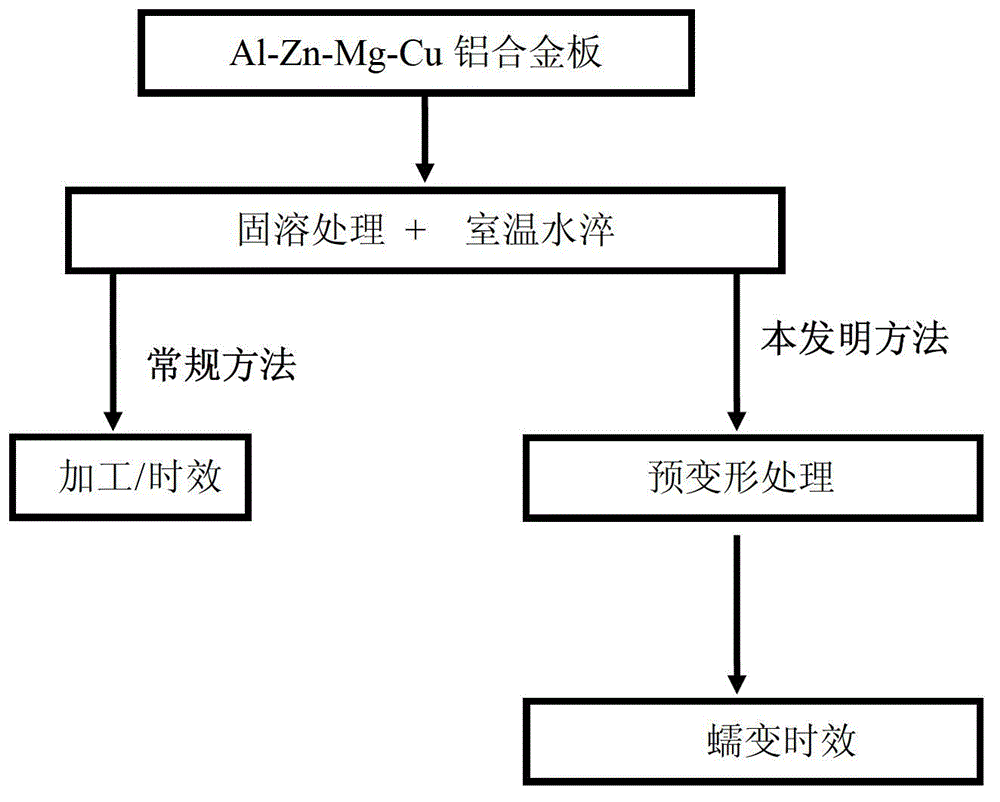

Al-Zn-Mg-Cu aluminum alloy deformation-solid solution heat treatment technology

The invention relates to an Al-Zn-Mg-Cu aluminum alloy deformation-solid solution heat treatment technology, which comprises the following steps: (1) pre-deformation, wherein the temperature range of pre-deformation is 400 DEG C - 420 DEG C, the deflection amount is 10% - 95%; (2) pre-solid solution, wherein the temperature range of pre-solid solution is 440 DEG C - 480 DEG C, the insulation timeis 30 - 120 minutes; (3) re-deformation, wherein the temperature range of pre-deformation is 400 DEG C - 420 DEG C, the deflection amount is 10% - 95%; (4) solid solution for short time, wherein the temperature range of solid solution is 470 DEG C - 485 DEG C, the solid solution time is 10 - 30 minutes. According to the invention, the deformation and solid solution are carried out alternatively,which avoids the problem that high dislocation concentration generated in the deformation process of single deformation-solid solution leads to the recrystallization of a substrate; the temperature of the pre-solid solution is higher than the general annealing temperature, the pre-solid solution process after pre-deforming reduces the dislocation concentration introduced by deformation through replying and performs a solid solution to most crystallization phases; the pre-solid solution for short time is performed again for dissolving the residual crystallization phases and inhibiting the crystallization of alloys. The invention has the advantages of simple process and convenient operation, and effectively reduces crystallization phases and re-crystallization of the Al-Zn-Mg-Cu system superhigh strength aluminum alloy, the alloy strength, plasticity and fracture toughness of the alloy after quenching and aging are substantially raised; the technology provided in the invention has significance to the development of the aerospace and traffic transportation fields, and is suitable for an industrial application.

Owner:湖南中创空天新材料股份有限公司

Method for self-repairing shape memory effect based joint sealant for concrete pavement through two steps

InactiveCN106337349AExtended service lifeImprove the quality of usePaving detailsCross-linkStrain energy

The invention provides a method for self-repairing a shape memory effect based joint sealant for a concrete pavement through two steps, belongs to the technical field of the joint sealant for the concrete pavement, and solves the problems of one-time repairing, poor repeatability, and microfracture repairing only of a current repairing method. A pre-deformation method is firstly used to give a shape memory function to the joint sealant in the horizontal direction, a prepressing strain energy is stored, the shape restoration force of the joint sealant mounted in a joint of the cement pavement is closed on a macrostructure scale when the temperature rises, a thermoplastic polymer nano-particle embedded in the joint sealant in advance is melt to implement cross-linked polymerization and curing reaction, then the self-repairing on a molecular scale is conducted, the conditions of a fracture or damage closure on the structure scale are observed, the self-healing process of the fracture or damage closure on the macrostructure scale is known, the interfacial energy of two free surfaces is measured, and the self-repairing effect of the two free surfaces on the molecular scale is evaluated. The method repeatedly implements self-repairing of the fracture of the joint sealant on the macro scale, and the durability of the joint sealant is improved.

Owner:NANJING FORESTRY UNIV

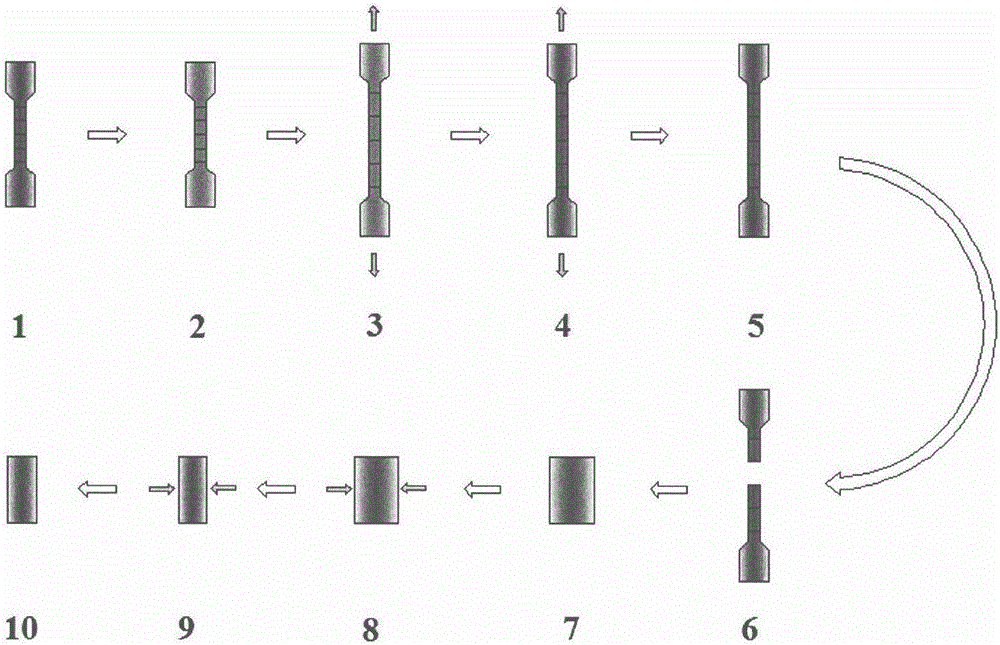

Method for creep age forming of Al-Zn-Mg-Cu series aluminium alloy plate

InactiveCN102978545AImprove mechanical propertiesSimple and fast operationCreep stressSolid solution

The invention relates to a method for creep age forming of an Al-Zn-Mg-Cu series aluminium alloy plate. The method is characterized in that a reasonable solid solution-quenching-pretreating-creep aging system is adopted, is suitable for plates with the thickness of 2 millimeters-30millimeters and comprises the following steps that solid solution is carried out at 470-485 DEG C for 30 minutes-120 minutes, quenching is then carried out, and the quenched plate is subjected to 0-10% predeformation treatment and creep aging at 120 DEG C-150 DEG C and is thermally insulated for 2-36 hours, wherein the creep stress is between 100 and 150 mega pascals, and the forming bending radius is above 1000 millimeters. The method is utilized to treat Al-Zn-Mg-Cu series aluminium alloy, so that the Al-Zn-Mg-Cu series aluminium creep formability can be effectively improved, and the residual stress of the alloy plate is reduced.

Owner:CENT SOUTH UNIV

Pre-deformation method capable of endowing cement pavement calking material with shape memory function

The invention provides a pre-deformation method capable of endowing a cement pavement calking material with a shape memory function, belongs to the technical field of cement pavement calking material preparation, and solves the problems of one-way shape memory function endowing , poor self-healing effect, complex temperature control requirement, high cost, limited preparation amount, poor durability and the like in the current pre-deformation method for the cement pavement calking material. The pre-deformation method comprises the following steps: stretching and deforming a calking material vertically to a design strain value at the temperature which is higher than a calking material glass transition temperature, and freezing a pre-stretching strain; applying compressive stress at a constant speed to a test piece in a vertical stretching direction at a normal temperature to enable the test piece to reach a preset compressive strain level, fixing the pre-compressive strain value, and endowing the calking material with the shape memory function in a two-dimensional direction; measuring the shape memory effect and other pavement performance of the calking material, and preferably selecting a group of reasonable stretching and compressive pre-strain value combination. According to the method provided by the invention, the difficulty in two-dimensional pre-deformation is reduced, so that the calking material has a better shape memory effect, and the durability of the calking material and a cement pavement are improved.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com