Preparation method for high-strength high-conductivity Cu-Ag-Fe alloy

A cu-ag-fe, high conductivity technology, applied in the field of non-ferrous metal alloys, can solve the problems that do not involve Cu-Ag-Fe ternary alloy homogenization, annealing and other heat treatment processes, so as to reduce impurity scattering and improve electrical conductivity Ratio, the effect of refining Cu dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of high-strength and high-conductivity Cu-Ag-Fe alloy, comprising the following steps:

[0039] Step 1, preparation of cast Cu-Ag-Fe master alloy:

[0040] A high-strength and high-conductivity Cu-Ag-Fe alloy, the composition of which is as follows: Cu:Ag:Fe: 94.1:5.4:0.5.

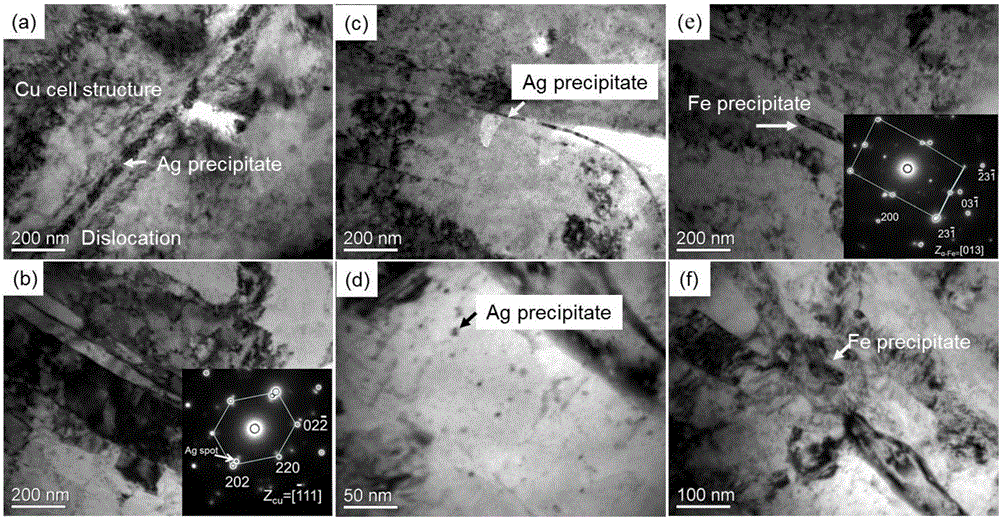

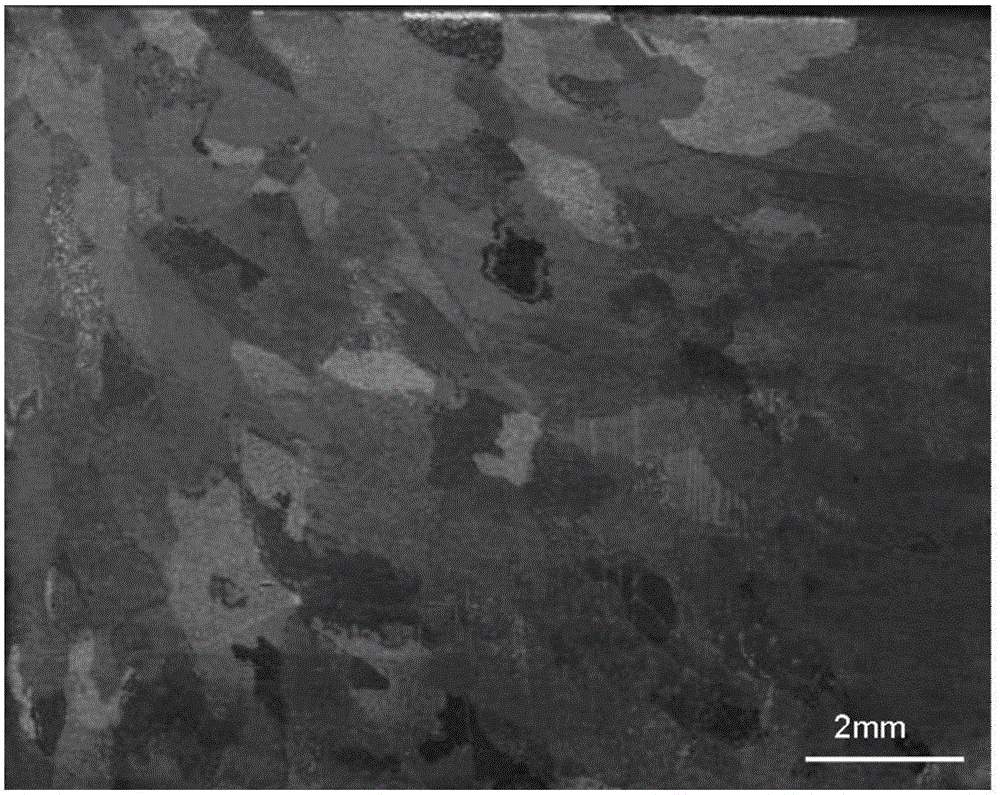

[0041] Using electrolytic Cu, Ag and pure Fe with a purity of more than 99.9wt% as raw materials, they are melted in a vacuum induction melting furnace according to the proportion, and then poured into a water-cooled copper mold at a pouring temperature of 1200°C to obtain as-cast Cu-Ag- Fe master alloy, its macrostructure diagram is shown in figure 1 ;

[0042] Step 2, solidification of Cu-Ag-Fe alloy under the action of alternating magnetic field:

[0043]Place the prepared cast Cu-Ag-Fe master alloy in the center of a 1T alternating magnetic field, heat it to 1200°C, keep it warm for 10 minutes, and then cool it rapidly to obtain a solidified Cu-Ag-Fe alloy;

[0044] Step...

Embodiment 2

[0056] A preparation method of high-strength and high-conductivity Cu-Ag-Fe alloy, comprising the following steps:

[0057] Step 1, preparation of cast Cu-Ag-Fe master alloy:

[0058] A high-strength and high-conductivity Cu-Ag-Fe alloy, the composition of which is: Cu:Ag:Fe is 95.0:3.0:2.0 by weight percentage.

[0059] Using electrolytic Cu, Ag and pure Fe with a purity of more than 99.9wt% as raw materials, they are melted in a vacuum induction melting furnace according to the proportion, and then poured into a water-cooled copper mold at a pouring temperature of 1300°C to obtain cast Cu-Ag- Fe master alloy;

[0060] Step 2, solidification of Cu-Ag-Fe alloy under the action of alternating magnetic field:

[0061] Place the prepared cast Cu-Ag-Fe master alloy in the center of a 0.5T alternating magnetic field, heat it to 1300°C, keep it warm for 30 minutes, and then cool it rapidly to obtain a solidified Cu-Ag-Fe alloy;

[0062] Step 3, homogenization of the alloy under t...

Embodiment 3

[0074] A preparation method of high-strength and high-conductivity Cu-Ag-Fe alloy, comprising the following steps:

[0075] Step 1, preparation of cast Cu-Ag-Fe master alloy:

[0076] A high-strength and high-conductivity Cu-Ag-Fe alloy, the composition of which is as follows: Cu:Ag:Fe: 87.5:11.0:1.5.

[0077] Using electrolytic Cu, Ag and pure Fe with a purity of more than 99.9wt% as raw materials, they are melted in a vacuum induction melting furnace according to the proportion, and then poured into a water-cooled copper mold at a pouring temperature of 1200°C to obtain as-cast Cu-Ag- Fe master alloy;

[0078] Step 2, solidification of Cu-Ag-Fe alloy under the action of alternating magnetic field:

[0079] Place the prepared cast Cu-Ag-Fe master alloy in the center of a 0.5T alternating magnetic field, heat it to 1200°C, keep it warm for 30 minutes, and then cool it rapidly to obtain a solidified Cu-Ag-Fe alloy;

[0080] Step 3, homogenization of the alloy under the actio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com