Patents

Literature

236results about How to "Reduce solid solubility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum based alloy

InactiveUS20060093512A1Improve mechanical propertiesIncrease the lattice constantSolid solutionAluminium alloy

An aluminum alloy comprising Al, Sc, Gd, Zr, and optionally Mg. The aluminum alloy is strengthened by an aluminum solid solution matrix and a dispersion of Al3X precipitate having an L12 structure where X comprises Sc, Gd and Zr. Mg is a preferred addition to the alloy containing Gd and Zr. The alloying additions control strengthening and coarsening kinetics of the alloy through control of diffusivity in the aluminum matrix and coherency strain of the Al3X precipitate.

Owner:RAYTHEON TECH CORP

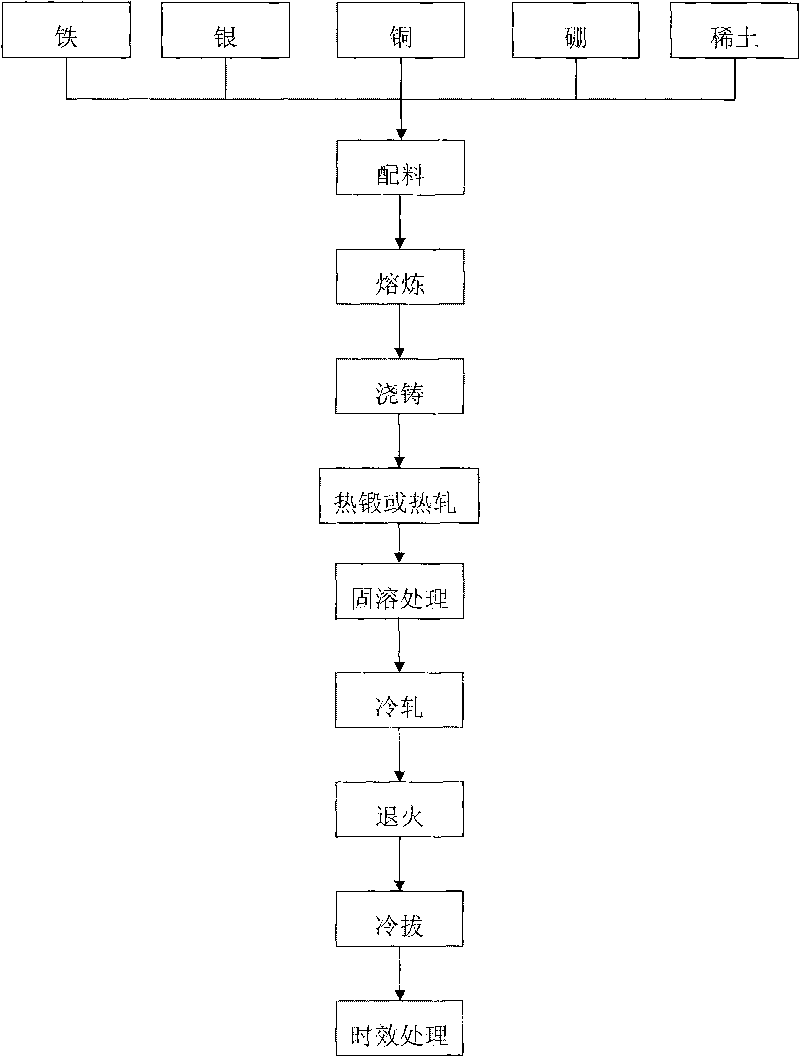

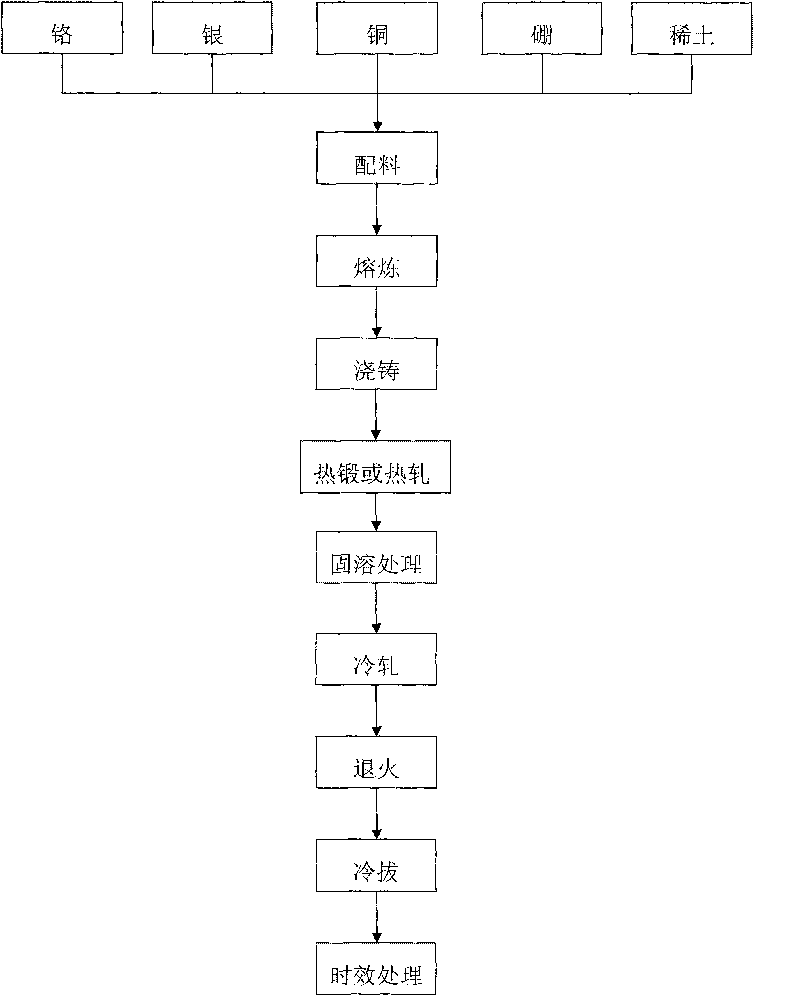

Cu-Fe in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Fe in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Fe and trace Ag and B, rare earth or rare earth compounds to prepare the high strength and high conductivity copper alloy material through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing wide application in the fields such as electronics, information, transportation, energy, metallurgy, electromechanics and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

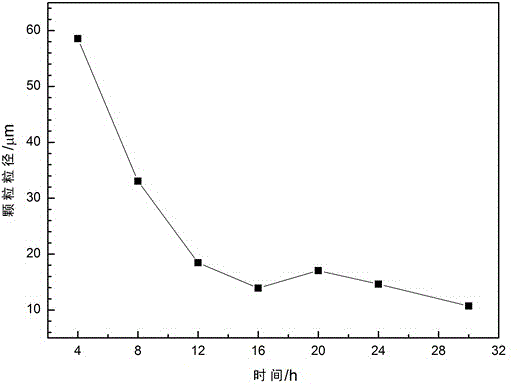

Method for manufacturing ultra-fine crystal magnesium/titanium layered polystyrene-plywood laminate

InactiveCN101244429AImprove performanceHigh bonding strengthRoll force/gap control deviceTemperature control devicePolystyreneTitanium

The invention relates to a production method of ultra-fine crystal magnesium / titanium laminated composite panel, which comprises the following steps: firstly, cleaning the surfaces of the metal materials; secondly, stacking the metal materials; thirdly, annealing the stacked sheets; fourthly, rolling the sheets after annealing; fifthly, cutting the rolled sheets into two identical parts, trimming and deburring; repeating the first step to the fourth step for lamination and ply rolling; sixthly, annealing the composite panel obtained from lamination and ply rolling to obtain the ultra-fine crystal magnesium / titanium laminated composite panel. The production method solves the problems of complicated technology, high cost, poor corrosion resistant performance of material and poor interface binding performance of the magnesium / titanium laminated composite panel existing in the prior art. The production method has the advantages of simple technology, low cost as well as good corrosion resistant performance and good interface binding performance of the composite panel.

Owner:HARBIN INST OF TECH

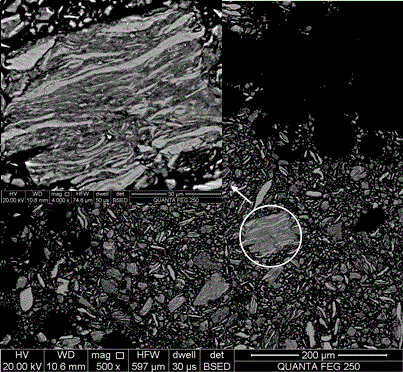

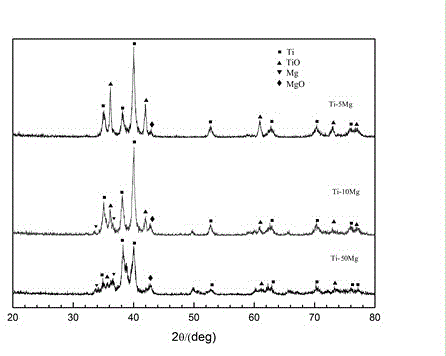

A Ti-Mg alloy material, a preparing method thereof and applications of the alloy material

The invention discloses a Ti-Mg alloy material applied as human tissue bone repair materials and a preparing method thereof. Phase composition of the alloy comprises Ti, Mg, TiO and MgO. The alloy comprises 70-80% of the Ti, 0-10% of the Mg, 8-20% of the TiO and 2-5% of the MgO. The Ti-Mg alloy is prepared by utilization of mechanical alloying and spark plasma sintering. The porosity of the alloy is smaller than 1%, the Vickers hardness of the alloy is HV400-HV500, the compressive strength of the alloy is 1600-1700 MPa, the elasticity modulus of the alloy is 12-13 GPa, the self-corrosion potential of the alloy ranges from -900 mV to -800 mV, the self-corrosion current density is 50-90 [mu]A / cm<2>. The alloy has characteristics of uniform structure, high compactness, good mechanical compatibility, capability of being biodegradable, and good corrosion resistance.

Owner:CENT SOUTH UNIV

Preparation of nontoxic magnesium alloy material for biological implantation

The invention relates to a method for preparing a magnesium alloy material suitable for biological implantation, which comprises the following steps: preparing raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.5 to 1.9 percent of Mn, 0.6 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; or preparing the raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.3 to 0.9 percent of Zr, 0.5 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; preheating smelting equipment and adding the Mg into the raw materials; heating the mixture under the protection of argon gas with the flow rate of between 5 and 6 L / min and the pressure of 14 MPa; adding a fire retardant into the molten liquid when the temperature of the molten liquid reaches between 650 and 660 DEG C, raising the temperature of the molten liquid to between 700 and 720 DEG C, adding other alloy elements into the molten liquid respectively, and performing melting reaction; and stirring the mixture until the mixture is uniformly mixed after alloy is completely molten, keeping the mixture stand for 30 to 40 minutes, pressing a deslagging agent into the solution for deslagging, casting the alloy solution into a cast die after keeping the alloy solution for 10 to 20 minutes at the temperature of between 690 and 710 DEG C, and preparing a Mg-Mn series or Mg-Zr series biomedical magnesium alloy material ingot.

Owner:NORTHEASTERN UNIV

Brass brazing alloy

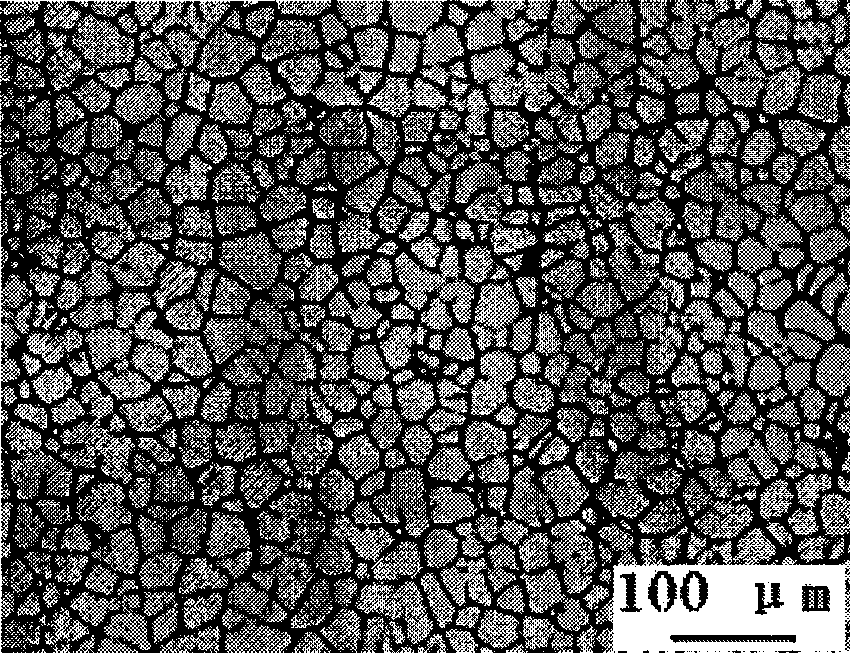

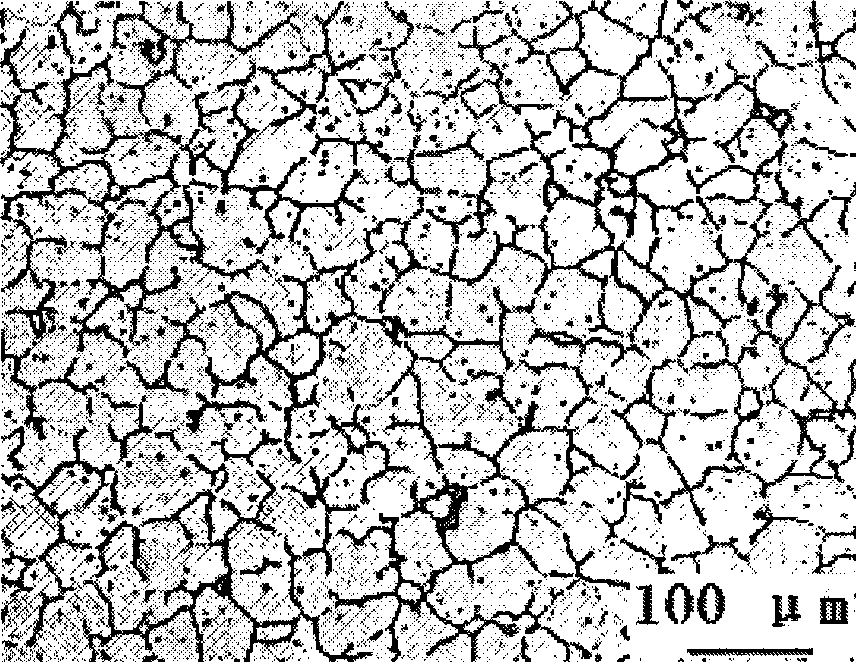

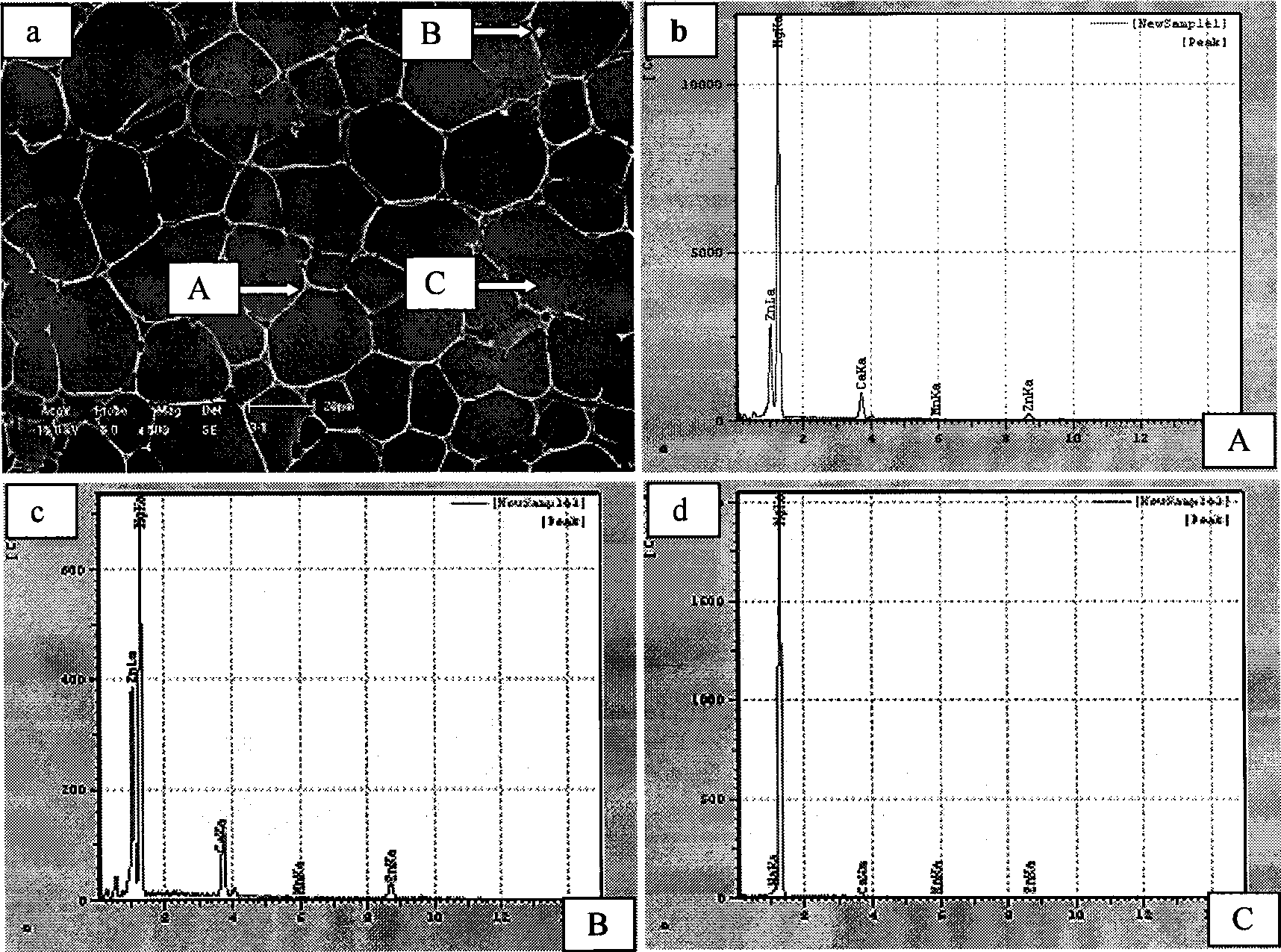

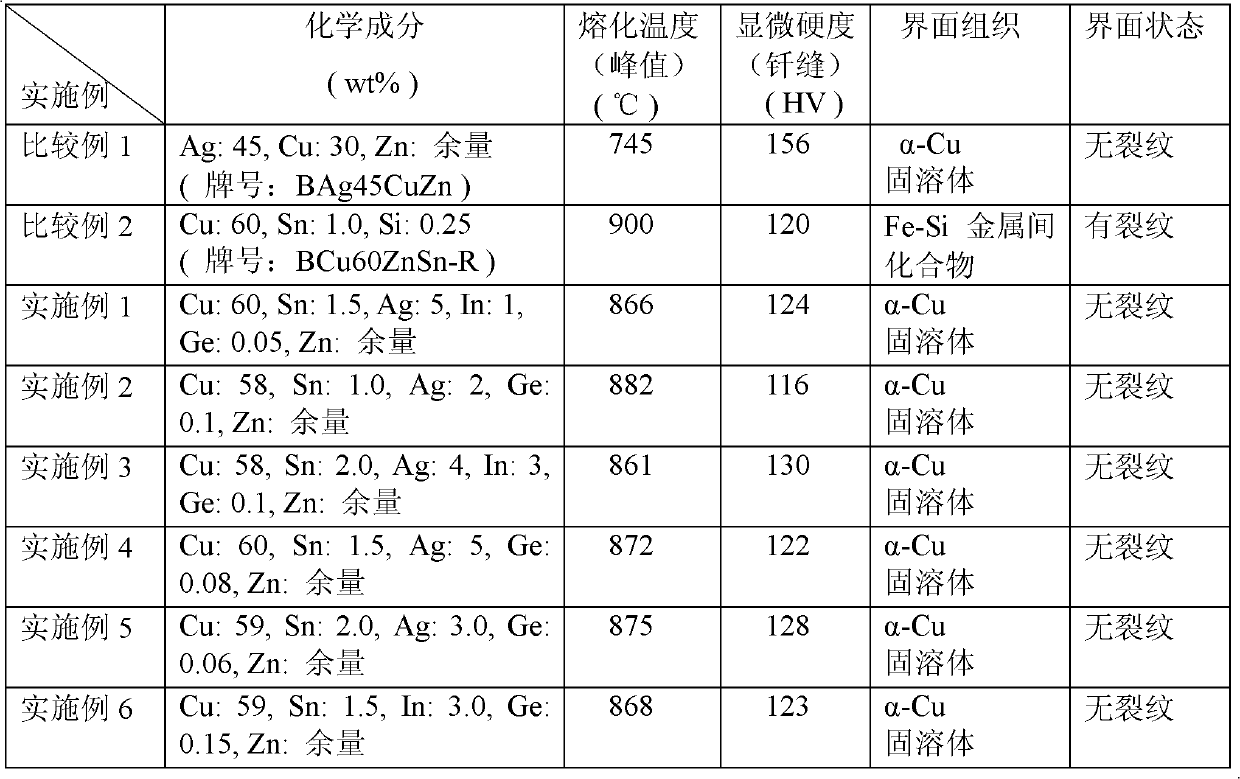

InactiveCN102601542AImprove reliabilityLow Ag contentWelding/cutting media/materialsSoldering mediaBraze alloyMelt temperature

The invention discloses brass brazing alloy, which comprises Cu, Zn, Sn, Ge, Ag and / or In. The brass brazing alloy consists of components including, by mass percentage, from 58 to 60% of Cu, from 0.5 to 3.0% of Sn, from 1.0 to 6.0% of Ag and / or from 1.0 to 5.0% of In, from 0.05 to 0.3% of Ge and the balance Zn. Compared with an existing brass brazing material, the brass brazing alloy has the advantages that melting temperature is low, the brass brazing alloy can replace a silver brazing material to be used for brazing steel / copper joints, and cost is low due to the fact that Ag content of the brass brazing alloy is low.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing composite Cu-Fe-Ag nano material at original position with high intensity and high conductance

A method of preparing high intensity and high conducting in-situ nano-composite: Cu-Fe-Ag. The steps: (1) Prepare Cu-Fe-Ag by using medium freguency induction furnace to smelt, and dealt it with ultrasonic or strong electric pulse. Make the ingot casting by water-cold Cu-model: (2) Forge the ingot casting and then draw it multiple times in room temperature in order to made Fe-icrostructural elongate by stretch until it forms nano fiber. (3) Heat treatment it when its cold forming process strain quantum is 2 - 3 so the soild-solution of Fe and Al can separate out as natrium rice level particles; (4) In the following forming process , this particles join in distortion, and form the enhanced fiber which particles are smaller than before. This process can make the material enhanced more. The present invention mixes the thinning of as-cast microstructure and deformation together. It increases the electric while enhances the intensity of the materials, and also can obtain materials in large sectional dimension.

Owner:SHANGHAI JIAO TONG UNIV

High-voltage resistant casting copper alloy

The present invention is one kind of high pressure cast copper alloy, and belongs to the field of non-ferrous metal material technology. The alloy has the chemical composition of ZCuSn3Zn8Pb6Ni1 added with Fe and Co, and consists of Sn 2.0-4.0 wt%, Zn 6.0-9.0 wt%, Pb 4.0-7.0 wt%, Ni 0.5-2.5 wt%, Fe 0.1-7.0 wt%, Co 0.5-7.0 wt% and Cu for the rest. Its smelting and casting process includes the following steps: feeding electrolytic copper or returned copper material, Pb and Sn into the furnace, adding protective cover and heating, adding Fe, Co and Ni after reaching 1200 deg.c, adding Zn after reaching 1250 deg.c and maintaining for0.5 hr, maintaining at 1250 deg.c for one other 10-15 min, skimming and casting at 1200 deg.c, cooling the casting to room temperature, heating to 800-1000 deg.c and maintaining of 3-5 hr, and water cooling and solid solution treatment. The cast copper alloy has refined crystal grain structure and high tensile strength.

Owner:UNIV OF SCI & TECH BEIJING

Vacuum induction smelting process for greatly lowering N element content in nickel-base high-temperature alloy

The invention relates to a vacuum induction smelting process for greatly lowering the N element content in nickel-based high-temperature alloy and belongs to the technical field of alloy smelting. Firstly, elements including Ni, Ta, Mo, Cr and Fe which are low in appetency with N in raw materials required for smelting are arranged from bottom to top in sequence in a crucible, and super-high-temperature refining N-removal is performed after the elements are heated and melted; melt is controlled to be lowered to a proper temperature after refining is finished, then strong nitrides are added in sequence to from elements including Nb, Ti and Al, and melting and refining are performed again; finally, when the melt is controlled to be lowered to a certain temperature, microelements including C, B and Zr which are prone to burning loss and volatilization are added; and meanwhile, stirring is performed, pouring is performed after alloy liquid is completely clean again, and smelting is finished. The vacuum induction smelting process has quite remarkable and excellent N-removal effect, the N content of the nickel-based high-temperature alloy smelted by the smelting process can be lowered to 6 ppm or below compared with that smelted by an existing smelting method, and vacuum induction smelting process is suitable for industrialized smelting of mother alloy of the nickel-based high-temperature alloy with a high requirement for the N content.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

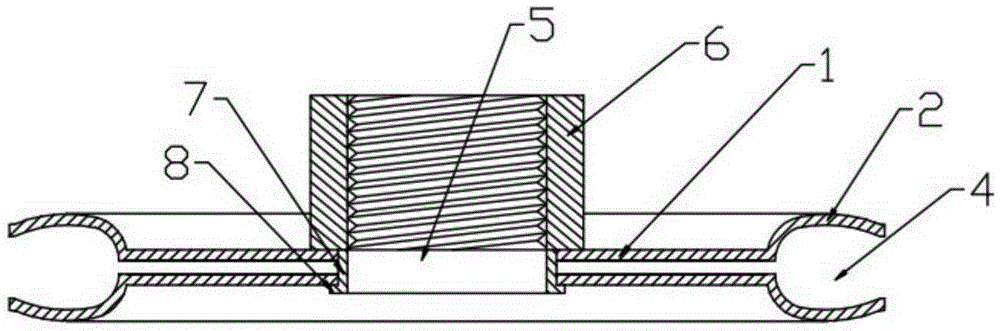

Metal wire polishing wheel

InactiveCN105415212ALight in massReduce quality problemsFlexible-parts wheelsMetallic material coating processesAlloy substrateEngineering

The invention provides a metal wire polishing wheel. The metal wire polishing wheel comprises an upper clamping plate and a lower clamping plate. A plurality of metal wire beams are installed between the edge parts of the upper clamping plate and the lower clamping plate in a central symmetrical mode. A fastener is installed between through holes of the upper clamping plate and the lower clamping plate. A longitudinal installation hole is formed in the middle of the fastener and internally provided with an internal thread. Both the upper clamping plate and the lower clamping plate are divided into the annular sunk parts in the middles and the annular protruding parts at the edges. The annular protruding part of the upper clamping plate and the annular protruding part of the lower clamping plate are symmetrical and form an annular installation groove of the metal wire beams. The metal wire beams are formed by twisting a plurality of metal wires made from an aluminum alloy composite material. The aluminum alloy composite material comprises an aluminum alloy substrate and a ceramic layer arranged on the surface of the aluminum alloy substrate through laser cladding. The metal wire polishing wheel is compact and firm in structure, convenient to install and use and good in thermal conductivity, heat dispersion, mechanical property and usability.

Owner:NINGBO DAHUA GRINDING WHEEL

Aluminum-copper-magnesium alloy wire rod and manufacturing technique thereof

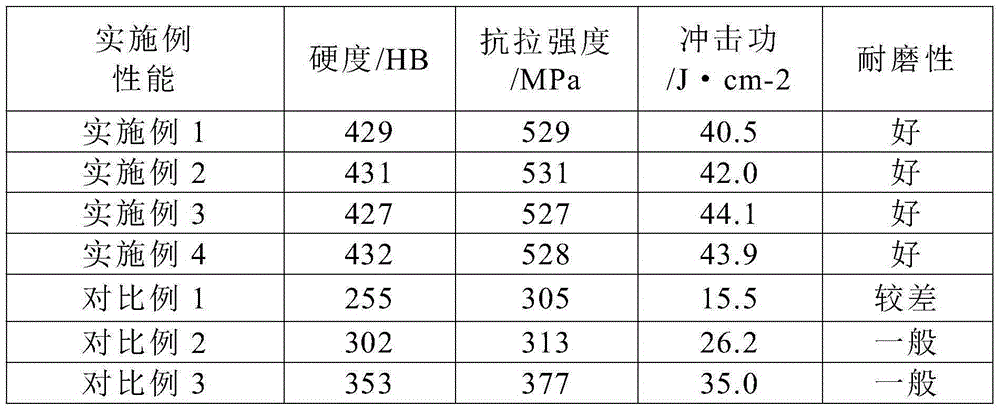

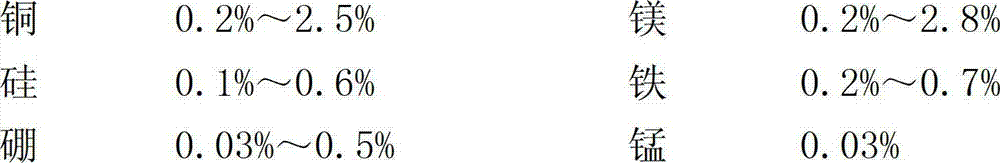

The invention relates to an aluminum-copper-magnesium alloy wire rod and a manufacturing technique of the aluminum-copper-magnesium alloy wire rod. The aluminum-copper-magnesium alloy wire rod is formed by the following raw materials in percentage by weight: 0.2-2.5% of copper, 0.2-2.8% of magnesium, 0.1-0.6% of silicon, 0.2-0.7% of iron, 0.03-0.5% of boron, 0.03% of manganese, 0.03% of zinc, 0.03% of chrome, 0.01% of titanium, and 96%-98% of aluminum. The manufacturing technique comprises the following steps: (1), smelting of aluminum alloy, (2), online treatment of aluminum alloy, (3), casting of aluminum alloy, (4), rolling of aluminum alloy wire rod, and (5), carrying out online aging treatment on the rolled aluminum alloy wire rod to obtain the wire rod, wherein the drawing out temperature is not higher than 60 DEG C. The aluminum-copper-magnesium alloy wire rod meets the performance requirements on the raw material aluminum alloy wire rod in copper clad aluminum alloy in the cable industry field, in particular the requirements on the performances in the aspects of tensile strength, percentage elongation and compressive creep, and the like.

Owner:庆毅 +1

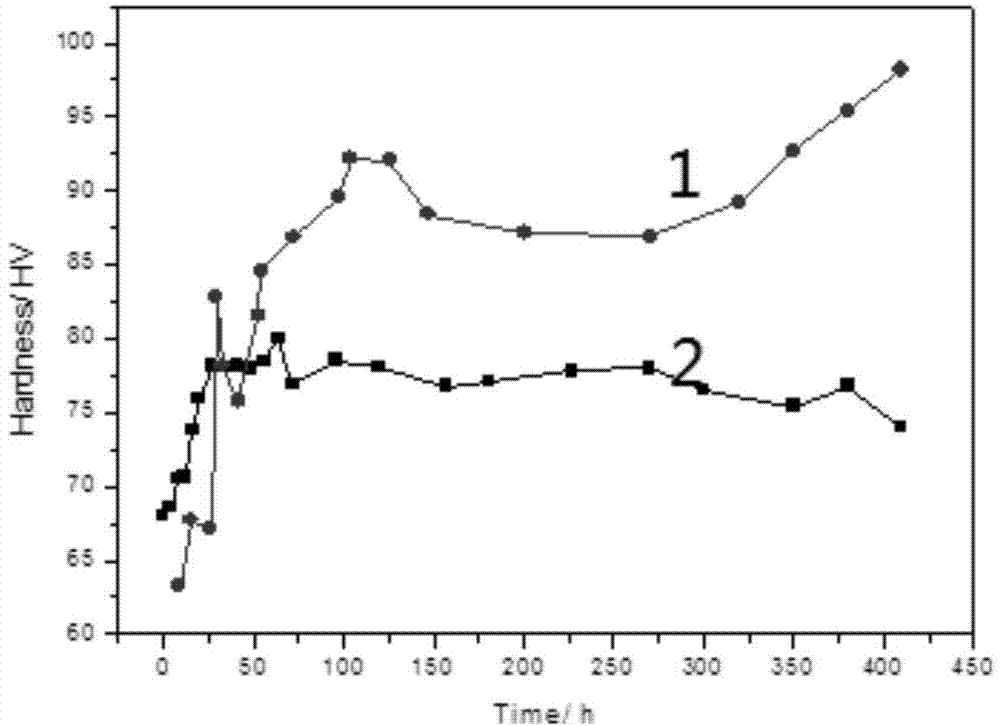

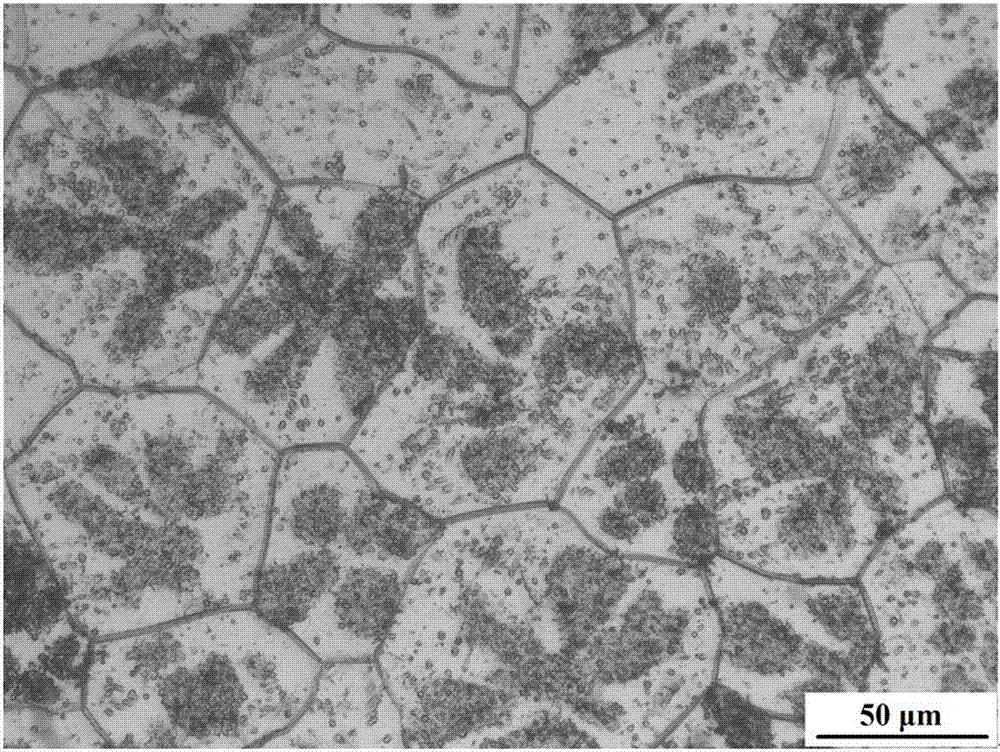

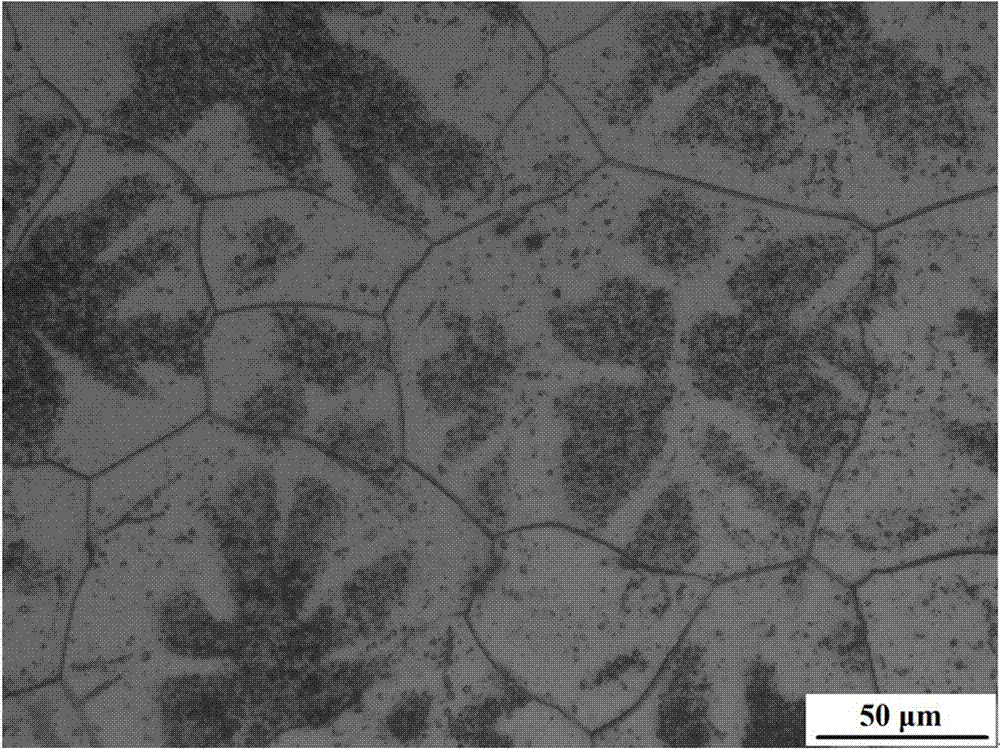

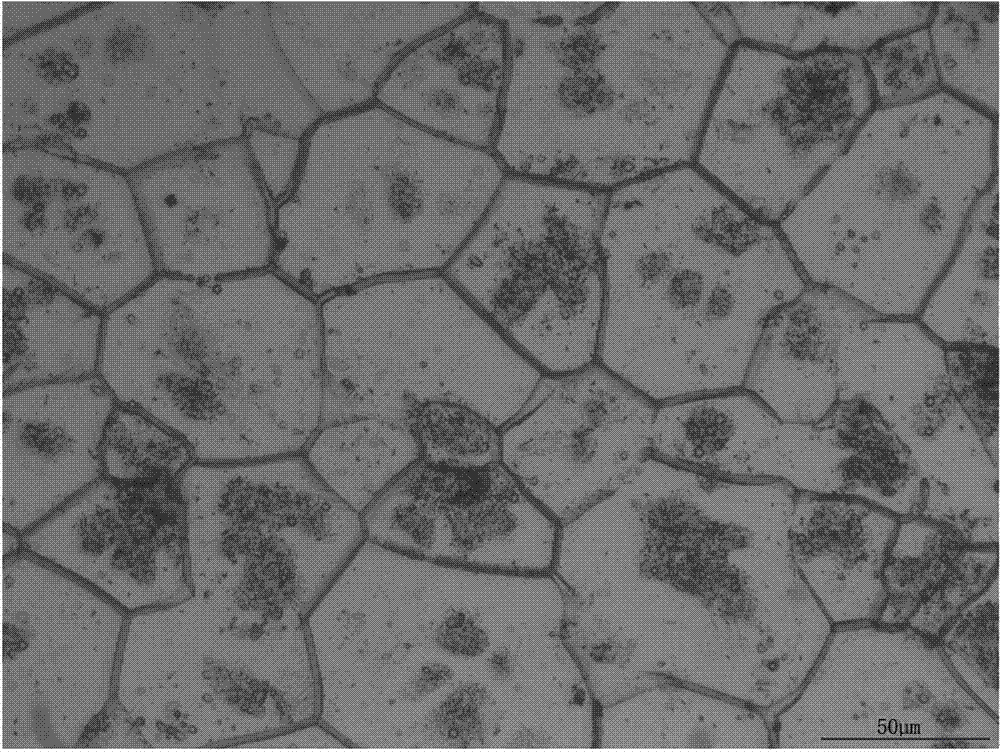

Magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and preparation method thereof

The invention discloses a magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and a preparation method thereof. Mass percent of components of the alloy is that 4 to 10% of zinc, 2 to 4% of aluminum, 0.1 to 0.5% of chromium, 0.1 to 1.0% of bismuth, 0.5 to 2.0% of calcium, the remaining is magnesium, and the total mass is 100%. The preparation method of the alloy comprises the following steps of preheating prepared alloy furnace materials, communicating a carbon dioxide and sulfur hexafluoride mixed gas to be served as a protection gas to perform smelting, performing diffusion annealing on obtained magnesium, zinc, aluminum, chromium, bismuth and calcium as-cast-condition alloy materials for 48 hours under 380 degrees, performing linear cutting to obtain aging thermal treatment samples and plate-shaped tensile samples, preserving heat of the above samples, performing water quenching and manual aging to obtain the magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening. The preparation method can obtain preparation the magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and relatively thin in as-cast structure and high in thermal stability and mechanical property.

Owner:NORTHEASTERN UNIV LIAONING

Multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and manufacturing method thereof

ActiveCN107083508AImprove room temperature and high temperature mechanical propertiesImproves strength and hardnessRare-earth elementCorrosion resistant

The invention discloses a multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and a manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy. The ingredients of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy comprise pure magnesium ingots, pure zinc ingots, Mg-Gd alloy, Mg-Y alloy, Mg-Nd alloy, Mg-Ca alloy, Mg-Zr alloy and nanometer-scale NdN particles. The elements in the raw materials comprise, by mass, 3.5-5.0% of Gd, 1.0%-3.0% of Y, 0.5%-0.8% of Nd, 0.8%-1.5% of Zn, 0.3%-0.8% of Ca, 0.3%-0.6% of Zr, 0.5%-1.5% of nanometer-scale NdN particles and the balance Mg. The sequence of the mass percentage contents of the three rare earth elements of the Gd, the Y and the Nd from large to small is Gd>Y>Nd, and the mass percentage of the total addition amount of the three rare earth elements of the Gd, the Y and the Nd does not exceed 10%. The particle size of the nanometer-scale NdN particles is 80-150 nm. The steps of pretreatment and cladding of the NdN particles, preheating of the ingredients, smelting, refining, doping, pouring, sectioned solution treatment and artificial aging treatment are sequentially conducted, and then the fine, dispersive nanometer-precipitated-phase microscopic-structure heat-resistant corrosion-resistant magnesium alloy product is obtained. By the adoption of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and the manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy, the manufacturing cost is low, and the heat resistance and corrosion resistance of the magnesium alloy are excellent.

Owner:YANGZHOU FENG MING METAL PROD +1

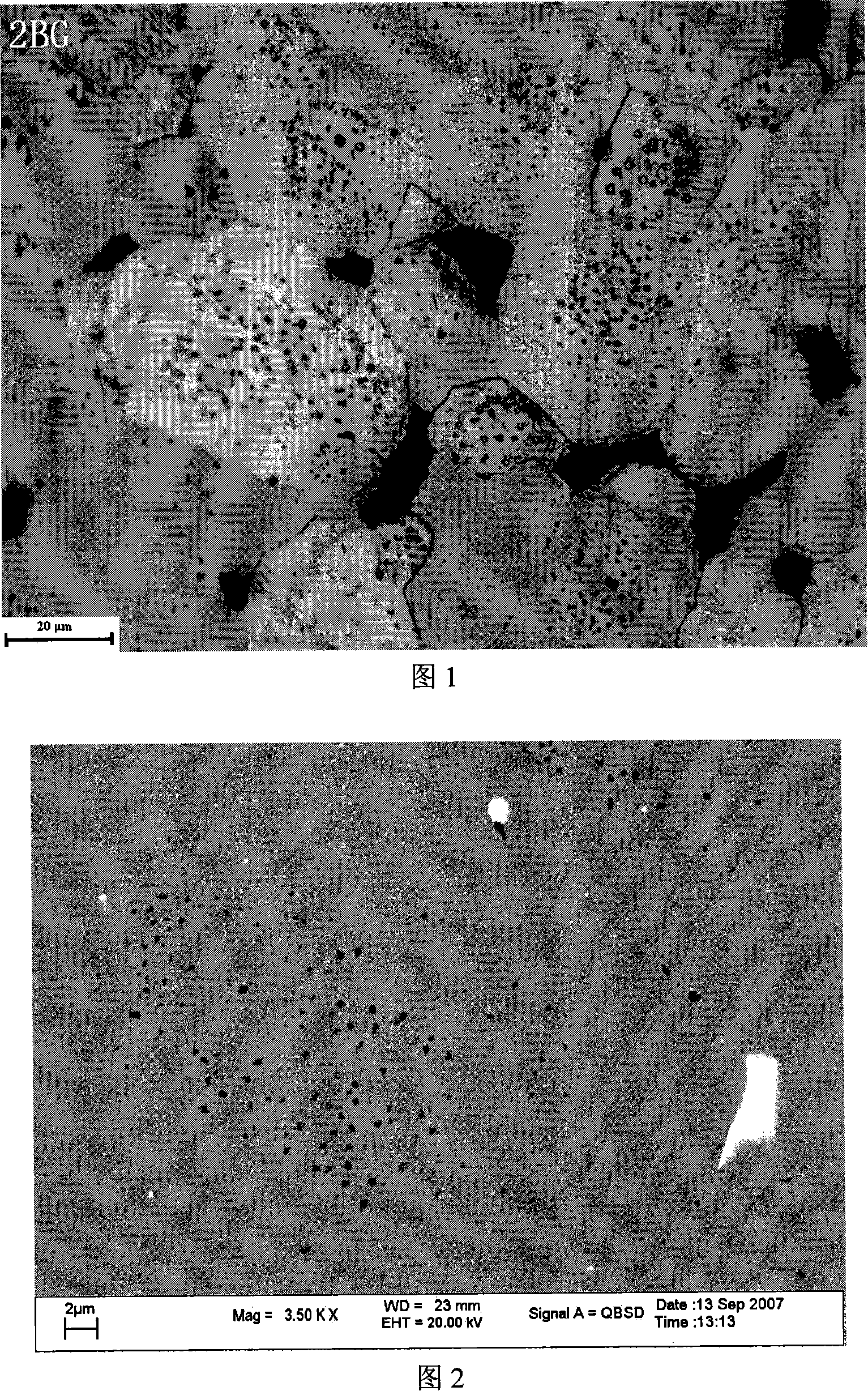

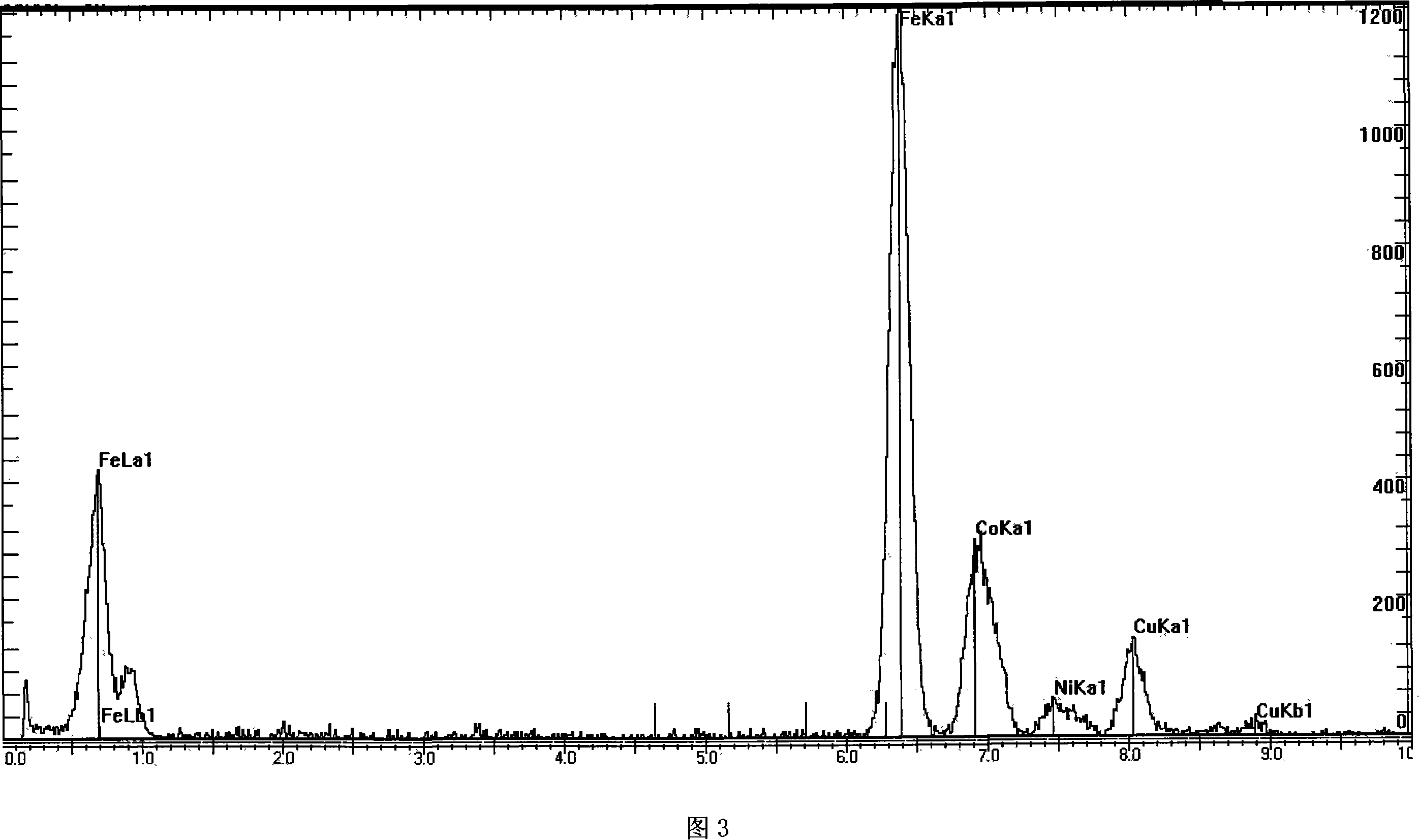

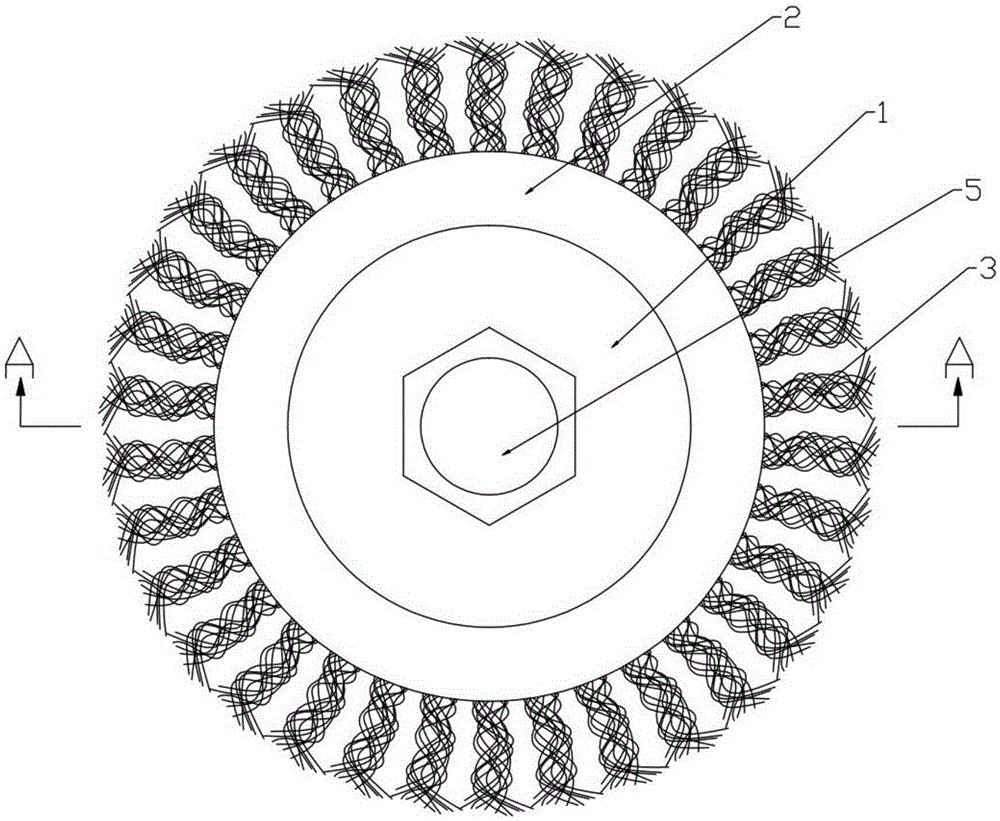

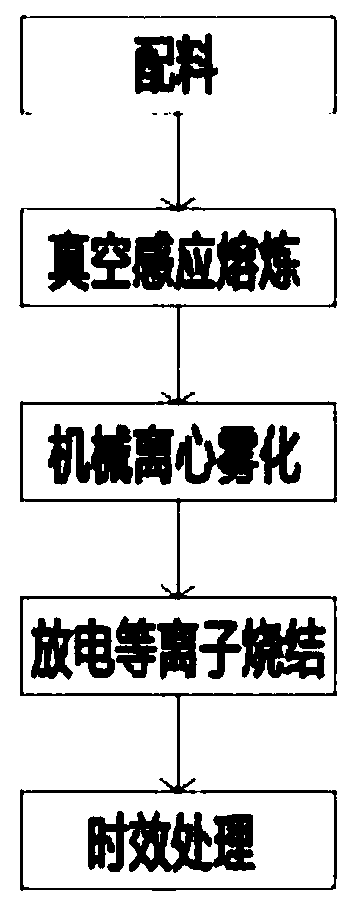

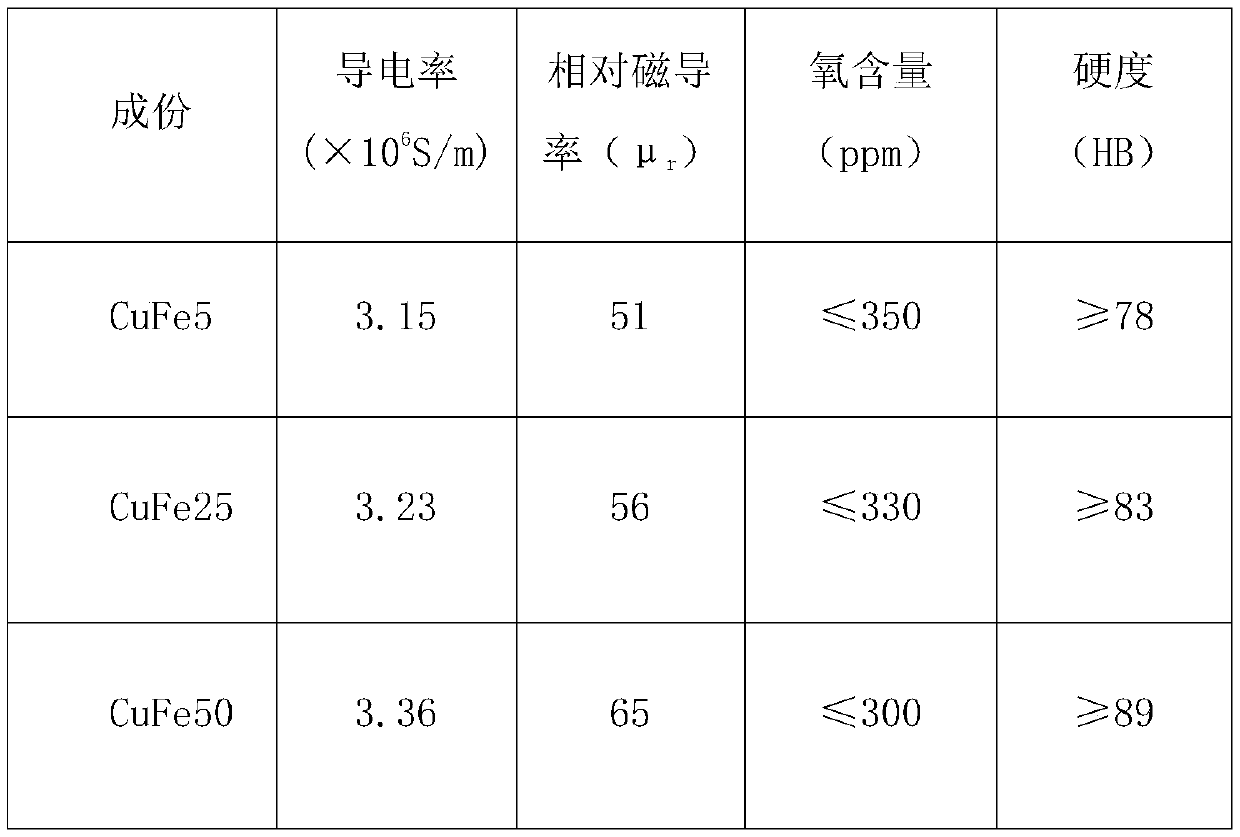

Method of copper and iron alloy materials for novel motor rotors

ActiveCN110484762AIncrease cooling rateOvercoming the problem of prone to macro segregationMagnetic/electric field screeningElectromagnetic shieldingSolid solubility

The invention discloses a method of copper and iron alloy materials for novel motor rotors, and belongs to the technical field of nonferrous metal material manufacturing. The method mainly comprises the steps of (1) burdening, (2) vacuum induction smelting, (3) mechanical centrifugal atomization, (4) discharge plasma sintering and (5) aging. Cu and Fe raw materials with higher purity are selected,fed silver is excellent in electric conductivity, and meanwhile, iron, silicon and copper are lower in solid solubility, so that the influence on electricity and heat conductivity of copper rods is lower, the solid solubility cannot be changed along with the temperature change, and alloys formed by Cu and Fe achieve higher electric conductivity; and through the mechanical centrifugal atomizationmode, Cu-Fe alloys are atomized as drops, and the drops are quickly condensed through low-temperature and high-purity argon, so that the cooling speed of the alloy drops can be accelerated, the macroscopic segregation of the alloys is overcome, and the electromagnetic shielding performance of the alloys is further improved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

High-strength high-plasticity magnesium alloy and preparation method thereof

The invention discloses high-strength high-plasticity magnesium alloy and a preparation method thereof. The high-strength high-plasticity magnesium alloy comprises, by mass, 7.5%-9.0% of Al, 0.5%-1.0% of Zn, 0.1%-0.5% of Mn, 0.1%-1.0% of La, 0.1%-1.0% of Y, 0.1%-1.0% of Nd, 0.1%-1.0% of Ca, and the balance Mg and inevitable impurity elements. Due to the compound addition of the multiple elements and the mutual influences between the elements, the solid solubility of the elements in a magnesium matrix can be reduced, and the usage amount of rare earth is reduced; moreover, the strengthening effect of the alloy can be obviously improved, and accordingly, the magnesium alloy with high strength and high plasticity is obtained.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

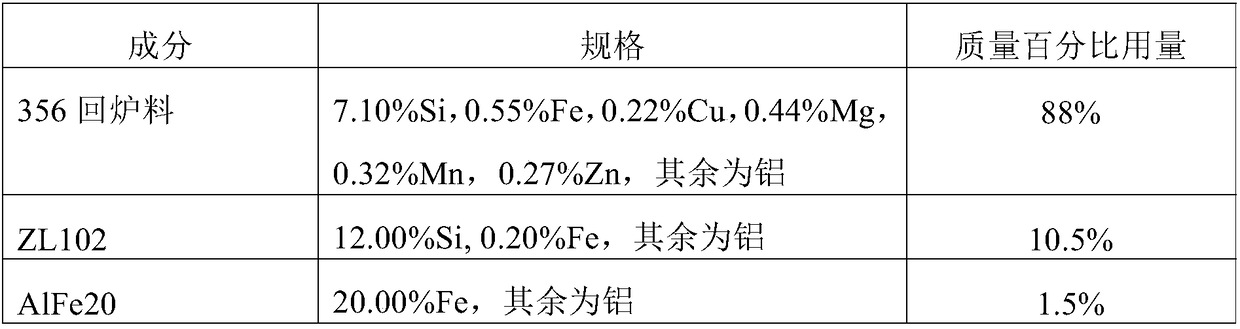

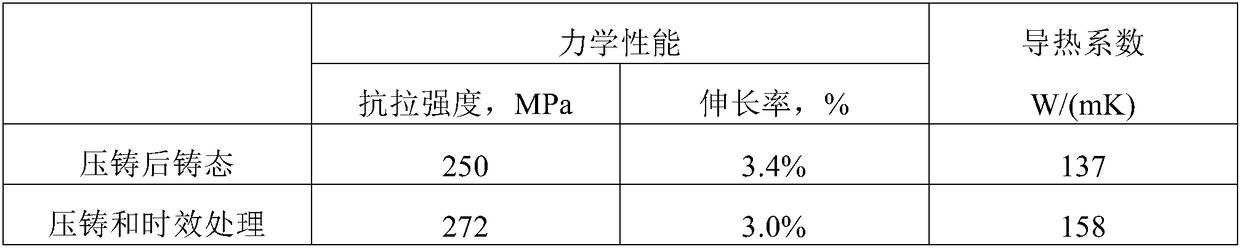

High-thermal-conductivity aluminum alloy and preparation method thereof

InactiveCN108359853ALow cost and environmentally friendlyConvenient sourceManganeseMechanical property

The invention provides a high-thermal-conductivity aluminum alloy and a preparation method thereof. A die-cast aluminum-silicon-magnesium-iron-manganese alloy material prepared by adopting a die-casting technology and an aging treatment process comprises the following components of, by mass, 5-10% of silicon, 0.5-1% of iron, 0.1-0.60% of magnesium, 0.10-0.40% of manganese, less than or equal to 0.5% of zinc, less than or equal to 0.4% of copper, less than or equal to 0.30% of other elements and the balance aluminum and inevitable trace impurities. According to the high-thermal-conductivity aluminum alloy, the relatively high heat conduction performance, the good mechanical property and the good die-cast forming performance are achieved, cost of the raw material is low, and the source is convenient to obtain; and the high-thermal-conductivity aluminum alloy is particularly suitable for manufacturing parts with light weight and high heat conduction requirements, and has very wide application prospects in the fields of communication, household appliances and the like.

Owner:NINGBO HELI TECH CO LTD

Aluminum lithium alloy for spaceflight and method for preparing proximate matter through aluminum lithium alloy

The invention relates to an aluminum lithium alloy for spaceflight and an aluminum lithium alloy proximate matter preparing method, and relates to the aluminum lithium alloy and the aluminum lithium alloy proximate matter preparing method. The aim is to solve the problems that the production difficulty of the aluminum lithium alloy is large, and the aluminum lithium alloy strength is low. The aluminum lithium alloy is composed of Mg, Li, Ti, Zr and Al, the Mg accounts for 5.5%-6.5%, the Li accounts for 2.2%-2.5%, the Ti accounts for 0.03%-0.12%, the Zr accounts for 0.15%-0.20%, the Zr+Ti is smaller than or equal to 0.25%, and the balance is the Al. The method includes the steps of raw material weighing, aluminum alloy molten liquid preparing, refining, spray forming, short bar cutting, blind die extrusion, heat extrusion, quenching, tension leveling and aging treatment. According to the aluminum lithium alloy and the aluminum lithium alloy proximate matter preparing method, through spray forming, the problems that the aluminum lithium alloy production difficulty is large, and the quality is poor are solved, the strength of extension reaches 485 Mpa, the ruled non-proportional extending strength reaches 345 Mpa, the percentage elongation after fracture reaches 10.0%, and blind die extrusion enables a casting ingot to be more compact.

Owner:NORTHEAST LIGHT ALLOY CO LTD

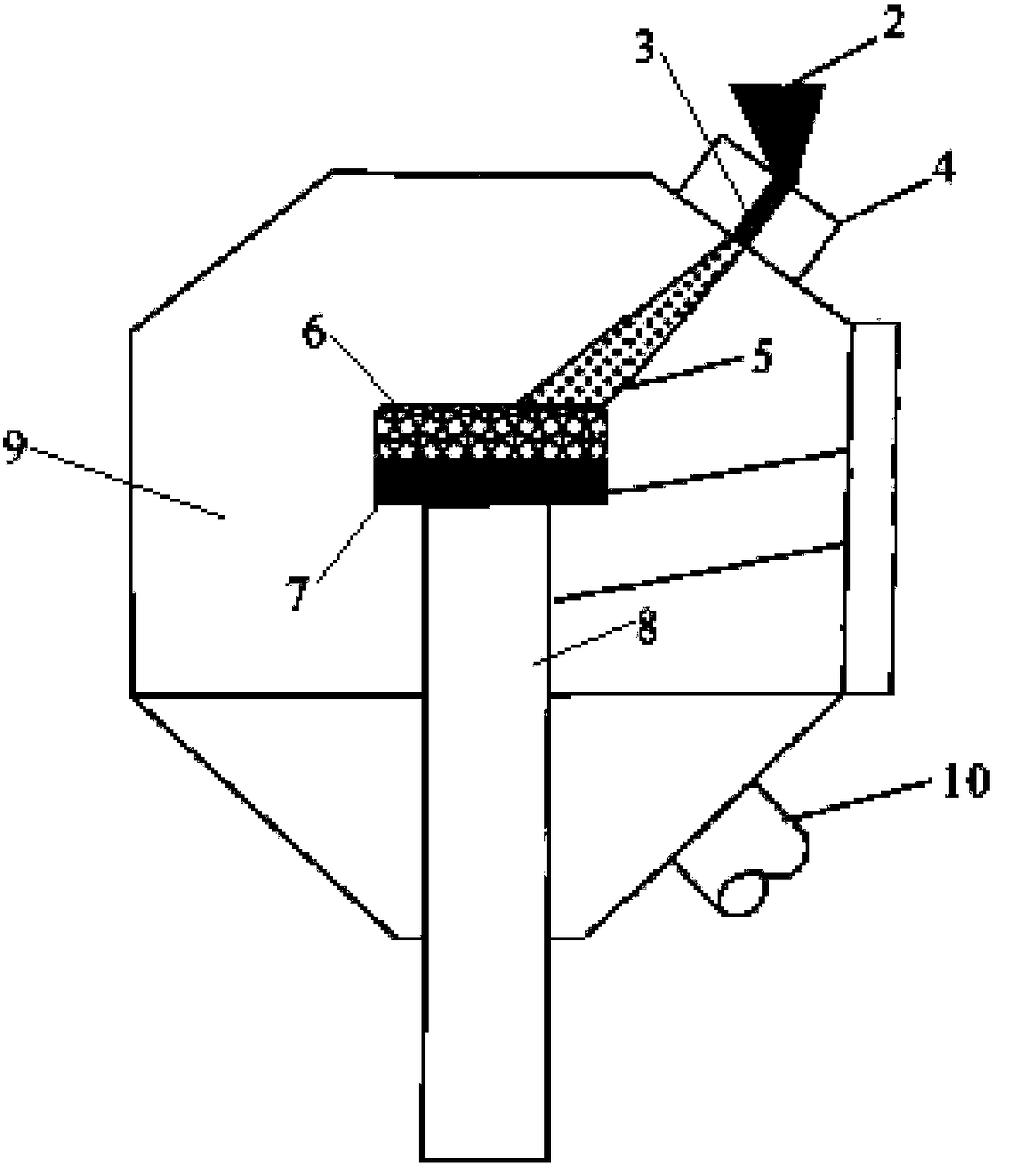

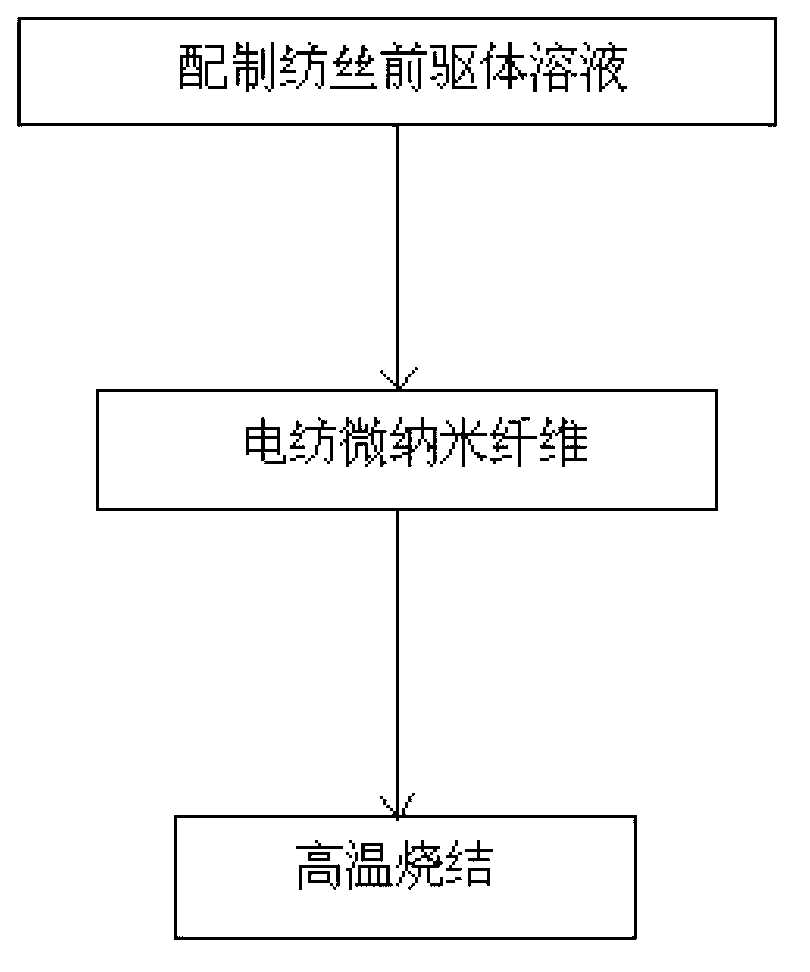

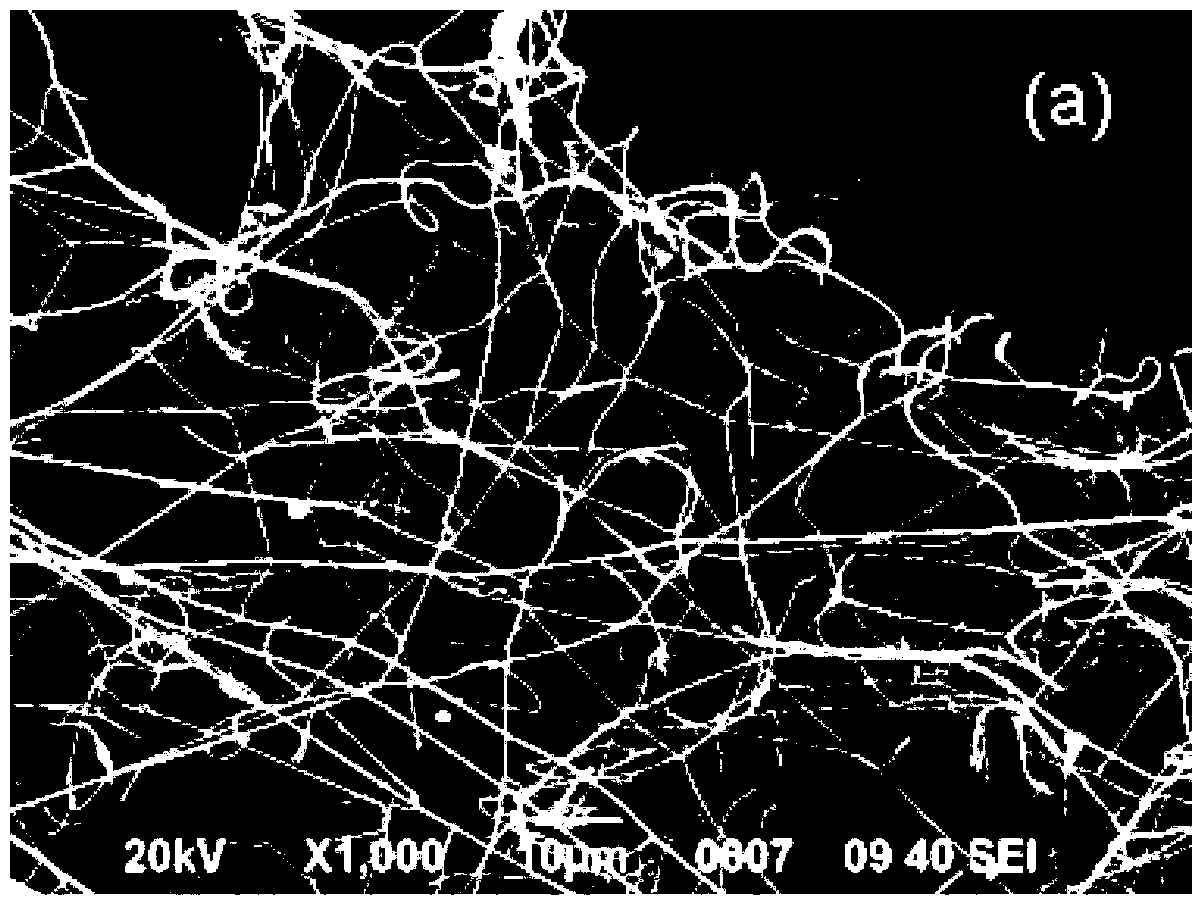

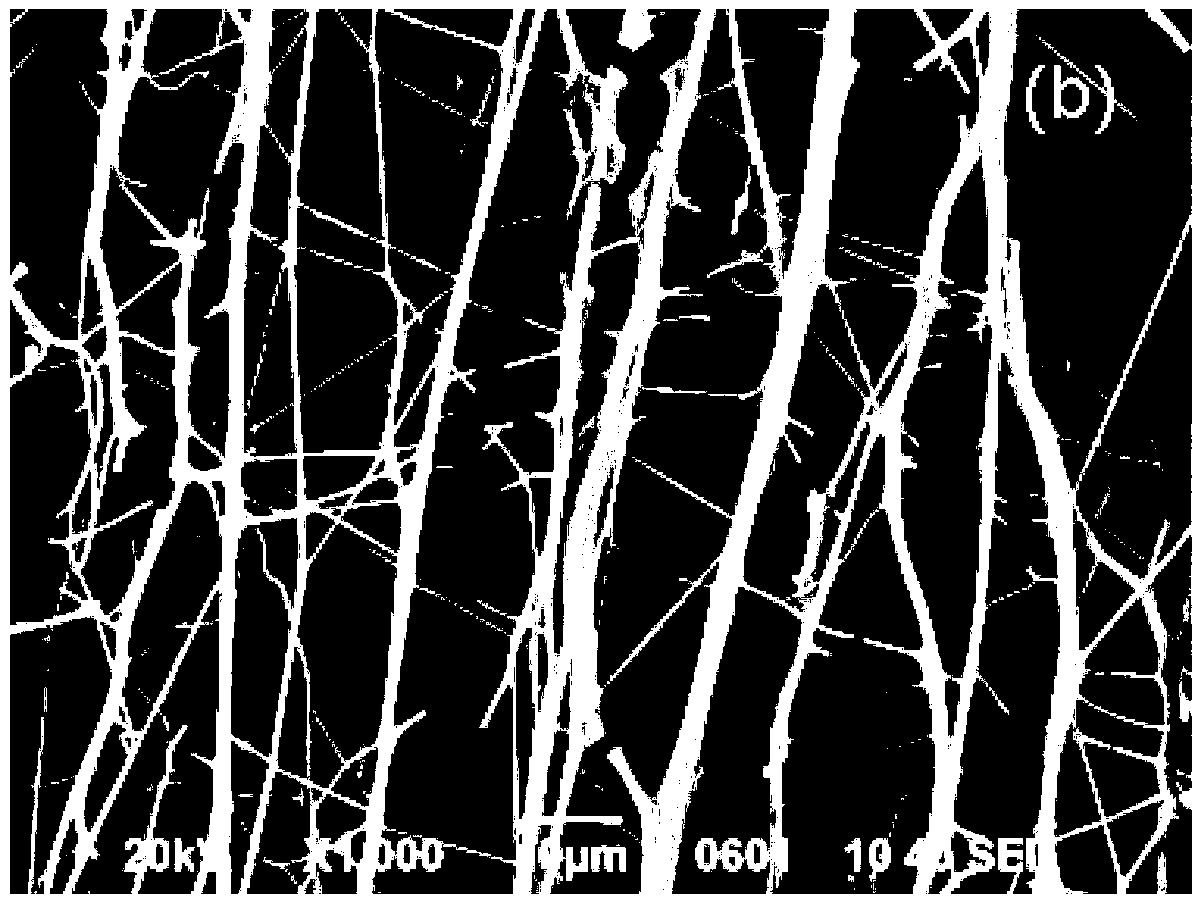

Preparation method of P-type zinc oxide micro/nano fibers

InactiveCN103011257ASolve the defects that are prone to generate more intrinsic donorsIt is easy to generate more intrinsic donor defects, and it is not easy to realizeMaterial nanotechnologyZinc oxides/hydroxidesFiberCerium nitrate

The invention belongs to the technical field of preparation of inorganic micro / nano fiber materials, and particularly relates to a preparation method of P-type zinc oxide micro / nano fibers, which comprises the steps of preparation of spinning precursor solution, electric spinning of micro / nano fibers and high-temperature sintering. The method specifically comprises the following steps: respectively preparing a polyvinylpyrrolidone ethanol solution and a lanthanum nitrate or cerium nitrate solution, and evenly mixing the two solutions to obtain a spinning precursor solution; using an aluminum foil as a collector electrode, putting a square silicon wafer with a silicon oxide insulating layer on the surface onto the aluminum foil, using the prepared precursor solution as the spinning solution, electrically spinning the micro / nano fibers by using a conventional electrostatic spinning device and method, and taking down the silicon wafer with micro / nano fibers for later use after finishing the electric spinning; and putting the silicon wafer with micro / nano fibers in a muffle furnace, and sintering at controlled temperature to obtain the P-type zinc oxide micro / nano fibers. The preparation method is easy and simple to operate, and has the advantages of reliable principle, strong practicality, high speed, high efficiency, low cost favorable product performance and environment friendliness.

Owner:QINGDAO UNIV

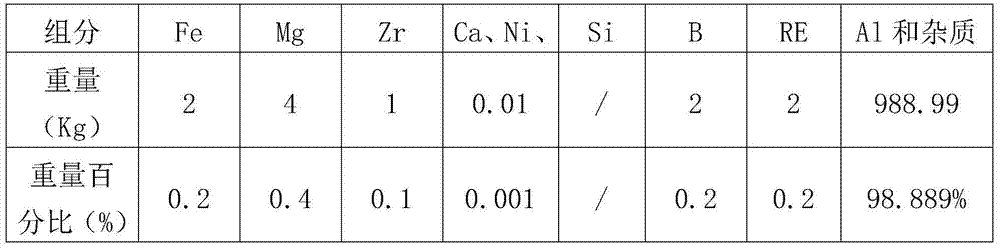

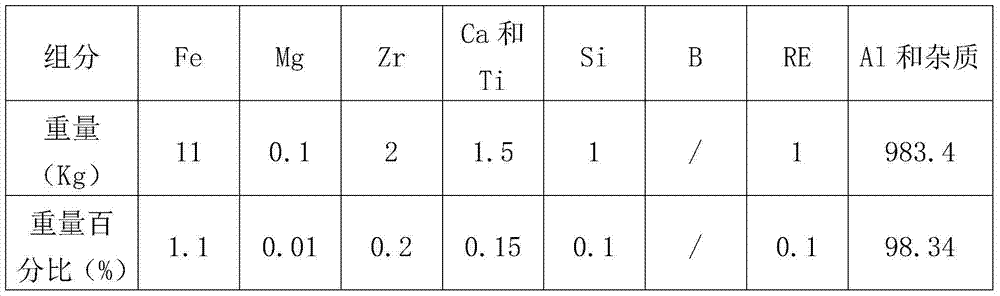

Al-Fe-Mg-Zr aluminum alloy used for coal mine cables, aluminum alloy cable and manufacturing method

PendingCN104299673AImprove performanceHigh mechanical strengthNon-insulated conductorsMetal/alloy conductorsCoalAluminium alloy

The invention discloses Al-Fe-Mg-Zr aluminum alloy used for coal mine cables. The Al-Fe-Mg-Zr aluminum alloy comprises 0.2 percent-1.1 percent of Fe, 0.01 percent-0.4 percent of Mg, 0.001 percent-0.2 percent of Zr, 0 percent-0.1 percent of Si, 0 percent-0.2 percent of B and the balance being Al and impurities, wherein the resistivity of the aluminum alloy is not larger than 0.028164 omega*mm<2> / m, the elongation at break is not lower than 10 percent, and ninety-degree fatigue bending frequency is larger than or equal to thirty. The aluminum alloy material is smelted, cast and rolled, so that an aluminum alloy rod is obtained; afterwards, the aluminum alloy rod is subjected to pulling, bunch stranding and softening, so that an aluminum alloy cable core is formed; next, the cable core is subjected to extruded insulation, cabling, sheath extrusion or armoring, so that an aluminum alloy cable is manufactured. The manufactured aluminum alloy cable has the advantages of being high in strength, high in electric conductivity, good in bending performance and the like, and therefore the requirements for cable performance in the field of coal mines can be satisfied.

Owner:ANHUI JOY SENSE CABLE

High-conductivity and high-shielding-effectiveness magnesium alloy and preparation method thereof

The invention provides high-conductivity and high-shielding-effectiveness magnesium alloy and a preparation method thereof, and belongs to the field of design of materials. The high-conductivity and high-shielding-effectiveness magnesium alloy is prepared from the following raw material components in percentage by mass: 0.5wt% to 3wt% of manganese, 0.1wt% to 0.5wt% of zirconium and the balance of pure magnesium and inevitable impurities. The preparation method comprises the following steps: firstly melting magnesium; adding magnesium-manganese intermediate alloy and magnesium-zirconium intermediate alloy; stirring, standing and then casting into a cast ingot; subsequently thermally homogenizing the cast ingot and rolling to obtain a corresponding plate. According to the preparation method disclosed by the invention, low-content magnesium-manganese intermediate alloy and magnesium-zirconium intermediate alloy are used for preparing novel high-conductivity and high-shielding-effectiveness wrought magnesium alloy; in comparison with an existing widely-used shielding material, the shielding material is low in cost, high in specific strength, higher than a traditional metal shielding material and a composite shielding material in specific shielding effectiveness, excellent in molding processability and applicable to the field of weight-sensitive electromagnetic protection.

Owner:CHONGQING UNIV

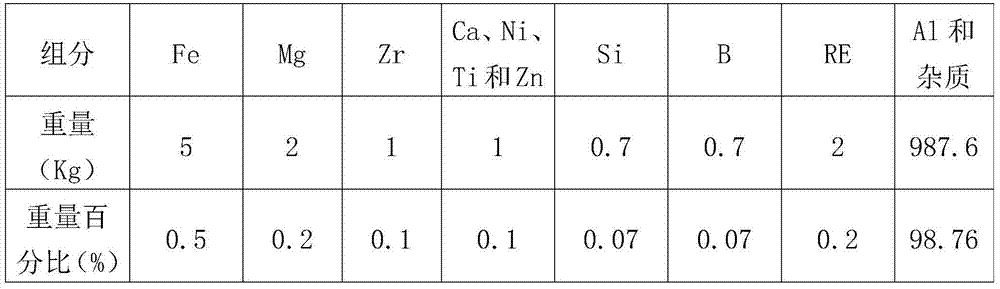

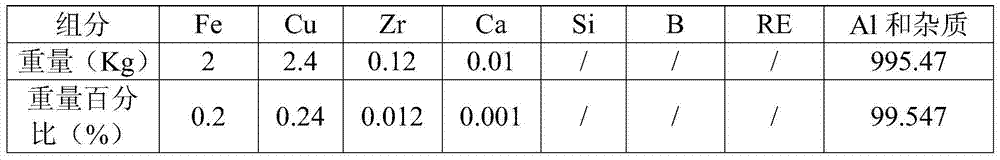

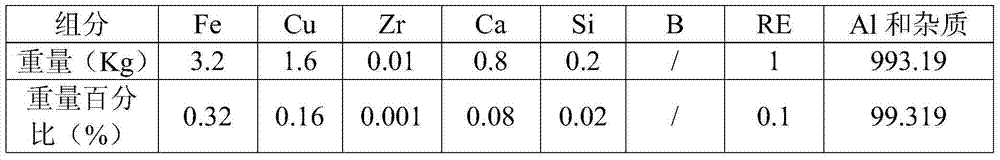

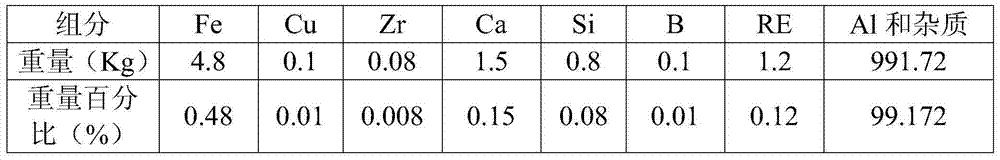

Al-Fe-Cu-Zr series aluminum alloy for cables for coal mines and aluminum alloy cable

PendingCN104294091AImprove performanceHigh mechanical strengthMetal/alloy conductorsCable/conductor manufactureAdditive ingredientHigh conductivity

The invention discloses an Al-Fe-Cu-Zr series aluminum alloy for cables for coal mines and an aluminum alloy cable. The aluminum alloy contains the ingredients in percentage by weight: 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.001-0.2% of Zr, 0-0.1% of Si, 0-0.2% of B, 0.001-0.15% of one element selected from Ca, Ni, Ti and Zn and the balance of Al and impurities. The aluminum alloy cable is produced through enabling the aluminum alloy to be subjected to the processes of melting, casting and rolling, so as to obtain aluminum alloy rods, then, carrying out drawing, stranding and softening, so as to form aluminum alloy wire cores, and then, carrying out extruded insulation, cabling and extruded sheathing or armoring on the conductor wire cores. The Al-Fe-Cu-Zr series aluminum alloy for the cables for the coal mines, disclosed by the invention, has the characteristics of high strength, high conductivity, good bending property and the like; the aluminum alloy cable produced from the aluminum alloy can meet the requirements on the properties of the cable in the field of the coal mines.

Owner:ANHUI JOY SENSE CABLE

Method for preparing in-situ deformation Cu-Ag composite material by using magnetic field

The invention relates to a method for preparing an in-situ deformation Cu-Ag composite material by using a magnetic field, belonging to the technical field of materials and comprising the following steps of: 1, with oxygen-free copper and electrolyzed silver as raw materials, preparing a Cu-Ag alloy liquid or Cu-Ag alloy ingot; 2, placing the Cu-Ag alloy liquid or Cu-Ag alloy ingot into a vacuum electric furnace, preserving the temperature and then cooling with the furnace, applying a static magnetic field or alternating-current magnetic field to obtain an as-cast Cu-Ag alloy; 3, preserving the temperature of the as-cast Cu-Ag alloy and then thermally forging to prepare a deformation Cu-Ag alloy; 4, drawing the formation Cu-Ag alloy to prepare a deformation Cu-Ag composite material; 5, thermally treating the deformation Cu-Ag composite material in vacuum, then drawing again; and 6, sequentially repeating the step 5 to obtain the in-situ deformation Cu-Ag composite material. The method provided by the invention effectively improves the ultimate tensile strength and the electric conductivity of the Cu-Ag alloy; and the prepared composite material has greatly improved property.

Owner:NORTHEASTERN UNIV

Cu-Cr in-situ composite with boron, silver and rare earth elements added and preparation method thereof

The invention discloses a Cu-Cr in-situ composite with boron, silver and rare earth elements added and a preparation method thereof. The invention is characterized by adopting multimode comprehensive strengthening technology such as multi-micro alloying, solid solution strengthening, aging strengthening, fine grain strengthening, distortion strengthening, fiber strengthening and the like, using Cu as the base and adding a little Cr and trace Ag and B, rare earth or rare earth compounds to prepare the high performance copper alloy in-situ composite through smelting, casting, hot forging or hot rolling, solid solution treatment, cold rolling or cold drawing, aging and the like. The prepared material has the advantages of high strength, good electric and thermal conductivity, simple preparation process and low cost, thus realizing industrial application in the aspects such as electrician switches, contact materials, resistance electrodes, rotor conductors of large electrical high speed turbine generators, overhead conductors of electric cars and electric trains, lead frames of very large scale integrated circuits and the like.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

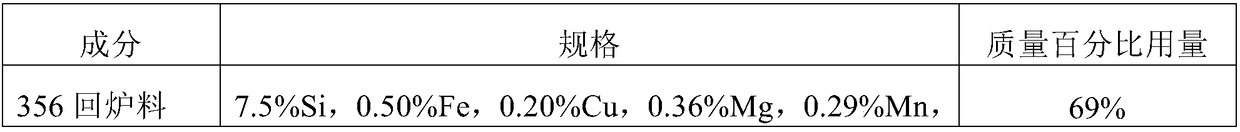

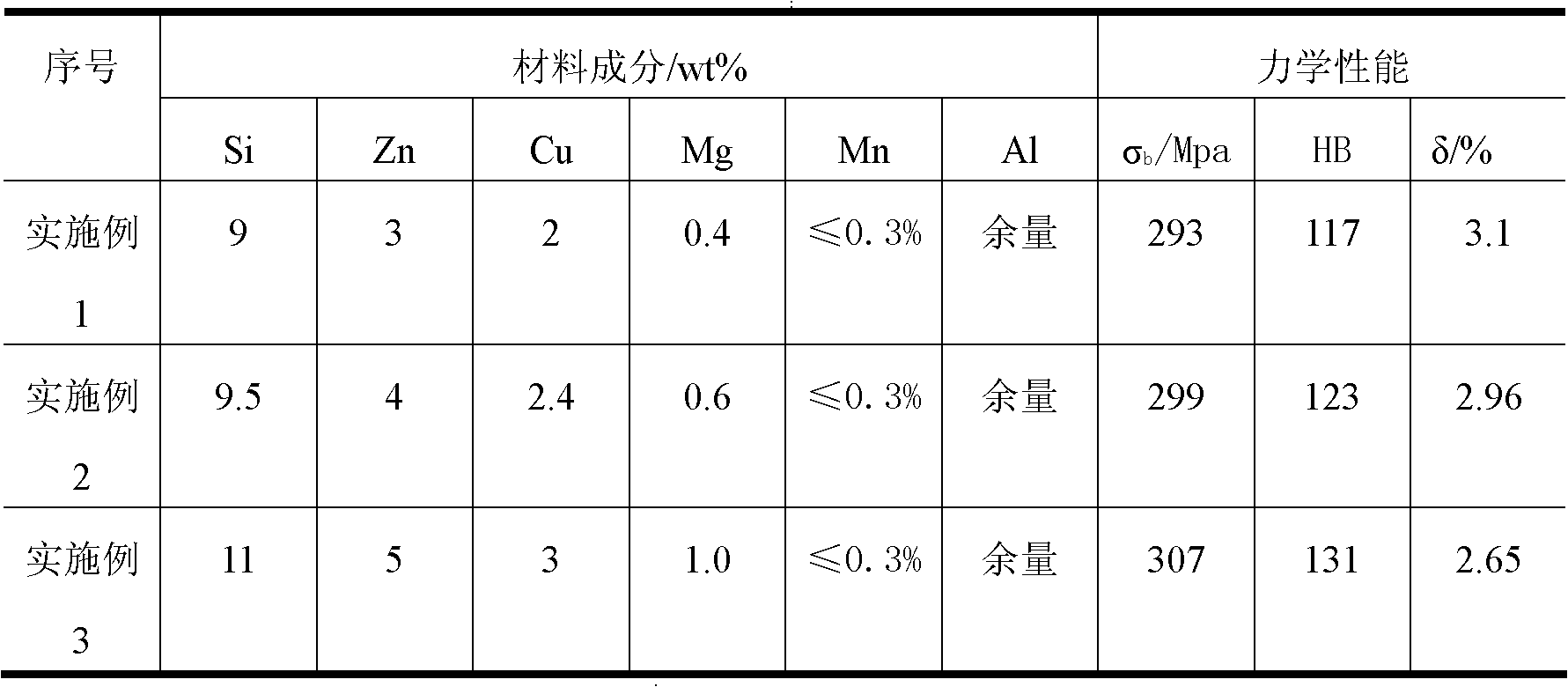

Casting aluminum-silicon alloy and strengthening method thereof

The invention discloses a casting aluminum-silicon alloy. The casting aluminum-silicon alloy comprises the following chemical components by weight percent: 9.0-11.0% of silicon, 3.0-5.0% of zinc, 0.4-1.0% of magnesium, 2.0-3.0% of copper, less than or equal to 0.3% of manganese and the balance of aluminum. The invention also discloses a strengthening method for casting the casting aluminum-silicon alloy. The method comprises the following steps: 1) adopting the smelting process: A) charging, B) melting and refining, C) performing modification, and D) pouring; and 2) performing heat treatment:A) performing solution treatment and performing aging treatment. By adopting the strengthening method, after the aging treatment, the number of strengthening phases can be increased and the strengthening phases with a good strengthening effect can be obtained; by adopting dispersion strengthening, the material can have higher strength and hardness than ZL108; because of the reduction of the hard and brittle silicon phase in the structure, the plasticity of the material is increased, the casting performance of the material is good and the product quality and dimensional accuracy of the castingare high. The application range of the casting aluminum-silicon alloy can be expanded.

Owner:镇江汇通金属成型有限公司 +1

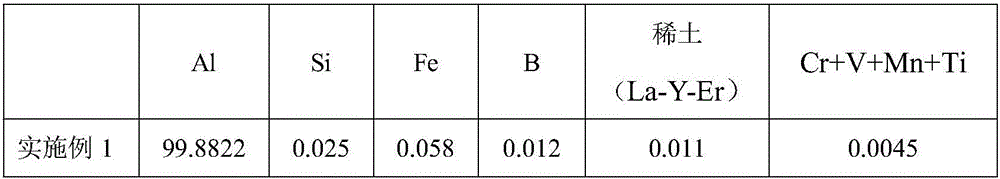

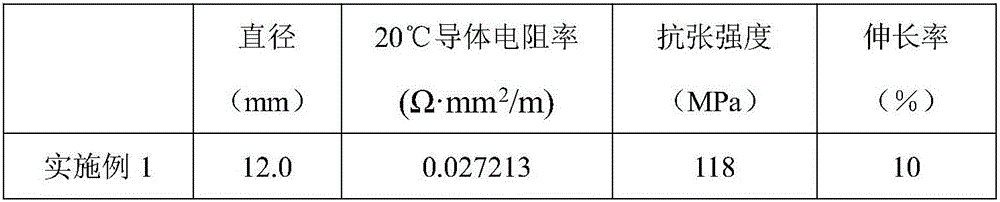

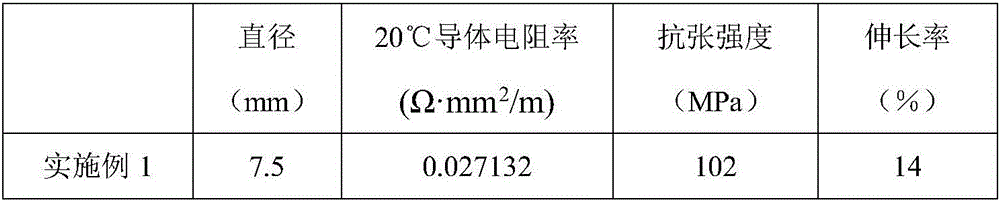

Low-cost 63% IACS high-conductivity duralumin conductor and manufacturing method thereof

ActiveCN105950893AImprove conductivityLow costNon-insulated conductorsConductive materialDuraluminRare earth

The invention discloses a low-cost 63% IACS high-conductivity duralumin conductor and a manufacturing method thereof. The method comprises the steps that firstly, electrician aluminum is smelted, wherein a 99.90% high-purity aluminum ingot is selected; secondly, rare earth treatment and boronizing treatment are conducted on molten aluminum, all elements in the molten aluminum comprise, by mass percent, smaller than or equal to 0.03 wt% of Si, smaller than or equal to 0.06 wt% of Fe, smaller than or equal to 0.005 wt% of (Cr+V+Mn+Ti), 0.01 wt%-0.03 wt% of B, 0.01 wt%-0.03 wt% of rare earth and larger than or equal to 99.88 wt% of Al, and the rare earth includes La, Y and Er; thirdly, the molten aluminum in the second step is continuously cast and rolled, an aluminum rod is produced, the aluminum rod with the diameter phi of 7.5 mm is extruded through an aluminum extruder, and aluminum wires of various shapes and specifications are formed through cold drawing and drawing; and fourthly, the aluminum wires are stranded to form the aluminum conductor according to the design requirement, wherein the tensile strength of the aluminum conductor is larger than or equal to 168 MPa, and the conductor resistance rate is smaller than or equal to 0.027350 omega.mm<2> / m at the temperature of 20 DEG C. The duralumin conductor has excellent electric conduction performance, the cost of the conductor is reduced by 15%-25%, and the economic efficiency of a circuit is further improved.

Owner:FAR EAST CABLE +3

High-conductivity 6 series aluminum alloy and production process therefor

InactiveCN110983124ALow thermal conductivityReduced mechanical propertiesExtrusion control devicesUltimate tensile strengthMechanical property

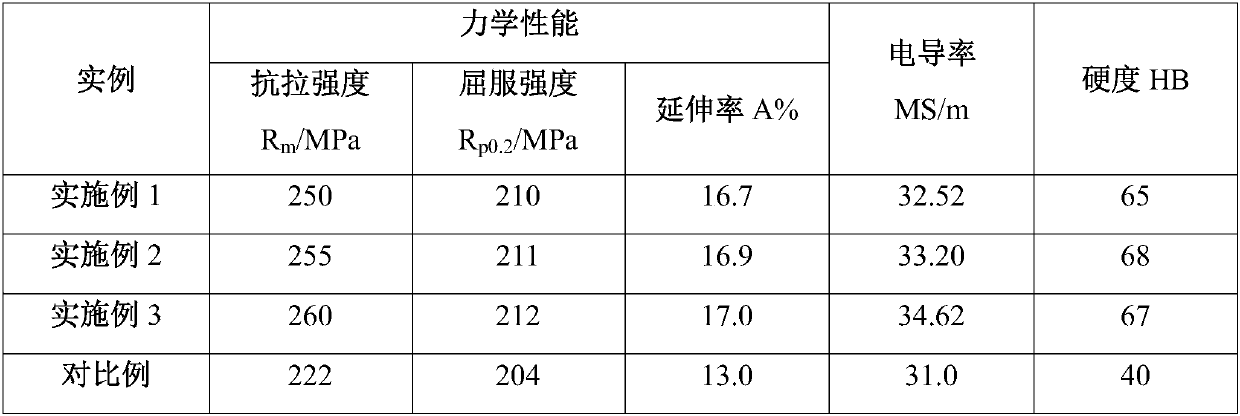

The invention belongs to the technical field of aluminum alloy production processes, and relates to a high-conductivity 6 series aluminum alloy and a production process therefor. The high-conductivity6 series aluminum alloy is prepared from the following element components in percentage by weight: 0.55%-0.60% of Si, 0.10%-0.15% of Fe, 0.05%-0.08% of Cu, 0.01%-0.02% of Mn, 0.60%-0.65% of Mg, 0.01%-0.02% of Cr, not greater than 0.01% of Ti, 0.05%-0.08% of Zn, not greater than 0.01% of V, 0.15%-0.18% of Gd, 0.015%-0.02% of B, not greater than 0.03% of single impurities, not greater than 0.10% ofimpurities and the balance Al; by improving a formula and the process, the tension strength of the aluminum alloy reaches 250 Mpa, the yield strength reaches 210 Mpa, the percentage elongation afterfracture reaches 16.7%, and the conductivity Gamma is equal to 32.52 MS / m; and the hardness HB is equal to 65, so that the mechanical property and the conductivity of the 6 series aluminum alloy are obviously improved.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

Magnesium-zinc-copper magnesium alloy containing cerium

The invention discloses a magnesium-zinc-copper magnesium alloy containing cerium, which is applicable to the field of metal materials. The magnesium-zinc-copper magnesium alloy containing cerium is prepared from the following components in percentage by weight: 6.0-10.0% of Zn, 3.0-10.0% of Cu, 0.15-1.80% of Ce, no more than 0.15% of inevitable impurities and the balance of Mg. Ce is added on the basis of the Mg-Zn-Cu alloy to refine the grain structure, thereby influencing the distribution of Zn and Cu in the alloy, and the type, shape and content of the second phase. The magnesium-zinc-copper magnesium alloy containing cerium has high room-temperature properties; and at room temperature, the tensile strength is not lower than 320 MPa, the yield strength is not lower than 260 MPa, and the elongation percentage is 9-11%.

Owner:CHONGQING UNIV

High conductivity rare earth hard aluminum conductor and preparation method

InactiveCN103093855AReduce solid solubilityReduce the effect of conductivityPower cablesMetal/alloy conductorsGadoliniumRare earth

The invention discloses a high conductivity rare earth hard aluminum conductor which comprises, by weight, 0.0887% to 0.145% of iron, iron with a weight ratio of 1.7 to 2.5 with the silicon, 0.01 % to 0.12 % of boron, 0.01% to 0.15% of gadolinium and aluminum. The invention further discloses a preparation method of the high conductivity rare earth hard aluminum conductor. The preparation method mainly comprises matching aluminum ingots, melting and carrying out boronizing, refining and other processes, the intensity of an obtained hard aluminum conductor is 160Mpa, electric conductivity is 63% IACS, and tensile strength is 160Mpa. Cables produced by utilizing the conductor can continue to be erected by using a traditional construction process, in a line operating process, line loss is reduced, and construction cost is saved.

Owner:SOUTHEAST UNIV +1

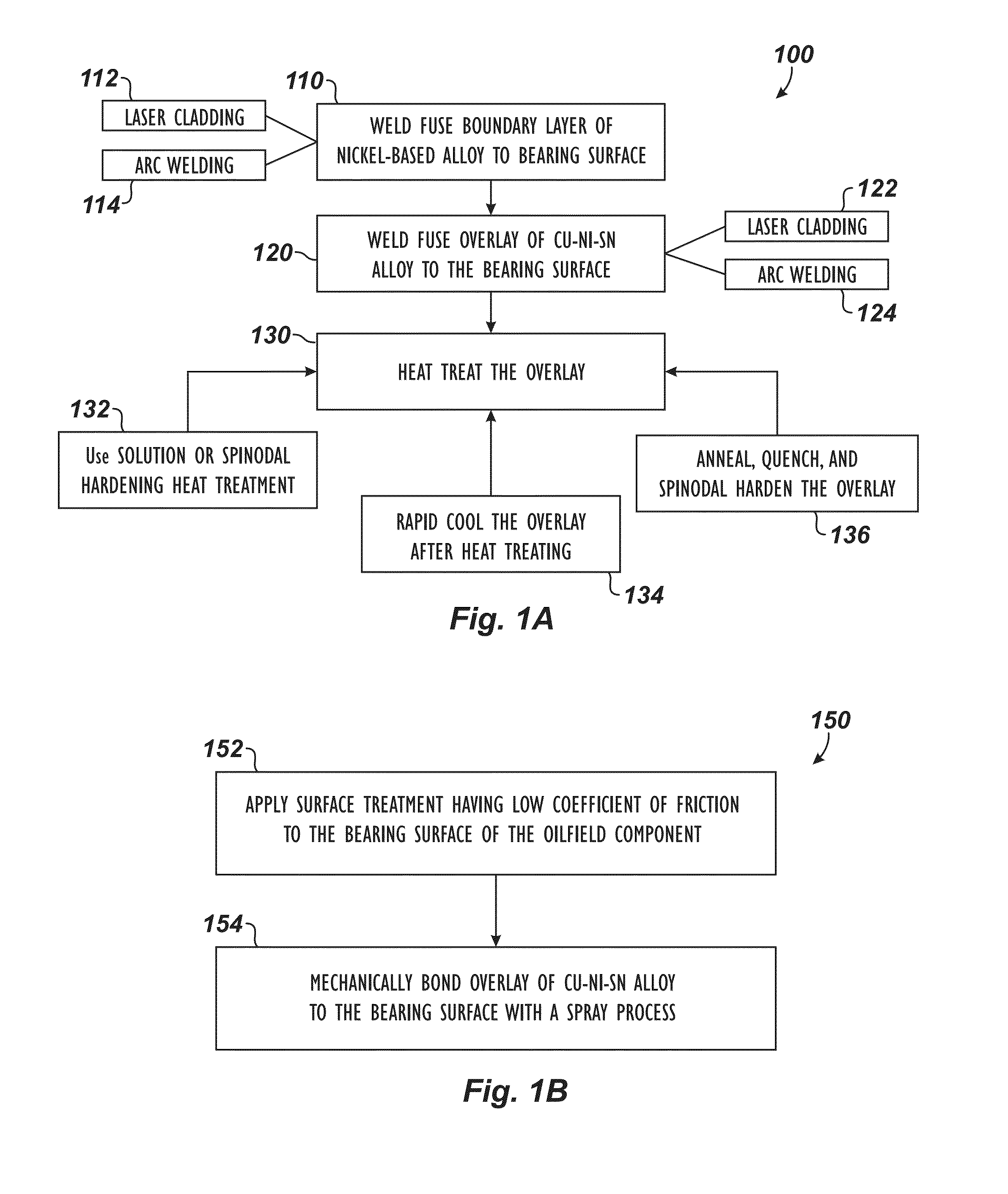

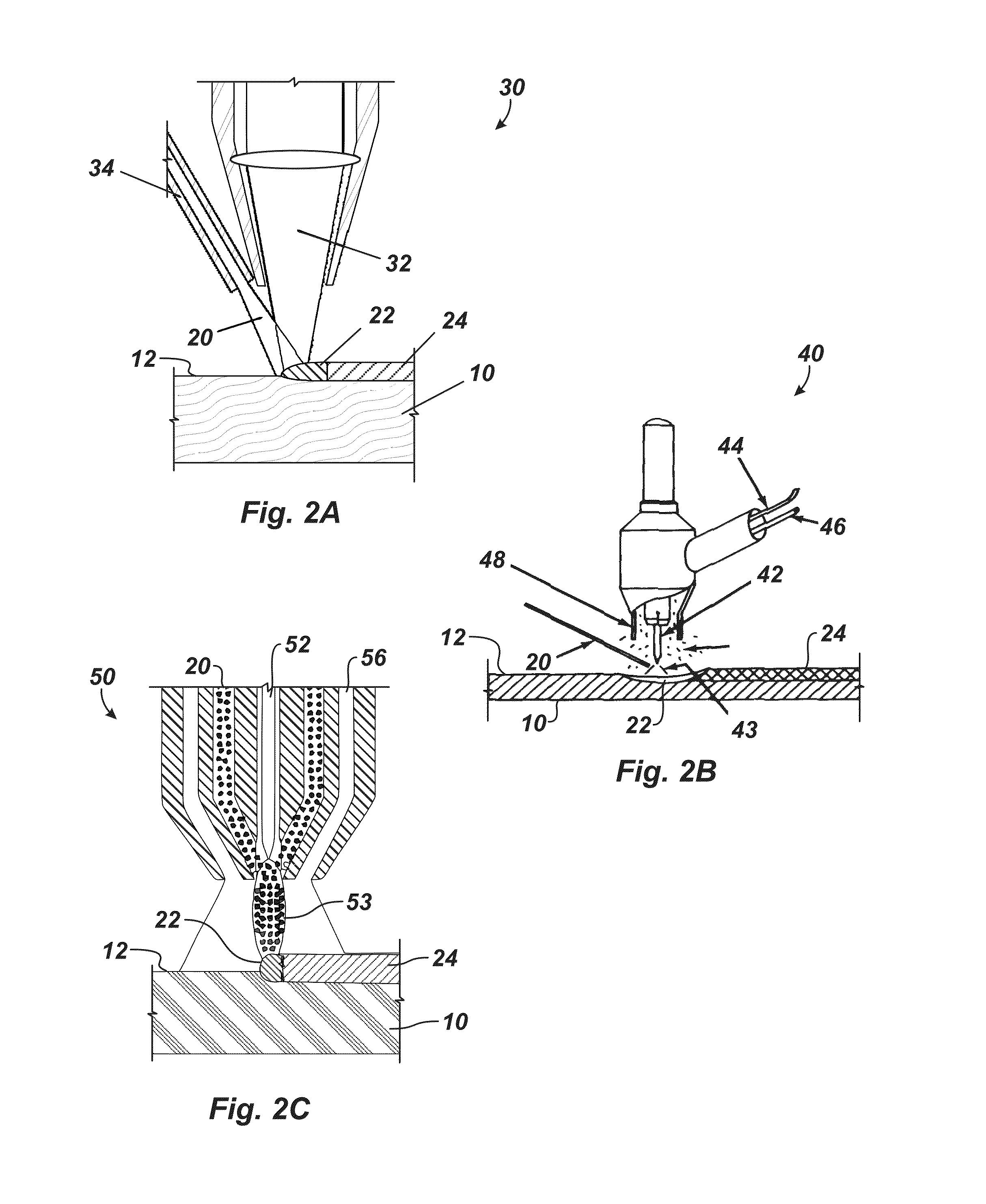

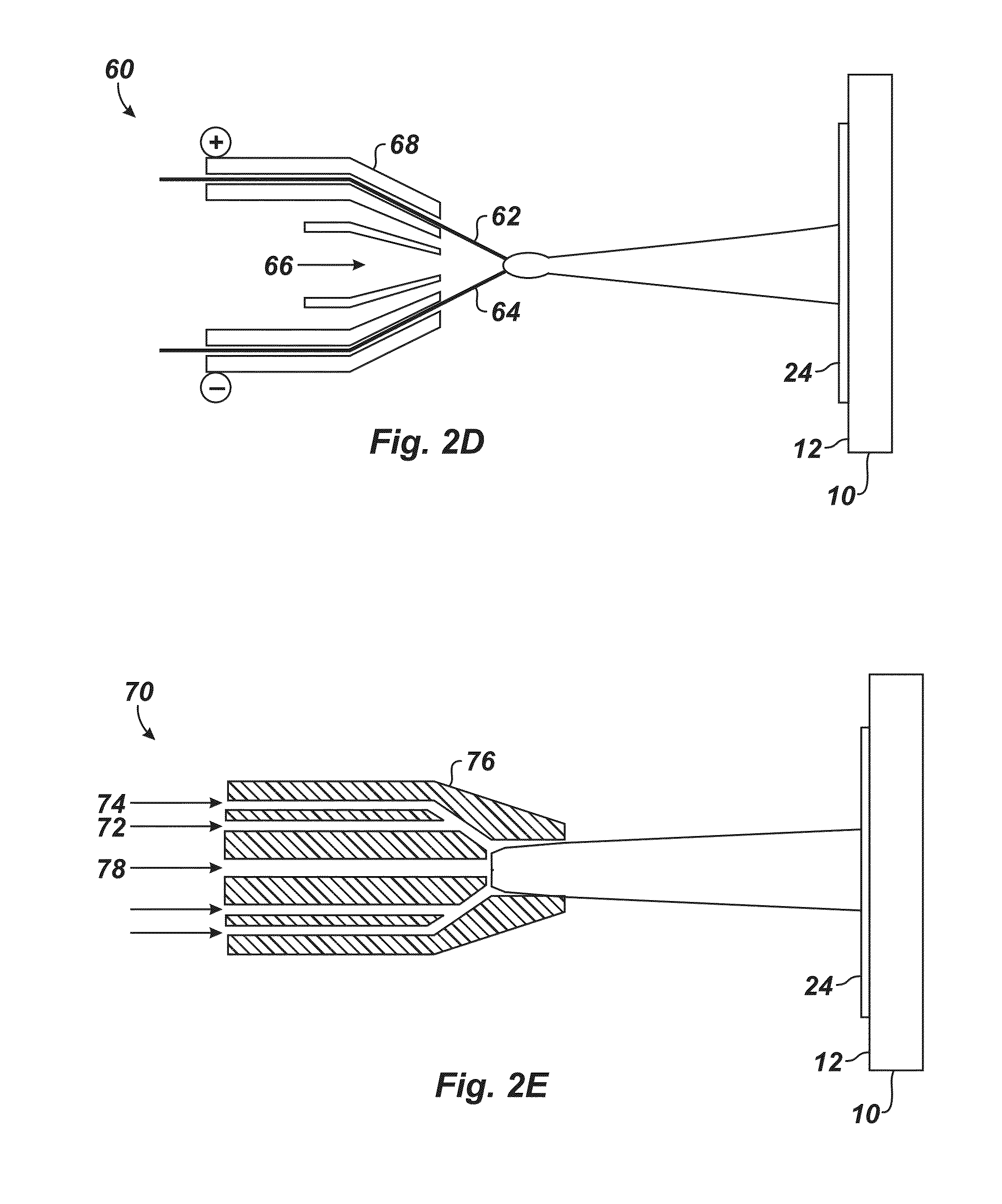

Cu-Ni-Sn Alloy Overlay for Bearing Surfaces on Oilfield Equipment

ActiveUS20150111793A1Reduce solid solubilityAvoid problemsDielectric heatingMolten spray coatingAlloyTungsten

A bearing surface of an oilfield component is treated by applying a surface treatment having a low coefficient of friction to the bearing surface of the oilfield component by weld fusing an overlay of a Cu—Ni—Sn alloy material to the bearing surface. Weld fusing the overlay of the Cu—Ni—Sn alloy material to the bearing surface can involve laser surface cladding the overlay of the Cu—Ni—Sn alloy material to the bearing surface, gas tungsten arc welding the overlay of the Cu—Ni—Sn alloy material to the bearing surface, or plasma tungsten arc welding the overlay of the Cu—Ni—Sn alloy material to the bearing surface.

Owner:WEATHERFORD TECH HLDG LLC

High-titanium-carbide steel bond hard alloy mold material

The invention discloses a high-titanium-carbide steel bond hard alloy mold material which comprises 55-65 wt% of titanium carbide and 35-45 wt% of iron-base binding phase. The iron-base binding phase comprises 0.2-0.6% of C, 1.5-4% of Cr, 0.8-1.8% of Mn, 2.0-4.0% of Mo, 2-8% of Ni, 0.5-2.0% of Cu, 0-1.01% of alloy additive and the balance of Fe. The preparation method comprises the following steps: thoroughly mixing the raw material powders according to the optimized proportion to obtain a mixed powder, and carrying out wet milling, filtration, drying, cold isostatic compaction, vacuum sintering and heat treatment to obtain the required mold material. The high-titanium-carbide steel bond hard alloy only adopts the normalizing heat treatment, the hardness reaches higher than HRA87, and the strength is high and satisfies the service performance of normal-temperature and high-temperature mold materials.

Owner:LAIWU JINWEI NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com