Patents

Literature

359results about How to "High ignition point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

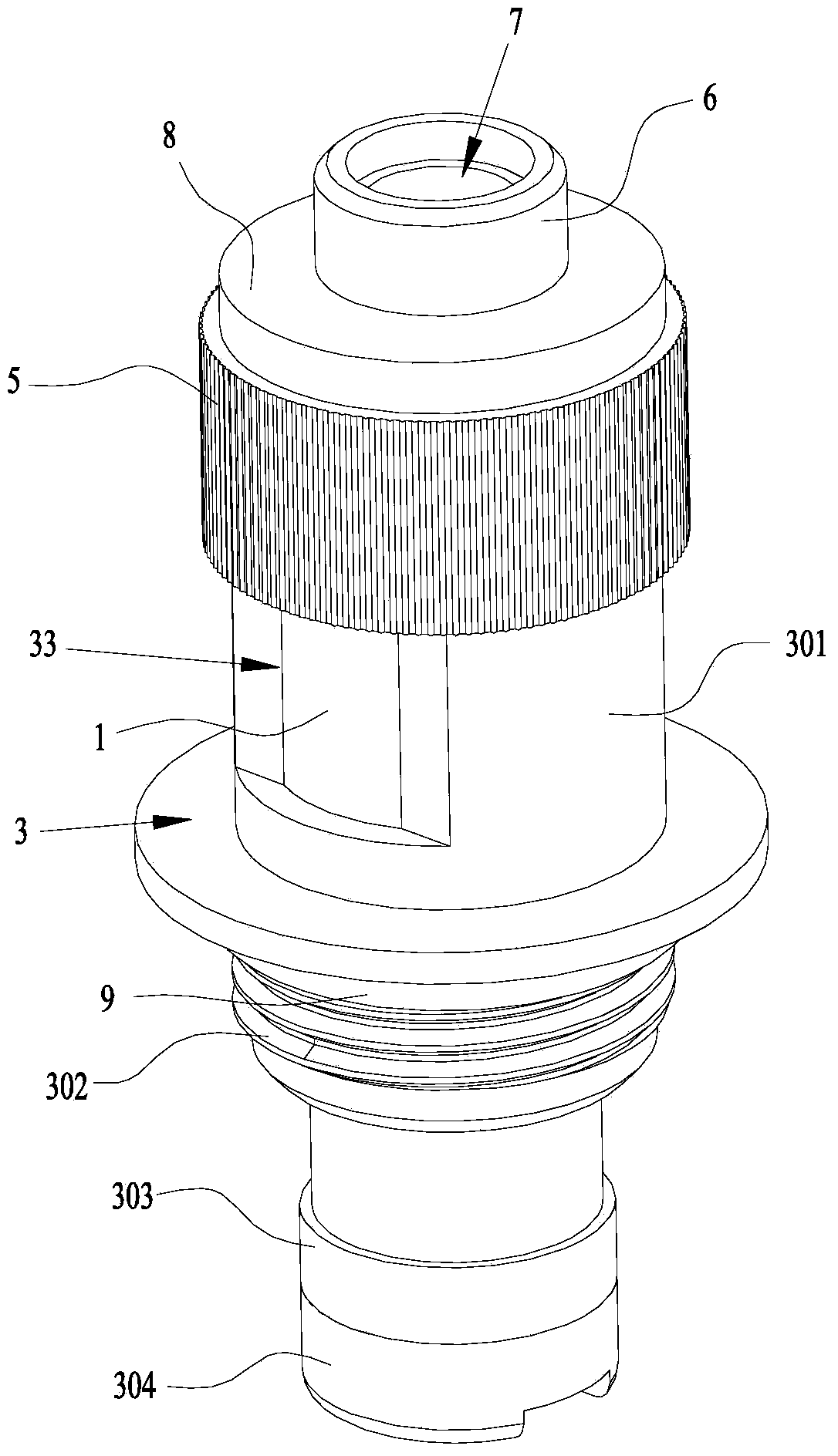

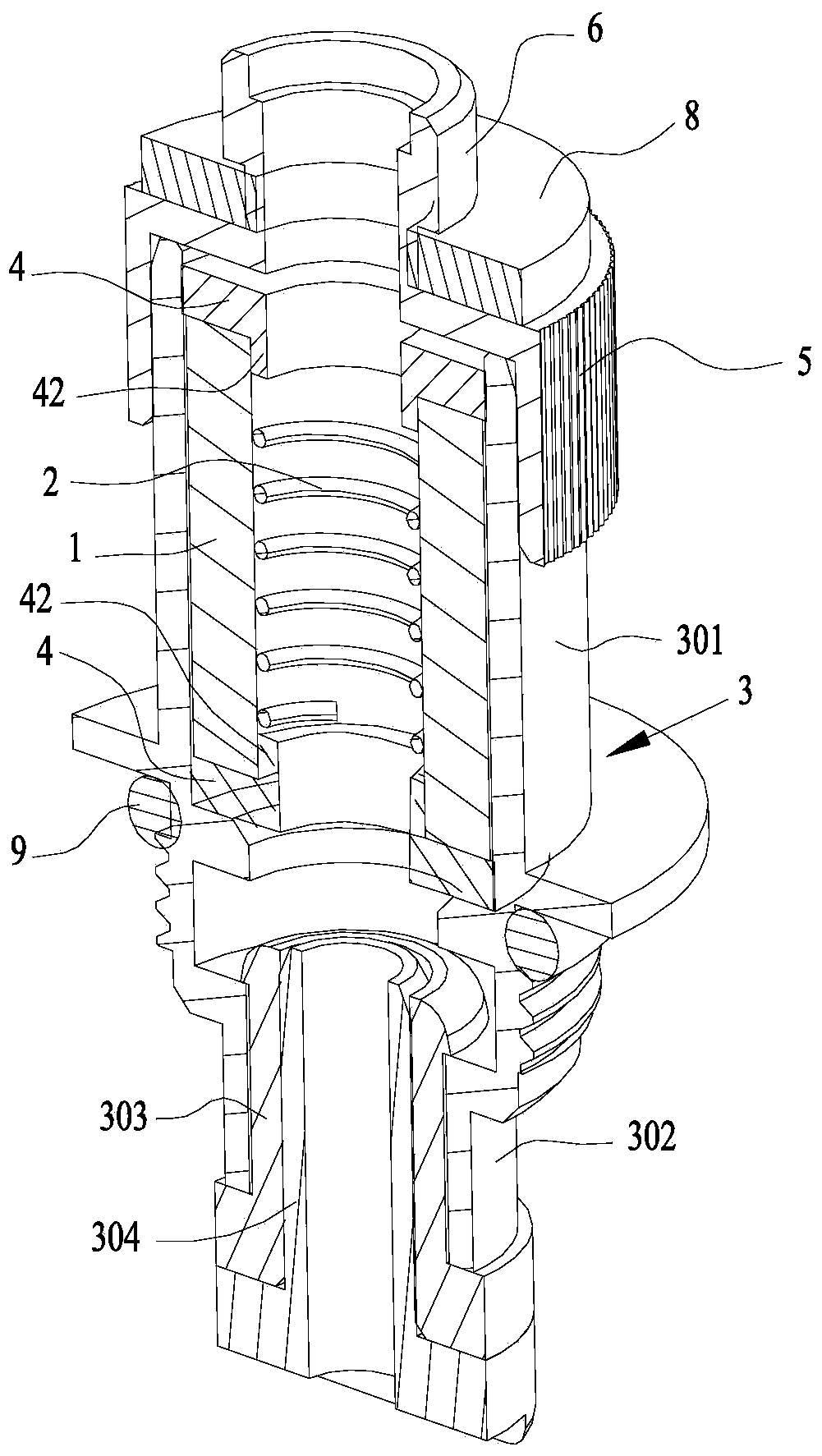

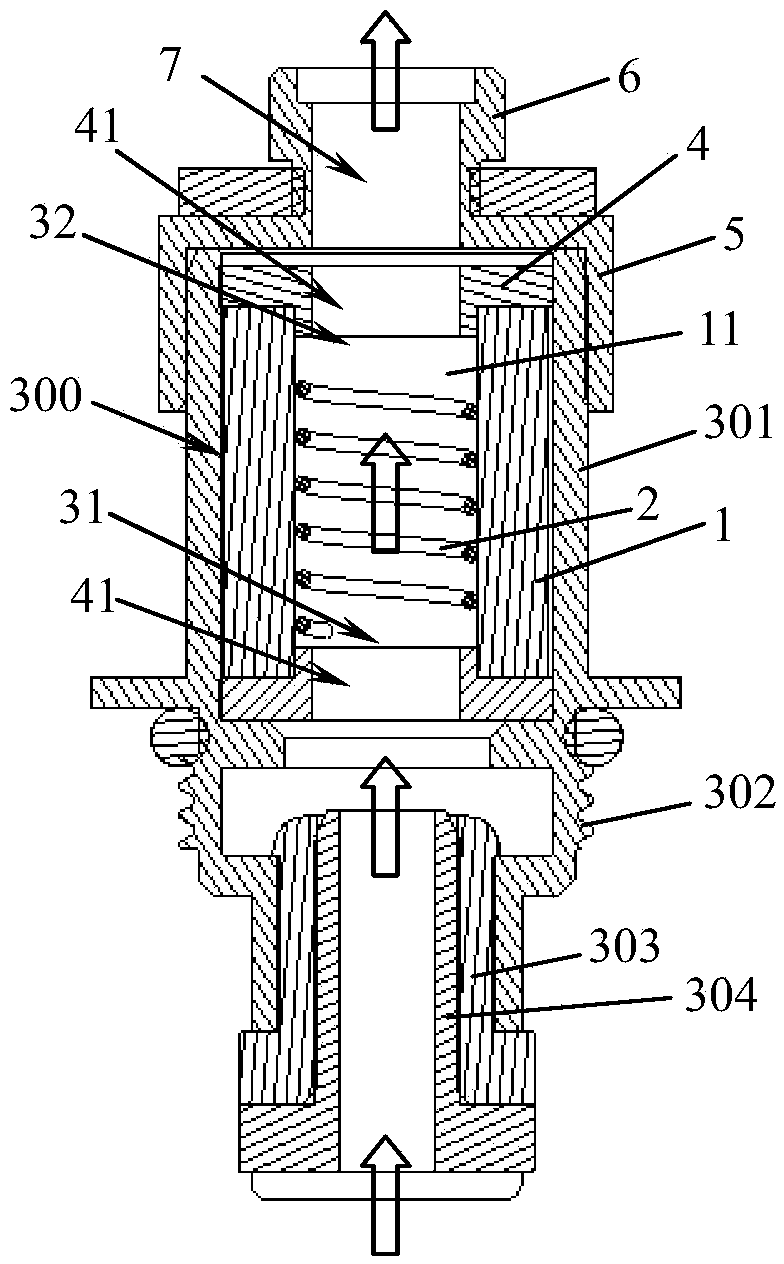

Heating assembly for electronic cigarette

ActiveCN104068476ALong-term efficient heating workImprove reliabilityTobacco devicesEngineeringElectronic cigarette

The invention discloses a heating assembly for an electronic cigarette. The heating assembly comprises a liquid guide ceramic body, a heating wire and a fixed seat, wherein an accommodating cavity is formed in the fixed seat, the liquid guide ceramic body is fixed in the accommodating cavity, an inlet and an outlet which are communicated with the accommodating cavity are formed in the both ends of the fixed seat, a cigarette liquid inlet communicated with the accommodating cavity is opened in the sidewall of the fixed seat, a fixing hole penetrates in the liquid guide ceramic body, an orifice at one end of the fixing hole is opposite to the inlet, and an orifice at the other end of the fixing hole is opposite to the outlet; and the heating wire is fixed in the fixing hole, in contact with the wall of the fixing hole, and electrically connected with the fixed seat. The heating assembly disclosed by the invention is high in atomization efficiency and reliability, and moreover, the generated cigarette smoke is good in taste.

Owner:SHENZHEN KANGER TECH CO LTD

Refrigerating machine oil combination and preparation method thereof

ActiveCN101177643AImprove solubilityGood fluidity at low temperatureLiquid hydrocarbon mixtures productionBase-materialsAlkaneSolubility

The invention relates to a refrigerant machine oil composition, comprising a mixed Alpha olefin polymer oil which is adopted as base oil and additive, wherein, a viscosity of the mixed Alpha olefin polymer oil at 40 DEG C ranges from 3 square millimeter per second to less than 6 square millimeter per second; the mixed Alpha olefin polymer oil is C15-C22 mixed isoolefine, C15-C22 mixed isoparaffin or the mixture of C15-C22 mixed isoolefine and C15-C22 mixed isoparaffin. The refrigerant machine oil composition provided by the invention has the advantages that: (1) good solubility with R600A refrigerating fluid, and floc point being lowered to minus 70 DEG C; (2) excellent fluidity in low temperature, with a pour point lowering to minus 70 DEG C, and a kinematic coefficient of the viscosity being less than 500 square millimeter per second at minus 40 DEG C; (3) comparatively apparent energy saving effect which is respectively higher than the refrigerant machine oil with a viscosity of 22 and 10 square millimeter per second by 14 percent and 4 percent at 40 DEG C.

Owner:BEIJING FRIENDLINK PETROCHEM T&D CO LTD

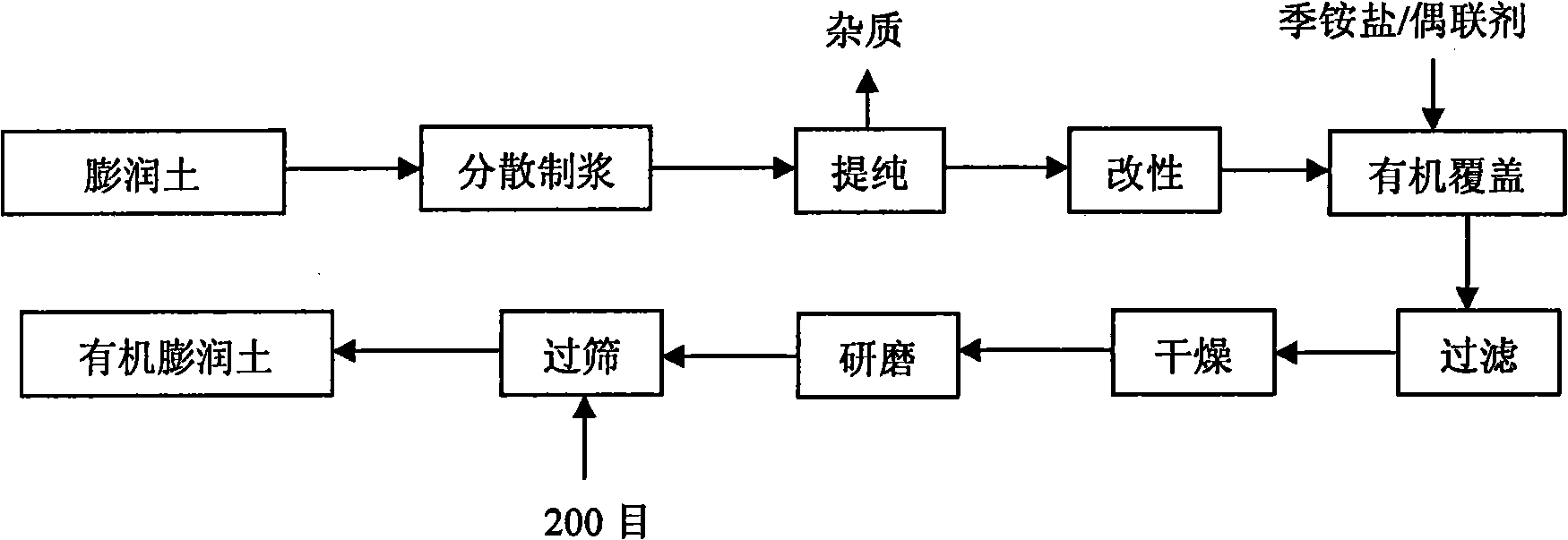

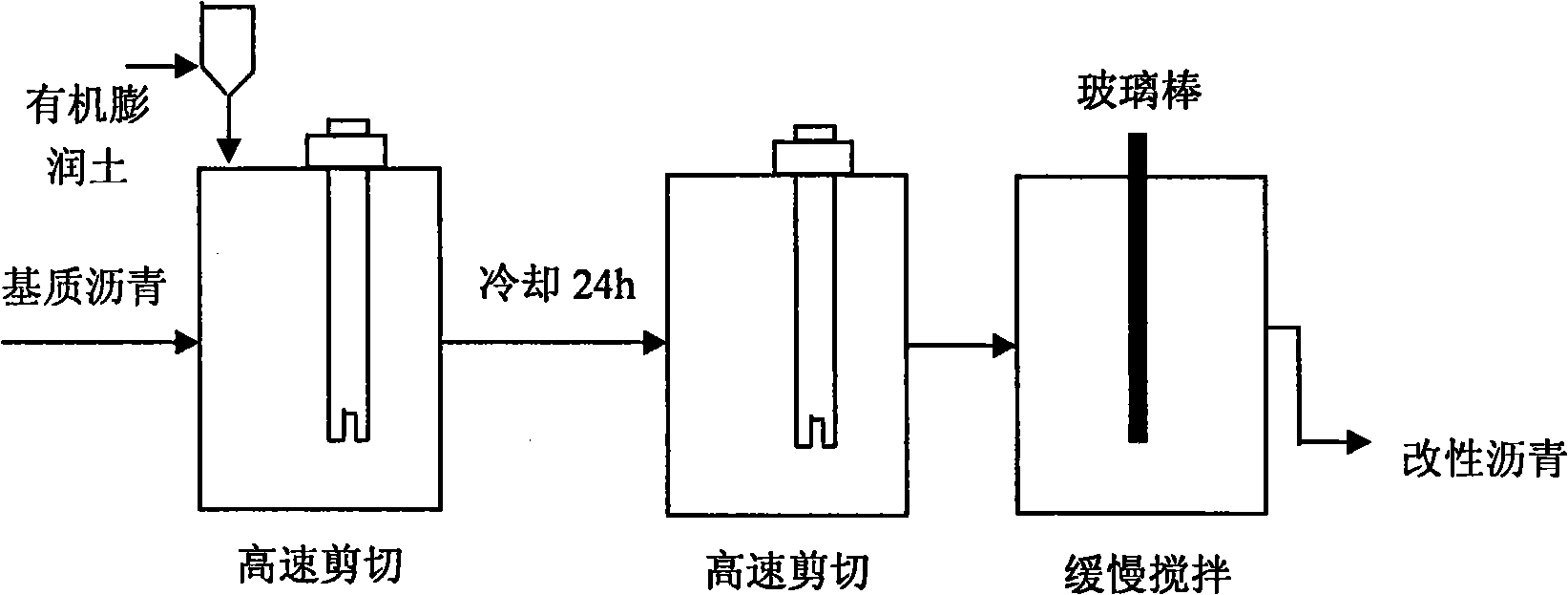

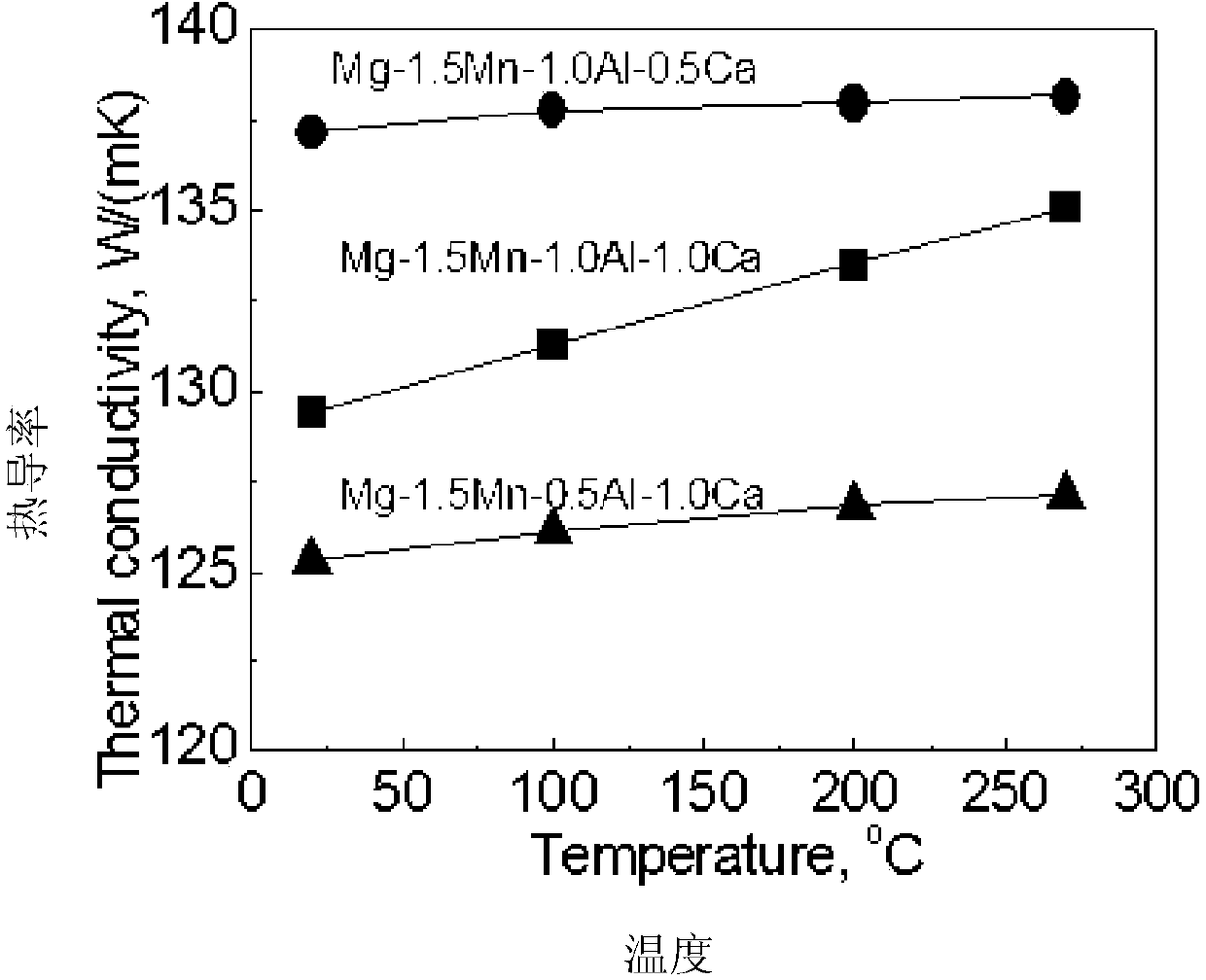

Phyllosilicate nano modified asphalt by dual processing of intercalation and coupling and preparation method thereof

InactiveCN101525492AImprove high temperature stabilityEnhanced toughening effectBuilding insulationsOrganificationCoupling

The invention adopts organic cation intercalator and coupling agent to carry out organification intercalation processing on laminated clay silicate, so as to prepare organification laminated clay silicate and mix the silicate with liquated road asphalt to form the modified asphalt. The invention also relates to the preparation process of the modified asphalt. The modified asphalt of the invention not only has better road performance than that of matrix asphalt but also prevents premature failure of asphalt road surface and lengthens service life of the road surface; in addition, the cost of materials and processing devices is far lower than the cost of polymer nano modified asphalt.

Owner:CHONGQING JIAOTONG UNIVERSITY

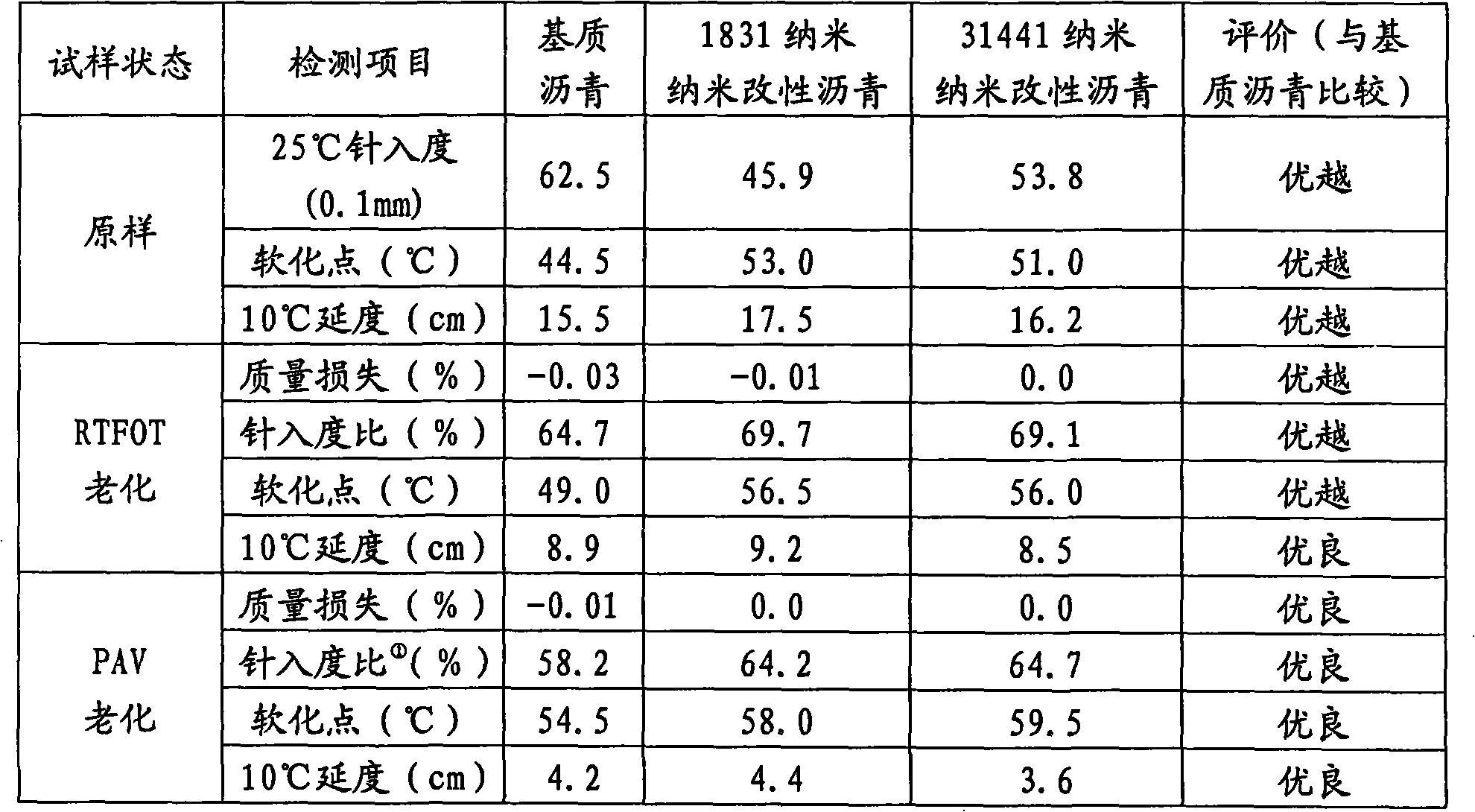

Bamboo floor machining process

ActiveCN102335943AIncrease profitHigh ignition pointWood working apparatusFlat articlesEngineeringAdditional values

The invention relates to a bamboo product machining method, in particular to a bamboo floor machining process which sequentially comprises the steps of: sawing bamboo, chipping, hacking, pressing, bleaching or carbonizing, gum-dipping, drying, stamping and forming. Bamboo fiber powder and bamboo charcoal powder which are subjected to gum dipping are doped during the stamping. After the machining process in the invention is adopted, because bamboo scraps and the bamboo fibers are fully utilized, the utilization rate of raw materials is greatly increased and the production cost is reduced. Meanwhile, a bamboo floor machined by adopting the two materials can be used for effectively purifying air in the family environment, thus the additional value of the bamboo floor is increased. Ammonium polyphosphate is added during the gum dipping, the fire point of the floor can be increased, and the safety property of the bamboo floor is improved.

Owner:JIANGXI NANFENG ZHENYU IND GRP

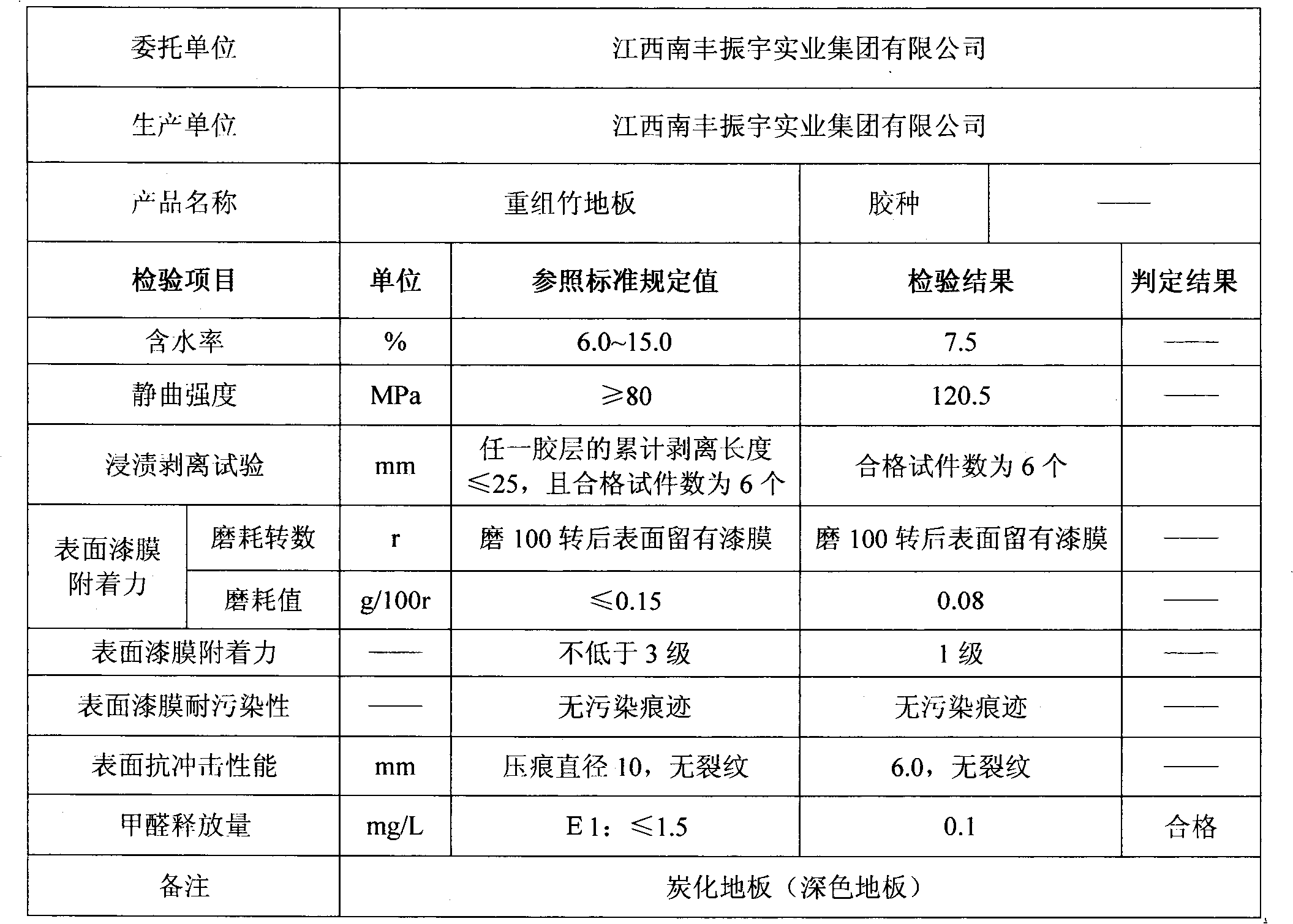

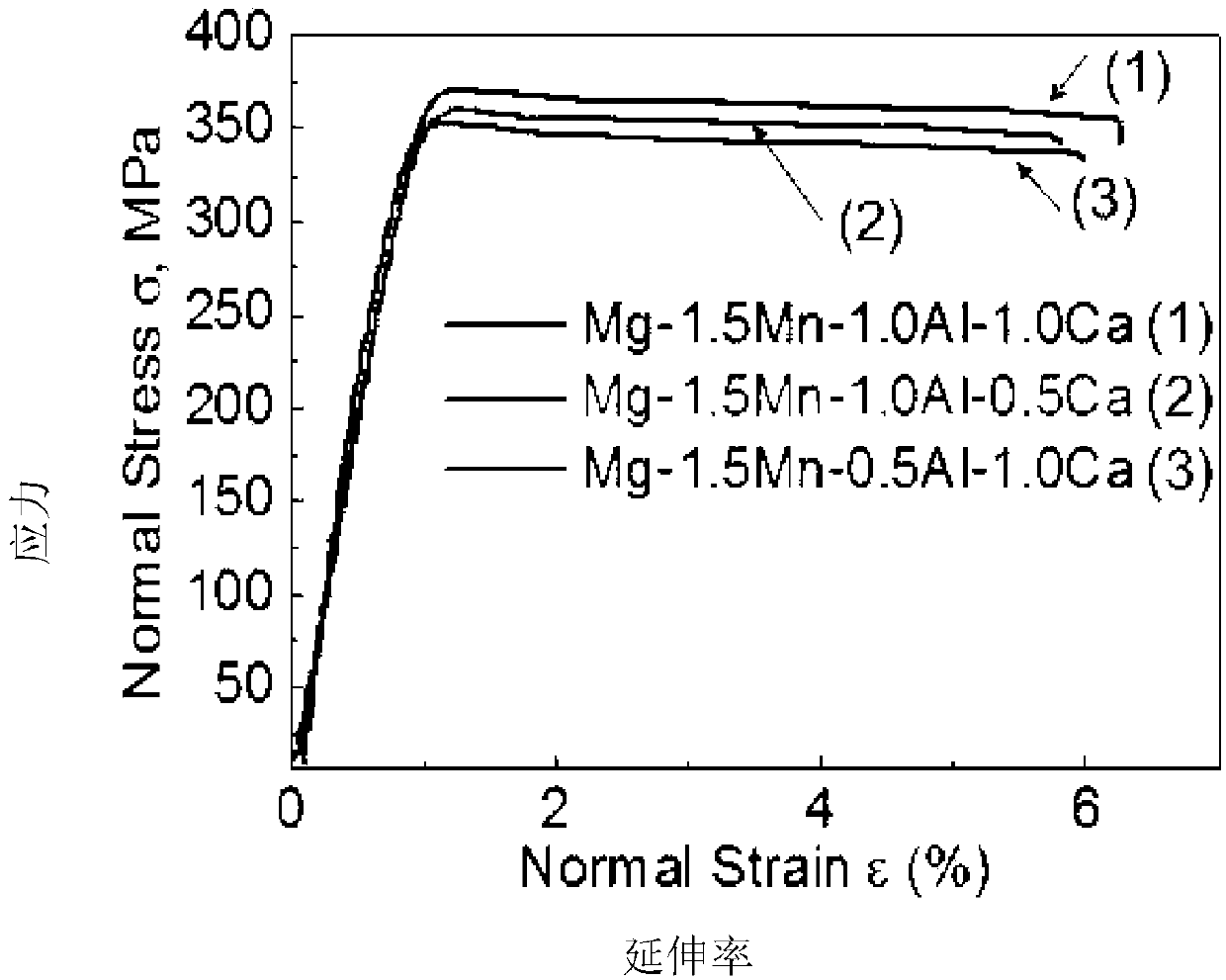

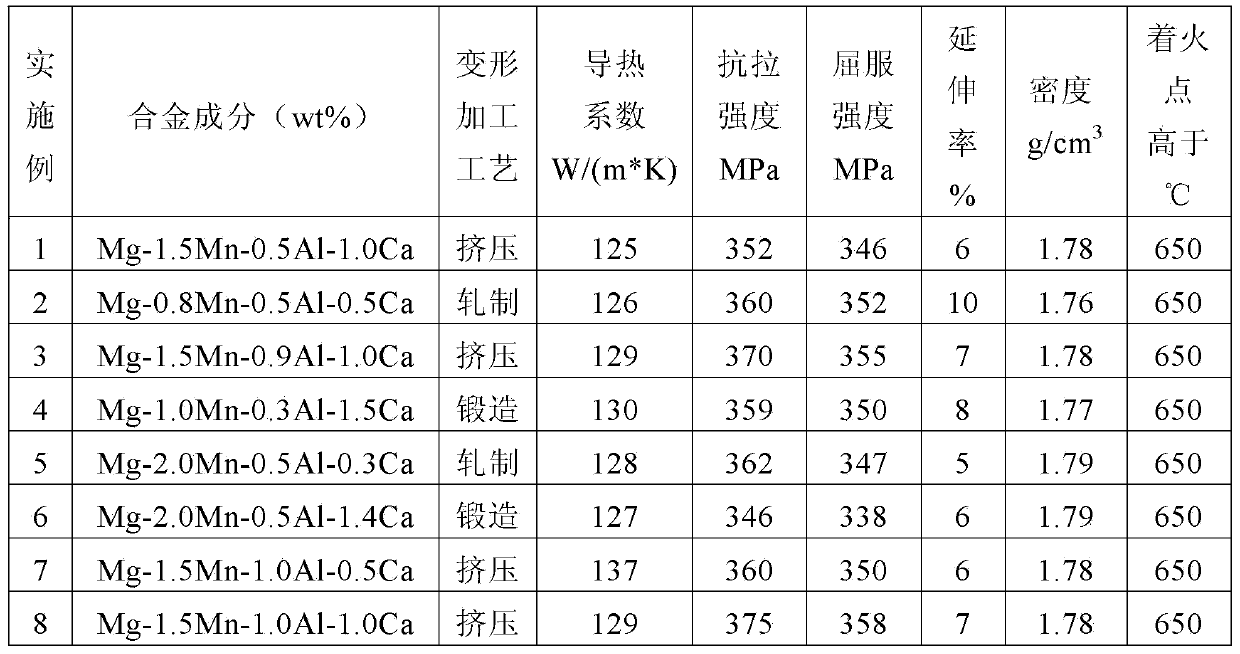

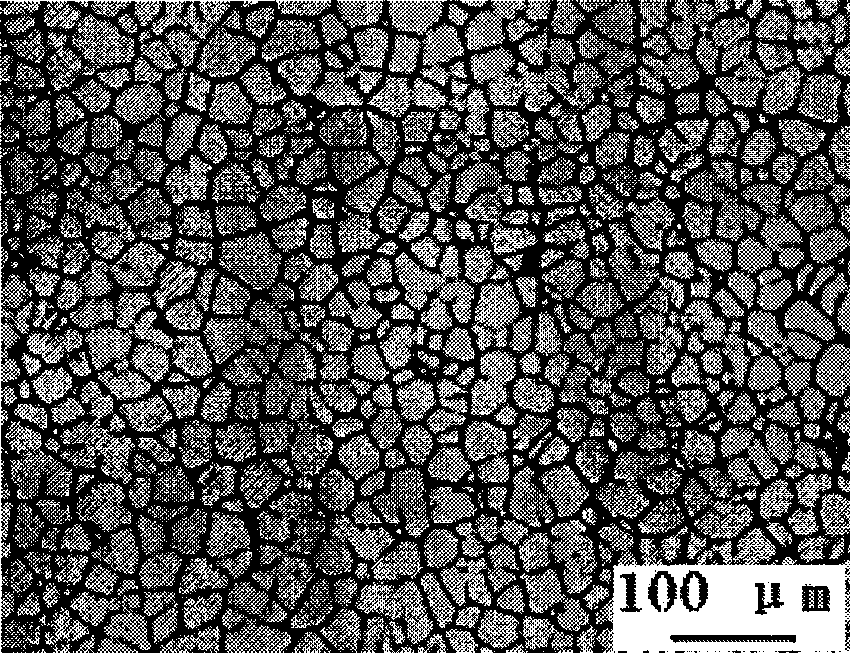

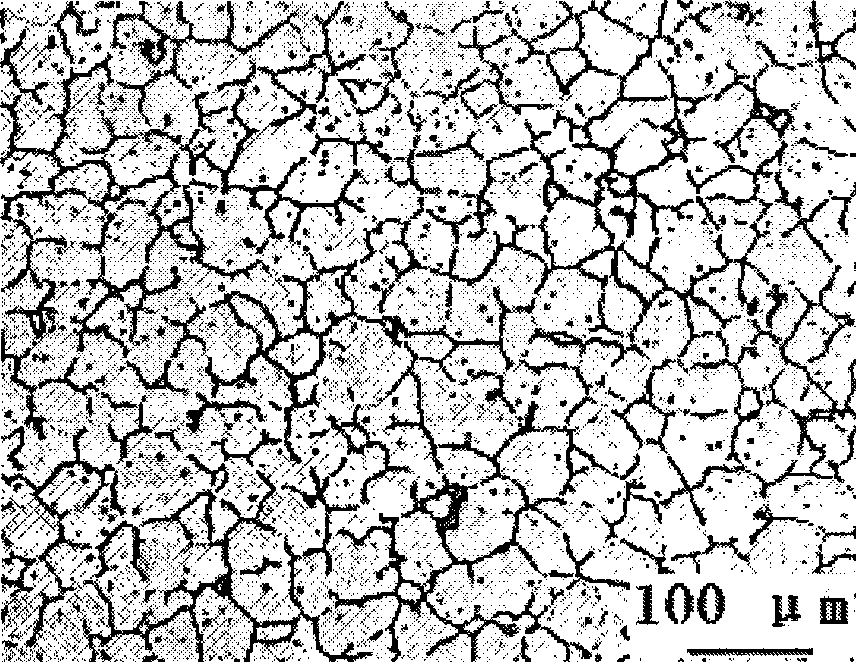

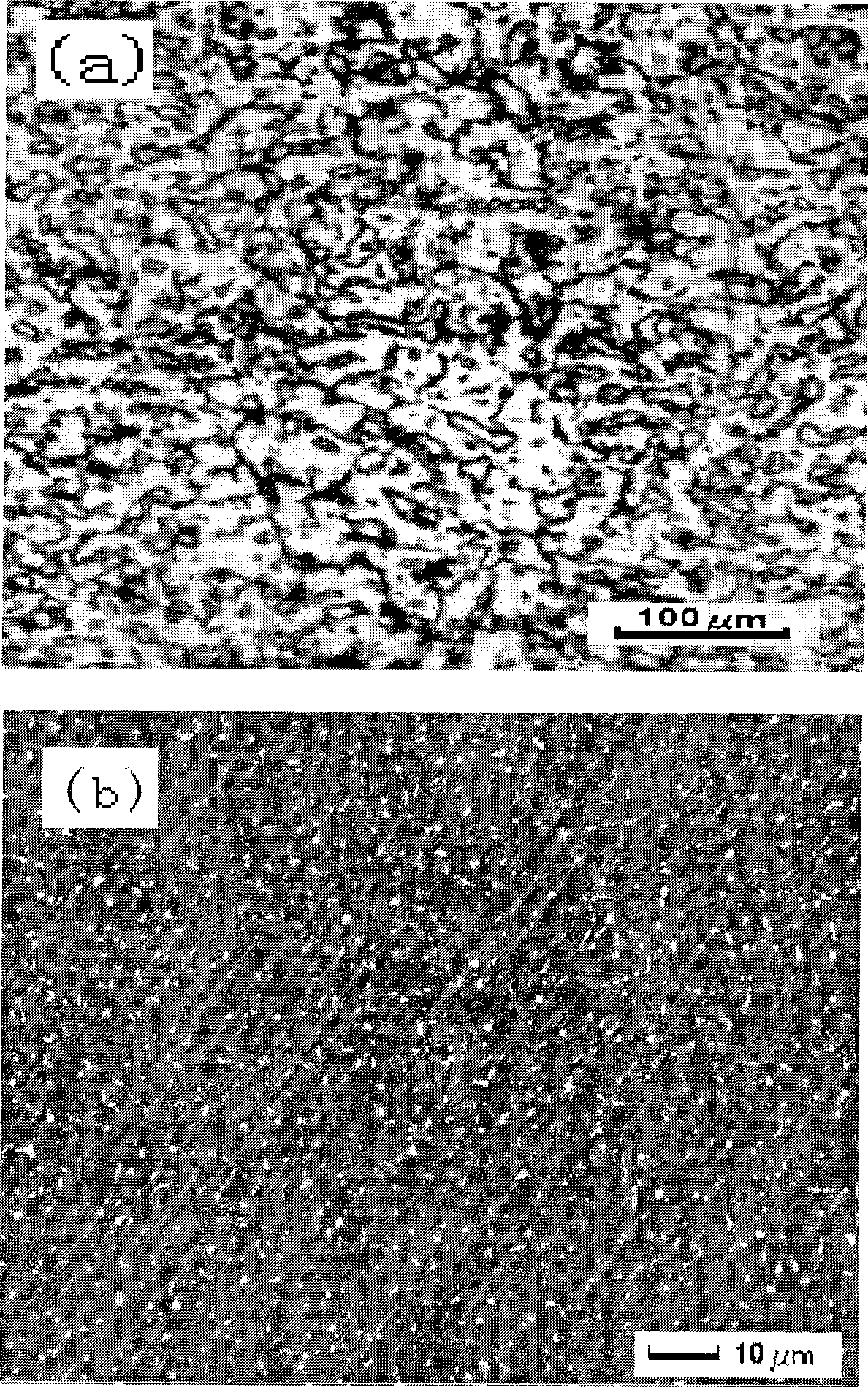

Rare-earth-free low-cost high-strength heat-conducting magnesium alloy and preparation method thereof

The invention relates to a rare-earth-free low-cost high-strength heat-conducting magnesium alloy and a preparation method thereof. The magnesium alloy is composed of the following chemical components in percentage by weight: 0.5-2.0 wt% of Mn, 0.3-1.5 wt% of Ca, 0.3-1.0 wt% of Al, and the balance of Mg and inevitable impurities. The magnesium alloy solves the problem of overhigh cost due to use of multiple rare-earth elements or high-price alloy elements, and the problems of sharp drop of heat conductivity coefficient, overhigh density and the like due to higher alloy element content caused by strength increase in the existing heat-conducting magnesium alloy; and the magnesium alloy has the advantages of higher heat conductivity coefficient, higher strength, higher flame resistance, lower cost and lower density.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation of nontoxic magnesium alloy material for biological implantation

The invention relates to a method for preparing a magnesium alloy material suitable for biological implantation, which comprises the following steps: preparing raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.5 to 1.9 percent of Mn, 0.6 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; or preparing the raw materials by the following chemical compositions in percentage by weight: 2.0 to 6.0 percent of Zn, 0.3 to 0.9 percent of Zr, 0.5 to 5.0 percent of Ca, less than or equal to 0.1 percent of total impurities, and the balance of Mg; preheating smelting equipment and adding the Mg into the raw materials; heating the mixture under the protection of argon gas with the flow rate of between 5 and 6 L / min and the pressure of 14 MPa; adding a fire retardant into the molten liquid when the temperature of the molten liquid reaches between 650 and 660 DEG C, raising the temperature of the molten liquid to between 700 and 720 DEG C, adding other alloy elements into the molten liquid respectively, and performing melting reaction; and stirring the mixture until the mixture is uniformly mixed after alloy is completely molten, keeping the mixture stand for 30 to 40 minutes, pressing a deslagging agent into the solution for deslagging, casting the alloy solution into a cast die after keeping the alloy solution for 10 to 20 minutes at the temperature of between 690 and 710 DEG C, and preparing a Mg-Mn series or Mg-Zr series biomedical magnesium alloy material ingot.

Owner:NORTHEASTERN UNIV

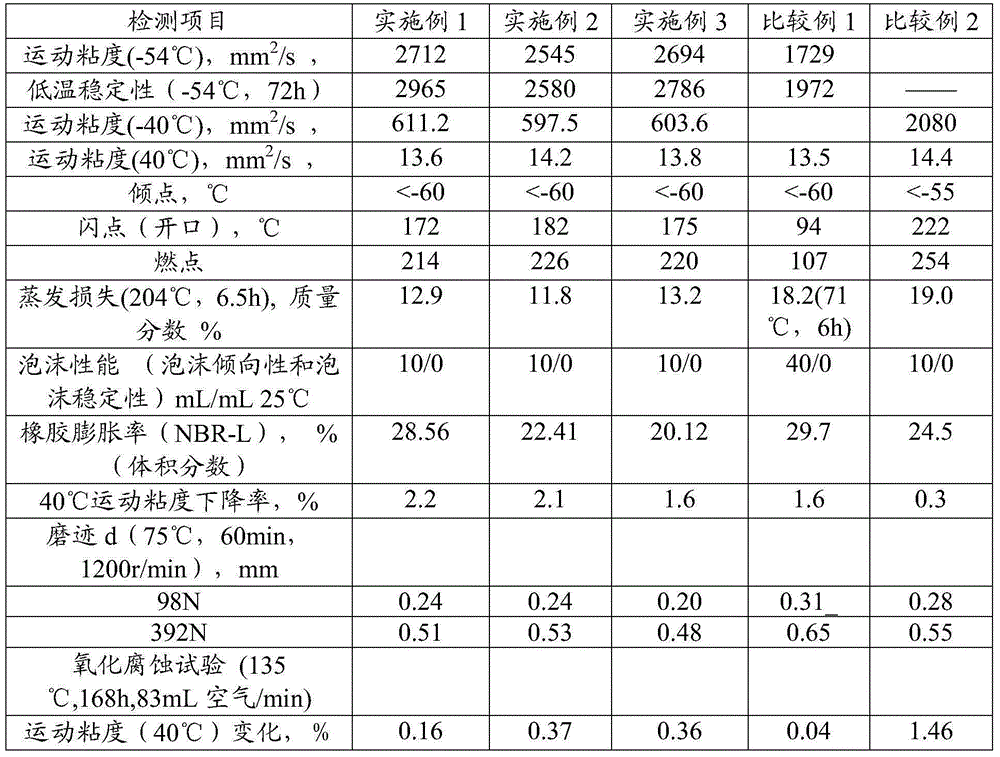

Hydraulic oil

ActiveCN104987942AGood low temperature performanceGood viscosity and film thicknessLubricant compositionOxidation stabilityAntioxidant

The invention provides a hydraulic oil. The hydraulic oil comprises, by weight, 70-90 parts of poly-alpha-olefin, 10-30 parts of a diester compound, 0.1-3 parts of an antioxidant, 0.1-0.5 parts of an antirust agent, 0.1-5 parts of an extreme pressure anti-wear agent, 0.0005-0.05 parts of an antifoaming agent, 0.001-0.1 parts of a coloring agent and 5-20 parts of a viscosity improver. The use amounts of all components and the comprehensive effects of all the components are controlled to make the hydraulic oil have good low-temperature performances and high flash point. Experiment results that the hydraulic oil can be used at -50DEG C, and the flash point of the hydraulic oil is 172-182DEG C. The hydraulic oil provided by the invention has the advantages of good viscosity-temperature properties, high burning point, good anti-foaming performance and good oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP

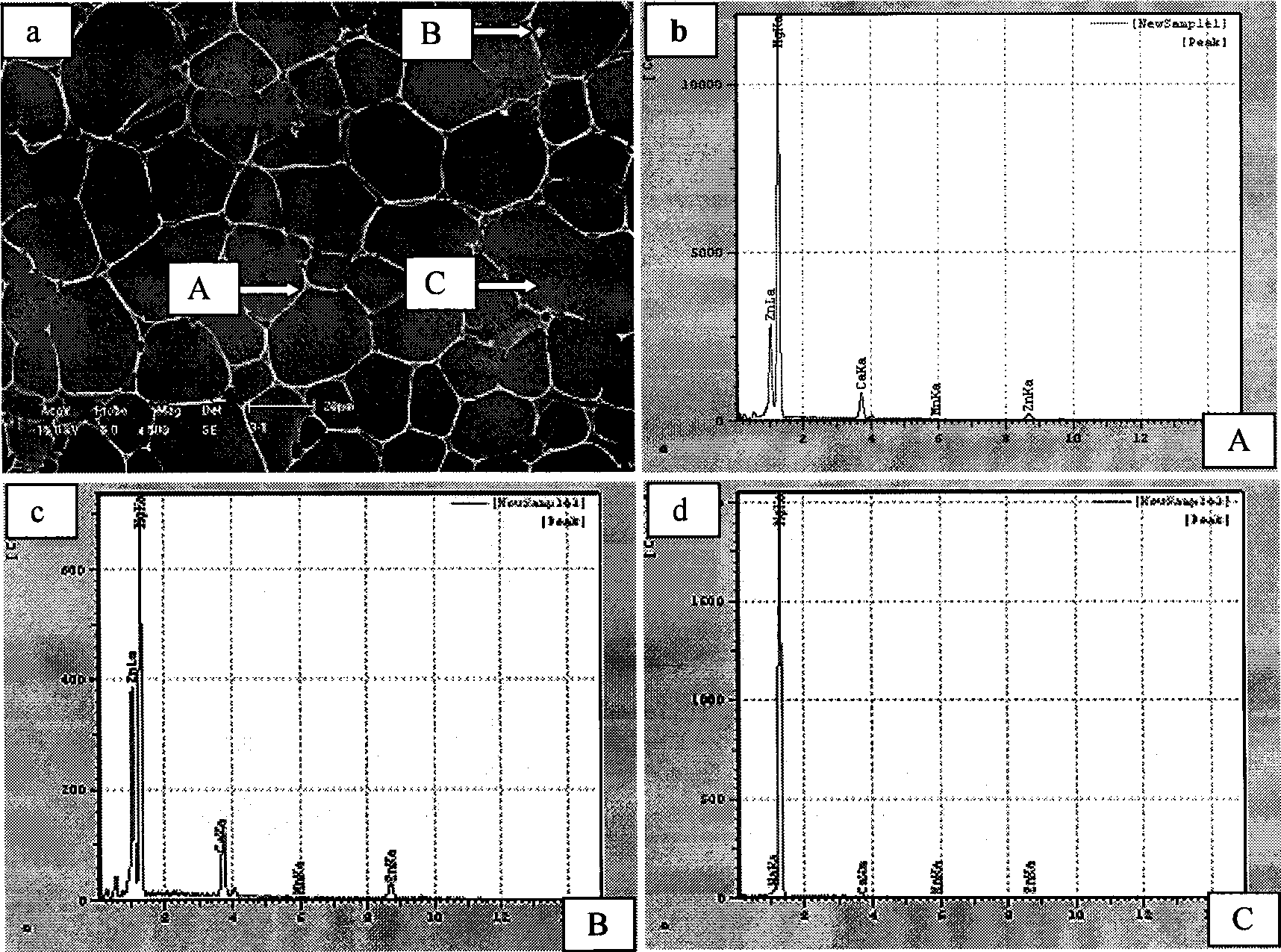

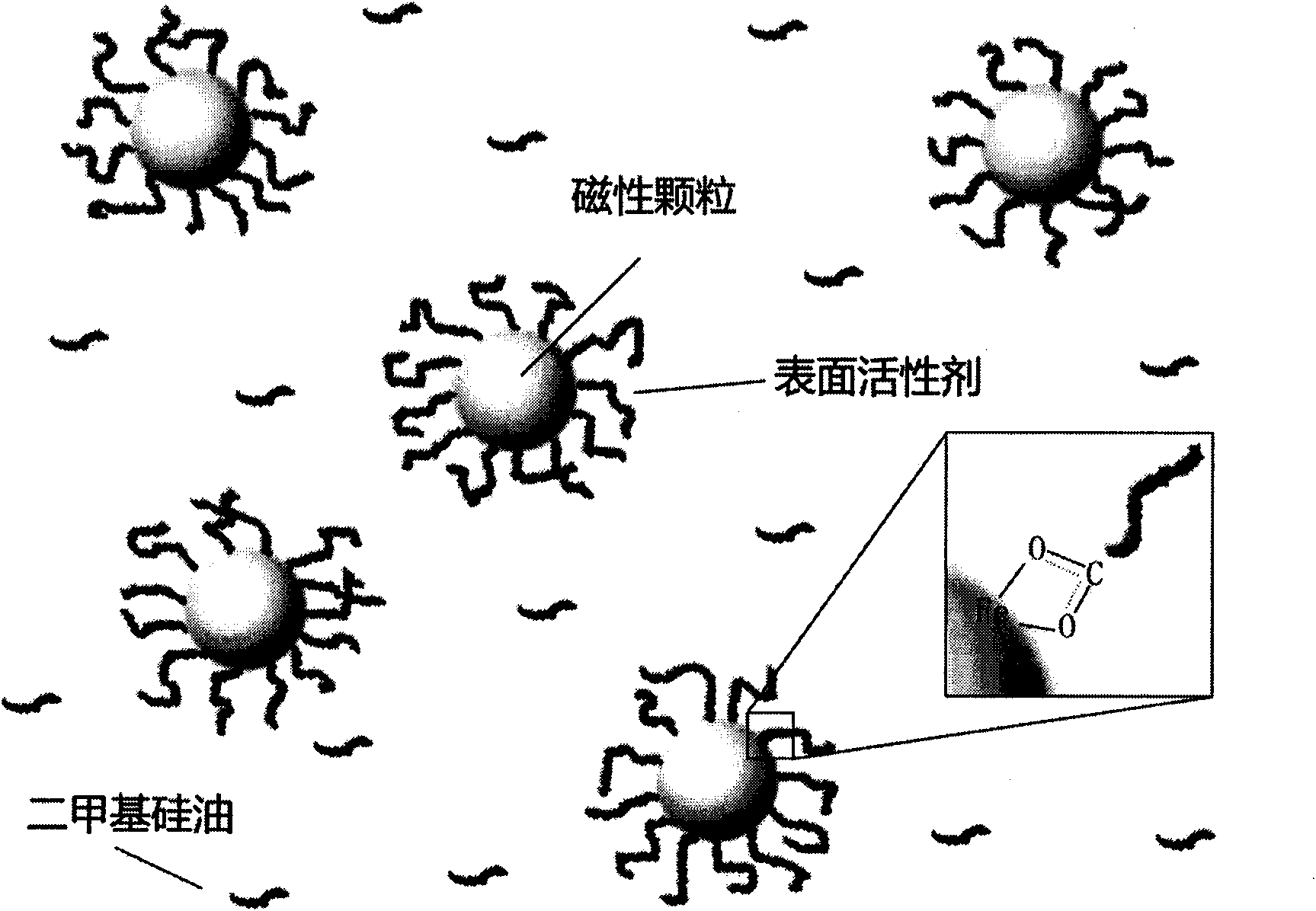

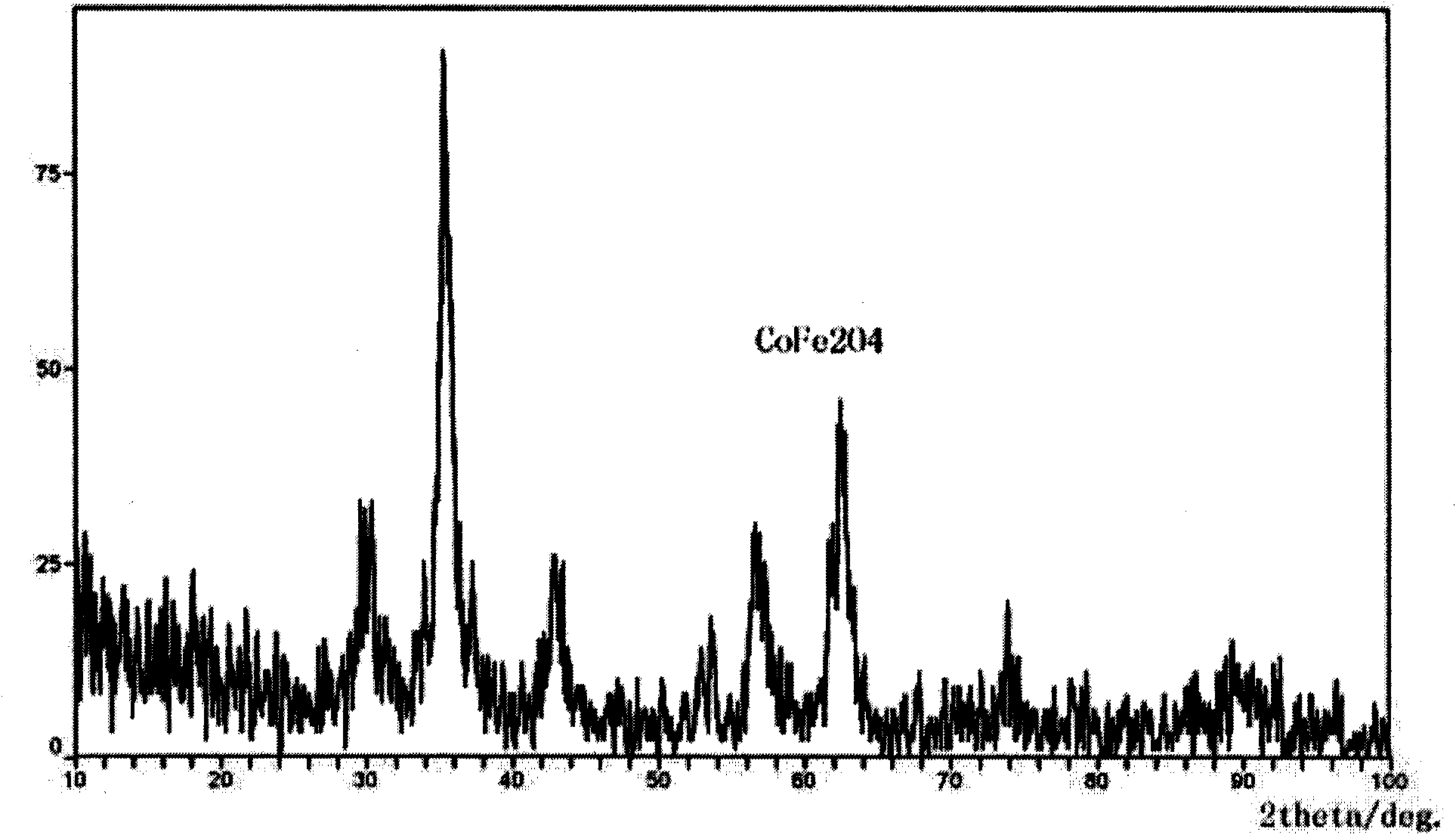

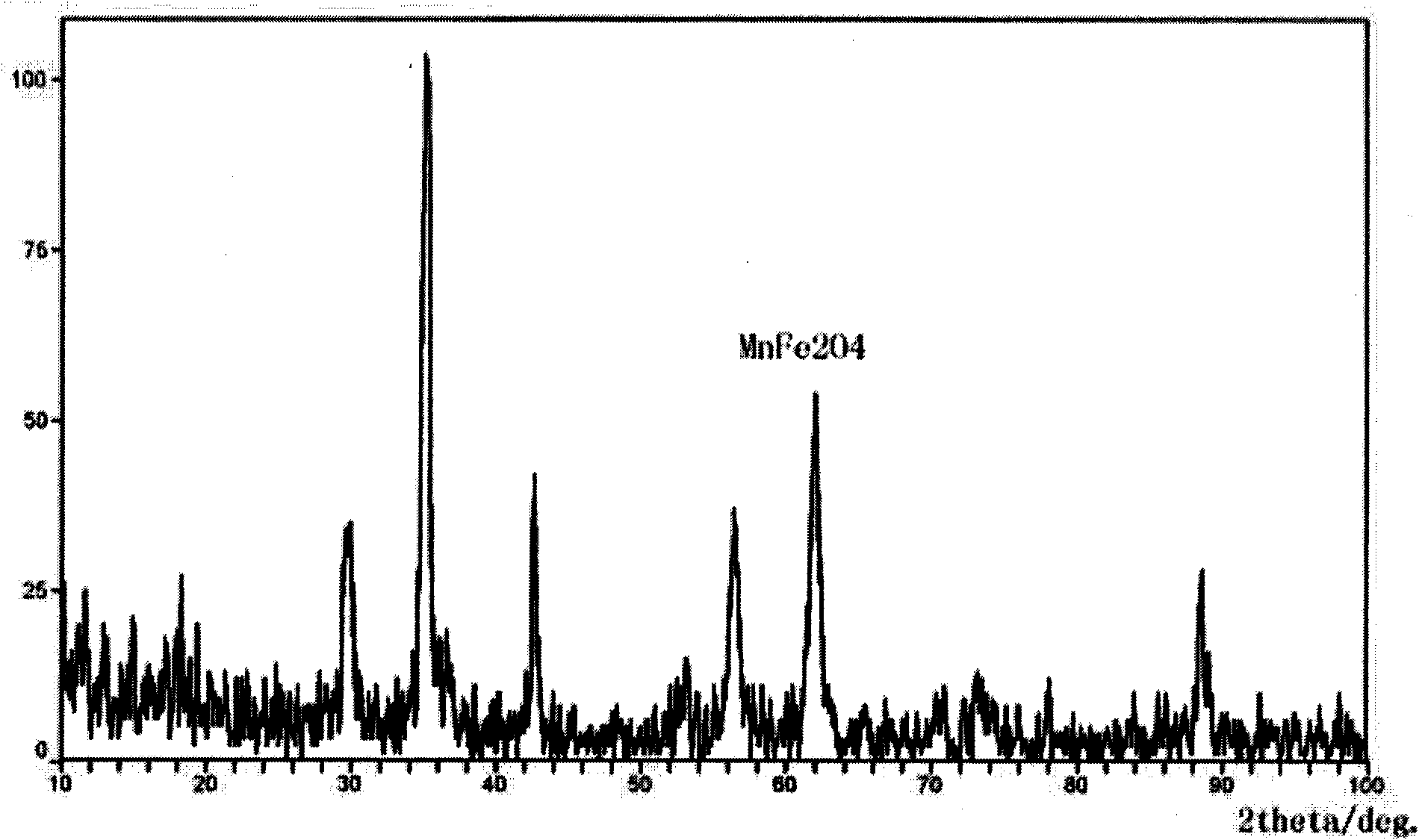

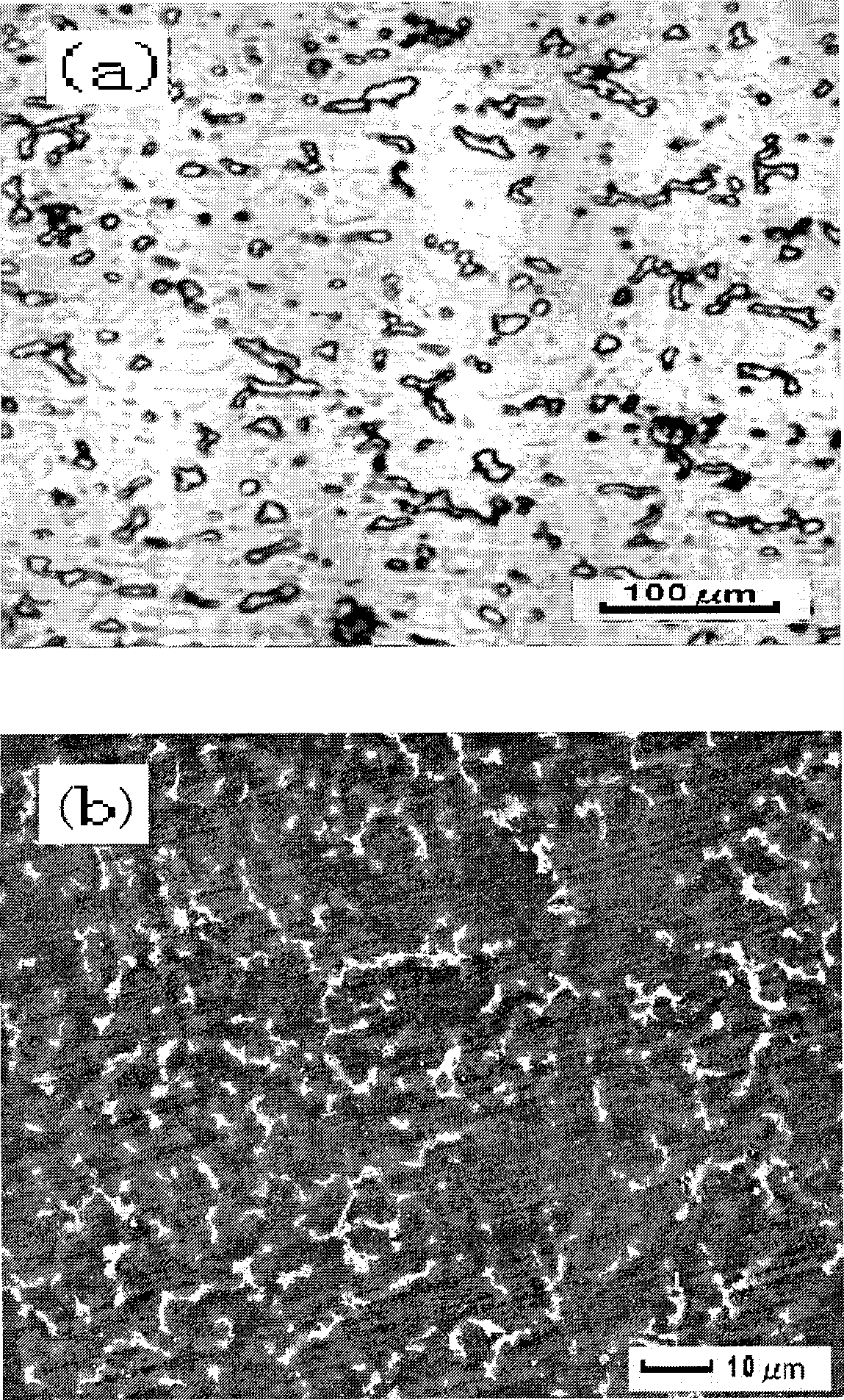

Oxidation resistant dimethyl silicon oil based magnetic fluid and preparation method thereof

InactiveCN101599335ASmall viscosity-temperature coefficientLow compression resistanceMagnetic liquidsOrganic/organic-metallic materials magnetismMethylene DichlorideMagnetic liquids

The invention provides oxidation resistant dimethyl silicon oil based magnetic fluid and a preparation method thereof; the dimethyl silicon oil based magnetic fluid is prepared by nano-magnetic particles, a surface modifier and carrier fluid, and the carrier fluid is the dimethyl silicon oil. The preparation method of the dimethyl silicon oil based magnetic fluid comprises the following steps: preparing the nano-magnetic particles; treating the nano-magnetic particles in an activated way; preparing the nano-magnetic particles which are modified by the surface modifier; adding the modified nano-magnetic particles which are purified into methylene dichloride, dispersing and filtering the mixture to obtain the methylene dichloride based magnetic fluid; adding the magnetic fluid into the dimethyl silicon oil to be stirred and dispersed, heating the mixture and maintaining the temperature between 50 and 90 DEG C, separating and precipitating the mixture to obtain the dimethyl silicon oil based magnetic fluid. The dimethyl silicon oil based magnetic fluid in the invention has the advantages of high stability, low temperature resistance and high temperature resistance. The preparation method is simple, high in efficiency and low in requirement on equipments, thus being easy to be applied in various fields and having wide application prospect.

Owner:SUN YAT SEN UNIV

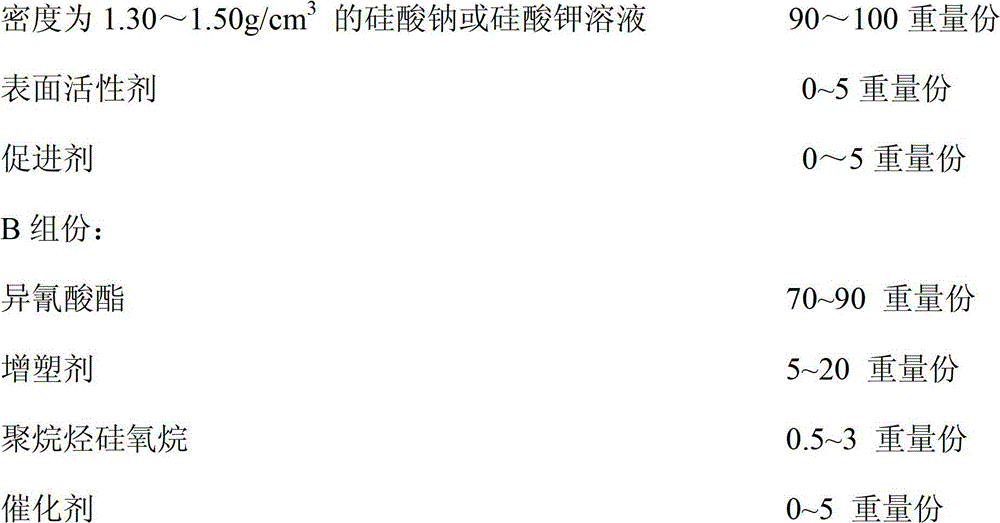

Chemical grouting material for reinforcing loose and broken bedrock

The invention relates to a chemical grouting material for reinforcing loose and broken bedrock. The invention provides a chemical grouting material for reinforcing the loose and broken bedrock, in order to improve the flash point, the burning point and the antistatic performance of the grouting material, reducing the temperature in polymerization reaction and lowering the cost. According to the technical scheme provided by the invention, the chemical grouting material for reinforcing the loose and broken bedrock comprises two components, including a component A and a component B; according to the formulas of the raw materials, the component A comprises 90 to 100 parts by weight of sodium silicate or potassium metasilicate solution, 0 to 5 parts by weight of surface active agent, and 0 to 5 parts by weight of accelerator; the component B comprises 70 to 90 parts by weight of isocyanate, 5 to 20 parts by weight of plasticizer, 0.5 to 3 parts by weight of polyalkane silicone, and 0 to 5 parts by weight of catalyst; the components A and B are uniformly mixed respectively; and in use, the components A and B are mixed according to the volume ratio of 1: 1. The chemical grouting material can be applied to quickly reinforcing the broken coal bed and rock bed and blocking water leakage.

Owner:HANGZHOU GUODIAN DAM SAFETY ENG

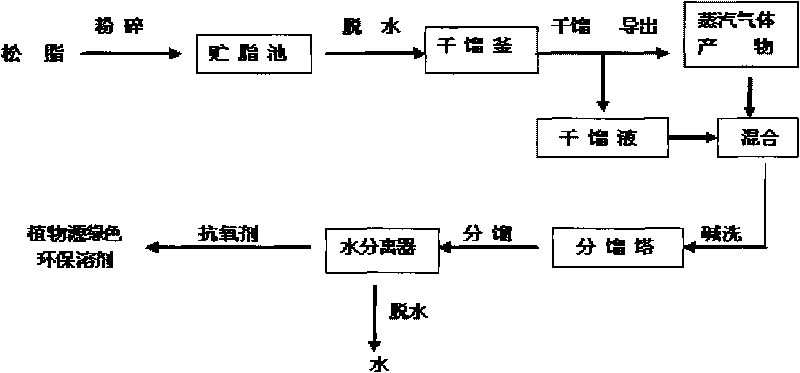

Plant source green and environment-friendly solvent and preparation thereof

The invention is suitable for the technical field of pesticide solvents, provides a plant source green and environment-friendly solvent and simultaneously provides a method for preparing the plant source green and environment-friendly solvent from destructive distillation turpentine. The plant source green and environment-friendly solvent comprises the following components in percentage by mass: 10 to 40 percent of pinene, 10 to 40 percent of D-limonene, 5 to 15 percent of longifolene, 5 to 15 percent of camphene, 3 to 15 percent of dehydroabietic acid, 1 to 10 percent of pinane and 0 to 2 percent of antioxygen. The preparation method comprises the following steps: (1) pulverizing and dehydrating the turpentine; (2) performing dry distillation and collecting lysate; (3) washing the turpentine by alkali liquor, standing the washed turpentine for fractional distillation; (4) performing dehydration; and (5) adding the antioxygen for uniform dissolution to prepare the plant source green and environment-friendly solvent. A raw material adopted by the solvent is the turpentine of pine trees, and is low in cost; the preparation method has simple process, environmental protection and lessenergy consumption; decomposition components give priority to safe and environment-friendly components, such as a terpene compound and the like and can be controlled; and the plant source green and environment-friendly solvent has low production cost, safety and environmental protection, and is beneficial for people.

Owner:SHENZHEN NOPOSION AGROCHEM

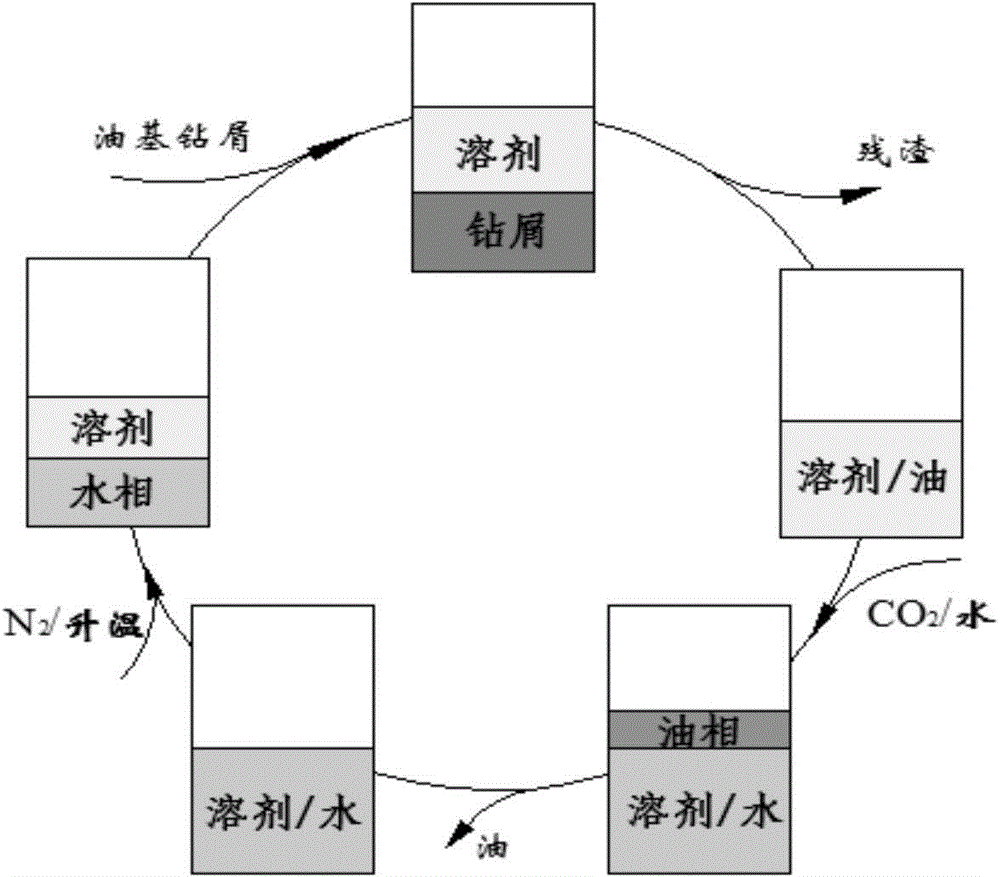

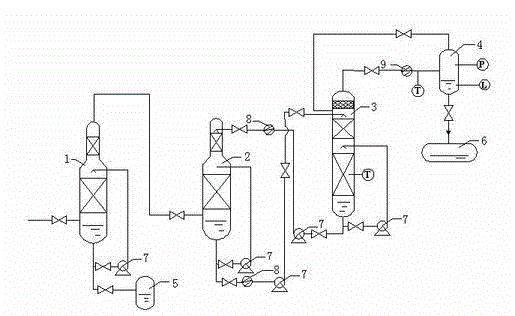

Oil-based drilling cutting treatment method

InactiveCN104804759AGood viscosity reductionHigh ignition pointLiquid hydrocarbon mixture productionHydrocarbon oils treatmentSolventHigh pressure

The invention discloses an oil-based drilling cutting treatment method. The oil-based drilling cutting treatment method comprises oil-based drilling cutting extraction, separation of an extract liquor, recycling of a switchable solvent, repeated separation and extraction, oil-based drilling cutting component analysis and the like. The method can be performed under a mild condition without high temperature, high pressure and other additional conditions, and changes of hydrophilic performance of the solvent can be intelligently controlled under the stimulus-response of CO2; the viscosity reduction effect on oil-based drilling cuttings is good, the separation capacity for mineral oil in the oil-based drilling cuttings is good, the recovery rate of oil can be up to 95% or higher, the ignition point of the switchable solvent CyNMe2 is high, the method does not have a biological accumulation effect, the recovery rate of the solvent can be up to 85% or higher, and the recovery efficiency can be further improved with methods such as infrared heating, addition of chemical agents and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Heat-preservation fireproof board and preparation method thereof

ActiveCN103951369AGood heat insulationHigh ignition pointSolid waste managementSilicon dioxideFire prevention

A heat-preservation fireproof board is prepared by the following raw materials: 80-100 parts by weight of magnesium oxide, 2-3 parts by weight of dimethyl silicone oil, 4-6 parts by weight of aluminum nitride powder, 20-30 parts by weight of anhydrous magnesium chloride, 3-5 parts by weight of hollow glass beads, 8-12 parts by weight of tetrapod-shaped zinc oxide whiskers, 3-6 parts by weight of aerosil, 3-5 parts by weight of polyvinyl acetate emulsion, 20-30 parts by weight of refractory materials, 3-6 parts by weight of rock wool, 3-5 parts by weight of methylisothiazolinone, 2-4 parts by weight of ferriferrous oxide, 5-8 parts by weight of methyl sodium silicate, 1-2 parts by weight of sodium dodecyl benzene sulfonate, and 130-150 parts by weight of water. By virtue of adding the multiple types of refractory materials, the board can be high in burning point and good in flame retardation effect; and with the addition of the fly ash hollow beads, the board can be good in heat insulation effect and fine in fireproof effect. In brief, the board of the invention is a novel inorganic heat-preservation and heat-insulation building material integrating characteristics of heat preservation, heat insulation, high strength, fire prevention, water proofing, sound absorption, sound insulation, and decoration.

Owner:安徽颐鑫节能材料有限公司

Device for recovery of carbon disulfide in viscose fiber production

InactiveCN103331078AInhibition releaseHigh ignition pointDispersed particle separationHigh absorptionVapor–liquid separator

The invention relates to the exhaust gas recovery field in the viscose fiber industry, and provides a device for recovery of carbon disulfide in viscose fiber production. The device is characterized in that: it comprises an alkali spray tower, an absorption tower, a heat exchanger, a desorption tower, a condenser and a gas-liquid separator. The spray tower is connected to the absorption tower, the absorption tower is in connection with the heat exchanger, the heat exchanger is connected to the desorption tower, the desorption tower is connected to the condenser, which is in connection with the gas-liquid separator. The device provided in the invention has the characteristics of simple structure, high absorption rate, low investment and operation cost, and suitability for industrialized application.

Owner:YIBIN HIEST FIBER +2

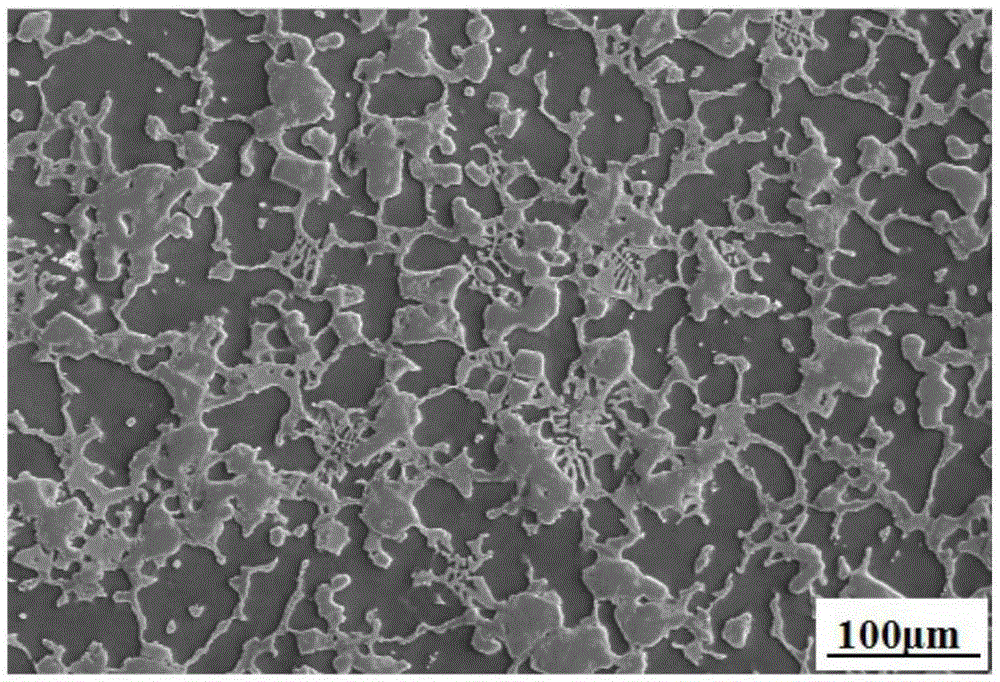

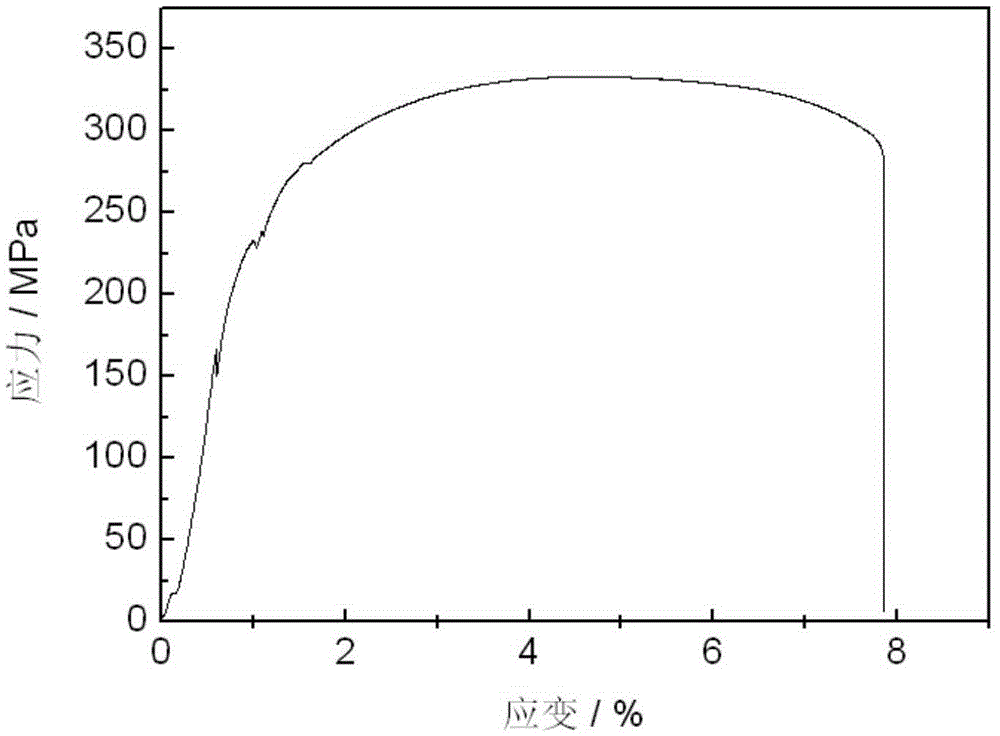

Heated and reinforced high-strength cast magnesium alloy and preparation method thereof

The invention provides a heated and reinforced high-strength cast magnesium alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 8.0-10.0 of Zn, 1.0-5.0 of Al, 1.0-5.0 of Sn, 0.1-1.0 of Cu, 0.3-0.8 of Mn, 0.3-0.5 of Ca, and the balance of Mg and inevitable impurity elements. According to the high-strength cast magnesium alloy, under a room-temperature stretch test, the tensile strength reaches 320-350 MPa, and the yield strength reaches 220-260 MPa. A heat treatment process of the magnesium alloy comprises solution treatment by 4-8 hours at a temperature of 330-380 DEG C, air cooling, aging by 8-16 hours at a temperature of 150-220 DEG C and obtaining of the high-strength cast magnesium alloy. The heat treatment process of the alloy is simple and easy to realize; and the aging treatment can form a lot of nanoscale strengthening phases in an alloy structure, so that the alloy strength can be prominently improved. The alloy contains no such noble metal as rare earth, and is an alloy system with low cost and wide applicability.

Owner:山东山科智镁新材料科技有限公司

Novel function flame-proof fibre and preparation method thereof

InactiveCN1920128AReduce surface temperatureDifficult to form diffusionFlame-proof filament manufactureMelt spinning methodsFiberCellulose

The invention relates to a functional frame-proof fiber and relative preparation, wherein it is characterized in that: it also comprises nanometer additive powder with tourmaline and tourmaline; and its components comprises cellulose at 75-95%; said nanometer additive powder at 5-25%; and its preparation comprises: preparing the tourmaline and tourmaline into nanometer additive powder; mixing the powder with cellulose with different ratios, via static mixer; using fusion mixing method to prepare the spinning liquid. The inventive fiber has lower cost and controllable parameter.

Owner:太原伦嘉生物科技股份有限公司

Water-soluble acrylic resin as lacquer in use for glass and preparation

This invention relates to a method for preparing water-soluble acrylic resin used as glass paint. The method comprises: performing free radical solution polymerization on acrylic acid monomer 15-57 wt. %, epoxy resin 1-15 wt. %, C1-4 alcohol 20-80 wt. % and initiator 0.1-10 wt. % at 60-160 deg.C to obtain epoxy-modified acrylic resin, adding a neutralizer and water so that the solid content of the solution is 20-60%, and stirring for dissolution. The coating layer of the water-soluble acrylic resin has high water-cooking resistance, and does not foam or strip after cooked in water for 1 h. Besides, the coating layer has high hardness (2-4 H) and high adhesiveness to glass (0 grade).

Owner:JIANGSU SANMU GROUP CORPORATION

Rare earth magnesium-alloy material for 3D printing and preparation method of same

ActiveCN104762541AImprove flame retardant performanceMicrostructureAdditive manufacturing apparatusRare-earth elementSlag

The invention belongs to the technical field of 3D printing materials and discloses a rare earth magnesium-alloy material for 3D printing and a preparation method of the same. The preparation method particularly comprises following steps: (1) weighing raw materials according to element mass ratio of Mg:Mn:Re being 85-97:2-10:1-5; (2) adding pure magnesium, pure manganese and magnesium alloy into a pre-heated crucible, adding a cover agent and smelting the mixture under atmospheric conditions; (3) after the mixture smelted completely, adding an Mg-Re intermediate alloy and pure rare earth elements, melting the components with stirring uniformly and increasing the temperature to 700-750 DEG C; (4) adding a refining agent for refining the alloy for 2-25 min, allowing the refined alloy to stand, removing floated slag, adding the refined alloy into a sand mould trough to obtain a rare earth magnesium alloy base metal; and (5) smelting and atomizing the base metal to obtain the rare earth magnesium-alloy material. The rare earth magnesium-alloy material is excellent in flame retarding performance, is easy to control in powder shape and particle size, can be smelted without protective gas so that a problem of flammability during preparation of the magnesium alloy powder through an atomization method is solved, and can be used for laser 3D printing.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

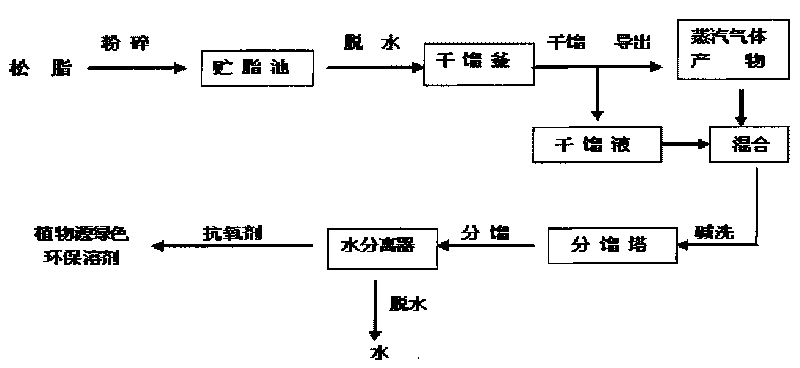

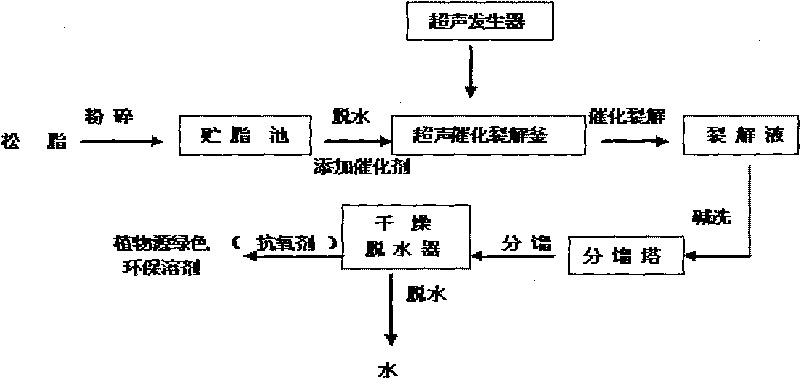

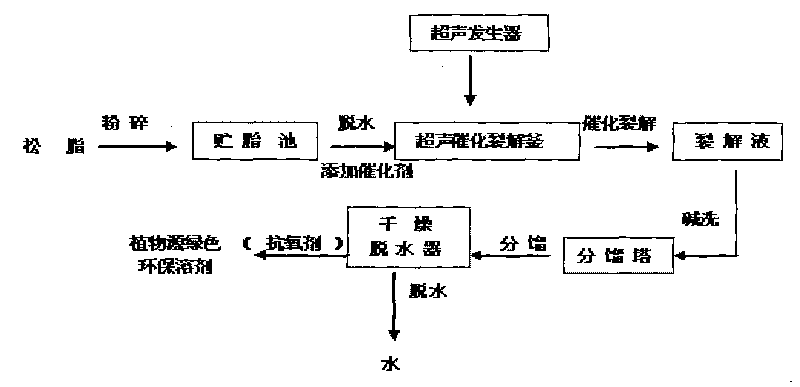

Method for preparing botanical solvent

The invention provides a method for preparing a botanical environment-friendly solvent, and in particular relates to a method for preparing the botanical environment-friendly solvent from pine resin through ultrasonic catalytic cracking. Raw materials for preparing the botanical environment-friendly solvent are all from the pine resin, and have low price; the ultrasonic catalytic cracking method adopted has simple process, mild cracking conditions, environmental protection, and low energy consumption; cracking products are mainly safe and environment-friendly components such as terpene compounds and the like; and the obtained botanical environment-friendly solvent has high yield, low price, no conflict with human, and safety and environmental protection.

Owner:SHENZHEN NOPOSION AGROCHEM

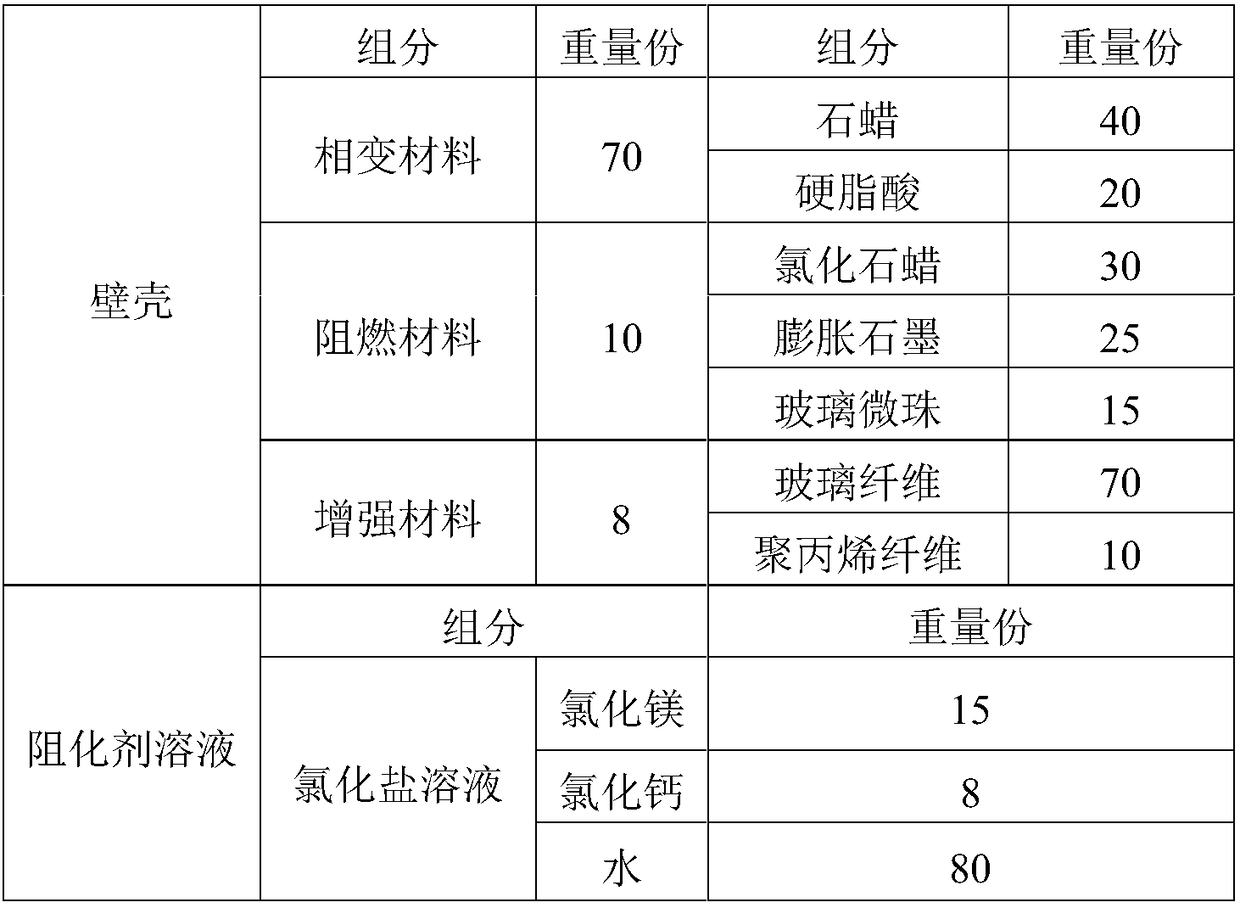

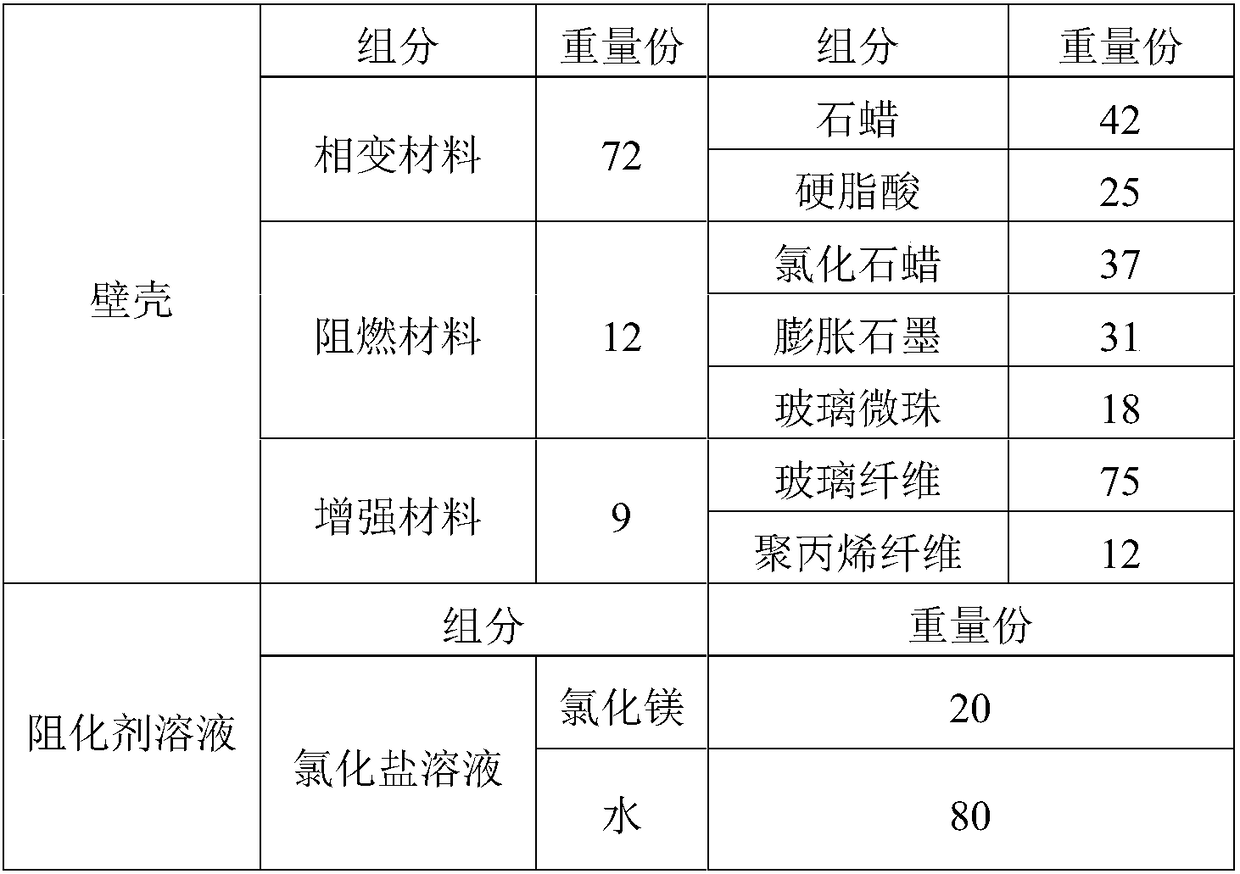

Composite microcapsule stopping agent for preventing coal spontaneous combustion and preparation method of composite microcapsule stopping agent

The invention relates to a composite microcapsule stopping agent for preventing coal spontaneous combustion and a preparation method of the composite microcapsule stopping agent. The stopping agent comprises a wall shell and a stopping agent solution sealed in the wall shell. The wall shell is mainly prepared from the following components of, by weight, 70-80 parts of phase-change materials, 10-20parts of flame-resistant materials and 8-12 parts of reinforcing materials. The stopping agent solution is ionic liquid or a chloride solution. The stopping agent solution is evenly composited to thecomposite phase-change materials to obtain a mixed emulsion, the mixed emulsion is sprayed into a dry porous medium in an emulsion-drop mode through a spraying device to enable mixed emulsion drops to be further atomized into mist drops with the particle diameter of 30-50 [mu]m, and after the mixed emulsion which is formed into the mist drops makes contact with cold air, the composite phase-change mixed materials are quickly solidified to wrap the stopping agent solution to form the composite microcapsule stopping agent. The stopping agent can be evenly distributed in coal seams, the coveragerange is wide, accumulation of heat is prevented, coal spontaneous combustion is resisted, and the preparation method can efficiently produce and process the composite microcapsule stopping agent.

Owner:CHINA UNIV OF MINING & TECH

Novel flame-retardant high-strength heat-resistant magnesium alloy and preparation thereof

The invention relates to a novel retardant high-strength heat resistant magnesium alloy and a preparation method thereof. The preparation method comprises the following steps: calcium, rare earth and strontium are added into a magnesium alloy together; while the burning point of the magnesium alloy is improved, the issue of the magnesium alloy is improved by alloying, the grain size is refined, and the mechanical properties and heat resistance of the magnesium alloy are improved. The preparation of the alloy is realized by the following technical proposal: an Al-Ca intermediate alloy, an Al-RE intermediate alloy and an Al-Sr intermediate alloy are added into the melted magnesium alloy AZ91D; and then, alloy elements are evenly scattered in the magnesium alloy flux through a mechanical or electromagnetic stirring method; the flux is placed stationarily, cast and shaped in a metal mould, to obtain the novel retardant high-strength heat resistant magnesium alloy.

Owner:JIANGSU UNIV

High-efficiency purification energy-saving filter core

ActiveCN101780345AImprove qualityImprove the lubrication effectLoose filtering material filtersLubricant mounting/connectionCombustionVegetable oil

The invention relates to a high-efficiency purification energy-saving filter core which is manufactured by adopting the stems and the poles of various plants, pulverizing, screening, and bulking the stems and the poles, mixing the processed stems and the processed poles as filter materials (100 parts) with various chemical substances (6.43-11.56 parts), then adding special vegetable oil and a magnetic substance (15-25 parts) and finally packaging with an oil-resistant and high-temperature resistant fabric. The filter core of the invention is suitable for the lubricating oil purification of various internal-combustion engines or mechanical equipment, thereby not only leaching the impurities of more than 0.01mm in online engine oil, but also enhancing the lubricating efficacy, improving the quality and the use function of the engine oil, enabling lubricating oil not to deteriorate or age after long-term use, keeping the due physicochemical index thereof and really achieving the purposes of energy saving and emission reduction.

Owner:GANSU HENGTONG FILTER IND

Flame-retardant environment-friendly material and manufacturing process thereof

The invention relates to an environment-friendly material with flame-retardant effect, which comprises 5-8 parts by mass of plastics, 1-3 parts by mass of kaolin, 0.5-1.5 parts by mass of bamboo powder, 2-4 parts by mass of flame retardants, 0.5-1 parts by mass of chemical additives. When compared with current products, the material of the invention has low cost and good kaolin viscosity, and can substitute 3%-5% of plastics; because of certain flame-retardant effect of kaolin, 3%-5% of flame retardants can be relatively reduced; and thus the cost is reduced, and large industrial demands become possible. The application scope of the new product is improved, and the market share is extended.

Owner:陈姜志 +1

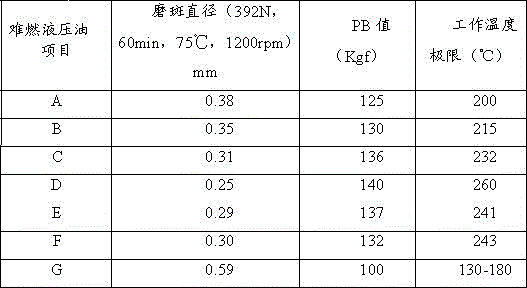

Preparing method for 1-hexyl-3-methylimidazole hexafluorophosphate ionic liquid and fire resistant hydraulic oil with the same

ActiveCN106543084AHigh flash pointHigh ignition pointOrganic chemistryBase-materialsAntioxidantEvaporation

The invention belongs to the field of fire resistant hydraulic oil, relates to environment-friendly total-synthesis fire resistant hydraulic oil, in particular to a preparing method for 1-hexyl-3-methylimidazole hexafluorophosphate ionic liquid and fire resistant hydraulic oil with the same. The preparing method for the 1-hexyl-3-methylimidazole hexafluorophosphate ionic liquid mainly includes the steps of 1-hexyl-3-methylimidazole preparing and hexafluorophosphate ionic liquid preparing. The fire resistant hydraulic oil is prepared in the mode that the ionic liquid, an extrcme pressure anti-wear additive, an antioxidant, a preservative, a pour point depressant and an antifoaming agent are mixed. The fire resistant hydraulic oil synthesized with the method is high in flash point and fire point, low in evaporation loss, high in viscosity index, excellent in lubricating performance, nontoxic, biodegradable and good in material applicability.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

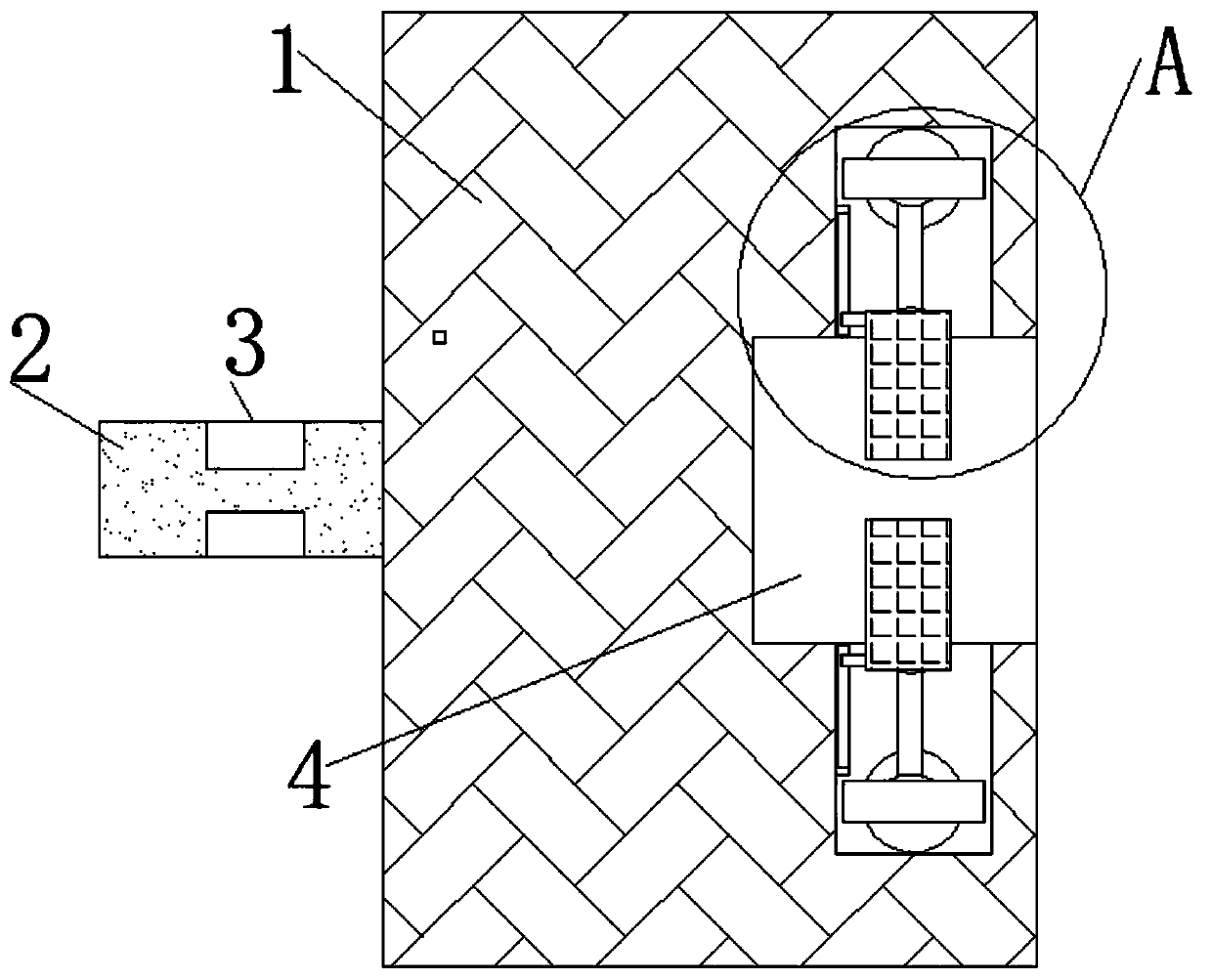

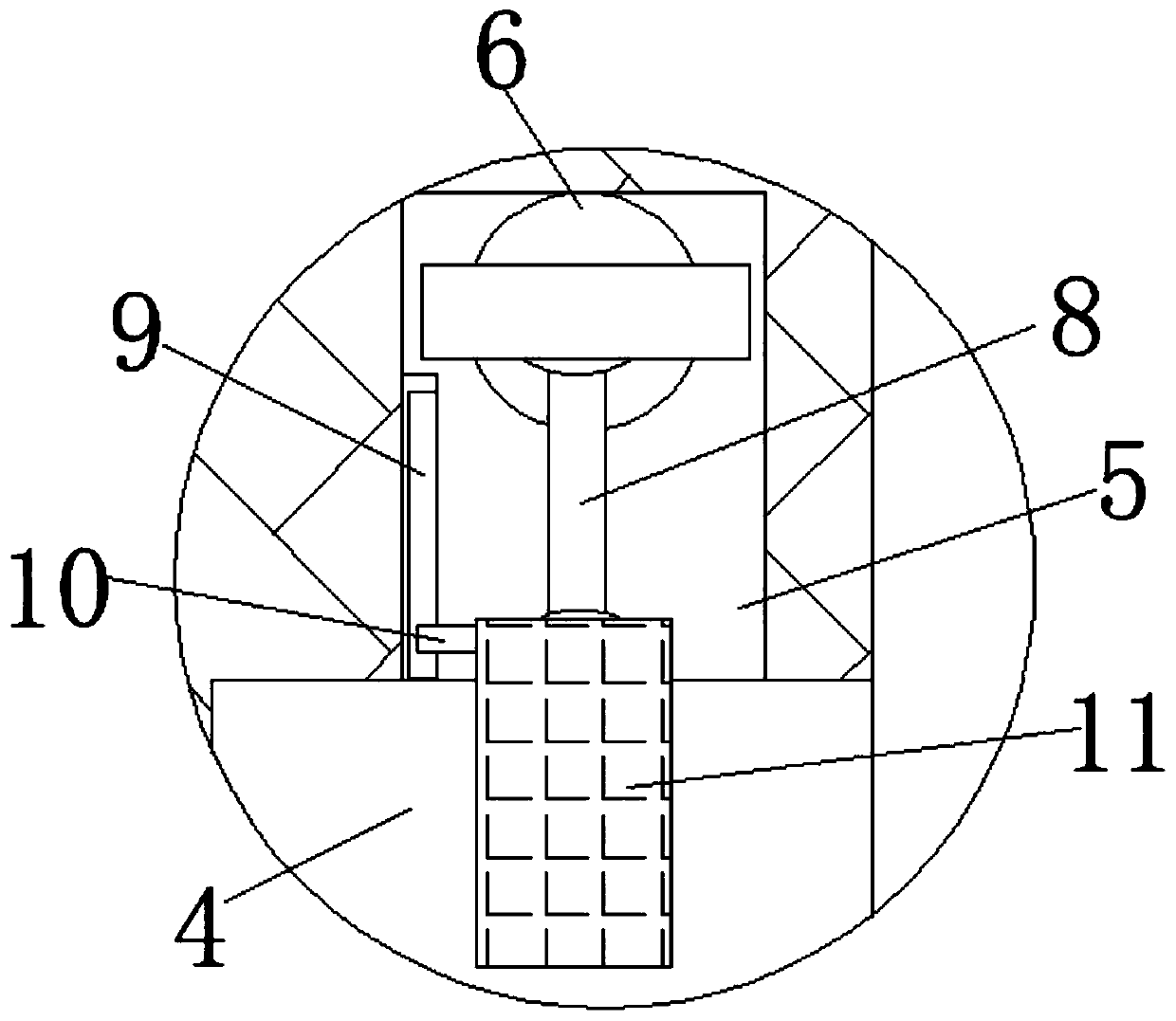

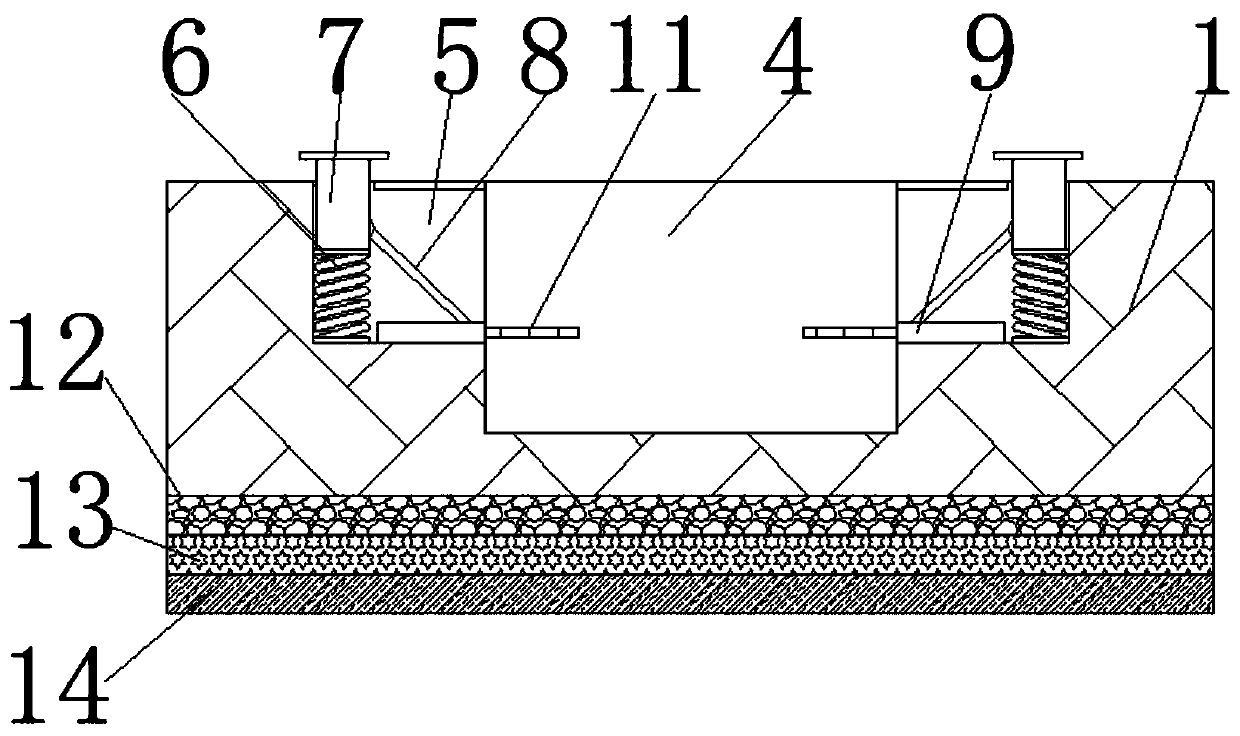

Assembly type energy-saving building part structure based on BIM

InactiveCN110685355AEasy to disassembleResolve unchanged disassemblyCo-operative working arrangementsBuilding constructionsMechanical engineeringStructure based

The invention belongs to the technical field of construction, and discloses an assembly type energy-saving building part structure based on a BIM. The structure comprises a wall plate and a BIM database cloud platform, a sensor and an RFID tag are embedded in the wall plate, a convex block is fixedly connected to one side of the wall plate, two connecting clamping grooves are formed in the outer surface of the convex block, a first clamping groove is formed in one side of the wall plate, two second clamping grooves are formed in the other side of the wall plate, and the second clamping groovesare symmetrically distributed about the first clamping groove. According to the assembly type energy-saving building part structure based on BIM, through a vertical rod, when two wall plates are detached, the vertical rod is lifted, clamping plates and the connecting clamping grooves are staggered, the convex block is drawn out, the effect of facilitating dismounting is achieved, the problems that the damage of invariant detaching and forced detaching caused by traditional connecting manners of welding, riveting and the like to a wall plate happens, , the wall plate can be damaged, and cannotbe used again, and resources are wasted are solved, and the effects of facilitating dismounting and circular use are achieved.

Owner:苏州嘉盛万城建筑工业有限公司

Flame-retardant and heat-resistant magnesium alloy and preparation method

InactiveCN104630586AImprove plasticityImprove flame retardant performanceRare-earth elementMechanical property

The invention provides a flame-retardant and heat-resistant magnesium alloy and a preparation method, wherein the flame-retardant property and the high-temperature mechanical property of the flame-retardant and heat-resistant magnesium alloy are increased simultaneously; and the flame-retardant and heat-resistant magnesium alloy comprises the following components in percentage by weight: 5-9% of Al, 0.3-1.4% of Zn, 0.1-0.6% of Sm, 0.1-0.8% of Nd, 0.2-1.5% of Y, 0.3-1.7% of Ca, 0.4-2.3% of Sr, and the balance of Mg. By adding proper rare earth elements including Sm, Nd and Y, the magnesium alloy tissue is improved; the flame-retardant property and the heat-resistant property of the alloy are increased; the total addition amount of the rare earth elements in the flame-retardant and heat-resistant magnesium alloy disclosed by the invention is 1-2%; researches show that few alkaline-earth elements including Ca and Sr are capable of obviously increasing the flame-retardant property of the magnesium alloy; furthermore, a high-melting-point strengthening phase is generated in the microscopic structure of the alloy; the microscopic structure of the magnesium alloy is improved; and the high-temperature mechanical property of the magnesium alloy is increased.

Owner:HENAN UNIV OF SCI & TECH

Preparation method for lightweight thermal insulation material

Provided is a preparation method for a lightweight thermal insulation material. The preparation method is characterized in that, one of carbon fibers or carbon fiber preoxidation filaments, three-dimensional hollow polyester fibers and low-melting-point polyester fibers at a mass ratio of 40-60:25-45:15-25 are mixed uniformly, the mixture is lapped to multiple layers through a lapping machine and sent to a baking box, baked at a controlled temperature of 180-220 DEG C until the low-melting-point polyester fibers are melted entirely, all the materials are melted and cohered together, and then cooling and shaping are carried out. The thermal insulation material is added with the carbon fibers with a low density, the global density is lowered, and the carbon fiber preoxidation filaments have a high ignition point and good fireproof performances after high temperature quenching. The thermal insulation material is added with the polyester fibers, the whole product is liable to forming, the flexibility is raised, the springback effect is excellent, folding and packaging are convenient, and human resource cost and material resource cost during the transport link and the cutting installation link are lowered greatly.

Owner:JILIN ZEXI TECH DEV

Environment-friendly type transformer oil with high ignition point and preparation method of transformer oil

The invention discloses environment-friendly type transformer oil with a high ignition point and a preparation method of the transformer oil and belongs to the technical field of lubricating oil. The environment-friendly type transformer oil with the high ignition point comprises components in percentage by weight as follows: 99.5%-99.8% of high-oleic rapeseed oil, 0.1%-0.4% of an antioxidant and 0.1%-0.4% of a metal deactivator. The invention further provides a preparation method of the transformer oil. The preparation method comprises steps as follows: the high-oleic rapeseed oil is heated to 50-80 DEG C, the antioxidant and the metal deactivator are added sequentially, the materials are stirred and mixed for 1-5 h, and the transformer oil is obtained after cooling and refined filtration. The transformer oil adopts a simple process, does not contain harmful substances, is biodegradable and cannot damage the environment and the human body; the performance is stable, good stability is kept between different batches, the ignition point is high, and risks of fire disasters and explosions are effectively reduced; the addition quantity of the antioxidant is low, the service period is long, and the transformer oil has excellent physicochemical and dielectric properties and meets the requirement of national standard.

Owner:青岛中科润美润滑材料技术有限公司

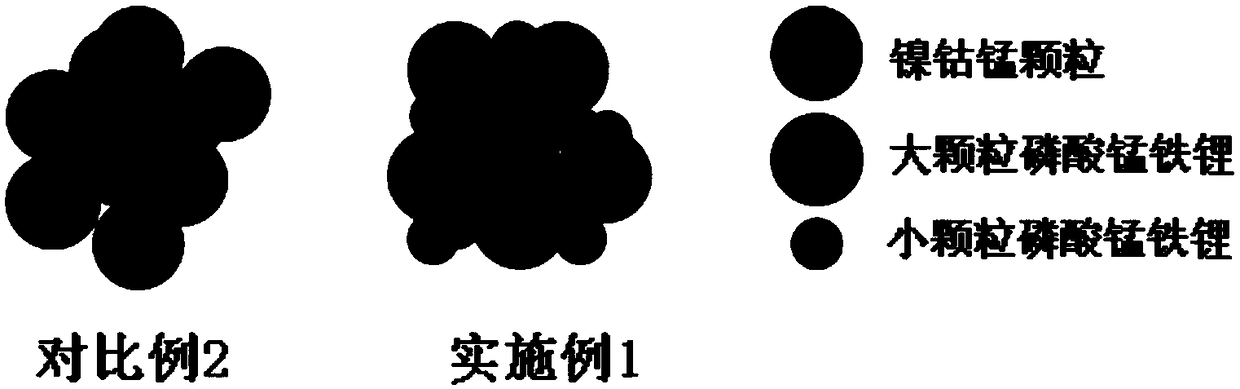

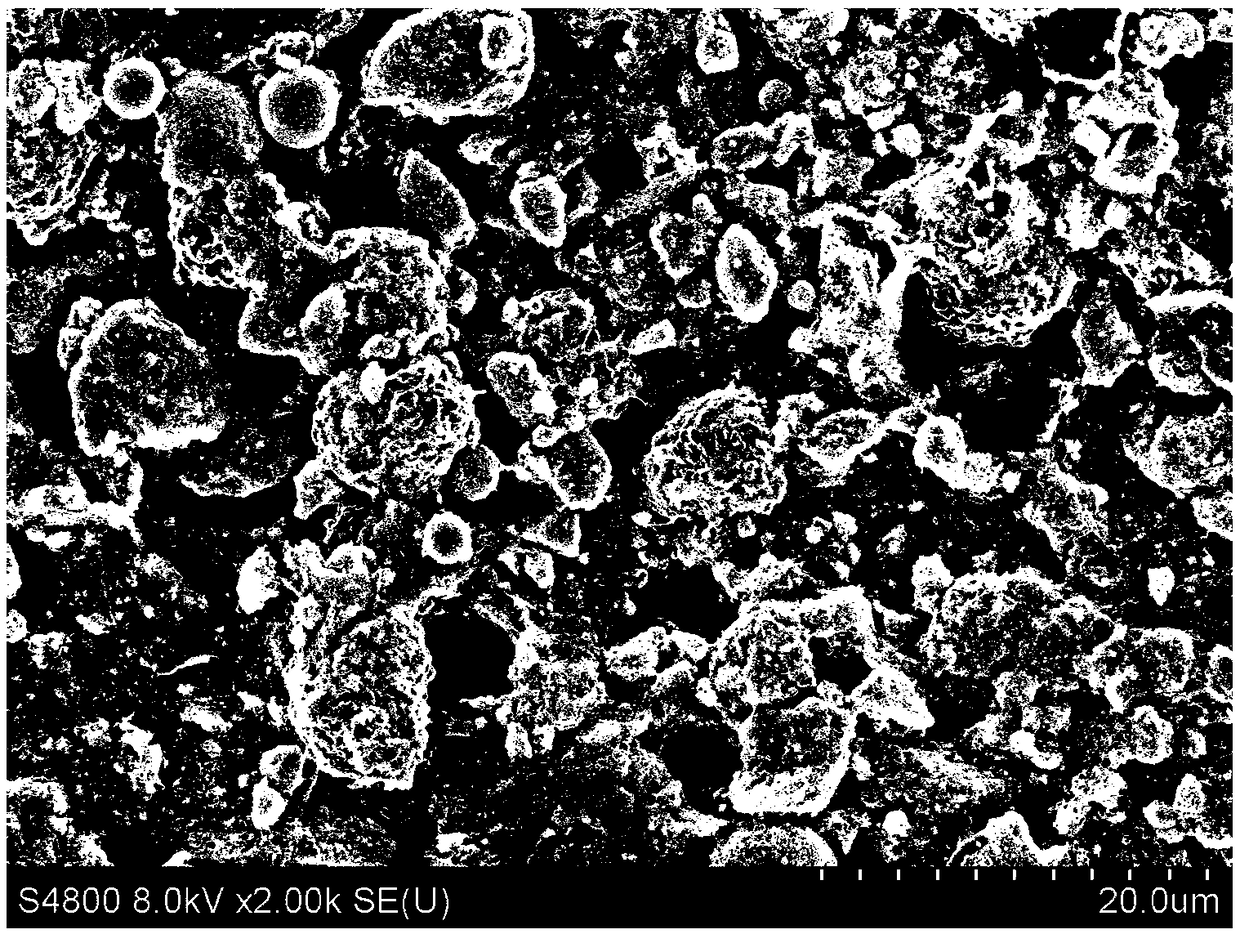

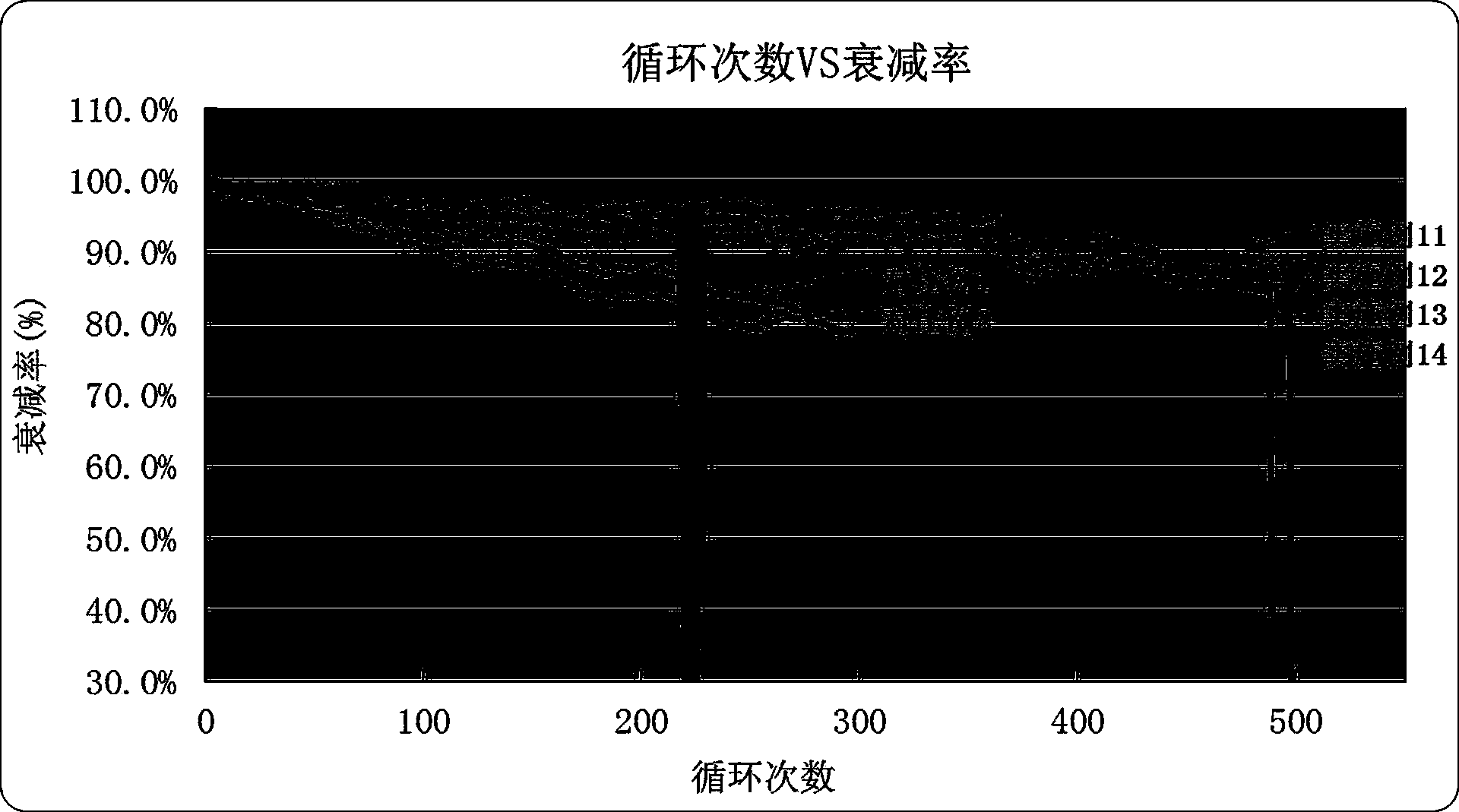

Positive material, positive plate and lithium ion battery

InactiveCN108777298ASmall heat releaseImprove securityCell electrodesSecondary cellsManganateIron phosphate

The invention provides a positive material, which is prepared from lithium manganese iron phosphate and a ternary material, wherein lithium manganese iron phosphate is LiMnzFe1-zPO4, and wherein z ismore than or equal to 0.6 and less than or equal to 0.9; the ternary material is lithium nickel cobalt manganate and / or lithium nickel cobalt aluminate; the D50 of lithium manganese iron phosphate is3.6-6.5mu m; the D50 of lithium nickel cobalt manganate is 8.5-11.0mu m; the D50 of lithium nickel cobalt aluminate is 10.0-14.0mu m; the D50 of the ternary material is 1.5-2.5 times that of lithium manganese iron phosphate. The ternary material is surrounded by the lithium manganese iron phosphate material, so that the heat release amount of the positive material is reduced, the ignition point ofthe positive material is increased, and the safety performance of a battery can be improved; furthermore, the cycle performance of the battery is improved. The invention also provides a positive plate and a lithium ion battery.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Electrolyte for polyoxometallate ionic liquid lithium ion battery and preparation method of electrolyte

ActiveCN104051783AIncrease transfer rateHigh ignition pointElectrolyte accumulators manufactureElectrolytic agentPhysical chemistry

The invention discloses electrolyte for a polyoxometallate ionic liquid lithium ion battery. The electrolyte comprises the following raw materials: ionic liquid and lithium polyoxometallate, wherein the ionic liquid is synthesized from imidazolium cations and polyoxometallate anions; the structural formula of the imidazolium cations is shown in the specification, wherein each of R1 and R2 is one of alkyl groups with 1-6 carbon atoms; the polyoxometallate anions refer to [XY12O40]<3-> or [XY12O40]<4->, wherein X is any one of two elements P and Si, and Y is any one of two elements Mo and W. Since the lithium polyoxometallate Li3XY12O40 is in a three-dimensional skeleton structure, lithium ions can be conducted in a three-dimensional skeleton, and the polarity caused by the ion transport problem of the battery is reduced; since the lithium polyoxometallate does not contain fluorine, the moisture problem and the safety problem caused by fluorine are avoided.

Owner:中国东方电气集团有限公司

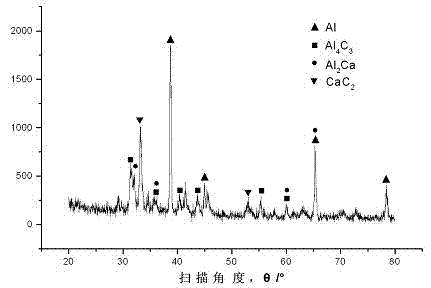

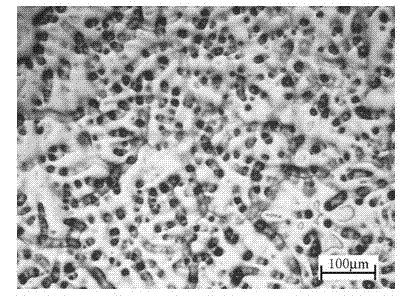

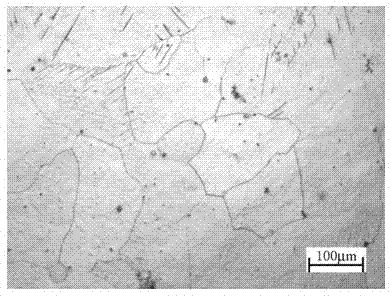

Aluminium calcium carbon grain refiner for Mg-Al series magnesium alloy and preparation method and application thereof

The invention discloses an aluminium calcium carbon grain refiner for Mg-Al series magnesium alloy and a preparation method and application thereof. The grain refiner provided by the invention comprises aluminium, calcium, carbon and magnesium; and by adding the aluminium calcium carbon grain refiner to magnesium alloy melt, fine heterogeneous phase particles, i.e. Al4C3, supply a large number of effective heterogeneous nucleation cores, Ca solute released by dissolved CaA12 (or CaAl4) particles restrains the growth of magnesium alloy grains, and the casting-state magnesium alloy grains are obviously refined and increased in terms of strength and plasticity under the composite refining effect. The grain refiner provided by using the method is a metal block and is convenient to add in the magnesium alloy melt; the addition amount and the component content of the grain refiner are easily controlled; and the purpose of high efficiency refinement can be achieved by adding a trace of grain refiner.

Owner:JINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com