Patents

Literature

1915results about "Lubricant mounting/connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

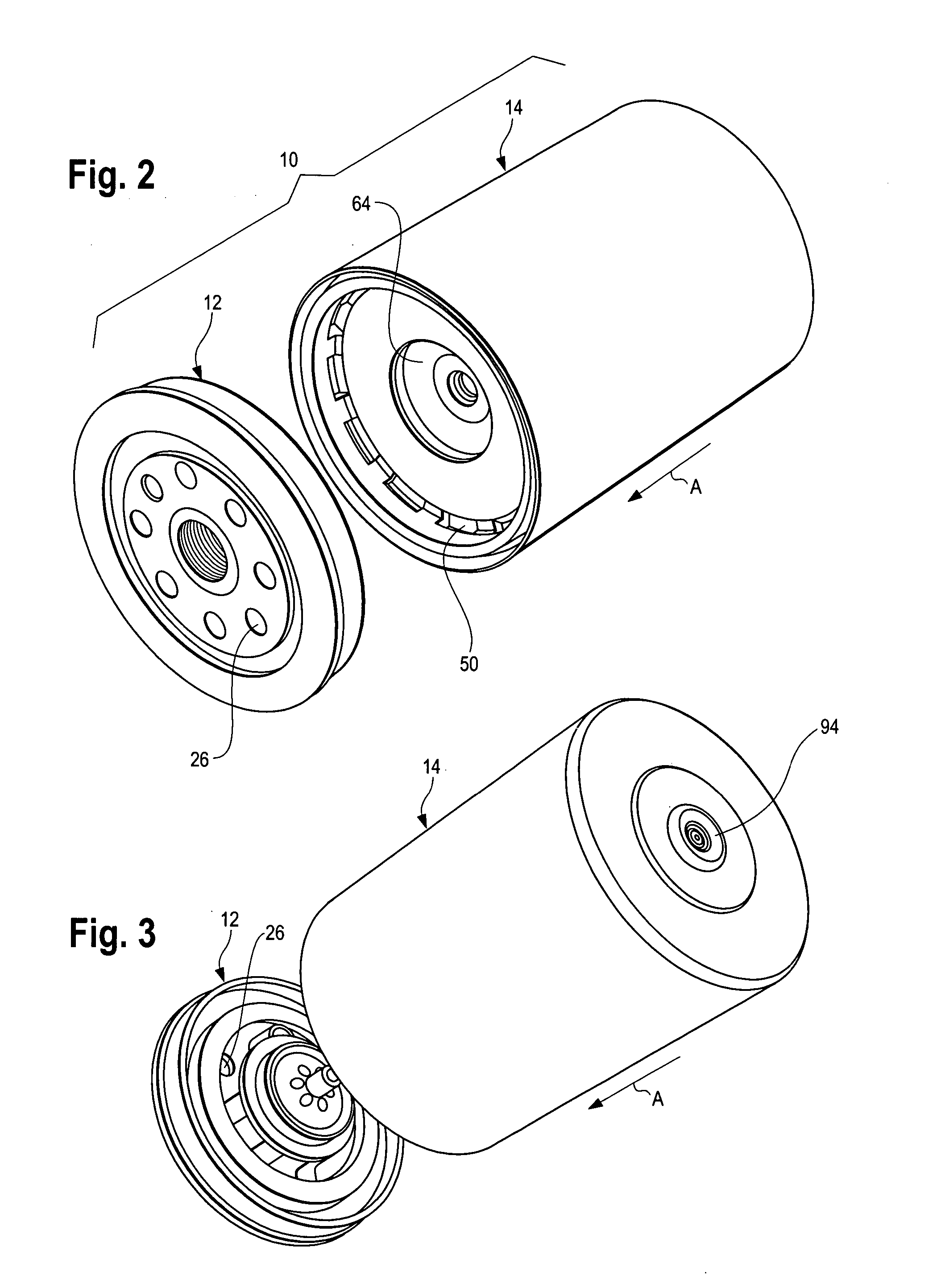

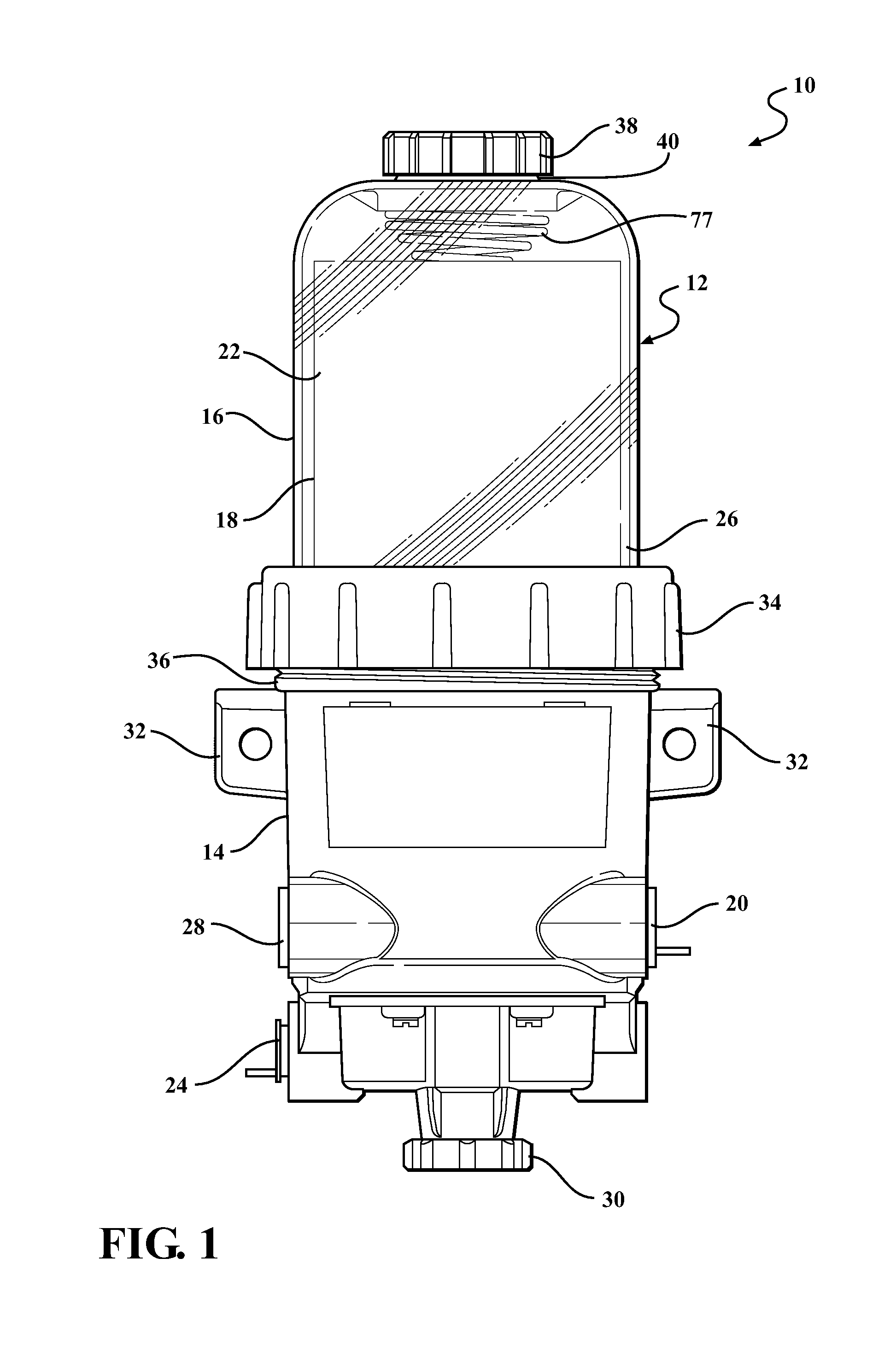

Fluid filter system

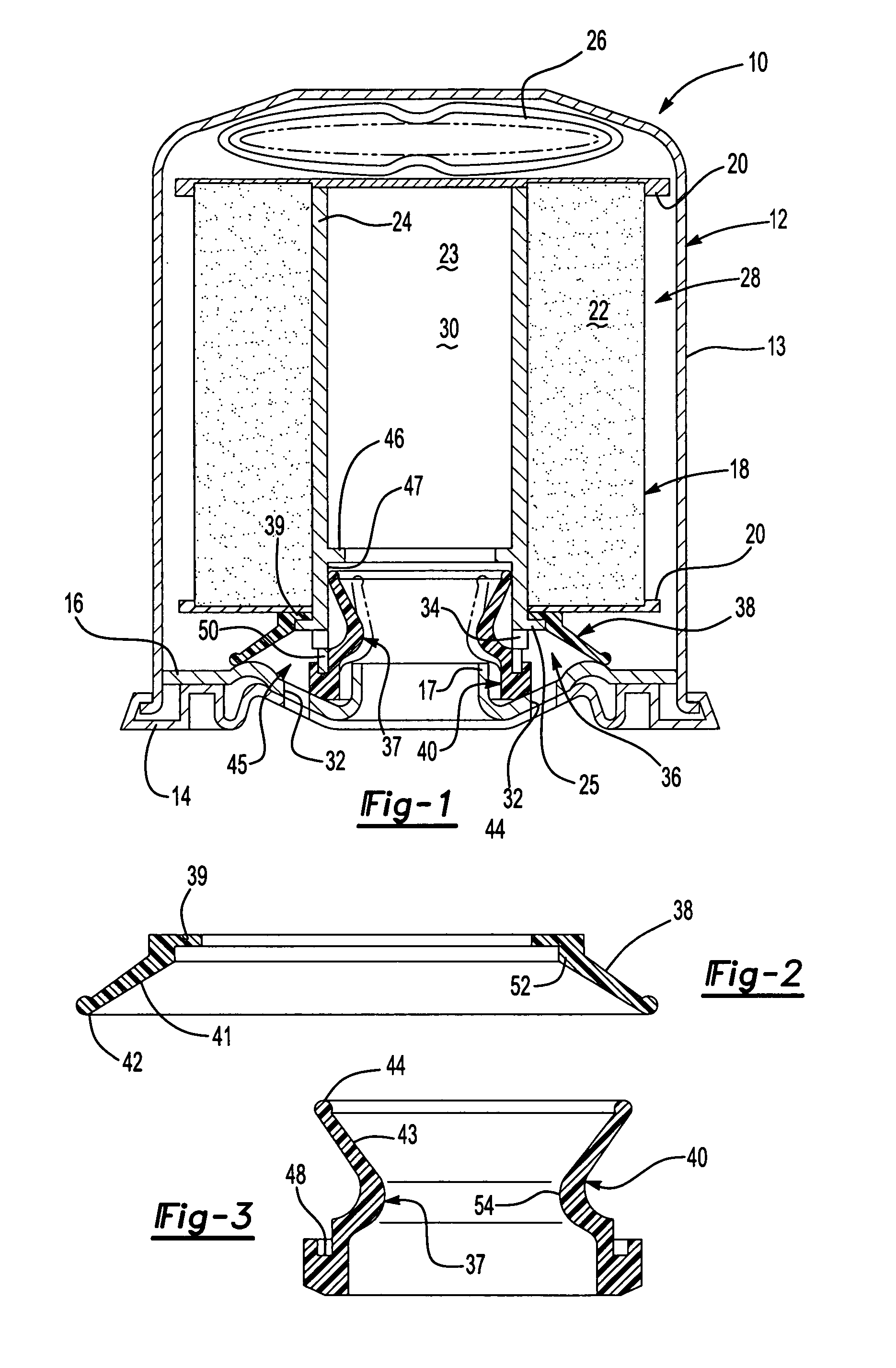

An endcap including a first plate member including a radial inner portion, a radial outer portion, and defining a longitudinal axis. The endcap also includes a flange disposed between the radial inner and outer portions of the first plate member and projecting axially along the longitudinal axis in a first direction. The endcap also includes a first seal member disposed adjacent the flange. The first seal includes a first portion thereof engaged with an axial facing surface of the first plate member and a second portion thereof engaged with a radially facing surface of the flange. The endcap further includes a second plate member disposed radially outward of the radial outer portion and a second seal member disposed adjacent the second plate member including at least a portion thereof axially spaced from the axially facing surface of the first plate member in a second direction along the longitudinal axis opposite the first direction.

Owner:DONALDSON CO INC +2

Slow release lubricant additives gel

A lubricant additive gel formed by the gellation of two or more lubricant additives for the slow release of the additive components into a fluid. The lubricant additive gel slowly releases into its component lubricant additives when contacted with the fluid such as an oil thereby serving as a lubricant fluid such as an oil thereby.

Owner:THE LUBRIZOL CORP

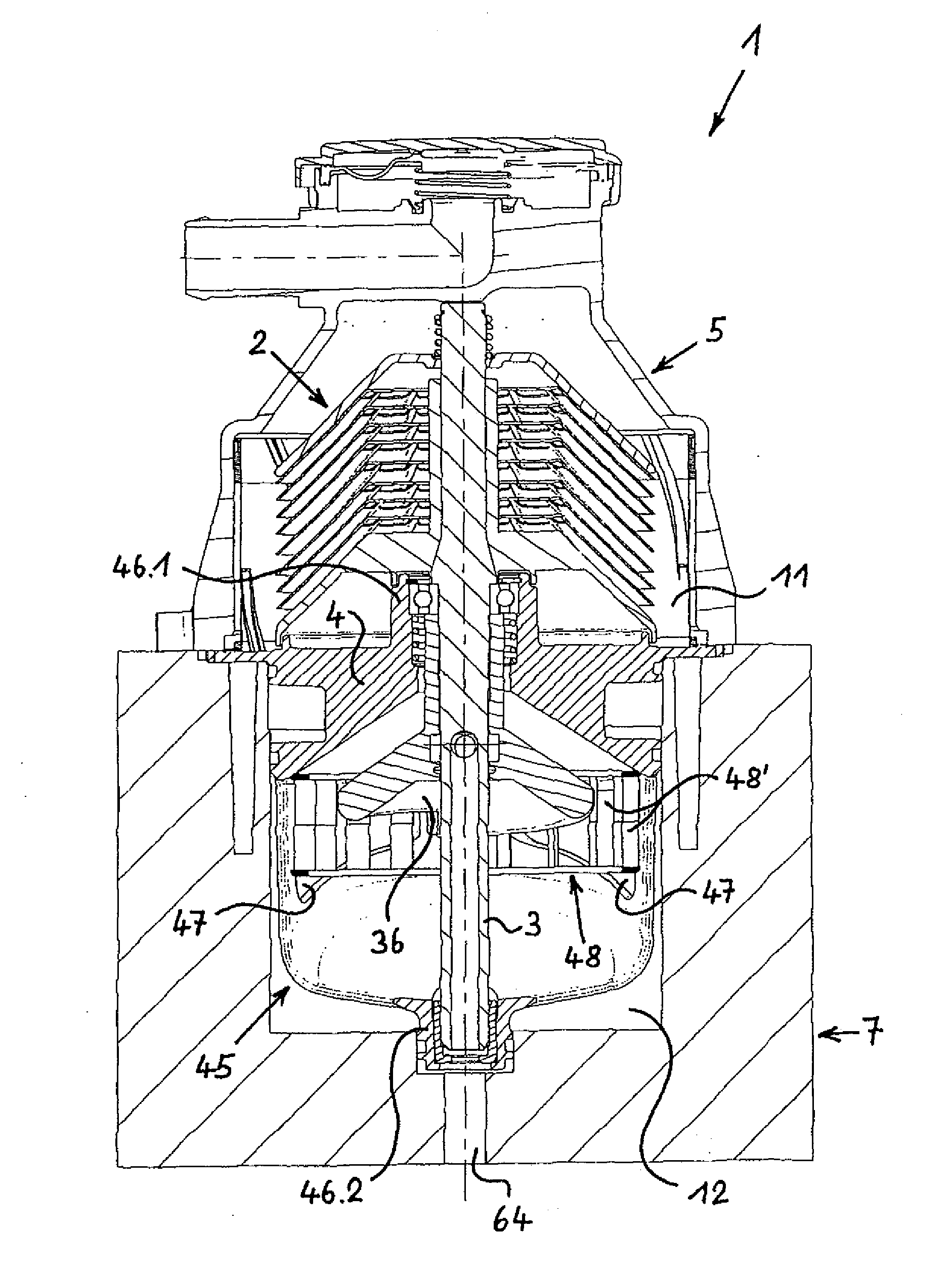

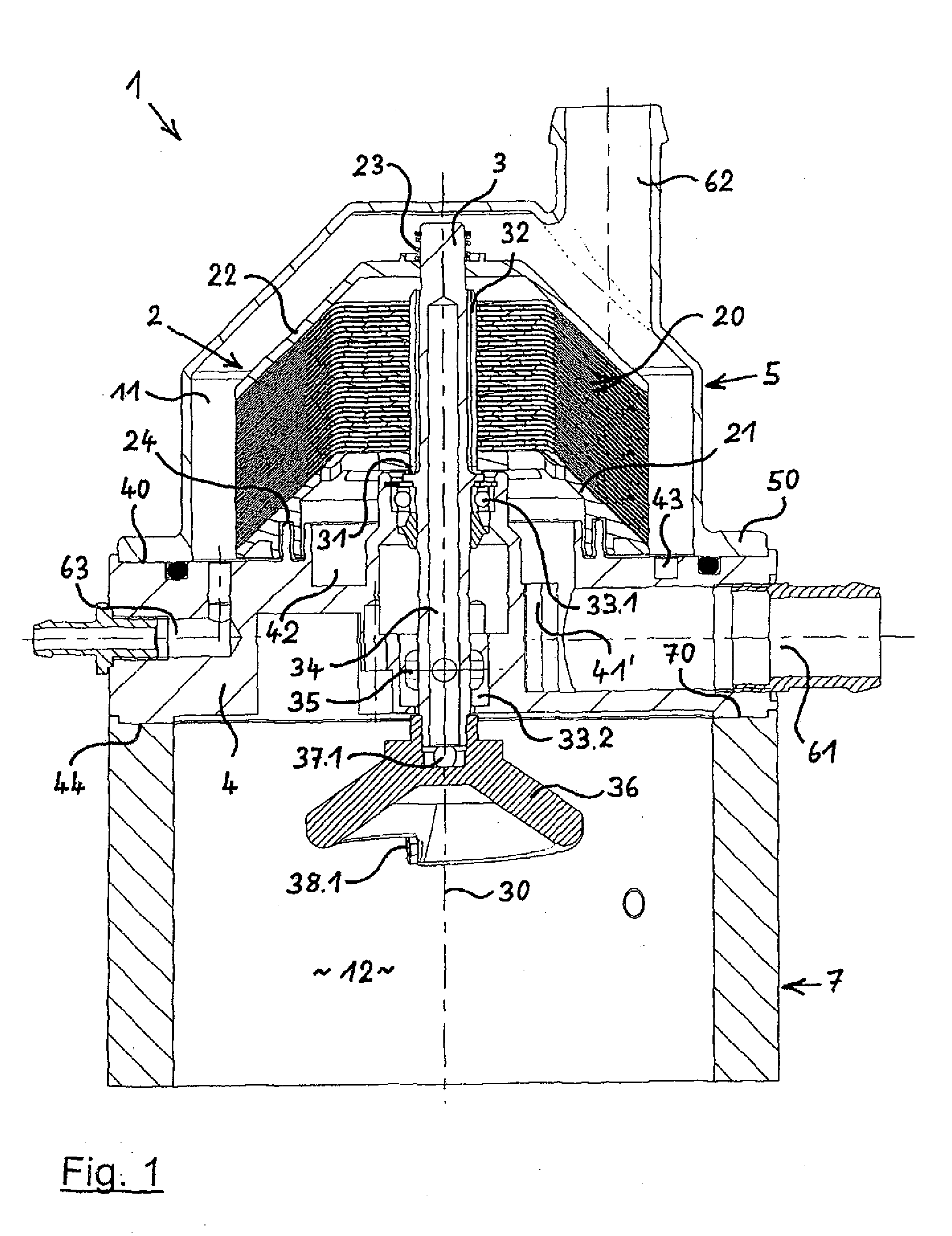

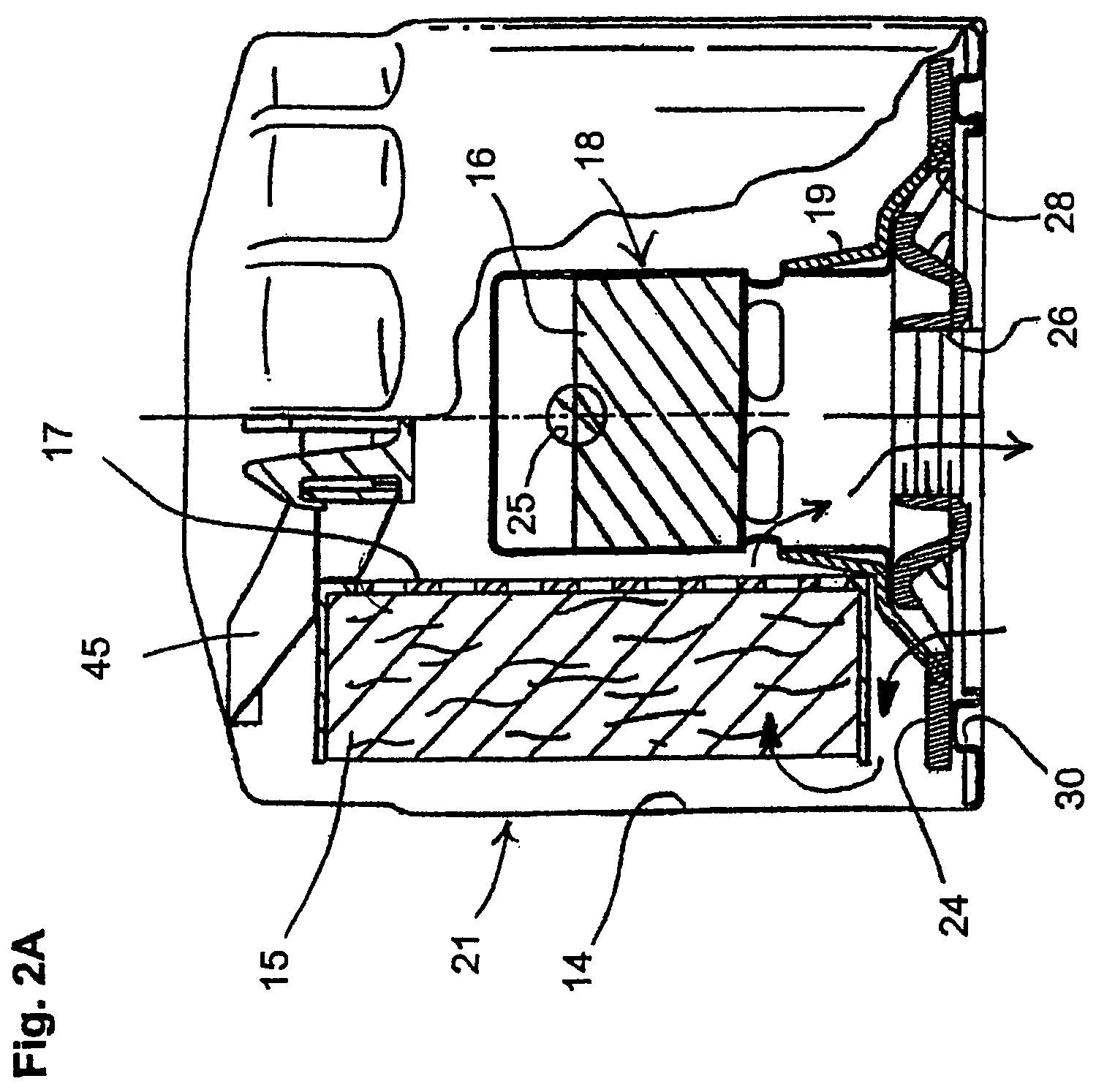

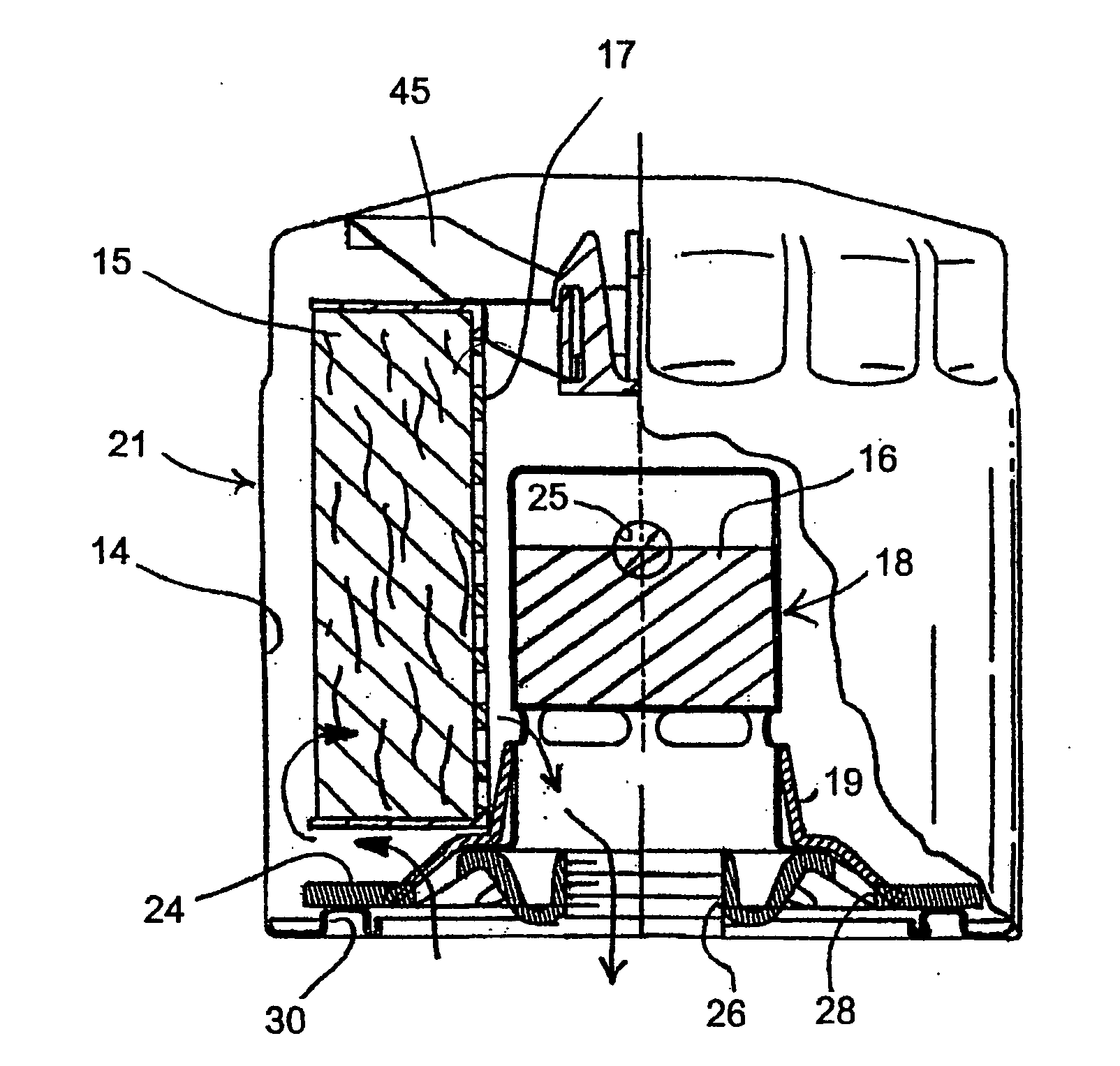

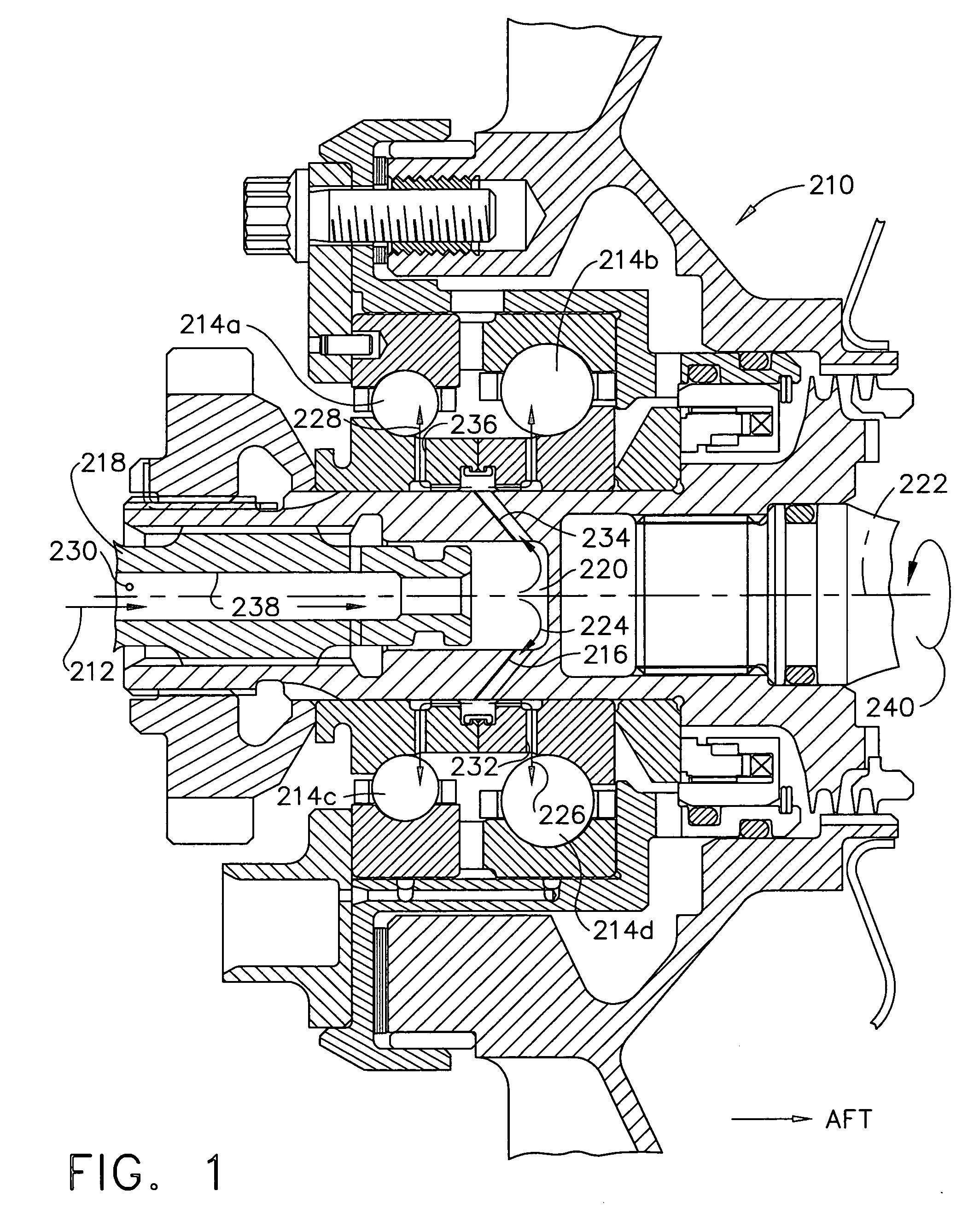

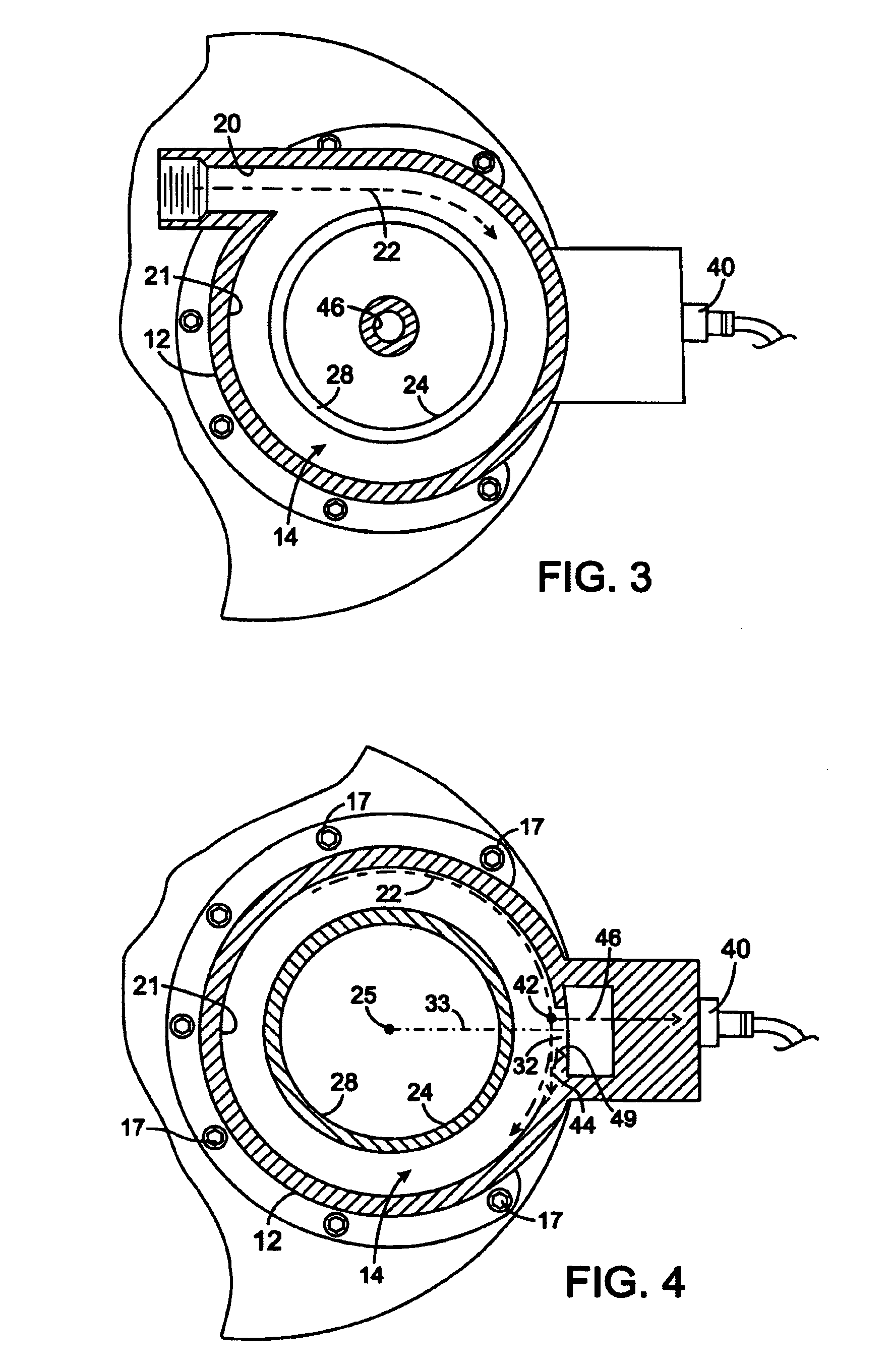

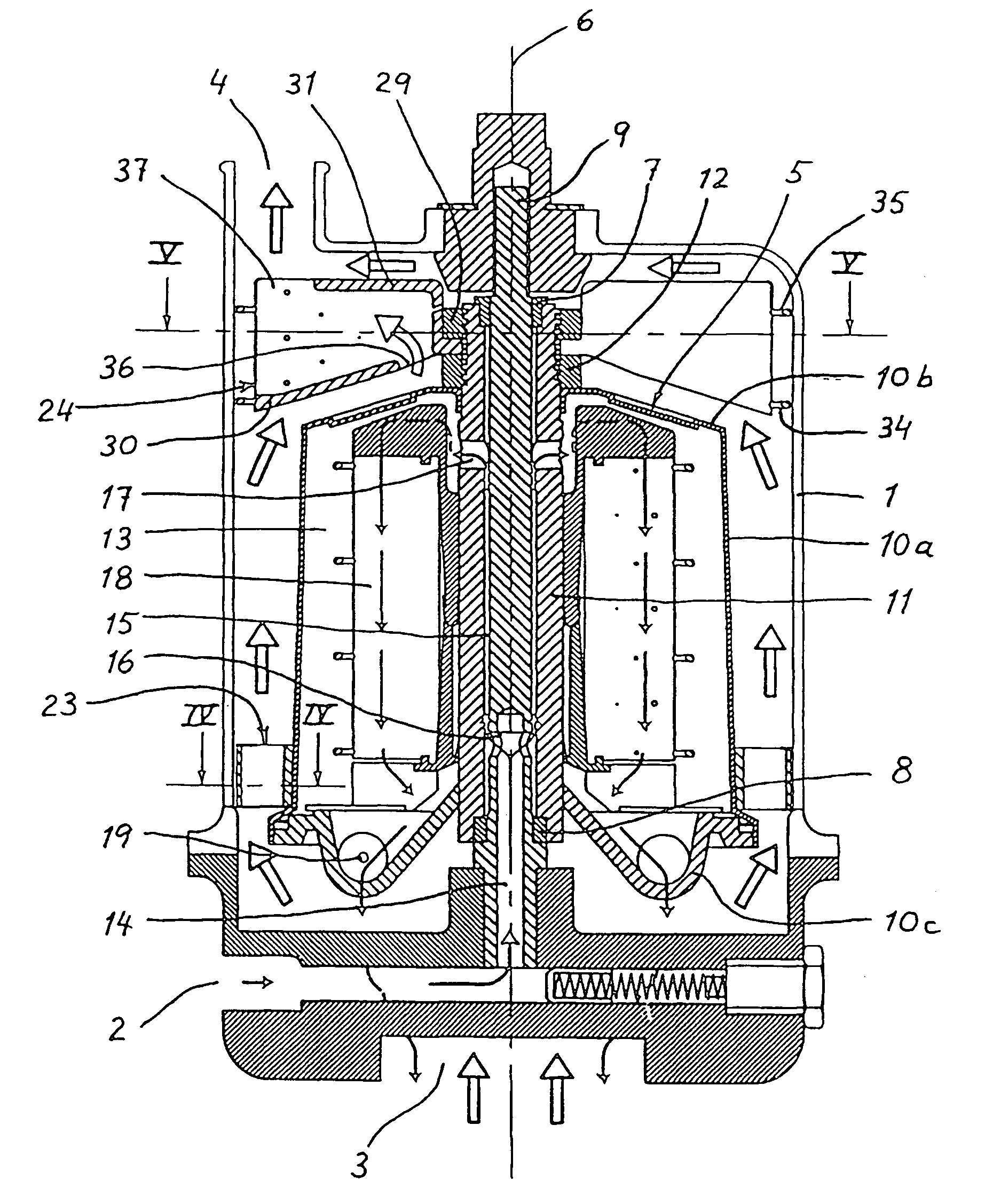

Separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, and functional module and internal combustion engine comprising a separator

ActiveUS20100180854A1Increase speedEasy to separateCombination devicesLubrication of auxillariesExternal combustion engineEngineering

A separator for separating oil mist from the crankcase ventilation gas of an internal combustion engine, especially of a motor vehicle. The separator includes a gas purification chamber inside which a rotatably mounted centrifugal rotor is arranged. The gas purification chamber has a crude gas inlet, a pure gas outlet, and an oil outlet. The crankcase ventilation gas can be conducted into a radially internal zone of the centrifugal rotor via the crude gas inlet, while pure gas that is liberated from oil mist can be discharged from the gas purification chamber via the pure gas outlet, and oil separated from the gas can be discharged from the gas purification chamber via the oil outlet. The separator further includes a rotary drive for the centrifugal rotor. The rotary drive is disposed in a drive chamber of the separator, can be operated using pressurized lubrication oil of the internal combustion engine, and is connected to the centrifugal rotor by means of a shaft extending from the drive chamber into the gas purification chamber, from which the drive chamber is separated. The rotary drive is formed by at least one thrust nozzle which is connected to the shaft and to which the pressurized lubrication oil of the internal combustion engine can be fed. The separator includes at least one part of a base that forms the separation between the gas purification chamber and the drive chamber and extends into the drive chamber, the part of the base being fitted with a seat for a bearing of the shaft. The bearing is located at a distance from the centrifugal rotor.

Owner:HENGST WALTER

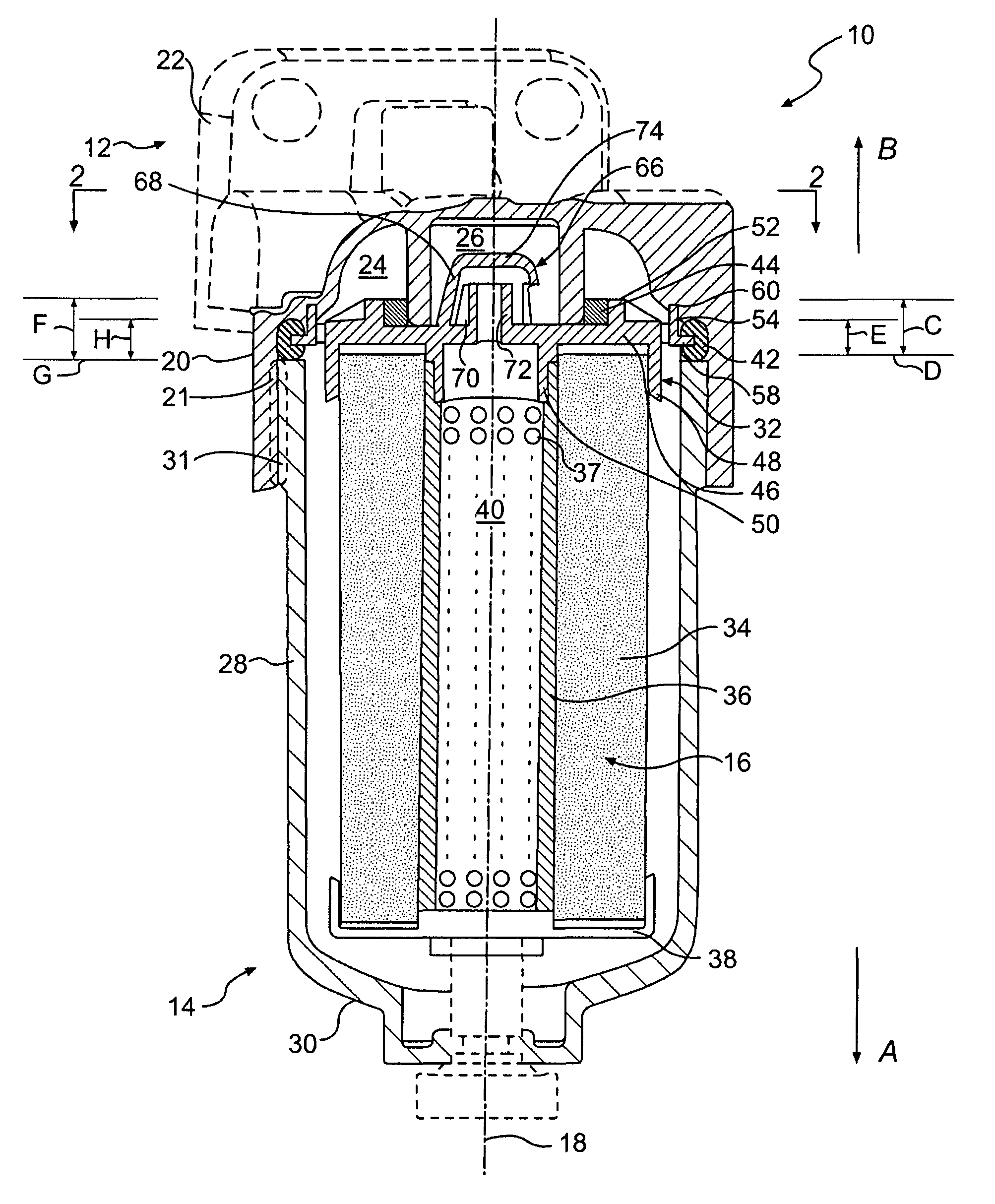

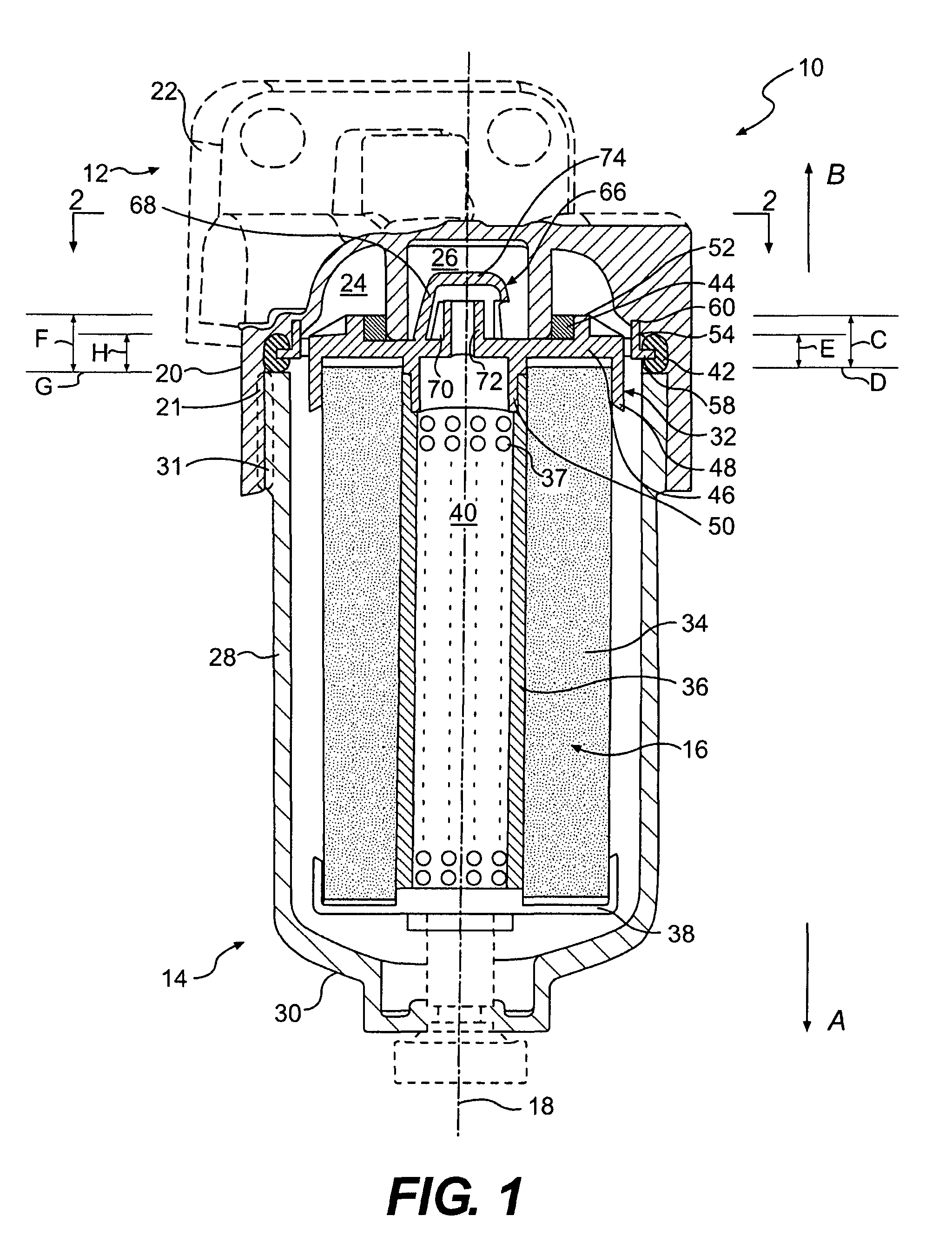

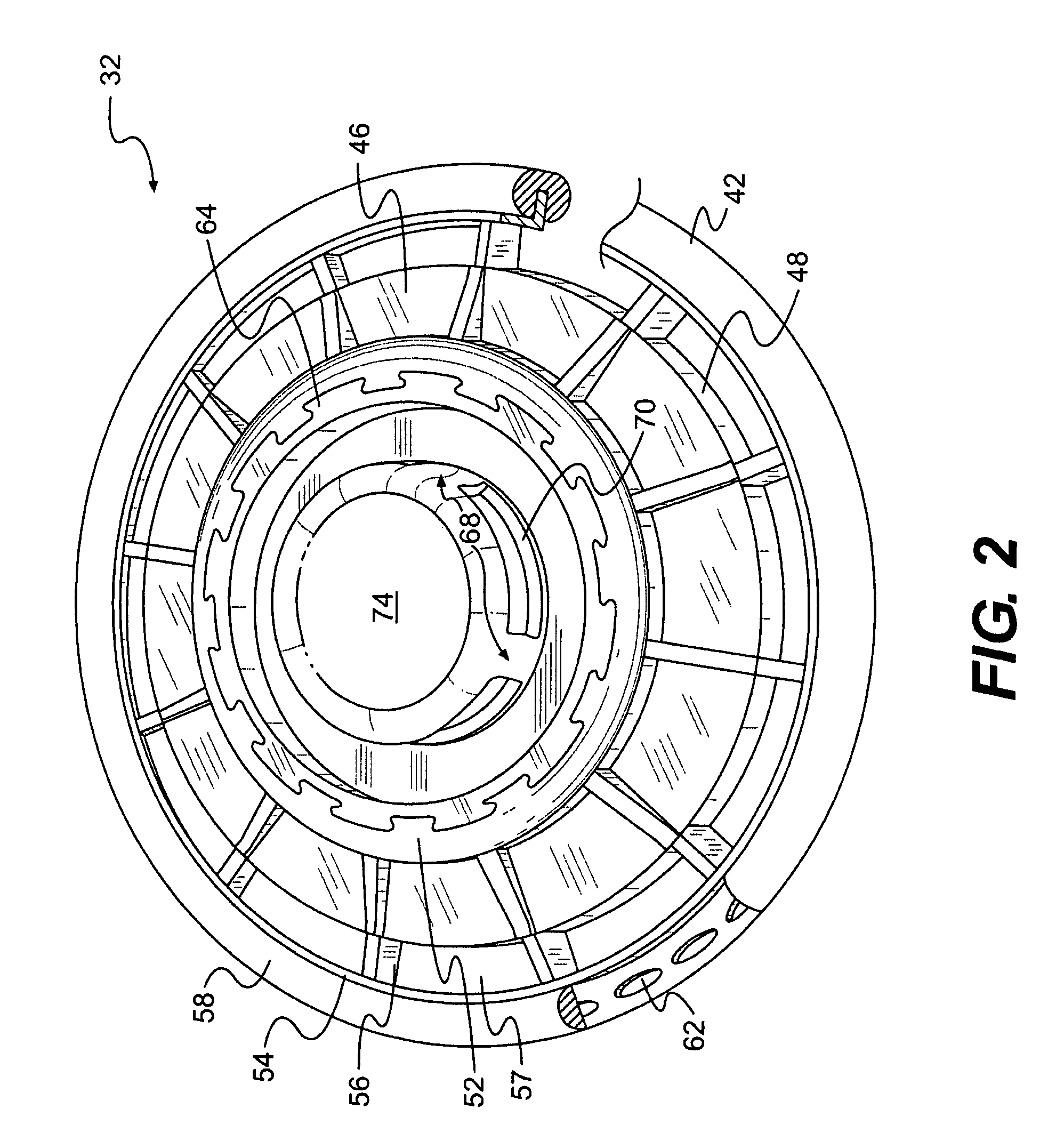

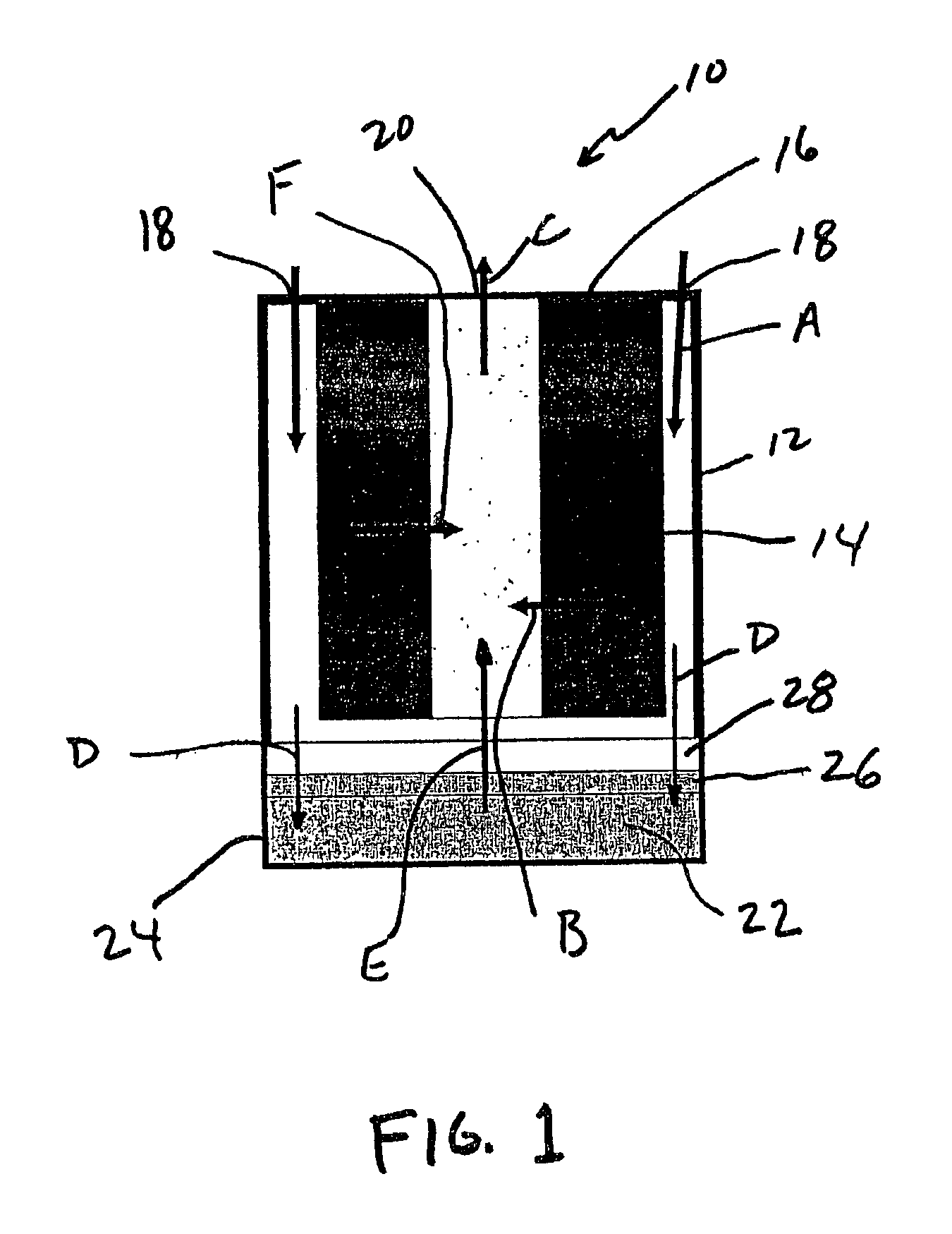

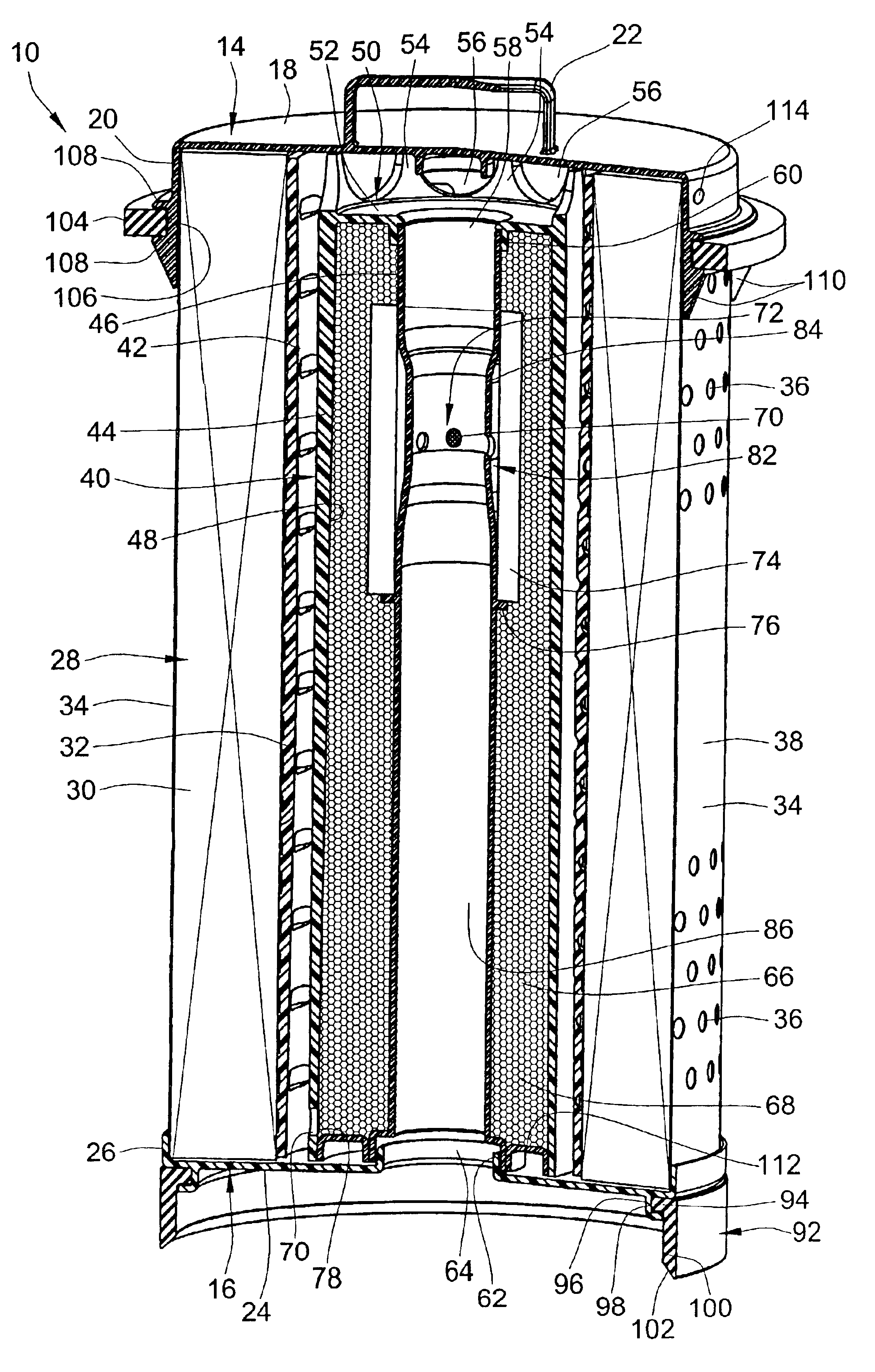

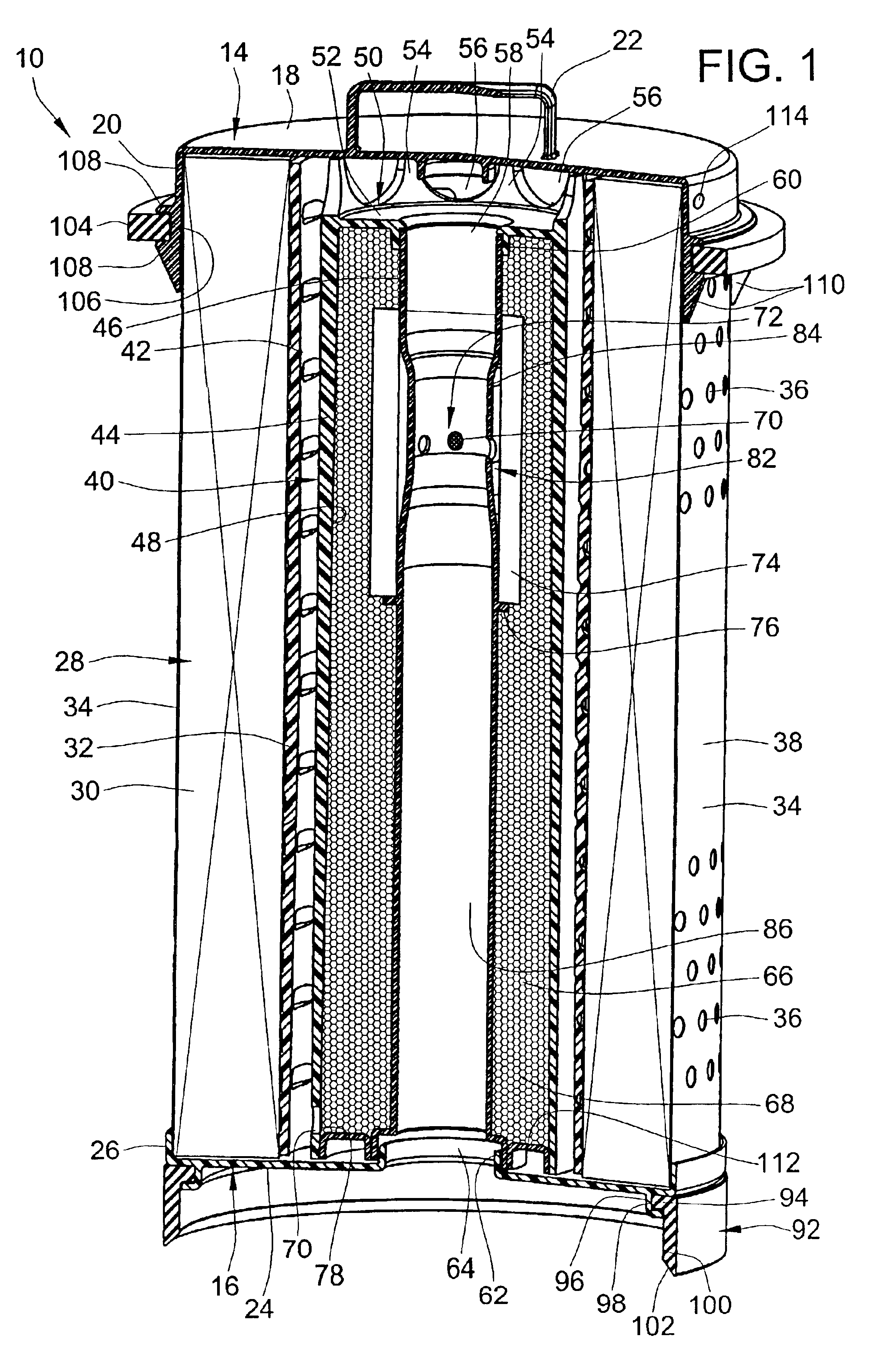

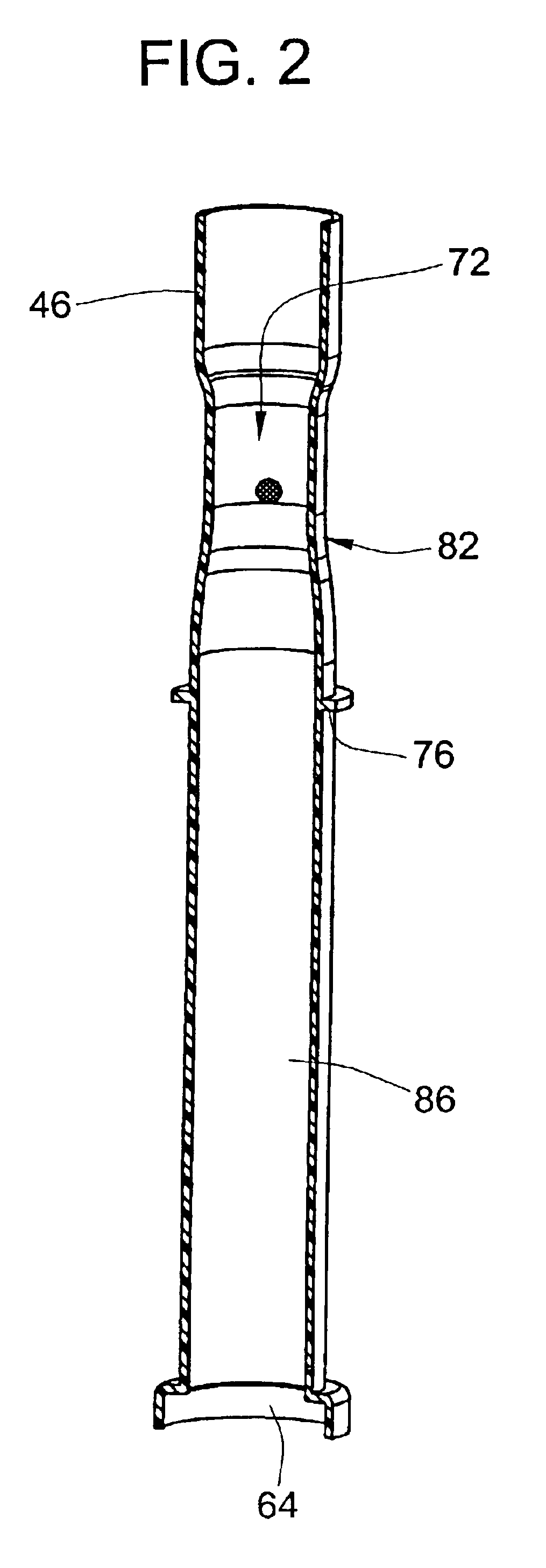

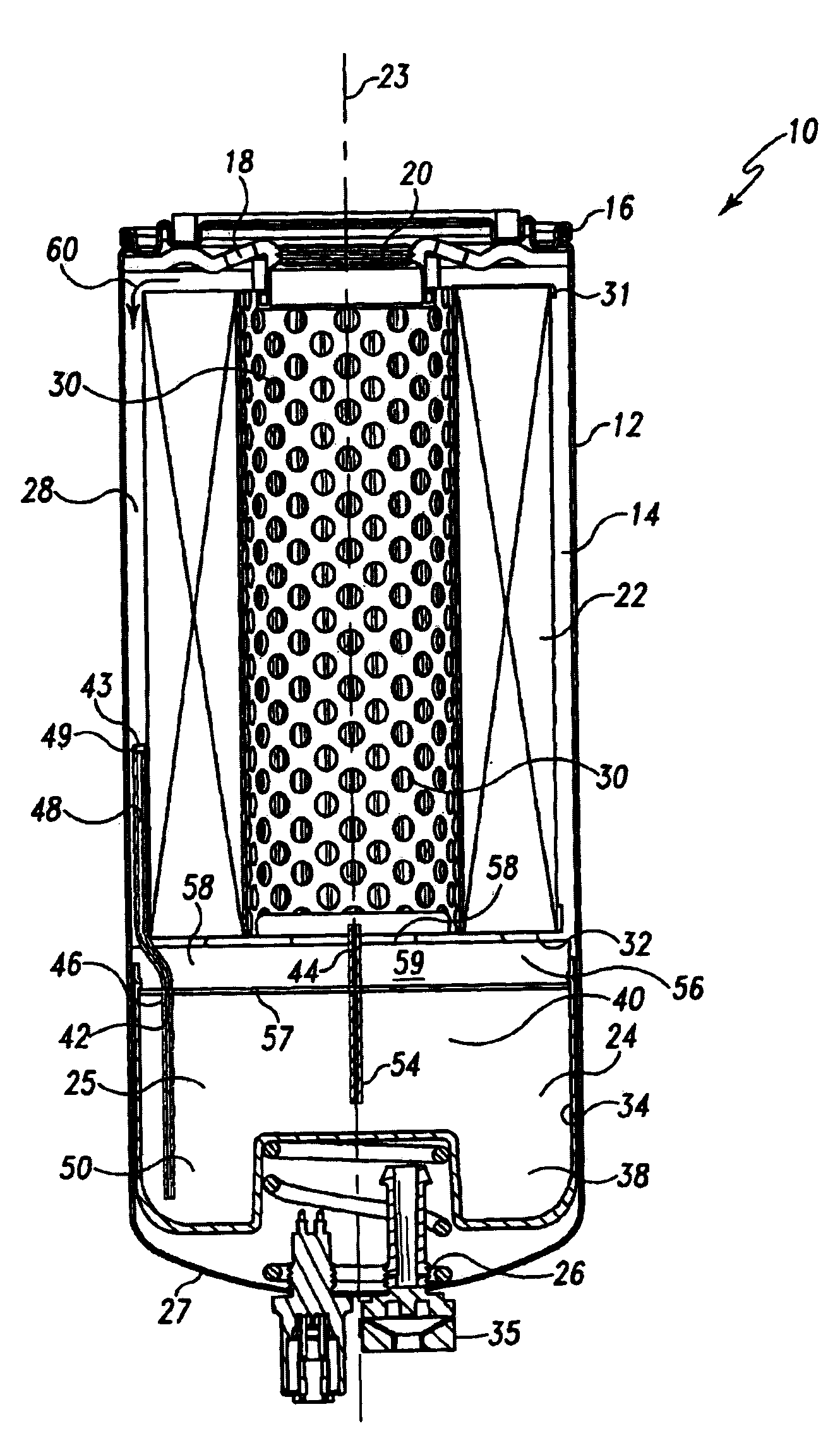

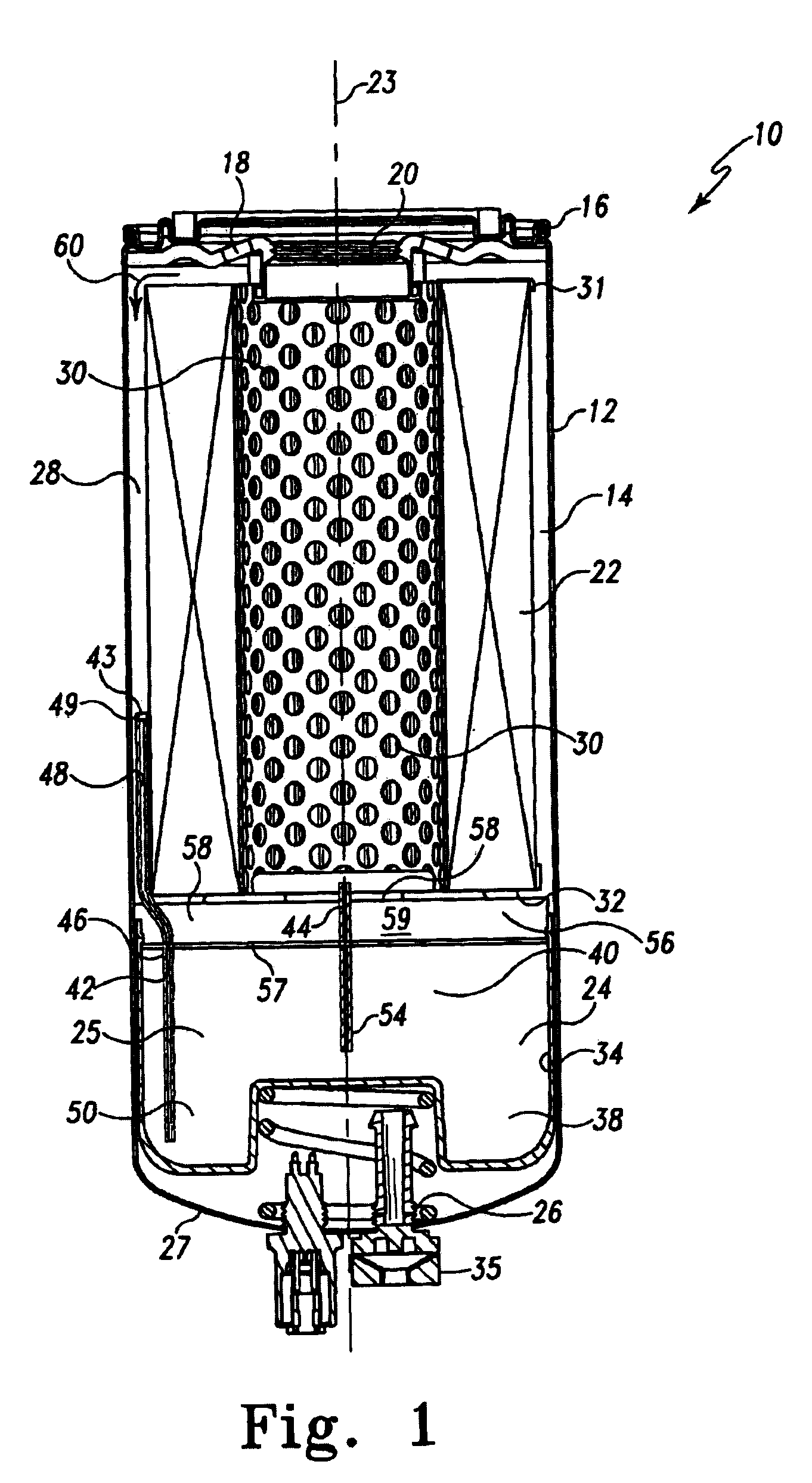

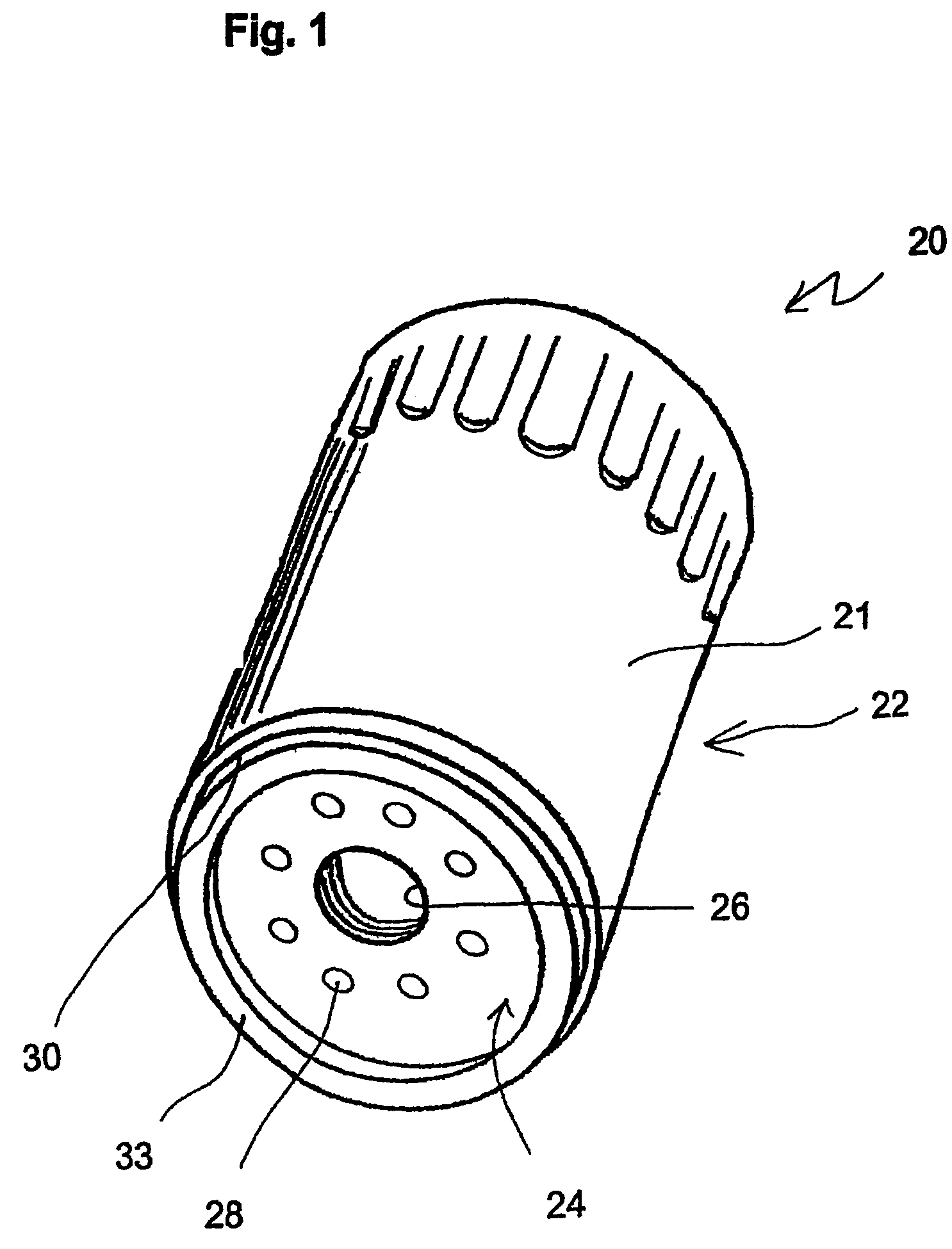

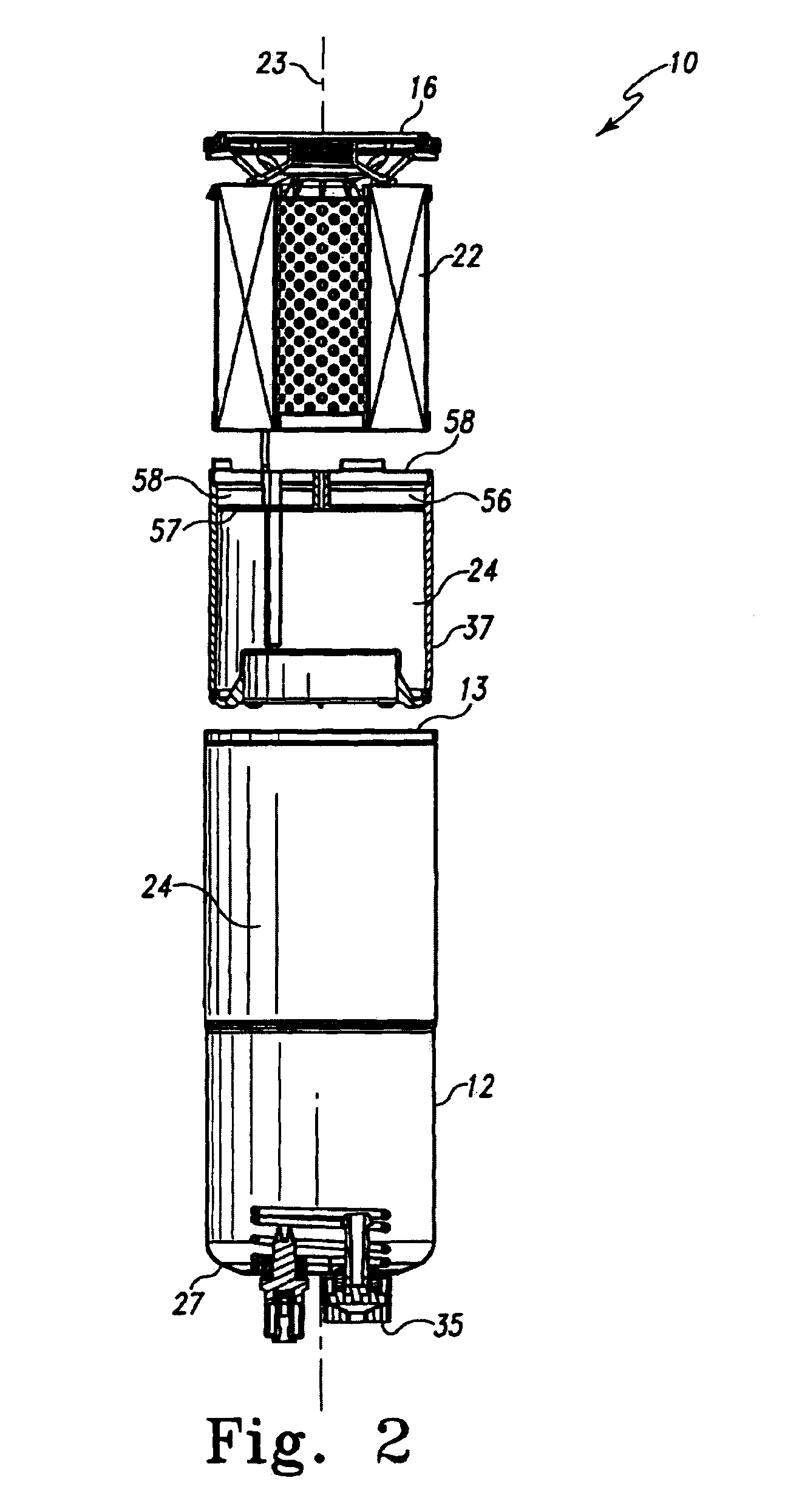

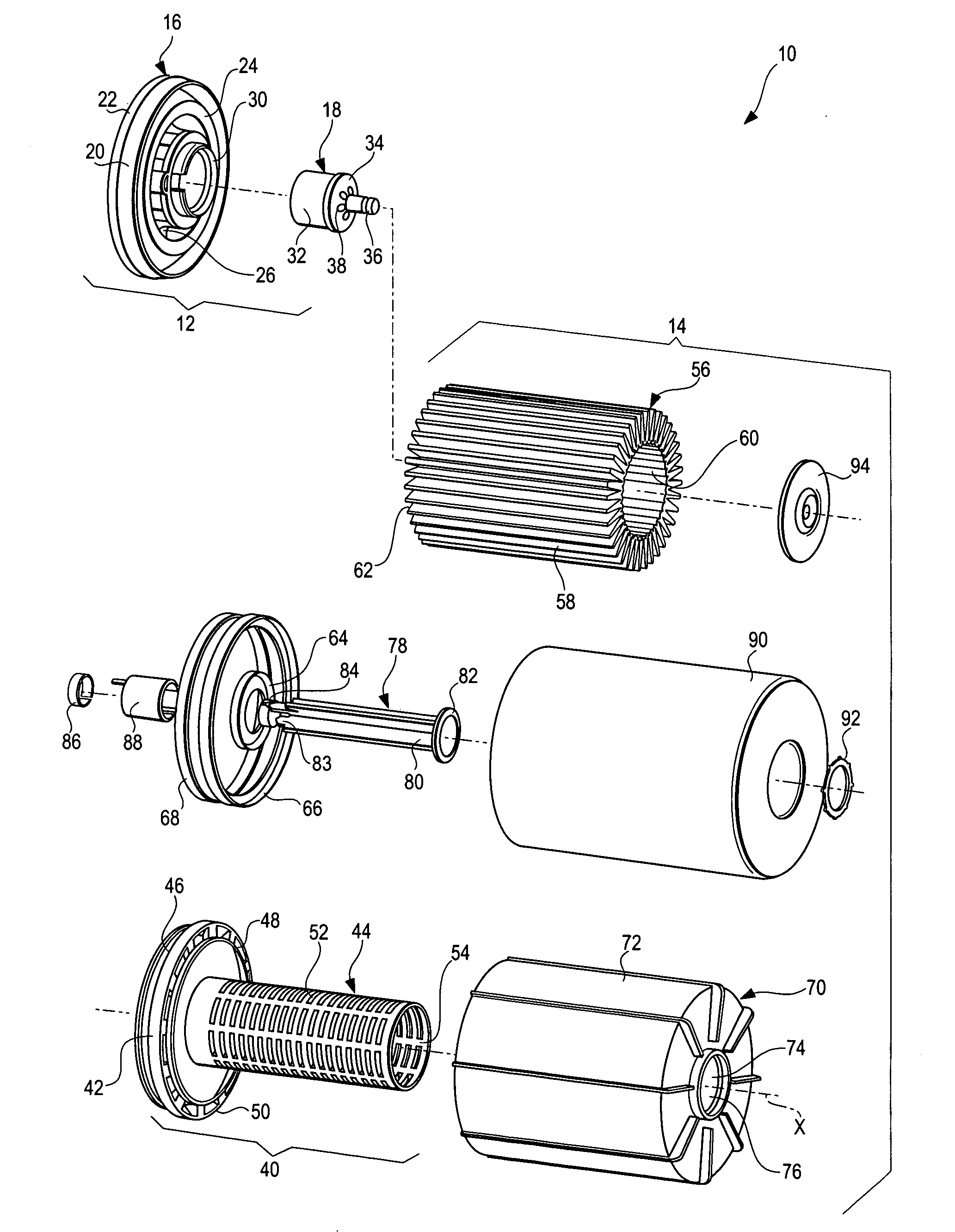

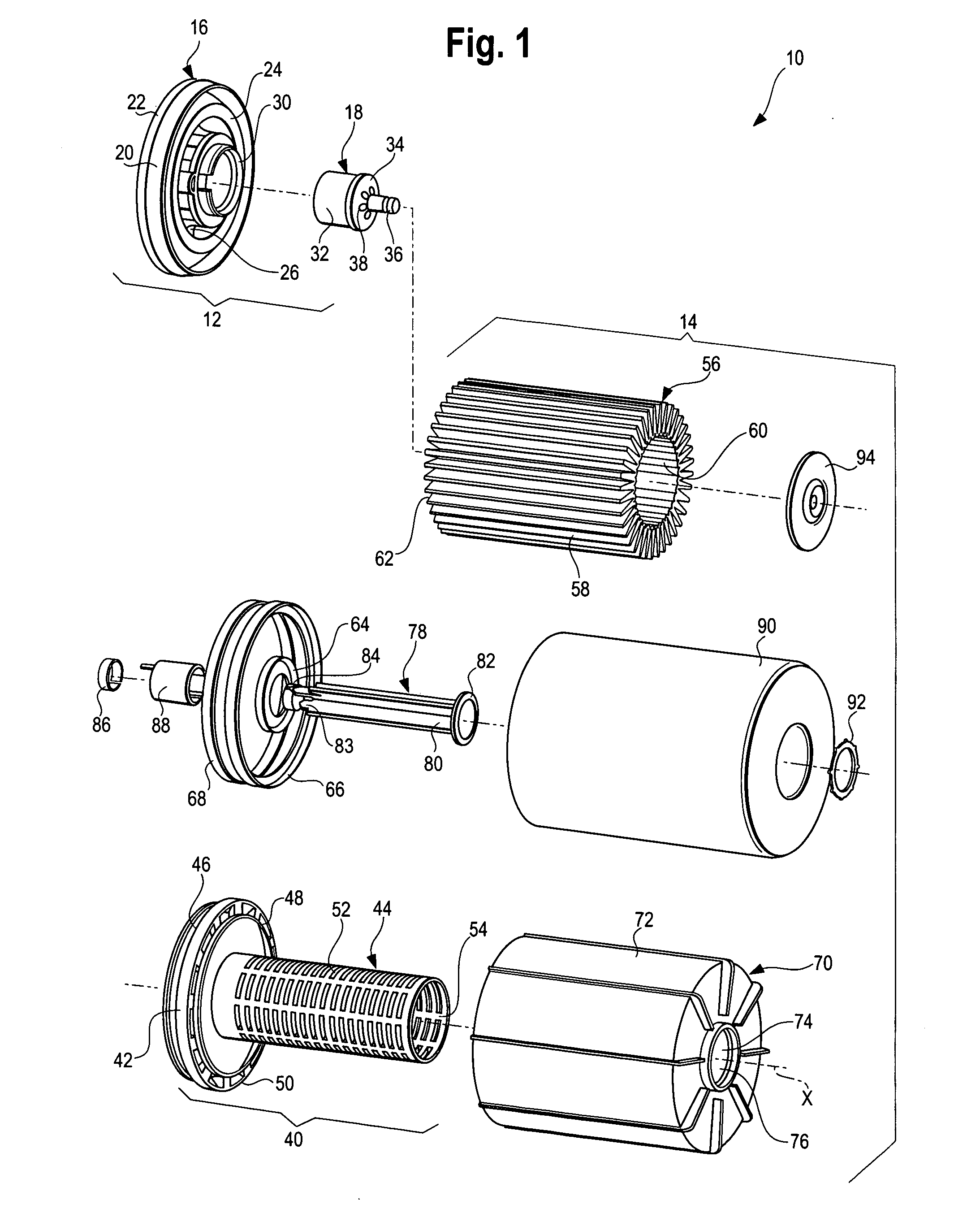

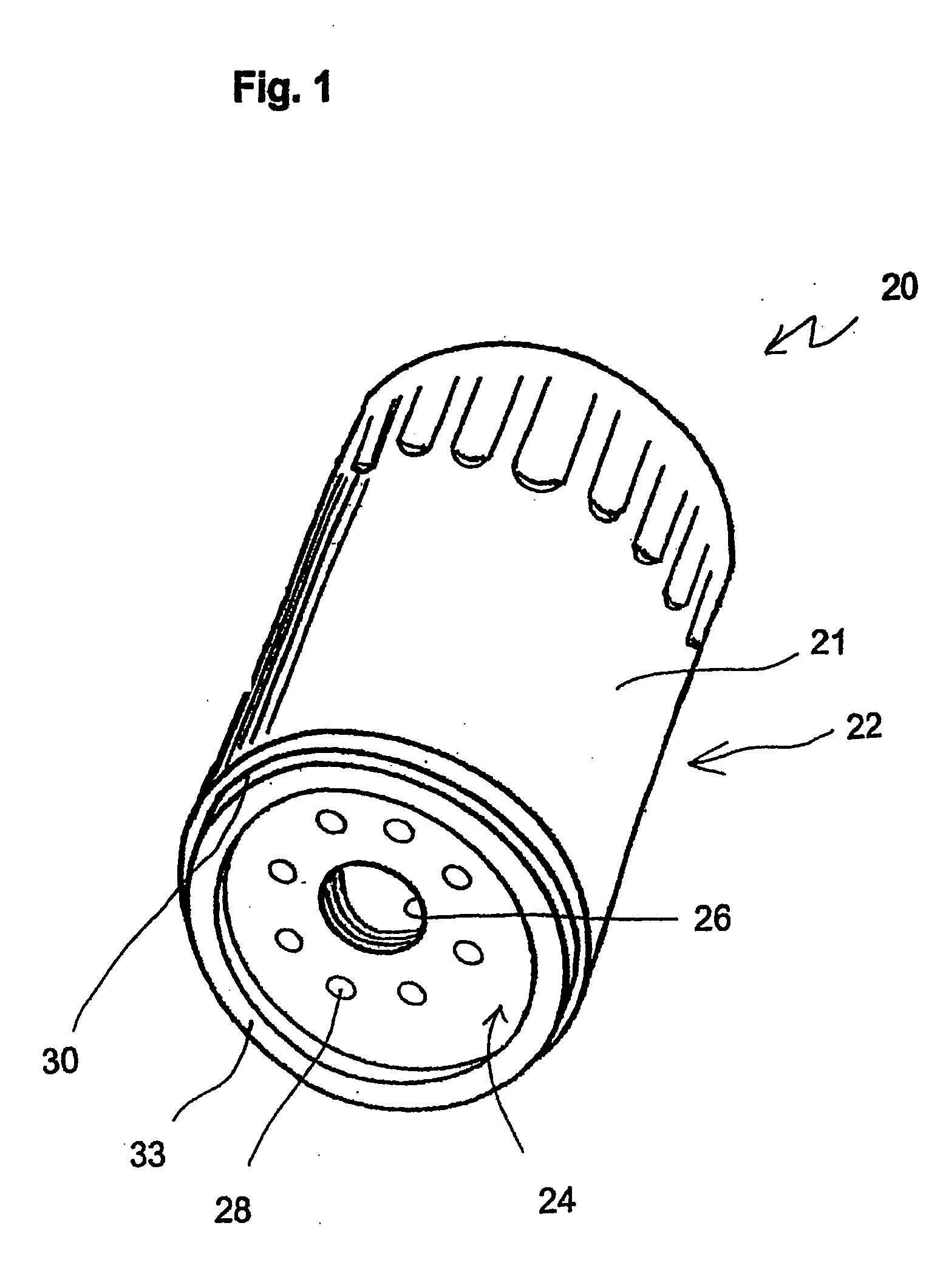

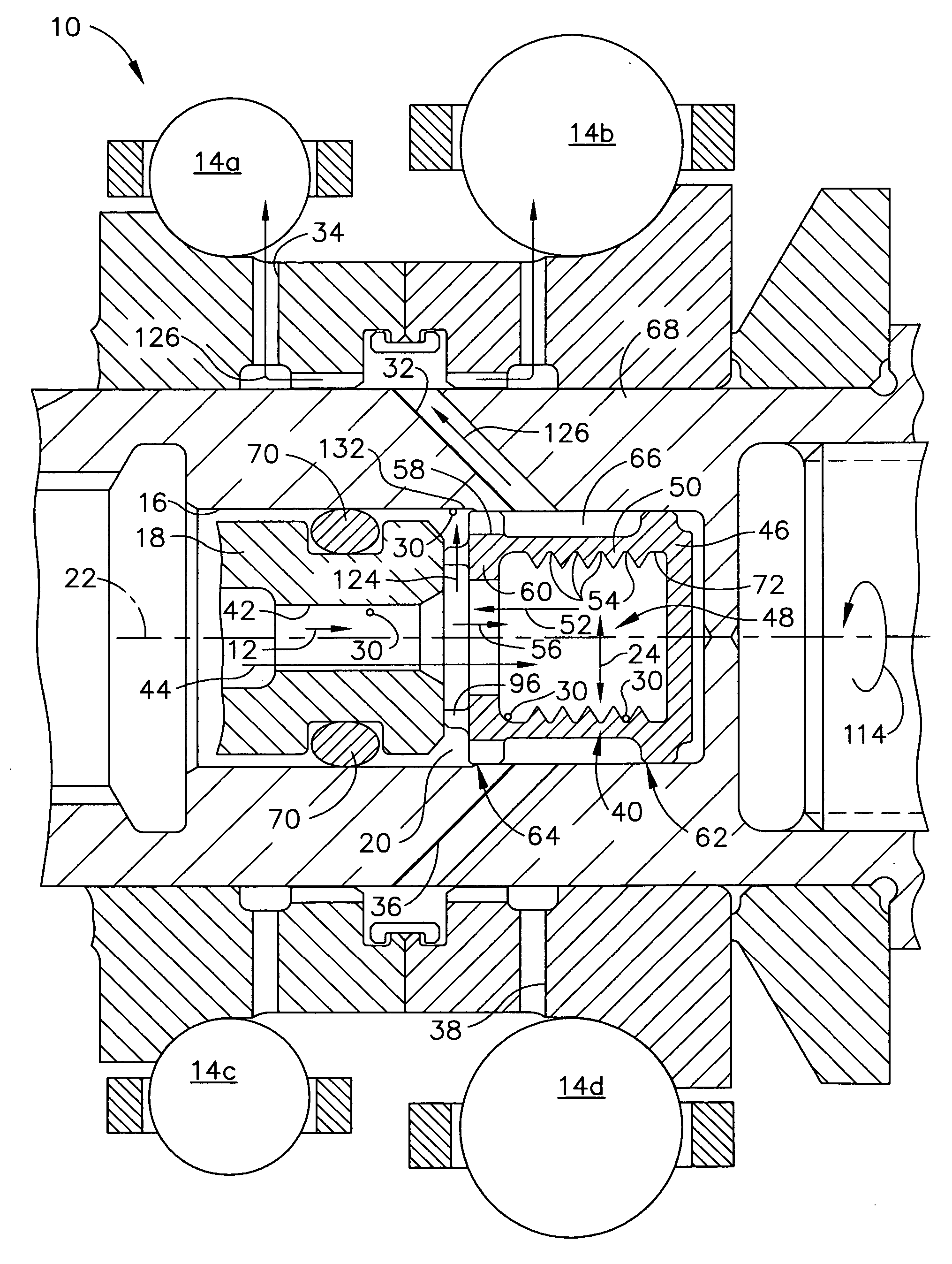

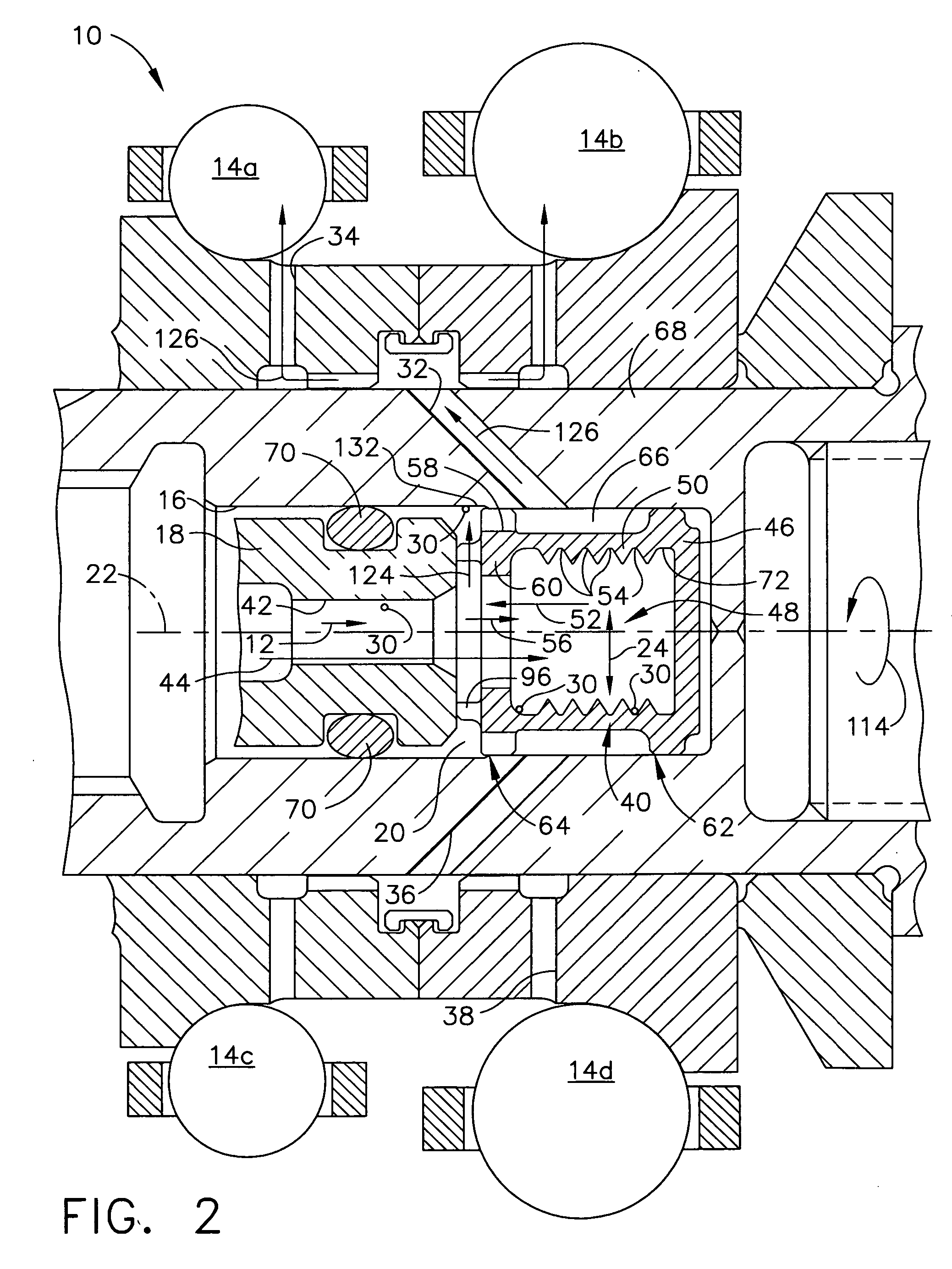

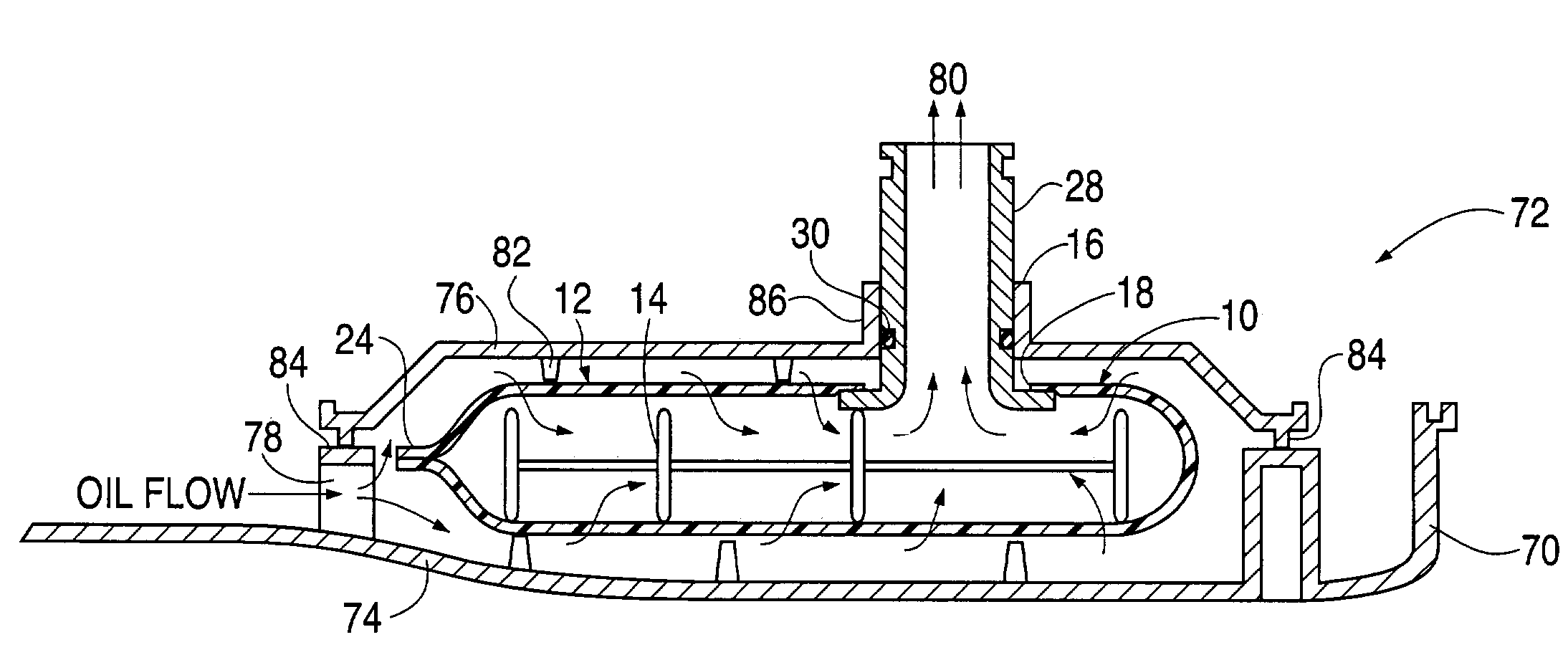

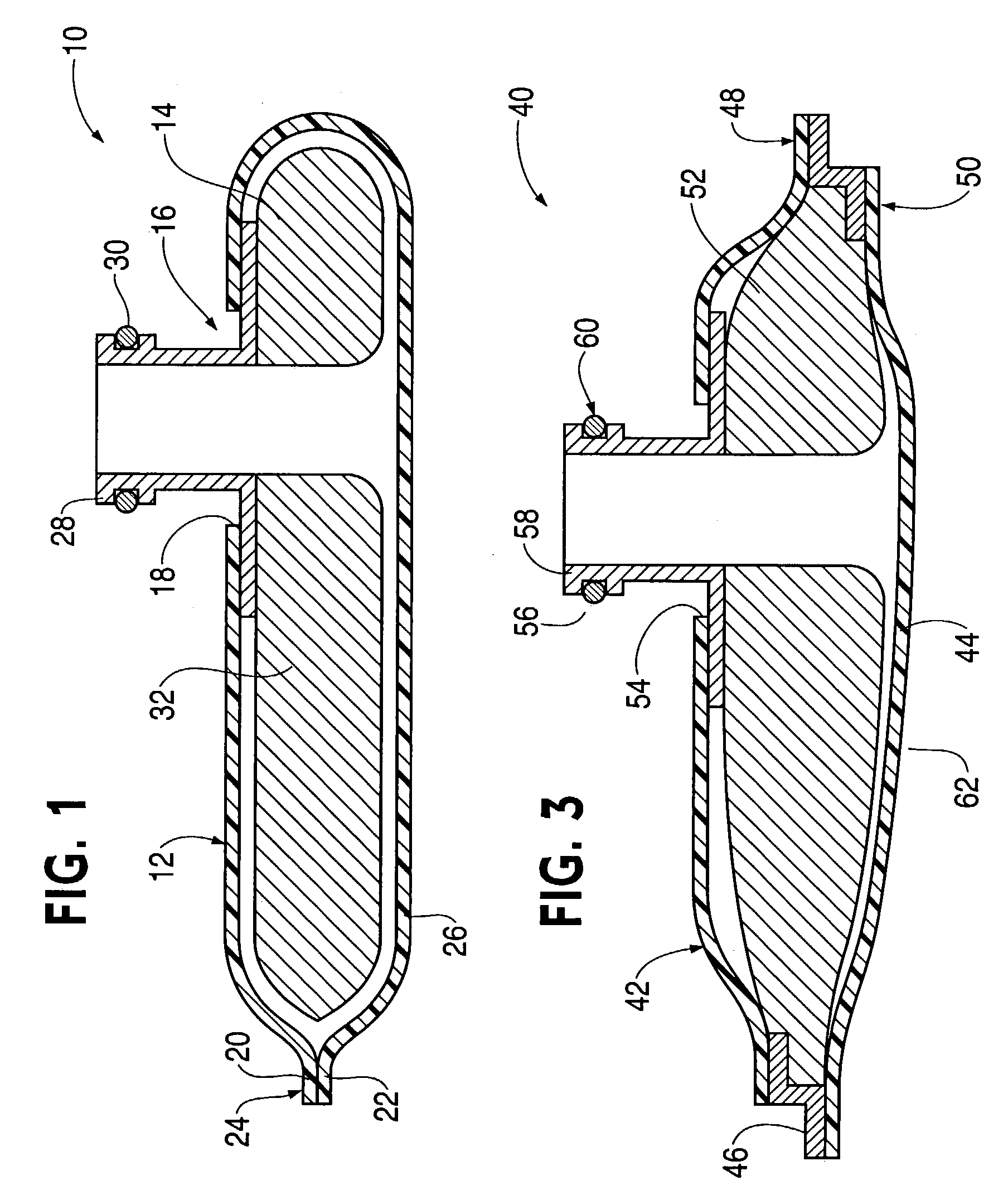

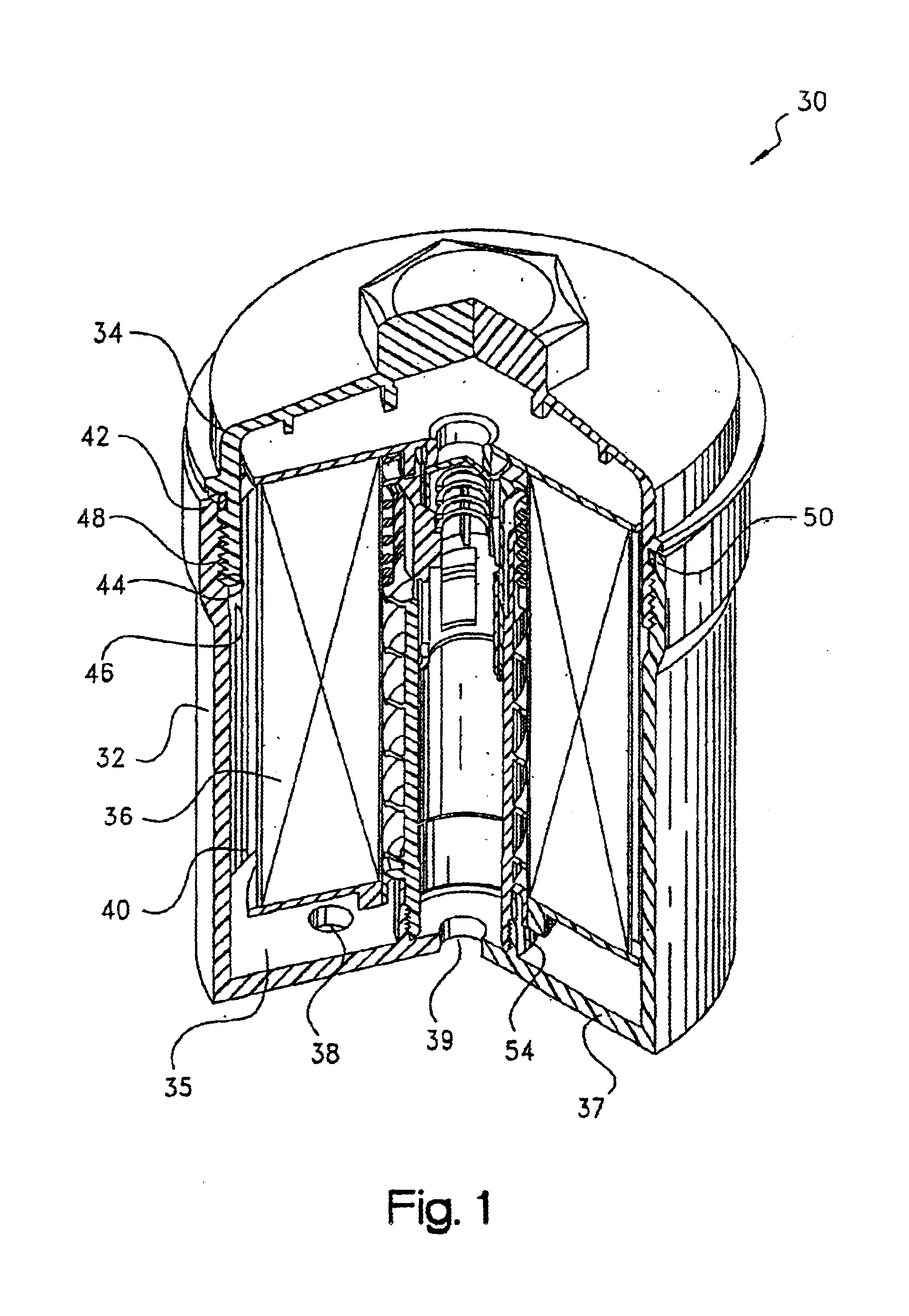

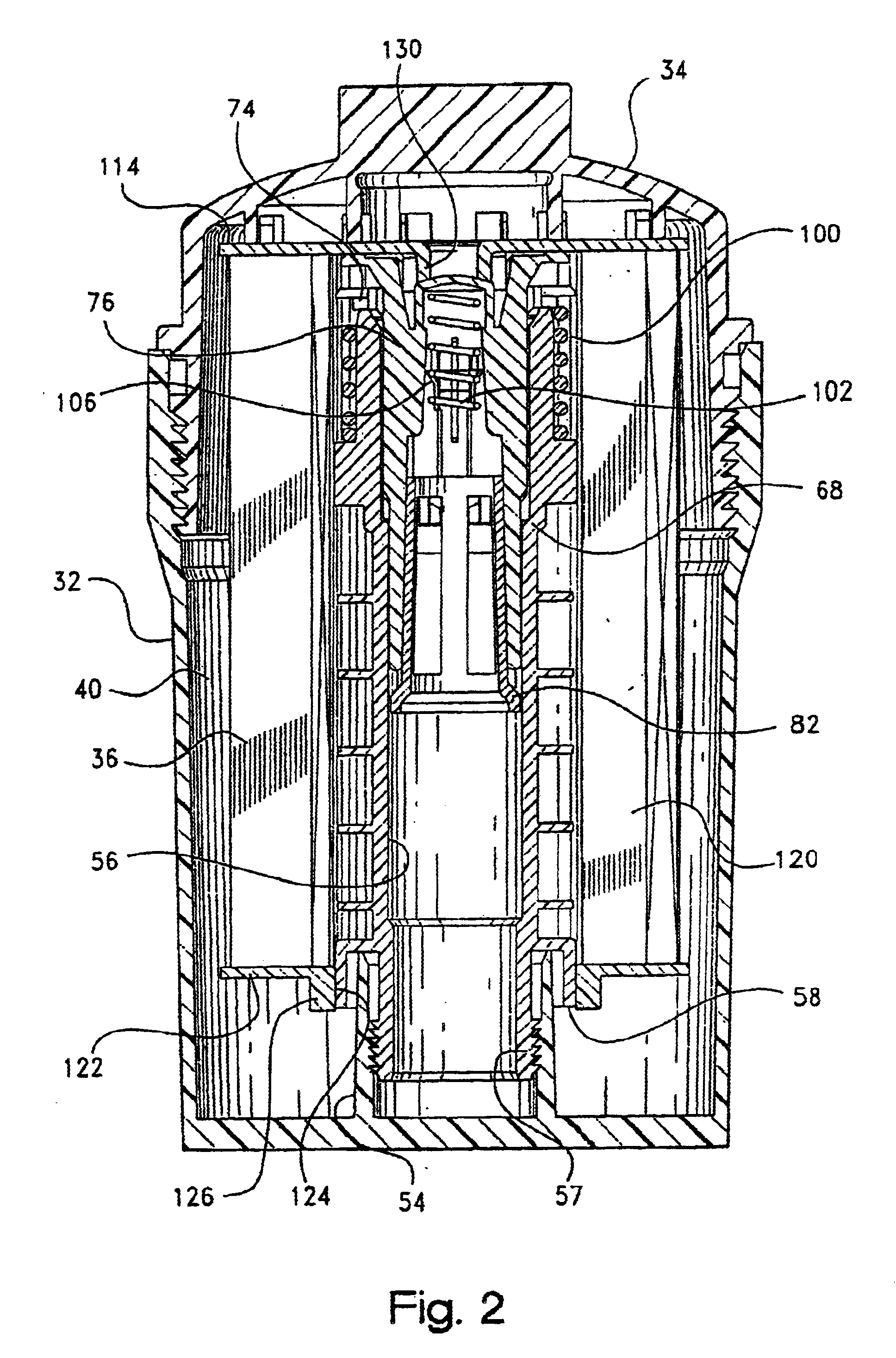

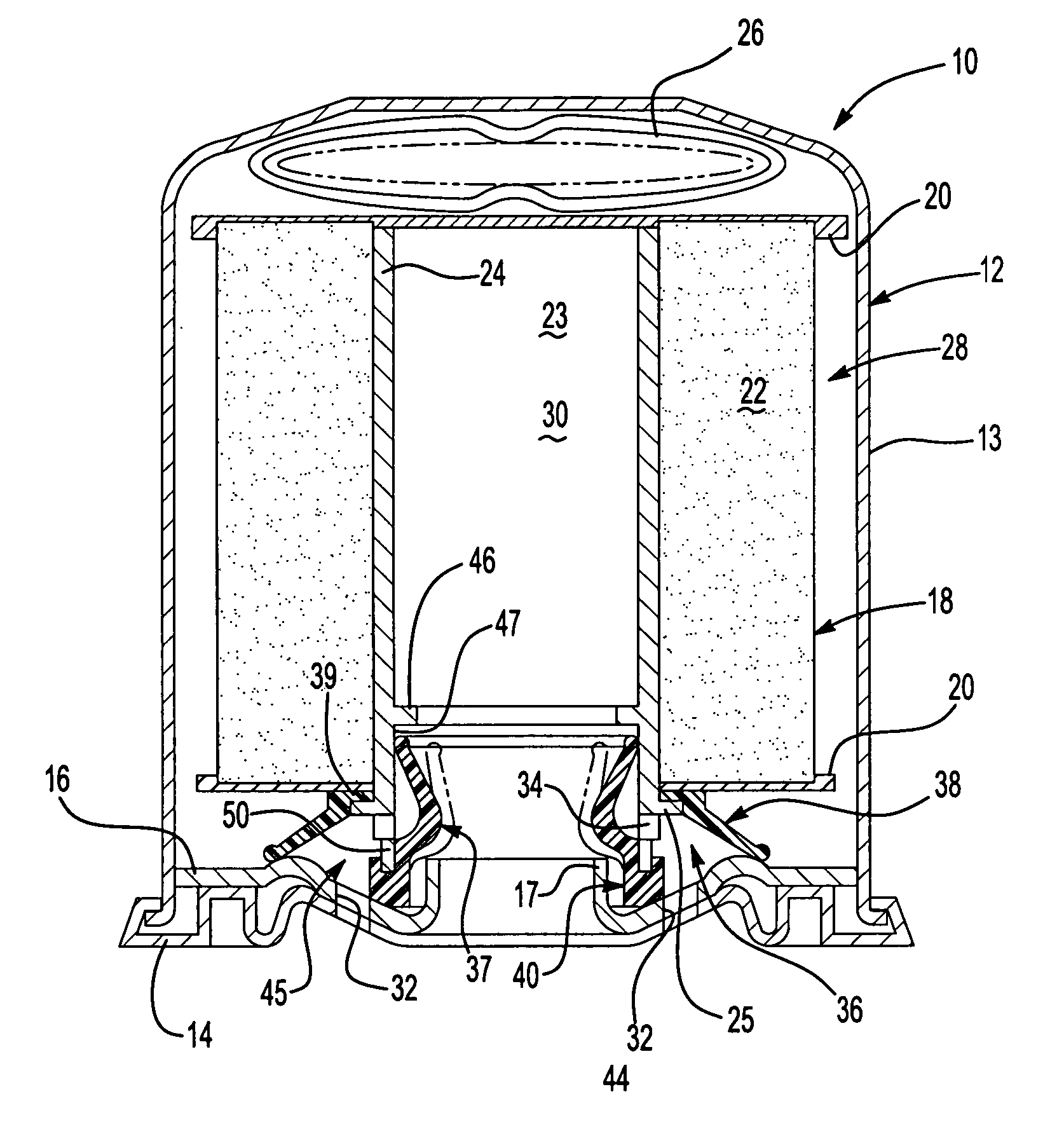

Environmentally friendly acid neutralizing full flow cartridge

InactiveUS6984319B2Burn completelyDispersed particle filtrationMachines/enginesParticulatesEngineering

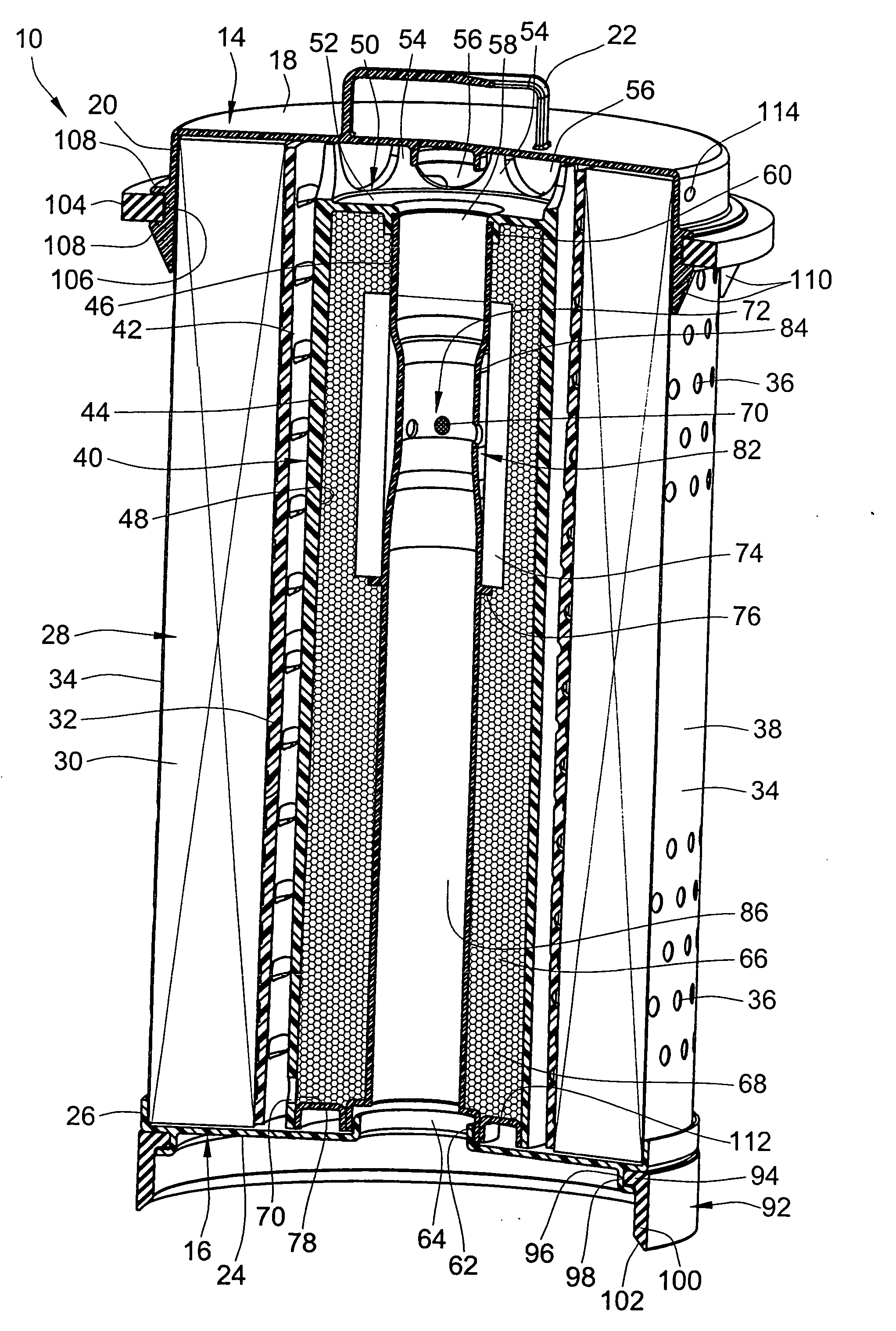

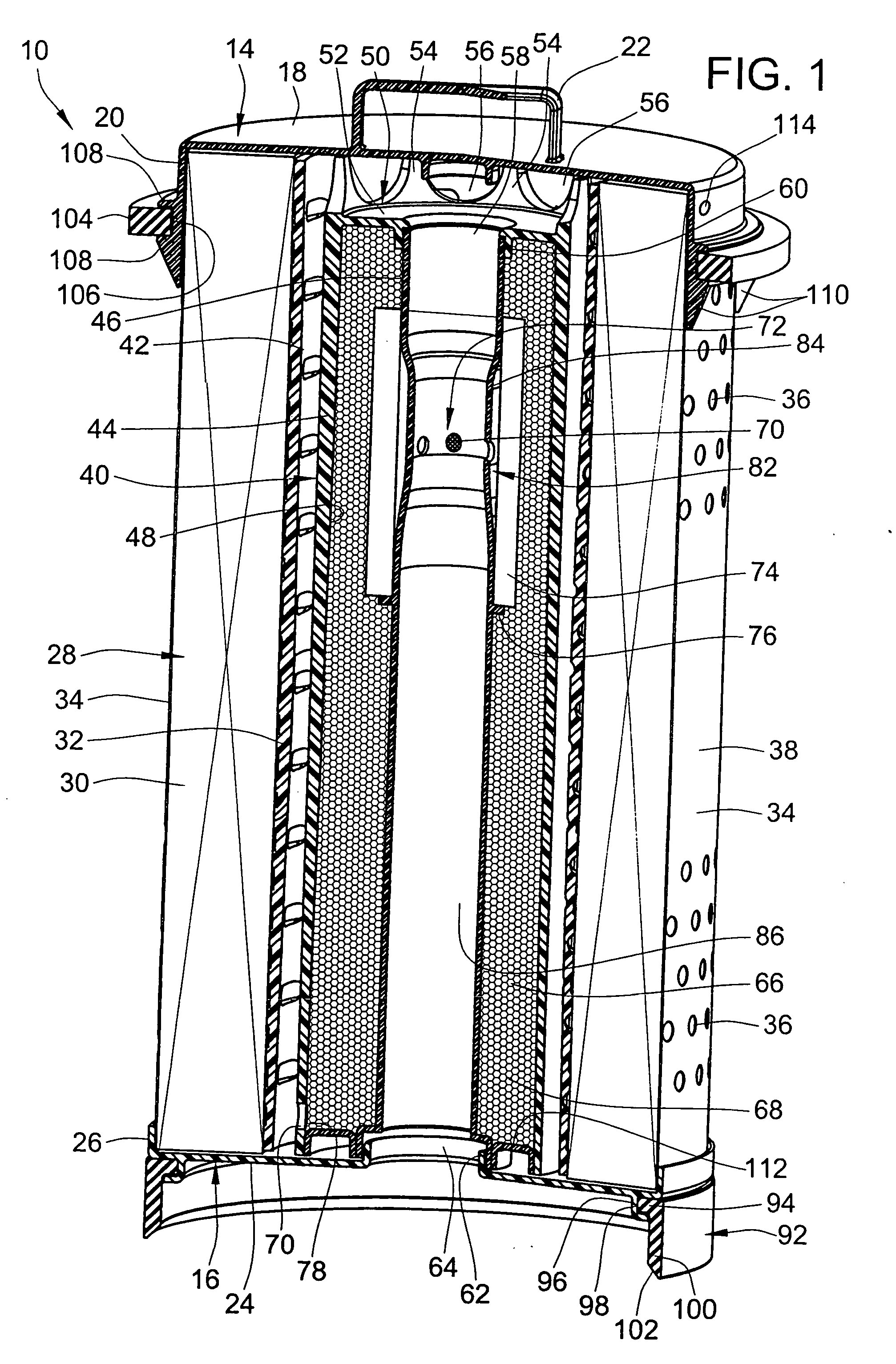

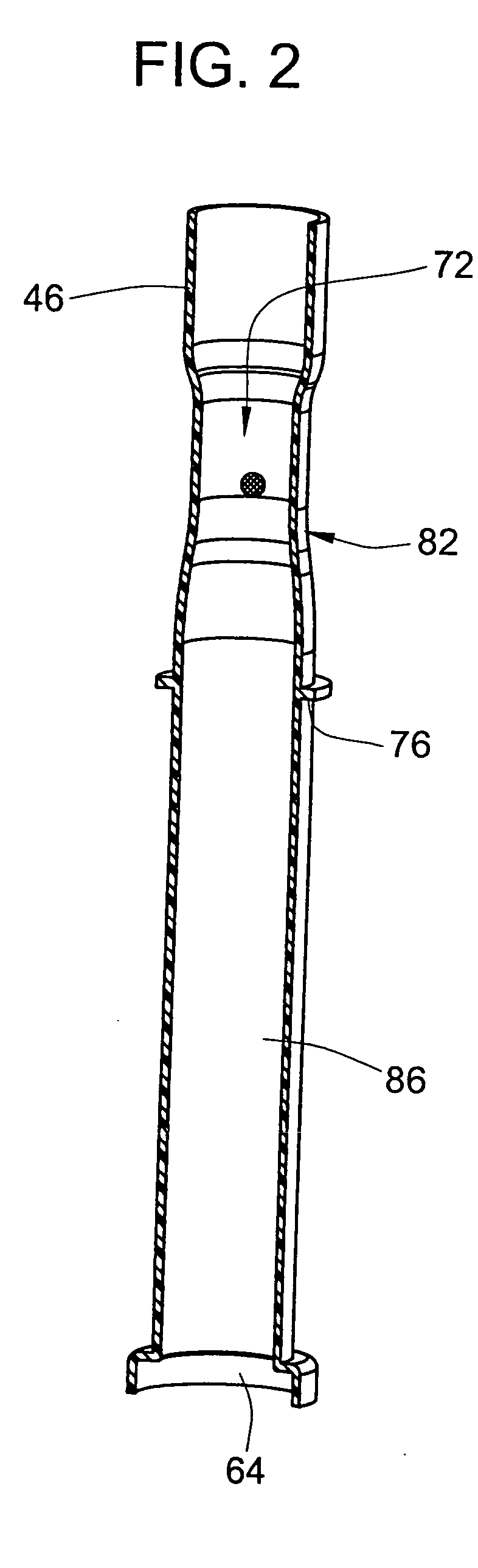

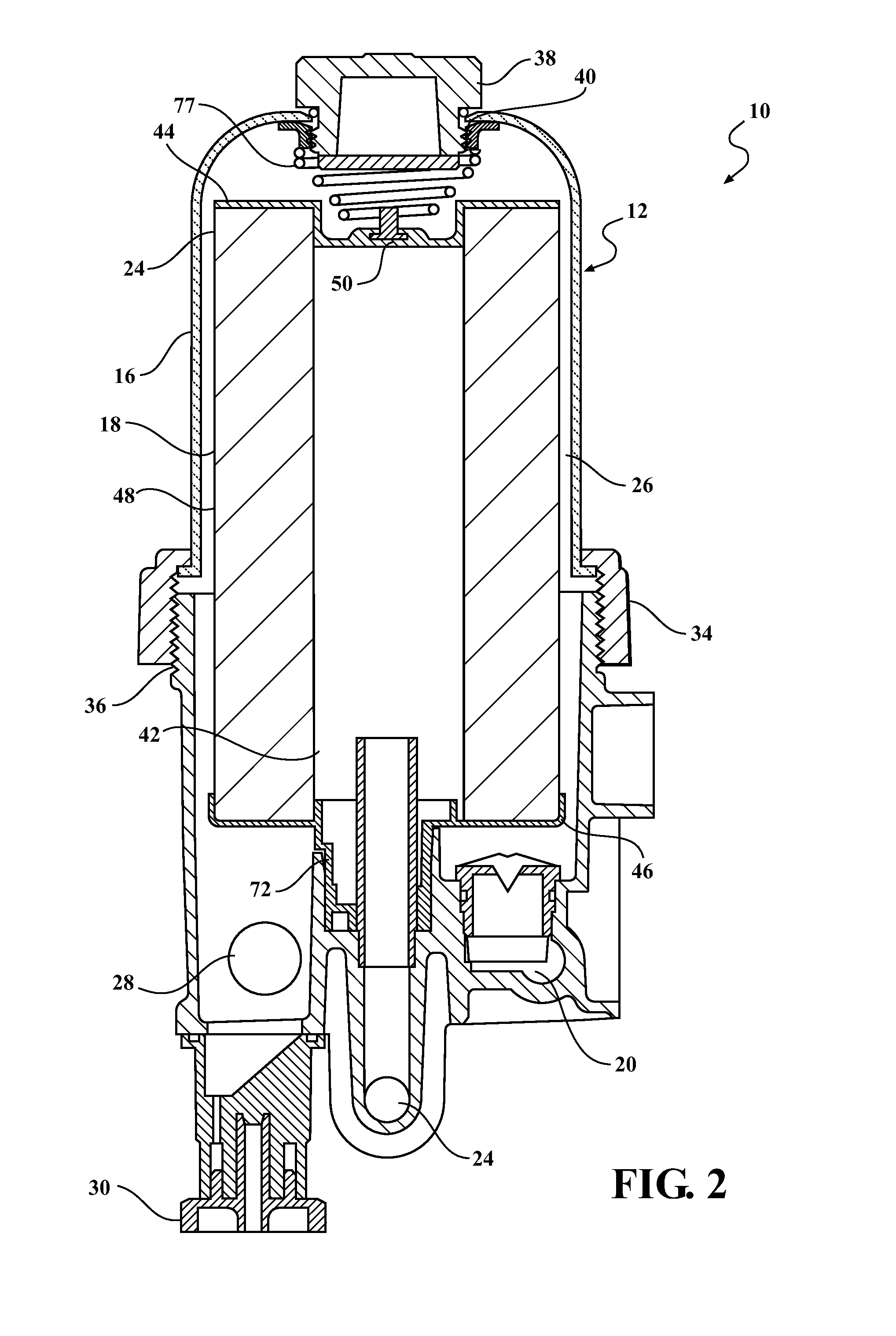

An environmentally friendly acid neutralizing filter cartridge is adapted to be mounted in a cartridge mounting body of an engine oil circuit for filtering particulates and neutralizing acid in oil. The filter cartridge comprises a support housing that comprises substantially no metal parts such that the filter cartridge can be readily incinerated. A full flow particulate filter and a bypass particulate filter are arranged in the support housing. A bed of acid neutralizing particles is contained in the support housing. The housing is configured such that a predetermined primary flow path is defined through the filter cartridge that passes through the full flow particulate filter and bypassing the bed of acid neutralizing particles; and a predetermined bypass path is defined through the filter cartridge that passes, in sequence, through the bed of acid neutralizing particles and the bypass particulate filter.

Owner:BALDWIN FILTERS

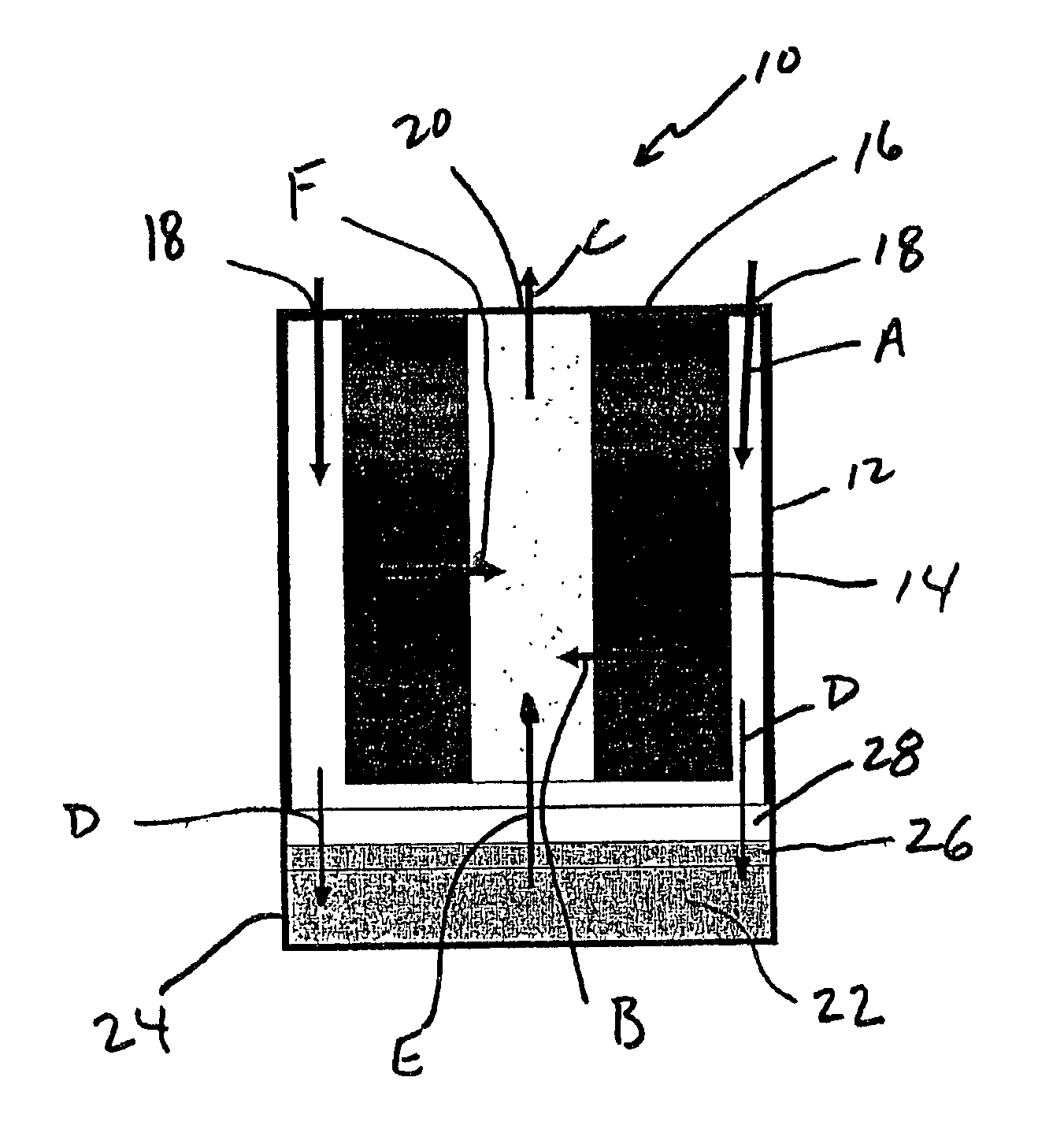

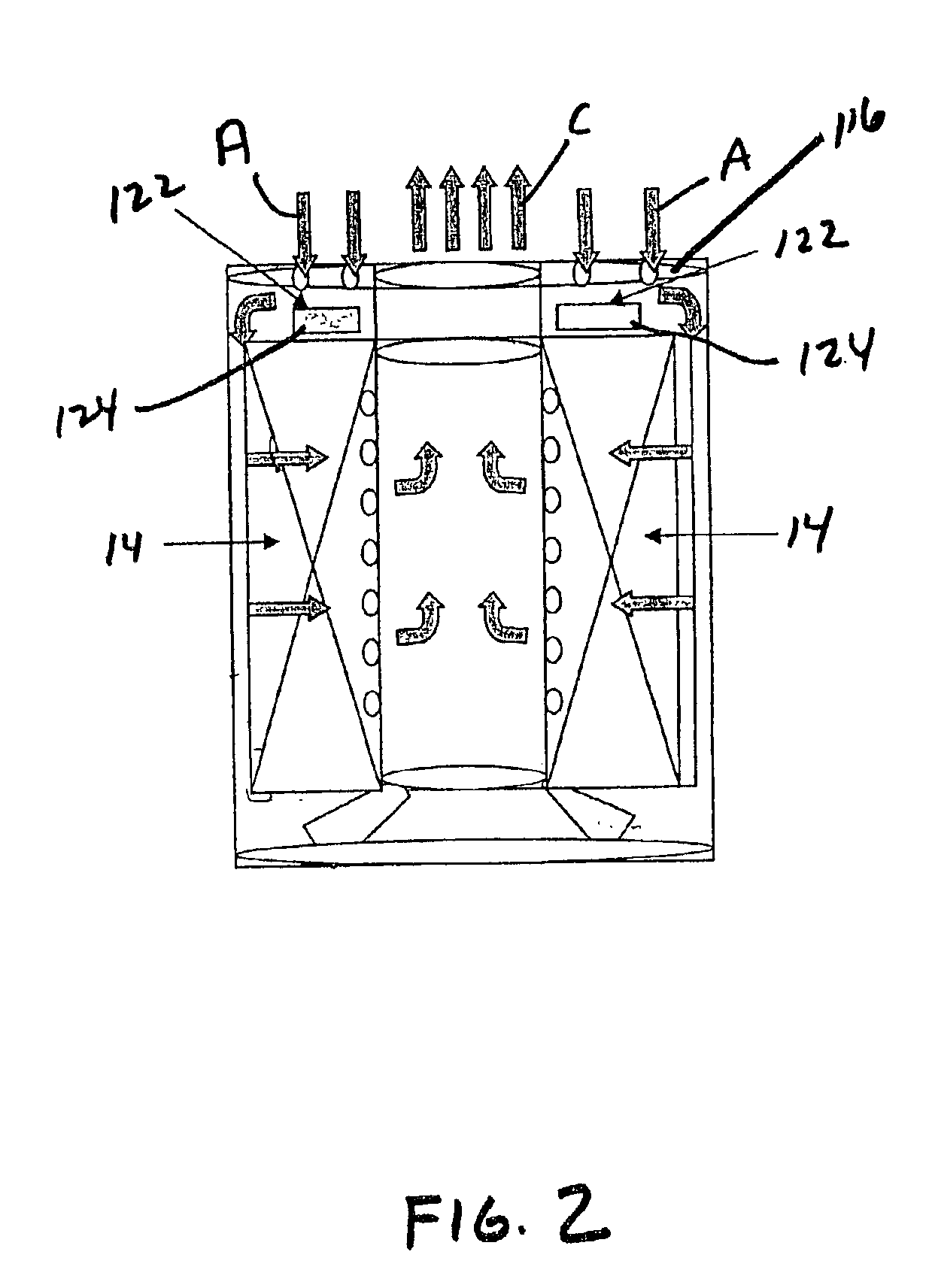

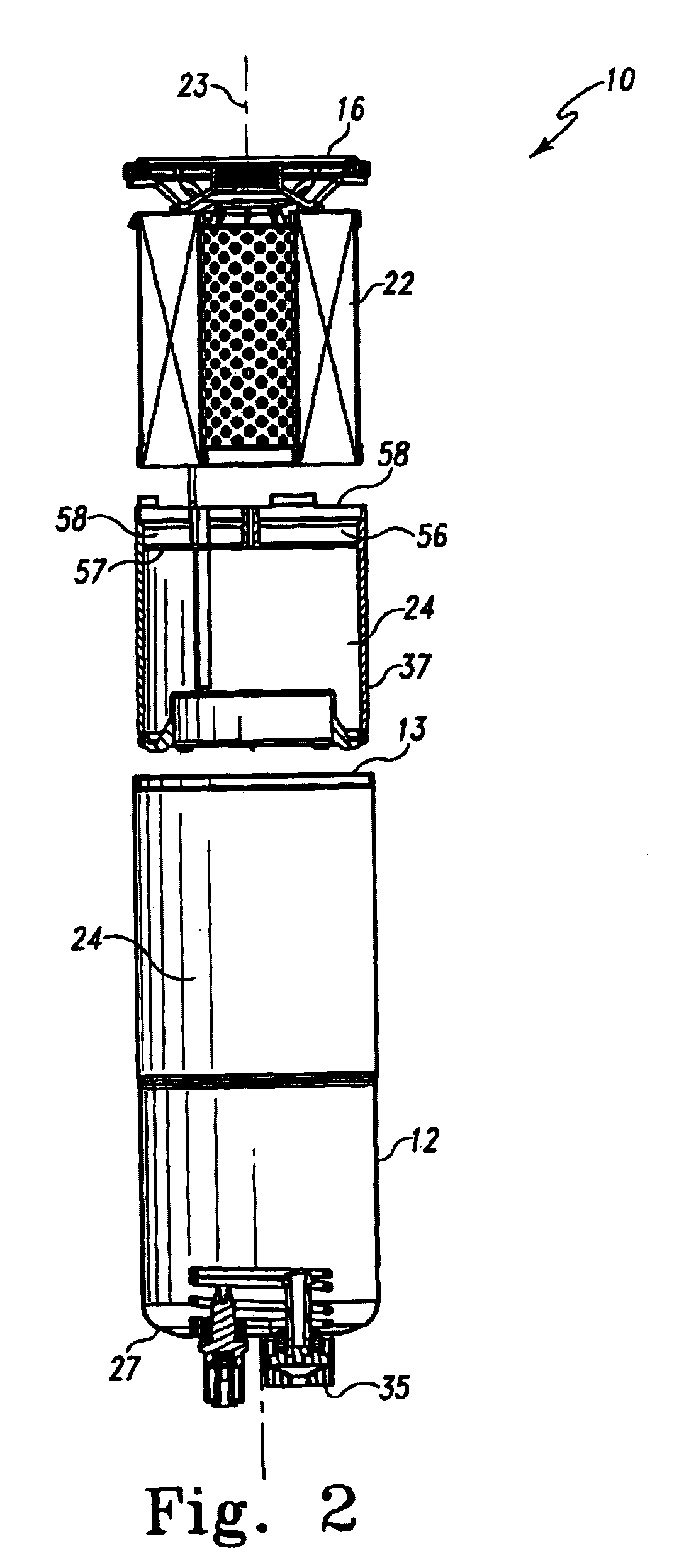

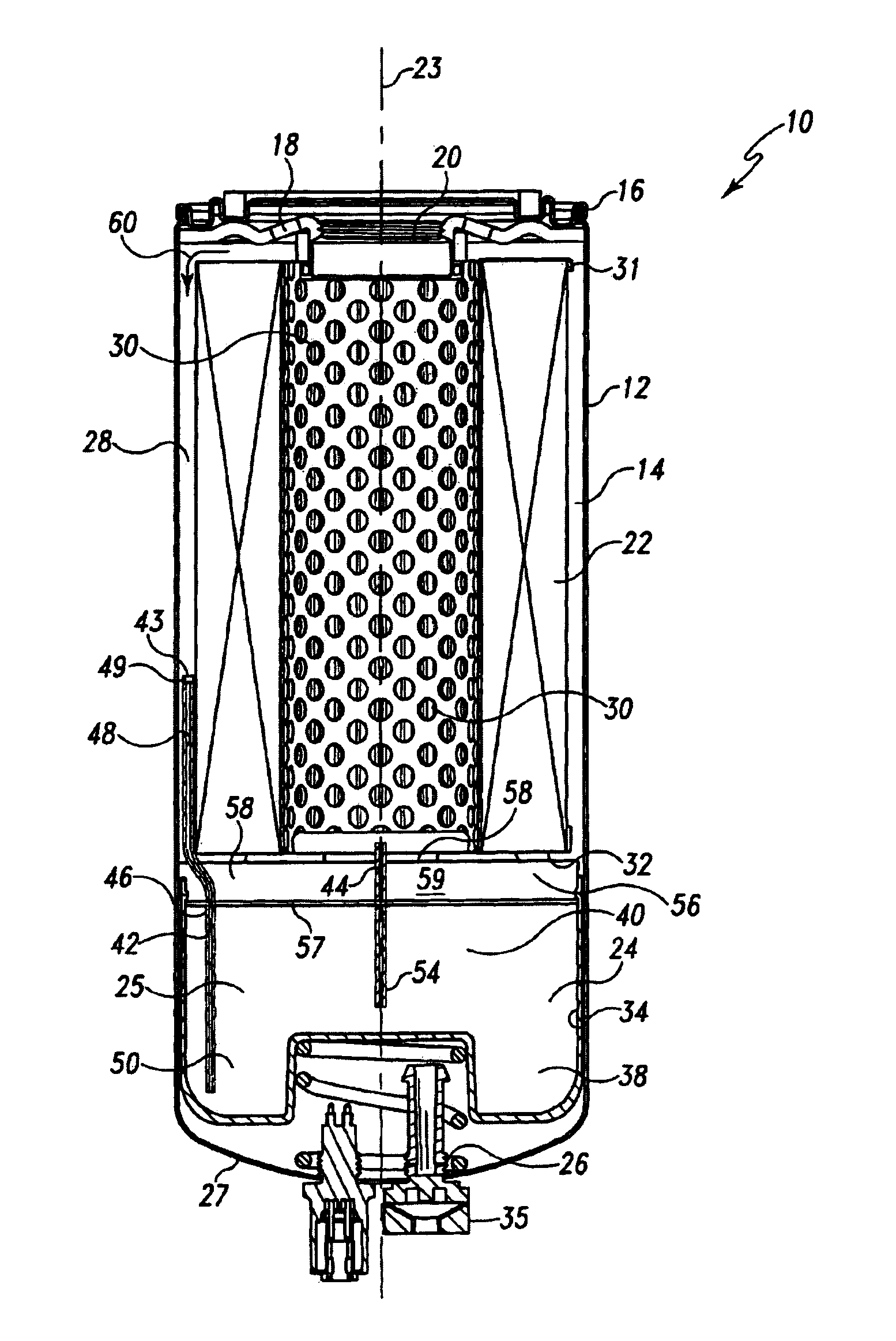

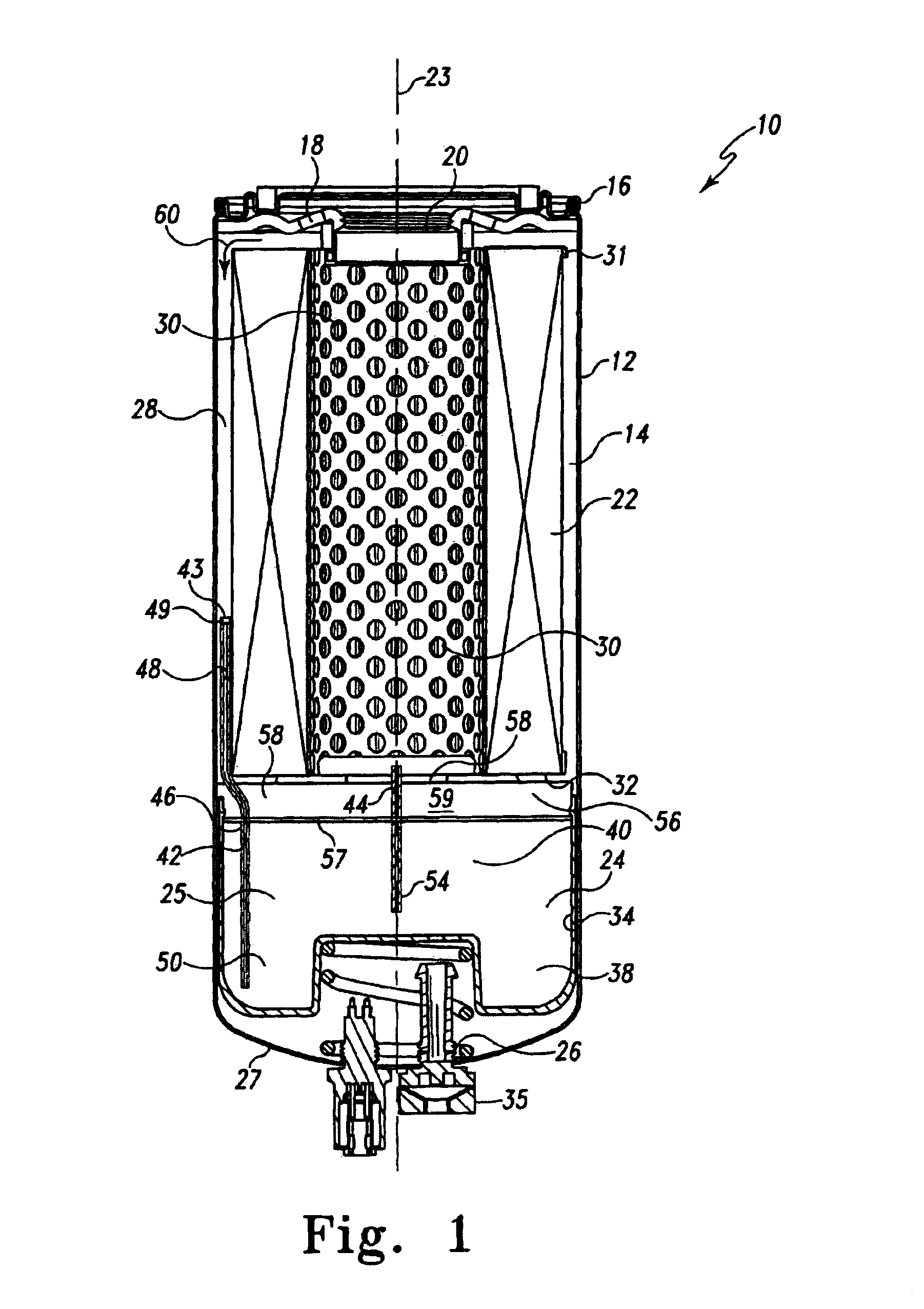

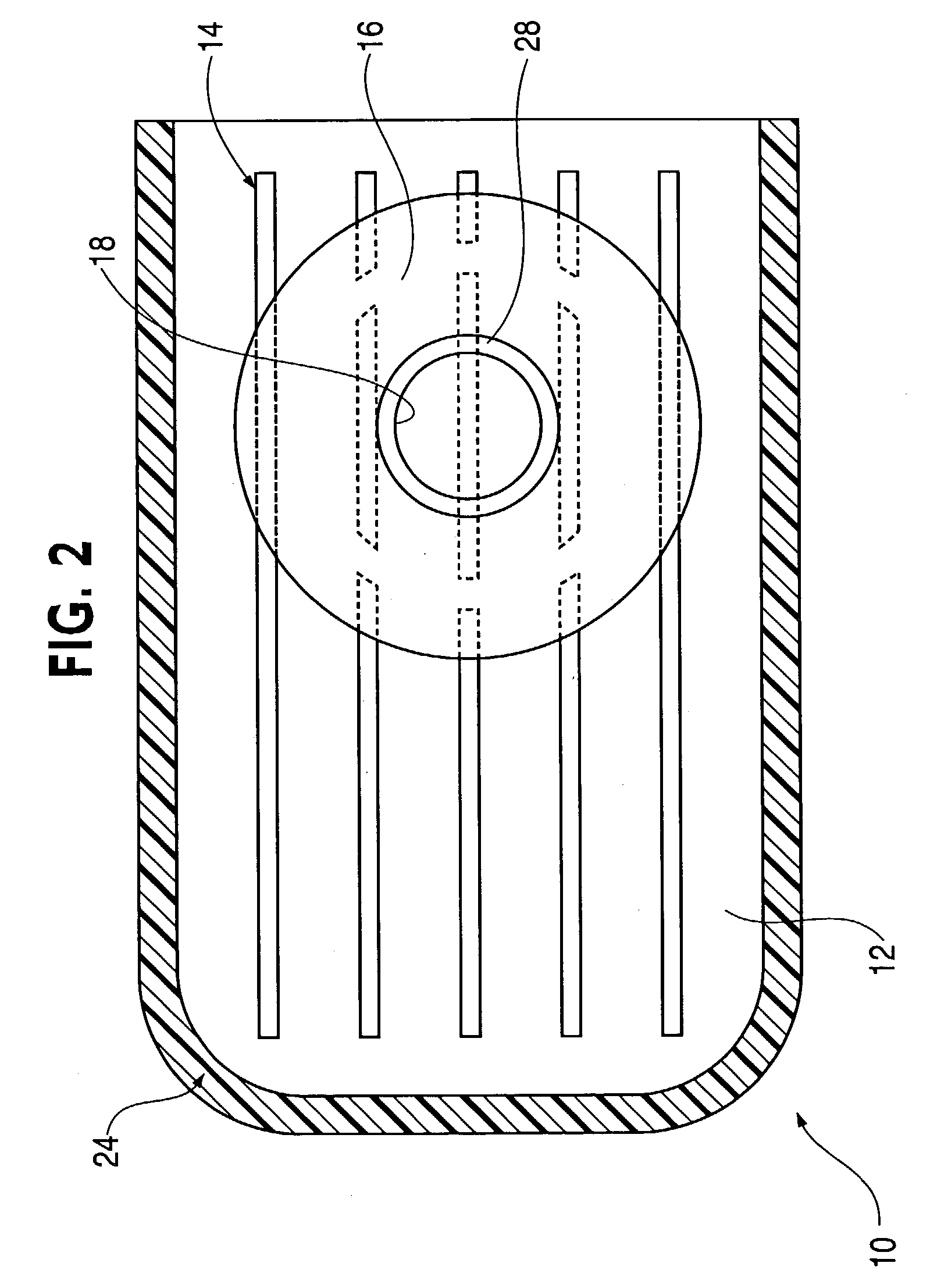

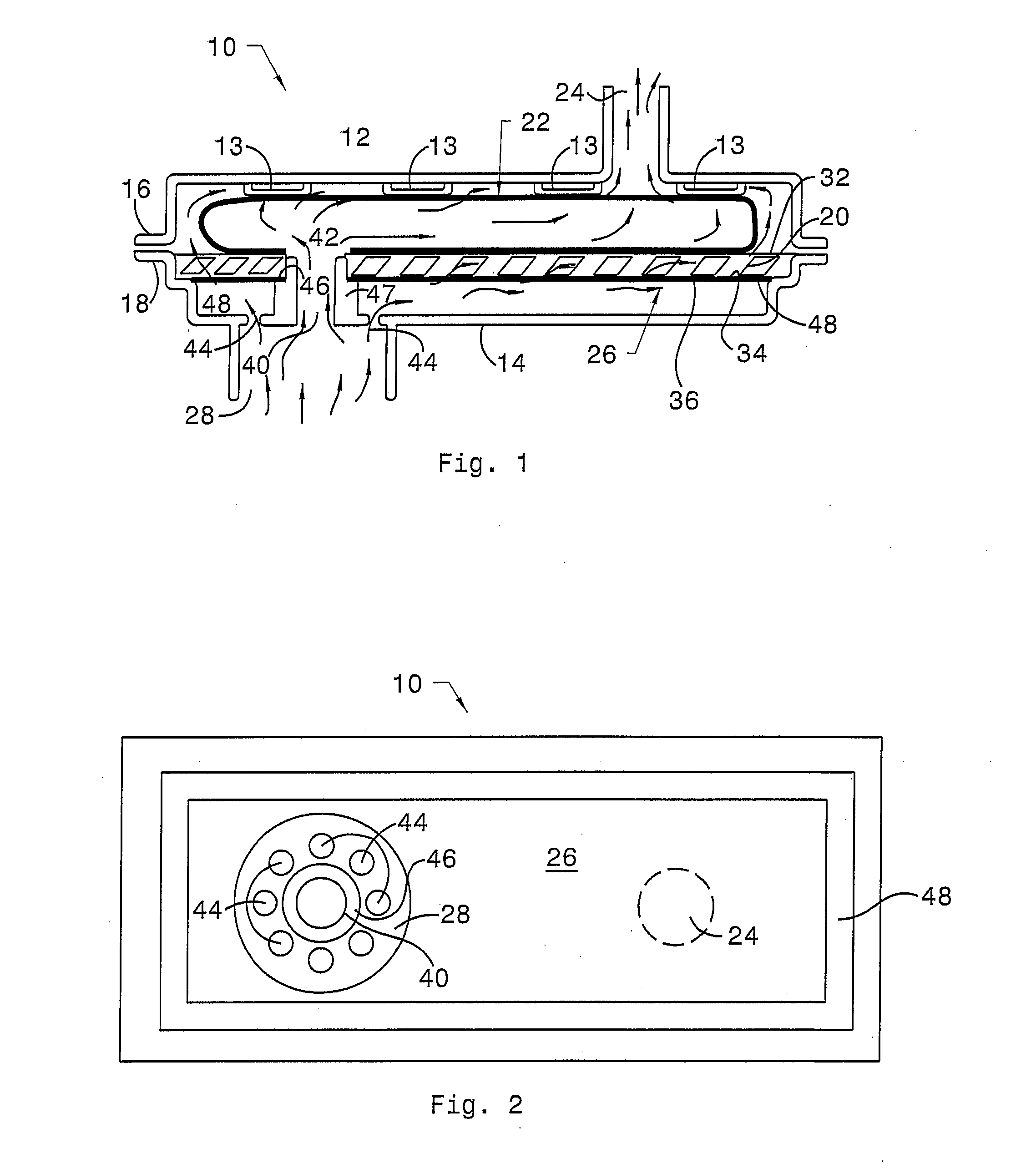

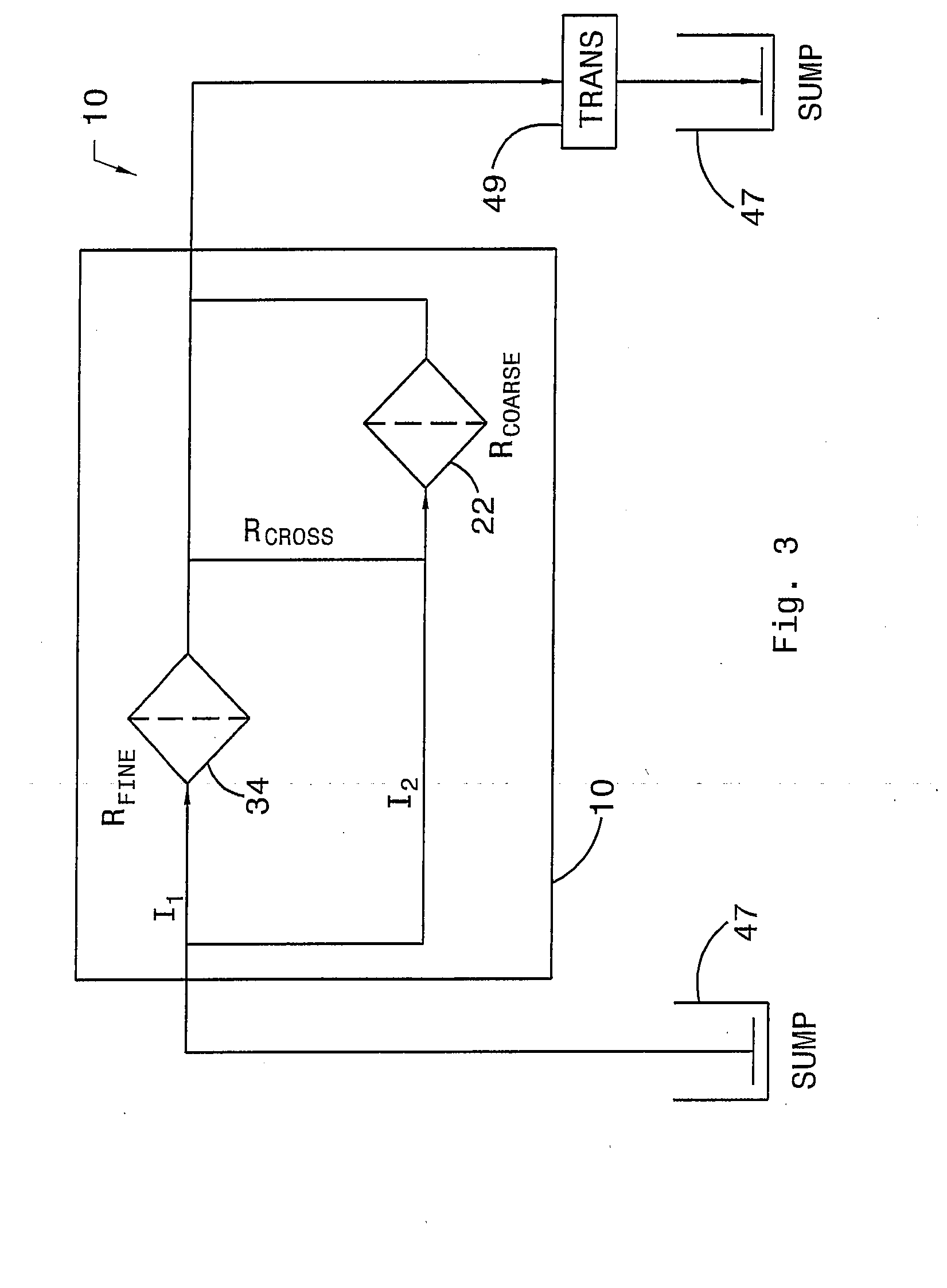

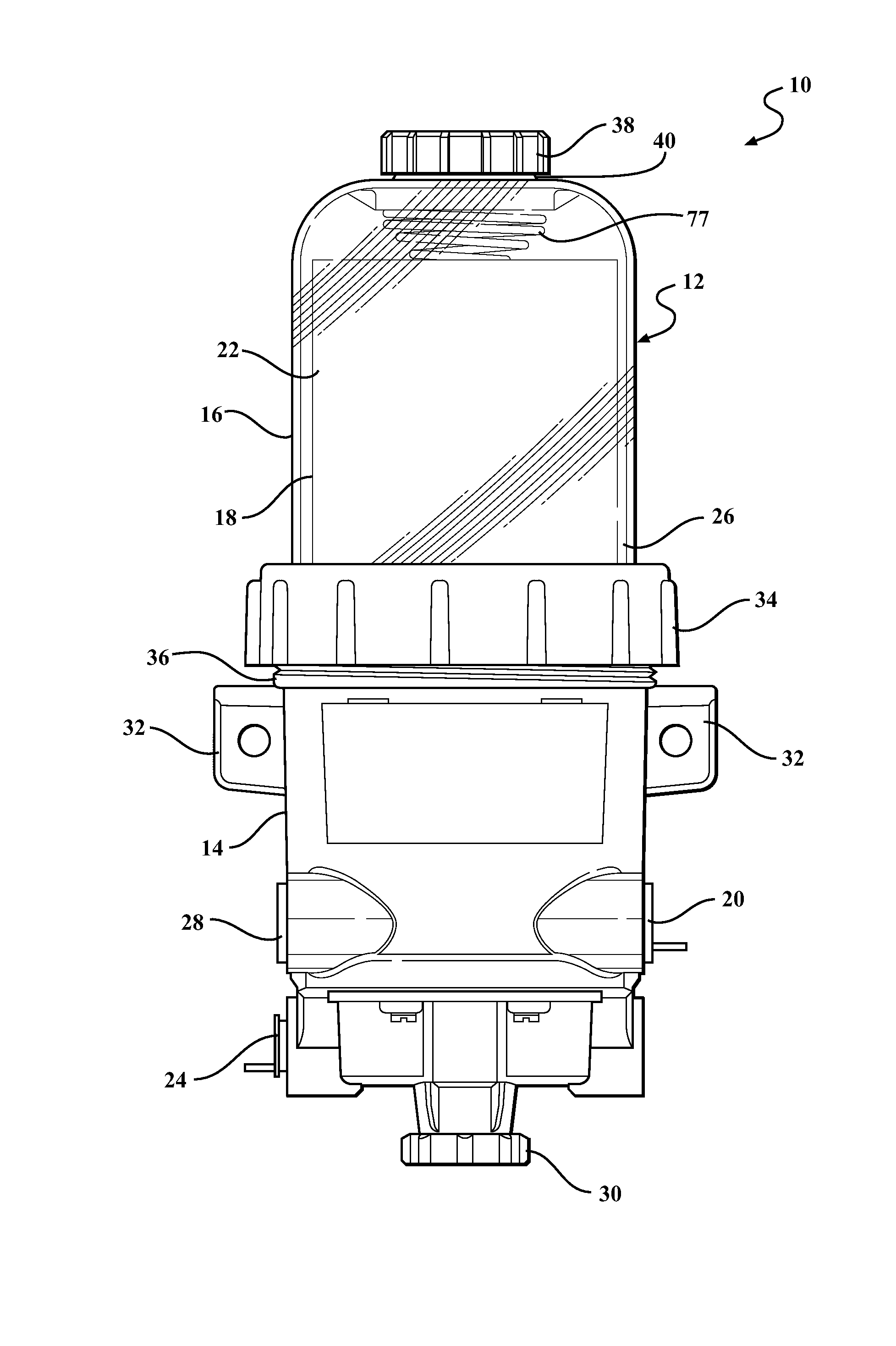

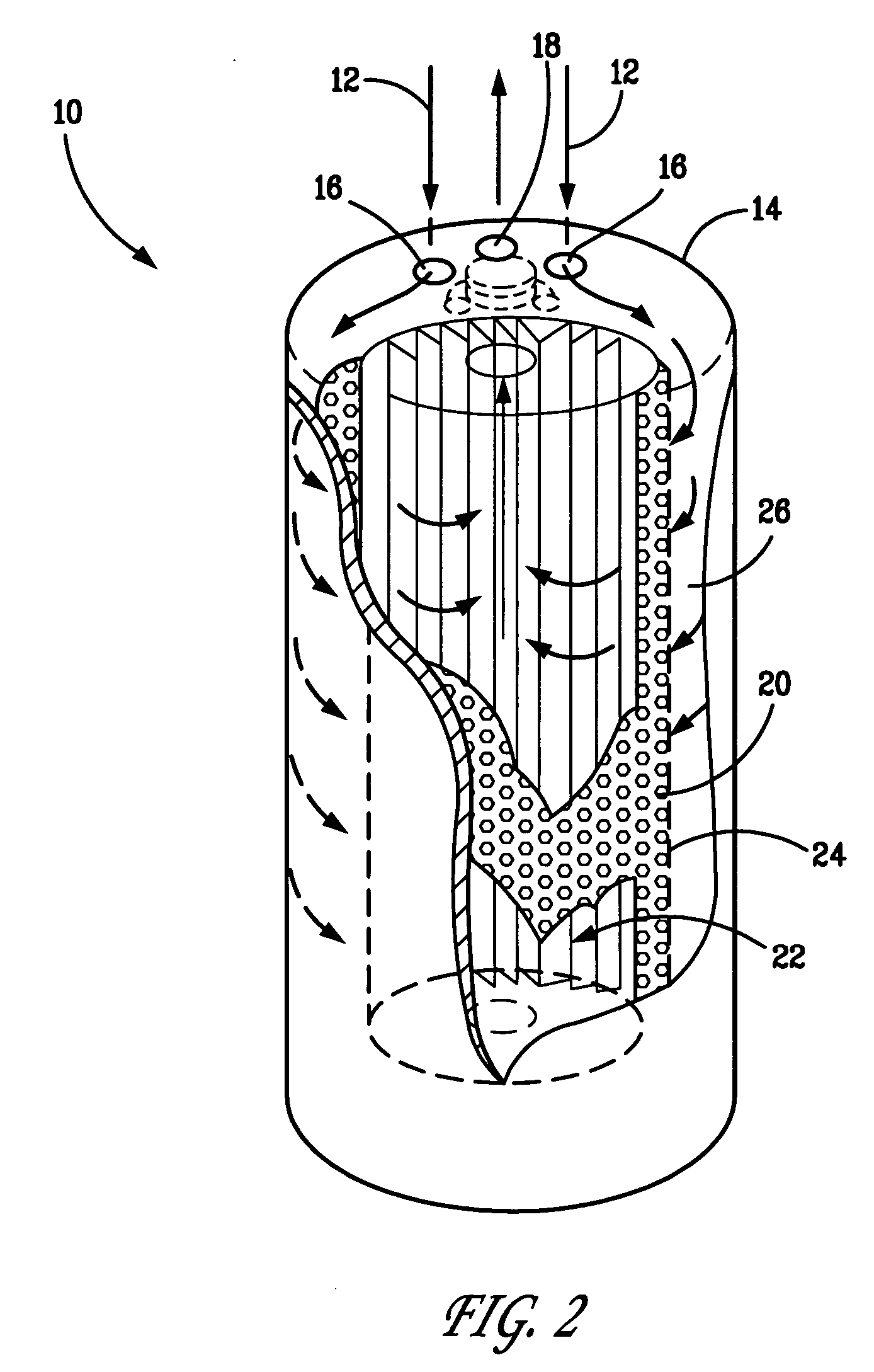

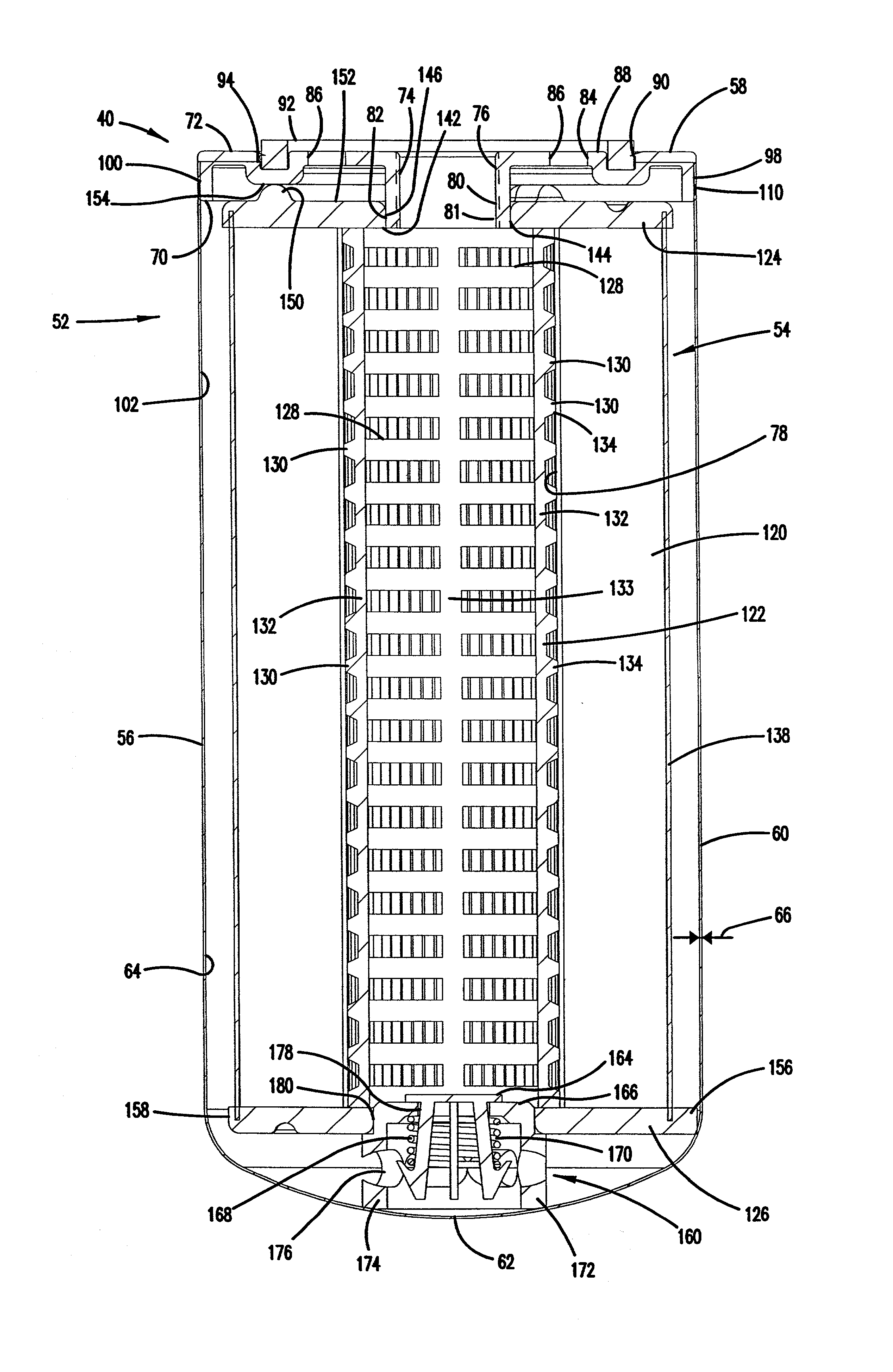

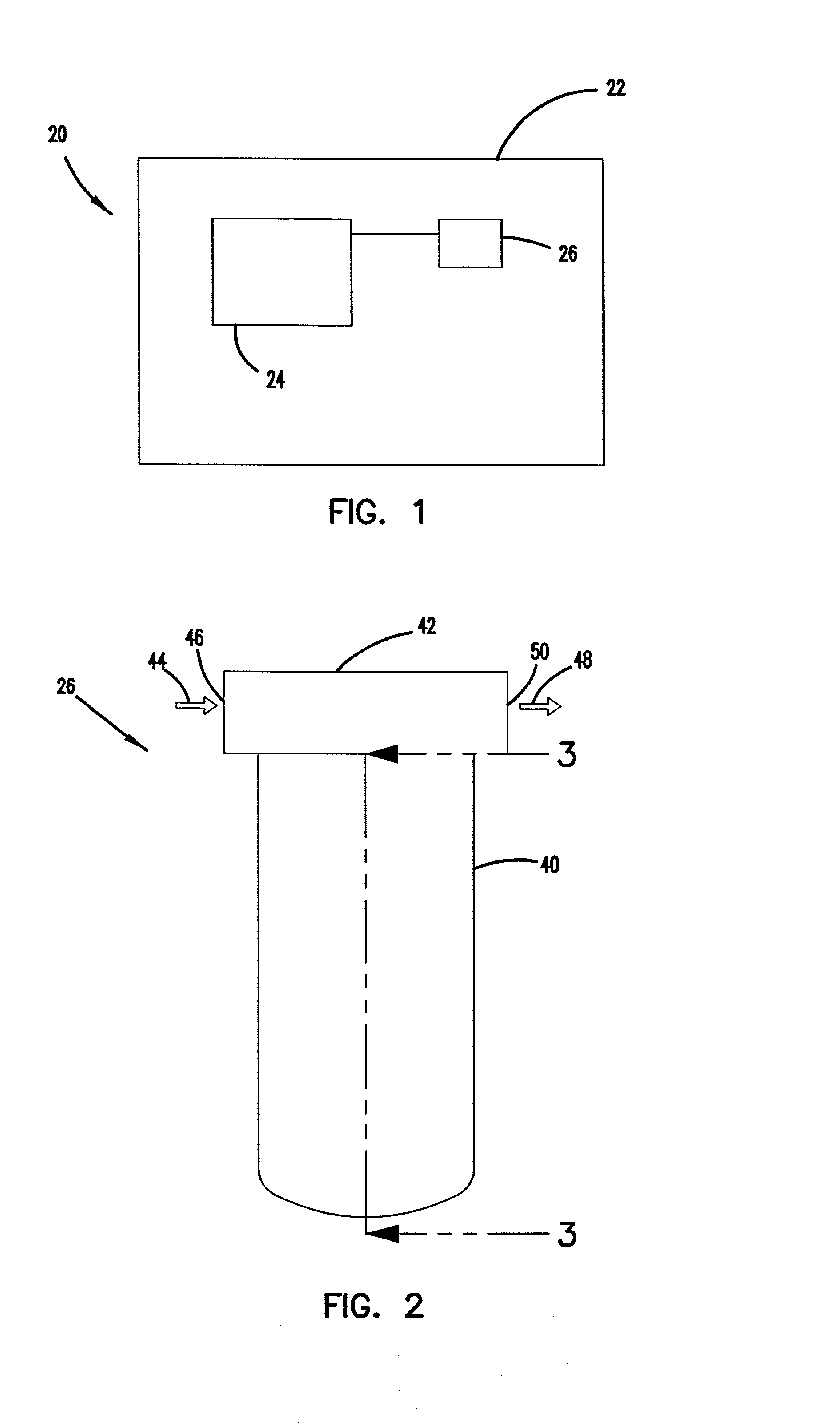

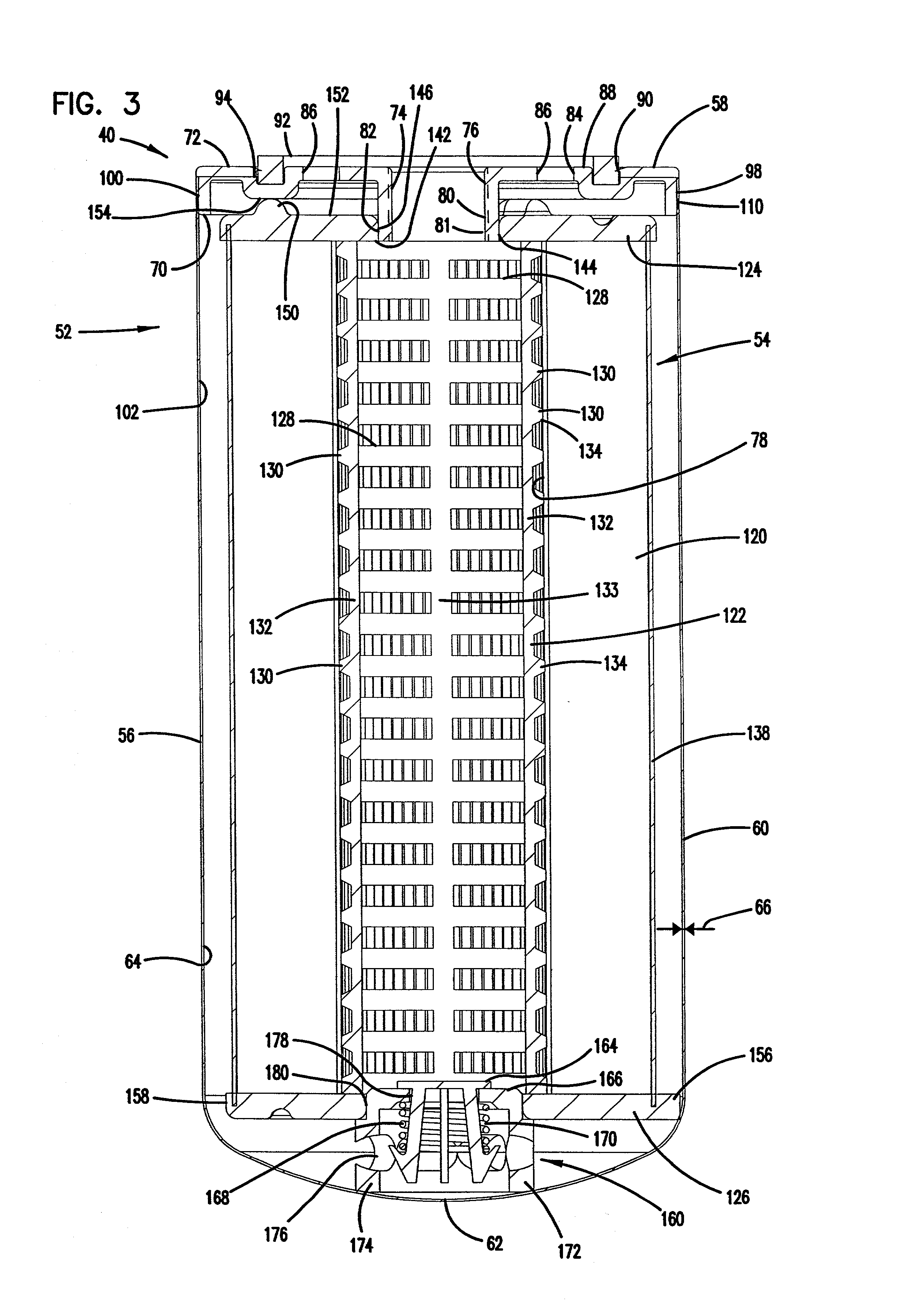

Liquid additive slow-release apparatus driven by a filter pressure gradient

The present invention provides a filter assembly containing a filter element and a container as a depot for a liquid additive. The container can include an inlet and an outlet, which are configured to allow a liquid to flow into the container mix with the contained additive and then flow out into the system. It has been observed that a liquid flowing through a filter assembly exhibits a pressure gradient within the filter. Consequently, the inlets and outlets to the container can be positioned to take advantage of the pressure gradient to enhance the addition of the additive to the liquid in the filter assembly.

Owner:CUMMINS FILTRATION INC

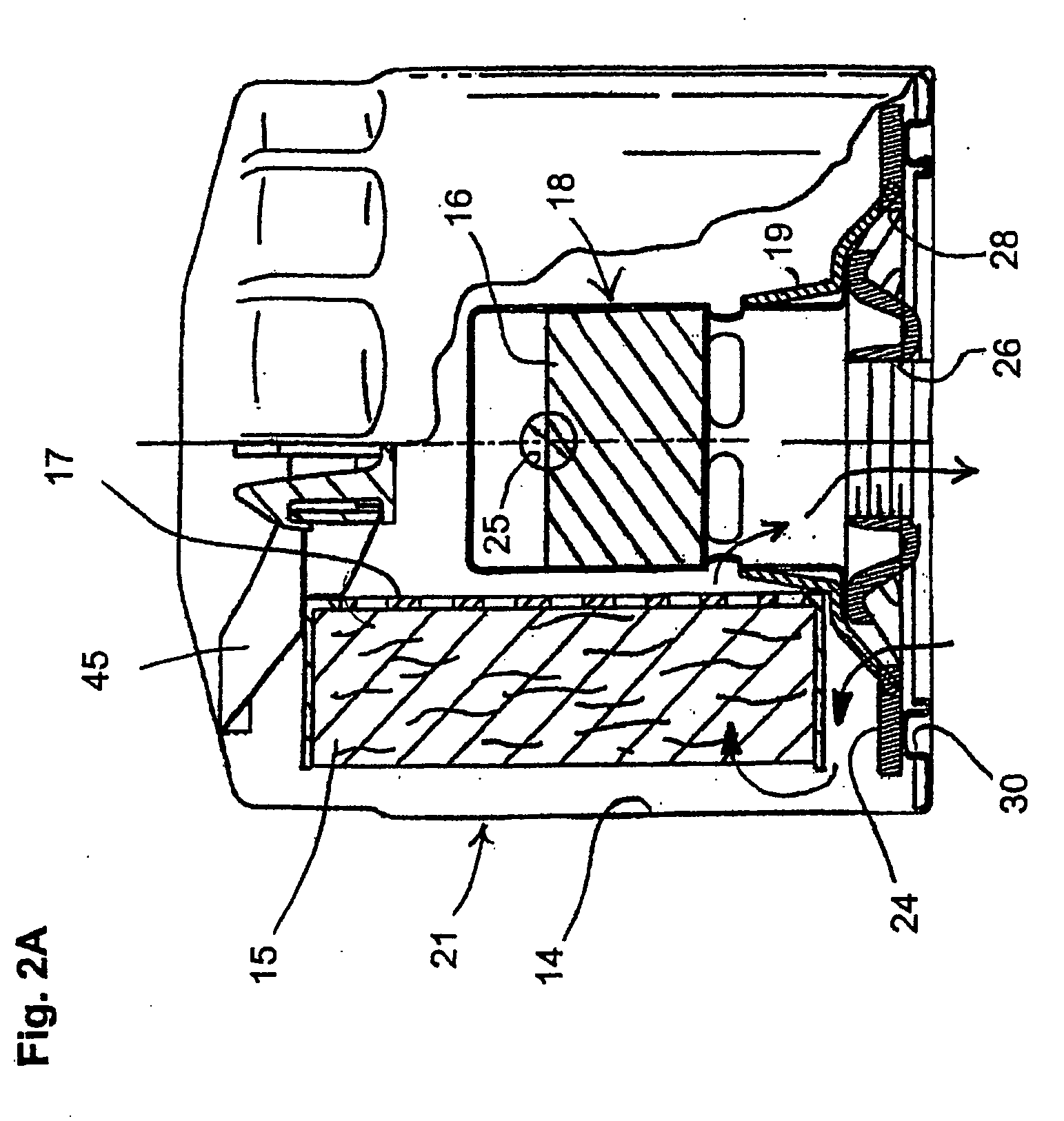

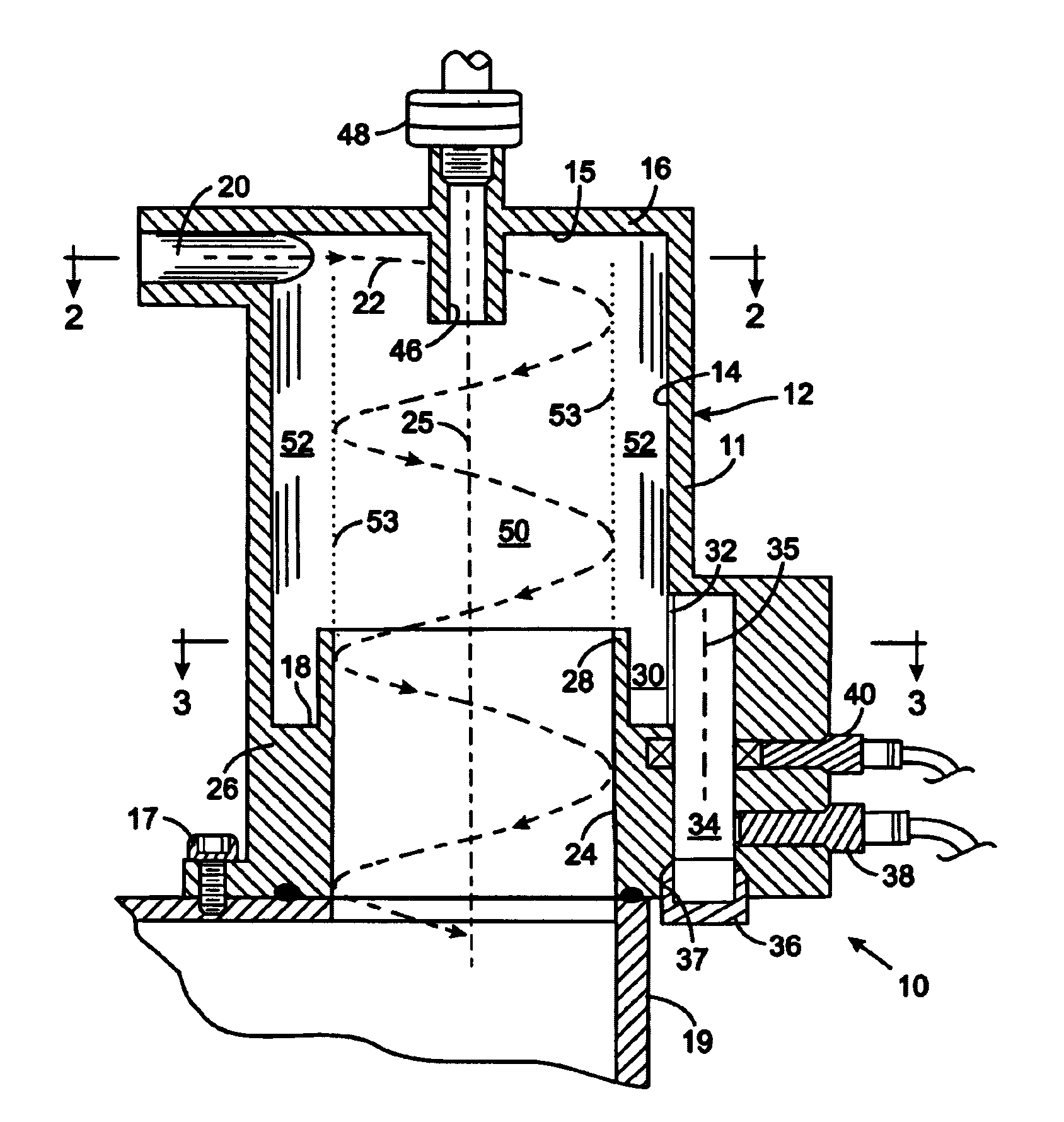

Additive dispersing filter and method of making

An oil-conditioning filter, for use with an internal combustion engine, includes a filter element and an additive cartridge, for gradually dispensing an oil additive over time. The additive cartridge has a beneficial oil-conditioning agent contained therein. Placement of the cartridge allows for fluid filtration through the filter element before fluid communication with the additive of the additive cartridge. An additive dispersing member is also described.

Owner:BMO HARRIS BANK N A AS SUCCESSOR COLLATERAL AGENT +1

Liquid additive slow-release apparatus driven by a filter pressure gradient

ActiveUS7156991B2Solid sorbent liquid separationCombustion enginesMechanical engineeringFilter element

The present invention provides a filter assembly containing a filter element and a container as a depot for a liquid additive. The container can include an inlet and an outlet, which are configured to allow a liquid to flow into the container mix with the contained additive and then flow out into the system. It has been observed that a liquid flowing through a filter assembly exhibits a pressure gradient within the filter. Consequently, the inlets and outlets to the container can be positioned to take advantage of the pressure gradient to enhance the addition of the additive to the liquid in the filter assembly.

Owner:CUMMINS FILTRATION INC

Environmentally friendly acid neutralizing full flow cartridge

InactiveUS20060113233A1Burn completelyDispersed particle filtrationMembrane filtersParticulatesEngineering

An environmentally friendly acid neutralizing filter cartridge is adapted to be mounted in a cartridge mounting body of an engine oil circuit for filtering particulates and neutralizing acid in oil. The filter cartridge comprises a support housing that comprises substantially no metal parts such that the filter cartridge can be readily incinerated. A full flow particulate filter and a bypass particulate filter are arranged in the support housing. A bed of acid neutralizing particles is contained in the support housing. The housing is configured such that a predetermined primary flow path is defined through the filter cartridge that passes through the full flow particulate filter and bypassing the bed of acid neutralizing particles; and a predetermined bypass path is defined through the filter cartridge that passes, in sequence, through the bed of acid neutralizing particles and the bypass particulate filter.

Owner:BALDWIN FILTERS

Oil filter assembly

An oil filter system includes an oil filter module and an adapter. The oil filter module includes a detent and an actuator. The adapter includes a protuberance and is configured to be secured to the engine. The oil filter module connects to the adapter when the detent secures to the protuberance as the oil filter module is urged into a connection position with the adapter. The oil filter module disconnects from the adapter when the actuator is actuated, thereby disengaging the detent from the protuberance.

Owner:WEINBERGER KEITH R +10

Additive dispersing filter and method of making

InactiveUS20050040092A1Extend life of engine oilExtended time intervalMachines/enginesSolid materialOil additiveEngineering

An oil-conditioning filter, for use with an internal combustion engine, includes a filter element and an additive cartridge, for gradually dispensing an oil additive over time. The additive cartridge has a beneficial oil-conditioning agent contained therein. Placement of the cartridge allows for fluid filtration through the filter element before fluid communication with the additive of the additive cartridge. An additive dispersing member is also described.

Owner:BMO HARRIS BANK N A AS SUCCESSOR COLLATERAL AGENT +1

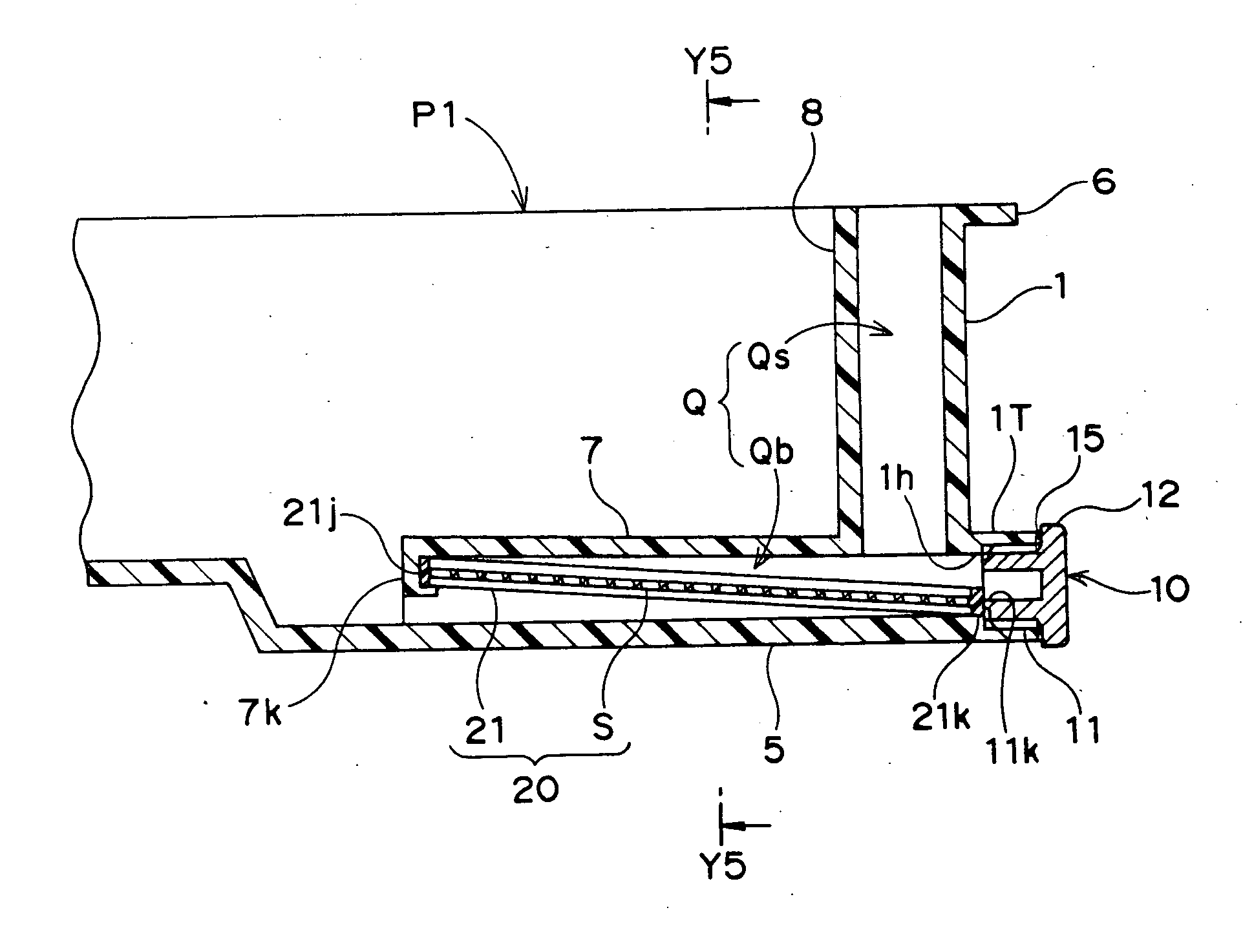

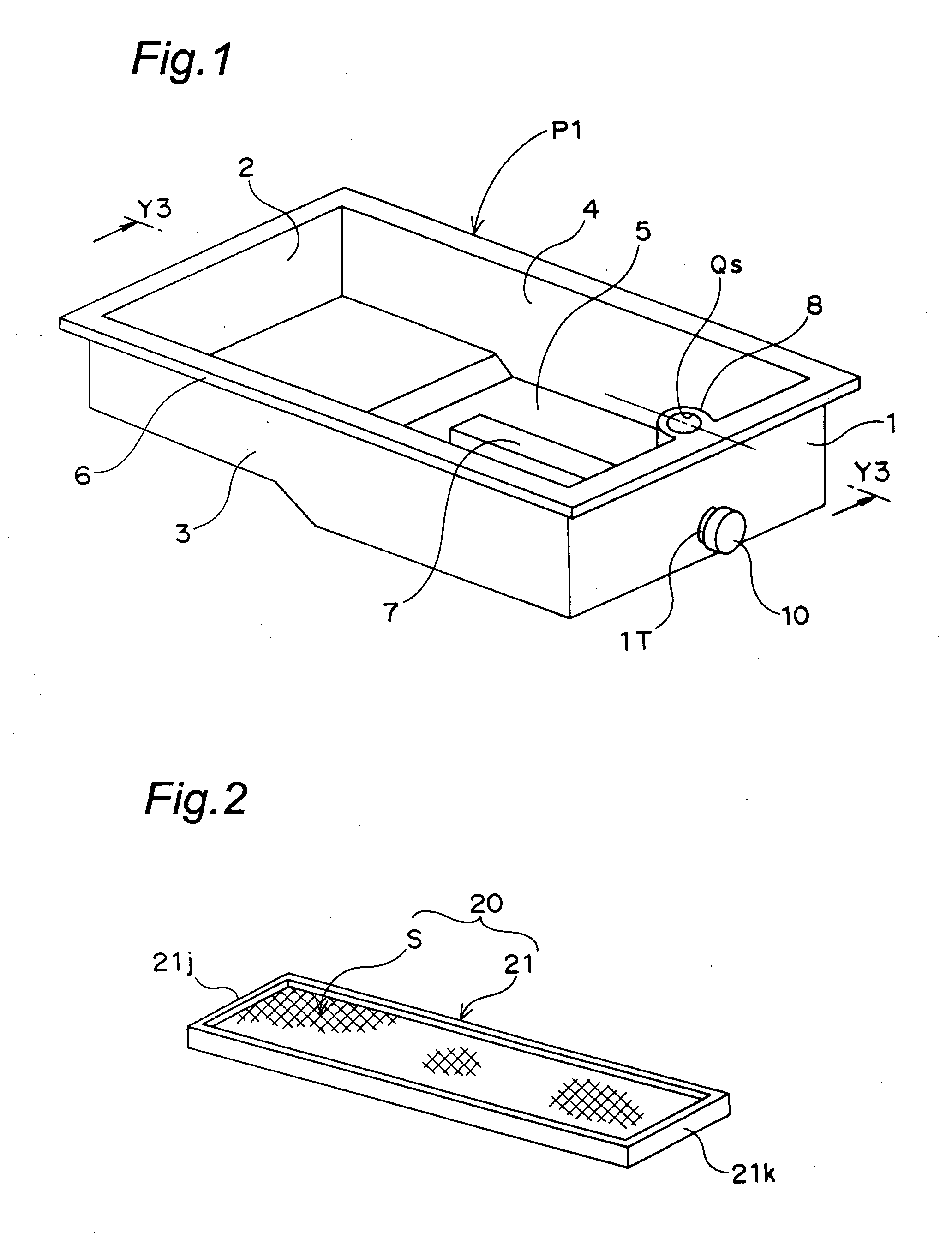

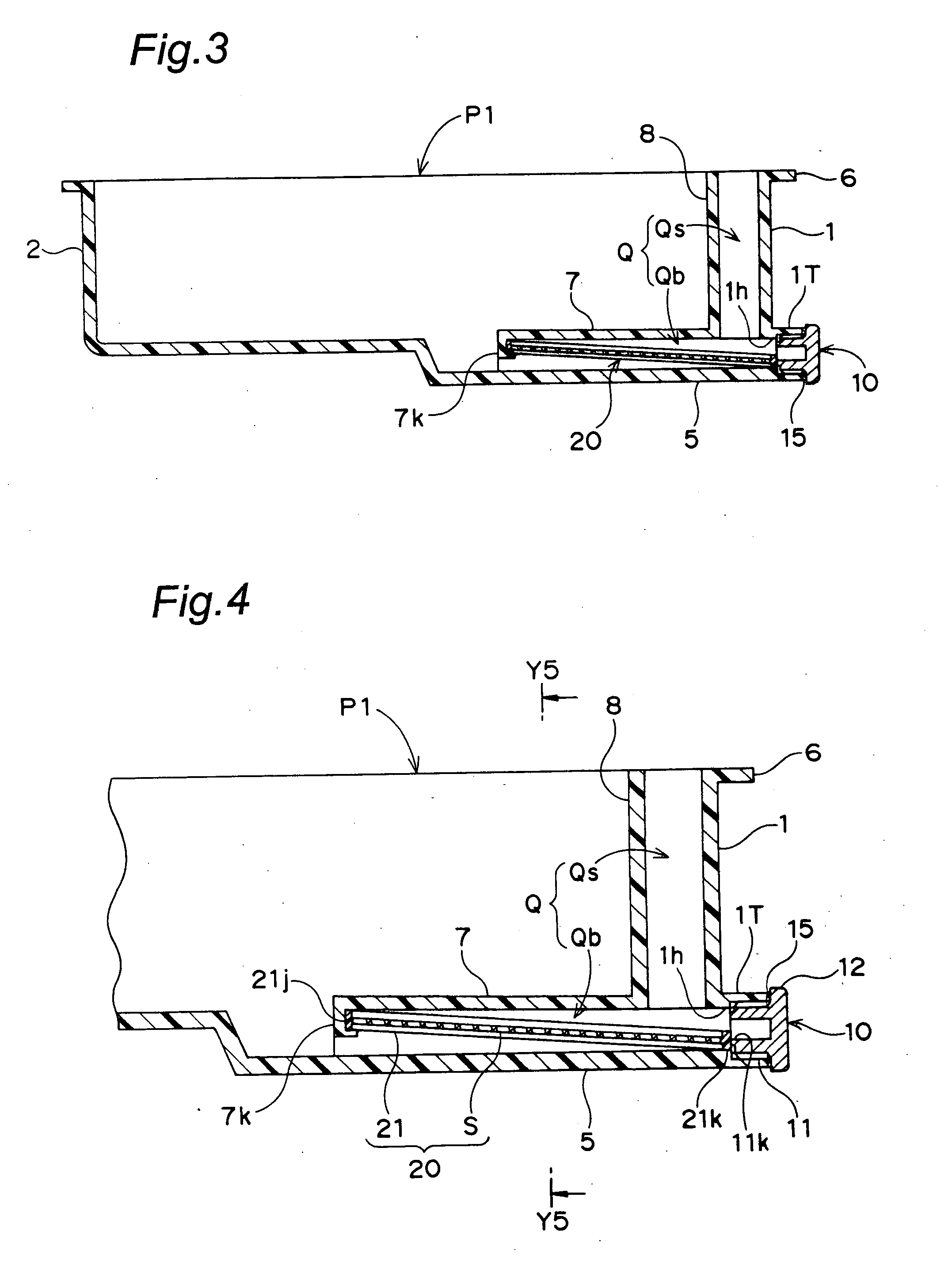

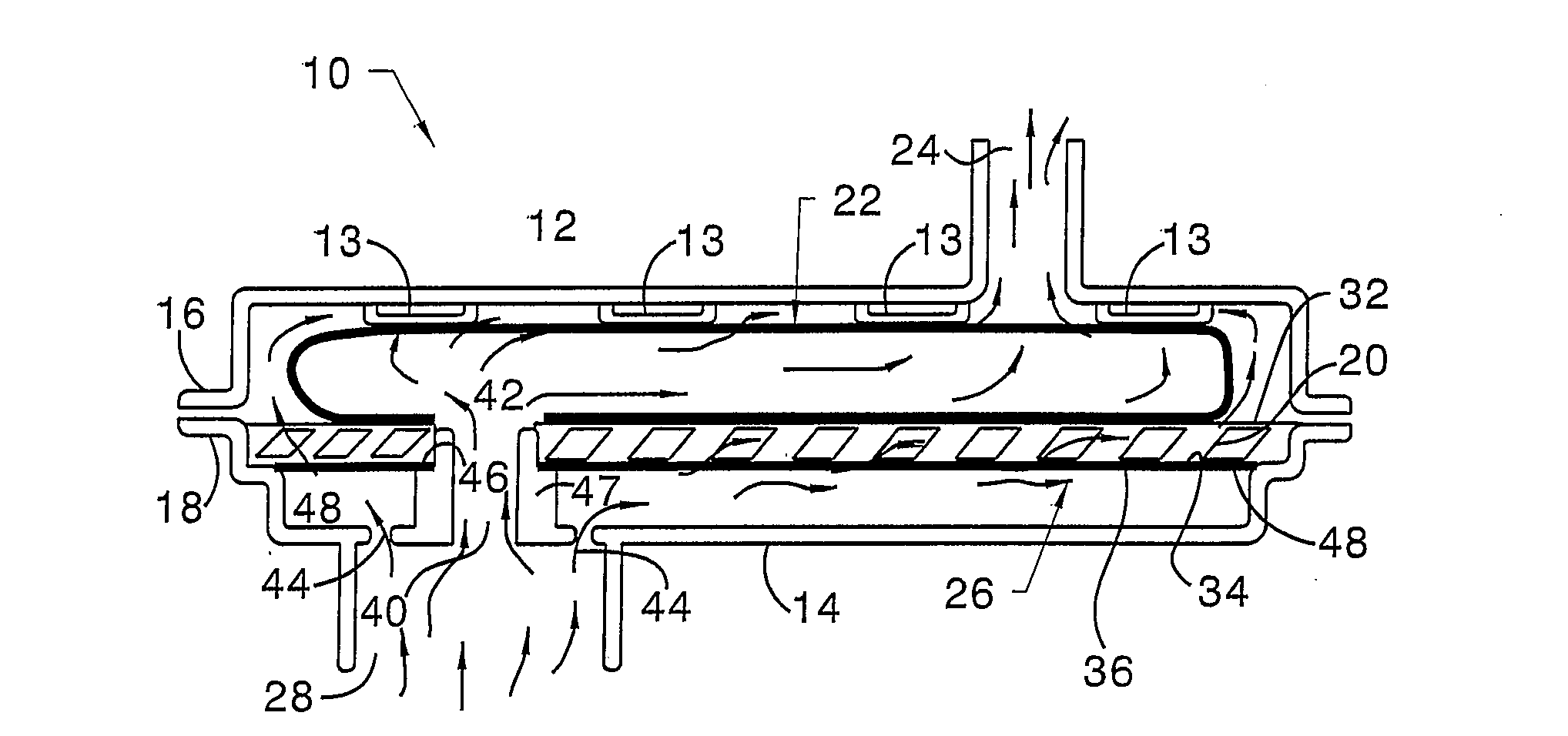

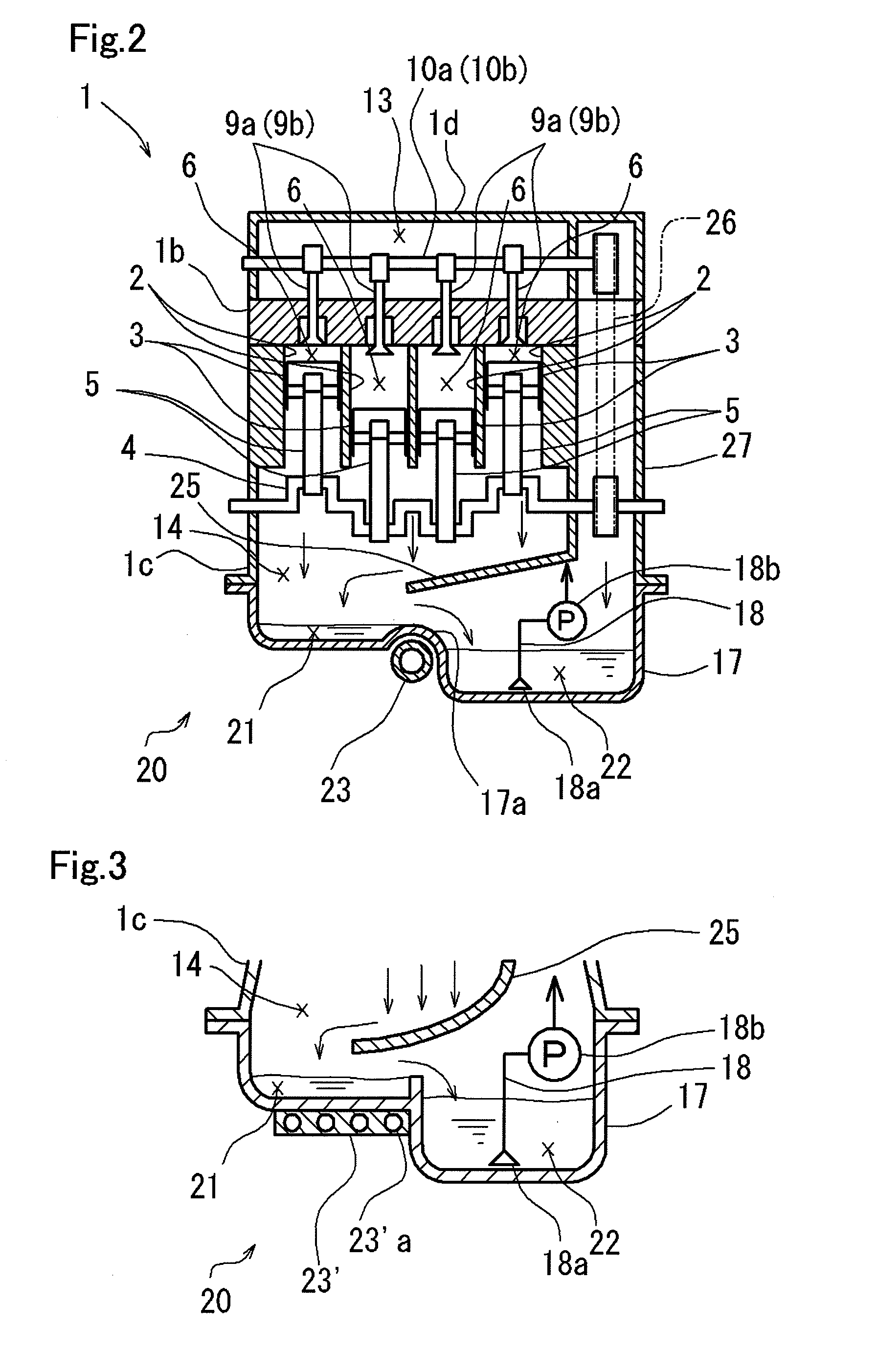

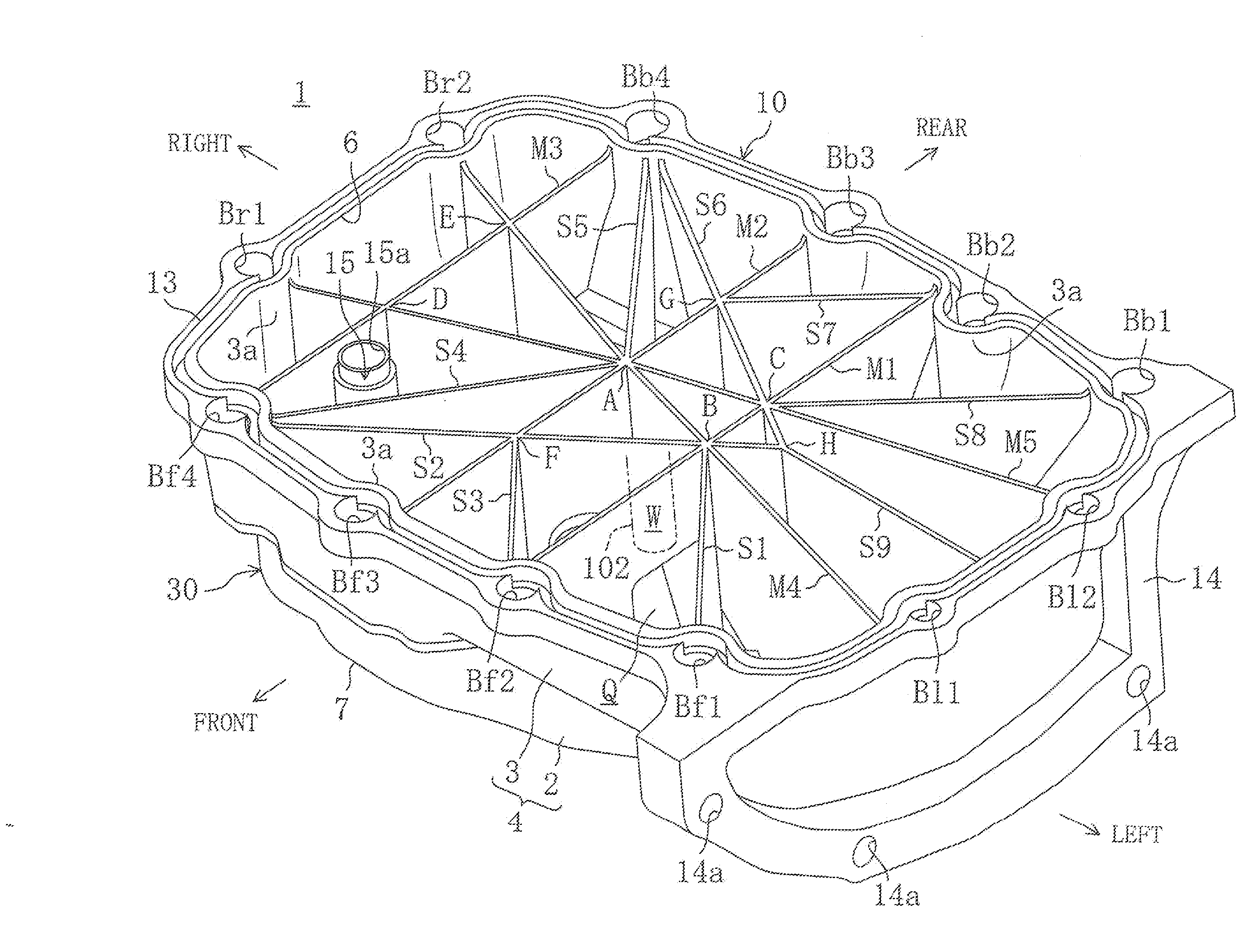

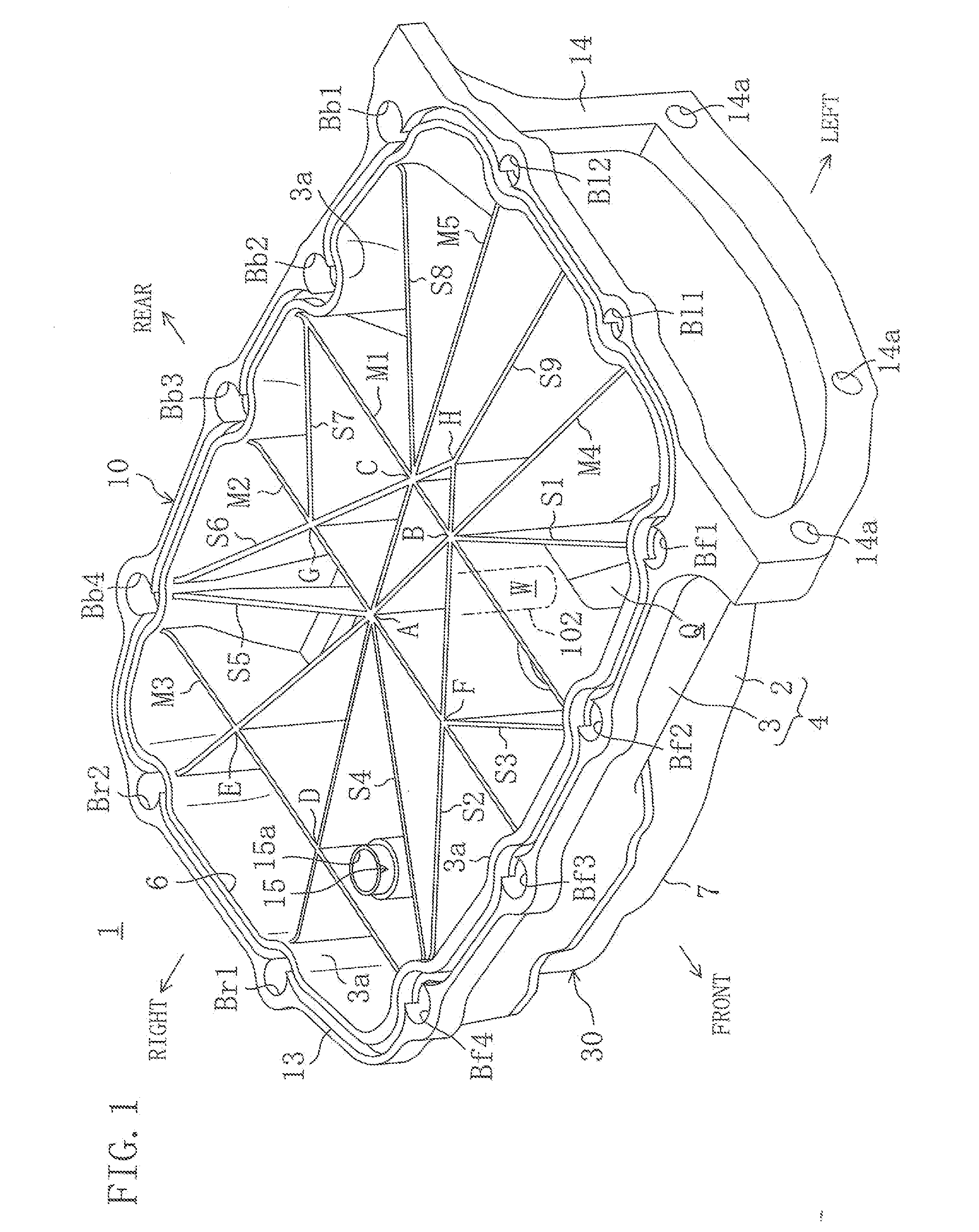

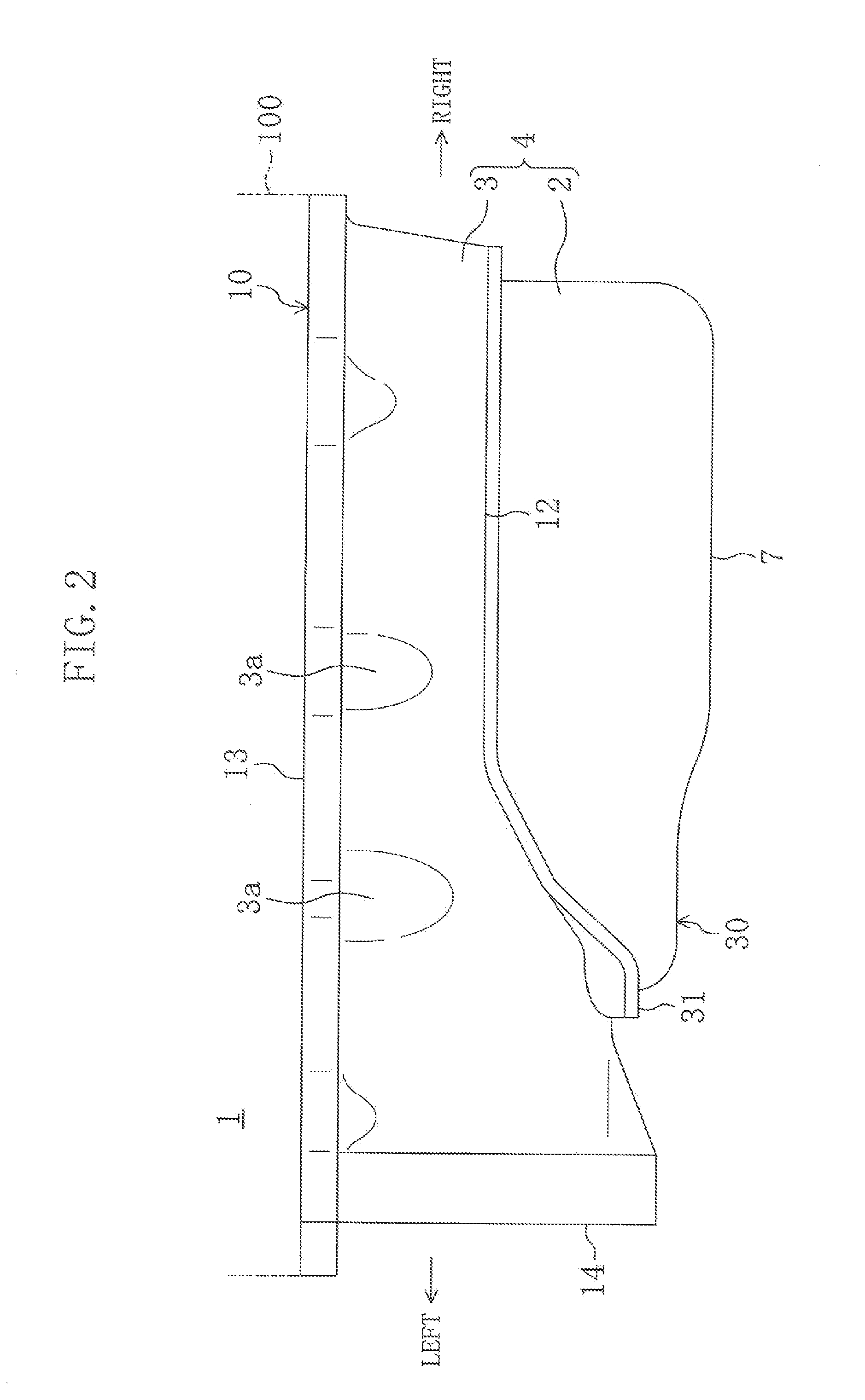

Oil pan with built-in filtering element

InactiveUS20060219620A1Supporting rigidity of the filter is highEasy to assembleOilsumpsMachines/enginesFilter elementWaste management

The present invention provides an oil pan with a built-in filtering element which does not easily receive influence of lateral swing of oil, which has high support rigidity of a filter, or which has excellent assembling operability of the filter, or which is light in weight as compared with a conventional oil pan. The oil pan P1 with a built-in filtering element has a filter 20. The filter 20 is provided therein with an oil flow path Q which is in communication with an oil pump. The filter 20 filters oil flowing toward the oil pump. An oil flow path includes a bottom flow path Qb having a flow path wall 7 extending along a bottom wall 5 of the oil pan, and a side flow path Qs having a flow path wall 8 extending along a first sidewall 1 of the oil pan. The first sidewall includes a drain hole 1h which opens at the bottom flow path and through which the filter can be inserted into the bottom flow path. The bottom flow path is provided with a filter retaining portion 7k which retains the inserted filter. The drain hole is provided with a plug fixing portion 1m which fixes a closing plug 10 of the drain hole. The closing plug is formed with a filter receiver 11k against which a terminal end 20k of the inserted filter is abutted.

Owner:DAIKYONISHIKAWA CORP

Multi-stage centrifugal debris trap

A centrifugal debris trap has a plurality of stages which may trap debris which may be located in a fluid stream between or within components downstream of the filtration system. The centrifugal debris trap includes a cylindrical chamber bound by an inner surface of a continuous wall radially disposed about a center axis at a first inner diameter; the inner surface separated from an outer surface of the continuous wall by a wall thickness; the continuous wall having a first wall end longitudinally separated along the center axis from a second wall end by a length; a plurality of grooves located between the first wall end and the second wall end; the plurality of grooves extending radially outward from the inner surface into a portion of the continuous wall; each of the plurality of grooves having a groove outer diameter that is greater than the first inner diameter; the cylindrical chamber being sealed at the first wall end by a back plate attached about a circumference of the first wall end; the cylindrical chamber being open at the second wall end through a ring attached to the second wall end about a circumference of the second wall end; the ring having a ring opening radially disposed about the center axis; and the ring opening having a second inner diameter less than the first inner diameter.

Owner:HONEYWELL INT INC

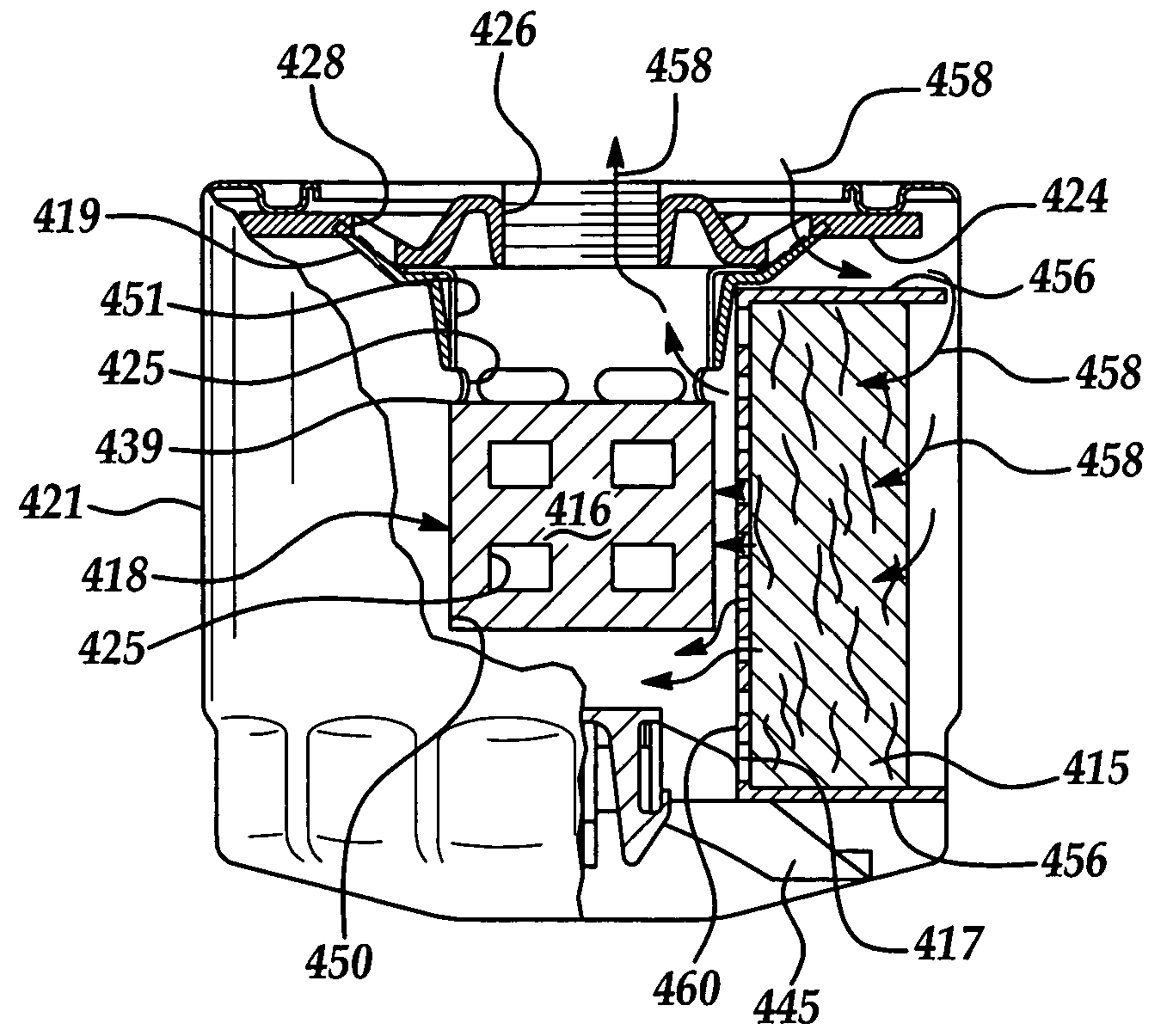

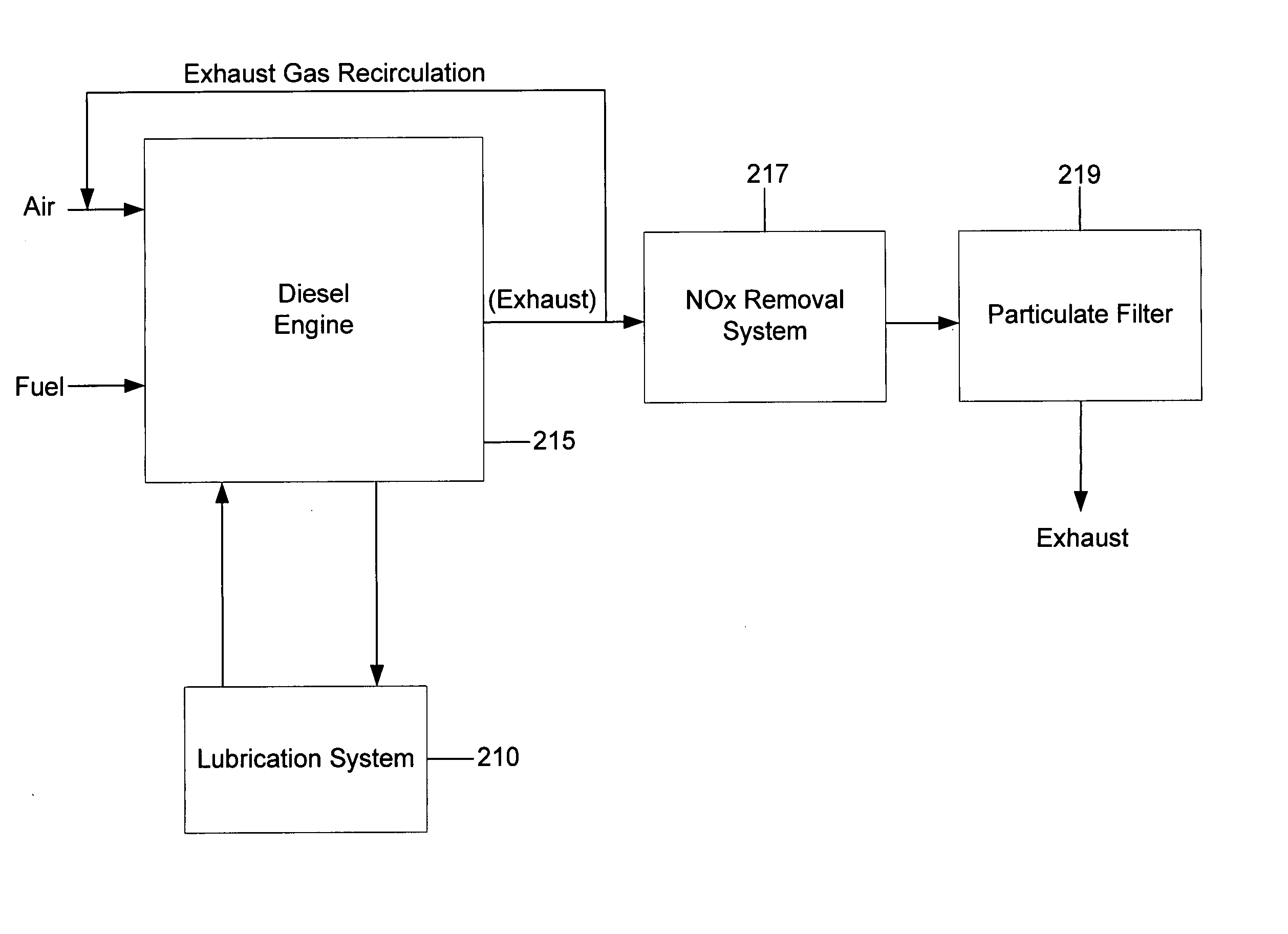

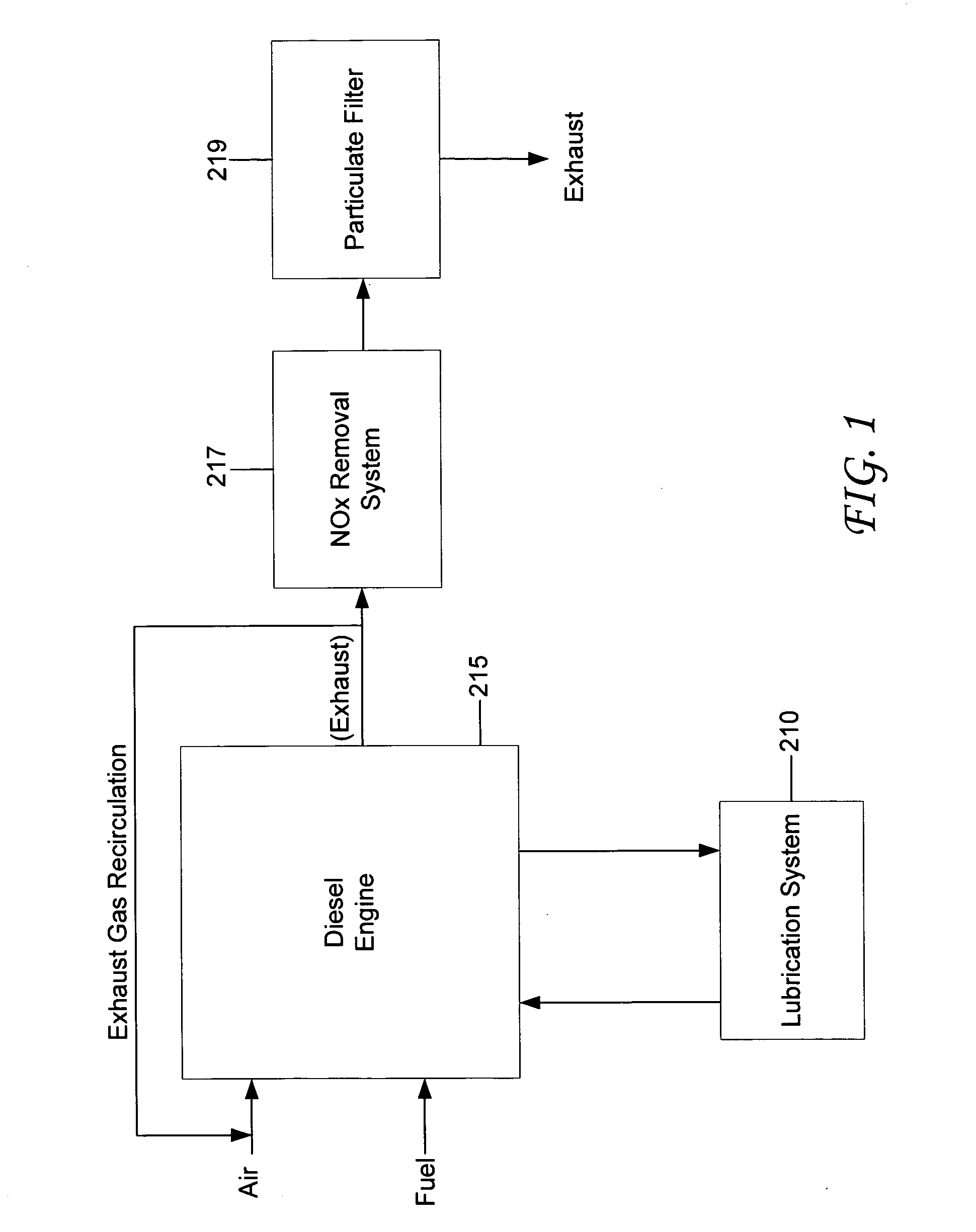

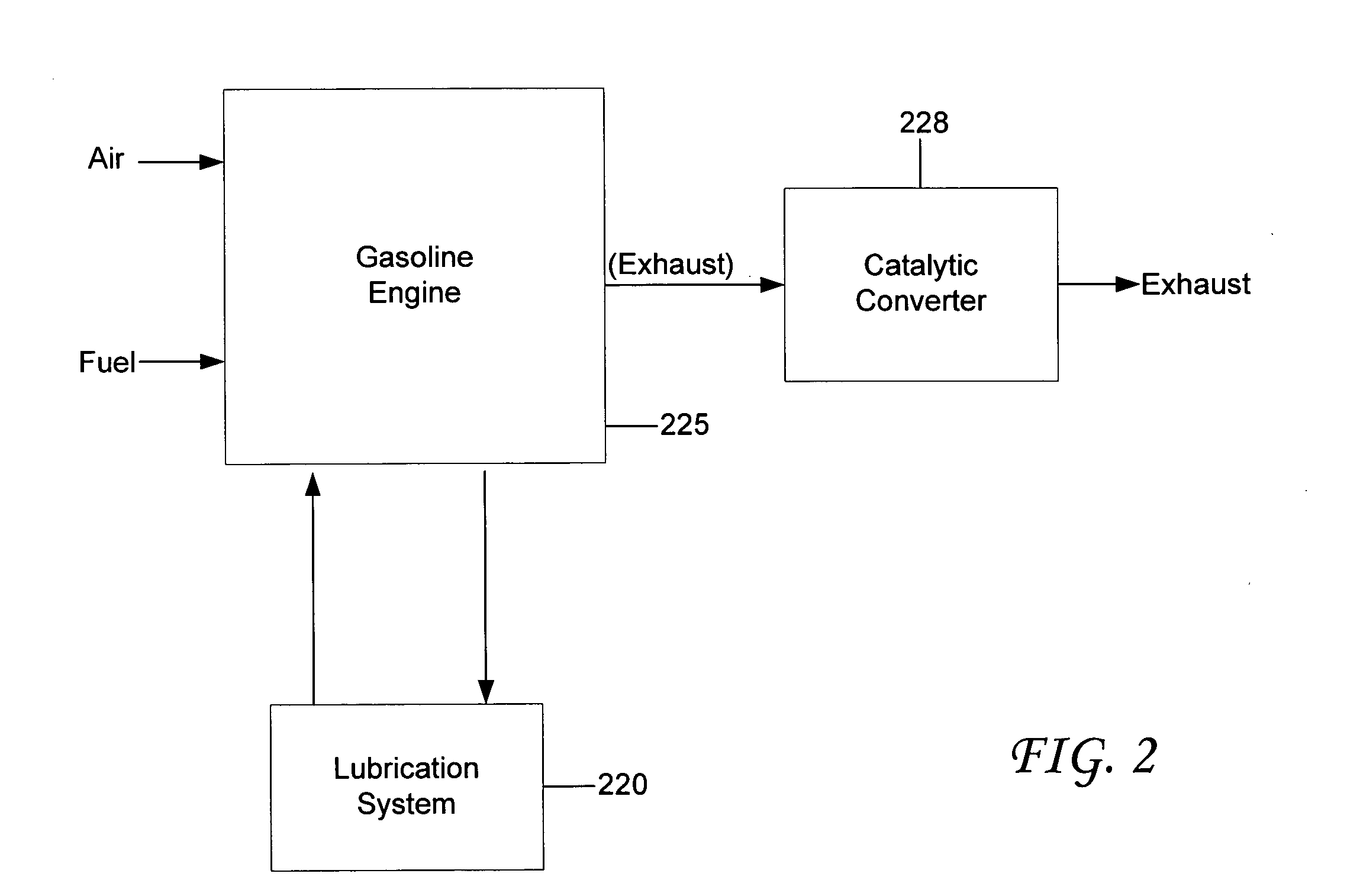

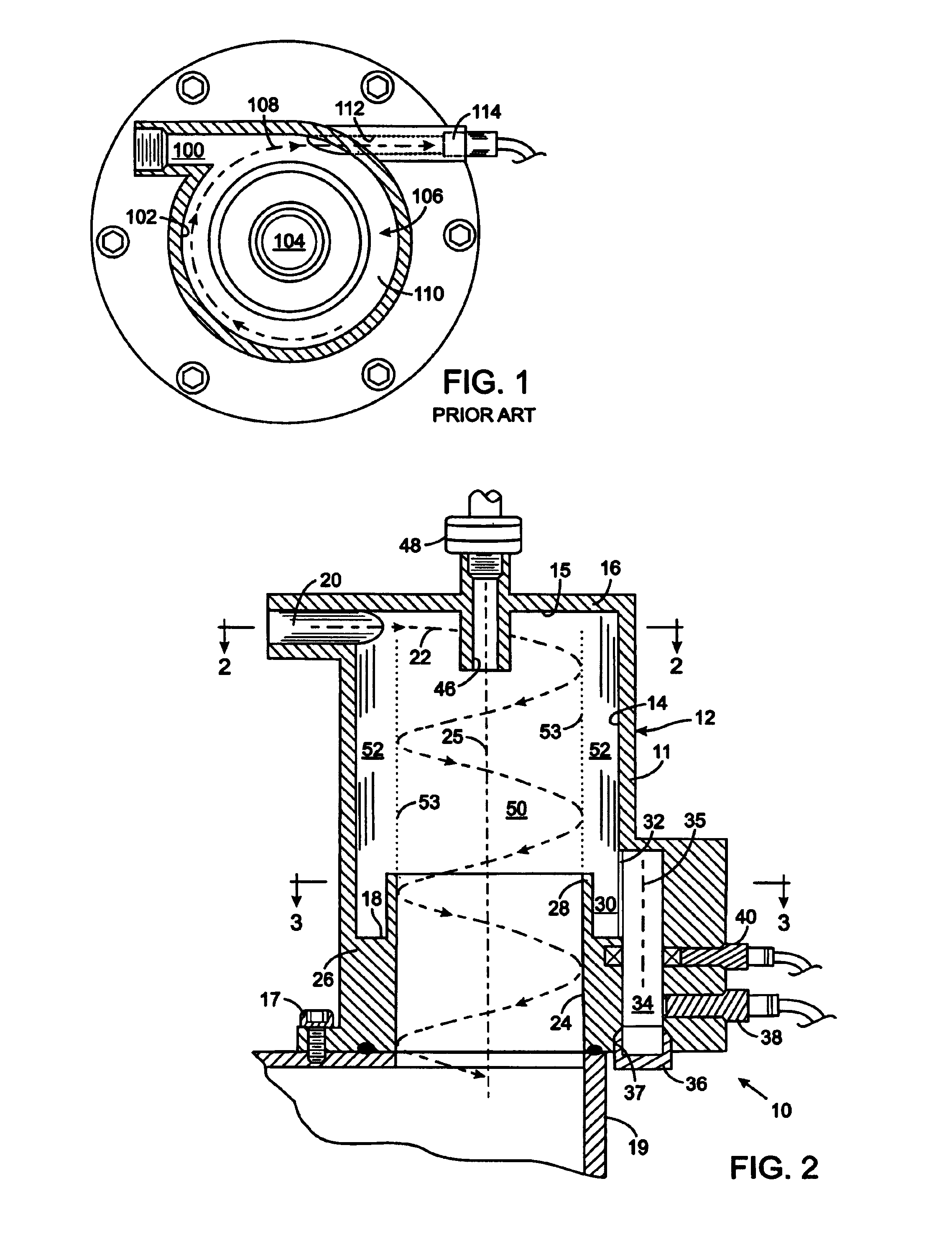

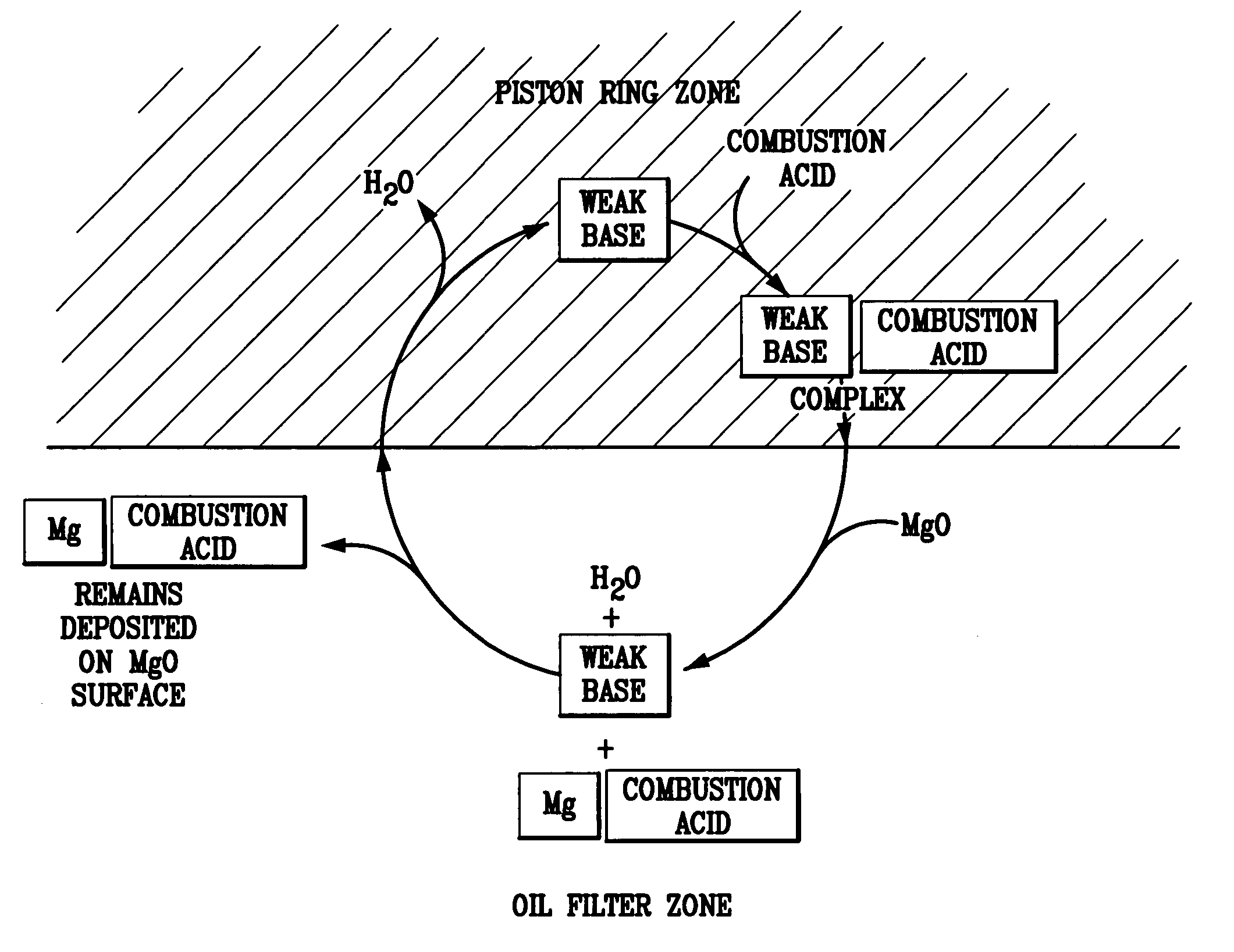

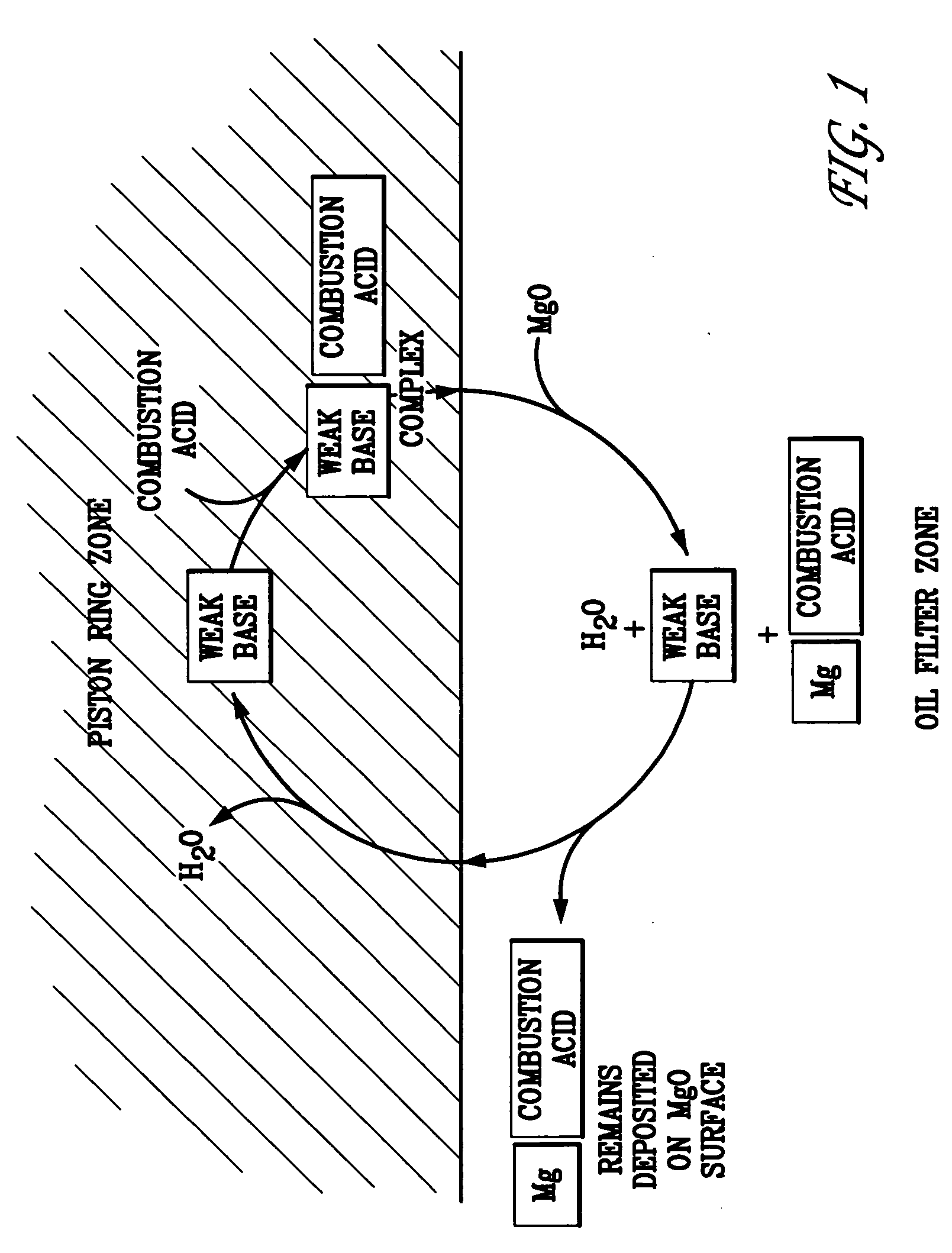

Materials and processes for reducing combustion by-products in a lubrication system for an internal combustion engine

InactiveUS20060260874A1Minimizes engine depositEfficient emissionsMachines/enginesLubricant mounting/connectionSolubilityExternal combustion engine

A lubrication system having an oil filter modified to replace or supplement the performance of lubricant additives that may be used within an internal combustion engine to increase the performance of a lubricant. The formulation of the lubricant is changed in accordance with the chemicals placed in the oil filter. For example, when the oil filter contains a strong base, the lubricant concentration of detergent will decrease, in some cases to zero, while the dispersant concentration in the lubricant will increase. The dispersant is the ideal weak base to neutralize combustion acid at the piston ring zone, carry the resultant weak base-combustion acid complex to the strong base in the oil filter, undergo ion exchange with the strong base, immobilize the acid in the oil filter and recycle back to the piston ring zone for reuse as an acid neutralization agent. The reduction or elimination of detergent from the lubricant will reduce the fouling of the emission filter and of deposit formation on engine parts such as the piston. The oil filter may also contain an additive which is slowly released into the lubricant. For example, a ZnDDP anti-wear additive may be slowly released from the oil filter to the lubricant. Because the ZnDDP has low molecular weight alkyl groups it has limited solubility in the lubricant. The rate of release is limited by the equilibrium concentration of the additive in the lubricant. As a result, a relatively constant concentration of the additive may be maintained in the lubricant. The resultant closed system allows the oil drain intervals to be significantly extended.

Owner:LUTEK

Outside-in flow engine and transmission filter and method

A suction-side transmission or engine filter includes a filter bag assembly having an outlet portion and a media bag enclosing an inner support structure, the filter bag assembly is contained at least partially within a housing having an outlet port. The outlet portion and outlet port are aligned and sealed together creating an outside-in fluid flow scheme.

Owner:FILTRAN LLC

Three-phase cyclonic fluid separator with a debris trap

An apparatus separates liquid, gas and solid components of a mixture in a fluid system. An inlet for receiving the mixture opens into a separation chamber tangentially with a cylindrical side wall and a gas outlet has an opening in a first end wall adjacent the inlet to allow gas to exit the separator. A fluid outlet is located in an opposing second end wall. A debris passage extends through the cylindrical side wall and oriented so that the radial velocity of the particles within the separation chamber directs the particles through the debris passage. The debris passage leads to a particle collection chamber in which the particles accumulate. Unlike prior separators that relied on the tangential velocity of the particles, the present apparatus utilizes the greater radial velocity to drive the particles from the separation chamber into the particle collection chamber.

Owner:EATON INTELLIGENT POWER LIMITED

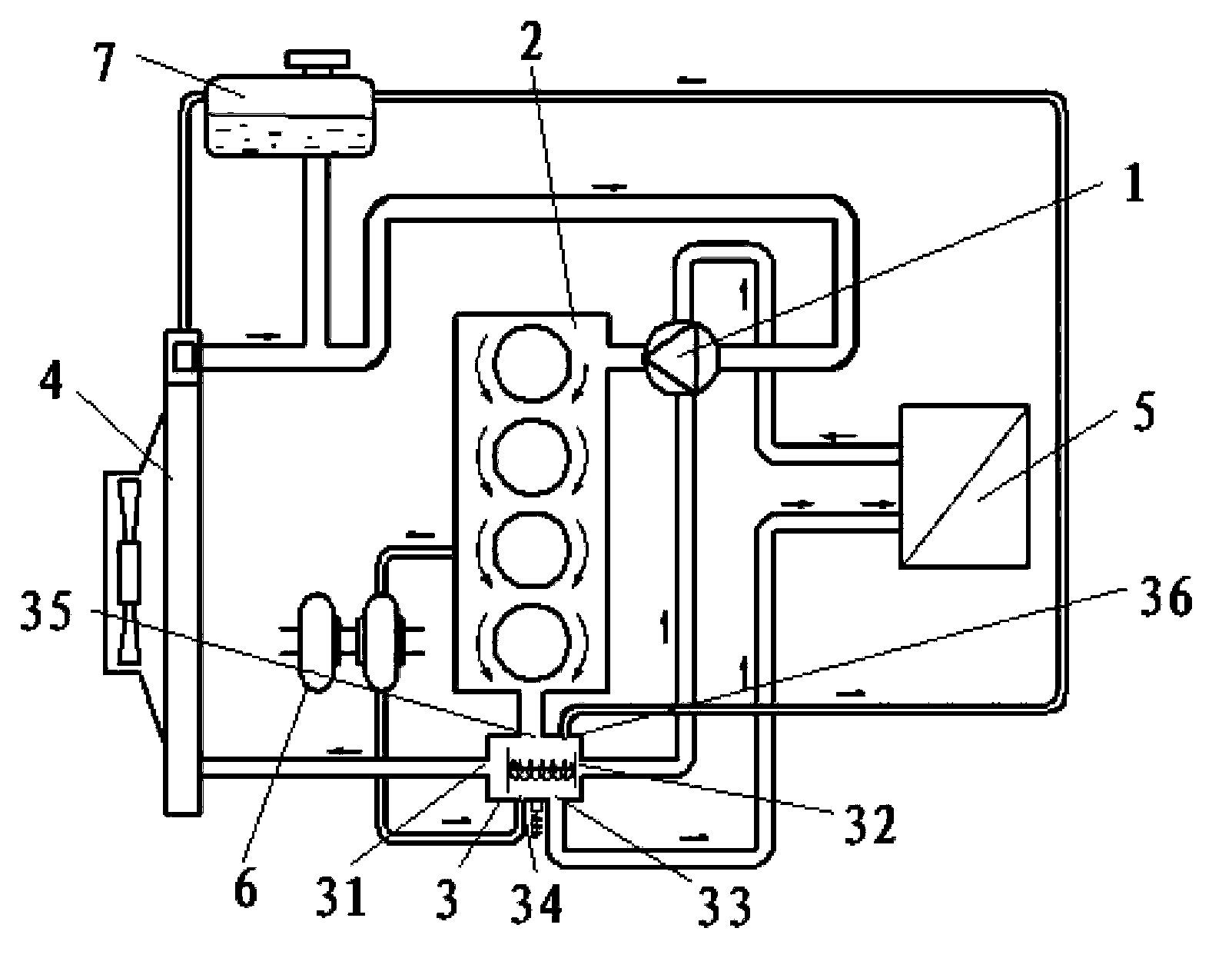

Engine cooling system, engine and vehicle

ActiveCN103670657AImprove fuel economyImprove comfortCoolant flow controlInternal combustion piston enginesThermostatAir conditioning

Owner:北京汽车动力总成有限公司

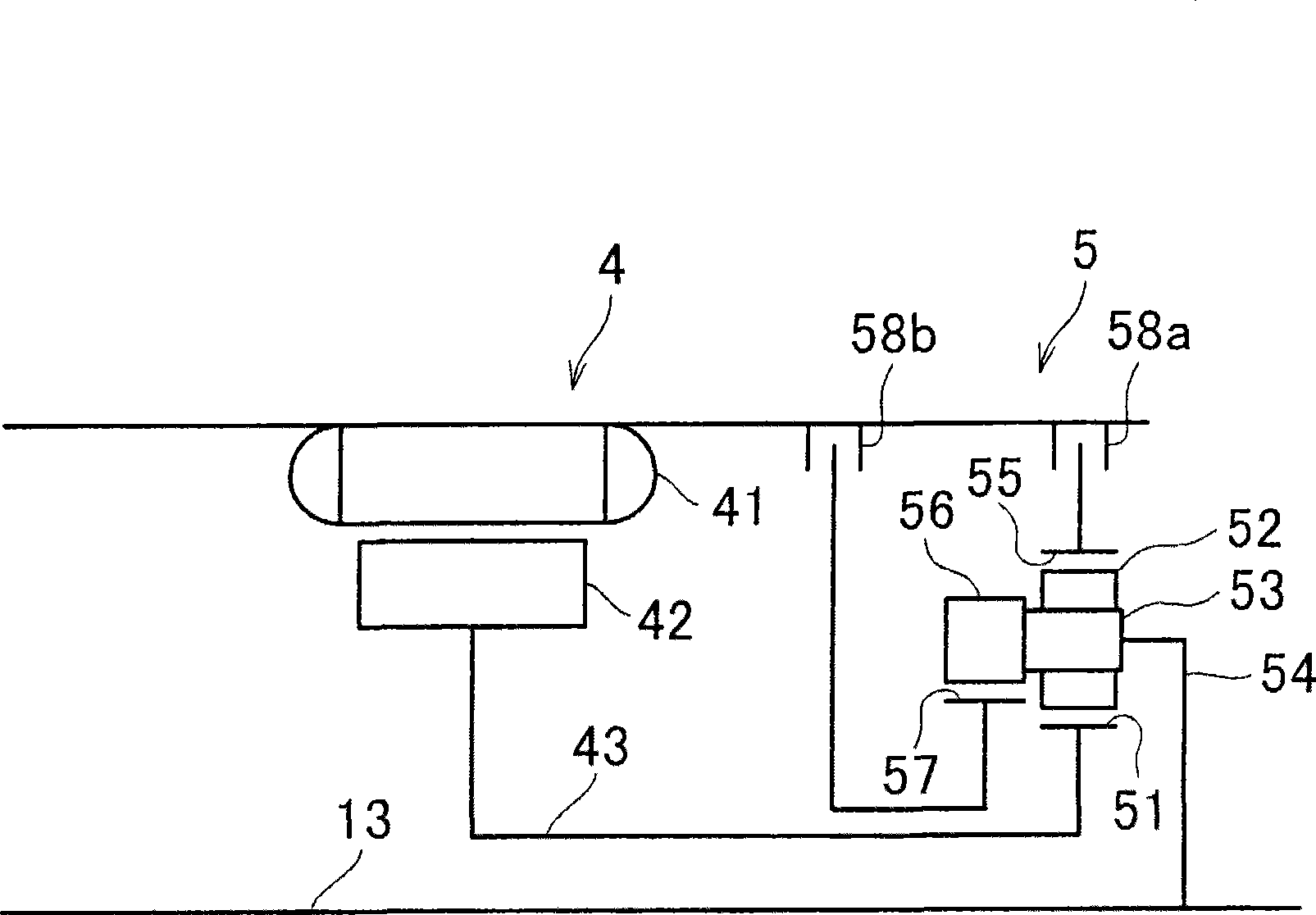

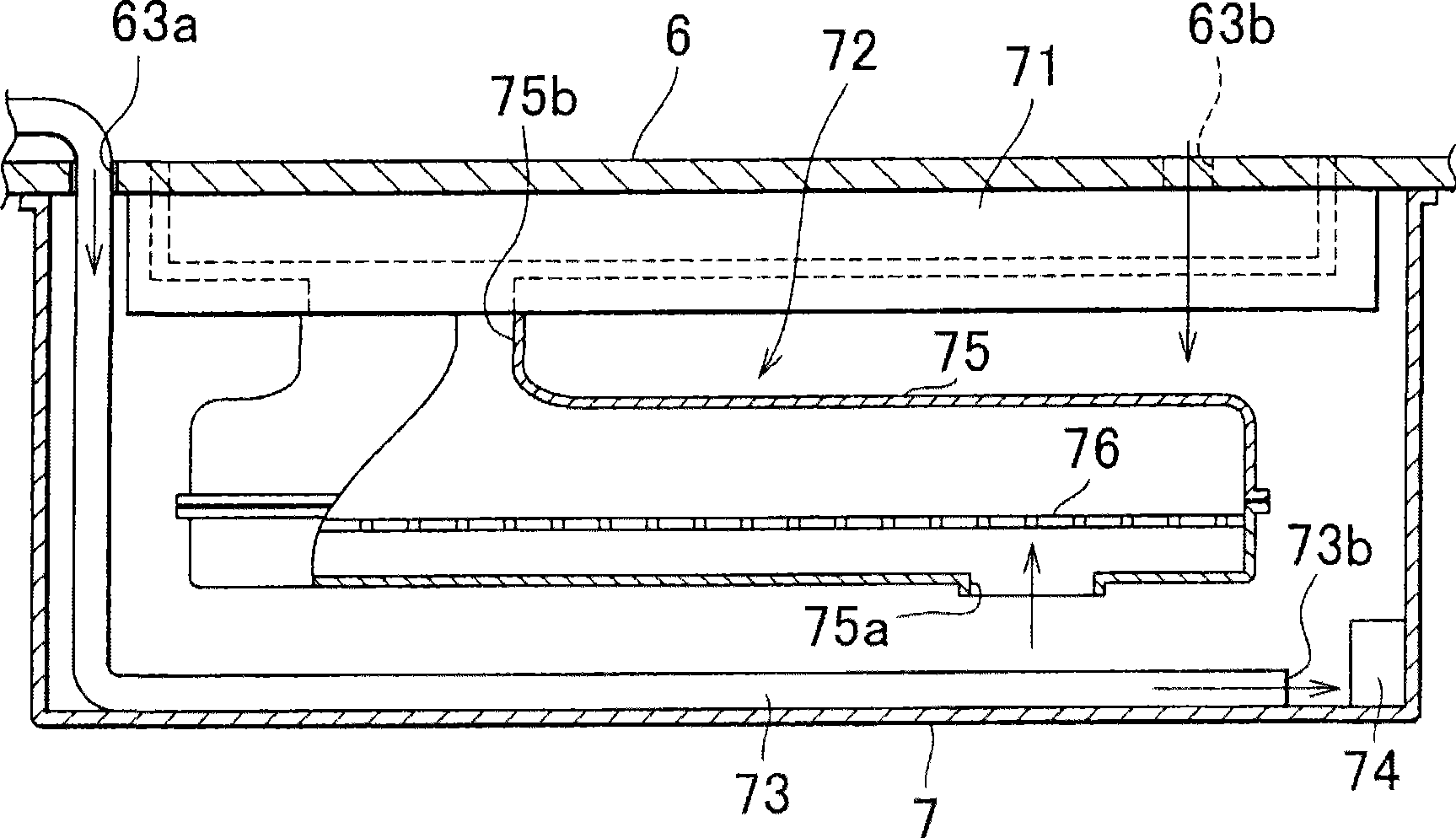

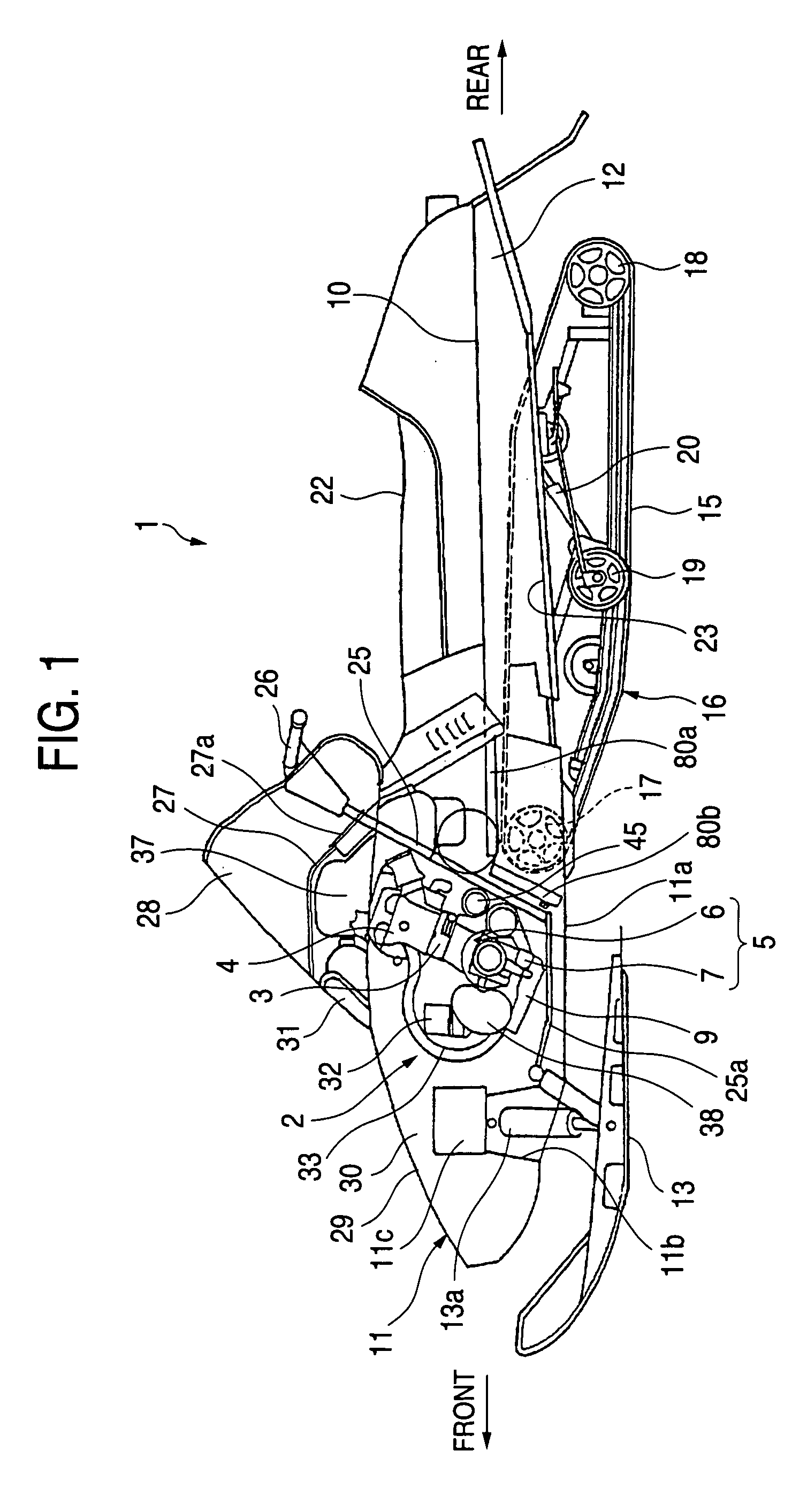

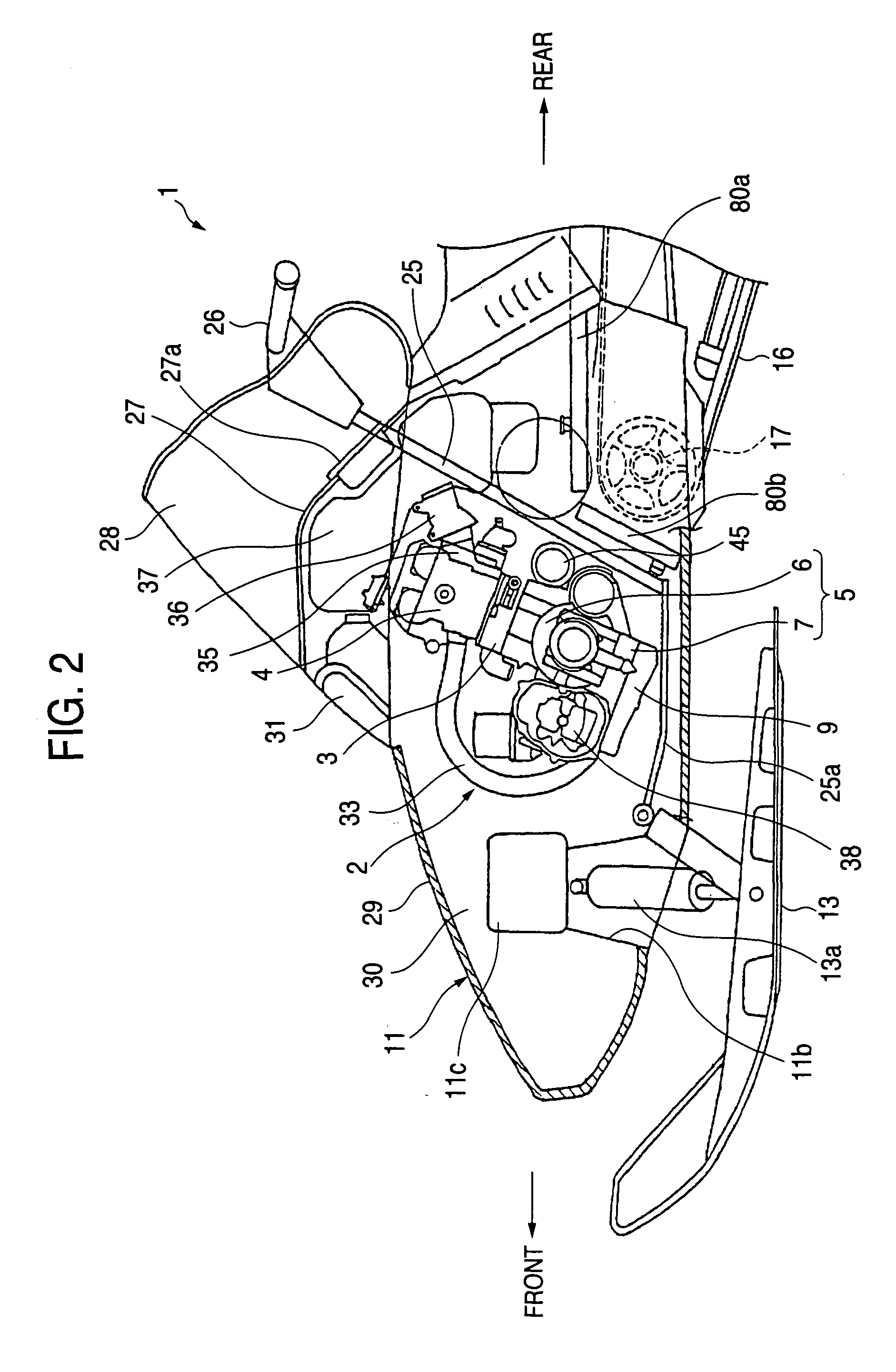

Oil lubricating structure

An oil lubricating structure includes a main body case (6) having a housing chamber (62a) in which a first dynamotor (2) is housed; an oil sump (7) which is provided below the main body case (6) and has an oil chamber in which oil collects; an oil supply portion which has an inlet port (75a) through which oil is drawn in from the oil chamber and which supplies oil collected in the oil chamber to the first dynamotor (2) through the inlet port; and an oil return hole (63a) which is formed in a bottom surface of the main body case (6) toward the front of the oil sump (7). A duct member (73) is provided in the oil chamber. One end portion (73a) of the duct member (73) is connected to the oil return hole (63a) and the other end portion (73b) of the duct member (73) is positioned farther to the rear than the inlet port (75a). Thus, an oil lubricating structure, which can prevent air from being sucked into the inlet port (75a) with the condition that the oil sump (7) and the main body case (6) are forward tipping when the vehicle is braked or move downwards, is provided.

Owner:TOYOTA JIDOSHA KK +1

Suction Filter for Automatic Transmission Fluid

ActiveUS20090294343A1High bulk densityLow costWater/sewage treatmentMultistage water/sewage treatmentEngineeringMedia filter

An assembly for filtering contaminants from automatic transmission fluid includes a housing including a first inlet and a second inlet, through which fluid enters the housing, and an outlet, through which fluid exits the housing; a first media filter located within the housing in a first fluid flow path between the first inlet and the outlet; and a second media filter located within the housing in a second fluid flow path between the second inlet and the outlet.

Owner:FORD GLOBAL TECH LLC

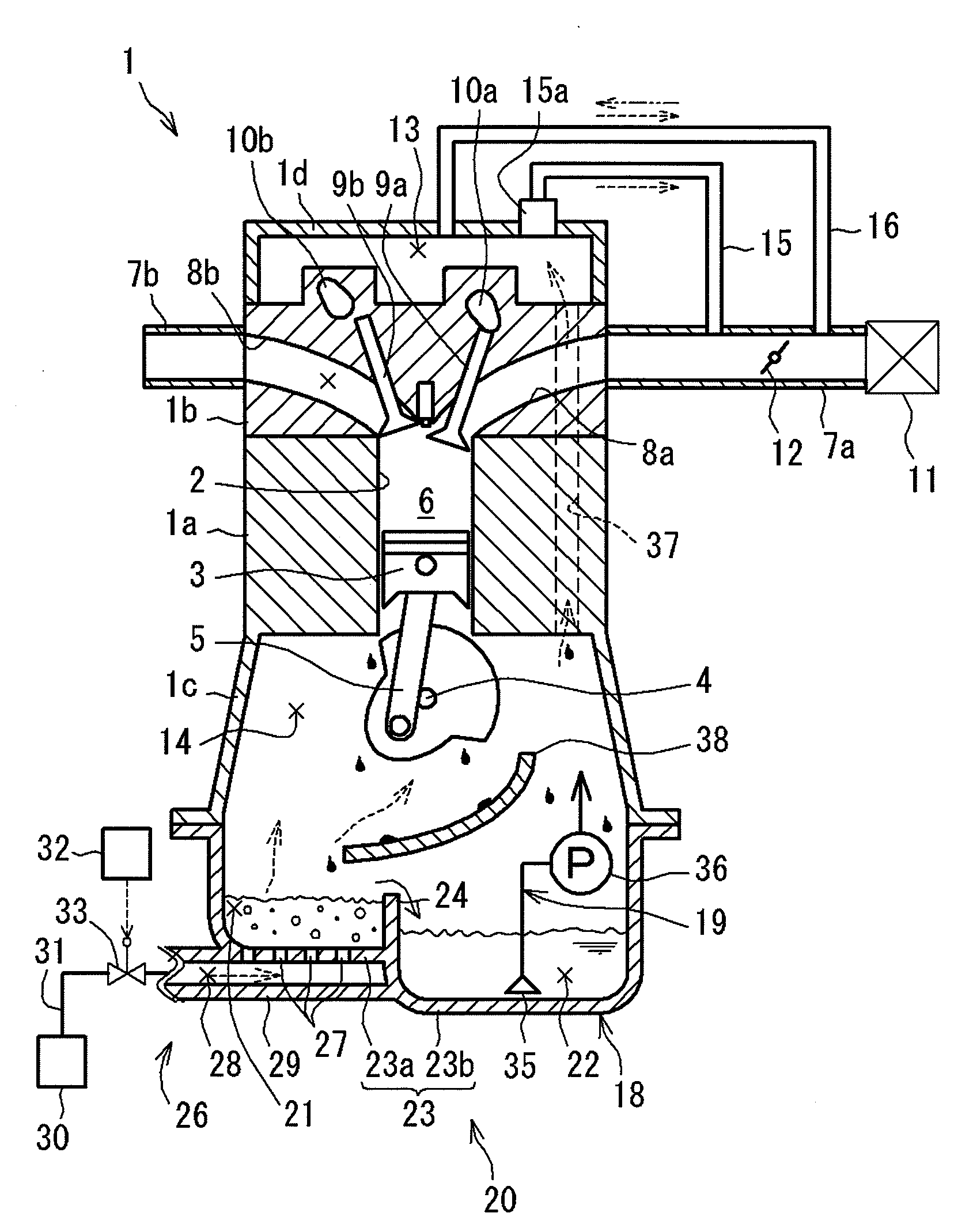

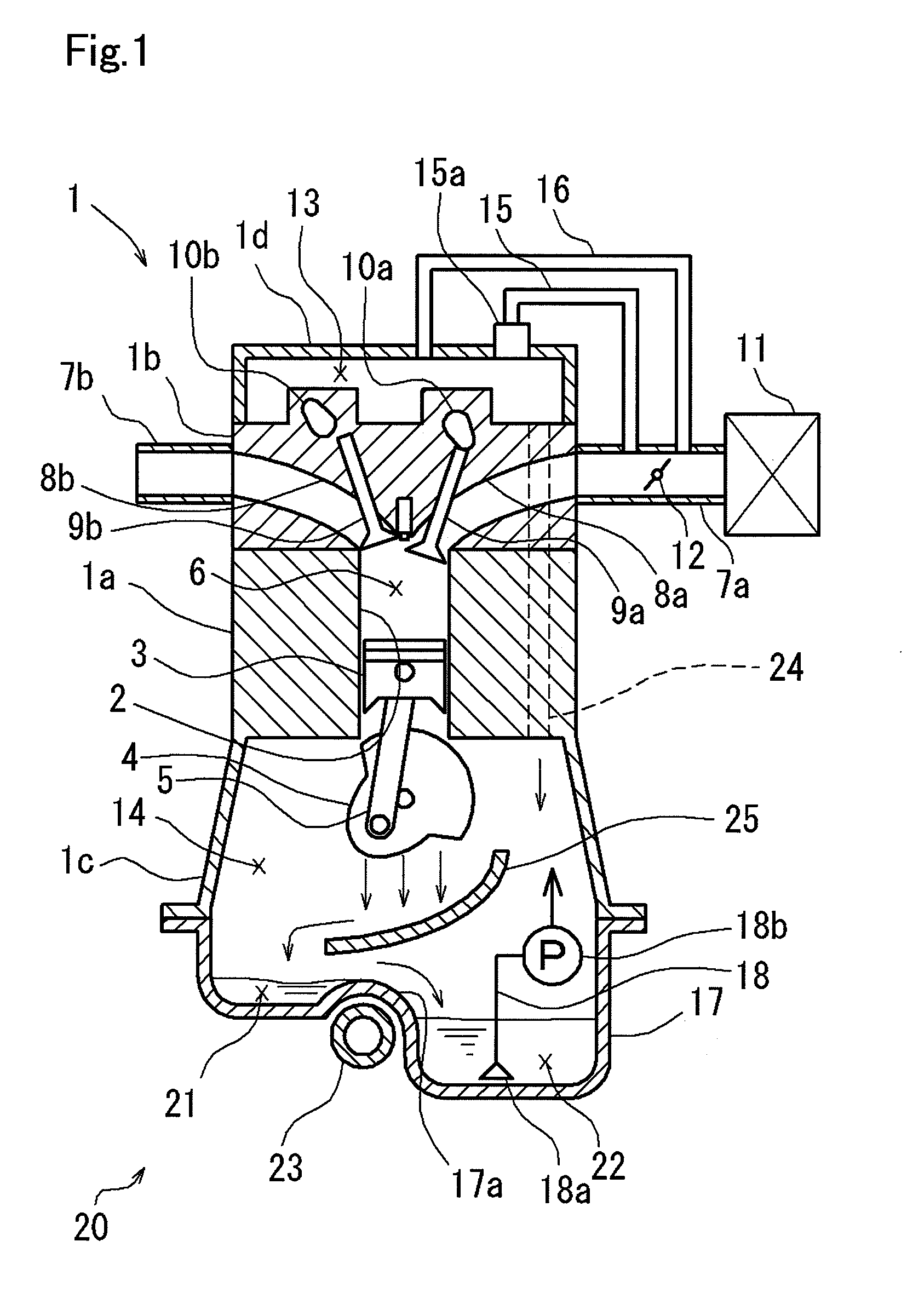

Diluting fuel-in-oil separating apparatus of internal combustion engine

InactiveUS20090277416A1Small volumePrevent degradationExhaust apparatusSilencing apparatusEngineeringInternal combustion engine

The diluting fuel-in-oil separating apparatus includes an oil container (an oil pan) and a fuel eliminator (a heater, a bubble generator). The oil container contains lubricating oil of the internal combustion engine, and has a first compartment and a second compartment divided from the first compartment, such that the lubricating oil is introduced from the first compartment into the second compartment. The fuel eliminator eliminates fuel from the lubricating oil in the first compartment. The second compartment is provided with an oil passage having an oil pump supplying the lubricating oil from the second compartment to lubricated parts of the internal combustion engine.

Owner:TOYOTA BOSHOKU KK

Apparatus for simultaneous cleaning of a liquid and a gas

InactiveUS7156901B2Low production costEasy to cleanCombination devicesDispersed particle filtrationEngineering

Owner:ALFA LAVAL CORP AB

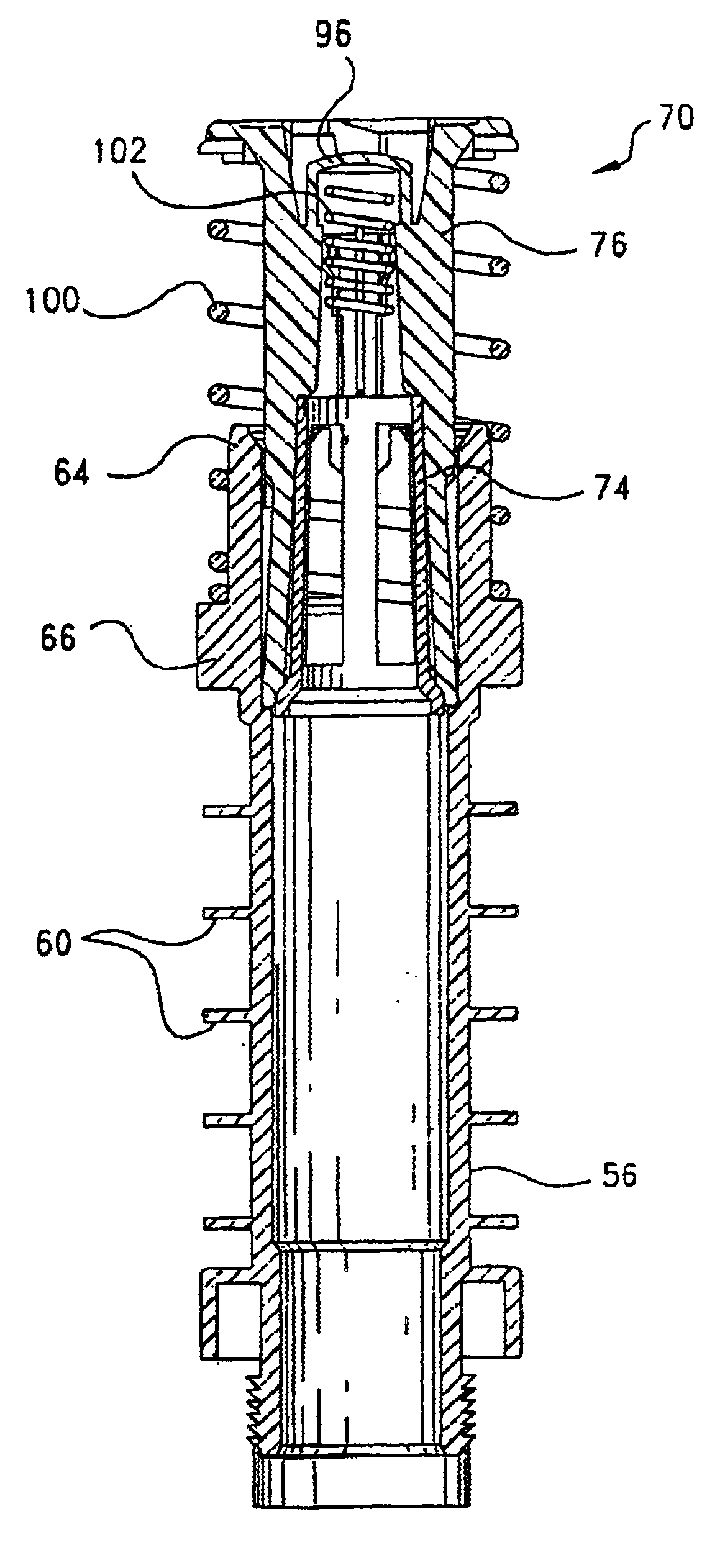

Extension and locking assembly for dripless element, and container therefore

InactiveUS6837993B2Mess and environmental issue be substantially reduceReduce environmental problemsCapsClosure lidsMechanical engineeringFilter element

A filter assembly includes housing enclosing a replaceable filter element. A support core is provided in the housing, and includes an extension and locking assembly. The element includes a ring of filtration media with a pair of end caps. The first end cap includes a central opening to receive the support core. The extension and locking assembly prevents the cover of the housing from being attached to the housing body without a proper filter element installed. The extension and locking assembly includes a bypass member and a locking member, which are in locking engagement when an element is absent in the housing. The second end cap includes internal protrusions which engage the locking member when the filter element is installed to disengage the bypass member from the support core, and allow the element to be inserted and the cover to be installed.

Owner:PARKER INTANGIBLES LLC

Fluid filter assembly with a filter cartridge and housing interface

A fluid filter assembly having a filter cartridge and housing interface to indicate whether a replacement filter cartridge is proper and desirable for the fluid filter assembly. A substantially cylindrical interface is connected to and extends from the filter cartridge and is matingly received by a bore provided in a boss of a housing of the fluid filter assembly. A means for indicating at least one characteristic of the filter cartridge is provided to ensure the replacement filter cartridge is proper and desirable for the fluid filter assembly.

Owner:DAVCO TECH

Materials, filters, and systems for immobilizing combustion by-products and controlling lubricant viscosity

InactiveUS20060261004A1Exchange capacity can be maximizedEconomic benefitWater/sewage treatmentMachines/enginesCombustionFiltration

A chemical filter for use within an internal combustion engine lubrication system. The chemical filter employs filtration media including particles having internal pores and interstitial pores formed between adjacent particles. The internal pores and the interstitial pores collectively define filtration media pores, and a strong base material is associated with at least some of the internal pores. The filtration media has a surface area greater than or equal to 25 m2 / gm that is derived from filtration media pores that are large enough to receive a combustion acid-weak base complex contained within oil flowing through the chemical filter. This enables an ion-exchange process to occur that immobilizes the combustion acids and regenerates the weak base, so as to extend the time intervals between oil drains, among other benefits.

Owner:LUTEK

Oil pan

InactiveUS20100162988A1Improve insulation performanceLow viscosityCasingsNon-fuel substance addition to fuelPetroleum engineering

An oil pan made of resin includes an oil reservoir. The oil reservoir includes a bottom wall and a peripheral wall rising from a periphery of the bottom wall and having an opening at a top of the oil reservoir. A rib is provided in the oil reservoir.

Owner:DAIKYONISHIKAWA CORP

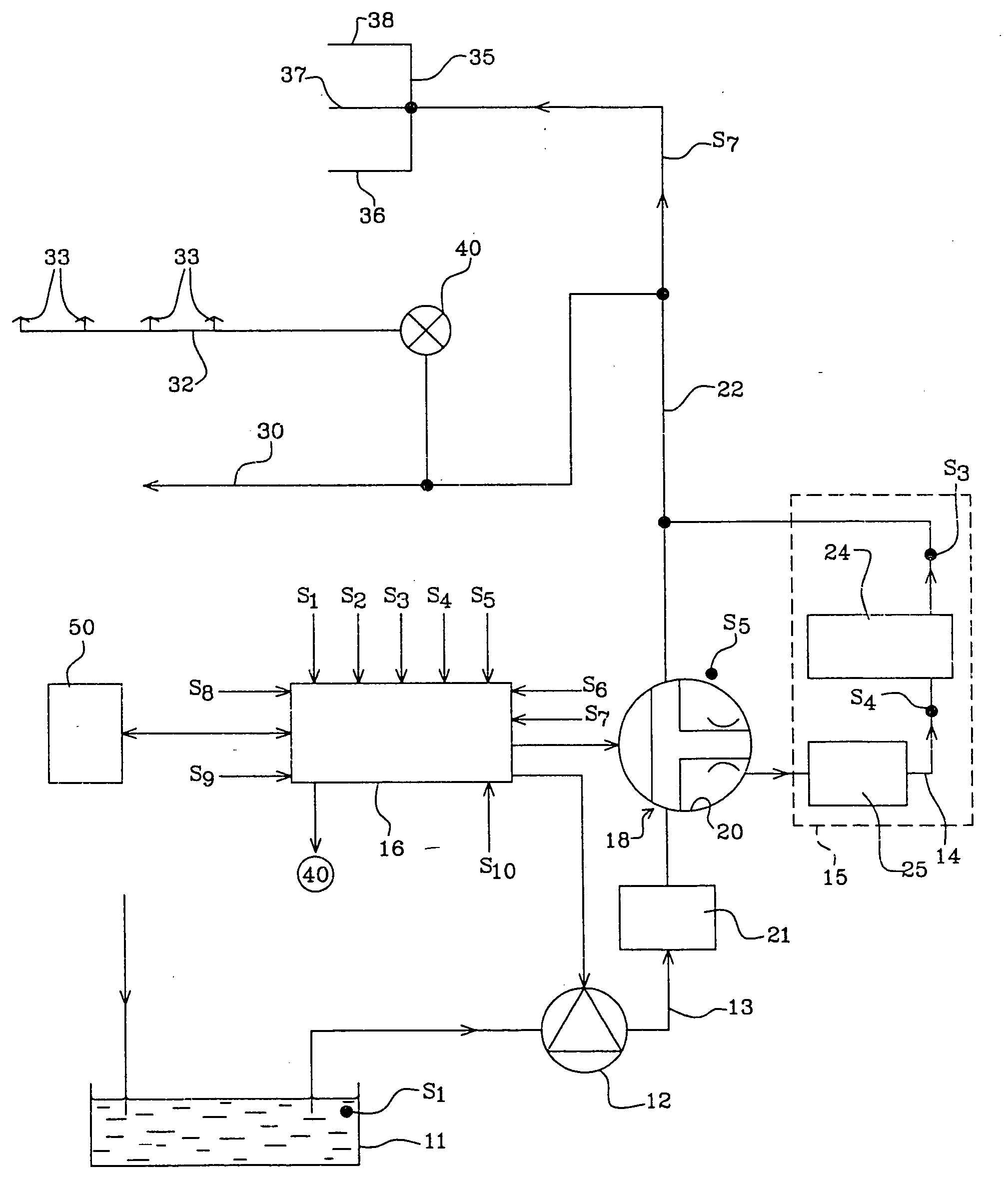

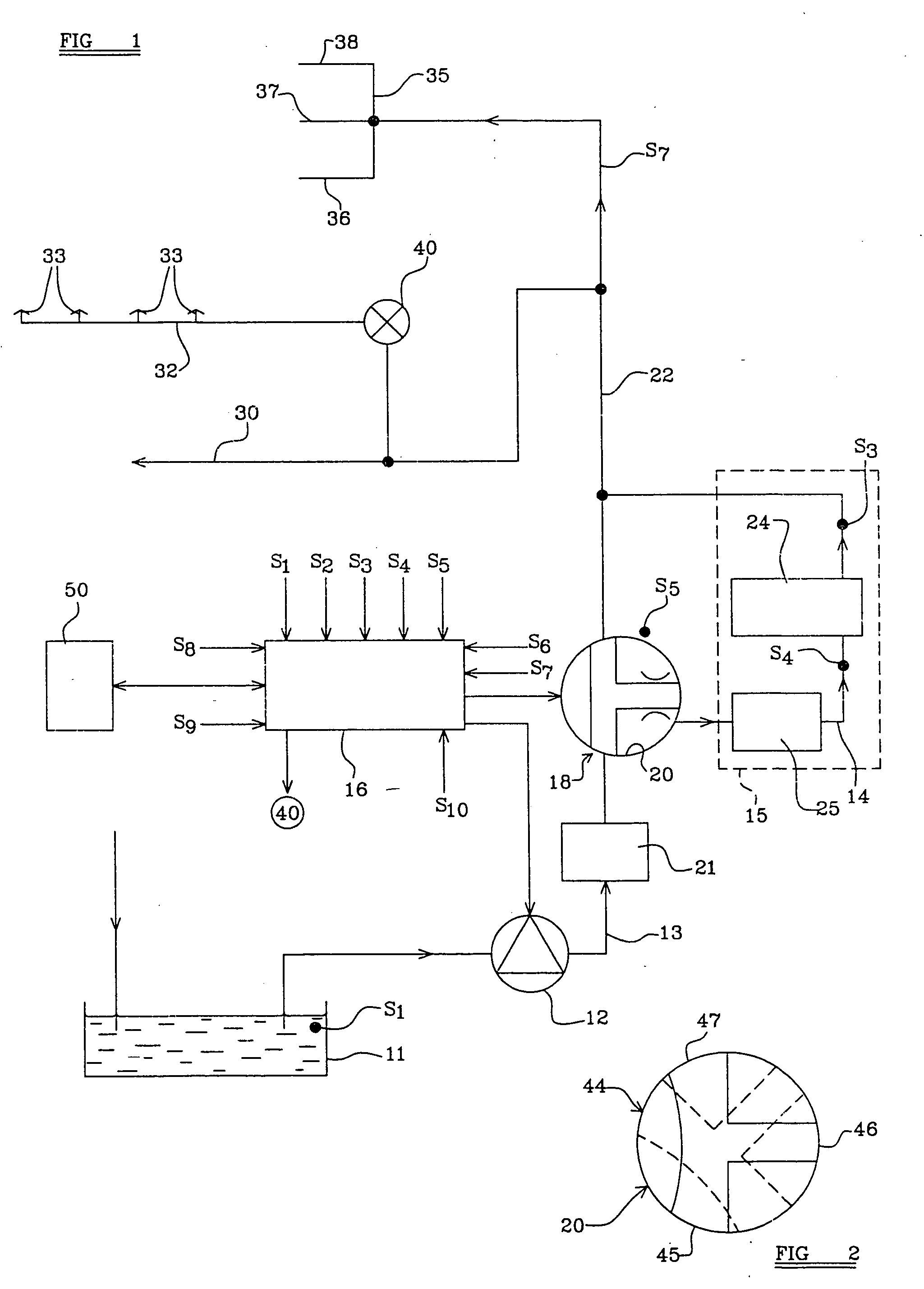

Engine lubrication system

InactiveUS20040031463A1Increase temperatureEasy to disassembleLubricant conduit arrangementsMachines/enginesSystem controllerLubrication

A lubrication system for an engine includes a sump for lubricant, a pump to pump lubricant along a lubricant feed line to lubrication positions within the engine, and a lubricant conditioner, and wherein the pump is an electrically driven pump which is controlled by a system controller, there being a diverter valve which is under the control of the controller selectively to divert at least a proportion of the lubricant from the lubricant feed line to the lubricant conditioner.

Owner:PIERBURG PUMP TECH UK

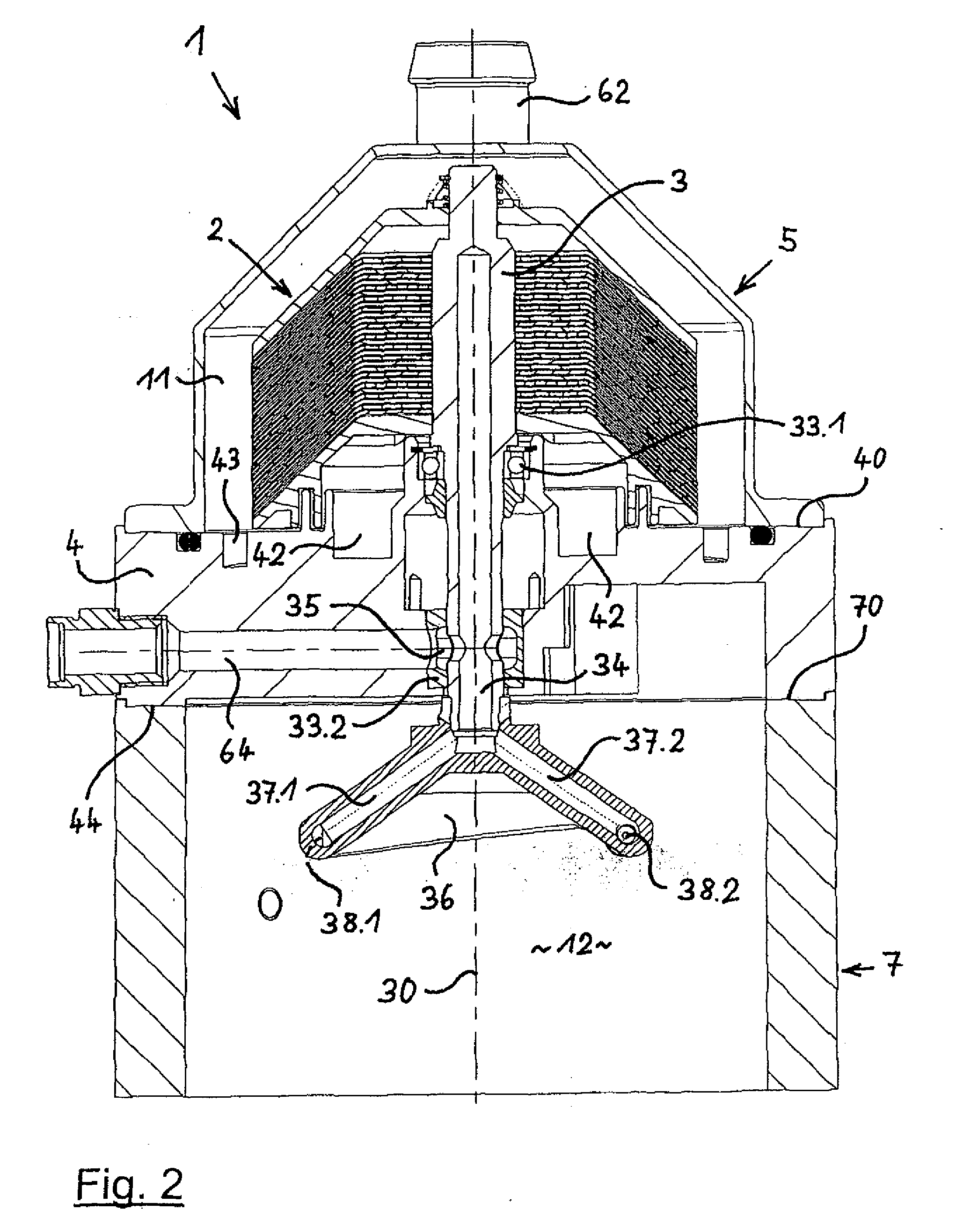

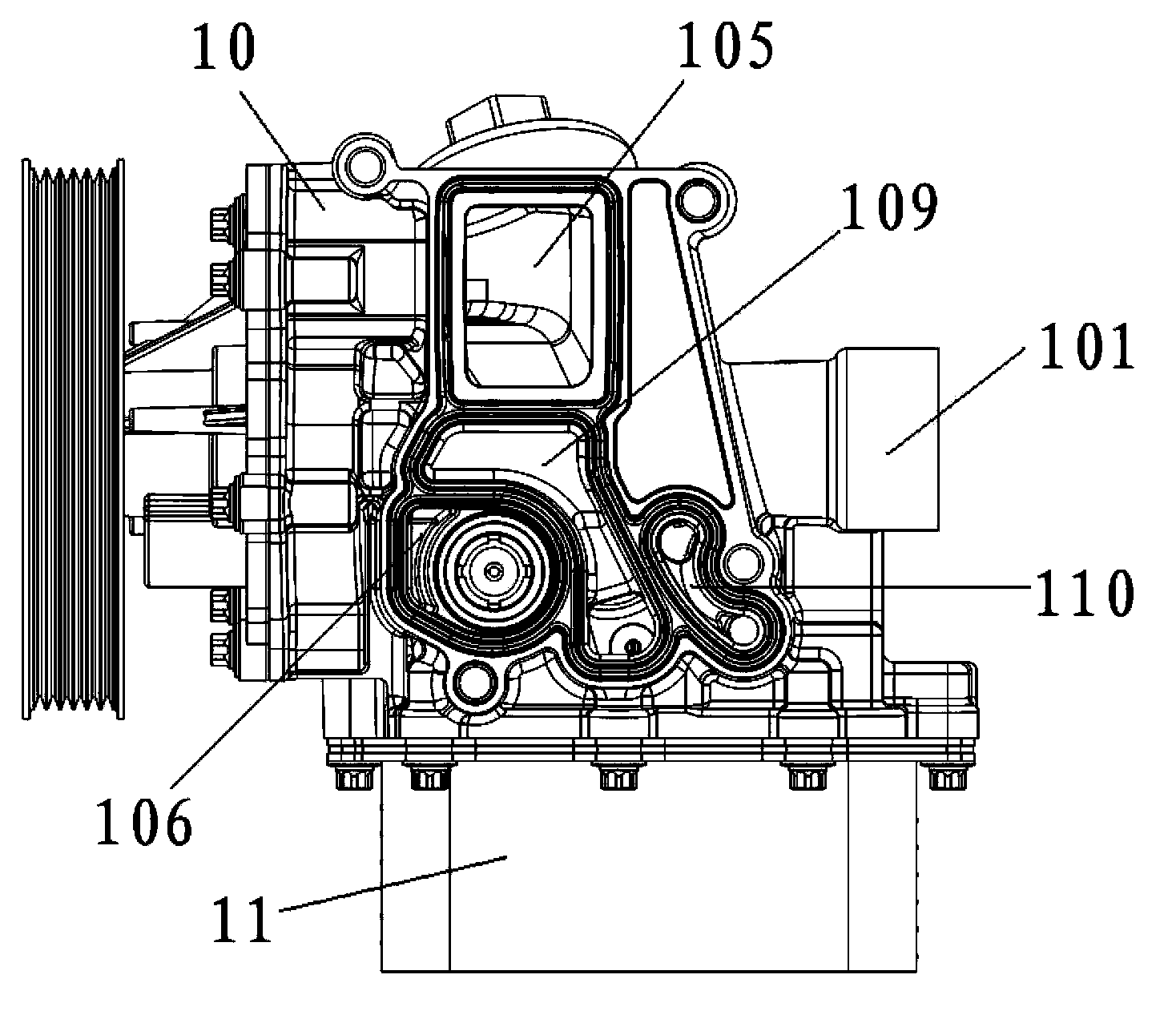

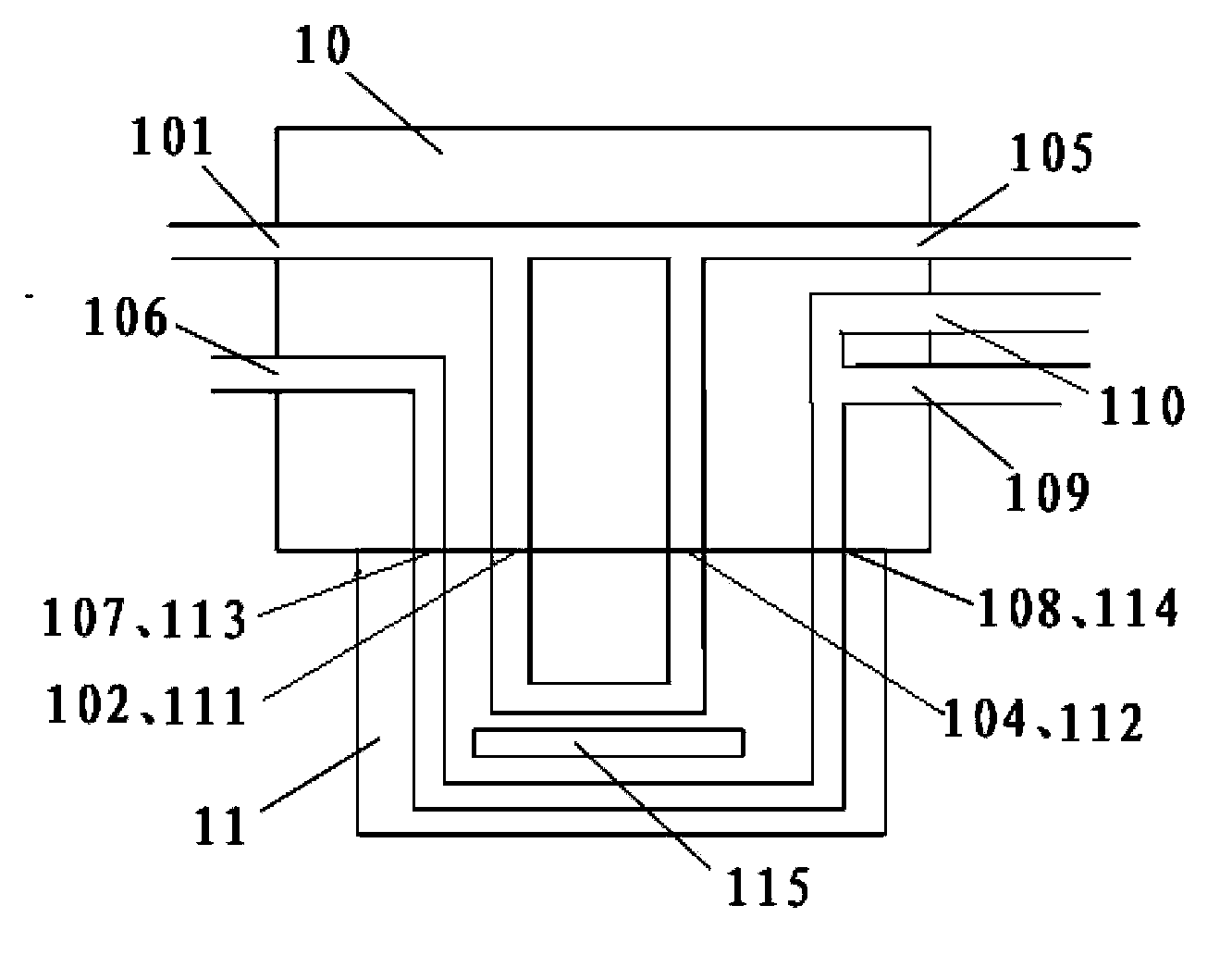

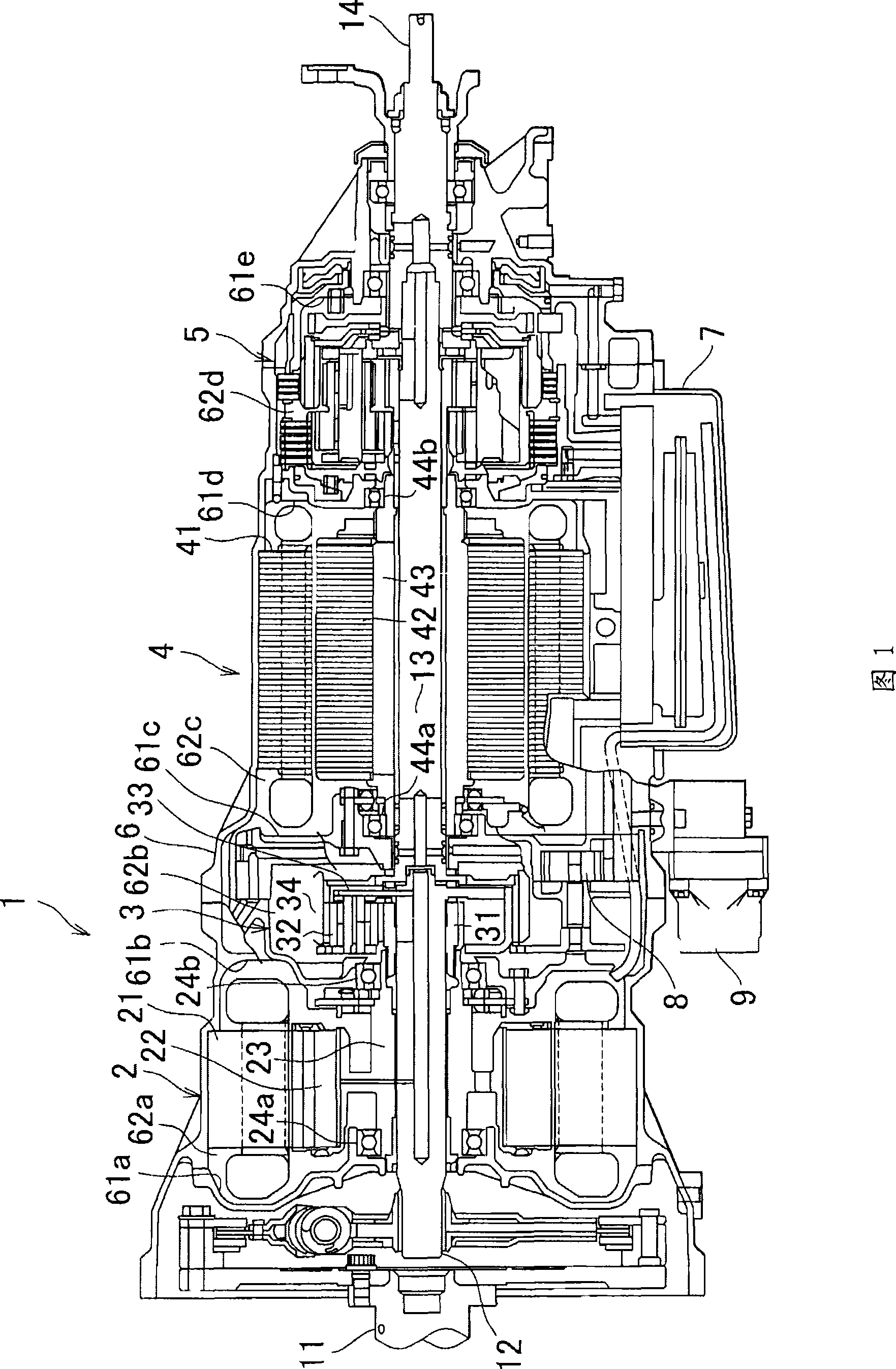

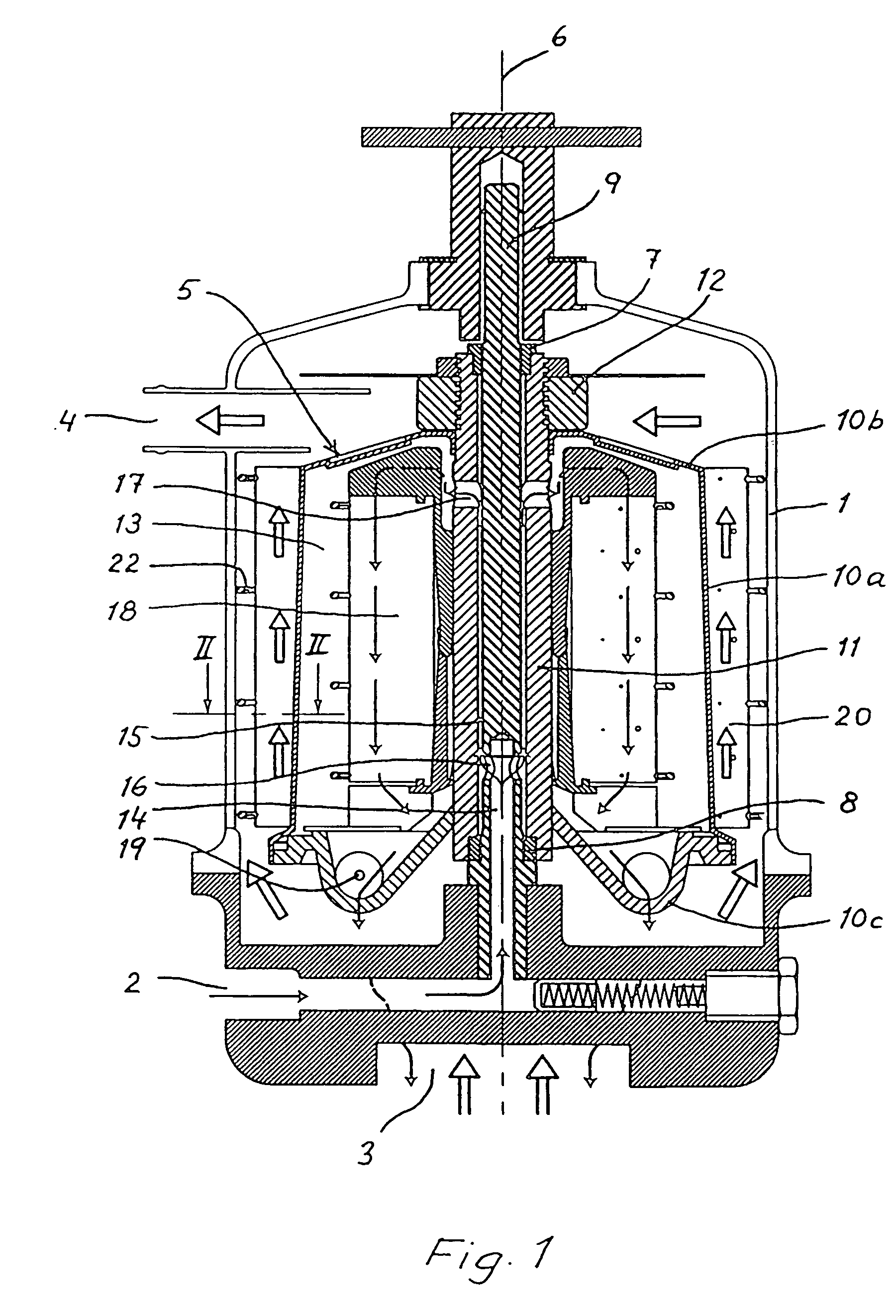

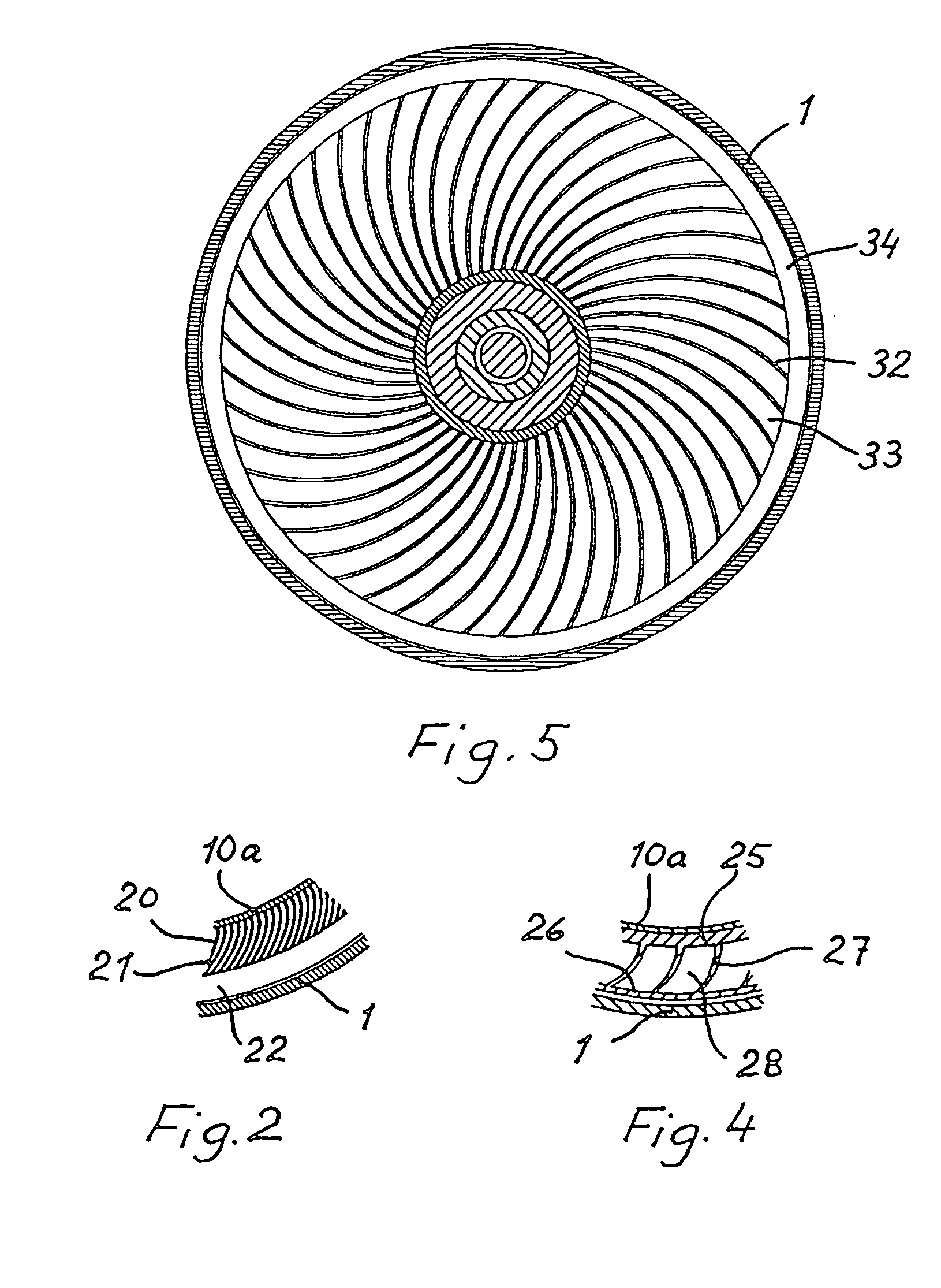

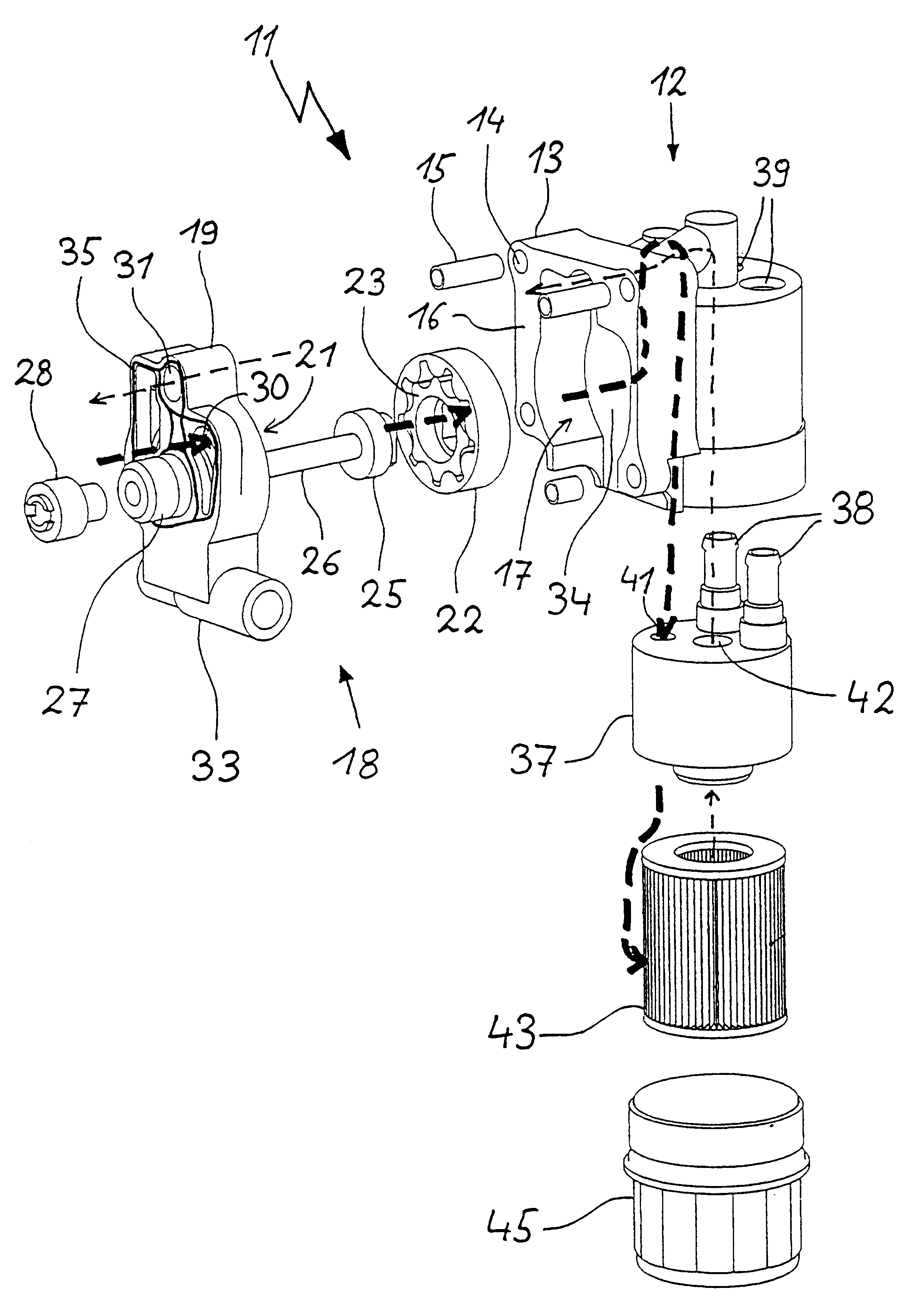

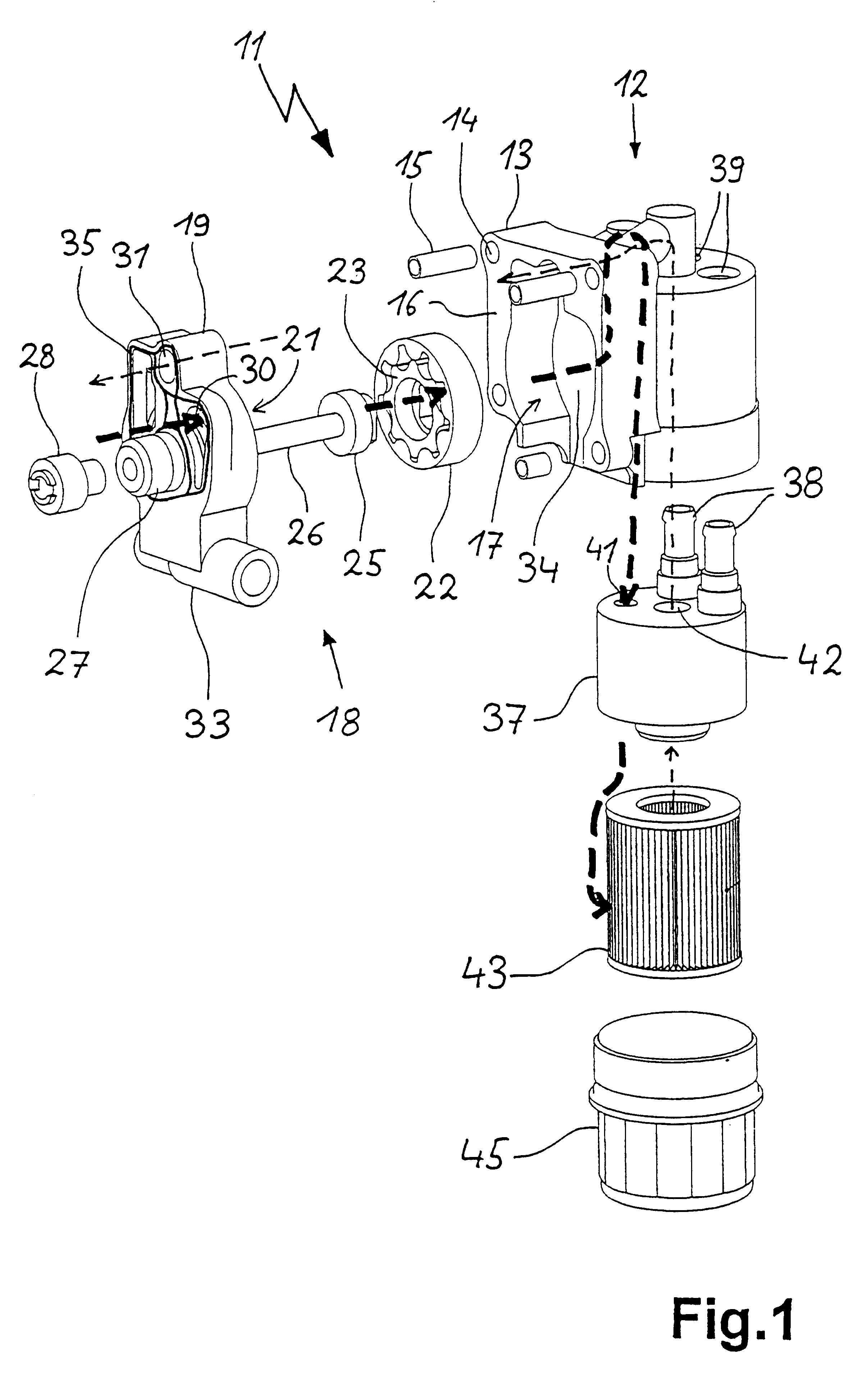

Oil pump module with filter in particular for internal combustion engine lubricating oil

InactiveUS6267094B1Sufficient integrationEasy to installCombustion enginesPressure lubrication with lubrication pumpExternal combustion engineInternal combustion engine

The invention concerns an oil pump module (11) for assembling in one structural unit, an oil pump (18), an oil cooler (37) and an oil filter (43). Said module has a base element (12) capable of being produced in the form of a plastic housing. An oil pump (18) is inserted from one side and, from the other side, an oil cooler (37) and an oil filter (43). Moreover, the oil pump (18) is sealingly pressed, by the base element (12), against an internal combustion engine frame, so as to be driven by said engine. The invention enables to obtain not only a particularly compact and light oil pump module (11), but also an entire pre-assembled unit, with complete module control at the supplier's.

Owner:MANN HUMMEL GMBH

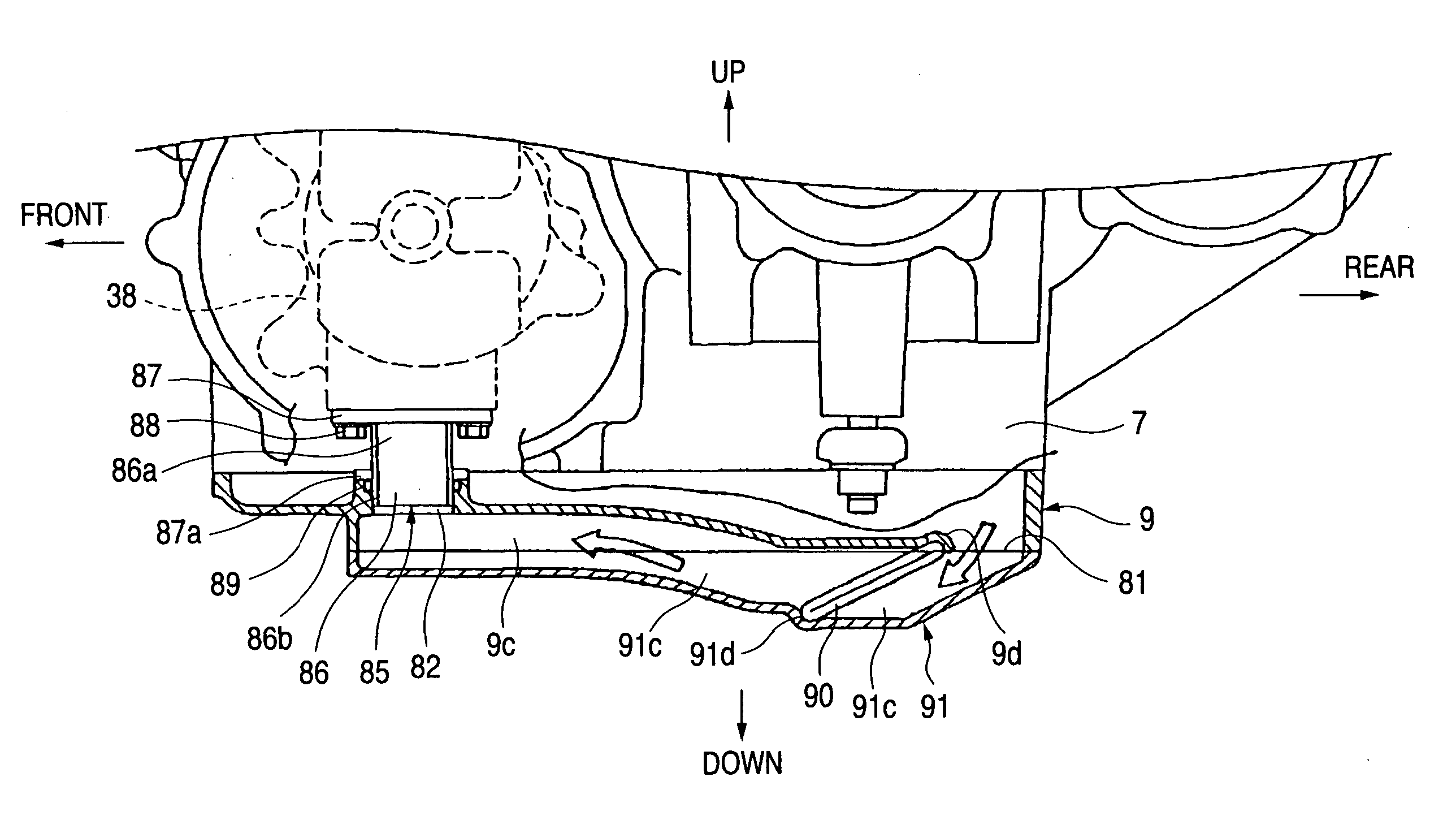

Oil pan structure for four-cycle engine

InactiveUS20040084250A1Reduce the overall heightSimple configurationCasingsOilsumpsCrankcaseLubrication

An oil pan structure for a four-cycle engine, in which oil stored in an oil pan is sucked up by an oil pump through an oil strainer and in which oil lubrication is performed by supplying the sucked oil again to each of parts of the engine to be lubricated. In this oil pan structure, a bottom portion of the oil pan is formed nearly like a bowl by being swelled to a side, which is opposite to a crankcase, from an attaching peripheral portion, to which a crankcase lower-part is attached, toward a central portion thereof. An oil pan cover covering a part of the bottom portion is separately provided thereon. Oil passages and are formed from the oil pan cover and the bottom portion. An oil introduction opening portion and an oil suction opening portion 82 are formed in the bottom portion.

Owner:SUZUKI MOTOR CORP

Two piece elastomer relief and anti-drain back valves for filter

InactiveUS20050161378A1Reduce in quantityEliminate the problemSettling tanks feed/dischargeEqualizing valvesElastomerDifferential pressure

Owner:PUROLATOR ADVANCED FILTRATION

Liquid filter construction and methods

Liquid filter constructions include a baffle plate secured to a can, by way of laser welding. A filter element is operably oriented within the interior of the can. The filter element includes a first end cap and a media pack secured to the first end cap. In some embodiments, the first end cap radially abuts an outer, annular surface of a tubular member of the baffle plate to form a radially directed seal between the first end cap and the tubular member. Liquid filter constructions of this type have a burst strength between 500-800 psi (about 3.4-5.5 MPa), along a longitudinal section of the can wall. Constructions of this type eliminate a roll or lock seam, an inner gasket, an inner compressive spring, and a gasket retainer. Systems for using liquid filters are described herein. Methods of constructing and using these types of filter arrangements are also described.

Owner:DONALDSON CO INC

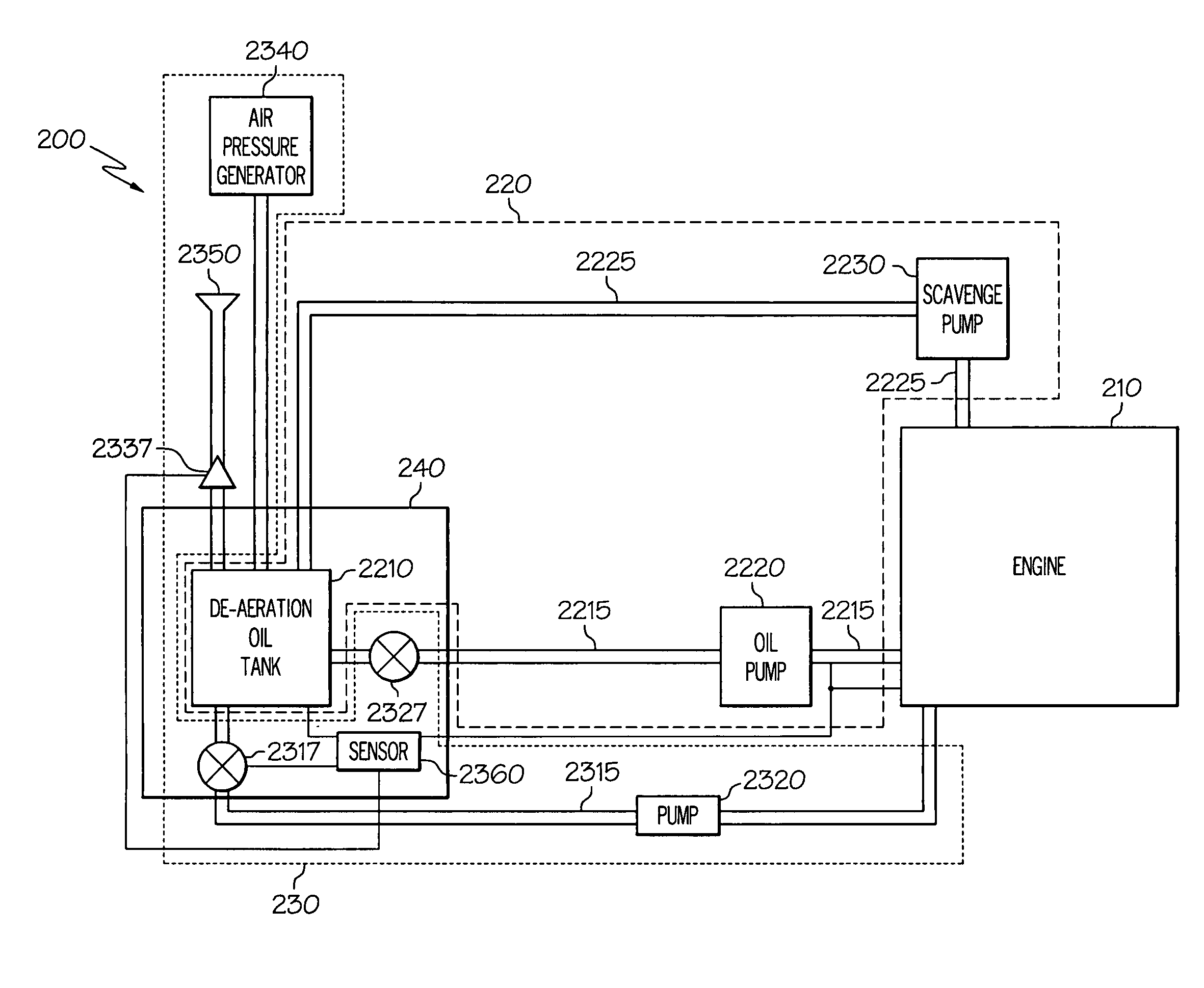

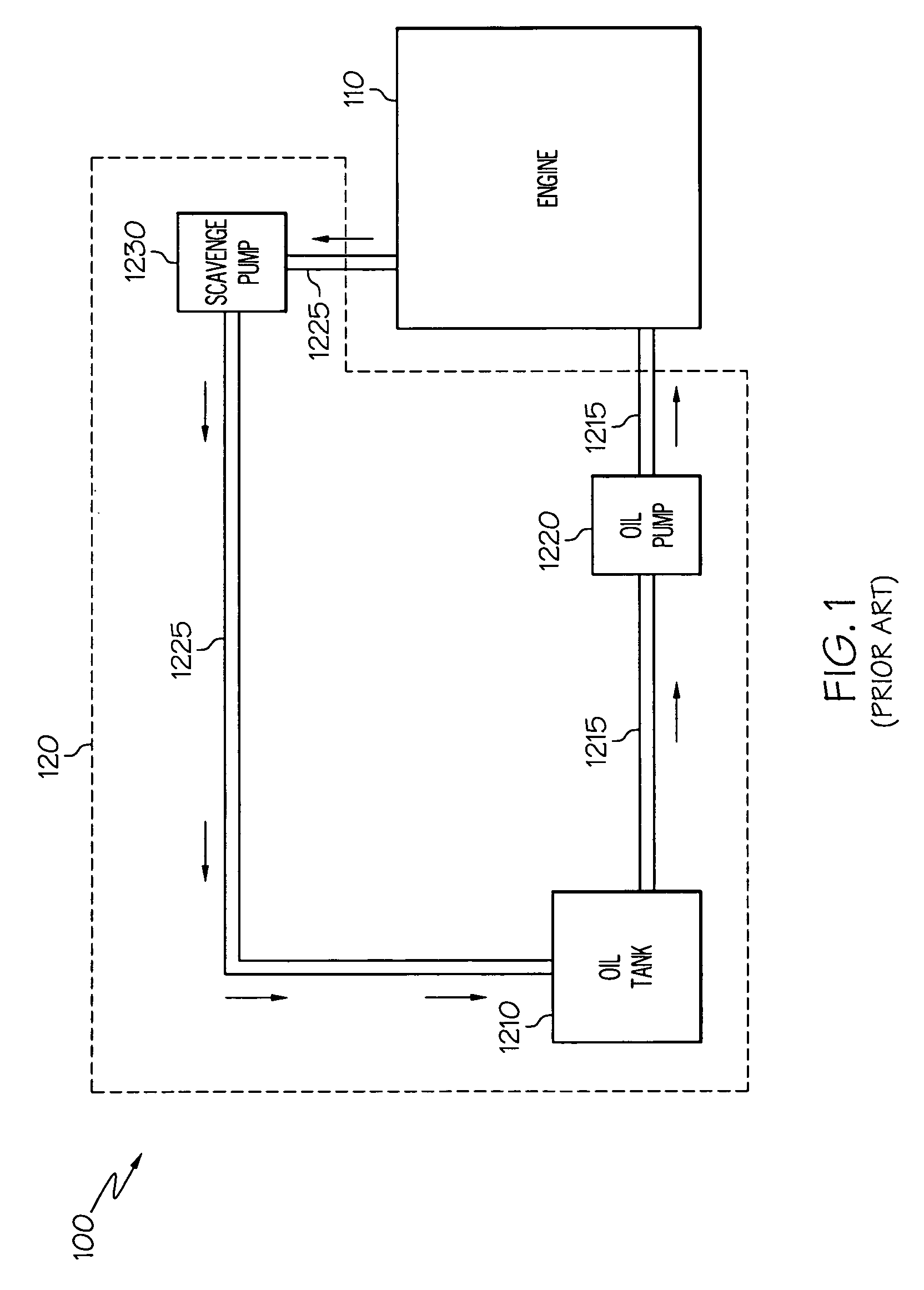

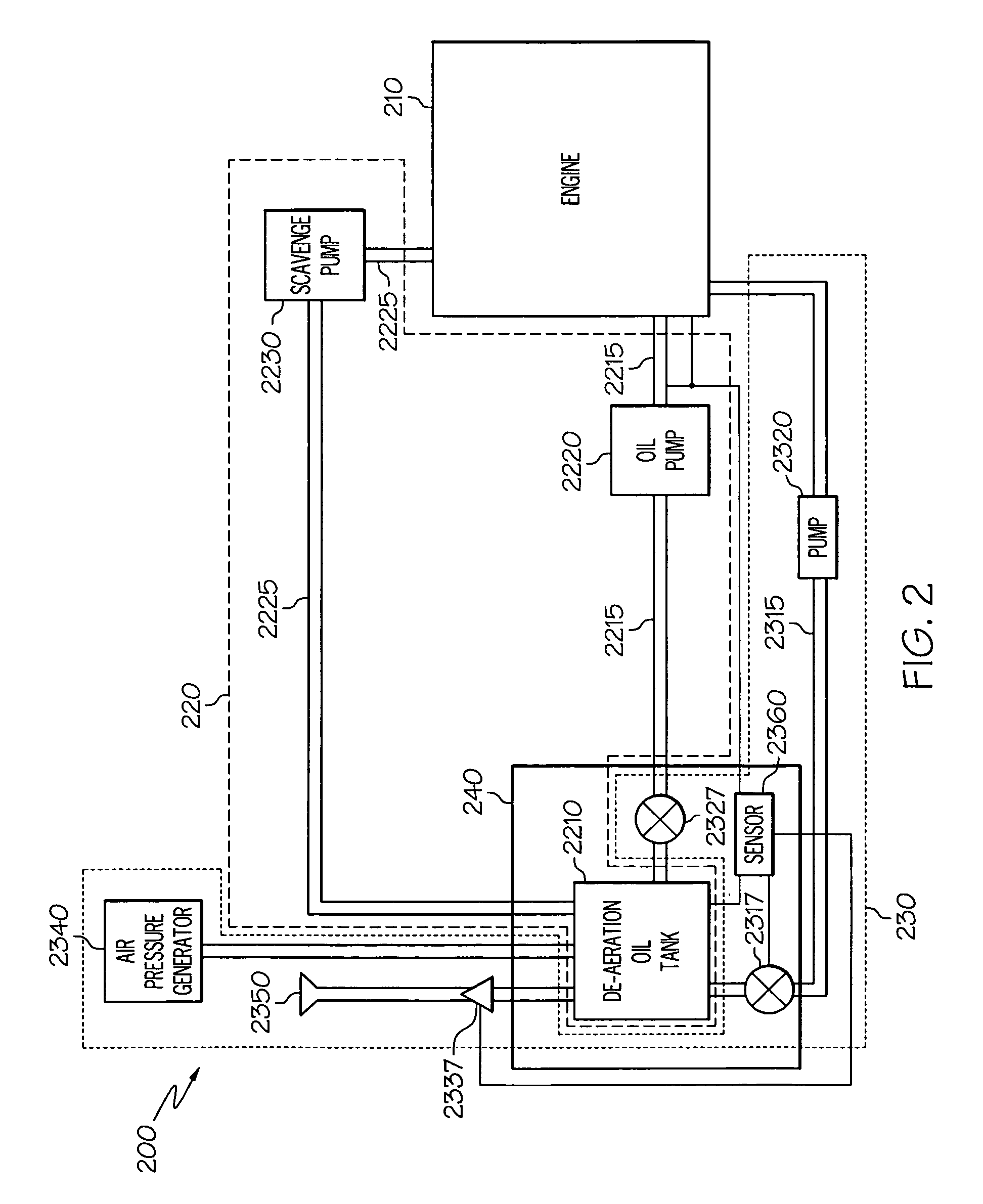

Emergency engine lubrication systems and methods

Emergency lubrication systems and methods for an engine are provided. One system includes a primary lubrication system including a de-aeration oil tank configured to store de-aerated oil until the oil is de-aerated, a first oil supply line configured to provide de-aerated oil to the engine, and a first valve configured to control the flow of oil through the primary lubrication system. The system further includes a secondary lubrication system including a second valve coupled to the de-aeration oil tank and configured to control the flow of oil through the secondary lubrication system, and a second oil supply line coupled to the engine and to the de-aeration oil tank via the second valve. One method includes the steps of detecting a predetermined event in the engine, preventing the aerated oil from entering the primary lubrication system, and using the aerated oil in the secondary lubrication system to lubricate the engine.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com