Environmentally friendly acid neutralizing full flow cartridge

a technology of acid neutralizing and full-flow cartridges, which is applied in the direction of lubricant mounting/connection, separation process, filtration separation, etc., can solve the problems of corroding wear of the diesel engine wear component affecting the life of the engine, and more than 70% of heavy-duty diesel engine wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

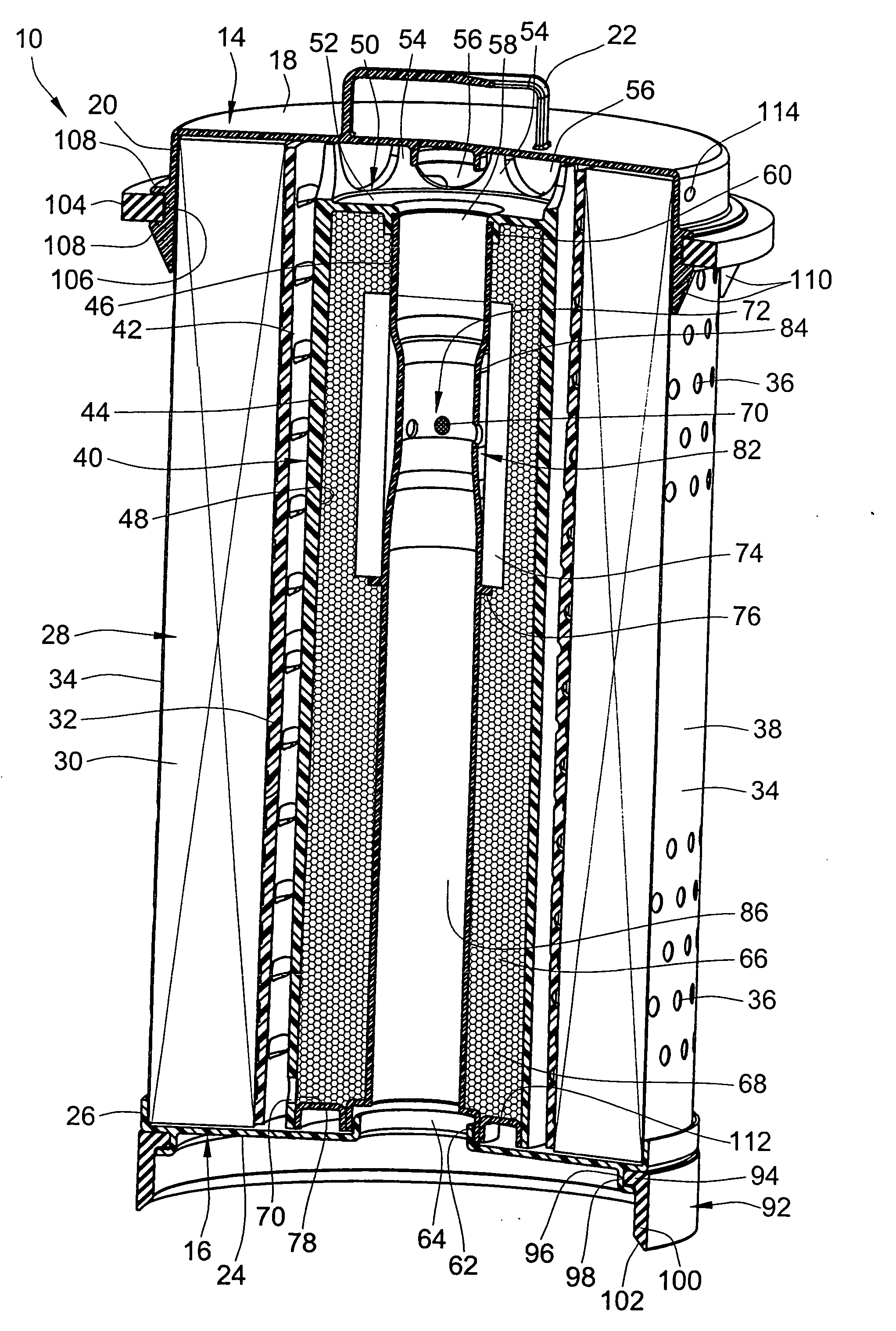

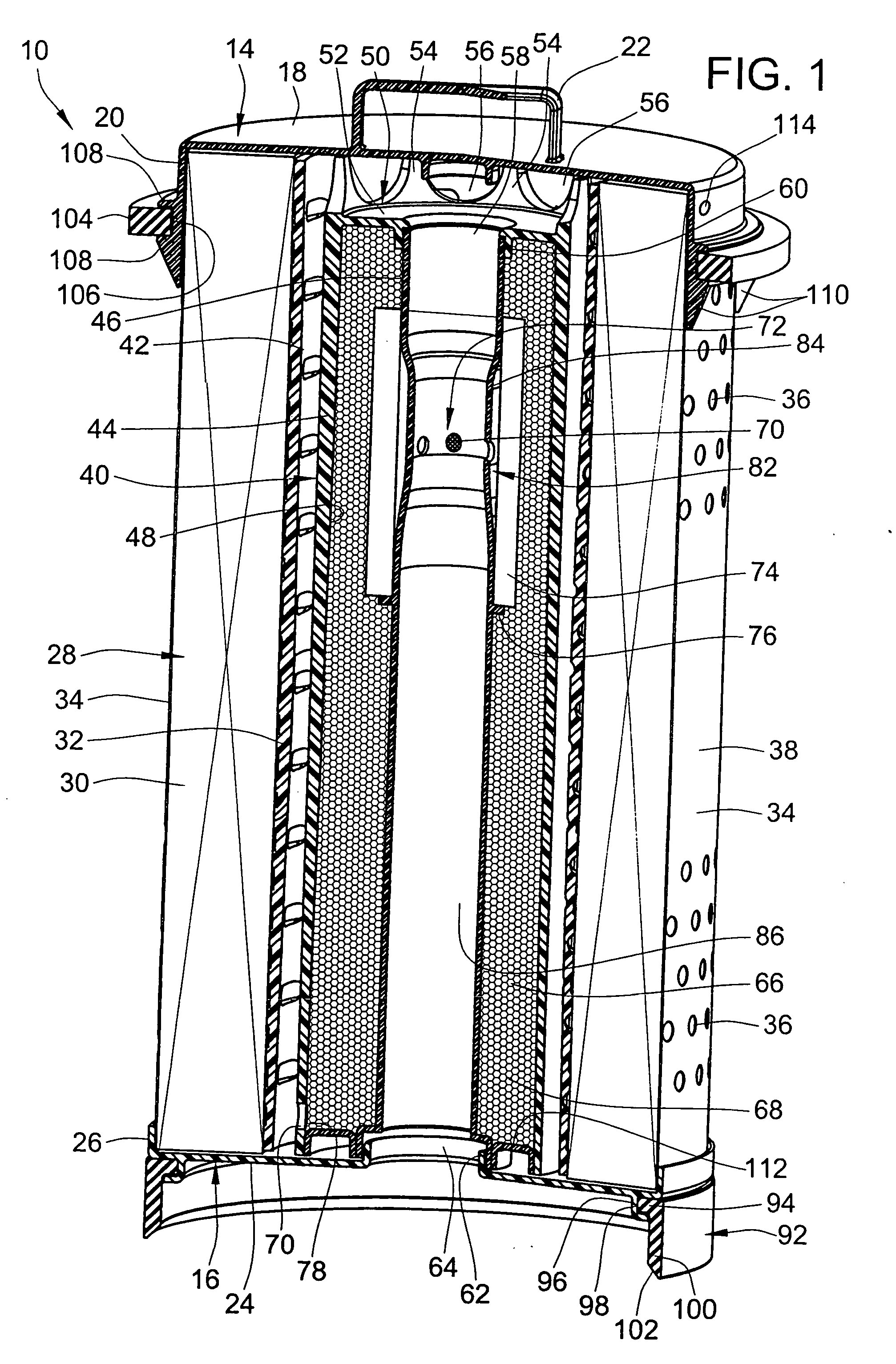

[0021] Referring to FIG. 1, an environmentally friendly acid neutralizing full flow filter cartridge 10 is illustrated in accordance with a preferred embodiment of the present invention. The filter cartridge 10 is adapted to be installed in a suitable cartridge mounting body 12 that may be positioned along an engine oil circuit that will be later described.

[0022] Referring to the filter cartridge shown in FIG. 1, the support housing or structural components for the filter cartridge are made with substantially no metal support parts such that the filter cartridge can be more completely incinerated for relatively complete disposal of spent filter cartridges. The filter cartridge 10 includes top and bottom end caps 14, 16 that are made of non-metallic material such as injection molded plastic or other suitable non-metallic material. The top end cap includes a plate or cover portion 18 and a downwardly depending radial skirt 20. Preferably a handle 22 is integrally provided along the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| corrosive wear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com