Patents

Literature

258results about How to "Reduce investment and operating costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

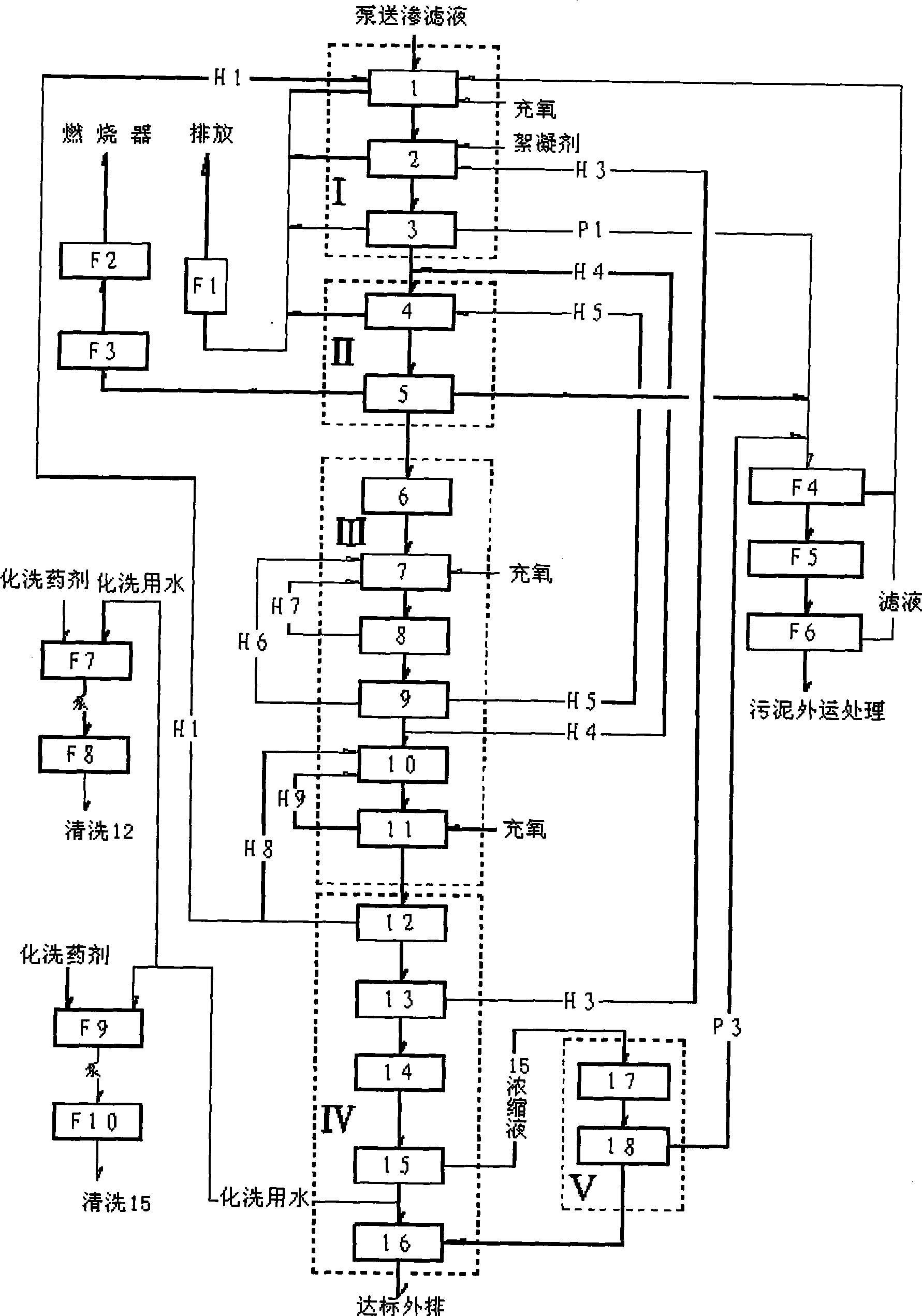

Treatment process for garbage leachate

ActiveCN101428938AImprove biodegradabilityPrevent rancidityTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationHydrolysis

The invention discloses a method for treating landfill leachate, which orderly comprises flocculation precipitation pretreatment, hydrolysis pre-acidification treatment, anaerobic treatment, aerobic treatment comprising shortcut nitrification-denitrification and secondary nitrification-denitrification, membrane separation treatment and oxidation flocculation treatment. The method has the advantages of having higher removal rate of ammonia nitrogen and lower energy consumption, realizing the up-to-standard discharge of leachate concentrated solution, ensuring sound operation of the whole system, greatly lowering the oxidation-reduction potential in the anaerobic reaction, and improving the anaerobic treatment effect, thereby making the landfill leachate fully meet the first-level discharge standard of the Integrated Wastewater Discharge Standard.

Owner:浙江永峰环保科技股份有限公司 +1

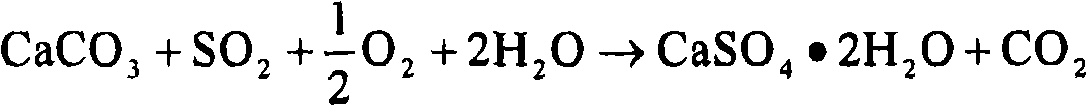

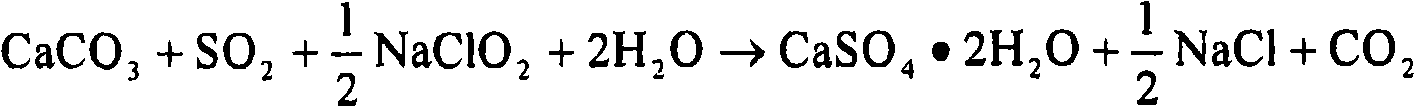

Mercury removal for smoke desulfurizing system by fortified wetting method

InactiveCN1895745AEnhance mercury removal abilityReduce investment and operating costsDispersed particle separationIonCoal

A process for intensifying the Hg removing action of a wet fume desulfurizing system includes such steps as spraying chemical oxidant into the fume generated by burning coal, gas-phase (or catalytic) oxidizing reaction to oxidize Hg, absorbing the mercury oxide along with the 2-valence Hg in the fume by desufurizing liquid, adding the S-contained chemical additive to said desulfurizing liquid, and converting the Hg ions in desulfurizing liquid to stable Hg compound.

Owner:SHANGHAI JIAO TONG UNIV +1

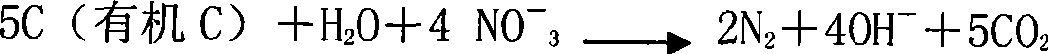

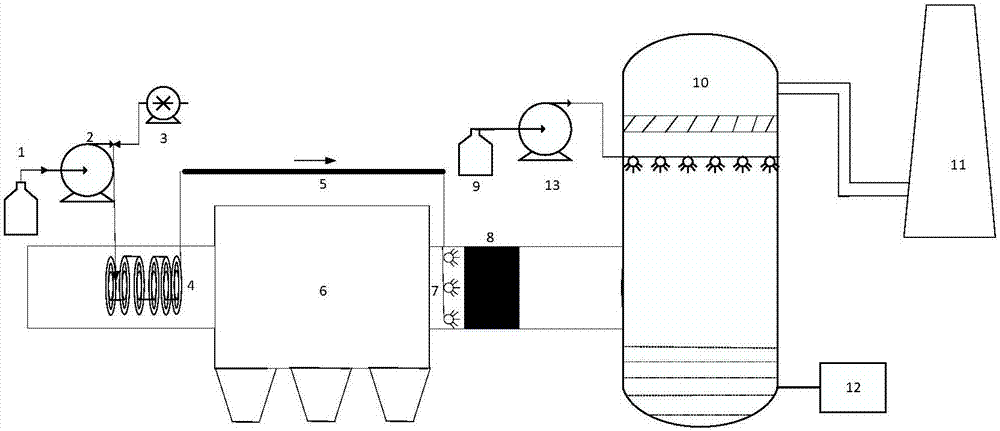

Two-stage drying and incineration method for sludge

InactiveCN103090396AStrong degree of harmlessnessReduce volumeSludge treatment by de-watering/drying/thickeningIncinerator apparatusEnvironmental resistanceFlue gas

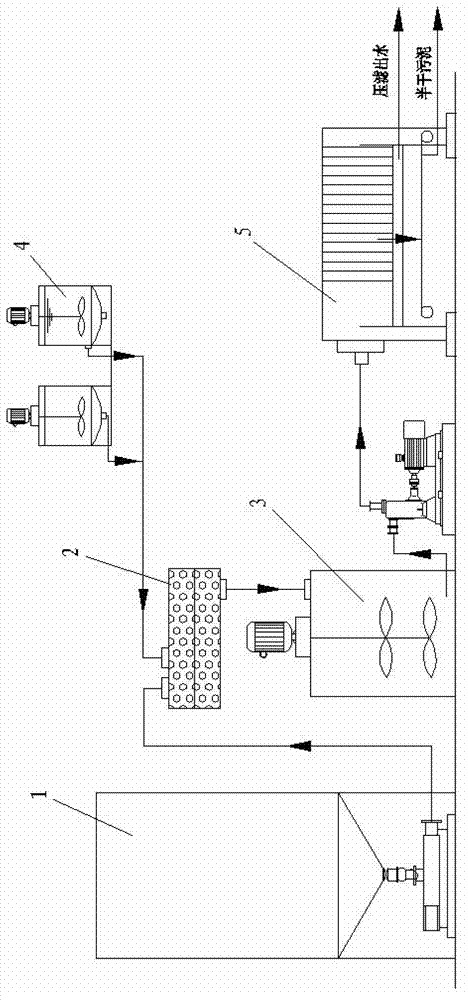

The invention discloses a two-stage drying and incineration method for sludge. The method comprises the following steps of: modifying and drying, namely adding a prepared modifier into a stirrer through an adding device, mixing the sludge and the modifier uniformly, then delivering the sludge into a modification mechanism, performing modification conditioning, delivering the sludge to a filter pressing system, performing deep dehydration, and reducing the water content of the modified and dried sludge to be 45 to 60 percent; drying with steam, namely reducing the water content of the dried sludge to be 35 percent; and incinerating the sludge and purifying flue gas. By adopting 'two-stage' drying and incineration, any auxiliary fuel is not required; the technology is advanced, the land occupation is low, and the investment cost and the operating cost are low; the volume of the sludge is minimized by incineration, and the reduction degree is highest; pathogens are killed at the high temperature of more than 850 DEG C, and the harmless degree is highest; the sludge incineration speed is high, and secondary pollution when the sludge is stored is avoided; and excellent environment-friendly performance is realized, and the incinerated ash can be recycled.

Owner:上海金自天正信息技术有限公司

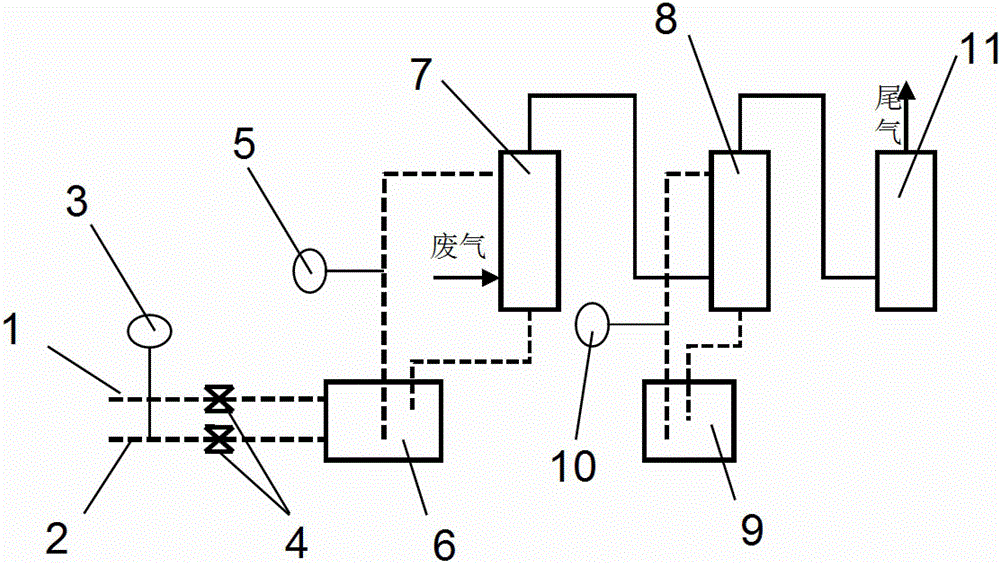

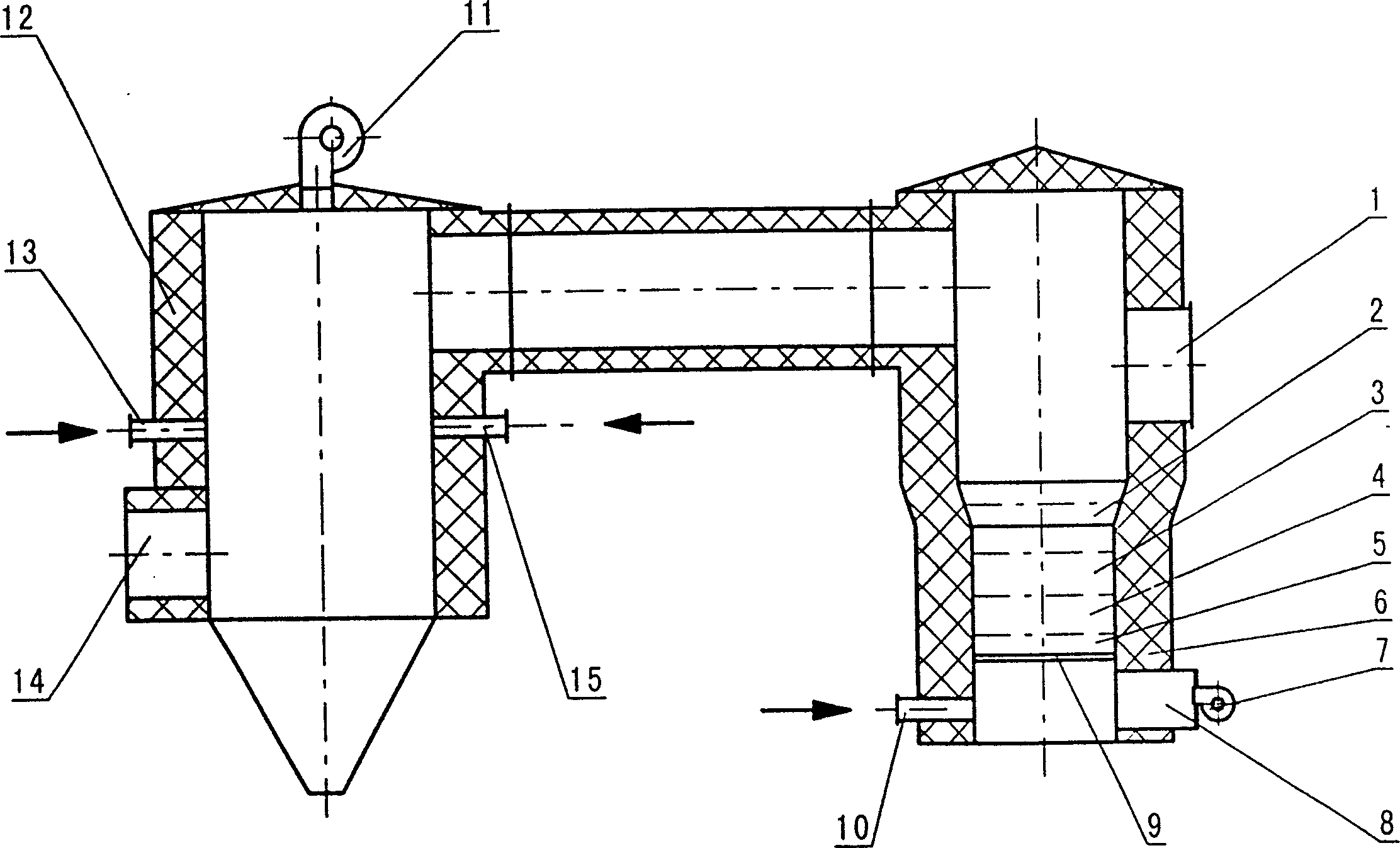

Integrative coordinated desulfurization, denitration, demercuration device and technique using spray bubbling method

ActiveCN101306322AReduce investment and operating costsSmall footprintDispersed particle separationInlet channelFlue gas

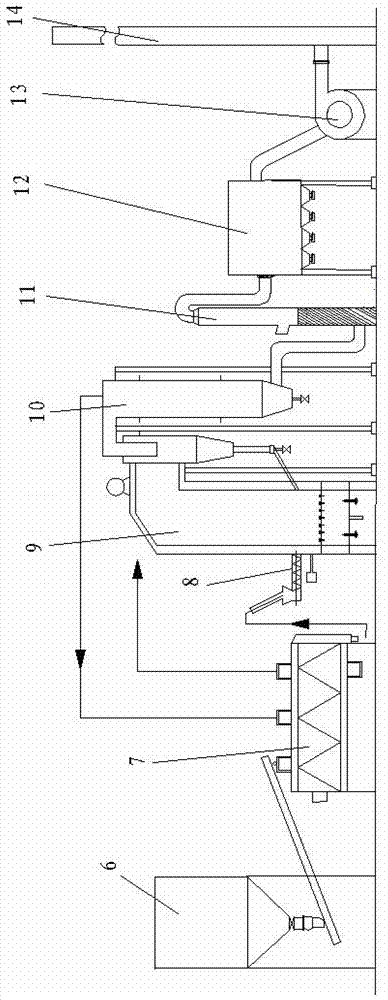

The invention relates to an integrated synergistic desulphurization, denitrification and demercuration device used for flue gas and a process for carrying out integrated synergistic desulphurization, denitrification and demercuration of the flue gas by using the device. The device comprises an original flue gas chamber (11), a tower body (6), a flue gas partition plate (8) and a bubbling jet pipe 5; wherein, the original flue gas chamber is fixed above the flue gas partition plate; the flue gas partition plate is fixed above the tower body; the three parts of the original flue gas chamber, the flue gas partition plate and the tower body are connected by an upper flange (12) and a lower flange (14); the upper end part of the bubbling jet pipe (5) is connected with the flue gas partition plate; the jet pipe communicates with the original flue gas chamber; an original flue gas inlet channel (10) is arranged outside the original flue gas chamber; and a purified flue gas outlet channel (15), a slurry discharge pipe (16), an oxidation wind pipe (1), a slurry return pipe (3) and a slurry adding pipe (4) are arranged outside the tower body.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

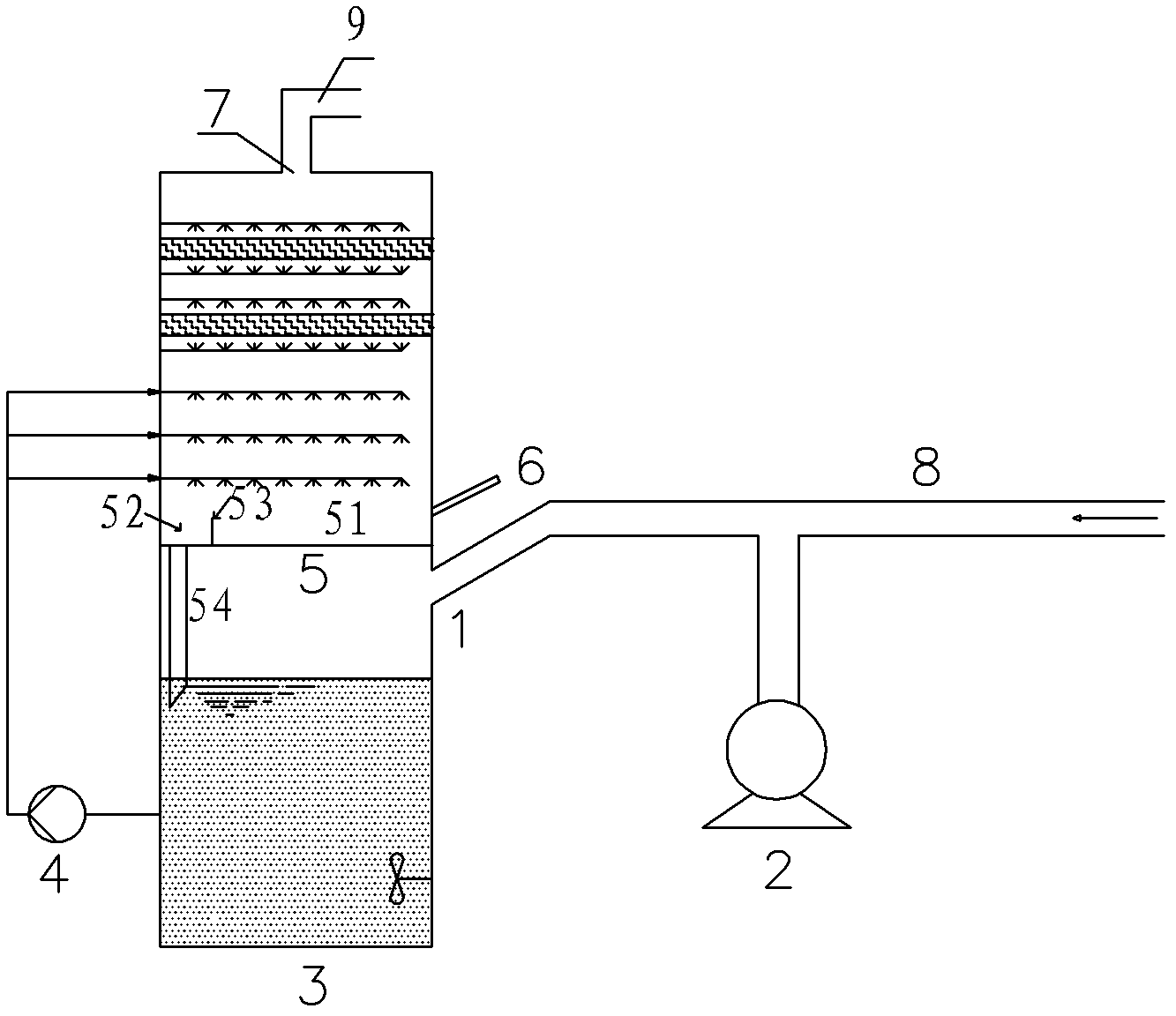

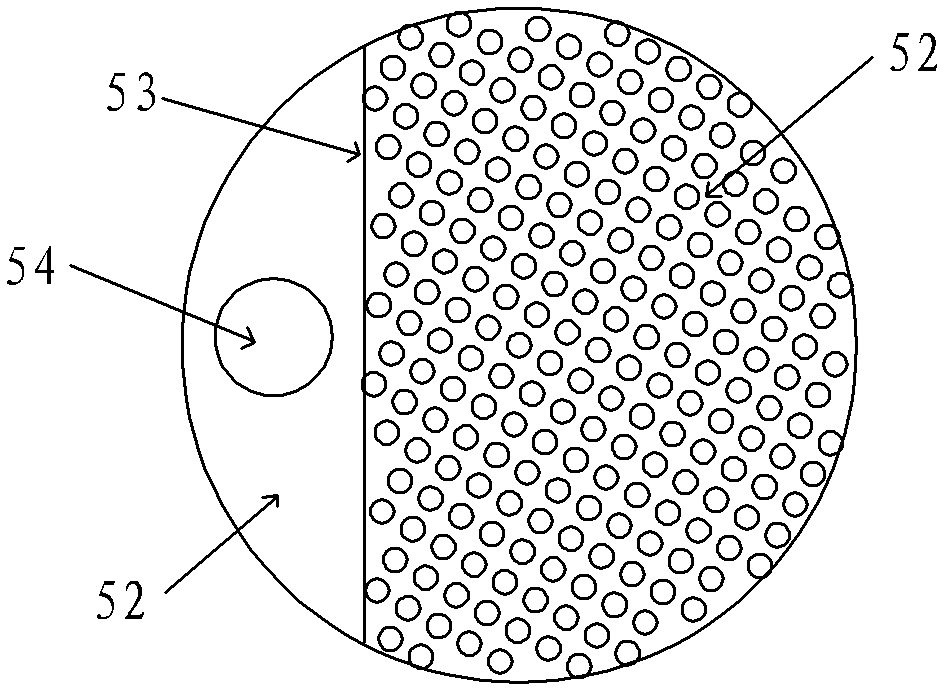

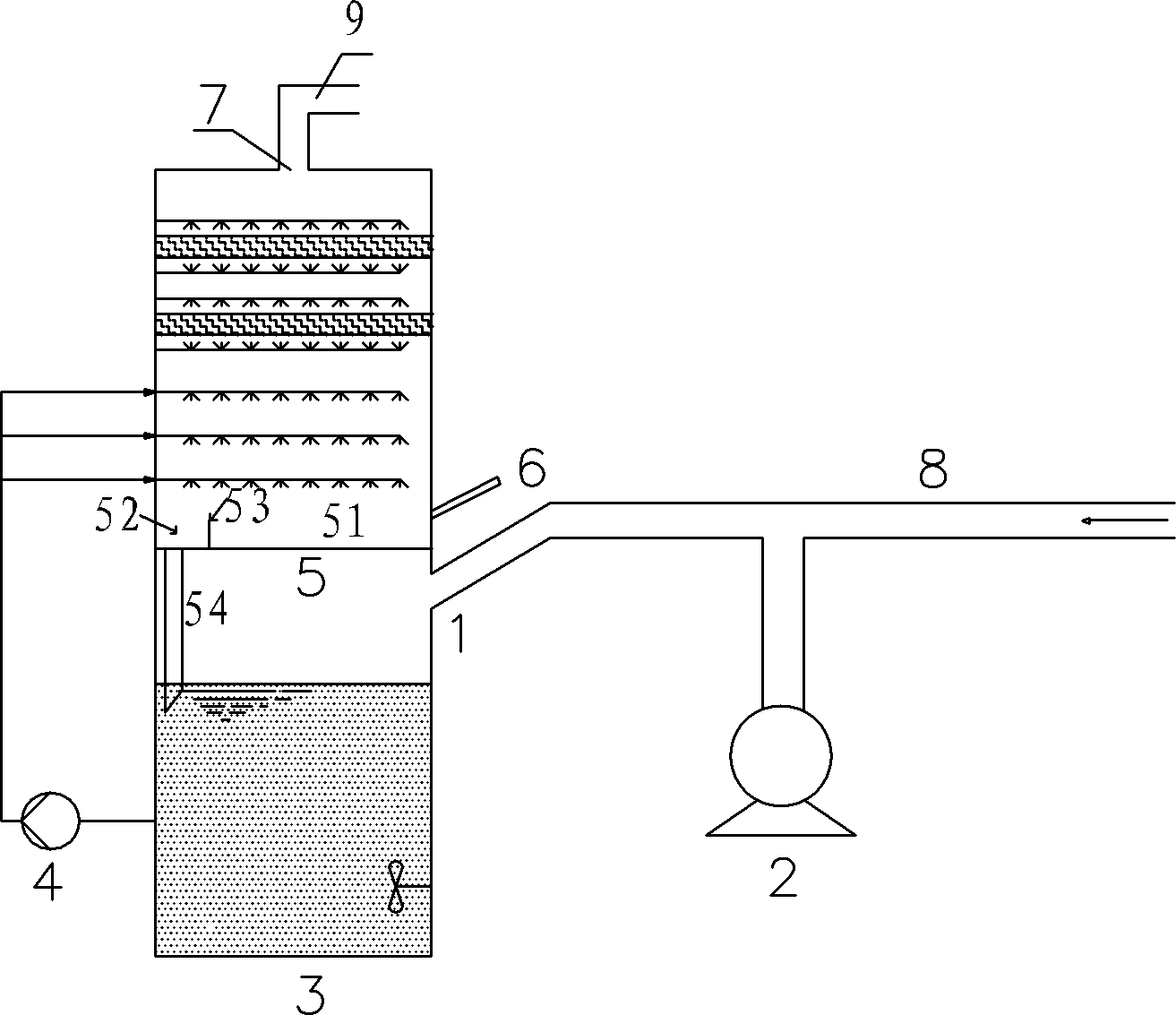

Processing method for malodorous gas of chemical area sewage plant

InactiveCN104001413AHigh and stable processing effectEasy to operateDispersed particle separationSorbentBiological filter

The invention discloses a processing method for a malodorous gas of a chemical area sewage plant, and particularly relates to a chemical absorption-biological oxidation-absorption combined processing method. The malodorous gas enters a chemical washing tower, is subjected to absorption, oxidation and humidification in the washing tower, then enters a biological filter tower, contacts with microbe inoculated on filler surfaces, then enters an absorption device after being degraded by the microbe, and is discharged after being further purified by an adsorbent. An empty bed residence time of the gas in the biological tower is 10-120 s; and an empty bed residence time of the gas in the absorption device is 0.5-120 s. A nutrition liquid needed by the microbe in the biological filter tower is effluent of a secondary sedimentation tank of a sewage treatment plant or diluted raw water of a buffer and homogenization tank. The chemical absorption-biological oxidation-absorption combined processing method can remove hydrogen sulfide and volatile organic compounds from the malodorous gas of the chemical area sewage plant efficiently and realizes standard discharge. The method has the advantages of simple process flow, simple operations, low investment and operation cost, high processing efficiency and no secondary pollution.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

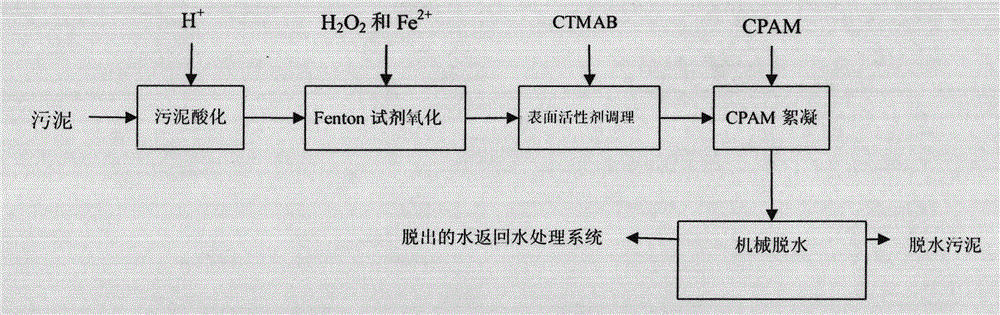

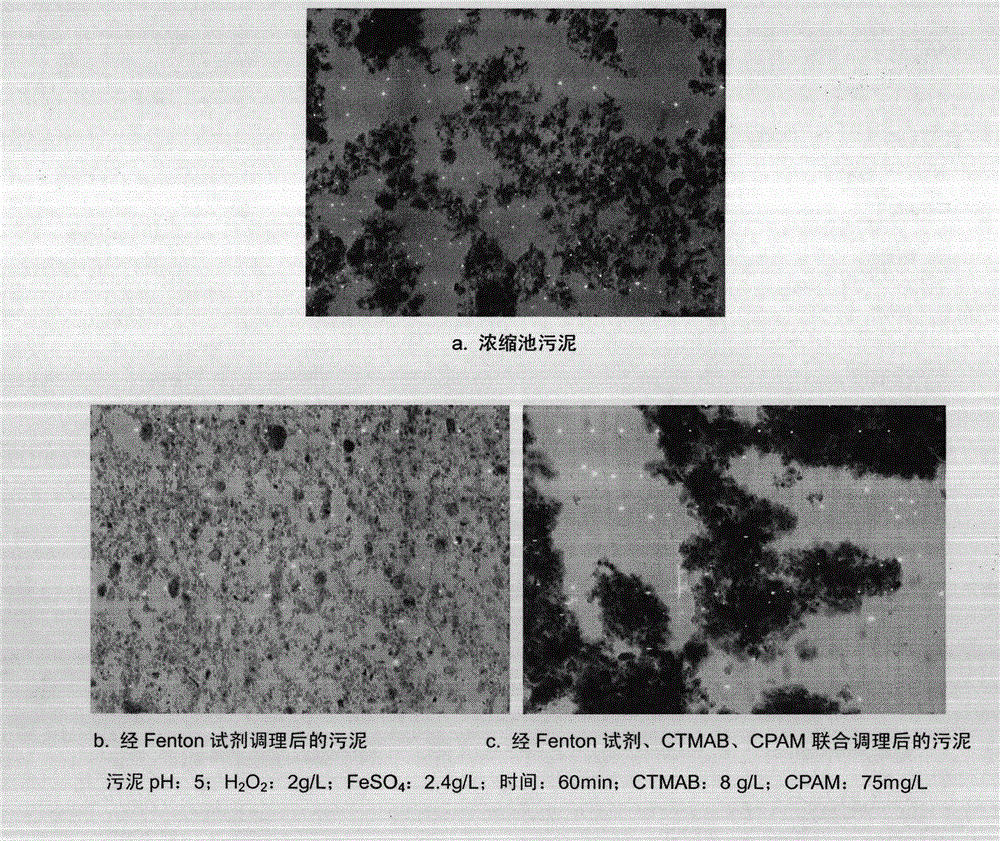

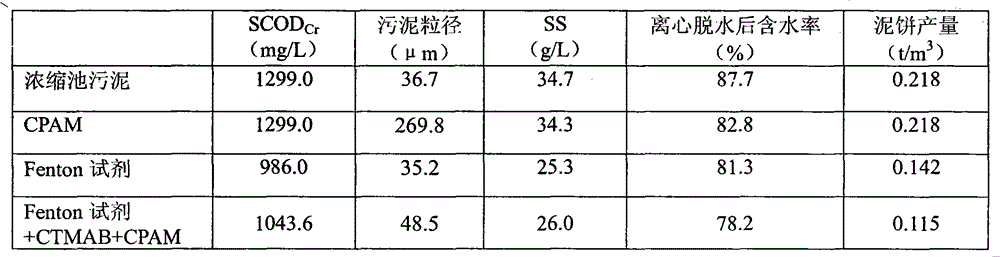

Joint-conditioning dehydration method for sludge

InactiveCN102910793AImprove dehydration effectIncrease solid contentSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationParticulatesFenton reagent

The invention is named as 'a joint-conditioning dehydration method for sludge', belonging to the technical field of environmental engineering and sludge treatment. The joint-conditioning dehydration method comprises the following steps of: adding H202 and FeSO4 into the sludge (with pH being equal to 5) acidified by mineral acid, degrading organic matter by virtue of strong oxidation of a Fenton reagent, and dissolving and cracking microbial cells and extracellular polymeric substances in the sludge; adding a surfactant CTMAB (Cetyl Trimethyl Ammonium Bromide) into the sludge to reduce the surface tension of the sludge and change the surface characteristics of the sludge, and transforming a part of interstitial water into free water; and flocculating sludge particulates with disperse structure, small particle diameter and large specific surface area by virtue of flocculation action of polyacrylamide (CPAM) to the sludge particulates. After the sludge is subjected to joint conditioning of the Fenton reagent, the surfactant and the CPAM, the moisture content of the sludge after being centrifugally dewatered is reduced to 78.2% from 87.7%, and the output of mud cakes is reduced to 0.115t / m<3> from 0.218t / m<3>, therefore, the dehydration property of the sludge can be improved remarkably, the investment and operation costs are reduced effectively, and an ideal sludge reduction goal is reached.

Owner:BEIJING NORMAL UNIVERSITY

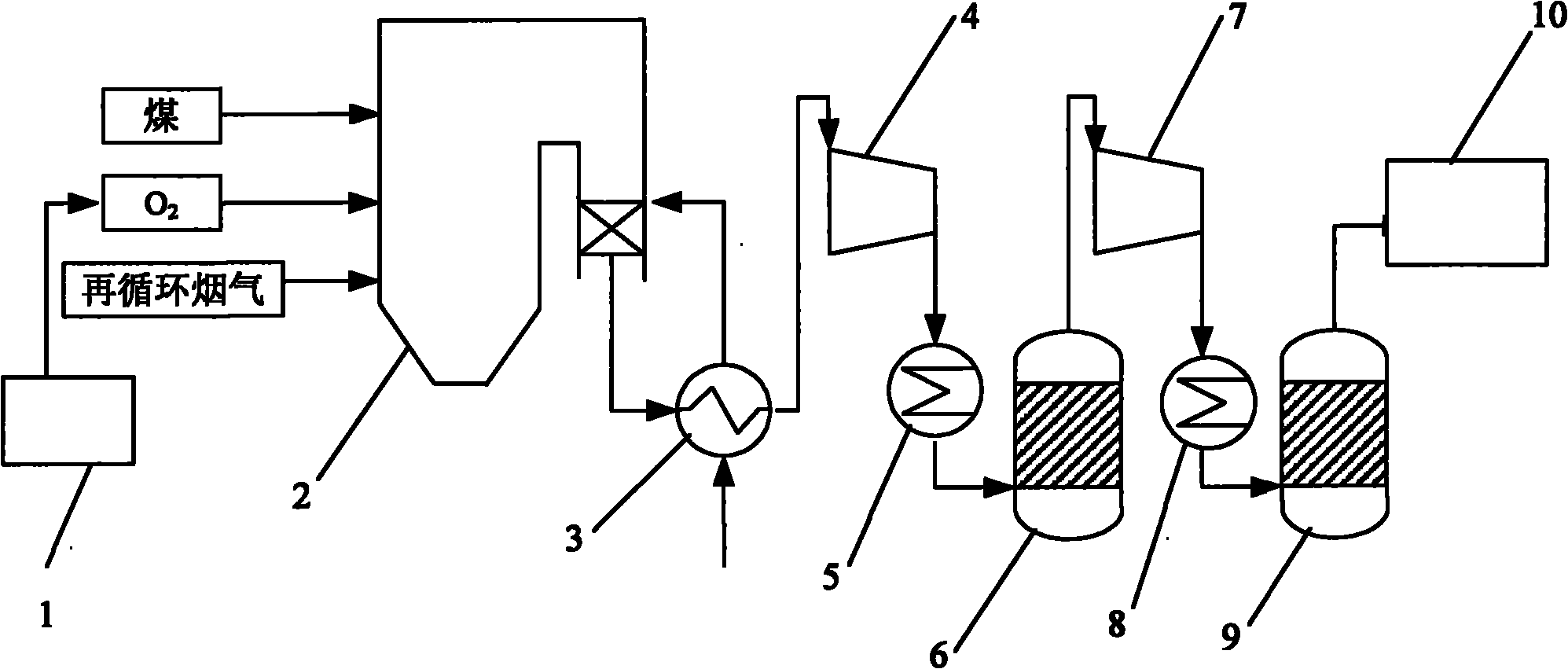

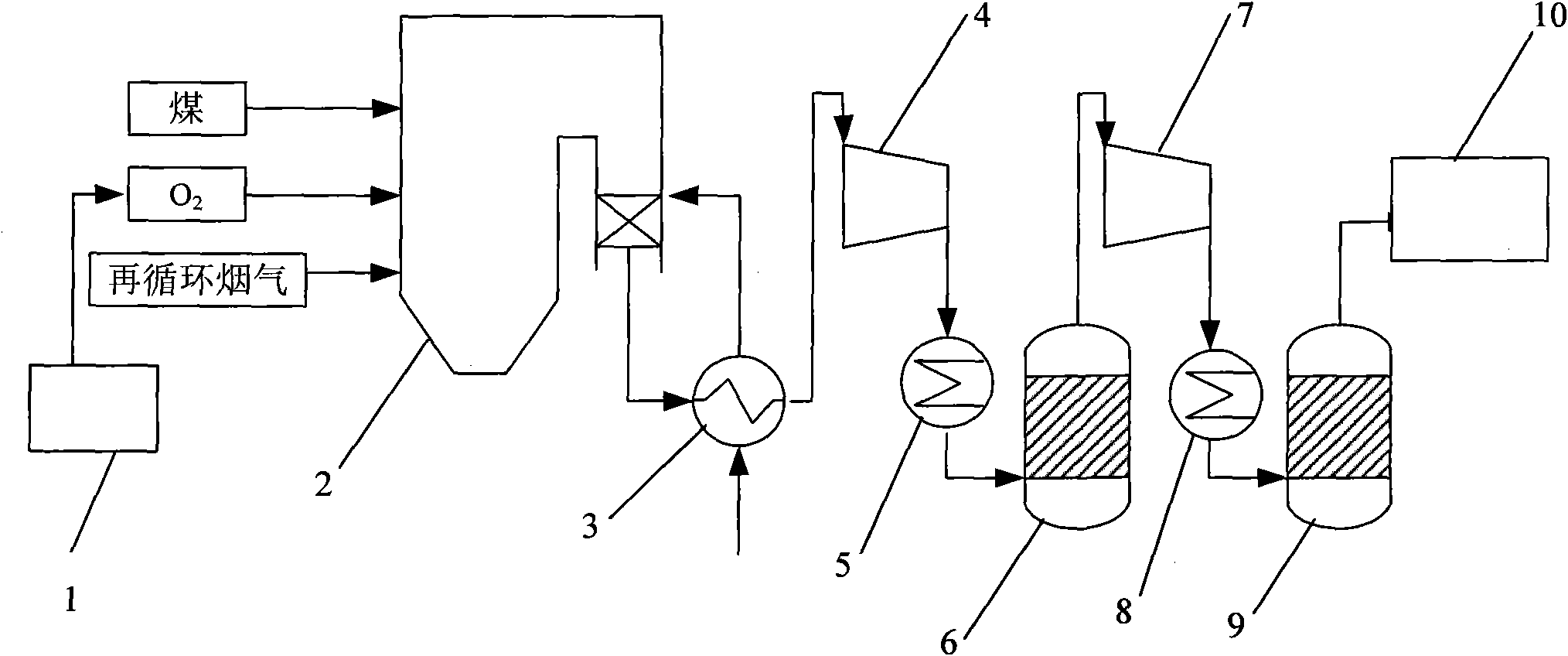

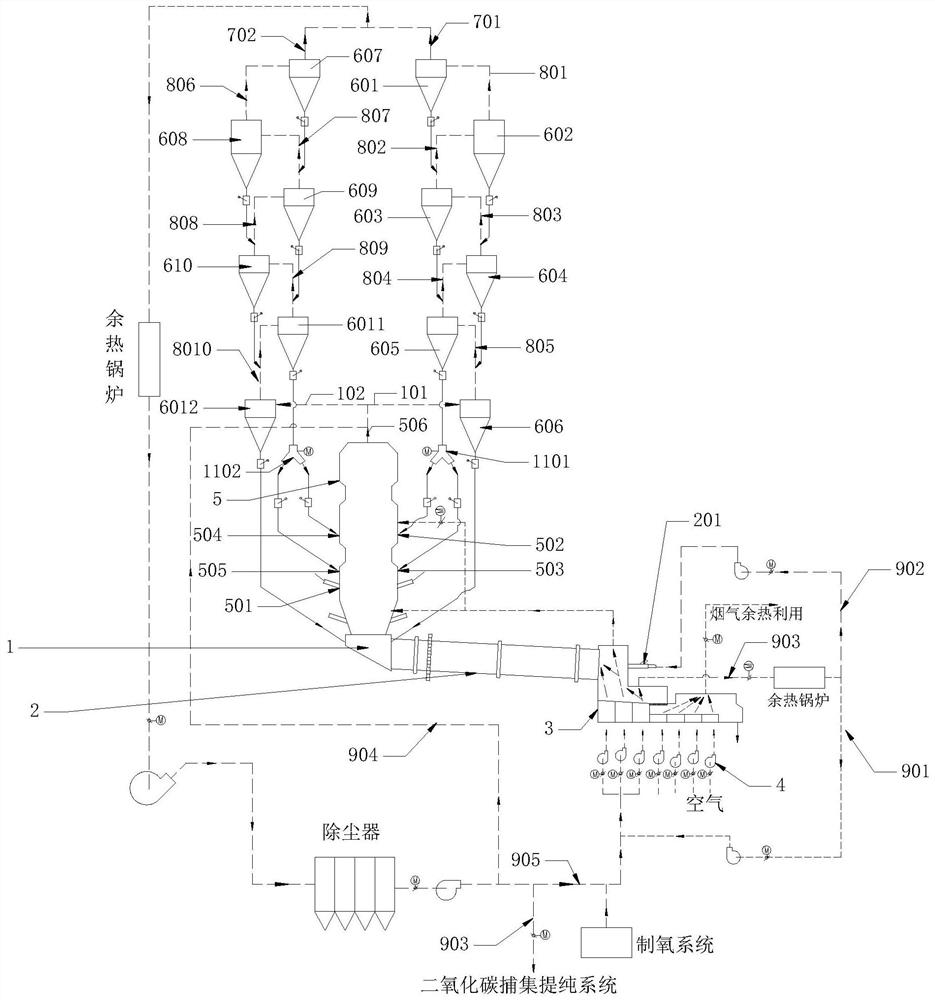

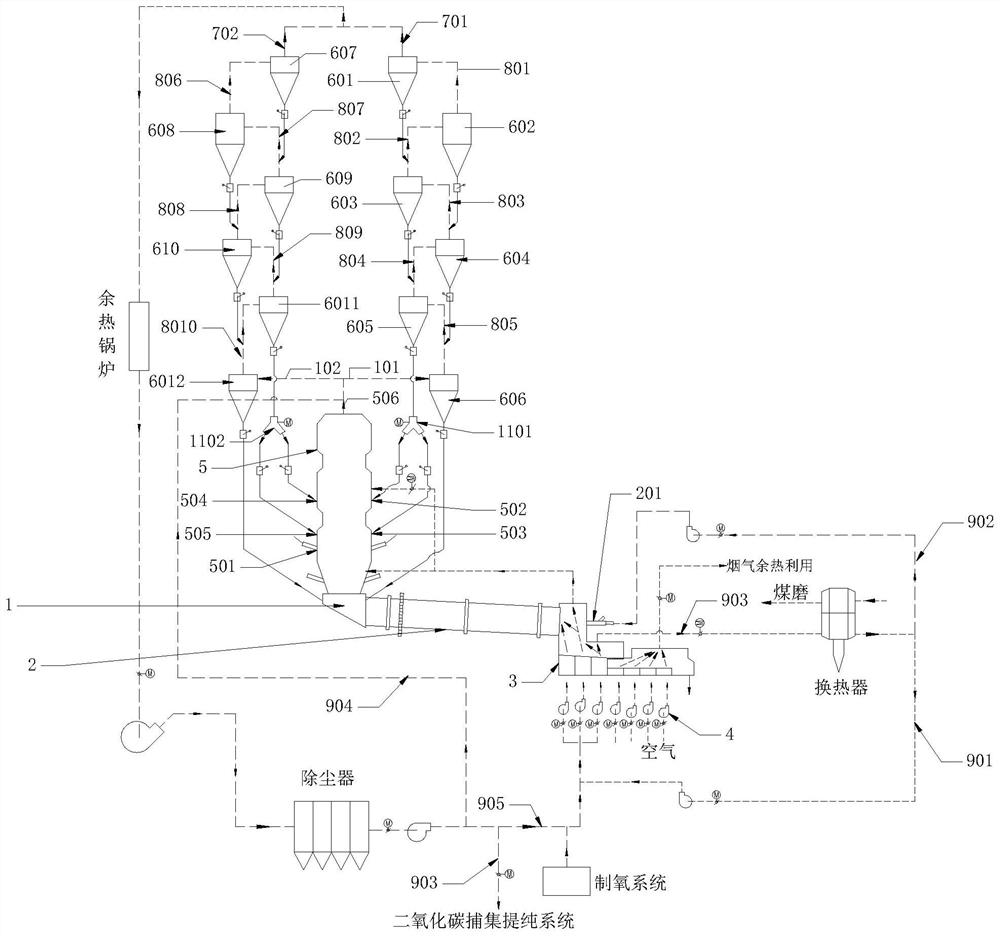

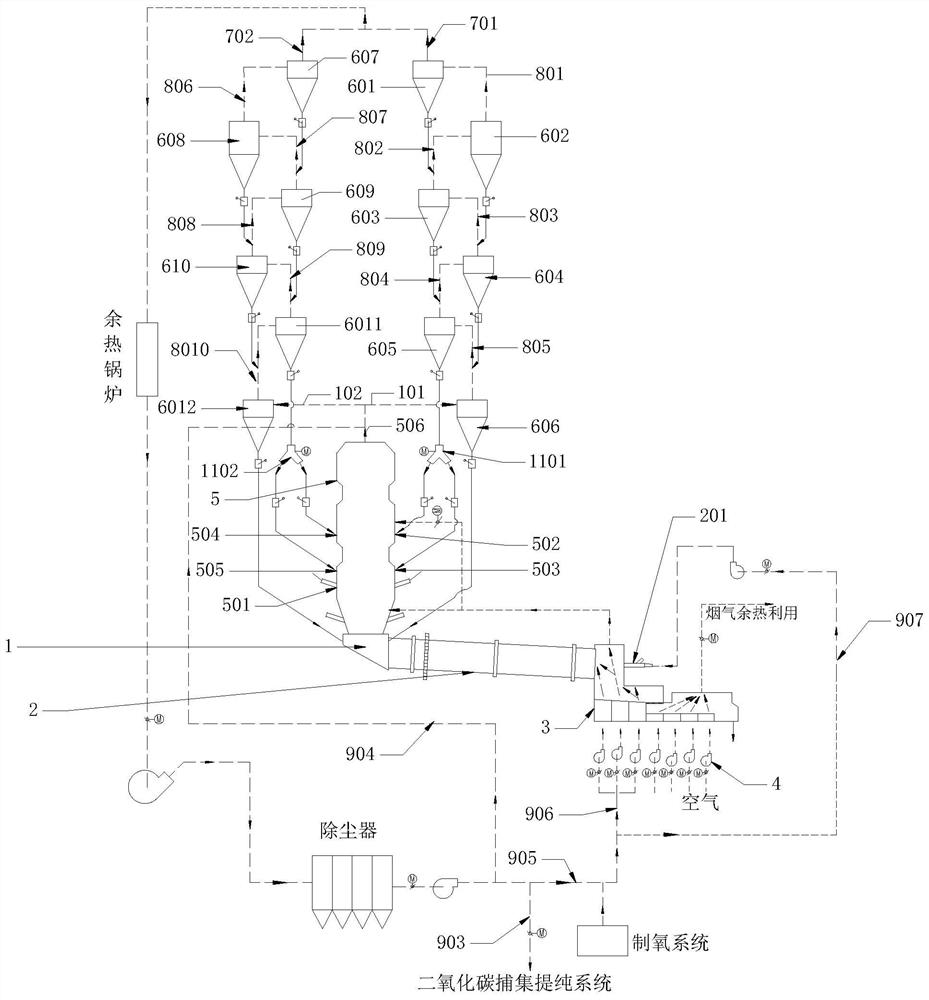

System for recycling SO2 and NO from oxygen-enriched combustion boiler fume CO2 collection

InactiveCN101837233AReduce investment and operating costsHigh purityCarbon compoundsLighting and heating apparatusProcess engineeringOxide sulfur

The invention relates to a system for recycling SO2 and NO from oxygen-enriched combustion boiler fume CO2 collection and belongs to boiler fume processing equipment. A method for recycling the SO2 and NO from the oxygen-enriched combustion boiler fume CO2 collection comprises the following steps of: heating boiler feed water by using the fume discharged by a boiler first; cooling the fume to the temperature of 30 DEG C and pressurizing the fume; reacting the SO2, the NO, O2 and H2O in the pressurized fume in a first contact tower, wherein the SO2 is totally oxidized to generate SO3 and dilute sulfuric acid; and continuously pressurizing the reacted fume to finish the recycling of the SO2 and the NO, wherein the NO is oxidized to NO2 in a second contact tower and is reacted with the water to generate dilute nitric acid. In the system, no catalyst is needed, the removal rate of sulfur oxides approaches 100 percent, and the removal rate of nitrogen oxides is over 90 percent. The system has the advantages of reducing content of residual oxygen and water, improving CO2 purity, reducing CO2 compression power consumption and dehydration power consumption, saving devices for low NOX combustion, desulfurization and denitration, and improving energy utilization efficiency by heating the boiler feed water with the heat of cooled fume, the heat generated by compression and the reaction heat in the contact tower.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for simultaneously removing PM2.5 granules, SO2 and NOx from flue gas and recycling by-product

InactiveCN101496986ANon-corrosiveNo cohesionCombination devicesExternal electric electrostatic seperatorWater vaporHigh pressure

The invention discloses a method for simultaneously removing PM2.5 particles, SO2 and NOx of smoke gas and reclaiming byproducts. The smoke gas to be treated is introduced to a pulse corona electric field and absorption liquid is sprayed to purify the smoke gas at the same time; the pulse corona electric field is produced by an acicular corona wire connected with negative pulse high voltage and a netty metal electrode connected with positive pulse voltage; the absorption liquid is sprayed on the netty metal electrode to form liquid film; after the PM2.5 particles are charged, the PM2.5 particles move to the liquid film by electrostatic force and are adsorbed and caught by the liquid film; vapor and oxygen of the smoke gas are decomposed into O, OH, O3, HO2 and other oxidative free radicals; SO2 and NO of the smoke gas are oxidized into high valent state substances which are easy to absorb; subsequently, the substances are absorbed by the absorption liquid; and the reacted absorption liquid is crystallized through sensible heat drying of the smoke gas to be treated to generate reclaimable byproducts. The method realizes simultaneous removing of the PM2.5 particles, SO2 and NOx of the smoke gas and recycles the removed byproducts.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

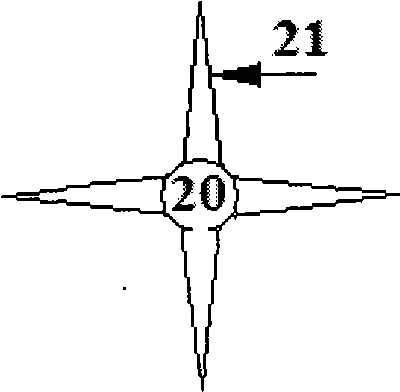

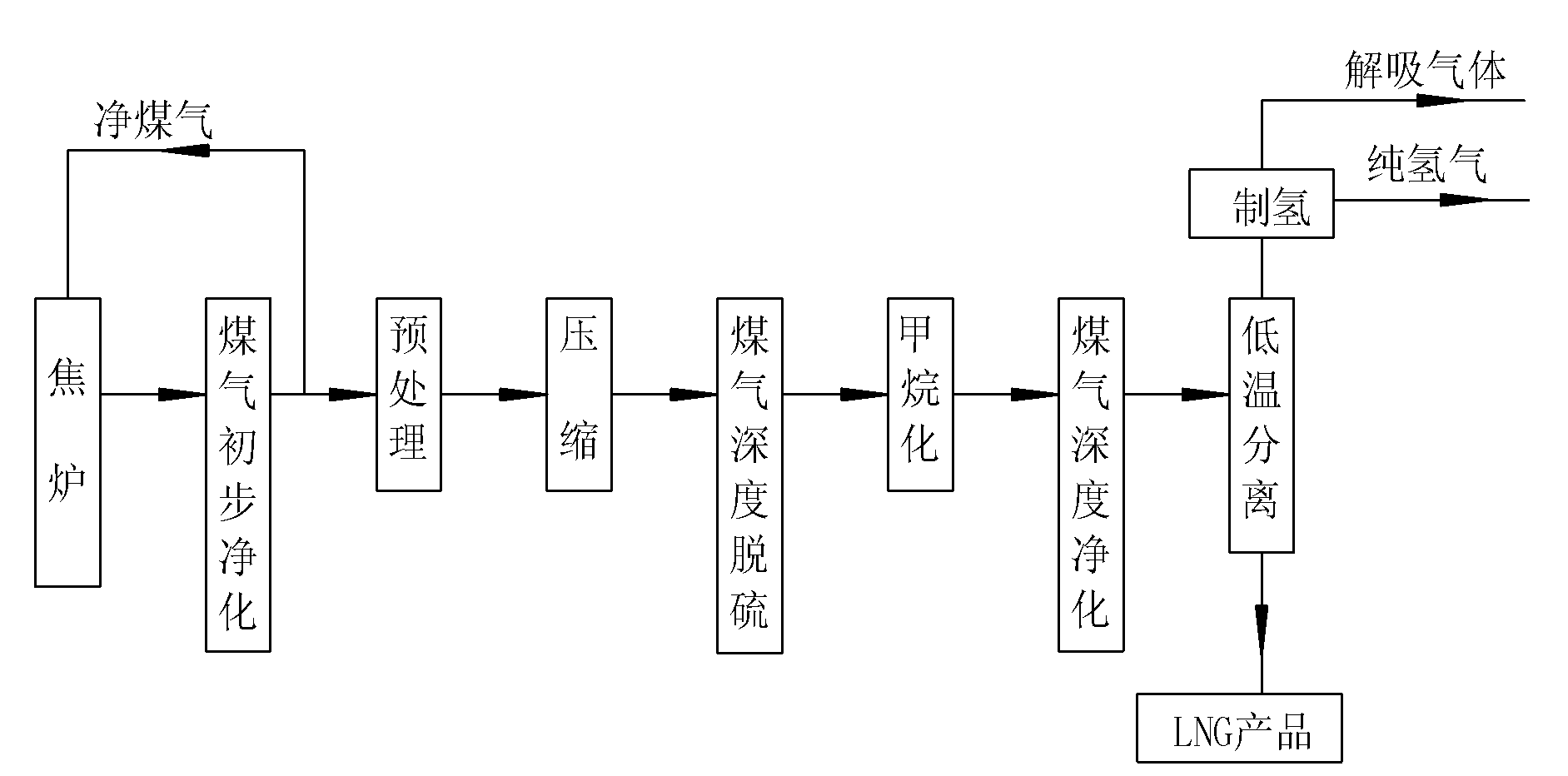

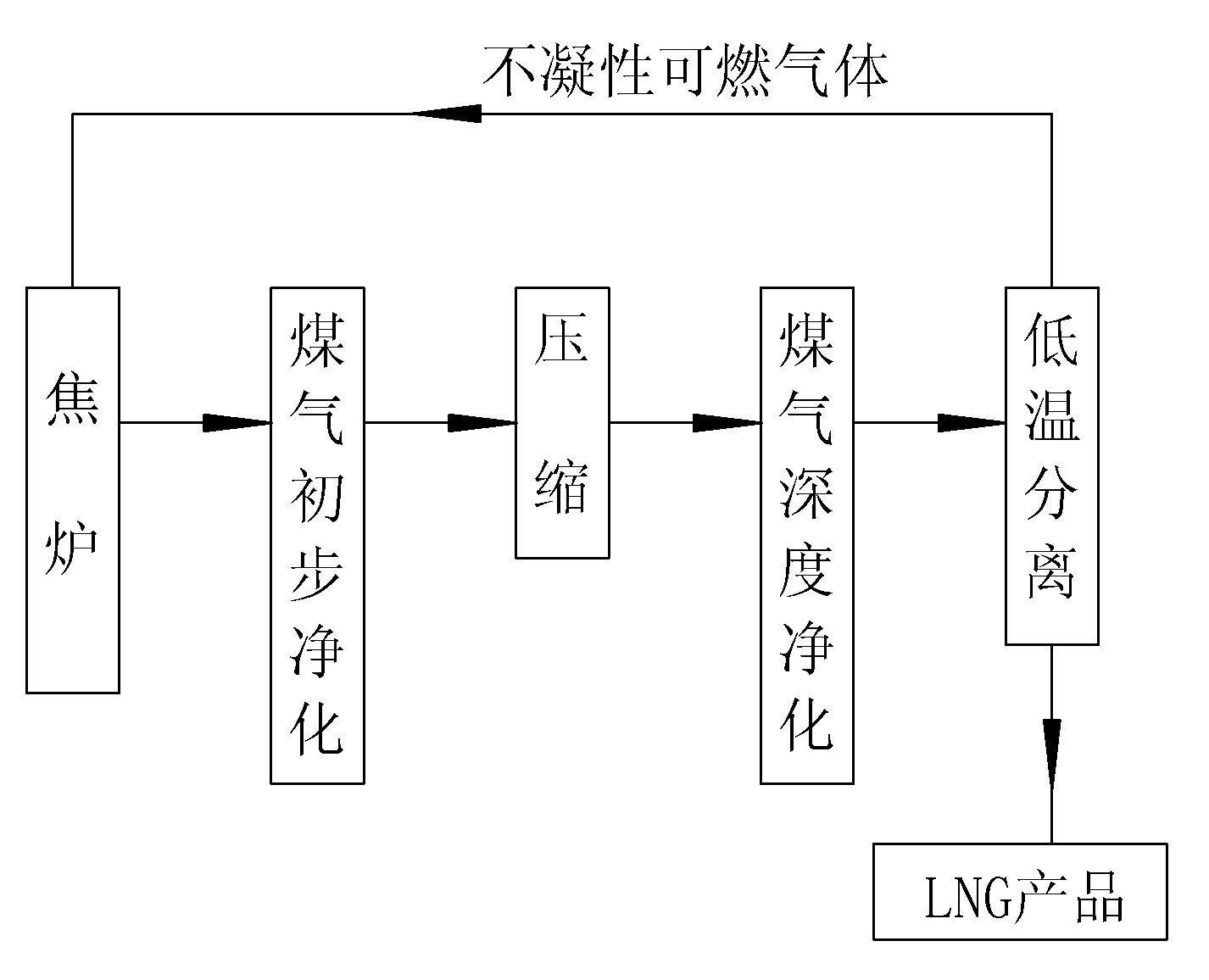

Process for purifying and liquefying coke oven gas

InactiveCN102031159AIncrease corporate profitsReduce investment and operating costsSolidificationLiquefactionLiquefied natural gasAdditive ingredient

The invention relates to a process for purifying and liquefying coke oven gas. Raw gas produced by a coke oven is primarily purified, compressed, deeply purified and then separated at a low temperature; a condensed methane ingredient is used as a liquefied natural gas (LNG) product; and uncondensable combustible gas is returned to the coke oven to serve as the gas for heating the coke oven. In the process, the uncondensable combustible gas which is liquefied by the coke oven gas is used for heating the coke oven, so that resources are reasonably utilized, and the problem of environmental pollution caused by impurity discharge and desorption gas combustion in the conventional coke oven gas liquefaction technology is solved; and in the process, a methanation step is saved, and investment cost and operation cost are greatly reduced.

Owner:姜辉

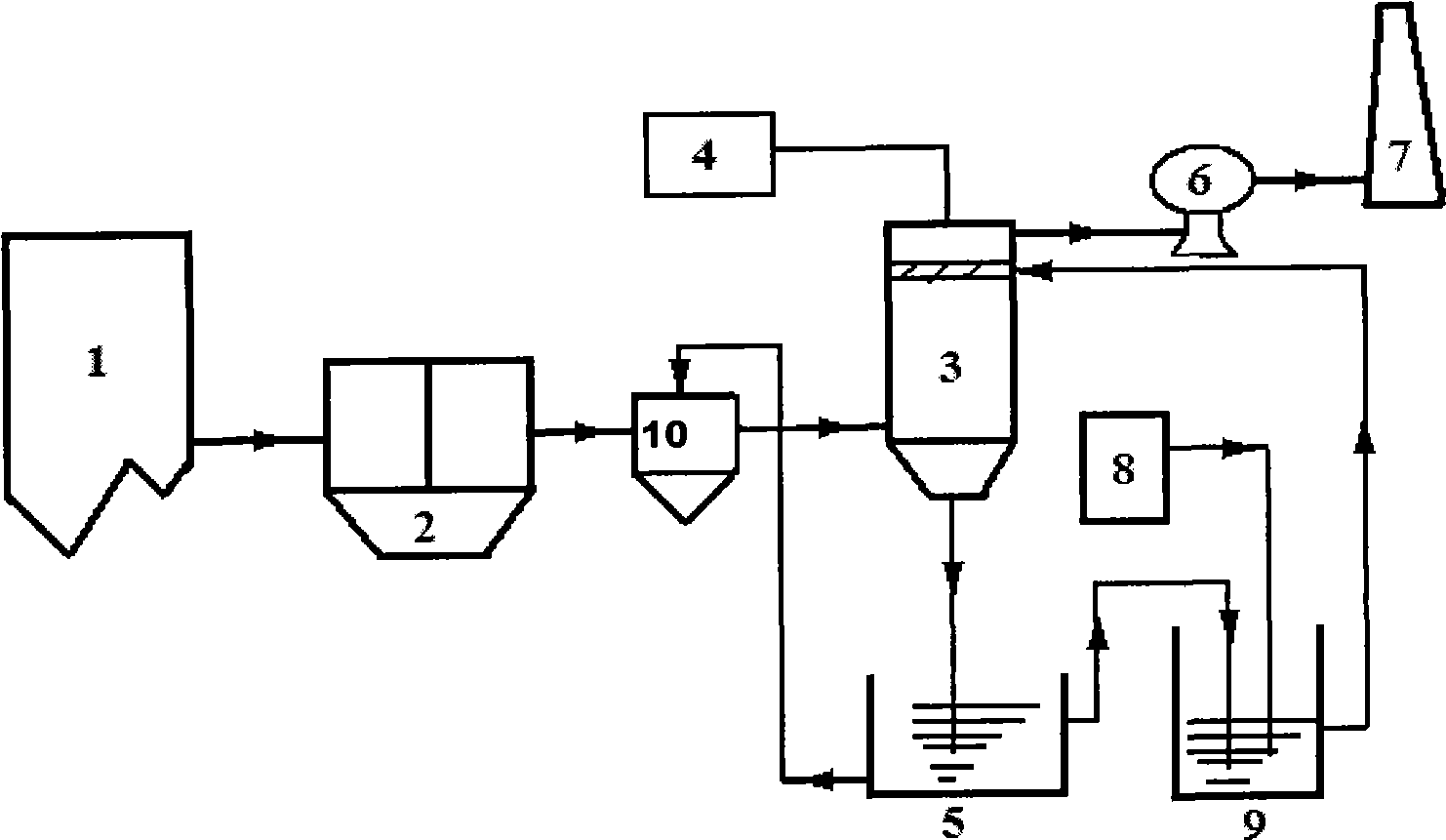

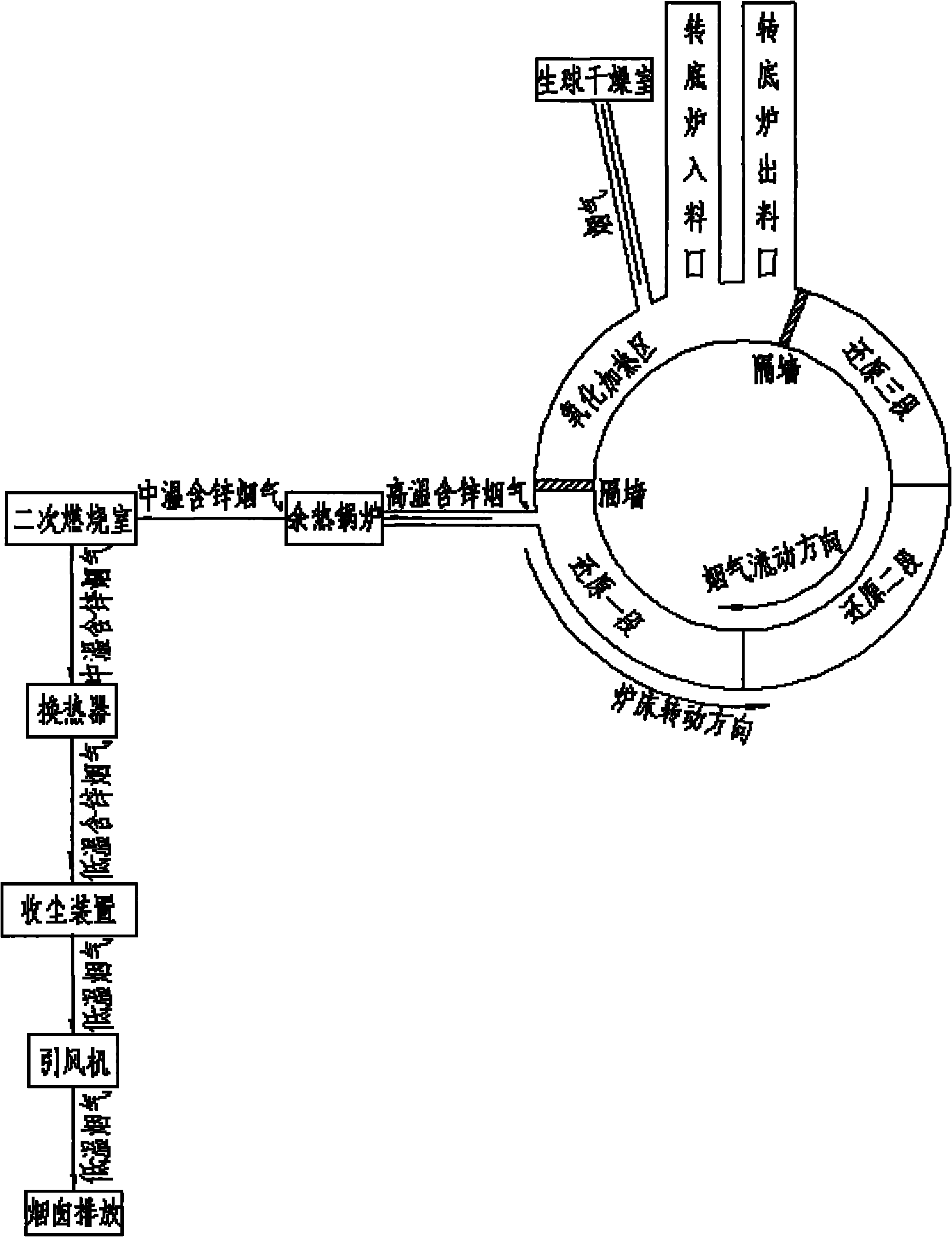

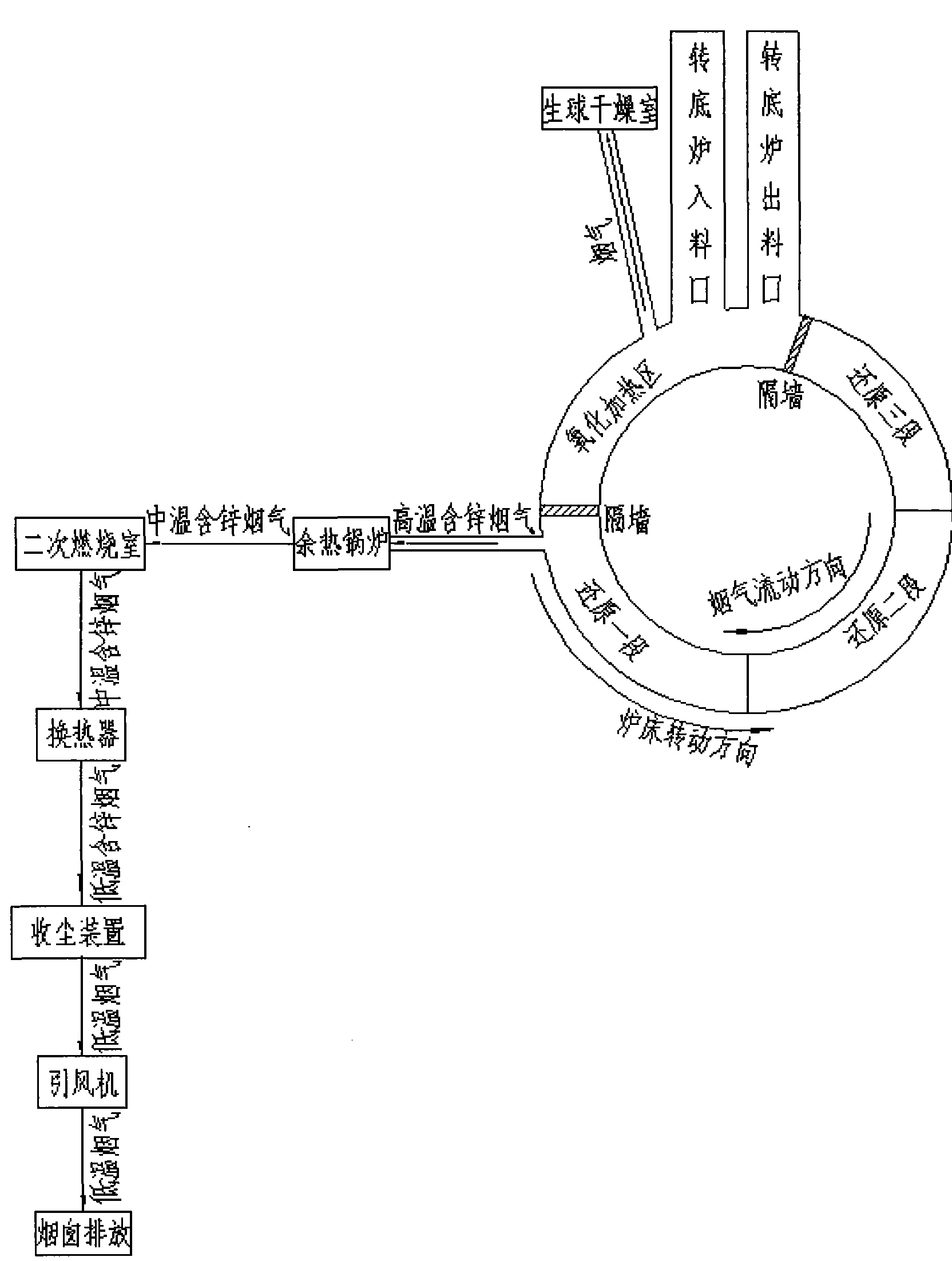

Process for processing smoke

InactiveCN101893387AHigh recovery rateReduce processingEnergy industryIncreasing energy efficiencyCombustionProcess engineering

The invention relates to a process for processing smoke, which is characterized in that: in the process, the smoke generated by a rotary hearth furnace is subjected to segmental processing. In the process for processing the smoke, the segmental processing is performed on the smoke generated by the rotary hearth furnace, and the low zinc content smoke in an oxidation heating region is used for drying a preheated green ball, so the waste heat of the smoke can be completely recycled, unburned gas can also be combusted completely to recycle usable waste heat further; the smoke in a high-temperature reducing region where the zinc is gasified and volatilized intensively is subjected to dust removal and zinc recycling after waste heat recycling and secondary combustion, and the amount of the smoke which needs to perform zinc recycling is reduced, so the equipment investment and operation cost of a smoke processing system are reduced; and due to the secondary waste heat recycling and the secondary combustion of the smoke in the high-temperature reducing region, the waste heat of the smoke in the region can be completely recycled, the recovery rate of the zinc is improved, and the environmental pollution is reduced.

Owner:CISDI ENG CO LTD

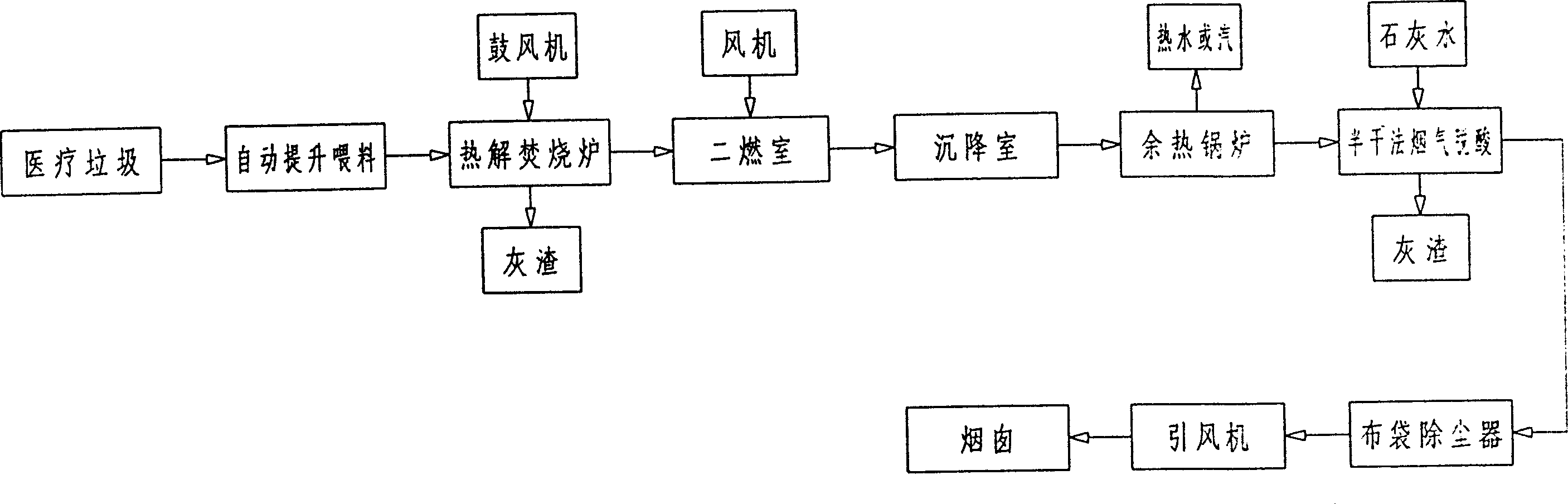

Process for burning medical refuse

ActiveCN1667315AReduce investment and operating costsBurn completelyIncinerator apparatusProduct gasEngineering

The invention relates to a medicine garbage burning technology. The medicine garbage is transferred to the material casting entrance by sealed special transport vehicle and casting equally, quantificatioally into the burning furnace by automatic lifting material feeding device. And the process of dehydration and drying, pyrolysis and gasification, burning, second burning, smoke sedimentation, waste heat recovery and smoke dealing with would be taken. Thus, the content reduce quantity would reach 99%. The invention can effectively avoid the produce of poisonous substance.

Owner:ZHENGCHANG GROUP JIANGSU

Method for removing SO2 and NOX in combustion coal flue gas through corona discharge and liquid phase oxidation

ActiveCN103611419ASimple structurePromote absorptionDispersed particle separationAir quality improvementFluid phaseFlue gas

The present invention discloses a method for concurrently removing SO2 and NOX in combustion coal flue gas through combination of corona discharge and liquid phase oxidation. The method comprises that: combustion coal flue gas requiring treatment is introduced into a corona discharge reactor inlet, is treated through a pre-oxidation spraying system, and then enters a corona discharge reactor electric field, and part of SO2 and part of NO in the flue gas are respectively oxidized into SO3 and NO2 with free radicals and active substances produced through high voltage corona electric field discharge; and with the combination effect of the electric field and the diffusion, SO3, NO2, the unoxidized SO2 and the unoxidized NO enter a spraying water type electrode liquid in the reactor in a migration manner, SO2 is further oxidized into S(VI) through liquid phase catalysis to finally form a high valence state acid, and NO and NO2 are subjected to absorption reduction through a urea solution so as to achieve a purpose of combustion coal flue gas purification. With the method, concurrent desulfurization and denitrification on coal flue can be achieved, the investment is low, running is economical, and characteristics of high desulfurization and denitrification efficiency, high corona discharge energy utilization rate, solution recycling, sulfur resource recycling and broad application prospect are provided.

Owner:浙江欧托电气有限公司

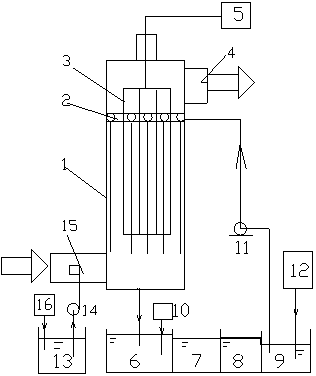

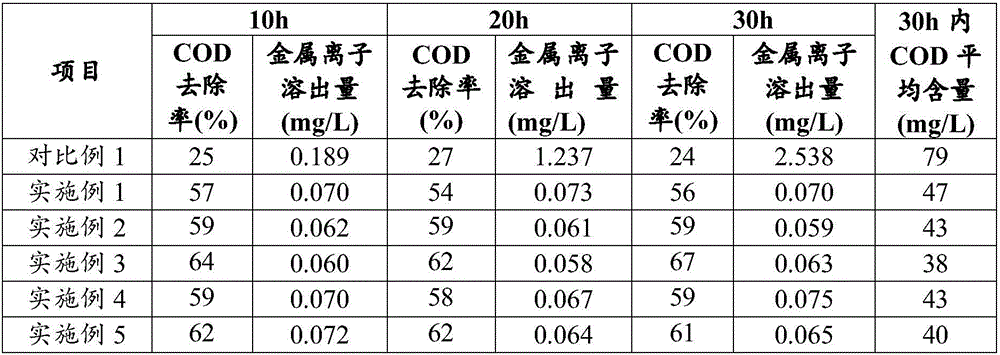

Preparation method of modified alumina carrier, catalytic ozone oxidation catalyst, and application of catalyst

ActiveCN106732509ANot easy to loseEasy to drainCatalyst carriersHeterogenous catalyst chemical elementsFree coolingRoom temperature

The invention relates to the technical field of water treatment, and especially relates to a preparation method of a modified alumina carrier, a catalytic ozone oxidation catalyst, and an application of the catalyst. The preparation method of the modified alumina carrier comprises the following steps: providing an alumina substrate; carrying out primary modifier spray immersion, primary drying and primary calcination on the alumina substrate, and naturally cooling the obtained calcined alumina substrate to room temperature; and carrying out secondary modifier spray immersion, secondary drying and secondary calcination on the alumina substrate, and naturally cooling the secondary calcined alumina substrate to obtain the modified alumina carrier. The catalytic ozone oxidation catalyst prepared from the modified alumina carrier greatly improves the COD removal rate, so the sewage treatment cost is reduced; the dissolution rate of metal ions is greatly reduced, so the service life of the catalyst is prolonged; and the catalyst has the advantages of low cost and simple preparation method, and is very suitable for industrial production.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

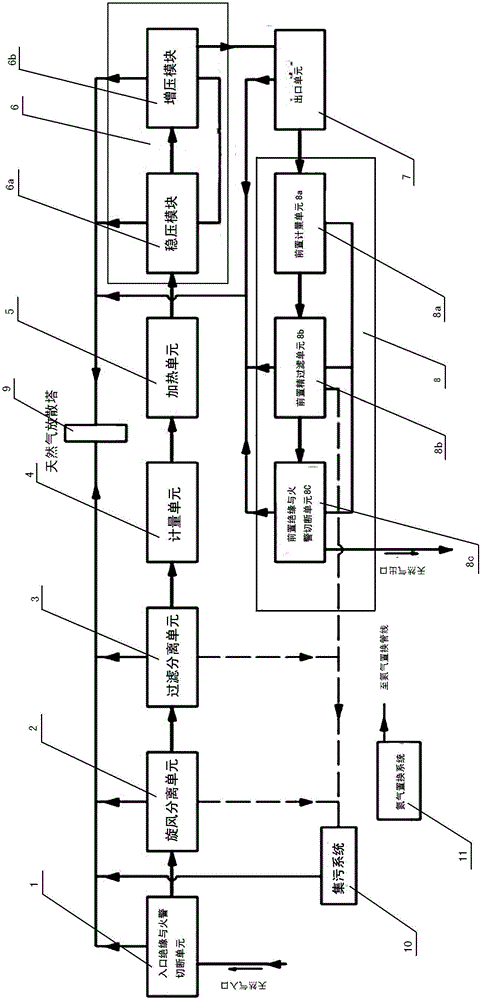

Method of removing multiple pollutants in flue gas through low-temperature gas-like phase catalytic oxidization

ActiveCN106943871AIncrease profitReduce consumptionGas treatmentDispersed particle separationGas phaseFlue gas

The invention discloses a method of removing multiple pollutants in flue gas through low-temperature gas-like phase catalytic oxidization and belongs to the technical field of flue gas purification. According to the method, a liquid-phase oxidant is activated into a gas-like phase by means of flue gas temperature, and the gas-like phase oxidant generates strong-oxidizing free radicals under effects of a catalyst; the multiple pollutants in flue gas are catalytically oxidized into soluble valences by the strong-oxidizing free radicals, wherein an oxidizing product is absorbed by an absorbent in a spray column, thereby achieving integrated removal of the soluble multiple pollutants. A high-active low-temperature catalyst is prolonged in service life, reduces consumption on the oxidant and saves investment and operation cost. The absorption product is high in content of nitrogen and sulfur, so that the product can be processed into a compound fertilizer raw material. The method can reach 99-100%, 90-95% and 90-95% in removal rates respectively on SO2, NO and Hg<0>, is suitable for boilers in various types and other flue gas purification fields, and has excellent economic and promotion value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

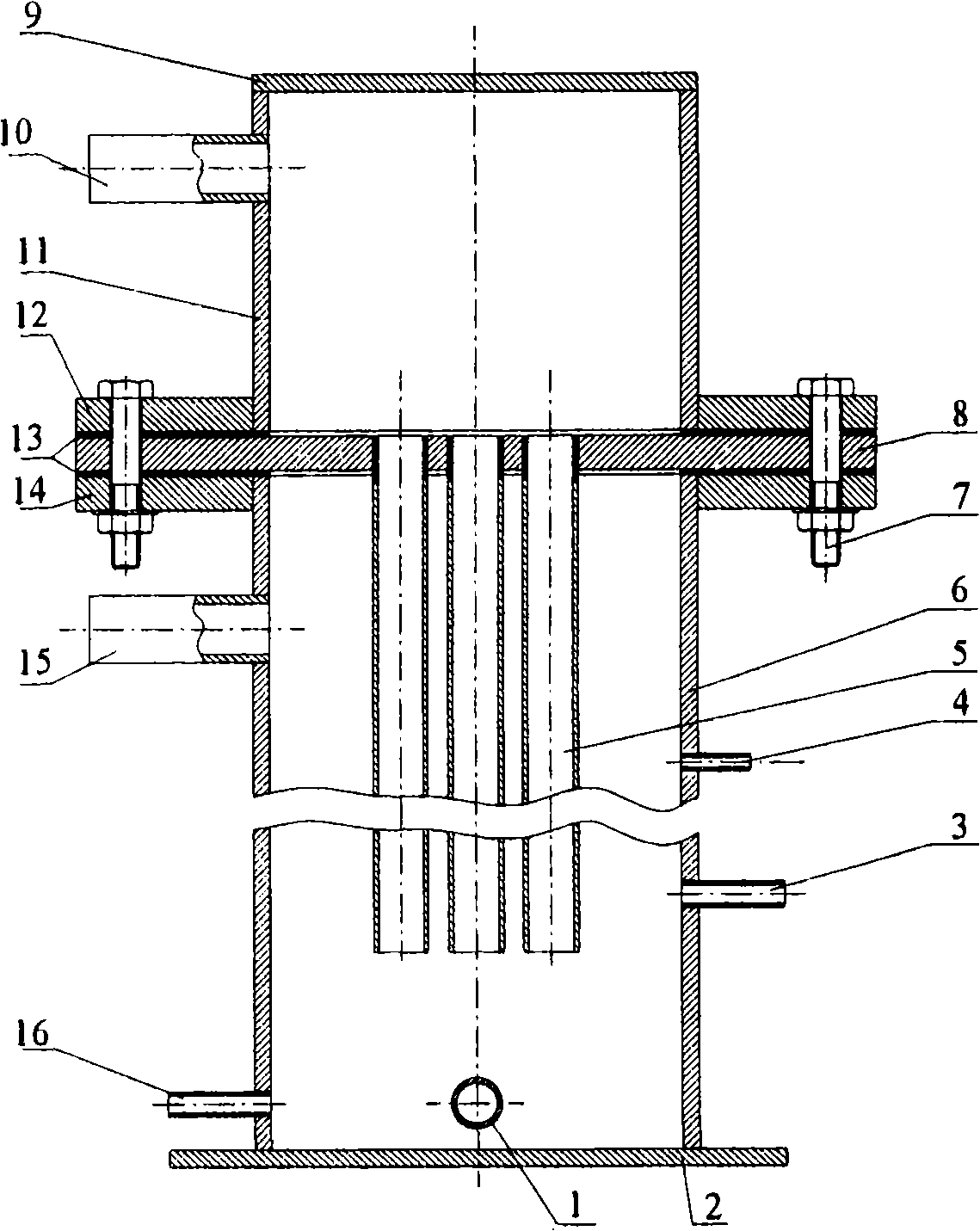

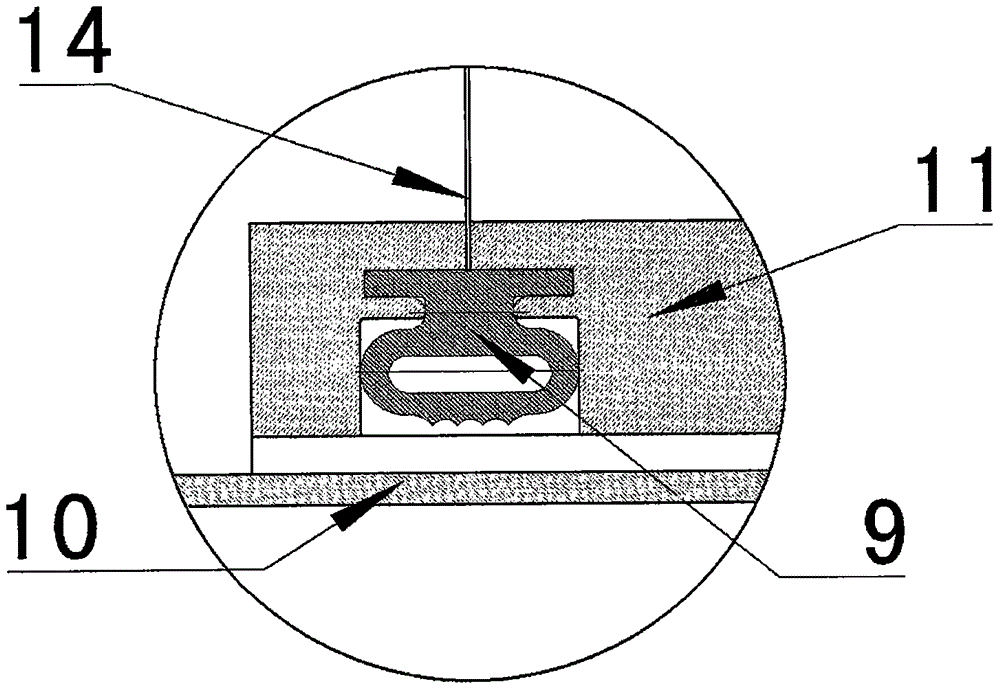

Air inflation axial sealing device used in vacuum environment

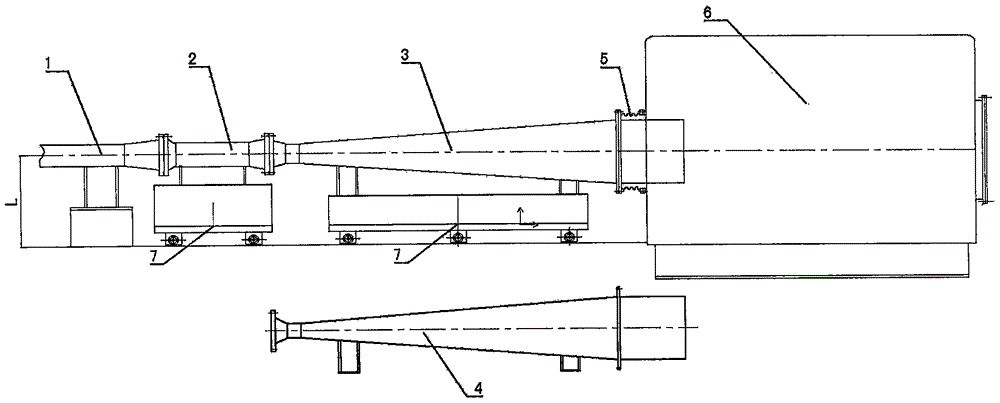

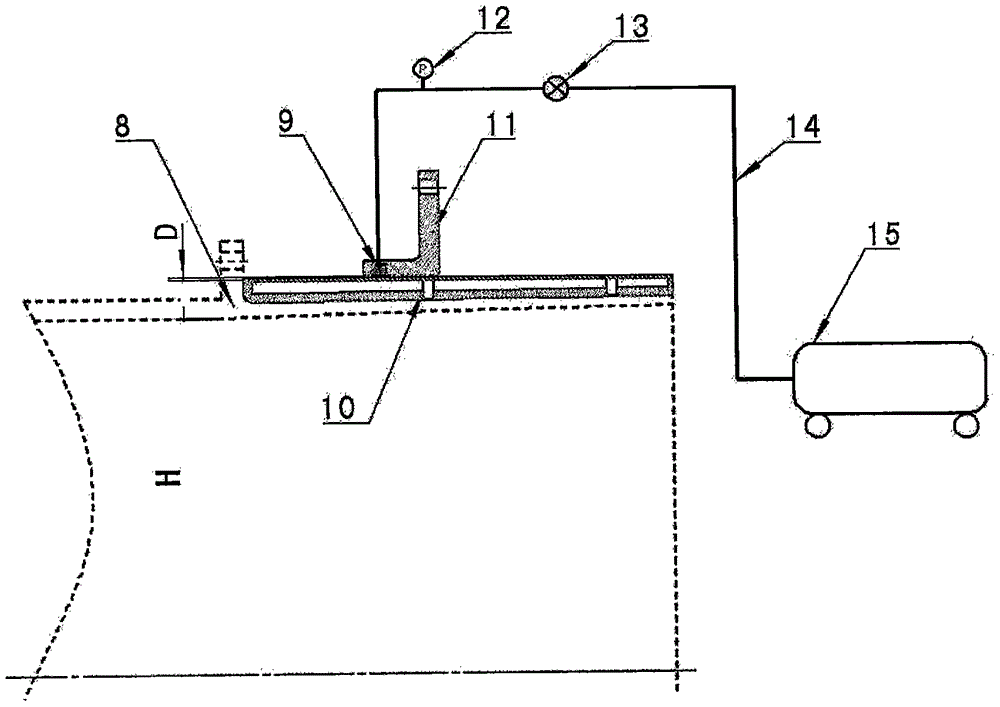

InactiveCN105697790AReduce investment and operating costsReduce labor intensity andEngine sealsAerodynamic testingSpeed of soundElectrical and Electronics engineering

The invention belongs to the field of hypersonic wind tunnels, and relates to an inflatable axial sealing device used in a vacuum environment, which includes an inflatable sealing ring, a sealing cylinder, an adapter sleeve, an inflating pipeline and an air compressor, wherein the inflatable sealing ring, the sealing The sealing cylinder body and the adapter sleeve have an axisymmetric structure; the inflatable sealing ring is installed in the groove of the adapter sleeve, and the inflatable interface of the inflatable sealing ring cooperates with the inflatable interface of the adapter sleeve; the sealing cylinder enters the adapter sleeve Inside, the sealing ring can fully contact the outer surface of the sealing cylinder after being inflated; the inflation pipe connects the air compressor and the inflation port of the inflatable sealing ring. The inflatable axial sealing device of the present invention solves the shortcomings of the bellows connection mode, reduces investment and operating costs, reduces labor intensity and difficulty in replacing pipeline equipment, improves the efficiency of pipeline equipment replacement, and obtains a good vibration isolation effect, which can be applied to Axial vacuum seal between pipeline equipment of different calibers.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

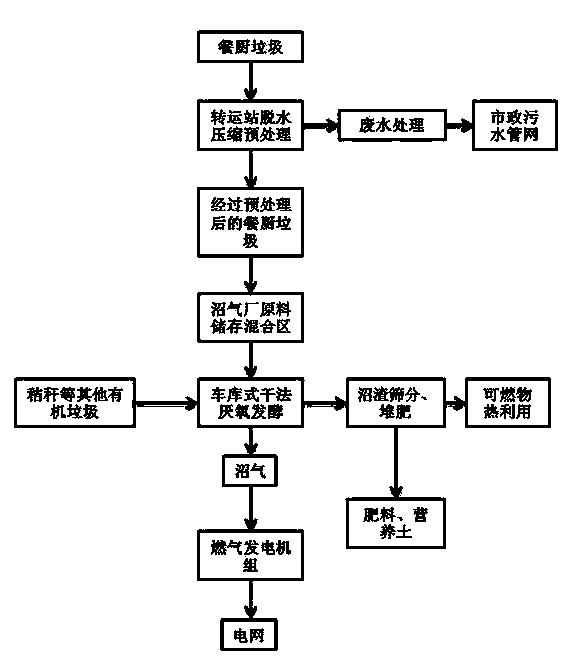

Garbage type dry fermentation comprehensive treatment method for kitchen wastes and organic wastes

InactiveCN103773809ASimple preprocessingReduce investment and operating costsBio-organic fraction processingEnergy inputSaw dustPre treatment

The invention discloses a garbage type dry fermentation comprehensive treatment method for kitchen wastes and organic wastes. The organic wastes are selected from garden wastes, sludge from sewage treatment plants, straws, animal wastes, wood flour, saw dust and the like. The method comprises the steps of carrying out dehydration and degreasing pretreatment on the collected kitchen wastes at a transfer station; mixing the pretreated kitchen wastes and organic wastes to carry out garbage type dry anaerobic fermentation, and the like. The method disclosed by the invention is characterized in that the fermentation raw materials are very simple in pretreatment; no stirring equipment is arranged in an anaerobic tank, and the fermentation raw materials do not need to be continuously stirred; feeding and discharging can be finished without the help of a pump; no any mobile mechanical equipment is arranged in the anaerobic tank. Therefore, organic raw materials with relatively high impurity contents can be fermented. Compared with a wet fermentation technology, the garbage type dry fermentation comprehensive treatment method has the effect of remarkably reducing the investment and operation costs.

Owner:徐蔚航

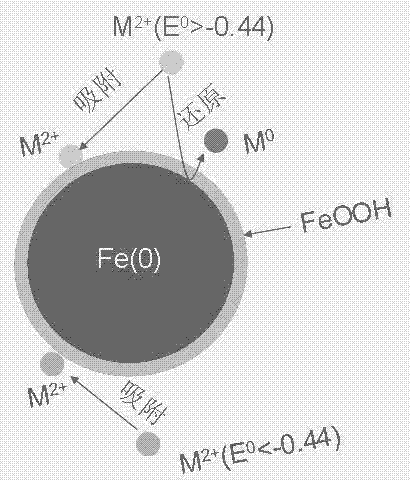

Integrated process for treating heavy metal wastewater

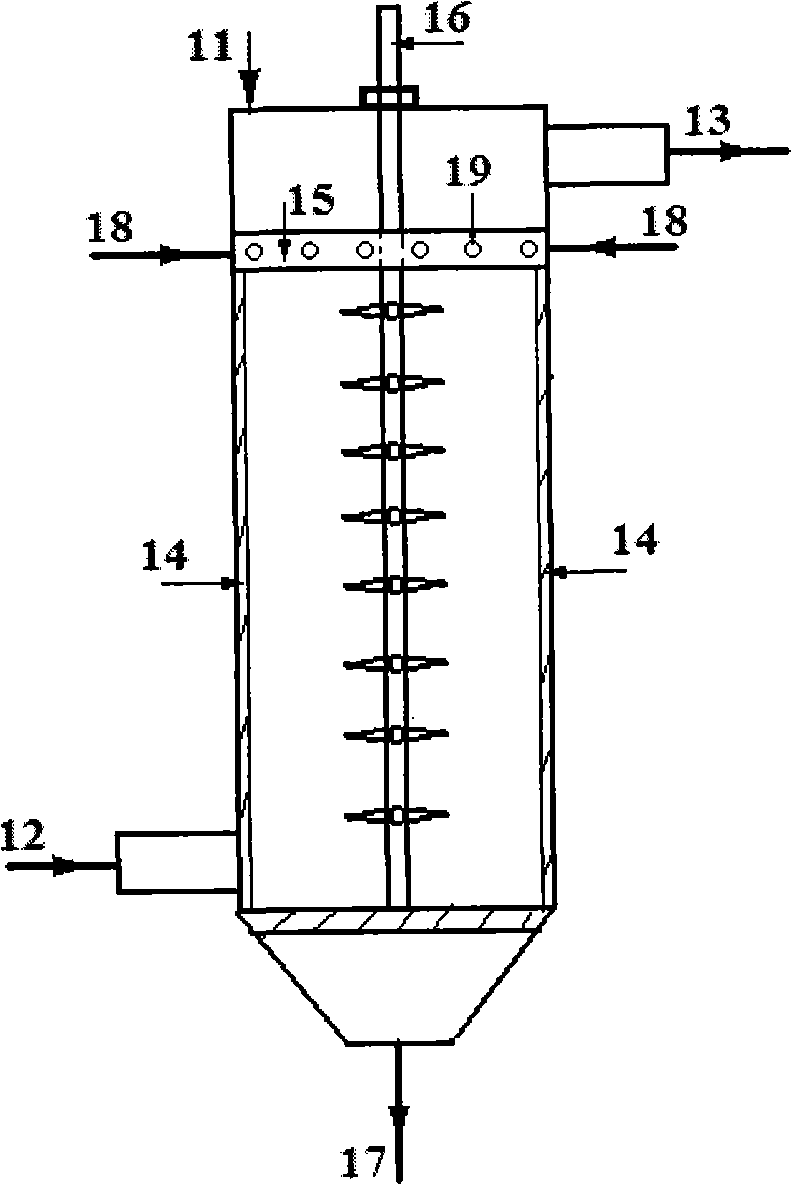

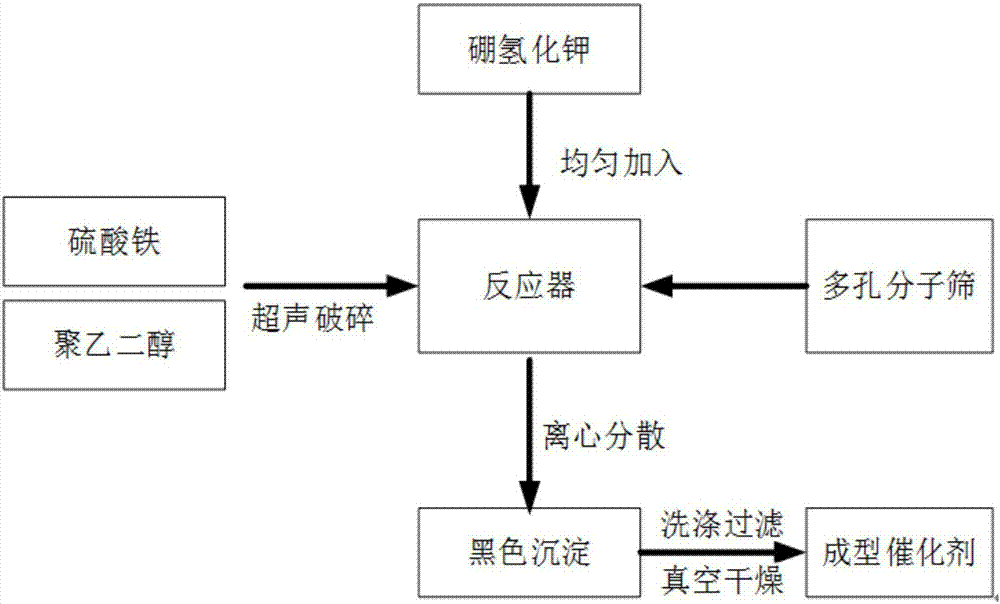

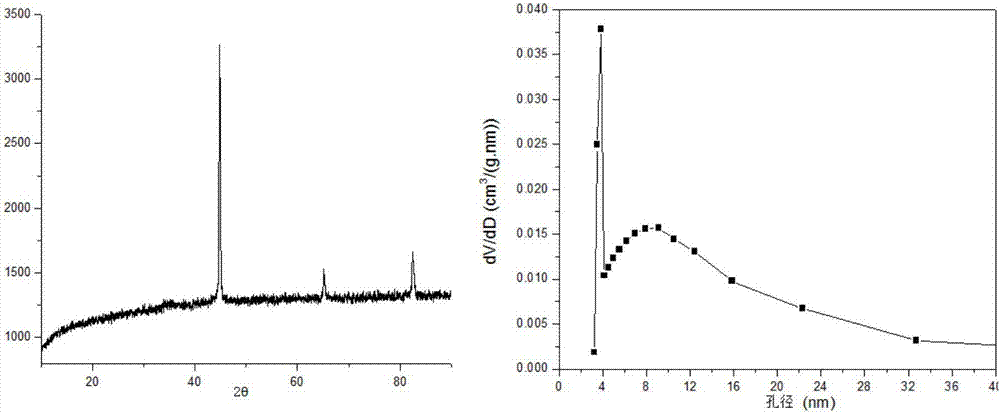

ActiveCN103112918AEasy to separate and recycleIncrease concentrationWater/sewage treatment by sorptionWater/sewage treatment by reductionPollutant emissionsZerovalent iron

The invention relates to an integrated process for treating heavy metal wastewater. A reactor adopted in the integrated process is simple to construct, compact in structure, high in heavy metal wastewater treatment efficiency, and easy to operate, manage and maintain. The integrated process is free of a nanometer zero-valent iron mixed solution refluxing device, capable of increasing the nanometer zero-valent iron by sufficiently utilizing flow fields, which are formed by a stirring device on the inner part of the reactor, and capable of realizing solid-liquid separation and zero-valent iron refluxing by utilizing the gravity of the nanometer zero-valent iron, so that the nanometer zero-valent iron is sufficiently mixed and circulated in the reactor, and the high-adsorption performance and strong reduction characteristic to the heavy metals are greatly utilized. An integrated device is used to treat simulated wastewater and the pre-treated electroplating wastewater containing heavy metals, so that the concentration of various heavy metals in the treated outlet water are better than the emission standards of the national pollutant I. Moreover, the reactor has short hydraulic retention time and high treatment efficiency, and is free of additionally added chemical coagulant, capable of separating and recycling the nanometer zero-valent iron containing heavy metals and capable of avoiding the secondary pollution of the heavy metals.

Owner:TONGJI UNIV

Dust-removal mercury-removal filter bag for bag-type dust remover and preparation method of filter bag

The invention discloses a dust-removal mercury-removal filter bag for a bag-type dust remover. The dust-removal mercury-removal filter bag is bag which is loaded with a mercury-removal catalyst and made of high-temperature filtration fiber; and the mercury-removal catalyst is a mixture of manganese oxide and cobalt oxide. The invention further discloses a preparation method of the dust-removal mercury-removal filter bag; the filter bag is loaded with the mercury-removal catalyst and applied to the bag-type dust collector; the catalyst can be used for oxidizing elemental mercury in coal-fired flue gas into bivalent mercury (Hg2+), so that absorption or adsorption of a flue gas pollutant purifying device is facilitated. The dust-removal mercury-removal filter bag is applied to controlling mercury emission of a coal-fired power plant, so that adsorbent is substituted by catalytic oxidation; on the basis of keeping the smoke dust removal effect, the removal efficiency of the elemental mercury is bigger than 30%, so that the flue gas mercy removal effect of the coal-fired power plant can be satisfied.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Cement kiln system capable of realizing zero emission of carbon dioxide and cement clinker preparation method

ActiveCN112321183ASmall amount of modification workLow retrofit costRotary drum furnacesHandling discharged materialPost-combustion captureThermodynamics

The invention provides a cement kiln system capable of realizing zero emission of carbon dioxide and a cement clinker preparation method. The system comprises a raw material preheating and pre-decomposing system, a smoke chamber, a rotary kiln and a cooling machine, wherein the smoke chamber, the rotary kiln and the cooling machine are sequentially communicated; the raw material preheating and pre-decomposing system comprises a decomposing furnace and a cyclone preheater, an air inlet of the cyclone preheater at the bottom end is connected with an air outlet pipe of the decomposing furnace, and low-temperature flue gas is exhausted from an air outlet of the cyclone preheater at the top end; a discharge port of the bottom end cyclone preheater is communicated with the smoke chamber, and a feed port of the top end cyclone preheater is used for feeding raw materials; the cooling machine comprises a first cooling area and a second cooling area, mixed gas of pure oxygen and high-concentration carbon dioxide flue gas is introduced into an air inlet of the first cooling area, and air is introduced into an air inlet of the second cooling area. The problems of low CO2 gas capture efficiencyof a CO2 capture and purification system, low CO2 concentration in flue gas entering the capture and purification system and high system investment and operation cost in the existing CO2 capture technology after combustion can be solved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

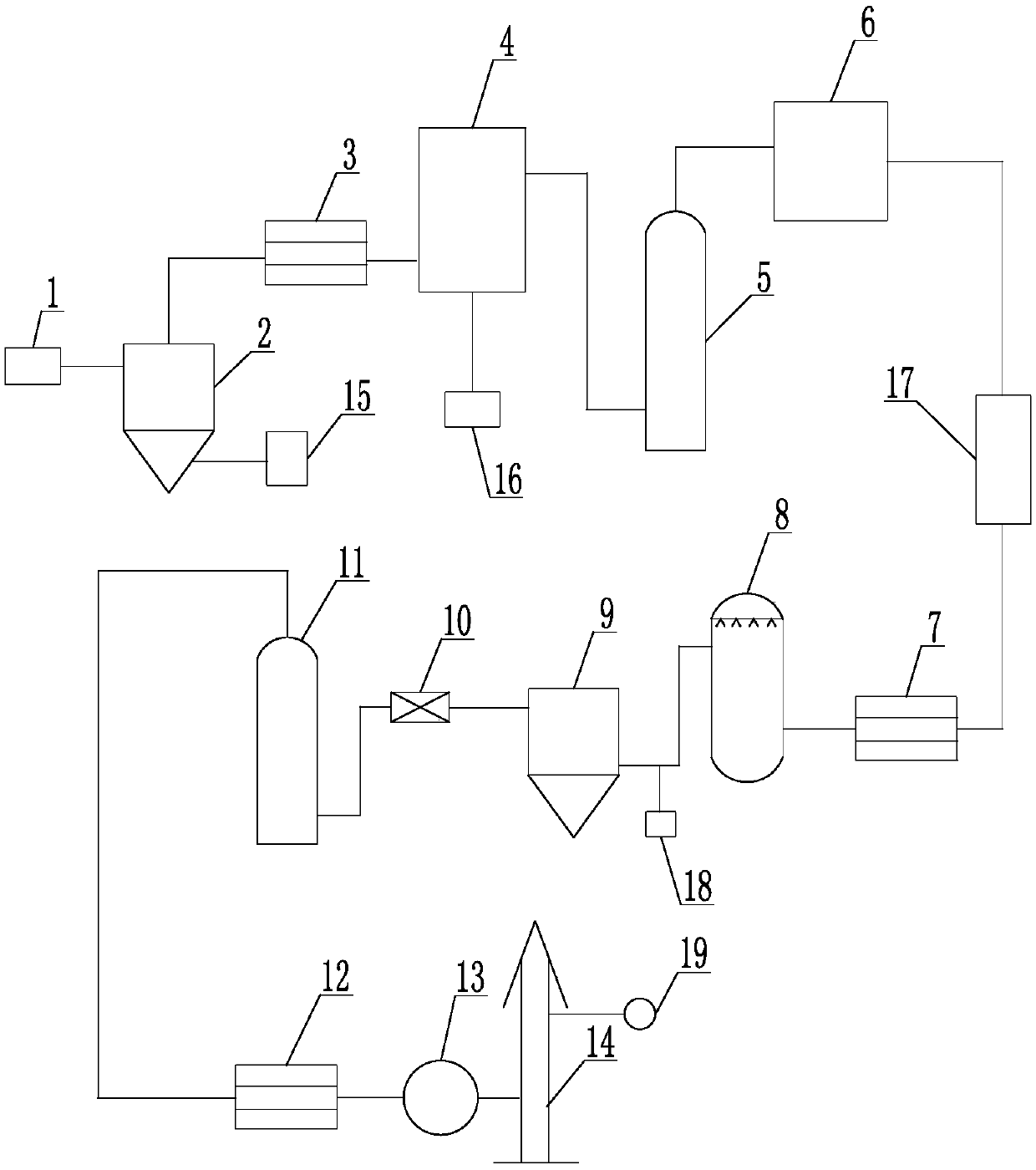

Resource recycling process and system for high-temperature plasma of chlorine-containing waste

InactiveCN109539272AFully harmless treatmentEfficient recyclingDispersed particle filtrationEmission preventionCombustion chamberDecomposition

The invention belongs to the technical field of industrial waste treatment, and particularly relates to a resource recycling process and system for high-temperature plasma of chlorine-containing waste. The method comprises the steps that (1) the chlorine-containing waste is conveyed into a plasma gasifier through a feeding system; (2) synthesis gas produced through splitting decomposition is cooled by a first-stage waste heat exchanger; (3) after entering an acid absorption system to absorb acid, the synthesis gas enters an alkaline tower to be further deacidified; (4) the deacidified synthesis gas enters a secondary combustion chamber to be combusted, and generated high-temperature flue gas is cooled by a second-stage waste heat exchanger; (5) after the cooled flue gas enters a quench cooler to be subjected to quenching, the flue gas enters a bag-type dust remover for dust removal; (6) the flue gas with dust removed enters a flue heater to be warmed; (7) the flue gas enters an SCR catalytic tower to remove nitric oxide in the flue gas; and (8) after the flue gas subjected to SCR treatment enters the heat exchanger for heat exchange, the flue gas is drawn out by an induced draft fan, and the flue gas is discharged into the atmosphere through a chimney. By means of the resource recycling process and system, resource, harmless, reducing and stabilizing treatment of the chlorine-containing waste is achieved, and the system operation cost is low.

Owner:SHANDONG BO RUN IND TECH

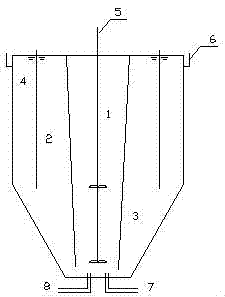

Sieve-plate tower used for sintering machine flue gas desulfurization and desulfurization process thereof

InactiveCN102512939ALarge specific surface areaImprove absorption efficiencyDispersed particle separationFlue gasSlurry

The invention discloses a sieve-plate tower used for sintering machine flue gas desulfurization and a desulfurization process thereof, and belongs to the field of resource and environment protection. The device comprises an absorption tower, wherein the absorption tower is provided with a flue gas inlet, a flue gas outlet and a desulfurizer inlet, a demisting layer, a spraying layer, a sieve plate and a pulp chest are sequentially arranged in the absorption tower from top to bottom, the desulfurizer inlet is positioned above the flue gas inlet, the sieve plate is positioned between the desulfurizer inlet and the flue gas inlet, an overflow weir is arranged above the sieve plate, the sieve plate is divided into an overflow area and a gas liquid contact area by the overflow weir, sieve pores of the sieve plate are arranged in the gas liquid contact area, the gas liquid contact area is positioned at one side of the sieve plate close to the desulfurizer inlet, and an overflow pipe is arranged under the overflow area. The desulfurization process comprises the following steps that: sintering machine flue gas enters the absorption tower to be reacted with the desulfurizer at the gas liquid contact area and then is discharged after sulfur dioxide is removed, and desulfurized pulp generated by the reaction of the flue gas and the desulfurizer overflows into the pulp chest of the absorption tower. The invention is used for removing the sulfur dioxide in the sintering machine flue gas, the flue gas desulfurization efficiency is improved, and the desulphurization energy consumption is reduced.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

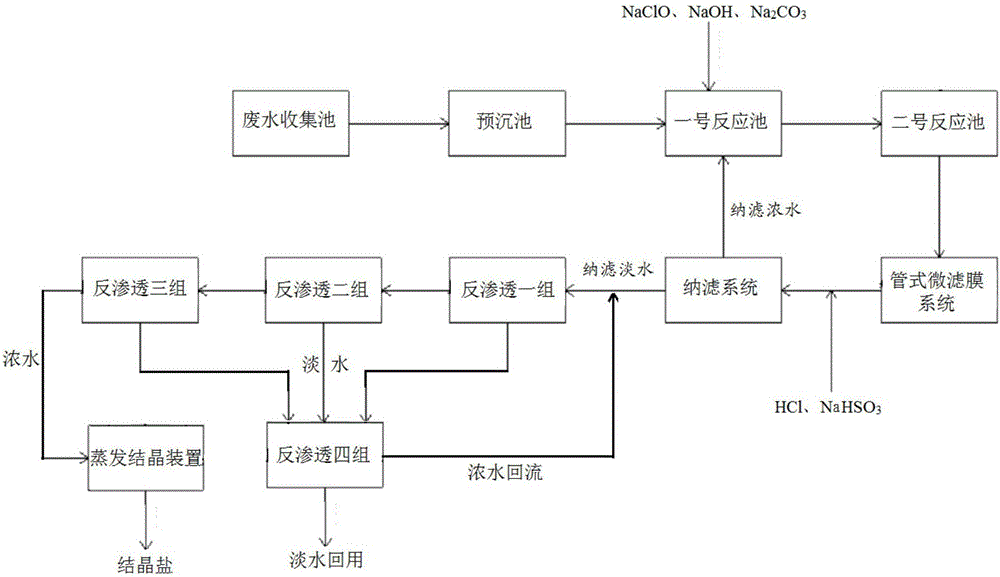

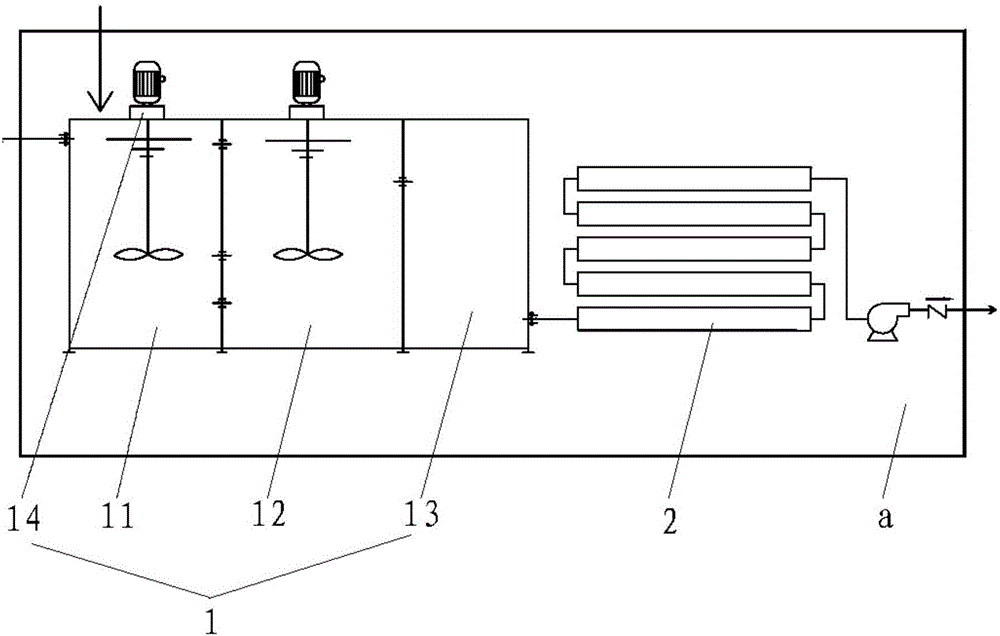

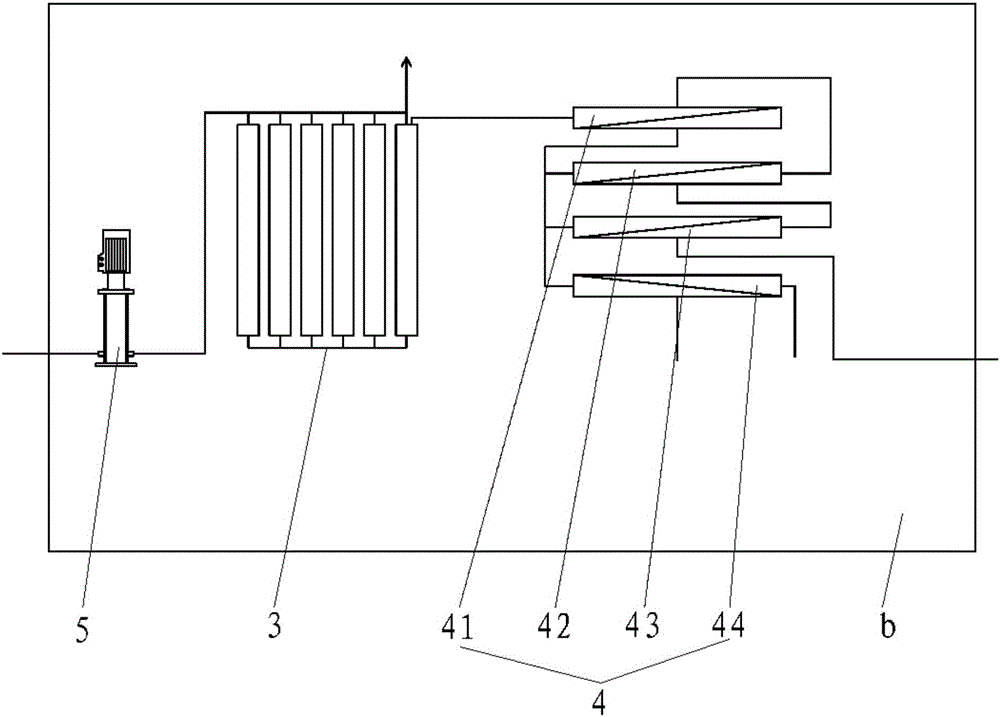

Treatment system of shale gas fracturing flowback fluid

InactiveCN106746126AEasy to recycleImprove concentration treatment effectWater contaminantsMultistage water/sewage treatmentAutomatic controlWater quality

The invention discloses a treatment system of a shale gas fracturing flowback fluid. The treatment system is characterized by comprising a reaction tank, a tubular microfiltration membrane system, a nanofiltration system and a reverse osmosis system, wherein a chemical agent is added to the reaction tank; chemical precipitation treatment is performed on waste water entering the reaction tank; a treated supernate is conveyed to the tubular nanofiltration system; treated fresh water is conveyed to the reverse osmosis system for treatment. The treatment system of the shale gas fracturing flowback fluid is compact in structure, small in floor area, short in treatment process, high in treatment efficiency, good in outlet water quality, low in power consumption, low in operating cost, convenient in automatic control, and high in economic benefit.

Owner:宜宾华洁环保工程有限责任公司

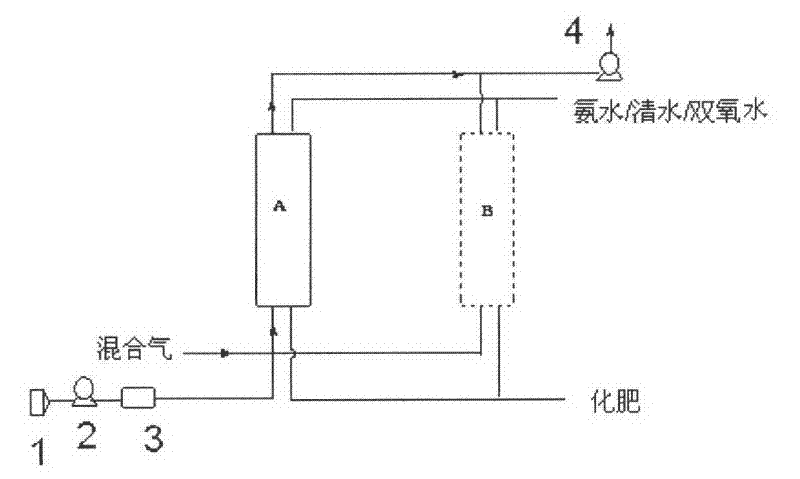

Method for performing smoke desulfurization and denitrification by using urea co-production preparation technology

InactiveCN104014232AImprove efficiencyReduce investment and operating costsOrganic chemistryChemical industryUreaChemistry

The invention relates to a method for performing smoke desulfurization and denitrification by using a urea co-production preparation technology. Ammonia gas generated by the method can be independently used for smoke desulfurization and denitrification, obtained cyanuric acid can also be independently used for smoke desulfurization and denitrification, and the ammonia gas and the cyanuric acid can be combined for simultaneously performing desulfurization and denitrification. The method has the advantages of being simple in operation, increasing the desulfurization and denitrification efficiency, and greatly lowering the desulfurization and denitrification operation cost; the operation cost of the method is lower than that of an existing desulfurization and denitrification method; the economic benefit of the method is remarkable, and the problems of high infrastructure investment, high operation and maintenance cost and complicated operation of an existing desulfurization and denitrification technology are overcome; and the method can be suitable for smoke or tail gas treatment of multiple industrial boilers and industrial kilns.

Owner:SHANDONG UNIV

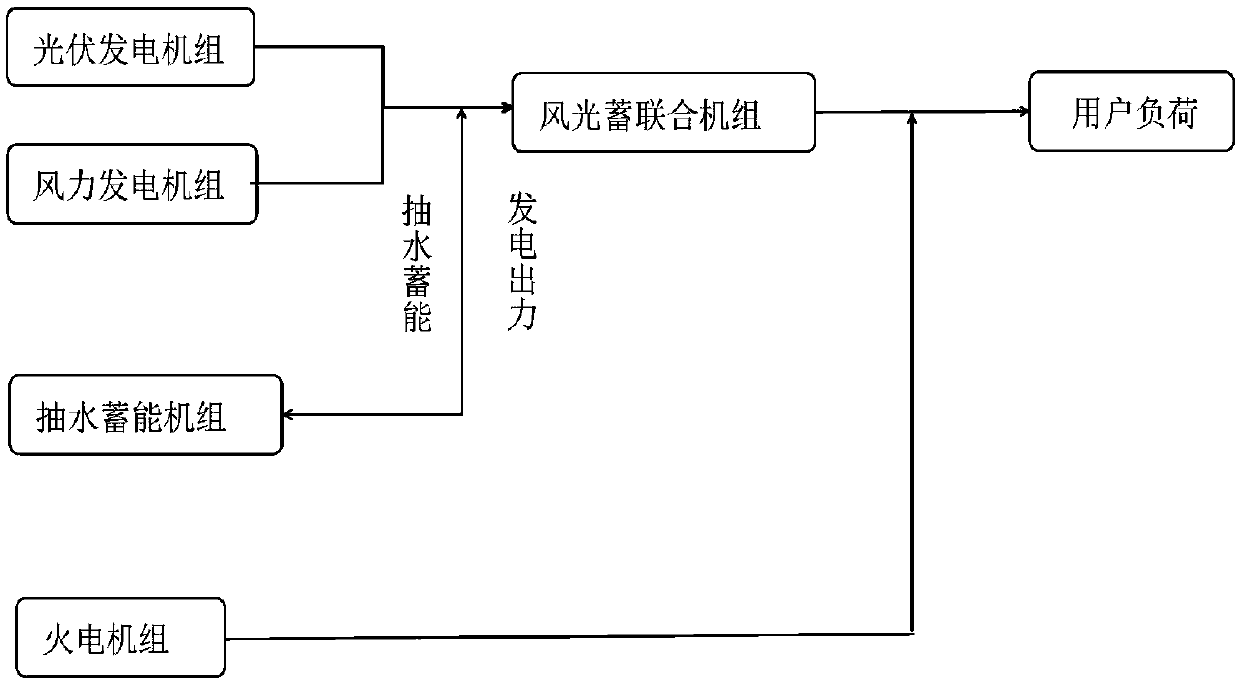

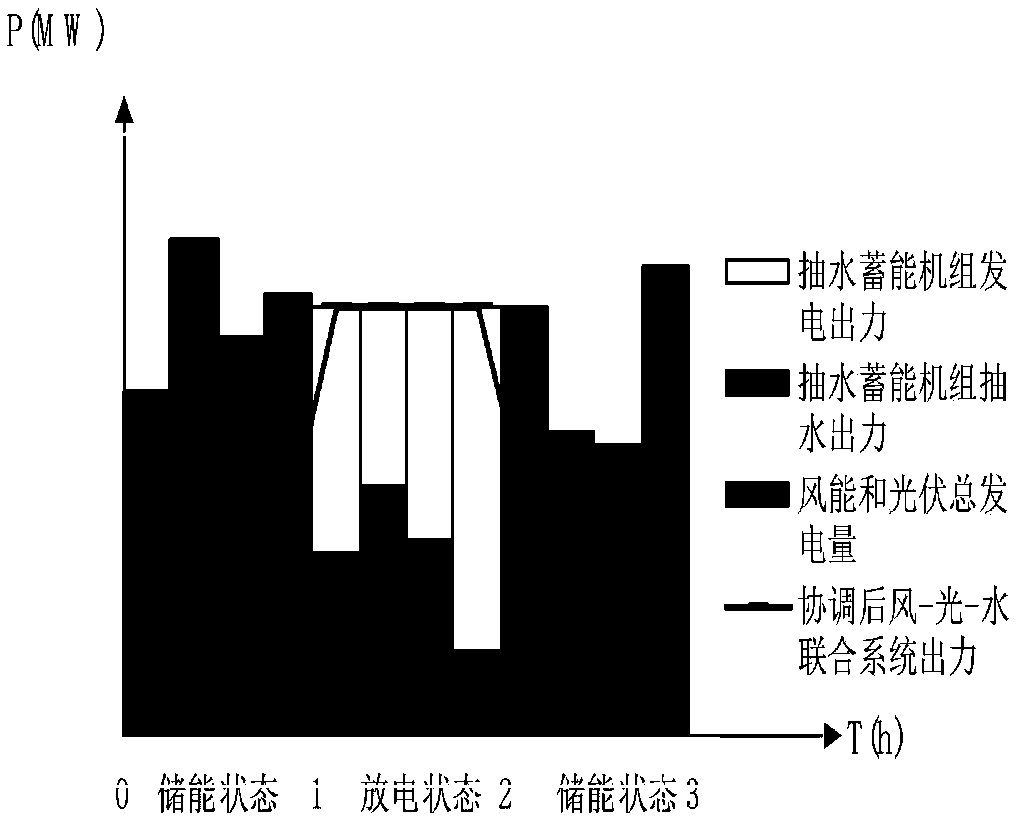

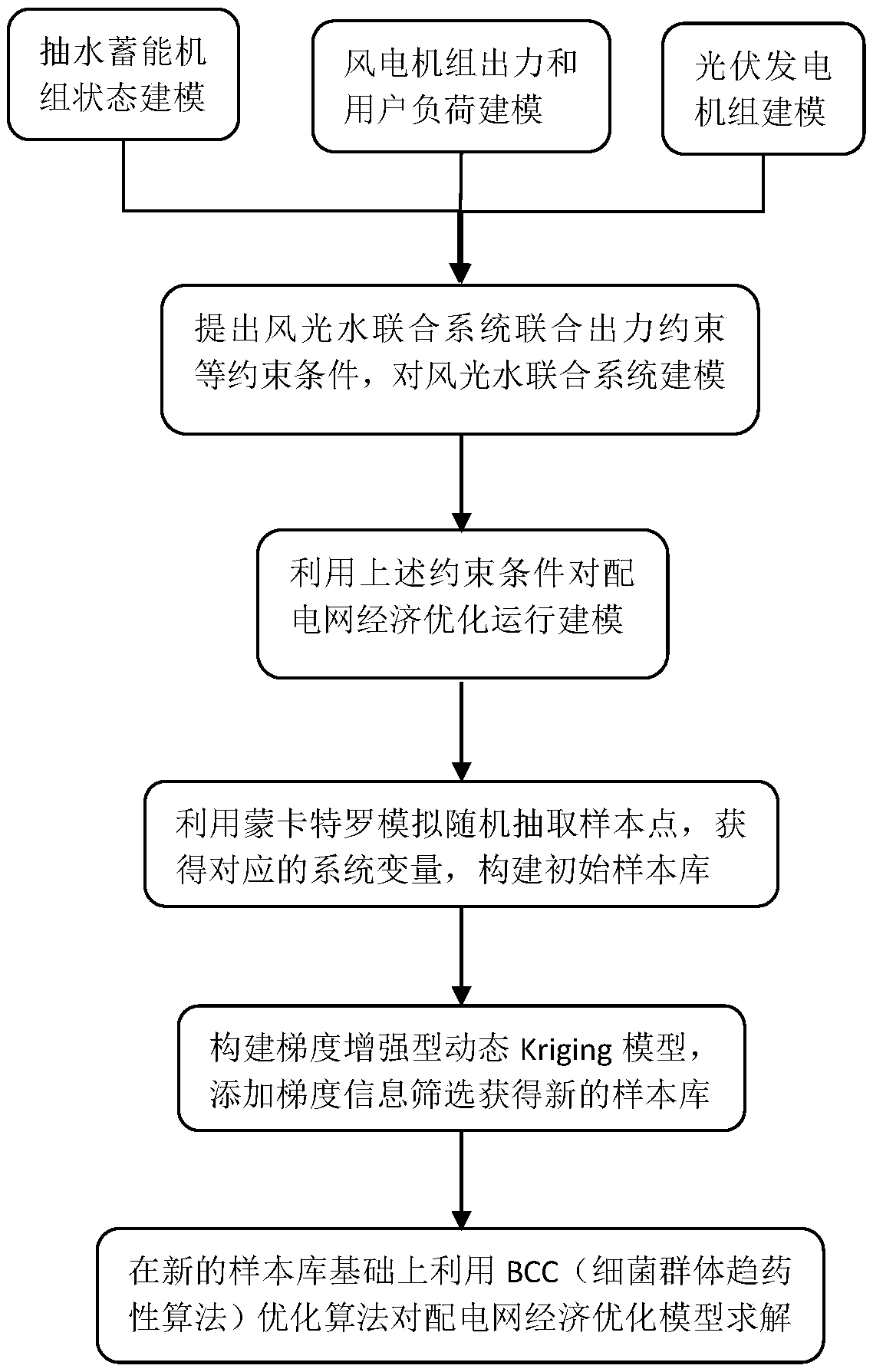

Distribution network economic optimal dispatching method based on improved dynamic kriging model

ActiveCN109103929AReduce the impact of power fluctuationsImprove power generation stabilityElectrical storage systemSingle network parallel feeding arrangementsNew energySimulation

The invention discloses a distribution network economic optimal dispatching method based on an improved dynamic kriging model, which comprises the following contents: modeling the state of a pumped storage unit; modeling wind turbine output and user load; modeling photovoltaic generator set; putting forward relevant constraint conditions of joint output constraint of a scenery-water combined system and modeling the scenery-water combined system; modeling the economic optimization operation of the distribution network by using the constraint conditions described in step 4; randomly selecting sample points by Monte Carlo simulation and obtaining the corresponding system variables to construct an initial sample database; constructing a gradient-enhanced dynamic Kriging model and obtaining anew sample library by adding gradient information; based on the new sample library, using the BCC optimization algorithm to solve the distribution network economic optimization model. The invention reduces the influence of the power fluctuation brought by the wind-solar new energy and smoothes the wind power and the photovoltaic power generation, improves the power generation stability of the wind-solar new energy, increases the consumption amount of the wind-solar new energy and reduces the investment and operation cost of the distribution network system.

Owner:无锡享源信息科技有限公司

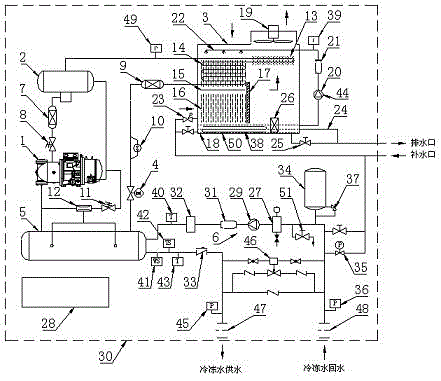

Integrated double-cooling water chilling unit

ActiveCN104457002AHigh level of integrationImprove efficiencyCompression machines with non-reversible cycleEvaporators/condensersWater cyclingWater processing

The invention provides an integrated double-cooling water chilling unit. The integrated double-cooling water chilling unit has the advantages of being high in integration degree, convenient to install, efficient, capable of saving energy and wide in application range, a heat exchanger is cleaned without shutdown, and the integrated double-cooling water chilling unit is convenient to use. The integrated double-cooling water chilling unit particularly comprises a closed refrigeration cycling system. The closed refrigeration cycling system is formed by a compressor, an oil separator, a double-cooling condenser, an expanding and throttling device and an evaporator which are connected together in series sequentially. A freezing water cycling device is arranged between an inlet and an outlet of the evaporator. The double-cooling condenser comprises a catch basin and a spraying device. The spaying device is communicated with the catch basin through a spraying water cycling pump and a first water processing device. A cooling coil, a flow equalizing plate, filler and the catch basin are arranged below the spraying device in sequence. A cooling fan is arranged at the top of the double-cooling condenser. A pre-cooler and a water collector are arranged below the cooling fan in sequence. The catch basin is provided with a first automatic water supplement device, an overflow pipe, an automatic drainage device and an on-line dirt sucker. One end of the pre-cooler is connected with a gas outlet of the oil separator, and the other end of the pre-cooler is connected with the expanding and throttling device through the cooling coil.

Owner:昆山台佳机电有限公司

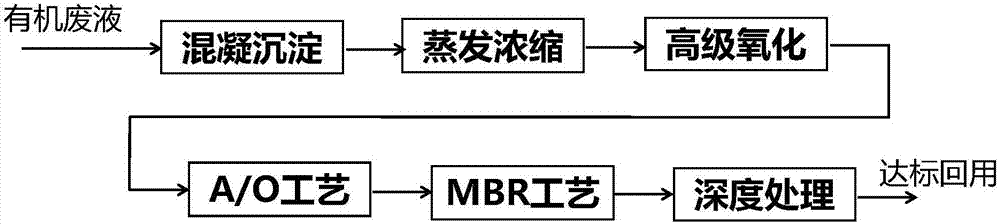

Zero-discharge reusing treatment method for organic waste liquid

InactiveCN107235607AAchieving zero emissionsAvoid influenceWater treatment parameter controlWater/sewage treatment by irradiationWater sourceWastewater

The invention belongs to the technical field of environmental protection, and relates to a zero-discharge reuse treatment method for organic waste liquid. The steps include coagulation precipitation, evaporation concentration, advanced oxidation, A / O process, MBR process and advanced treatment. The invention realizes the zero discharge of the organic waste liquid, avoids the influence of waste water discharge on the environment, and the organic waste liquid can reach the recycling standard after being treated, thus saving a lot of water sources.

Owner:SINGAPORE SUZHOU IND PARK ENVIRONMENTAL PROTECTION TECH CO LTD

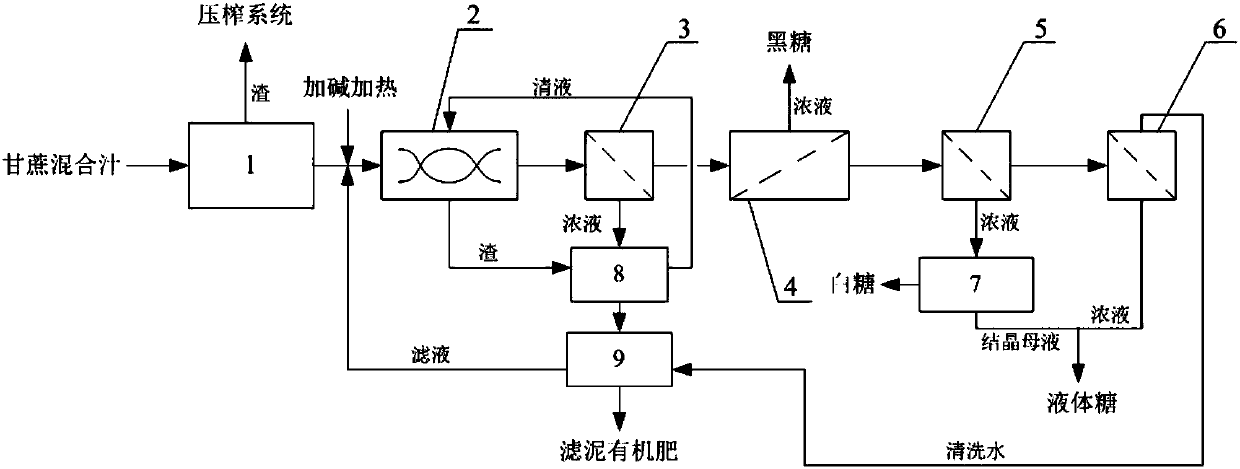

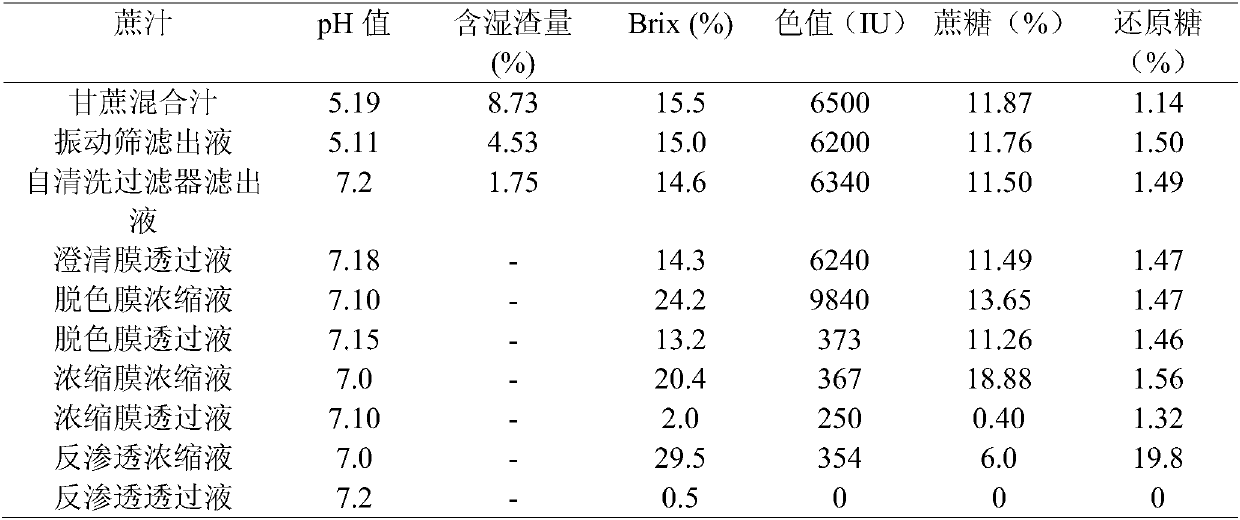

All-component utilization sugar cane-to-sugar system and treatment method thereof

InactiveCN107937628AAvoid accumulationReduce investment and operating costsSugar crystallisationPurification by physical meansChemistryMother liquor

The invention provides an all-component utilization sugar cane-to-sugar system and a treatment method thereof. The all-component utilization sugar cane-to-sugar system comprises a pretreatment unit, amulti-stage membrane filtration unit and a concentrated liquid treatment unit, wherein the pretreatment unit comprises a vibration sieve and a solid-liquid separation device, the multi-stage membranefiltration unit comprises a clarification membrane, a decolorization membrane, a concentration membrane and a reverse osmosis membrane, and the concentrated liquid treatment unit comprises a horizontal centrifuge and a rotary drum vacuum filter. With the system and the method of the present invention, the accumulation of the concentrated liquid of the clarification membrane in the system can be avoided, and the high-value utilization of the concentrated liquid of the decolorization membrane, the permeated liquid of the concentration membrane and the crystallization mother liquor can be achieved; and no chemical agent is added during the whole process, all the components in the sugar cane mixing juice are subjected to high-value utilization, no waste honey is produced, and the sucrose recovery rate can be greater than 95%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

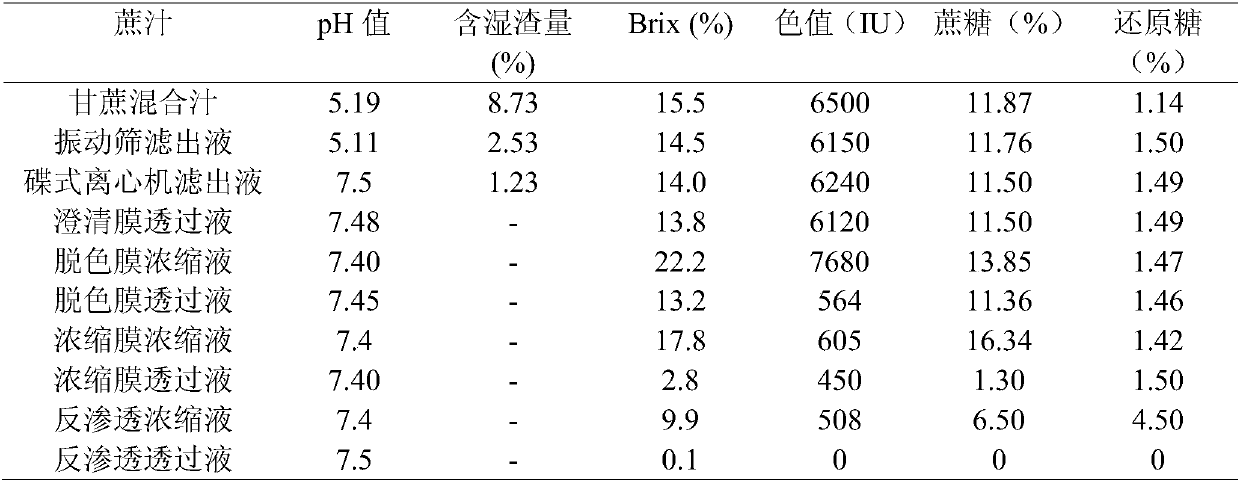

Method for desorbing acidic gas by oxidization process

InactiveCN102266714AImprove removal efficiencyReduce investment and operating costsDispersed particle separationAir quality improvementFertilizerNitric oxide

The invention provides a method for desorbing an acidic gas by an oxidization process and relates to desorption of SO2 and NO(x) in a CO2 system. The acidic gas consisting of the SO2 and the NO(x) is oxidized by hydrogen peroxide serving as an oxidant and dissolved in water to form acid, so that the acidic gas can be separated from other gases. According to the concentration of the acidic harmfulgas in the system, a suction process and an absorption process are adopted respectively. As the CO2 does not take part in the reaction, the load of the deacidified gas as well as the investment and energy consumption cost are reduced. The acidic solution is converted into a fertilizer after being treated by ammonia water, so that secondary pollution is avoided and an additional value of the process is increased; therefore, the method is particularly suitable for desorption of a little of sulfur oxide and nitric oxide.

Owner:TIANJIN UNIV

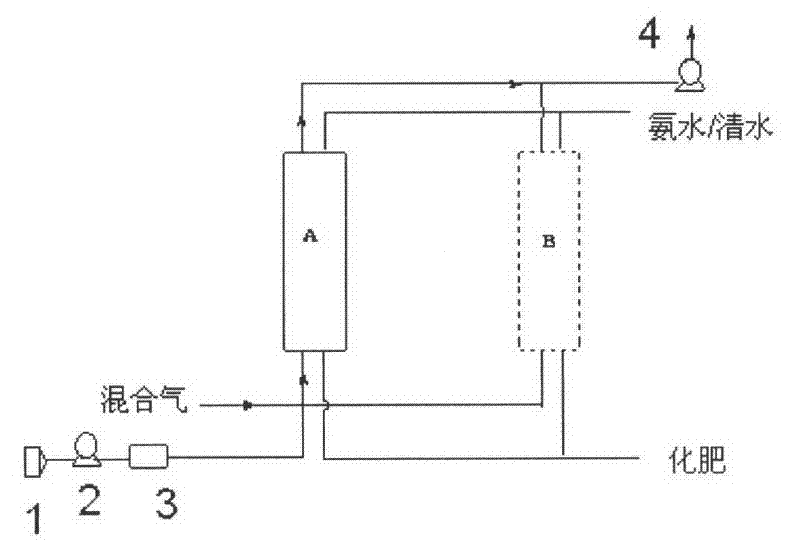

Physicochemical-artificial wetland combined process for strengthening treatment of fluorine and arsenic sewage

InactiveCN104773898ASmall footprintGood effect in removing fluoride and arsenicMultistage water/sewage treatmentConstructed wetlandCollection system

The invention provides an adsorption-artificial wetland combined treatment system for strengthening treatment of sewage containing fluorine and arsenic; the system is composed of an adsorption device and an artificial wetland treatment device which are connected in order. The adsorption device is composed of a water inlet system, an adsorption packing layer and a water outlet system, the water inlet system allows water to be introduced from the lower layer, and the sewage is adsorbed by an adsorption packing and then is discharged from the upper layer water outlet system; the artificial wetland treatment device comprises an upper-layer wetland, a lower-layer wetland, a water inlet system and an effluent collection system, the upper layer of the water inlet system is used for distributing water, the sewage passes through the upper-layer wetland and the lower-layer wetland and then is discharged out of the device by the effluent collection system. With adsorption-artificial wetland combined treatment, the life of the artificial wetland can be prolonged. The system has the advantages of small occupation area and good removal effect on fluorine and arsenic.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES +1

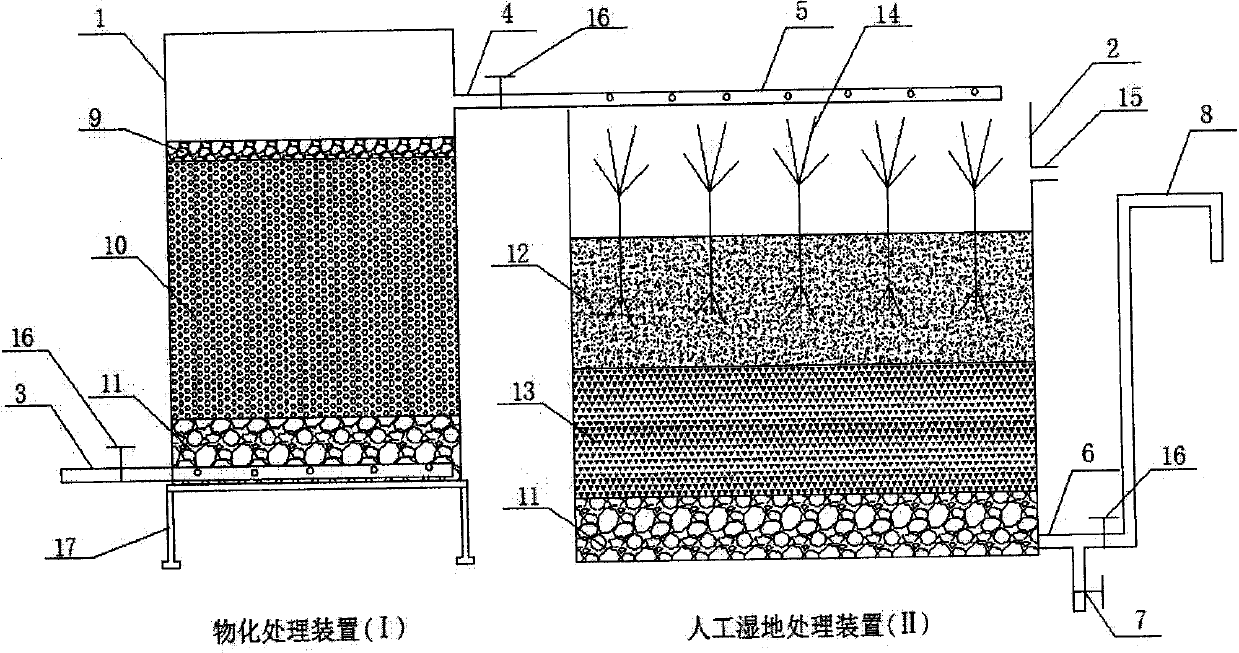

Natural gas pressure regulator station system

ActiveCN104100836AReduce investment and operating costsImprove stability and securityPipeline systemsPressure regulatorNatural gas

The invention discloses a natural gas pressure regulator station system. The natural gas pressure regulator station system is characterized by comprising an inlet insulation and fire alarm cut-off unit, a cyclone separation unit, a filter separation unit, a measuring unit, a pressure regulating unit and an outlet unit, which are sequentially connected together. A pressure regulator station is far away from a gas user, a front module of the natural gas pressure regulator station system is arranged in front of the gas user, the front module comprises a front measuring unit, a front fine filter unit and a front insulation and fire alarm cut-off unit. The natural gas pressure regulator station system has advantages that the investment and operation cost can be reduced, and the stability and safety for supplying the natural gas can be improved; a complete auxiliary facility is also provided on the basis of a heating unit and a front unit for the gas consumption characteristics and upstream gas source parameters of the gas user, so that the safety and stability of the pressure regulator station system in operation can be guaranteed, and the requirements of the gas user on high natural gas parameter accuracy and high response speed can be met.

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com