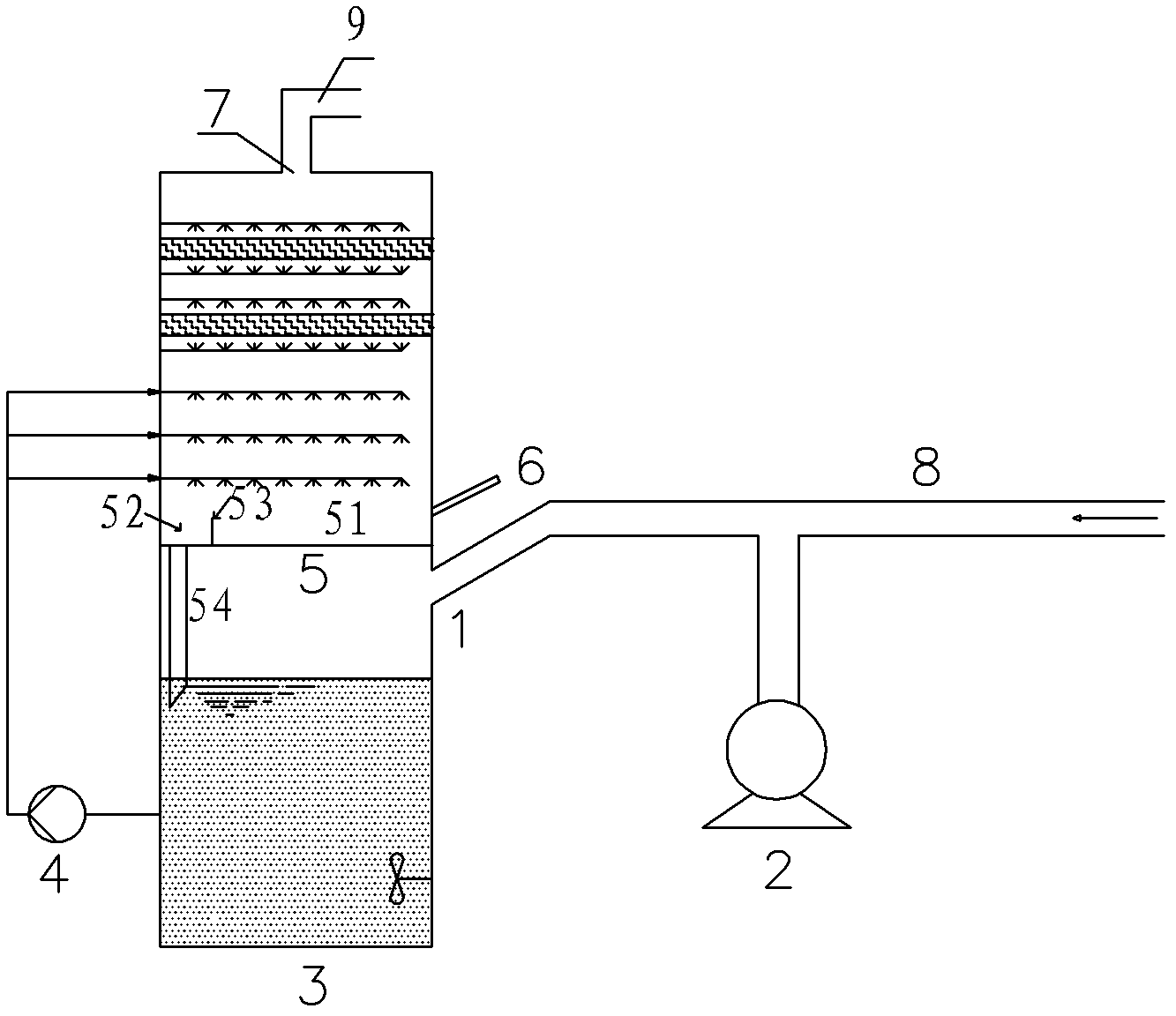

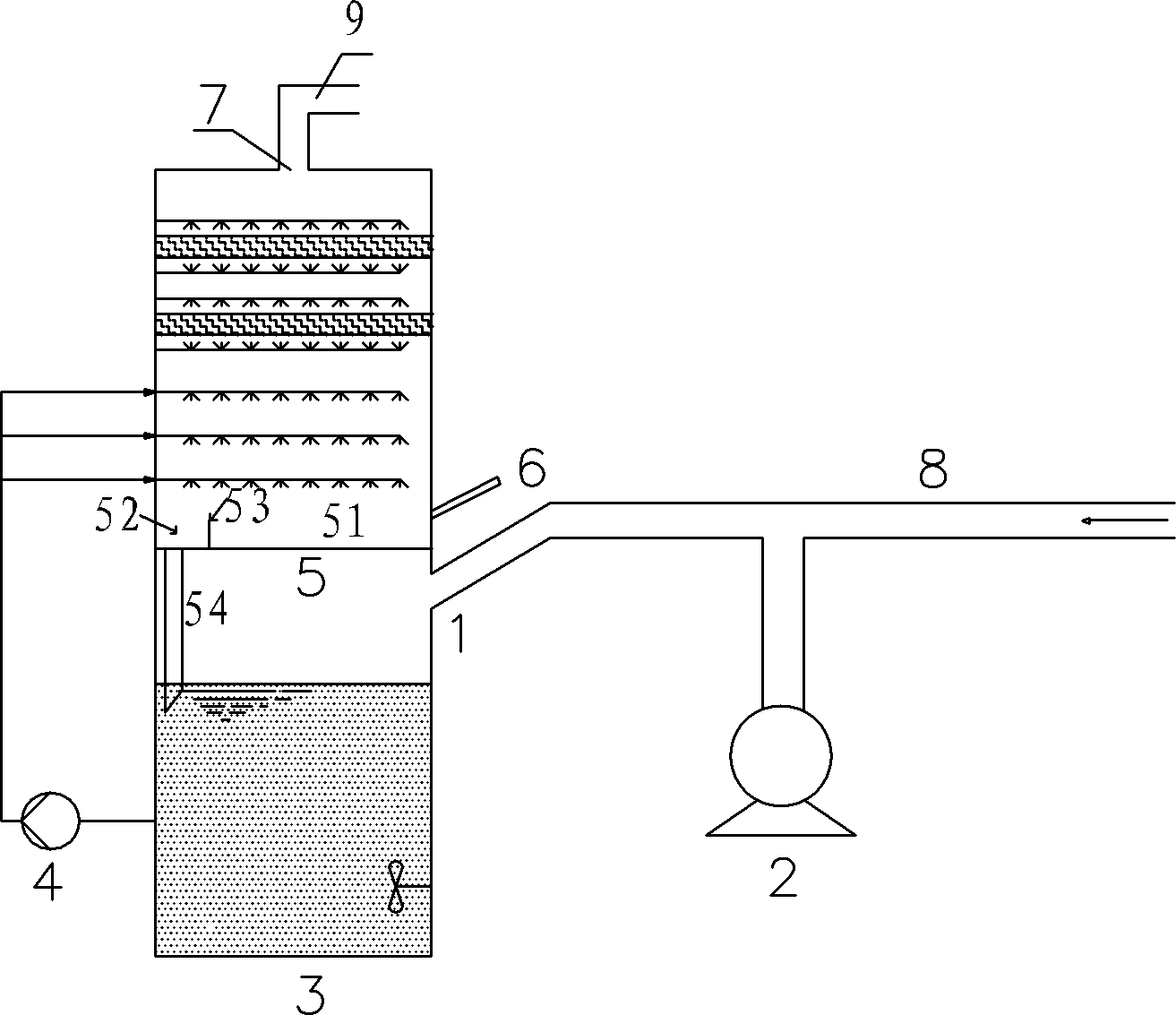

Sieve-plate tower used for sintering machine flue gas desulfurization and desulfurization process thereof

The technology of a sintering machine and a sieve tray tower is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., and can solve the problems of difficulty in controlling the pH value of the system slurry, increasing the resistance of the sieve tray layer, and wasting system energy consumption, etc. Achieve the effect of reducing investment and operating costs, increasing desulfurization capacity and desulfurization efficiency, and improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

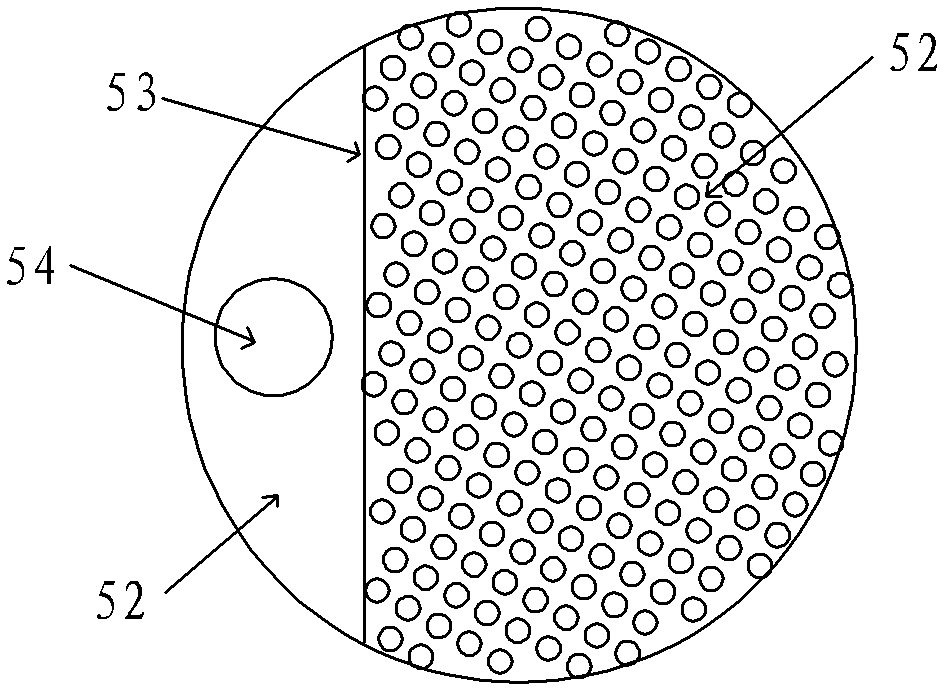

[0032] A steel group 1×200m 2 The flue gas desulfurization project of the sintering machine adopts the sieve plate tower and its desulfurization process of the present invention for flue gas desulfurization, and the desulfurizing agent is limestone. The liquid-gas ratio of wet desulfurization is 6L / m 3 , the pH control is 5.4, the residence time of the slurry in the gas-liquid contact area is 100s (that is, the height of the overflow weir is 33cm), the thickness of the sieve plate is 2cm, the opening rate is 45%, and the pore diameter is 6cm. The area ratio of the flow area is 7:3, the diameter of the overflow pipe is 70cm, the length is 400cm, and the inlet SO 2 The concentration is 2360mg / Nm 3 , SO after desulfurization 2 The concentration is 86mg / Nm 3 , the purity of the gypsum is 92.8%, and the residual amount of desulfurizer in the gypsum is less than 0.2%.

Embodiment 2

[0034] A steel group 2×160m 2 The flue gas desulfurization project of the sintering machine adopts the sieve plate tower and its desulfurization process of the present invention for flue gas desulfurization, and the desulfurizing agent is lime. The wet desulfurization liquid-gas ratio is 5L / m 3 , the pH control is 5.2, the residence time of the slurry in the gas-liquid contact area is 130s (that is, the height of the overflow weir is 35cm), the thickness of the sieve plate is 2cm, the opening rate is 48%, and the pore diameter is 7cm. The area ratio of the flow area is 13:5, the diameter of the overflow pipe is 60cm, the length is 380cm, and the inlet SO 2 The concentration is 1830mg / Nm 3 , SO after desulfurization 2 The concentration is 65mg / Nm 3 , the purity of the gypsum is 93.1%, and the residual amount of desulfurizer in the gypsum is less than 0.2%.

Embodiment 3

[0036] A steel group 1×180m 2 The flue gas desulfurization project of the sintering machine adopts the sieve plate tower and its desulfurization process of the present invention for flue gas desulfurization, and the desulfurizing agent is limestone. The liquid-gas ratio of wet desulfurization is 7L / m 3 , the pH control is 5.4, the residence time of the slurry in the gas-liquid contact area is 90s (that is, the height of the overflow weir is 32cm), the thickness of the sieve plate is 2cm, the opening rate is 50%, and the pore diameter is 6cm. The area ratio of the flow area is 7:3, the diameter of the overflow pipe is 65cm, the length is 370cm, and the inlet SO 2 The concentration is 2010mg / Nm 3 . SO after desulfurization 2 The concentration is 71mg / Nm 3 , the purity of the gypsum is 91.6%, and the residual amount of desulfurizer in the gypsum is less than 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com