Catalyst for preparing propylene through propane catalytic dehydrogenation and preparation method thereof

A catalytic dehydrogenation and catalyst technology, which is applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of not yet established propane dehydrogenation production units, etc., and achieve good industrial development and application prospects, propylene selectivity Good and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a catalyst for propane catalytic dehydrogenation to prepare propylene, which is prepared by an equal-volume continuous impregnation method, and the steps are as follows:

[0026] 1) Weigh 3.0g of self-made powder MCM-41 carrier and bake at 550°C for 4h;

[0027] 2) Use SnCl with a concentration of 0.0168mol / L 2 Immerse the MCM-41 carrier roasted in step 1) in 9.0ml of ethanol solution for 12h, then remove the solvent with a rotary evaporator at 60°C and -0.08Mp, dry at 120°C for 12h, and roast at 550°C for 4h;

[0028] 3) Then use H with a concentration of 0.0068mol / L 2 PtCl 6 Immerse the sample treated in step 2) in 9.0ml of aqueous solution for 12h, remove the solvent with a rotary evaporator at 60°C and -0.08Mp, dry at 120°C for 12h, and calcinate at 550°C for 4h to finally obtain Catalyst A.

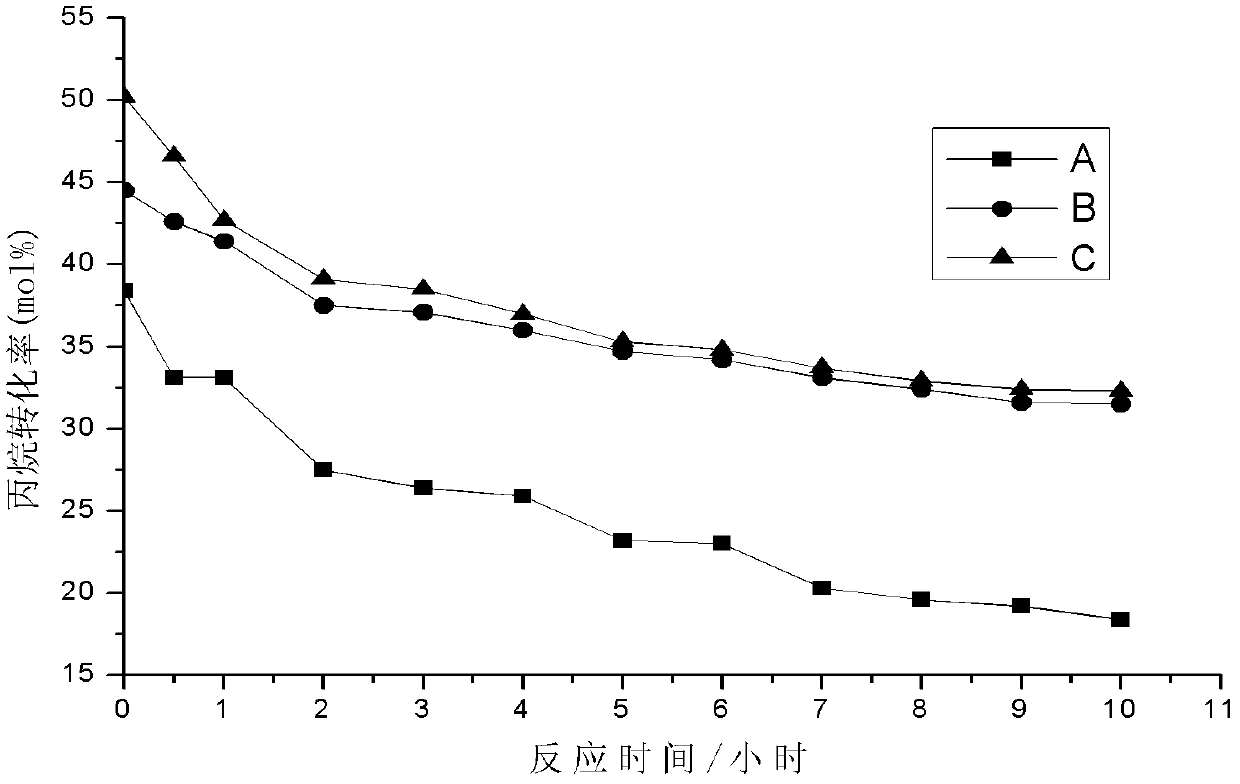

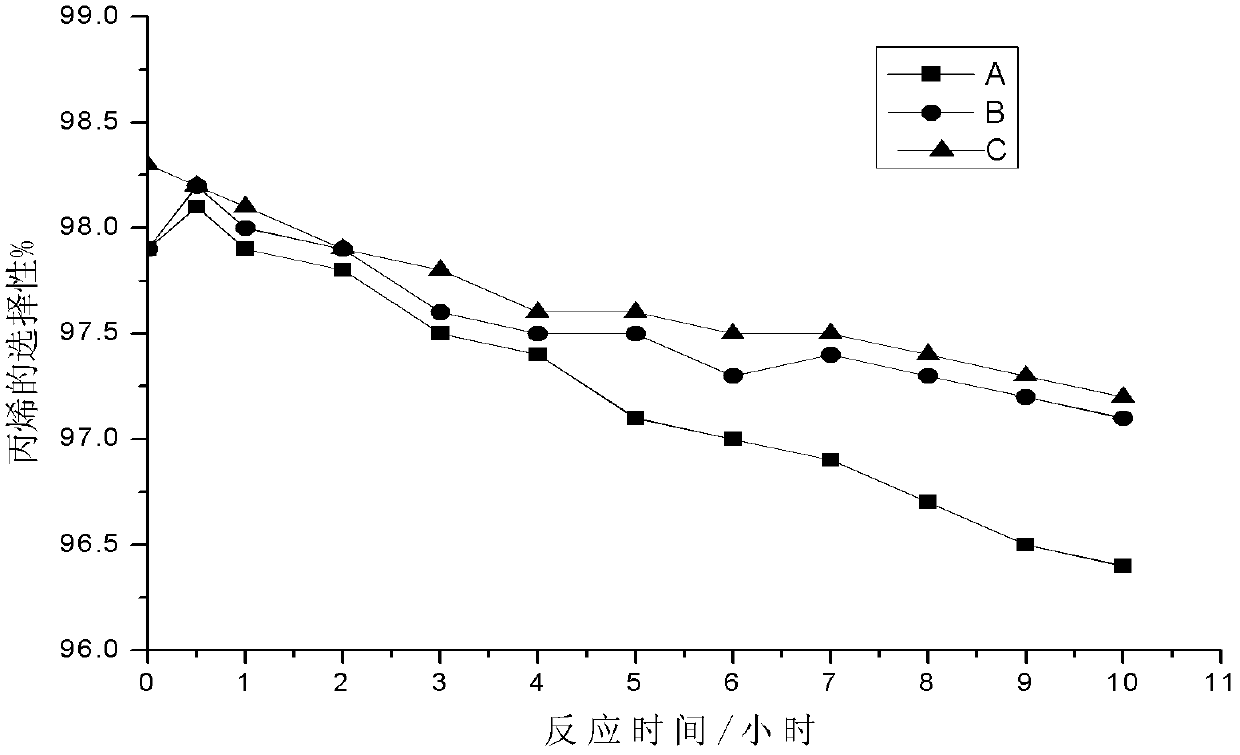

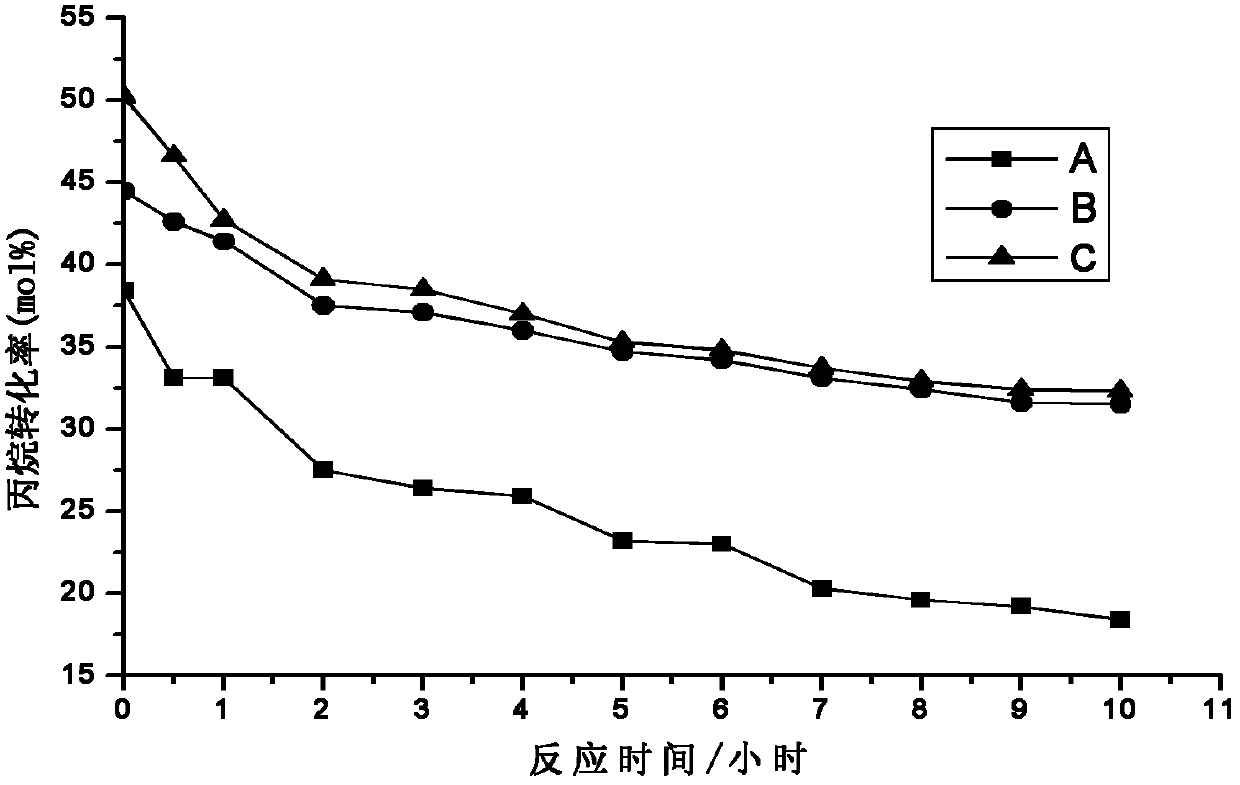

[0029] Catalyst A component is: Pt-Sn / MCM-41, catalytic reaction temperature is 550-620°C, pressure is 0.1Mp, reaction gas hourly space velocity (GSH...

Embodiment 2

[0031] A method for preparing a catalyst for propane catalytic dehydrogenation to prepare propylene, which is prepared by an equal-volume continuous impregnation method, and the steps are as follows:

[0032] 1) Weigh 3.0g of self-made powder MCM-41 carrier and bake at 550°C for 4h;

[0033] 2) Ce(NO 3 ) 3 Immerse 9.0ml of aqueous solution for 12h, then remove the solvent with a rotary evaporator at 60°C and -0.08Mp, dry at 120°C for 12h, and roast at 550°C for 4h;

[0034] 3) Immerse the sample after step 2) with 0.0168mol / L SnCl 2 9.0ml of ethanol solution, the preparation process is exactly the same as step 2);

[0035] 4) Finally, the impregnation concentration of the sample after step 3) is 0.0068mol / L H 2 PtCl 6 Aqueous solution 9.0ml, its preparation process and conditions are the same as step 2), catalyst B can be prepared.

[0036] The component of catalyst B is: Pt-Sn-Ce / MCM-41, and the detection condition of catalytic application is identical with embodiment 1...

Embodiment 3

[0038] A method for preparing a catalyst for propane catalytic dehydrogenation to prepare propylene, which is prepared by an equal-volume continuous impregnation method, and the steps are as follows:

[0039] 1) Same as step 1) of Example 2;

[0040] 2) Same as step 2) of Example 2;

[0041] 3) Same as step 3) of embodiment 2;

[0042]4) The sample treated in step 3) was treated with Ca(NO 3 ) 2 Soak 9.0ml of the solution for 12h, then remove the solvent with a rotary evaporator at 60°C and -0.08Mp, dry at 120°C for 12h, and roast at 550°C for 4h;

[0043] 5) Immerse the above treated sample in 0.0068mol / L H 2 PtCl 6 Add 9.0ml of aqueous solution, then remove the solvent with a rotary evaporator at 60°C and -0.08Mp, dry at 120°C for 12 hours, and calcinate at 550°C for 4 hours to prepare catalyst C.

[0044] The component of catalyst C is: Pt-Sn-Ce-Ca / MCM-41, and the detection condition of catalysis application is identical with embodiment 1, and gas product after reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com