Patents

Literature

3751 results about "Naphtha" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Naphtha (/ˈnæpθə/ or /ˈnæfθə/) is a flammable liquid hydrocarbon mixture. Mixtures labelled naphtha have been produced from natural gas condensates, petroleum distillates, and the distillation of coal tar and peat.

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

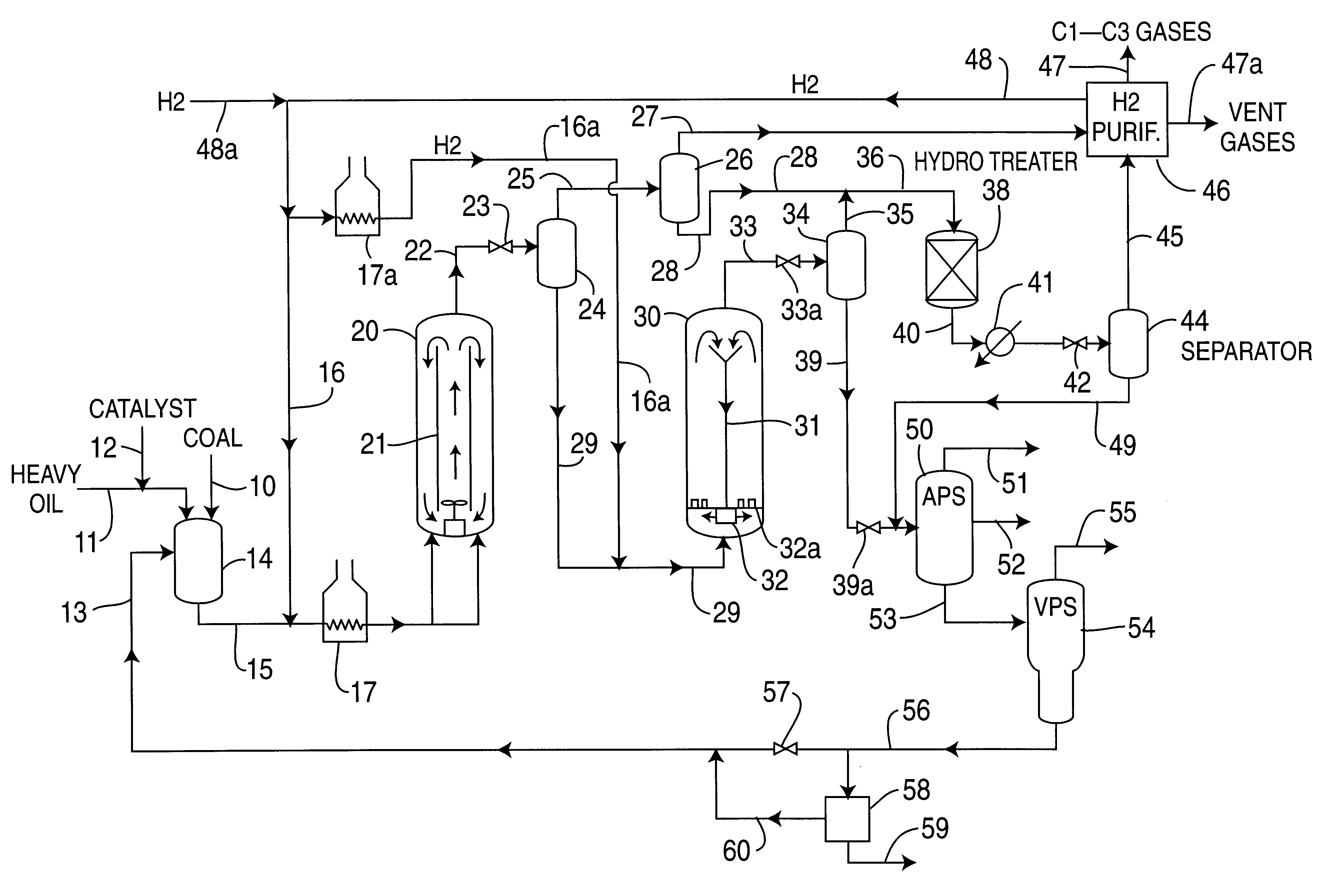

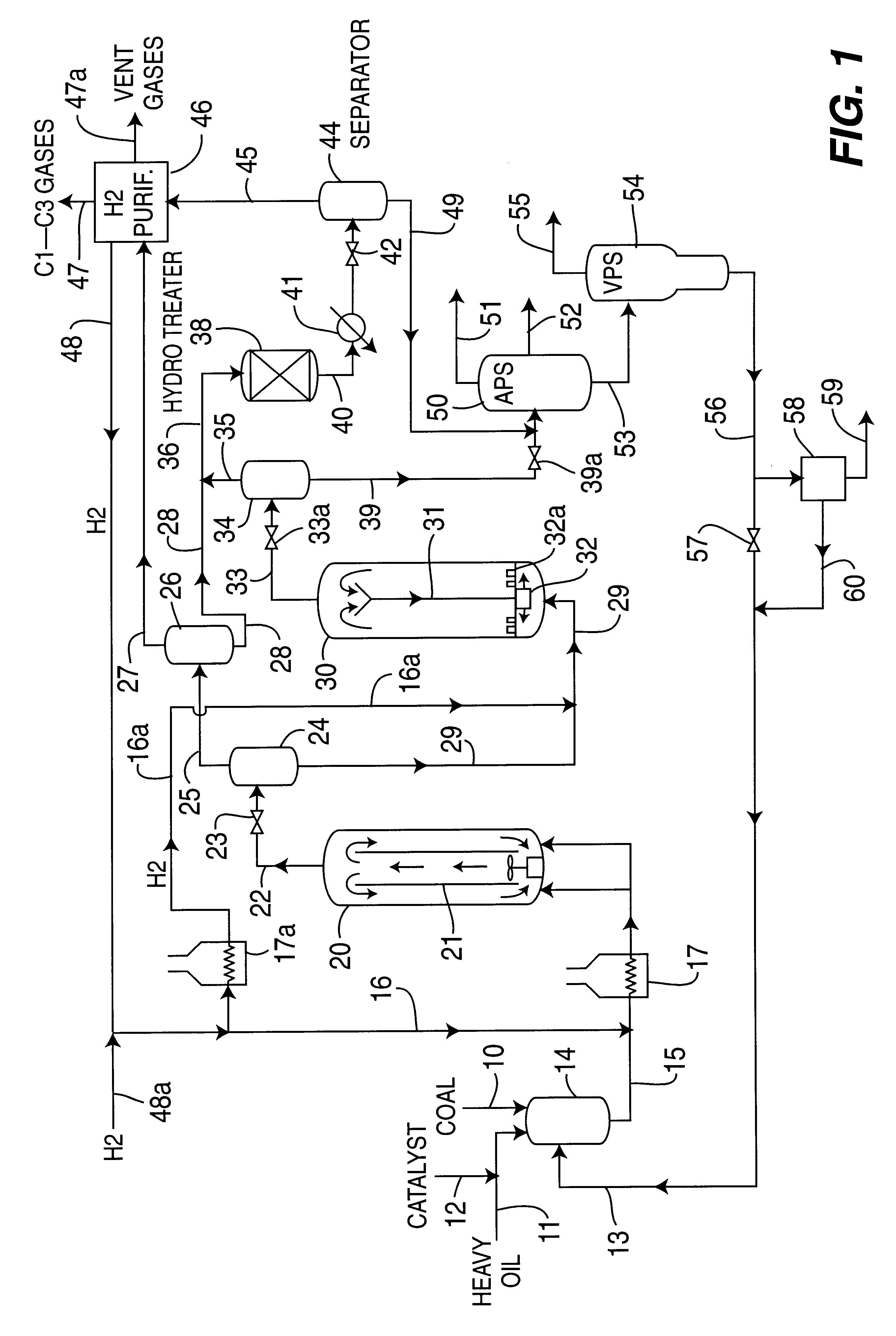

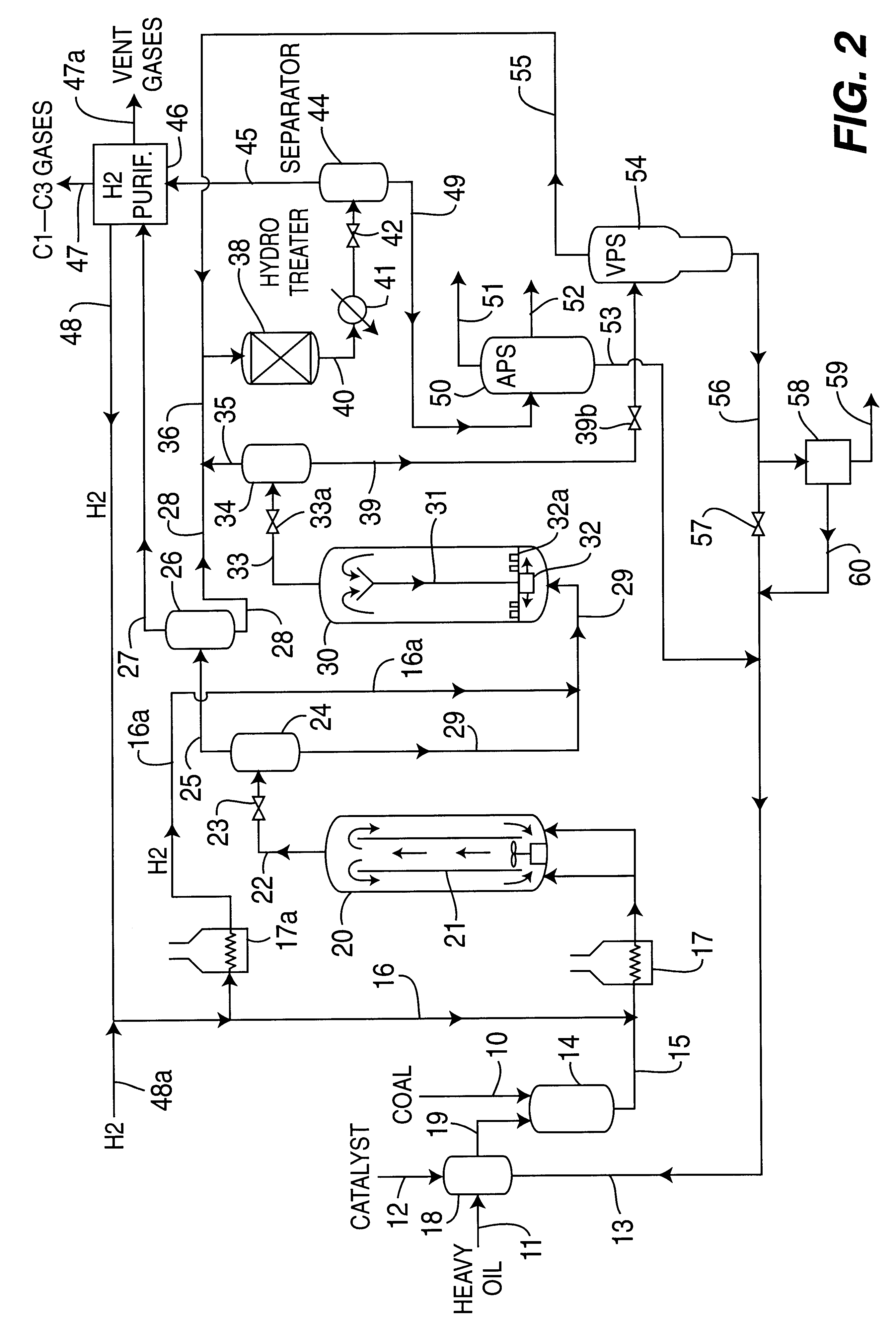

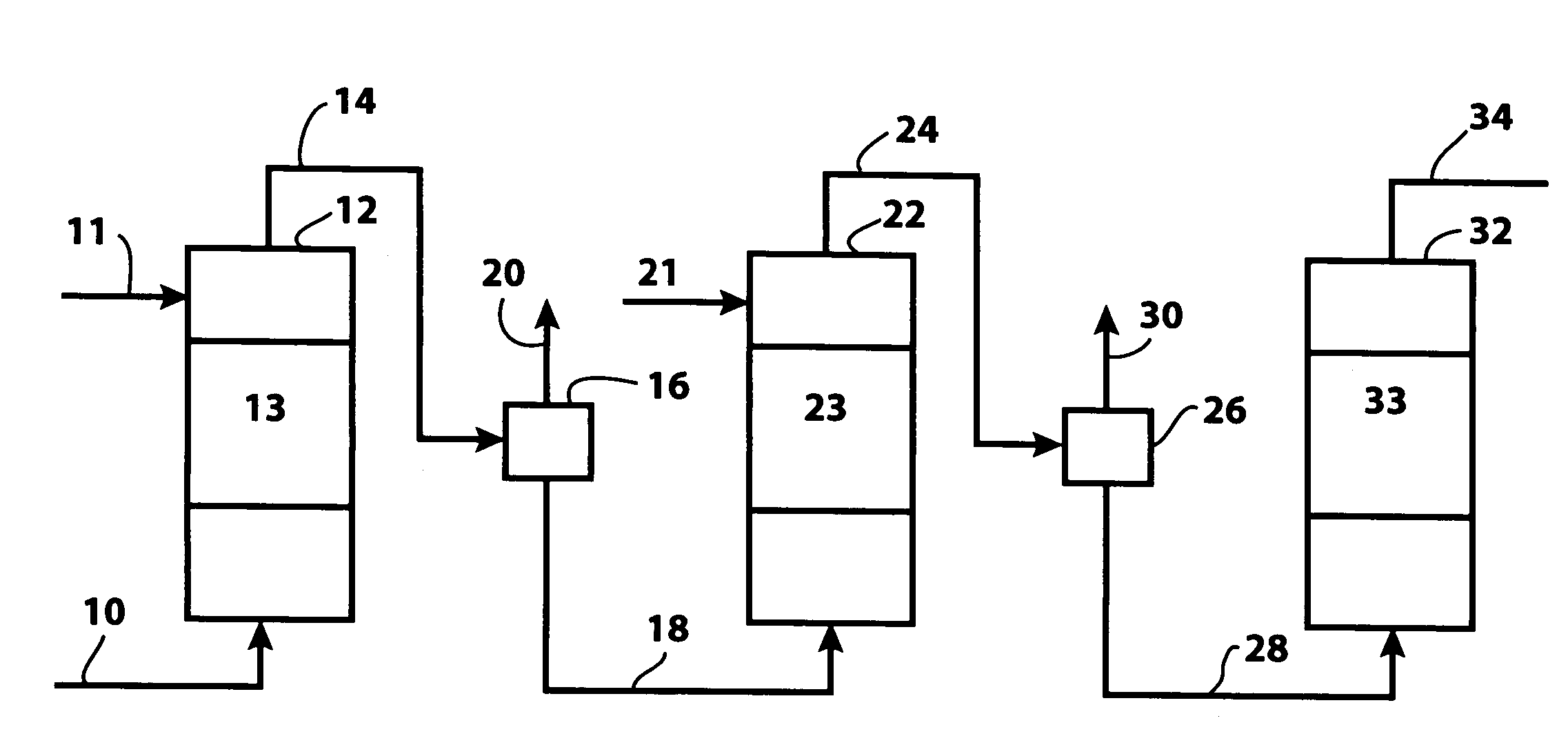

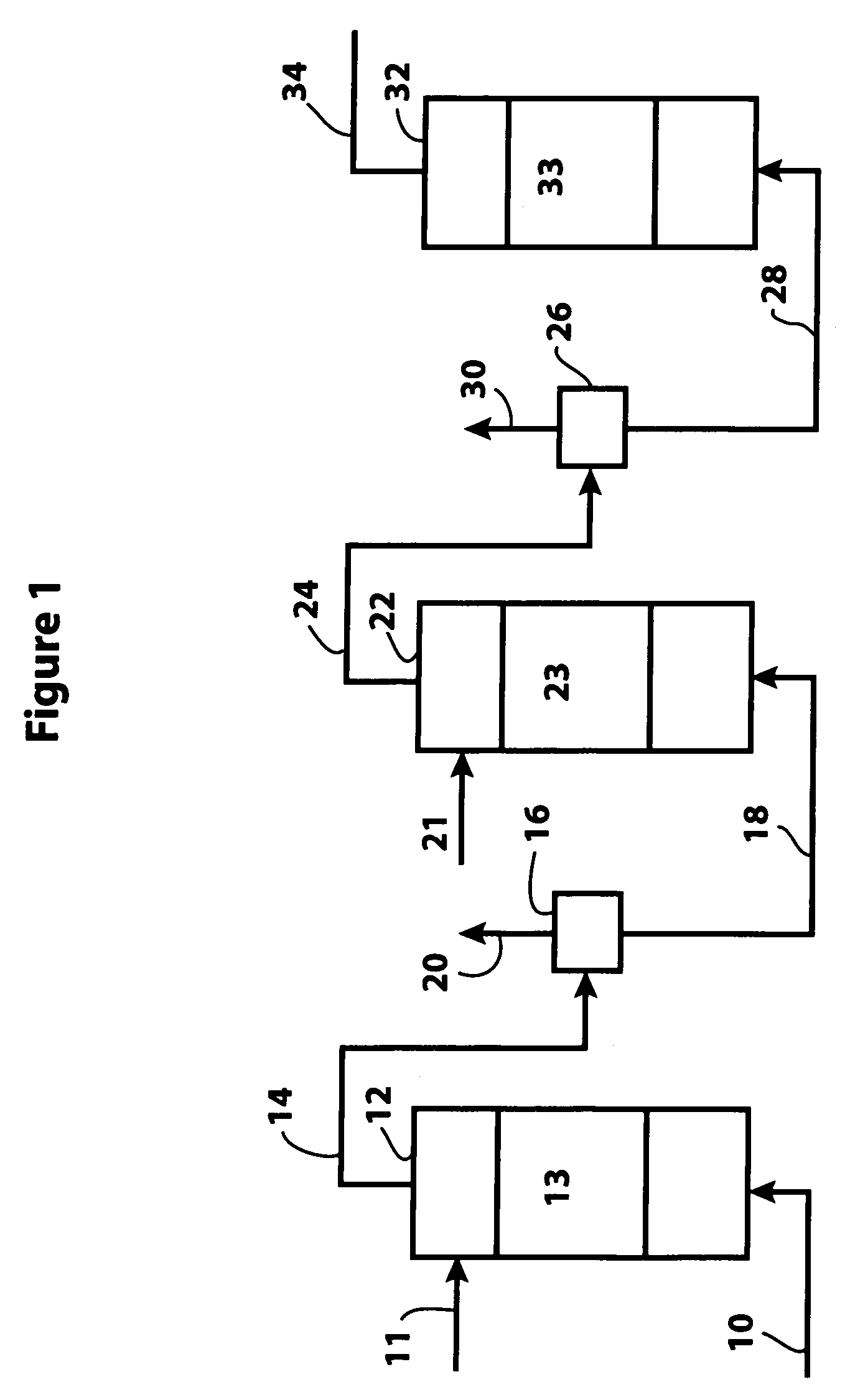

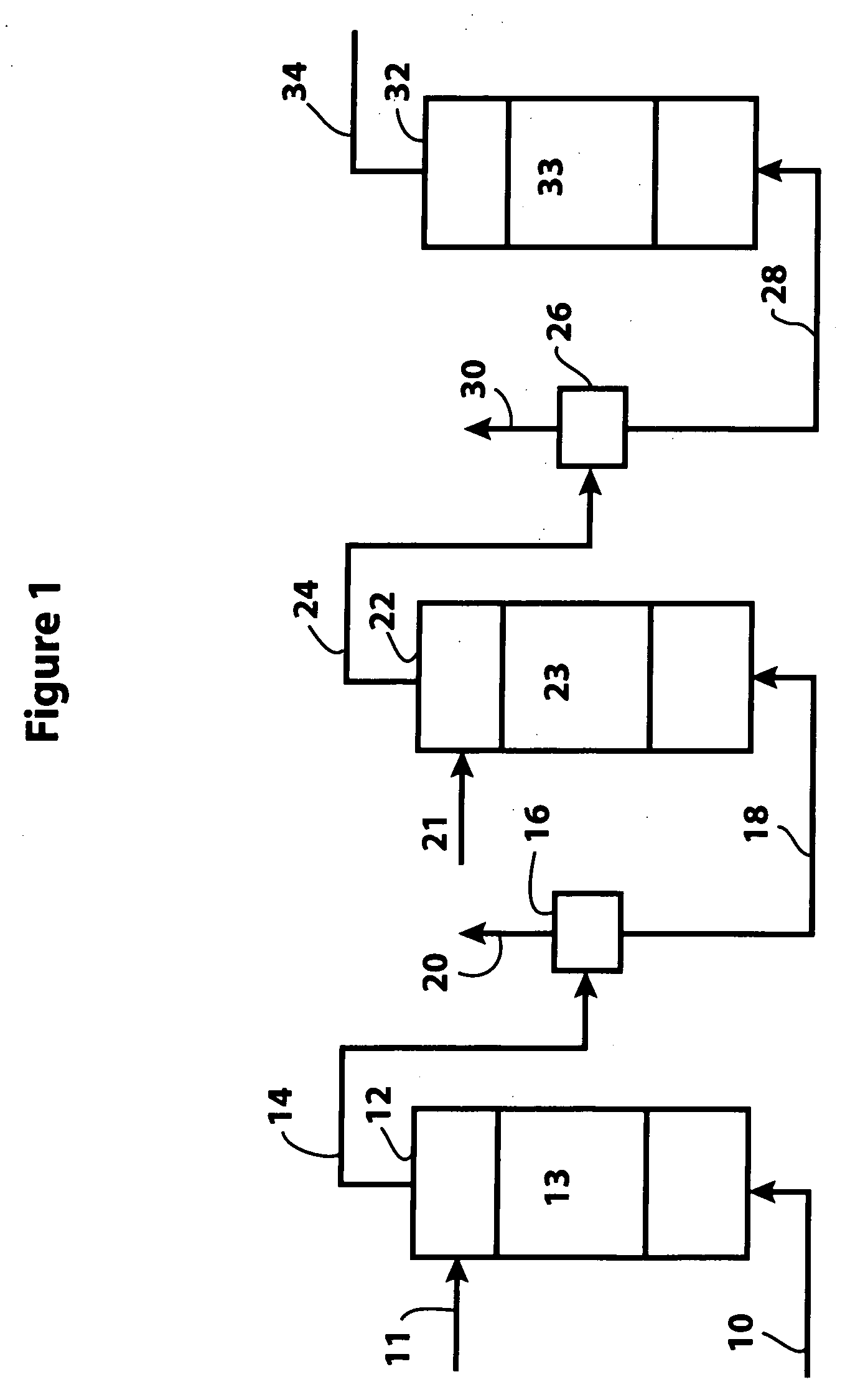

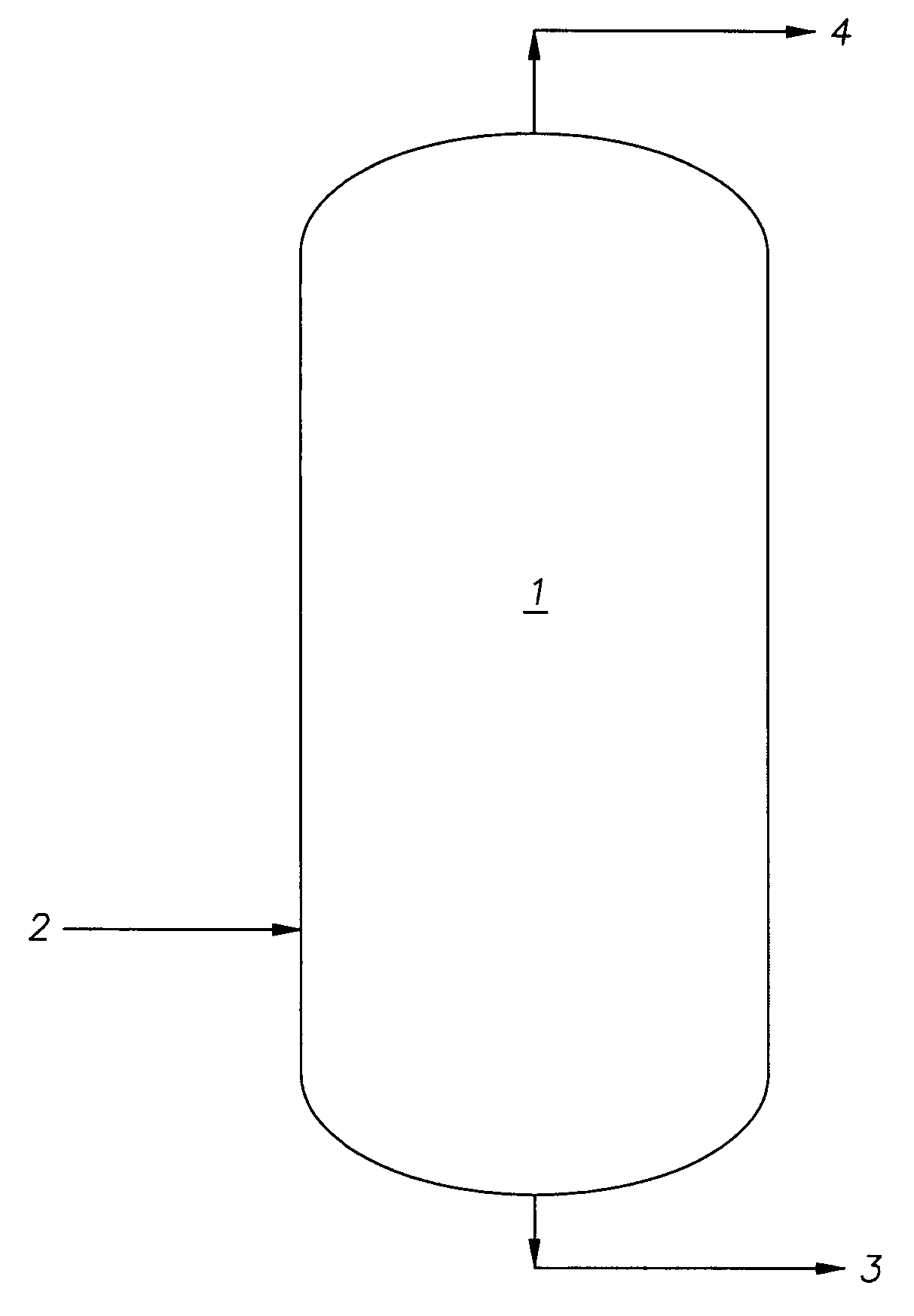

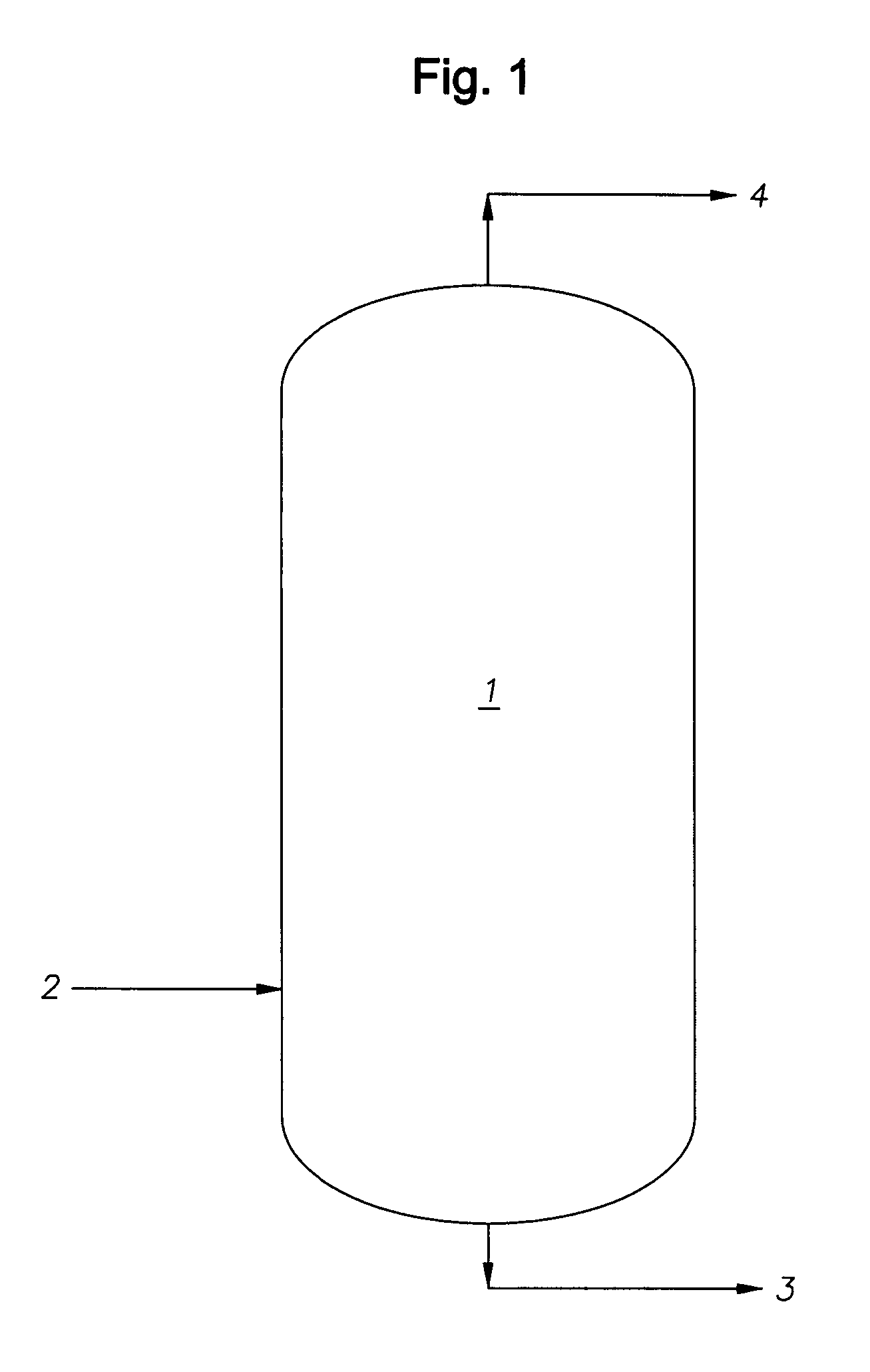

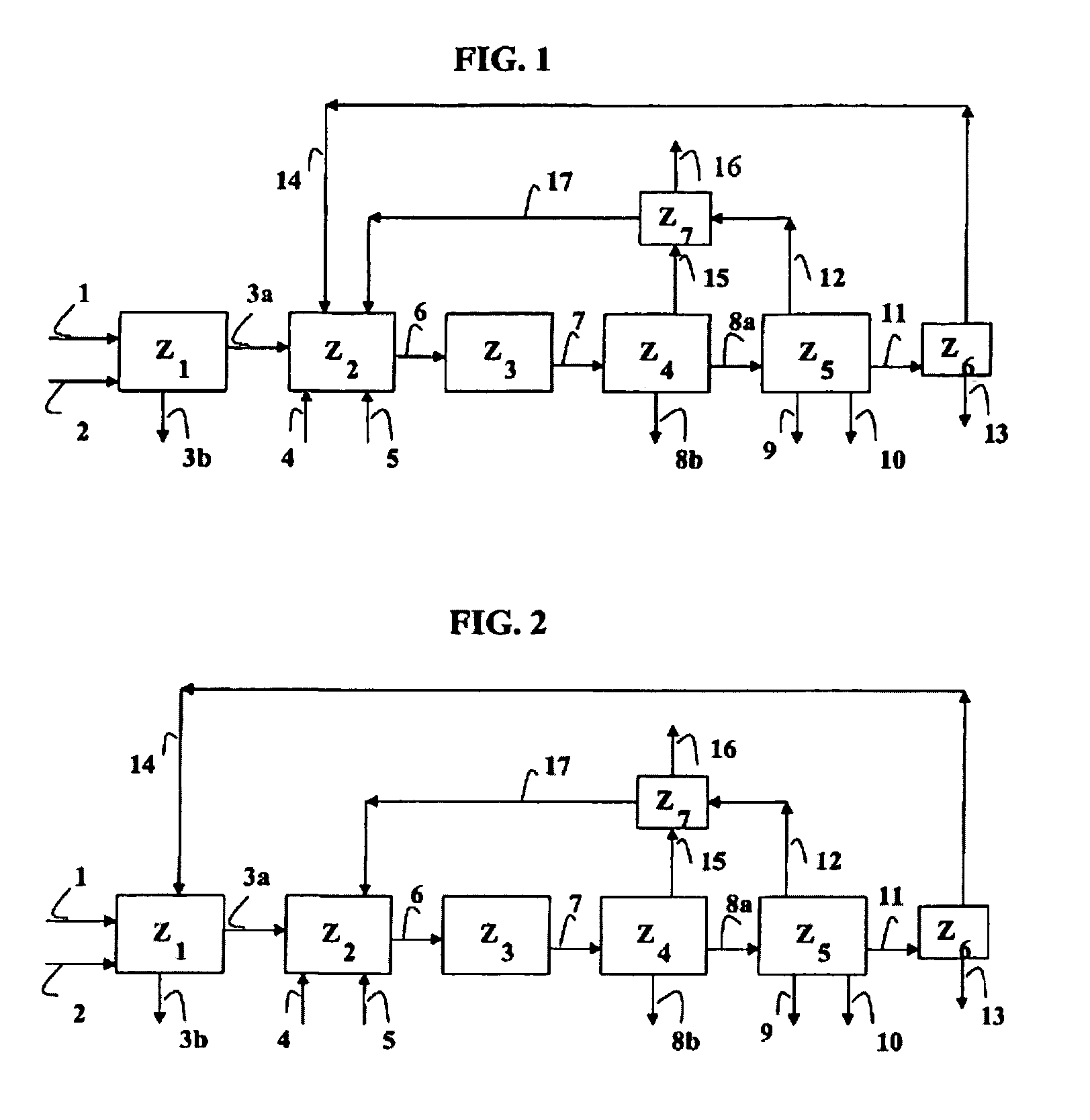

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

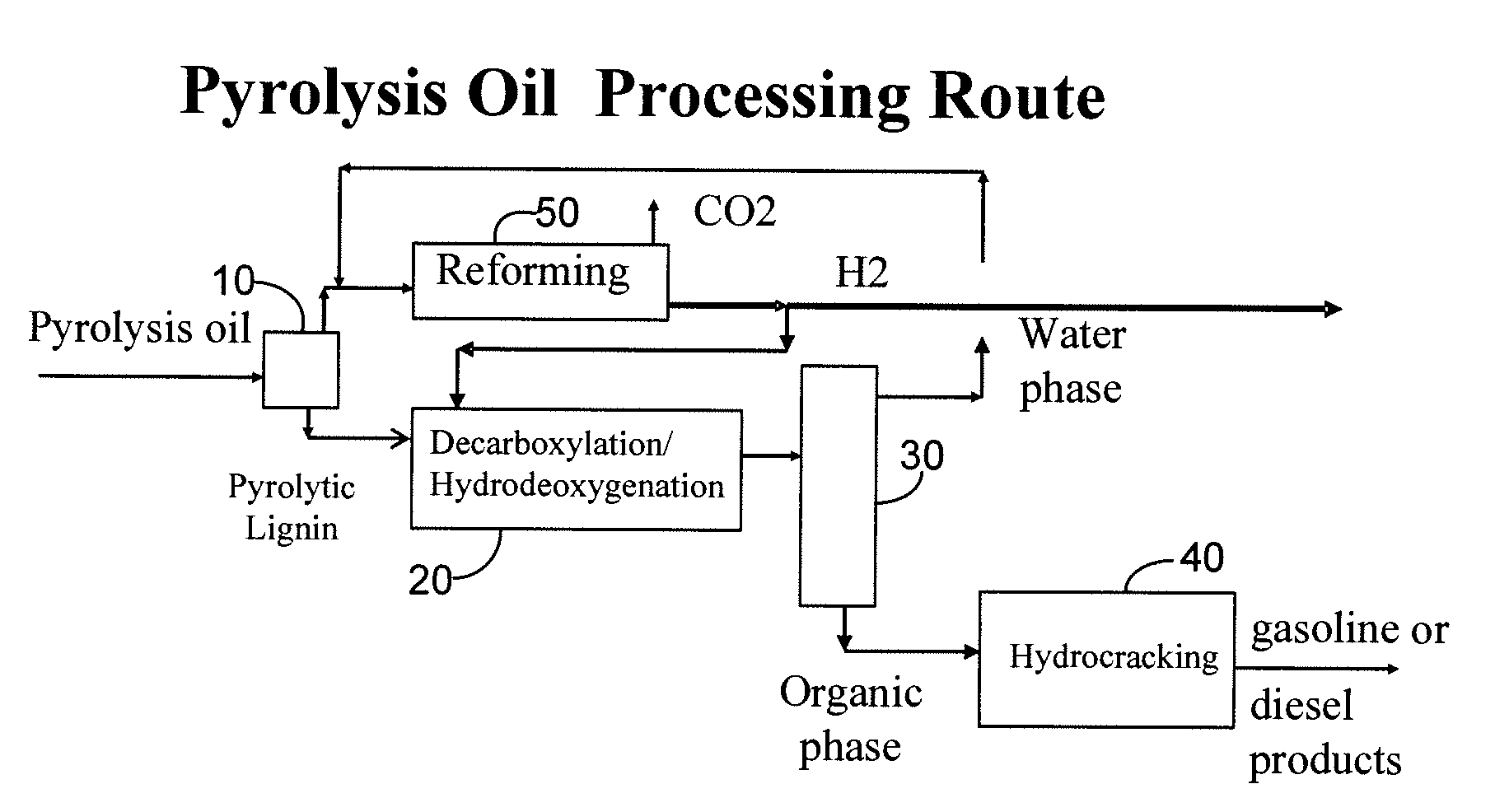

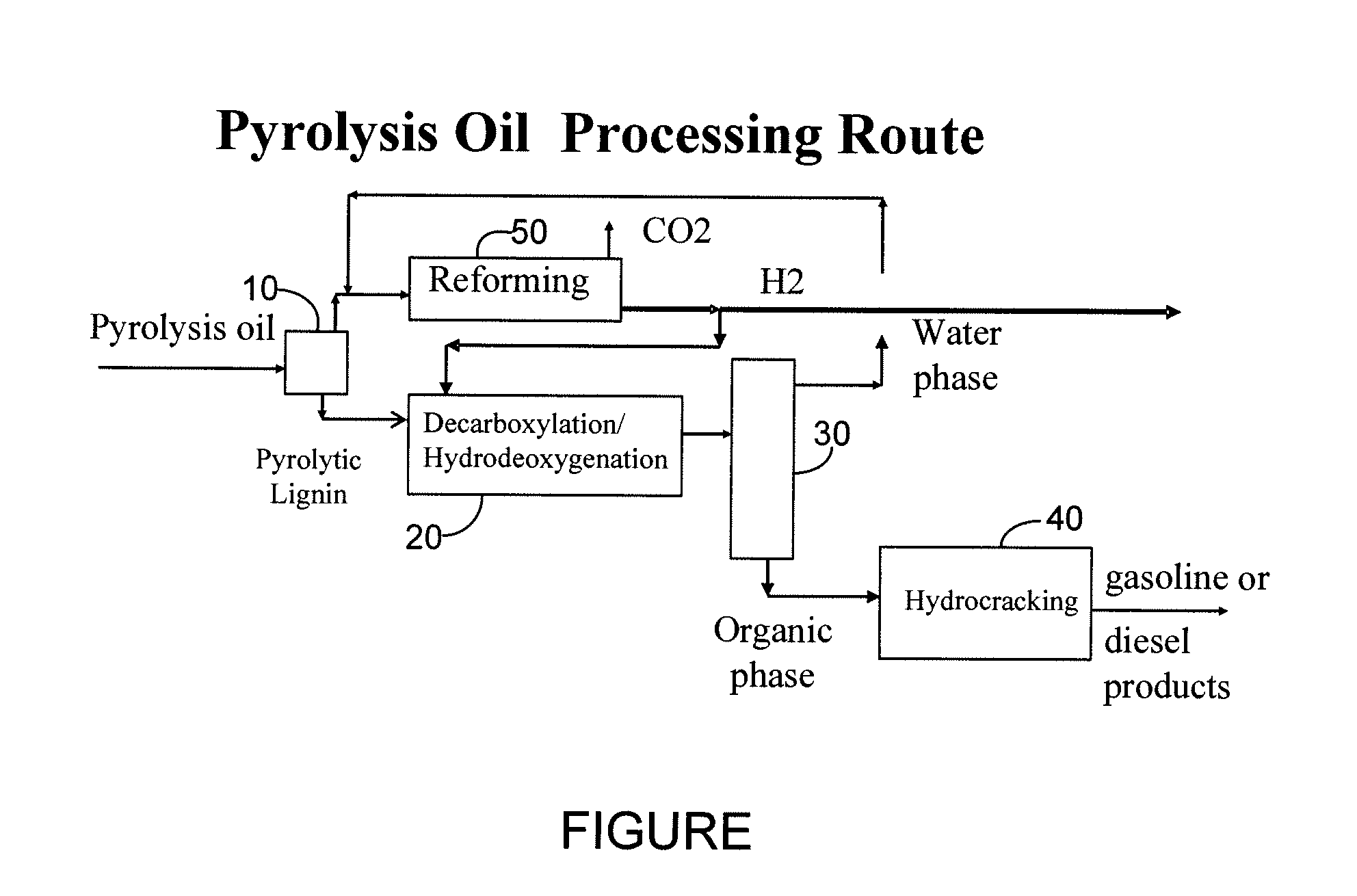

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS7578927B2Treatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

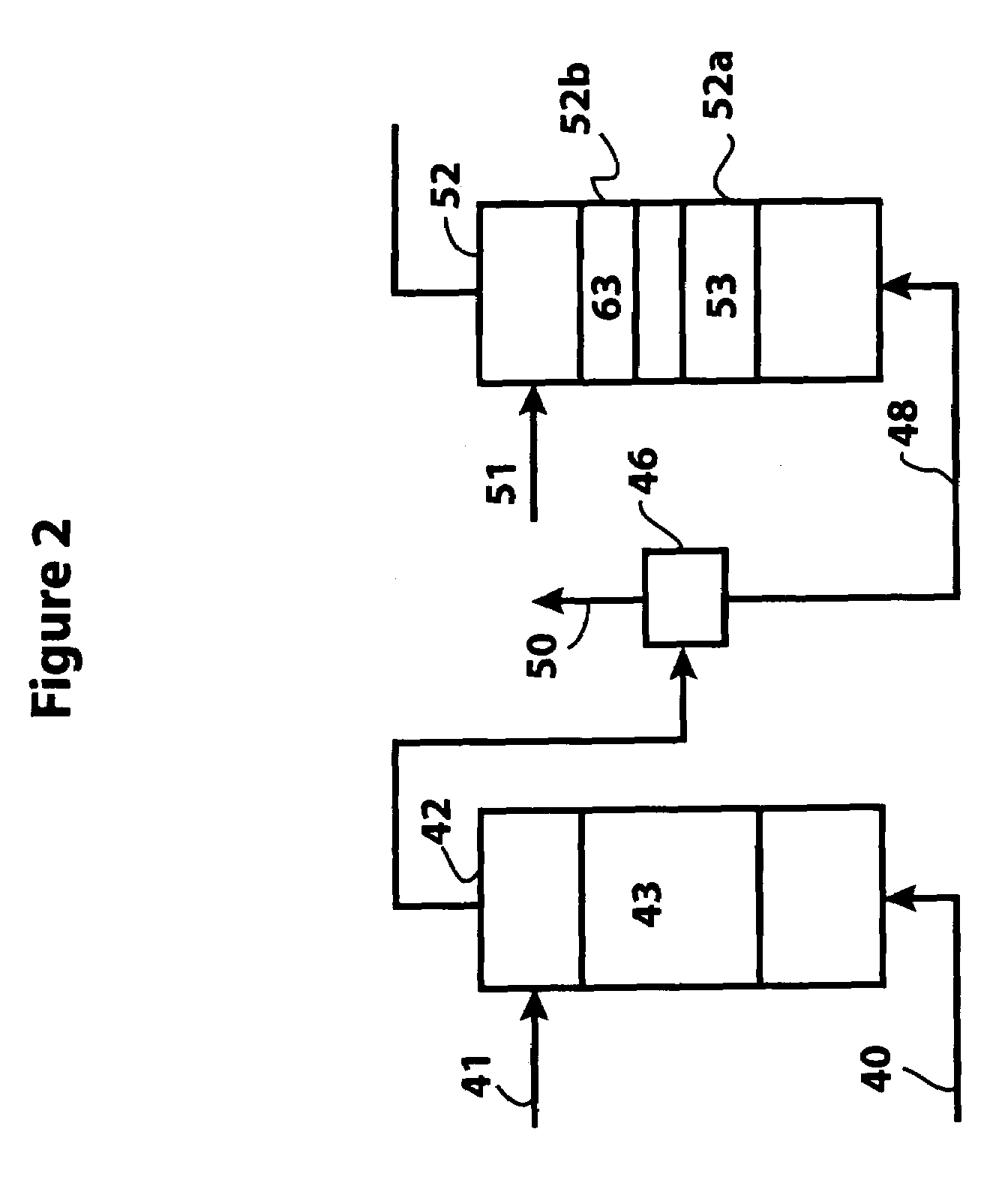

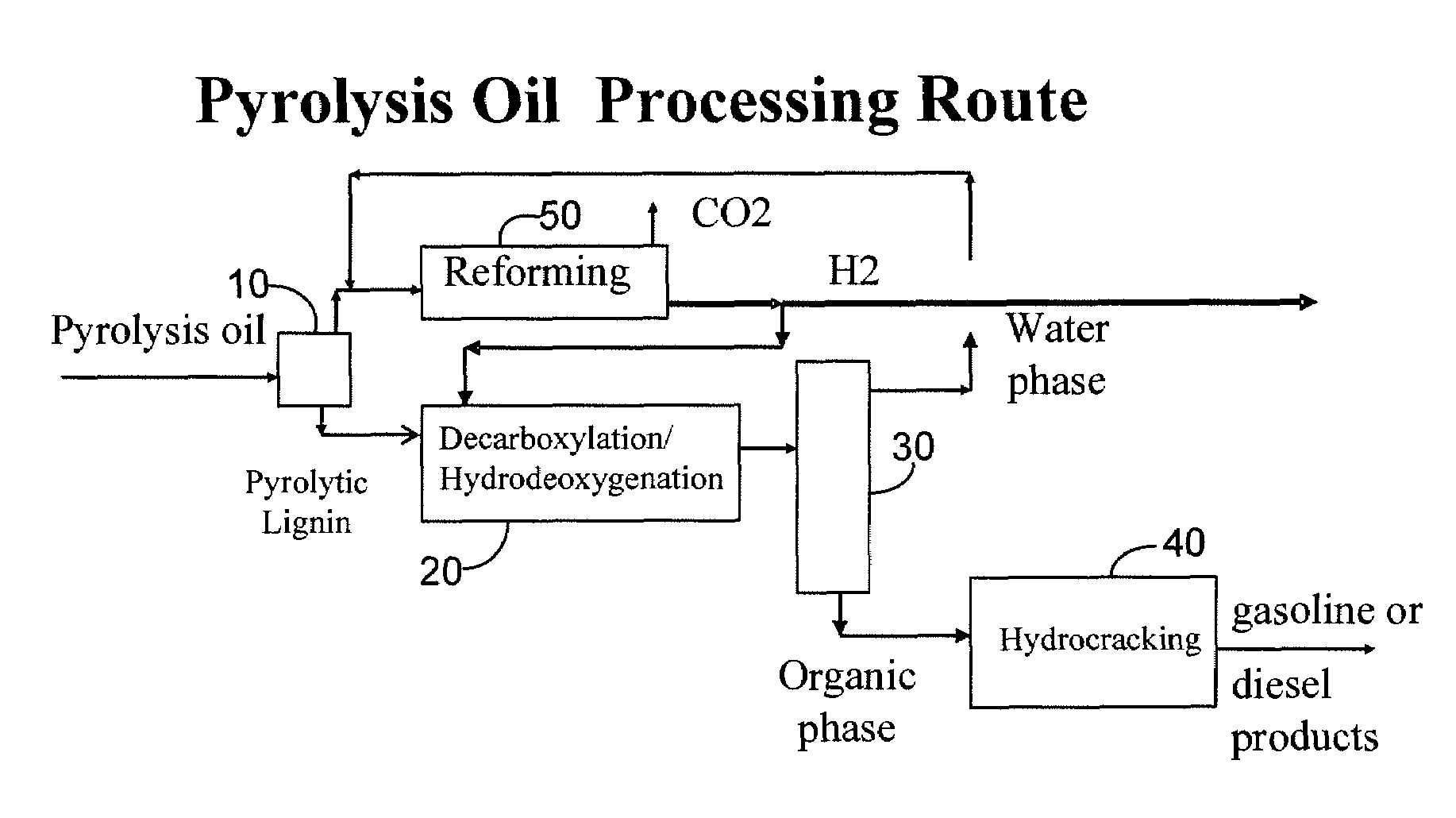

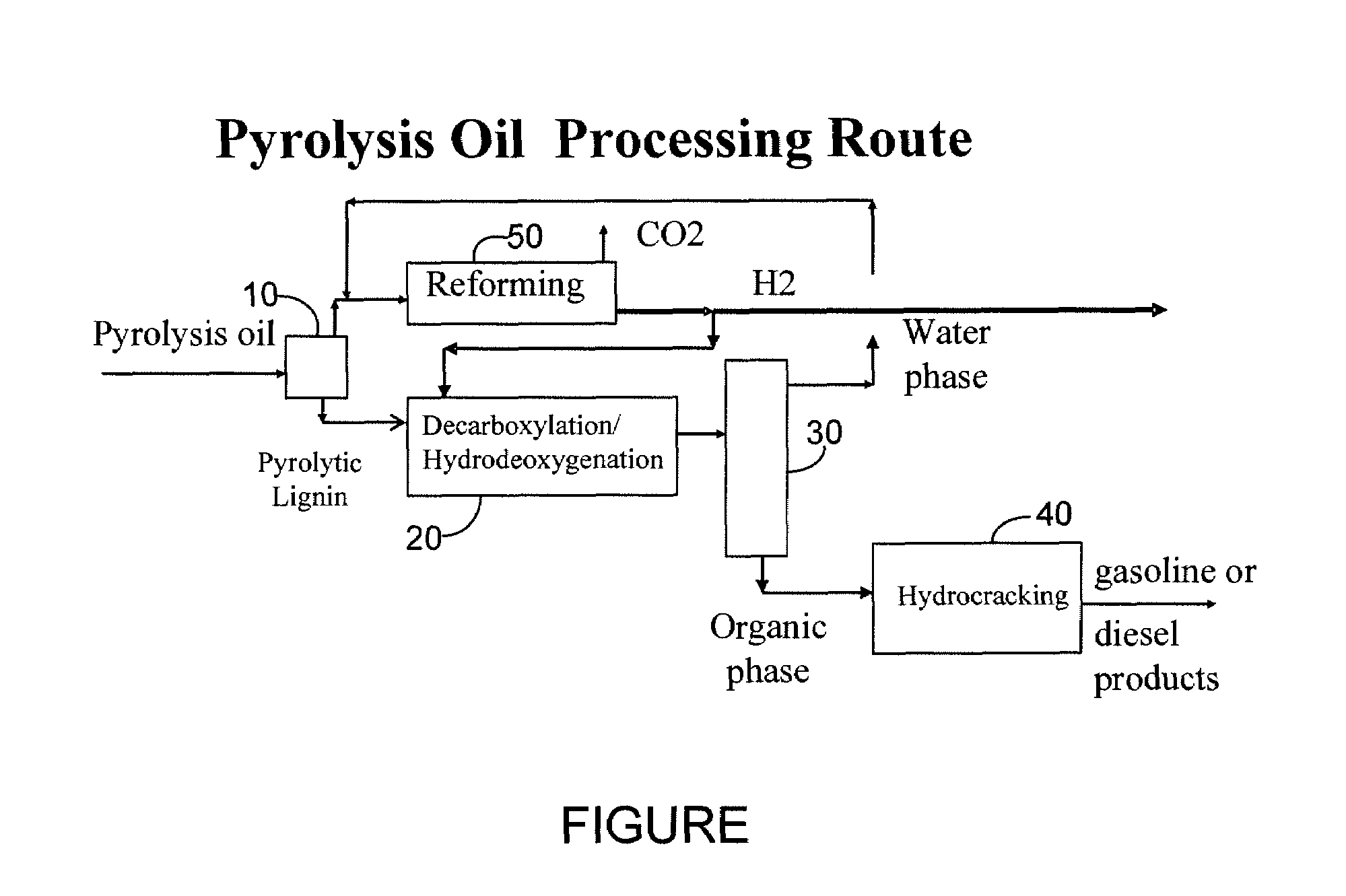

A process for the conversion of biomass to a liquid fuel is presented. The process includes the production of diesel and naphtha boiling point range fuels by hydrocracking of pyrolysis lignin extracted from biomass.

Owner:UOP LLC

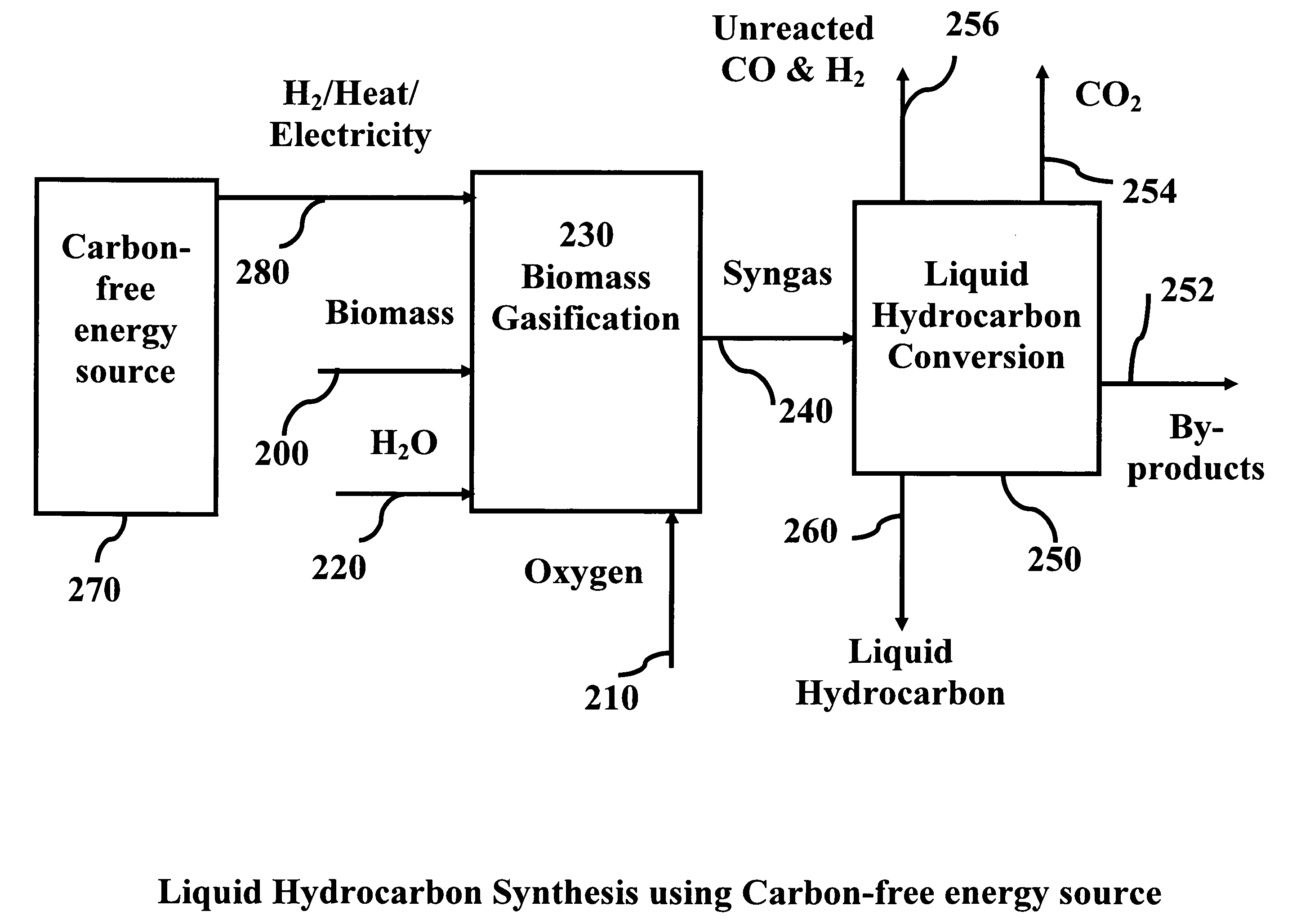

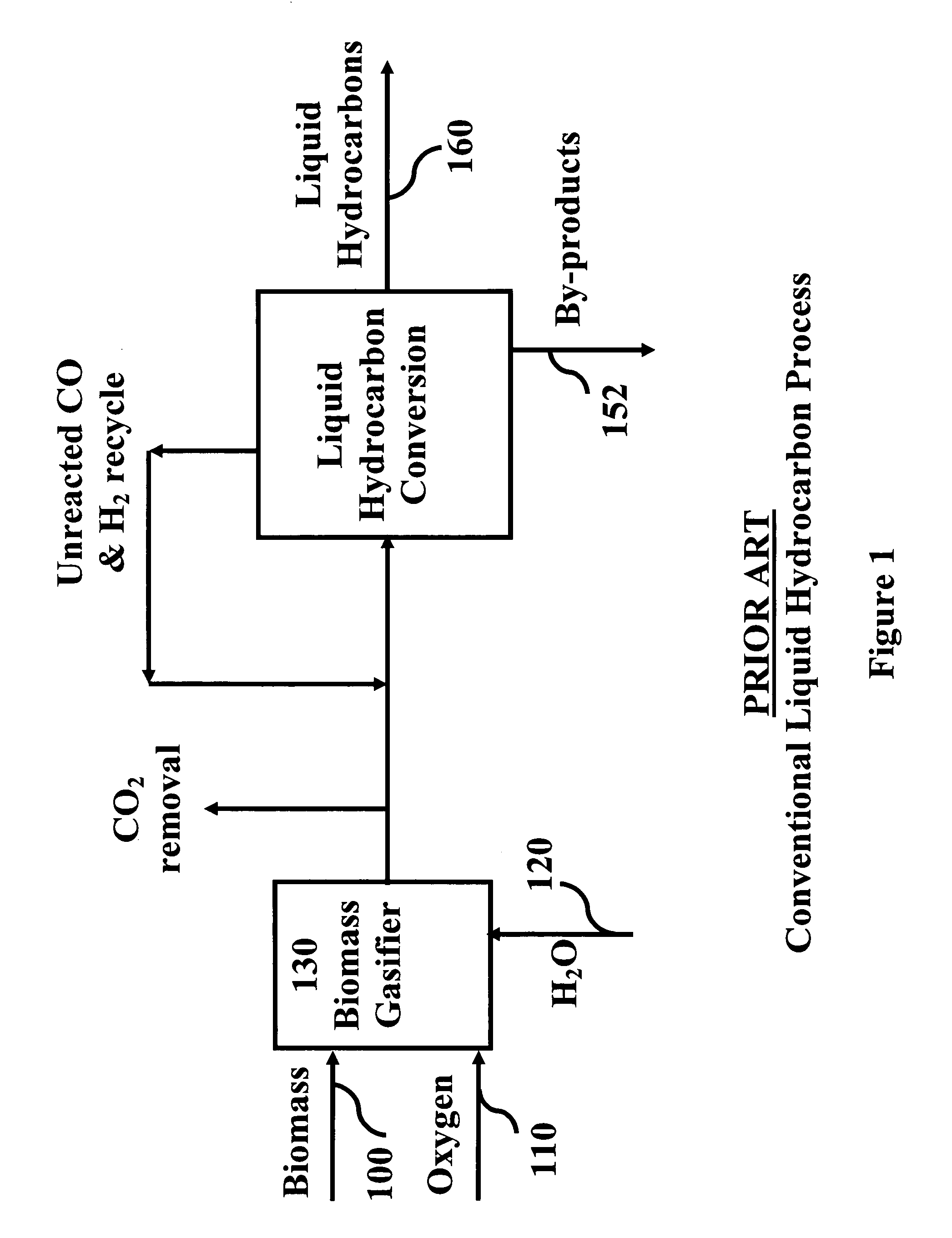

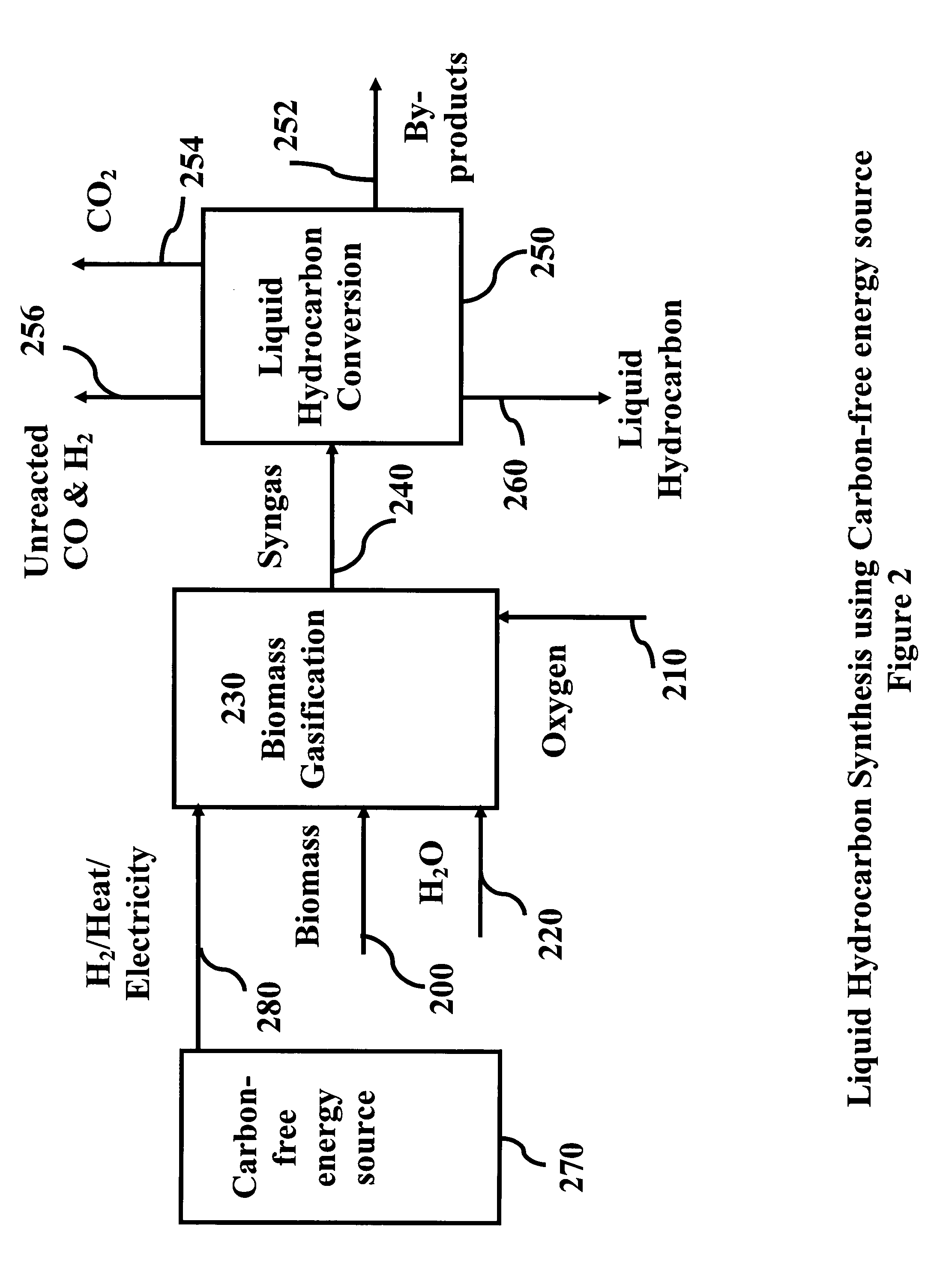

System and process for producing synthetic liquid hydrocarbon

ActiveUS20080115415A1Improve carbon efficiencyReduce area requirementsMuffle furnacesCarbon compoundsOxygenElectrolysis of water

Production of synthetic liquid hydrocarbon fuel from carbon containing moieties such as biomass, coal, methane, naphtha as a carbon source and hydrogen from a carbon-free energy source is disclosed. The biomass can be fed to a gasifier along with hydrogen, oxygen, steam and recycled carbon dioxide. The synthesis gas from the gasifier exhaust is sent to a liquid hydrocarbon conversion reactor to form liquid hydrocarbon molecules. Unreacted CO & H2 can be recycled to the gasifier along with CO2 from the liquid hydrocarbon conversion reactor system. Hydrogen can be obtained from electrolysis of water, thermo-chemical cycles or directly by using energy from carbon-free energy sources.

Owner:PURDUE RES FOUND INC

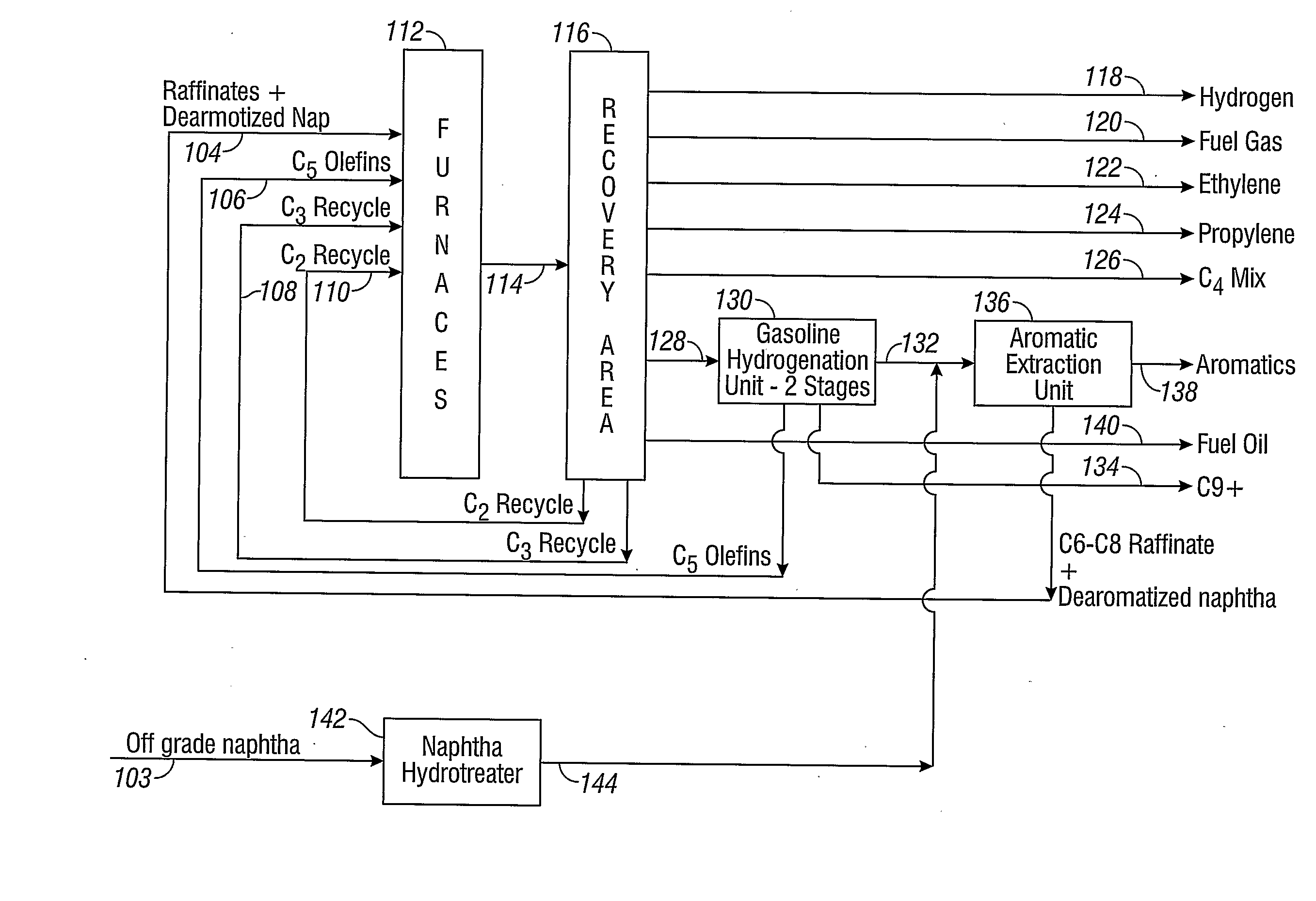

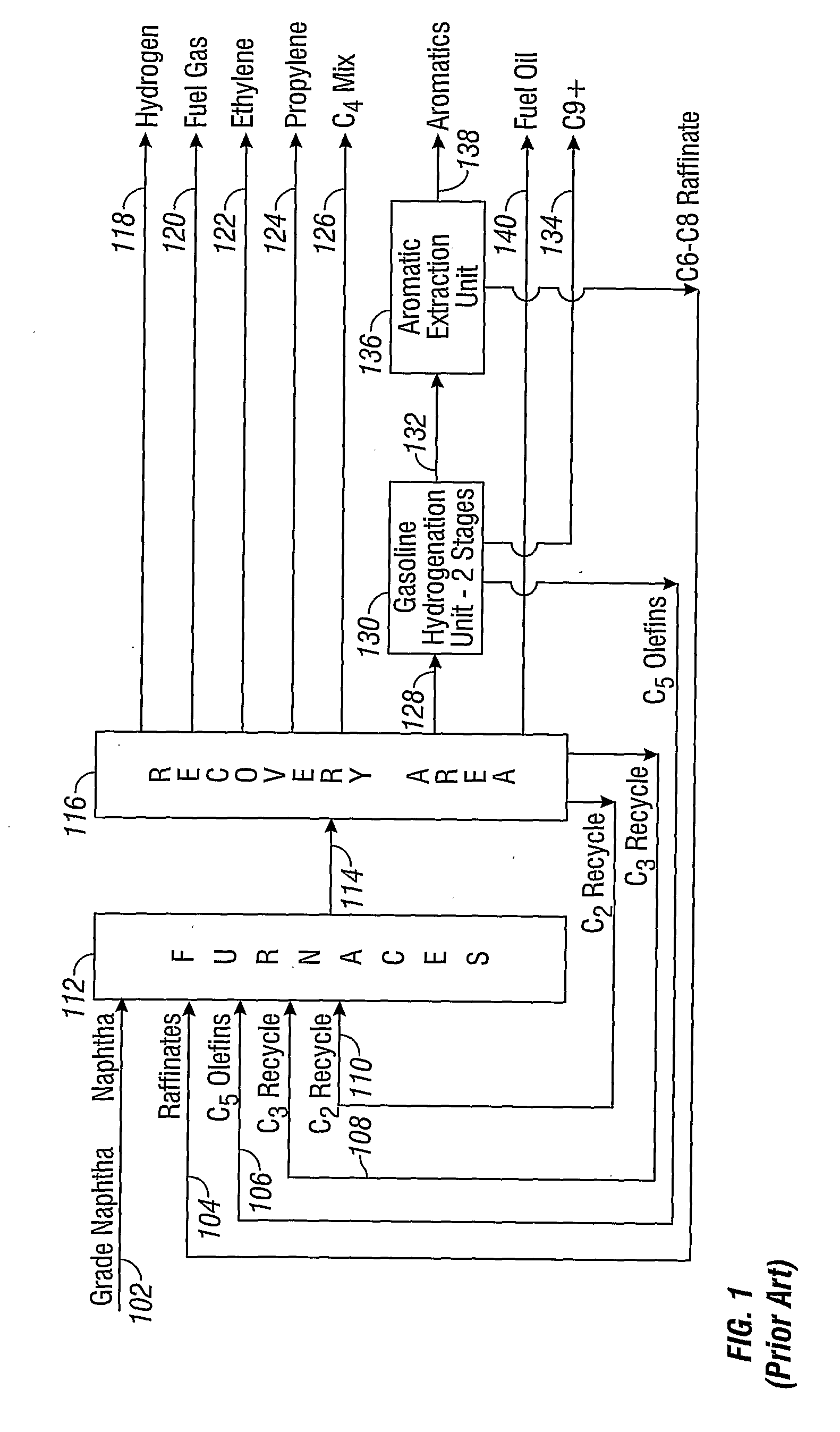

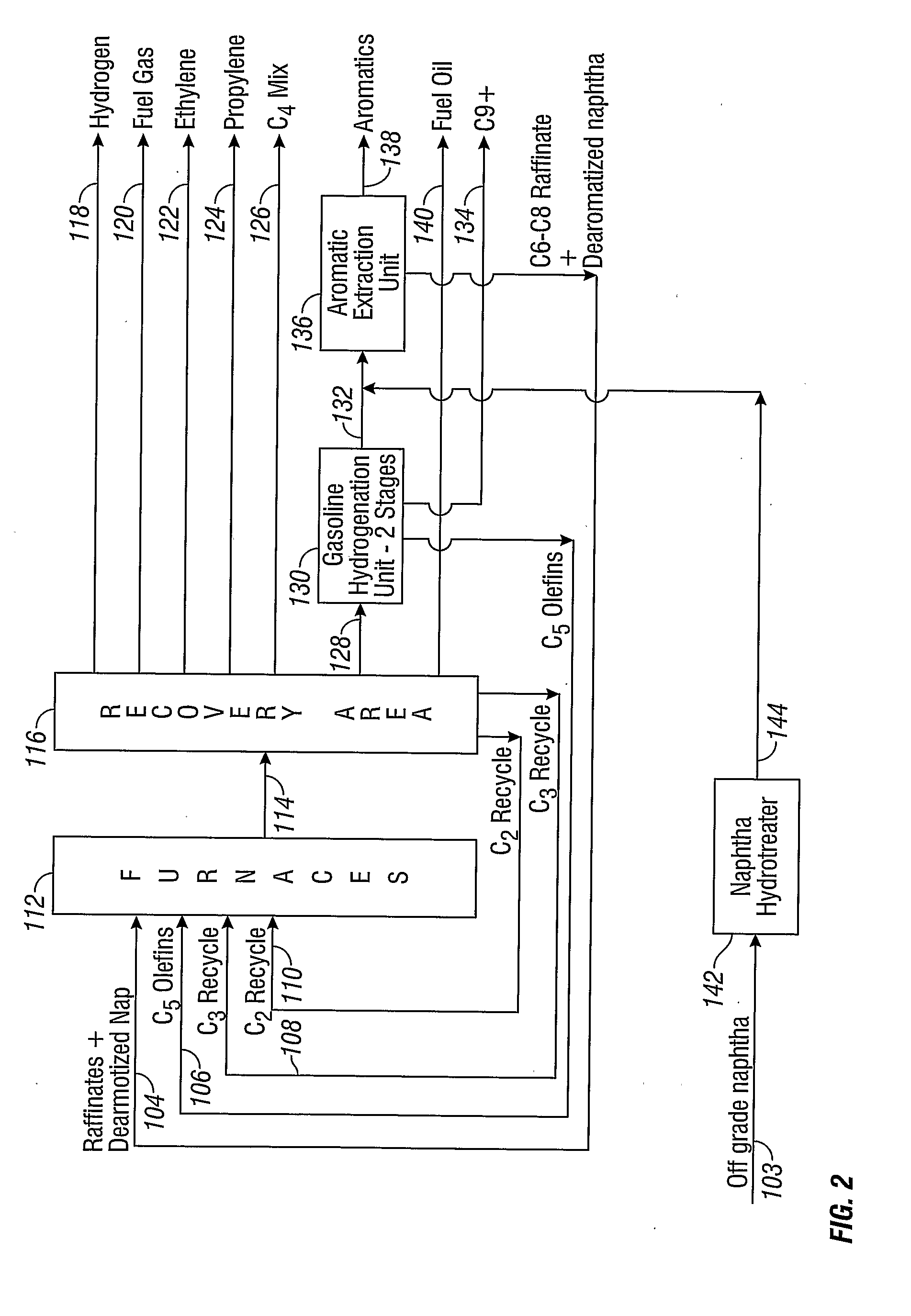

Steam Cracking with Naphtha Dearomatization

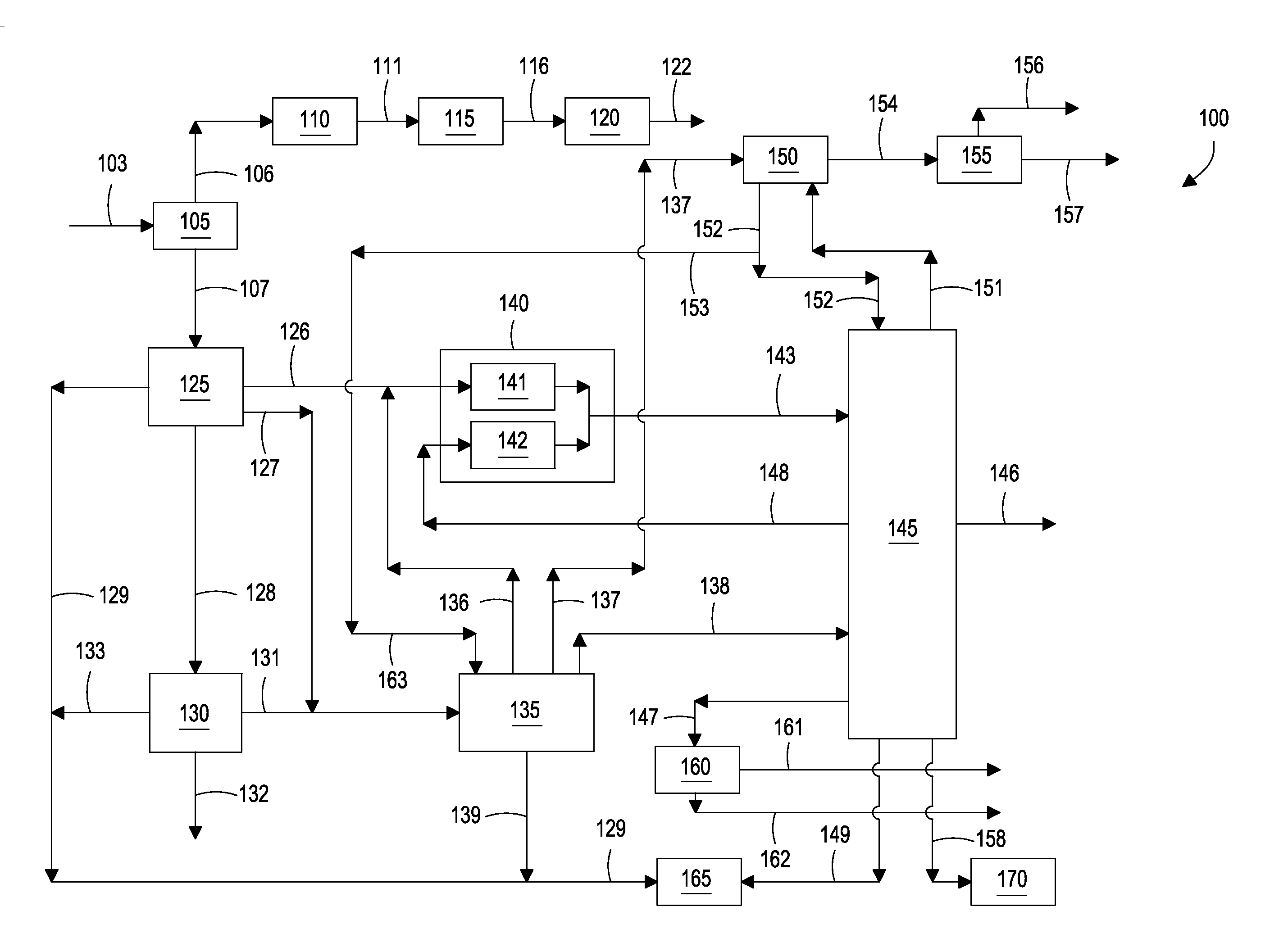

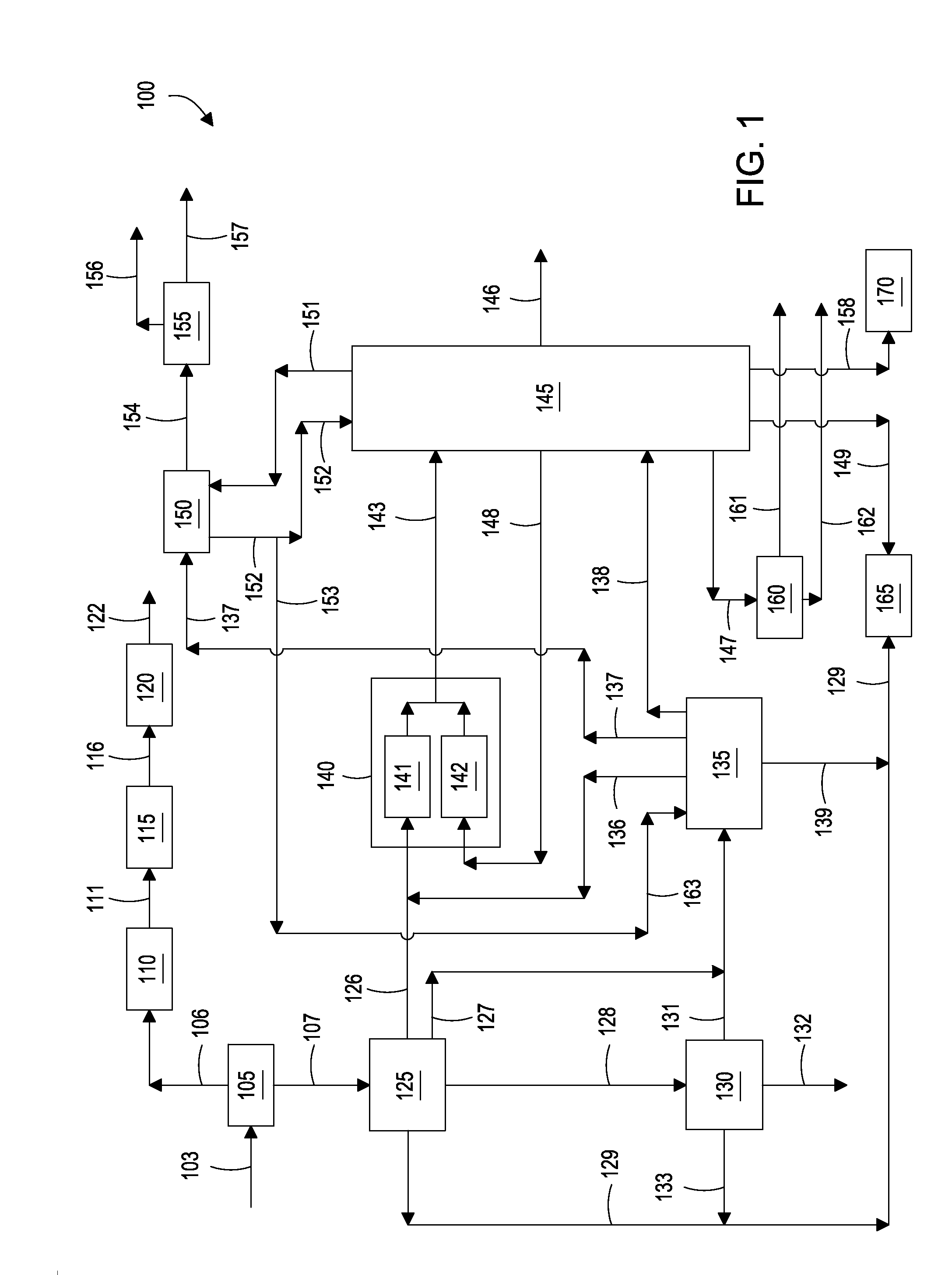

Disclosed is a process for upgrading a naphtha feed stream comprising light naphtha, heavy naphtha, or a combination thereof, for supplying to a cracking process. A naphtha feed stream can be supplied to a hydrotreater 142 to remove impurities, followed by dearomatization in an aromatics extraction unit 136. A dearomatized naphtha stream 104 can be supplied to a cracking process 112 and a recovery process 116 to produce various streams including ethylene 122 and propylene 124 for collection, ethane 110 and propane 108 for recycle to the cracking process 112, and a pyrolysis gas stream 128 which can be further treated to produce a C5 olefins stream 106, a C6-C8 stream 104, a C9+ stream 134, and a fuel oil stream 140.

Owner:BHIRUD VASANT L

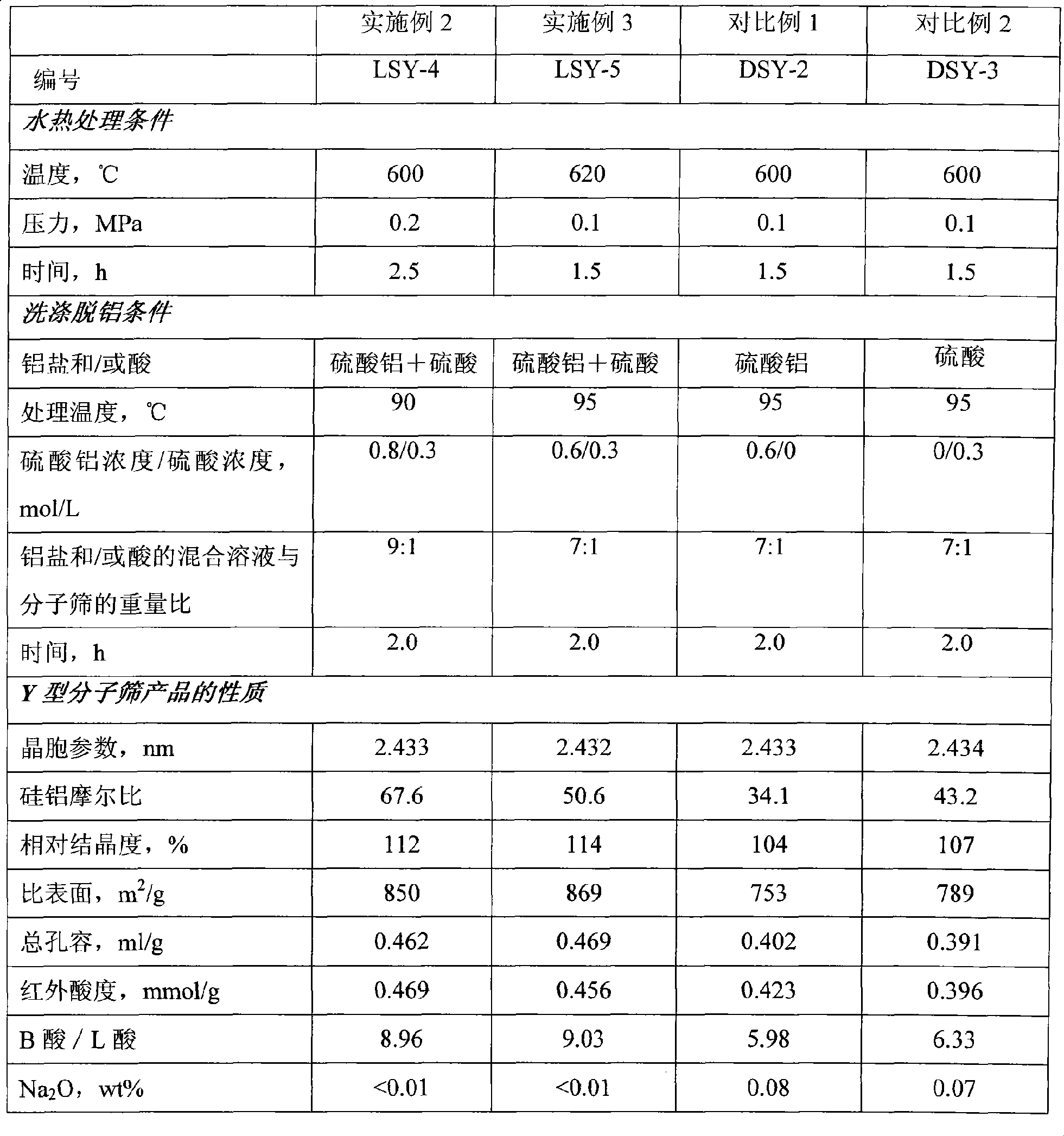

Hydrocracking catalyst and preparation method thereof

ActiveCN101380589AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingCrystallinityCell parameter

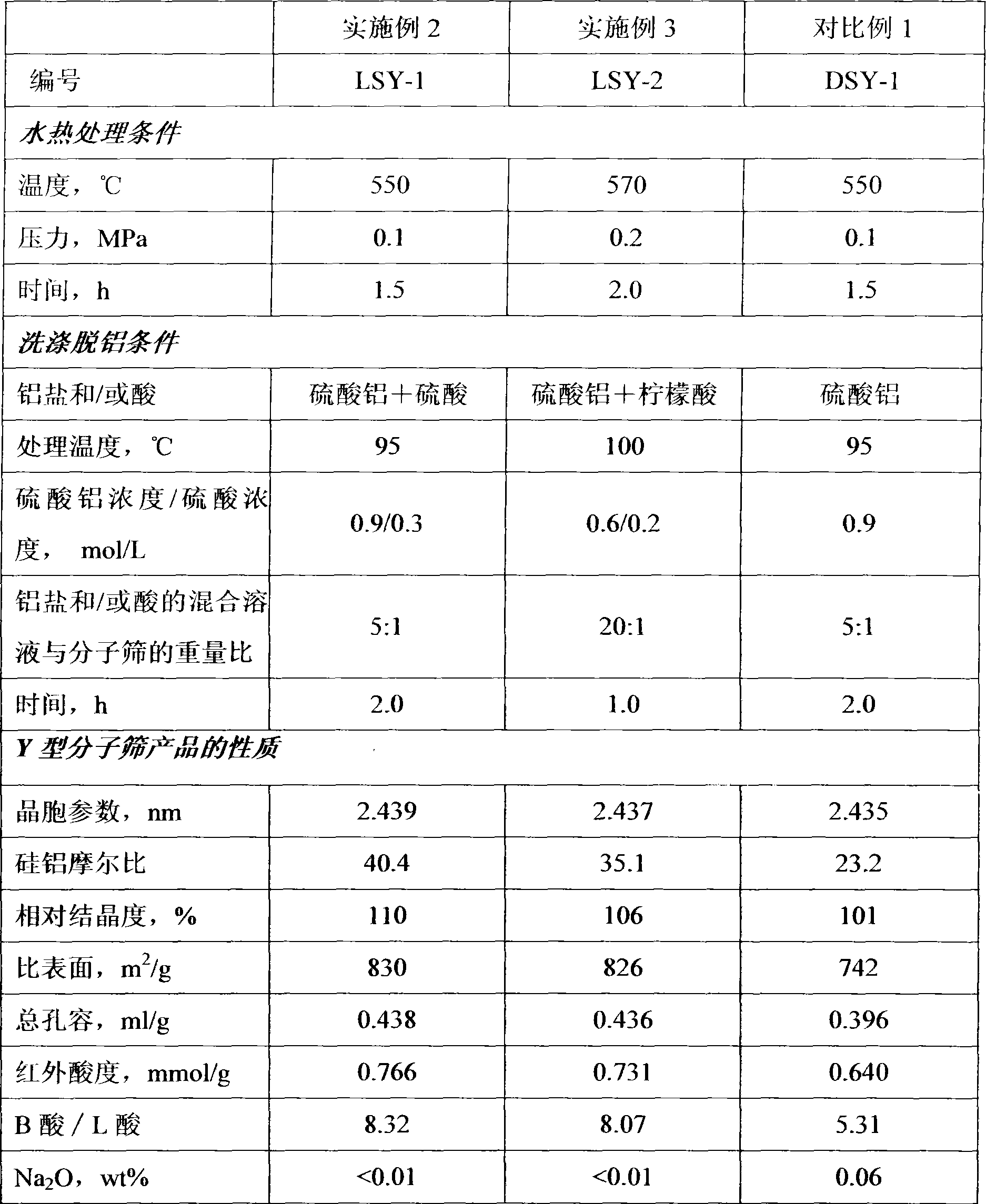

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation active metals and a carrier containing modified Y molecular sieve, alumina and amorphous aluminium silicon, wherein, the Y molecular sieve is prepared by the following method: the Y molecular sieve undergone hydro-thermal treatment by mixed water solution of aluminium salt and acid is adopted; the performance of the Y molecular sieve is as follows: specific surface is 800m<2> / g-900m<2> / g, total aperture volume is 0.40ml / g-0.50ml / g, relative crystallinity is 90%-130%, cell parameter is 2.434-2.440nm, aluminium silicon mol ratio is 20-100, infrared acid volume is 0.3-0.8mmol / g, the mol ratio of acid B and acid L is above 7.0, sodium oxide content is less than or equal to 0.05wt%. The catalyst prepared by the invention has the advantages of high catalytic activity, good target product selectivity and can produce heavy naphtha, aviation fuel and diesel fuel, and the like, with high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

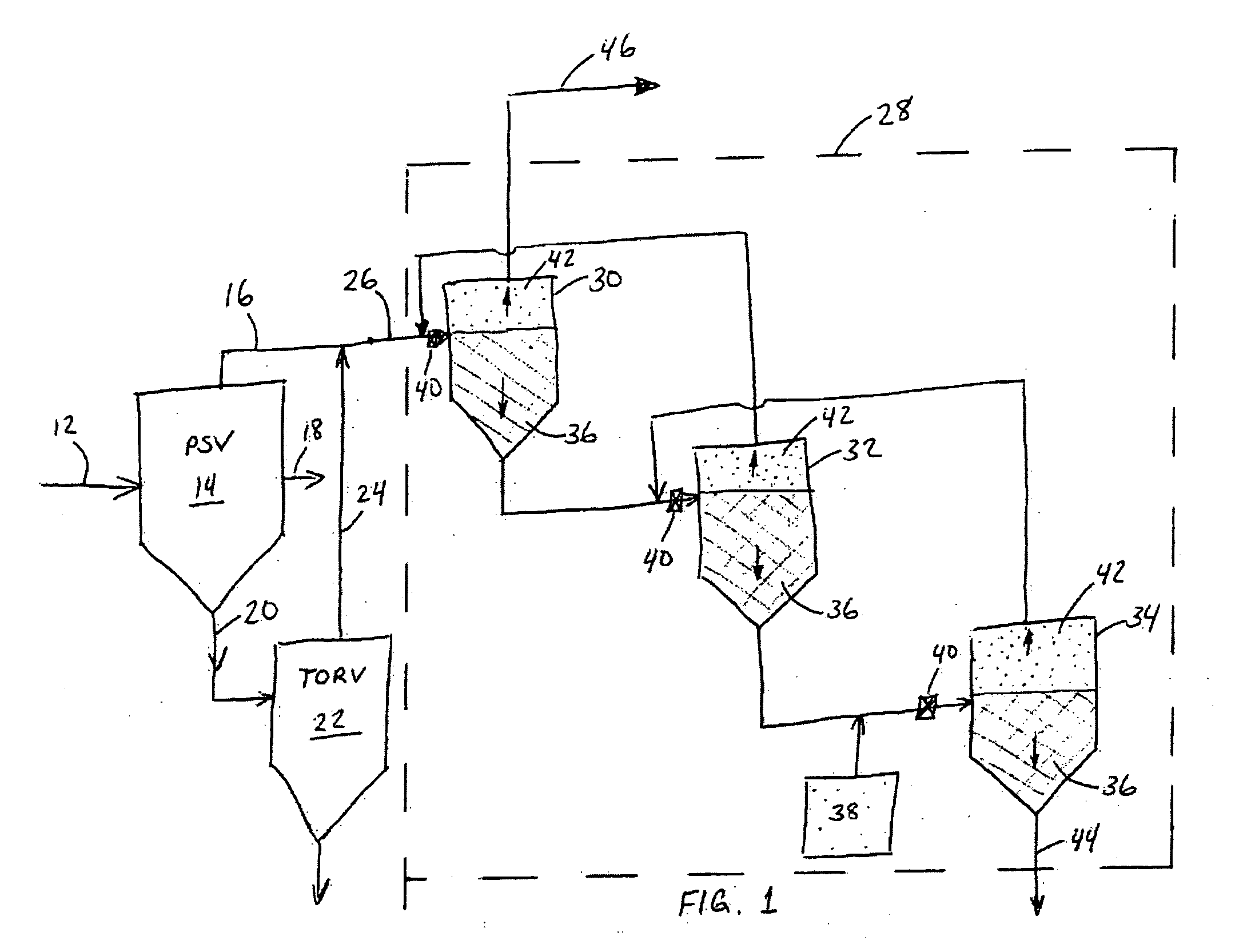

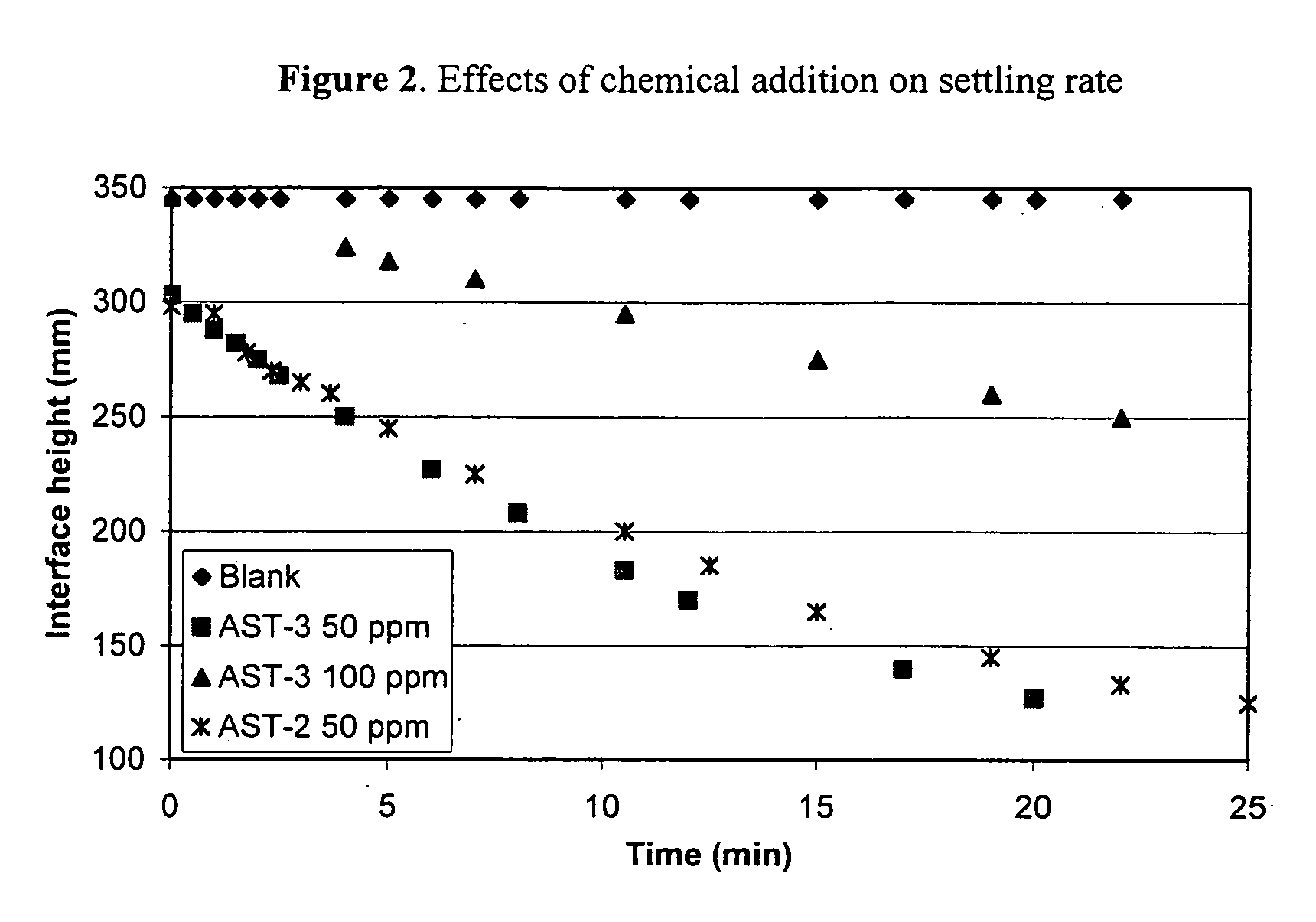

Zone settling aid and method for producing dry diluted bitumen with reduced losses of asphaltenes

A method includes diluting a bitumen source, such a bitumen froth from a hot water extraction process, with a hydrocarbon diluent such as naphtha, contacting the bitumen with a zone settling aid such as a polyoxyalkylate block polymer, flocculating water and fine solids in the diluted bitumen, separating the flocculated water and fine solids from the solvent-diluted bitumen, and producing dry, clean diluted bitumen. Preferably, the diluted bitumen will have less than 1.0 wt % water, but most preferably less than 0.7 wt % water. The method may further comprise maintaining the diluted bitumen under conditions that avoid the precipitation of asphaltenes from the bitumen, preferably such that the dry, clean diluted bitumen comprises essentially all, such as greater than 96%, of the asphaltene content from the bitumen source. Counter-current flow may be performed in a series of zone settling stages, such as with gravity settling.

Owner:SYNCRUDE CANADA LTD +1

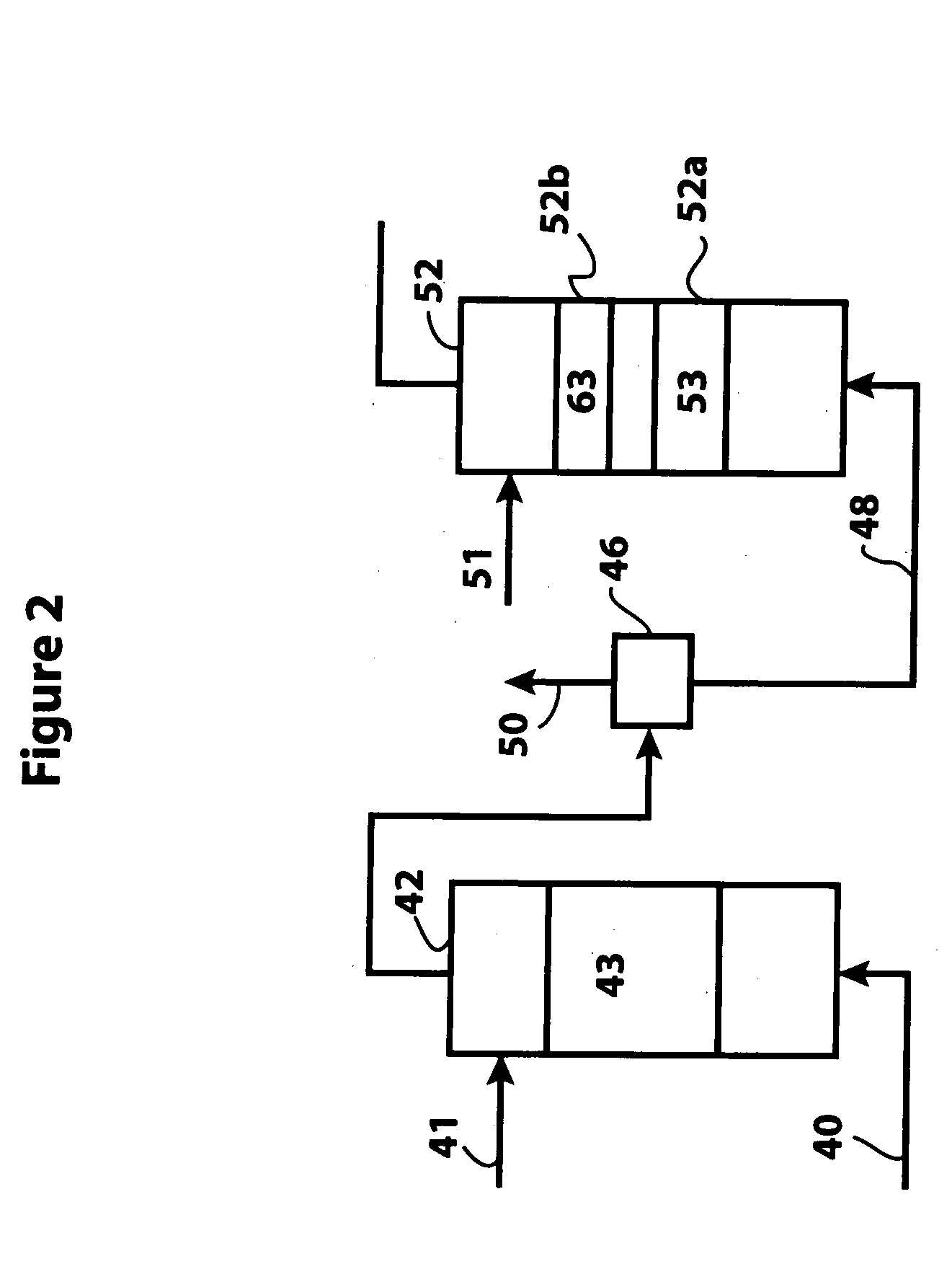

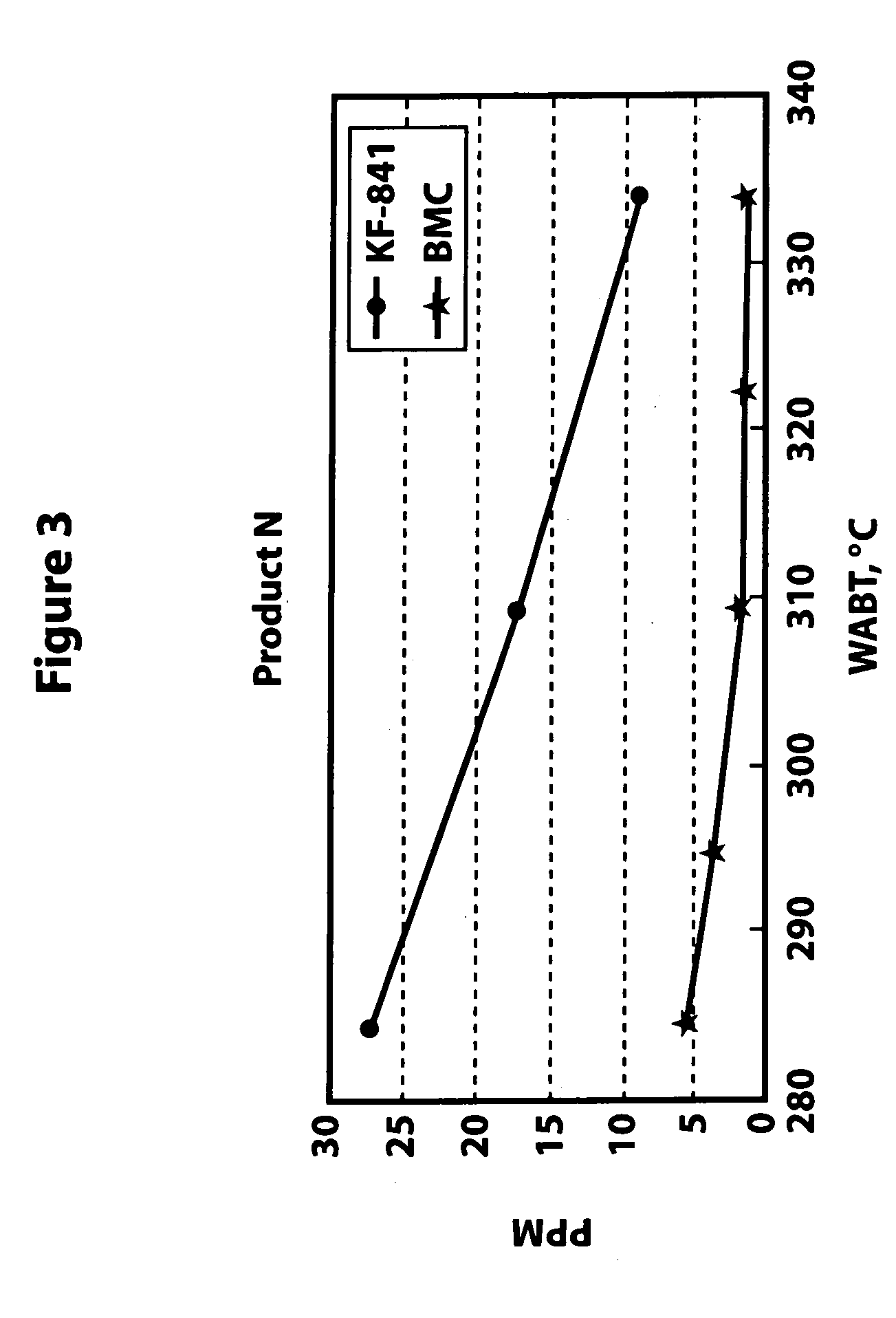

Process for upgrading naphtha

A method for upgrading a naphtha feed to a naphtha product containing less than about 10 wppm of nitrogen and less than about 15 wppm sulfur, the method comprising contacting said naphtha feed with hydrogen in the presence of a bulk multimetallic catalyst under effective reactor conditions to hydrodesulfurize and hydrodenitrogenize said naphtha feed to produce said naphtha product, wherein said bulk multimetallic catalyst comprises at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

Fluid cat cracking with high olefins prouduction

InactiveUS20020003103A1Increase productionMaximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300.degree. F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

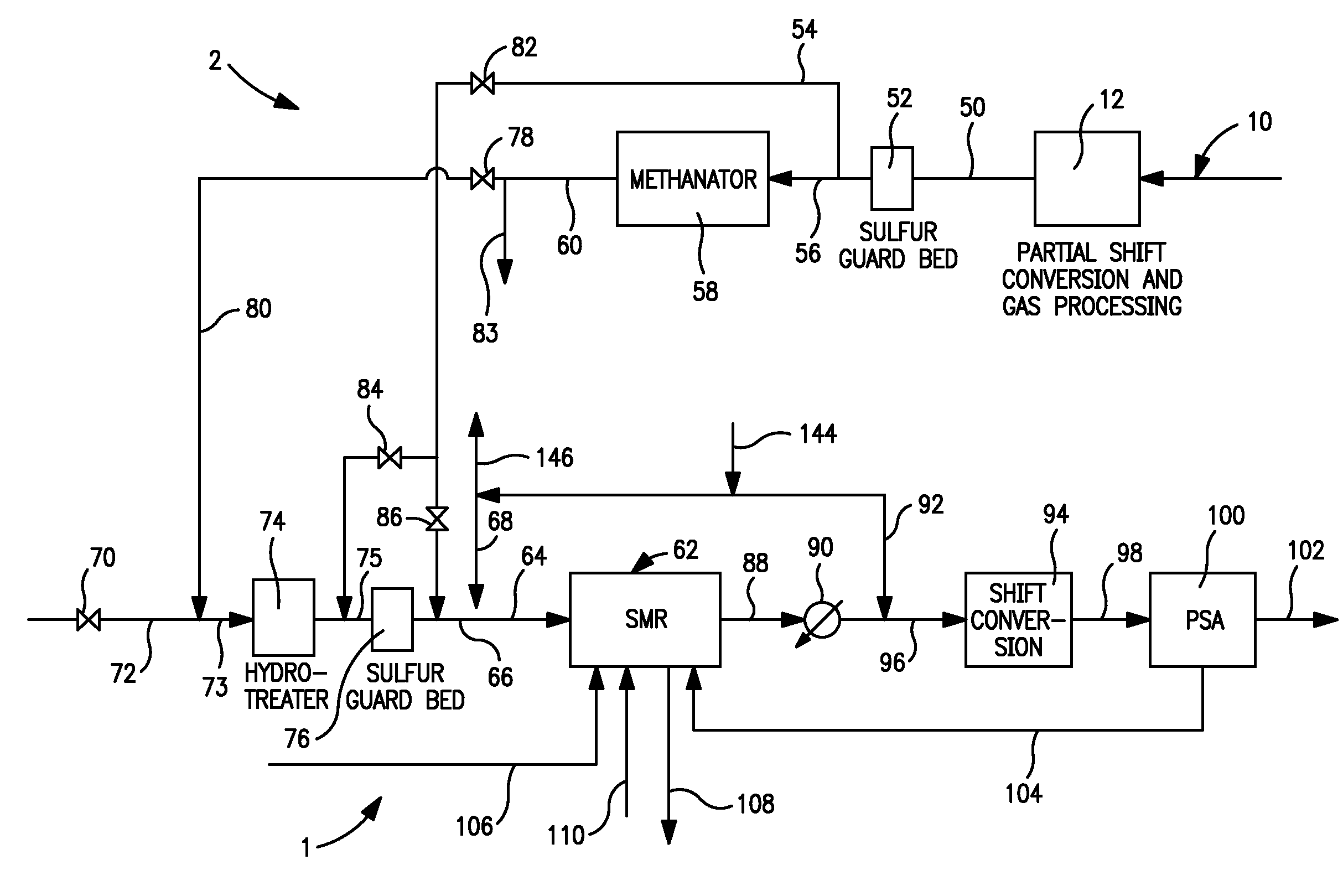

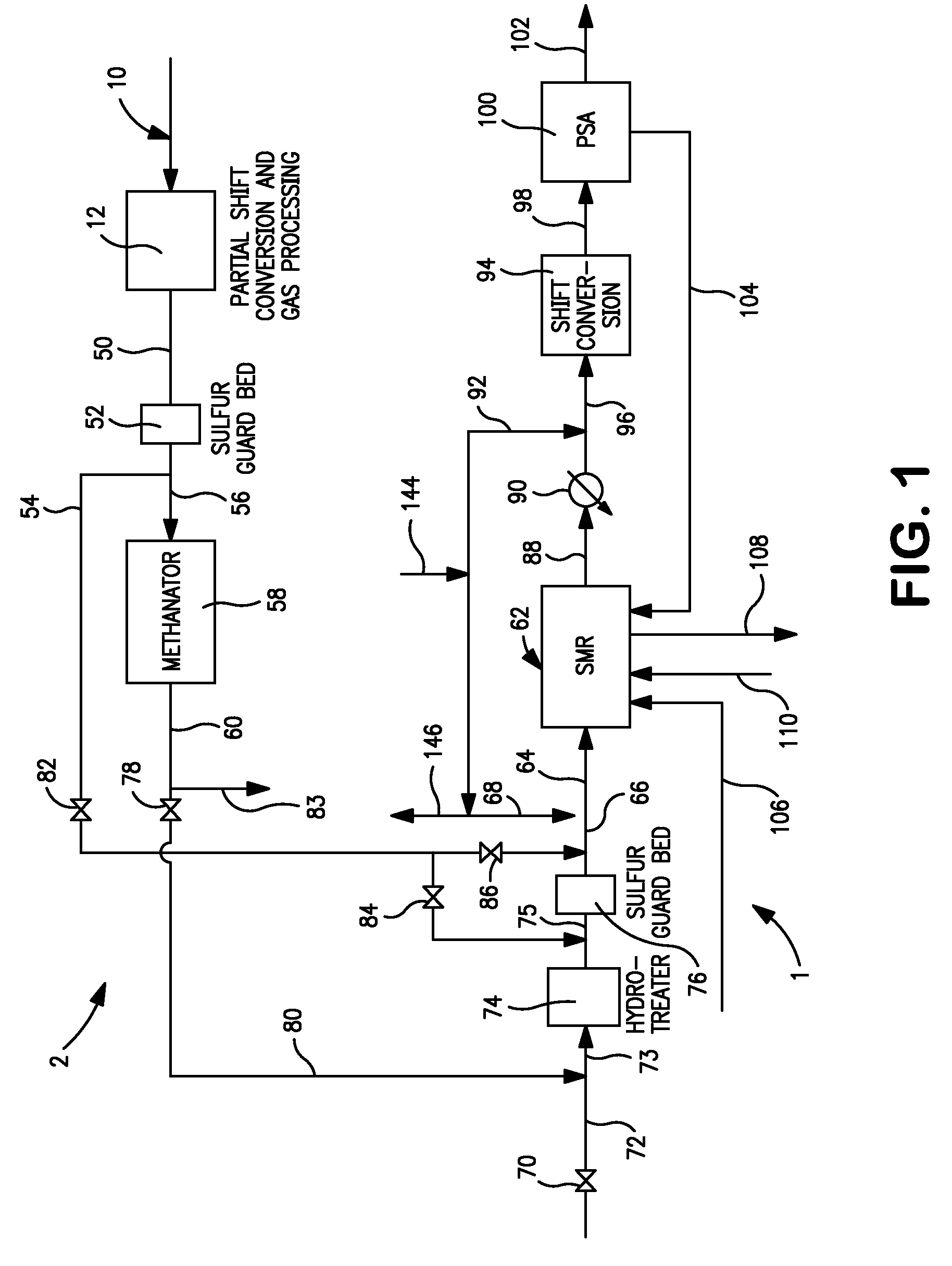

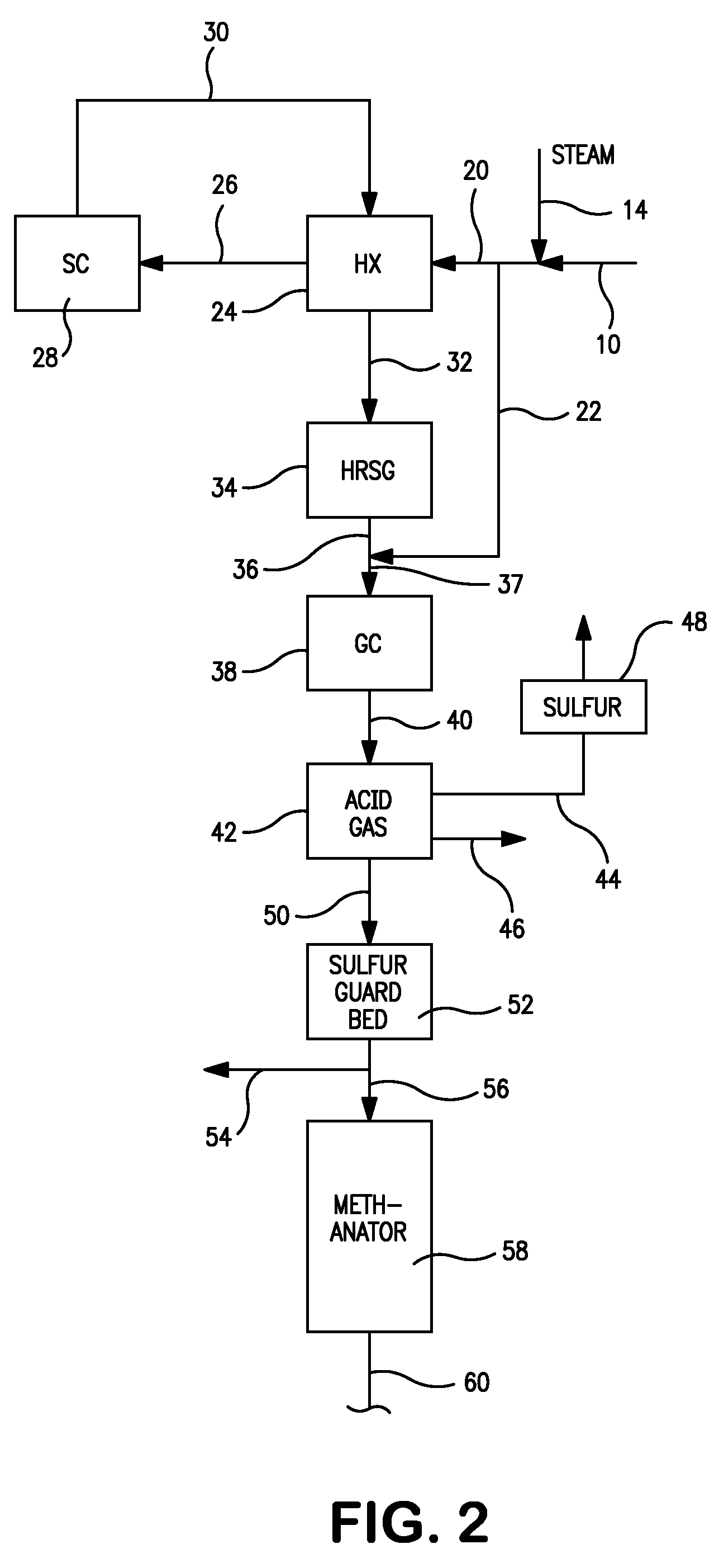

Hydrogen production method

ActiveUS7931888B2Maximize productionSteam flow rate essentially constantHydrogenCombustible gas catalytic treatmentMethane reformerMethane

A method of producing a hydrogen product stream in which a steam stream is reacted with a hydrocarbon containing stream within a steam methane reformer. The resulting product stream is subjected to a water gas shift reaction and then to pressure swing adsorption to produce the hydrogen product stream. The hydrocarbon stream is alternatively formed from a first type of feed stream made up of natural gas, refinery off-gas, naphtha or synthetic natural gas or combinations thereof and a second type that is additionally made up of a hydrogen and carbon monoxide containing gas. During use of both of the types of feed streams, the flow rate of the steam stream is not substantially changed and reformer exit temperatures of both the reactant and the flue gas side are held essentially constant.

Owner:PRAXAIR TECH INC

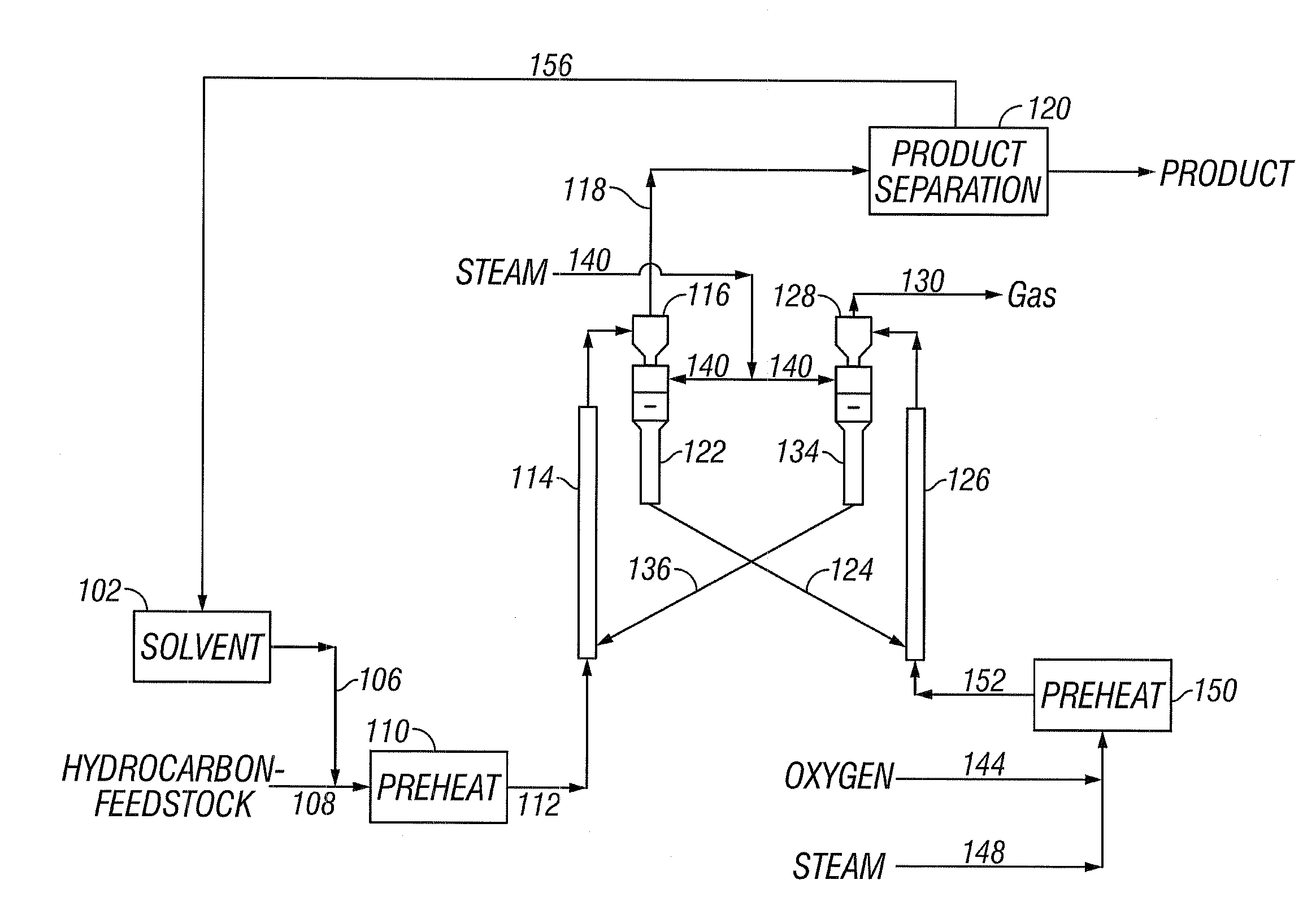

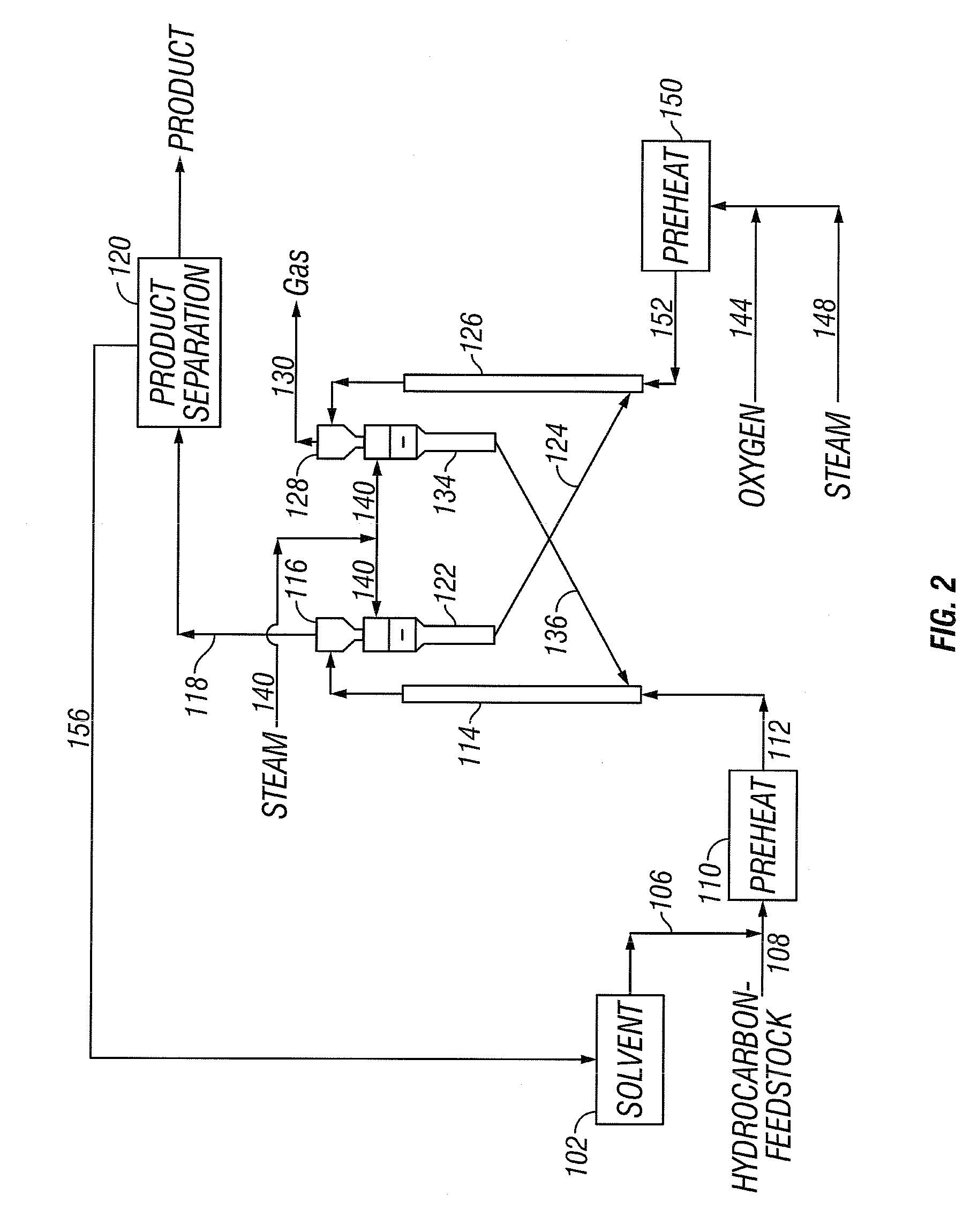

Upgrading of tar using POX/coker

ActiveUS8083931B2Reduce and eliminate needThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaPartial oxidation

The invention is directed to a process wherein a feedstock or stream comprising steam cracker tar is passed to a vacuum pipestill. A deasphalted cut of tar is obtained as an overhead (or sidestream) and a heavy tar asphaltenic product is obtained as bottoms. In preferred embodiments, at least a portion of the bottoms product is sent to a partial oxidation unit (POX) wherein syn gas may be obtained as a product, and / or at least a portion of the bottoms product is used to produce a light product stream in a coker unit, such as coker naphtha and / or or coker gas oil. In another preferred embodiment at least a portion of the overheads product is added to refinery fuel oil pools and in yet another preferred embodiment at least a portion of the overheads product is mixed with locally combusted materials to lower soot make. Two or more of the aforementioned preferred embodiments may be combined.

Owner:EXXONMOBIL CHEM PAT INC

Combined process for processing heavy oil

ActiveCN1844325AEasy to handleExtended service lifeTreatment with hydrotreatment processesKeroseneFuel oil

The invention discloses a group technology for heavy oil upgrading, in which the job steps include: (1) full or moiety of heavy oil individually or mixed with catalytic clarified oil entering solvent deasphalting plant, after the solvent deasphalting treatment, obtaining a deasphalted oil and a degreasing asphalt; (2) the degreasing asphalt obtained by step (1) individually or mixed with another moiety of heavy oil entering coking plant for coking treatment, in which the obtained tar heavy oil returns to solvent deasphalting plant or enters heavy oil hydrotreating plant, or moiety of tar heavy oil returns to solvent deasphalting plant and another moiety of tar heavy oil enters heavy oil hydrotreating plant, catalytic plant or hydrocracking plant; (3) the deasphalted oil obtained by step (1) individually or mixed with vacuum residual oil, non-pressure residual oil, pressure-relief residual oil, catalytic cycle stock and one or more than one heavy oil of tar heavy oil obtained by step (2) entering heavy oil hydrotreating plant for hydrotreatment, after hydrotreatment, obtaining fractions of benzin naphtha, plane kerosene and diesel and hydrogenating heavy oil. The invention can improve the charge-in nature, alleviate the operating condition and prolong the cycle length of the heavy oil hydrotreating plant, which provides better raw oil for downstream plants including catalytic plant.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Method for producing aromatic hydrocarbon by adopting raw materials containing methanol

InactiveCN102199446ABoost octaneImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionNaphthaAromatic hydrocarbon

The invention discloses a method for producing aromatic hydrocarbon by adopting raw materials containing methanol. The raw material containing methanol comprises the methanol and Fischer-Tropsch synthesis naphtha. In the method, the raw materials containing methanol and a catalyst undergo a contact reaction under the condition of producing the aromatic hydrocarbon by using the methanol. By adopting the method disclosed by the invention, the problem that great removed heat is needed to be adopted in the prior art is solved; and the method has the advantages of simple flow and simpleness and convenience for operation. By adopting the method provided by the invention and a good method for processing and utilizing Fischer-Tropsch synthesis naphtha components, aromatic hydrocarbon products are produced or the octane value of the Fischer-Tropsch synthesis naphtha components is increased to gasoline mediated components with a high octane value.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Production of liquid fuels by a concatenation of processes for treatment of a hydrocarbon feedstock

ActiveUS7214720B2Maximize conversion of carbonReduce and to upgrade naphthaThermal non-catalytic crackingCatalytic crackingNaphthaKerosene

The invention relates to an installation and a process for the production of liquid fuels starting from a solid feedstock that contains the organic material in which:a) the solid feedstock is subjected to a gasification stage so as to convert said feedstock into synthesis gas,b) the synthesis gas is subjected to a purification treatment,c) the purified synthesis gas is subjected to a conversion stage that comprises the implementation of a Fischer-Tropsch-type synthesis so as to convert said synthesis gas into a liquid effluent and a gaseous effluent,d) the liquid effluent is fractionated so as to obtain a gaseous fraction, a naphtha fraction, a kerosene fraction and a gas oil fraction, ande) at least a portion of the naphtha fraction is recycled in gasification stage a).

Owner:INST FR DU PETROLE +1

Gasoline and diesel production from pyrolytic lignin produced from pyrolysis of cellulosic waste

InactiveUS20080053870A1High yieldTreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyCelluloseNaphtha

Owner:UOP LLC

Multi component catalyst and its use in catalytic cracking

A multi component catalyst and catalytic cracking process for selectively producing C3 olefins. The catalyst comprises a first molecular sieve having an intermediate pore size, a second molecular sieve and, optionally a third molecular sieve having a large pore size. At least one of the channels of the second molecular sieve has a pore size index that is less than the pore size index of at least one channel of the first molecular sieve. The process is carried out by contacting a feedstock containing hydrocarbons having at least 5 carbon atoms is contacted, under catalytic cracking conditions, with the multi component catalyst. The catalyst finds application in the cracking of naphtha and heavy hydrocarbon feedstocks.

Owner:EXXONMOBIL CHEM PAT INC

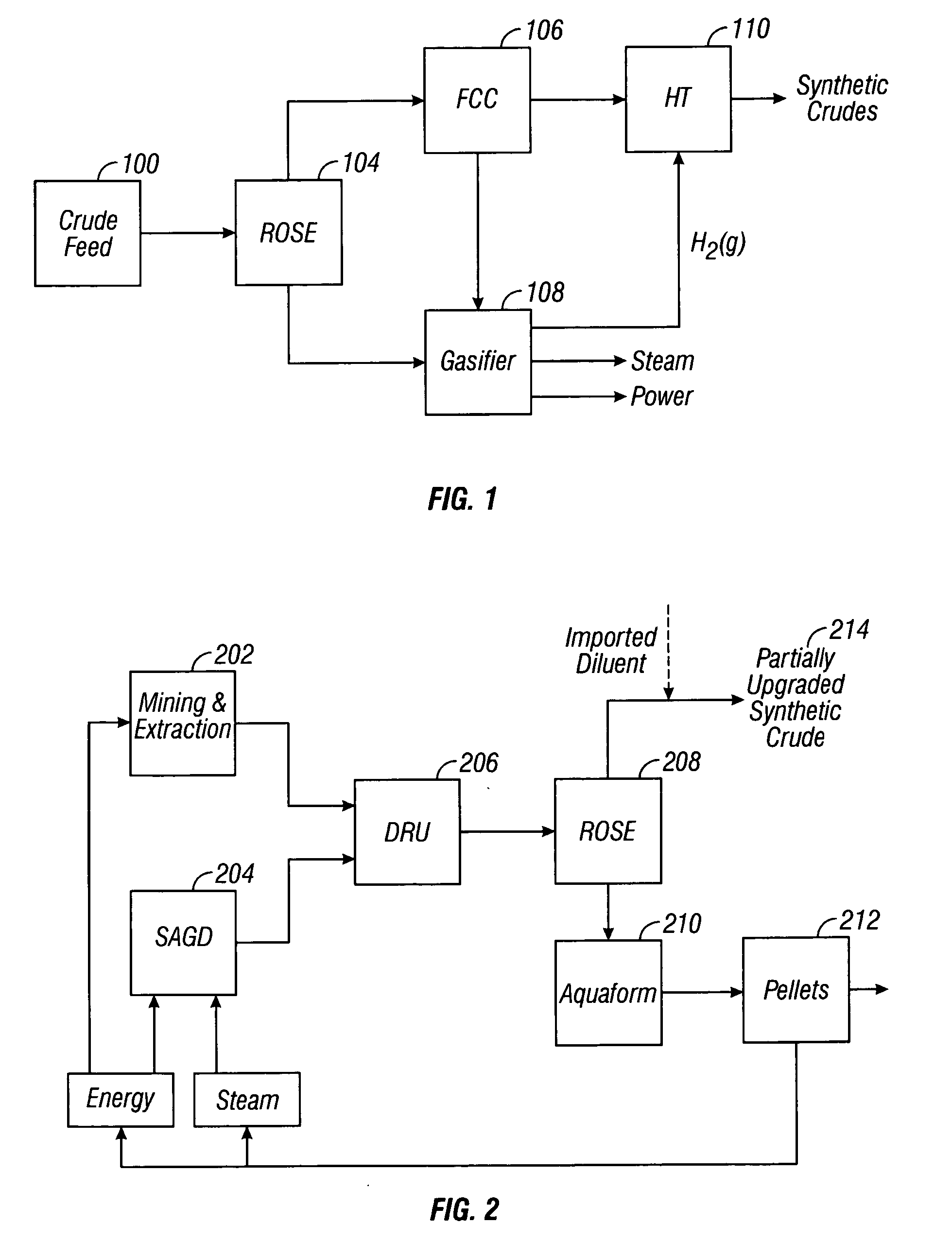

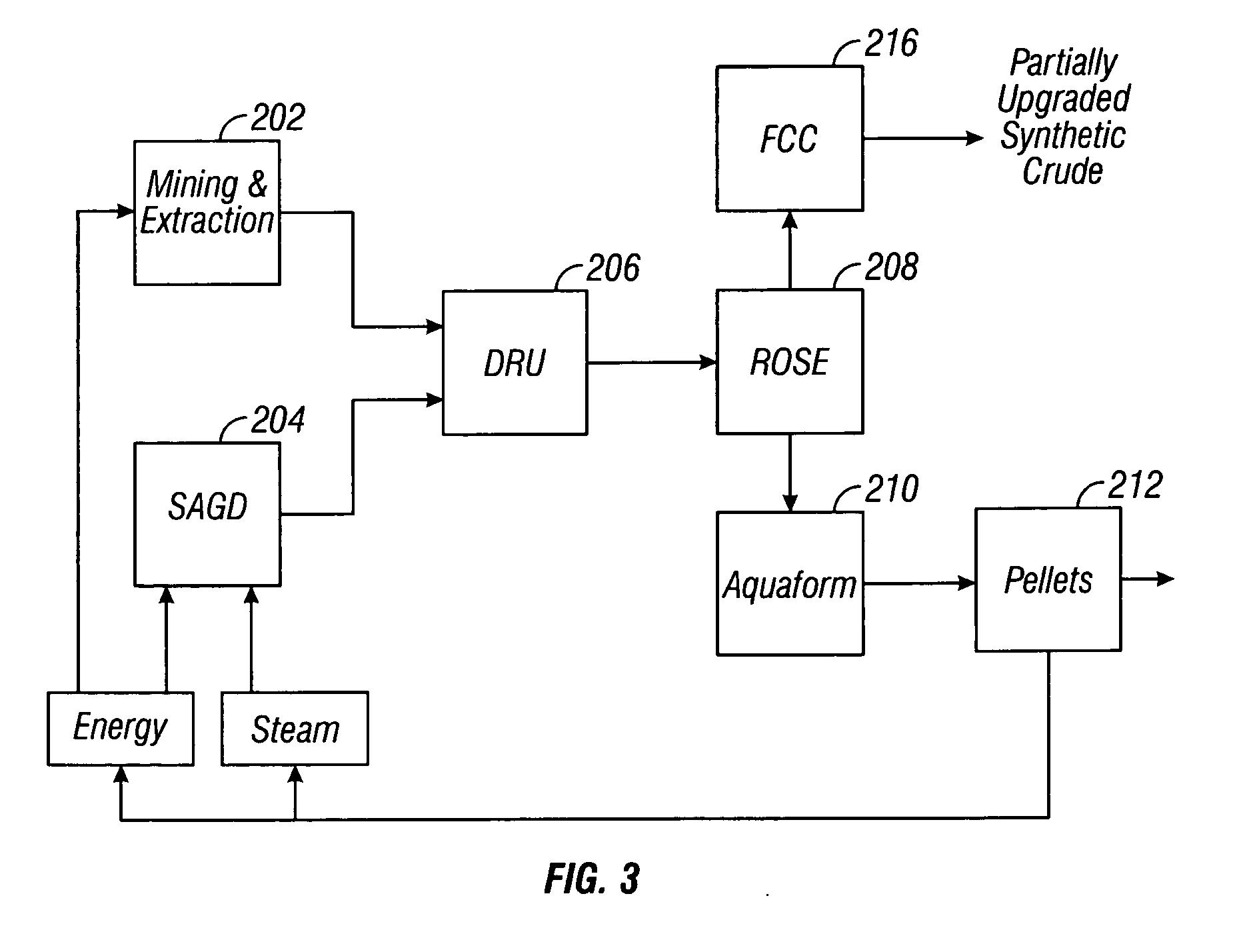

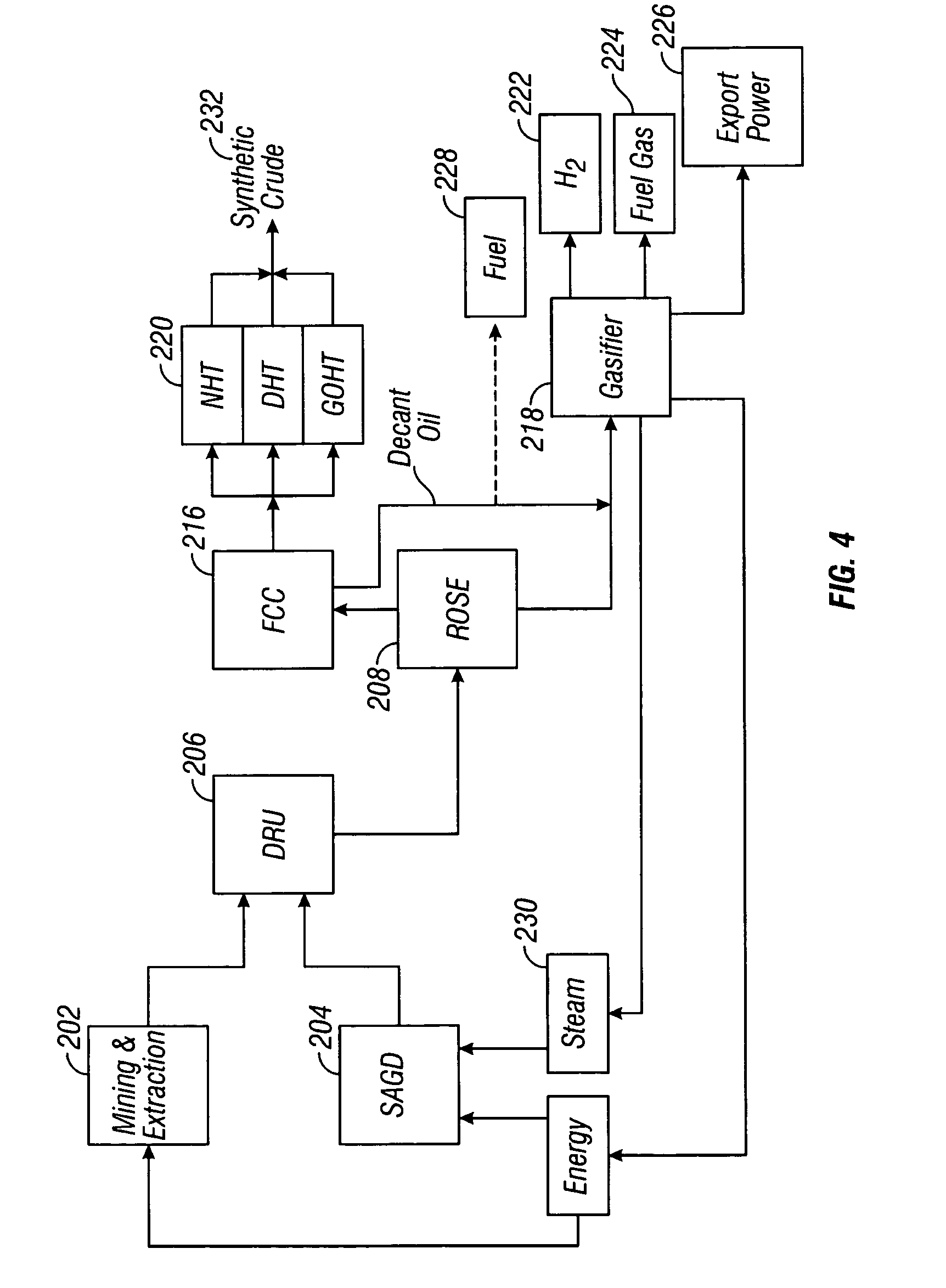

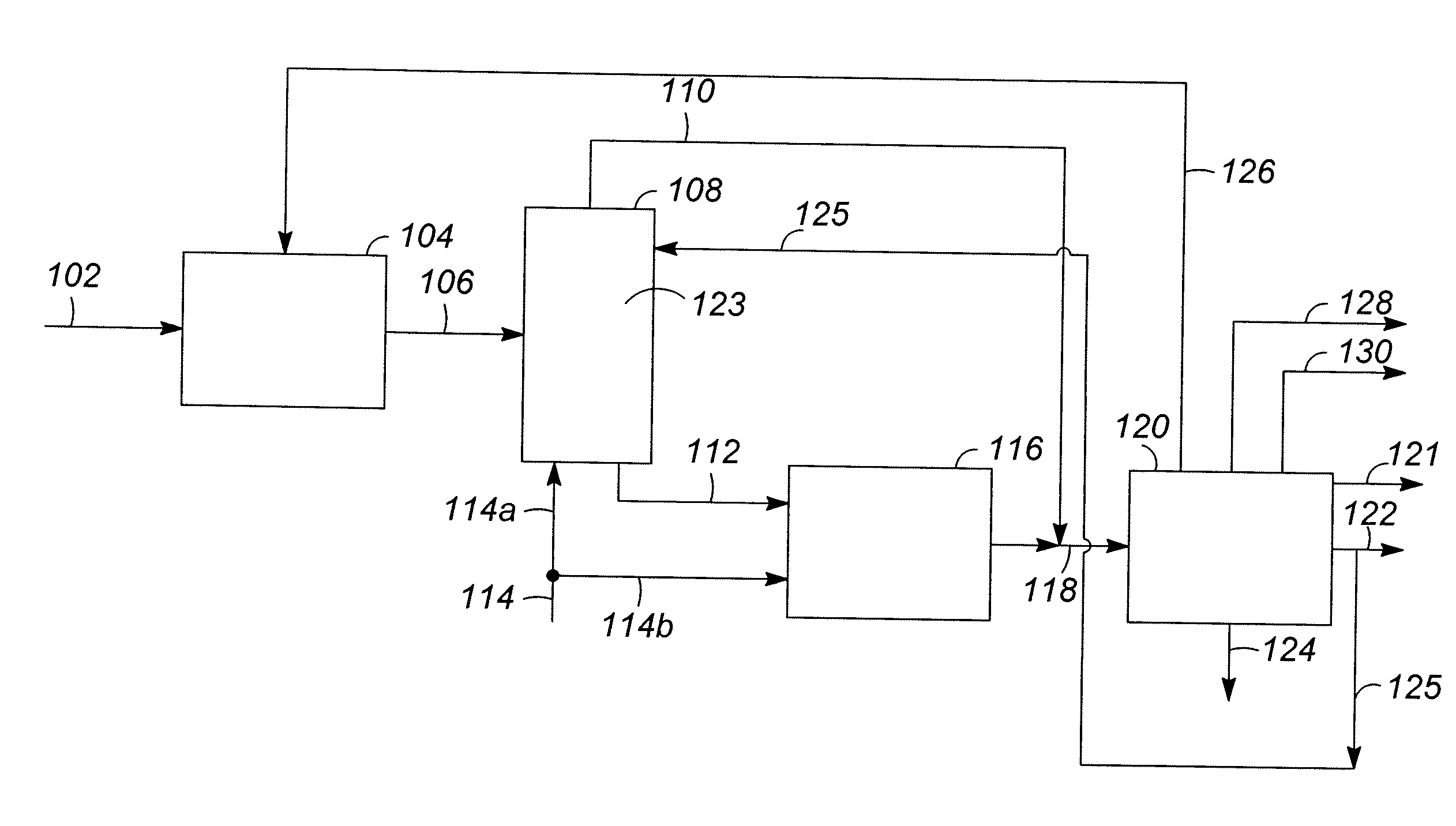

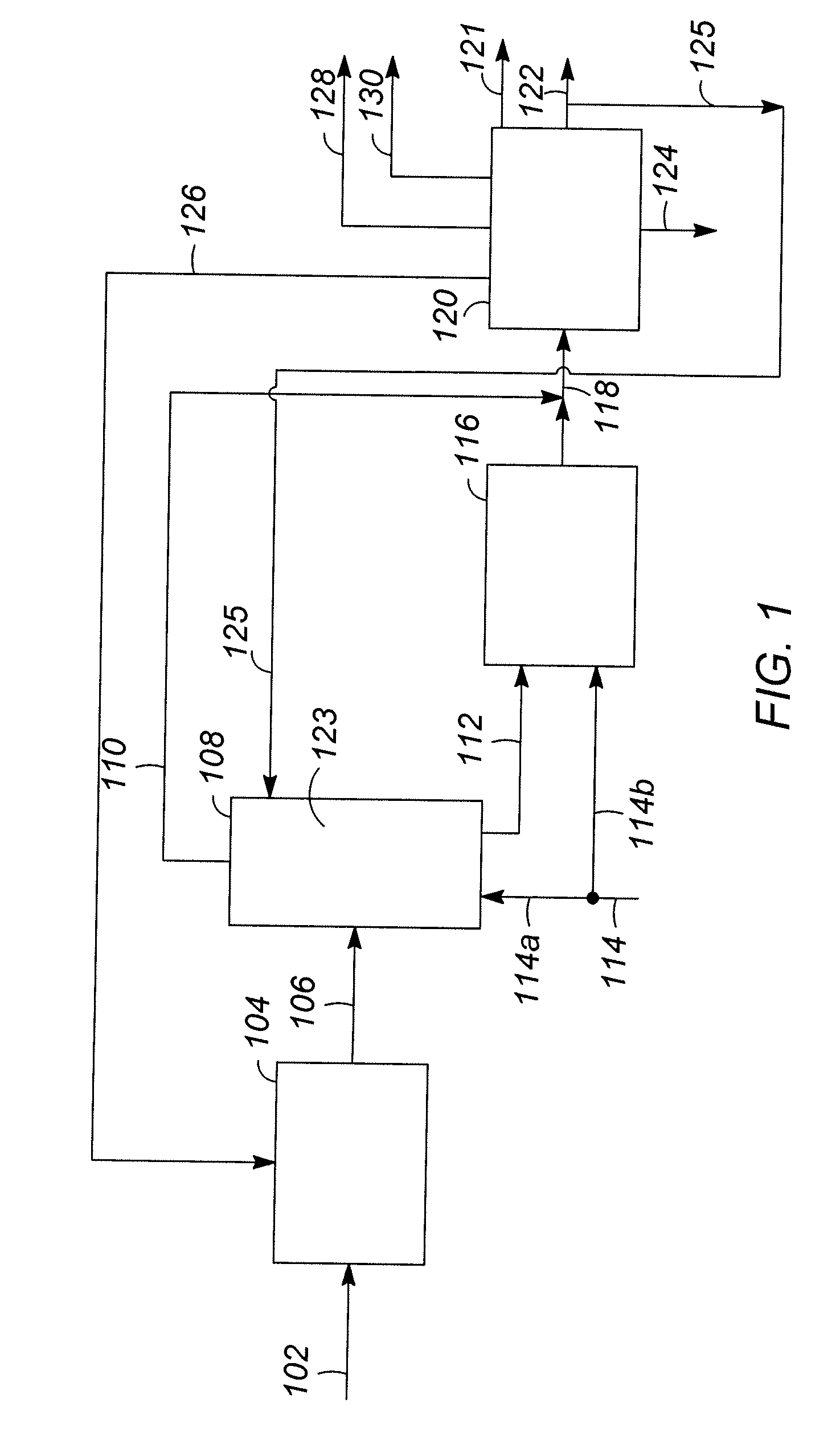

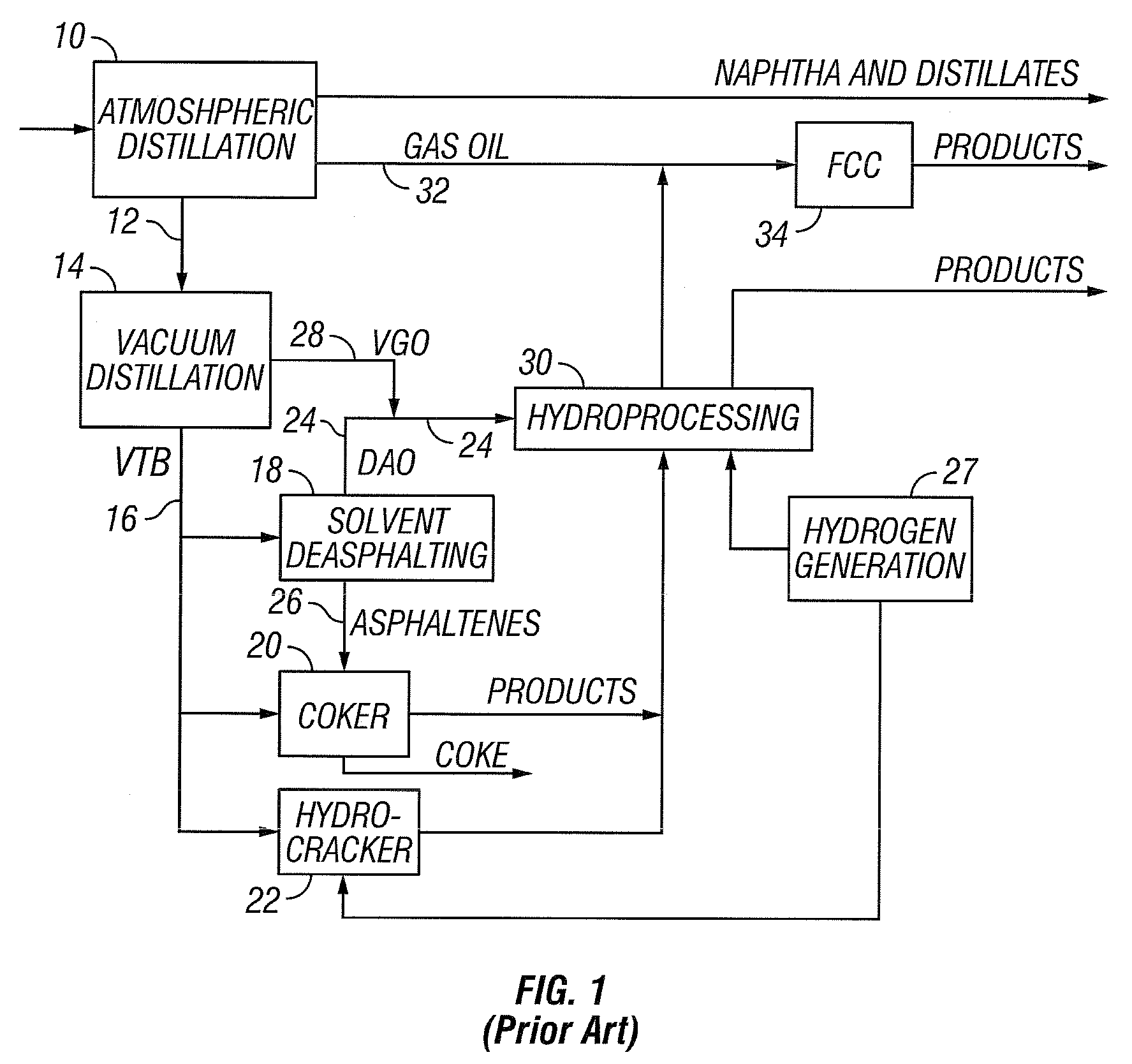

Heavy Oil and Bitumen Upgrading

ActiveUS20060042999A1Reduce metal contentEasy to liftThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionNaphthaHydrogen

Disclosed is a process for the upgrading and demetallizing of heavy oils and bitumens. A crude heavy oil and / or bitumen feed is supplied to a solvent extraction process 104 wherein DAO and asphaltenes are separated. The DAO is supplied to an FCC unit 106 having a low conversion activity catalyst for the removal of metals contained therein. The demetallized distillate fraction is supplied to a hydrotreater 110 for upgrading and collected as a synthetic crude product stream. The asphaltene fraction can be supplied to a gasifier 108 for the recovery of power, steam and hydrogen, which can be supplied to the hydrotreater 110 or otherwise within the process or exported. An optional coker 234 can be used to convert excess asphaltenes and / or decant oil to naphtha, distillate and gas oil, which can be supplied to the hydrotreater 220.

Owner:KELLOGG BROWN & ROOT LLC

Hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN101450320AHigh ratio of silicon to aluminumLarger than surfaceMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst for producing heavy naphtha in great abundance and a preparation method thereof. The catalyst contains hydrogenation active metals and a carrier which consists of modified Y molecular sieves and alumina, wherein the Y molecular sieves are obtained by using a mixed aqueous solution of aluminum salts and an acid to perform hydro-thermal treatment. The properties of the modified Y molecular sieves are as follows: the specific surface area is between 750 m<2> / g and 850 m<2> / g; the total pore volume is between 0.35 and 0.48 ml / g; the relative crystallinity is between 90 and 130 percent; the cell parameter is between 2.437 and 2.445 nanometers; the silicon-aluminum mol ratio is between 15 and 70; the infrared acid amount is between 0.5 and 1.0 mmol / g; the B acid / L acid is more than 7.0; and the content of sodium oxide is less than or equal to 0.05 weight percent. The hydrocracking catalyst has the characteristics of good catalytic activity, high heavy naphtha selectivity, high yield, high latent content of heavy naphtha arene, and so on.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Systems and methods for residue upgrading

ActiveUS20080223754A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionNaphthaReaction zone

Systems and methods for processing hydrocarbons are provided. A hydrocarbon can be distilled to provide a distillate, a gas oil, and a residue. The residue can include, but is not limited to asphaltenes and non-asphaltenes. The residue can be mixed with a solvent to provide a mixture. The asphaltenes can be selectively separated from the mixture to provide a deasphalted oil. At least a portion of the deasphalted oil and at least a portion of the gas oil can be hydroprocessed to provide a hydroprocessed hydrocarbon. At least a portion of the distillate and at least a portion of the hydroprocessed hydrocarbon can be cracked in a first reaction zone to provide a first cracked product comprising C2 hydrocarbons, C3 hydrocarbons, C4 hydrocarbons, and naphtha.

Owner:MARVELL TECHNOLOGY GROUP LTD +1

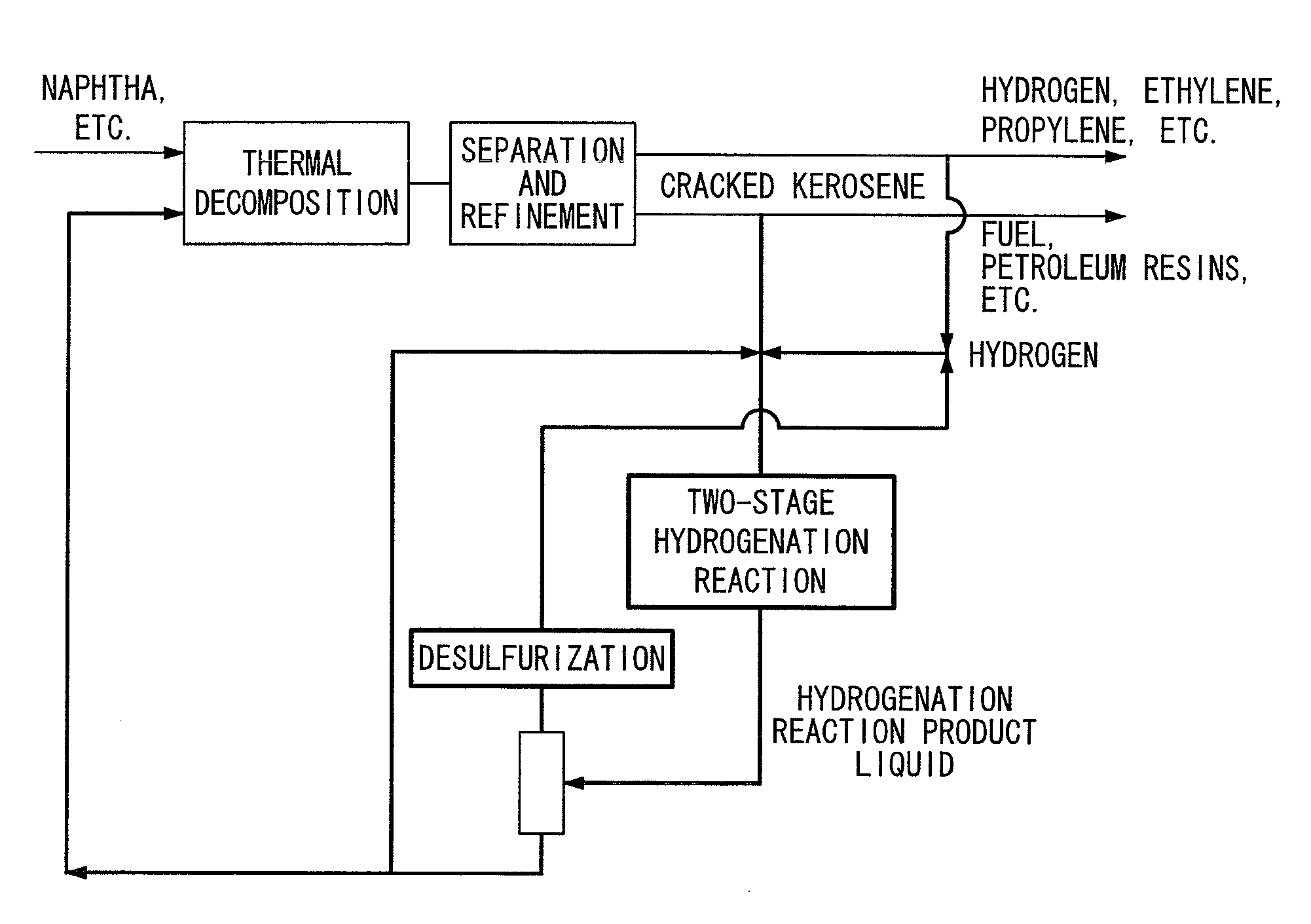

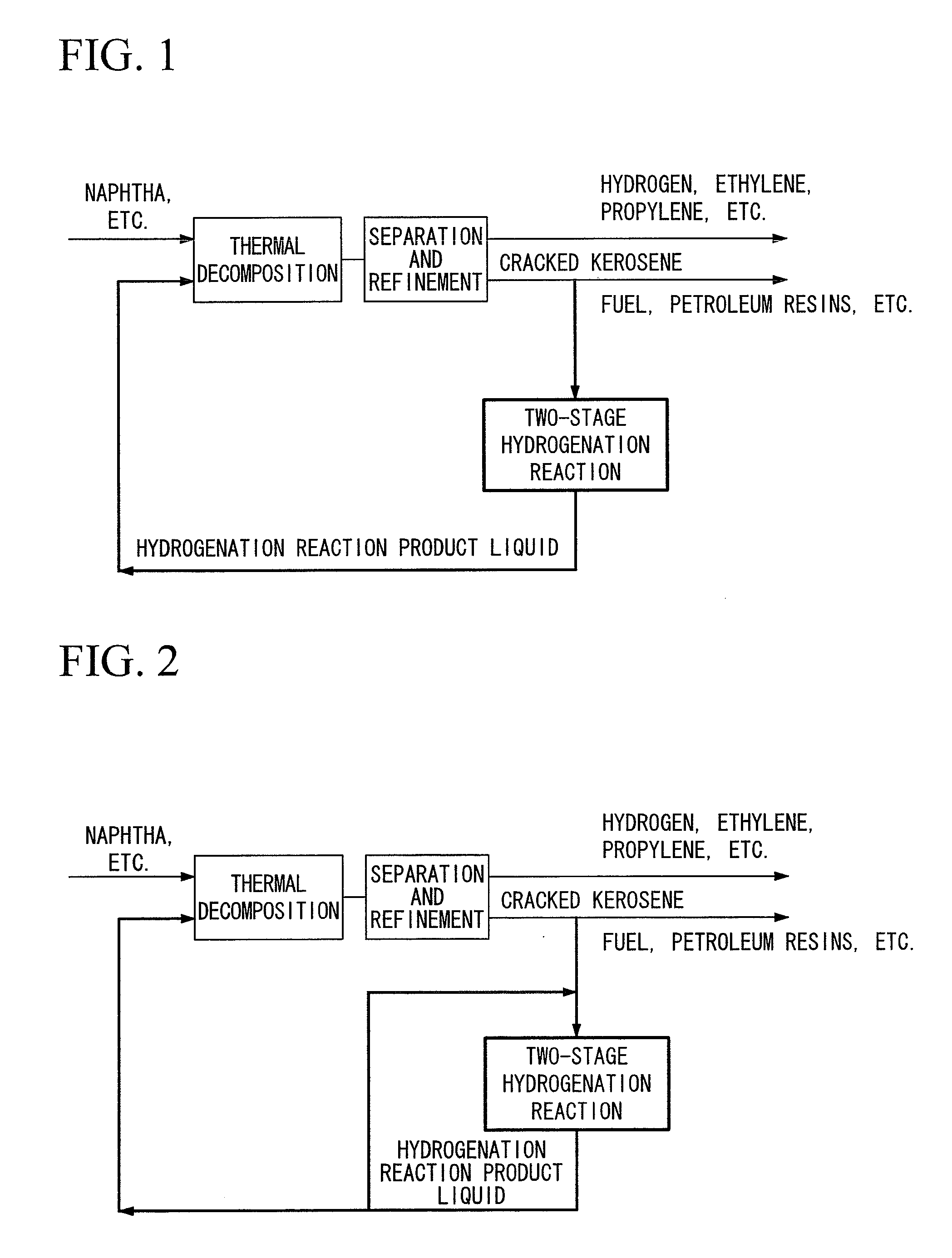

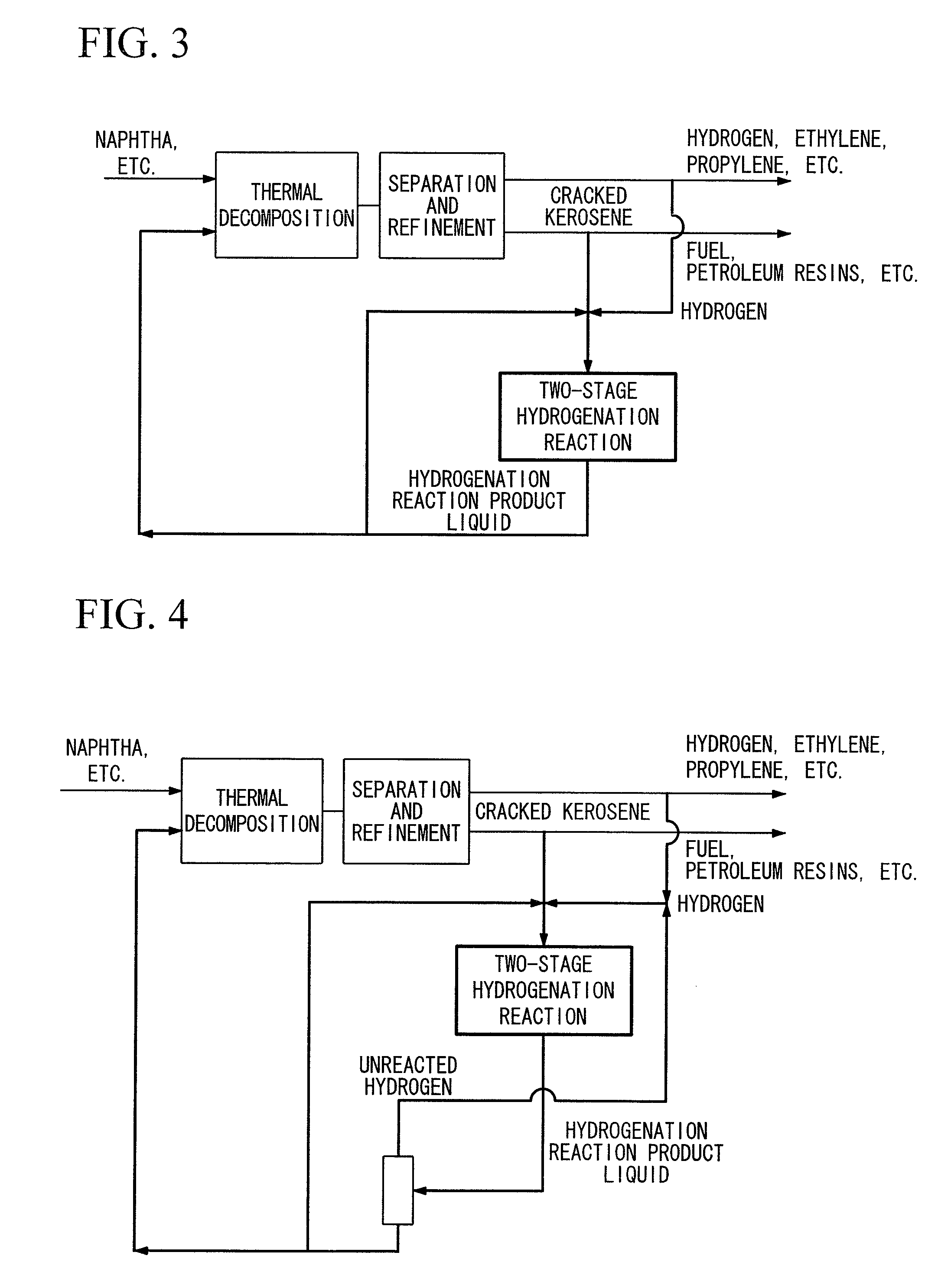

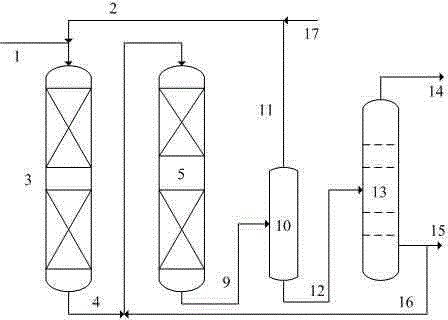

Hydrogenation method and petrochemical process

InactiveUS20100087692A1Long catalyst lifeHigh yieldThermal non-catalytic crackingHydrocarbon by dehydrogenationBenzeneNaphtha

The present invention provides a hydrogenation method capable of converting cracked kerosene into the raw materials for petrochemical cracking having a high thermal decomposition yield by a hydrogenation reaction. The present invention is a petrochemical process for producing at least any of ethylene, propylene, butane, benzene or toluene by carrying out a thermal decomposition reaction at least using naphtha for the main raw material, wherein cracked kerosene produced from a thermal cracking furnace is hydrogenated using a Pd or Pt catalyst in a two-stage method consisting of a first stage (I), in which a hydrogenation reaction is carried out within the range of 50 to 180° C., and a second stage (II), in which a hydrogenation reaction is carried out within the range of 230 to 350° C., followed by re-supplying all or a portion of these hydrogenated hydrocarbons to a thermal cracking furnace.

Owner:SHOWA DENKO KK

Catalytic cracking diesel fuel hydroconversion method

ActiveCN104611029AReduce hydrogenationHigh yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

The present invention discloses a catalytic cracking diesel fuel hydroconversion method. According to the method, catalytic diesel fuel and hydrogen are mixed and then enter a hydrorefining reactor to carry out a hydrorefining reaction; the hydrorefining reaction effluent directly enters a hydrocracking reactor and then is subjected to a contact reaction with the grading catalyst bed layer inside the hydrocracking reactor, wherein at least two cracking catalyst bed layers are arranged inside the hydrocracking reactor, and the hydrogenation activity of the hydrocracking catalyst presents the decrease tendency according to the reaction material flowing direction; and the hydrocracking reaction effluent is subjected to separation and fractionation to obtain the naphtha and the diesel fuel. With the method of the present invention, the diesel fuel hydrocracking effect can be ensured while the excessive hydrogenation and the secondary cracking of the naphtha can be reduced and the chemical hydrogen consumption can be reduced so as to increase the octane number and the liquid yield of the naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of Transportation Fuel from Renewable Feedstocks

ActiveUS20090229172A1Reduce first amountMinimize the numberBiofuelsLiquid hydrocarbon mixture productionNaphthaHigh pressure hydrogen

A process has been developed for producing a diesel boiling point range product and an aviation boiling point range product from renewable feedstocks such as plant and animal oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction which is then isomerized and selectively cracked to form the diesel boiling point range product and the aviation boiling point range product. A portion of the diesel boiling point range product, aviation boiling point range product, naphtha product, LPG, or any combination thereof can be optionally used as a rectification agent in the selective hot high pressure hydrogen stripper to decrease the amount of product carried in the stripper overhead.

Owner:UOP LLC

Reforming process using high density catalyst

InactiveUS20060102520A1High densityIncreased pinning marginCatalytic naphtha reformingCatalyst activation/preparationMössbauer spectroscopyMass ratio

A catalyst and a process for using the catalyst are disclosed generally for the conversion of hydrocarbons. The catalyst has an increased average bulk density and a decreased mass ratio of platinum-group metal. The process using the catalyst obtains unexpected high activity and stability for the reforming of naphtha range hydrocarbons. Mössbauer spectroscopy is used to characterize the extent of tin association with platinum and determine an effective molar tin ratio appropriate for alumina supports with densities above 0.6 g / cc.

Owner:UOP LLC

High temperature naphtha desulfurization using a low metal and partially deactivated catalyst

InactiveUS6231754B1Catalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsNaphthaThiol

A high temperature naphtha desulfurization process with reduced olefin saturation employs a partially spent and low metals content hydrodesulfurization catalyst having from 2-40% the activity of a new catalyst. The catalytic metals preferably include Co and Mo in an atomic ratio of from 0.1 to 1. The catalyst is preferably at least partially regenerable, has less than 500 wppm of a total of one or more of nickel, iron and vanadium and preferably has no more than 12 wt. % catalytic metal calculated as the oxide. This permits selective deep desulfurization, with reduced olefin saturation, low product mercaptan levels and little or need for downstream mercaptan removal.

Owner:EXXON RES & ENG CO

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

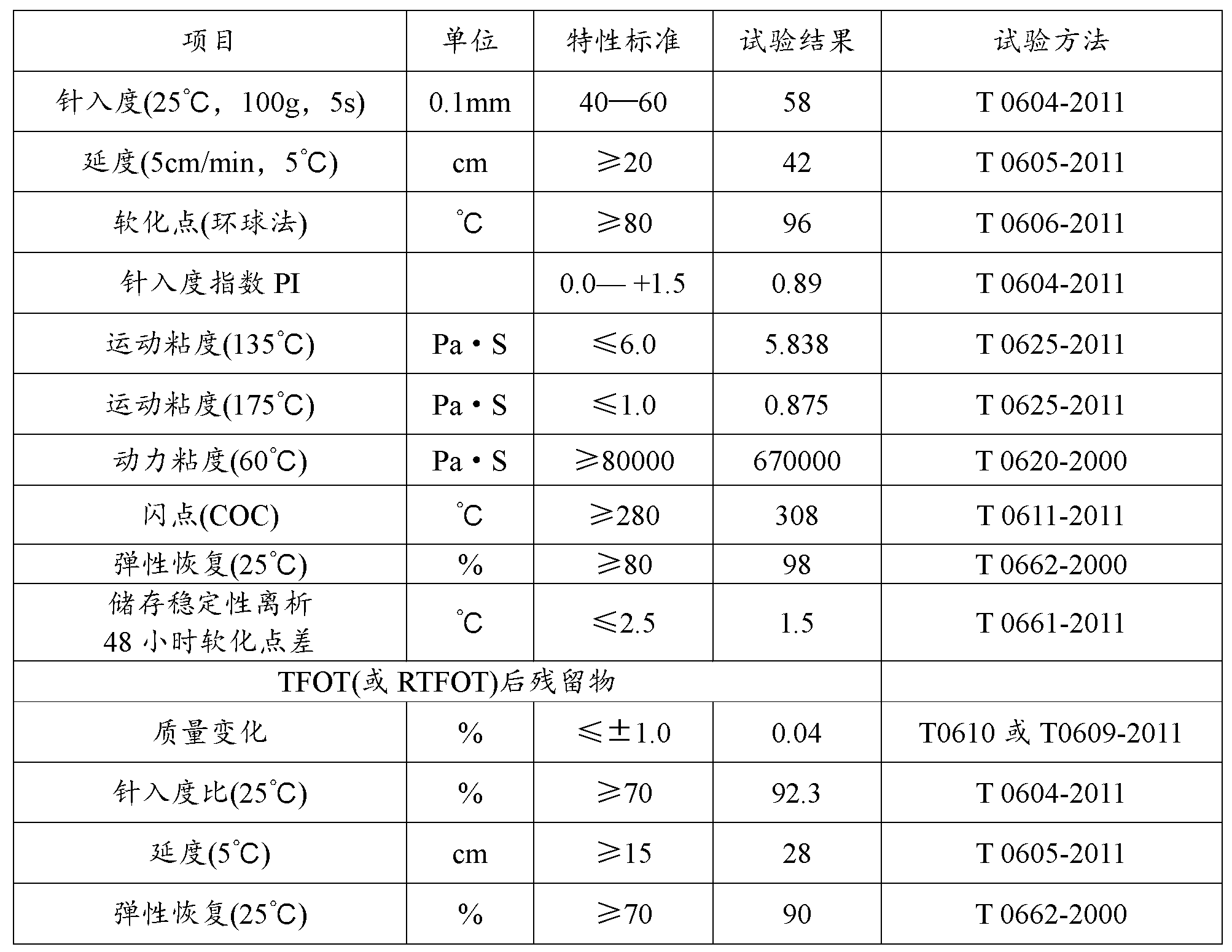

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

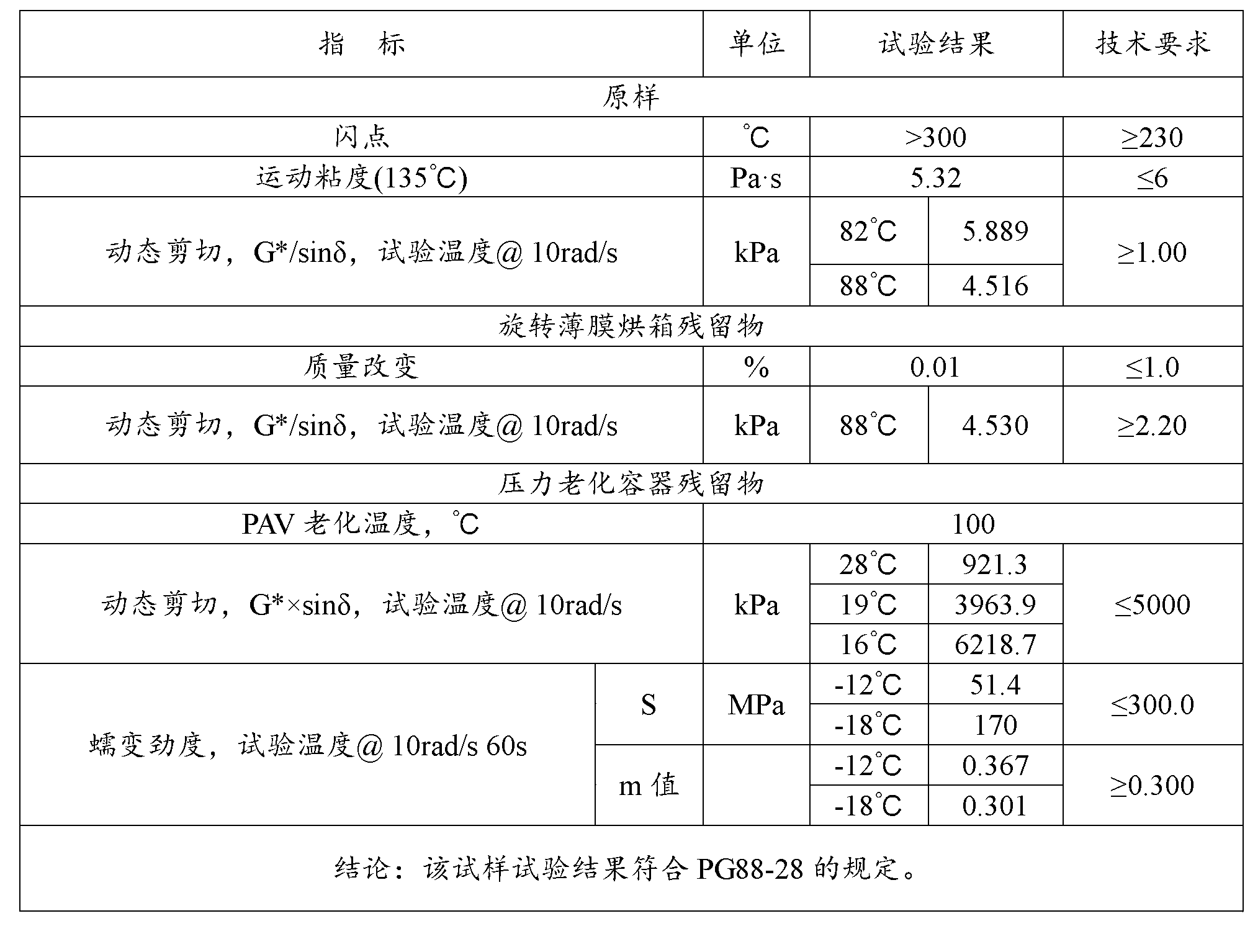

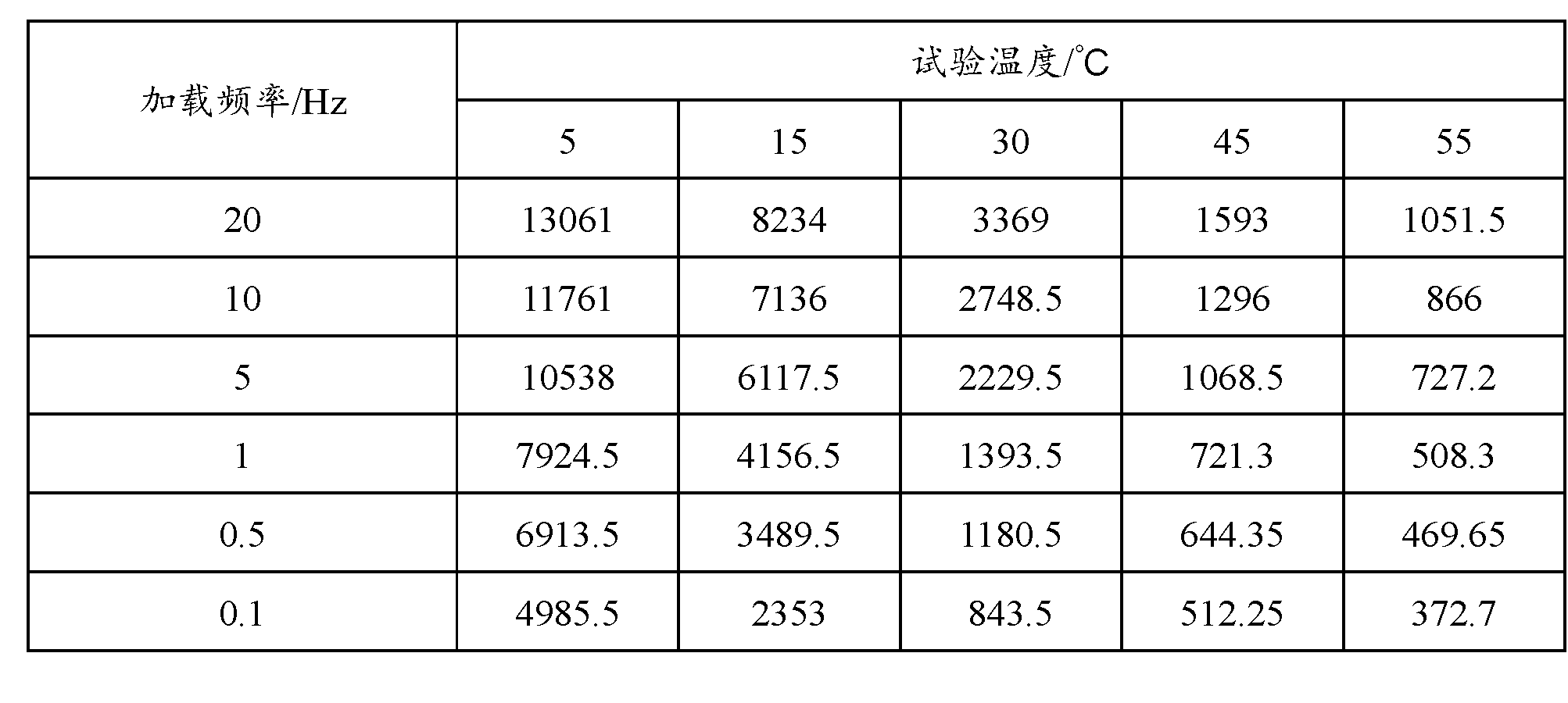

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

Method for desulfurizing a fuel for use in a fuel cell power plant

A fuel processing system is operable to remove substantially all of the sulfur present in an undiluted hydrocarbon fuel stock supply used to power a fuel cell power plant in a mobile environment, such as an automobile, bus, truck, boat, or the like, or in a stationary environment. The power plant hydrogen fuel source can be gasoline, diesel fuel, naphtha, light hydrocarbon fuels such as butane, propane, natural gas, or other like fuels which contain relatively high levels of organic sulfur compounds such as mercaptans, sulfides, disulfides, and the like. The undiluted hydrocarbon fuel supply is passed through a nickel desulfurizer bed wherein essentially all of the sulfur in the organic sulfur compounds react with the nickel reactant, and are converted to nickel sulfide while the desulfurized organic remnants continue through the remainder of the fuel processing system. The system does not require the addition of steam or a hydrogen source to the fuel stream prior to the desulfurizing step. The system operates at relatively low temperatures and can be used to desulfurize either a liquid or a gaseous fuel stream.

Owner:UNITED TECH CORP

Thermostable strong acid cation resin catalyst and its preparing method

ActiveCN1569334ARaise the partial pressure of the gas phaseImprove uniformityOrganic-compounds/hydrides/coordination-complexes catalystsAlkanePurification methods

The present invention solves the problem that the existing strong acid resin catalyst has bad high temperature mechanical intensity and complex hole purification technics, brings forward a simple preparing method for pressurization polymerization and hole purification method, the pressurization polymerization improves the uniformity of polymer bead body structure and the high temperature mechanical stability for resin, the extraction is executed by solvent naphtha first and the boiling is executed by halogeno-alkane, the hole purification method is simplified. The prepared strong acid cation resin catalyst has high temperature resistant and excellent catalytic activity and its high temperature stability is better than same kind of product.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

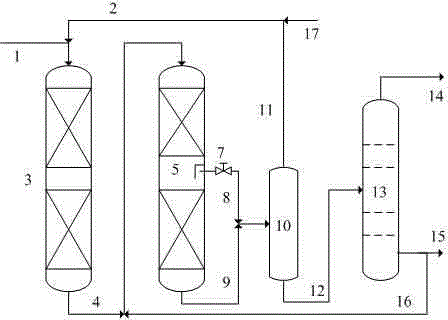

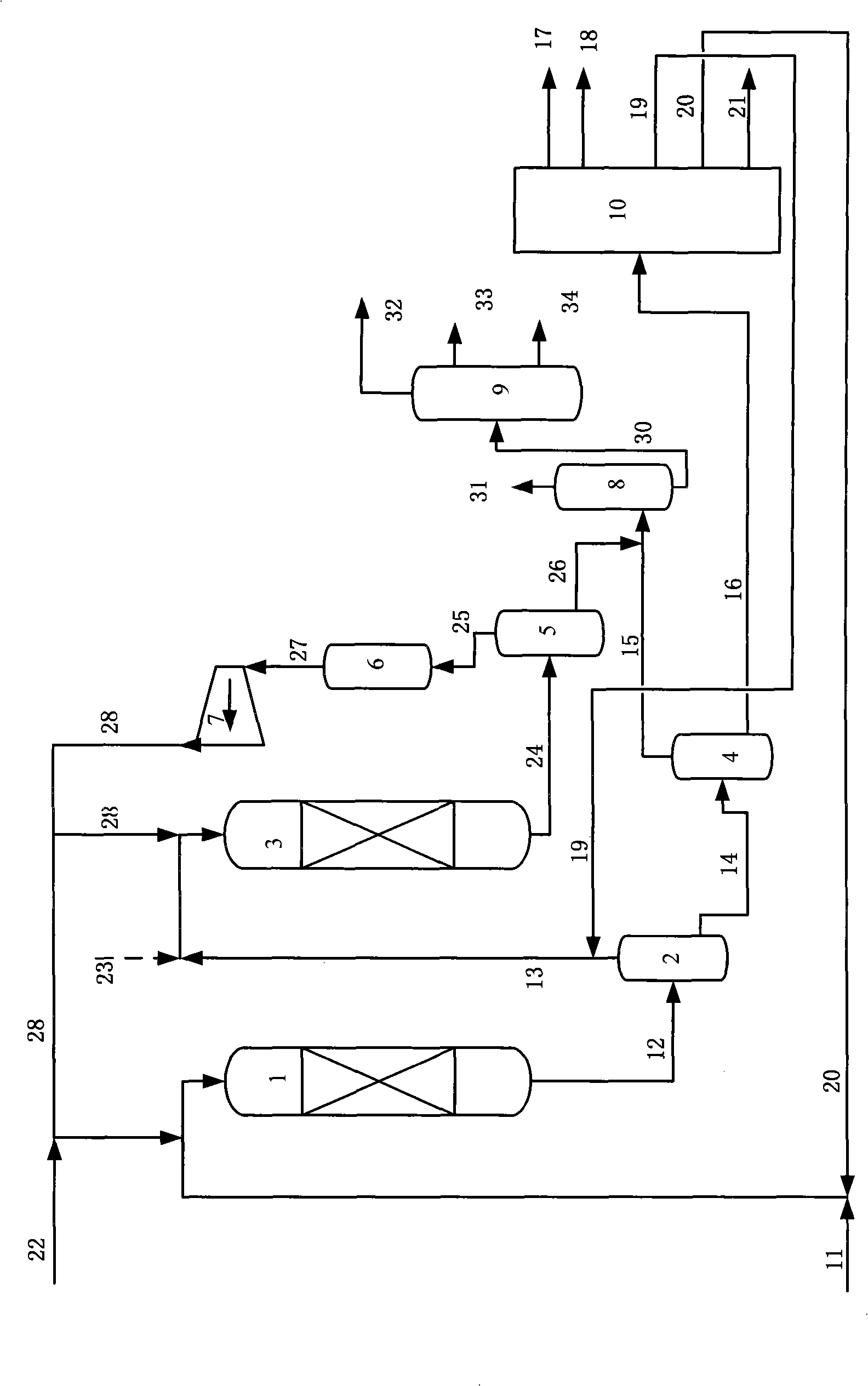

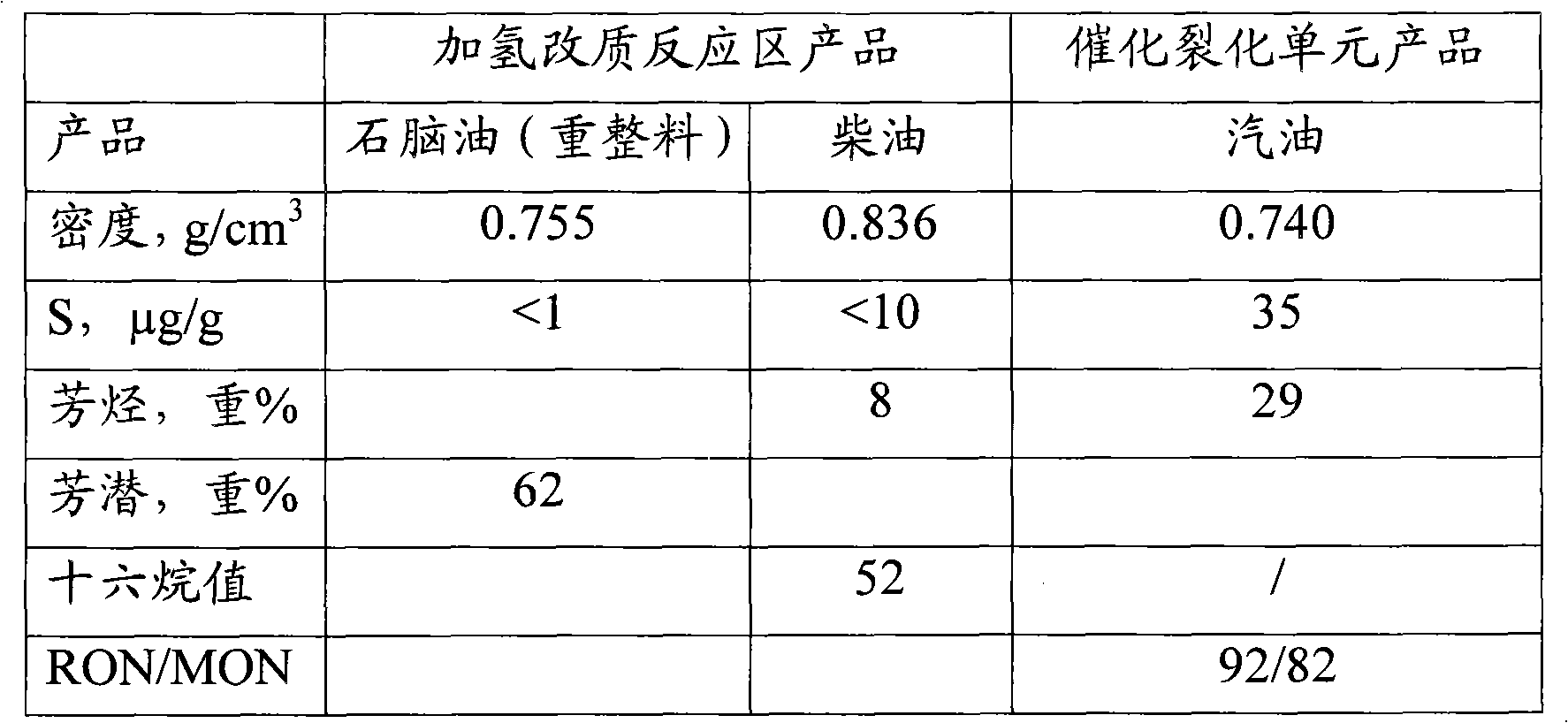

Optimized hydrogenation-catalytic cracking combination process

The invention relates to an optimized hydrogenation-catalytic cracking combination process, comprising the following steps: wax oil raw materials react in a hydrotreating reaction area; obtained hydrogenation wax oil is taken as catalytic cracking raw oil and directly enters a catalytic cracking unit without being fractionated; catalytic heavy cycle oil circulates back the hydrotreating reaction area; gas phase material flow at the top of a high-pressure hot separator, catalytic light cycle oil and optional crude diesel oil enter a hydrogenation upgrading reaction area carry out hydrogenationupgrading reaction; and reaction products thereof are fractionated to obtain hydrogenation naphtha and hydrogenation diesel. A hydrotreating unit and a hydrogenation upgrading unit shares a hydrogensystem, the device investment and operation cost are lowered, the product scheme is flexible, and high-quality low-sulphur gasoline, high-quality diesel and reforming raw materials can be produced atthe same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

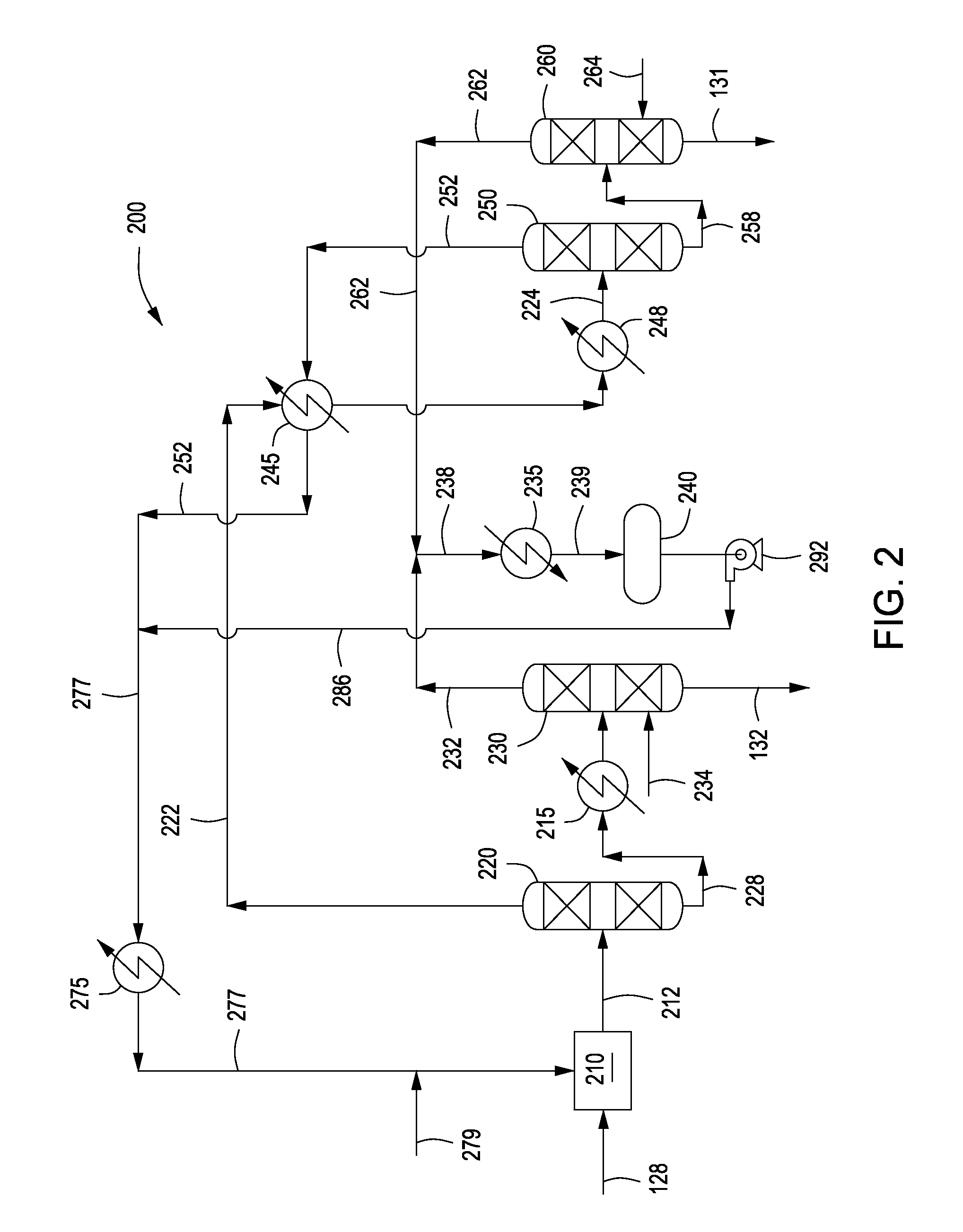

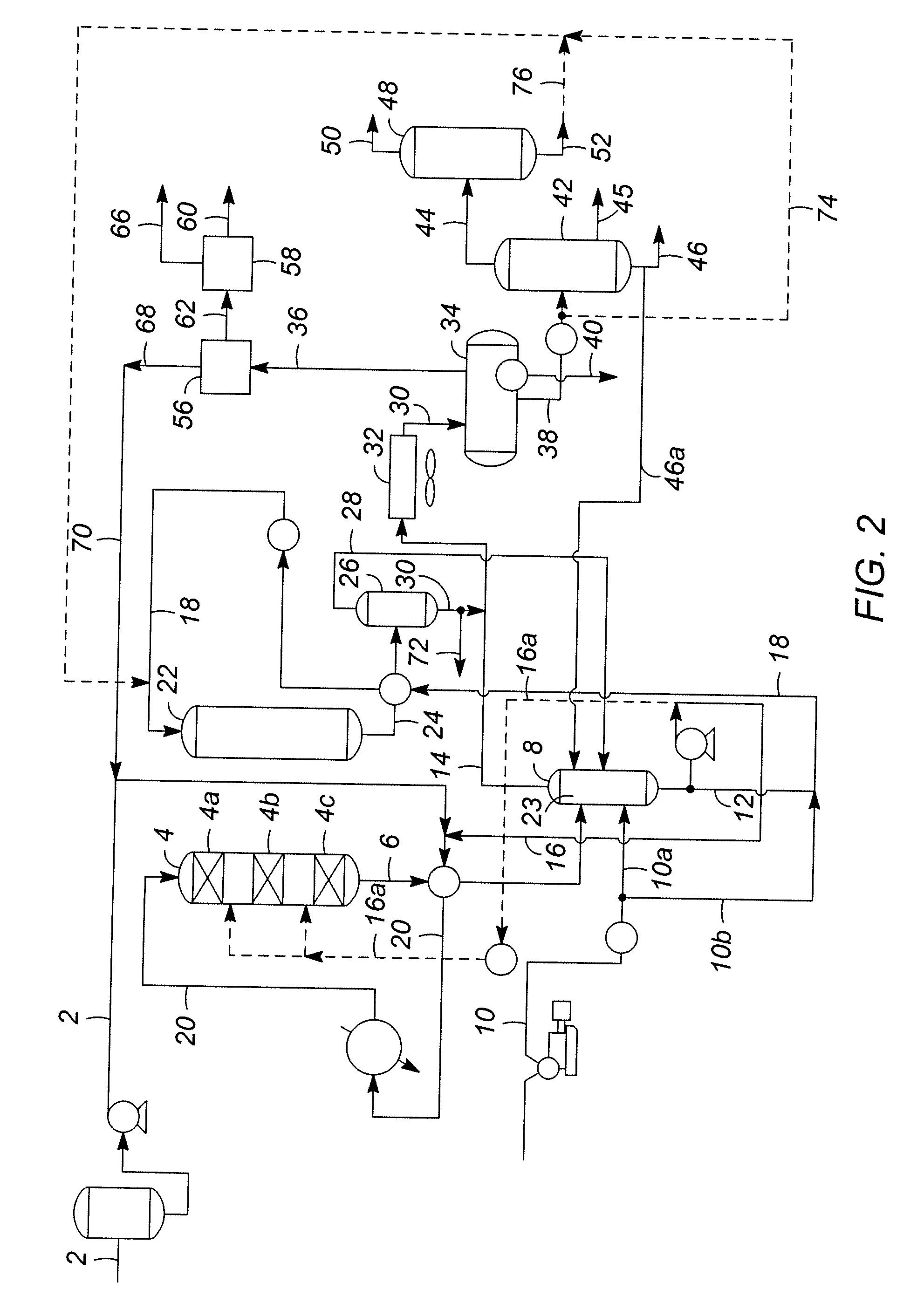

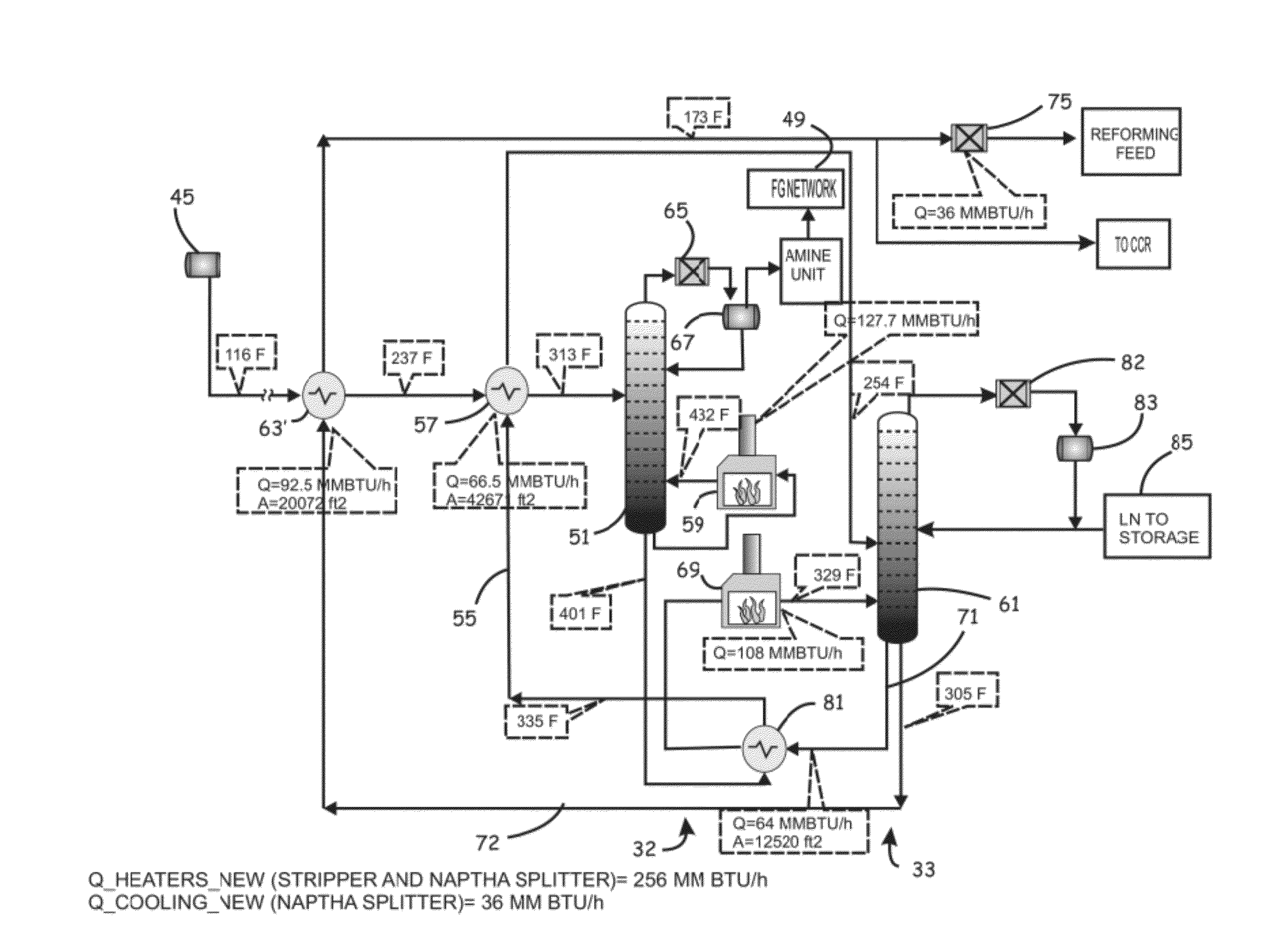

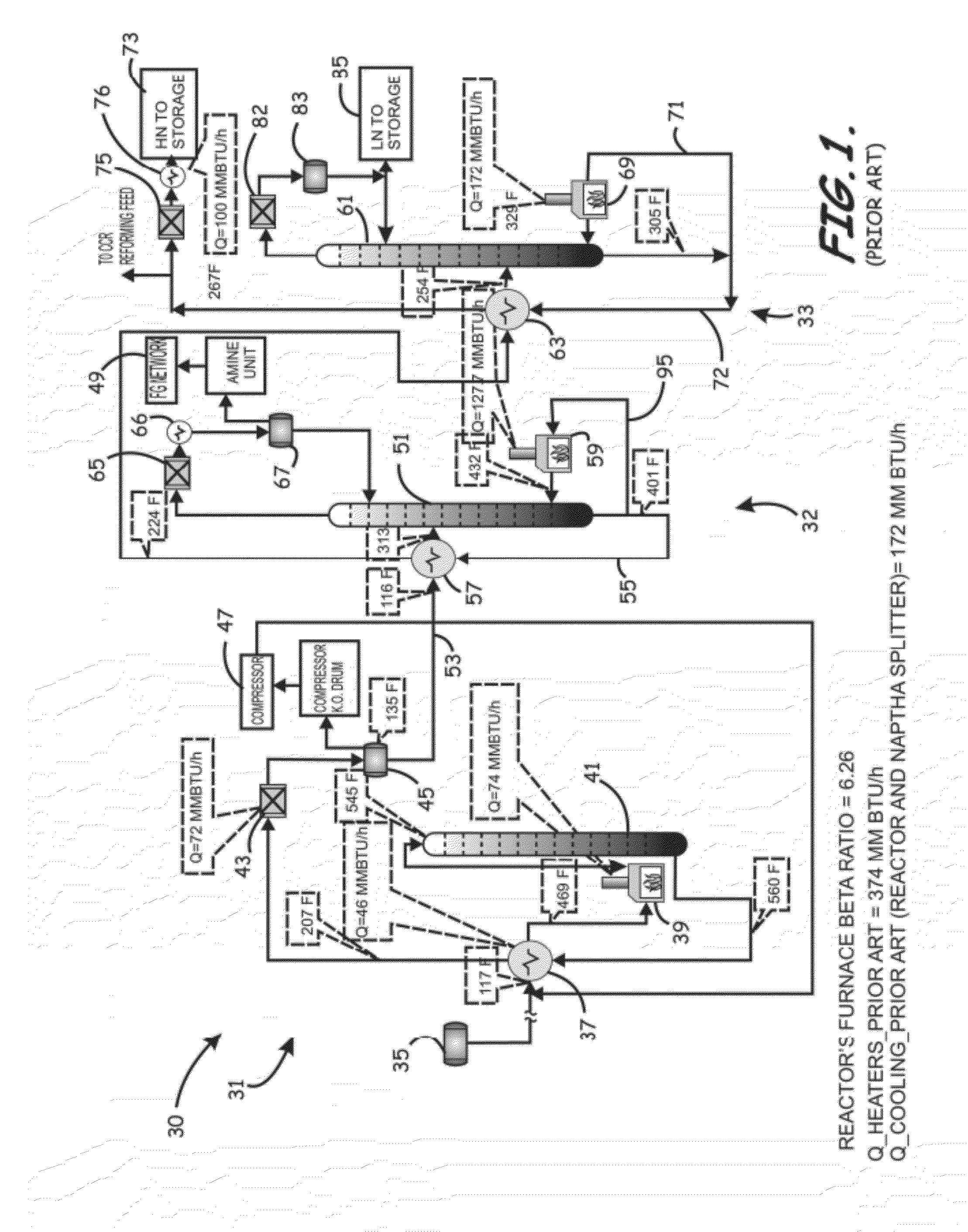

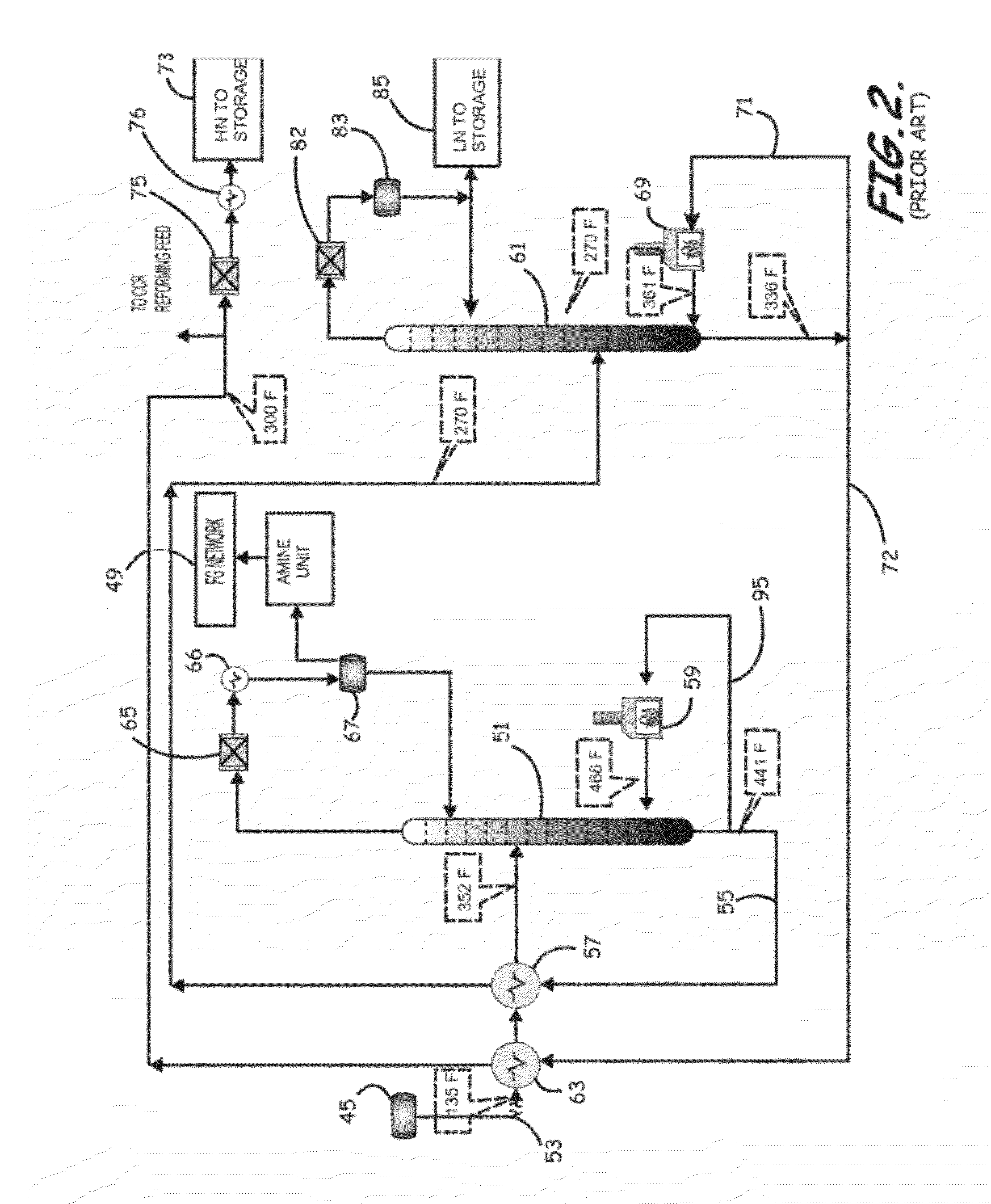

Energy-Efficient and Environmentally Advanced Configurations For Naptha Hydrotreating Process

ActiveUS20120279900A1Less emissionsLower ratioRecuperative heat exchangersThermal naphtha reformingProcess systemsNaphtha

Systems and methods of hydrotreating different naphtha feed stocks destined for a refining reforming unit and other applications with less energy consumption than conventionally possible, while producing less greenhouse gas emissions, and / or using a lesser number of heaters and correspondingly less capital investment in such heaters, air coolers, and water coolers, are provided. According to the more examples of such systems and methods, such reductions are accomplished by directly integrating a naphtha stripping process section with a naphtha splitting process section. Additional reductions can also be accomplished through directly integrating a naphtha hydrotreat reaction process section with the naphtha stripping process section.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com