Fluid cat cracking with high olefins prouduction

a technology of high olefins and flue cat, which is applied in the cracking process of hydrocarbon oil, hydrocarbon oil treatment products, physical/chemical process catalysts, etc., can solve the problems of limited olefins yield from the cracking reaction, high cost of adding additional vessels to an existing fcc unit, etc., and achieves the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

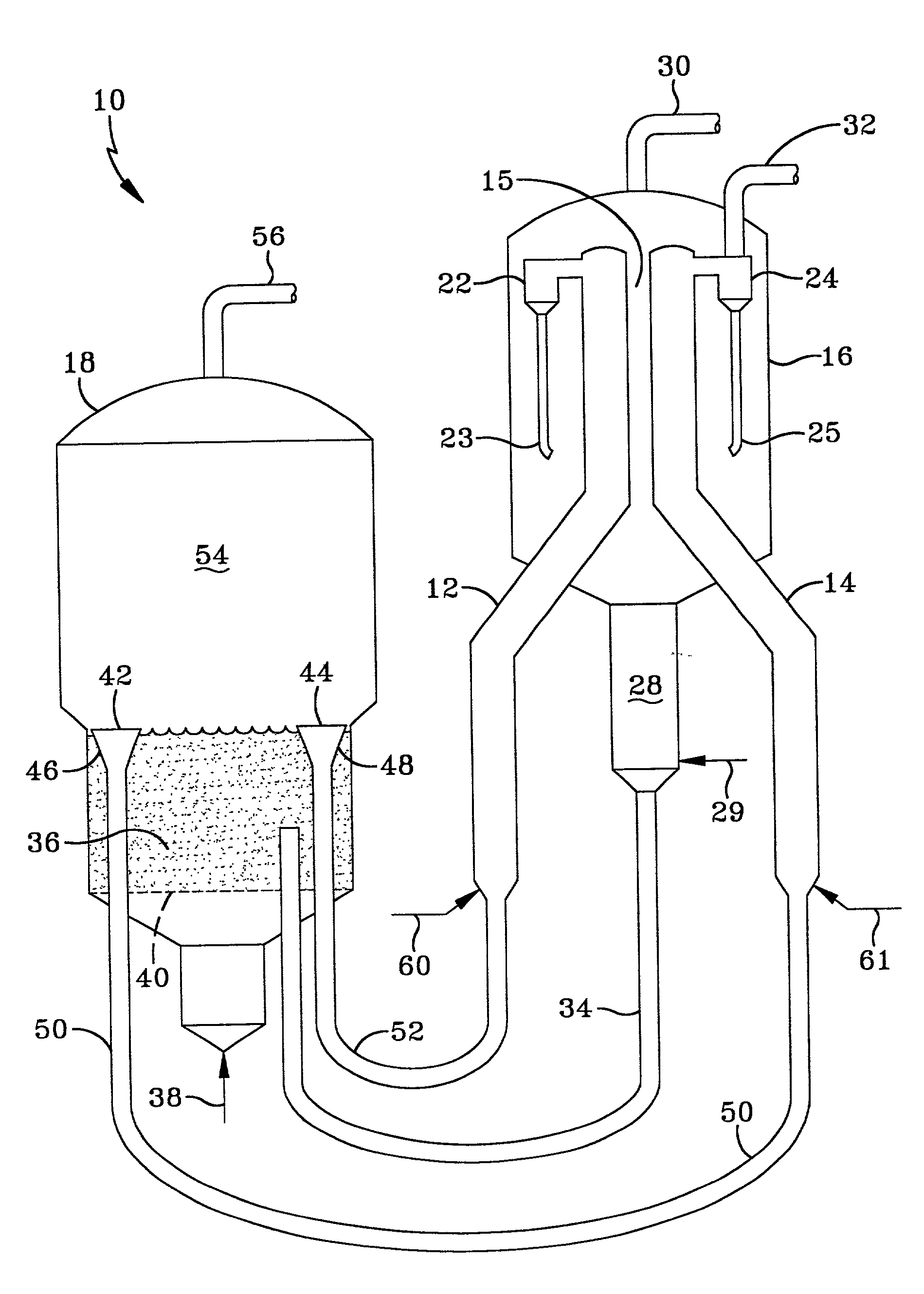

Image

Examples

example

[0021] A commercial FCC unit operating with only an FCC feed riser and a cracking catalyst which comprised a mixture of ZSM-5 and a USY zeolite-containing catalyst, was compared with the process of the invention (Base+), using data generated in pilot plants. The commercial unit was processing a vacuum gas oil feed (API=20.8), using a catalyst blend of a commercial USY-containing catalyst and a commercially available ZSM-5 catalyst. The blend contained about 34 wt. % of a USY zeolite and 0.2 wt. % ZSM-5. The MAT activity of this catalyst blend was 71. With a riser outlet temperature of 975.degree. F. (524.degree. C.) and a catalyst to oil weight ratio of 5, the yields obtained in the Table below, under BASE FCC, were achieved.

[0022] Two different pilot plants were used to demonstrate the improved FCC process of the invention. A circulating pilot plant was used to simulate the primary riser for cracking fresh feed and a bench scale unit was used to crack 60-430.degree. F. boiling rang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| unit cell size | aaaaa | aaaaa |

| unit cell size | aaaaa | aaaaa |

| mole ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com