Patents

Literature

551results about "Hydrocarbon oil cracking process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

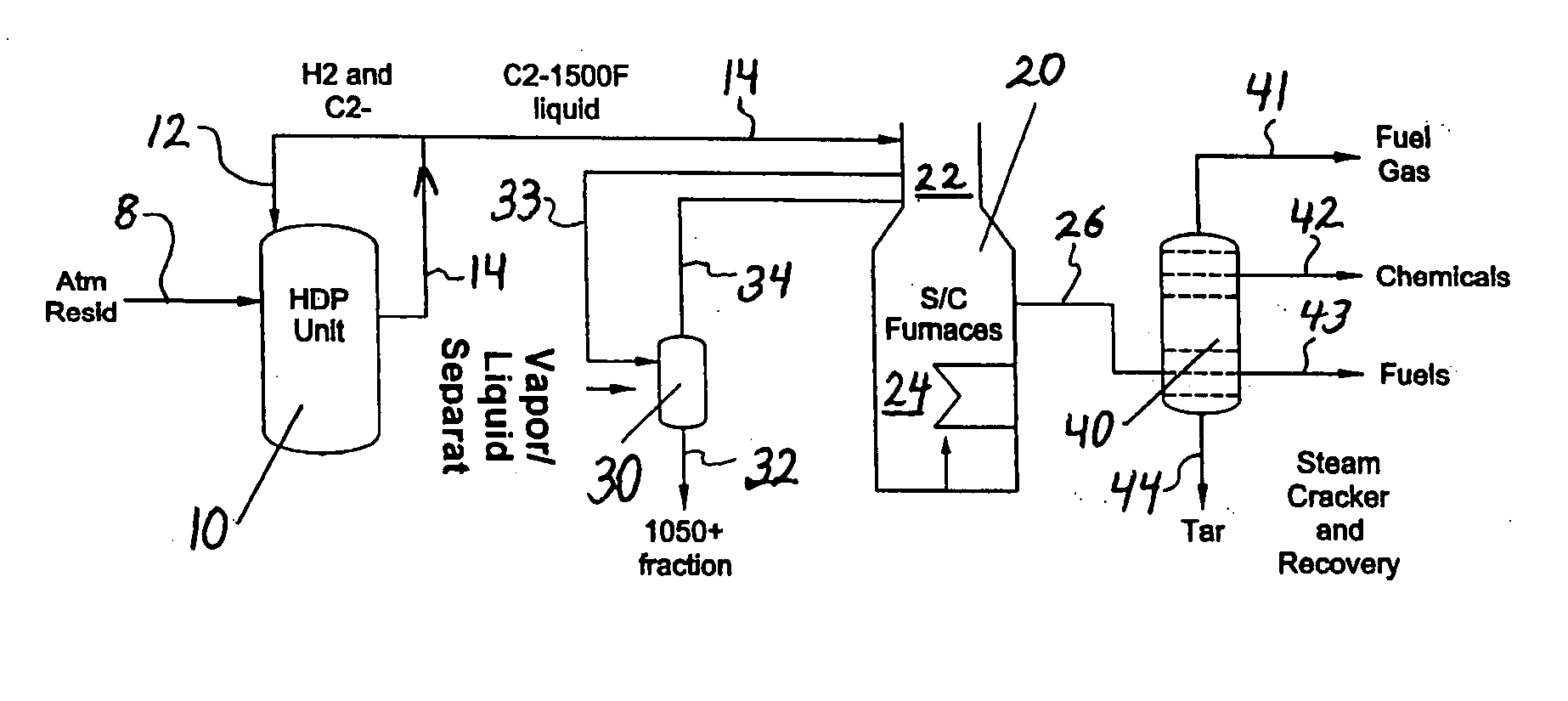

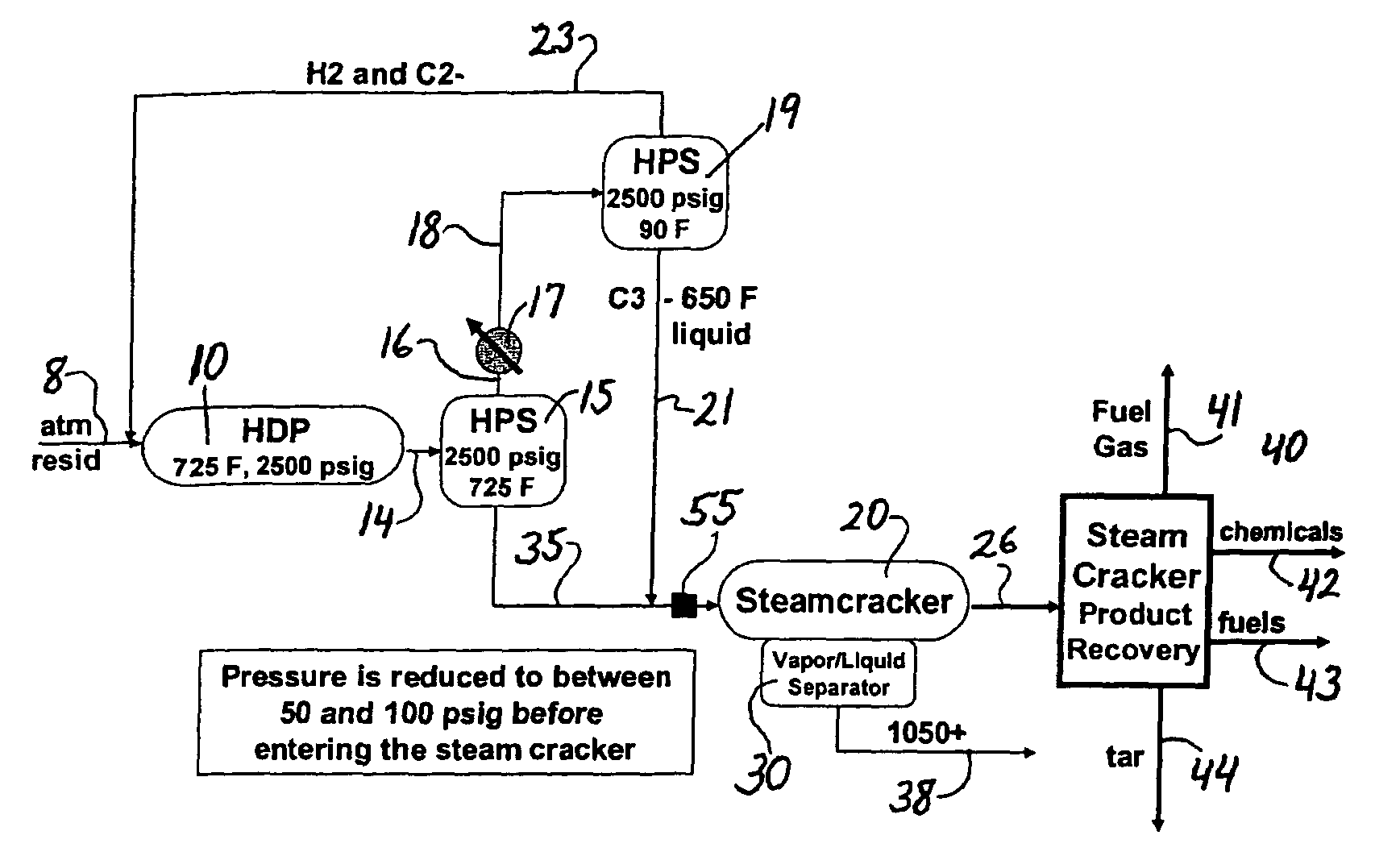

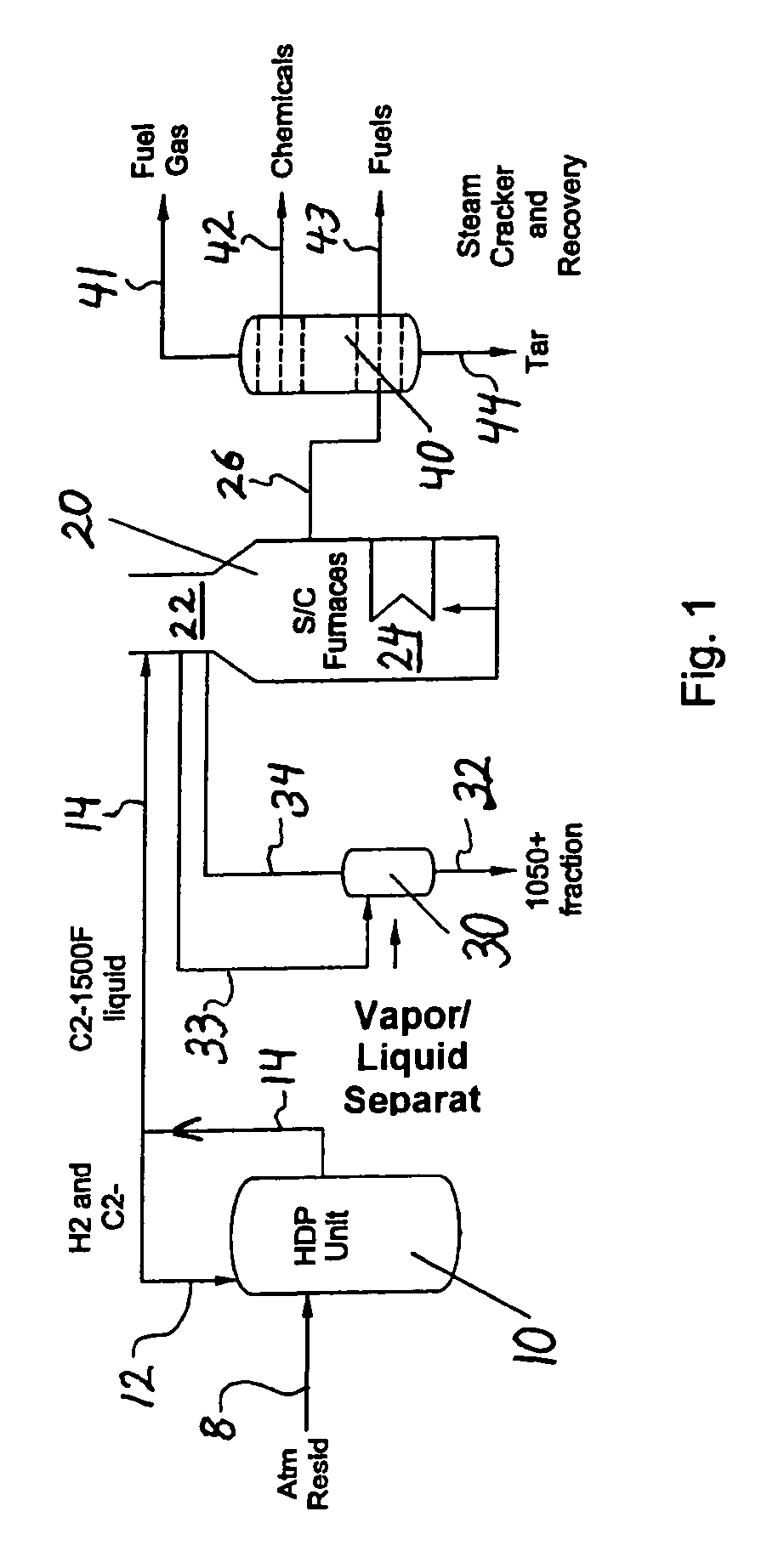

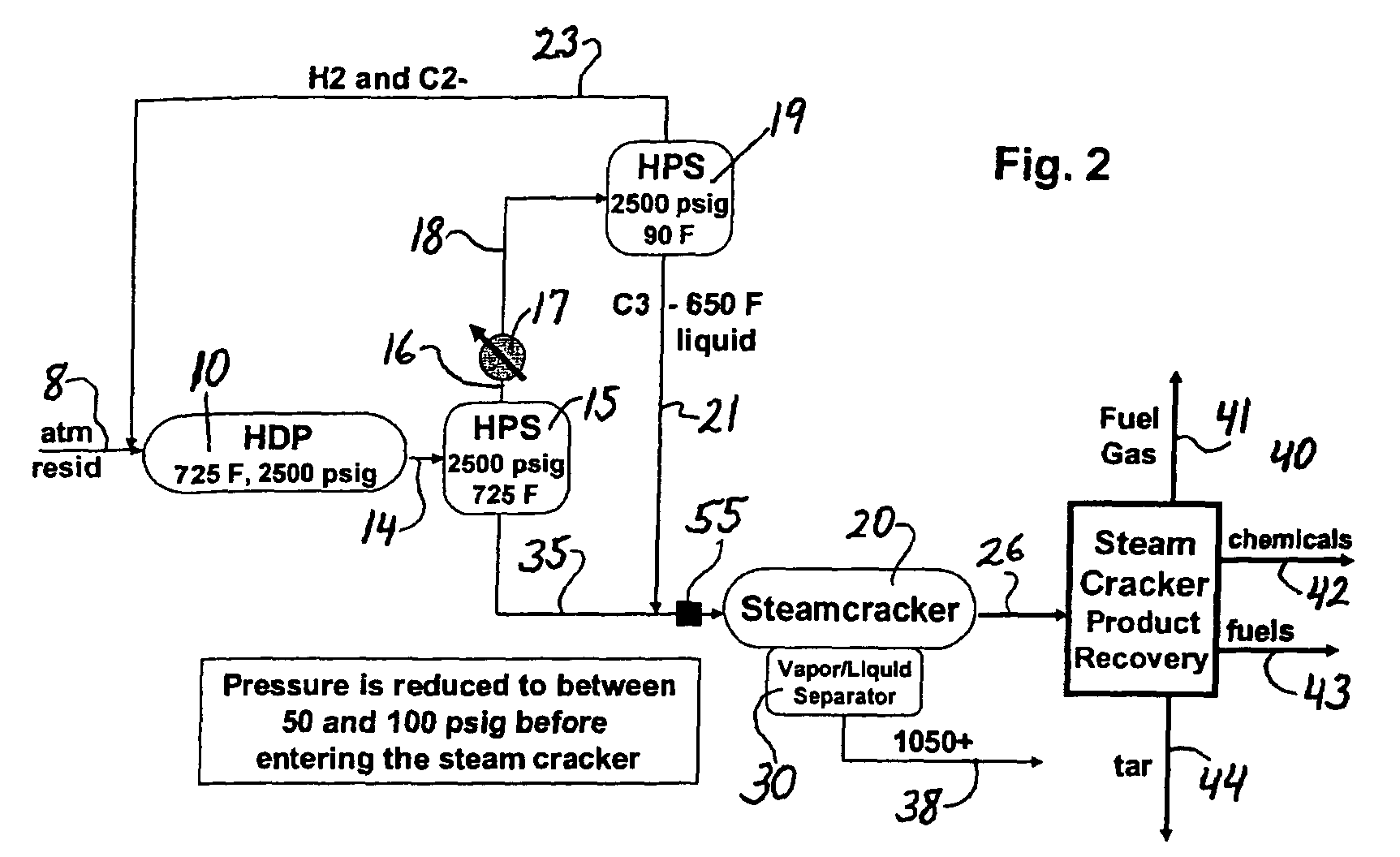

Hydrocarbon resid processing

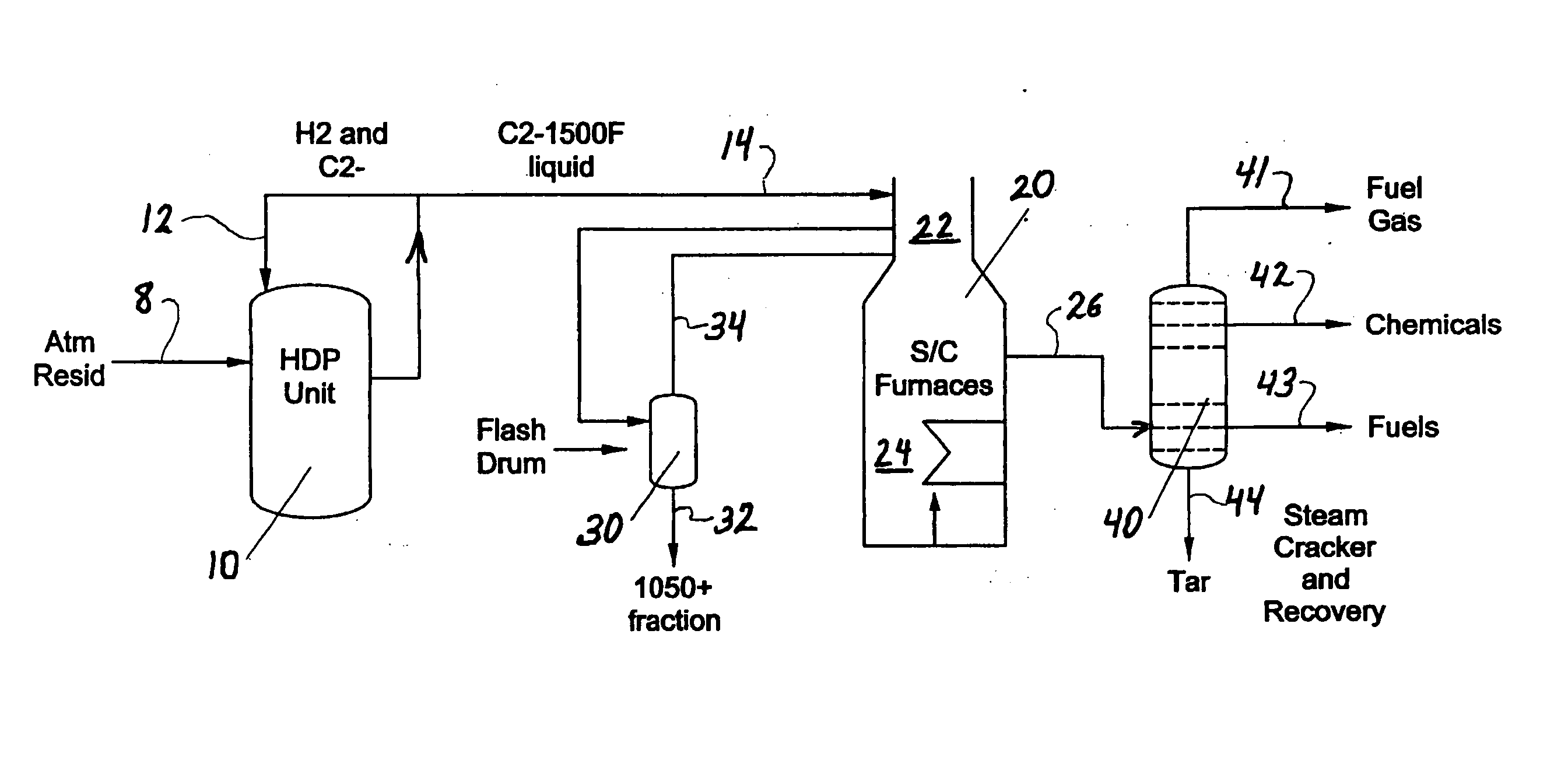

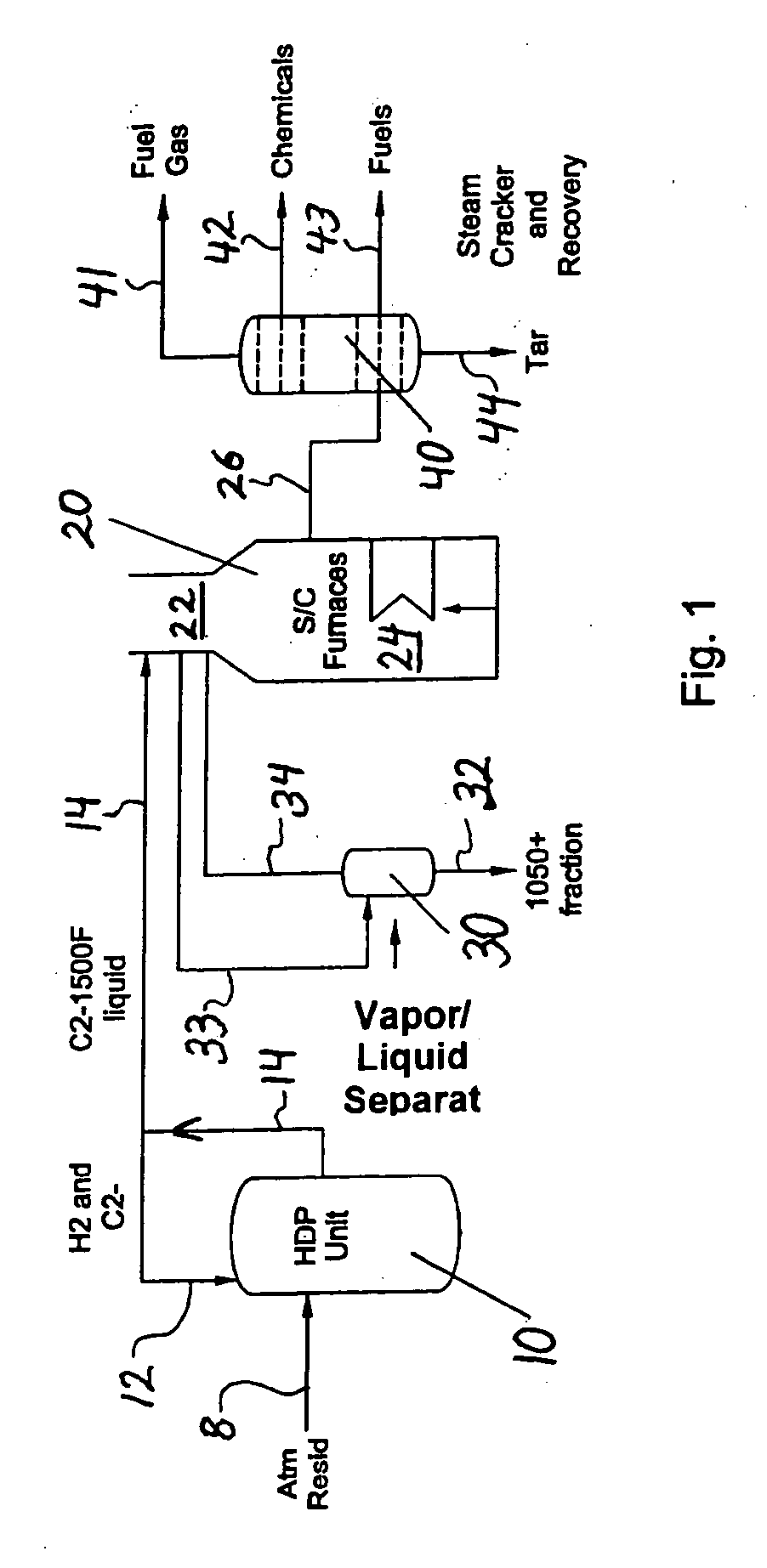

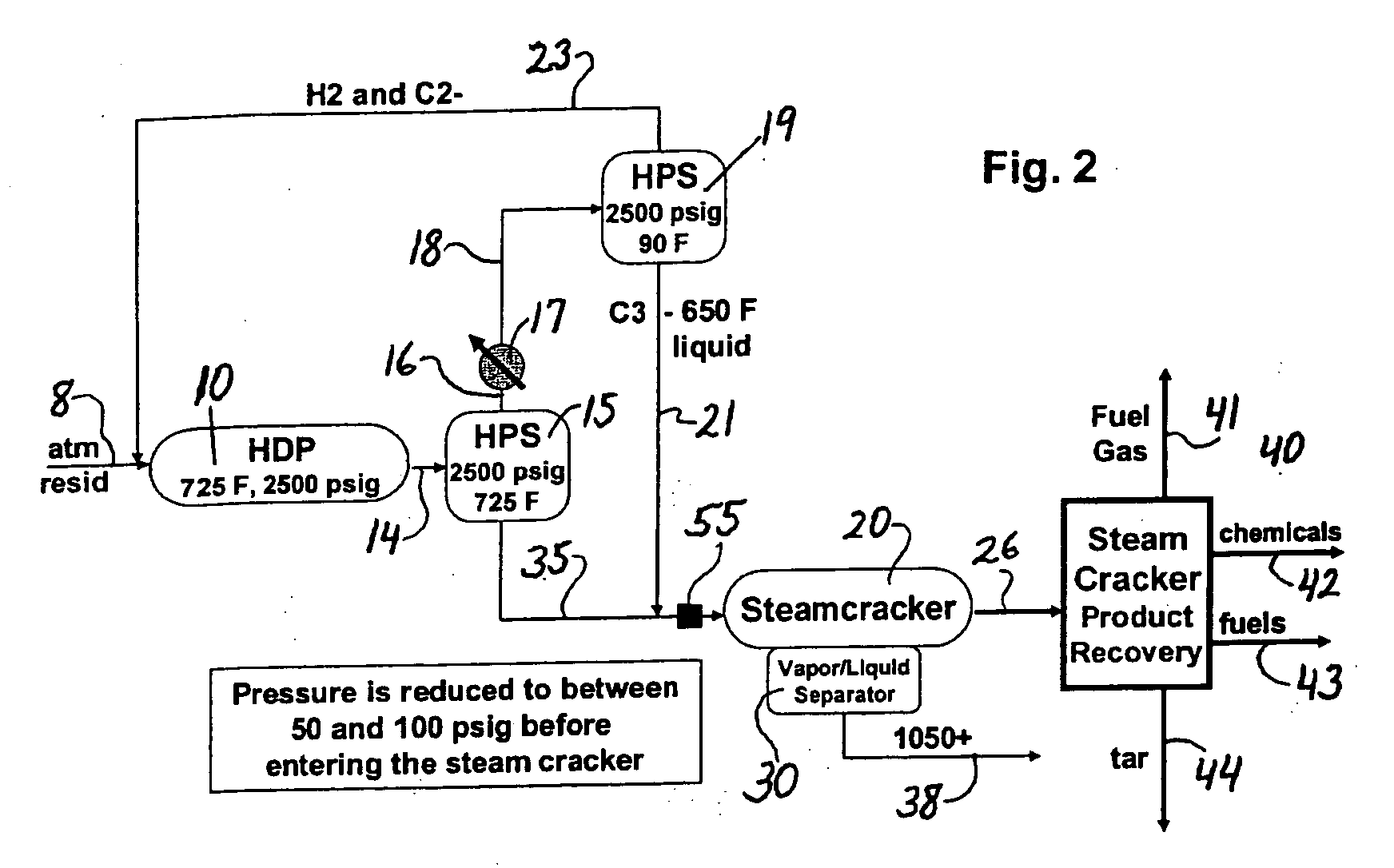

ActiveUS20070090018A1Increase in severityReduce pressureThermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonChemistry

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is severely hydrotreated and passed to a steam cracker to obtain an olefins product.

Owner:EXXONMOBIL CHEM PAT INC

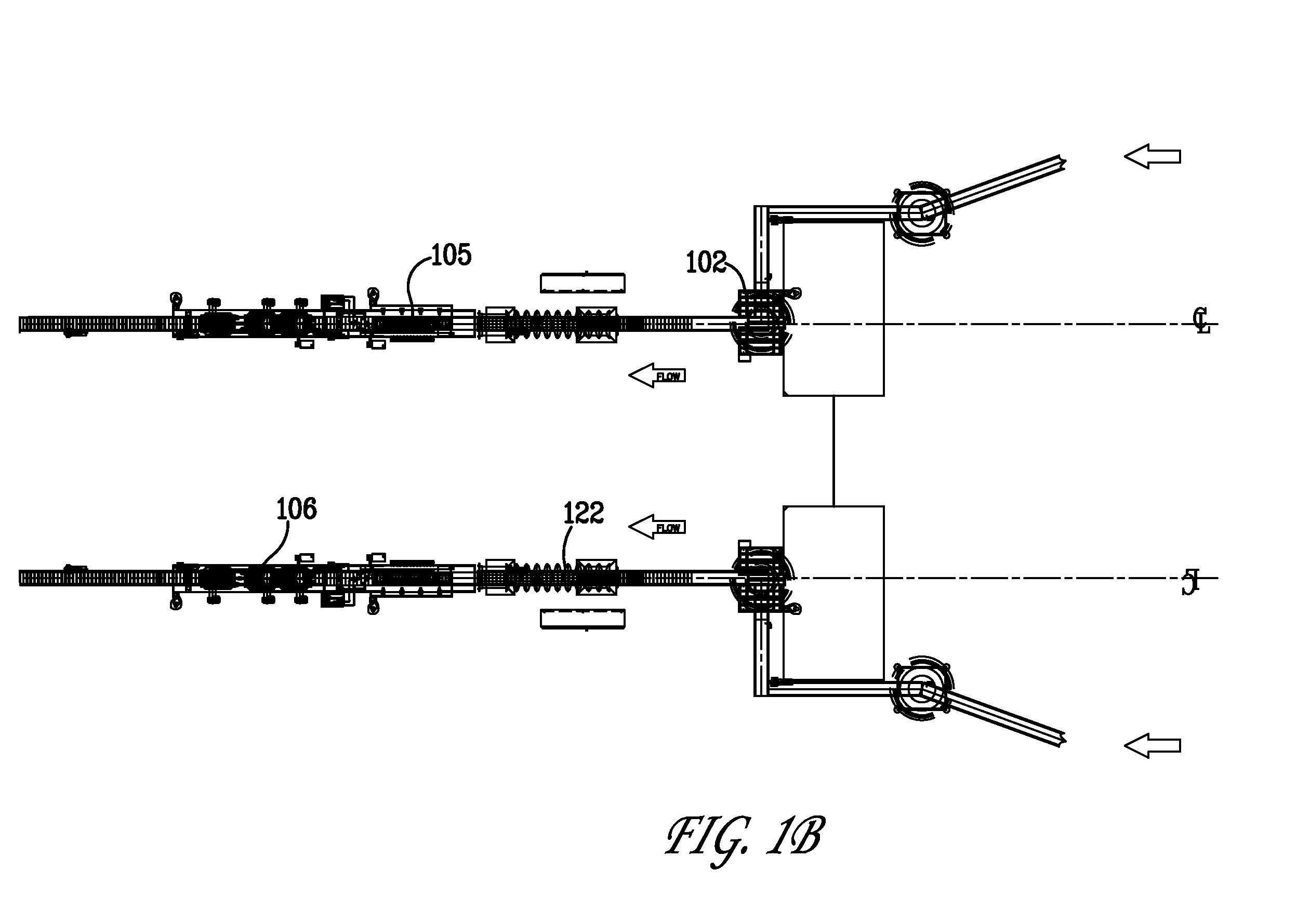

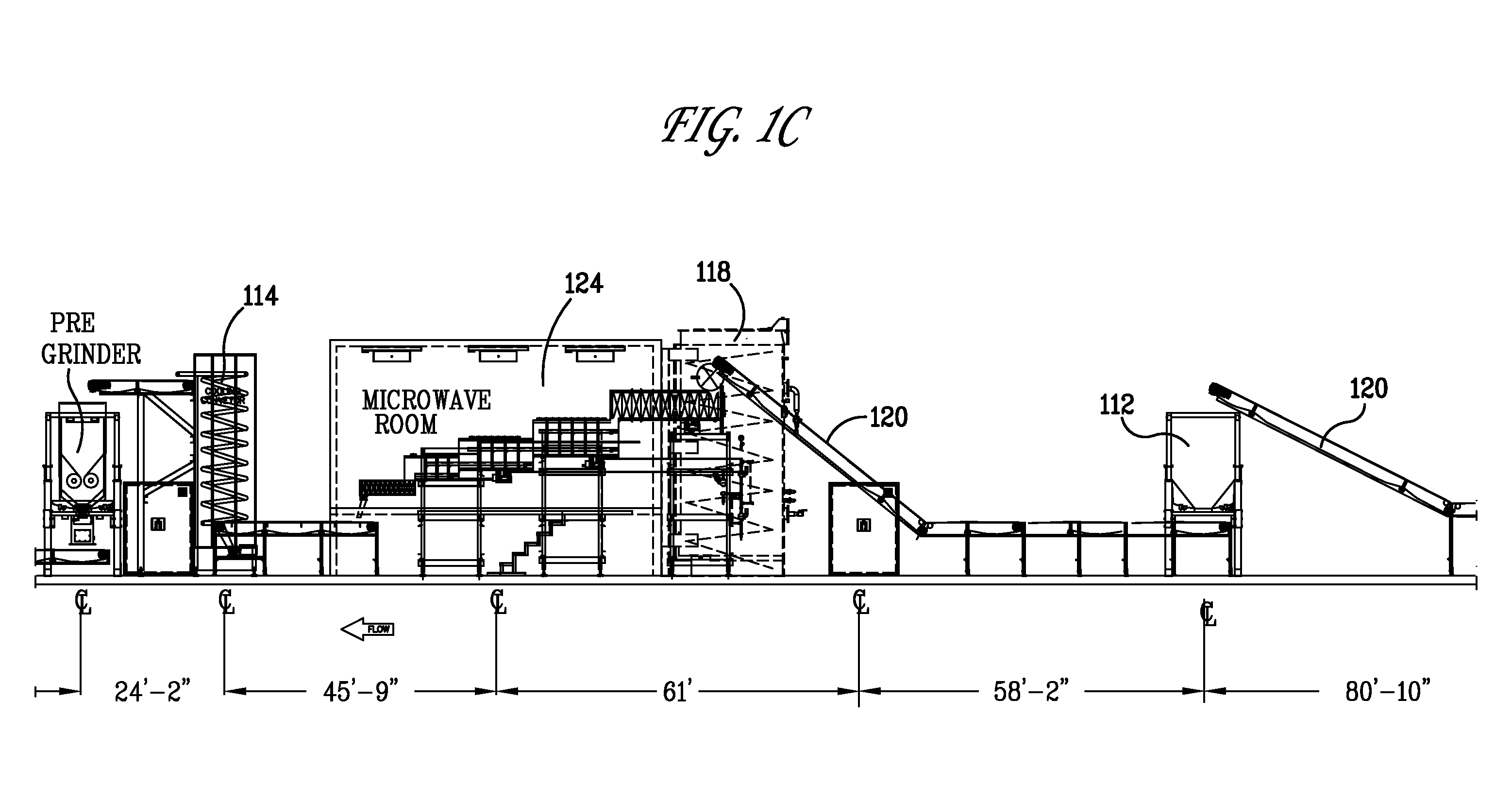

Microwave-based recovery of hydrocarbons and fossil fuels

InactiveUS20070131591A1Organic compounds purification/separation/stabilisationHydrocarbon oil cracking processHydrocotyle bowlesioidesPetroleum

The present invention provides methods for decomposing and extracting compositions for the recovery of petroleum-based materials from composites comprising those petroleum-based materials, comprising subjecting the compositions and / or composites to microwave radiation, wherein the microwave radiation is in the range of from about 4 GHz to about 18 GHz. The present invention also provides for products produced by the methods of the present invention and for apparatuses used to perform the methods of the present invention.

Owner:UNIVERSAL ALTERNATIVE FUELS INC +1

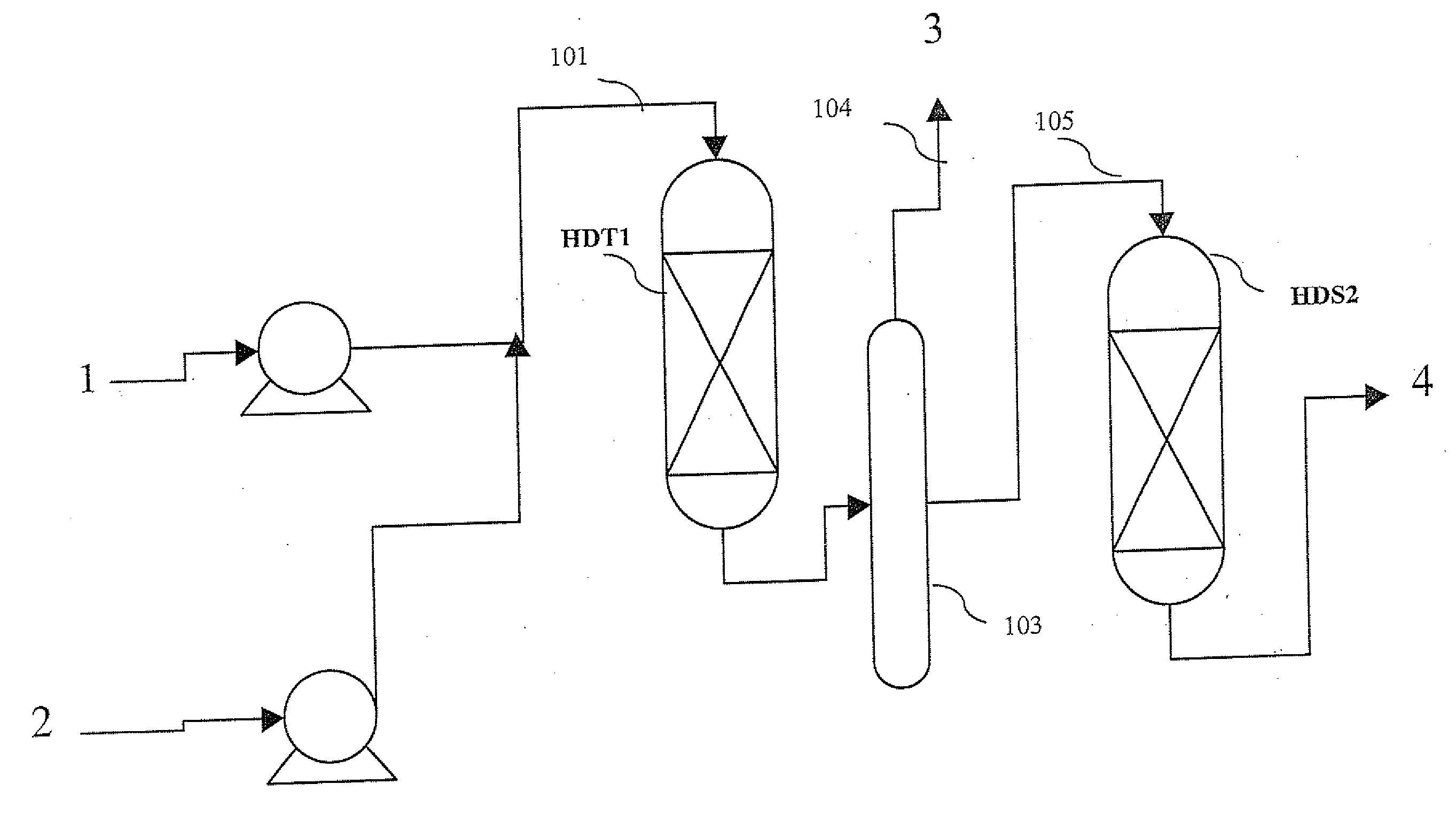

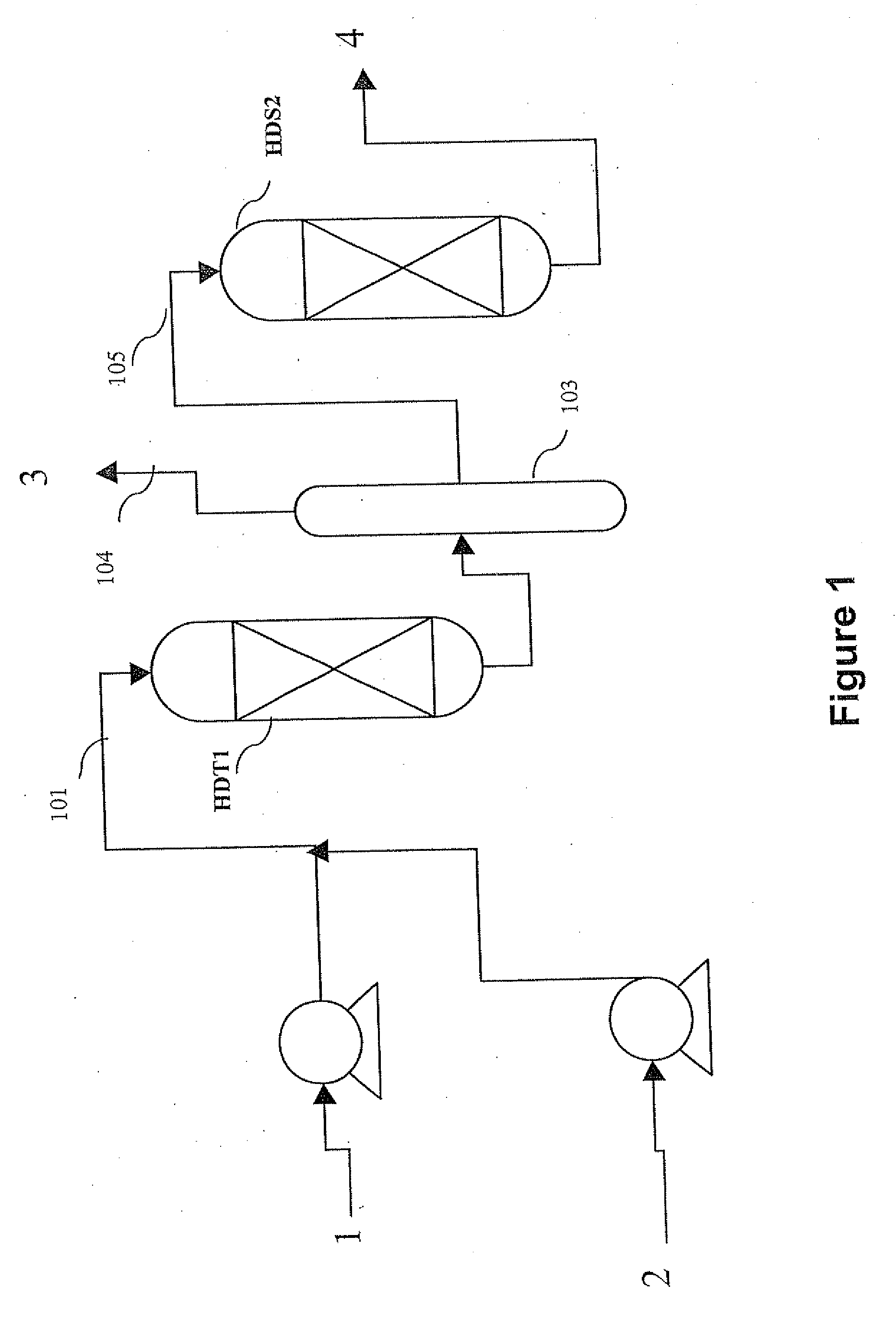

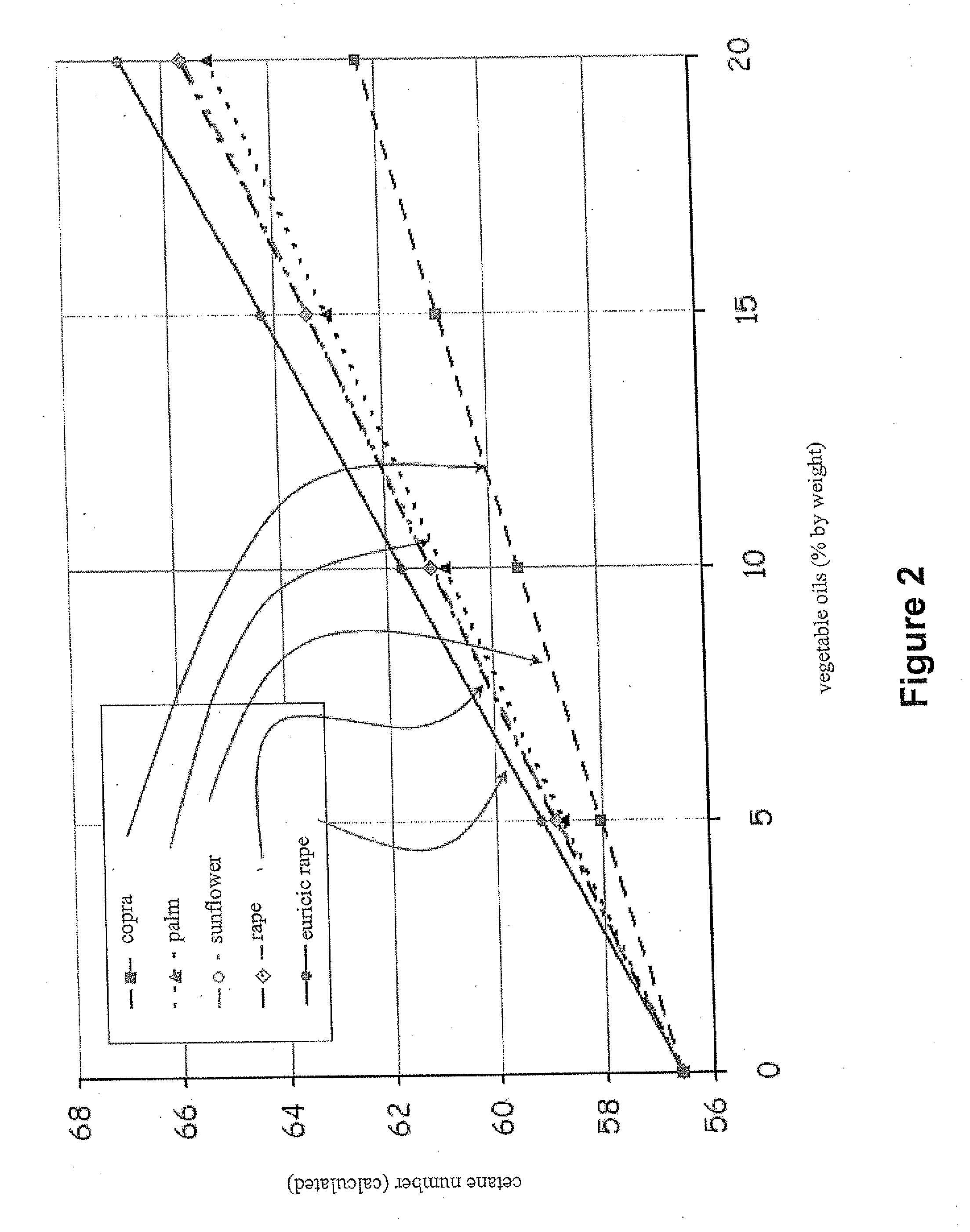

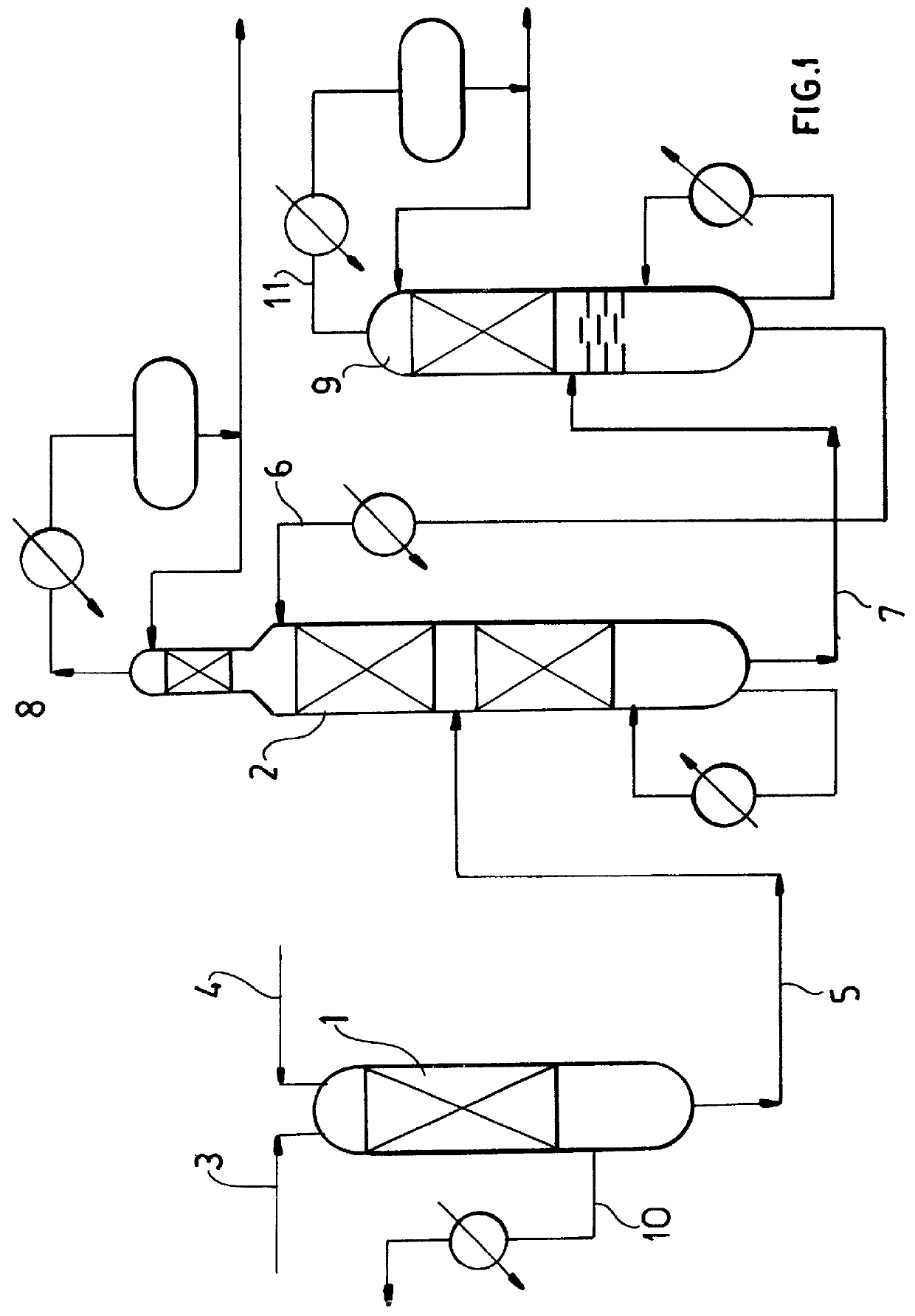

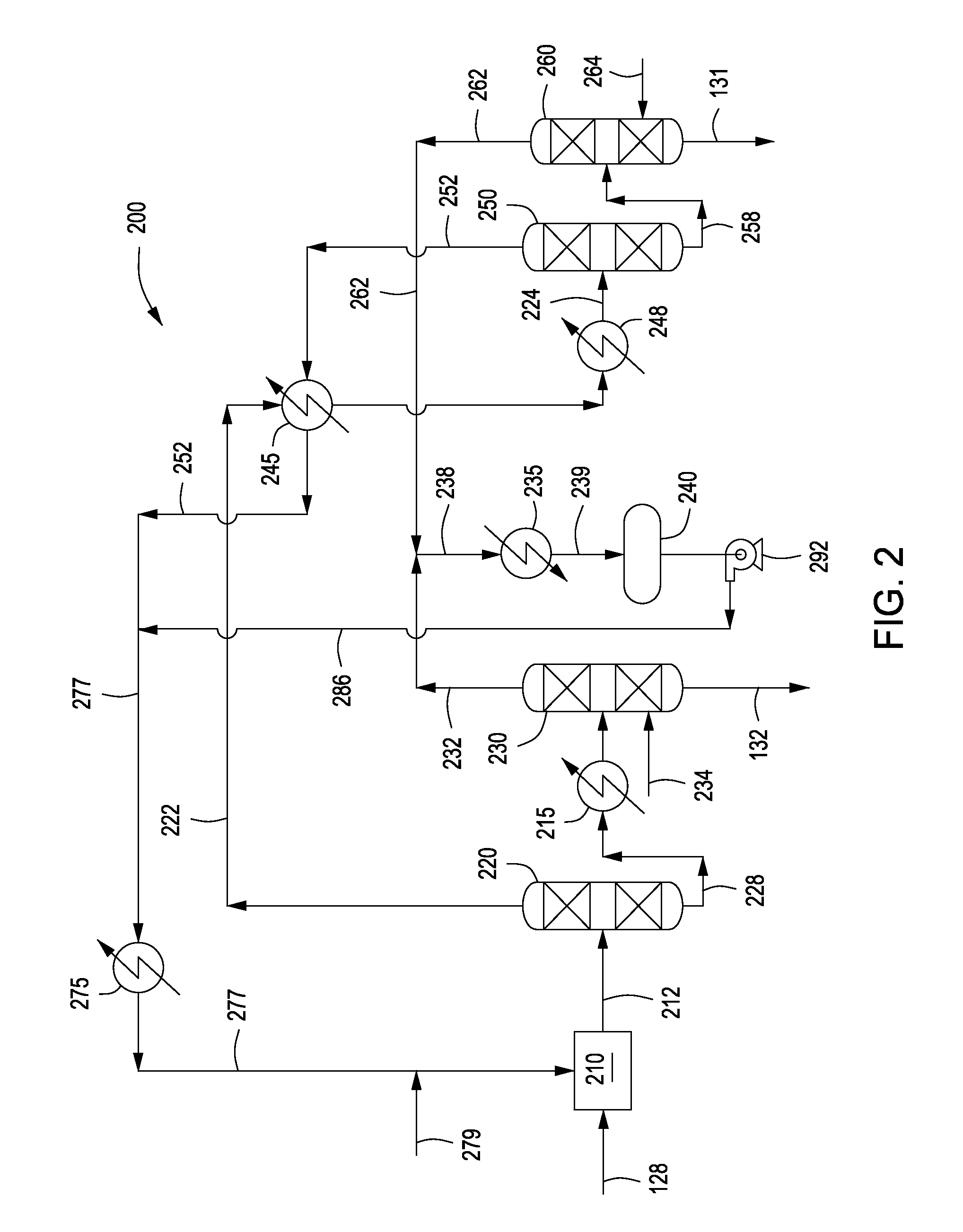

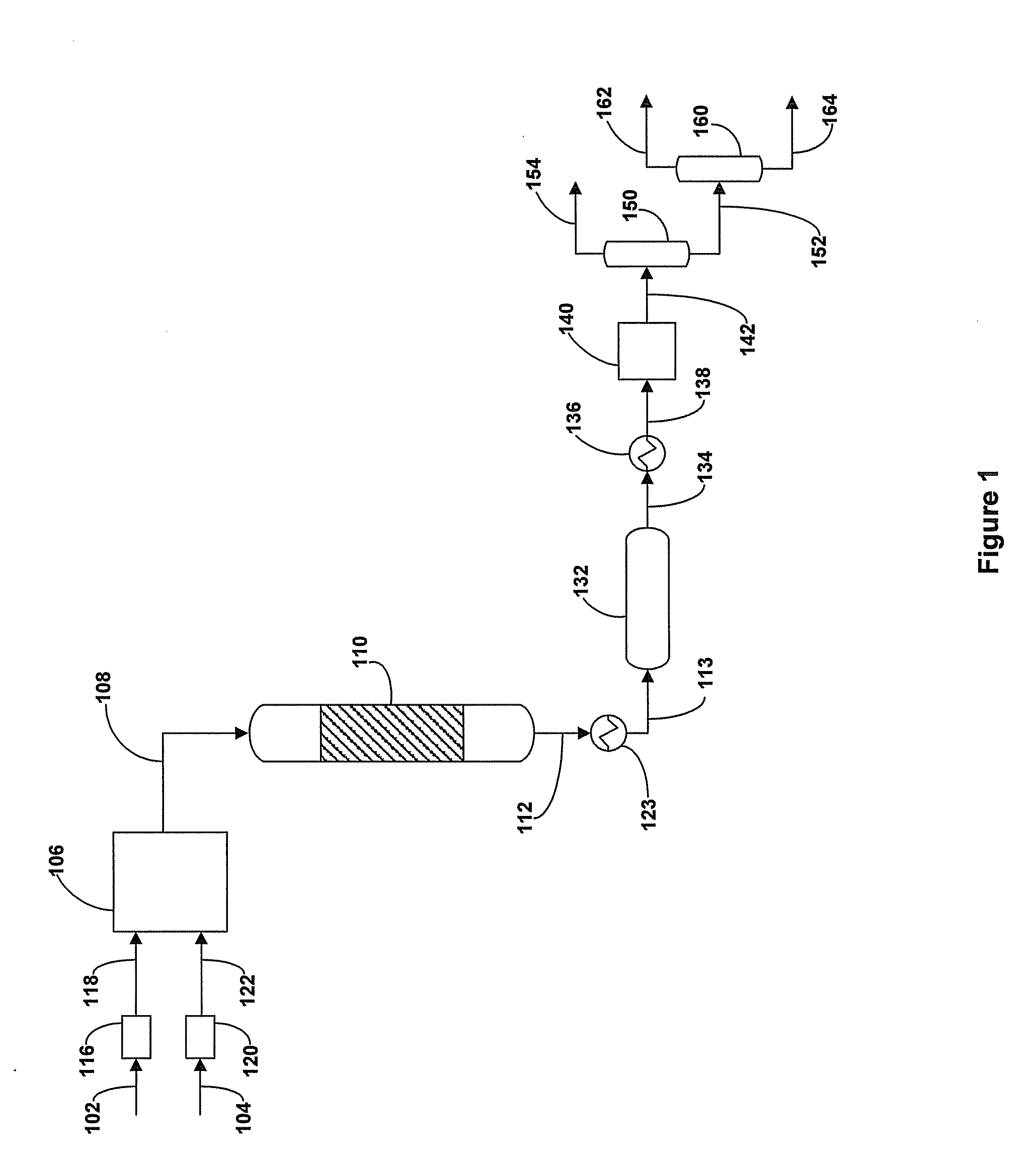

Methods of hydrotreating a mixture made up of oils of animal or vegetable origin and of petroleum cuts with intermediate stripping

ActiveUS20080161614A1Low costLimit consumption of hydrogenThermal non-catalytic crackingCatalytic crackingVegetable oilVolumetric Mass Density

The invention relates to a hydrotreating method (HDT) using two plants working under different operating conditions with an intermediate stripping for co-treating a mixture made up of oils of vegetable or animal origin and petroleum cuts (gas oil cuts (GO) and middle distillates) in order to produce gas oil fuel bases meeting specifications. The first plant (HDT1) is more particularly dedicated to the reactions concerning oils of vegetable or animal origin in comixture while pretreating the hydrocarbon feed, whereas the second plant (HDS2) works under more severe conditions to obtain diesel fuel according to standards, in particular in terms of effluent sulfur content, density and cold properties. The process economy, the activity and the stability of the catalyst of the second plant are greatly improved by the intermediate stripping.

Owner:INST FR DU PETROLE

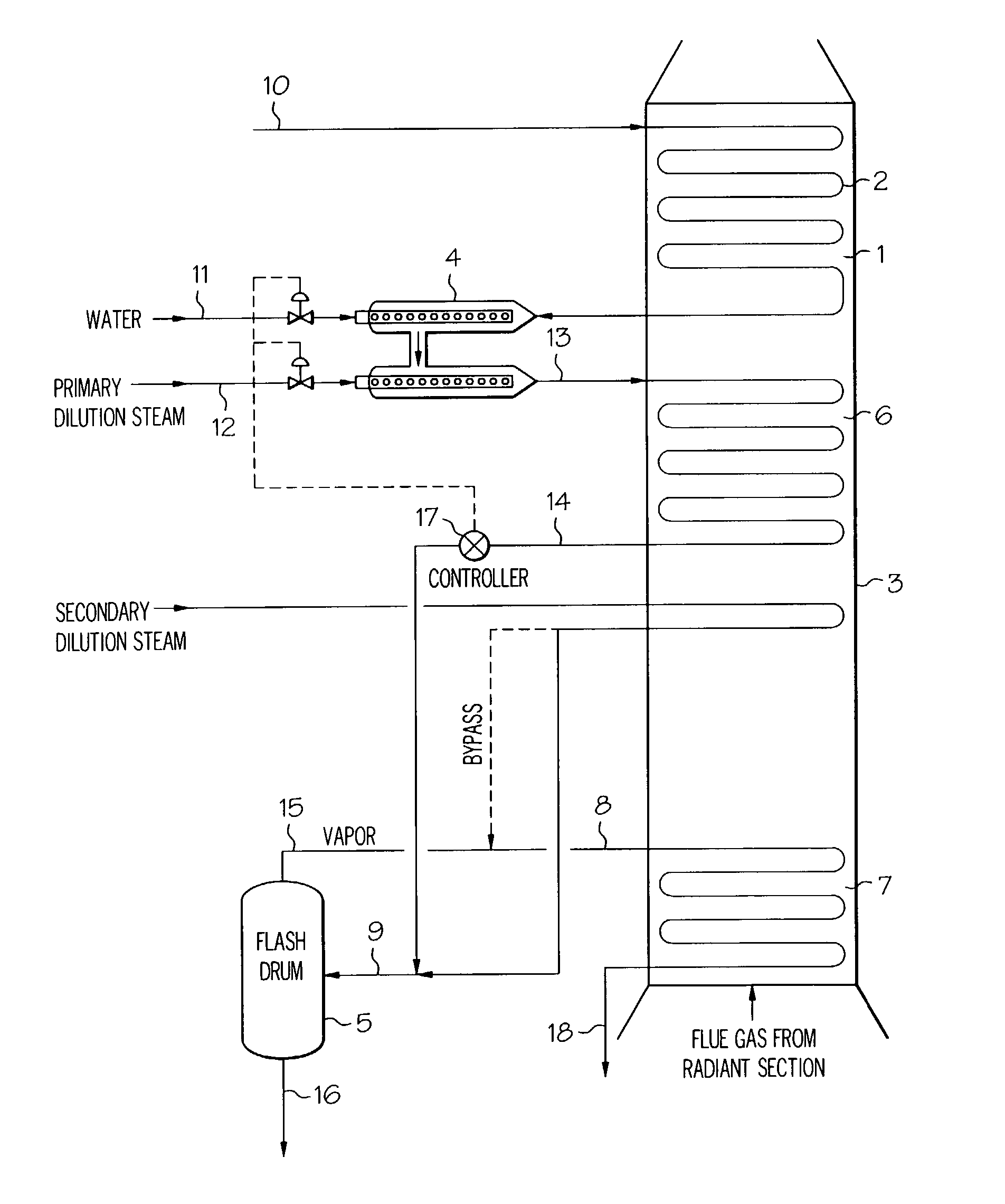

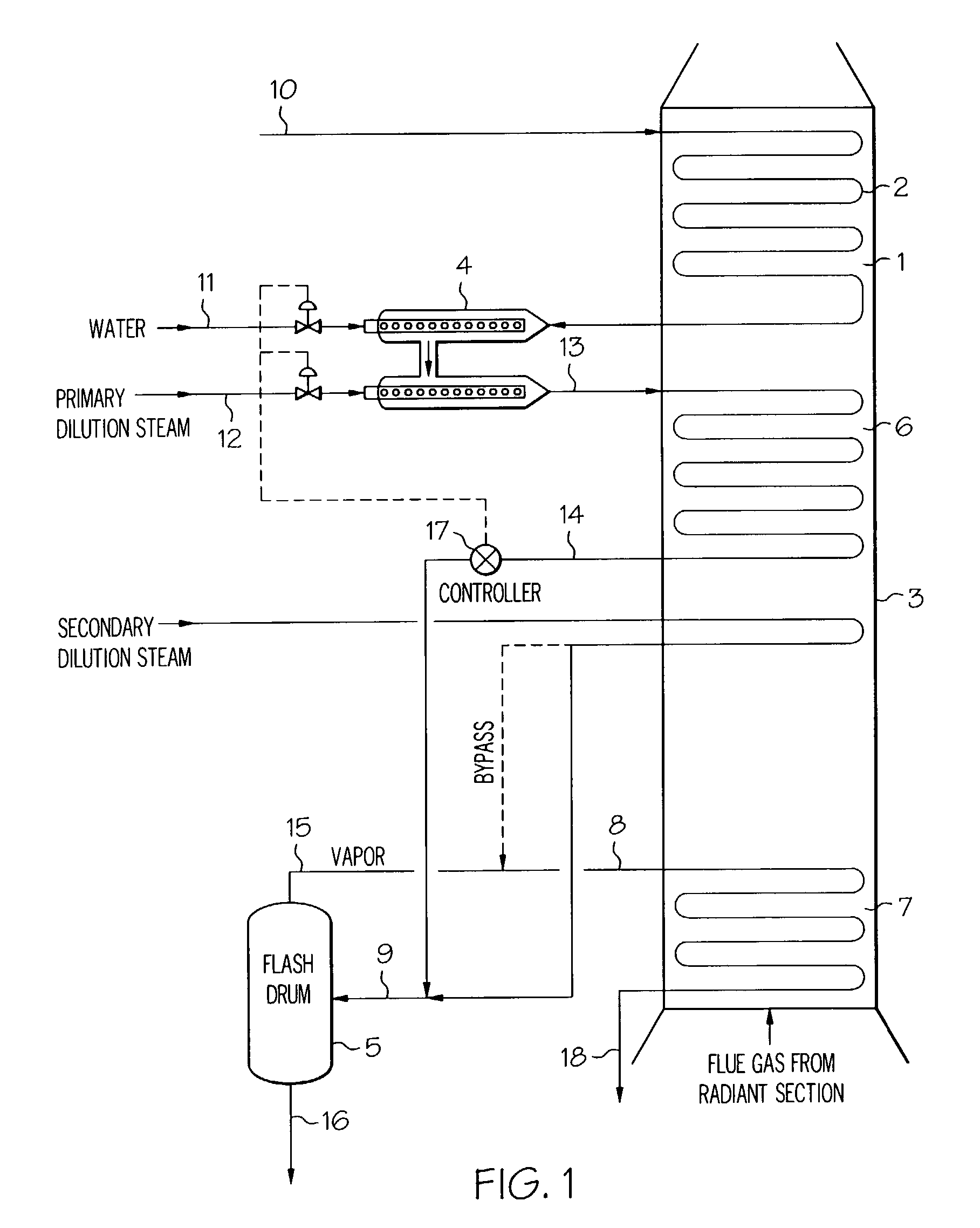

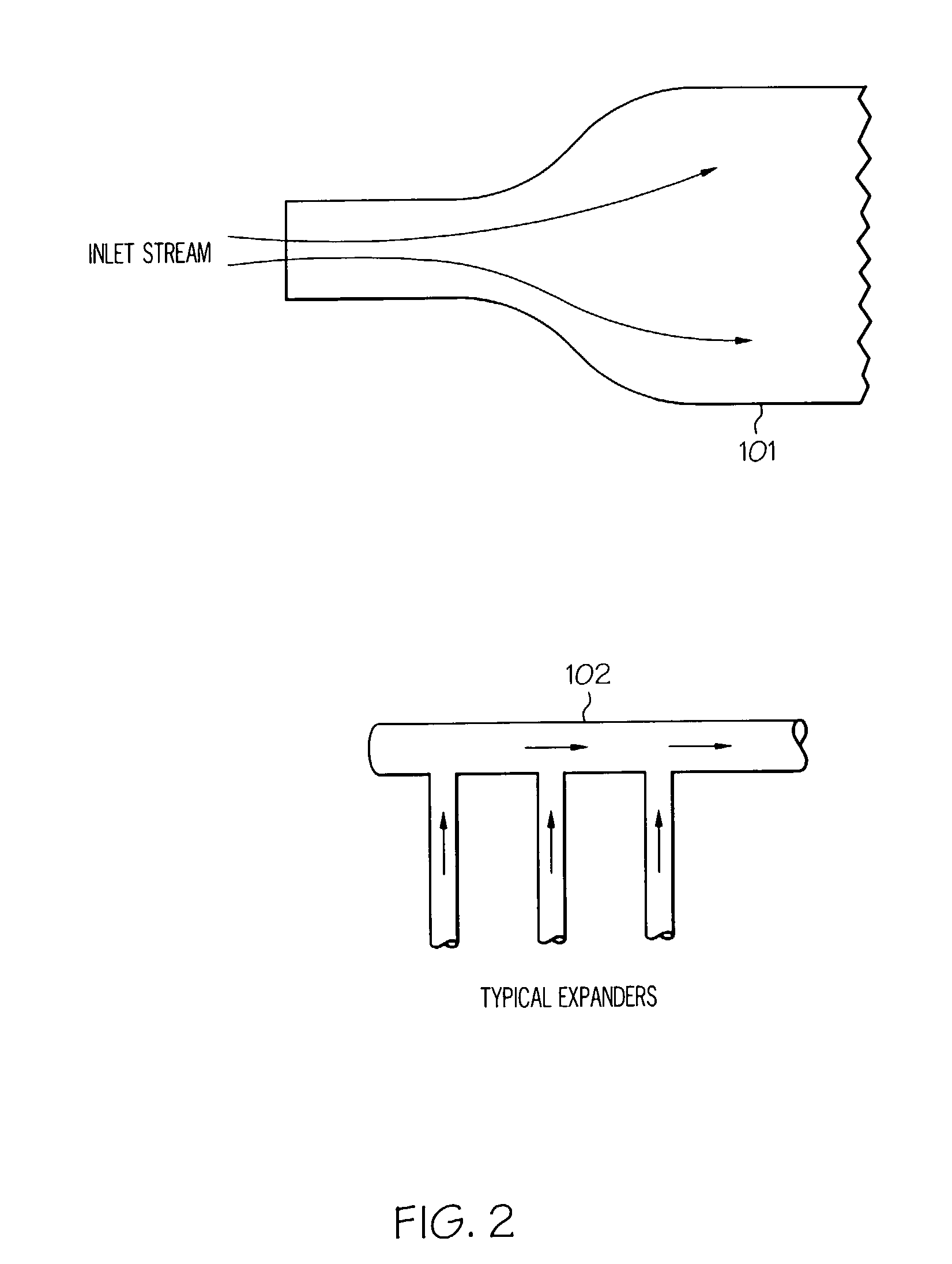

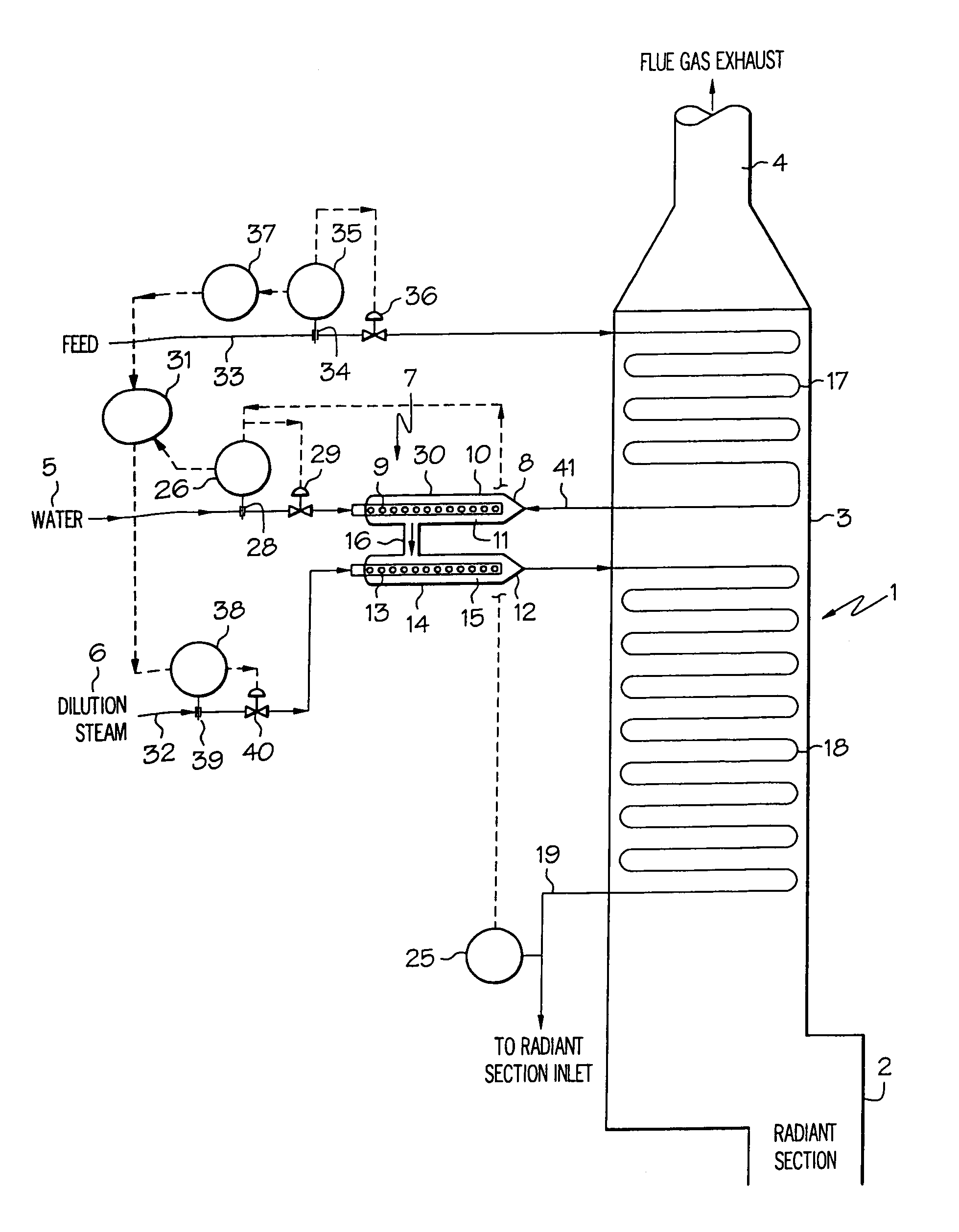

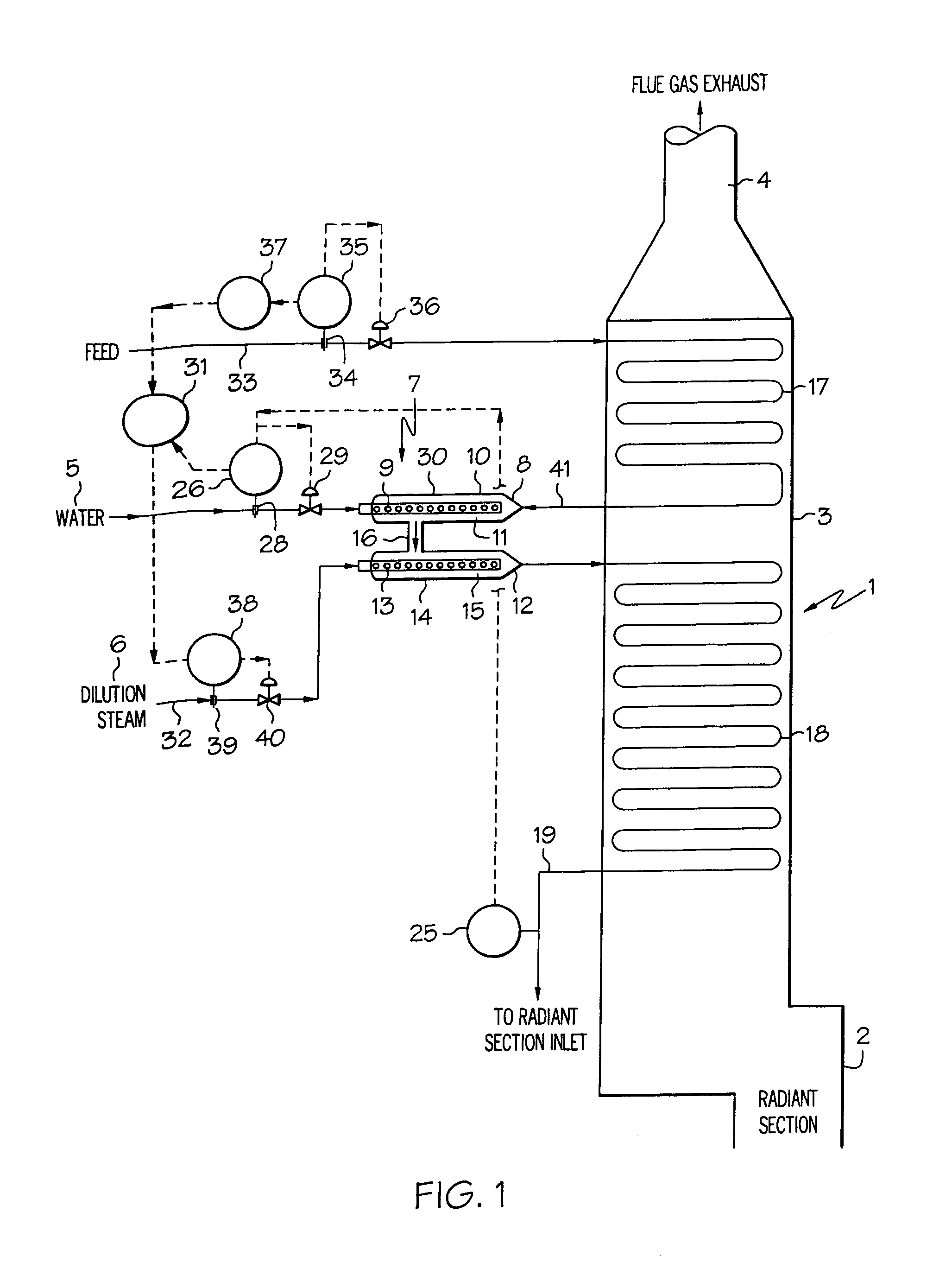

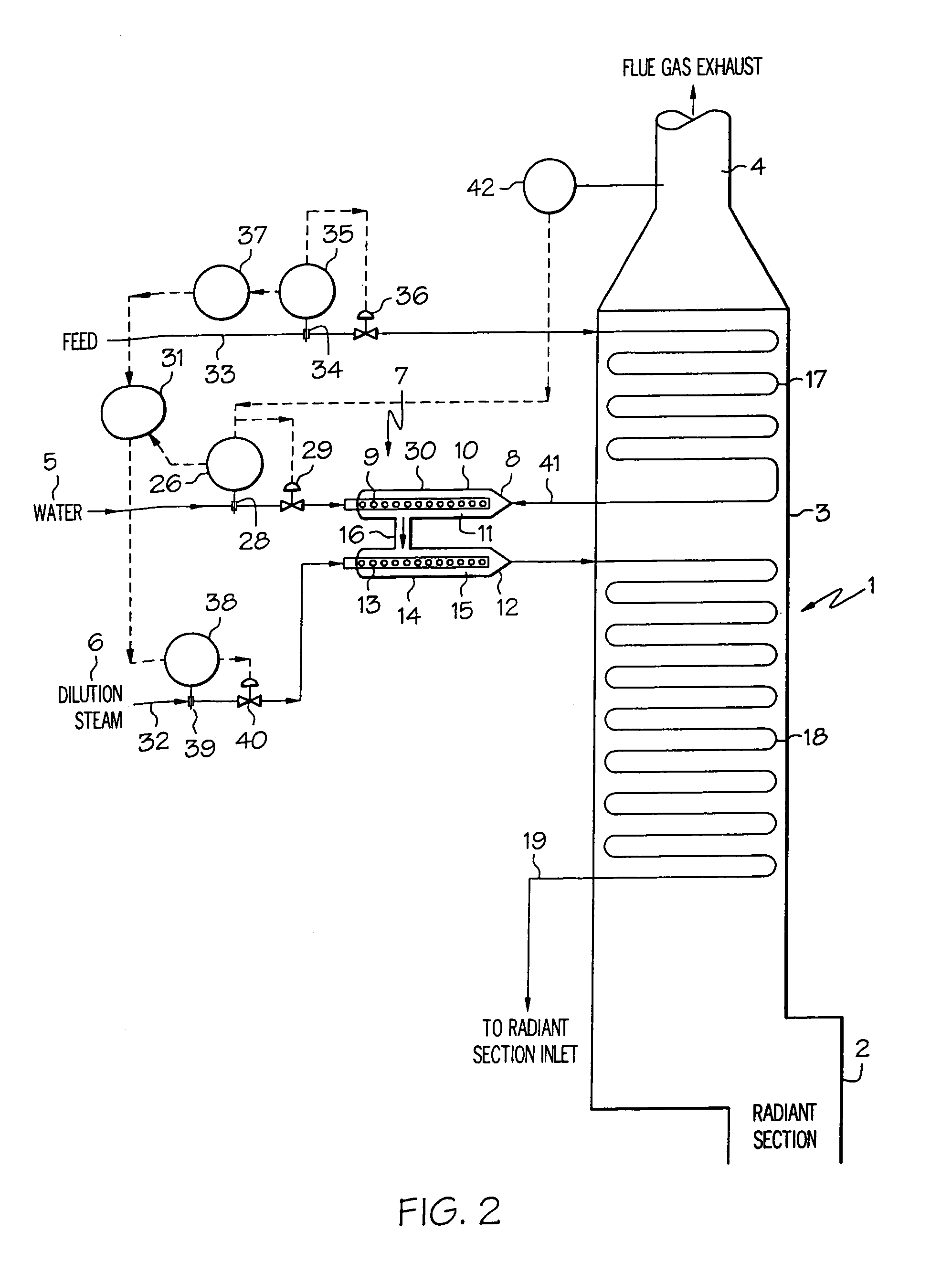

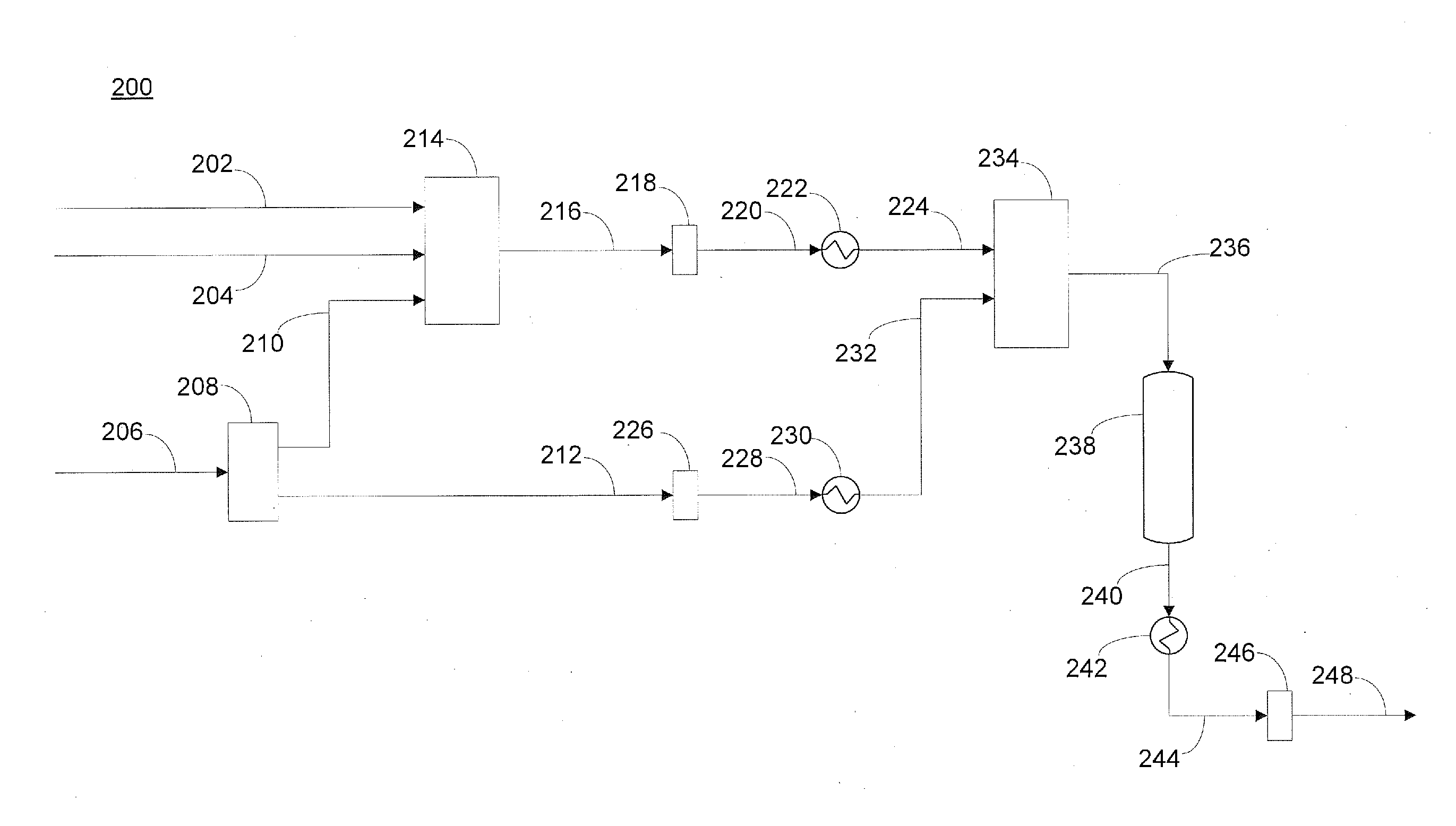

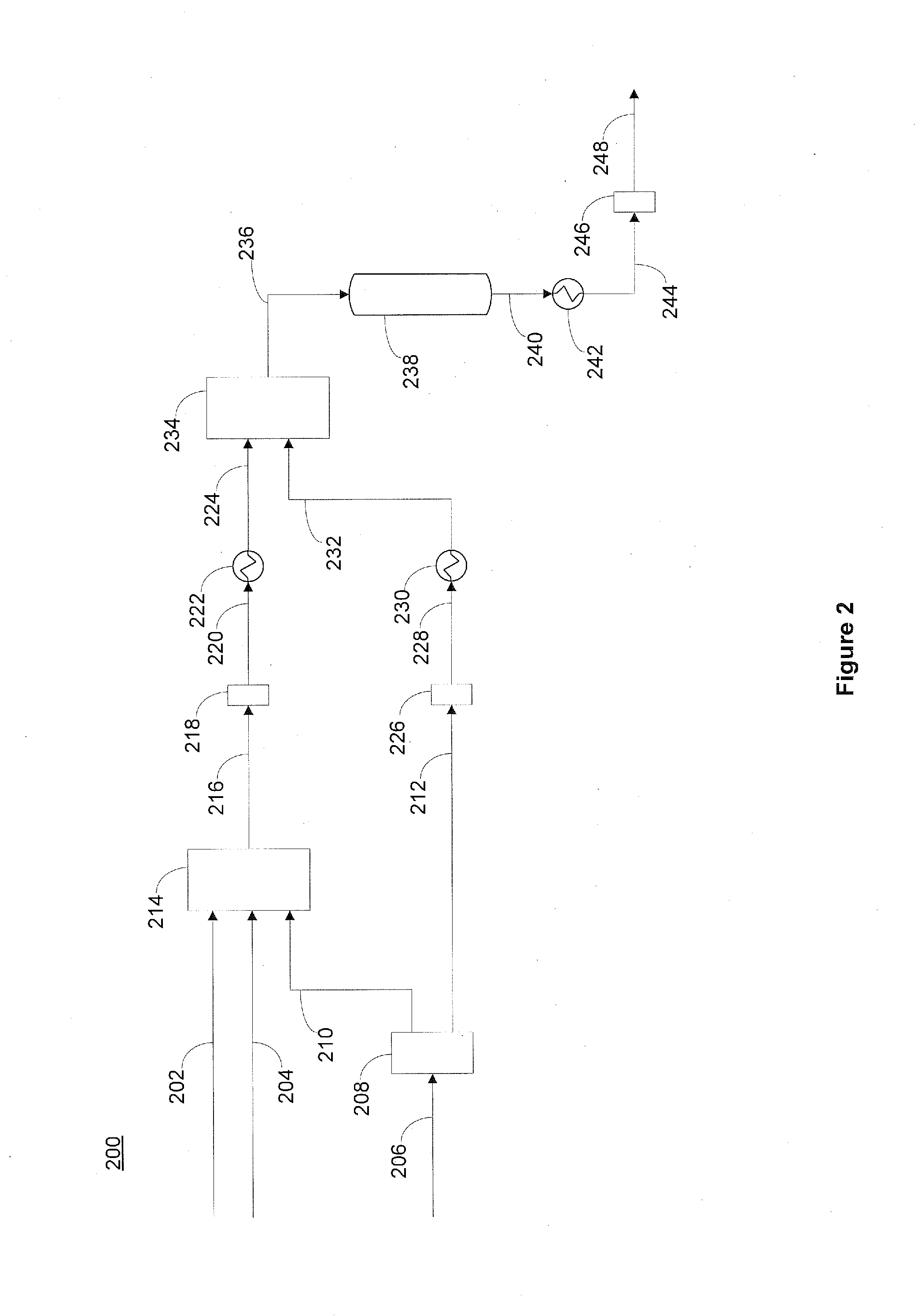

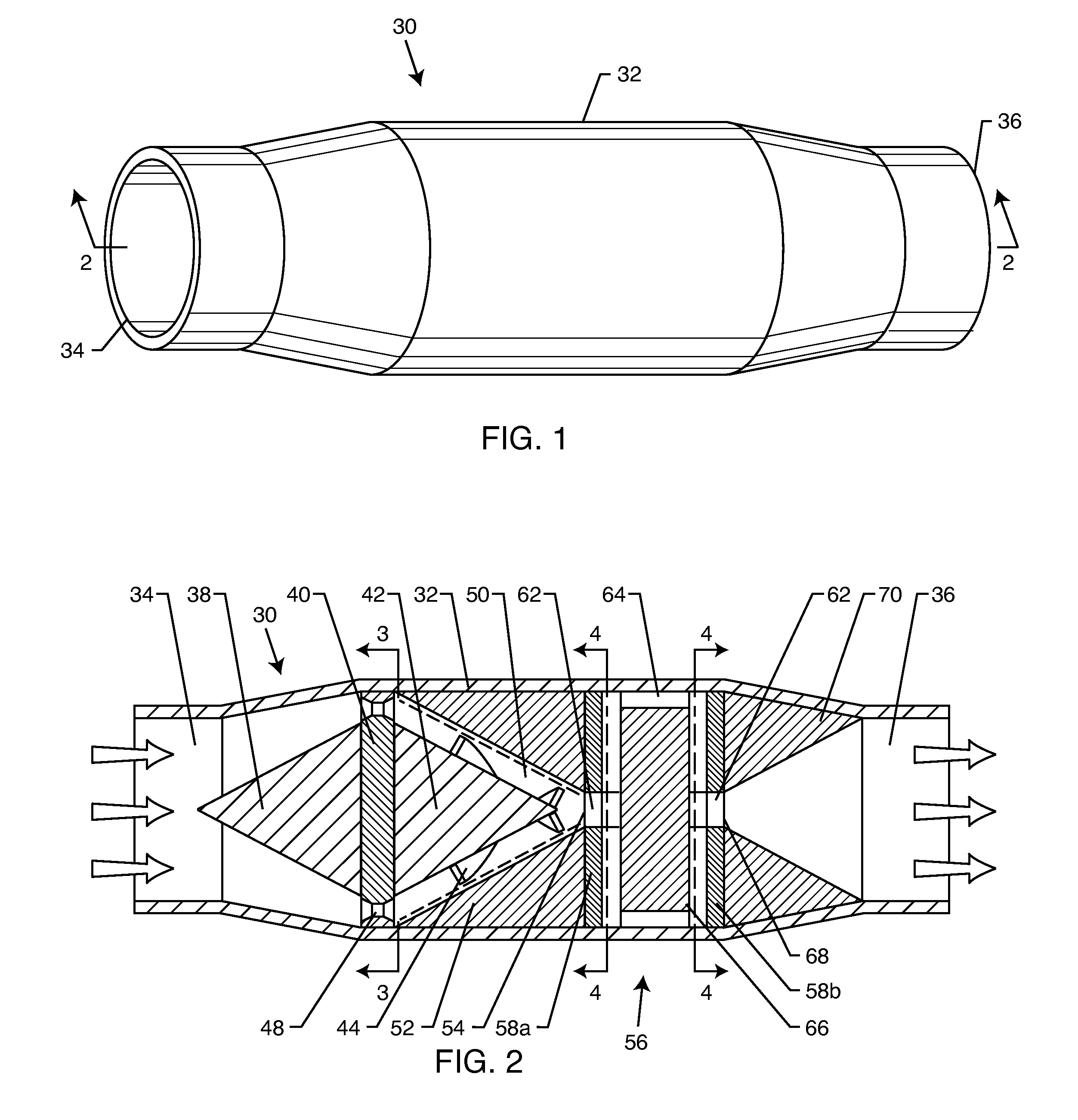

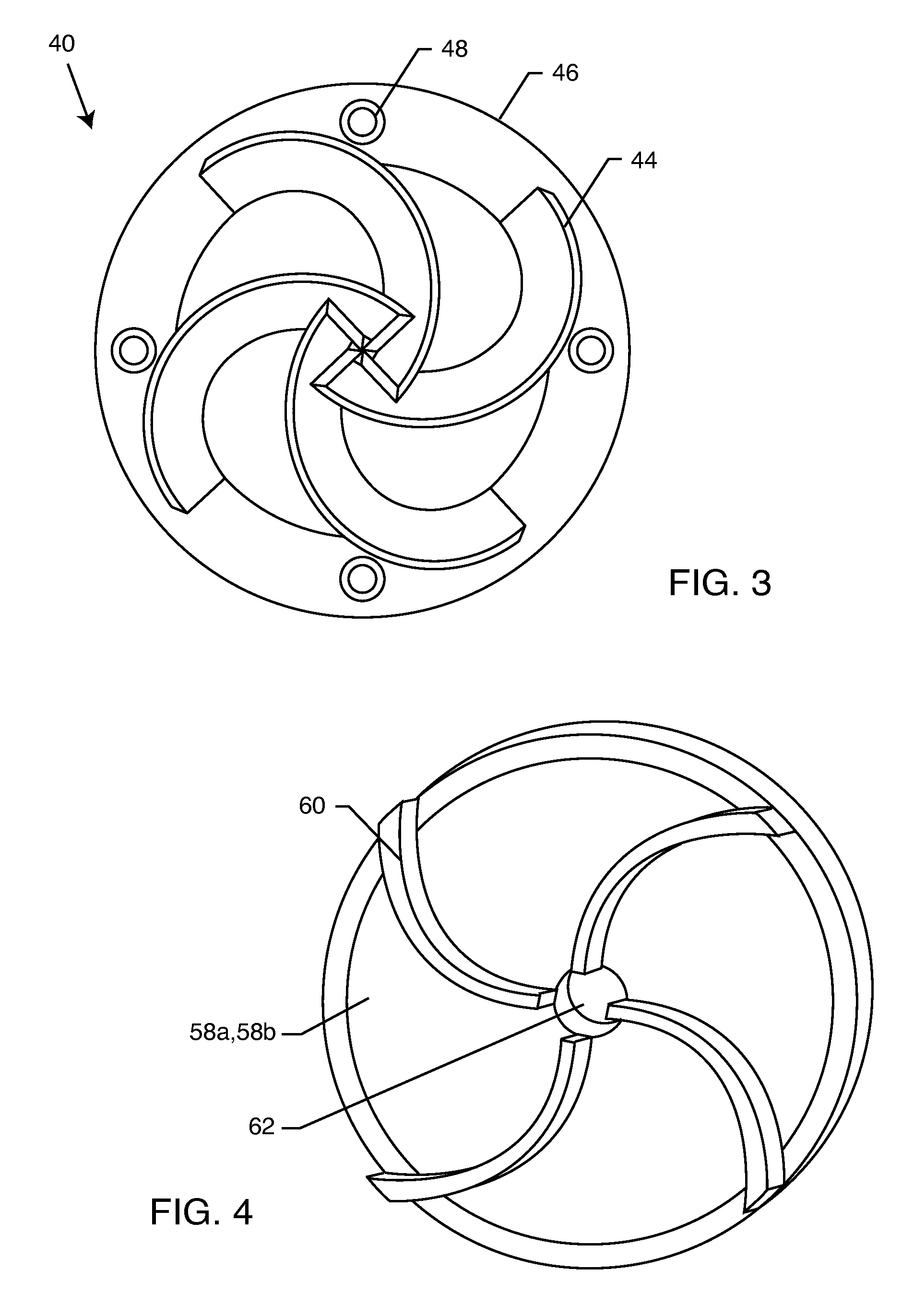

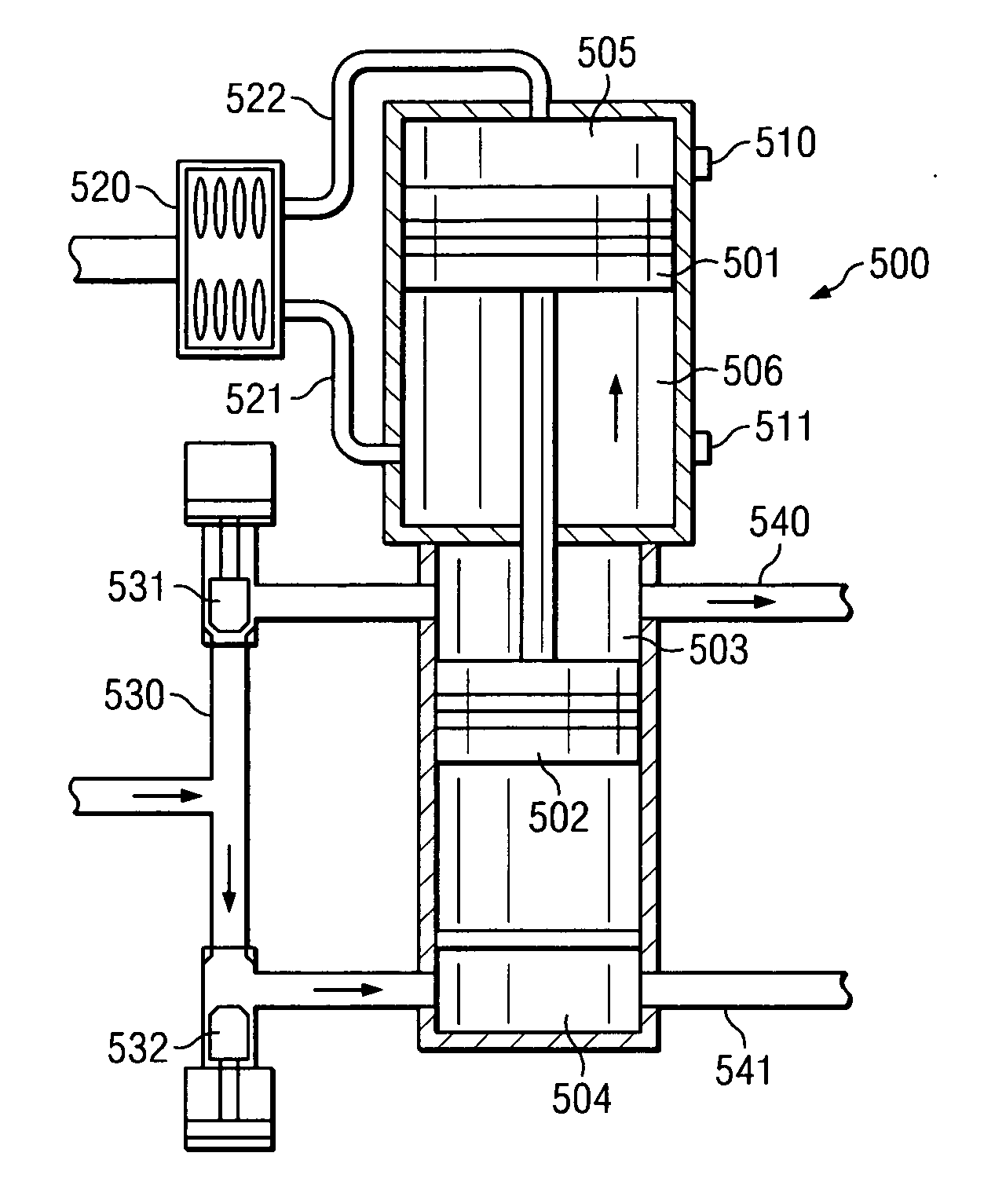

Converting mist flow to annular flow in thermal cracking application

ActiveUS7097758B2Reduce flow rateShorten speedThermal non-catalytic crackingHydrocarbon oil cracking processGas phaseEngineering

A process to increase the non-volatile removal efficiency in a flash drum in the steam cracking system. The gas flow from the convection section is converted from mist flow to annular flow before entering the flash drum to increase the removal efficiency. The conversion of gas flow from mist flow to annular flow is accomplished by subjecting the gas flow first to at least one expander and then to bends of various degrees and force the flow to change directions at least once. The change of gas flow from mist to annular helps coalesce fine liquid droplets and thus being removed from the vapor phase.

Owner:EXXONMOBIL CHEM PAT INC

Process for cracking hydrocarbon feed with water substitution

InactiveUS7090765B2Thermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonHydrocotyle bowlesioides

A process for treating hydrocarbon feed in a furnace, the process comprising: (a) heating hydrocarbon feed, (b) adding water to the heated feed, (c) adding dilution steam to the heated feed to form a mixture, (d) heating the resulting mixture and feeding the resulting heated mixture to the furnace, wherein the water in (b) is added in an amount of from at least about 1% to 100% based on water and dilution steam by weight.

Owner:EXXONMOBIL CHEM PAT INC

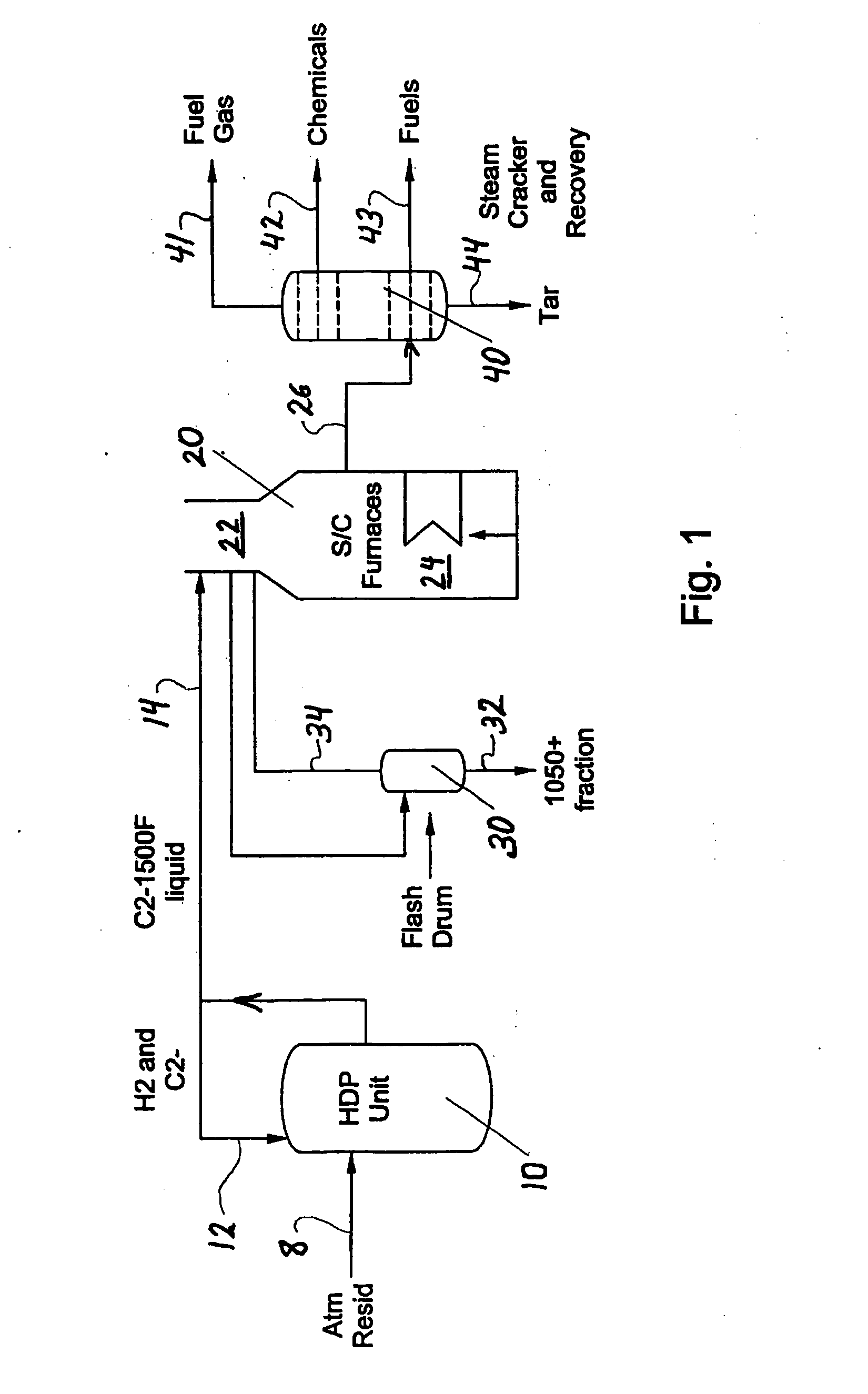

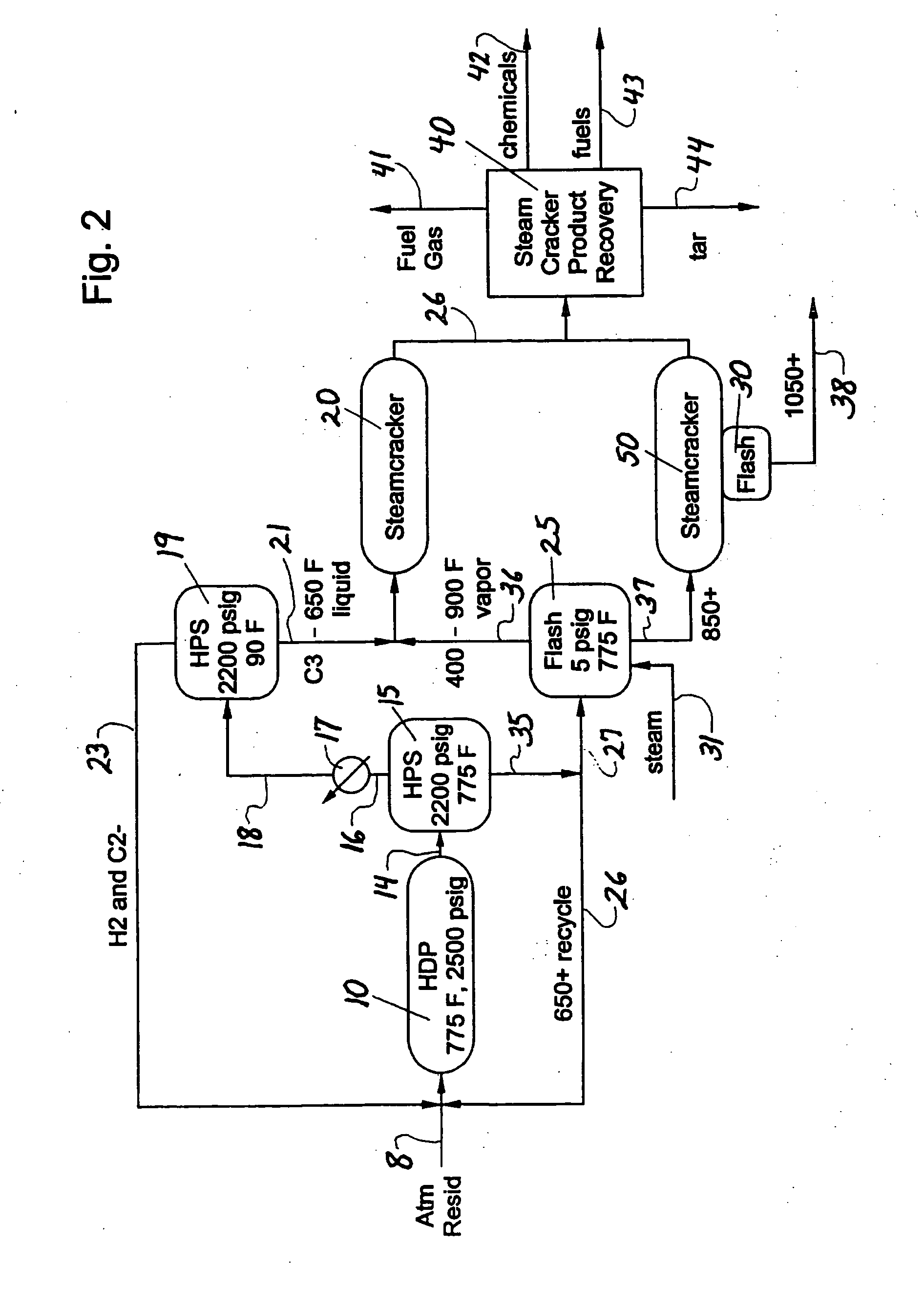

Resid processing for steam cracker feed and catalytic cracking

ActiveUS20070090020A1High hydrogen contentEliminate needThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringAlkene

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

Fluid cat cracking with high olefins prouduction

InactiveUS20020003103A1Increase productionMaximize lightThermal non-catalytic crackingTreatment with plural serial cracking stages onlyNaphthaOrganic chemistry

The propylene production of a fluid catalytic cracking unit employing a large pore zeolite cracking catalyst, produces more propylene by adding a naphtha cracking riser and a medium pore zeolite catalytic component to the unit, and recycling at least a portion of the naphtha crackate to the naphtha riser. The large pore size zeolite preferably comprises a USY zeolite and the medium pore size is preferably ZSM-5. Propylene production per unit of naphtha feed to the naphtha riser is maximized, by using the 60-300.degree. F. naphtha crackate as the feed.

Owner:EXXON RES & ENG CO

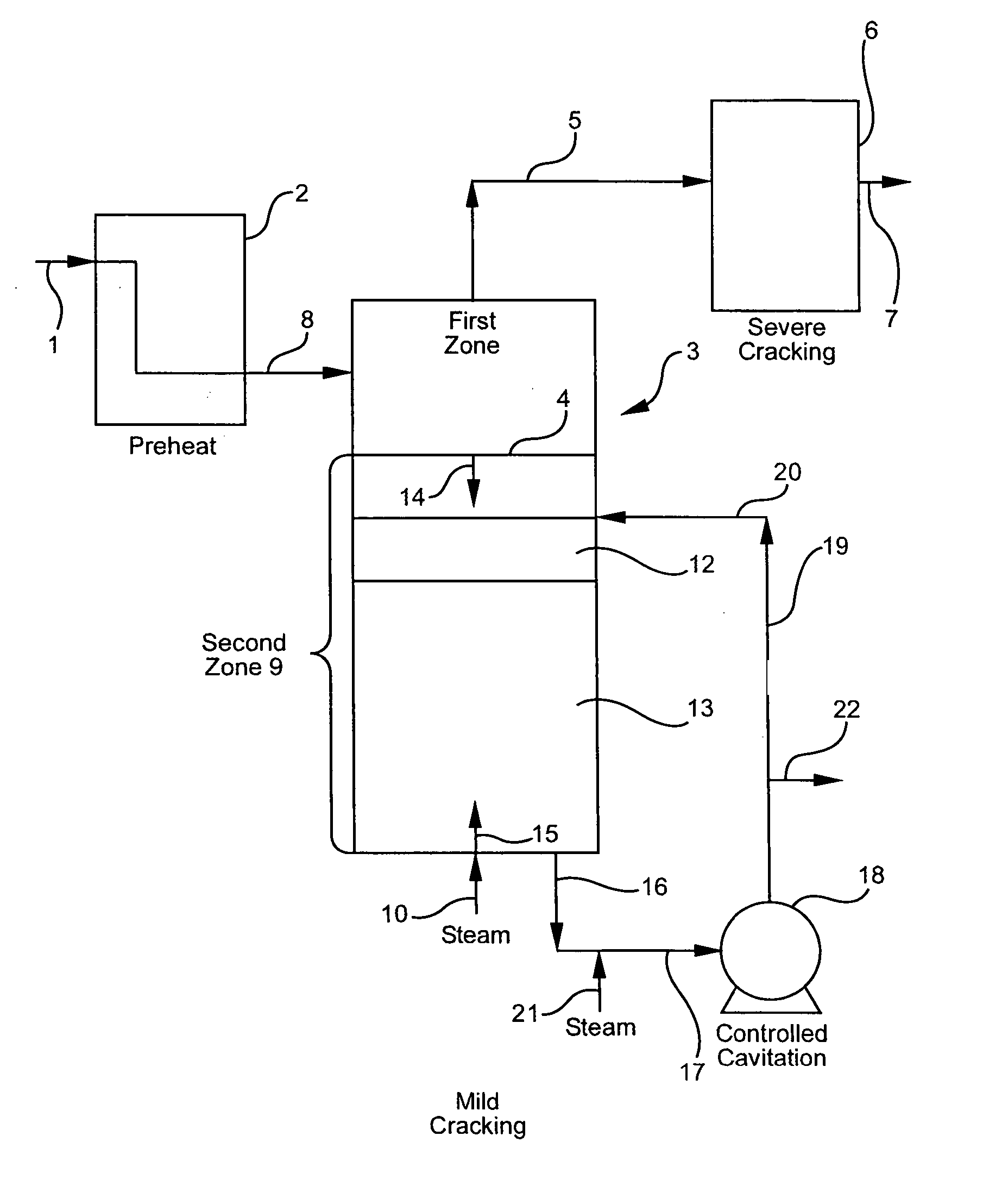

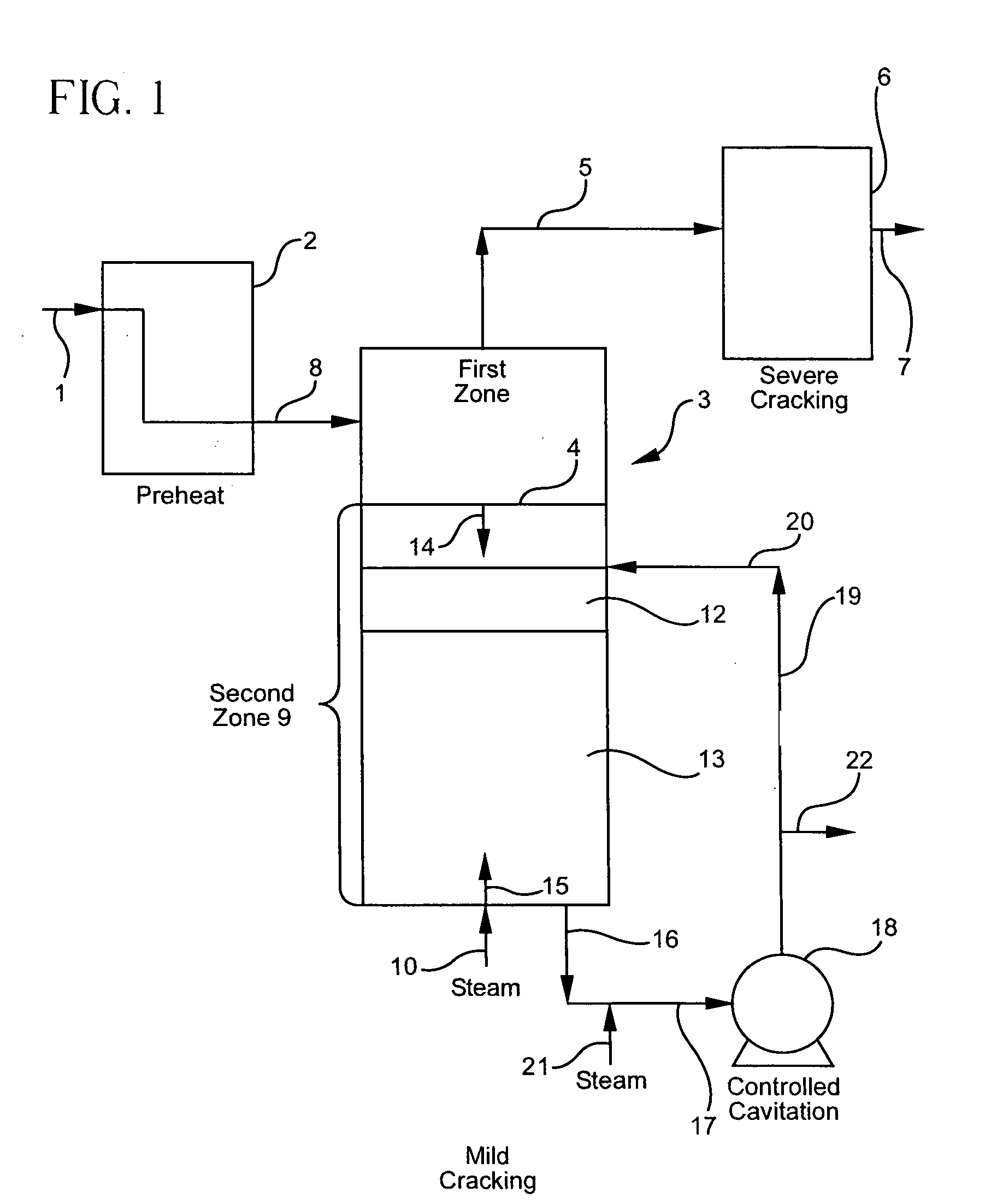

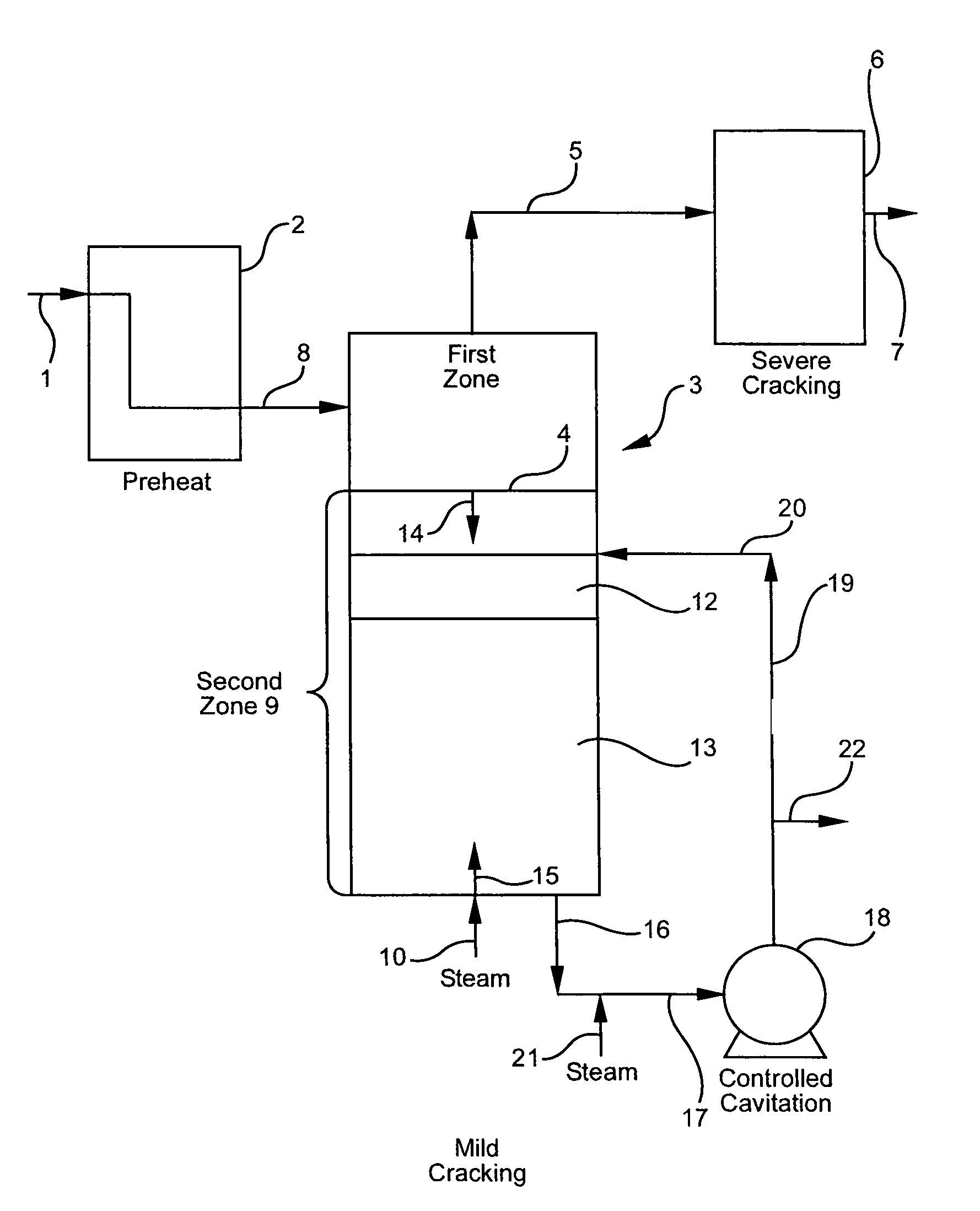

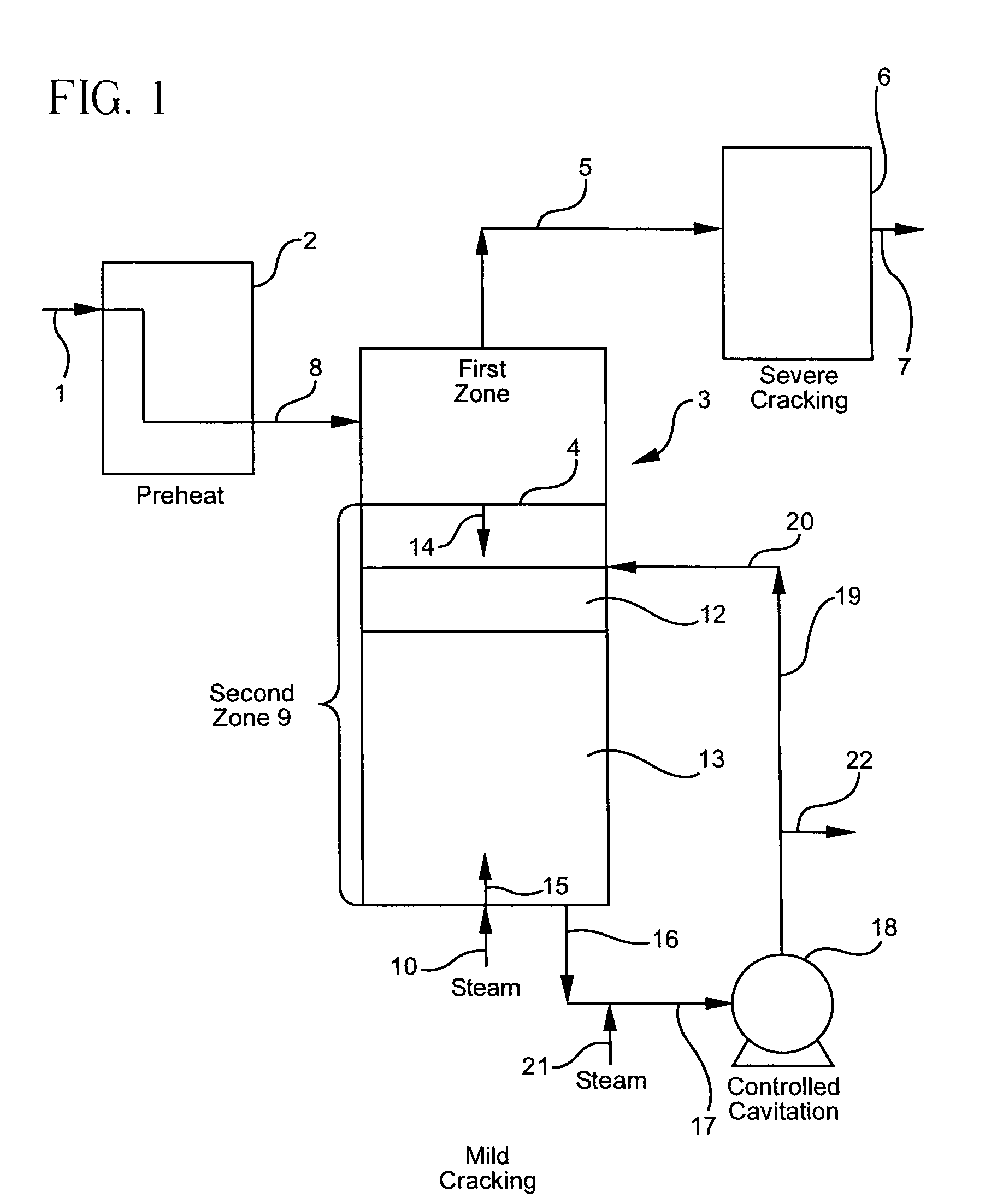

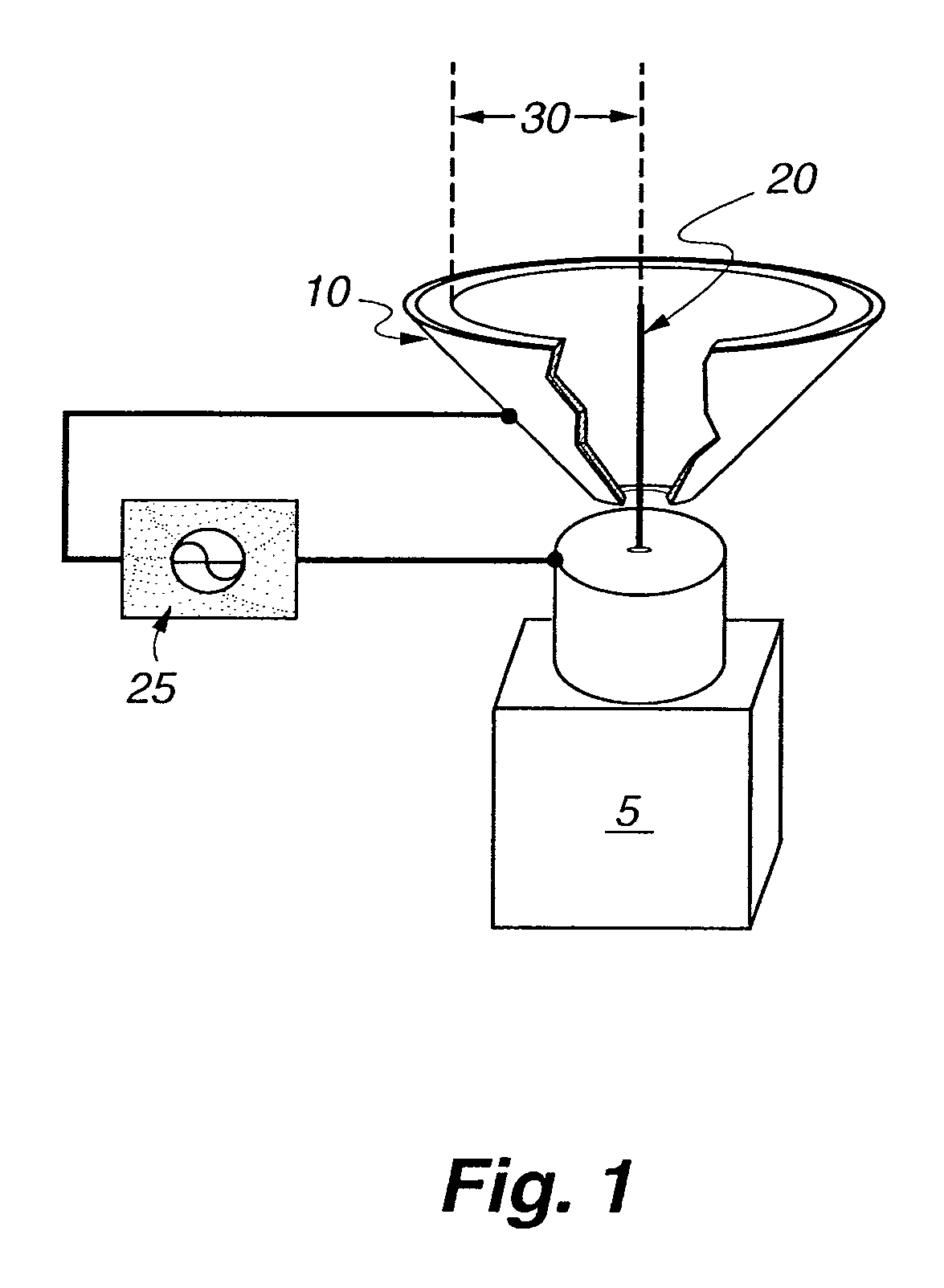

Olefin production utilizing whole crude oil and mild controlled cavitation assisted cracking

InactiveUS20050010075A1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild thermal cracking assisted with controlled cavitation conditions until substantially vaporized, the vapors being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

Process for generating pure benzene from reformed gasoline

InactiveUS6124514AReduce benzene contentAchieve separationThermal non-catalytic crackingCatalytic crackingBenzeneExtractive distillation

A process is disclosed for generating pure aromatic compounds from a reformed gasoline which contains aromatic compounds, olefins, diolefin, and triolefins, which comprises the steps of: (a) selectively hydrogenating the olefins, diolefins and triolefins in the reformed gasoline to obtain a mixture of hydrogenated, non-aromatic compounds and aromatic compounds; and (b) separating the aromatic compounds from the hydrogenated, non-aromatic compounds in the mixture formed during step (a) by either extractive distillation, liquid-liquid extraction or both to obtain the pure aromatic compounds.

Owner:BASF AG

Production of liquid fuels by a concatenation of processes for treatment of a hydrocarbon feedstock

ActiveUS7214720B2Maximize conversion of carbonReduce and to upgrade naphthaThermal non-catalytic crackingCatalytic crackingNaphthaKerosene

The invention relates to an installation and a process for the production of liquid fuels starting from a solid feedstock that contains the organic material in which:a) the solid feedstock is subjected to a gasification stage so as to convert said feedstock into synthesis gas,b) the synthesis gas is subjected to a purification treatment,c) the purified synthesis gas is subjected to a conversion stage that comprises the implementation of a Fischer-Tropsch-type synthesis so as to convert said synthesis gas into a liquid effluent and a gaseous effluent,d) the liquid effluent is fractionated so as to obtain a gaseous fraction, a naphtha fraction, a kerosene fraction and a gas oil fraction, ande) at least a portion of the naphtha fraction is recycled in gasification stage a).

Owner:INST FR DU PETROLE +1

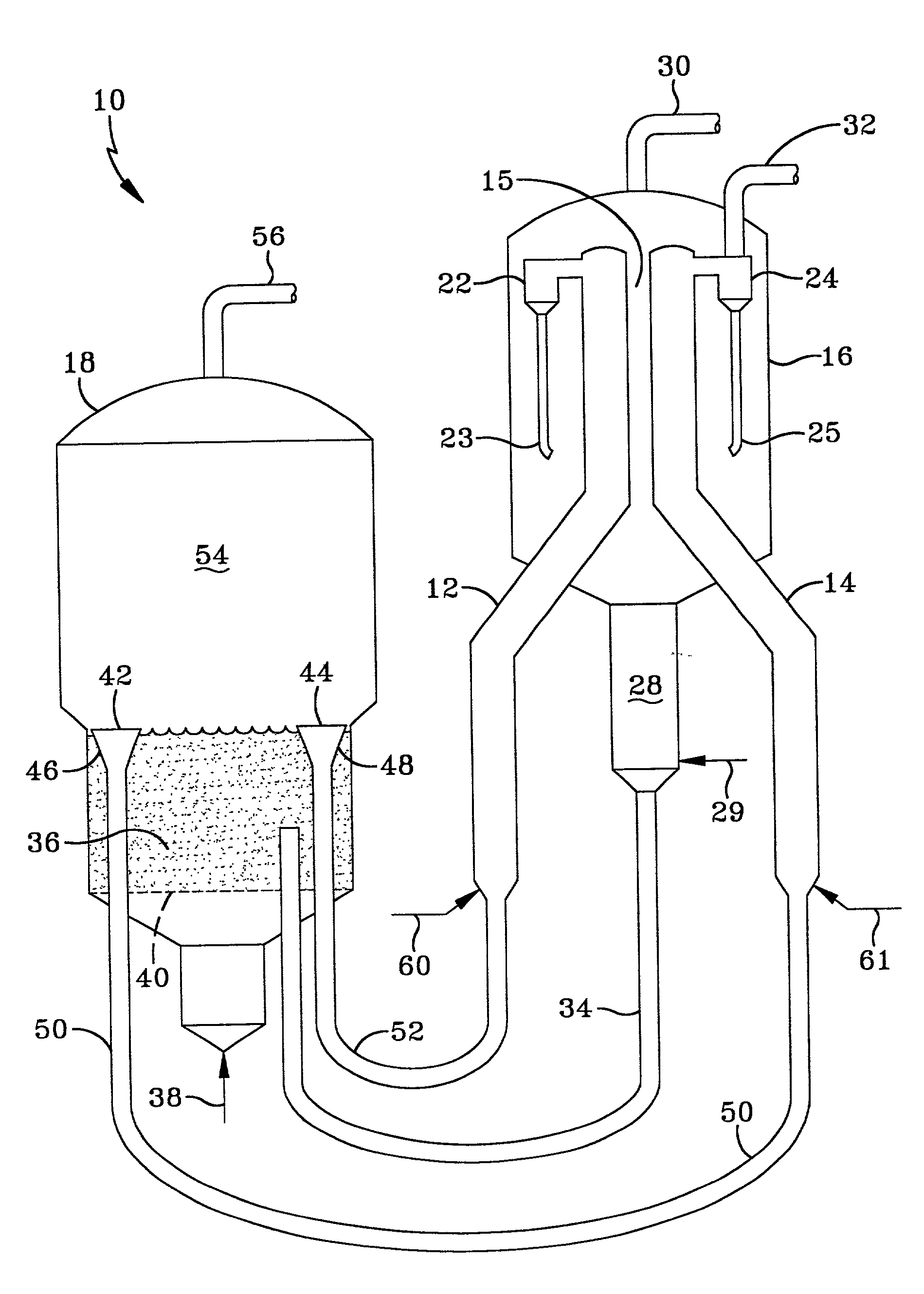

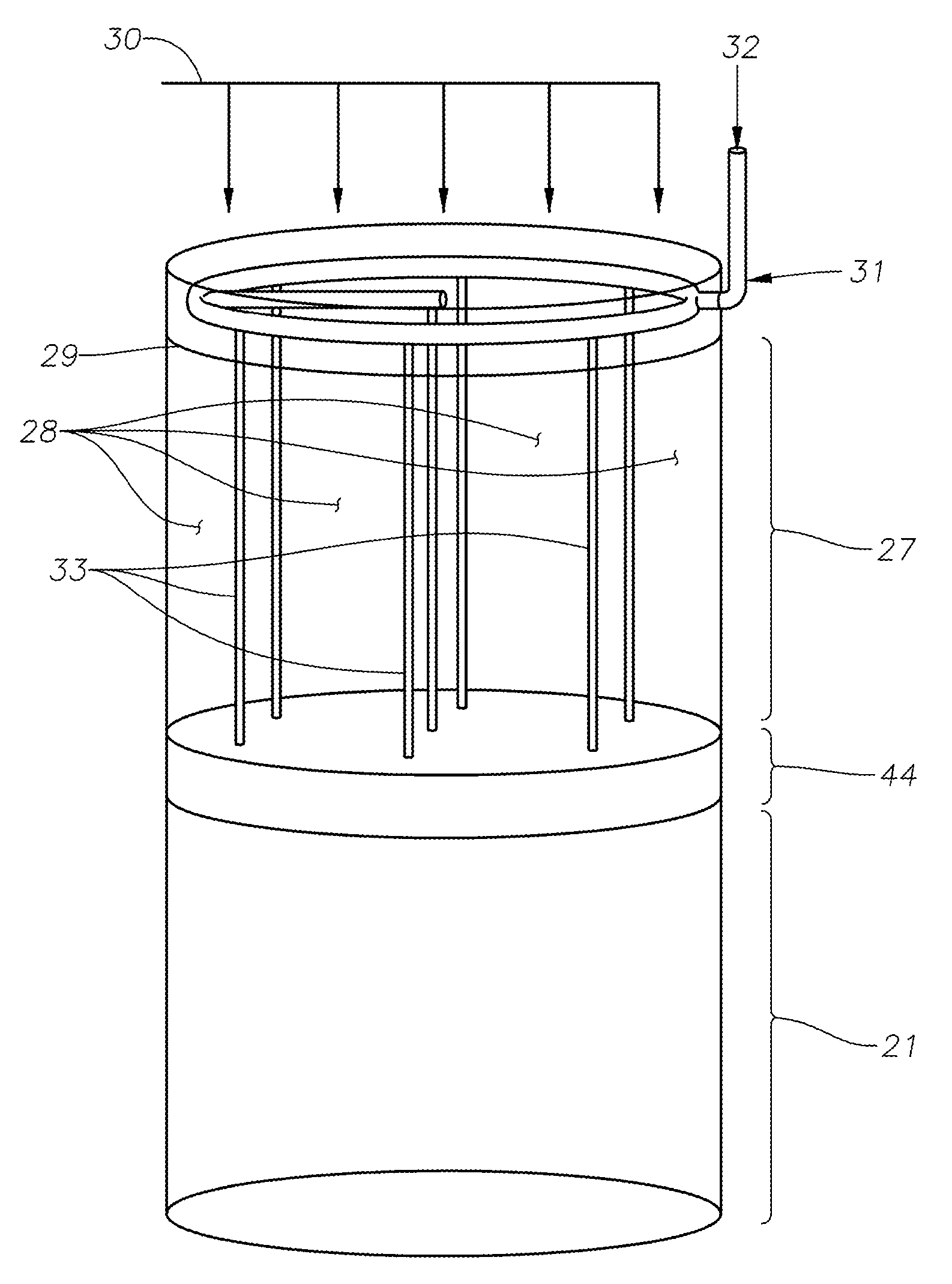

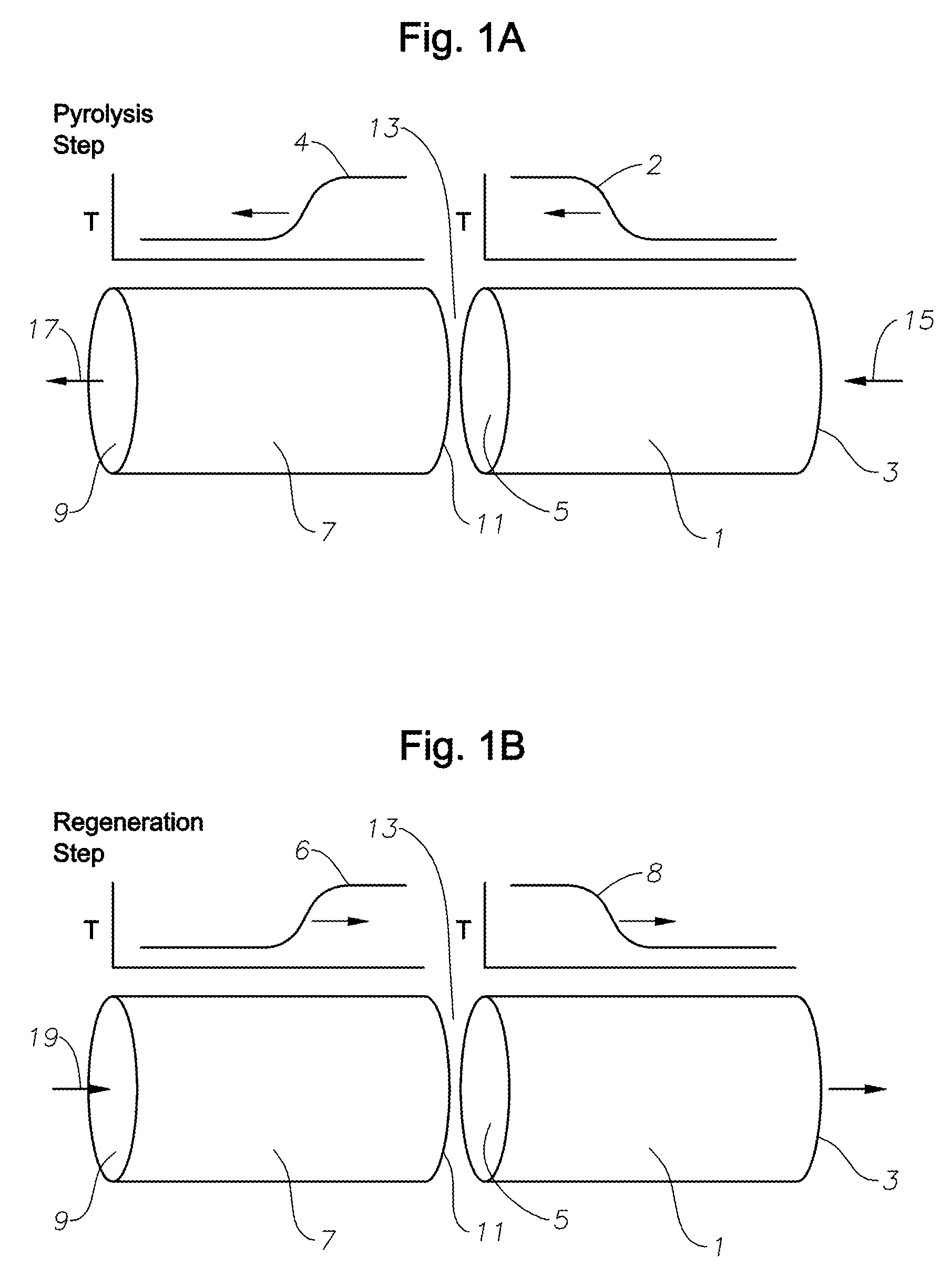

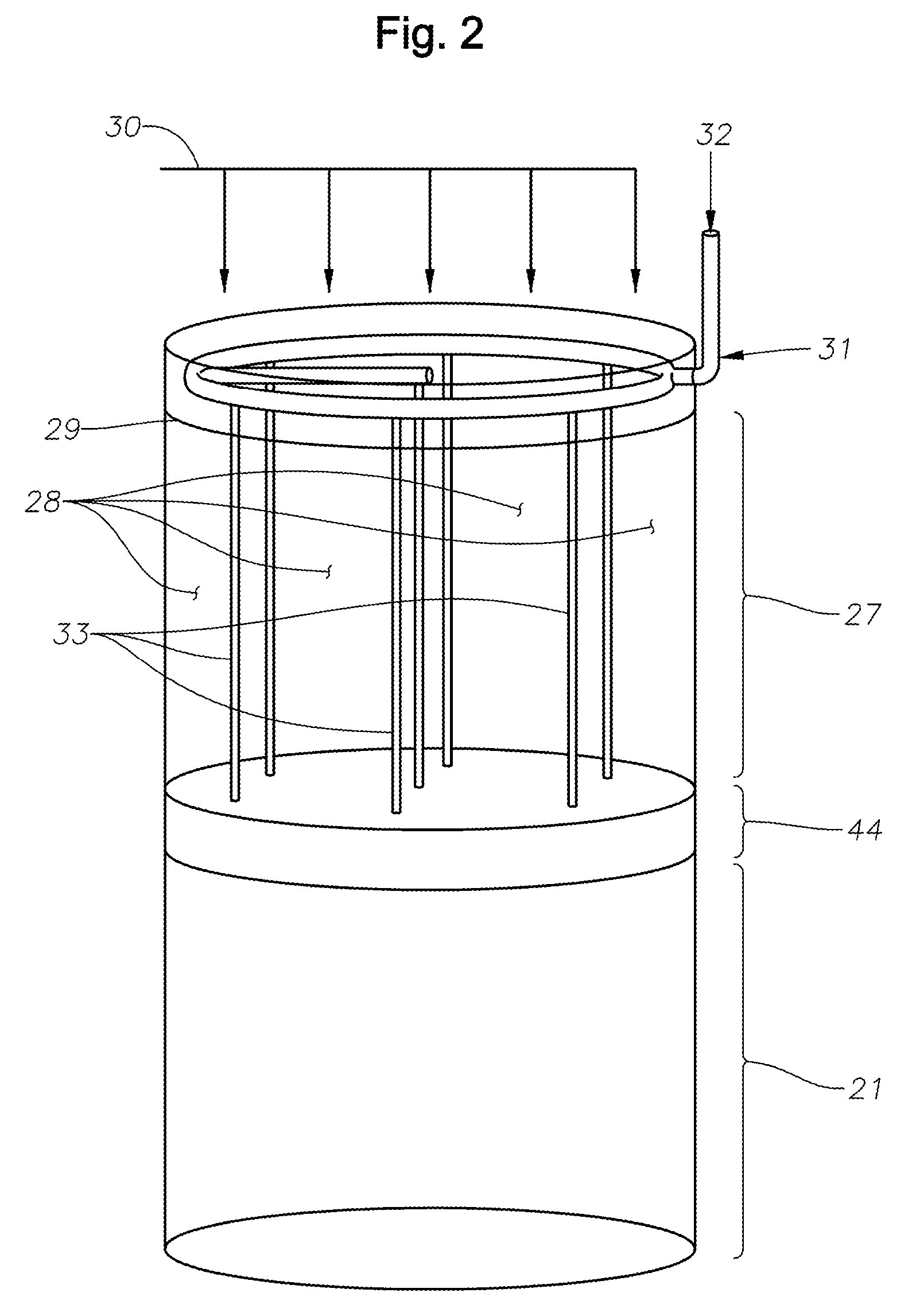

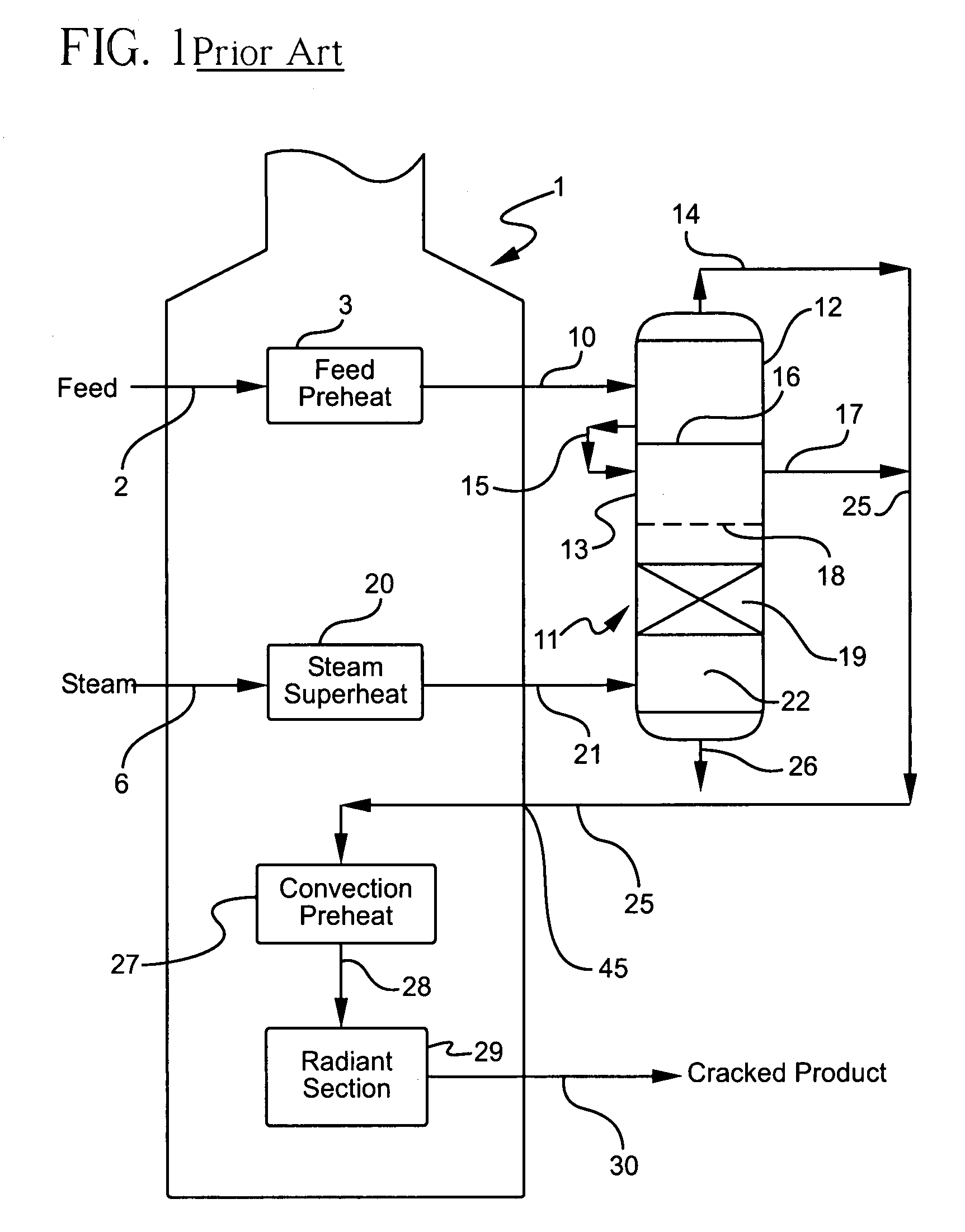

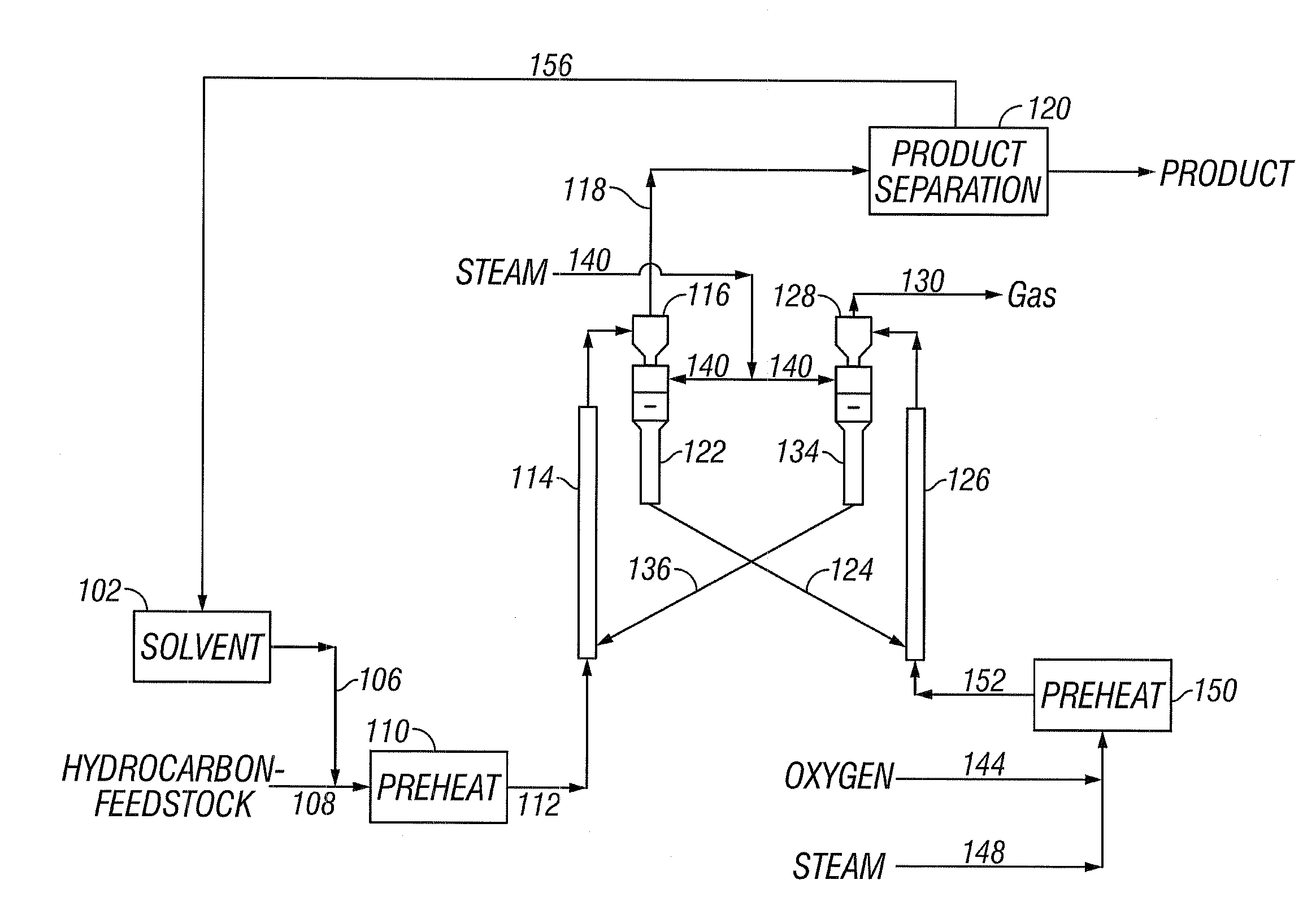

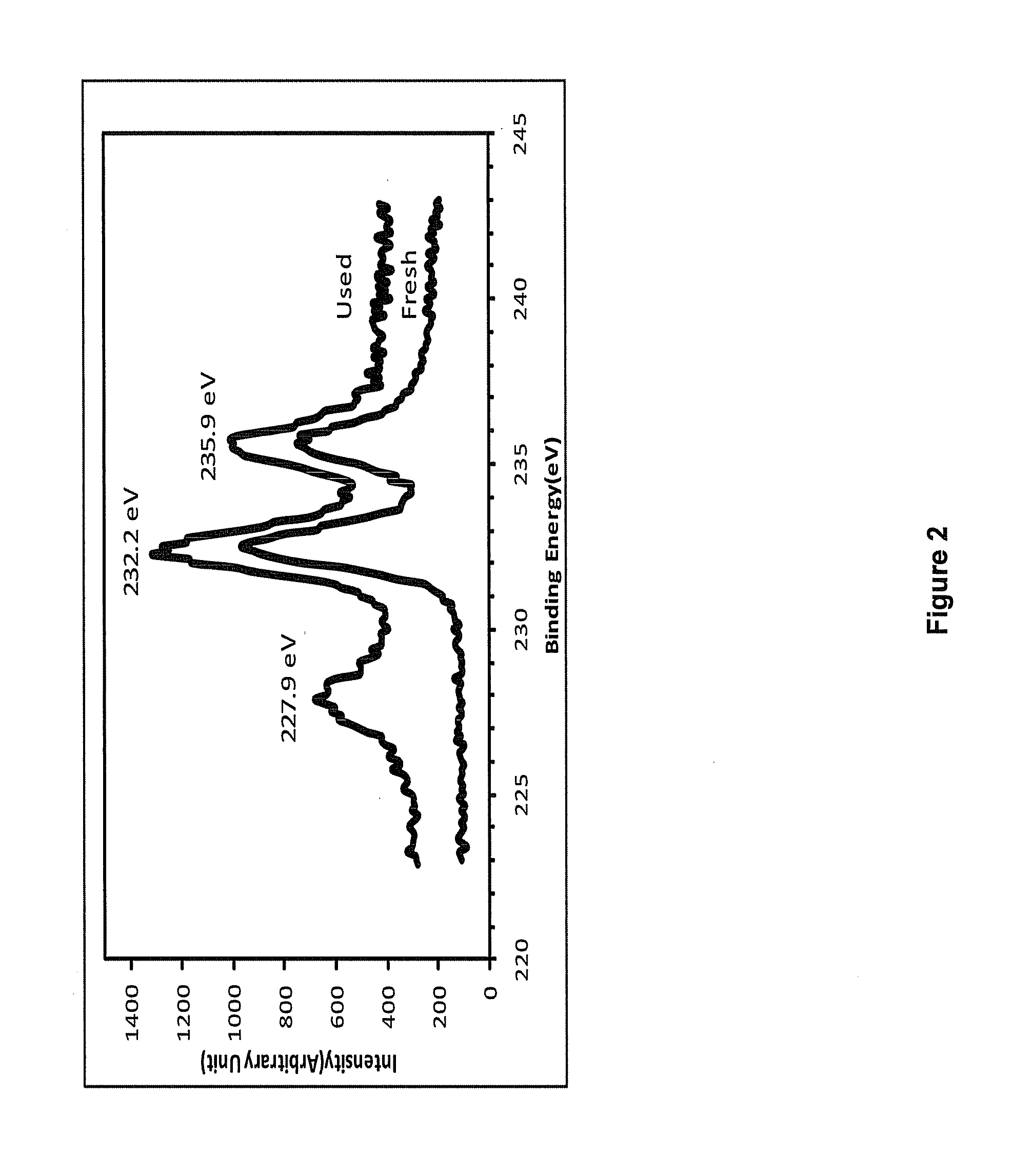

Pyrolysis reactor conversion of hydrocarbon feedstocks into higher value hydrocarbons

ActiveUS20090008292A1Thermal non-catalytic crackingCatalytic crackingReactor systemProcess engineering

In one aspect, the inventive process comprises a process for pyrolyzing a hydrocarbon feedstock containing nonvolatiles in a regenerative pyrolysis reactor system. The inventive process comprises: (a) heating the nonvolatile-containing hydrocarbon feedstock upstream of a regenerative pyrolysis reactor system to a temperature sufficient to form a vapor phase that is essentially free of nonvolatiles and a liquid phase containing the nonvolatiles; (b) separating said vapor phase from said liquid phase; (c) feeding the separated vapor phase to the pyrolysis reactor system; and (d) converting the separated vapor phase in said pyrolysis reactor system to form a pyrolysis product.

Owner:EXXONMOBIL CHEM PAT INC

Microwave-based recovery of hydrocarbons and fossil fuels

InactiveUS7629497B2Organic compounds purification/separation/stabilisationHydrocarbon oil cracking processPetroleumFossil fuel

The present invention provides methods for decomposing and extracting compositions for the recovery of petroleum-based materials from composites comprising those petroleum-based materials, comprising subjecting the compositions and / or composites to microwave radiation, wherein the microwave radiation is in the range of from about 4 GHz to about 18 GHz. The present invention also provides for products produced by the methods of the present invention and for apparatuses used to perform the methods of the present invention.

Owner:UNIVERSAL ALTERNATIVE FUELS INC +1

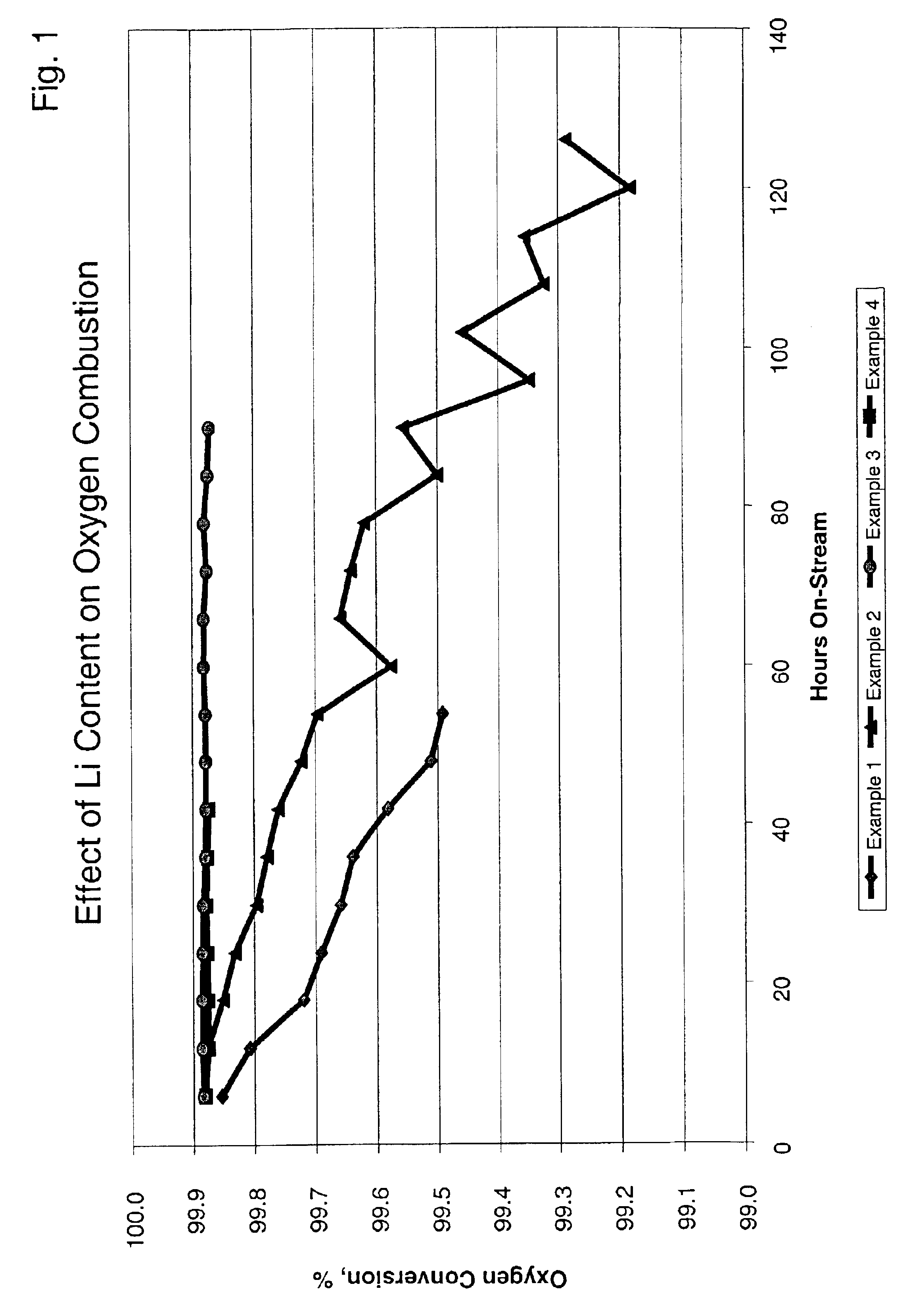

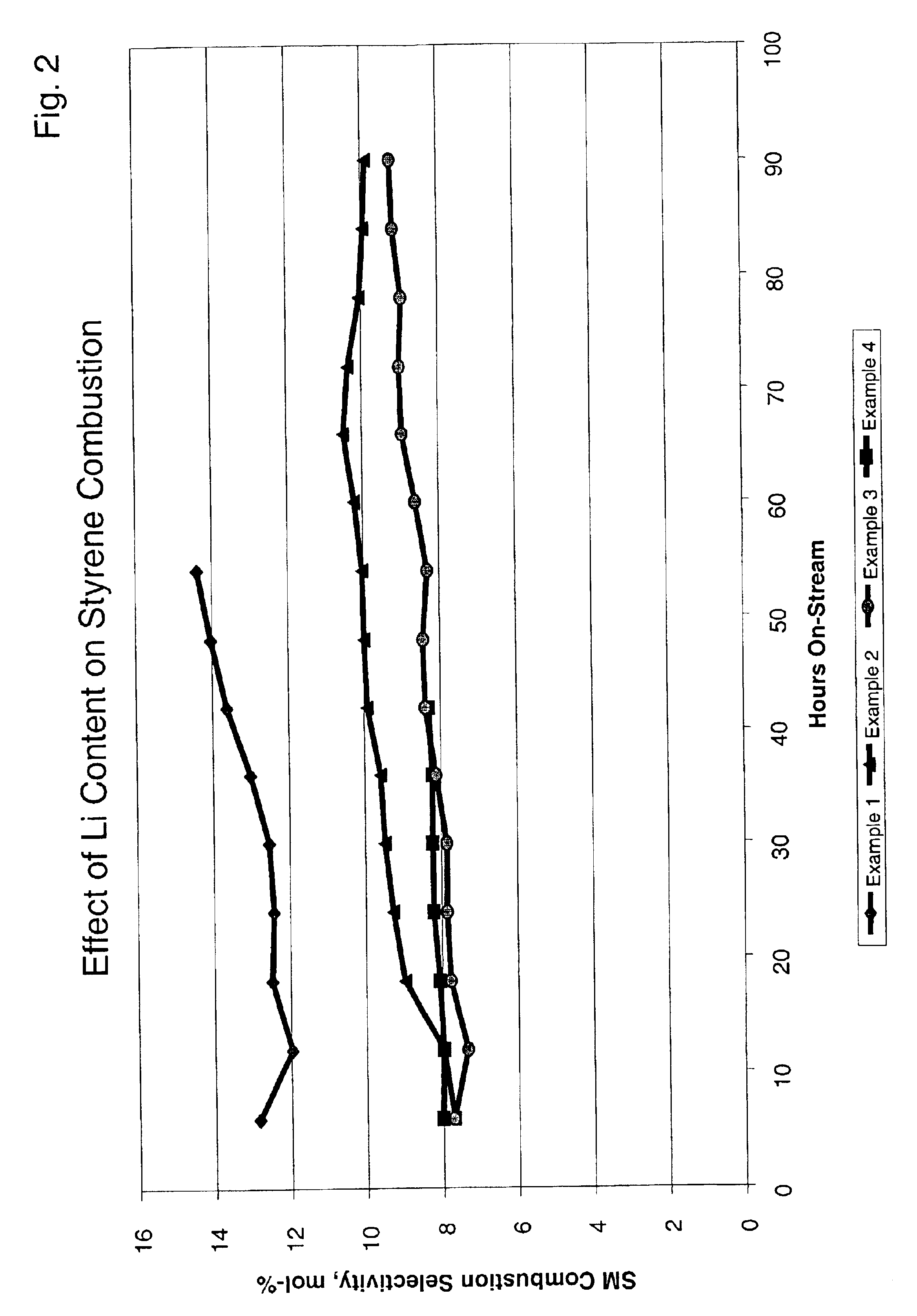

Lithium aluminate layered catalyst and a selective oxidation process using the catalyst

InactiveUS6858769B2Thermal non-catalytic crackingHydrocarbon by isomerisationHydrogenDehydrogenation

A catalyst for the selective oxidation of hydrogen has been developed. It comprises an inert core such as cordierite and an outer layer comprising a lithium aluminate support. The support has dispersed thereon a platinum group metal and a promoter metal, e.g. platinum and tin respectively. This catalyst is particularly effective in the selective oxidation of hydrogen in a dehydrogenation process.

Owner:UOP LLC

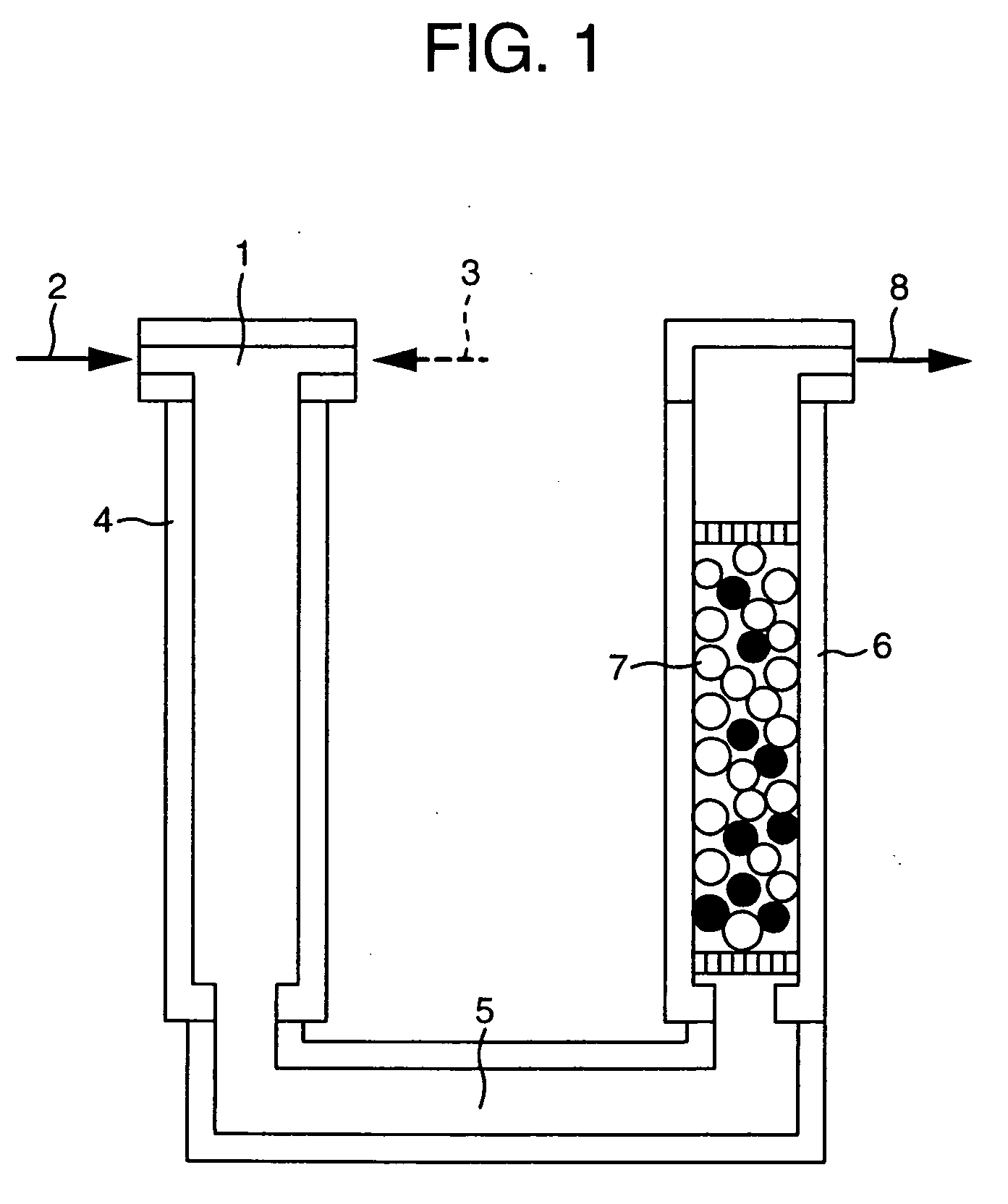

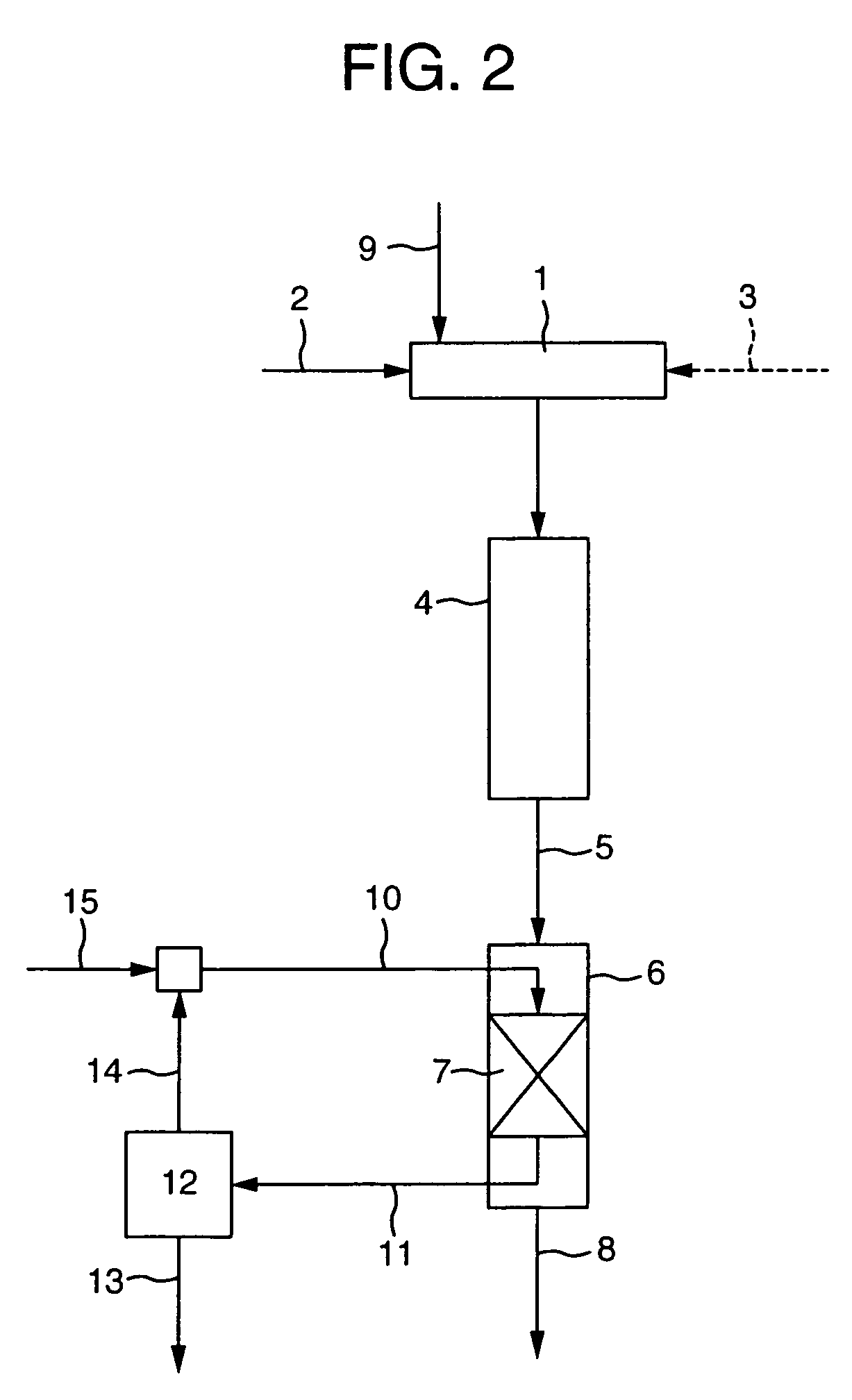

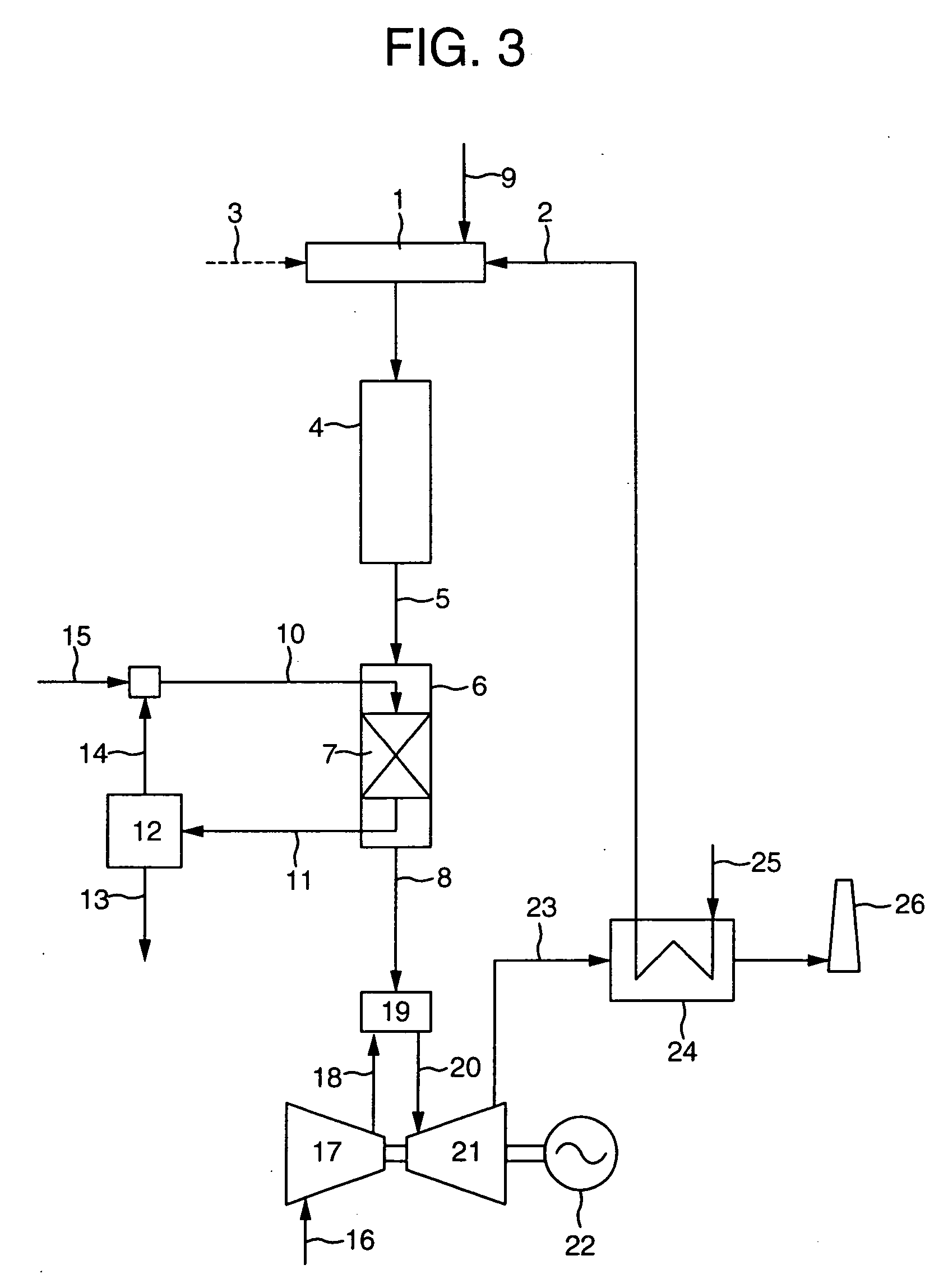

Heavy oil reforming method, an apparatus therefor, and gas turbine power generation system

InactiveUS20060011511A1Reduce equipment costsReduce runningThermal non-catalytic crackingHydrogenScavengerCombustor

Owner:HOKARI NOBUYUKI +4

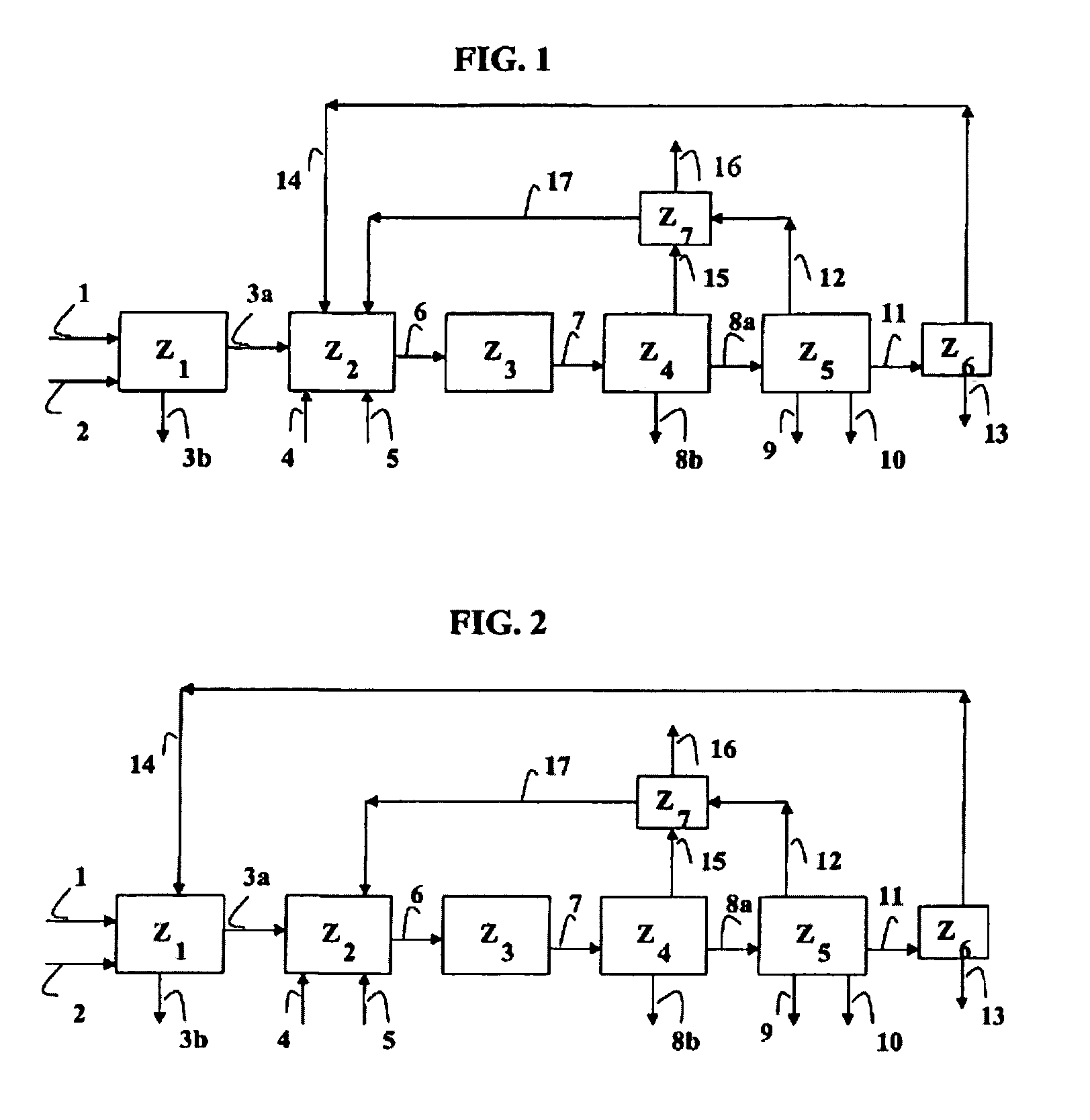

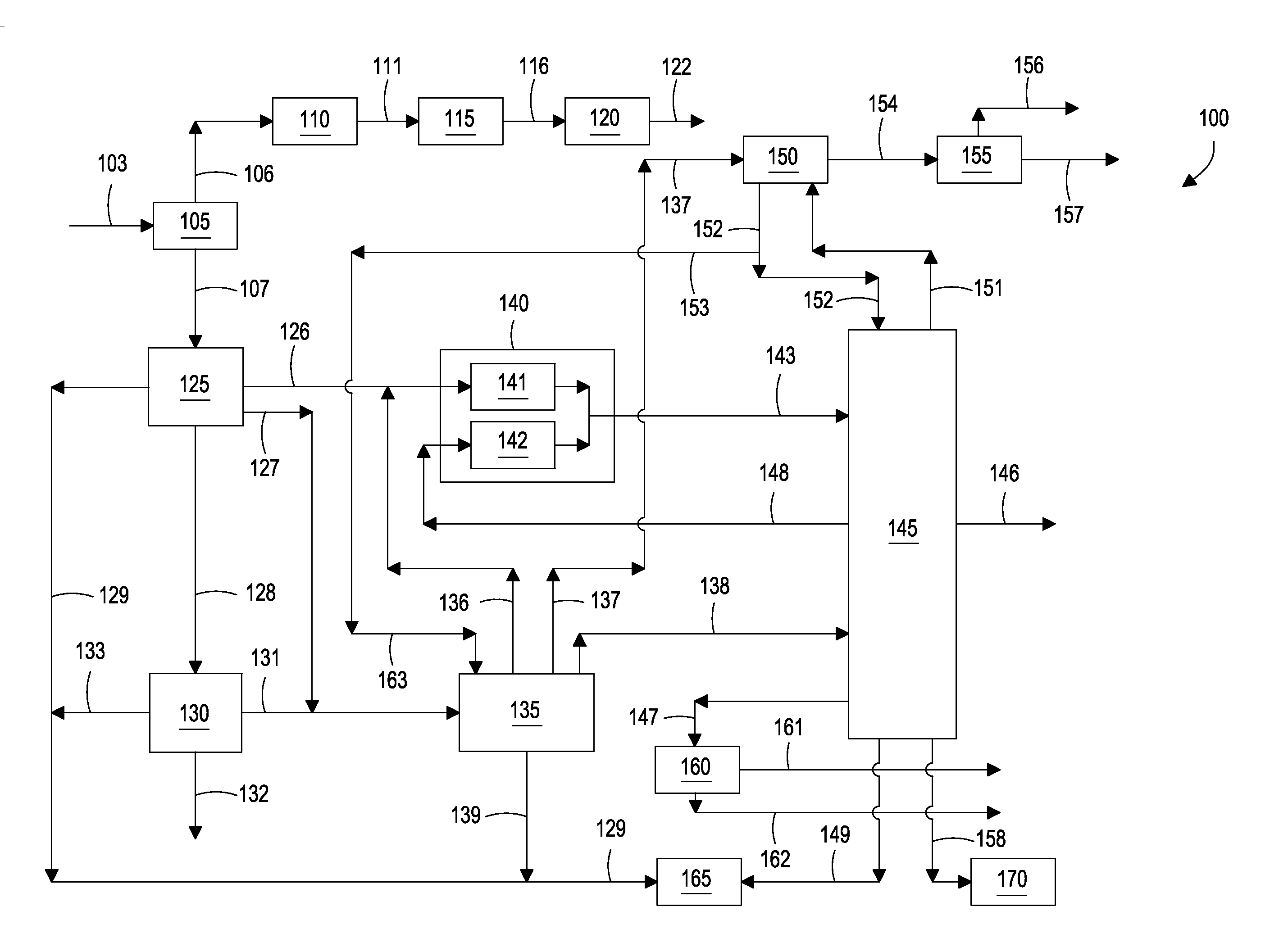

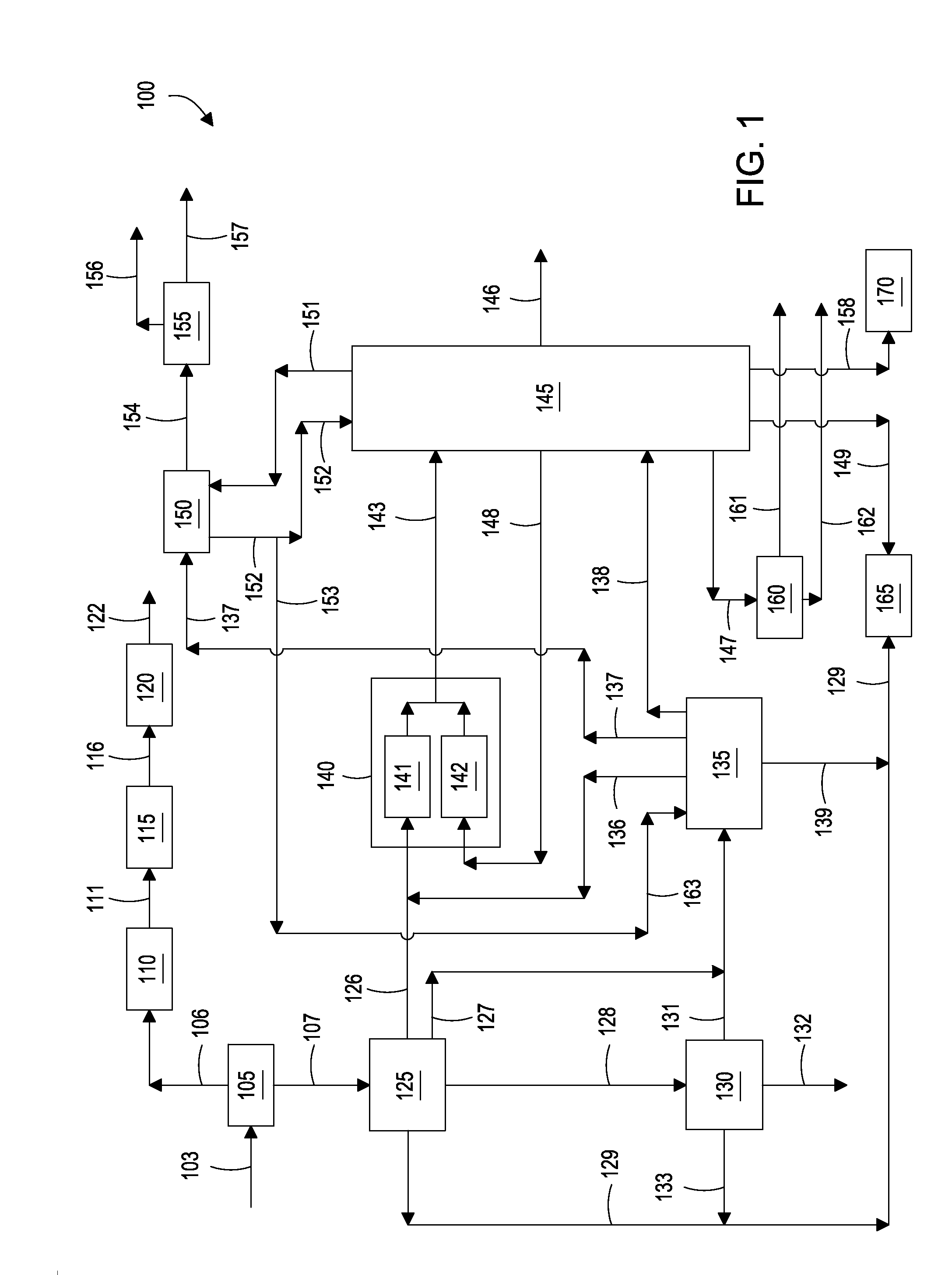

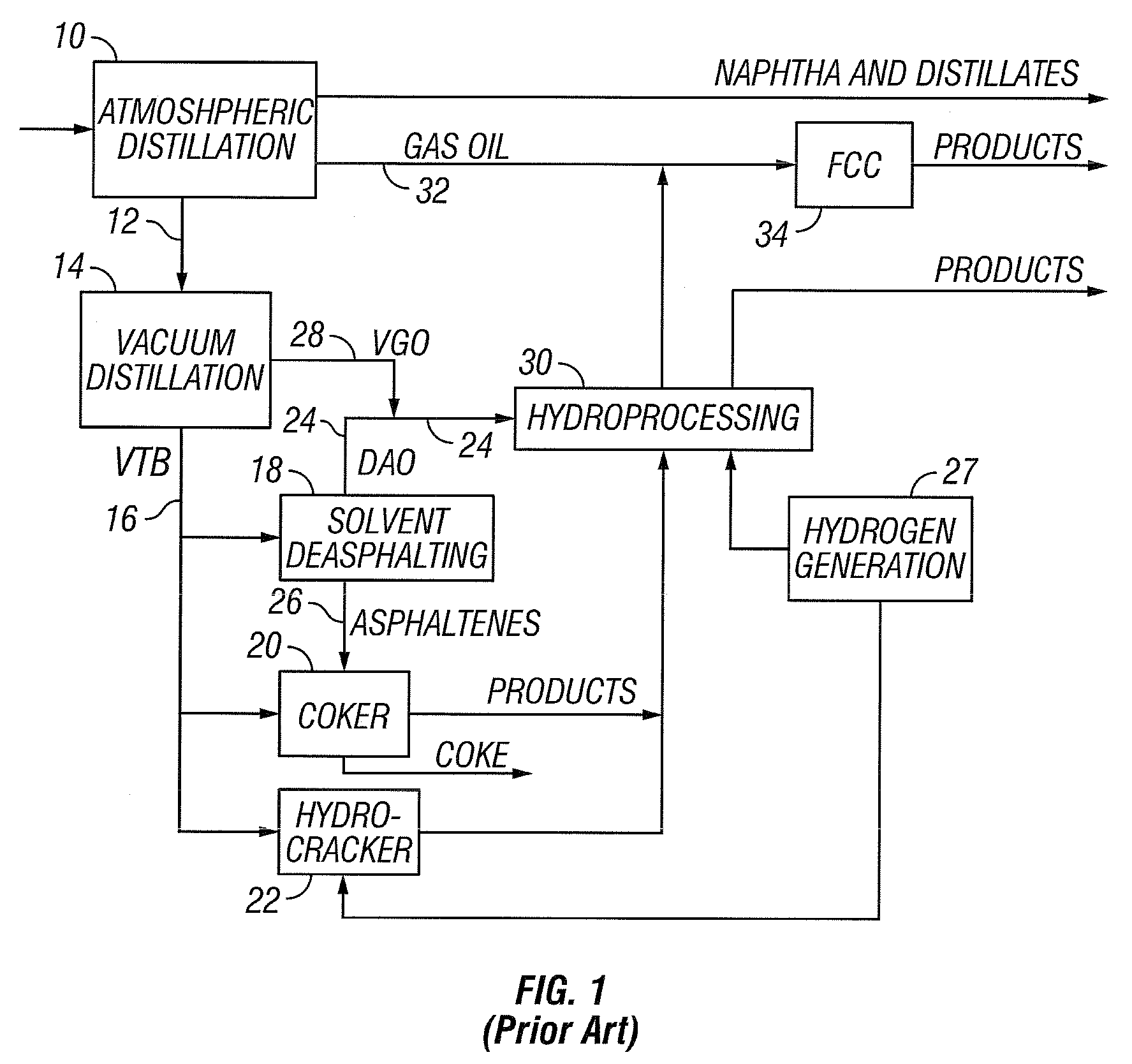

Systems and methods for residue upgrading

ActiveUS20080223754A1Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by selective extractionNaphthaReaction zone

Systems and methods for processing hydrocarbons are provided. A hydrocarbon can be distilled to provide a distillate, a gas oil, and a residue. The residue can include, but is not limited to asphaltenes and non-asphaltenes. The residue can be mixed with a solvent to provide a mixture. The asphaltenes can be selectively separated from the mixture to provide a deasphalted oil. At least a portion of the deasphalted oil and at least a portion of the gas oil can be hydroprocessed to provide a hydroprocessed hydrocarbon. At least a portion of the distillate and at least a portion of the hydroprocessed hydrocarbon can be cracked in a first reaction zone to provide a first cracked product comprising C2 hydrocarbons, C3 hydrocarbons, C4 hydrocarbons, and naphtha.

Owner:MARVELL TECHNOLOGY GROUP LTD +1

Olefin production utilizing whole crude oil and mild controlled cavitation assisted cracking

InactiveUS6979757B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationAlkene

A method for utilizing whole crude oil as a feedstock for the pyrolysis furnace of an olefin production plant wherein the feedstock after preheating is subjected to mild thermal cracking assisted with controlled cavitation conditions until substantially vaporized, the vapors being subjected to severe cracking in the radiant section of the furnace.

Owner:EQUSR CHEM LP

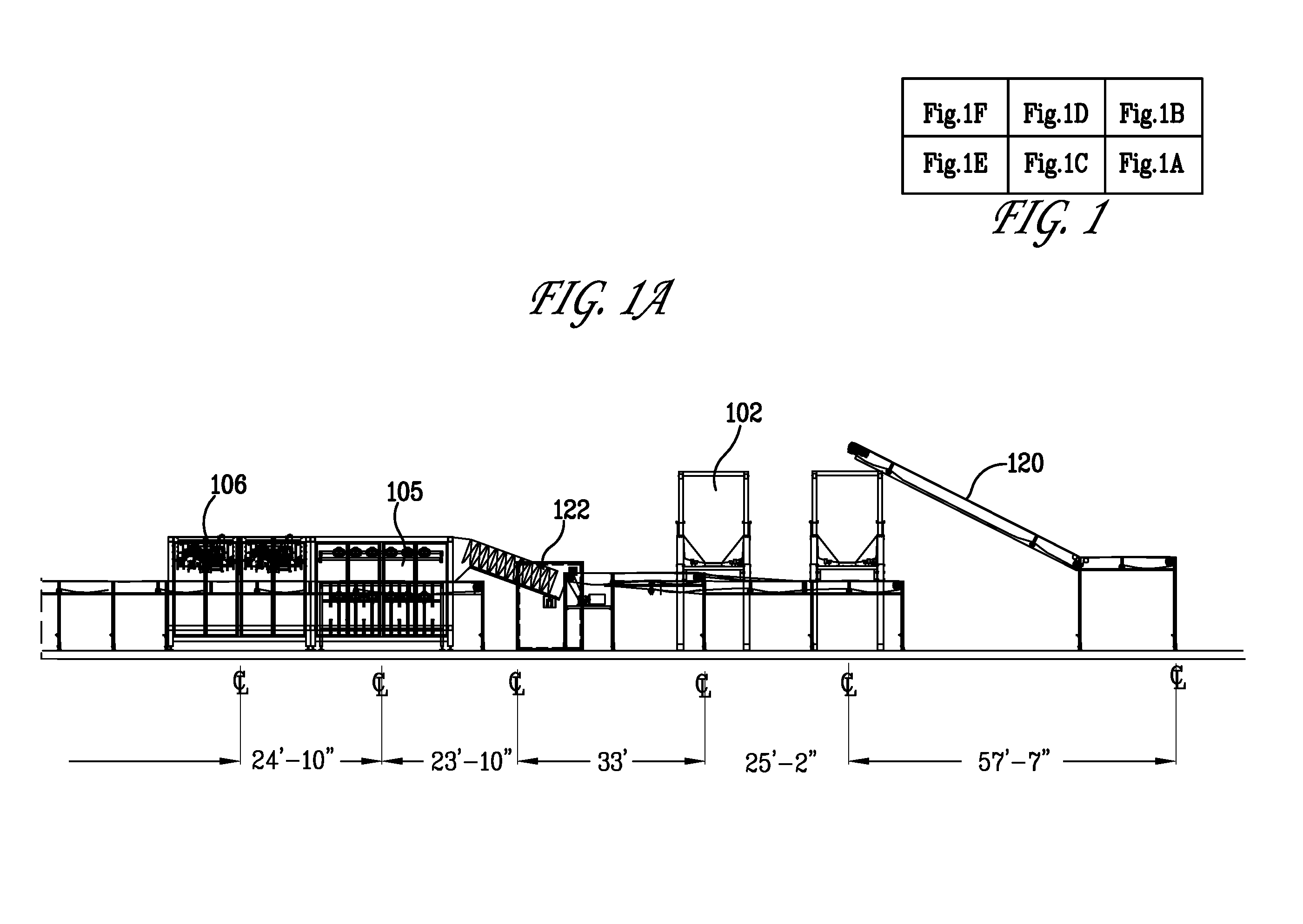

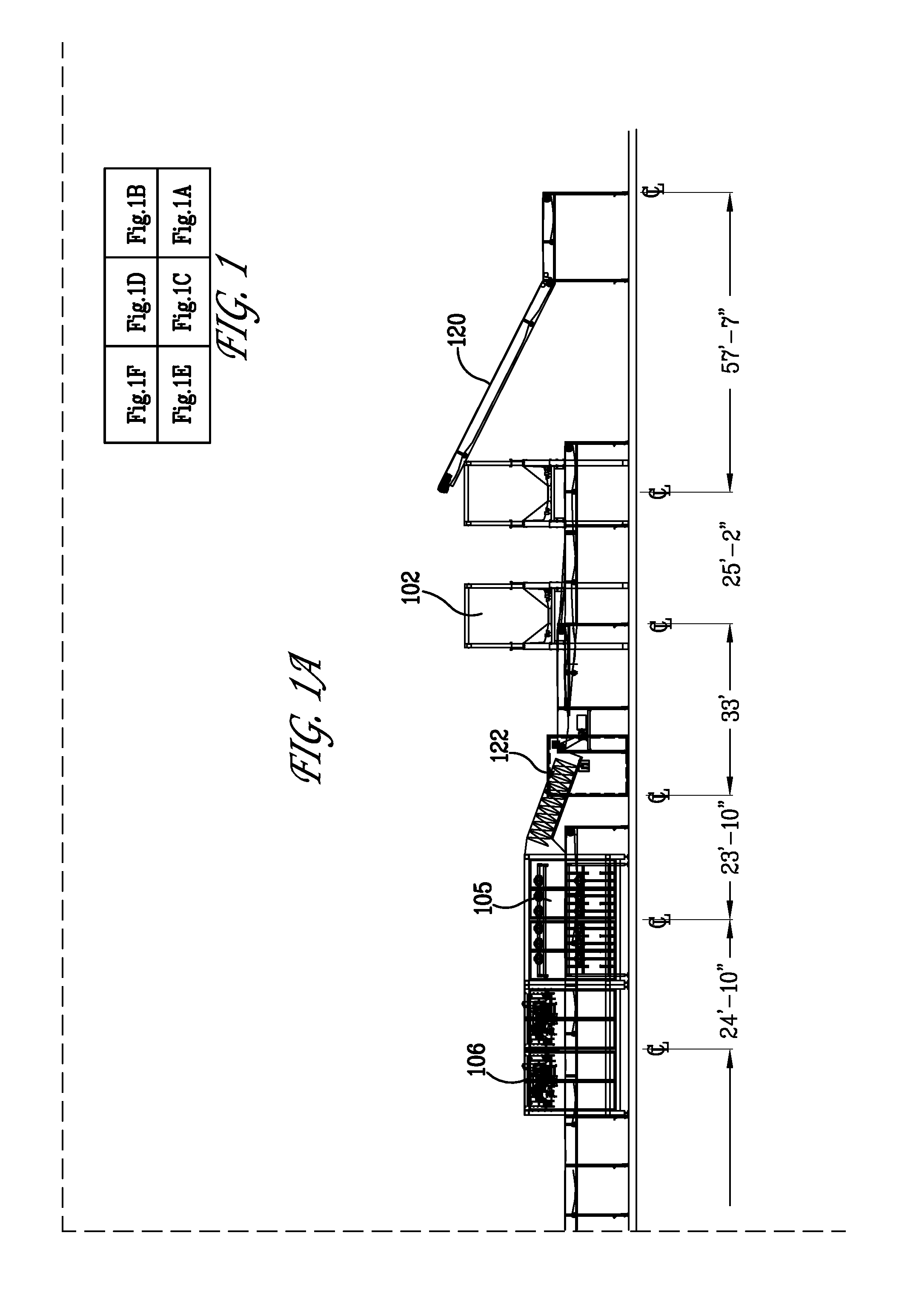

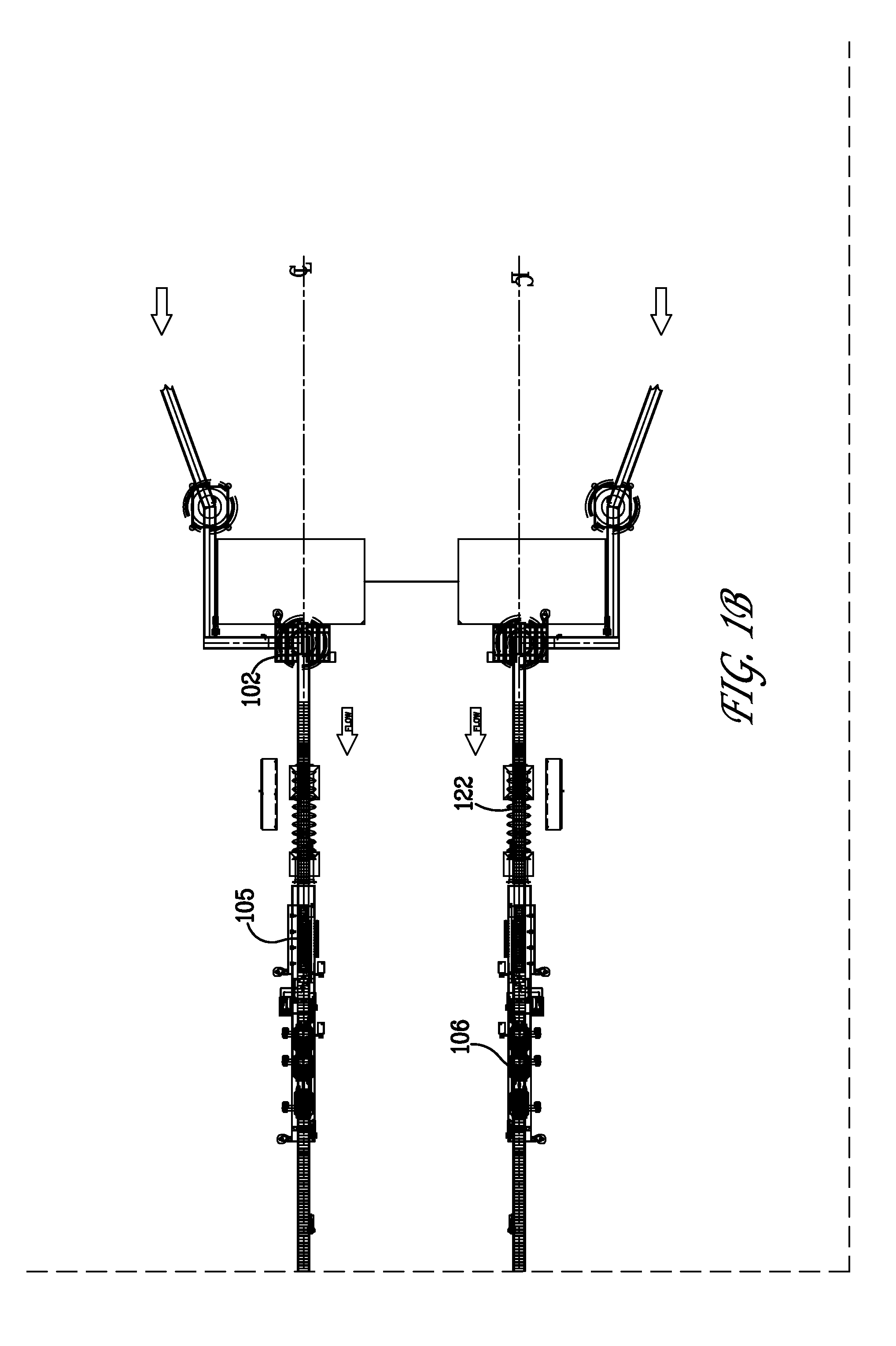

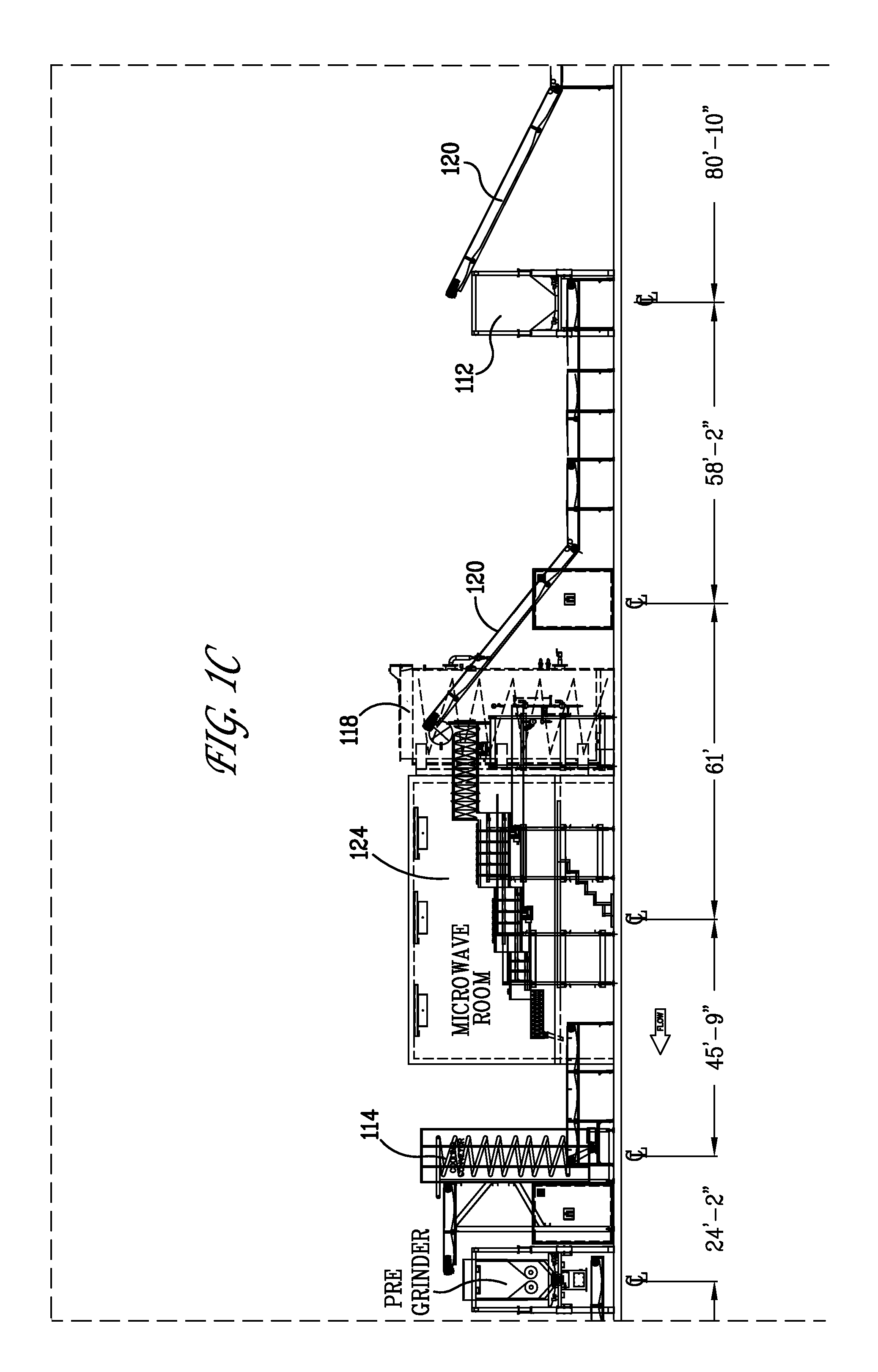

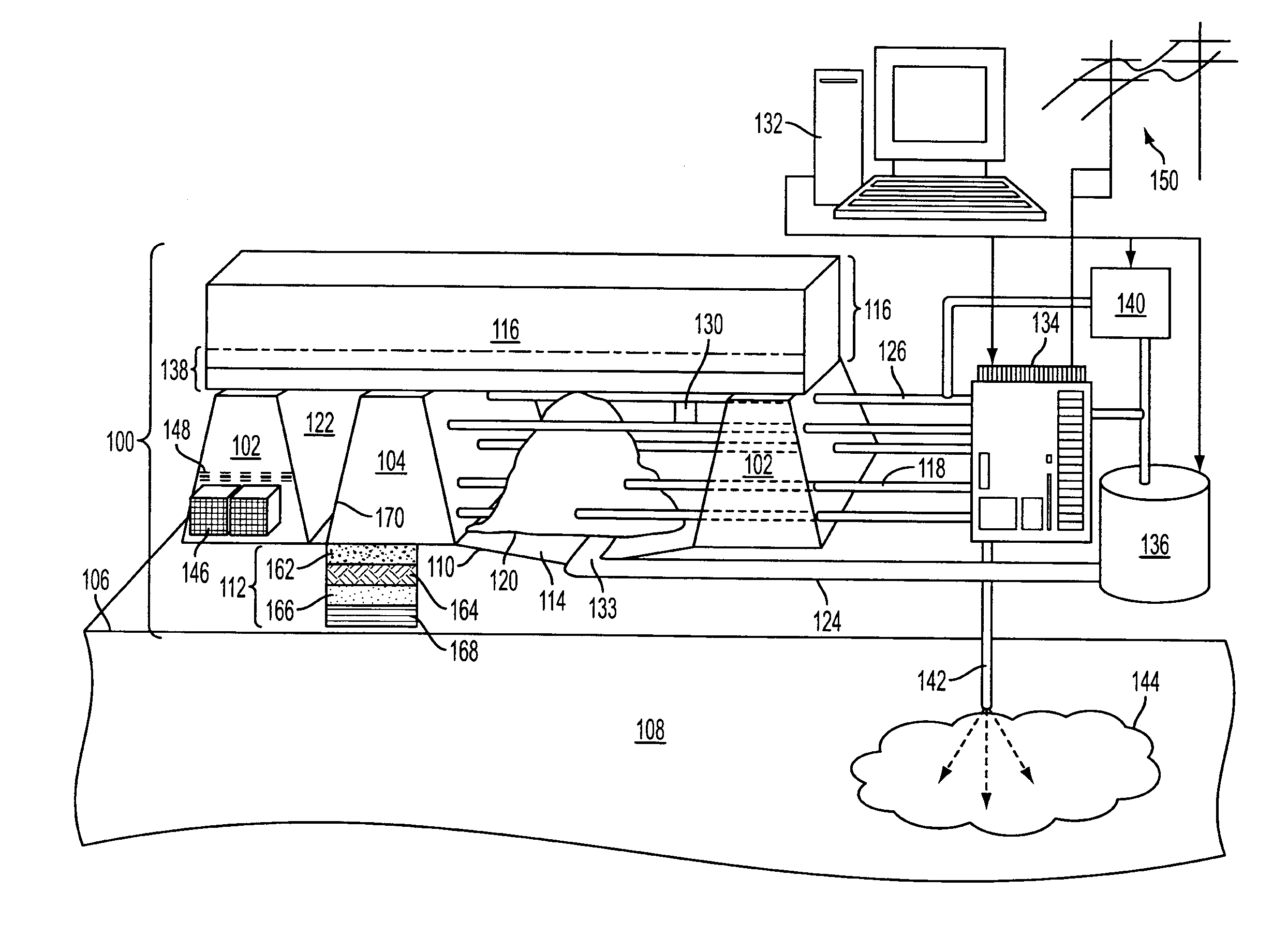

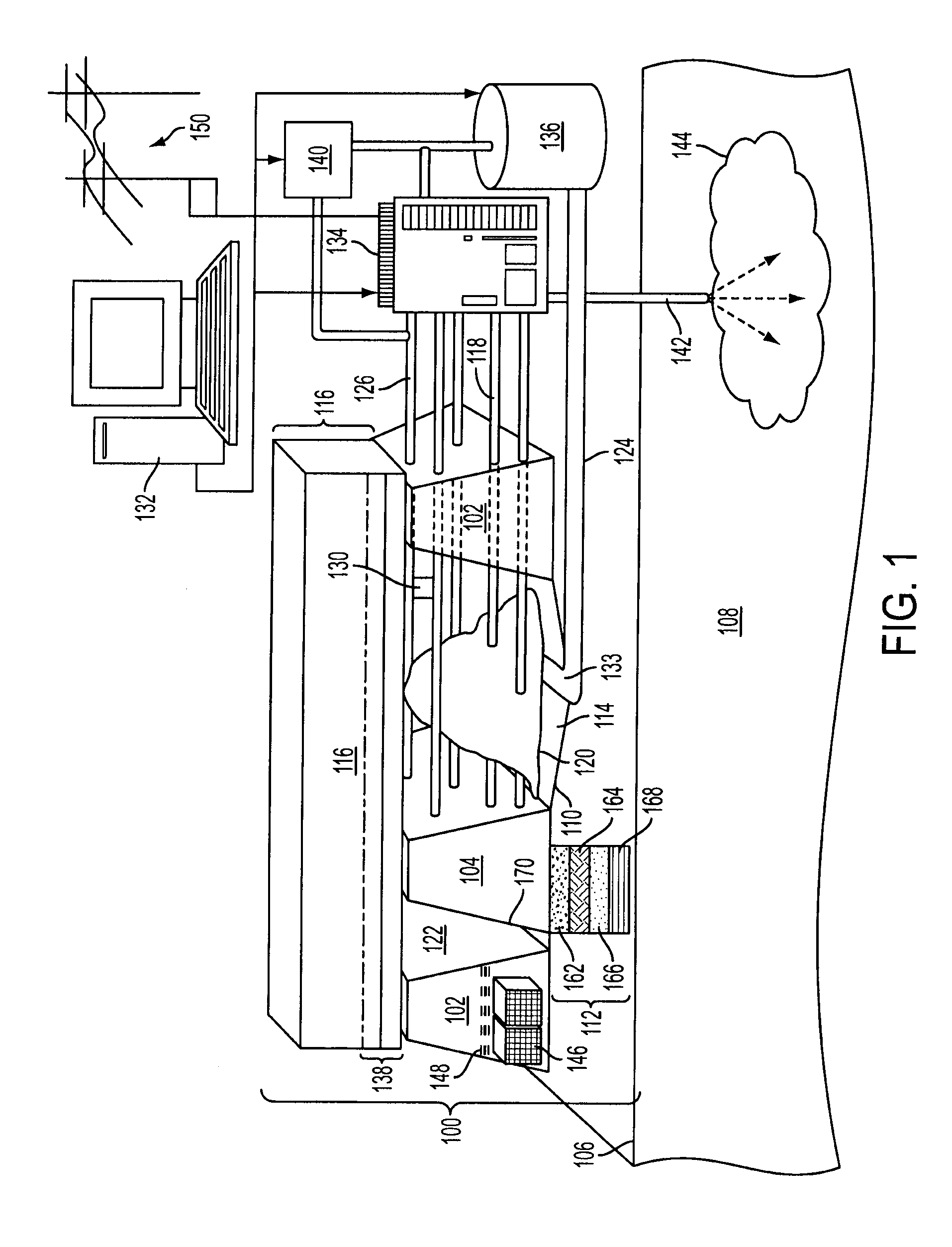

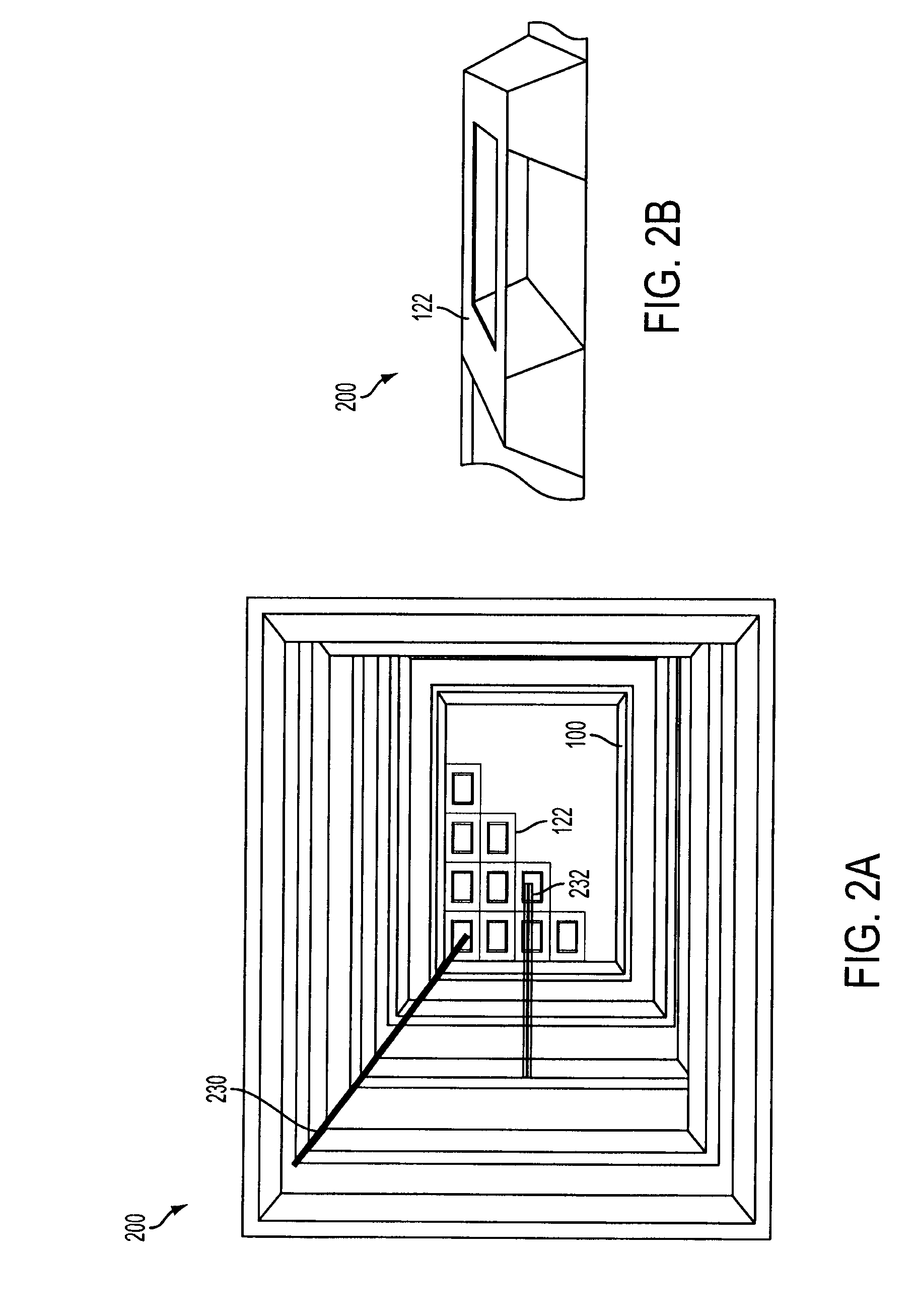

Methods of recovering hydrocarbons from hydrocarbonaceous material using a constructed infrastructure and associated systems

ActiveUS20080190818A1Reduce processing costsIncrease volume outputThermal non-catalytic crackingSolid waste disposalEngineeringHydrocarbon

A method of recovering hydrocarbons from hydrocarbonaceous materials can include forming a constructed permeability control infrastructure. This constructed infrastructure defines a substantially encapsulated volume. A comminuted hydrocarbonaceous material can be introduced into the control infrastructure to form a permeable body of hydrocarbonaceous material. The permeable body can be heated sufficient to remove hydrocarbons therefrom. During heating the hydrocarbonaceous material is substantially stationary as the constructed infrastructure is a fixed structure. Removed hydrocarbons can be collected for further processing, use in the process, and / or use as recovered.

Owner:RED LEAF RESOURCES

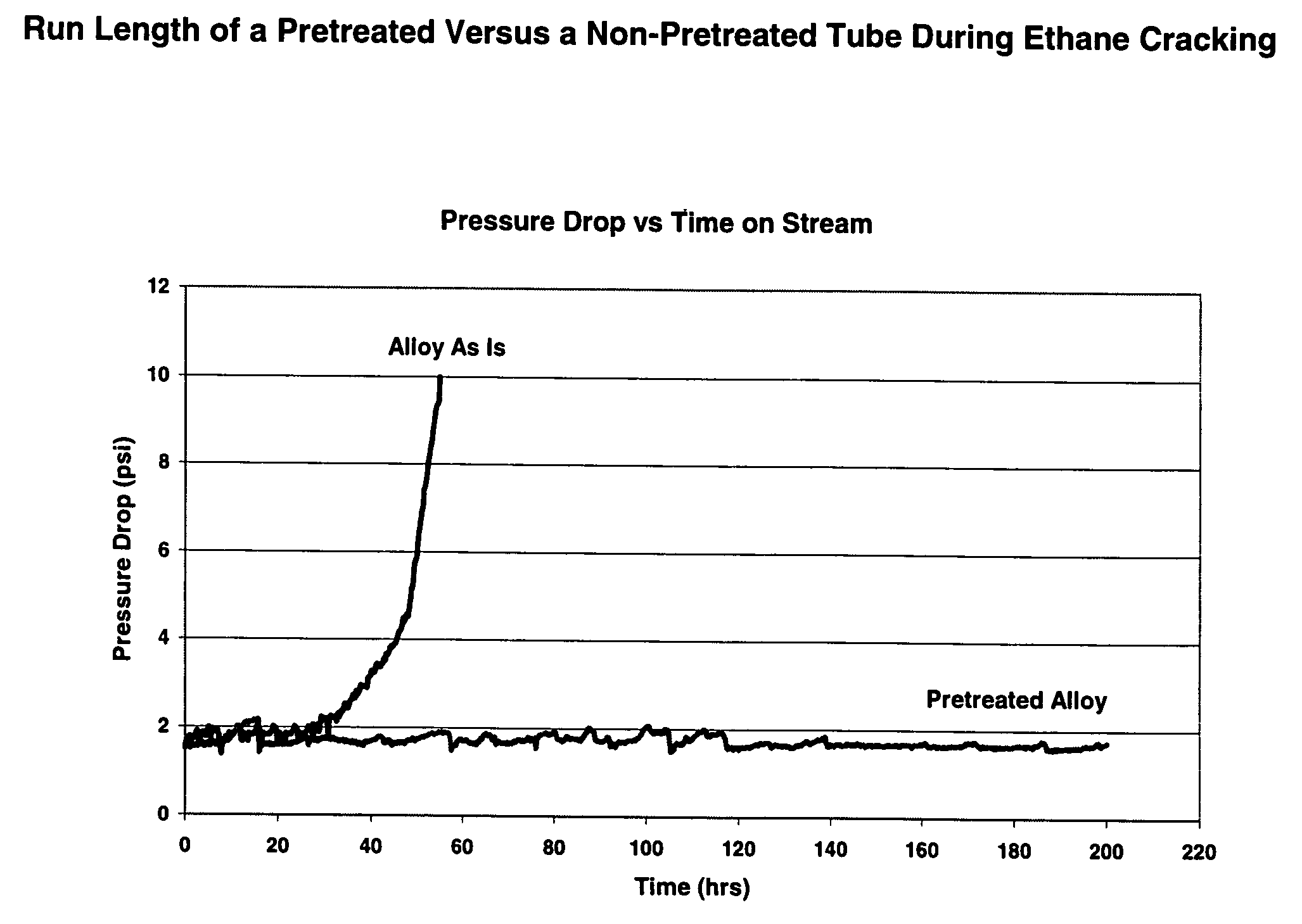

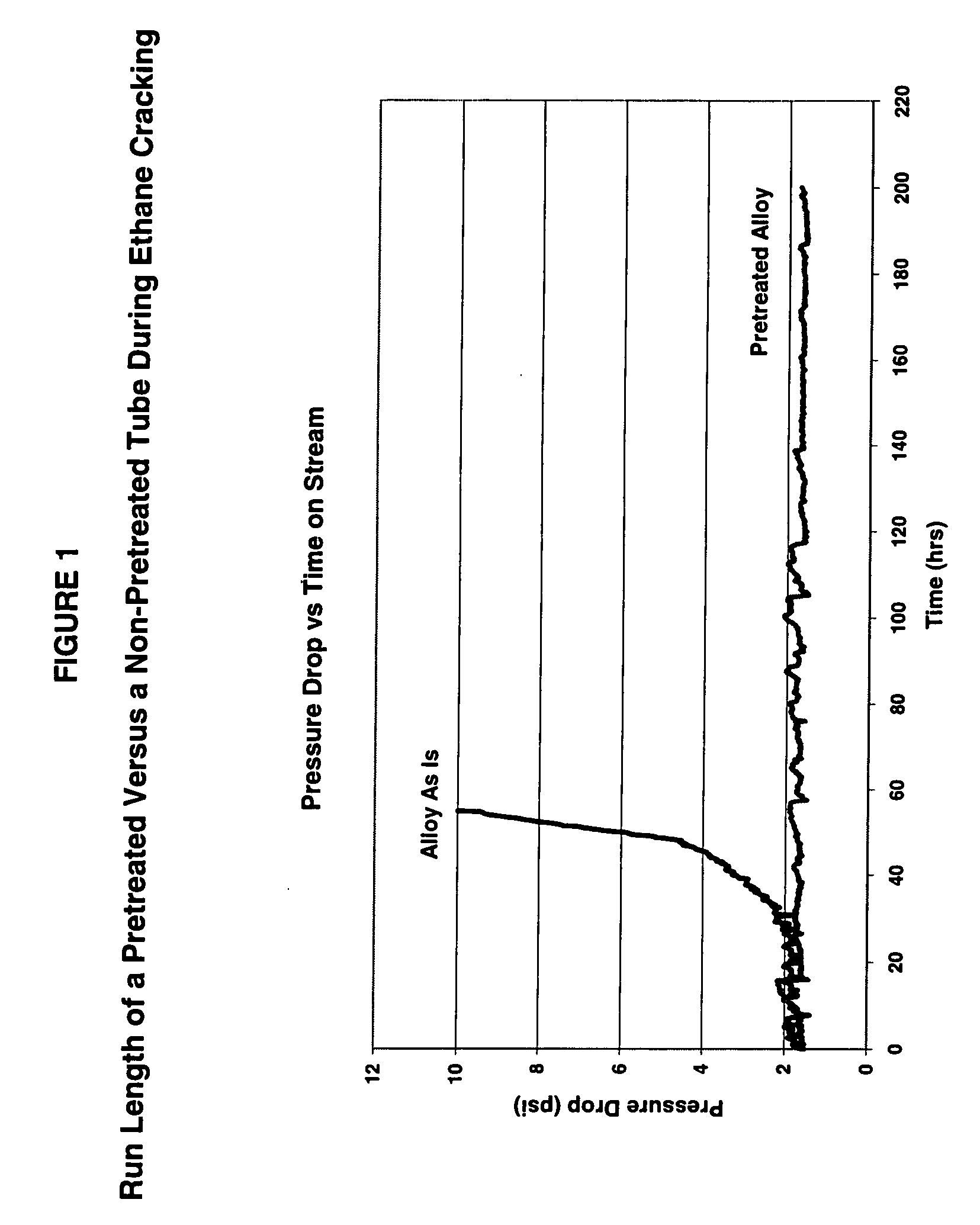

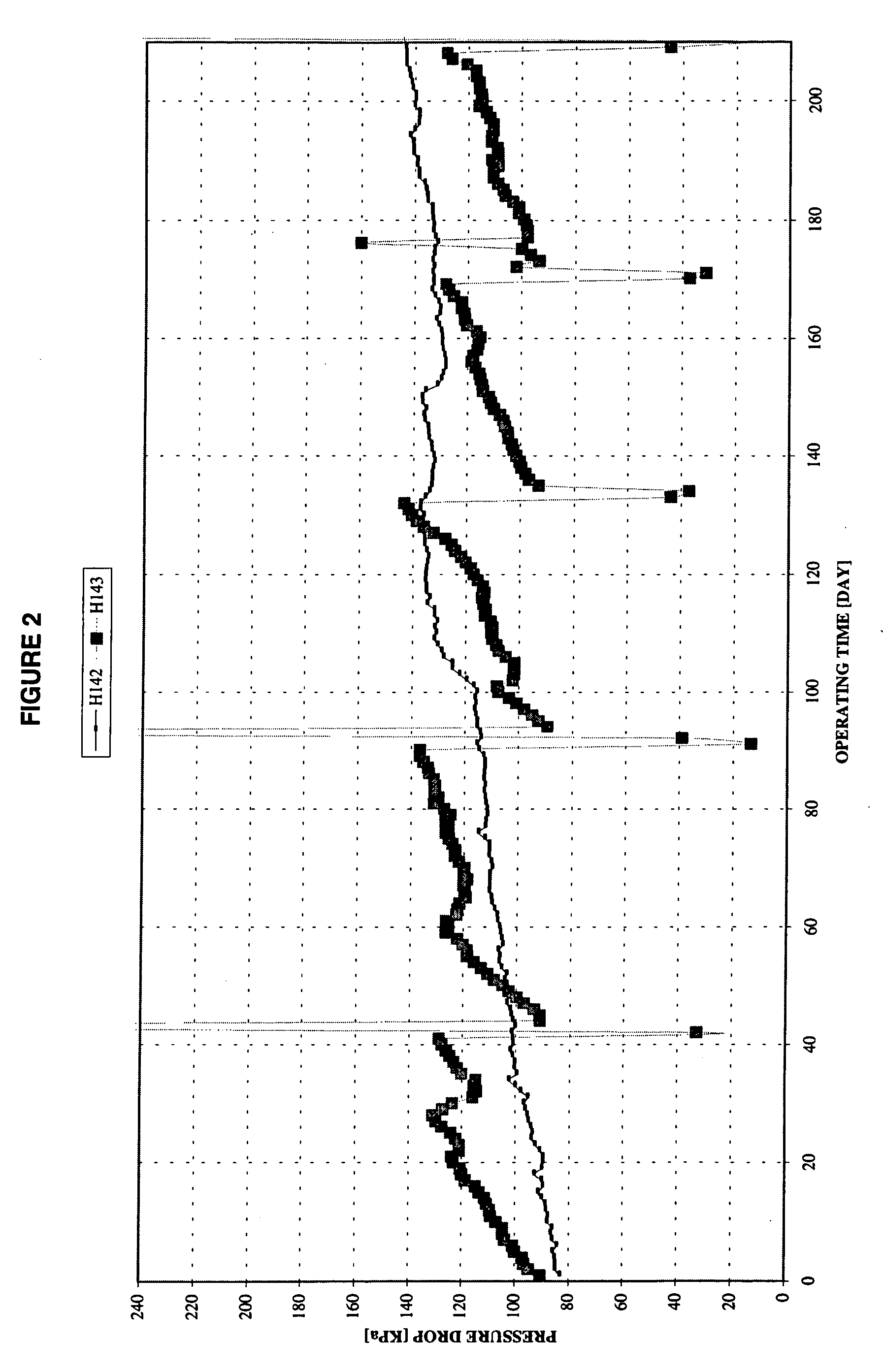

Thermal cracking process using tubes, pipes, and coils made of novel stainless steel matrix

A thermal cracking process using tubes, pipes, and coils made of.An outermost surface covering not less than 55% of stainless steel, said surface having a thickness from 0.1 to 15 microns and being a spinel of the formula MnxCr3-xO4 wherein x is from 0.5 to 2 is not prone to coking and is suitable for hydrocarbyl reactions such as furnace tubes for cracking.

Owner:NOVA CHEM (INT) SA

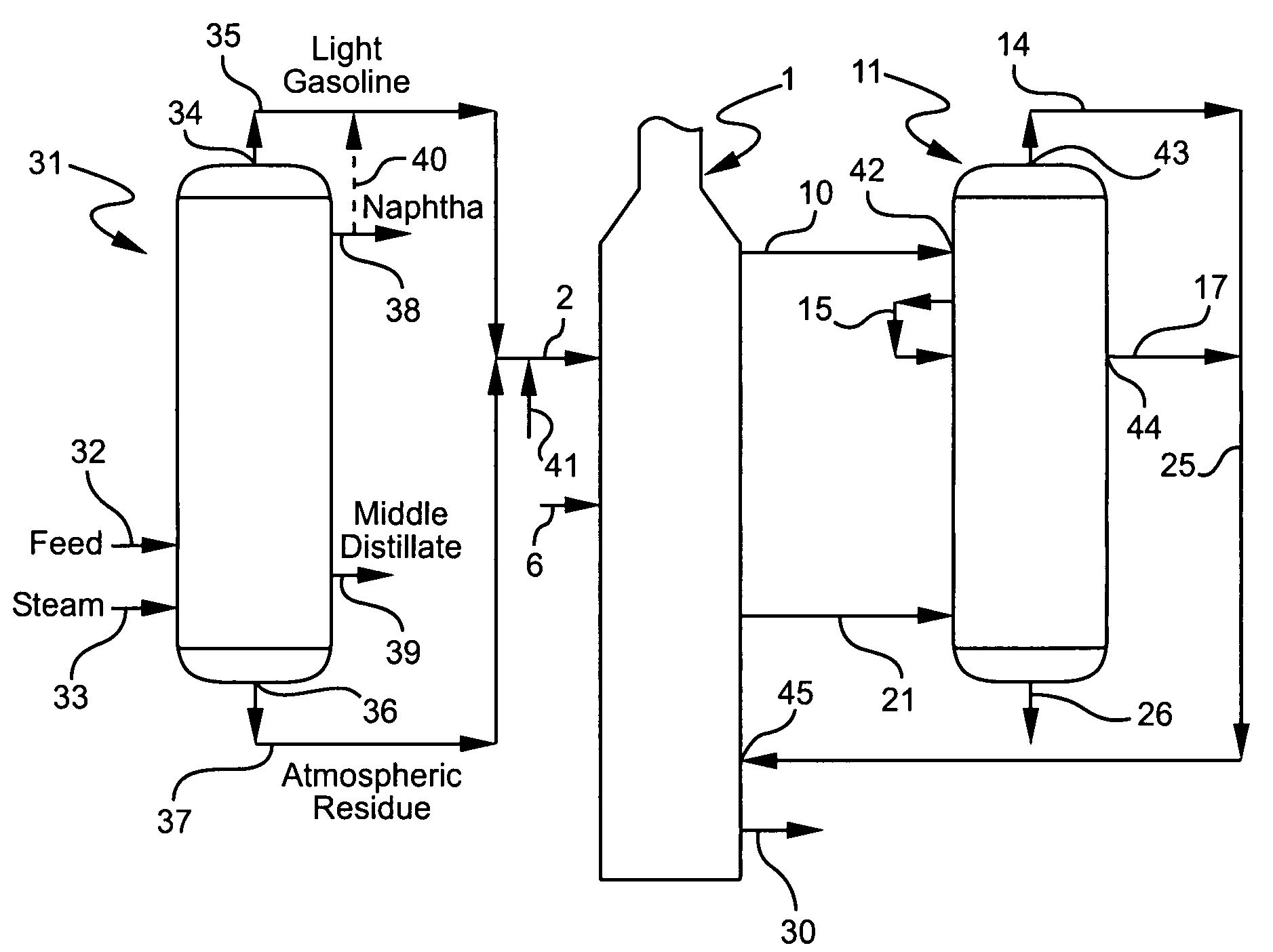

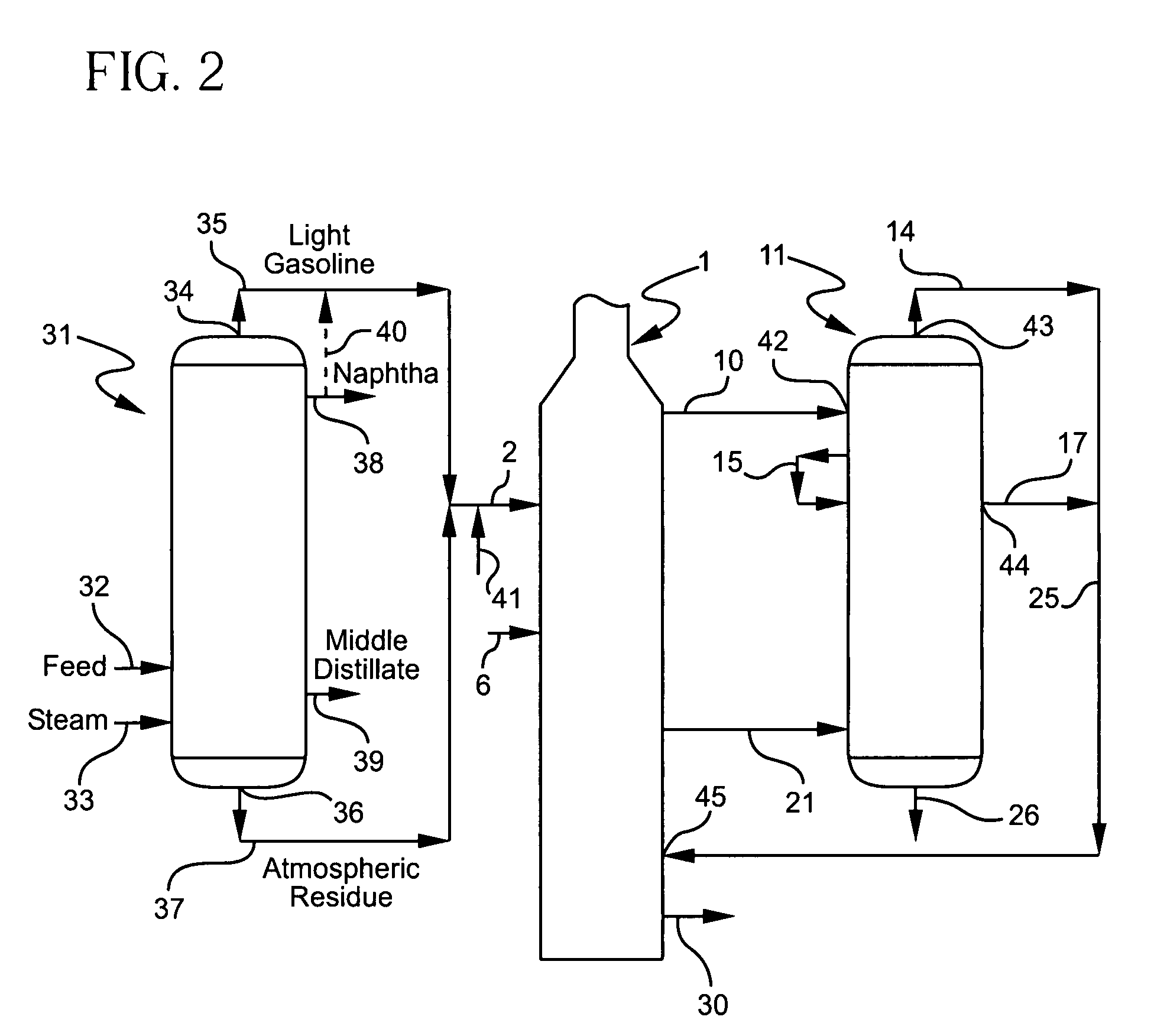

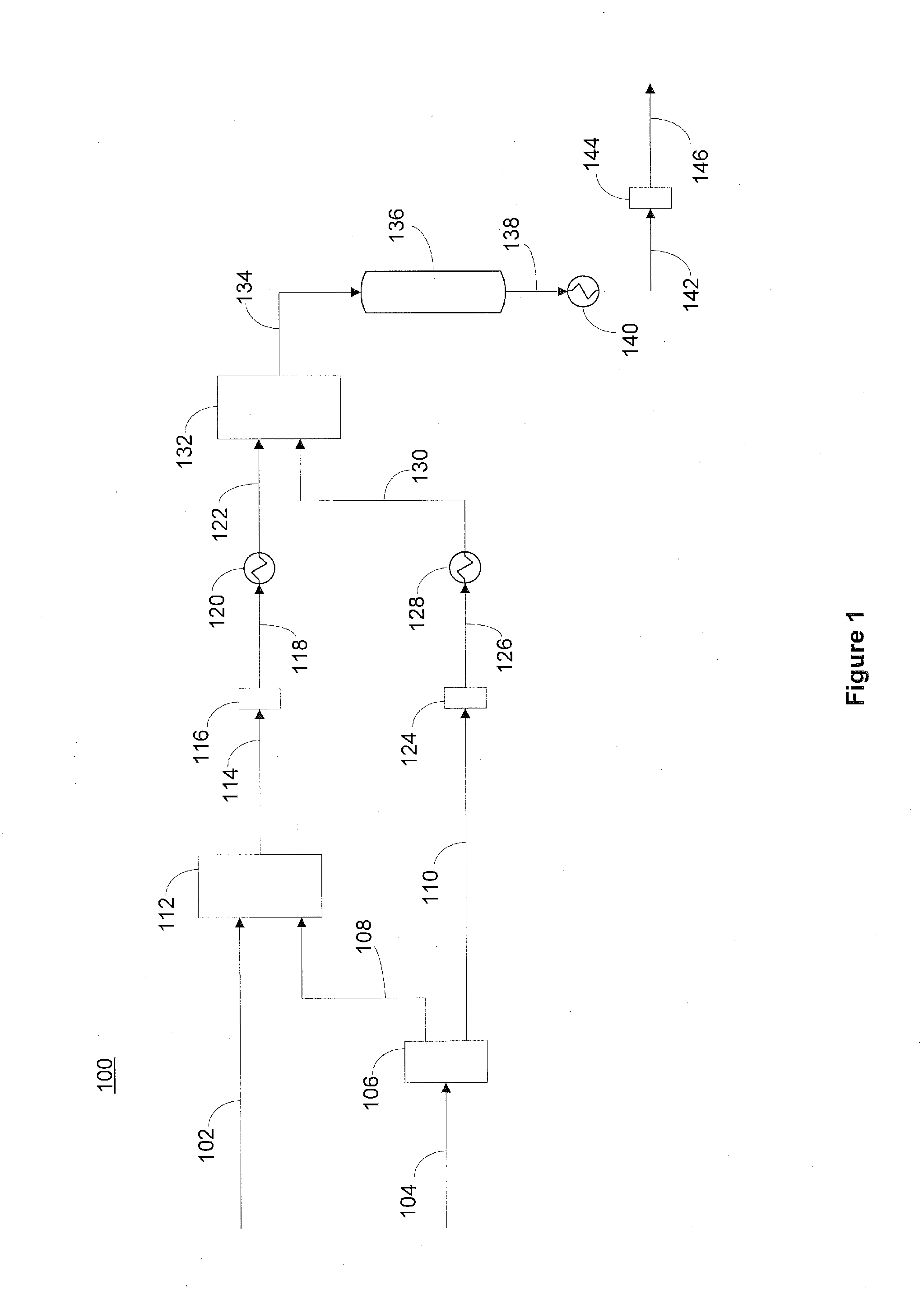

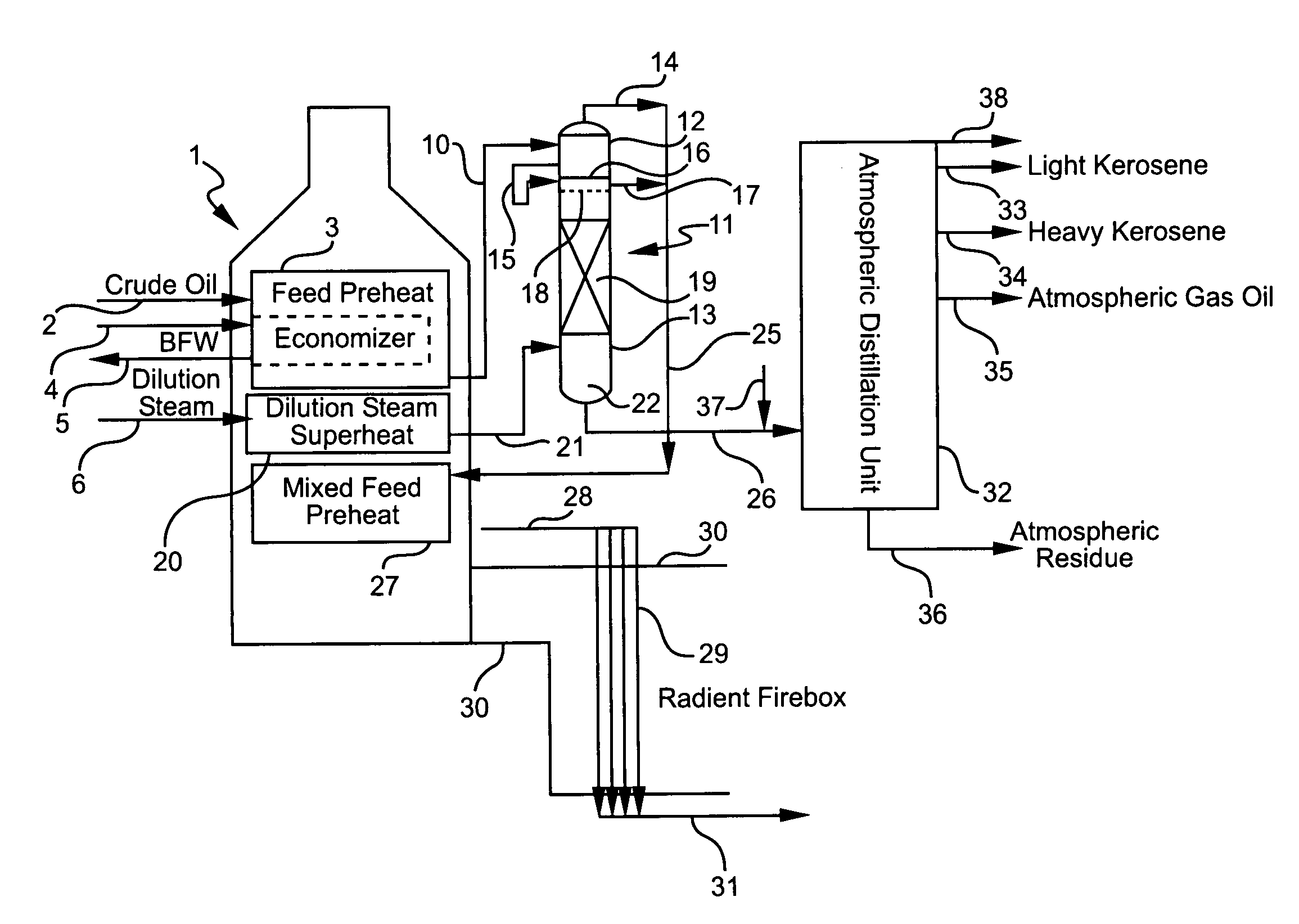

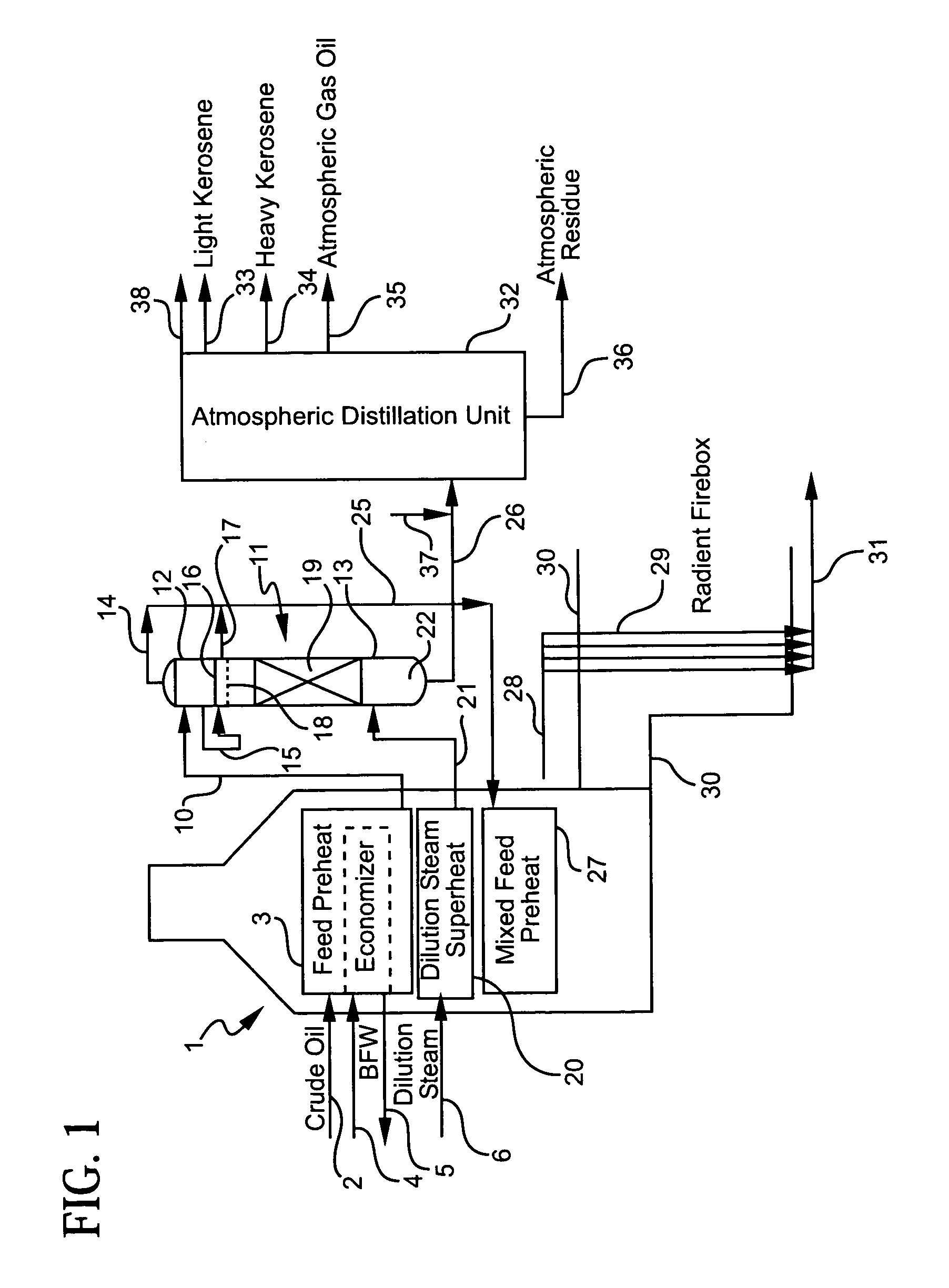

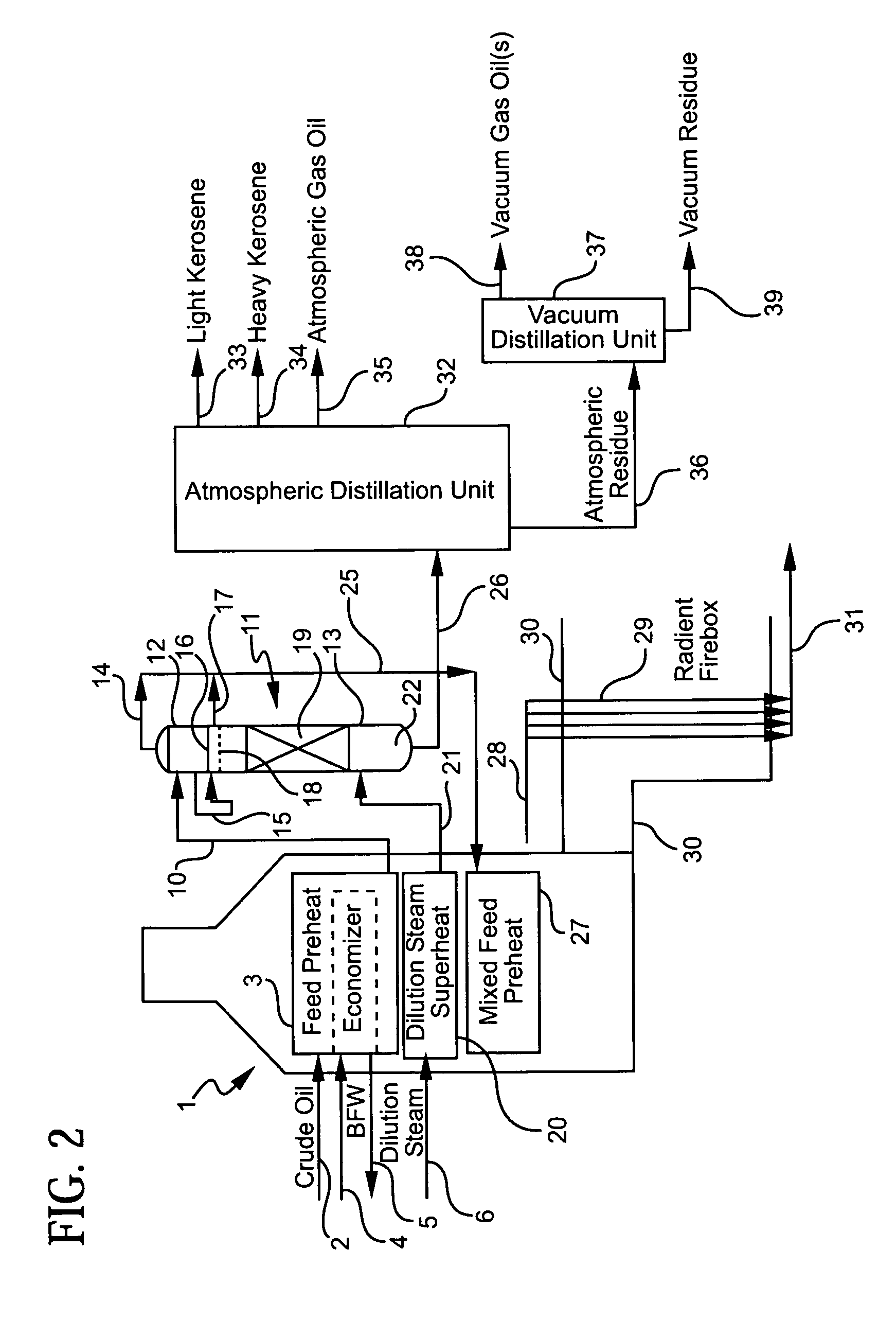

Hydrocarbon thermal cracking using atmospheric distillation

ActiveUS7404889B1Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyDistillationGasoline

A method for thermally cracking a hydrocarbonaceous feed wherein the feed is first processed in an atmospheric thermal distillation step to form a light gasoline and atmospheric residuum mixture. The light gasoline / residuum combination is gasified at least in part in a vaporization step, and the gasified product of the vaporization step is thermally cracked.

Owner:EQUSR CHEM LP

Resid processing for steam cracker feed and catalytic cracking

ActiveUS7972498B2Eliminate needHigh hydrogen contentThermal non-catalytic crackingHydrocarbon oil cracking processProcess engineeringAlkene

The invention concerns integration of hydroprocessing and steam cracking. A feed comprising crude or resid-containing fraction thereof is treated by hydroprocessing and visbreaking and then passed to a steam cracker to obtain a product comprising olefins.

Owner:EXXONMOBIL CHEM PAT INC

Supercritical water process to upgrade petroleum

ActiveUS20130140214A1Proceed efficientlyThermal non-catalytic crackingCatalytic crackingSludgePetroleum

Provided is a process for the supercritical upgrading of petroleum feedstock, wherein the process includes the use of a start-up agent, wherein the use of the start-up agent facilitates mixing of the petroleum feedstock and water, thereby reducing or eliminating the production of coke, coke precursor, and sludge.

Owner:SAUDI ARABIAN OIL CO

Olefin production utilizing whole crude oil/condensate feedstock with enhanced distillate production

InactiveUS7550642B2Maximize recoveryThermal non-catalytic crackingTreatment with plural serial stages onlyLiquid productNatural-gas condensate

A method processing a liquid crude and / or natural gas condensate feed comprising subjecting the feed to a vaporization step to form a vaporous product and a liquid product, subjecting the vaporous product to severe thermal cracking, and subjecting the liquid product to crude oil refinery processing.

Owner:EQUSR CHEM LP

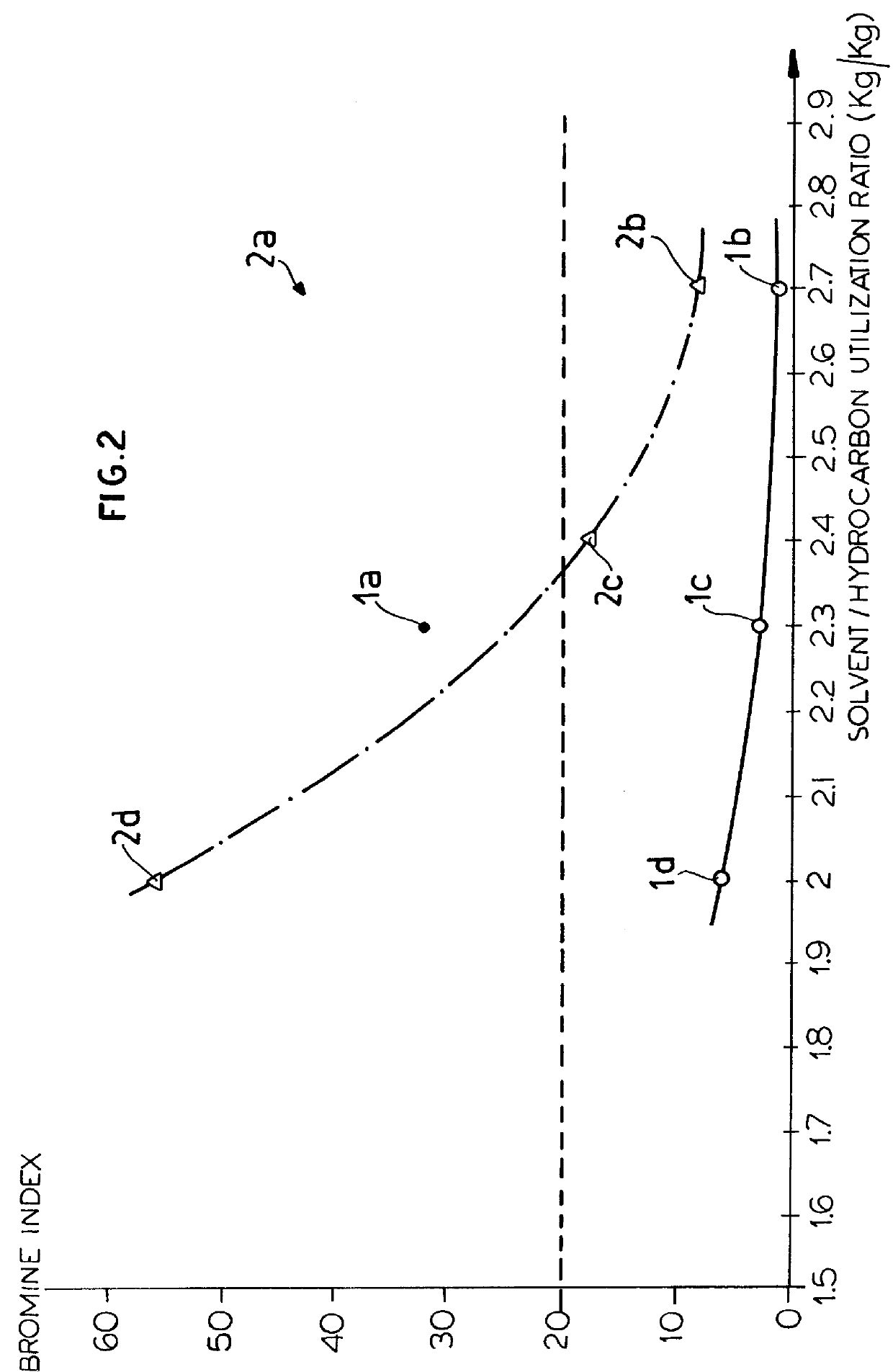

Supercritical hydrocarbon conversion process

ActiveUS7144498B2Thermal non-catalytic crackingTreatment with plural serial cracking stages onlyReaction temperatureUnit operation

Supercritical conversion of hydrocarbons boiling above 538° C. (1000° F.) with a solvating hydrocarbon at a weight ratio of solvating hydrocarbon to high-boiling hydrocarbons of at least 2:1 and at conditions above the critical temperature and pressure of the high-boiling hydrocarbons-solvent mixture, in the presence of hot fluidized solids. The hydrocarbons are supplied to a reaction zone at a temperature below that of the hot solids supplied thereto, whereby the resulting hydrocarbons-solids suspension has a thermal equilibrium temperature corresponding to the reaction temperature. The conversion has high rates of sulfur, nitrogen and metals removal, nearly complete conversion to lower molecular weight products, high naphtha and distillate selectivity, and low coke formation. The supercritical conversion can replace crude distillation, vacuum distillation, solvent deasphalting, coking, hydrocracking, hydrotreating, and / or fluid catalytic cracking, and / or used in parallel with such unit operations for debottle-necking or increasing capacity.

Owner:KELLOGG BROWN & ROOT LLC

High-activity isomerization catalyst and process

InactiveUS6881873B2Improve performanceImprove stabilityThermal non-catalytic crackingHydrocarbon by isomerisationAlkaneSulfation

A catalyst and process is disclosed to selectively upgrade a paraffinic feedstock to obtain an isoparaffin-rich product for blending into gasoline. The catalyst comprises a support of a sulfated oxide or hydroxide of a Group IVB (IUPAC 4) metal, a first component of at least one lanthanide element or yttrium component, which is preferably ytterbium, and at least one platinum-group metal component which is preferably platinum.

Owner:UOP LLC

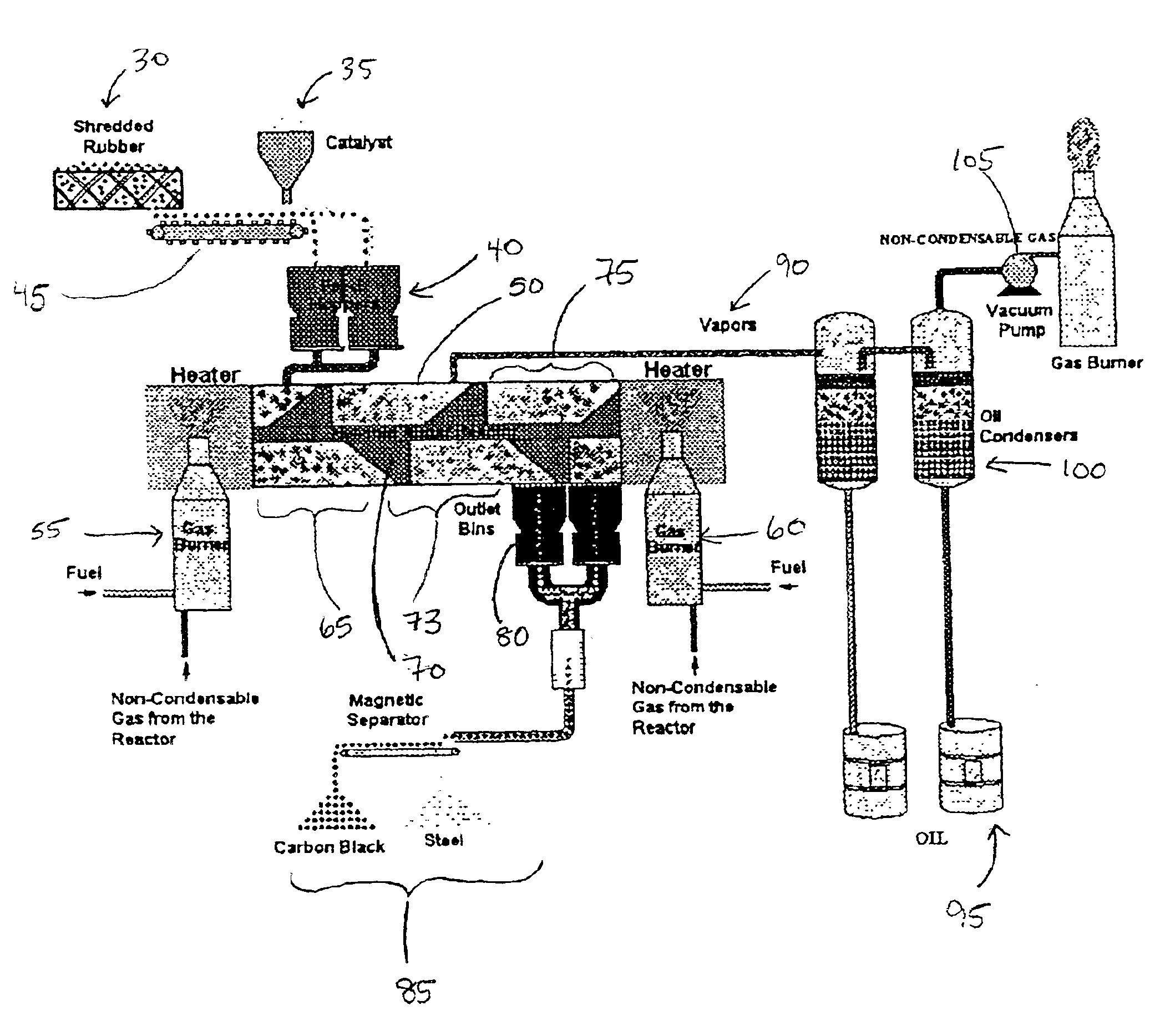

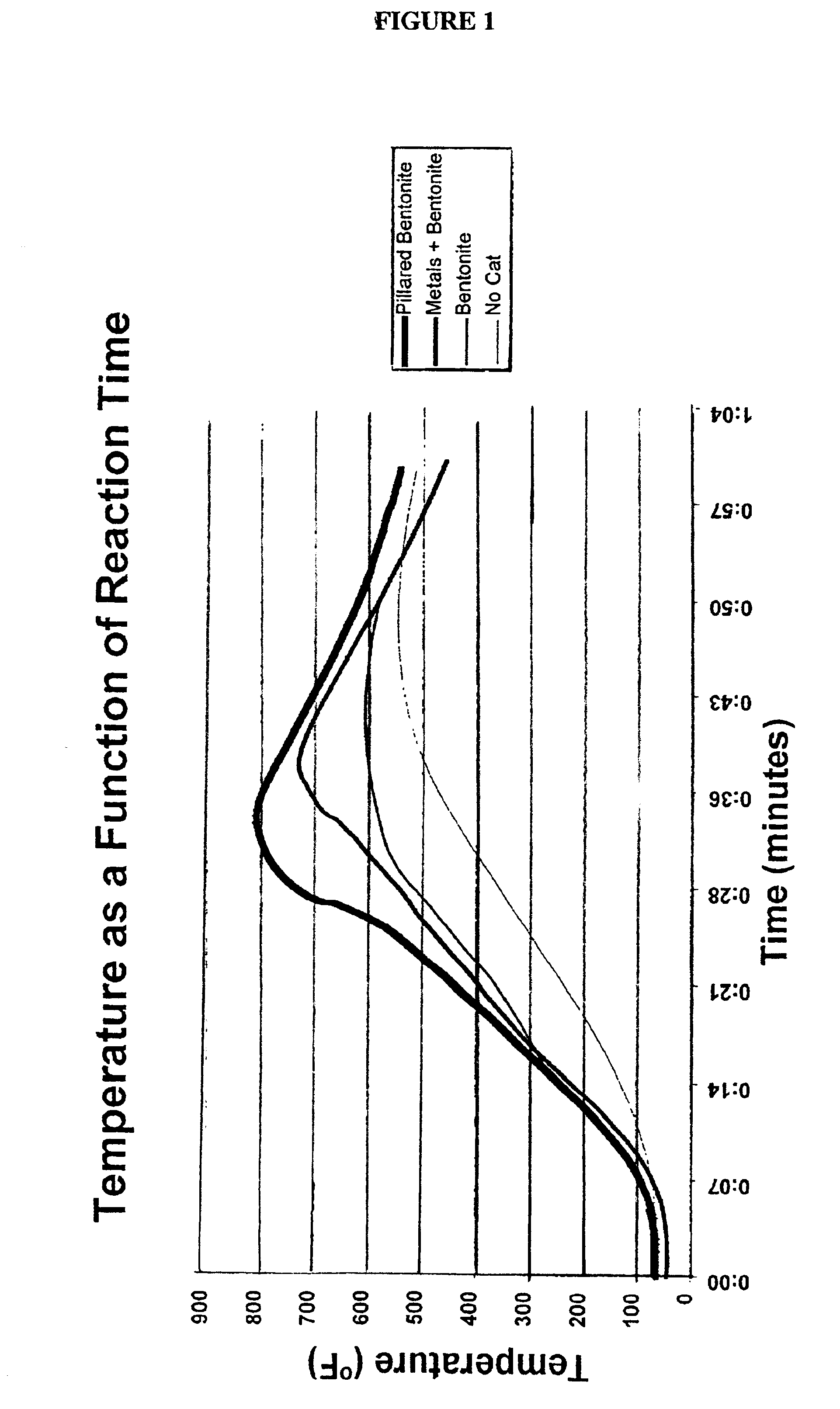

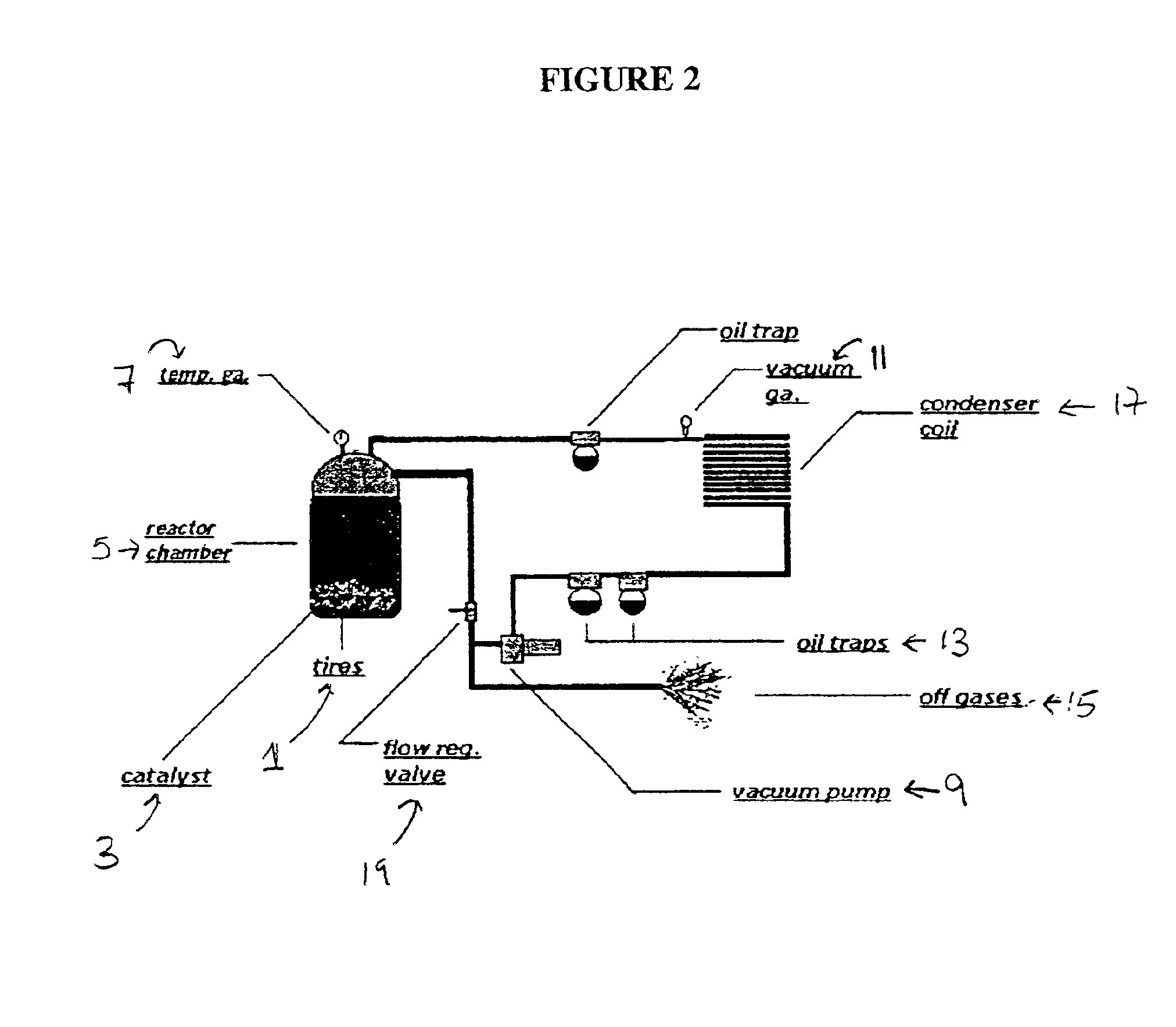

Low energy method of pyrolysis of hydrocarbon materials such as rubber

A low energy method of pyrolysis of rubber or other hydrocarbon material is provided. The hydrocarbon material is heated while maintaining a vacuum, using a clay catalyst. In an additional embodiment, the temperature of the reaction chamber and corresponding fuel input is varied either over time or spatially within the reaction chamber, to take advantage of the exothermic properties of the reaction. With the method of the present invention, a higher quality solid reaction product can be achieved, as well as a liquid having reduced polyaromatic hydrocarbons and oxidized organic contaminants.

Owner:DELTA ENERGY GRP LLC

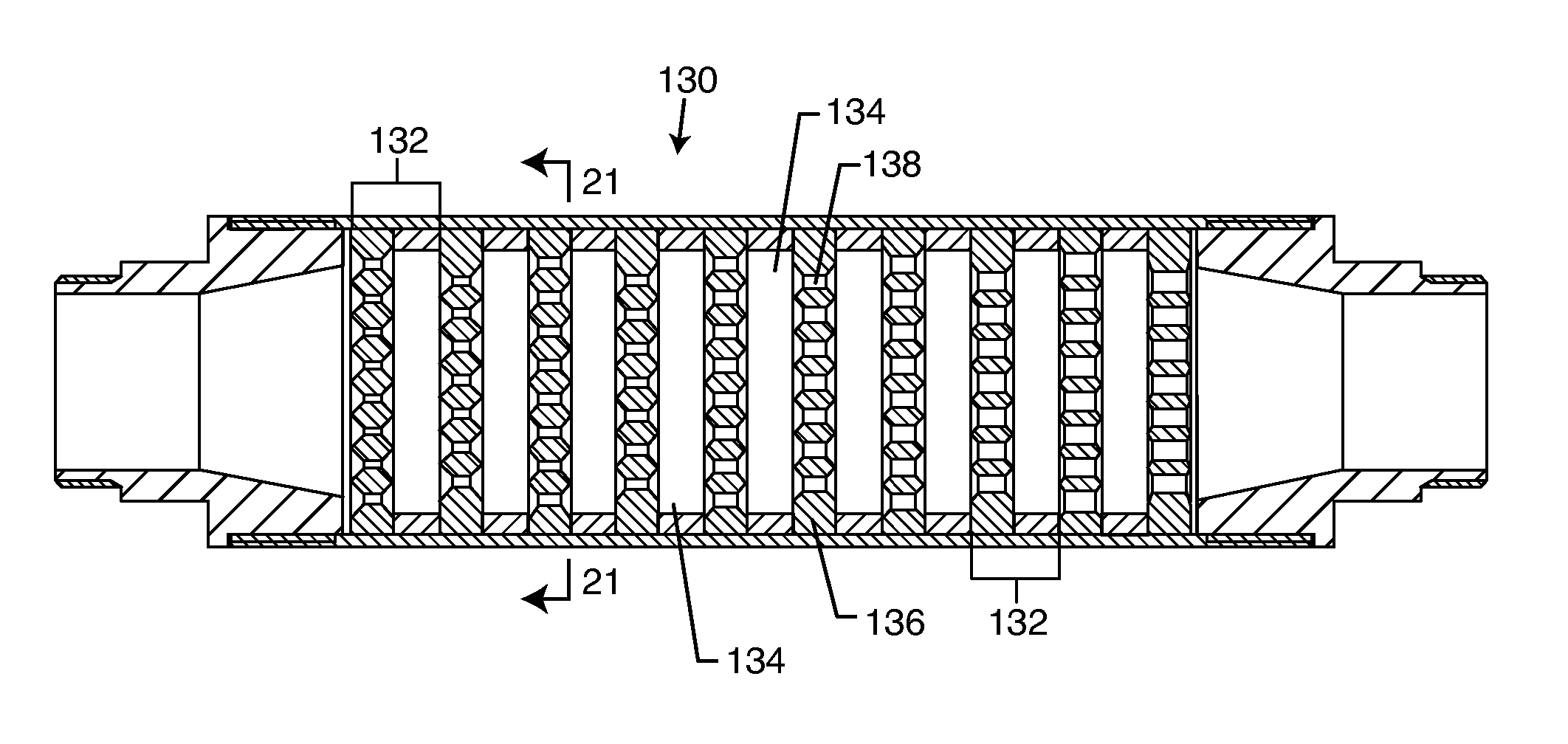

Flow-through cavitation-assisted rapid modification of crude oil

ActiveUS20100101978A1Improve effectivenessThermal non-catalytic crackingTreatment with plural serial cracking stages onlyCavitationChemical composition

A device and method are provided for manipulating petroleum, non-conventional oil and other viscous complex fluids made of hydrocarbons that comprise enforcement of fluid in a multi-stage flow-through hydrodynamic cavitational reactor, subjecting said fluids to a controlled cavitation and continuing the application of such cavitation for a period of time sufficient for obtaining desired changes in physical properties and / or chemical composition and generating the upgraded products. The method includes alteration of chemical bonds, induction of interactions of components, changes in composition, heterogeneity and rheological characteristics in order to facilitate handling, improve yields of distillate fuels and optimize other properties.

Owner:CAVITATION TECH

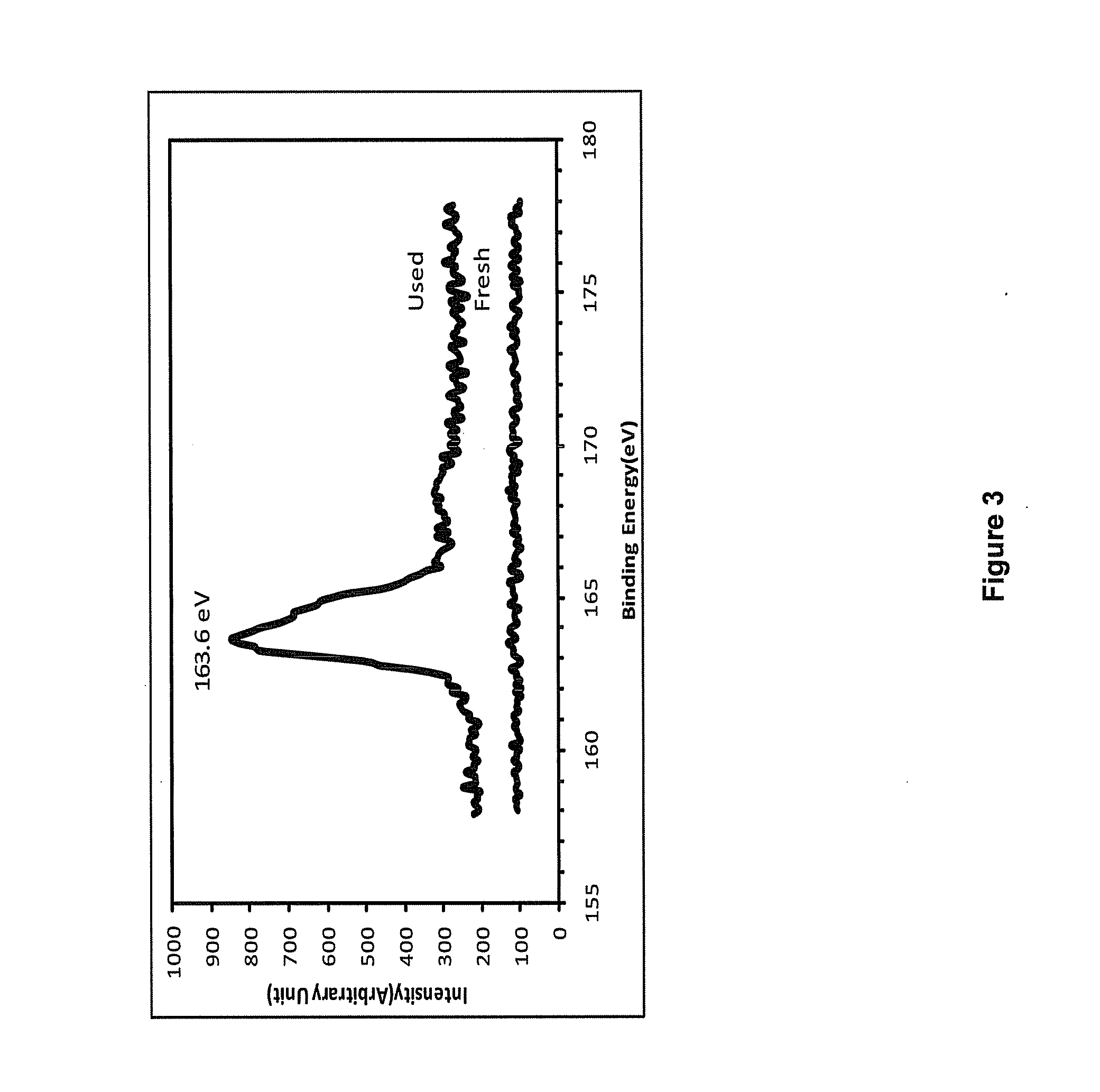

Petroleum Upgrading and Desulfurizing Process

ActiveUS20120181217A1Reduce dwell timeSmall sizeThermal non-catalytic crackingMolecular sieve catalystsSorbentWater flow

A petroleum feedstock upgrading method is provided. The method includes supplying a mixed stream that includes hydrocarbon feedstock and water to a hydrothermal reactor where the mixed stream is maintained at a temperature and pressure greater than the critical temperatures and pressure of water in the absence of catalyst for a residence time sufficient to convert the mixed stream into a modified stream having an increased concentration of lighter hydrocarbons and / or concentration of sulfur containing compounds. The modified stream is then supplied to an adsorptive reaction stage charged with a solid adsorbent operable to remove at least a portion of the sulfur present to produce a trimmed. The trimmed stream is then separated into a gas and a liquid streams, and the liquid stream is separated into a water stream and an upgraded hydrocarbon product stream.

Owner:SAUDI ARABIAN OIL CO

System for improving crude oil

InactiveUS20060231462A1Increase heightEnhancing crude oilThermal non-catalytic crackingSemi-permeable membranesAPI gravityFiltration

Crude oil can be refined through a filtration media. Cavitation bubbles having localized areas of very high temperatures and pressures may be created thereby causing several physical and chemical phenomena, including thermal cracking of carbon-carbon bonds as the crude moves through the flux cartridge membrane. Heavy hydrocarbons are residues are thereby cracked into smaller lowering boiling molecules having a higher API gravity. Once the relatively smaller hydrocarbons pass through the flux cartridge membrane into the flux cartridge, the effluent can be routed to a second separator annulus. It should also be pointed out that lighter hydrocarbons formed can volatilize and special provisions may be needed to efficiently capture these gases.

Owner:LJC TECH

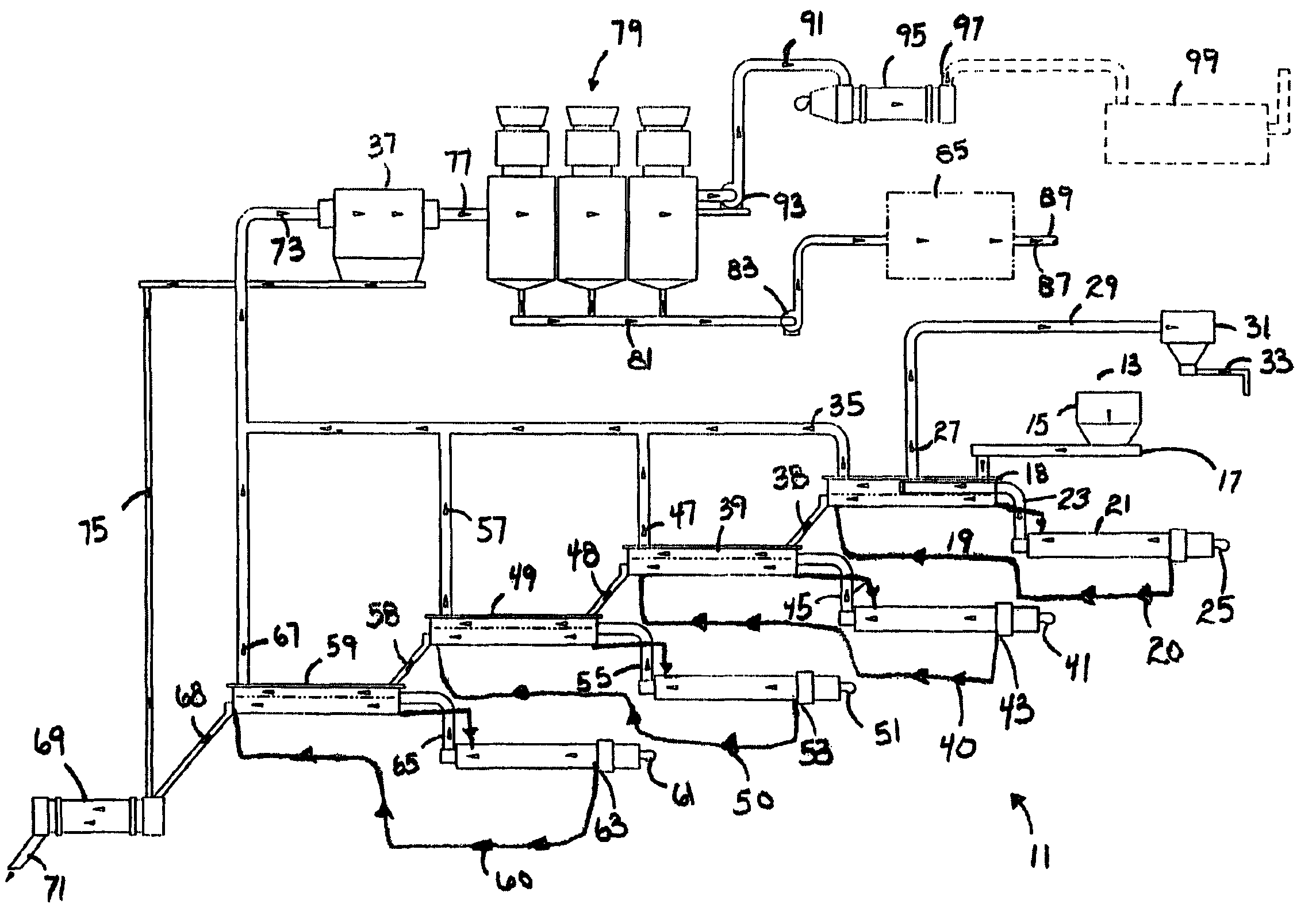

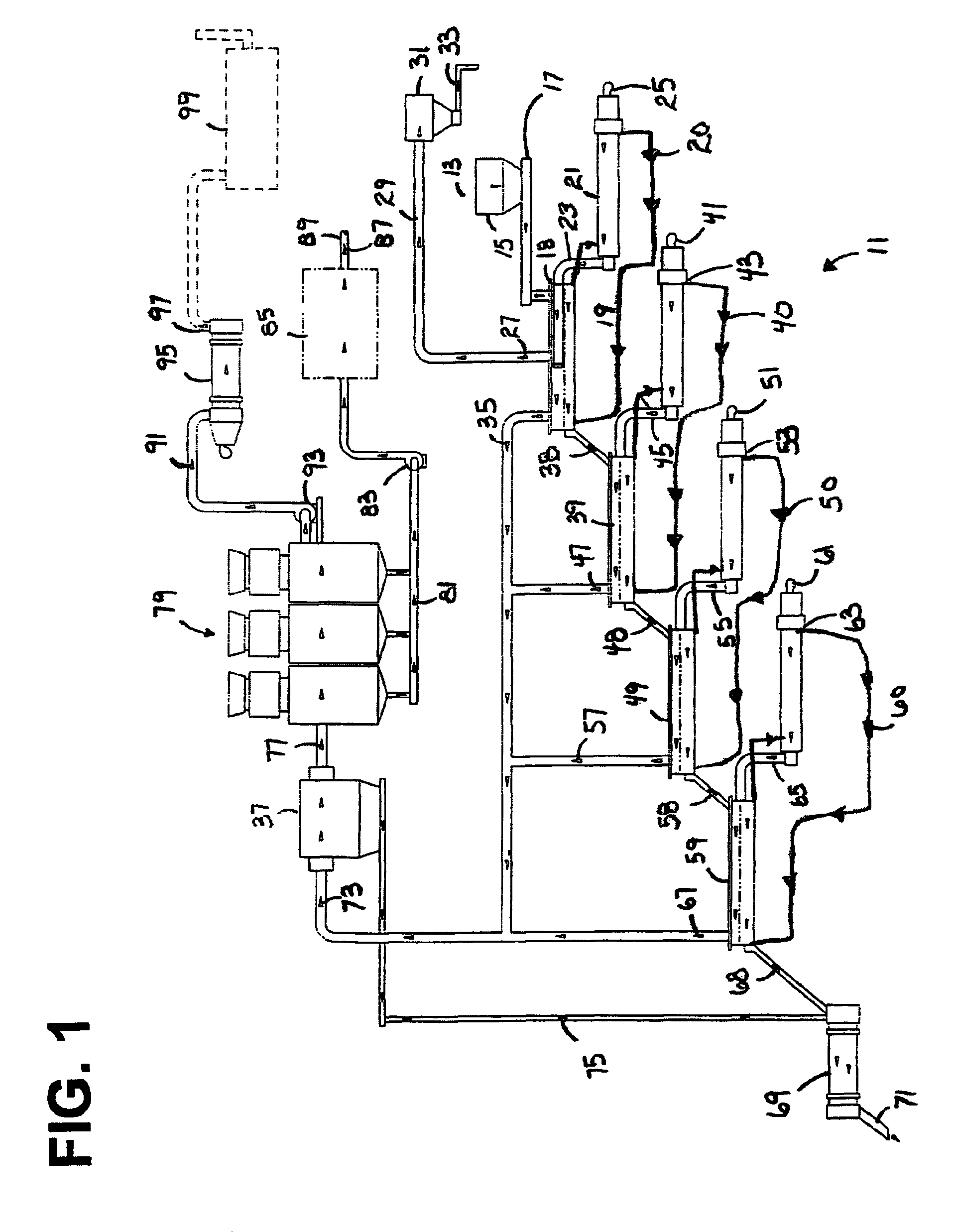

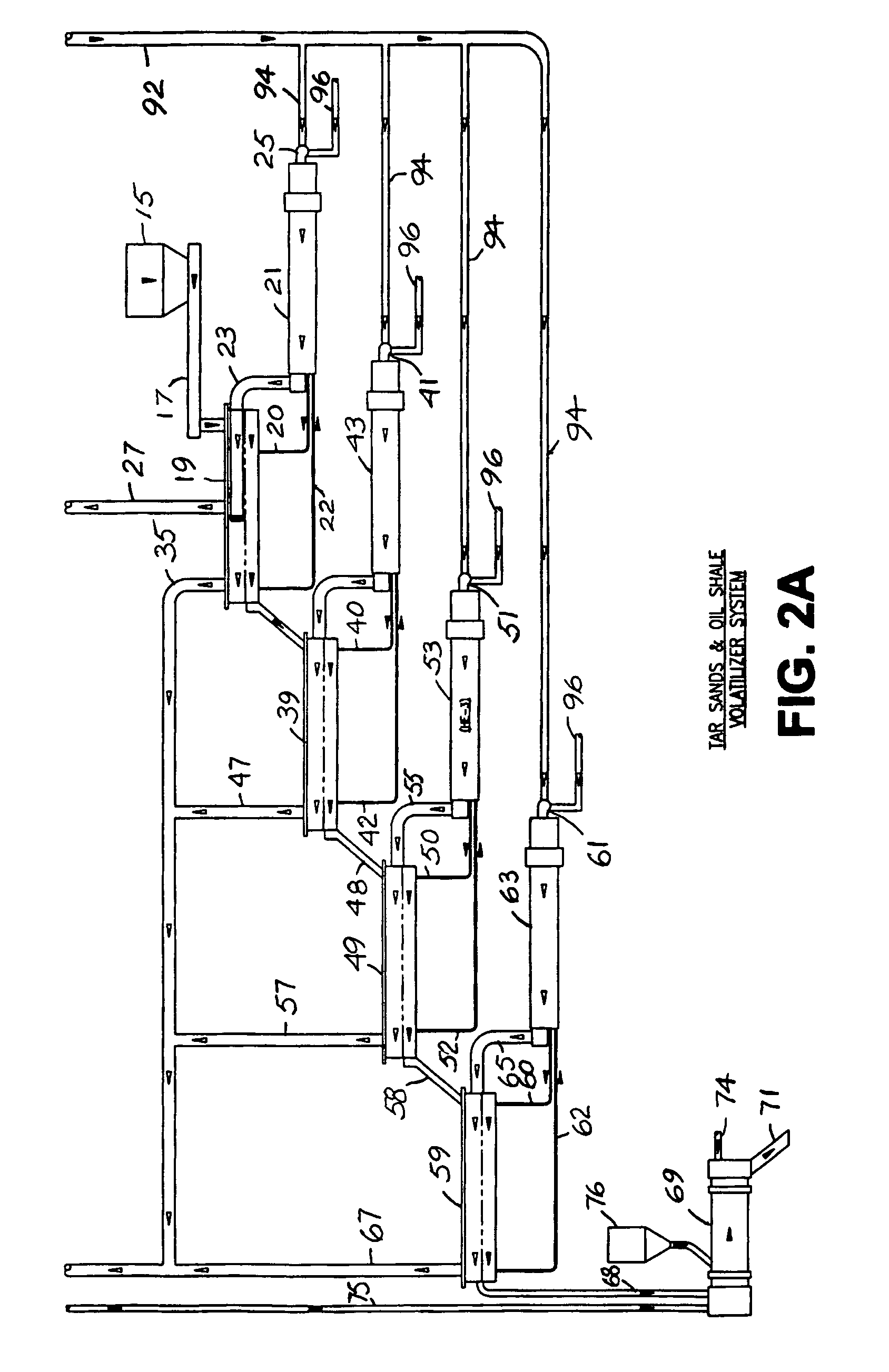

Thermal recovery of petroleum crude oil from tar sands and oil shale deposits

InactiveUS7807048B2Rule out the possibilityEliminate needHydrocarbon oil cracking processIndirect heating destructive distillationParticulatesFuel oil

A tar sand volatilizer system thermally removes petroleum crude oil from tar sands or shale oil. A series of heated augers or thermal screws are used to elevate material temperature gradually using conductive heat transfer. The thermal screws blades and auger case receive a heated fluid. The screws are driven by variable speed drive systems. The unit is sized for any throughput rate desired. Hot clean material discharges into a rotary cooler and re-hydrator unit. The exhaust gases are pulled through a high temperature filter collector for particulate removal. The particulate free petroleum vapor laden hot gas exits the filter house into a multi stage condenser system with water chillers where the vapor temperature is gradually cooled. A microwave upgrader system processes crude oil using catalyst injected microwave technology to produce a diesel like fuel oil in a continuous process stream.

Owner:COLLETTE JERRY R

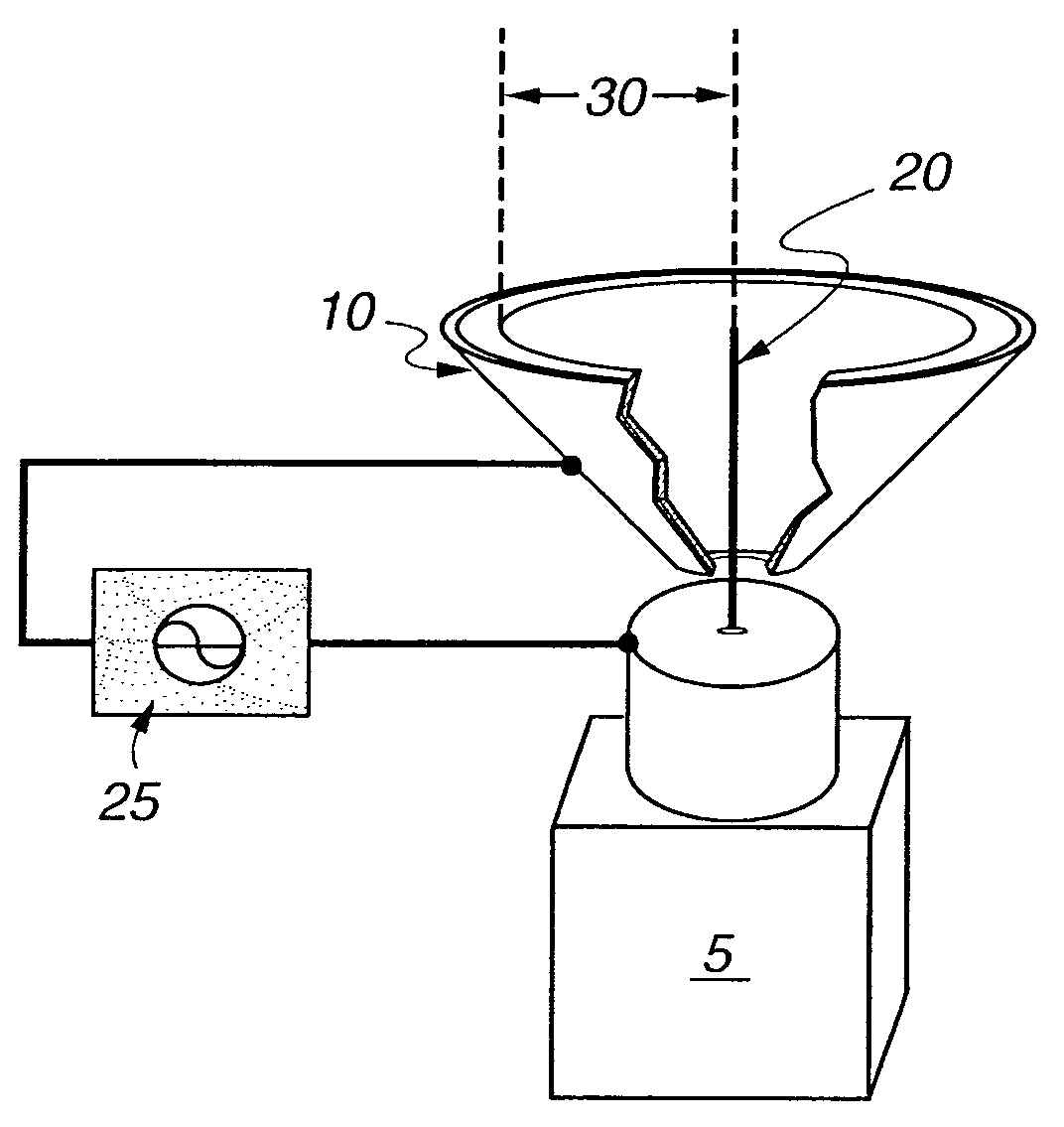

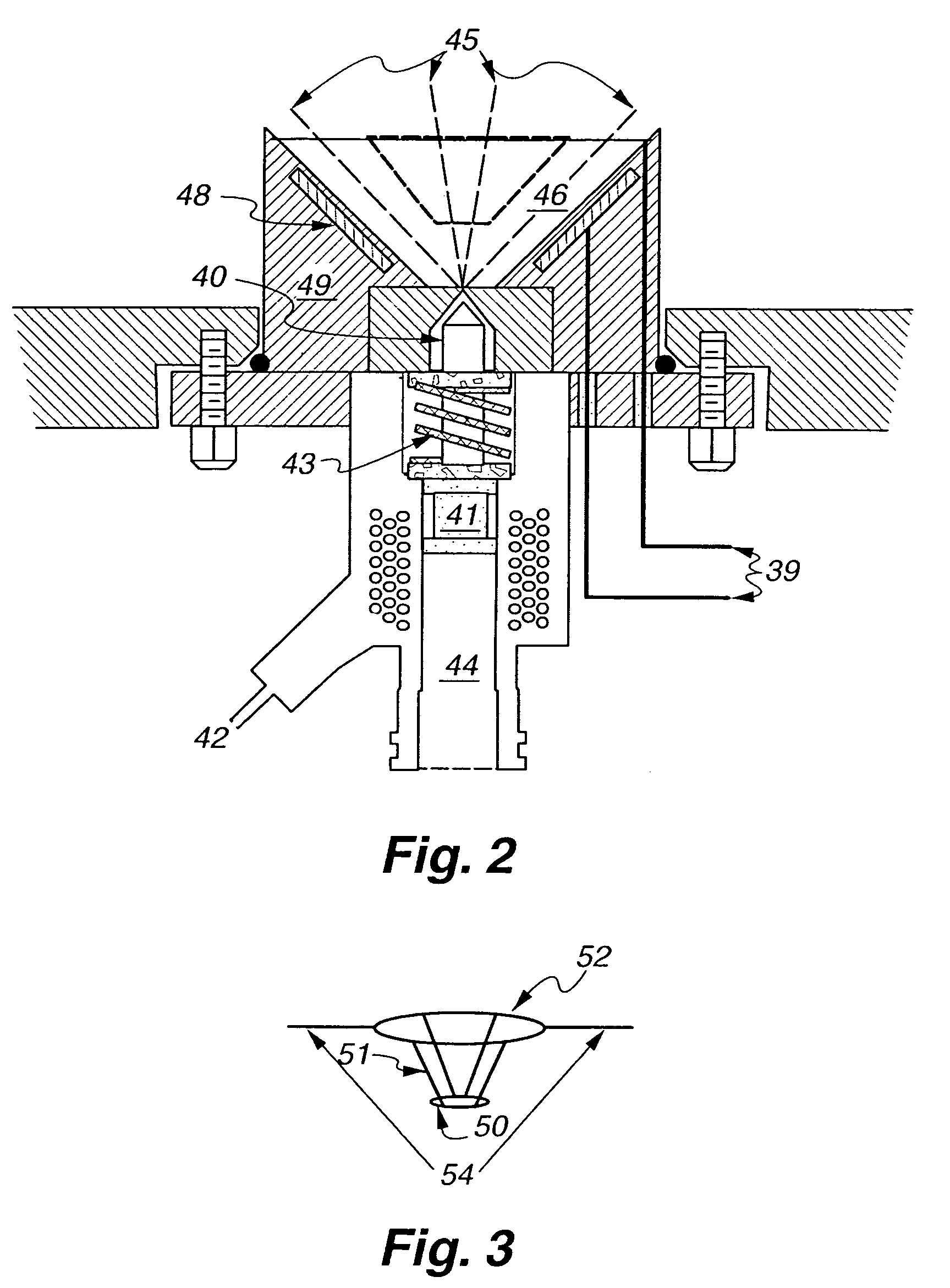

Fuel injector utilizing non-thermal plasma activation

A non-thermal plasma assisted combustion fuel injector that uses an inner and outer electrode to create an electric field from a high voltage power supply. A dielectric material is operatively disposed between the two electrodes to prevent arcing and to promote the formation of a non-thermal plasma. A fuel injector, which converts a liquid fuel into a dispersed mist, vapor, or aerosolized fuel, injects into the non-thermal plasma generating energetic electrons and other highly reactive chemical species.

Owner:LOS ALAMOS NATIONAL SECURITY

Popular searches

Hydrocarbons Treatment with hydrotreatment processes Distillation separation Liquid-gas reaction processes Refining by aromatic hydrocarbon hydrogenation Hydrocarbon by hydrocarbon cracking Hydrocarbon oils treatment products Liquid hydrocarbon mixture production Chemical/physical/physico-chemical stationary reactors Microwave heating

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com