Patents

Literature

31 results about "Type synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The six types of chemical reactions are synthesis, decomposition, single-replacement, double-replacement, acid-base, and combustion. Chemical reactions can be generalized by chemical groups. These groups are labeled A, B, C, and D. Synthesis and decomposition reactions occur when chemical groups combine or separate.

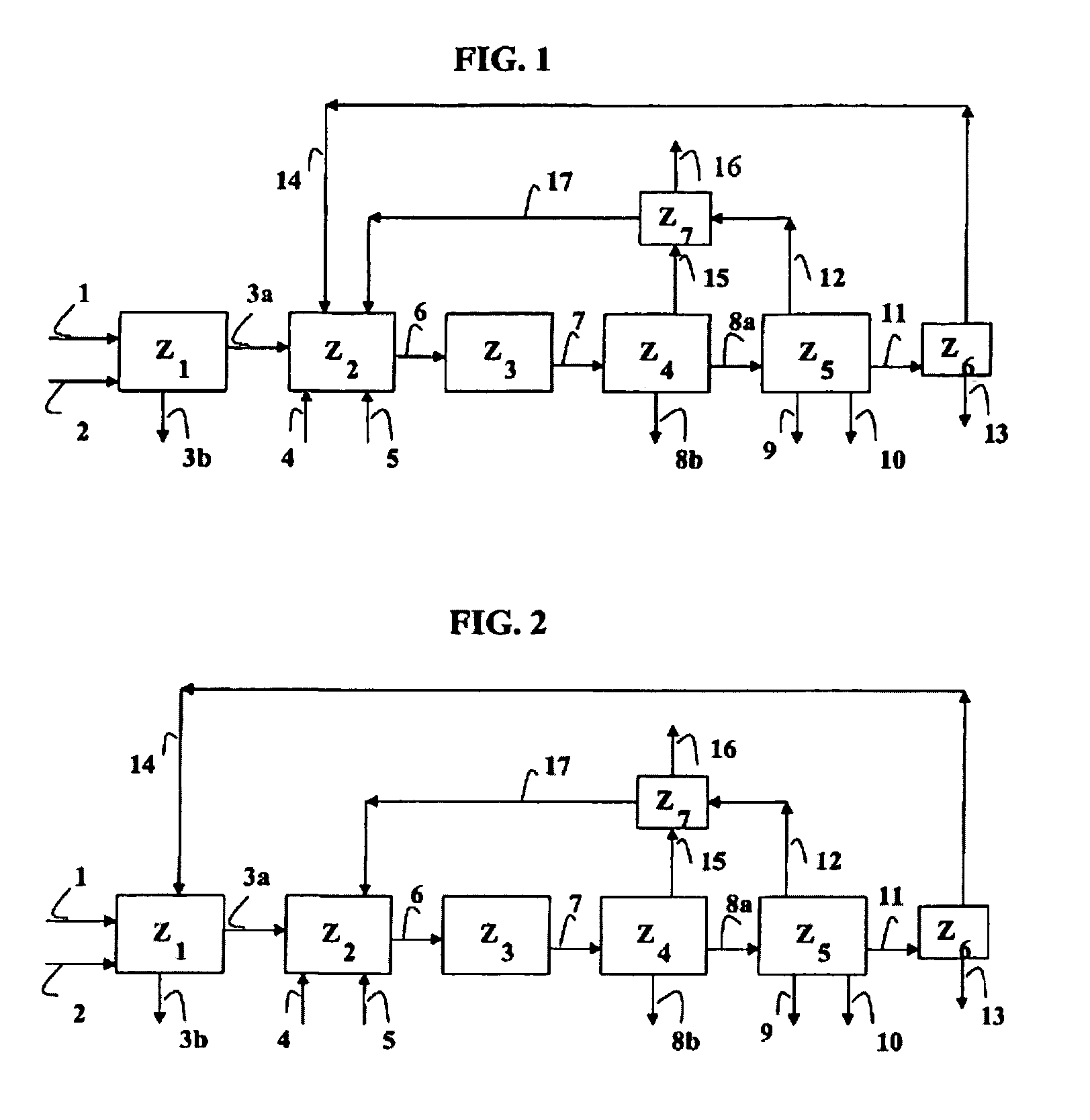

Production of liquid fuels by a concatenation of processes for treatment of a hydrocarbon feedstock

ActiveUS7214720B2Maximize conversion of carbonReduce and to upgrade naphthaThermal non-catalytic crackingCatalytic crackingNaphthaKerosene

The invention relates to an installation and a process for the production of liquid fuels starting from a solid feedstock that contains the organic material in which:a) the solid feedstock is subjected to a gasification stage so as to convert said feedstock into synthesis gas,b) the synthesis gas is subjected to a purification treatment,c) the purified synthesis gas is subjected to a conversion stage that comprises the implementation of a Fischer-Tropsch-type synthesis so as to convert said synthesis gas into a liquid effluent and a gaseous effluent,d) the liquid effluent is fractionated so as to obtain a gaseous fraction, a naphtha fraction, a kerosene fraction and a gas oil fraction, ande) at least a portion of the naphtha fraction is recycled in gasification stage a).

Owner:INST FR DU PETROLE +1

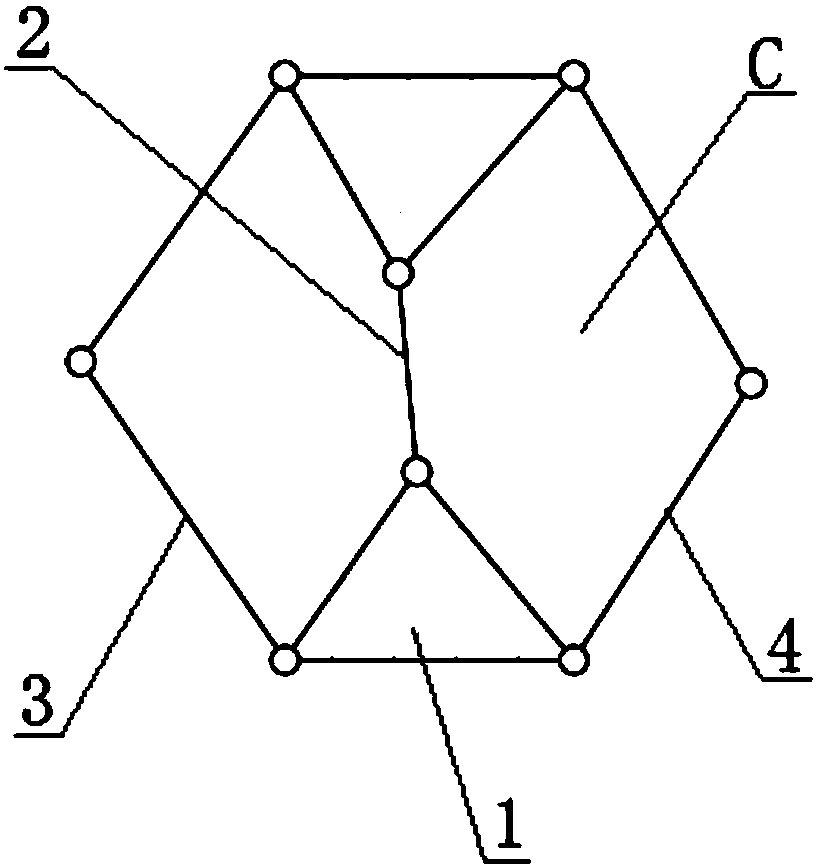

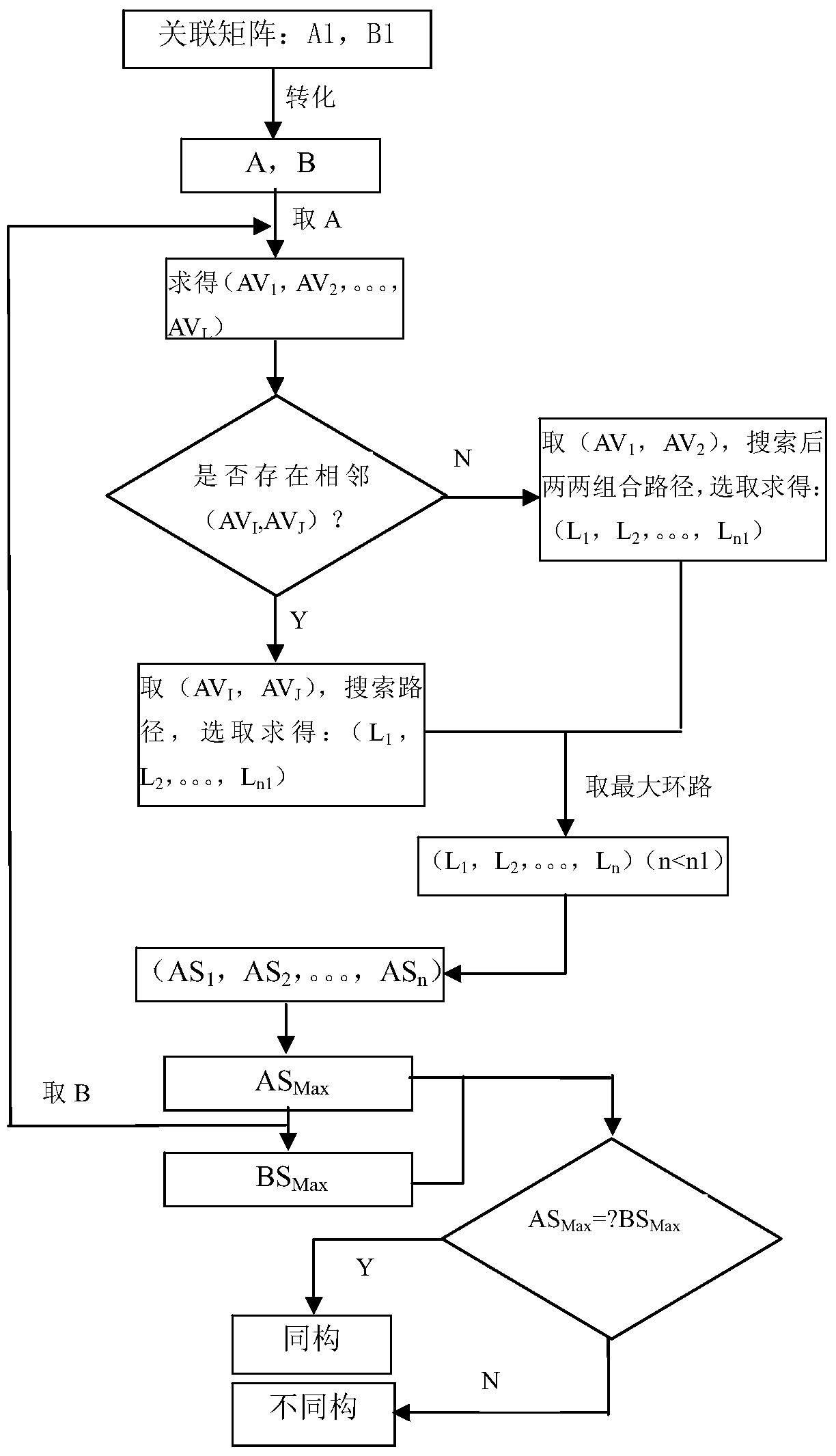

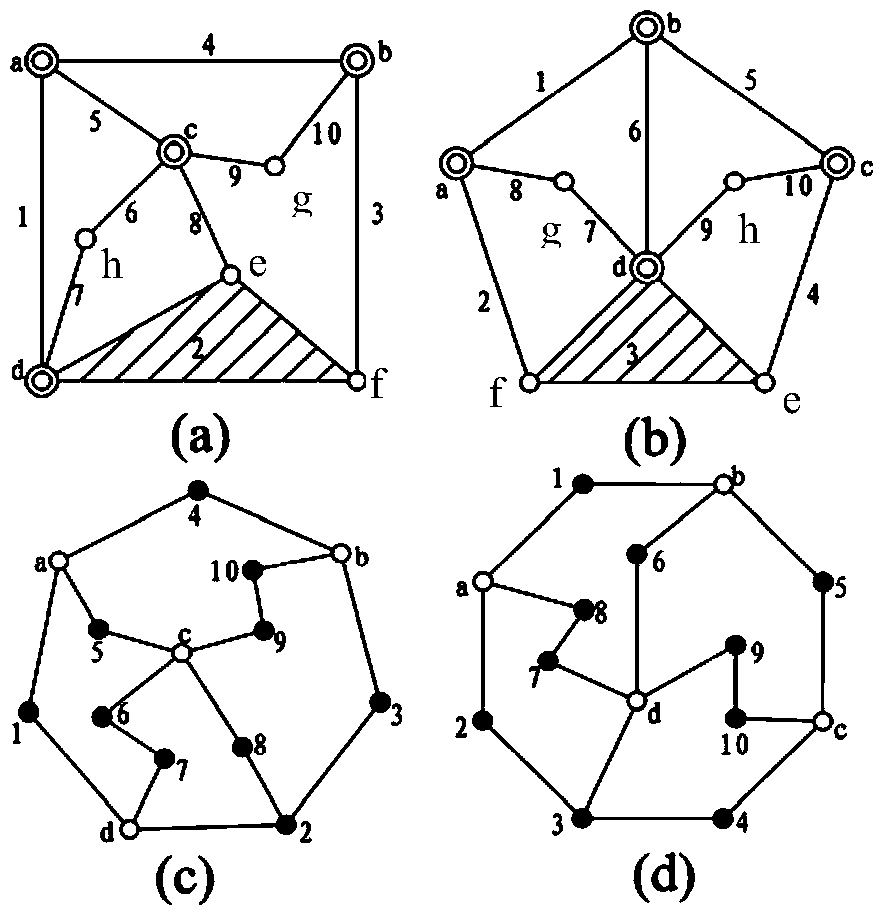

Isomorph identification method for complex-hinge-containing kinematic chains based on topological characteristic loop codes

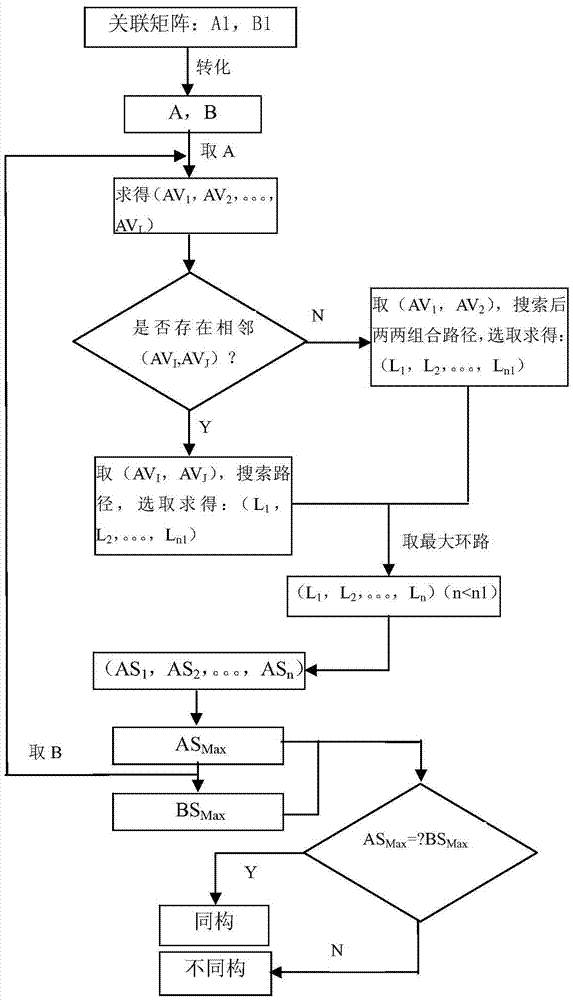

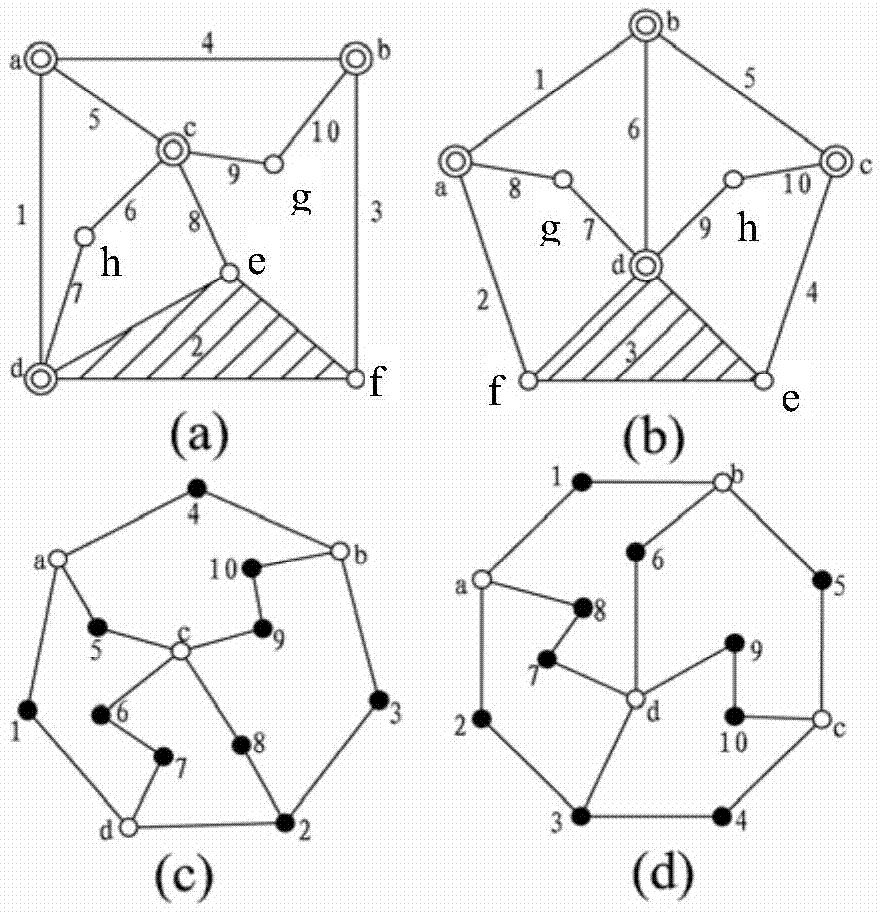

ActiveCN105447277AImprove automationGood isomorphic effectSpecial data processing applicationsTheoretical computer scienceKinematic chain

The invention provides an isomorph identification method for complex-hinge-containing kinematic chains based on topological characteristic loop codes. The isomorphic identification method comprises the following steps: first, calculating maximum loops of all excessive freedom degree vertexes according to a bi-color topological diagram adjacent matrix of the kinematic chains and to a corresponding algorithm; generating standardized bi-color topological diagram loop codes based on the maximum loops; taking the largest loop code as the topological characteristic loop code of the corresponding kinematic chain, wherein the topological characteristic loop code is in one-to-one correspondence with the kinematic chain, is unique, and represents the topological invariance of the kinematic chain; and finally, the purpose of isomorph identification can be realized via topological characteristic loop codes of two kinematic chains. The isomorph identification method has the advantages that calculation and simulation are conducted in an MATLAB; more than 3000 types of kinematic chains containing 10 or less complex hinges can be constructed when the isomorph identification method is combined with a corresponding type synthesis method; and results show that the isomorph identification method is practical, reliable and effective.

Owner:QUANZHOU INST OF EQUIP MFG

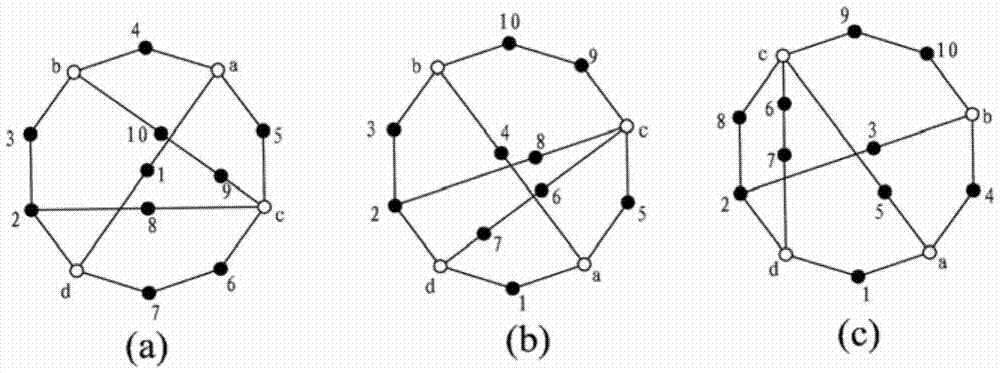

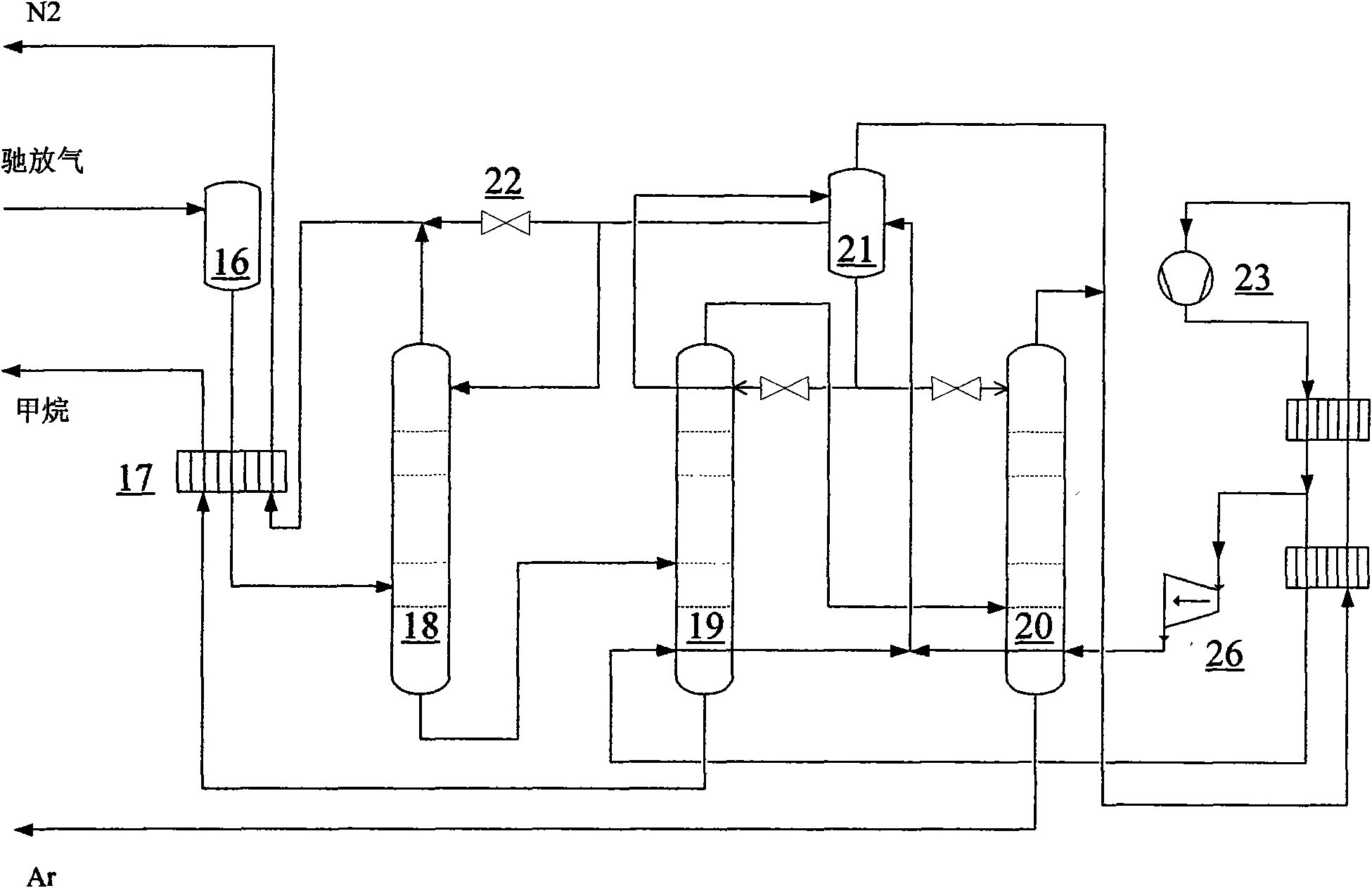

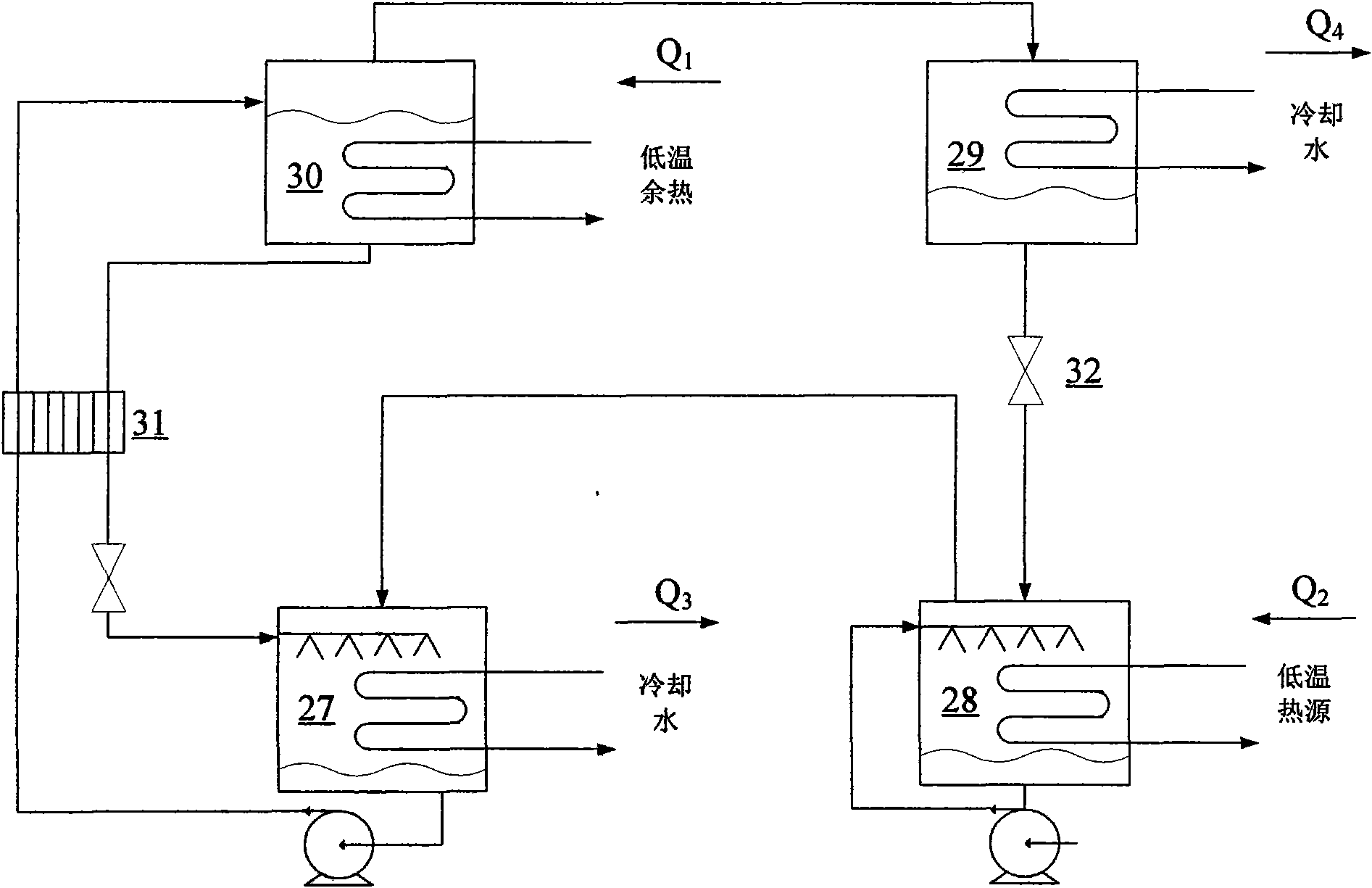

Natural gas type synthesis ammonia energy-saving and emission-reduction technology

InactiveCN101643220AEmission reductionReduce energy consumptionEnergy inputNoble gas compoundsProcess systemsCombined method

The invention discloses a natural gas type synthesis ammonia energy-saving and emission-reduction technology, which is characterized in that: a methodology of process systems engineering is adopted torealize mass-energy comprehensive integration, particularly comprising the following steps: carbon dioxide in one section of furnace flue gas is recovered by adopting a combined method of membrane separation and chemical adsorption; deeply cooling, distilling and recovering argon gas in purge gas of a hydrogen recovery device; a great quantity of low-temperature waste heat at the outlet positionof the top of a regenerating tower and an ice engine is recycled by adopting heat pump technology, so as to save cold of the ice engine and pre-heating boiler water; a similar device is used as a reference, the proposal is close to zero discharge, greenhouse gas emission load can be reduced by 50 percent to 100 percent, and carbon dioxide and argon gas are by-products at the same time, and the unit consumption of a product can reach 31GJ / tNH3, and compared with the original process, the energy saving can reach 5 percent to 15 percent. The technology is particularly suitable for the existing synthesis ammonia device which takes natural gas as raw material, so as to carry out energy-saving and emission-reduction technology reconstruction, the energy consumption of the natural gas type synthesis ammonia device based on the design of the proposal is the lowest level in the national similar devices.

Owner:董宏光 +1

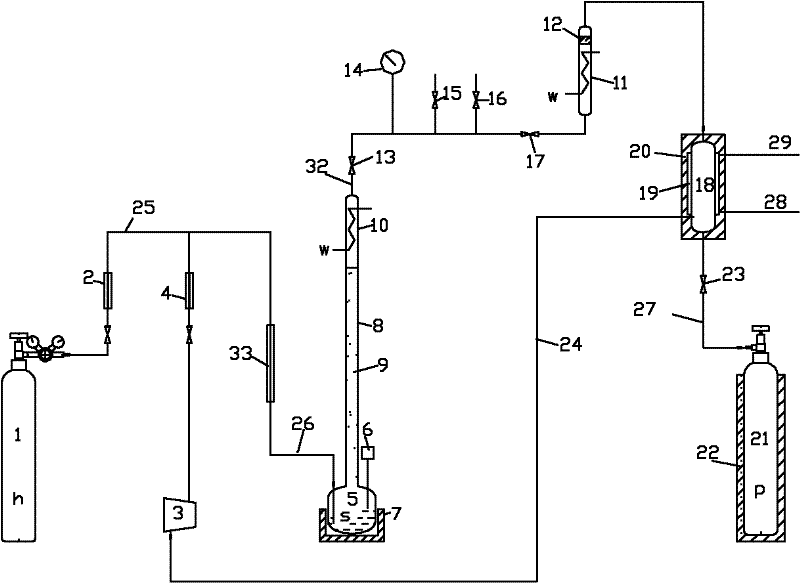

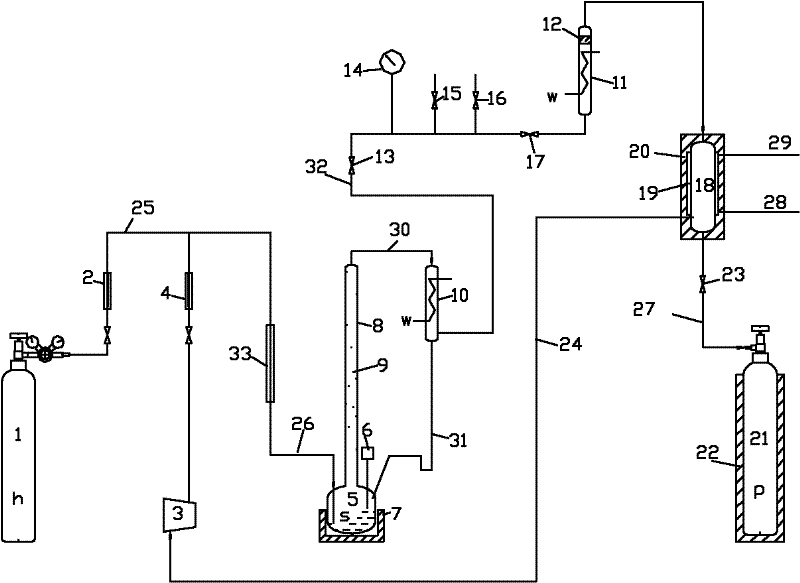

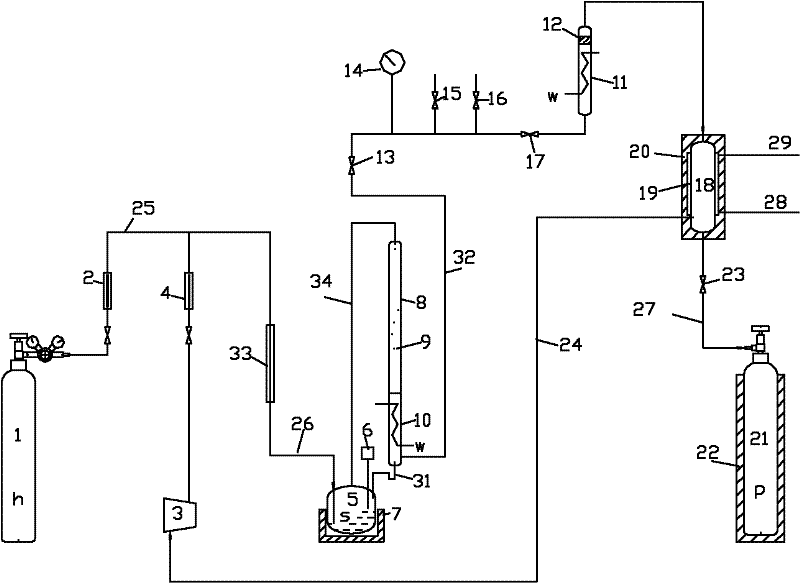

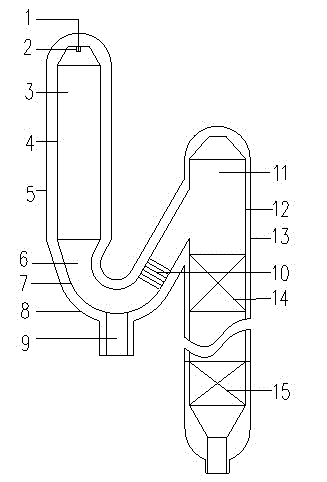

Hydrogen selenide preparation device and method

InactiveCN102674268ALarge surface areaIncrease the chance of meeting and respondingBinary selenium/tellurium compoundsHydrogenStream flow

Disclosed are a hydrogen selenide preparation device and a method. According to the method, the hydrogen selenide is directly synthesized by hydrogen and selenium(Se), a hydrogen inlet pipeline (26) is fed into a selenium liquefaction and vaporization device (5), a primary synthetic reaction between the hydrogen and the selenium is started, synthesized an H2Se / Se / H2 mixing gas-liquid stream is fed into a filling tower-type synthesis reactor (8) and subjected to a continuous synthetic reaction, the Se in a selenium condensation separator (10) is condensed into liquid, then is separated and flows back to the synthesis reactor or the selenium liquefaction and vaporization device for continuing reacting, an H2Se / H2 mixing gas stream flows into a hydrogen selenide condensation separator (18), non-condensable gas hydrogen in the hydrogen selenide condensation separator is separated and conveyed back to the hydrogen inlet pipeline (26), the non-condensable gas hydrogen and the hydrogen are combined for supplying hydrogen, and finally, the H2Se is condensed and collected in the hydrogen selenide condensation separator.

Owner:DALIAN LIFANG CHEM TECH

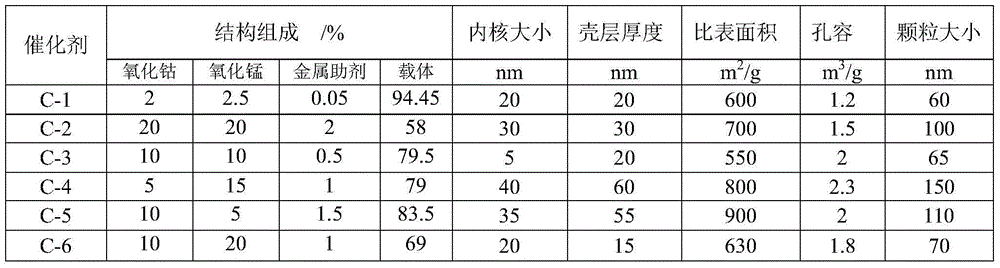

Catalyst for directly manufacturing low-carbon olefin through nuclear shell type synthesis gas and preparation method and application

ActiveCN104888838AShort crystallization timeShort processing cycleHydrocarbon from carbon oxidesMolecular sieve catalystsActive componentManganese oxide

The invention discloses a catalyst for directly manufacturing low-carbon olefin through nuclear shell type synthesis gas. The catalyst is prepared from active components, auxiliaries and a carrier in weight percent as follows: 2.0-20% of cobalt oxide, 2.5-20% of manganese oxide, 0.05-2.0% of metal additive oxide, and 58-95% of carrier. The catalyst disclosed by the invention is high in selectivity, and capable of greatly reducing the CO2 selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Synthesis gas preparing system and method

ActiveCN107868962ALarge specific surface areaImprove conversion efficiencyCellsElectrolysisChemistry

The invention discloses a synthesis gas preparing system and method. The synthesis gas preparing system comprises a solid oxide electrolytic tank, a feed gas supply system, a fused salt supply systemand a synthesis gas mixing chamber. The solid oxide electrolytic tank comprises a cathode, an anode and an electrolyte. The cathode is in contact with feed gas, and the anode is in contact with the fused salt mixed with carbon powder and a catalyst. According to the synthesis gas preparing system and method, coupling of a solid oxide electrolytic tank technology and a coal gasification technologyis achieved, O2 generated in the electrolysis / co-electrolysis reaction process is subjected to coal gasification reaction with the carbon powder to generate CO, the high temperature fused salt is utilized to serve as a dispersing agent of the carbon powder, the specific surface area of the coal gasification reaction is enlarged, accordingly the transformation efficiency and the yield of the synthesis gas are improved, energy consumption per unit output is reduced, and the specific proportion of needed synthesis gas can be further adjusted. The synthesis gas preparing system and method are suitable for distributed type synthesis gas production factories, and have the characteristics of being high in energy efficiency, simple in operation, high in safety, capable of being produced in batches and the like.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

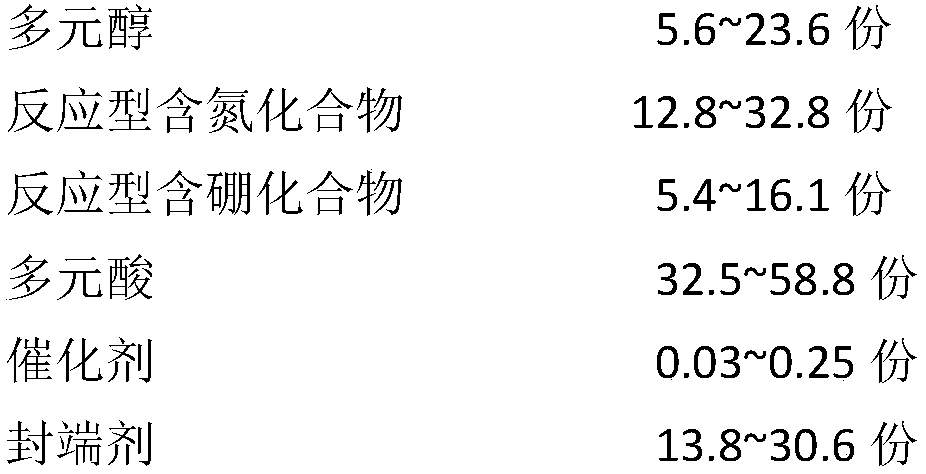

N-B synergistic high-flame-resistance type curing agent and synthesis method thereof

ActiveCN108424513AAchieve flame retardant optimizationPromote crystallizationSynthesis methodsReaction temperature

The invention relates to an N-B synergistic high-flame-resistance type curing agent and a synthesis method thereof. The N-B synergistic high-flame-resistance type curing agent is prepared from polyol,a reaction type nitrogen-containing compound, a reaction type boron-containing compound, polybasic acid, a catalyst and an end-capping agent by a sectional type synthesis method and by adjusting theproportion of the components, the reaction temperature and the reaction time. In the curing agent, the acid value range is 80 to 180 mgKOH / g, the melt viscosity range is 800 to 6000 mPa*s / 180 DEG C, the softening point range is 75 to 125 DEG C, the N content range is 1.9 to 4.8 percent by weight and the B content range is 0.35 to 1.05 percent by weight. The curing agent has a nitrogen (N) and boron (B) flame-resistant element non-migratory and multi-branched structure, so that the curing agent has excellent flame resistance and flame-resistant durability, is easy to crystallize, low in viscosity and easily compatible, is applied to an electronic packaging material and can realize zero halogen, zero phosphorus, flame resistance and excellent flame-resistant durability of the electronic packaging material.

Owner:吴天航

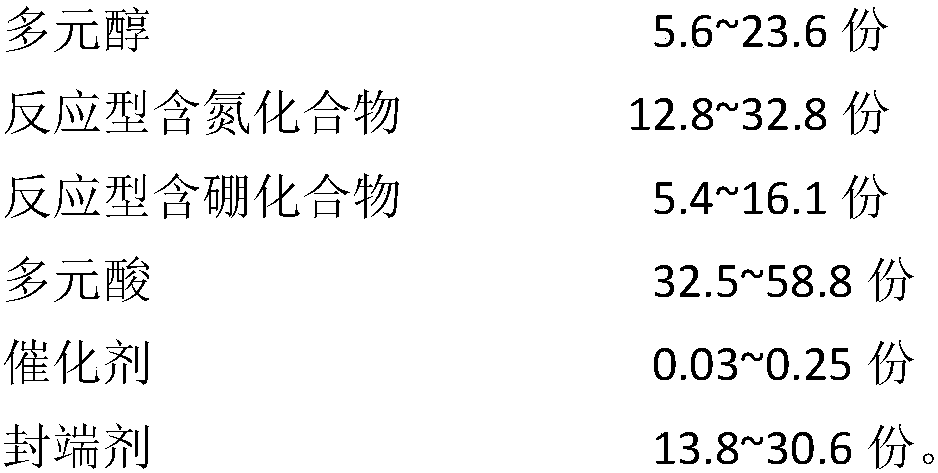

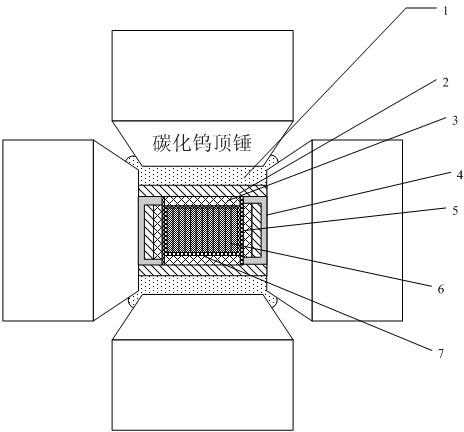

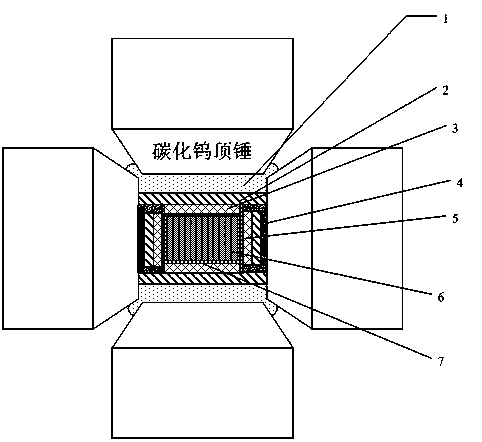

Indirect heating-type synthesis assembly for high-temperature and high-pressure artificial single crystal synthesis by using cubic press

InactiveCN102600768AImprove stabilityIncrease temperatureUltra-high pressure processesPyrophylliteNiobium

The invention relates to an indirect heating-type synthesis assembly for single crystal synthesis by using a cubic press. The indirect heating-type synthesis assembly comprises pyrophyllite powder pressing block which is internally lined with a dolomite casing. The indirect heating-type synthesis assembly is characterized in that a cylindrical metal cup made of metal niobium, tantalum, molybdenum or tungsten is arranged in the dolomite casing, an aluminum oxide ceramic high-temperature pipe is wrapped outside the cylindrical metal cup and the aluminum oxide ceramic high-temperature pipe is made of alpha-aluminum oxide and talc through high-temperature sintering; metal conducting strips are respectively arranged on the two sides of the metal cup and are connected with the metal cup; and the two ends of the dolomite casing are respectively sealed by composite conducting plugs and the composite conducting plugs are connected with the metal conducting strips. The indirect heating-type synthesis assembly uses high-melting-point metals to make the metal cup which is also used as an electric heating element, aluminum oxide ceramic materials are additionally used for making the high-temperature protection pipe, the indirect heating-type synthesis assembly is suitable for synthesizing artificial single crystals such as diamonds by using the cubic press, the requirements of higher temperature and longer heating time are satisfied, the stability of single crystal synthesis technology and equipment is improved, the losses of anvils are reduced and favorable conditions are provided for the synthesis of gem grade diamonds.

Owner:常熟市怡华金刚石有限公司 +1

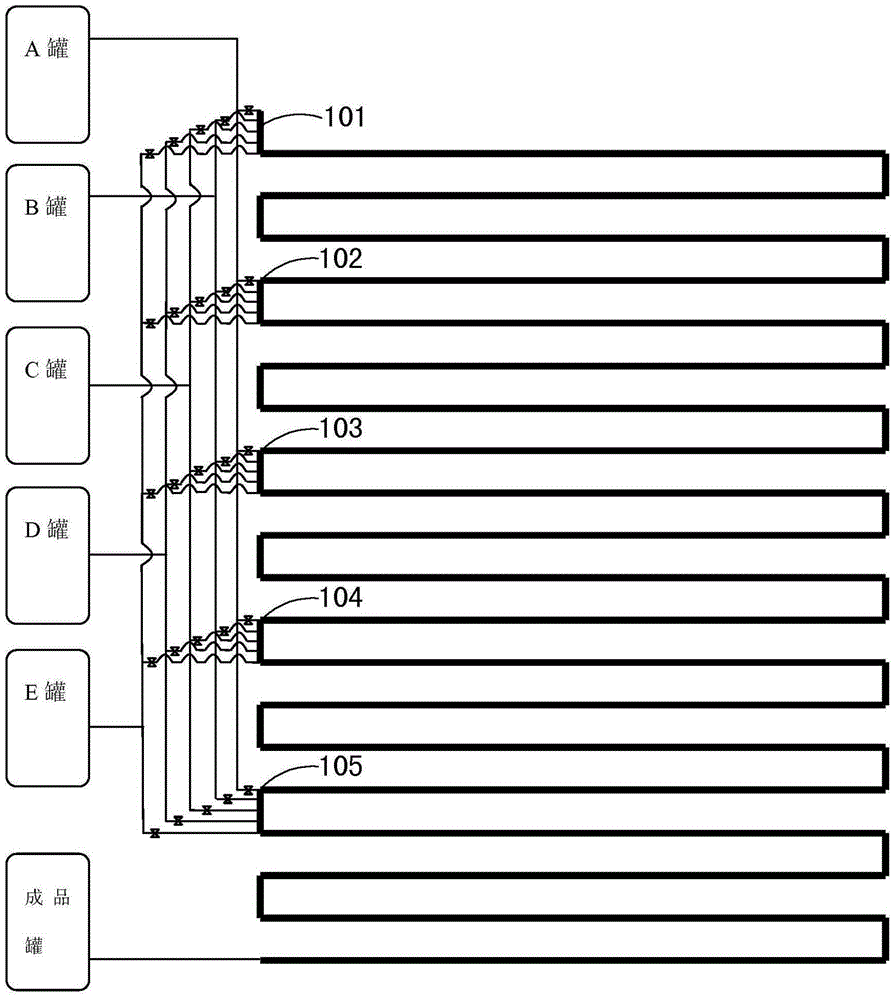

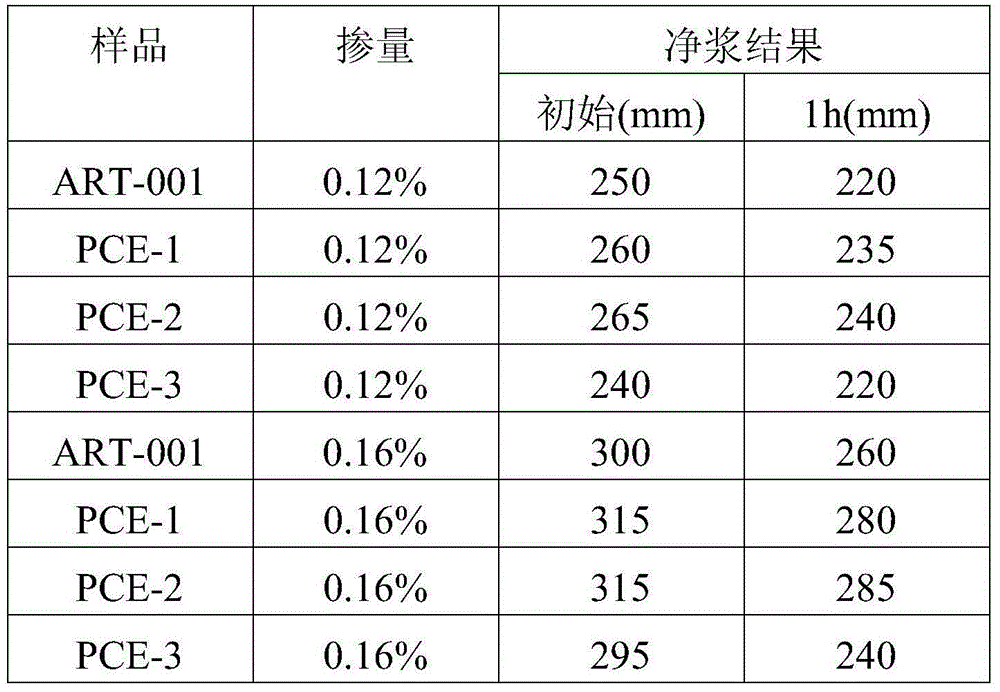

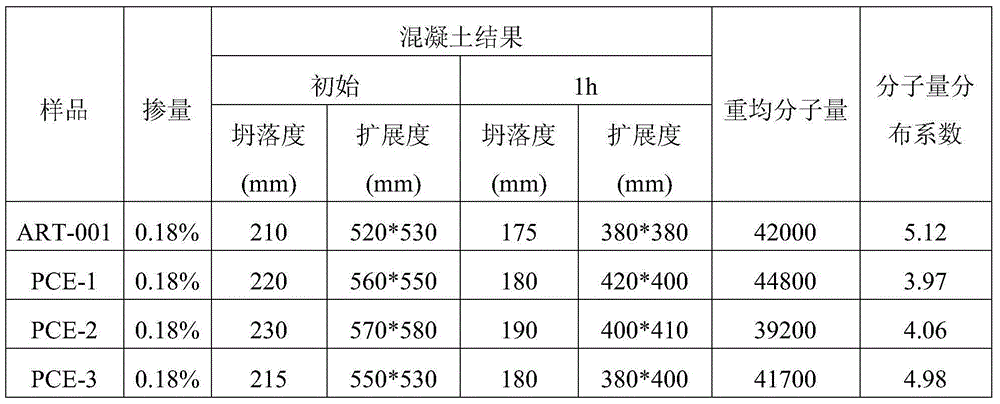

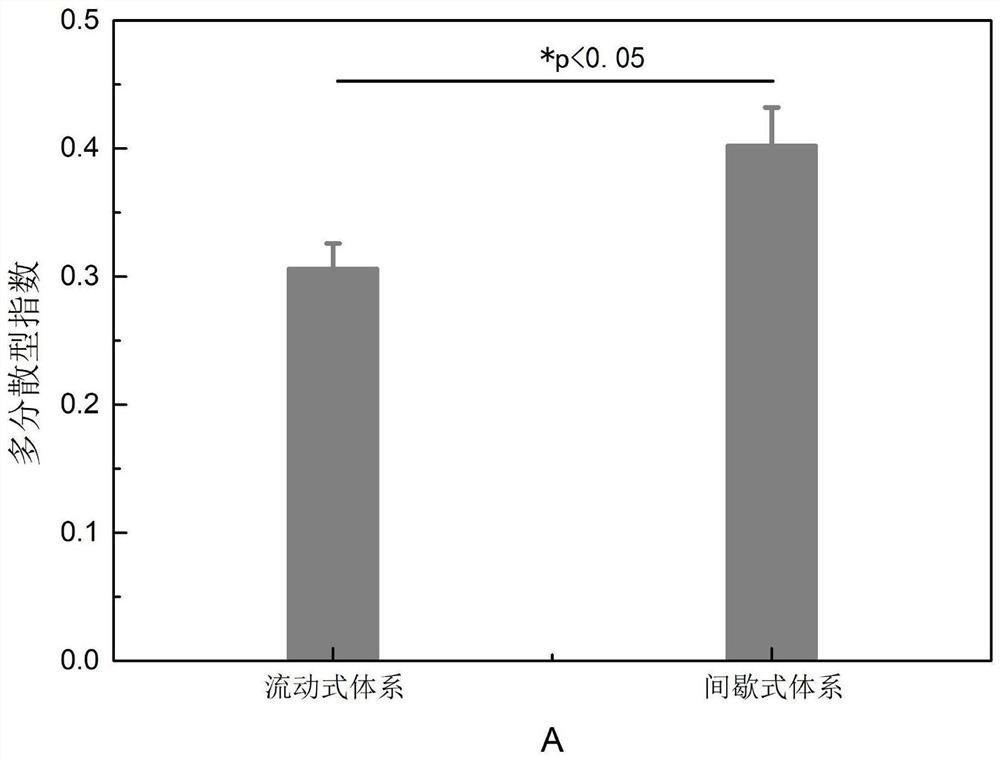

Method for continuous synthesis of polycarboxylic acid water reducer

The invention provides a method for continuous synthesis of a polycarboxylic acid water reducer. The method comprises providing a tubular reactor with a first feeding point, a second feeding point, a third feeding point, a forth feeding point and a fifth feeding point, continuously adding a mixed raw material to the first feeding point, the second feeding point, the third feeding point, the forth feeding point and the fifth feeding point according to a ratio and carrying out a reaction process to obtain the polycarboxylic acid water reducer. The mixed raw material comprises an unsaturated polyether macromonomer, an acrylic acid monomer, an initiator and a chain transfer agent. The method well controls a polycarboxylic acid water reducer synthesis process. The polycarboxylic acid water reducer has product performances better than those of the existing water reducer product prepared through a batch-type synthesis method and has a narrow molecular weight distribution range.

Owner:LIAONING OXIRANCHEM INC

Inflaming-retarding epoxy resin for electronic packaging material and copper-clad plate and synthesis method thereof

ActiveCN102260403AImprove flame resistanceImprove water resistanceFireproof paintsOther chemical processesEpoxyNitrogenous heterocyclic compound

The invention provides an inflaming-retarding epoxy resin for an electronic packaging material and a copper-clad plate and a synthesis method thereof. In the invention, the inflaming-retarding epoxy resin for the electronic packaging material and the copper-clad plate is prepared from liquid epoxy resin, polycyclic diphenol / polycyclic dicarboxylic acid, organic boric acid and a nitrogen-containing heterocyclic compound by using a sectional type synthesis method in the presence of a catalyst through controlling reaction temperature, reaction time and other conditions, wherein the epoxide number of the epoxy resin is 0.05-0.2eq / 100g, the softening point of the epoxy resin is 70-130 DEG C, the nitrogen content of the epoxy resin is 0.5-5wt%, and the boron content of the epoxy resin is 0-1.6wt%. According to the invention, the inflaming-retarding property and water tolerance of the epoxy resin are further improved through combining the flame resistance of condensed ring or biphenyl and inflaming-retarding properties of nitrogen-containing heterocyclic ring and organic boron, thereby meeting the non-halogen non-phosphorus requirements of an electronic component packaging material and a copper-clad plate.

Owner:天津凯华绝缘材料股份有限公司

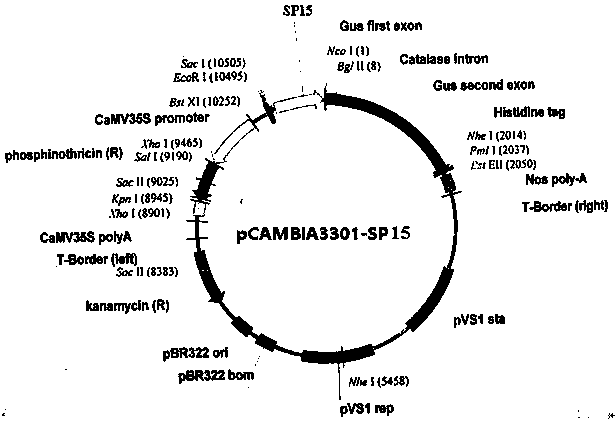

Plant drought induced type synthesis promoter SP15 and application thereof

ActiveCN109837278ASolve the problem of not being able to fine-tune genesVector-based foreign material introductionAngiosperms/flowering plantsNucleotideNucleotide sequencing

The invention discloses a plant drought induced type synthesis promoter SP15. The nucleotide sequence of the plant drought induced type synthesis promoter SP15 is shown as SEQID No.1. A plant expression vector is formed by that a nucleotide sequence as shown in the SEQID No.1 is inserted to a vector plasmid. The invention further relates to an application of the promoter SP15 to breeding of drought resisting genetically-modified plant, and belongs to an artificially synthesized promoter. The expression situation of the SP15 promoter driving report genes GUS identified in a soybean hairy root transformation system indicates that the SP15 promoter can be induced by drought stress, and the expression intensity is equivalent to a CaMV 35s promoter.

Owner:JILIN AGRICULTURAL UNIV

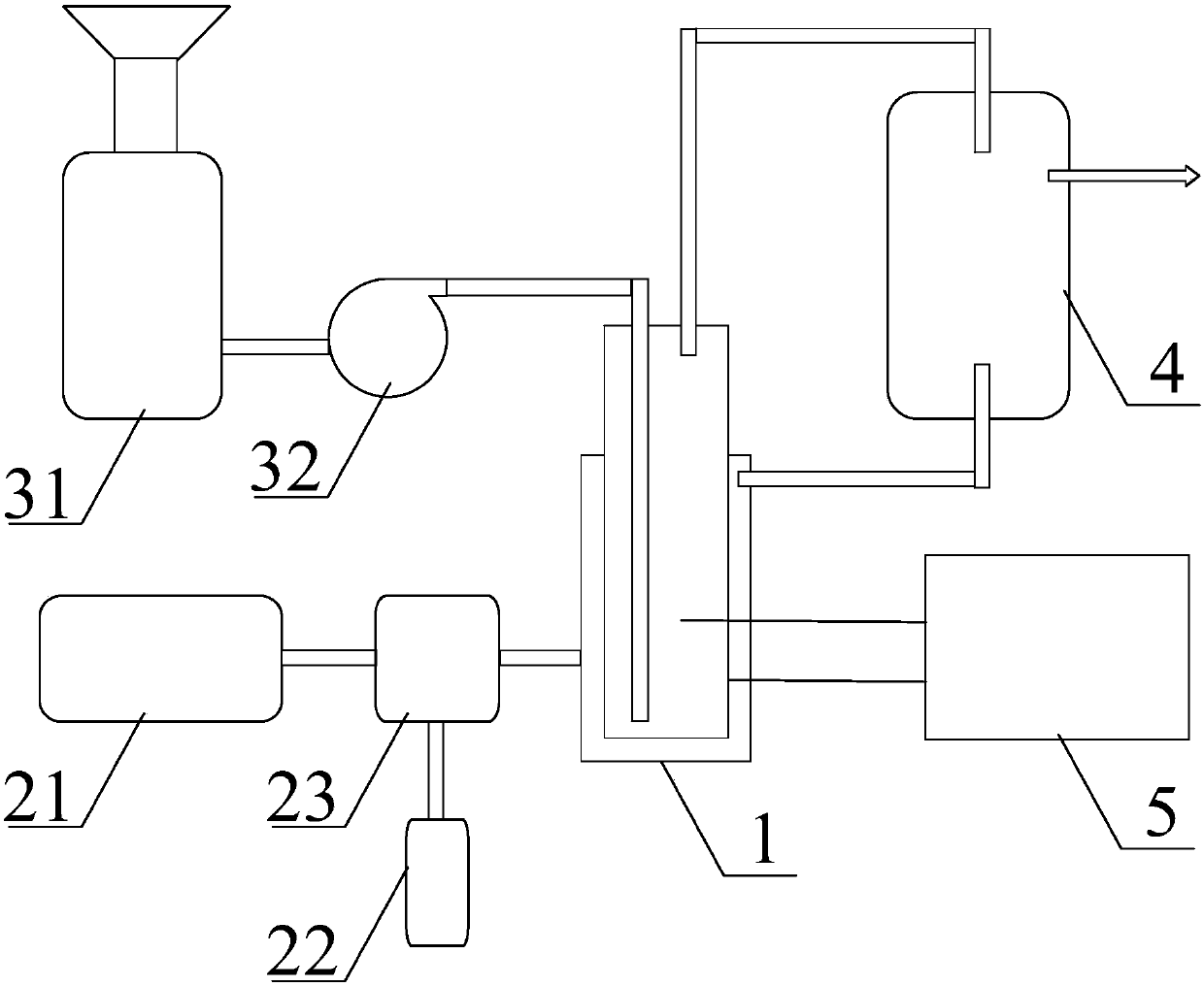

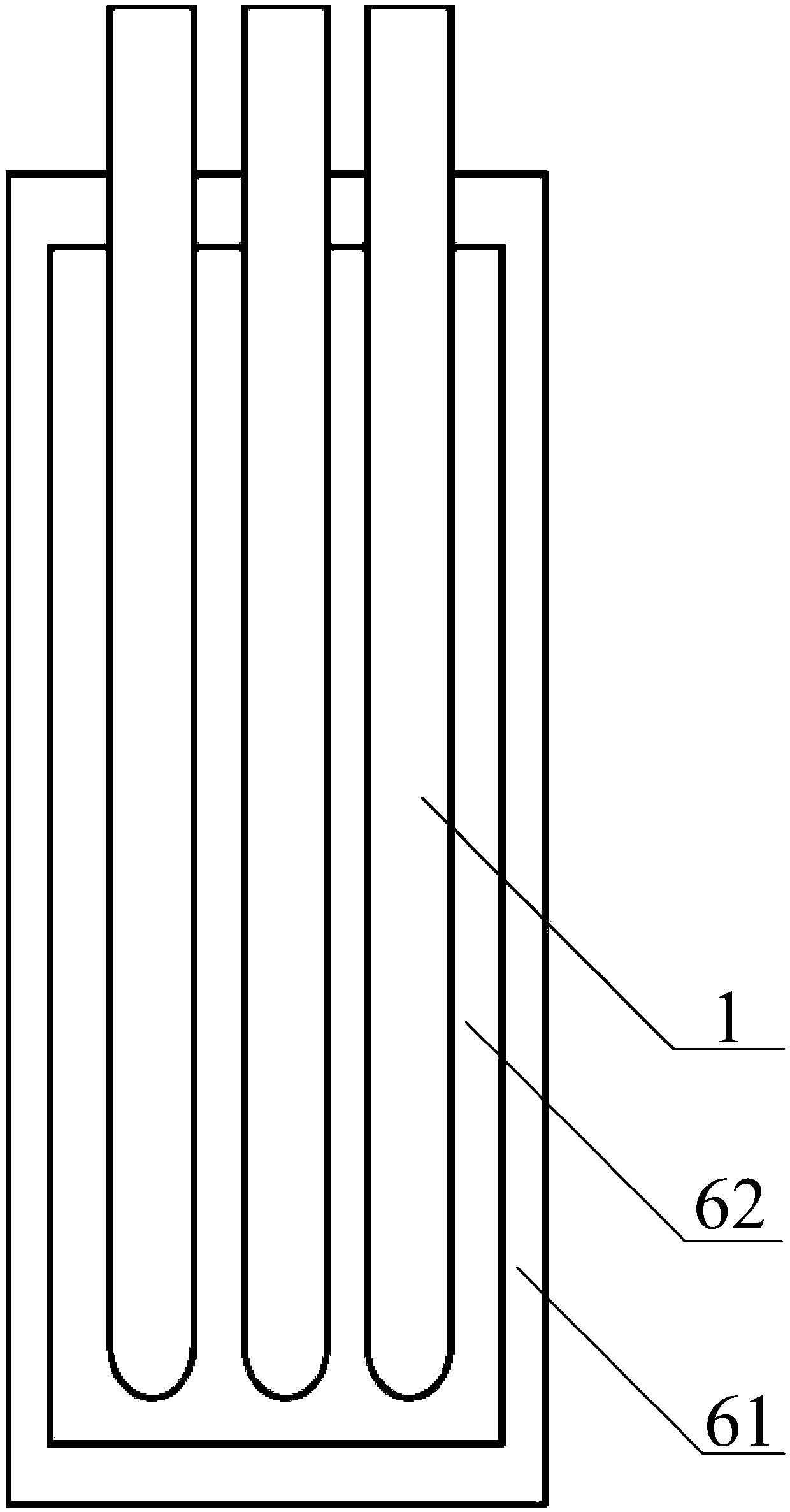

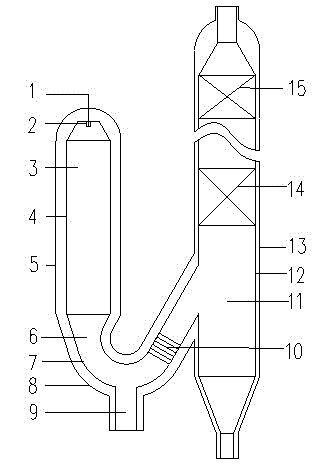

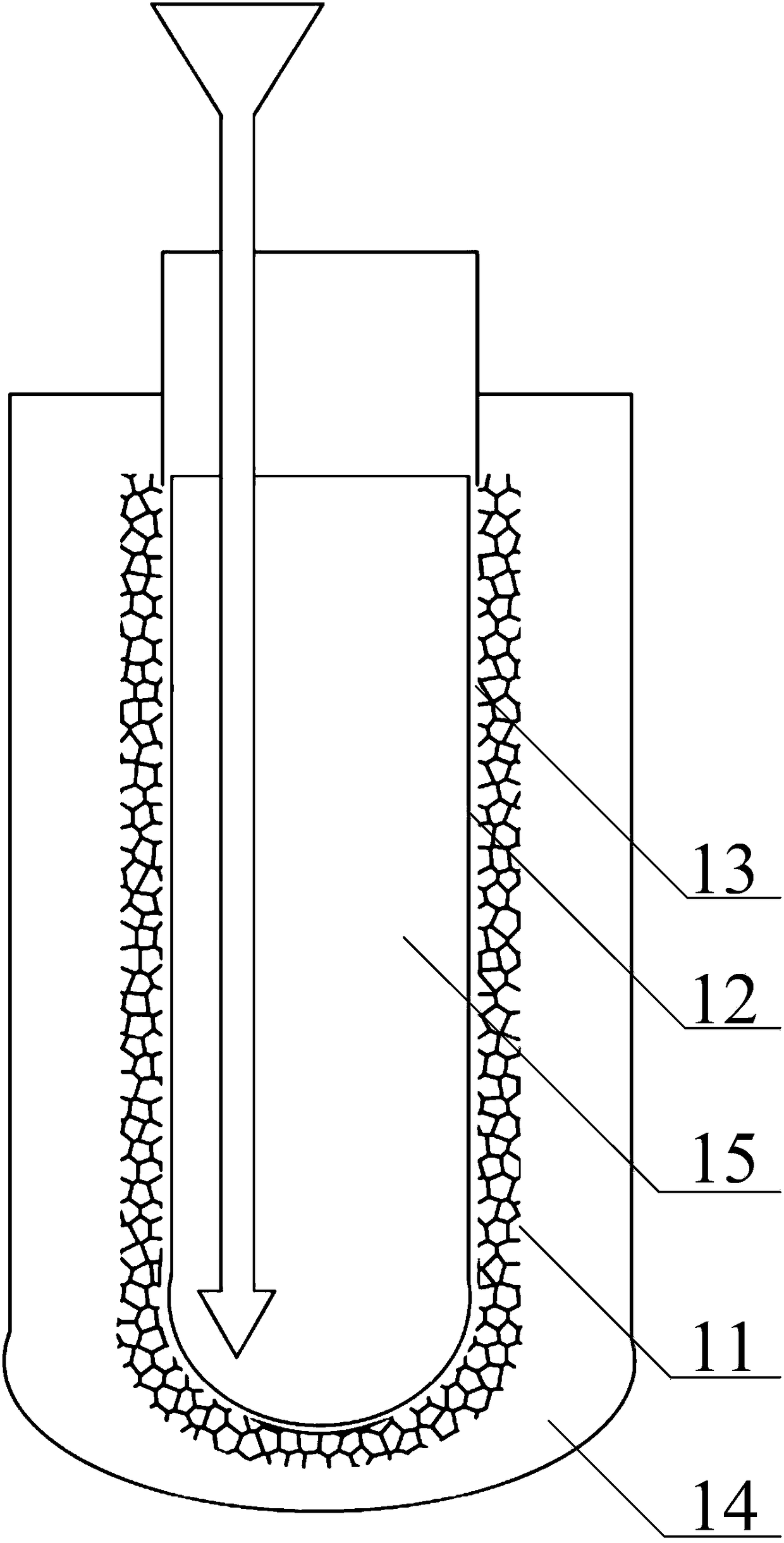

Total heat recovery type synthesis gas cooler with residue chamber

InactiveCN103146437ASolve slaggingSolve the blockageChemical industryGas purification by non-gaseous materials condensationSyngasLiquid slag

The invention discloses a total heat recovery type synthesis gas cooler with a residue chamber. The total heat recovery type synthesis gas cooler comprises a synthesis gas cooler and a U-shaped residue chamber, wherein one end of the U-shaped residue chamber is communicated with the synthesis gas cooler, and a residue outlet is arranged on the bottom part of the residue chamber. The total heat recovery type synthesis gas cooler further comprises a gasification reaction chamber, and the bottom outlet of the gasification reaction chamber is communicated with the other end of the U-shaped residue chamber. A residue catcher is arranged in a passage in which the residue chamber turns to the synthesis gas cooler. The total heat recovery type synthesis gas cooler with residue chamber disclosed by the invention is used for effectively separating liquid slag and ash drops from the synthesis gas before the high temperature synthesis gas enters the synthesis gas cooler so as to solve such common problems of the synthesis gas cooler as scorification, blockage and contamination, and the like; and ash concentration in the synthesis gas is greatly decreased, so that the attrition of a convection heating surface is alleviated, the gas flow rate in the synthesis gas cooler can be correspondingly increased, the heat exchange is reinforced, the equipment is more compact and the production cost is lowered.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

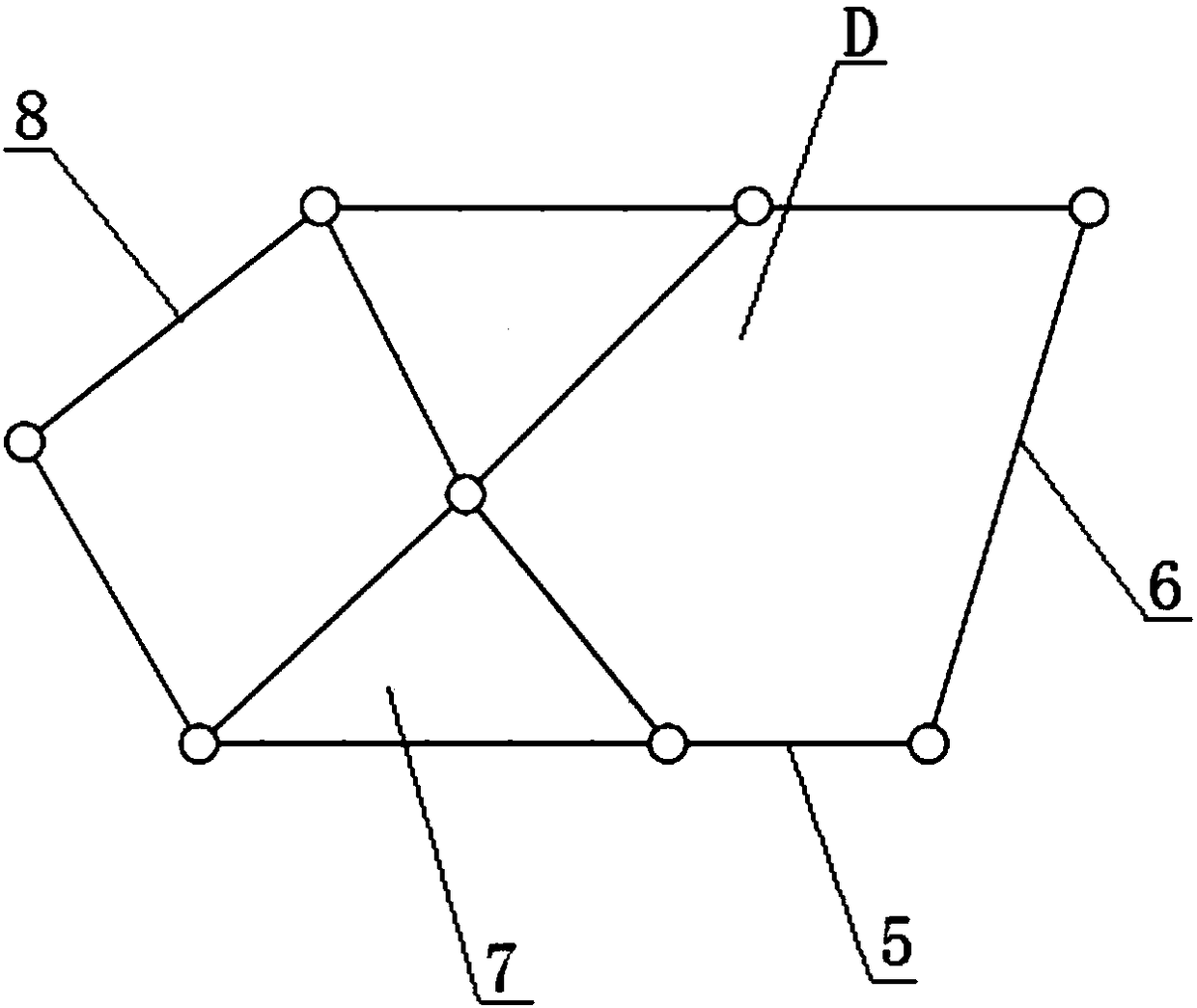

Metamorphic hand design method based on metamorphic principle

InactiveCN108262761AMake up for the errorImprove crawling efficiencyGeometric CADGripping headsRegenerative designKinematic pair

The invention relates to the field of mechanism kinematic chains, and discloses a metamorphic hand design method based on a metamorphic principle. The metamorphic hand design method based on the metamorphic principle comprises the steps of through number synthesis, obtaining a digital synthesis result regarding to the component number, the kinematic pair number, a loop and each multielement component number, then carrying out type synthesis, obtaining a kinematic chain, further selecting the kinematic link meeting the requirement to select components for regenerative design, and thus obtaininga design scheme of a metamorphic hand. According to the metamorphic hand design method based on the metamorphic principle provided by the invention, the metamorphic hand is designed through a combination method of the kinematic chain based on the metamorphic principle, so that irregular objects with different sizes are grabbed, the grabbing efficiency and the system reliability are improved, a robot error is remedied, and a higher additional value is brought for an assembling system.

Owner:WUHAN UNIV OF SCI & TECH

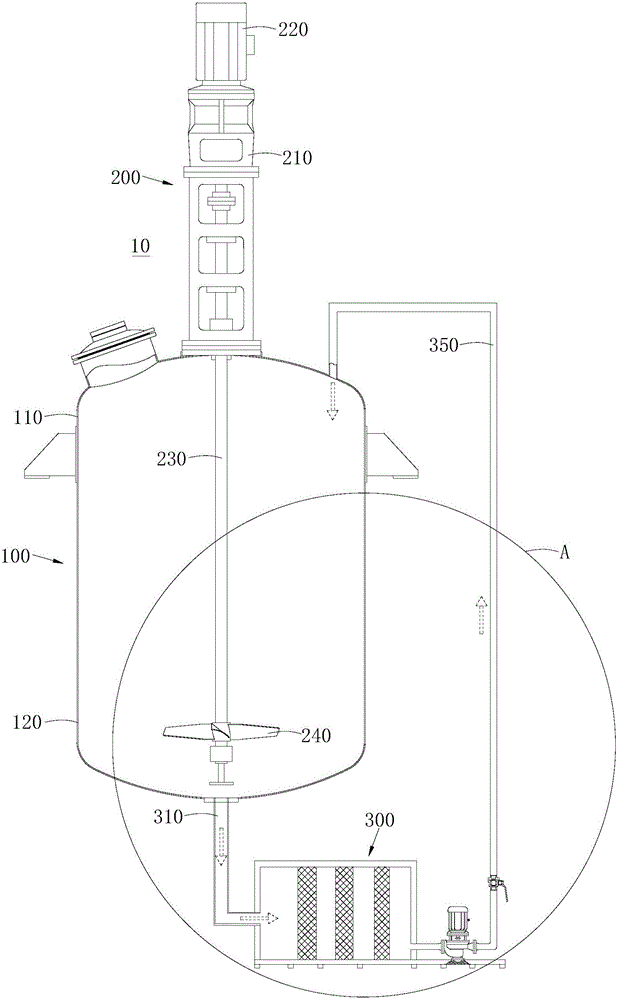

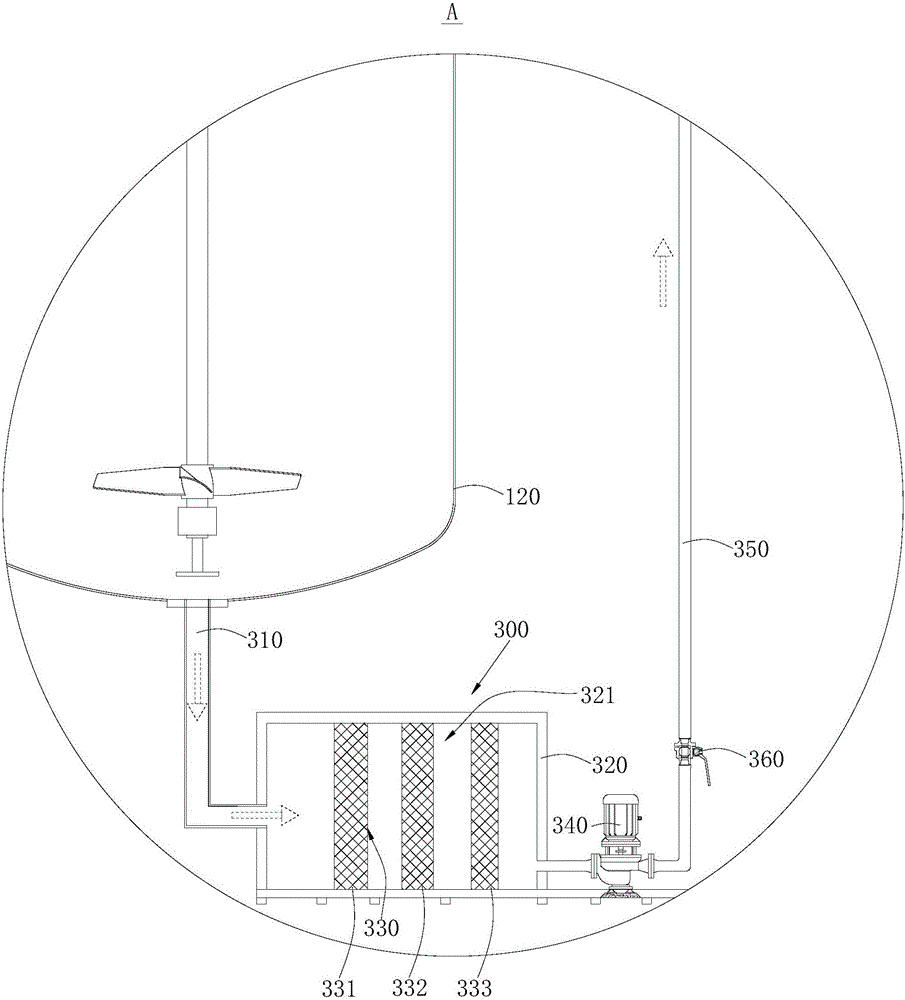

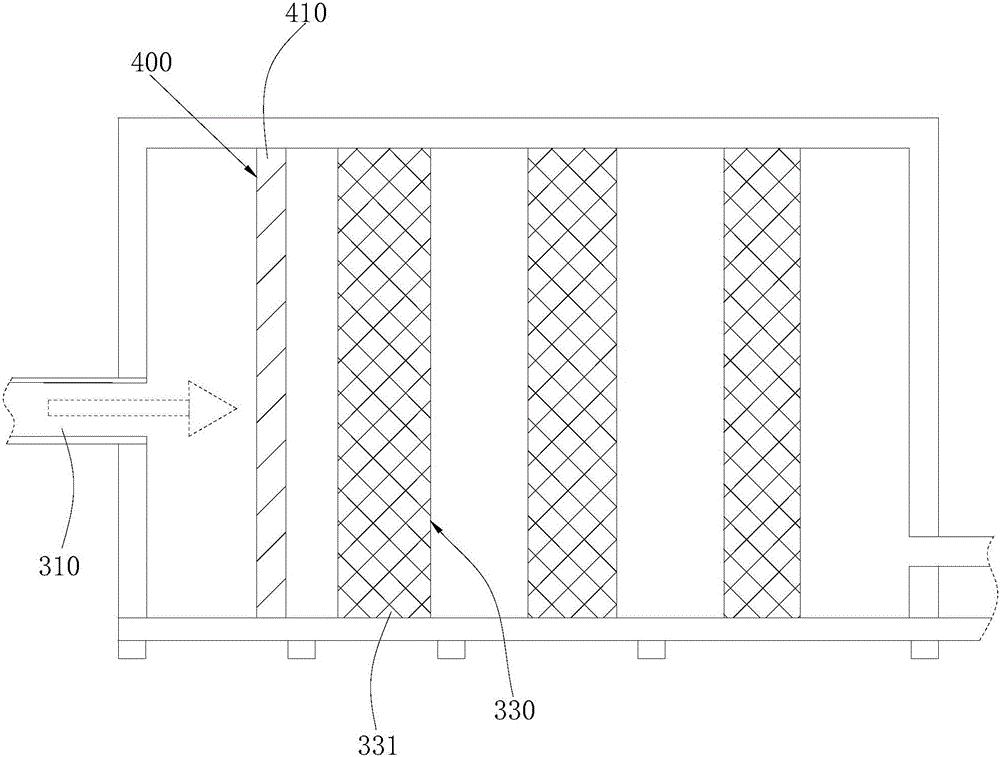

Kettle type synthesis equipment

ActiveCN105964206AThe operation of removing impurities is simple and convenientIncrease productivityChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsDrive shaftControl engineering

The invention provides kettle type synthesis equipment. The kettle type synthesis equipment comprises a kettle body, a stirring and mixing device, a material filtering device and a pressure buffering device. An upper sealing end and a lower sealing end are arranged at the two ends of the kettle body respectively. The stirring and mixing device comprises a mounting rack, a driving motor, a driving shaft and a stirring paddle. The material filtering device comprises a material pumping pipe body, a filtering box body, a filter screen assembly, a filtering pump body, a reflowing pipe body and a valve. The pressure buffering device is located between the material pumping pipe body and a first filter screen; the pressure buffering device comprises a plurality of buffering plate bodies. The kettle type synthesis equipment is provided with the kettle body, the stirring and mixing device and the material filtering device, and the material filtering device can be used for circularly filtering materials to remove impurities; the operation of removing the impurities is relatively simple and convenient, and the production efficiency is relatively high.

Owner:南通嘉浩防腐工程有限公司

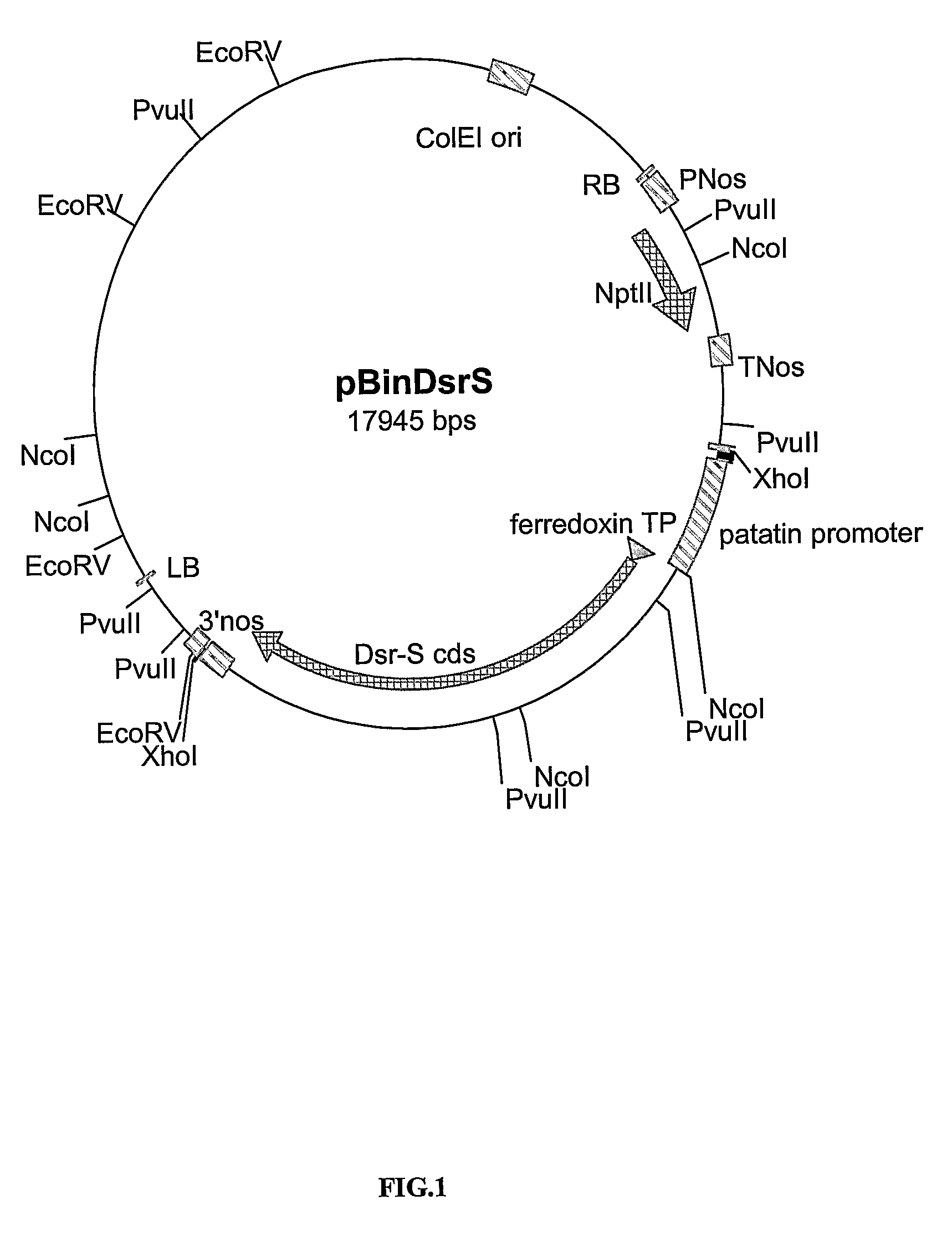

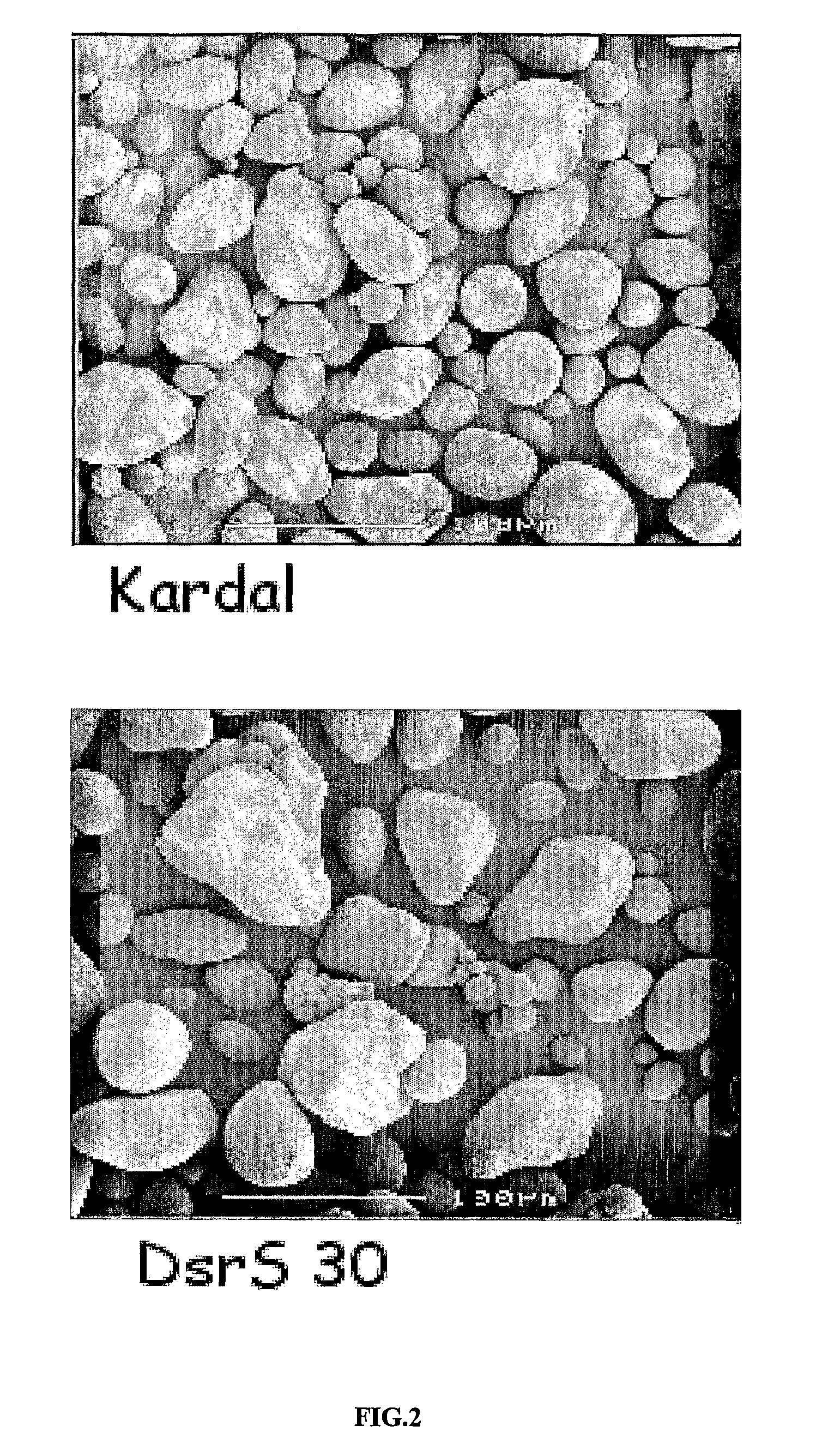

Transformed plant expressing a dextransucrase and synthesizing a modified starch

InactiveUS8053635B2Sugar derivativesOther foreign material introduction processesGlucansucrasePlant cell

The present invention relates to plant cells and plants, which are genetically modified, wherein the genetic modification leads to the expression in plastids of such plant cells and plants of an enzyme having the activity of a dextransucrase. Furthermore, the present invention relates to means and methods for the manufacture of such plant cells and plants. Plant cells and plants of this type synthesis a modified starch. The present invention therefore also relates to the starch synthesized by the plant cells and plants according to the invention as well as to methods for the manufacture of the starch and to the manufacture of starch derivatives of this modified starch.

Owner:BAYER INTELLECTUAL PROPERTY GMBH

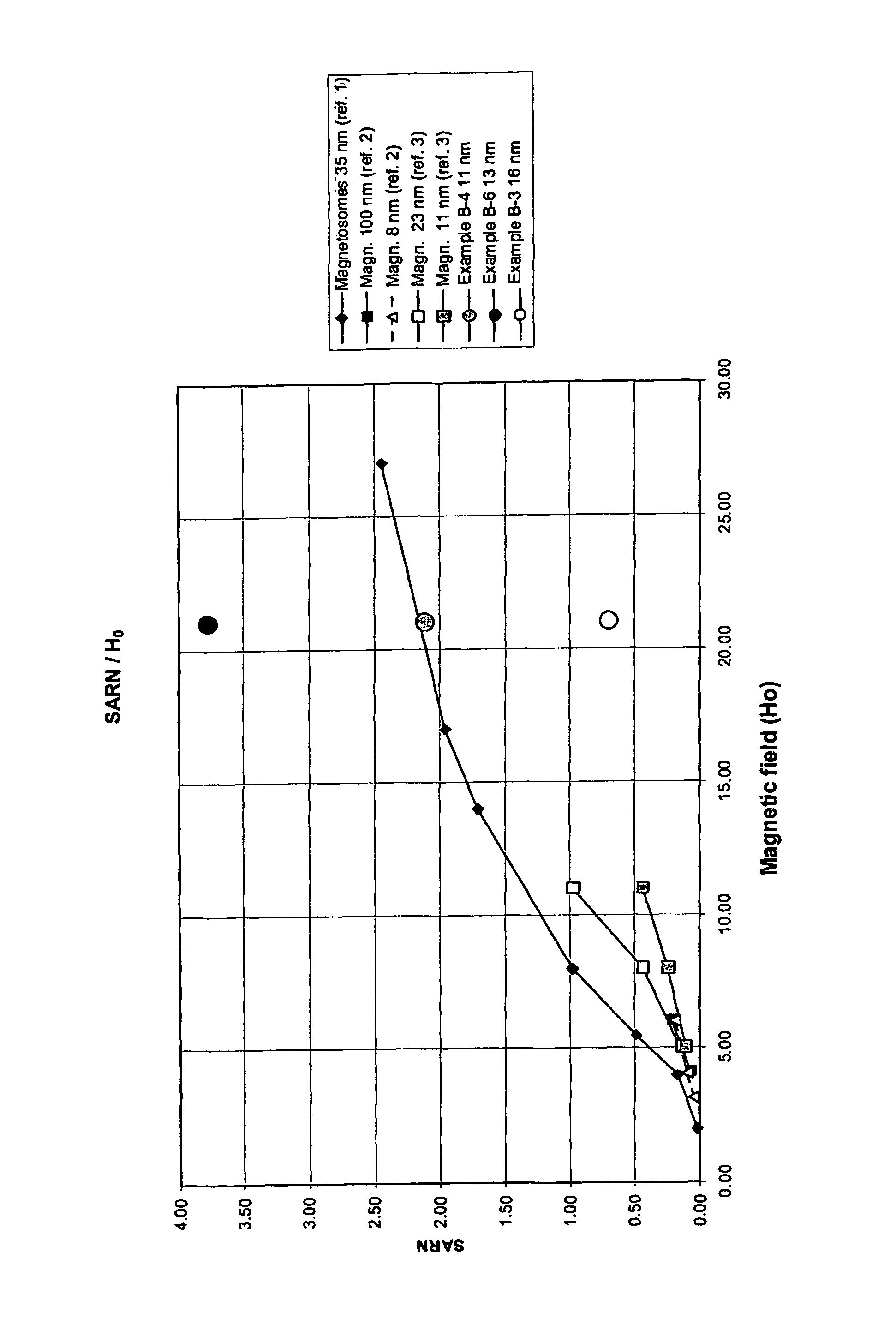

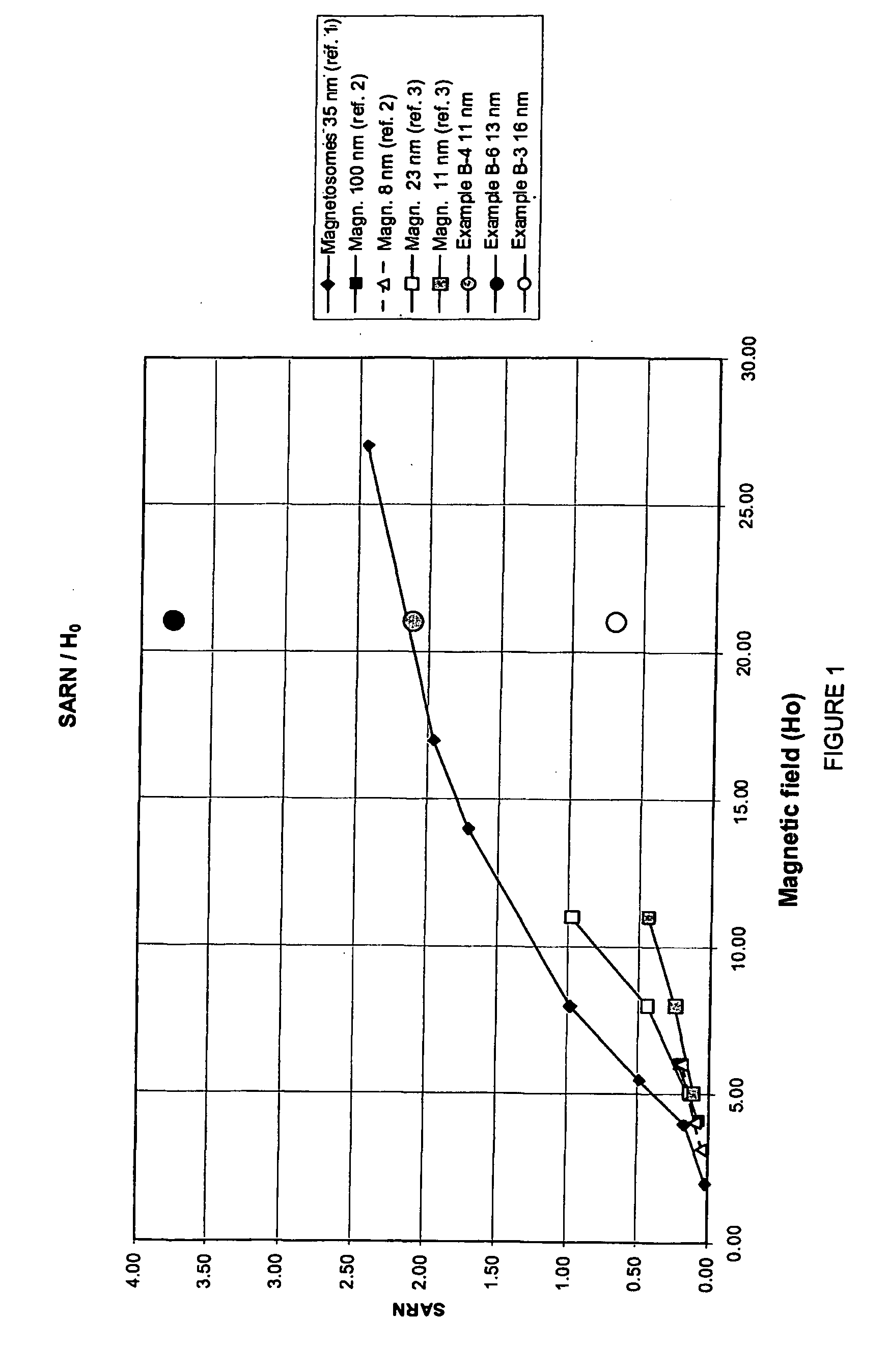

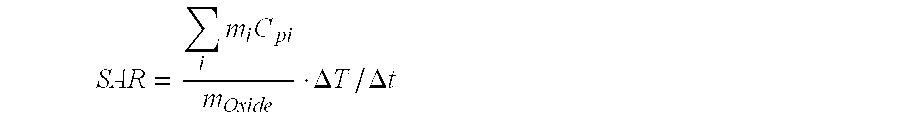

Magnetite in nanoparticulate form

ActiveUS9096443B2Improve efficiencyEasy and efficientHeavy metal active ingredientsMaterial nanotechnologyNanoparticleMagnetosome

The present invention relates to a process for the polyol-type synthesis of nanoparticulate magnetite starting from mixtures of Fe0 and Fe1III in the presence of a mineral acid. The magnetite particles obtainable from the process have uniform size characteristics and have even presented higher SAR (Specific Absorption Rate) values than those of magnetosomes.

Owner:COLOROBBIA ITALA

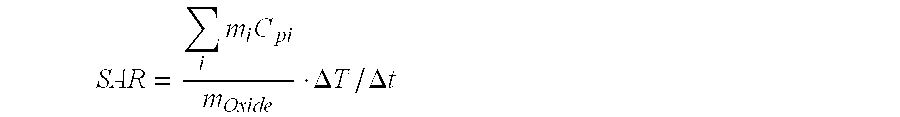

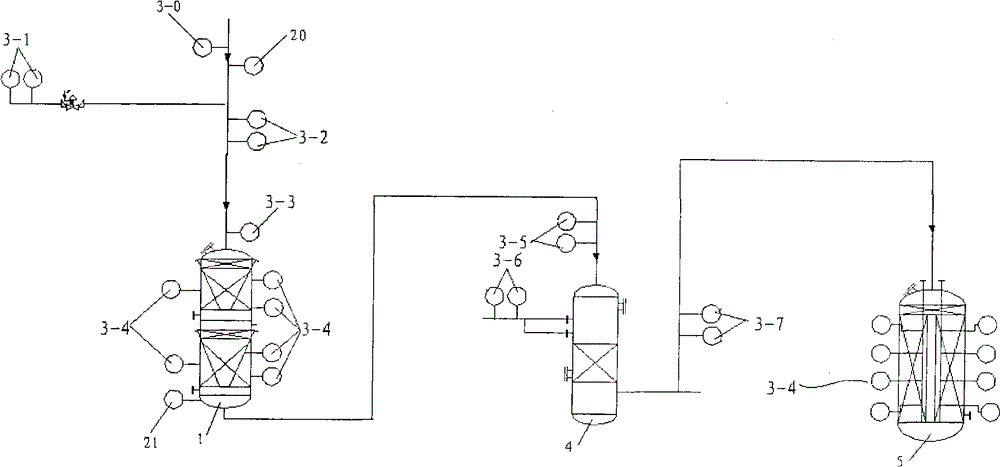

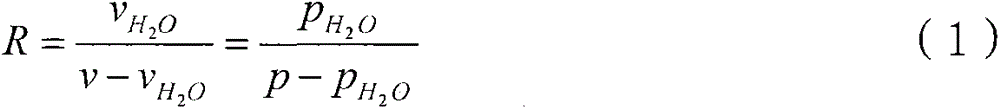

System for determining steam-gas ratio of inlets of all shift converters at conversion section of tandem type synthesis ammonia plant

The invention relates to a system for determining the steam-gas ratio of inlets of all shift converters at the conversion section of a tandem type synthesis ammonia plant. The system comprises an intelligent secondary meter cluster unit with a communication function and a gas composition analytical unit, wherein a temperature adjusting device is arranged between two adjacent shift converter sections; a temperature adjusting method comprises the steps of adding steam, spraying water for chilling and heat exchange; the determination system comprises a sensor group unit arranged on a series-connected line of a plurality of shift converter sections and pipelines, the sensor group unit comprises a sensor combination arranged in a main pipeline in front of a shift converter section to be detected for determining the temperature and the pressure of gas in the main reaction pipeline before steam adding or cold water chilling, a sensor combination for determining the temperature and the pressure of the gas in the main reaction pipeline after steam adding or cold water chilling, and a sensor combination for measuring the temperature and the pressure of chilled water or steam in a pipeline where the steam or chilled water is added. The system can statically, automatically and continuously measure the steam-gas ratios of all shift converter sections.

Owner:HUBEI CHINA SHAFTS TECH

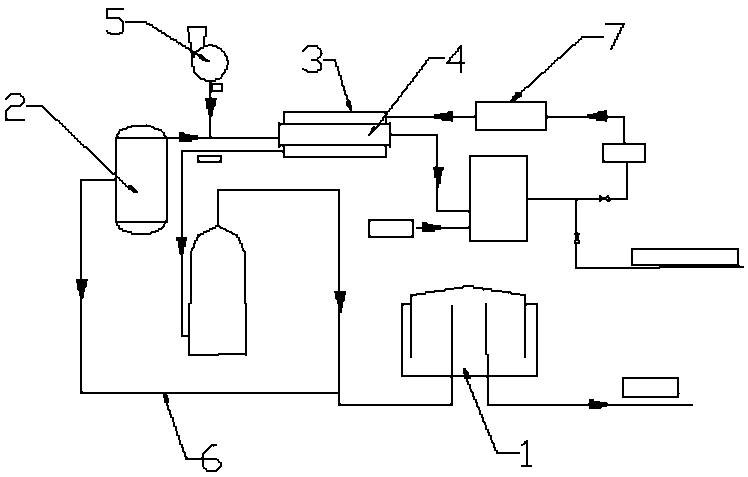

Energy-saving type synthesis ammonia semi-oxygen-enriched gas making device and process

PendingCN109081304AReduce the proportionReduce power consumptionEnergy inputGasification processes detailsNitrogenAir blower

The invention provides an energy-saving type synthesis ammonia semi-oxygen-enriched gas making device and process. The device comprises a gas cabinet, a PSA (pressure swing adsorption) nitrogen generation system and an air mixing cabinet, wherein the air mixing cabinet wraps a gas making coal-gas pipe; nitrogen and oxygen-enriched air which are separated by the PSA nitrogen generation system are recycled separately; a gas making air blower is connected between the PSA nitrogen generation system and the air mixing cabinet through a pipe; the oxygen-enriched air and gas making blowing air are mixed in the air mixing cabinet; the PSA nitrogen generation system is further connected with the gas cabinet through a nitrogen delivering pipe; the air mixing cabinet is connected with the gas cabinetthrough a pipe; and the gas making coal-gas pipe is connected with a waste gas, waste water and solid waste furnace. The energy-saving type synthesis ammonia semi-oxygen-enriched gas making device and process have the beneficial effects that investments on equipment are less, the functional degree of the nitrogen generation system is high, and the safety factor is high.

Owner:SHANDONG SHUNTIAN CHEM GRP

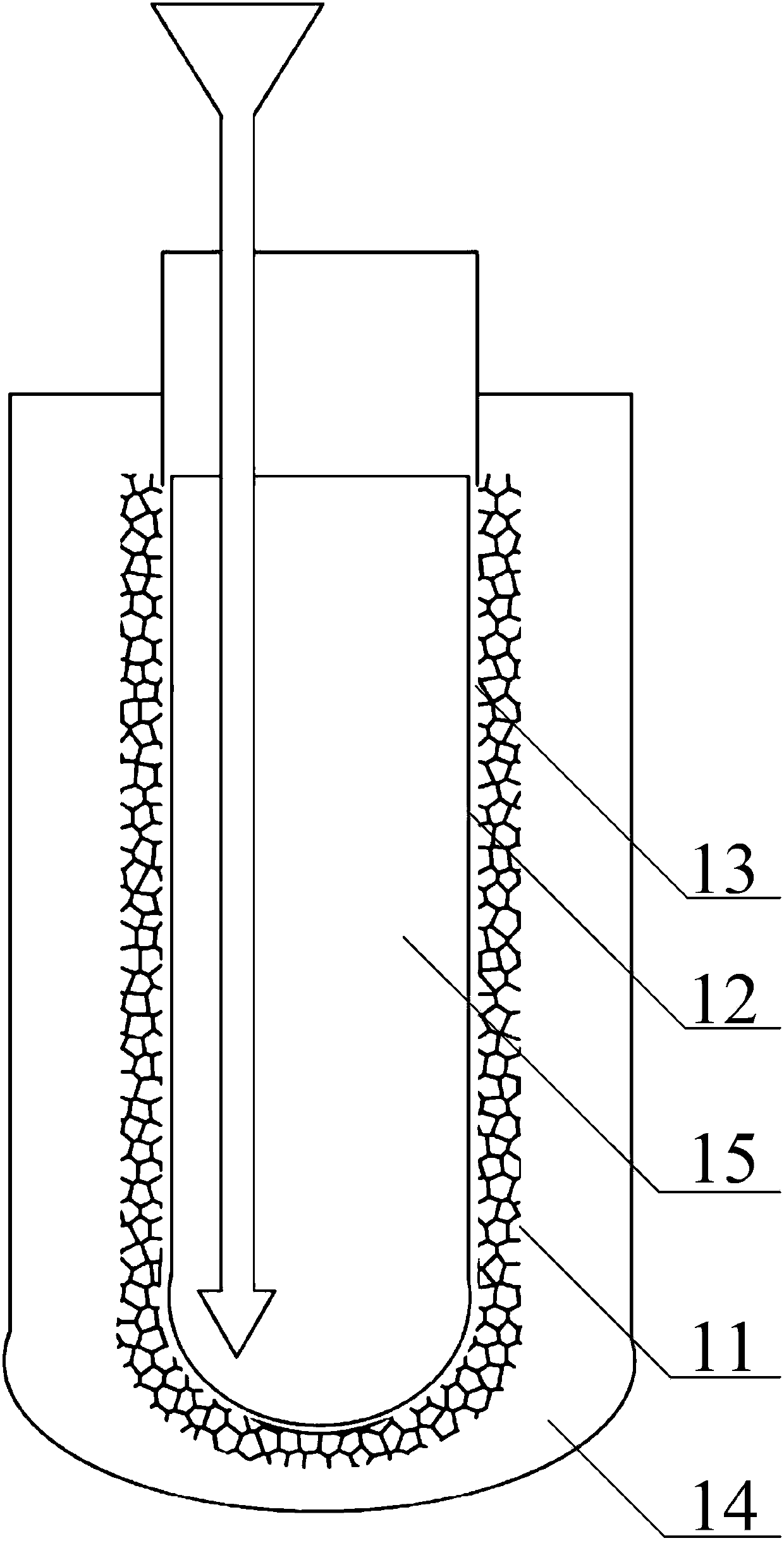

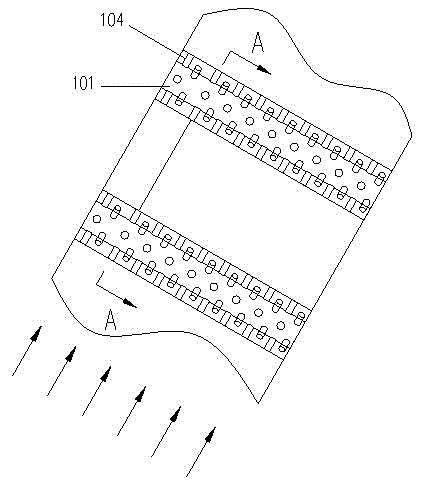

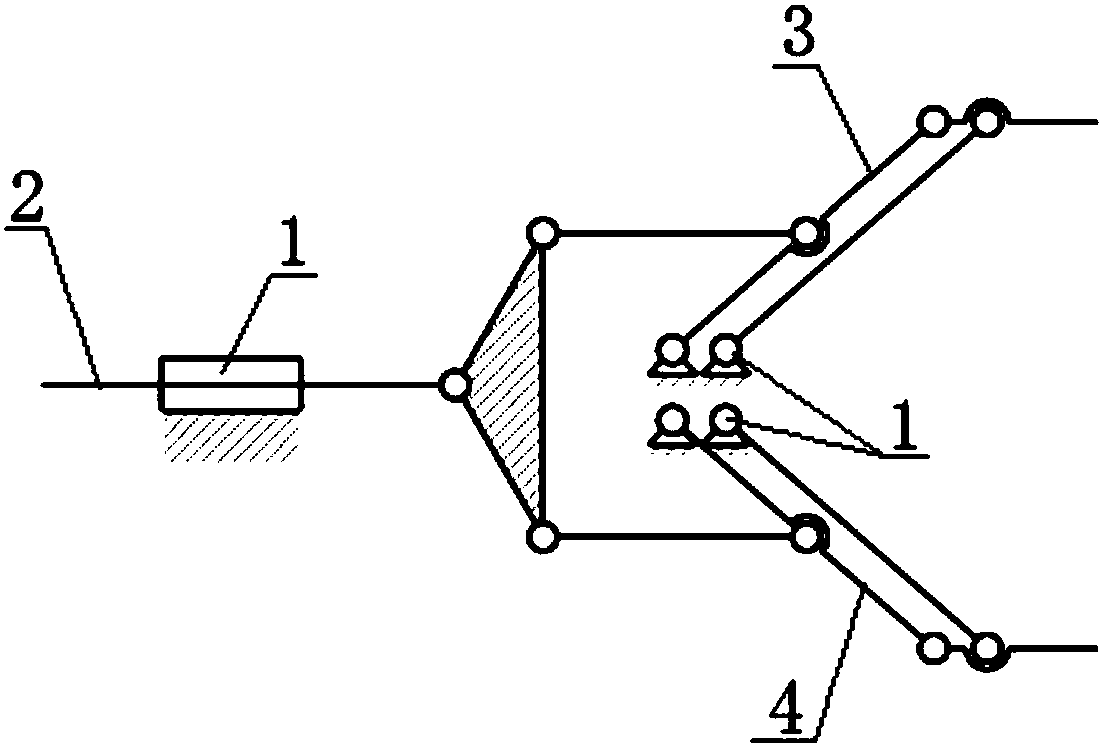

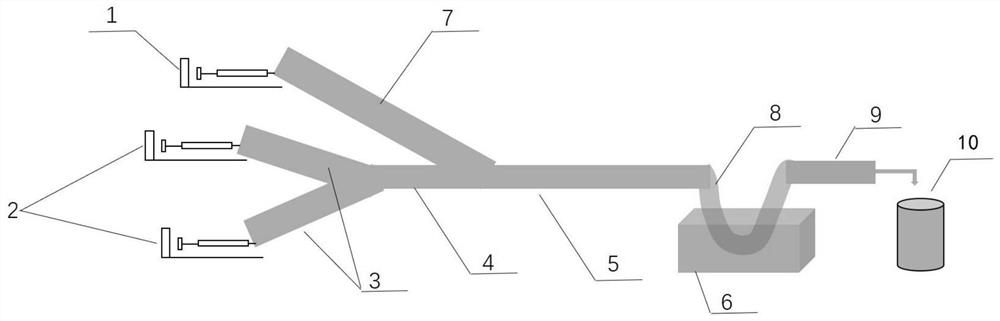

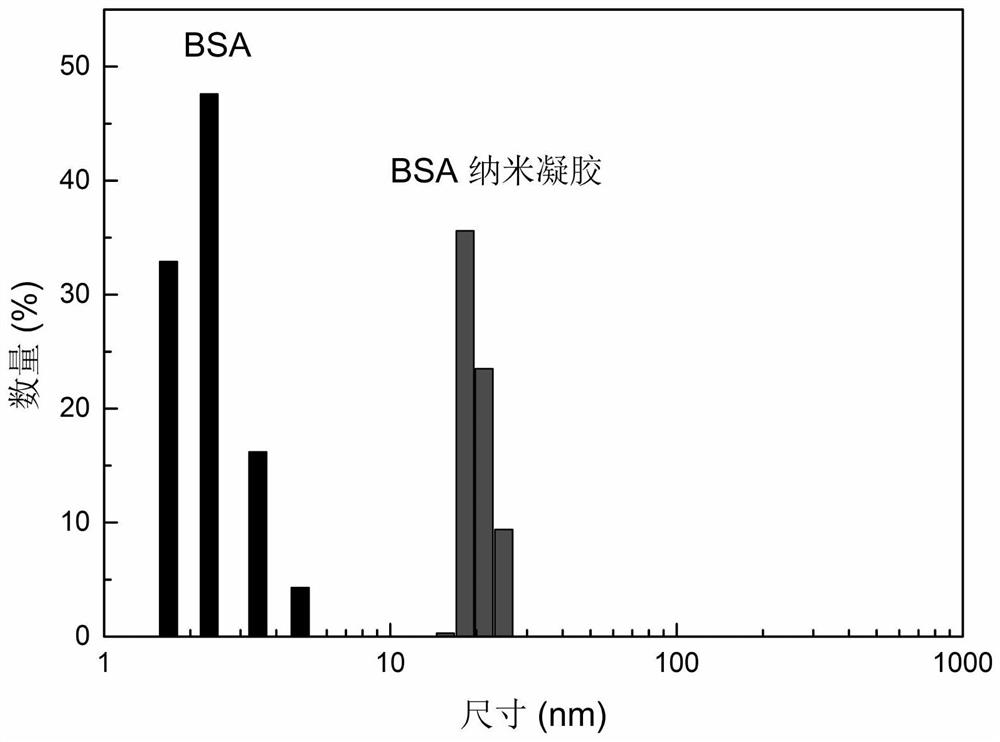

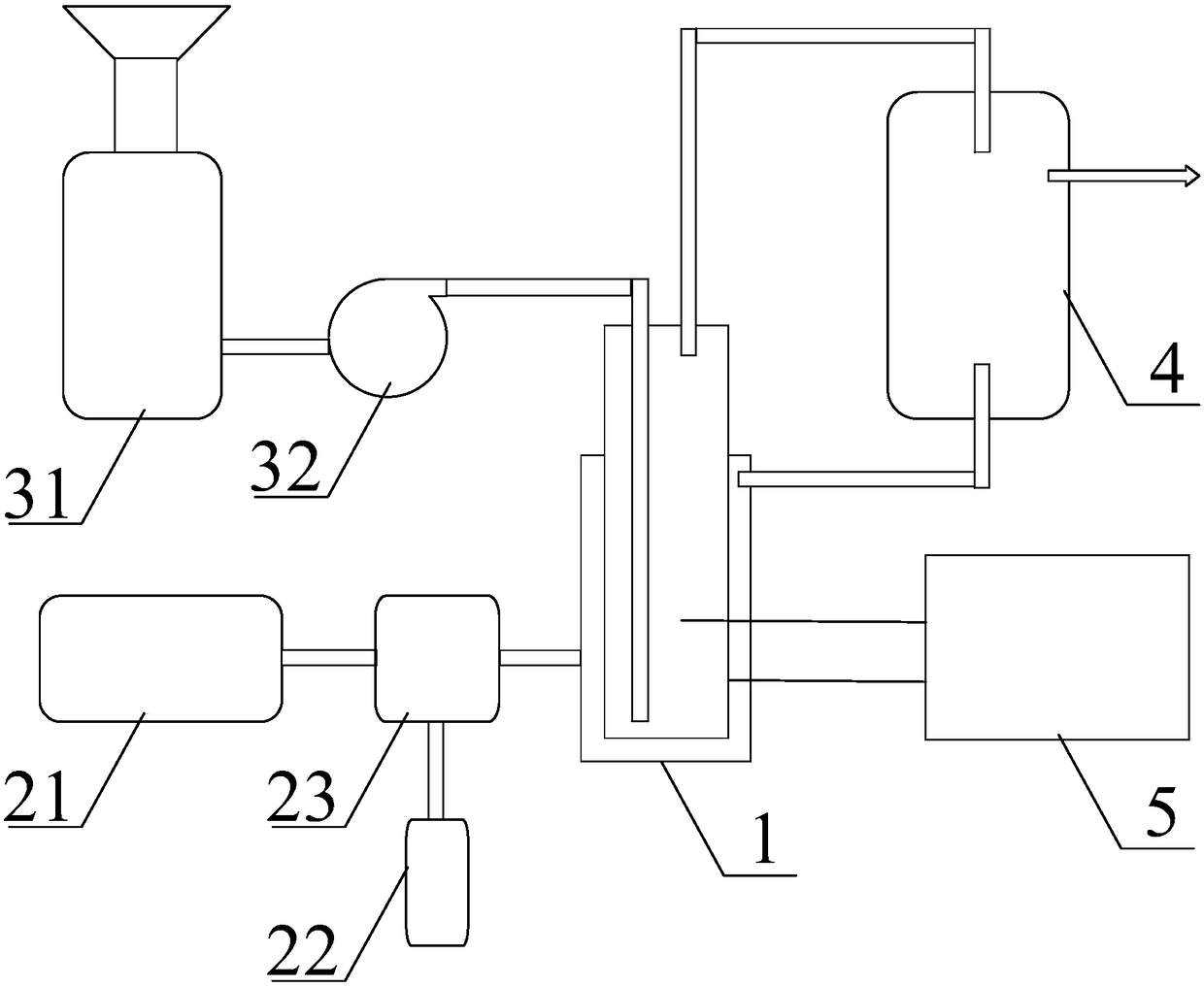

Flow type synthesis device and synthesis method of nanogel

PendingCN113975227AWell mixedReduce pollutionAerosol deliveryOintment deliveryCollection systemMaterial synthesis

The invention belongs to the technical field of biomedical material synthesis, and particularly relates to a flow type synthesis device of nanogel. The device comprises an injection pump sample introduction system, a pipeline synthesis system, a product post-treatment system and a product collection system which are connected in sequence, the injection pump sample introduction system comprises a liquid sample introduction system, a gas sample introduction system and a liquid mixing pipeline, the liquid sample introduction system is connected with one end of a pipeline synthesis system through the liquid mixing pipeline, and the gas sample introduction system is directly connected with the pipeline synthesis system. The invention further provides a method for synthesizing the nanogel by using the flow type synthesis device. The invention has the beneficial effects that the specific surface area of heat exchange between reactants and the outside can be increased, the influence of temperature on the reactants and polymerization reaction is reduced, and uniform mixing of liquid is facilitated; the synthesis method is simple to operate and mild in synthesis condition, and has a wide application prospect in the biomedical field.

Owner:TIANJIN UNIV

A synthesis gas preparation system and method thereof

ActiveCN107868962BLarge specific surface areaImprove conversion efficiencyCellsElectrolysisTransformation efficiency

The invention discloses a synthesis gas preparation system and a method thereof. The synthesis gas preparation system includes a solid oxide electrolysis cell, a feed gas supply system, a molten salt supply system and a synthesis gas mixing chamber; the solid oxide electrolysis cell includes A cathode, an anode and an electrolyte, the cathode is in contact with the gas phase of the raw material, and the anode is in contact with the molten salt mixed with carbon powder and catalyst. The present invention realizes the coupling of solid oxide electrolytic cell technology and coal gasification technology, produces CO by gasifying O2-produced in the electrolysis / co-electrolysis reaction process with carbon powder coal, and uses high-temperature molten salt as a dispersant for carbon powder, Increase the specific surface area of the coal gasification reaction, thereby improving the conversion efficiency and yield of synthesis gas, reducing the energy consumption per unit of output, and can further adjust the specific ratio of the required synthesis gas; the invention is suitable for distributed synthesis gas production plants, It has the characteristics of high energy efficiency, simple operation, high safety, and mass production.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

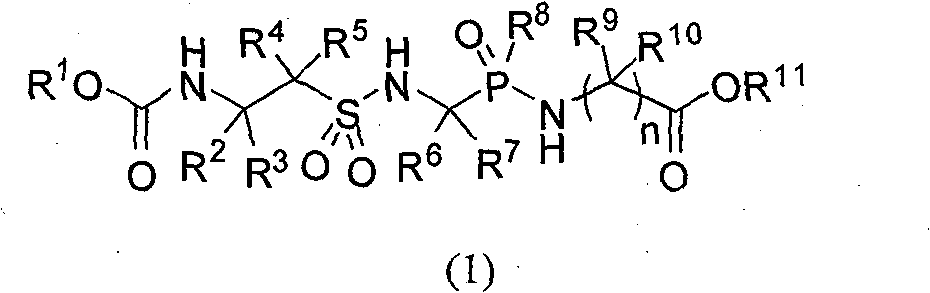

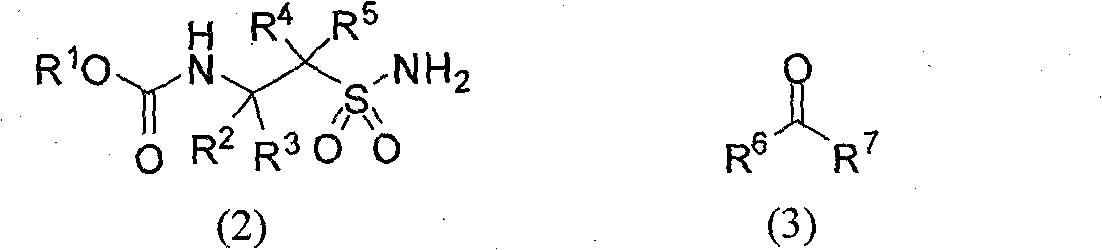

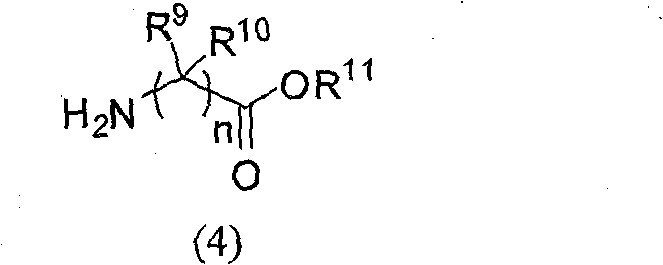

Sulfuryl hypo-phosphono hybridation peptide and preparation method thereof

InactiveCN101619075BEasy to manufactureRaw materials are easy to getGroup 5/15 element organic compoundsArylOrganic solvent

The invention provides a sulfuryl hypo-phosphono hybridation peptide and a preparation method thereof. The sulfuryl hypo-phosphono hybridation peptide has a structure represented by the formula (1), is formed by condensing sulfamic acid, amino phosphinic acid and amino acid, and can be used as medicament, enzyme inhibitor, antibacterialagent, hapten for preparing bzyme, and the like. The sulfurylhypo-phosphono hybridation peptide can be prepared in such a way that sulfamide, aldehyde or ketone, alkyl or aryl phosphine oxide react in organic solvent for a period of time, amino-acid ester or salt thereof is added in the reaction mixture in the presence of alkaline to carry out ammonolysis. The method has simple and easy-obtained materials, simple process, high synthesis efficiency, is an atomic and economic gathering-type synthesis method and can be used for preparing optical active sulfuryl hypo-phosphono hybridation peptide.

Owner:BEIJING UNIV OF CHEM TECH

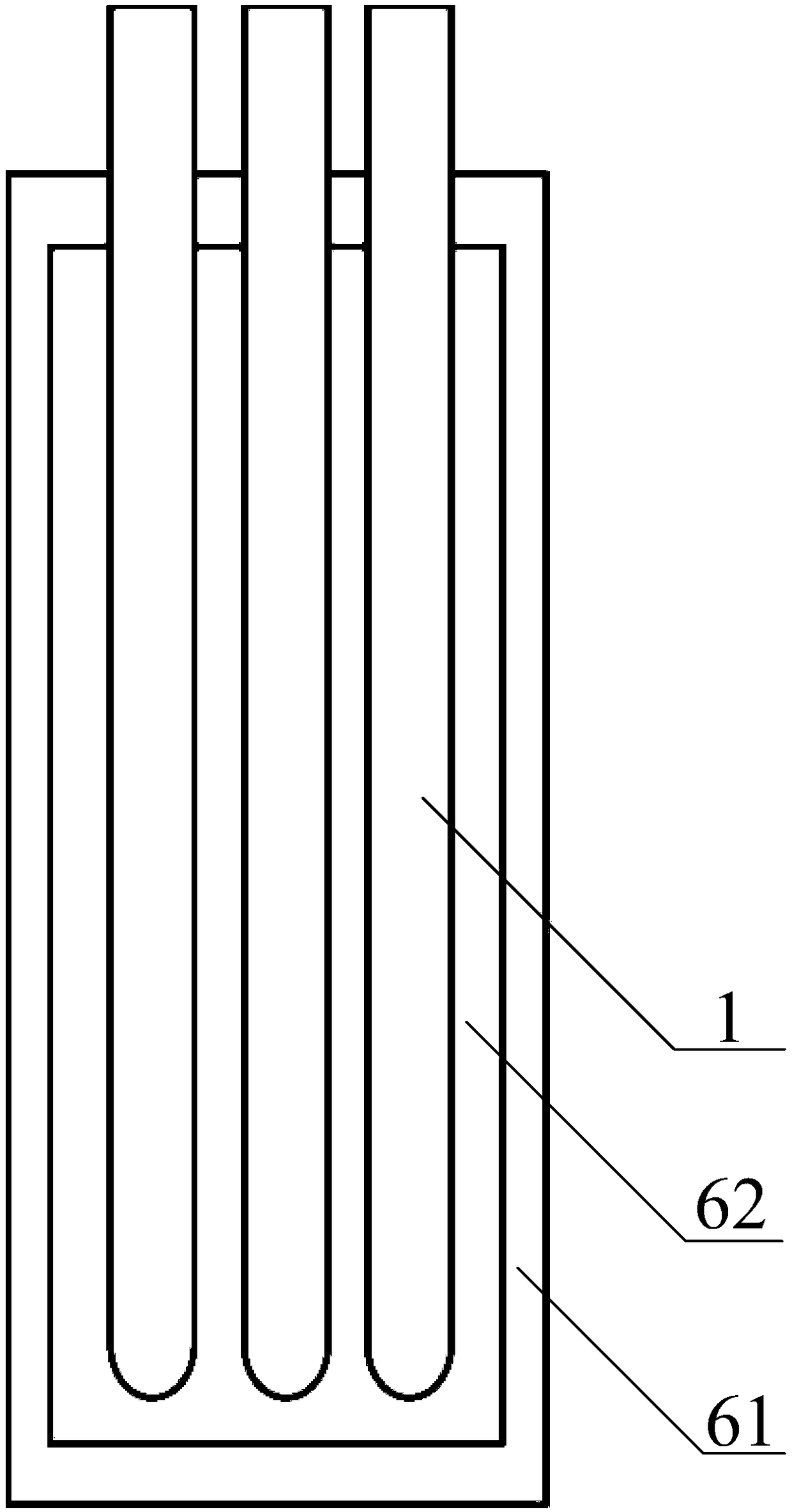

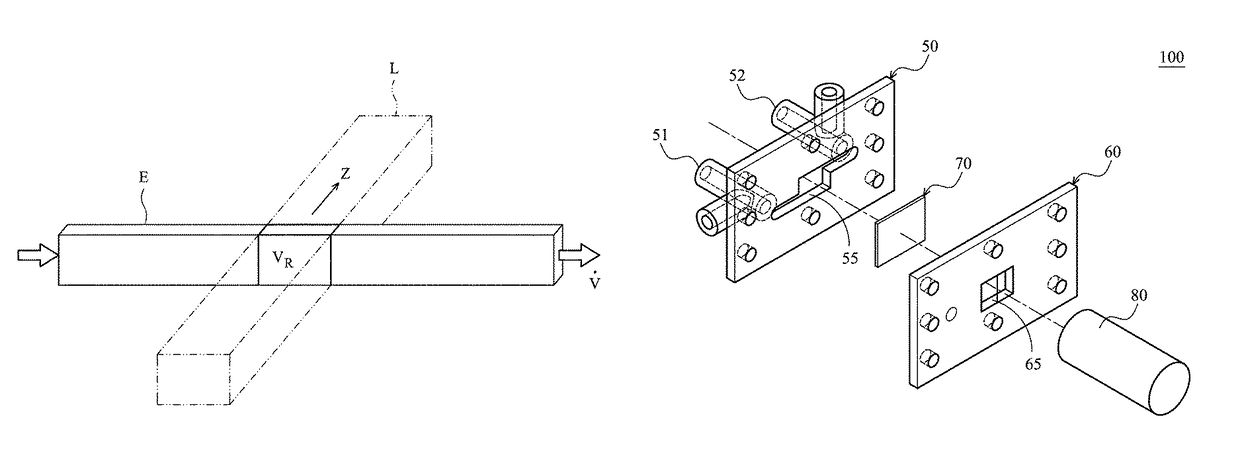

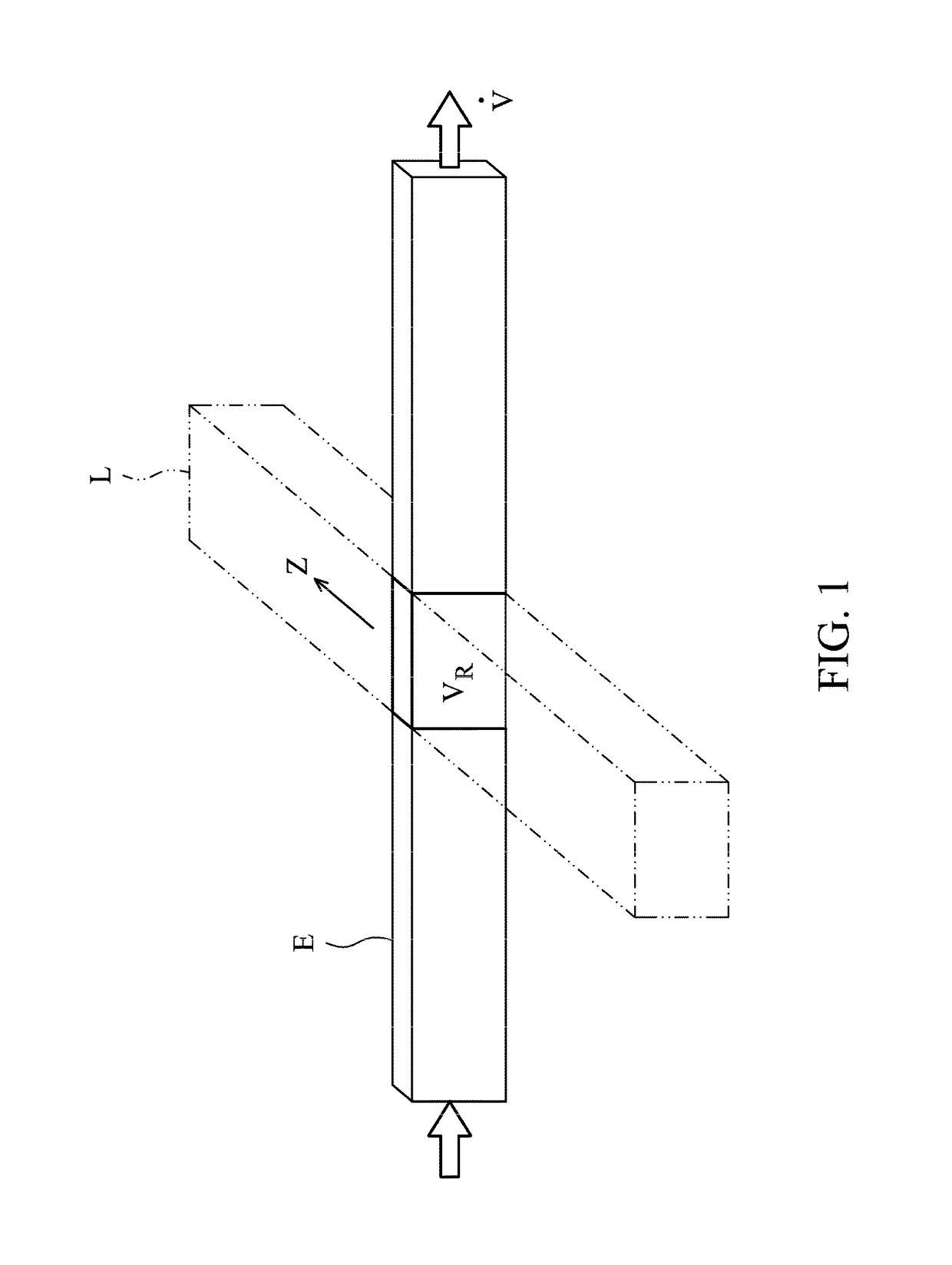

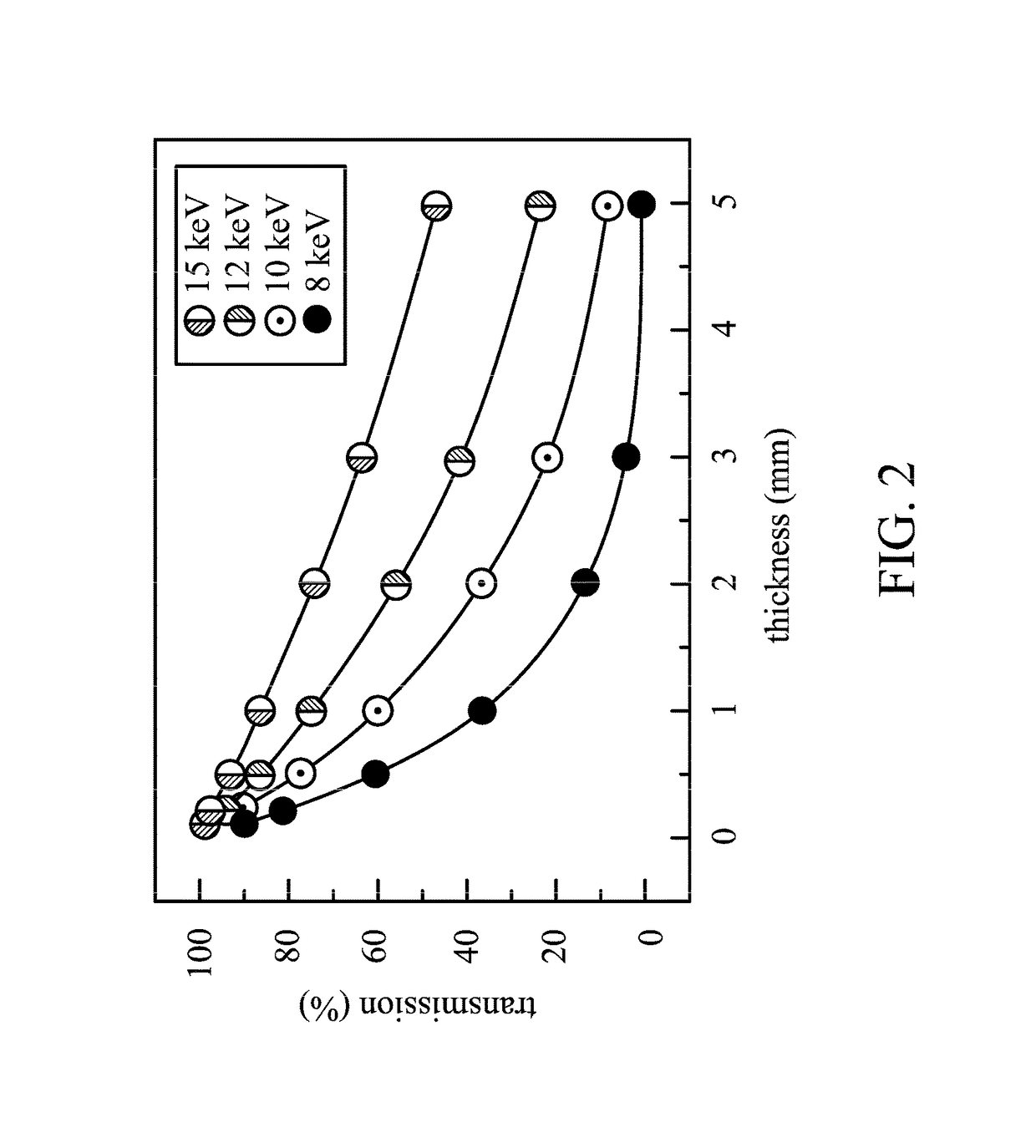

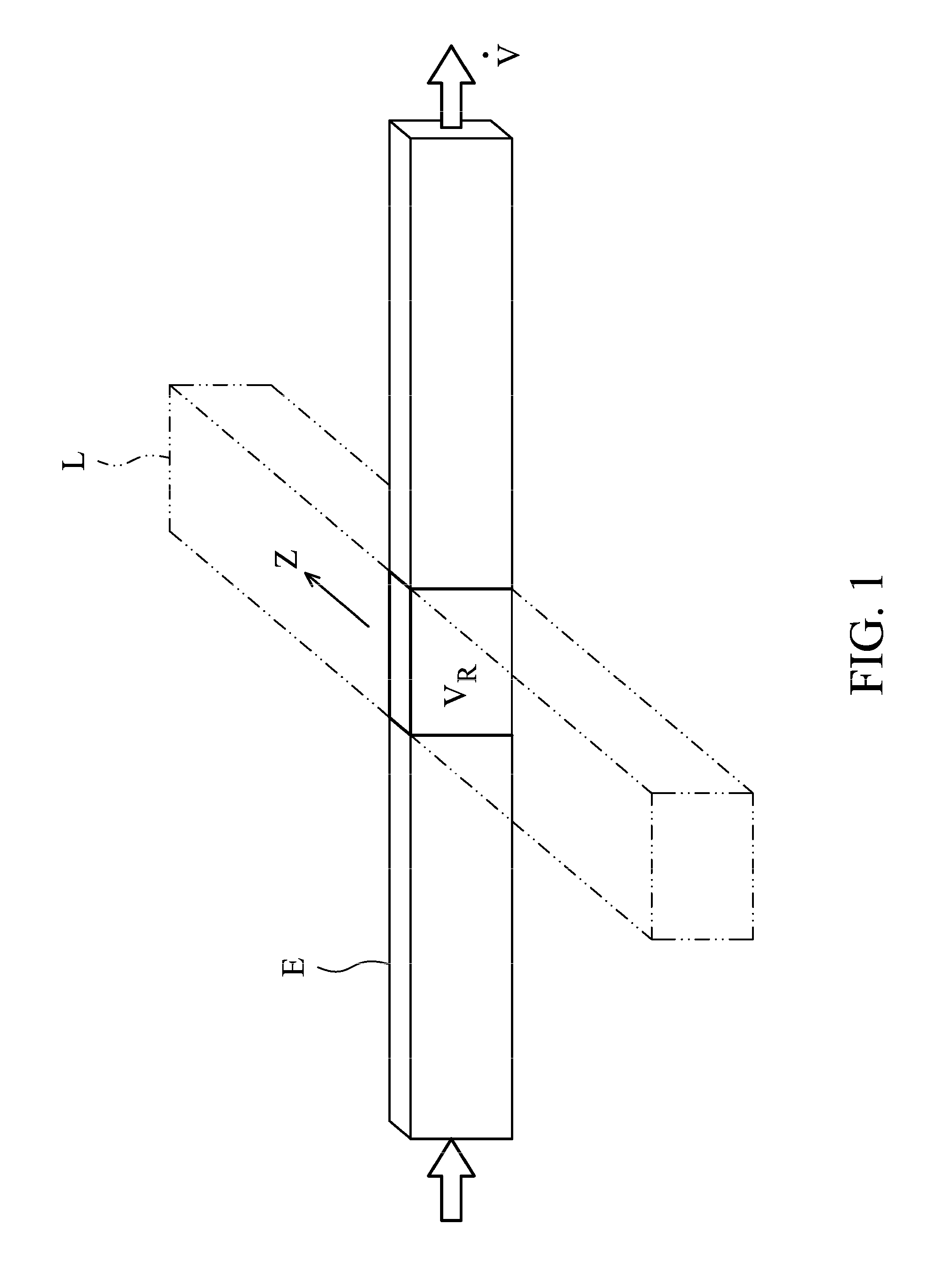

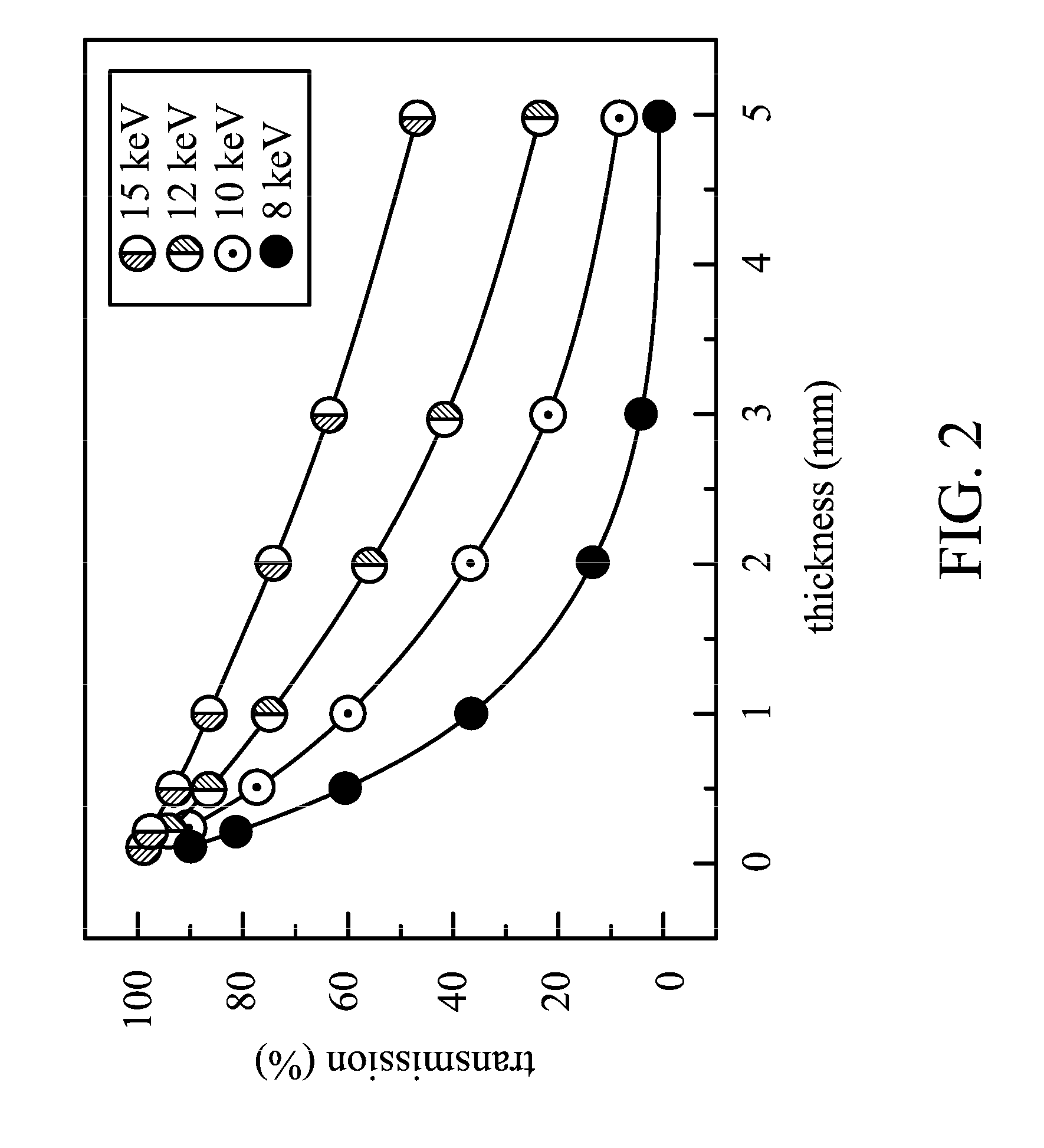

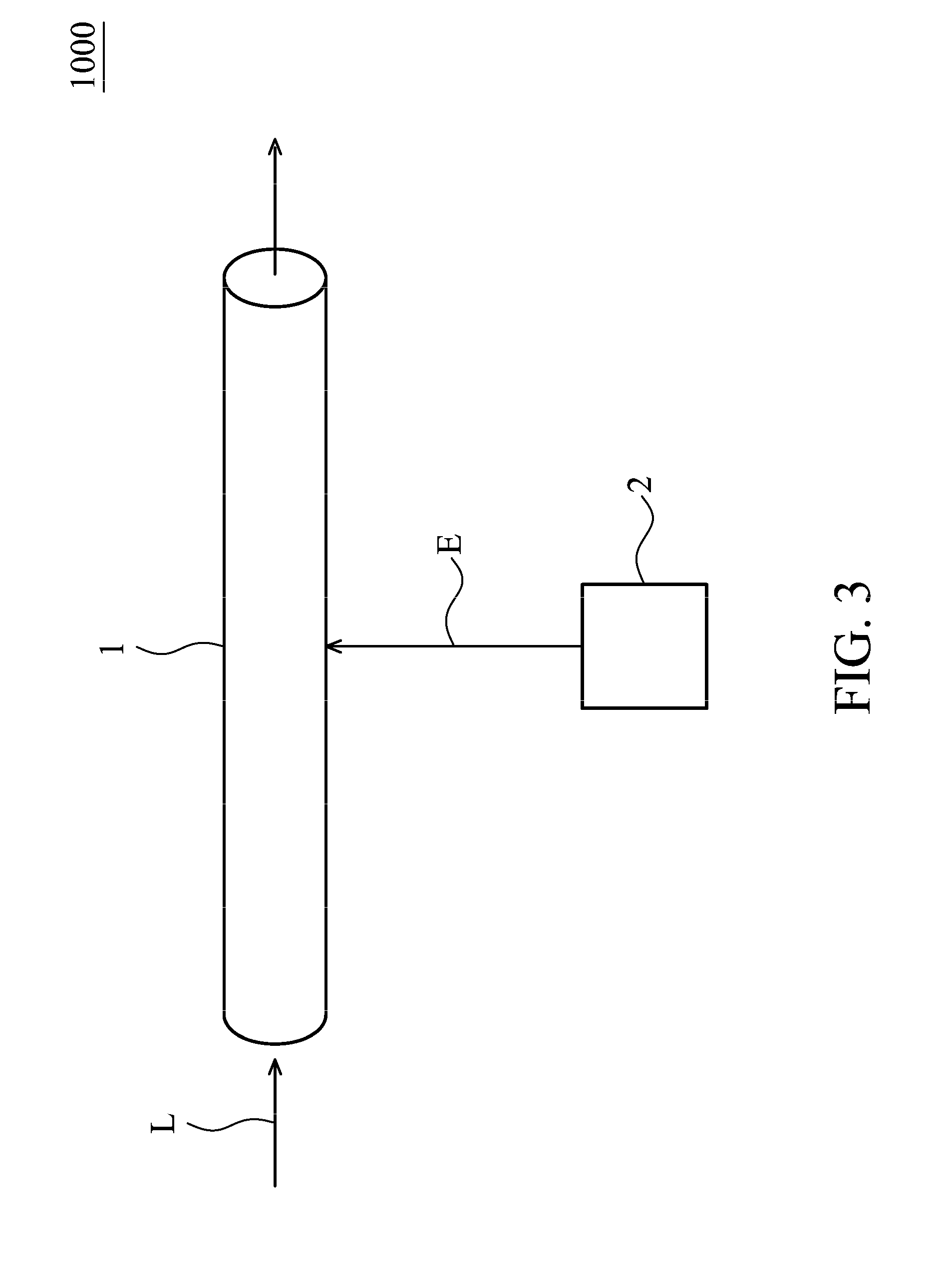

Convection-free flow-type reactor and flow-type synthesis method

ActiveUS9884306B2Process control/regulationChemical/physical/physico-chemical microreactorsSynthesis methodsNuclear engineering

Owner:ACAD SINIC

Convection-free flow-type reactor and flow-type synthesis method

ActiveUS20150008117A1Chemical/physical/physico-chemical microreactorsHydrocarbonsBeam sourceSynthesis methods

A convection-free flow-type reactor includes a reactor body. The reactor body includes a reaction chamber to house a fluid. An inlet is in communication with the reaction chamber to allow input of a reactant fluid. An outlet is in communication with the reaction chamber to allow output of a product fluid. An energy beam source device provides an energy beam to irradiate the reactant fluid in the reaction chamber. The disclosure further provides a convection-free flow-type synthesis method.

Owner:ACAD SINIC

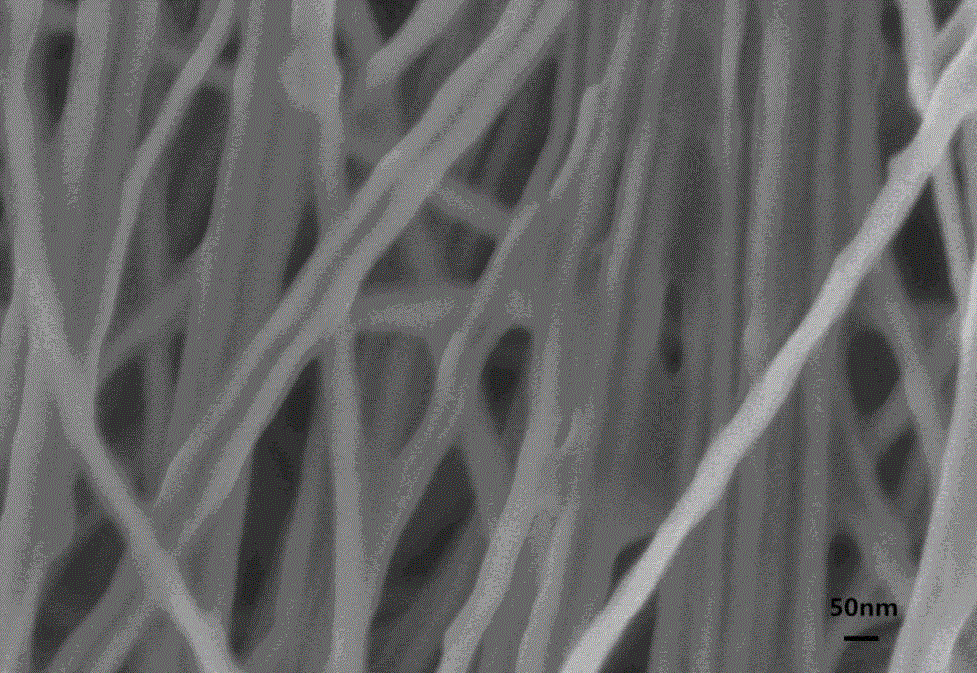

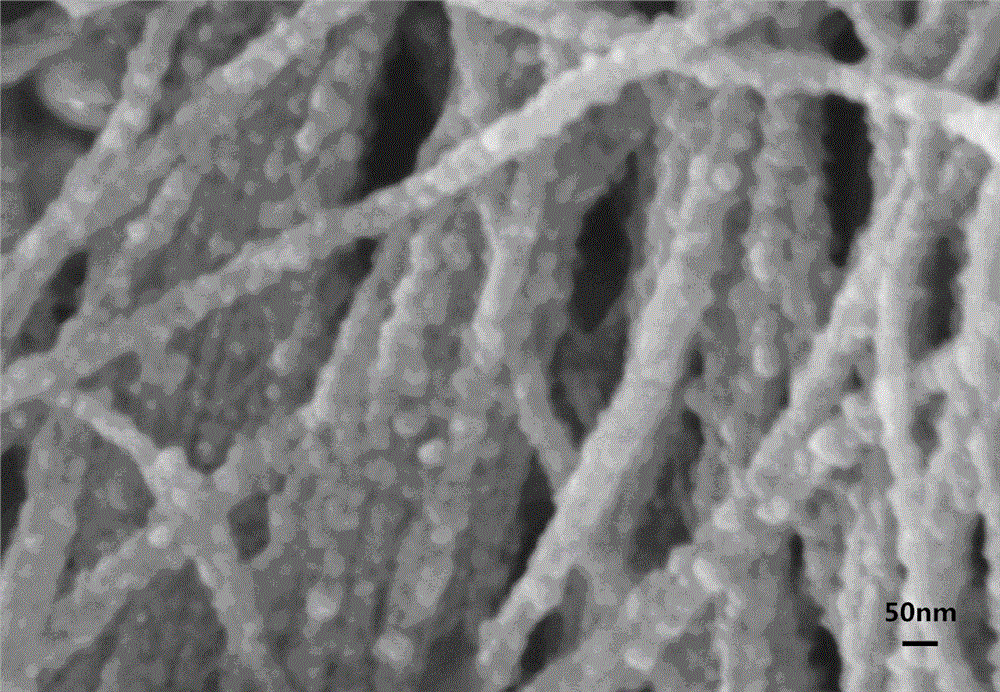

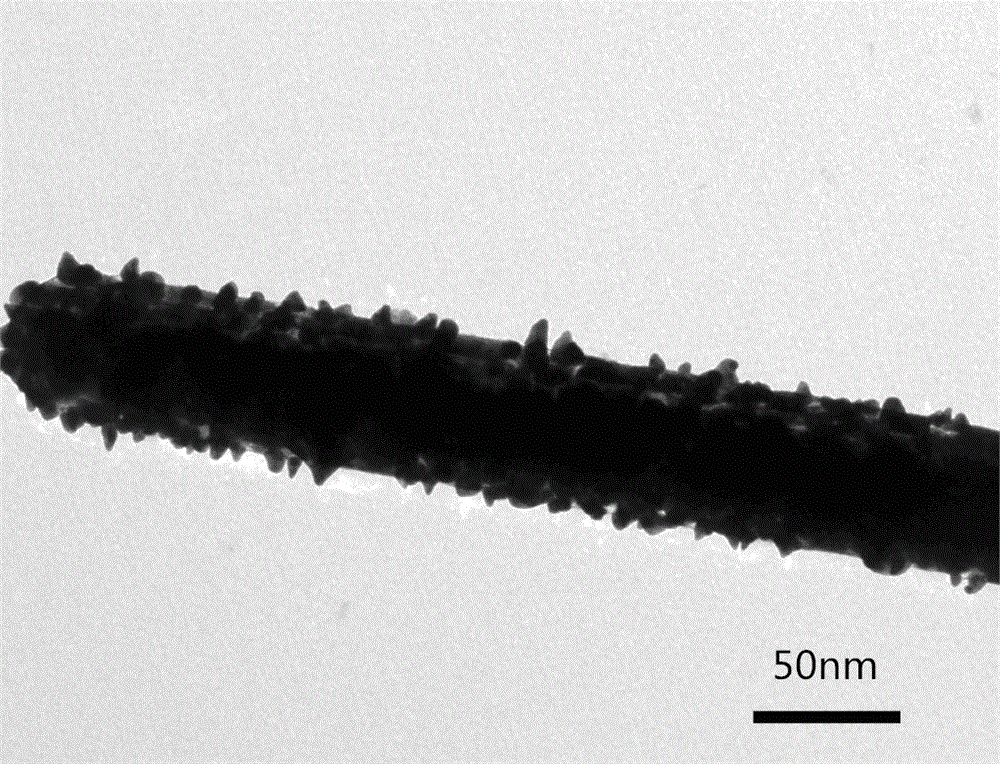

A Synthesis Method of Cable Type Silver Chloride Coated Copper Nanostructure

InactiveCN104841947BImprove control abilityImprove general performancePhysical/chemical process catalystsNanostructureCopper salt

The invention relates to a synthesis method of a cable-type silver chloride-wrapped copper nanostructure: specifically: 1. Solution preparation. Prepare reaction substrate copper salt, reducing agent and structure directing agent mixed solution, surfactant solution, silver salt solution. 2. The synthesis method of copper nanowires. The mixed solution containing copper salt, reducing agent and structure directing agent is magnetically stirred for a certain period of time at room temperature, then transferred to an oil bath, kept at a specific temperature for a certain period of time, after the reaction is completed, cooled to room temperature, and the sample is centrifuged. Wash and collect the product. 3. Quantum dots of silver chloride. Add a certain concentration of silver salt solution dropwise into a specific and certain concentration of surfactant solution, and magnetically stir for a certain period of time to obtain a milky white solution. 4. The synthesis method of silver chloride loaded copper nanowires. Add copper nanowires into the milky white solution, and stir magnetically for a certain period of time. The invention has simple process, common preparation conditions, stable product appearance, high purity, simple product treatment, and is suitable for medium-scale industrial production.

Owner:TONGJI UNIV

Improved type synthesis process of rubber aid

InactiveCN108164749AIncrease resistance to thermo-oxidative agingBlock thermal oxidation reactionHydroxybenzoate EthersReaction temperature

The invention discloses an improved type synthesis process of a rubber aid. The synthesis process particularly comprises the following steps: adding an N-(4-methyl phenyl)2-N'-(1,3-dimenthyl butyl)p-phenylenediamine anti-ageing agent and an N,N'-diphenyl p-phenylenediamine anti-ageing agent into an acetone organic solvent simultaneously, stirring uniformly, adding vinyl stearate amide, and mixinguniformly to obtain a mixed solution; under the stirring condition, adding water and ethyl acrylate into the mixed solution, continuously adding para-hydroxybenzole dropwise after mixing uniformly, and controlling the reaction temperature to 50 DEG C, and after complete dropwise addition of the para-hydroxybenzole, heating to 80 DEG C, continuously performing reaction, cooling to room temperature,and performing extraction, washing, and drying to obtain a finished product. According to the synthesis process provided by the invention, the integrated step is simple, preparation of the anti-ageing agent can be completed at low temperature and within short time, the synthesis cost is greatly reduced and the economic benefit is improved.

Owner:昕中和成都胶业有限公司

Indirect heating-type synthesis assembly for high-temperature and high-pressure artificial single crystal synthesis by using cubic press

InactiveCN102600768BImprove stabilityIncrease temperatureUltra-high pressure processesPyrophylliteNiobium

The invention relates to an indirect heating-type synthesis assembly for single crystal synthesis by using a cubic press. The indirect heating-type synthesis assembly comprises pyrophyllite powder pressing block which is internally lined with a dolomite casing. The indirect heating-type synthesis assembly is characterized in that a cylindrical metal cup made of metal niobium, tantalum, molybdenum or tungsten is arranged in the dolomite casing, an aluminum oxide ceramic high-temperature pipe is wrapped outside the cylindrical metal cup and the aluminum oxide ceramic high-temperature pipe is made of alpha-aluminum oxide and talc through high-temperature sintering; metal conducting strips are respectively arranged on the two sides of the metal cup and are connected with the metal cup; and the two ends of the dolomite casing are respectively sealed by composite conducting plugs and the composite conducting plugs are connected with the metal conducting strips. The indirect heating-type synthesis assembly uses high-melting-point metals to make the metal cup which is also used as an electric heating element, aluminum oxide ceramic materials are additionally used for making the high-temperature protection pipe, the indirect heating-type synthesis assembly is suitable for synthesizing artificial single crystals such as diamonds by using the cubic press, the requirements of higher temperature and longer heating time are satisfied, the stability of single crystal synthesis technology and equipment is improved, the losses of anvils are reduced and favorable conditions are provided for the synthesis of gem grade diamonds.

Owner:常熟市怡华金刚石有限公司 +1

Magnetite in nanoparticulate form

ActiveUS20120251437A1High hyperthermic efficiencyEasy and efficientMaterial nanotechnologyHeavy metal active ingredientsNanoparticleMagnetosome

The present invention relates to a process for the polyol-type synthesis of nanoparticulate magnetite starting from mixtures of Fe0 and FelIII in the presence of a mineral acid. The magnetite particles obtainable from the process have uniform size characteristics and have even presented higher SAR (Specific Absorption Rate) values than those of magnetosomes.

Owner:COLOROBBIA ITALA

A Method for Isomorphism Recognition of Kinematic Chains Containing Complex Hinges Based on Topological Feature Loop Codes

ActiveCN105447277BImprove automationGood isomorphic effectSpecial data processing applicationsTheoretical computer scienceMATLAB

The invention provides an isomorph identification method for complex-hinge-containing kinematic chains based on topological characteristic loop codes. The isomorphic identification method comprises the following steps: first, calculating maximum loops of all excessive freedom degree vertexes according to a bi-color topological diagram adjacent matrix of the kinematic chains and to a corresponding algorithm; generating standardized bi-color topological diagram loop codes based on the maximum loops; taking the largest loop code as the topological characteristic loop code of the corresponding kinematic chain, wherein the topological characteristic loop code is in one-to-one correspondence with the kinematic chain, is unique, and represents the topological invariance of the kinematic chain; and finally, the purpose of isomorph identification can be realized via topological characteristic loop codes of two kinematic chains. The isomorph identification method has the advantages that calculation and simulation are conducted in an MATLAB; more than 3000 types of kinematic chains containing 10 or less complex hinges can be constructed when the isomorph identification method is combined with a corresponding type synthesis method; and results show that the isomorph identification method is practical, reliable and effective.

Owner:QUANZHOU INST OF EQUIP MFG

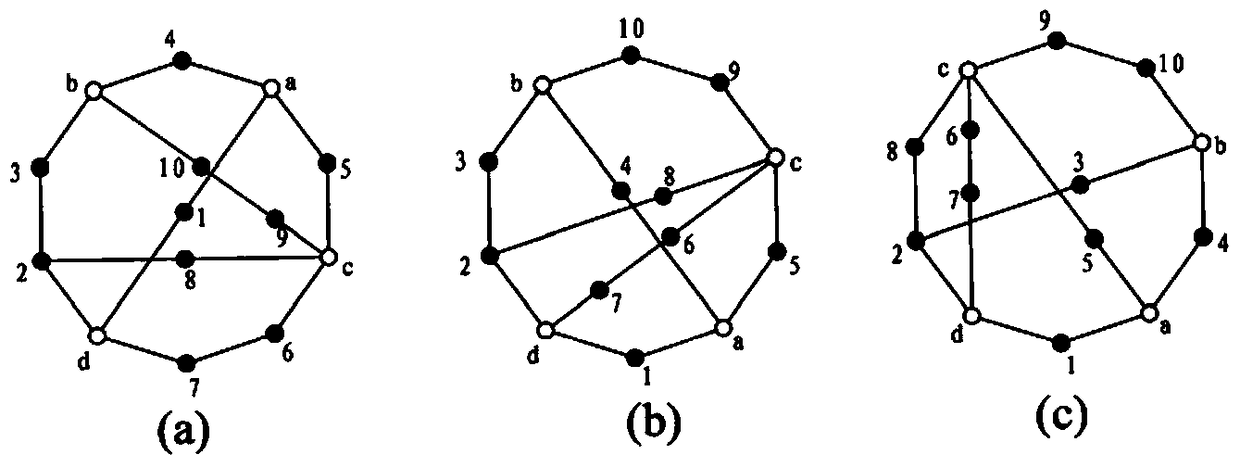

Preparation method of 3-[4-(3-pyridyl)-1H-imidazolyl-2-sulfo]-1-propylanmine

InactiveCN104211681AFew reaction stepsThe reaction step is stableOrganic chemistryHydrobromideSynthesis methods

The invention discloses a preparation method of 3-[4-(3-pyridyl)-1H-imidazolyl-2-sulfo]-1-propylanmine which is represented in the description. The preparation method adopts a converge type synthesis route, and comprises the following steps: taking 3-acetylpyridine as the raw material, subjecting 3-acetylpyridine to bromination reactions so as to obtain 3-bromoacetylpyridine hydrobromide; taking N-(3-bromopropyl)phthalimide as the raw material, making N-(3-bromopropyl)phthalimide carry out condensation reactions with thiourea, then making the reaction product carry out ring-closing reactions with 3-bromoacetylpyridine hydrobromide, and finally subjecting the reaction product to hydrazinolysis reactions so as to obtain the target product. The synthesis method has the advantages of easily-available and cheap raw material, fewer reaction steps, stability, simple operation, high yield, and suitability for industrial massive production.

Owner:INST OF MATERIA MEDICA CHINESE ACAD OF MEDICAL SCI

Compound and synthesis method and application thereof

ActiveCN110105344AStrong inhibitory activitySugar derivativesGroup 5/15 element organic compoundsChemical synthesisDisease

The invention relates to a compound and a synthesis method and application thereof. The compound has the structure shown in the general formula I. The compound has the quite good restraining activityfor different tumor cell lines and has the ideal anti-tumor and anti-skin-disease treatment effect under the illumination condition. The invention further relates to the synthesis method of the compound. A chemical full-synthesis route is adopted in the method; the converging type synthesis route can be applied to the chemical synthesis of similar-structure compounds and related derivatives, and the broad development space is developed for novel anti-tumor and anti-skin-disease medicines.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 3-[4-(3-pyridyl)-1H-imidazolyl-2-sulfo]-1-propylanmine Preparation method of 3-[4-(3-pyridyl)-1H-imidazolyl-2-sulfo]-1-propylanmine](https://images-eureka.patsnap.com/patent_img/c39880c3-ff85-4775-9554-c629628e5bb7/BDA00003268204700011.PNG)

![Preparation method of 3-[4-(3-pyridyl)-1H-imidazolyl-2-sulfo]-1-propylanmine Preparation method of 3-[4-(3-pyridyl)-1H-imidazolyl-2-sulfo]-1-propylanmine](https://images-eureka.patsnap.com/patent_img/c39880c3-ff85-4775-9554-c629628e5bb7/BDA00003268204700021.PNG)

![Preparation method of 3-[4-(3-pyridyl)-1H-imidazolyl-2-sulfo]-1-propylanmine Preparation method of 3-[4-(3-pyridyl)-1H-imidazolyl-2-sulfo]-1-propylanmine](https://images-eureka.patsnap.com/patent_img/c39880c3-ff85-4775-9554-c629628e5bb7/FDA00003268204600011.PNG)