N-B synergistic high-flame-resistance type curing agent and synthesis method thereof

A synthesis method and curing agent technology are applied in the field of N-B synergistic high flame retardant curing agent and its synthesis field to achieve the effects of excellent flame retardancy, easy compatibility and excellent processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

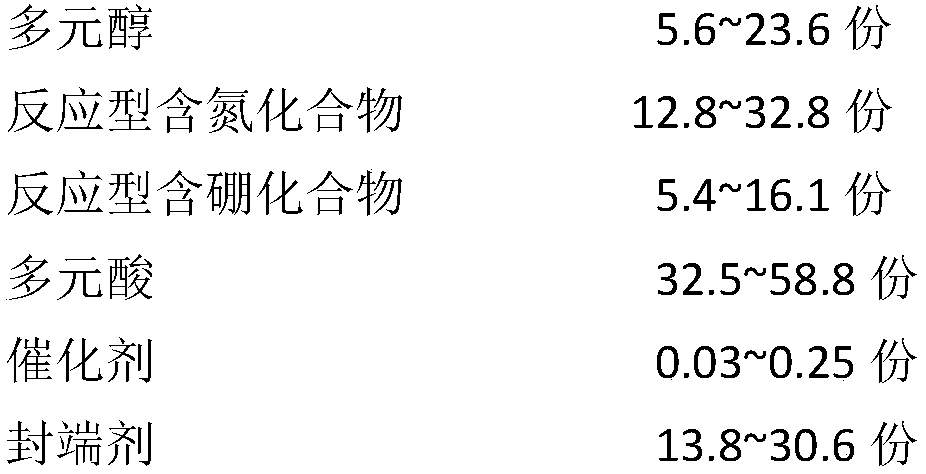

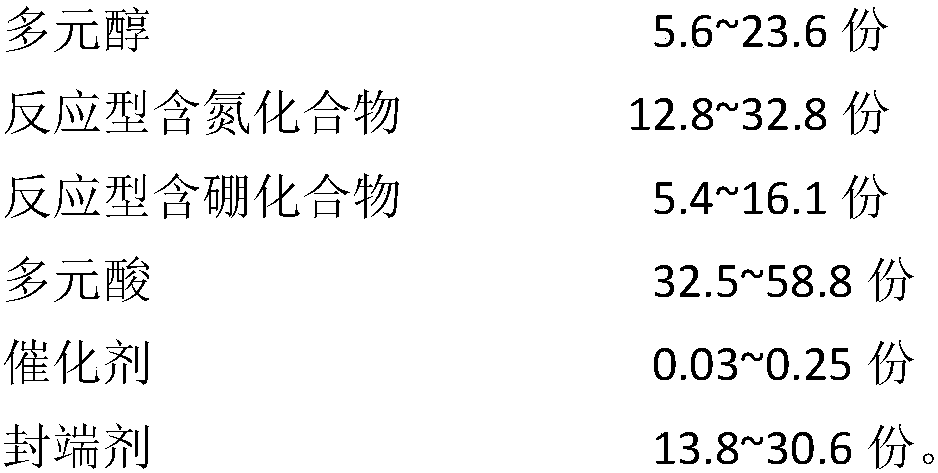

Method used

Image

Examples

Embodiment 1

[0034] A kind of synthetic method of N-B synergistic high flame retardant curing agent (A), the steps are as follows:

[0035] (1) After finishing the four-neck flask, stirrer, distillation column, condenser tube and temperature-controlled heating mantle, add 120g of neopentyl glycol and 168.21g of 1,3-dimethylol-5,5-dimethylhydantoin, and raise the temperature To 110~130℃, stirring and melting;

[0036] (2) Add 85.48g of 3-carboxyphenylboronic acid and 0.37g of ethyltriphenylphosphine bromide; slowly raise the temperature to 150°C under nitrogen, and distill out by-product water. During the reaction, control the temperature of the distillation column to not exceed 100°C, and then carry out segmented esterification reaction, 150~160°C for 1~3h, 160~170°C for 1~2h;

[0037](3) Cool down to 150°C, add 248.83g of isophthalic acid, 84.18g of adipic acid and 0.33g of ethyltriphenylphosphine bromide, slowly raise the temperature to 150°C under nitrogen, and carry out a segmented es...

Embodiment 2

[0042] A kind of synthetic method of multi-branched N-P synergistic flame retardant flexible curing agent (B), the steps are as follows:

[0043] (1) After finishing the four-neck flask, stirrer, distillation column, condenser tube and temperature-controlled heating mantle, add 105g of neopentyl glycol and 184.33g of 1,3-dimethylol-5,5-dimethylhydantoin, and raise the temperature To 110~130℃, stirring and melting;

[0044] (2) Add 76.32g of 3-carboxyphenylboronic acid and 0.36g of ethyltriphenylphosphine bromide; slowly raise the temperature to 150°C under nitrogen, and distill out by-product water. During the reaction, control the temperature of the distillation column to not exceed 100°C, and then carry out segmented esterification reaction, 150~160°C for 1~3h, 160~170°C for 1~2h;

[0045] (3) Cool down to 150°C, add 239.26g of isophthalic acid, 105.23g of adipic acid and 0.34g of ethyltriphenylphosphine bromide, slowly raise the temperature to 150°C under nitrogen, and car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com