Epoxy resin composition with excellent flame resistance and flame resistant durability and preparation method thereof

A technology of epoxy resin and flame retardancy, applied in the field of epoxy resin composition and its synthesis, to achieve the effects of excellent flame retardancy, good processability and processability, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

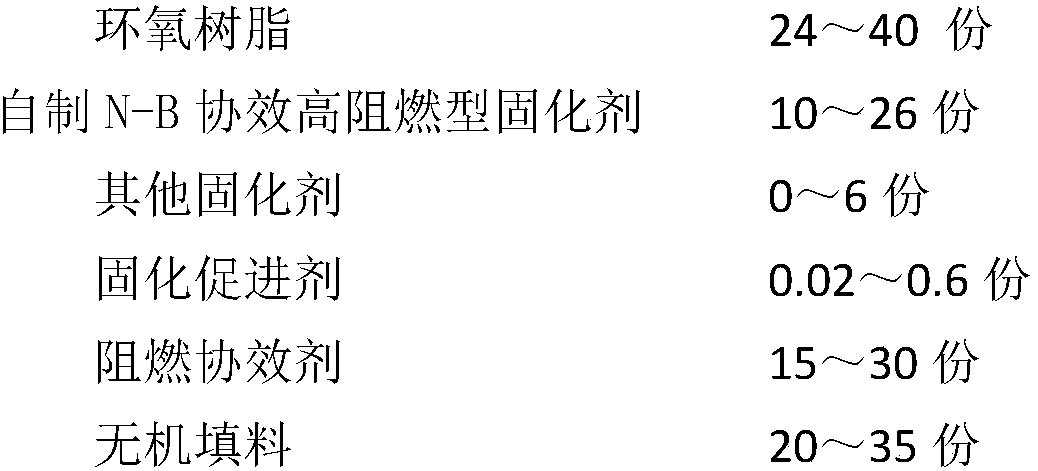

[0039] A preparation method of an epoxy resin composition with excellent flame retardancy and flame-retardant durability is as follows:

[0040] Premix epoxy resin, self-made N-B synergistic high flame retardant curing agent (A), other curing agents, curing accelerators and inorganic fillers according to the ratio of parts by mass. The premixing time is 3 to 10 minutes, and the speed is 600 ~1200r / min; melt extrusion mixing, extruder temperature 80~160°C, extruder speed 800~2400r / min, tablet cooling and crushing, crushing and sieving through ACM mill to obtain the epoxy resin combination.

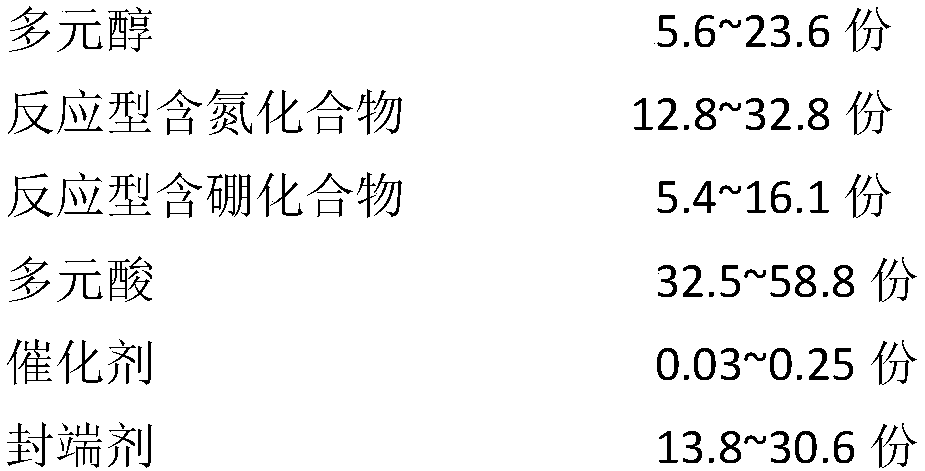

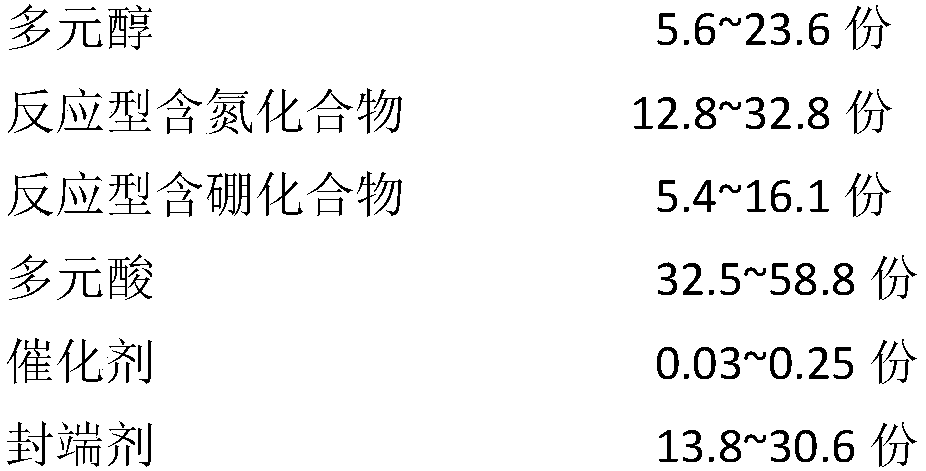

[0041] Wherein, the synthetic method of N-B synergistic high flame retardant curing agent (A):

[0042] (1) After finishing the four-neck flask, stirrer, distillation column, condenser tube and temperature-controlled heating mantle, add 120g of neopentyl glycol and 168.21g of 1,3-dimethylol-5,5-dimethylhydantoin, and raise the temperature To 110~130℃, stirring and melting;

[0043] (2) A...

Embodiment 2

[0049] A preparation method of an epoxy resin composition with excellent flame retardancy and flame-retardant durability is as follows:

[0050] Premix epoxy resin, self-made N-B synergistic high flame retardant curing agent (B), other curing agents, curing accelerators and inorganic fillers according to the ratio of parts by mass. The premixing time is 3 to 10 minutes, and the speed is 600 ~1200r / min; melt extrusion mixing, extruder temperature 80~160°C, extruder speed 800~2400r / min, tablet cooling and crushing, crushing and sieving through ACM mill to obtain the epoxy resin combination.

[0051] Wherein, the synthetic method of N-B synergistic high flame retardant curing agent (B):

[0052] (1) After finishing the four-neck flask, stirrer, distillation column, condenser tube and temperature-controlled heating mantle, add 105g of neopentyl glycol and 184.33g of 1,3-dimethylol-5,5-dimethylhydantoin, and raise the temperature To 110~130℃, stirring and melting;

[0053] (2) A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com