Patents

Literature

1567 results about "Neopentyl glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neopentyl glycol (IUPAC name: 2,2-dimethylpropane-1,3-diol) is an organic chemical compound. It is used in the synthesis of polyesters, paints, lubricants, and plasticizers. When used in the manufacture of polyesters, it enhances the stability of the product towards heat, light, and water. By esterification reaction with fatty or carboxylic acids, synthetic lubricating esters with reduced potential for oxidation or hydrolysis, compared to natural esters, can be produced.

Polyolefin fibers and method for the production thereof

InactiveUS6811716B1Poor propertyPoor processabilityOther chemical processesFibre typesFiberPolyolefin

A method for producing hydrophobic polyolefin-containing fibers or filaments, in particular cardable staple fibers, using spin finishes applied after spinning and stretching, that comprise at least one water-insoluble ester of a mono-, di-, tri- or tetrahydric alcohol with a molecular weight not exceeding 500 and a branched or straight chain fatty acid with between 12 and 30 carbon atoms, e.g. a water-insoluble ester of ethylene or propylene glycol, glycerol, neopentyl glycol, trimethylolethane or trimethylolpropane and at least one saturated or unsaturated fatty acid residue having 12-24 carbons atoms, an anionic or nonionic antistatic agent preferably being applied after crimping; fibers produced by the method; and nonwovens produced from such fibers.

Owner:FIBERVISIONS LP

Drilling fluid lubricating agent

ActiveCN101486896AMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionStearateTrimethylolpropane

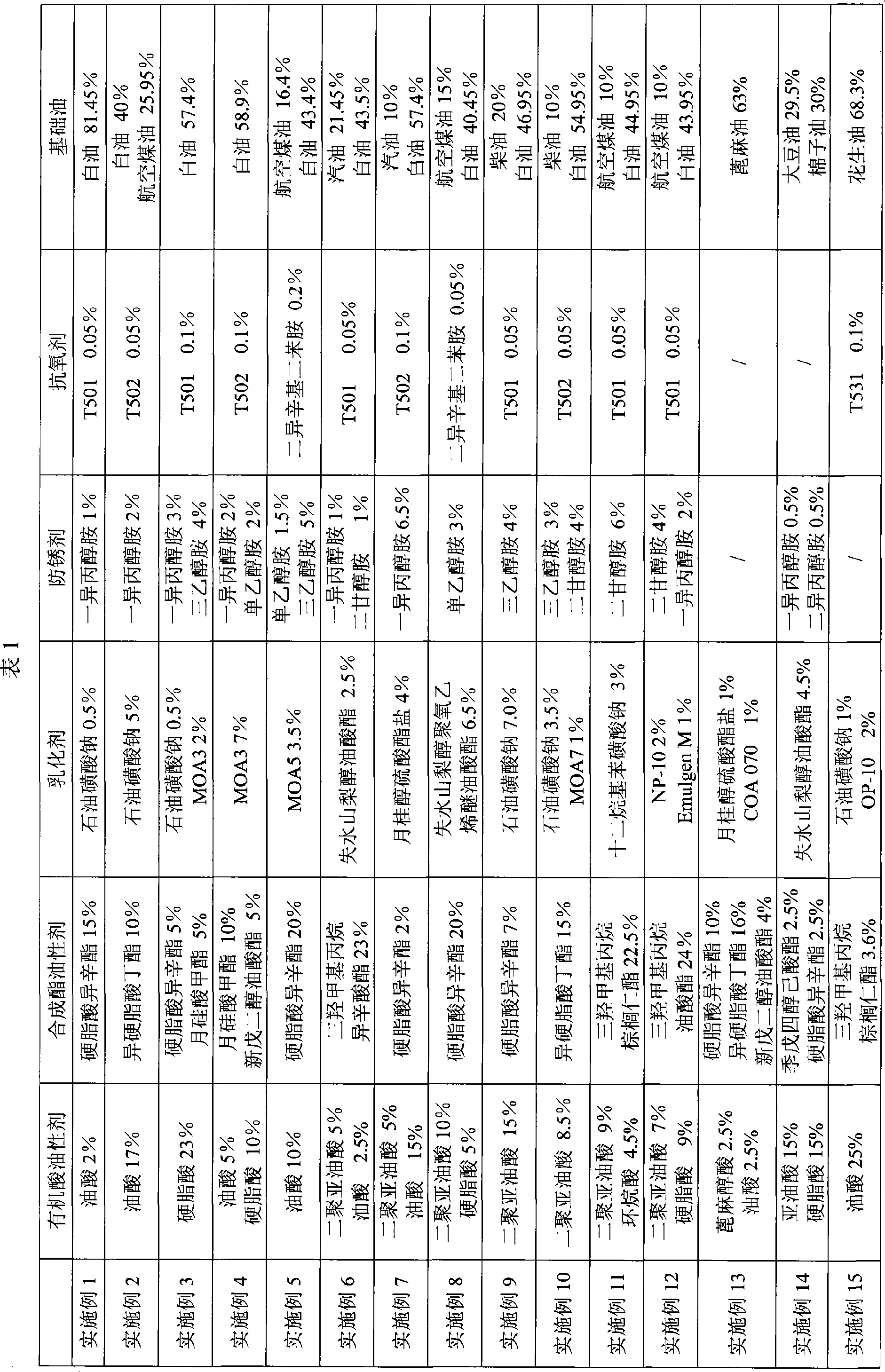

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil composition for refrigerators and compressors with the composition

ActiveUS20100147016A1Improve compatibilityImprove sealingPositive displacement pump componentsHeat-exchange elementsPolyolesterCarboxylic acid

A lubricating oil composition for refrigerators comprising a base oil which comprises as a main component a polyol ester compound obtained from a polyhydric alcohol selected from among pentaerythritol, dipentaerythritol, trimethylolpropane, and neopentyl glycol and a C4 to C20 aliphatic monocarboxylic acid and which has an acid value of 0.02 mgKOH / g or less and a hydroxyl value of 5 mgKOH / g or less. A compressor using the lubricating composition. The lubricating oil composition is applicable to such refrigerators that use a refrigerant having a specific structure, such as an unsaturated fluorinated hydrocarbon compound, and being usable in current car air conditioner systems, and has excellent compatibility with the refrigerant, good sealing properties, capability of imparting a low coefficient of friction to sliding members and, yet, excellent stability. The compressor uses the lubricating composition.

Owner:IDEMITSU KOSAN CO LTD

Room-temperature self-crosslinking water-soluble polyurethane acrylic resin and preparation method and application thereof

InactiveCN101544738ALow viscosityImprove conversion ratePolyureas/polyurethane adhesivesInksPolymer scienceAcrylic resin

The invention discloses a room-temperature self-crosslinking water-soluble polyurethane acrylic resin and a preparation method and an application thereof. The preparation method adopts an in-situ emulsion polymerization method and improves the prior preparation method, introduces tetramethyl benzene dimethylene diisocyanate or 2, 4 methyl cyclohexyl diisocyanate, and dipropylene glycol or neopentyl glycol functioning as chain extendor in raw materials, thereby lowering the viscosity of polyurethane prepolymer, and achieving the purpose of performing the synthetic reaction without organic solvent; oil-soluble evocating agent and water-soluble evocating agent are adopted to together evocate radical copolymerization so that oil-soluble monomer and water-soluble monomer can more effectively perform the radical copolymerization, thereby improving the reaction conversion rate. In addition, the combination of the two evocating agents also leads emulsion in the reaction to keep stable without easily jellifying and layering. The resin can be used for preparing plastics, aluminum foil package compound gel, paper-plastics compound gel, water color ink, water oil polish, water wooden ware paint or water plastic paint.

Owner:SUN YAT SEN UNIV

Marine concrete corrosion resistant additive and preparation thereof

The invention relates to the technical field of building material, in particular to a maritime work concrete corrosion-proof additive. The maritime work concrete corrosion-proof additive consists of a calcium sulphoaluminate expansion agent, a methyl naphthalene sulphonic acid water reducing agent, organosilicon hydrophobic powder, neopentylene glycol, milled slag powder, polypropylene fibers, silicon ash, superfine fly ash and arenaceous quartz. The maritime work concrete corrosion-proof additive can reduce the water consumption for mixing concrete, improve the water retention and cohesiveness, and improve the resistance of the concrete to seawater erosion and the durability.

Owner:TONGJI UNIV

Lubricating oil composition for refrigerators

ActiveUS20100133463A1Improve compatibilityLow global warming potentialHeat-exchange elementsAdditivesPhosphorous acidScavenger

A lubricating oil composition for refrigerators including (A) a base oil containing as a main component a polyol ester compound obtained from a polyhydric alcohol selected from among pentaerythritol, dipentaerythritol, trimethylolpropane and neopentyl glycol and a C4 to C20 aliphatic monocarboxylic acid, (B) a phosphorus-based additive comprised of a phosphoric acid triester and / or a phosphorous acid triester, and (C) at least one acid scavenger selected from among glycidyl esters, glycidyl ethers and α-olefin oxides.The lubricating oil composition is applicable to such refrigerators that use a refrigerant having a specific structure, such as an unsaturated fluorinated hydrocarbon compound, and being usable in current car air conditioner systems, and has excellent compatibility with the refrigerant, good sealing properties, capability of imparting a low coefficient of friction to sliding members and, yet, excellent stability.

Owner:IDEMITSU KOSAN CO LTD

H-grade low-temp. beading polyurethane paint wire-covering paint

InactiveCN1394926AEasy to control smoothnessReduce dosagePolyurea/polyurethane coatingsPolyisocyanurateAdipic acid

The present invention relates to a H-grade low-temp. direct-welding enamelled wire enamel, said enamel liquor mainly includes three portions of hydroxyl component, closed type isocyanate component and solvent. The hydroxyl component is formed from raw materials of dihydric alcohol terephthate or amidoimide dihydric alcohol, new pentanediol or 2-methyl-1,3-propanedio, glycerine, 1,1,1-trihydroxymethyl propane, tri(alpha-hydroxyethyl) isocyanate, adipic acid and phthalic anhydride. The acid value of polyester polybasic alcohol is less than 2, hydroxy value is 70-250, number-average molecular weight is 2000-7000 and molecualr weight distribution index is 2-3. The isocyanate component is made up by using general raw material TDI and MDI through the processes of cyclic self-polymerization or addition with small quantity of tribasic alcohol and closing with dimethyl phenol.

Owner:NANJING UNIV

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

New elastic fiber and preparation method thereof

InactiveCN101357980ADyeing processConjugated synthetic polymer artificial filamentsPolytrimethylene terephthalateCopolyester

The invention provides a high elasticity fiber, which is a bicomponent composite fibre. One component of the bicomponent composite fiber is synthetic high contractility copolyester HSPET, which is prepared with terephthalic acid, m-phthalic acid, glycol and neopentyl glycol through esterification and polycondensation reaction; and the other component of the bicomponent composite fiber is polytrimethylene terephthalate. After the bilateral composite fiber is heated, a helical tridimensional curled structure is got so that the fiber has excellent elastic elongation and elastic recovery. The bicomponent composite fiber is a novel functional fibrous material applicable for weaving elastic textiles.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Universal refrigerant resistant solvent-free impregnating resin for high and low voltage motor and preparation method thereof

ActiveCN102604384ASolve defects such as inability to be used universallyLow VOC contentLow voltageSolvent free

The invention relates to a universal refrigerant resistant solvent-free impregnating resin for a high and low voltage motor and a preparation method thereof. The impregnating resin is composed of 45-65 parts of unsaturated polyesterimide resin solution with 65-75% of solid content, 15-35 parts of oxazolidone resin solution with 75-85% of solid content, 10-25 parts of environment-friendly dilutingagent, 3-8 parts of curing agent, 1-3 parts of initiating agent and 0.01-0.06 part of polymerization inhibitor; the raw material formula of an unsaturated polyesterimide resin comprises a first monomer, a second monomer and a third monomer, wherein the first monomer is selected from one or multiple of neopentyl glycol, propoxylation bisphenol A and trihydroxyethyl isocyanurate; the second monomeris selected from one or multiple of isophthalic acid, hexanedioic acid, trimellitie anhydride and maleic anhydride; and the third monomer is a compound containing imide groups. The resin provided by the invention has low content of VOC (Volatile Organic Compounds), resists novel refrigerating fluids such as R134a and is universal for the high and low voltage motor.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

UV-LED (ultraviolet-light emitting diode) photocureable coating and preparation method thereof

ActiveCN103980812AOxidizingImprove curing effectPolyurea/polyurethane coatings(Hydroxyethyl)methacrylateFunctional monomer

The invention discloses a UV-LED (ultraviolet-light emitting diode) photocureable coating and a preparation method thereof. The photocureable coating is characterized by consisting of the following components in percentage by mass: 20-30% of high-functionality fatty acid polyurethane acrylate oligomer 6197, 10-20% of two-functionality polyurethane acrylate 6071, 10-20% of TMPTA (trimethylolpropane triacrylate) serving as a three-functionality functional monomer and an active diluent, 0.1-0.3% of foam inhibitor TEGO920, 10-20% of NPGDA (neopentyl glycol diacrylate) serving as a two-functionality functional monomer and an active diluent, 10-20% of HEMA (hydroxyethyl methacrylate) serving as a single-functionality functional monomer and an active diluent, 0.2-0.5% of flatting agent BYK358N, and 5-10% of HABI-L (hexaarylbiimidazole-L) serving as a photo-initiator. The photocureable coating has the advantages of quick curing, energy conservation, environmental friendliness and the like, and the production efficiency of UV-LED photocuring is promoted.

Owner:SHANGHAI ZHENGOU IND

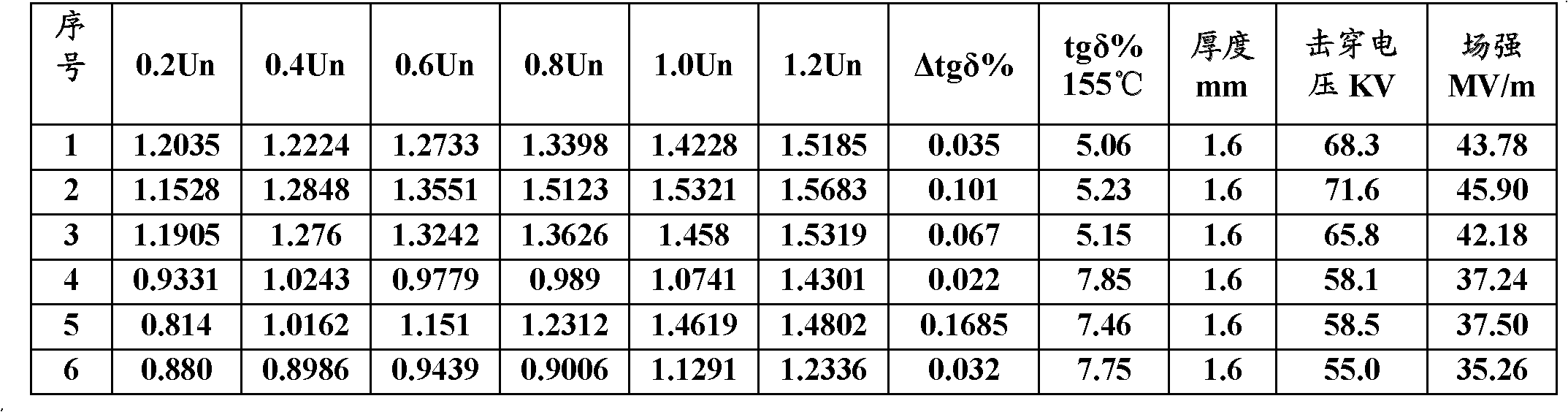

Polyester resin for mixed powder coating and preparation method thereof

ActiveCN101704945AUniform reaction rateGood solvent resistancePowdery paintsPolyester coatingsLow temperature curingAdipic acid

The invention relates to the field of powder coatings, in particular to a polyester resin for a mixed thermal transfer powder coating and a preparation method thereof. The polyester resin for the mixed thermal transfer powder coating comprises the following components and contents: 1 mole percent of acids, 1.05-1.20 mole percent of alcohols, 10-15wt% of trimellitic anhydride and 0.1-1.0wt% of recomposed onium salts, wherein the alcohols accounting for the total alcohol mol percent comprise 10-90 mol% of neopentyl glycol, 0-45 mol% of dimethyl-1,3-propanediol, 0-20 mol% of ethanediol, 10-25 mol% of diethylene glycol; and the acids accounting for the total acid mol percent comprise 80-100 mol% of terephthalic acid, 0-10 mol% of m-phthalic acid and 0-10 mol% of mol% of adipic acid. The functionality of the polyester resin is regulated according to the amount of the branched components of the trimellitic anhydride, thus the obtained cured film has better surface appearance, low temperature (160 DEG C) curing is realized, the curing percent of film coating at low temperature is high, the curing film has fine solvent resistance and the transfer-printed transfer printing film is clear, vivid and easy to tear.

Owner:HUANGSHAN SHENJIAN NEW MATERIAL CO LTD

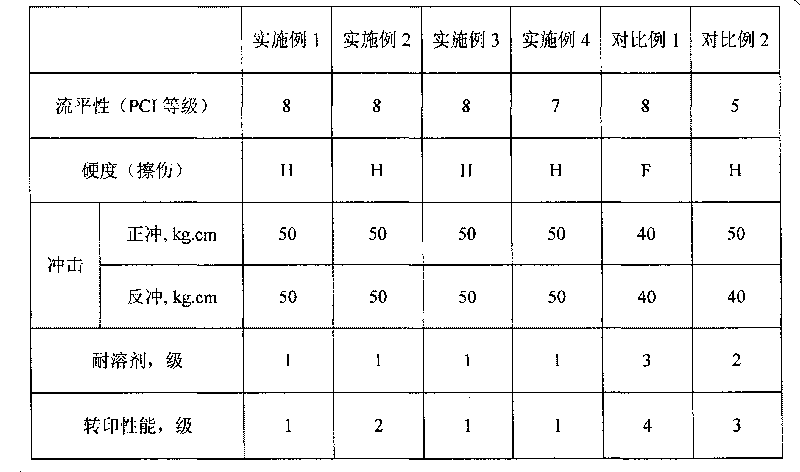

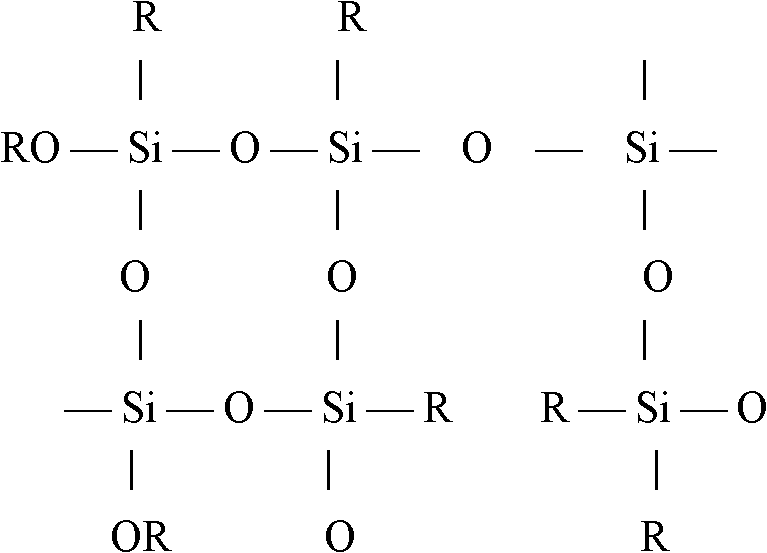

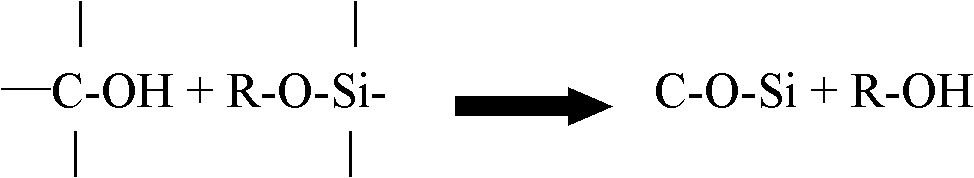

Preparation method of modified hydroxyl polyester resin

ActiveCN102167807AAdequate responsePolyurea/polyurethane coatingsPowdery paintsReaction temperatureAcid value

The invention discloses a preparation method of modified hydroxyl polyester resin. The method comprises the working procedures of reaction, curing and mixing. The reaction working procedure comprises the following steps: rising the temperature of a synthesis kettle to 90-100 DEG C, adding neopentyl glycol, trimethylolpropane and organosilicon resin in turn, sealing the kettle after feeding, heating, filling nitrogen to perform production protection, heating to 240 DEG C, keeping the reaction temperature for 2 hours, reducing the temperature of the kettle to 225 DEG C, adding m / p-phthalic acid and butyltin oxide, heating to 240 DEG C, keeping the temperature to react for 3 hours, and reducing the top temperature of the reaction kettle to less than 70 DEG C to sample and analyze, wherein the acid value is 8-10mgKOH / g. Compared with the prior art, by adopting the preparation method, organosilicon resin can fully react; and the modified polyester is transparent, the condition that organosilicon resin is pale and milky when not reacted completely does not exist.

Owner:ANHUI SHENJIAN NEW MATERIALS

Modified polyester and preparation method thereof

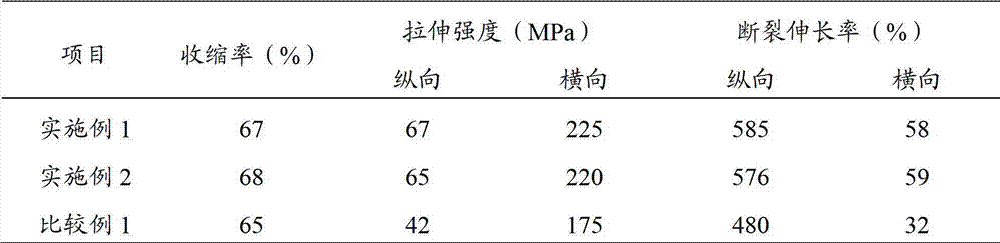

The invention provides modified polyester obtained by copolymerizing isophthalic acid, neopentyl glycol, 1,4-cyclohexanedimethanol, terephthalic acid and ethylene glycol. The modified polyester has the beneficial effects that isophthalic acid, neopentyl glycol and 1,4-cyclohexanedimethanol are taken as modifying agents to modify PET (polyethylene glycol terephthalate), that is, isophthalic acid, neopentyl glycol, 1,4-cyclohexanedimethanol, terephthalic acid and ethylene glycol are taken as raw materials to undergo copolymerization to obtain a PET copolymer; by using isophthalic acid, neopentyl glycol and 1,4-cyclohexanedimethanol as the modifying agents, not only can the shrinkage of the modified polyester be increased but also the fragility of the modified polyester can be reduced, so that the modified polyester can not be broken when serving as tags for bottles and the yield is increased; and results show that the shrinkage of the modified polyester film provided by the invention is over 60%, the longitudinal tensile strength is over 60MPa, the lateral tensile strength is over 200MPa, the longitudinal elongation at break is over 500% and the lateral elongation at break is over 50%.

Owner:WEIFANG FUWEI PLASTIC

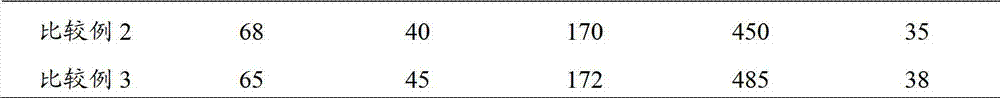

Fire retardant in use for cellulose and fabricating method

InactiveCN1563160AImprove flame retardant performanceMaintain flame retardant functionCelluloseEthylenediamine

The molecular formula of designed fire retardant for cellulose is C12H26O4P2S2N2 named as DDPSN. The preparing method includes reacting on trichloro-thiophosphorus with neophenyl dialcohol for 1.5-3 h. under dissolving of benzene or pyridine at 45-75 deg.C temperature, washing and distillating to remove benzene, forming DDSP by benzinum recrystallization and by drying for 24h. with airflow, reacting on drid DDSp with ethylene diamine for 3-5 hr. at 10-30 deg.C temp under dissolving of chloroform or carbon terochloride and obtaining DDPSN by ethyl ether recrystallization through 24 hr. drying with airflow.

Owner:TIANJIN POLYTECHNIC UNIV

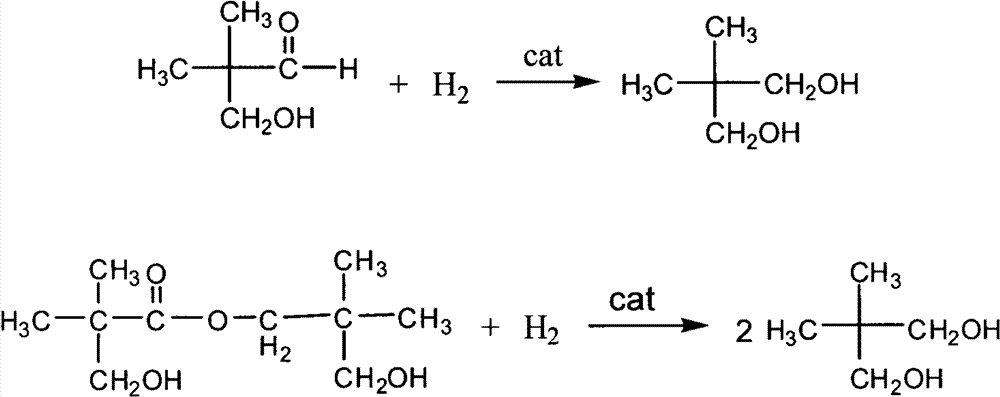

Method for preparing neopentylene glycol

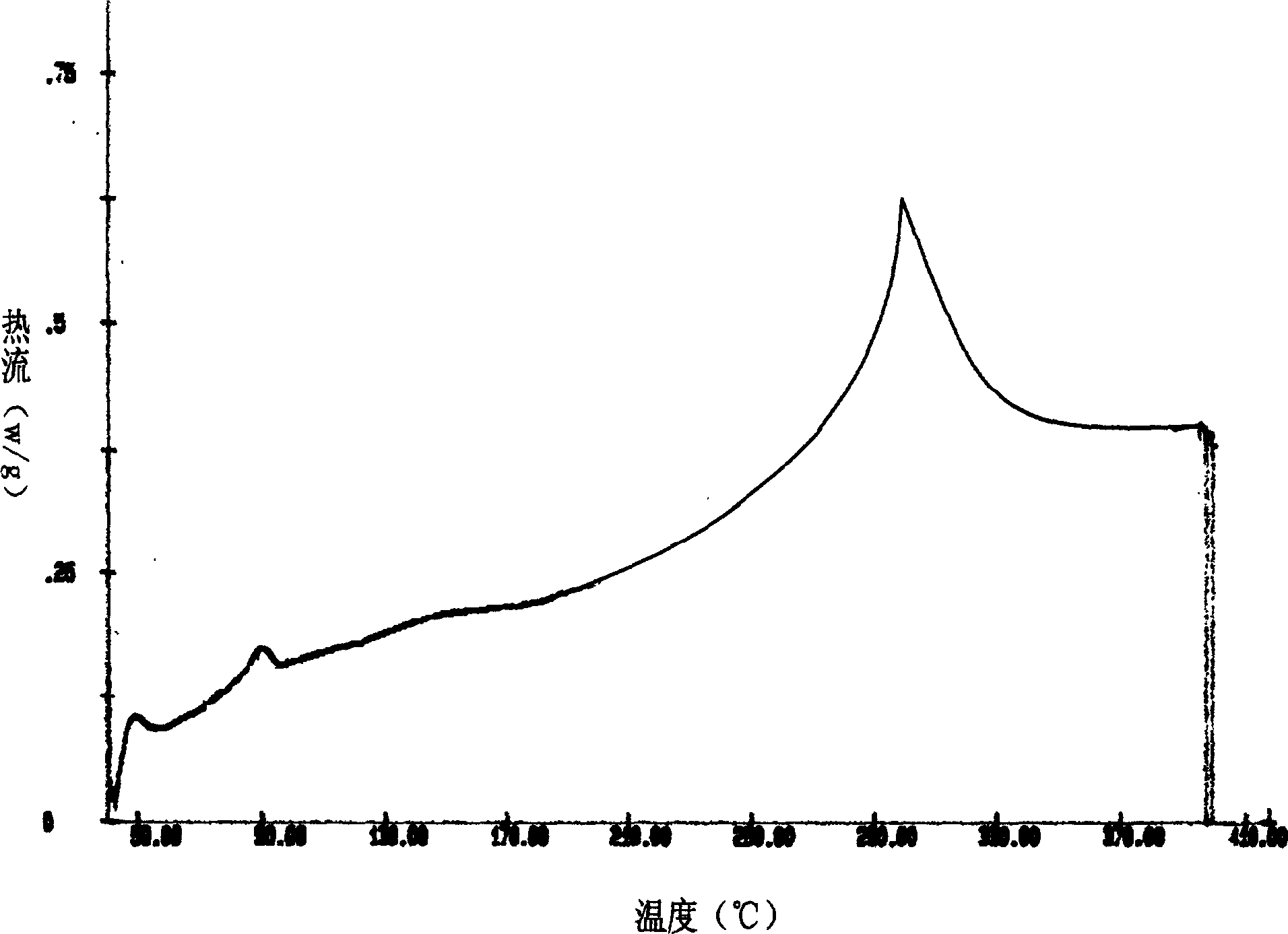

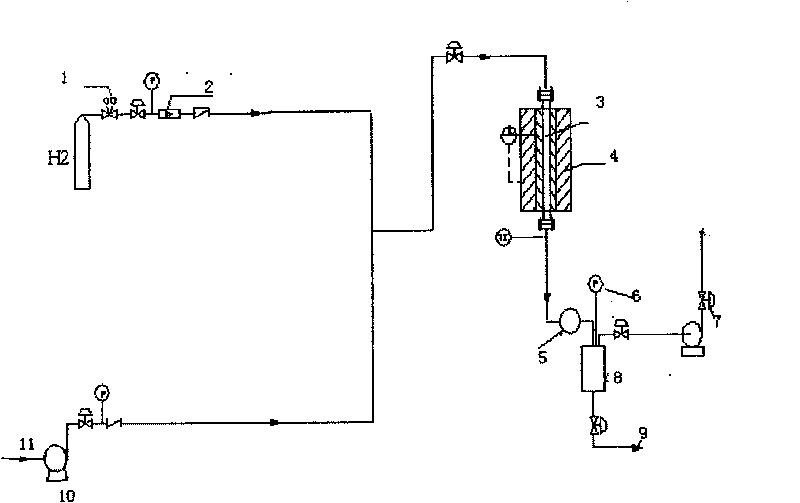

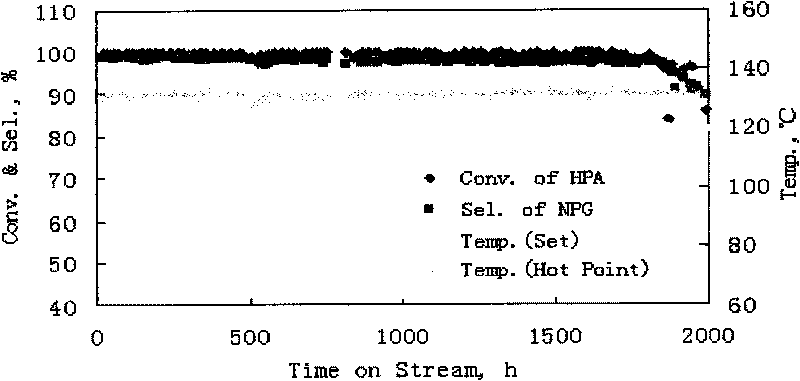

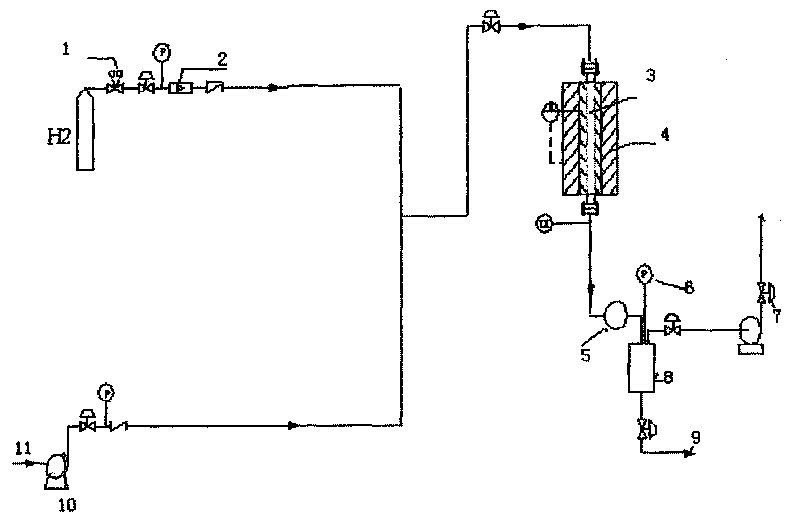

InactiveCN101735015ALarge amount of processingOrganic compound preparationHydroxy compound preparationOrganic solventHydrogenation reaction

The invention provides a method for preparing neopentylene glycol. In the method, in the presence of an organic solvent, hydroxyl pivalaldehyde(HPA) serving as a starting raw material undergoes a hydrogenation reaction in the presence of a copper-based catalyst to form the neopentylene glycol(NPG), wherein the reaction pressure is 1 to 5MPa, the reaction temperature is between 100 and 140 DEG C, a molar ratio of the hydrogen gas to the hydroxyl pivalaldehyde is 1-20:1, and the used organic solvent is saturated fatty alcohol or a mixture thereof. The conversion rate of the HPA in the raw material is over 99.5 percent, the selectivity of the generated NPG is over 97 percent, and the catalyst lifetime is over 2,000 hours.

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD

Water-in-oil type emulsified cosmetic

ActiveUS20100166684A1High affinityLittle occurrenceCosmetic preparationsOrganic active ingredientsIrritationMedicine

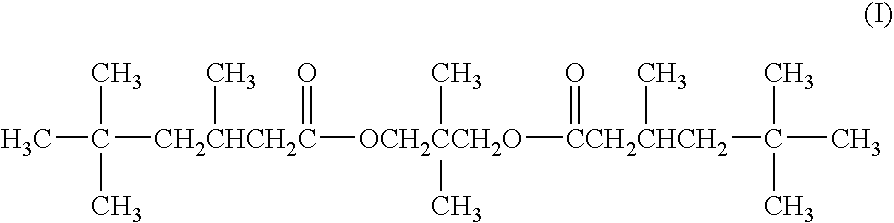

There is provided a novel water-in-oil type emulsified cosmetic comprising a diester of neopentylglycol with isononanoic acid. Said cosmetic exhibits not only the refreshed feeling on use without unfavorable stickiness after application, but also proper oily feeling. There are obtained good affinity to the skin, little occurrence of creasing and / or make-up deterioration, no oily sheen upon the elapse of long periods of time after application, and little irritation to the skin and excellent safety to the skin. In addition, the present cosmetic is able to be removed with commercially available cleansing agents. Moreover, the dispersibility of pigments as well as the storage stability is excellent.A water-in-oil type emulsified cosmetic comprising (A) 10 to 60 parts by mass of a diester represented by the following formula (I):(B) 1.0 to 11 parts by mass of a nonionic surfactant, (C) 0.3 to 11 parts by mass of an oil-soluble and / or water-soluble thickener, (D) 0.1 to 30 parts by mass of fine particles, and (E) 5.0 to 75 parts by mass of water, wherein the total of (A), (B), (C), (D) and (E) is 100 parts by mass.

Owner:KOKYU ALCOHOL KOGYO

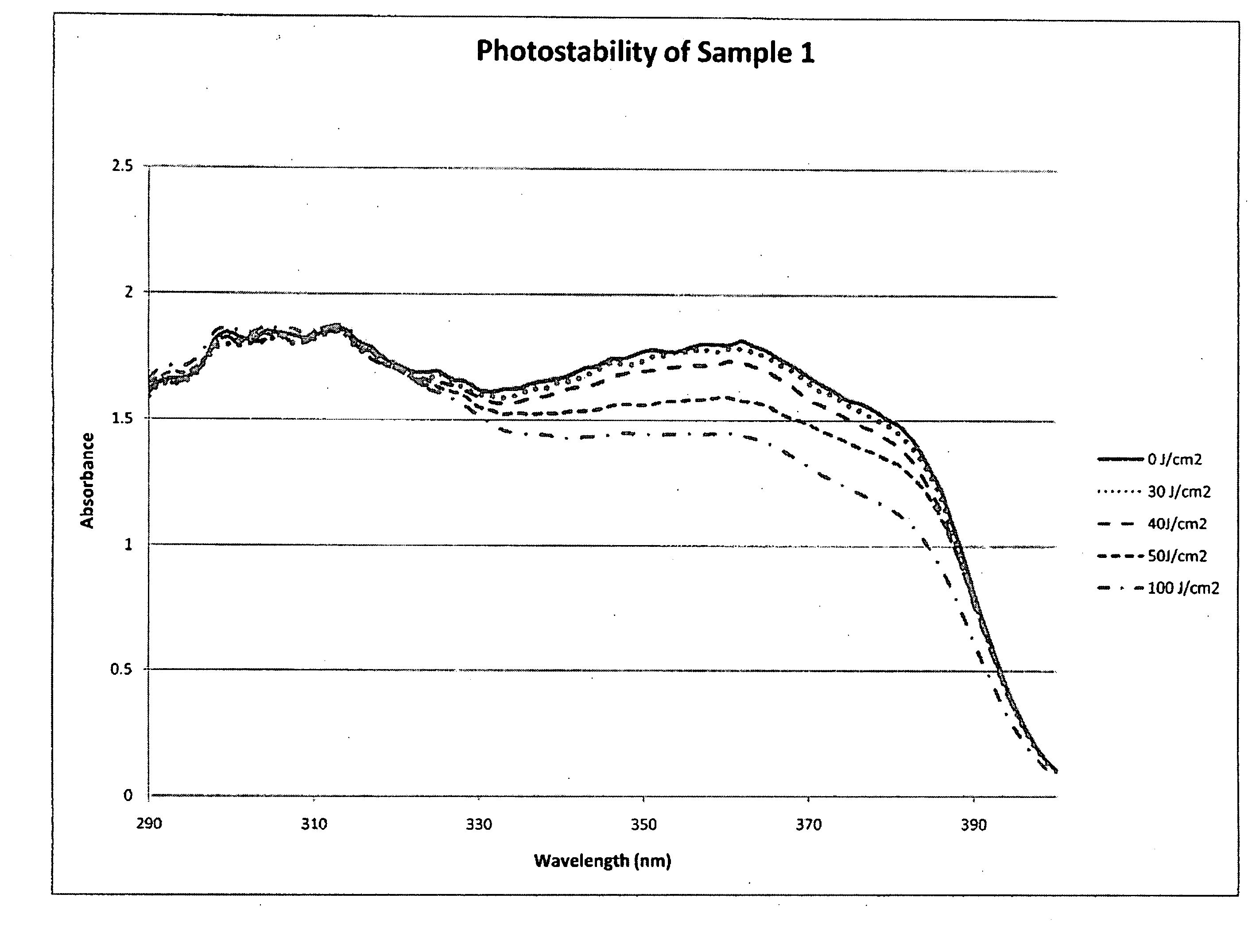

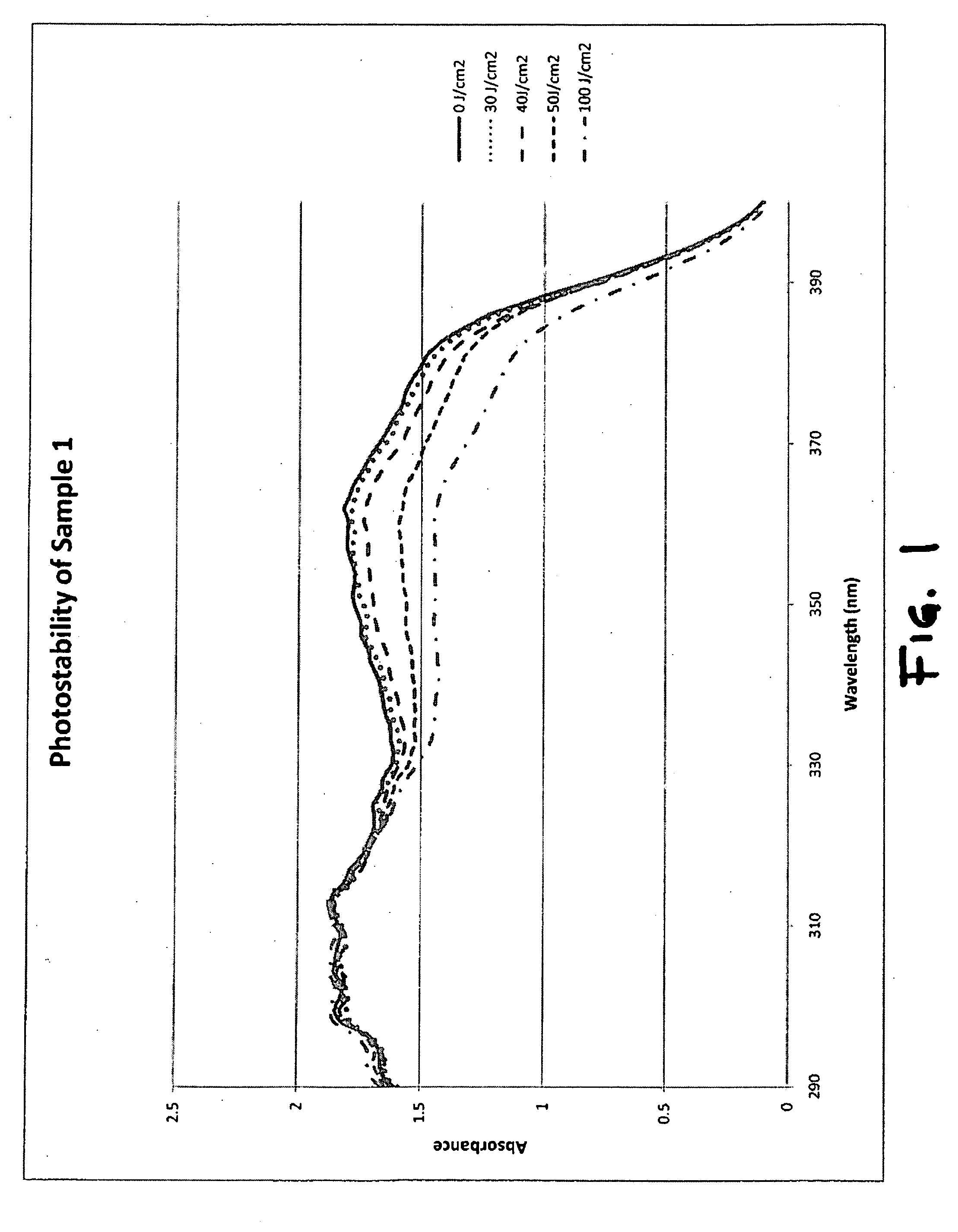

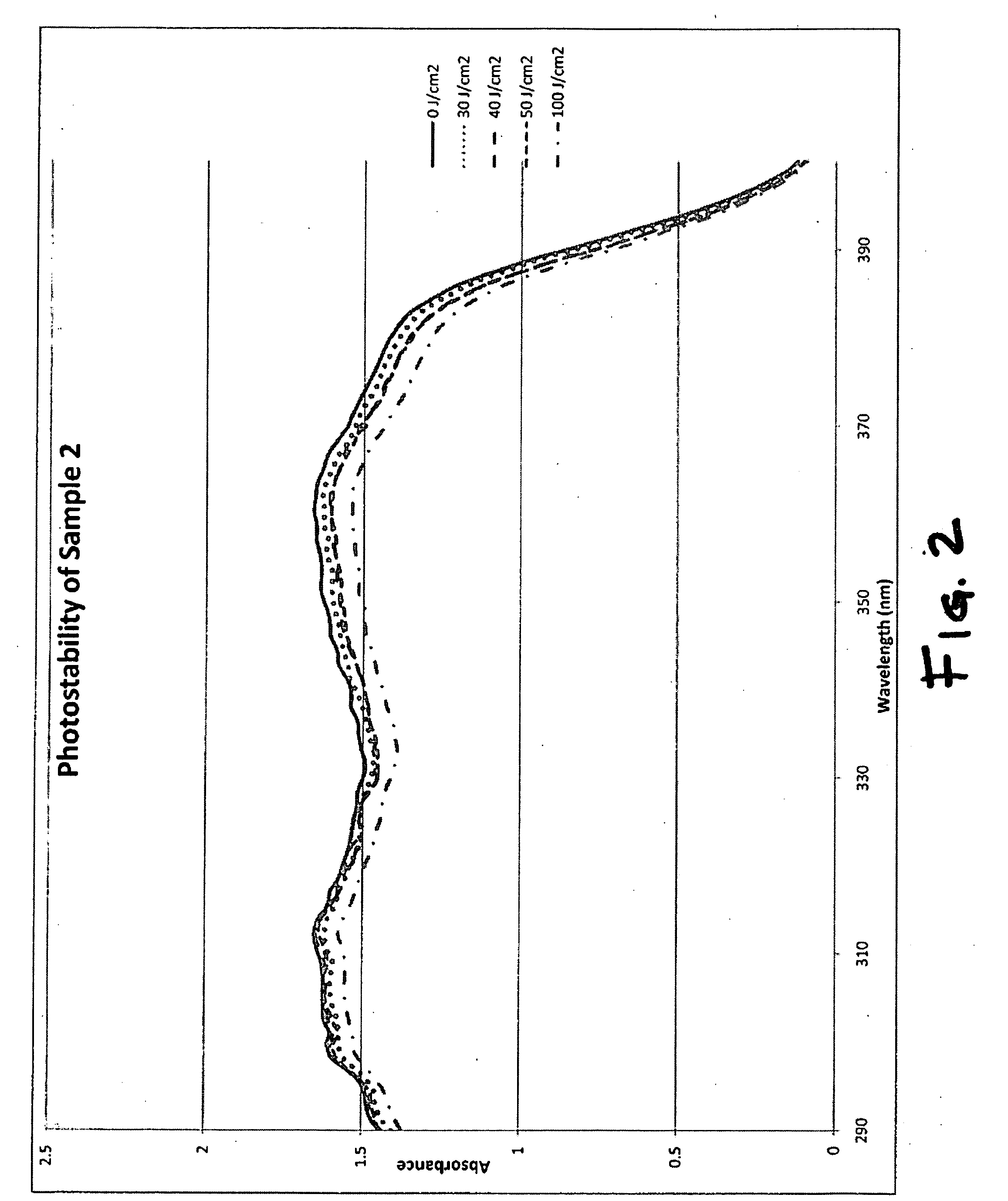

Sunless tanning composition with photostablized sunscreen

InactiveUS20090068130A1Achieve effectCosmetic preparationsToilet preparationsWater basedUv protection

In one aspect, a cosmetic composition includes a sunless tanning agent and a sunscreen agent. A photostabilizer is added to stabilize the sunscreen agent from the destabilizing effect of the sunless tanning agent. In this manner, UV protection is provided to the user when the cosmetic composition is applied to skin. In another aspect, a water-based sunless tanning / sunscreen composition includes a sunless tanning agent, a sunscreen agent, and a photostabilizer. The sunless tanning agent is DHA, and the sunscreen is avobenzone. Because the avobenzone degrades when exposed to UV radiation when used with DHA, the photostabilizer is added to enable the avobenzone to retain most of its original ability to absorb the UV radiation. The photostabilizer is a low molecular weight copolymer of adipic acid and neopentyl glycol.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

Preparation method of neopentyl glycol

ActiveCN103449970AReduce saponification processing stepsHigh purityOrganic compound preparationHydroxy compound preparationPolymer sciencePtru catalyst

The invention provides a preparation method of neopentyl glycol, and belongs to the technical field of the preparation of alcohols. The preparation method includes the following steps: (1) regulating the pH value of a hydroxypivalaldehyde solution to 7.5-10; (2) obtaining a neopentyl glycol crude product by catalytic hydrogenation of hydroxypivalaldehyde treated by the step (1) under the effect of a hydrogenation catalyst at the temperature of 110-140 DEG C and with the pressure of 2.0-5.0 Mpa; and (3) purifying the neopentyl glycol crude product obtained in the step (2). The content of esters and other side products in the neopentyl glycol crude product prepared by the preparation method of the neopentylene glycol is extremely low, and the yield and purity of the neopentyl glycol are improved. In addition, a hydroxypivalaldehyde raw material system can be directly used for catalytic hydrogenation without any treatment, processes of aldol condensation and catalytic hydrogenation for preparation of the neopentyl glycol can be reduced, and the production efficiency can be improved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

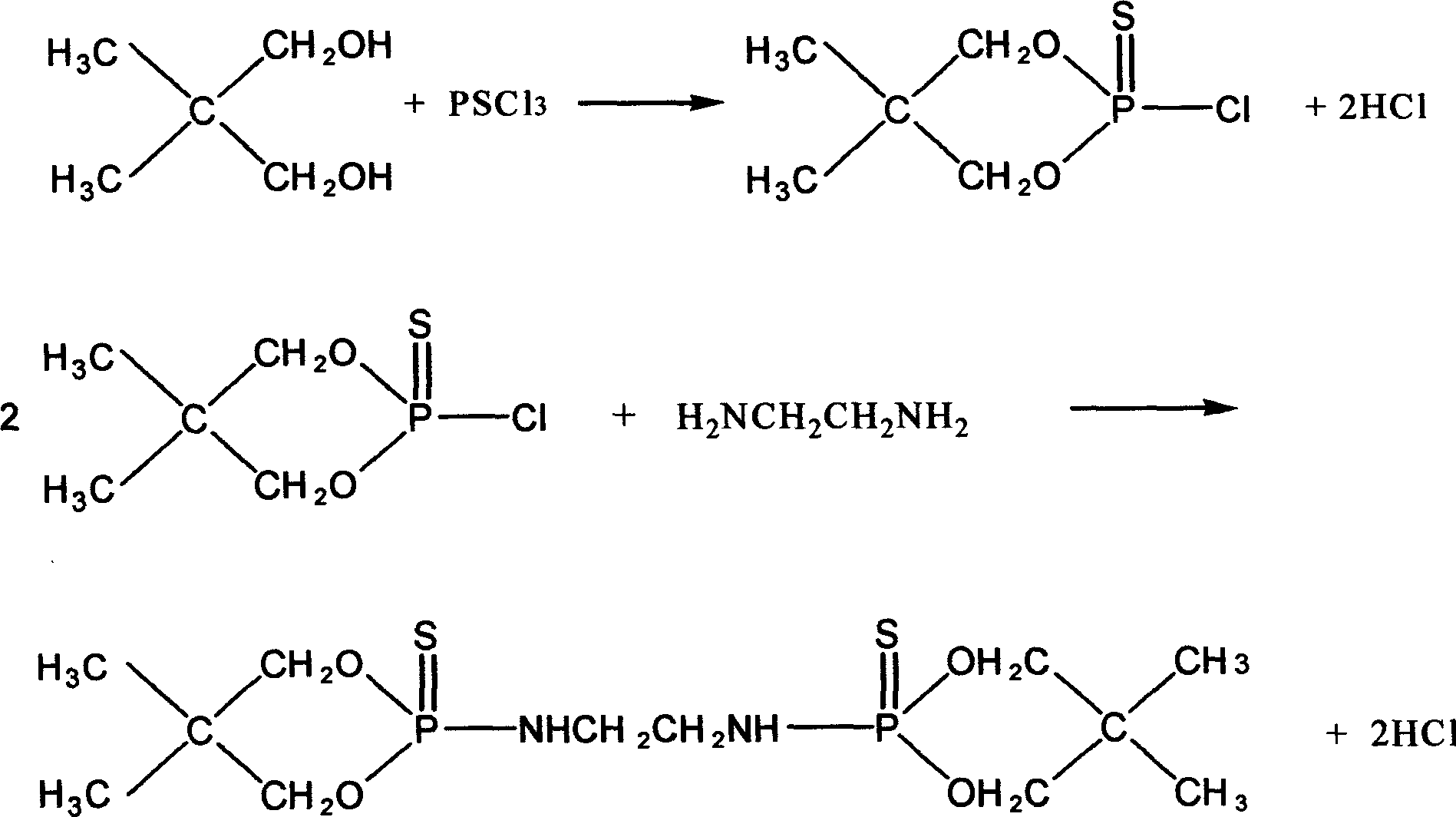

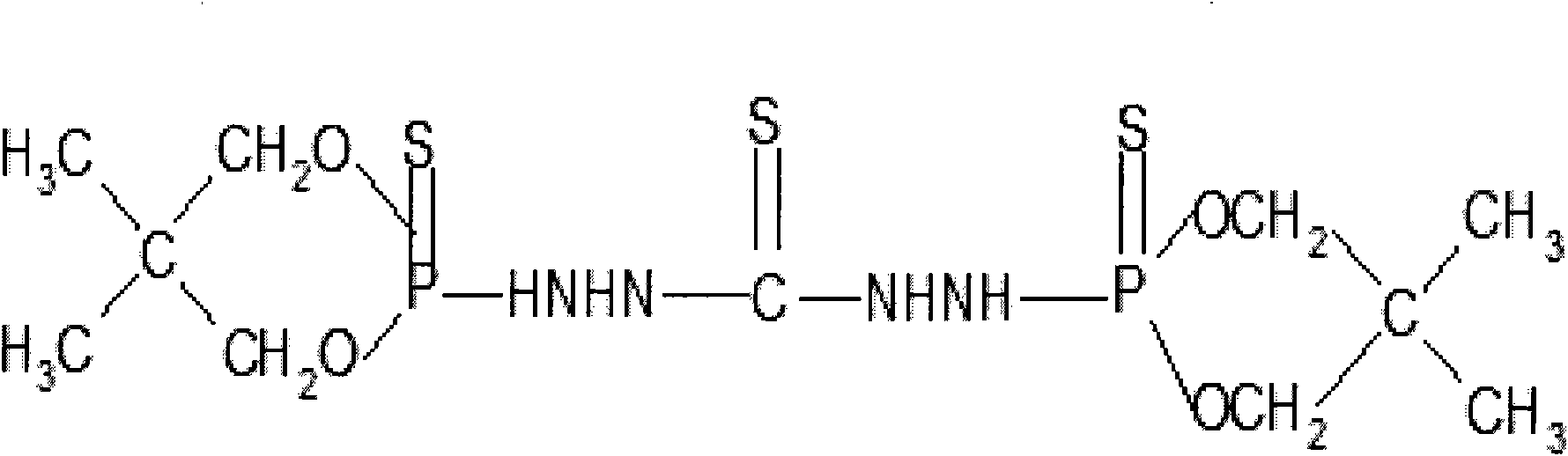

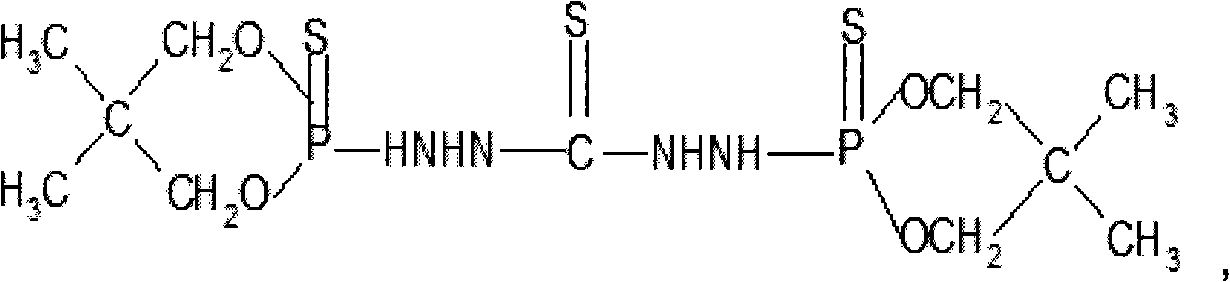

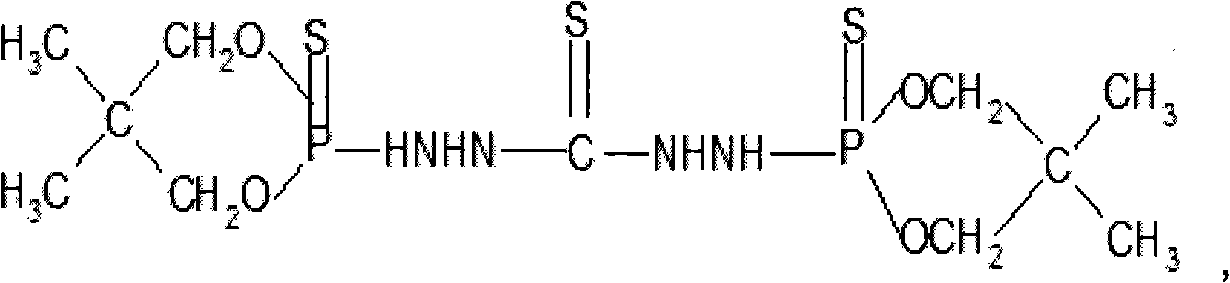

Intumescent flame retardant and synthesis method thereof

InactiveCN101974167AImprove moisture resistanceThe synthesis method is simpleGroup 5/15 element organic compoundsIce waterSynthesis methods

The invention discloses an intumescent flame retardant and a synthesis method thereof. The structural formula of the flame retardant is as shown in the figure, and the chemical name of the flame retardant is N,N'-bis(5,5-dimethyl-2-phospha-2-sulfo-1,3-dioxane-2-yl) dithiosemicarbazide. The synthesis method comprises the following steps: adding neopentyl glycol into a reaction vessel filled with a first solvent, dropwise adding phosphorus thiochloride at 50-100 DEG C, reacting for 2-10 h, carrying out reduced pressure distillation, washing with water, and drying to obtain a white solid, namely 2-sulfo-2-chloro-5,5-dimethyl-1,3,2-dioxaphosphorinane; and adding the white solid to a second solvent, adding dithiosemicarbazide and acid binding agent, reacting at 40-120 DEG C for 2-10 h, filtering, pouring the filtrate into ice water, dropwise adding a defined amount of inorganic acid until the pH value of the filtrate is 7 and white solid powder is separated out, washing, filtering, and drying to obtain the finished product.

Owner:TIANJIN POLYTECHNIC UNIV

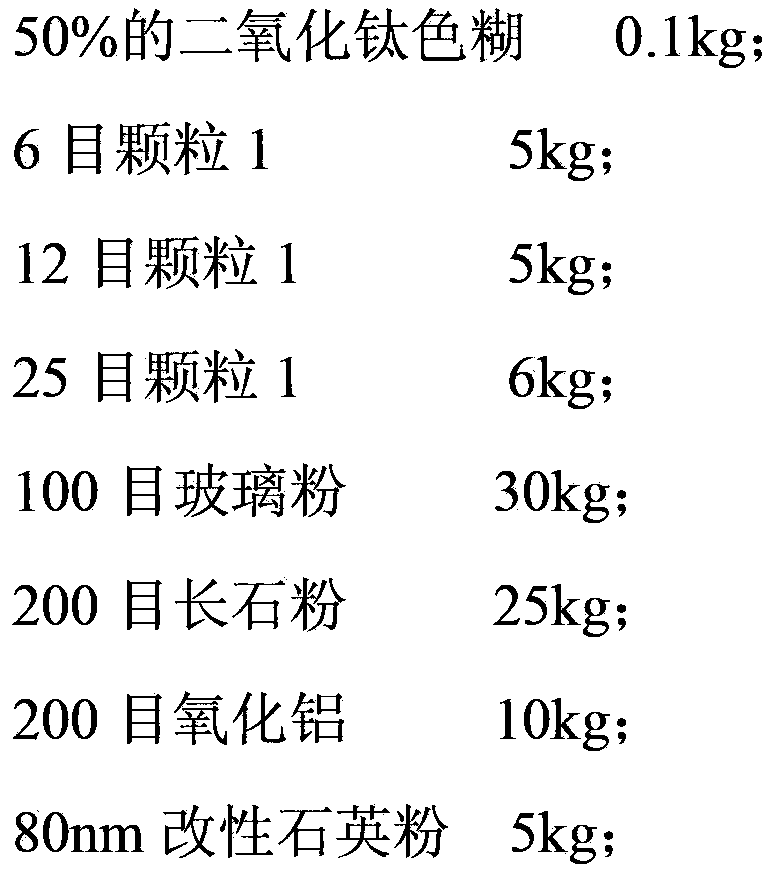

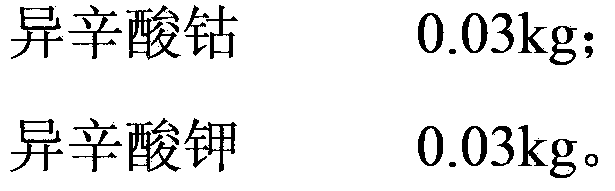

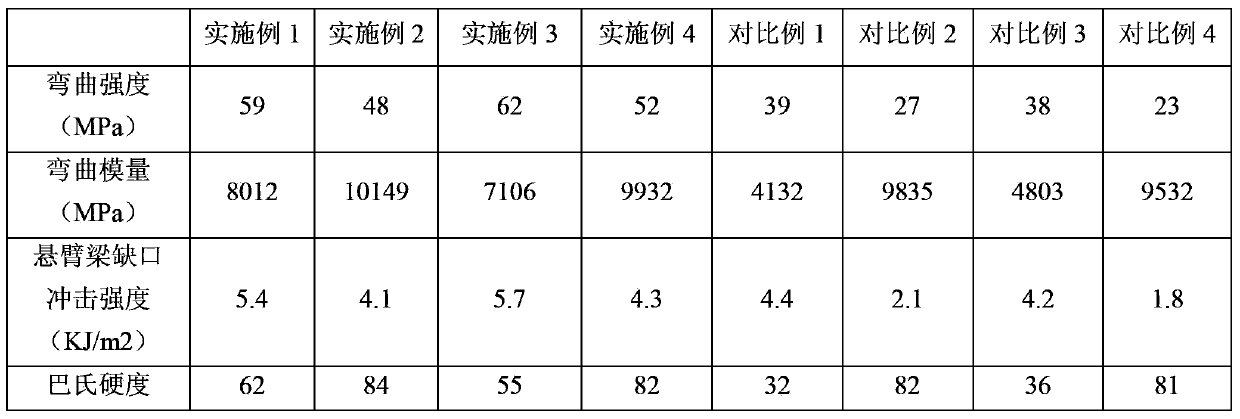

Artificial solid plane materiel and manufacturing method thereof

The invention provides an artificial solid plane materiel and a manufacturing method thereof. The artificial solid plane materiel comprises the following components in percentage by weight: 5%-45wt% of unsaturated polyester resin, 1%-6wt% of curing agents, 0.01%-2wt% of curing accelerators, 0.01%-10wt% of modifying agents and 60%-83wt% of fillers, wherein the content of neopentyl glycol is required to be 20-40 percent by weight and the content of maleic anhydride is required to be 10-35 percent by weight when the unsaturated polyester resin is synthesized. Because the artificial solid plane materiel provided by the invention adopts special unsaturated polyester resin different from artificial marbles and artificial quartz stones and the fillers obtained by mixing and collocating soft and hard powder, a finished product integrates the advantages of the unsaturated polyester resin and the fillers and overcomes the defects of the unsaturated polyester resin and the fillers, thereby having a wide market prospect.

Owner:GUANGDONG FUSHENG INNOVATIVE MATERIAL TECH LTD

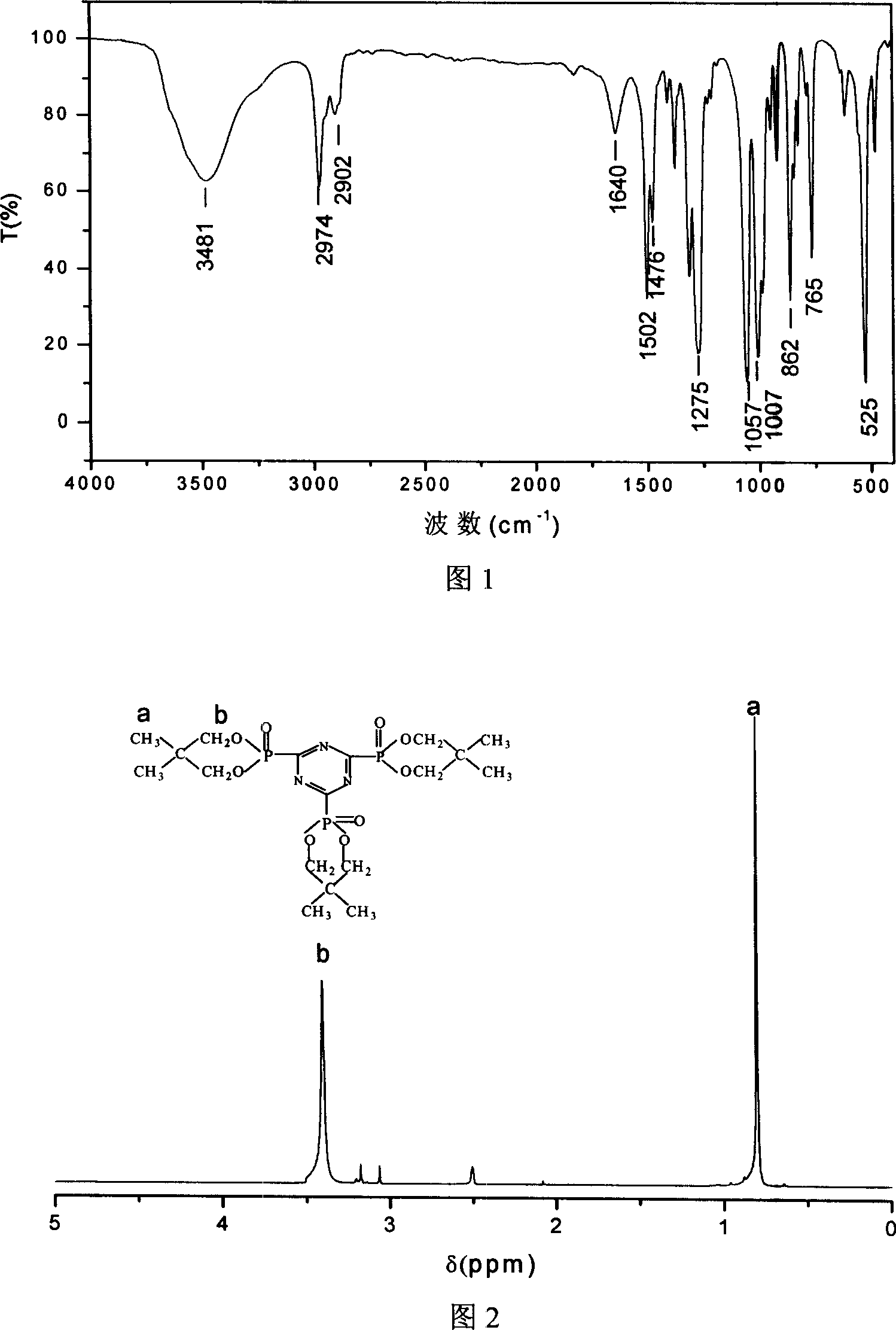

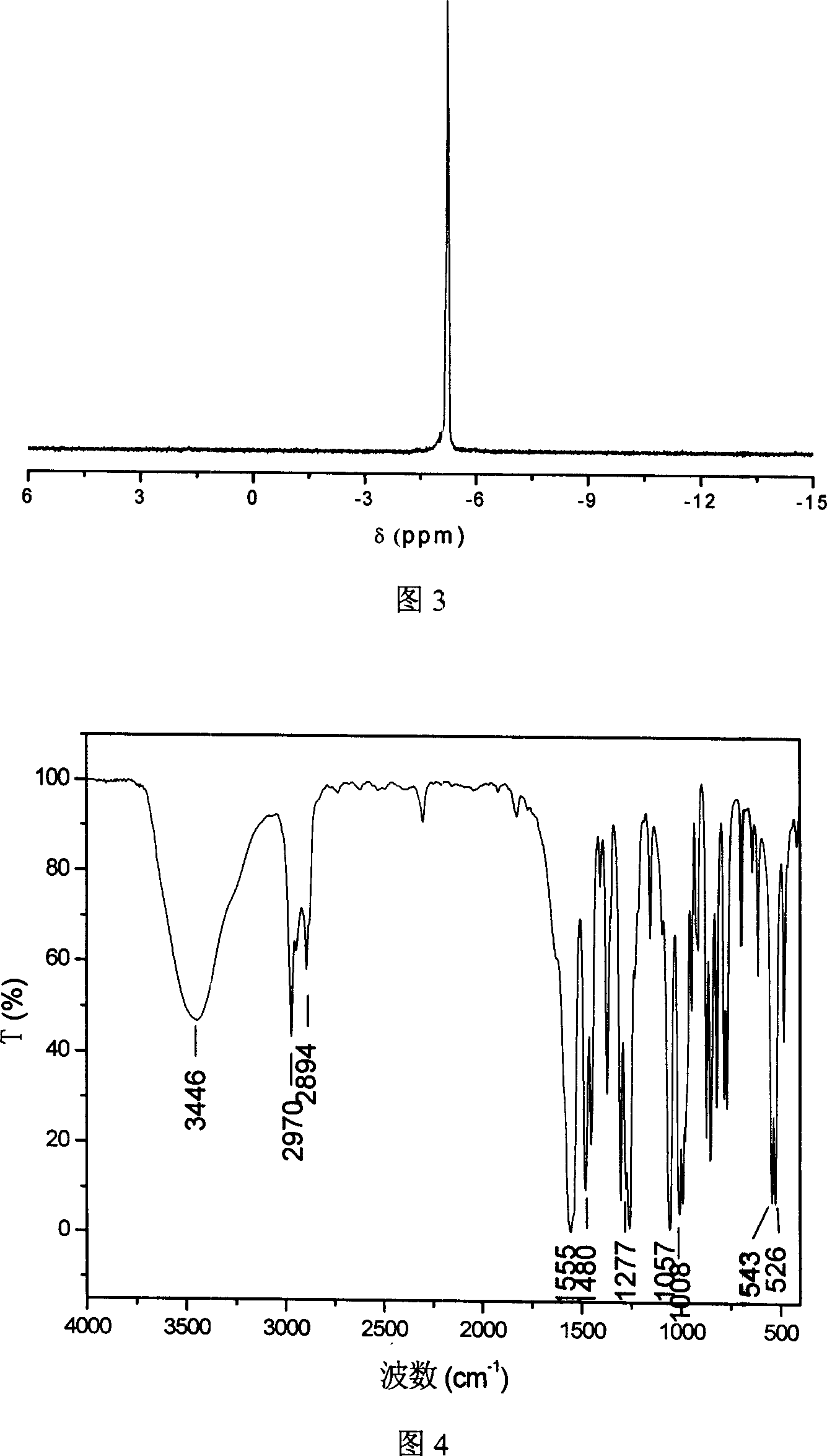

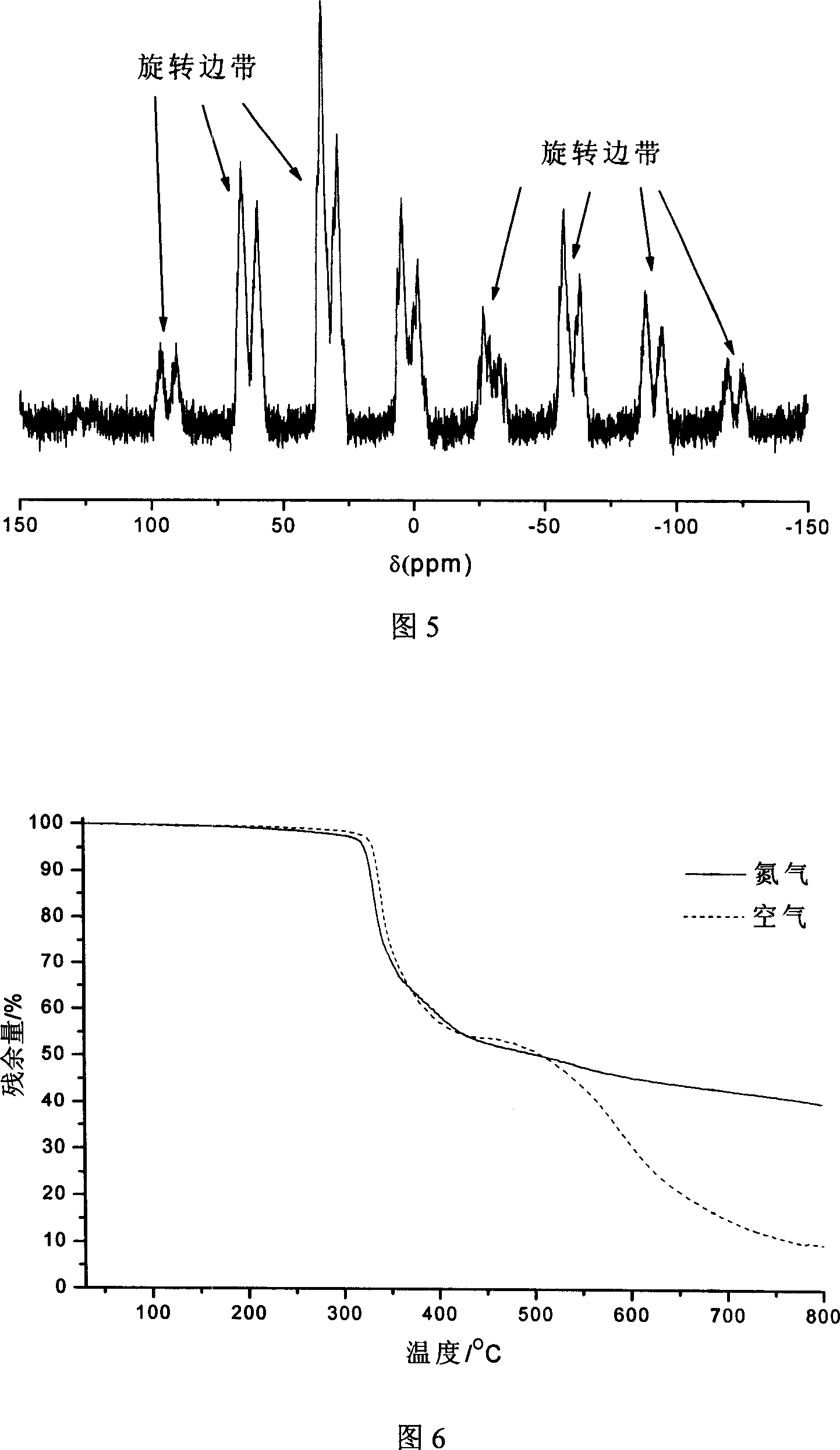

Triazine ring combustion inhibitor containing phosphorus and its preparing process

InactiveCN101007953AImprove thermal stabilityHigh decomposition temperatureGroup 5/15 element organic compoundsPhosphateReaction temperature

The invention discloses a phosphoric triazine radical containing fire retarding agent and the preparing method. The method comprises following steps: putting neopentyl glycol phosphite ester and cyanuric acid of same equivalent weight in organic solvent, reacting for 2- 10 hours at normal temperature to 140 Deg. C, getting 1, 3, 5- triazine neopentyl glycol phosphate; then putting got 1, 3, 5- triazine neopentyl glycol phosphate and diamine of same equivalent weight in inert liquid for replace reaction and getting phosphoric triazine radical containing fire retarding agent, the reacting temperature is from normal temperatur to 160 Deg. C, reacting time is 6- 72 hours. The number average molecular weight of product is 2000- 20000, and the decompostion temperature is 240- 400 Deg. C. The invention increases the fire retarding agent's decompostion temperature, which enables it not to decompose during macromolecular material processing; and the expanded fire retarding agent ploymer prepared in this invention contains P, N and C element, which is multifunctional.

Owner:SOUTH CHINA UNIV OF TECH

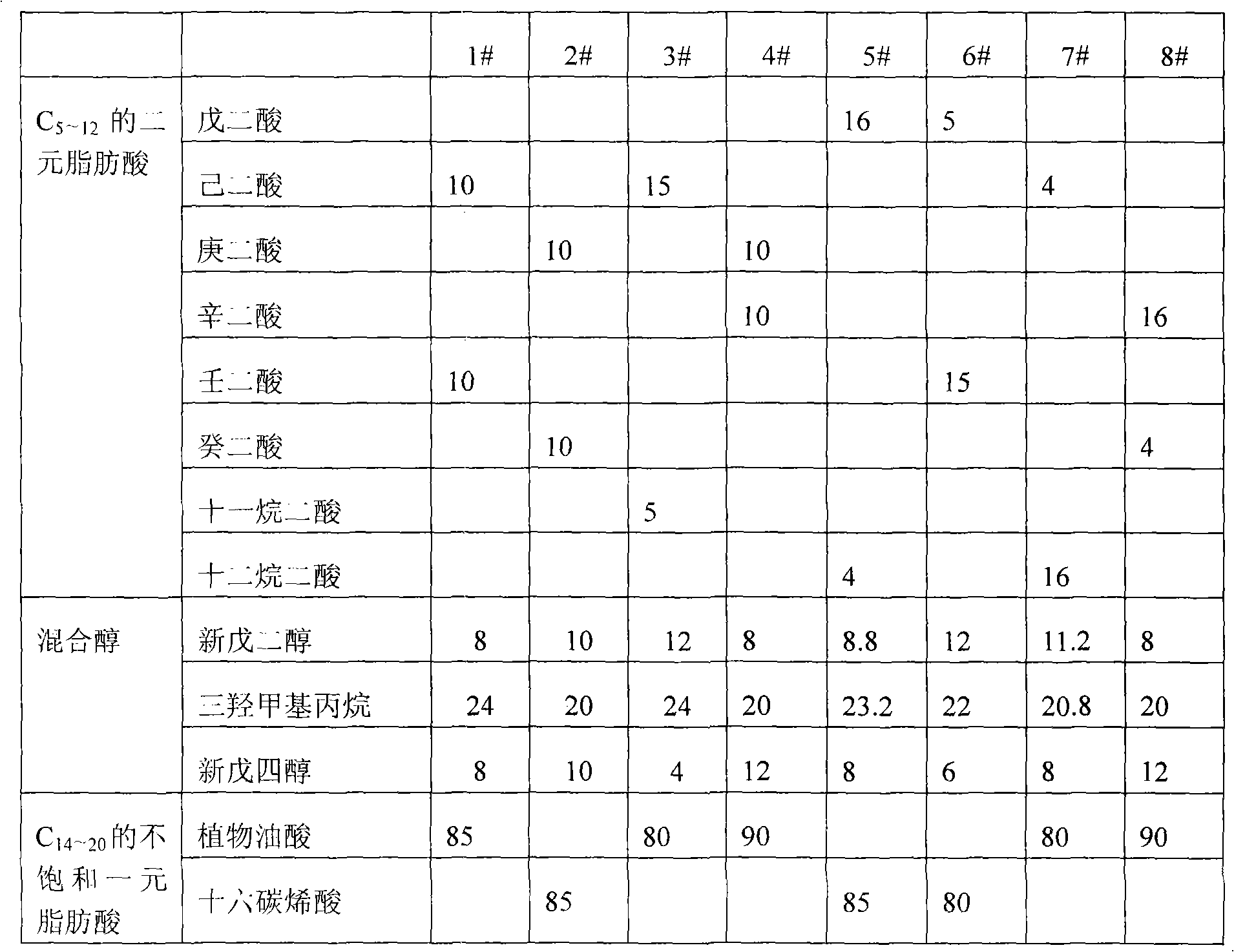

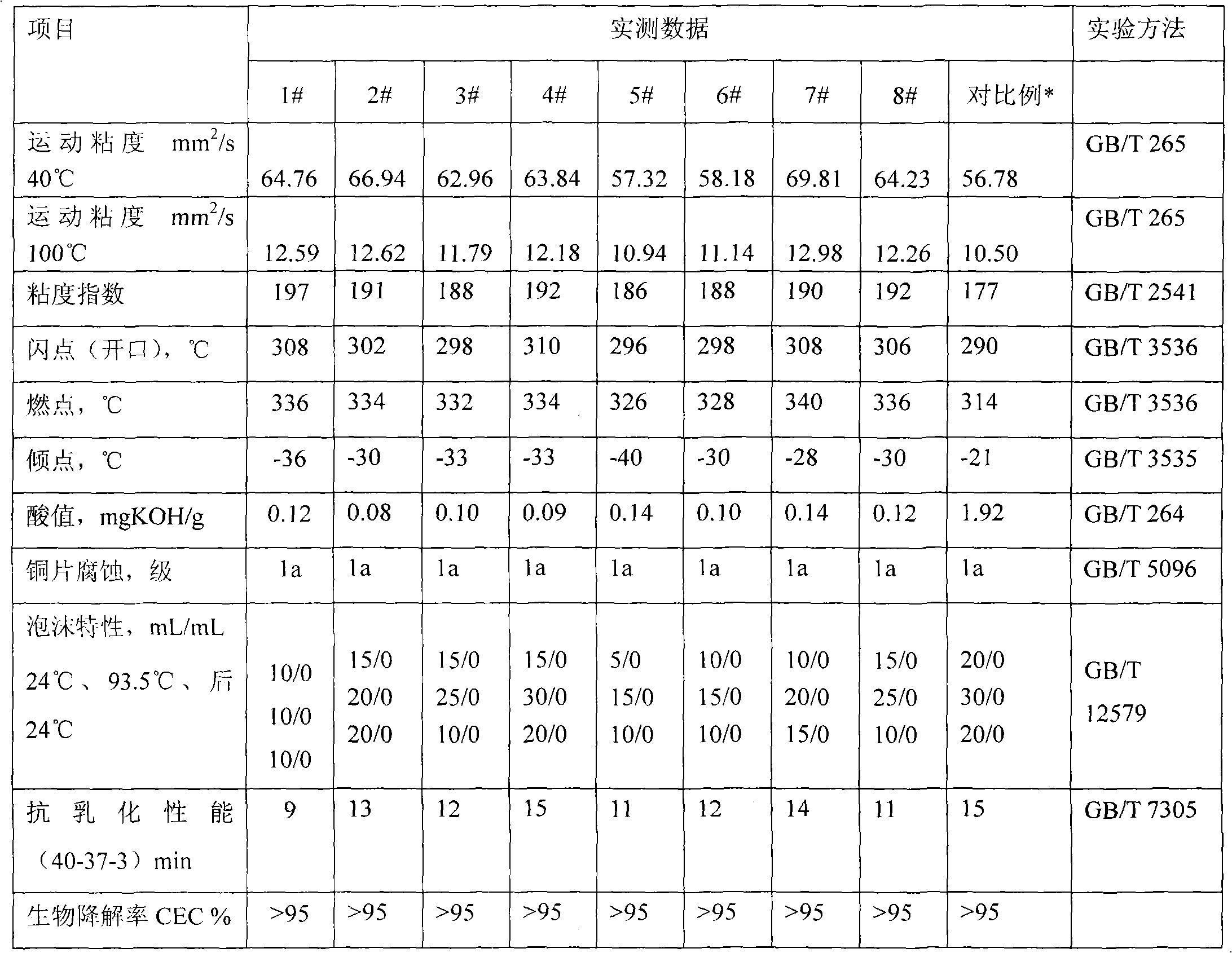

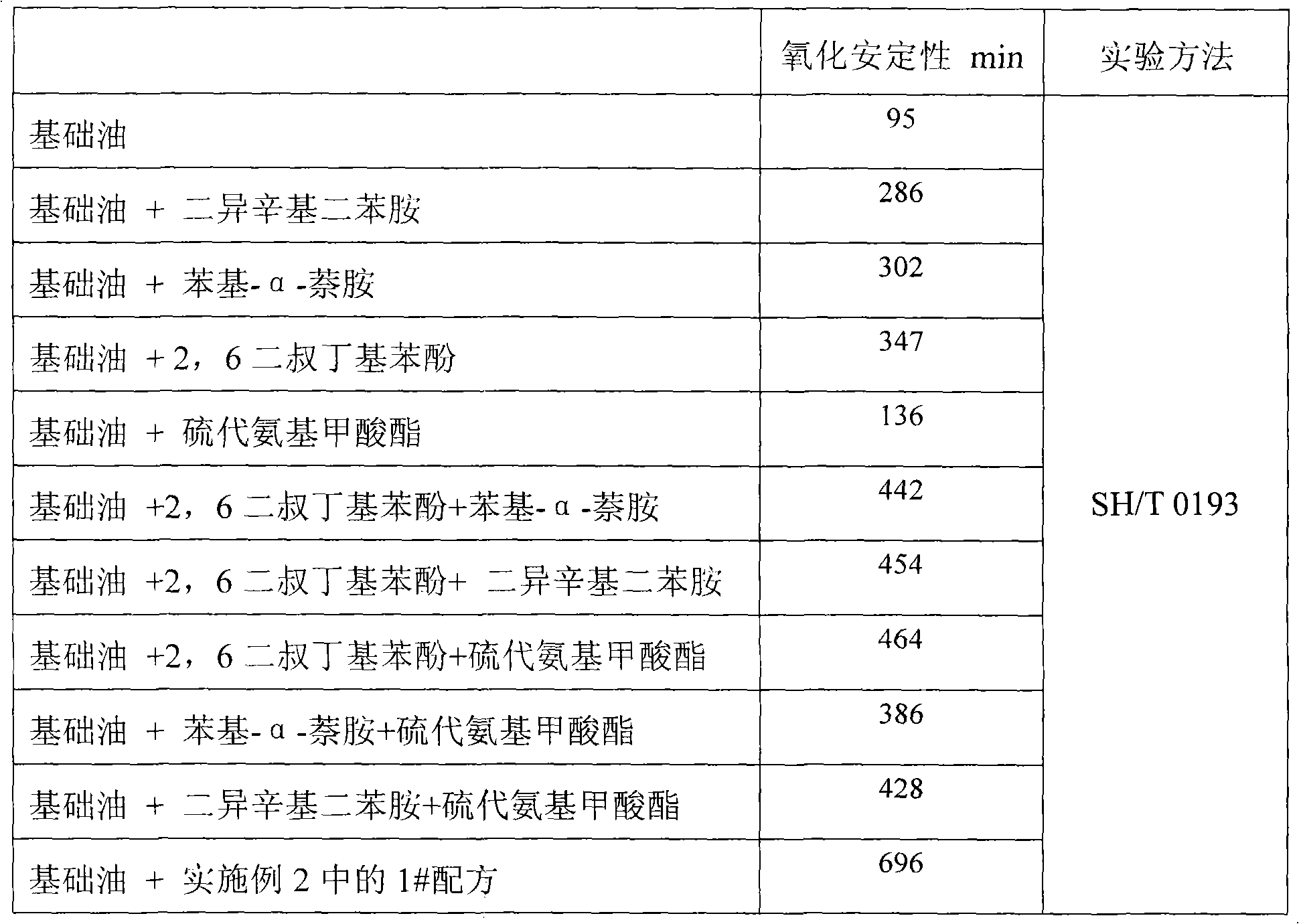

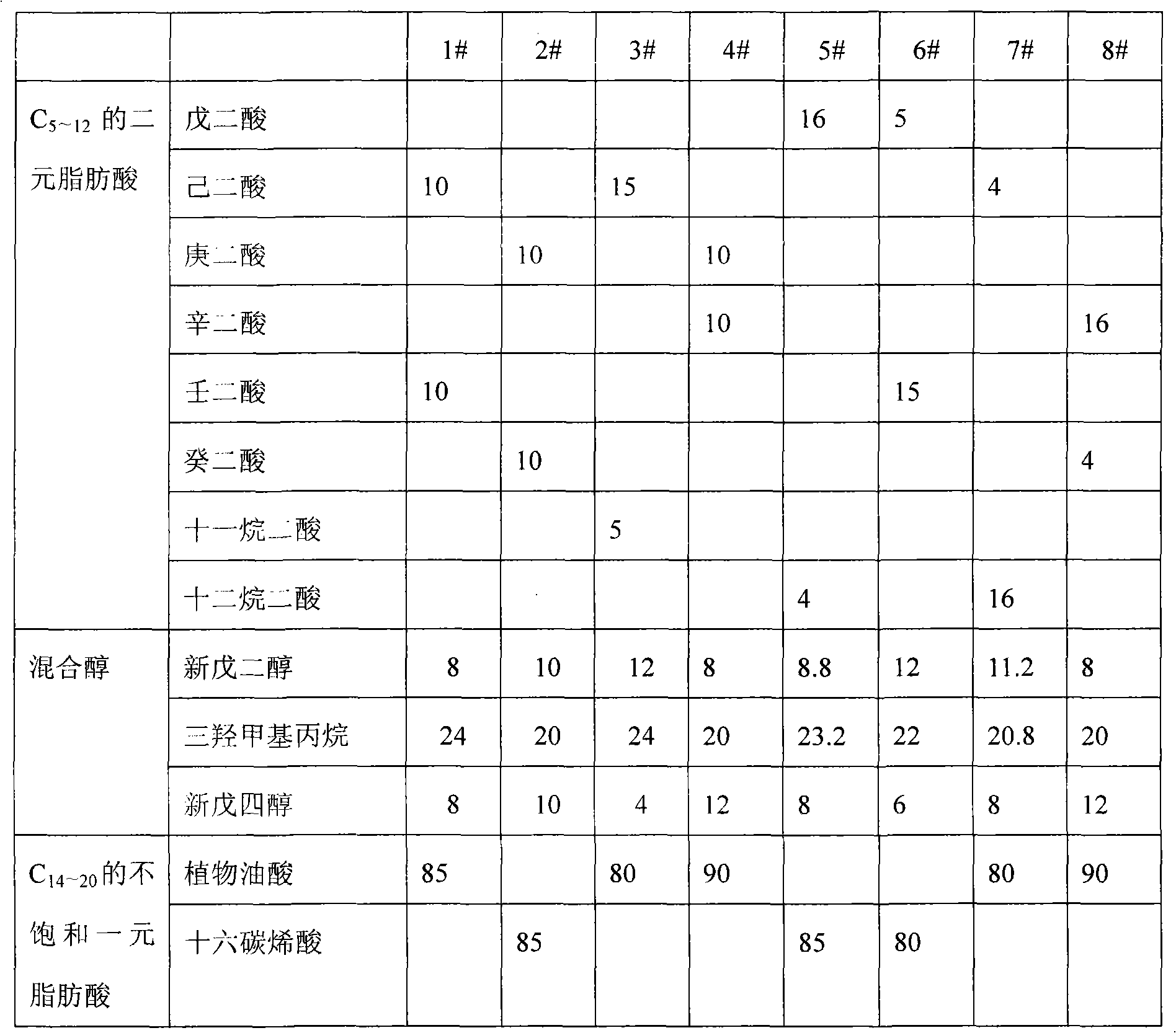

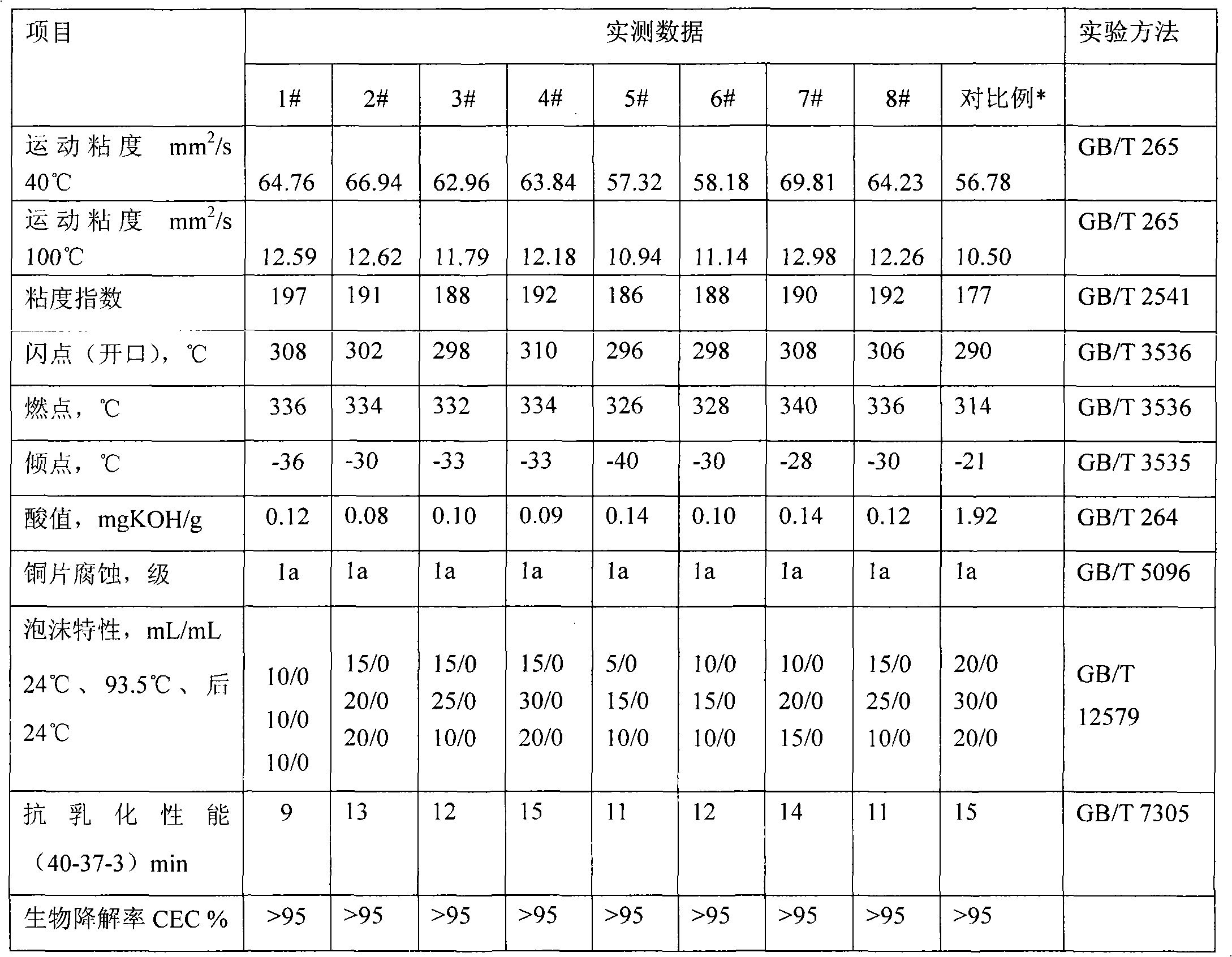

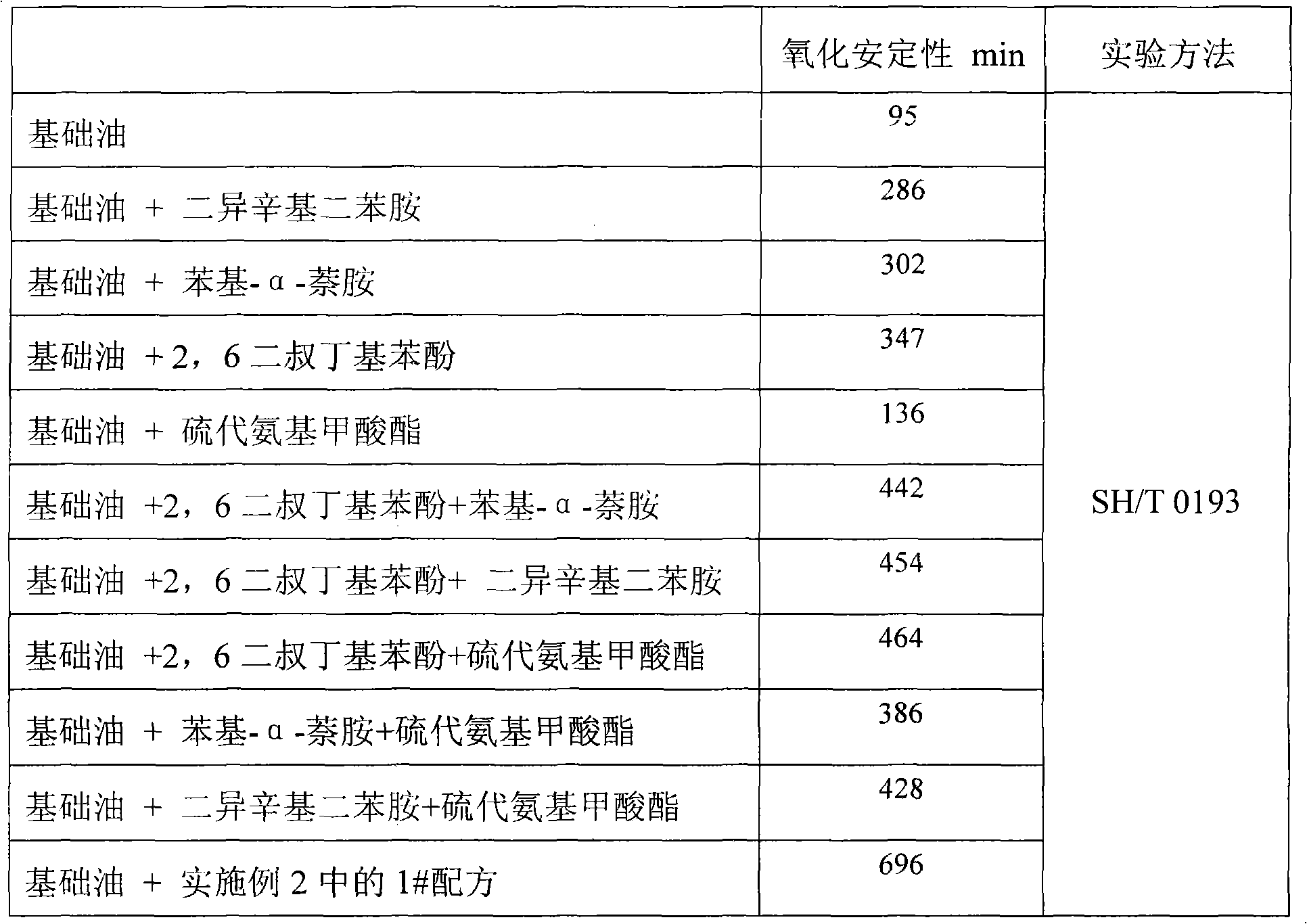

Flame-retardant hydraulic oil and preparation and application thereof

ActiveCN101831346AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceLubricant compositionAntioxidantHigh pressure

The invention provides flame-retardant hydraulic oil, which comprises the following components in percentage by weight: 1.9 to 4.5 percent of antioxidant, 1.5 to 3.5 percent of extreme-pressure abrasion resistant agent, 5 to 50ppm of antifoaming agent, 0.1 to 0.4 percent of anti-rusting agent and 92 to 97 percent of base oil, wherein the base oil is neopentyl polyol diacid composite ester which is prepared by fully esterifying carboxyl of aliphatic dibasic acid of C5-12 with mixed alcohol consisting of neopentyl glycol, trimethylolpropane and pentaerythritol and terminating the esterified product with unsaturated unitary fatty acid of C14-20. The flame-retardant hydraulic oil provided by the invention can be applied to various high-temperature and high-pressure hydraulic systems easy to contact naked flame. Compared with mineral-based (compressor) hydraulic oil, the flame-retardant hydraulic oil has the advantages of energy conservation, reduced oil consumption, reduced environmental pollution and prolonged service life, and can fully meet the working requirements of the high-temperature and high-pressure hydraulic systems easy to contact naked flame.

Owner:上海海都化学科技有限公司 +1

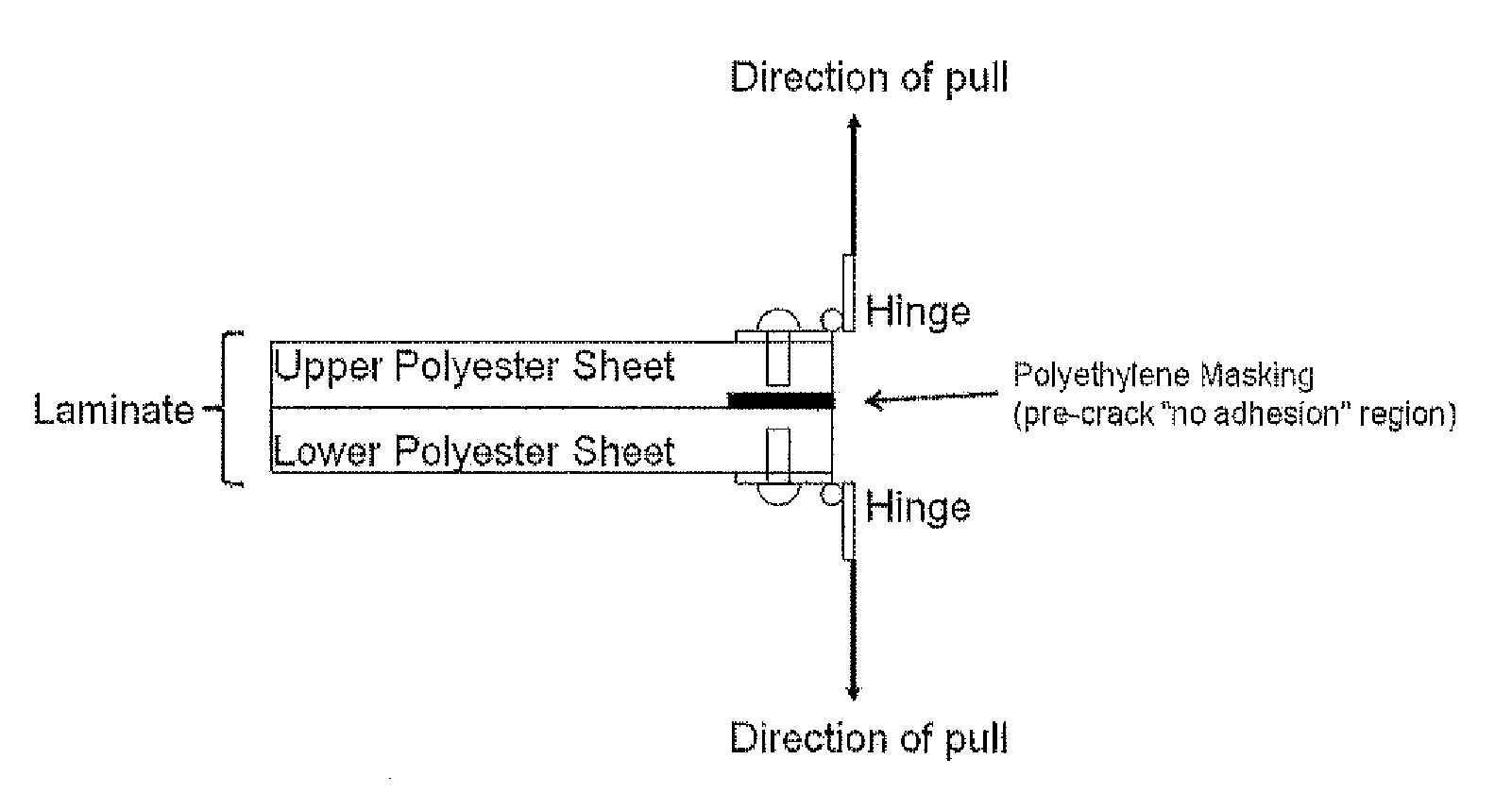

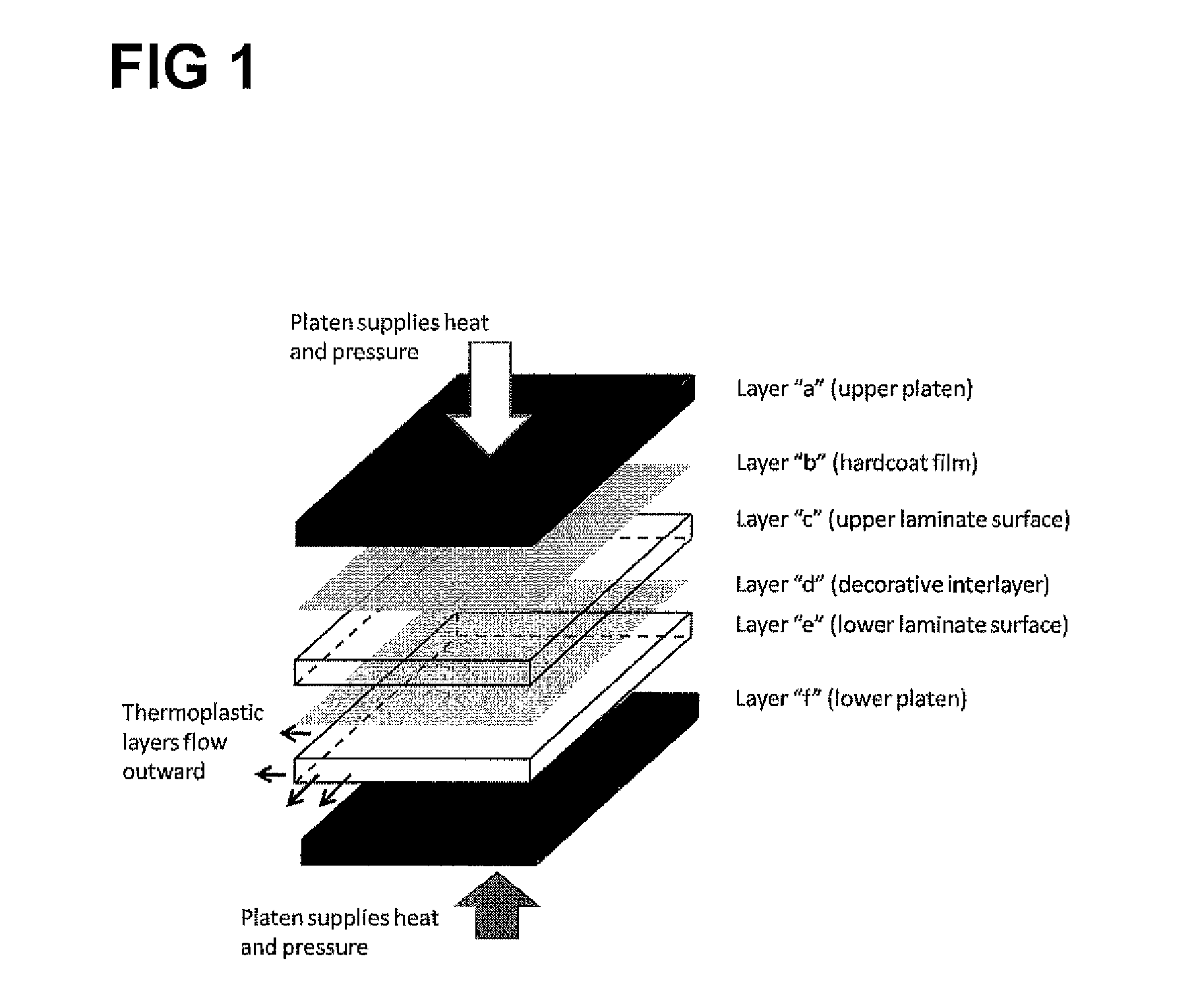

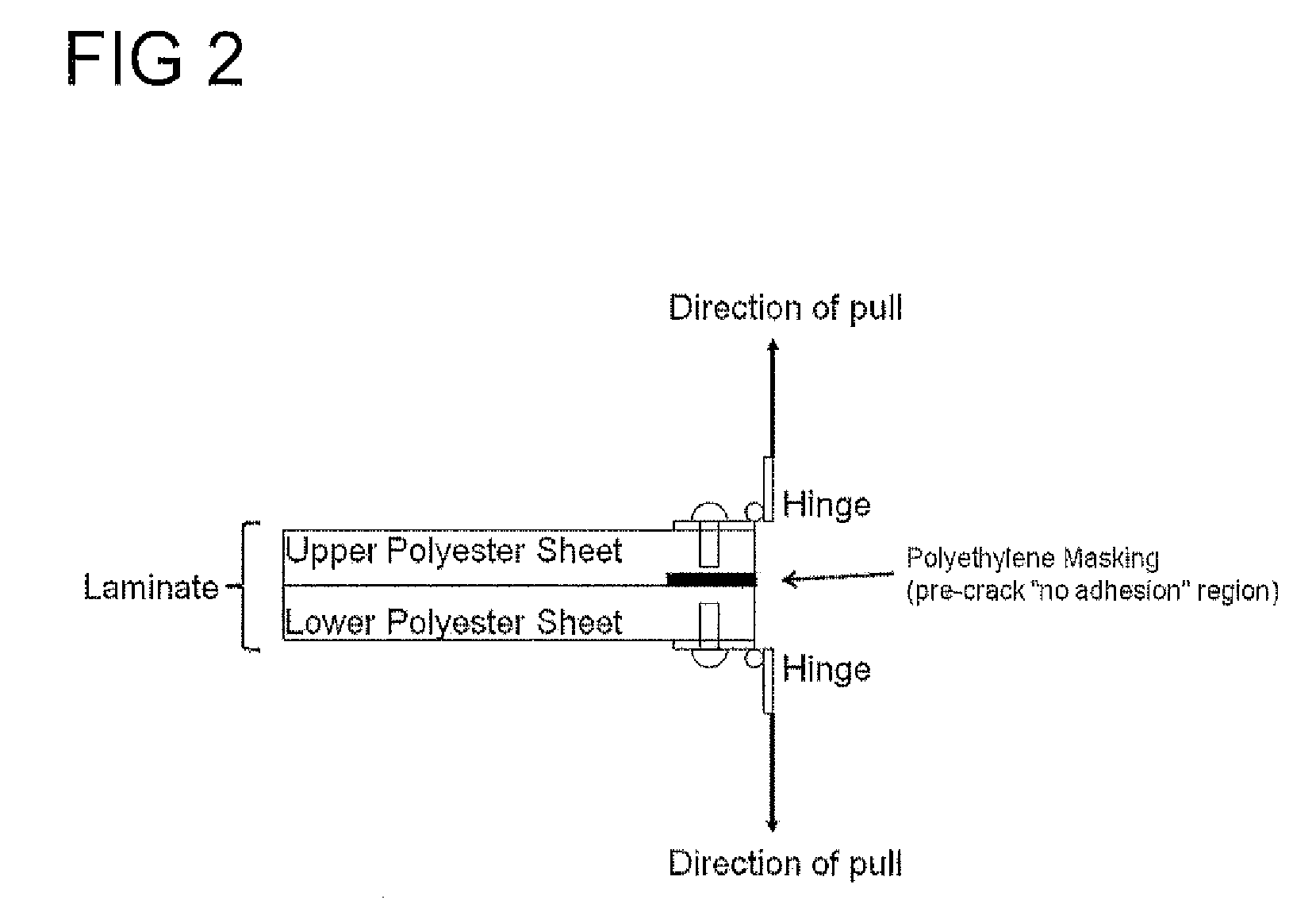

Lamination process optimization utilizing neopentyl glycol-modified polyesters

ActiveUS20120328849A1Decorative surface effectsRecord information storageProcess optimizationCyclohexanedimethanol

Thermoplastic articles made from polyesters modified by neopentyl glycol laminate more quickly than cyclohexanedimethanol-modified versions yet retain the properties that make modified polyesters the material of choice in this market—water-like color and clarity, high impact strength, low lamination temperature and low flammability. For situations where a faster cycle time is not needed, articles laminated with neopentyl glycol-modified polyesters can alternatively be manufactured at lower temperatures.

Owner:EASTMAN CHEM CO

Preparation method for non-crystalline low-melting point polyester hot melt adhesive

The present invention discloses a preparation method for a non-crystalline low-melting point polyester hot melt adhesive. The method comprises the following steps: (1) adopting neopentyl glycol, diethylene glycol, ethylene glycol, adipic acid, sebacic acid and m-phthalic acid as raw materials, and carrying out an esterification reaction under an effect of a catalyst; and (2) adding a stabilizer, a condensation polymerization catalyst and an antioxidant to the product from the step (1), and carrying out a reduced pressure condensation polymerization reaction to obtain a copolyester with a melting point less than 120 DEG C. The polyester hot melt adhesive of the present invention shows a transparent state at the high temperature and the room temperature, does not crystallize, has a good fluidity in low temperature use, and has excellent wettability.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

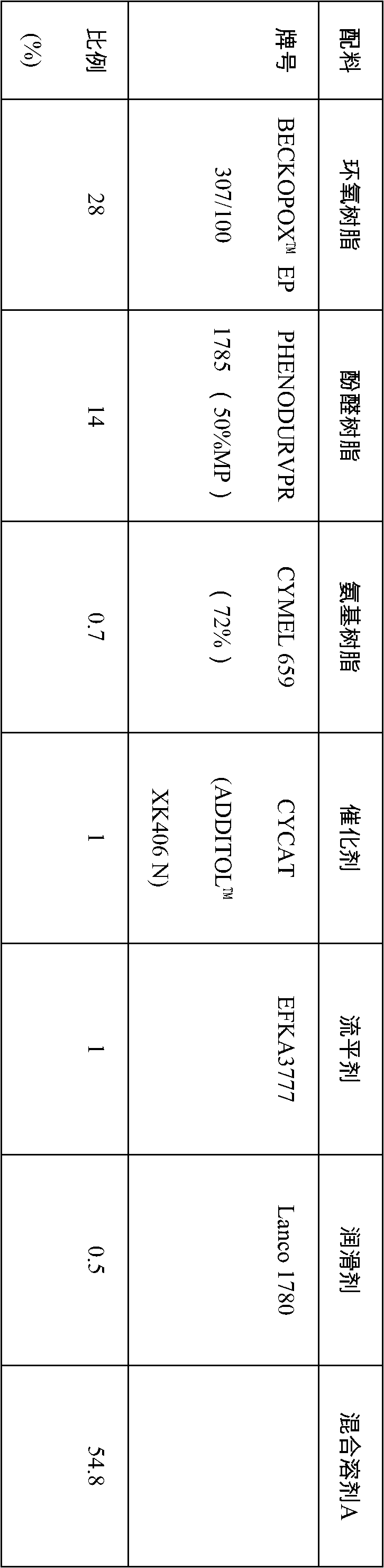

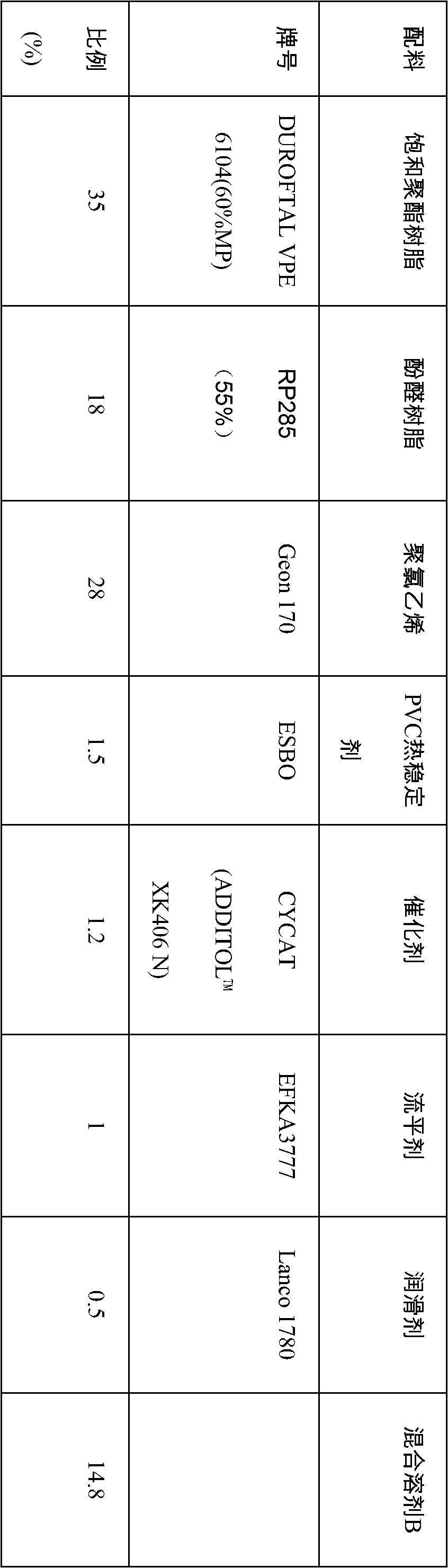

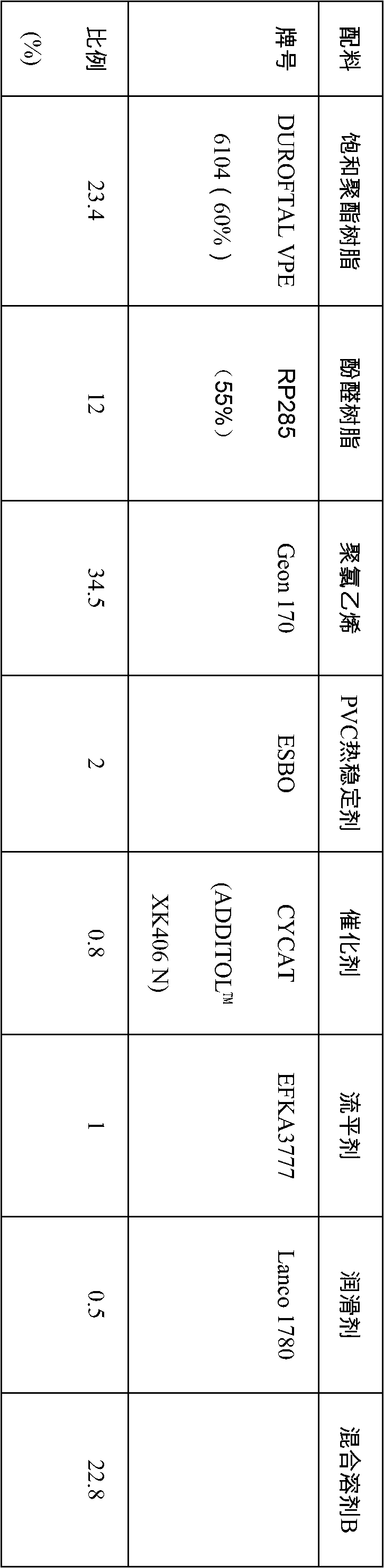

Coating composition and application of coating composition to metal base material

The invention discloses a coating composition and an application of the coating composition to a metal base material. The solid content of the coating composition is 40-70%. The coating composition comprises the following components of, by weight, 5-60% of saturation polyester resins, 0-25% of crylic acid resins, 2-30% of crossing-link agents, 20-80% of polyvinyl chloride homopolymer, 0-15% of additives, 0-40% of pigments and the balance dilution solvents, wherein average molecular weight Mn of the saturation polyester resins is 3000-8000, the vitrification temperature of the saturation polyester resins is 10-20 DEG C, the acid value of the saturation polyester resins is 0-5, the hydroxyl value of the saturation polyester resins is 30-90, and the saturation polyester resins are free of neopentyl glycol. The coating composition is free of bisphenol-A diglycidyl glycerol ether (BADGE) and bisphenol A (BPA). According to the coating composition, the polyester resins which meet requirements can be easily obtained, improved space of resin performances is large, 40%-70% of the solid content of final products can be achieved, and a large quantity of organic solvents are saved.

Owner:HANGZHOU CPMC +1

Environmentally acceptable polymer suspensions for oil field applications

ActiveUS7524796B1Low viscosityFacilitate cross-linkingFlushingDrilling compositionHydrophilic polymersCarrier fluid

Polymer suspensions prepared with non-aqueous, oil-free carrier fluids, for use in oil or gas well servicing. The polymer suspensions typically comprise a hydrophilic polymer, an organic clay, a stabilizer, and a carrier fluid selected from propylene glycol and butylene glycol. The addition of isopropyl alcohol, a polar activator, lowers the viscosity of the suspension. The further addition of neopentyl glycol further lowers viscosity and improves cross-linking of the polymer. The composition is both stable and environmentally acceptable.

Owner:HEILMAN WILLIAM J +1

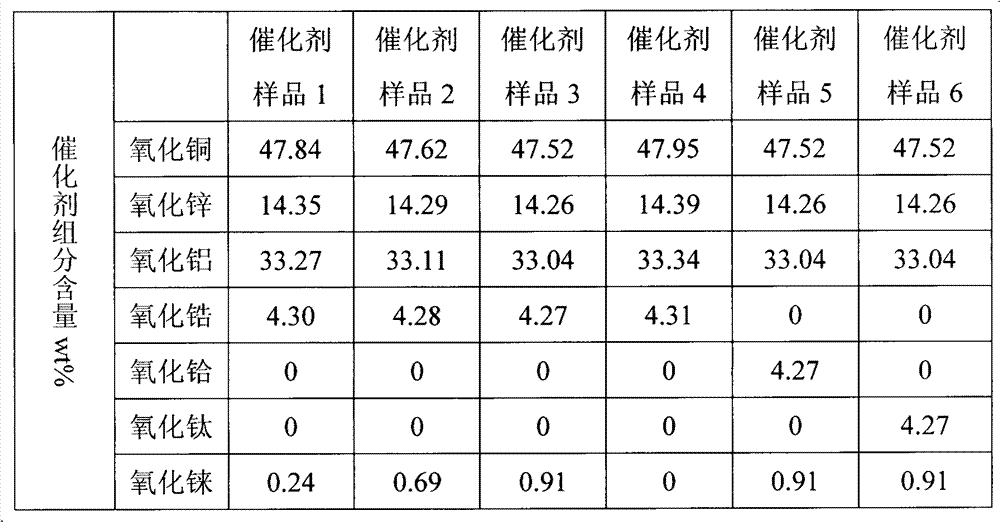

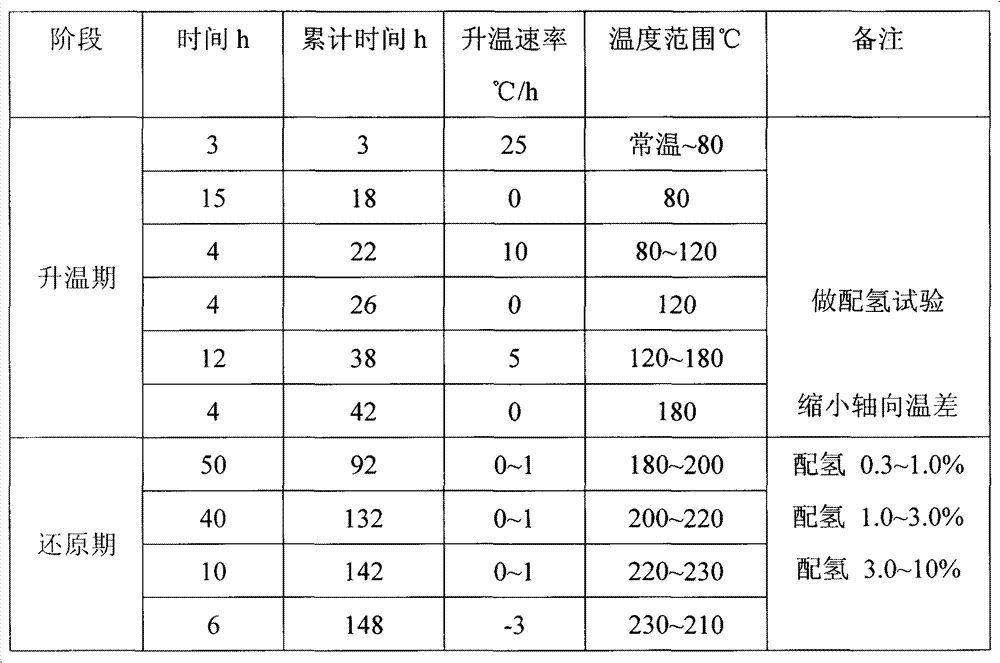

Catalyst for preparing neopentyl glycol by hydrogenation and preparation method of catalyst

ActiveCN102728370AImprove hydrogen absorption performanceIncrease the number of contactsOrganic compound preparationHydroxy compound preparationPolymer scienceCopper oxide

The invention relates to a catalyst for preparing neopentyl glycol (NPG) by hydrogenation and a preparation method of the catalyst. Based on the total weight of the catalyst, the catalyst contains 15-50wt% of copper oxide, 10-30wt% of zinc oxide, 20-40wt% of alumina, 1-15wt% of one or two or three kinds of titanium oxide, zirconium oxide or hafnium oxide. In addition, 0.1-1wt% of rhenium oxide is also added. The catalyst is prepared by a co-precipitation method, then the mixed gas of hydrogen and nitrogen is used to reduce and activate the catalyst for preparing NPG by hydrogenation. With the adoption of the catalyst provided by the invention, the raw material of hydrogenation has high conversion, and the NPG has high selectivity.

Owner:WANHUA CHEM GRP CO LTD +1

Lubricating oil and grease base oil, and preparation method and applications thereof

ActiveCN101812349AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceBase-materialsOil and greaseEvaporation

The invention provides base oil, in particular to a neopentyl polyalcohol dibasic acid complex ester. The neopentyl polyalcohol dibasic acid complex ester is prepared in a way that: completely esterifying C5-12 binary fatty acid carboxyl with the mixture of neopentyl glycol, trimethylolpropane and pentaerythritol, and blocking with C14-20 unsaturated monobasic fatty acid. The base oil provided bythe invention has the characteristics of high flash point, high flammability point, low pour point, high viscosity index, low evaporation loss, high thermal oxidation stability and high biodegradation rate. The invention can be used as syntholube and grease base oil, especially syntholube base oil used under the conditions of high temperature and high pressure. The invention is especially suitable to be used in fire resistant hydraulic fluid, high-temperature chain oil, high-temperature grease and the like in severe working spaces at which naked flame can is accessible under the conditions ofhigh temperature and high pressure.

Owner:上海海都化学科技有限公司 +1

Polyester resin for low-temperature cured powder paint and preparation method of polyester resin

ActiveCN102718952ARaise the conversion temperatureLow hydroxyl valuePowdery paintsPolyester coatingsPhosphorous acidPolymer science

The invention relates to polyester resin for low-temperature cured powder paint and a preparation method of the polyester resin. The polyester resin is characterized by comprising the following ingredients in percentage by mass: 0 to 10 percent of ethylene glycol, 10 to 40 percent of neopentyl glycol, 0 to 8 percent of 1,6-ethylene glycol, 0 to 5 percent of 1,4-cyclohexanedimethanol, 20 to 60 percent of terephthalic acids, 2 to 15 percent of adipic acid, 0.05 to 0.2 percent of monobutyltin oxide, 0.02 to 0.15 percent of triphenyl phosphate, 0 to 5 percent of adipic acid, 2 to 40 percent of m-phthalic acid and 0 to 5 percent of methacrylic acid. The polyester resin and the preparation method have the advantages that the curing at the low temperature condition of 130 DEG C to 140 DEG C can be realized, in addition, the storage stability is good, and the like.

Owner:广东伊诗德新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com