Patents

Literature

125results about How to "Oxidizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for coprocessing heavy metal waste water and organic waste water and generating electric power

InactiveCN102324542AOxidizingBiochemical fuel cellsBiological water/sewage treatmentElectric power systemCo-processing

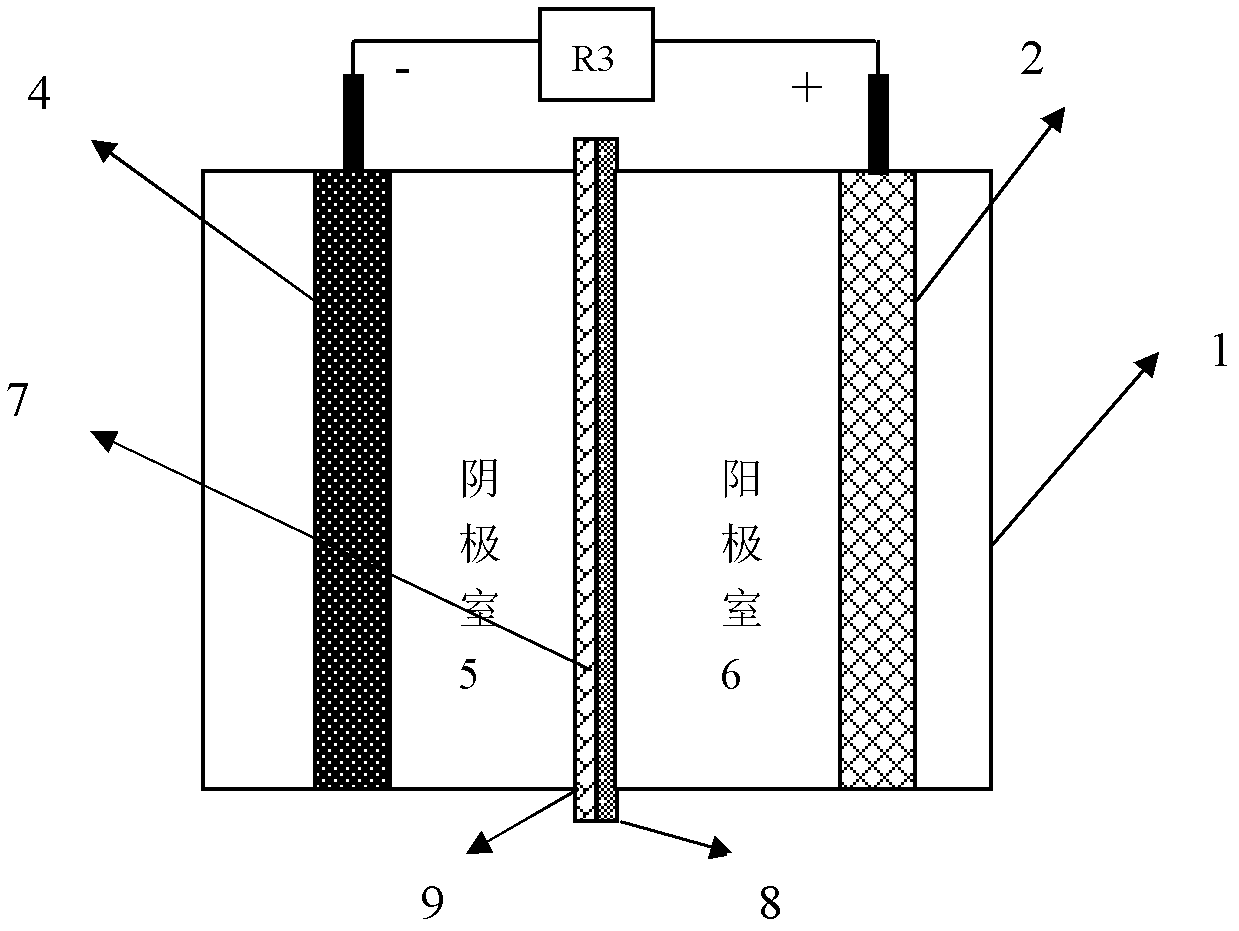

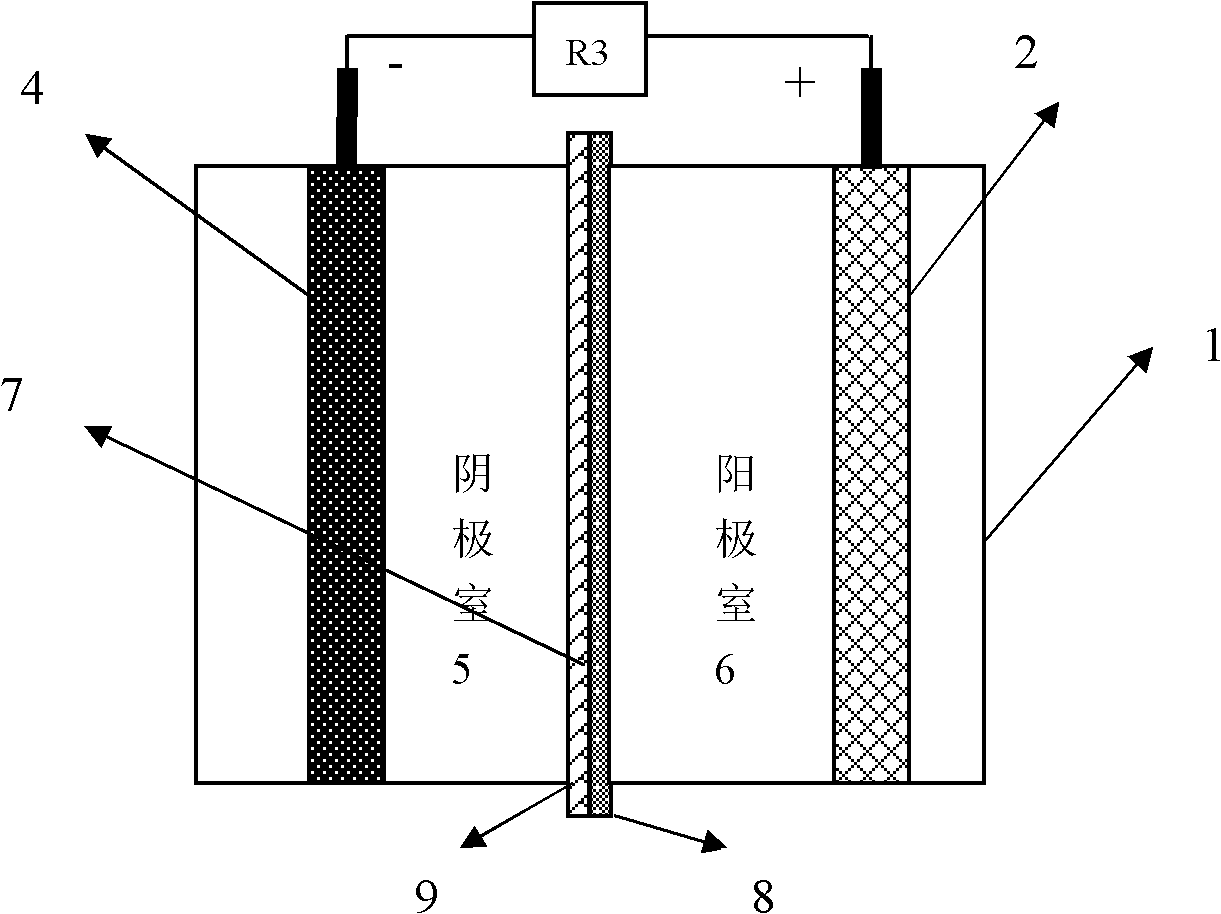

The invention provides a device for coprocessing heavy metal waste water and organic waste water and generating electric power. The device comprises an electrolytic cell which is separated into an anode chamber and a cathode chamber by a bipolar membrane, wherein an anode and a cathode are respectively arranged in the anode chamber and the cathode chamber, the anode and the cathode are connected with a resistor through a lead, the anode is composed of electric power generating microbes and an anode substrate, the cathode is made from metallic titanium with electrochemical inertia or carbon materials, the anode chamber contains the waste water containing organic pollutants, and the cathode chamber contains the heavy metal waste water. According to the invention, the organic pollutants are oxidized into carbon dioxide by the electric power generating microbes attached to the anode in the same electrochemical cell, and electrons and protons can be simultaneously released, the protons can combine with hydroxyls dissociated from the bipolar membrane to generate water, while the electrons can be transmitted to the cathode by an external circuit, the electrons can reduce the heavy metal in the heavy metal waste water to metal elementary substances and the metal elementary substances deposit on the surface of the cathode, and the protons dissociated from the bipolar membrane can combine with negative ions to generate acid or can be neutralized to water in the cathode chamber.

Owner:XI AN JIAOTONG UNIV

Repair method of arsenic-polluted soil

ActiveCN105414164AImprove stabilityOxidizingContaminated soil reclamationBiological activationWater content

The invention discloses a repair method of arsenic-polluted soil. The repair method comprises the following steps: 1) activation: an activating agent is added in the arsenic-polluted soil, and is uniformly stirred for reaction; 2) oxidation: manganese dioxide is added in the arsenic-polluted soil activated in the step 1), and is uniformly stirred for oxidation; 3) stabilization: a stabilizing agent is added in the arsenic-polluted soil oxidized in the step 2), and is uniformly stirred for standing; and 4) acid and alkali adjustment: plant ash is added in the arsenic-polluted soil stabilized in the step 3), is uniformly stirred, and is naturally cultivated; and meanwhile, the water content of the soil is adjusted. The repair method combines a leaching technology with a stabilizing technology, and is simple in operation, wide in raw material source and excellent in stabilizing effect.

Owner:武汉市秀谷科技有限公司

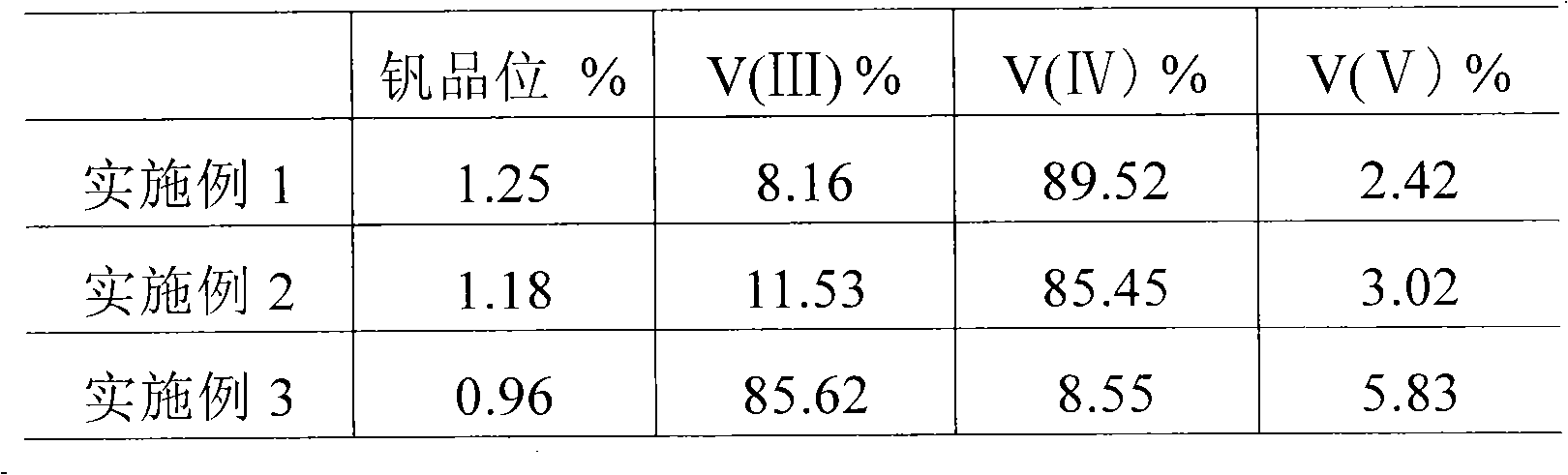

Leaching method of vanadium in vanadium-containing stone coal

InactiveCN101775506AImprove leaching rateImprove leaching effectProcess efficiency improvementKeroseneCoal

The invention relates to a leaching method of vanadium in vanadium-containing stone coal. The leaching method is characterized by comprising the following steps of: adding 98 percent of sulfate and fluorite into the vanadium-containing stone coal, adding water, controlling the liquid-solid weight ratio, leaching and filtering to obtain leachate; regulating the pH value of the leachate by using lime milk, extracting the leachate at room temperature by using 10 percent of P204 and 5 percent of TBP which are diluted by using kerosene, and carrying out back extraction on a load organic phase by using the sulfate; and after adding sodium chlorate into back extraction liquid, adding ammonia water, regulating the pH value, filtering and calcining a precipitate to obtain vanadium pentoxide. The method has simple process, high vanadium leaching rate, little reagent consumption quantity and little pollution and realizes the recycle of wastewater. The method is suitable for leaching the vanadium in the vanadium-containing stone coal.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +2

Method of for desulfurization by wet oxidation of hydrogen sulfide at medium-high temperature

InactiveCN102559292AFast and efficient oxidation removalRaise the reaction temperatureGas purification by catalytic conversionIonWet oxidation

The invention relates to a new method for desulfurization by wet oxidation of hydrogen sulfide using iron-based ionic liquid at medium-high temperature. The iron-based ionic liquid is heatproof liquid with strong absorption and oxidation properties. Application of the iron-based ionic liquid can not only effectively absorb hydrogen sulfide gas within a concentration range of 0-100% at 70-240 DEG C, but also can oxidize hydrogen sulfide gas into elemental sulfur in a fast and efficient way. The sulfur is cooled and separated, and the iron-based ionic liquid is regenerated and reused after being subjected to oxygen oxidation. Adjustment of the pH of a reaction system is not needed during the process of high-temperature oxidation of hydrogen sulfide in the iron-based ionic liquid, and the acidity characteristic of the iron-based ionic liquid can avoid production of sulfur-containing by-products. Wet oxidation of hydrogen sulfide can be realized at a temperature ranging from 70 DEG C to 240 DEG C through adjustment of flow and concentration of hydrogen sulfide gas and adoption of combined process of absorption-oxidation-separation-regeneration, the desulfurization percent can reach over 99%, and no secondary pollution is produced.

Owner:BEIJING UNIV OF CHEM TECH

Superlong vanadium dioxide nanowire film and preparation method thereof

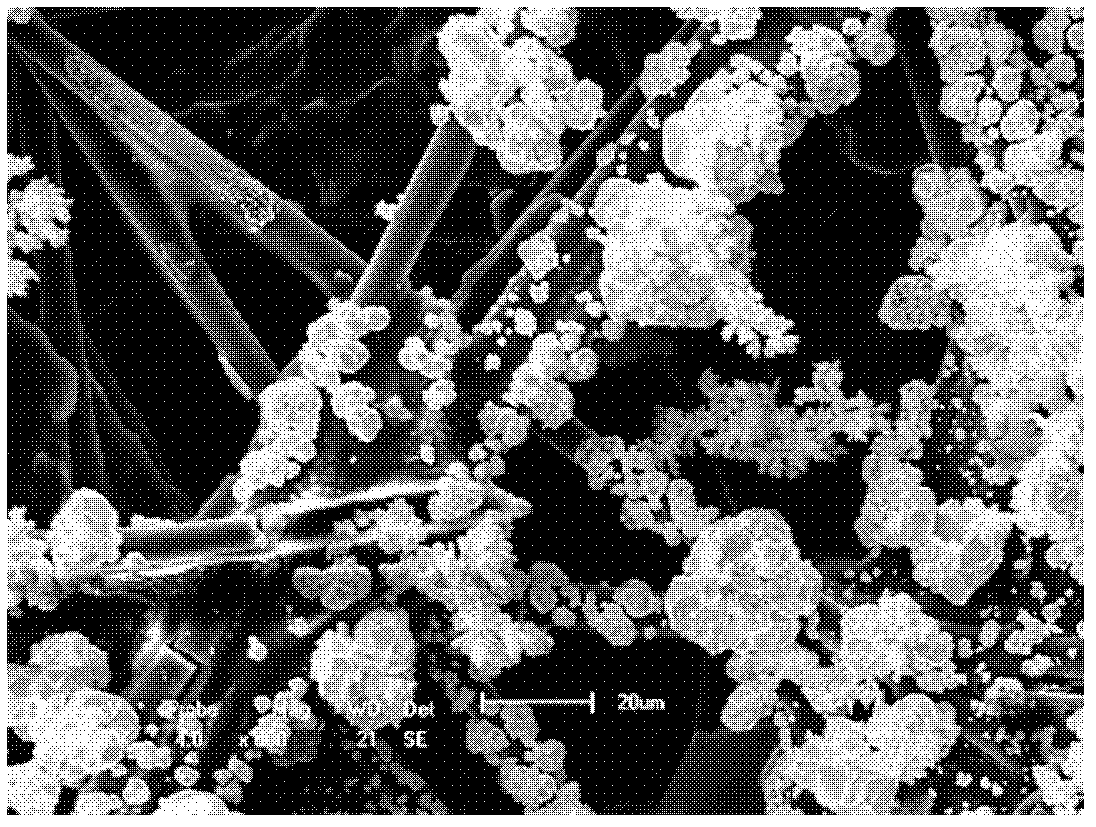

InactiveCN104192904AControl lengthReduce sizeMaterial nanotechnologyVanadium oxidesVanadium dioxideOxalate

The invention particularly relates to a superlong vanadium dioxide nanowire film and a preparation method thereof. The technical scheme is as follows: the method comprises the following steps: dissolving vanadium pentoxide used as a vanadium source in oxydol, wherein the mass-volume ratio of the vanadium pentoxide to the oxydol is (0.05-5):(0.1-20) g / ml; adding distilled water, and stirring for 0.1-10 hours to form an orange-red transparent solution; adding a 1.25-125 g / L oxalic acid solution, and stirring for 5 minutes-1 hour; and finally, putting the uniformly mixed solution into a hydrothermal kettle, reacting at 80-200 DEG C for 6-96 hours, cooling to room temperature, washing, and carrying out vacuum drying to finally obtain the vanadium dioxide superlong nanowire film of which the length reaches nano scale. The preparation method is simple and reliable in technique; and the prepared superlong vanadium dioxide nanowire has the advantages of uniform distribution, high yield and controllable length, and is suitable for the field of electrochemistry.

Owner:WUHAN UNIV OF SCI & TECH

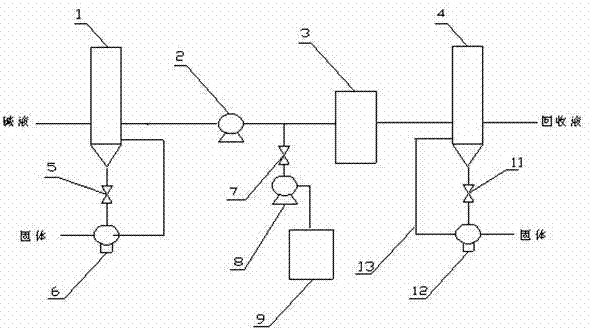

Process and system for recycling and decoloring denim mercerizing alkali and penetrant

ActiveCN103498312AOxidizingFunctionalTextile treatment machine arrangementsMultistage water/sewage treatmentDenimProcess engineering

The invention discloses a process and system for recycling and decoloring denim mercerizing alkali and penetrant. The process includes the steps that denim mercerizing alkali liquor is placed in a first precipitation tank; the liquor on the upper portion enters a conveying pipeline through a flow pump after precipitation, meanwhile, a metering pump pumps a decolorising agent into the liquor in the conveying pipeline, and then the decolorising agent and the liquor are conveyed to an evaporation concentrator together; the decolorising agent and the liquor enter a second precipitation tank after being evaporated and concentrated; supernatant liquor obtained after precipitation is conveyed to a production line directly; solid substances in precipitation liquor on the lower portion are separated and conveyed to a waste solid storage tank after the precipitation liquor on the lower portion is treated through a centrifugal machine, and clear liquor returns the first precipitation tank and is conveyed backed to the production line. The system comprises the first precipitation tank, the flow pump, the metering pump, a decolorising agent box, the evaporation concentrator and the second precipitation tank. The first precipitation tank, the flow pump, the evaporation concentrator and the second precipitation tank are connected directly through pipelines, and the decolorising agent box is connected to the metering pump below the pipeline where the flow pump and the evaporation concentrator are connected. The process for recycling and decoloring the denim mercerizing alkali and penetrant is simple, the useful alkali and penetrant are recycled, and production cost is greatly reduced.

Owner:SHENZHEN YUEPENG ENVIRONMENTAL PROTECTION TECH

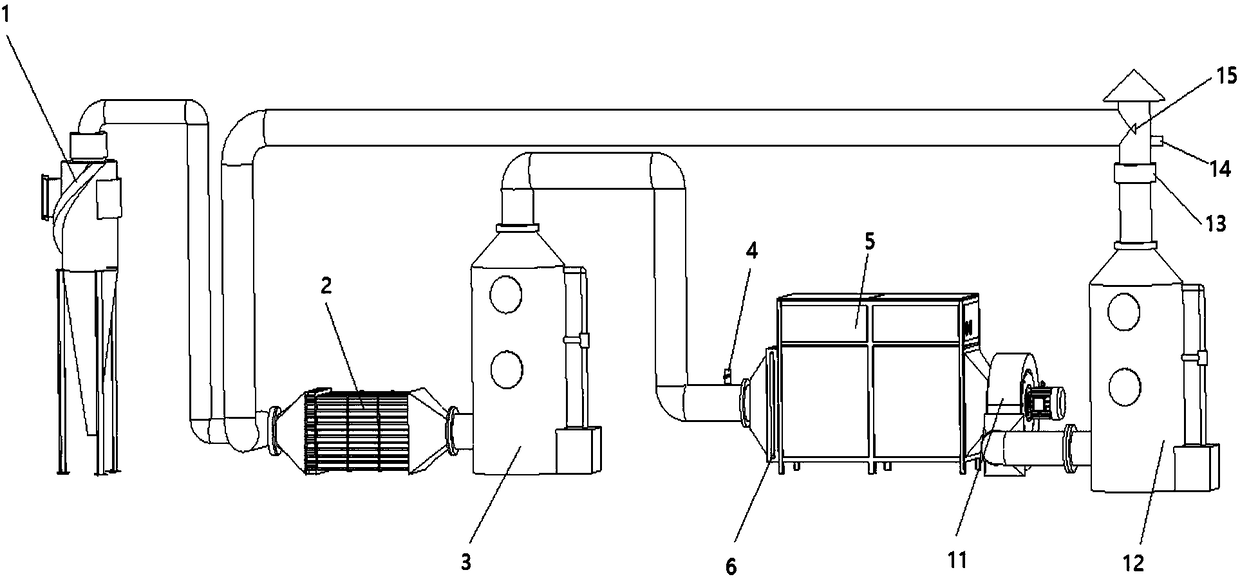

Photolysis oxidation cracking treatment method for tail gas based on volatile oil and gas purification technology

PendingCN108096969AEnergy-saving and efficient processingEasy to handleCombination devicesParticulatesMicrocontroller

The invention discloses a photolysis oxidation cracking treatment method for tail gas based on a volatile oil and gas purification technology. The photolysis oxidation cracking treatment method comprises the following steps: allowing organic waste gas to enter a cyclone defogging and dedusting cooler, allowing macromolecular pollutants to be degraded and decomposed into micro-molecular substancesthrough an oil and gas purifying electric-field device, allowing treated organic waste gas to enter a front-end spraying tower, allowing dust particles to be fixed in a spraying solution, allowing treated organic waste gas to enter a photolysis oxidation cracking cabin through an air pipe, and subjecting waste gas to oxidation treatment; in the oxidation treatment process of the waste gas, allowing a waste gas concentration detection sensor arranged at the inlet position of the photolysis oxidation cracking cabin to detect the concentration of the waste gas in real time and feedback a signal to a single-chip microcomputer control system, and controlling lamp tubes of a high-energy ultraviolet lamp group module and an ozone supply module to regularly and cooperatively open and close; and allowing treated gas to enter a dry flue gas comprehensive treatment tank and an ozone filter screen so as to realize super purified emission after waste gas treatment. The photolysis oxidation crackingtreatment method provided by the invention can realize energy-saving and highly-efficient operation of a whole system, prolongs the service life of a lamp group module, improves the treatment effectof the organic waste gas, avoids the problem of secondary pollution caused by a traditional wet process, and realizes super purified emission.

Owner:QINGDAO UNIV OF SCI & TECH

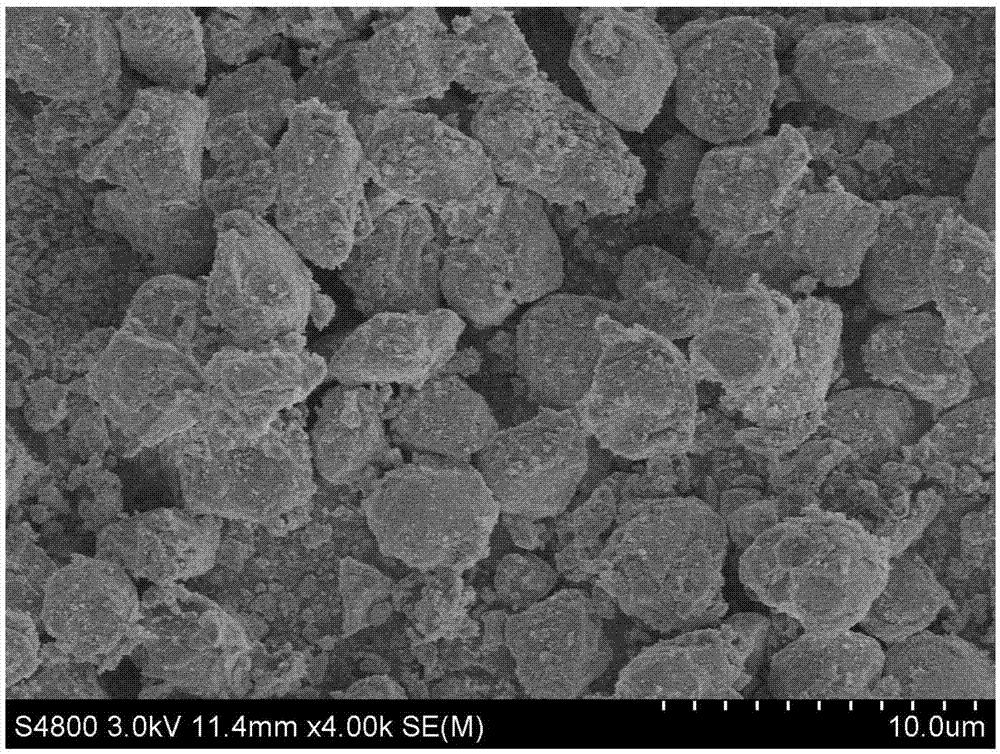

Method for producing nanometer humus refined powder

The invention discloses a method for producing nanometer humus refined powder. The method for producing nanometer humus refined powder comprises the following production steps: raw material treatment: crushing brown coal into fine particles with a grain size smaller than 16 meshes through a crusher, then drying the fine particles to water content of 9 to 13 percent by using cold drying, and performing filtration and screening for future use; proportioning treatment: mixing brown coal with reagent according to a ratio of 100:1, and putting the proportioned materials into a grinder; grinding treatment: grinding the proportioned materials to a nanometer scale by using a planetary trajectory ball-milling equipment with balls and a cylinder which are made of special materials, emit less heat and dissipate heat quickly, so as to change molecular structures and generate nanometer humus medium powder in a machine body; packaging treatment: settling, outputting and packaging the nanometer humus powder to obtain the nanometer humus refined powder disclosed by the invention. The nanometer humus refined powder obtained through the method can be used for conditioning soil activity, controlling saline-alkali soil and sand soil, controlling heavy metal pollutants in soil, reducing radioactive contamination and purifying sewage.

Owner:ZHEJIANG FENGYU ECOLOGICAL TECH CO LTD

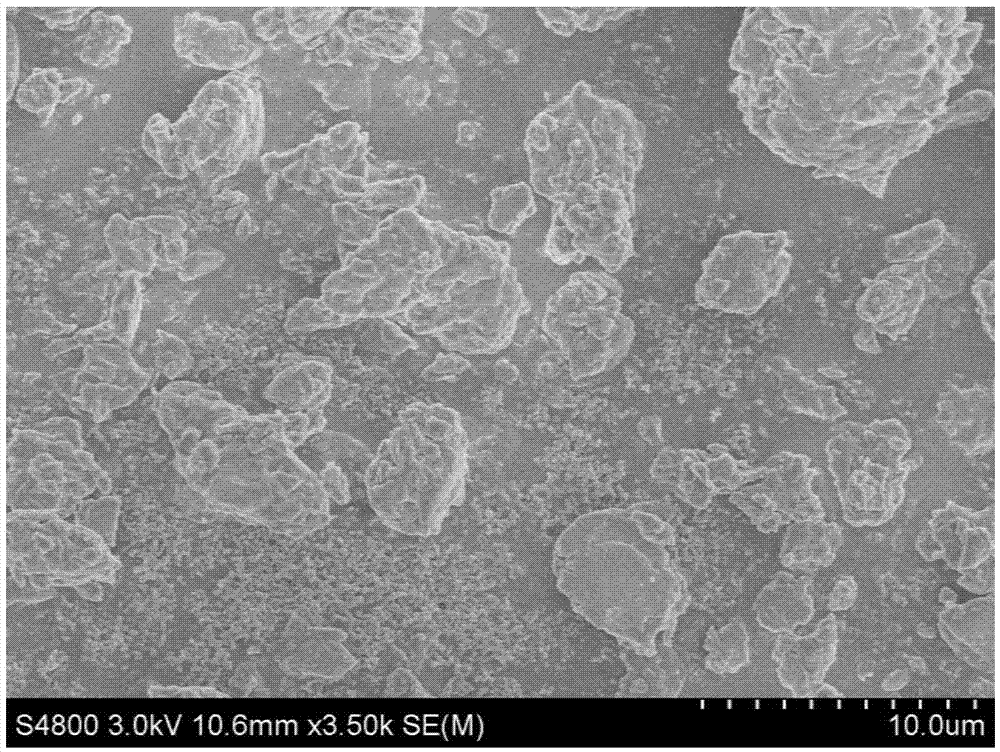

Method for preparing periclase-silicon carbide-carbon composite powder through in-situ reaction

The invention relates to a method for preparing periclase-silicon carbide-carbon composite powder through in-situ reaction. The method comprises the following steps of: stirring and mixing 40 to 80 weight percent of periclase powder, 5 to 25 weight percent of monatomic silicon powder, 10 to 30 weight percent of graphite and 1 to 10 weight percent of phenolic resin, performing compression moulding, and naturally drying for 24 hours; performing heat treatment at the temperature of between 110 and 300DEG C for 8 to 24 hours, keeping temperature of between 1,000 and 1,700DEG C for 1 to 12 hours in the reducing atmosphere, and naturally cooling; and crushing into powder of which the granularity is less than 10 mu m. The preparation process is simple, and magnesite raw materials are rich; and the prepared periclase-silicon carbide-carbon composite powder has high melt erosion resistance, permeability and thermal shock resistance, can improve the service performance of high temperature materials and has long service life.

Owner:WUHAN UNIV OF SCI & TECH

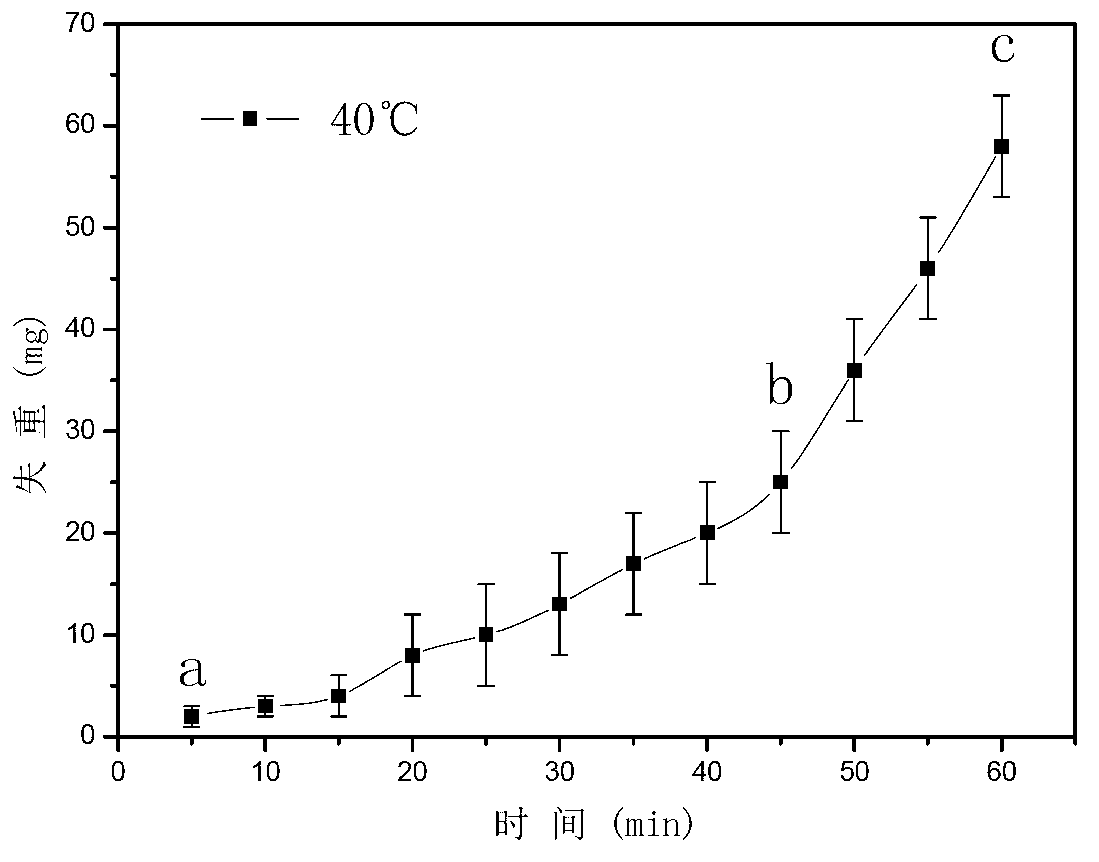

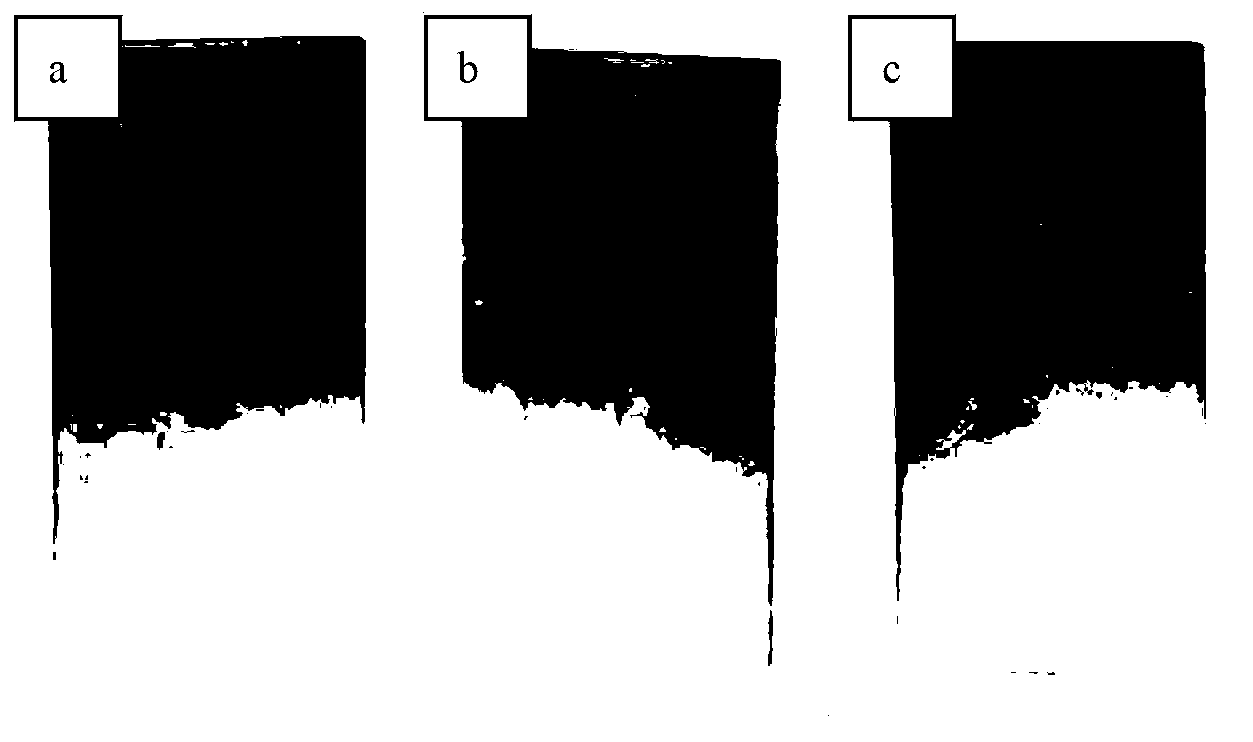

Energy-saving and environment-friendly aluminum alloy anode oxide film stripping process

The invention discloses an energy-saving and environment-friendly aluminum alloy anode oxide film stripping process. A film stripping solution used in the film stripping process is an environment-friendly mixed solution containing sulfuric acid, oxalic acid and a corrosion inhibitor, the operating temperature is 25-40 DEG C, and the film stripping time is 25-60min or the film stripping operation is carried out until all films are stripped. The film stripping solution comprises 10-40g / L of sulfuric acid, 10-50g / L of oxalic acid and 20-40g / L of corrosion inhibitor, wherein the corrosion inhibitor comprises 5-20g / L of adipate and 15-40g / L of ammonium molybdate. The energy-saving and environment-friendly aluminum alloy anode oxide film stripping process has the advantages of no hexavalent chromium, no environment pollution, lower usage temperature and less damage to a matrix, and is a novel energy-saving and environment-friendly aluminum alloy anode oxide film stripping process.

Owner:BEIHANG UNIV +1

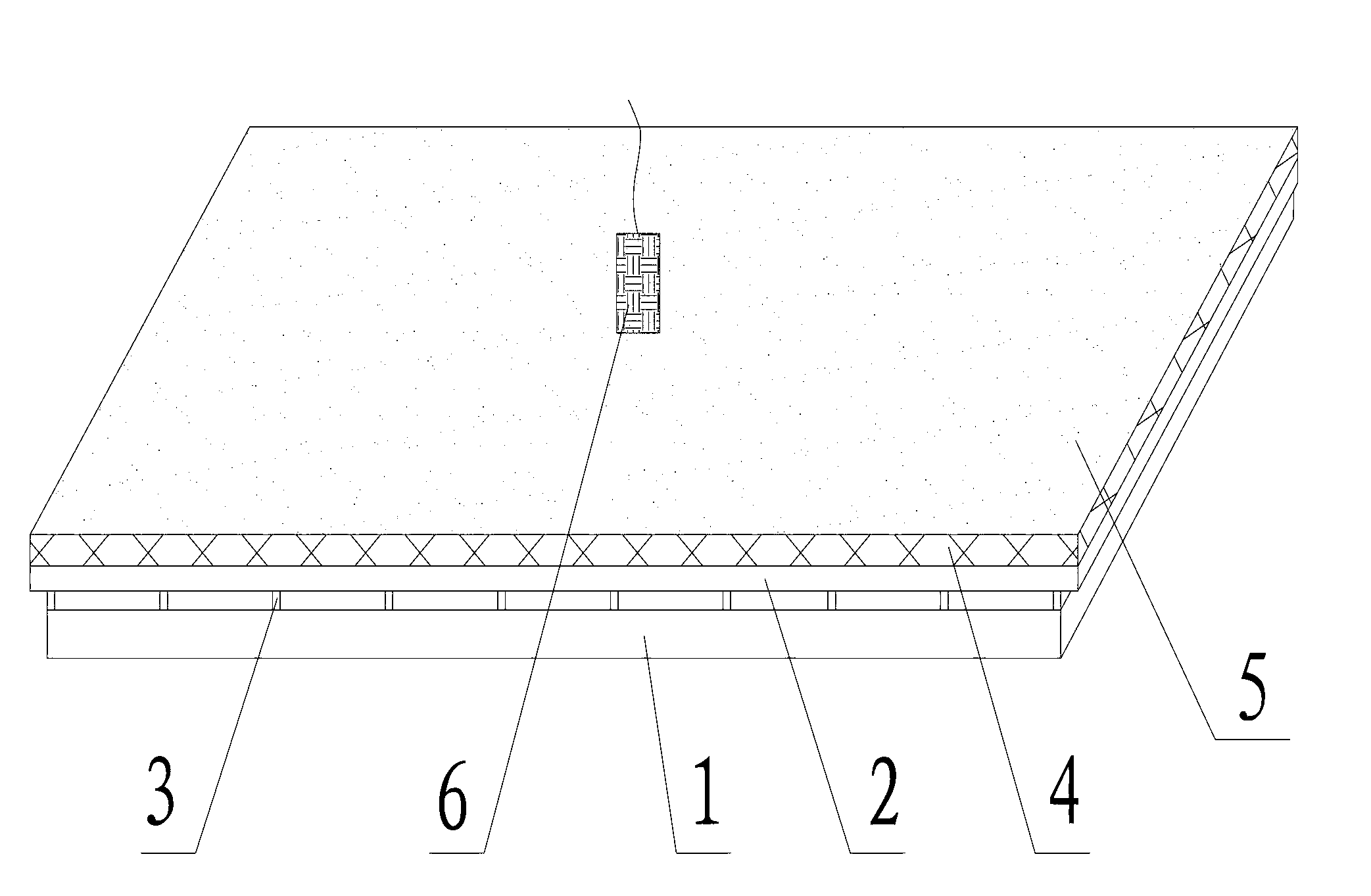

Explosive cladding explosive and preparation method and applications thereof

ActiveCN103058800ALow costExcellent caking resistanceExplosivesNon-electric welding apparatusExplosive claddingExplosive Agents

The present invention provides an explosive cladding explosive prepared from expanded ammonium nitrate explosive, calcium nitrate, graphite and magnesium stearate according to a certain ratio. The present invention also provides a method for preparing the explosive, and the method comprises weighing all raw materials and placing the raw materials in an automatic drug mixing machine to mix uniformly to obtain an explosive cladding explosive. Further, the present invention also provides a method for preparing explosive clad plates by using the explosive, and the method comprises: laying a clad plate on the top of a baseplate, and laying support columns between the clad plate and the baseplate; positioning an explosive frame on the clad plate, overlying the explosive inside the explosive frame, and placing a detonating primer on the explosive; and detonating the explosive by using the detonating primer to obtain the explosive clad plate. The explosive cladding explosive of the invention is good in formula design, simple in a blending method, low in cost, excellent in performance and anti-caking performance; and the explosive clad plate prepared by using the explosive cladding explosive of the invention has a high interlaminar bonding rate and high combination strength, and is for large-scale industrial production.

Owner:XIAN TIANLI CLAD METAL MATERIALS

Preparation method of flower-like TiO2/graphene photocatalyst and application thereof

InactiveCN105435766APromote oxidationImprove microwave absorption performancePhysical/chemical process catalystsPentachlorophenolMicrowave method

The present invention relates to a preparation method of a flower-like TiO2 / graphene photocatalyst and application thereof. According to the photocatalyst disclosed by the present invention, titanium chloride (TiCl4) is taken as a titanium source, and a bromide N-butyl pyridine ionic liquid is taken as a shape control agent, so that the photocatalyst is prepared and formed through a hydrothermal microwave method; and the photocatalyst is specially applied to residual sodium pentachlorophenol in a vineyard, so that chemical toxic substances on grapes are reduced. In the preparation process, graphene oxide can be directly reduced into graphene by microwaves without the need of adding any other reducing agent, so that the purpose of green chemistry is achieved. The catalytic performance of the synthesized catalyst is greatly improved, the degradation of contaminants in industry is facilitated, and the synthesized catalyst has a good prospect in industrial applications.

Owner:CHANGAN UNIV

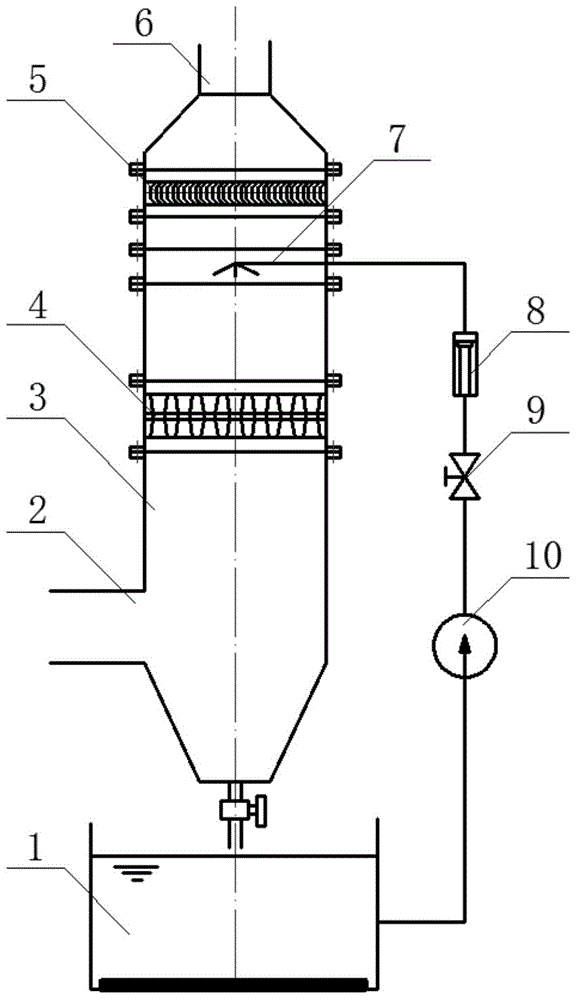

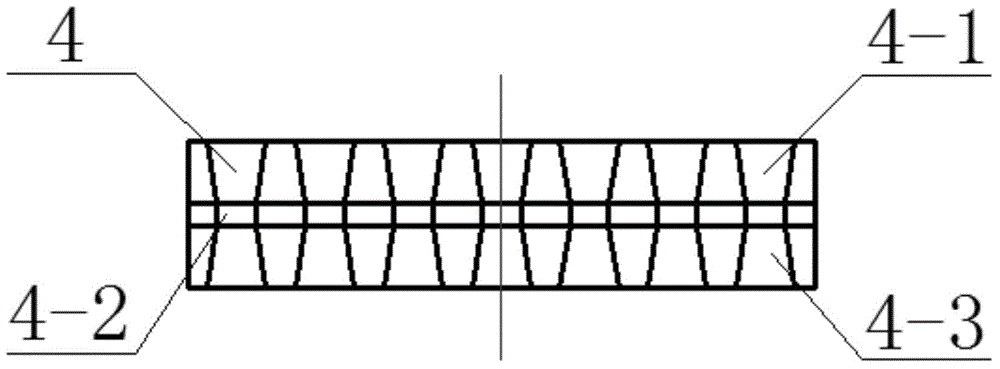

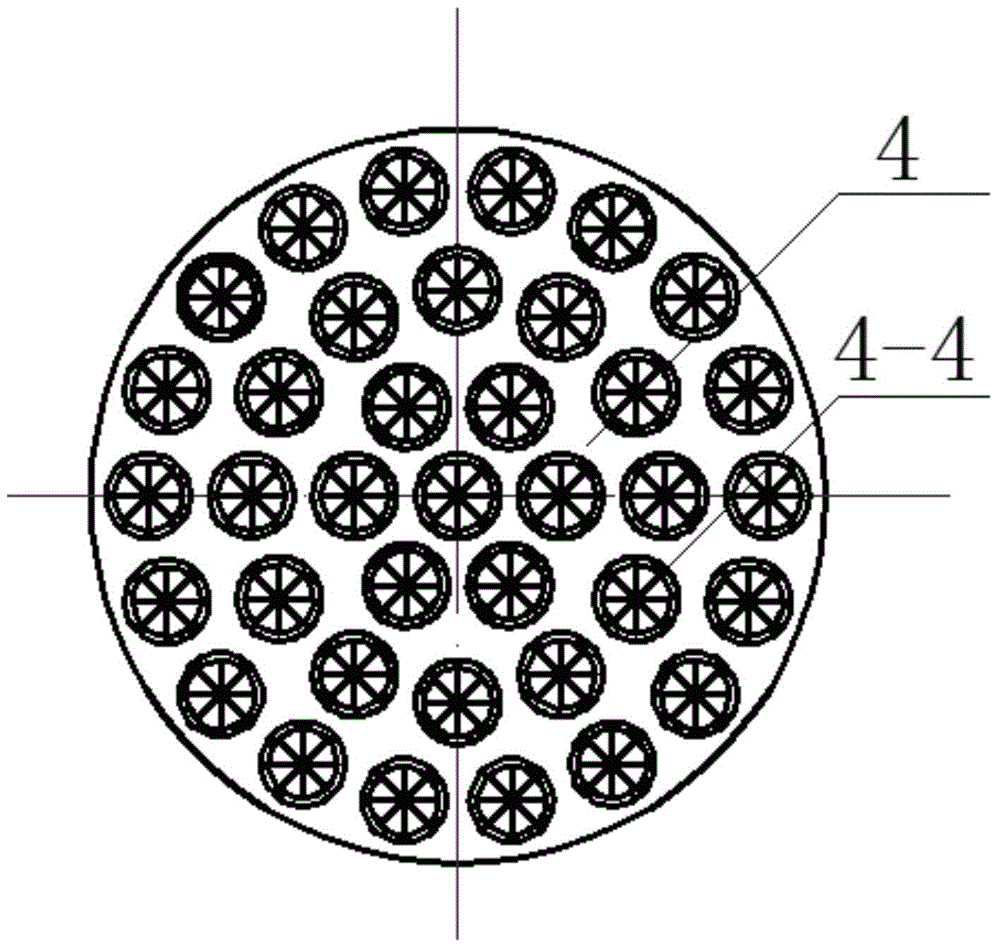

Smoke washing device with scaling-shaped hole plate

ActiveCN104399367AIncrease flow rateEnhanced rotation perturbationCombination devicesLiquid storage tankEngineering

The invention relates to a smoke washing device with a scaling-shaped hole plate. The smoke washing device comprises a tower body and a circulation liquid storage tank, wherein the circulation liquid storage tank is arranged below the tower body; the scaling-shaped hole plate, a spraying layer and a demister are sequentially arranged in the tower body from bottom to top; a smoke inlet is formed in the lower part of the tower body; an absorption tower outlet is formed in the top of the tower body; a seriflux circulation pump, a flow control valve and a flowmeter are sequentially arranged on a pipeline connected between the circulation liquid storage tank and the tower body; an oxidizing seriflux film is sprayed downwards by the spraying layer; upstream smoke and spraying liquid descending along the wall face are subjected to intensive mixing and heat and mass transfer by the scaling-shaped hole plate. The seriflux film is torn in the smoke-liquid collision process, smoke-liquid mixture rushes out of the inner hole of a gradually expanded hole plate slantly to go into the space of the spraying layer and the scaling-shaped hole plate, and therefore, the seriflux film forms a secondary atomization state and smoke-liquid collision and mixing are further strengthened.

Owner:XI AN JIAOTONG UNIV

Novel nano scarfing gas

The invention provides a novel nanometer scarfing gas, including liquid mother solution composed by hydrocarbons or alkane compound, is characterized in: also including one or several adjuvant mixed in the mother solution. The scarfing gas has advantages of high burning value, complete burning, quickly cutting, and regular shape of flame easy controlling, good efffect of cutting or soldering.

Owner:李华

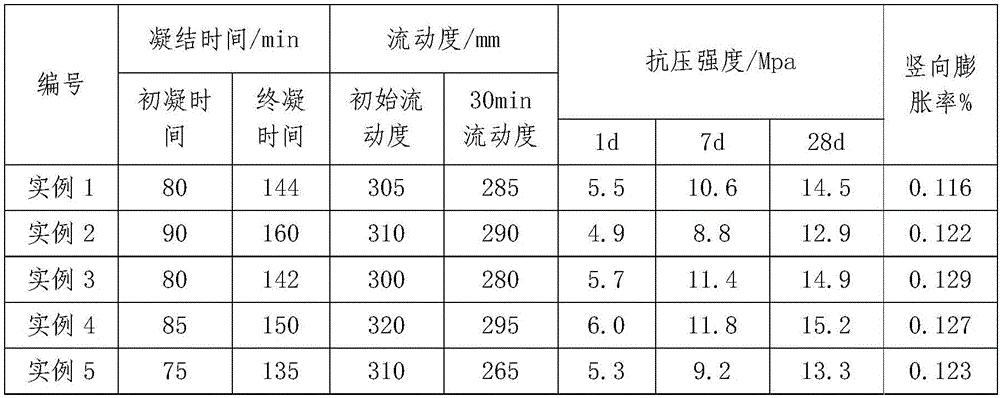

Phosphorus-based grouting filling material suitable for old goaf treatment

The invention discloses a phosphorus-based grouting filling material suitable for old goaf treatment. The phosphorus-based grouting filling material is prepared through the following steps: uniformly mixing, by weight, 40-60 parts of phosphorus slag powder, 30-40 parts of fly ash, 6-10 parts of an active activator and 3-8 parts of an expanding agent, adding the above obtained mixture, 0.5-1.5 parts by weight of a water reducer, 0.5-1 part by weight of a water retaining agent and 30-50 parts by weight of water to a stirring pool, uniformly stirring, adding 100-200 parts by weight of phosphorus tailings, and uniformly stirring. The phosphorus-based grouting filling material has the advantages of fast strength development, high filling efficiency, no shrinkage, and suitableness for long-distance pumping, the initial setting time is not smaller than 70min, the final setting time is not greater than 200min, the initial fluidity is not smaller than 300mm, the 30min fluidity retention value is not smaller than 260mm, the 1d compressive strength is not smaller than 4.9MPa, the 7d comprehensive strength is not smaller than 8.8MPa, the 28d compressive strength is not smaller than 12.9MPa, and the vertical expansion rate is not smaller than 0.1%.

Owner:HUBEI UNIV OF TECH

Method for producing hydrochloric acid-liquid caustic soda-composite material by utilizing industrial waste impure salt

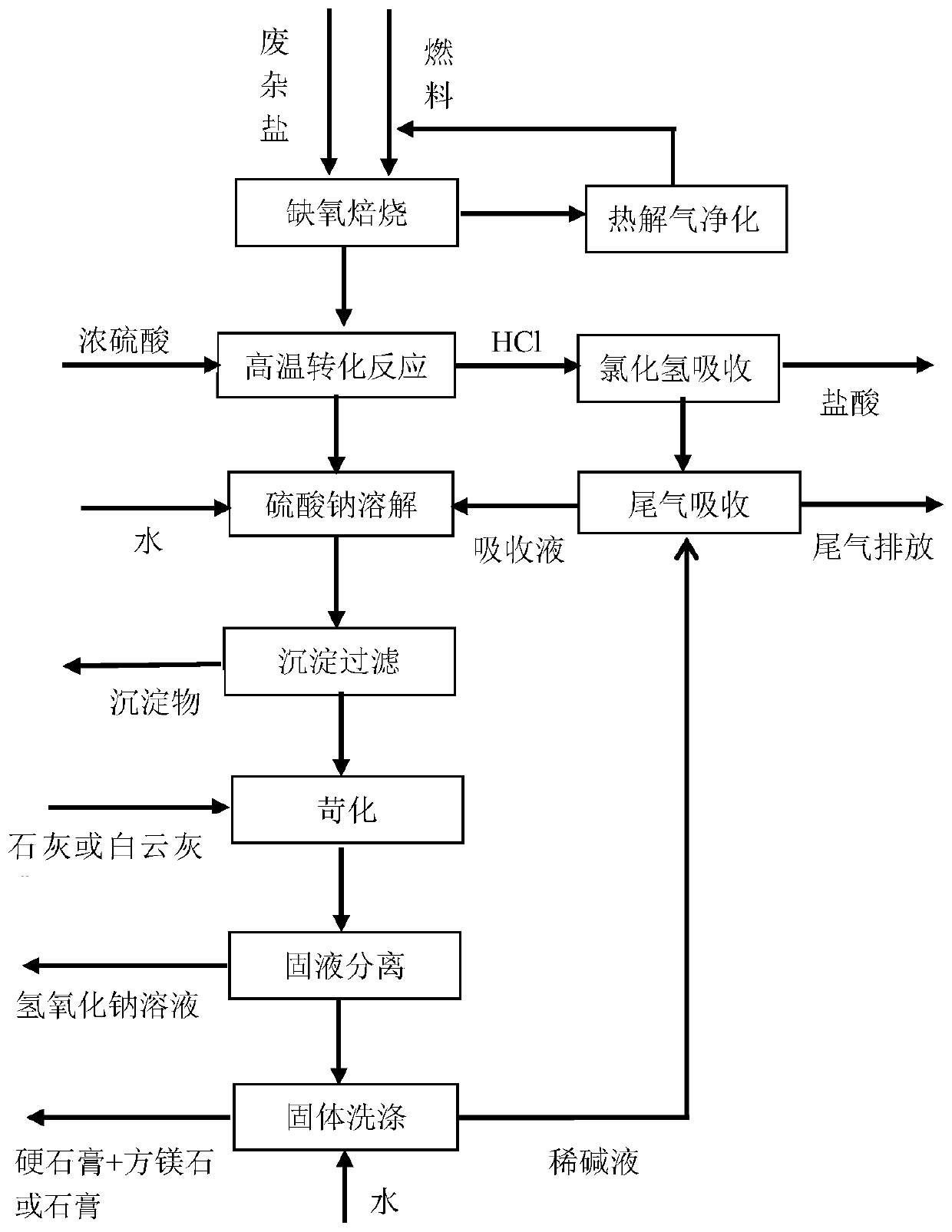

PendingCN111470526ARealize closed loopSolve resource problemsCalcium/strontium/barium sulfatesSpecial form destructive distillationDolomiteSodium sulfate

The invention discloses a method for producing a hydrochloric acid-liquid caustic soda-composite material by utilizing industrial waste impure salt. The method comprises the following steps: roastingthe industrial waste impure salt in a high-temperature oxygen-deficient atmosphere to decompose organic matters and easily-decomposed inorganic matter impurities in the industrial waste impure salt, reacting with concentrated sulfuric acid at high temperature to convert into hydrochloric acid, and dissolving, purifying and causticizing byproduct sodium sulfate with dolomite ash or lime to obtainliquid caustic soda and a composite material. According to the method disclosed by the invention, the industrial raw materials of hydrochloric acid and liquid caustic soda are obtained by taking the waste impure salt, the concentrated sulfuric acid, the dolomite ash or the lime as raw materials, so that closed cycle of wastewater and waste liquid is realized, pollution-free emission of waste gas is realized, and the recycling problem of the industrial waste impure salt containing organic matters is solved.

Owner:安徽科安废盐资源化有限公司

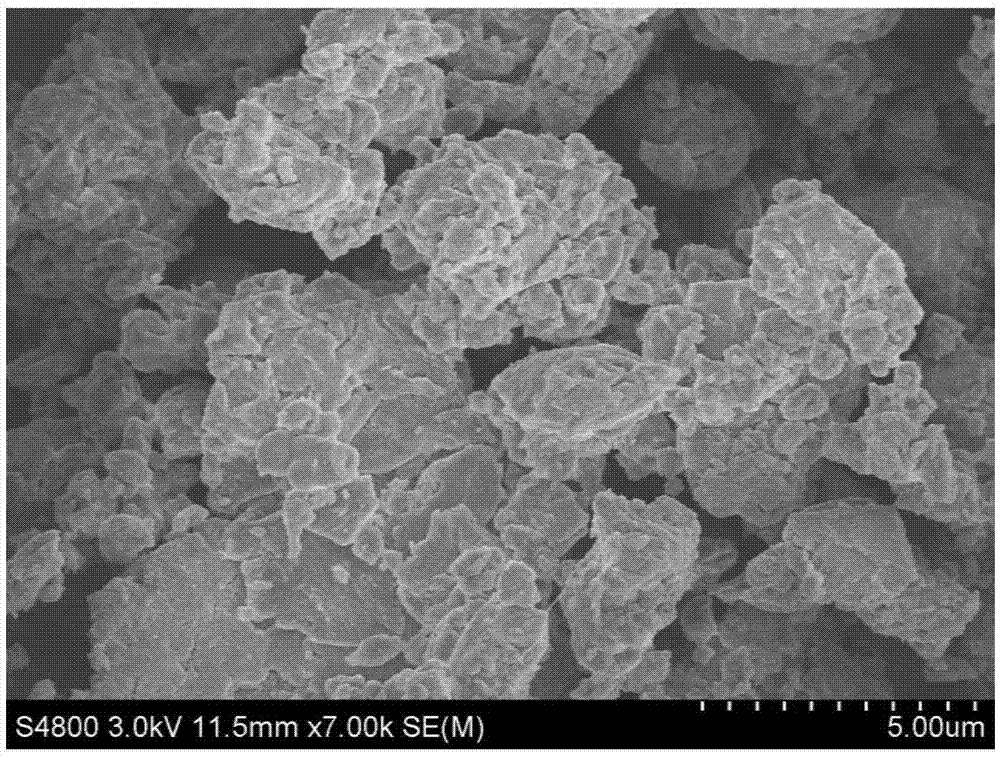

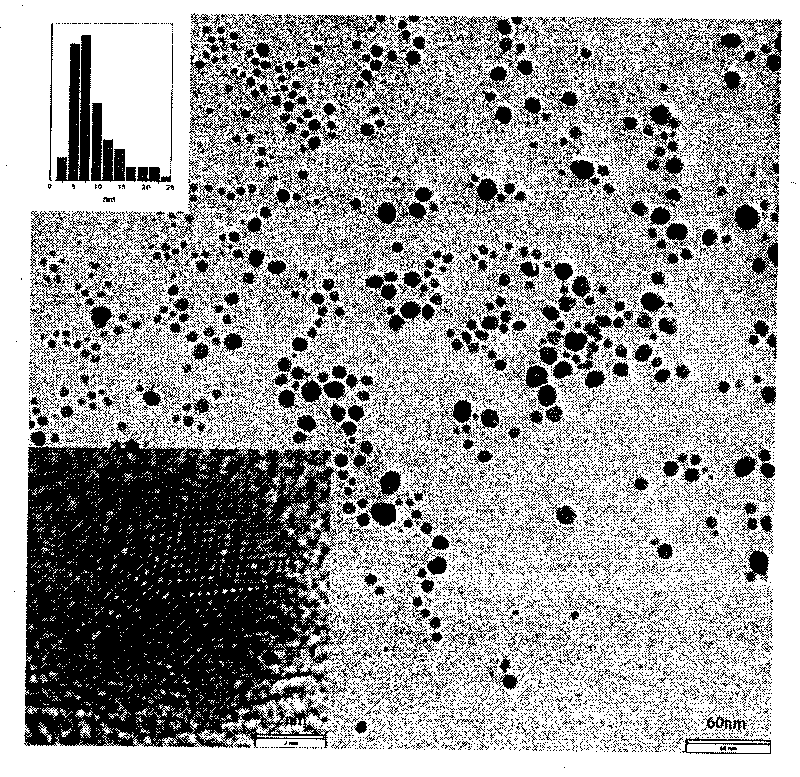

Preparation method of nano silver solution and polyaniline/ silver nanocomposite

The invention discloses a preparation method of nano silver solution and polyaniline / silver nanocomposite, belonging to the field of nanometer preparation and polymer inorganic matter nanocomposite. Linear alkyl benzene sulphonic acid is used as protective agent; silver oxide colloid generated by sodium hydroxide and silver nitrate serves as a precursor; aniline reduces the silver oxide colloid to prepare nano silver solution. In the preparation method of polyaniline / silver nanocomposite, the nano silver solution prepared by the above steps is directly adopted; the preparation method simplifies the fussy steps for removing the protective agent and reducing agent and saves material and energy compared with other in-situ oxidation styles; nano silver particles have favourable composite effect with generated polyaniline matrix; the whole preparation process is carried out at constant temperature and pressure; the adopted solvent is deionized water, and the preparation process is simple, needs fewer devices and has low comprehensive cost.

Owner:BEIHANG UNIV

Preparation process of fluffy, warm-keeping and anti-mildew down quilt

ActiveCN110004728AIncrease warmthImprove bulkBiochemical fibre treatmentDry-cleaning apparatus for textilesFiberImpurity

The invention discloses a preparation process of a fluffy, warm-keeping and anti-mildew down quilt. The preparation process has the advantages that filling down feather fibers are preprocessed to remove impurities and dust on the down feather fibers, then the down feather fibers are modified, sterilizing and antibacterial active N<+> is introduced into the down feather fibers, the pre-modified down feather fibers is mixed with metal ions, phenolic hydroxyl groups and alcoholic hydroxyl groups on the pre-modified down feather fibers can complex with Ni<2+> and Fe<3+>, and the antibacterial andanti-mildew performance of the down fibers is further increased; in addition, the warm-keeping performance of the down feather can be increased by introducing the Ni<2+> and the Fe<3+> which have goodfar infrared radiation ability into the down feather fibers, and the introduced Ni<2+> and Fe<3+> can generate a static effect to increase the fluffiness of the down feather; the preparation processis scientific and reasonable, the defect that existing down feather fibers are not resistant to mildew is improved, the down feather fibers can still have good antibacterial and anti-mildew performance after repeated washing, and the prepared down quilt is good in washability.

Owner:宁波博洋家纺集团有限公司

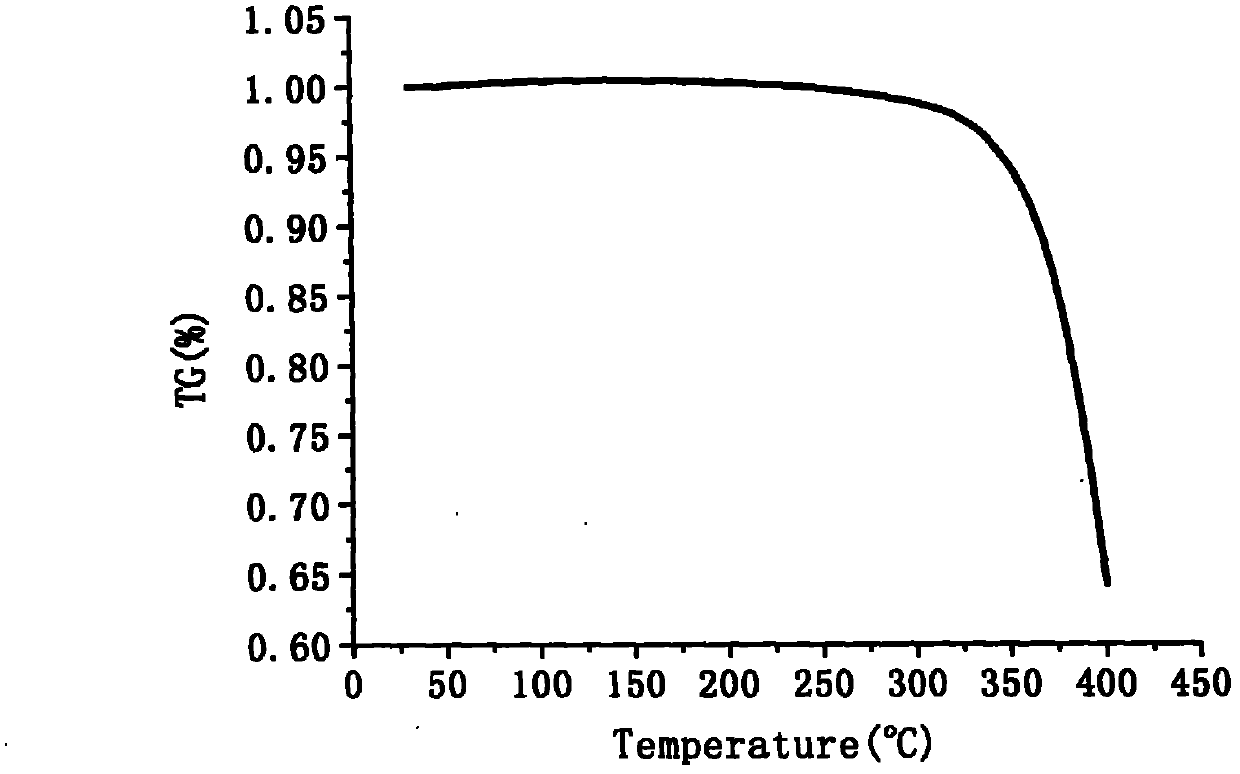

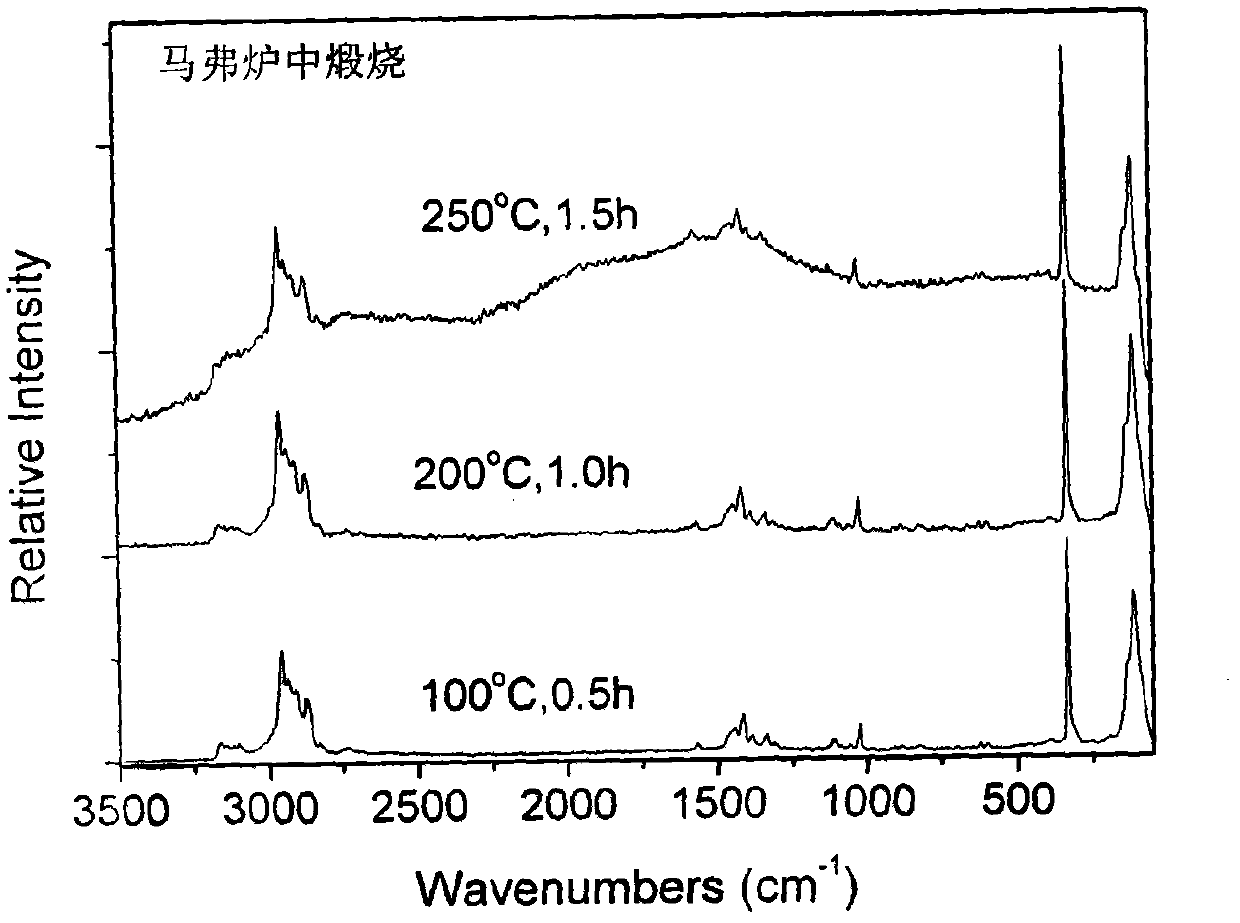

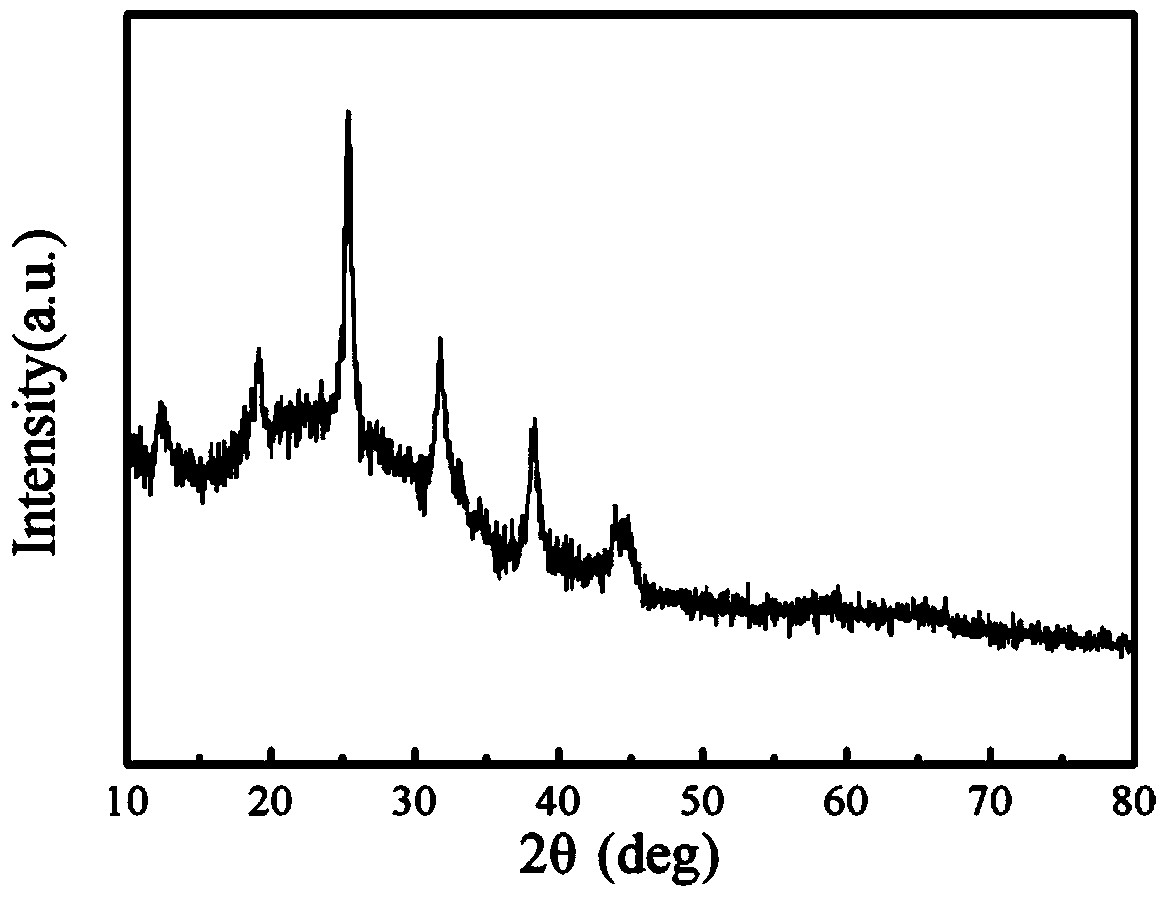

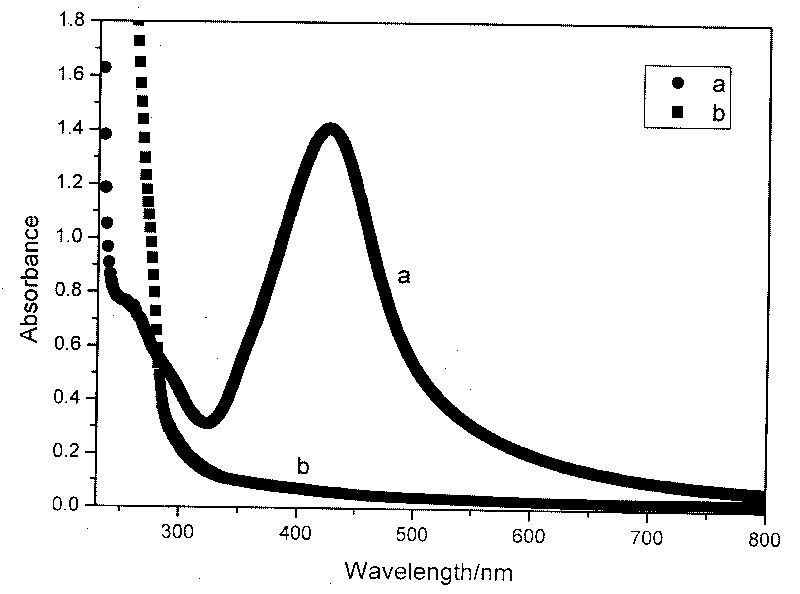

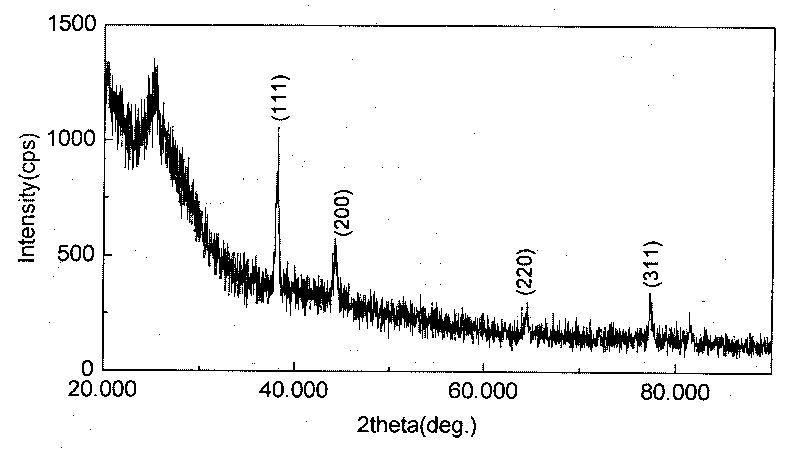

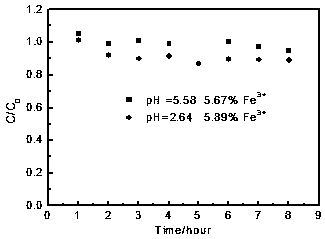

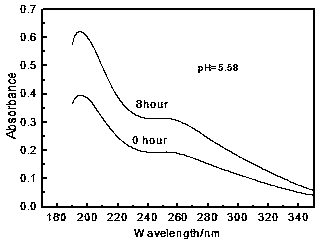

Method for performing catalytic oxidation on hydrogen sulfide through 1-butyl-3-methylimidazole ethylene diamine tetraacetic acid (EDTA) iron

InactiveCN103935965AOxidizingReduce surface tensionSulfur preparation/purificationSolubilityAcetic acid

The invention relates to a method for performing catalytic oxidation on hydrogen sulfide through hydrophilic 1-butyl-3-methylimidazole ethylene diamine tetraacetic acid (EDTA) iron ([Bmim][Fe(EDTA)]. Compared with conventional Fe-EDTA, the [Bmim][Fe(EDTA)] has one more cation [Bmim]<+>. Due to existence of [Bmim]<+>, an aqueous solution of the [Bmim][Fe(EDTA)] has the following characteristics that 1, the surface tension is low, aggregation of newly generated sulfur is promoted, and sulfur blockage formed by floating of fine sulfur is avoided; 2, according to the [Bmim]<+> structure, hydrogen sulfide is dissolved, the hydrogen sulfide has relatively high solubility in the aqueous solution of the [Bmim][Fe(EDTA)] even if under acid conditions, and a desulfuration side reaction is avoided under the acid condition. When the hydrogen sulfide is subjected to catalytic oxidation through [Bmim][Fe(EDTA)], the degradation rate is far lower than that of Fe-EDTA, degradation byproducts of Fe-EDTA are detected through an ultraviolet spectrum, and degradation byproducts of the [Bmim][Fe(EDTA)] are not detected. The infrared spectrum proves that sulfur-oxygen byproducts are not generated in the process of performing catalytic oxidation on the hydrogen sulfide in the aqueous solution of the [Bmim][Fe(EDTA)]. The XRD (X-Ray Diffraction) proves that the catalytic oxidation product is sulfur, and the yield of the sulfur is positively correlated to iron concentration.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

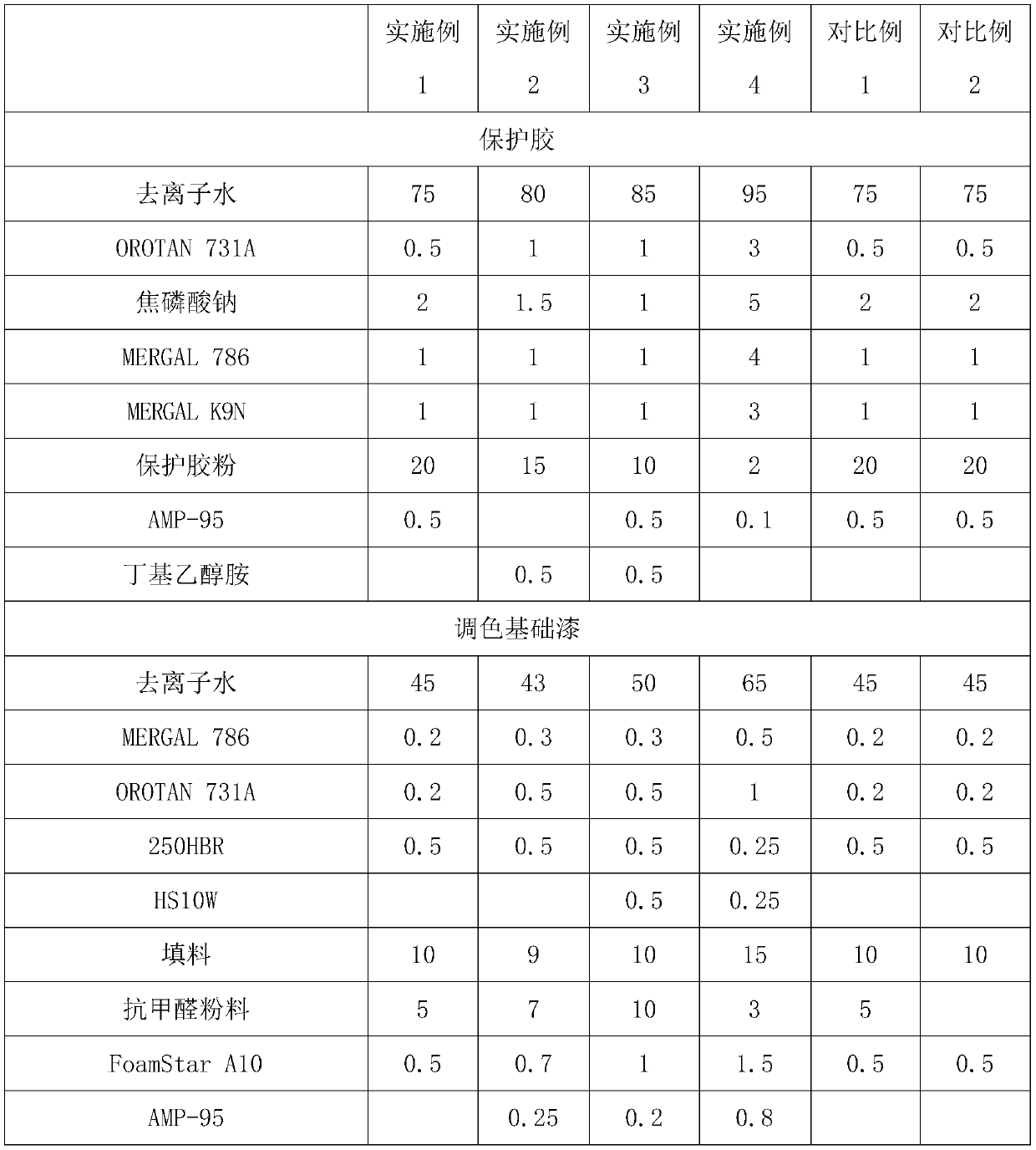

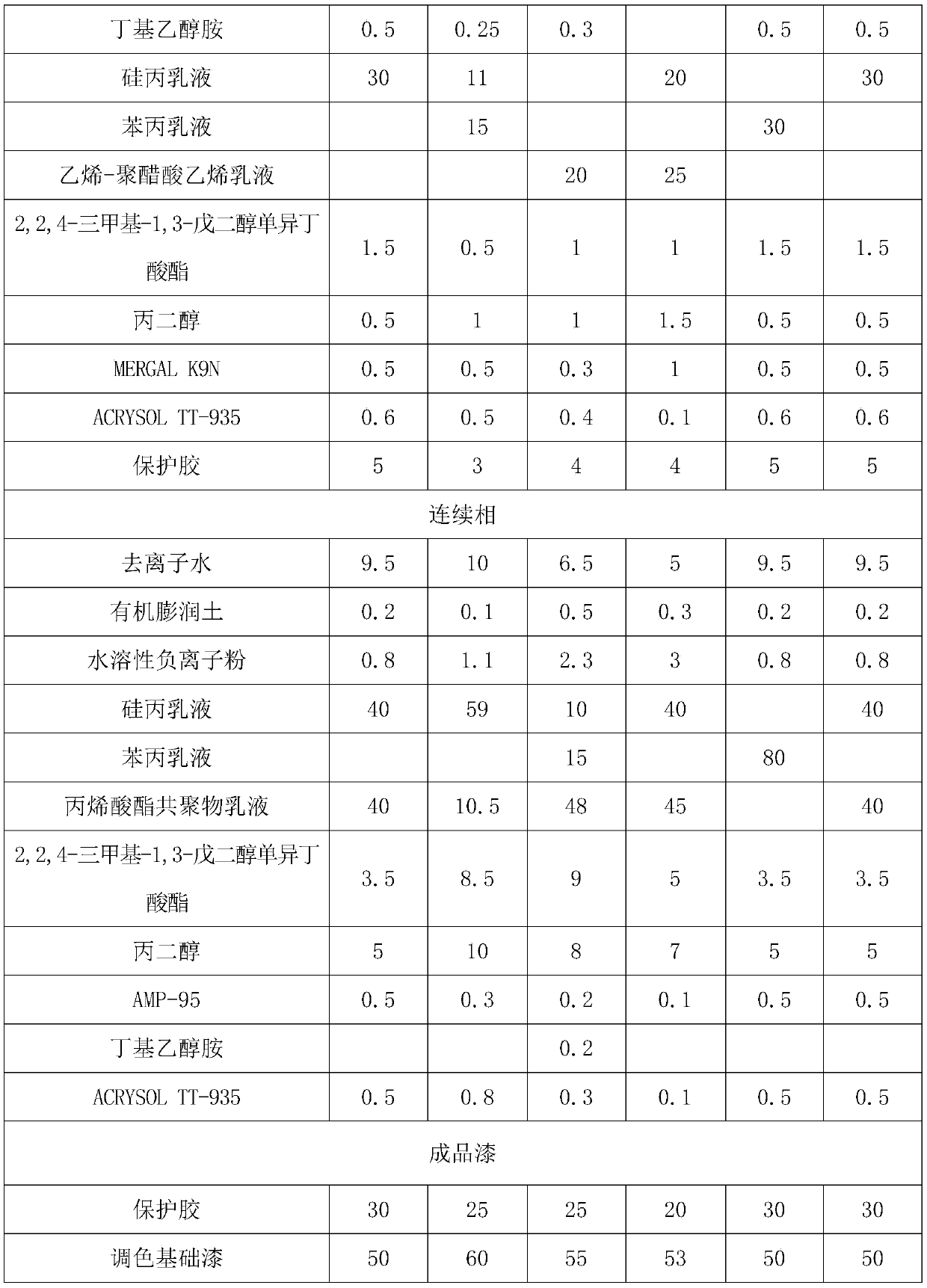

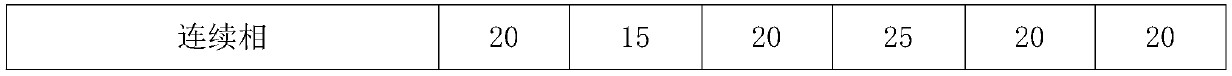

Odor removal formaldehyde-resistant liquid granite-imitated coating and preparation method thereof

PendingCN110437693AEfficient and durable anti-formaldehyde to remove VOCRich pore structureAntifouling/underwater paintsPaints with biocidesEmulsionDefoaming Agents

The invention discloses an odor removal formaldehyde-resistant liquid granite-imitated coating and a preparation method thereof. The coating is prepared from a protective adhesive, color matching basepaint and a continuous phase, wherein the protective adhesive is prepared from deionized water, a dispersant, a viscosity reducer, a mildew preventive, a sterilizing agent, protective rubber powder and a pH modifier, the color matching base paint is prepared from deionized water, a mildew preventive, a dispersant, cellulose, a filler, formaldehyde-resistant powder, a defoaming agent, a pH modifier, an odor removal emulsion, a coalescing agent, an antifreezing agent, a sterilizing agent, a thickener and a protective adhesive, and the continuous phase is prepared from deionized water, organbentonite, water-soluble anion powder, an odor removal emulsion, a coalescing agent, an antifreezing agent, a pH modifier and a thickener. According to the odor removal formaldehyde-resistant liquid granite-imitated coating, the environment-friendly odor removal emulsions are used as base materials, the water-soluble anion powder and the formaldehyde-resistant powder are added, the environment-friendly odor removal emulsions, the water-soluble anion powder and the formaldehyde-resistant powder are subjected to the synergistic action, thus formaldehyde is effectively decomposed, and a product has the outstanding formaldehyde purification efficiency and lasting efficiency.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

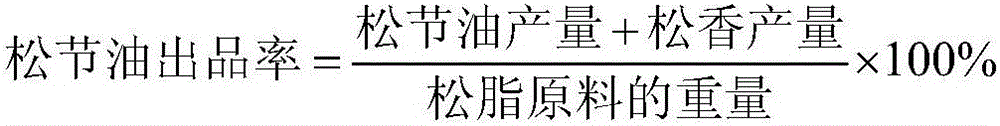

Pine resin processing method with pine resin processing yield increased

The invention relates to the field of pine resin processing and discloses a pine resin processing method with pine resin processing yield increased. The method includes the steps of pre-treatment, dissolution, water washing, clarification, residue recovery, distillation, and finish product collection. In the method, a raw material is pre-treated and is water-washed under supersonic wave; and during the dissolution, an internal heating coil is employed for heating the raw material, zeolite added to break the raw material; and meanwhile, through the residue recovery, vacuum distillation and the like, efficiency of pine resin processing is improved and yield of pine resin is increased. The method is free of big modification on devices and can achieve stable control, thereby achieving stable production and yield increasing.

Owner:广西兴业县新贵松脂厂

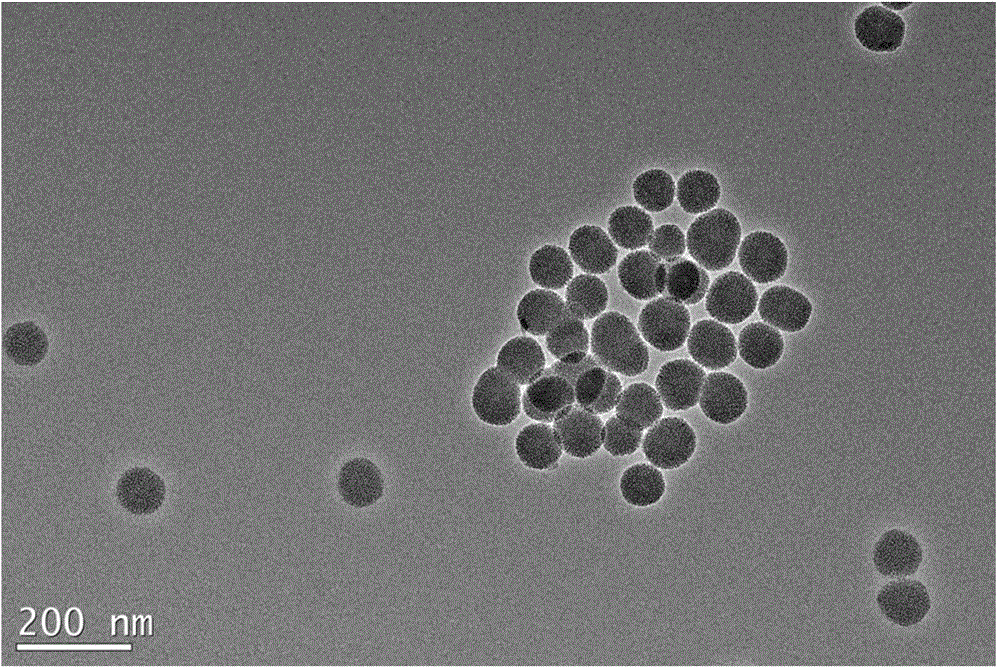

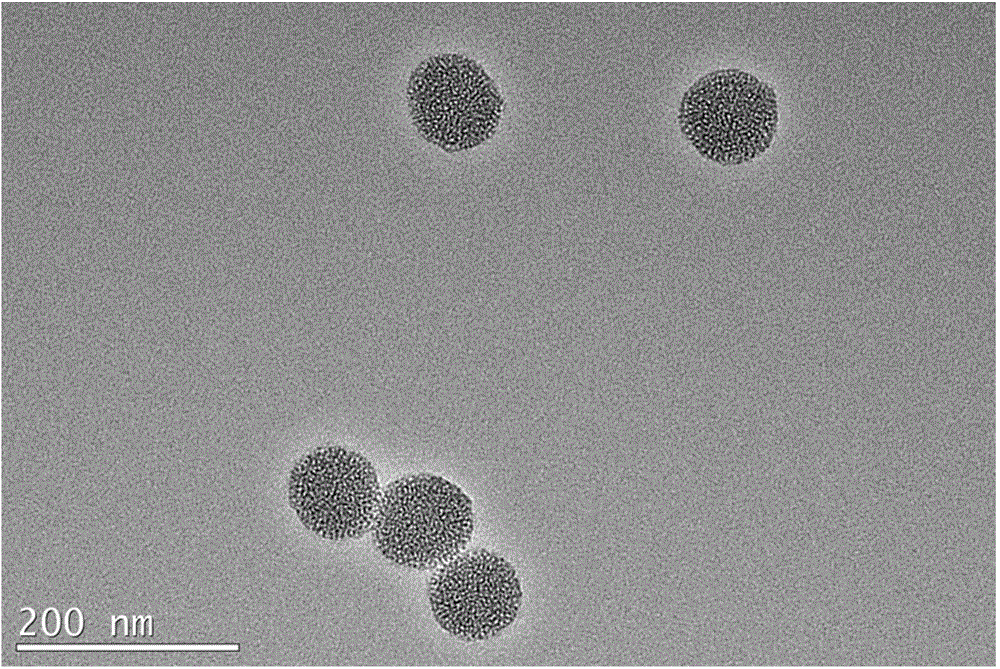

A monodisperse nanometer mesoporous silica-titanium dioxide composite sphere and a synthetic method thereof

ActiveCN105731466AOxidizingEvenly distributedMaterial nanotechnologySilicaMicroreactorMesoporous silica

A synthetic method of a monodisperse nanometer mesoporous silica / titanium dioxide composite sphere is provided. A mole ratio of ethanol, water, a template, an alkali and a silicon source which are raw materials is (0-11.0):115:(0.05-0.5):(0.03-8.0):1. The mass of a titanium source is 1-10% of the mass of a liquid mixture of the titanium source and the silicon source. The composite sphere is synthesized rapidly through the method. The method is simple in process and short in preparation time. The particle size of a product synthesized through the method is controllable in a range from 20 nm to 200 nm. The inside and the surface of the composite sphere can be functionalized, so that the composite sphere has high theoretical research and practical application value in the fields of adsorption separation, catalysis, environment protection, microreactors, synthesis of sensing and nanometer materials, and the like.

Owner:PETROCHINA CO LTD

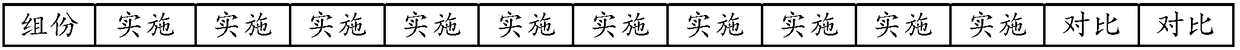

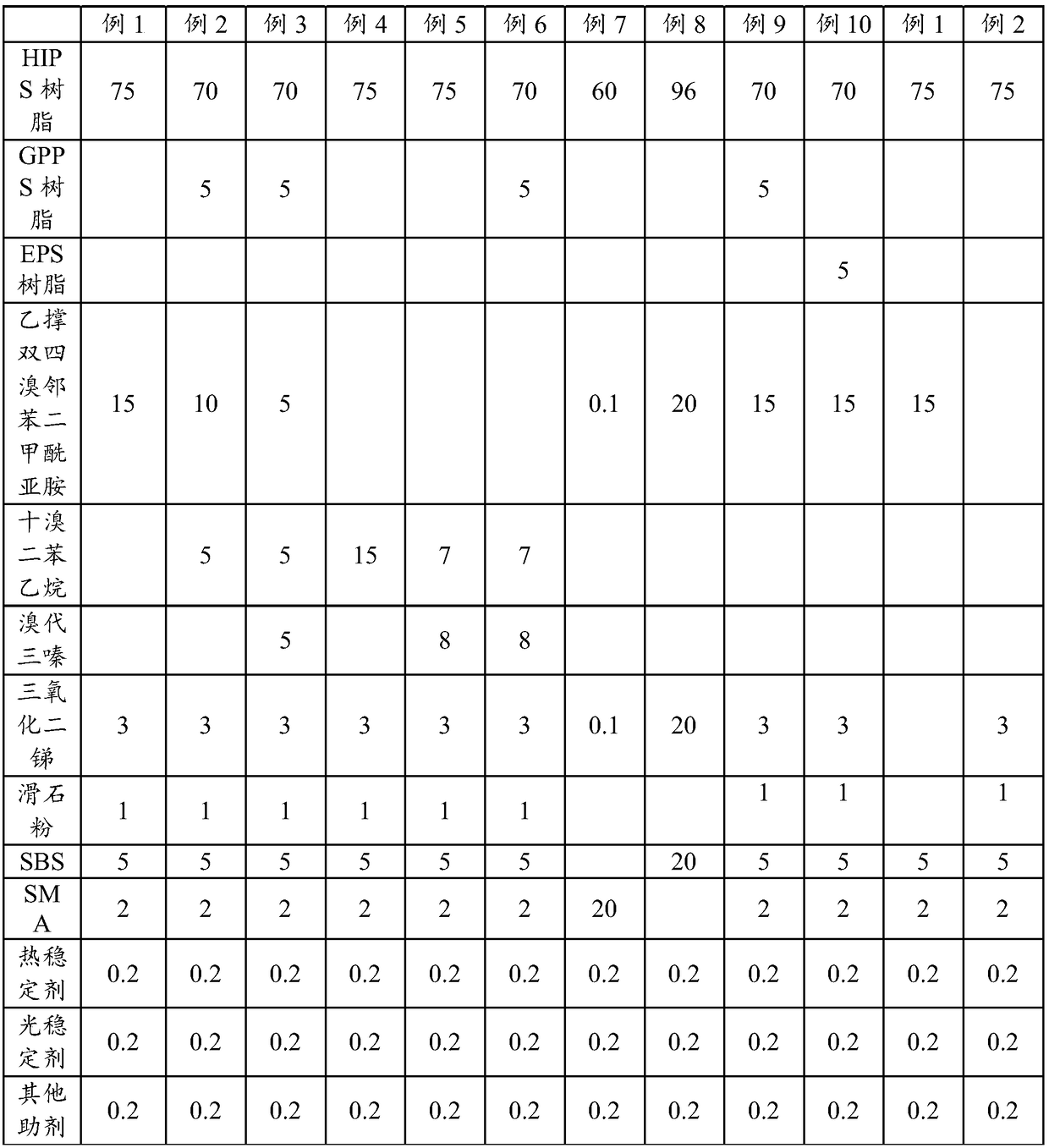

Environment-friendly flame-retardant polystyrene composite material and preparing method thereof

The invention discloses an environment-friendly flame-retardant polystyrene composite material. The environment-friendly flame-retardant polystyrene composite material is prepared from, by weight, 60-96 parts of PS resin, 0.1-20 parts of a fire retardant and 0.1-20 parts of a flame retardant synergist, wherein the fire retardant is at least one of decabromodiphenyl ethane, brominated epoxy resin,tri cyanurate, ethylene ditetrabromo-phthalic imide, tetrabromo bisphenol A and eight bromo ether; the flame retardant synergist is at least one of antimonous oxide and talcum powder. In the environment-friendly flame-retardant polystyrene composite material, through the synergistic interaction effect of the fire retardant and the flame retardant synergist, the composite material has the good flame resistance; as a compatilizer and a toughening agent are added, the composite material has the good yellowing resistance and toughness. The invention also discloses a preparing method for the environment-friendly flame-retardant polystyrene composite material.

Owner:WUHAN JINFA TECH CO LTD +1

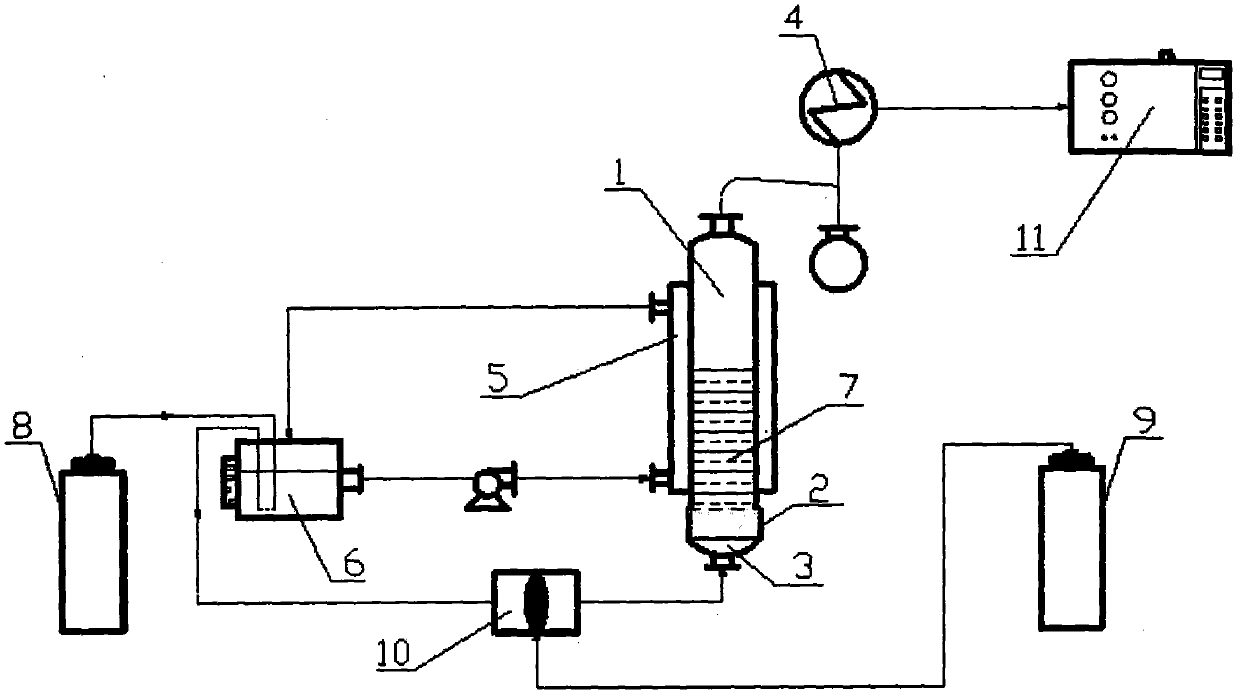

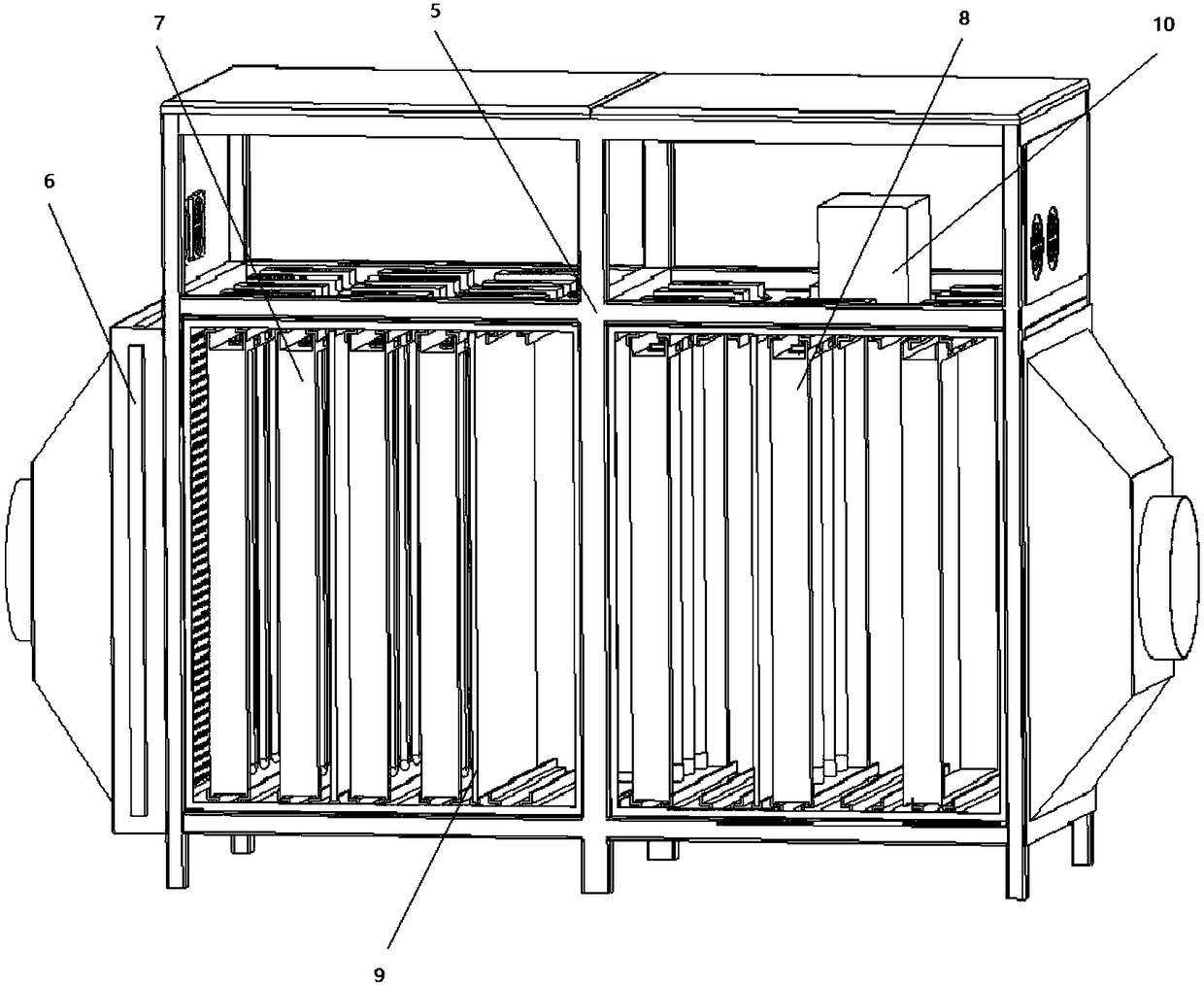

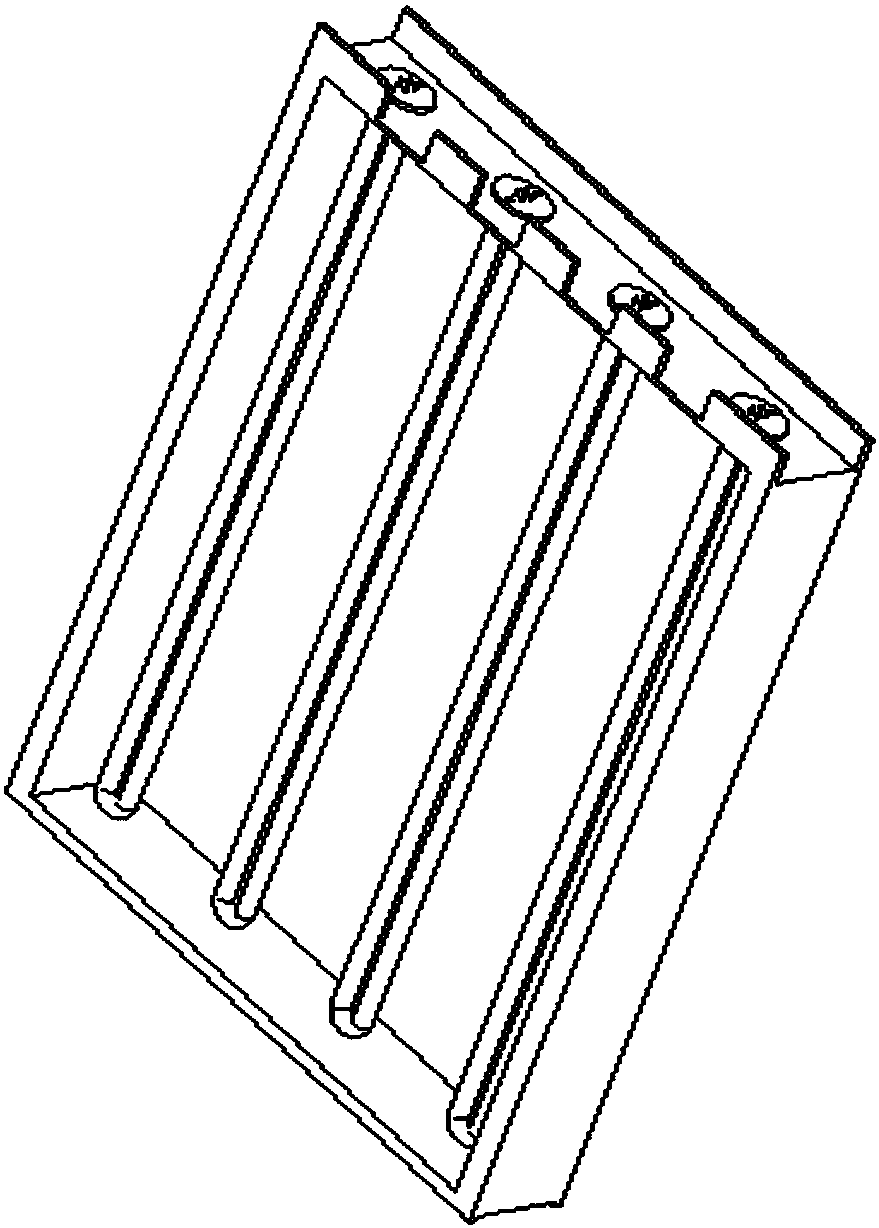

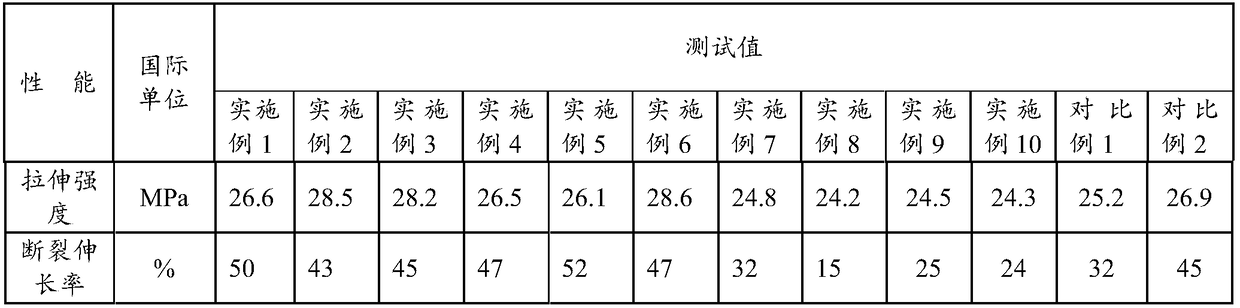

MCFB fuel gas purifying device capable of jointly removing various pollutants

InactiveCN101543712AMaintain moisture content uniformityEasy to removeCombination devicesMulti pollutantFluidized bed

The invention discloses an MCFB fuel gas purifying device capable of jointly removing various pollutants, which comprises a connecting flue, a primary fuel gas uniform distribution device, a secondary fuel gas uniform distribution device, a Venturi, multistage humidification and activation devices, a dust catcher, an ash circulation device, a draught fan, a fluidized bed reactor, a Venturi diffuser and a composite absorbent preparation device, wherein the lower end of the fluidized bed reactor is sequentially connected with the Venturi diffuser, the Venturi, the secondary fuel gas uniform distribution device, the primary fuel gas uniform distribution device and the connecting fuel; the upper part of the fluidized bed reactor is sequentially connected with the dust catcher and the draught fan; the bottom part of the dust catcher is connected with the Venturi diffuser through the ash circulation device; the multistage humidification and activation devices are arranged in the fluidized bed reactor and the Venturi diffuser; and the composite absorbent preparation device is connected with the Venturi diffuser. The multistage humidification and activation technology of the invention improves the pollutant purification efficiency, solves the problem of adhesion and blockage of materials in a tower, and realizes joint, high-efficiency and low-consumption removal of various pollutants in fuel gases.

Owner:ZHEJIANG UNIV

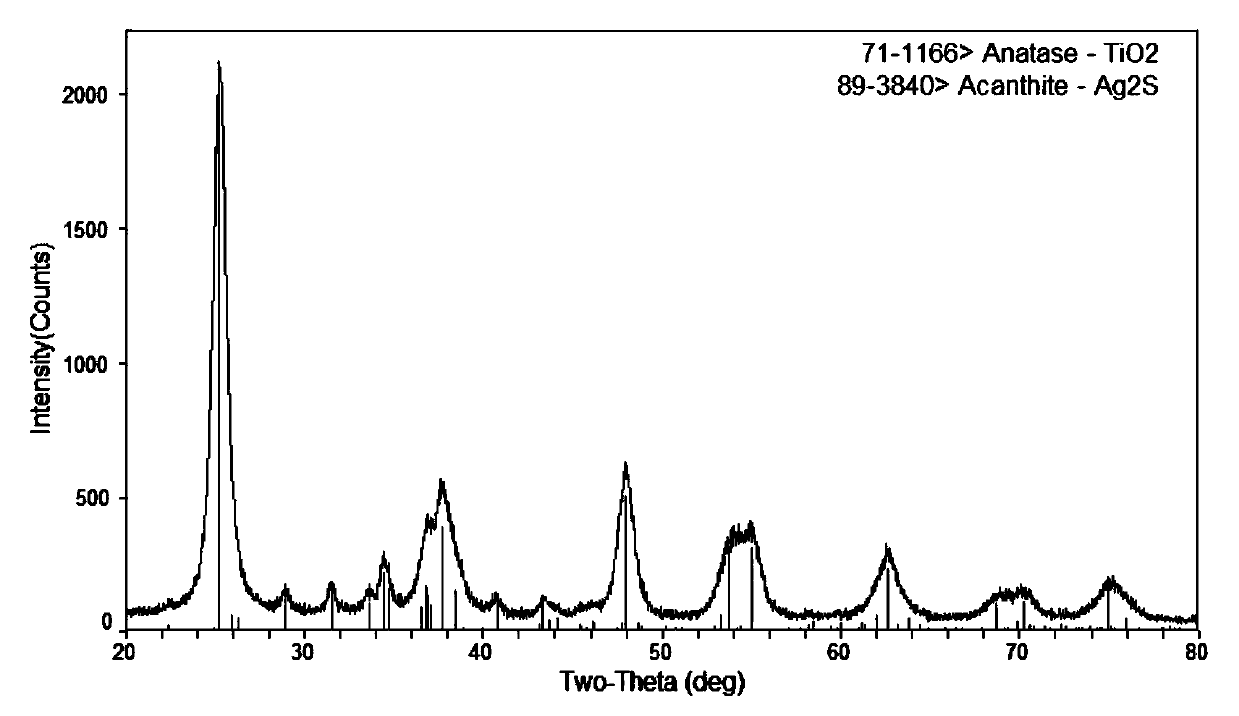

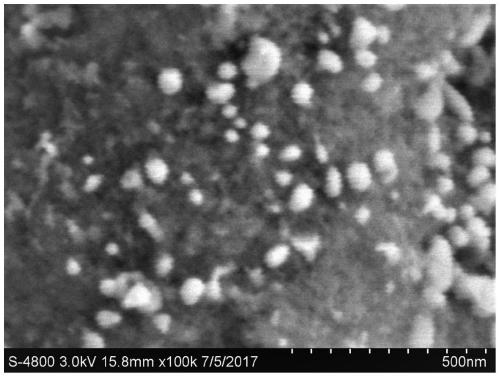

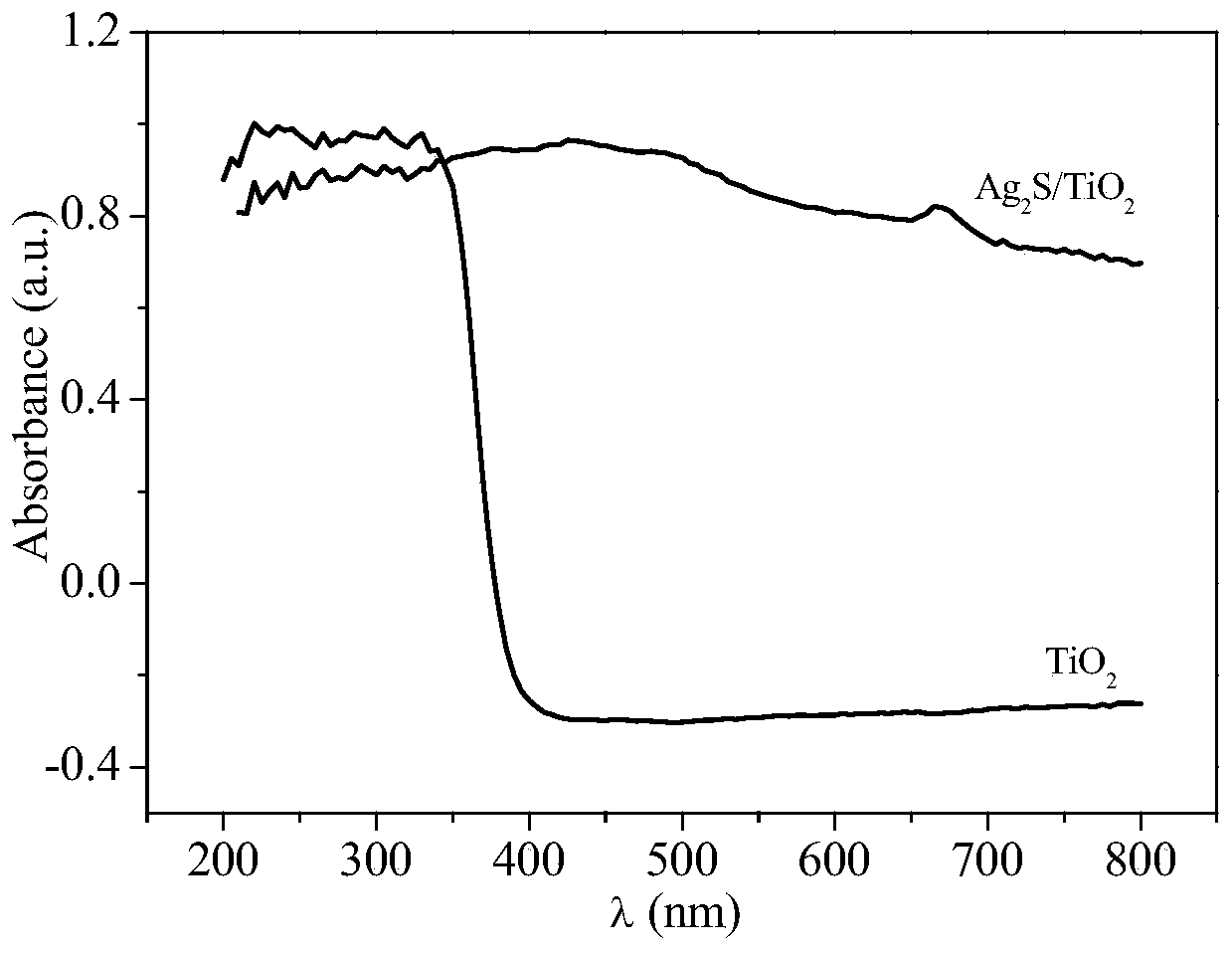

Preparation method of Ag2S/TiO2 composite photocatalyst and application thereof

ActiveCN110180557ALess types of raw materialsSimple processWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic degradationPollutant

The invention discloses a preparation method of an Ag2S / TiO2 composite photocatalyst and application thereof. According to the preparation method, with metatitanic acid and silver nitrate as raw materials and citric acid as a complexing agent for silver ions, the Ag2S / TiO2 composite photocatalyst is prepared by a sol-gel technology in combination with a thermal treatment technology. The preparation method of the composite photocatalyst is simple, the raw material cost is low, and the synthesized photocatalyst has very good visible light responsiveness. Data in the embodiment show that the Ag2S / TiO2 photocatalyst provided by the invention has a degradation rate of 98% for an aqueous methylene blue solution with the concentration of 50mg / L when the catalyst content is 1mg / mL and simulated sunlight irradiation lasts for 60min, so that the Ag2S / TiO2 photocatalyst can be widely applied to photocatalytic degradation of organic pollutants.

Owner:CHAOHU UNIV

Method for planting berchemiella wilsonii nakai

InactiveCN102498916AImprove water permeabilityPromote absorptionSeed and root treatmentHorticultureGerminationPotassium permanganate

The invention discloses a method for planting berchemiella wilsonii nakai to solve the problems of low germination rate and breeding difficulty of berchemiella wilsonii nakai. The method includes: firstly, treating seed coat, namely placing seeds in concentrated sulfuric acid 5-10mol / L for soaking for 2-5 minutes; secondly, secondarily treating the seeds, namely placing the seeds treated in the step one into potassium permanganate solution 0.05-0.2mol / L for soaking for 5-10 minutes; thirdly, accelerating germination, namely placing the seeds treated in the step two into potassium nitrate solution with 1%-3% mass concentration for soaking for 20-50 days; and fourthly, performing transplantation and field planting, namely transplanting the germinating seeds to a field. By means of treatments such as seed coat treatment, germination acceleration and the like for the seeds, the germination rate of berchemiella wilsonii nakai can be improved evidently, and significance on protecting berchemiella wilsonii nakai is achieved.

Owner:CHENGDU SHENGERJIA SCI & TECH

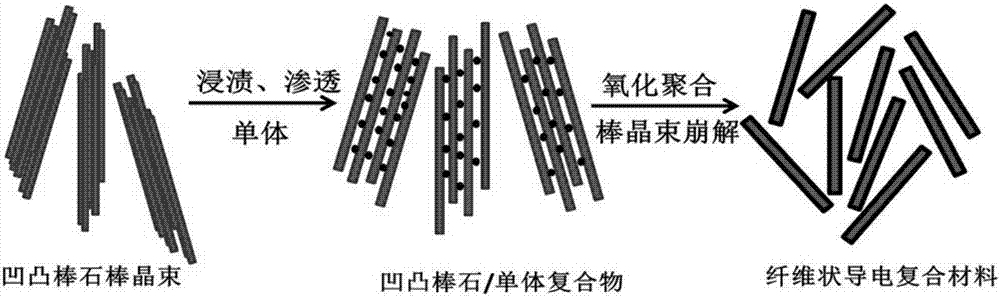

Integrated preparation technology for attapulgite rod-like crystal beam dissociation and conduction composite material

The invention belongs to the field of the clay mineral deep processing and high-valued utilization, and particularly relates to an integrated preparation technology for an attapulgite rod-like crystal beam dissociation and conduction composite material. The preparation technology comprises the following steps: dispersing natural attapulgite clay in deionized water, adding a conductive polymer monomer and dipping for a long time, adding inorganic acid solution, continuously executing the dipping reaction, ultrasonic-dispersing, filtering, washing a filter cake and drying, to obtain the attapulgite / conducting polymer composite material.

Owner:CHANGZHOU UNIV

Green environmentally-friendly method for smelting high-purity silicon

The invention discloses a green environmentally-friendly method for smelting high-purity silicon. According to the method provided by the invention, most impurities in silicon mud can be effectively removed by using specific slag forming agents in combination with specific mixed gas blowing, and the high-purity silicon with purity of 99.999% or more can be obtained; and the method has low costs, is green, environmentally friendly and worthy for promotion and use, and facilitates development of a solar photovoltaic industry.

Owner:BAOXING YIDA PHOTOVOLTAIC BLADE MATERIAL

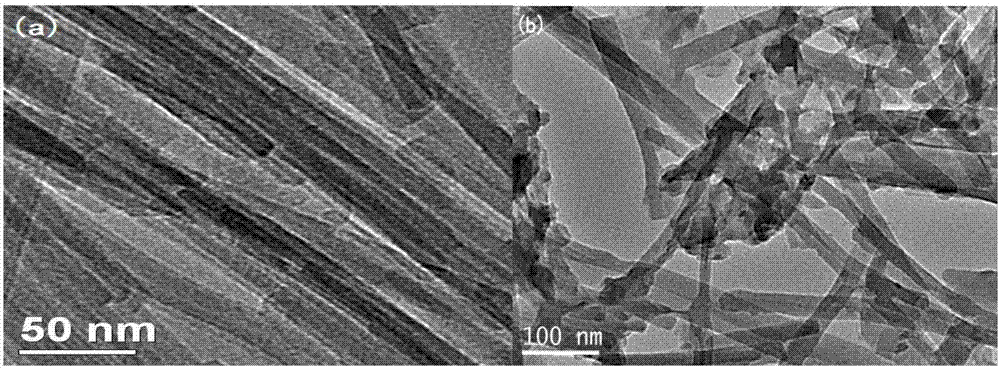

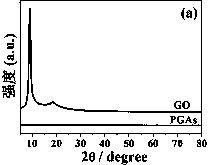

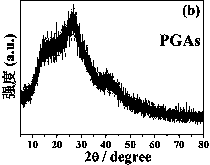

Preparation of multifunctional graphene-based material and application of multifunctional graphene-based material in supercapacitor and water treatment

InactiveCN108242341AAvoid reunionImprove enrichment capacityHybrid capacitor electrodesOrganic-compounds/hydrides/coordination-complexes catalystsPorosityPolypyrrole

The invention discloses the preparation of a multifunctional graphene-based material and the application of the multifunctional graphene-based material in a supercapacitor and water treatment. A graphene and a pyrrole monomer are combined by using a hydrothermal method to obtain a polypyrrole / reduced graphene oxide aerogel (PGAs). The aerogel has the porosity of graphene and the reducibility of polypyrrole. The disadvantage of excessive agglomeration of pyrrole can be solved well by the porosity and dispersibility of the graphene, and thus the advantages are fully exerted. A prepared graphene-based aerogel is placed into a three-dimensional electrode reaction system to play a role of as a third particle electrode and is used for removing a mixed solution of hexavalent chromium (Cr(VI)) andbisphenol A (BPA). In addition, the prepared material is used as an electrode and is applied to the supercapacitor, and the related performance is tested. The realization of a multifunctional material facilitates the alleviation of environmental pressure and accords with the current trend of energy conservation and environmental protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Chemical deodorization method for sludge

ActiveCN108191184AIncrease contentStrong contentSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationWater storage tankSURFACTANT BLEND

The invention discloses a chemical deodorization method for sludge. The method comprises steps as follows: to-be-treated sludge is put in an adjusting tank, the water content of the to-be-treated sludge is adjusted, the sludge in the adjusting tank is pumped into a reaction tank, a high ferrate solution is added to the reaction tank, the sludge in the reaction tank is stirred, quick lime and a surfactant are added to the reaction tank, the sludge in the reaction tank is continuously stirred, the sludge in the reaction tank is pumped into a dewatering tank, diatomite and zeolite are added to the dewatering tank, the sludge in the dewatering tank is stirred and settled in the dewatering tank, a liquid supernatant obtained after settlement is discharged into a water storage tank, dewatering treatment is performed through sludge dewatering equipment, discharged water is conveyed to the water storage tank, discharged sludge is conveyed to a mud tank, and mud conveyed into the mud tank is taken out and transported from the mud tank after being left to stand for specified time. The sludge deodorization effect is effectively improved, so that sludge is effectively utilized, pollution of sludge to the environment is reduced, and the application value of sludge is increased.

Owner:JIANGSU FENGYUAN ENVIRONMENTAL TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com