Odor removal formaldehyde-resistant liquid granite-imitated coating and preparation method thereof

A granite-like coating and formaldehyde-resistant technology, applied in the field of coatings, can solve problems such as ineffective removal, achieve good adsorption performance, eliminate indoor odors, and efficiently and lastingly resist formaldehyde and VOC.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of above-mentioned anti-formaldehyde powder comprises the following steps:

[0062] (1) Slowly add coconut shell activated carbon, nano-silicon chips, and tourmaline into the water, stir for 10 minutes, and the stirring speed is 300-600r / min. During this period, pay attention not to stick powder on the inner wall of the container and the stirring shaft;

[0063] (2) After stirring, ultrasonically disperse for 10 minutes;

[0064] (3) After the ultrasonic dispersion is completed, add diatom mud at a stirring speed of 600-800r / min, adjust the stirring speed to 1200-1500r / min, and stir for 20 minutes;

[0065] (4) After the stirring is completed, the obtained slurry is vacuum-dried until the water content is less than 0.5%, pulverized and sieved to obtain the formaldehyde-resistant powder.

[0066] The preparation method of this clean taste anti-formaldehyde liquid imitation granite coating comprises the following steps:

[0067] (1) Preparation of...

Embodiment

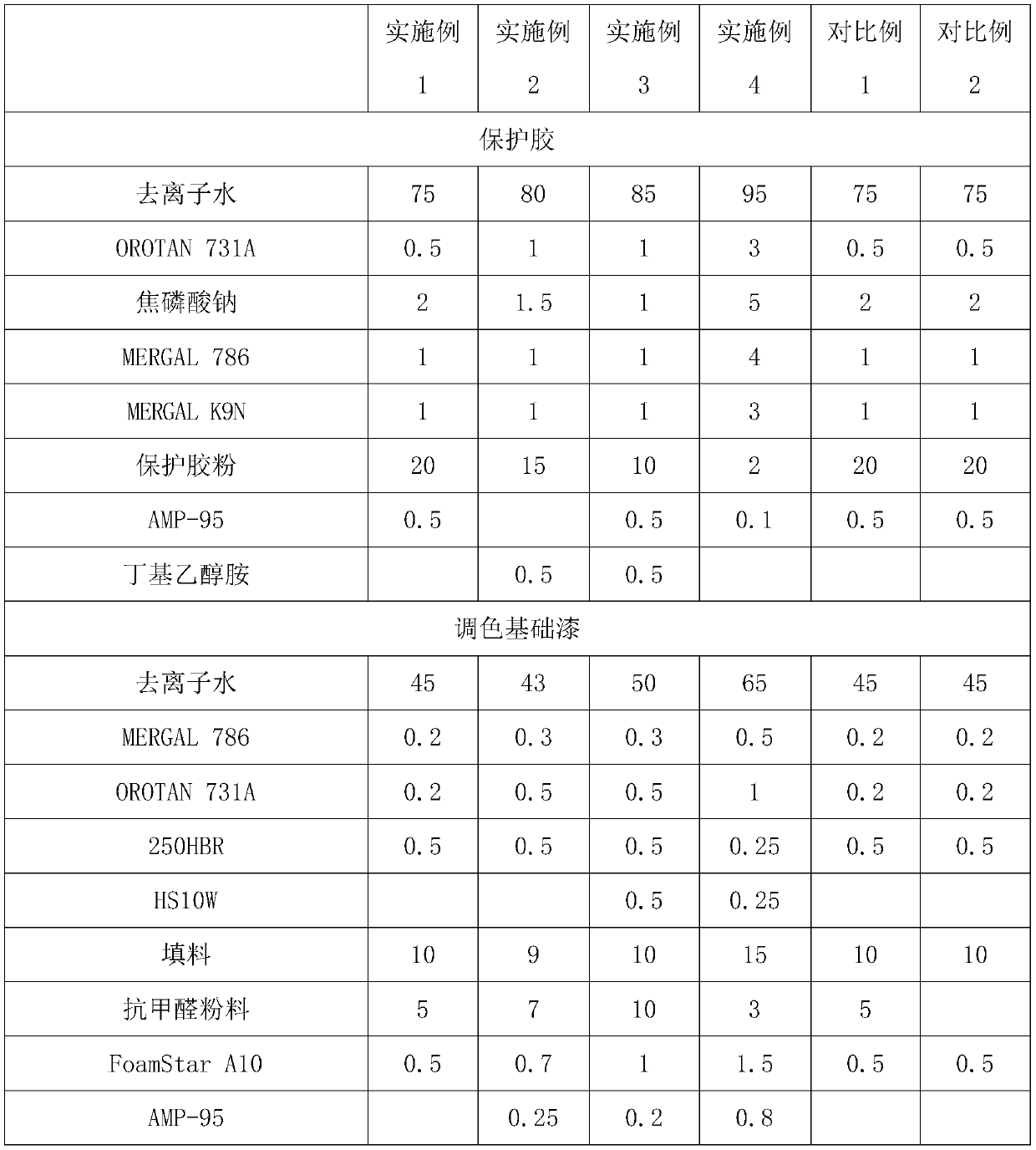

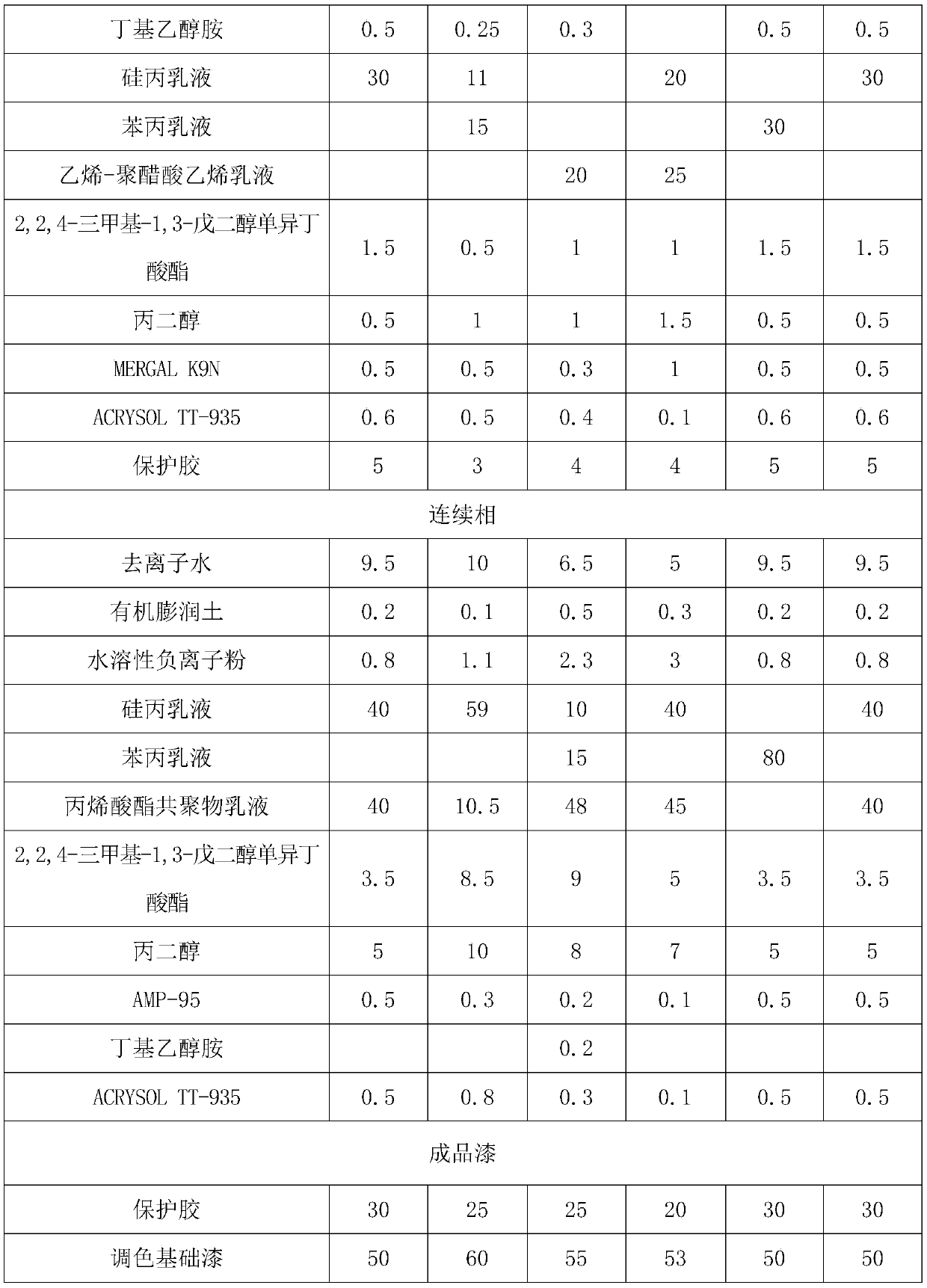

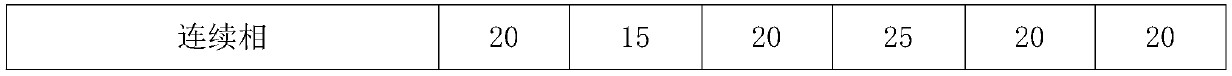

[0088] Formulation: as shown in Table 1 below.

[0089] Preparation:

[0090] (1) Prepare the protective glue for use: add deionized water into a suitable container, and start stirring at a stirring speed of 500r / min, add a dispersant, a viscosity reducer, an antifungal agent, a bactericide, and a pH regulator, and stir for 2 minutes; Adjust the stirring speed to 1400r / min, add protective rubber powder, and stir for 30 minutes to prepare a protective rubber solution;

[0091] (2) Prepare toning base paint for later use:

[0092] a. Add deionized water into the container and start stirring;

[0093] b. At a stirring speed of 400r / min, add antifungal agent and dispersant evenly and slowly and stir for 2 minutes;

[0094] c. At a stirring speed of 700r / min, add cellulose and stir for 8 minutes;

[0095] d. At a stirring speed of 800r / min, slowly add filler, anti-formaldehyde powder, defoamer, pH regulator, after adding, adjust the speed to 1300r / min, and stir for 20min;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com