Polyester flat microporous membrane and preparation method thereof

A technology of microporous membrane and polyester, which is applied in the field of polyester flat microporous membrane and its preparation, can solve the problems such as no polyester porous membrane has been found, and achieve the effects of highlighting anti-pollution, long cleaning cycle and narrow pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

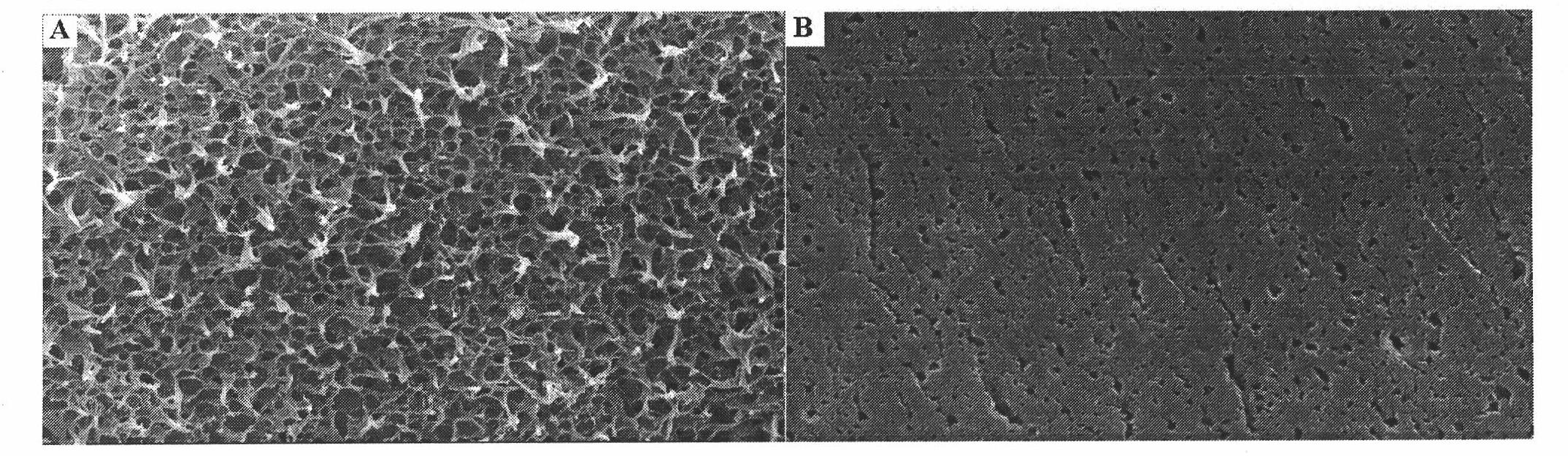

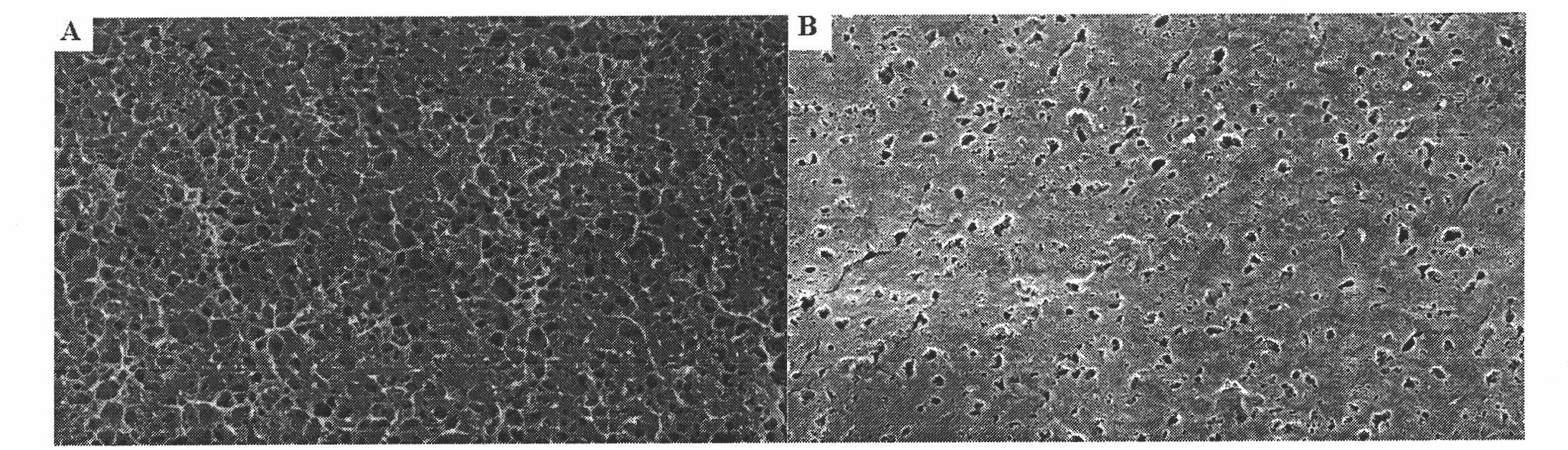

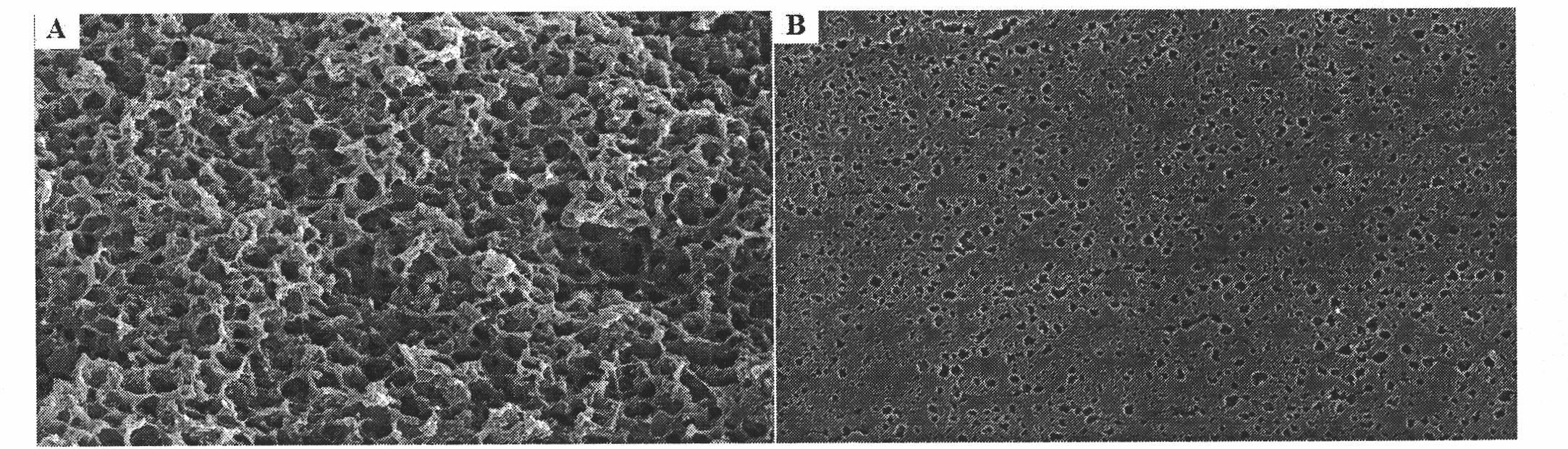

Image

Examples

preparation example Construction

[0057] The steps of a preparation method of a polyester flat microporous membrane are:

[0058] 1) The polyester with a mass percentage of 10-49.9%, the modifier with a mass percentage of 0.1-20%, and the diluent with a mass percentage of 50-89.9% are mixed at 200-300°C Membrane solution;

[0059] 2) Scraping the film-forming solution on a stainless steel carrier or a glass carrier to form a liquid film with a thickness of 40-600 microns, and immersing it in a coagulation bath at 0-100°C to solidify into a precursor film;

[0060] 3) immersing the precursor membrane in an extractant at 0-50° C. for 24-48 hours, and drying to obtain a flat polyester microporous membrane.

[0061] The steps of the preparation method of another kind of polyester flat microporous membrane are:

[0062] 1) The polyester with a mass percentage of 10-49.9%, the modifier with a mass percentage of 0.1-20%, and the diluent with a mass percentage of 50-89.9% are mixed at 200-300°C Membrane solution; ...

Embodiment 1

[0072](1) Preparation of film-making solution: polyethylene terephthalate (molecular weight: 100,000), diphenyl ether, and polymethacrylate derivatives (molecular weight: 50,000) were mixed at 200 with a ratio of 49.9:50:0.1 Mix uniformly at ~300°C to obtain a membrane-forming solution.

[0073] (2) Precursor film formation: Scrape the film-forming solution at 200-300°C on the carrier at 200°C to form a liquid film of 50-600 microns, and immerse the carrier with the liquid film in water to solidify it into a precursor film.

[0074] (3) Extraction to form pores: soak the precursor membrane in absolute ethanol at 50° C. for 24 hours, take it out and dry it to obtain the polyester flat microporous membrane.

[0075] Each implementation condition and the structure and performance of the obtained polyester flat microporous membrane are as shown in Table 1.

[0076] Table 1

[0077]

Embodiment 2

[0079] The preparation steps are the same as in Example 1, and the various implementation conditions and the structure and properties of the obtained polyester flat microporous membrane are shown in Table 2.

[0080] Table 2

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com