Patents

Literature

963results about How to "Extended cleaning cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

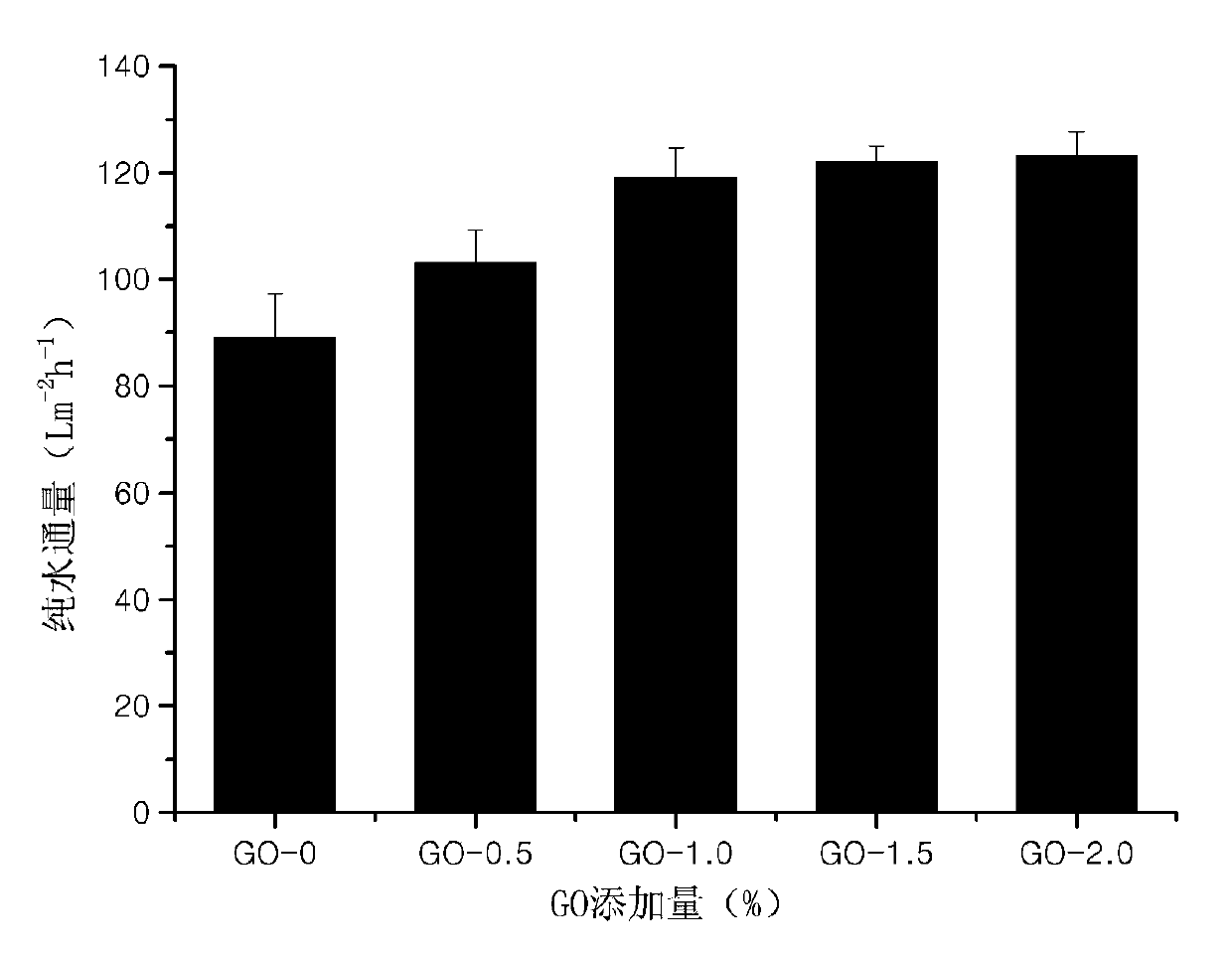

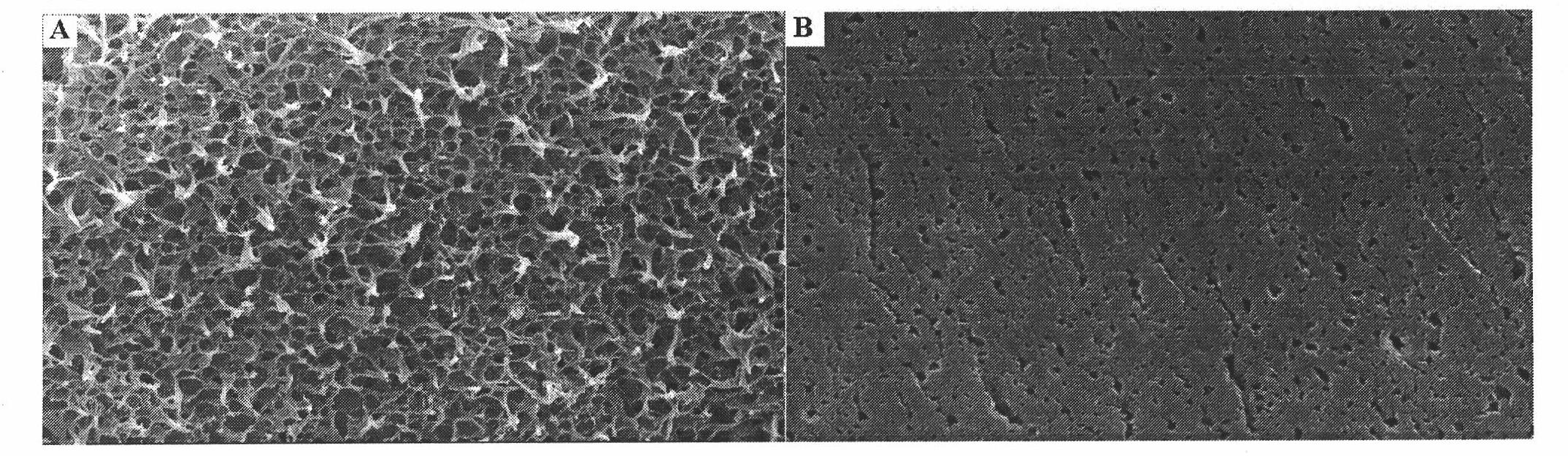

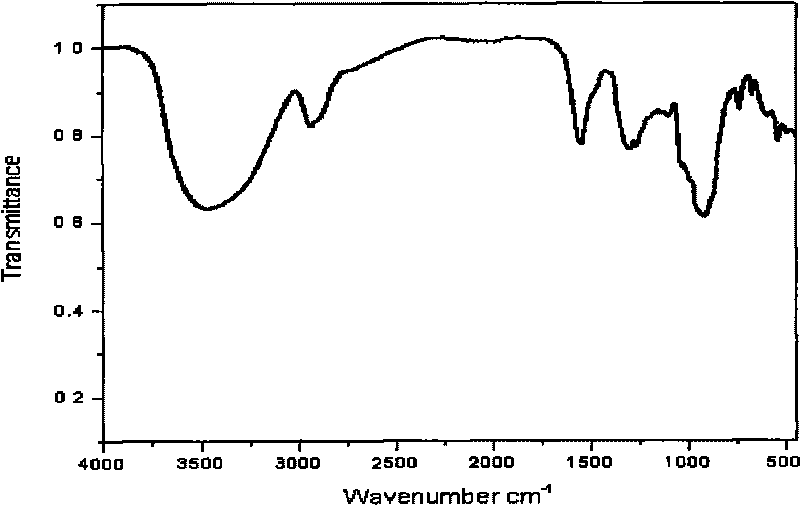

Preparation method of polymer/graphene nano composite membrane

ActiveCN103611432AImprove hydrophilicityImprove anti-pollution performanceSemi-permeable membranesChemical industryOrganic solvent

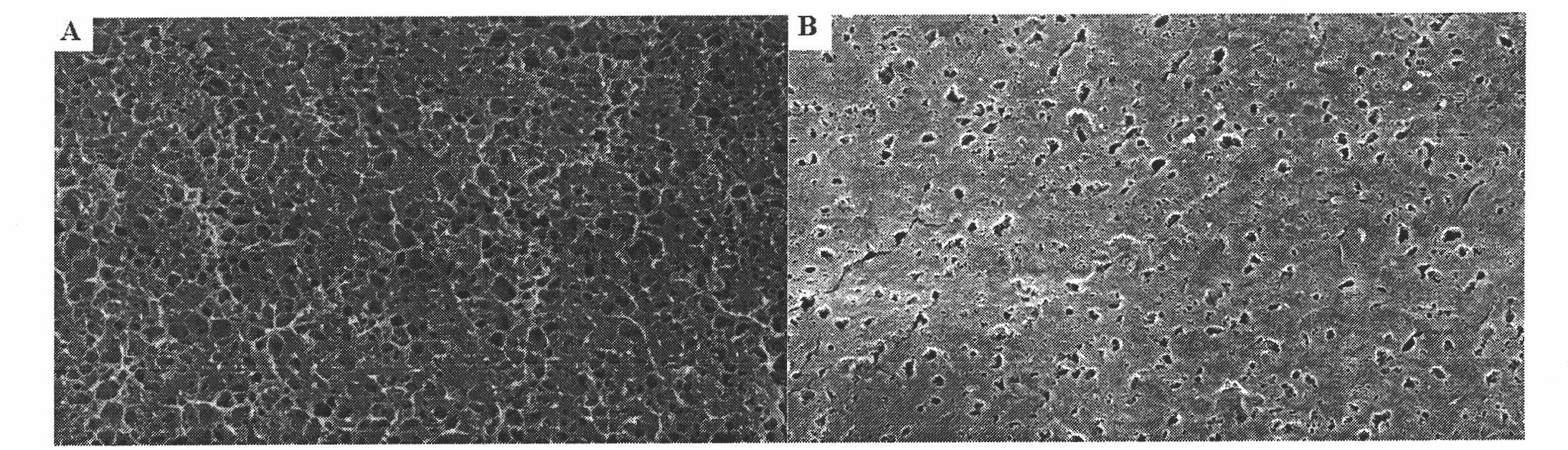

The invention relates to a preparation method of a polymer / graphene nano composite membrane, and aims to solve the problem that the existing polymer membrane material can not be applied in a large scale because the existing polymer membrane material is poor in hydrophilic property, is polluted easily and particularly is polluted by microbes and extracellular polymer easily. The preparation method disclosed by the invention comprises the steps of 1, taking a graphene nano material, a polymer, an organic solvent, an organic additive and an inorganic additive in parts by weight; 2, preparing a graphene nano material suspension; 3, preparing a membrane casting solution; 4, preparing a membrane by using the membrane casting solution in a coagulation bath medium to obtain a coagulation membrane, and then soaking the coagulation membrane in deionized water. The nano composite membrane disclosed by the invention is good in hydrophilic property, the irreversible pollution level of the nano composite membrane is significantly reduced, the anti-pollution capacity of the polymer membrane is effectively improved, the water flux is improved, and the polymer / graphene nano composite membrane disclosed by the invention is applied to the field of chemical industry.

Owner:HARBIN INST OF TECH

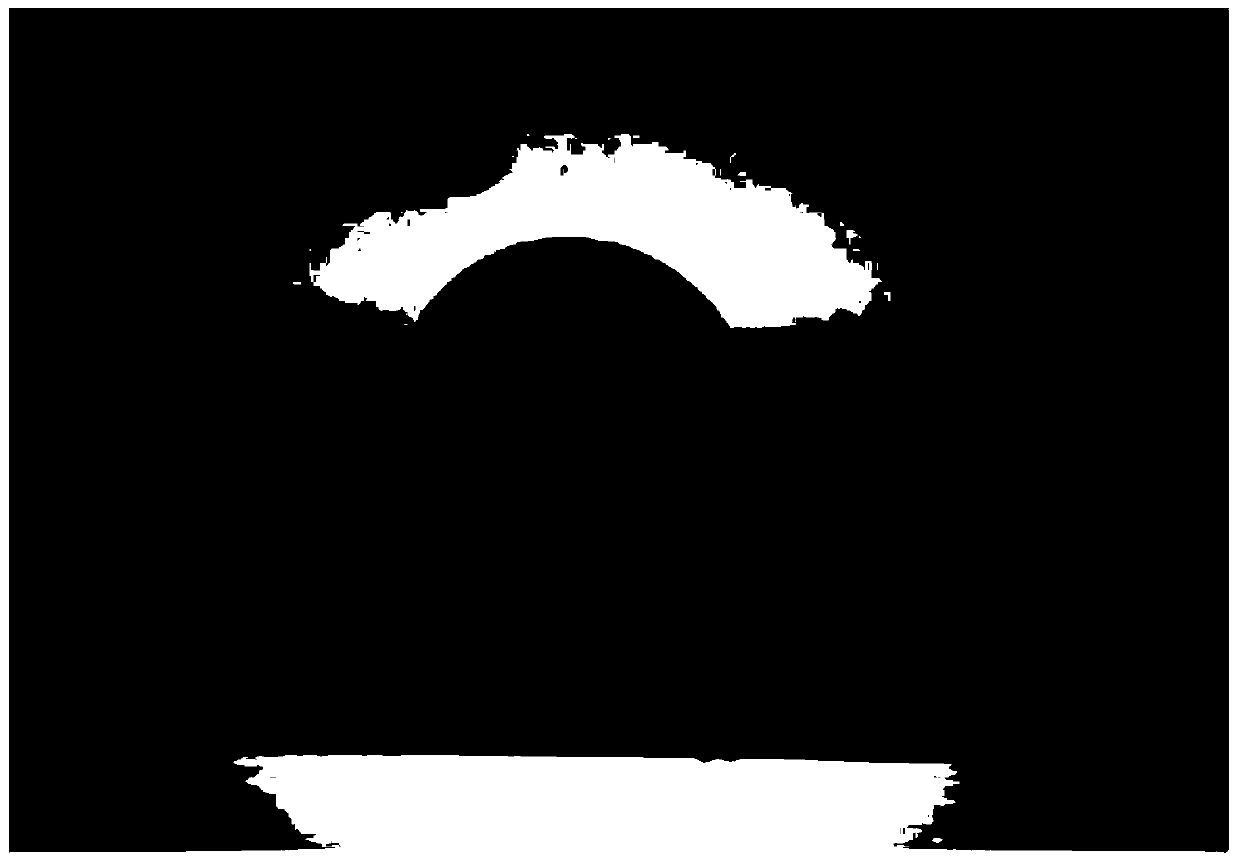

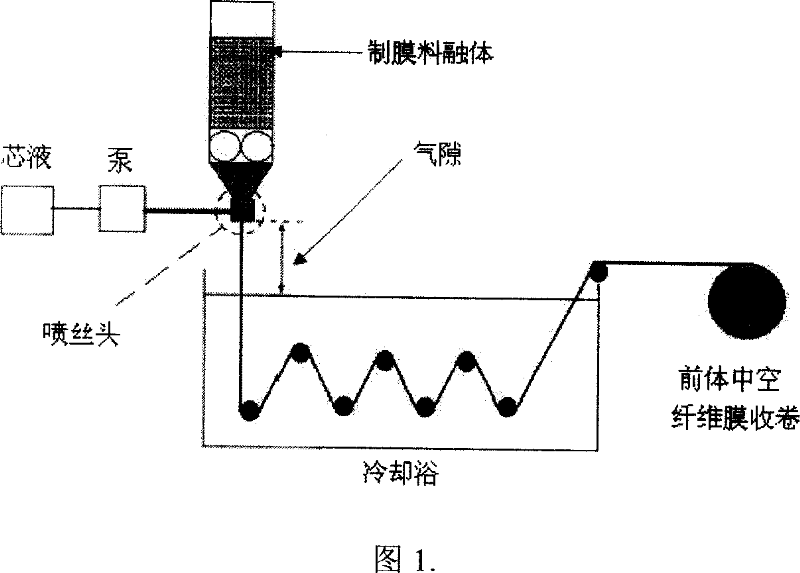

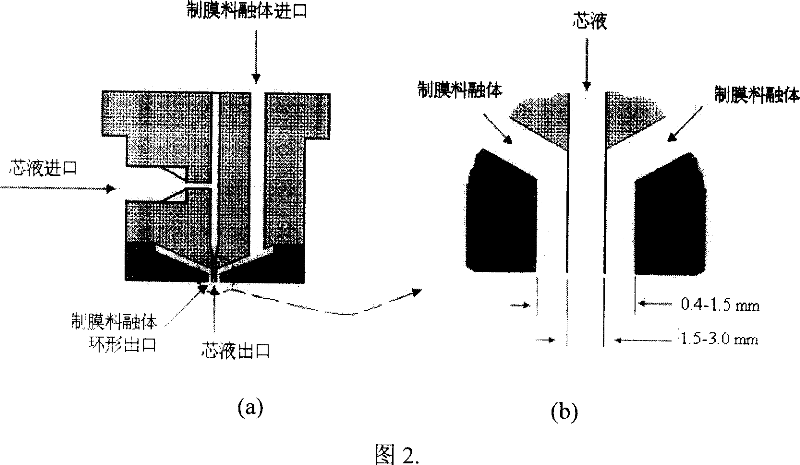

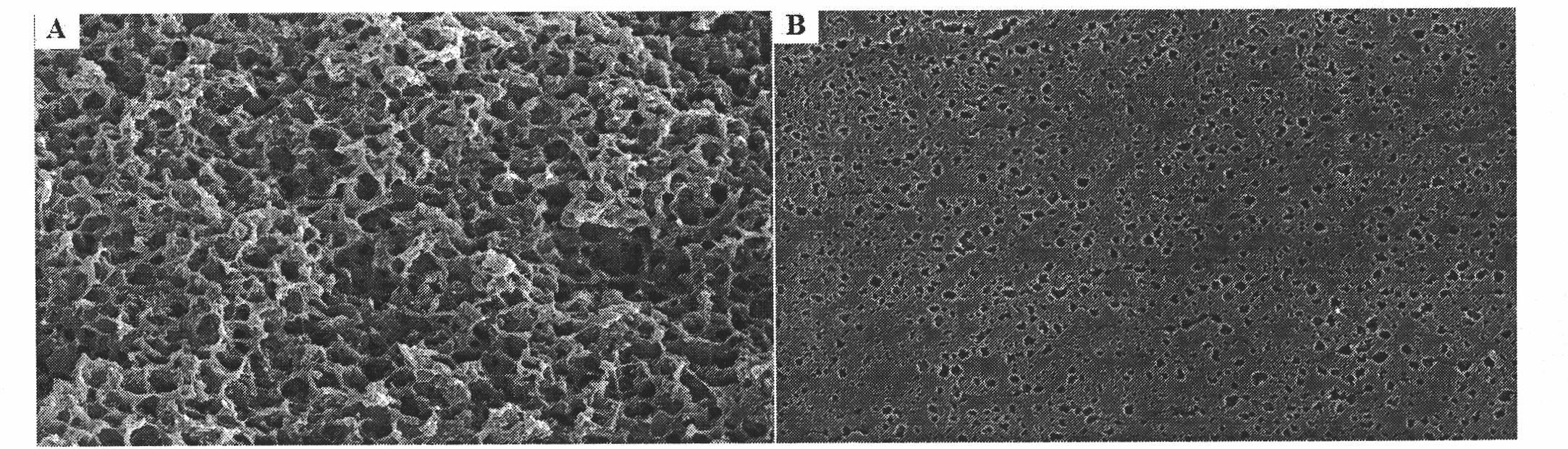

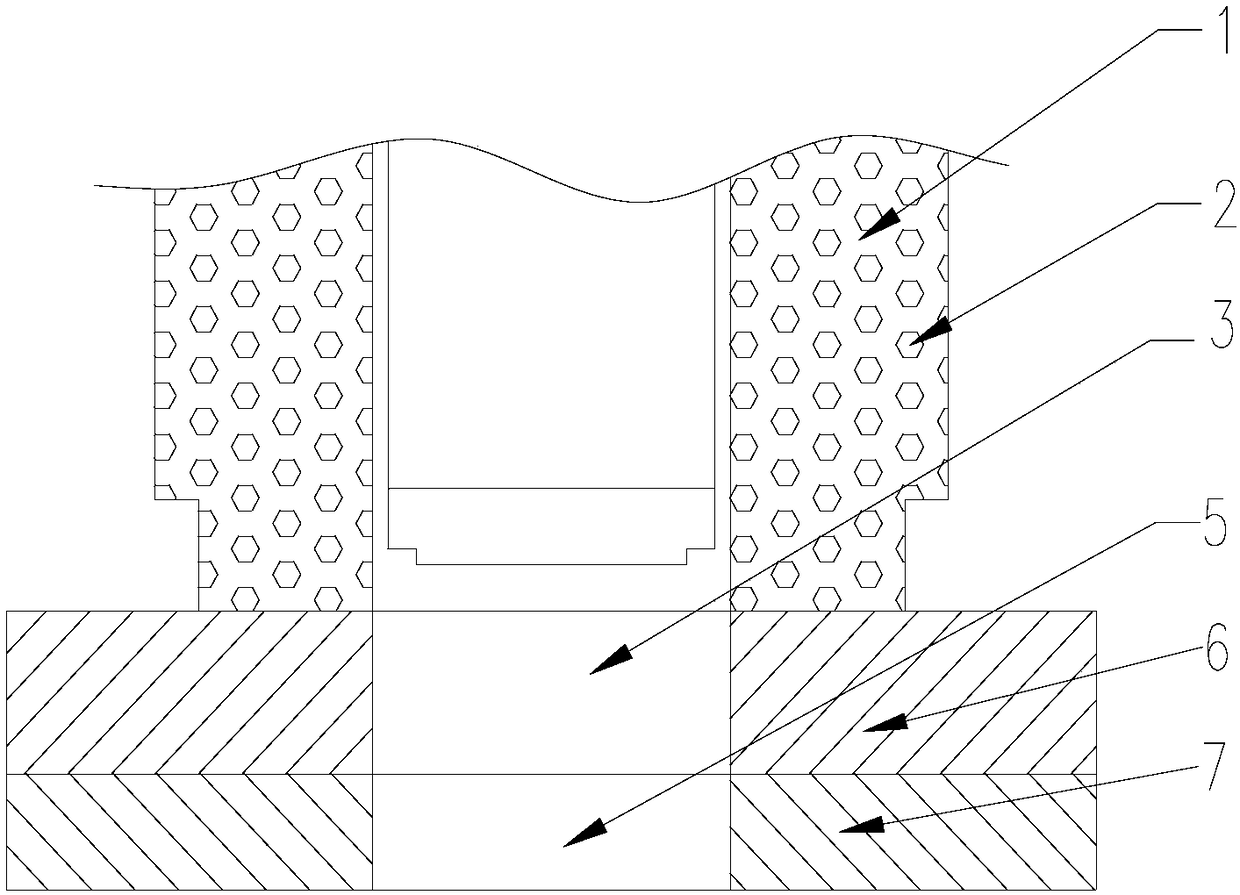

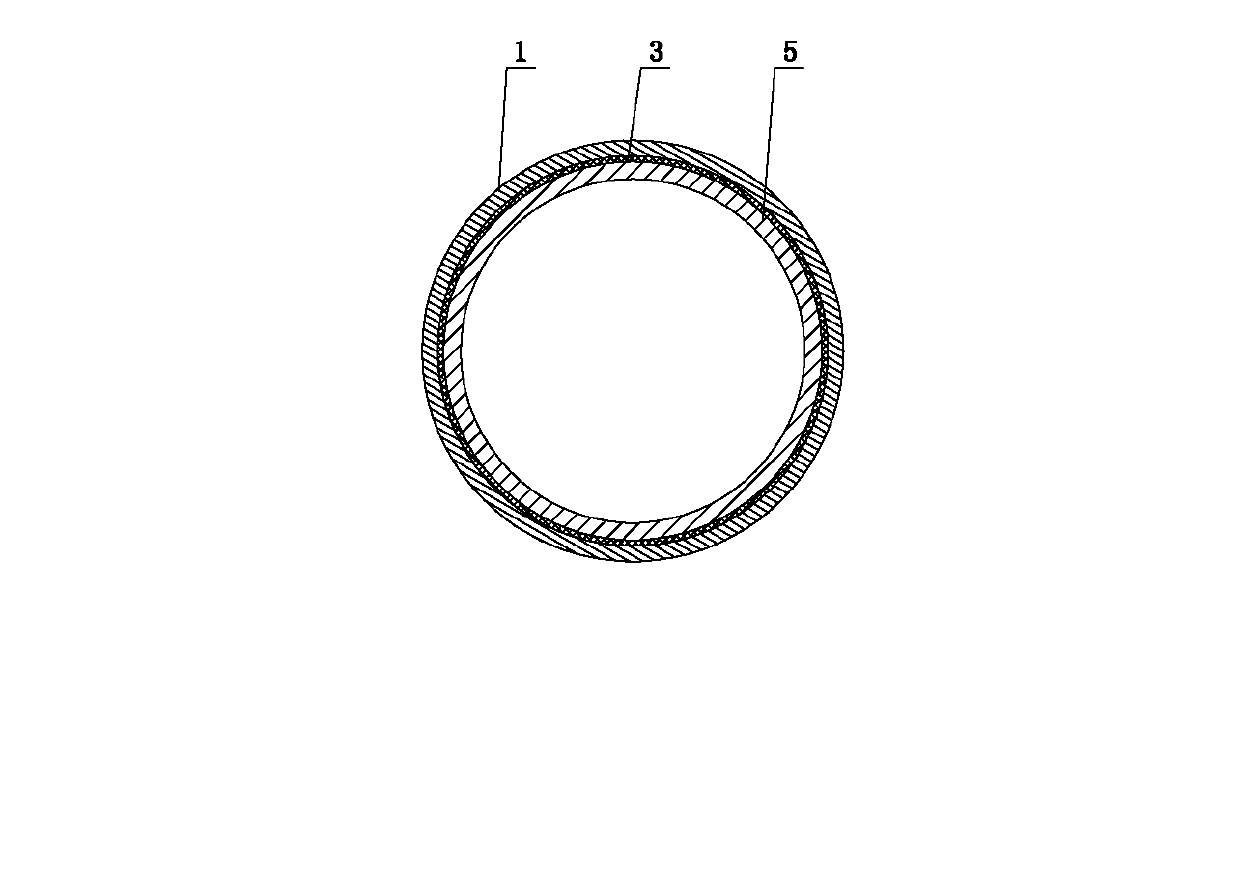

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

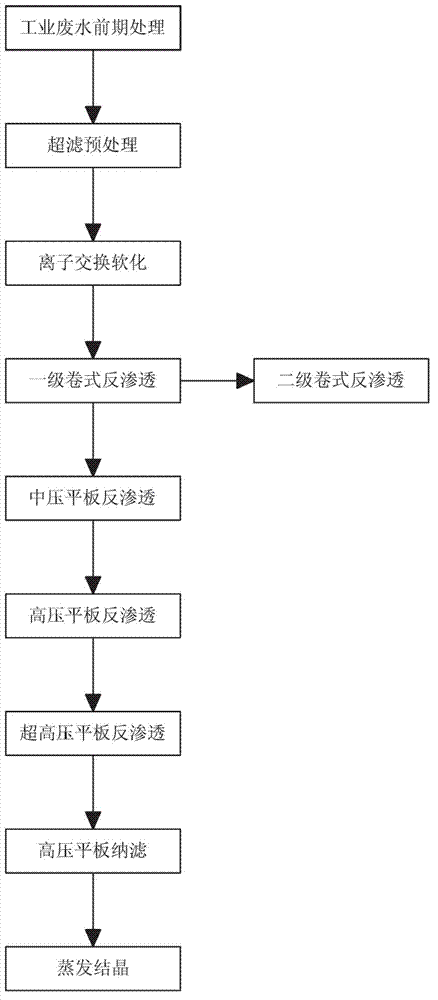

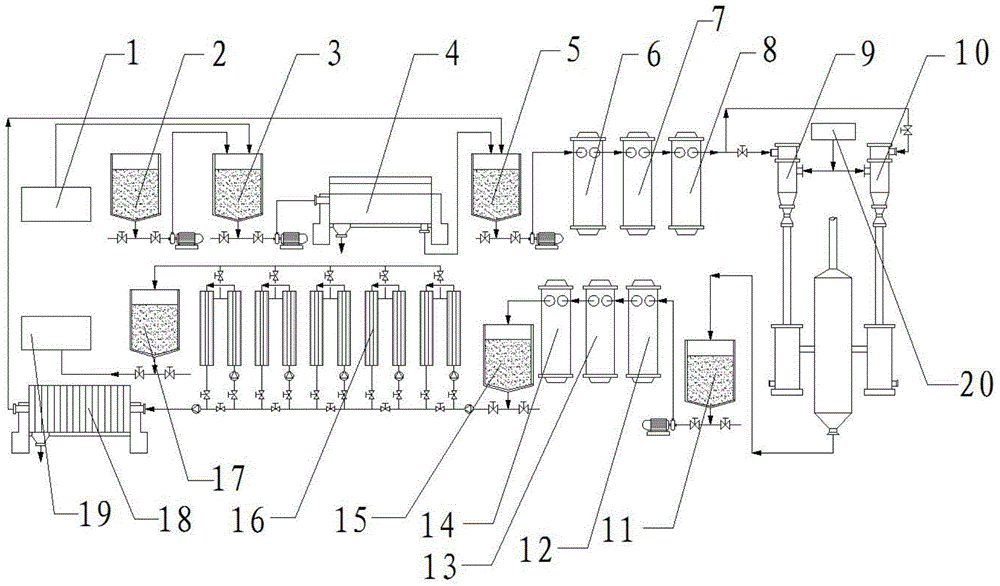

Process for deeply treating and recycling high-salinity industrial waste water

InactiveCN102807296AExtended cleaning cycleExtended service lifeGeneral water supply conservationMultistage water/sewage treatmentIndustrial waste waterUltrafiltration

The invention discloses a process for deeply treating and recycling high-salinity industrial waste water, which belongs to the technical field of environmental protection and comprehsnive resource utilization. Combined equipment is adopted, and comprises ultrafiltration equipment, ion exchange softening equipment, volume-type reverse osmosis equipment, medium-pressure flat plate reverse osmosis equipment, high-pressure flat plate reverse osmosis equipment, ultrahigh-pressure flat plate reverse osmosis equipment, high-pressure flat plate filtration equipment, secondary reverse osmosis equipment and the like. After being treated with a combined process, industrial waste water can be concentrated by 36-180 times; in combination with evaporative crystallization equipment, zero discharge of industrial waste water can be realized, and salts in industrial waste water can be recovered; and after secondary reverse osmosis treatment, produced water can be recycled by 100 percent. The process has the advantages of flexible combined process, small floor area, saving in investment, high efficiency, low running cost, stable and reliable effect, and the like.

Owner:BEIJING NEWBIOLINK TECH DEV

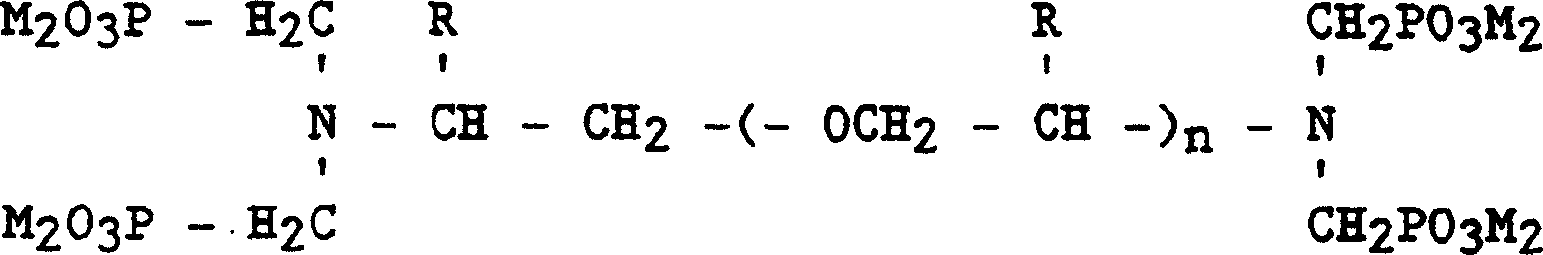

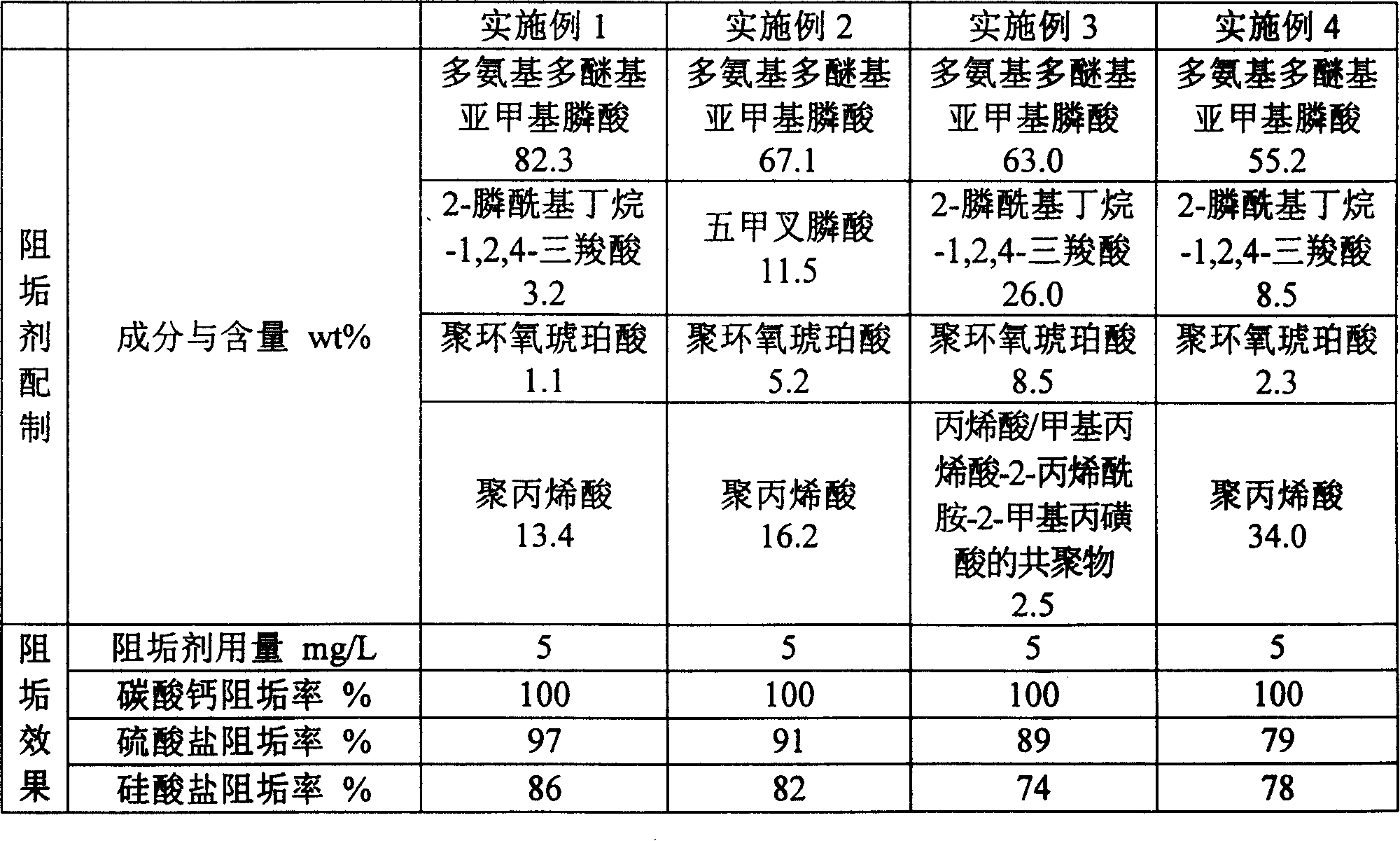

Antisludging agent and application of the same in water treatment

ActiveCN101172718AGood scale resistanceExtended cleaning cycleScale removal and water softeningInorganic saltsSulfate radicals

The invention provides antisludging agent and the application method thereof. The antisluding agent comprises polyether polyamino methylene phosphonates, polyepoxysuccinic acid, Aroset and organic phosphonic acid. The antisludging agent is applicable in the water quality with dense calcium, dense sulfate radical and soluble silica, and has great antisludging and dispersing effect. The antisludgingagent which is led into the high-density reverse osmosis water treatment system is added to effectively restrict polcard, sulfate, silicate and other inorganic salts from being deposited and foulingon the film surface, thereby prolonging the cleaning period of the reverse osmosis film.

Owner:CHINA PETROLEUM & CHEM CORP +1

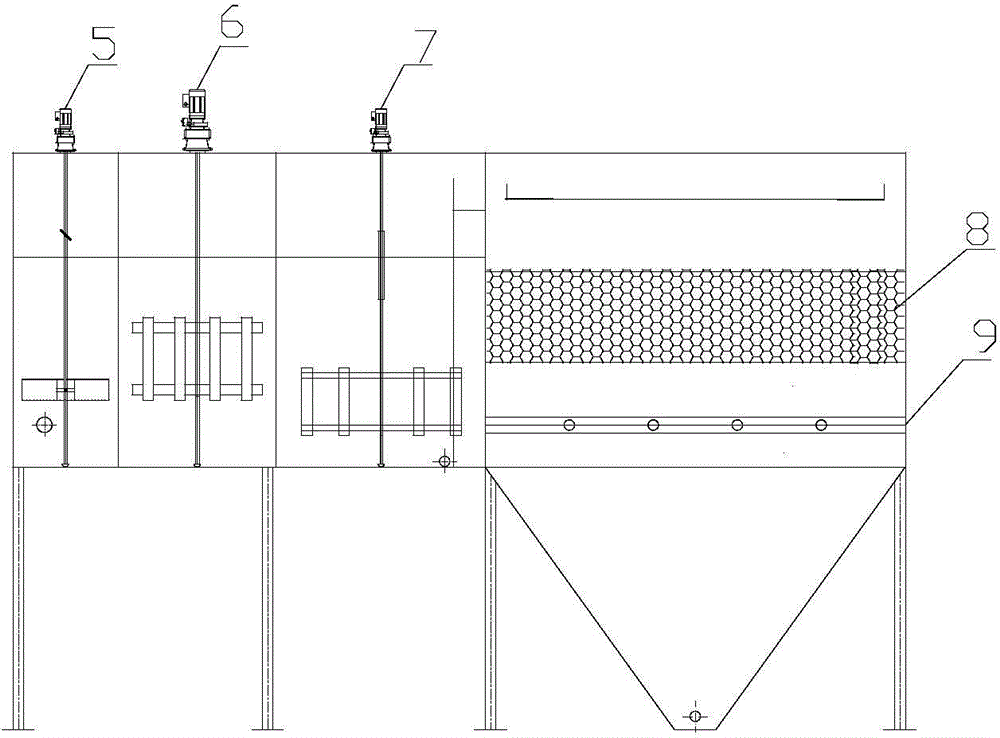

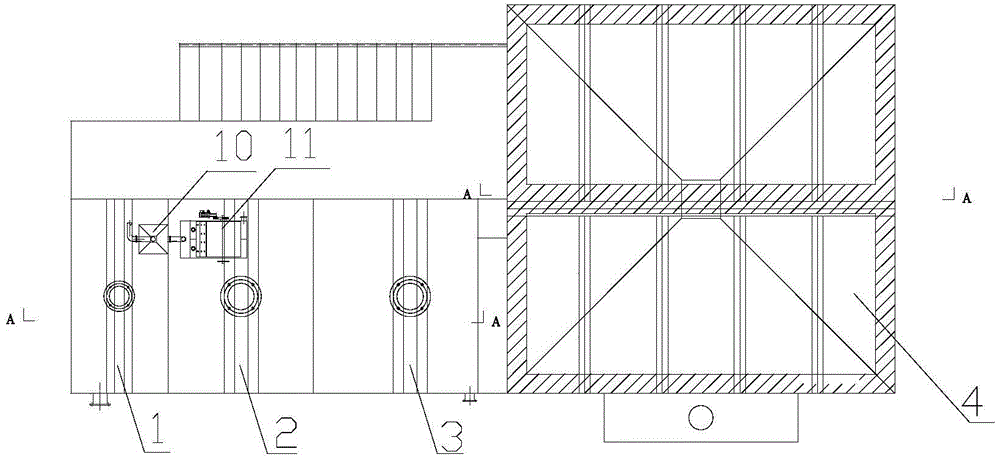

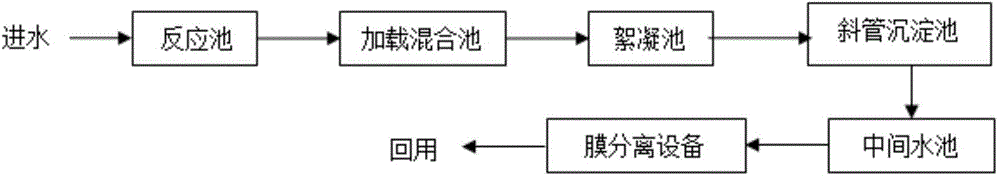

Wastewater reuse method combining magnetic loading coagulation clarification and membrane separation

ActiveCN103819045AAvoid or reduce pollutionLow costMultistage water/sewage treatmentParticulatesSolubility

The invention discloses a wastewater reuse method combining magnetic loading coagulation clarification and membrane separation. The method comprises the following steps: (1) a coagulant is added into a reaction tank to form small flocs; (2) the small flocs enter a loading and mixing tank to generate magnetic coagulation cores with magnetic carriers; (3) after the magnetic coagulation cores enter a flocculation tank, a flocculant is added to generate large-particle magnetic floccules; (4) after the magnetic floccules are stirred and dispersed strongly by a high-speed dispersion machine, magnetic carriers which are recycled via a magnetic drum separator return to the step (2), supernatant liquor enters a middle water tank via the collection by a water collecting pipe, after being pressurized by a water pump, the supernatant liquor enters membrane separating equipment for fine filtration, and filtered water is discharged for reusing. The method is used for removing particulate matters, colloid and a part of dissolved organic matters in advance before membrane filtration, so that membrane pollution degrees can be effectively avoided or reduced, and the cleaning period and the service life of membrane components are increased. The method can be used for the resource reutilization of the wastewater in industries of printing and dyeing, electroplating, paper-making and the like, as well as the upgrading and reconstruction and the tail water reuse of sewage treatment plants.

Owner:浙江立丰环保设备有限公司

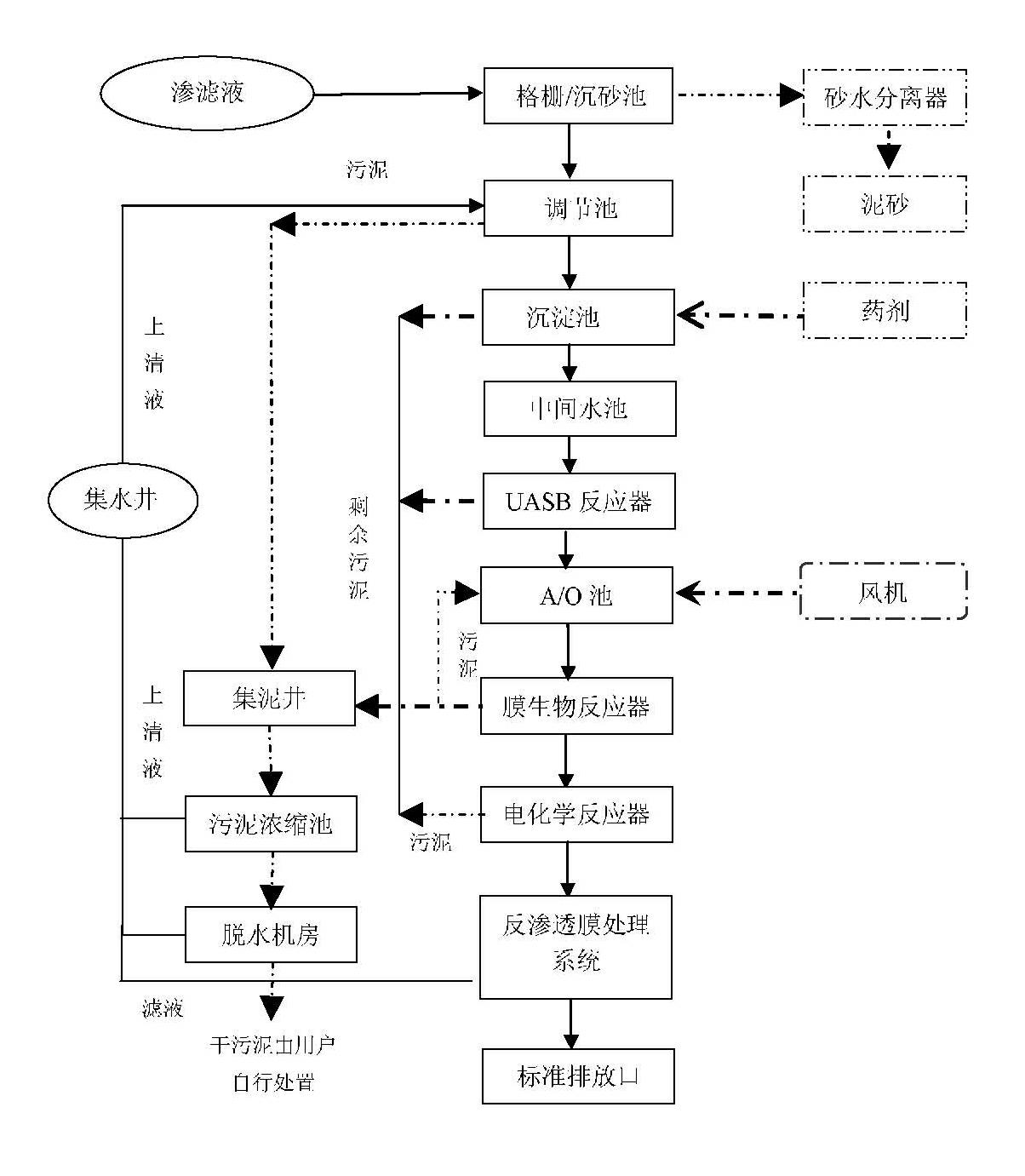

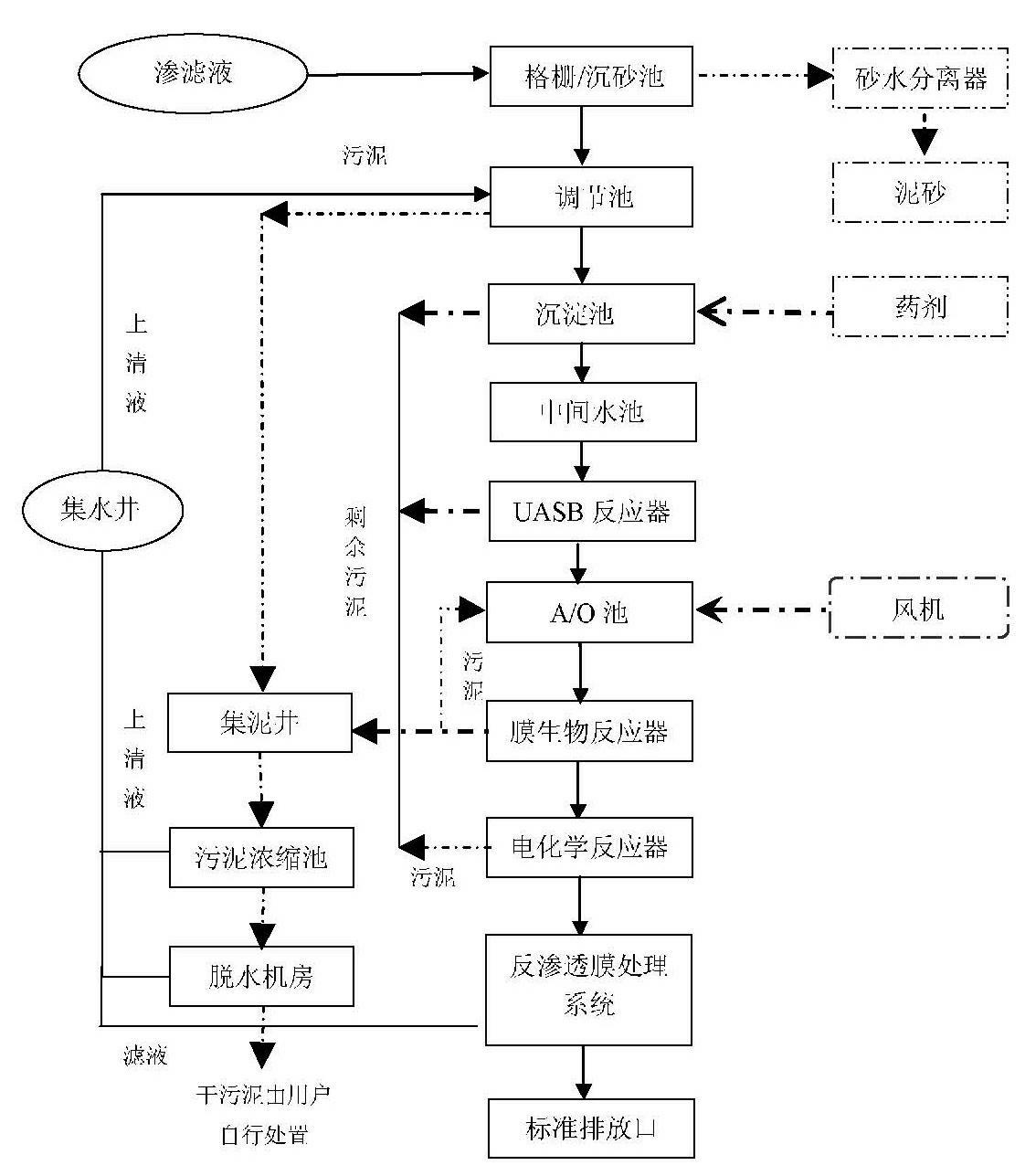

Treatment method and treatment system for percolate in garbage-burning plant

ActiveCN102153233AExtended cleaning cycleReduce loadMultistage water/sewage treatmentActivated sludgeGrating

The invention relates to a treatment method and a treatment system for percolate in a garbage-burning plant. The treatment method for garbage-burning percolate includes the steps as follows: the percolate is collected by a pipeline and then enters a coarse grating, a fine grating and a sand setting tank to be subjected to sand setting, and then flows into an adjusting tank for mixing and stirring; effluent of the adjusting tank is lifted to a settling tank by a lift pump of the adjusting tank; by adjusting pH value and adding coagulant, the effluent of the adjusting tank is coagulated and settled so as to remove most water suspended matters and part of insoluble organic matters; the effluent of the settling tank flows into a middle water tank and is heated by a steam-jet heating system to 35 DEG C; and the heated effluent of the middle water tank is subjected to biochemical treatment. In the invention, a pre-treatment unit is arranged in front of the adjusting tank, thus reducing the load of follow-up units and simultaneously prolonging the cleaning period of the adjusting tank; and an MBR (Meane Biological Reactor) system is adopted for effectively intercepting activated sludge to further improve the effect of a biochemical treatment unit, and simultaneously a secondary settling tank in a traditional biochemical treatment technology is replaced and the operation is simplified.

Owner:浙江博世华环保科技有限公司

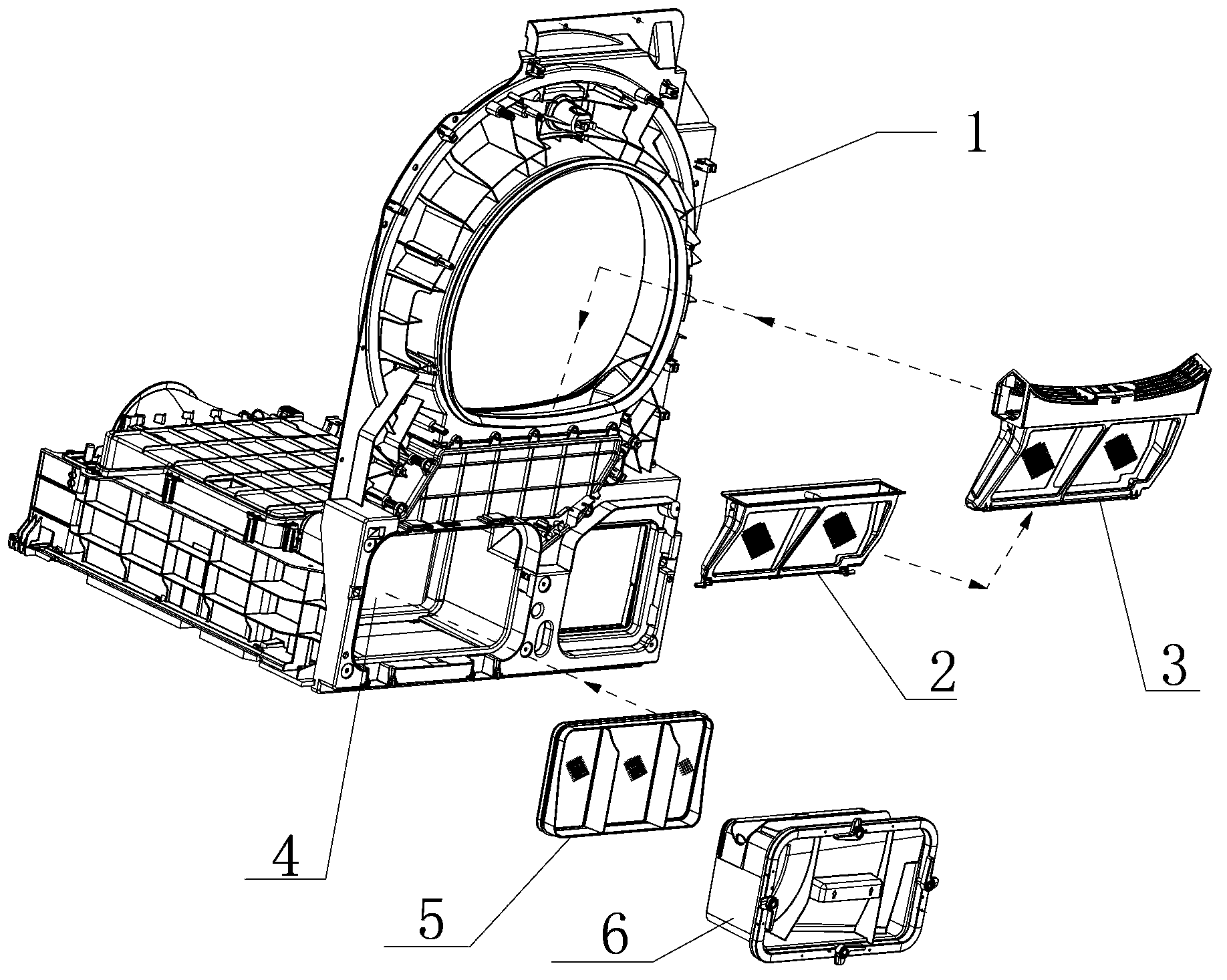

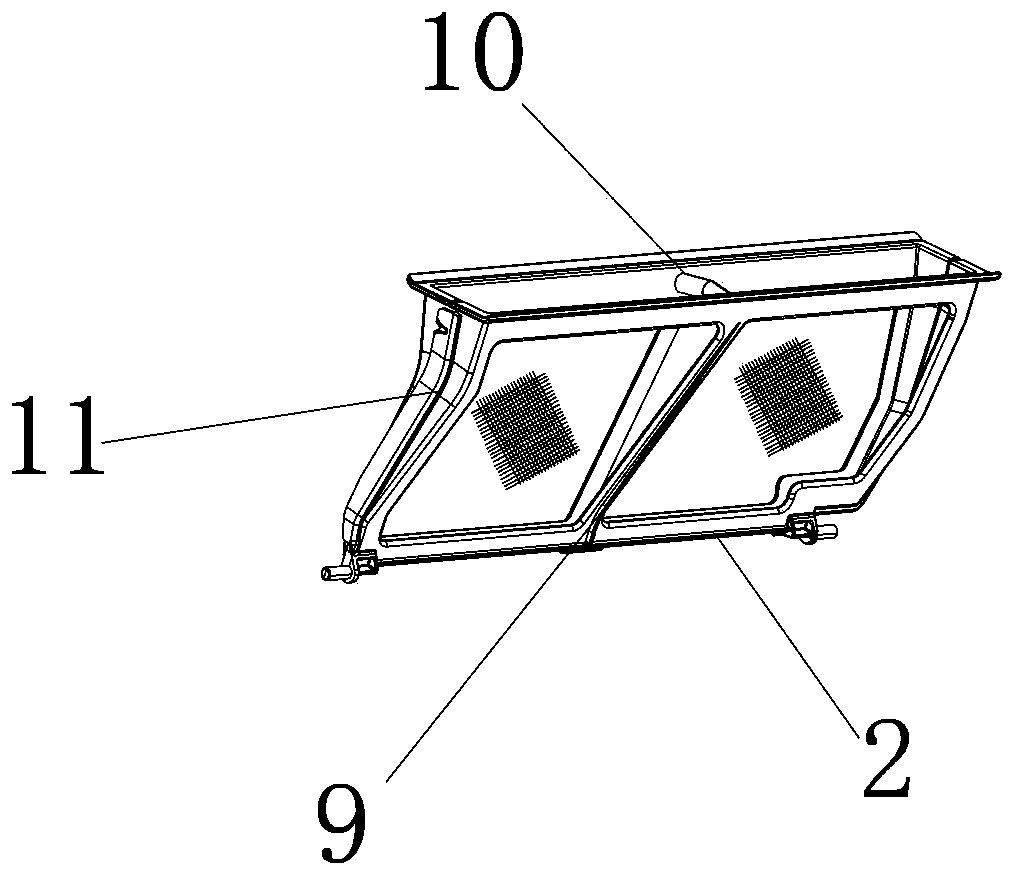

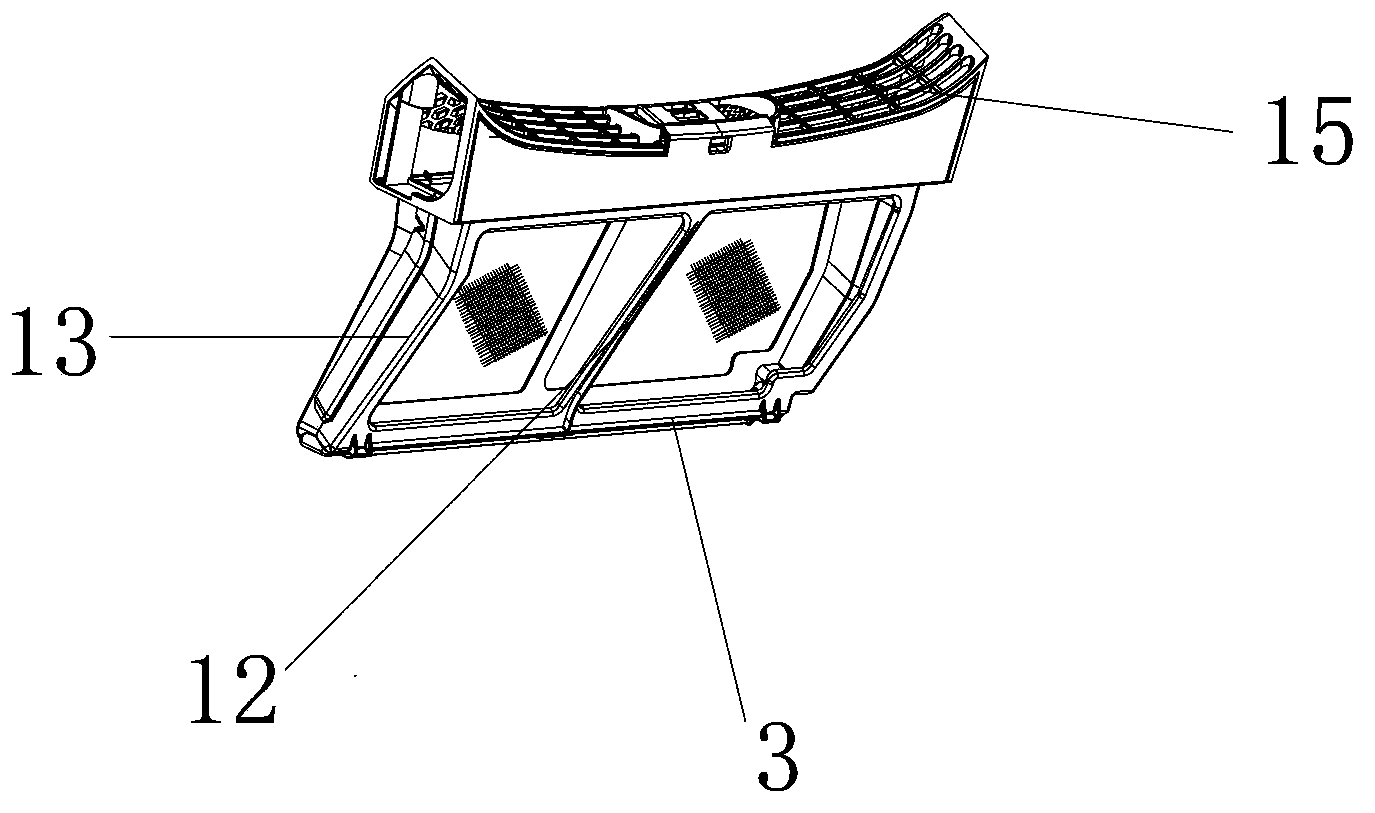

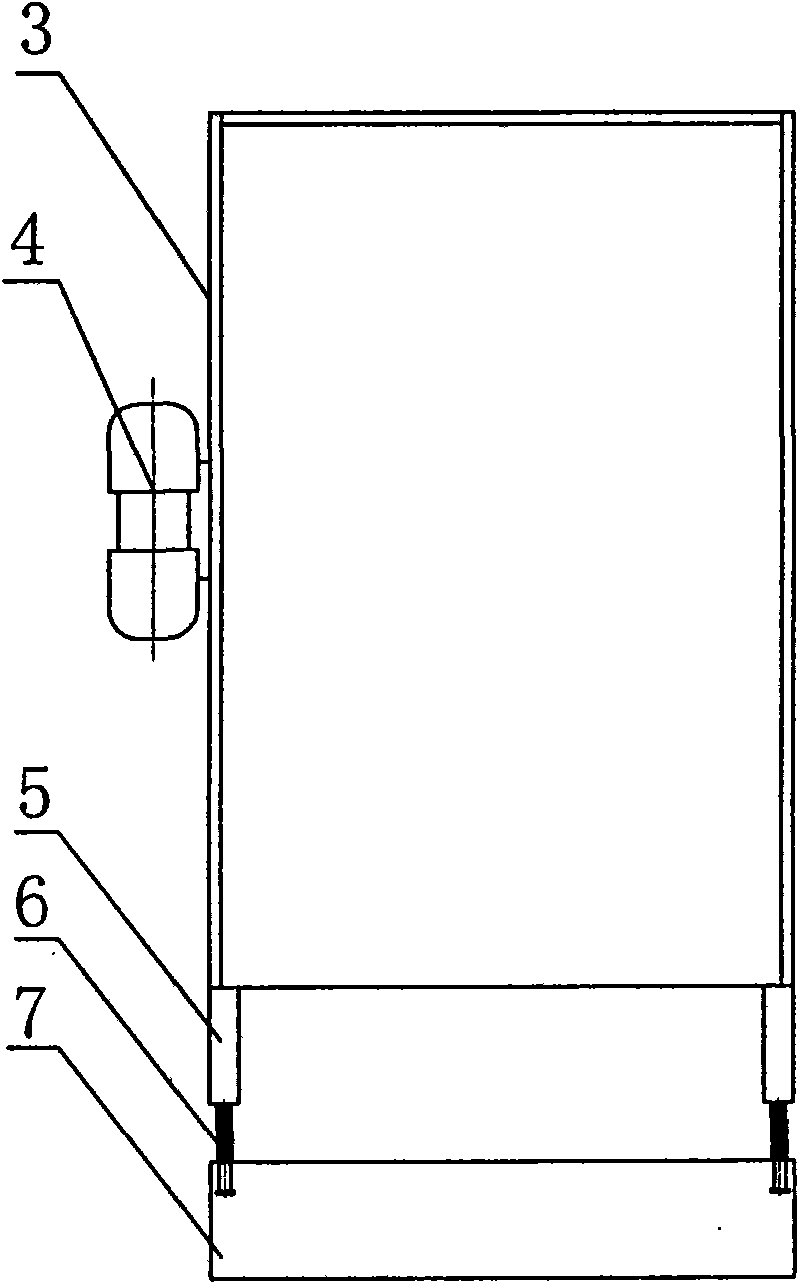

Thread crumb filtering device of clothes dryer and clothes dryer

ActiveCN103898726AExtended service lifeExtended cleaning cycleTextiles and paperLaundry driersEngineeringEvaporator

The invention provides a thread crumb filtering device of a clothes dryer and the clothes dryer. The thread crumb filtering device is arranged on air paths of the clothes dryer and comprises a first thread crumb filtering layer, a second thread crumb filtering layer and a third crumb filtering layer. The mesh number of filtering screens of the first thread crumb filtering layer and the mesh number of filtering screens of the third crumb filtering layer are the same or are approximately the same, and the difference value is 0-20. The mesh number of filtering screens of the second thread filtering layer is smaller than the minimum value of the mesh number of the first crumb filtering device and the mesh number of the third crumb filtering device, and the difference value is smaller than 100. The first crumb filtering layer and the second thread crumb filtering layer are mounted below a door body of a front air path on an air outlet of a roller of the clothes dryer after being clamped with each other. The third layer thread crumb filtering layer is arranged in an inside air path of the clothes dryer and placed at the front end of an evaporator arranged on the clothes dryer, thread crumbs can be filtered in a layered mode, the fact that the drying effect is influenced due to thread crumb plugging of the evaporator and a condenser is avoided, and air path space is saved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

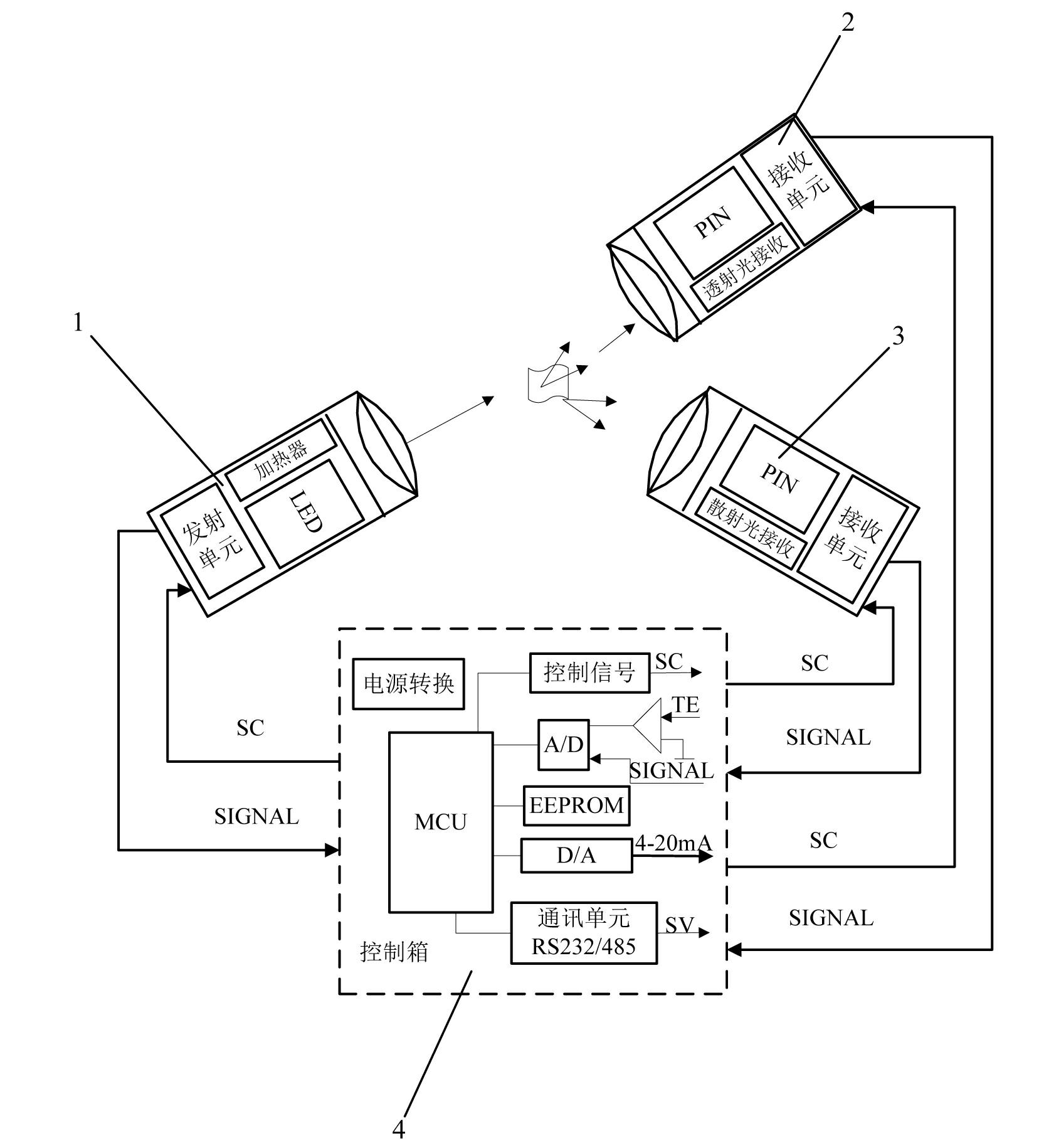

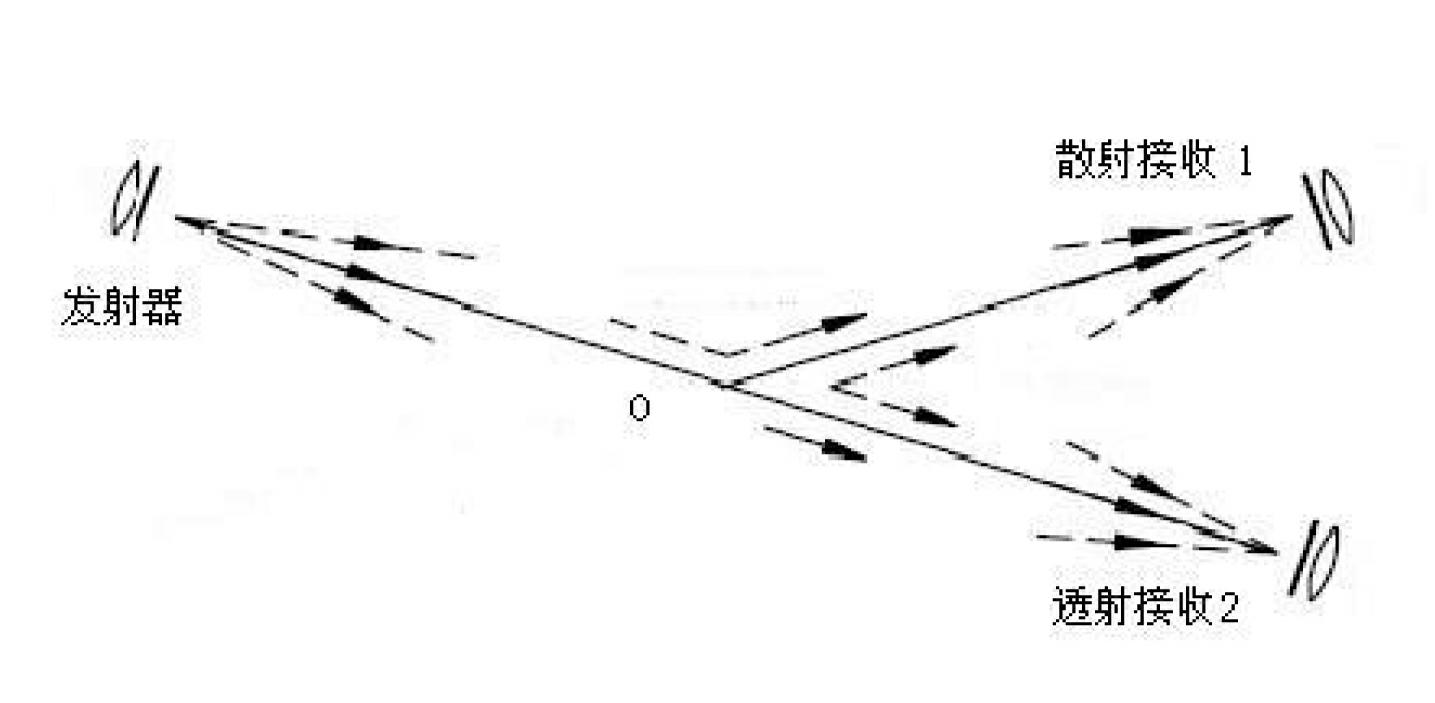

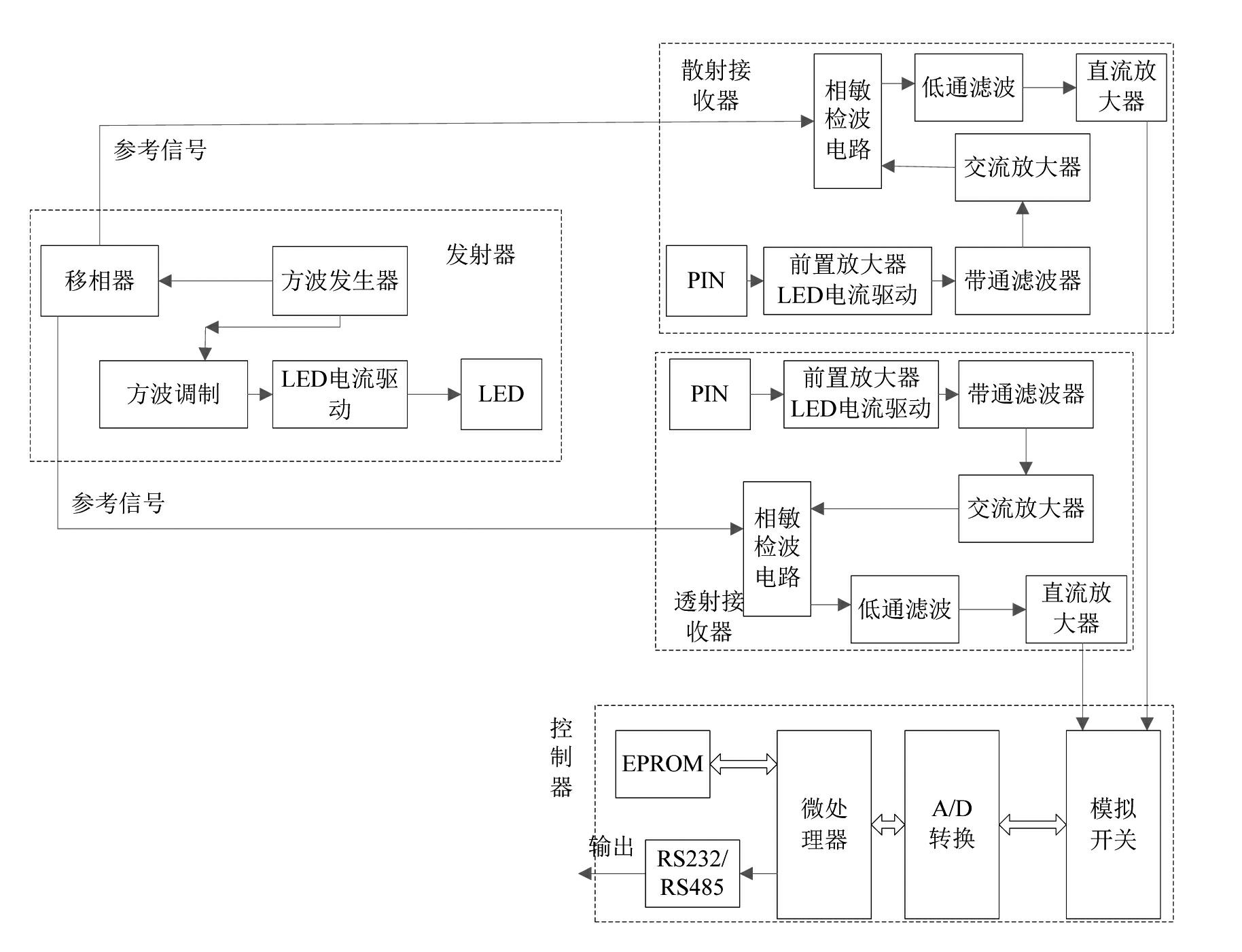

Forward scattering and transmission combined visibility measuring instrument and measuring method thereof

ActiveCN102636459AReduce pollutionExtended cleaning cycleScattering properties measurementsTransmissivity measurementsMeasuring instrumentExtinction

The invention discloses a forward scattering and transmission combined visibility measuring instrument and a measuring method thereof. The forward scattering and transmission combined visibility measuring instrument comprises a transmitter, a transmission receiver, a scattering receiver and a controller, wherein the transmitter is used for transmitting a light signal to the transmission receiver and the scattering receiver; the transmission receiver is used for converting a received optical signal into a transmission electric signal; the scattering receiver is used for converting the received optical signal into an electric signal; and the controller is used for receiving the electric signals sent from the transmission receiver and the scattering receiver and calculating according to the two electric signals to obtain visibility. Comparison measurement is carried out on a scattered signal and a transmission signal to obtain atmospheric extinction coefficient, thus atmospheric visibility is obtained. Measurement of a transmission light is added on the basis of forward scattering measurement, and a transmission measured value is taken as reference and can correct the visibility, so as to reduce pollution of environmental dust to a lens and influence of factors, such as power reduction caused by ageing of a light-emitting diode, to a measuring result of an instrument, thus measurement accuracy of the instrument is improved and a cleaning period of the lens is prolonged.

Owner:REMOTE SENSING APPLIED INST CHINESE ACAD OF SCI

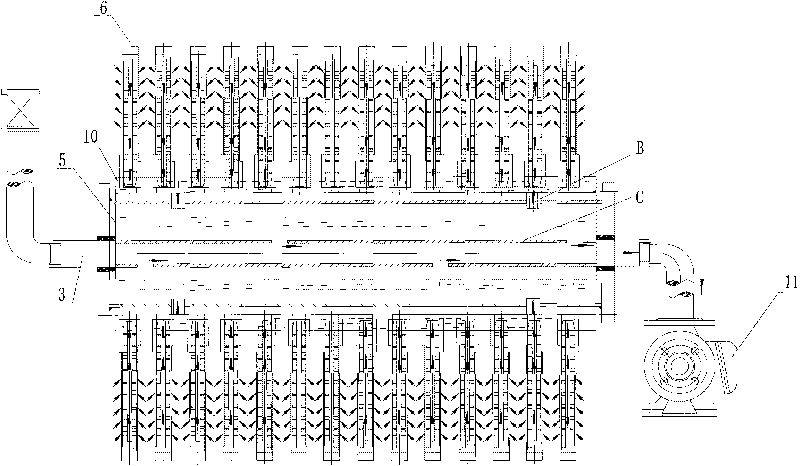

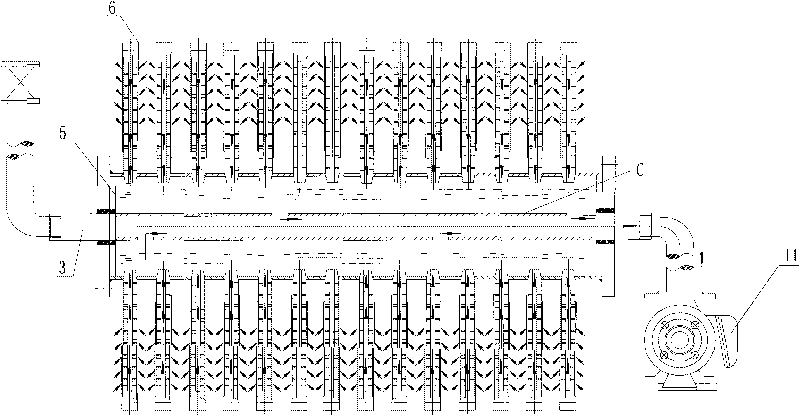

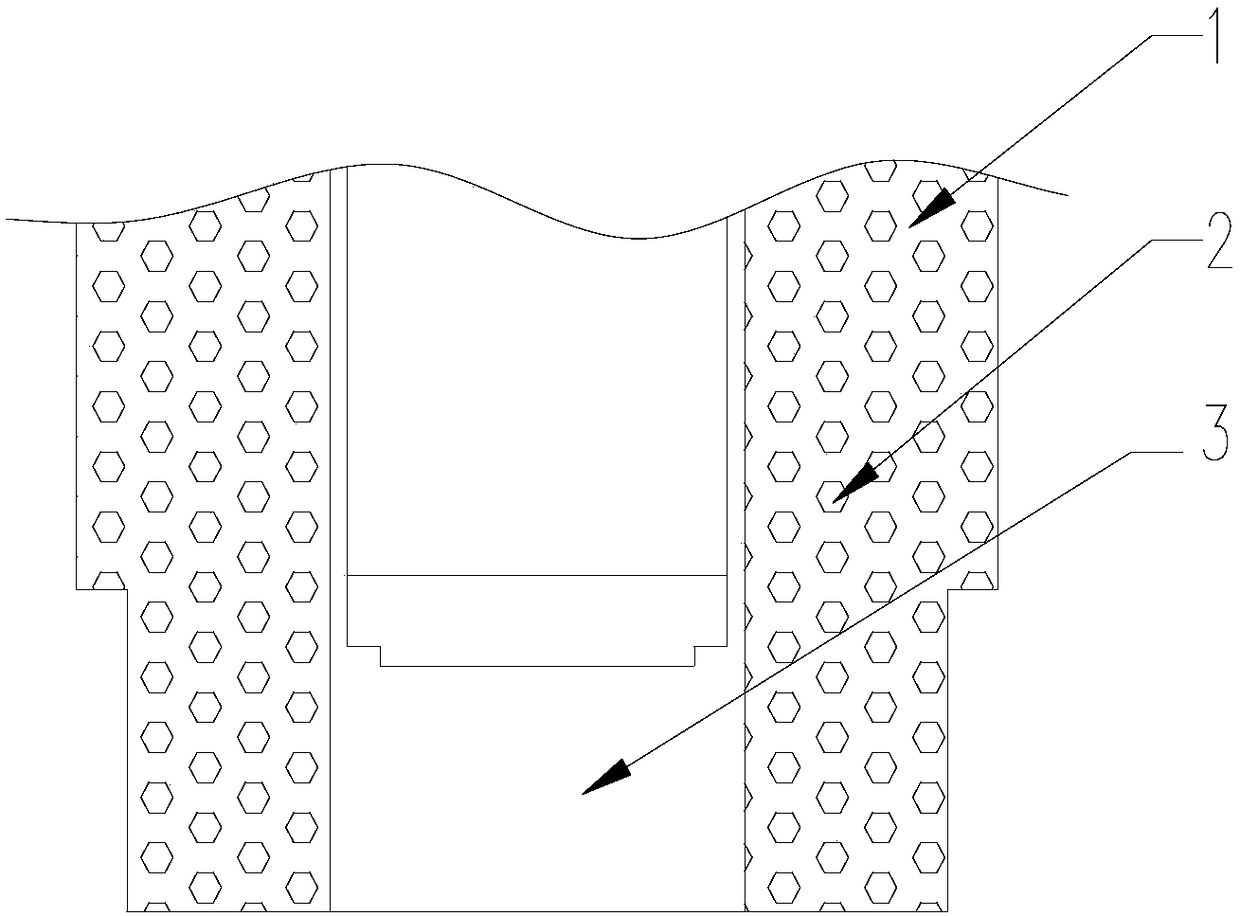

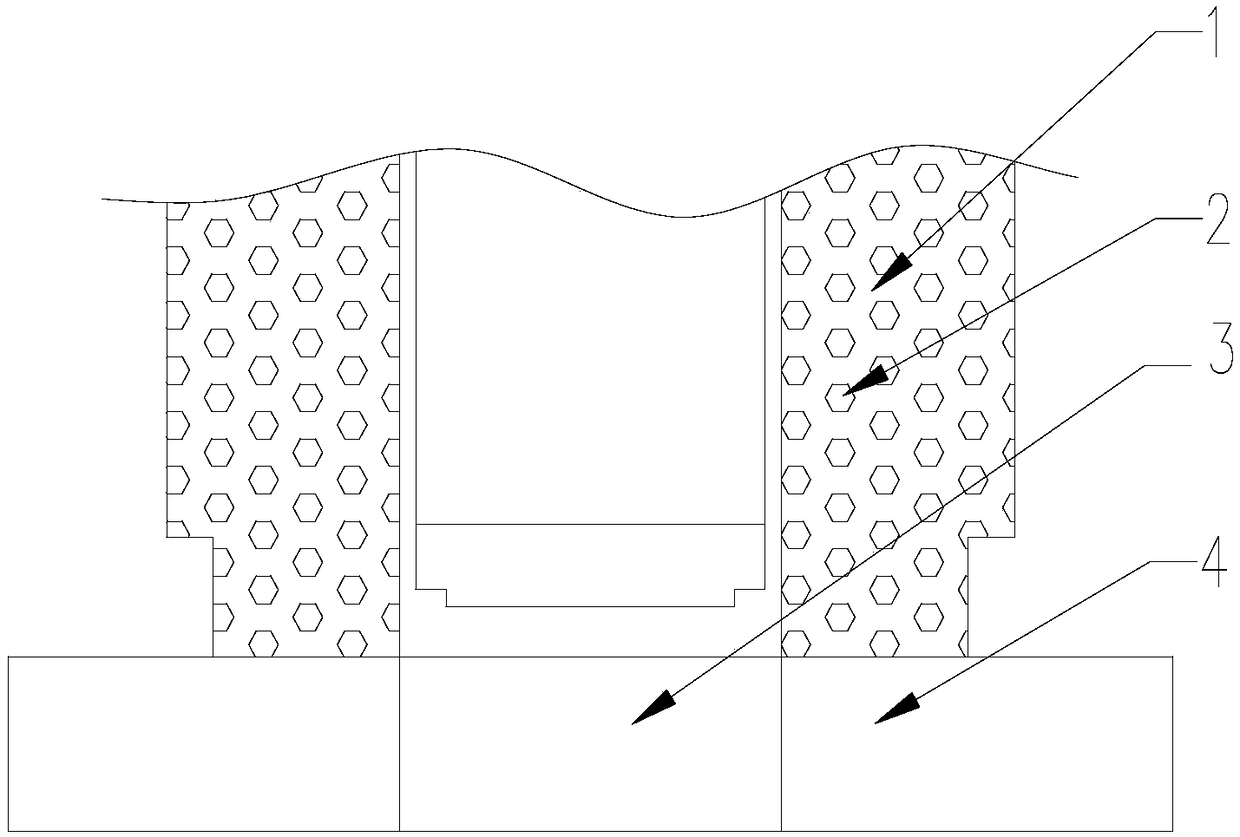

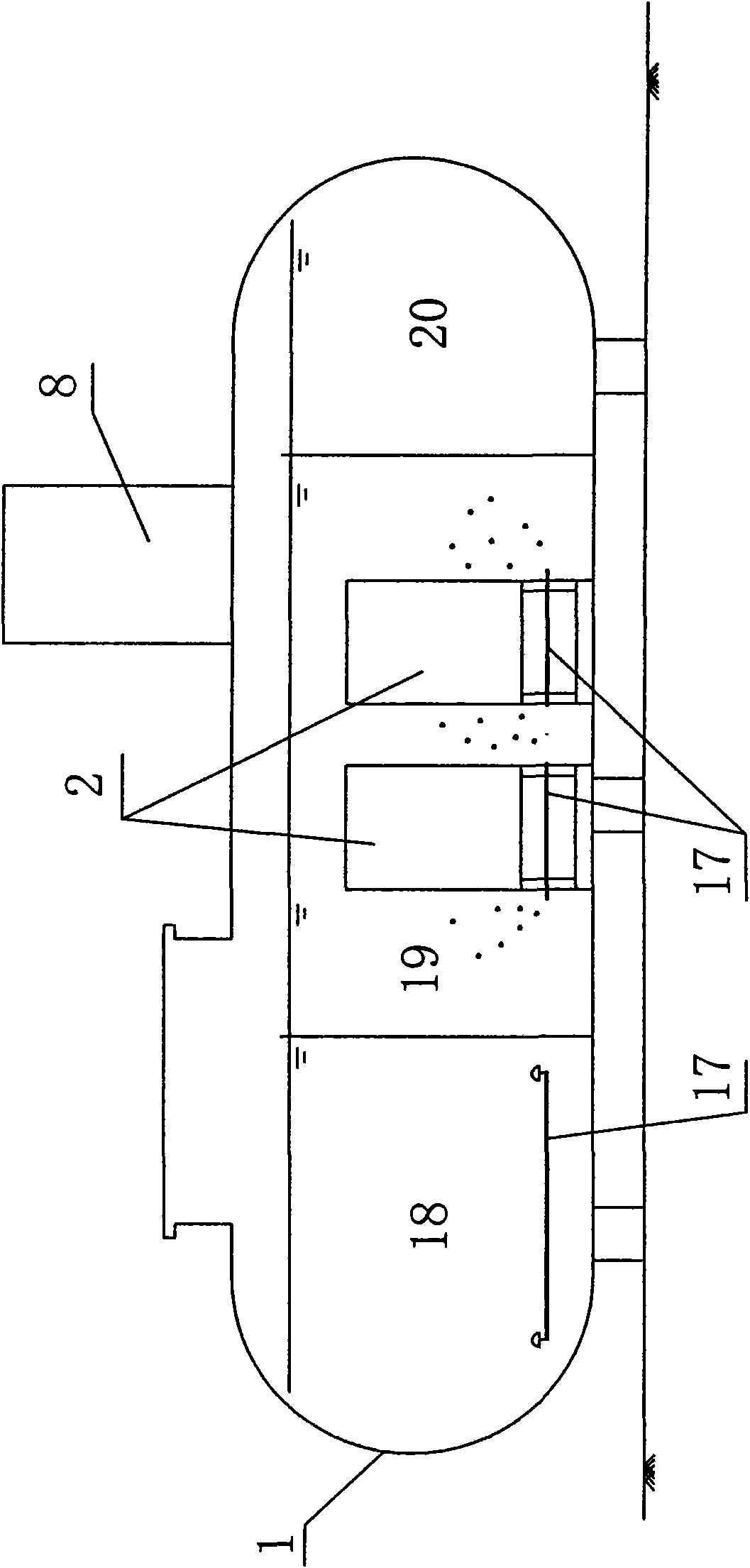

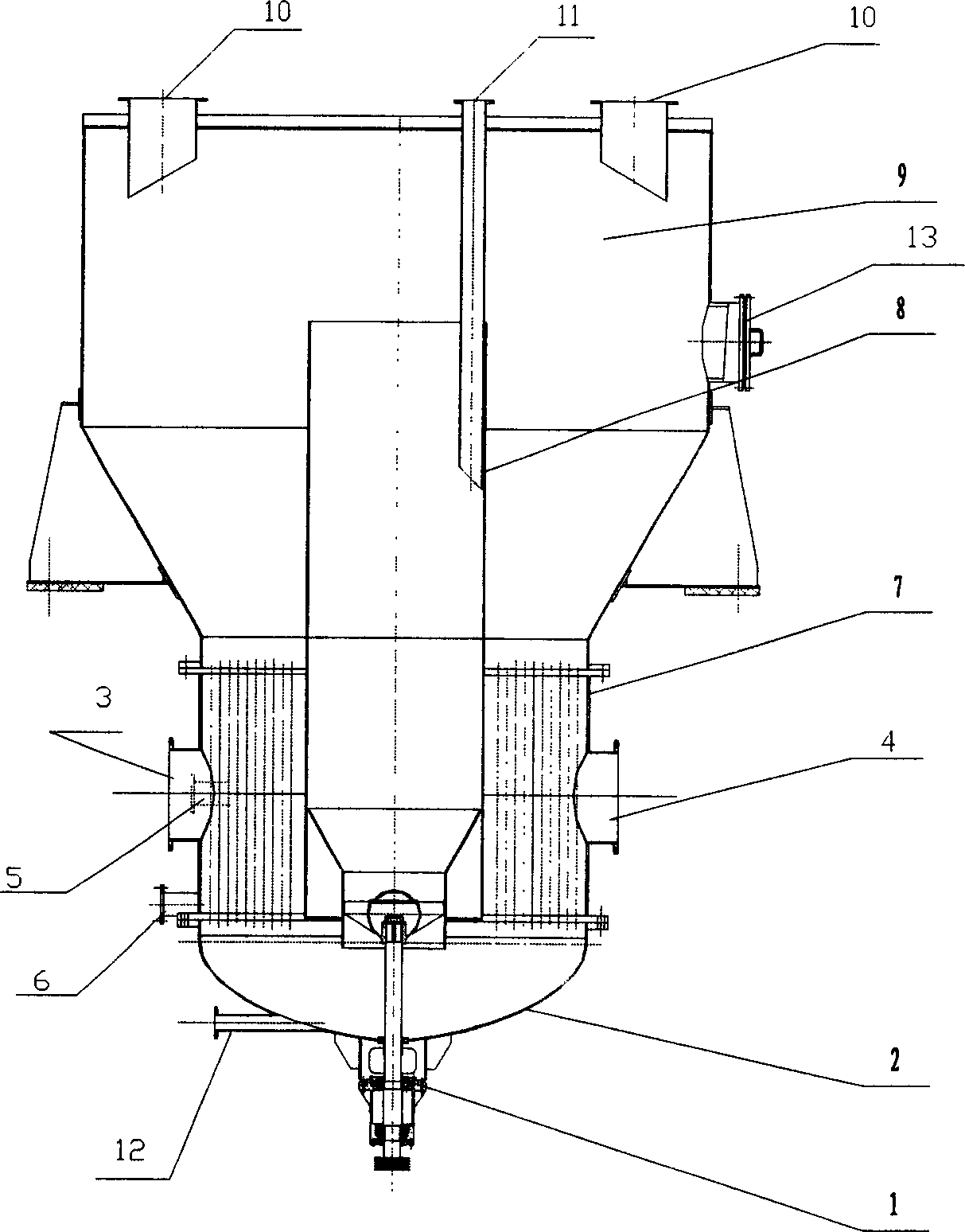

Rotary membrane separation device and application thereof

ActiveCN101700472AAchieve filtration separationImplement the filter operationSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisParticulatesColloid

The invention relates to a rotary membrane separation device and an application thereof. The two ends of a hallow shaft are fixed on the bracket; the hollow shaft is sheathed with a revolving drum the two ends of which support on the hollow shaft in a revolving and free manner; the chamber of the revolving drum is communicated with the cavity of the hollow shaft through the communication hole on the hollow shaft; the excircle of the revolving drum is provided with a collecting pipe along the axial direction; a communication opening is arranged at the joint of the collecting pipe and the revolving drum; the chamber of the collecting pipe is communicated with the chamber of the revolving drum through the communication opening; the collecting pipe is provided with a filtering membrane component the two side surfaces of which are stuck with filtering membrane materials; the effluent opening at the bottom part of the filtering membrane component is communicated with the collecting pipe; the filtering membrane component chamber constitutes a channel with the cavity of the hollow shaft via the collecting pipe chamber and the revolving drum chamber; one port of the hollow shaft is connected with a suction pump and the other end is connected with a standby conduit; one end surface of the revolving drum is fixedly provided with a transmission gear which is driven by a motor. The device can conveniently realize the separation of particulate matters, colloid, microorganisms and molecular mixtures in water or other solvent medium.

Owner:SUZHOU MOHAI SEPARATION TECH

Polymetafluoroethylene/organic clay nanometer composite ultra-low pressure ultrafiltering membrane and its preparation method

InactiveCN101053784AIncreased pure water fluxSolve pollutionSemi-permeable membranesFiberUltrafiltration

The invention relates to a polyvinylidene fluoride / organic clay nano composite ultralow pressure ultrafiltration membrane and a preparation method thereof, and to a nano composite membrane and a preparation method thereof. The invention resolves the problem that the existing membrane material has a bad hydrophilicity and a low surface energy and is easily be polluted, and the existing modified method has the disadvantage that it can not run under ultralow pressure and the running cost is high. It is composed of 20-50 shares by weight of PVDF, 0.1-20 shares by weight of organic clay, 10-1000 shares by weight of disperse medium, 10-50 shares by weight of organic addition agent and 0.1-30 shares by weight of inorganic additive. The invention adds the organic clay, inorganic additive, organic addition agent and PVDF in turns into the disperse medium to get the casting film liquor after 3-48 hours dissolution and 5-24 hours stewing deaeration; plate membrane, tubular type membrane, hollow fibre membrane, and comparable membrane module can be prepared. The invention can change the hydrophilicity of the composite membrane, resolve the pollution of exiting membrane effectively, increase the water flux and retain ratio, extend the washing period, raise the treating capacity, and realize the large scale use and run in ultralow pressure.

Owner:HARBIN INST OF TECH

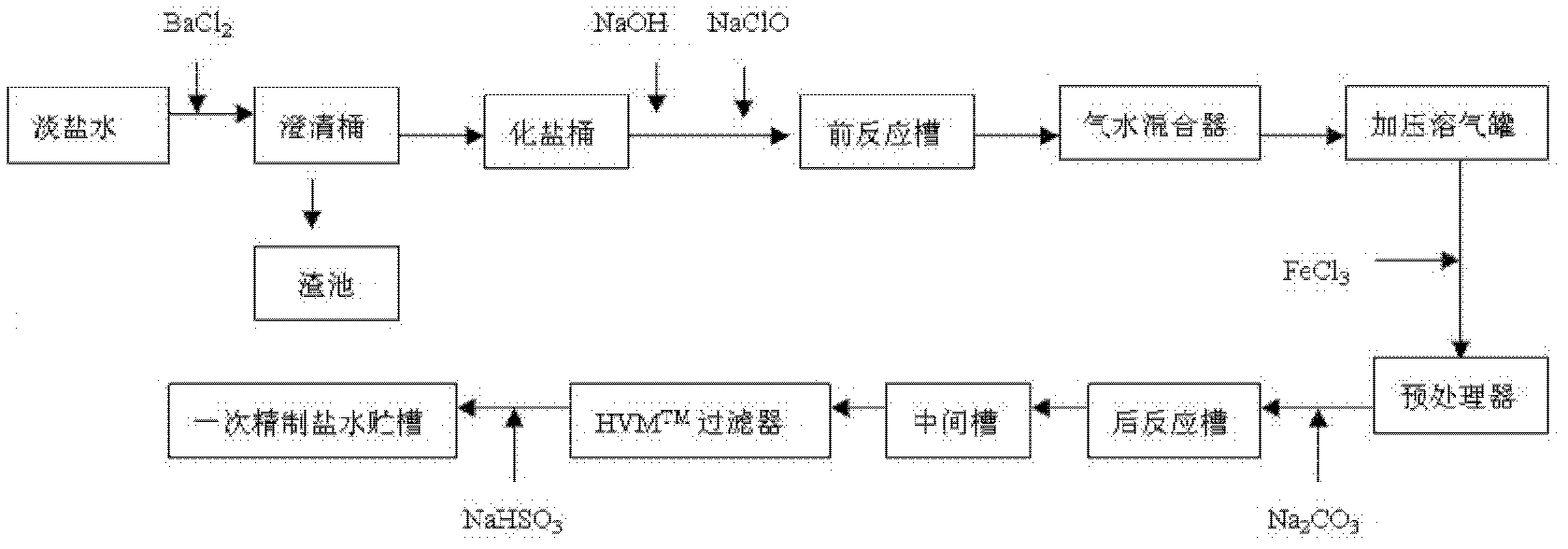

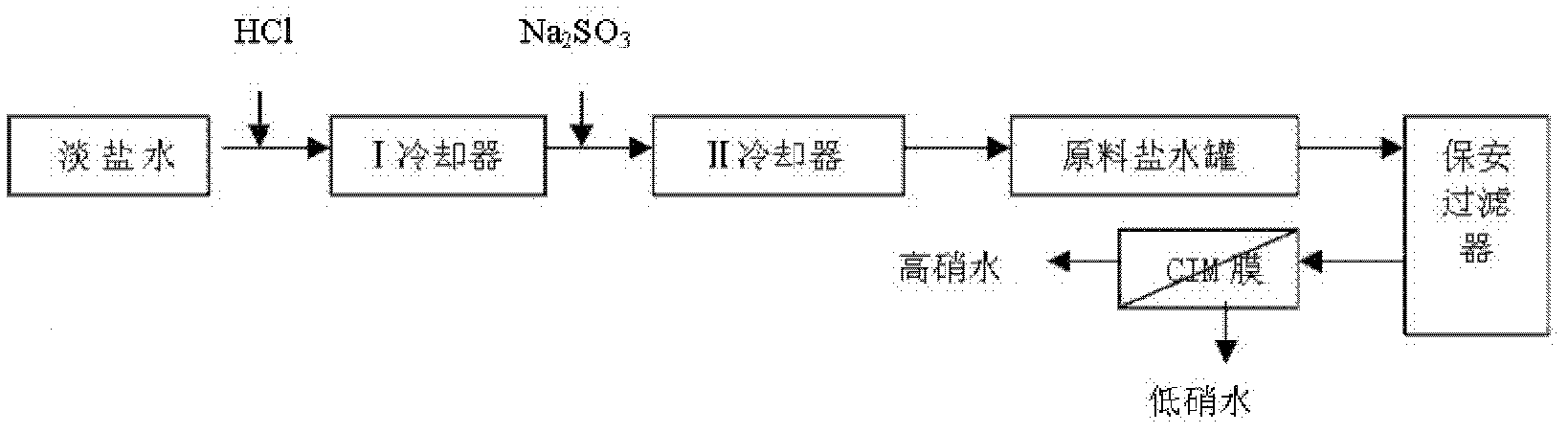

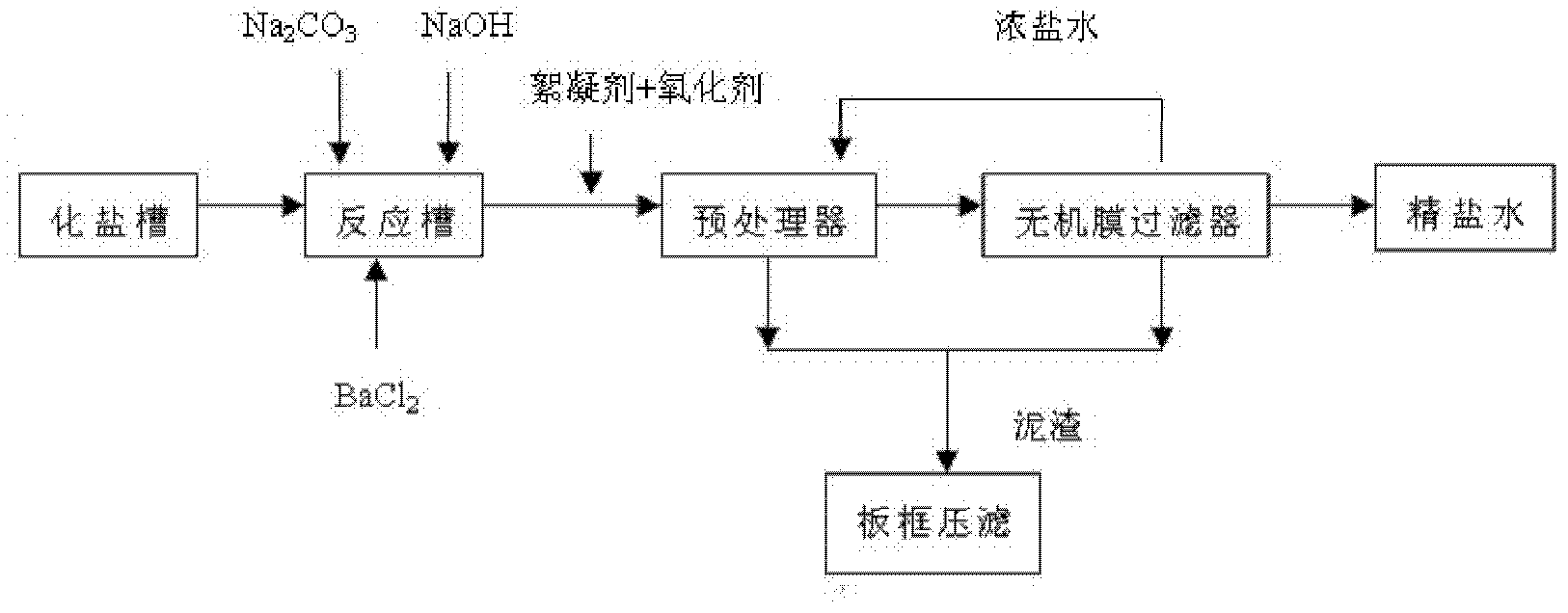

Double-membrane-method technology for refining brine and equipment for the same

ActiveCN102627300AAvoid secondary pollutionReduce manufacturing costAlkali metal halide purificationHigh concentrationUltrafiltration

The invention relates to double-membrane-method technology for refining brine and equipment for the same. After pretreatment, brine to be treated enters a filtration procedure to form high-concentration nitrate-containing water and refined brine; pretreatment refers to carrying out a removal procedure of calcium and magnesium ions, a removal procedure of ammonium, a reduction procedure and a pH adjusting procedure to the brine to be treated; the filtration procedure refers to the steps that: the pretreated brine is pumped to gas-stripping tubular type membrane module for ultrafiltration, thereby organic impurities, suspended matters and partial precipitates of the brine are intercepted; pressure raising is carried out to the brine which permeates a tubular type membrane, then the brine directly enters nanofiltration membrane module for nanofiltration; the brine which can not permeate the tubular type membrane returns the removal procedure of calcium and magnesium ions; and in a high pressure state, sulfate ions are intercepted by a nanofiltration membrane to form high-concentration nitrate-containing water, and chloride ions and sodium ions permeate smoothly the nanofiltration membrane to form refined brine. The technology in the invention is simple, low energy consumption, small land-occupation area, low investment and low production cost, a stable operation system, strong impact-resistance load capability and no secondary pollution.

Owner:CHINA PETROCHEMICAL CORP +3

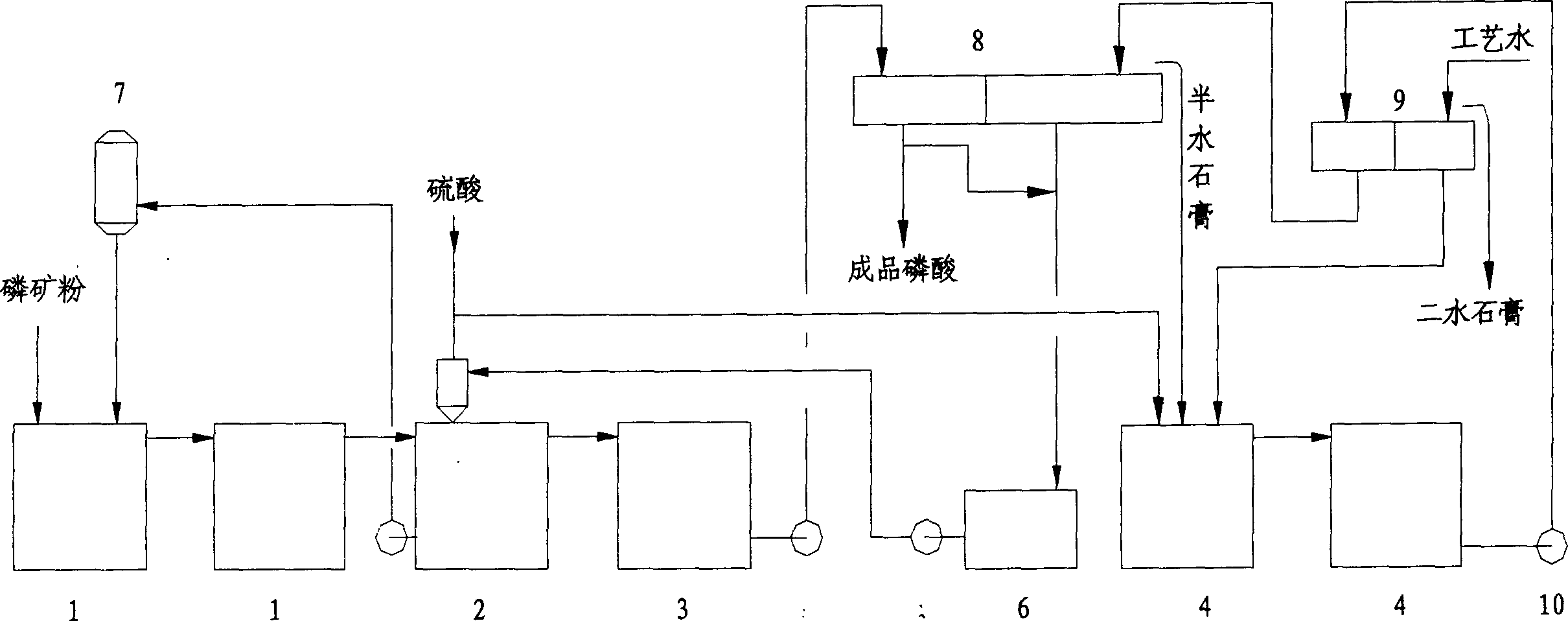

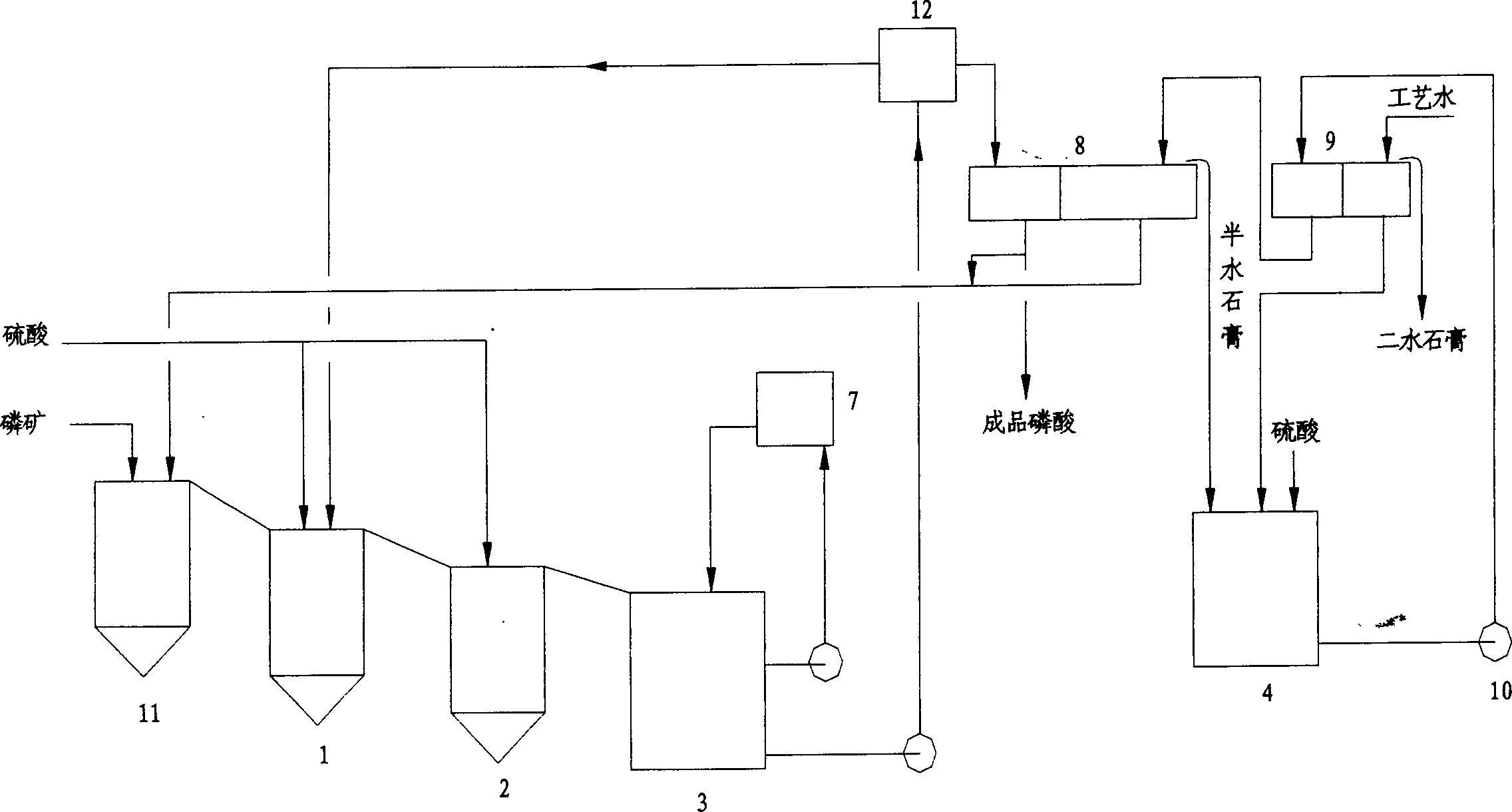

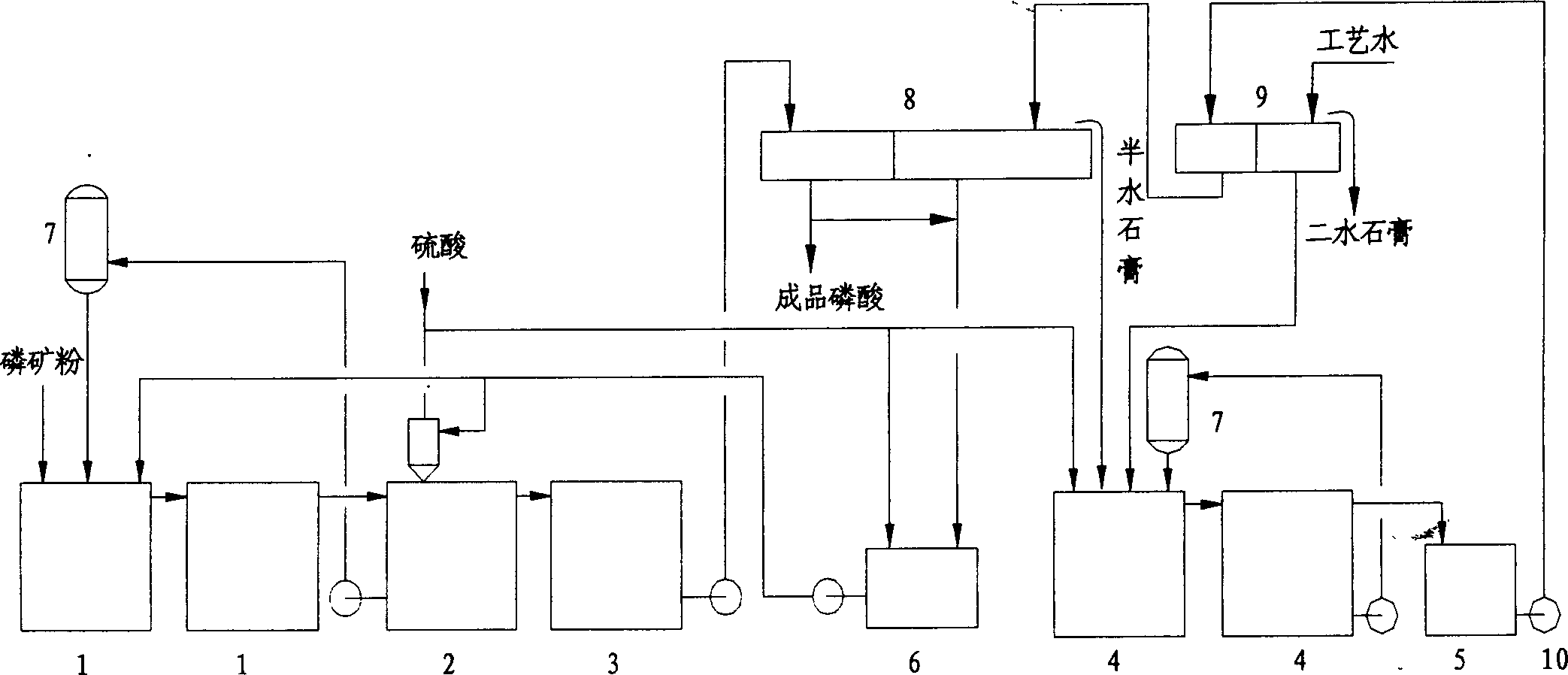

Production process of semiwater-diaquo phosphoric acid

InactiveCN1421385AWide adaptabilityReasonable processPhosphorus compoundsO-Phosphoric AcidSulfate radicals

Of the production process of semiwater-diaquo phosphoric acid, the technological keys include the calcium separating rate in the first reaction tank in the semiwater reaction part being controlled in50-60 %; the two-place addition of sulfuric acid in the semiwater reaction part including the partial addition to acid mixer for mixing with phosphoric acid and other partial addition to dilute phosphoric acid tank for controlling the concentration of sulfate radical in 8-10 %; pumping partial dilute phosphoric acid added with sulfuric acid into the first reaction tank while the other part being fed to acid mixer and the second reaction tank; and one increased vacuum flash distilling slurry cooler in the diaquo reaction part. The present invention has wide phosphate are adaptability.

Owner:YUNNAN RED PHOSPHORUS CHEM

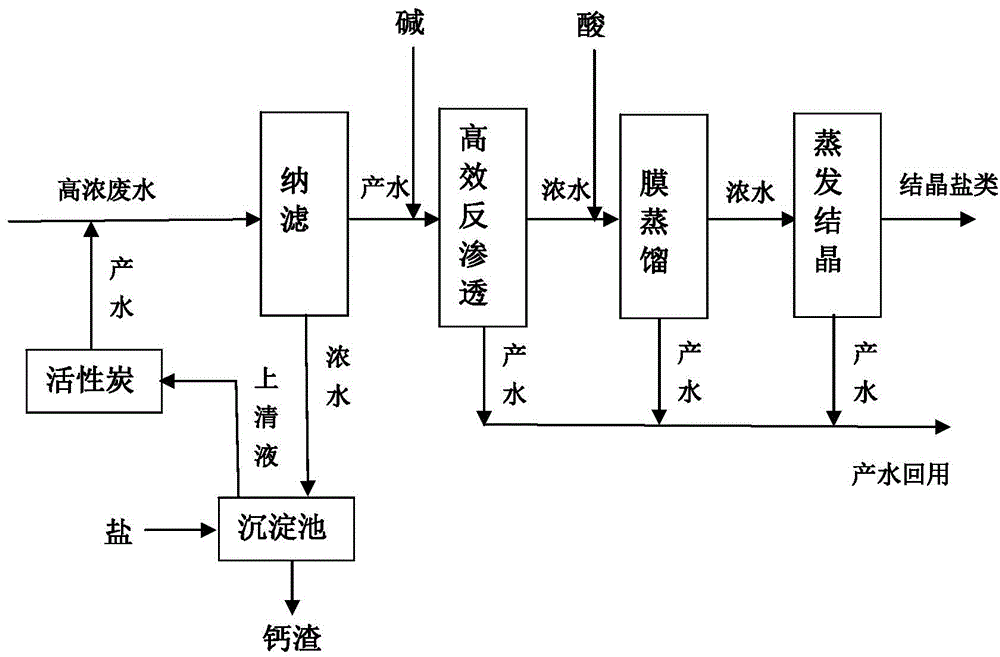

High-concentration wastewater zero-discharging method

ActiveCN105198143ARealize in-depth treatment and even zero discharge problemsEfficient reverse osmosis treatmentEnergy based wastewater treatmentMultistage water/sewage treatmentHigh concentrationReverse osmosis

The invention relates to the field of industrial wastewater treatment, in particular to a high-concentration wastewater zero-discharging method. Accoridng to the method, a 'nanofiltration + efficient reverse osmosis + membrane distillation + evaporative crystallization' method is adopted to treat high-concentration wastewater. Firstly, nanofiltration is adopted to remove hardness, multivalent ions and parts of organic matter in the high-concentration wastewater so as to obtain nanofiltration producing water and nanofiltration concentrated water, then an efficient reverse osmosis technology is adopted to conduct deep concentration treatment on the nanofiltration producing water, deep concentration treatment is conducted on the obtained efficient reverse osmosis concentrated water through membrane distillation to obtain membrane-distillation concentrated water, further evaporative crystallization treatment is performed to enable salt solids in the membrane-distillation concentrated water to crystallize out, and centralized drying disposal is performed, wherein salt is added into the nanofiltration concentrated water to perform precipitation treatment so as to obtain calcium residues, supernate obtained after precipitation is subjected to activated carbon adsorption and then is mixed with the high-concentration wastewater, and the mixed liquid is fed into a nanofiltration unit for circular treatment. By means of the high-concentration wastewater zero-discharging method, water resources are recycled to the most degree while the problem of high-concentration wastewater discharging is solved, and zero discharging of high-concentration wastewater is basically achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

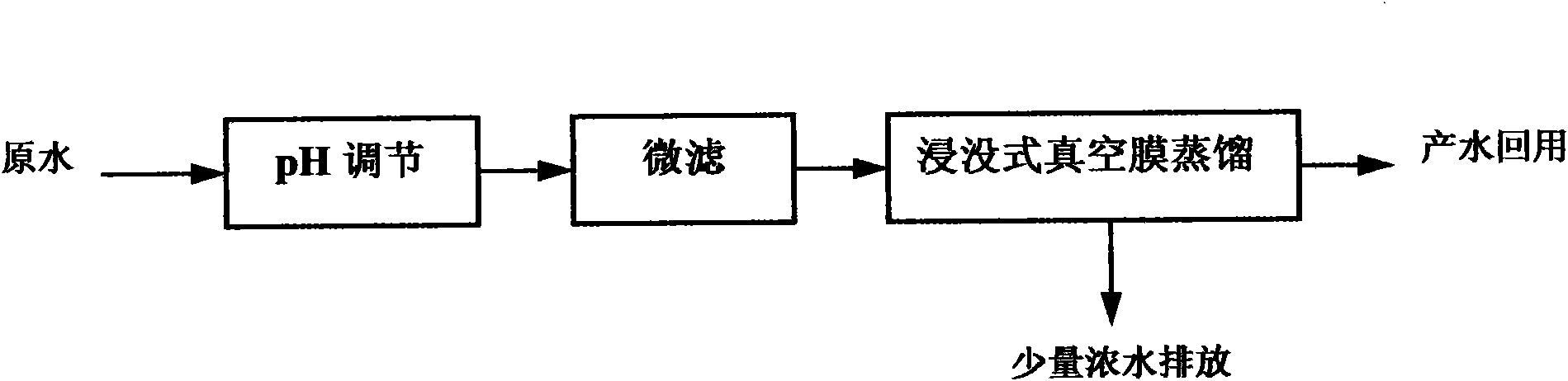

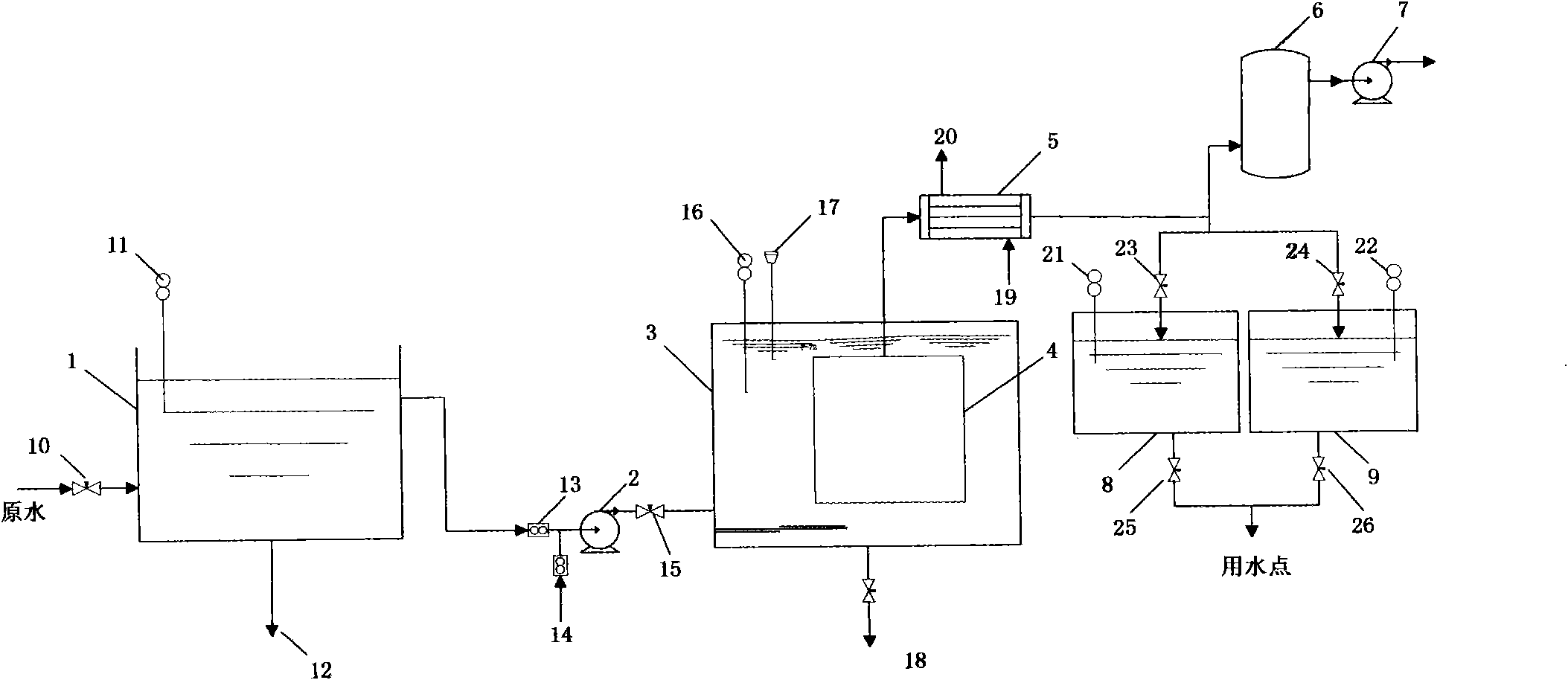

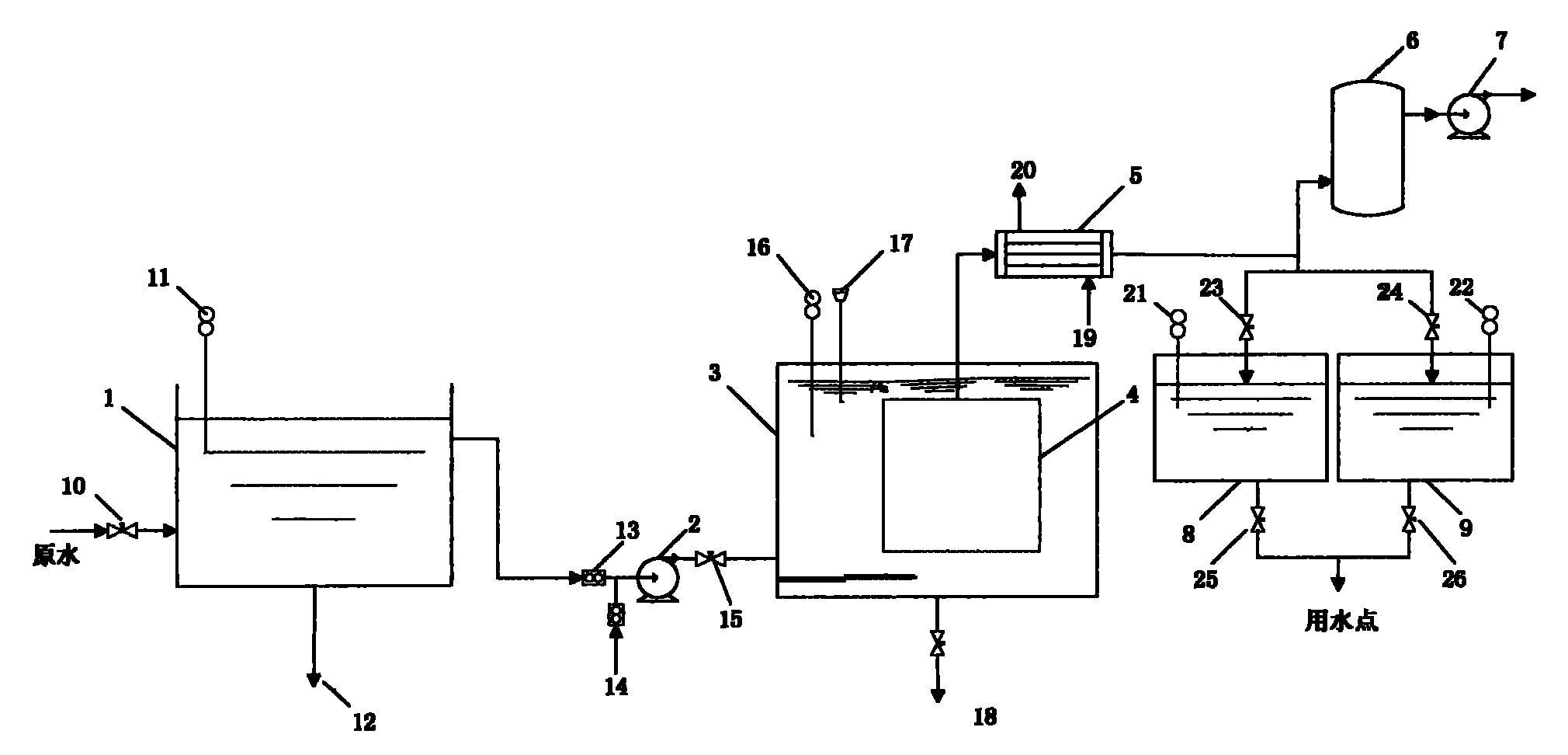

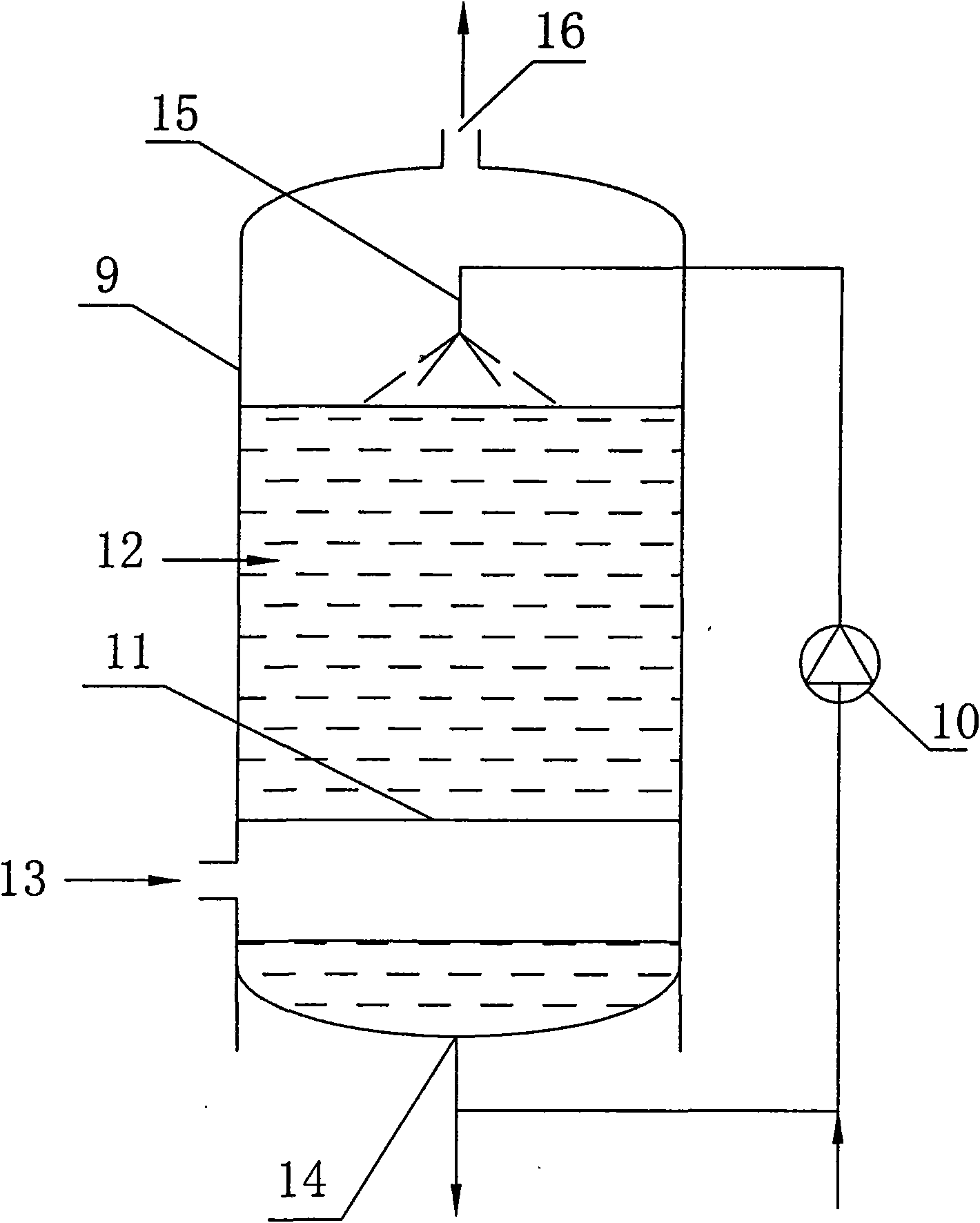

Immersed vacuum membrane distillation plant and sewage treatment technology using the same

ActiveCN102417210AIncreased distillation throughputReduce pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentConcentration polarizationMeasuring instrument

The invention relates to an immersed vacuum membrane distillation plant and a sewage treatment technology using the same. The immersed vacuum membrane distillation plant comprises a raw water storage tank, a gas dissolving pump, a raw water heating water tank, a membrane distillation hydrophobic membrane module, a condenser, a vacuum buffer tank, a vacuum pump, a water producing tank, a valve, a measuring instrument, and an automatic controller. The sewage treatment technology is characterized in that: raw water is subject to pH regulation, microfiltration and other pretreatment, then the pretreated raw water enters into the raw water storage tank, the sewage in the raw water storage tank is subject to gas-water mixing through the gas dissolving pump, and then the gas-water mixture enters into the raw water storage tank for heating to a specific temperature, membrane distillation is carried out at the specific temperature, the produced water after membrane distillation is directly reused, and a little thick water is treated concentrately. According to the invention, the use of the plant in sewage treatment reduces the effect of concentration polarization and temperature difference polarization in the sewage, reduces membrane pollution, increases the membrane distillation flux, prolongs the operation period of the membrane module, reduces the heat loss of the pipeline, and increases the heat utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

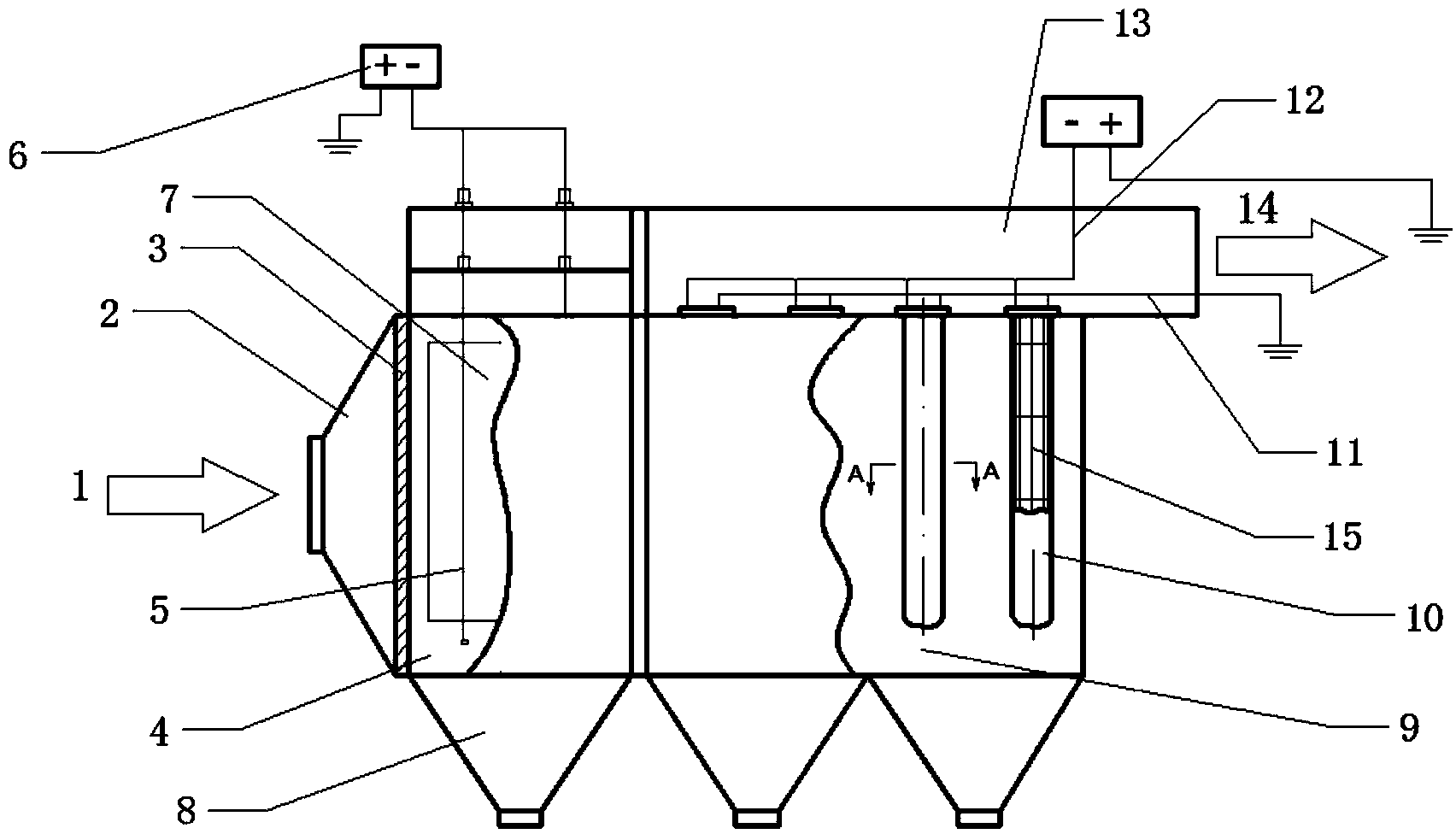

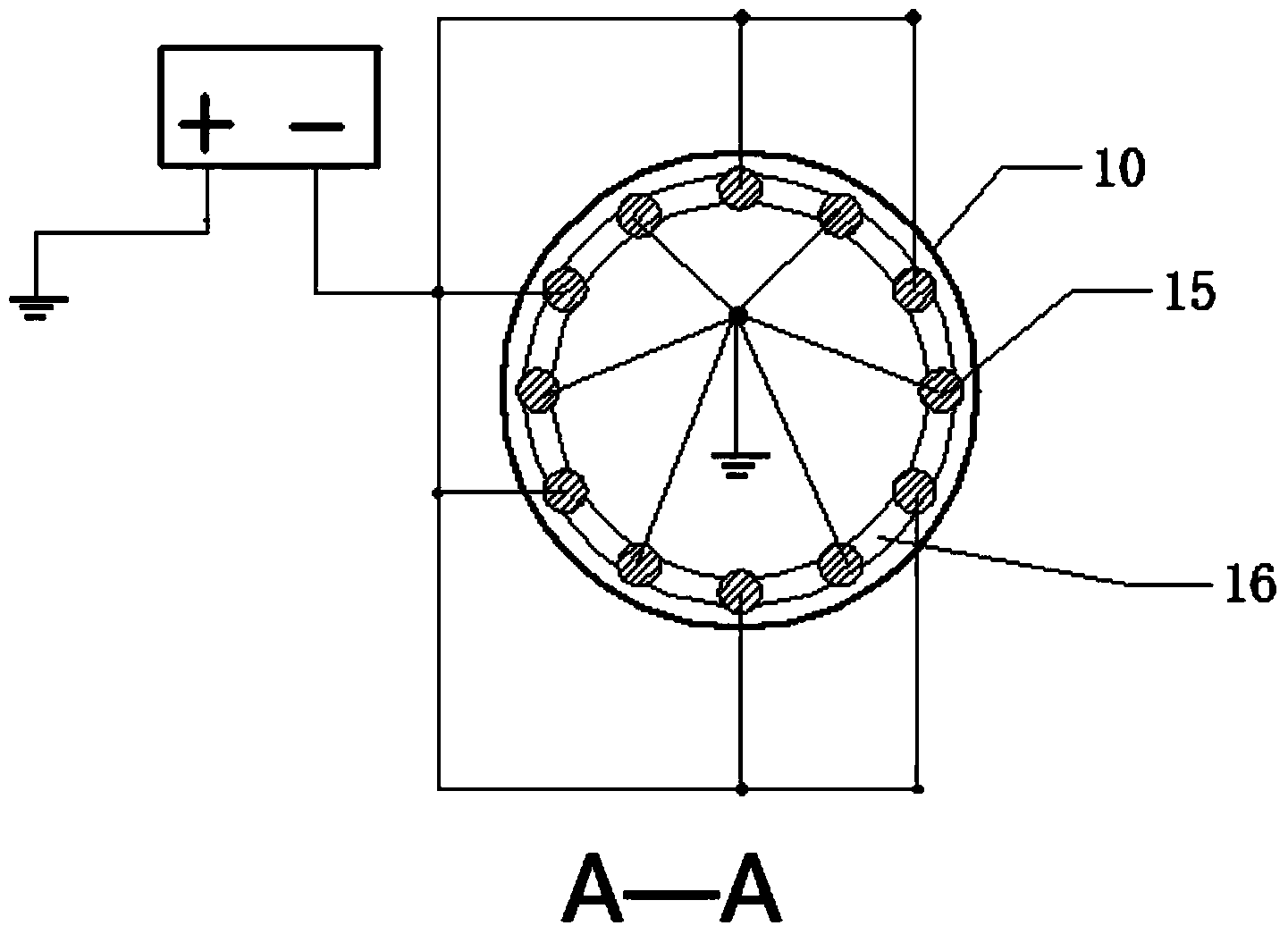

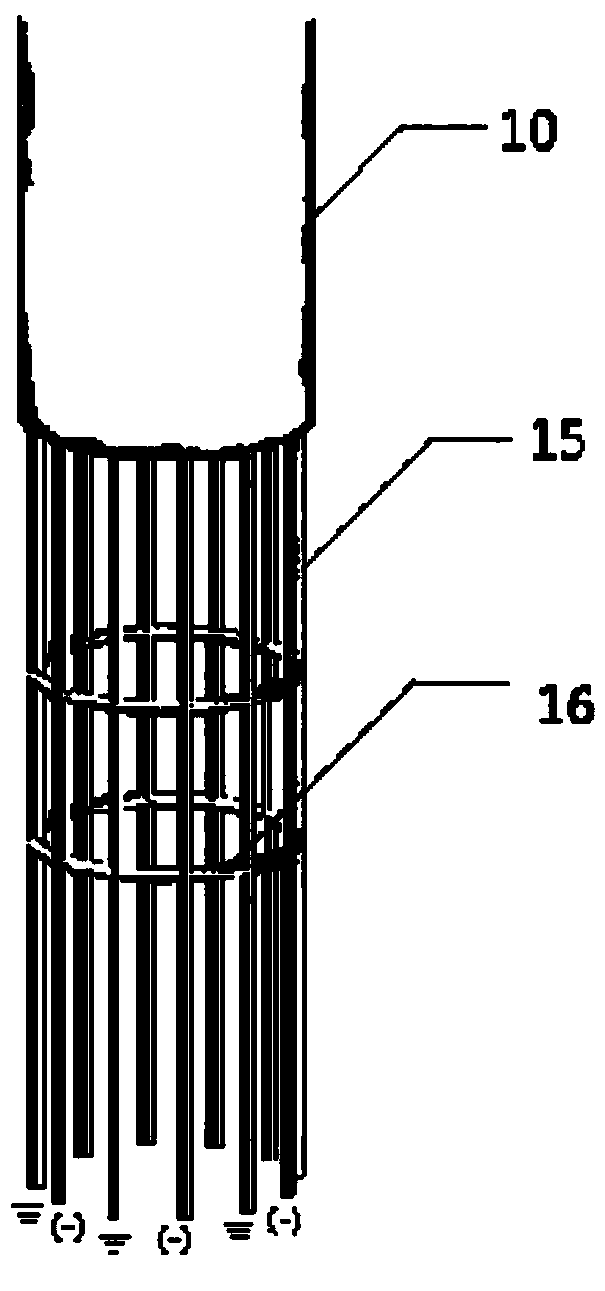

Electrostatically-enhanced electric-bag compound dust remover

ActiveCN103657316ADifficult to enterExtend your lifeCombination devicesFiltrationHigh-voltage direct current

An electrostatically-enhanced electric-bag compound dust remover comprises a high-voltage power supply arranged outside a casing and a compound dust removing area arranged in the casing; the compound dust removing area comprises a forestage electrostatic dust removing area and a rear-stage bag type dust removing area, wherein the forestage electrostatic dust removing area comprises a high-voltage discharge polar line and a dust collecting pole plate; filtering bags uniformly distributed are arranged in the bag type dust removing area; conductive cage bones are arranged in the filtering bags; vertical reinforcement bars in the conductive cage bones are connected with the ground and the negative pole of a high-voltage direct-current power supply, and each two adjacent vertical reinforcement bars are opposite in polarity; a plurality of insulating rings are arranged in the vertical direction; the vertical reinforcement bars are fixed on the insulating rings. The electrostatically-enhanced electric-bag compound dust remover has the characteristics that a non-uniform electric field is added in the bag type dust removing area, so that charged dust particles are distributed non-uniformly on the surfaces of the filtering bags; meanwhile, the particles are polarized into chains through the electric field, and then the probability of collecting the particles can be increased, so that the air-to-cloth ratio can be improved, the filtration resistance can be lowered at the same time, the soot cleaning frequency can be reduced, and the dust remover has the advantages of low energy consumption and long service life.

Owner:TSINGHUA UNIV

Polyester flat microporous membrane and preparation method thereof

InactiveCN101985085AAchieve hydrophilicAchieve hydrophilizationSemi-permeable membranesCell seperators/membranes/diaphragms/spacersPolyesterMicrometer

The invention discloses a polyester flat microporous membrane and a preparation method thereof. The microporous membrane comprises the following materials in percentage by mass: 60-99.9% of polyester and 0.1-40% of modifier; or 20-40% of non-woven fabric, 60-79.9% of polyester and 0.1-30% of modifier. The preparation method is realized on the basis of a thermally induced phase separation process and comprises the following steps: mixing the polyester, the modifier and diluter into a homogeneous solution at high temperature; scraping the homogeneous solution into a liquid membrane, cooling andcuring into a membrane so as to form a precursor membrane subject to microphase separation, and extracting to obtain a flat microporous membrane. The prepared polyester flat microporous membrane is in a spongeous structure with the pore diameter of 0.05-5.0 micrometers and the porosity of 30-80%, and has the advantages of narrow pore diameter distribution, uniform pore size, easily controlled pore size, high strength, symmetrical structure and the like, thereby being a filter membrane material for water treatment and a lithium ion battery diaphragm material with high performance, low cost andlong life.

Owner:ZHEJIANG UNIV

Low-shrinkage high-strength polyester industrial yarn and preparation method thereof

ActiveCN108385189AIncrease the cross-sectional areaReduce the temperatureSpinnerette packsFibre typesYarnThermal insulation

The invention relates to a low-shrinkage high-strength polyester industrial yarn and a preparation method thereof. The preparation method comprises: carrying out solid phase condensation polymerization tackifying on a modified polyester, melting, metering, extruding, cooling, oiling, drawing, carrying out heat setting, and winding, wherein the unchanged longitudinal height is maintained during thecooling, the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method, and the oil agent for oiling contains 67.30-85.58 wt% of crown ether. According to the present invention, the preparation method is simple; the material of the prepared low-shrinkage high-strength polyester industrial yarn is the modified polyester with the molecular chain including a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the fracture strength is more than or equal to 7.3 cN / dtex, and the dry heat shrinkage rates at the conditions comprising 177 DEG C, 10 min and 0.05 cN / dtex and the conditions comprising 190 DEG C, 15 min and 0.01 cN / dtex respectively are 1.8+ / -0.5% and 3.5+ / -0.5%.

Owner:JIANGSU HENGLI CHEM FIBER

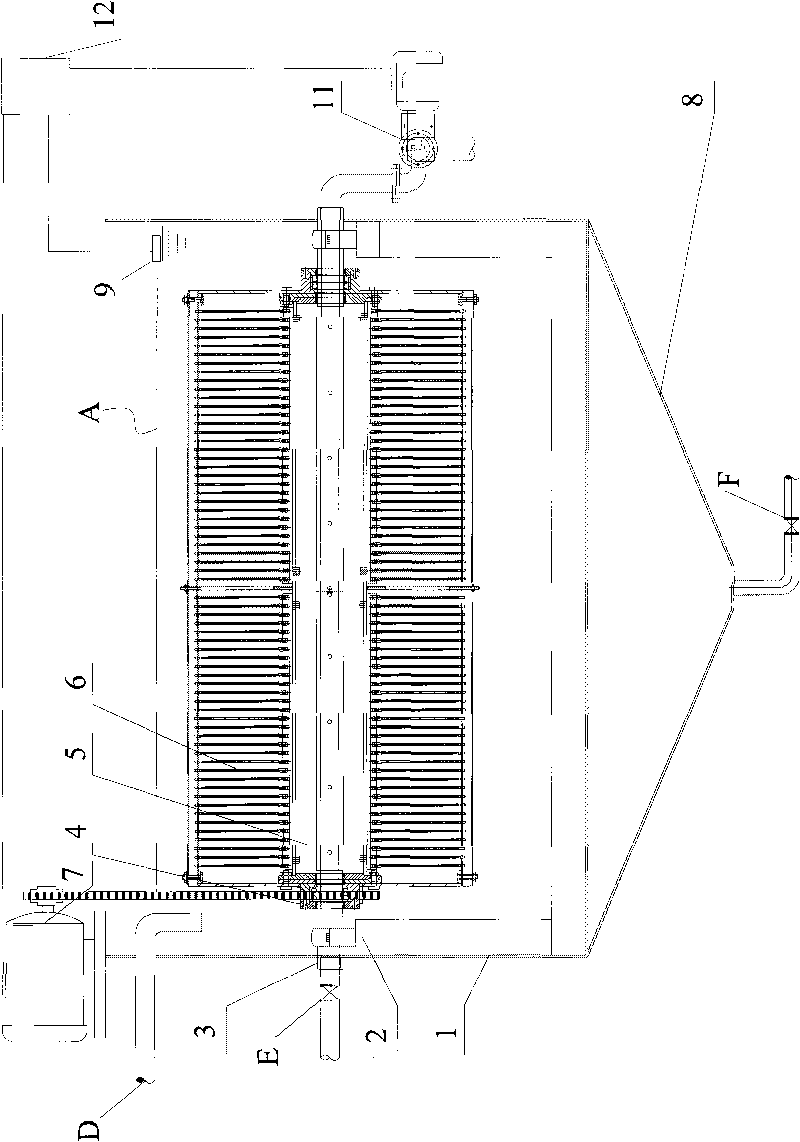

Vibration-type membrane bioreactor

ActiveCN101565232AStable fluxExtended service lifeSustainable biological treatmentBiological water/sewage treatmentVibrating membraneBiochemical engineering

The invention relates to a vibration-type membrane bioreactor, which is characterized by comprising a preheating device, a membrane bioreactor, a biological deodorization device, a vibrating device and a clear water tank unit, wherein the preheating device is a biochemical area in an equipment body; the membrane bioreactor is arranged in a membrane filtration area in the equipment body; the vibrating device is arranged on the membrane bioreactor; the biological deodorization device is arranged on the top of the equipment body; a water outlet at the bottom of the biological deodorization device is communicated with the inside of the equipment body; and the clear water tank unit is a clear water area in the equipment body. The vibration-type membrane bioreactor takes the pressure above the membrane pressure difference of 20 Kpa as a membrane pollution control index, automatically vibrates membrane components, accelerates the falling of membrane pollutants, and prolongs the cleaning period from the prior offline cleaning for one time per 6 months to cleaning for once per 8-9 months, thereby saving 30 to 50 percent of chemical agents, making the membrane flux more stable and the operation cycle of the MBR longer, and prolonging the service life of a membrane.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

Method for preparing polymer/montmorillnoite nano composite hydrophilic membrance

InactiveCN1709558ASolve pollutionChange hydrophilicitySemi-permeable membranesParticulatesHigh surface

A preparation method of polymer / Mengtuotu composite hydrophilic membrane relates to preparation craft of composite membrane disposed by water. The step is: Dissolving polymer and organic Mengtuotu respectively in medium of 30 Deg. to 95 Deg. C for 3 to 20 hours; Mixing the admixture for 1 to 20 hours; Add organic matter and inorganic matter and mixing for 5 to 24 hours, it becomes cast-iron liquid; Make membrane. The present invention makes use of high surface energy of Nami Mengtuotu particulate to counteract the disfigurement the low surface energy of polymer. The changeable character of Nami Mengtuotu is different from others; it not only changes hydrophilic character of composite pottery but also changes hydrophilic character in interface of inner hole. The present invention can solve the membrane pollution problem effectively, increases flowing and sectional flowing rate, prolongs the cycle of cleaning and can be applied on a large scale.

Owner:HARBIN INST OF TECH

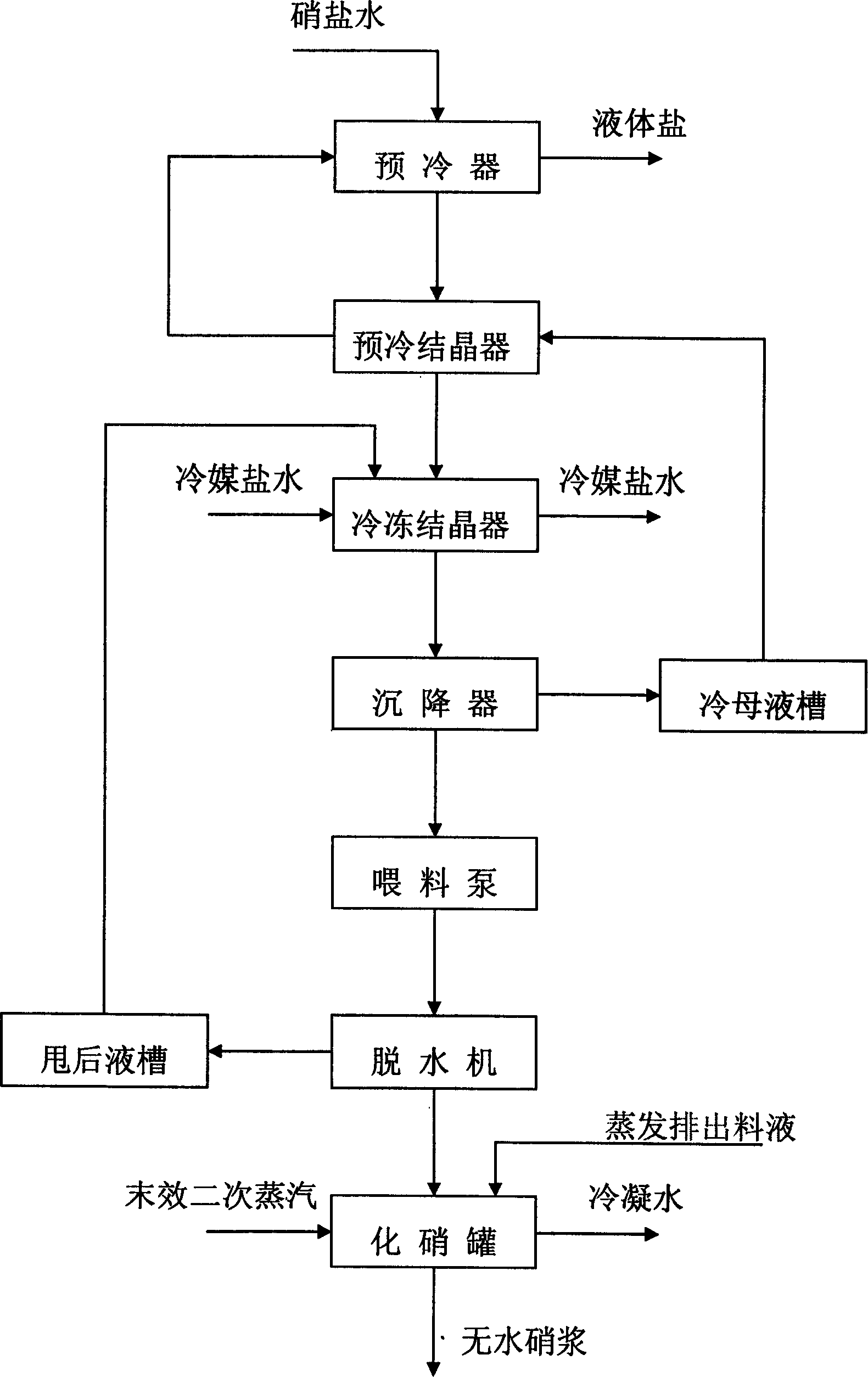

Process for preparing anhydrous mirabilite by freezing method

ActiveCN1837050AEasy to operateReasonable heat transfer temperature differenceChemical industryAlkali metal sulfite/sulfate dehydrationMirabiliteSodium sulfate

The invention discloses a new technics about the production of freezing method absolute nitrate, containing steps as follows: getting the solution contains saltpeter across precooler to doing coolant elementary cooling by cold mother liquor; switching the feed liquid from precooler to precooler crystallizer; adding the feed liquid from precooler crystallizer in cooler crystallizer to freeze the feed liquid to -5-7Deg C for the saltpeter separating of second phase refrigeration; Adding the feed liquid from cooler crystallizer in depressor for solid-liquid separation; passing the discharged sodium sulfate from precooler through screw pump to feed the dewatering machine; putting the dewatered sodium sulfate in saltpeter melting tank, mixing with the swinged liquid of evaporate discharged feed liquid or absolute nitrate plasm, making sodium sulfate autolyze by end effect quadratic steam heating. In the saltpeter melting procedure of this method, adopting hot material and sodium sulfate mixing melt saltpeter, at the same time, using low-grade second steam heat energy heat up the feed liquid, compared to the former pervaporation, this method is more reasonable, energy saving and ensure the quality of product.

Owner:ENG TECH INST CO LTD OF CNSIC

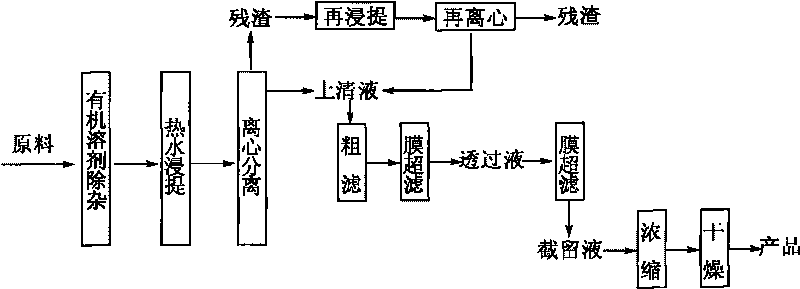

Method for separating sweet tea polysaccharide by ultrafiltration membranes

The invention relates to a method for separating sweet tea polysaccharide by ultrafiltration membranes, more particularly comprising: reflux extracting pretreated sweet tea by water or mixed solvent of water and ethanol; carrying out two-step purification process of centrifugation and filtration of a micro-filtering film on leach liquor, and then ultra-filtering by the ultrafiltration membranes with two specifications; and finally, separating the sweet tea polysaccharide and impurities by decompressing and concentrating trapped liquid. The method is simple, convenient and efficient, and has low cost, no pollution and higher purity of polysaccharide, thus being suitable for industrial production.

Owner:TIANJIN POLYTECHNIC UNIV

Phosphoric acid equipment pipeline scale inhibitor

ActiveCN102874938AExtended cleaning cycleShorten cleaning timeScale removal and water softeningPhosphorus compoundsSodium polyacrylateSodium Acrylate

The invention discloses a phosphoric acid equipment pipeline scale inhibitor and belongs to the field of scale prevention. The phosphoric acid equipment pipeline scale inhibitor is mainly composed of, by weight percentage, 0.5-1% of sodium dodecyl benzene sulfonate, 0.3-0.8% of sodium stearate, 1-2.5% of sodium lignin sulfonate and 1.5-2% of sodium polyacrylate. When in use, the scale inhibitor is heated to the temperature ranging from 20 DEG C to 80 DEG C and added in a phosphoric acid equipment pipeline, and addition amount of the scale inhibitor is 0.03-0.05% of phosphoric acid by wet process. By adopting the phosphoric acid equipment pipeline scale inhibitor, operation cycle of a phosphoric acid concentration system is prolonged, cleaning time is reduced, device operating rate is increased, and temperature application range of the scale inhibitor is wider than that of the prior art, so that the phosphoric acid equipment pipeline scale inhibitor has huge application value.

Owner:WENGFU (GRP) CO LTD

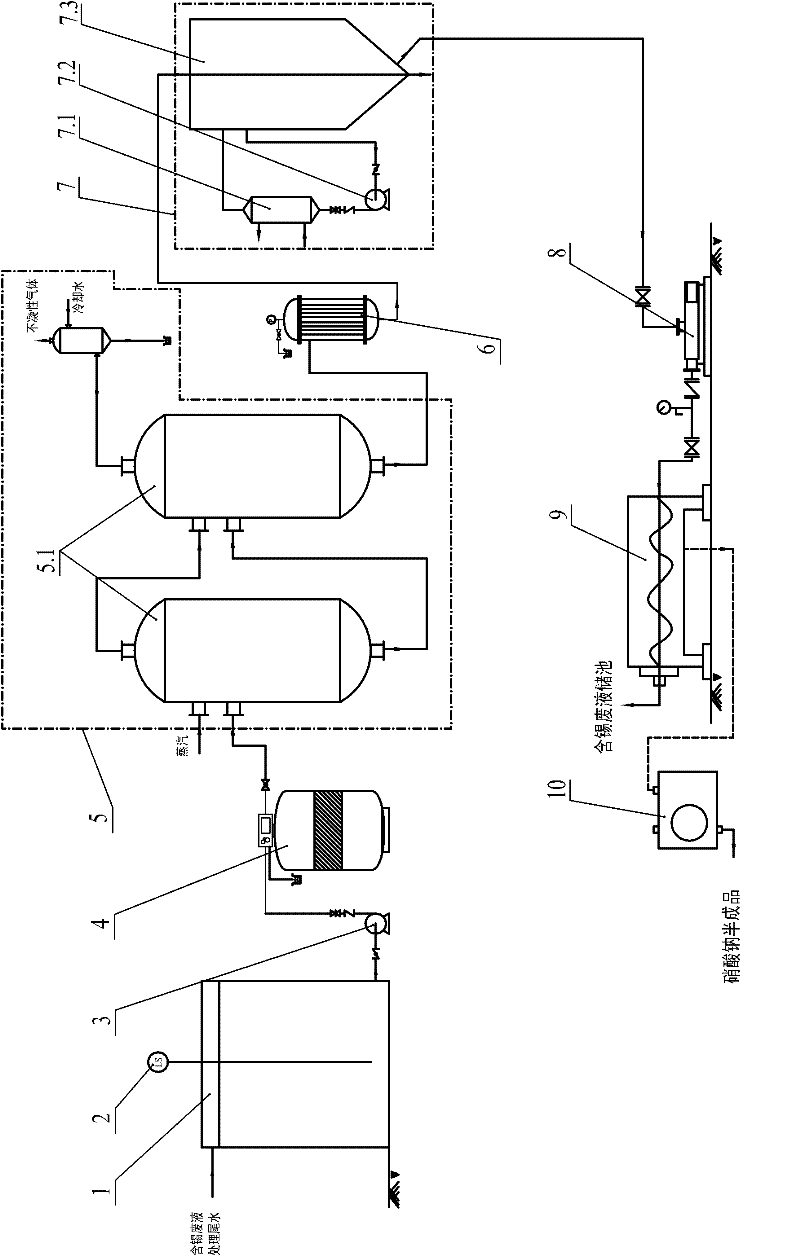

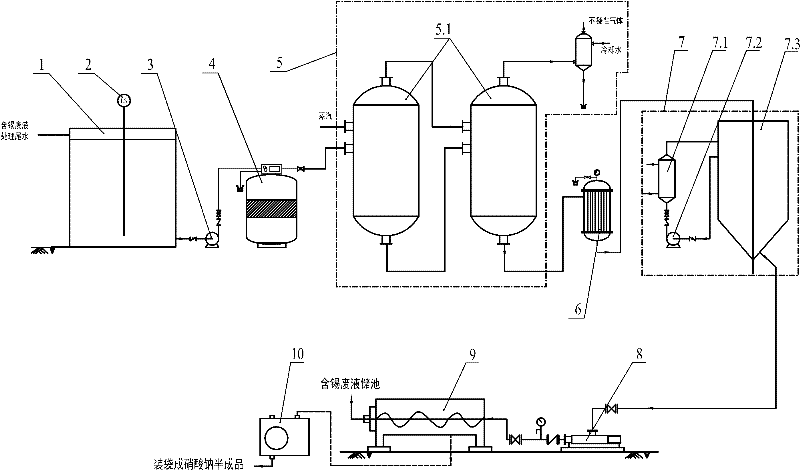

System and technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water

ActiveCN102351220AEasy to operate and manageGuaranteed operating efficiencyAlkali metal nitratesMultistage water/sewage treatmentFiltrationSlag

The invention relates to a system and a technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water. The system for recovering sodium nitrate from tin-containing waste liquid treatment tail water comprises a waste water storage pool, a purification refining device, a multi-effect evaporator, a filter, a crystallization device, a centrifugal machine and a drying machine. The technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water comprises the following steps of collecting tin-containing waste liquid treatment tail water, storing the collected tin-containing waste liquid treatment tail water in the waste water storage pool, feeding the tin-containing waste liquid treatment tail water in the waste water storage pool into the purification refining device to carry out purification refining, feeding the tin-containing waste liquid treatment tail water subjected to purification refining into the multi-effect evaporator, feeding steam into the multi-effect evaporator to carry out circulation evaporation, feeding the steam obtained by the previous step into the filter to carry out heat filtration, feeding the filtrate into the crystallization device to carry out crystallization to obtain crystals, carrying out centrifugation of the obtained crystals by the centrifugal machine to obtain solid slag and a mother solution, transferring the solid slag to the drying machine to carry out drying to obtain a sodium nitrate finished product, and feeding the mother solution back to the waste water storage pool for recycle. The system for recovering sodium nitrate from tin-containing waste liquid treatment tail water has the advantages of relatively low recovery cost, simple and convenient operation management, long-term and stable operation and no discharge of pollutants.

Owner:无锡金品环境技术有限公司

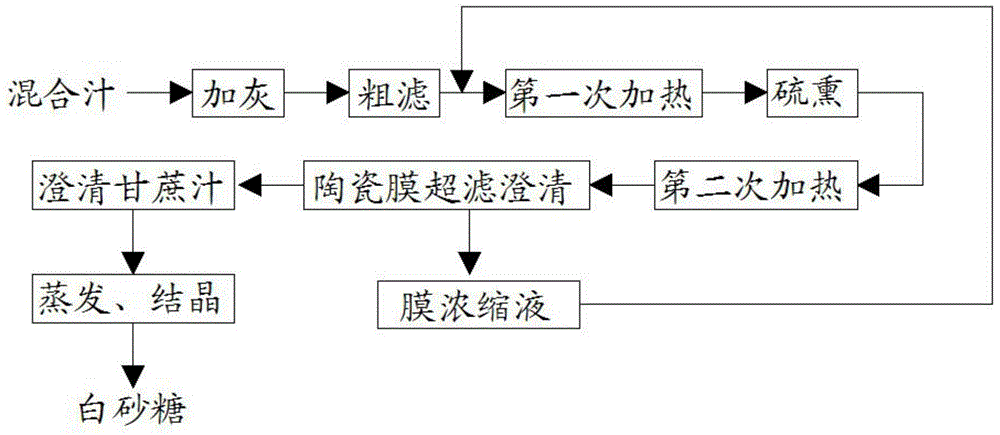

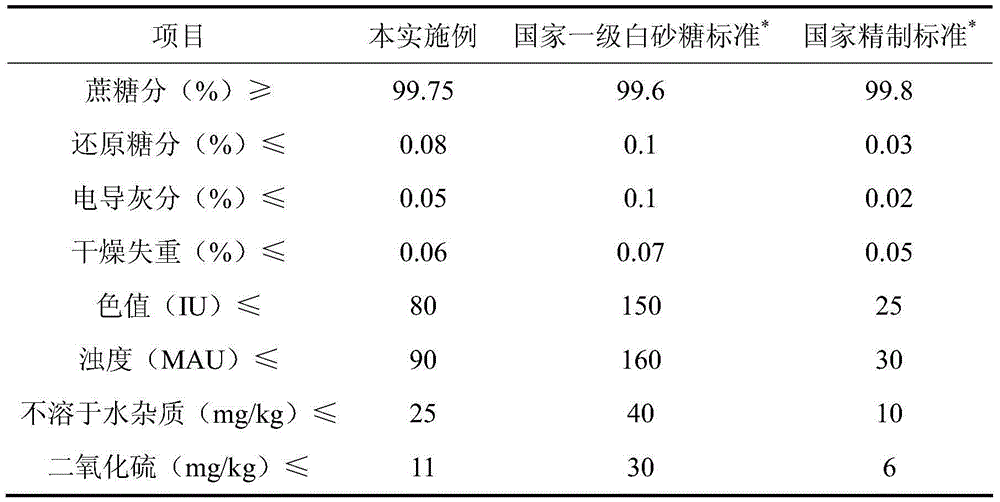

Sugar manufacture clarification process

ActiveCN104805226AReduce sulfur contentReduce color valuePurification using alkaline earth metal compoundsSugar crystallisationSulfurTurbidity

The invention discloses a sugar manufacture clarification process which comprises the following steps: adding lime milk into mixed cane juice to adjust the pH value to be 7.5-7.8, thereby obtaining lime-milk-added cane juice; filtering the lime-milk-added cane juice by using a horizontal screw centrifuge, thereby obtaining roughly filtered cane juice; heating the roughly filtered cane juice to be 55-65 DEG C, thereby obtaining cane juice which is heated for the first time; stoving the cane juice which is heated for the first time with SO2 until the intensity of sulfitation is 4-6 mL, thereby obtaining stoved cane juice; heating the stoved cane juice to be 80-90 DEG C, thereby obtaining cane juice which is heated for the second time; performing ultrafiltration clarification on the cane juice which is heated for the second time by using a ceramic membrane, thereby obtaining clear cane juice and membrane concentrated liquid; filtering the membrane concentrated liquid by using a plate-and-frame filter press, and returning the filtered membrane concentrated liquid to a roughly filtered cane juice storage tank. As a conventional sugar manufacture clarification process through a sulfurous acid method is combined with a membrane separation technique, a novel sugar manufacture clarification process is developed, the clarified cane juice prepared by using the process is low in color value, high in purity and low in turbidity, and the white sugar prepared from the cane juice is good in quality.

Owner:GUANGXI UNIV

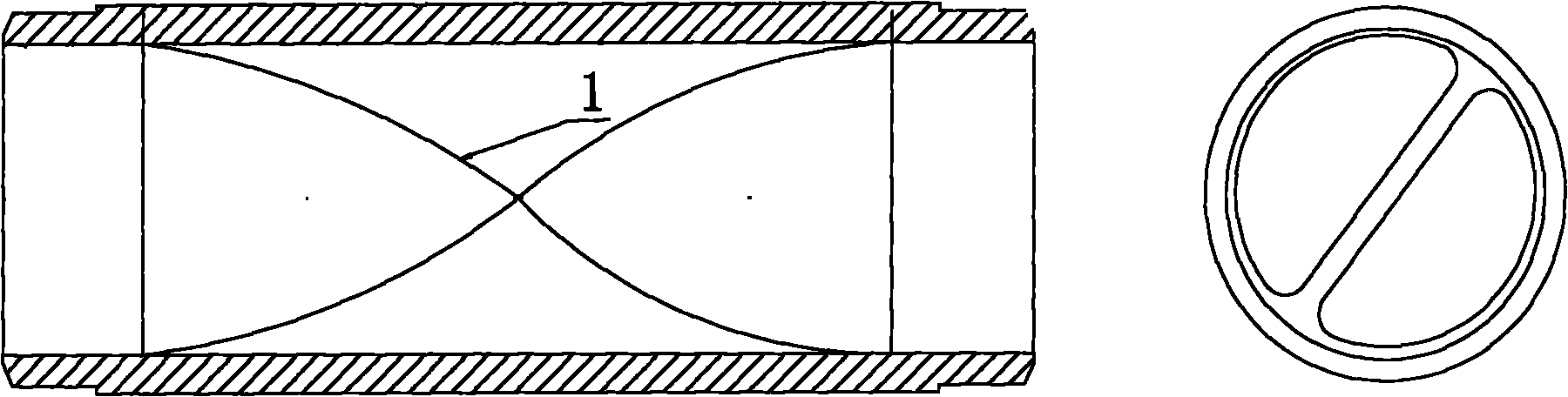

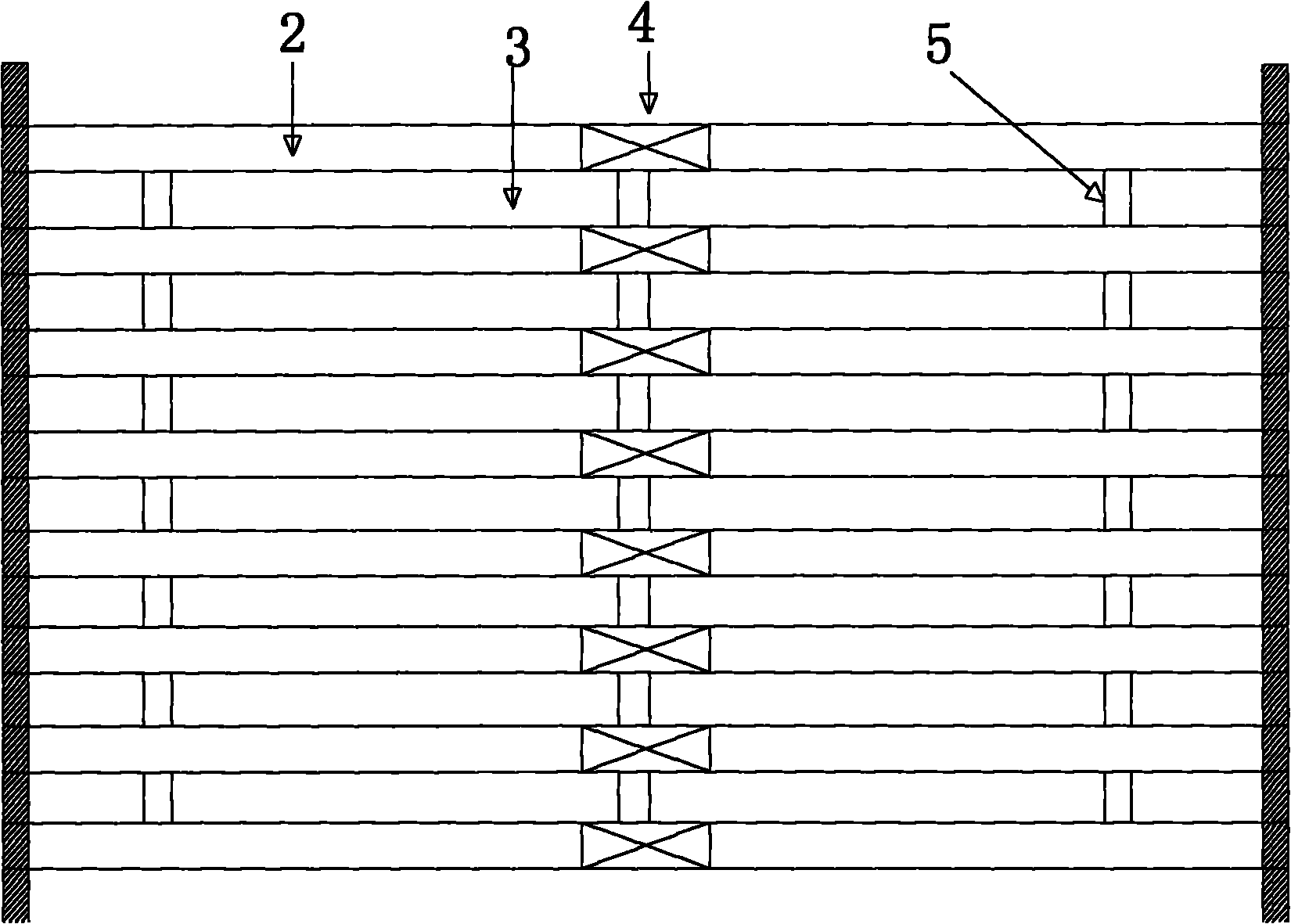

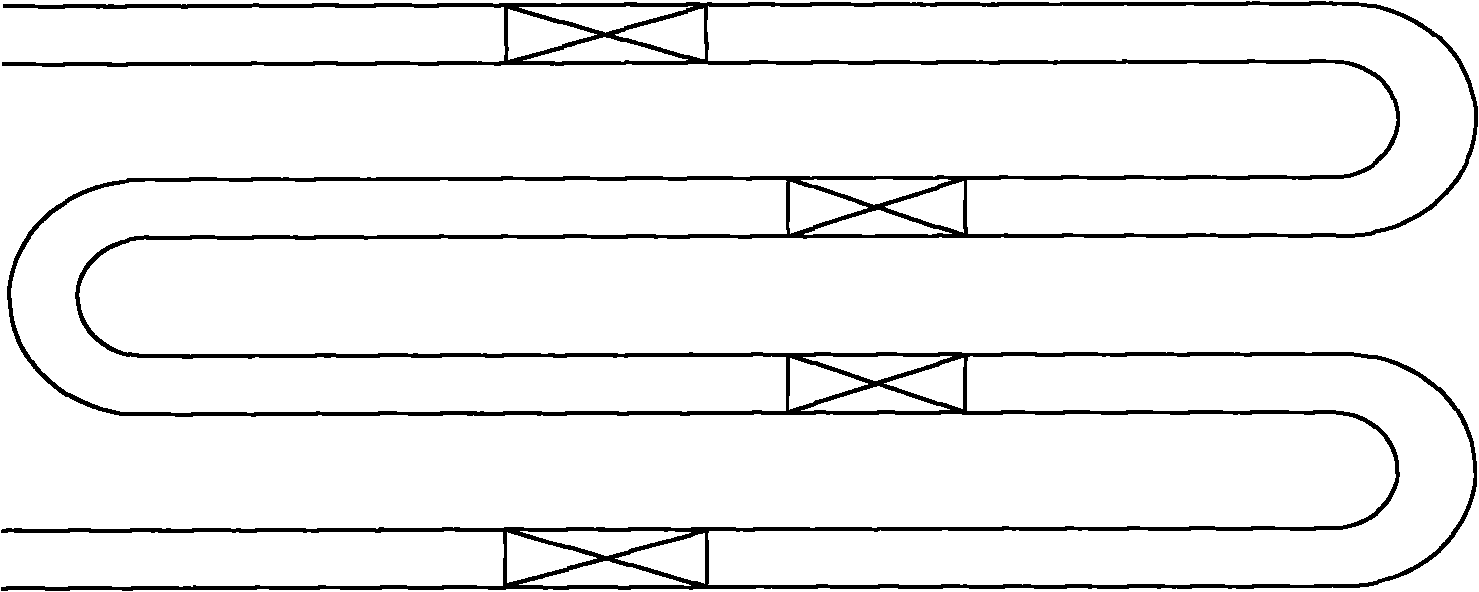

Heat exchanger with twisted sheet

InactiveCN101846469AExtended cleaning cycleIntensified intensityStationary conduit assembliesStationary tubular conduit assembliesEngineeringEnhanced heat transfer

The invention discloses a heat exchanger with a twisted sheet. In order to overcome the limitation of a traditional enhanced heat transfer technology of a tubular heat exchanger, the twisted sheet is adopted by the invention and welded in the heat exchange tube of the heat exchanger, thereby improving the heat transfer effect of the heat exchanger and prolonging the operation cycle of the heat exchanger.

Owner:CHINA PETROLEUM & CHEM CORP +1

Scale dispersant for water scrubber and application method of scale dispersant

ActiveCN106745857AReduce differential pressureImprove efficiencySpecific water treatment objectivesScale removal and water softeningRoom temperatureInjection point

The invention discloses a scale dispersant for a water scrubber. The scale dispersant is obtained through mixing and stirring the raw materials in percentage by weight: 1-5% of a dispersing agent, 30-40% of an emulsifier, 30-40% of a penetrant and the balance of solvent at room temperature for an hour and then filtering. An injection point of the scale dispersant is in front of an overhead circulating pump of the water scrubber. The additive amount of the scale dispersant for the water scrubber is 200-500ppm and the scale dispersant is continuously injected. The scale dispersant for the water scrubber has the beneficial effects that scales left in the water scrubber and a heat exchanger can be greatly reduced, the differential pressure of the water scrubber is obviously reduced, the efficiency of the heat exchanger is greatly improved and the cleaning period of the heat exchanger can be prolonged twice.

Owner:天津市瑞德赛恩新材料开发有限公司

High-concentrated emulsified oil waste water treating method

A process for treating the sewage containing high content of emulsified oil includes such steps as removing the floating oil in an oil-isolating pool, removing suspended in oil regulating pool, demulsifying and air-floating separating to remove the waste oil and floc in top layer, electrolyzing in electrolyzer, air-floating separating for removing waste oil and floc, and biochemical treating. Its advantages are high efficiency, low cost and short period.

Owner:詹伯君

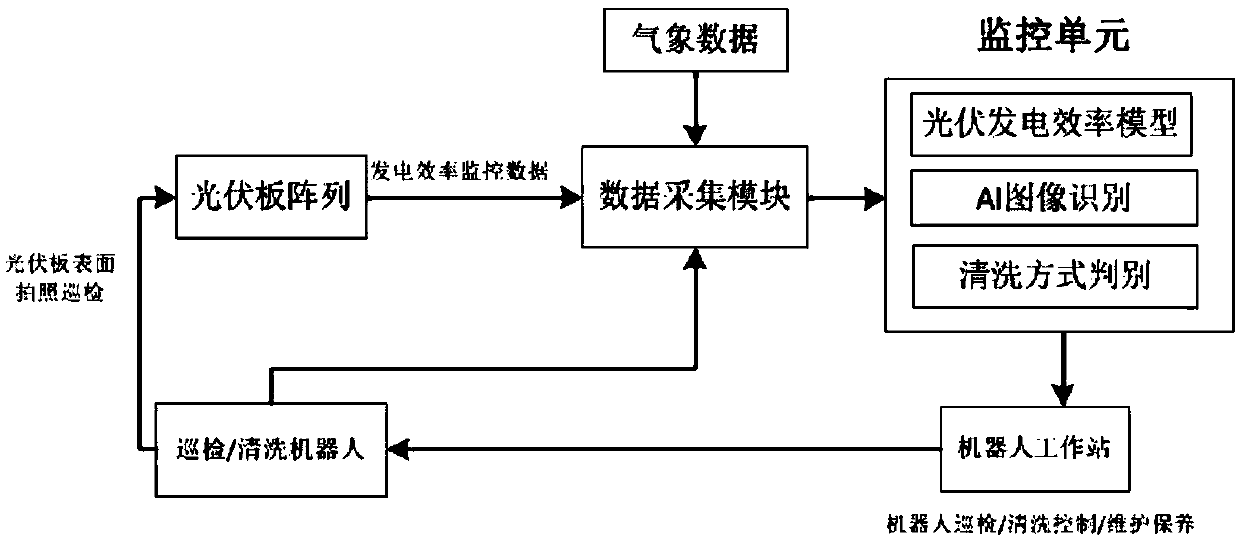

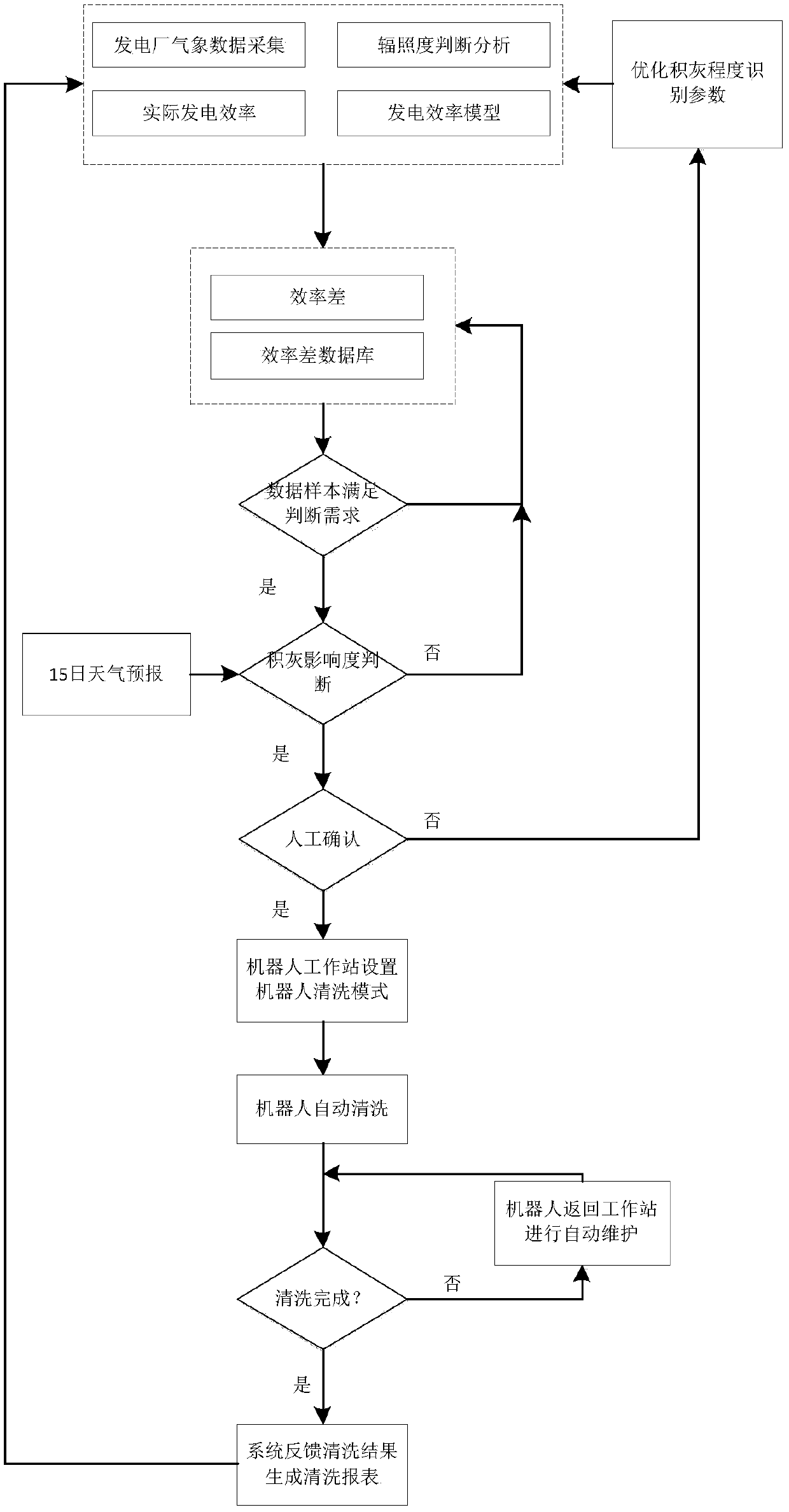

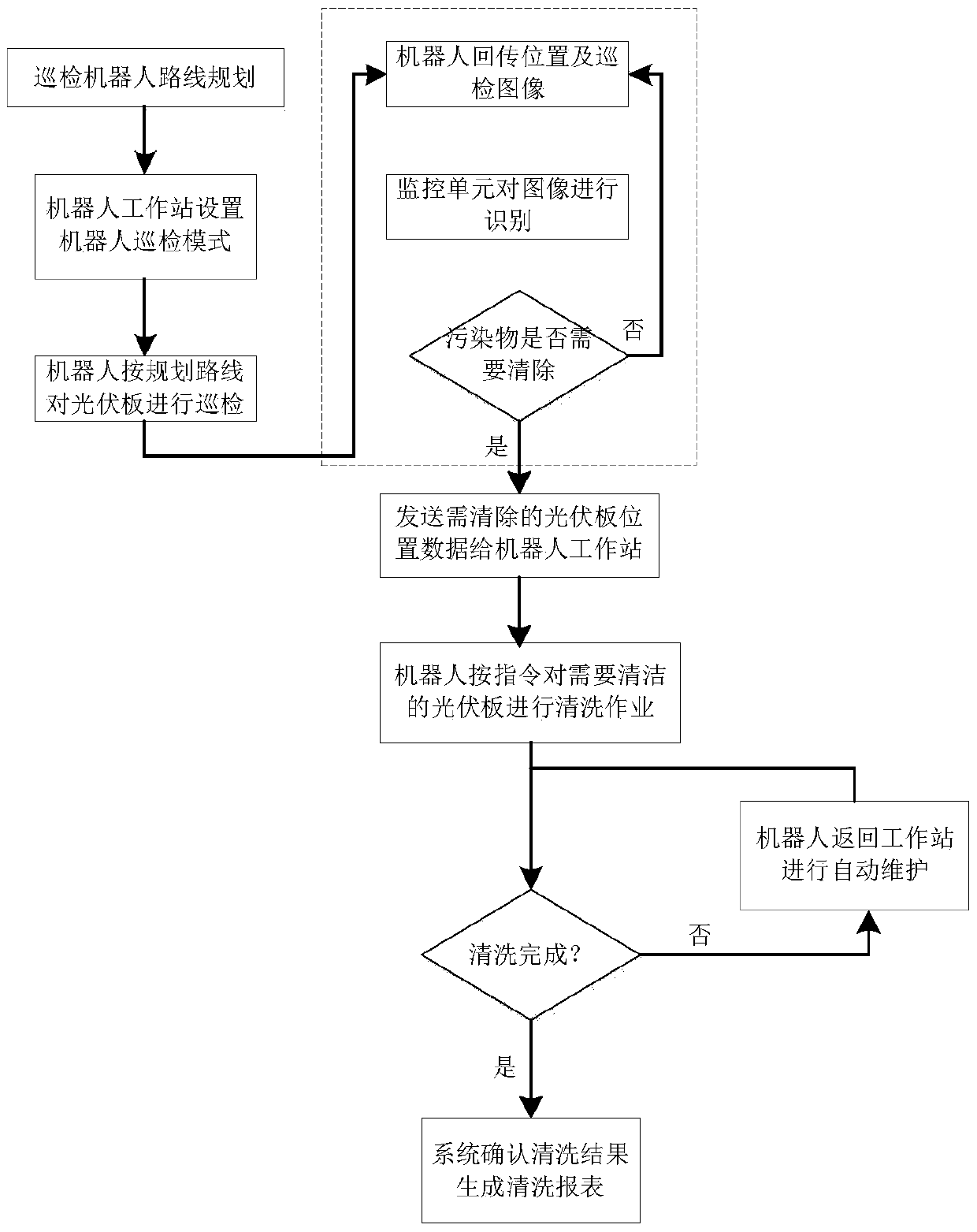

Intelligent control system and control method for cleaning of solar photovoltaic panel

InactiveCN109546954AExtend your lifeExtended cleaning cyclePhotovoltaicsTotal factory controlOperational costsData acquisition

The invention discloses an intelligent control system and control method for the cleaning of a solar photovoltaic panel, and belongs to the technical field of solar photovoltaics. The system is composed of a meteorological data module, a data acquisition module, a monitoring unit, a robot workstation and an inspection cleaning robot. The monitoring unit is used for collecting and recording a powergeneration current and the real-time meteorological data of a power plant and comparing the power generation current and the real-time meteorological data with a normal power generation efficiency attenuation model built in the system to obtain a real state that the accumulated dust affects the power generation efficiency. Through comparing the optimal cost operation data, an optimized scheme forcleaning the photovoltaic array is obtained, and the automatic cleaning robot is controlled to automatically clean the photovoltaic panel. Compared with the prior art, the system can automatically recognize local pollution of the photovoltaic panel and automatically clean he local pollution, can effectively prolong the overall cleaning period of a solar power plant, reduces the overall cleaning frequency, prolongs the service life of the photovoltaic panel, reduces the operation cost, optimizes the cleaning period, and achieves the optimization of the power generation efficiency and the operation cost.

Owner:YANGZHOU POLYTECHNIC INST

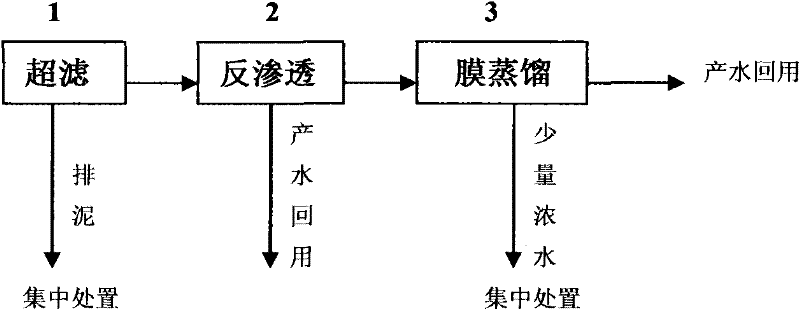

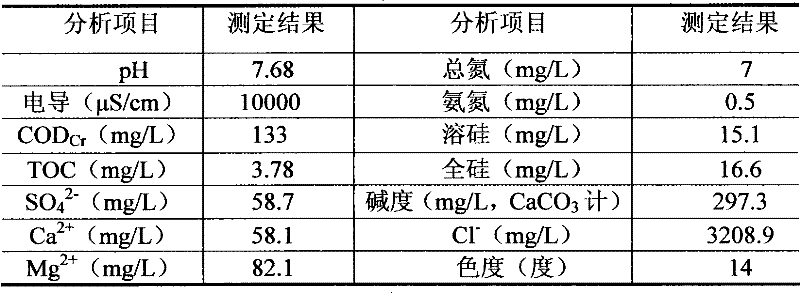

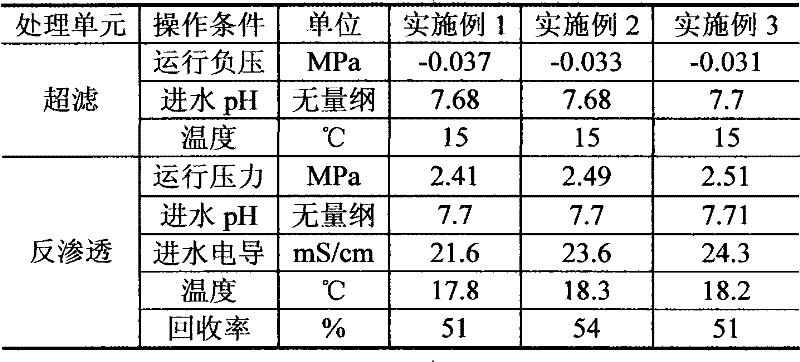

A kind of advanced treatment and reuse method of olefin polymerization catalyst production wastewater

ActiveCN102295377AHigh desalination rateEnhanced couplingGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisSocial benefitsUltrafiltration

The invention relates to an advanced treatment and reuse method of wastewater in olefin polymerization catalyst production. In the method, a coupled process flow comprising ultrafiltration, reverse osmosis and membrane distillation is adopted; by using the process flow, the advanced treatment and reuse of biochemical effluent of wastewater in the olefin polymerization catalyst production can be achieved; and produced water by reverse osmosis and membrane distillation of the biochemical effluent treated by the process flow of wastewater in the olefin polymerization catalyst production can meetthe process water requirement. According to the invention, the recovery rate of the whole system is up to above 90%, thereby realizing the reuse of the biochemical effluent of the wastewater in the olefin polymerization catalyst production and realizing the advanced treatment and reuse of high-salt sewage. Thus, the method provided by the invention has obvious social benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel high-strength HDPE (High-Density Polyethylene) composite tube and production method thereof

ActiveCN102996913AExtended service lifeInhibition of oxidative degradationRigid pipesCorrosion resistantOxidative degradation

The invention discloses a novel high-strength HDPE (High-Density Polyethylene) composite tube, which is obtained by composting an HDPE core tube, and a modified PE (Poly Ethylene) layer, wherein the innermost layer is the HDPE core tube which is enwrapped by a PE bonding layer, and the modified PE layer enwraps the PE bonding layer. The composite tube disclosed by the invention has the characteristics of good shock resistance, high compression strength, high wear resistance and the like. The HDPE core tube is corrosion resistant so that the composite tube is long in service life and capable of resisting the invasion by various corrosive media, such as an acid, an alkali and a salt, the modified PE layer is adopted so that plastic oxidative degradation is inhibited, tube ultra-violet resistance performance is improved, and tube service life is prolonged, and the PE bonding layer adopts a thermoplastic elastic body so that material performance is greatly improved, bonding capacity between the core tube and the modified PE layer is improved, and service life can reach 60 years.

Owner:HUBEI HUIFENG PLASTIC PIPE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com