Patents

Literature

193results about How to "Easy for industrial production and application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

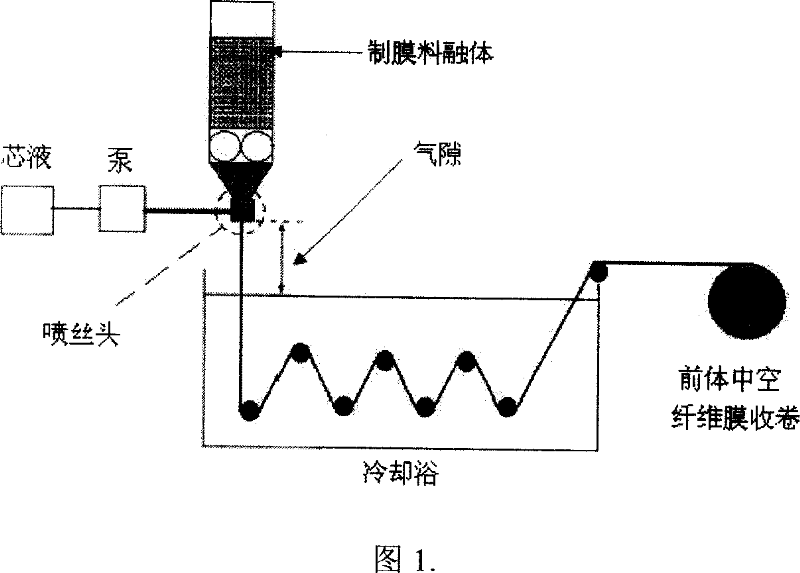

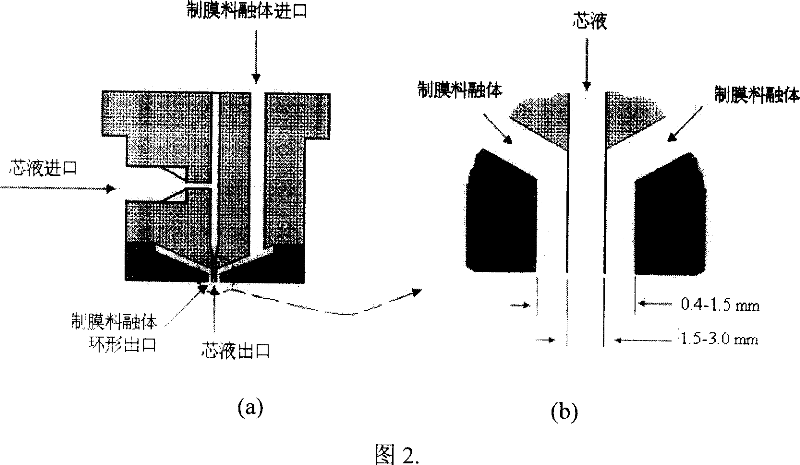

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

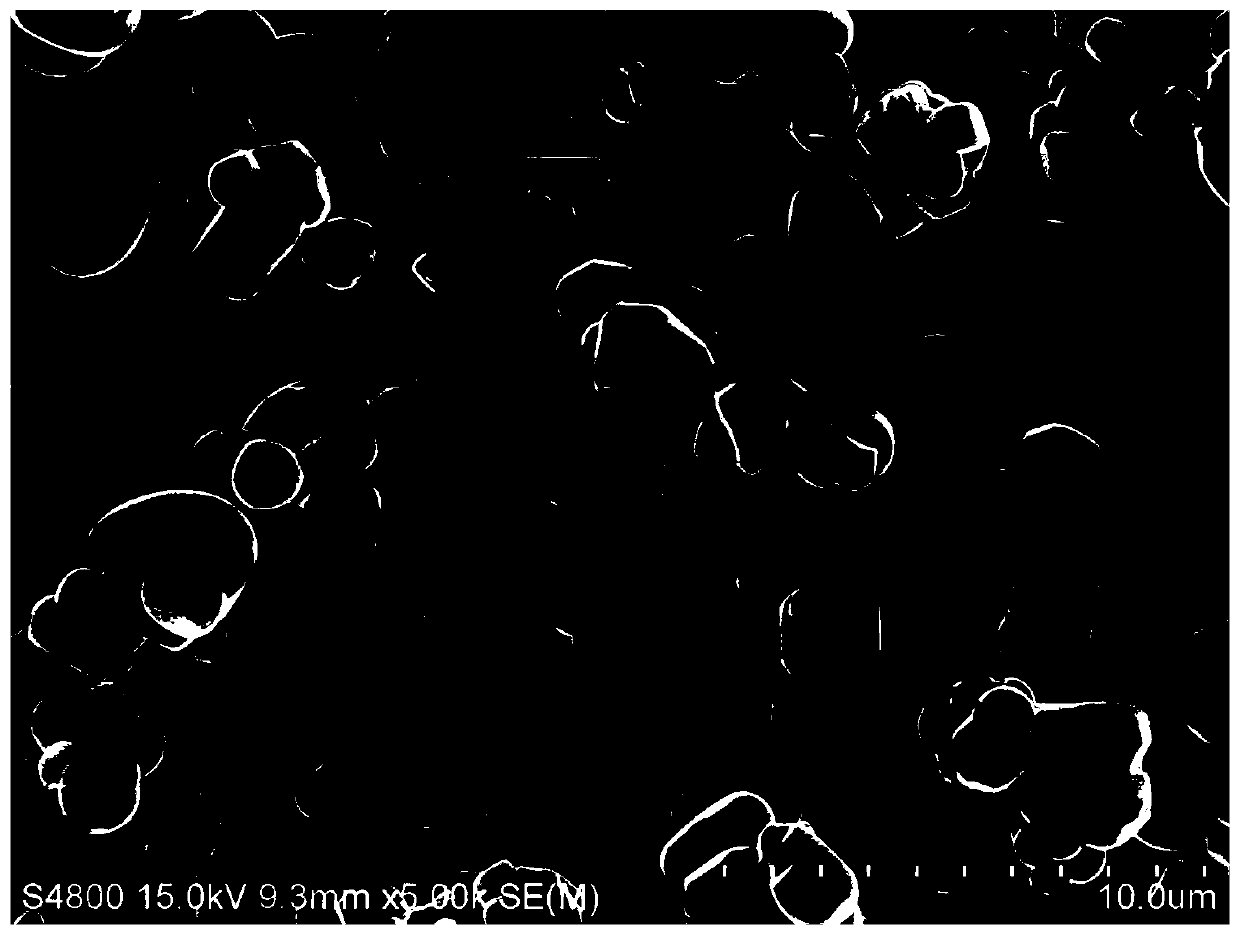

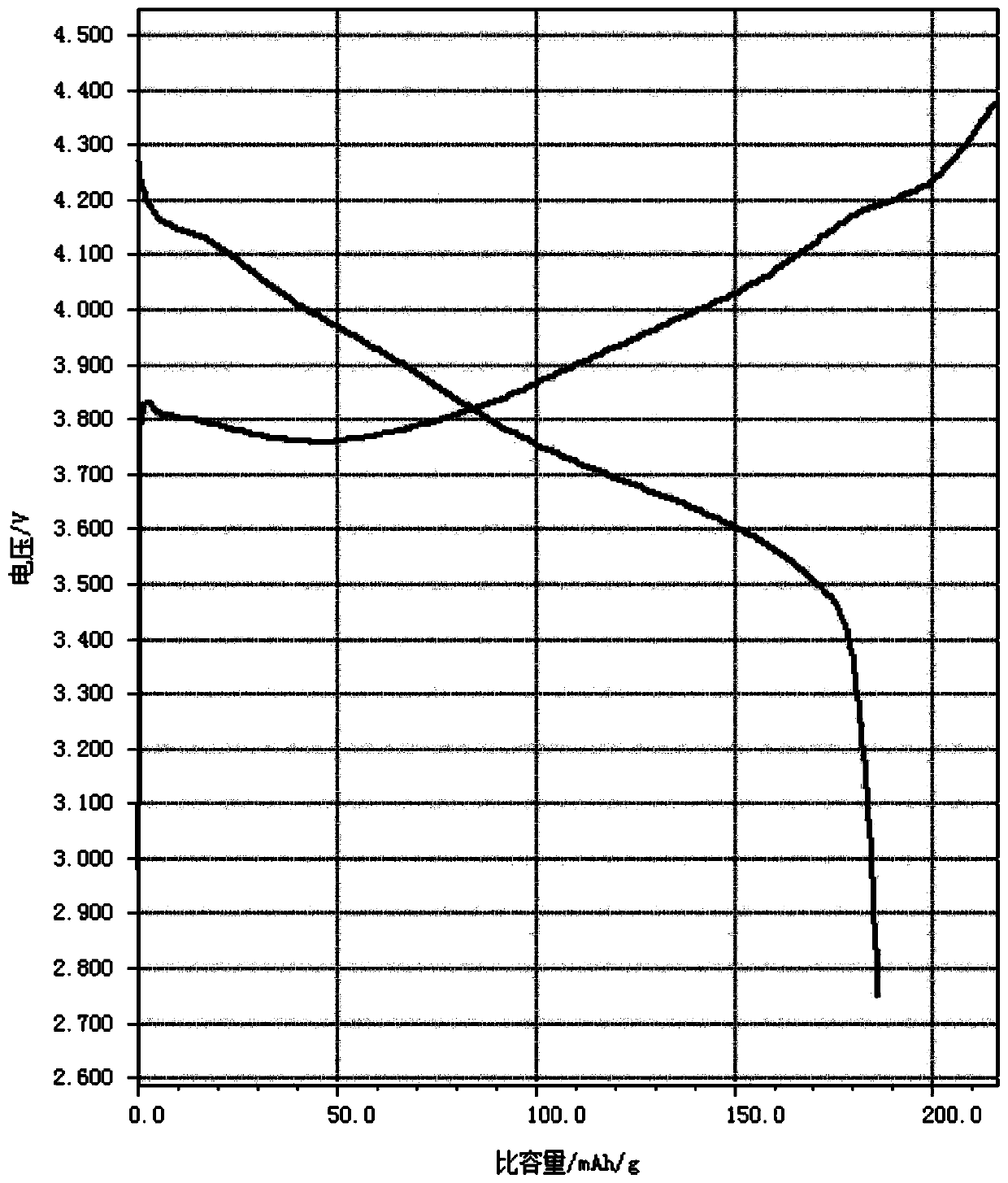

Sodium-titanium phosphate/carbon composite material and preparation method and use thereof

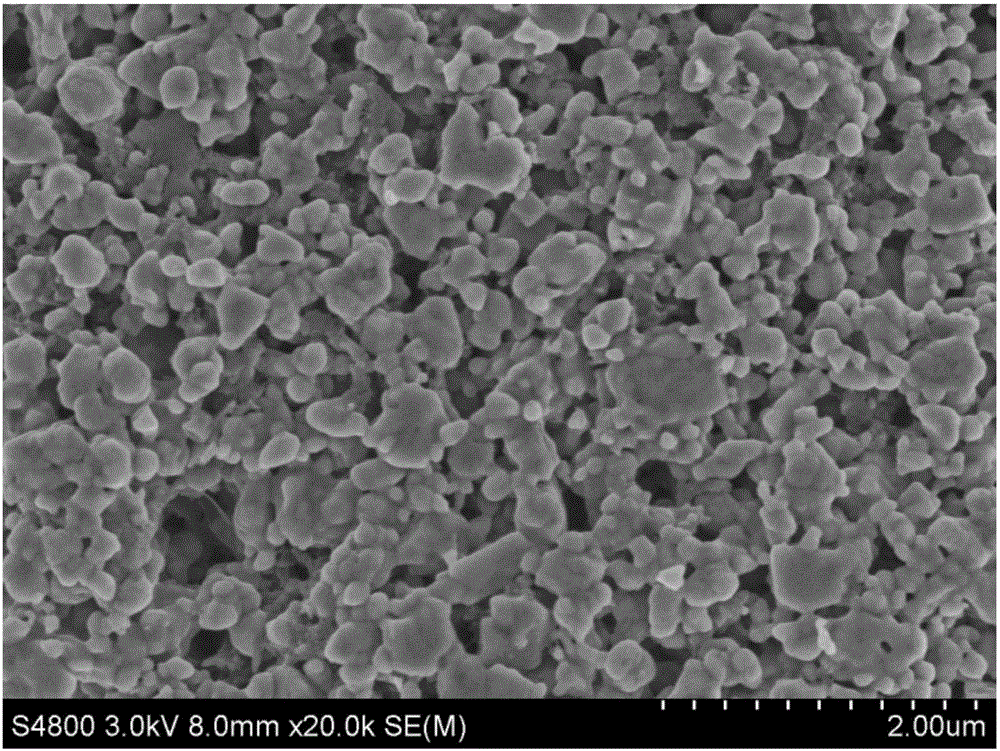

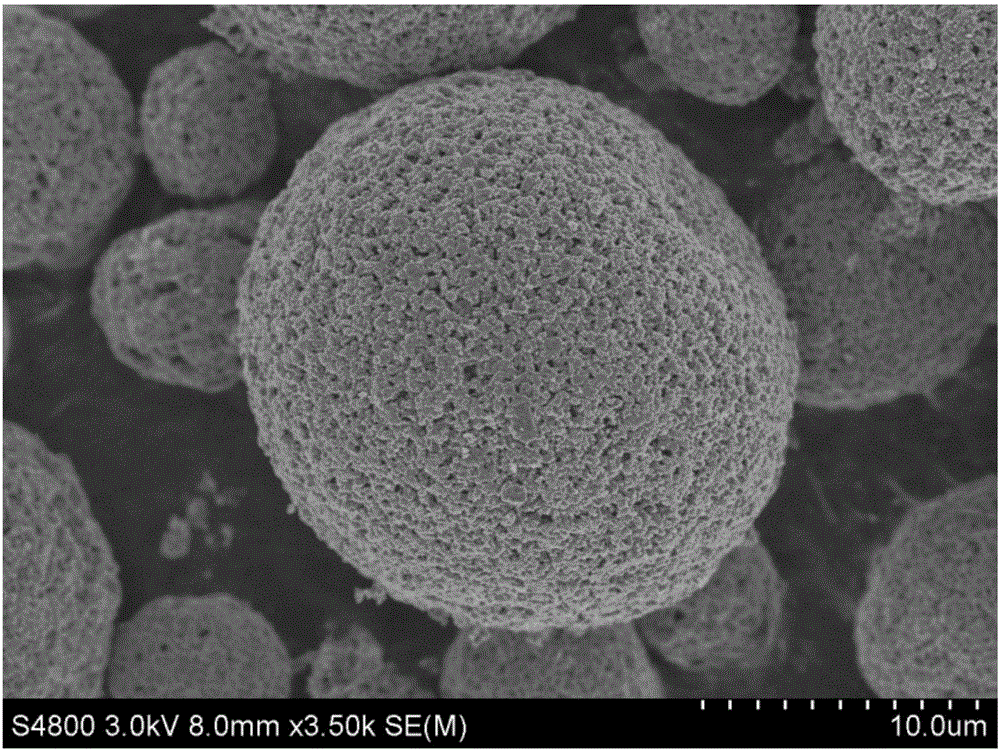

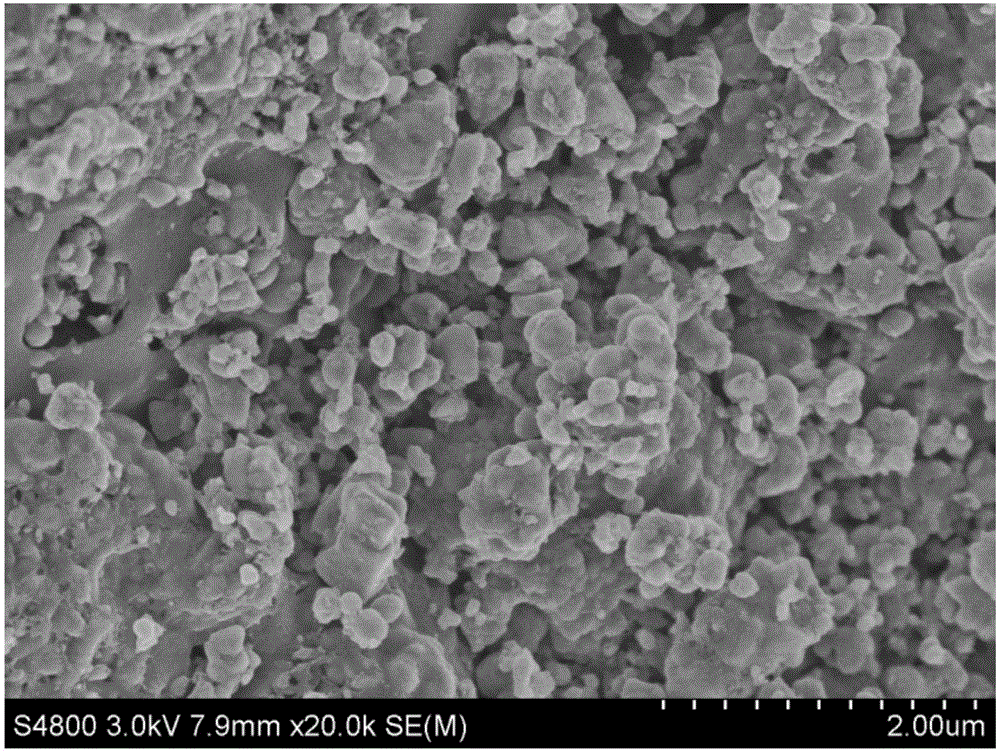

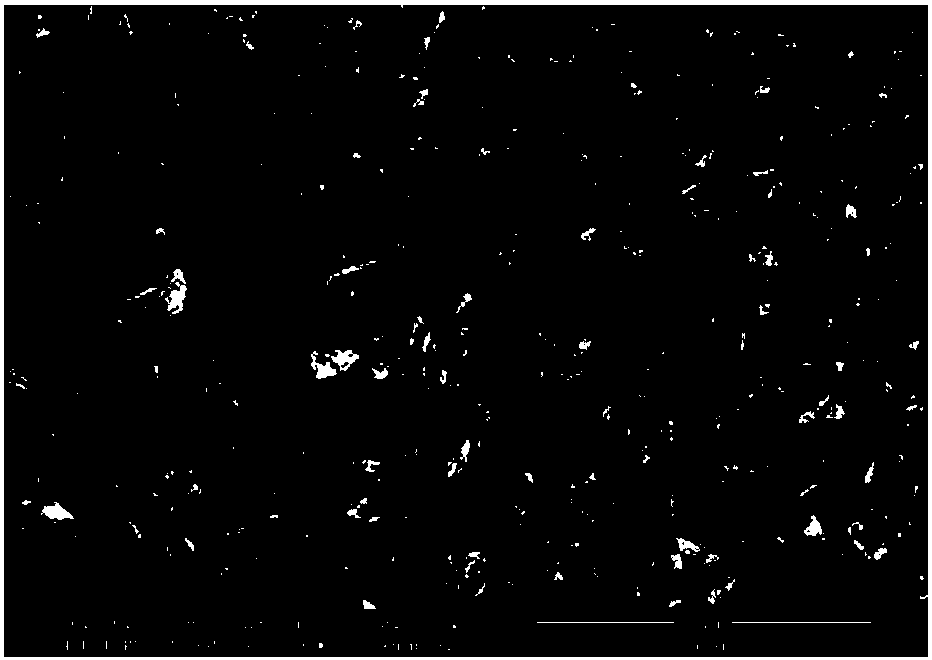

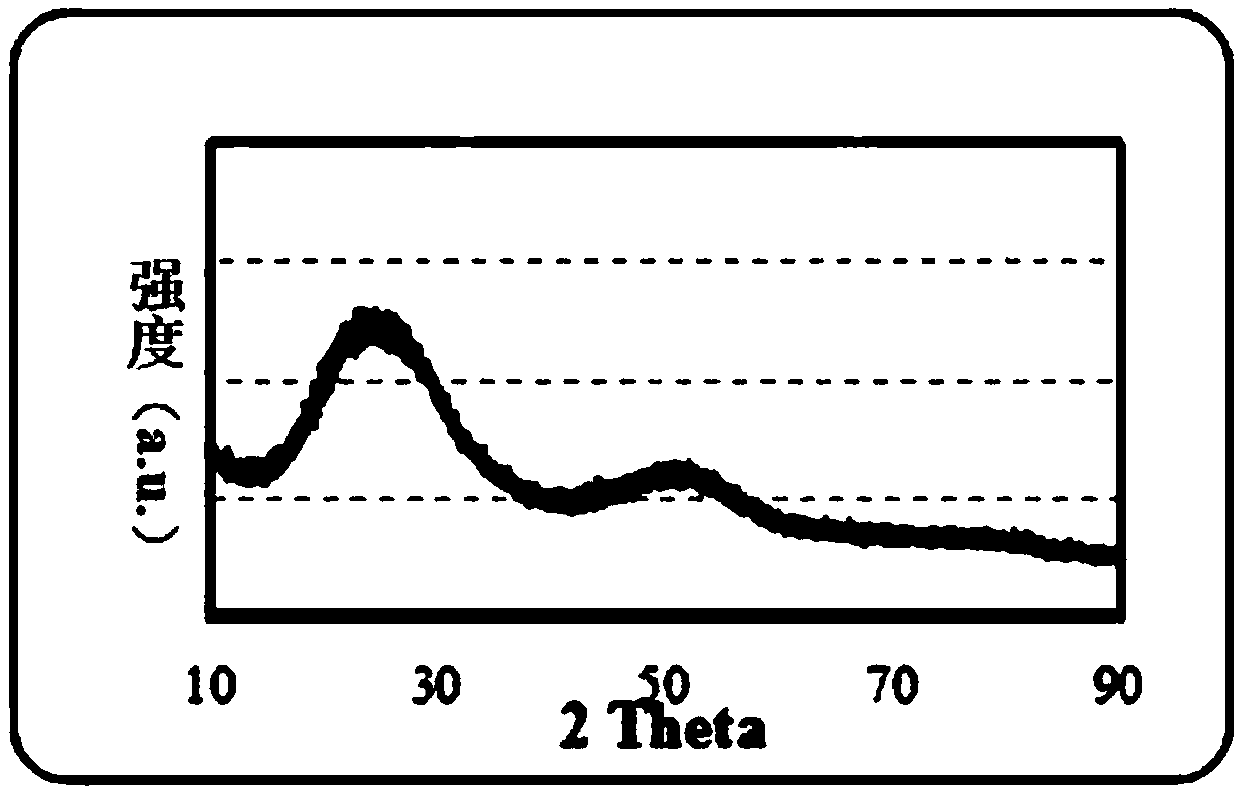

InactiveCN106784696AUneven solutionImprove uniformityCell electrodesSecondary cellsCarbon layerCarbon coating

The invention belongs to the field of electrode material synthesis, and relates to a sodium-titanium phosphate / carbon composite material and a preparation method and use thereof. The sodium-titanium phosphate / carbon composite material comprises secondary particles formed by clustering primary particles, the primary particles comprise sodium-titanium phosphate particles and carbon layers coated on the surfaces of the sodium-titanium phosphate particles, and the carbon layers are prepared through two times of carbon coating. According to the sodium-titanium phosphate / carbon composite material and the preparation method and use thereof, by means of preparing a precursor of the sodium-titanium phosphate and then adopting a spray drying method to carry out primary carbon coating and secondary carbon coating, the sodium-titanium phosphate / carbon composite material having a uniform and compact coating carbon layer is prepared, and the problem that the coating carbon layer obtained by the primary carbon coating is not uniform is solved. The composite material is good in stability, electrodes prepared from the sodium-titanium phosphate / carbon composite material and assembled batteries have excellent electrochemical properties, the discharge capacity is above 115mAh / g, and the capacity retention ratio is above 95% after 500 weeks of circulation.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Conductive polymer-carbon coated silicon oxide composite material and preparation method thereof

ActiveCN107658455AWide range of temperature selectionUniform covering structureCell electrodesSecondary cellsSilane couplingCarbon source

The invention discloses a conductive polymer-carbon coated silicon oxide composite material and a preparation method thereof. The conductive polymer-carbon coated silicon oxide composite material comprises a conductive polymer, a silane coupling agent, carbon and silicon oxide, wherein the carbon is directly coated on a surface of a silicon oxide particle, the silane coupling agent is absorbed toa surface of the carbon, and the conductive polymer is embedded into carbon gaps and also is uniformly coated on the surface of the carbon by a bridge chain effect of the silane coupling agent. The preparation method of the conductive polymer-carbon coated silicon oxide composite material comprises three steps of highly mixing the silicon oxide and a carbon source, performing high-temperature sintering (curing and carbonization) and coating the polymer. The prepared composite material is very uniform in coating structure and has relatively low volume expansion effect and excellent electrochemical performance, the initial charge-discharge efficiency can be obviously improved, and particularly, relatively poor cycle property of a silicon oxide negative electrode material is improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of cannabinol compound

ActiveCN106860492AResidue reductionEasy to industrializeNervous disorderPlant ingredientsUltrasonic assistedOrganic solvent

The invention discloses a preparation method of a cannabinol compound. The method comprises the following steps: screening industrial cannabis plant materials; drying and carrying out ultra-micro pulverization; putting the materials into an ultrasonic extraction device with a stirring function; adding a weak-polar or non-polar organic solvent and weak acid, and carrying out ultrasonic assisted extraction; filtering and adding active carbon in filtrate; filtering and evaporating to remove the solvent so as to obtain extractum of industrial cannabis extract; sufficiently dissolving the extractum by adopting a high-polar organic solvent; freeing, sealing, filtering and evaporating to remove the solvent, so as to obtain a primary product of the industrial cannabis extract; stirring the primary product and slowly adding an alkali solution; centrifuging and filtering; slowly adding an acid solution into filtrate; separating to obtain an industrial cannabis extract product containing the rich cannabinol compound. The method disclosed by the invention has the advantages of high extraction efficiency, low cost, few product impurities, small pollution and easiness of being industrially realized.

Owner:上海阿尔福斯医药科技有限公司

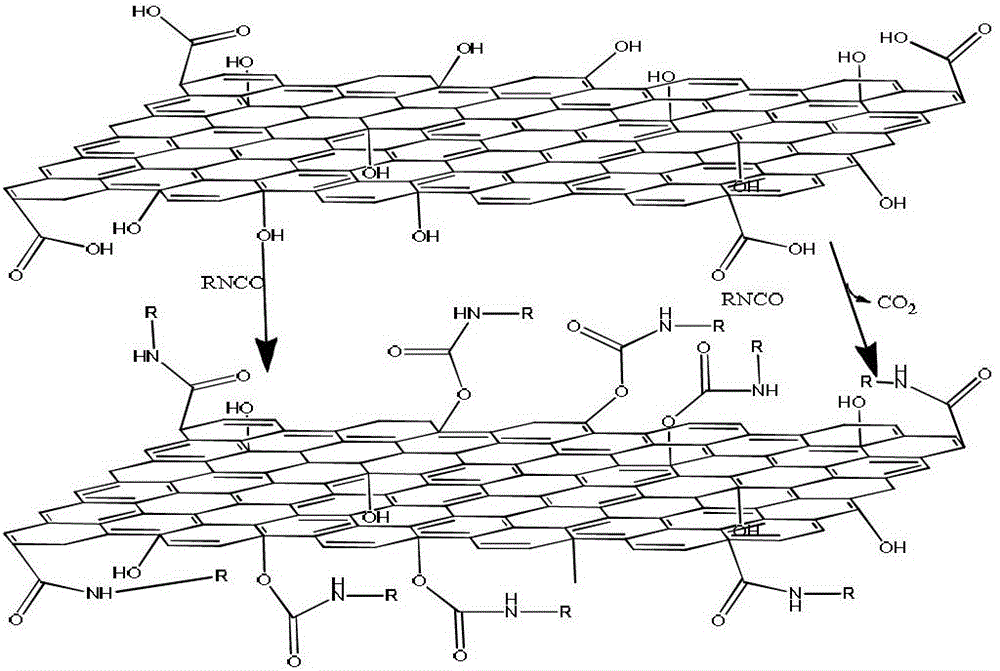

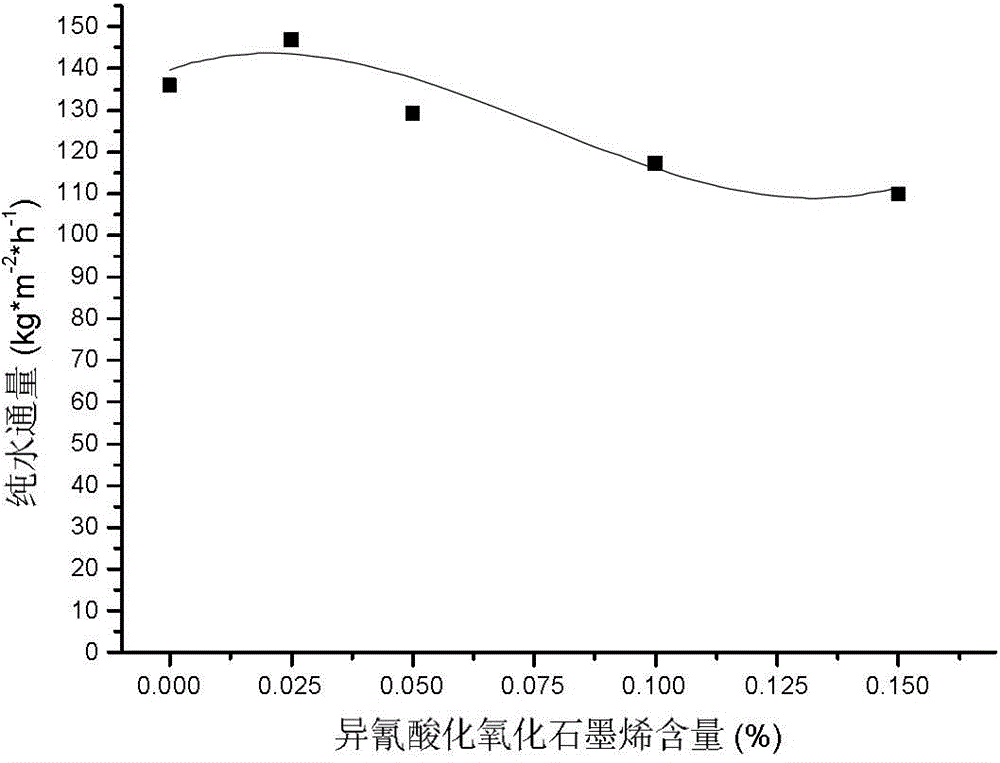

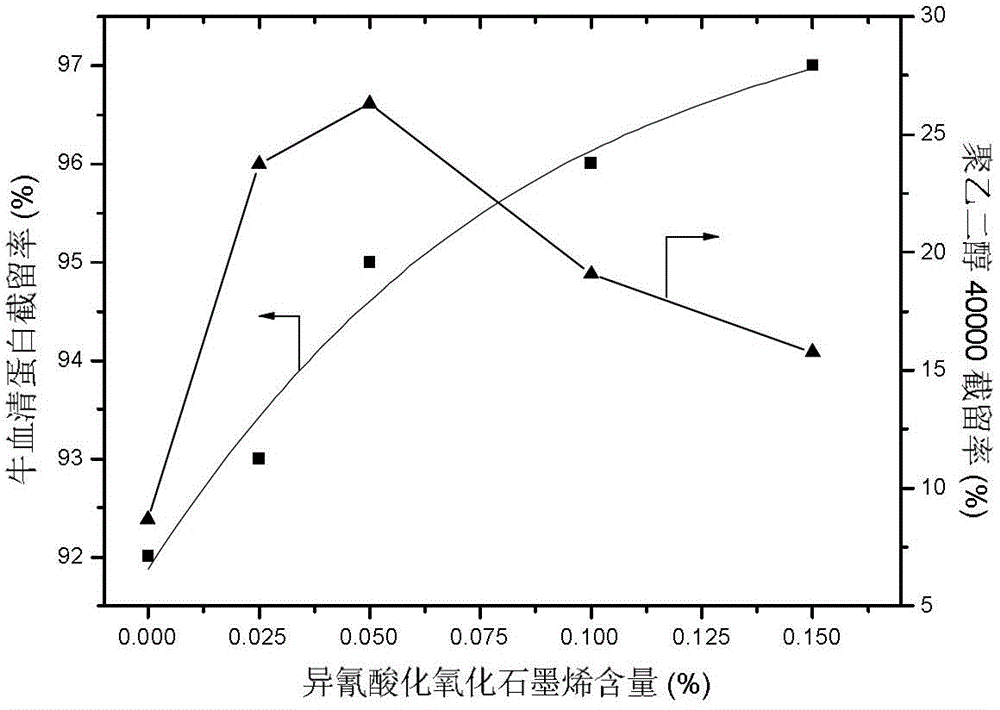

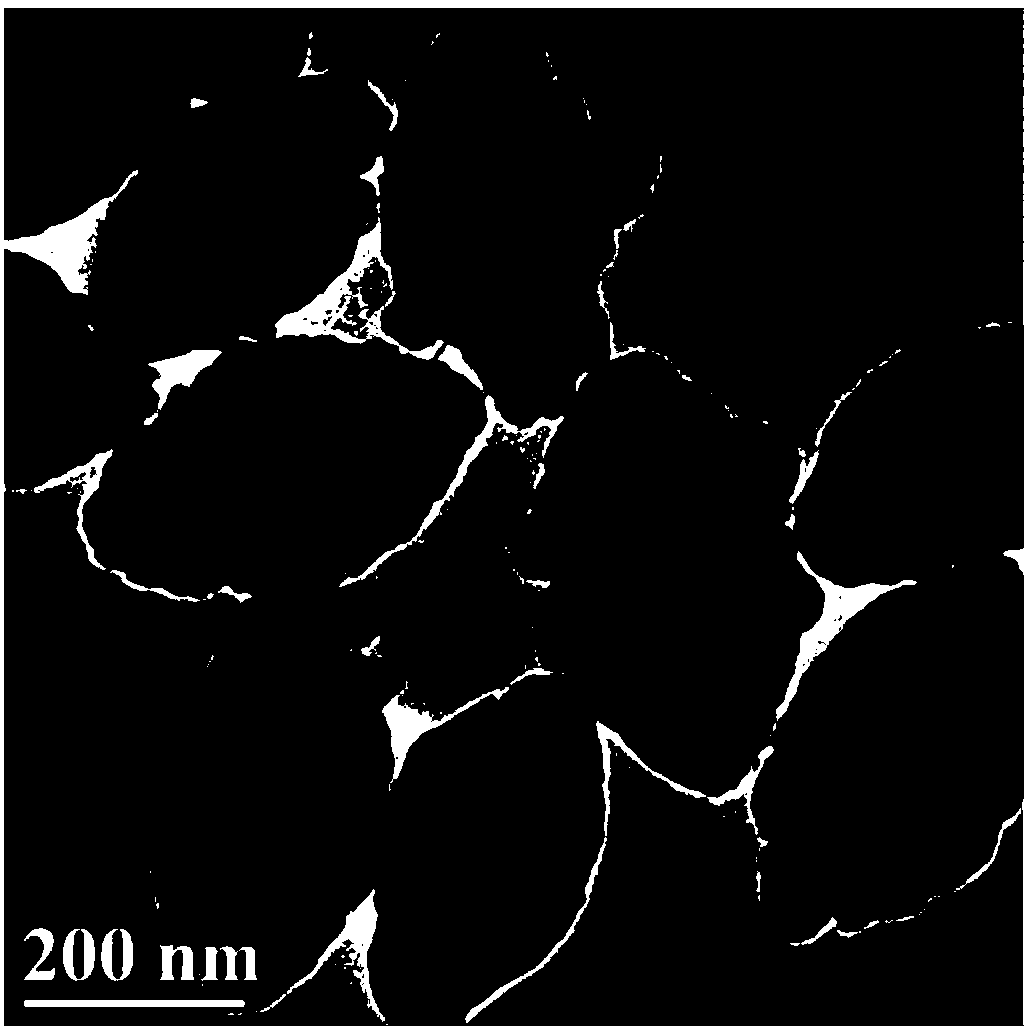

Preparation method of ultrafiltration membrane for improving antibacterial property and anti-fouling performance through modified graphene

InactiveCN102974237AImprove antibacterial propertiesIncrease the ability to resist other pollutionSemi-permeable membranesOrganic solventUltrafiltration

The invention discloses a preparation method of an ultrafiltration membrane for improving antibacterial property and anti-fouling performance through modified graphene. The preparation method comprises the following steps in sequence: modifying graphene; drying; adding an organic solvent in modified graphene; dispersing and treating uniformly; adding a membrane additive and a membrane material and uniformly mixing, so as to obtain the membrane casting solution; defoaming the membrane casting solution under vacuum; pouring the membrane casting solution on the surface of a dried and flat plate; stably and quickly scrapping through a membrane scraper; and transferring to gel solution, so as to obtain the ultrafiltration membrane. According to the preparation method, the modified graphene is added, so that the antibacterial property of the ultrafiltration membrane is improved, the application value is high, and the capacities of resisting other pollutions are improved to a certain extent; the modified graphene can be uniformly dispersed into the solvent or the membrane casting solution well, so that the contact and the compatibility of the modified graphene and the membrane can be greatly improved, and more benefits are provided for realizing the characteristics of the modified graphene; and the graphene serving as the raw material is convenient to prepare, and the graphene modification method is simple and easy for industrial production and application.

Owner:ZHEJIANG UNIV

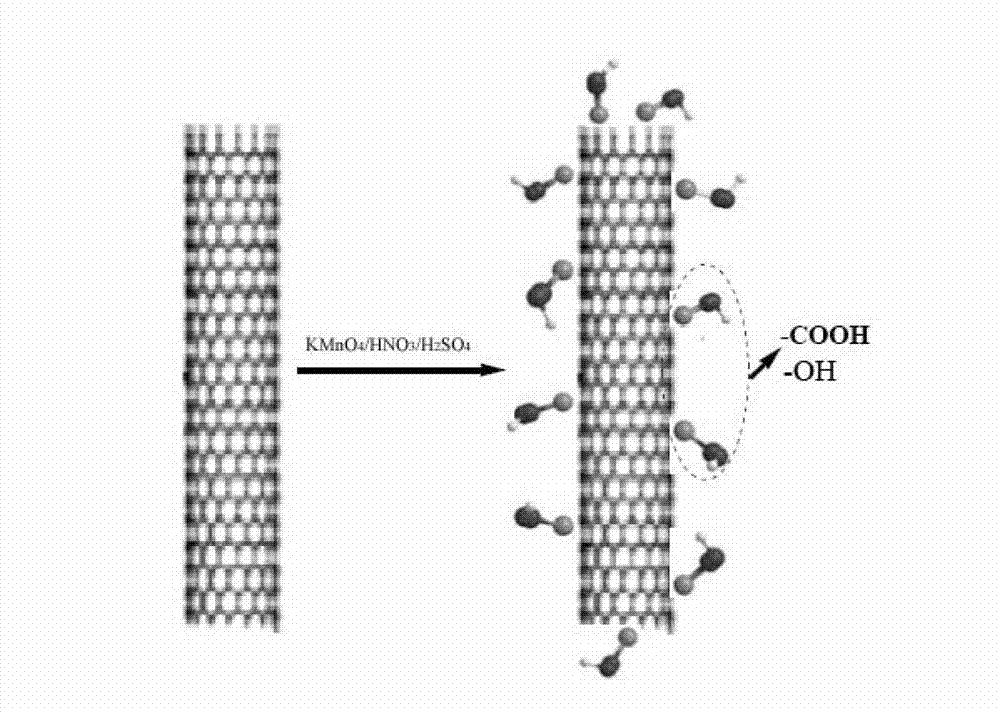

Preparation method of ultrafiltration membrane with enhanced antibacterial property by using modified carbon nanotubes

ActiveCN102961981AModification is simple and easyInhibition of biological contaminationSemi-permeable membranesOrganic solventUltrafiltration

The invention discloses a preparation method of an ultrafiltration membrane with enhanced antibacterial property by using modified carbon nanotubes. The preparation method comprises the following steps of: modifying carbon nanotubes; drying; adding an organic solvent into the modified carbon nanotubes; dispersing the modified carbon nanotubes in the organic solvent uniformly; adding a membrane additive and membrane materials; blending uniformly to obtain a membrane casting solution; pouring the membrane casting solution to the surface of a flat plate after vacuum defoaming; scraping stably and rapidly with a scraper; and placing the flat plate in a gel phase to obtain the ultrafiltration membrane. The addition of the modified carbon nanotubes can be used for improving the antibacterial property of the ultrafiltration membrane, and improving the resistance of the ultrafiltration membrane to other pollutants to a certain extent, so that the ultrafiltration membrane has wide application value. The preparation method provided by the invention is simple and easy to apply in industrial production.

Owner:ZHEJIANG UNIV

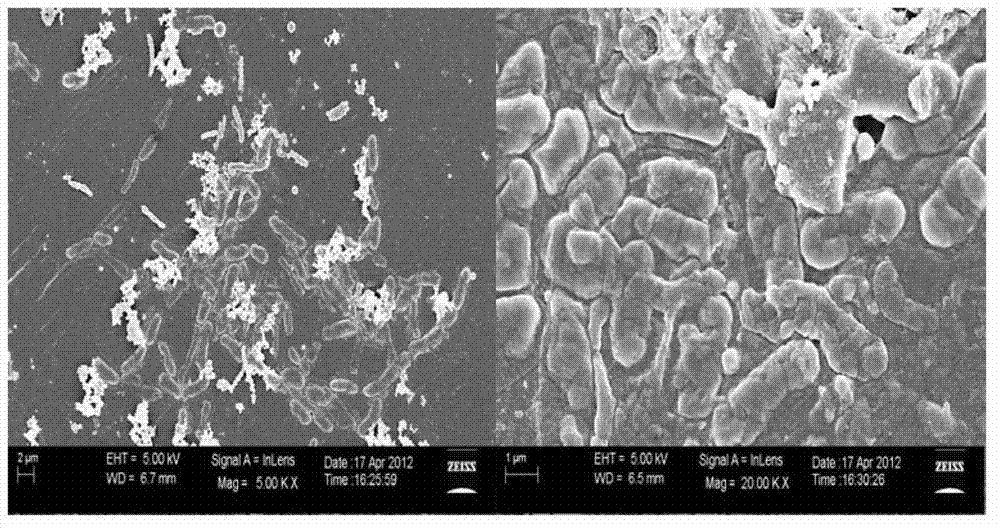

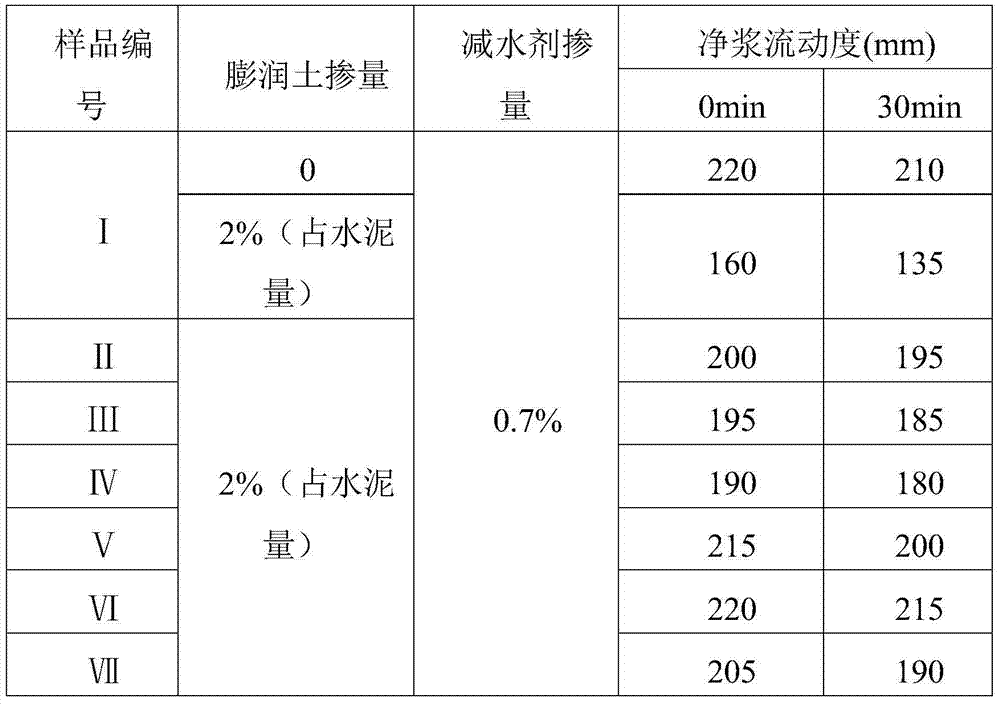

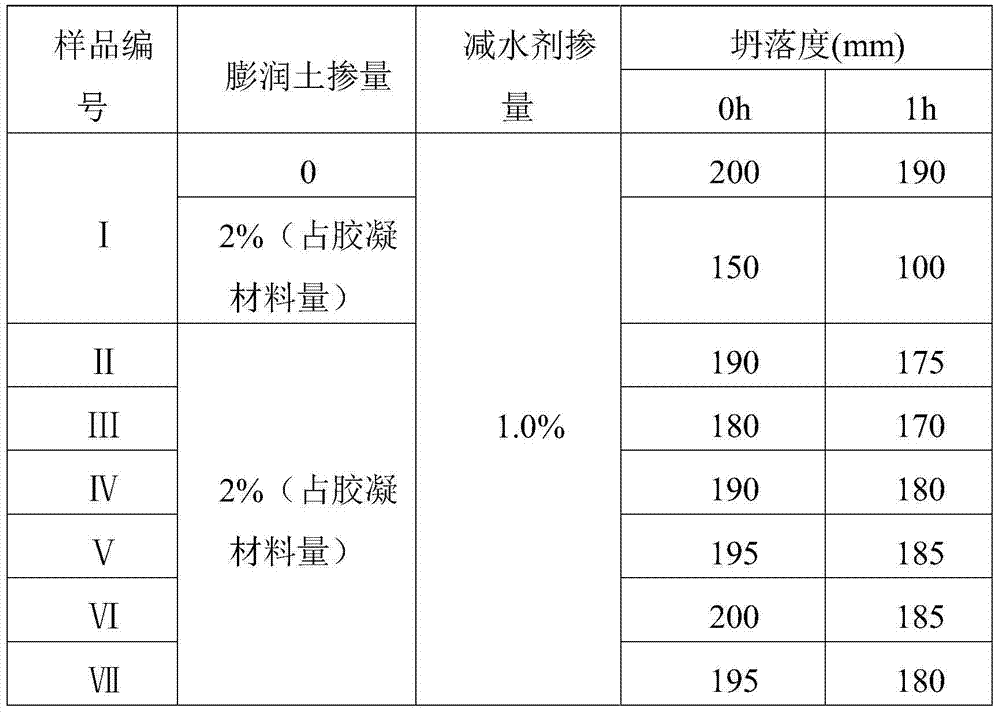

Treating agent for inhibition of harm of montmorillonite clay to concrete and using method thereof

The invention discloses a treating agent for inhibition of harm of montmorillonite clay to concrete and a using method thereof, and the treating agent belongs to the technical field of concrete additives, is used for inhibition of harm of the montmorillonite clay to concrete with a poly carboxylic acid doped water reducing agent, and solves the problem of complex technology, high cost, and bad effect of technological means in the prior art. The treating agent for inhibition of harm of montmorillonite clay to concrete comprises the following components by mass: 25%-35% of an intercalation adsorbent, 45%-55% of a dispersing agent and 10%-25% of a stabilizer. When in use, the dosage of the treating agent for inhibition of harm of montmorillonite clay to concrete is 0.01% to 0.03% of the dosage of a cementitious material in the concrete. The treating agent can effectively reduce the poly carboxylic acid doped water reducing agent adsorption of the montmorillonite clay, improves concrete performance, and has the advantages of simple preparation process, small dosage, and low cost of production and use.

Owner:SHANGHAI CONSTRUCTION GROUP

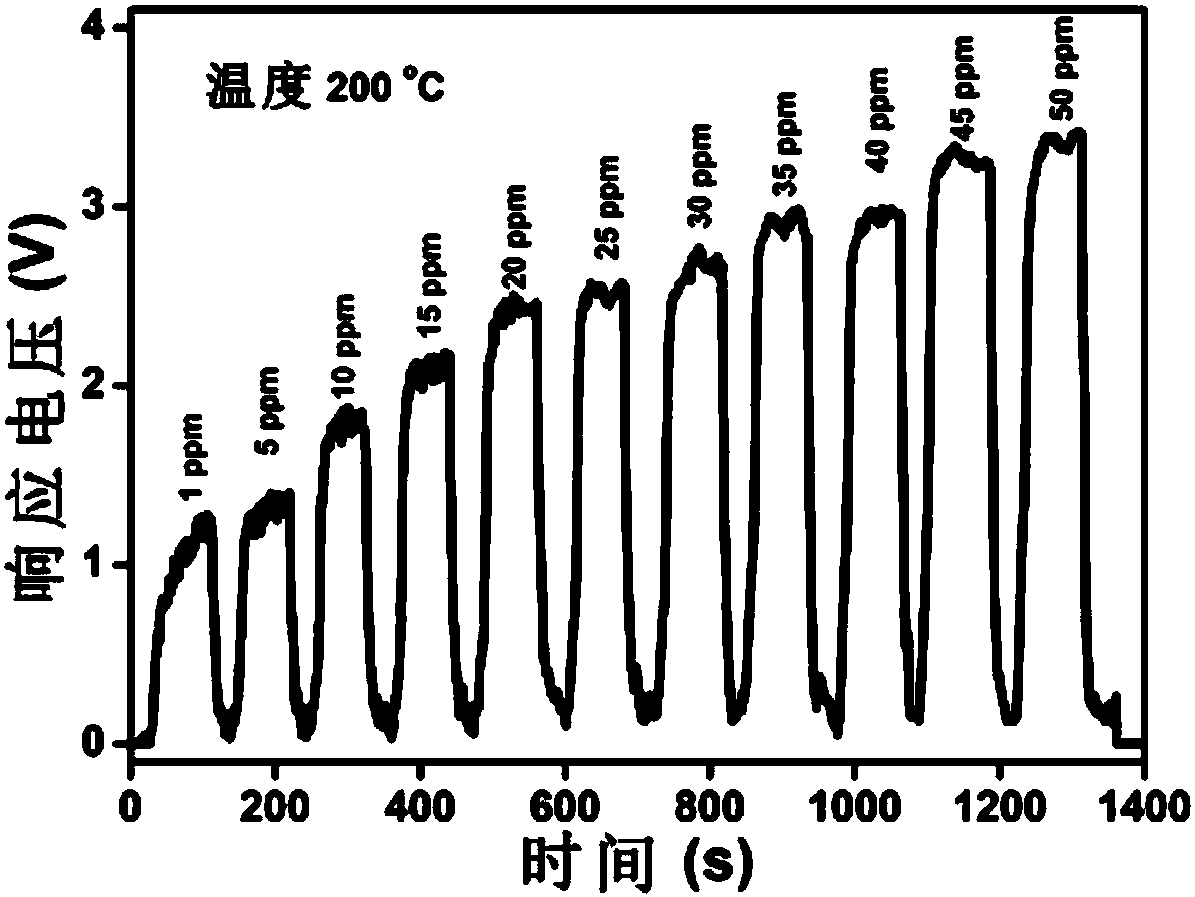

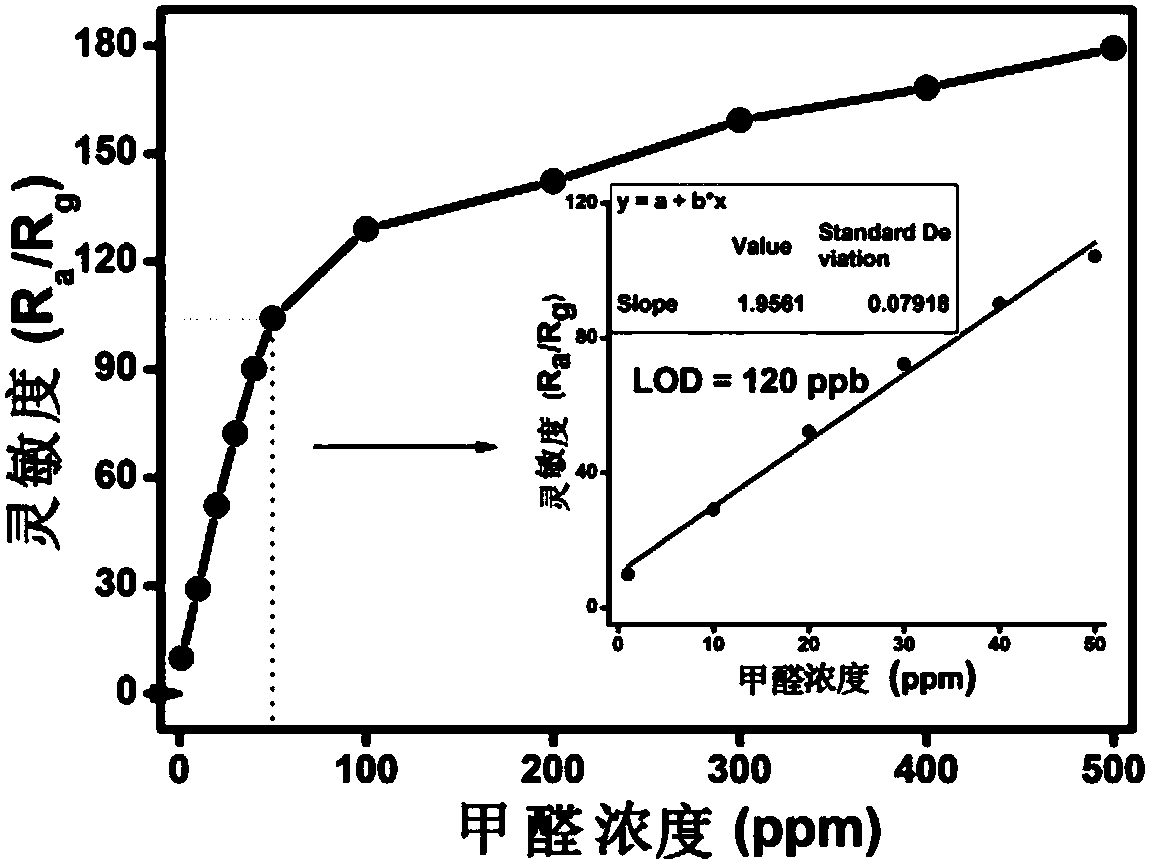

Nickel-doped tin oxide nano-material, formaldehyde gas sensor, and preparation method

ActiveCN107827150ASimple preparation processExtensive sources of raw materialsMaterial analysis by electric/magnetic meansNickel oxides/hydroxidesTin dioxideMetallic Nickel

The invention discloses a nickel-doped tin oxide nano-material which includes nickel-doped tin dioxide nano-particles, wherein atomic number percentage of doped nickel is 0.1-10%, and the particle size of the nano-particles is not more than 250 nm, the surfaces of the nano-particles are rough ellipsoid shaped. The invention also provides a preparation method and an application of the nickel-dopedtin oxide nano-material, and provides a formaldehyde gas sensor comprising the same, and a preparation method and an application thereof. The nickel-doped tin oxide nano-material and the nickel-dopedtin oxide-based formaldehyde gas sensor have high responding speed and sensitivity, good selectivity, low work temperature, ultra-low detection limit and good long-time stability.

Owner:SHANGHAI JIAO TONG UNIV

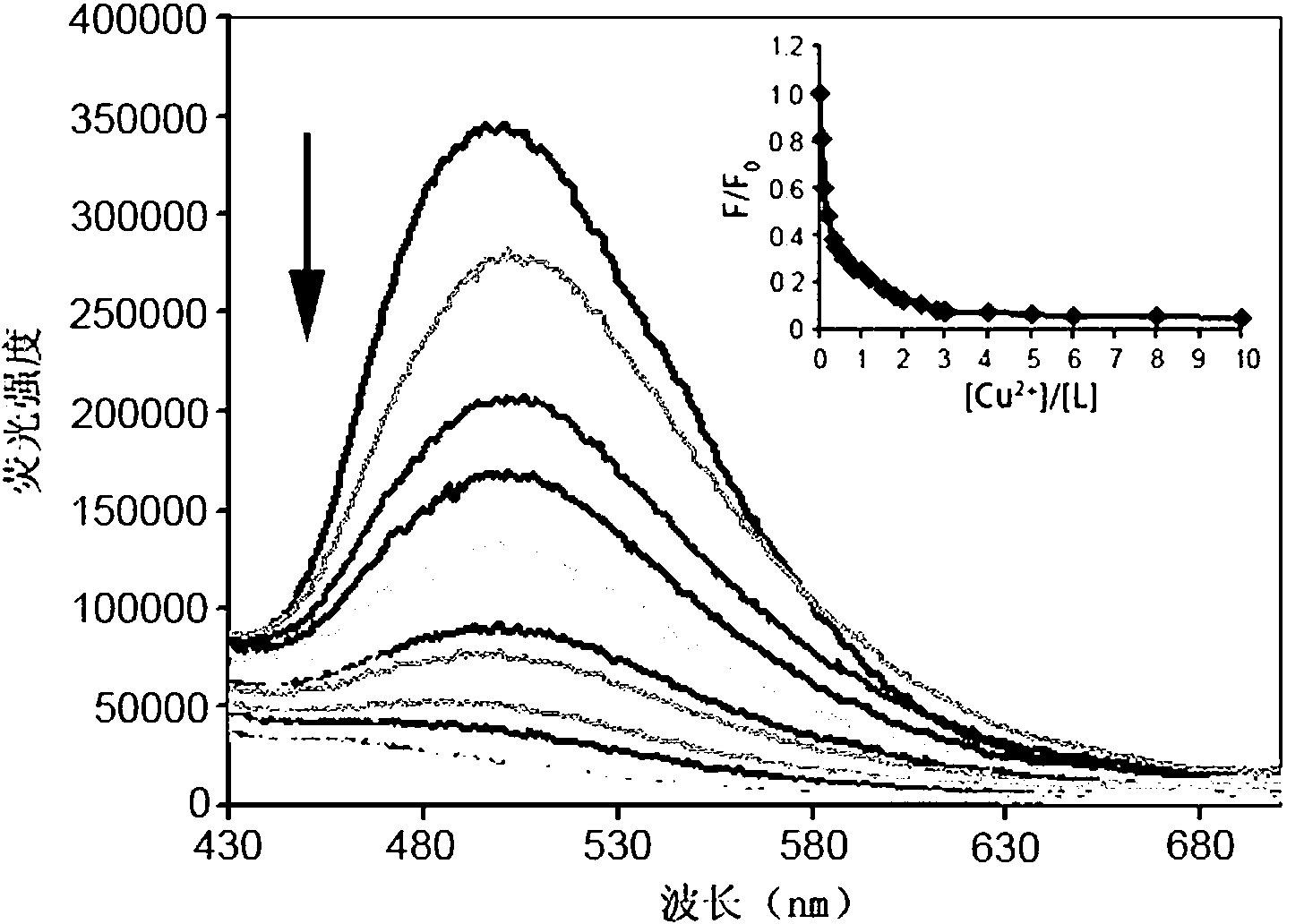

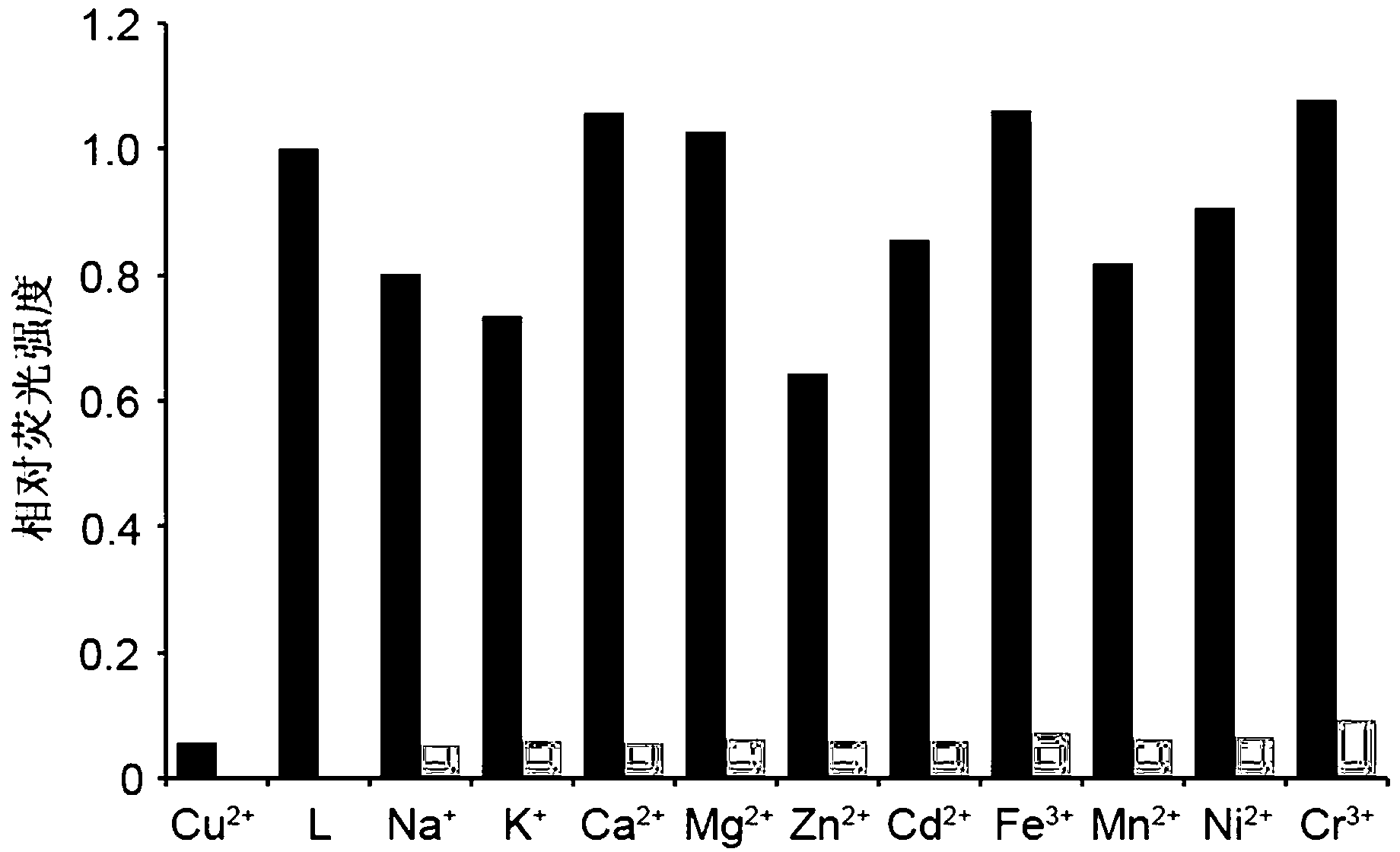

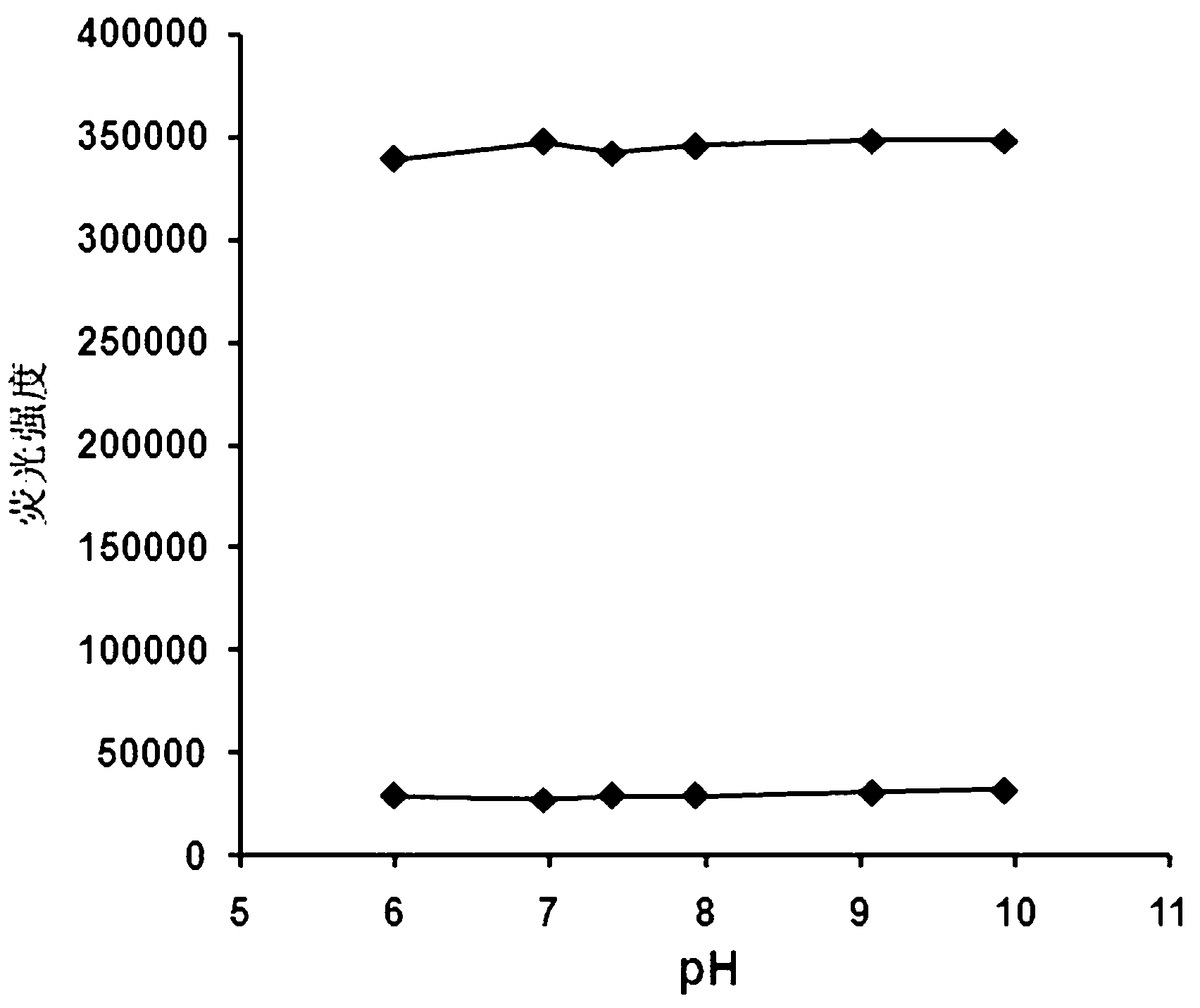

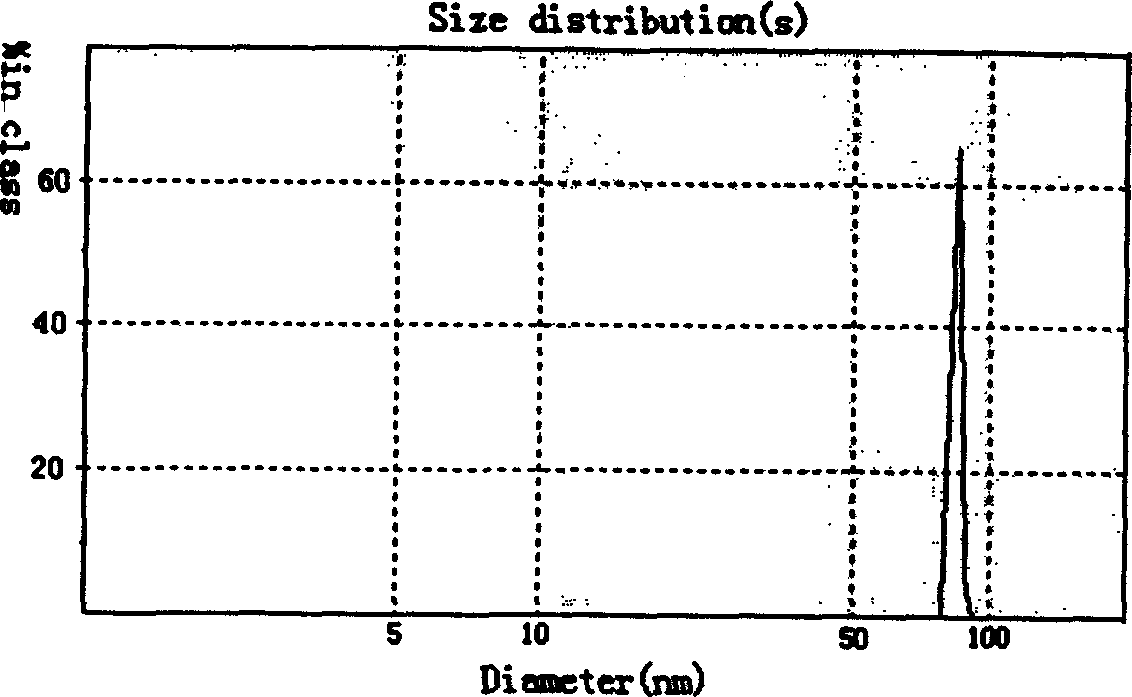

C3 symmetrical fluorescent molecular probe as well as preparation method and application thereof

InactiveCN103242826AEnhanced redshiftTo achieve specific identificationOrganic chemistryFluorescence/phosphorescenceCu2 ionsMolecular probe

The invention discloses a C3 symmetrical fluorescent molecular probe as well as a preparation method and application thereof and belongs to the technical field of metal ion analysis and detection. A structural formula of the C3 symmetrical fluorescent molecular probe is good in selectivity and high in sensitivity, is applied to a fluorescence sensor, can be used for specifically identifying copper ions and cadmium ions and is beneficial to analysis and detection of the copper ions and the cadmium ions in environment. The C3 symmetrical fluorescent molecular probe has the advantages that the preparation method is simple, the yield is high, the reproducibility is good, raw materials are easily obtained, and the cost is low, industrial production is facilitated and application prospect is good.

Owner:ZHENGZHOU UNIV

Nanometer modified epoxy powder coating preparation process

InactiveCN1546585AEnhance aggregation abilityLow costPowdery paintsEpoxy resin coatingsEpoxyNanometre

The invention discloses a nanometer modified epoxy powder coating preparation process comprising, dissolving epoxy resin into 1-2 times mass of acetone, charging 1%-15% mass fraction of nano particles based on epoxy resin, dispersing the system with ultrasonic wave 15-300 minutes while mechanically agitating, removing acetone through decompression to obtain nano modified epoxy resin, carrying out molten extrusion into in bolt extrusion machine, pressing into sheets or strips by means of tablet press machine.

Owner:宁波市鄞州东海粉末涂料有限公司

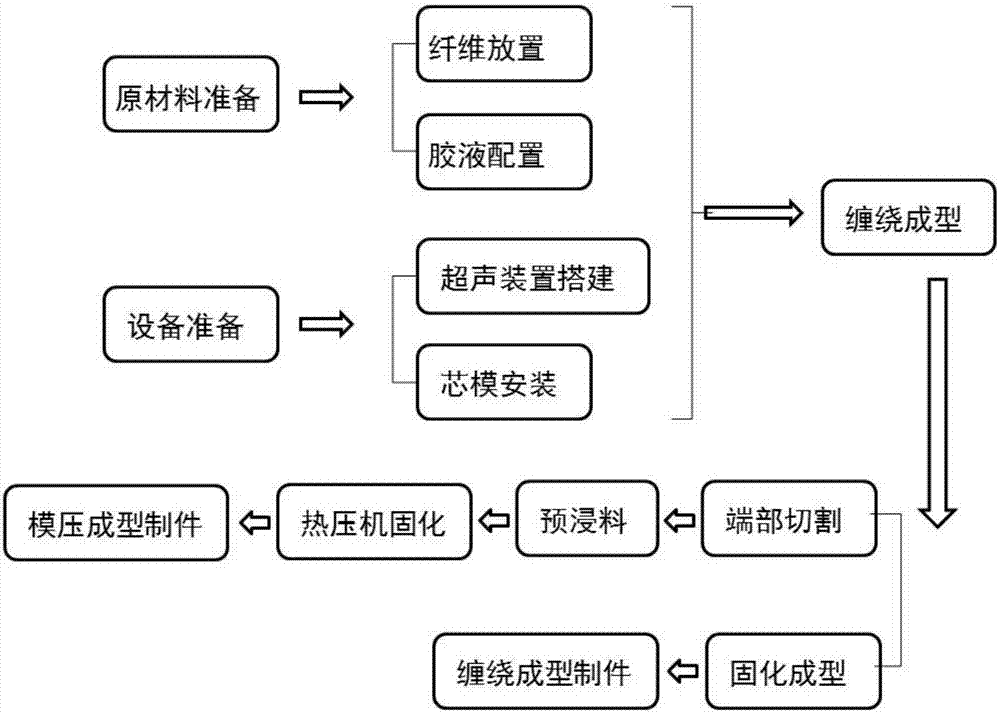

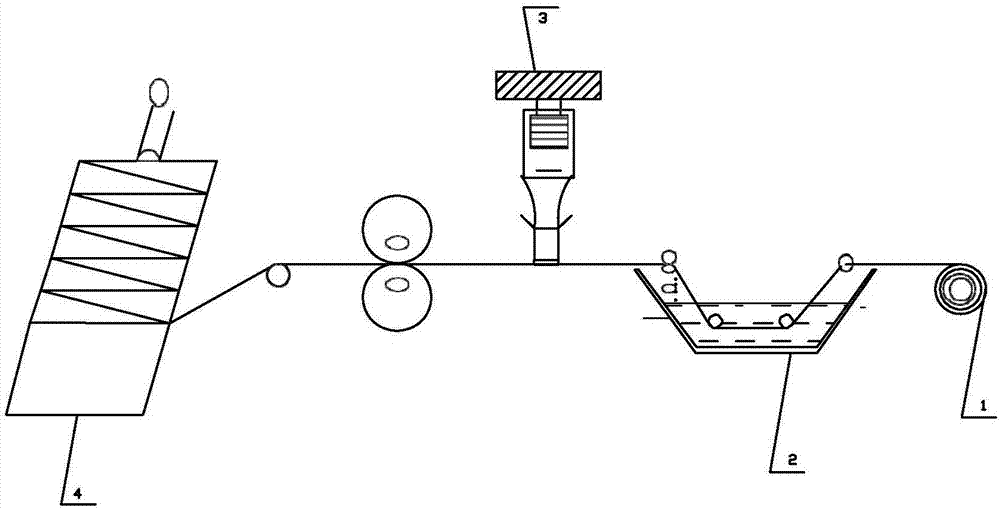

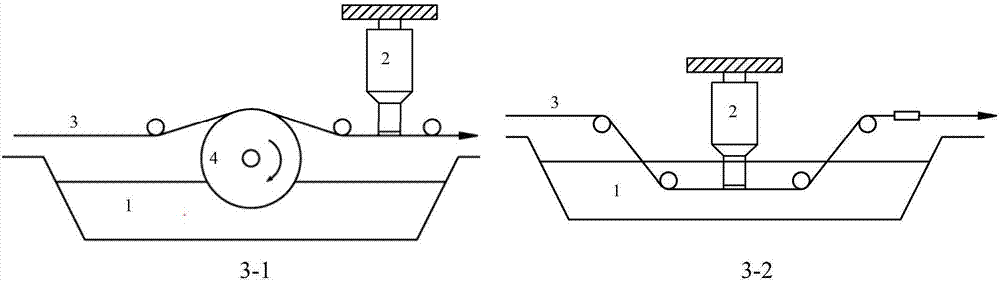

Preparation method for poly-p-phenylene benzobisoxazole fiber reinforced resin matrix composite material

The invention discloses a preparation method for a poly-p-phenylene benzobisoxazole (PBO for short) fiber reinforced resin matrix composite material. According to the method, the PBO fiber reinforced resin matrix composite material is prepared by adopting a wet-process winding forming technology, and an online ultrasonic treatment device is introduced in the preparation process; the device is simple to install, easy to disassemble, convenient to operate, capable of performing production continuously and high in production efficiency; and the parameters and the installation position of the online ultrasonic treatment device can be adjusted, and therefore the improvement of the fiber infiltration quality of resin can be realized. The method can be used for preparing wet-process winding formed composite products, such as pressure vessels and pipelines and can also be used for preparing prepregs serving as intermediate materials of hot-press formed composite products. Compared with a composite material prepared by a traditional method, the PBO fiber composite material prepared by the method has the advantages that the defects are few, the interface bonding performance is high, and particularly the interlaminar shear strength can be obviously improved, and therefore the problem that the interlaminar performance of the PBO fiber reinforced composite material layer is poor can be solved, and the use performance and application benefits of the PBO fiber reinforced composite material can be effectively improved.

Owner:BEIHANG UNIV

Preparation method and application of graphene-wrapping fluorine-doped lithium titanate nanowire

ActiveCN108288703AReduce formation costIncrease contact areaMaterial nanotechnologyNegative electrodesNanowireTwo step

The invention provides a preparation method and application of a graphene-wrapping fluorine-doped lithium titanate nanowire and belongs to the technical field of lithium-ion battery energy material production. According to the preparation method, industrial-grade TiO2 which is low in cost is used as a raw material, a hydrothermal method is used as a basis, through two-step conversion, industrial-grade TiO2 which is low in cost is converted into the lithium titanate nanowire in a specific shape, the cost of forming the lithium titanate nanowire is greatly lowered, and industrial production andapplication are facilitated. Meanwhile, the lithium titanate nanowire is doped with liquid-phase fluorine and wrapped by graphene in situ, and the electric conductivity of the lithium titanate material is increased through the synergistic effect of the shape, ion doping and graphene wrapping. The obtained graphene-in-situ-wrapping fluorine-doped lithium titanate nanowire has the charging and discharging specific capacity close to a theoretical value, and the rate capability of the material is remarkably increased.

Owner:CENT SOUTH UNIV

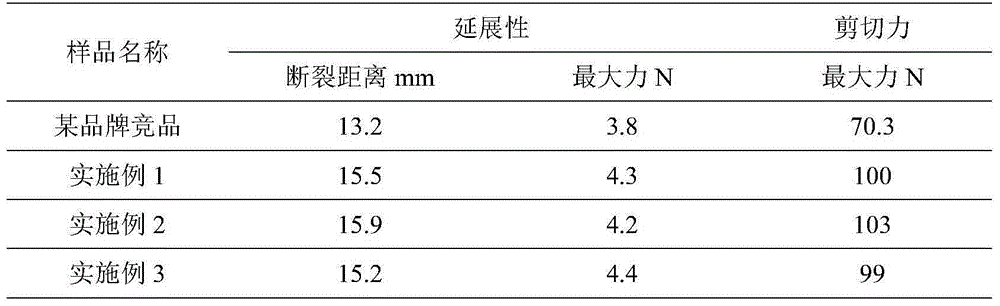

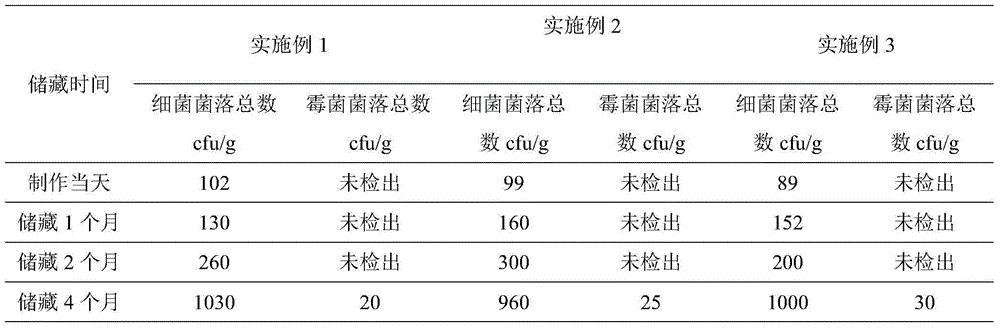

Method for preparing microwave instant taco through sour dough

ActiveCN105010463AEasy to prepareReduce energy consumptionBaking processesBakery productsNutrientExpiration date

The invention discloses a method for preparing a microwave instant taco through sour dough and belongs to the technical field of food production. According to the method, firstly, liquid sour dough paste fermented through lactobacillus plantarum is prepared; secondly, the sour dough is taken to prepare taco dough, and the taco is prepared through the steps of fermenting, cooking and the like. According to the taco prepared through the method, the product technology can be effectively simplified, the product cost can be reduced, the amount of chemical addition agents can be decreased, the taco can be stored at least for four months at the normal temperature, the shelf expiration date of the product is effectively prolonged, the aging speed of the product is reduced, and the taco has the advantages of being nutrient, health, easy to process and the like.

Owner:JIANGNAN UNIV

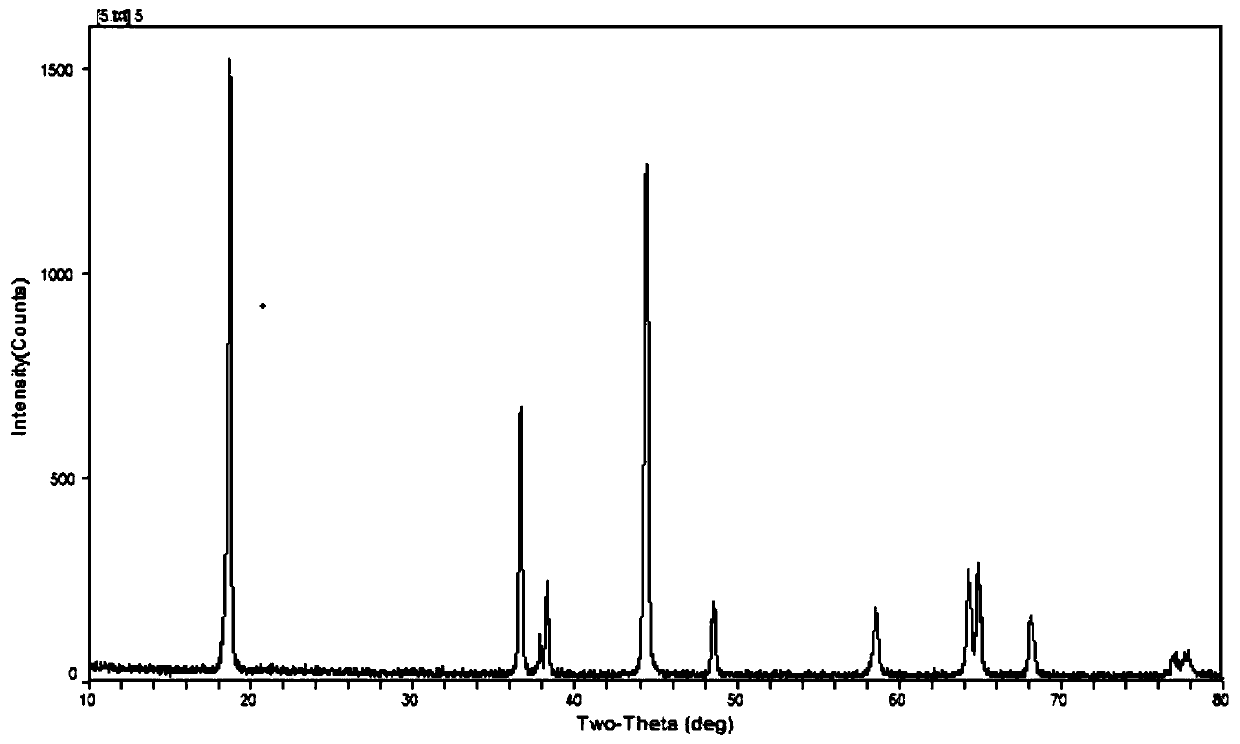

Method for preparing lithium nickel cobalt manganese oxide single-crystal ternary material

ActiveCN110459760AImprove electrochemical performanceImprove cycle performanceCell electrodesSecondary cellsLithium carbonateDry mixing

The invention relates to the field of ternary positive electrode materials, and discloses a method for preparing a lithium nickel cobalt manganese oxide single-crystal ternary material. The method comprises the following steps: (1) mixing a precursor (Ni0.5Co0.2Mn0.3)OH with battery grade lithium carbonate, and adding a zirconium compound to enable the mass content of zirconium in the obtained mixture is 0.1-0.25% of the total mass of the mixture; (2) performing dry mixing on the mixture obtained in step (1); (3) roasting the mixture obtained in step (2) to obtain a material block; and (4) carrying out rotating wheel based grinding, air flow based grinding and sieving in sequence on the material block obtained in step (3), wherein the average particle size D50 of the battery grade lithiumcarbonate is 10-12 microns. The method has a simple preparation process and can be easily applied to industrial application. The obtained lithium nickel cobalt manganese oxide single-crystal ternary material has excellent electrochemical performance, stable material performance and good cycling performance.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

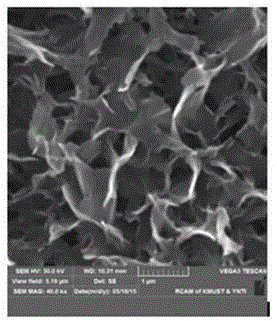

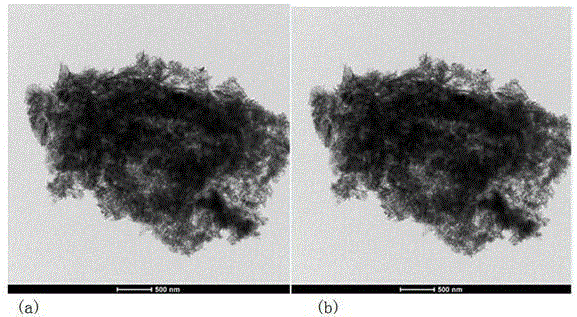

Preparation method and application for nanosheet formed by carbon-coated titanium dioxide nanotube

ActiveCN105355864AGood cycle stabilityEasy to operateCell electrodesSecondary cellsPotassium permanganateCarbon coated

The invention relates to a preparation method and an application for a nanosheet formed by a carbon-coated titanium dioxide nanotube, and belongs to the technical field of lithium ion battery electrode material preparation. The preparation method comprises the steps of preparing the nanosheet formed by the titanium dioxide nanotube firstly; then performing a hydrothermal reaction between the nanosheet formed by the titanium dioxide nanotube and a glucose solution, and performing carbonization to obtain the nanosheet formed by the carbon-coated titanium dioxide nanotube; makingthe nanosheet formed by the carbon-coated titanium dioxide nanotube react with a potassium permanganate solution to obtain the manganese dioxidecoated nanosheet formed by the carbon-coated titanium dioxide nanotube; performing a hydrothermal reaction between the manganese dioxidecoated nanosheet formed by the carbon-coated titanium dioxide nanotube and a ferric salt-containing solution, and then performing annealing to obtain the nanosheet formed by the carbon-coated titanium dioxide nanotube loaded with iron trioxide. The nanosheet prepared by the invention is used as the lithium battery positive electrode material for assembling batteries and the prepared lithium ion battery is relatively high in the specific discharge capacity.

Owner:KUNMING UNIV OF SCI & TECH

Doped high-nickel high-voltage NCM positive electrode material and preparation method thereof

PendingCN110797529AReduce consumptionIncrease profitCell electrodesSecondary cellsHigh energyManganese

The invention discloses a doped high-nickel high-voltage NCM positive electrode material and a preparation method thereof, and belongs to the field of lithium ion batteries. The preparation method comprises the following steps: simultaneously doping manganese and cobalt to obtain an NCM precursor; and adding a dopant M into the precursor, and sintering the precursor in a high-pressure oxygen atmosphere to obtain a lithium ion battery positive electrode material. The positive electrode material has very high specific discharge capacity and excellent cycling stability, can meet the high-rate charging and discharging requirement, and can achieve long-life safe cycling under high voltage. The positive electrode material is prepared by combining four-solution parallel-flow co-precipitation witha high-pressure solid-phase synthesis method, and the prepared product has the advantages of high purity, high crystallization quality, high particle density, uniform distribution of particles, excellent electrochemical performance and low manufacturing cost, is an ideal positive electrode material with high energy density, and has a wide application prospect.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

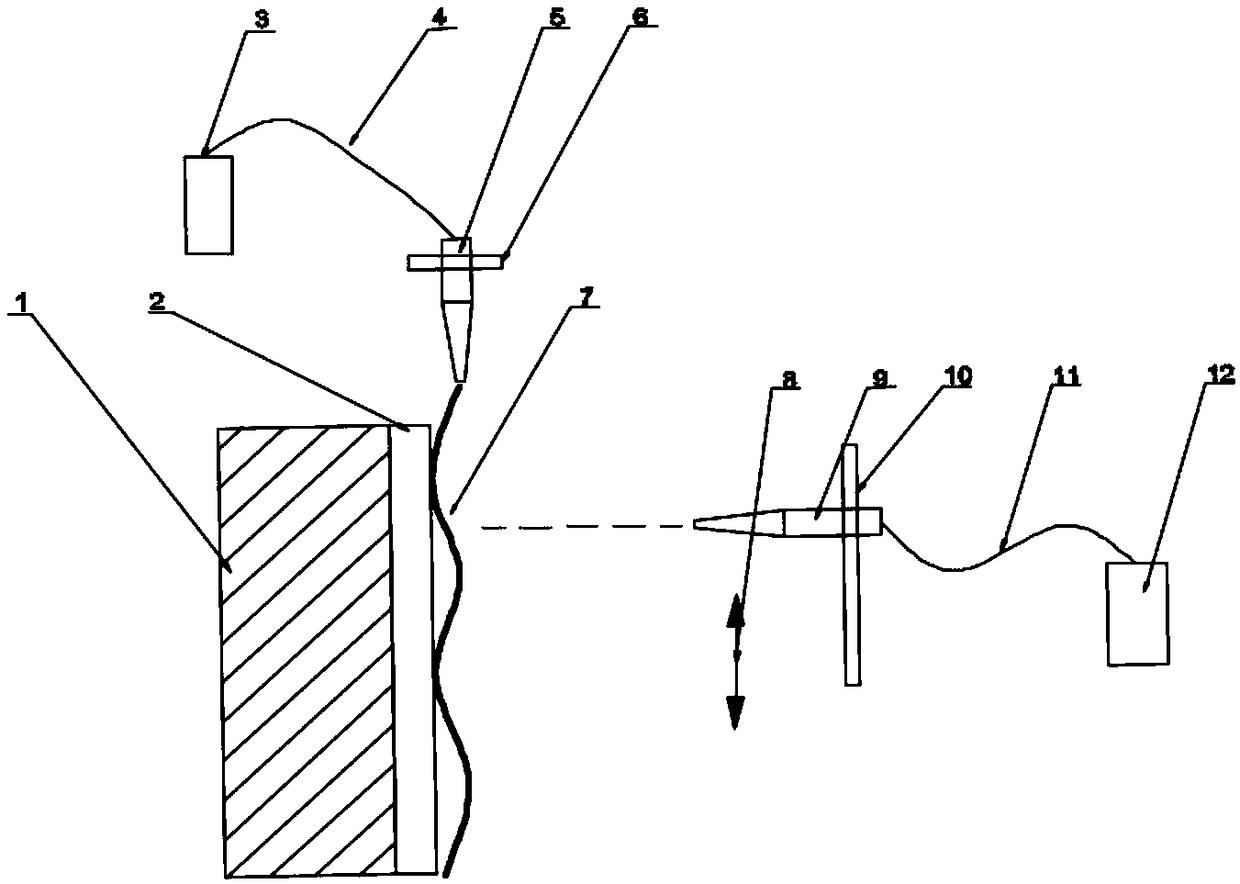

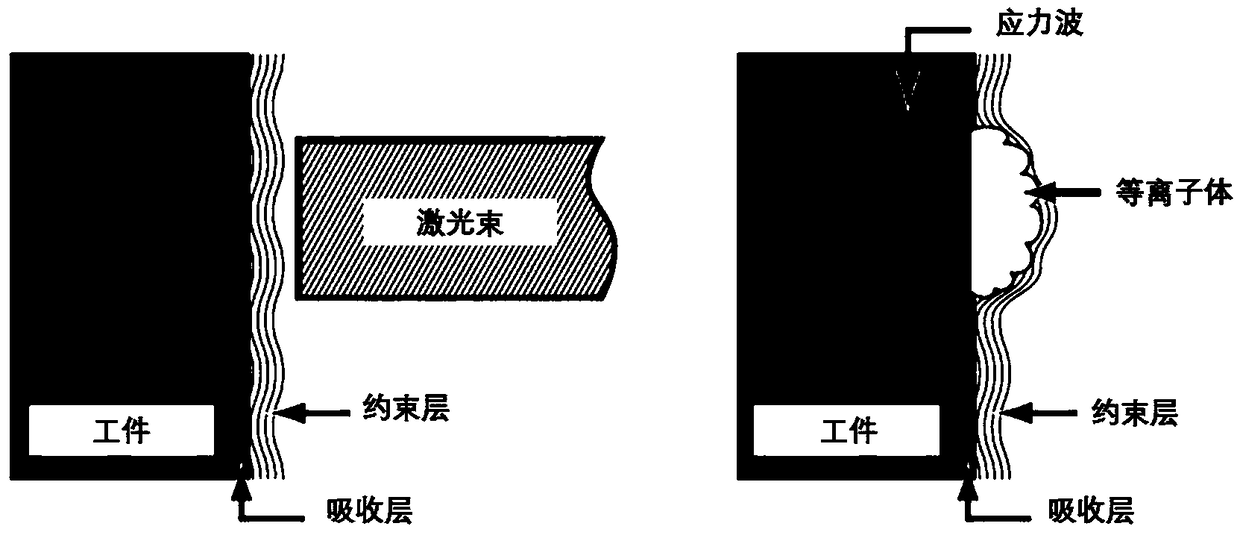

Laser shock peening method based on liquid nitrogen restraint layer

The invention belongs to the laser shock peening field and discloses a laser shock peening method based on a liquid nitrogen restraint layer. The method comprises the following steps: (a) cooling thesurface of a to-be-machined workpiece, coating the surface of the to-be-machined workpiece with a material for absorbing laser energy so as to form an absorbing layer, fixing the to-be-machined workpiece, and spraying liquid nitrogen to the absorbing layer to form a flowing liquid nitrogen layer, namely the restraint layer; and (b) irradiating the surface of the to-be-machined workpiece with laser. The laser penetrates through the restraint layer and arrives at the absorbing layer, the absorbing layer absorbs plasma produced through the gasification of the laser energy, is heated and expandedalong the continuous absorbing of the laser energy and finally explodes to generate high-pressure shock waves towards the inside of the to-be-machined workpiece to enable the to-be-machined workpieceto generate plastic deformation, so that then dislocation density and compactness of crystalline grains in the to-be-machined workpiece are increased, and the crystal lattice size is decreased. According to the laser shock peening method, the dislocation density of the crystalline grains is increased, the crystal lattice size is decreased, the fatigue resistance of the surfaces of blades of an aviation engine is increased, and the service life of the aviation engine is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

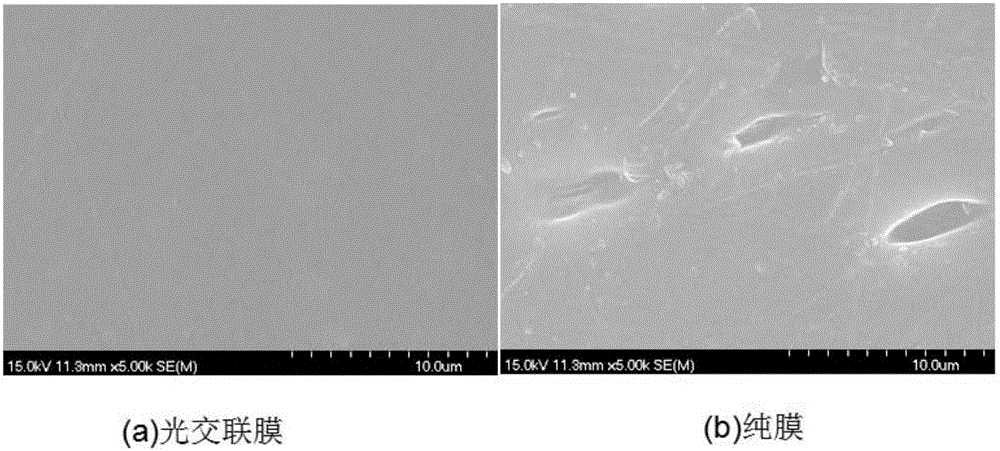

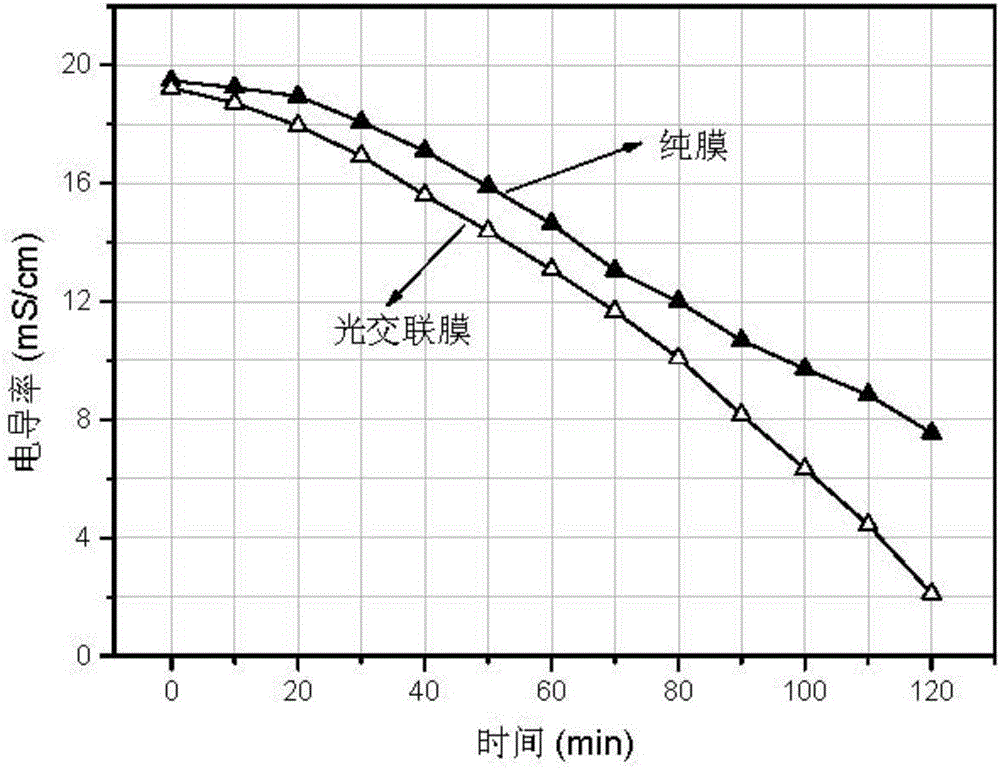

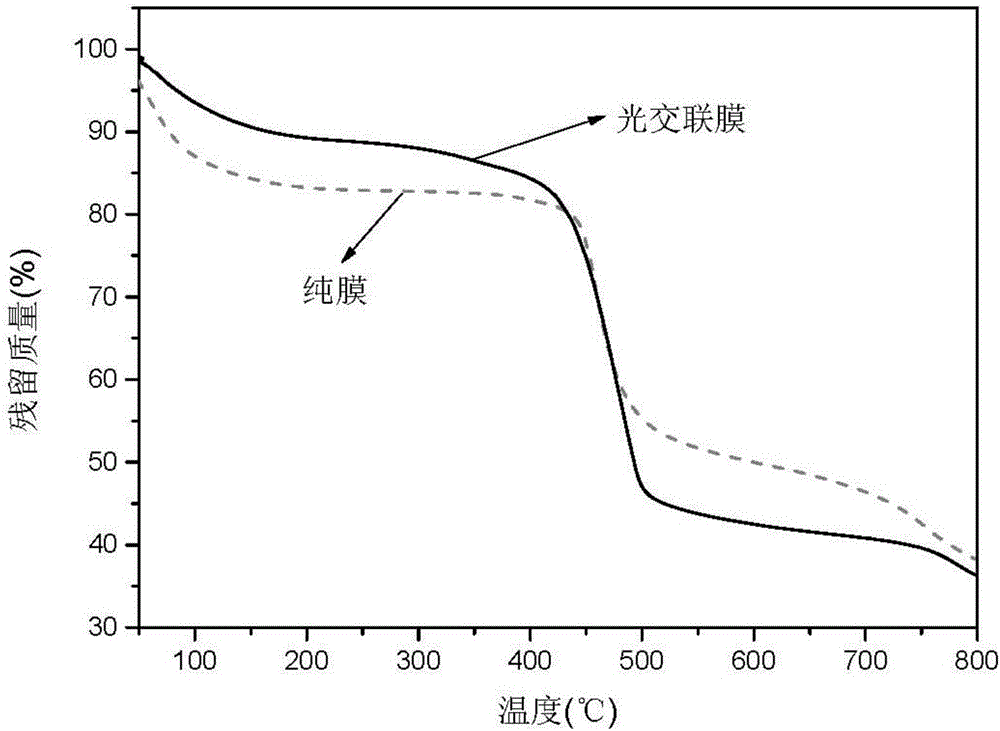

Preparation method of photo-crosslinked sulphonated polysulfone ion exchange membrane

ActiveCN106188591AHigh ion exchange capacityImprove mechanical propertiesCation exchangersN dimethylformamidePolysulfone membrane

The invention discloses a preparation method of a photo-crosslinked sulphonated polysulfone ion exchange membrane. The method comprises the following steps that 1, sulphonated polysulfone with a certain sulfonation degree is dissolved in a solution prepared from N,N-dimethylformamide (DMF), stirring is conducted, and standing and cooling are conducted at room temperature; 2, a photoinitiator and a cross-linking agent are added in the solution obtained in the first step, stirring is conducted, a uniform solution is obtained, standing is conducted, and a membrane casting solution is obtained; 3, the membrane casting solution obtained in the second step is poured on a glass plate, an automatic membrane scraper is used for rapid scraping in the mode of being perpendicular to the glass plate, and a membrane is formed; 4, the membrane obtained through scraping in the third step is rapidly subjected to ultraviolet irradiation, the membrane is rapidly put in vacuum of 50 DEG C to 80 DEG C to be dried, and the photo-crosslinked sulphonated polysulfone membrane is obtained. The exchange membrane obtained through the method is good in chemical stability, low in swelling degree and high in ion exchange capacity.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH +1

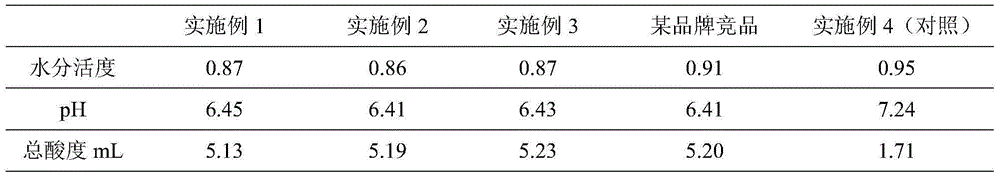

Production method for soybean yoghurt with good texture

The invention discloses a production method for soybean yoghurt with good texture. The method comprises the following steps: adding soybean into water and soaking the soybean in a NaOH3 solution; carrying out mashing with hot water having a temperature of 80 to 90 DEG C, adding Alcalase protease during soaking of soybean, carrying out uniform mixing with stirring and then carrying out treatment at 25 to 35 DEG C for 6 to 14 h, or adding Alcalase protease into prepared soybean milk and carrying out heat preservation at 40 to 80 DEG C; and adding cane sugar, lactose and glucose, then carrying out treatment at 70 to 121 DEG C after full dissolving, inoculating an activated direct bacterial strain XPL-1 after cooling, carrying out culturing at 37 to 45 DEG C for 5 to 12 h and then carrying out refrigeration so as to obtain the soybean yoghurt. According to the invention, due to moderate degradation of soybean protein by the Alcalase protease, gel formed among polypeptide chains is more uniform and fine, so the texture of the soybean yoghurt is obviously improved.

Owner:SOUTH CHINA UNIV OF TECH

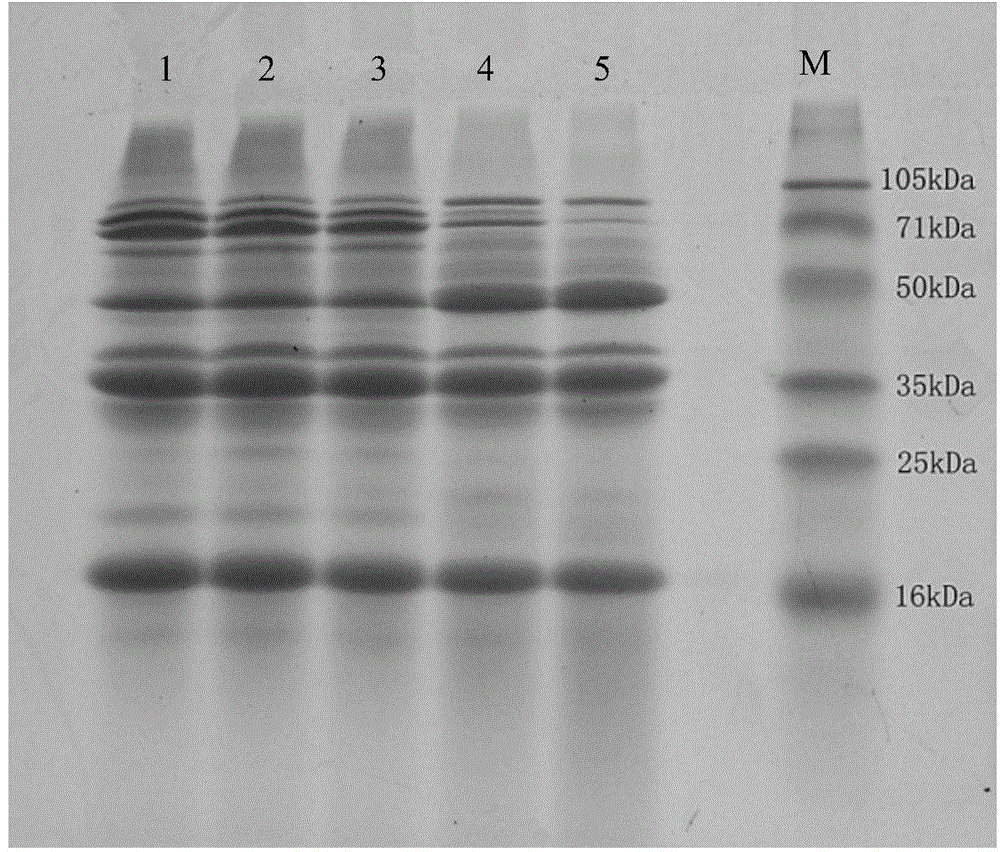

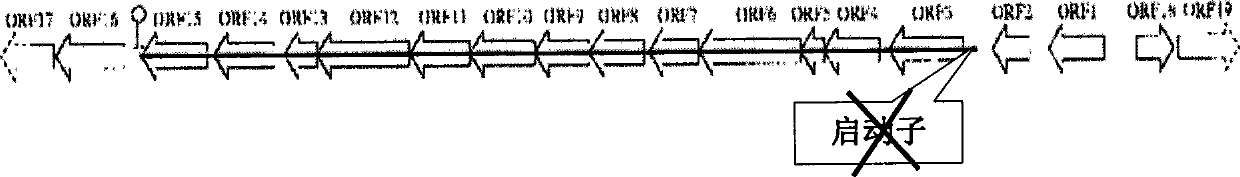

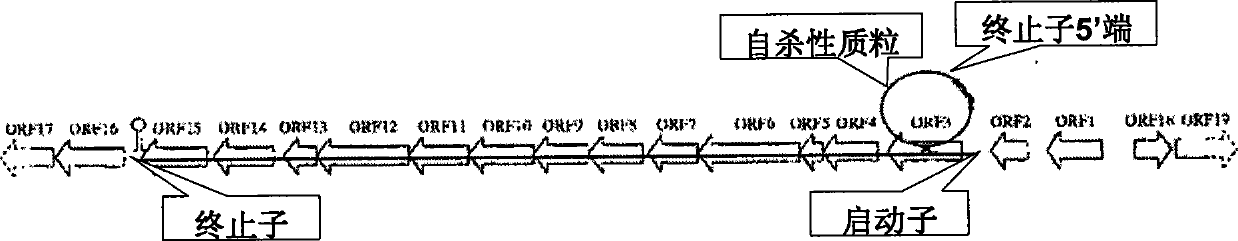

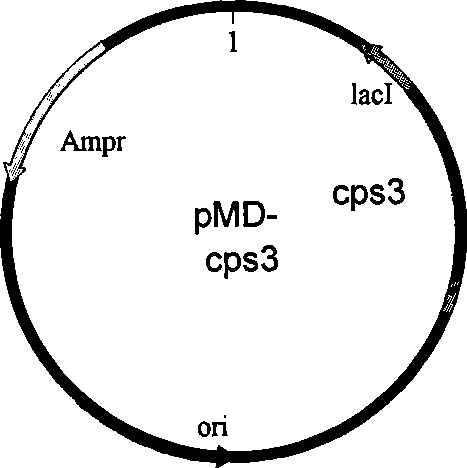

Method for constructing klebsiella with deleted capsula

ActiveCN101397547ALow viscosityReduce pathogenicityBacteriaMicroorganism based processesPathogenicityViscosity

The invention discloses a method for constructing Klebsiella without capsules, pertaining to the technical field of biochemical engineering. In PDO producing bacteria, a gene knockout method is adopted to knock out the promoter of the capsule protosome or integrate a terminator behind the promoter so as to stop the transcription of the capsule protosome, thus leading the capsules of the Klebsiella to be partially or completely deleted. Therefore, the fermentation liquor viscosity of the Klebsiella is reduced, the separation and extraction difficulty of POD products is reduced, simultaneously, the thalli pathogenicity is lowered, thereby being favorable to the PDO industrial production application of the Klebsiella.

Owner:TSINGHUA UNIV +1

Mushroom mycelium solid medium and method for culturing mushroom mycelium by using same

InactiveCN102674928ASimple processHigh in LentinanHorticultureFertilizer mixturesMyceliumLENTINULA EDODES MYCELIUM

The invention provides a mushroom mycelium solid medium and a method for culturing mushroom mycelium by using the same. The mushroom mycelium solid medium is prepared from the following raw materials proportionally: 35-42% of bagasse, 3.5-7% of rice bran, 3.5-7% of corn starch, 0.4-0.6% of gypsum, 0.4-0.6% of sugar, 0.4-0.6% of salt and 45-55% of water. The method for culturing the mushroom mycelium by using the mushroom mycelium solid medium comprises the following steps of: weighing the raw materials in proportion, and mixing the raw materials to prepare into the mushroom mycelium solid medium; bagging and sterilizing the prepared mushroom mycelium solid medium; inoculating the mushroom mycelium on the solid medium; and placing the solid medium in a spawn-running room for carrying out spawn running. The solid medium provided by the invention is used for culturing the mushroom mycelium, so that the production technology is simple and the production cost is low; and the contents of lentinan and various types of active substances in the cultured mushroom mycelium are high, so that the mushroom mycelium solid medium and the method are especially suitable for industrialized production and application.

Owner:福建省菌芝堂生物科技有限公司

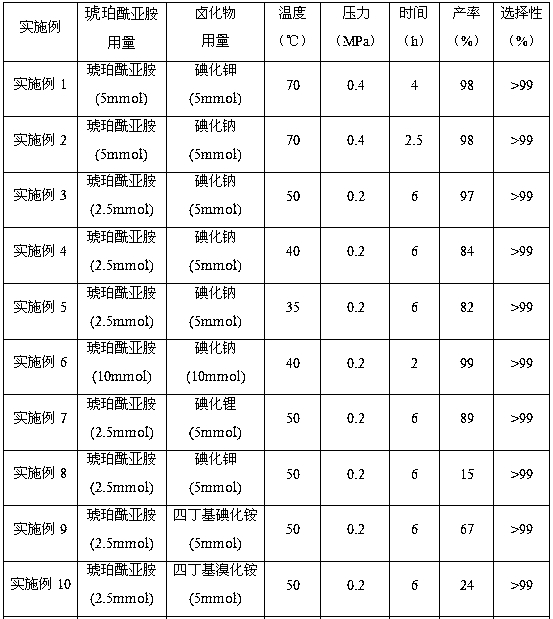

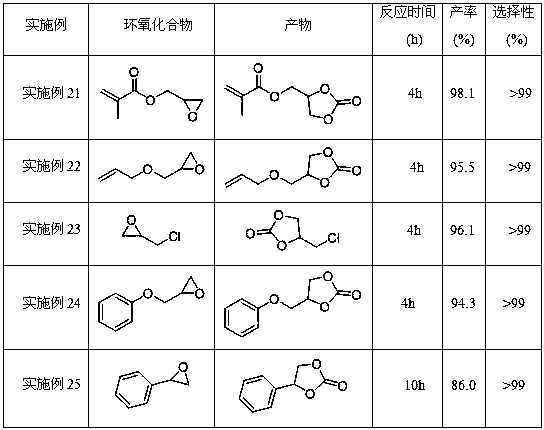

Method for preparing cyclic carbonate by utilizing combined catalysis of succinimide and halide

ActiveCN108299375AEfficient synthesisMild reaction conditionsOrganic chemistryReaction temperatureCarbonate

The invention discloses a method for preparing cyclic carbonate by utilizing combined catalysis of succinimide and halide. According to the method, carbon dioxide and an epoxy compound serve as raw materials, and the cyclic carbonate is catalytically prepared under the synergistic action of the succinimide and the halide, wherein the reaction pressure is 0.1-1.0MPa, the reaction temperature is 25-90 DEG C, and the reaction time is 1-10h. Compared with the prior art, the ingredients in a catalytic system disclosed by the invention are cheap, simple and easy to obtain, the reaction condition ismoderate, the substrate is strong in adaptability, the corresponding cyclic carbonate can be efficiently synthesized, and the method has a relatively good industrialized application prospect.

Owner:HENAN UNIVERSITY

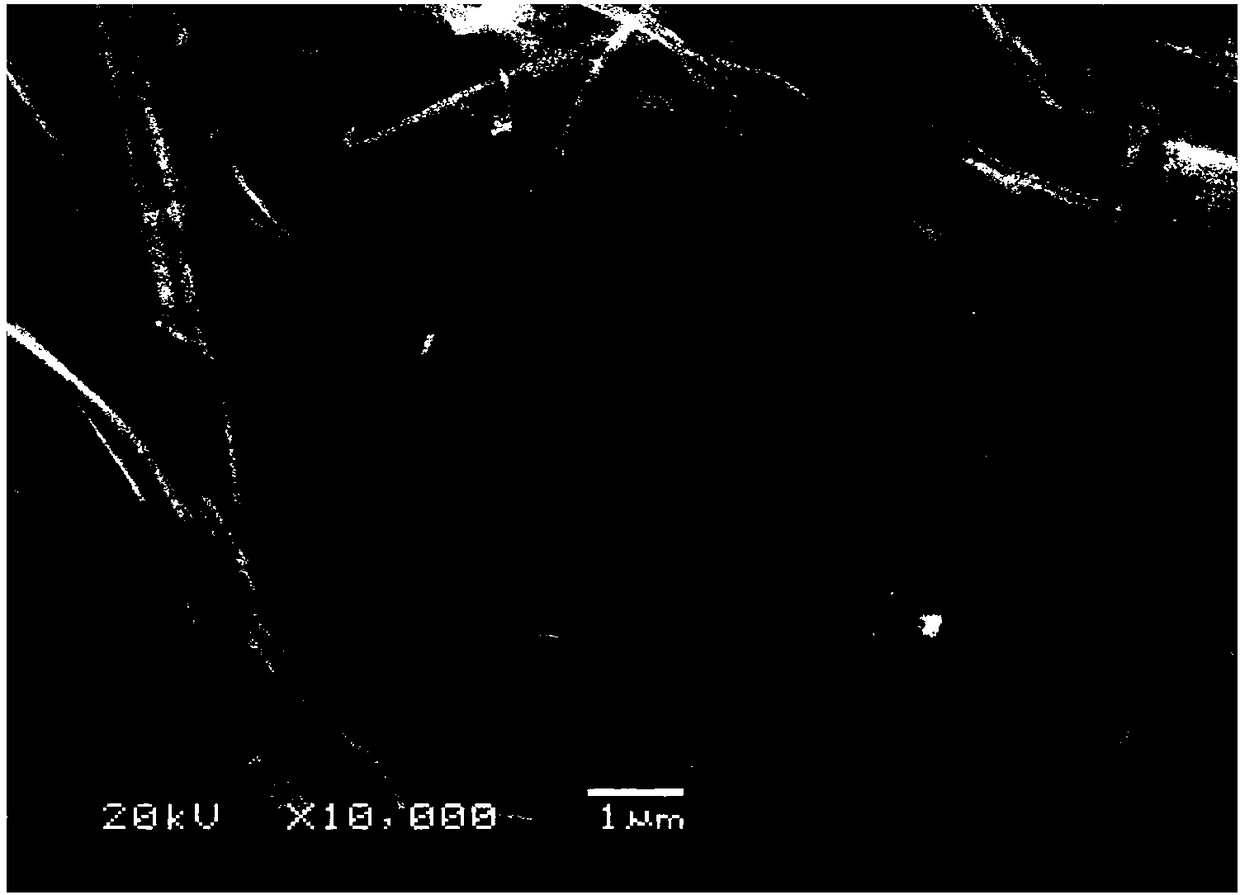

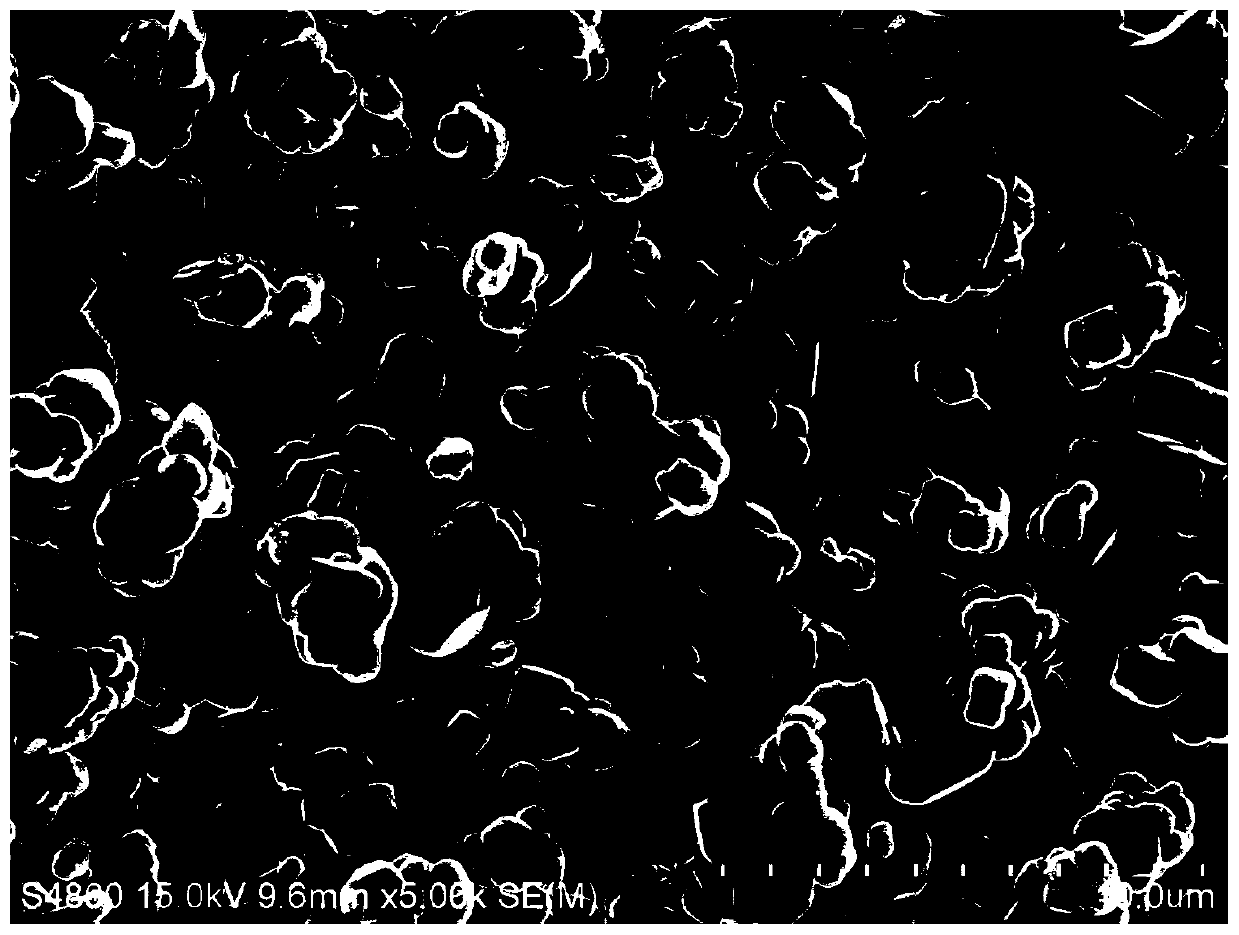

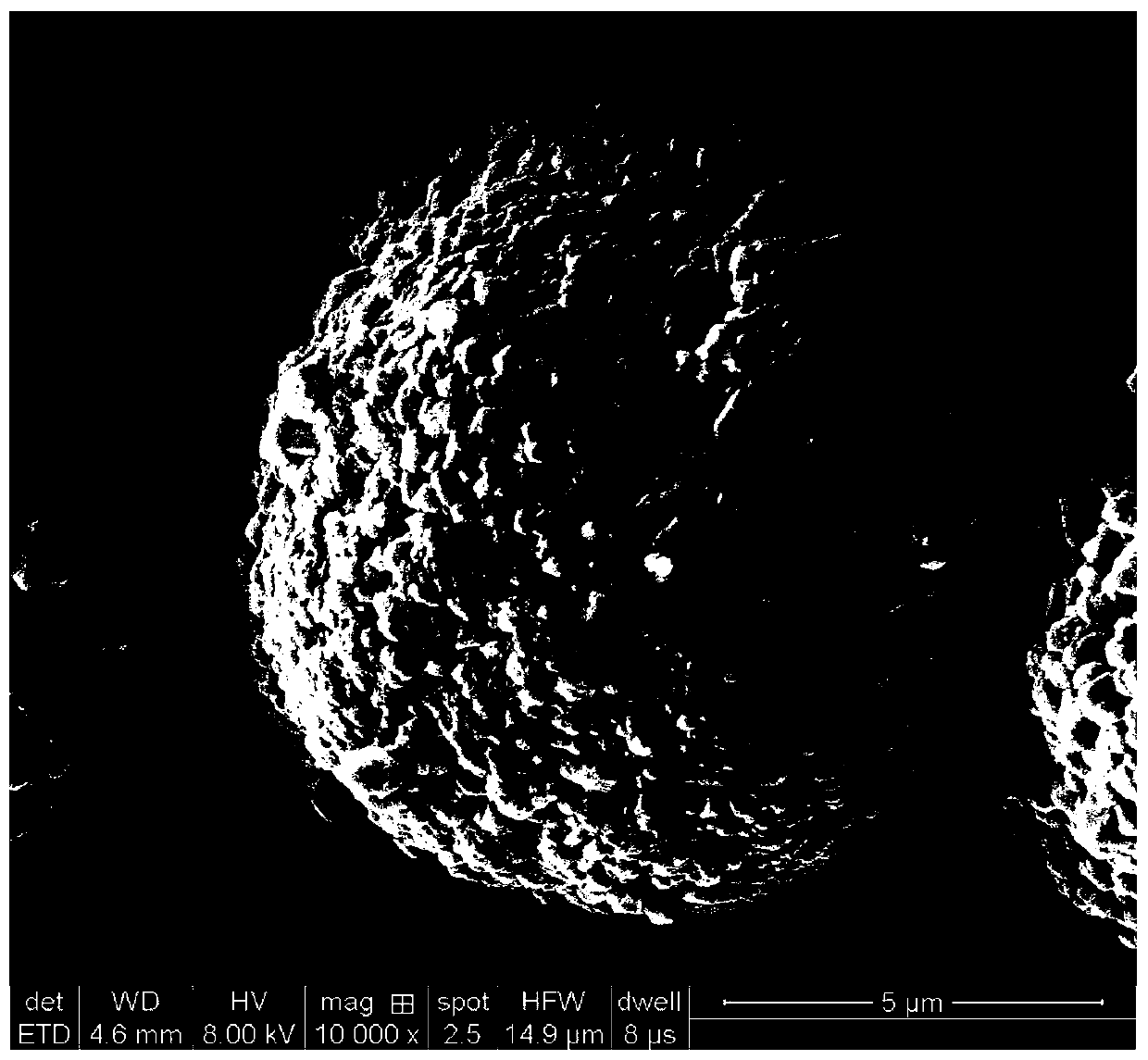

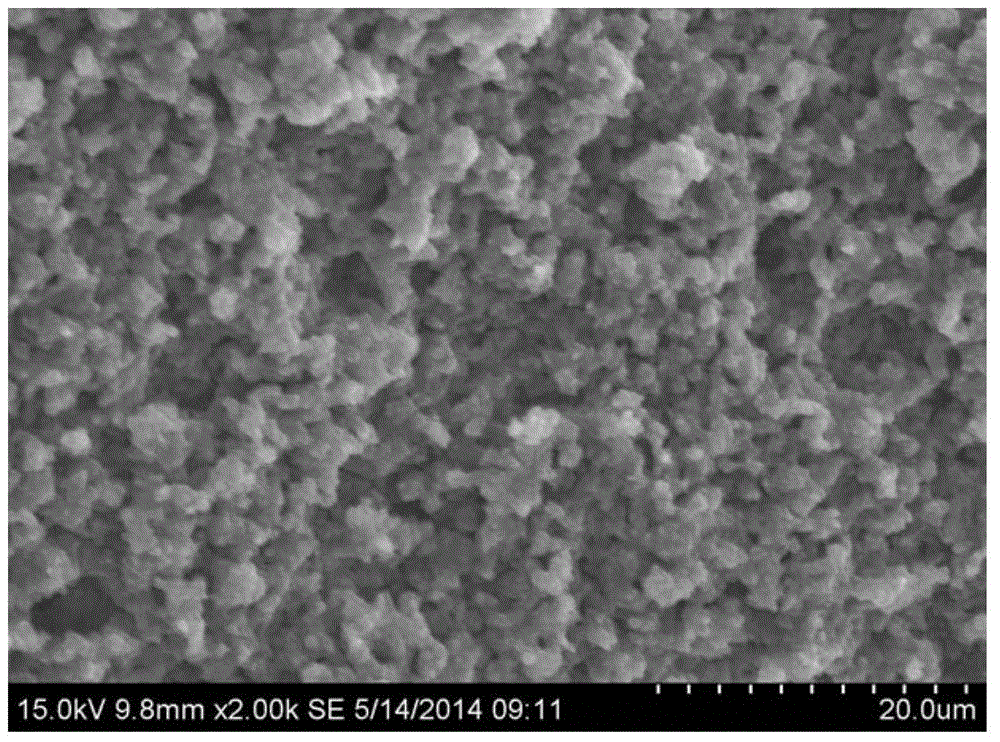

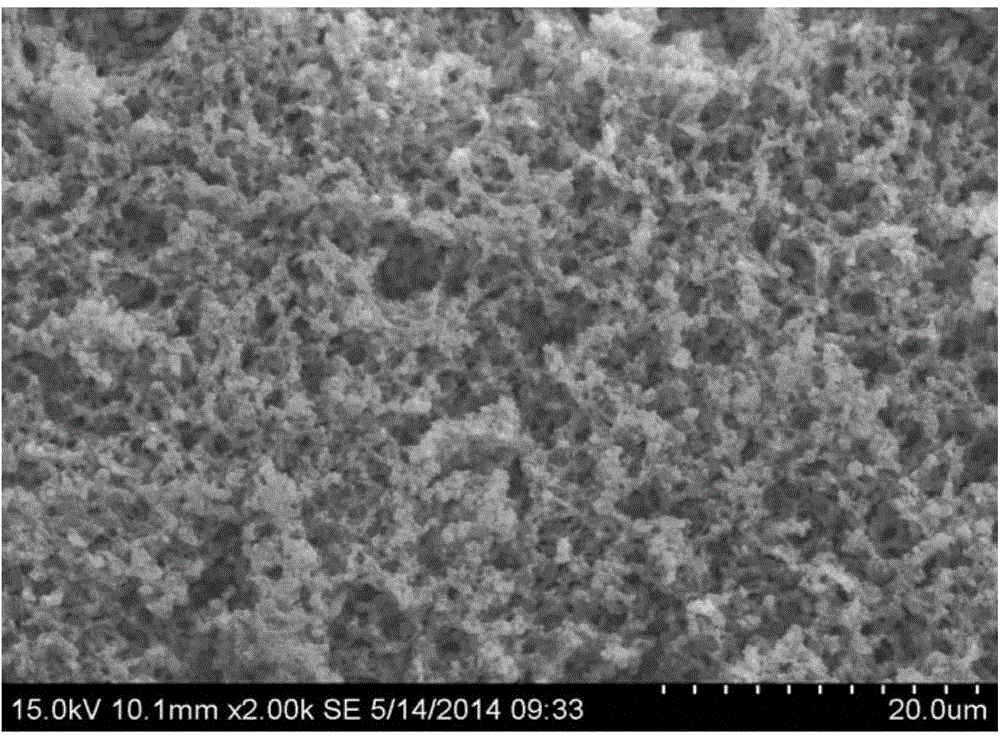

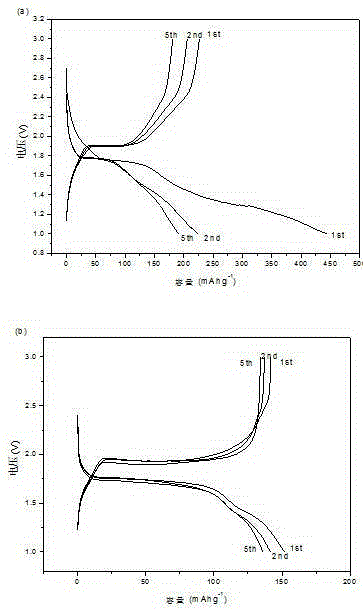

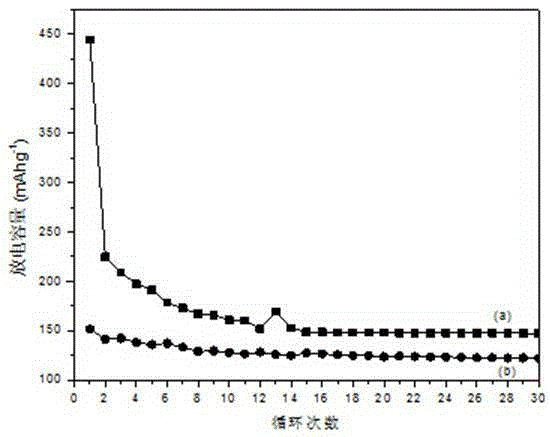

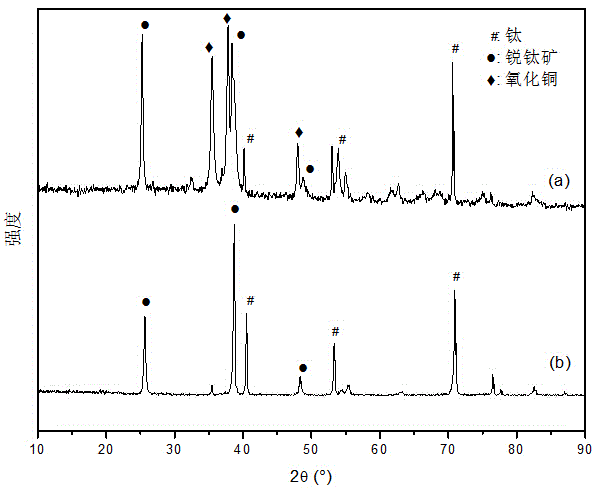

Manufacturing method for copper oxide loaded titanium dioxide nano through tube array and application of copper oxide loaded titanium dioxide nano through tube array

InactiveCN105390688AHigh charge and discharge capacityEasy for industrial production and applicationMaterial nanotechnologyCell electrodesCopper oxideLithium-ion battery

The invention relates to a manufacturing method for a copper oxide loaded titanium dioxide nano through tube array and an application of the copper oxide loaded titanium dioxide nano through tube array, and belongs to the technical field of manufacturing of electrode materials of lithium ion batteries. The method comprises the following steps of: (1) in a fluorine-containing electrolyte solution, taking a pure titanium sheet as a positive electrode, manufacturing a highly ordered titanium dioxide nanotube array with a positive electrode oxidation method, and removing a blocking layer at the bottom of the titanium dioxide nanotube array with a voltage-increasing method when the positive electrode oxidation is ended to obtain a titanium dioxide nano through tube array; and (2) putting the manufactured nano through tube array in a copper ion-containing salt solution, manufacturing a copper loaded titanium dioxide nano through tube array with an electrodeposition method, and then performing calcining in air to obtain the copper oxide loaded titanium dioxide nano through tube array. The copper oxide loaded titanium dioxide nano through tube array manufactured with the method serves as a positive electrode material of a lithium ion battery to be subjected to battery assembly; and by detecting electrochemical performance of the battery, it is shown that the lithium ion battery manufactured from the electrode material has a relatively high specific discharge capacity.

Owner:KUNMING UNIV OF SCI & TECH

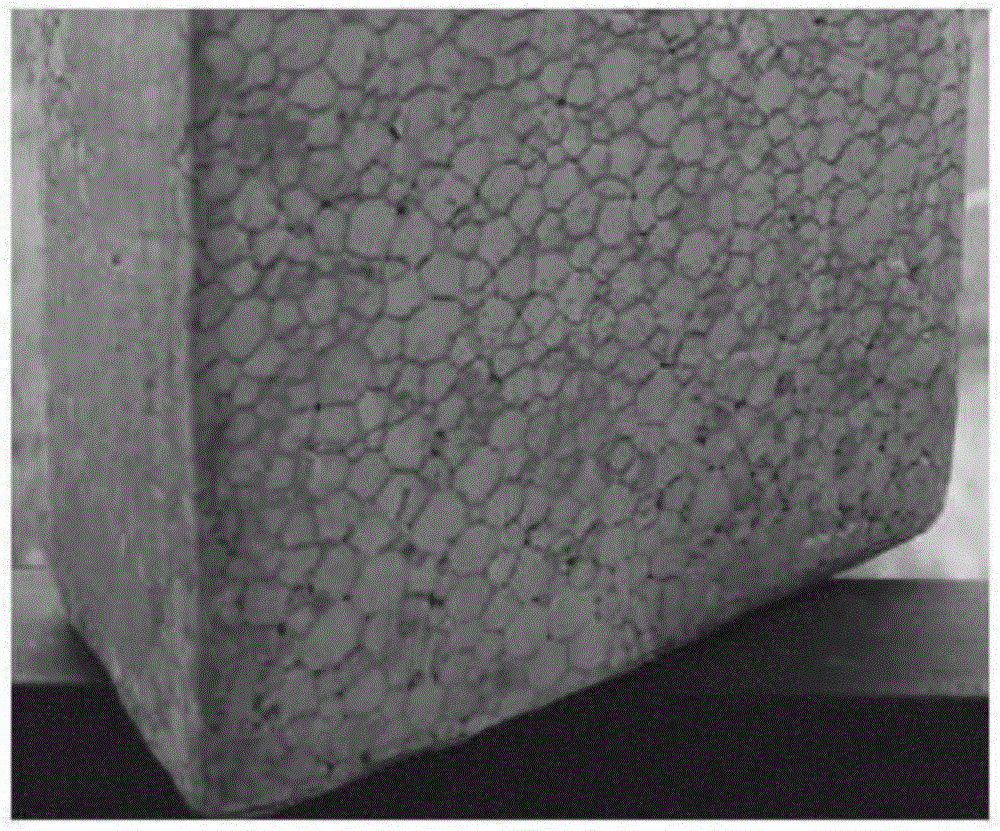

Water-phase suspension granulation method for preparing gradient flame-retardant foamable polystyrene beads on basis of waste polystyrene materials and products of water-phase suspension granulation method

ActiveCN105566670AExcellent reflective infrared characteristicsRealize resource utilizationPolystyrene beadOil phase

The invention belongs to the field of high-value recycling of waste polystyrene foam materials, and particularly relates to a water-phase suspension granulation method for preparing gradient flame-retardant foamable polystyrene beads on the basis of waste polystyrene materials and products of the water-phase suspension granulation method. The water-phase suspension granulation method includes forming oil phases by inorganic-organic gradient cooperative flame-retardant heat-insulation systems, organic solvents and the waste polystyrene materials; forming water-phase dispersion media by surfactants, inorganic-organic synergistic suspension agents and deionized water; stably suspending and dispersing oil-phase liquid drop in the water-phase media under the actions of mechanical stirring by means of water-phase suspension granulation; heating and steaming out the organic solvents to cure gradient flame-retardant polystyrene beads; acquiring gradient flame-retardant polystyrene heat-insulation plates by means of pentane filling and foaming molding. The waster-phase suspension granulation method and the products have the advantages that waste polystyrene is used as a raw material, is recycled by the aid of physical processes and is used for preparing the gradient flame-retardant foamable polystyrene beads, accordingly, waste can be utilized, and the gradient flame-retardant performance and heat-insulation effects of the gradient flame-retardant foamable polystyrene beads can be improved; the organic solvents can be recycled, accordingly, the water-phase suspension granulation method and the products are environmental friendly, and industrial production can be facilitated.

Owner:WUHAN POLYTECHNIC UNIVERSITY

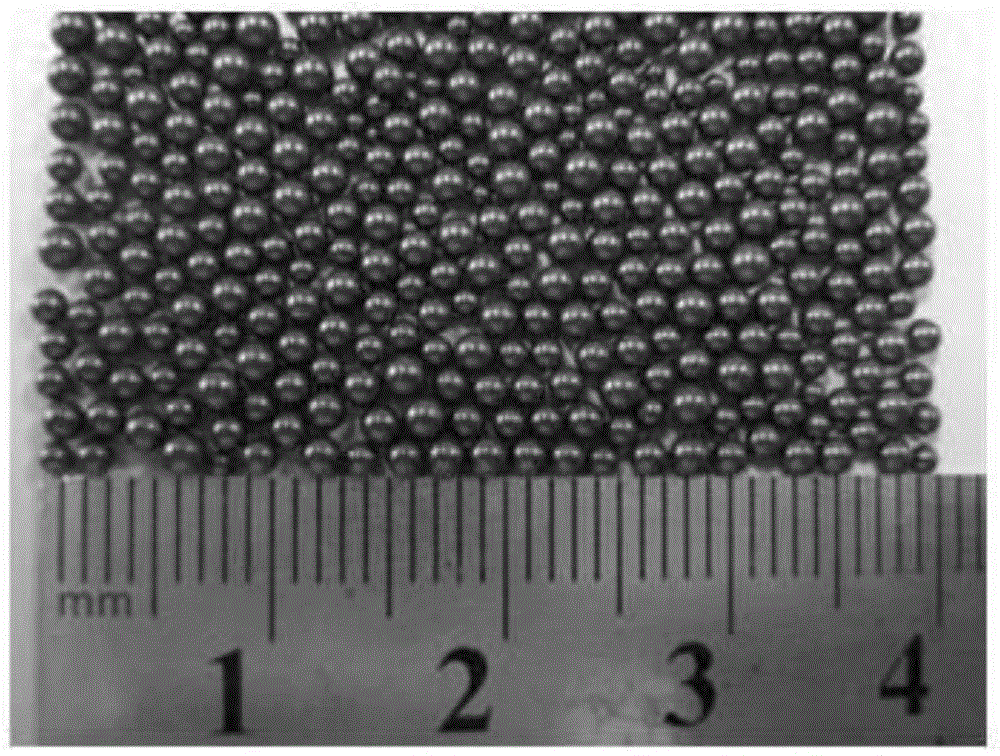

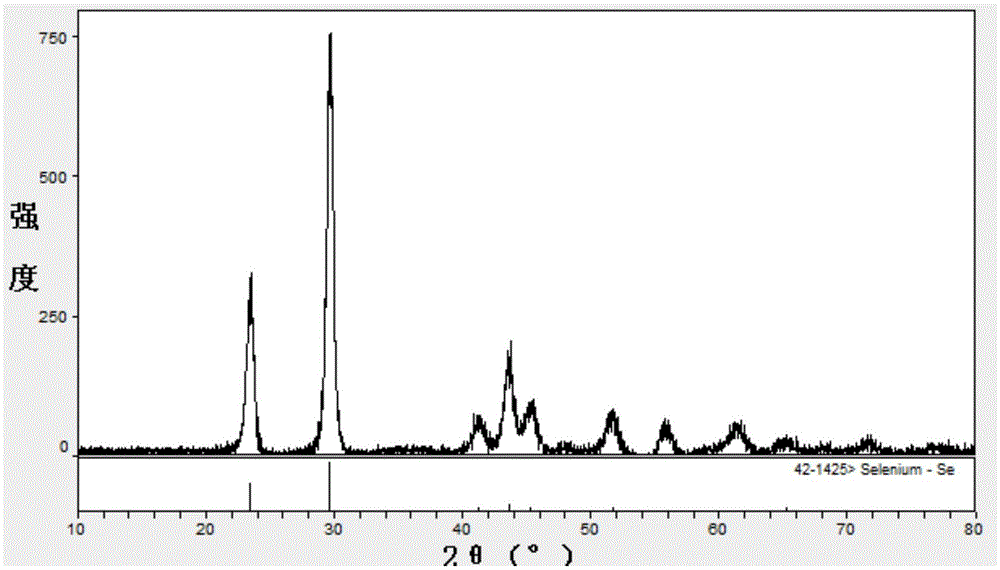

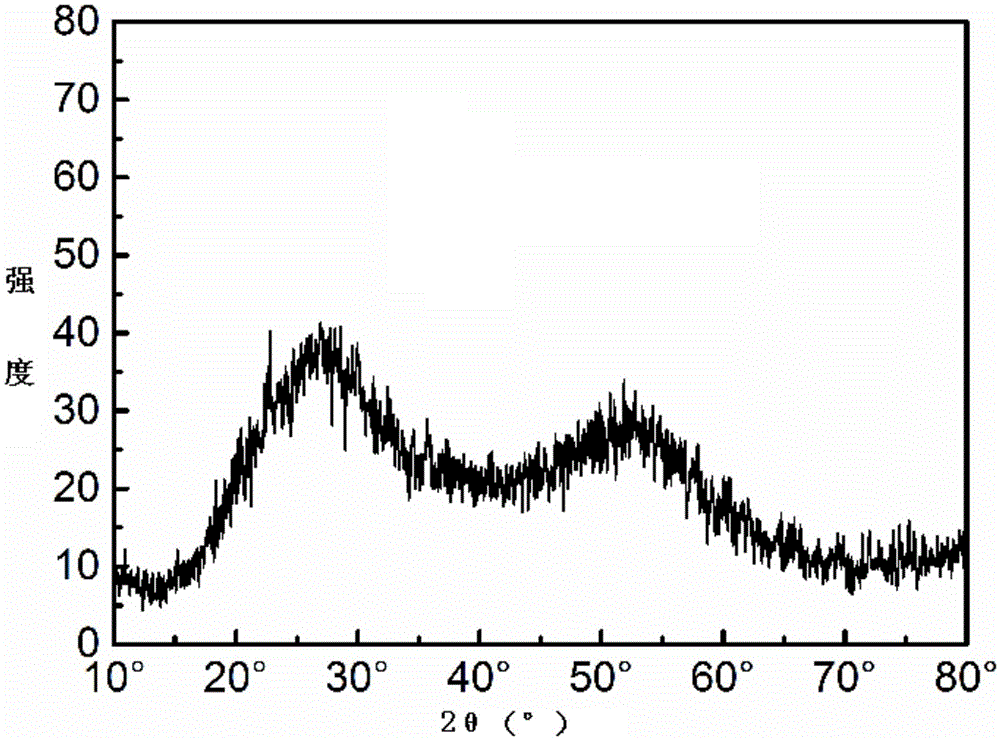

Method for catalytically reducing selenium

ActiveCN105668528AReduce descent speedAvoid it happening againHydrogen peroxideElemental selenium/telluriumCatalytic functionReduction potential

The invention discloses a method for catalytically reducing selenium. According to the method, by using oxydol as a catalyst, a reducer is added into a hexavalent-selenium-containing solution to react so as to reduce the selenium into the selenium simple substance, wherein the standard oxidation-reduction potential of the reducer is lower than the standard oxidation-reduction potential in the process of converting the hexavalent selenium into the selenium simple substance. The hexavalent-selenium-containing selenic acid or selenate solution is reduced by one step to prepare the simple substance selenium product. The oxydol, which is used as the catalyst, effectively lowers the descending speed of the solution reduction potential on the premise of performing the catalytic function, so that the reduction reaction process is carried out mildly, thereby effectively preventing the selenium in the solution from overreduction to generate negatively bivalent selenium ions or compounds thereof, and solving the problems of low recovery rate and the like caused by selenium overreduction.

Owner:CENT SOUTH UNIV

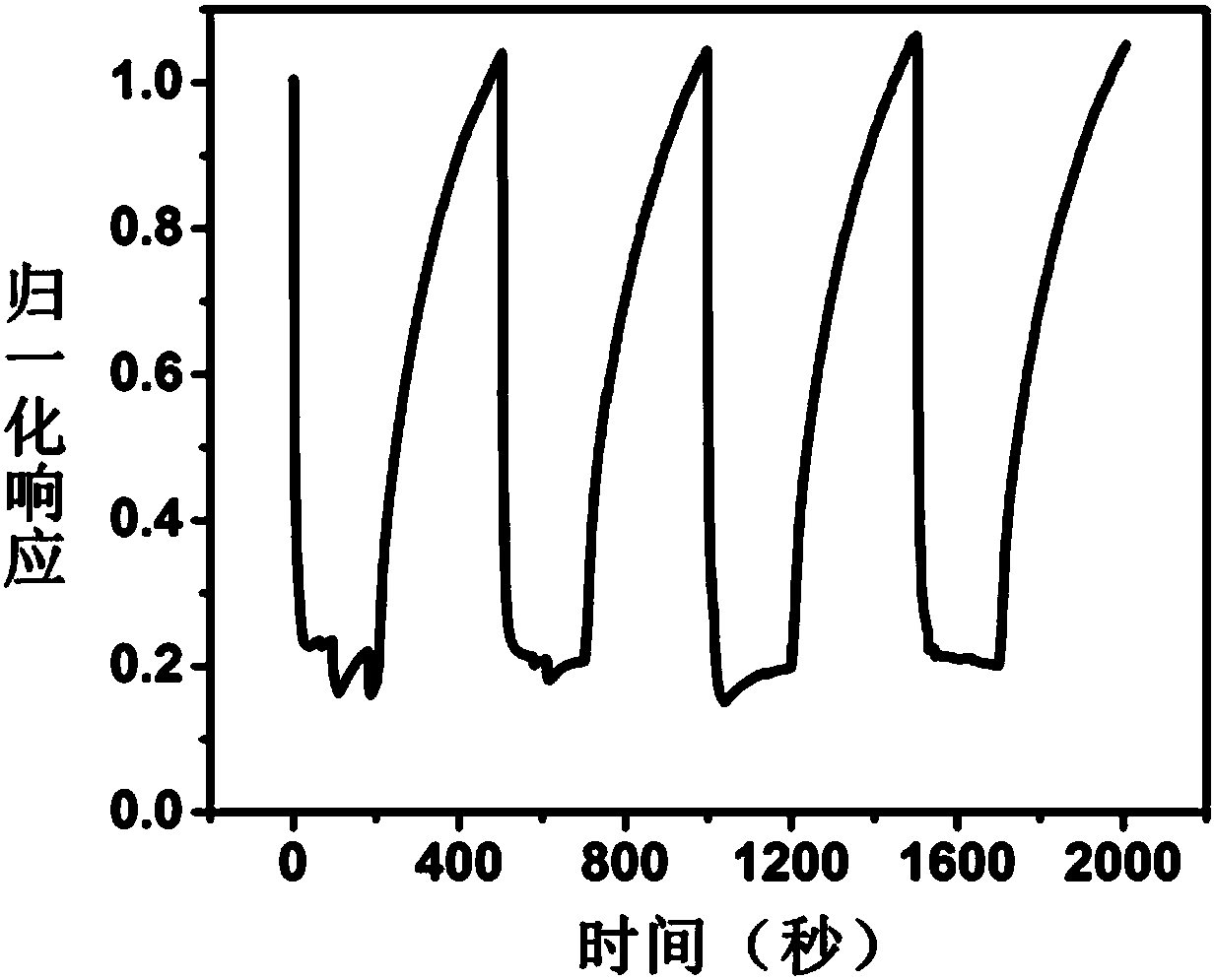

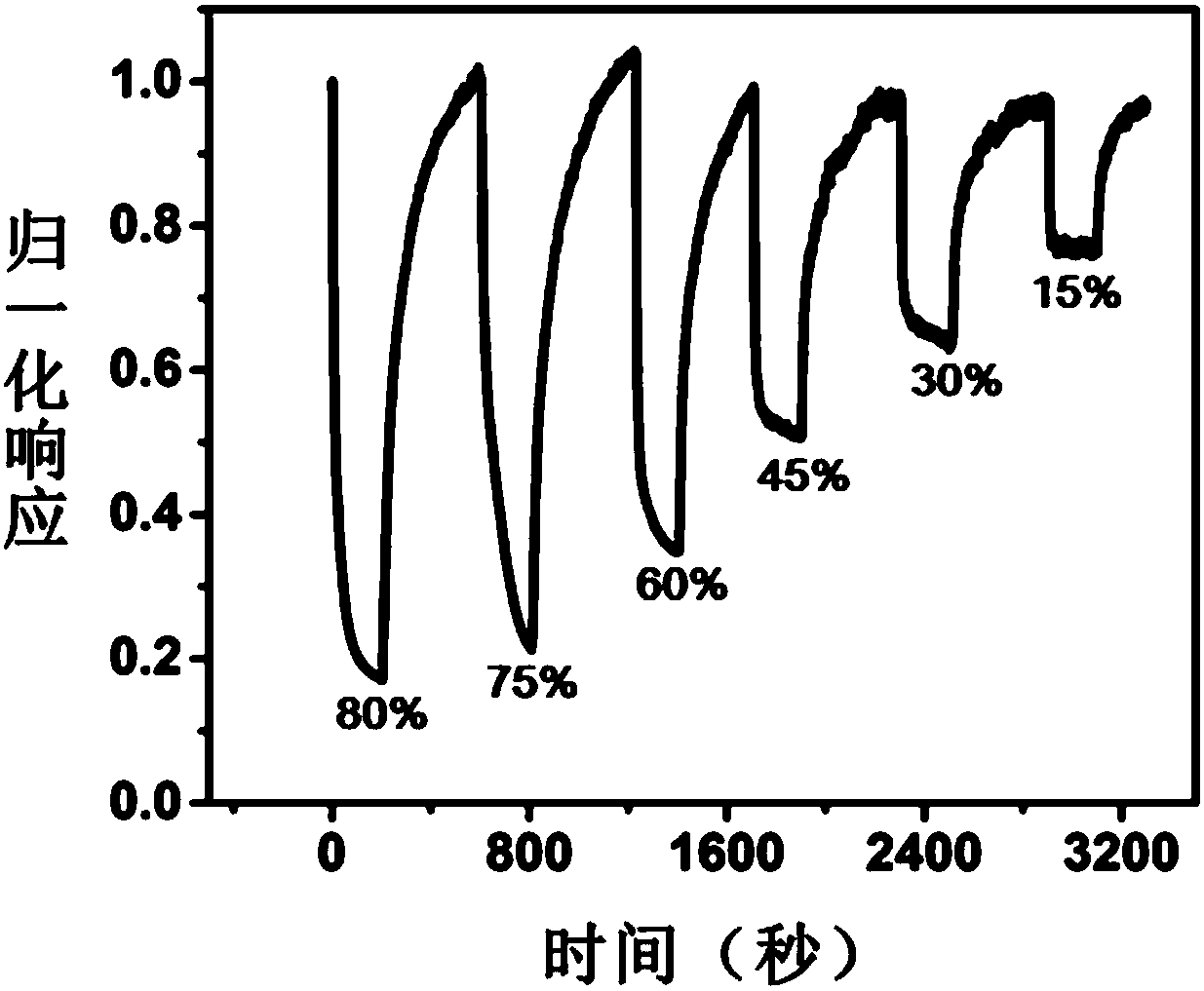

Carbon dot-doped molybdenum disulfide sheet-based humidity sensor and preparation method thereof

ActiveCN108169284ASimple preparation processLow priceMaterial analysis by electric/magnetic meansRepeatabilityMoisture sensor

The invention discloses a carbon dot-doped molybdenum disulfide sheet-based composite, wherein the carbon dot-doped molybdenum disulfide sheet composite is in a shape of a two-dimensional nano sheet.The present invention also provides a preparation method and use of the carbon dot-doped molybdenum disulfide sheet-based composite. The present invention also provides a humidity sensor including thecarbon dot-doped molybdenum disulfide sheet-based composite and a preparation method and use thereof. The carbon dot-doped molybdenum disulfide sheet-based composite and the humidity sensor includingthe carbon dot-doped molybdenum disulfide sheet-based composite are wide in response range and linear in response, and have fast response, high sensitivity, and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

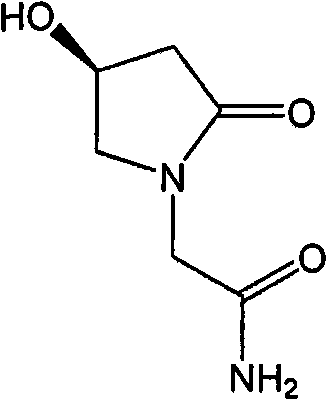

Preparation method of (s)-4-hydroxy-2-oxo-1-pyrrolidineacetamide

A preparation method of (s)-4-hydroxy-2-oxo-1-pyrrolidineacetamide. The preparation method comprises the following steps of crude product preparation and crystallization, wherein the step of crystallization adopts acetone and water as solvents. Levo-oxiracetam prepared through the preparation method has high purity above 99.3 wt% and low impurity content of 0 to 0.5 wt%. The preparation method has the advantages that a material addition mode adopted by the preparation method realizes that frequency of addition of an inorganic base is reduced; operation is simple; and the preparation method is in favor of industrialized production.

Owner:CHONGQING RUNZE PHARM CO LTD

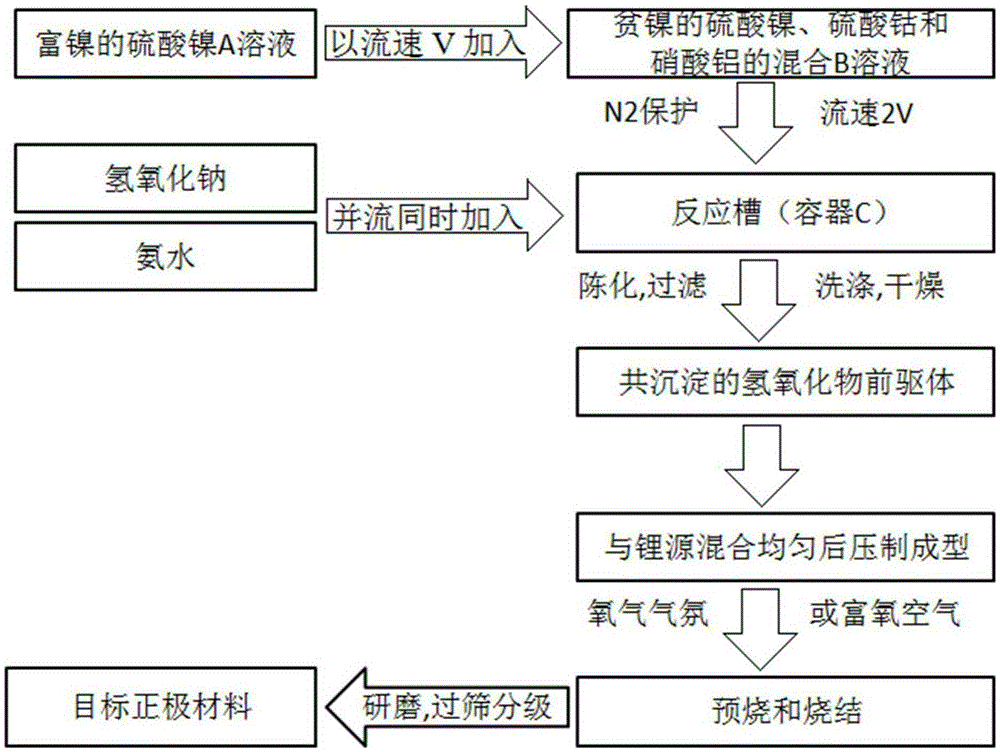

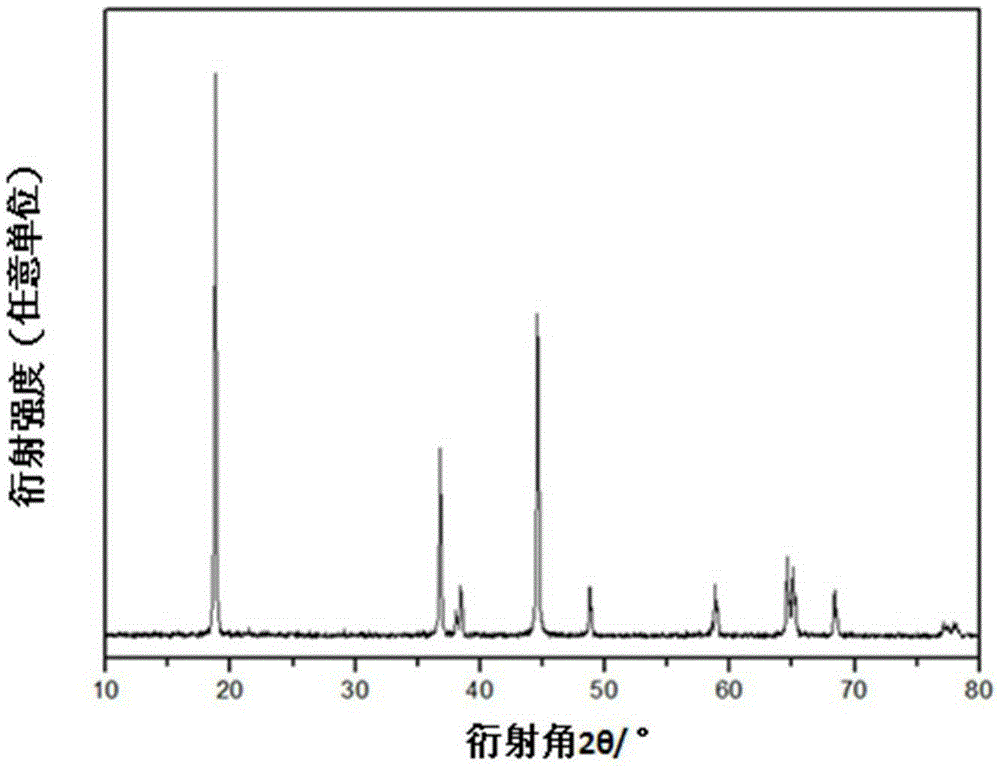

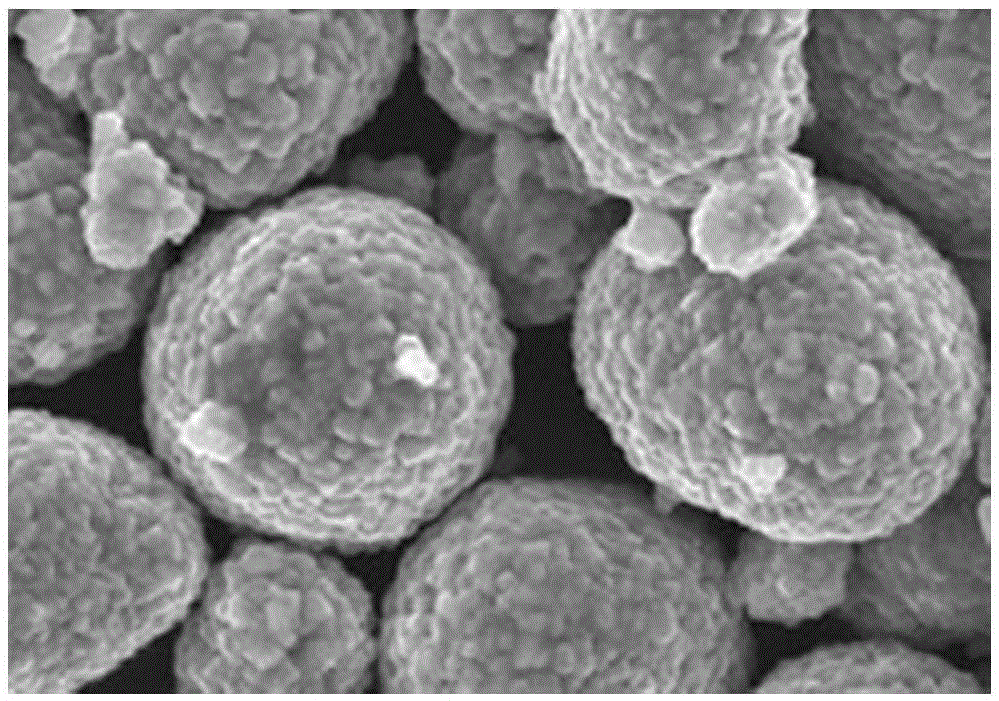

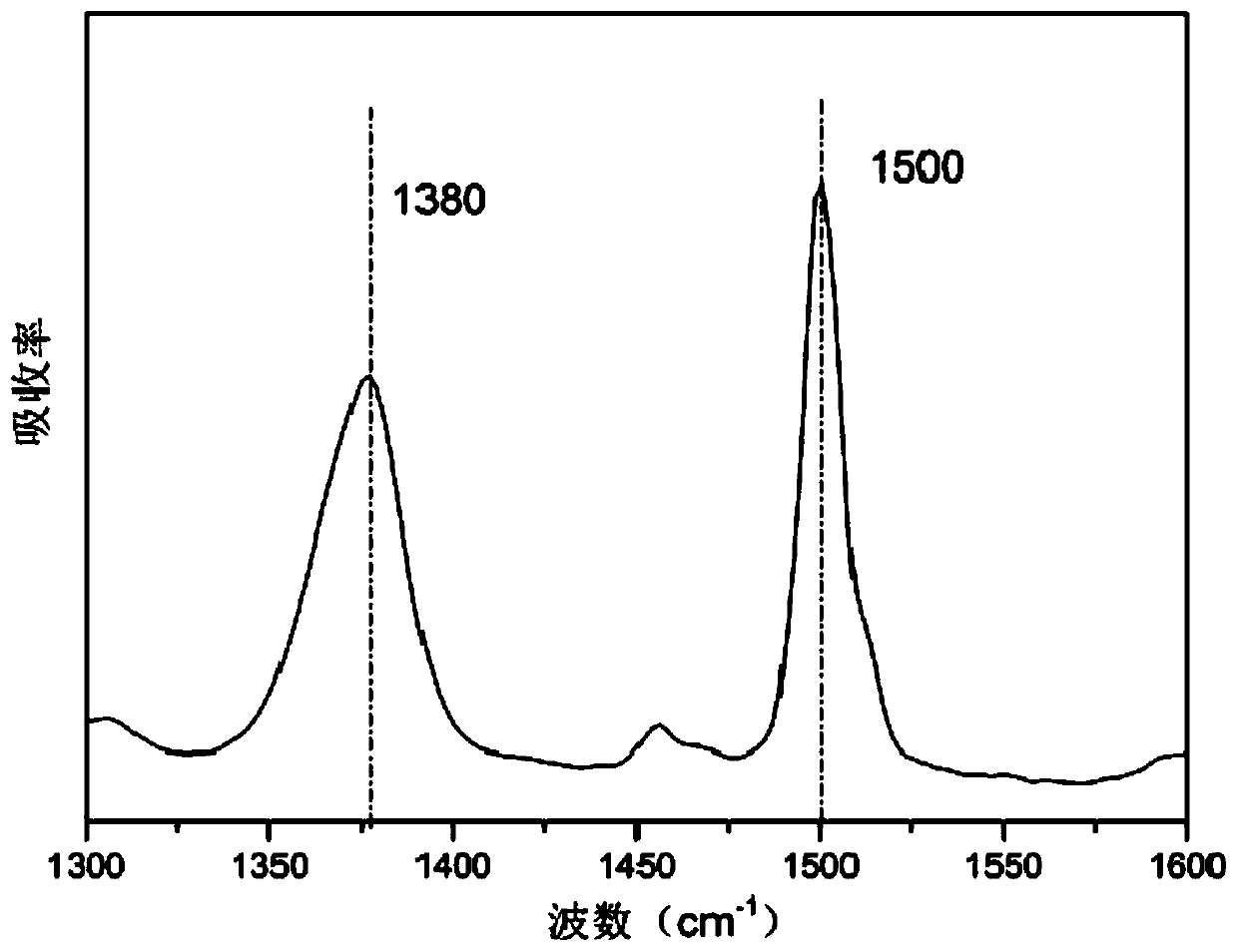

High-capacity cathode material for lithium ion batteries and preparation method thereof

InactiveCN105336944AMeet the demand for high-rate charge and dischargeOvercoming the need for high-rate charging and dischargingCell electrodesSecondary cellsFiltrationMixed materials

The invention discloses a high-capacity cathode material for lithium ion batteries and a preparation method thereof. The high-capacity cathode material is LiNi1-x-yCoxAlyO2. While Nickel sulfate solution rich in nickel is added into mixed solution of nickel, cobalt and aluminum poor in nickel, the mixed solution is added to a reaction tank; sodium hydroxide and ammonia-water solution are added into the reaction tank, and a coprecipitate Ni1-x-yCoxAly(OH)2+y precursor is prepared; the precursor undergoes ageing, filtration, washing and drying and then is mixed with a lithium source, and the mixed material is formed by compression; the material formed by compression is placed in a tube furnace to be presintered and sintered in oxygen airflow or oxygen-enriched air flow, and a target product is obtained. The prepared high-capacity cathode material for the lithium ion batteries is free of impure phase and high in crystallization quality, the product particle size distribution is uniform, the high-capacity cathode material has very high discharged specific capacity and cycling stability, an operation process is simple, raw material sources are extensive, the manufacturing cost is low, and large-scale industrial production is achieved easily.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

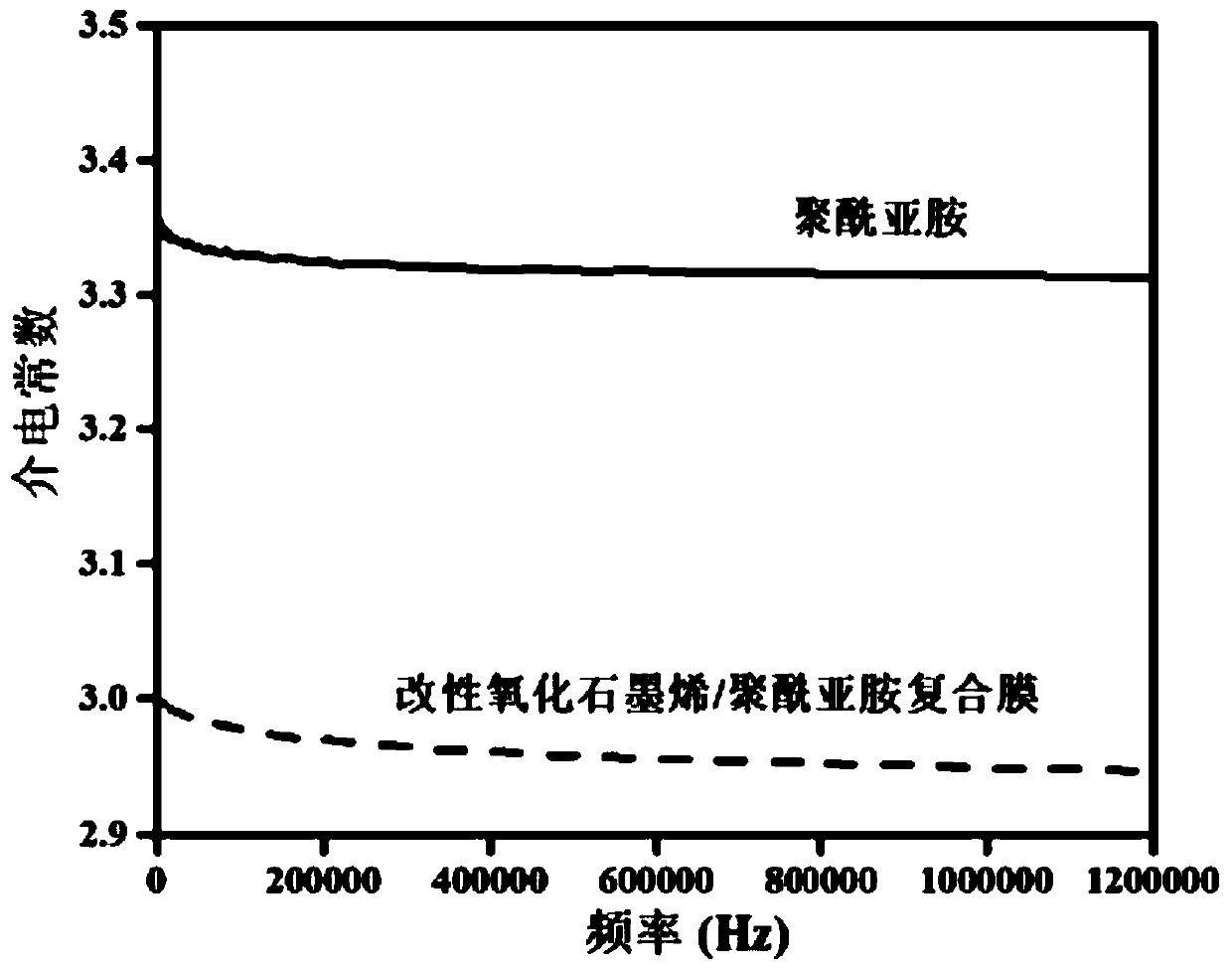

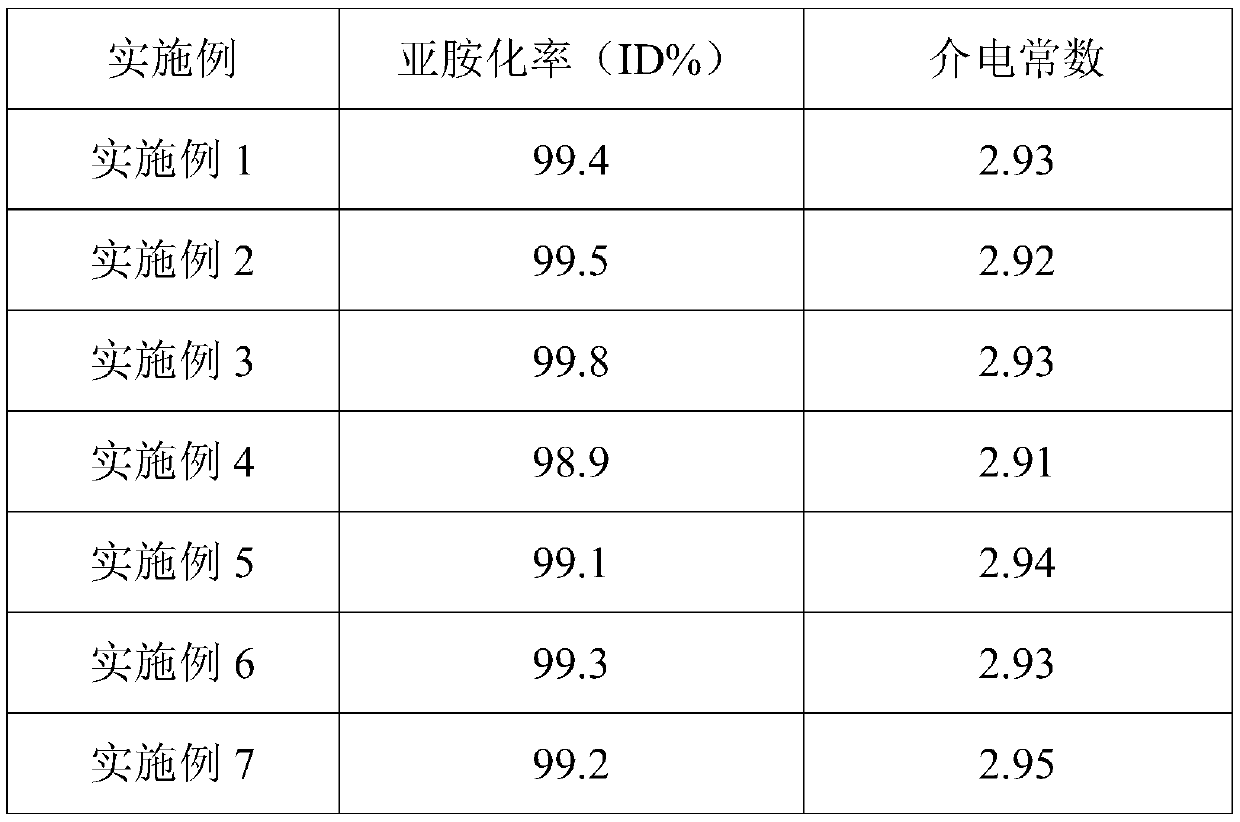

Modified graphene oxide, slurry and composite film, and preparation methods and applications thereof

ActiveCN110818951AImprove imidization rateLow dielectric constantCarbon compoundsSemiconductor/solid-state device manufacturingComposite filmOrganic solvent

The invention provides modified graphene oxide, slurry and a composite film, and preparation methods and applications thereof. The modified graphene oxide is graphene oxide modified by a curing accelerator; the slurry comprises modified graphene oxide, polyimide and / or a polyimide precursor, and an organic solvent; the composite film is formed by solidifying the slurry; the composite film has a high imidization rate, a low dielectric constant and a low curing temperature, so that the composite film can be used as a special functional plastic to be applied to advanced packaging of semiconductors, warping of ultrathin wafers and reconstructed wafers can be well avoided, and damage to heat-labile elements can be effectively avoided.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

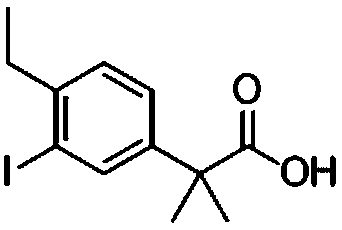

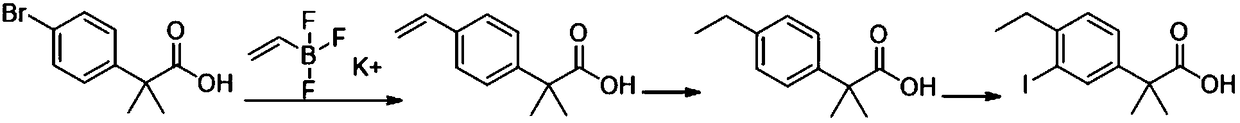

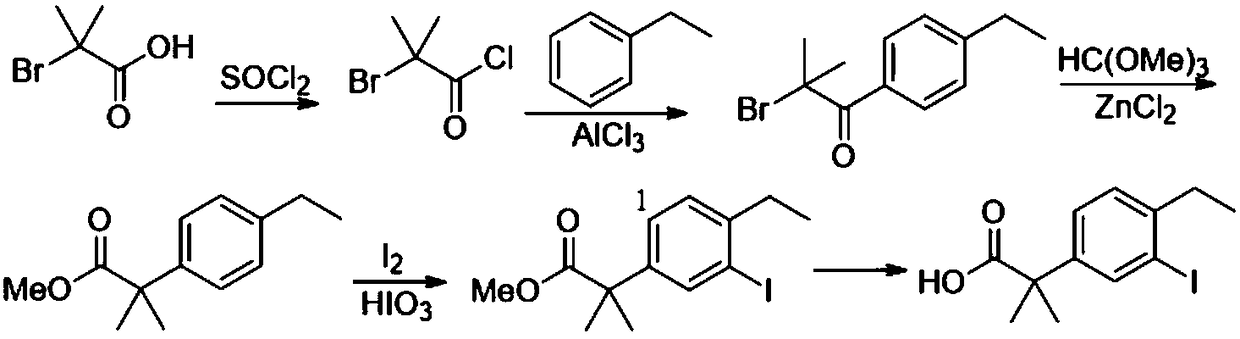

Preparation method of alectinib intermediate

ActiveCN109384664AAvoid residueQuality improvementOrganic compound preparationCarboxylic acid esters preparationPropanoic acidPurification methods

The invention discloses a preparation method of 2-(4-ethyl-3-iodine) phenyl-2-methyl propionic acid as an alectinib intermediate. According to the preparation method, the operation danger class and production cost are reduced by optimizing and improving a preparation route method, optimizing reaction conditions and improving aftertreatment and purification methods; the requirement for the anti-corrosion class of container equipment for reaction is low, operation safety is good, aftertreatment is environmentally friendly, the impurity content of the obtained 2-(4-ethyl-3-iodine) phenyl-2-methylpropionic acid as the alectinib intermediate is low, the purity and quality of the intermediate product are greatly improved while the yield is improved, the difficulty of process control in an alectinib crude drug production process is reduced, and the quality and yield of the crude drug of alectinib are improved; and the various steps of the preparation method are operated simply, a solvent andprocess conditions are safe and easy to run, environmentally friendly production is realized, and the application prospect is wide.

Owner:成都正善达生物医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com