Preparation method for poly-p-phenylene benzobisoxazole fiber reinforced resin matrix composite material

A technology of fiber-reinforced resin and benzobisoxazole, which is applied in the field of preparation of poly-p-phenylenebenzobisoxazole fiber-reinforced resin-based composite materials, and can solve the problem that fiber surface modification methods are not easy for large-scale industrial production, PBO Problems such as poor interface properties between layers of fiber-reinforced resin-based composite materials, etc., to achieve the effects of easy operation, improved wetting effect, and various types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

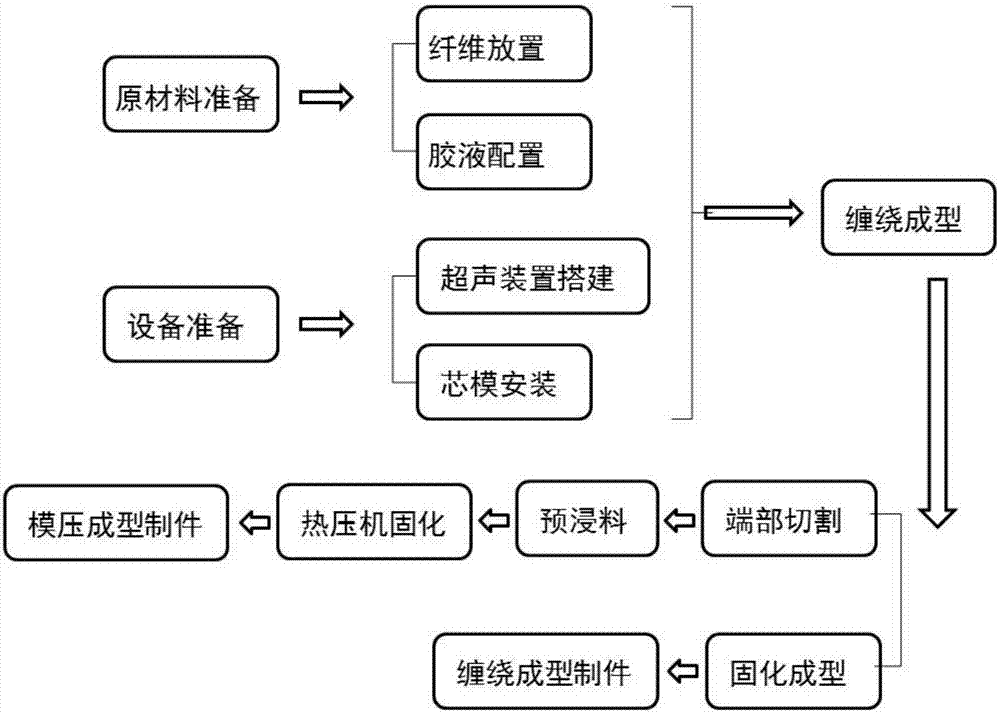

Method used

Image

Examples

specific Embodiment 1

[0032] (1) Material preparation: 100 parts of epoxy resin, and 13 parts by weight of modified imidazole curing agent. In parts by weight, 2% of the total weight of the KH560 silane coupling agent was weighed, and stirred evenly at a temperature of 10° C. to 30° C. The resin system used in the wet winding molding process is obtained, which is left to stand for use.

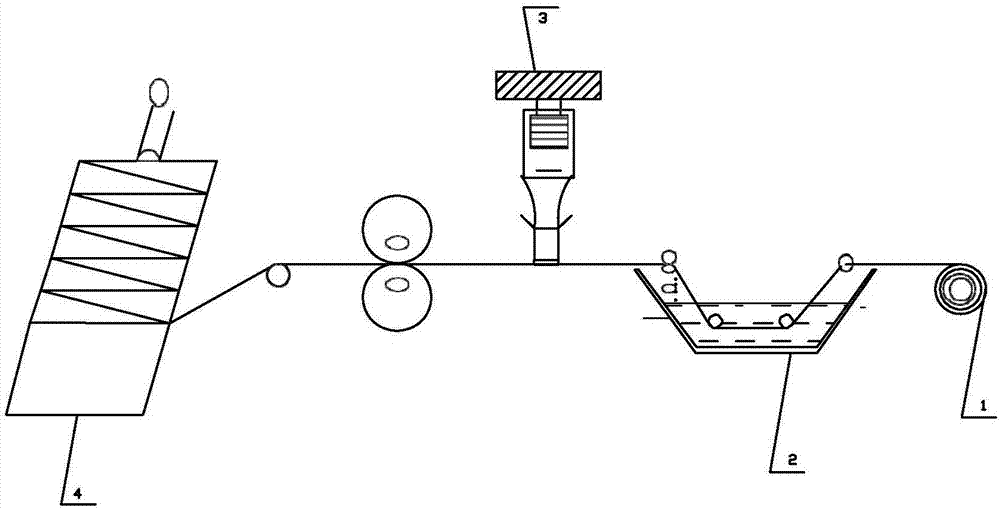

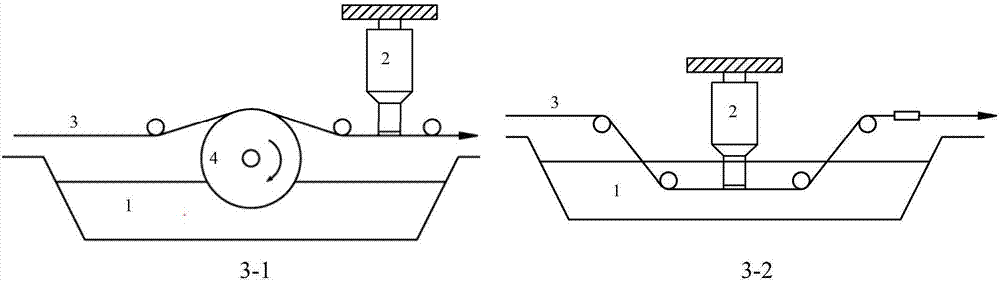

[0033](2) Device preparation: PBO fiber is placed on the creel. According to the distribution of the rollers of the winding equipment, the PBO fibers are wound between the rollers in sequence, and the attached Figure 3-1 Way dipping. Select the steel mandrel as the lining, and install the mold on the winding machine for use. Build an ultrasonic device, firmly connect the ultrasonic cluster probe and the ultrasonic vibration generator, fix the ultrasonic cluster probe, place the probe after fiber dipping, and make the probe contact with the fiber. The glue solution prepared in step (1) is placed in a dipping tan...

specific Embodiment 2

[0037] (1) Material preparation: Bismaleimide resin is used as the resin system for preparing prepregs in wet winding process.

[0038] (2) Device preparation: PBO fiber is placed on the creel. According to the distribution of the rollers of the winding equipment, the PBO fibers are wound between the rollers in sequence, and the attached Figure 3-2 Way dipping. A metal circular cylinder with a diameter of 1m is selected as the mandrel for preparing the prepreg, and the surface of the mandrel is pasted with release paper. Build an ultrasonic device, firmly connect the ultrasonic cluster probe and the ultrasonic vibration generator, fix the ultrasonic cluster probe, and place the probe in the fiber dipping tank with a distance of about 2 mm between the probe and the fiber. The glue solution prepared in step (1) is placed in a dipping tank. Adjust the parameters of the ultrasonic vibration generator, set the ultrasonic power at 450W, the ultrasonic frequency at 40kHz, and con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com