Patents

Literature

3031results about How to "Improve molding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

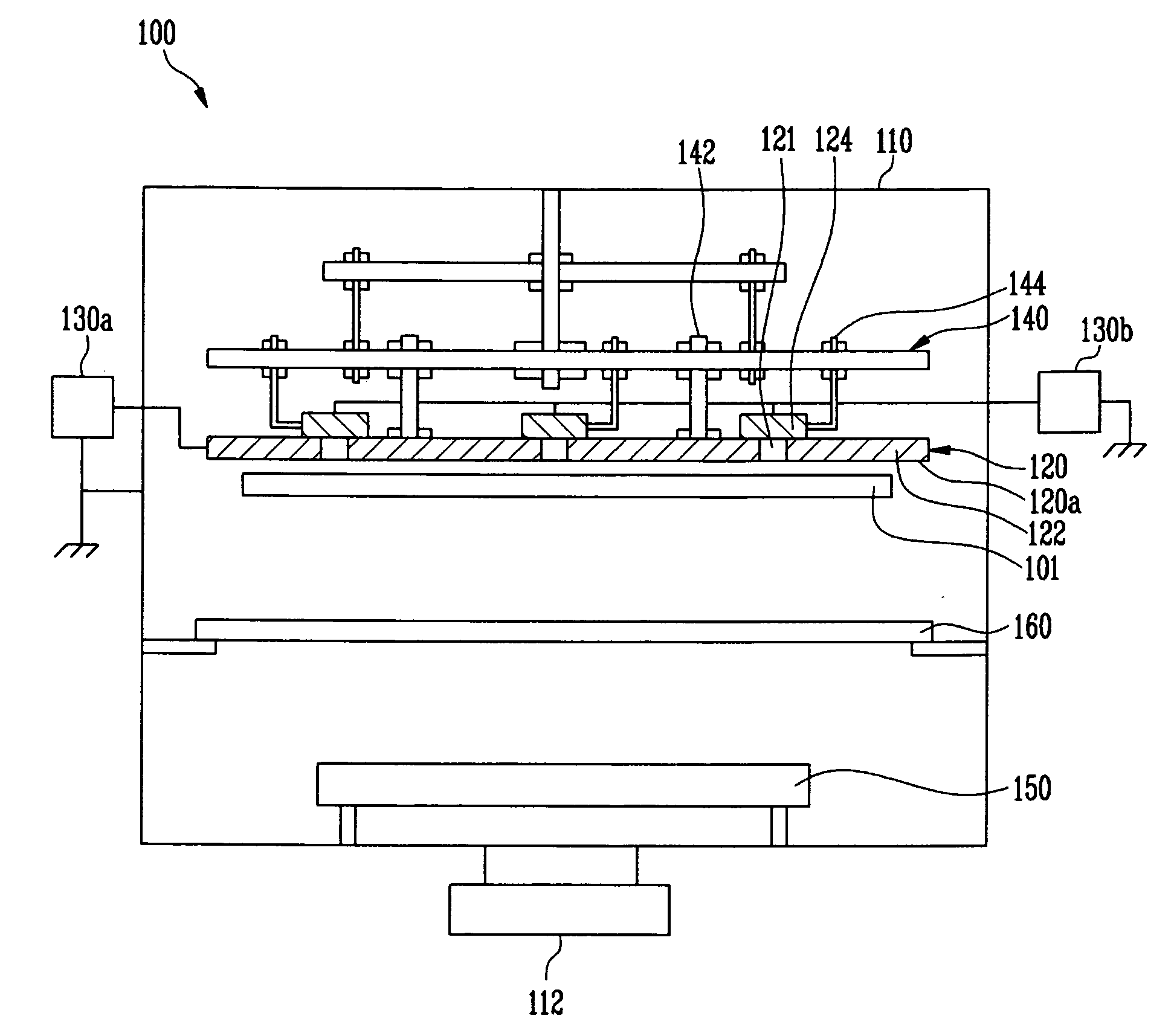

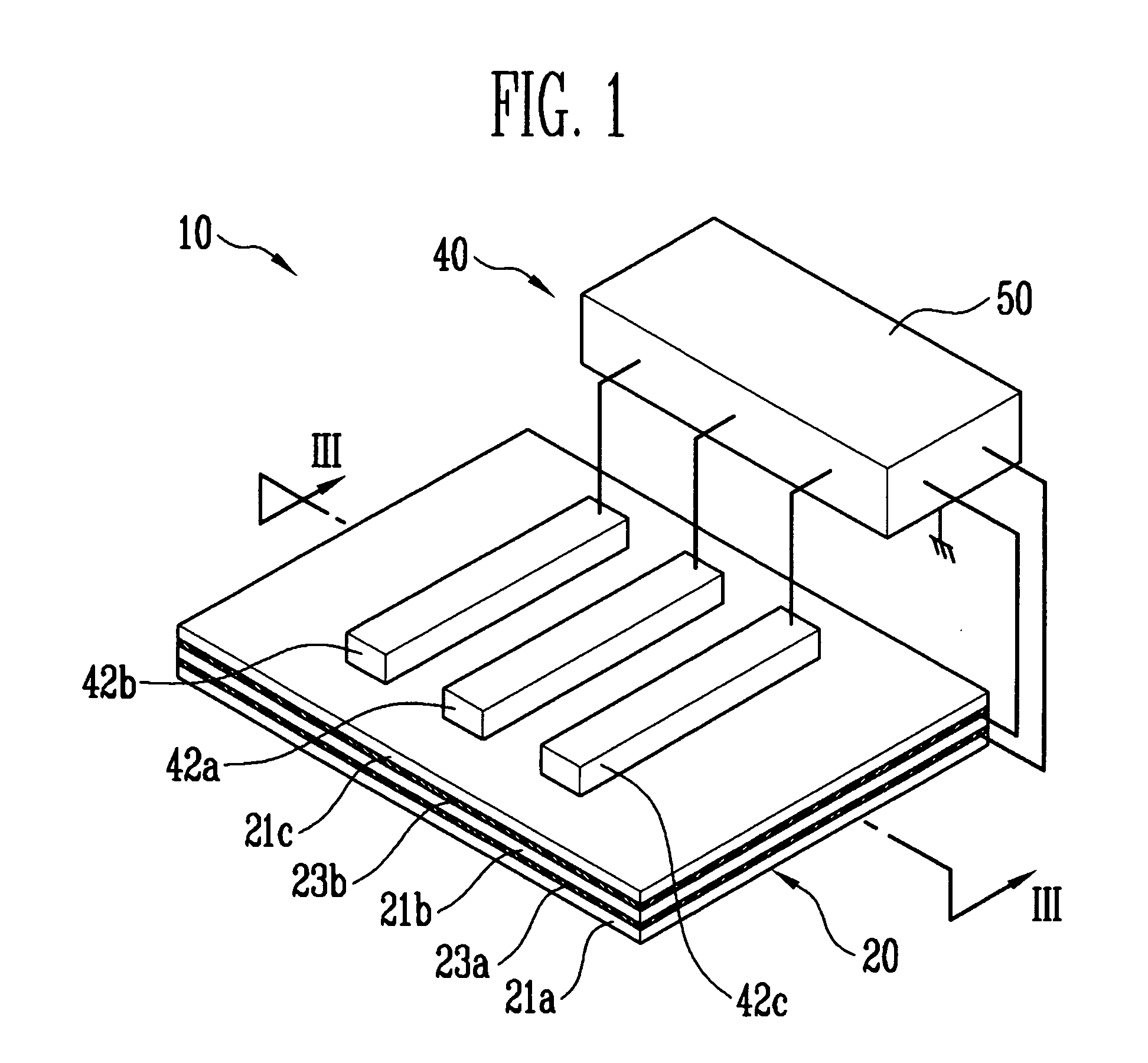

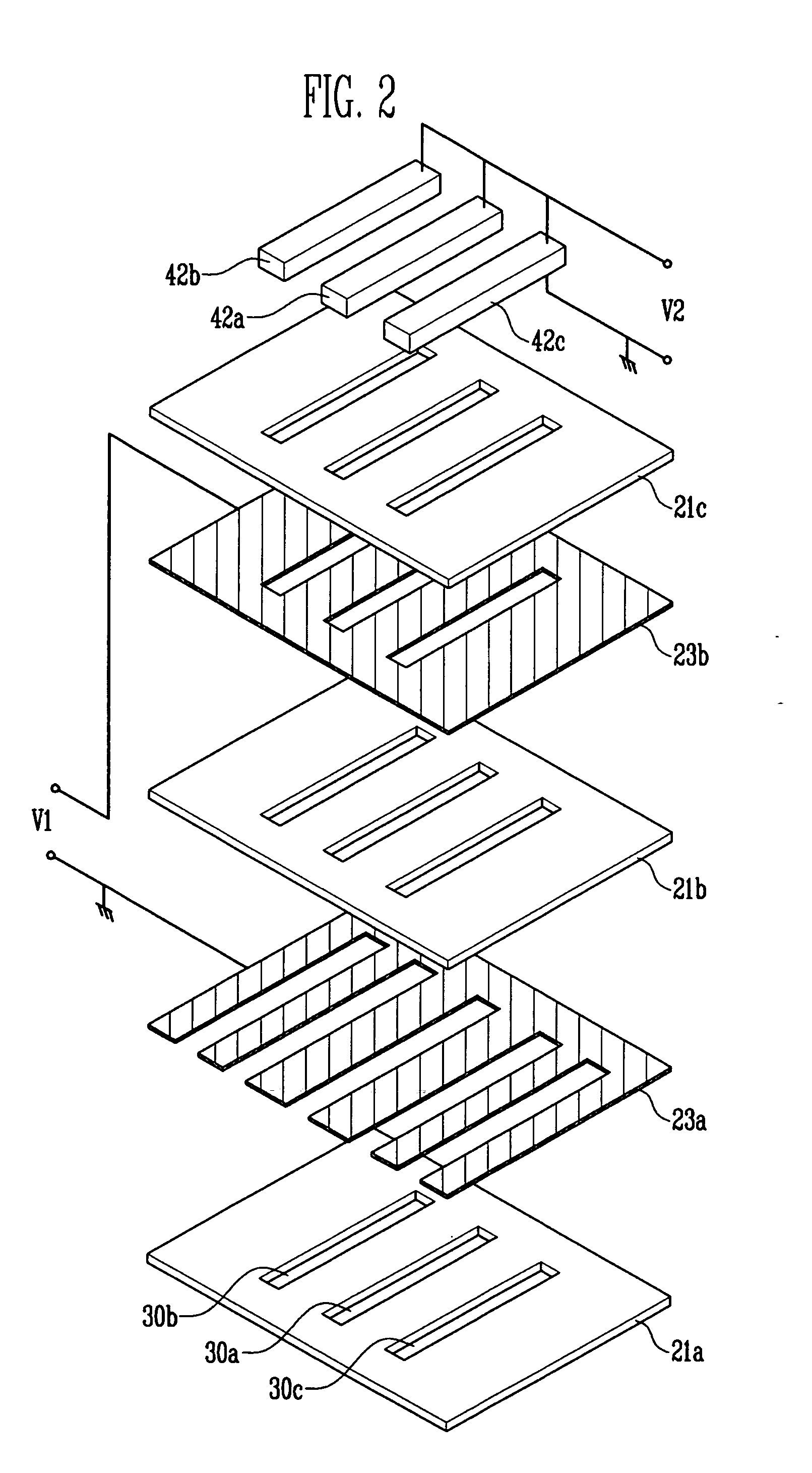

Electrostatic chuck and device of manufacturing organic light emitting diode having the same

ActiveUS20100188794A1Stable controlEasy to implementElectroluminescent light sourcesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

The present invention discloses an electrostatic chuck sucking and supporting a substrate with an electrostatic force and an OLED manufacturing apparatus having the same. The electrostatic chuck includes an insulating plate having at least one opening penetrating a center thereof, a pair of electrodes mounted on the insulating plate, a first controller applying a voltage to the pair of electrodes, and an electrostatic charge removing unit disposed near the insulating plate and emitting ions into the at least one opening to remove electrostatic charges distributed around a side of the insulating plate.

Owner:SAMSUNG DISPLAY CO LTD

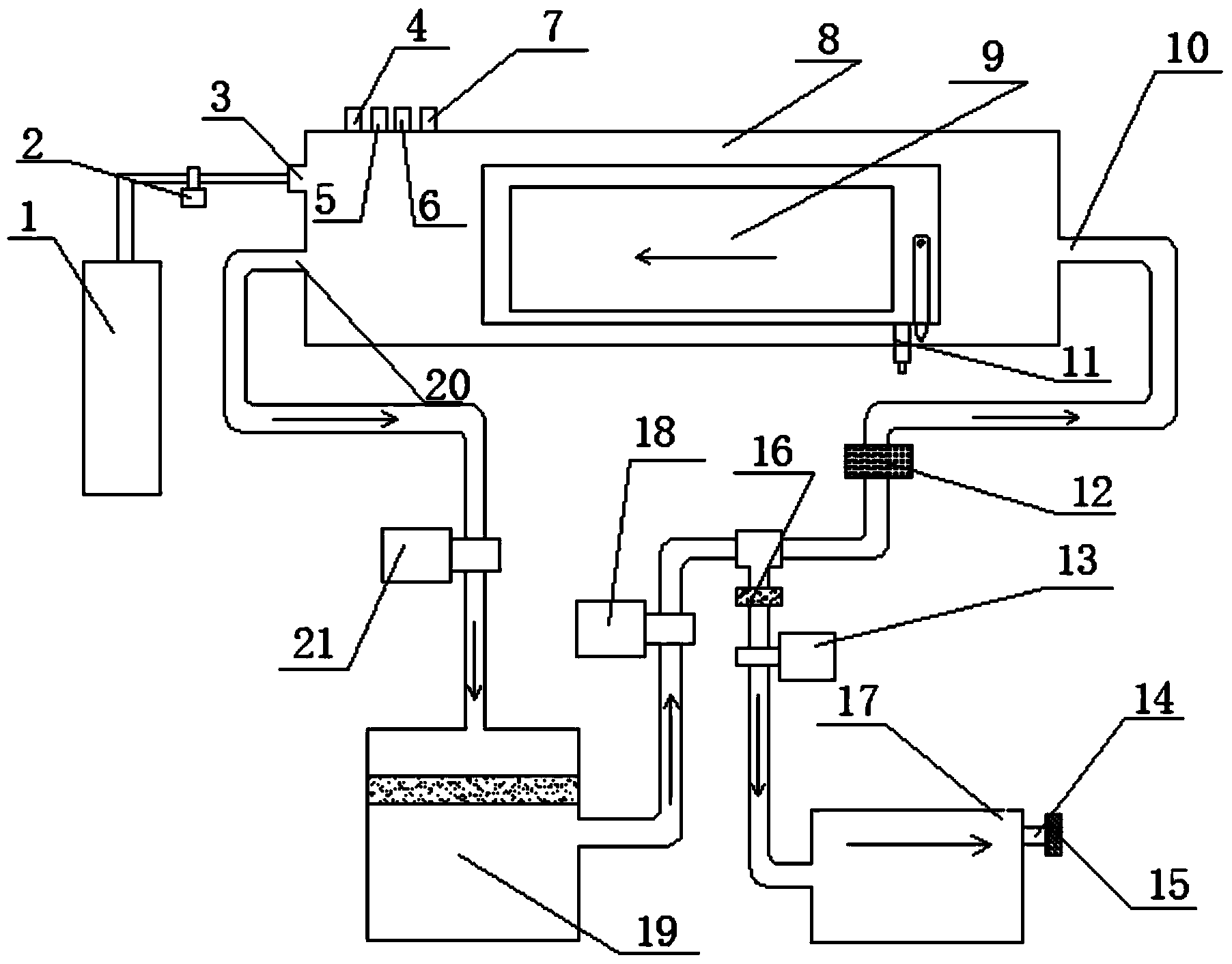

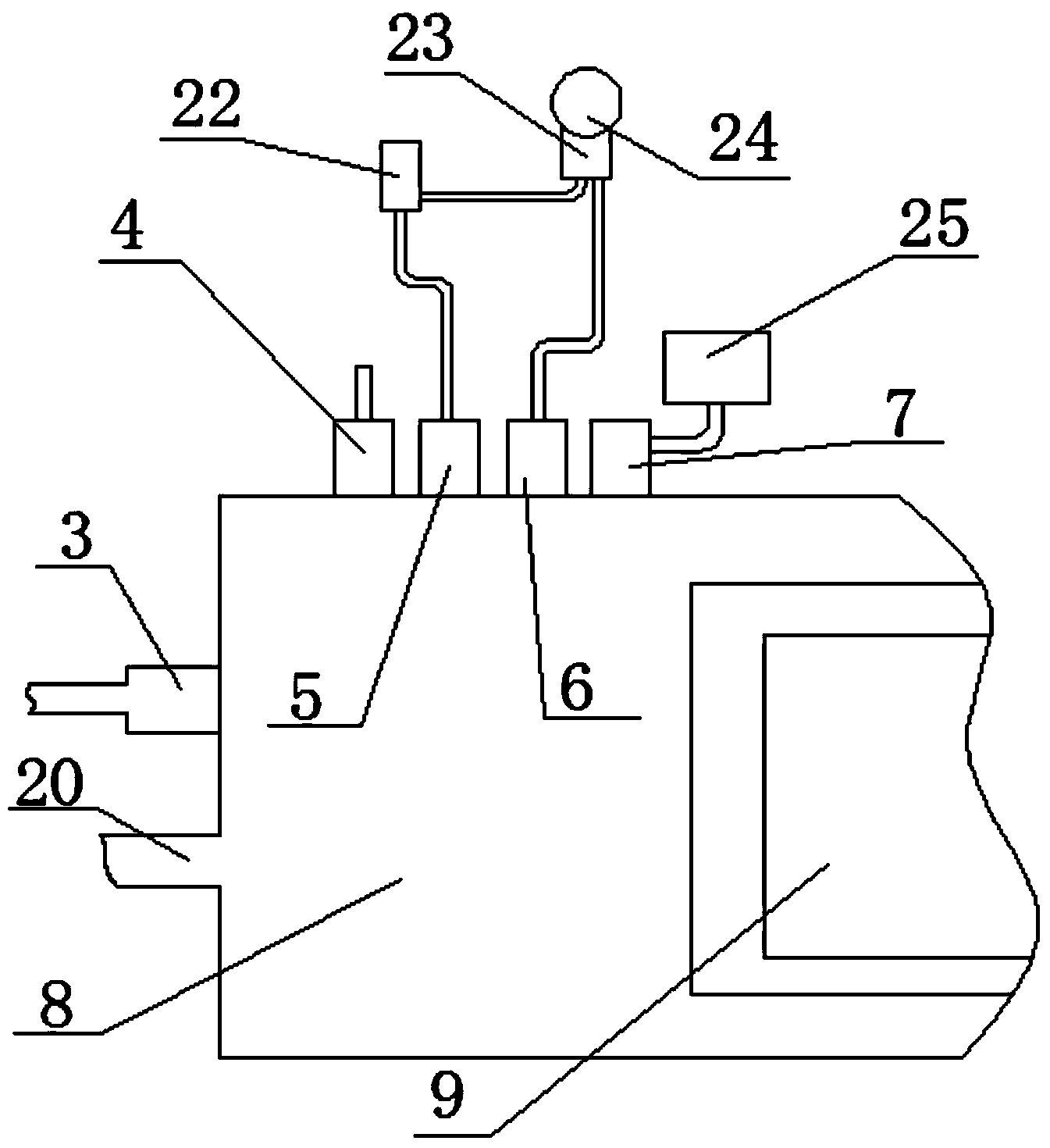

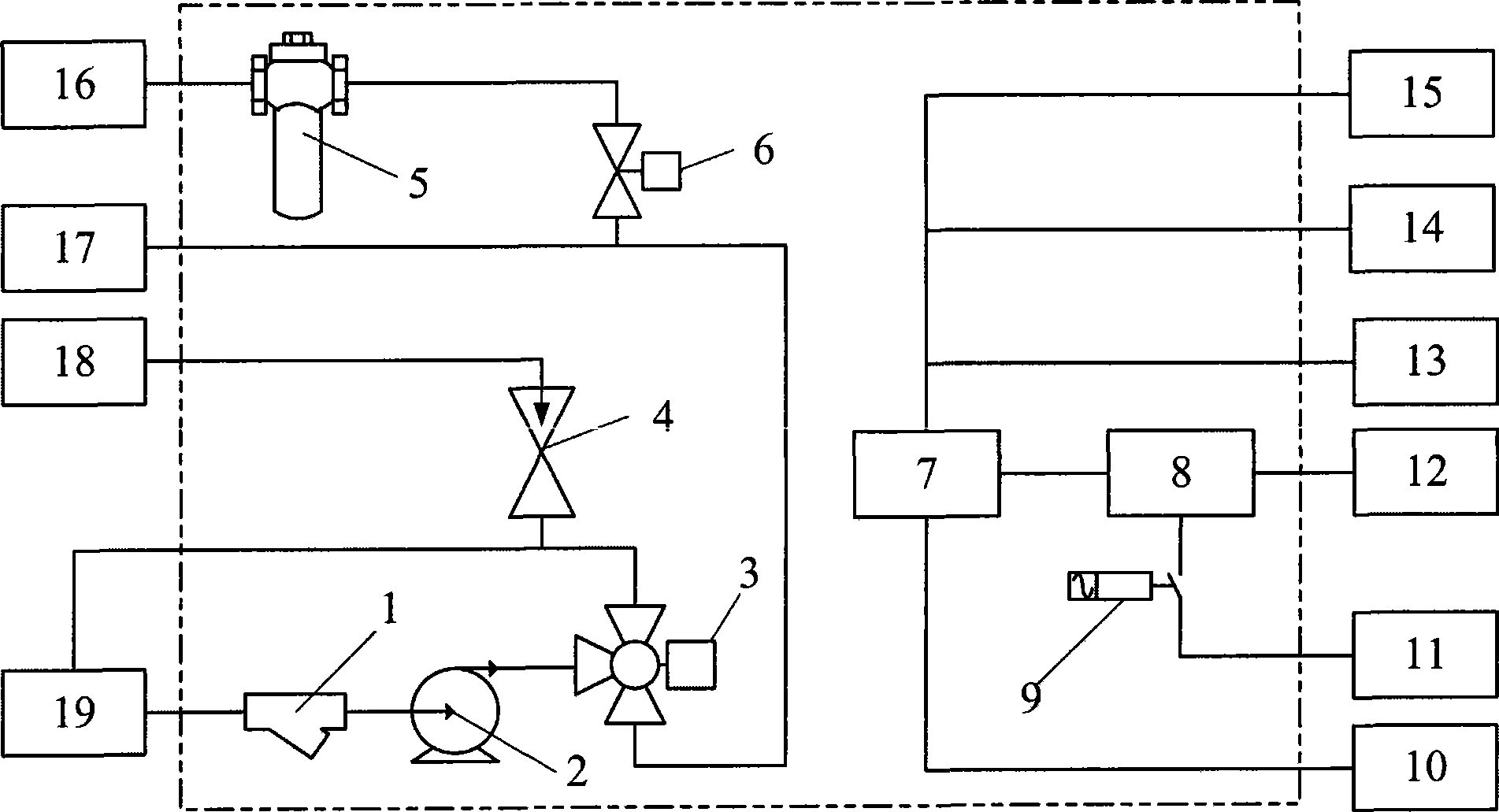

Method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for metal 3D printer

ActiveCN104353832ALow oxygenReduce usageAdditive manufacturingIncreasing energy efficiencyMolecular sieveSolenoid valve

The invention discloses a method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for a metal 3D printer. A gas inlet and a gas outlet are respectively formed in two ends of a forming chamber; the gas inlet and the gas outlet are mutually connected through a gas circulating pipeline; a first pneumatic butterfly valve, a dust purifier, a second pneumatic butterfly valve and a water removal drier are arranged on the gas circulating pipeline; a branch pipeline is arranged on the gas circulating pipeline between the second pneumatic butterfly valve and the water removal drier; the tail end of the branch pipeline is connected with a vacuum pump; a molecular sieve and a vacuum pipeline solenoid valve are arranged on the branch pipeline; the forming chamber is connected with an inert gas source. According to the method, firstly the oxygen content in the forming chamber is reduced to a required range before machining, and gas circulating purification is started during machining, so that gas purity degree in the forming chamber is kept; pressure detection and oxygen content detection are introduced, so that the oxygen content and pressure are within a reasonable range at all time during machining. The method and the equipment improve the forming efficiency and quality of the 3D printer, and guarantee the safety and the reliability of the machining process.

Owner:SOUTH CHINA UNIV OF TECH

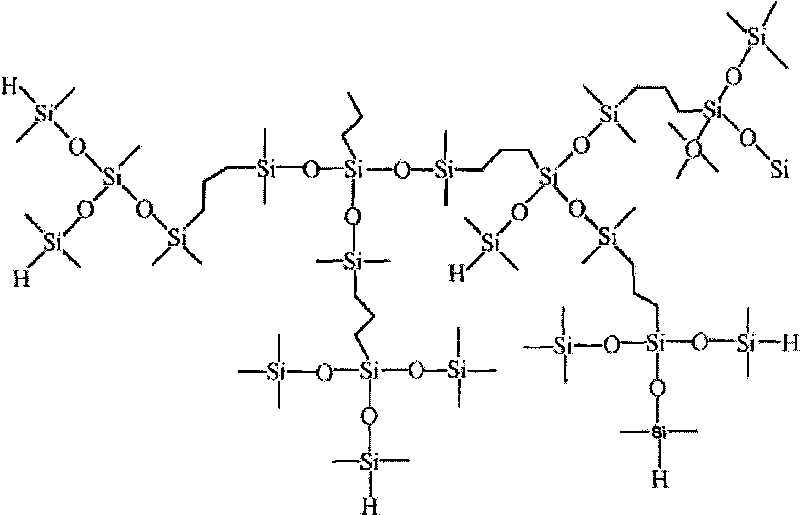

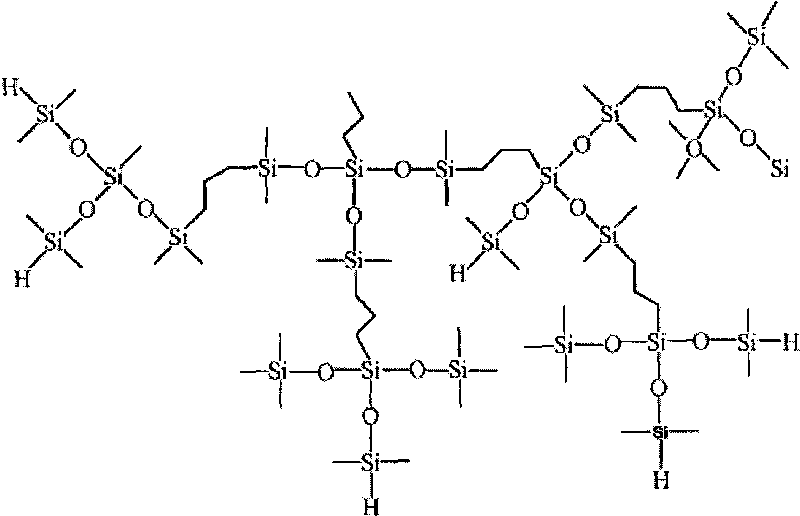

Thermoplastic halogen-free and low-smoke flame-retardant polyolefin sheathed plastic and preparation method and application thereof

InactiveCN101747551AImprove molding qualityImprove liquidityPlastic/resin/waxes insulatorsInsulated cablesPolyolefinAntioxidant

The invention discloses a thermoplastic halogen-free and low-smoke flame retardant polyolefin sheathed plastic which comprises the following components by weigh part: 30-80 of polyolefin resin, 0-30 of blend resin, 5-20 of grafted materials, 100-150 of inorganic fire retardants, 0.5-30 of coupling agents, 0.5-1.5 of antioxidants and 1-4 of hyperbranched polymers. Compared with the prior art, because hyperbranched polysiloxane is added into the halogen-free low-smoke flame retardant polyolefin sheathed plastic, a prepared product plays a toughening role while improving the system mobility. The obtained halogen-free low-smoke flame retardant polyolefin sheathed plastic adapts to quick production and has the advantages of good flame retardant property, good cracking resistance property, storing mechanical property and good extruding and forming quality.

Owner:上海新上化高分子材料有限公司

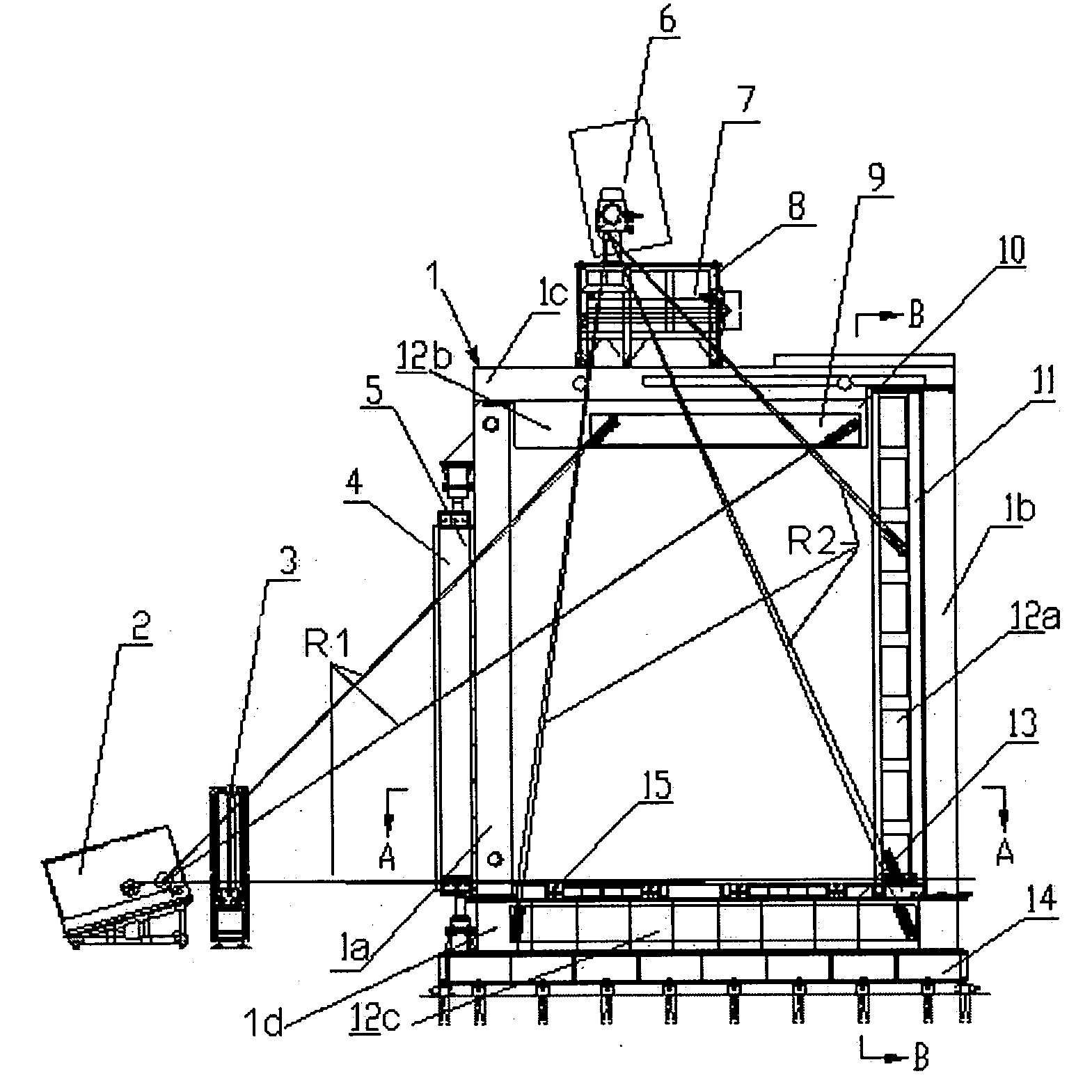

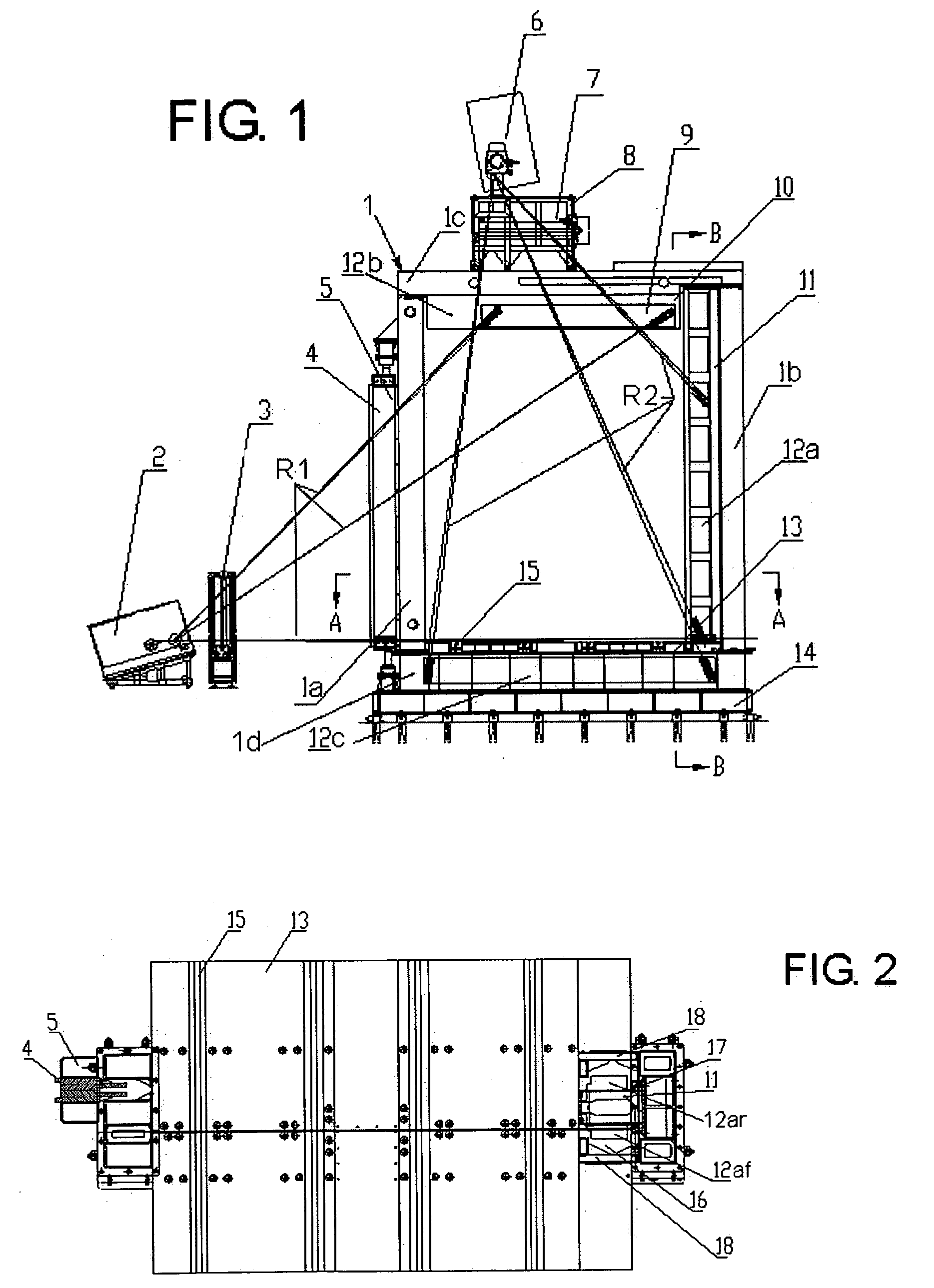

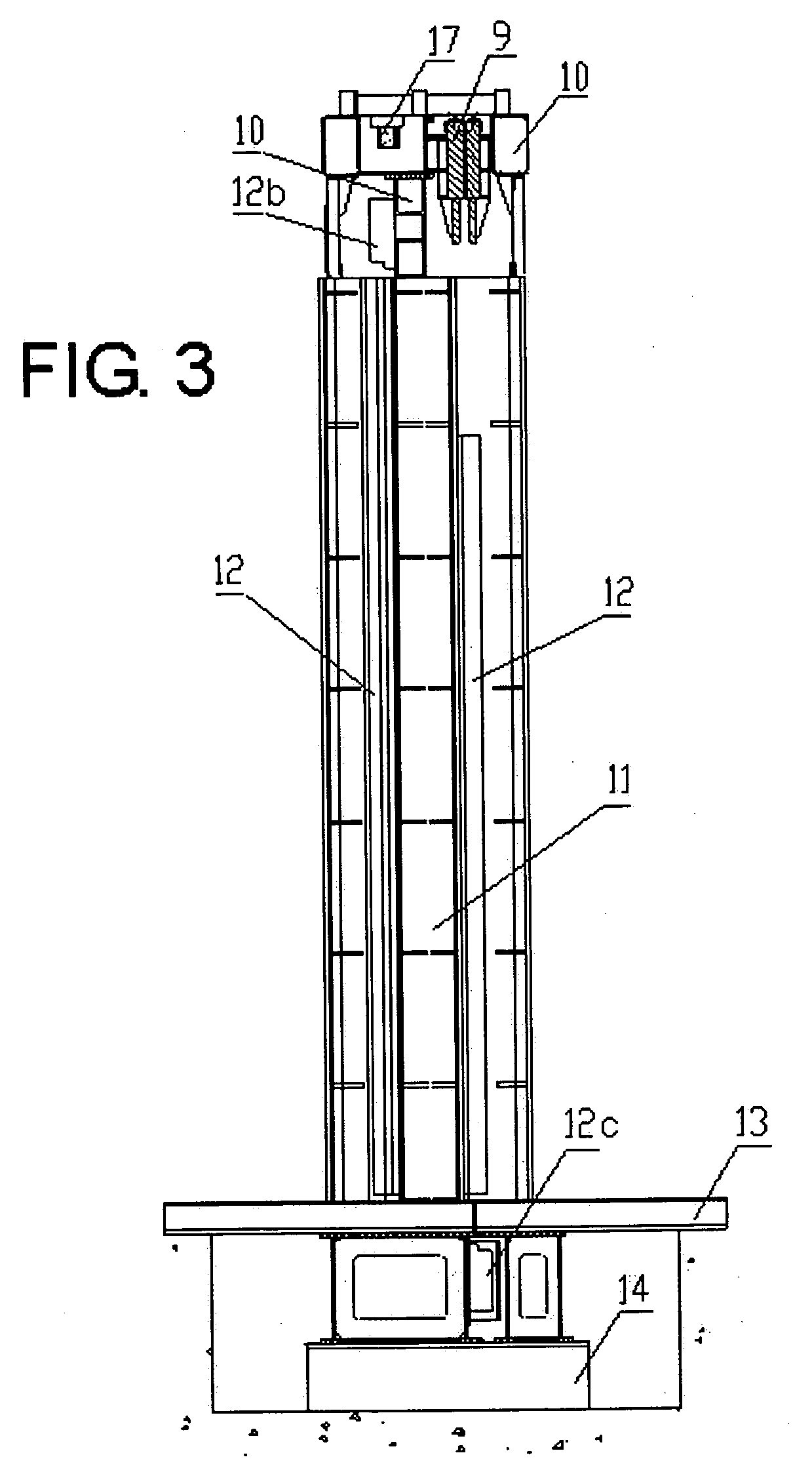

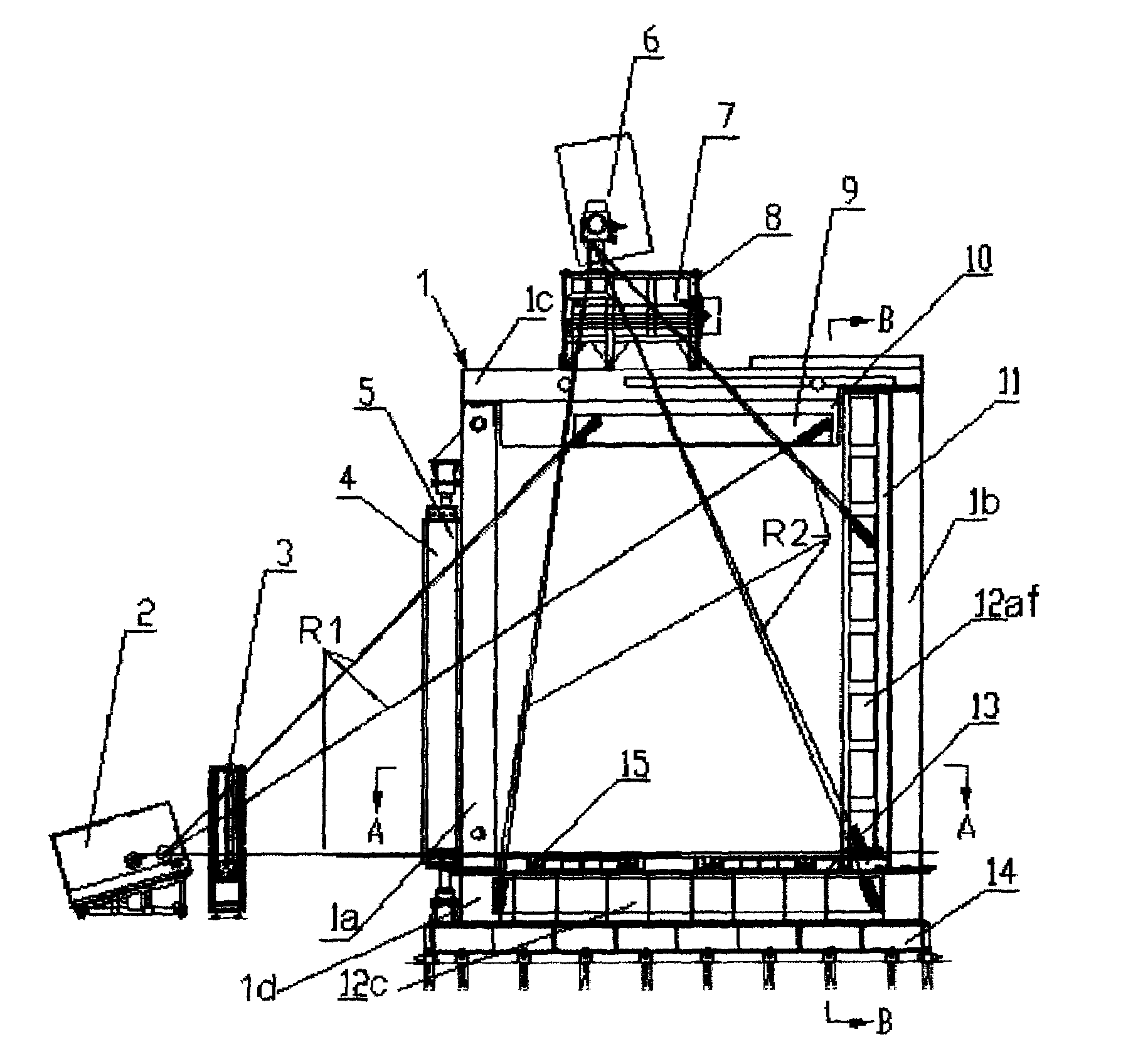

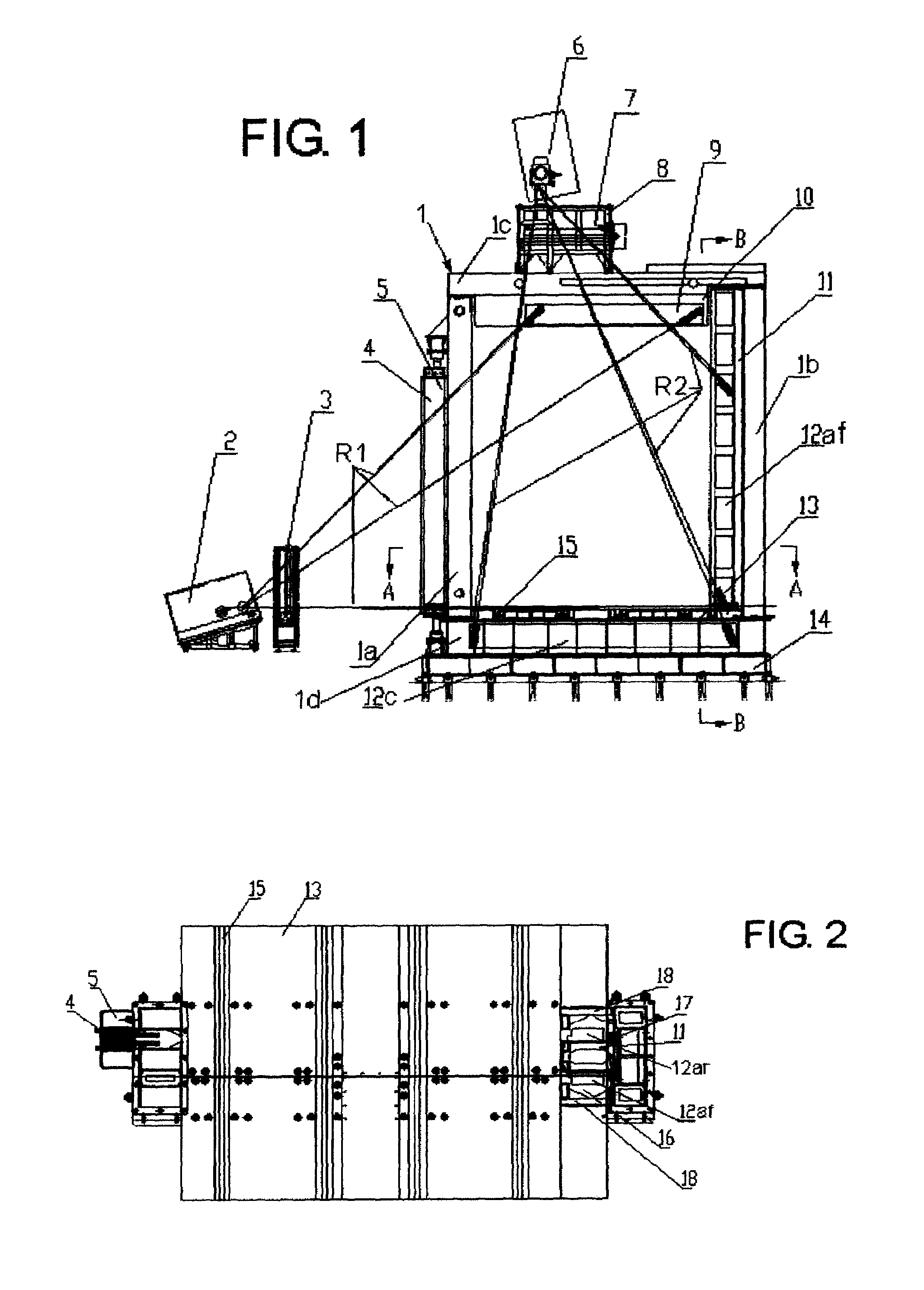

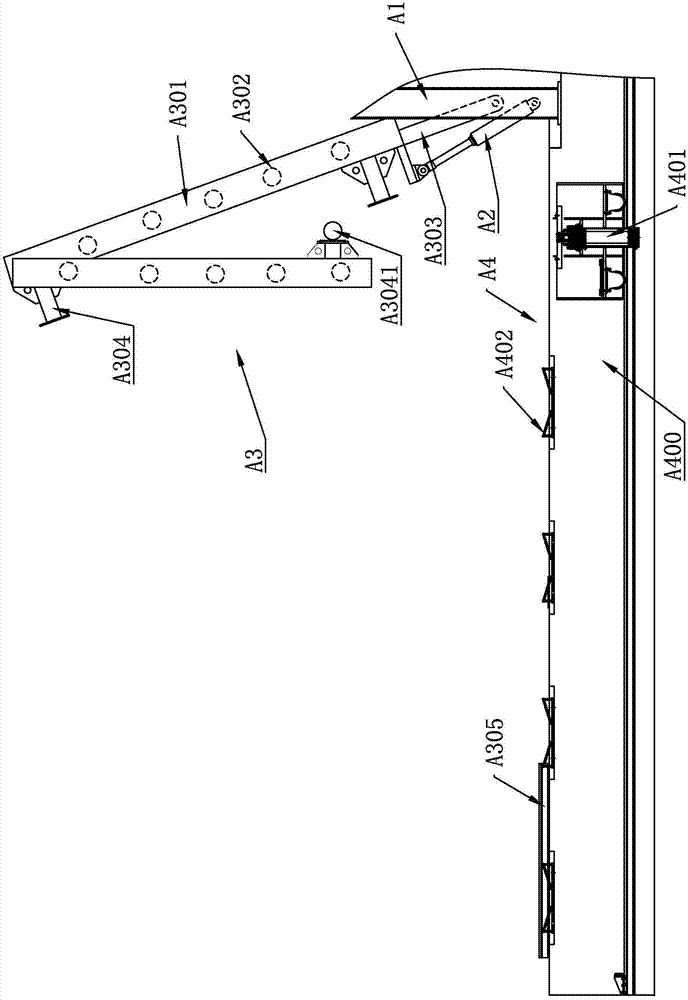

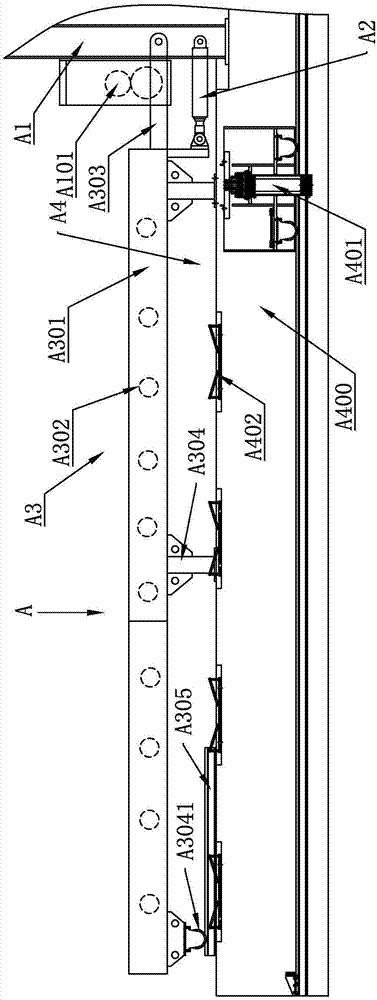

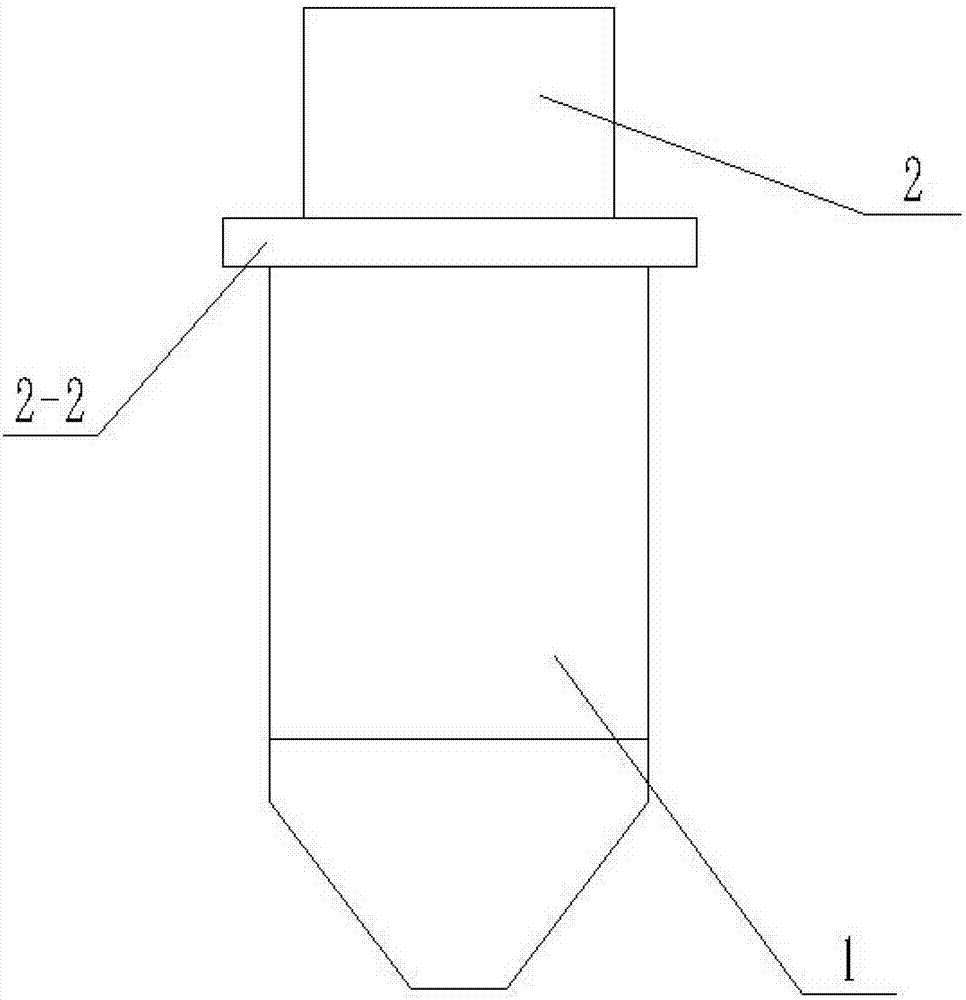

Double-radiant-source framework for container detecting system

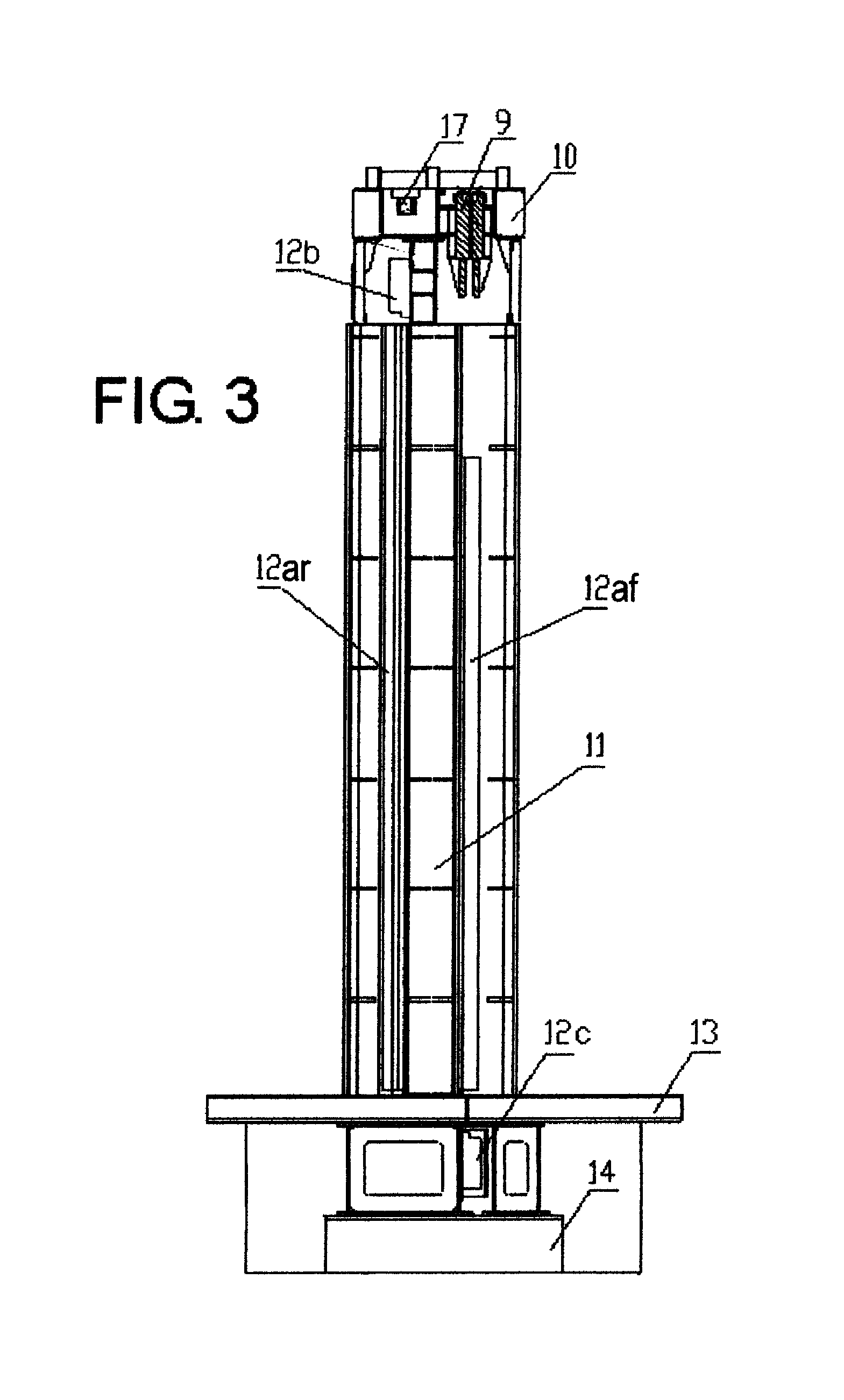

ActiveUS20060018428A1Easy to useEasy to installMaterial analysis by transmitting radiationNuclear radiation detectionLight beamTower

A double-radiant-source framework used for a container detecting system, which belongs to the technical field of radiation detection, having a horizontal accelerator, a vertical accelerator and a gantry tower composed of a left vertical girder, a right vertical girder, an upper cross girder, and a lower cross girder. A horizontal collimator and a vertical collimator are disposed in front of the frontal face each of the horizontal accelerator and the vertical accelerator. The horizontal collimator and the vertical collimator are fixed on the left vertical girder and the upper cross girder of the gantry tower, respectively. The radiation beams defined by the horizontal collimator and the vertical collimator are two planes oriented parallel to each other. A double-detector arm is disposed inside the right vertical girder of the gantry tower, and detector modules are disposed inside the double-detector arm for receiving the two different planes of radiation beams defined by and emitted from the horizontal collimator and the vertical collimator. Detector modules are disposed inside the upper cross girder and the lower cross girder respectively for receiving separately radiation beams defined by and emitted from the horizontal collimator and the vertical collimator. The container detecting system can reduce the area covered by the scanning channel of the system, and make the transportation, installation and use convenient, and improve the quality of the detected images.

Owner:TSINGHUA UNIV +1

Double-radiant-source framework for container detecting system

ActiveUS7215737B2Reduce areaQuality improvementMaterial analysis by transmitting radiationNuclear radiation detectionEngineeringTower

A double-radiant-source framework used for a radiation detecting system for containers, having a horizontal accelerator, a vertical accelerator and a gantry tower composed of a left vertical girder, a right vertical girder, an upper cross girder, and a lower cross girder. A horizontal collimator and accelerator, and a vertical collimator and accelerator, are fixed on the left vertical girder and the upper cross girder of the gantry tower, respectively, and emit radiation beams as two planes oriented parallel to each other. Detector modules are disposed inside the double-detector arm of the right vertical girder, and inside the upper cross girder and the lower cross girder, respectively, to receive the two emitted planes of radiation beams. The container detecting system can reduce the area covered by the scanning channel of the system, and make the transportation, installation and use convenient, and improve the quality of the detected images.

Owner:TSINGHUA UNIV +1

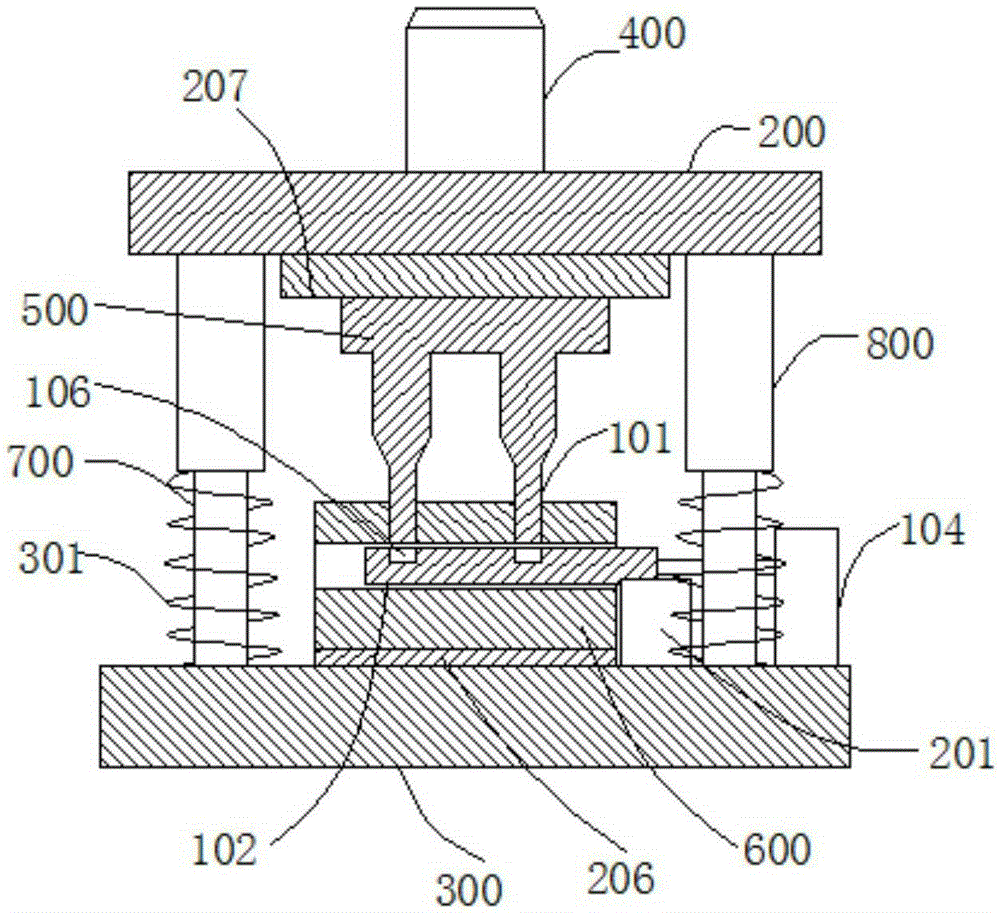

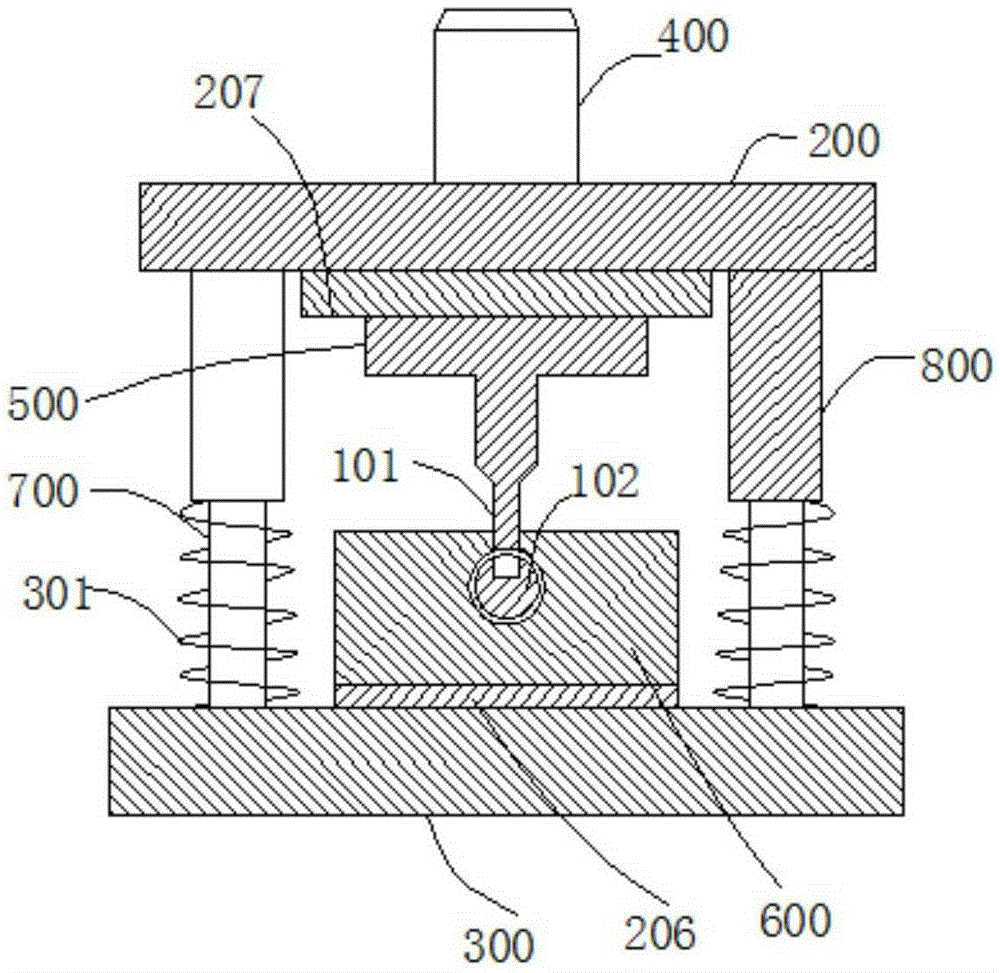

Thermal punch forming technique and forming mold for super-strength steel

The invention provides an ultra-high strength steel thermal punching molding process and a molding die thereof. Before the thermal punching molding of ultra-high strength steel sheet, the thermal punching molding process is used for heating parts which are in contact with the ultra-high strength steel sheet in a die and need to be punched, so as to lead the surface temperature of the parts to reach or exceed martensite temperature of the ultra-high strength steel. Then, the ultra-high strength steel sheet which is heated to be totally austenitized is put in the die to be punched and molded. When closed, the thermal punching die is cooled. The die parts which are in contact with the molded parts are utilized for quenching the molded parts. The thermal punching molding die comprises a convex die, a concave die and a control unit. An electrothermal element and a cooling water channel are arranged in the convex die and the concave die. A temperature sensor is arranged in the convex die and the concave die. A reset switch and a pressure plate are respectively arranged on lateral sides of the concave die and the convex die. The ultra-high strength steel thermal punching molding process and the molding die thereof avoid cracks on surfaces and at the inner parts of the molded parts, eliminate the part molding resilience and ensure the precision and the quality of products.

Owner:SHANDONG UNIV

Environmental-friendly magnesium alloy mold releasing agent

InactiveCN101898227AHigh quality moldingImprove liquidityFoundry mouldsFoundry coresPreservativeSynthetic Polymeric Macromolecules

The invention discloses an environmental-friendly magnesium alloy mold releasing agent which comprises organic silicon, a synthetic macromolecular compound, grease, an antirust corrosion inhibitor, a preservative, a surface active agent and water. The environmental-friendly magnesium alloy mold releasing agent has excellent flowing property, thus the generation of poor flowing property can be greatly reduced. The product has excellent adsorbing performance, thus the lubricating mold releasing performance of the product can be obviously improved; the product has excellent heat insulating performance, thus the molding quality of a workpiece can be obviously improved; meanwhile, the environmental-friendly magnesium alloy compression-casting mold releasing agent has environmental protection and high performance.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

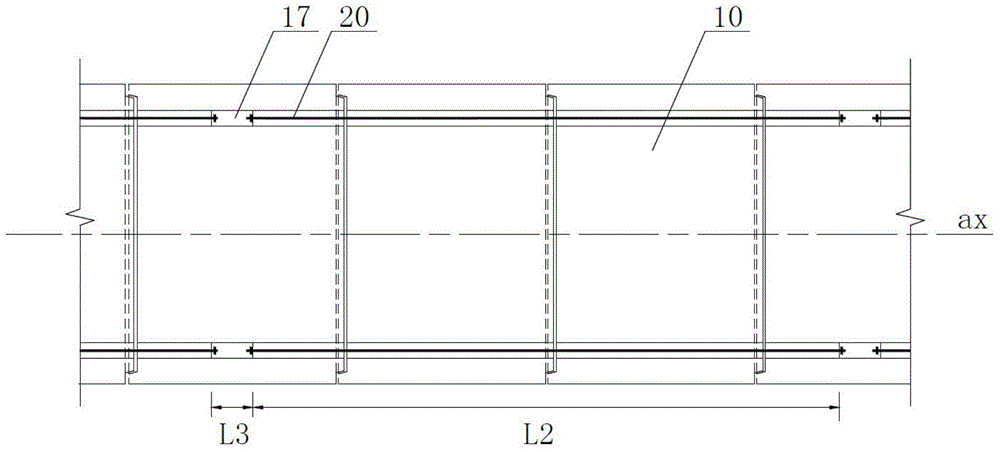

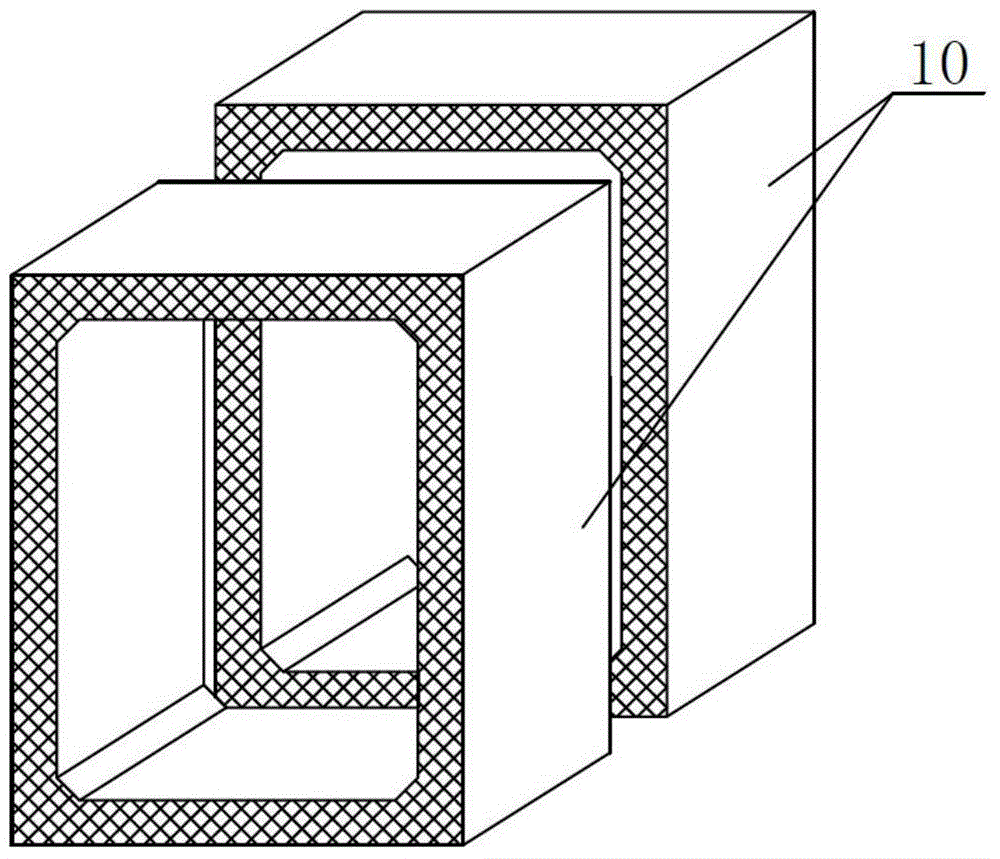

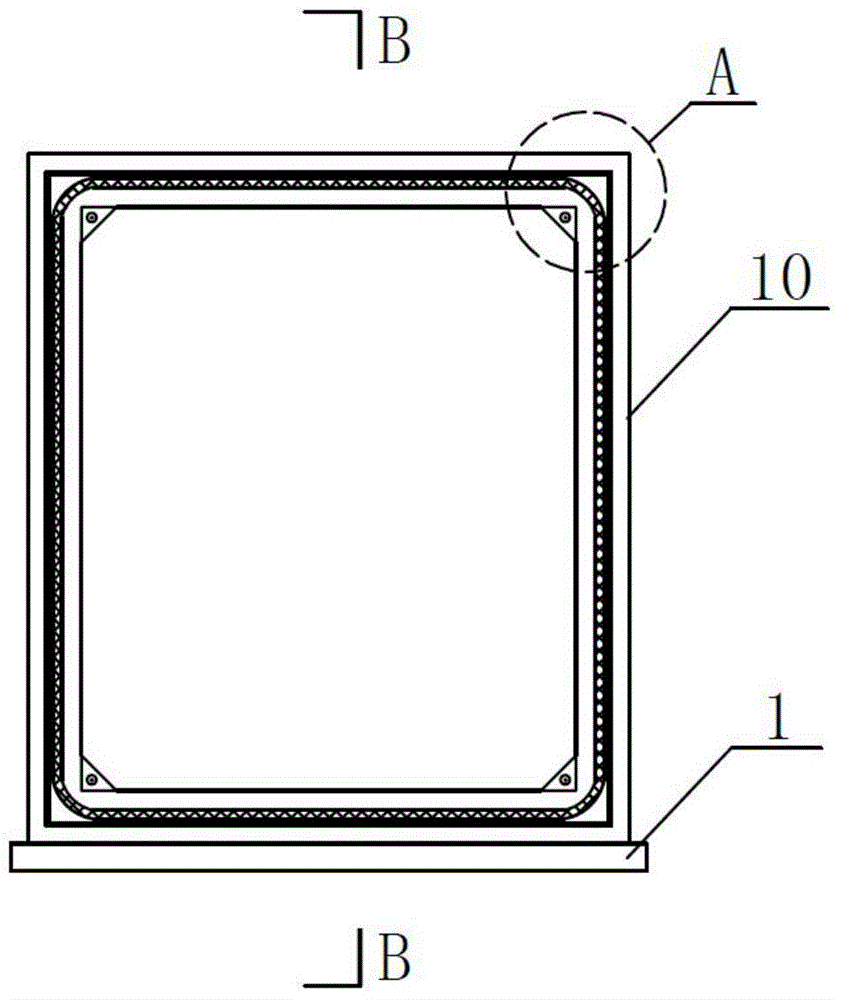

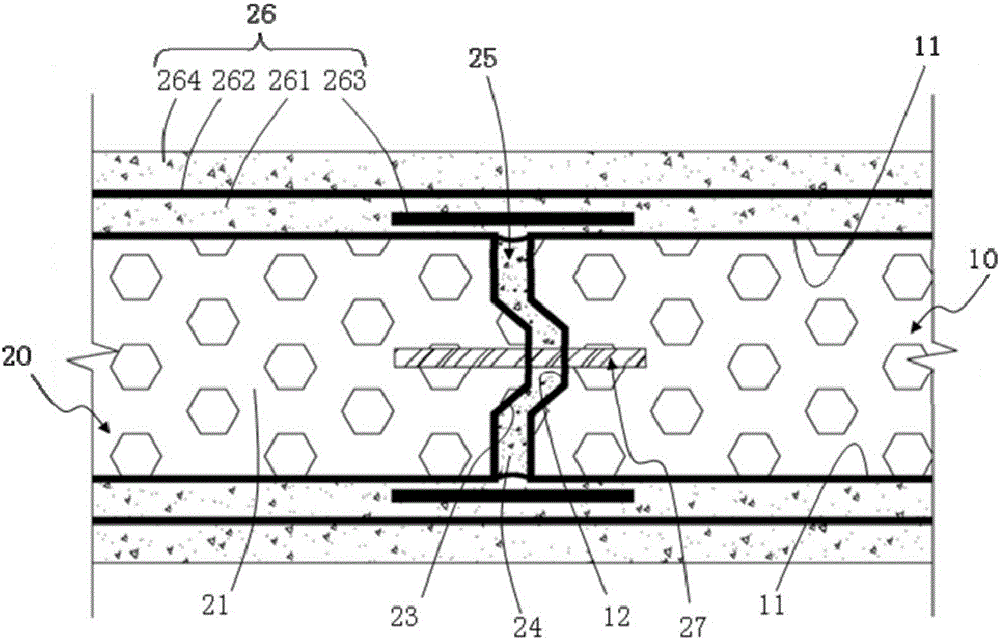

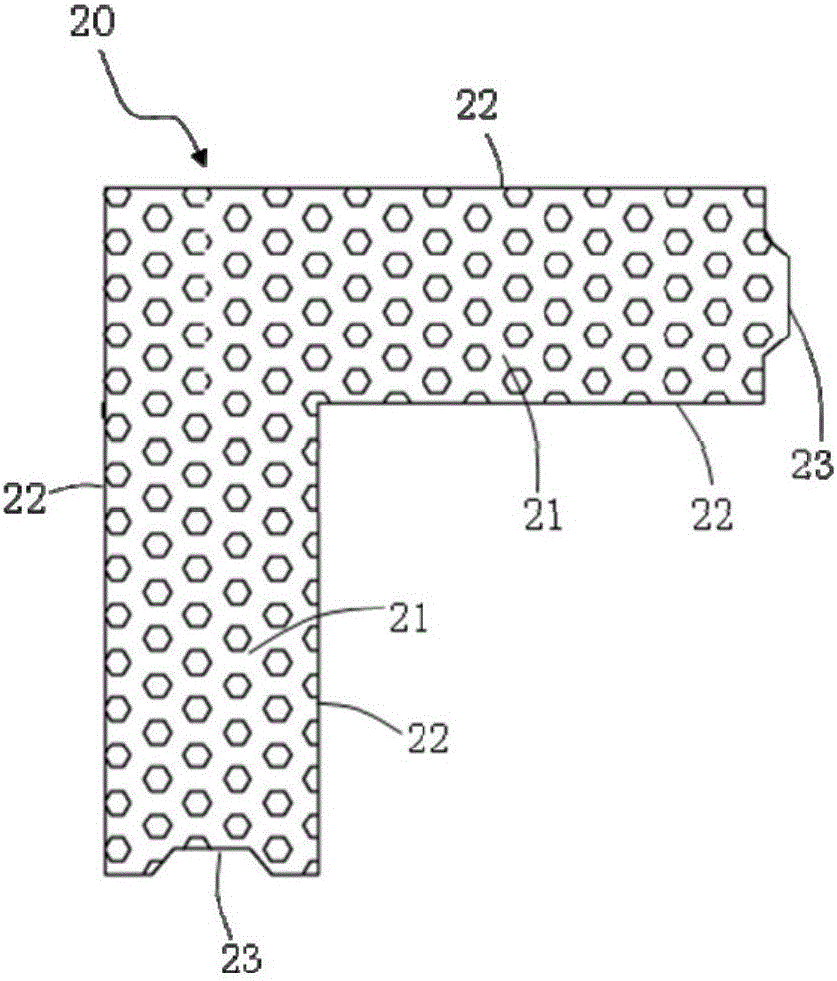

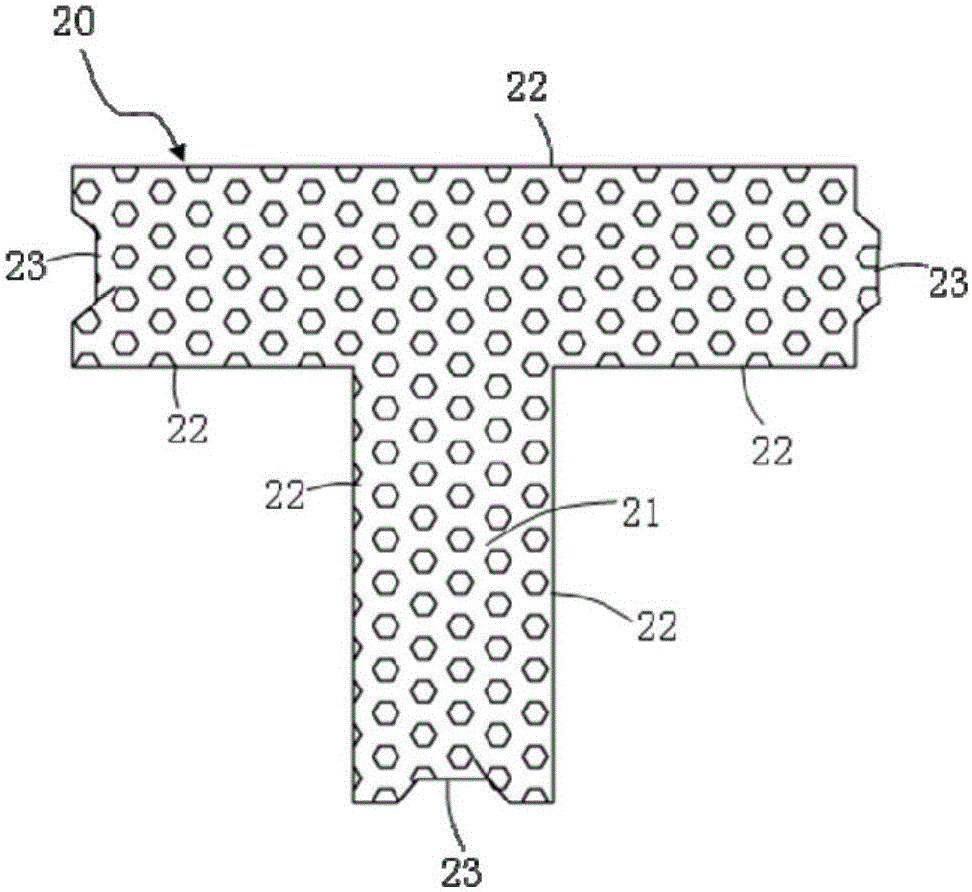

Pre-assembled single-compartment municipal tunnel and construction method thereof

PendingCN104947709ADoes not affect structural reinforcementGuaranteed StrengthArtificial islandsUnderwater structuresButt jointSpatial structure

The invention discloses a pre-assembled single-compartment municipal tunnel and a construction method thereof, relates to the technical field of pre-assembled municipal spatial structure and construction and solves the problem that a cast-in-place structure of an existing tunnel is long in construction period and quality is hard to control. The pre-assembled single-compartment municipal tunnel is assembled by several pre-assembled pipe joints arranged on a concrete cushion layer and provided with longitudinal joints in sequence via butt joint, a plurality of supports with through holes are embedded in the corner of the edge of the inner wall of each pre-assembled pipe joint, pipe joint connectors with pre-stressed rebars inside sequentially penetrate the supports of the pre-assembled pipe joints along the axis, and two ends of the pipe joint connectors are anchored on the supports on the outer side respectively. The construction method includes structurally calculating according to the geological conditions and the surroundings of the tunnel; preassembling pipe joints, excavating a foundation pit of the tunnel, casting the concrete cushion layer in the foundation pit in place, sequentially docking the pre-assembled pipe joints above the concrete cushion layer via the longitudinal joints, and filling the soil back to the foundation pit.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

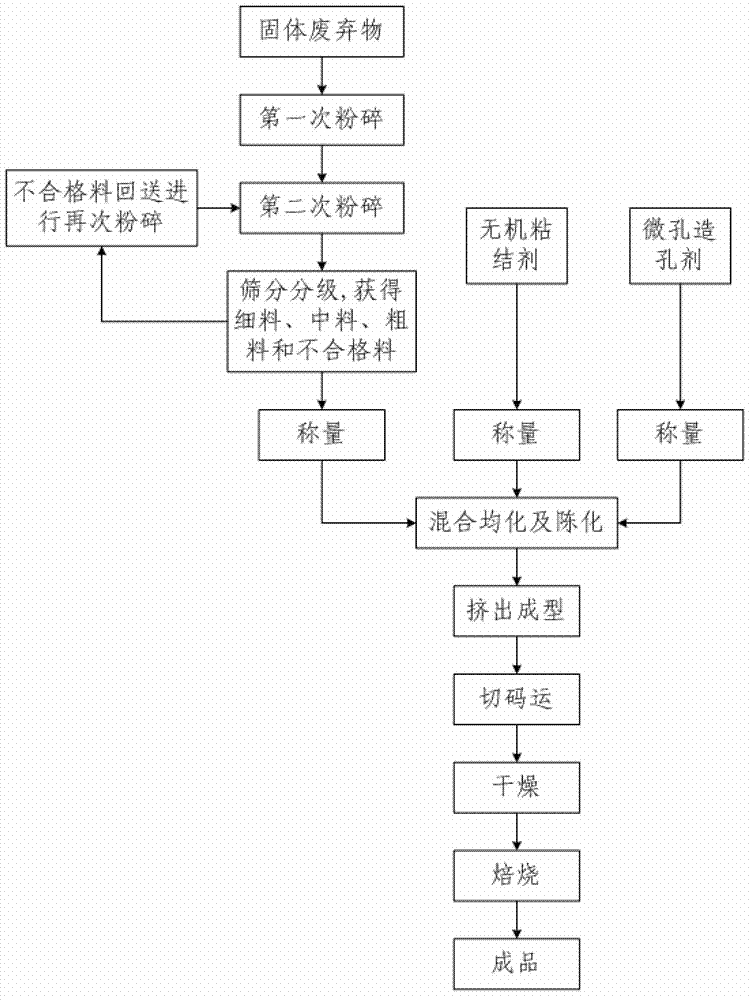

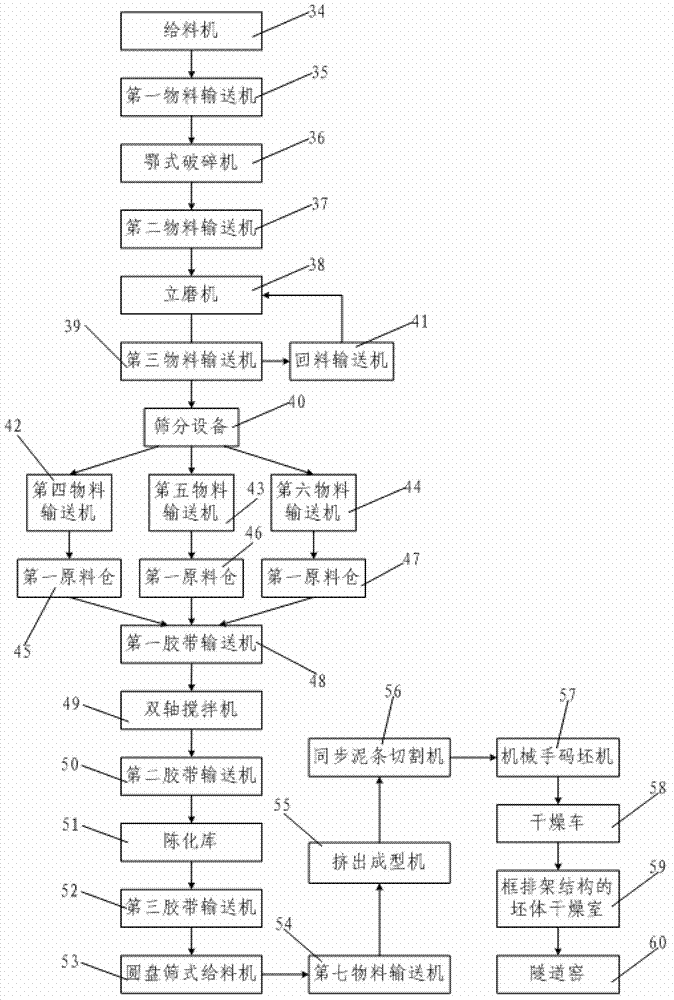

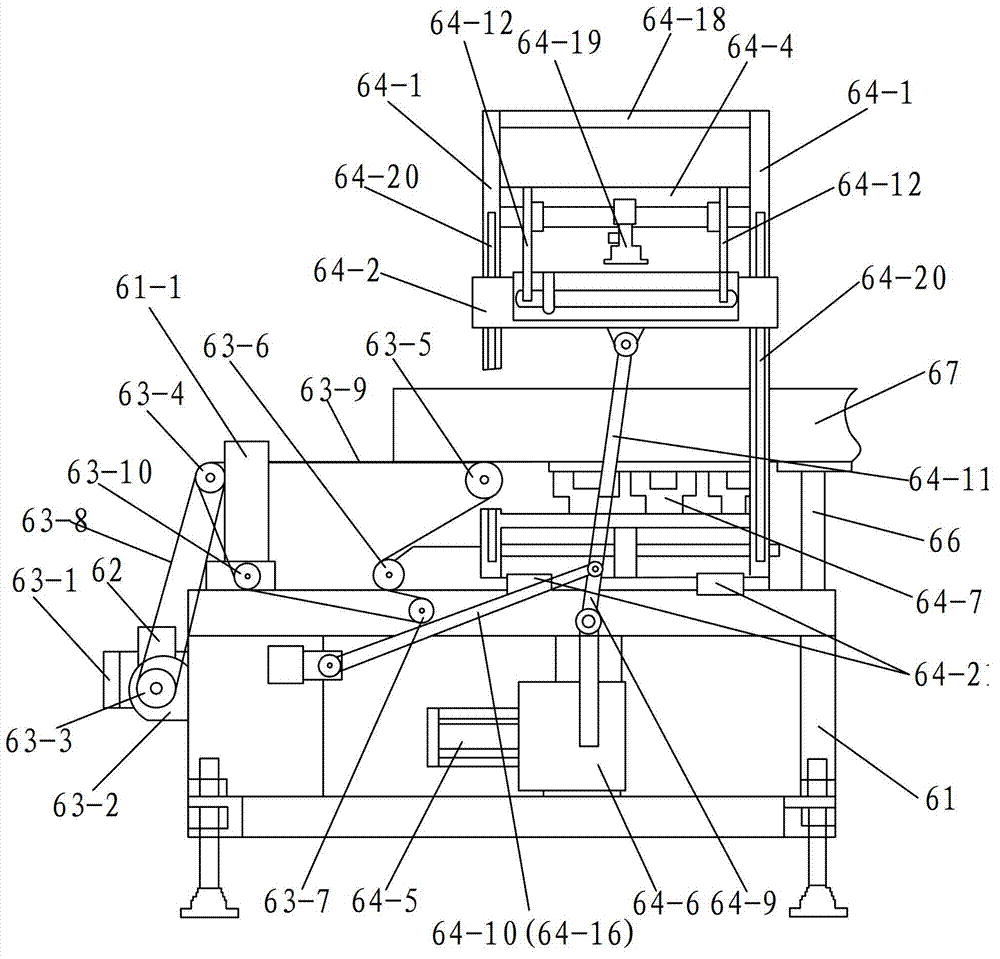

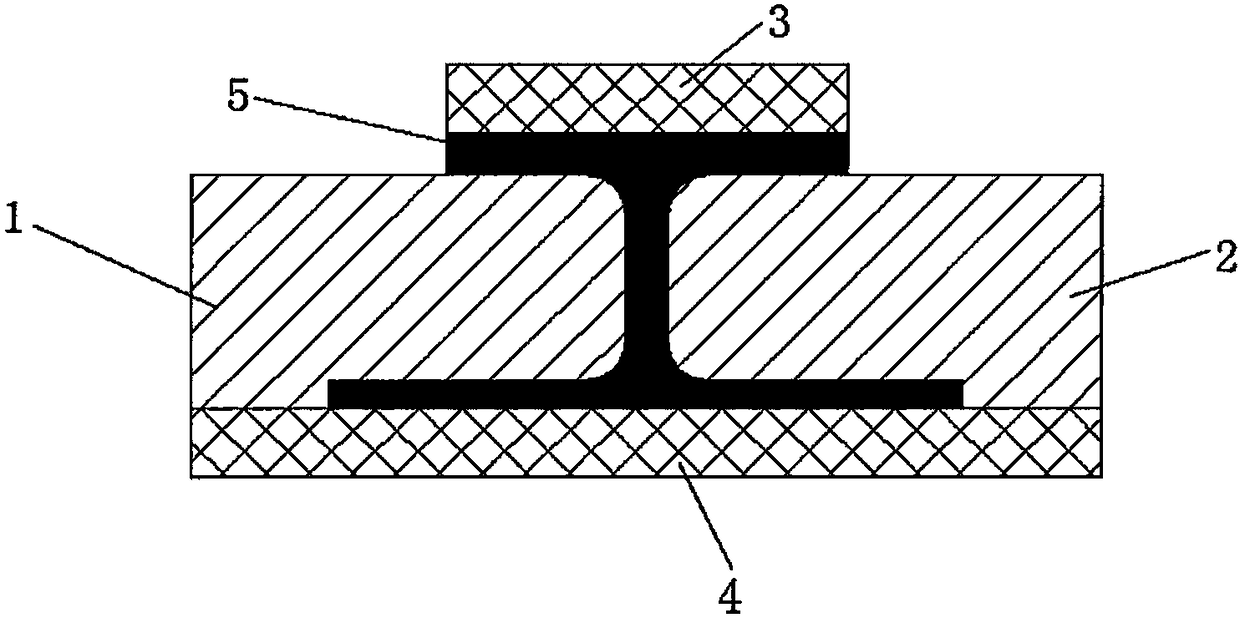

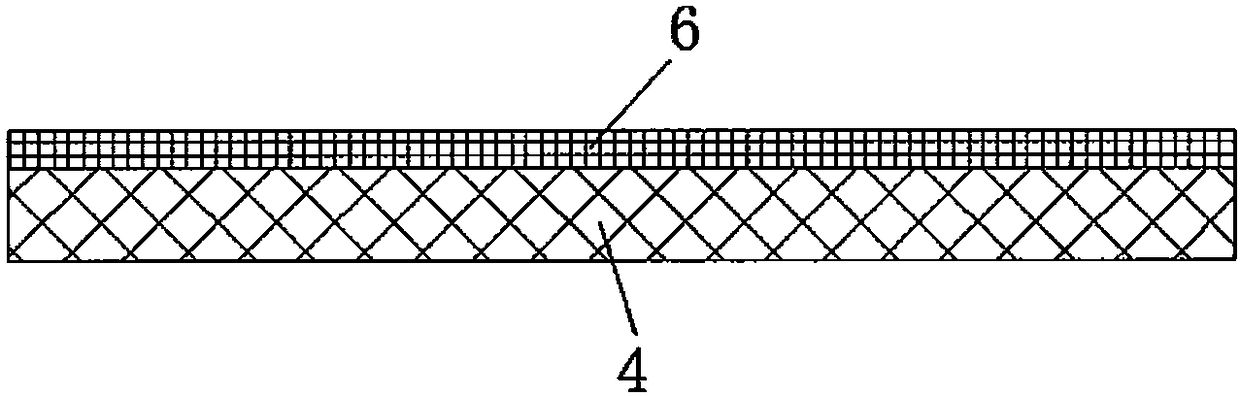

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

Composite material I-shaped stringer molding process

The invention provides a composite material I-shaped stringer molding process, which comprises: manufacturing a hard mold tool; manufacturing a soft mold process cover plate; manufacturing a lower edge strip soft mold; molding an I-shaped stringer core mold; molding an I-shaped stringer lower edge strip flat plate; molding an I-shaped stringer upper edge strip flat plate; molding a stringer wick strip; combining to obtain an I-shaped stringer tool; preparing a vacuum bag; curing; and demolding. According to the present invention, the part manufactured according to the process has good appearance quality, the generation of internal defects cannot be caused, the molding quality of the thin part can be improved, and the requirements on the manufacture precision and the matching precision of the molding tool are reduced so as to reduce the manufacturing cost of the part.

Owner:COMAC +1

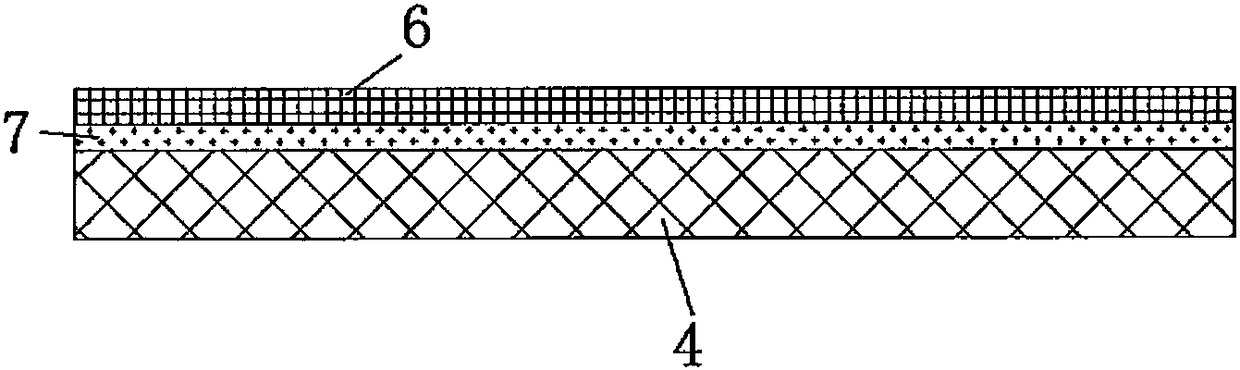

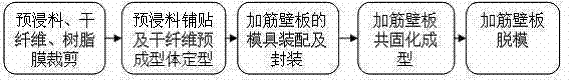

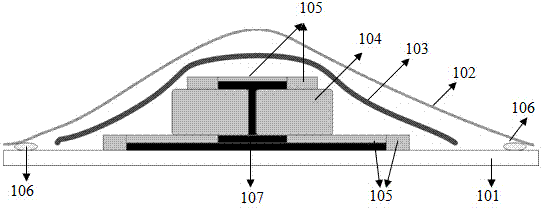

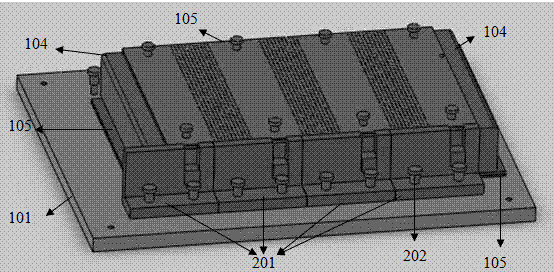

Prepreg/resin film infiltration co-curing forming method for composite stiffened wallboards

The invention discloses a prepreg / resin film infiltration co-curing forming method for composite stiffened wallboards. The method comprises the following steps: 1, tailoring prepregs, dry fibers and resin films; 2, spreading the prepregs and sizing dry fiber preforms; 3, assembling and packaging a mould for the stiffened wallboards; 4, co-curing and forming the stiffened wallboards; and 5, demolding the stiffened wallboards. According to the method, a skin is prepared by adopting prepreg spreading, ribs are prepared by the dry fiber preforms and the resin films, and in combination with the characteristics of a prepreg autoclave process and a resin film melting process, the ribs, the skin and the adhesive interface of the ribs and the skin are cured in an autoclave at the same time, thus realizing the co-curing forming of the stiffened wallboards with different rib forms and different material systems. The method can significantly improve the forming efficiency of the stiffened wallboard structure, reduce the manufacture cost, improve the quality of products and improve the flexibility and designability of the manufacturing process and is of great significance to the efficient low-cost manufacture of the composite material stiffened wallboard structure.

Owner:SHANGHAI AIRCRAFT MFG +1

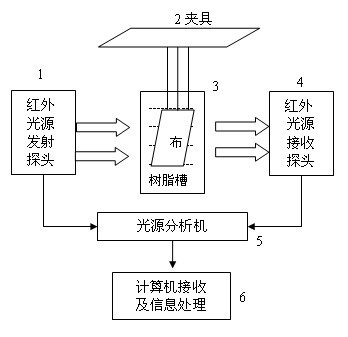

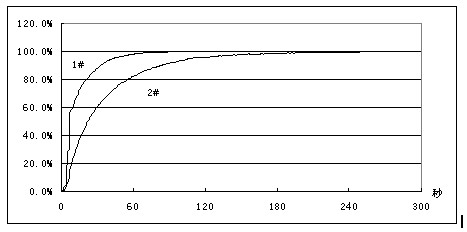

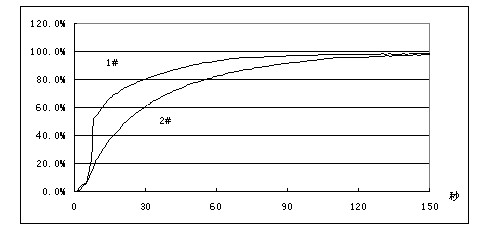

Glass fiber cloth infiltrating testing method

InactiveCN101995366AEnhanced interface bindingAvoid Glue AbnormalitiesSurface/boundary effectGlass fiberTransmittance

In a glass fiber cloth infiltrating testing method, the perspective test for the glass fiber cloth in the infiltrating process in resin is carried out through an infrared transmitting light source; the incompletely permeant glass fiber sample has bad light transmittance and the completely permeant sample has good light transmittance according to the difference of reaction and infiltration degrees between the resin and the glass fiber cloth on different time points and the difference of the light transmittance of infrared waves for the glass fiber cloth, thereby obtaining the time-varying curve of the light transmittance of the testing sample in infiltrating process; and the data is converted into light transmittance data so as to analyze and compare the infiltrating property of the testing glass fiber cloth by testing and drawing the curve.

Owner:SHANGHAI GRACE FABRIC

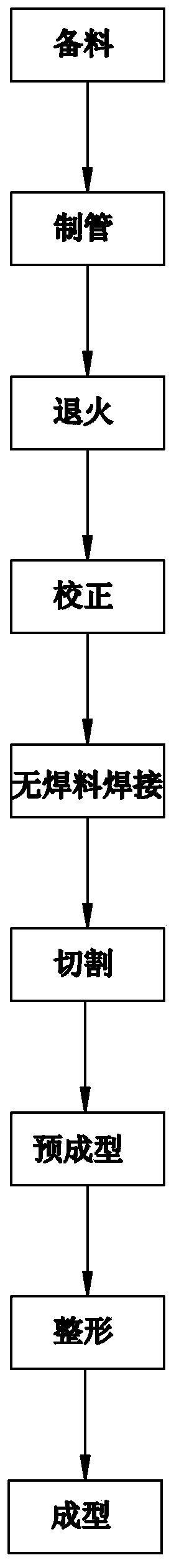

Gold and silver hollow bracelet processing technology

ActiveCN103416925AReduce processing technologyGuaranteed purity and colorJewelleryNanotechnologySheet material

The invention discloses a gold and silver hollow bracelet processing technology and belongs to the technical field of jewelry processing technologies. The processing technology comprises the following steps: preparing material: according to the specifications for processing gold and silver hollow bracelets, preparing sheet material with corresponding specifications; manufacturing a pipe: processing the sheet material into a round pipe with a gap and straightening the round pipe; annealing; calibrating: straightening the gap; welding without welding material: eliminating gap through high-temperature heating to form a gapless round pipe; cutting: cutting the gapless round pipe according to the finished size of a gold and silver hollow bracelet, and polishing two ends of the gapless round pip; pre-forming: processing the gapless round pipe into an open type circular ring, and forming a closed circular ring by performing high-temperature heating on the open type circular ring; shaping: shaping the shape of the closed circular ring until specified requirements are met; forming: processing the closed circular ring into a hollow bracelet with elliptic sections. Through the processing steps, since a only a piece of sheet material is needed, the hollow bracelet can be manufactured, the processing technology is reduced, the processing efficiency is improved, the forming effect is good, and meanwhile, the gap is closed automatically through high temperature, so that welding without welding material is achieved, and the purity and fineness are guaranteed.

Owner:SHENZHEN SUNFEEL JEWELRY CO LTD +1

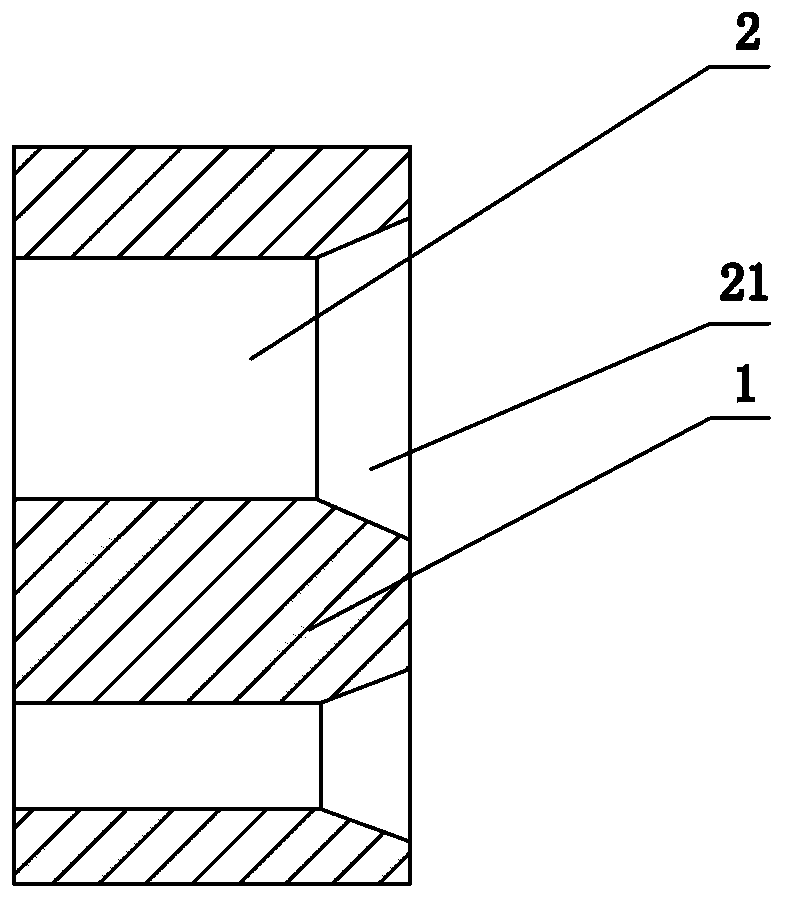

Large-diameter rotary digging pile construction technology for ultra-deep dumped unconsolidated soil bodies

ActiveCN102758430ASolve the pile problemSimple structureDirectional drillingBulkheads/pilesCounter pressureLower grade

The invention discloses a large-diameter rotary digging pile construction technology for ultra-deep dumped unconsolidated soil bodies, wherein low grade concrete is reinjected in a hole collapse section for countering pressure in the rotary digging pile construction process, so that the collapse of soil bodies around a pile hole is prevented; after the concrete is finally solidified and reaches a certain strength, the peripheral soil bodies are solidified, and a rotary digging operation is carried out in site for excavating soil, so that the reinjected concrete forms a protective wall; and the operations are carried out in circles till the hole is formed. The large-diameter rotary digging pile construction technology disclosed by the invention is a construction technology capable of carrying out large-diameter rotary digging pile construction on the unconsolidated soil bodies.

Owner:中建五局第三建设有限公司 +1

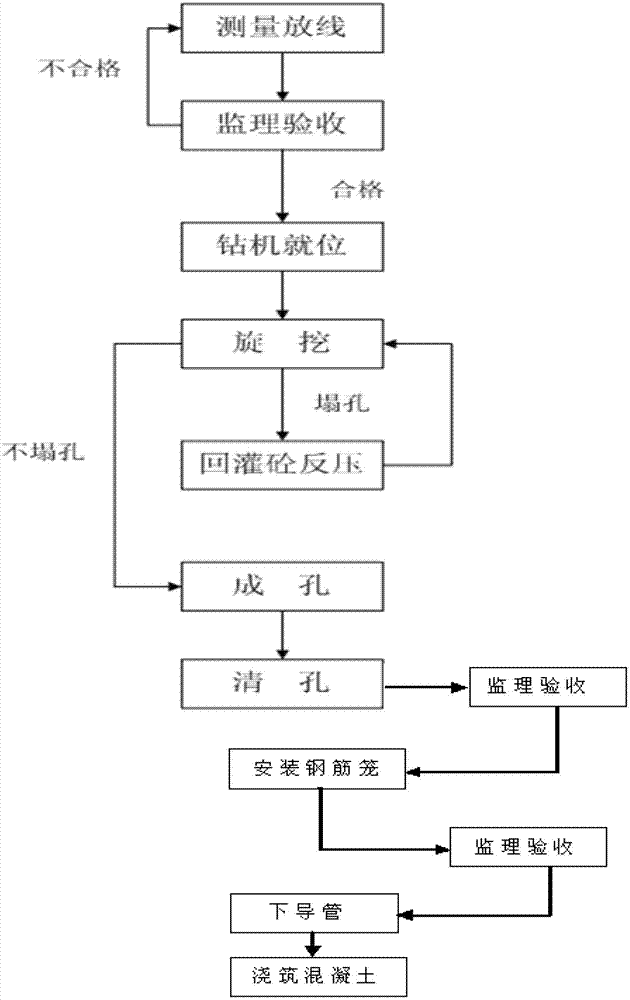

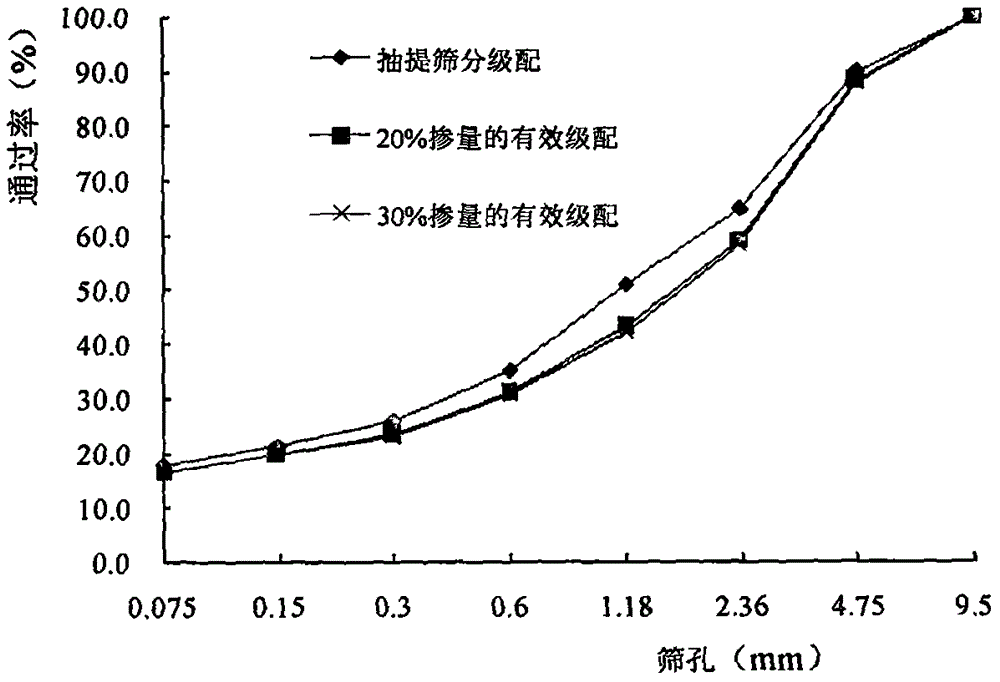

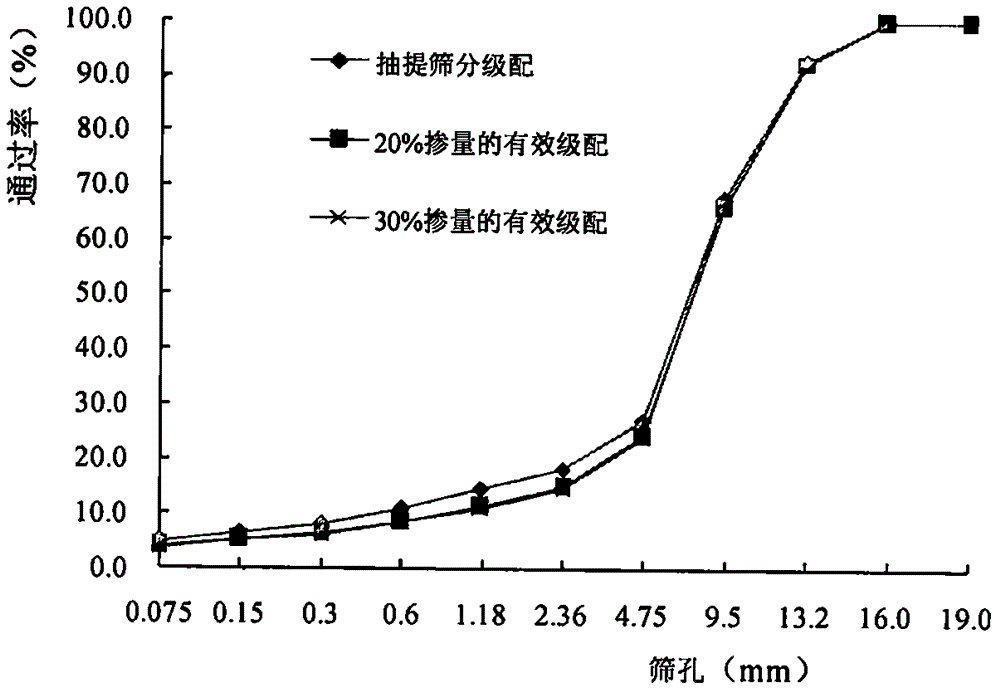

Optimum design method for mineral aggregate gradation of hot recycled asphalt mixture

ActiveCN106202651AEasy to useImprove molding qualitySpecial data processing applicationsRoad surfaceDesign methods

The invention discloses an optimum design method for mineral aggregate gradation of a hot recycled asphalt mixture. The method comprises the steps of (1), determining engineering design gradation ranges; (2), testing the gradation of old mineral aggregates in new mineral aggregates and recycled asphalt pavement (RAP) materials; (3), testing the proportion of the old mineral aggregates with different specifications of fine particles, and the old mineral aggregates without coarse particles contained in the recycled asphalt pavement (RAP) materials, and carrying out discount calculation on the gradation of the old mineral aggregates according to test results; and (4), carrying out gradation optimum design on the hot recycled asphalt mixture according to the test and measurement results in the (1)-(3) and the engineering design gradation range. The gradation design method is high in practicability, the designed gradation of the recycled asphalt mixture is remarkably enabled to be more consistent with the engineering practice, the pavement performance of the hot recycled mixture is improved, and the service life of the hot recycled asphalt pavement is prolonged.

Owner:SHANDONG JIAOTONG UNIV

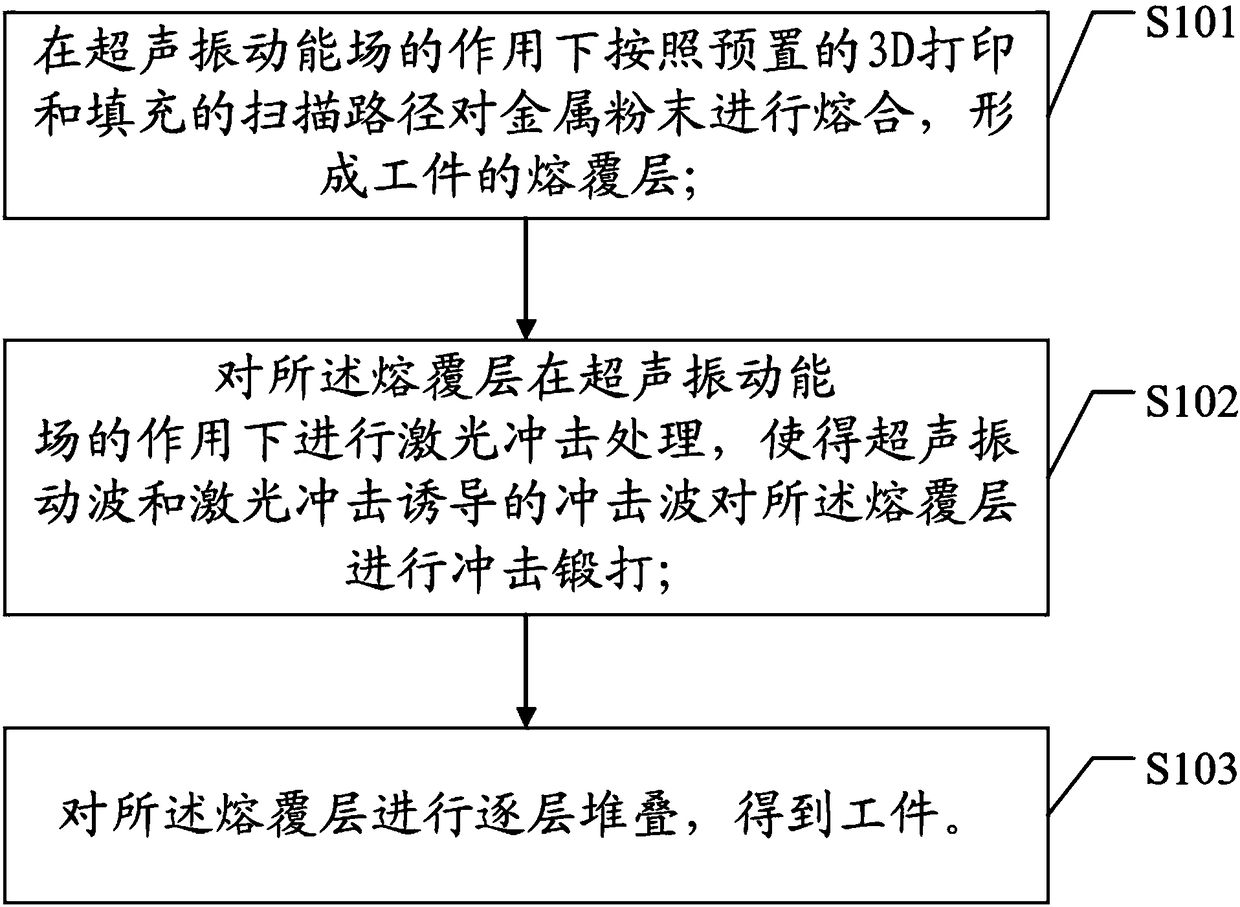

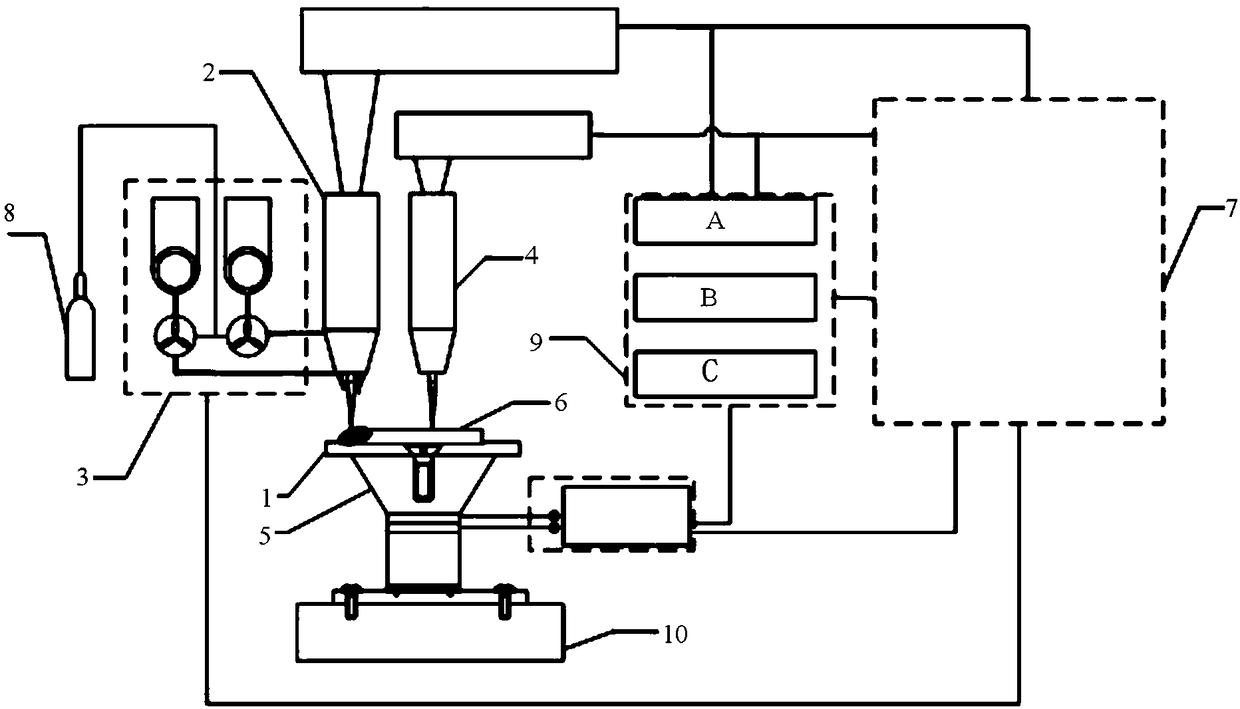

Method and device for carrying out 3D (Three-Dimensional) printing and composite manufacturing on metal

PendingCN108176857AImprove internal qualityImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyShock waveUltrasonic vibration

The invention belongs to the technical field of 3D (Three-Dimensional) printing, and particularly relates to a method and a device for carrying out 3D printing and composite manufacturing on metal. The method for carrying out the 3D printing and the composite manufacturing on the metal comprises the following steps: S101, fusing metal powder under the action of an ultrasonic vibration energy fieldaccording to a preset 3D printing and filling scanning path, thus forming cladding layers of a workpiece; S102, simultaneously carrying out laser shock processing on the cladding layers under the action of the ultrasonic vibration energy field, and impacting and forging the cladding layers through ultrasonic vibration waves and shock waves induced by laser shock; S103, stacking the cladding layers layer by layer, thus obtaining the workpiece. Aiming at the problem existing when an existing metal 3D printing technology is used for manufacturing metal parts, the method disclosed by the invention has the advantages that internal defects of pores, poor fusion, shrinkage porosity and cracks of metal cladding layers and thermal stress can be removed to the maximum, the internal quality and themechanical dynamical comprehensive performance of the metal parts can be increased, and the problems of macroscopic deformation and cracking can be effectively controlled.

Owner:GUANGDONG UNIV OF TECH

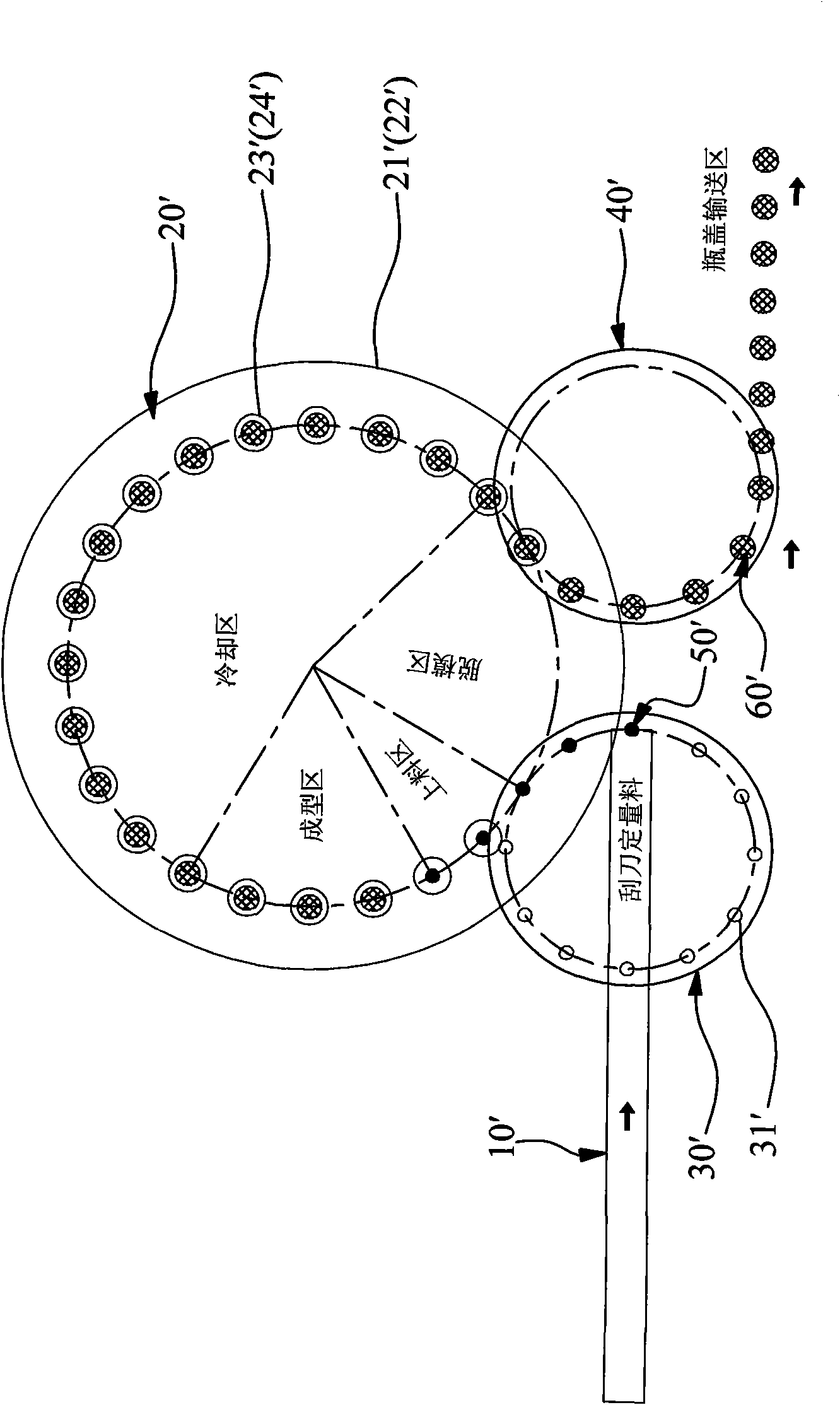

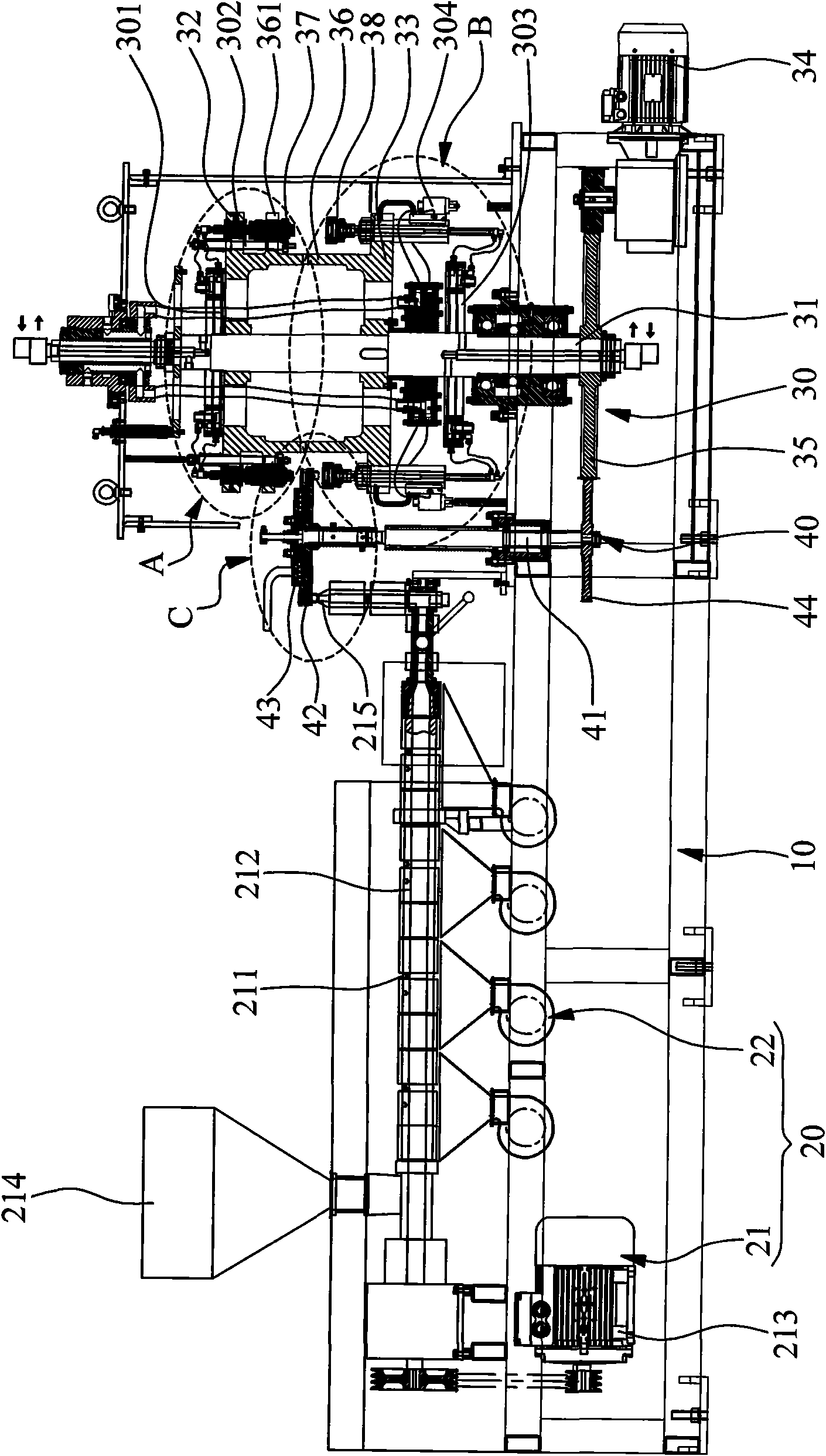

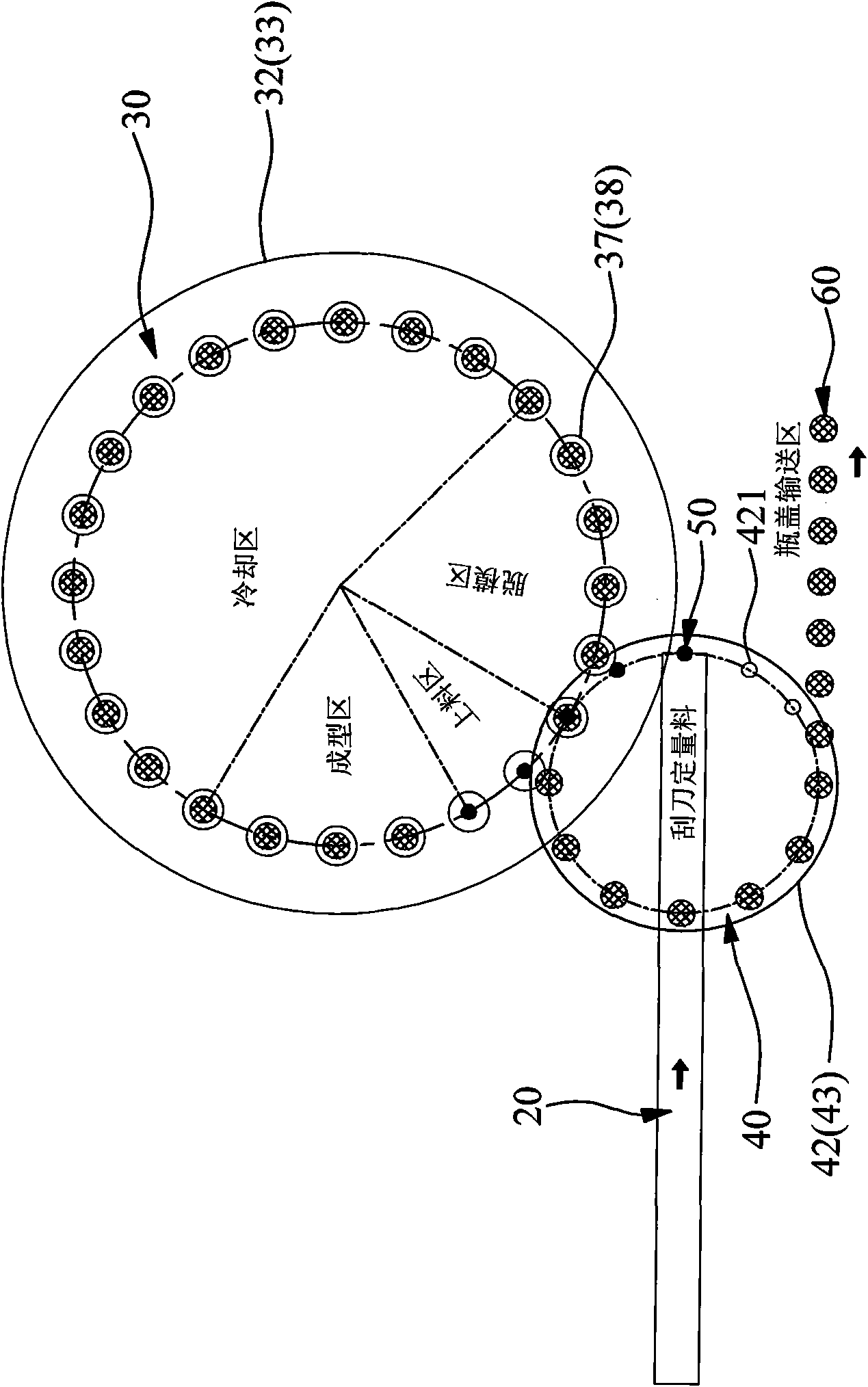

Mould pressing lid maker

The invention discloses a mould pressing lid maker, which comprises a frame and an extrusion mould group, a pressing mould group and a feeding and discharging mechanism that are arranged on the frame; the extrusion mould group has an extrusion port; an upper mould pressing plate and a lower mould pressing plate of the pressing mould group are integrated and are arranged on a first rotating shaft of the pressing mould group; the upper mould pressing plate is provided with upper moulds; the lower mould pressing plate is provided with bottom moulds; the feeding and discharging mechanism is arranged between the extrusion mould group and the pressing mould group and comprises a second rotating shaft and a rotating plate that is arranged on the second rotating shaft, a scraper and a material pushing device are arranged below the rotating plate, and a toggle device is arranged above the rotating plate; and therefore, feeding operation is carried out by utilizing the scraper, and discharging operation is carried out by utilizing the toggle device, thus realizing the feeding and discharging at the same work station. The mould pressing lid maker has compact structure and makes full use of all the upper moulds and the bottom moulds, and the rotating speed of the upper mould pressing plate and the lower mould pressing plate can be set as rapidly as possible, thus enhancing the work efficiency of the mould pressing lid maker and the production capacity.

Owner:GUANGZHOU JEEPINE INTELLIGENT COMPRESSION MOLDING MACHINE CO LTD

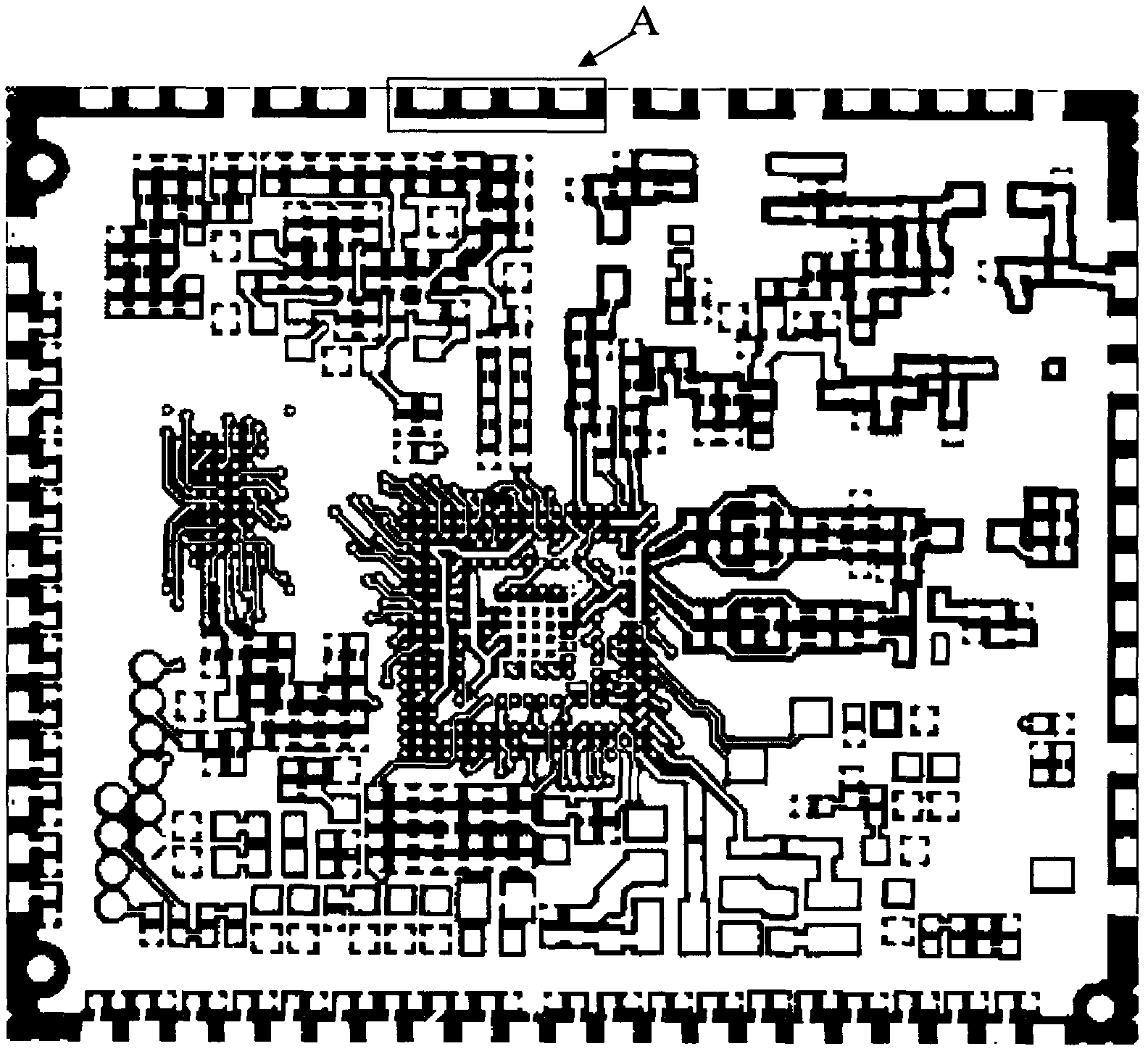

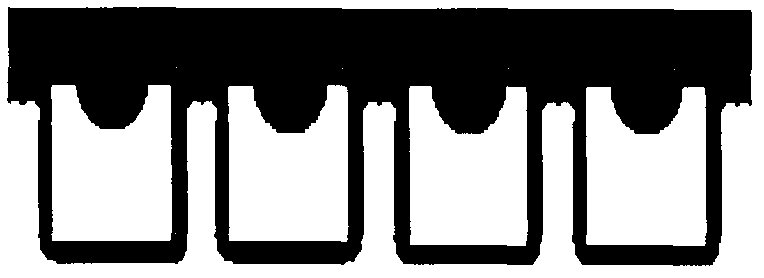

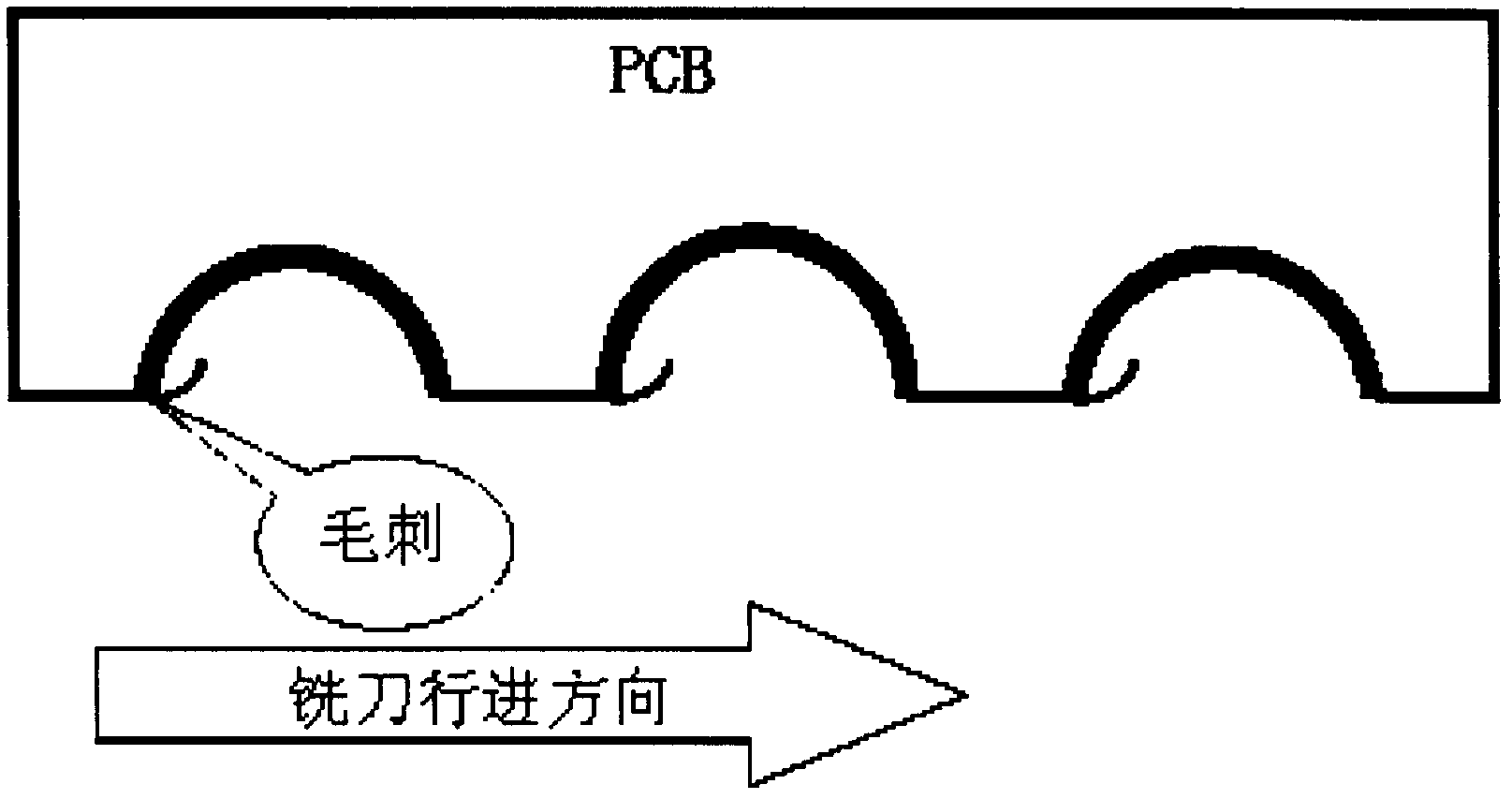

Metal half hole molding method and manufacture method of printed circuit board

InactiveCN103179805AImprove molding qualityOvercoming the problem of residual copper wire burrsPrinted element electric connection formationCopper wirePrinted circuit board

The invention provides a metal half hole molding method. A metal half hole of a printed circuit board (PCB) is molded through a board milling procedure before the procedures of film removing, alkaline etching and tin removing in the manufacture process of the PCB. A manufacture method of the PCB is further provided. The manufacture method includes the metal half hole molding method which is used for manufacturing the metal half hole of the PCB. By means of the metal half hole molding method and the manufacture method of the PCB, the metal half hole is molded by milling the board before the procedures of film removing, alkaline etching and tin removing, the problem of residual copper wire burr is solved, and the effect of improving molding quality of the metal half hole is achieved.

Owner:ZHUHAI FOUNDER TECH MULTILAYER PCB +1

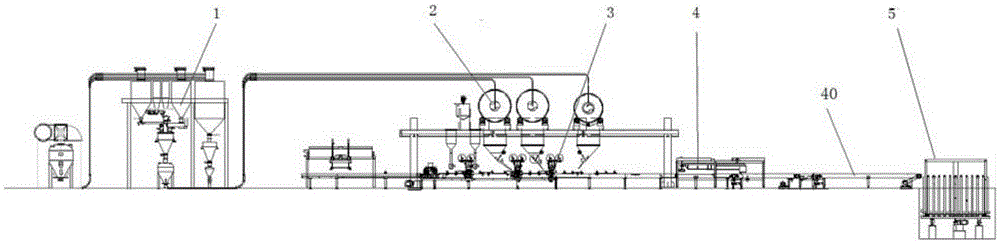

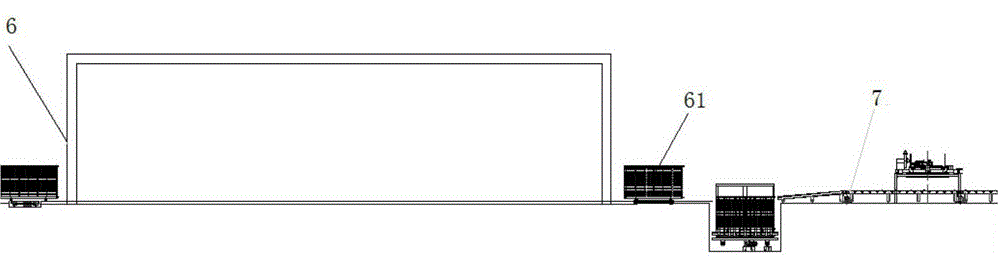

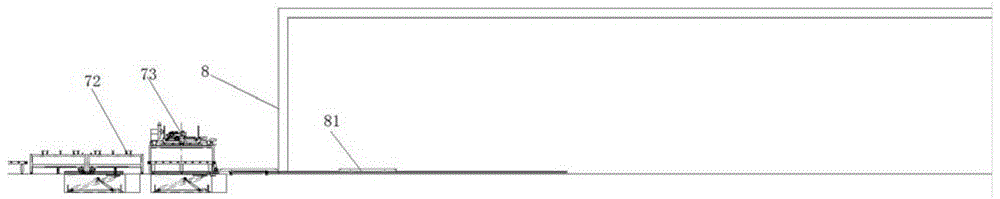

Automatic production line for plate

ActiveCN105252641ARealize automated productionFit closelyDischarging arrangementCeramic shaping plantsProduction lineCropping system

The invention discloses an automatic production line for a plate. The automatic production line comprises a measurement burdening system, a stirring system, a paving forming system, an automatic cropping system, an automatic stacking system, a first-time maintenance system, an automatic demolding system, a second-time maintenance system, a four-side cutting system and an automatic sanding system which are arranged in the machining direction of the plate. Raw materials used for producing the plate are fed into the measurement burdening system, and a plate finished product is obtained from the automatic sanding system. According to the automatic production line for the plate, automatic production of the plate can be achieved, and the work efficiency is improved. The whole production flow is close in coordination and achieved through automatic control. The usage amount of manpower is low. The production takt is compact and efficient. In addition, burdening for the product is accurate and efficient. The forming quality is high. The product quality is high. In addition, the layout is reasonable, the structure is compact, and the occupied space is small.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Method for manufacturing X100 pipeline steel submerged arc straight weld pipe

ActiveCN101205597AIncrease productivityImprove molding qualityArc welding apparatusWelding/cutting media/materialsSteel tubeSteel plates

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

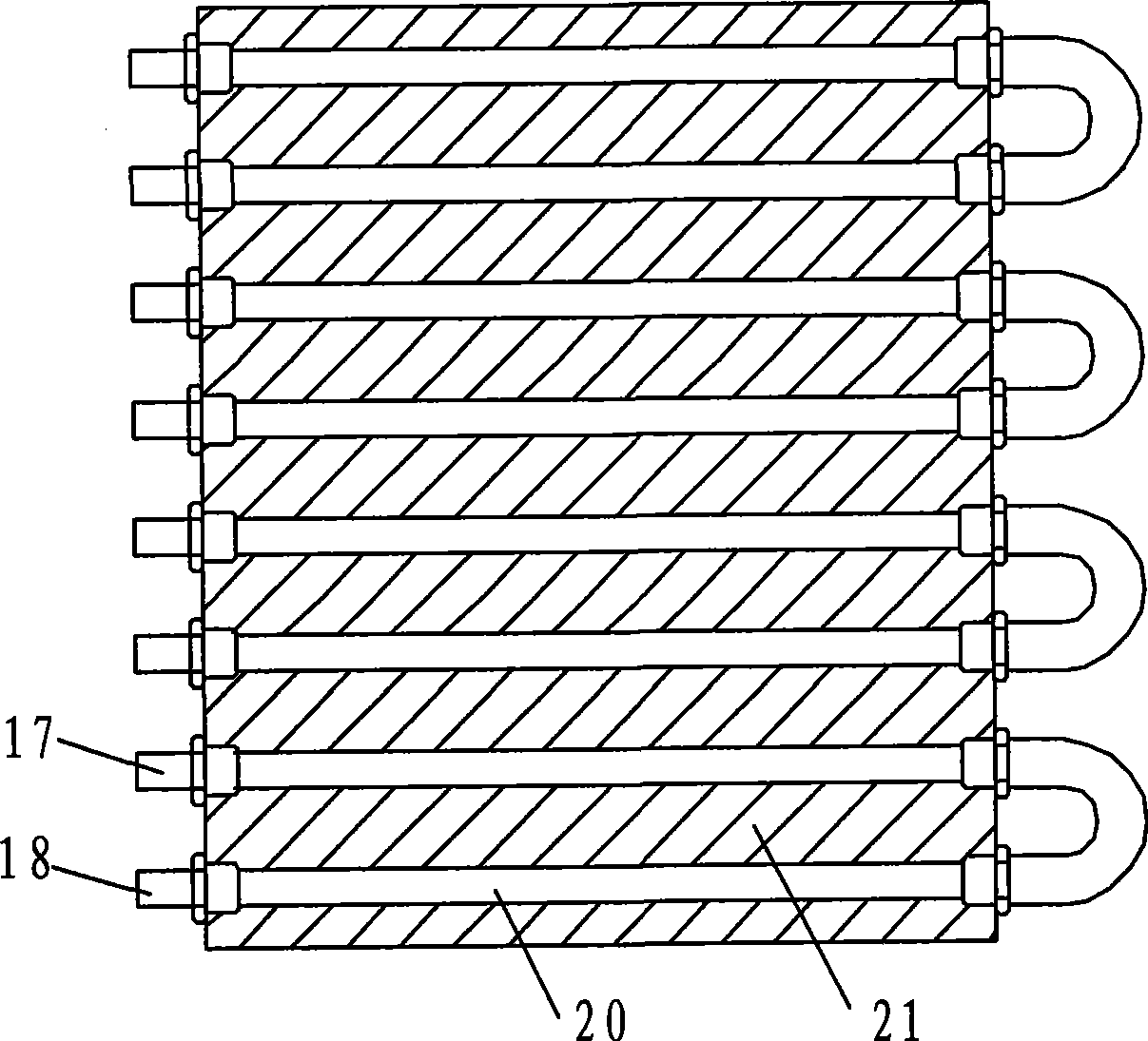

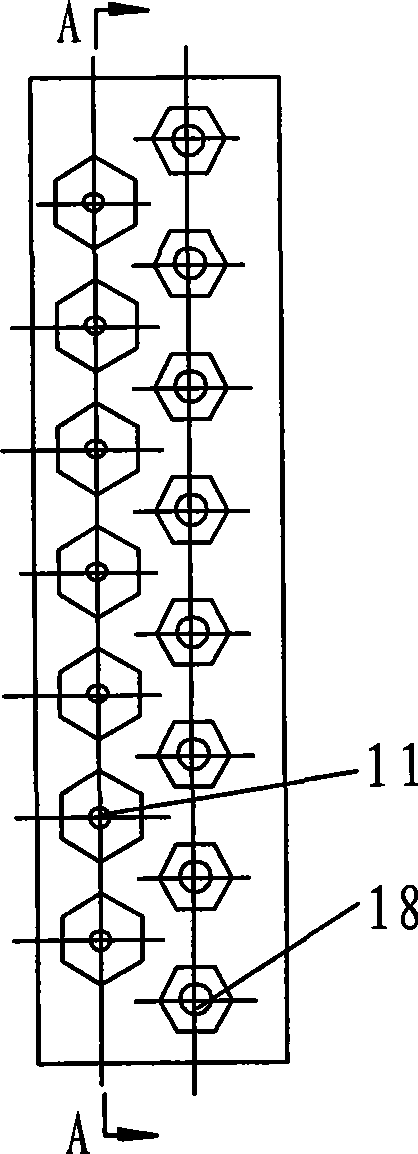

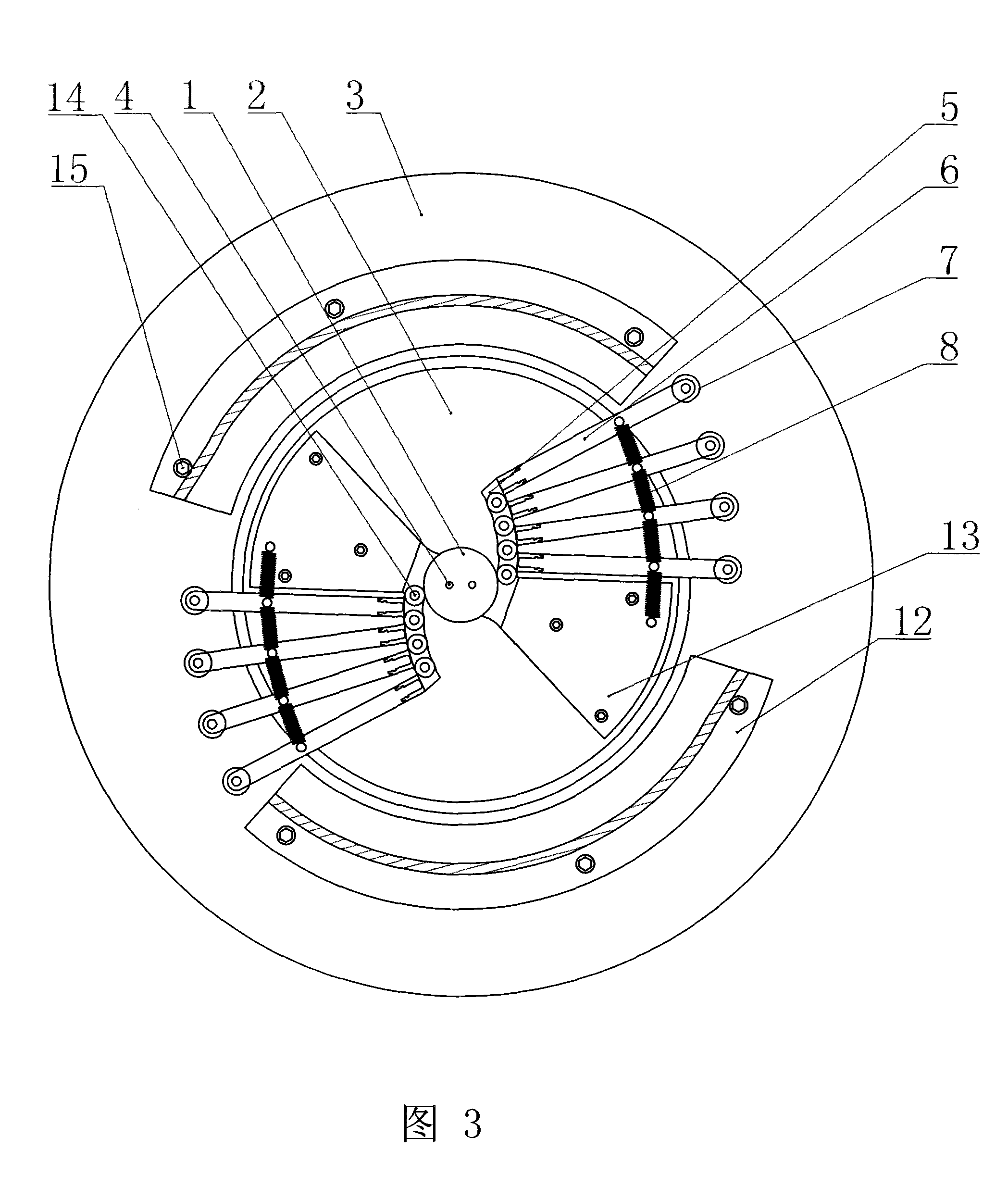

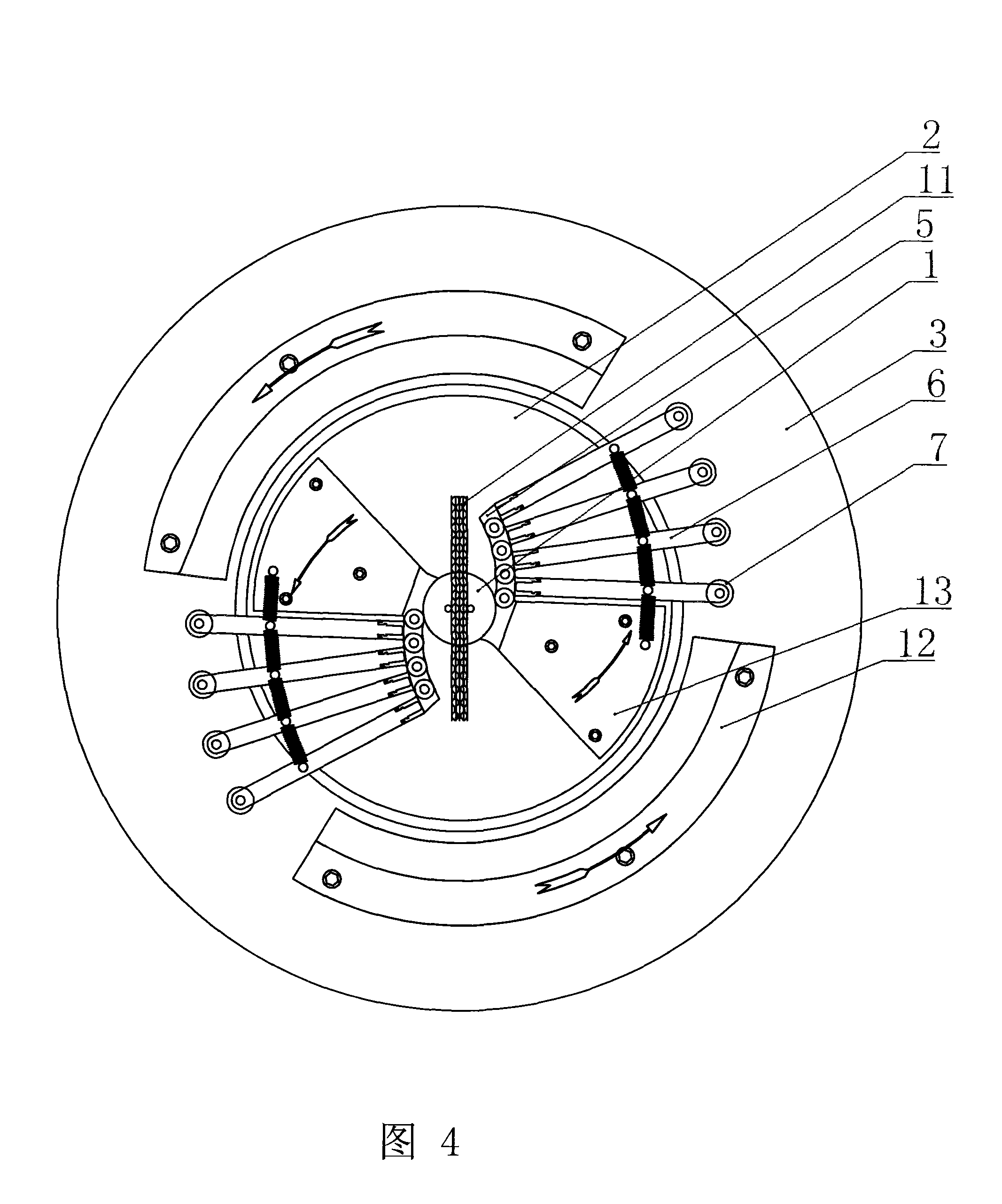

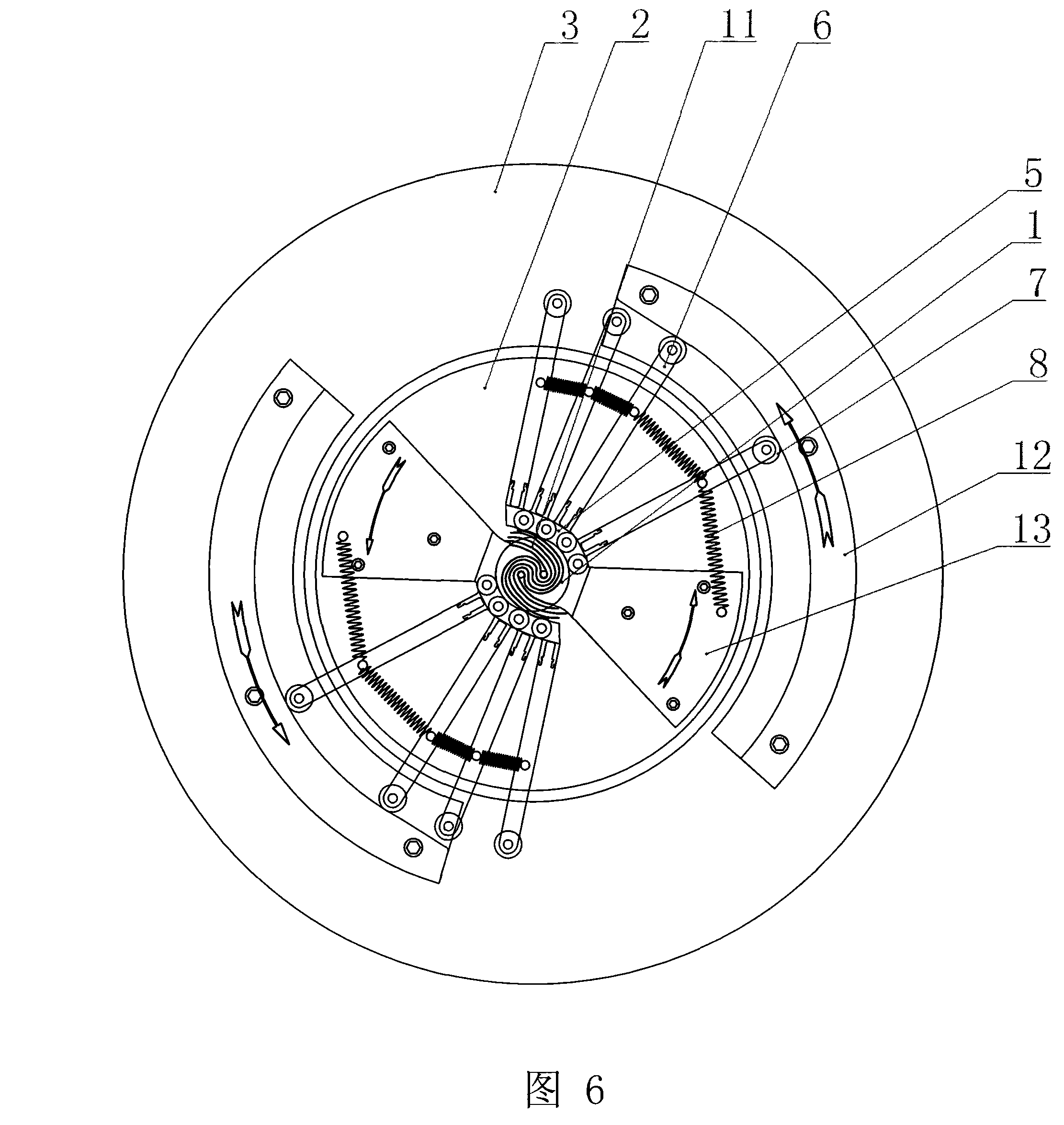

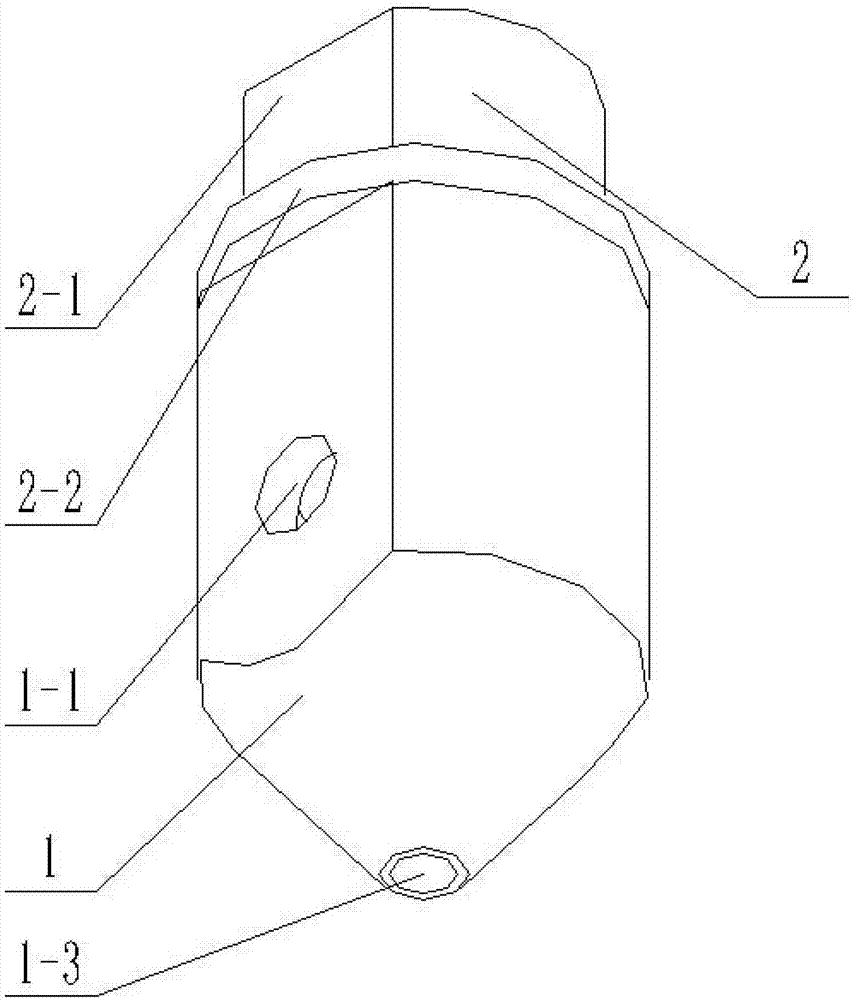

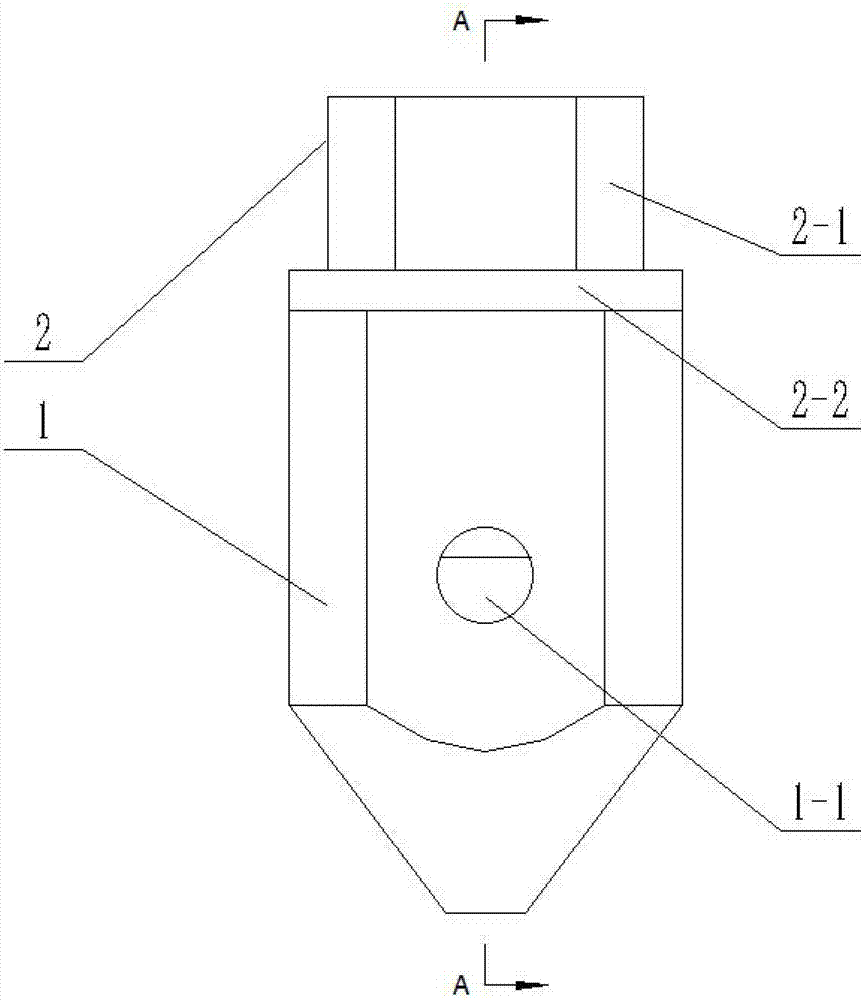

Apparatus for preparing S type metallic honeycomb

ActiveCN101251036AWill not deformImprove molding qualityPhysical/chemical process catalystsExhaust apparatusChain structureHoneycomb

The invention relates to a device for preparing an S-shaped metal beehive, comprising a fixed pole (1) and two groups of forming sections (5) which can be mutually closed section by section to form a section mould, wherein, two coaxial fixed rods (4) are arranged on the top of the fixed pole (1). The invention is characterized in that: each group of forming sections (5) consist of at least three sections; a chain structure is hinged between each section by utilization of a pin pole; the forming sections (5) can be gradually deformed from a straight line or a curve with small curvature to a curve with large curvature; the two groups of forming sections (5) are closed to form the section mould the cross section of which is round, obround or elliptical. Due to adoption of the technical proposal, the metal stack fixed rods (namely the S-shaped center) are immobile during the rolling process; corrugated tooth profiles can be straightened by the sectional closed section mould during the rotation process even an inner core material piece is slightly longer, and residual tooth profiles can be straightened into flat sheets and then attached to the circumference of an inner core of the beehive; moreover, an S-shaped central tooth profile is always immobile and then can not be deformed, thereby the forming quality and the finished product rate are improved.

Owner:南京亿达高科环保技术有限公司 +1

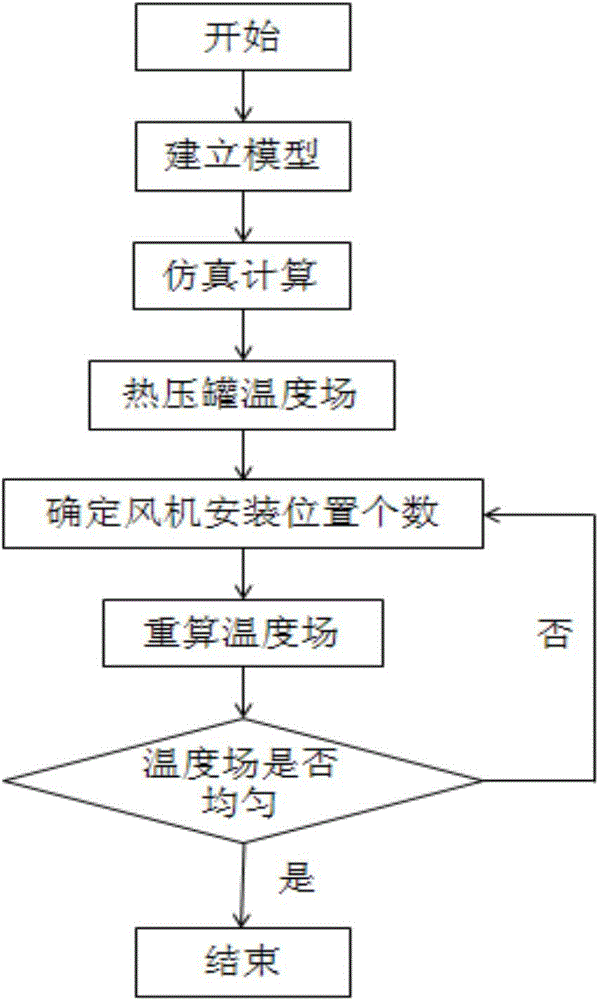

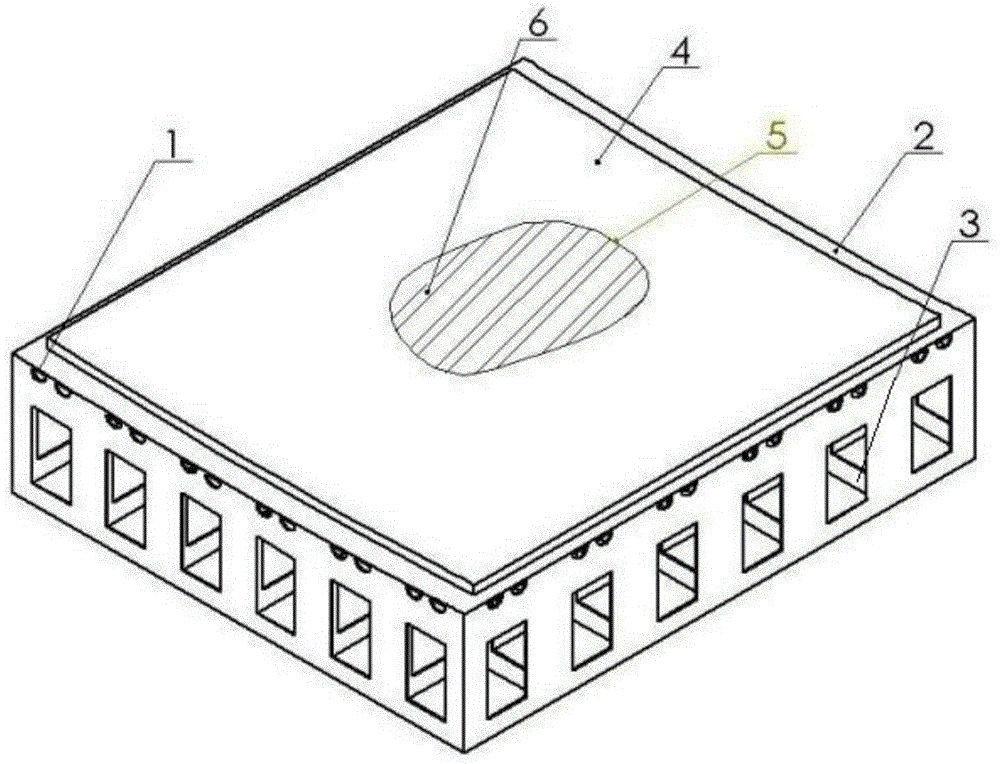

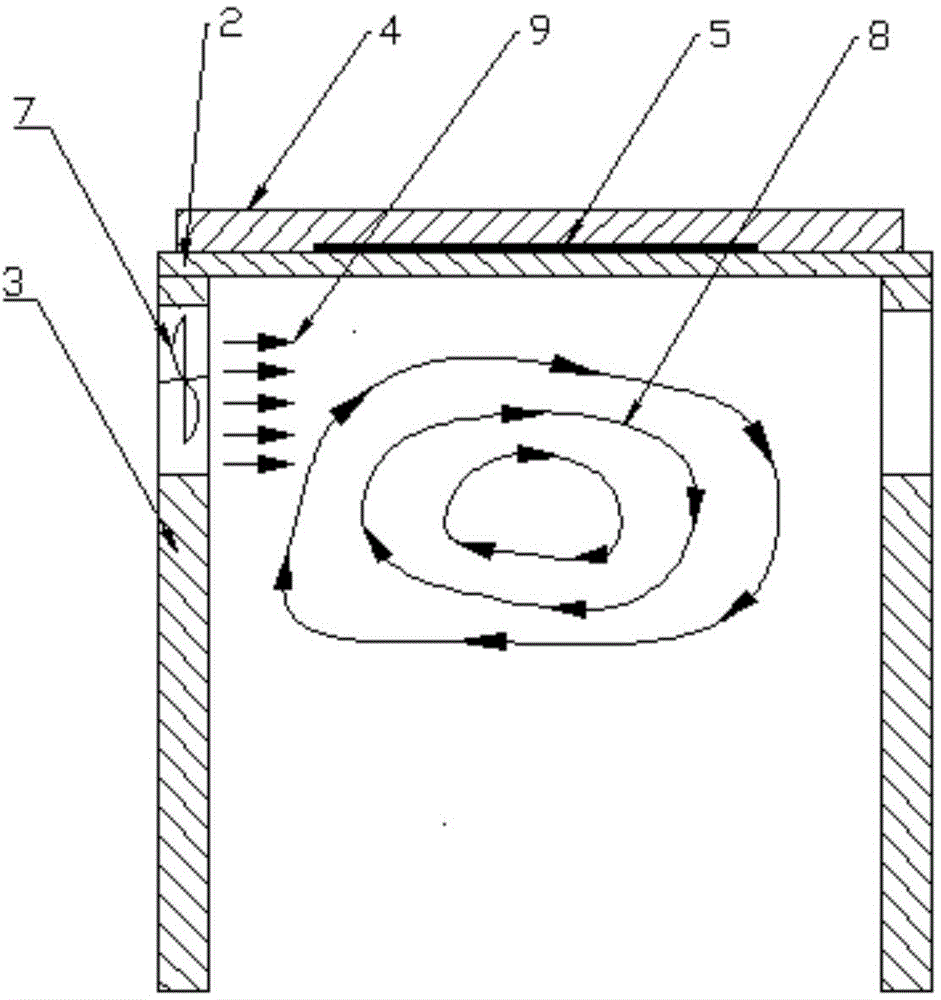

Method for adjusting uniformity of temperature of flow field in hot-pressing tank

ActiveCN104441698ASmall temperature differenceReduce internal stressFinite element methodEngineering

The invention discloses a method for adjusting the uniformity of the temperature of the flow field in a hot-pressing tank, belongs to the technical field of forming of the hot-pressing tank for composite materials and relates to a method for adjusting the uniformity of the temperature of the flow field in the hot-pressing tank. The method is characterized by adopting a finite element method to simulate a forming process of the hot-pressing tank of a composite-material part, carrying out temperature compensation on a low-temperature area of a mold, adopting a blowing device to change the flowing speed of fluid of the low-temperature area in the hot-pressing tank, increasing the heat-exchange rate between the fluid of the area and the outside, and enabling the temperature of the flow field of the hot-pressing tank to be uniform. The method comprises the following steps of: adopting Catia software to establish a model, and importing Ansys ICEM to divide grids; simulating the flow field and the temperature field in the process of the hot-pressing tank by a fluid analysis software and determining the position of the low-temperature area of the flow field in the hot-pressing tank; determining the installing position and the air speed of the blowing device in the low-temperature area; and changing the flowing speed of the fluid of the low-temperature area in the hot-pressing tank by the blowing device and thus enabling the temperature of the flow field of the hot-pressing tank to be uniform. The method disclosed by the invention has the advantages that the forming quality of the composite-material part is improved, not only is the cost saved, but also the efficiency is improved.

Owner:DALIAN UNIV OF TECH

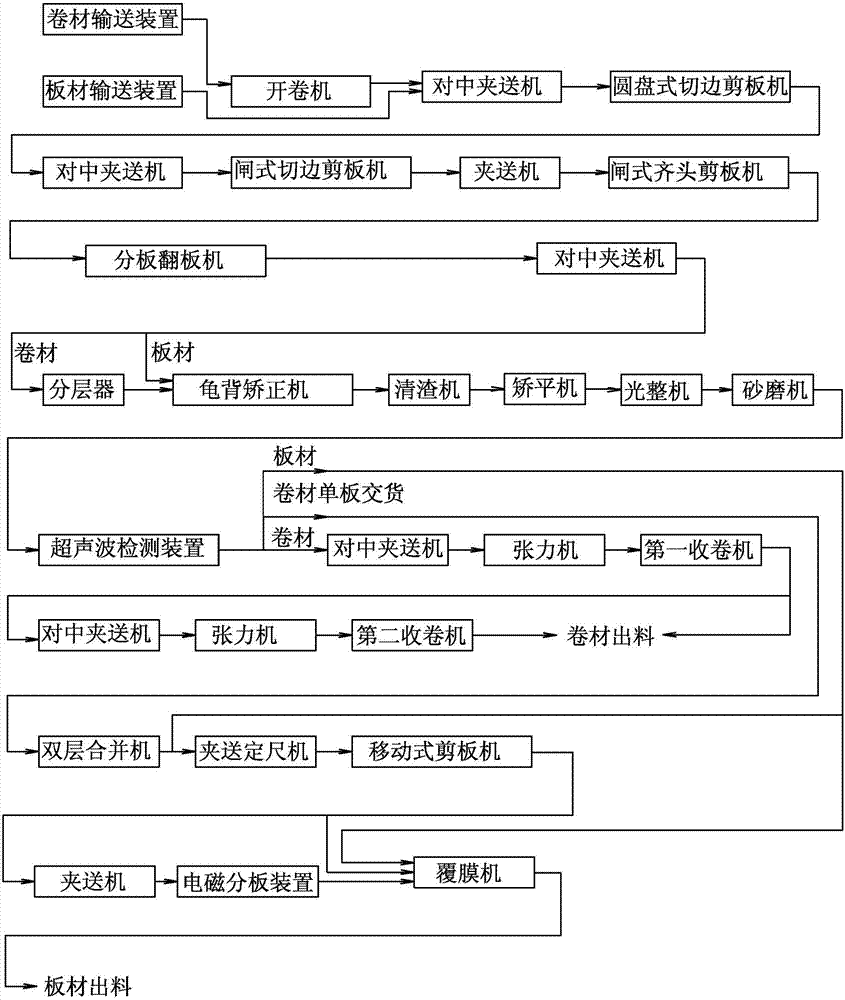

Hot rolling double-layer thermometal composite coiled material/plate finishing production line

ActiveCN107052820AReduce investmentReduce space occupancyShearing machinesOther manufacturing equipments/toolsProduction lineComposite plate

The invention discloses a hot rolling double-layer thermometal composite coiled material / plate finishing production line. The hot rolling double-layer thermometal composite coiled material / plate finishing production line comprises a feeding device, an uncoiler, a centring clamping machine, a disk type edge cutting plate shearing machine, a brake type edge cutting plate shearing machine, a brake type flushing plate shearing machine, a plate separating and turnover machine, a layering device, a turtle back straightening machine, a residue cleaning machine, a leveller, a temper mill, a sand mill, an ultrasonic detecting device, a tensioner, a first rolling machine, a second rolling machine, a double-layer combining machine, a clamping shear gauge, a movable plate shearing machine, a plate dividing machine and a film laminating machine all of which are sequentially arranged according to the advancing direction of a plate or a coiled material. The production can machine the double-layer thermometal composite coiled material and can also machine the double-layer thermometal composite plate, one machine has two functions, the production line integrates high rigidity, high precision, high stability and high efficiency of a machine tool, the working procedures are arranged reasonably, the structural design is compact, the production efficiency is high, running is stable and reliable, the investment and the energy consumption are low, operation is safe, and debugging is convenient.

Owner:山东易川新材料科技股份有限公司

Additive manufacturing apparatus of continuous fiber reinforced composite material

ActiveCN107139459ASmall diameterSmall size3D object support structuresApplying layer meansTemperature monitoringFiber-reinforced composite

The invention discloses an additive manufacturing apparatus of a continuous fiber reinforced composite material. The apparatus has a simple nozzle structure and smaller dimension, and can improve moulding precision; a vertical distance between an outlet of an internal nozzle and an outlet of an external nozzle is adjustable, in order to control centering of the fiber composite material, and improve moulding quality. An additive manufacturing nozzle of the continuous fiber reinforced composite material is installed on a two-dimensional moving platform, a workbench is arranged below the additive manufacturing nozzle of the continuous fiber reinforced composite material, and the workbench is installed on a one-dimensional moving platform; a filament extruding mechanism, a heating device and a temperature monitoring device are installed on the additive manufacturing nozzle of the continuous fiber reinforced composite material and follows motion of the two-dimensional moving platform; the heating device is used for heating the additive manufacturing nozzle of the continuous fiber reinforced composite material; a temperature monitoring device is used for measuring the temperature of the additive manufacturing nozzle of the continuous fiber reinforced composite material; a controlling means is used for controlling the working states of the two-dimensional moving platform, the one-dimensional moving platform, the filament extruding mechanism, the heating device, and the temperature monitoring device.

Owner:陕西众德科创科技有限责任公司

Light-weight partition wall structure and installing method thereof

The invention provides a light-weight partition wall structure and an installing method thereof. The light-weight partition wall structure is mainly characterized in that the part of a partition wall turning corner is prefabricated into an integrally formed turning corner component; a square steel pipe filled with polyphenyl granule cement is prefabricated into a construction column; and a ring beam formed by matching square steel with a U-shaped clamp element is used as a component of a light-weight partition wall, so that the technical problems of the existing polyphenyl granule light-weight ribbon board partition wall are solved; and the technical effects of shortening the construction period and practically improving the installing quality of the light-weight partition wall are achieved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

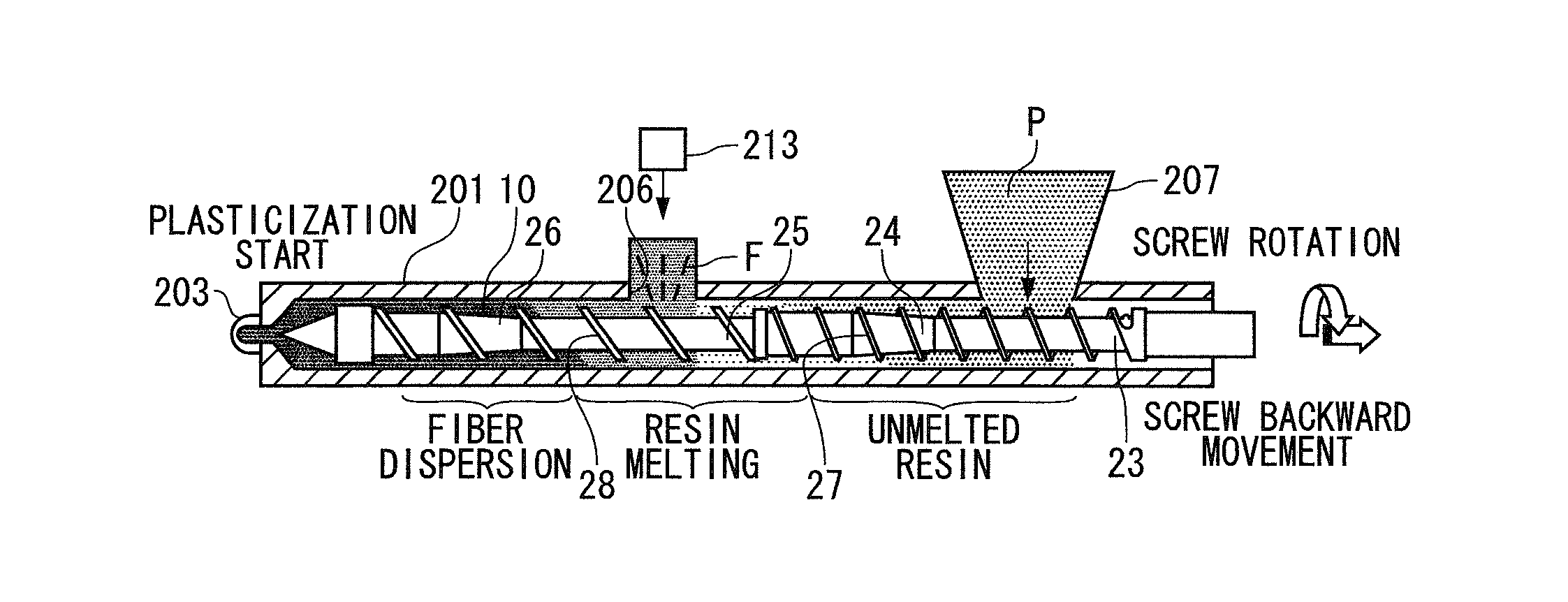

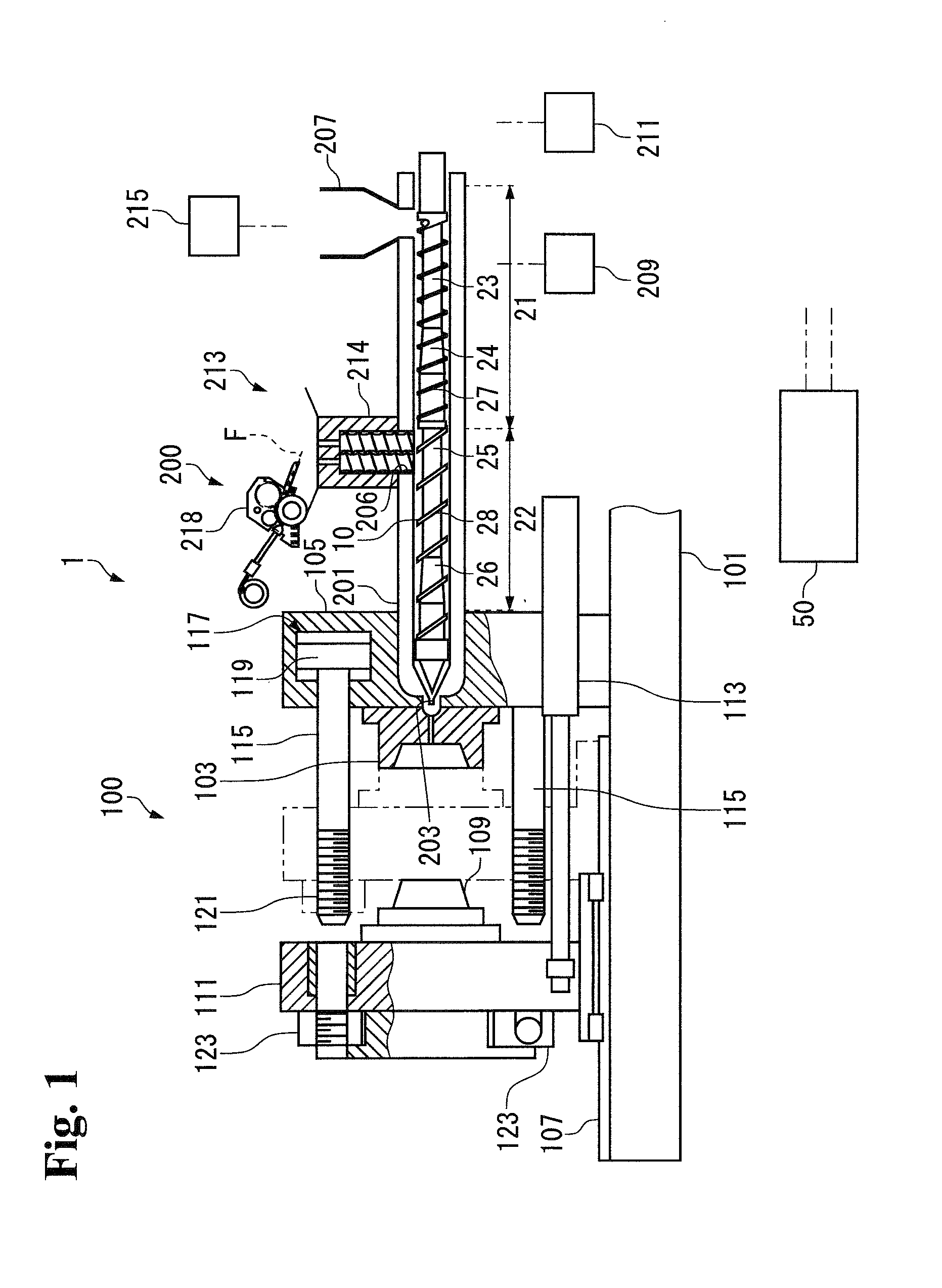

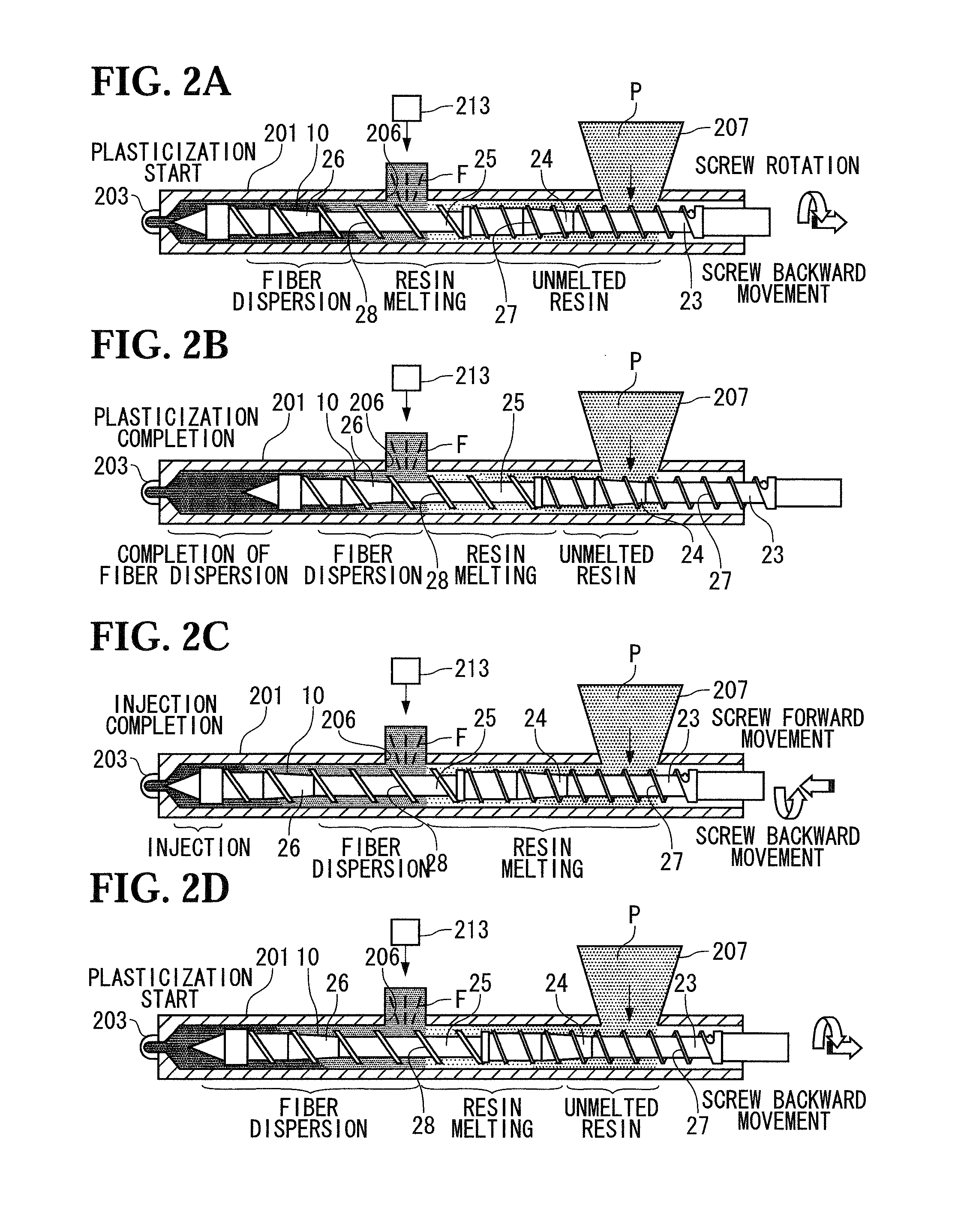

Injection molding apparatus and injection molding method

The injection molding apparatus of the present invention includes: a heating cylinder; a screw that is provided rotatably in an inner portion of the heating cylinder; a resin feed hopper that feeds a resin pellet; and a fiber feed device that is provided ahead of the resin feed hopper and feeds reinforcing fibers into the heating cylinder. The screw includes a first stage that is located on a rear side, and in which the resin pellet is melted, and a second stage that is located on a front side, and in which the melted resin pellet and the reinforcing fibers are mixed, and a lead of a second flight provided in the second stage is larger than a lead of a first flight provided in the first stage.

Owner:U MHI PLATECH CO LTD +1

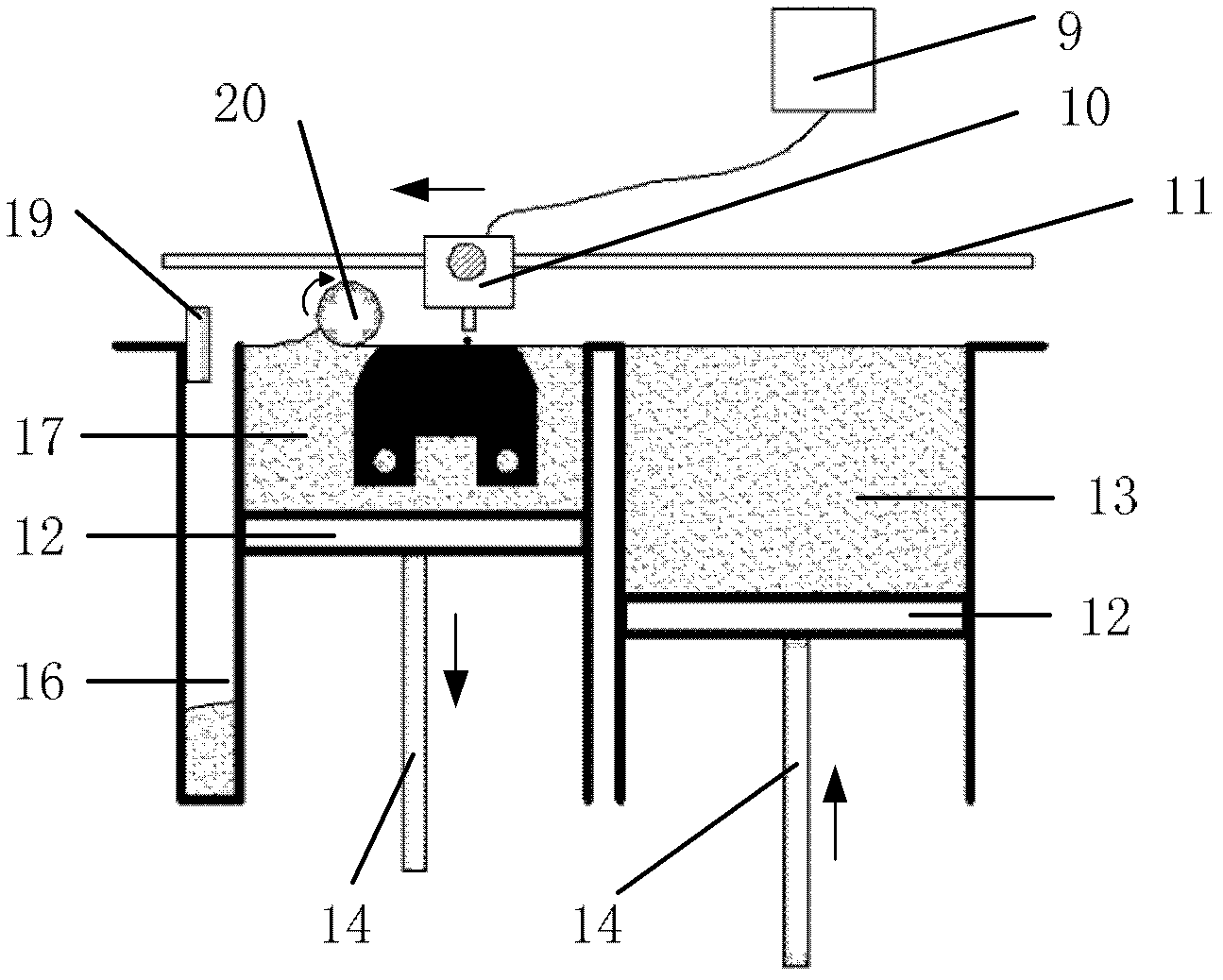

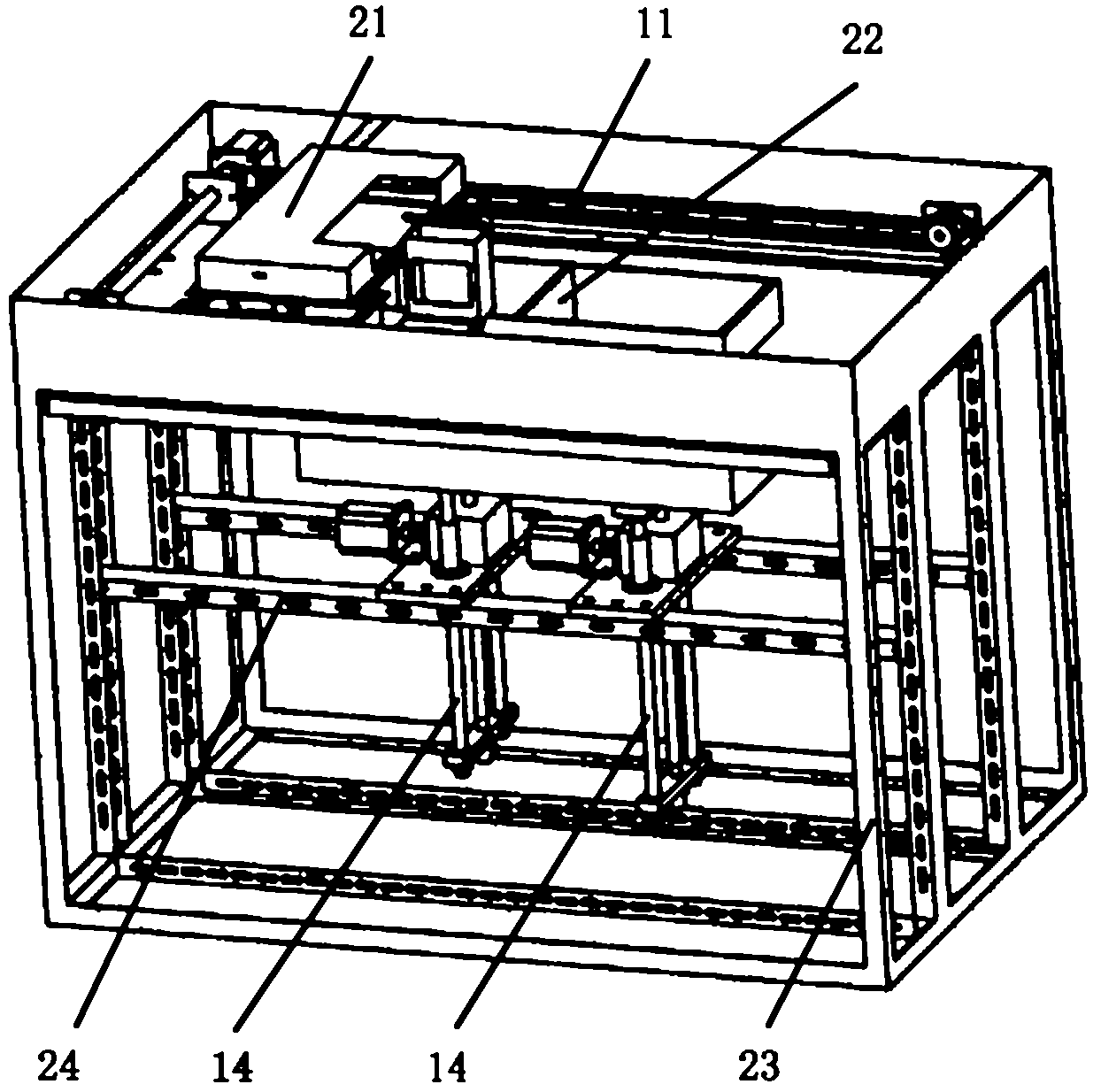

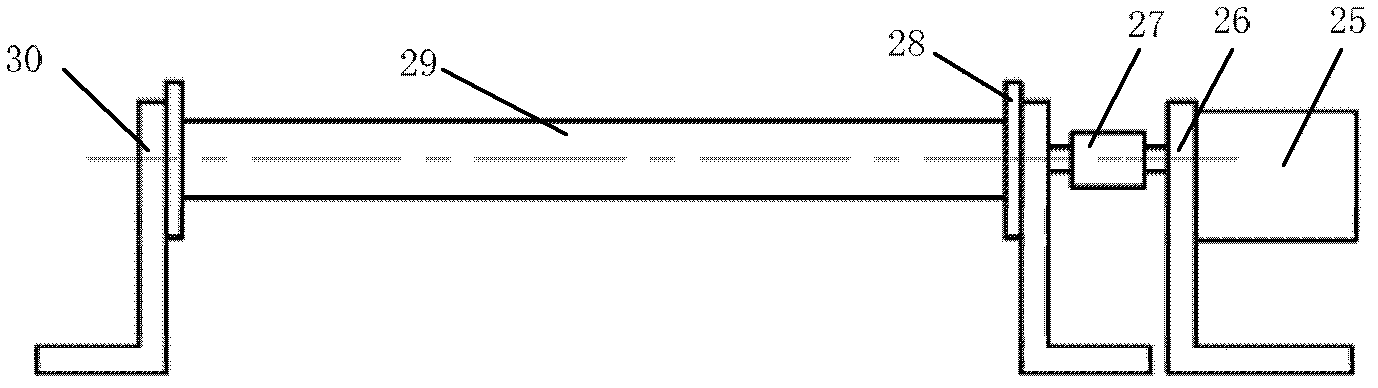

Piezoelectric-type three-dimensional printing forming system and forming method thereof

InactiveCN102602146AMake up for the shortcomings of insufficient rigidity of the supporting structureCompact structureManufacturing driving meansTypewritersEngineering3 dimensional printing

The invention discloses a piezoelectric-type three-dimensional printing forming system and a forming method thereof. The system comprises a box body and a supporting framework thereof, an X-direction movement mechanism (11), a bearing structure (21) which is connected onto the X-direction movement mechanism, a powder storage cavity (13), a forming cavity (17), a three-dimensional image layering discrete mechanism, a powder pavement mechanism (20) and a piezoelectric-type spray head (10), wherein the powder storage cavity (13) and the forming cavity (17) are arranged below the bearing structure, and the powder pavement mechanism (20) and the piezoelectric-type spray head (10) are loaded on the bearing structure (21). The piezoelectric-type spray head can spray a solution without heating the solution, so that more varieties of solutions can be sprayed, and the piezoelectric-type three-dimensional printing forming system can be applied to the emerging fields such as biology, pharmacy and the like. Caking ingredients can be mixed into powder through the system, so that sufficient caking ingredients can be added to achieve satisfactory caking strength. In addition, the piezoelectric-type three-dimensional printing forming system has advantages of compact structure, simpleness in operation, low equipment expense and high forming precision.

Owner:HUAZHONG UNIV OF SCI & TECH

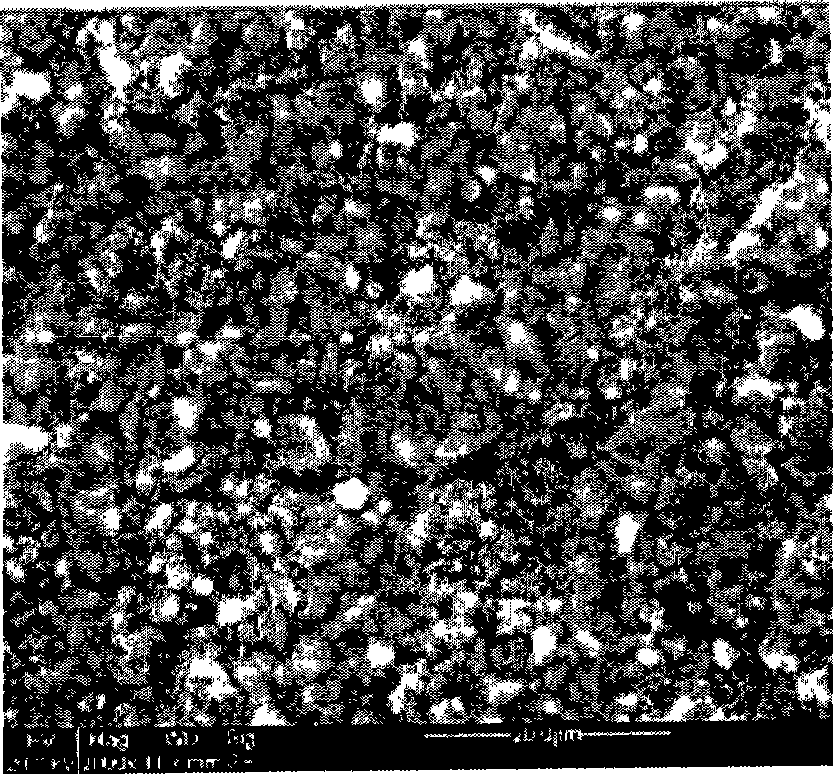

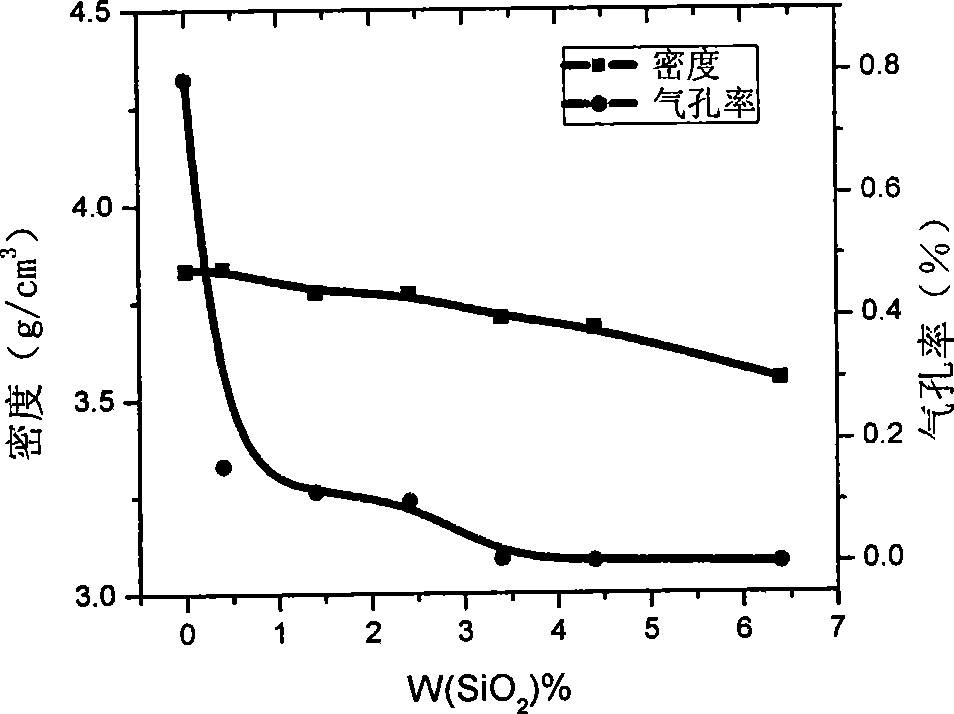

Preparation of black alumina substrate for multilayered wiring

InactiveCN101483417ALower sintering temperatureLower firing temperatureImpedence networksBasal laminaPlasticizer

The present invention discloses a method for preparing material of black alumina substrate used in multilayer wiring, namely adopts solid phase method, adds elements of Co, Mn, Cr, Si, Ti, B, V etc. into principal crystalline phase Al2O3 powder, modify oxide of alumina through adulterating, which recedes firing temperature, and brings out a black oxide of alumina organic doctor-blade casting method on the basis of modified powder, selects doctor-blade casting agent, double solvent and composite plasticizer that suitable for oxide of alumina; uniform and stable slurry with high solid content is obtained, bisque forming quality is enhanced; use doctor blade method for tape-casting, equipment simple and operational, natural drying process convenient, drying process will not lead rupture of billet body and phenomenon of unable stripping; obtained film body compact, and use mechanical drilling method to prepare stack basal lamina and obtain black alumina substrate used in multilayer wiring.

Owner:HUAZHONG UNIV OF SCI & TECH

Punching die

InactiveCN105251865ASimple structureEasy to processShaping toolsPerforating toolsPunchingEngineering

The invention provides a punching die, and belongs to the field of die equipment. The punching die is used for performing punching forming on multiple holes in a metal tube and comprises an upper die base, a lower die base, a die shank, a male die, a female die, guide columns and guide sleeves, wherein the male die is installed on the lower surface of the upper die base, and the female die is installed on the upper surface of the lower die base. The male die is provided with a plurality of punching parts arranged in the extension direction of the cavity of the female die at intervals. The punching die further comprises an inclined slider core-pulling mechanism. The inclined slider core-pulling mechanism comprises a core-pulling slider; the core-pulling slider is provided with a plurality of second forming holes and is pulled out of the cavity of the female die when the punching die is opened; when the punching die is assembled, the core-pulling slider is inserted into the cavity of the female die and enables the second forming holes to correspond to the punching parts in a one-to-one mode. When the punching die punches multiple holes, the metal tube is does not deform easily, the forming quality of the holes is high, the machining efficiency is improved, and the machining cost is reduced.

Owner:中山风火脚轮制造有限公司

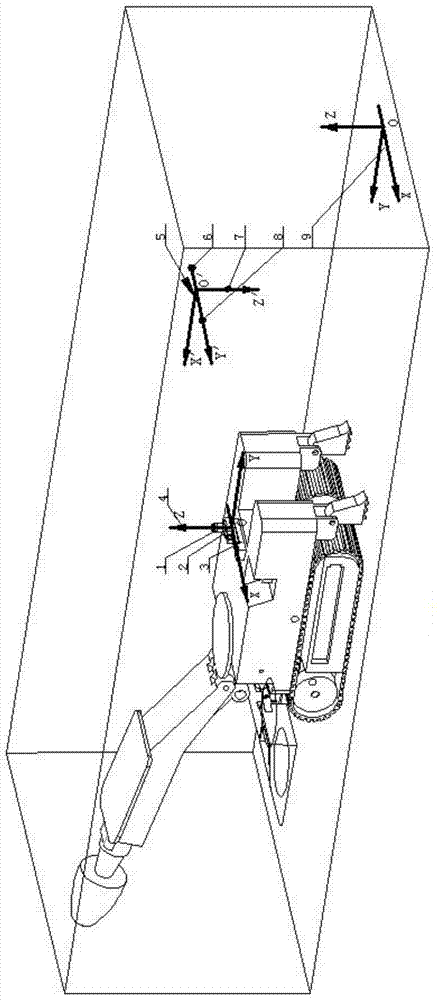

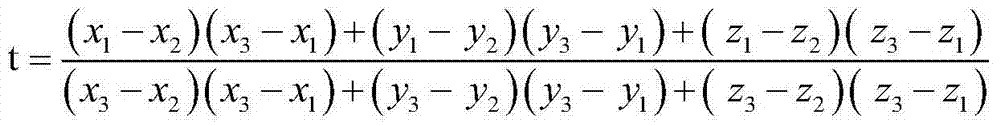

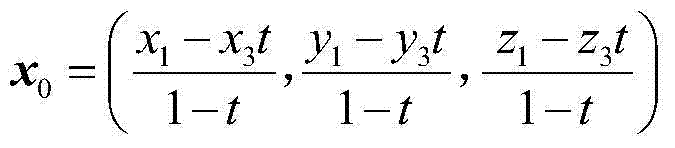

Rotating-sector-laser-based position and pose measurement method of cantilever excavator

InactiveCN104729501AImprove reliabilityHigh precisionSurveying instrumentsNavigation instrumentsCantileverExcavator

The invention relates to a position and post measurement method of a cantilever excavator at an excavating workface of a coal mine. The method comprises the following steps that a space point three-dimensional coordinate measuring system for measuring angles based on rotating sector laser is fully utilized, namely, the sector laser transmission end of the system is mounted on a cantilever excavator body, while the sector laser receiving end (including three non-collinear sector laser receivers) is fixedly mounted at the back of a coal road excavated by the cantilever excavator; the coordinate values of a sector laser receiver relative to a space geodetic coordinate system can be measured by other measurement modes; the coordinate values of the sector laser receiver relative to the transmission end are measured through the sector emission transmission end and then are converted for calculating to obtain the three-dimensional coordinate values of three fixed points (non-collinear) on the cantilever excavator, relative to the space geodetic coordinate system; if the three-dimensional coordinate values of three fixed points (non-collinear) on a space rigid body, relative to the space geodetic coordinate system are known, the position and pose data of the space rigid body can be calculated.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com