Method for adjusting uniformity of temperature of flow field in hot-pressing tank

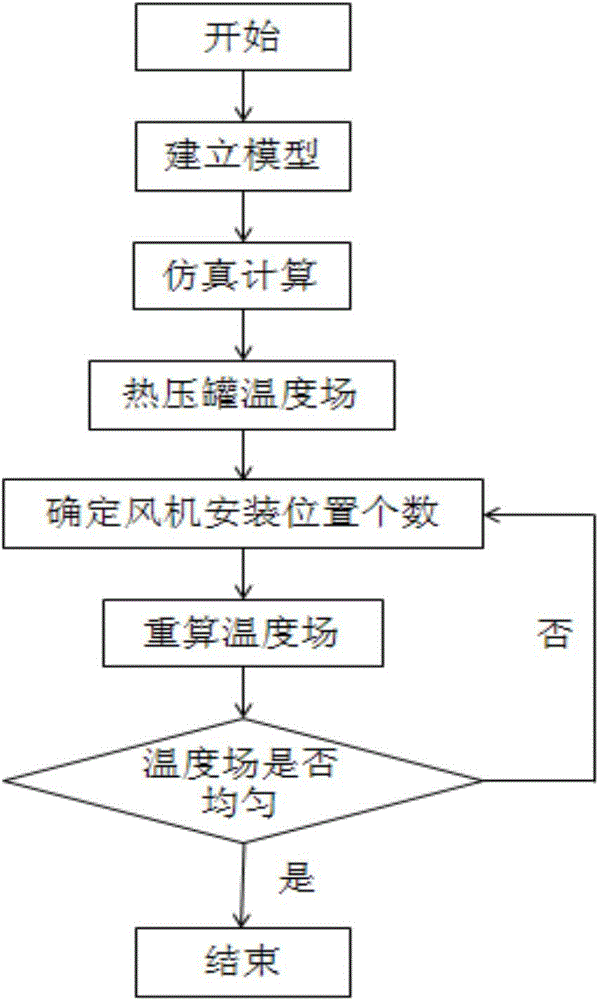

An autoclave and uniformity technology, which is used in the field of adjusting the temperature uniformity of the flow field in the autoclave, can solve the problems of uneven temperature and high cost, and achieve the goal of improving molding quality, improving efficiency, and reducing internal stress and deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

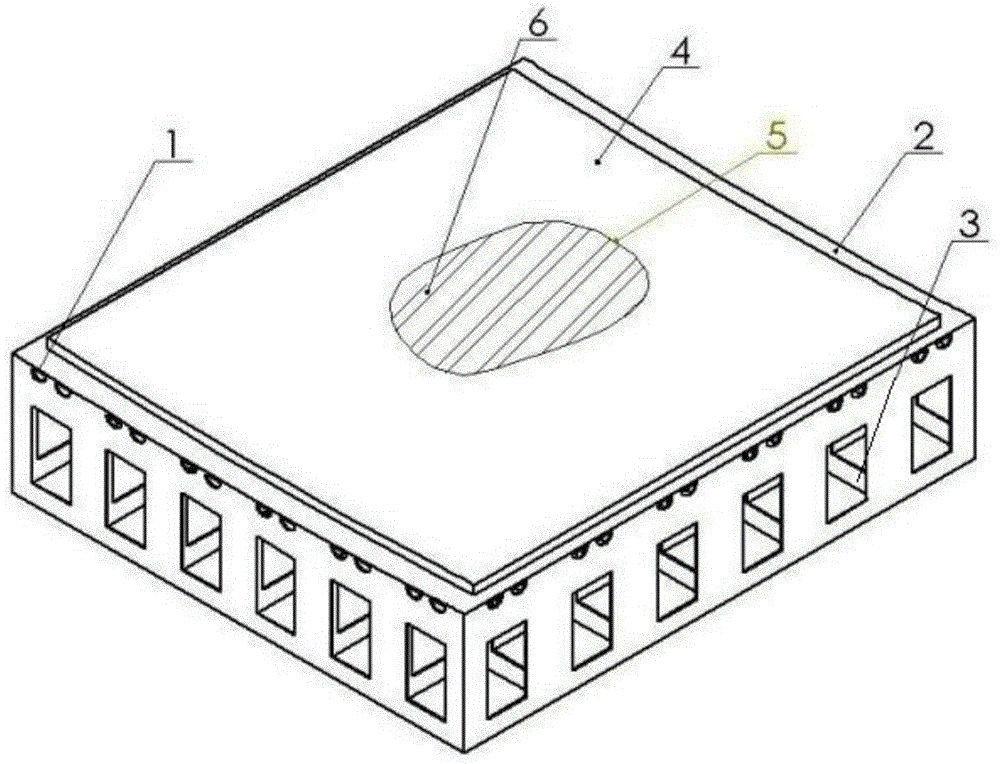

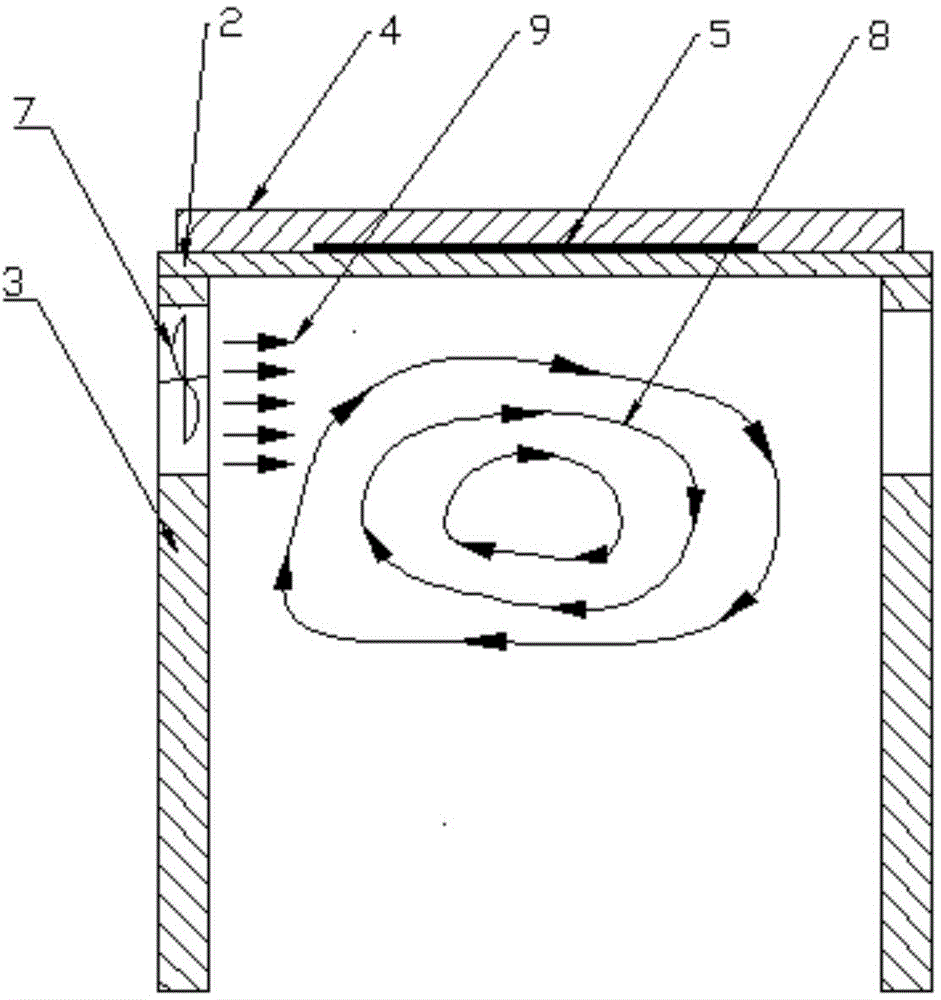

[0016] Below in conjunction with accompanying drawing, describe technical scheme of the present invention in detail, the autoclave model size that the present invention adopts is The size of the frame mold is 1500×1700×400mm in length, width and height, and the shape is as figure 2 shown. Composite member 4 adopts 0 / 90° laminated glass fiber / polyester resin composite material with a single layer thickness of 0.635mm. The 0-degree direction of the layup is along the length of the mold, and the thickness direction is the normal direction of the mold surface, with a total thickness of 25mm, and a total of 40 layers of glass fiber / polyester resin composite materials. According to the autoclave process, define the air density, viscosity, thermal conductivity in the tank, the density, specific heat capacity and thermal conductivity of the mold and other parameters, set the temperature process route of the autoclave, and use the turbulence model. To define the boundary conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com