Patents

Literature

3659results about How to "Reduce internal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

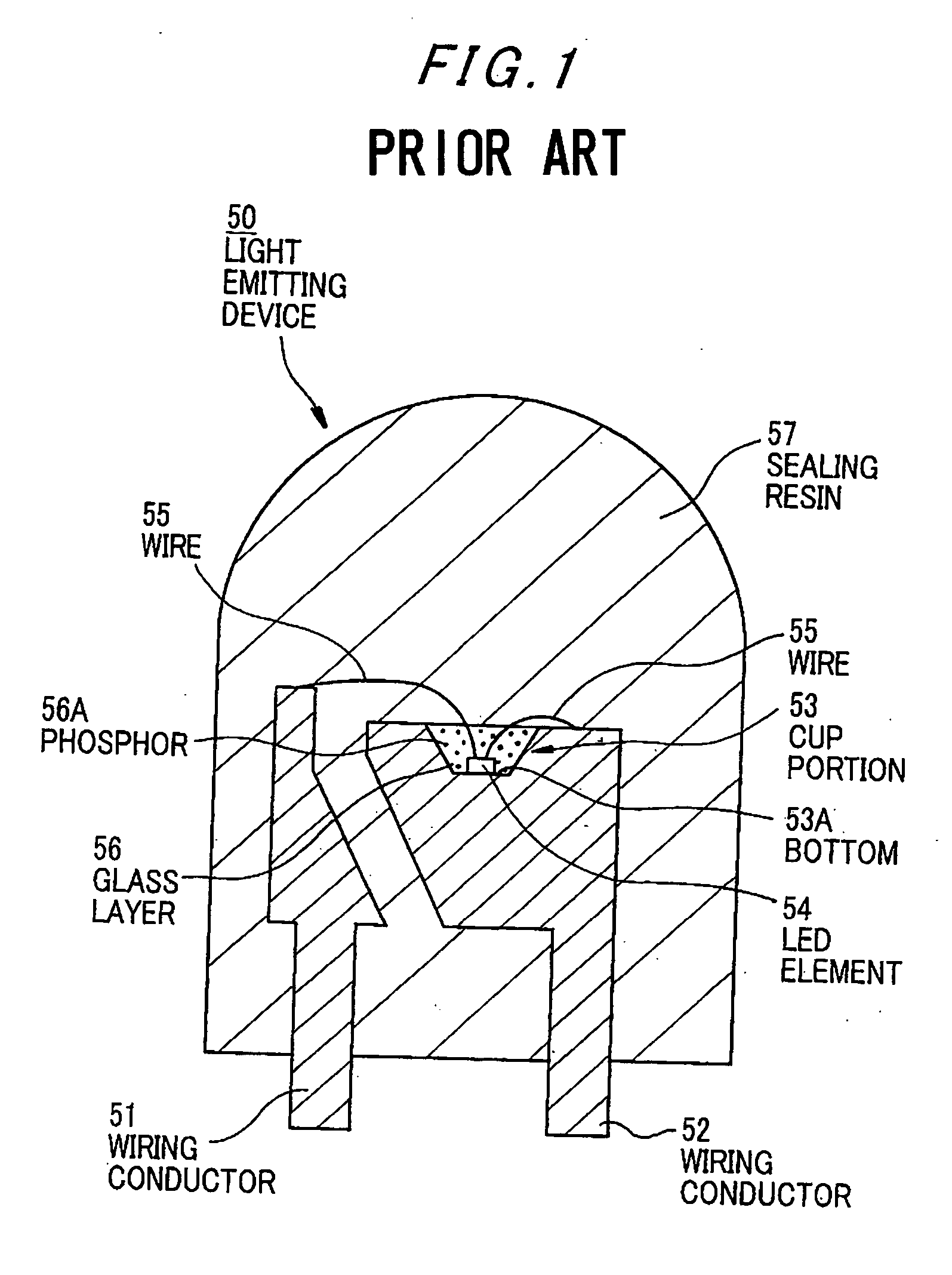

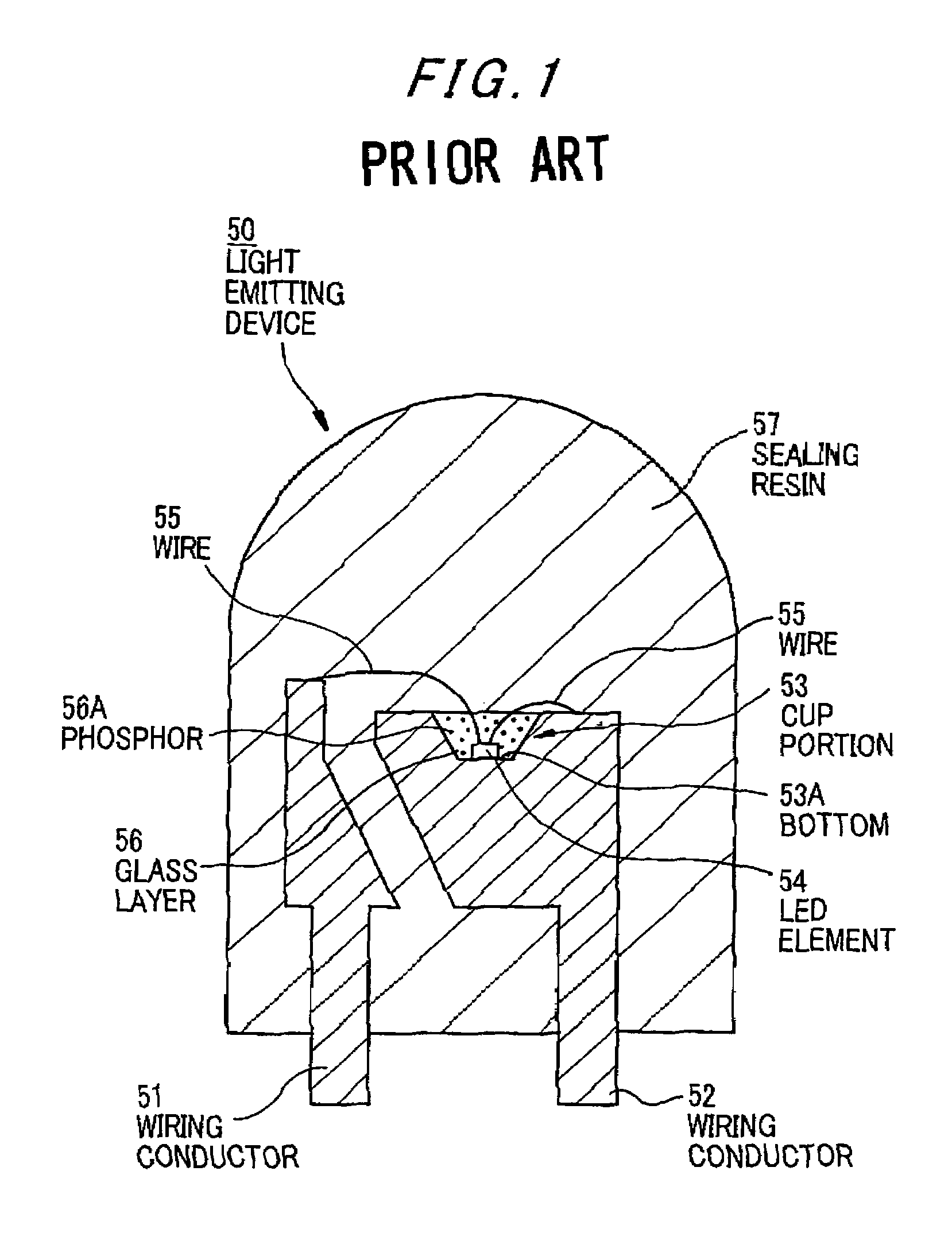

Light emitting device

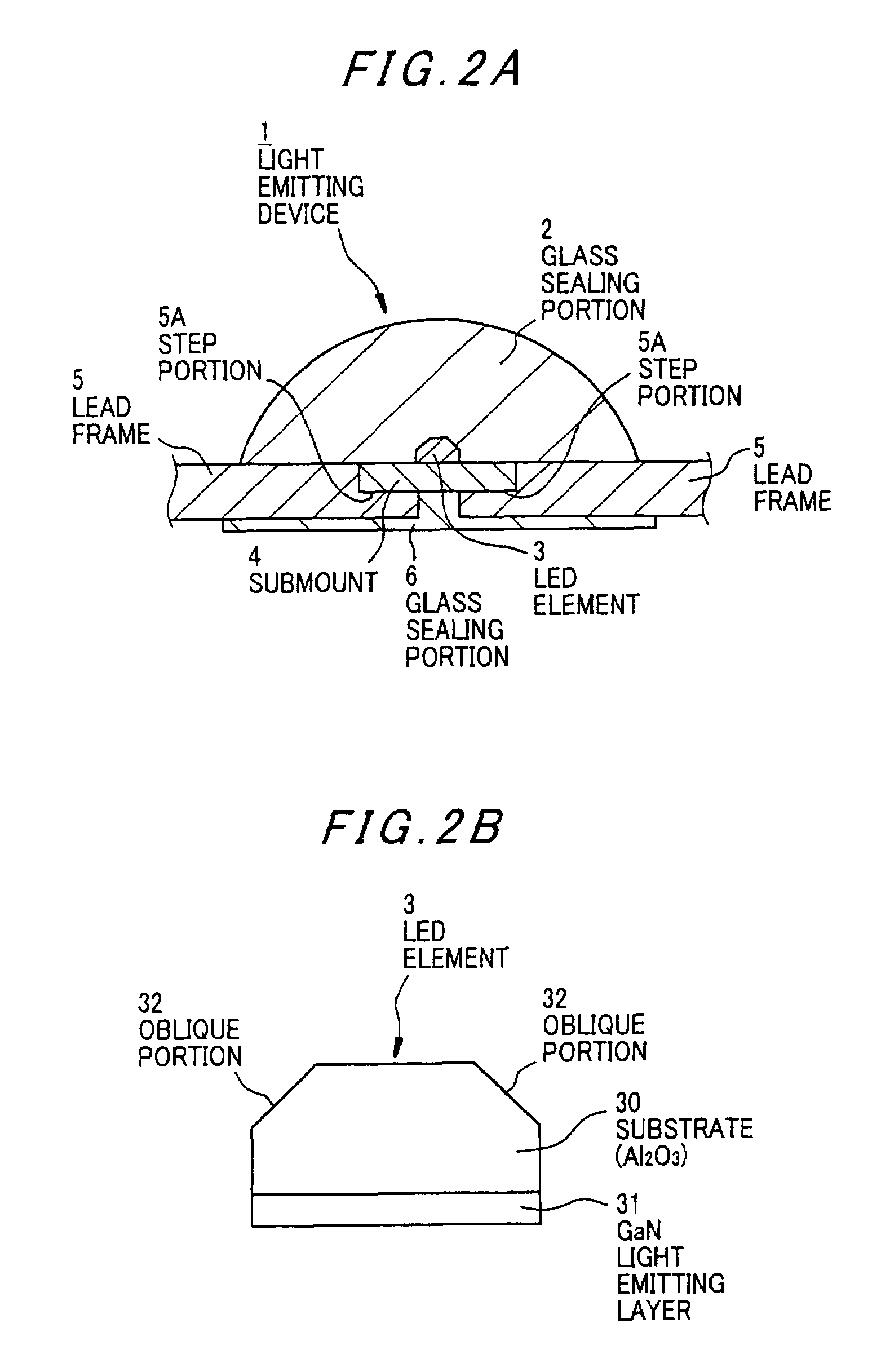

ActiveUS20060012299A1Avoiding pressure injuriesDifference in stressDischarge tube luminescnet screensElectroluminescent light sourcesThermal expansionLight emitting device

A light emitting device has: a light emitting element; a lead that is electrically connected to the light emitting element at its one end and serves as a terminal to supply a power source to the light emitting element; a metal base that the light emitting element is mounted thereon and radiates heat of the light emitting element; and a sealing member that is of transparent resin or glass and covers the light emitting element. The lead is secured to the metal base by a heat-resisting insulating member with a thermal expansion coefficient nearly equal to that of the metal base.

Owner:TOYODA GOSEI CO LTD

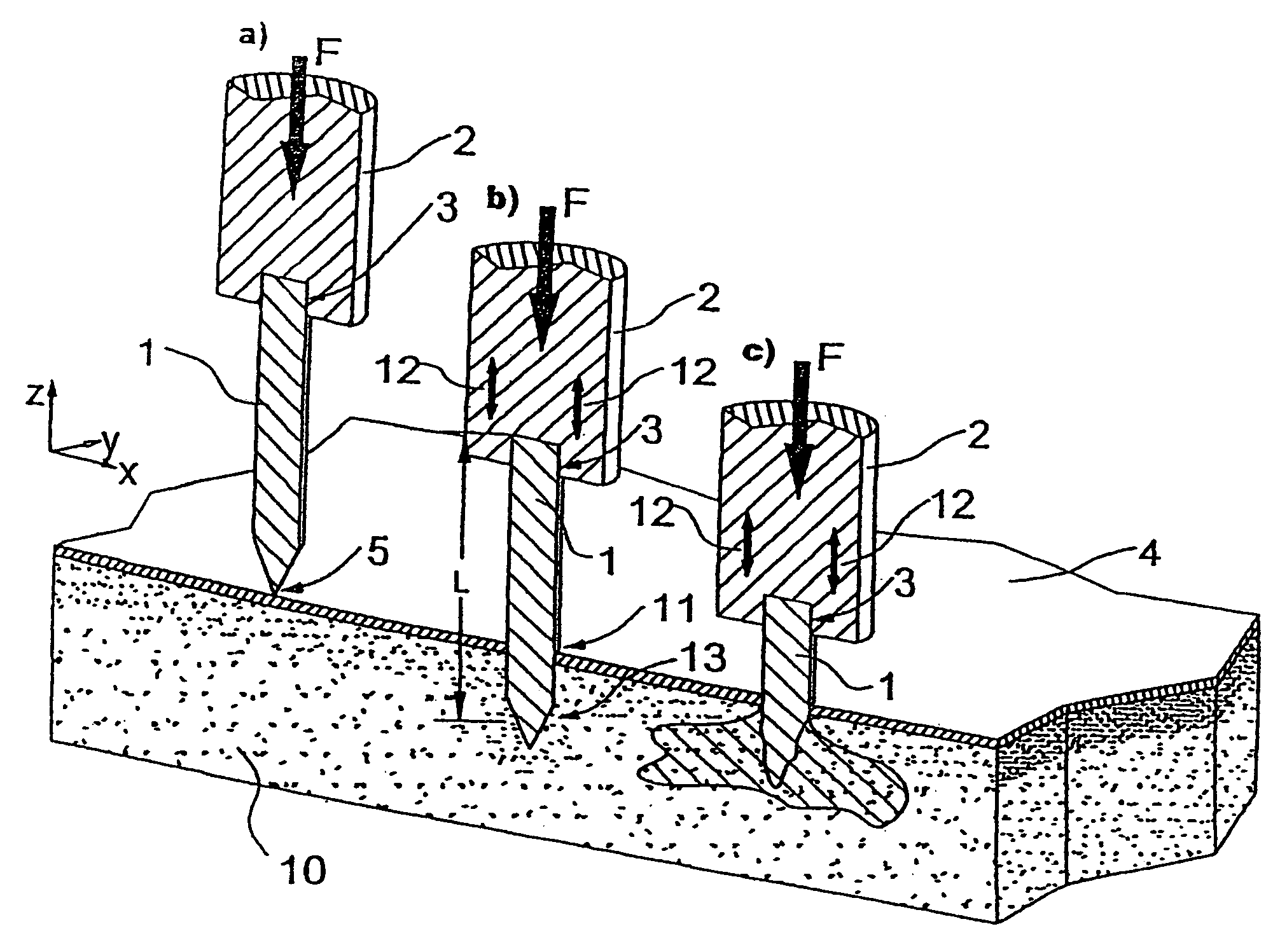

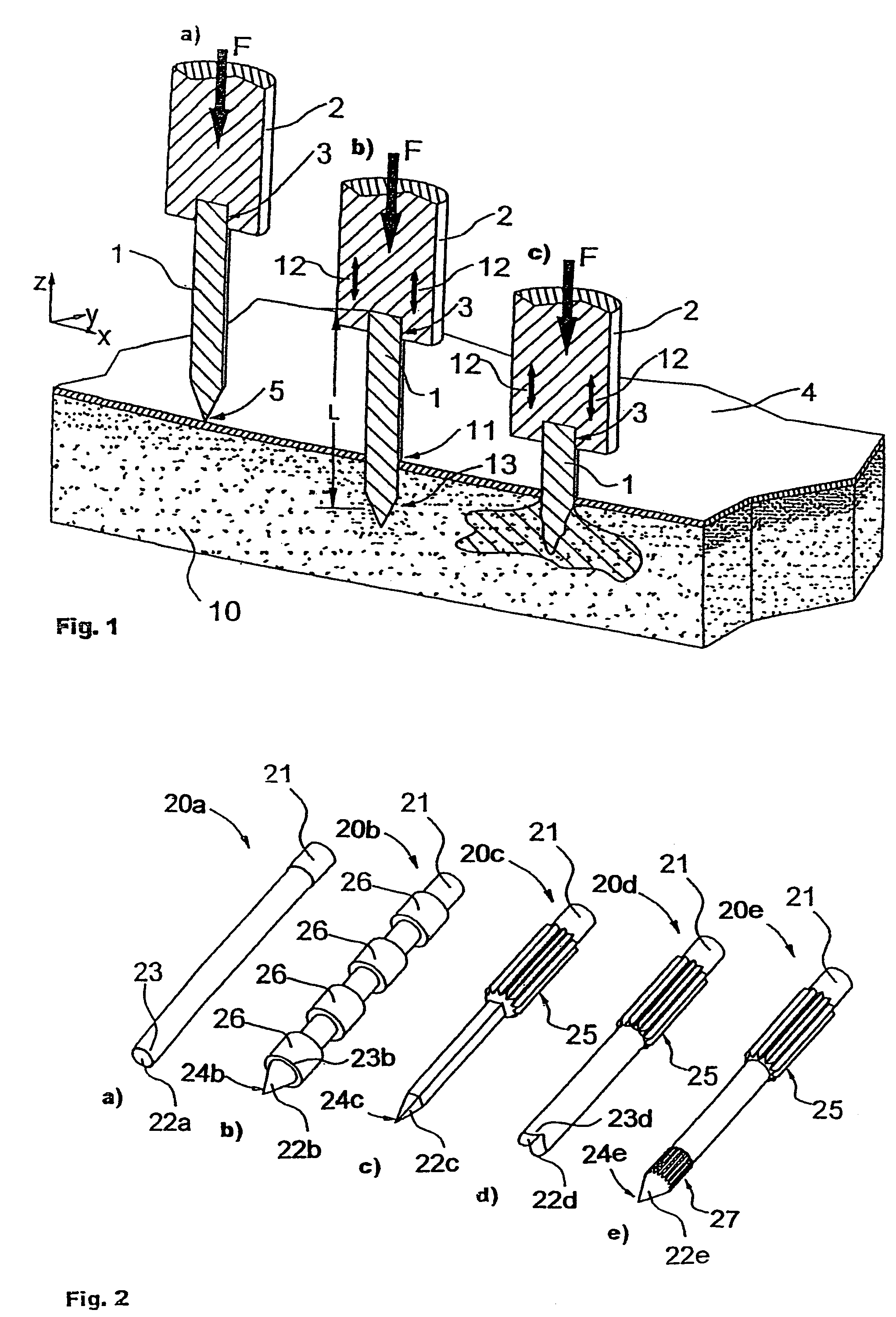

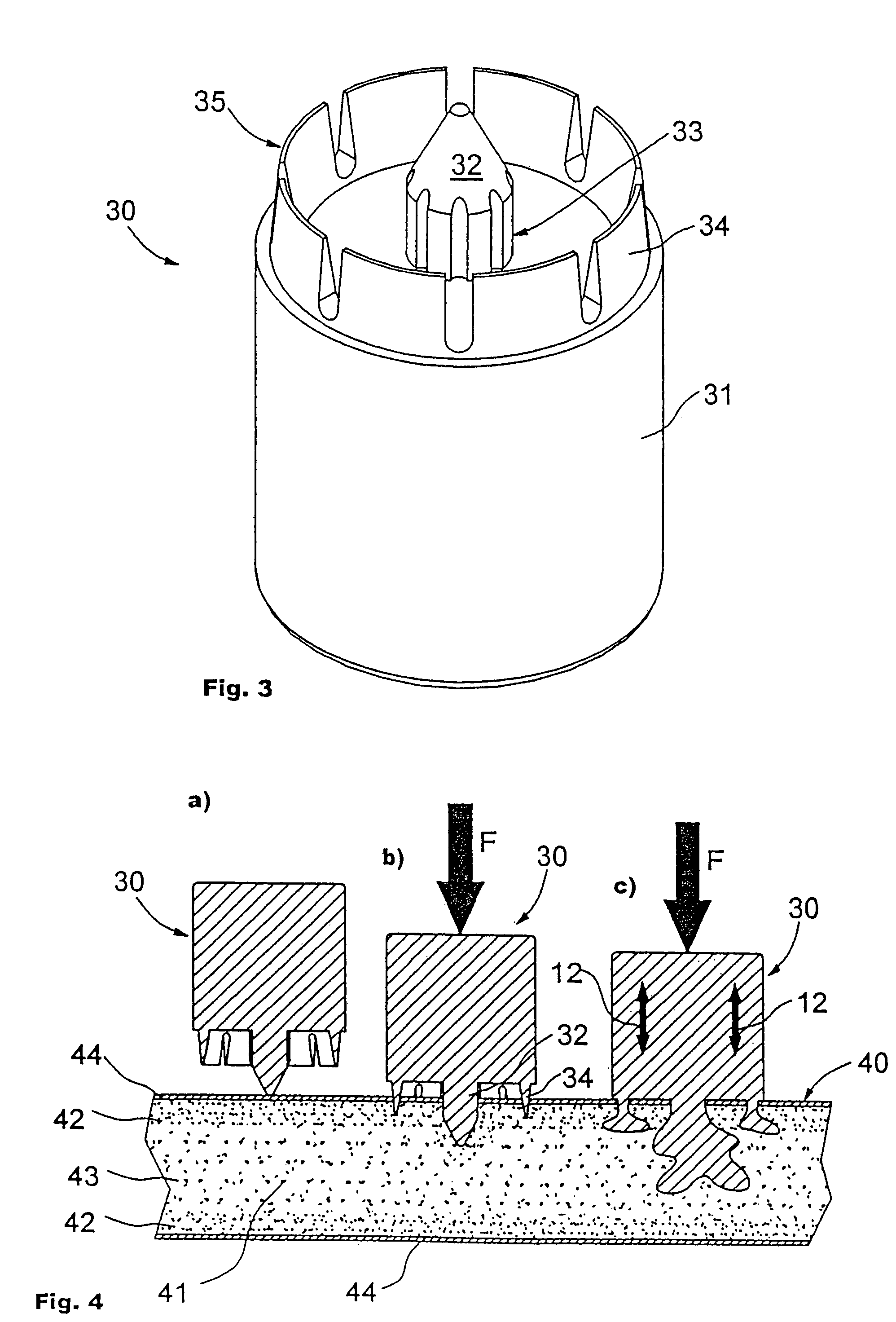

Integral joining

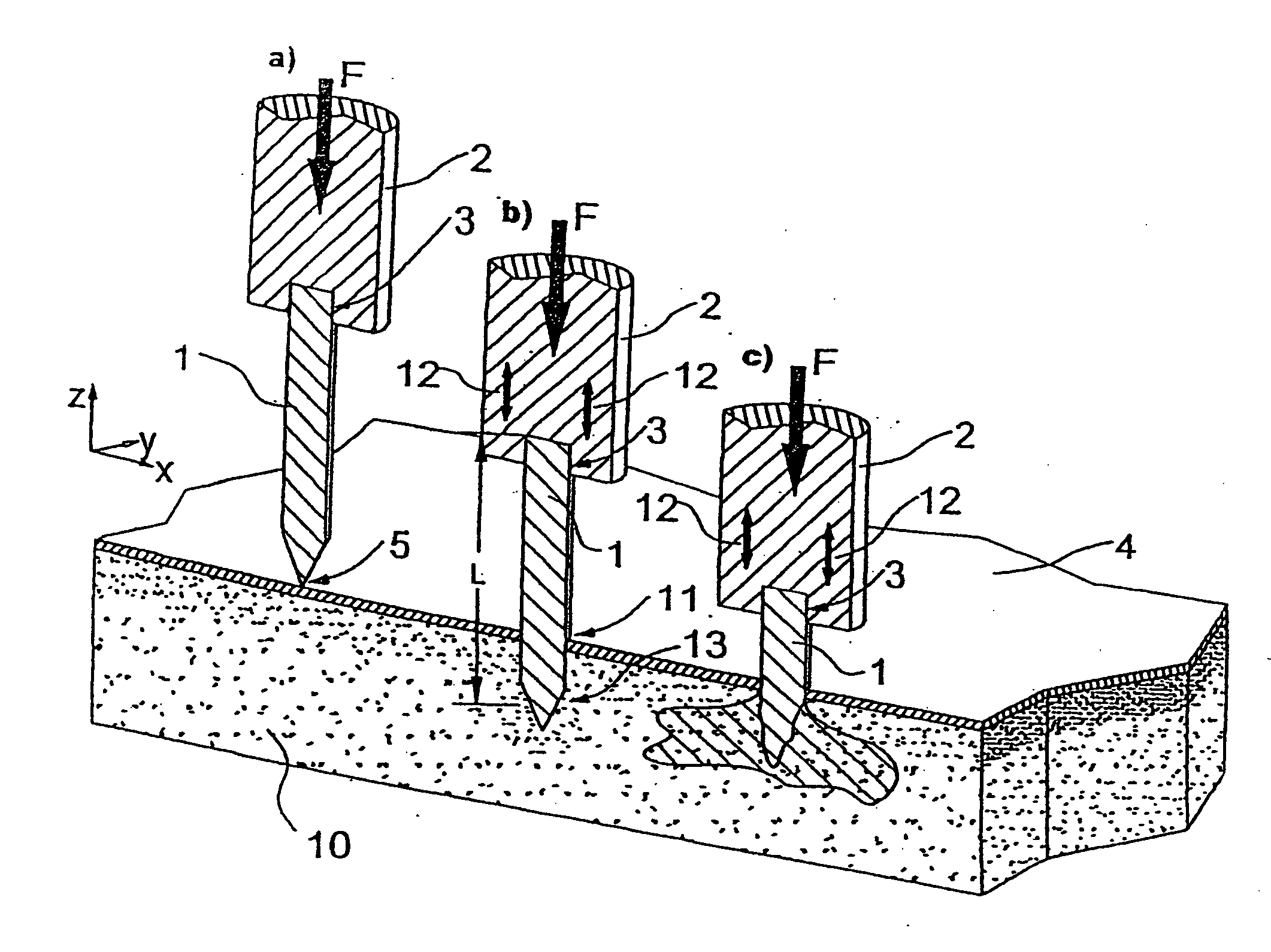

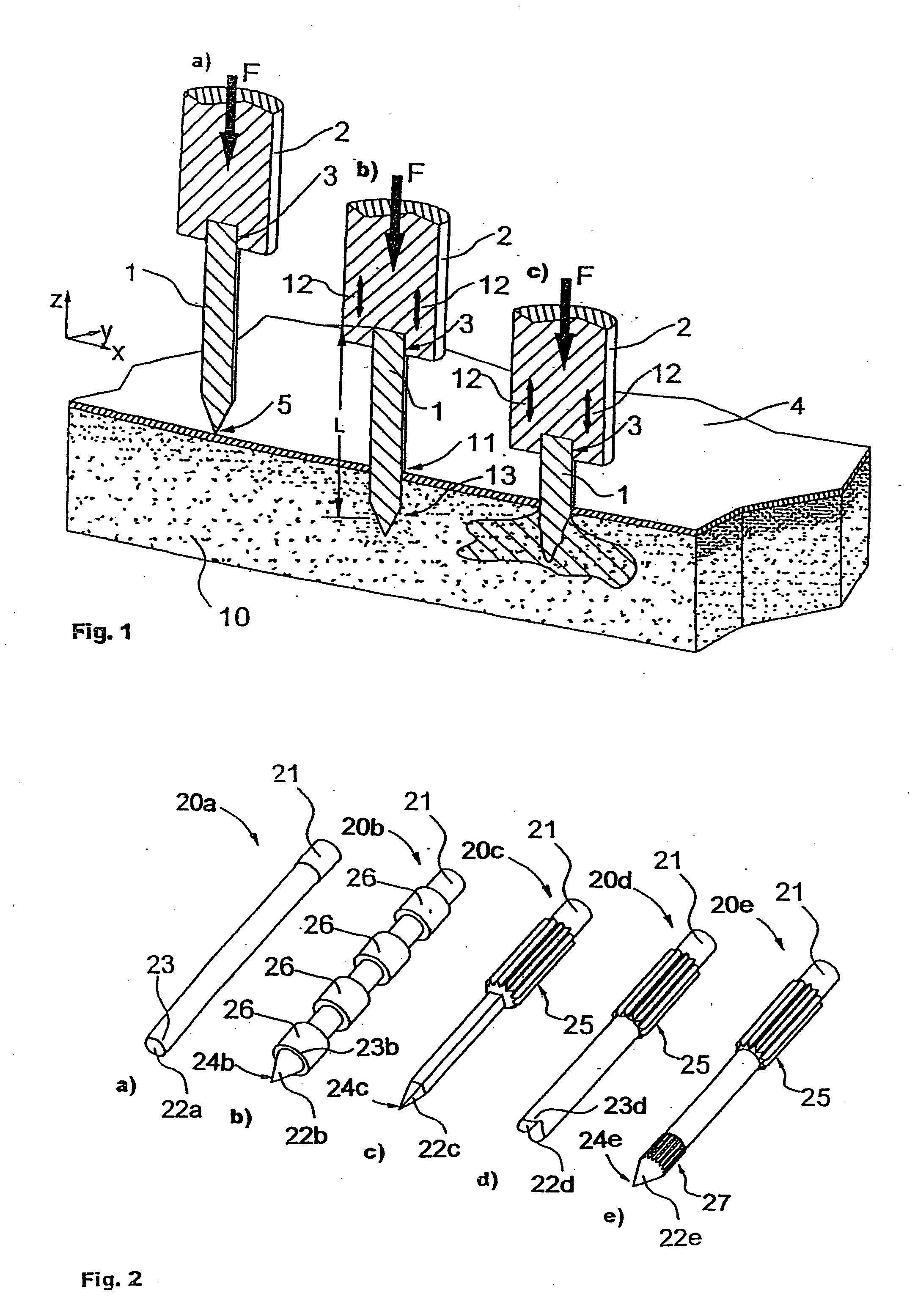

InactiveUS7160405B2Optimum introduction of loadHarmful stress concentrationLaminationLamination apparatusMaterials science

Owner:WOODWELDING

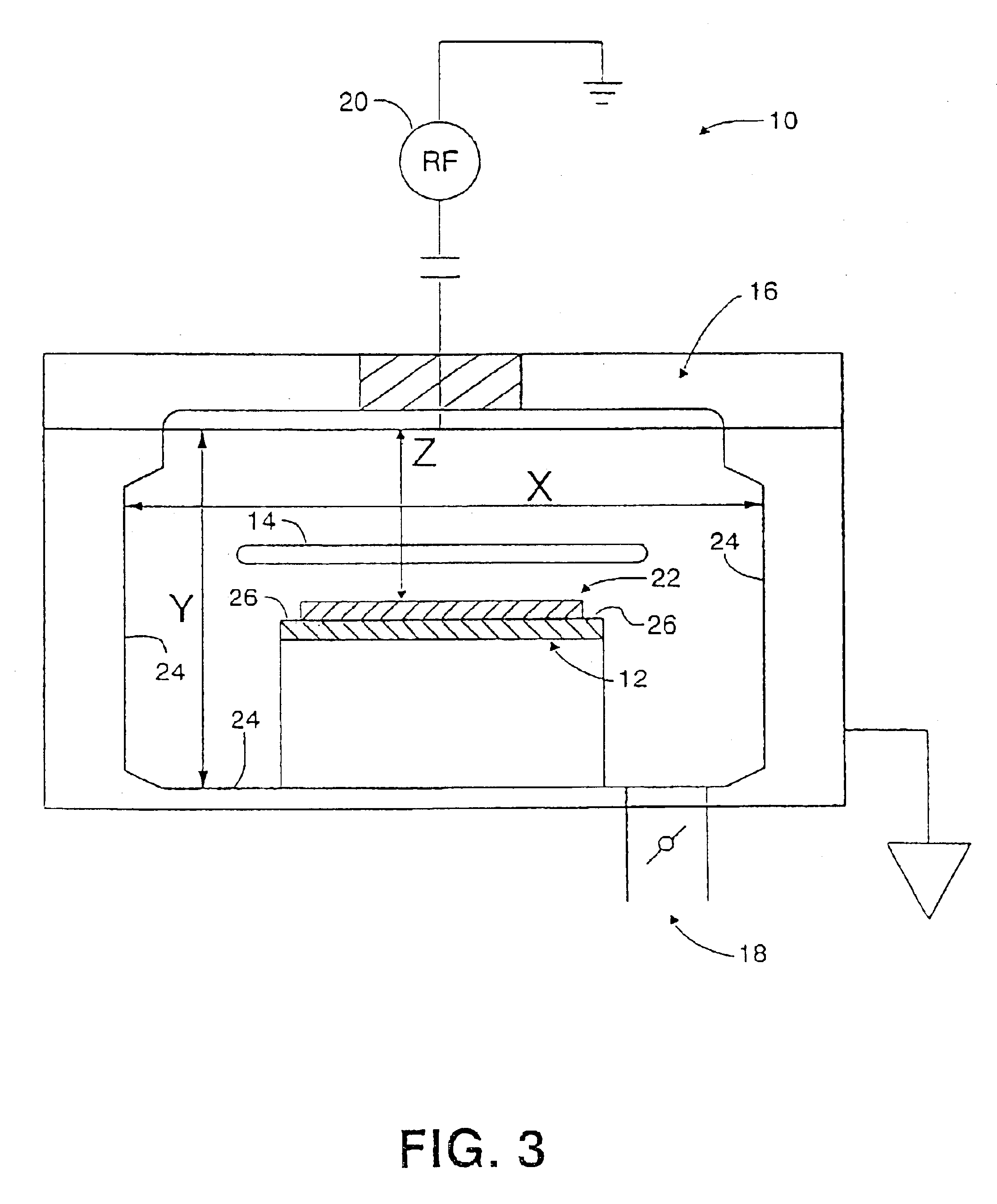

Method of forming a silicon nitride layer

ActiveUS7229502B2Uniform thicknessReduce internal stressVacuum evaporation coatingSputtering coatingNitrogenEngineering

A method of forming a silicon nitride layer is provided. A deposition furnace having an outer tube, a wafer boat, a gas injector and a uniform gas injection apparatus is provided. The wafer boat is positioned within the outer tube for carrying a plurality of wafers. The gas injector is positioned between the outer tube and the wafer boat. Similarly, the uniform gas injection apparatus is positioned between the outer tube and the wafer boat. Gas injected into the uniform gas injection apparatus is uniformly distributed throughout the entire deposition furnace. To form a silicon nitride layer on each wafer, a silicon-containing gas is passed into the deposition furnace via the gas injector and a nitrogen-mixed carrier gas is passed into the deposition furnace via the uniform gas injection apparatus.

Owner:MACRONIX INT CO LTD

Integral joining

InactiveUS20050126680A1Optimum introduction of loadHarmful stress concentrationLaminationLamination apparatusMaterials science

Owner:WOODWELDING

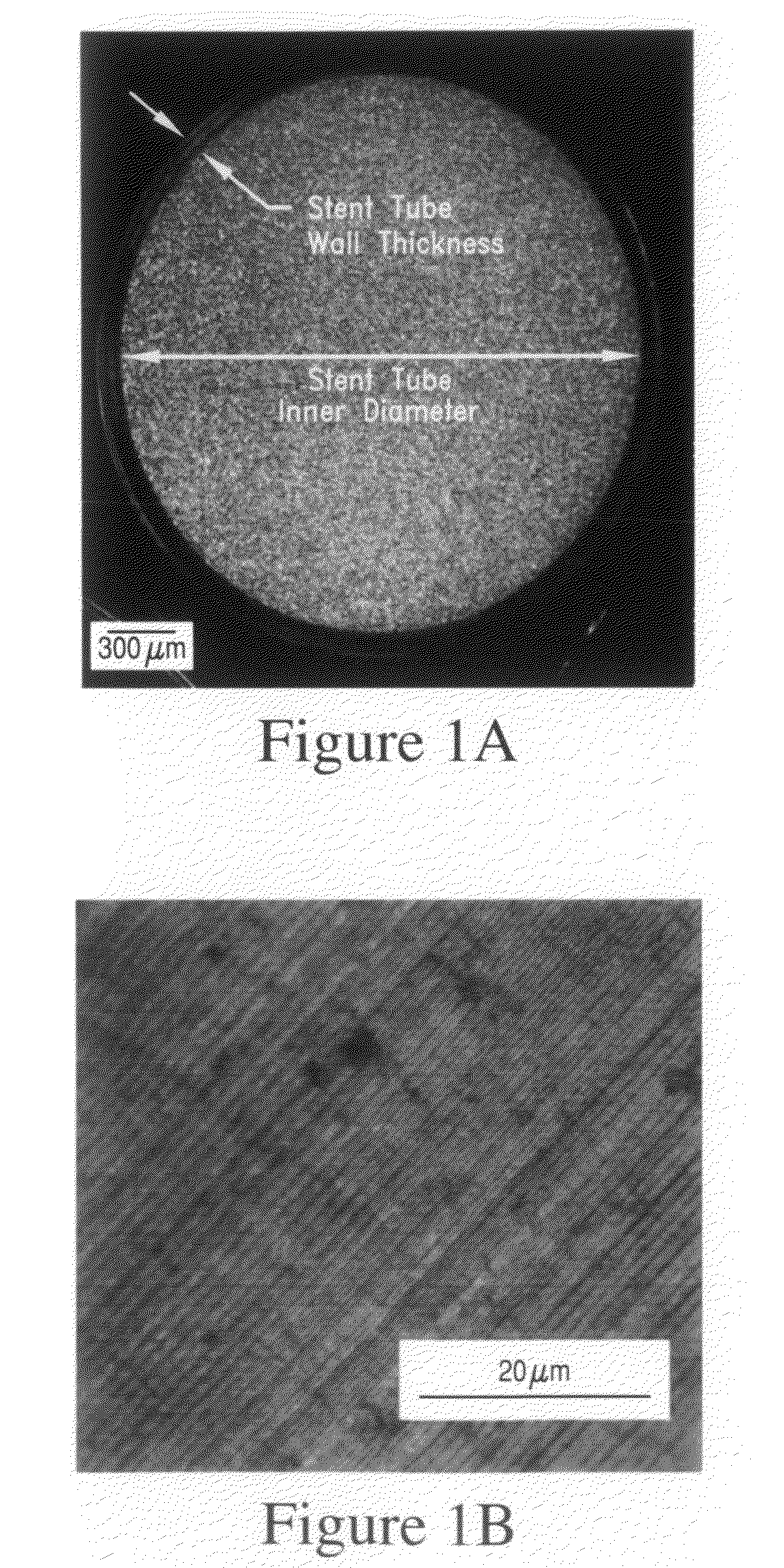

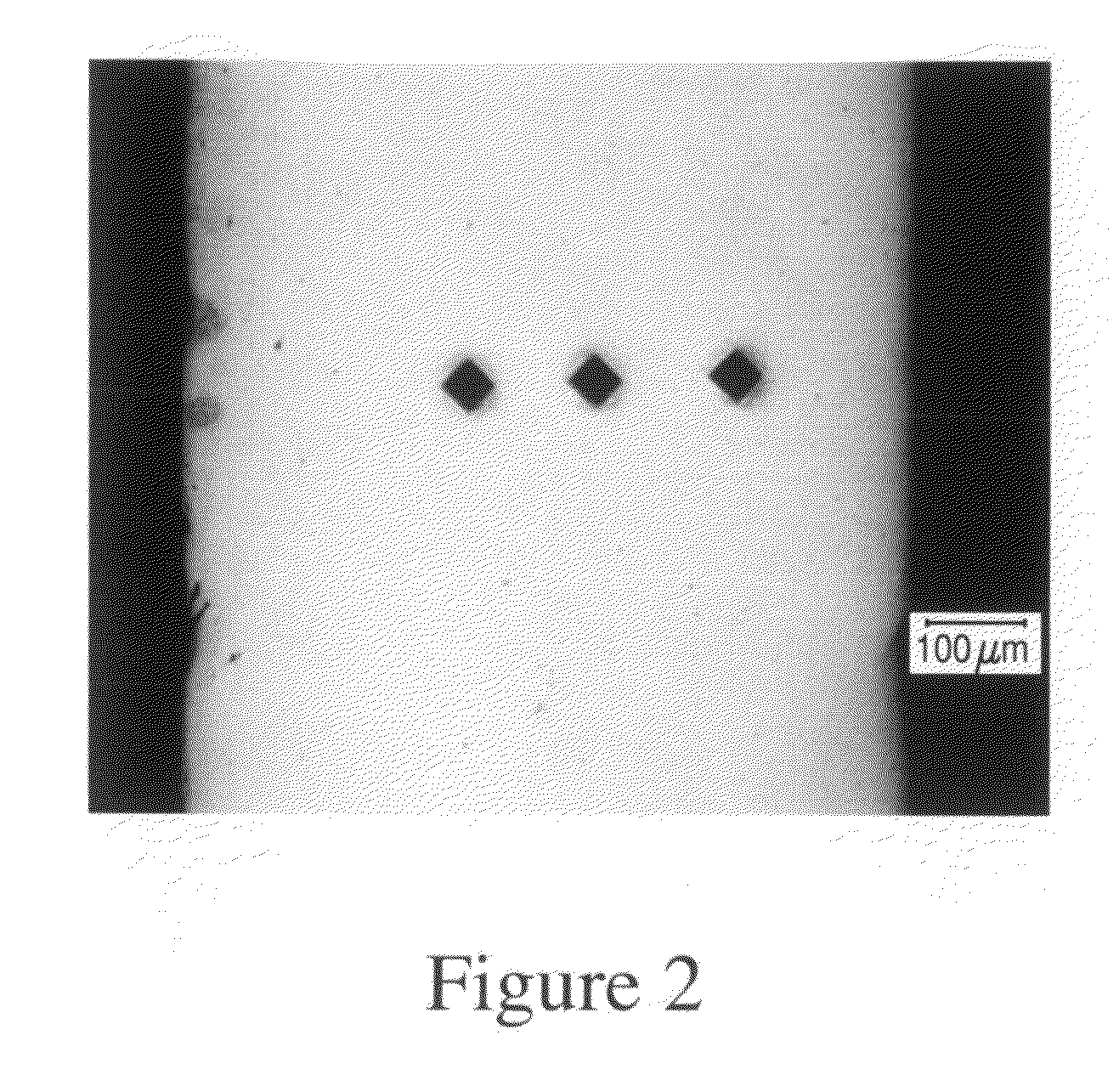

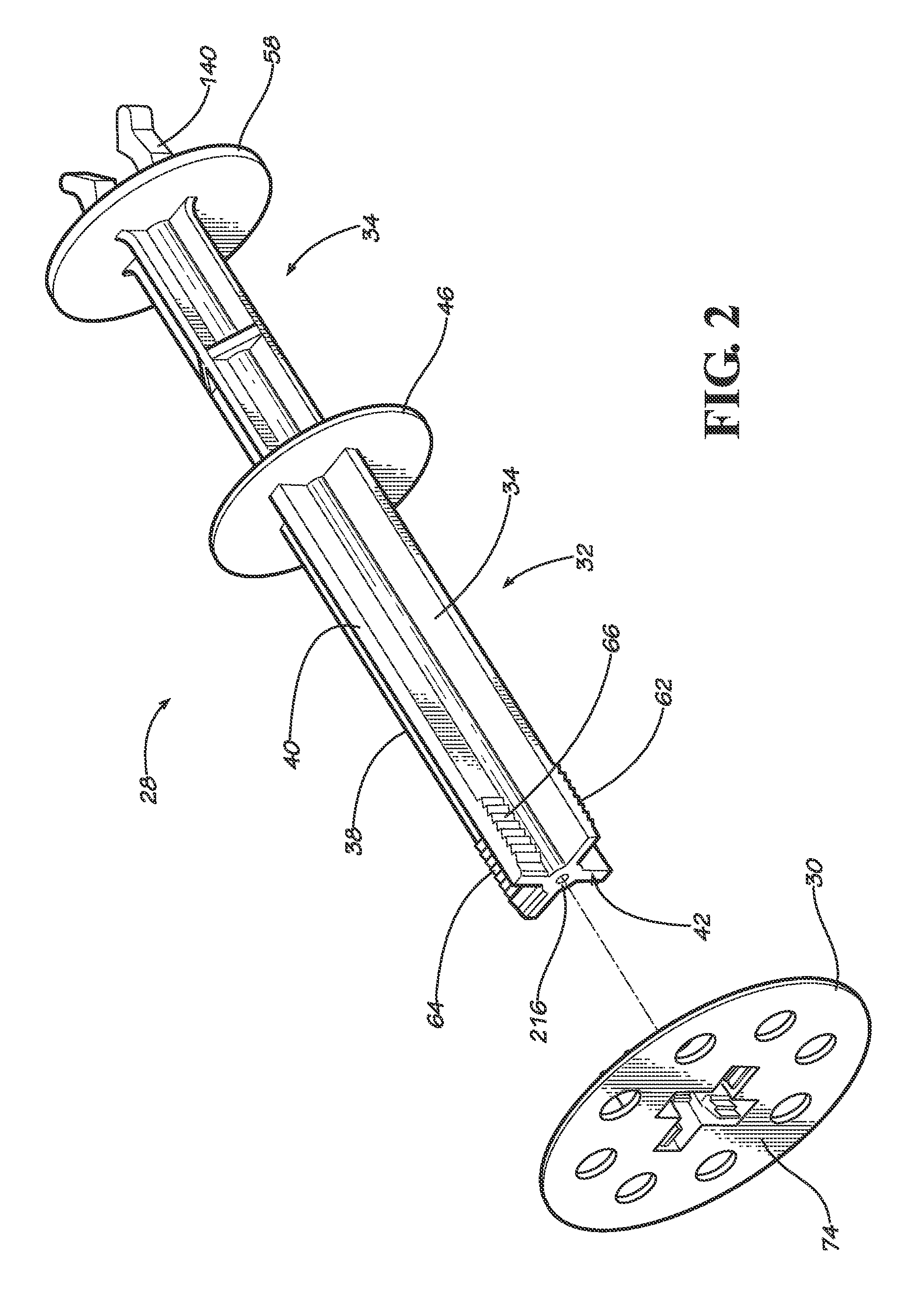

In-vivo biodegradable medical implant

ActiveUS20100076556A1Good lubricity and strengthPrevent premature degradationSuture equipmentsBone implantBiodegradable implantsMetallic materials

In-vivo biodegradable medical implants, containing at least in part at least partially fine-grained metallic materials that are strong, tough, stiff and lightweight, are disclosed The in-vivo biodegradable implants are used in a number of stent applications, for fracture fixation, sutures and the like. The in-vivo biodegradable medical implants enable the reduction of implant size and weight and consequently result in reducing the release of implant degradation products into the body

Owner:INTEGRAN TECH

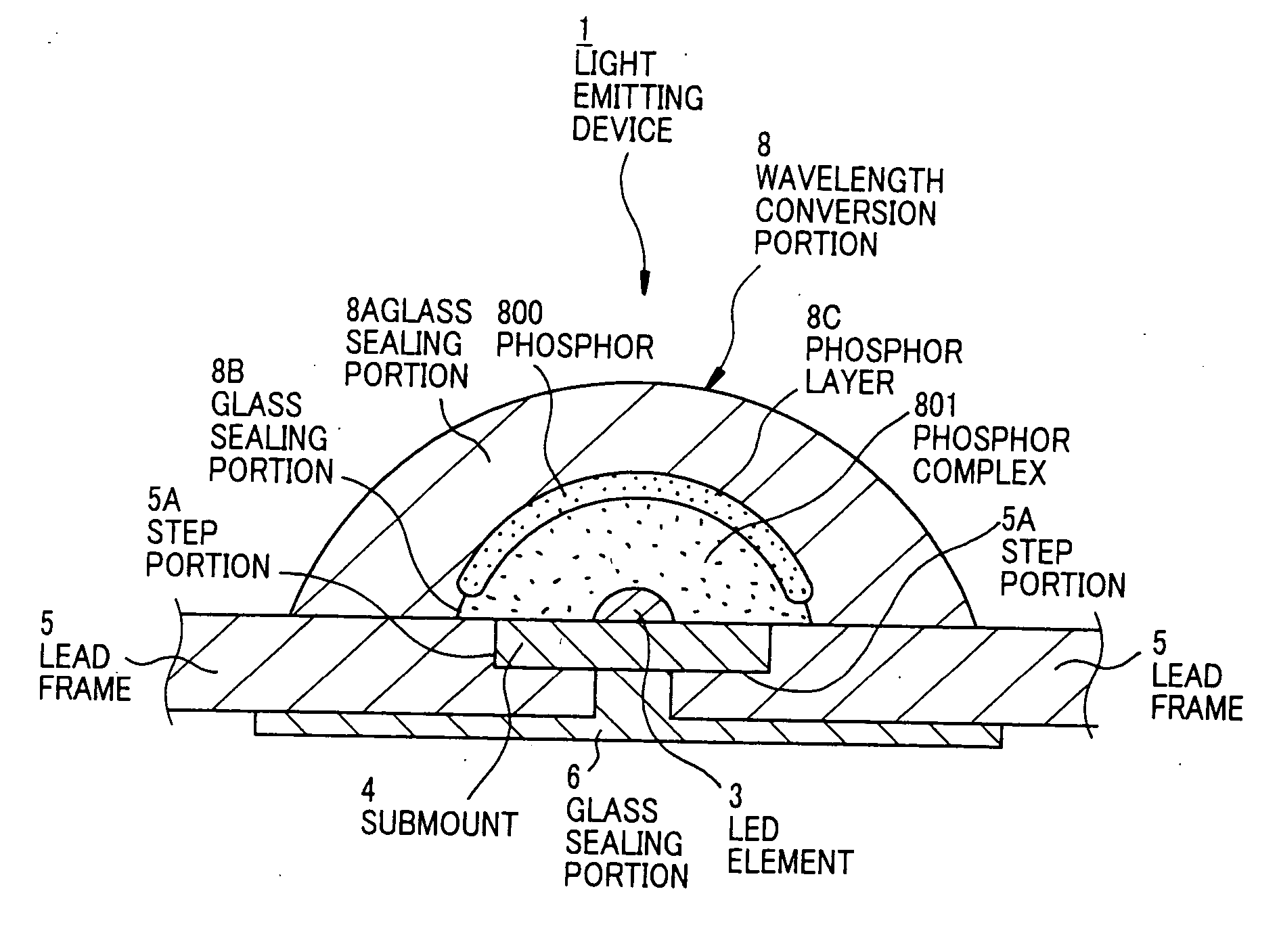

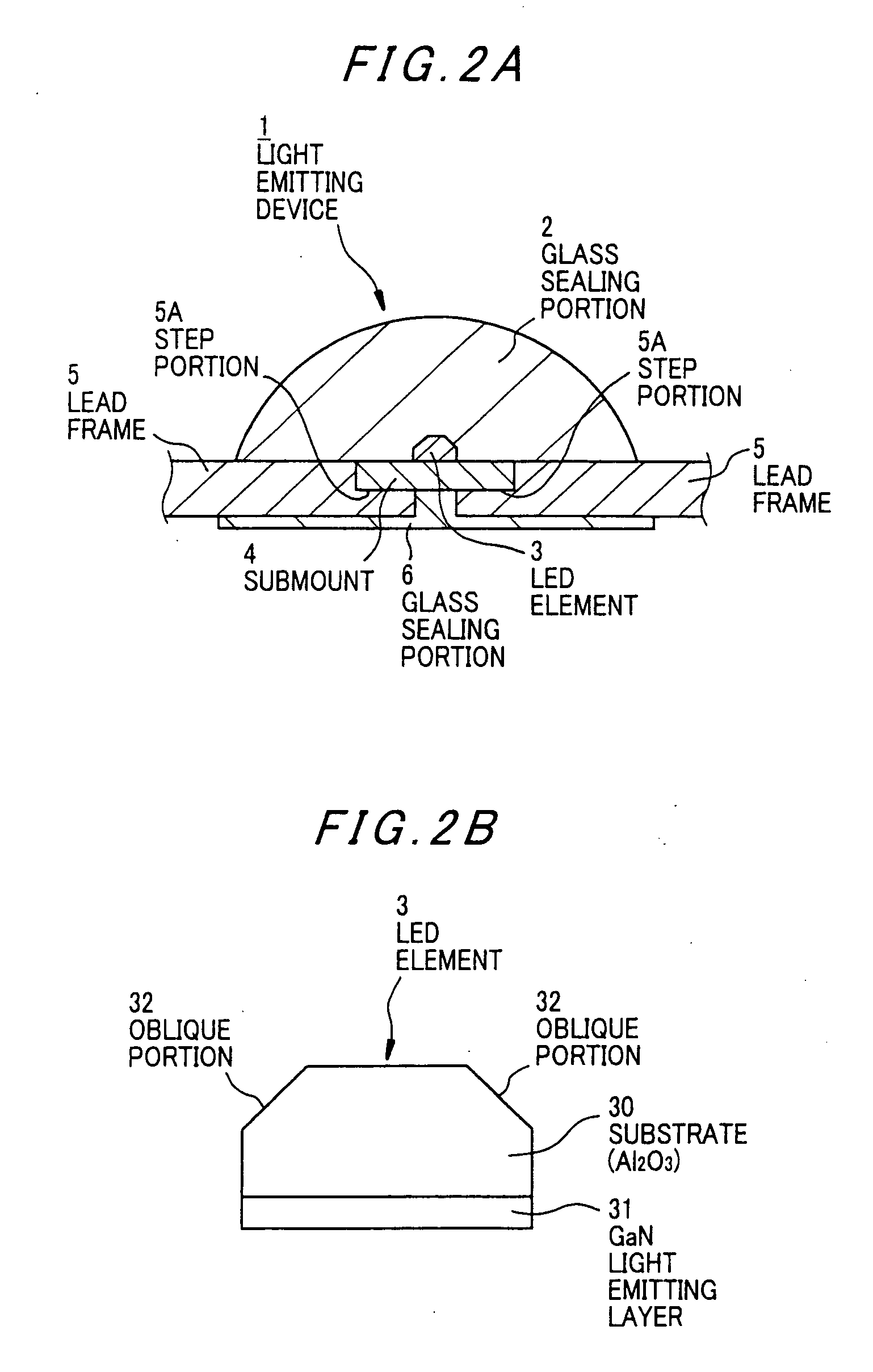

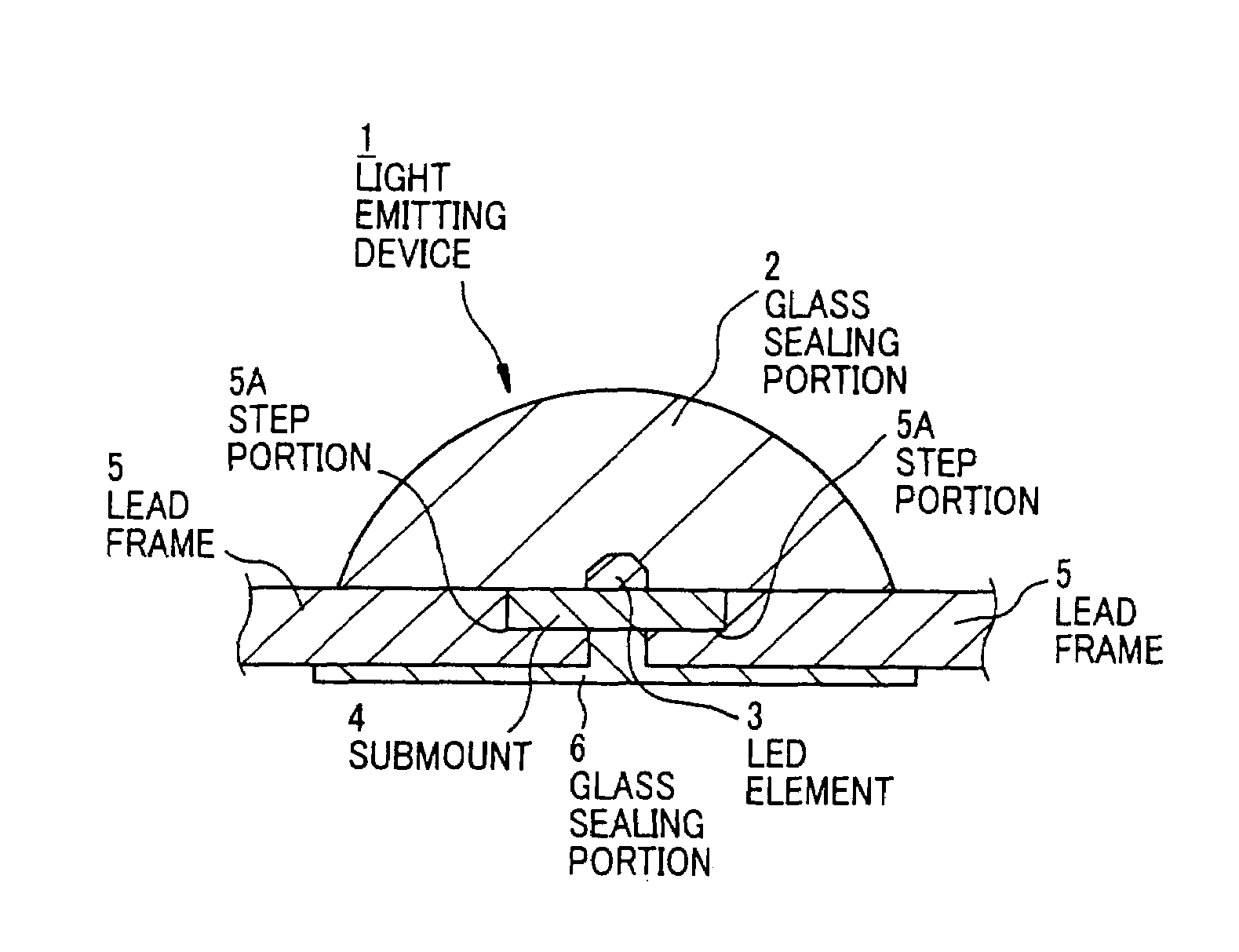

Light emitting device provided with a submount assembly for improved thermal dissipation

ActiveUS7391153B2Lowing of residual bubbleReduce internal stressDischarge tube luminescnet screensElectroluminescent light sourcesThermal expansionLight emitting device

A light emitting device has: a light emitting element; a lead that is electrically connected to the light emitting element at its one end and serves as a terminal to supply a power source to the light emitting element; a metal base that the light emitting element is mounted thereon and radiates heat of the light emitting element; and a sealing member that is of transparent resin or glass and covers the light emitting element. The lead is secured to the metal base by a heat-resisting insulating member with a thermal expansion coefficient nearly equal to that of the metal base.

Owner:TOYODA GOSEI CO LTD

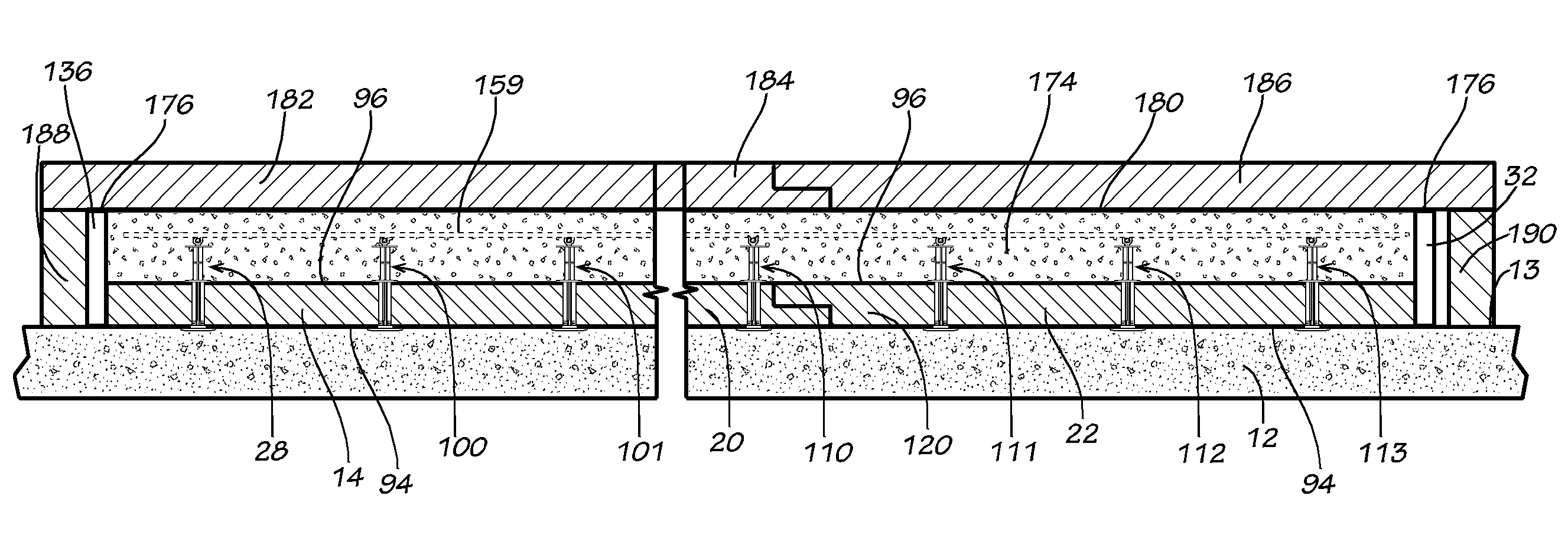

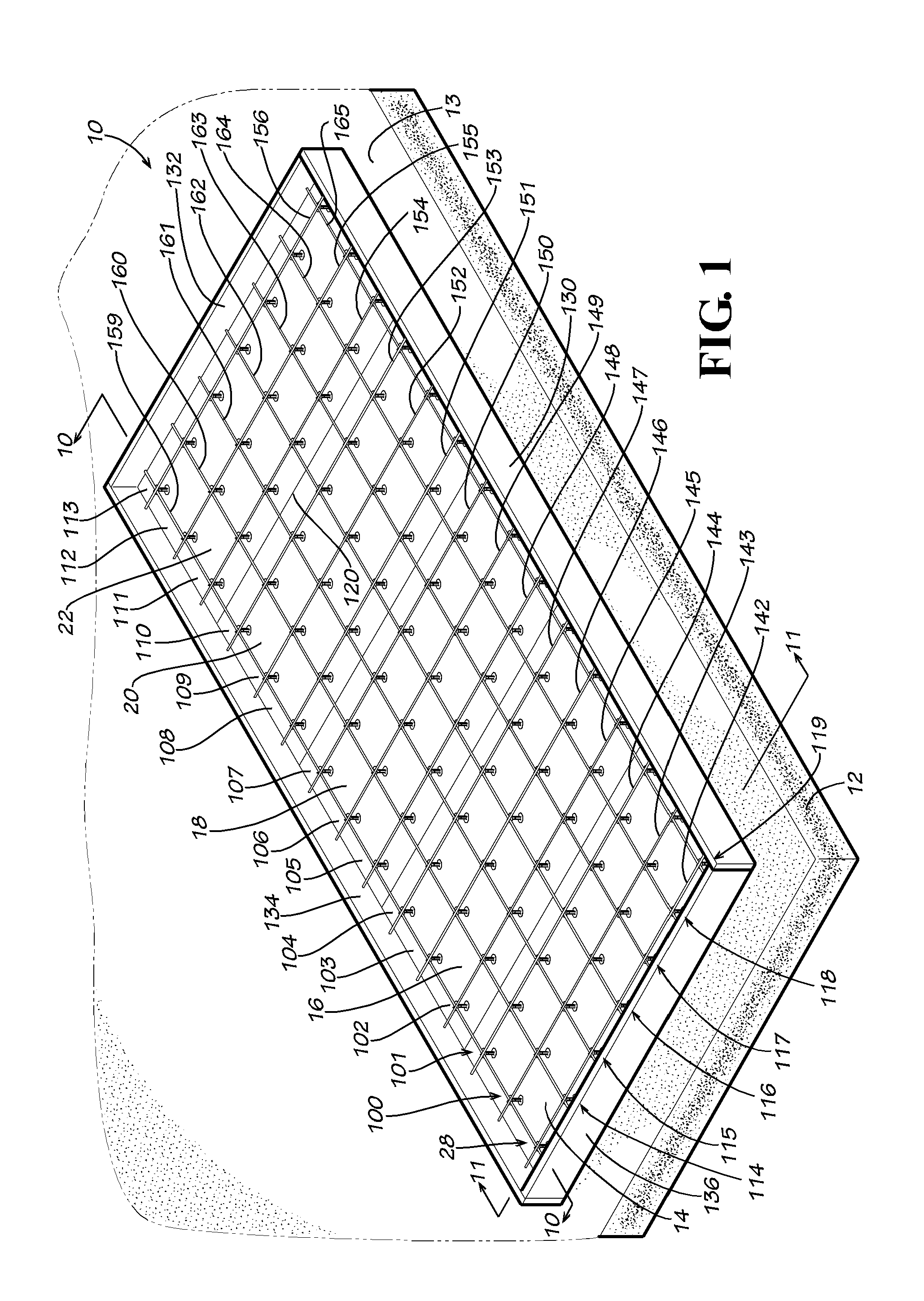

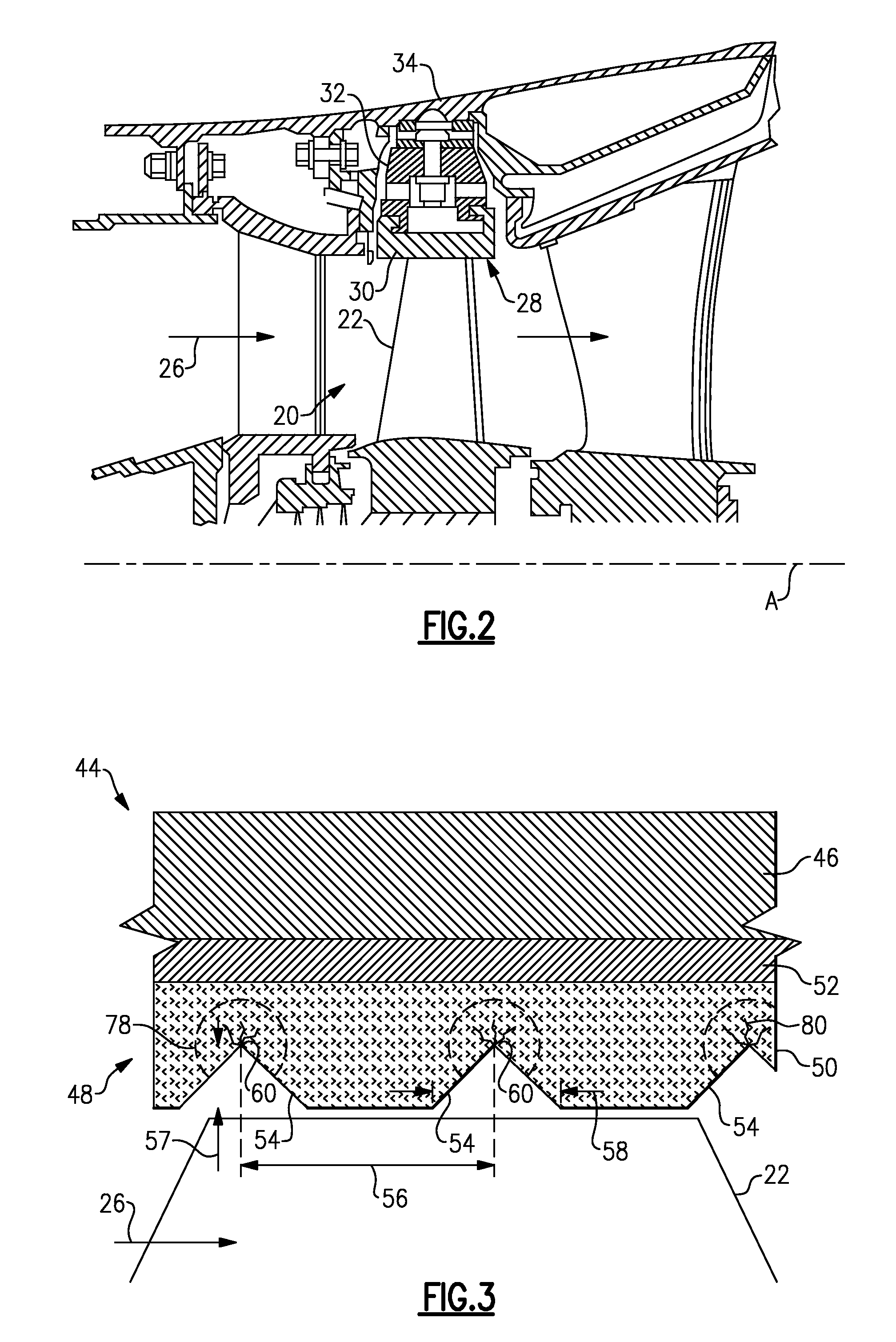

Precast concrete structures, precast tilt-up concrete structures and methods of making same

ActiveUS8555584B2Reduce internal stressReduce the amount requiredConstruction materialCovering/liningsPolystyreneExpanded polystyrene

Owner:CIUPERCA ROMEO ILARIAN

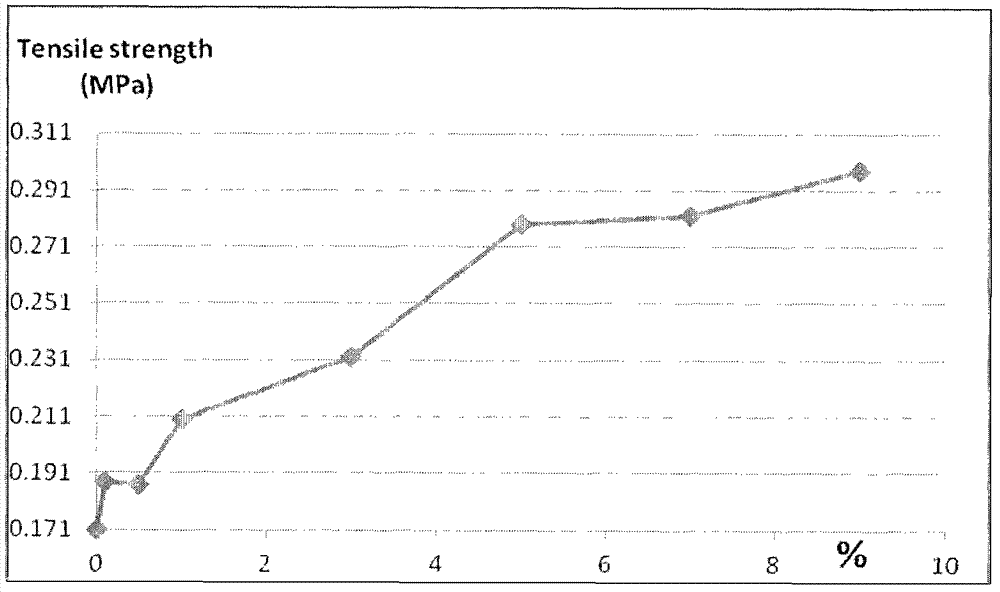

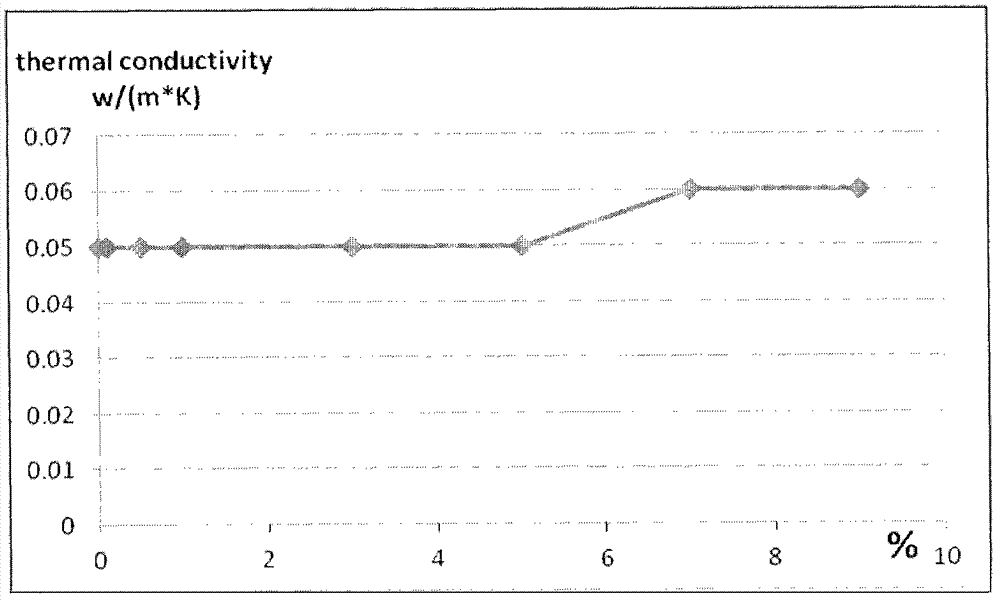

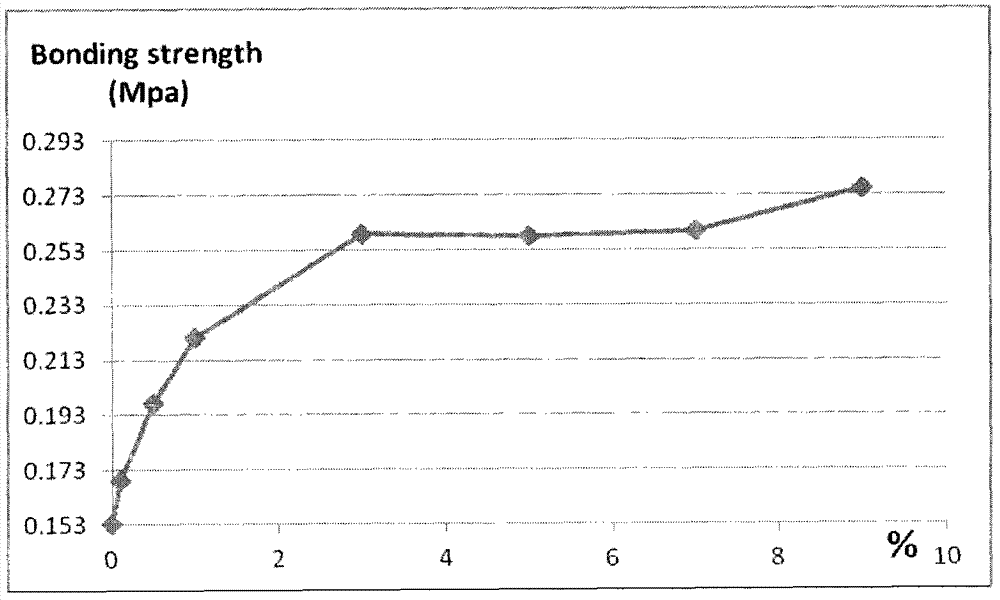

Nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick

The invention belongs to the field of building materials, relates to a use of a nano-material in a building exterior wall heat-retaining system and provides a nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is characterized in that nano-particles are used so that compressive strength, tensile strength and bonding strength are improved. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is prepared by adding a nano-material having a nanoscale particle size into a mixed system of cement, an auxiliary gel material, a polymer binder, an inorganic light heat-retaining material, fibers and water, uniformly mixing, carrying out pressing molding of the mixture, carrying out organic polymer crosslinking and cement hydration drying, and carrying out waterproof layer coating. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick has the advantages of excellent flame resistance, high compressive strength, high tensile strength, high bonding strength and good insulation effects.

Owner:平湖市法而特建筑保温科技有限公司

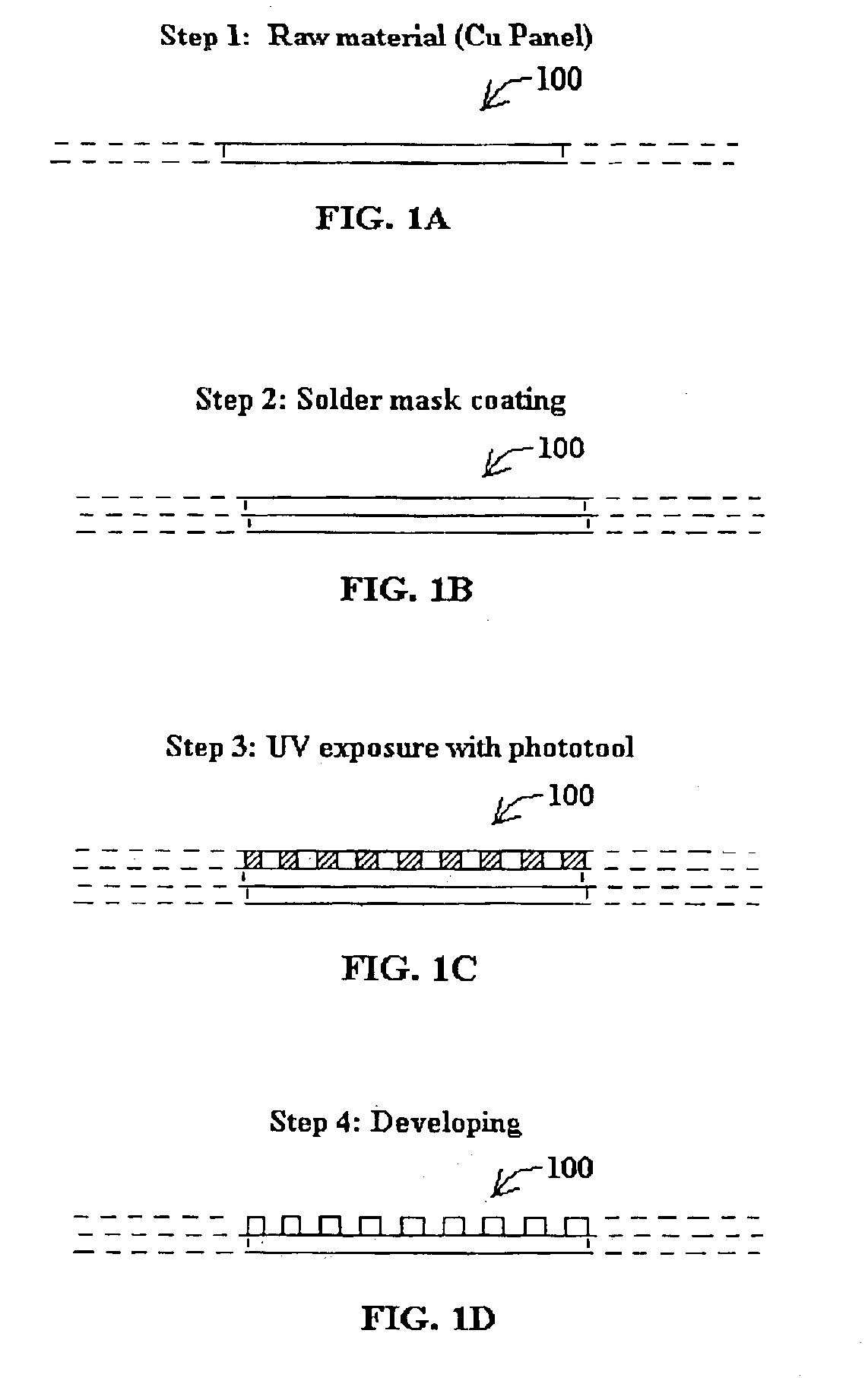

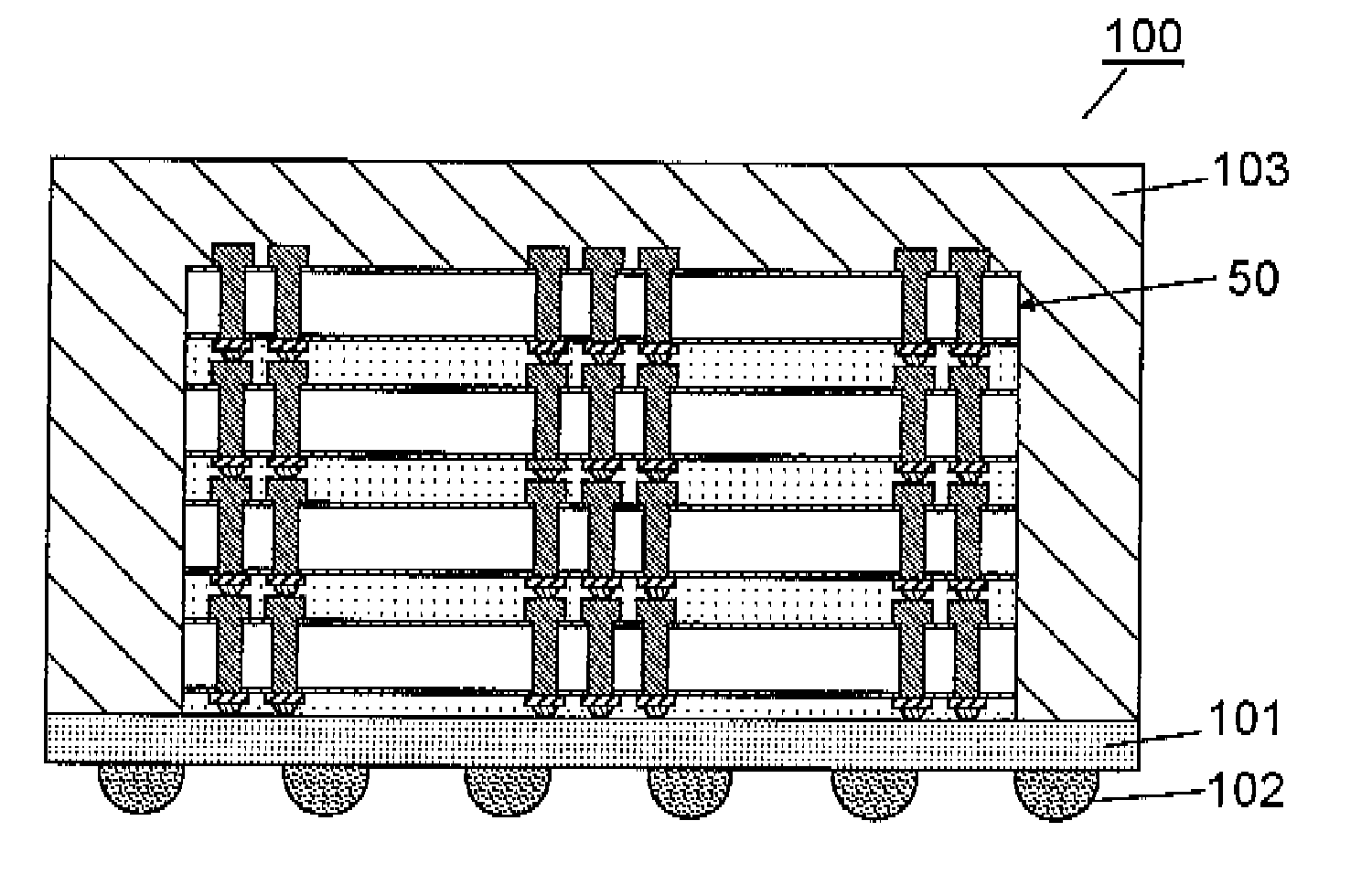

Leadless plastic chip carrier with etch back pad singulation and die attach pad array

InactiveUS6872661B1Mitigate internal stressReduces lineSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A leadless plastic chip carrier has a plurality of die attach pads on which a singulated semi-conductor die is mounted. At least one row of contact pads circumscribes the plurality of die attach pads and a power / ground ring is intermediate the contact pads and the die attach pads. Wire bonds connect the semiconductor die, the contact pads and the power / ground ring. An overmold covers the semi-conductor die, the die attach pads, the power / ground ring and the contact pads such that each of the die attach pads and the contact pads has one exposed surface.

Owner:UTAC HEADQUARTERS PTE LTD

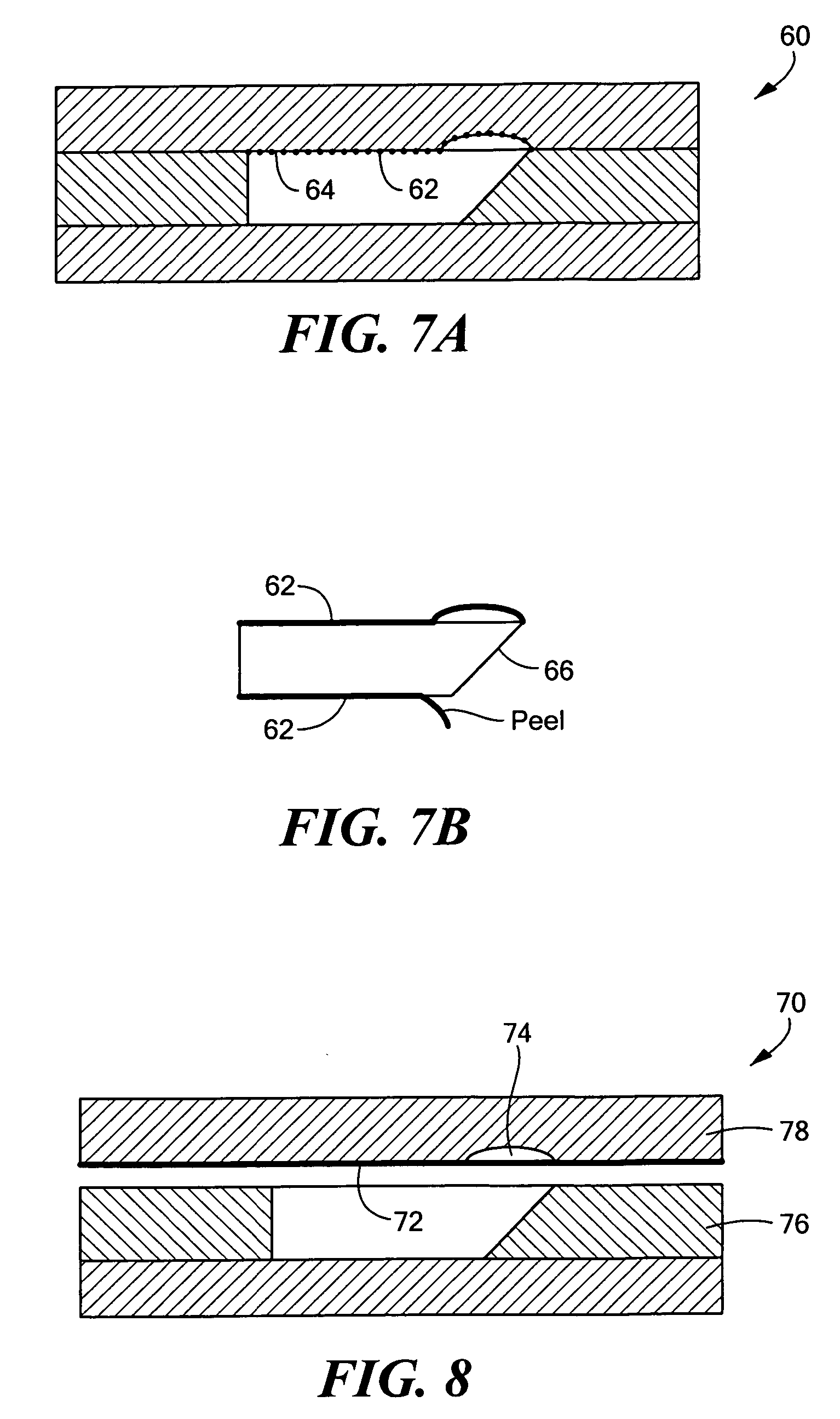

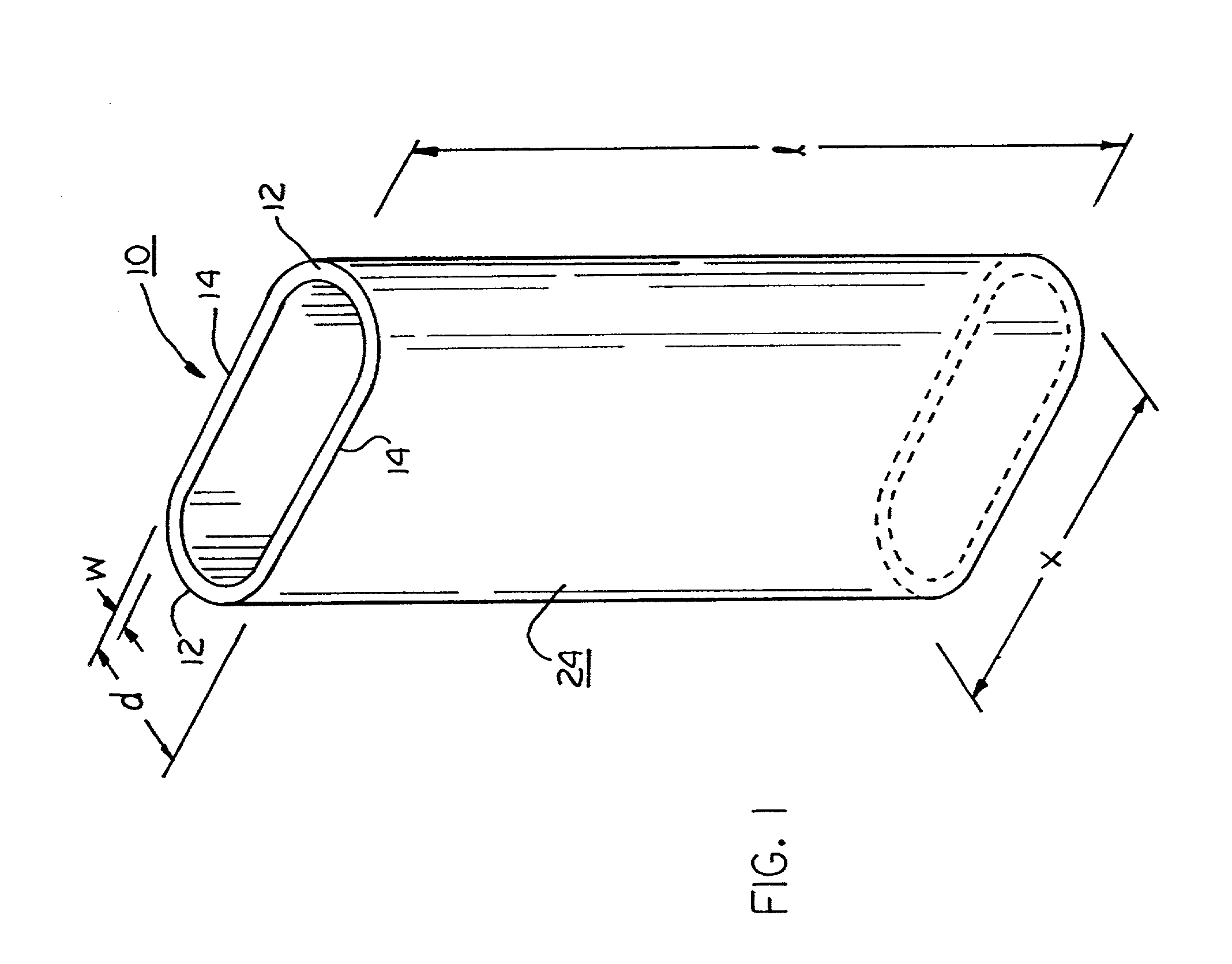

Method for producing high quality optical parts by casting

InactiveUS20060192307A1Quality improvementIncrease costOptical articlesPolymer sciencePolymer thin films

A casting method, rather than injection molding, to produce polymer optical components and systems is provided. The casting process controls shrinkage and stress, thus providing both high bulk uniformity and high quality, accurate surfaces, by incorporating polymer films into the mold. The films may remain incorporated into the part or may optionally be removed from the part after removal from the mold. In addition, the incorporation of separately produced components within the cast part is also provided, eliminating post-casting assembly manufacturing steps.

Owner:GOOGLE LLC

Environmental-friendly waterproof polymer mortar

InactiveCN101560084AImprove adhesionStrong bondSolid waste managementSilicate CementConstruction aggregate

The invention relates to environmental-friendly waterproof polymer mortar, which comprises the following components in portion by weight: 50 to 230 portions of low-clinker silicate cement, 200 to 450 portions of quartz sand, 80 to 120 portions of fly ash, 1 to 18 portions of re-dispersible polyethylene vinyl acetate latex powder, 1 to 10 portions of dispersible polyvinyl acetate vinyl versatate latex powder, 0.2 to 0.6 portion of water reducing agent, 0.05 to 0.3 portion of antifoaming agent, and 0.25 to 2.25 portions of polypropylene fibers. A gel material prepared from steel slag, tailings and the fly ash replaces silicate cement and partial aggregate in the prior mortar; the modified waterproof polymer mortar has the advantages of excellent impermeability, good mechanical property and construction property, simple production technology, and easy manufacture, greatly consumes industrial and mining wastes, controls the ecological environment, and lowers the cost; and the product has reliable quality and wide market; and the environmental-friendly waterproof polymer mortar can be popularized and applied in large area.

Owner:黑龙江省学府环艺雕塑有限公司

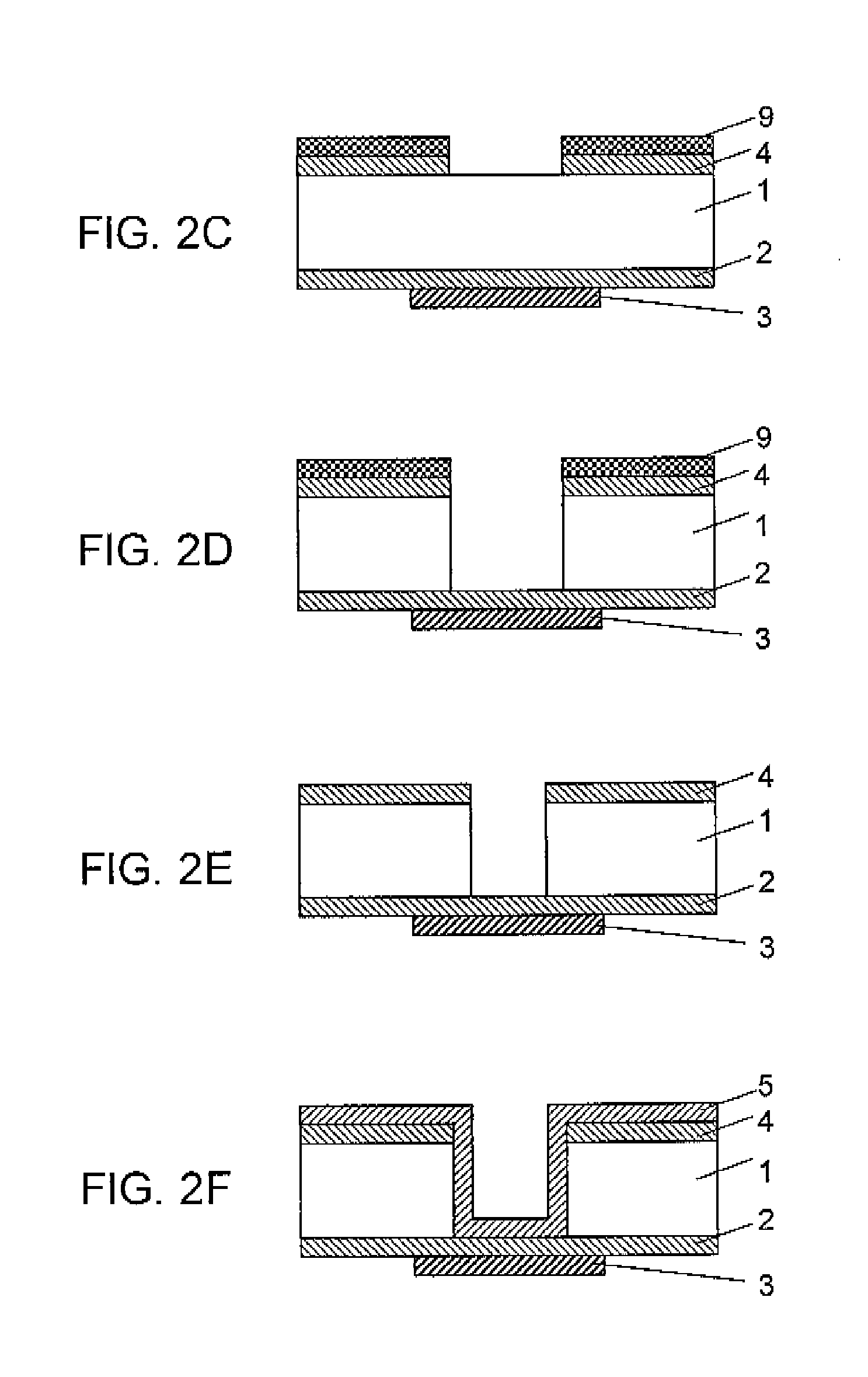

Method for manufacturing semiconductor device

ActiveUS20120276733A1Reduce internal stressLower resistanceSolid-state devicesSemiconductor/solid-state device manufacturingResistPhotoresist

In order to provide a semiconductor device that includes a conductive layer on one surface of a semiconductor substrate with an insulating layer therebetween, a bump on the other surface of the semiconductor substrate, and a through-electrode through the semiconductor substrate connecting the conductive layer with the bump, a through-hole is formed from the other surface of the semiconductor substrate to be connected to the conductive layer, a seed metal film is formed on the through-hole and the other surface, a photoresist is formed thereon, a mask layer is formed by processing the photoresist with a pattern larger than the through-hole, a plated film is grown by electrolytic plating so as to integrally form the through-electrode and a part of the bump.

Owner:LONGITUDE LICENSING LTD

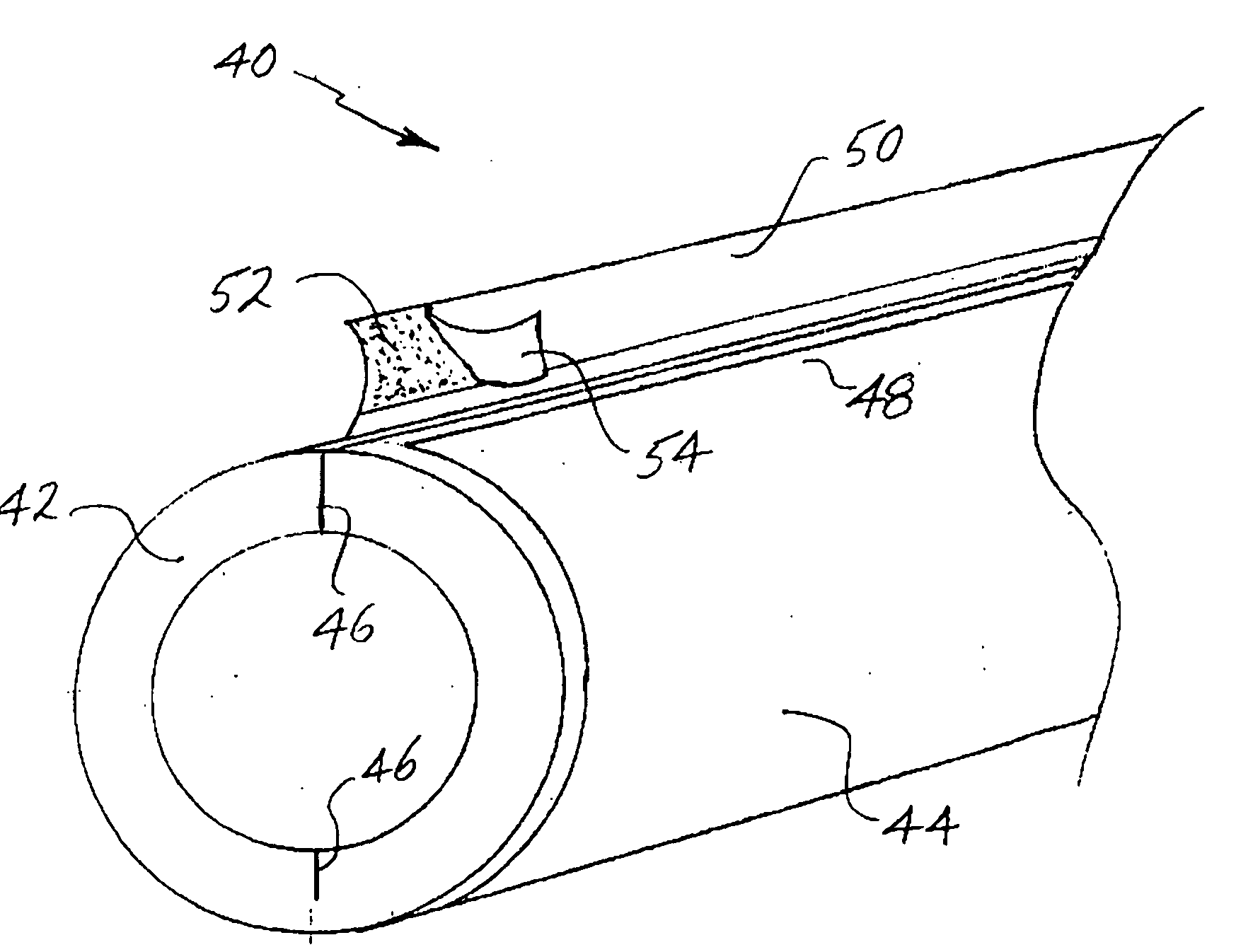

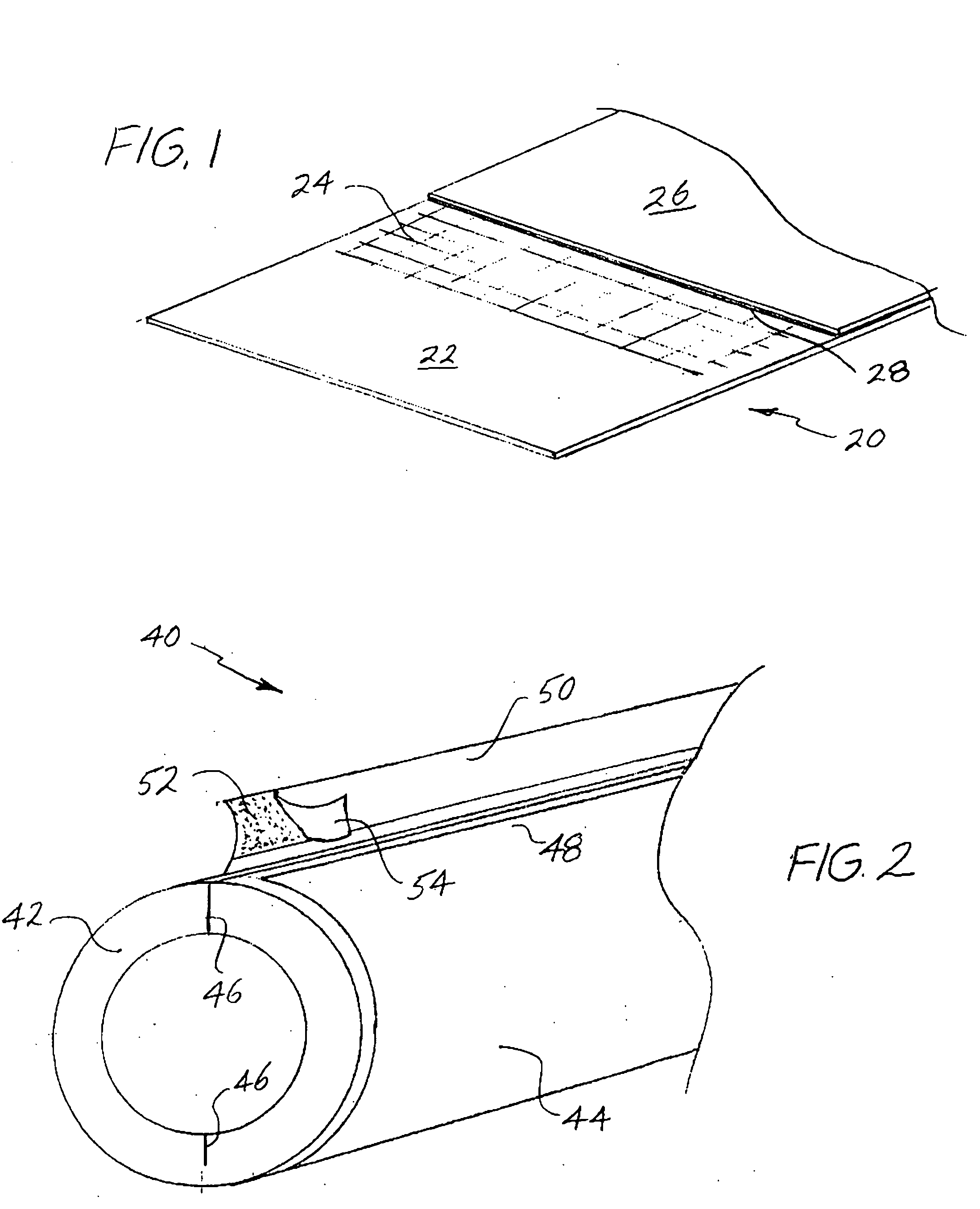

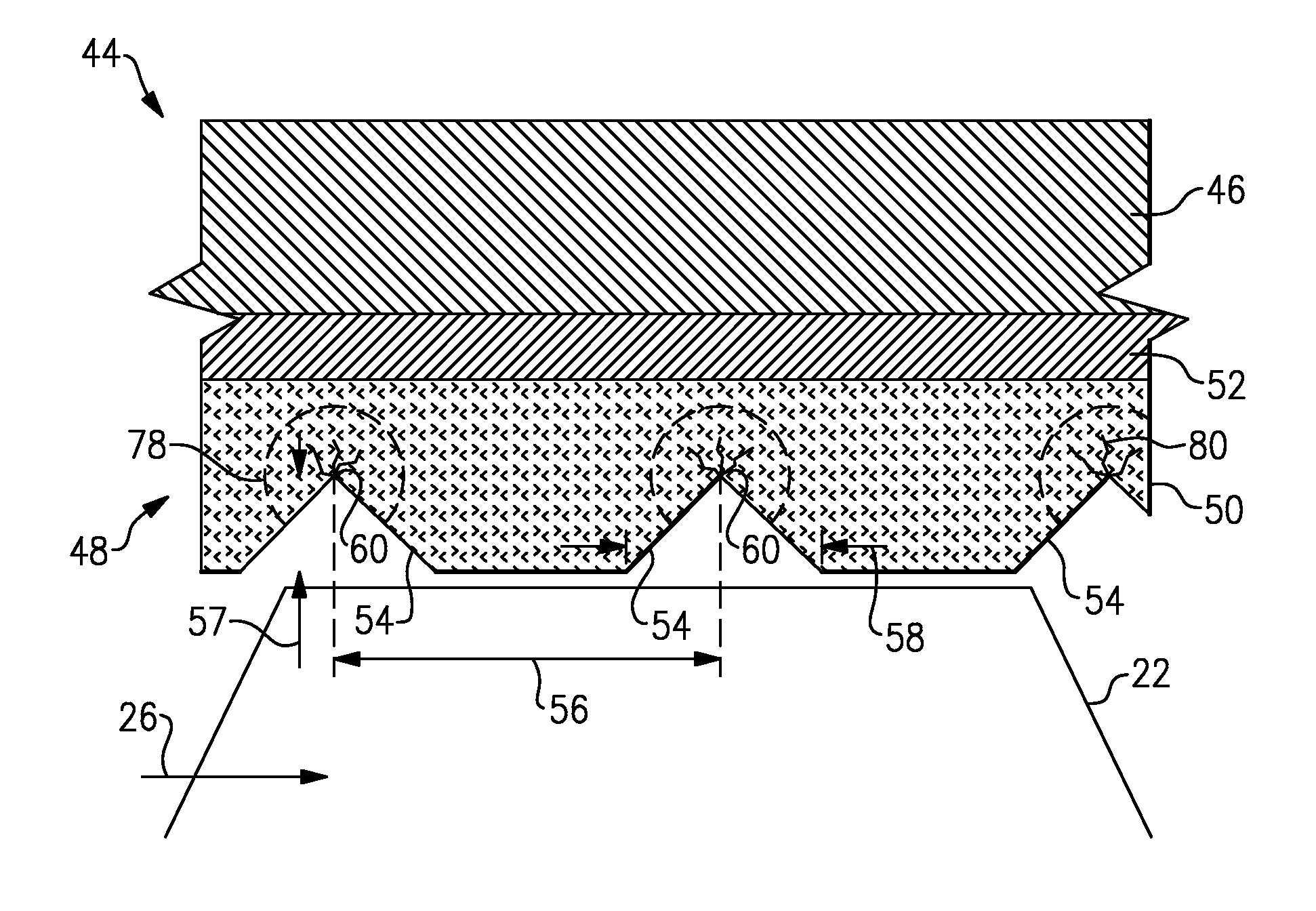

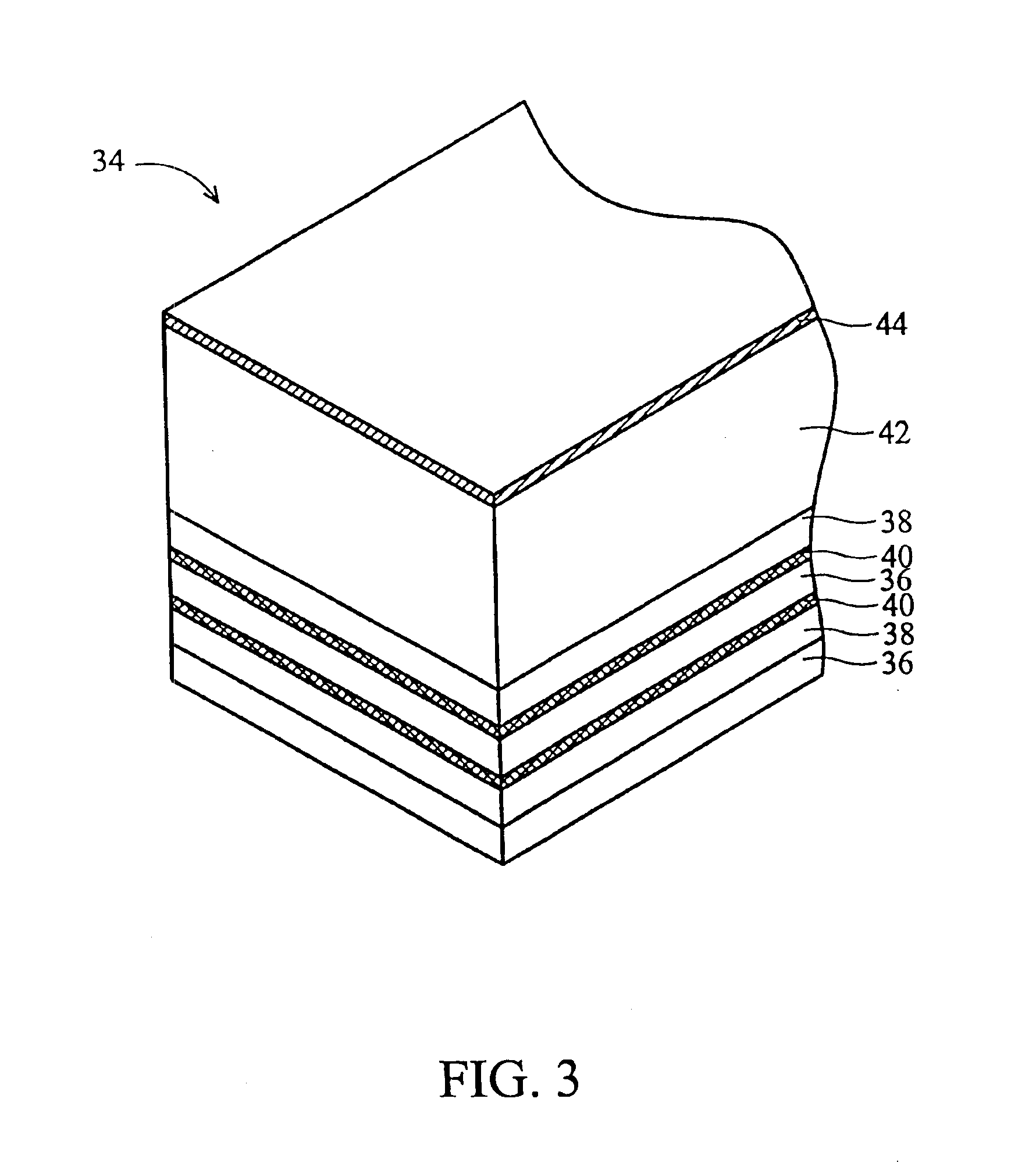

Facing and faced insulation products

ActiveUS20080081138A1Less moistureLess expansionPipe protection by thermal insulationGlass/slag layered productsWood veneerFiber

A facing laminate for insulation products includes: a foil or metallized polymeric film sheet layer forming an inner layer of the laminate that is adapted be bonded directly to a surface of an insulation product; a paper composite sheet layer, which may include synthetic and / or inorganic fibers, forming an outer exposed layer of the laminate; and a scrim intermediate and bonded to the foil or metallized polymeric film sheet and paper composite sheet layers. The facing laminate may include a humectant and / or a water, oil, and / or grease repellant component. The paper composite sheet layer of the laminate exhibits greater dimensional stability and reduced wrinkling when the laminate is exposed to conditions of high humidity. Insulation products to be faced with this facing laminate include pipe insulation, duct board, duct wrap insulation, metal building insulation, and other building insulation products.

Owner:JOHNS MANVILLE CORP

High-temperature-resistant, anti-corrosion and thermal-insulation coating and preparation technology thereof

ActiveCN104673063AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentCross linker

The invention discloses a high-temperature-resistant, anti-corrosion and thermal-insulation coating which comprises components in parts by weight as follows: 45-60 parts of film-forming resin, 20-30 parts of a pigment and filler, 15-30 parts of an aid and 25-30 parts of a solvent. The invention further designs a preparation technology of the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The technology comprises steps as follows: firstly, mixing the film-forming resin with the pigment and the filler, sequentially adding an antifoaming agent, a leveling agent, a coupling agent, a crosslinking agent and a curing agent, and evenly stirring the mixture at the normal temperature to obtain the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The coating has the advantages of environment-friendliness, low cost, high hardness, long service life, good heat resistance, good flexibility, good high-temperature resistance and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

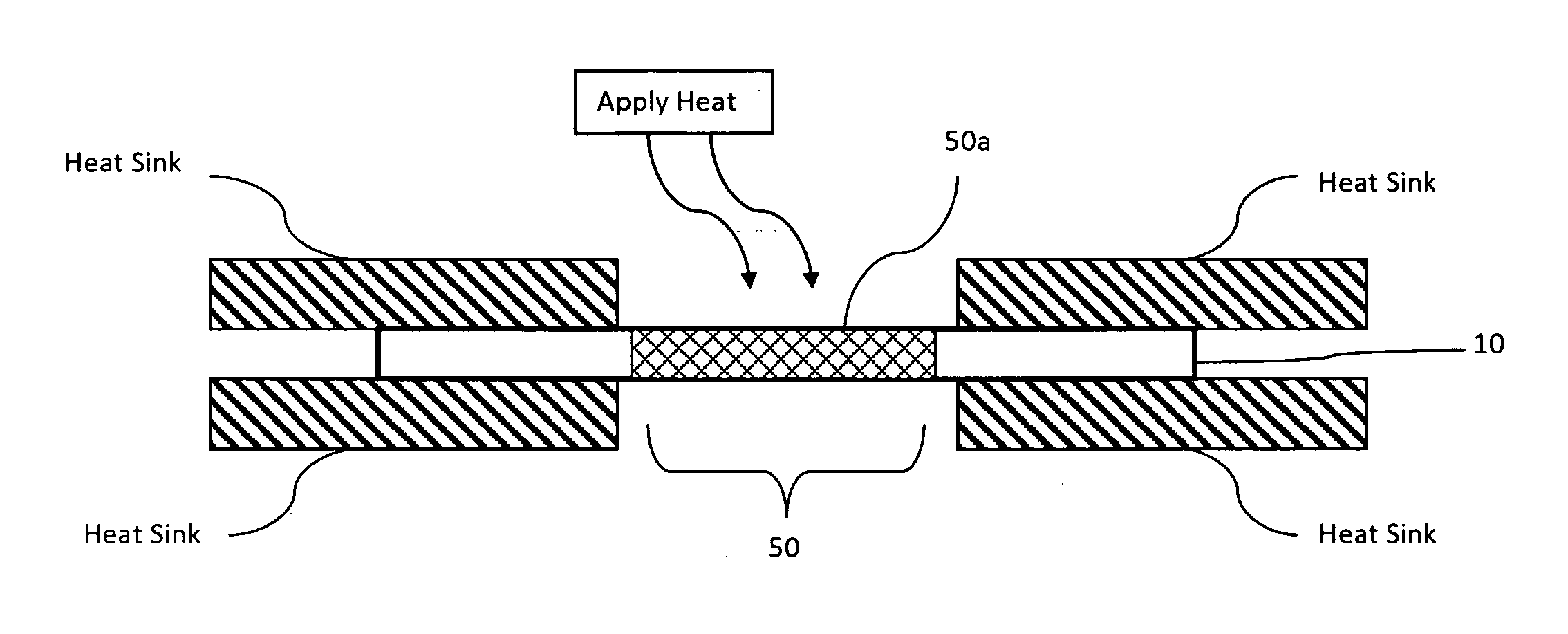

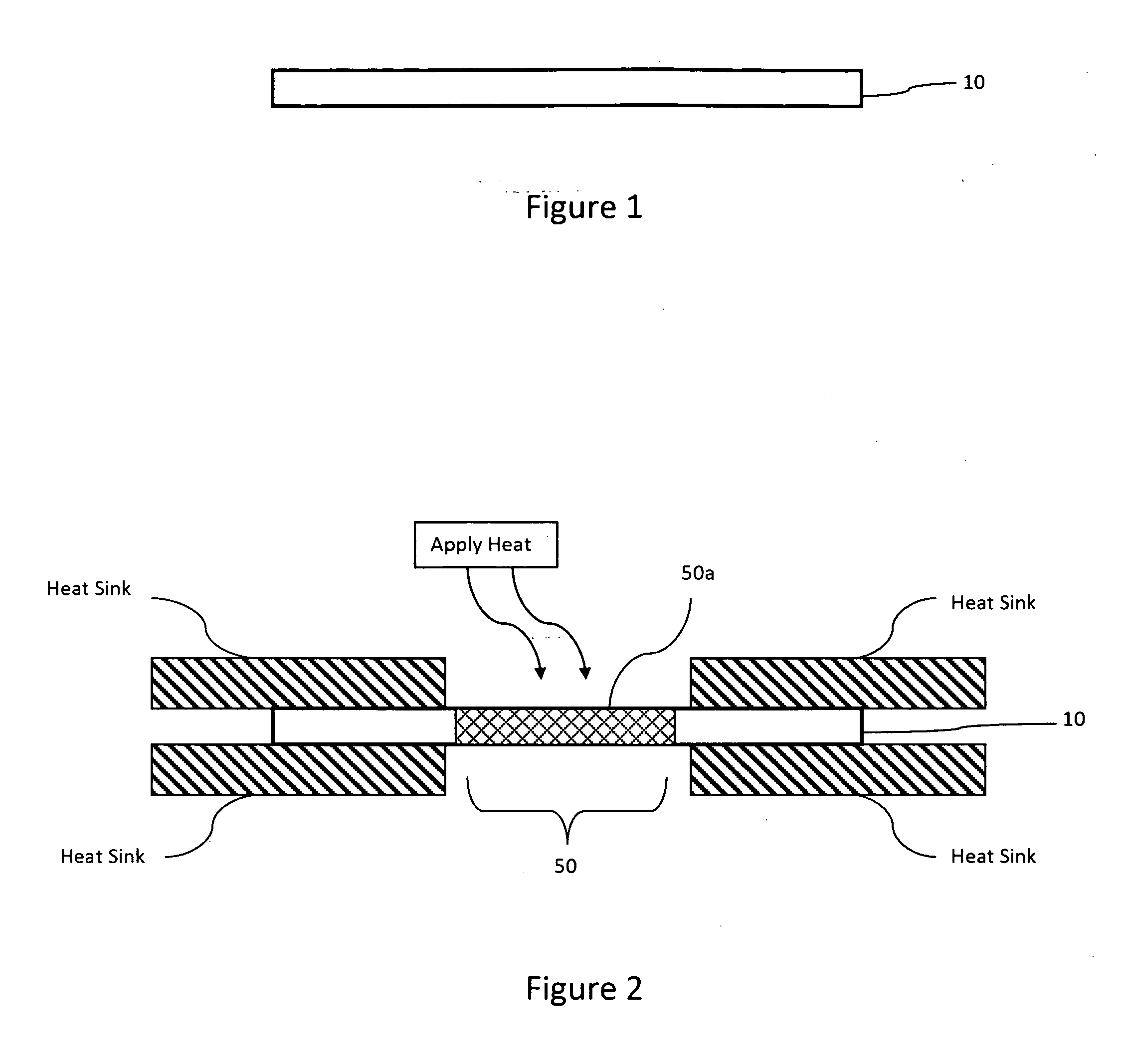

Metal card

ActiveUS20110189620A1Easy embossingSimple equipmentOther heat production devicesCharge manipulationMetalWear and tear

A method and apparatus for treating a selected region of a metal layer, used to form a metal card, by annealing the selected metal region so the selected region becomes soft and ductile, while the rest of the metal layer remains stiff. The softened, ductile, selected metal region can be embossed with reduced power and with reduced wear and tear on the embossing equipment. Alternatively, the annealed metal layer can undergo additional processing steps to form an assembly which can then be embossed. The method may include the use of a fixture for holding the metal layer, with the fixture having a window region for enabling heat to be applied to soften the region of the metal layer within the window region. The fixture includes apparatus for cooling the portion of the metal layer outside of the window region and for preventing the temperature of the metal layer outside the window region from rising above predetermined limits.

Owner:COMPOSECURE LLC

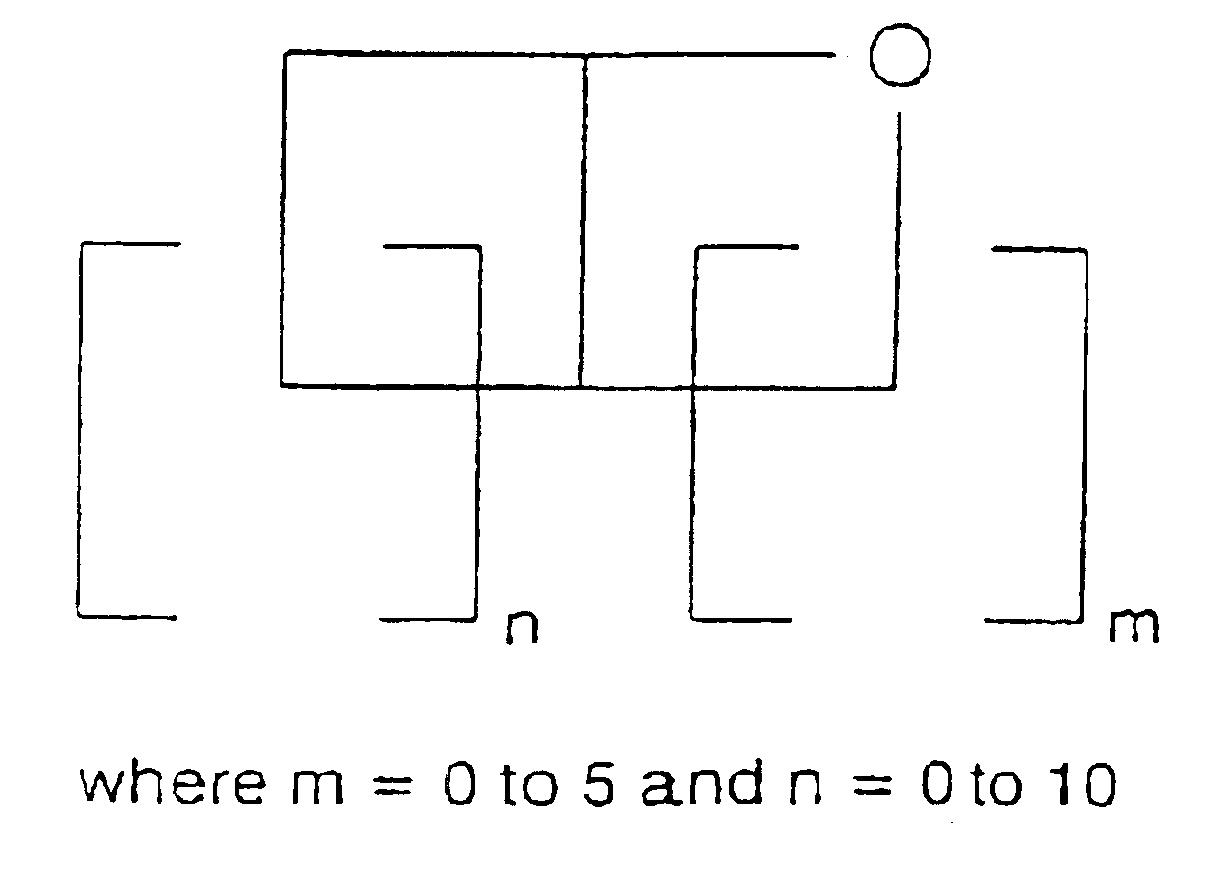

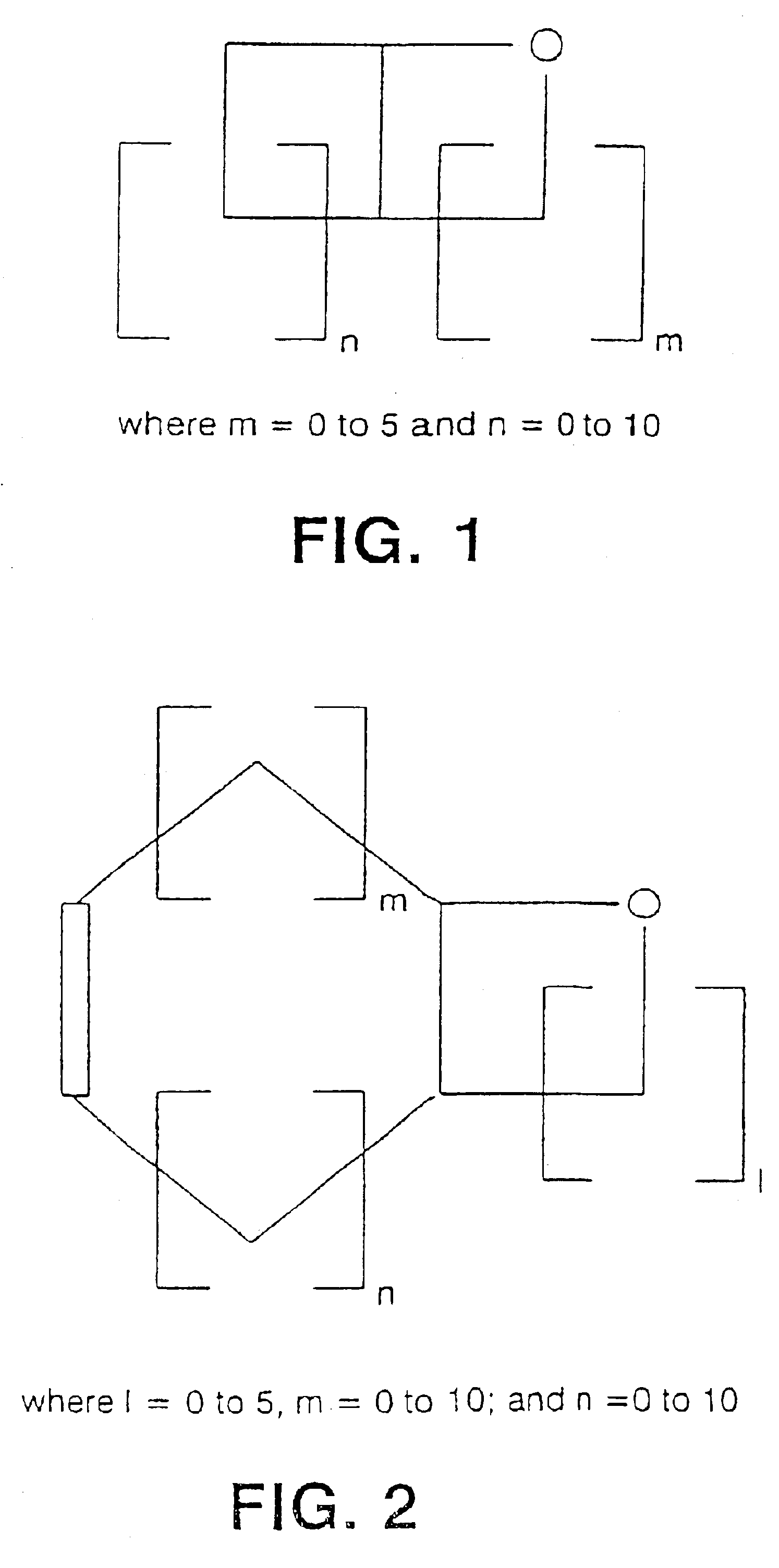

Method for fabricating an ultralow dielectric constant material

InactiveUS6770573B2Increase depositionSimple methodSemiconductor/solid-state device detailsSolid-state devicesParallel plateGas phase

A method for fabricating a thermally stable ultralow dielectric constant film comprising Si, C, O and H atoms in a parallel plate chemical vapor deposition process utilizing plasma enhanced chemical vapor deposition ("PECVD") process is disclosed. To enable the fabrication of thermally stable ultralow dielectric constant film, specific precursor materials are used, such as, cyclic siloxanes and organic molecules containing ring structures, for instance, tetramethylcycloterasiloxane and cyclopentene oxide. To stabilize plasma in the PECVD reactor and thereby improve uniformity of the deposited film, CO2 is added to TMCTS as a carrier gas, or CO2 or a mixture of CO2 and O2 are added to the PECVD reactor.

Owner:INTEL CORP

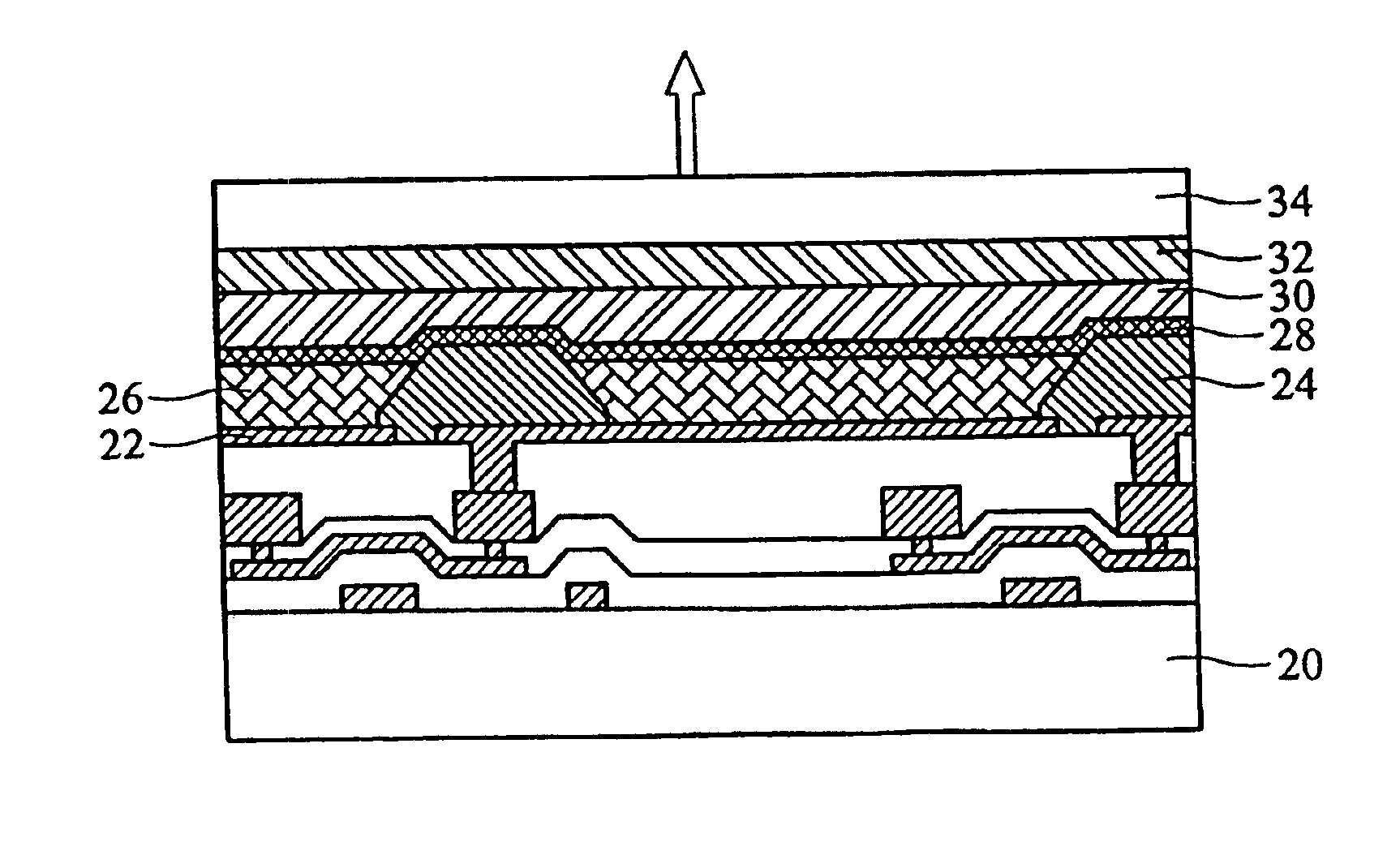

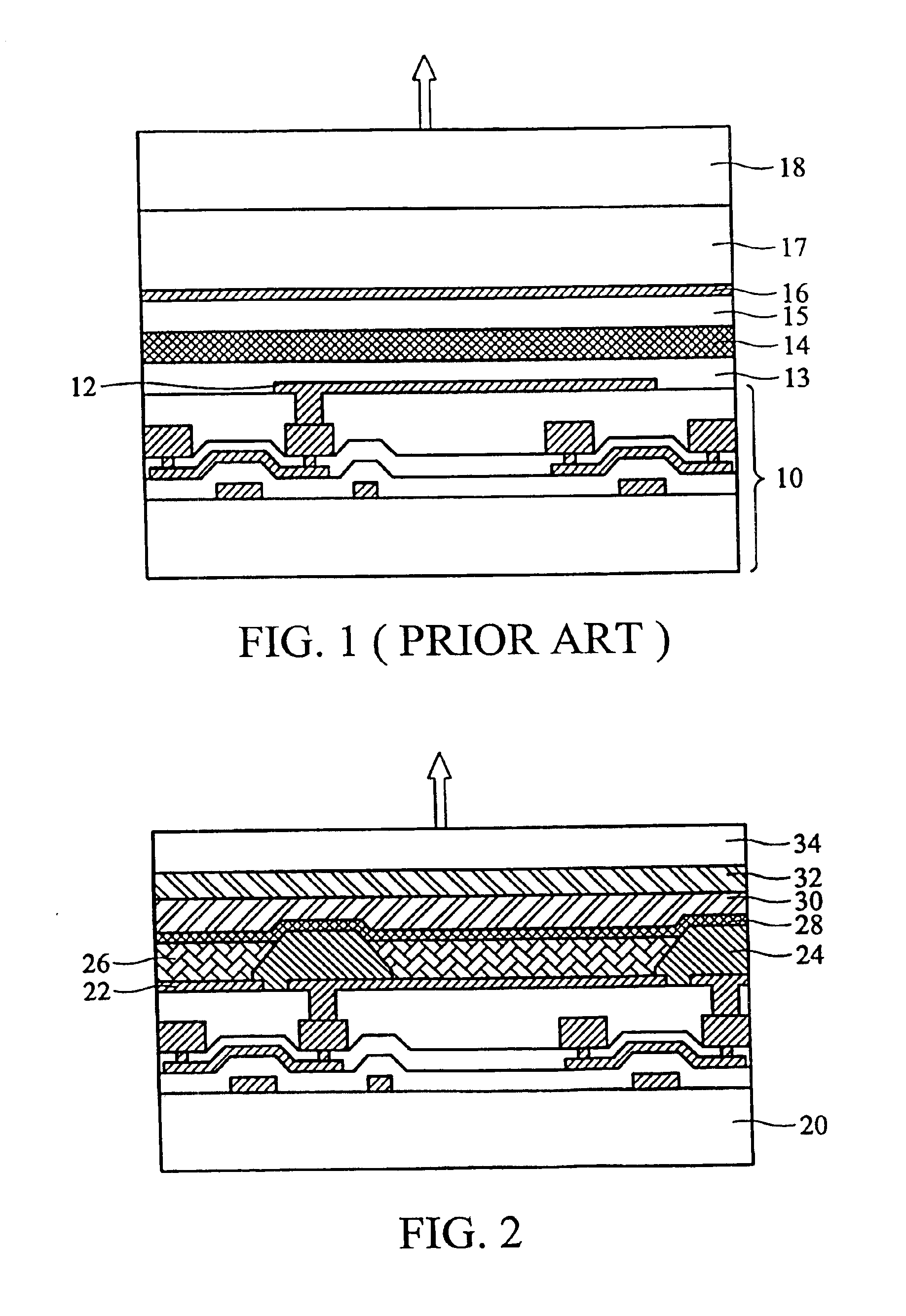

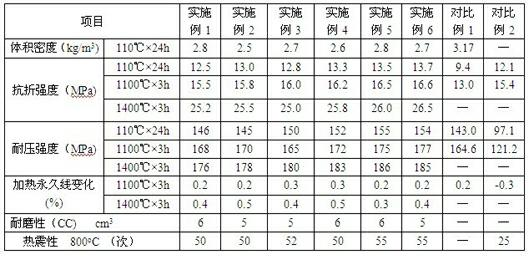

Method of sealing organic electro-luminescent display

InactiveUS6872114B2Increase the aperture ratioImprove moisture resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOrganic electroluminescence

A top-emission organic electro-luminescent display (OLED) has a substrate with at least a anode layer, an organic fluorescent film, at least a cathode layer, a barrier layer and a protection layer. A transparent sealing structure is glued to the top of the substrate. Wherein, the transparent sealing structure has an adhesion layer glued to the protection layer, a plurality of organic resin layers formed on the adhesion layer, a plurality of inorganic barrier layers disposed between the organic resin layers, a flexible polymer film formed on the organic resin layer, and a hard coat formed on the flexible polymer film.

Owner:INNOLUX CORP

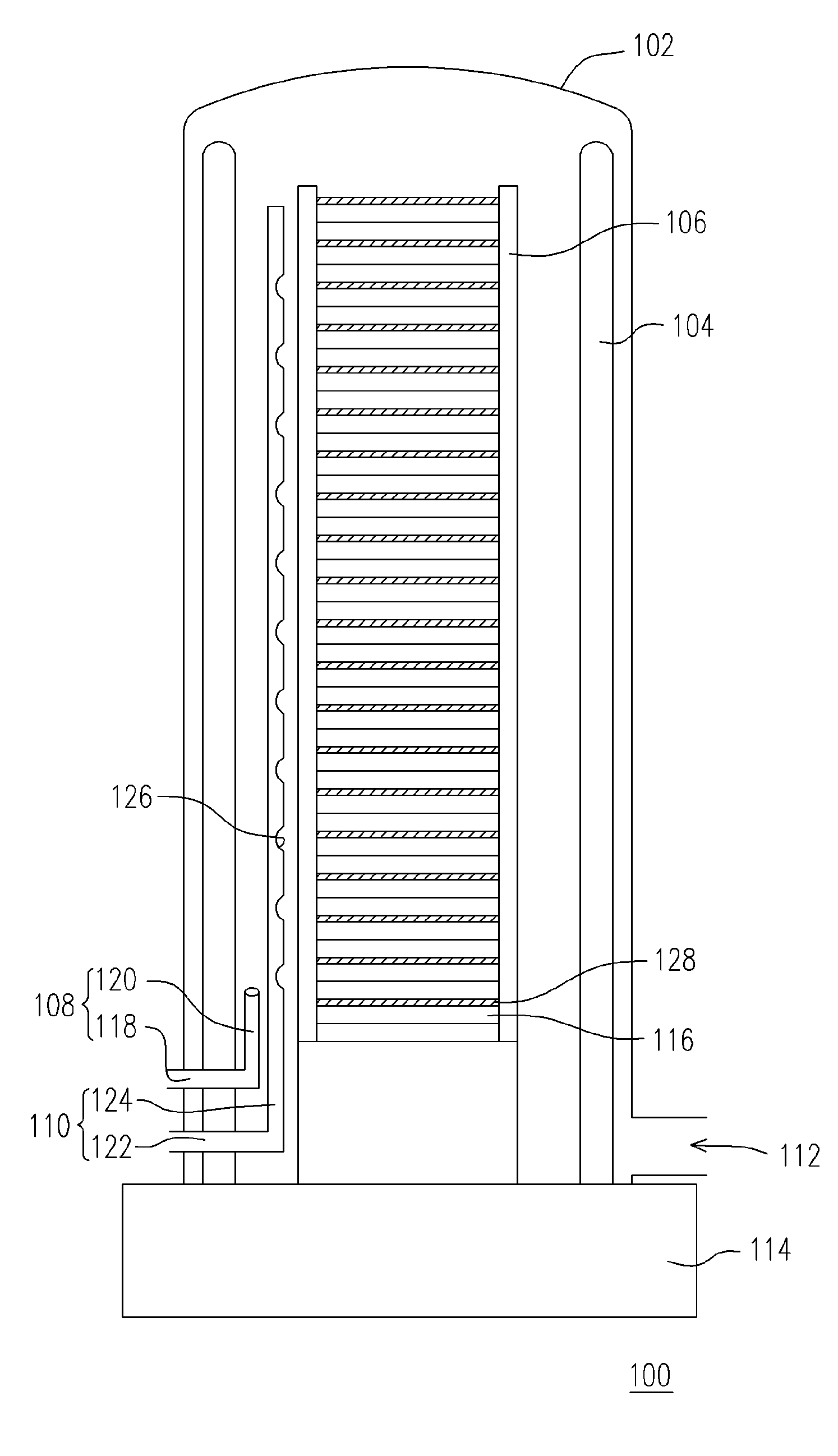

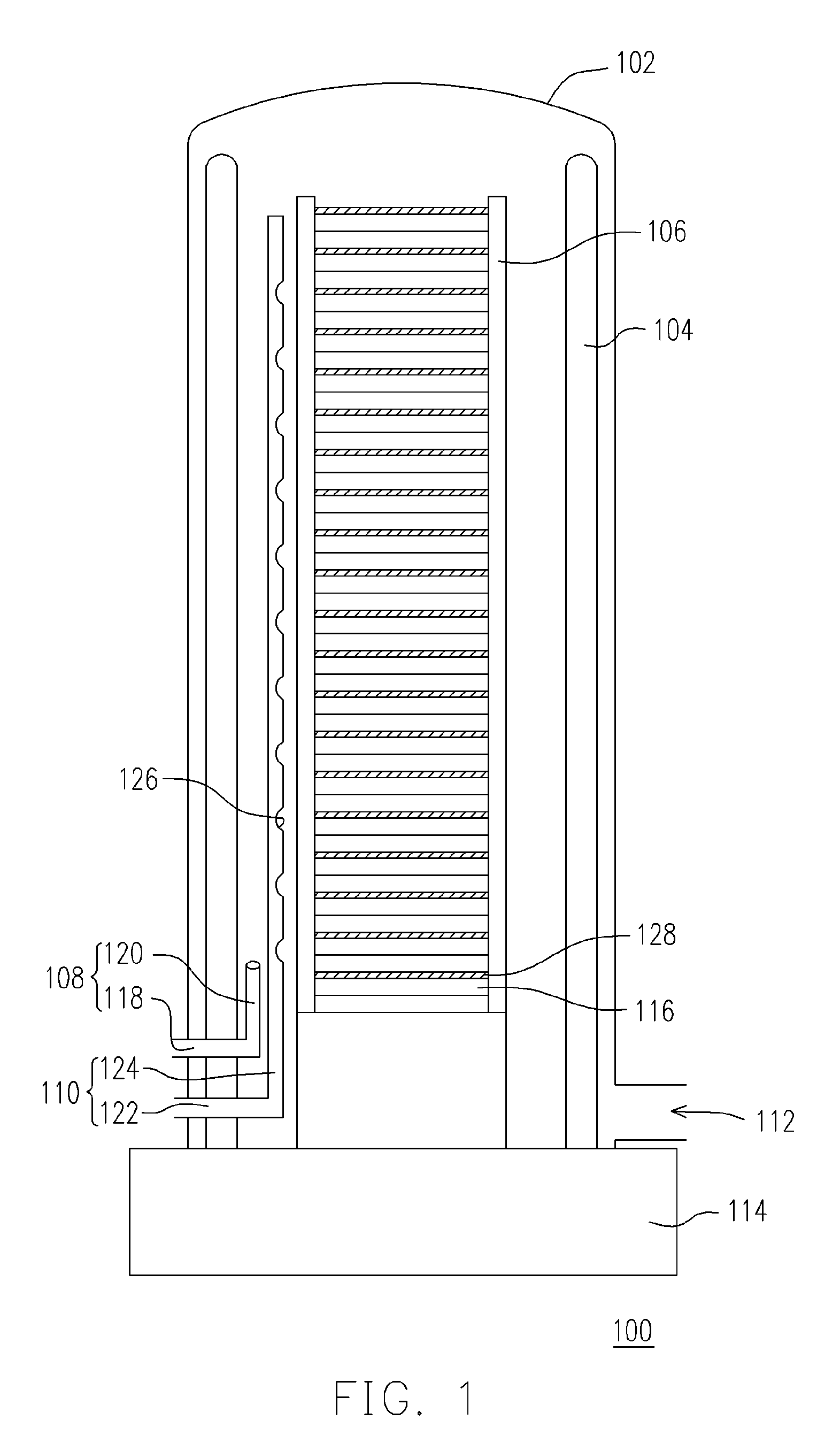

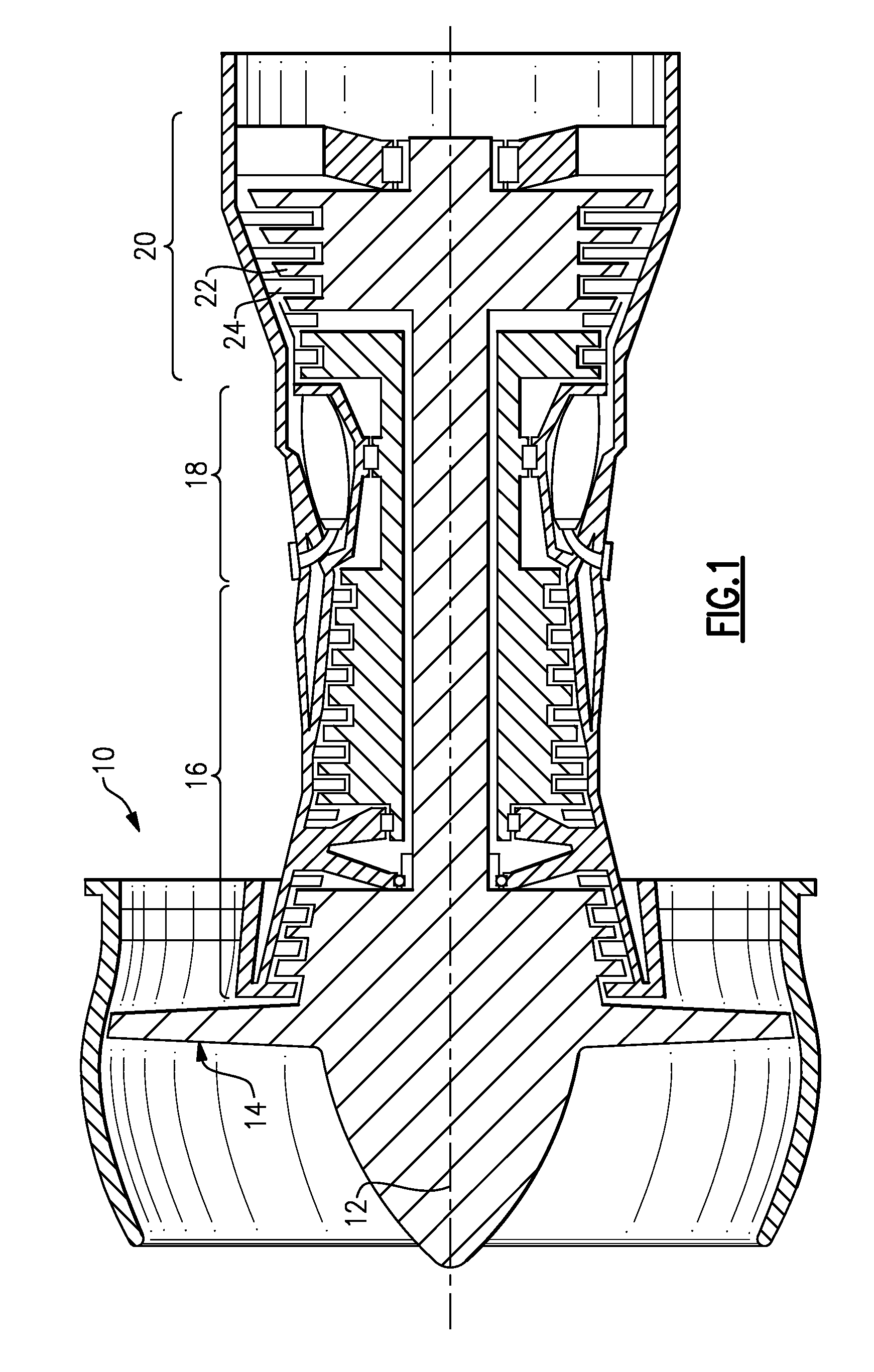

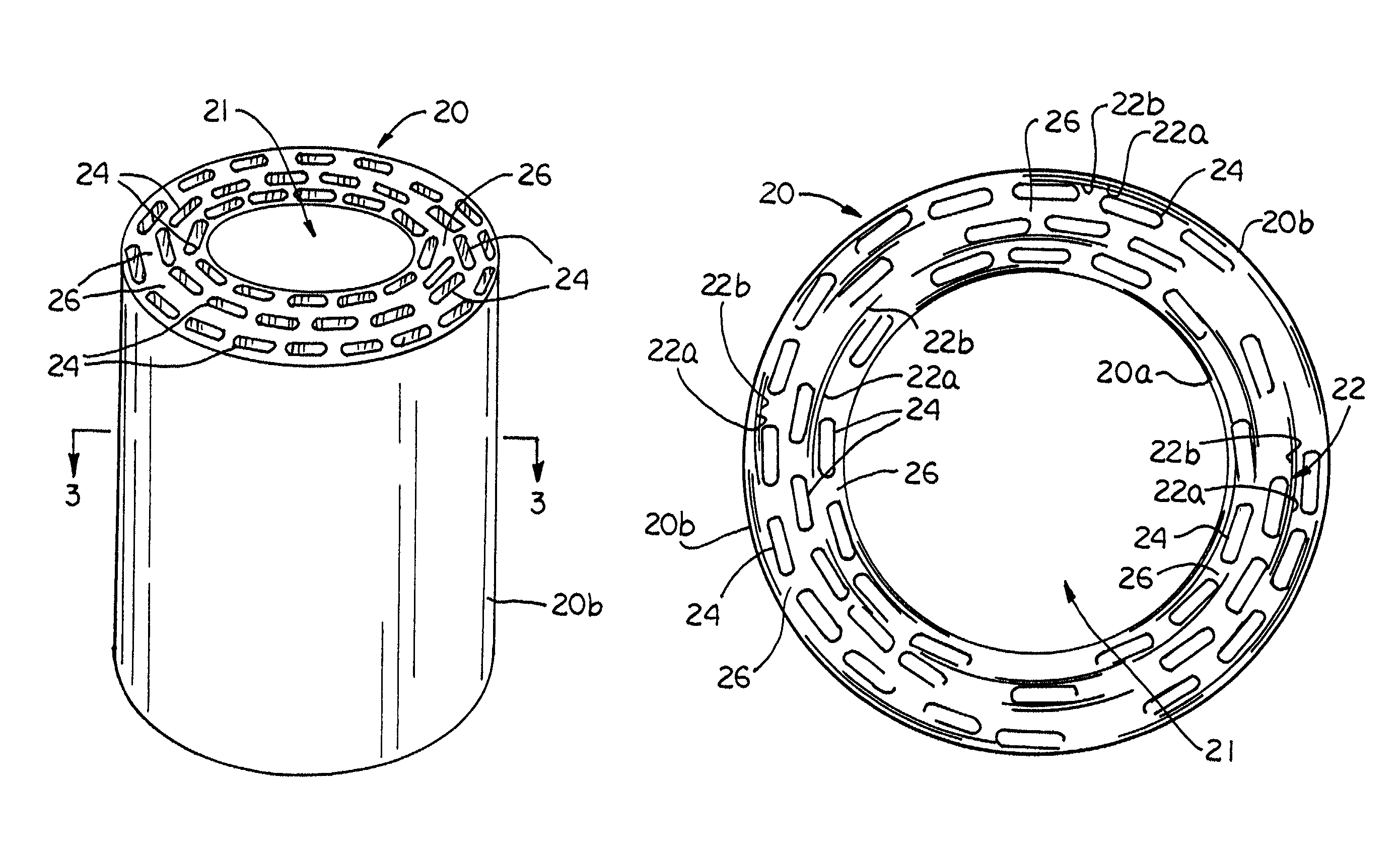

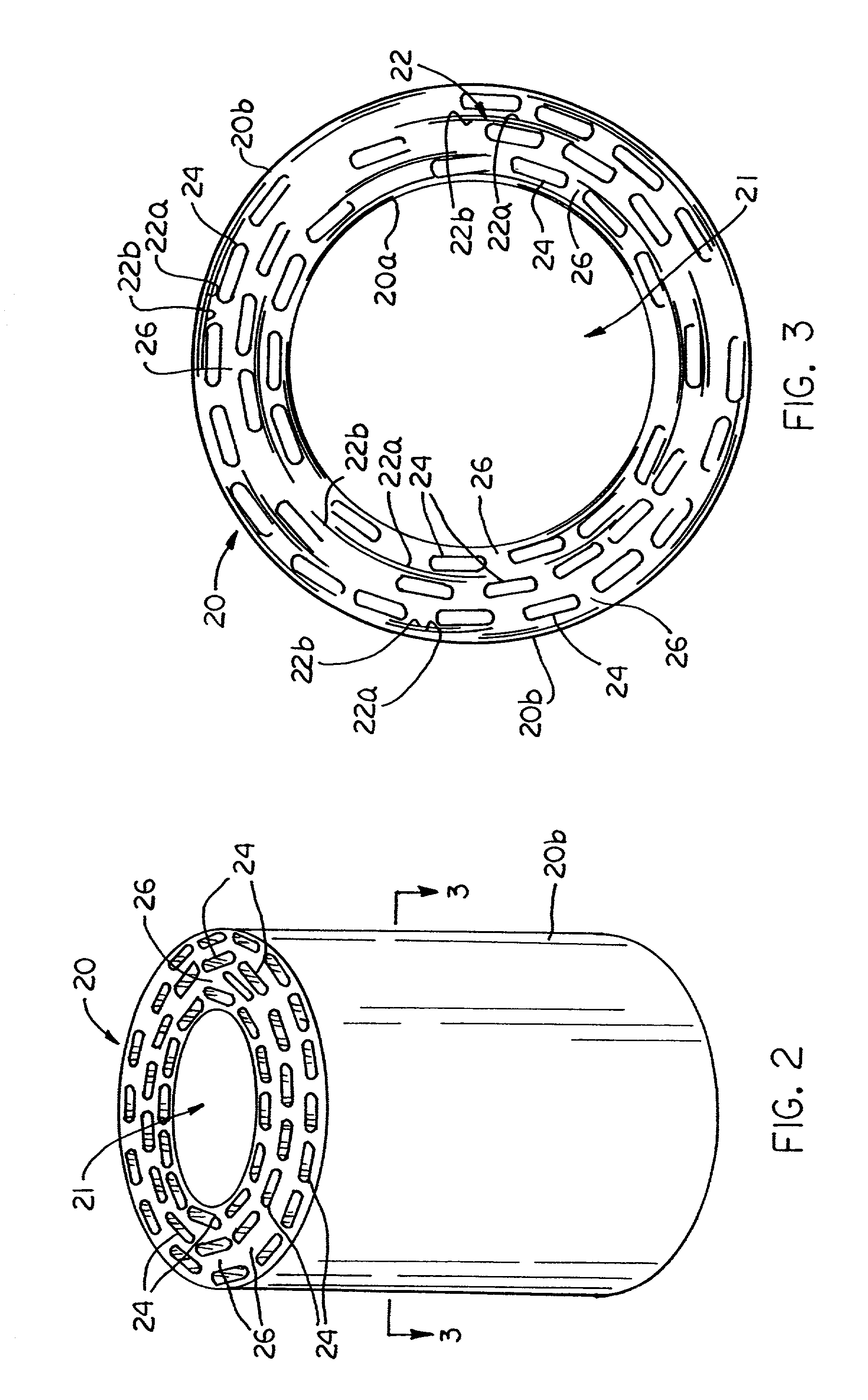

Integrated cooling duct for resin-encapsulated distribution transformer coils

InactiveUS7023312B1Preventing epoxy leakageEliminate distractionsTransformers/inductances coolingTransformers/inductances coils/windings/connectionsDistribution transformerEngineering

A dry-type, resin-encapsulated transformer coil that includes multiple layers formed from a length of conductive material, and multiple cooling ducts that are formed of thermoplastic material and spaced between the layers of conductive material. The thermoplastic material forming the cooling ducts and the resin that encapsulates the multiple layers of conductive material are thermally and electrically compatible.

Owner:HITACHI ENERGY SWITZERLAND AG

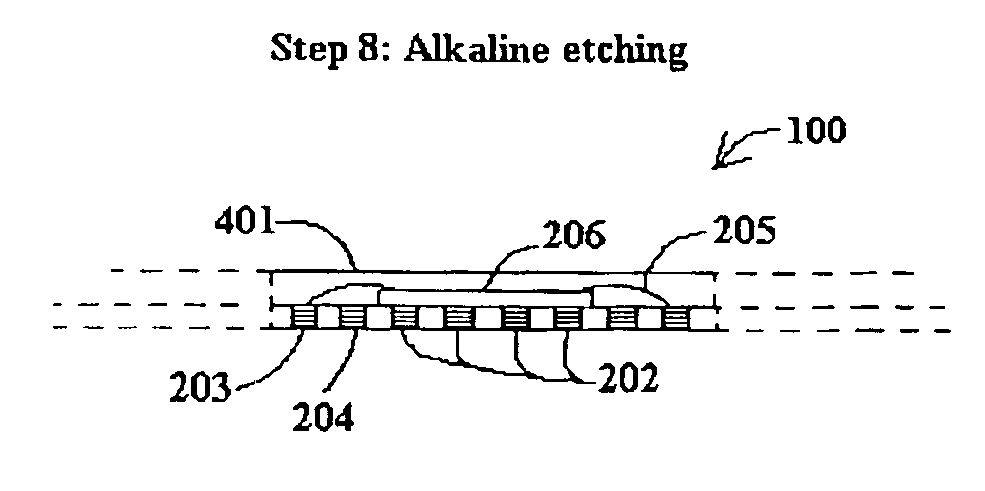

Novel ti-supported lead dioxide electric pole and preparation method thereof

InactiveCN101417831ALow costReduce internal stressWater/sewage treatment by sorptionAcid etchingLead dioxide

The invention relates to a novel titanium substrate lead dioxide electrode and a preparation method thereof, which belong to the field of water treatment technology application. The titanium substrate lead dioxide electrode adopts titanium material as a carrier; after the titanium substrate undergoes acid etching, pyrolytic process is adopted to plate a tin-stibium oxide bottom layer; alkaline solution is then used for electroplating an alpha-PbO2 intermediate layer; acidic composite electroplating solution is used for preparing a fluorine-containing beta-PbO2 surface layer doped with an active metal (such as bismuth, nickel, lanthanum, cerium and erbium) and a particle with high absorption performance (such as powdered activated carbon and chitosan), thus obtaining a novel titanium substrate lead dioxide electrode. The titanium substrate lead dioxide electrode prepared by the method has low cost and long service life. Using the electrode as an anode and applying certain applied voltage can realize efficient removal and mineralization to the organic contaminants in the water. With simple operation and convenient management, the method is applicable to small-scale and dispersible wastewater and feed water treatment.

Owner:BEIJING NORMAL UNIVERSITY

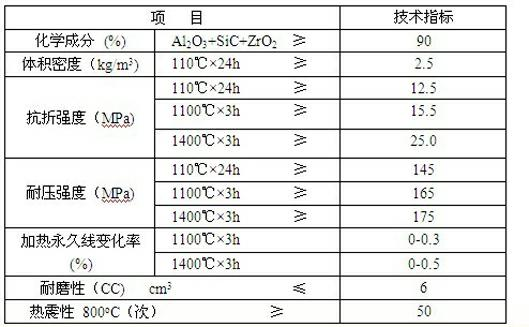

Special castable for kiln outlet

The invention discloses a special castable for a kiln outlet, which belongs to the field of refractory materials. According to the invention, the special castable comprises the following components in percentage by weight: 8-25% of silicon carbide, 10-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 1-5% of zirconium diboride, 1-5% of silicon nitride,5-15% of alumina micropowder, 3-6% of pure calcium aluminate cement, 0.5-1% of explosion-proof fiber and 0.06-0.2% of sodium tripolyphosphate, which is an additive. By using the special castable for the kiln outlet, disclosed by the invention, the phenomenon of poor wear resistance, block falling and the like in the kiln outlet can be effectively improved; the service life of the cement kiln outlet can be largely prolonged; and the special castable for the kiln outlet, disclosed by the invention, has the advantages of high temperature resistance, heat shock resistance, wear resistance, high strength, irreversible micro expansion and the like.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

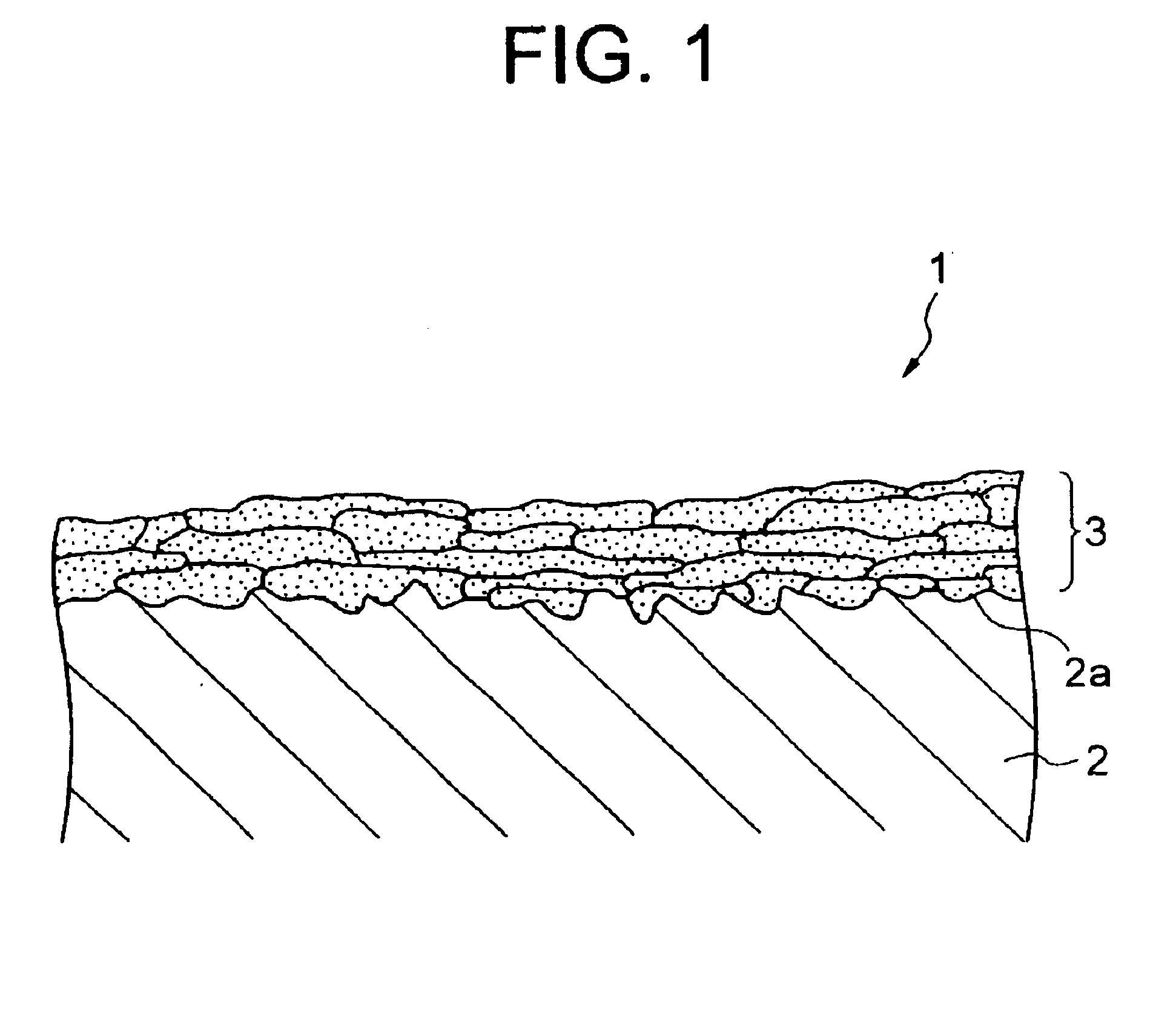

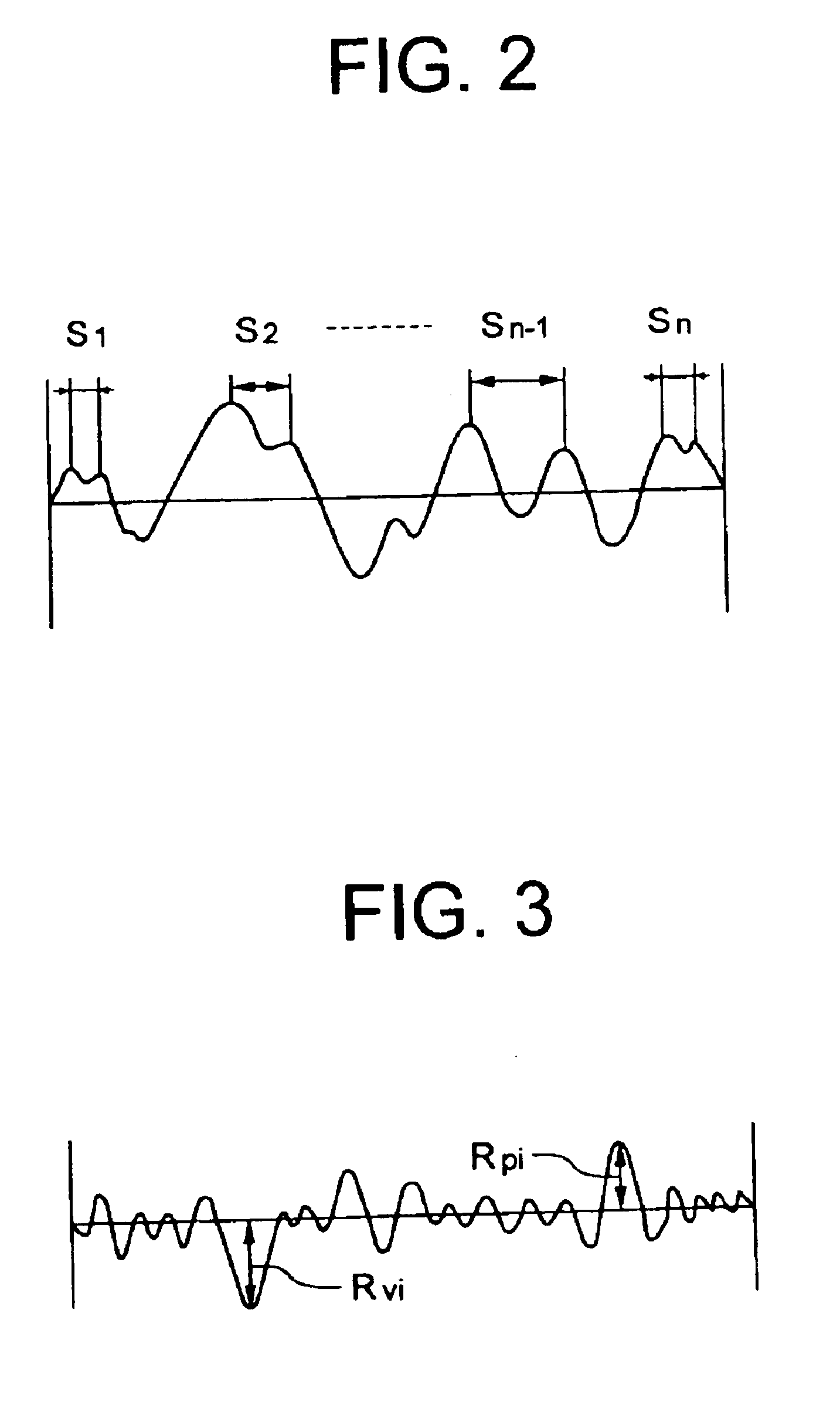

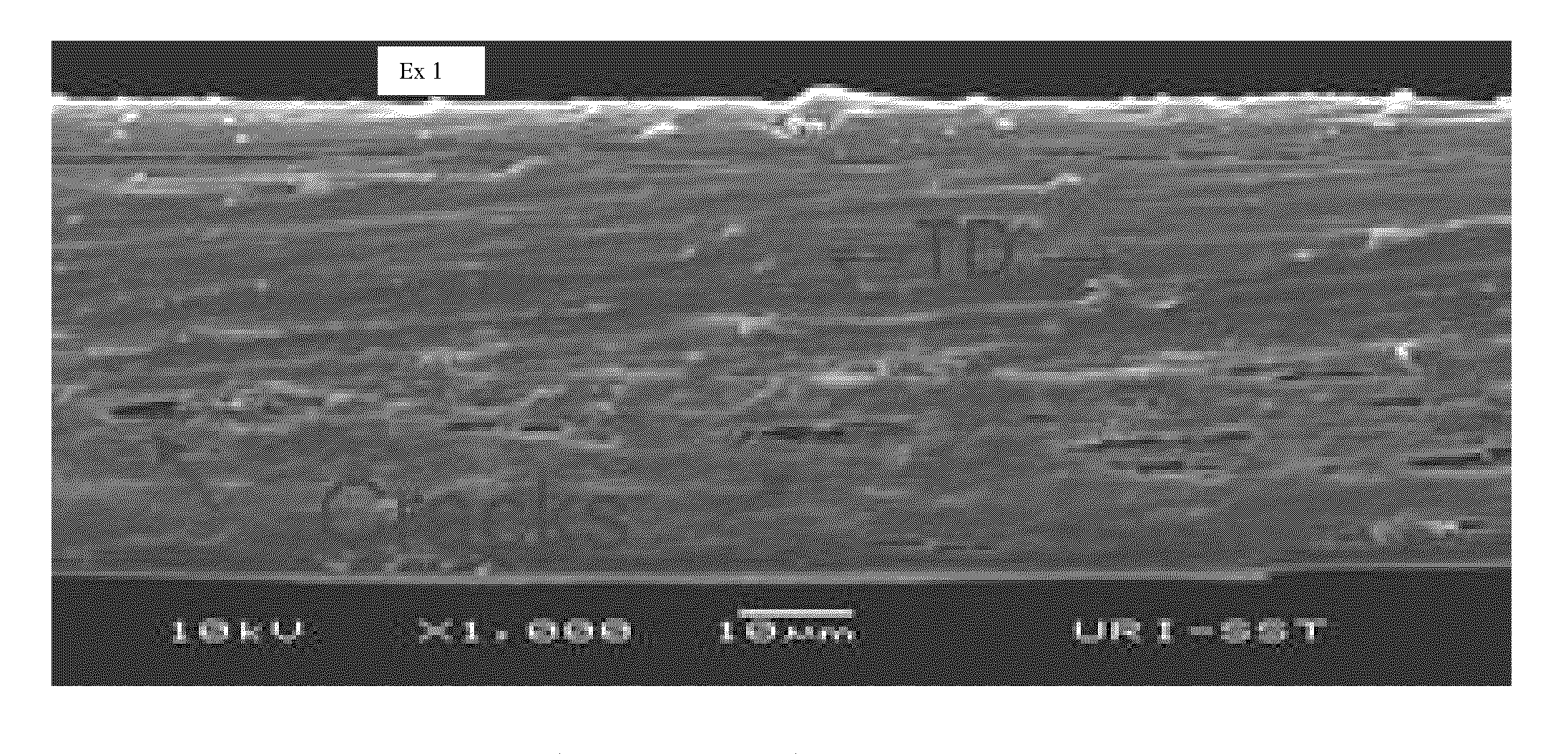

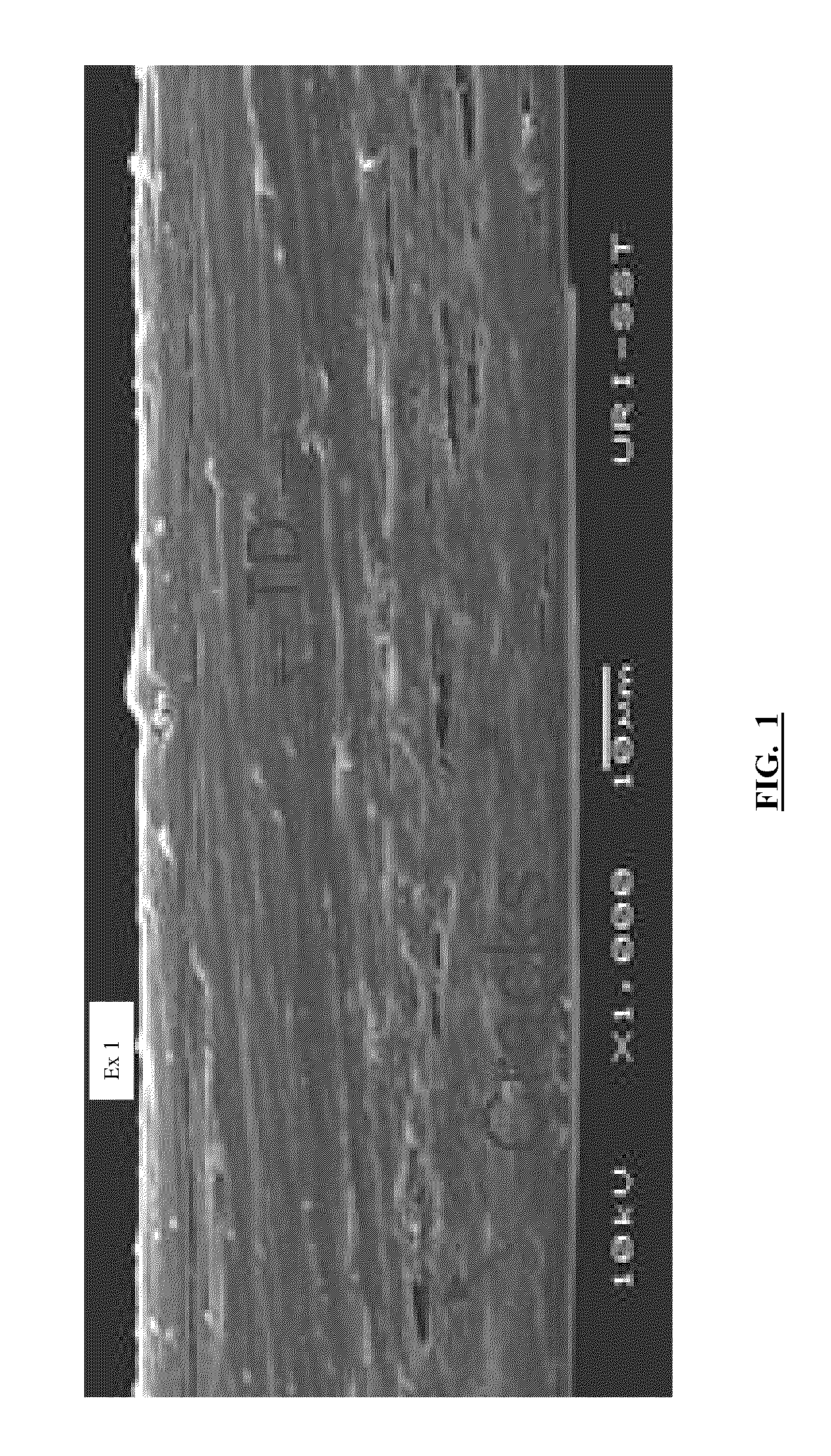

Components for vacuum deposition apparatus and vacuum deposition apparatus therewith, and target apparatus

InactiveUS6855236B2Hardness be lowSuppress peelingCellsMolten spray coatingHardnessVacuum deposition

A component for a vacuum deposition apparatus comprises a component body and a spray deposit formed on a surface of a component body. A spray deposit has surface roughness in which a mean spacing S of tops of local peak of profile is in the range from 50 to 150 μm, and distances to a bottom of profile valley line Rv and to a top of profile peak line are in the ranges from 20 to 70 μm, respectively. Furthermore, a spray deposit has a low hardness coat selected from an Al base spray deposit of Hv 30 (Vickers hardness) or less, a Cu base spray deposit of Hv 100 or less, a Ni base spray deposit of Hv 200 or less, a Ti base spray deposit of Hv 300 or less, a Mo base spray deposit of Hv 300 or less and a W base spray deposit of Hv 500 or less. Such component for a vacuum deposition apparatus may suppress, with stability and effectiveness, peeling of deposition material adhering on a component during deposition. In addition, the number of apparatus cleaning and of exchange of components may be largely reduced. A target comprises a similar spray deposit. A vacuum deposition apparatus is one in which above component for a vacuum deposition apparatus is applied in a holder of a sample to be deposited, a deposition material source holder, a preventive component and so on.

Owner:KK TOSHIBA

Conductive graphene printing ink and preparation method thereof

The invention provides a conductive graphene printing ink. The conductive graphene printing ink is composed of 0.001-80wt% of graphene, 1-60wt% of a linking material, 0.1-30wt% of an assistant, and the balance solvent. The invention also provides a preparation method of the conductive graphene printing ink. The conductive graphene printing ink has the advantages of good toughness, good die molding performance, good adhesion and good impact resistance; chemically doped graphene and chemically modified graphene in the graphene have good conductive, mechanical and thermal performances. The molecules of the chemically doped graphene comprise one or more of polyaniline, polyacetylene, polythiophene, polyparaphenylene and polypyrrole, and the functional groups of the chemically modified graphene comprise one or more of an anilino group, a pyrryl group, an imidazolyl group, a benzenesulfonic acid group, a thienyl group, a furyl group, a phenyl group, a hydroxy group, an ester group and derivative groups thereof, so the conductive performance, the mechanical performances and the dispersion stability of graphene in the printing ink are improved.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

Method to produce matte and opaque biaxially oriented polylactic acid film

ActiveUS20090311544A1Minimize shrinkage effectReduce internal stressOther chemical processesSynthetic resin layered productsMaterials scienceMetal

A biaxially oriented laminate film including a core layer including a blend of crystalline polylactic acid polymer and an inorganic antiblock particle which is biaxially oriented at low transverse direction orientation temperatures to impart a degree of cavitation around the particles such that a matte or opaque appearance is obtained. The laminate film may further have additional layers such as a heat sealable layer disposed on one side of the core layer including an amorphous polylactic acid resin and / or a polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

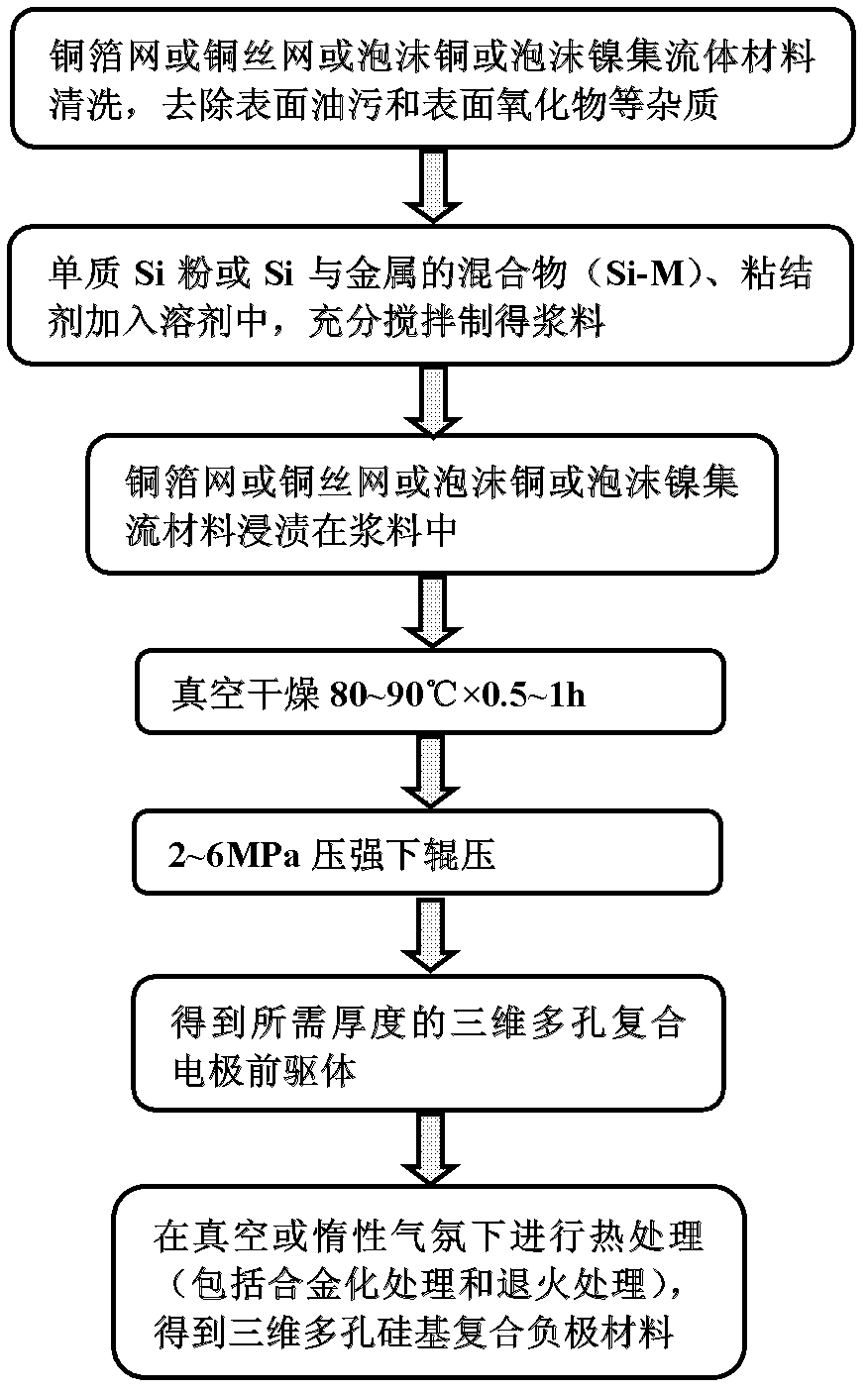

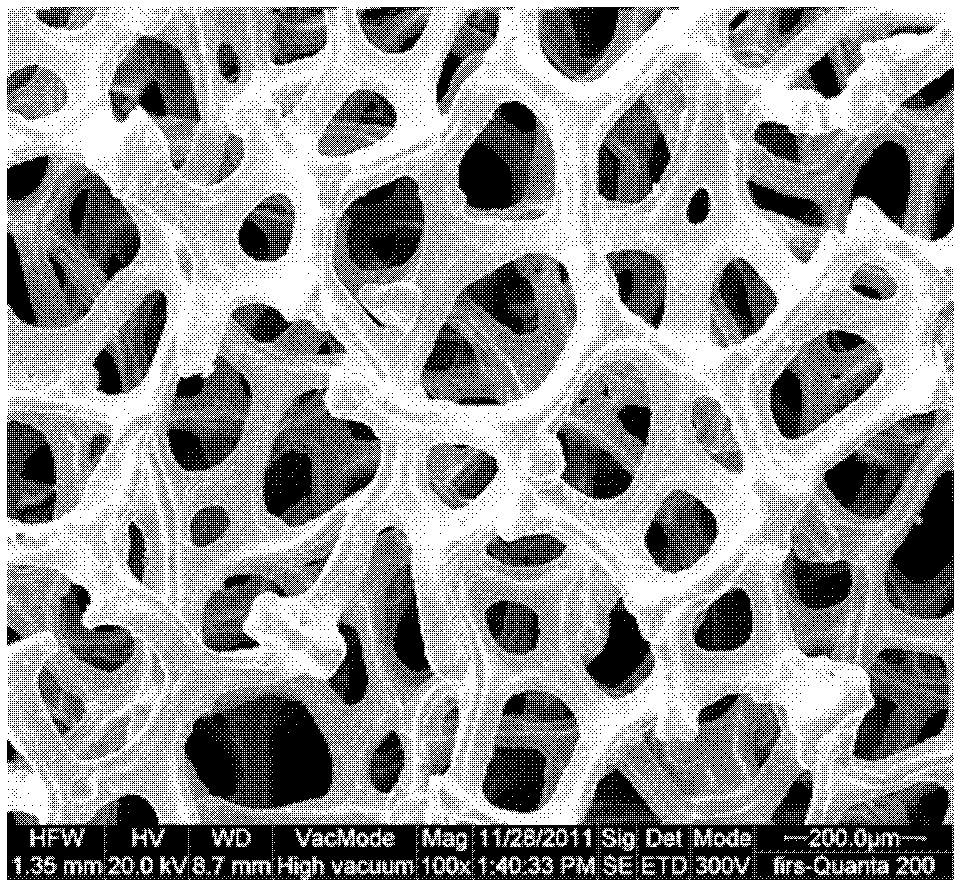

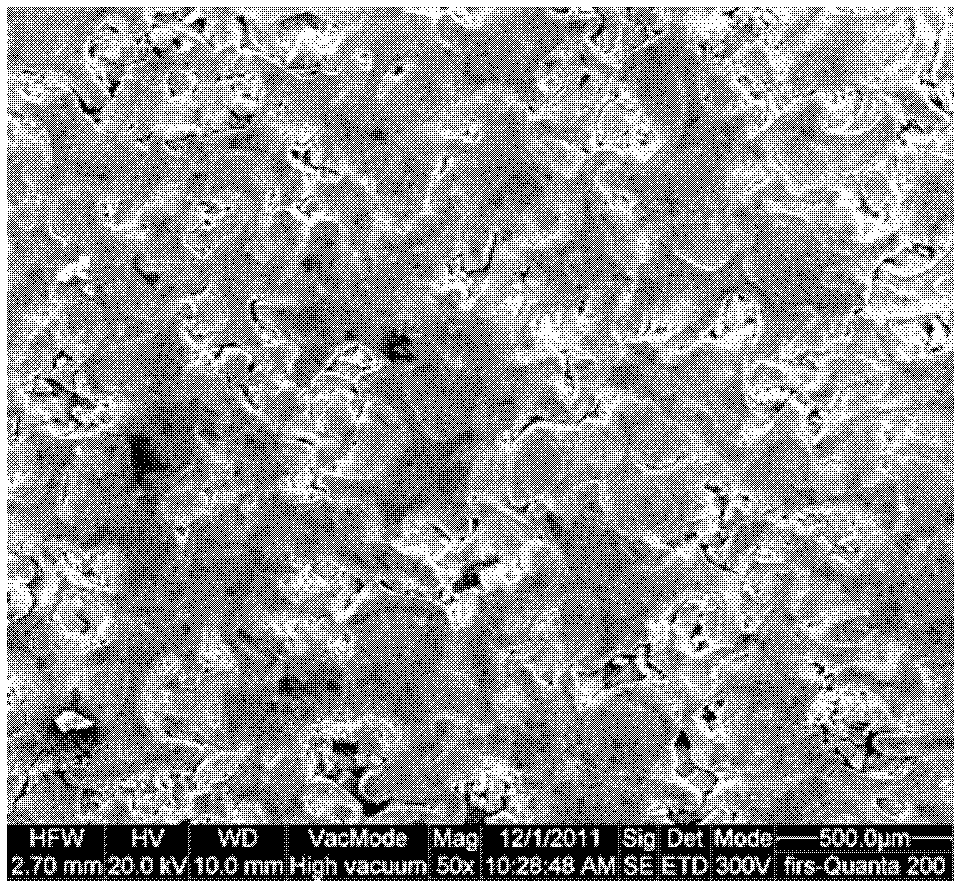

Three-dimensional porous silicon-based composite negative electrode material of lithium ion cell and preparation method thereof

ActiveCN102683655AEasy to operateReduce processing costsElectrode carriers/collectorsSecondary cellsCopper wireCopper foil

The invention discloses a three-dimensional porous silicon-based composite negative electrode material of a lithium ion cell and a preparation method thereof. A collection body material, such as a copper foil net or a copper wire net or foam copper or foam nickel, which has a three-dimensional net structure, enables electrode active substances to be uniformly dispersed in the material and the surface of the material, and has high temperature resistant characteristic and excellent conductivity, is adopted; and a sizing material containing simple substance silicon or a mixture of simple substance silicon and metal M is combined with the copper foil net or copper wire net or foam copper or foam nickel by a dipping method, and then the three-dimensional porous silicon-based composite negative electrode material is formed by a heat treatment (alloying and annealing treatment) manner. According to the invention, based on the three-dimensional porous structure, the forming of silicon metal alloy as well as excellent binding force between the negative electrode material and the three-dimensional porous collection body material, the cell prepared from the porous silicon-based composite negative electrode material has higher discharge specific capacity and first charge-discharge efficiency and excellent cycle performance.

Owner:SHANGHAI SHANSHAN TECH CO LTD

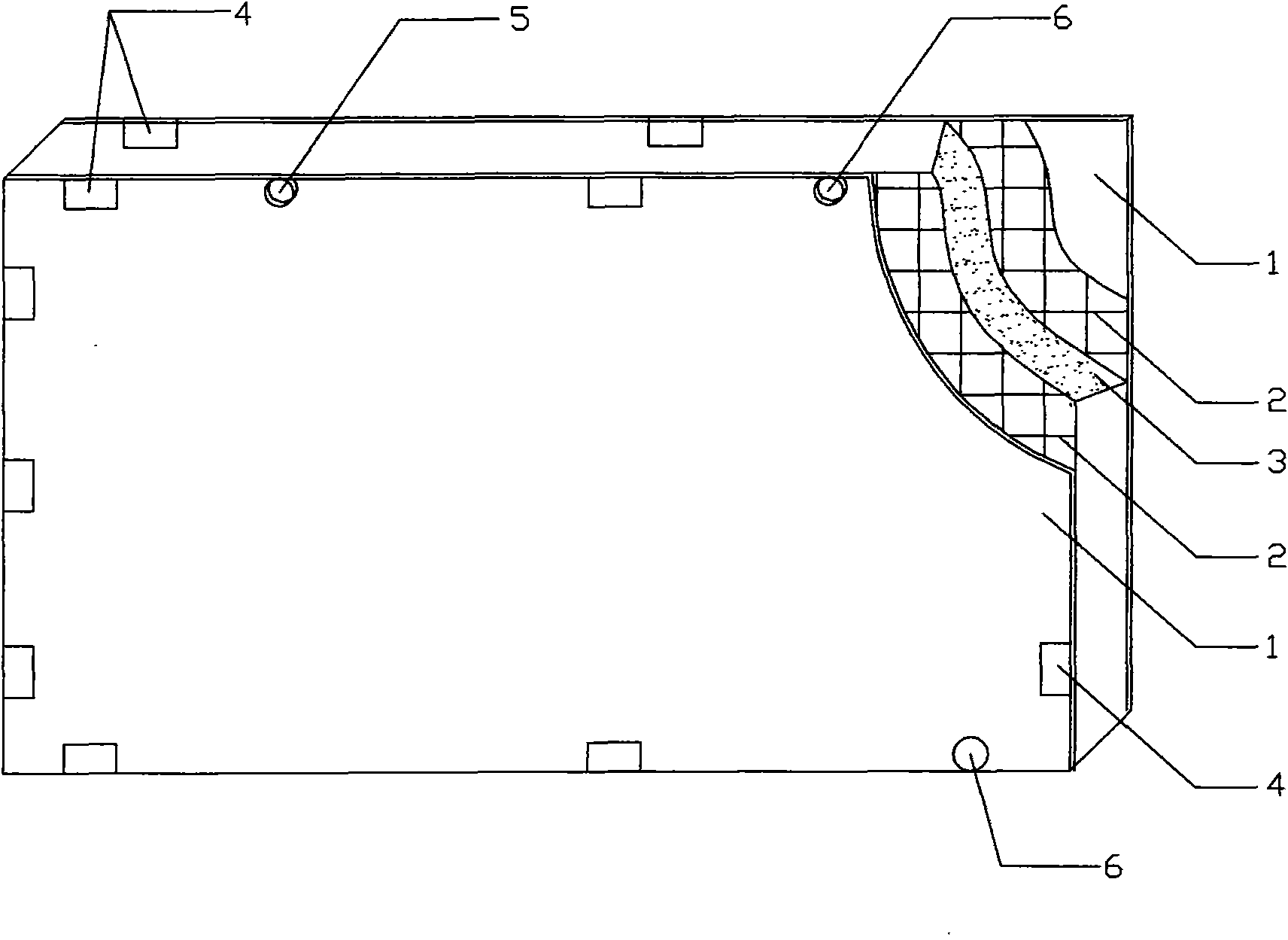

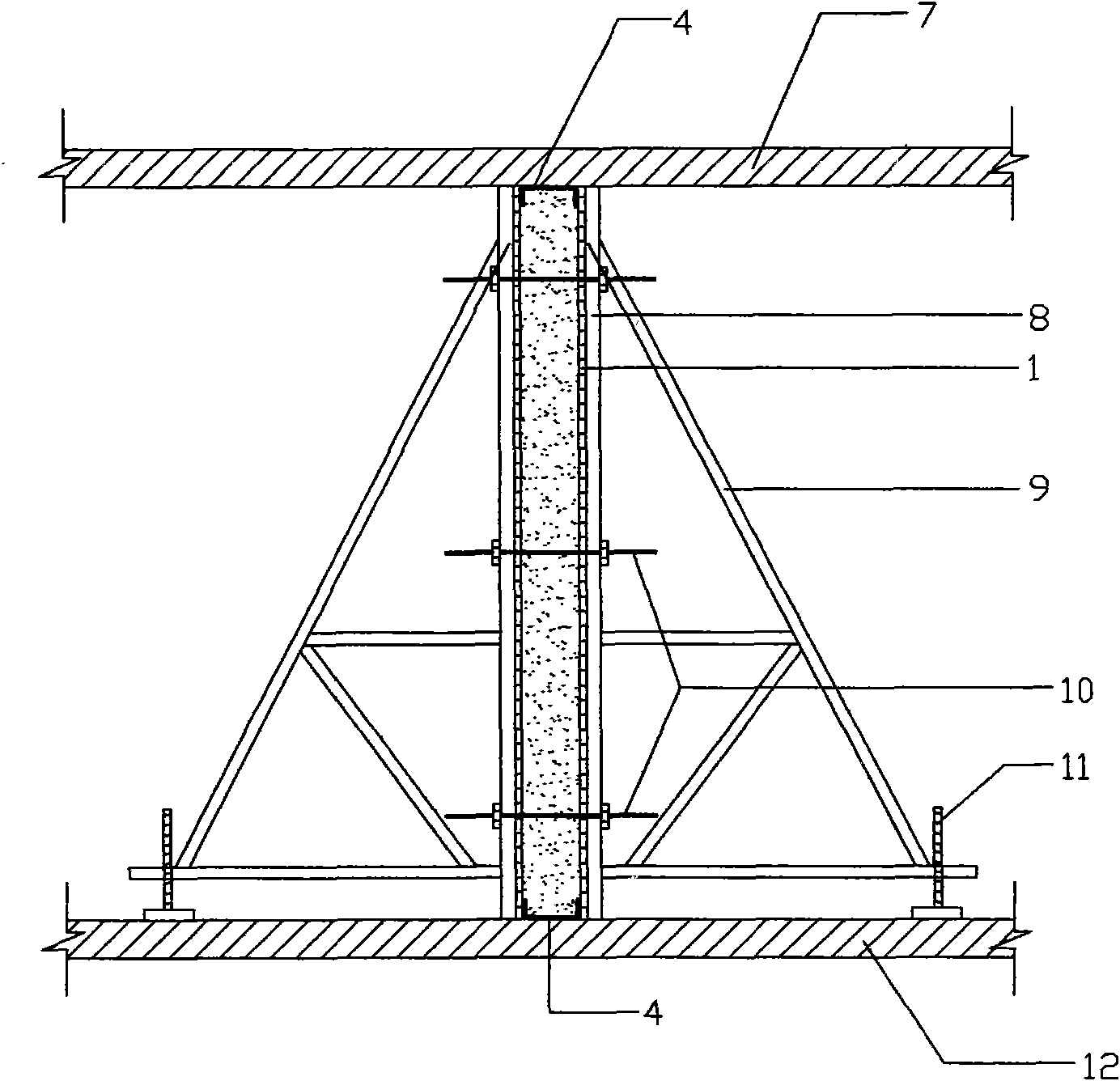

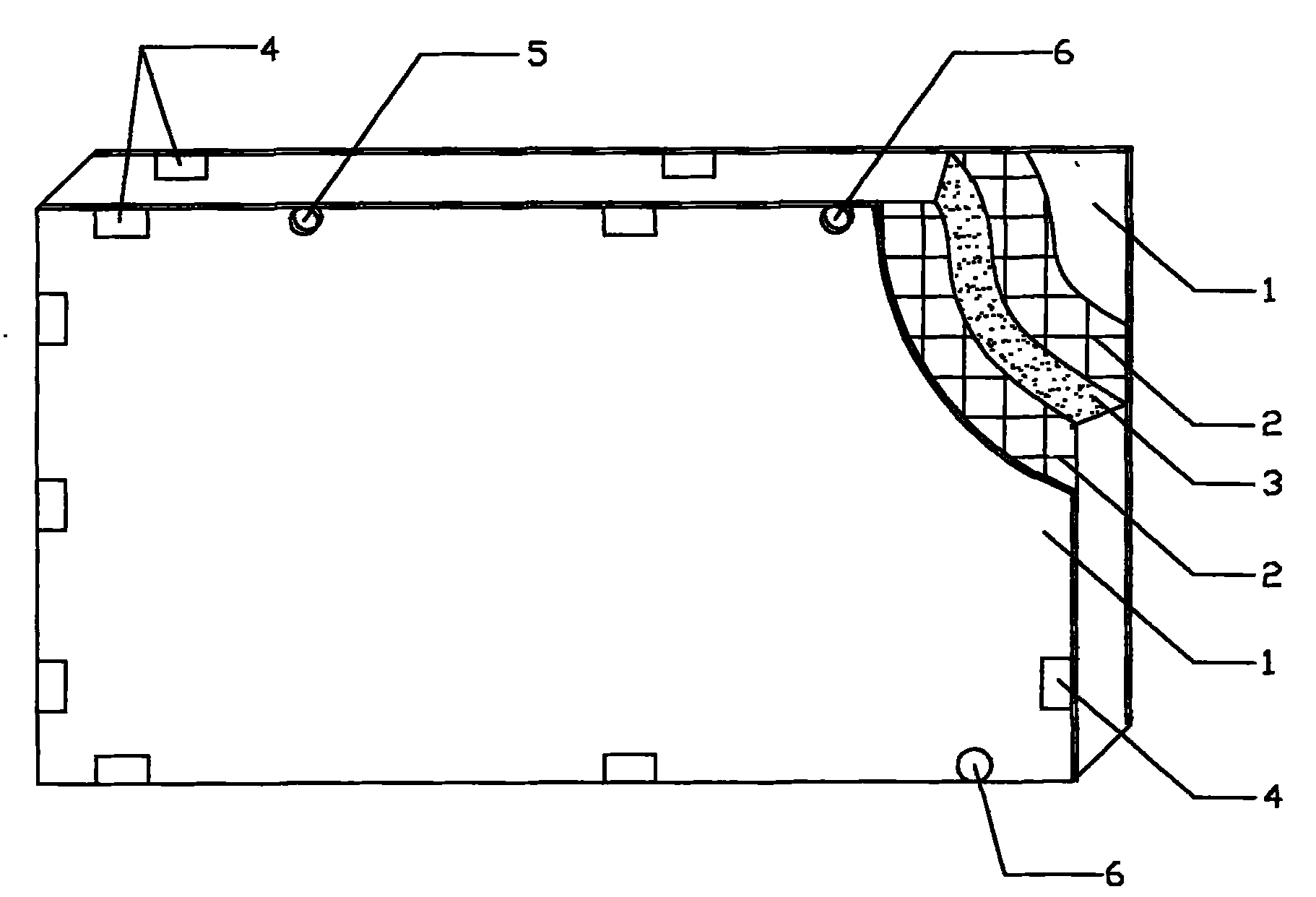

Construction method for cast-in-place integral light-weight partition wall

InactiveCN101858114AReduce crackingHigh tensile strengthWallsBuilding material handlingEarthquake resistanceKeel

The invention discloses a construction method for an interior partition wall. The construction of the partition wall is characterized by comprising the following steps: erecting templates at both sides of a wall body, and fixing the templates by using outside removable keels; and then casting light aggregate concrete or manufactured-in-place aerated concrete in the templates so as to cast the wall body into an complete whole, wherein the permanent templates can be made of thistle boards, plastic boards, cement boards or insulation boards; the casting of the light aggregate concrete is transferred by a booster pump; and the casting of the concrete can be started from the lower part, middle part or the upper part of the wall body until the concrete is spread all over the whole wall body. The wall body constructed by using the method meets the requirements of light weight, sound insulation and heat insulation for the traditional partition wall, and simultaneously, the common quality problems of plastering, wall surface cracking and poor earthquake resistance in the construction of the traditional partition wall are avoided or reduced because of the one-piece casting. Meanwhile, by erecting the permanent templates in the construction of the wall body, the molded wall surface is smooth and level, and the floated coat construction is omitted, thereby greatly raising the construction speed of the wall body, and lowering the construction cost.

Owner:段风雷

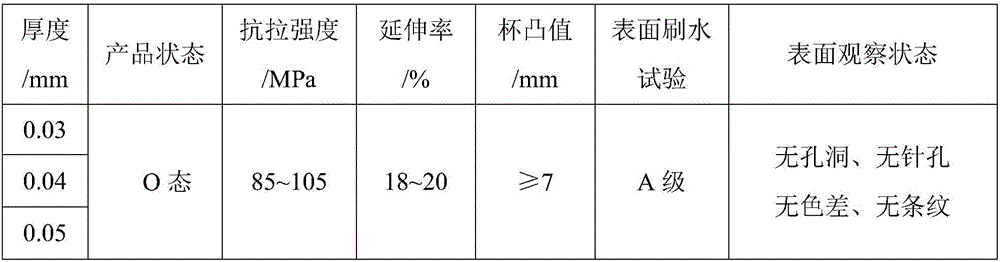

Lithium-battery 8021 soft packaging aluminum foil and production method thereof

ActiveCN106191544AReduce hydrogen contentImprove sealingJackets/cases materialsMetallurgyIngot casting

The invention discloses lithium-battery 8021 soft packaging aluminum foil and a production method thereof. Aluminum alloy containing Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti and the balance Al is smelted and subjected to ingot casting, then an ingot is subjected to surface milling and soaking treatment; and the lithium-battery 8021 soft packaging aluminum foil is obtained after the steps of hot rolling, cold rolling, annealing, foil rolling, roll combining, combined roll annealing and roll dividing. The lithium-battery 8021 soft packaging aluminum foil prepared through the good technological process is a finished product in the O state, the ductility reaches 18-20%, the cupping value is larger than or equal to 7 mm, and the fracture resistance, stamping resistance and the like of the soft packaging aluminum foil are effectively improved. The aluminum foil has no holes or pinholes completely, so that a lithium battery soft package prepared from the aluminum foil has good airtightness and is free of liquid leakage and safe to use. The lithium-battery 8021 soft packaging aluminum foil has good social and economical benefits and broad application prospects.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

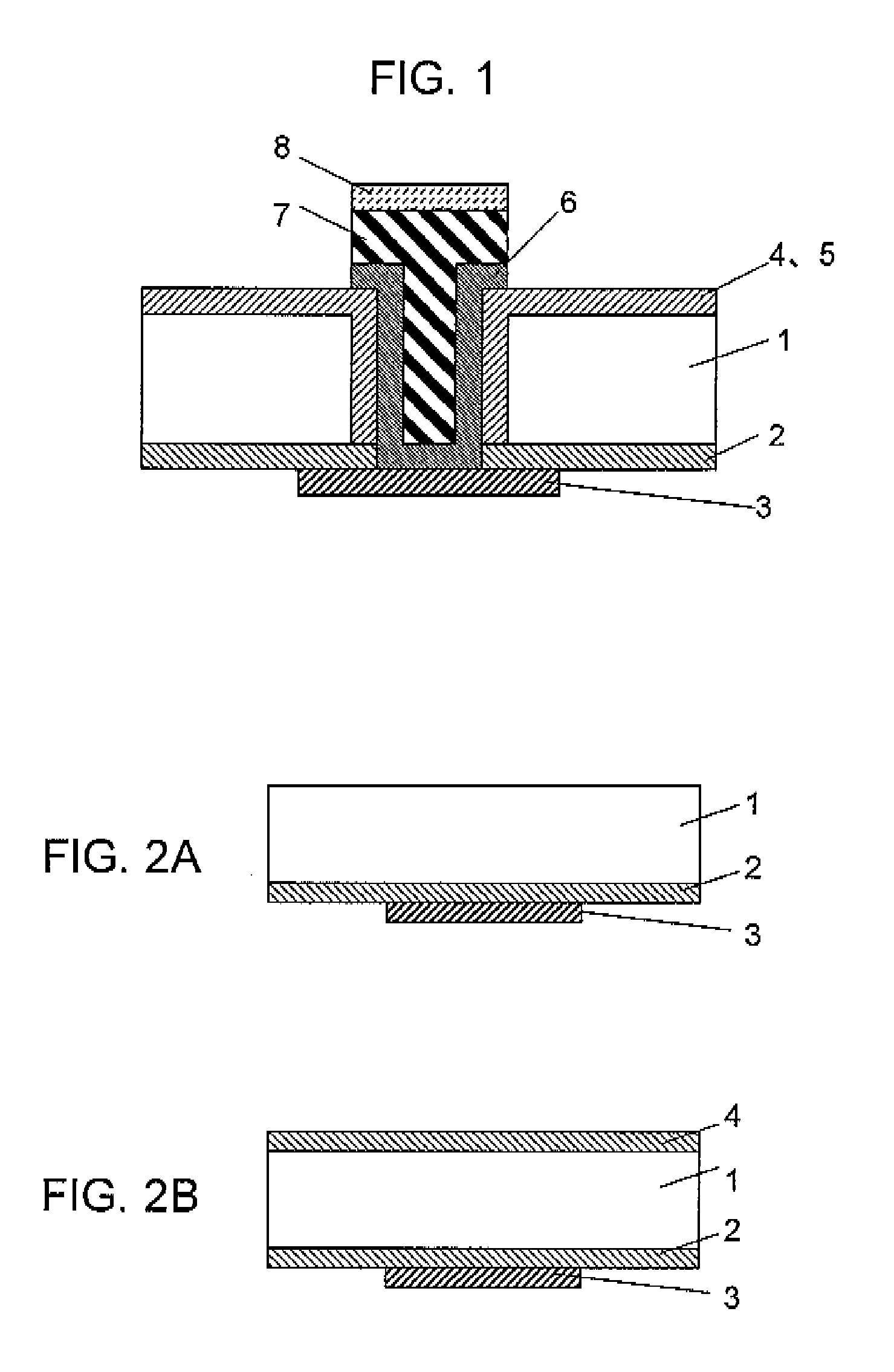

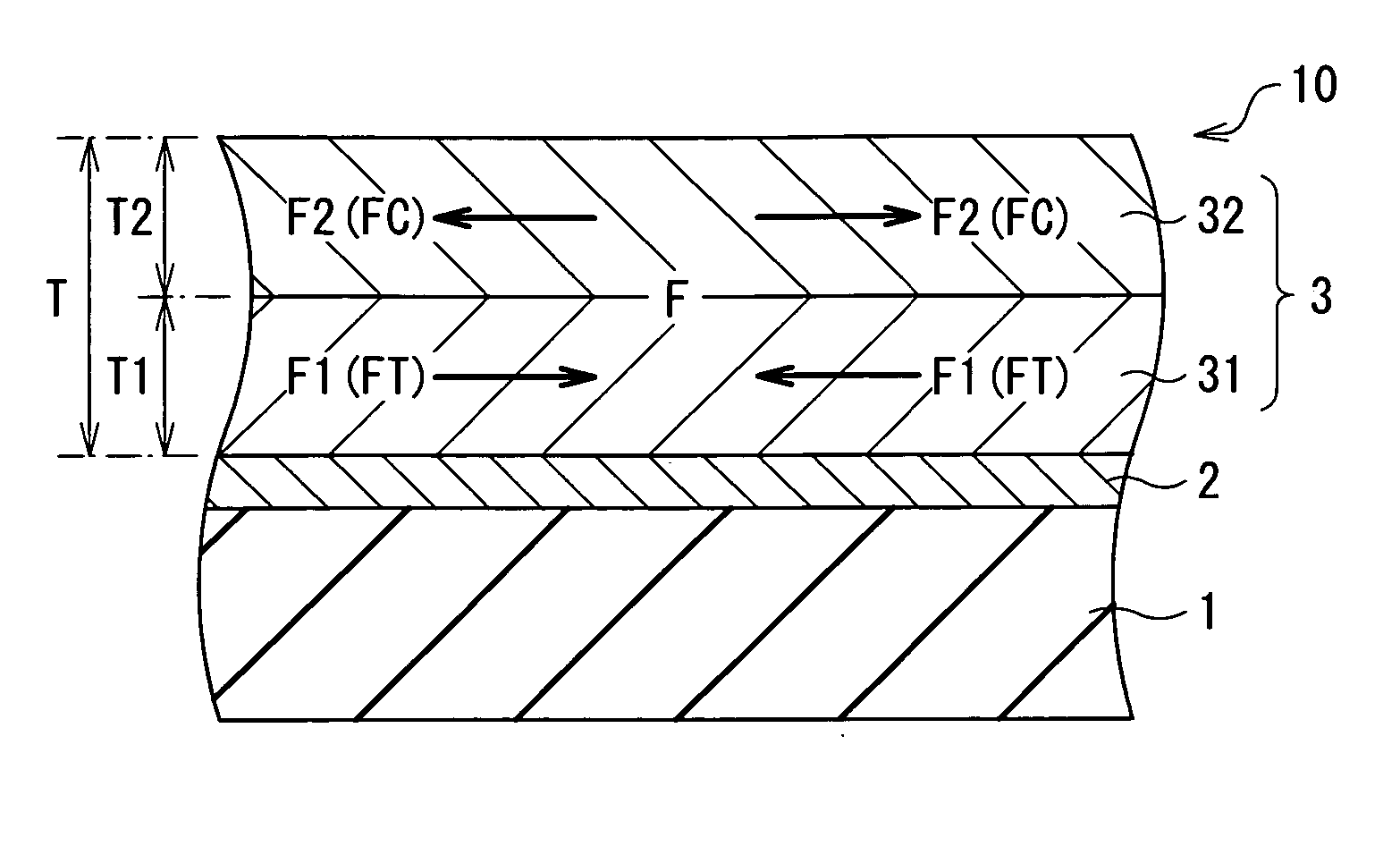

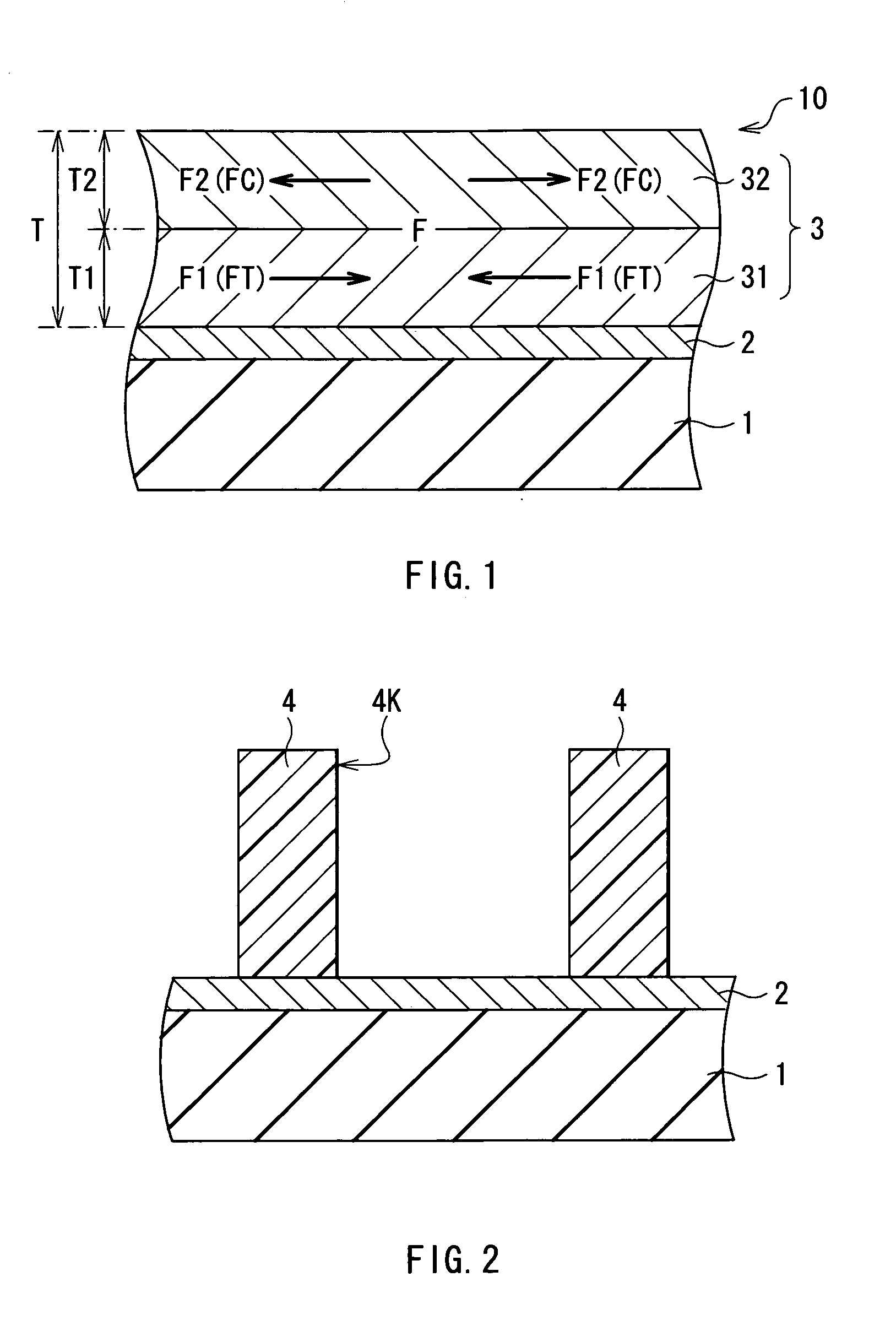

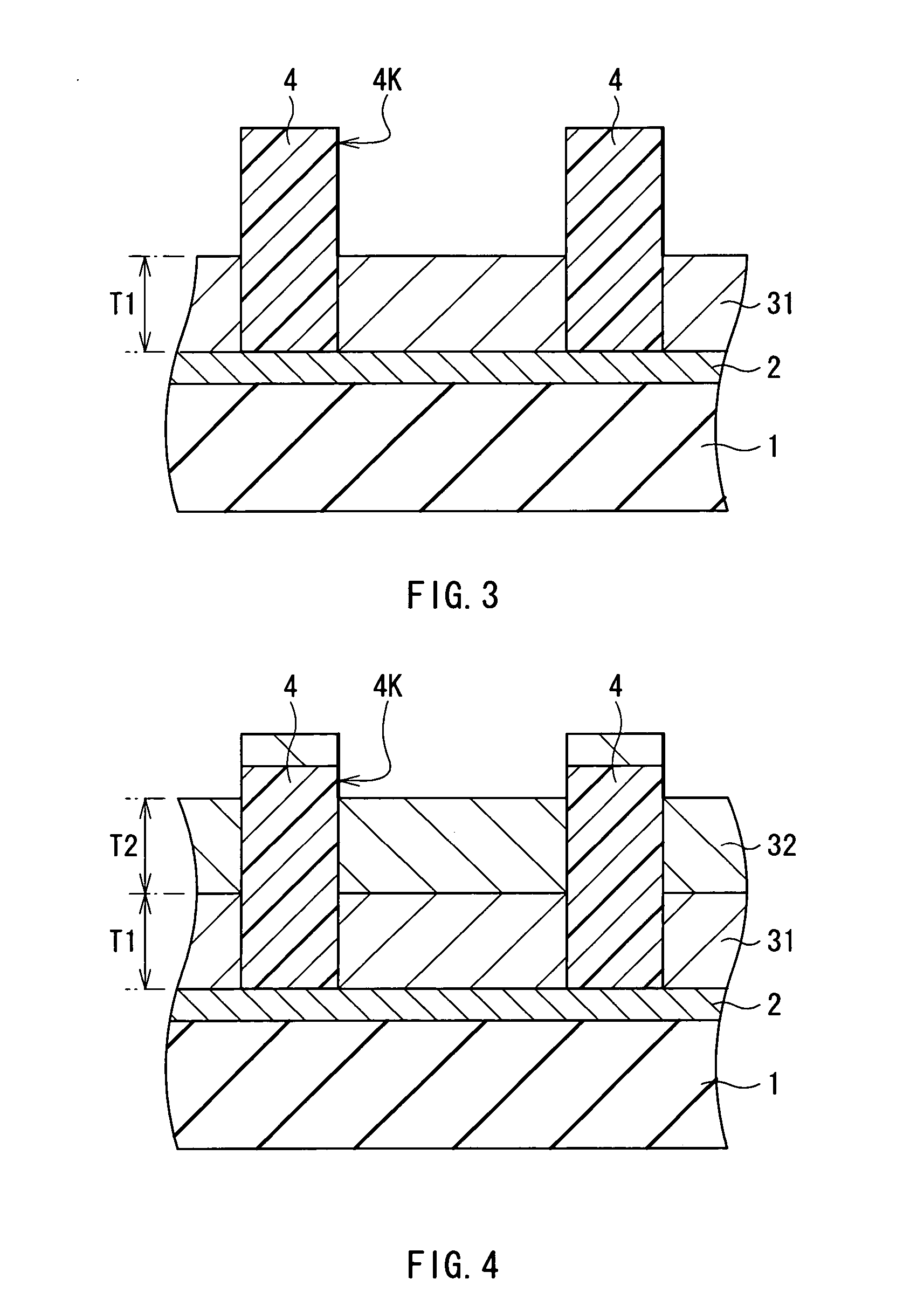

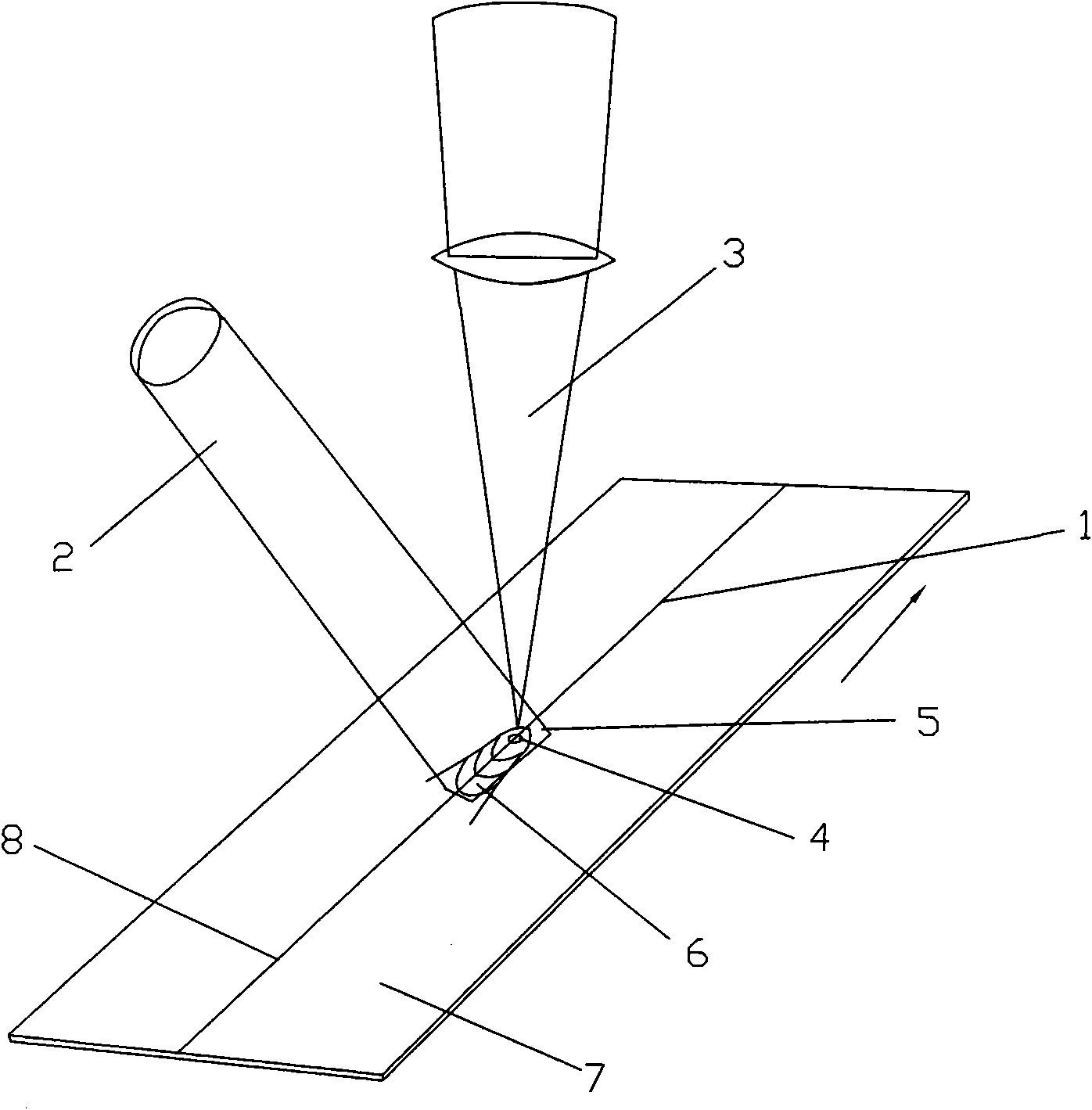

Composite substrate, method of manufacturing the same, a thin film device, and method of manufacturing the same

InactiveUS20060222821A1Control deformationAvoid deformationPrinted circuit aspectsPrinted circuits stress/warp reductionComposite substrateOptoelectronics

A composite substrate capable of suppressing a deformation of the substrate in response to the influence of internal stress of a conductive film is provided. When a conductive film is formed on a substrate, the conductive film is formed so as to have a laminated structure including a main conductive film which has a tensile stress FT as its internal stress F1 and a sub-conductive film which has a compressive stress FC as its internal stress F2. In this manner, the tensile stress FT of the main conductive film is offset by use of the compressive stress FC of the sub-conductive film. Thereby, unlike the case where the conductive film is formed so that only the main conductive film may be included without including the sub-conductive film, the substrate becomes less deformable in response to the influence of the internal stress F of the conductive film.

Owner:TDK CORPARATION

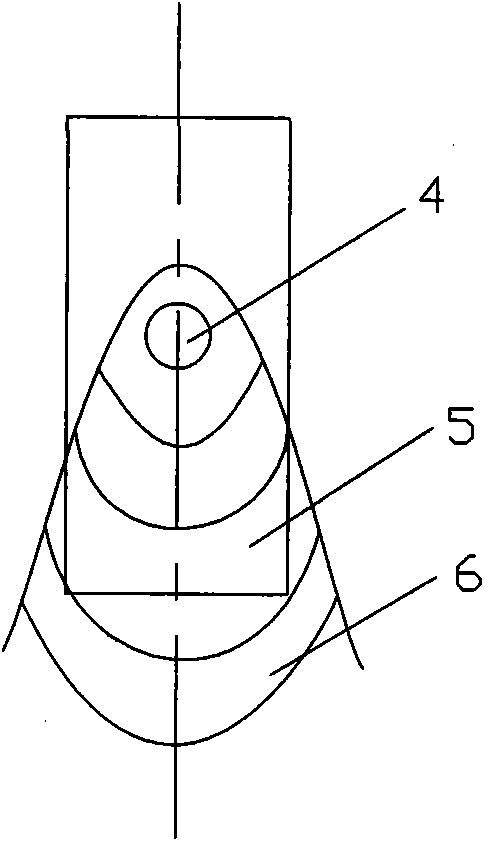

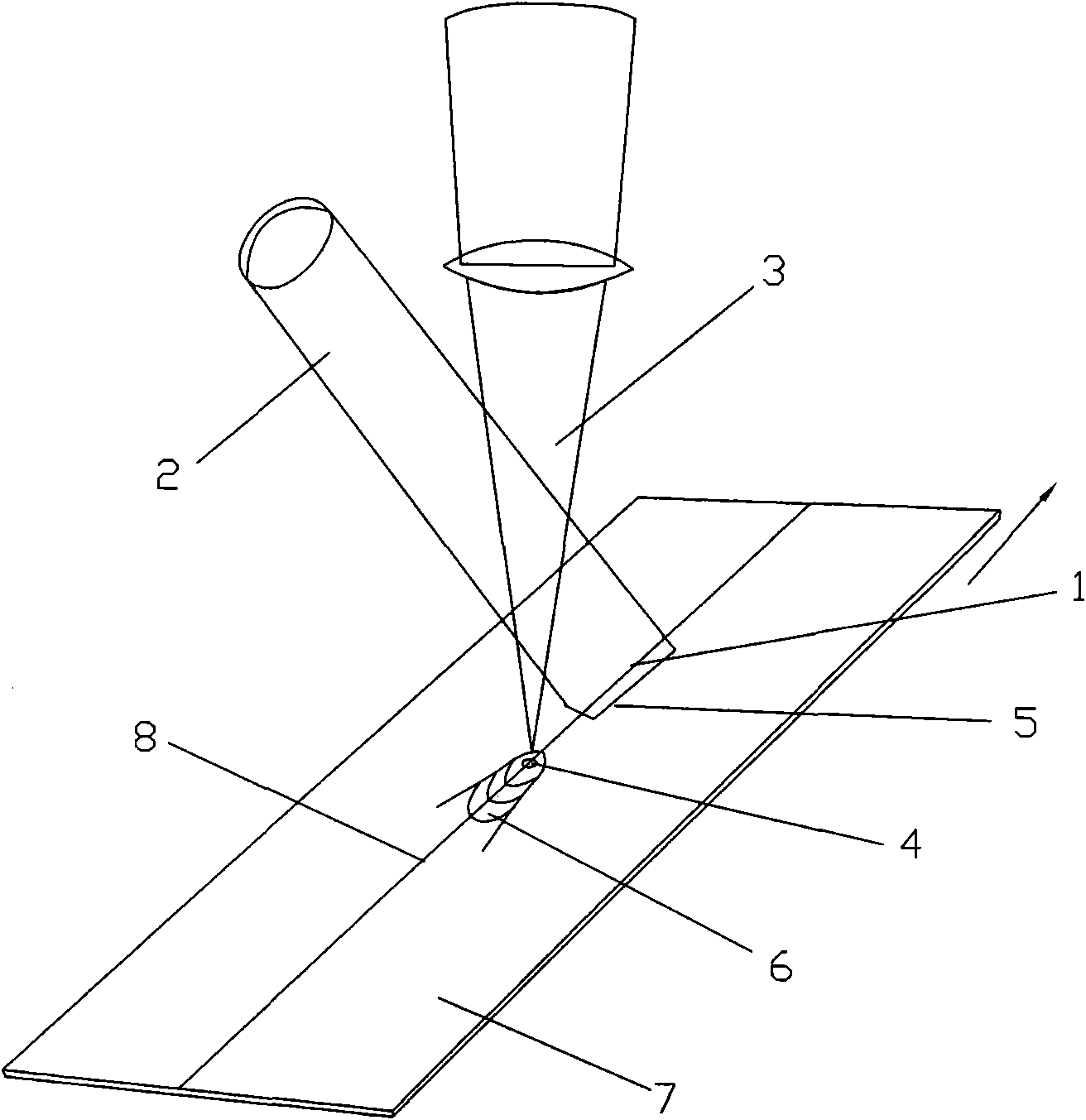

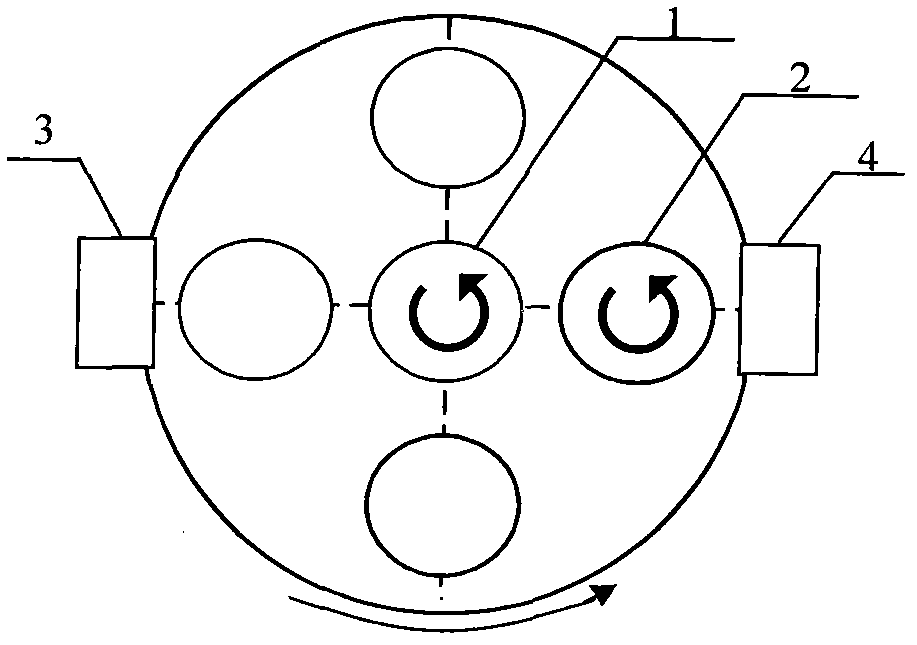

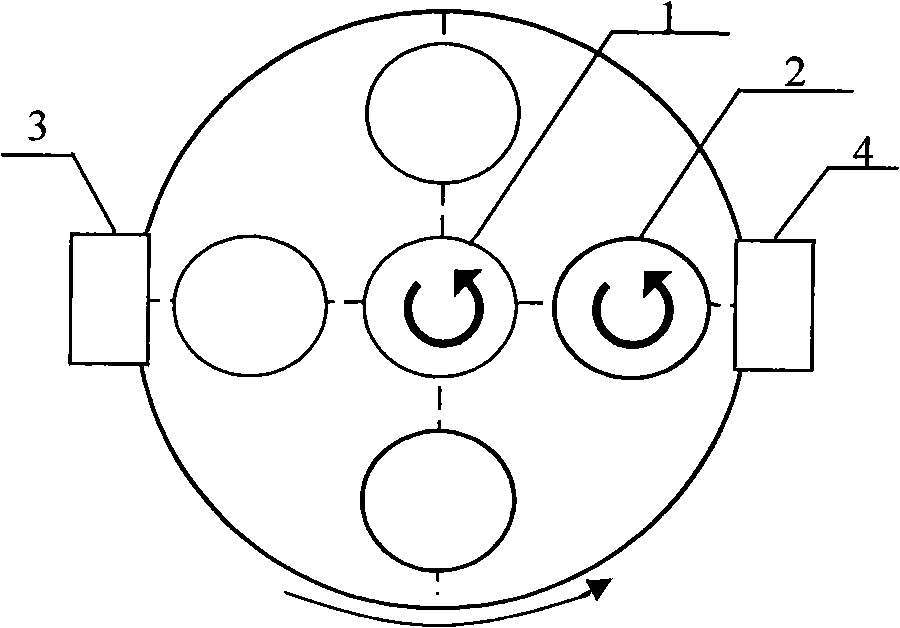

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

TiAlN/TiAlCN multilayer coating of substrate surface and preparing method thereof

ActiveCN102011090AMitigate defectsAlleviate dislocationVacuum evaporation coatingSputtering coatingSputteringHardness

The present invention discloses a TiAlN / TiAlCN multilayer coating of substrate surface and preparing method thereof, wherein a transitional layer is between a substrate and a TiAlN / TiAlCN multilayer coating; the multilayer coating is formed by alternating periodic arrangement of TiAlN films and TiAlCN films; in a period, the thickness sum of the TiAlN films and the TiAlCN films is 1-20 nano; the percentage by weight of C atom in the TiAlCN films is 0.1-5%. The multilayer coating of the present invention has the advantages of high hardness, low internal stress and high tenacity; the cutting efficiency and corrosion resistance of the substrate can be improved, and the service life of the substrate can be prolonged. In the present invention, the multilayer coating is deposited by high power pulse magnetron sputtering technique; the problems that cathode arc ion plating and depositing speed is too fast to prepare a nano epitaxial film and that target poisoning is caused during the procedure for preparing films by DC magnetron sputtering are solved; the nano modulation period is controlled via adjusting the autorotation and revolution speeds of the substrate and adjusting the quantity of targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com