Compound welding method by using semiconductor laser and CO2 laser

A hybrid welding and laser welding technology, applied in the field of laser applications, can solve the problems of not being able to adapt to high-speed, high-quality modern production, difficulty in obtaining large penetration depth, hardenable structure of joints, etc., and achieve changes in thermal conductivity anisotropy and solidification Shrinkage, reducing welding defects, reducing the effect of hardened structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

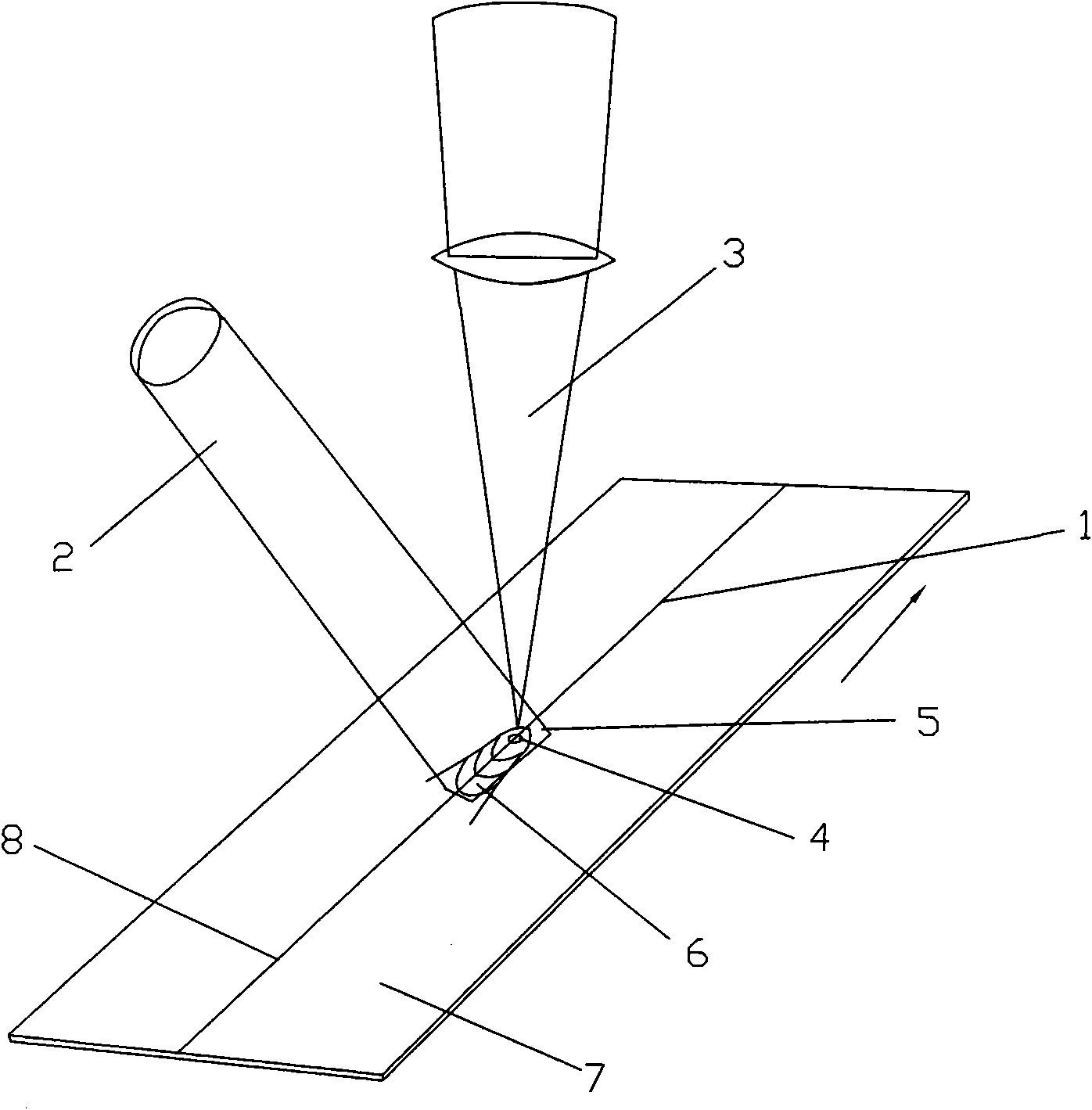

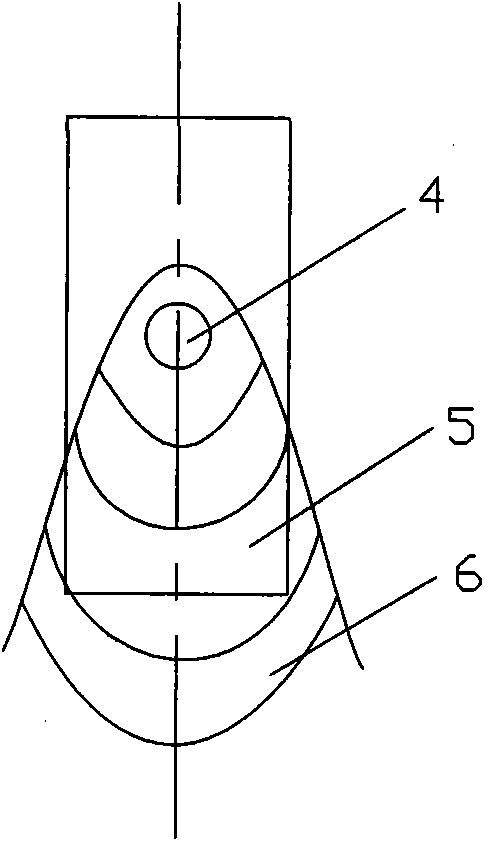

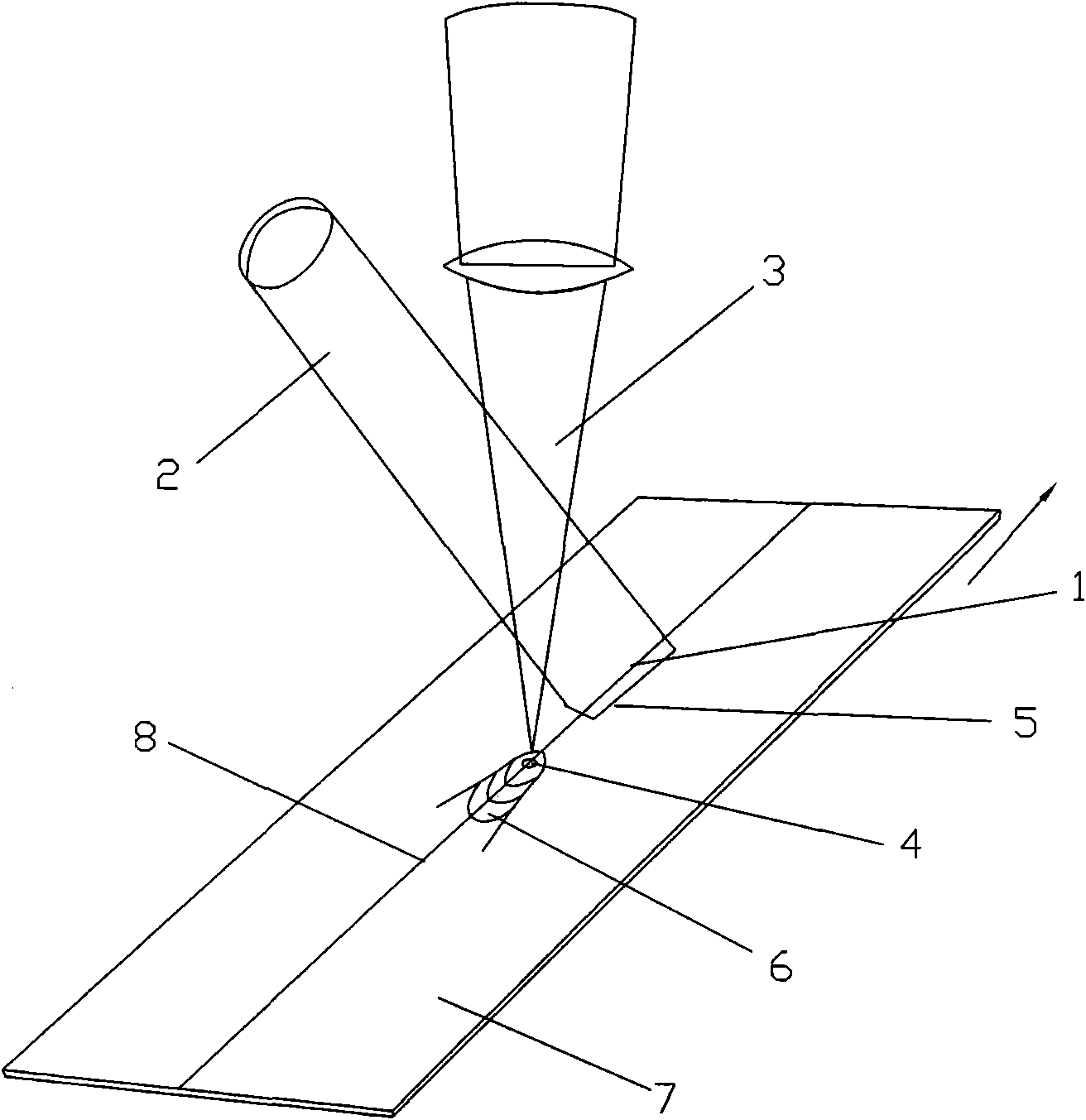

[0028] see figure 1 , figure 2 , which shows the first embodiment of the present invention, using a semiconductor laser and CO 2 laser, CO 2 The laser is in the normal welding position, the semiconductor laser is on one side of the weld, and the semiconductor laser 2 is focused on the steel plate 7 by CO 2 The molten pool 6 generated by the laser 3, and maintains a synchronized welding speed while CO 2 The laser spot 4 is located within the semiconductor laser spot 5, so that the welding direction is consistent with the slow axis direction of the semiconductor laser; the semiconductor laser is used to preheat the unwelded part 1 of the metal to be welded, and the part to be welded that enters the semiconductor laser spot 5 Heating to 200-400°C while using CO 2 Laser welding; with the movement of the steel plate 7, the CO 2 The welded metal part 8 after laser welding, and then use the semiconductor laser to perform post-weld heat treatment on the welded part 8 of the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com