Patents

Literature

885results about How to "Reduce cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

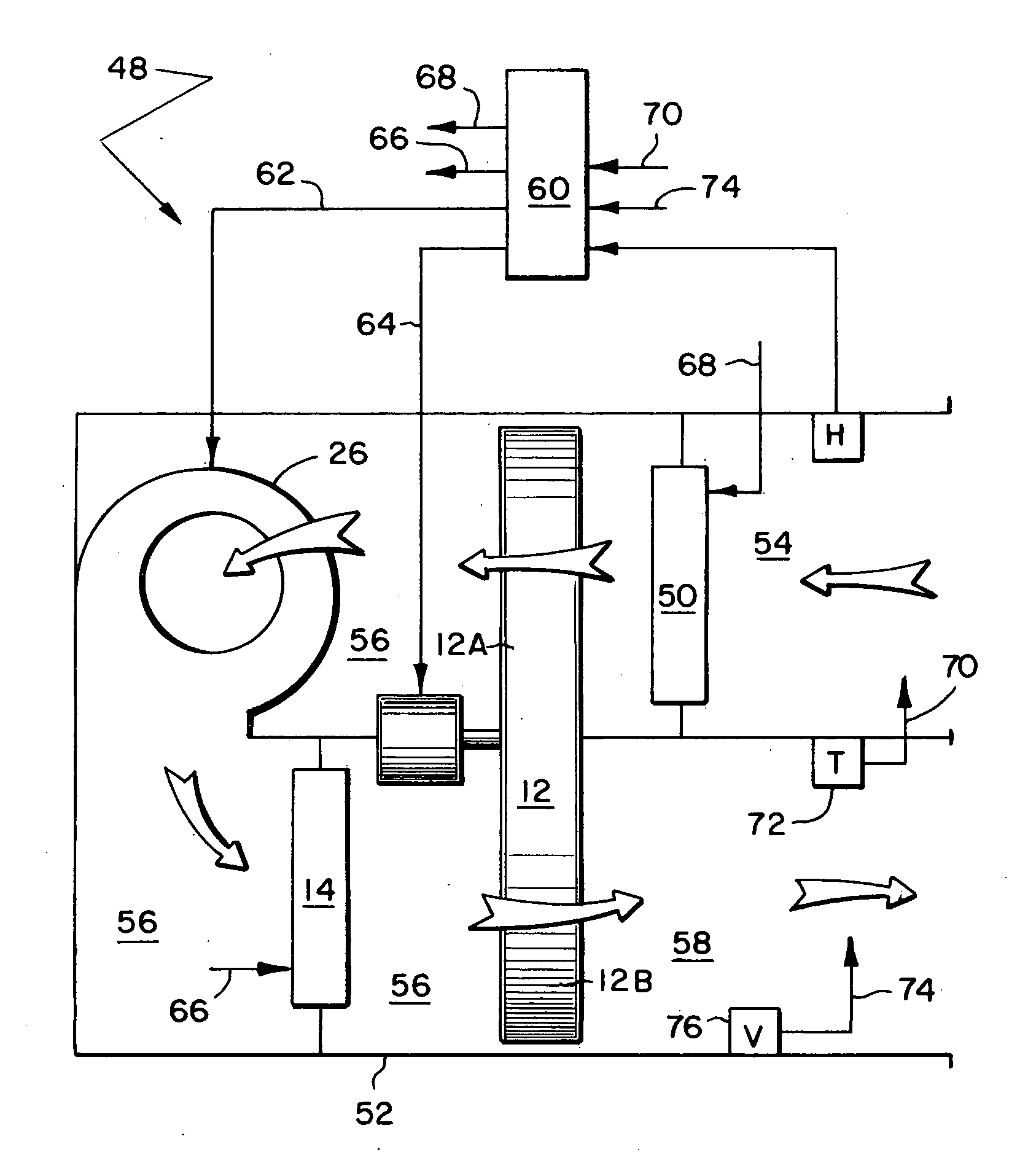

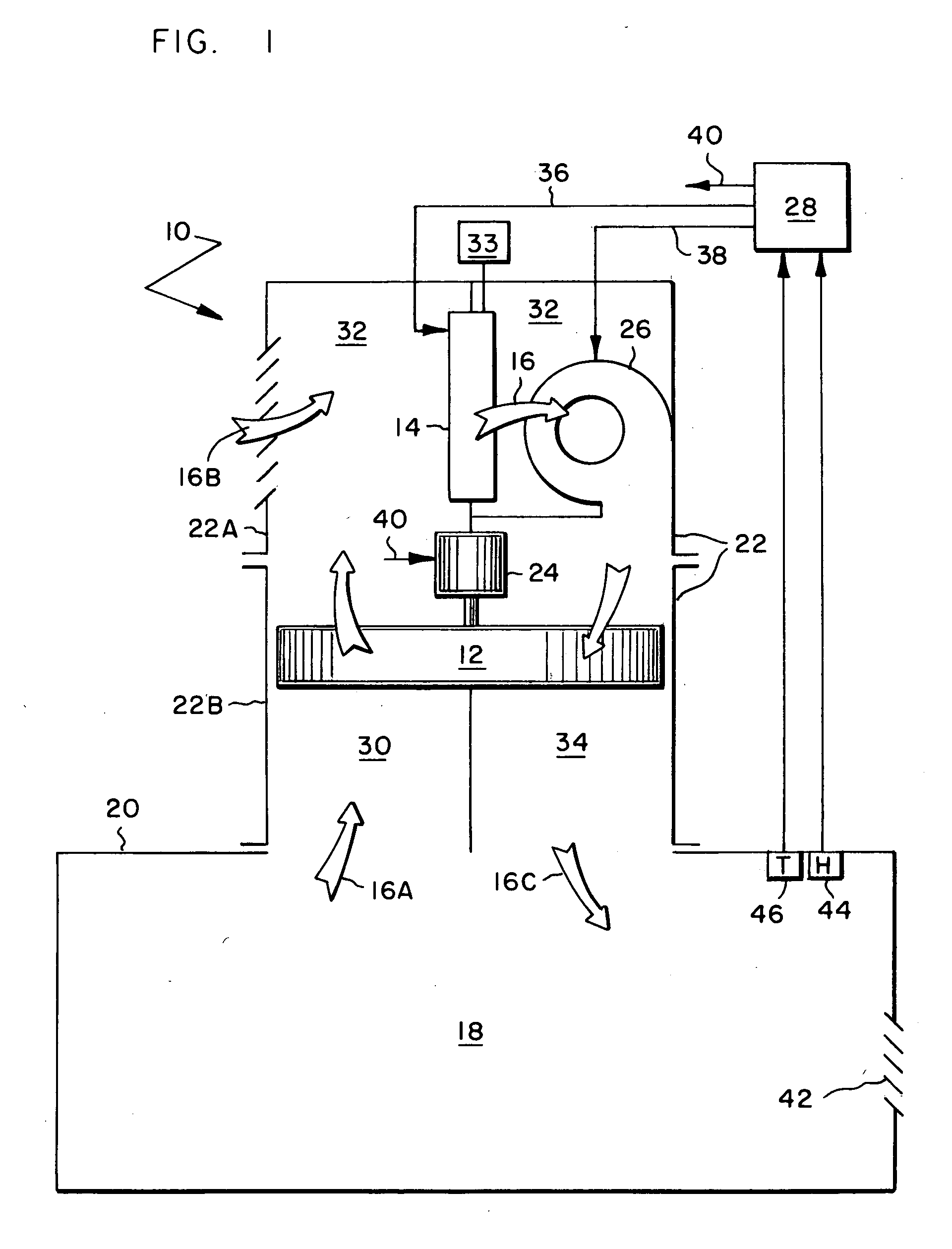

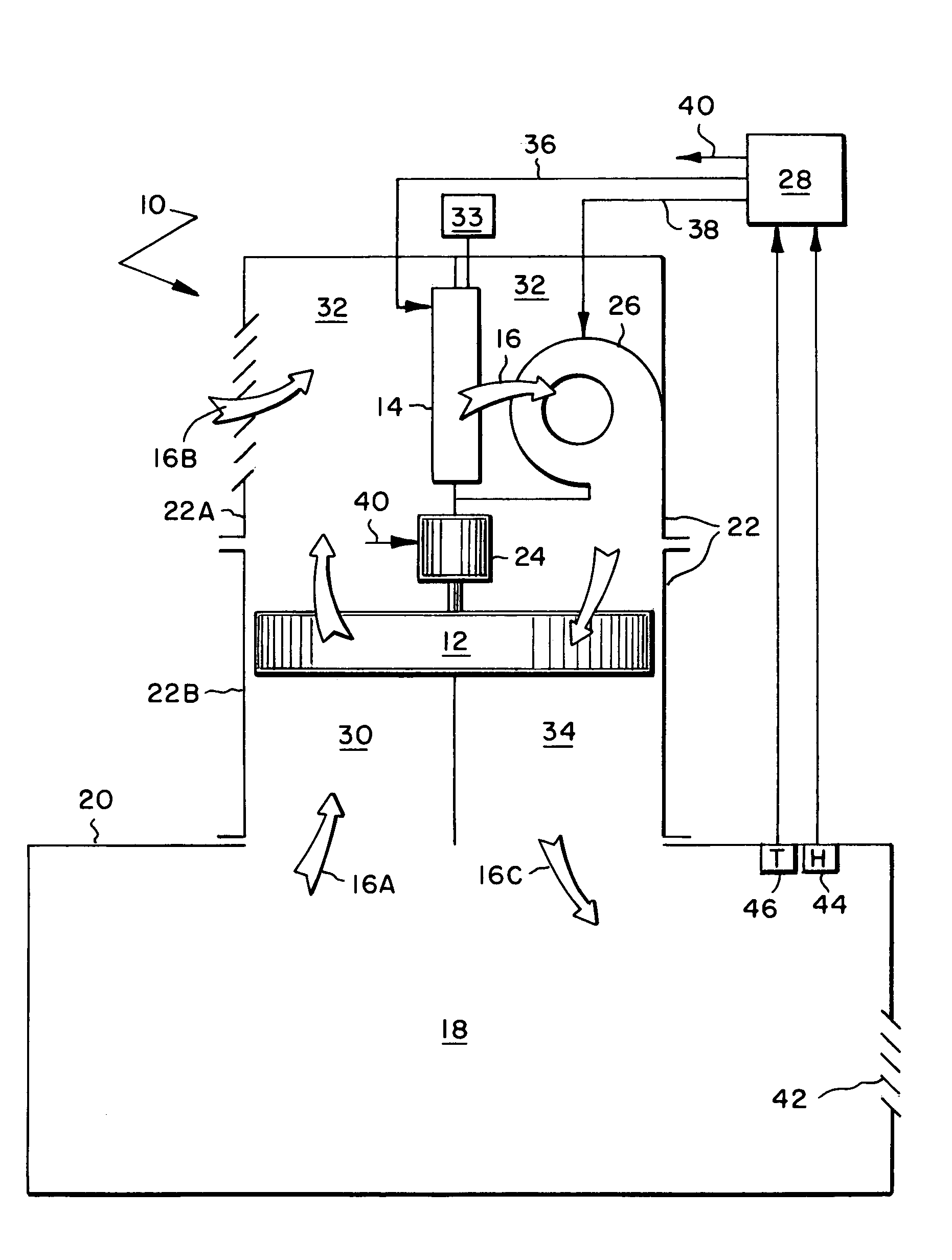

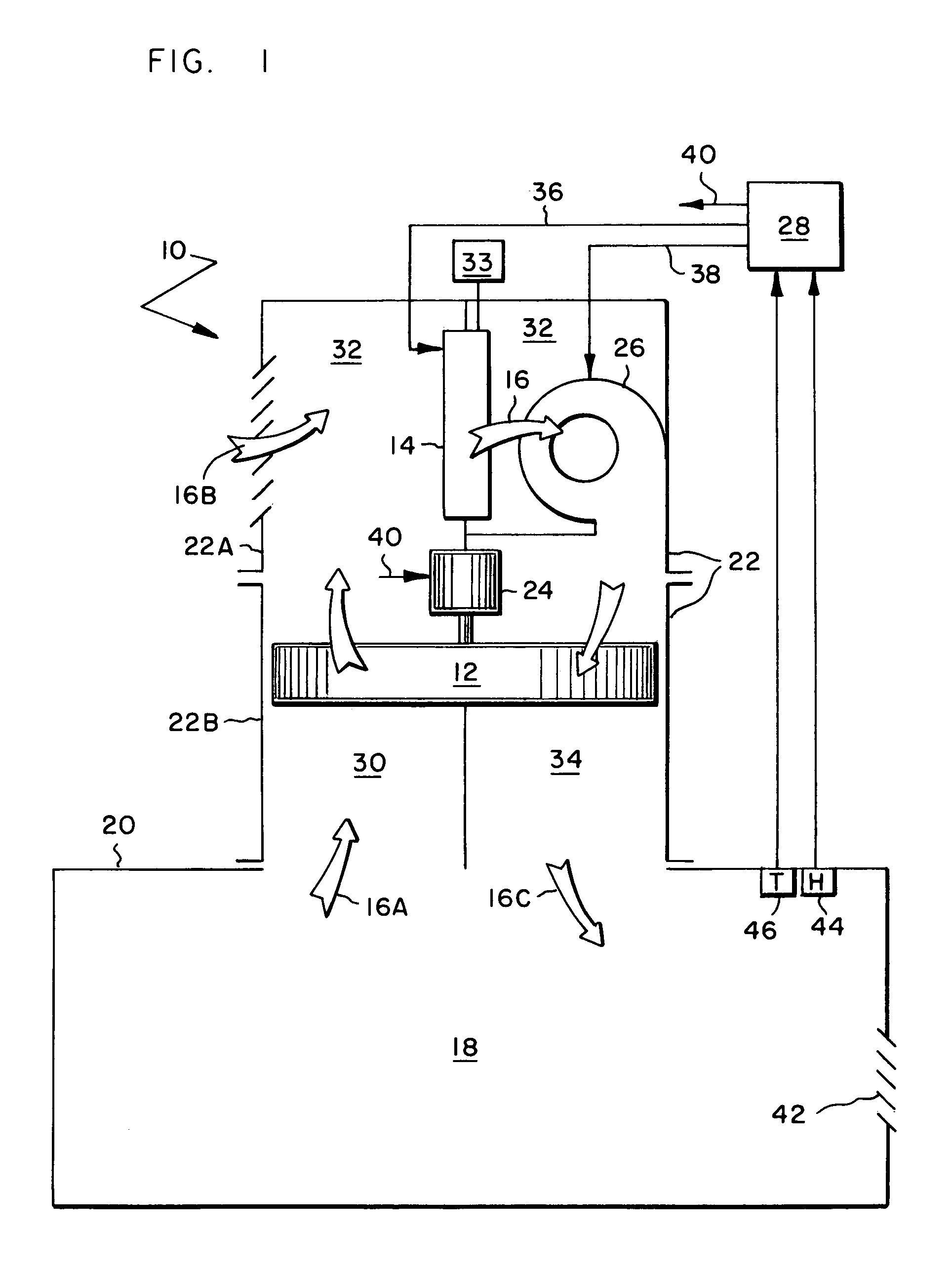

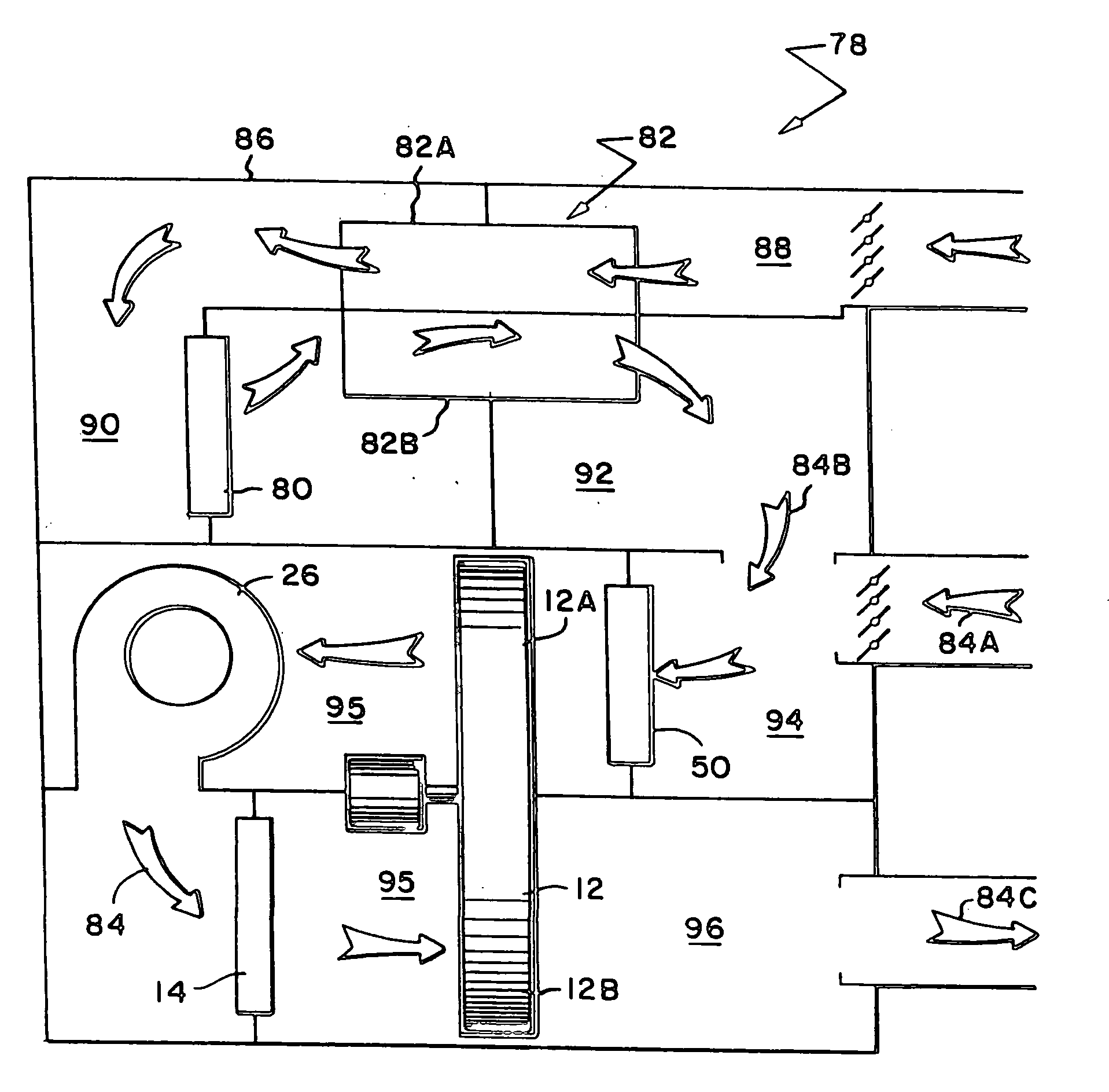

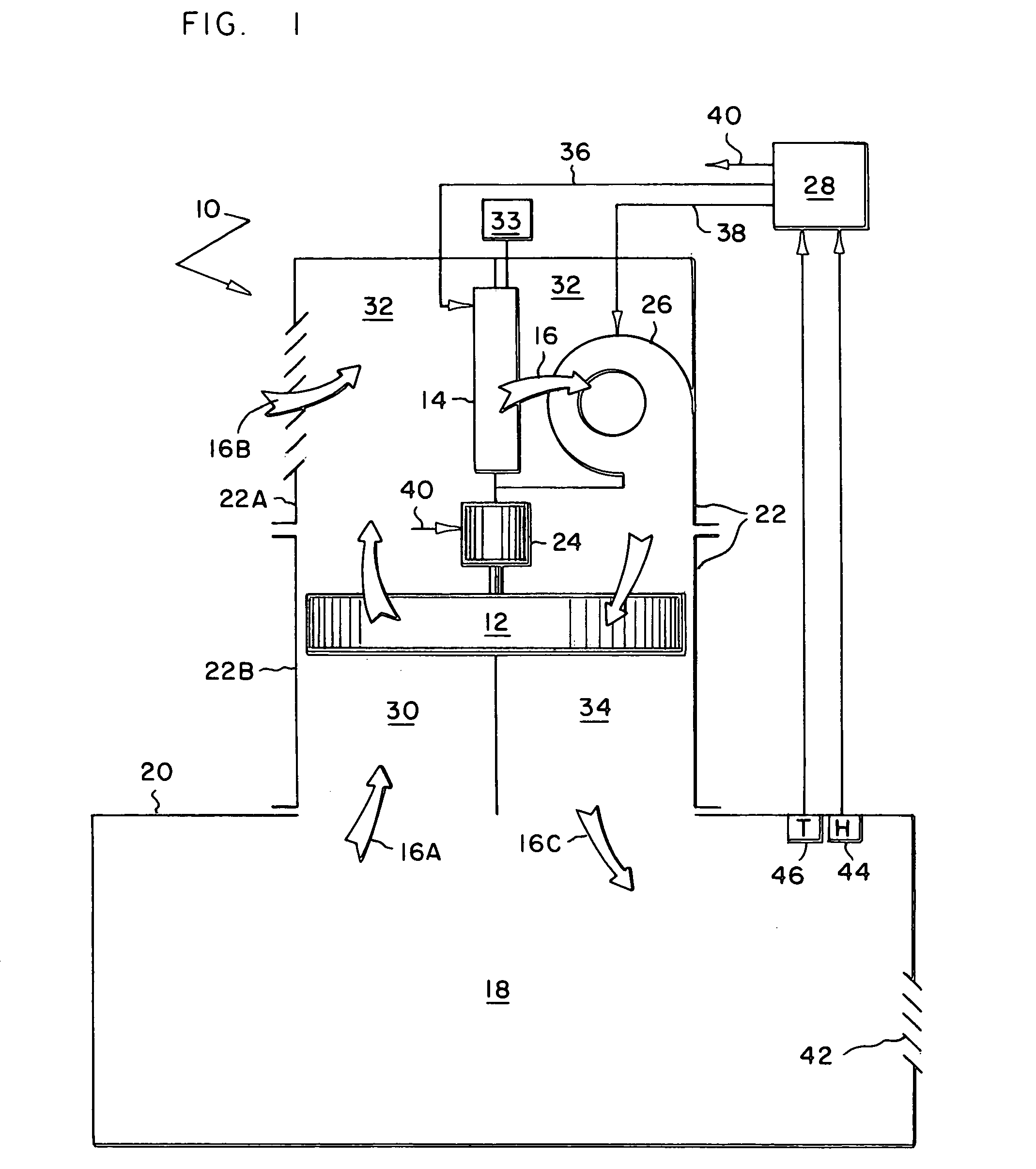

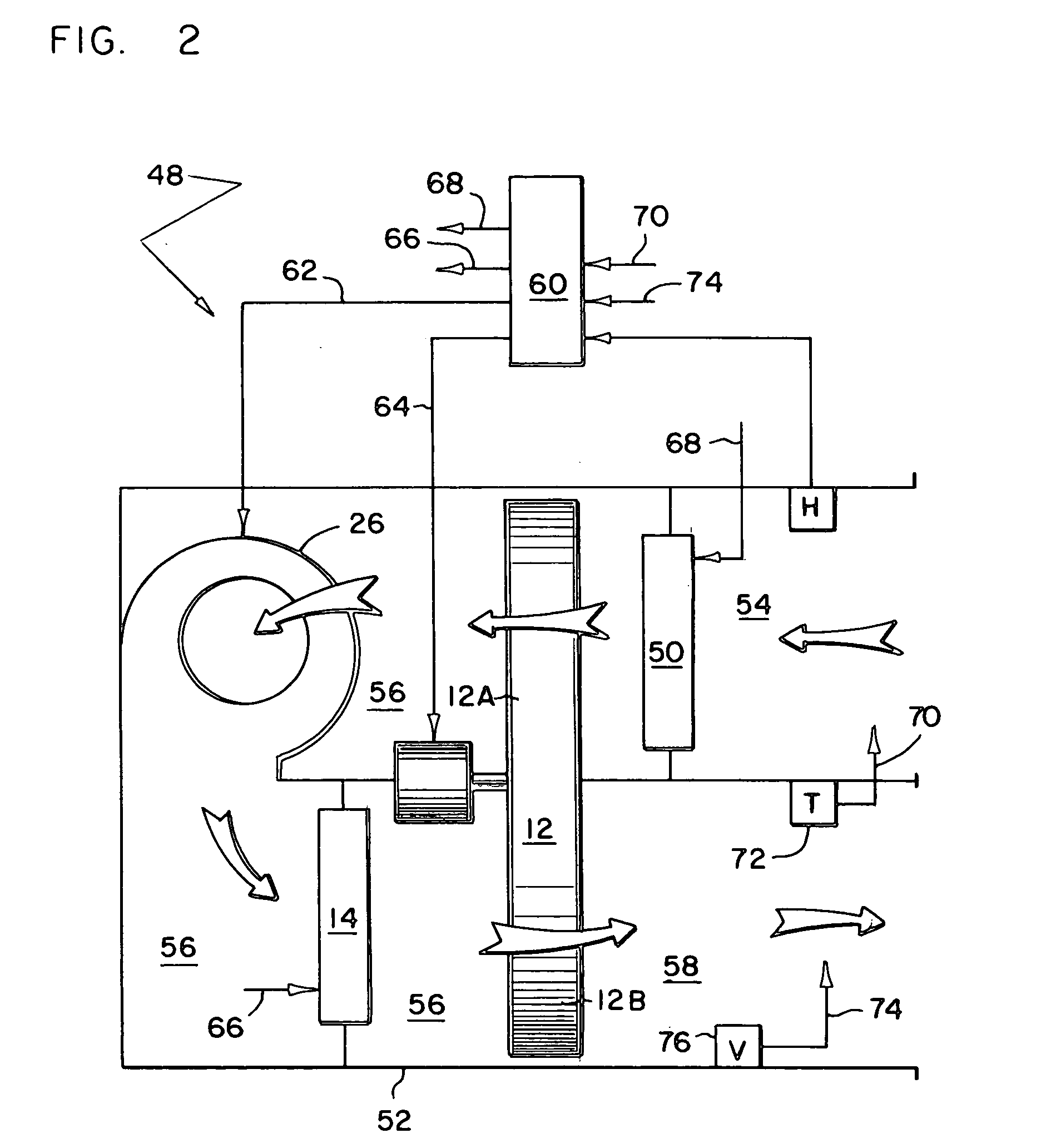

HVAC desiccant wheel system and method

ActiveUS20050262862A1Improve efficiencyReduce humidityMechanical apparatusAir treatment detailsEngineeringHeat exchanger

Owner:TRANE INT INC

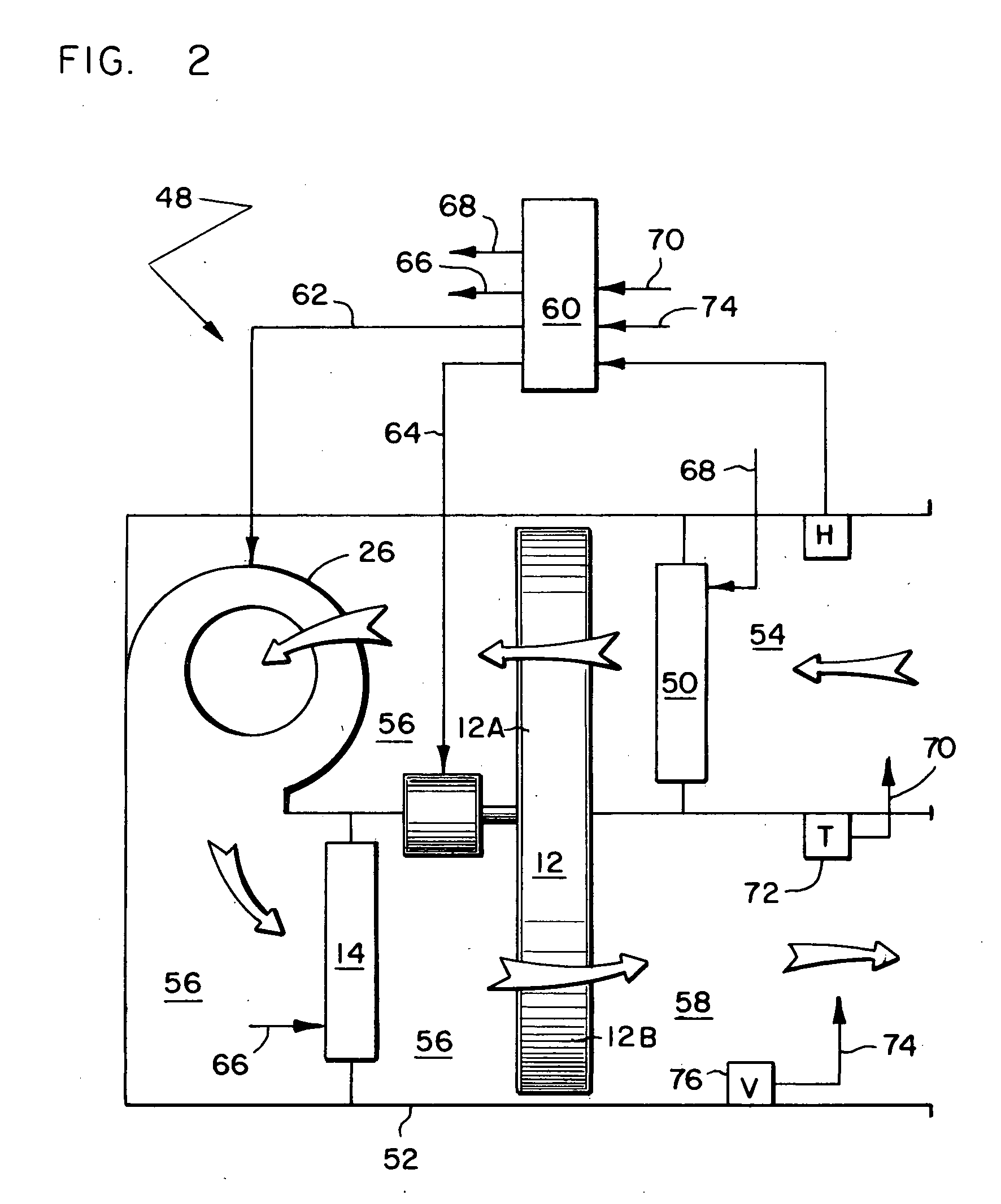

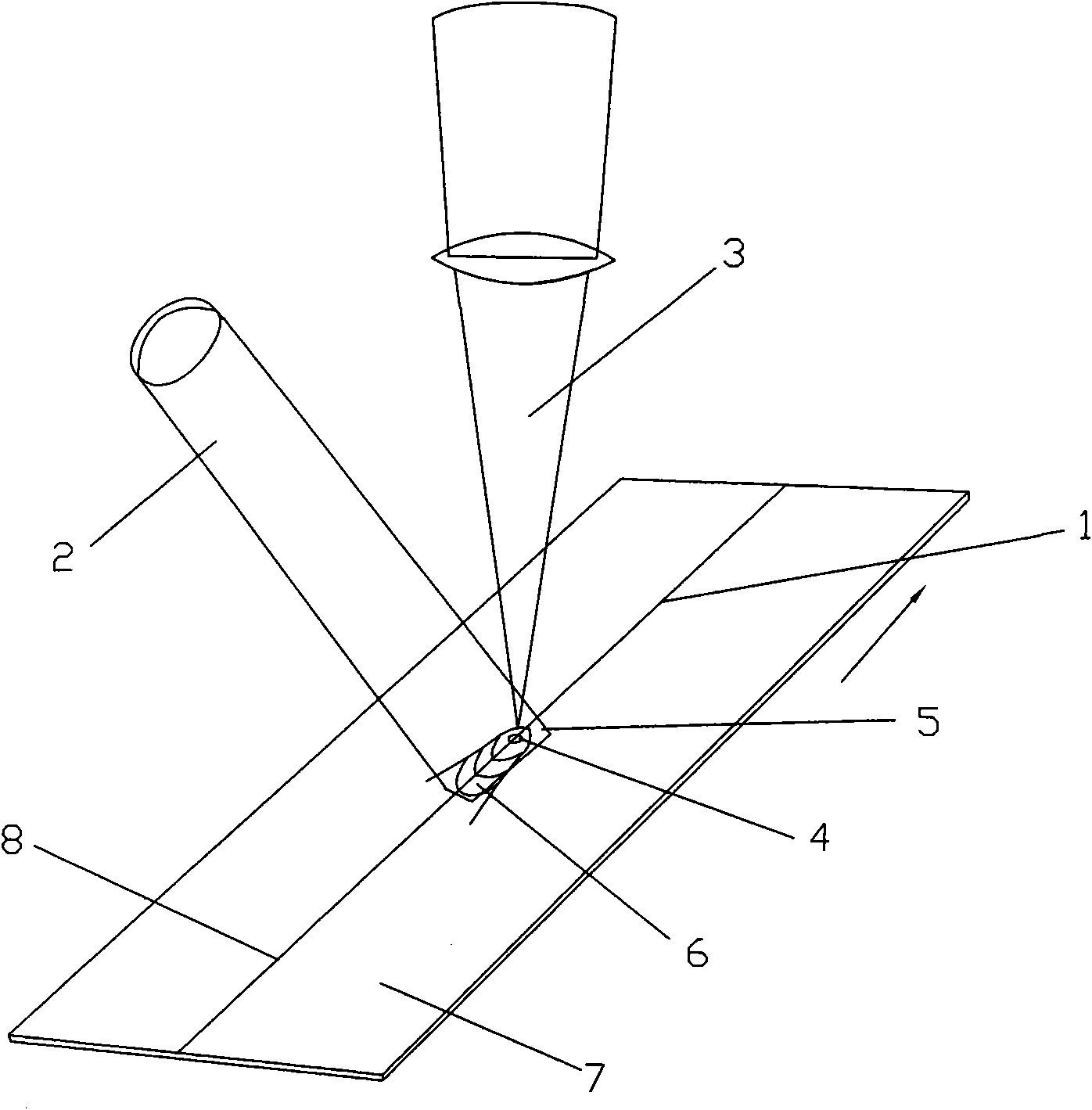

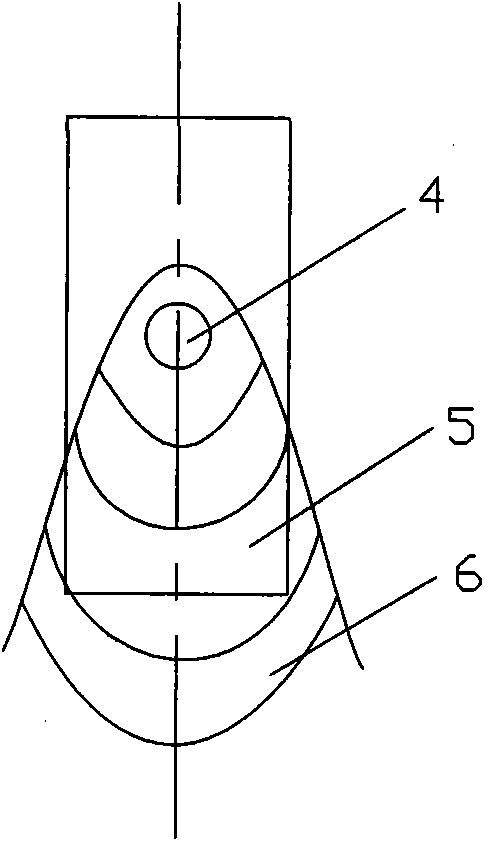

Ultrasound wave auxiliary laser braze (fuse) welding method

InactiveCN101195183AIncrease the amount of weld fillerImproved weld formationSoldering apparatusWelding/soldering/cutting articlesUltrasonic assistedWeld strength

Owner:HARBIN INST OF TECH

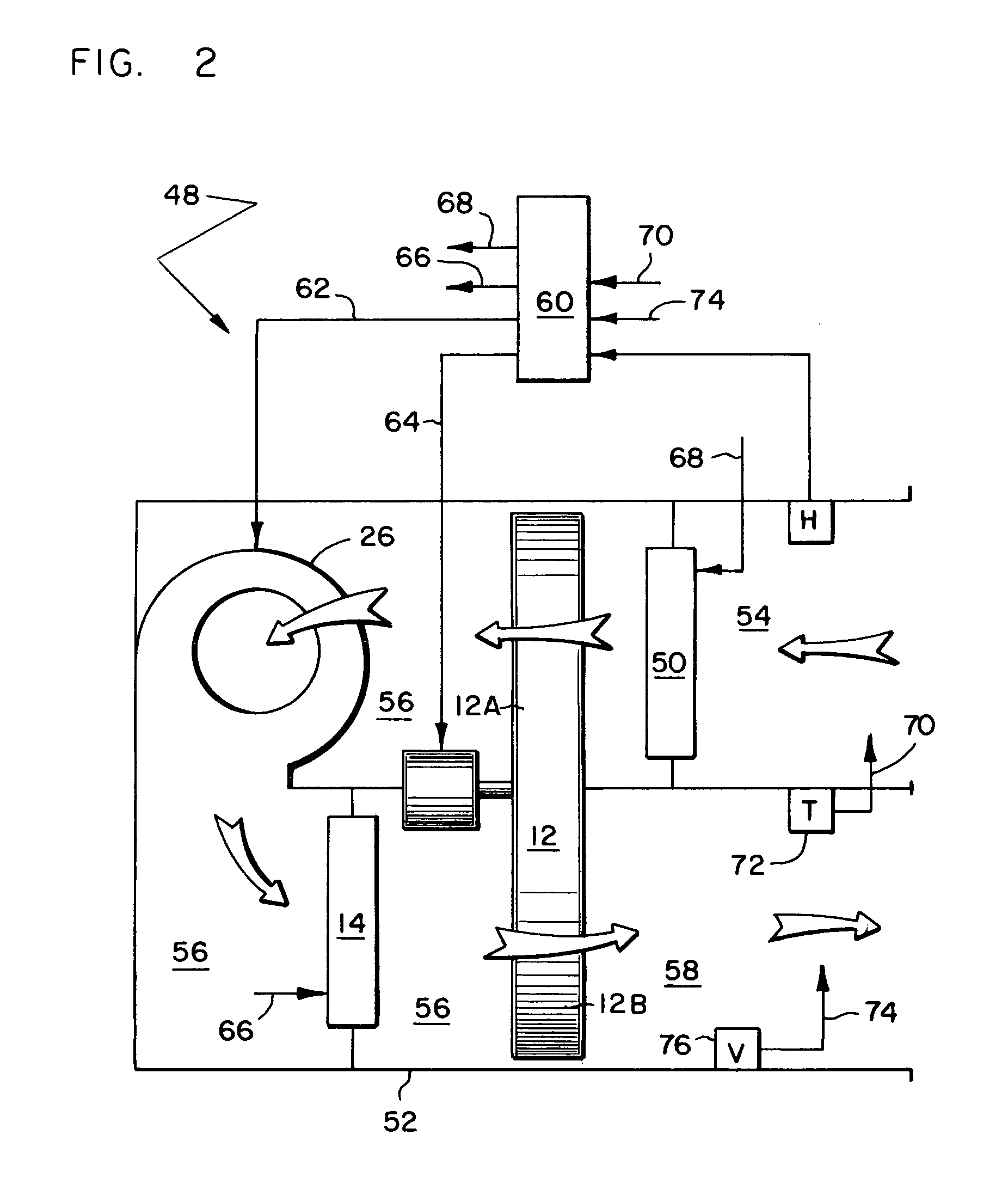

HVAC desiccant wheel system and method

InactiveUS6973795B1Improve efficiencyReduce humidityMechanical apparatusAir treatment detailsHeat exchangerAirflow

Owner:TRANE INT INC

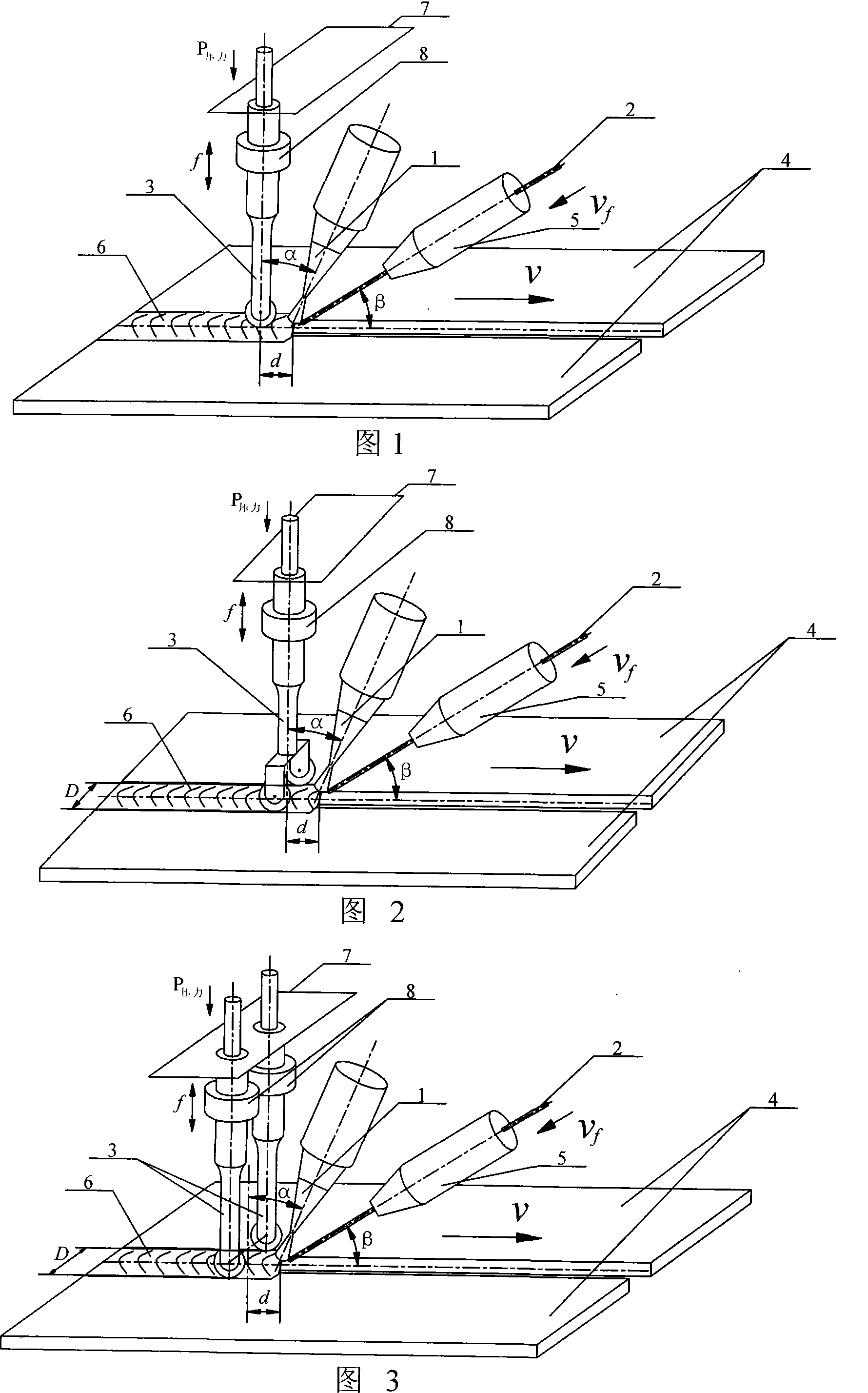

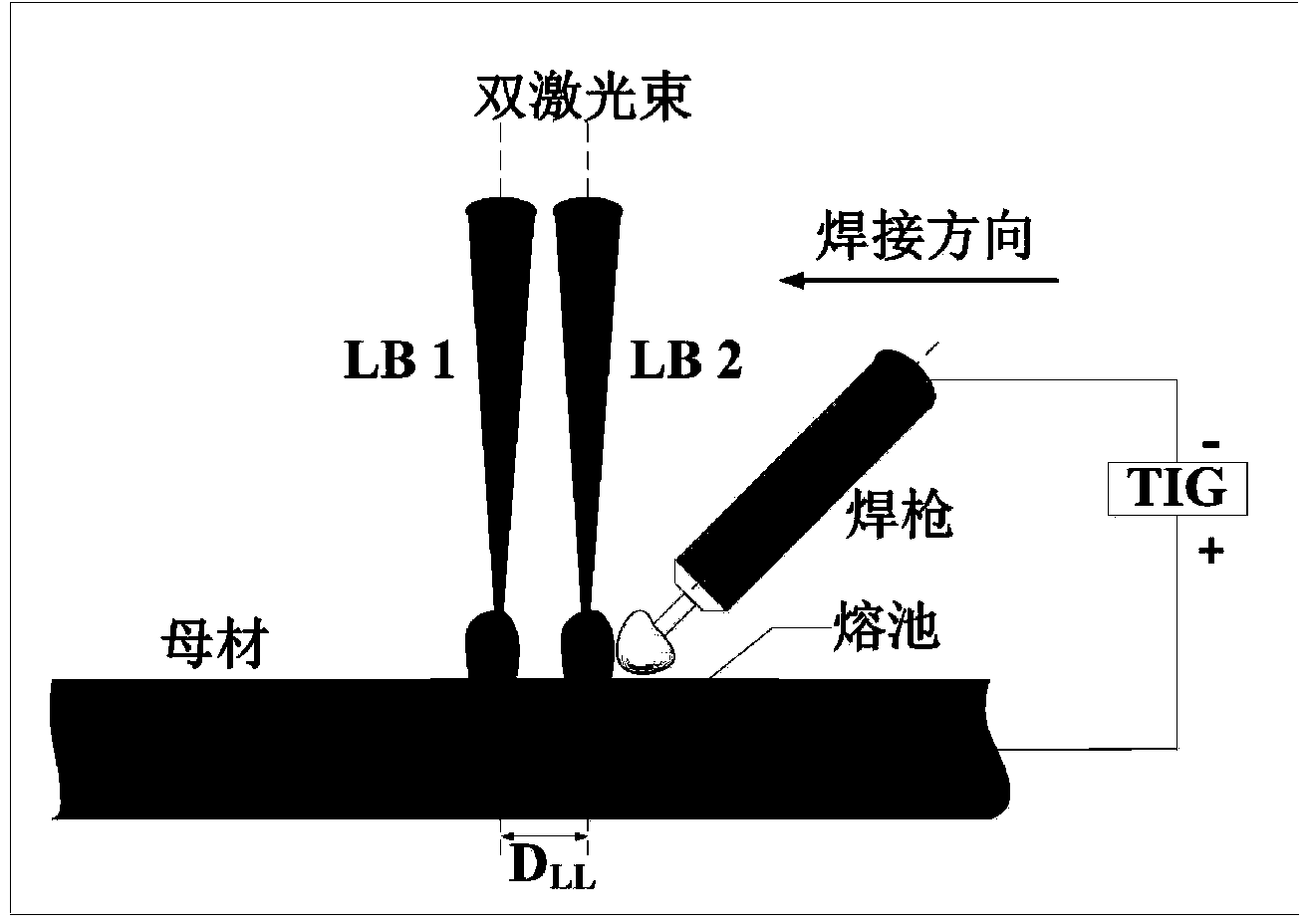

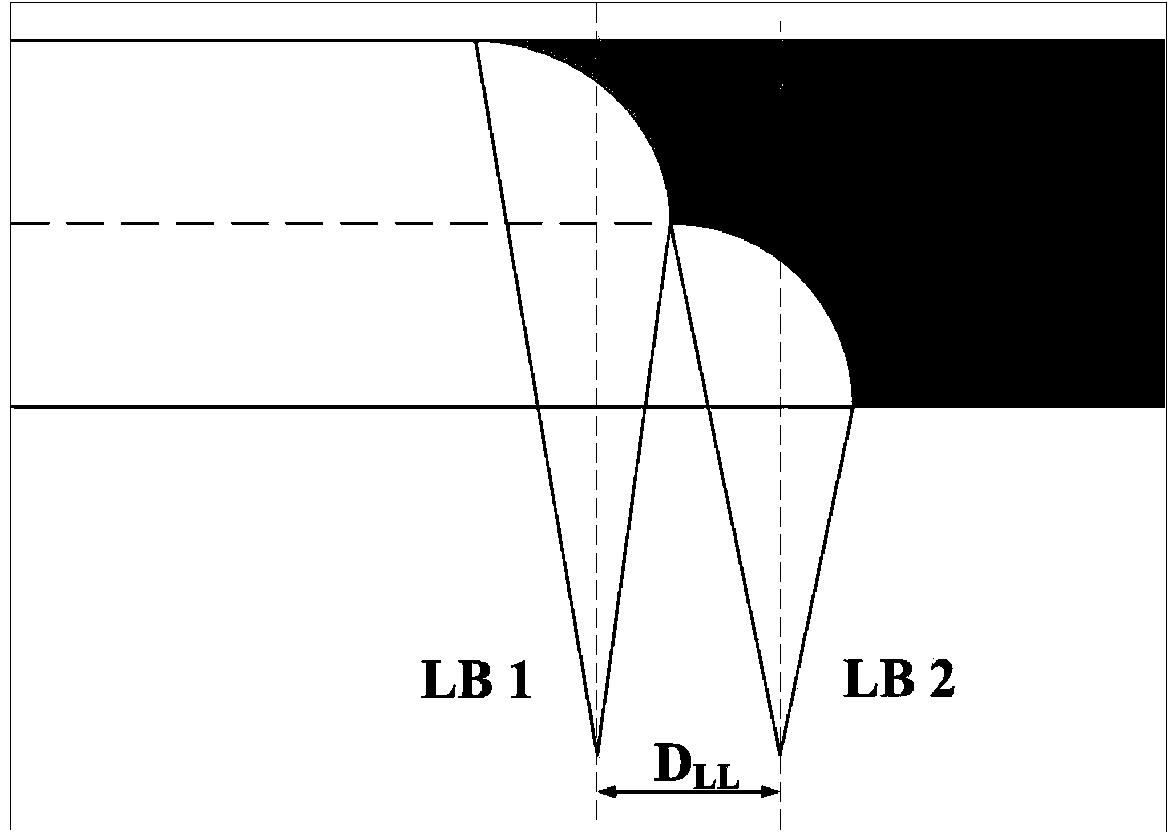

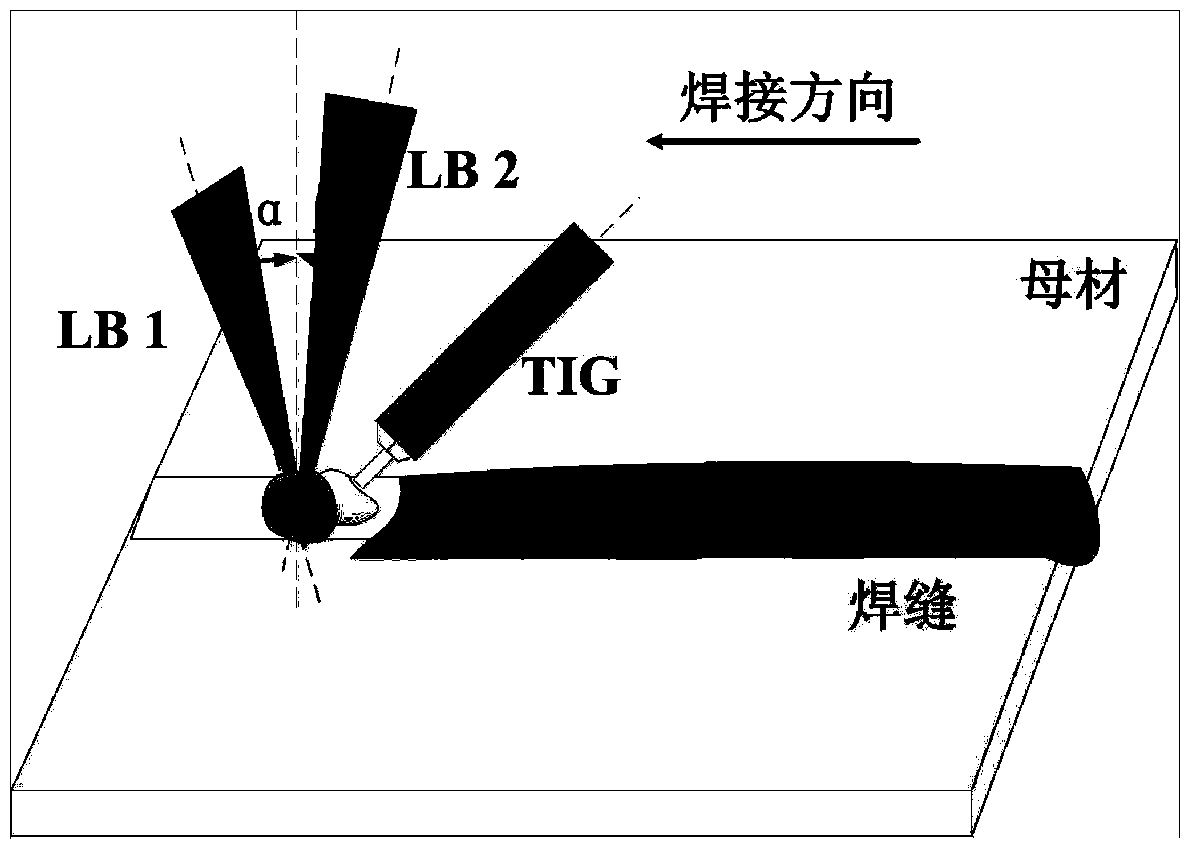

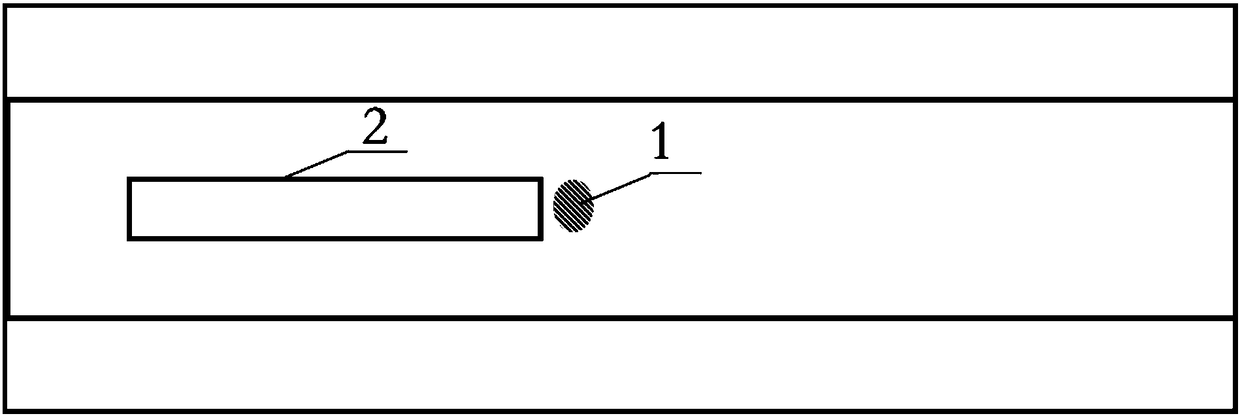

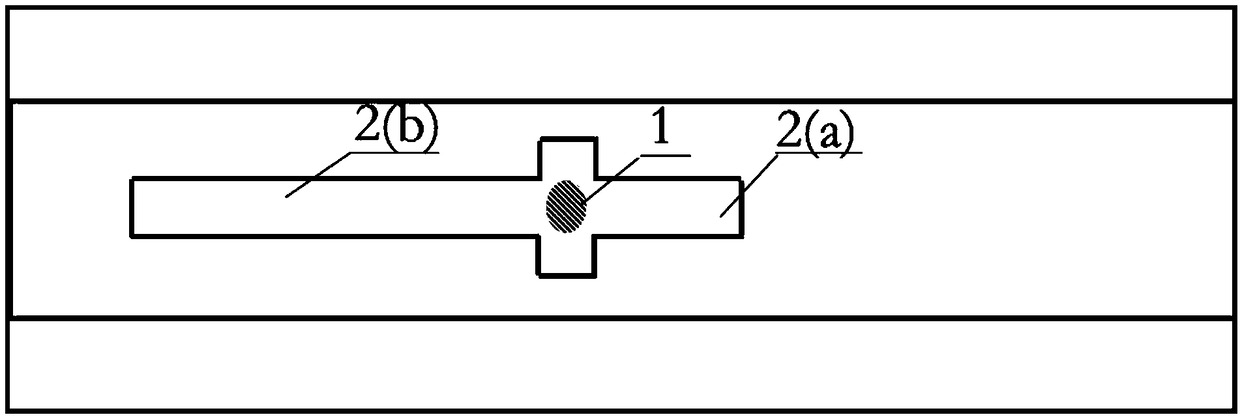

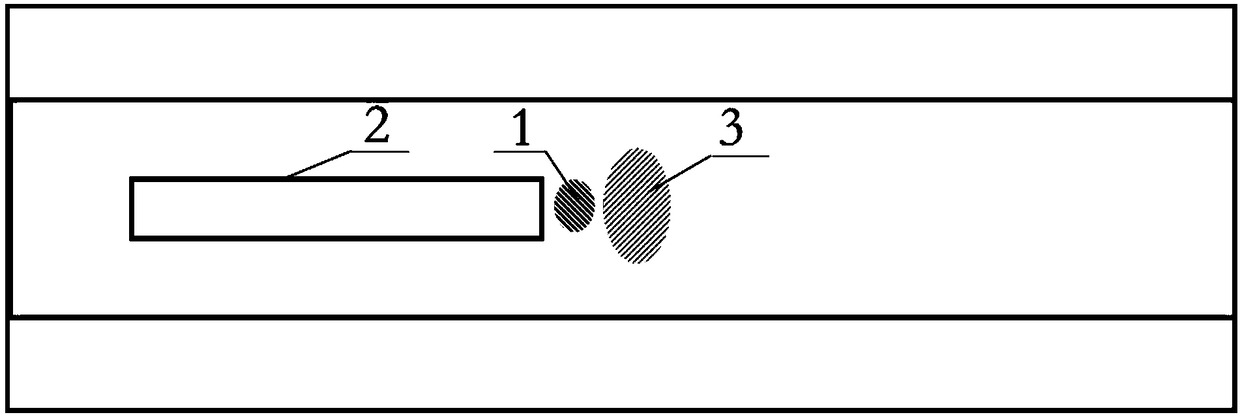

Method for removing aluminum alloy laser welding air holes

InactiveCN103862178ARealize the coupling effectSmall sizeWelding/soldering/cutting articlesLaser beam welding apparatusLaserWelding process

The invention relates to a method for removing aluminum alloy laser welding air holes. The method solves the problem that air hole defects are easily generated in the laser welding and laser-TIG hybrid welding process of aluminum alloy. The method comprises the steps that in the bifocal laser-TIG hybrid welding process of the aluminum alloy, namely, in the aluminum alloy welding process, two beams of lasers (LB1 and LB2) and a TIG electric arc are adopted to jointly act on a welded area, a welding joint bears the combined action of the three heat sources at the same time, and the action modes of the two lasers can be divided into three kinds which comprise a serial distribution mode in the welding direction, a parallel distribution mode perpendicular to the direction of the welding joint and a crossing distribution mode between the serial distribution mode and the parallel distribution mode. According to the welding method, the air hole rate is zero, and air hole defects of the aluminum alloy laser welding are overcome. The method is applied to the field of aluminum alloy laser welding.

Owner:HARBIN INST OF TECH

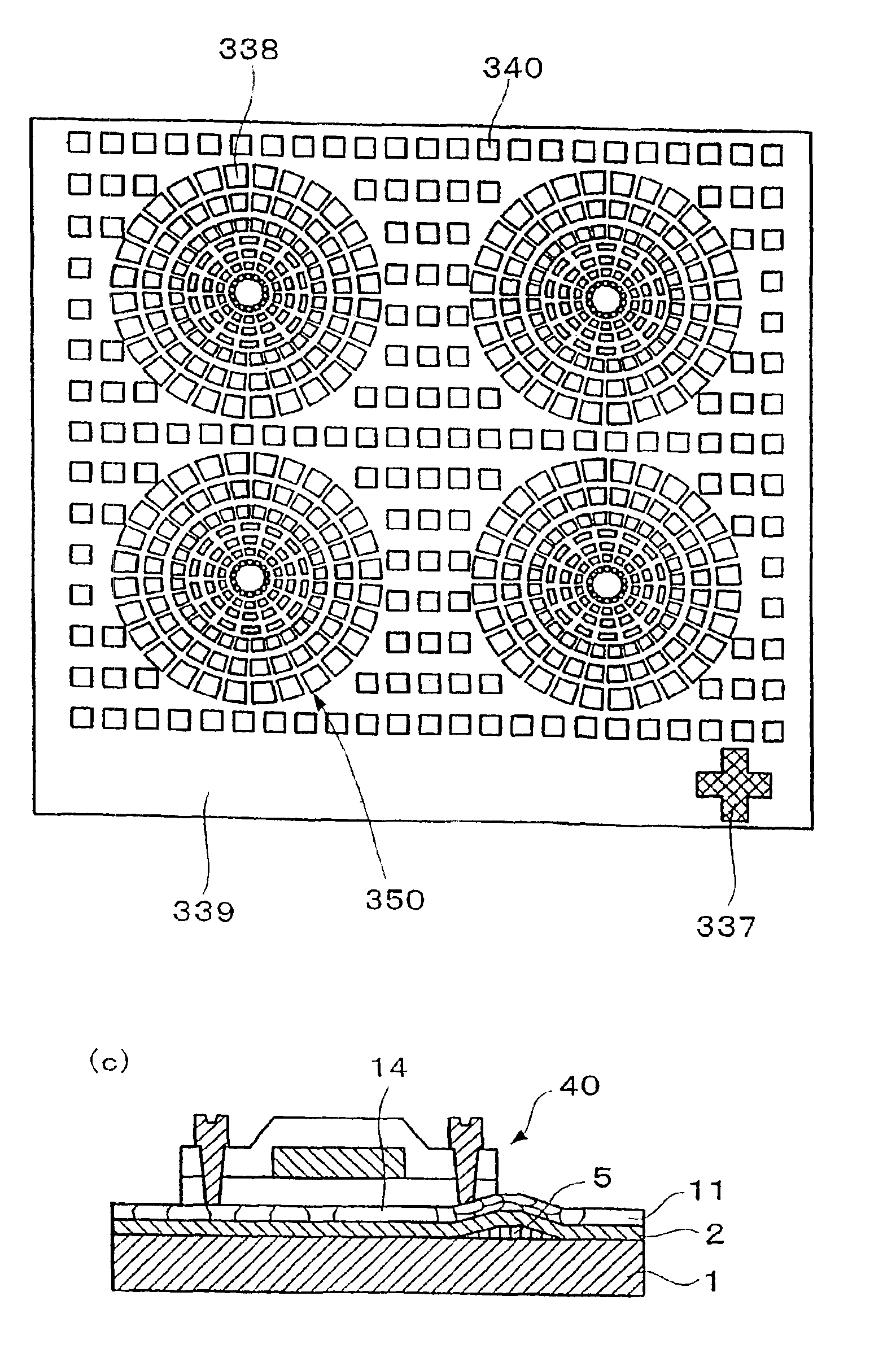

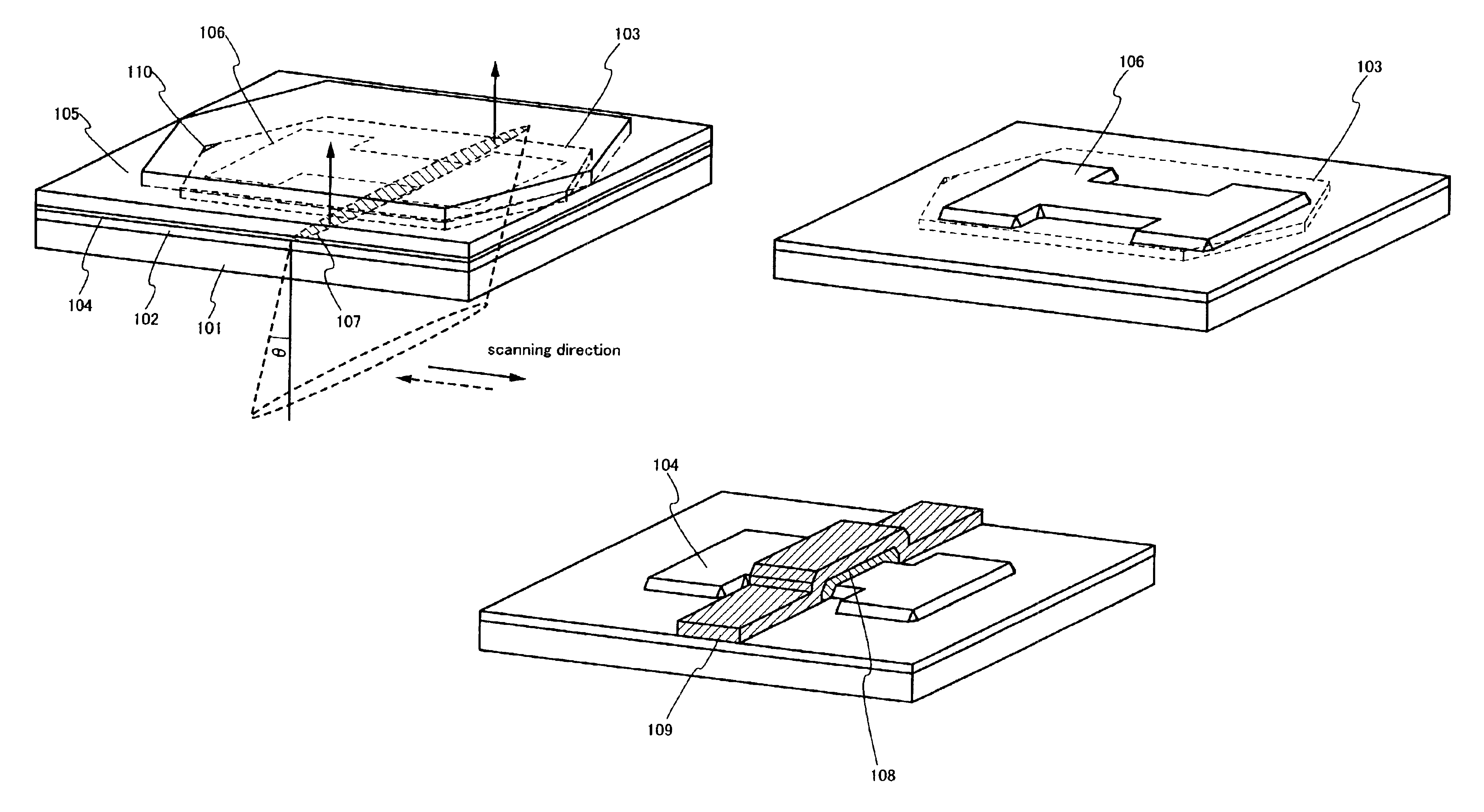

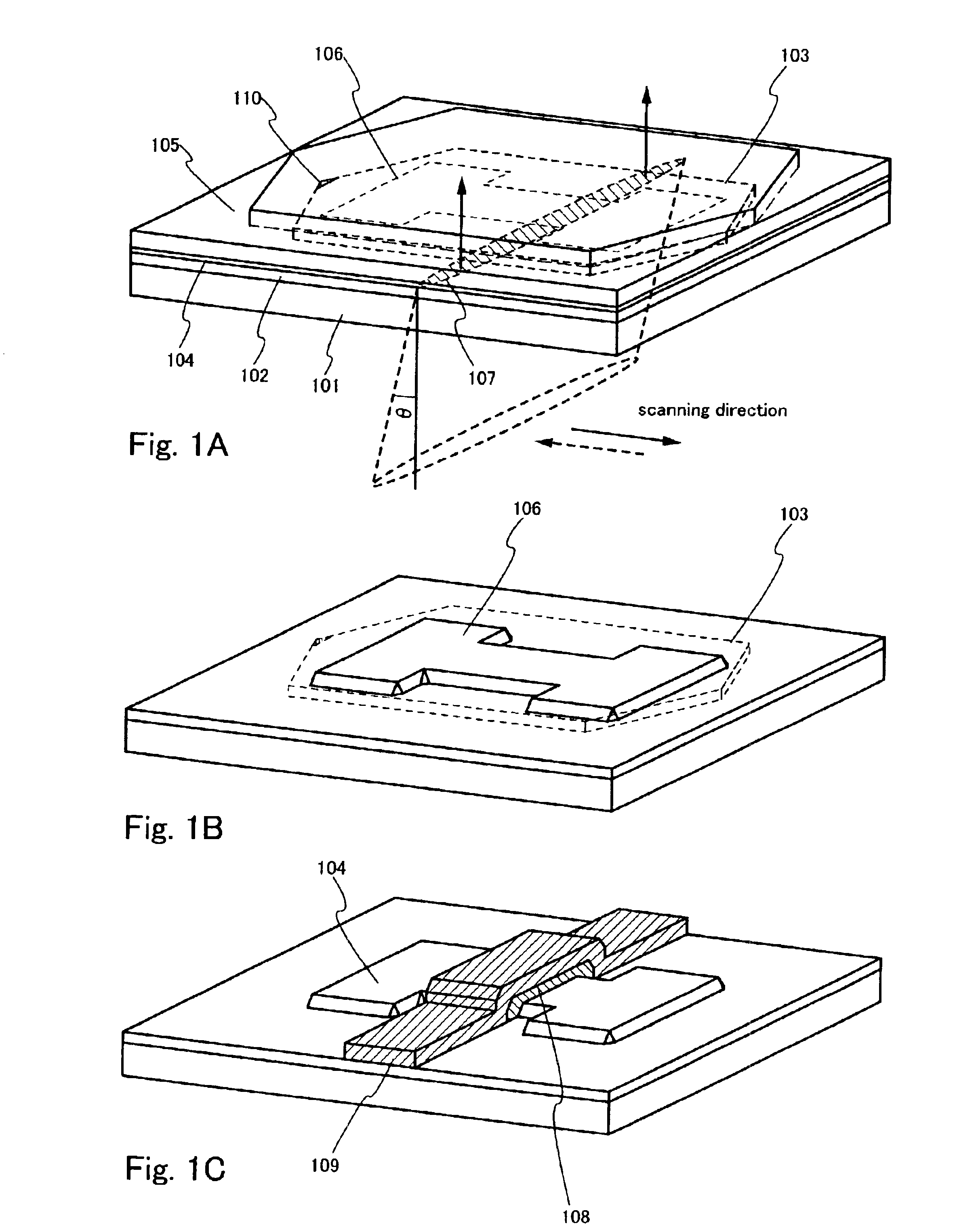

Semiconductor device, liquid crystal display device, EL display device, method for fabricating semiconductor thin film, and method for manufacturing the semiconductor device

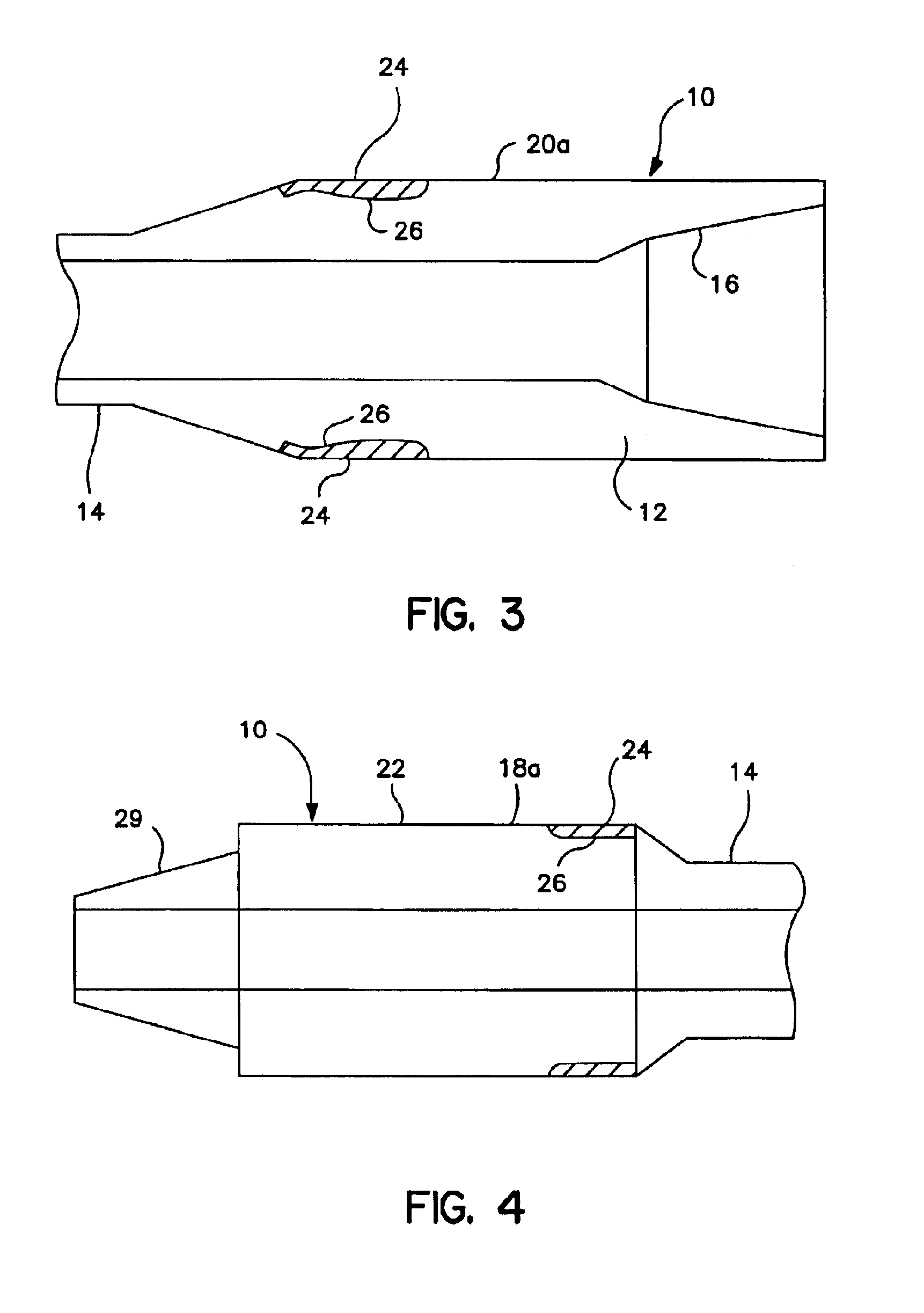

This invention concerns with a semiconductor device which is characterized in that the device is provided with a thin film transistor 40 having a polycrystalline semiconductor layer 11, the semiconductor layer 11 including a channel area 22, highly doped drain areas 24, 17 positioned on both sides of the channel area 22 and LDD areas 18a, 18b positioned between the channel area 22 and the highly doped drain areas 24, 17 and lower in dopant density than the highly doped drain areas 24, 17, wherein any diameter of the crystal 14 at least partly existing in the LDD area 18b is larger than the size of other crystals 15.

Owner:JOLED INC

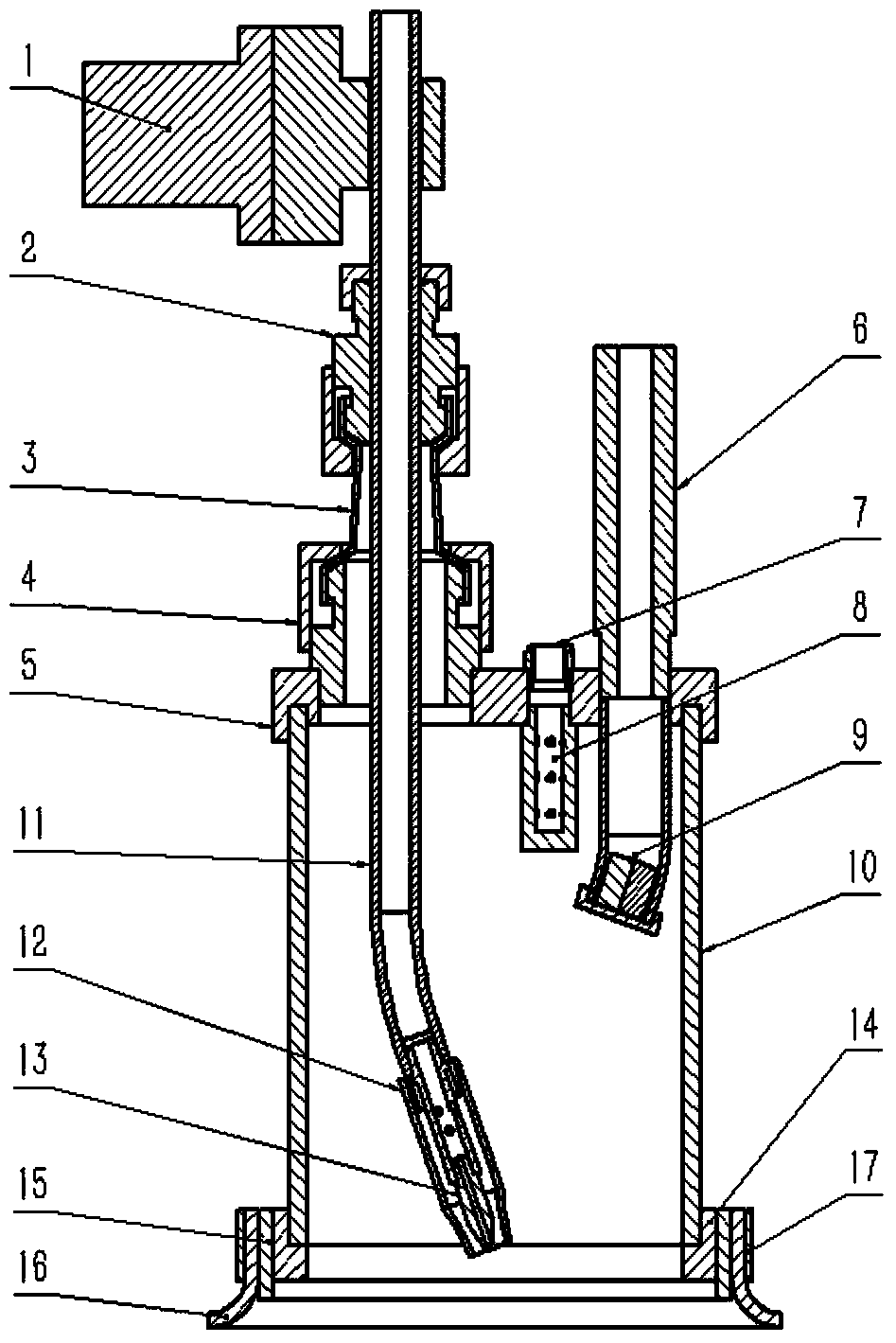

Special portable miniature drainage cover for automatic underwater local dry-method welding

InactiveCN103433606ARealize free adjustmentAvoid unfusedElectrode supporting devicesWelding accessoriesEngineeringCopper

The invention provides a special portable miniature drainage cover for automatic underwater local dry-method welding. A drainage cover body of the drainage cover comprises an upper end cover, an organic glass cover and a lower end cover. A clamping rod, an air inlet quick plug connector, a lower locking sleeve, a cooling air chamber and an underwater camera component are fixed to the upper side of the upper end cover and the lower side of the upper end cover through threaded connection respectively, and the upper end cover and lower end cover are connected with the organic glass cover through threads. A welding oscillator is clamped on the upper portion of a copper welding torch of a welding gun. According to the structure of a drainage sealing device, drainage felt and a felt skirt are arranged on the periphery of the lower end cover, and the drainage felt and the felt skirt are fastened on the lower end cover through hose clamps; the copper welding torch of the welding gun is fastened through an upper locking sleeve and the lower locking sleeve, the welding gun is inserted into the organic glass cover, and an elastic rubber leather sheath is arranged between the upper locking sleeve and the lower locking sleeve. The special portable miniature drainage cover for automatic underwater local dry-method welding has the advantages of being simple in structure, exquisite, convenient and fast to use, low in cost, obvious in drainage effect, and stable and reliable in welding process. Moreover, a connector with the quality of on-land welding is formed, the welding efficiency is improved and the special portable miniature drainage cover is easy to popularize.

Owner:TIANJIN UNIV

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

Method of manufacturing a semiconductor device by crystallization of a semiconductor region by use of a continuous wave laser beam through the substrate

InactiveUS7132375B2Enlarge regionImprove featuresTransistorSolid-state devicesCrystal orientationActive layer

A technique is provided for forming a crystalline semiconductor film whose orientation is uniform by control of crystal orientation and obtaining a crystalline semiconductor film in which concentration of an impurity is reduced. A configuration of the invention is that a first semiconductor region is formed on a substrate having transparent characteristics of a visible light region, a barrier film is formed over the first semiconductor region, a heat retaining film covering a top and side surfaces of the first semiconductor region is formed over the barrier film, the first semiconductor region is crystallized by scanning a continuous wave laser beam from one edge of the first semiconductor region to the other through the substrate, then the heat retaining film and the barrier film are removed and a second semiconductor region is formed as an active layer of TFT by etching the crystallized first semiconductor region. A pattern of the second semiconductor region formed by etching is formed in a manner that a scanning direction of the laser beam and a channel length direction of the TFT are arranged in almost the same direction in order to smooth drift of carriers.

Owner:SEMICON ENERGY LAB CO LTD

Process method for welding aluminum and aluminum alloy material by laser

InactiveCN101850472ASmall sizeEasy to closeGrinding machinesWelding/soldering/cutting articlesOrganic solventHigh energy

The invention relates to laser welding and discloses a process method for welding aluminum and aluminum alloy material by laser. The process method comprises steps of: (1) selecting an Nd:YAG laser with high beam quality and high energy density; (2) adopting double-beam laser to weld aluminum and aluminum alloy material, wherein the distance between the two beams is 0.6-1.0 mm, and the energy ratio of the two beams is larger than 1:1; (3) surface treatment of a material to be welded: removing greasy dirt and dust with an organic solvent and removing an oxidation film by mechanical cleaning and / or chemical cleaning; and (4) utilizing the two-beam laser to weld the aluminum and the aluminum alloy material. A needle body, a sleeve and a lead of the invention are manufactured into a whole; therefore, the invention solves adaptability of the laser welding to assembly precision, enhances the stability of welding process and improves welding line quality.

Owner:武汉楚天激光(集团)股份有限公司

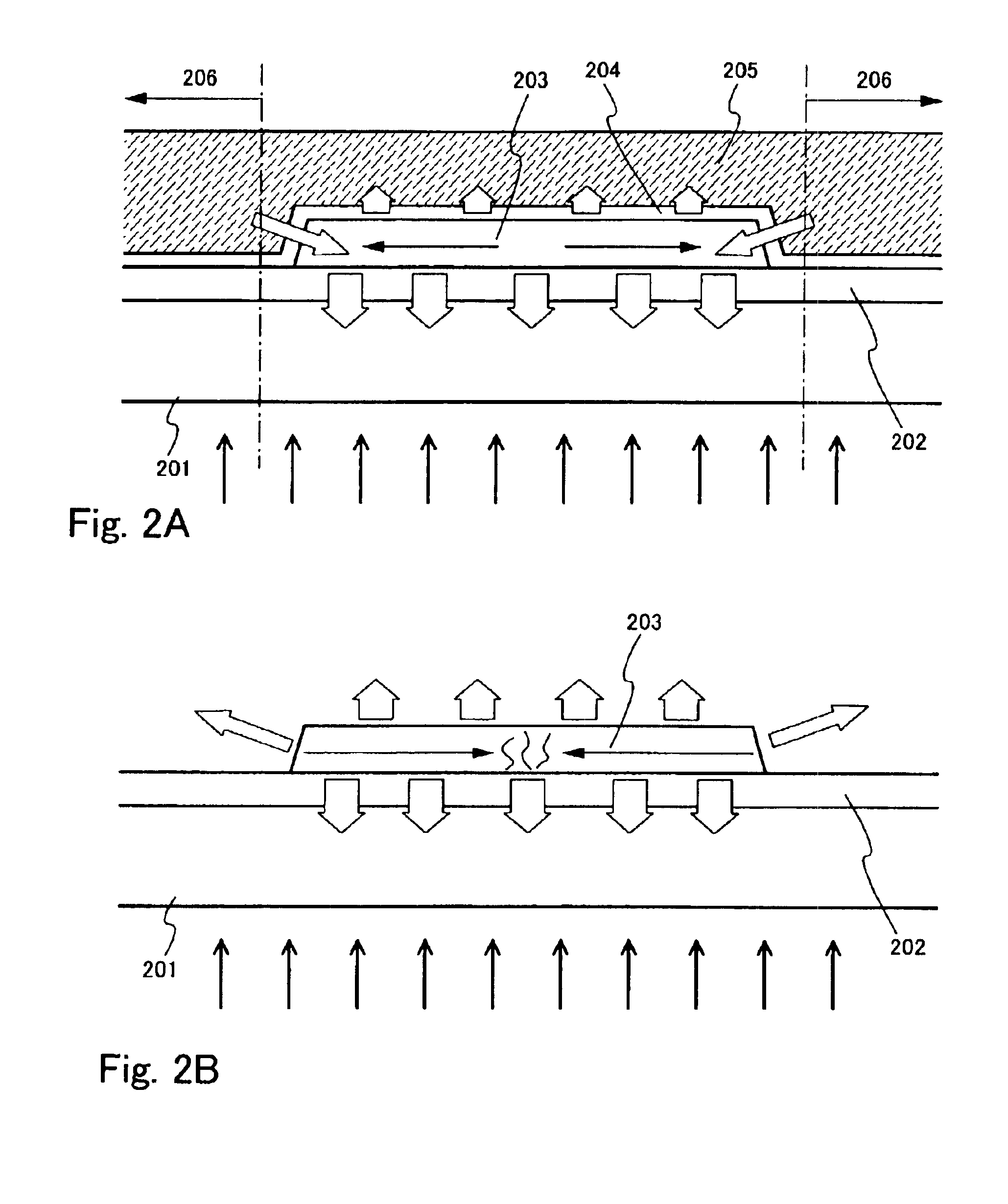

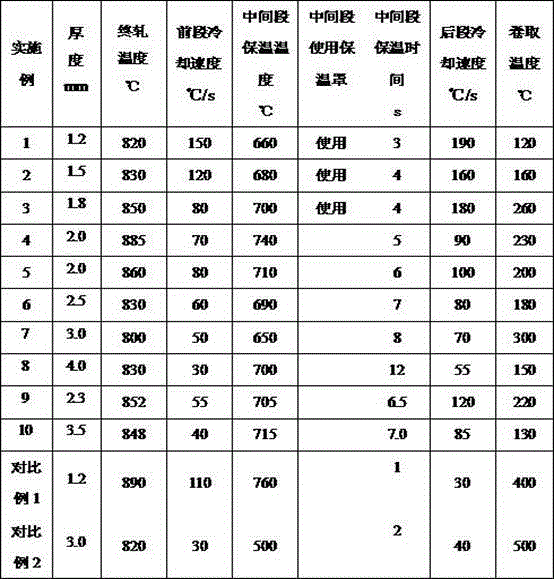

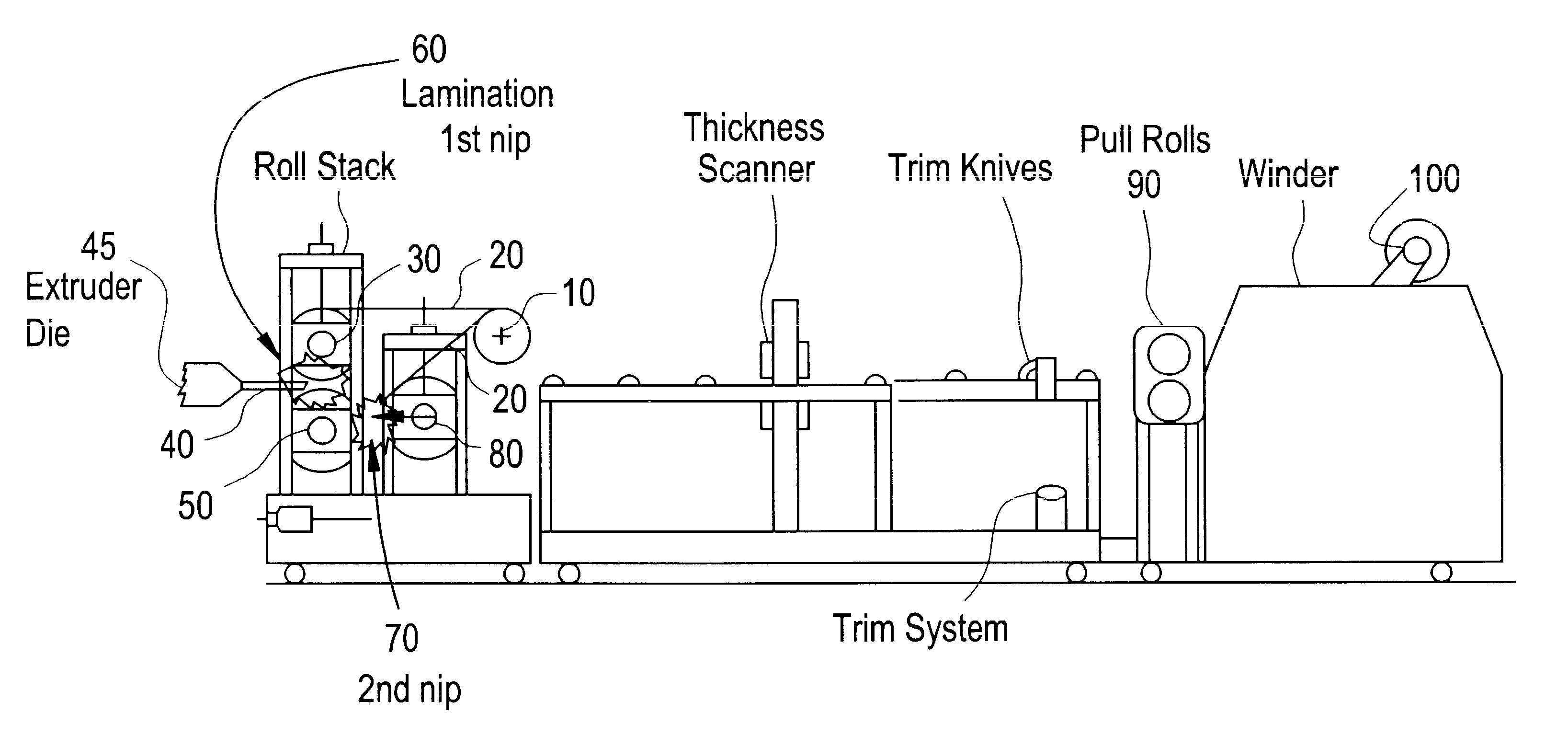

Tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel and production method thereof

The invention provides tensile strength more than or equal to 780MPa grade hot-rolled dual phase steel. The dual-phase steel comprises the following components in percentage by weight: 0.05-0.08 percent of C, not more than 0.5 percent of S, 0.6-1.2 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.006 percent of N, 0.01-0.1 percent of Als, 0.05-0.25 percent of Ti, less than or equal to 0.6 percent of Cr or less than or equal to 0.003 percent of B or mixture of Cr and B. The production method by using CSP comprises the following steps: melting and continuously casting to form a slab; heating the continuous cast slab; rolling; carrying out laminar cooling; reeling; and naturally cooling to room temperature. The hot-rolled dual phase steel has the tensile strength of more than or equal to 780MPa, elongation of more than or equal to 15 percent and yield ratio of less than or equal to 0.70. An insulation cover additionally covers the intermediate insulation section, and the band steel cooling speed is reduced, so that generation of pearlite phase change can be effectively prevented. Production of hot-rolled dual phase steel with thickness of 1.2-4.0mm can be realized, the product has the advantages of uniform structure, small molding resilience and no cracking, existing equipment is utilized without adopting ultra fast cooling and other equipment, the production efficiency is high, and the investment is small.

Owner:武汉钢铁有限公司

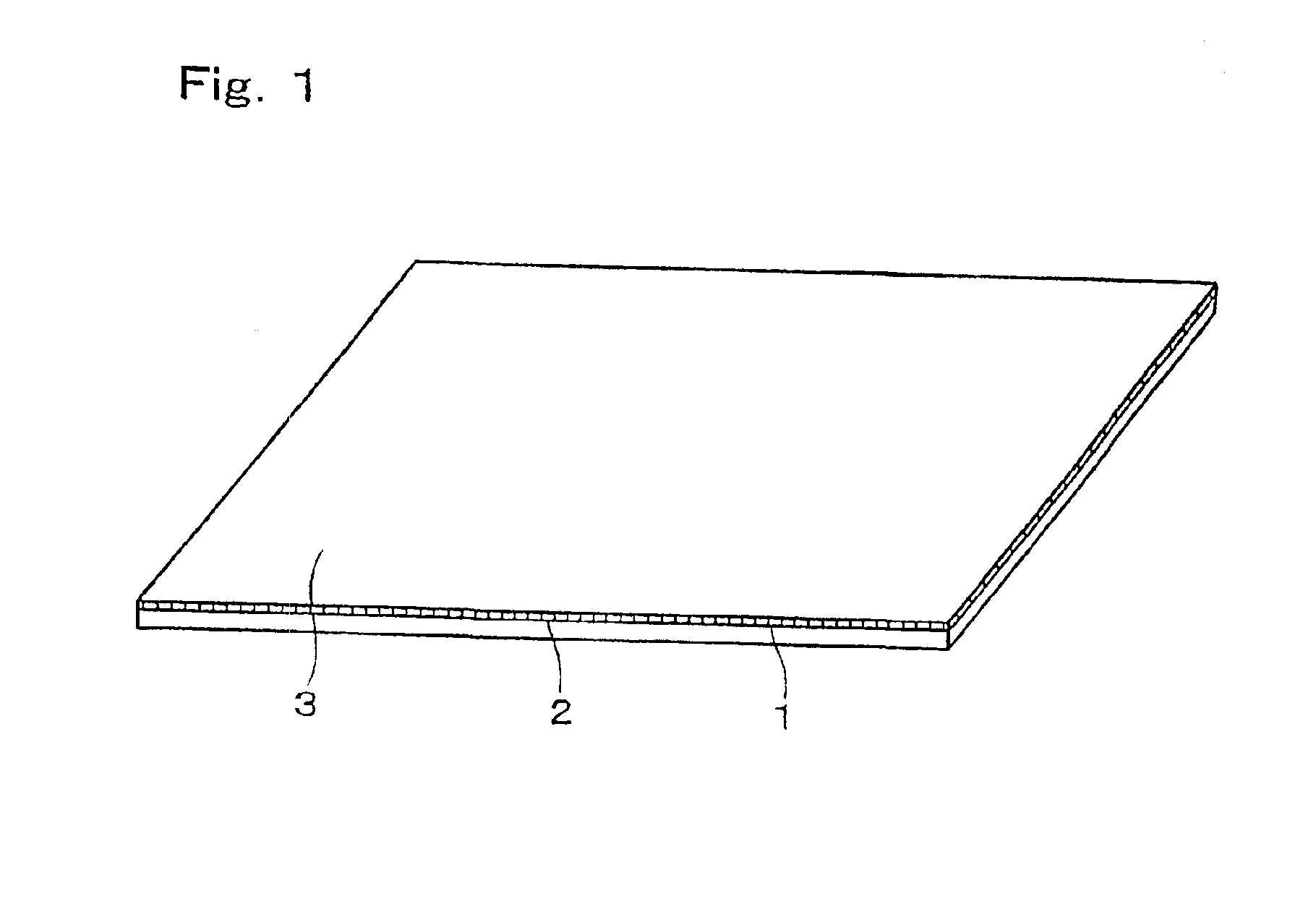

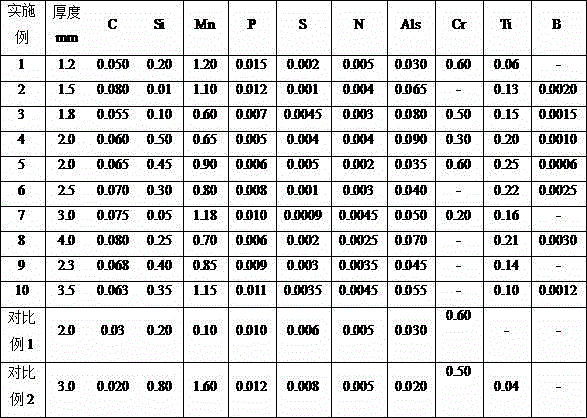

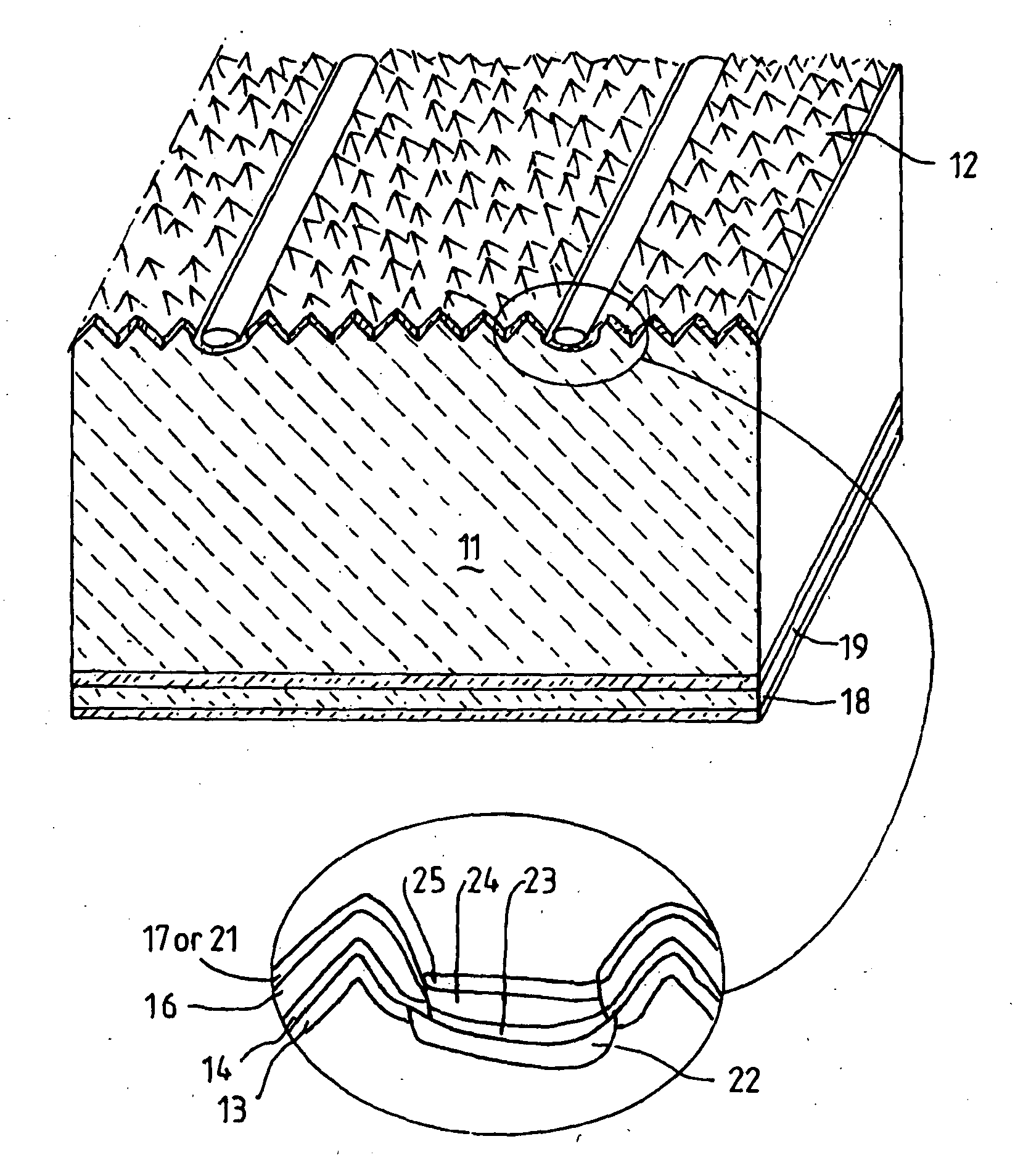

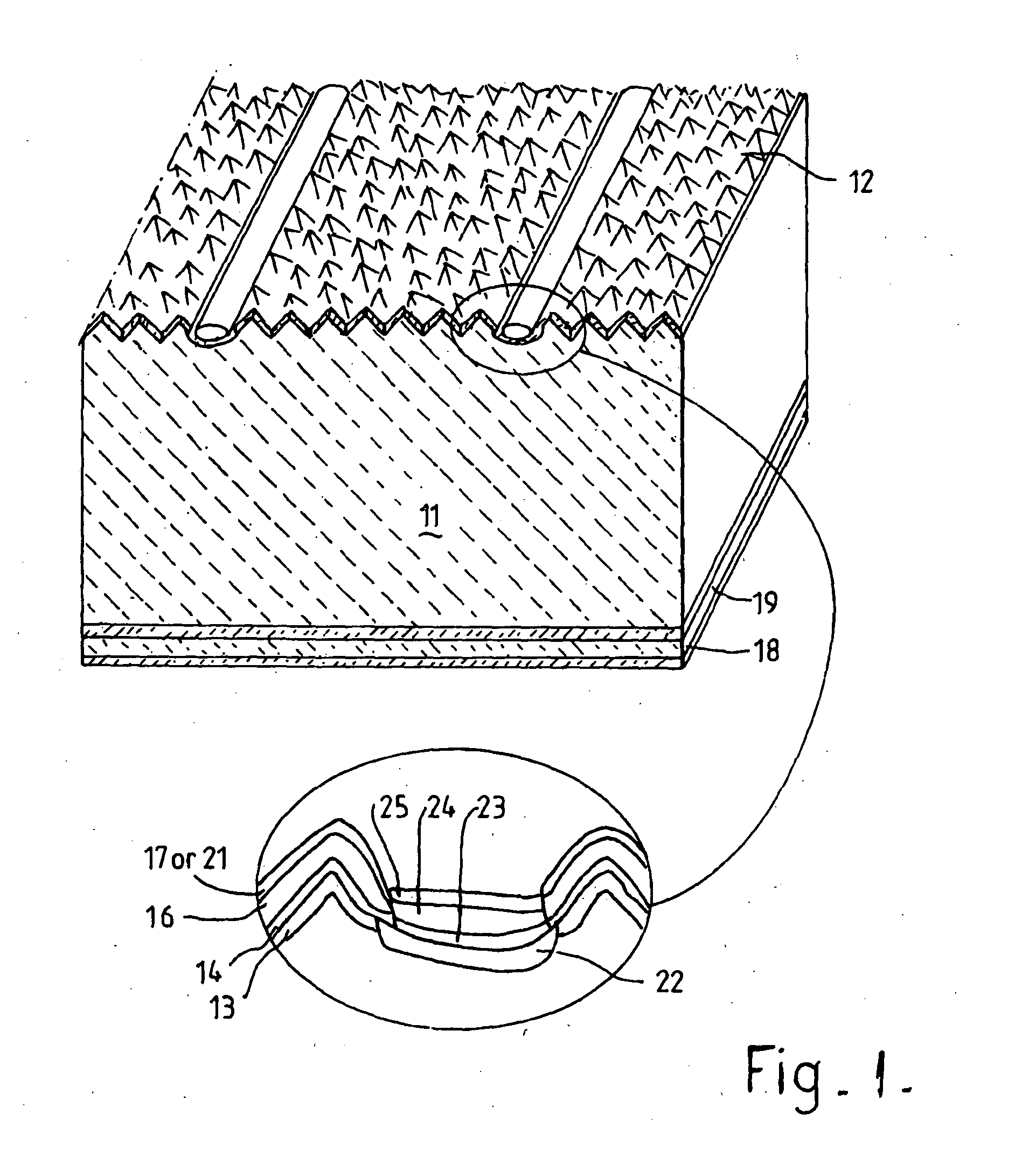

Insert mold decorating film for thermoplastic resin

InactiveUS6682805B1Low compressive strengthReduce shear stressDecorative surface effectsDuplicating/marking methodsPolycarbonateThermoplastic

A multi-layer printable thermoplastic film consisting of at least a fluoride polymer film having laminated thereto a polycarbonate film. The printable film is preformed (vacuum molding or thermoforming) and then inserted into a mold which has the configuration of the preformed printable film. A base layer of a thermoplastic such as a polycarbonate resin is injection molded to the exposed surface of the preformed printable film. The molded structure has exterior automotive applications such as lens, etc.

Owner:SABIC GLOBAL TECH BV

Hardfacing alloy, methods, and products thereof

InactiveUS20130094900A1Reduce yieldReduce heat flowMolten spray coatingArc welding apparatusBorideNiobium

Disclosed is a hardfacing alloy deriving its usefulness from carbides and borides of molybdenum and niobium. The alloy does not rely on chromium as an alloying agent. The hardfacing alloy is capable of being applied to a number of industrial substrates in a crack-free manner, and once applied convert the substrate to a wear- and abrasion-resistant material having an extended service life, even when subjected to harsh wear conditions.

Owner:DEVASCO INT

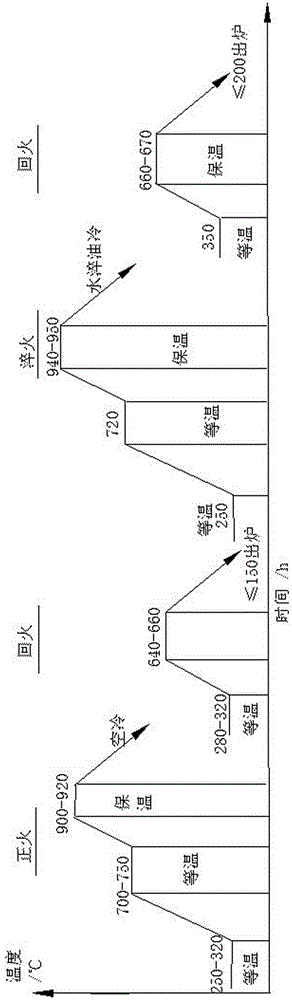

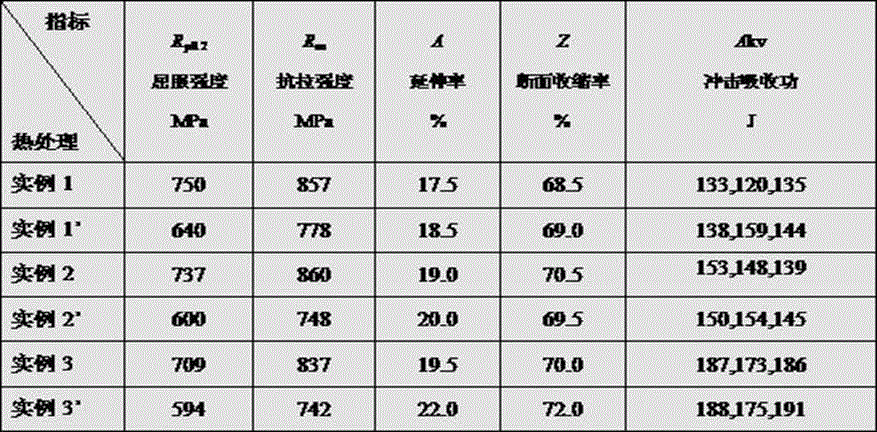

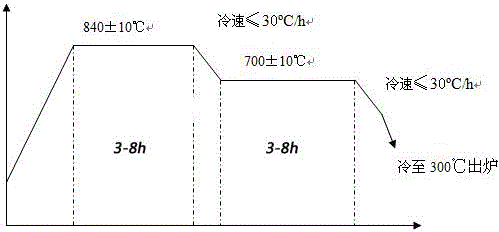

Heat treatment method for strength of 28CrMoNiV steel capable of improving industrial steam turbine rotor forge piece

A heat treatment method for strength of 28CrMoNiV steel capable of improving an industrial steam turbine rotor forge piece. The technology comprises the steps that (1), a normalizing and tempering manner is adopted in a preparation heat treatment technology and is used for refining crystalline grains and improving a material internal tissue, residual stress is reduced, and the good foundation is laid for conditioning heat treatment; a ladder heating manner is adopted in heating of normalizing and quenching, and fast heating is avoided; in the rising process, if the heating speed is too high, residual stress obtained after quenching is overlapped, and the problems that the defect of the forge piece is expanded, and even, the forge piece is cracked are possibly caused; in a quenching cooling process, a water quenching oil cooling manner is adopted, the cooling speed of a workpiece in the high-temperature stage is improved, and meanwhile, the cooling speed of a Martensite transition zone is reduced; in the water cooling initial stage, the workpiece vertically moves in a front-and-back manner in water, the quenching effect of the workpiece is fully ensured, and meanwhile, the structural stress and heat stress are reduced; in the medium heat treatment, the tempering temperature is properly reduced, impact toughness is ensured, and meanwhile, the strength of the force piece is improved.

Owner:HANGZHOU TURBINE POWER GRP +1

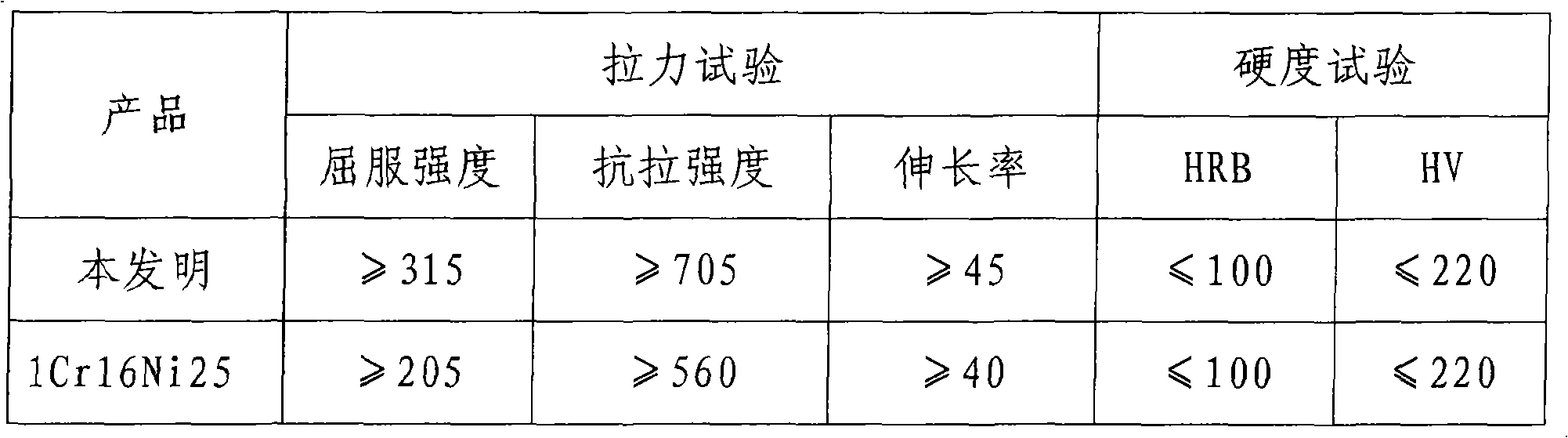

Ultra high-temperature resistant nickel-chrome alloy and manufacturing method thereof

InactiveCN101684530AImprove high temperature resistanceImprove oxidation resistanceNickelHeat processing

The invention provides an ultra high-temperature resistant nickel-chrome alloy and a manufacturing method thereof, wherein the ultra high-temperature resistant nickel-chrome alloy has a higher meltingpoint, can resist the high temperature higher than 1300 DEG C for a long time and has better tensile strength and yield strength simultaneously. The ultra high-temperature resistant nickel-chrome alloy basically comprises the following components in percentage by weight: 21-25 of Cr, 58-63 of Ni, Al which is not less than 1 and not more than 1.7, Cu which is not less than 0.5 and not more than 1.0, C which is not less than 1 and more than 0.1, Si which is not less than 0.5 and more than 0, Mn which is larger than 0 and not more than 1.0, S which is larger than 0 and less 0.015, and the balance of Fe. The manufacturing method comprises the following steps: mixing the materials according to the alloy components and then smelting; carrying out secondary refining; first heating the mixture to900-1200 DEG C, keeping the temperature for 10-40 minutes, and then forging; cold processing; and water cooling. The invention improves the high-temperature resistant performance, the tensile strength and the yield strength of the alloy, and has better comprehensive benefit. The manufacturing method solves the problems of alloy smelting and heat processing, and improves the product purity.

Owner:杭正奎

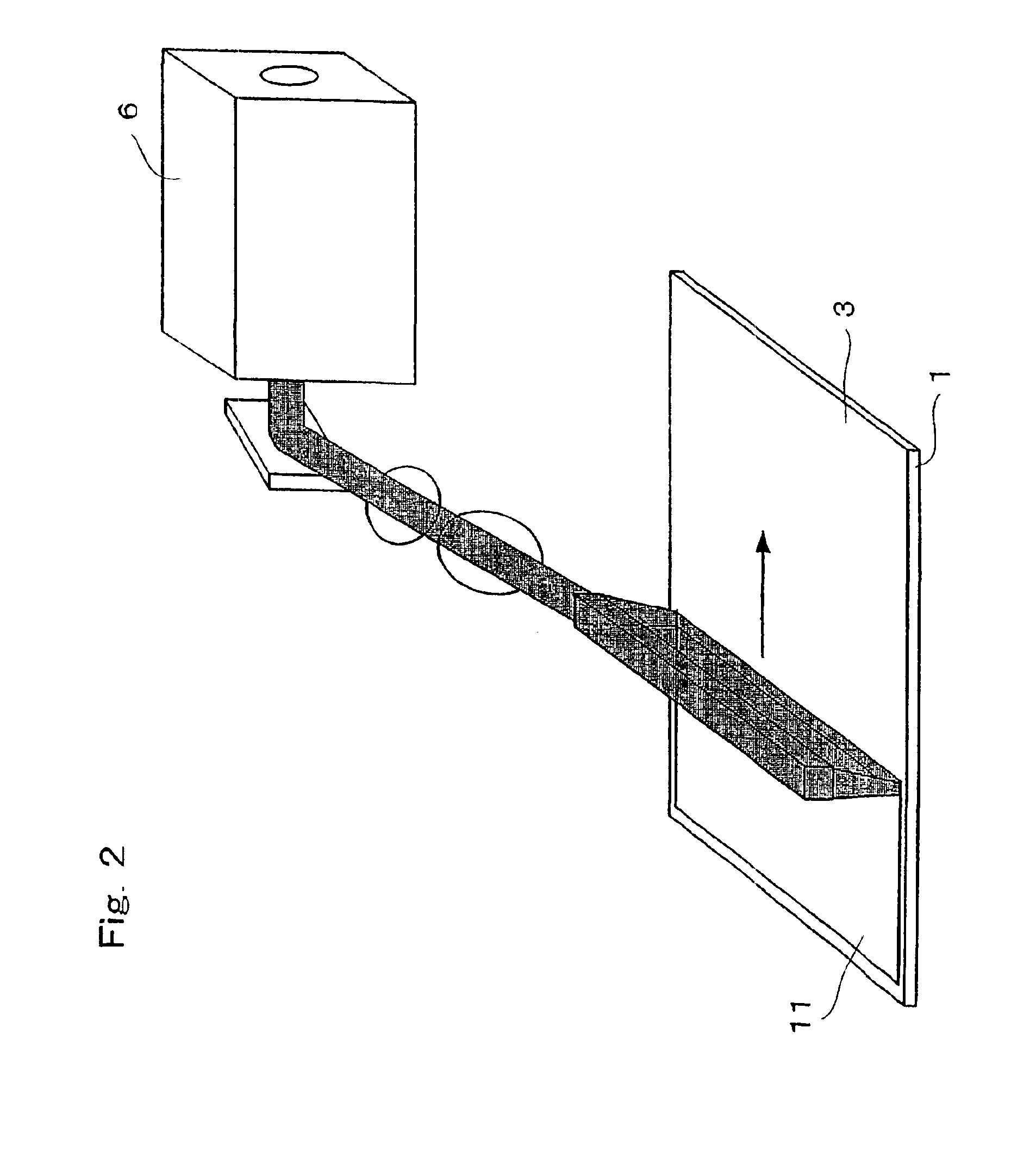

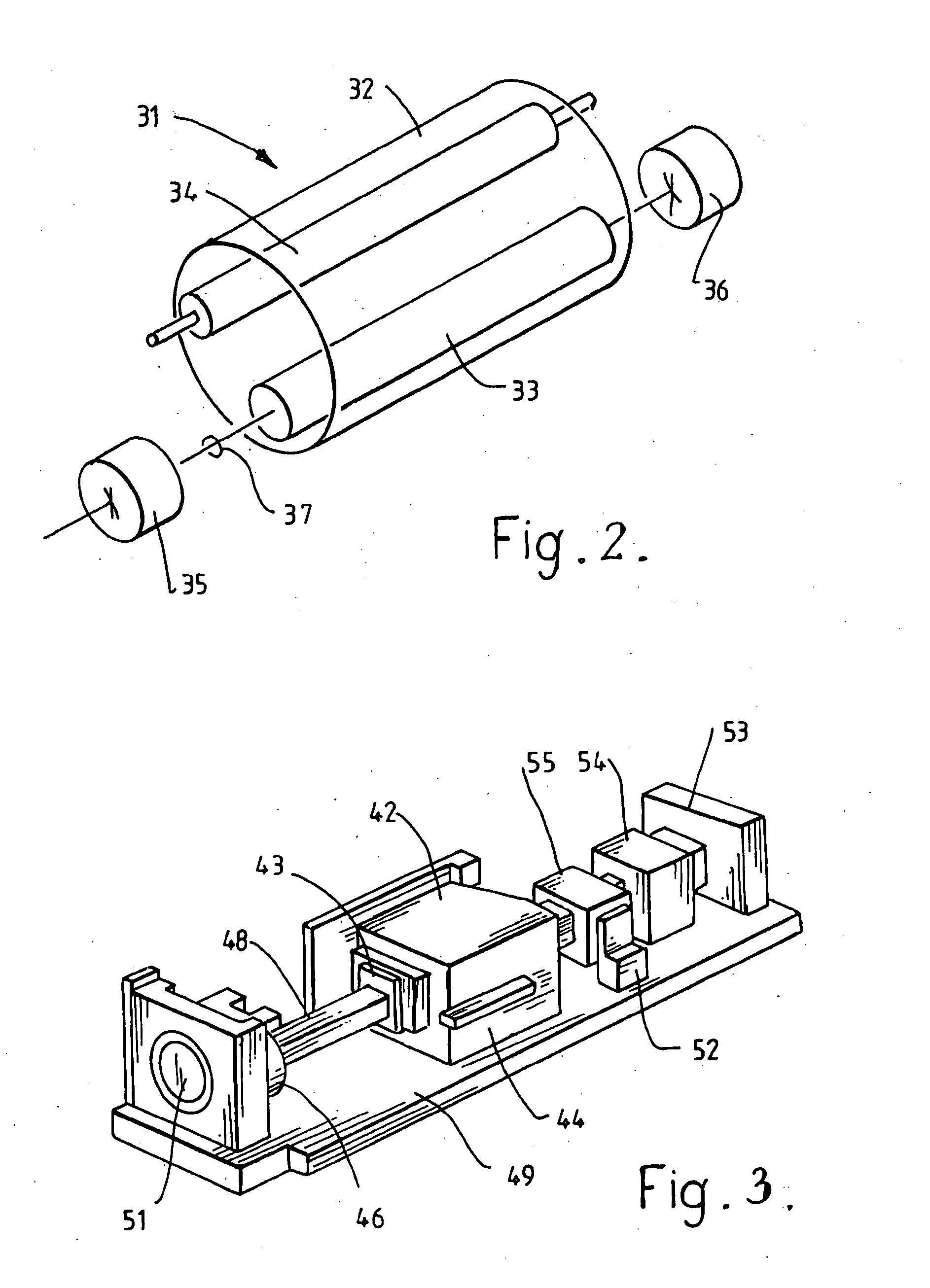

Sinter magnet made from rare earth-iron-boron alloy powder for magnet

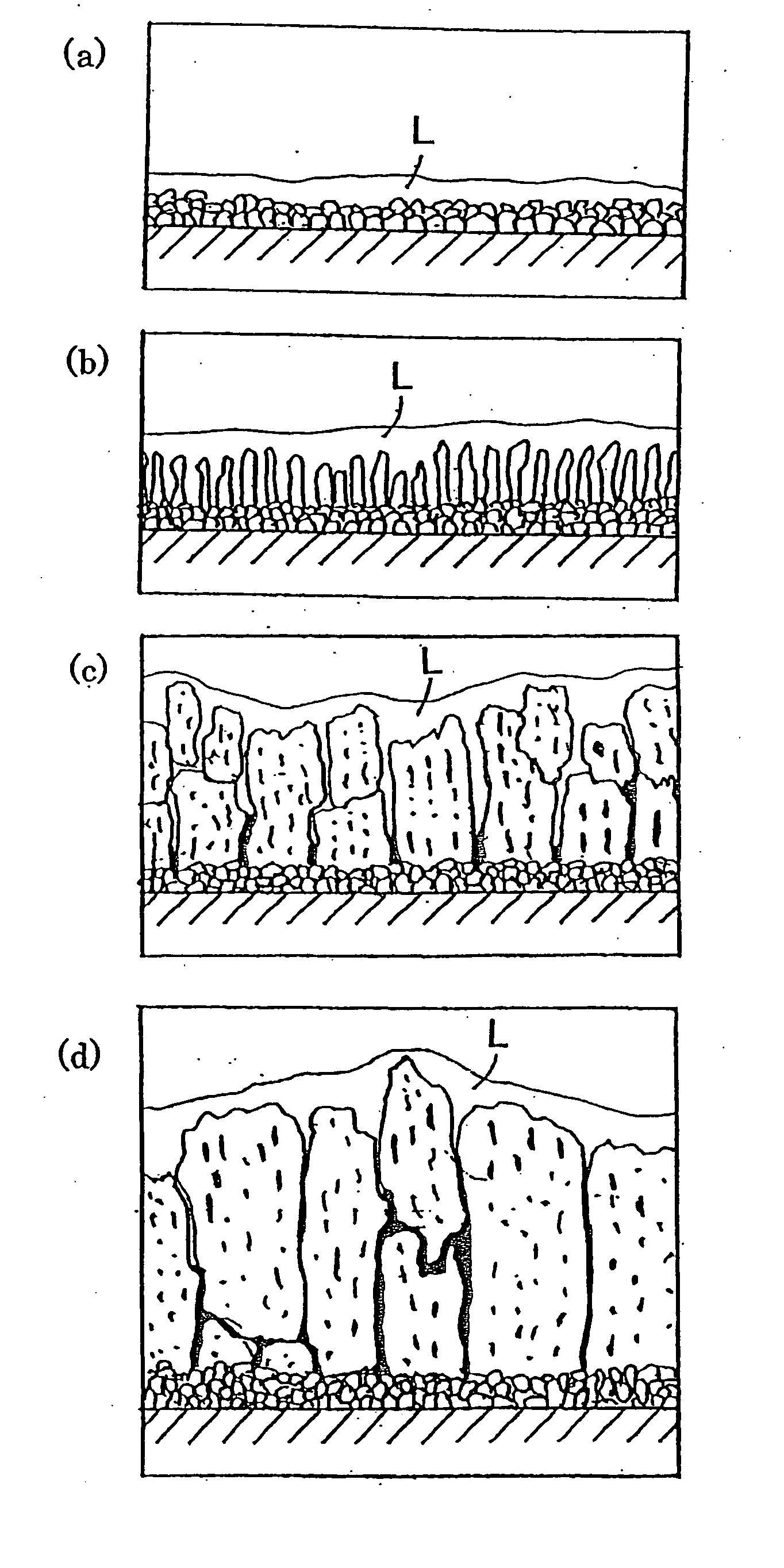

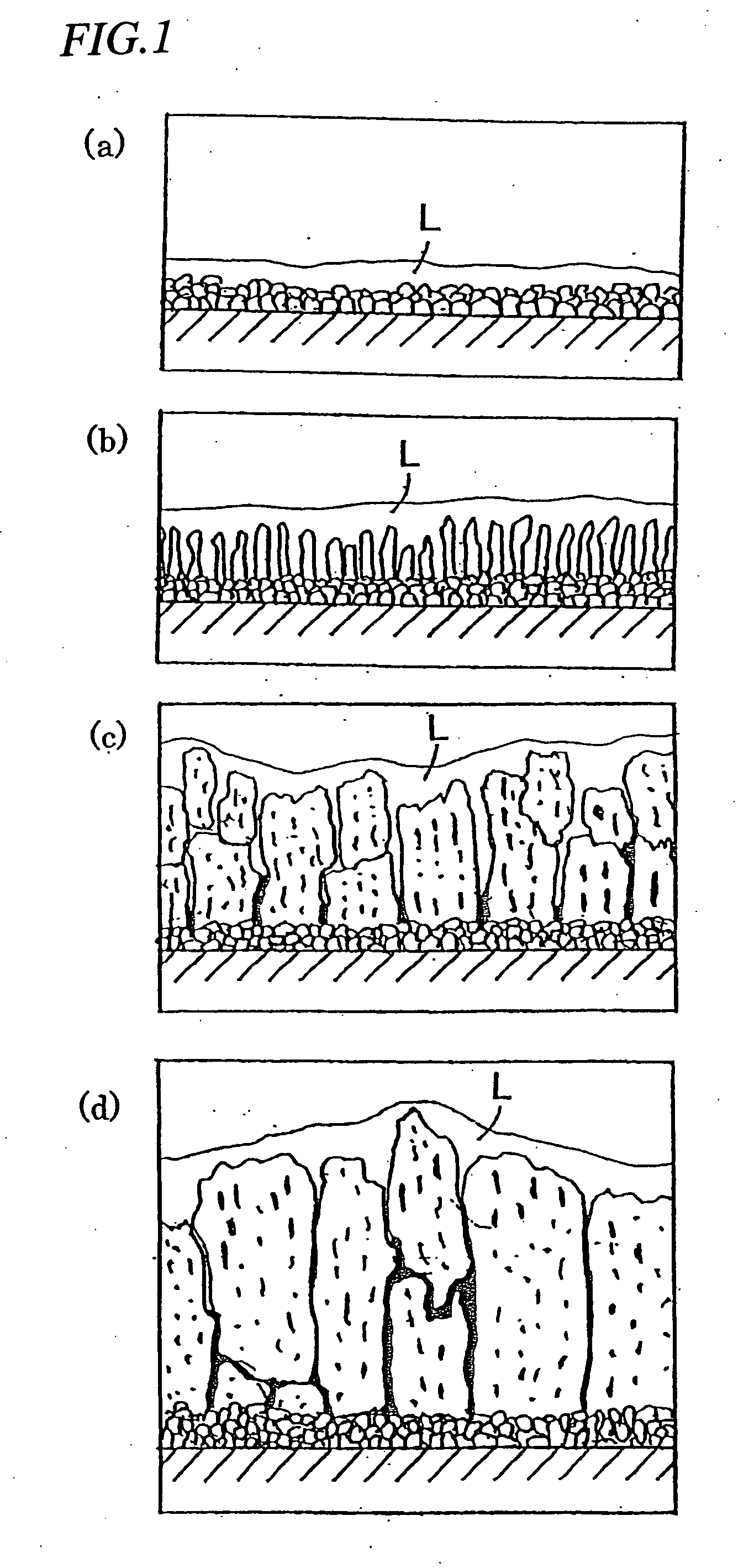

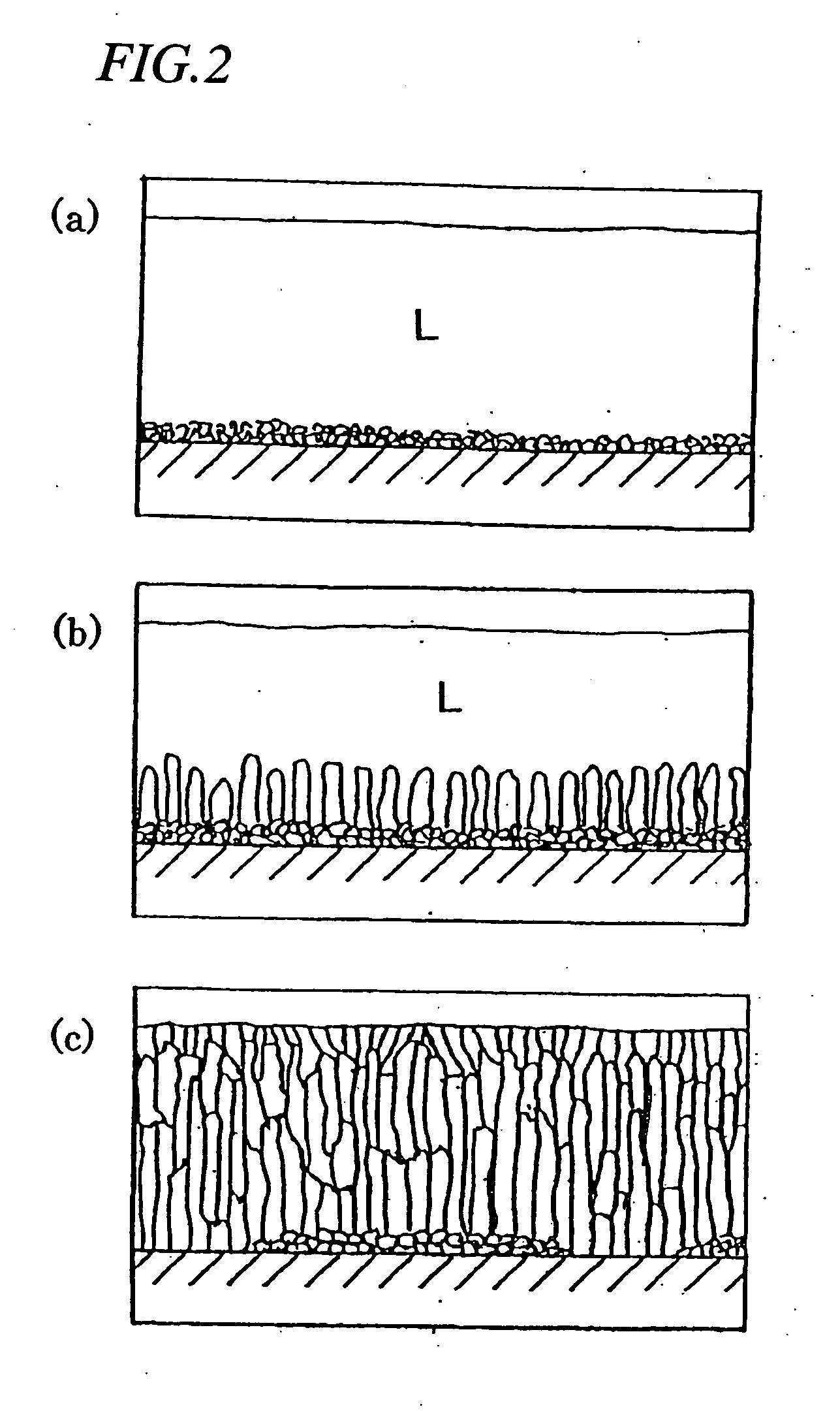

InactiveUS20060016515A1Reduce cooling rateInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementHigh concentration

A rare-earth-iron-boron based alloy powder, in which a heavy rare-earth element such as Dy is present at a higher concentration in a main phase than in a grain boundary phase and which can be sintered easily, and a method of making such an alloy powder are provided. A rare-earth-iron-boron based magnet alloy according to the present invention includes, as a main phase, a plurality of R2Fe14B type crystals (where R is at least one element selected from the group consisting of the rare-earth elements and yttrium) in which rare-earth-rich phases are dispersed. The main phase includes Dy and / or Tb at a higher concentration than a grain boundary phase does.

Owner:HITACHI METALS LTD

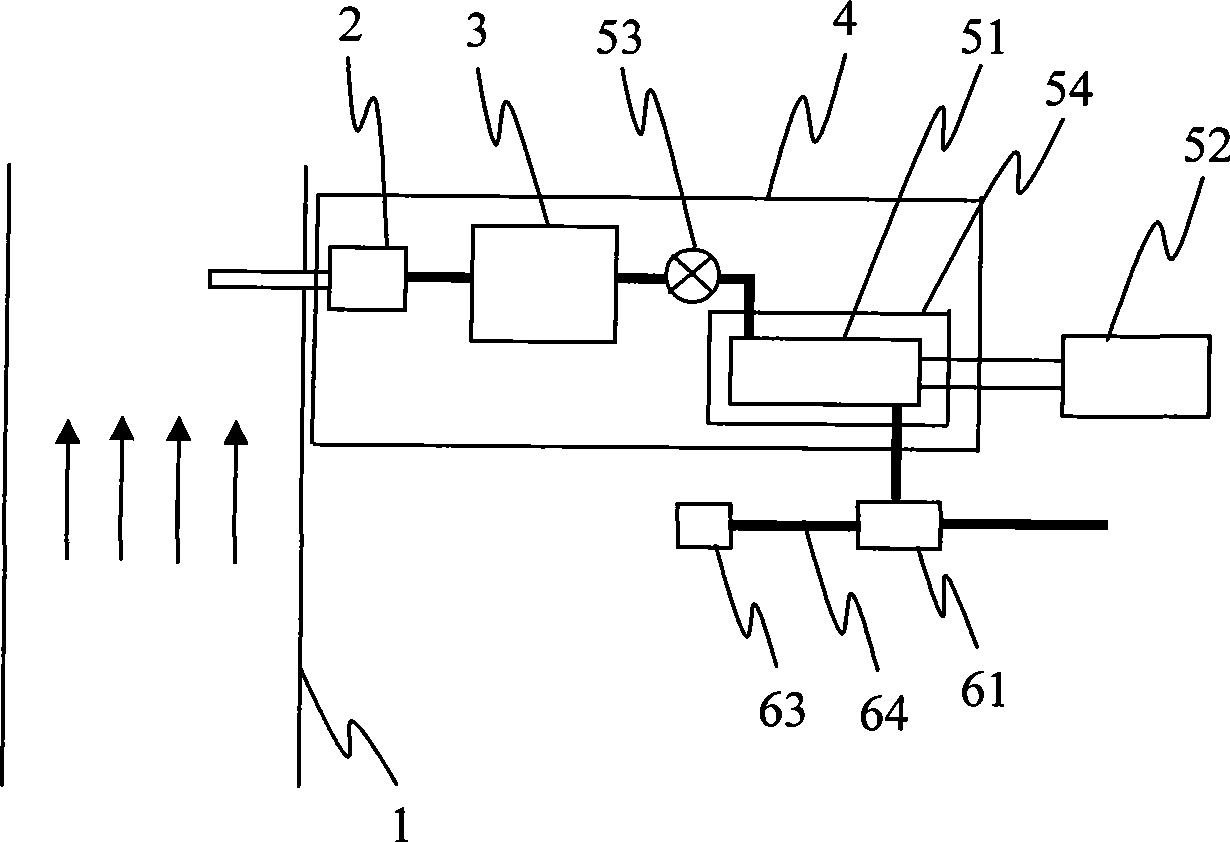

Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

ActiveCN108456879AReduce temperature gradientAvoid crackingFurnace typesMetallic material coating processesMelting tankHeat-affected zone

The invention discloses a method for efficiently compounding a fusion-covering reinforced steel rail through laser and an auxiliary heat source. The laser and the auxiliary heat source act on a to-be-fusion-covered area on the surface of the steel rail simultaneously, as a main heat source, the laser makes the material of a fusion-covering layer and the material on part of the base of the surfaceof the steel rail quickly fused simultaneously to form a fusion pool, the auxiliary heat source and the laser heat source move in the same direction at the same speed and preheat and / or postheat the laser fusion pool, a heat influence area and the surface layer of the base of the steel rail, the temperature gradient of the steel rail is lowered, thus the cooling speed of the steel rail is lowered,and the phenomena of transforming of a martensite in a heat influence area and cracking are avoided. Through the compounding effect, the critical cooling time for transforming an austenite to a pearlite is shortened in the heat influence area wherein the cooling time is larger than a CCT curve or a TTT curve, so that the mechanical performance among the fusion-covering layer, the heat influence area and the base is reasonably matched, the rigidity curve is smooth in distribution, and the overall fatigue performance is good. The method can fuse-cover a metal layer on the surface of a field ofa railway steel rail on line and can also achieve fuse-covering machining on the surface of the steel rail in a production workshop.

Owner:HUAZHONG UNIV OF SCI & TECH +1

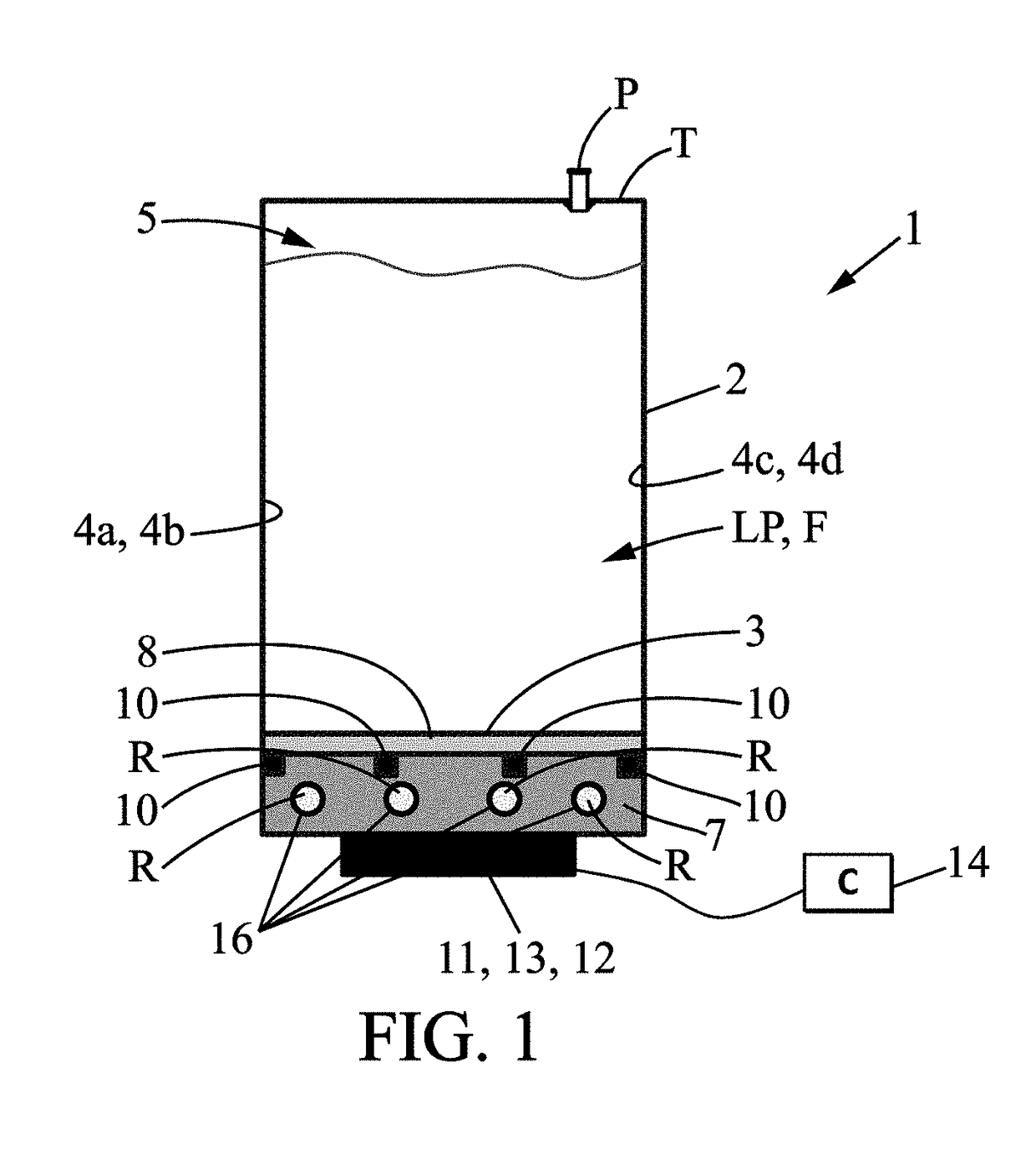

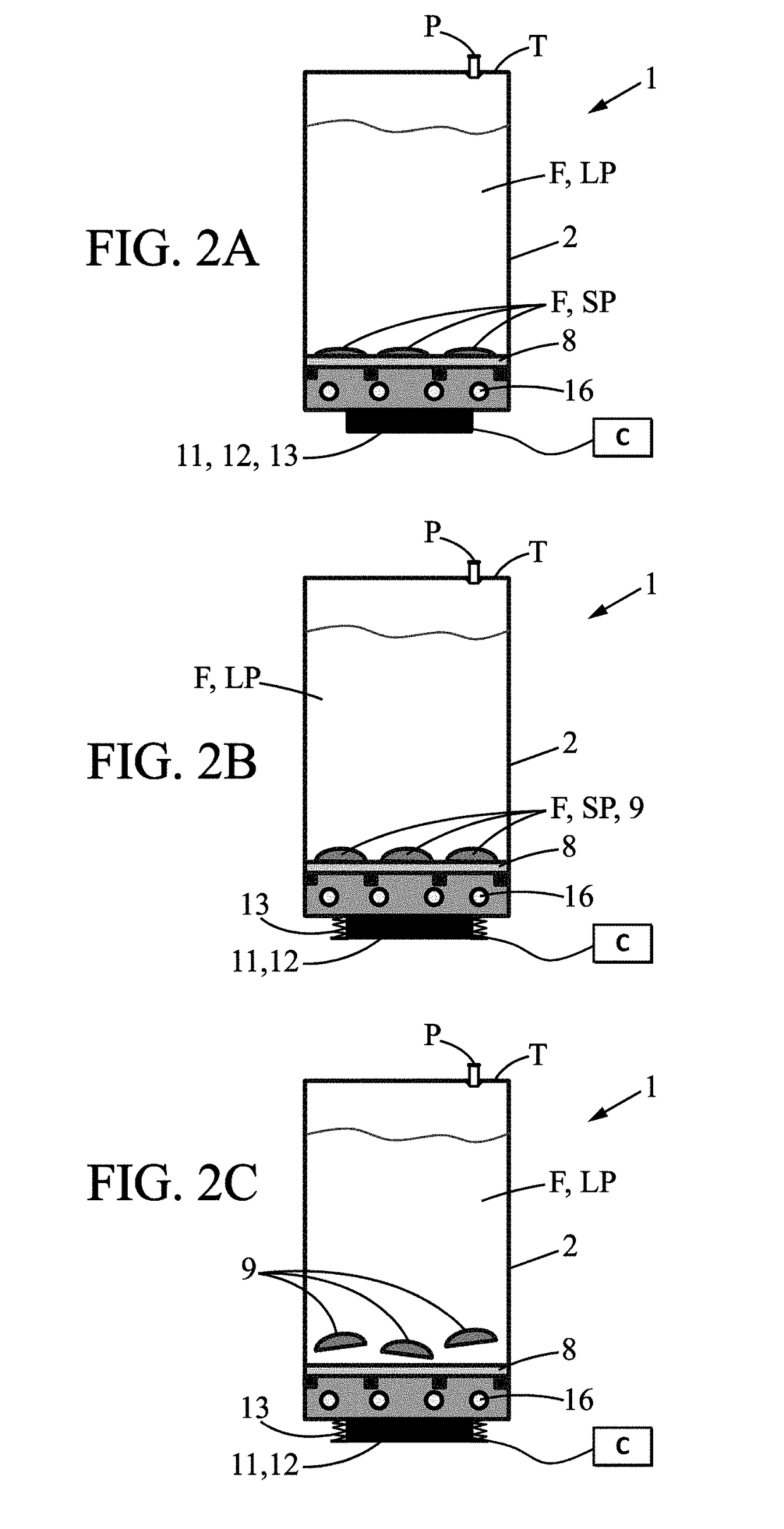

Method and system for freezing biopharmaceutical fluid

ActiveUS20190029248A1Easy to implementPromote sheddingLighting and heating apparatusIce productionEngineeringMechanical engineering

Disclosed is a method and system for freezing a biopharmaceutical fluid which is hold in a disposable container. The method includes the steps of arranging the container on the heat transfer surface area, cooling the heat transfer surface area to cool the bottom surface of the container until freezing and forming a layer of ice or an ice block of biopharmaceutical fluid inside the container; dislodging the ice layer or ice block frozen to the container. The steps of cooling the heat transfer surface area and dislodging the ice layer or ice block are repeated until the container is filled with a matrix of frozen biopharmaceutical fluid and liquid biopharmaceutical fluid, the liquid biopharmaceutical fluid occupying interstitial passages between ice layers or ice blocks of biopharmaceutical fluid. The cooling is then maintained until the freezing of the entire biopharmaceutical fluid held in the container.

Owner:SARTORIUS STEDIM NORTH AMERICA INC

Method for preparing TiAl+Ti2AlNb composite materials by laser melting deposition

ActiveCN110449581ATurn up the plasticityControl the preheating temperatureAdditive manufacturing apparatusTransportation and packagingStress concentrationLaser additive manufacturing

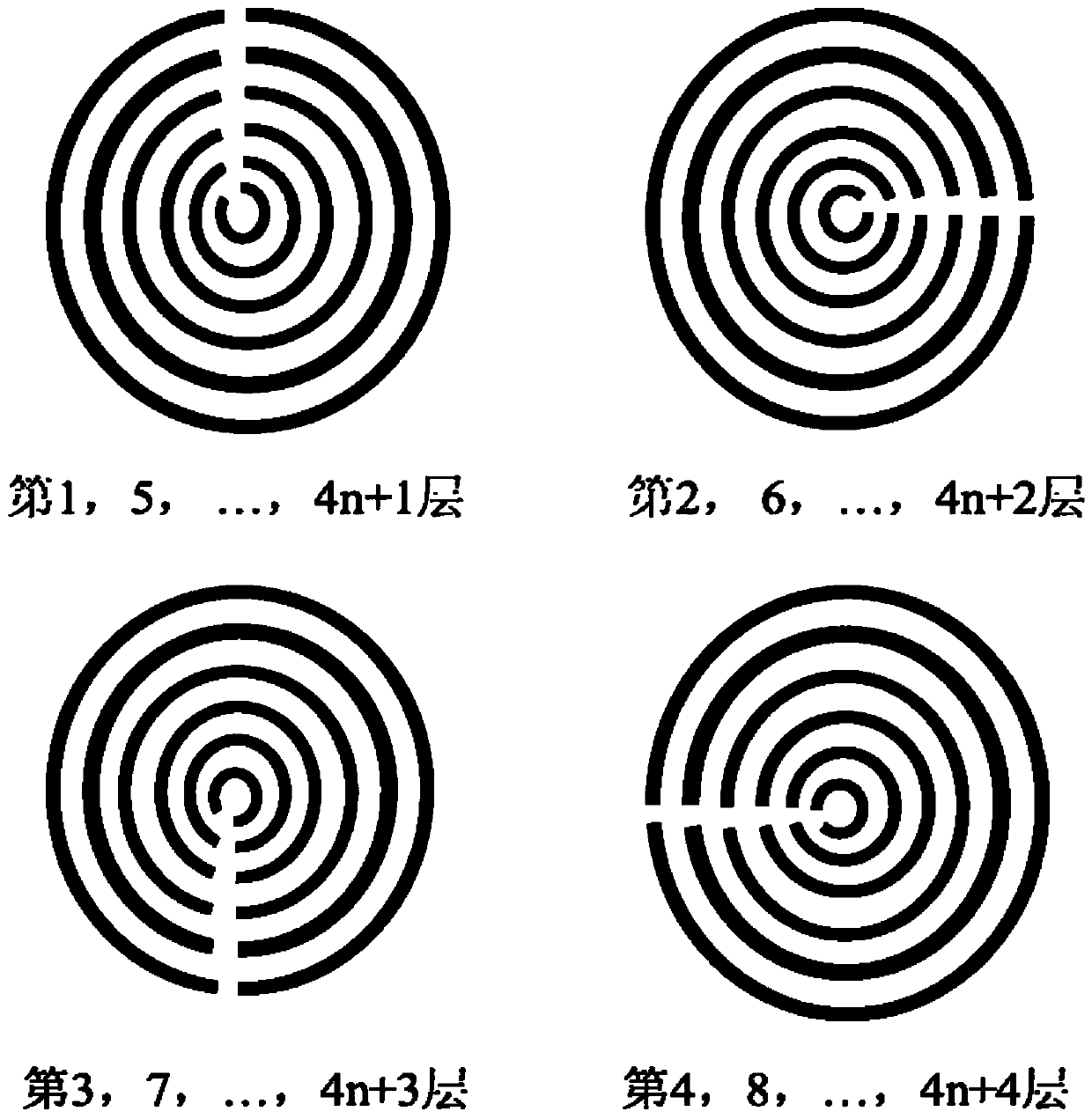

The invention belongs to the technical field of laser added material manufacturing, and relates to a method for preparing TiAl+Ti2AlNb composite materials by laser melting deposition. The laser melting deposition method is adopted to form the TiAl+Ti2AlNb composite materials; and the feeding quantity of Ti2AlNb is adjusted to achieve a pinning effect in composite material structures to improve overall plasticity of the materials. Meanwhile, circular samples are formed, and scanning paths are changed to concentric arcs to prevent the tensile stress of linear scanning paths of rectangular samples; and concentric circle openings on each layer are converted by 60-90 degrees, that is, the positions of scanning initial points on each layer are changed, so that the thermal stress concentration isreduced to prevent cracks. The heat input quantity in the forming process is controlled, and the substrate preheating temperature in the forming process is adjusted to slow down the formed metal solidification speed and cooling speed, so that the stress is released for a longer time.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

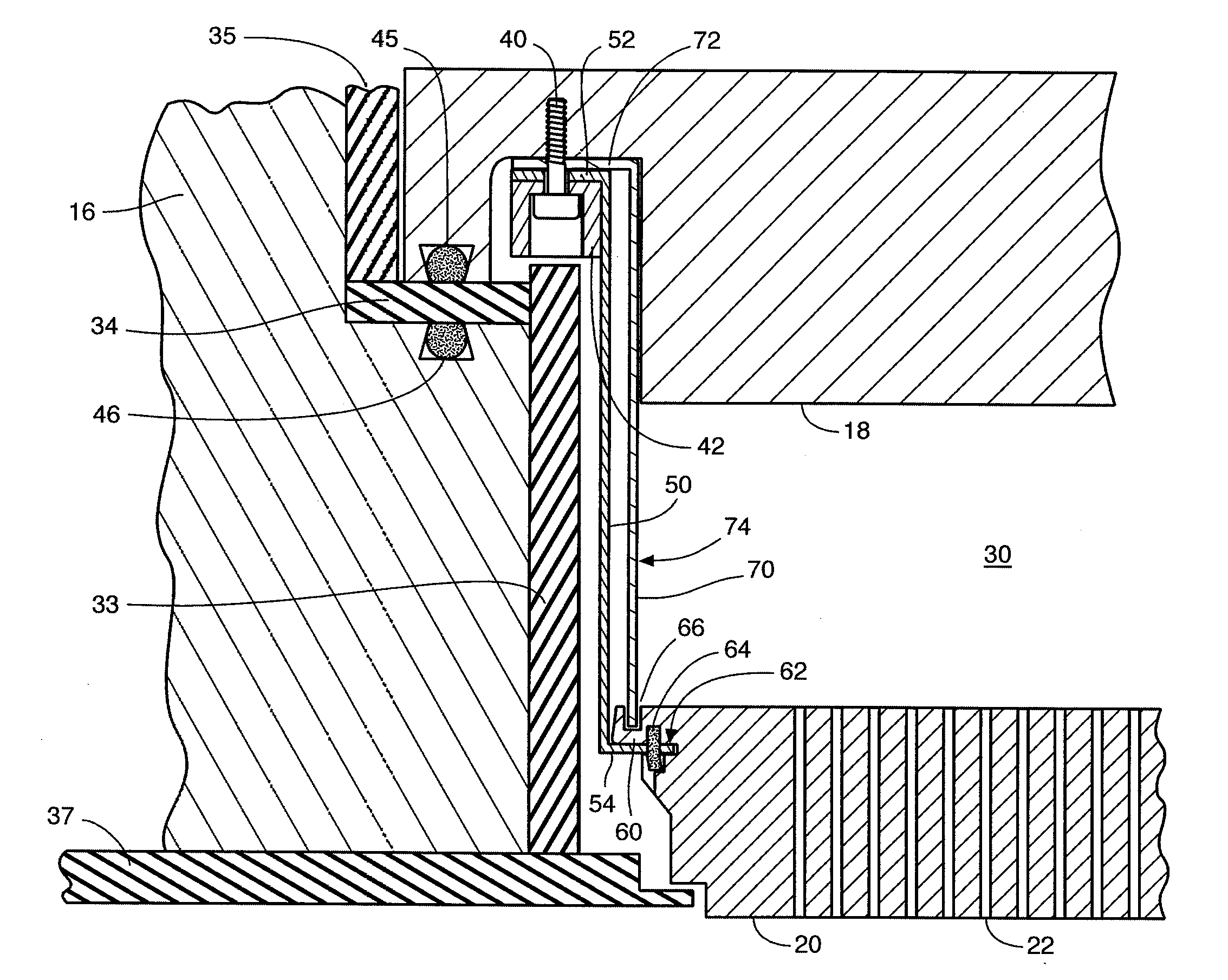

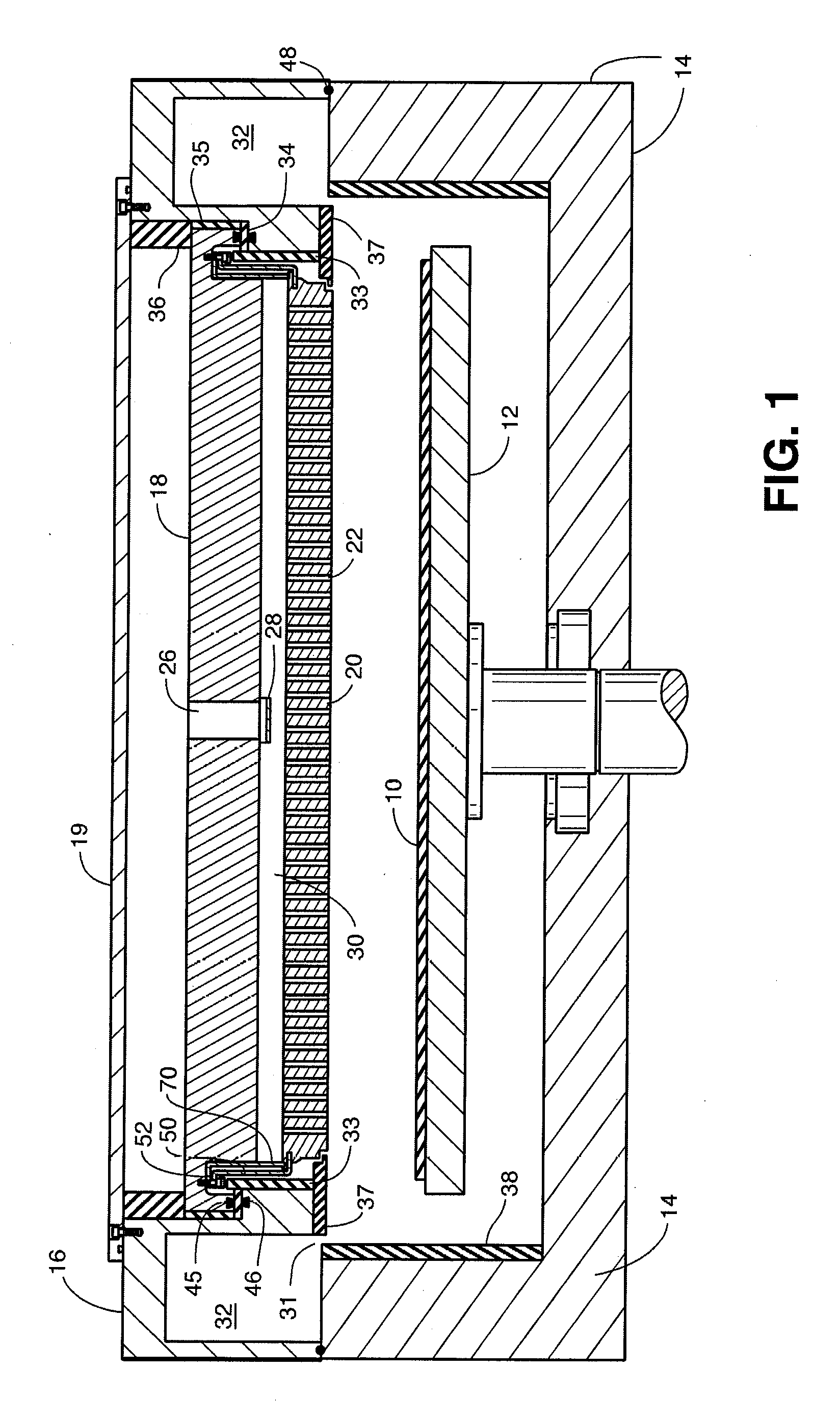

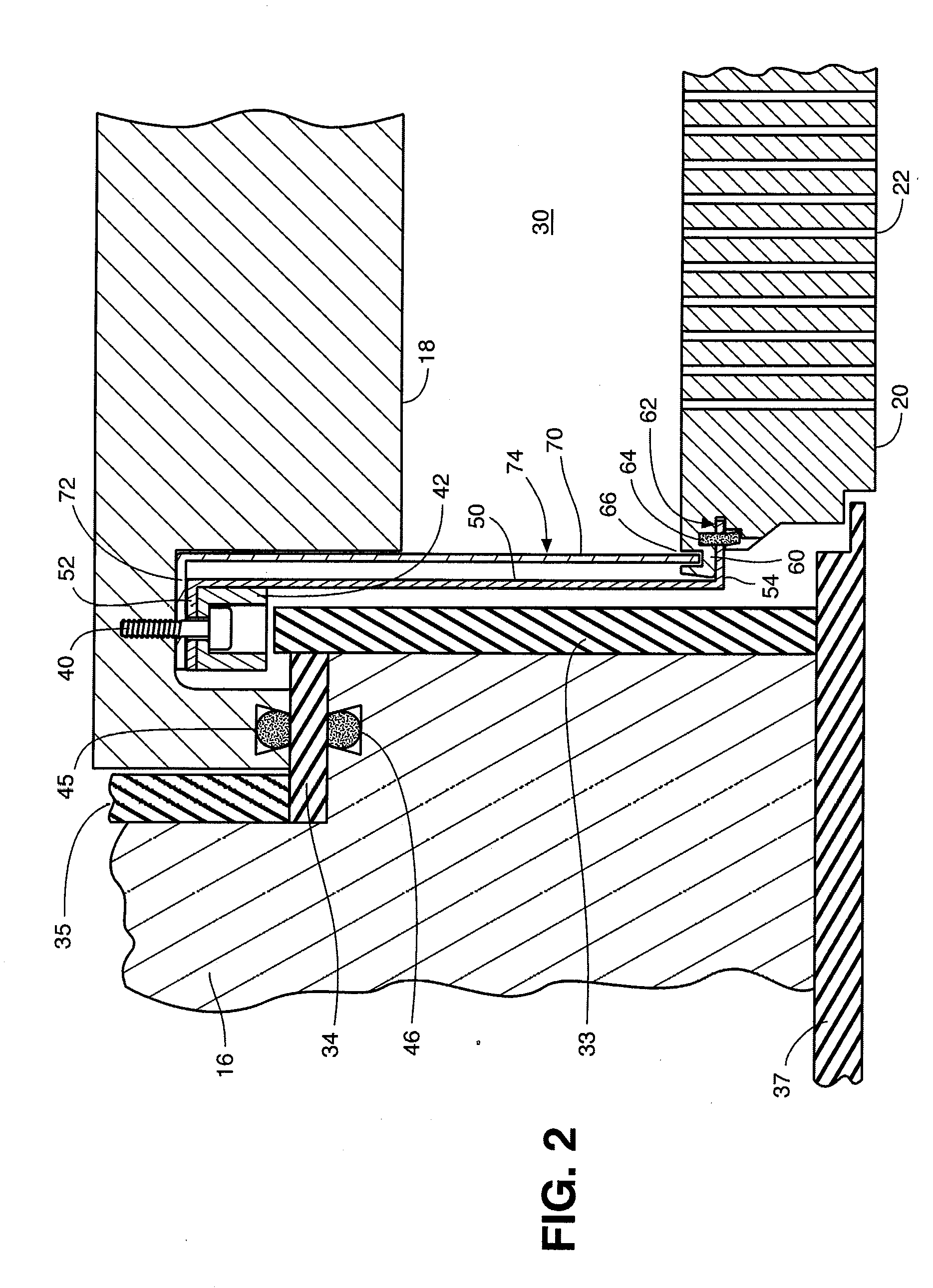

Suspension for showerhead in process chamber

ActiveUS20080099146A1Reduce thermal stressReduce heat transfer rateElectric discharge tubesSemiconductor/solid-state device manufacturingHermetic sealEngineering

Stress within a suspension wall for suspending a showerhead in a process chamber is ameliorated by one or more of: (1) Openings in the suspension wall that reduce exposure of the suspension wall to process gas or ambient atmosphere when the chamber lid is opened.(2) A substantially vertical arrangement of one or more rifts in the suspension wall which facilitate horizontal buckling or flexing of the suspension wall. (3) A plurality of suspension walls whose respective central portions are coplanar. (4) A gas sealing skirt that helps protect the suspension wall from direct contact with process gas. The gas sealing skirt is connected to either the chamber wall or the showerhead but is not connected to both.

Owner:APPLIED MATERIALS INC

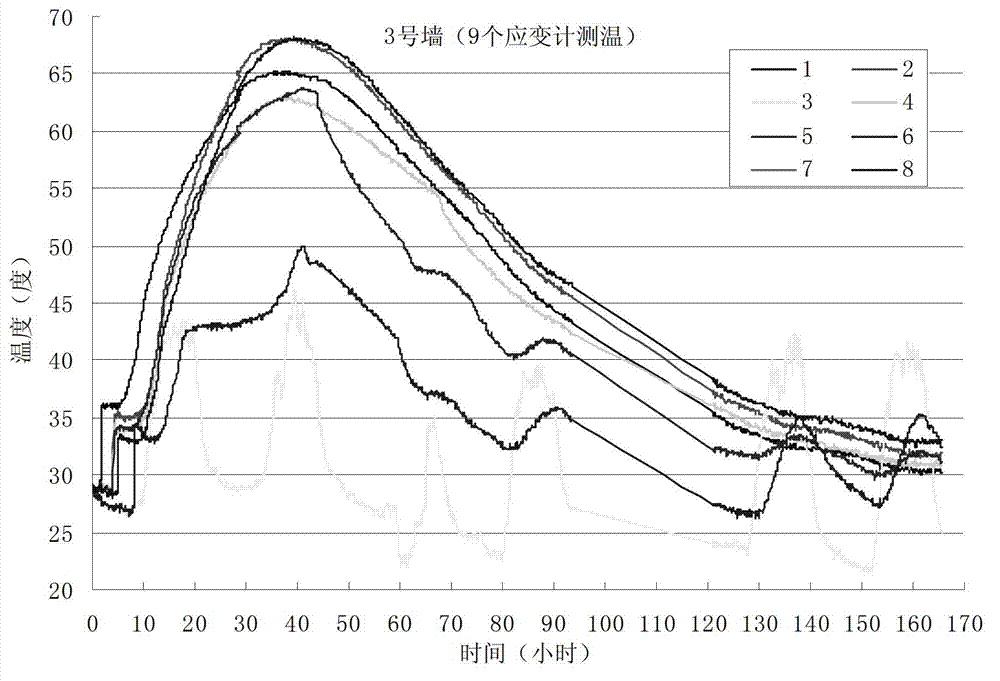

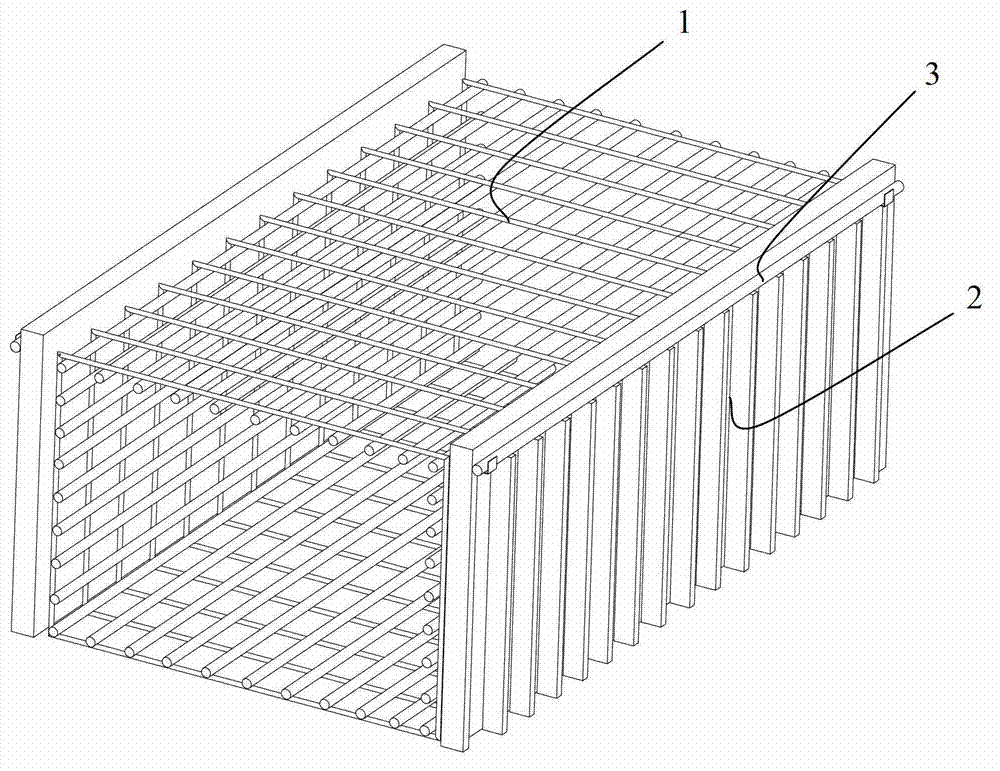

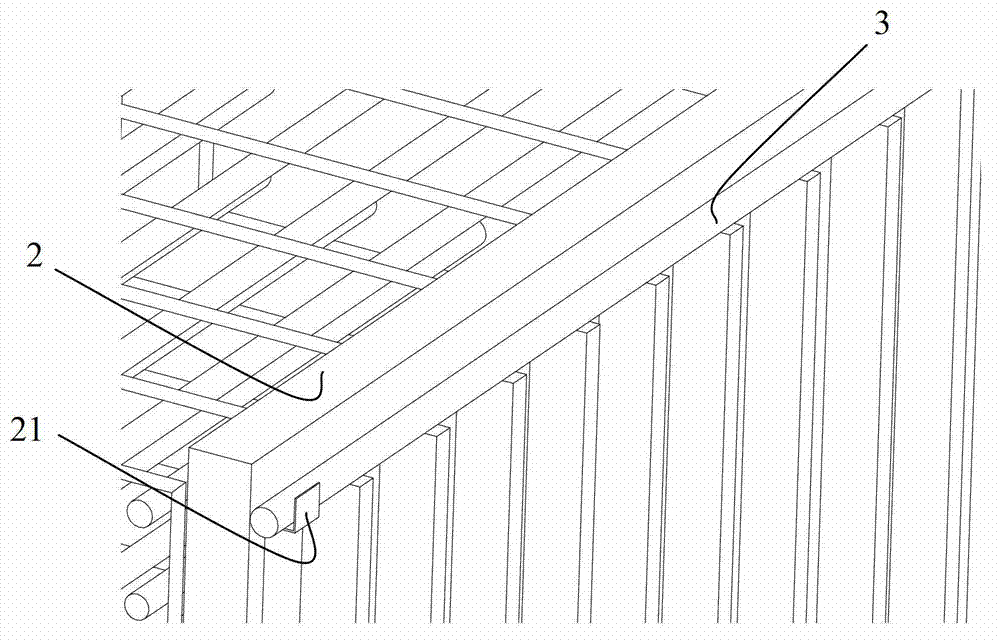

Wall maintaining method based on automatic temperature measurement and temperature stress reduction

InactiveCN102966242ASimple structureEasy to operateCeramic shaping apparatusBuilding material handlingPeak valueTemperature measurement

The invention provides a wall maintaining method based on automatic temperature measurement and temperature stress reduction, which comprises the following steps: before casting the concrete wall, mounting temperature sensors of a wireless thermodetector at positions with different heights and different thicknesses inside the to-be-cast concrete wall; after casting the concrete, reading the temperature in the concrete through the temperature sensors; based on the read temperature, carrying out the following operations: spraying water to the outer side of the template during the temperature rising process as heat is released due to hydration heat of cement at the early stage of the concrete wall; when the temperature inside the wall is raised to a peak value, stopping spraying, covering thin film on the outer side of the concrete wall to keep temperature of the wall, and delaying the rate of temperature fall of the wall. The structure is simple, and easy to operate. The method can actively protect the wall from temperature crack at the early stage by virtue of spraying the concrete and covering the thin film on the surface to control the temperature inside the concrete, and meanwhile improve the construction quality of the wall.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

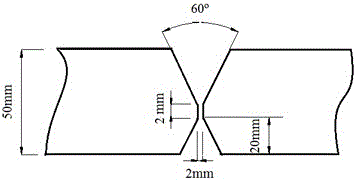

Gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates

ActiveCN106270957AHigh strengthGuaranteed toughness and plasticityArc welding apparatusWelding/cutting media/materialsEngineeringSlow cooling

The invention provides a gas protection welding method of 1000 MPa-level engineering machine high-strength steel thick plates. Welding base materials are Rm1000-1100 MPa engineering machine quenched and tempered steel plates in equal-thickness flat plate butt joint, a groove is a double-side V-shaped asymmetric groove, the angle of the groove is 60 degrees, a truncated edge is 2-3 mm long, and an assembly gap is 2 mm wide. According to welding materials, bottoming welding wires are 700 MPa-level solid-core gas-protected welding wires with the diameter of 1.2 mm, and filling and surface covering welding wires are 1000 MPa-level solid-core gas-protected welding wires with the diameter of 1.2 mm. The welding method includes the welding steps that bottoming welding is conducted, filling welding is conducted, surface covering welding is conducted, slow cooling is conducted after welding, and joint areas in the range of 300 mm on the two sides of a weld joint are covered with asbestos cloth. Preheating is not needed, after-heating is not conducted, strength and toughness of a joint are ensured, the variety of welding gas and replacement frequency of equipment and the welding wires are reduced, the high-strength advantage of high-strength steel can be fully achieved, and maneuverability is high.

Owner:武汉钢铁有限公司

Deposit welding rod containing rare earth and production method

InactiveCN101190481AReduce segregationReduce subcoolingWelding/cutting media/materialsSoldering mediaRare earthRoom temperature

The invention provides a surfacing electrode containing rare earths with a welding core but without a coating. The composition of the welding core is 3.2% to 6.5% of C, 0.4% to 2.5% of Si, 0.4% to 2.0% of Mn, 0.01% to 1.0% of Re, 10% to 35% of Cr, 0.0% to 2.0% of Mo, 0.0% to 2.8% of Ni, 0.0% to 2.5% of W, 0.0% to 1.5% of V, 0.0% to 1.0% of Ti, 0.0% to 1.5% of Nb, 0.0% to 0.5% of Cu, 0.0% to 0.6% of Al, not more than 0.08% of S, not more than 0.08% of P, not more than 0.08% of , not more than 0.08% of <N>, and 59.64% to 85.99% of Fe. The welding rod is suitable for the build-up welding of burning single-roll crusher hammer; the hardness HRC of the build-up welding layer at room temperature is not less than 50 and crack is allowable for build-up welding layer.

Owner:PANZHIHUA UNIV

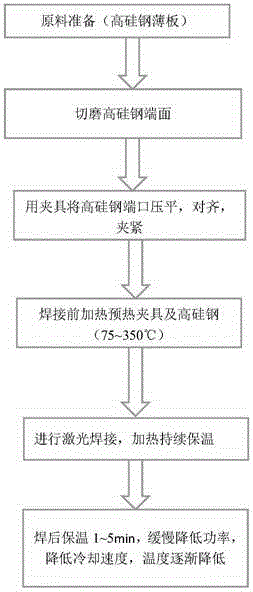

Laser welding method of high silicon steel

ActiveCN106041305ARealize welding formingImprove cooling conditionsWelding/soldering/cutting articlesLaser beam welding apparatusAlloySlow cooling

The invention belongs to the field of the metallurgy technology and material science, and aims at providing a laser welding process method of brittle high silicon steel. Quick welding of strip tension rolling in the rolling preparation process of a high silicon steel thin strip is met. According to the mass ratio, an adopted alloy is prepared from 93%-96.5% of Fe and 3.5%-7% of Si; and the thickness ranges from 0.1 mm to 3.5 mm. According to the method, laser welding and a supplementary heat source are combined, and double-face or single-face welding is adopted; preheating carried out before welding is utilized for controlling the temperature rise speed, and heat preservation during welding and heat preservation carried out after welding are utilized for slow cooling to control the temperature reduction speed; and the temperature gradient and welding stress in the weld joint cooling process are reduced, and welding forming of the brittle high silicon steel is achieved. By means of the adoption of the method, cracks generated by the too high welding stress of the brittle high silicon steel can be avoided well, and the yield and the mechanical performance of the brittle high silicon steel are increased.

Owner:UNIV OF SCI & TECH BEIJING

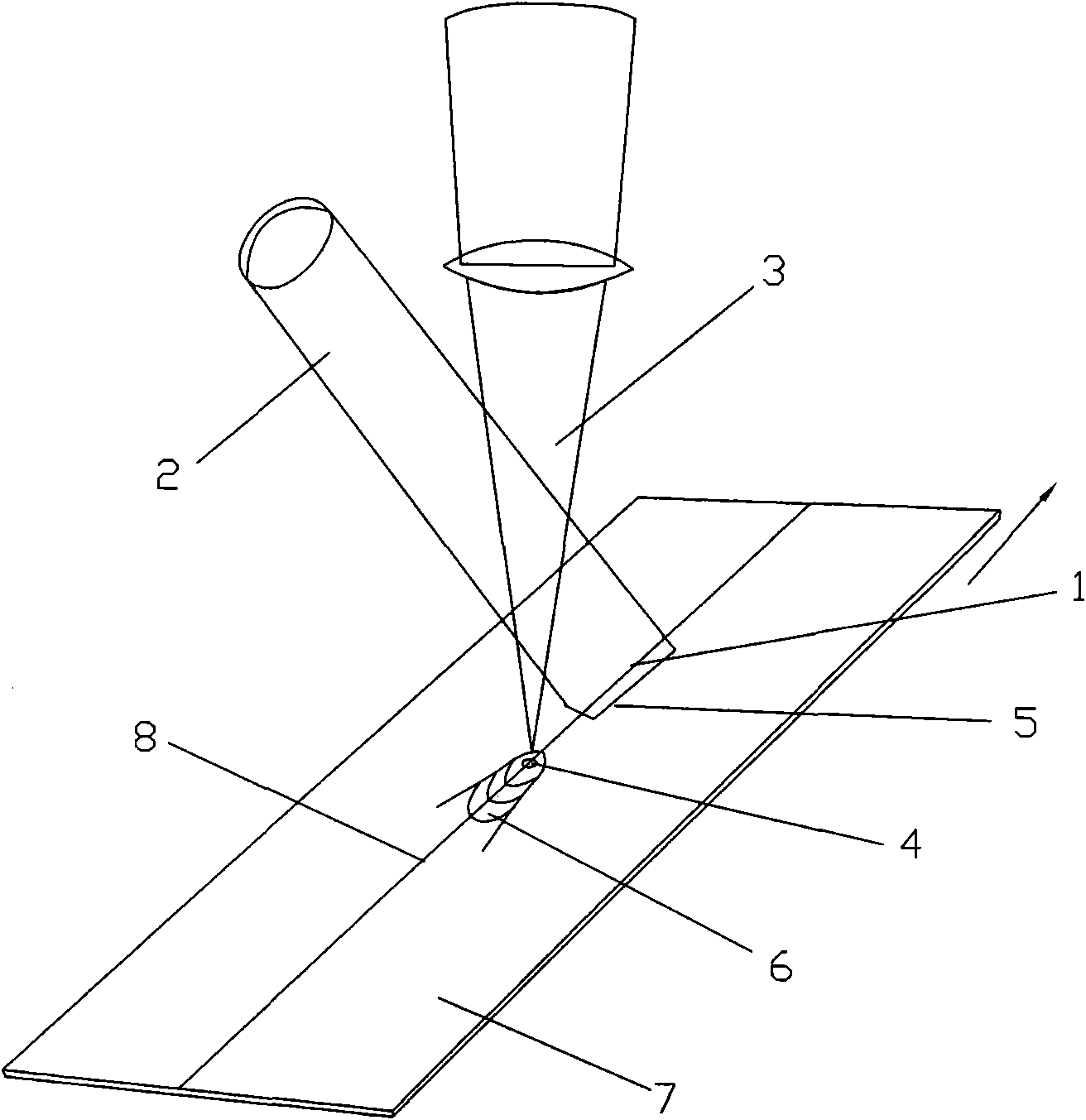

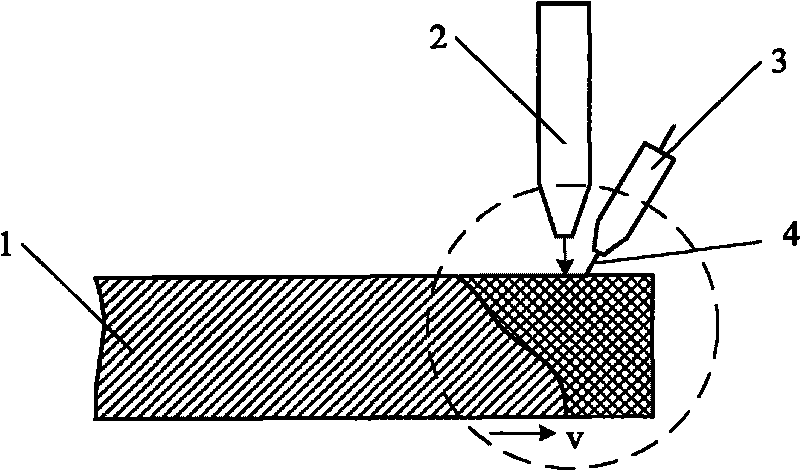

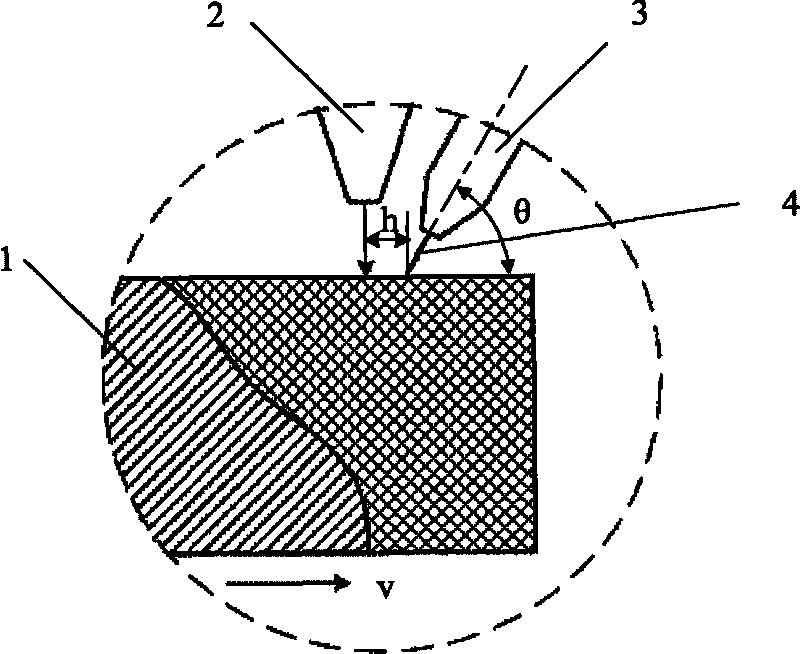

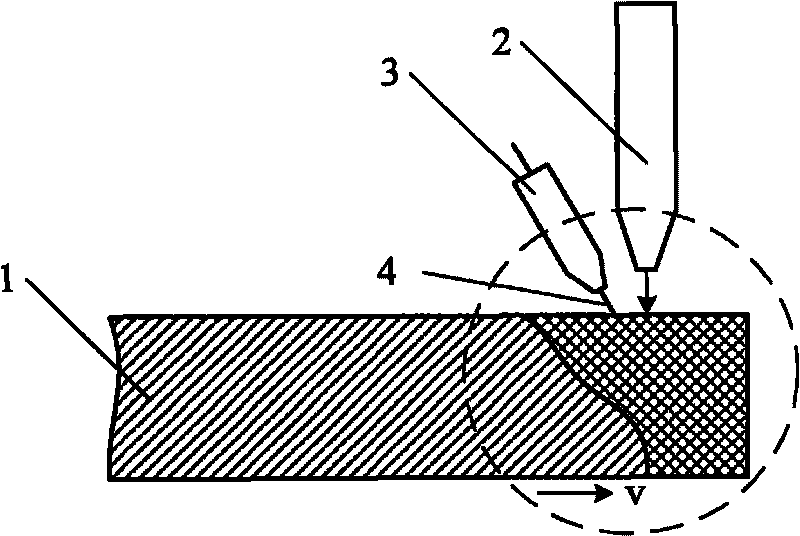

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

Photovoltaic device structure and method

ActiveUS20120125424A1Reduce defectsReduce cooling rateSemiconductor/solid-state device manufacturingPhotovoltaic energy generationMolten stateSemiconductor materials

A surface region of a semiconductor material on a surface of a semiconductor device is doped during its manufacture, by coating the surface region of the semiconductor material with a dielectric material surface layer and locally heating the surface of the semiconductor material in an area to be doped to locally melt the semiconductor material with the melting being performed in the presence of a dopant source. The heating is performed in a controlled manner such that a region of the surface of the semiconductor material in the area to be doped is maintained in a molten state without refreezing for a period of time greater than one microsecond and the dopant from the dopant source is absorbed into the molten semiconductor. The semiconductor device includes a semiconductor material structure in which a junction is formed and may incorporate a multi-layer anti-reflection coating. The anti-reflection coating is located on a light receiving surface of the semiconductor material structure and comprises a thin layer of thermal expansion mismatch correction material having a thermal expansion coefficient less than or equal to that of the semiconductor material, to provide thermal expansion coefficient mismatch correction. An anti-reflection layer is provided having a refractive index and thickness selected to match the semiconductor material structure so as to give good overall antireflection properties to the solar cell.

Owner:NEWSOUTH INNOVATIONS PTY LTD

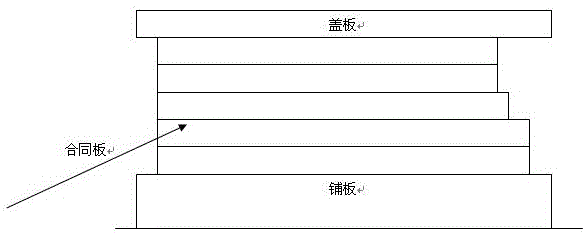

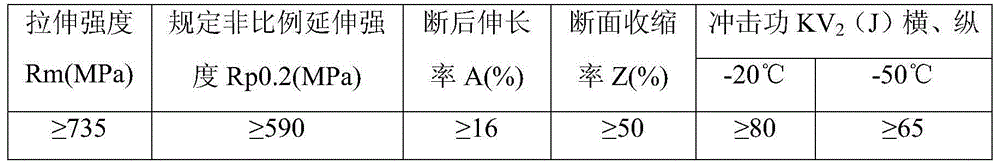

Hot-working die steel plate and preparation method thereof

The invention relates to a hot-working die steel plate. The steel plate is composed of, by mass, 0.45-0.55% of C, 0.20-0.80% of Si, 0.50-0.80% of Mn, 3.00-3.50% of Cr, 1.30-1.80% of Mo, 0.05-0.20% of V, 0.02-0.10% of Nb, 0.01-0.04% of Als, 0-0.015% of P, 0-0.005% of S and the balance Fe and inevitable impurities. The technological process comprises the steps of steel making, casting of steel ingots, heating, blooming, hydrogen diffusion, heating, steel rolling and heat treatment. A brand-new production method of the hot-working die steel plate is provided. The steel plate has the good comprehensive mechanical performance, and the preparation method of the steel plate is good in production stability and concise in technological process and facilitates batch production of hot-working die steel.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

HVAC desiccant wheel system and method

InactiveUS20070163279A1Improve efficiencyReduce humidityAir treatment detailsRefrigeration safety arrangementDesiccantEngineering

Owner:TRANE INT INC

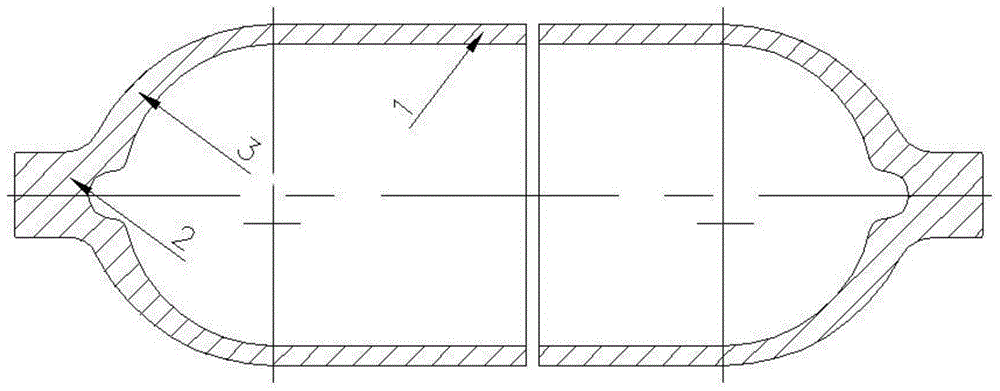

High-pressure seamless 10CrNi3MoV steel cylinder and manufacturing process thereof

ActiveCN104451419AImprove toughnessAvoid brittlenessFurnace typesHeat treatment furnacesHigh probabilityHigh pressure

The invention belongs to the field of machinery manufacturing, particularly relates to a high-pressure seamless 10CrNi3MoV steel cylinder and a manufacturing process thereof, and aims to solve the technical problems of difficulty in manufacturing process determination, poor low-temperature toughness of materials, high probability of deformation and cracking and the like of the current welded type high-pressure seamless 10CrNi3MoV steel cylinder. The scheme is that the high-pressure seamless 10CrNi3MoV steel cylinder adopting seamless 10CrNi3MoV steel pipes as raw materials is provided. The invention further provides a manufacturing process of the high-pressure seamless 10CrNi3MoV steel cylinder. A cylinder body and a seal head of the high-pressure seamless 10CrNi3MoV steel cylinder are seamlessly connected, so that the welding defect is overcome, and meanwhile, with the adoption of the manufacturing process, the low-temperature toughness of steel is further improved.

Owner:CHENGDU GREAT HIGH PRESSURE VESSEL

Fume emission continuous monitoring method and system

ActiveCN101387603ACondensation will notAvoid pollutionWithdrawing sample devicesMaterial analysis by optical meansMeasurement deviceMaintainability

The invention discloses a smoke discharge continuous monitoring method, comprising the steps that: a, sampling device works to continuously sample the smoke in a smoke pipeline; b, the valve at the inlet of the gas chamber is opened to transmit the sampled smoke into the gas chamber; c, a measurer measures the parameters of the smoke in the gas chamber, and in power off, the valve at the inlet of the gas chamber is closed, the clean gas without corrosive components and much water is exchanged with the residue gas in the gas chamber. The invention further discloses a smoke discharge continuous monitoring system. The invention has the advantages that the smoke discharge continuous monitoring method and the smoke discharge continuous monitoring system can prevent corroding and damage the gas chamber, polluting the gas chamber and blocking the gas pipeline, having simple structure, maintainability, stability and wide application in smoke discharge continuous monitoring.

Owner:FOCUSED PHOTONICS +1

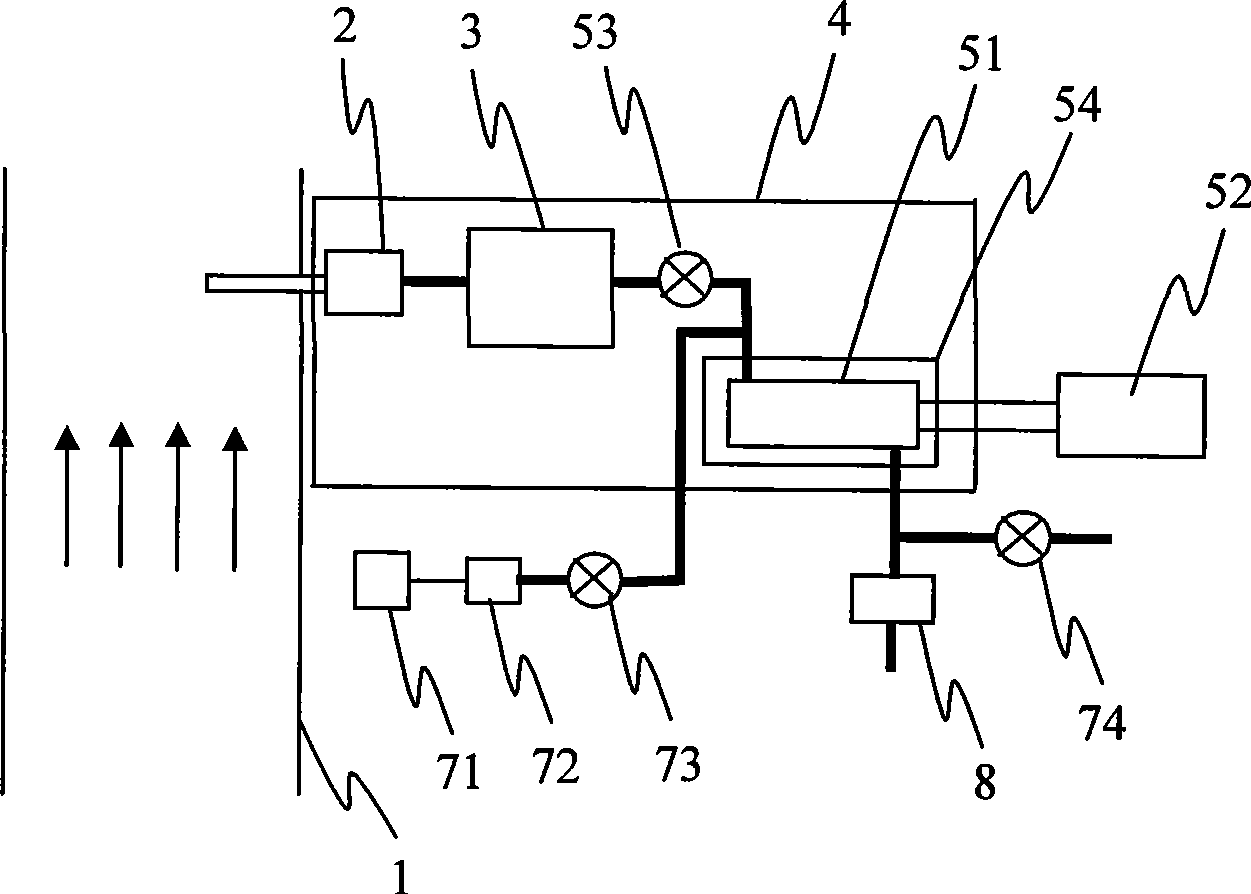

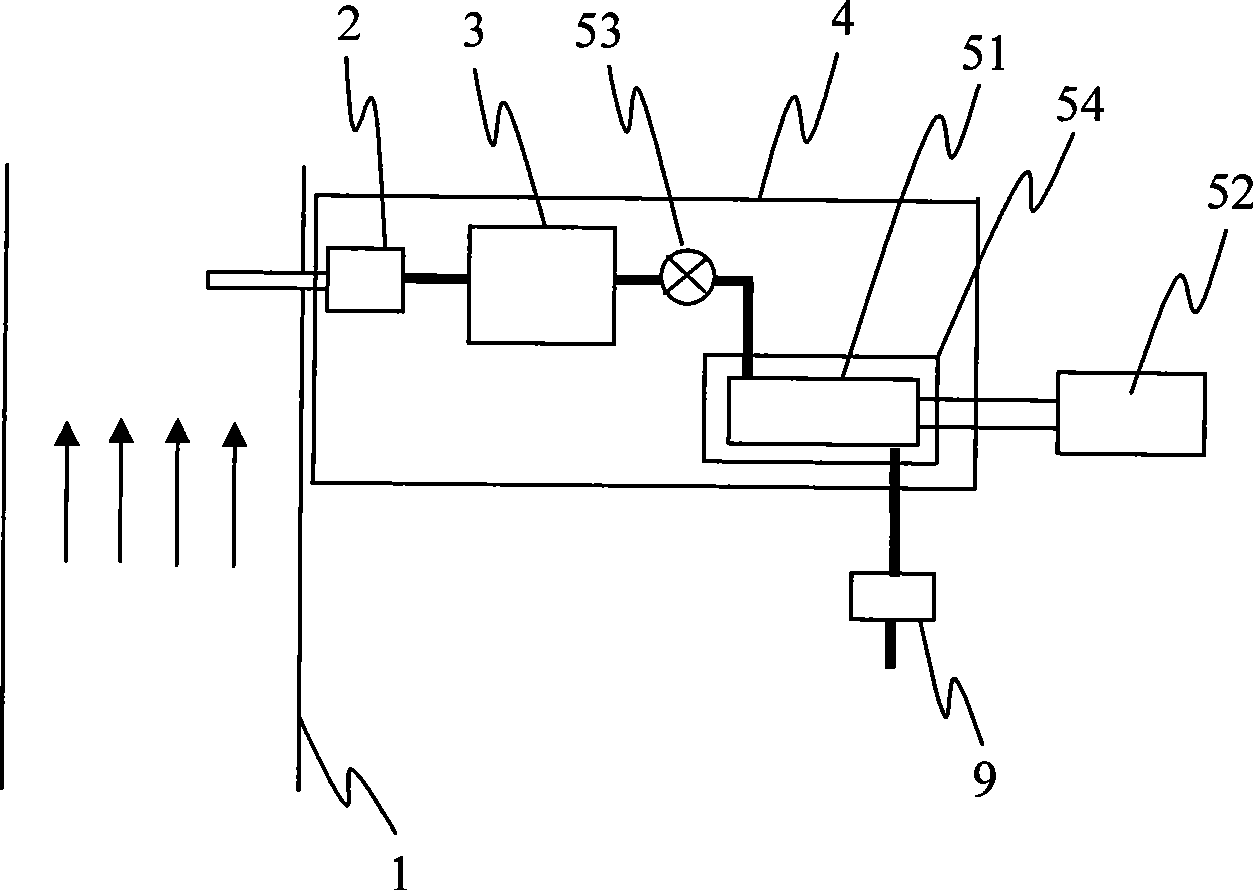

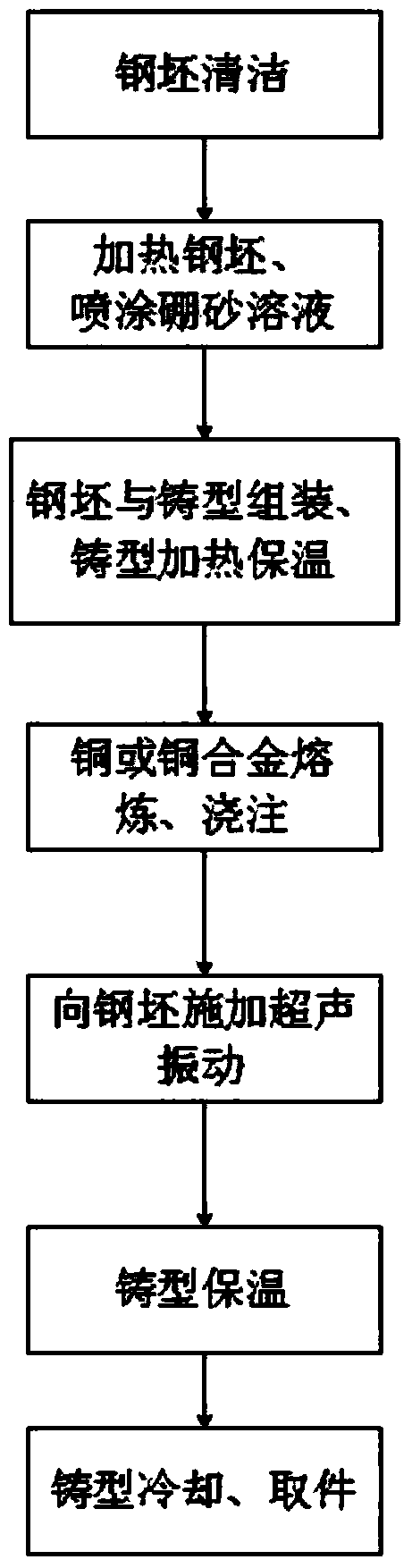

Copper-steel bimetal casting improved technology

The invention provides a copper-steel bimetal casting improved technology. Copper or copper alloy in a certain thickness is directly cast on a steel base body through a static cast type casting method, and the main technical process comprises the steps of: cleaning a steel billet, heating the steel billet and spraying a borax solution on the heated steel billet, combining the cast, heating and keeping the heat, melting and pouring the copper or copper alloy, performing ultrasonic vibration on the steel billet, and keeping the high temperature of the cast. Through the copper-steel bimetal casting improved technology provided by the invention, the ultrasonic vibration and stirring step is added on the basis of the static embedding process technology, a copper or copper alloy layer in a certain thickness and without segregation can be obtained by casting on steel billets in various types and various sizes, and good metallurgical bonding can be realized between the copper or copper alloy layer of the obtained cast and the steel billet.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com