Special portable miniature drainage cover for automatic underwater local dry-method welding

A local dry method and drainage cover technology, applied in the direction of welding rod characteristics, welding accessories, electrode support devices, etc., can solve the problems that the molten pool is not easy to spread, restrict the flexibility of divers, and cannot be repaired, so as to ensure the flexibility of multiple plugging and unplugging , The welding process is stable and reliable, and the effect that meets the needs of the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

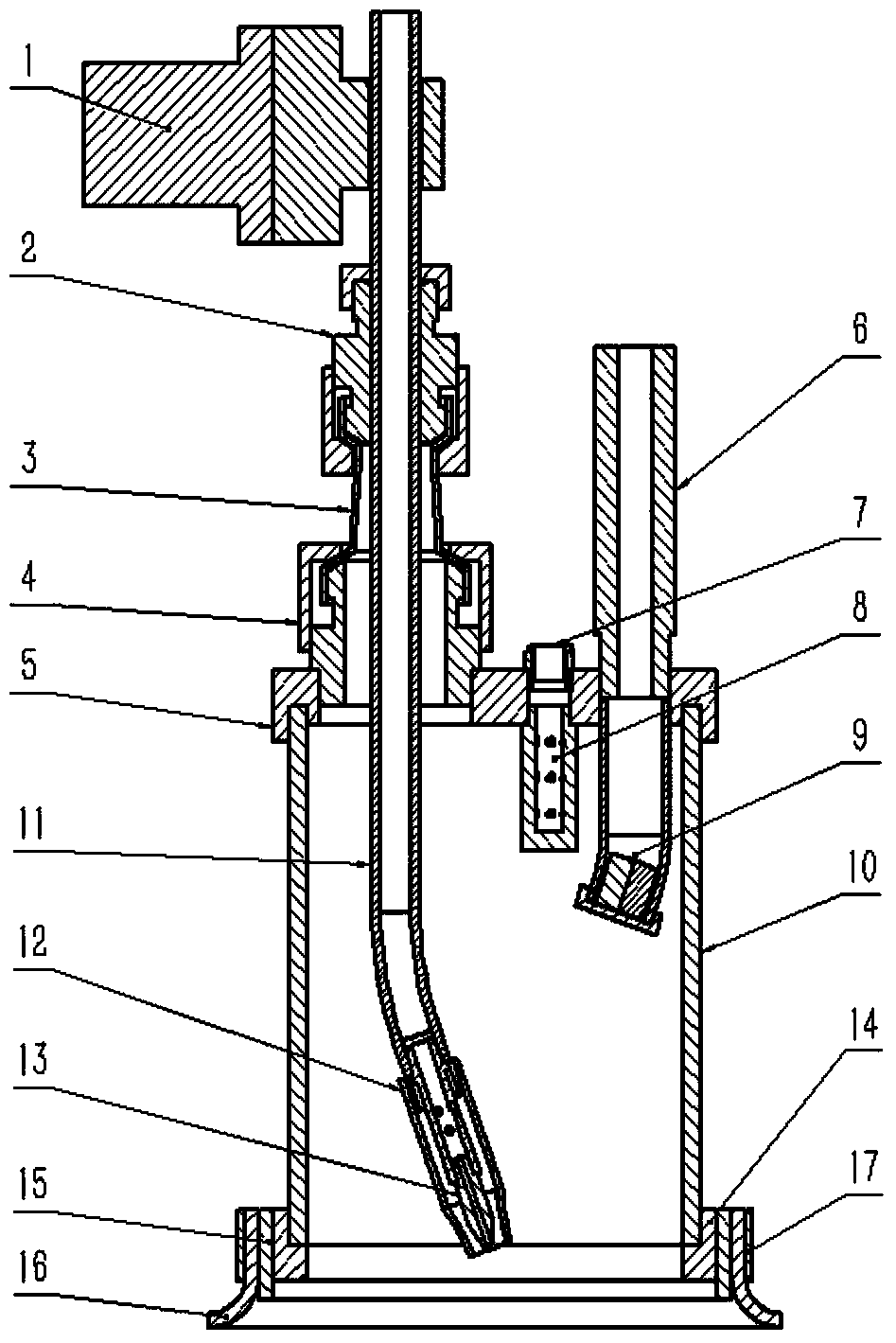

[0019] The structure of the portable underwater partial dry automatic welding micro-drainage cover of the present invention is described in conjunction with the accompanying drawings and embodiments.

[0020] The design concept of the portable underwater partial dry automatic welding micro-drainage cover of the present invention is to use gas to drain the water in the welding local area to form a smaller gas phase area, so that the arc can burn stably in it, and realize stable and reliable welding. process and form joints that approach onshore weld quality. The device can be used for underwater welding by using ordinary land-based solid wire or flux-cored wire. During the welding process, workers on the water surface can clearly see the arc combustion process and the shape of the molten pool. The device can be used for welding in muddy water environment or underwater environment with low visibility and harsh environment, such as underwater environment with high water velocity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com