Patents

Literature

49results about How to "The welding process is stable and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

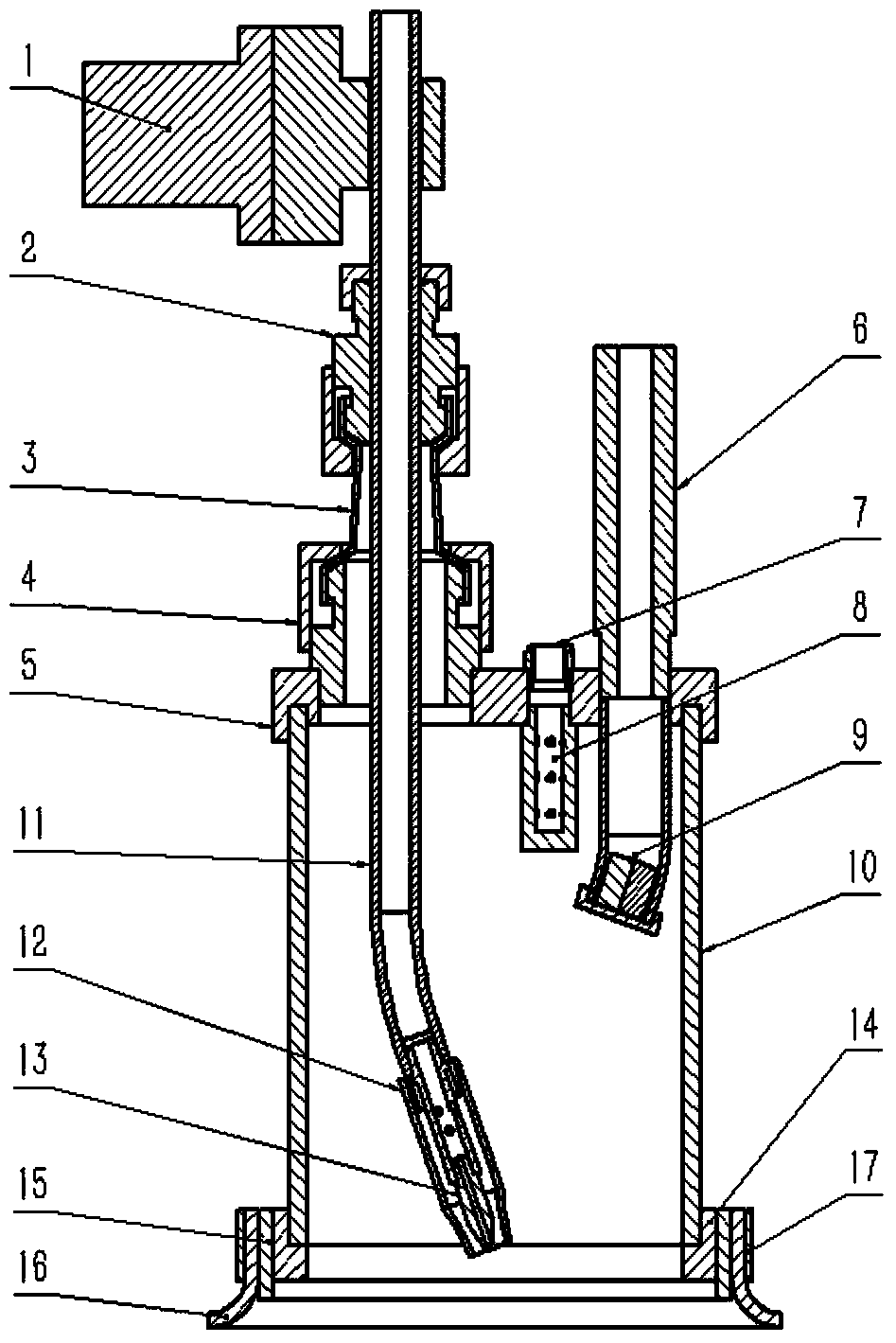

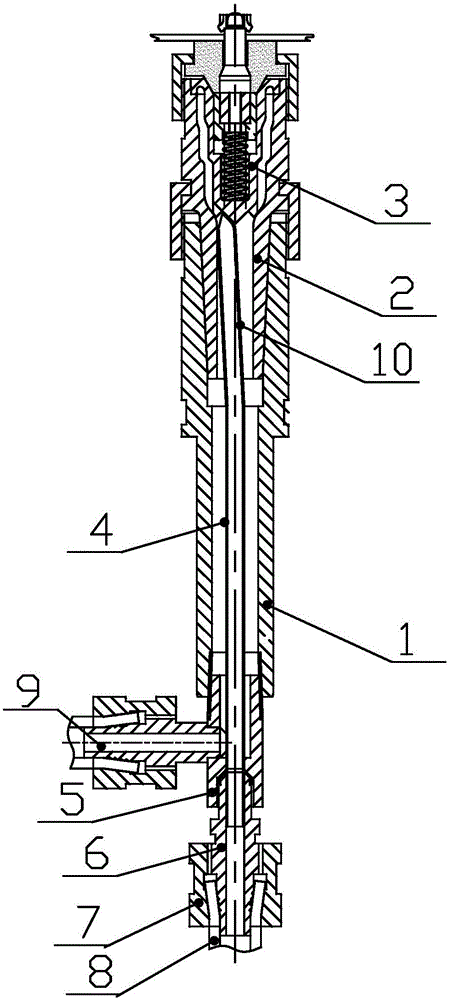

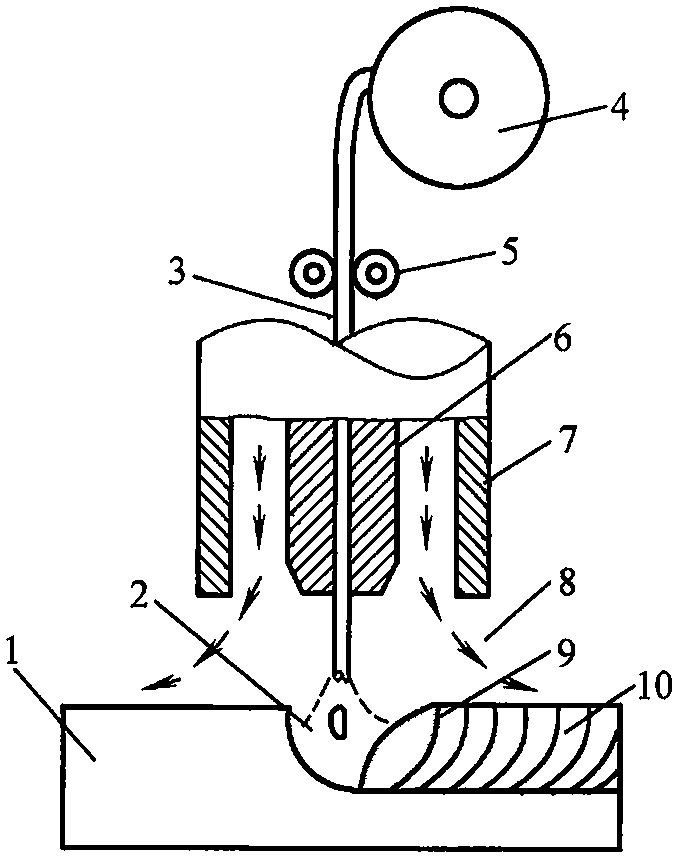

Special portable miniature drainage cover for automatic underwater local dry-method welding

InactiveCN103433606ARealize free adjustmentAvoid unfusedElectrode supporting devicesWelding accessoriesEngineeringCopper

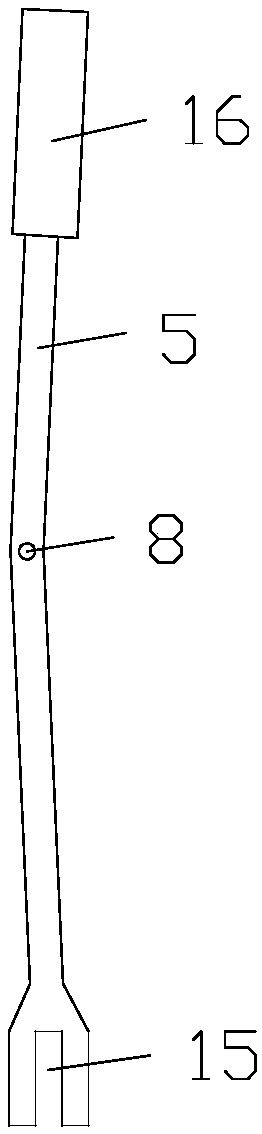

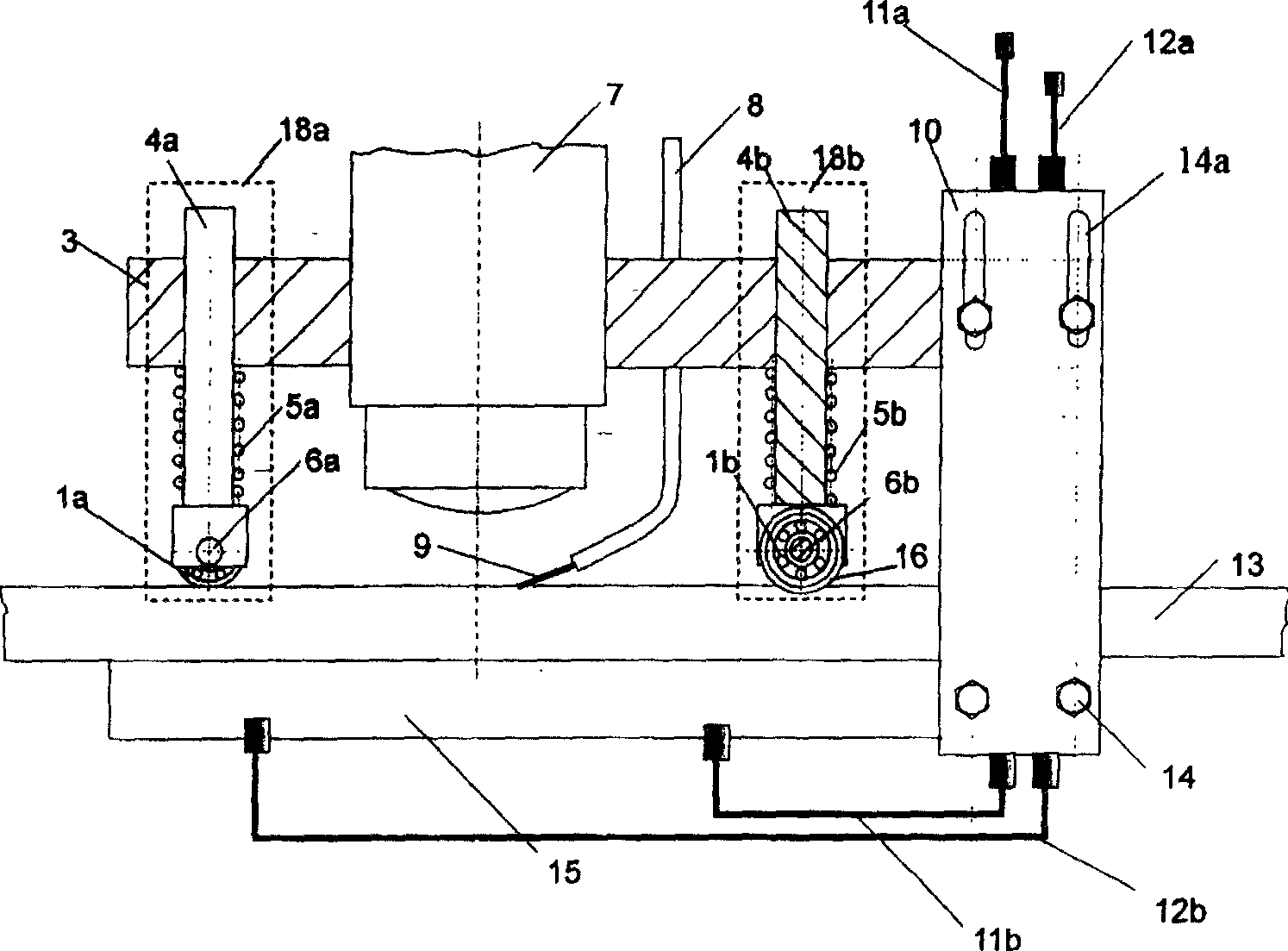

The invention provides a special portable miniature drainage cover for automatic underwater local dry-method welding. A drainage cover body of the drainage cover comprises an upper end cover, an organic glass cover and a lower end cover. A clamping rod, an air inlet quick plug connector, a lower locking sleeve, a cooling air chamber and an underwater camera component are fixed to the upper side of the upper end cover and the lower side of the upper end cover through threaded connection respectively, and the upper end cover and lower end cover are connected with the organic glass cover through threads. A welding oscillator is clamped on the upper portion of a copper welding torch of a welding gun. According to the structure of a drainage sealing device, drainage felt and a felt skirt are arranged on the periphery of the lower end cover, and the drainage felt and the felt skirt are fastened on the lower end cover through hose clamps; the copper welding torch of the welding gun is fastened through an upper locking sleeve and the lower locking sleeve, the welding gun is inserted into the organic glass cover, and an elastic rubber leather sheath is arranged between the upper locking sleeve and the lower locking sleeve. The special portable miniature drainage cover for automatic underwater local dry-method welding has the advantages of being simple in structure, exquisite, convenient and fast to use, low in cost, obvious in drainage effect, and stable and reliable in welding process. Moreover, a connector with the quality of on-land welding is formed, the welding efficiency is improved and the special portable miniature drainage cover is easy to popularize.

Owner:TIANJIN UNIV

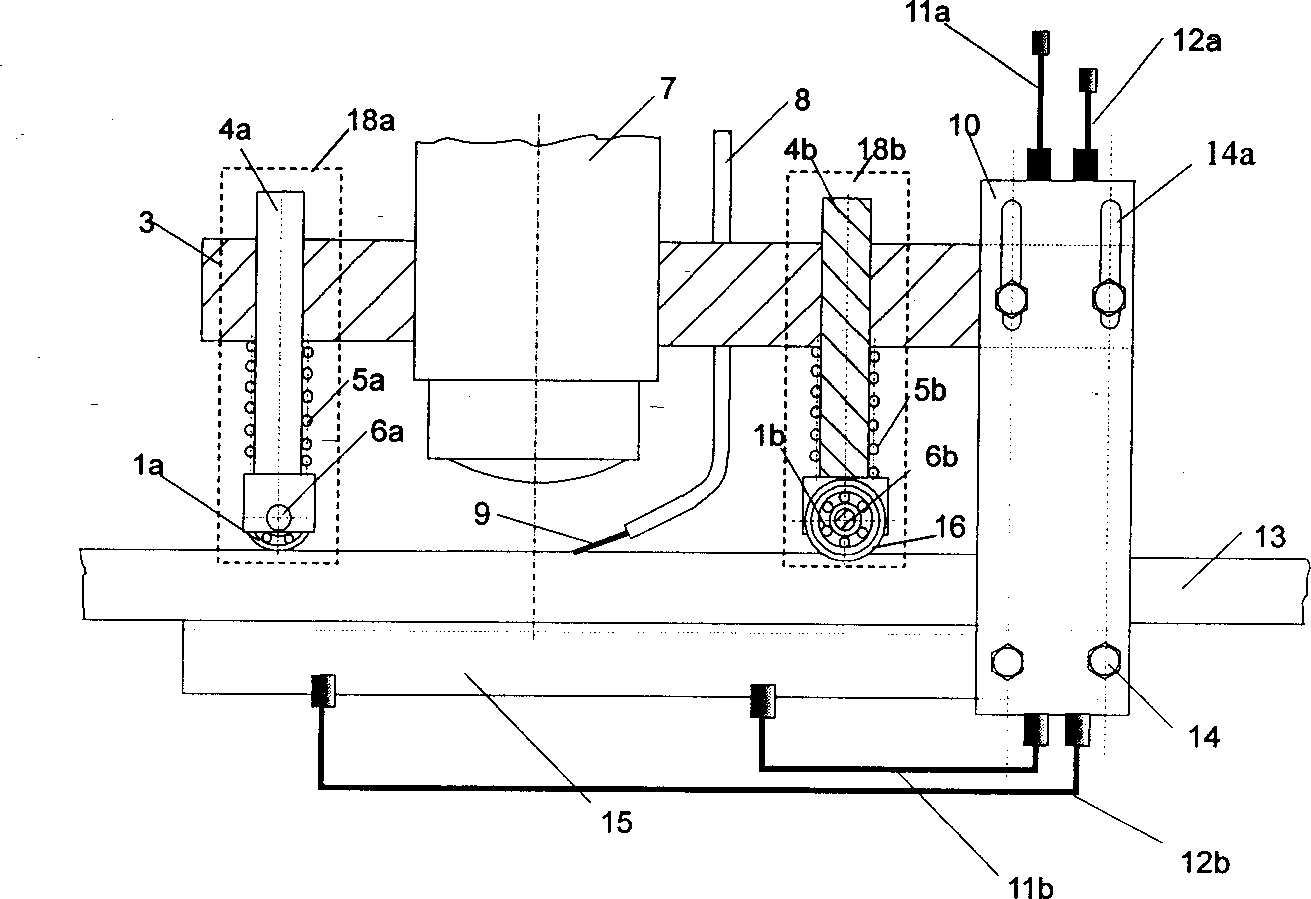

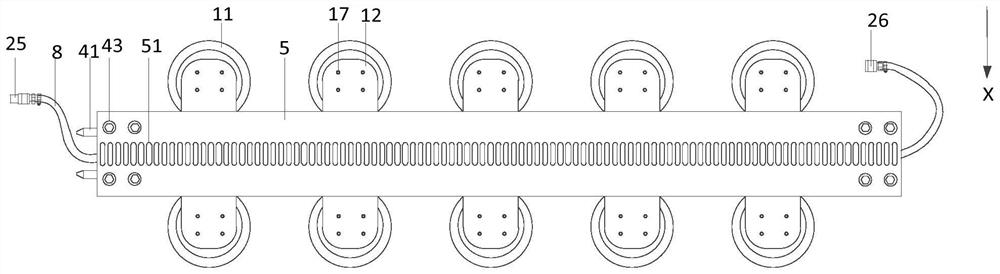

Railless walking single-pass full-penetration arc welding equipment and method

InactiveCN1367061AGuarantee welding qualityIncrease productivityArc welding apparatusEngineeringMetal

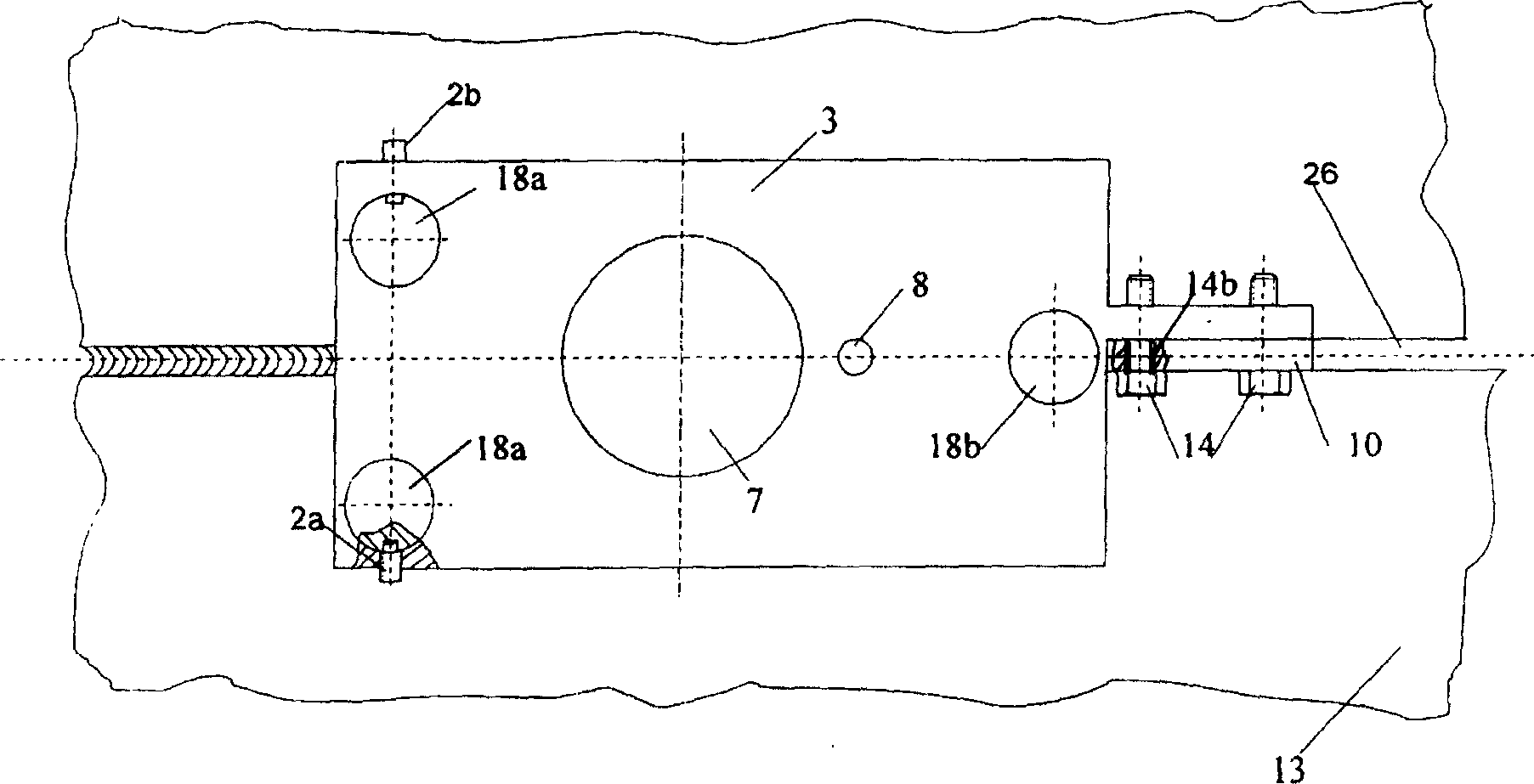

A single-pass full-fusion arc welding equipment includes metal connecting plate, backing pad, welding wire, welding device, metal fixing plate, guide wheel mechanism and two-rolling supporting wheel mechanisms and driving mechanisms, the metal connecting plate is perpendicularly placed into the preset weld gap of metal to be welded, on the supporting shaft of the described rolling supporting wheel mechanism and guide wheel mechanism three pressure springs are respectively mounted by the action of these springs the metal to be welded and the backing pad and be held in tight contact. This invention is adoptable to the plasma welding and gas shielded welding processes, and is suitable for automatic single-pass welding or manual single-pass welding in large metal plate structures, and its welding quality is high.

Owner:张绍彬

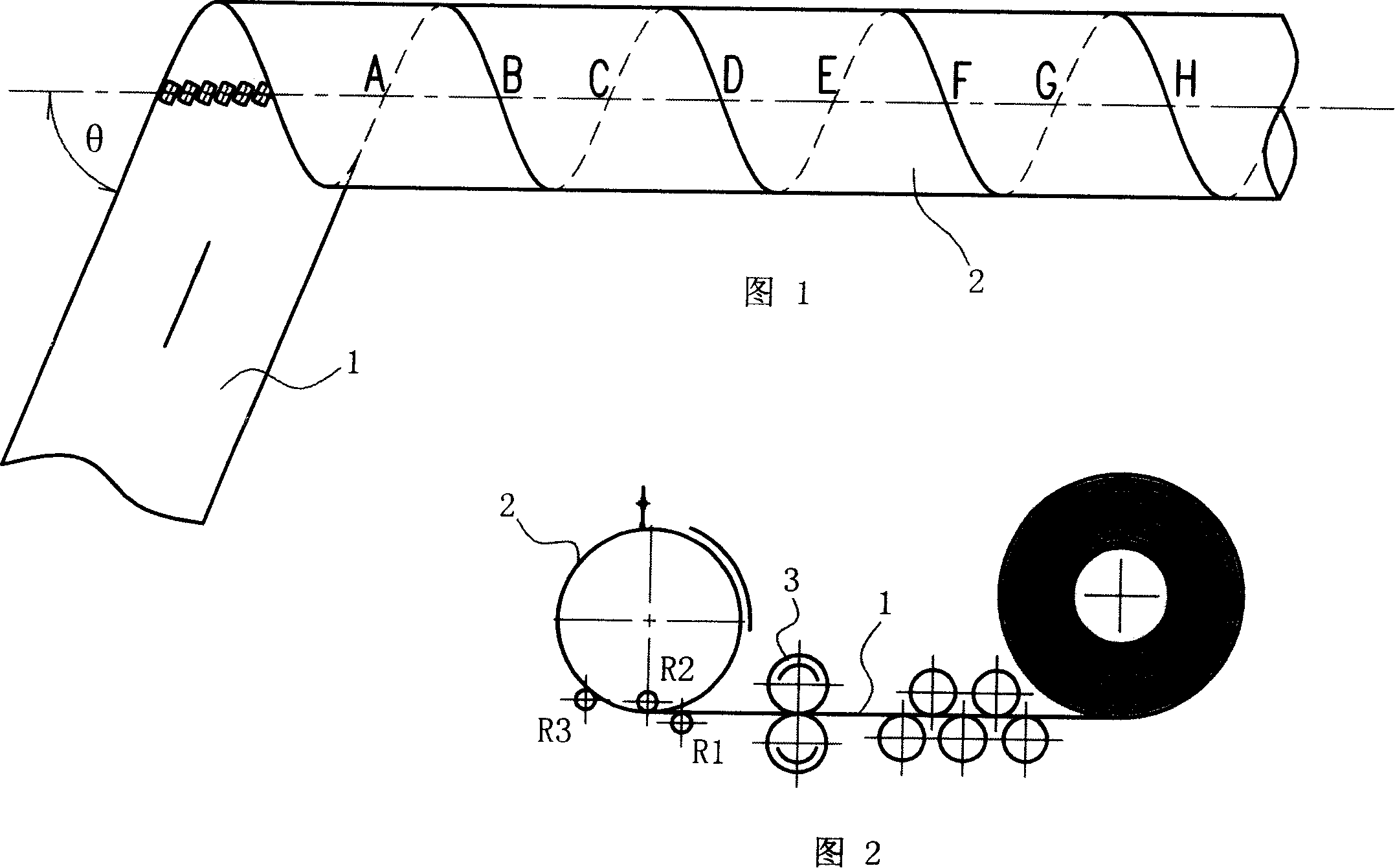

Welding method for welding steel pipe spirally

The invention discloses a welding method for welding a steel pipe spirally. The welding method comprises the steps of: uncoiling a plate coil, flattening, milling edges, forming, welding and tracking detection. The welding method is characterized in that firstly the plate coil is uncoiled and flattened into a steel belt, and edge-milled into an X-shaped groove, the steel belt is conveyed to a spiral welded steel pipe former continuously according to the spiral angle; the formed steel-belt spiral steel pipe adopts a process with combination of internal and external submerged-arc welding and double-wire serial electric-arc and submerged-arc automatic welding, and then pre-internal welding, refined internal welding and external welding are carried out; a tracking sensor is adopted to detect the lowest point of a V-shaped groove of the formed seam at a distance before internal welding of the groove welded of the steel pipe to be welded to realize automatic tracking of refined welding and internal welding. The welding method disclosed by the invention has the advantages that the process with combination of internal and external submerged-arc welding and double-wire serial electric-arc and submerged-arc automatic welding and the tracking detection system is adopted, the welding deviation phenomenon and the fluctuation of welding offset can be avoided, the workload for correction and adjustment is reduced, the welding process is stable and reliable and the quality of the welding seam is ensured.

Owner:方晓东

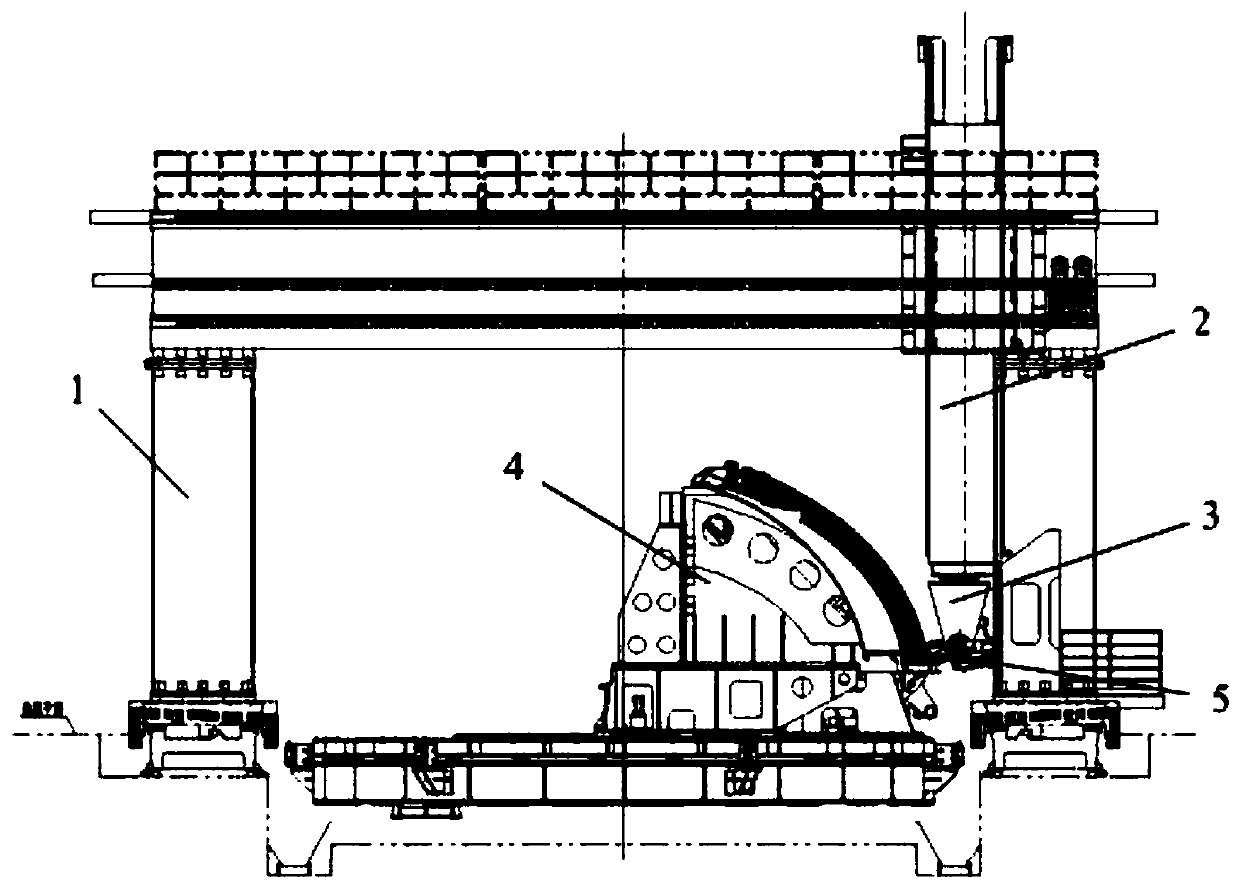

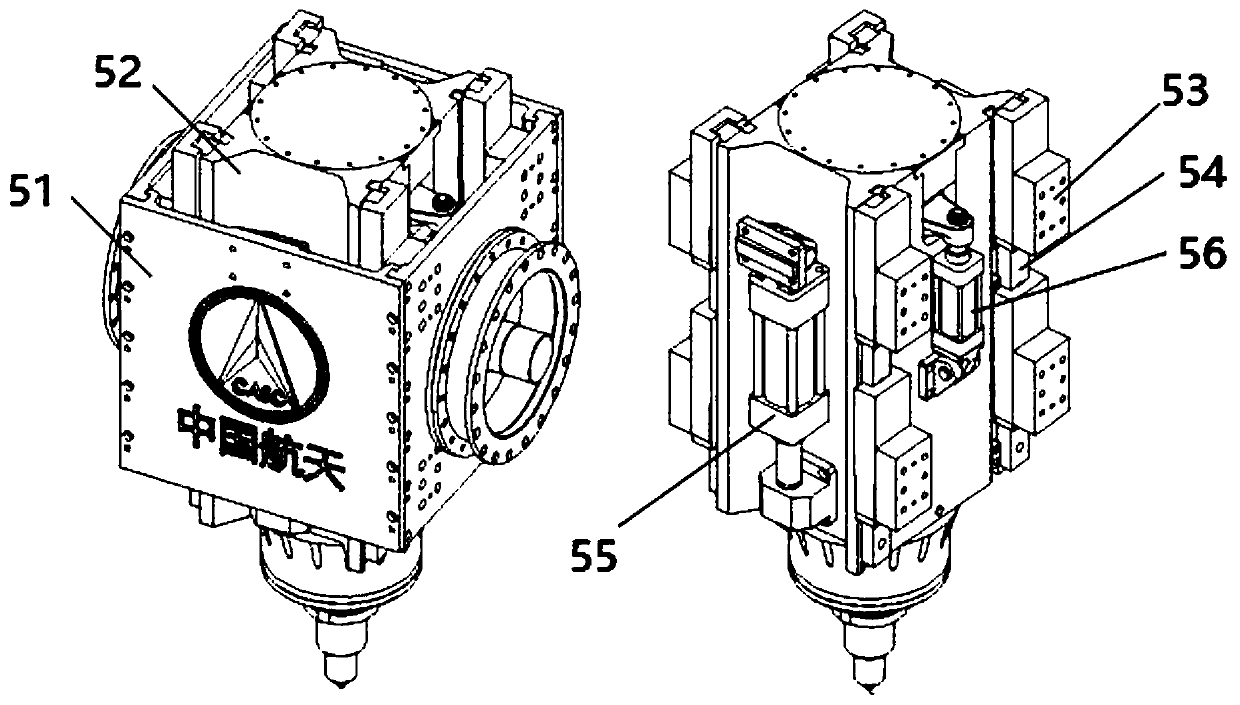

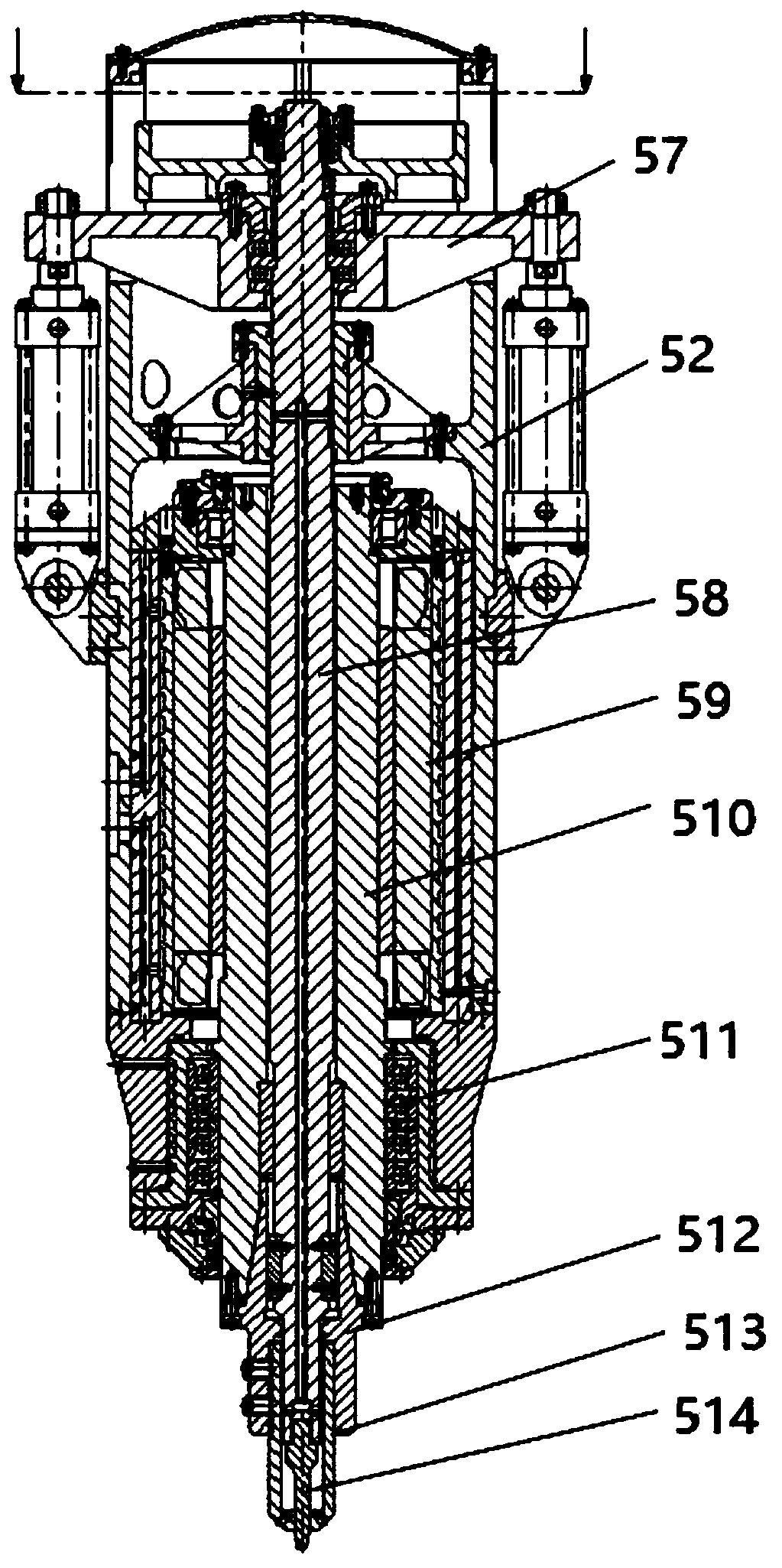

Hydraulically-driven constant-pressure constant-displacement friction stir welding spindle unit

ActiveCN111545891AThe welding process is stable and reliableWeld firmlyNon-electric welding apparatusFriction weldingDisplacement control

The invention discloses a hydraulically-driven constant-pressure constant-displacement friction stir welding spindle unit which is used for solving the problem of constant-pressure constant-displacement control in the heavy-load friction stir welding process. The friction stir welding spindle unit is mounted in a fork-shaped structural part at the end of a ram of a gantry body frame, and welding of a longitudinal seam of the box bottom is completed along a welding track through the gantry body frame and a double-fork piece; the friction stir welding spindle unit is characterized in that an outer sliding box and a main shaft shell are driven by pressing two groups of symmetrical shaft shoulders into a servo oil cylinder, a cylinder body tailstock of the servo oil cylinder is fixedly connected with the outer sliding box, a plunger of the servo oil cylinder is fixedly connected with the main shaft shell through a connecting piece, and the plunger extends out or retracts back through a control oil cylinder, so that the outer sliding box and the main shaft shell move relatively, in other words, the motion is the pressing motion of a shaft shoulder, and the axis is defined as a Z1 axis;sliding blocks are fixedly connected with the outer sliding box, a linear guide rail is fixedly connected with the main shaft shell, and the four sets of symmetrically-arranged sliding blocks and thelinear guide rail form a guide mechanism for shaft shoulder press-in movement; the servo oil cylinder of the Z1 axis is connected with a high-frequency proportional valve.

Owner:CAPITAL AEROSPACE MACHINERY +1

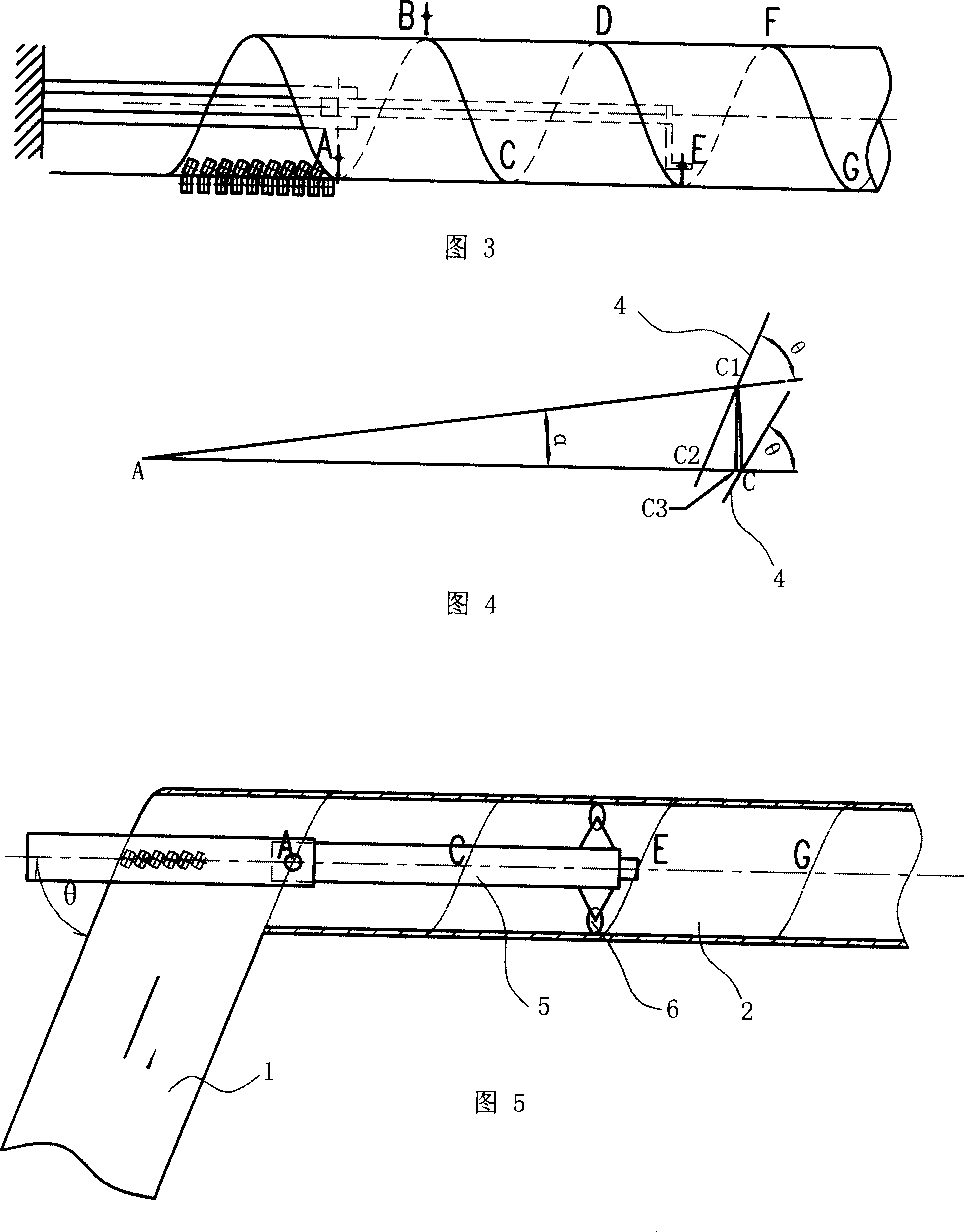

Method for soldering spiral welded pipe

A spiral welding pipe welding method with simple and convenient manufacture process and high welding quality includes that the metal strip is continuously fed to a spiral welding pipe shaper by the spiral angle theta and the pre-internal welding of a spiral seam formed by the steel strip is carried out by a first internal welding gun arranged at the initial position I (A) of the steel strip spiral forming pipe. The invention is characterized in that an external welding gun is arranged at the position about odd-number times pitch away from the position I (A) in the extension direction of the spiral welding pipe to carry out the external welding to the steel strip spiral seam; a secondary internal welding gun is arranged at the position III (E) at least two pitches away from the position I (A) in the extension direction of the spiral welding pipe to carry out the finishing internal welding to the steel strip spiral seam. The invention is suitable for manufacturing the spiral steel pipes.

Owner:冯白茹

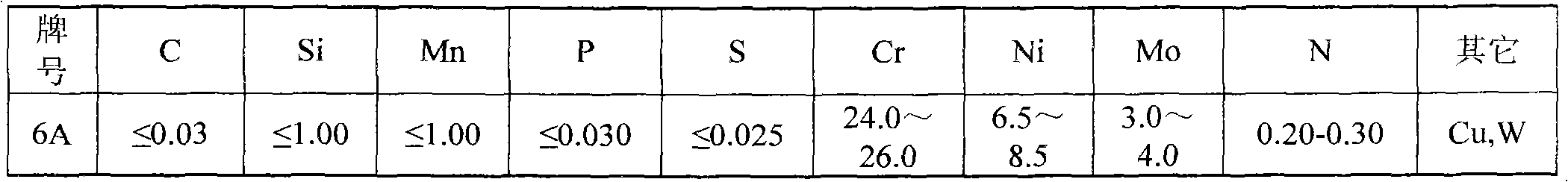

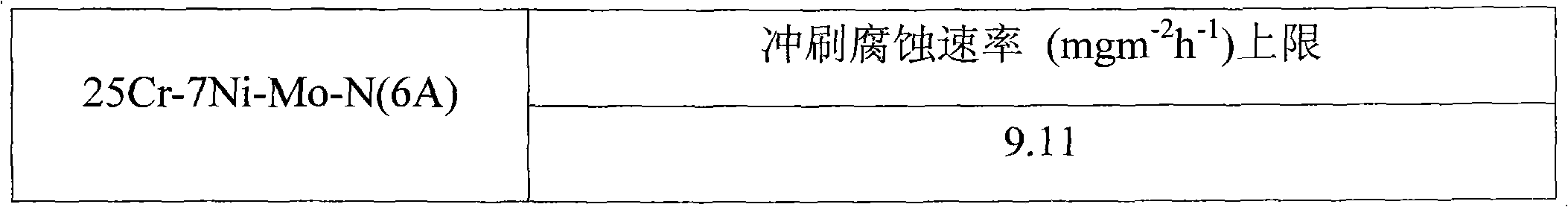

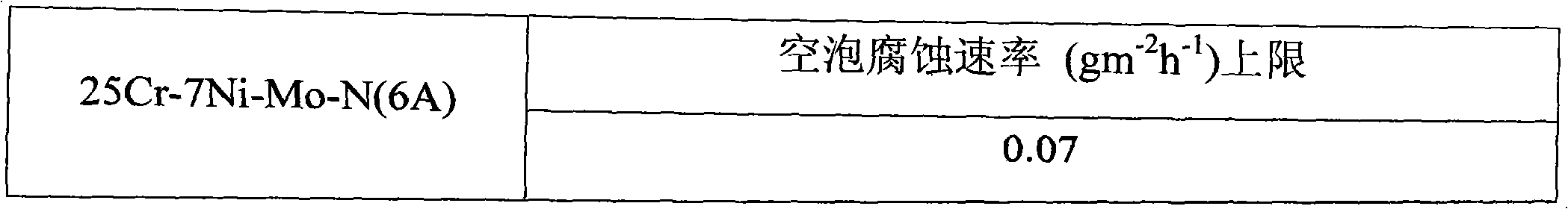

Repair welding wire for flaws of cast two-phase stainless steel 6A

ActiveCN101972903AIncrease content ratioPromote precipitationWelding/cutting media/materialsSoldering mediaCavitationManganese

The invention discloses a repair welding wire for flaws of cast two-phase stainless steel 6A. The two-phase stainless steel 6A refers to 25Cr-7Ni-Mo-N(6A), and the repair welding wire basically comprises: carbon: not larger than 0.03%, silicon: not larger than 0.7%, manganese: not larger than 0.7%, chrome: 25.0-26.0%, molybdenum: 3.0-3.2%, copper:0.5-0.7%, tungsten: 0.5-1.0%, nickel: larger than 8.5-9.0%, nitrogen: 0.30-0.40%, other unavoidable impurities and elements: smaller than 0.06%, and the balance of iron. The repair welding wire with phi 2mm is finally formed by carrying the steps of refining, hot forging, multiple cold pulling and annealing on the basic constituents, satisfies the requirements of the two-phase stainless steel 6A on erosion corrosion resistance and cavitation corrosion resistance, and guarantees that a flawed repair welded position of the cast two-phase stainless steel 6A has favorable erosion corrosion resistance and cavitation corrosion resistance.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

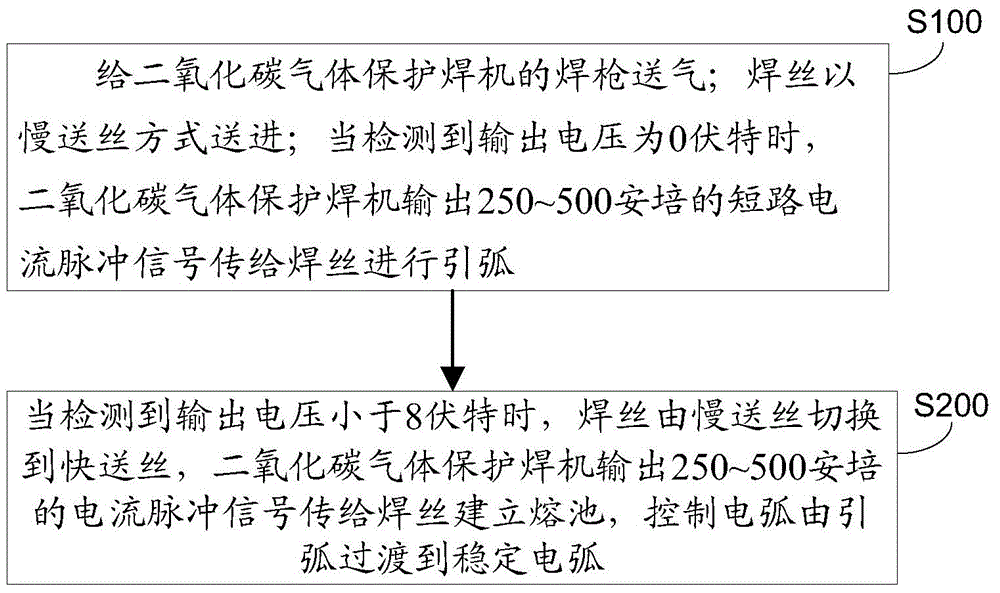

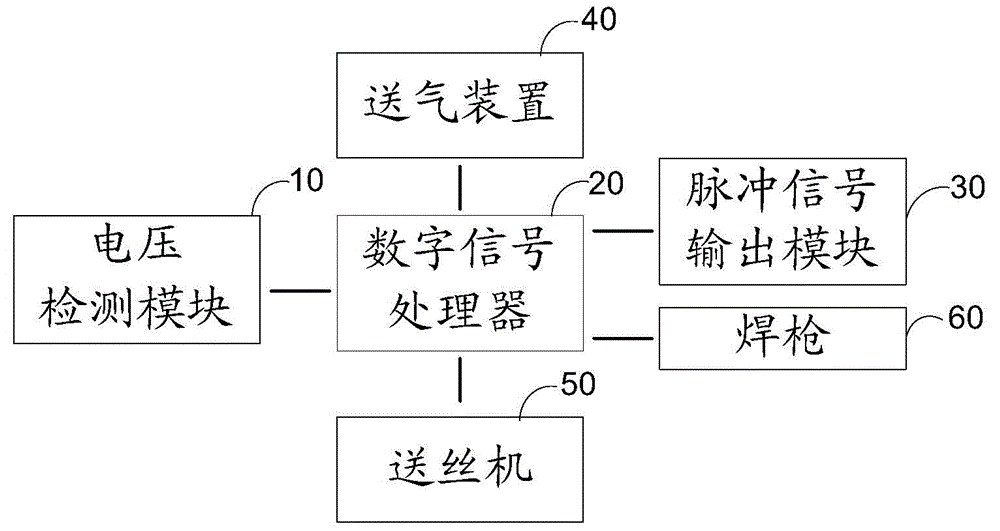

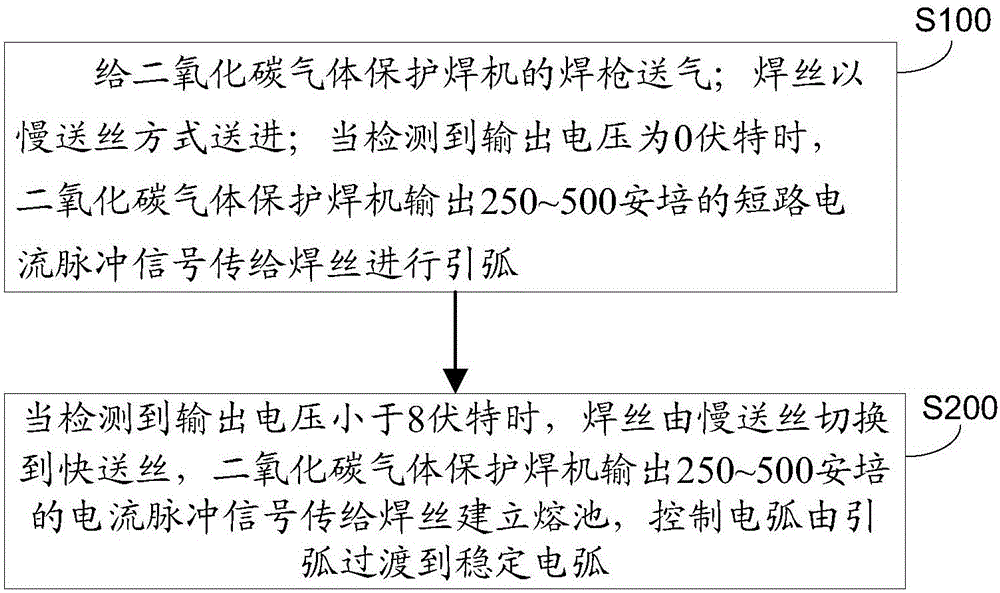

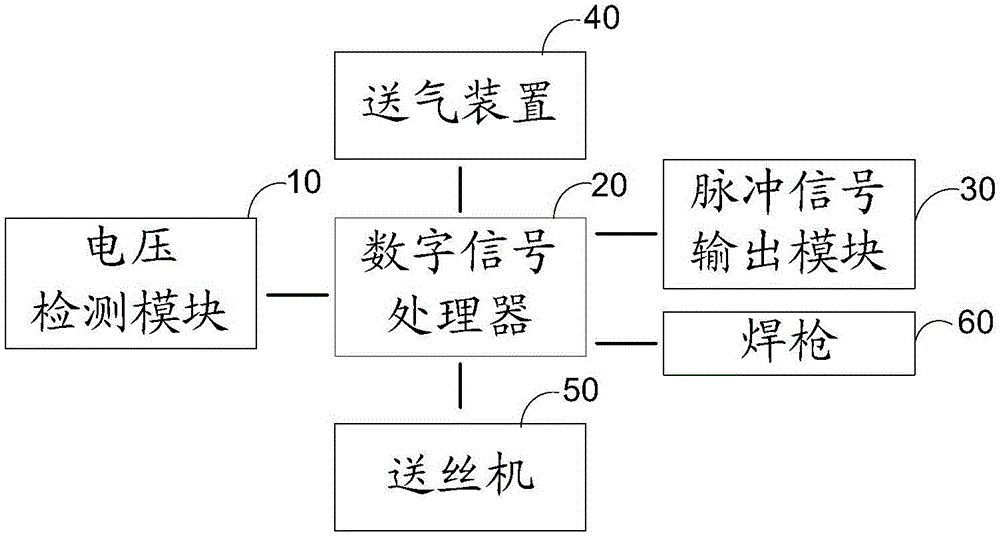

Carbon dioxide gas shielded welding machine and method of controlling arc strike by adopting digital pulse

ActiveCN104096947AReduced maximum peak powerReduce transient impact stressArc welding apparatusEngineeringImpact stress

The invention discloses a method of controlling the arc strike of a carbon dioxide gas shielded welding machine by adopting digital pulse. The method comprises the steps of feeding gas for a welding gun; feeding a welding wire in a slow wire feeding mode; when the output voltage is detected to be 0 volt, outputting a 250-500 ampere short-circuit current pulse signal to the welding wire for arc strike; when the output voltage is detected to be smaller than 8 volts, switching from the slow wire feeding mode of the welding wire into a quick wire feeding mode, outputting a 250-500 ampere short-circuit current pulse signal to the welding wire to build a molten pool, and controlling an arc to be subjected to transition from arc strike to a stable arc. According to the method, the transient impact stress which is borne by a hardware power device is reduced, and the service life is prolonged; the arc strike time is shortened, the arc strike process is stable, the reliability is strong, and the arc strike success rate is high; the molten pool is built in the arc strike process, and thus a basic is established for normal, stable and reliable welding in the future. The invention further discloses a carbon dioxide gas shielded welding machine.

Owner:SHENZHEN RILAND IND

Hot melting bushing welder

The invention discloses a hot melting bushing welder and belongs to the welding field. The hot melting bushing welder comprises a rack, a fixing mechanism, a guiding mechanism and a hot melter, wherein the guiding mechanism and the fixing mechanism are mounted on the rack; the fixing mechanism comprises a pipefitting fixing device and a bushing fixing device for separately fixing pipefittings andbushings, the pipefitting fixing device is connected to the guiding mechanism, and the position of the pipefitting fixing device can be changed by means of the guiding mechanism; the bushing fixing device is also connected to the guiding mechanism, and the position of the bushing fixing device can be changed by means of the guiding mechanism; and the hot melter is used for heating the pipefittingsand the bushings. By matching the guiding mechanism with the fixing mechanism, the condition that at least two persons are needed to hold the pipefittings and the bushings at the left and right endsto apply forces during welding in the prior art is overcome, the manpower is reduced, and meanwhile, the whole welding process is steady and reliable, lasting in force, the welding difficulty is reduced directly, and the hot melting bushing welder can be widely applied to hot melting welding of plastic pipefittings such as PE pipes and PVC pipes in industries.

Owner:SINOHYDRO BUREAU 12 CO LTD

Preparation method for aluminum foil welding solder organic flux

InactiveCN105414801ADevice deformation is smallThe welding process is stable and reliableWelding/cutting media/materialsWelding/soldering/cutting articlesTriethanolamineBrass

The invention provides a preparation method for an aluminum brazing organic flux. An alumina film can be damaged at the temperature of 180 DEG C-275 DEG C, deformation is small after the alumina film is welded, stabilizing and shaping is achieved, corrosion is avoided, corrosion to aluminum and aluminum alloy is very small, the welding temperature is far from the melting point of an aluminum material, the welding process is reliable, and the brazing qualified rate is greater than 98%. According to the technical scheme, 70 wt%-90 wt% of triethanolamine, 1 wt%-5 wt% of zinc tetrafluoroborate hydrate, 5 wt%-10 wt% of cadmium fluoroborate, and 5 wt%-10 wt% of ammonium fluoroborate are added; the zinc tetrafluoroborate hydrate, the cadmium fluoroborate and the ammonium fluoroborate are weighed at the room temperature and put into a mortar to be ground into fine powder, and grinding and mixing are uniform; the uniformly ground and mixed drug is poured into the weighed triethanolamine, and after being stirred uniformly, the drug is placed for a certain period of time. The welding problems of the aluminum, the aluminum alloy, aluminum bronze and aluminum brass at the temperature of 180 DEG C-275 DEG C are solved through the preparation method.

Owner:四川泛华航空仪表电器有限公司

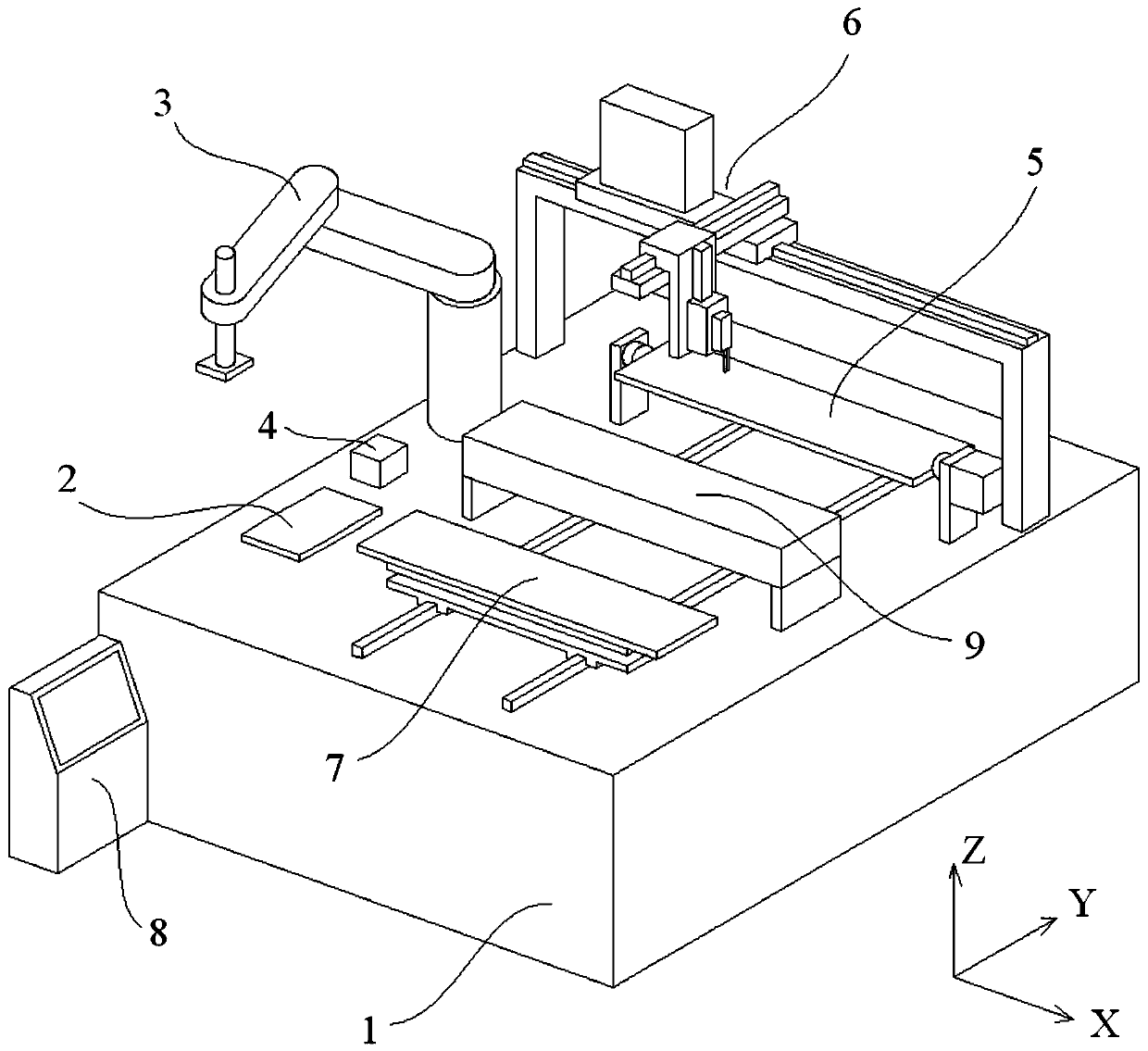

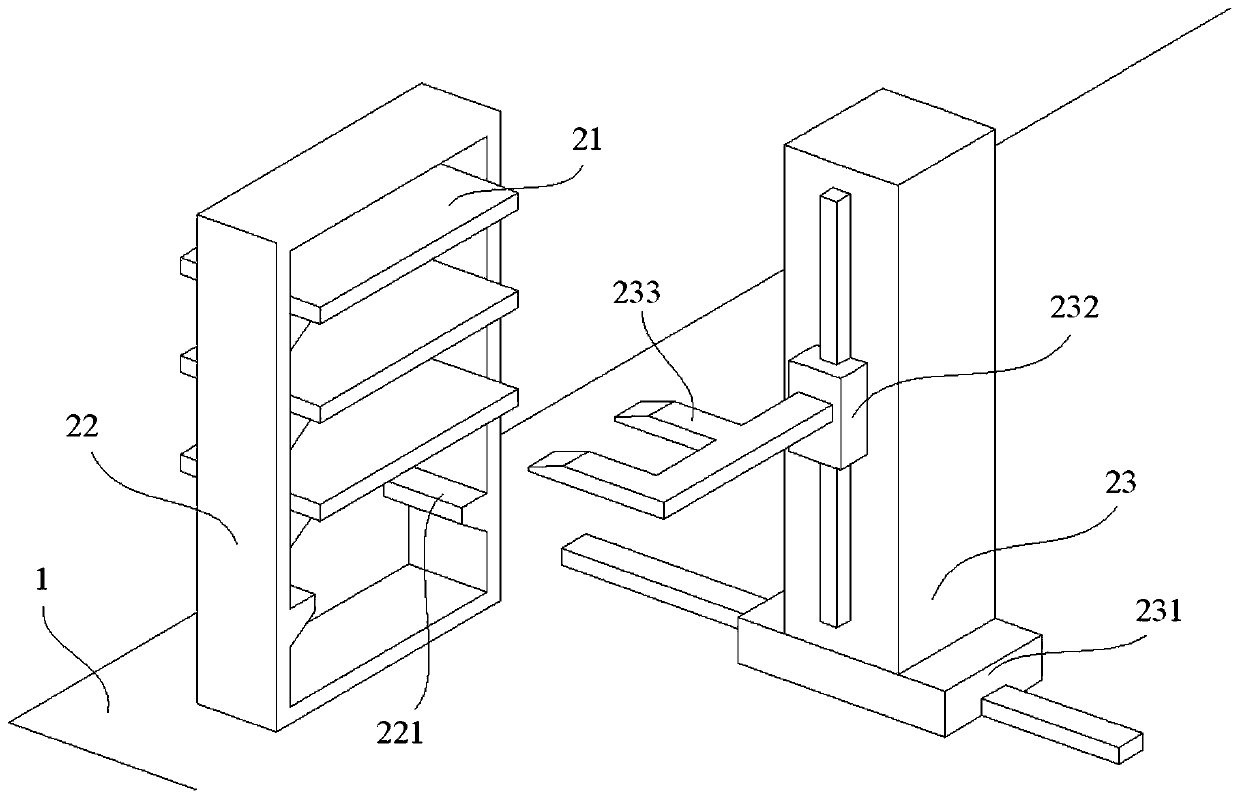

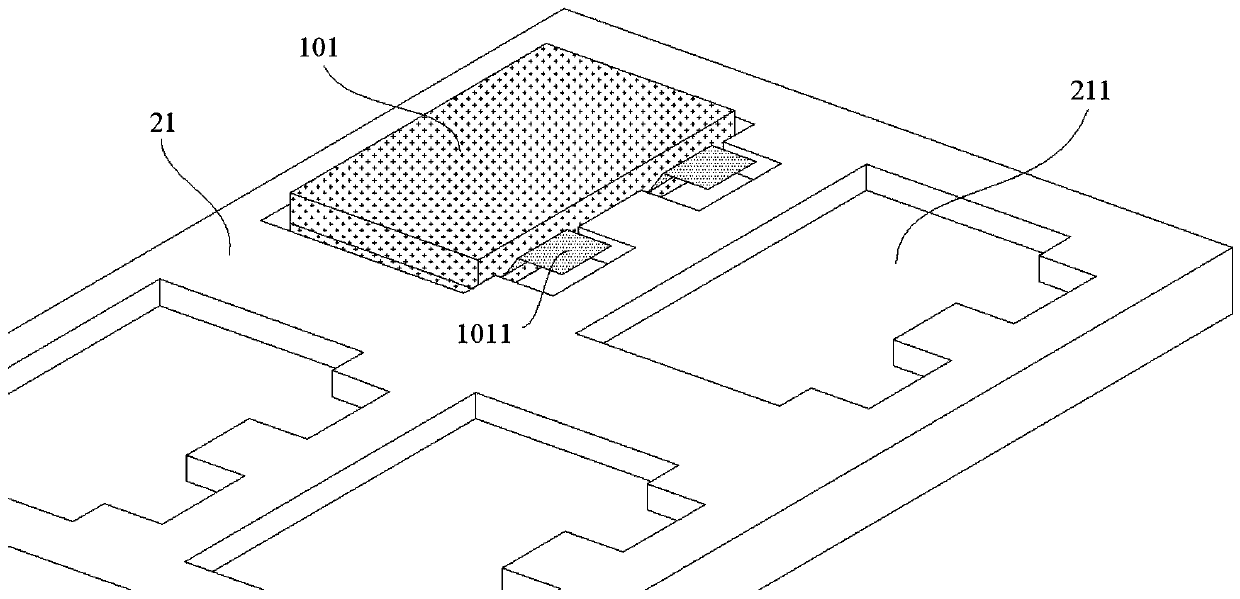

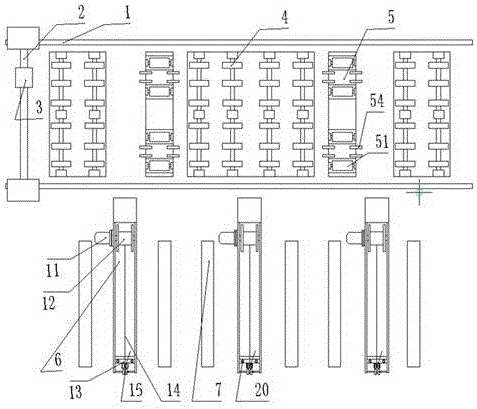

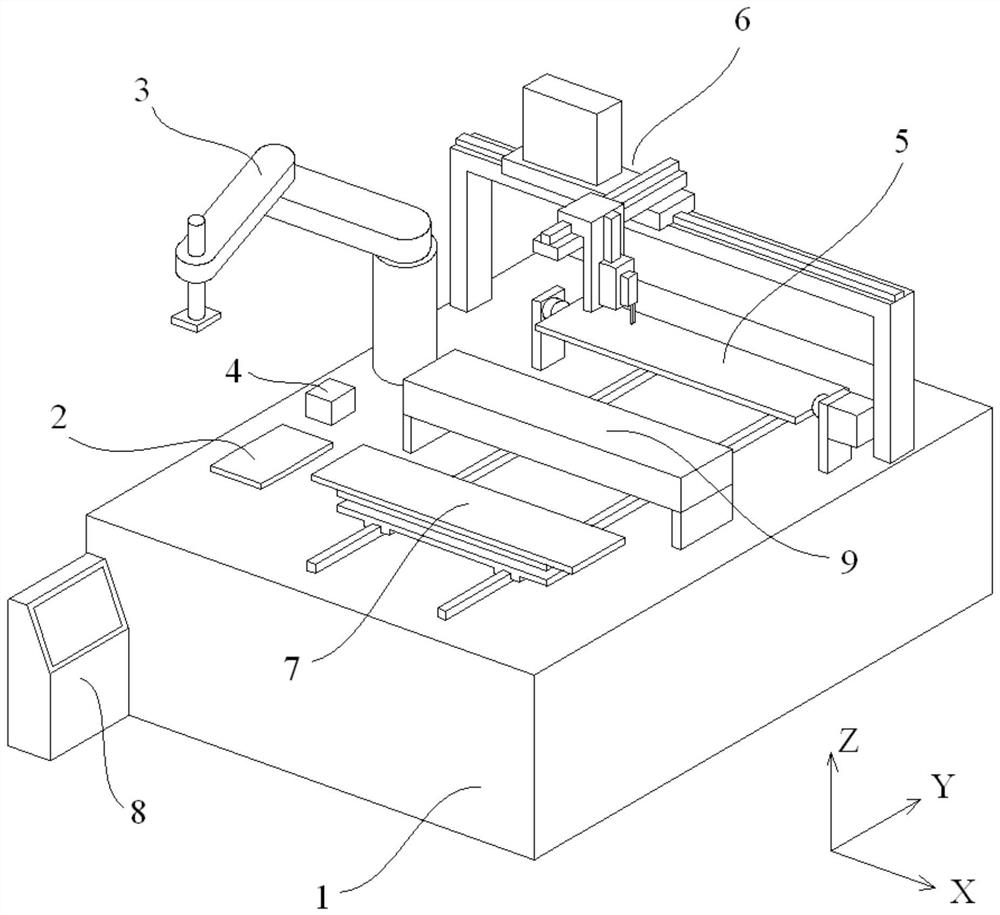

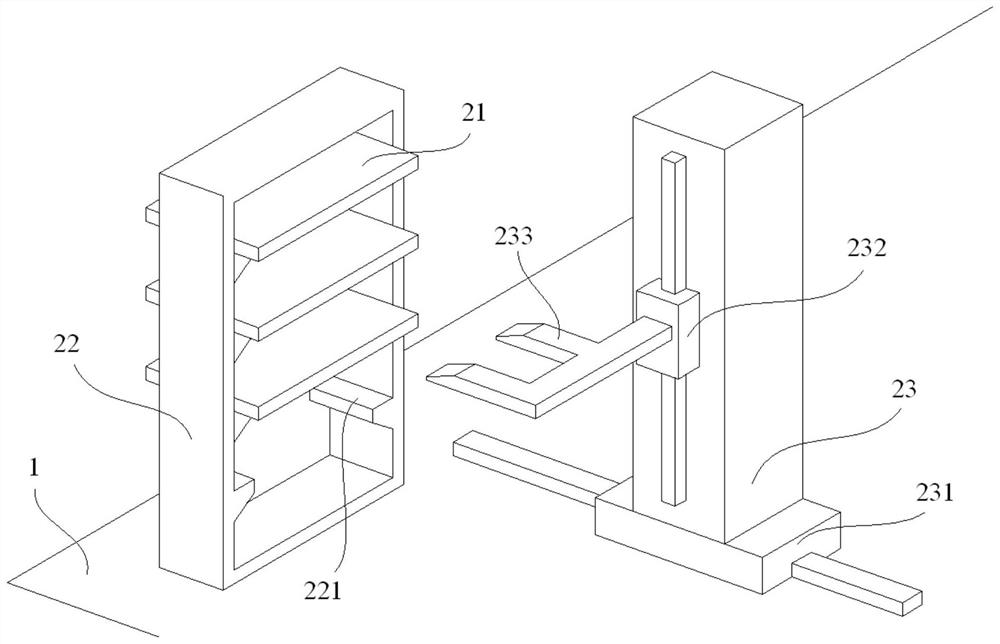

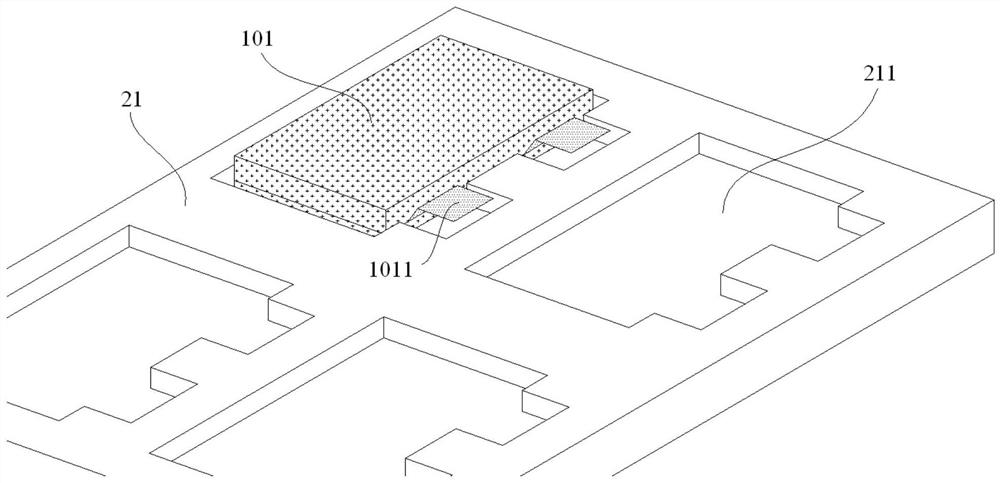

Solar battery series welding equipment and using method thereof

ActiveCN111375876ARealize fully automatic operationIncrease productivityMetal working apparatusElectrode maintenanceComputer control systemElectrical battery

The invention discloses solar battery series welding equipment and a using method thereof. The welding equipment comprises a base, a battery carrying system, a positioning camera, a welding platform,a welding system, a discharging system and a computer control system, wherein the battery carrying system is used for carrying stacked solar batteries to be welded; the positioning camera is used forshooting images of the stacked solar batteries to obtain position information of the stacked solar batteries; the welding platform can be turned over by 180 degrees after series welding is completed;the welding system is a resistance welding system capable of moving in the three-dimensional direction; the discharging system is used for transferring and / or storing welded solar battery modules; andthe computer control system is used for receiving the series welding requirements of the solar battery modules and controlling the operation of the battery carrying system, the positioning camera, the welding platform, the welding system and the discharging system according to the requirements. The solar battery series welding equipment achieves full-automatic series welding of the solar batteries for a space, and has the advantages of being high in production efficiency, high in precision, high in reliability and good in applicability.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Friction stir welding method for heterogeneous metal layered composite plate

ActiveCN112025078AAvoid dilutionImprove performanceWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingComposite plate

The invention belongs to the technical field of friction stir welding, and particularly relates to a friction stir welding method for a heterogeneous metal layered composite plate. In order to solve the dilution problem of a composite plate body in the friction stir welding process of the composite plate, a compensation plate made of the same material as the composite plate body is added to a preset to-be-welded position on one side of the composite plate body in the composite plate, then friction stir welding is conducted, so that the dilution problem of the composite plate body in the friction stir welding process is avoided, and therefore the mechanical property and the functionality of a heterogeneous bimetal layered composite board joint are ensured. The dilution problem of the composite plate body is the key technical problem urgently needing to be solved in welding of the heterogeneous composite plate with the low composite layer proportion through the friction stir welding technology, the problem is solved through a simple, easy and reliable method, the obtained welding joint is high in comprehensive performance, and the wide industrial application prospect is achieved.

Owner:SHENYANG AEROSPACE UNIVERSITY

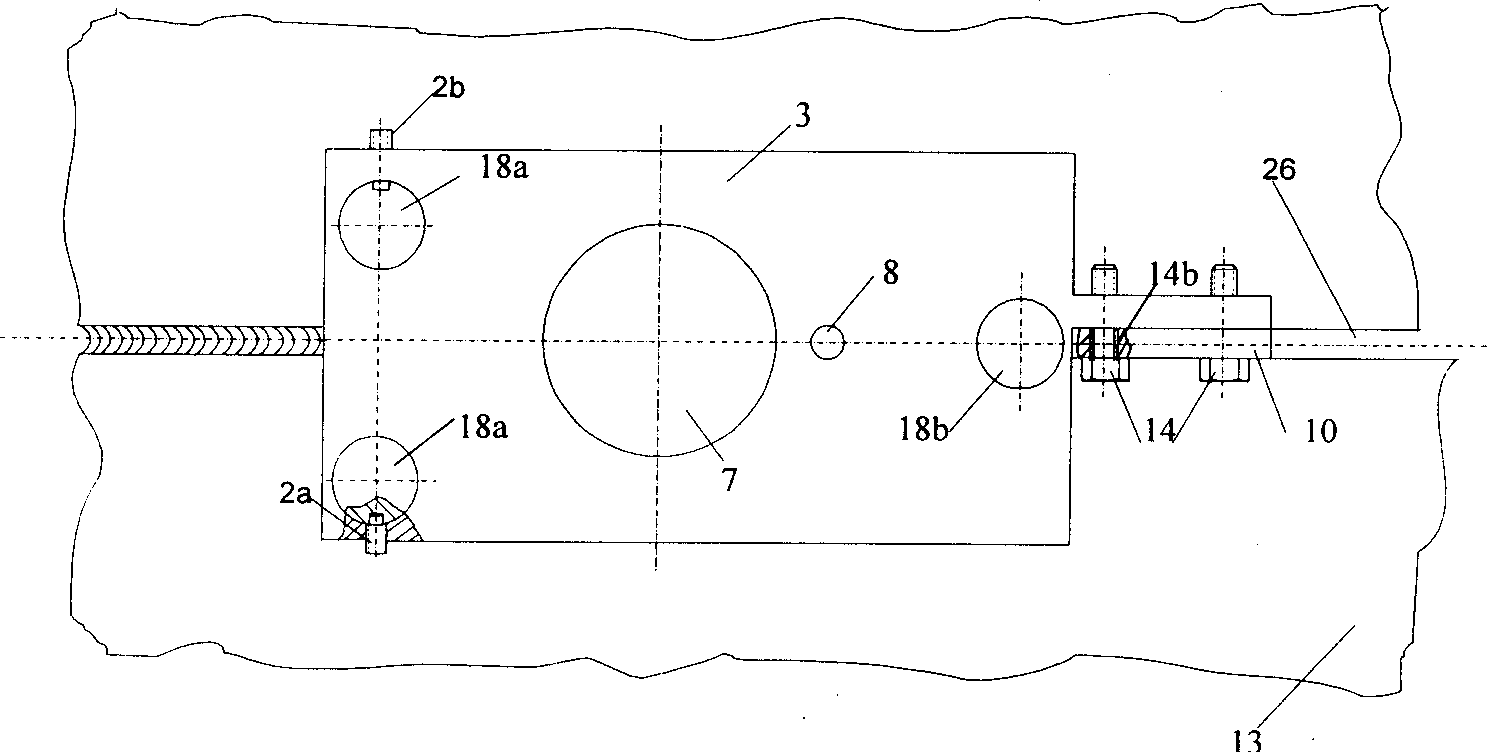

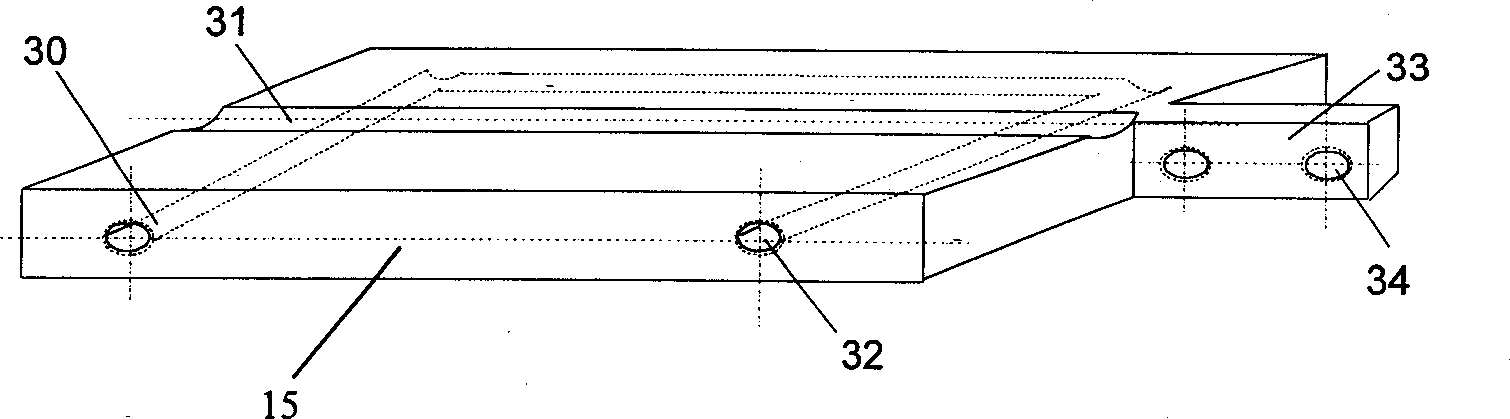

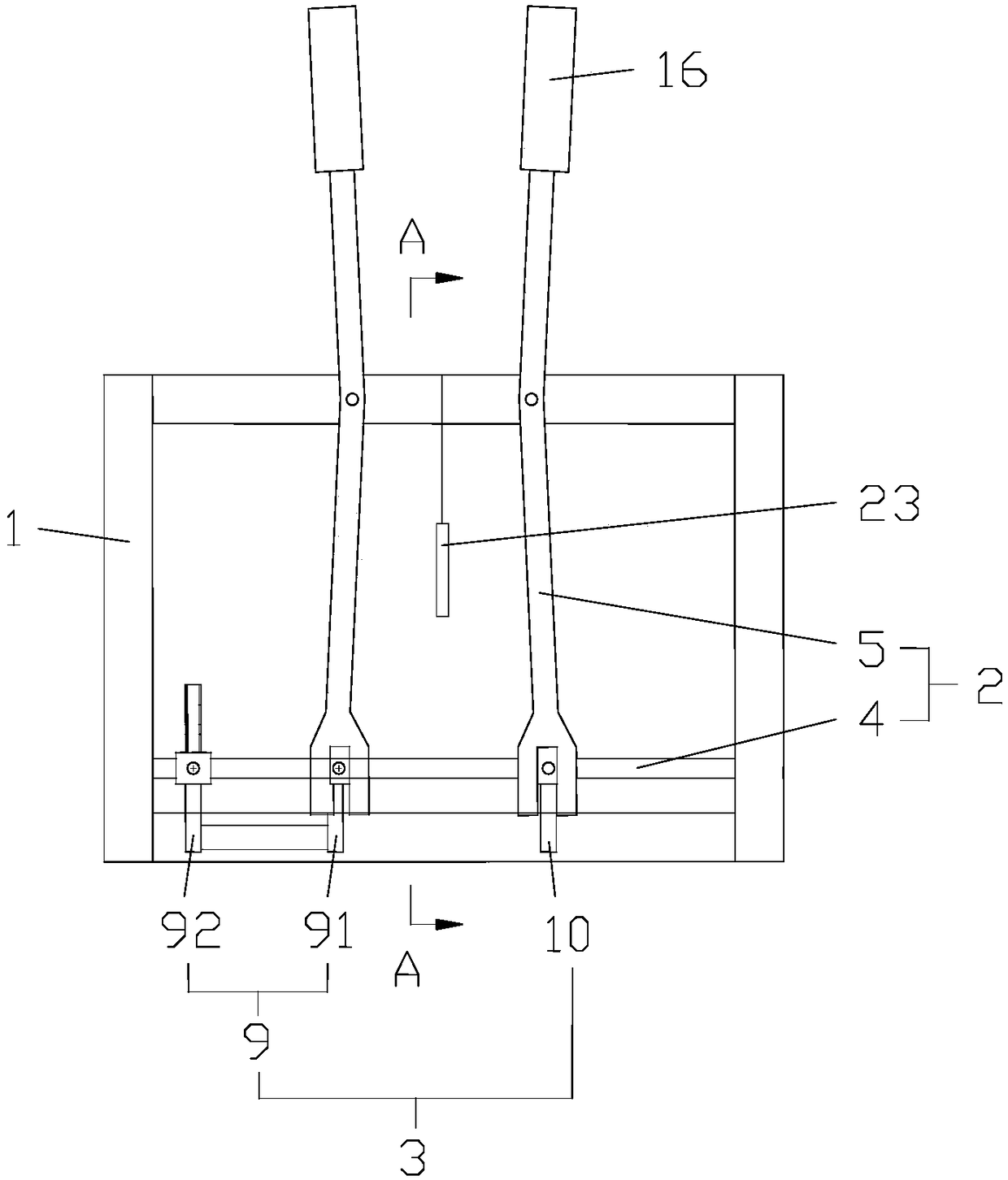

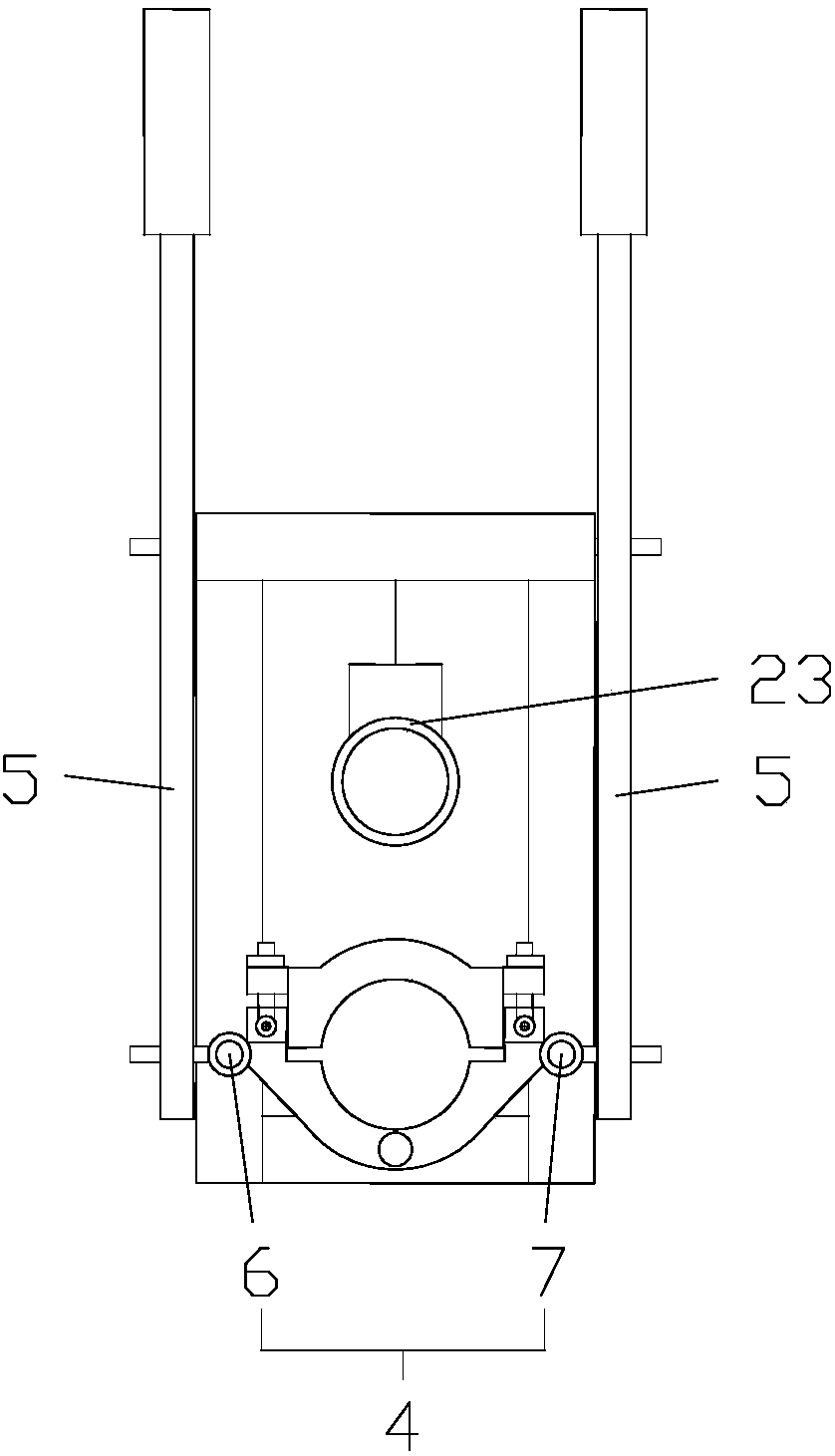

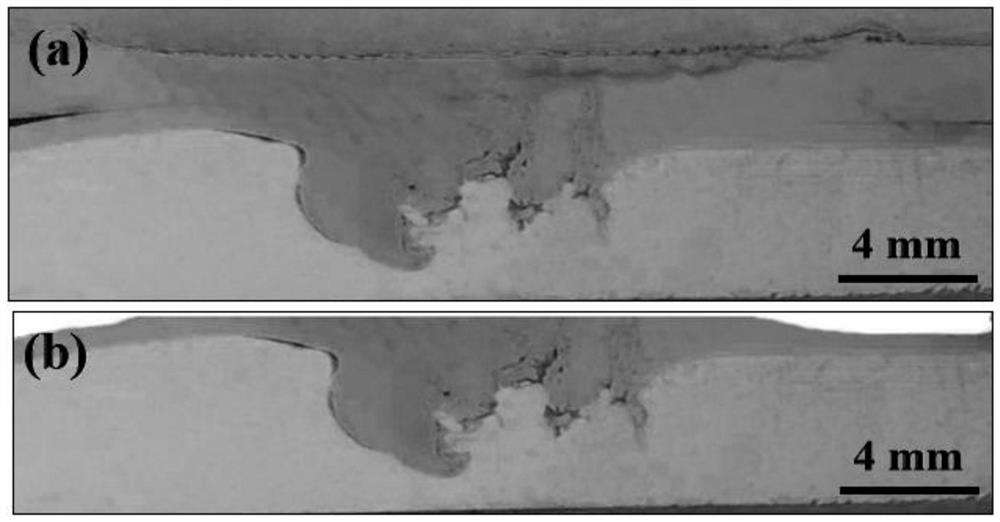

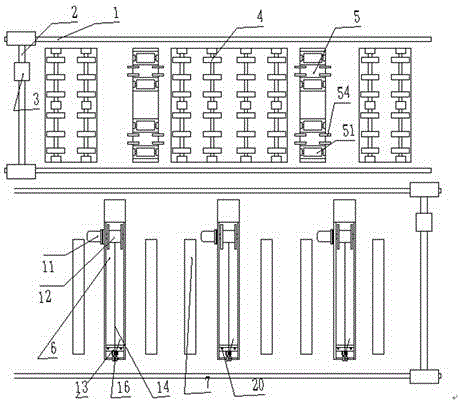

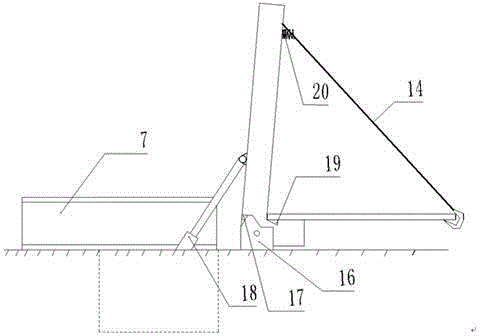

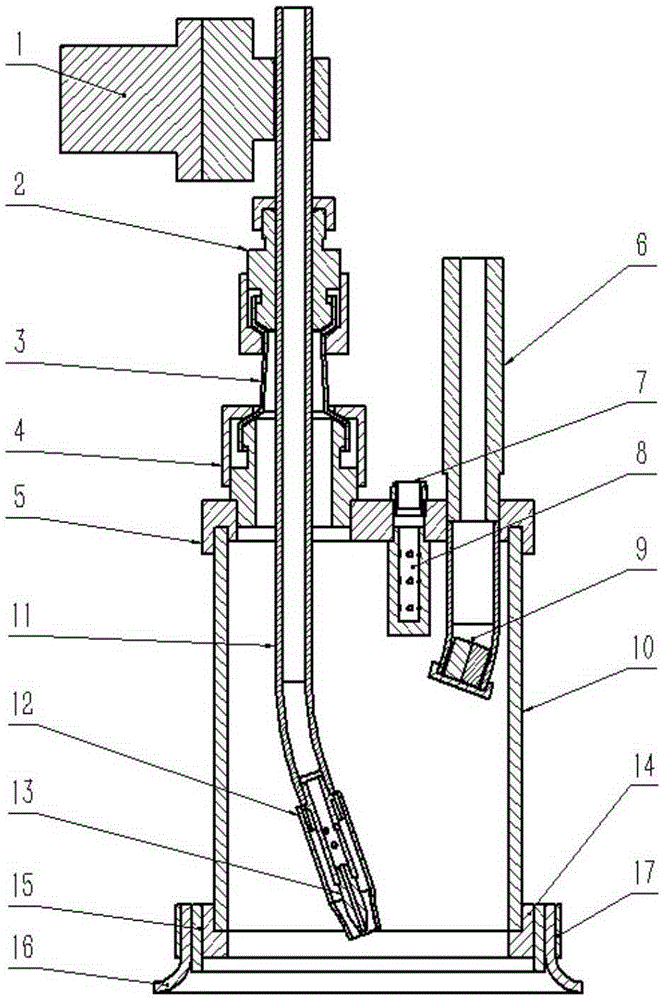

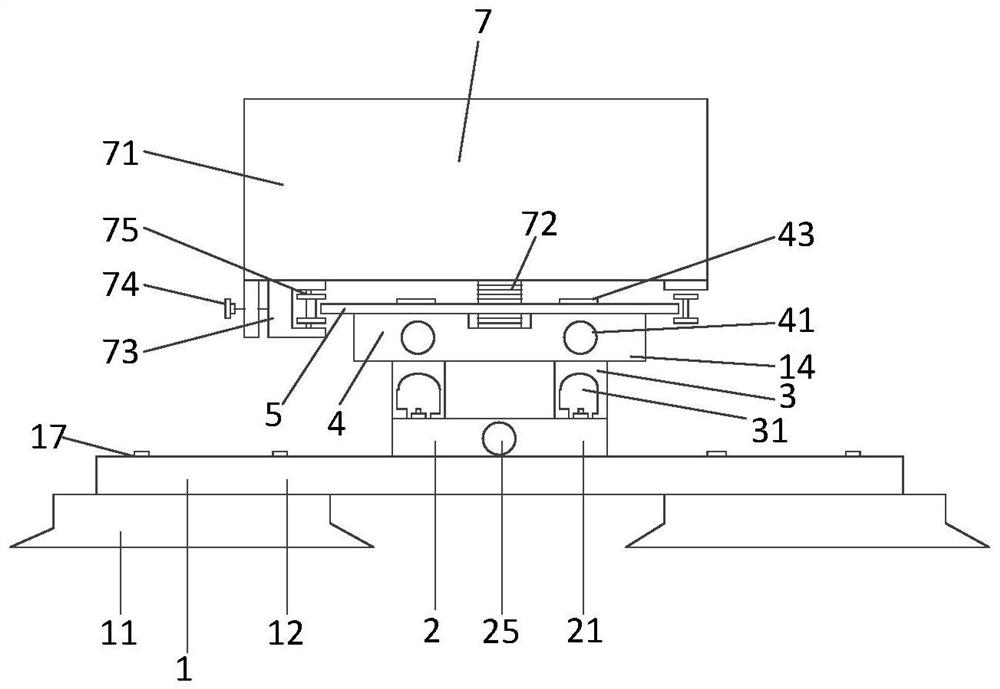

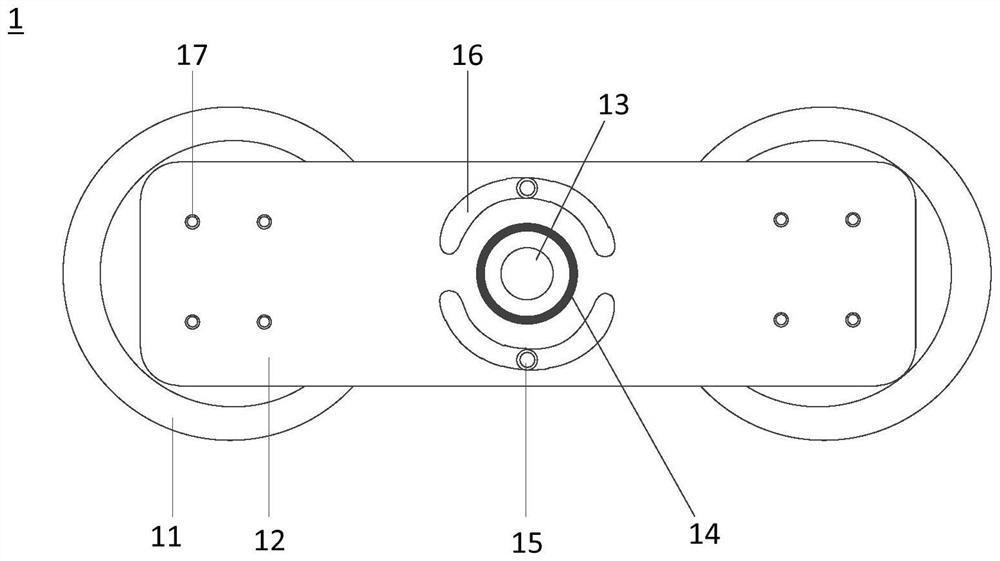

Welding system for large thick-wall steel plate

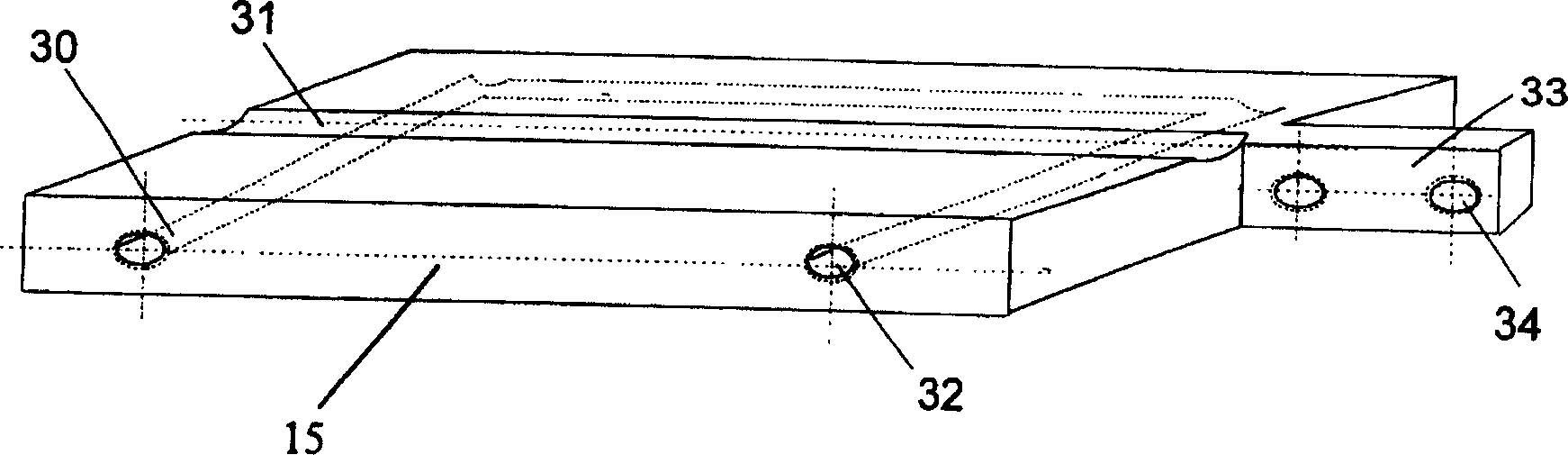

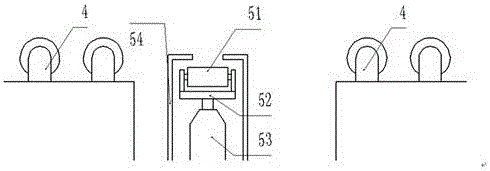

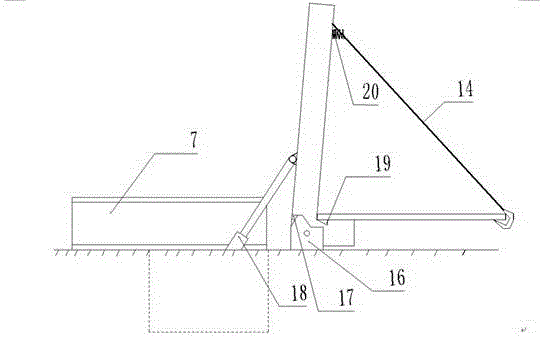

ActiveCN104476091AEasy dockingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderButt welding

The invention discloses a welding system for a large thick-wall steel plate. The system comprises a portal type welding mechanism and a steel plate supporting structure. The system is characterized in that the steel plate supporting structure is arranged between two steel rails (1) of the portal type welding mechanism; the steel plate supporting structure is composed of a plurality of groups of carrier rollers (4) and is also equipped with a holding mechanism (5) which is mounted on a lifting hydraulic cylinder (53); an overturning bracket (6) which is hinged to a supporting seat (16) is arranged at one side of the portal type welding mechanism, and the overturning bracket (6) is that the rear surface is connected with a rotating hydraulic cylinder (18), the bottom part is equipped with a steel wire coil (12), and the top part is equipped with a fixed pulley (16); the steel wire coil (12) is connected with a motor (11). With the adoption of the welding system, the abutting, welding, side overturning and other processes in the welding process of a thick steel plate can be done; the stability and reliability in welding and overturning are ensured; workers can operate conveniently; the production efficiency is raised.

Owner:GUIZHOU HUITONG SHENFA STEEL STRUCTURE

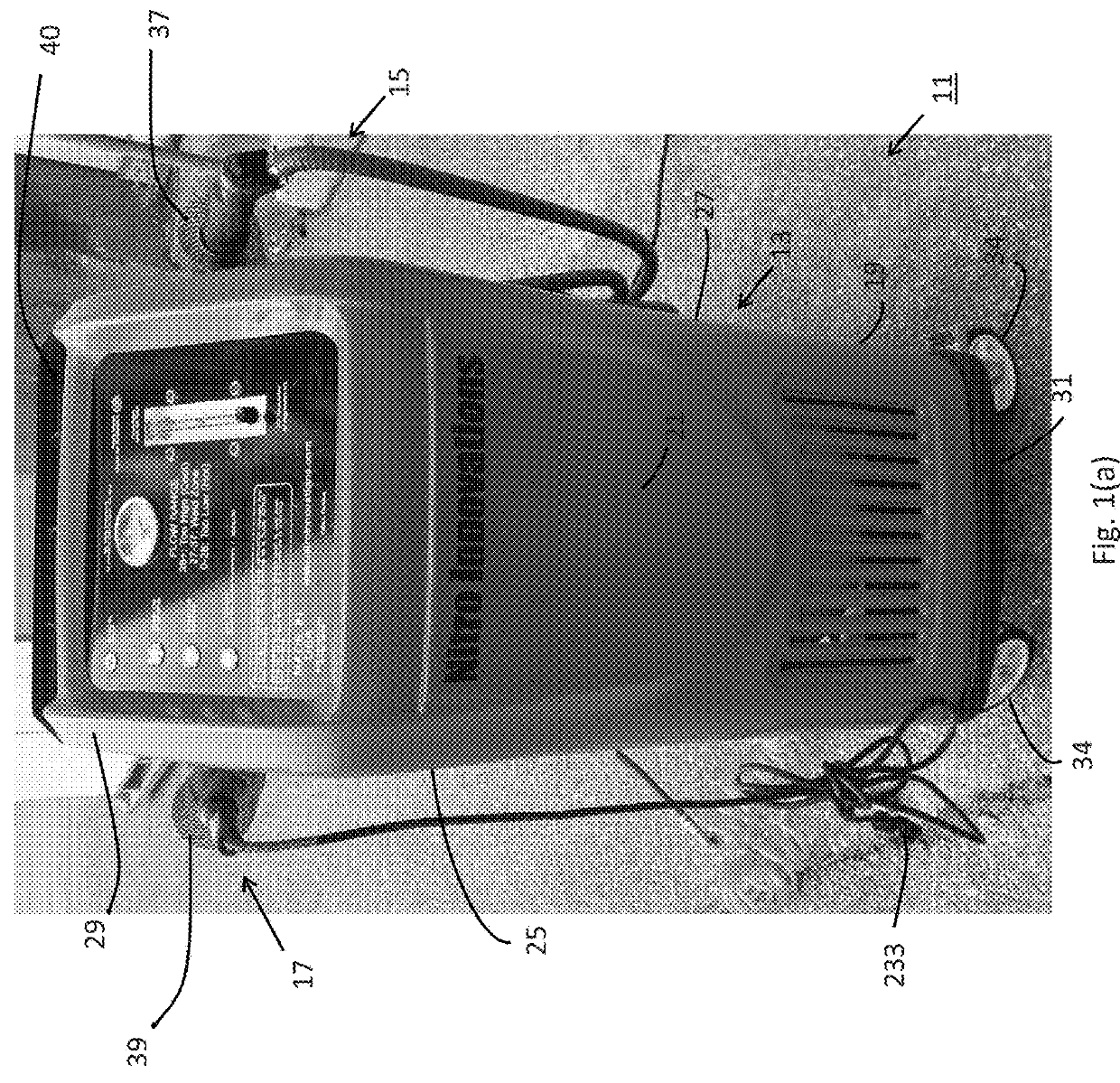

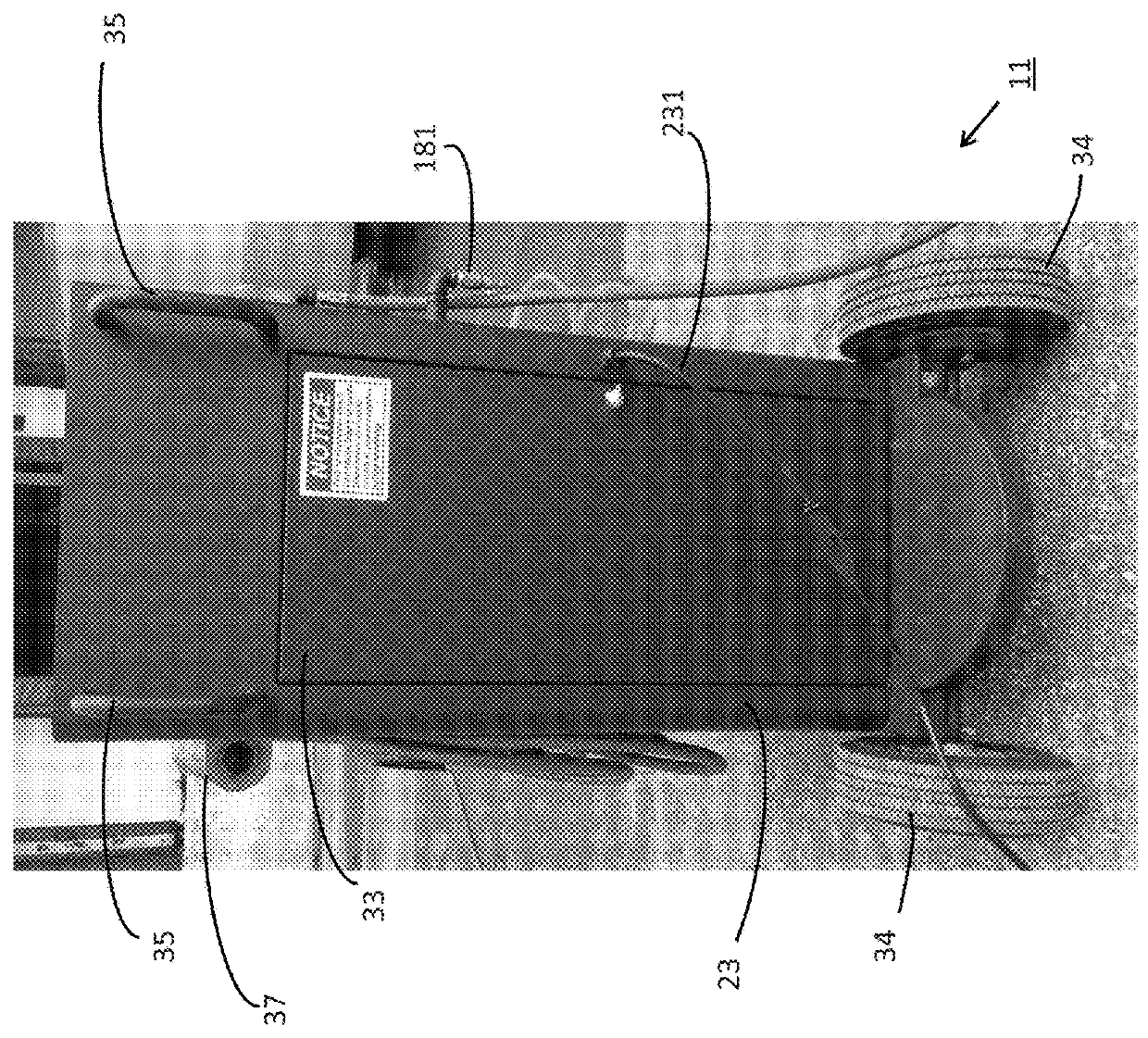

Device for welding plastic

InactiveUS20180093424A1The welding process is stable and reliableDurable and safe to useDomestic articlesWelding/soldering/cutting articlesPlastic materialsEngineering

A device for welding plastic materials includes a handheld, wand-type applicator that dispenses a focused stream of oxygen-free air for optimum fusion. The applicator comprises a heating coil that warms the dispensed air to a sufficient temperature to sufficiently meld the plastic materials. A weld air delivery system delivers the supply of oxygen-free air to the weld applicator. A separate coolant air delivery system includes a tank that collects a reserve supply of ambient air that is used to cool the heating coil when applicator is not actively welding plastic materials. The inclusion of separate delivery systems ensures that ambient air is used to cool applicator, whereas oxygen-free air is preserved for use in welding applications. For safety purposes, a switch deactivates the heating coil when the pressure of the reserve air in the tank falls beneath a predefined threshold that is considered necessary to adequately cool the applicator.

Owner:LEWIS TIMOTHY C

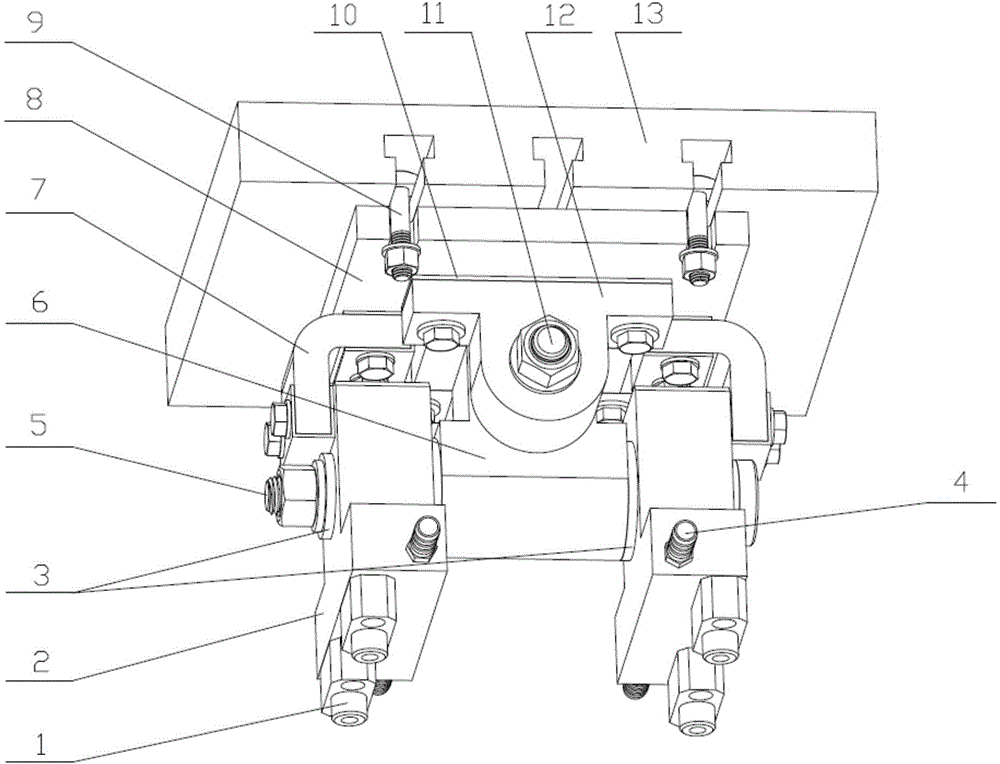

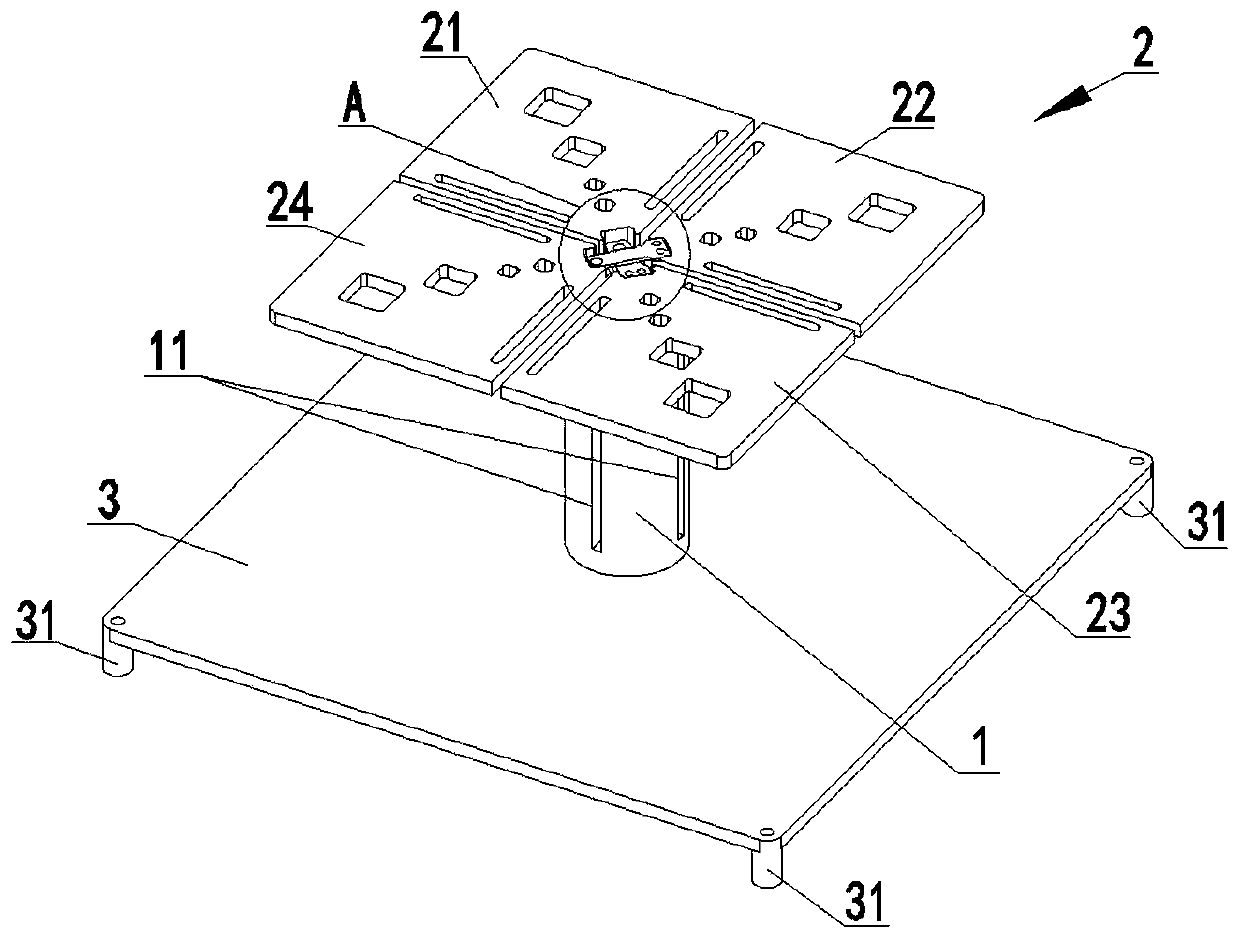

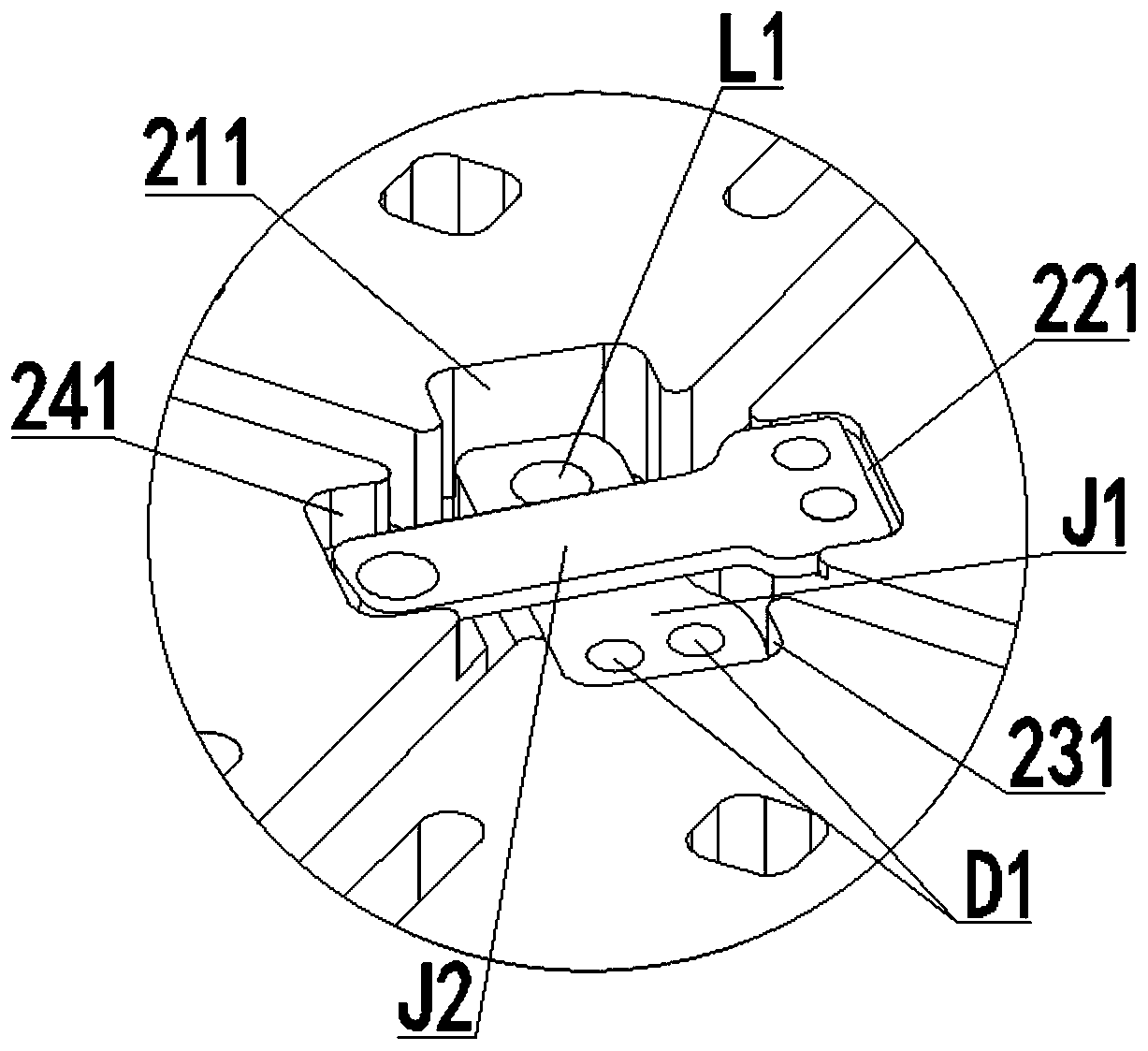

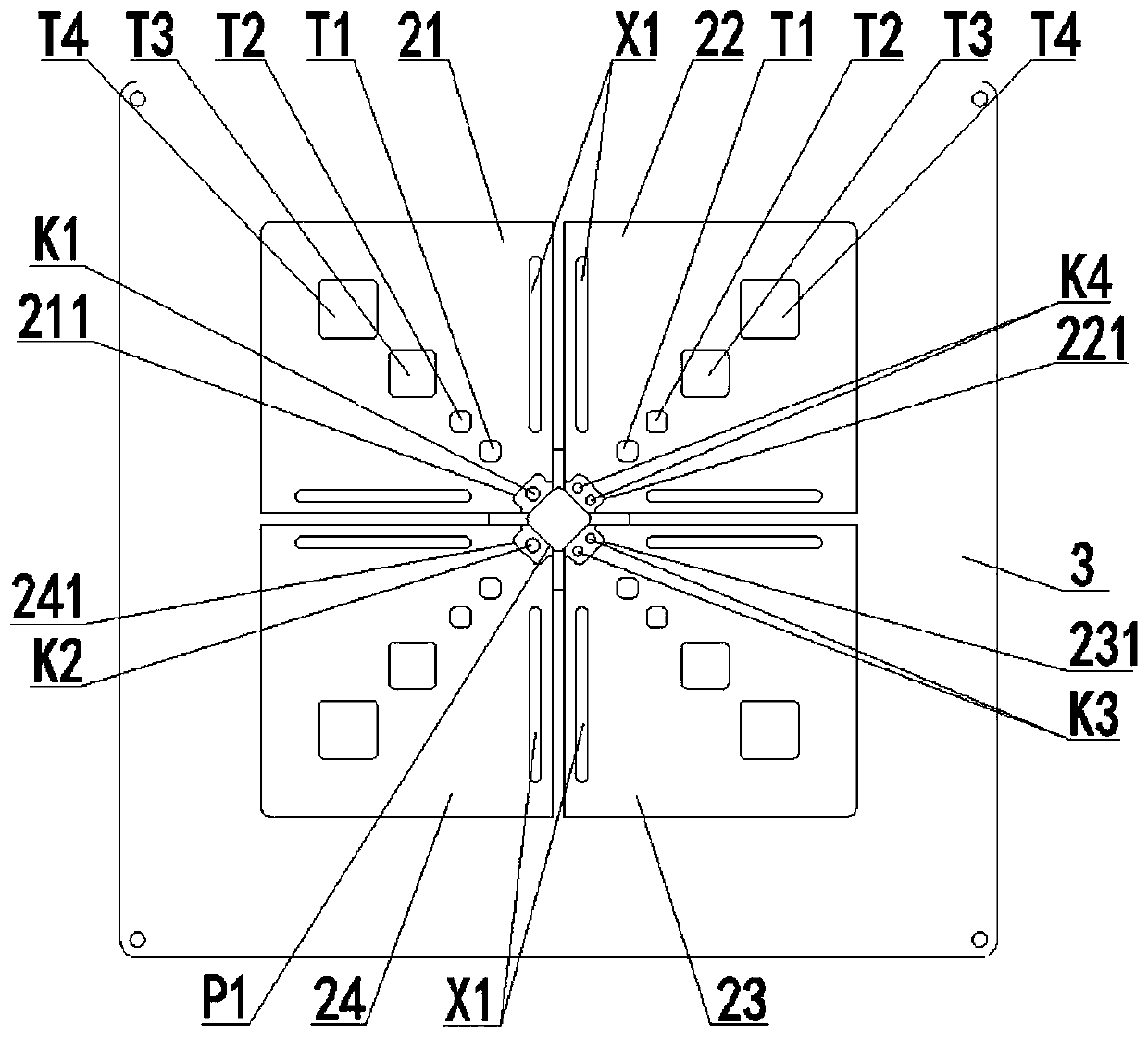

Floating simultaneous-four-point-projection-welding upper electrode structure

ActiveCN104384699ASolve the processImprove repeated service lifePressure electrodesMaintainabilityReusability

The invention relates to the technical field of electrodes, in particular to a floating simultaneous-four-point-projection-welding upper electrode structure which comprises a baseplate, shaft seats, a steering shaft seat, upper electrode head seats and an upper electrode body. Compared with the prior art, the floating simultaneous-four-point-projection-welding upper electrode structure has the advantages of simple structure, reliability in positioning, convenience in machining and high rigidity, the manufacturability problem of the projection-welding upper electrode structure is solved, welding of multiple bolts and a plate can be completed in one step, the welding process is stable and reliable, welding quality is stable, production efficiency is improved, and production cost is lowered; welding quality is guaranteed effectively, so that welding heat energy input can be lowered properly, and energy resources are saved; whenever the end face of an upper electrode head is worn, a user only needs to restore flatness of the end face, so that reusability of an upper electrode is improved, projection-welding electrode manufacturing cost is lowered, and tool maintainability is improved.

Owner:SHANGHAI TRACTOR & INTERNAL COMBUSTION ENGINE

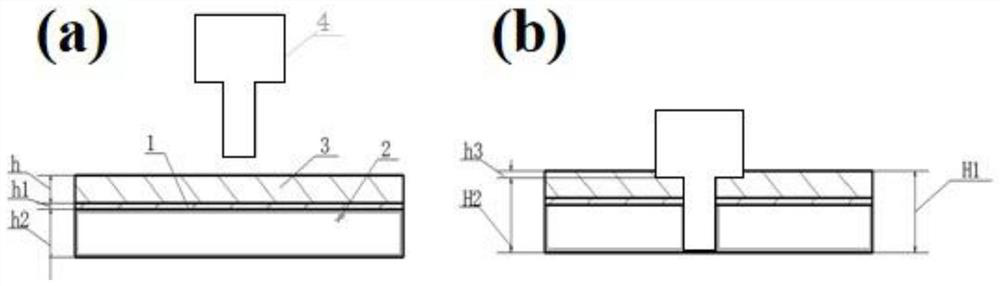

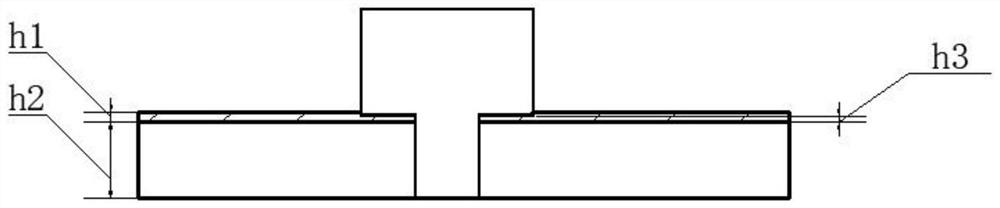

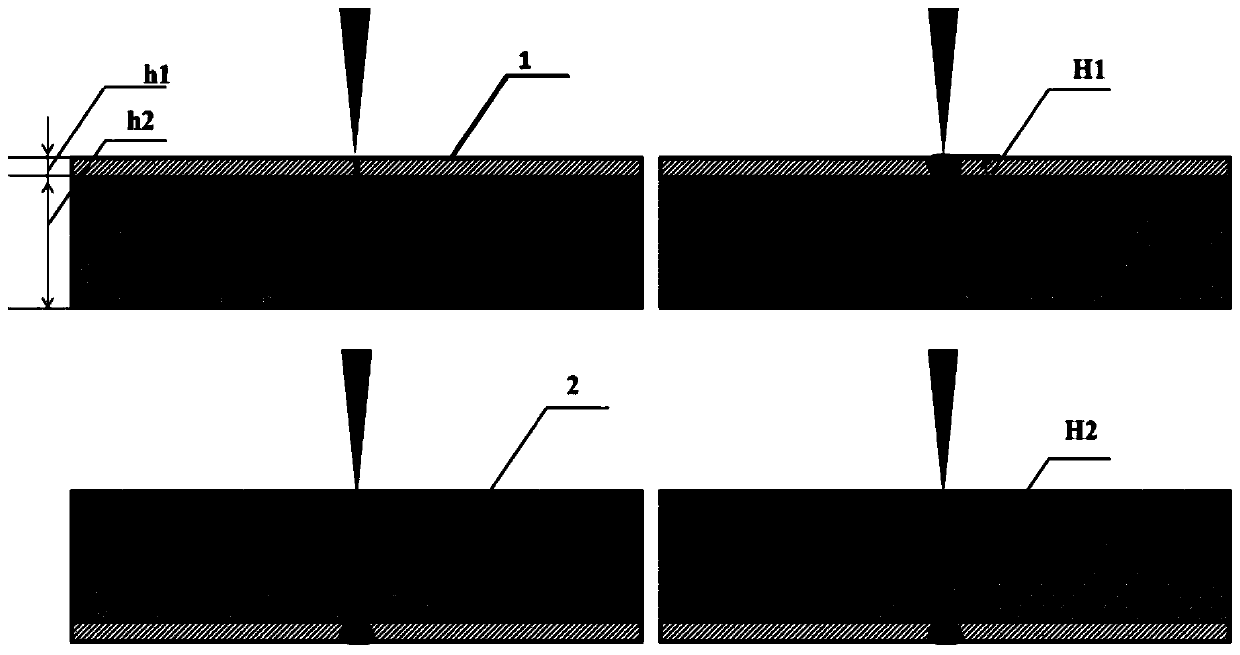

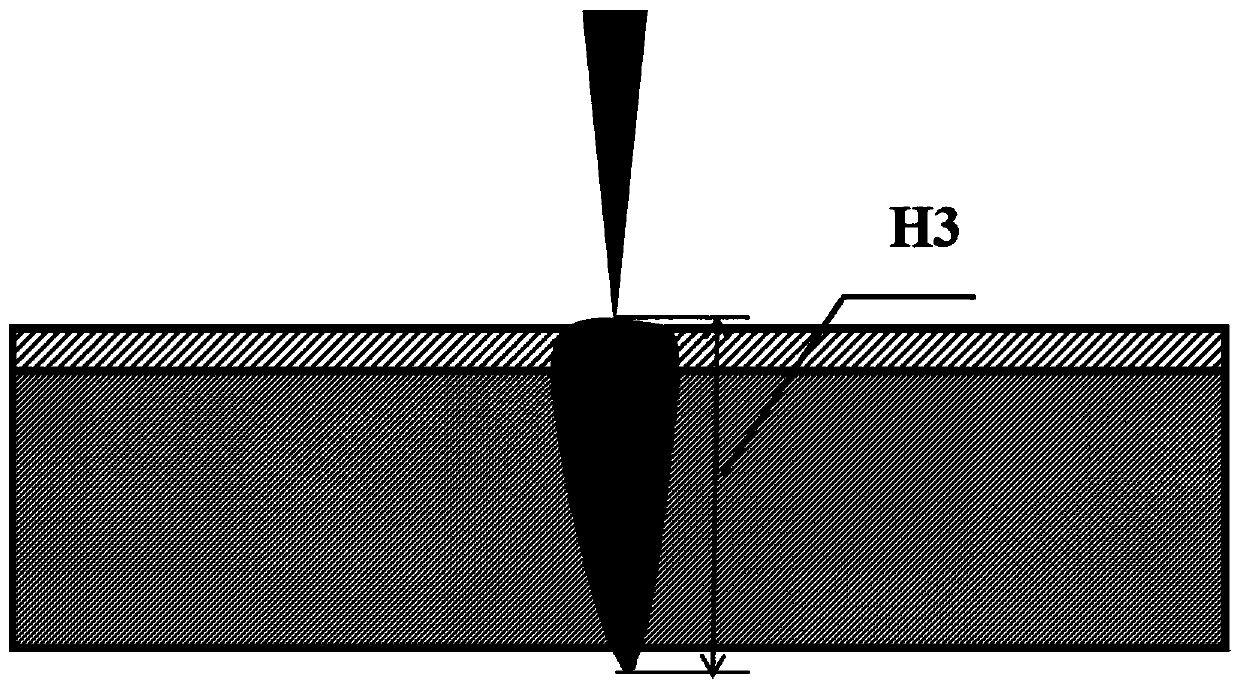

High-energy beam welding method for dual-metal layered composite board

ActiveCN110421241AReduce compound reactionReduce generationElectron beam welding apparatusPlasma welding apparatusEngineeringButt joint

A high-energy beam welding method for a dual-metal layered composite board includes the following steps that (1) the material of the to-be-welded dual-metal layered composite board, the thickness h1 of a compounding board and the thickness h2 of a base board are determined, dust and oil stains on butt-joint surfaces of the composite board are removed, and the cleanliness of the butt-joint surfacesis maintained; (2) the to-be-welded composite board is subjected to butt-joint assembling and welded through a high-energy beam heat source, and it is guaranteed that the depth of fusion H1 is greater than or equal to 1.0h1 and less than or equal to 1.15h1; and (3) the composite board with the compounding board welded in the step (2) is overturned and fixed, the base board is welded through the high-energy beam heat source, and it is guaranteed that the depth of fusion H2 is greater than or equal to 0.9h2 and less than or equal to 1.0h2, and the sum of H1 and H2 is less than or equal to h1+h2+0.30mm and greater than or equal to h1+h2+0.01mm, so that high-energy beam welding of the dual-metal layered composite board is completed. The welding method solves the problems that when existing high-energy beam welding technologies are used for single-face welding and double-face forming of dual-metal layered composite boards, compounding boards are seriously diluted and the comprehensive performance of joints is obviously affected, and has the advantages that under the condition of no machining groove, the diluting rate of compounding boards can be obviously lowered and the joint performance of metal layered composite boards is improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

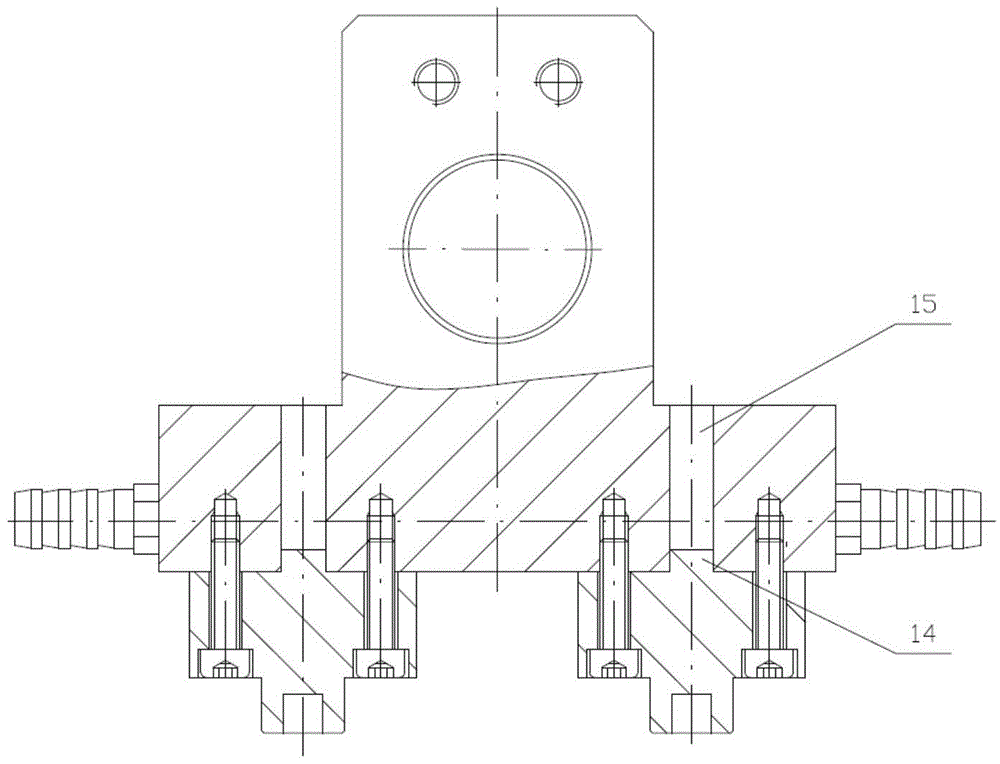

Cooling system of device special for welding of projection welding nut

PendingCN106735822AExtend the life cycleExtended service lifeCooled electrodesEngineeringCooling efficiency

The invention provides a cooling system of a device special for welding of a projection welding nut. The cooling system comprises an upper electrode body cooling system and a lower electrode body cooling system, wherein the upper electrode body cooling system comprises an upper water inlet mechanism and an upper water outlet mechanism; the upper water inlet mechanism and the upper water outlet mechanism are connected with a hollow upper holding rod of an upper electrode body; the lower electrode body cooling system comprises a lower water inlet mechanism and a lower water outlet mechanism; and the lower water inlet mechanism and the lower water outlet mechanism are connected with a hollow lower holding rod of a lower electrode body. According to the cooling system, the water inlet / outlet mechanisms and direct pipelines are added in the electrode bodies, cold water can enter the electrode bodies through the water inlet / outlet mechanisms and the direct pipelines to cool the electrode bodies, water cooling cycle operation is carried out through the water inlet / outlet mechanisms and the direct pipelines, the cooling efficiency is improved, the welding process is stable and reliable, the continuous working time is effectively prolonged, the production efficiency is improved, the tooling maintenance cost is reduced, and the utilization cycle and service life of electrodes are prolonged.

Owner:重庆太乙机械有限公司

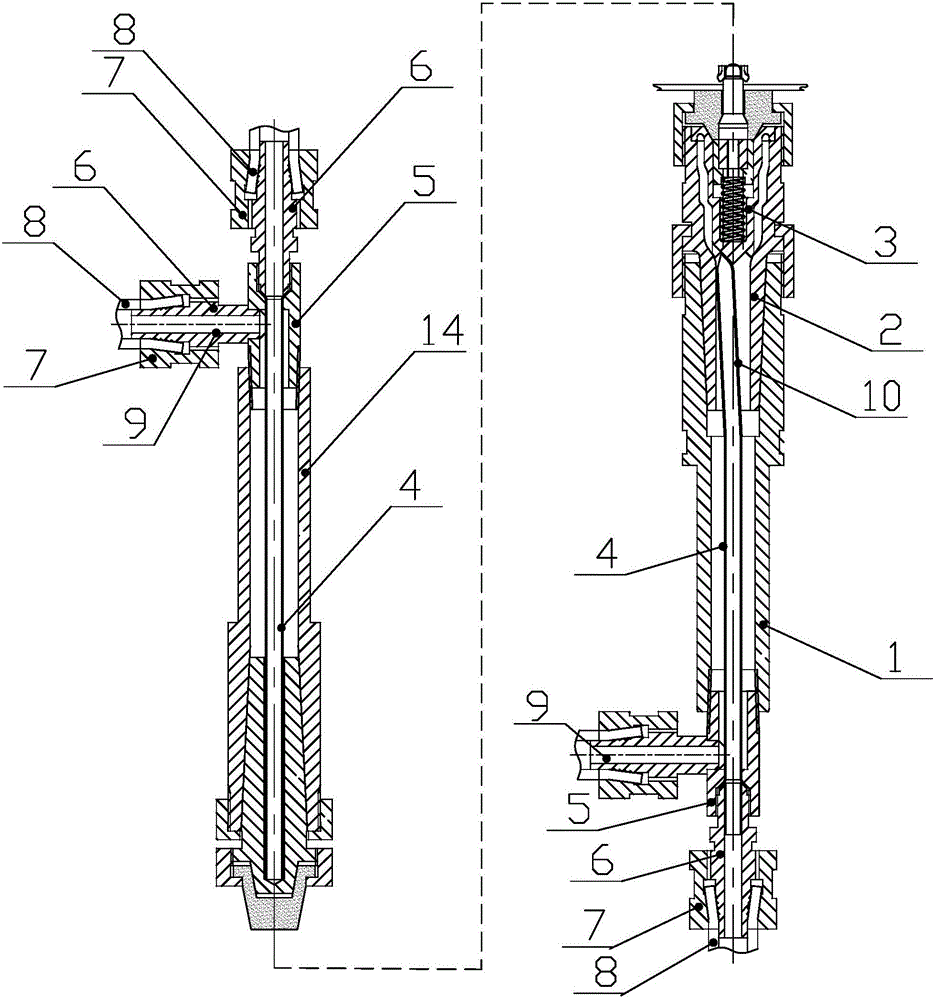

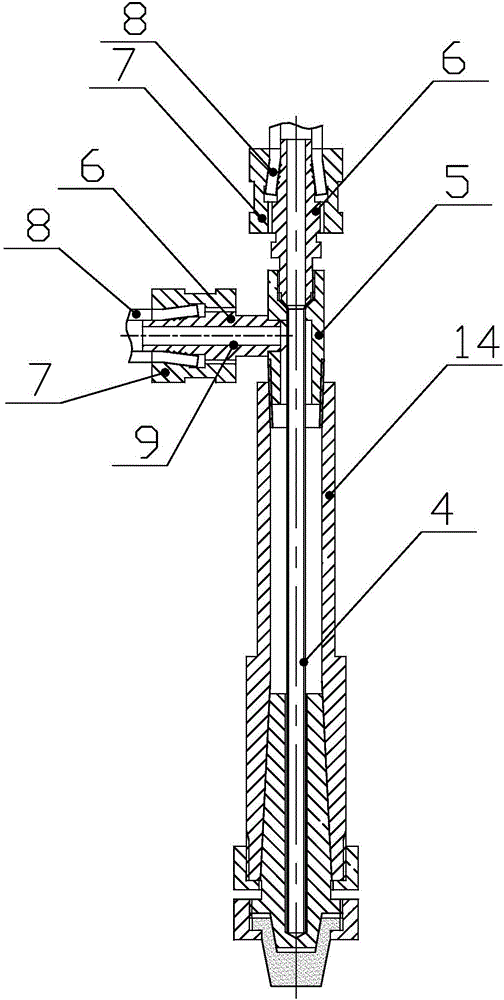

Portable underwater partial dry automatic welding special micro drain cover

InactiveCN103433606BRealize free adjustmentAvoid unfusedElectrode supporting devicesWelding accessoriesOrganic glassCopper

The invention provides a special portable miniature drainage cover for automatic underwater local dry-method welding. A drainage cover body of the drainage cover comprises an upper end cover, an organic glass cover and a lower end cover. A clamping rod, an air inlet quick plug connector, a lower locking sleeve, a cooling air chamber and an underwater camera component are fixed to the upper side of the upper end cover and the lower side of the upper end cover through threaded connection respectively, and the upper end cover and lower end cover are connected with the organic glass cover through threads. A welding oscillator is clamped on the upper portion of a copper welding torch of a welding gun. According to the structure of a drainage sealing device, drainage felt and a felt skirt are arranged on the periphery of the lower end cover, and the drainage felt and the felt skirt are fastened on the lower end cover through hose clamps; the copper welding torch of the welding gun is fastened through an upper locking sleeve and the lower locking sleeve, the welding gun is inserted into the organic glass cover, and an elastic rubber leather sheath is arranged between the upper locking sleeve and the lower locking sleeve. The special portable miniature drainage cover for automatic underwater local dry-method welding has the advantages of being simple in structure, exquisite, convenient and fast to use, low in cost, obvious in drainage effect, and stable and reliable in welding process. Moreover, a connector with the quality of on-land welding is formed, the welding efficiency is improved and the special portable miniature drainage cover is easy to popularize.

Owner:TIANJIN UNIV

Method for in-furnace welding of titanium alloy ingot

ActiveCN111014877AWeld firmlyThe welding process is stable and reliableWelding accessoriesIngot castingTitanium alloy

The invention belongs to the technical field of titanium alloy ingot casting and smelting and specifically relates to the method for in-furnace welding of a titanium alloy ingot. Aiming at in-furnacewelding of the titanium alloy ingot with a specification of phi450mm-phi650mm, definite parameters such as welding time, current, voltage and stable arc are given, so stability and reliability of an in-furnace welding course are ensured. An original welding method of instant adjustment of welding parameters based on experience of an operator is optimized to a method for welding which can be completed by direct parameter inputting of the operator, so welding seam quality is improved; labor strength is reduced; and stability of a smelting speed of over-welding seam smelting is ensured. The method has the beneficial effects that operations are easy and can be realized easily; influences of differences in operator experience are eliminated; operations are completed by equipment step by step according to instructions; and welding seam quality is very stable

Owner:西部超导材料科技股份有限公司

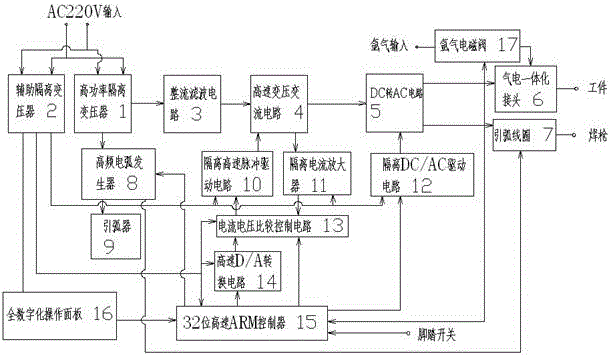

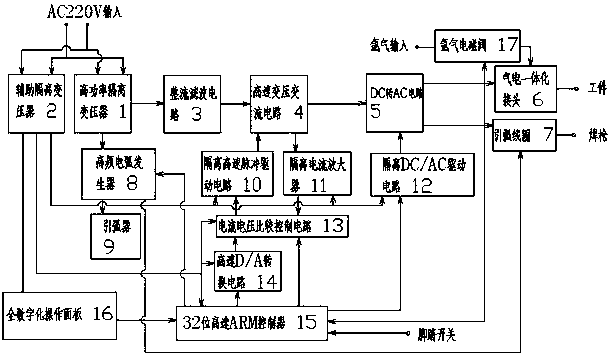

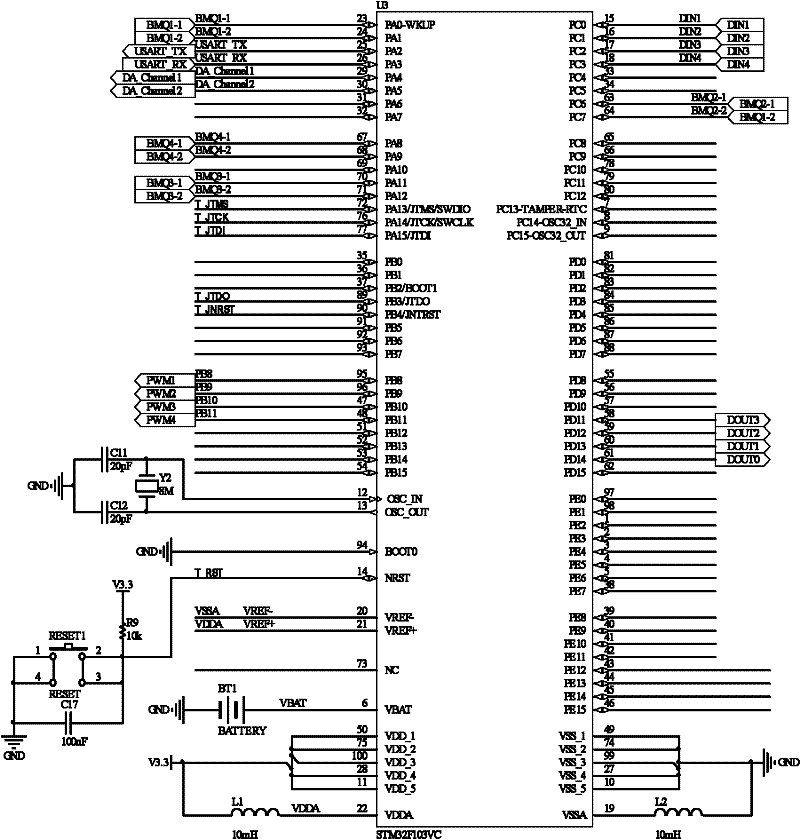

Multi-function precise aluminum welding machine circuit

ActiveCN106513936AReduce tungsten burning lossReduce temperature riseArc welding apparatusAluminiumEngineering

The invention discloses a multi-function precise aluminum welding machine circuit. The multi-function precise aluminum welding machine circuit is characterized in that the multi-function precise aluminum welding machine circuit comprises a high-power insulating transformer and an auxiliary insulating transformer, and the output end of high-power insulating transformer is connected to a rectification smoothing circuit; and the auxiliary insulating transformer is connected to a full-digitization operating faceplate, a 32-bit high-speed ARM controller and the like. According to the multi-function precise aluminum welding machine circuit, a plurality of welding modes can be achieved, and a continuous precise aluminum welding mode is an original function, so that the function that a thin aluminum plate can be precisely welded is achieved, the heat input quantity is greatly lowered, and deformation of a product is small; and the easy, convenient and quick operating property can be enough to surpass laser welding repair, so that the requirements of users for a larger range are met.

Owner:安徽华生机电集团有限公司

Satellite-borne L wide beam antenna

PendingCN110890619ASimple structureFeeder welding is stable and reliableAntenna adaptation in movable bodiesRadiating elements structural formsPolarizerWide beam

The invention discloses a satellite-borne L wide beam antenna. The antenna comprises a metal supporting body extending along a vertical direction, a square oscillator transversely extends from the topend of the metal support body, and the metal support body is vertically provided with four choke grooves which are arranged along the circumferential direction and are adjacent to each other at an angle of 90 degrees. The choke grooves extend upwards and divide the square oscillator into four square secondary oscillators which separately a first secondary oscillator, a second secondary oscillator, a third secondary oscillator and a fourth secondary oscillator which are sequentially adjacent in the circumferential direction. The first secondary oscillator and the third secondary oscillator which are opposite to each other form a first oscillator pair, and the second secondary oscillator and the fourth secondary oscillator which are opposite to each other form a second oscillator pair. A gap is reserved between the lower end of each choke groove and the bottom face of the metal supporting body, the lower end of the metal supporting body is connected with a bottom plate, and a circular polarizer is arranged below the bottom plate and is connected with a signal input port. The satellite-borne L wide beam antenna adopts the arrangement form of the symmetrical oscillators and is simplein structure, the feeder welding is stable and firm, and the width of beams is increased.

Owner:江苏屹信航天科技有限公司

A multifunctional precision aluminum welding machine circuit

ActiveCN106513936BImprove stabilityImprove consistencyArc welding apparatusEngineeringSmoothing circuits

Owner:安徽华生机电集团有限公司

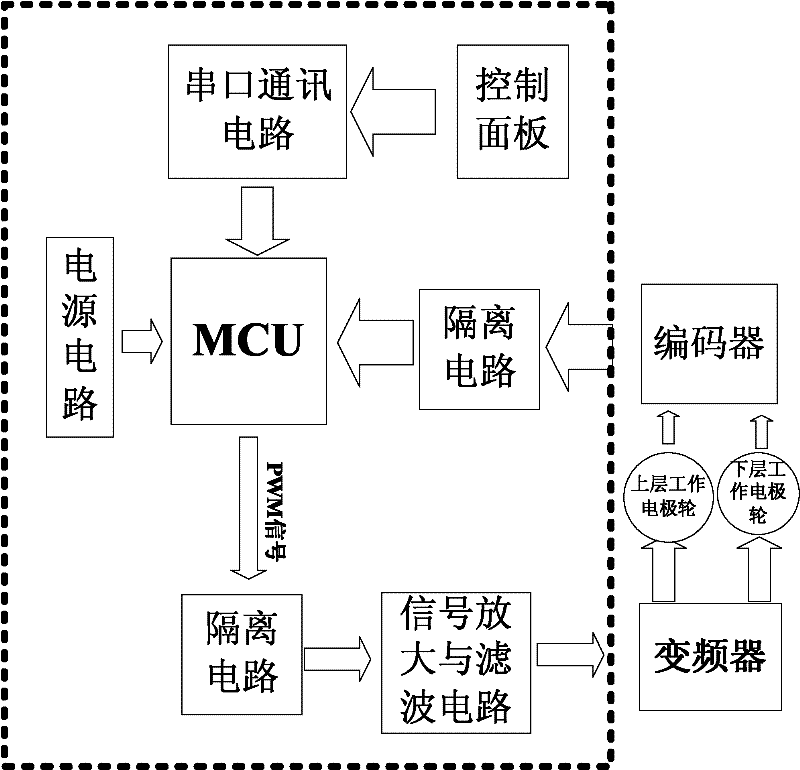

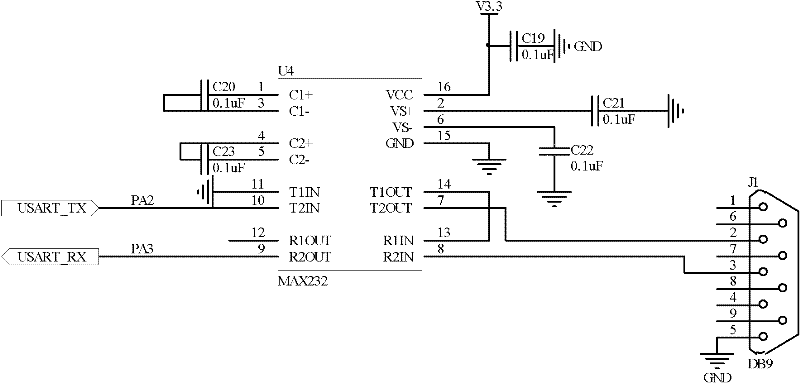

Seam welder electrode wheel synchronous control system and method

InactiveCN102310257ASame line speedPrecision weldingWelding with roller electrodesSynchronous controlPwm signals

The invention relates to a seam welder electrode wheel synchronous control system and method for solving the problem that the linear speed of rotation is inconsistent because the diameters of a motor head of a seam welder are inconsistent due to abrasion, and relates to the control field of seam welder electrode wheel rotation. The invention is used for controlling the synchronous rotation of two electrode wheels. A coder is used for acquiring the speed signal of the working electrode wheel and feeding back the signal to an MCU (Microprogrammed Control Unit) controller, and a PWM (Pulse-Width Modulation) signal with certain frequency and duty ratio is generated through the analysis calculation of the MCU. The signal is used for controlling the rotation speed of the next layer of electrode wheel through isolation and filter amplification, and the electrode wheel is kept to have the same linear speed with the former layer of electrode wheel.

Owner:BEIJING UNIV OF TECH

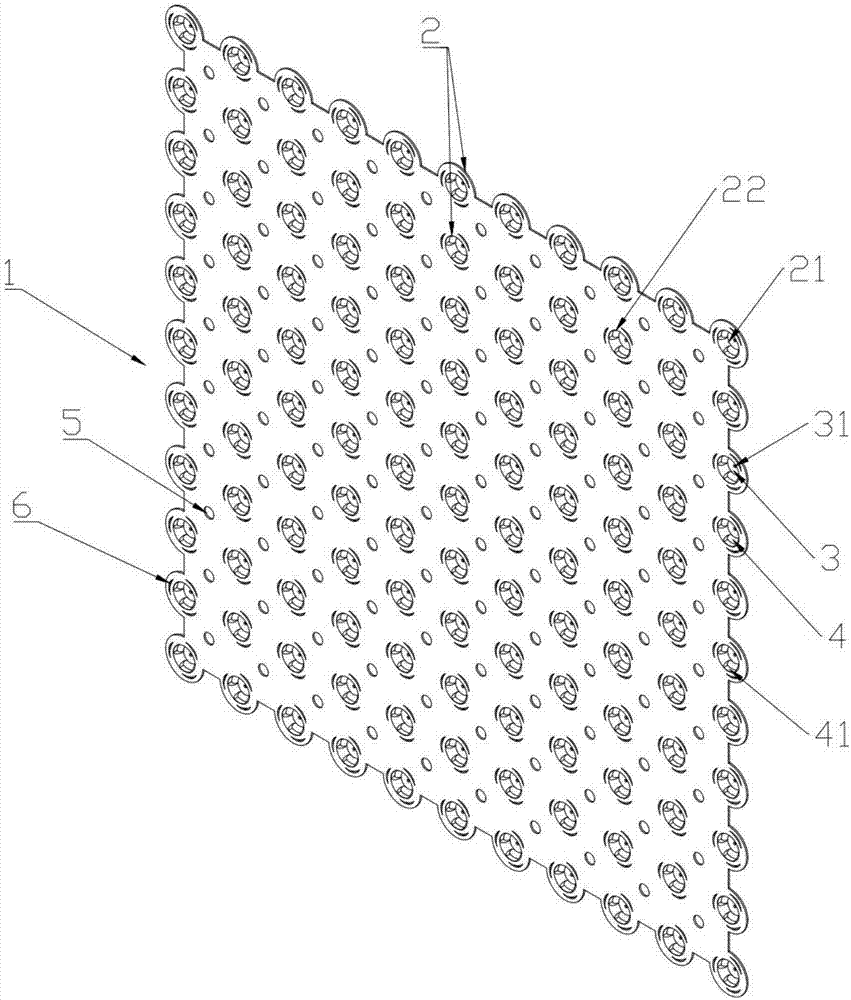

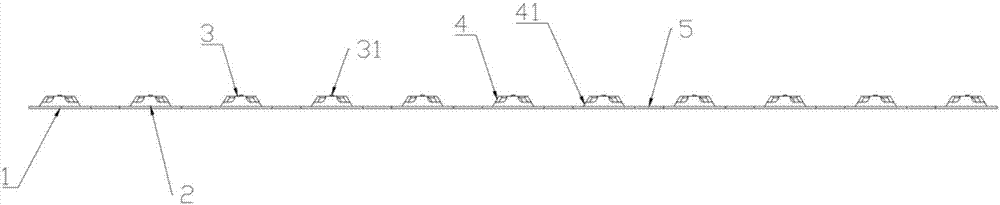

Lithium ion battery pack convergence board

InactiveCN107171149ALow resistivityReduce the probability of deformationCoupling device connectionsVehicle connectorsEngineeringLithium ion battery pack

The invention belongs to the technical field of an electric automobile lithium ion battery pack and specifically relates to a lithium ion battery pack convergence board. The lithium ion battery pack convergence board comprises a convergence board body, a plurality of welding through holes arranged on the convergence board body, and a plurality of convergence sheets. The convergence sheets and the welding through holes are not located on the same plane. The convergence sheets and the welding through holes are same in number, shape and axle center. A plurality of connecting parts are arranged at peripheries of the convergence sheets equidistantly. The connecting parts and the welding through holes are connected. The lithium ion battery pack convergence board provided by the invention is low in cost, low in density, low in cost and firm in welding, has suitable resistivity and is easy to process.

Owner:江苏艾鑫科能源科技有限公司

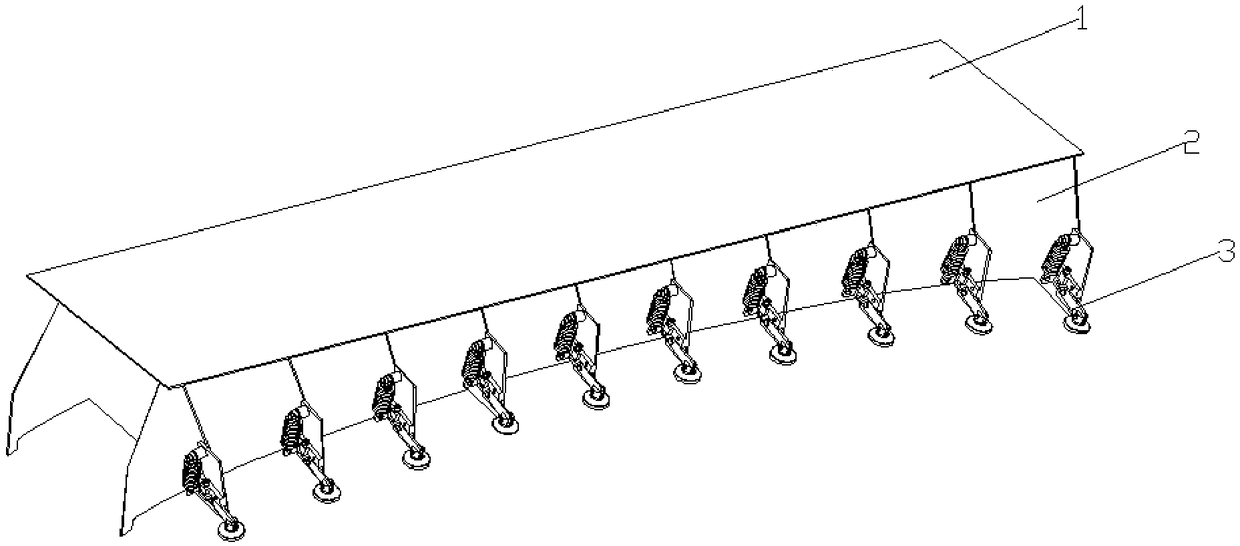

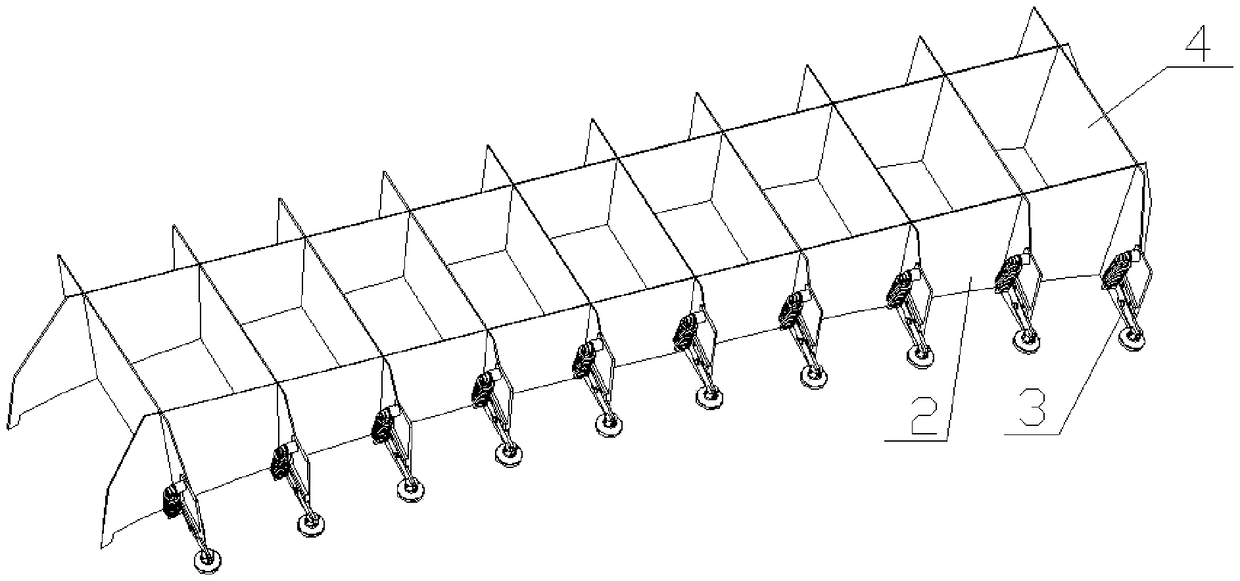

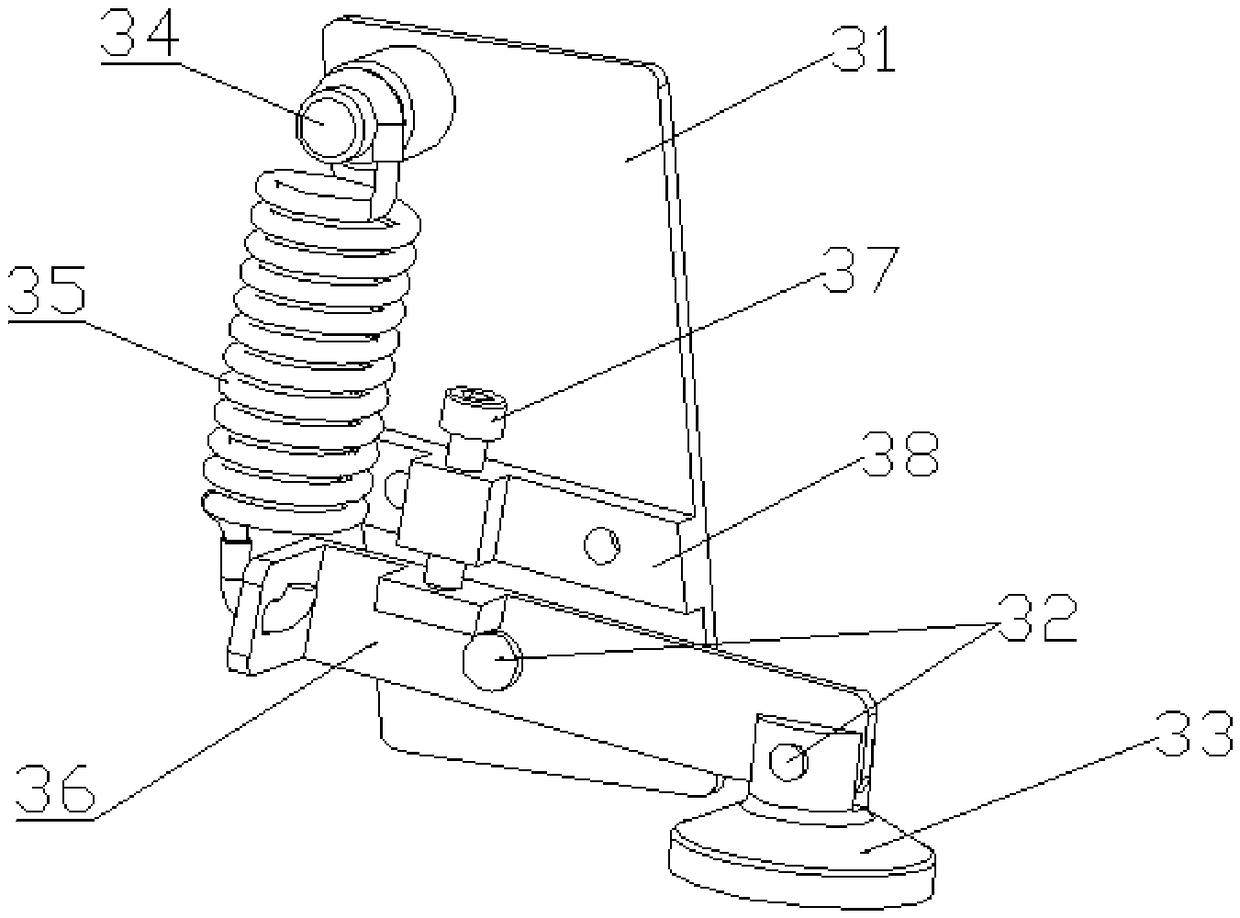

Weld joint positioning device and welding equipment for aluminum alloy automatic butt joint trolley

The invention discloses a welding seam positioning device and welding equipment for an aluminum alloy automatic butt welding trolley, the welding seam positioning device comprises a walking track and at least one suction cup assembly, the walking track is provided with a first surface and a second surface which are oppositely arranged, and the first surface of the walking track is used for being connected with the welding trolley; the at least one suction cup assembly is fixedly arranged on the second surface of the walking track so that the walking track can be sucked to the preset welding seam position. The walking track can be fixed to the preset welding seam position of the non-magnetic material to be welded through the suction cup assembly, accurate positioning of butt joint welding seams of non-magnetic materials such as aluminum alloy is achieved, and the automatic welding process stable in quality and high in efficiency is guaranteed.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Carbon dioxide gas shielded welding machine and method of arc ignition controlled by digital pulse

ActiveCN104096947BReduced maximum peak powerReduce transient impact stressElement comparisonArc welding apparatusEngineeringImpact stress

The invention discloses a method of controlling the arc strike of a carbon dioxide gas shielded welding machine by adopting digital pulse. The method comprises the steps of feeding gas for a welding gun; feeding a welding wire in a slow wire feeding mode; when the output voltage is detected to be 0 volt, outputting a 250-500 ampere short-circuit current pulse signal to the welding wire for arc strike; when the output voltage is detected to be smaller than 8 volts, switching from the slow wire feeding mode of the welding wire into a quick wire feeding mode, outputting a 250-500 ampere short-circuit current pulse signal to the welding wire to build a molten pool, and controlling an arc to be subjected to transition from arc strike to a stable arc. According to the method, the transient impact stress which is borne by a hardware power device is reduced, and the service life is prolonged; the arc strike time is shortened, the arc strike process is stable, the reliability is strong, and the arc strike success rate is high; the molten pool is built in the arc strike process, and thus a basic is established for normal, stable and reliable welding in the future. The invention further discloses a carbon dioxide gas shielded welding machine.

Owner:SHENZHEN RILAND IND

Railless walking single-pass full-penetration arc welding equipment and method

InactiveCN1159127CGuarantee welding qualityIncrease productivityArc welding apparatusEngineeringMetal

A single-pass full-fusion arc welding equipment includes metal connecting plate, backing pad, welding wire, welding device, metal fixing plate, guide wheel mechanism and two-rolling supporting wheel mechanisms and driving mechanisms, the metal connecting plate is perpendicularly placed into the preset weld gap of metal to be welded, on the supporting shaft of the described rolling supporting wheel mechanism and guide wheel mechanism three pressure springs are respectively mounted by the action of these springs the metal to be welded and the backing pad and be held in tight contact. This invention is adoptable to the plasma welding and gas shielded welding processes, and is suitable for automatic single-pass welding or manual single-pass welding in large metal plate structures, and its welding quality is high.

Owner:张绍彬

A welding system for large wall thickness steel plates

ActiveCN104476091BEasy dockingEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderButt welding

The invention discloses a welding system for large-scale thick steel plates, comprising a gantry type welding mechanism and a steel plate support structure, characterized in that: the steel plate support structure is arranged between two rails (1) of the gantry type welding mechanism, and the steel plate The support structure is composed of multiple sets of rollers (4), and is equipped with a lifting mechanism (5), which is installed on the lifting hydraulic cylinder (53); one side of the gantry type welding mechanism is equipped with a flip bracket (6 ), the overturning bracket (6) is hinged on the support (16), the back of the overturning bracket (6) is connected to the rotating hydraulic cylinder (18), the bottom is equipped with a wire plate (12), the top is equipped with a fixed pulley (15), and the steel wire Disc (12) is connected with motor (11). The device can be used to complete the processes of butt jointing, welding and turning over in the thick steel plate welding process. The welding and turning process is stable and reliable, which is convenient for workers to operate and improves the production efficiency.

Owner:GUIZHOU HUITONG SHENFA STEEL STRUCTURE

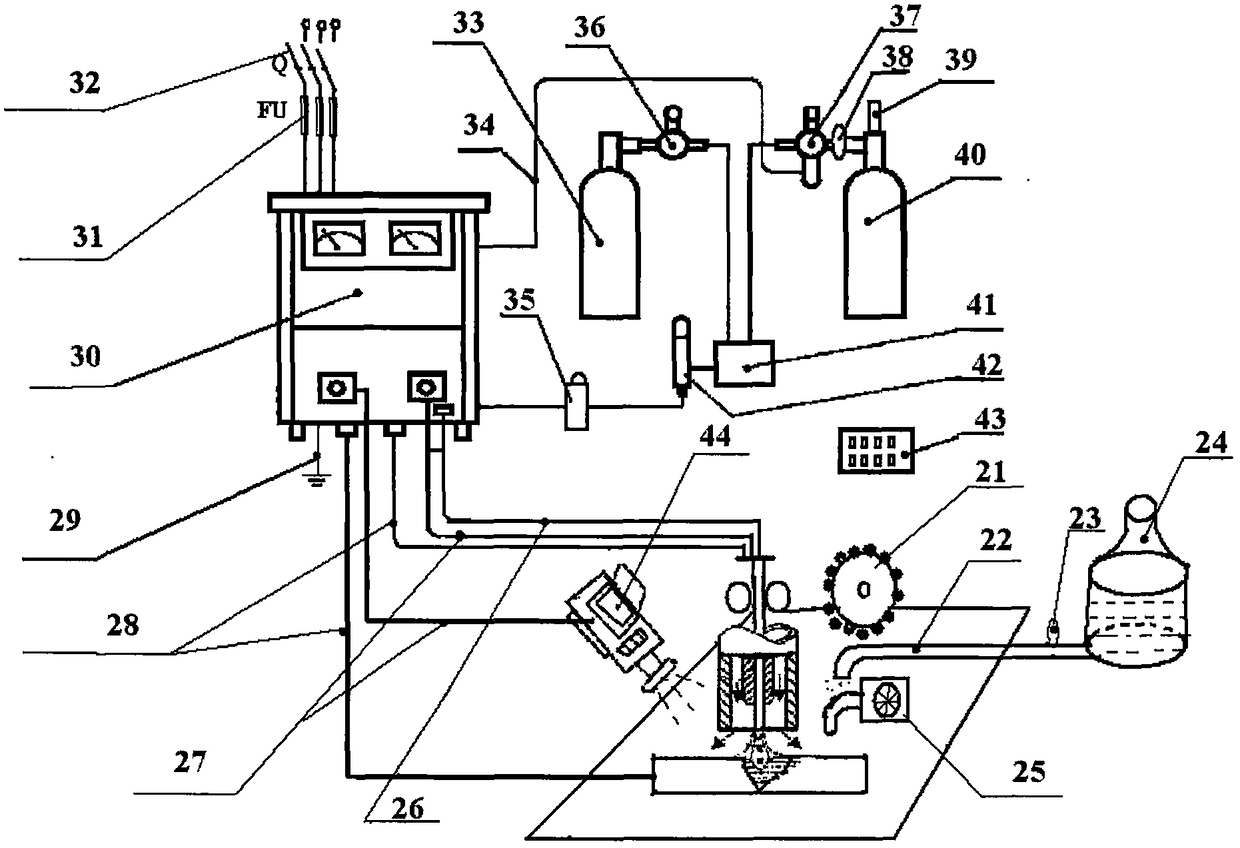

Automatic aluminum alloy plate welding equipment with acetone cleaning device

ActiveCN106583889BImprove welding qualityImprove liquidityWelding accessoriesMelting tankEngineering

The invention relates to mechanical washing and welding devices, in particular to an automated aluminum alloy plate welding device with an acetone washing unit. The device consists of a welding piece, an electric arc, a spraying gun, an electric hot air blower, an inert gas pipeline, a CCD camera and the like. The negative pole of a power supply cabinet and control system is connected with the welding piece through welding electric wires, and the power supply cabinet and control system has two superposed pulses; and the CCD camera is a color CCD camera, the pixel is 250 thousand-280 thousand, and the color resolution is 420 lpi. According to the automated aluminum alloy plate welding device, the CCD camera is used for monitoring the conditions of molten pools, welding wires and weld joints when aluminum alloy thick plates are welded, so that the parameters such as pulse current and the forward speed of a welding gun are adjusted in time, and the weld joint quality of an aluminum alloy is greatly improved. Before welding is conducted, acetone is sprayed for washing, mechanical strength of the weld joints is high, and the automated aluminum alloy plate welding device is suitable for the fine machinery manufacturing industry and an aluminum alloy welding occasion with very high welding requirements.

Owner:宿迁保沃纳米科技有限公司

A kind of solar cell series welding equipment and using method thereof

ActiveCN111375876BRealize fully automatic operationIncrease productivityMetal working apparatusElectrode maintenanceComputer control systemThermodynamics

The invention discloses a solar cell series welding equipment and its use method. The welding equipment includes: a base, a battery transportation system, a positioning camera, a welding platform, a welding system, a discharging system, and a computer control system; the battery transportation system is used It is used to transport laminated solar cells to be welded; the positioning camera is used to take images of laminated solar cells to obtain their position information; the welding platform can be flipped 180° after the series welding is completed; the welding system is a resistor that can move in three dimensions. Welding system; the unloading system is used to transfer and / or store welded solar cell components; the computer control system is used to receive the series welding requirements of solar cell components and control the battery handling system, positioning camera, welding platform, and welding as required The operation of the system and discharging system. The invention realizes fully automatic series welding of space solar cells, and has the advantages of high production efficiency, high precision, high reliability and good applicability.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Novel laser welding jig for trial-manufacture vehicle and use method thereof

PendingCN109048094AEnsure flexible dynamic balanceConstant pressureLaser beam welding apparatusChinese charactersEngineering

The invention provides a novel laser welding jig for a trial-manufacture vehicle. The novel laser welding tire film clamp comprises an upper cover plate, tire mold framework X-direction positioning plates, a spring pressing mechanism and partition plates; the number of the tire mold framework X-direction positioning plates is provided are two, and are made of rectangular plates correspondingly, one ends of the tire mold framework X-direction positioning plates are of polygonal structures, extending blocks are arranged at the top angles of the lower ends of the tire mold framework X-direction positioning plates, and a plurality of equal-spacing notches are formed in the upper side walls of the tire mold framework X-direction positioning plates; and the plurality of partition plates are arranged, one ends of the partition plates are clamped in the notches of the two tire mold framework X-direction positioning plates in a buckling mode to form a tire mold framework, the tire mold framework is in a plurality of connected Chinese character "jing" structures, and the upper cover plate is fixedly arranged on the tire mold framework; the spring pressing mechanism is fixedly arranged at oneends of the partition plates; and the invention further provides a use method of the novel laser welding jig for the trial-manufacture vehicle. According to the jig, the manual adjustment amount of the jig is reduced to the maximum degree, so that the trial manufacture efficiency of sample cars is improved, and the sample car trial manufacture is made to reflect actual production to a higher degree.

Owner:SHANGHAI YIRUI AUTOMOBILE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com